Zero-emission method for preparing olefin from coal

A coal-to-olefin, zero-emission technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of insufficient utilization of C resources, large emissions, and inability to achieve efficient utilization of synthesis gas, etc. Achieve the effect of avoiding greenhouse gas emissions, reducing carbon emissions, and achieving diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

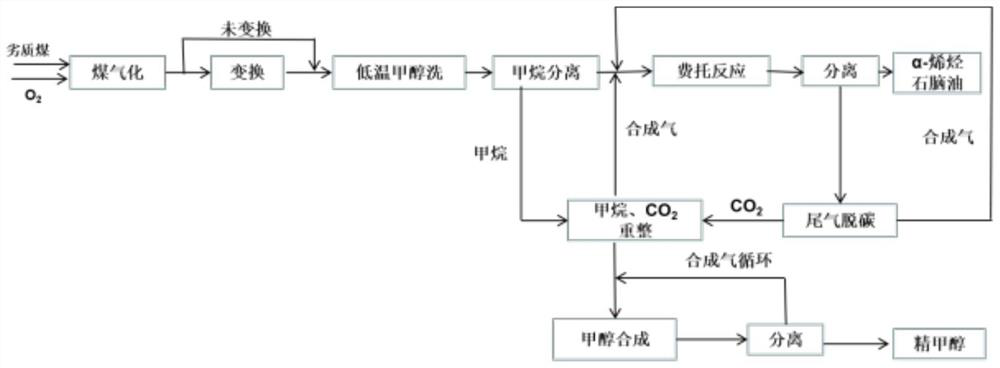

[0070] refer to figure 1 The process flow in , using bituminous coal as raw material, carries out the cascade production of high-carbon olefins and low-carbon olefins:

[0071] (1) Preparation and purification of pure syngas

[0072] Pass oxygen into bituminous coal to obtain crude gas through pulverized coal pressurized gasification technology (gasification pressure 4.5MPa, gasification temperature 1200°C), and the composition of the volume percentage of crude gas is CO:H 2 :CO 2 :CH 4 :H 2 S=48.29:24.31:14.26:12.96:0.18, 67% by volume of crude gas was subjected to sulfur-tolerant shift under the catalysis of Qingdao Lianxin QDB-04 catalyst at 250°C, 3.5MPa, and the volumetric air velocity calculated with dry gas was 4000h -1 , the transformed water / gas molar ratio is 0.35, and the transformed crude gas is mixed with another 33% untransformed crude gas by volume and sent to the low-temperature methanol washing unit.

[0073] After the crude gas enters the low-temperatur...

Embodiment 2

[0083] refer to figure 1 The process flow in , using bituminous coal as raw material, carries out the cascade production of high-carbon olefins and low-carbon olefins:

[0084] (1) Preparation and purification of pure syngas

[0085] Using bituminous coal as raw material, feeding oxygen through pulverized coal pressurized gasification technology (gasification pressure 4.5MPa, gasification temperature 1200 ℃) to obtain crude gas, the composition of the volume percentage of crude gas is CO:H 2 :CO 2 :CH 4 :H 2 S=48.29:24.31:14.26:12.96:0.18, the crude gas is subjected to sulfur-tolerant shift at 250℃, 3.5MPa, Qingdao Lianxin QDB-04 catalyst, and the volume space velocity calculated by dry gas is 4000h -1 , the transformed water / gas molar ratio is 0.35, mixed with another 33% untransformed crude gas and sent to the low temperature methanol washing unit.

[0086] The mixed crude gas enters the low-temperature methanol washing unit, and is washed with low-temperature methanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com