Patents

Literature

258 results about "Coal processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

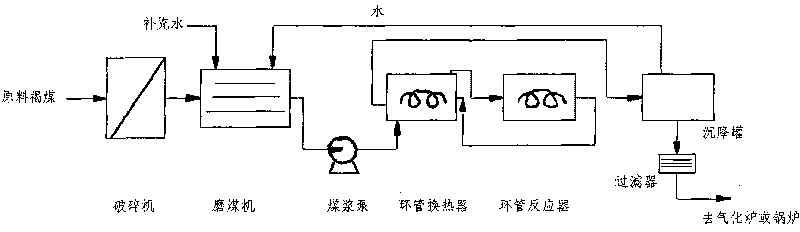

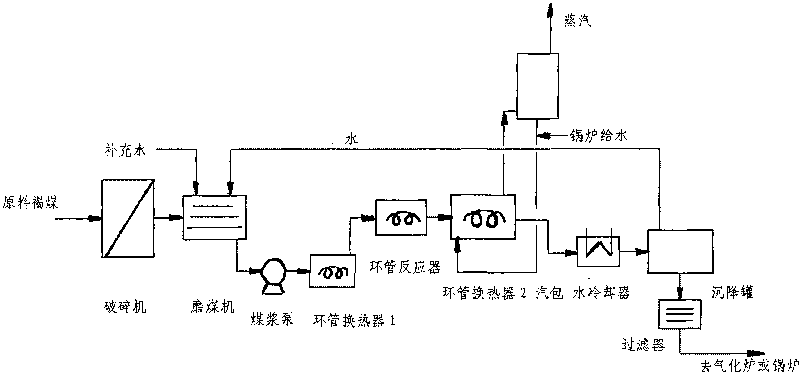

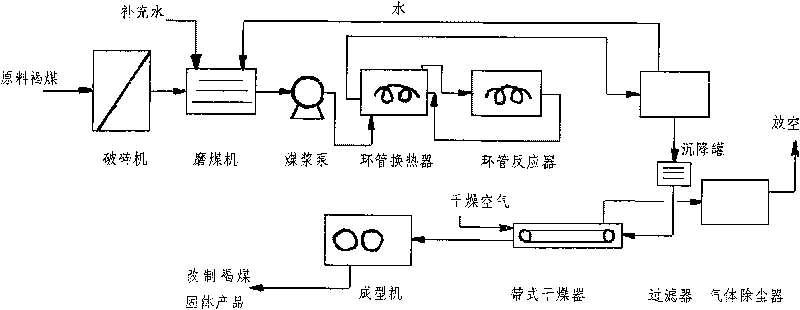

Method for modifying lignite

The invention relates to a method for modifying lignite, belonging to the technical field of coal processing. In the method, the lignite is broken, sent into a coal mill, and is ground into coal pulp after water is added. Due to high content of internal water of the lignite, the concentration of the water-coal-slurry is relatively low, generally 30-55%. Modified water-coal-slurry is obtained after treatment under high temperature and pressure, wherein the internal water of lignite particles in the modified water-coal-slurry is reduced, and the water used for lubrication among the particles is more than needed water content of the water-coal-slurry. Measure of settlement or / and other specific measure, is / are needed to separate the excess water, and the concentration of the water-coal-slurry is increased from 30-50% to 50-70%, thereby increasing the calorific value of the lignite.

Owner:TSINGHUA UNIV +1

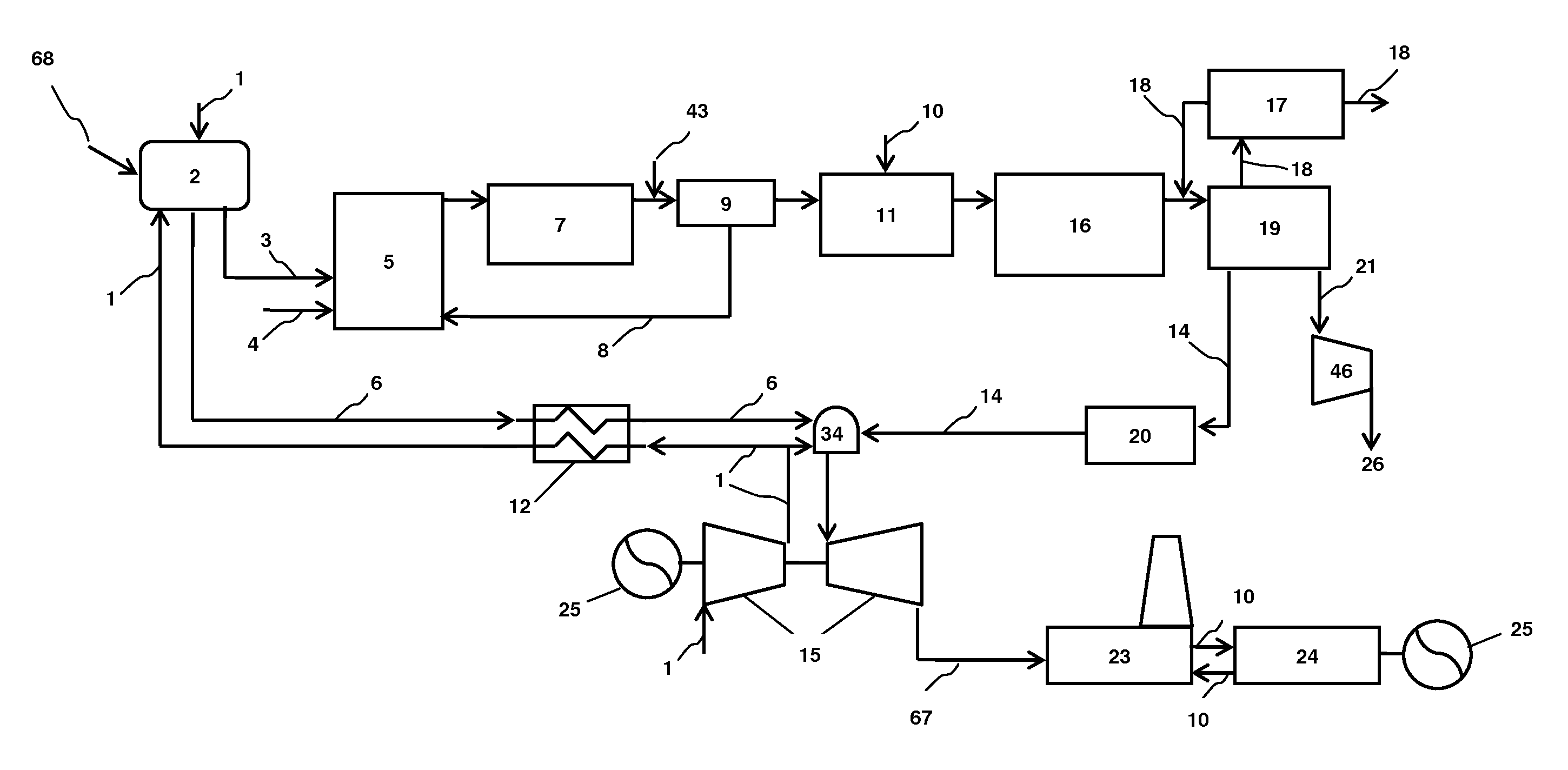

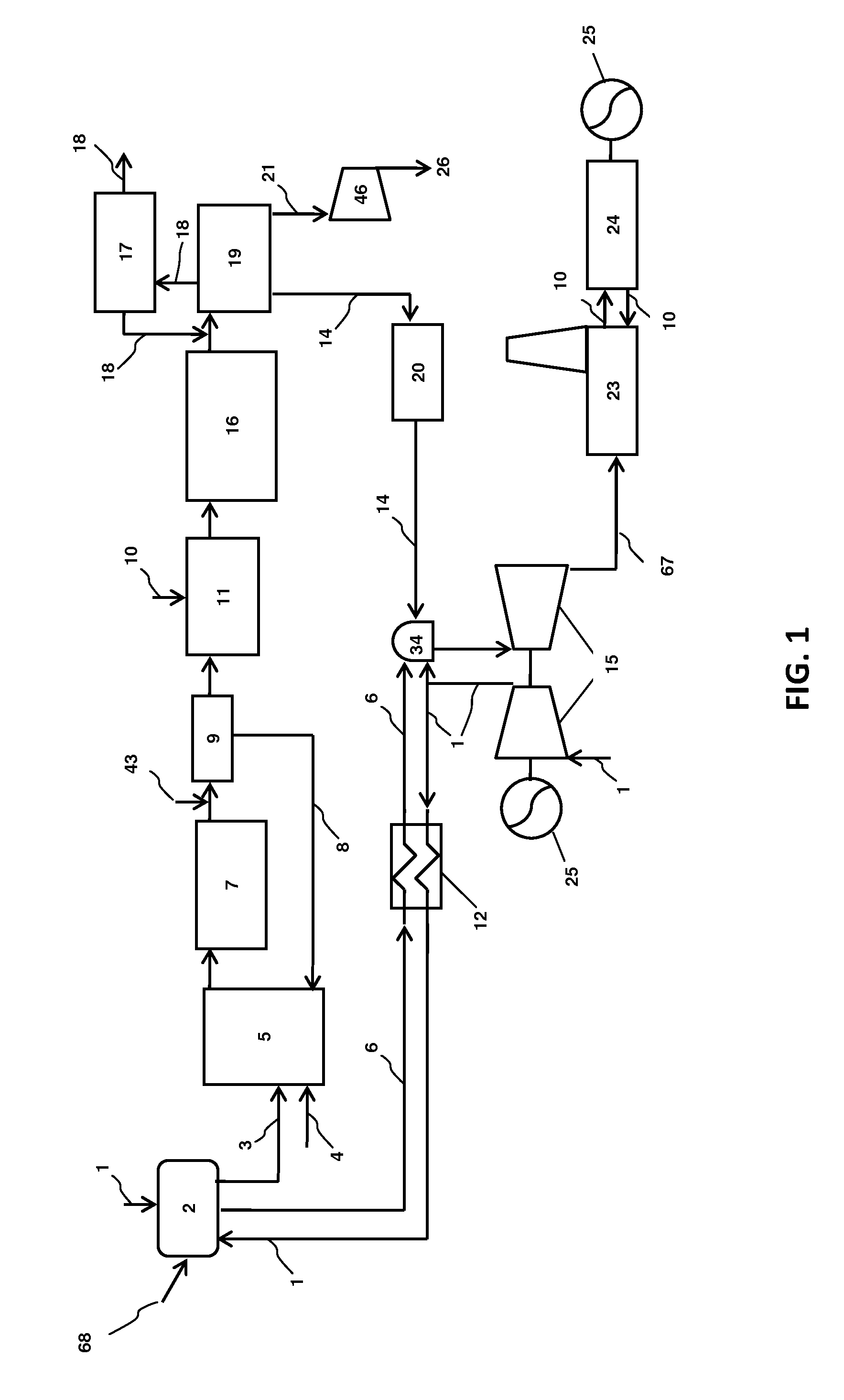

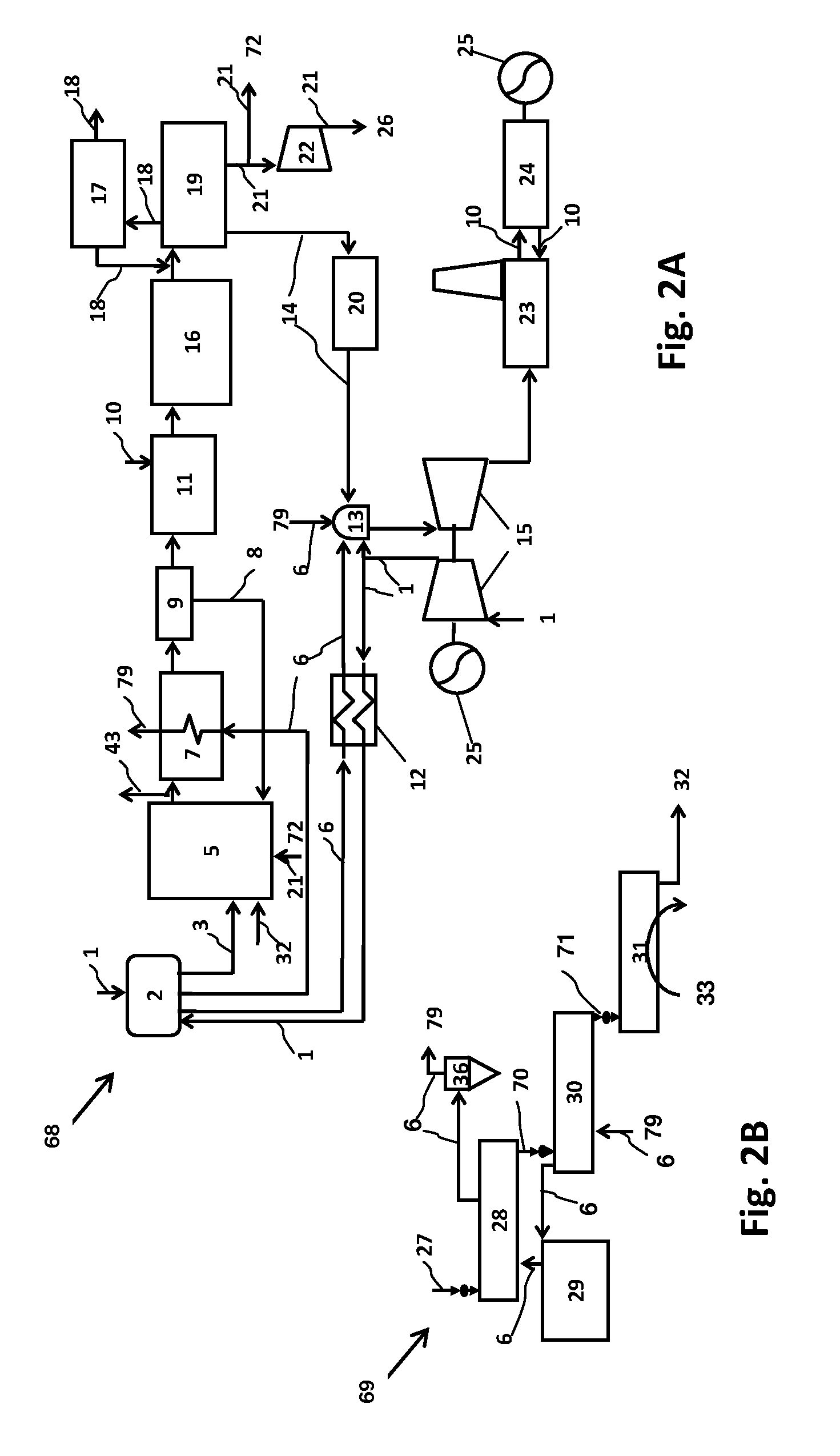

Efficient low rank coal gasification, combustion, and processing systems and methods

ActiveUS9181509B2Easily and efficiently retrofittedDrying gas arrangementsSolid fuelsCombustionPower station

Efficient coal pre-processing systems (69) integrated with gasification, oxy-combustion, and power plant systems include a drying chamber (28), a volatile metal removal chamber (30), recirculated gases, including recycled carbon dioxide (21), nitrogen (6), and gaseous exhaust (60) for increasing the efficiencies and lowering emissions in various coal processing systems.

Owner:WESTERN RES INST INC

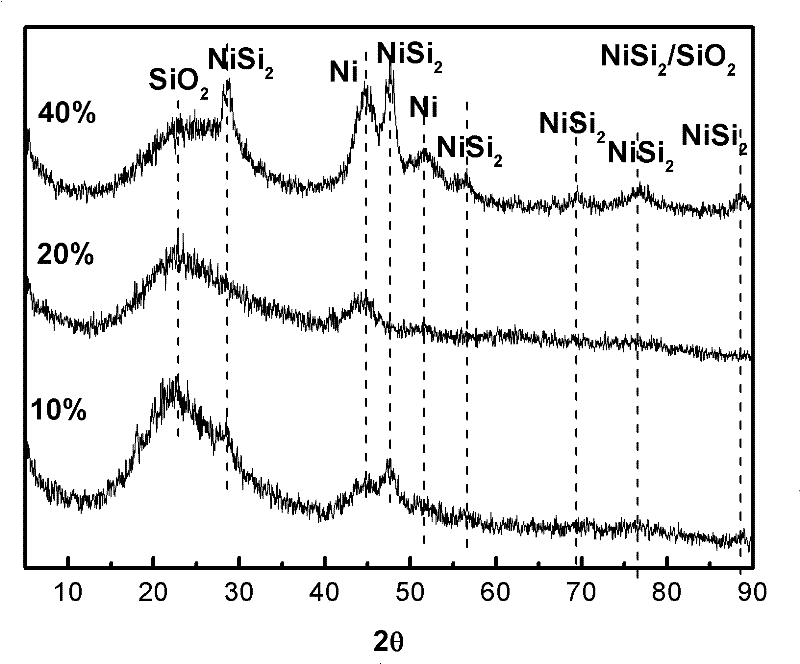

Methanation catalyst and application thereof

InactiveCN102327769AImprove thermal stabilityImprove anti-sinteringPhysical/chemical process catalystsHydrocarbon from carbon oxidesForming gasMethanation

The invention which belongs to the technical field of coal processing utilization and coal conversion relates to a highly efficient and stable metal silicide catalyst of for the preparation of methane through carrying out coal-formed gas methanation. The stable metal silicide catalyst is formed through reducing a uniformly dispersed supported metal which is adopted as a precursor in hydrogen, siliconizing a mixed gas SiH4 / H2 at a low temperature and normal pressure. The preparative metal silicide catalyst has a high activity and a methane selectivity to CO methanation; and in addition, compared with traditional metal catalysts, the metal silicide catalyst of the invention has the advantages of high thermostability, high anti-sintering, high carbon deposition resistance, difficult loss of carbonyl compounds formed from active components, strong sulfur resistance and the like.

Owner:DALIAN UNIV OF TECH

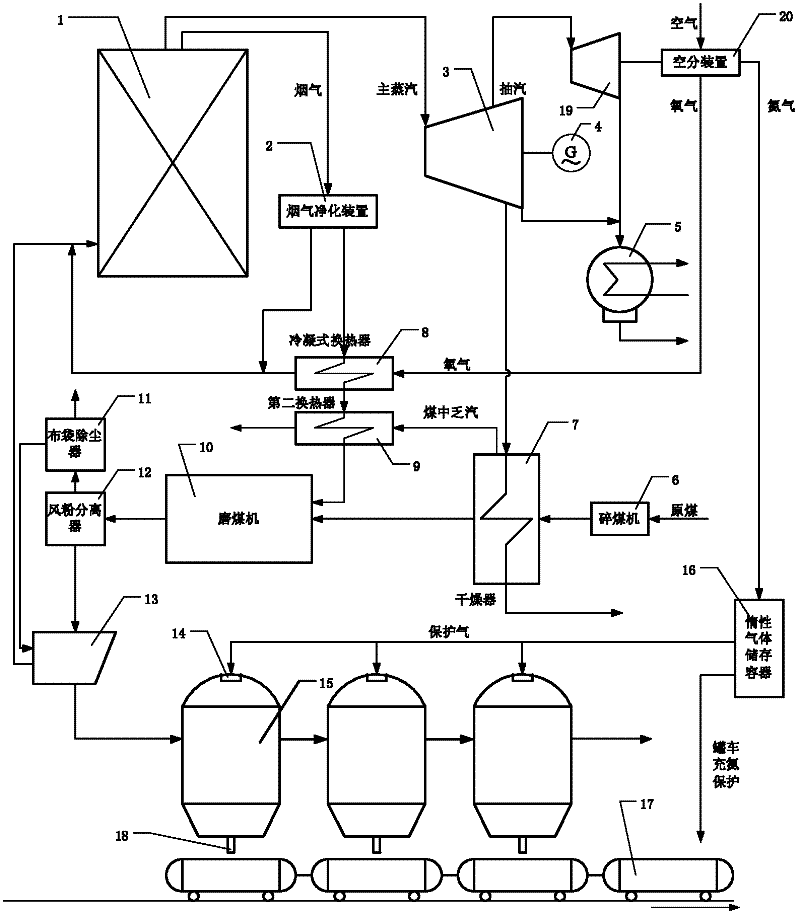

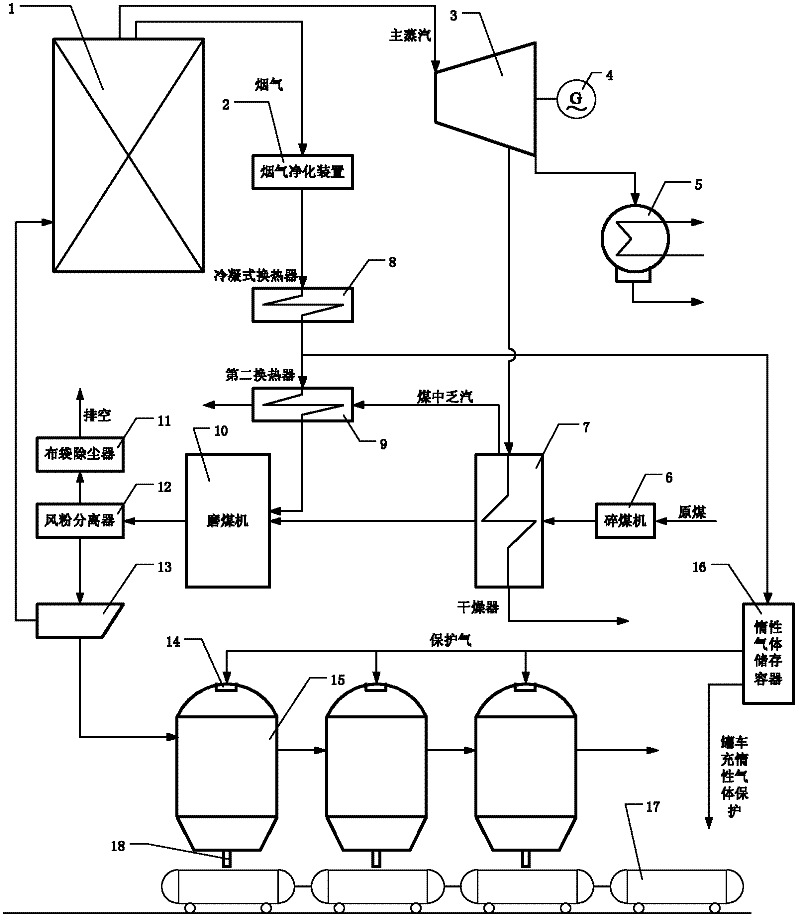

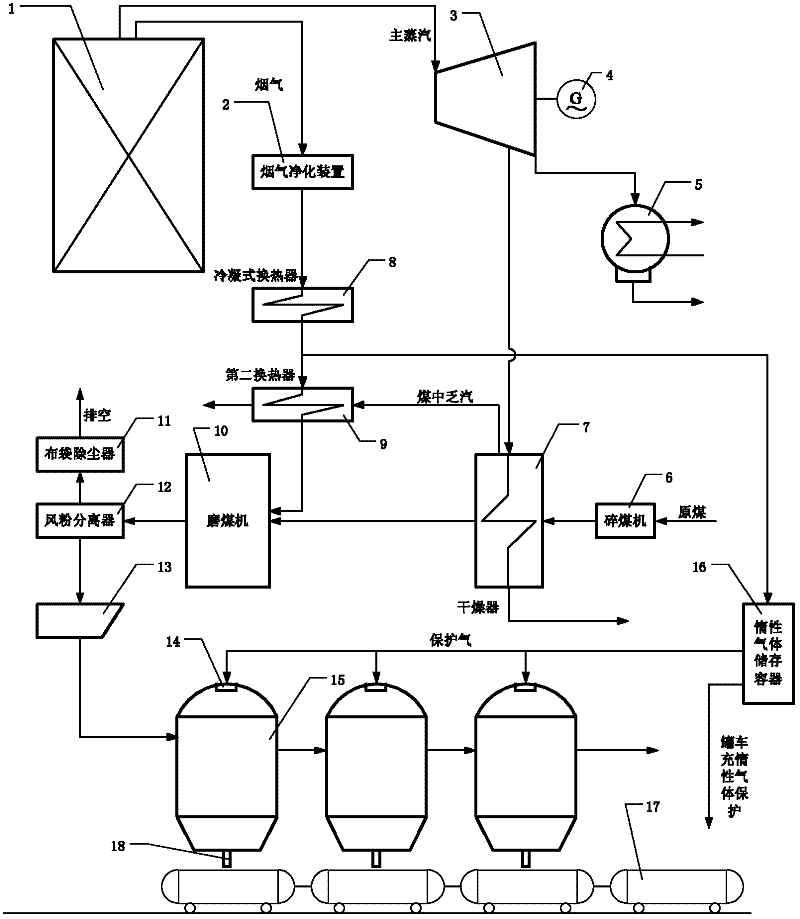

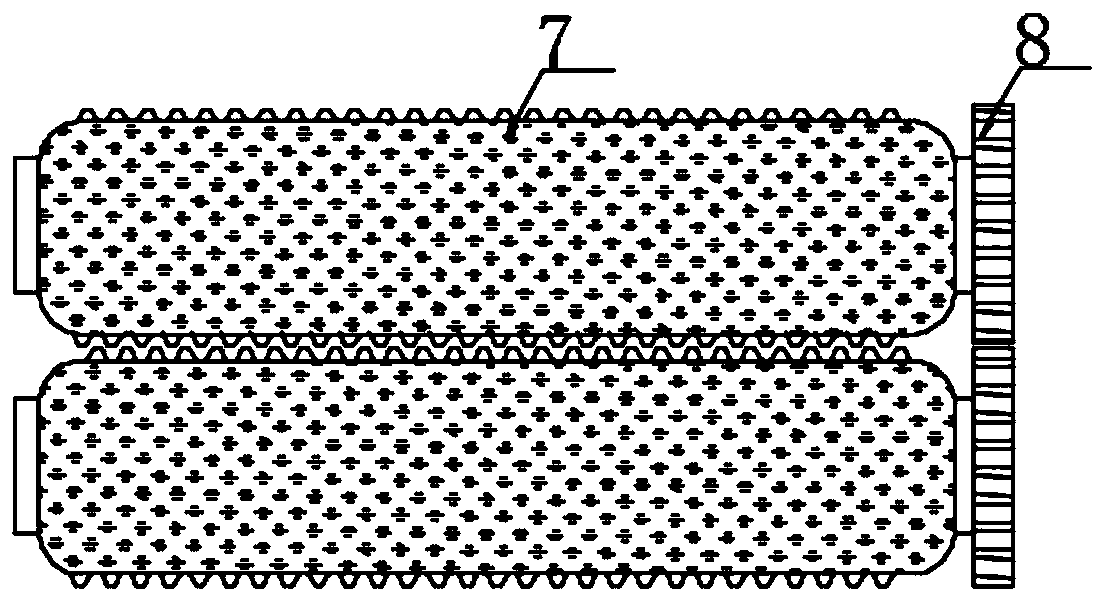

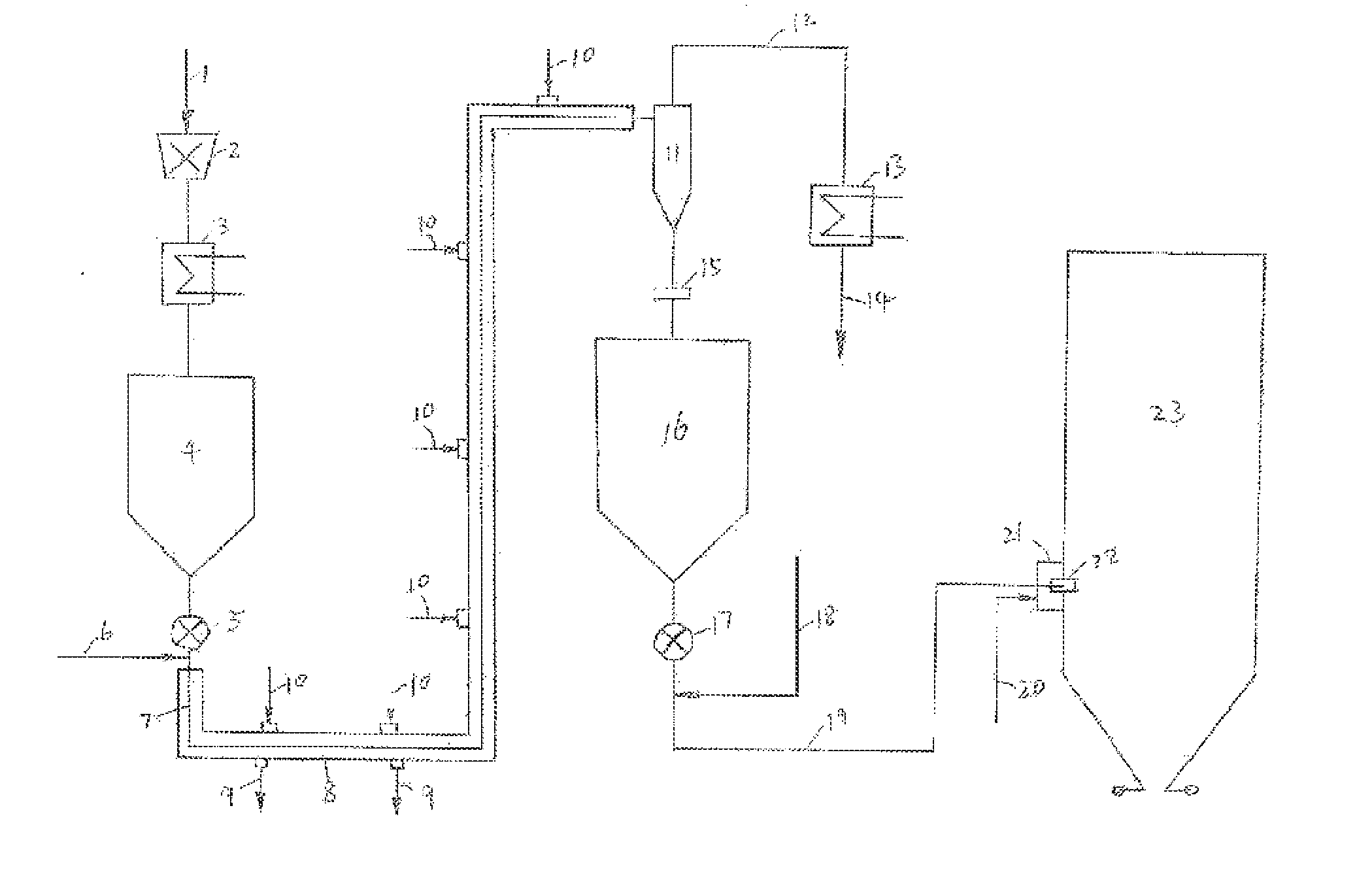

Large-scale centralized preparation system for pulverized coal and distribution method

InactiveCN102410552AGuaranteed feasibilityEnsure safetyLump/pulverulent fuel preparationCoal briquetteDistribution method

The invention discloses a large-scale centralized preparation system for pulverized coal and a distribution method. In the invention, raw coal is dried in a drying system by virtue of heat energy from a power generation enterprise in a raw coal producing area; dried coal briquettes are input into a grinding system so as to be processed into qualified pulverized coal; then the qualified pulverized coal is conveyed to coal-based power enterprises and other pulverized coal users for use by means of conveying equipment; and the whole pulverized coal processing and transportation process is in an inert environment so as to ensure the safe operation of the whole system. The large-scale centralized preparation system and the distribution method are mainly applied to large-scale centralized pulverized coal manufacturing factories in mining areas, wherein the factories provide the pulverized coal for the coal-based power enterprises and other pulverized coal users by a mode of conveying the qualified pulverized coal.

Owner:XI AN JIAOTONG UNIV

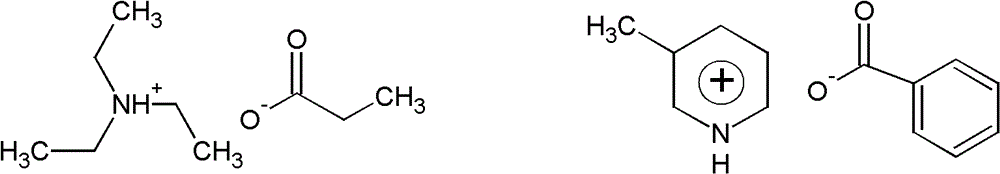

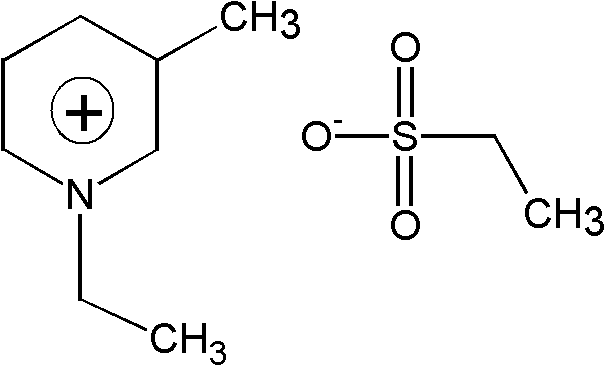

Method for extraction and separation of carbon-containing coal residues based on ionic liquid

InactiveCN103059894AEasy to recycleReduce manufacturing costWorking-up pitch/asphalt/bitumen by selective extractionAutomatic controlQuinoline

The invention provides a technology for separating asphaltene materials from carbon-containing solid residues generated in a coal processing process based on an ionic liquid extracting agent. The technology employs pyridine and ammonium ionic liquid as the extracting agent to separate the asphaltene materials from carbon-containing residues through two steps of extraction and reverse extraction at a certain temperature and pressure, and provides high-quality raw materials for modifying and preparing mesophase asphalt and further producing high performance carbon materials. The ionic liquid used by the method is easy to synthesize, is cheap, has low viscosity and is easy to regenerate. Compared with a convention extraction separation method by using an organic solvent, the method can obviously increase separation selectivity of the asphaltene materials in the residues, has relatively low H / C ratio and sulfur content of the extract, and almost contains no soluble substances such as quinoline. The technology has the advantages of environment protection, energy conservation, simple equipment, convenient operations, low investment, simplified production process, easily realizable automatic control, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

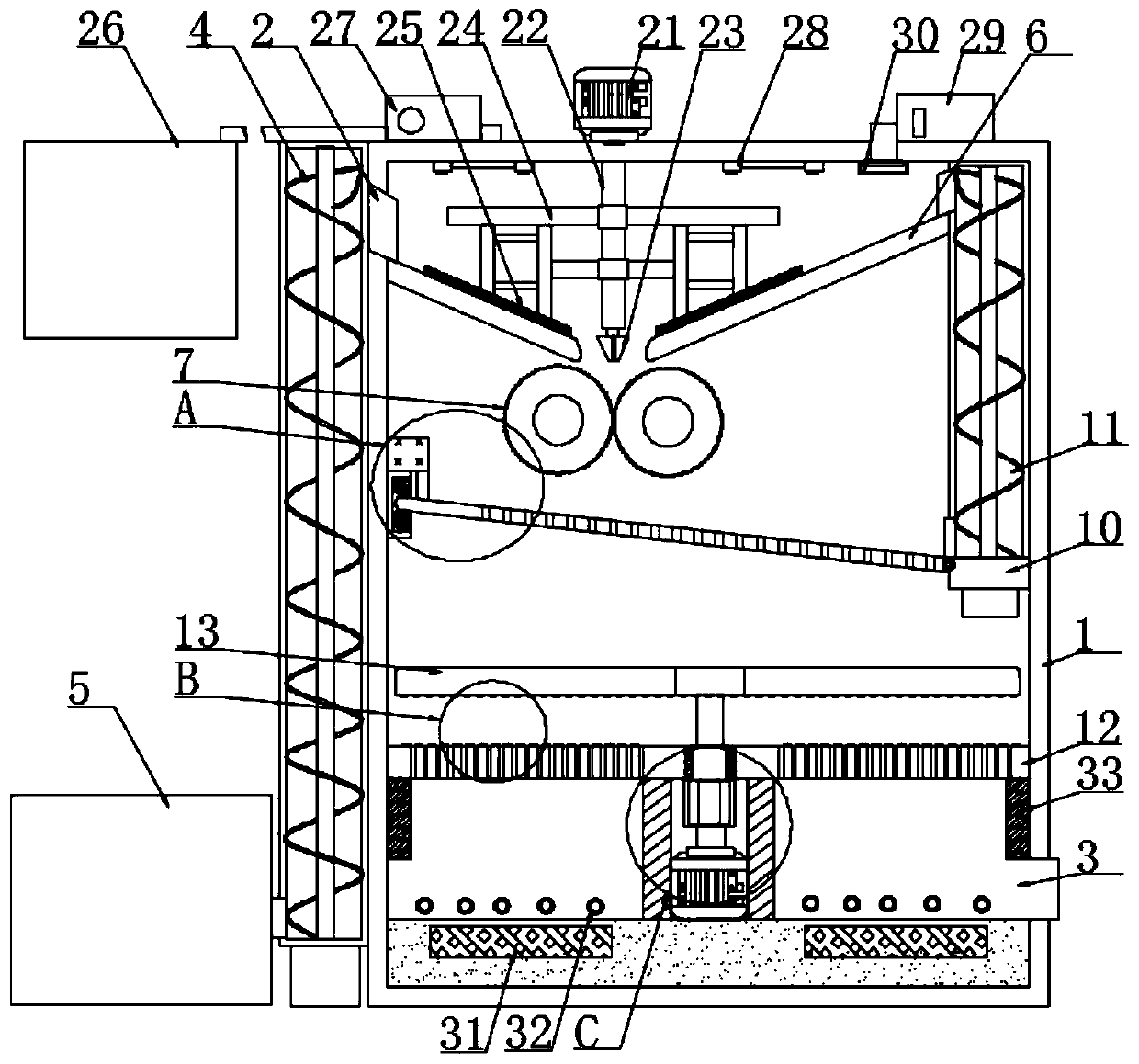

Coal processing equipment for coal mines

ActiveCN110354974AAutomatic realization of multi-stage crushing operationsAvoid blockageSievingScreeningMultiple stagesCoal processing

The invention discloses coal processing equipment for coal mines, and belongs to the technical field of coal processing equipment. The coal processing equipment comprises a coal crushing and screeningmechanism, a screening cabinet, a grinding table, a conveyor belt and a coal grinding mechanism; the coal crushing and screening mechanism comprises a coal crushing assembly, a secondary crushing assembly, a reciprocating vibration assembly, an upper separation net and a lower separation net; the screening cabinet is internally provided with a dust removal assembly, and a feeding channel communicating with the interior of the screening cabinet is formed in the top of the screening cabinet; and two discharging channels are formed in the left side of the screening cabinet, and the discharging channels communicate with the interior of the screening cabinet. The coal processing equipment has the beneficial effects that coal can be automatically crushed at multiple stages through the coal crushing and screening mechanism, the upper separation net and the lower separation net can vibrate intermittently under the effect of the reciprocating vibration assembly, the situation that the upper separation net and the lower separation net are blocked is avoided, and generated dust can automatically fall through the dust removal assembly.

Owner:XIAOYUN COAL MINE JINING MINING IND GRP CO LTD

Catayst for hydrogenation refining metal sulfer phosphorus compound

InactiveCN1850335AHigh catalytic activityRealize deep desulfurizationCatalyst carriersRefining to eliminate hetero atomsOil processingPhosphate

The present invention relates to a melattothiophosphide hydrofining catalyst to the field of coal processing, petroleum processing and petrochemical technology. It the concrete, it relates to a solid catalyst for hydrofining petroleum fractions (gasoline, kerosene and diesel oil, etc.). Said invention also provides the concrete steps of said catalyst preparation method.

Owner:DALIAN UNIV OF TECH

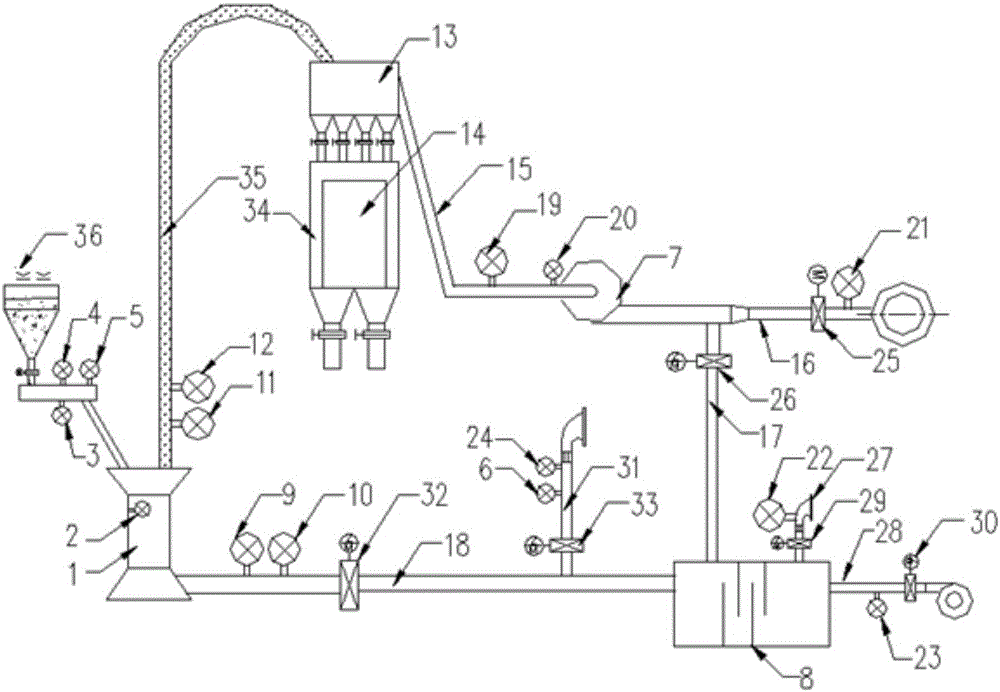

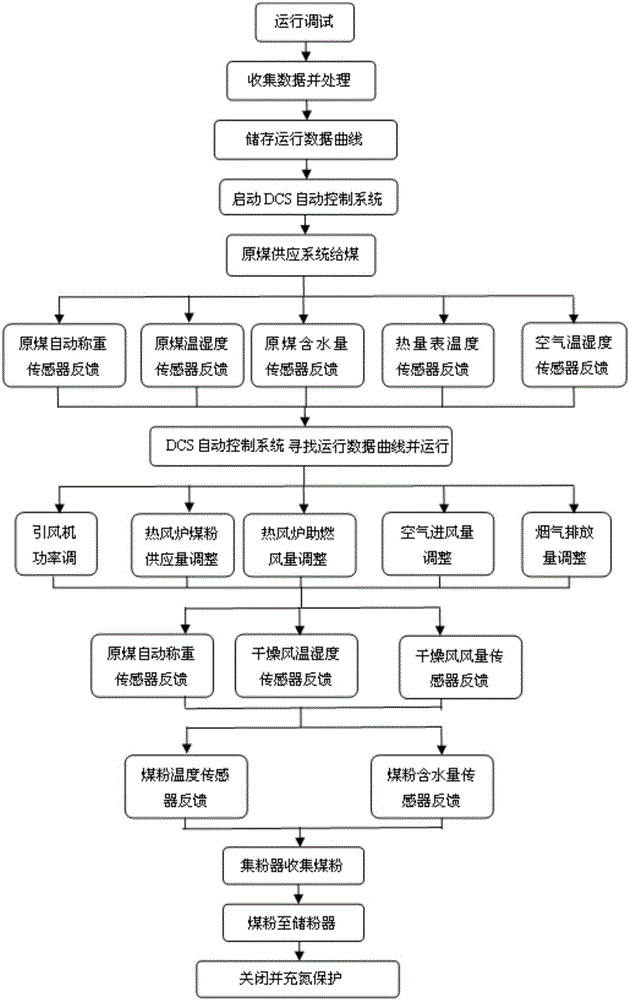

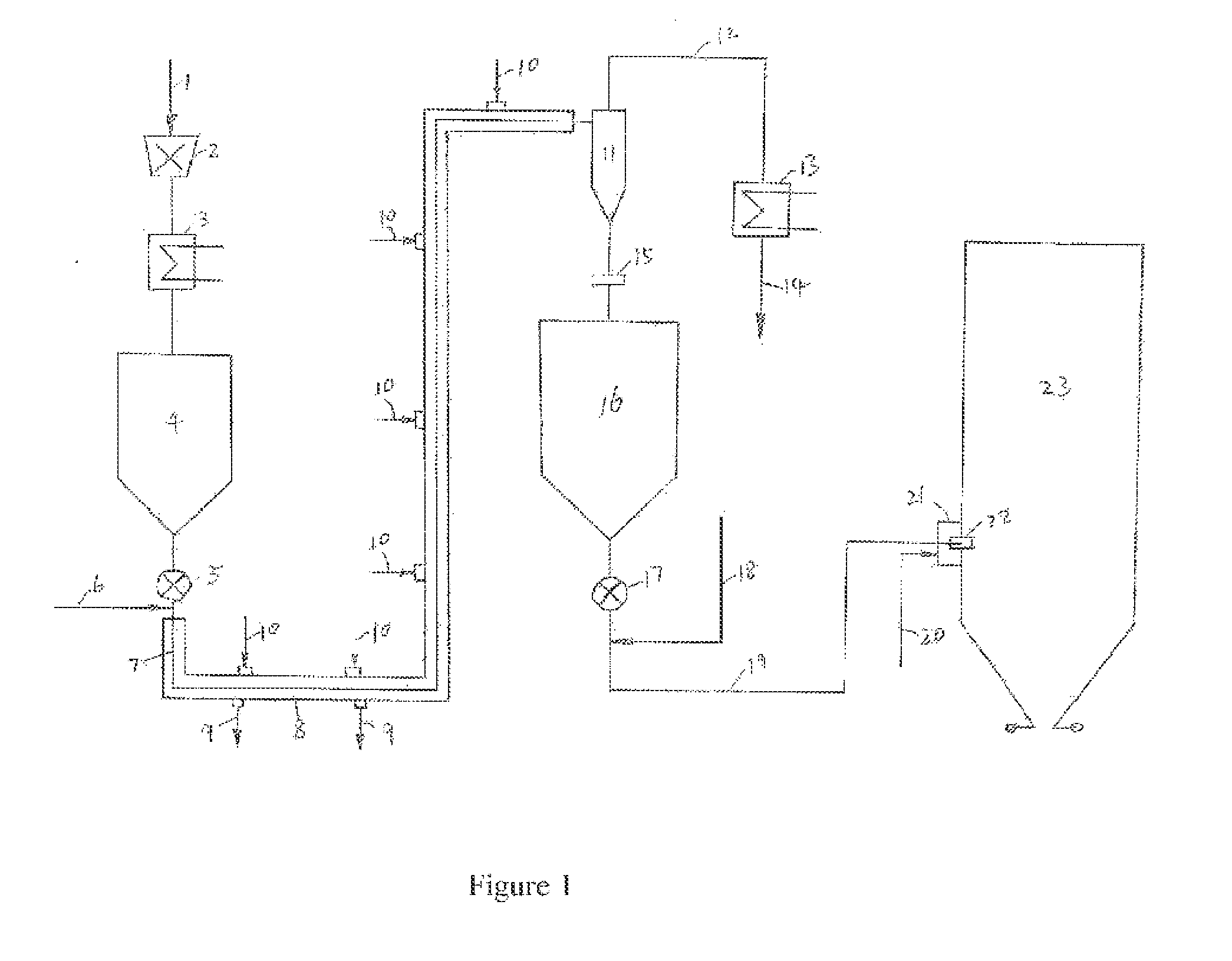

Pulverized coal milling device and method

ActiveCN105864811AReduce leakageReduce heat lossLump/pulverulent fuel preparationElectricityAir volume

The invention belongs to the technical field of coal processing, and relates to a pulverized coal milling device and method. The main structure of the pulverized coal milling device comprises a DCS automatic control system, a coal mill, a raw coal supplier, a pulverized coal collecting and storage system and an induced air negative-pressure drying system, wherein the DCS automatic control system is separately connected with the coal mill, the raw coal supplier, the pulverized coal collecting and storage system and the induced air negative-pressure drying system through electric information and controls the operation of the above devices; and the pulverized coal milling method comprises the three steps of operation debugging, formal pulverized coal production and subsequent processing. One time of input and multiple times of output can be realized for pulverized coal milling data, and the whole process is automatically controlled; the DCS automatic control system controls the temperature and air volume of drying air; pulverized coal during a milling process is dried by utilizing low-temperature drying air circulation; a full-negative-pressure pulverized coal conveying mode is adopted by the induced air negative-pressure drying system; and the pulverized coal milling device is simple in structure, scientific and reliable in principles, simple and convenient in operation, precise in control, high in coal milling efficiency, good in safety performance and low in cost, and is energy-saving and emission-reducing.

Owner:山东中科洁能科技有限公司 +1

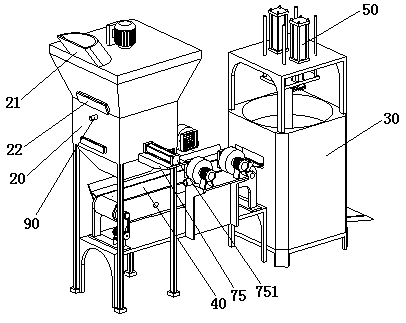

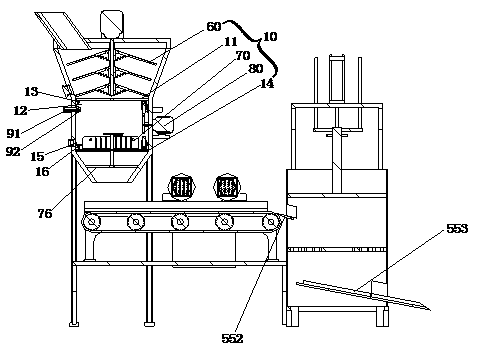

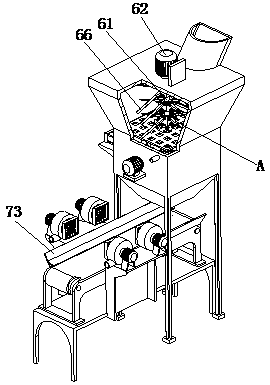

Efficient coal processing pulverizing device

InactiveCN109909043AImprove crushing efficiencyImprove crushing effectSievingGas current separationSlide plateEngineering

The invention discloses an efficient coal processing pulverizing device. A box is included. A feeding port is formed in the top of one side of the box. A discharging port is formed in the bottom of one side of the box. A first packing auger feeder is arranged on the top of one side of the box. A crusher is arranged on one side of the first packing auger feeder. The output end of the crusher is matched with the input end of the first packing auger feeder. The output end of the first packing auger feeder is matched with the feeding port. Two obliquely-distributed sliding plates are arranged in the box. The crusher is used for crushing coal blocks into small blocks, the small blocks are conveyed into the box through the first packing auger feeder, the small blocks are crushed into particles through extrusion of two tool rollers to fall onto the surface of a first sieve plate, small particles leak, large particles are elevated through a second packing auger feeder to be pulverized again, coal particles falling onto a second sieve plate become powder through a grinding device and fall down through second sieve holes, the coal pulverizing efficiency and pulverizing effect are improved, the coal combustion rate is guaranteed, and resource waste is reduced.

Owner:BEIJING HAOHUA ENERGY RESOURCE +1

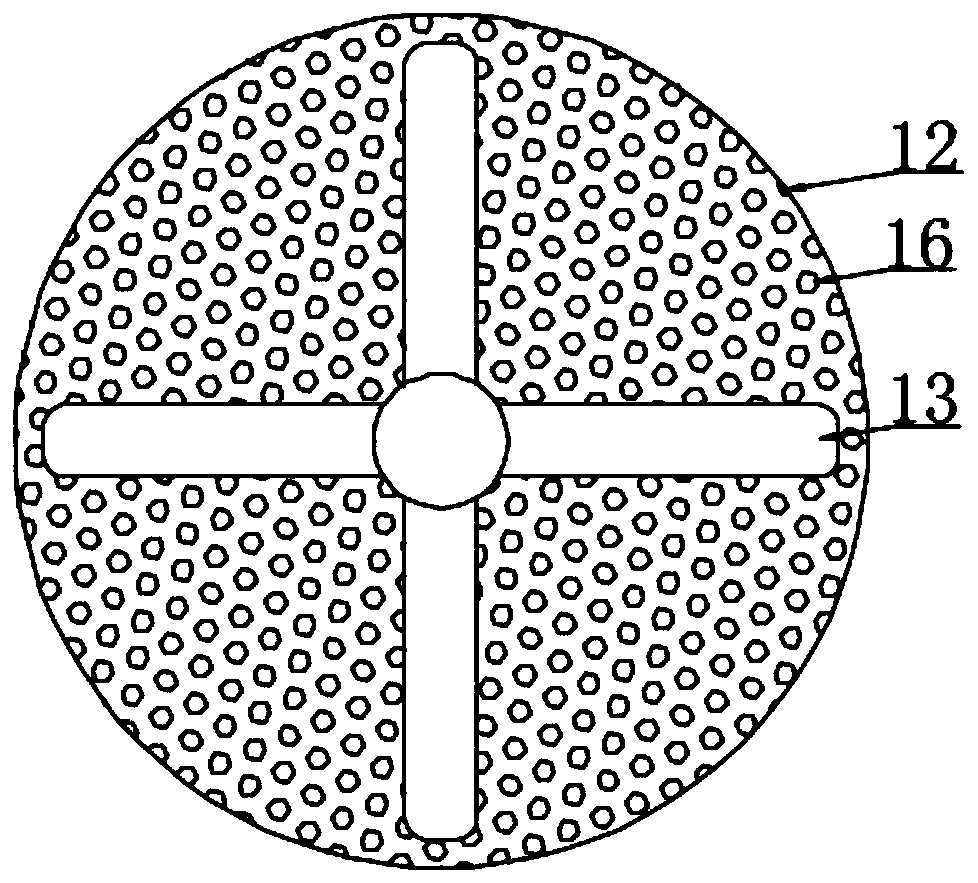

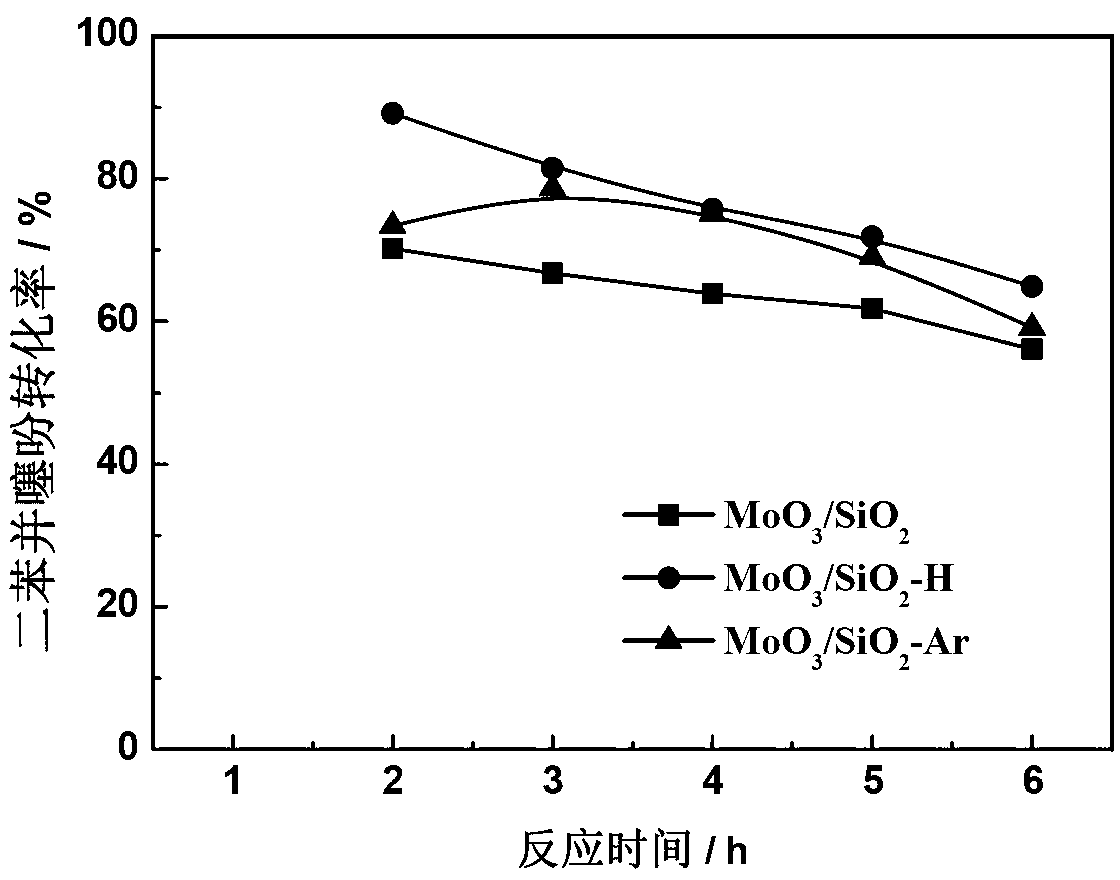

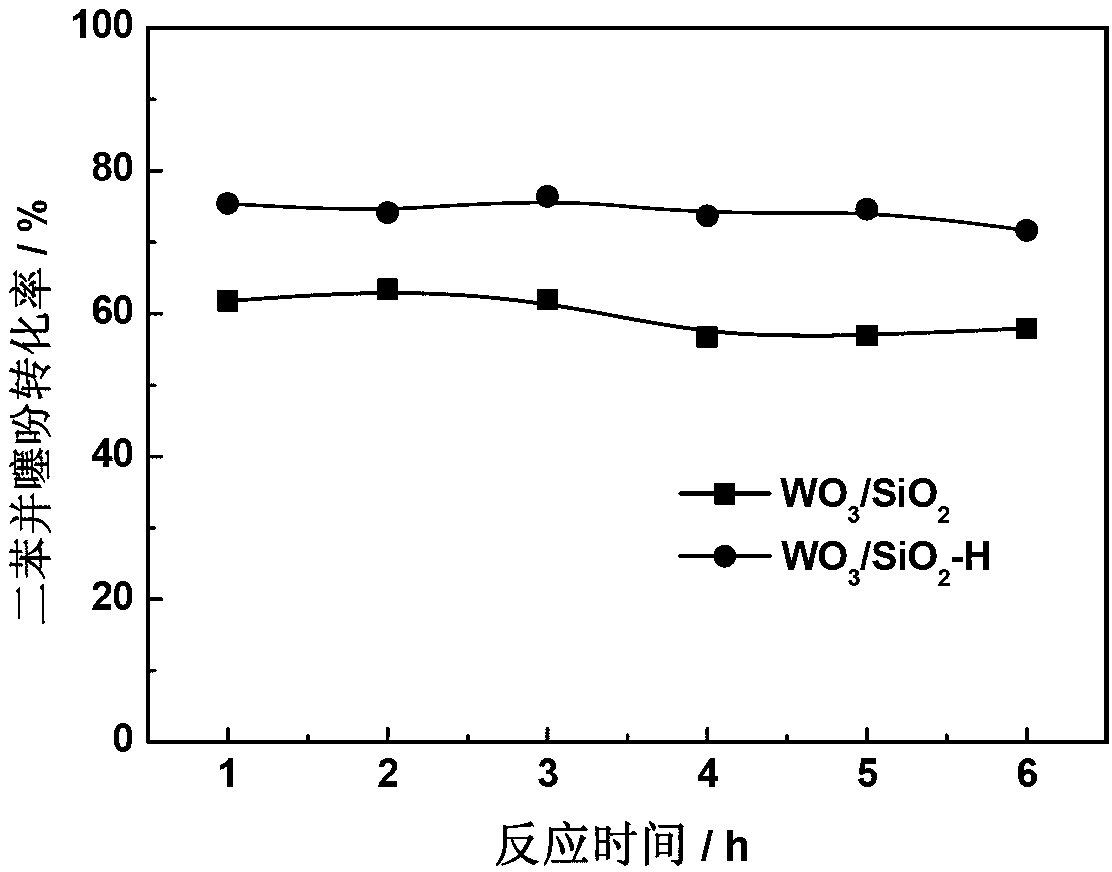

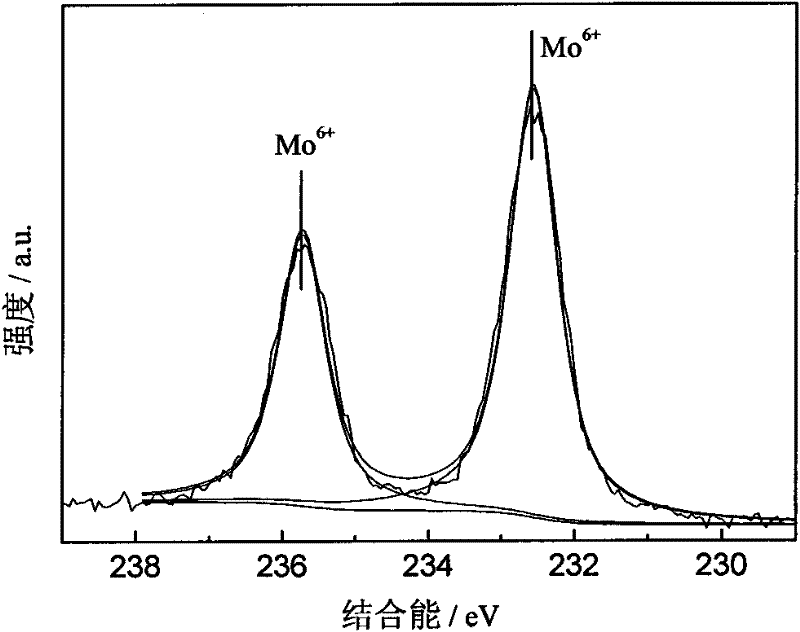

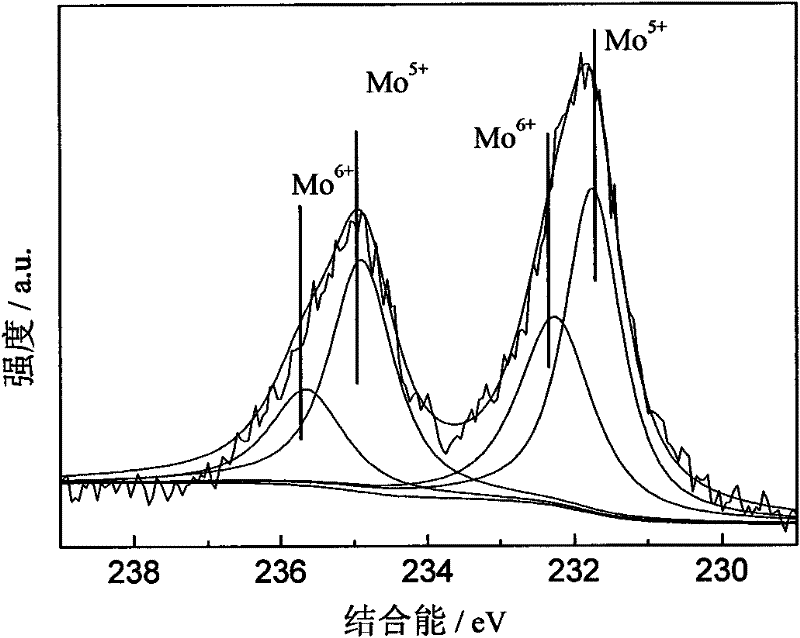

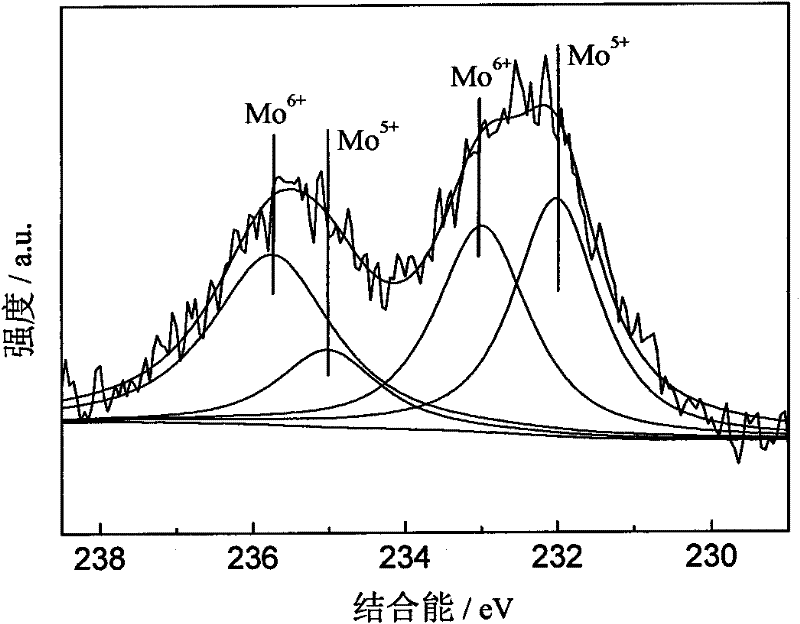

Method for preparing supported molybdenum-oxide-based and tungsten-oxide-based oxidation desulfurization catalysts

InactiveCN103240076AHigh activityReduce sulfur contentMetal/metal-oxides/metal-hydroxide catalystsOil processingHydrogen

The invention discloses a method for preparing supported molybdenum-oxide-based and tungsten-oxide-based oxidation desulfurization catalysts, belonging to the technical fields of coal processing, petroleum processing and petrochemical industry and relating to a method for preparing catalysts for removing thiophene-type heteroaromatic sulfide-containing solids from distillate oil and chemical materials by oxidation. The method is characterized by preparing the catalysts in a way of implementing plasma treatment on the molybdenum-oxide-based or the tungsten-oxide-based catalyst supported by a porous supporter under a hydrogen or inert gas atmosphere. The method has the effect and the benefit of remarkably enhancing the oxidation desulfurization activity of the supported molybdenum-oxide-based and tungsten-oxide-based catalysts, and has wide application prospect in the field of deep desulfurization.

Owner:DALIAN UNIV OF TECH

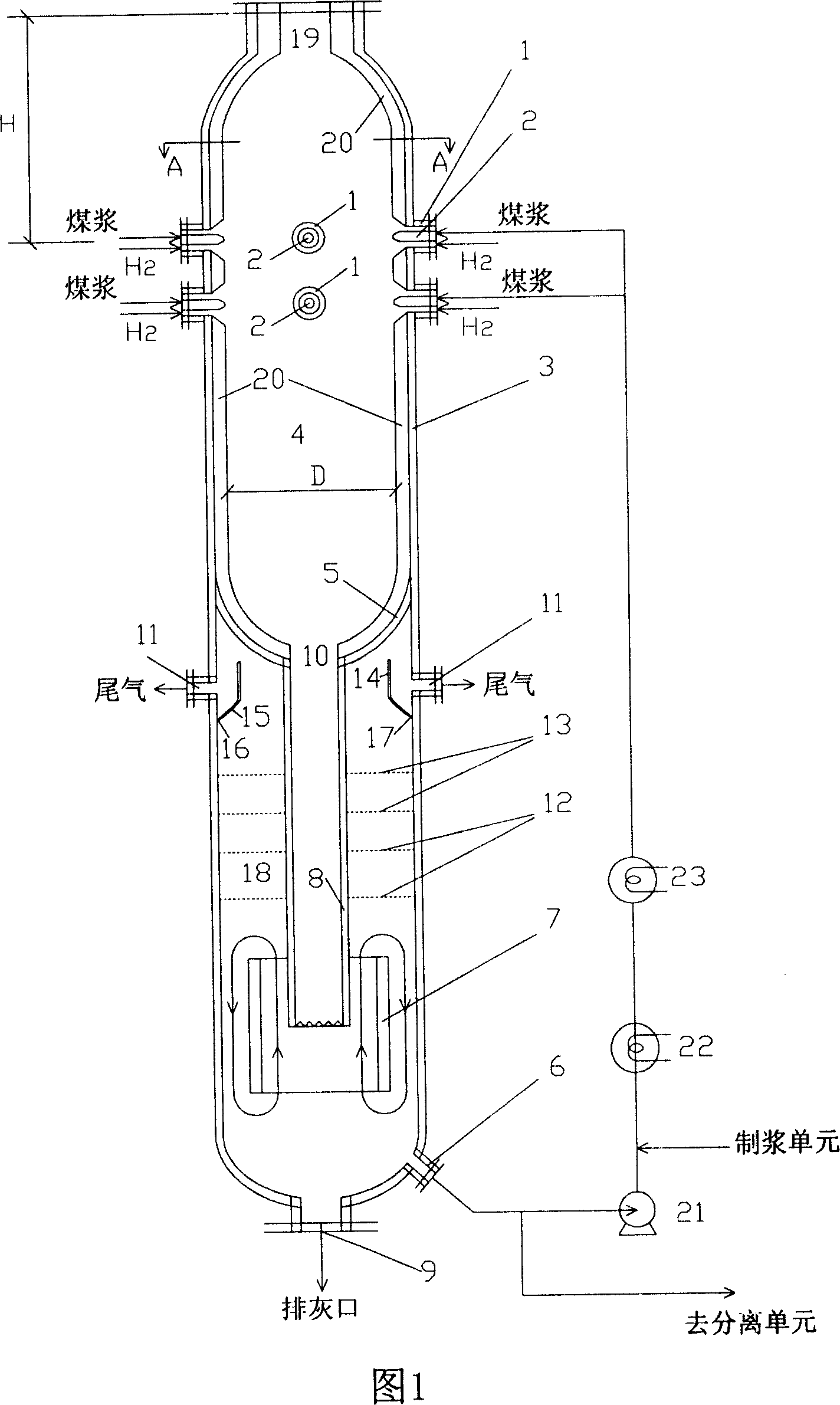

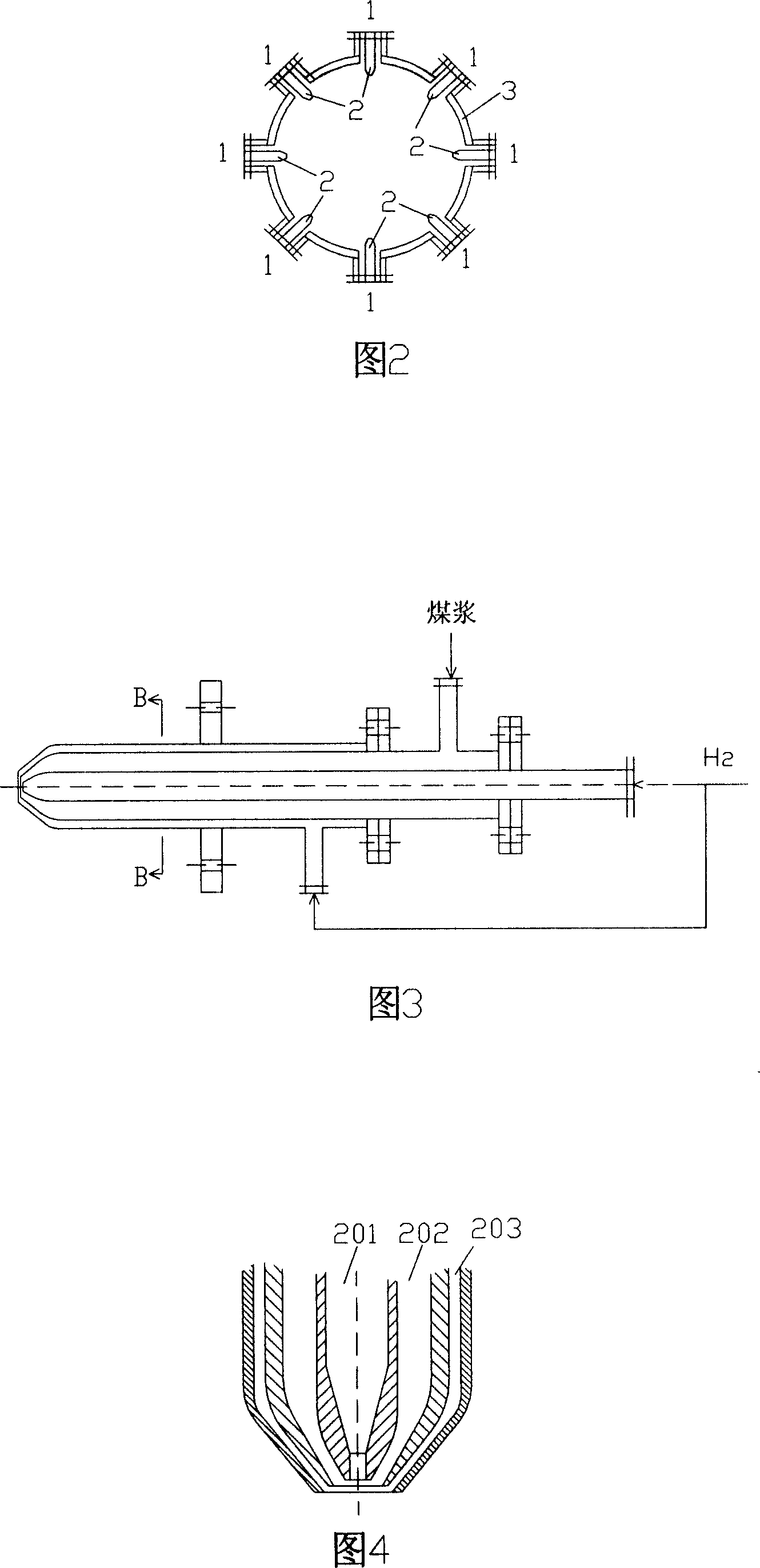

Coal hydrogenation reaction device and its industrial application

InactiveCN1935943AFlexible and convenient operation controlAchieve atomizationLiquid hydrocarbon mixture productionChemical/physical/physico-chemical nozzle-type rreactorsHydrogenation reactionRefractory

The invention discloses coal hydrogenation reacting device and its industry application. The reacting device includes air flow bed, bubbling bed, coal slurry circulating pump, and heat exchanger. The air flow bed and bubbling bed are set in the shell body of the same cylindrical form internal lining refractory materials. And the former is at the above. The latter is at the under. The device and method can be used in direct liquefaction with 5 million ton oil product per year, 40 thousand ton coal processing quantity per day, increase H2 transmission rate to prevent coal slurry precipitation, has convenient operation control, realize slurry pulverization and the mixture of the fog drop and H2 by nozzle itself crossing jet and the impacting flow formed by the opposed nozzle.

Owner:EAST CHINA UNIV OF SCI & TECH

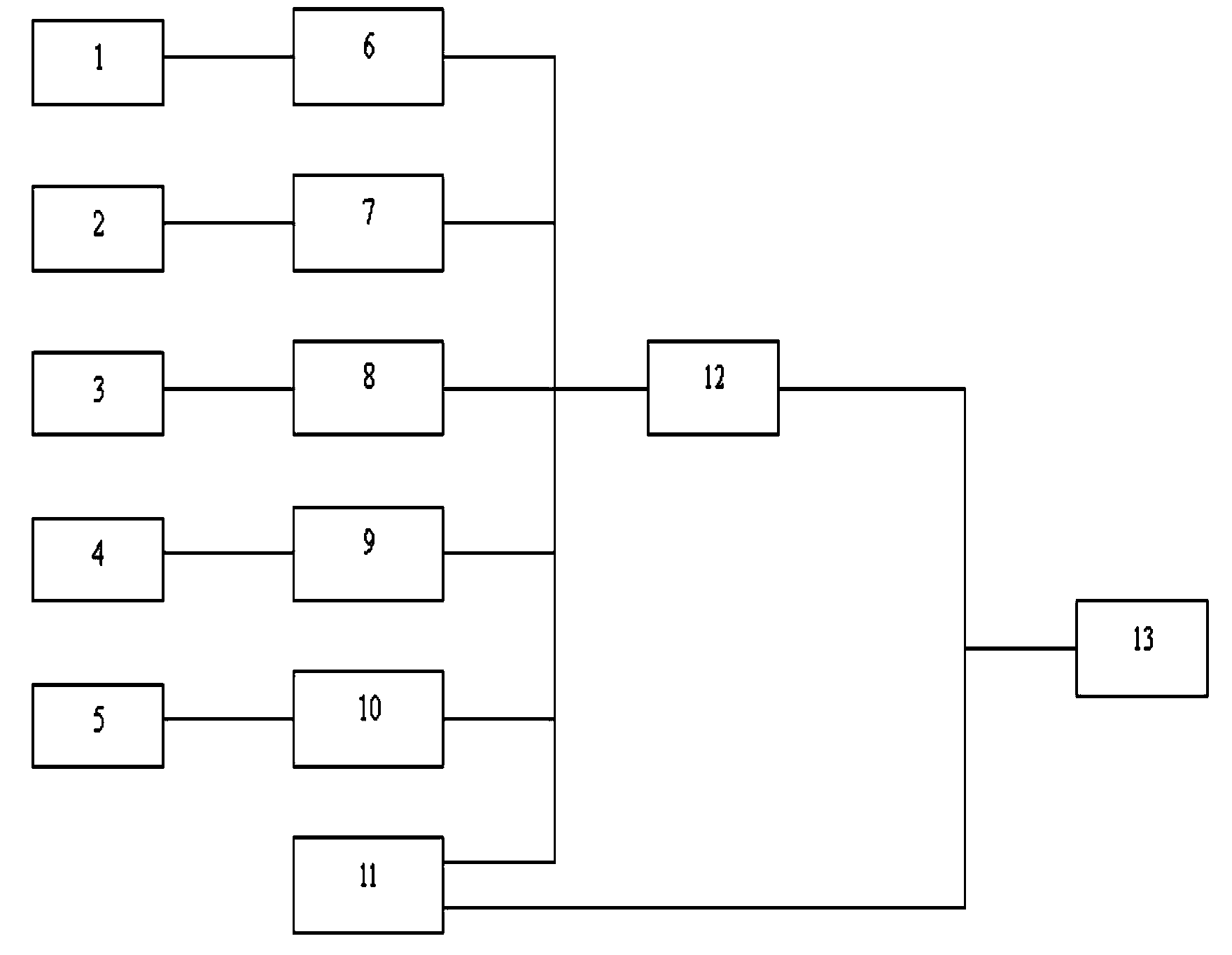

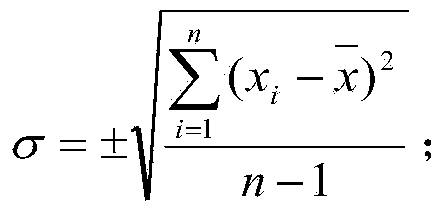

Monitoring system for ash fouling in power station boiler air preheater and working method of system

The invention discloses a monitoring system for ash fouling in a power station boiler air preheater and a working method of the system. The system comprises an as-fired coal processing unit, an ash processing unit, a flue gas processing unit, a static-pressure processing unit, a smoke temperature processing unit, a pressure-drop calculating unit and an ash fouling evaluating unit; each processing unit comprises a sampling module and an analysis module; and each sampling module acquires corresponding information and transmits to the corresponding analysis module, and the corresponding analysis module performs data analysis and transmits the result to a pressure-drop calculating module, the pressure-drop calculating module calculates out an air-preheater flue gas side pressure drop value subjected to correction on the deviation of the flue gas flow and the smoke temperature from the design value and transmits to a ash fouling evaluating module, and the ash fouling evaluating module determines the ash clogging degree of the air preheater according to the flue gas side pressure calculation value and the design value. The system and the method realize real-time monitoring on ash fouling of the air preheater, and because the smoke side pressure drop value of the air preheater is subjected to correction on deviation of the flue gas flow and the smoke temperature from the design value, the accuracy for ash fouling evaluation is guaranteed.

Owner:STATE GRID CORP OF CHINA +1

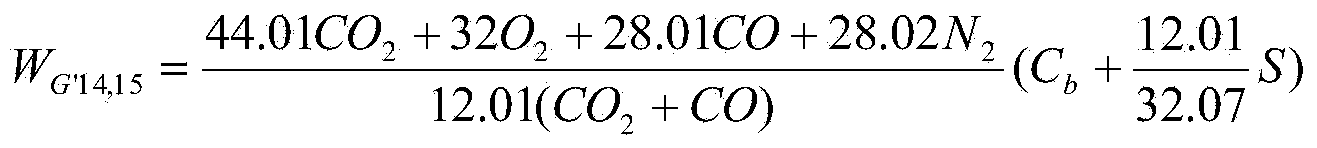

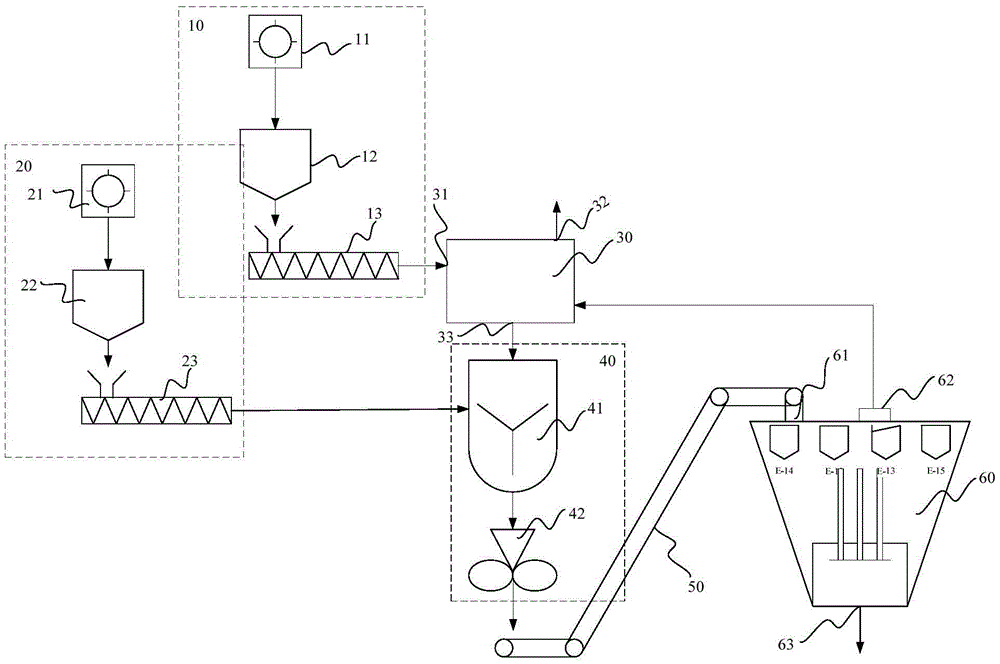

System and method for production of calcium carbide

ActiveCN105668568AReduce energy consumptionChemical industryCalcium carbideElectric arc furnaceMaterials science

The invention provides a system and method for production of calcium carbide, wherein the system for production of calcium carbide includes a low-rank coal processing unit, a quick lime processing unit, a pyrolysis device, a hot press molding unit, a high temperature conveying device and an electric arc furnace; the pyrolysis device is provided with a raw material inlet, an oil gas outlet and a solid product outlet, and the raw material inlet is connected with the low-rank coal processing unit; the hot pressing molding unit is connected with the pyrolysis device and the quick lime processing unit; the high temperature conveying device is connected with the hot press molding unit; the electric arc furnace is provided with a molded material inlet, a furnace gas outlet and a calcium carbide outlet, and the molded material inlet is connected with the high temperature conveying device. Therefore, pyrolysis sensible heat can be fully utilized, the power consumption of the electric arc furnace is reduced, the energy consumption is reduced, and the energy utilization rate is increased.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

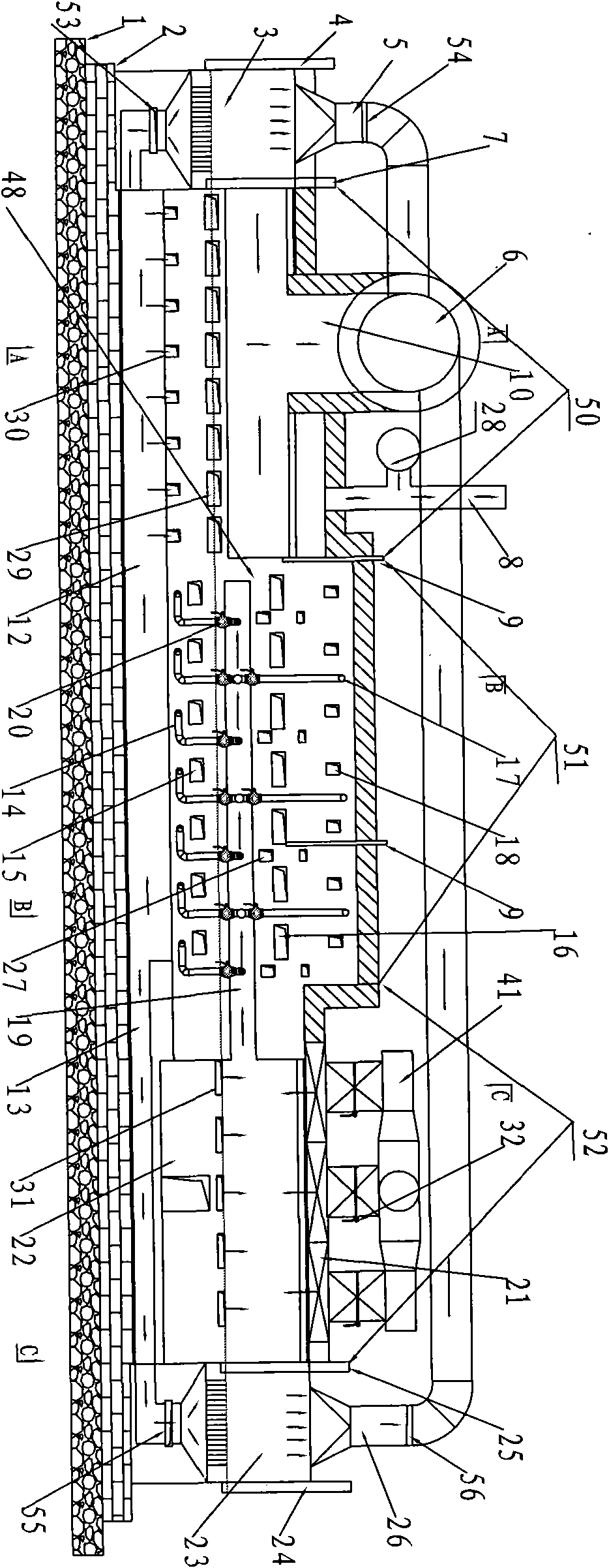

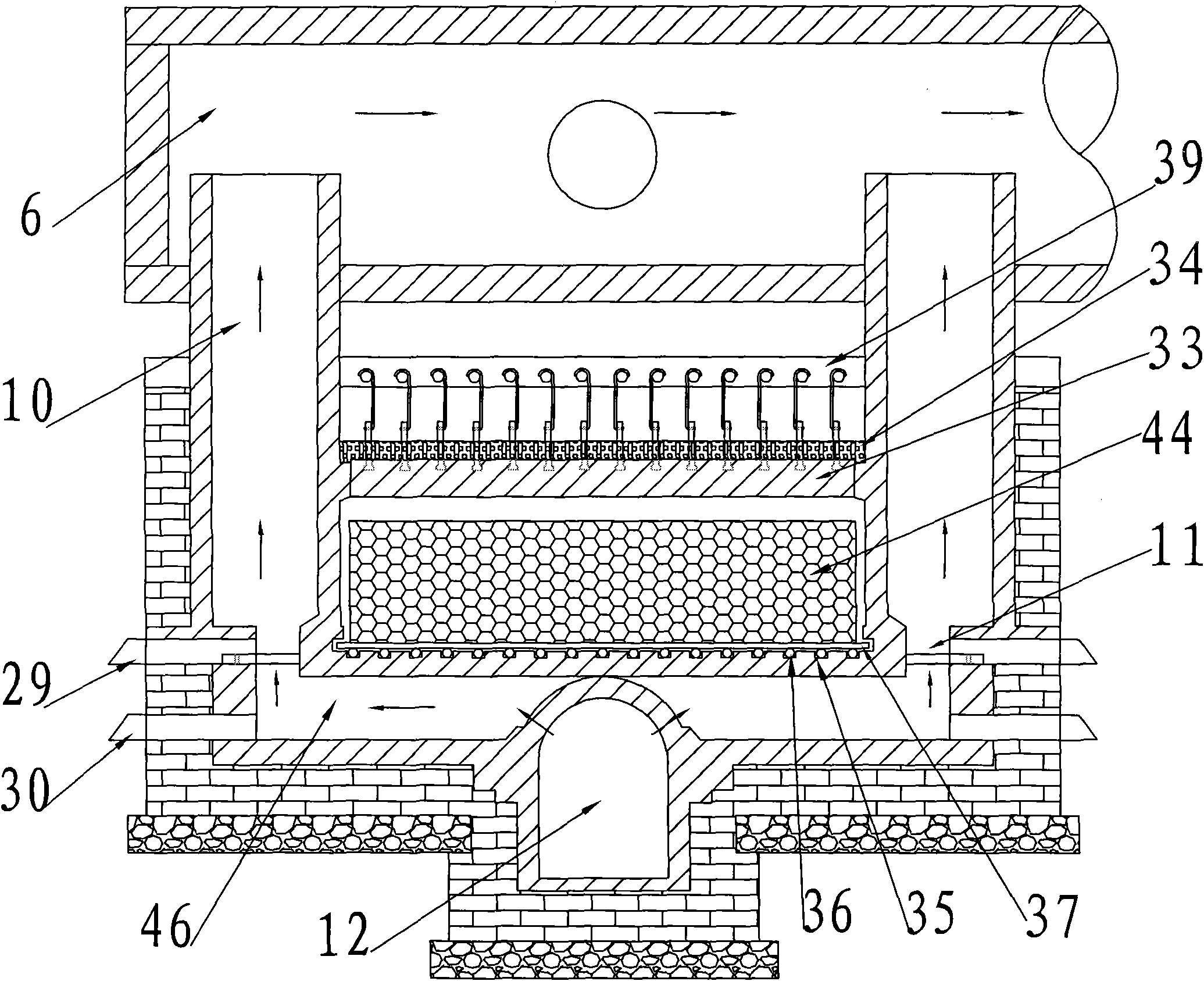

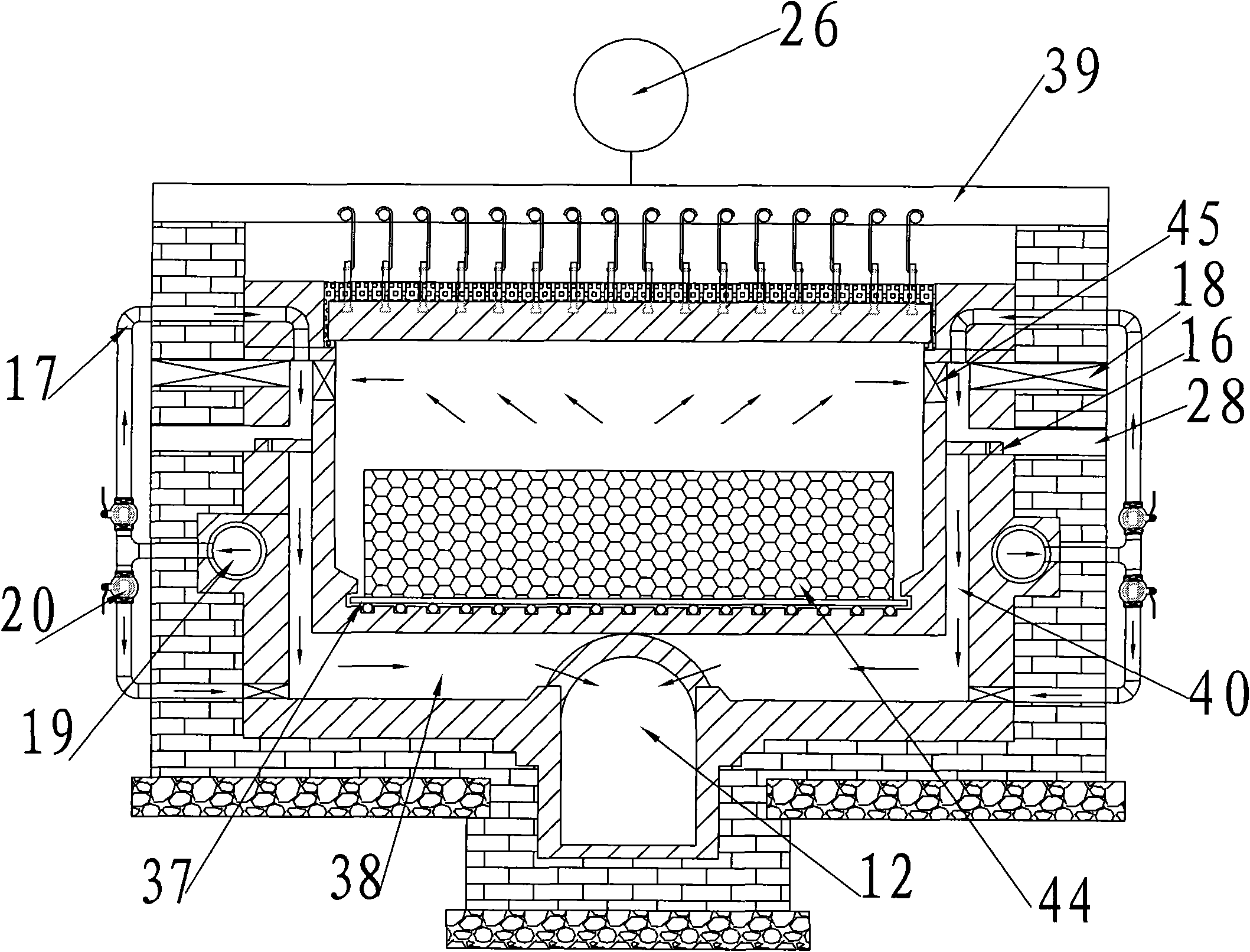

Movable slide bed tunnel type coke oven and use method thereof

InactiveCN101792676AReduce the amount of gasLow energy consumption for cokingMechanical conveying coke ovensHorizontal chamber coke ovensWater sourceFlue gas

The invention relates to a movable slide bed tunnel type coke oven and a use method thereof, and belongs to the field of coal processing and conversion and coking equipment. The coke oven comprises an oven body (48), a front sealing door (7) of the coke oven body, a back sealing door (25) of the coke oven body, a sub-flue (10), a bottom flue (12) and a main flue (6), and is characterized by comprising a coaling preparation chamber (3), a preheating section (50), a carbonization section (51), coke dry quenching section (52) and a coke outlet preparation chamber (23), each part has different structures, and the five parts are connected in series and communicated with each other; and a movable slide bed (37) of loading briquettes or tamping coal materials (44) sequentially pass through the five parts of the coke oven by intermittently moving on a slideway (35) of the slide bed, so that the coal materials are carbonized into coke. The produced coke has uniform specification, large lumpiness, good strength, high heat energy utilization rate, high degree of mechanization, and clean emission of flue gas, and the invention effectively protects atmosphere and water sources and realizes clean production.

Owner:GUIZHOU SUNNY CLEAN ENERGY TECH DEV

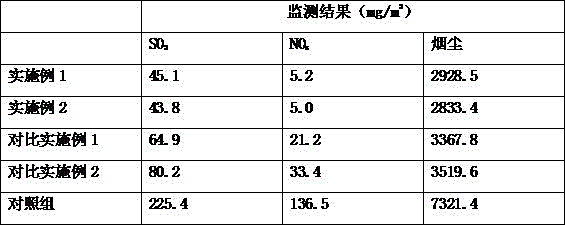

Coal denitration agent

InactiveCN106345269AStable and strong adsorptionImprove denitrification effectGas treatmentDispersed particle separationZinc Acetate DihydratePollution

The invention discloses a coal denitration agent, which belongs to the technical field of coal processing and is specifically made of the following materials: activated carbon, graphene, urea, slaked lime, barium succinate, zinc palmitate soap, alginate, methyl cellulose, Modified attapulgite, calcium carbonate, titanium dioxide, calcium stearate, magnesium acetate, zinc acetate. The denitrification agent prepared by the invention has a denitrification removal rate as high as 95%, has obvious effects, does not produce secondary pollution, has a long effective use time, and has good popularization value.

Owner:马鞍山科宇环保设备股份有限公司

Deep oxidation desulfurization catalyst

InactiveCN1724614AAchieve productionReduce sulfur contentHydrocarbon oils refiningOil processingKerosene

The invention belongs to coal processing, petroleum processing, and petroleum chemistry technology field. It adopts load type catalyst that is made up from multi-hole bearer to carry Mo-P oxide, which has great activity to the oxidization of sulfur compound. In the fixed bed reactor and the temperature between 40-90 degree centigrade, and using organic peroxide as oxidizing substance, the sulfur compound in distillated oil would be oxidized into sulfoxide or sulphone, which could be extracted by solution or adsorbed by solid adsorbent to realize deep de-sulfurization. The invention has broad application prospect.

Owner:DALIAN UNIV OF TECH

Preparation method for supported Mo-based oxidation and desulfurization catalyst

InactiveCN102294236AHigh activityRealize deep desulfurizationMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsOrganic acidPetrochemical

Owner:DALIAN UNIV OF TECH

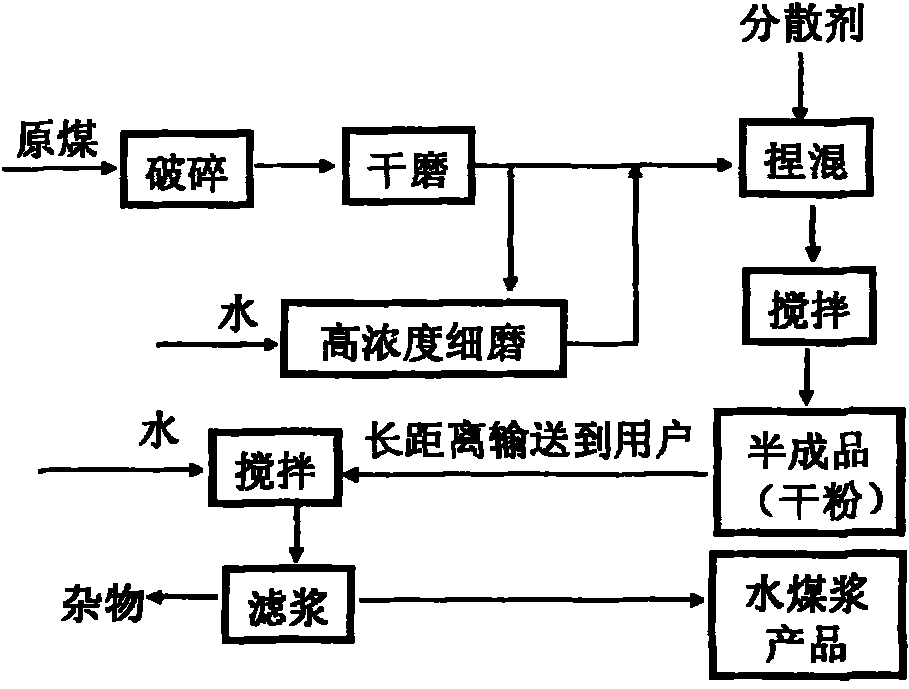

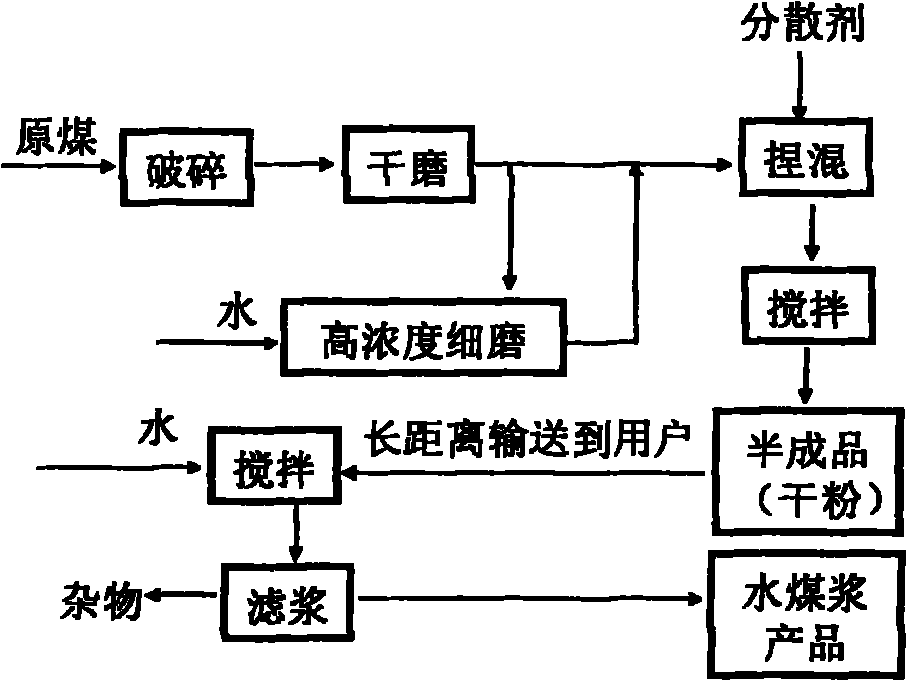

Process for preparing coal water slurry from coal dust

InactiveCN101995029AReduce shipping costsReasonable particle size distributionLump/pulverulent fuel preparationCoal waterHigh concentration

The invention relates to a process for preparing coal water slurry from coal dust, and belongs to the technical field of coal processing. The invention provides a process for preparing the coal water slurry from the coal dust for solving the problems. By the process, the conveying cost of the coal water slurry is reduced substantially, and size distribution is more reasonable simultaneously through the grading of wet-dry particles so as to achieve the accumulation efficiency as high as possible. The process of the invention comprises the following steps of: firstly, crushing raw coal and then performing dry grinding, adding water into residual coal granules subjected to dry grinding and fine screening to perform high-concentration fine grinding, and mixing with coal dust obtained by the dry grinding and the fine screening; secondly, adding a dispersing agent, kneading, mixing and stirring to prepare a dry powdery semifinished product, and after conveying to users for long distance, adding water and stirring; and finally, filtering the slurry and removing impurities to prepare a product of the coal water slurry.

Owner:陈驰

Coal deep processing method and coal processing method

ActiveCN108296009AIncrease varietyConducive to screeningWet separationEconomic benefitsProcess engineering

The invention relates to the field of coal processing technology and provides a coal deep processing method and a coal processing method. The coal deep processing method includes the steps that raw coal is screened and graded through a screen net, and crude oversize products and crude screen underflow are obtained; the crude oversize products are separated through a jigging machine, first clean coal, first middle coal and first gangue are obtained, the first clean coal is divided into block clean coal and powder clean coal, and the block clean coal, the powder clean coal, the first middle coaland the first gangue enter a block clean coal bin, a powder clean coal bin, a middle coal bin and a gangue bin correspondingly to be warehoused; the crude screen underflow is subjected to dressing bywashing through three product hydrocyclones so that second clean coal, second middle coal and second gangue can be obtained; the second clean coal is combined into the powder clean coal bin to be warehoused; the second middle coal is combined into the middle coal bin to be warehoused; and the second gangue is combined into the gangue bin to be warehoused. By means of the coal deep processing method and the coal processing method, the variety of commercial coal is greatly increased, the product stability is high, and economic benefits of enterprises can be increased easily. Besides, the coal processing method can be used for performing deep processing on the raw coal so that the variety of the commercial coal can be improved.

Owner:INNER MONGOLIA YITAI COAL

Coking additive agent and use thereof

The invention relates to a coking additive and the application thereof, belonging to the coal processing field. The technical problem to be solved is to improve the coke quality and in particular to lower the thermal reaction of the coke. The coking additive is SiO2 powder which can pass through a sieve 100. The best purity of the additive is larger than 99 percent. SiO2 is creatively applied to the improvement of the performance of the coke by the invention. The reaction of the obtain coke can be lowered by 2-6 percent points. At the same time, with low cost, the coke additive of the invention brings no secondary pollutions. Residuals in the coke bring no negative effects on the blast furnace smelting. And the coking additive is especially applied to the industrialized production.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

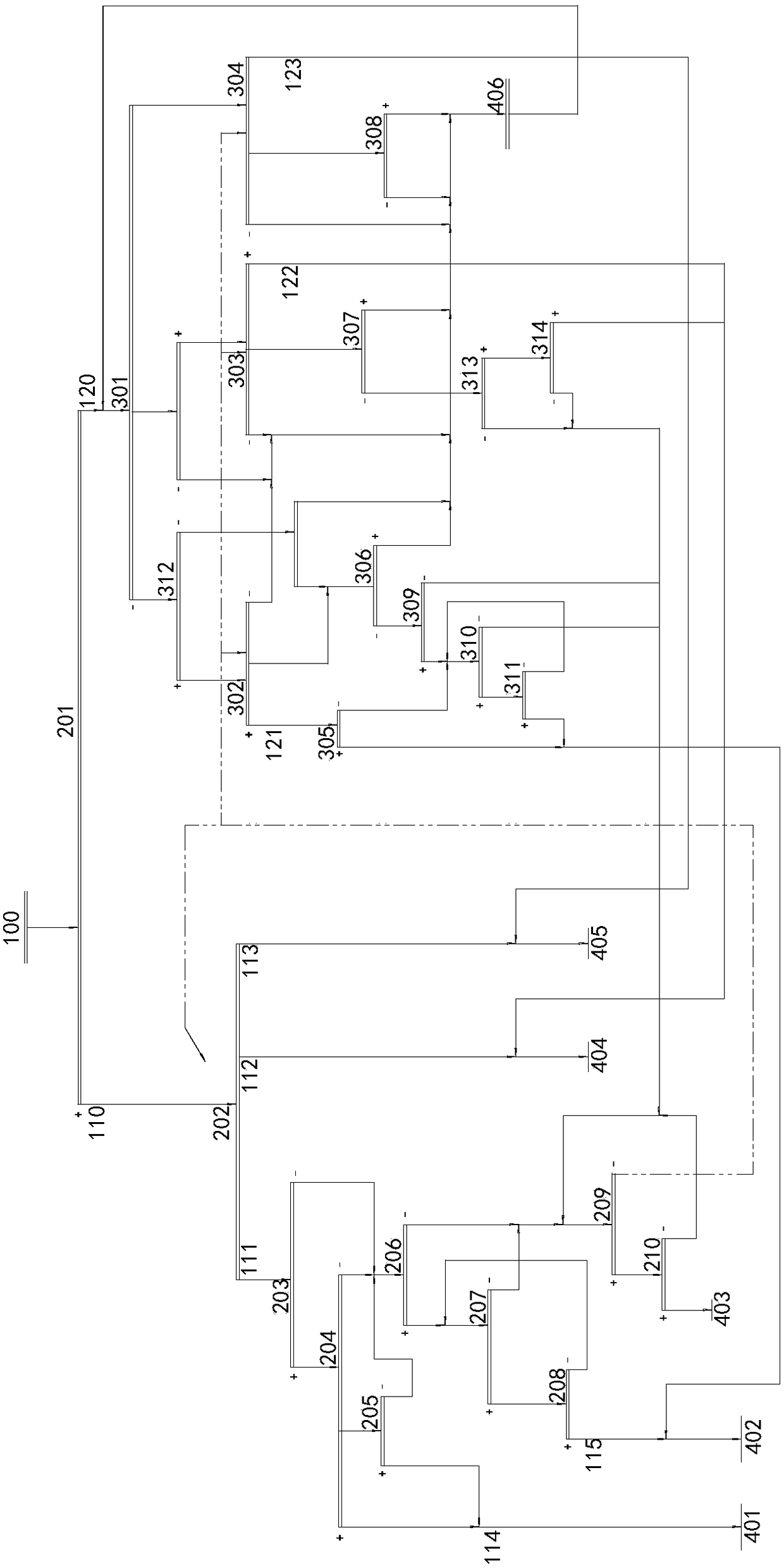

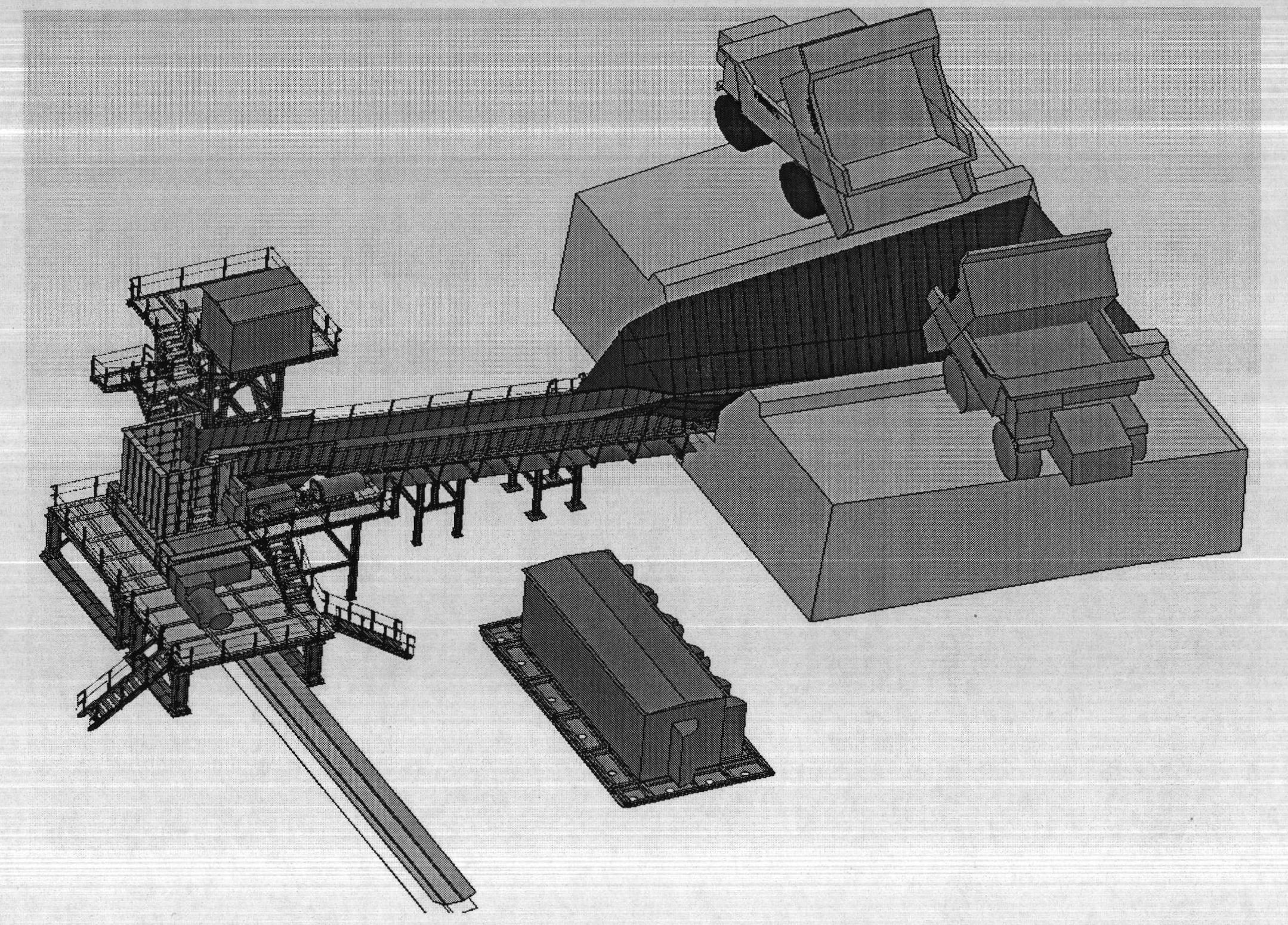

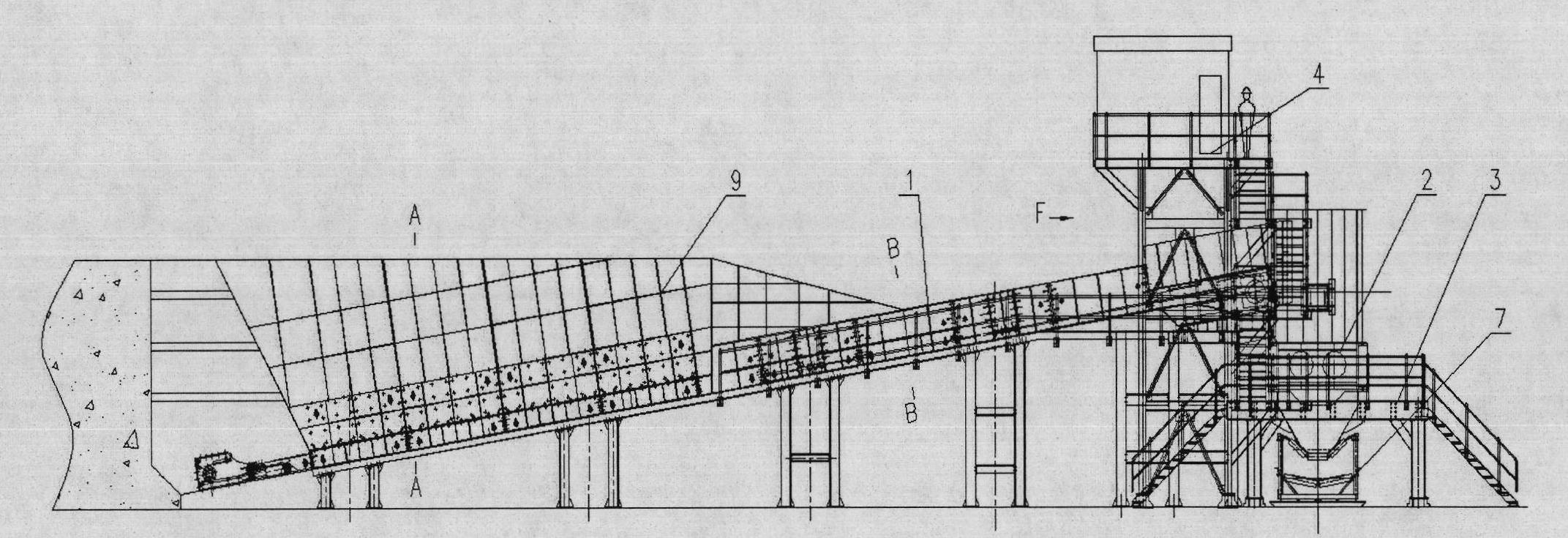

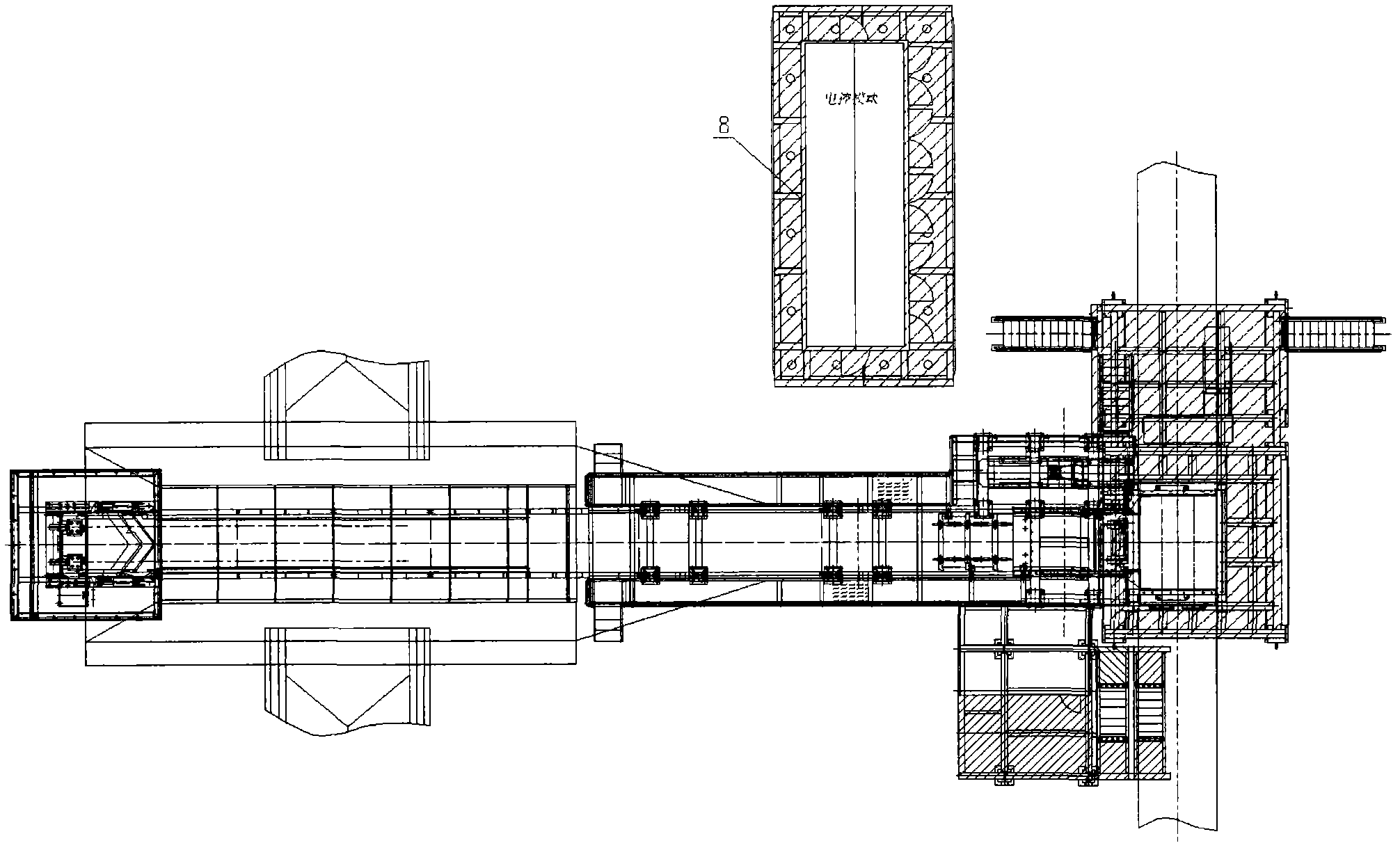

Semi-fixed crushing station

The invention relates to a novel semi-fixed crushing station for raw coal processing in an open pit coal mine, wherein the crushing station mainly consists of a scraper machine, a scraper machine material receiving section coal flow height limiter, a double-tooth-roller crushing machine, a crushing machine support platform, an operation room, a phase change distribution chamber and the like, wherein the scraper machine is in inclined arrangement, the inclined angle is 5 degrees to 11 degrees, the height of a machine head of the scraper machine can be regulated through regulating the length of a hoisting conveying section tank body of the scraper machine or through regulating the inclined angle of the scraper machine, scraper machine material receiving section is provided with a coal flow height limiter, the requirement that the height of the coal layer in the scraper machine is 400 to 700mm is met, the scraper machine adopts the variable-frequency driving, the speed of the scraper machine is regulated according to the height of the coal layer of the scraper machine, all modules are mutually independent, the moving and the installation are convenient, an operation room adopts an independent basis, and the influence on the body and mental health of operators as well as electric control equipment, which is caused by vibration, is reduced. The novel semi-fixed crushing station has the advantages that the starting of the scraper machine is stable, the operation is reliable, the instantaneous overload of the system can be effectively prevented, and the popularization and application values are realized.

Owner:WUHAN DESIGN & RES INST OF CHINA COALTECH & ENG GROUP

Method for separating and detecting complicated mixed state arsenic in coal

InactiveCN103335991AOptimizing the arsenic removal and fixation processShort detection timeFluorescence/phosphorescenceSteelmakingArsenic pollution

The invention relates to detection of arsenic contents in raw coal used in such municipal administration and industries as a thermal power plant, a thermomax company, a coking plant, steelmaking, coal industry and the like. The invention provides an effective method for separating and detecting complicated mixed state arsenic in coal, and the method can be realized by common reagents and conventional instruments, thereby being convenient, quick and low in cost. The method is used for separating and measuring mixed inorganic and organic arsenic in different macroscopic coal ingredients in the coal by cooperatively utilizing density fractionation, sequential extraction and column chromatography. According to the method, the defects that the content of the arsenic element in the coal is low and the arsenic element belongs to a plurality of kinds of complicated mixed states to be difficultly separated and detected are overcome, such information of the arsenic element in the coal as enrichment characteristic, main speciation distribution and micro chemical structure can be obtained so as to judge the category and transportation law of arsenic-containing pollutants in residues, wastewater and waste gases generated in such coal processing and utilization procedures as coal washing and coal combustion, and therefore efficient arsenic removing and arsenic fixing processes can be typically developed and optimized.

Owner:XINJIANG NORMAL UNIVERSITY

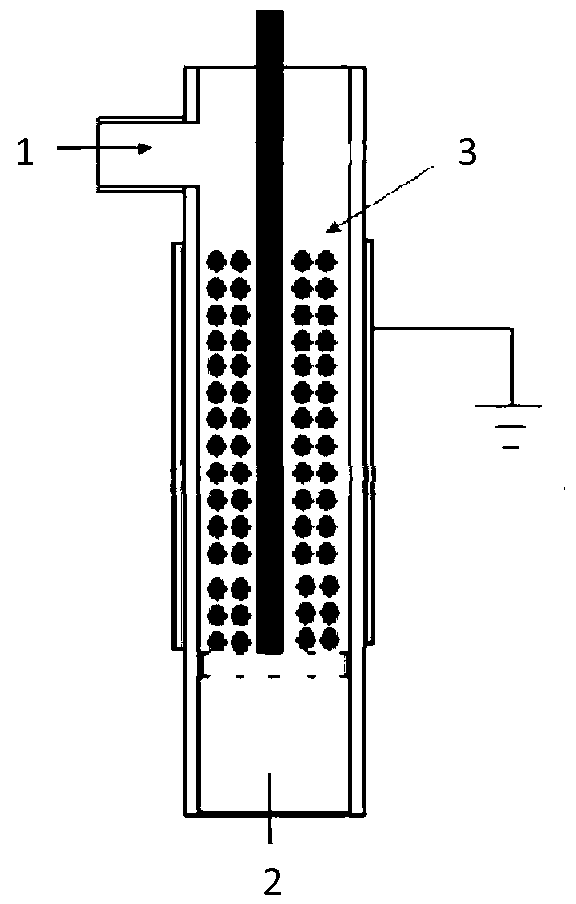

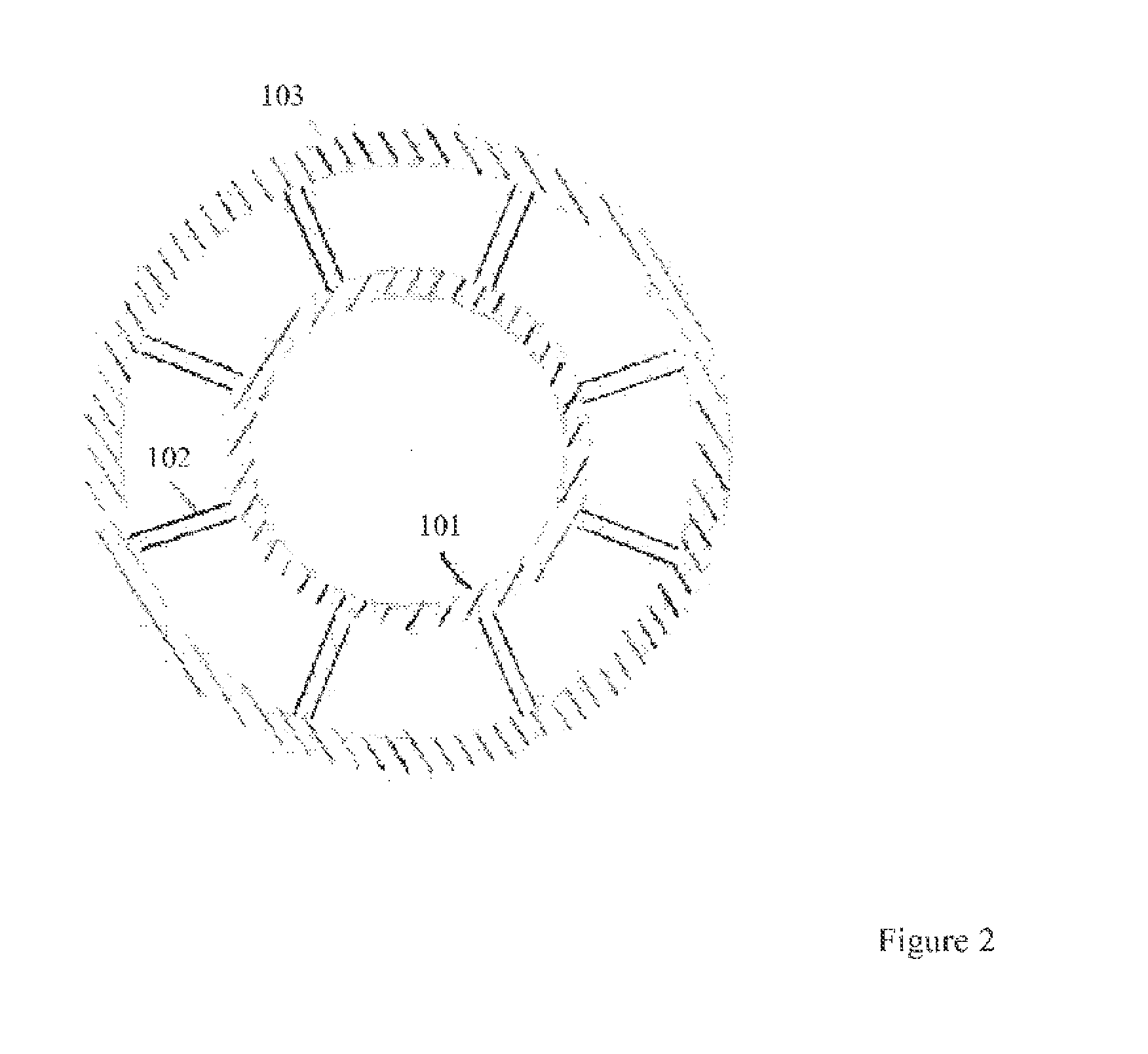

Dry production method of low-dust low-sulfur coal powder

The invention relates to a production method of low-dust low-sulfur coal powder, in particular to a dry production method of low-dust low-sulfur coal powder, which belongs to the technical field of coal processing and comprises the following steps: pulverizing raw material coal (raw coal or washed coal) to the granularity range of 0-200 micrometers by a coal pulverizer and synchronously drying thecoal in the process of fine pulverization; feeding the pulverized and dried coal powder into a frictional electrical separator by an air flow conveyor or feeder; separating the coal powder by the frictional electrical separator to remove dust minerals and inorganic sulfur; and collecting the materials separated by the frictional electrical separator through a dust remover so as to obtain the low-dust low-sulfur coal powder with high heating value. The dry production method has the advantages of simple technique and low cost. The product does not need to be dehydrated or dried, or need coal-slurry water treatment system with high investment and cost. The low-dust low-sulfur coal powder can be used for preparing high-grade active carbon and other carbon materials, can be combusted in glassand ceramic furnaces and various coal powder boilers, and can be used for preparing high-quality fine coal water slurry. The dry production method has the advantages of high heat productivity, low pollution and convenient transportation.

Owner:章新喜 +2

Coked coal powder forming adhesive and its production process

InactiveCN1789392ANo pollution in the processImprove thermal stabilitySolid fuelsAdjuvantSodium Bentonite

The invention, belonging to coal processing technology field, relates to coke powder figuration adhesive, comprising the following steps: adding the water, sodium humate, cationic starch, bentonite, sodium silicate, ZCM-1 water-soluble flocculating agent, carbonic oxide combustion adjuvant into autoclave, stirring, heating, cooling and getting the product. Using the said product, the coke powder can be processed to formed coke. The formed coke possesses the advantages of high fixed carbon, high strength, fire resistant, no explosion, no looseness and no cicatrisation.

Owner:程绍水

Low-rank coal processing apparatus and method

InactiveUS20130305972A1Improve efficiencyImprove cost effectivenessDrying solid materials with heatFuel feeding arrangementsCombustionProcess engineering

An apparatus for the simultaneous drying and transport of low-rank coal is described. The apparatus has a first pipe having an inner wall surface surroundingly defining a first flow channel and an outer wall surface; a low-rank coal supply system to supply particulate low-rank coal to an inlet of the first flow channel; a transport gas supply to supply transport gas to an inlet of the first flow channel; a heating apparatus to apply heat to an outer wall surface of the first pipe along at least part of the length thereof for example in the form of a drying fluid supply to supply a drying fluid, configured such that a drying fluid is brought into contact with the outer wall surface of the first pipe along at least part of the length thereof. A system of design of thermal power plant incorporating such an apparatus is also described. A method for the simultaneous drying and transport of low-rank coal is also described. A system and method for supplying dried low-rank coal for combustion are also described.

Owner:DOOSAN BABCOCK

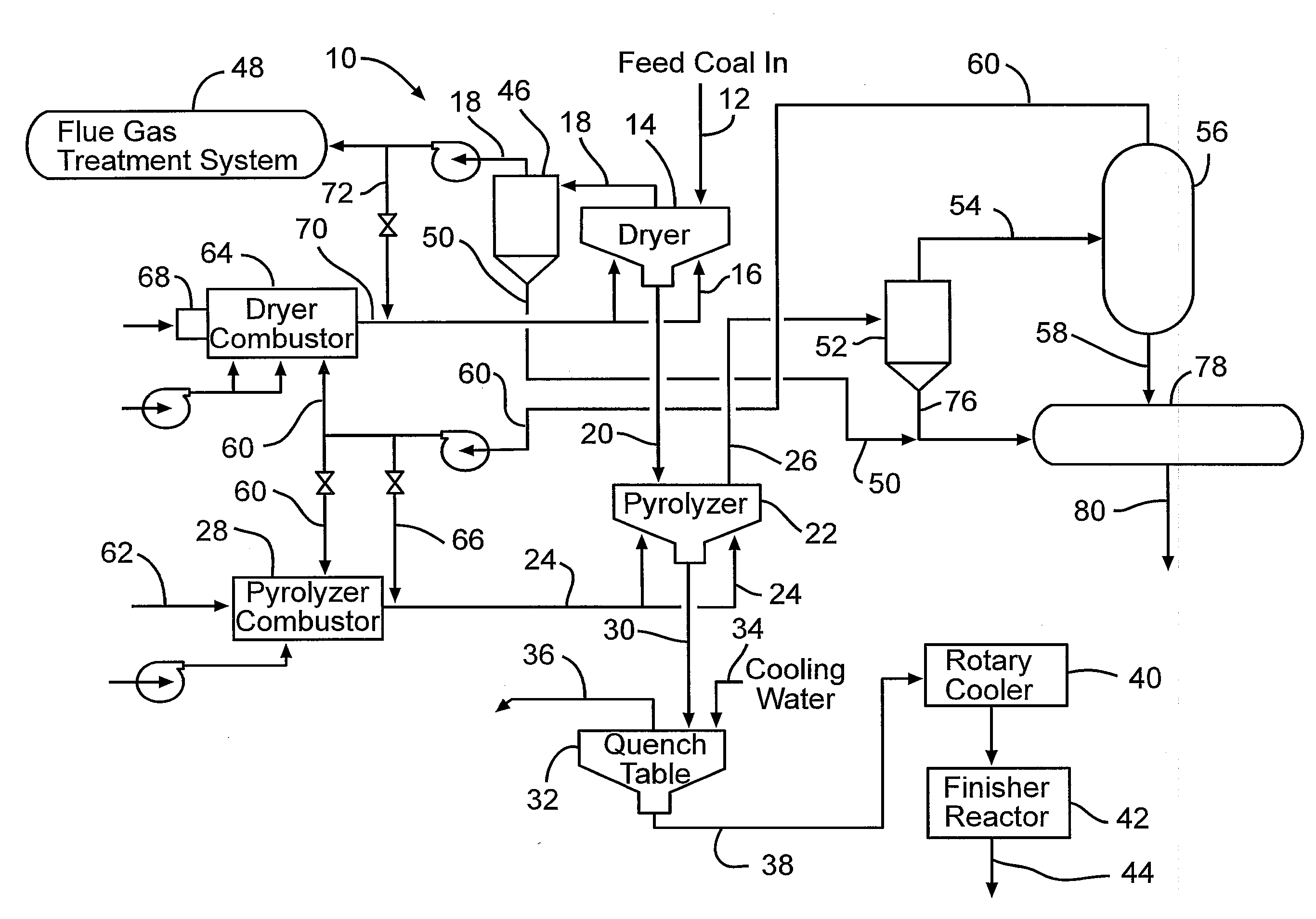

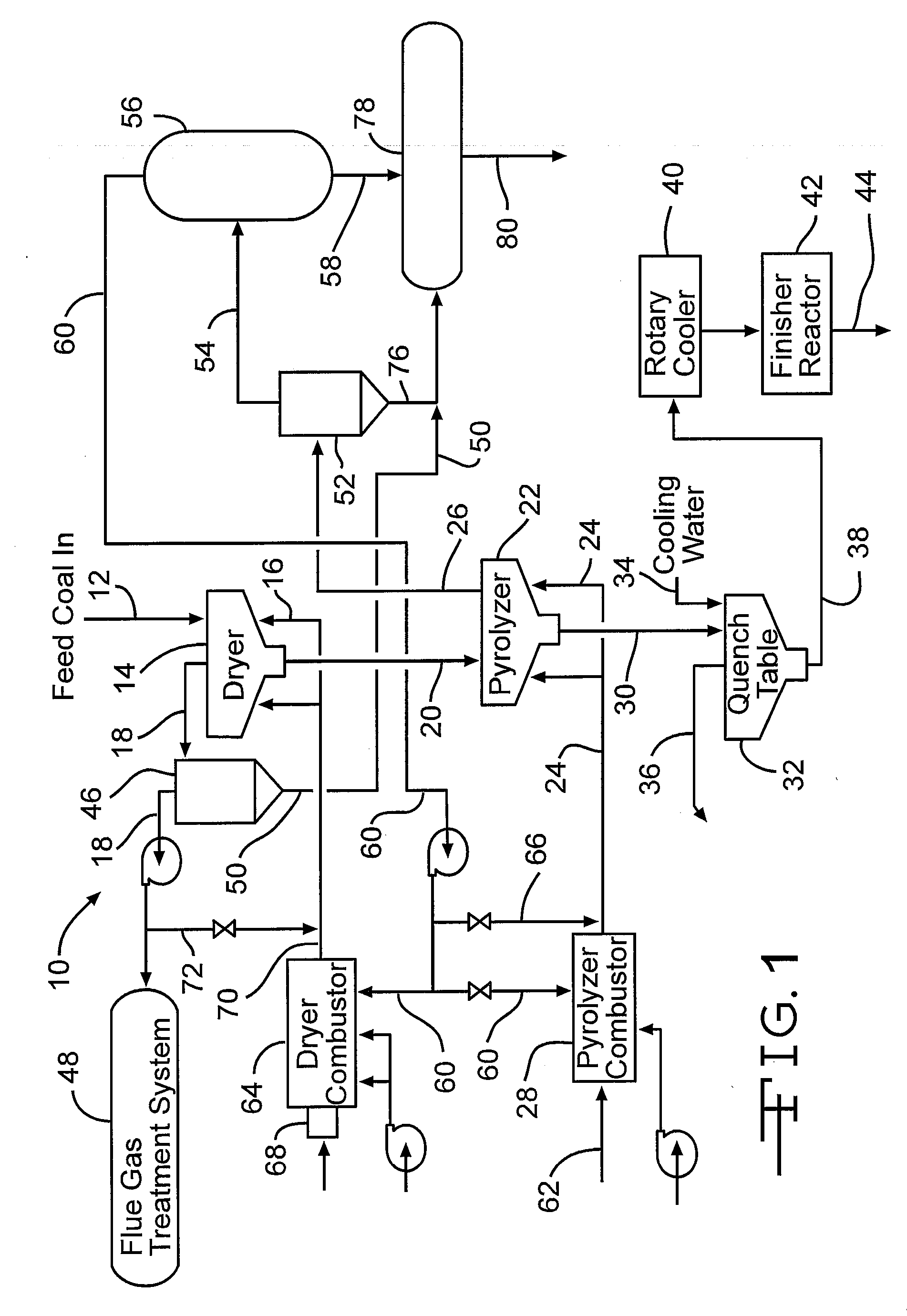

Coal processing to upgrade low rank coal having low oil content

ActiveUS20120305379A1Low volatile contentCoke quenchingDirect heating destructive distillationCombustorTar

A method of treating untreated low calorific coal containing moisture and organic volatiles includes feeding untreated coal to a dryer, and drying the coal. The dried coal is subjected to a pyrolyzing step where oxygen-deficient gases are brought into contact with the coal, thereby lowering the volatile content of the coal and producing a stream of pyrolysis effluent gases. The pyrolysis effluent gases are subjected to a separation process to separate lean fuel gases from liquids and tars, wherein the separation process removes less than about 20 percent of the pyrolysis effluent gases as the liquids and tars, with the remainder being the lean fuel gases. The lean fuel gases are returned to the dryer combustor, the pyrolyzer combustor, or the pyrolyzer.

Owner:NAT INST OF CLEAN AND LOW CARBON ENERGY +1

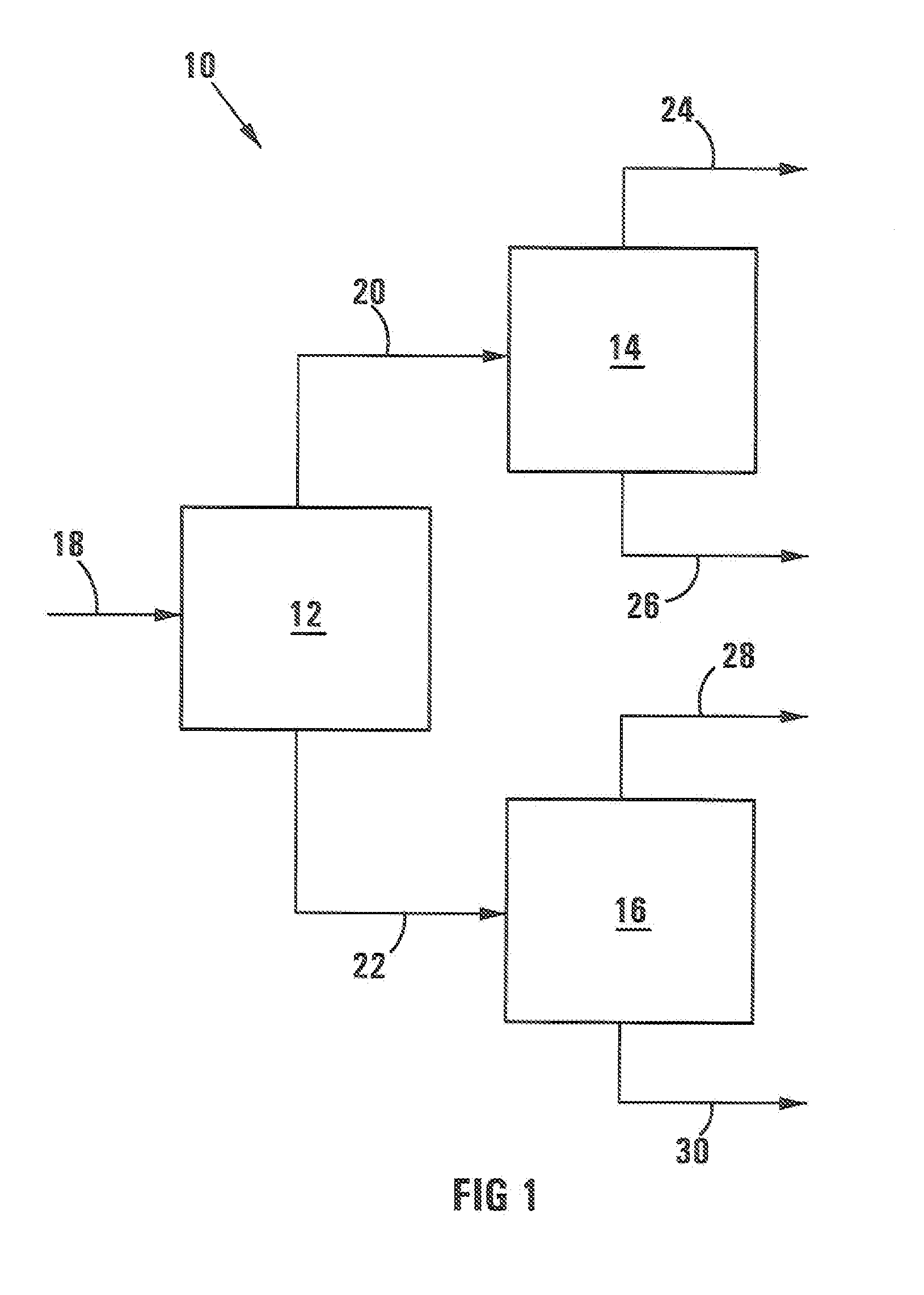

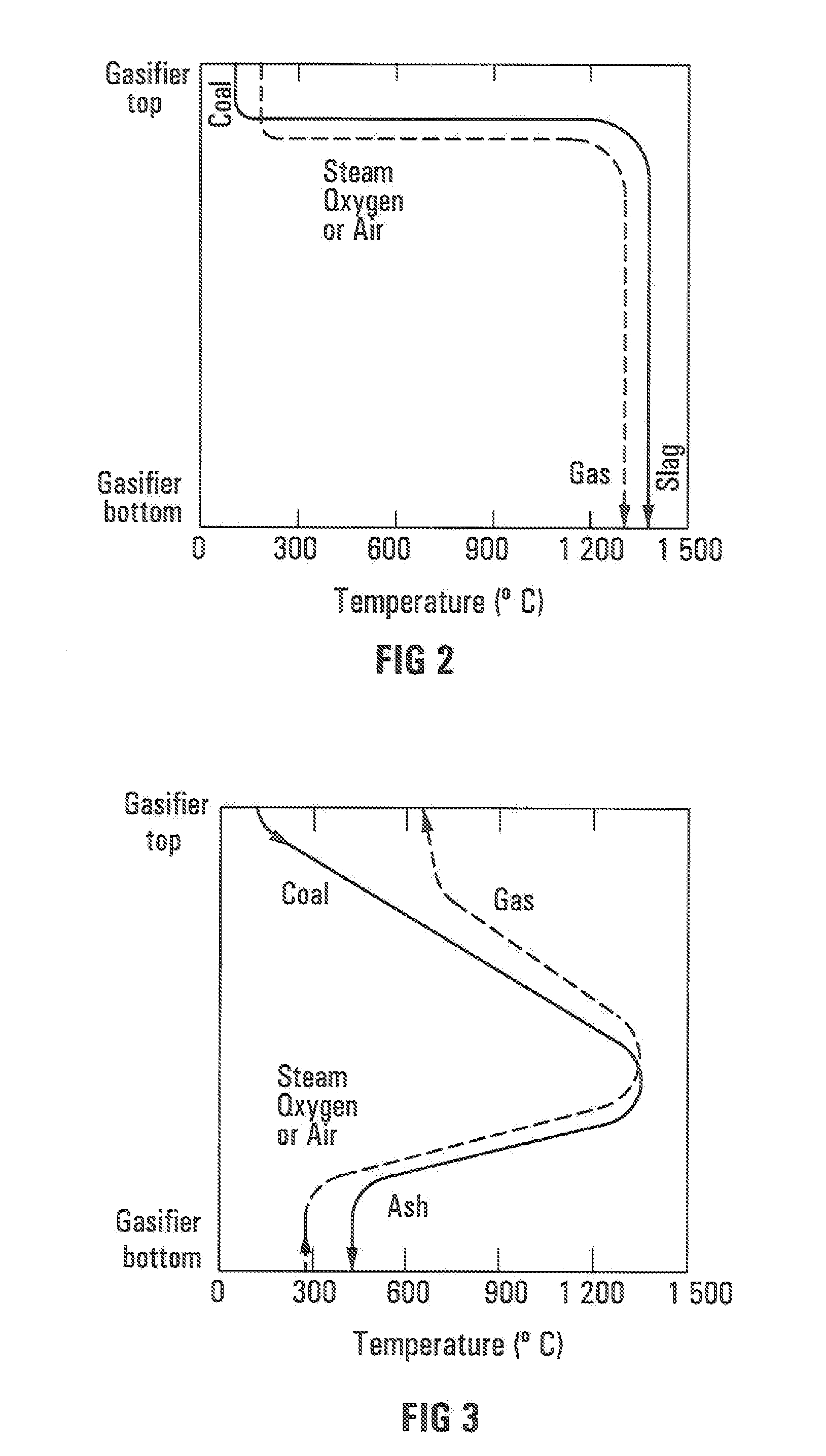

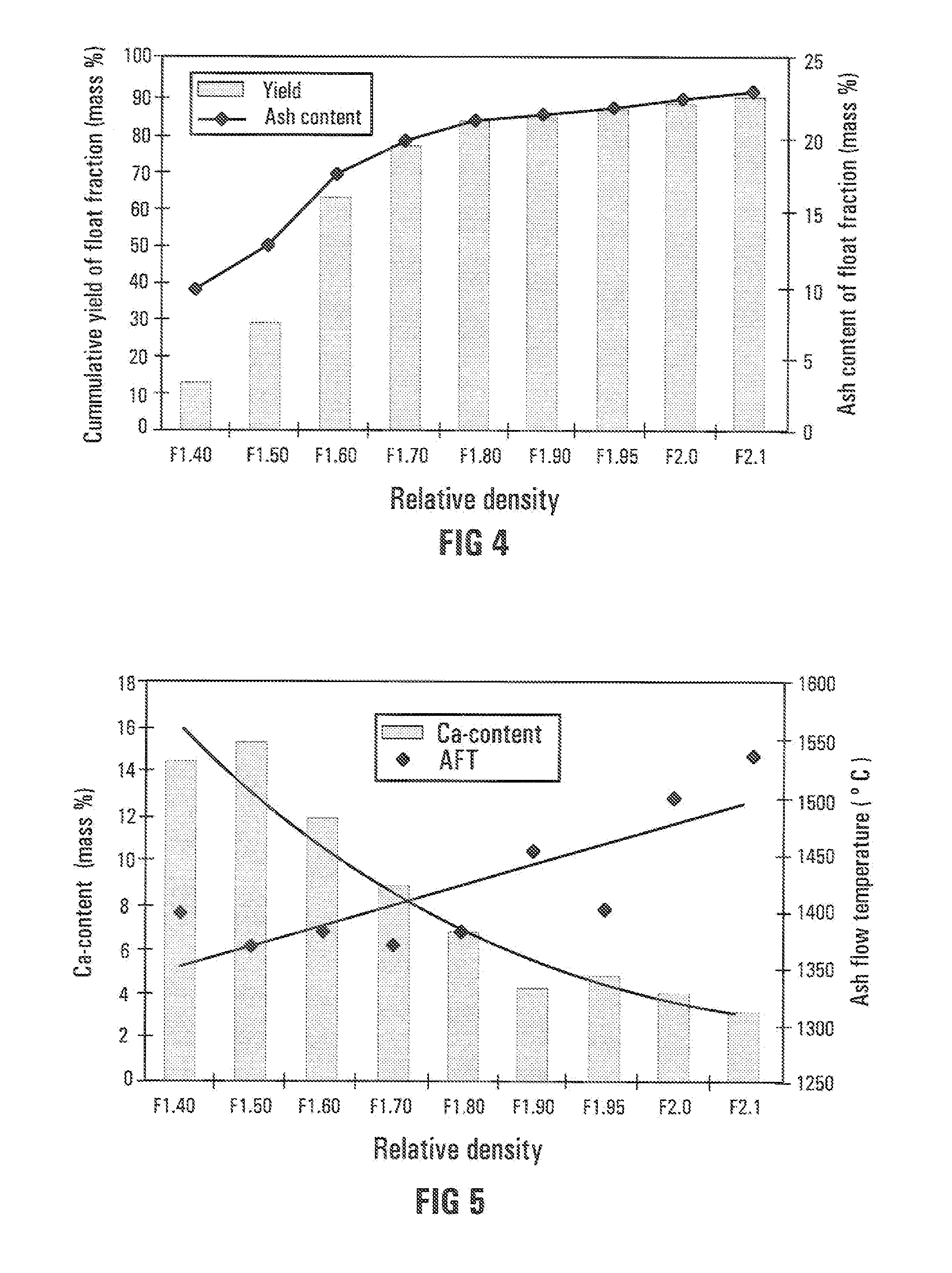

Gasification of coal

InactiveUS20110120013A1Low viscosityAvoid excessive additionSolid fuelsGasification processes detailsProcess engineeringMaceral

A coal processing operation (10) includes in a dense media separation stage (12), subjecting a coal feedstock (18) which includes minerals to dense media separation producing a first coal stream (20) and a second coal stream (22). Coal in the first coal stream (20) is lower in ash and has a lower ash fusion temperature than coal in the second coal stream (22). Coal from the first coal stream (20) is processed in a high temperature coal processing operation (44), and coal from the second coal stream (22) is processed in a medium temperature coal processing operation (16).

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Method for preparing filtering absorbing material used for water treatment

InactiveCN101125292ARaw materials are cheap and easy to getEasy to prepareOther chemical processesWater/sewage treatmentWater vaporMetallurgy

The invention relates to a preparing method for a filtering and absorbing material to process the water. The method is to place the raw material with grain diameter smaller than ten millimeter between 120 DEG C and 150 DEG C for four minutes and dry the raw material between 150 DEG C and 400 DEG C; then the temperature is raised by 6 to 8 DEG C per minute until reaching 510 to 650 DEG C, and keep the temperature for forty to seventy minutes to carbonize the material; and then the temperature is raised by 6 to 8 DEG C per minute until reaching 800 DEG C, firstly activate with the water vapor and the activate with the smoke for ten to twenty minutes between 840 DEG C and 950 DEG C. The raw material of the invention can adopts the anthracite, the meager coal, the dry coal, the coking coal, the fat coal, the bottle coal, the flaming coal and the lignite and other coal processing products such as coke, the goal coal and the coke powder. The raw material of the filtering and absorbing material of the invention is cheap and easy to get; the preparing method is also very simple; and the invention is applicable to large batch production.

Owner:张大伟

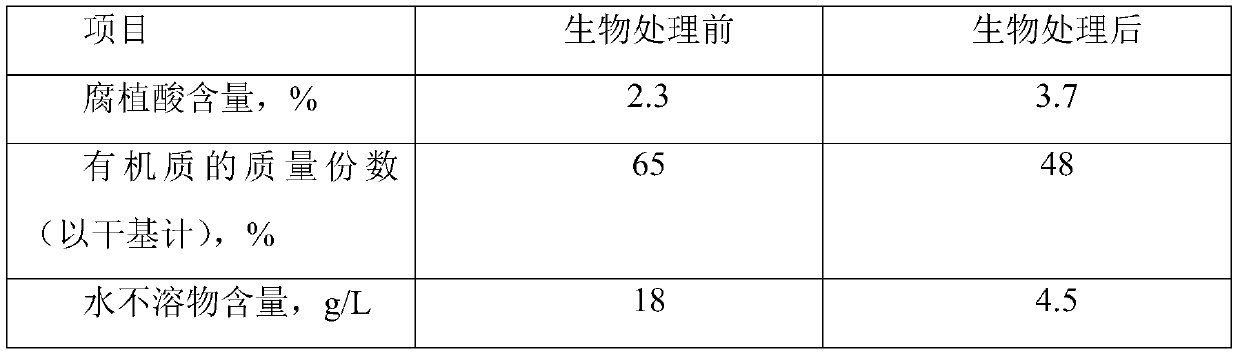

Microbial degradation method of coal waste and application thereof

InactiveCN109851450APromote resource utilizationPromote environmental protectionBio-organic fraction processingFungiMicrobial agentPseudomonas fluorescens

The invention relates to a microbial degradation method of coal waste, which comprises the following steps: coal slime is dried and then crushed; mushroom residue, yeast peptone and rice bran are added and uniformly mixed, and a compound microbial agent of Bacillus stearothermophilus, Bacillus mucilaginosus, Bacillus subtilis, Bacillus amyloliquefaciens, Streptomyces, Trichoderma and Pseudomonas fluorescens according to the weight ratio is added; after mixing, the stacking is in a long strip shape, when the temperature on the position below the stacking surface by 30 cm decreases to below 35 DEG C, the stacking is turned over 48-72 hours per time, and the fermentation time is 28-45 days. The invention is beneficial to promoting the utilization of coal slime resources, effectively utilizingsolid waste generated in the process of coal processing and use and in agricultural production and living, and is beneficial to environmental protection. And the method makes full use of the rare mineral elements and humic acid in coal slime to serve the revitalization of rural areas and the sustainable environment of green agriculture.

Owner:叶荫人

Method for treating semi-coke wastewater obtained by producing coal

InactiveCN104310694AWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentChemical oxygen demandCoking wastewater

The invention relates to a method for treating semi-coke wastewater by producing coal and belongs to the field of wastewater treatment in coal processing. In order to solve the problem that phenols in wastewater cannot be recycled, the invention provides a treatment method which can be used for treating semi-coke wastewater and recovering phenol matters. The treatment method is used for treating semi-coke wastewater by adopting a liquid membrane separating technology, taking tributyl phosphate (TBP) as a carrier, kerosene as a membrane solvent and a NaOH solution as an internal aqueous phase and recovering phenols. The COD (chemical oxygen demand) removal rate of phenol by virtue of use of treatment method reaches over 83% and the phenol removal rate reaches over 85%. The oil phase after treatment can be recycled and the aqueous phase after treatment can be recovered.

Owner:SHAANXI HUALU CHEM ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com