Efficient coal processing pulverizing device

A pulverizing device and coal technology, applied in heating devices, household refrigeration devices, drying gas layout, etc., can solve the problems of poor pulverizing effect, low pulverizing efficiency, low coal burning rate, etc., to prevent coal from sticking to machines and preventing accumulation. The effect of blocking and improving the combustion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

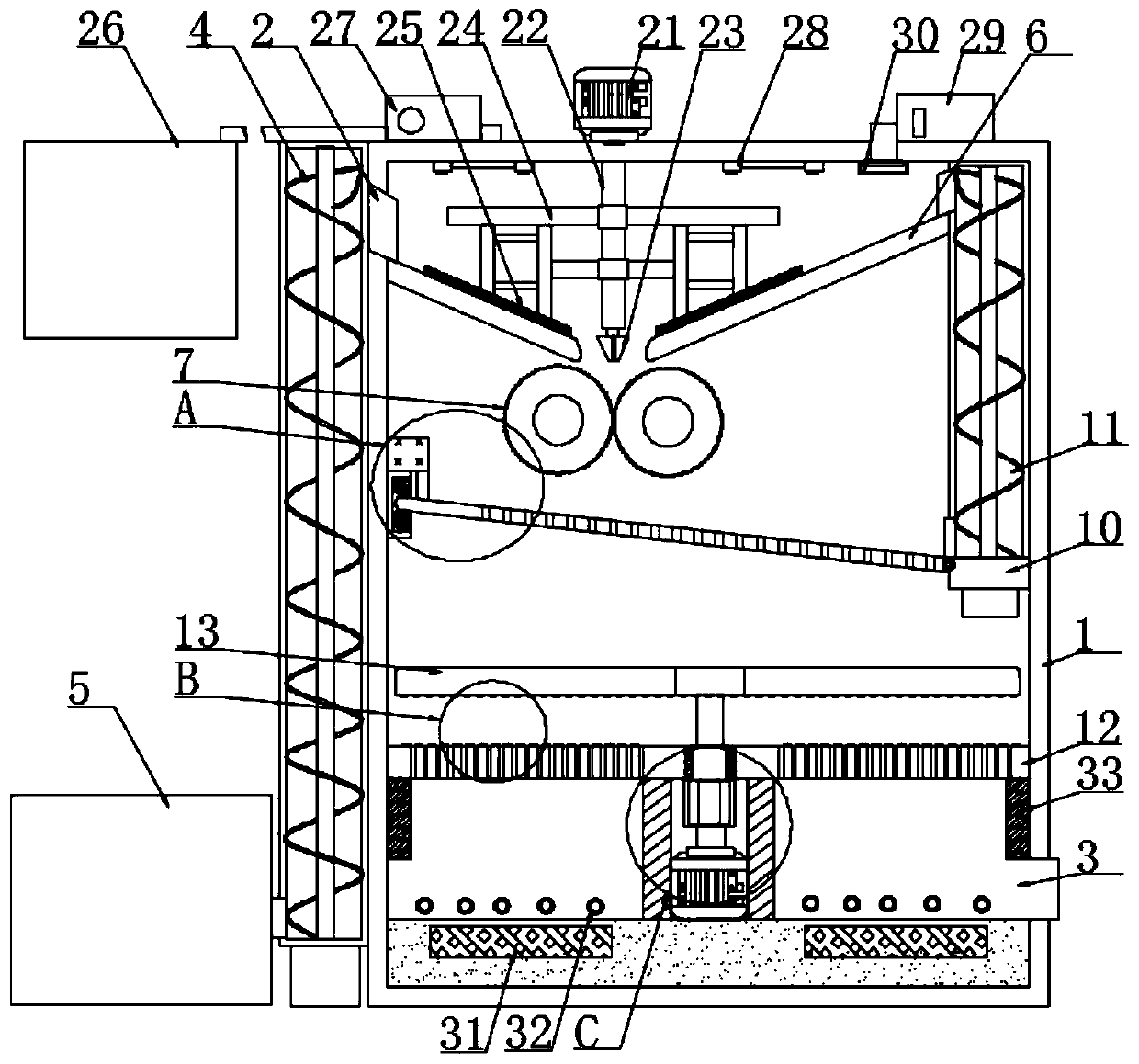

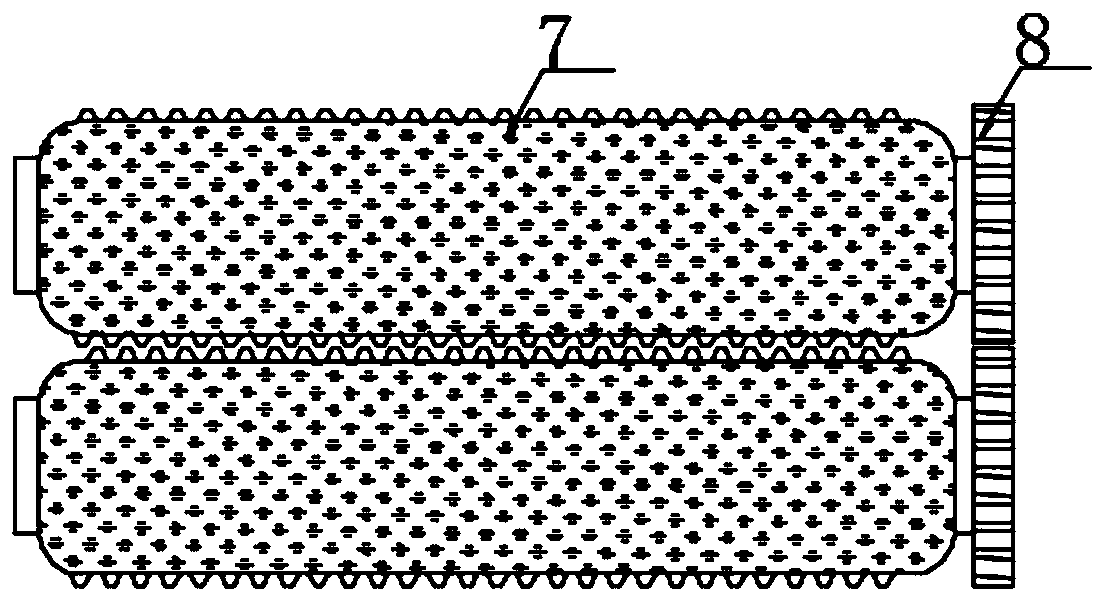

[0029] according to Figure 1-6 A high-efficiency coal processing and crushing device shown includes a box body 1, the top of one side of the box body 1 is provided with a material inlet 2, and the bottom of one side of the box body 1 is provided with a discharge port 3, and the box body 1 is provided with a discharge port 3. The top of one side of the body 1 is provided with a first Jiaolong feeder 4, and one side of the first Jiaolong feeder 4 is provided with a crusher 5, and the output end of the crusher 5 is connected to the input end of the first Jiaolong feeder 4. Matching, the output end of the first Jiaolong feeder 4 matches the feed port 2, and the box body 1 is provided with two obliquely distributed slide plates 6, and the bottoms of the two slide plates 6 are provided with two side-by-side distributed One cutter roller 7, two said cutter rollers 7 one ends are meshed by two gears 8, one side of said gear 8 is provided with a motor, two said cutter rollers 7 bottom...

Embodiment 2

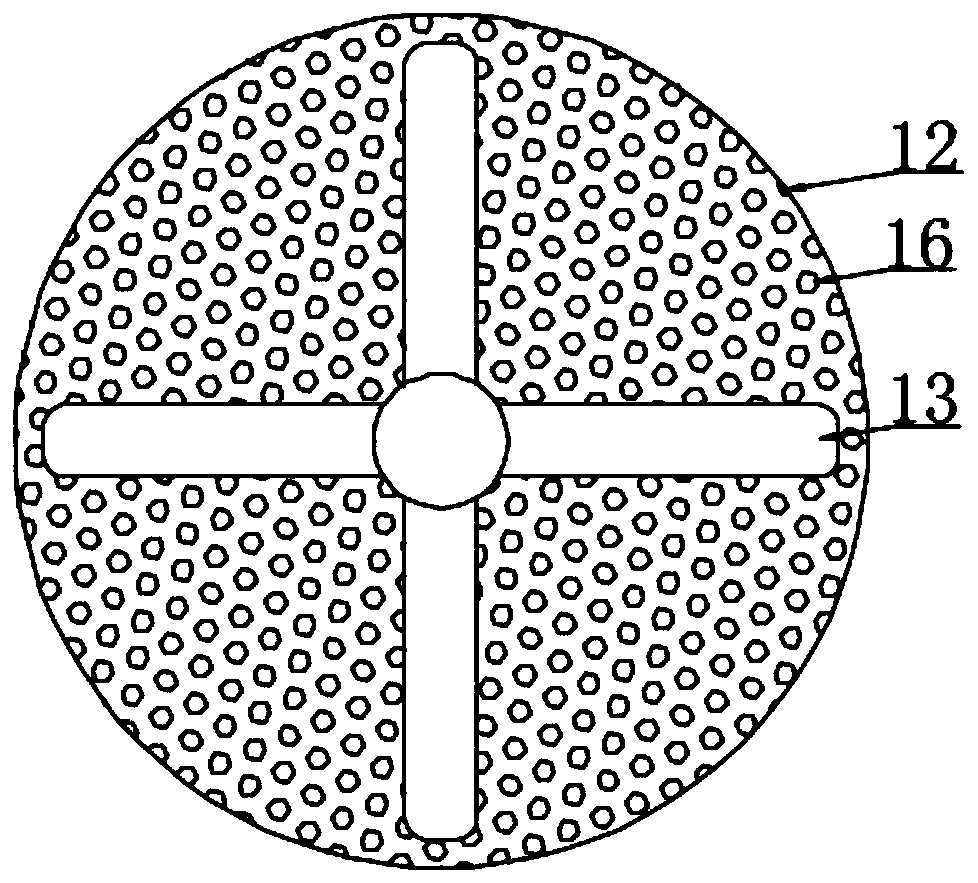

[0032] according to figure 1 , Figure 5 and Figure 6 A high-efficiency coal processing and crushing device is shown, the grinding device includes a second sieve plate 12, a grinding plate 13, a first motor 14 and a cylinder 15, and the second sieve plate 12 is fixed to the inner wall of the box body 1 connected, the surface of the second sieve plate 12 is provided with a number of second sieve holes evenly distributed, a bump 16 is provided between the two second sieve holes, and a grinding plate is provided on the top of the second sieve plate 12 13, the bottom of the grinding plate 13 is provided with a protrusion 16, the axis of the second sieve plate 12 and the grinding plate 13 is penetrated by a cylinder 15, and the bottom end of the cylinder 15 is fixedly connected with a first motor 14;

[0033] The output shaft of the first motor 14 is in transmission connection with the cylinder 15, the connection between the cylinder 15 and the second sieve plate 12 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com