Ejecting-type jet flow cavitation generator and cavitation cell disruption device

A cell crushing and generator technology, applied in biochemical cleaning devices, enzymology/microbiology devices, biochemical instruments, etc., can solve problems affecting the recovery rate of active proteins, limited cavitation generator design, protein denaturation, etc. Achieve the effect of avoiding chemical oxidation, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

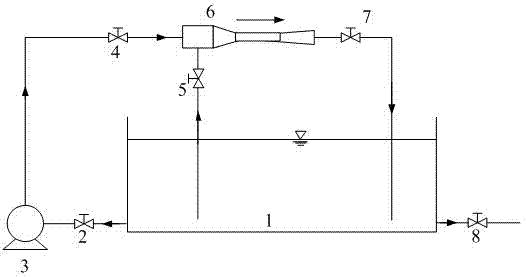

[0032] This specific implementation includes a cell container 1 for storing the cell solution to be broken, a high-pressure centrifugal pump 3 connected to the cell container 1 through a pipeline, and a cavitation generator 6 connected to the outlet of the high-pressure centrifugal pump 3 through a pipeline, see figure 1 .

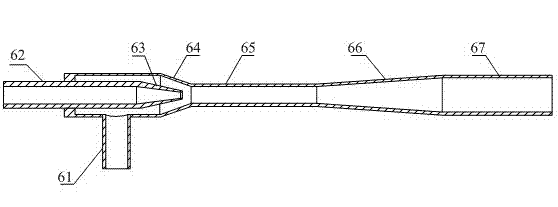

[0033] cavitation generator 6 see figure 2 , comprising a suction chamber 64, the nozzle is socketed in the suction chamber 64, the nozzle includes a nozzle inlet section 62 and a nozzle outlet section 63, the outlet end of the nozzle stretches into the suction chamber 64, and the high-pressure centrifugal pump 3 is connected to the inlet of the nozzle inlet section 62 through a pipeline After the suction chamber 61, the throat pipe 65, the diffusion pipe 66 and the outlet pipe 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com