Patents

Literature

5560results about How to "Improve crushing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Power having nutrition of paddy, bean, fruit, vegetables and tea with the functions of equalizing the nutrition, losing weight and reducing blood sugar

ActiveCN101116510ABalanced nutritionHave weight lossPre-extraction tea treatmentMetabolism disorderFiberGlucose polymers

The present invention provides a low-lipid, high-fiber, balanced-nutritional, instant-taking and instant-resolving powder made from all natural components including corn, bean, flower, vegetable, fruit, tea and bi-usage plants for both food and medication. The nutritional powder provided by the present invention has not only the functions to balance the nutrition, but also the effect to decrease the body weight, lower the blood glucose, and effectively prevent and treat the diabetes.

Owner:湖南湘泉药业股份有限公司

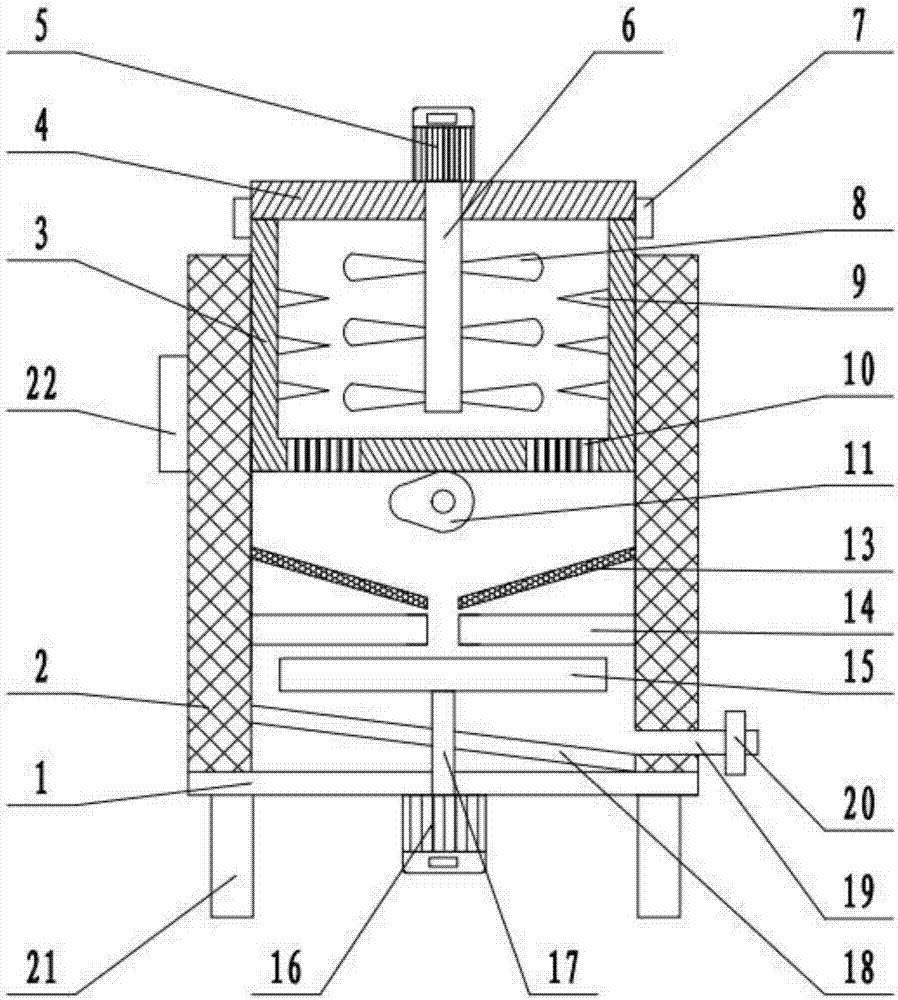

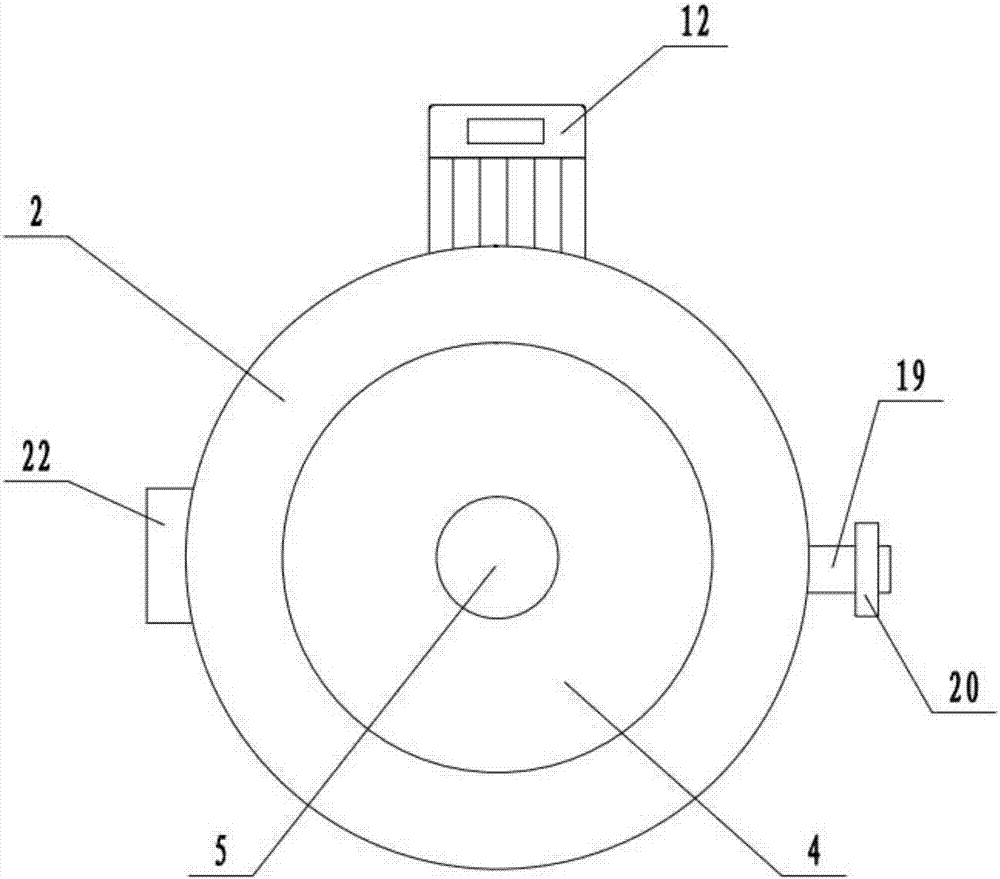

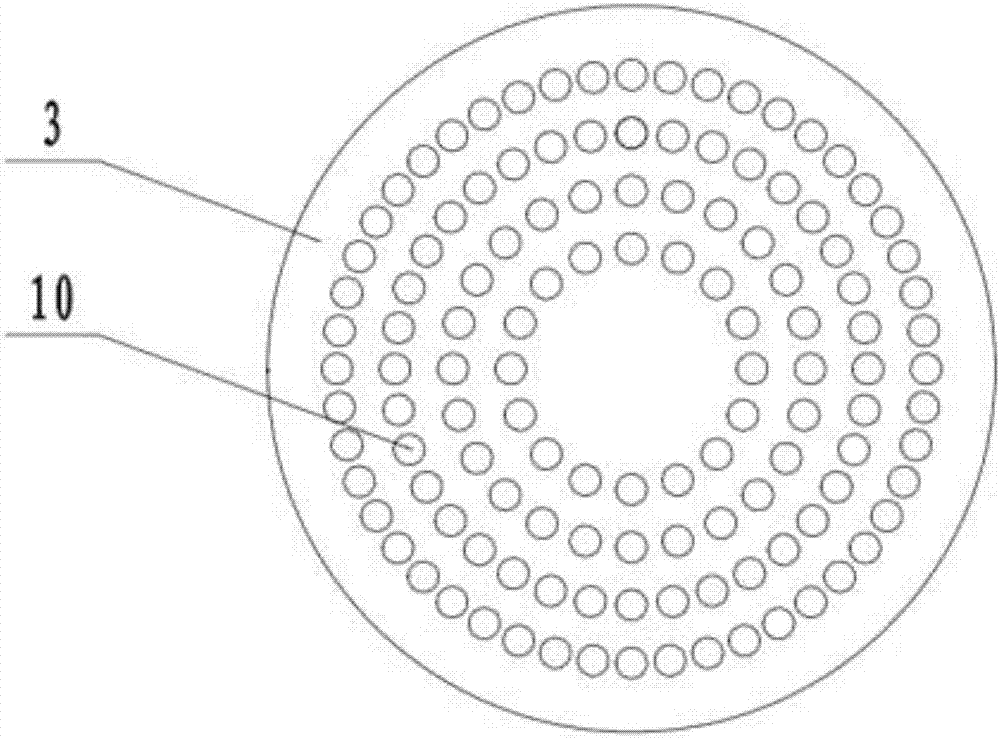

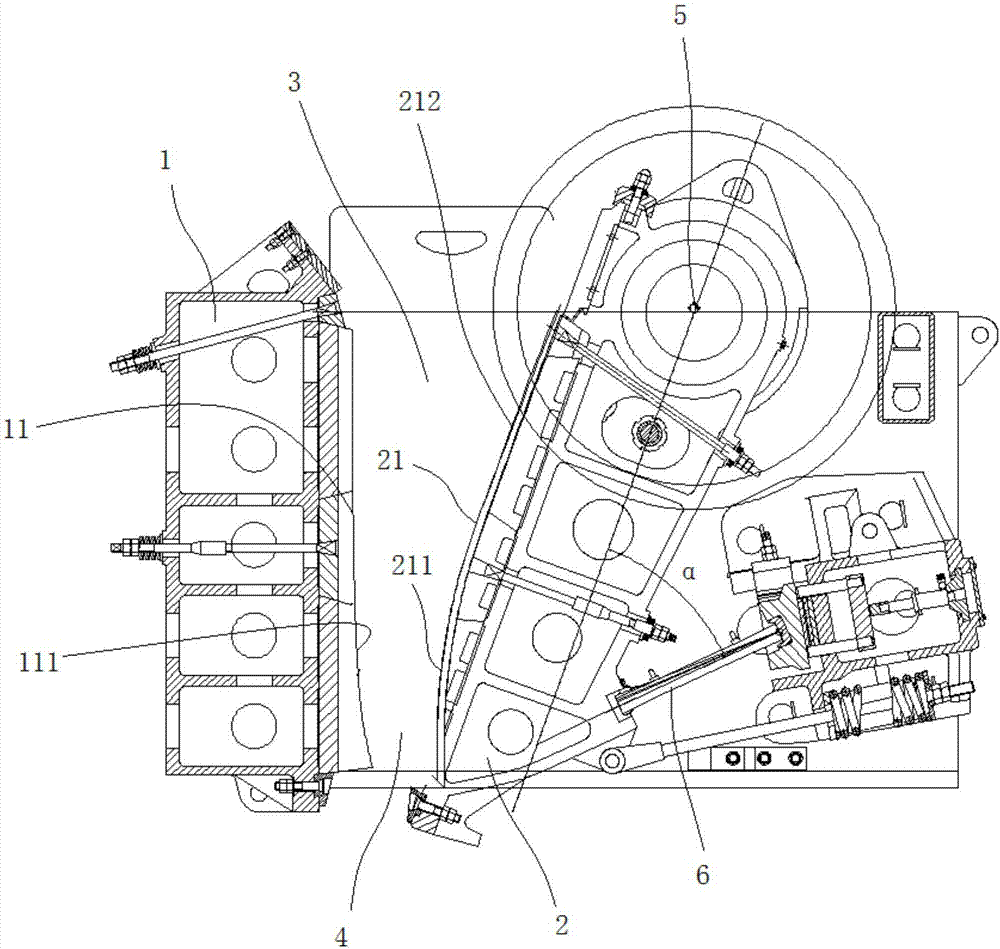

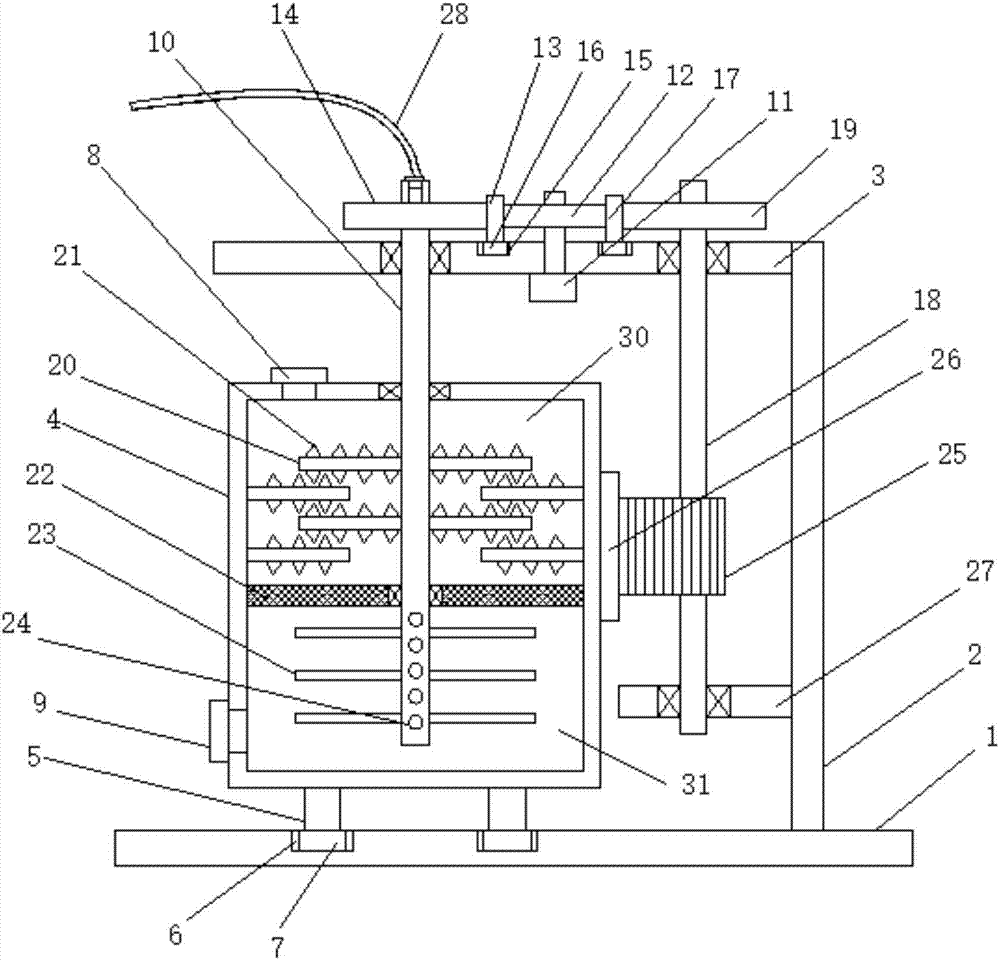

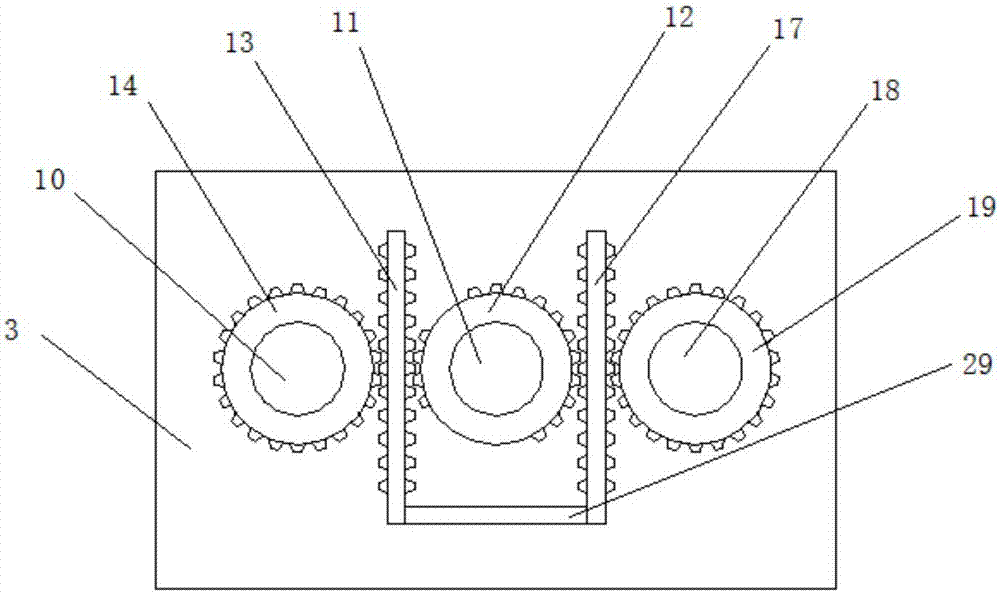

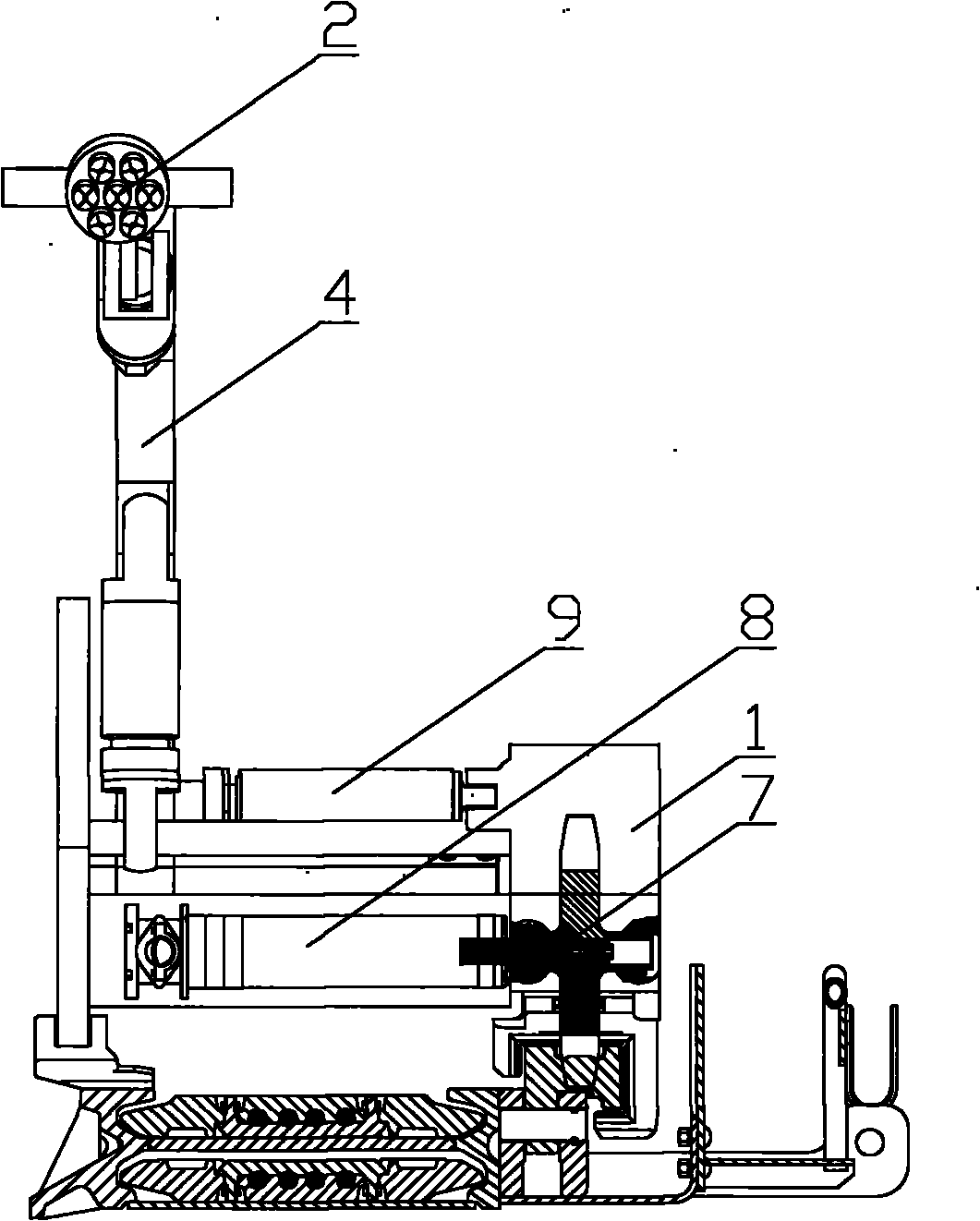

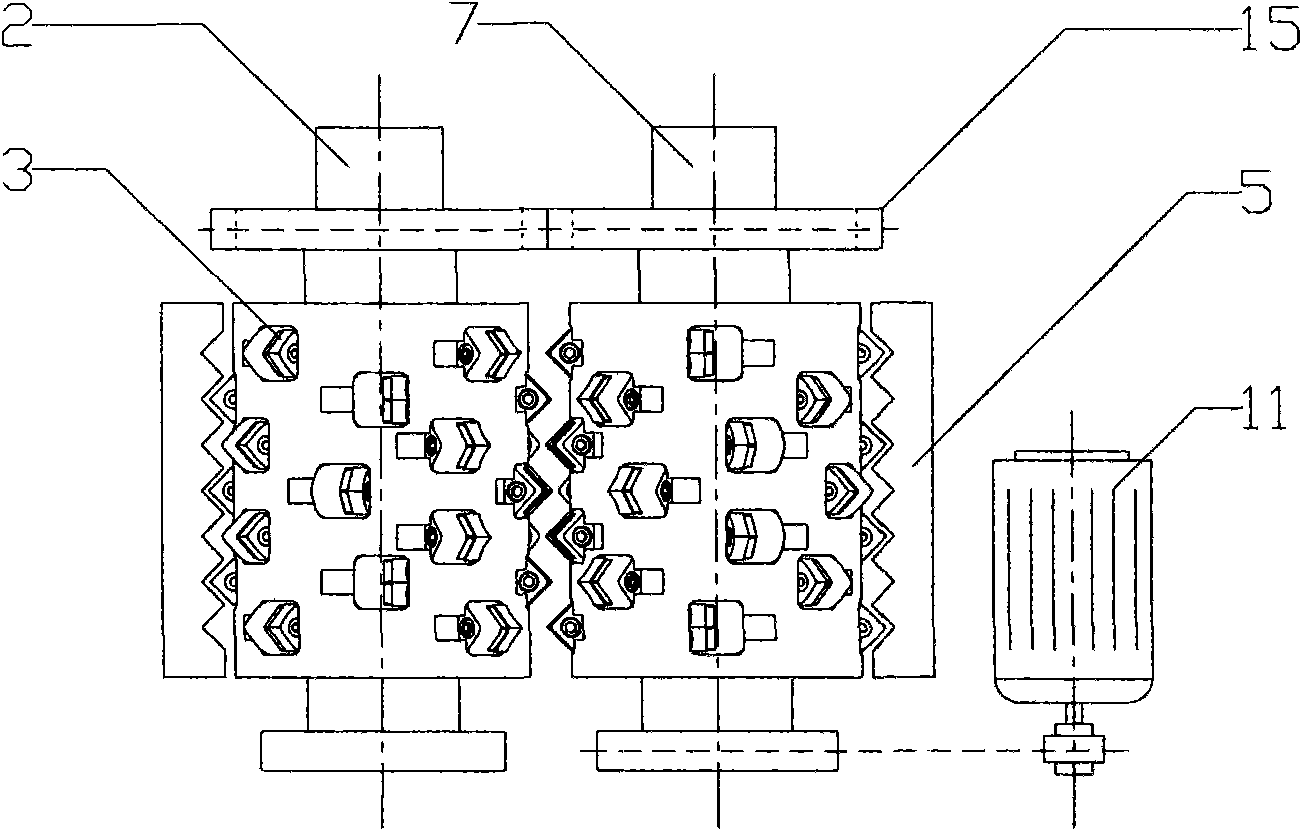

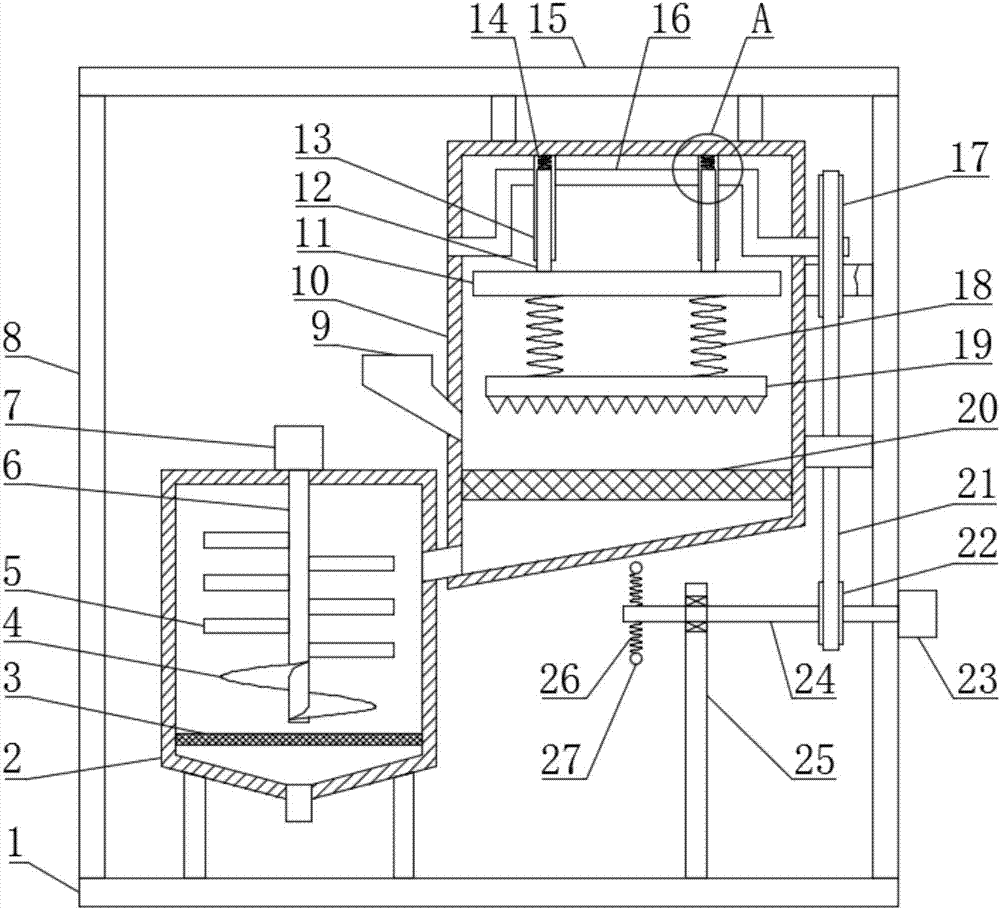

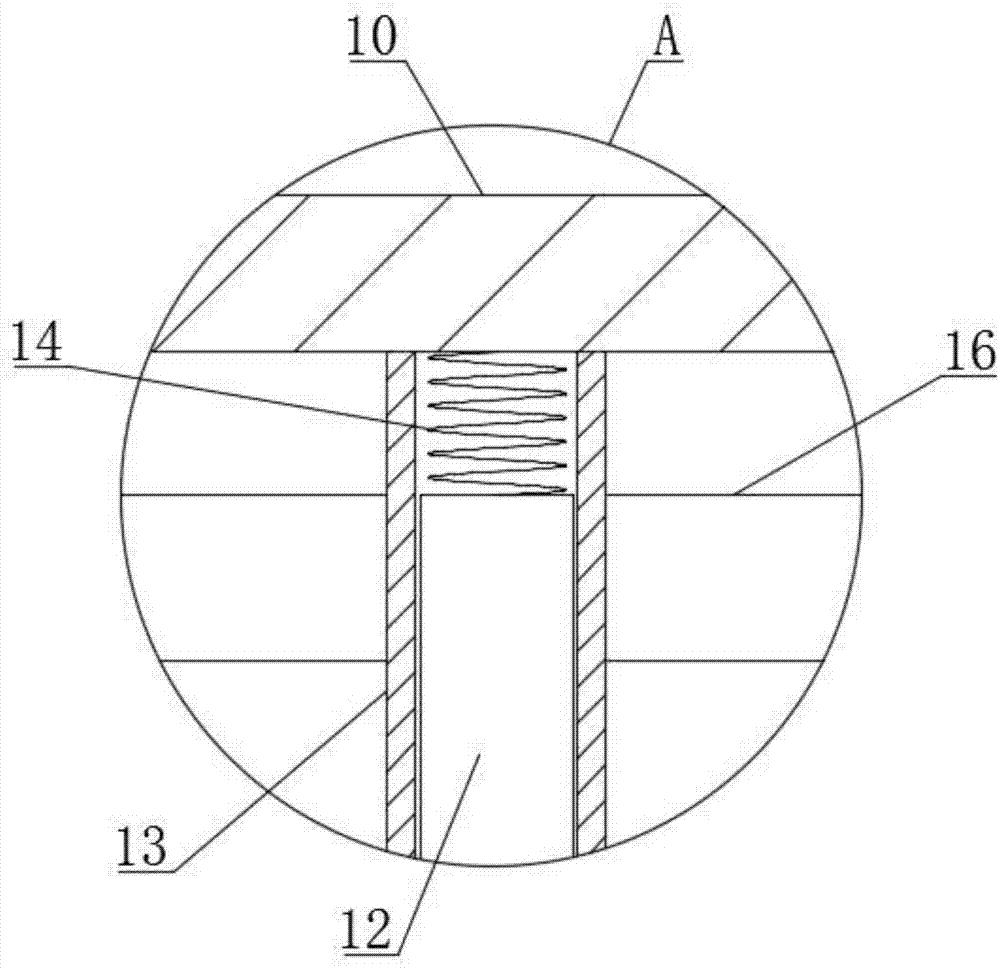

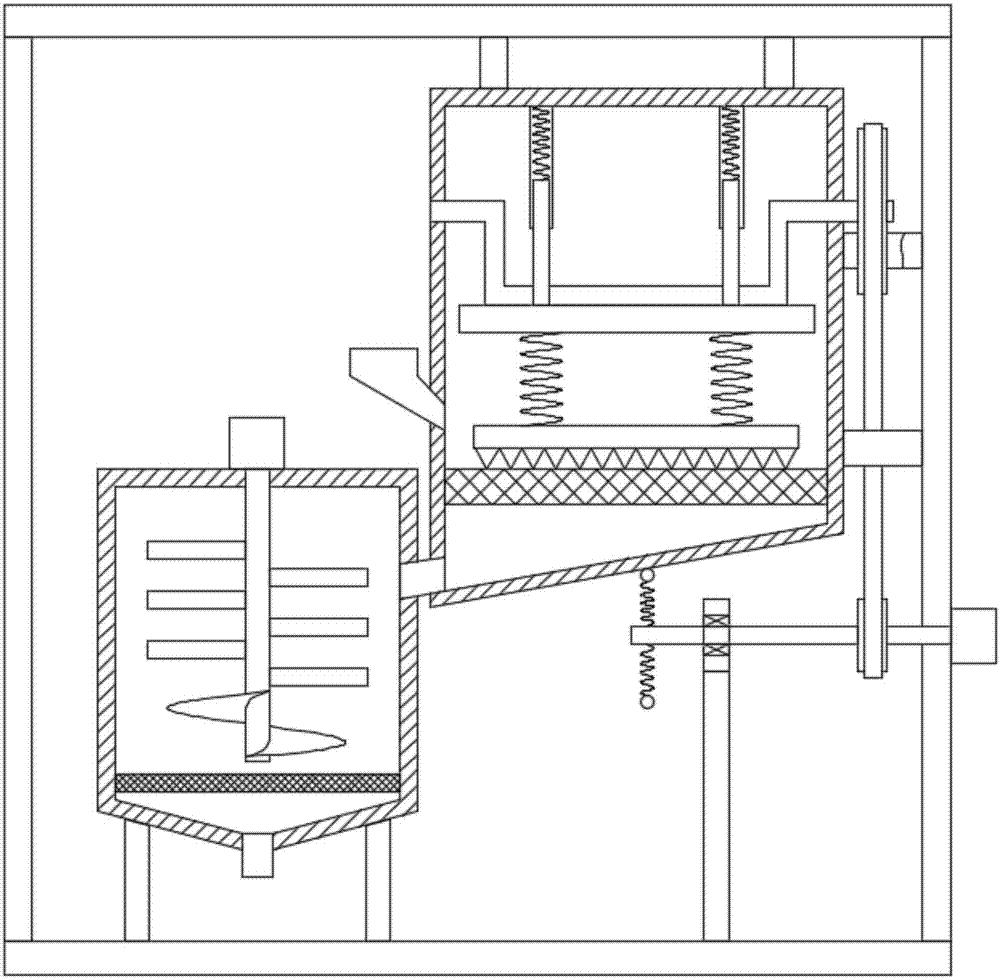

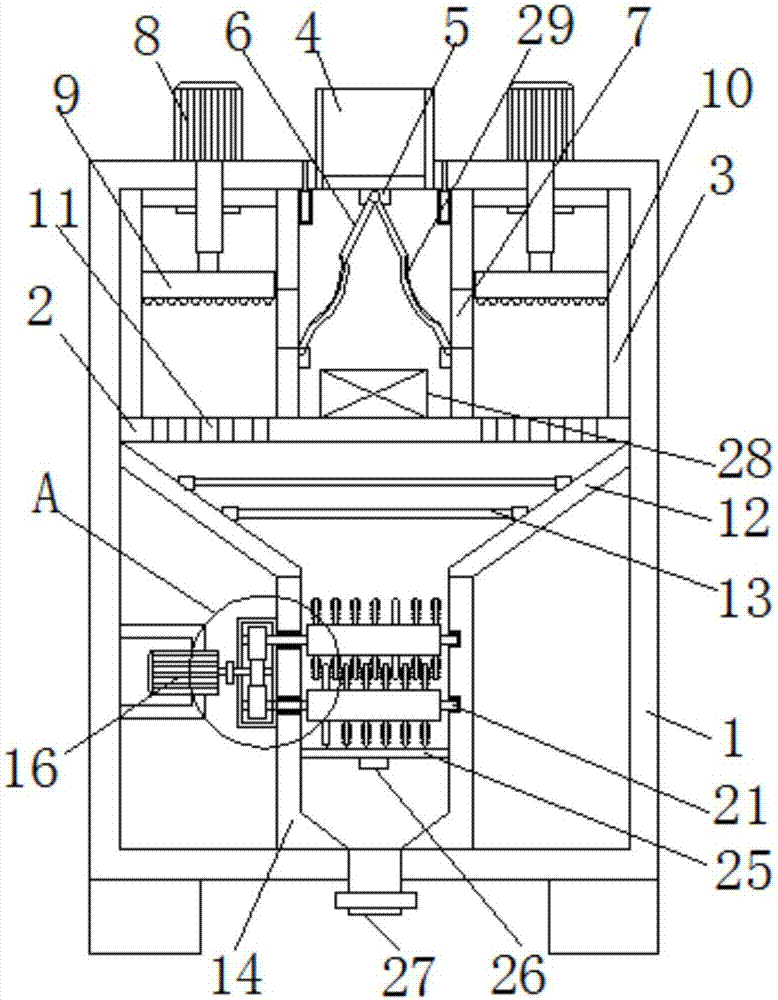

Crushing quantitative mixing pharmaceutical device for traditional Chinese medicinal material

InactiveCN107233836AImprove crushing efficiencyImprove qualityTransportation and packagingRotary stirring mixersMotor shaftEngineering

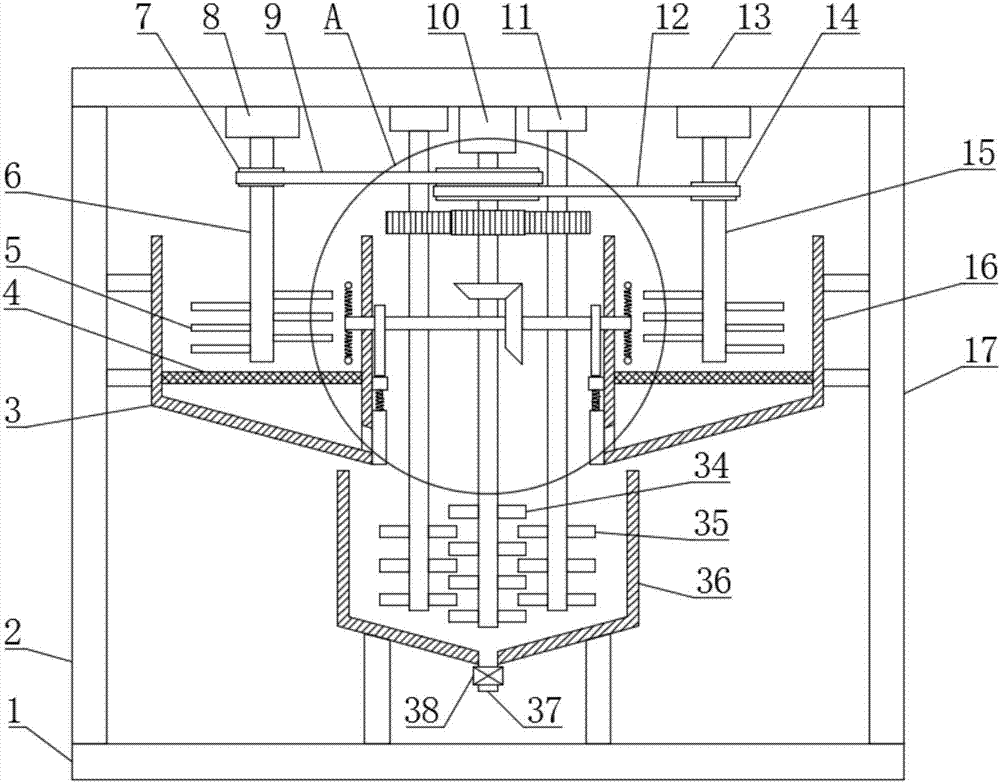

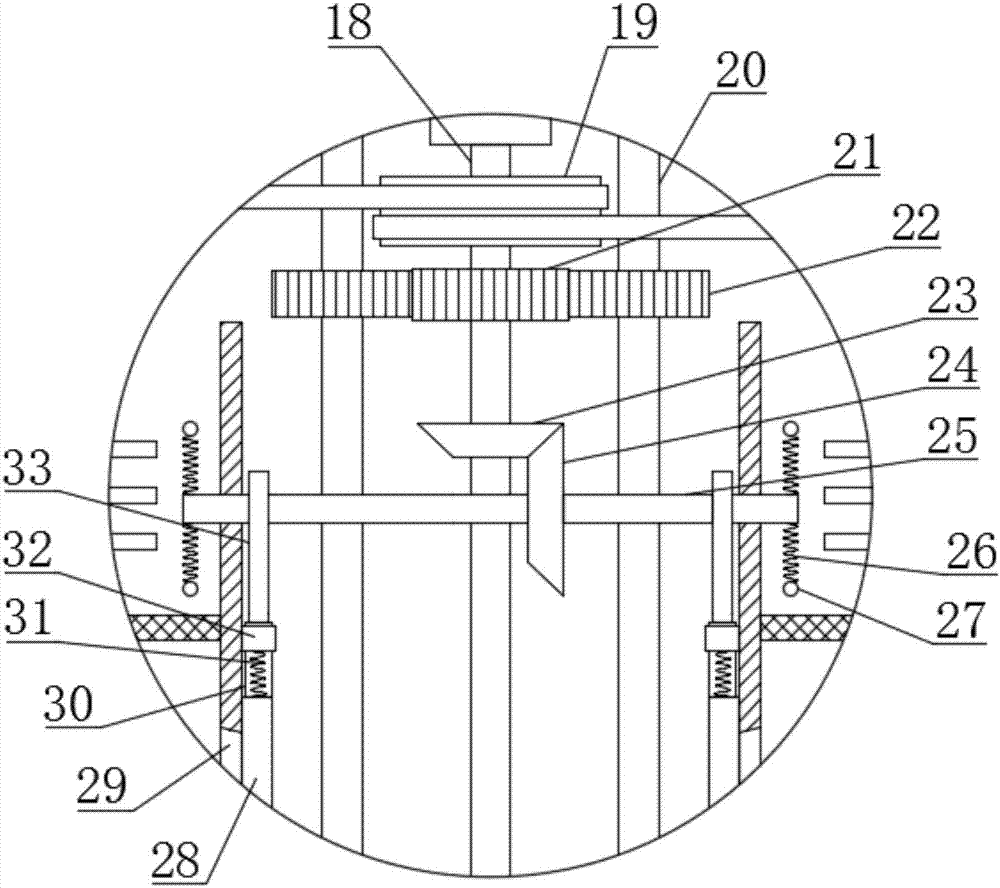

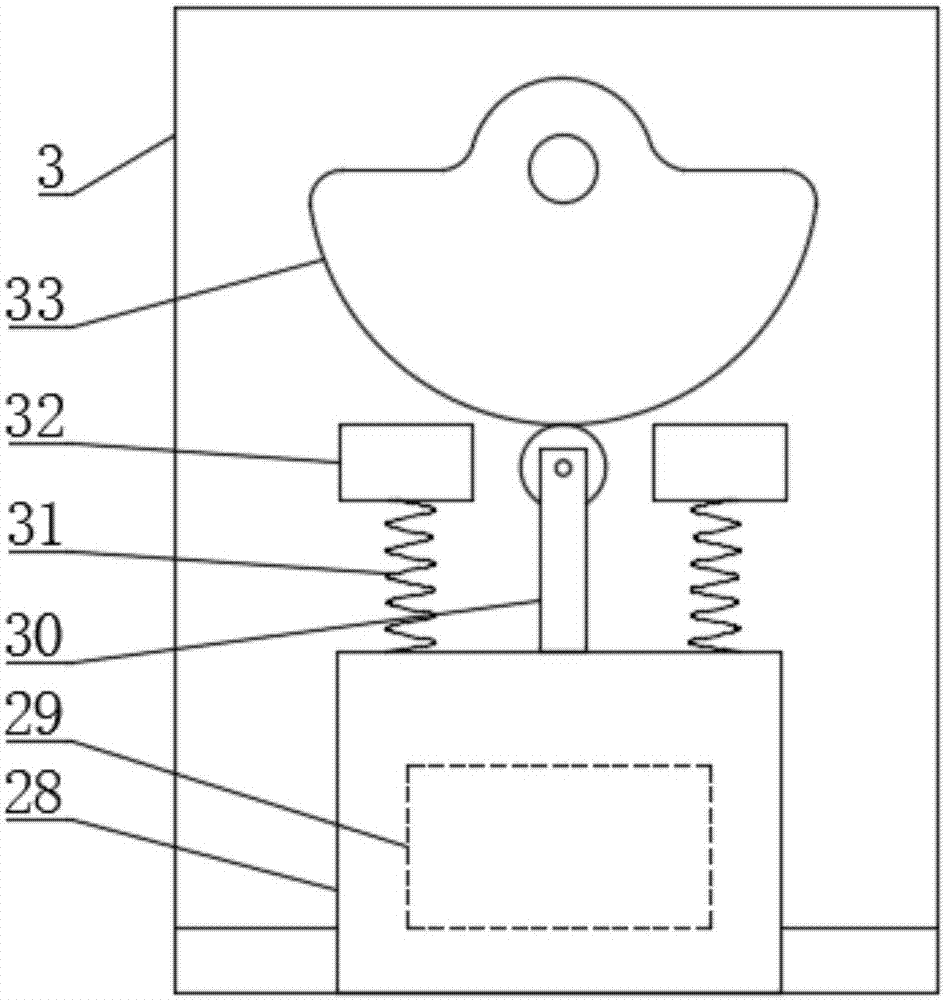

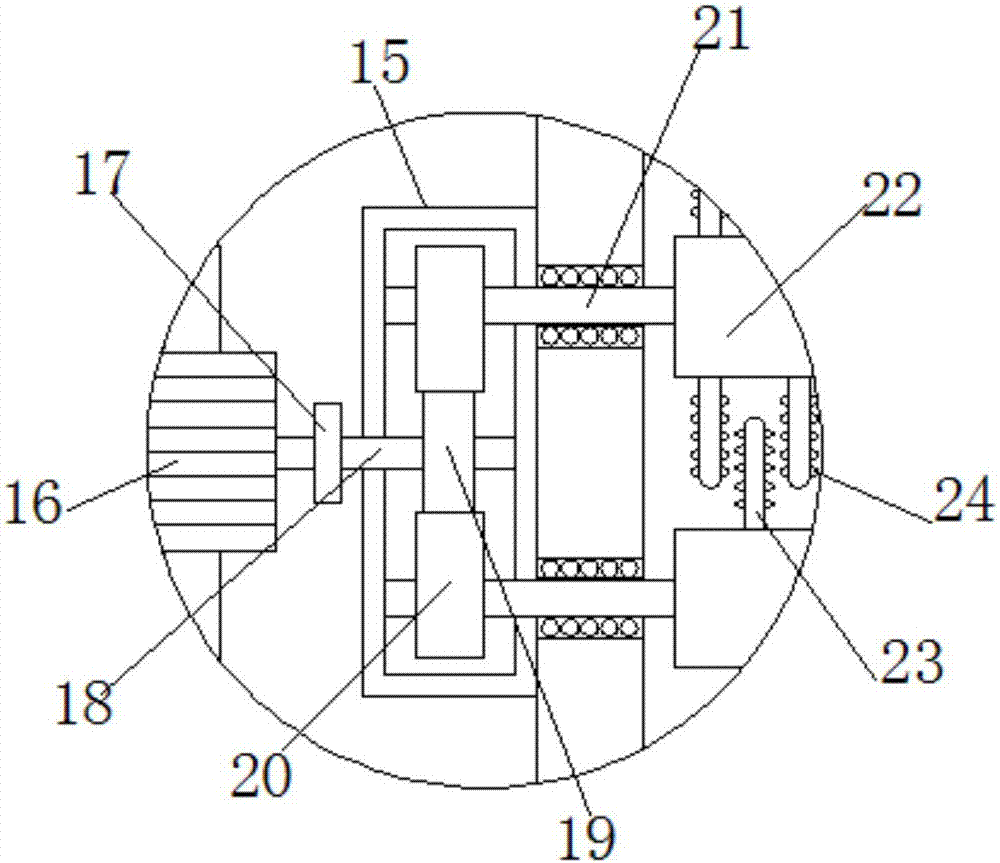

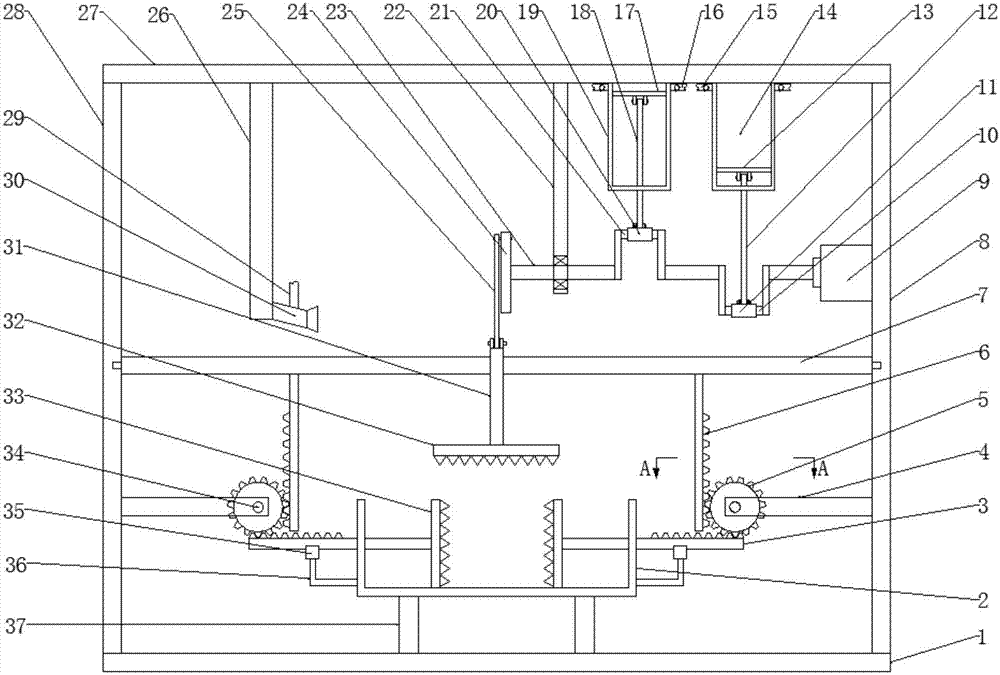

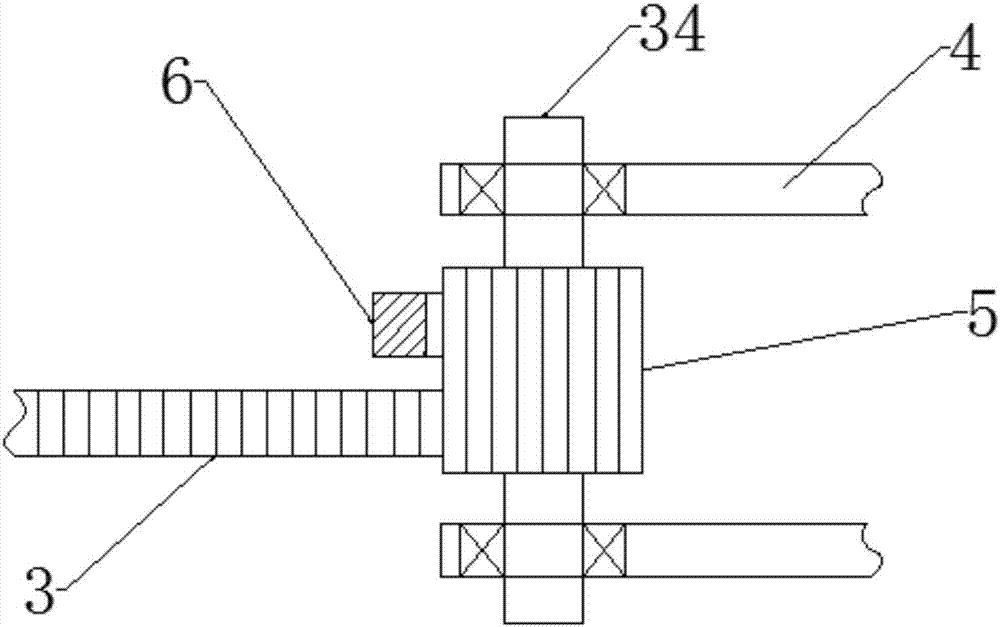

The invention discloses a crushing quantitative mixing pharmaceutical device for a traditional Chinese medicinal material. The crushing quantitative mixing pharmaceutical device comprises a base, wherein the left and right ends of the base are provided with a left supporting plate and a right supporting plate respectively; the right side of the left supporting plate is fixedly provided with a first crushing box through a bracket; the left side of the right supporting plate is fixedly provided with a second crushing box through a bracket; the tops of the left supporting plate and the right supporting plates are provided with a top plate; the left and right sides of the bottom of the top plate are provided with first mounted bearings; the left and right first mounted bearings are connected with a first rotating shaft and a second rotating shaft respectively; the bottoms of the first rotating shaft and the second rotating shaft are both provided with crushing blades; the center of the bottom of the top plate is provided with a reducing motor; a motor shaft at the bottom end of the reducing motor is connected with a third rotating shaft; the bottom of the third rotating shaft is also provided with a first agitating rod; the base is also fixedly provided with a mixing box through a bracket; the mixing box is located below a discharge opening; the first agitating rod is located in the mixing box. The crushing quantitative mixing pharmaceutical device can be used for synchronously crushing multiple traditional Chinese medicinal materials and mixing the crushed traditional Chinese medicinal materials, and is high in pharmaceutical efficiency.

Owner:邹铁梅

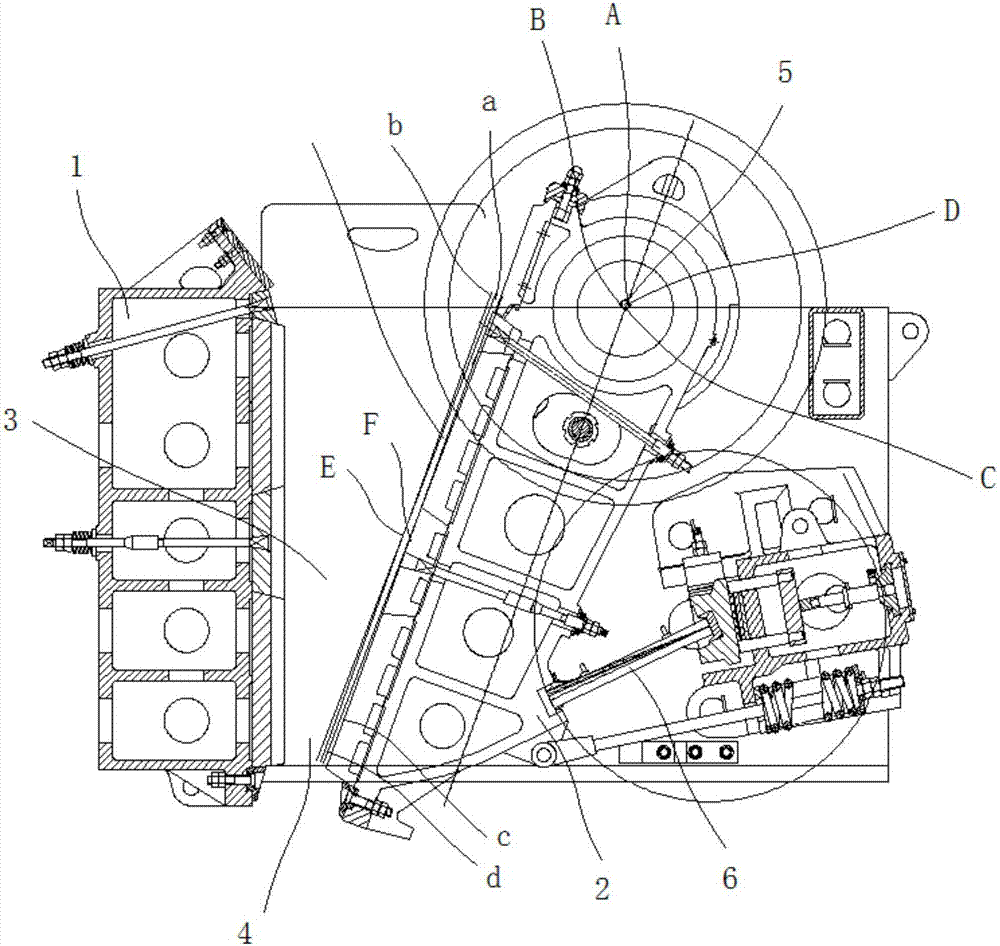

Swing type coffee bean crushing and grinding equipment

The invention discloses swing type coffee bean crushing and grinding equipment. The equipment comprises a base, supporting feet, a left fixing frame, a right fixing frame and a crushing tank; the leftfixing frame is fixedly connected at the left end of the base; the right fixing frame is fixedly connected at the right end of the base; the crushing tank is arranged between the left fixing frame and the right fixing frame; a motor is fixedly connected on the upper surface of the crushing tank; a crankshaft is arranged inside the crushing tank; a sliding block is arranged below a feeding port; the right end of a connecting rod is hinged to the side wall of the sliding block; a plurality of main crushing blades are distributed on the crankshaft; a plurality of auxiliary crushing blades are fixedly connected on the inner walls of the left side and the right side of the crushing tank; a fixing rod is arranged below the main crushing blades; a sieve plate is arranged below the fixing rod; and a grinding hammer head is fixedly connected at the lower end of the crankshaft. Coffee beans are intermittently placed into the crushing tank, so that the coffee beans are crushed more thoroughly, and the crushing efficiency is improved; the coffee beans are crushed through cooperation of the main crushing blades with the auxiliary crushing blades; and the sieve plate is vibrated up and down, sothat the crushed coffee beans fall to the bottom of the crushing tank favorably.

Owner:张先吉

Industrial continuous ore crushing device

The invention relates to an ore crushing device, in particular to an industrial continuous ore crushing device, and aims at achieving the technical purpose of providing an industrial continuous ore crushing device which is continuous and reliable in work, convenient to maintain and repair and high in ore crushing efficiency. In order to achieve the technical purpose, the industrial continuous ore crushing device comprises a bottom plate, an L-shaped support, a feeding hopper, a first support rod, a second support rod, a crushing barrel and the like; the L-shaped support is connected to the right side of the top of the bottom plate in a bolt connection mode, the feeding hopper is arranged at the top end of the L-shaped support, the first support rod and the second support rod are arranged on the inner side of the L-shaped support, the first support rod is located over the second support rod, a discharging device is arranged at the left end of the first support rod, and the crushing barrel is arranged under the discharging device. According to the industrial continuous ore crushing device, when ore is crushed, the effects of being continuous and reliable in work, convenient to maintain and repair and high in ore crushing efficiency are achieved.

Owner:李翔

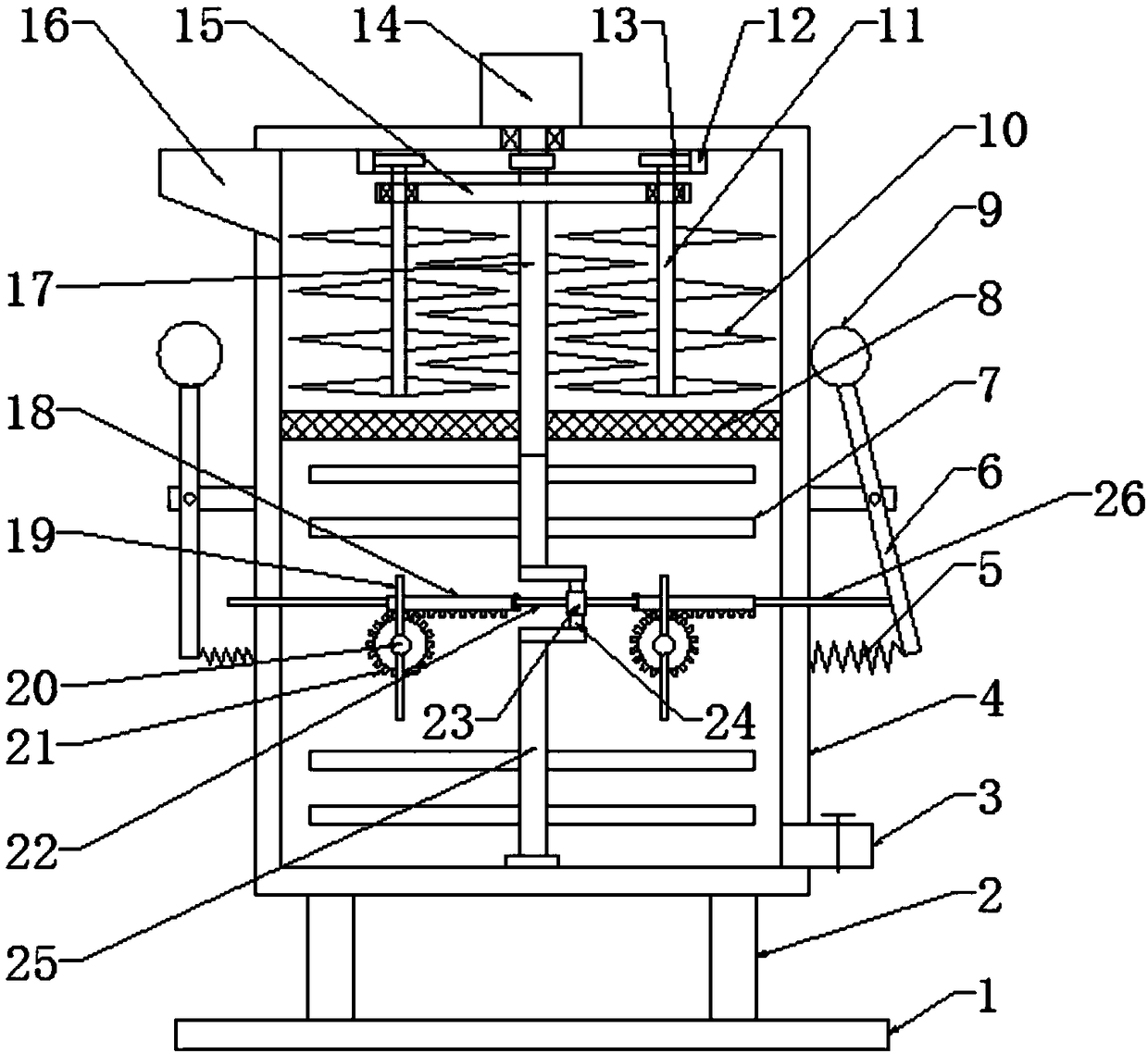

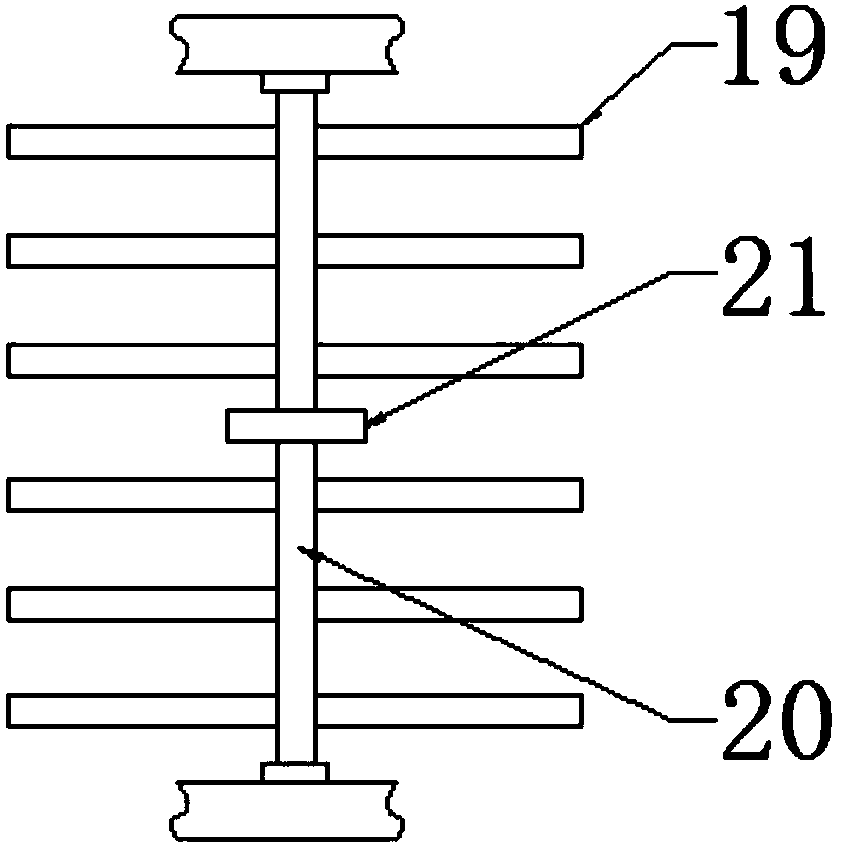

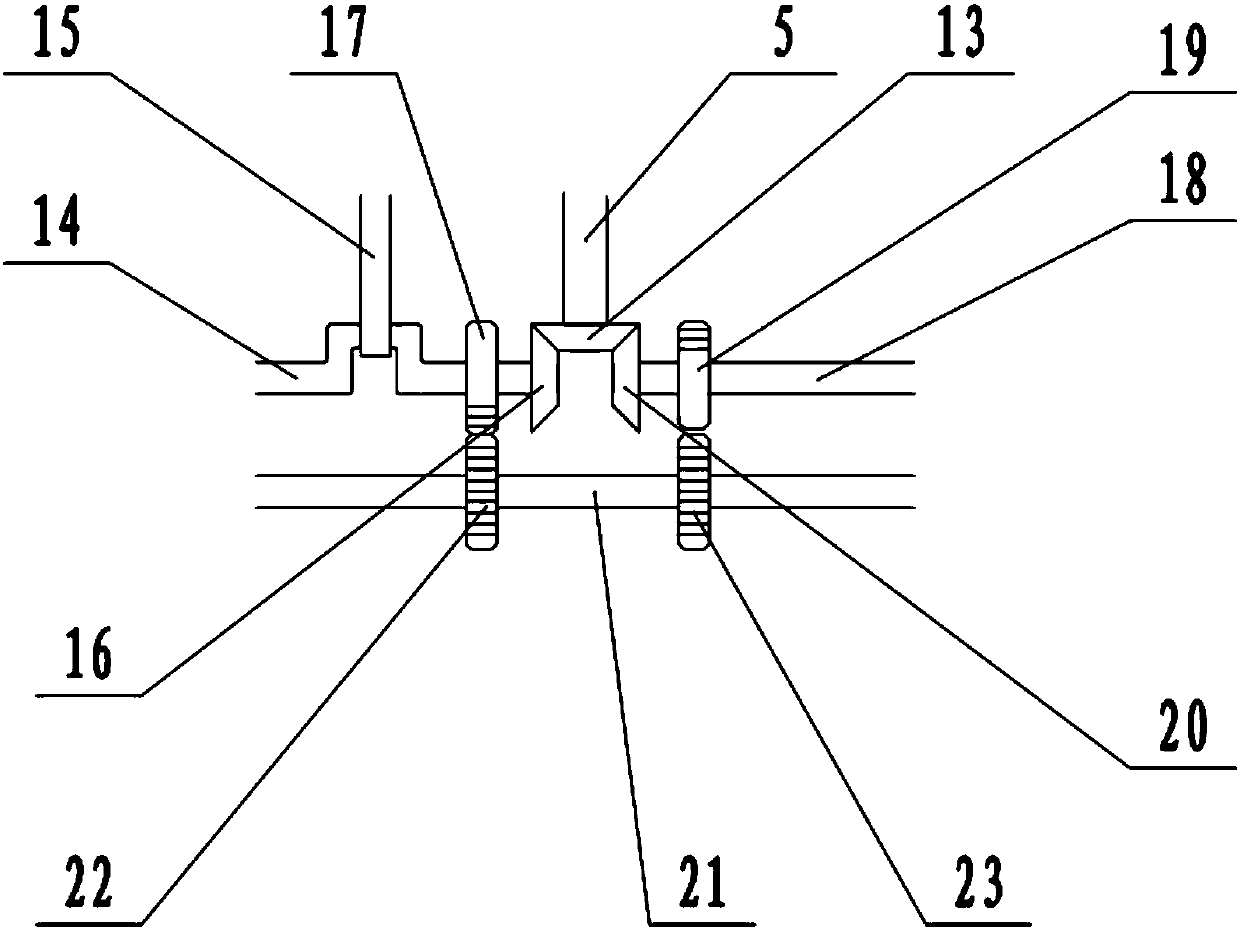

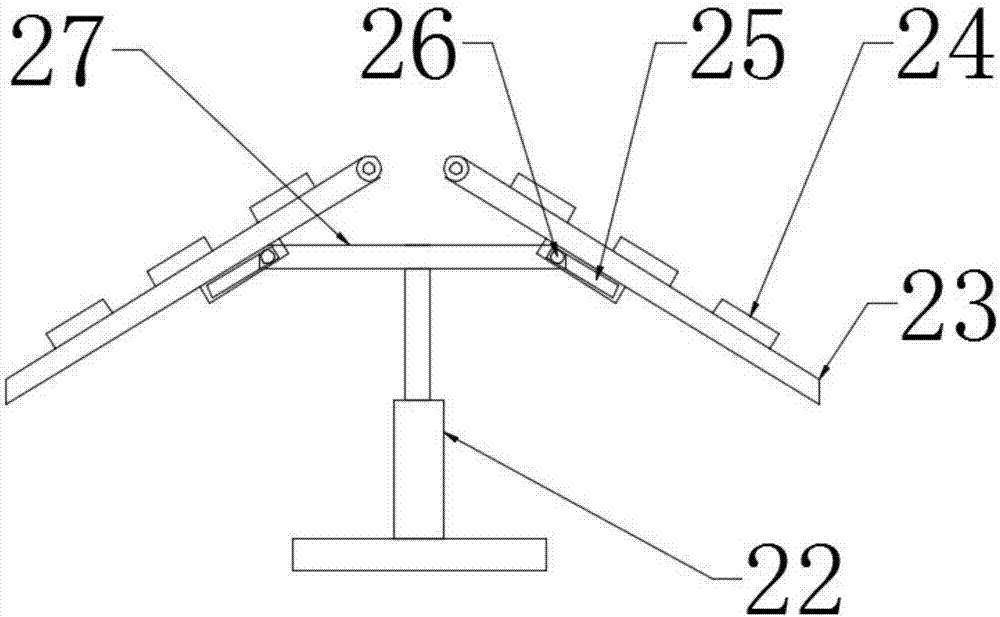

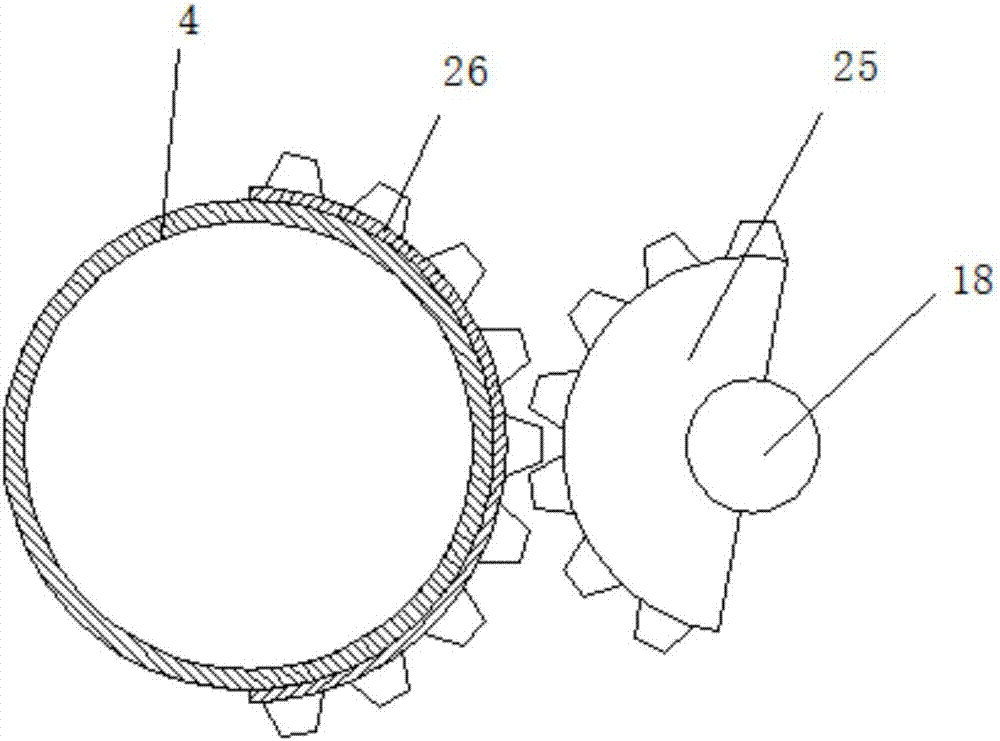

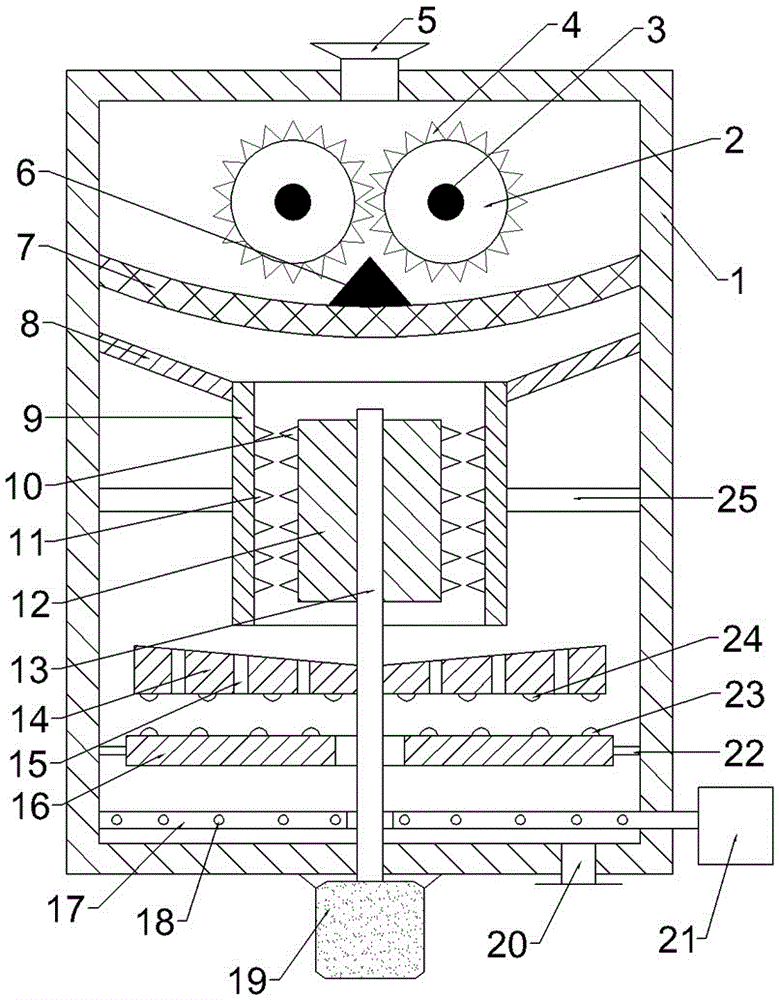

Efficient agricultural fertilizer stirring and crushing device

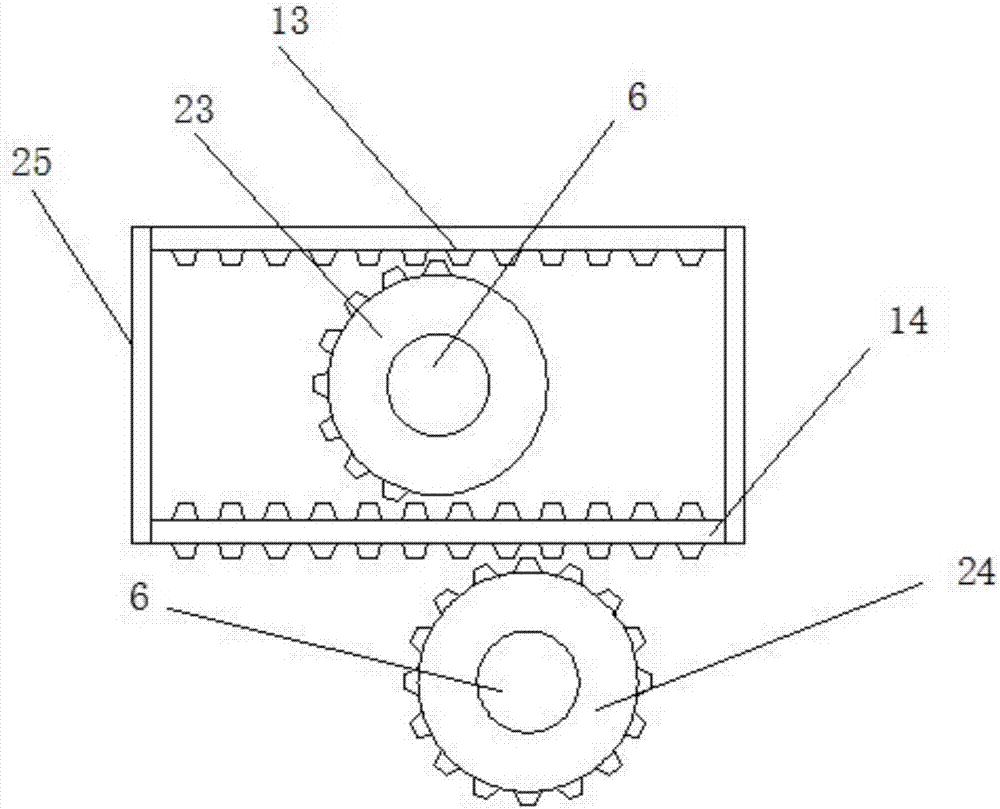

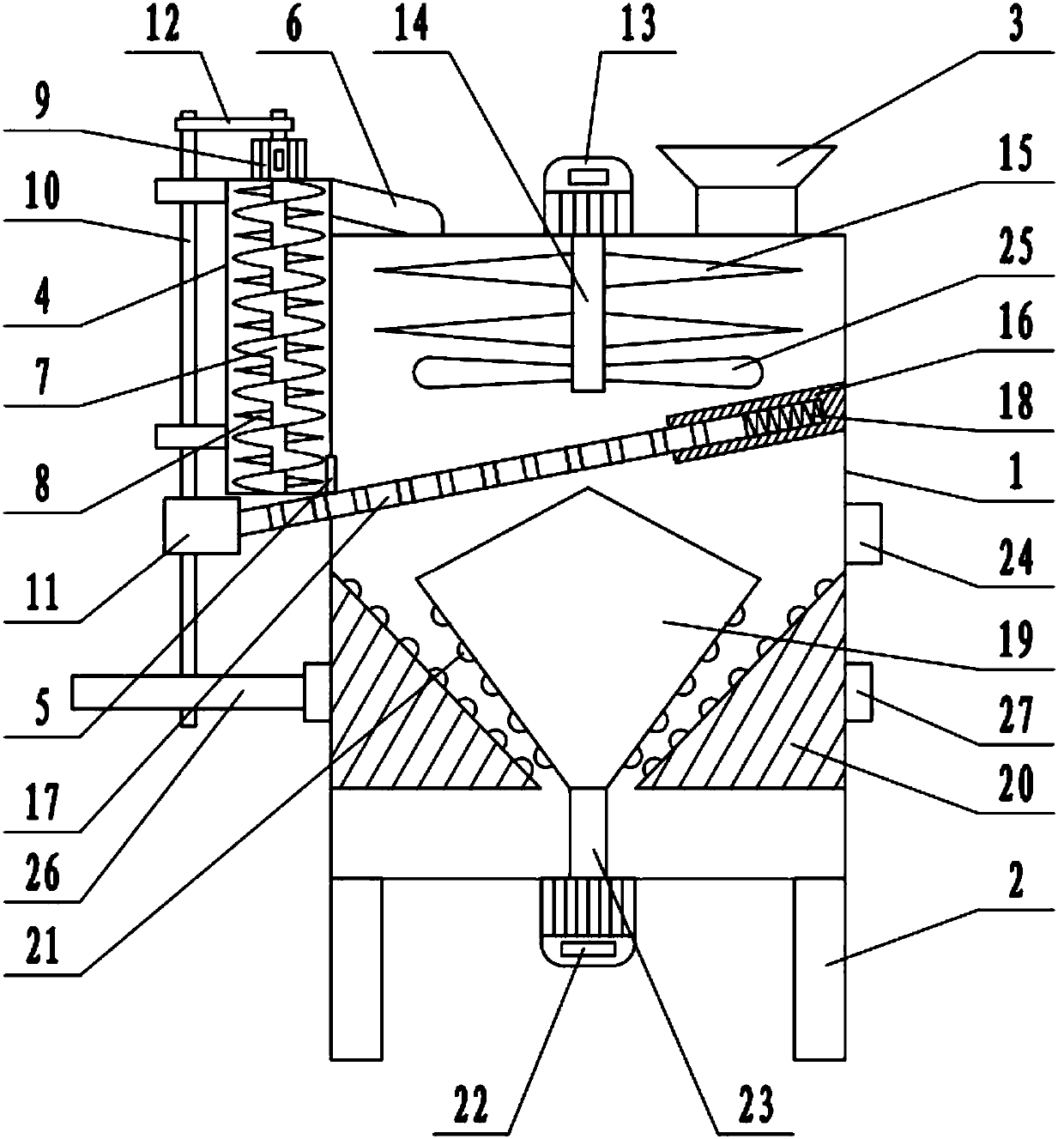

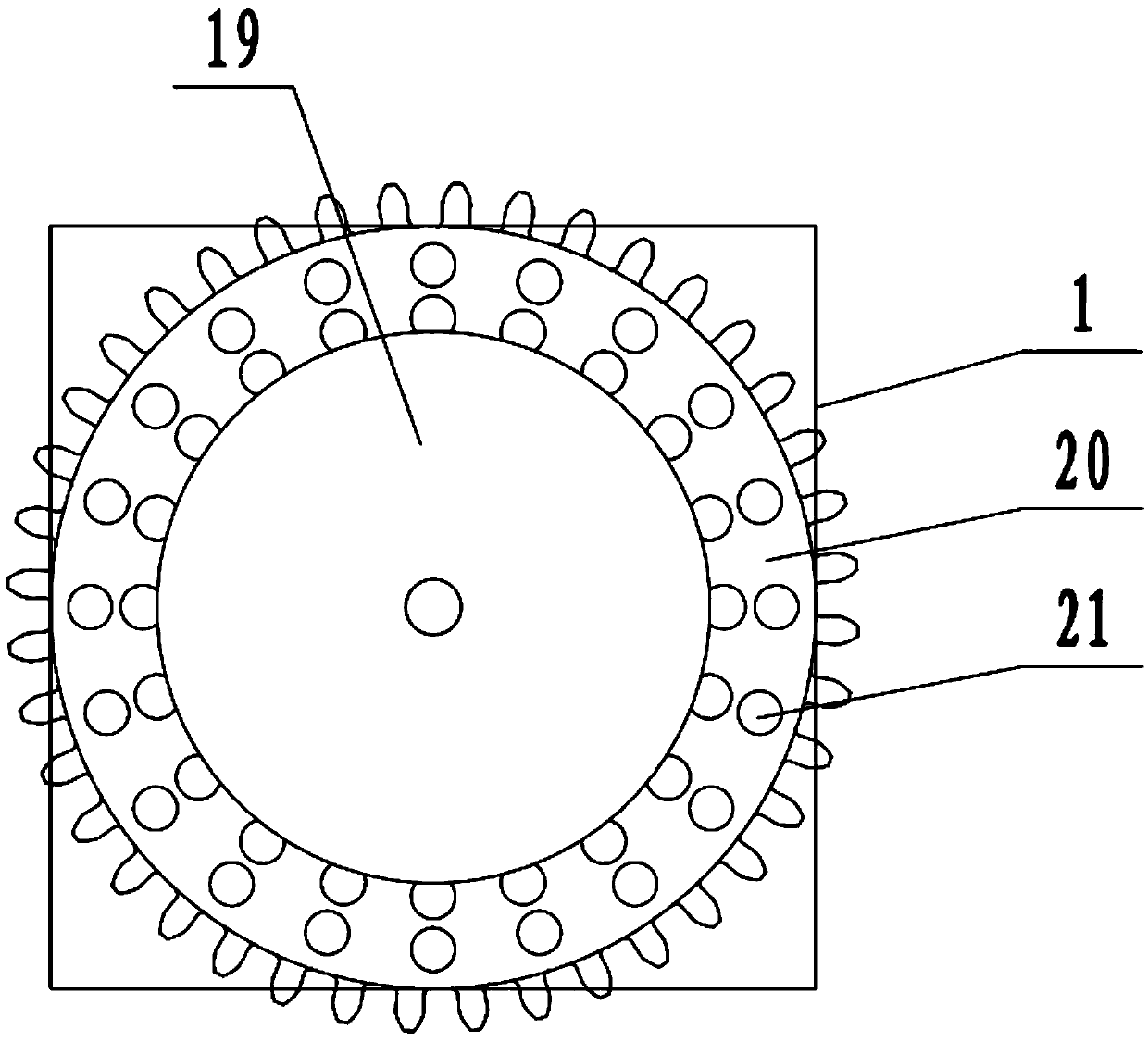

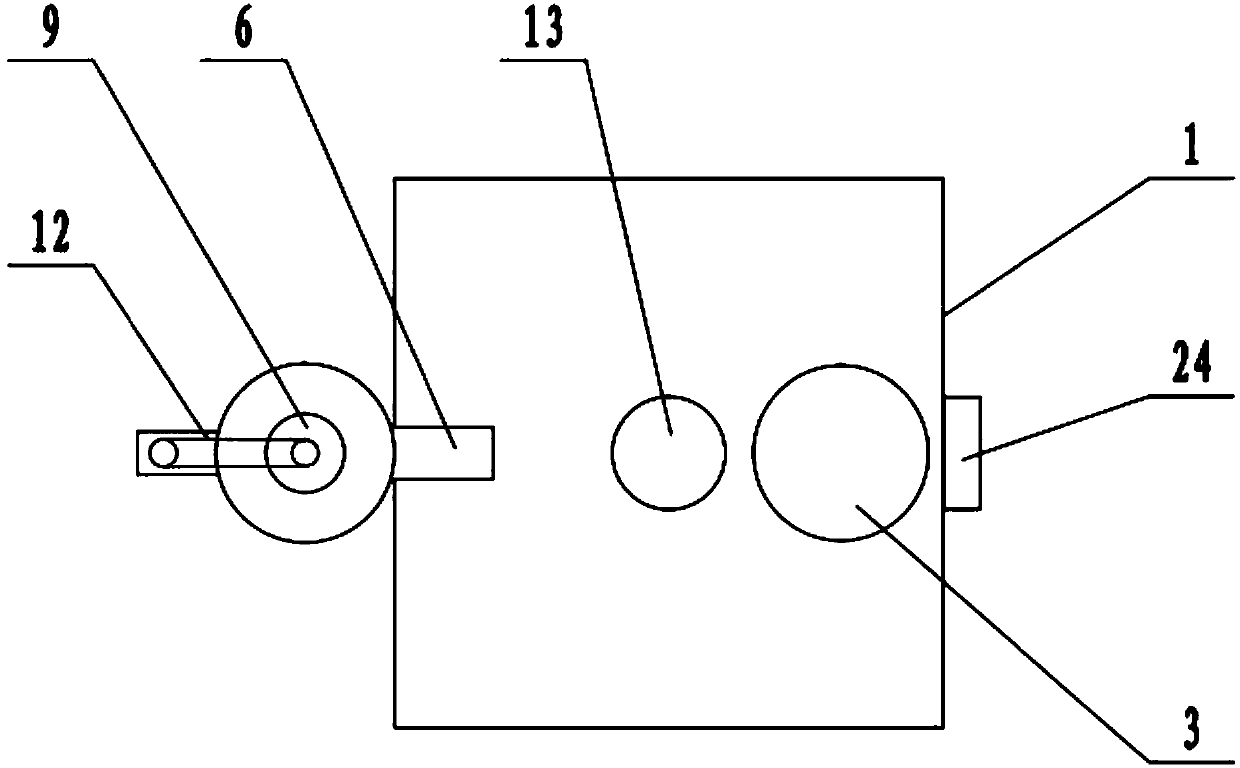

InactiveCN107486295AImprove crushing efficiencyImprove stirring efficiencyTransportation and packagingMixer accessoriesDrive shaftGear wheel

The invention discloses an efficient agricultural fertilizer stirring and crushing device. A feeding inlet is fixedly connected to the upper end of a device body, movable partition plates are arranged at the lower end of the feeding inlet and hinged to the device body, the middle of the lower portion of each movable partition plate is hinged to the upper end of a supporting rod, the lower end of each supporting rod is hinged to a threaded sliding block, a two-way threaded rod is connected to the threaded sliding blocks in a threaded and sleeved manner, and the left end of the threaded sliding block is fixedly connected with a semicircular gear; and the upper end and the lower end of each semicircular gear are each intermittently meshed with a pinion, the pinions at the upper ends are rotationally connected with the device body, the pinions at the lower ends are fixedly connected with a driven shaft, the left end of each pinion is fixedly connected with a big gear wheel, and the left end of the driven shaft is fixedly connected with a second bevel gear. According to the efficient agricultural fertilizer stirring and crushing device, a bevel gear set is used for driving the semicircular gears to rotate positively or negatively, and then the two-way threaded rod is driven to rotate positively or negatively along with the semicircular gears; and the two-way threaded rod drives the threaded sliding blocks to move left and right to control intermittent feeding of the movable partition plates at the same time of driving a stirring roller to achieve stirring crushing. The device is simple and practical in structure, and the crushing and stirring efficiency of fertilizers are greatly improved.

Owner:田楷

Dry-type sand making method and dry-type sand making machine thereof

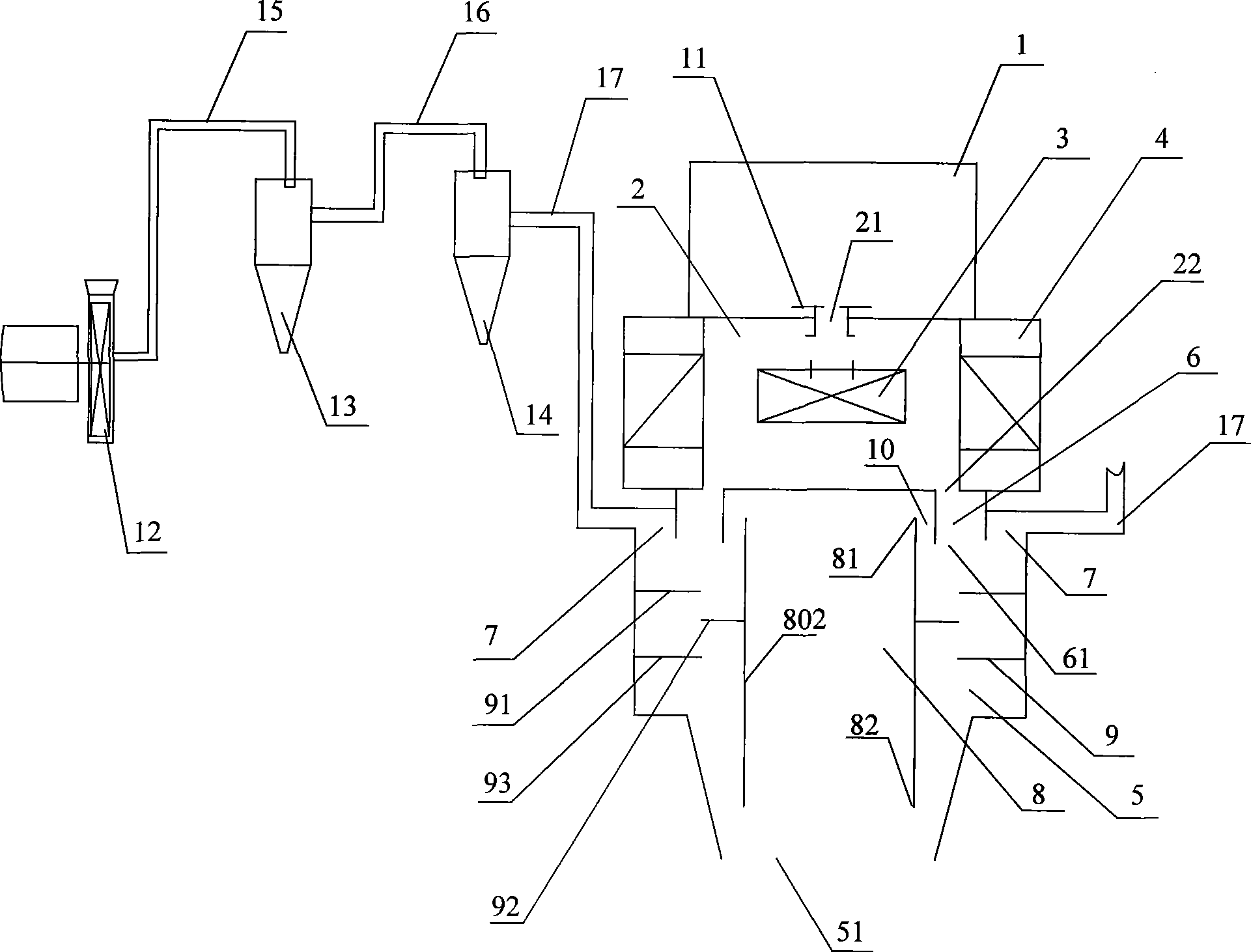

The invention discloses a dry sand maker which comprises a hollow crushing cavity (2). A hollow dust removal cavity (5) is arranged under the hollow crushing cavity (2); the upper end of a feeding channel (6) is hermetically connected with a feeding mouth (22) and the lower end (61) thereof is positioned in the dust removal cavity (5) on which an air vent (7) is also arranged; an air duct (8) is arranged in the dust removal cavity (5); the lower end (61) of the feeding channel (6) is staggered with the upper end (81) of the air duct (8) in the horizontal direction; the bottom surface of the dust removal cavity (5) is provided with an outlet (51); a dust absorption component is hermetically connected with the lower end (82) of the air duct (8) or the air vent (7) after passing through the outlet (51). The invention also provides a method for drying sand making simultaneously. By adopting the dry sand maker, the drying sand making can have the advantages of high production efficiency and low environmental pollution.

Owner:吴核明

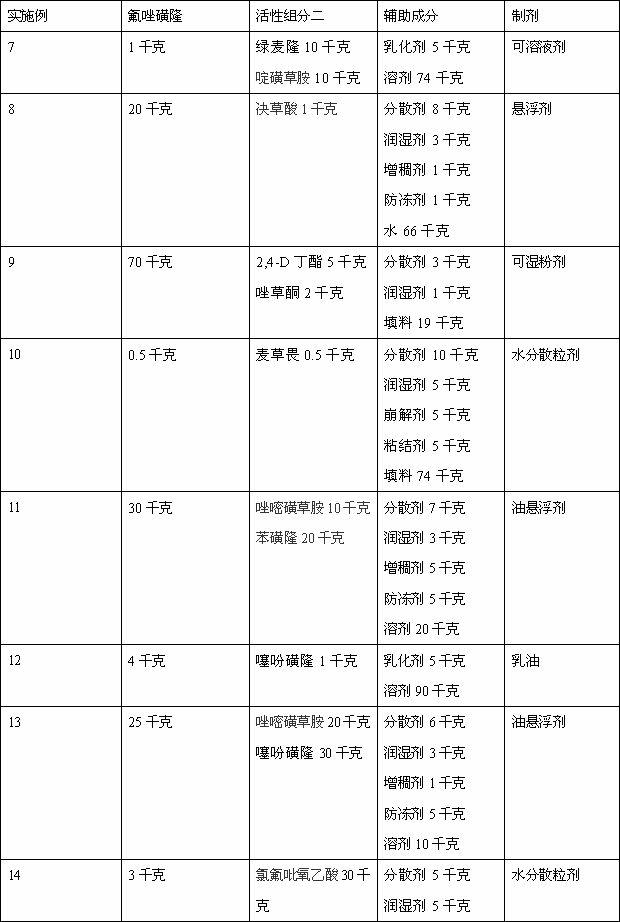

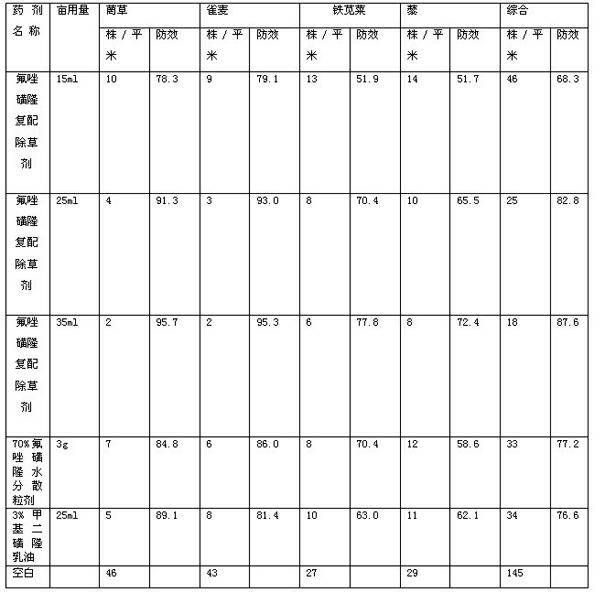

Flucarbazone-Na compounded herbicide

InactiveCN102428945APrevent flocculationAvoid layeringBiocideAnimal repellantsFluroxypyrFluoroglycofen-ethyl

The invention discloses a flucarbazone-Na compounded herbicide which comprises an active component I (flucarbazone-Na), an active component II and auxiliary components, wherein the active component II is one or a combination of several of mesosulfuron methyl, isoproturon, chlortoluron, pyroxsulam, Clodinafop-propargyl, carfentrazone-ethyl, tribenuron-methyl, fluroxypyr, methoxone, 2,4-D-butyl ester, dicamba, bromoxynil, thifensulfuron methyl, amidosulfuron, bensulfuron-methyl, flumetsulam, fluoroglycofen-ethyl and florasulam; the auxiliary components comprise an auxiliary agent and also comprise one of a filler and a solvent; the auxiliary agent is one or a combination of two of an emulsifying agent, a dispersant, a wetting agent, a disintegrant, an agglomerant, an antifreezing agent and a thickening agent; the mass sum of the active component I (flucarbazone-Na) and the active component II is 1%-85% of the total mass of the flucarbazone-Na compounded herbicide; and the mass ratio of the active component I to the active component II is (1:20)-(20:1). The flucarbazone-Na compounded herbicide disclosed by the invention is a novel herbicide for preventing and removing weeds in a wheatland.

Owner:河北博嘉农业有限公司

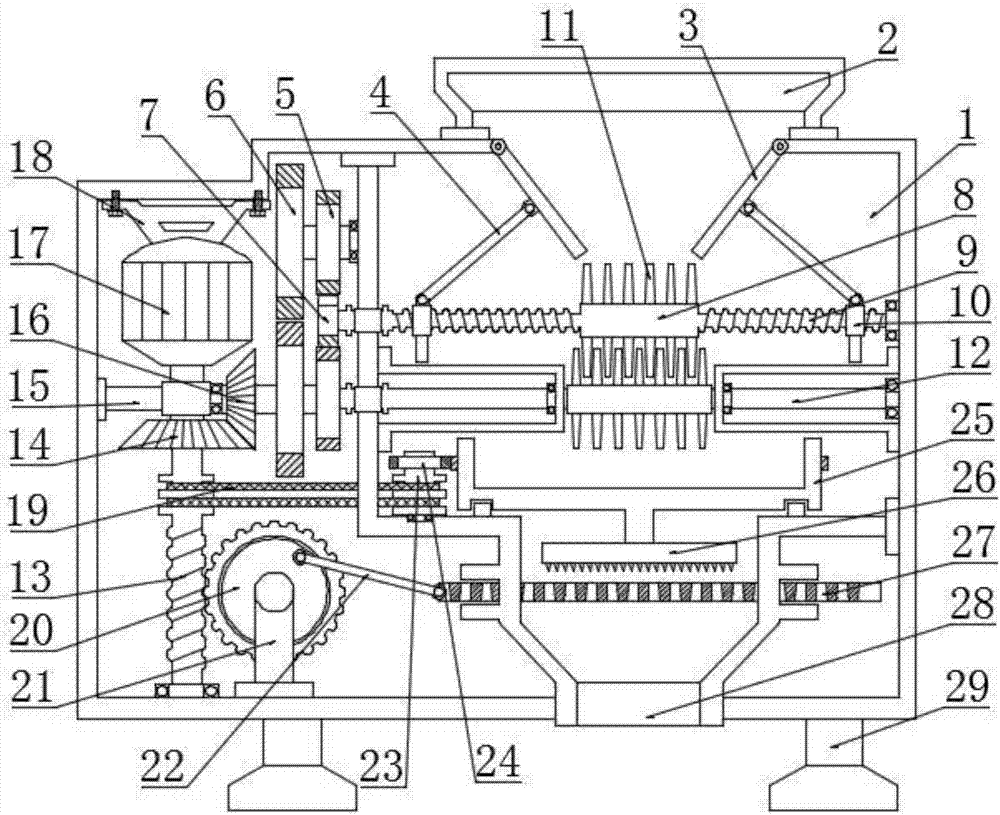

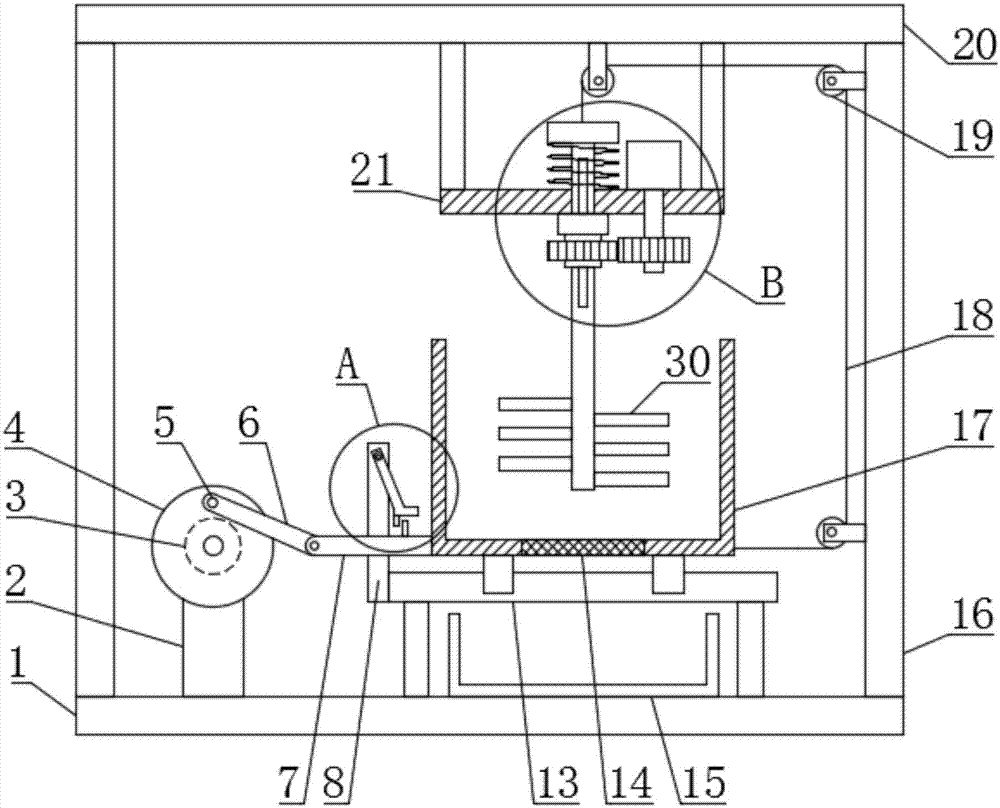

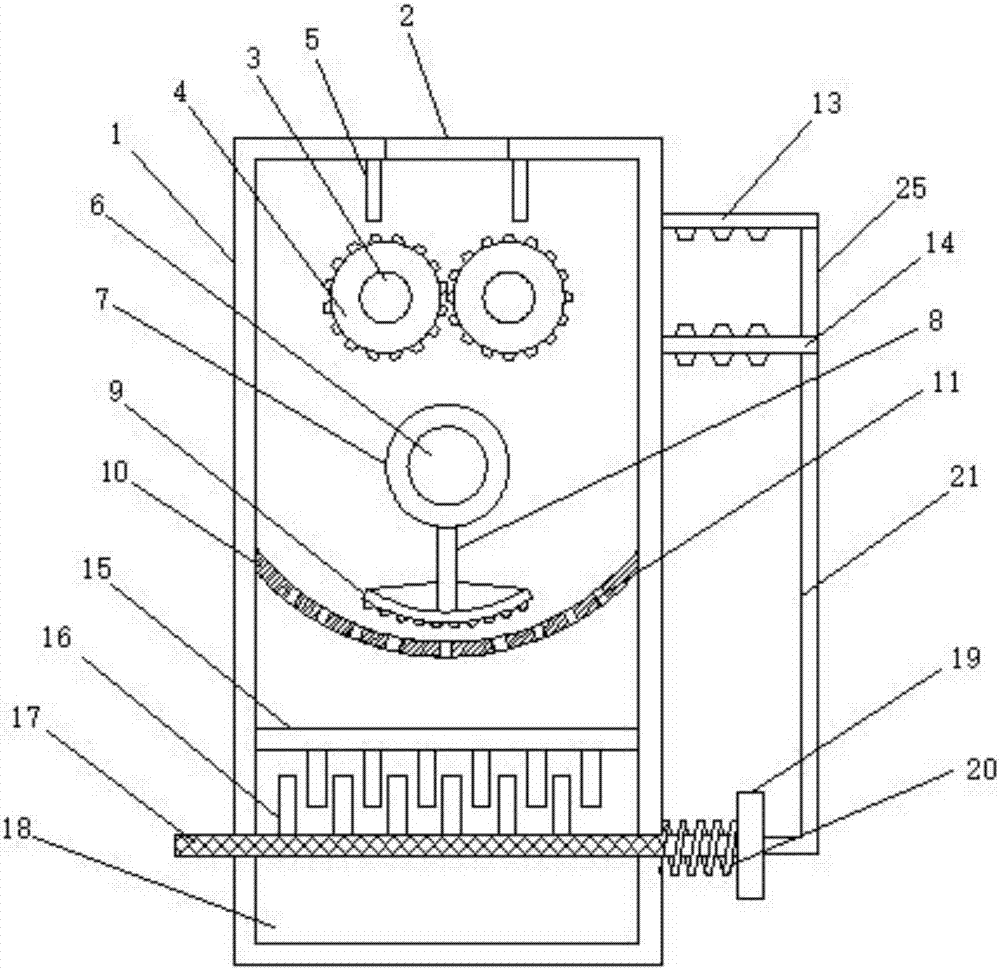

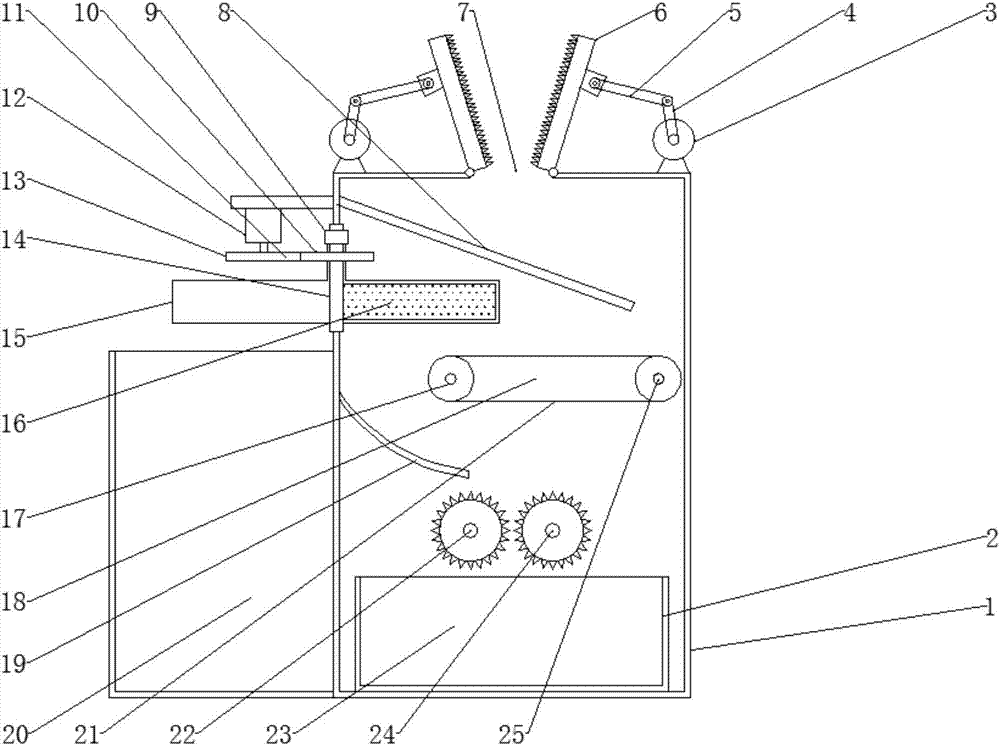

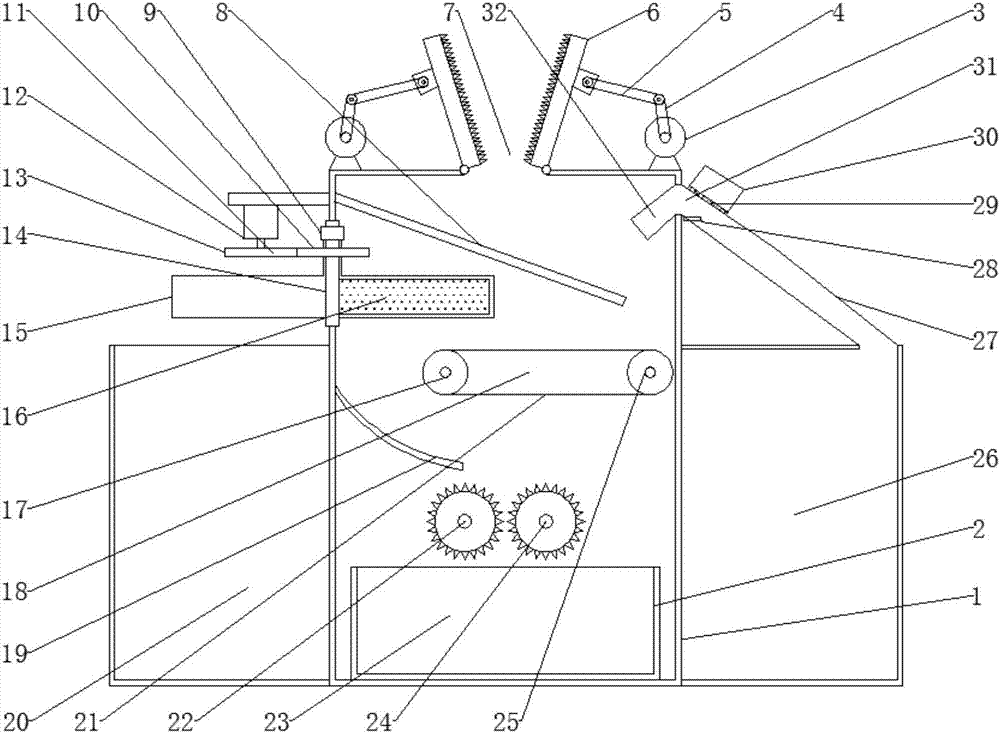

High-efficiency fodder crushing, vibrating and screening device

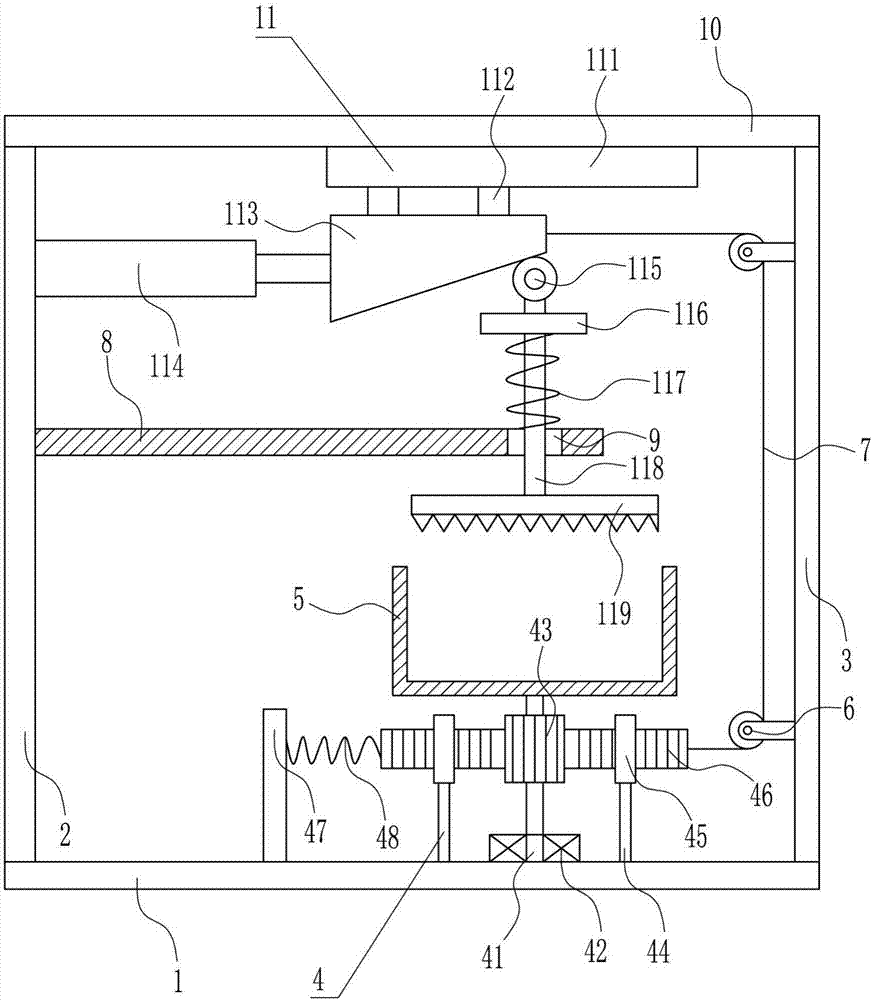

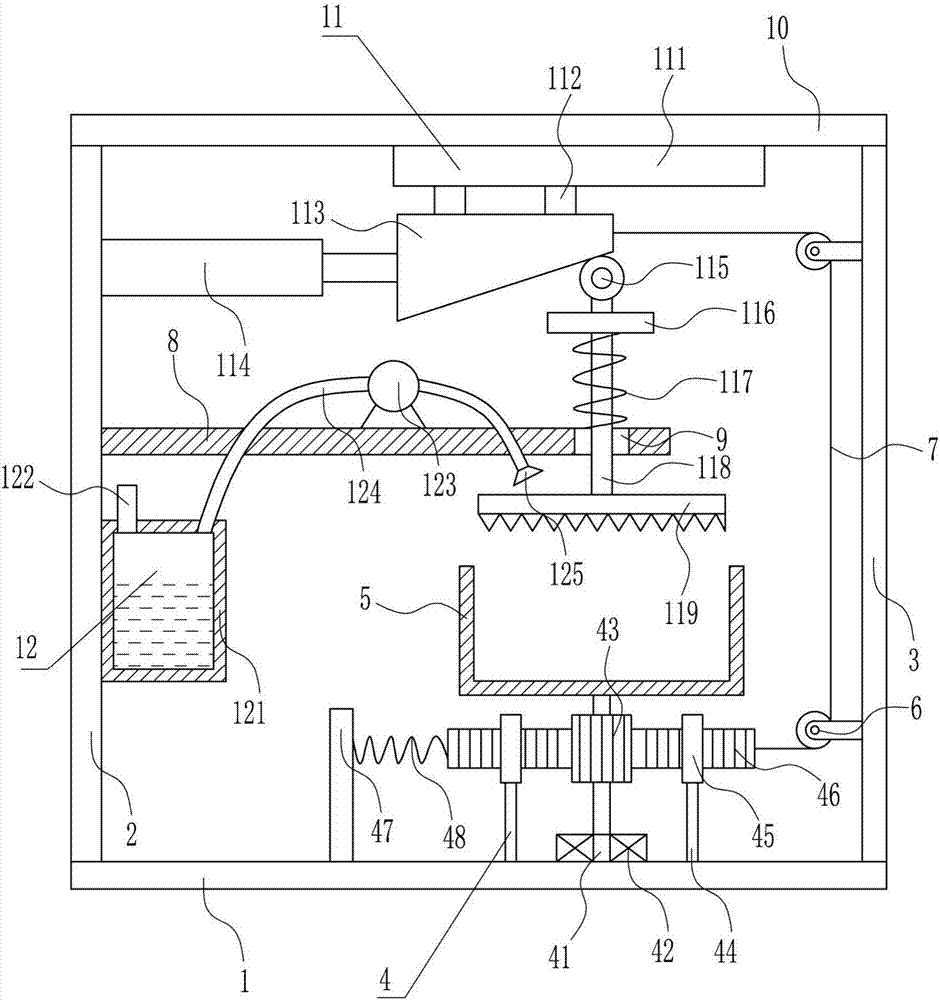

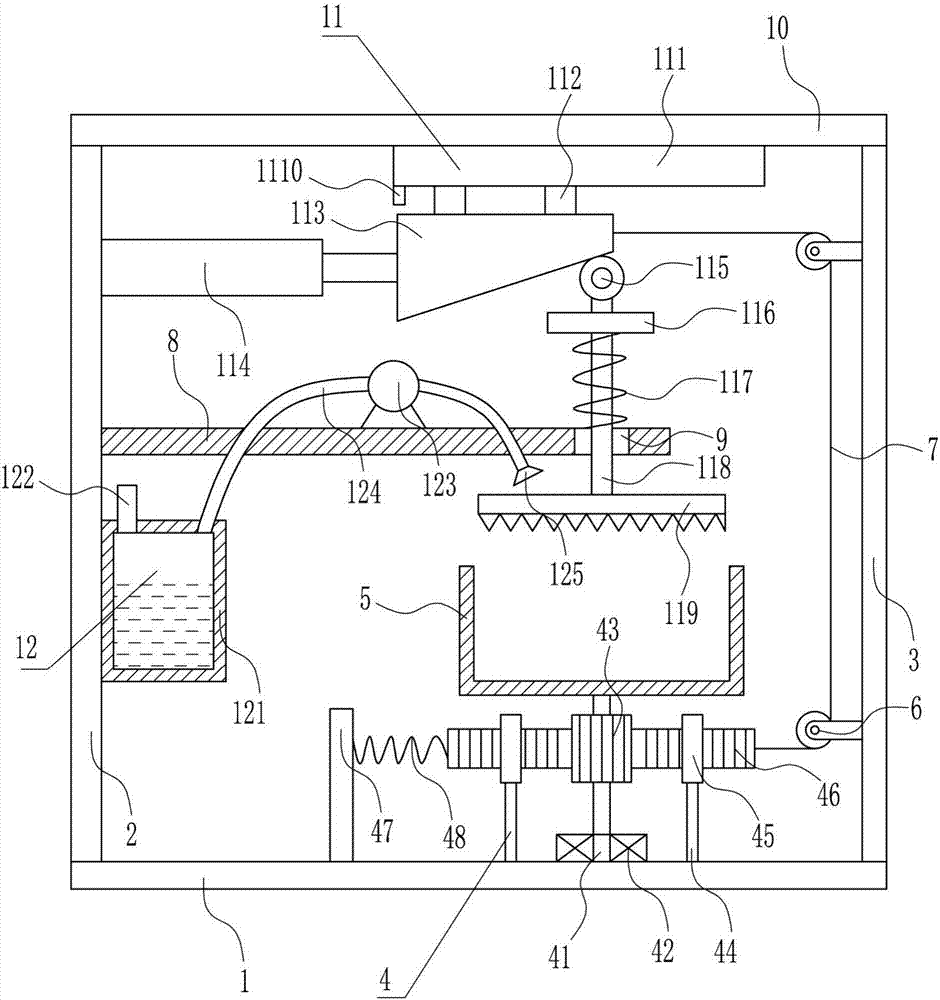

InactiveCN107486299AExpand the crushing rangeImprove crushing efficiencySievingScreeningElectric machineryMotor shaft

The invention discloses a high-efficiency feed crushing and vibrating screening device, which comprises a base, a slide rail is fixed on the top of the base through a bracket, a crushing box is slidably connected above the slide rail, a screen is arranged at the bottom of the crushing box, and a bottom left corner of the crushing box is connected with a Moving rod; the top of the base is also provided with a fixed seat, the front side wall of the fixed seat is provided with a deceleration motor, the motor shaft at the front end of the deceleration motor is installed with a rotating disc, the top of the front end of the rotating disc is provided with a pin shaft, and the pin shaft is rotatably connected with a connecting rod , the connecting rod is hinged with the moving rod; the left end of the slide rail is fixedly provided with a fixed rod, the top of the front side wall of the fixed rod is hinged with a knocking rod, the bottom of the knocking rod is fixedly provided with a baffle, and the top of the moving rod is provided with a push plate. During the feed grinding process of the present invention, the grinding box moves left and right by rotating the disc, thereby driving the feed to shake; during the grinding process, the knocking rod knocks on the side wall of the grinding box to prevent the feed from sticking to the inner wall of the grinding bucket and avoid screen blockage.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

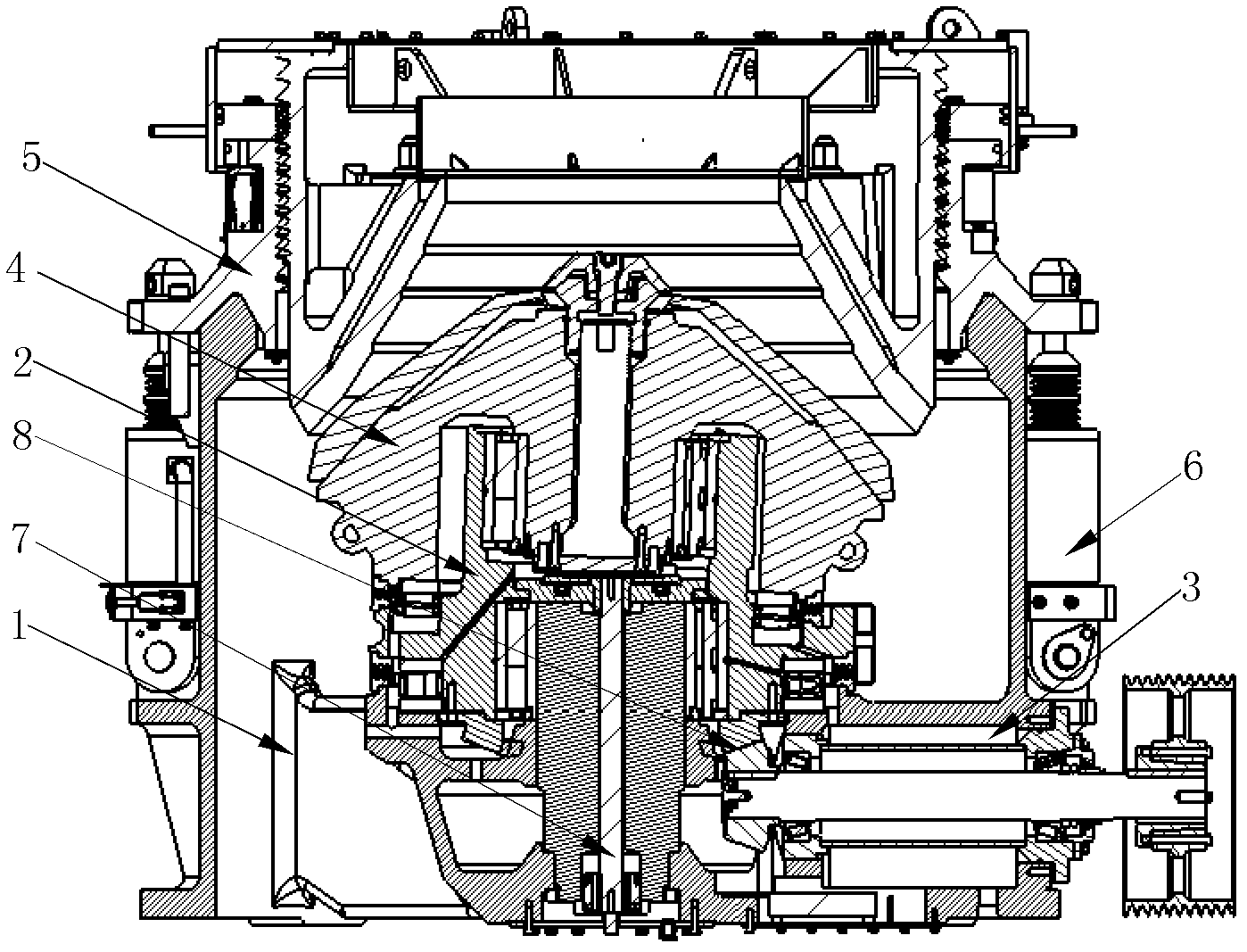

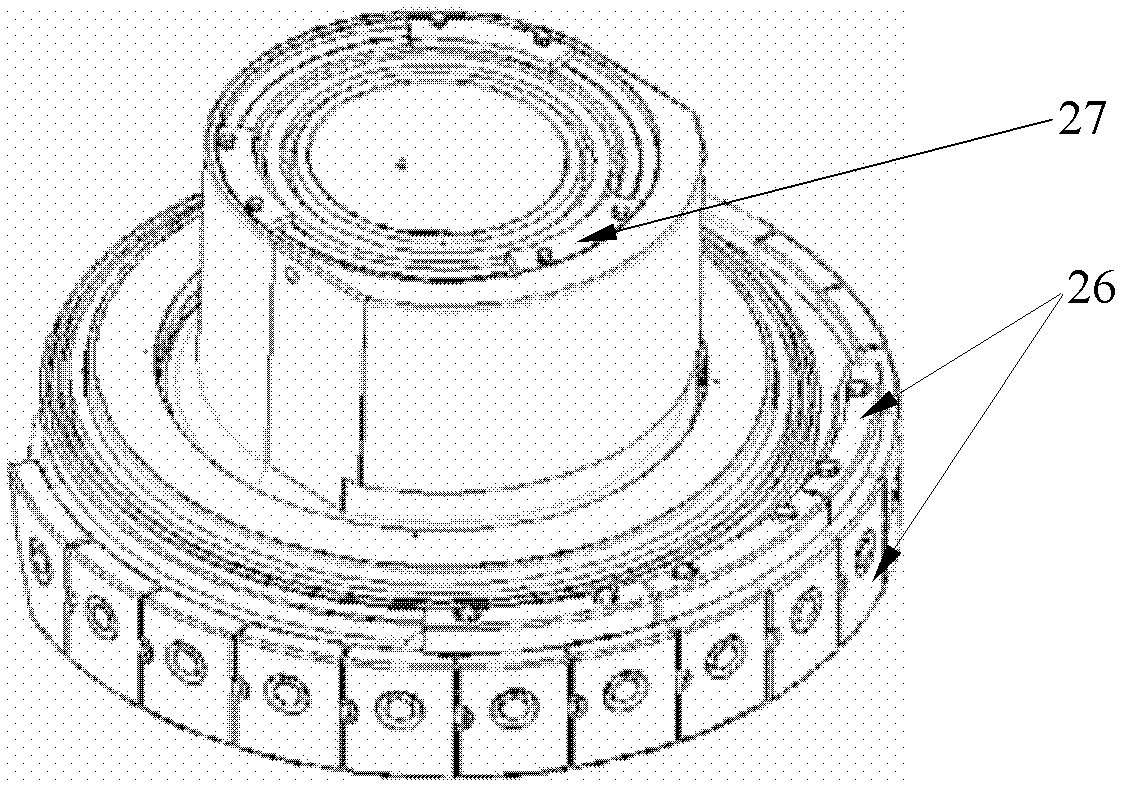

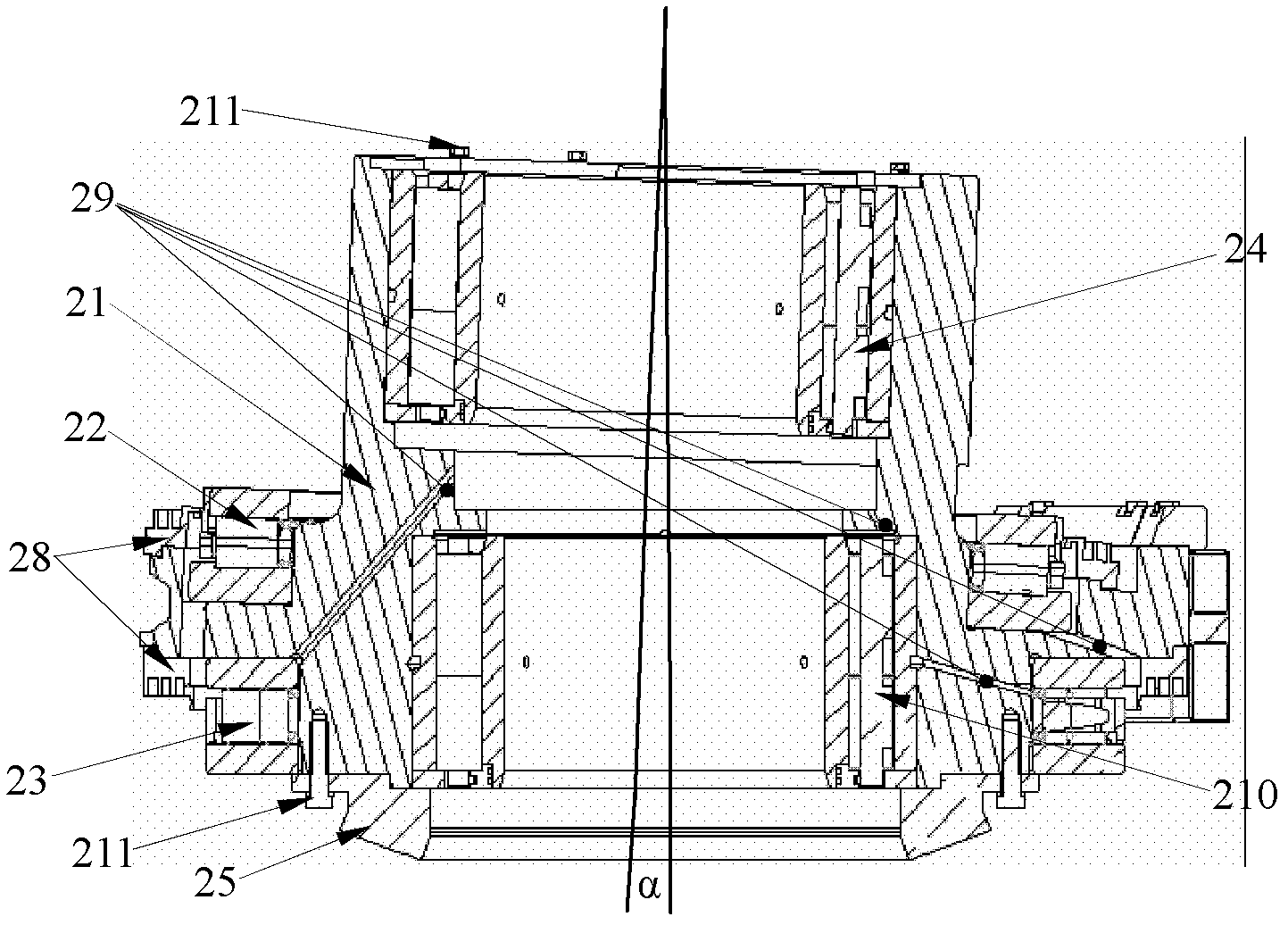

Multi-cylinder hydraulic antifriction bearing taper crusher

ActiveCN102357371AIncrease speedImprove crushing efficiencyGrain treatmentsRolling-element bearingWorking pressure

The invention discloses a multi-cylinder hydraulic antifriction bearing taper crusher, which comprises a lower machine frame, an eccentric sleeve mechanism, a transmission set, a movable tapper, an upper machine frame set and an iron passing and cavity clearing device. The upper machine frame set is arranged above the lower machine frame, the transmission set and the eccentric sleeve mechanism are both installed on the lower machine frame, the transmission set is connected with the eccentric sleeve mechanism where the movable tapper is arranged, the iron passing and cavity clearing device is directly installed on the lower machine frame and the upper machine frame set, the eccentric sleeve mechanism adopts an antifriction bearing type eccentric sleeve mechanism, the iron passing and cavity clearing device adopts a relief valve type iron passing and cavity clearing device, and a movable tapper body rotating-proof device is connected to the bottom of the movable tapper. The multi-cylinder hydraulic antifriction bearing taper crusher improves crushing efficiency and output of the taper crusher, and prolongs service life of a machine, reduces using cost of equipment. The iron passing and cavity clearing device can not only bear higher working pressure of a system, but also be safe and reliable, convenient to assemble and capable of controlling a tapper body to rotate according to certain direction, thereby improving production efficiency and saving energy.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

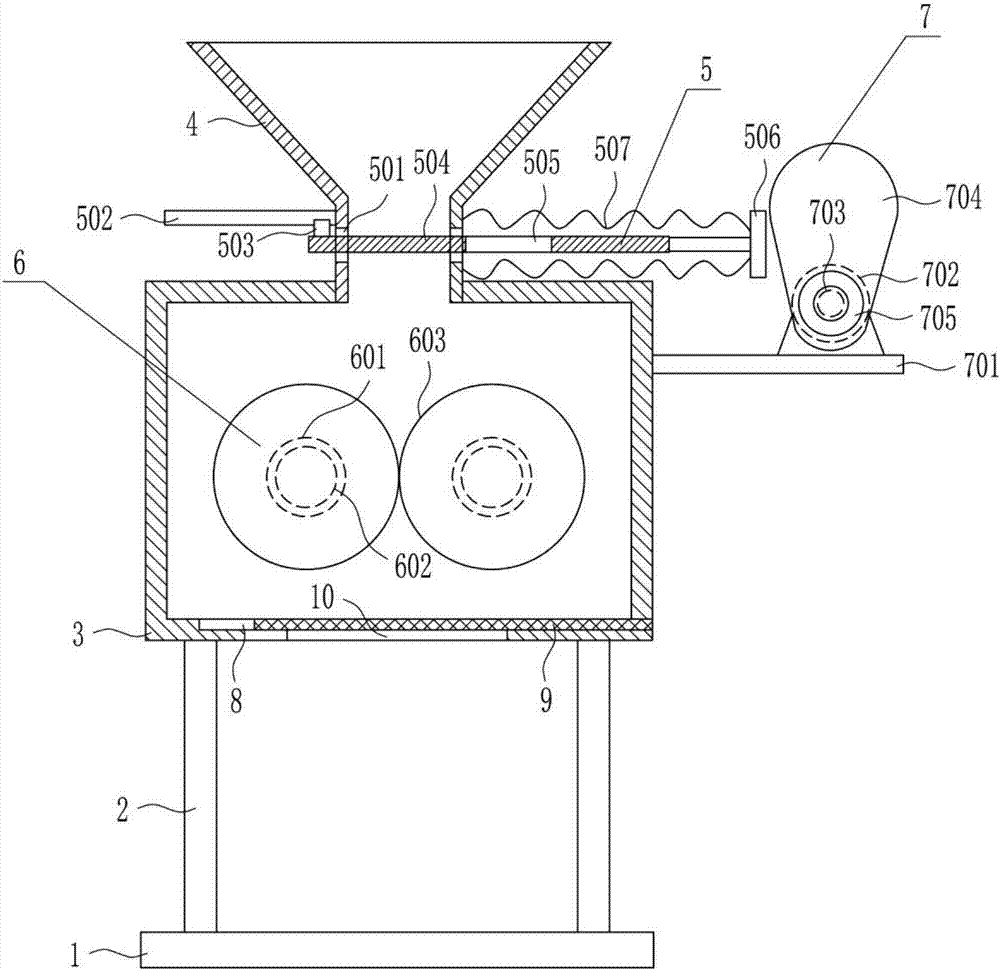

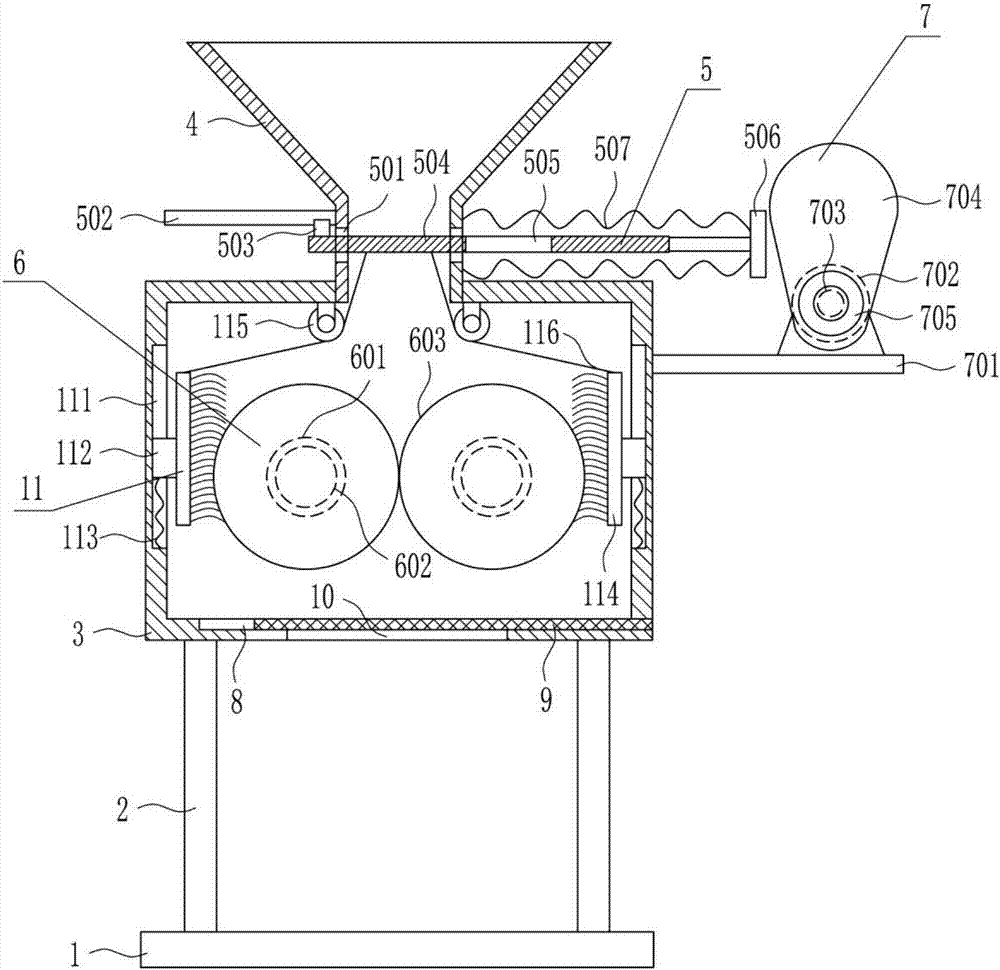

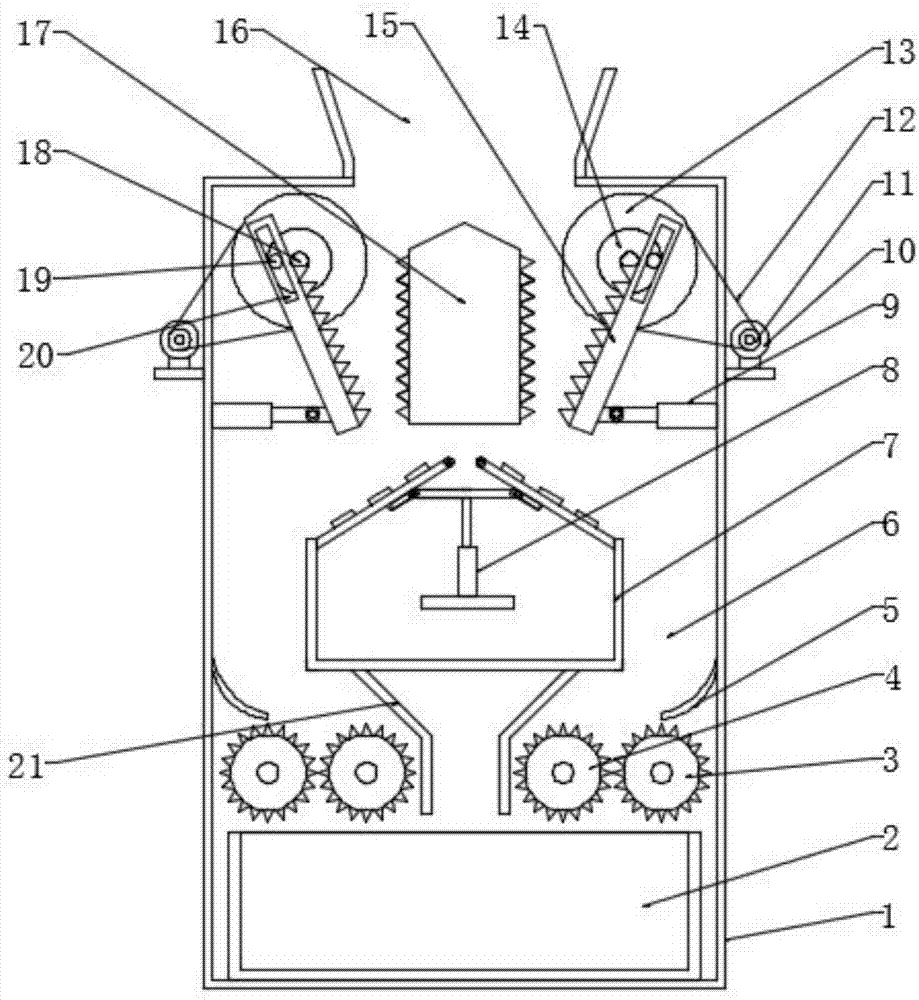

Crushing and stirring integrated equipment for feed production

InactiveCN108142969AMix well and evenlyAvoid vibrationFeeding-stuffTransportation and packagingKnife bladesCrankshaft

The invention discloses crushing and stirring integrated equipment for feed production. The crushing and stirring integrated equipment comprises a bottom plate, a stirring tank, a motor, a first rotating shaft, a mesh screen, a supporting plate, second rotating shafts, first gears, inner gear rings, a first crushing blade, second crushing blades, a crankshaft, a connecting rod journal, racks, second gears, third rotating shafts and knocking devices, wherein each knocking device comprises a swinging rod, a spring and a knocking ball. According to the crushing and stirring integrated equipment disclosed by the invention, the motor, the first rotating shaft, the second rotating shafts, the first gears and the inner gear rings are arranged and cooperate with each other to sufficiently and uniformly crush feed raw materials, so that the crushing efficiency is improved; the crankshaft, the connecting rod journal, the racks, the second gears and the third rotating shafts are arranged, so thatthe stirring manners are diversified, the stirring and mixing efficiency is improved, and the mixing of feeds is more sufficient and uniform; and the knocking devices are arranged, so that the situation that too many feeds are stuck to the side walls of the stirring tank, and waste is generated can be avoided.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

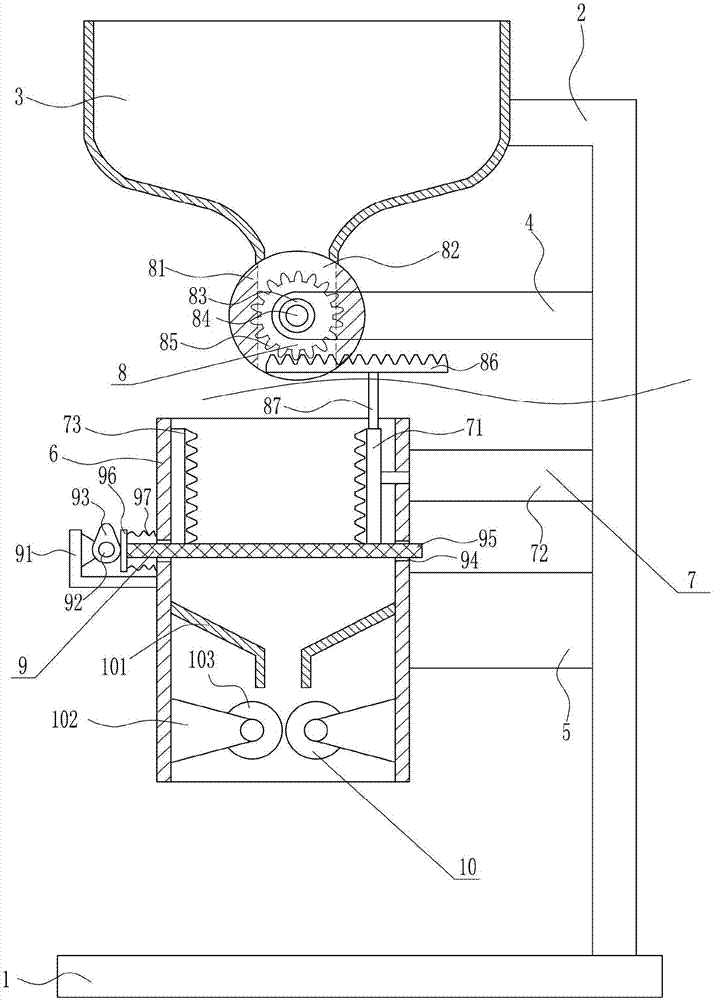

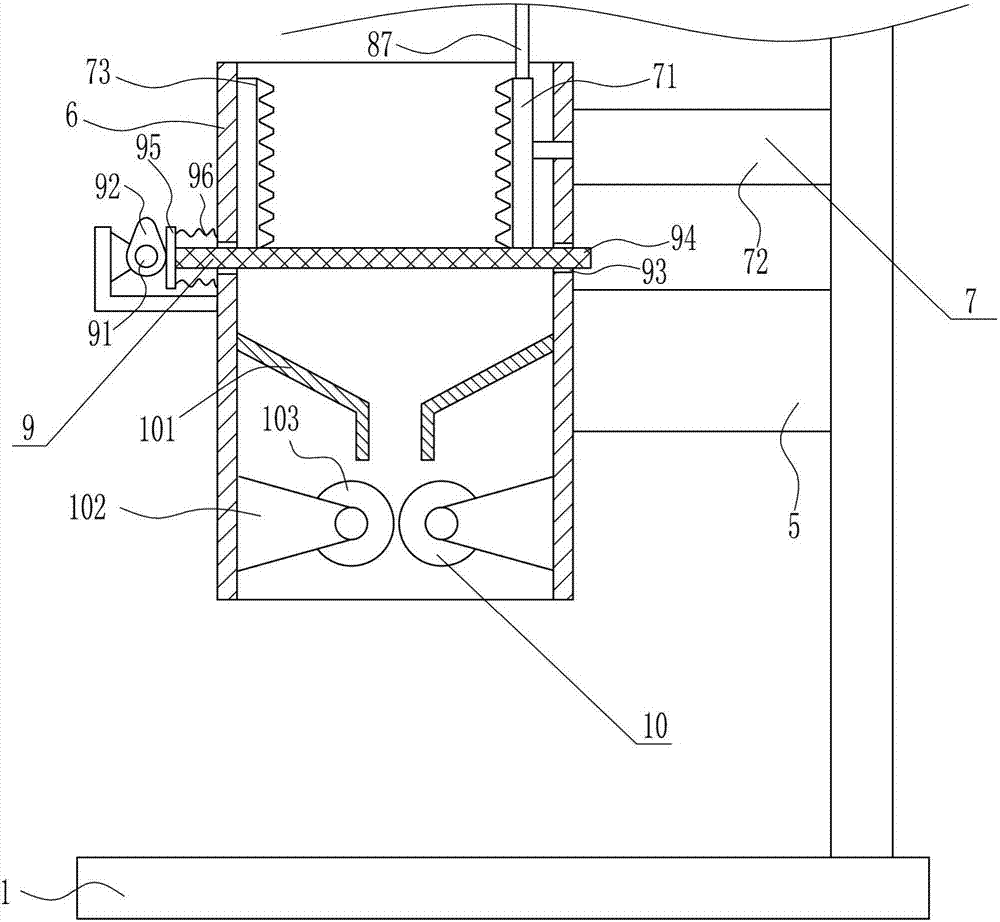

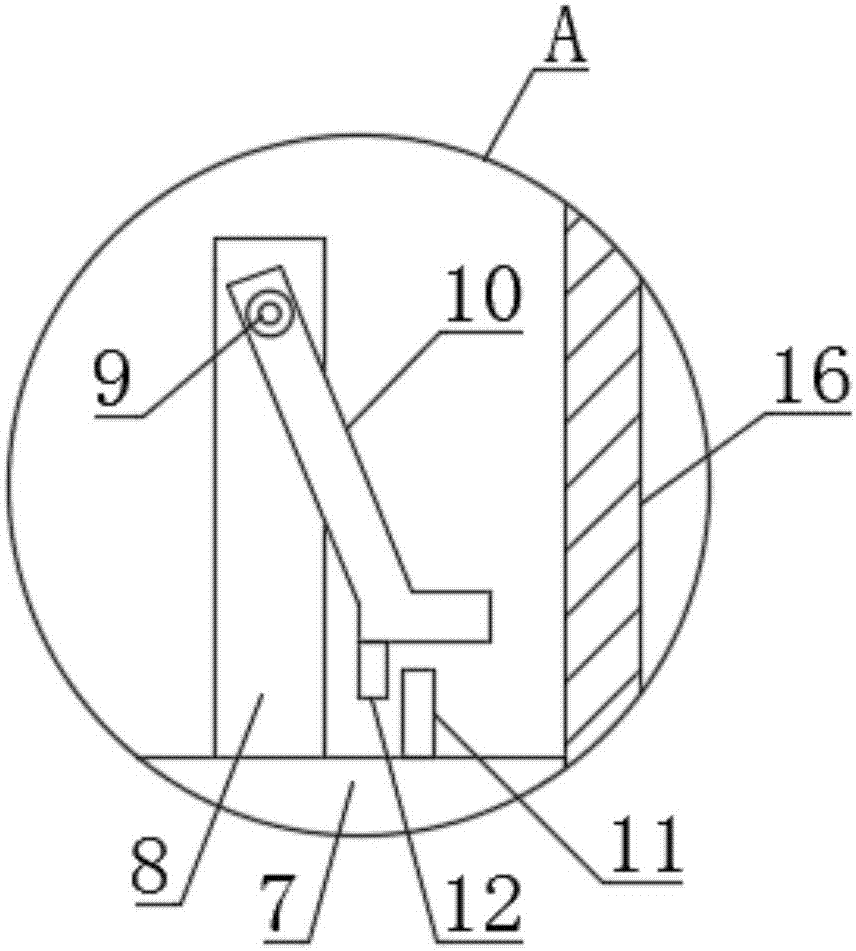

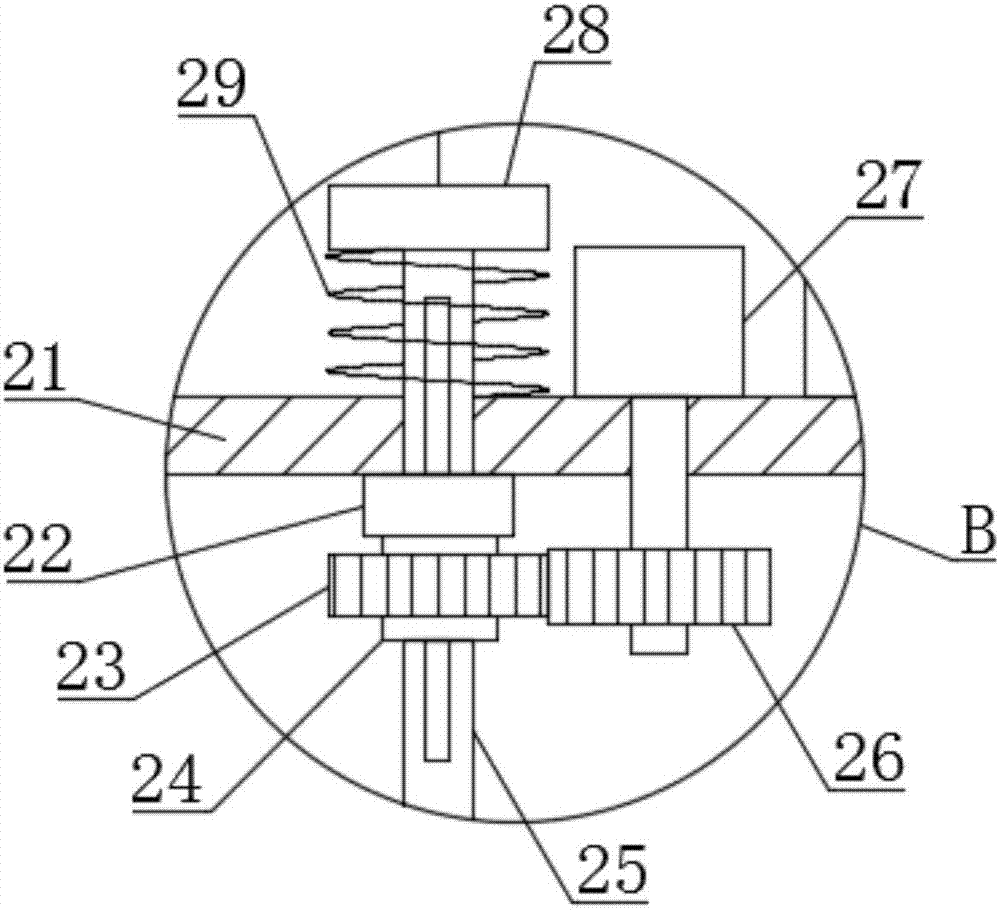

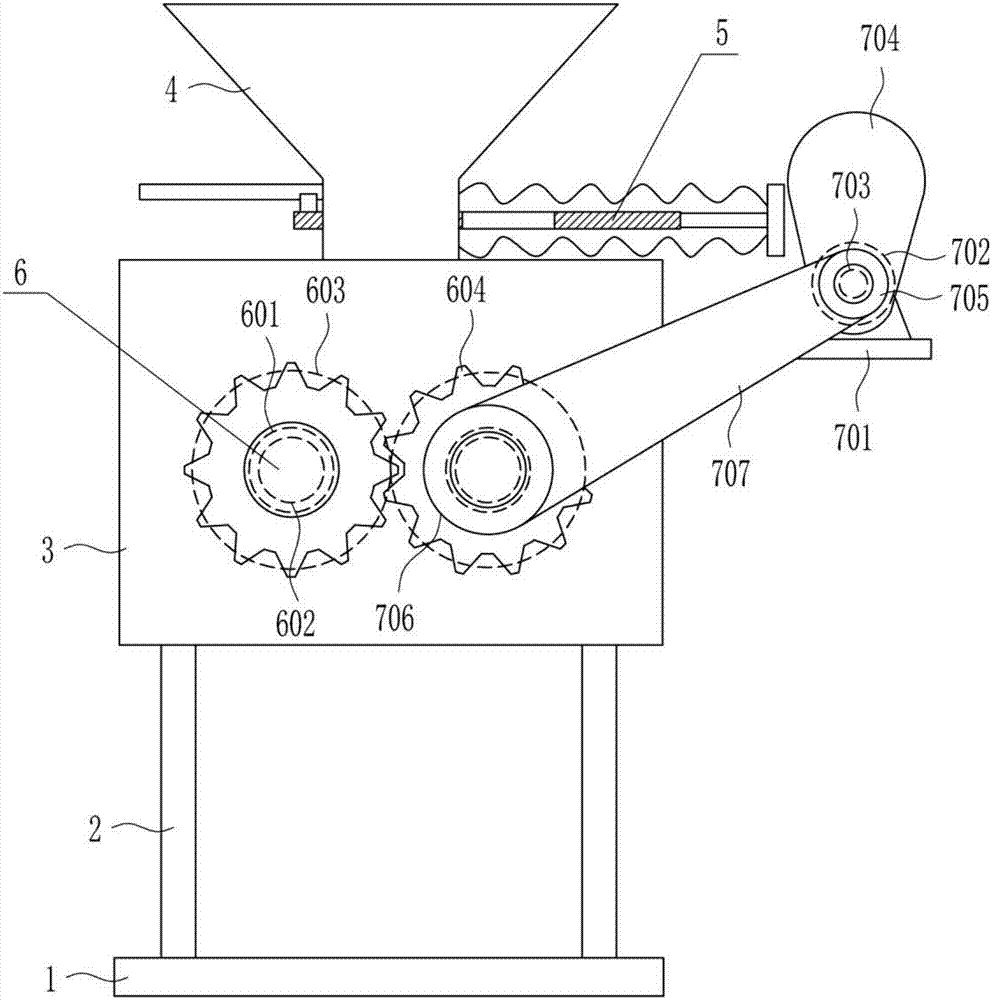

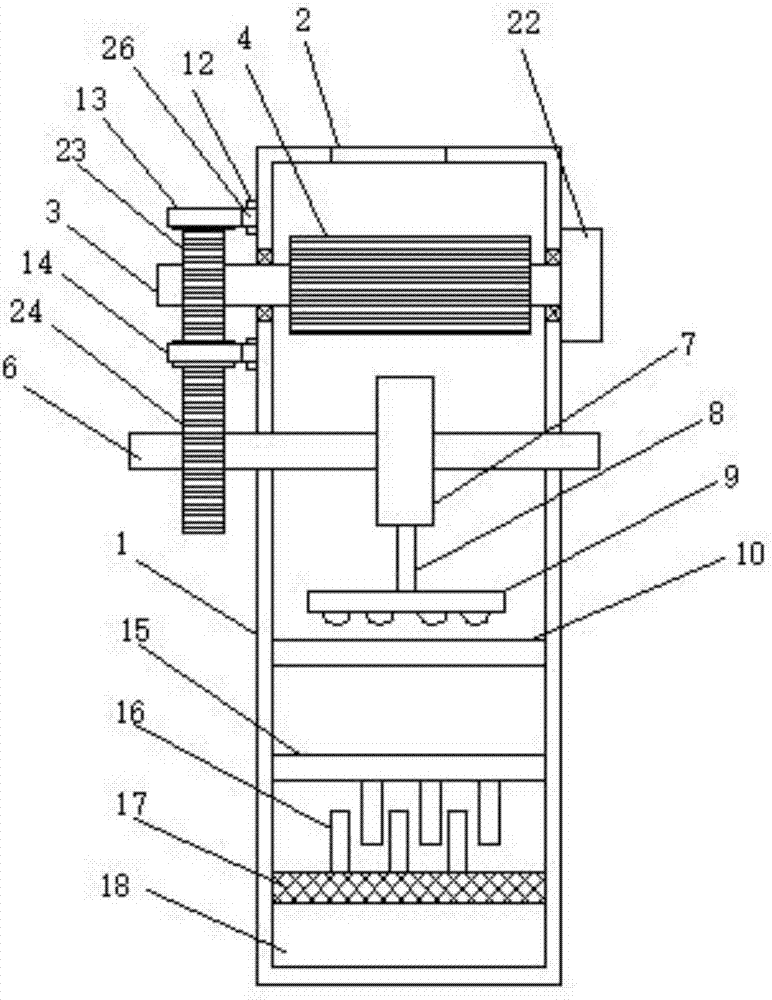

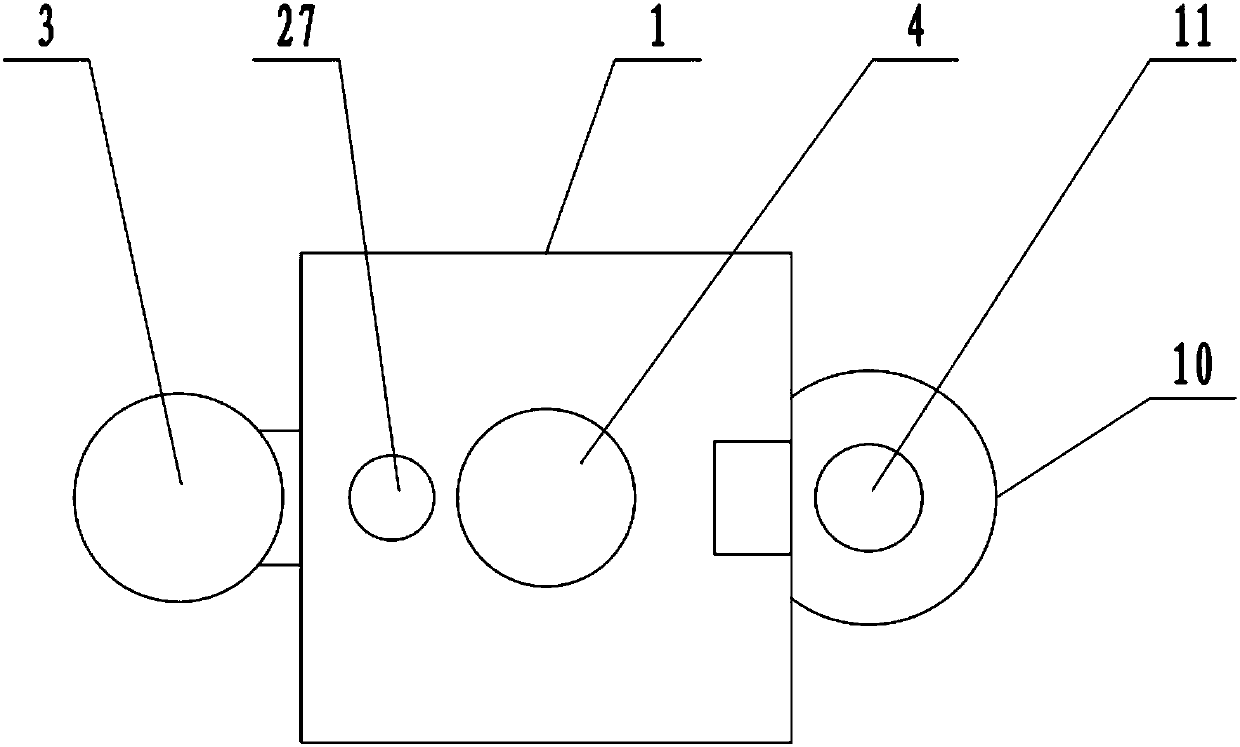

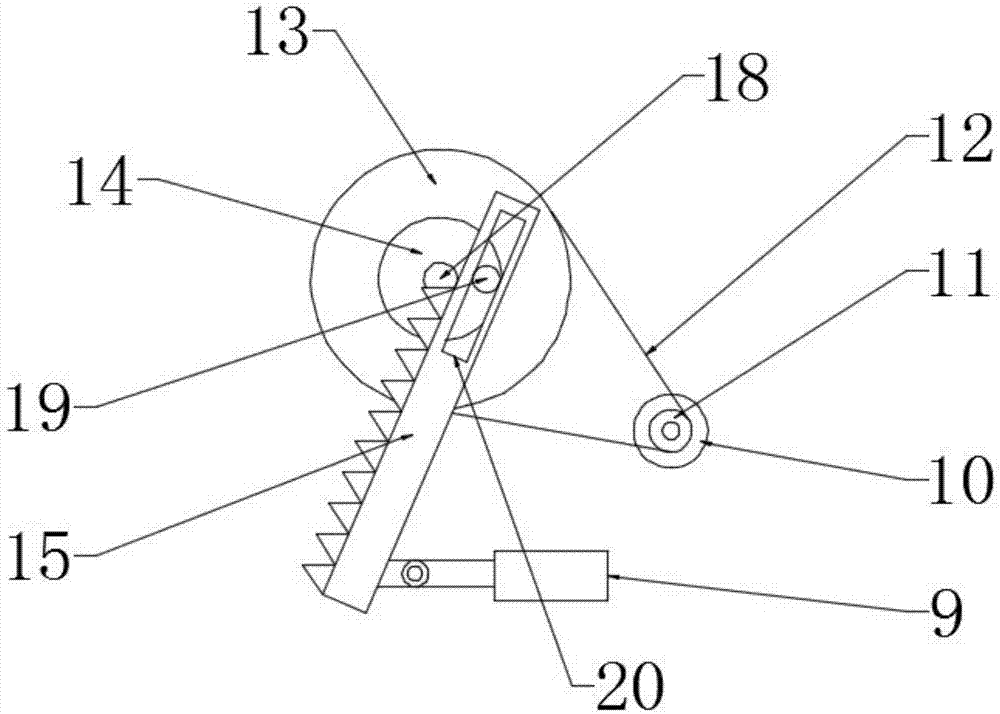

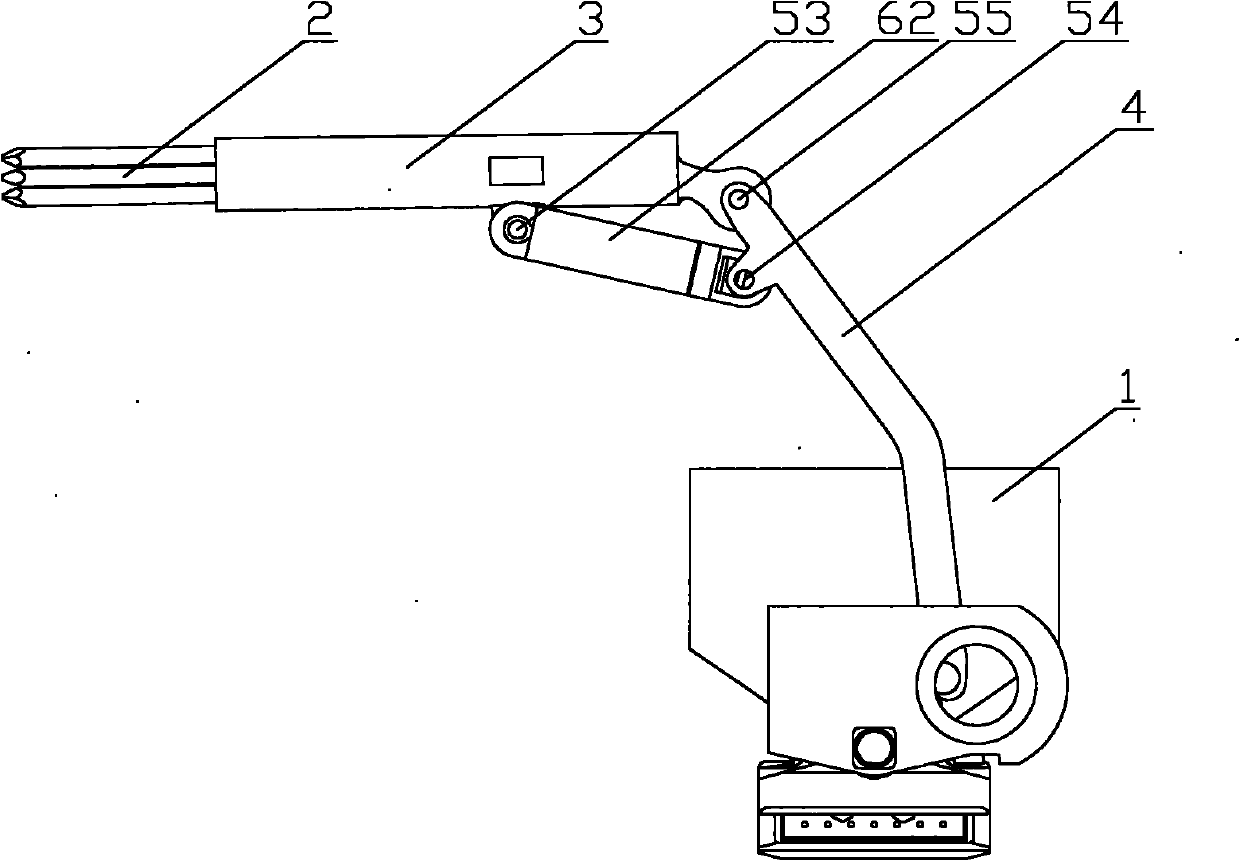

Pellet feed crushing machine for breeding

ActiveCN107971063AAvoid feeding too fastImprove crushing efficiencySievingFeeding-stuffEngineeringMechanical engineering

The invention relates to a crushing machine for breeding, in particular to a pellet feed crushing machine for breeding. The technical problem to be solved is to provide the pellet feed crushing machine for breeding which is time-saving and labor-saving and is capable of improving the crushing efficiency and the feeding efficiency. In order to solve the technical problem, the pellet feed crushing machine for breeding is provided and comprises a base and the like; supporting rods are vertically connected to the left side and the right side of the top of the base correspondingly, a box body is connected between the top ends of the two supporting rods, the top of the box body is provided with a first discharging hopper, a discharging device is arranged in the first discharging hopper, a crushing device is arranged in the box body, and a driving device is arranged on the upper portion of the right side surface of the box body. According to the crushing machine, the driving device can drivethe discharging device and the crushing device to work at the same time, the discharging device performs discharging accordingly to enable the pellet feed in the first discharging hopper to fall intothe box body, the crushing device performs crushing on the pellet feed which falls into the box body accordingly, so that the effect of improving the crushing efficiency is achieved.

Owner:湖南省好运来机电设备有限公司

Sandstone smashing and grinding device for building engineering

The invention discloses a sandstone crushing and grinding device for construction engineering, which comprises a box body and a feeding port, the feeding port is arranged on the top wall of the box body, and two first horizontal shafts are arranged inside the box body , the inside of the box is also provided with a second horizontal shaft whose axis is parallel to the axis of the first horizontal shaft, one end of one of the first horizontal shafts is provided with a semi-circular gear, and an upper rack is arranged above the semi-circular gear, and the semi-circular gear A double-sided rack is arranged under the gear, a rotating gear is arranged at one end of the second horizontal axis, a swing rod is arranged on the rotating sleeve, a swing grinding disc is arranged at the lower end of the swing rod, and a side and the inner wall of the box are arranged under the swing grinding disc. connected to the fixed grinding disc, and the bottom of the box is also provided with a screen plate and a plurality of cross bars. The invention has the advantages of simple structure, high crushing efficiency, good crushing effect on sand and stone crushed three times, and can screen sand and stone grains at the same time, and has strong practicability.

Owner:宋衡星

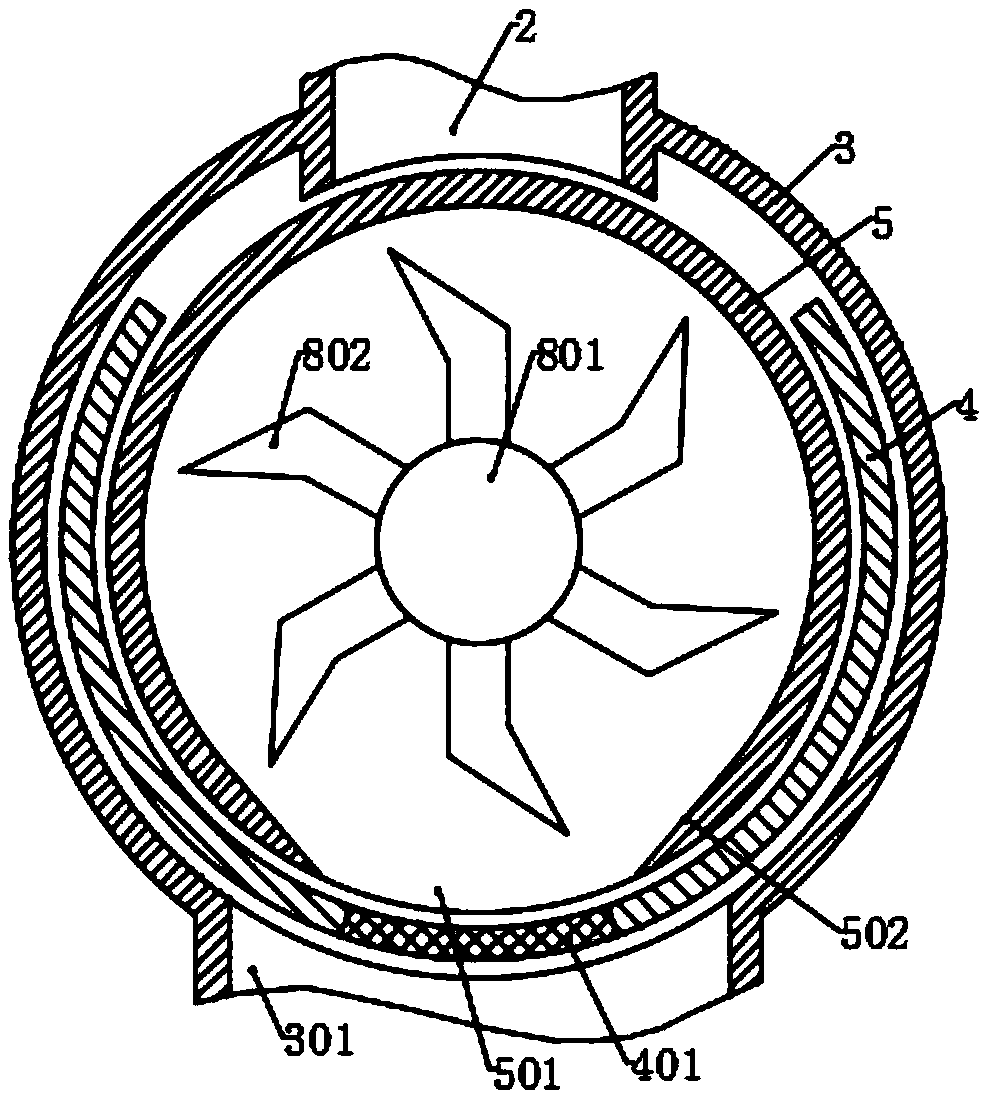

Self-circulation Chinese herbal medicine crushing and grinding integration device

InactiveCN107790244ACrushed fullyImprove crushing effectGrain treatmentsReciprocating motionElectric machinery

The invention discloses a self-circulation Chinese herbal medicine crushing and grinding integration device. The self-circulation Chinese herbal medicine crushing and grinding integration device comprises a shell, support legs, a feed port, a crushing motor, a crushing shaft, a crushing blade, a conical grinding hammer and a grinding motor; the left side wall of the shell is fixedly connected witha circulating cylinder; a screw rod is arranged in the circulating cylinder; the upper surface of the circulating cylinder is fixedly connected with a double-shaft motor; the upper surface of the shell is fixedly connected with the crushing motor; a shaft extension end of the crushing motor is fixedly connected with the crushing shaft; a screen plate is arranged below the crushing shaft; a grinding table is arranged below the screen plate; the conical grinding hammer is arranged in the grinding table; traditional Chinese medicines are crushed by using the crushing blade, and are stirred by using stirring blades during crushing, so that the traditional Chinese medicines are crushed more sufficiently; the crushed traditional Chinese medicines fall onto the screen plate, and the screen plateperforms a left-right reciprocating motion to improve the efficiency of the traditional Chinese medicine passing through the screen plate; and the conical grinding hammer and the grinding table are matched to crush the traditional Chinese medicines, and are opposite in rotating direction to improve the grinding efficiency.

Owner:李欢欢

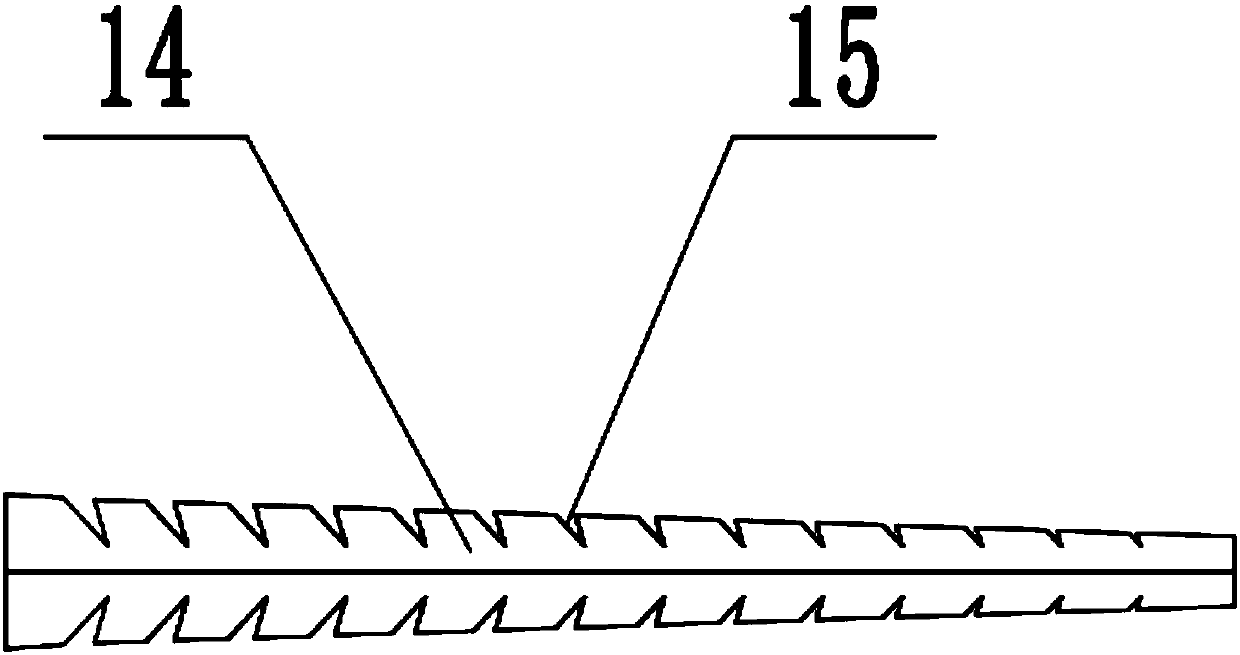

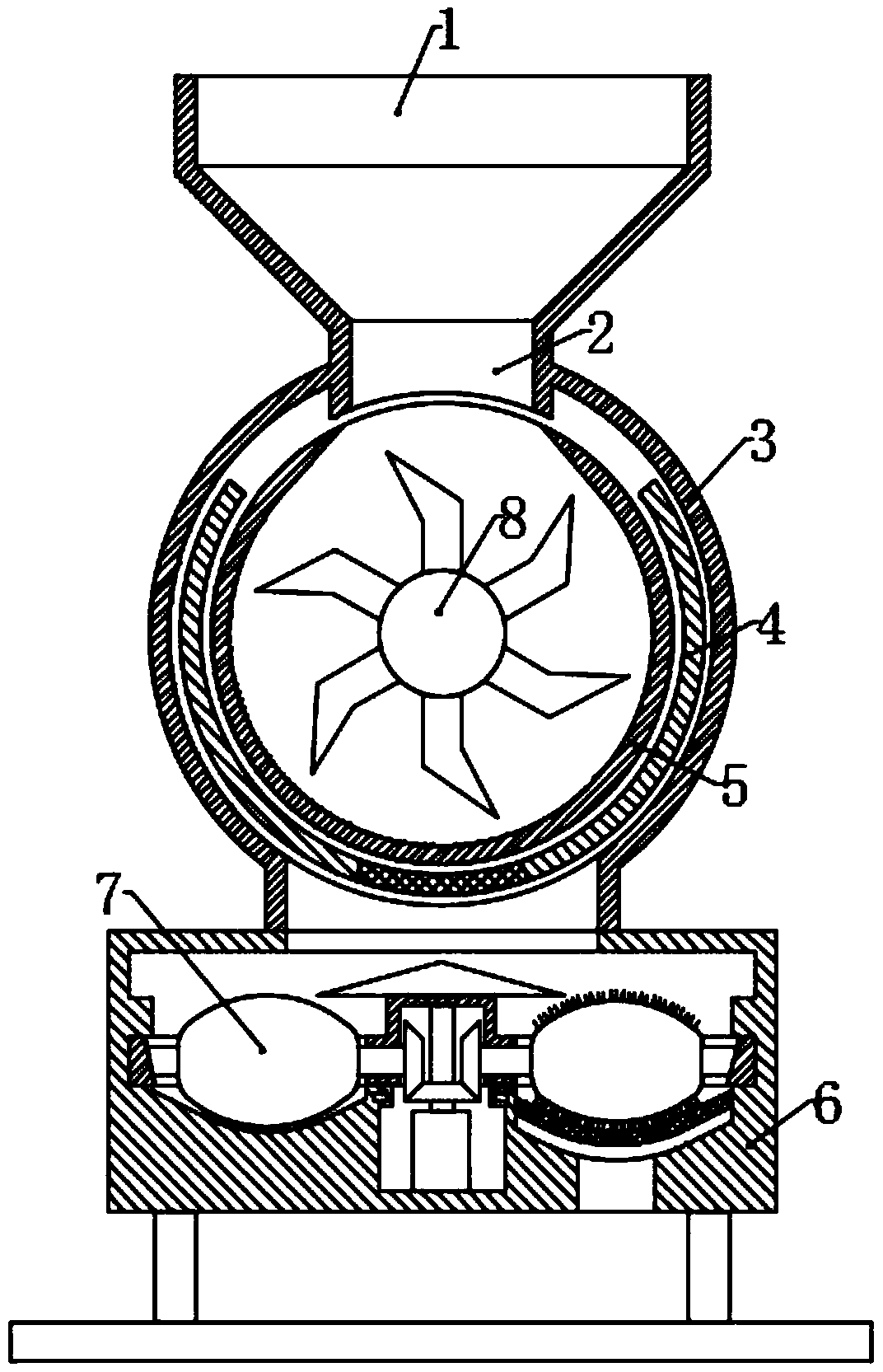

Vibration type material crushing and grinding integrated machine

The invention discloses a vibration type material crushing and grinding integrated machine which comprises a base, a sleeve, a tank, a tank cover and support legs. The vibration type material crushing and grinding integrated machine is characterized in that the lower end of the sleeve is fixedly connected with the base; the tank is mounted in the sleeve; the tank is in sliding connection with the inner wall of the sleeve; the upper surface of the tank cover is fixedly connected with a crushing motor; a shaft extending end of the crushing motor is fixedly connected with a rotary shaft; the rotary shaft is fixedly connected with crushing vanes; screening holes are formed in the bottom of the tank; a cam is arranged under the tank; a through hole is formed in the middle of a guide plate; the crushing motor drives the crushing vanes to rotate to crush materials; the crushing vanes are matched with crushing cutting blades on the inner wall of the tank, and the crushing efficiency is improved; the cam rotates to drive the tank to vibrate up and down along the inner wall of the sleeve, so that the crushing effect is further improved, and crushed materials can penetrate through the screening holes to fall off conveniently; and an upper grinding plate and a lower grinding plate are matched for use, and ridges on the surfaces of the crushed materials are ground off, so that the materials are ground into balls.

Owner:惠安县丽佳智能设备有限公司

Self-circulation type coffee bean grinding and drying integrated machine

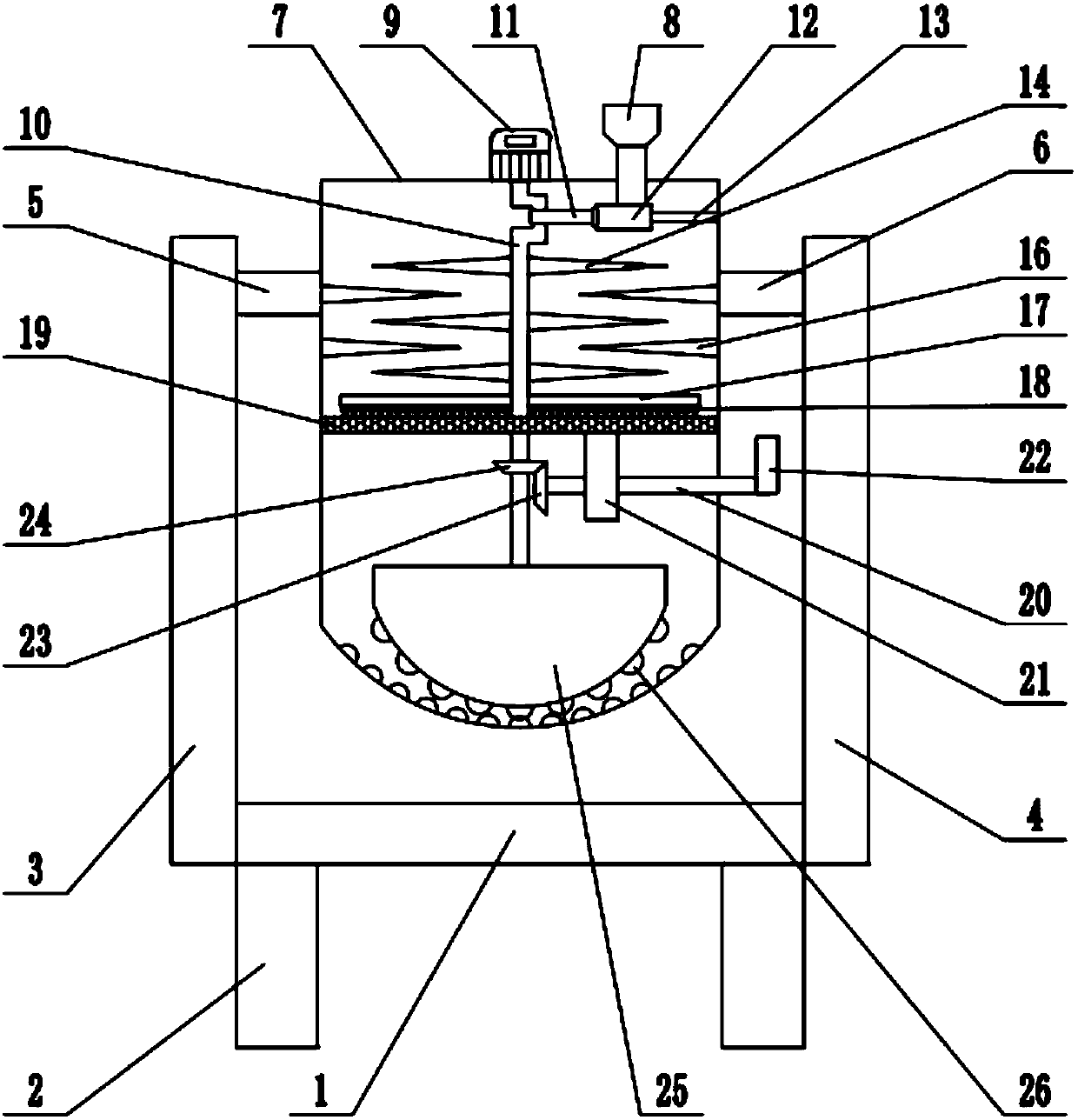

InactiveCN107597329AEvenly heatedImprove drying efficiencyGrain treatmentsFood treatmentDrive shaftPulp and paper industry

The invention discloses a self-circulation type coffee bean grinding and drying integrated machine. The machine comprises a shell, support legs, a feed port, a smashing motor, a smashing shaft, main smashing blades and a heating plate. The upper surface of the shell is fixedly connected with the smashing motor. The shaft extension end of the smashing motor is fixedly connected with the smashing shaft. The main smashing blades are distributed on the sidewall of the smashing shaft. A screen plate is arranged below the main smashing blades. A crankshaft is arranged below the screen plate. The journal of the crankshaft is sleeved with a connecting rod. The upper end of the connecting rod is hinged to the lower surface of the screen plate. A transmission shaft is further arranged below the screen plate. The middle portion of the crankshaft and the middle portion of the transmission shaft are sleeved with a first semi-gear and a second semi-gear correspondingly. A rotary shaft is arranged below the transmission shaft. A scraping plate is arranged below the rotary shaft. The machine conducts cyclic smashing on coffee beans in the smashing process to make smashing more thorough. The smashed coffee beans fall onto the bottom of the shell. The screen plate vibrates up and down to make the smashed coffee beans to pass through the screen plate. The coffee beans are turned over repeatedly through the scraping plate. Accordingly, the coffee beans are heated more uniformly.

Owner:杨鹏

Crushing and grinding device for production and processing of traditional Chinese medicinal materials

InactiveCN108940503AAvoid enteringImprove subsequent grinding efficiencyGrain treatmentsEngineeringMaterials processing

The invention discloses a crushing and grinding device for production and processing of traditional Chinese medicinal materials in the technical field of traditional Chinese medicinal material processing. The crushing and grinding device comprises a feeding hopper, a feeding pipe, a fixing case, a screening case, a crushing case and a grinding case. According to the crushing and grinding device, the traditional Chinese medicinal materials are put into the feeding hopper and then enter the crushing case along the feeding pipe, a crushing mechanism is used for crushing the traditional Chinese medicinal materials, and a feeding inlet of the crushing case conducting crushing rotates to face downwards; the traditional Chinese medicinal materials are screened through the screening case, and thenthe feeding inlet of the crushing case is rotated to face upwards; the traditional Chinese medicinal materials which do not penetrate through a first screening mesh return to the crushing case through the shovel face at the feeding inlet and are subjected to secondary crushing along with next batch of to-be-crushed medicinal materials, and the traditional Chinese medicinal materials enter the grinding case and are ground through a grinding mechanism; and meanwhile, completely ground medicine powder is fed into a powder outlet through a rotating brush, so that the situation that powder particles are too fine due to the fact that ground medicine powder is left in a grinding groove and ground repeatedly is avoided, and the grinding effect is good.

Owner:周意

Efficient crushing device for construction waste recovery

InactiveCN107350004AAdjustable sizeGood for subsequent crushingMagnetic separationGrain treatmentsHydraulic cylinderIron removal

The invention discloses an efficient crushing device for construction waste recovery. The efficient crushing device comprises a box body, and a preliminary breaking mechanism is fixedly arranged at the upper part of the inner chamber of the box body. The preliminary breaking mechanism comprises a fixed breaking plate, a movable breaking plate, a disc, a hydraulic cylinder and a motor. An iron removal mechanism is arranged under the preliminary breaking mechanism, and a first crushing roller and a second crushing roller are arranged under the iron removal mechanism. In the falling process of massive construction wastes, the preliminary breaking mechanism breaks the massive construction wastes step by step, so that metal in the wastes is exposed. Moreover, follow-up crushing is facilitated, and the crushing efficiency is improved. The size of broken particles of construction wastes can be adjusted, and the breaking degree can be adjusted. The construction wastes are subjected to second level of crushing through the first crushing roller and the second crushing roller, and the construction wastes are crushed more thoroughly. The crushing effect is good, and the crushing efficiency is high. The metal, such as steel bars in the construction wastes can be removed through the iron removal mechanism and are collected. The efficient crushing device has the advantages of simple structure and convenience in operation.

Owner:广西综改咨询服务有限公司

Jaw crusher

The invention discloses a jaw crusher. The jaw crusher comprises a fixed jaw with a fixed jaw crushing face and a movable jaw with a movable jaw crushing face. A crushing cavity is formed between the movable jaw crushing face and the fixed jaw crushing face. A discharging port is formed in the bottom of the crushing cavity. The movable jaw gets close to or gets away from the fixed jaw under the joint action of a spindle and a toggle plate of the jaw crusher. The position, close to the position of the discharging port, of the movable jaw crushing face is provided with a first hook face crushing face, and the first hook face crushing face deviates and extends in the direction away from the fixed jaw when extending towards the discharging port. When materials in the crushing cavity need to be discharged, the upward force applied to the materials through the first hook face crushing face can be reduced, or the upward force is not applied to the materials any more, and therefore material rising is reduced or the materials do not rise again any more in the material falling process, centralized abrasion on the movable jaw crushing face from the materials is reduced or centralized abrasion on the movable jaw crushing face from the materials cannot be caused, the discharging efficiency is improved, and the movable jaw crushing face is not prone to damage.

Owner:NENGCHENG GRP

High-efficiency crushing device for construction waste recovery

InactiveCN106944182AEasy to reproduceAvoid affecting service lifeGas current separationMagnetic separationIron removalArchitectural engineering

The invention discloses a high-efficiency crushing device for recycling construction waste, which includes a machine body, a first motor, a first connecting rod, a second connecting rod and a movable jaw plate are symmetrically arranged on the top of the body, and the first motor is driven to connect the first connecting rod. The other end of the first connecting rod is hinged with the second connecting rod, and the other end of the second connecting rod is hinged with a movable jaw plate. The bottom of the movable jaw plate is connected to the top of the body through a hinge. An inclined plate is fixed in the lower part of the body, a conveying device is arranged under the inclined plate, an iron removal device is arranged above the conveying device, an arc-shaped plate is fixed under the left end of the conveying device, and a secondary crushing device is arranged under the right end of the arc-shaped plate. The invention is provided with a first motor, a first connecting rod, a second connecting rod and a movable jaw plate, which can pre-shred the construction waste, and is provided with an iron removal device to remove metals such as steel bars and steel bars in the construction waste to avoid Damage the device and affect the service life of the device.

Owner:合肥红蔻健康管理有限公司

Swing-type concrete block crushing, mixing and stirring device

InactiveCN107336355AImprove processing efficiencyAffectMixing operation control apparatusPretreatment controlEngineeringDrive motor

The invention discloses a swing type concrete block crushing and mixing device, which comprises a bottom plate, a side plate, a top plate and a mixing drum. Double-sided rack and right double-sided rack, the mixing drum is provided with a rotating shaft coaxial with it, the top of the rotating shaft is provided with a left gear, the left gear meshes with the left double-sided rack, and the mixing drum A sieve plate is installed inside, and the sieve plate divides the mixing drum into a crushing chamber and a mixing chamber. A crushing rod is arranged on the shaft section of the rotating shaft in the crushing chamber and on the side wall of the crushing chamber, and a crushing rod is arranged on the crushing rod. The blade is provided with a mixing rod at the bottom of the rotating shaft in the mixing chamber. The invention has the advantages of simple structure, continuous crushing and mixing of concrete blocks, improved working efficiency, sufficient and uniform crushing and mixing, high mixing and crushing efficiency, simple operation and strong practicability.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

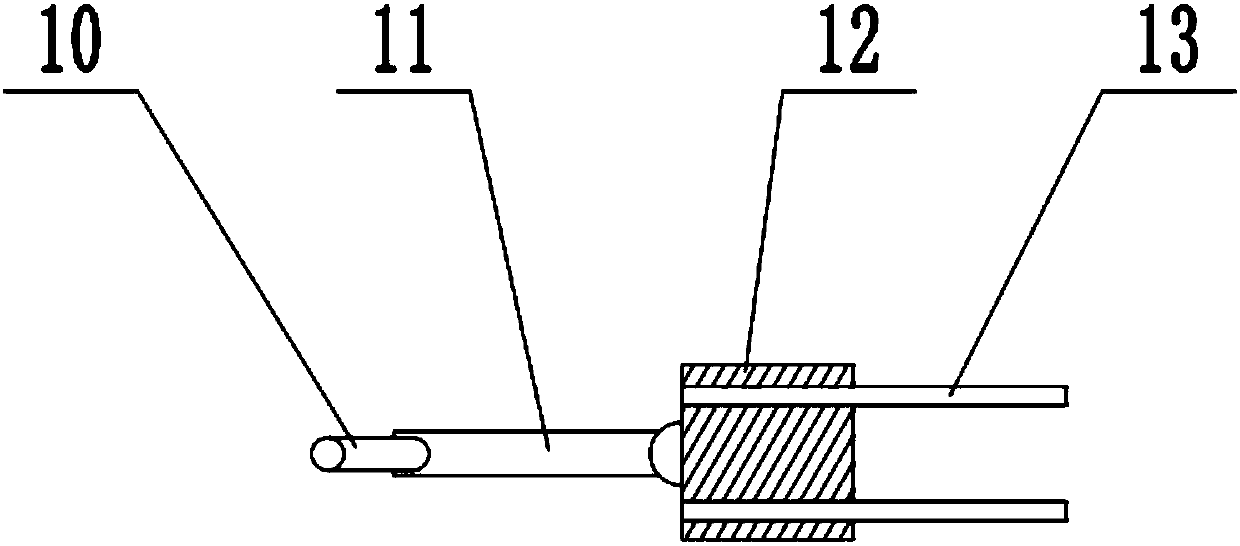

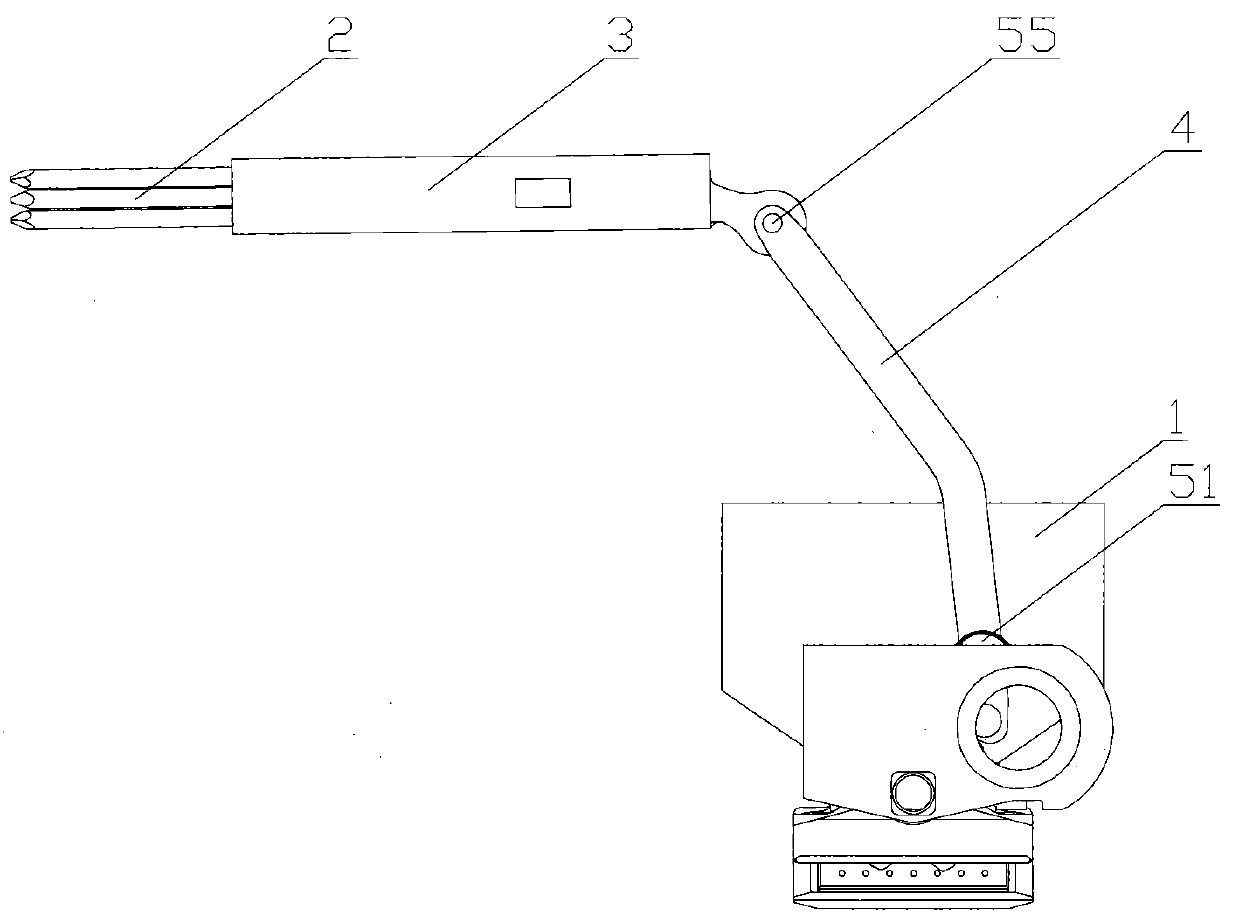

Coal mining device and crushing mechanism thereof

InactiveCN101906969AImprove crushing efficiencyPrevent flying outDriving meansEngineeringCentrifugal force

The invention discloses a crushing mechanism for a coal mining device, comprising a main body part (1), a power component installed on the main body part (1) and a work component (2) driven by the power component, wherein the power component is used for driving the work component (2) to do the reciprocating straight line motion. In the work process of the crushing mechanism, the straight line motion does not generate a centrifugal force, thereby preventing the crushed coals from flying out in crushing process and guaranteeing the personal safety of the staffs in the tunnel; meanwhile, the coal crushed by the straight line motion is not cut into powders so as to prevent coal dusts from flying in the tunnel and to improve the air quality in the tunnel; in addition, the single motion stroke of the straight line motion is large so as to improve the crushing efficiency of the crushing mechanism. The invention further discloses a coal mining device including the crushing mechanism.

Owner:SANY HEAVY EQUIP

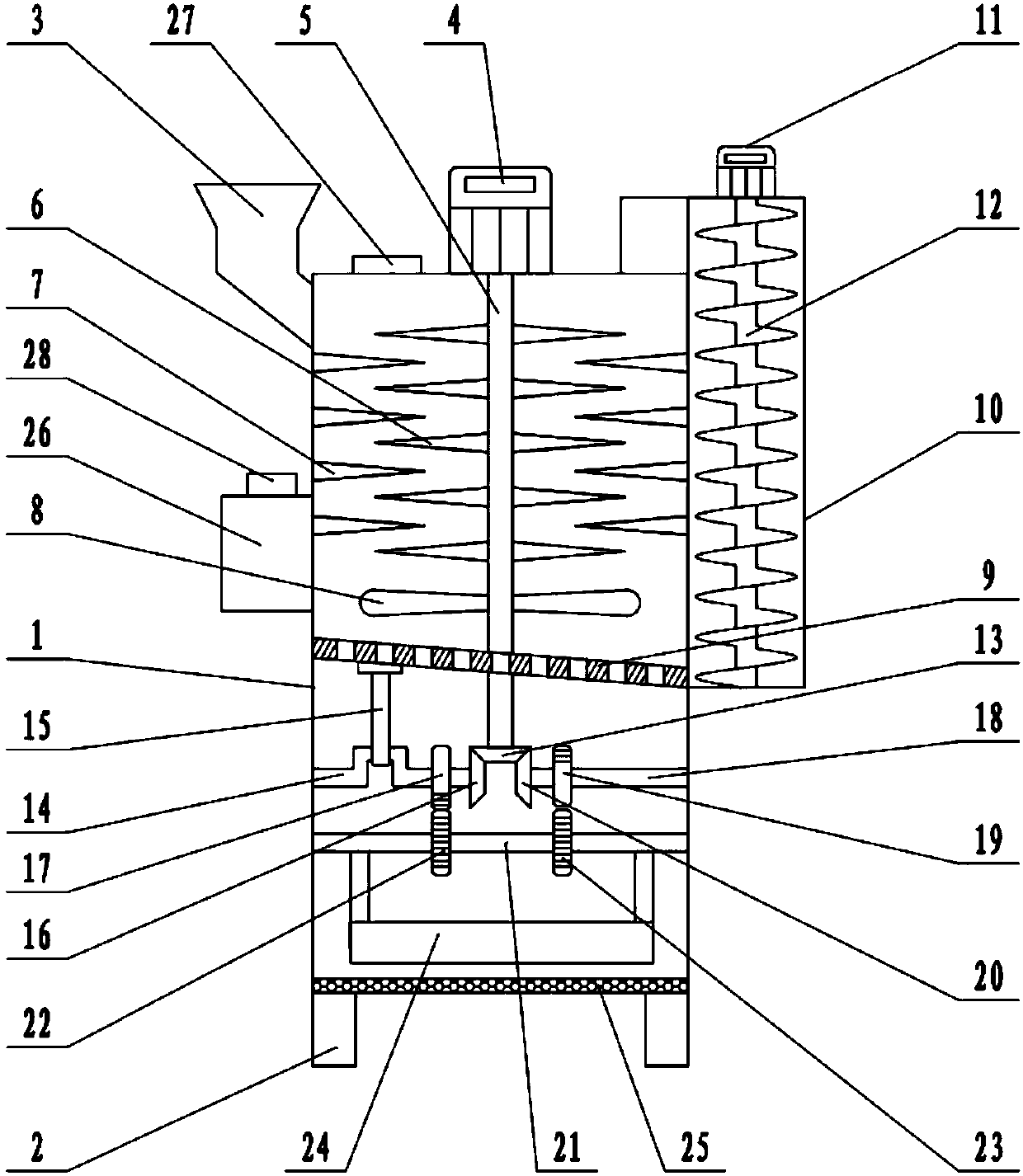

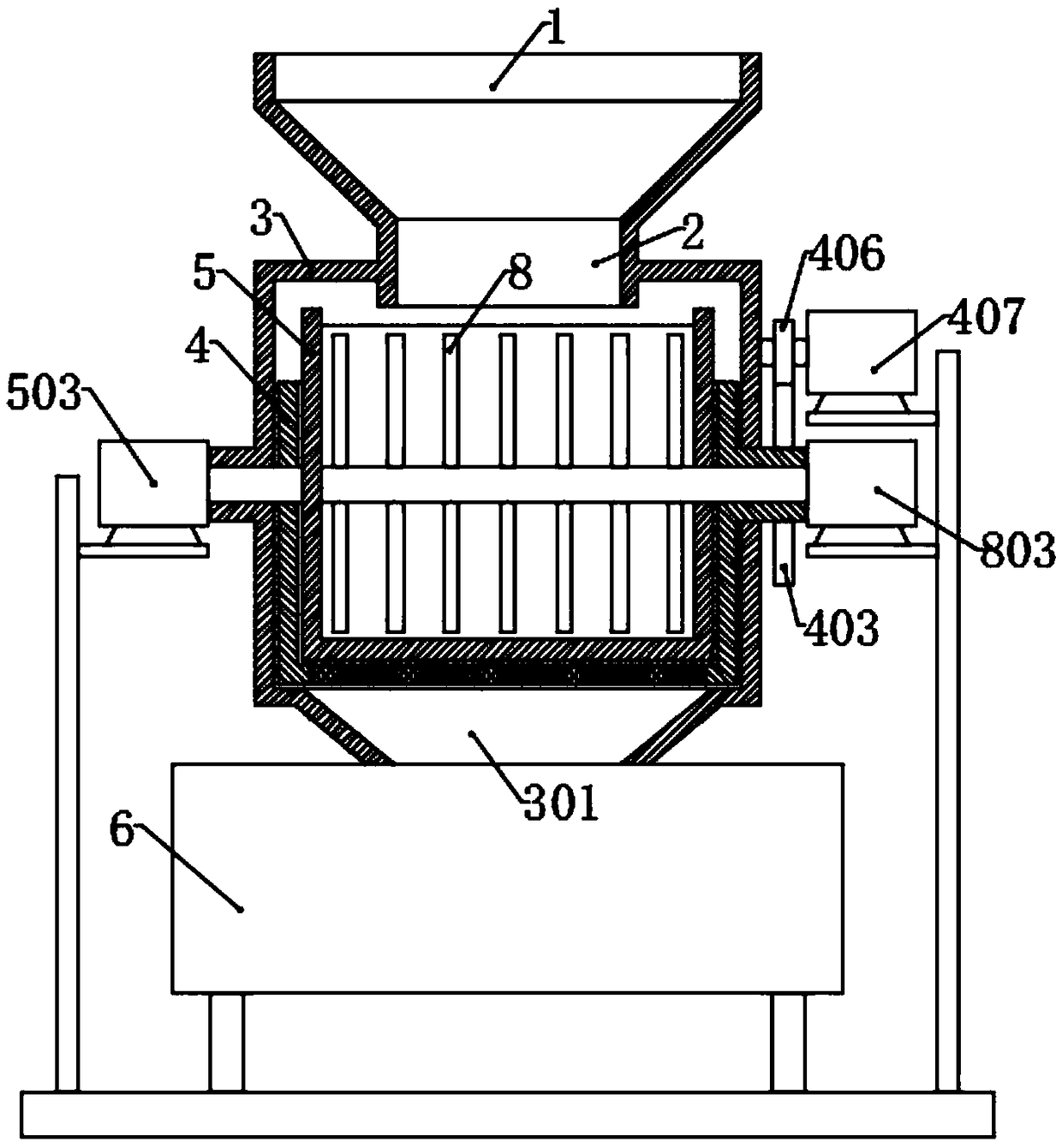

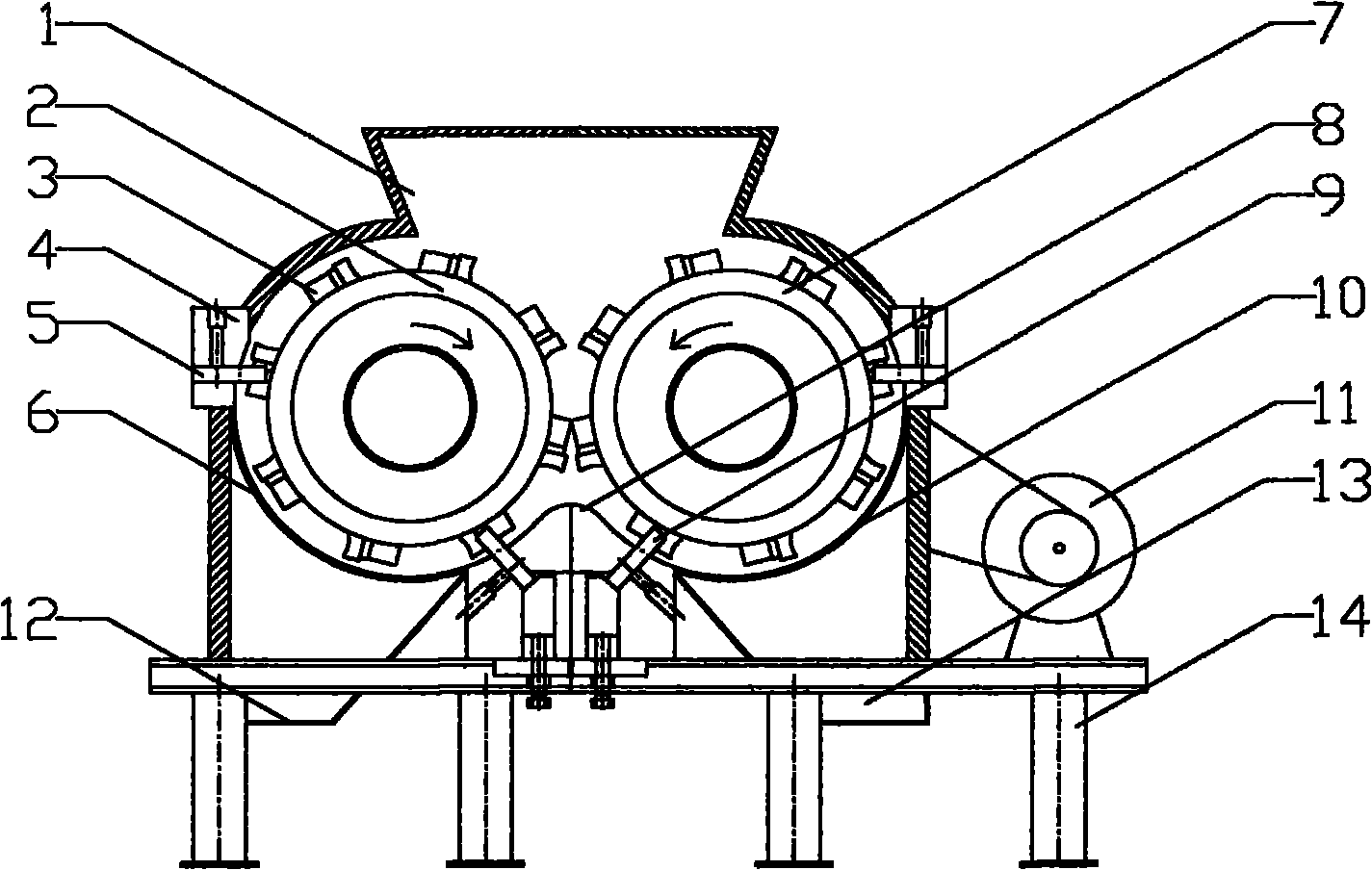

Multifunctional biomass energy pulverizing equipment

InactiveCN106269165AImprove crushing efficiencyReasonable structural designCocoaGrain treatmentsEngineeringMechanical engineering

The invention provides multifunctional biomass energy pulverizing equipment. The equipment comprises a shell, wherein a feed hopper is arranged at the top of the shell; a pair of pulverizing rolls is arranged in the shell below the feed hopper and is supported by pulverizing roll shafts arranged in the centers; a plurality of pulverizing teeth are uniformly arranged on the pulverizing rolls; a screen is arranged below the pulverizing rolls and is shaped like a circular arc; a guide plate is arranged below the screen and is shaped like a hopper; a sleeve is arranged at an opening in the lower end of the guide plate; a rotating shaft is arranged in the sleeve; the lower end of the rotating shaft extends below the shell and is connected with a motor; a rotator is arranged on the rotating shaft in the sleeve and is shaped like a cylinder. The equipment has the beneficial effects that the materials are pulverized triply and the grain sizes of the materials are gradually reduced and meet the using requirements; the pulverizing efficiency is high; the equipment has the advantages of reasonable structural design, simplicity and convenience in operation, good pulverizing effects, and the like, and has certain popularization and application values.

Owner:王少平

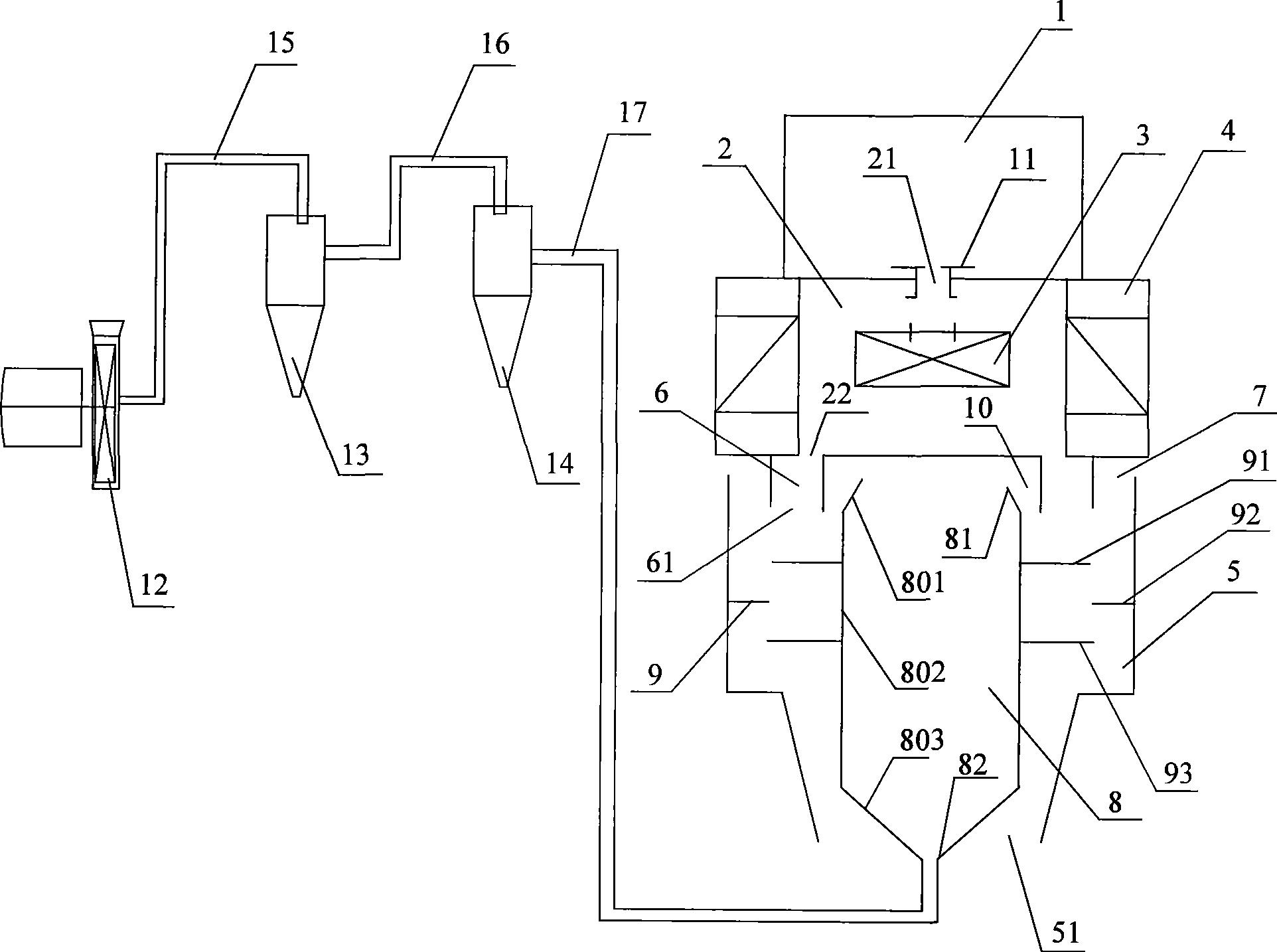

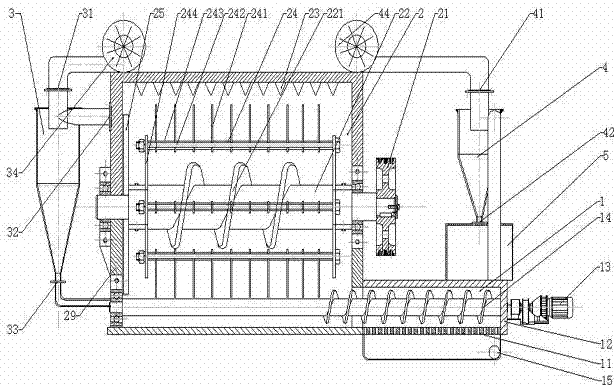

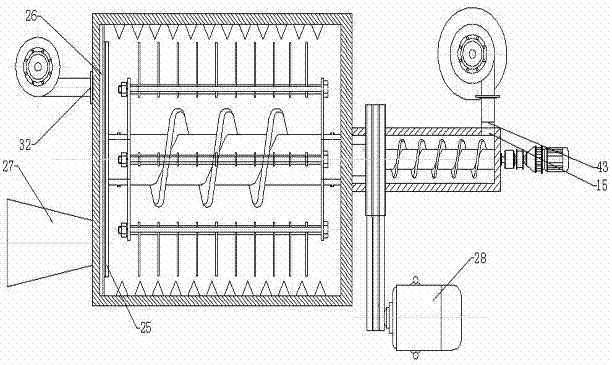

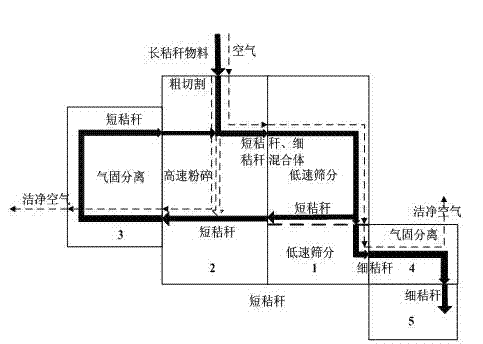

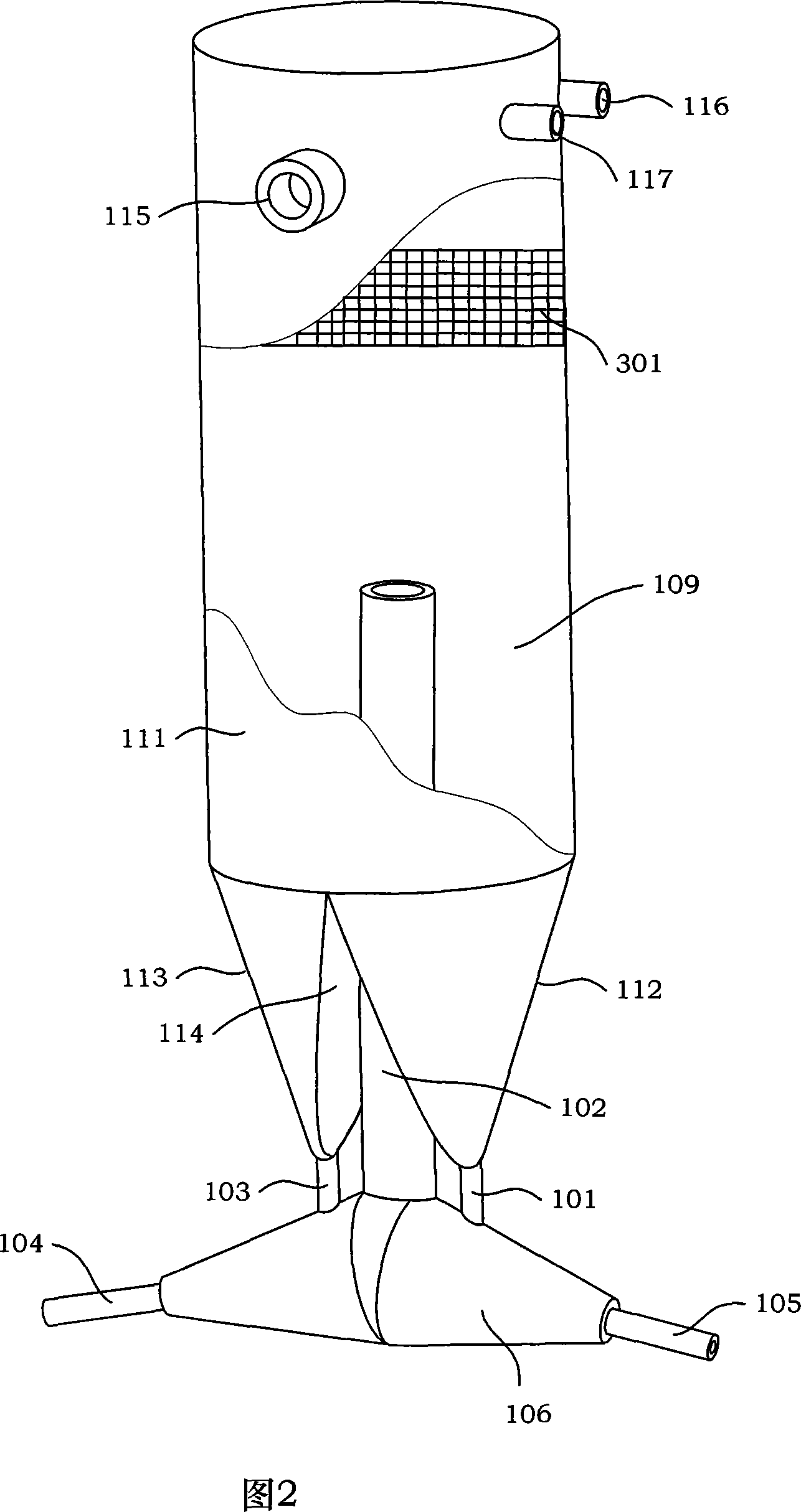

Straw cutting, crashing and sieving integrated device and method

ActiveCN103084286AIncrease production capacityPromote sustainable developmentVortex flow apparatusCuttersCycloneAgricultural engineering

The invention discloses a straw cutting, crashing and sieving integrated device and a method and belongs to the technical field of agricultural machines. The straw cutting, crashing and sieving integrated device comprises a sieving chamber, a cutting and crashing chamber, a first cyclone separator, a second cyclone separator and a storage bin. According to the straw cutting, crashing and sieving integrated device provided by the invention, low-speed sieving is distinguished from high-speed cutting and crashing, and the sieving capacity of a material is enhanced due to the agitation effect of sieving blades, so that a thin material can be sufficiently sieved, and a coarse and short material can be returned back to the cutting and crashing chamber again for secondary crashing; and meanwhile, the crashing efficiency is improved. The straw cutting, crashing and sieving integrated device provided by the invention has the advantages of compact structure and small occupied area due to the integrated design of the sieving chamber and the cutting and crashing chamber. The straw cutting, crashing and sieving integrated device provided by the invention is applicable to straw resourceful treatment of small-size facility horticulture planting enterprises and individual farmers; the machining environment is improved; the labor intensity is reduced; the machining efficiency is improved; the production cost is reduced; and the high-efficiency production and the sustainable development of facility horticulture cleaning can be promoted.

Owner:万华禾香板业(公安县)有限责任公司

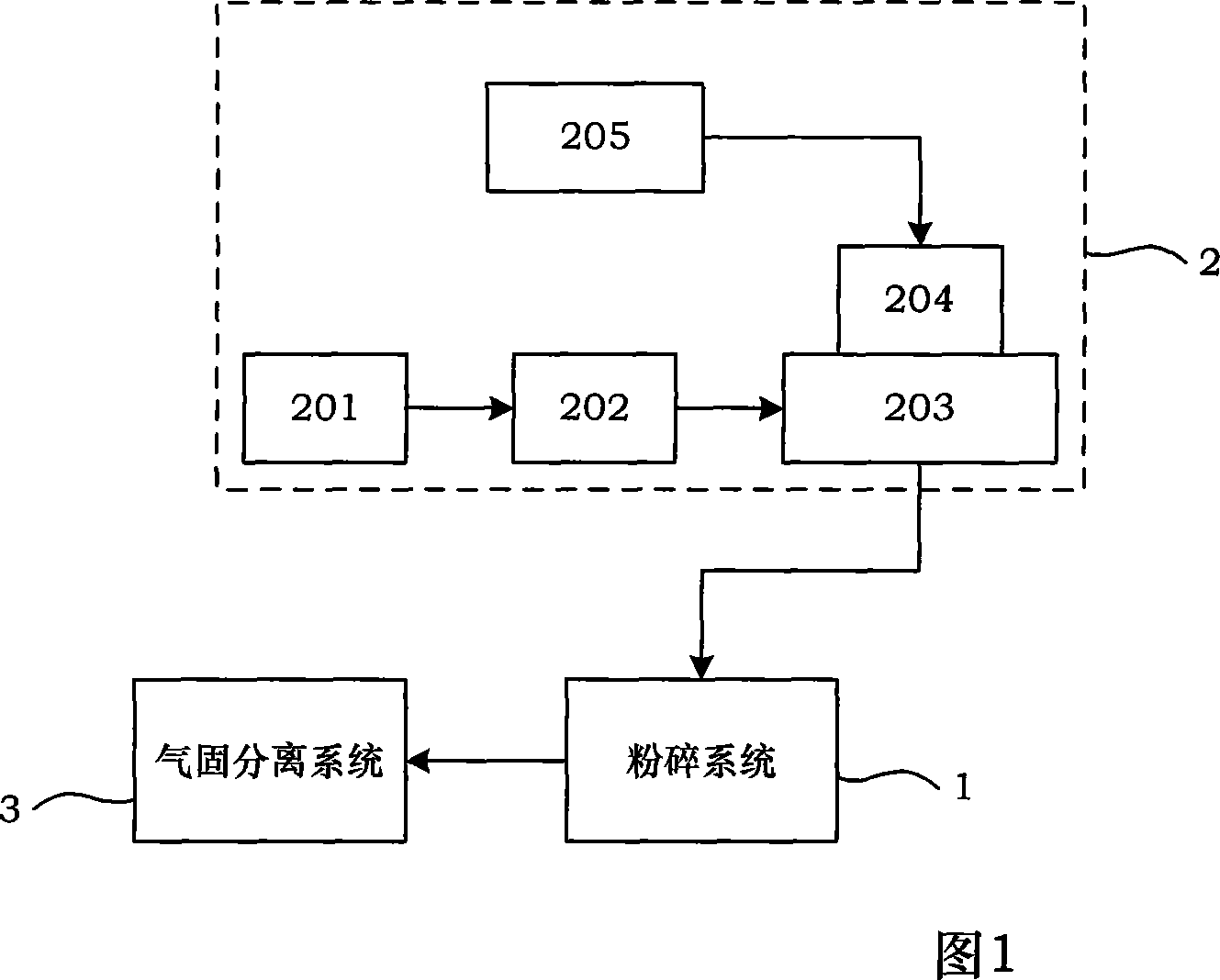

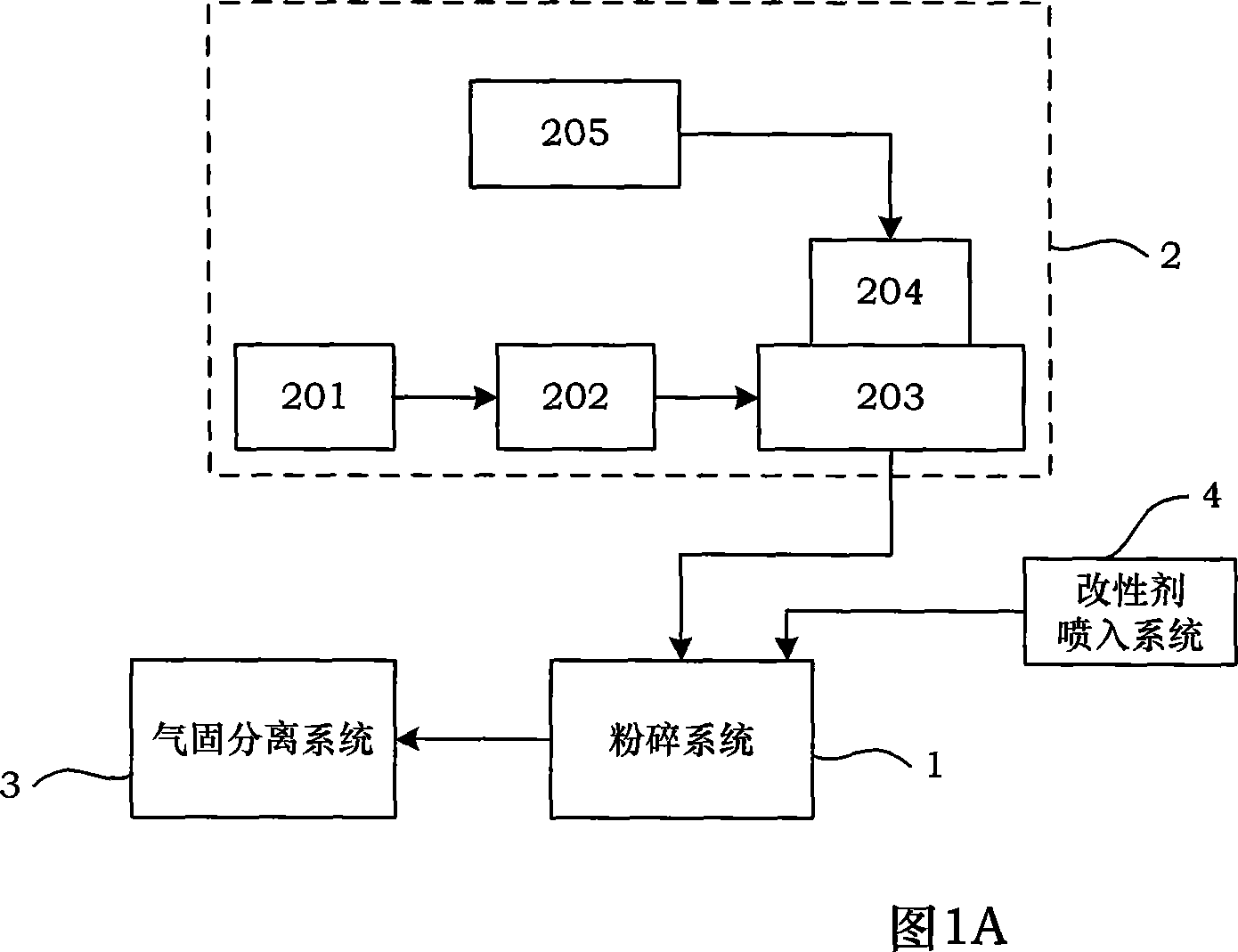

Technique and equipment for preparing Nano granules in high purity by using method of comminution by gas stream

InactiveCN101049580AEasy accessGood for collision smashingDispersed particle filtrationGrain treatmentsNanoparticleEngineering

An apparatus for preparing high-purity nanoparticles by airflow pulverizing method is composed of an air source system, a pulverizing system consisting of left and right reflux pipes and flow-up pipe to form a circulating loop of material, and air-solid separating system. Its process features that the raw material is carried by two supersonic jets for mutual and cyclic collision to obtain nanoparticles.

Owner:BEIHANG UNIV

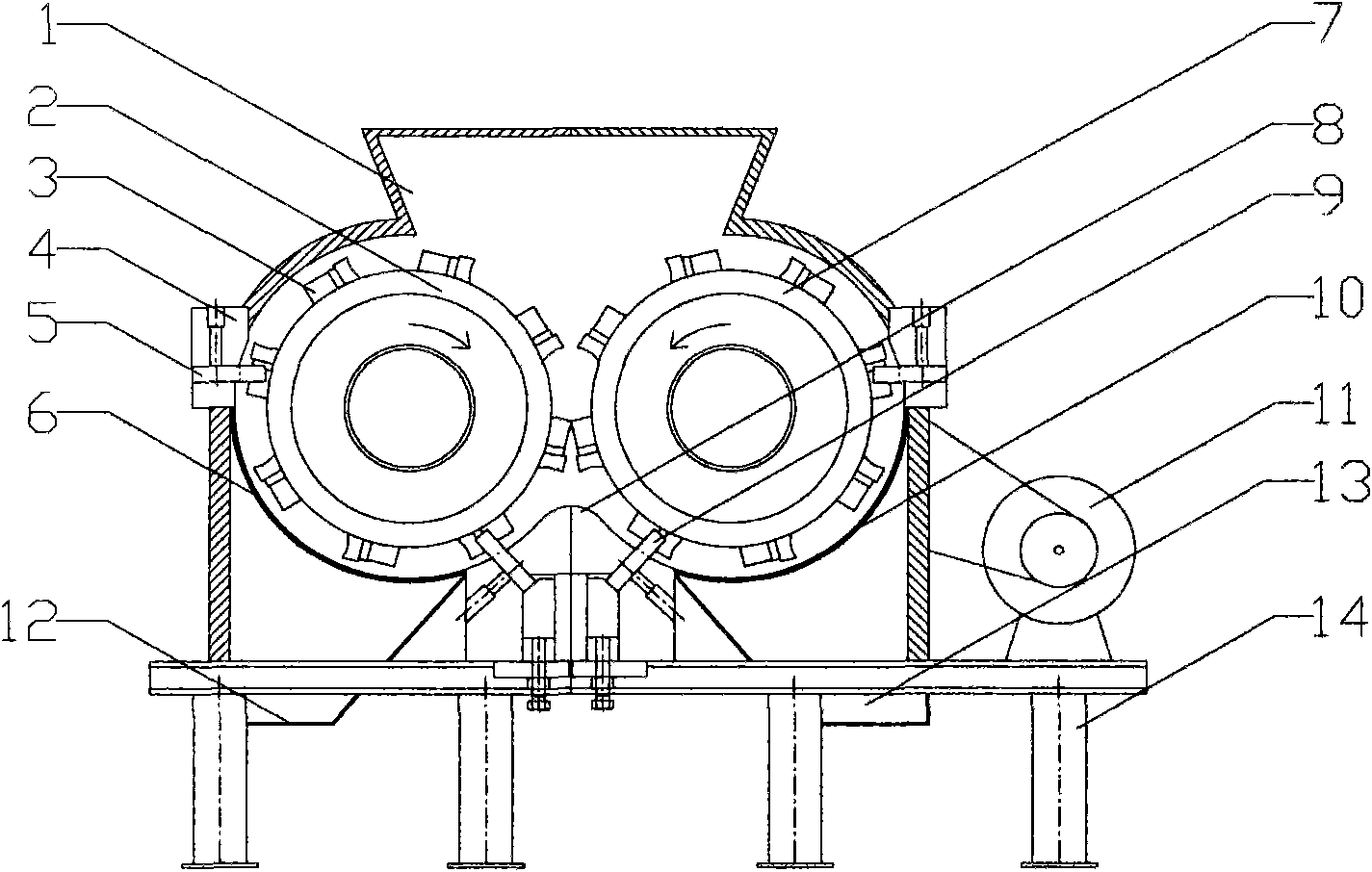

High-efficiency combined type domestic garbage crusher

The invention relates to a high-efficiency combined type domestic garbage crusher, which belongs to the technical field of domestic garbage crushing and comprises a feed hole, a crushing system, a discharge system and a transmission system, wherein the crushing system comprises dual knife rolls, a moving knife group, a static knife group and a knife adjusting device; the discharge system comprises a left screen, a right screen and two discharge holes; and the transmission system comprises a motor and a synchronous gear group, and the synchronous gear group ensures the synchronous running of the dual knife rolls. The left knife roll and the right knife roll are arranged side by side in parallel, a certain gap is reserved between the two knife rolls, and the two knife rolls are connected by the synchronous gear group and run in opposite directions; and the knife rolls are provided with rotating moving knives, the bottoms of the knife rolls are provided with bottom blocks, the bottom blocks are provided with bottom static knives, and simultaneously a frame is provided with a side static knife. Firstly, domestic garbage is crushed in the gap between the two knife rolls, is crushed at the position of the bottom knives after being compressed, then passes through the left screen and the right screen and is respectively discharged from the left discharge hole and the right discharge hole; and the side static knife can crush the garbage with bigger size again. The invention has the advantages of large treatment capacity, high crushing efficiency and low energy consumption.

Owner:SHOUGANG CORPORATION

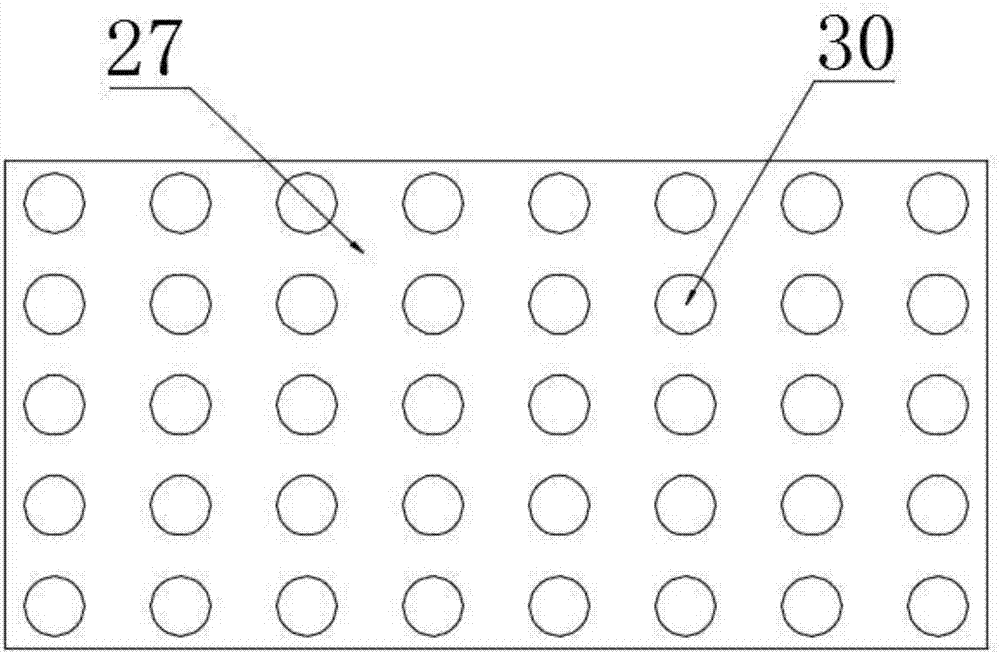

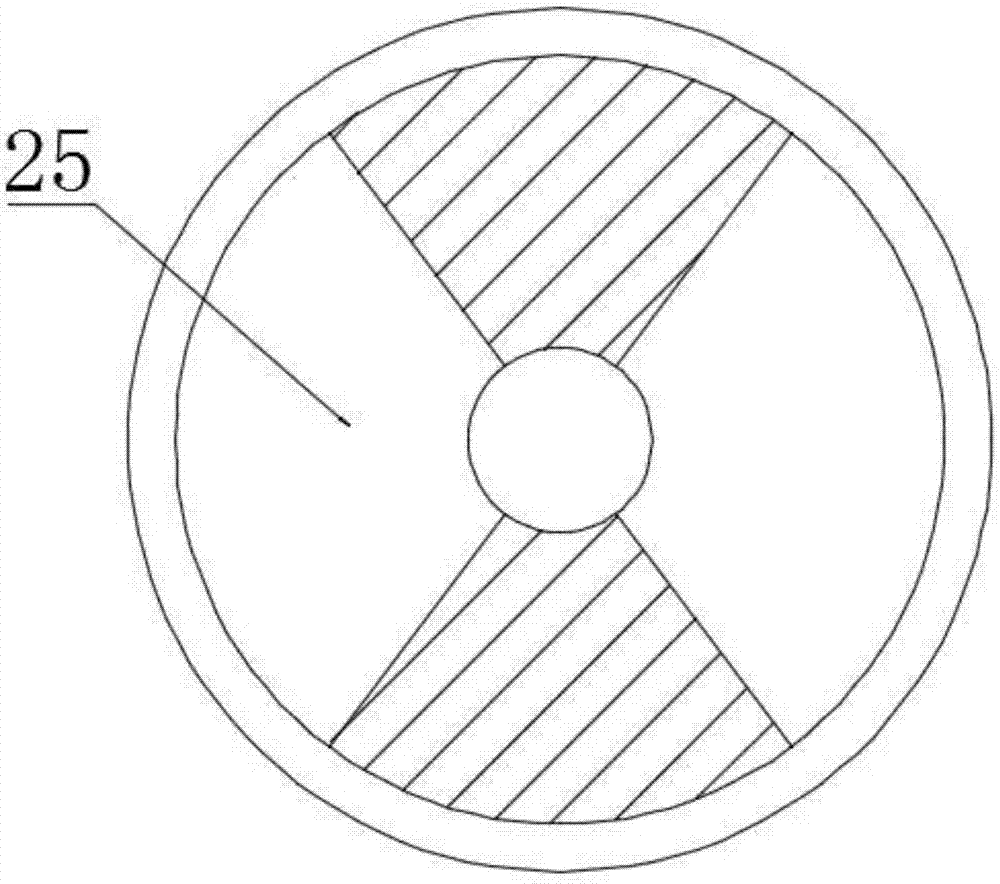

Efficient ore pulverizing device

The invention discloses a high-efficiency ore crushing device, which comprises a base. Support plates are arranged on the left and right sides of the base. A top plate is arranged on the top of the support plate. A crushing box is connected to the bottom of the top plate through a bracket. The limit rod is slidingly connected in the position sleeve. The top of the limit rod is connected to the top of the crushing box through a tension spring. The bottom of the limit rod is fixedly connected with a lifting plate. A pressing plate is also provided, and several through holes are evenly arranged on the pressing plate. A crankshaft cooperating with the lifting plate is arranged on the top of the crushing box, and the right end of the crankshaft passes through the right side wall of the crushing box and a second pulley is installed. The invention rotates the crankshaft so that the crushing plate moves downward to perform preliminary crushing of the ore. During the crushing, the ore is initially screened, the smaller particles fall through the through hole of the pressing plate, and the larger ore continues to be crushed. The crushing effect is good and the crushing efficiency is high.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

Building construction waste recycling device

ActiveCN107362855ALabor intensiveAvoid accumulationSolid waste managementGrain treatmentsScrapWaste recycling

The invention discloses a building construction waste recycling device. The building construction waste recycling device comprises a housing, wherein a transverse partition is fixedly connected between inner walls at the two sides of the housing; the inner walls at the two sides of the housing are fixedly connected with stamping barrels; the bottoms of the stamping barrels are fixedly connected with the upper surface of the transverse partition; a charge hole is fixedly connected in the middle position of the upper surface of the housing; the bottoms at the two sides of the charge hole are fixedly connected with connecting blocks through transverse rods; the connecting blocks are movably connected with separating inclined plates through pin rolls; and one side, away from each connecting block, of each separating inclined plate is fixedly connected with the side surface of the corresponding stamping barrel through a fixed block. The building construction waste recycling device has the advantages of preliminarily crushing and separating building waste; the building waste is re-separated after being preliminarily crushed, so that normal crushing of a crushing device is prevented; and moreover, the building construction waste recycling device further has the advantages of high waste crushing efficiency and uniform crushing, and solves the problem that building waste cannot be effectively recycled directly.

Owner:盛尔建设集团有限公司

Efficient breaking device of waste bricks serving as wall material for building

InactiveCN107377064AReduce labor intensityBroken fastUsing liquid separation agentGrain treatmentsCircular discBrick

The invention discloses a high-efficiency crushing device for waste bricks of building wall materials, which comprises a bottom plate, a crushing frame, a first crushing plate, a first rack, a gear, a second crushing plate, a first connecting rod, a guide rod, a second rack, second connecting rod, disk, crankshaft, motor, first connecting rod journal, second connecting rod journal, first piston rod, second piston rod and nozzle, the present invention is provided with motor, crankshaft, circle The plate, the first connecting rod and the second connecting rod are used to crush waste bricks from top to bottom through the cooperation of the above parts, and the crushing speed is fast. There are guide rods, second racks, gears and first racks. Cooperate with the first crushing plate to crush the waste bricks from the left and right sides, making the crushing more thorough and even, improving the crushing efficiency and reducing the labor intensity of the staff. There are first connecting rod journal and second connecting rod journal , the first piston rod, the second piston rod and the nozzle, through cooperation to achieve continuous water spraying and dust reduction, to avoid affecting the health of the staff.

Owner:伍超群

Quick crushing device for building ceramic chips

InactiveCN107029820ANot diffusedImprove crushing efficiencyUsing liquid separation agentGrain treatmentsVertical barMaterials science

The invention relates to a crushing device for building ceramic chips, in particular to a quick breaking device for building ceramic chips. The technical problem to be solved by the present invention is to provide a quick crushing device for building ceramic chips that saves time and labor, has high crushing efficiency, and can absorb dust so as not to affect the surrounding environment. In order to solve the above-mentioned technical problems, the present invention provides such a rapid crushing device for building ceramic chips, which includes a bottom plate, a left side plate, a right side plate, a rotating device, a crushing frame, a pulley, a pull wire, etc.; the top of the bottom plate is provided with a rotating device , the rotating device includes a rotating shaft, a bearing seat, a gear, a vertical rod, a sliding sleeve, a rack, a fixed plate and a first spring, and the right side of the top of the bottom plate is installed with a bearing seat through bolt connection. The invention can suck the dust away when the ceramic sheet is crushed by the dust suction device, can protect the surrounding environment from being diffused by the dust, saves time and labor, has high crushing efficiency, and can suck the dust.

Owner:何伯春

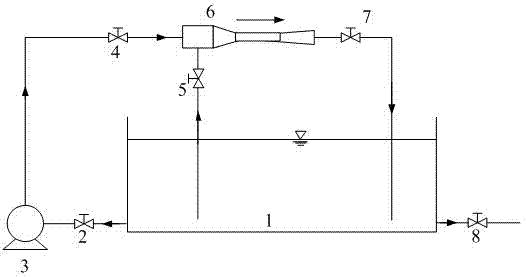

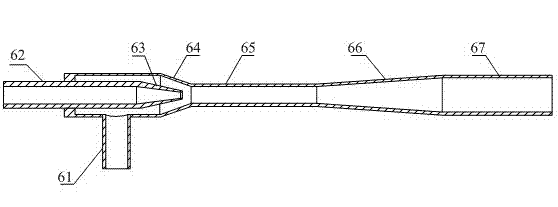

Ejecting-type jet flow cavitation generator and cavitation cell disruption device

ActiveCN103244468ASimple structureLow costBioreactor/fermenter combinationsBiological substance pretreatmentsCentrifugal pumpPiping

The invention discloses an ejecting-type jet flow cavitation generator and a cavitation cell disruption device. The cavitation generator comprises a nozzle, a suction chamber, a throat pipe, a diffuser and an outlet pipe. The nozzle is connected in the suction chamber in a sleeved manner, and a suction pipe is arranged on the side of the suction chamber. The cavitation cell disruption device comprises a container, a high-pressure centrifugal pump and the above cavitation generator, wherein the container is used for storing cells to be disrupted, the high-pressure centrifugal pump is connected with the container through a water pipe, and the cavitation generator is connected with the high-pressure centrifugal pump through the pipe. Valves are respectively arranged on an entrance of the nozzle, the suction pipe and the outlet pipe to control degree of cavitation. In the cavitation cell disruption device, high-pressure liquid sucks up low-pressure liquid to cause cavitation to happen in the tail end of the suction chamber and the throat pipe, cells are disrupted by microjet and shock waves produced from bubble collapse, and drastic shearing actions between the other two fluids can also have tearing effect to the cells. The ejecting-type jet flow cavitation generator and the cell disruption device for cavitation cells are simple in structure, low in cost, free of moving components, reliable in operating, strong in cavitation transport, high in crushing efficiency, and thereby applicable to mass application.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com