Crushing and grinding device for production and processing of traditional Chinese medicinal materials

A grinding device and technology of Chinese herbal medicines, applied in the direction of grain processing, etc., can solve the problems of reducing the grinding efficiency, affecting the grinding effect, and low grinding efficiency, and achieve the effects of improving the grinding effect, improving the grinding efficiency, and improving the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

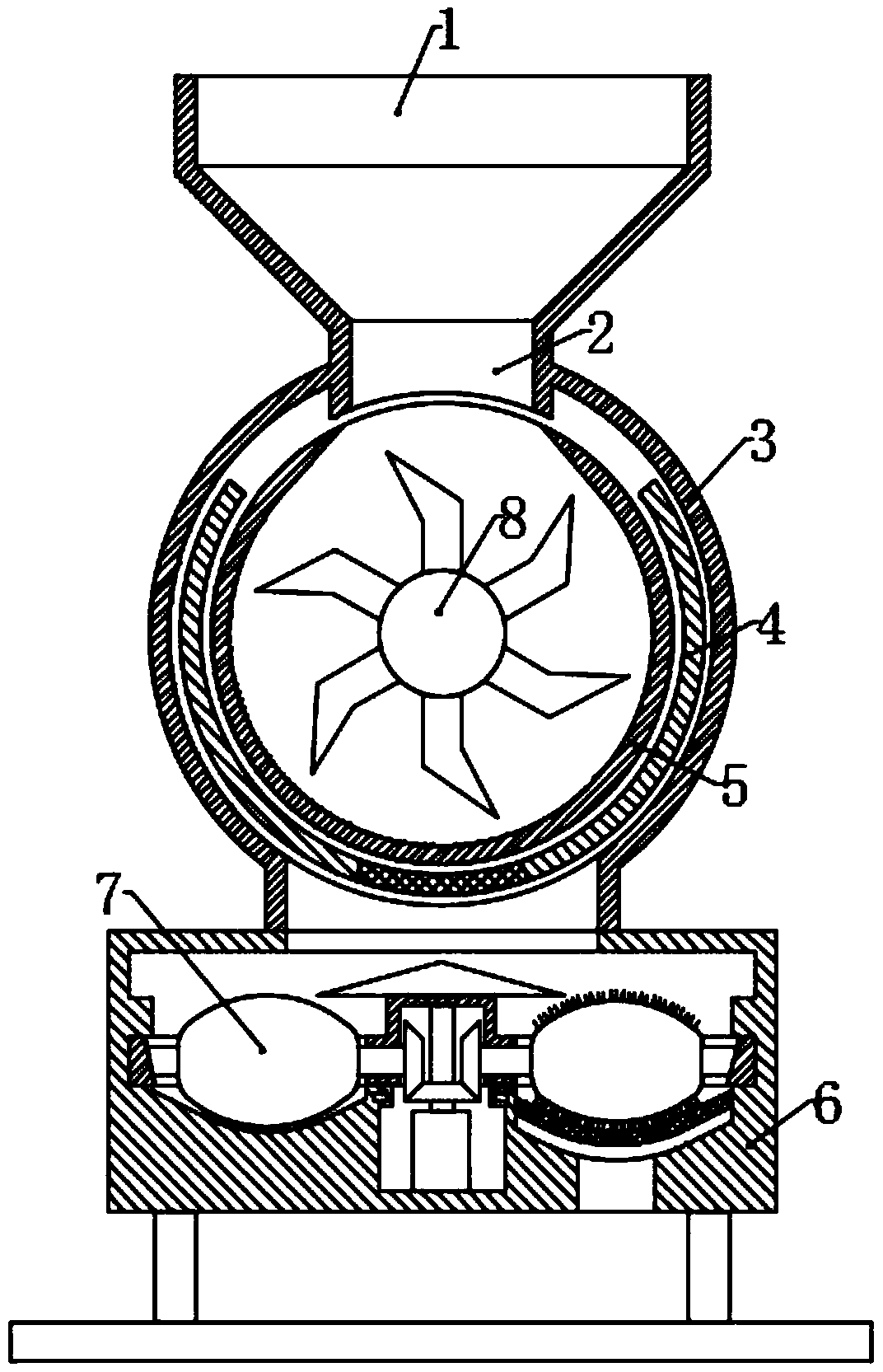

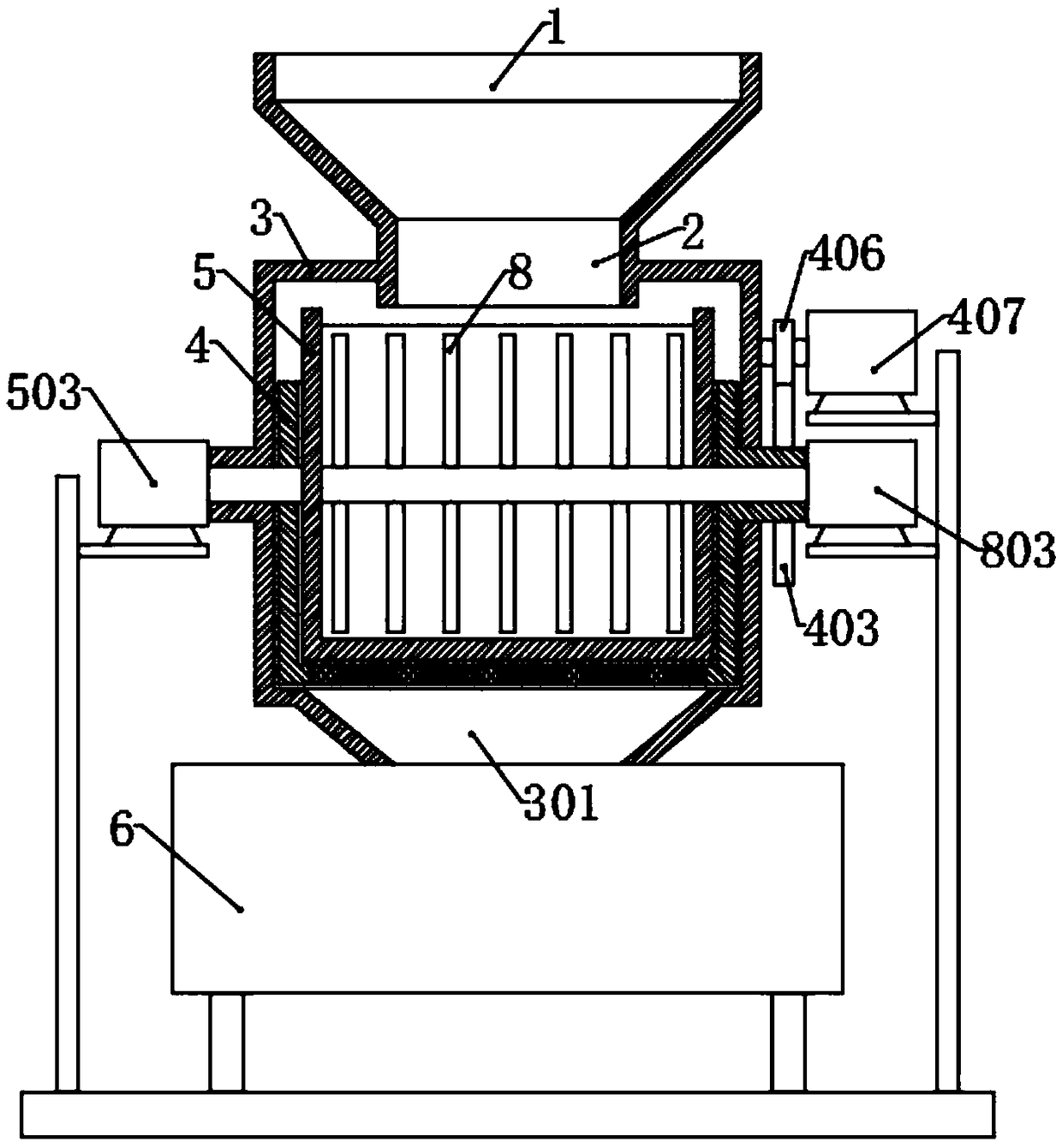

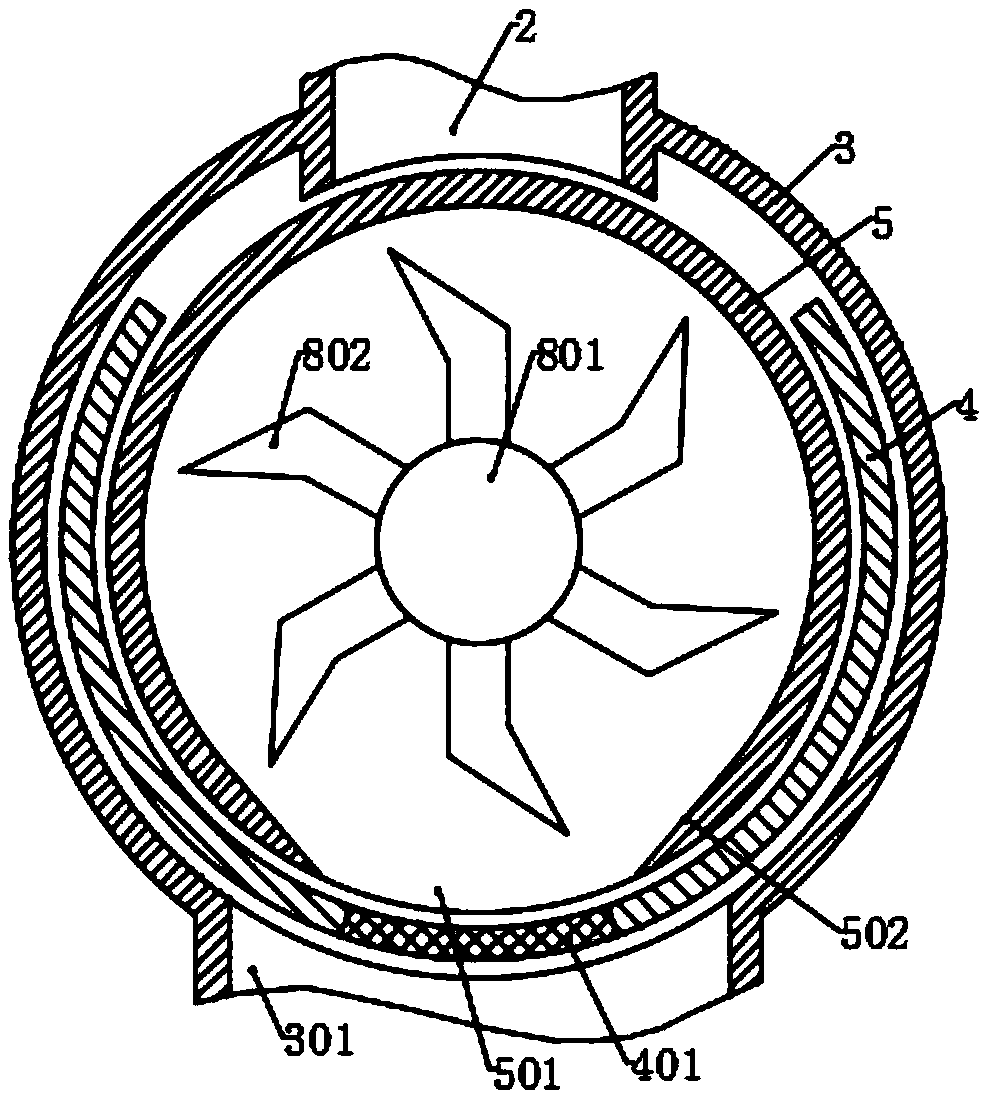

[0047] Please refer to the accompanying drawings, the present invention provides a technical solution: a crushing and grinding device for the production and processing of Chinese herbal medicines, including a feed hopper 1, a feed pipe 2, a fixed box 3, a screening box 4, a crushing box 5 and a grinding box 6. The top of the feed pipe 2 communicates with the bottom end of the feed hopper 1, the bottom end passes through the fixed box 3 and is located at its upper part, the bottom of the fixed box 3 is provided with a discharge port 301, and through the discharge port 301 and the grinding The top of the box 6 is connected, and the grinding box 6 is provided with a grinding mechanism 7. The screening box 4 is located in the fixed box 3, and the crushing box 5 is located in the screening box 4. The fixed box 3, the screening box 4 and the crushing box 5 are all The cylindrical shape placed horizontally, and the axis lines of the three coincide, and the crushing mechanism 8 is arra...

Embodiment 2

[0055] On the basis of Embodiment 1, the grinding body 702 is a revolving body, and its axis of rotation is the central axis of the grinding shaft. The busbar includes a first circular arc in the middle, and the two ends of the first circular arc are tangentially connected with a second circular arc. The center of the second circular arc coincides with the surface of the grinding shaft. The outer profile of the rotating brush 704 is identical to the profile of the grinding body 702. The middle of the bottom surface of the grinding tank 601 corresponds to the grinding body 702 as an arc shape, and the two ends are connected tangentially. sloped surface.

[0056] The working principle of this embodiment is basically the same as that of Embodiment 1. When the crushed Chinese herbal medicine enters the grinding box 6, the second circular arc of the grinding body 702 is located between the slopes of the grinding groove 601. The gap is larger, and gradually decreases towards the midd...

Embodiment 3

[0058] On the basis of the second embodiment, an extrusion mechanism 9 is also included. The extrusion mechanism 9 is located in the feed pipe 2 and includes two symmetrically arranged extrusion rollers. The two ends of the extrusion rollers are rotationally connected with the feed pipe 2. And one end is provided with extruding gear, and two extruding gears mesh with each other, and one of extruding gears is connected with the fifth motor.

[0059] The working principle of this embodiment is basically the same as that of Embodiment 2. When the Chinese herbal medicine is being fed, the fifth motor is turned on, and the fifth motor makes the two extrusion rollers rotate simultaneously and in reverse through the two meshing extrusion gears, so that the traditional Chinese medicine The material is extruded in advance before entering the crushing box 5, so that the overall shape of the Chinese medicinal material is changed and becomes looser, which makes the subsequent crushing more...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com