Dry-type sand making method and dry-type sand making machine thereof

A kind of sand making machine and dry technology, which is applied in the direction of grain processing, etc., can solve the problems of difficult control of dusty airflow overflow, the surrounding environment and equipment, production personnel are greatly affected, and the operating cost is increased, so as to achieve good dust removal effect, The effect of improving the production environment and improving the crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

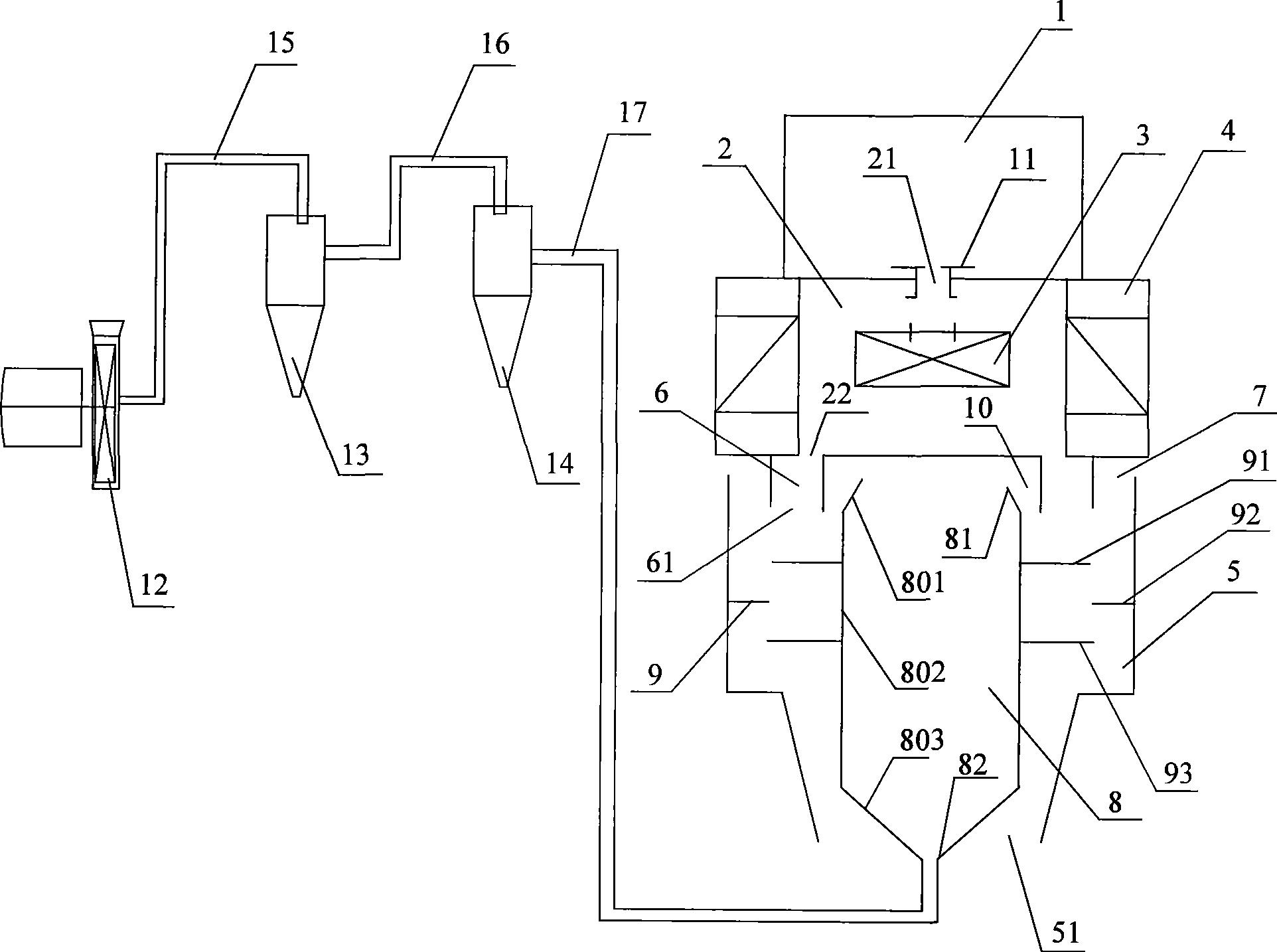

Embodiment 1

[0023] Embodiment 1, figure 1 A dry sand making machine is provided, which includes a barrel-shaped hollow crushing working chamber 2, and the center of the upper surface of the crushing working chamber 2 is provided with a circular through hole as the feed port 21; The mouth 21 is provided with a gate adjusting device 11, and the gate adjusting device 11 is used to adjust the opening size of the feeding port 21. Above the crushing working chamber 2 is provided a feed bin 1 which communicates with a feed port 21 . An annular through hole is provided on the lower surface of the crushing working chamber 2 as the feeding port 22 ; the center of the circular through hole overlaps with the central axis of the crushing working chamber 2 . A rotor 3 is provided in the crushing working chamber 1, and the rotor 3 is driven by a motor located outside the crushing working chamber 1 through a transmission shaft (this is the prior art, for clarity of the drawing, the corresponding motor a...

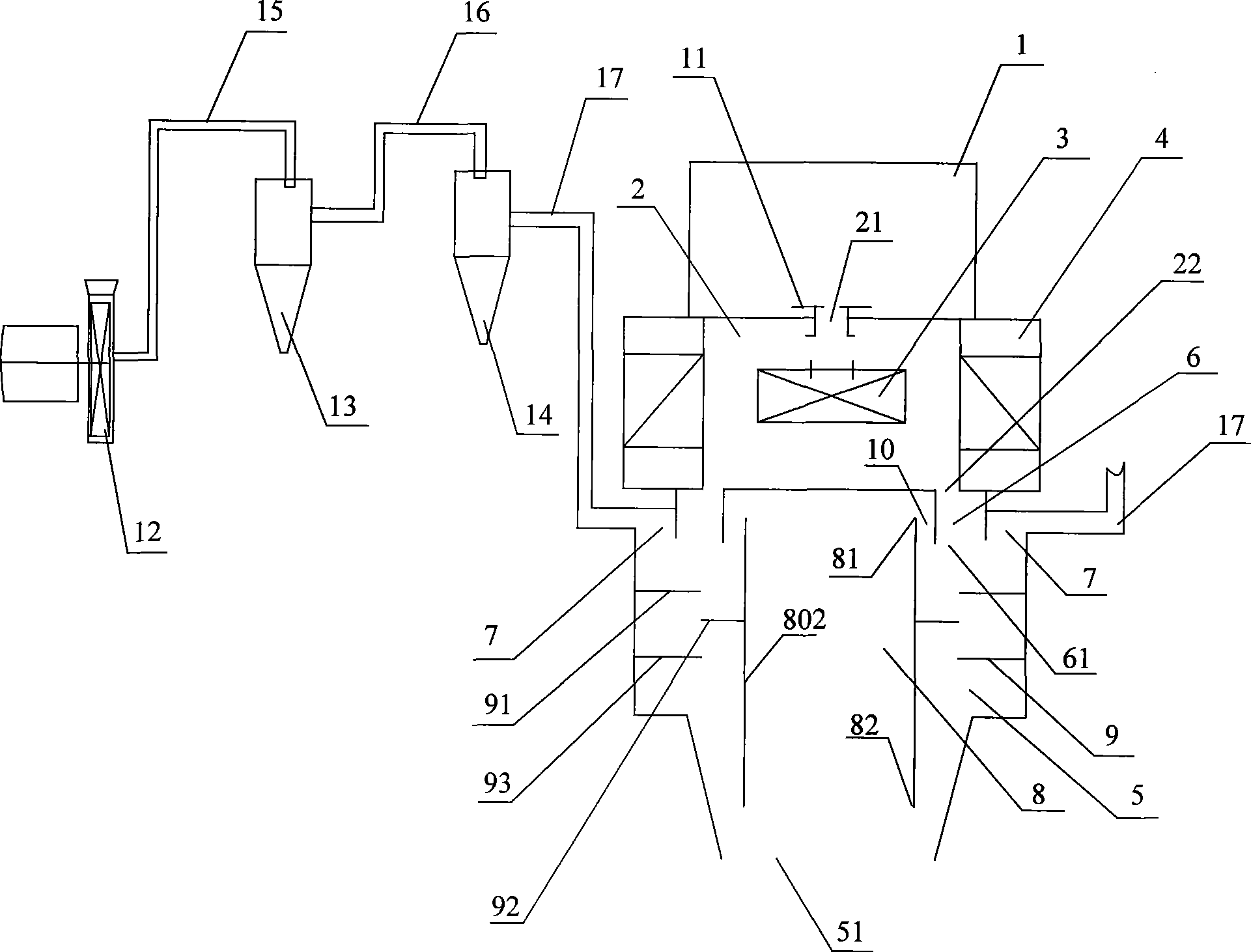

Embodiment 2

[0045] Embodiment 2, figure 2 Another dry sand making machine is given, the air duct 8 is only formed by a topless and bottomless cylindrical shape 802 (that is, the upper neck 801 and the lower neck 803 in Embodiment 1 are canceled), at this time The gap between the outer surface of the air duct 8 (i.e. the outer surface of the cylinder 802) and the inner ring surface of the feeding channel 6 forms a pipeline settlement zone 10; this pipeline settlement zone 10 is a circular ring with uniform thickness up and down. body. The other end of the pipeline III17 is canceled to be connected with the seal of the lower end 82 of the air duct 8, and changed into: the other end of the pipeline III17 is connected to the air vent 7 in a sealed manner. That is to say, the present embodiment 2 is to change the dust removal structure in the middle of the ventilation shown in the embodiment 1 into the dust removal structure of the ventilation around, and the rest of the structures are the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com