Wet honeycomb type desulfurization and dust removal device

A desulfurization and dust removal, honeycomb-type technology, which is applied in the fields of combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of poor light spherical spherical surface trapping effect affecting desulfurization and dust removal, and achieve the effect of improving dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

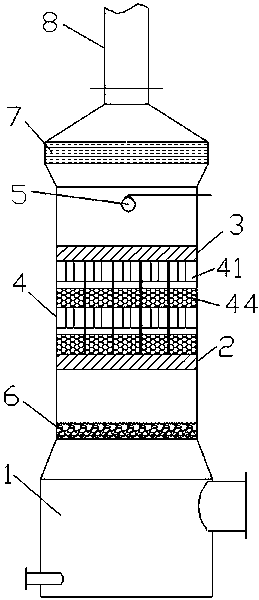

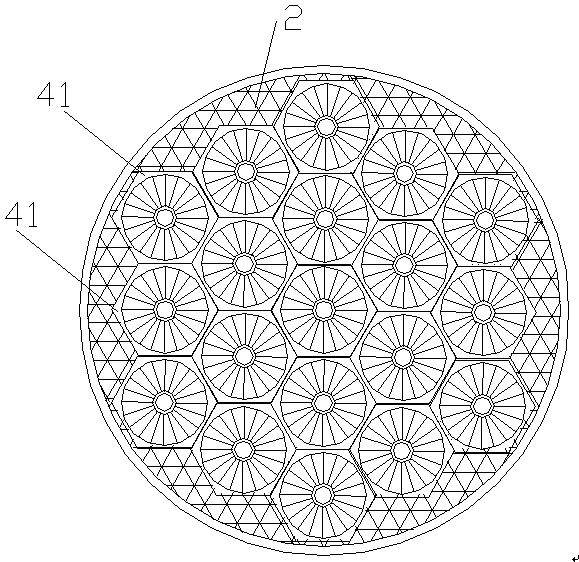

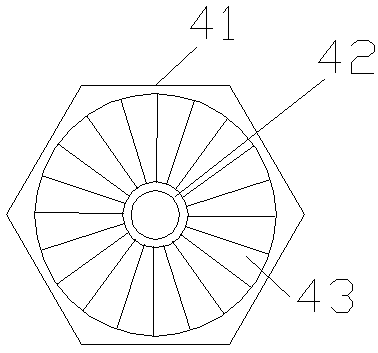

[0012] Such as figure 1 , figure 2 and image 3 As shown, a wet honeycomb type desulfurization and dust removal device includes a tower body 1, a lower sieve plate 2 and an upper sieve plate 3 are arranged in the middle of the tower body 1, and a turbulence chamber is formed between the lower sieve plate 2 and the upper sieve plate 3 4. A water film deduster 6 is set under the lower sieve plate 2, a spray mechanism 5 is set above the upper sieve plate 3, a demister 7 is set above the tower body 1, the top of the tower body 1 is connected with the chimney 8, and the turbulence chamber 4 is placed Several honeycomb turbulence chambers 41, the inner wall of the honeycomb turbulence chamber 41 is circular, and a fixed-point hollow shaft 42 is arranged in the middle of each honeycomb-type turbulence chamber 41, and a plurality of fan blades 43 are connected to the bottom of the fixed-point hollow shaft 42. Quality hollow ball 44.

[0013] The working principle of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com