Patents

Literature

90results about How to "Full collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

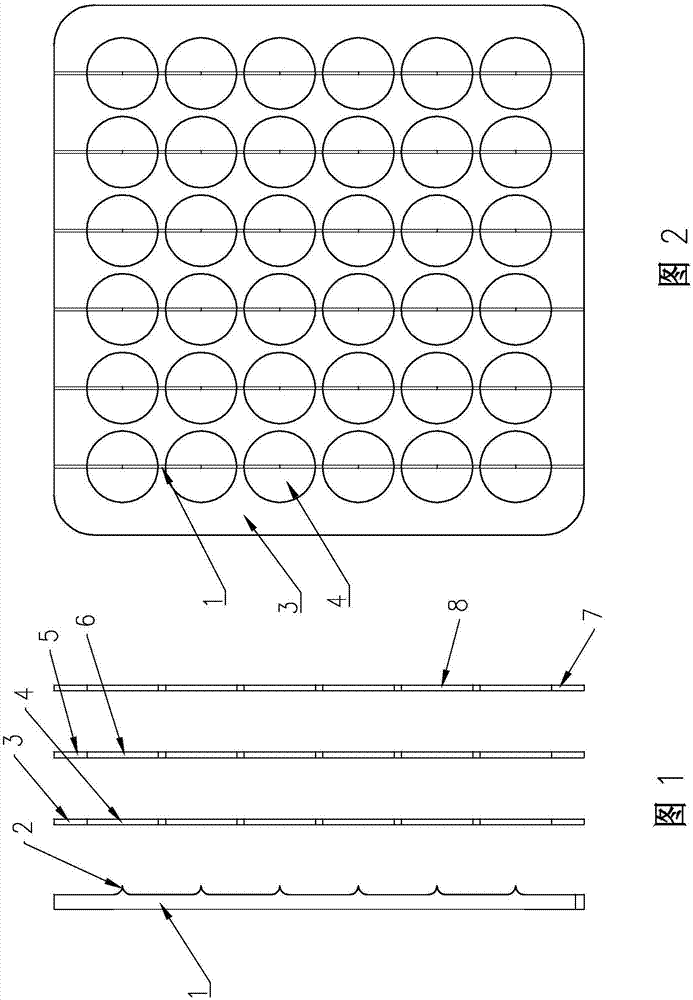

Dry-type sand making method and dry-type sand making machine thereof

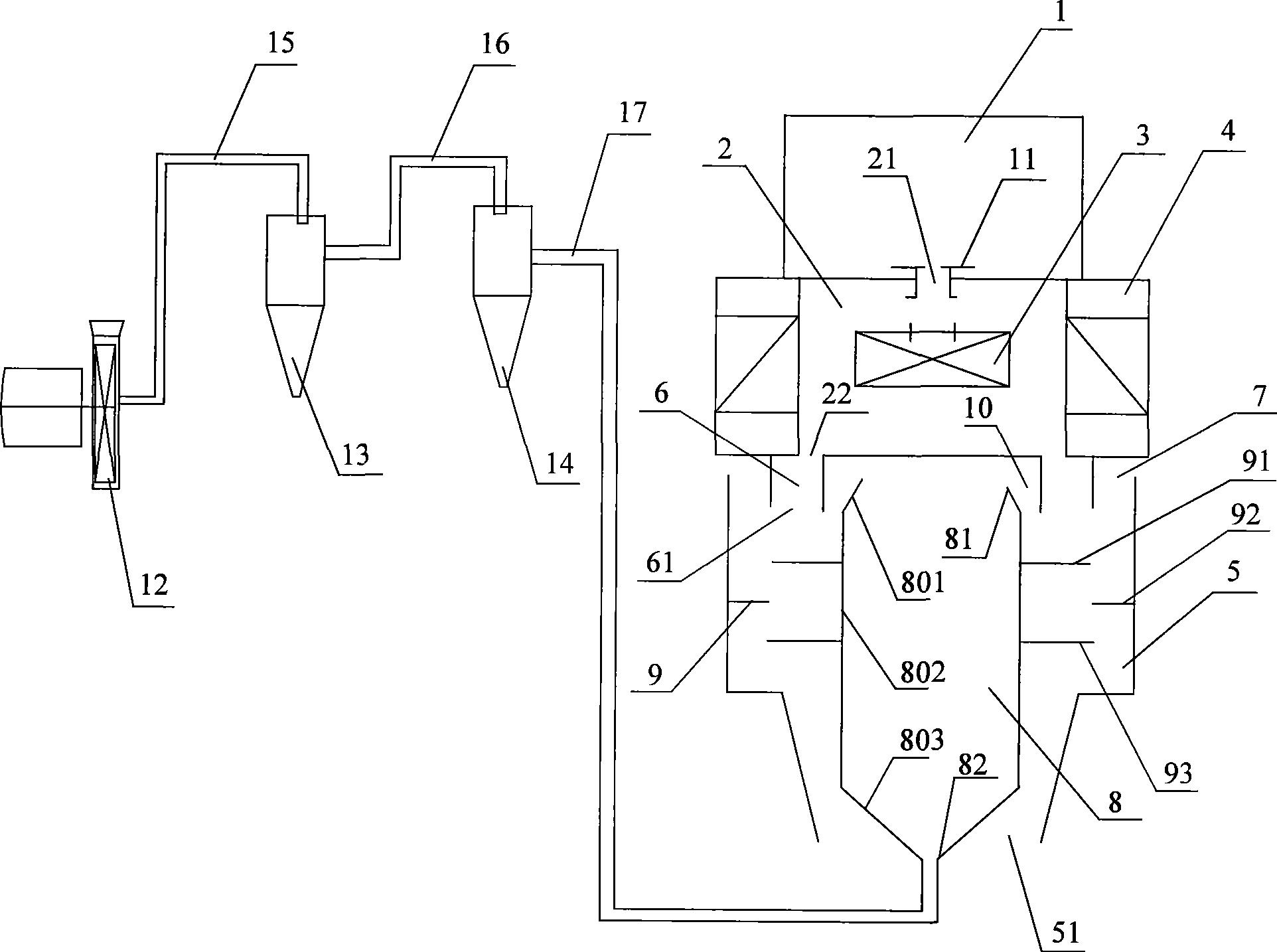

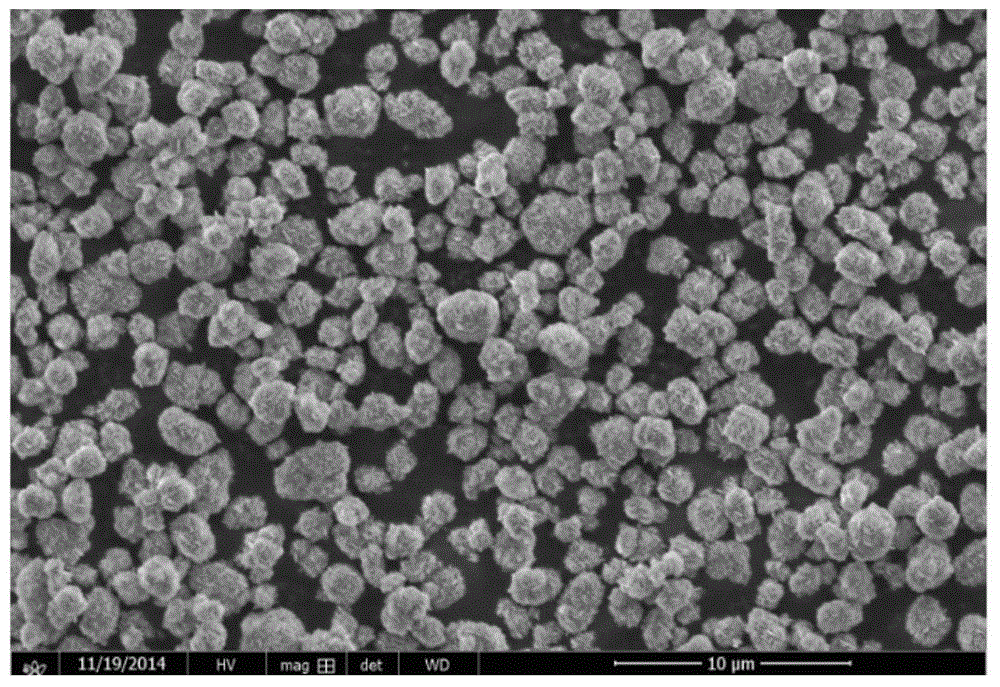

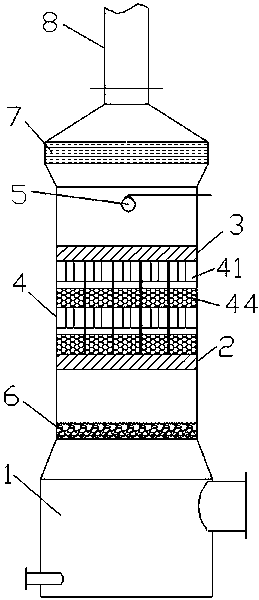

The invention discloses a dry sand maker which comprises a hollow crushing cavity (2). A hollow dust removal cavity (5) is arranged under the hollow crushing cavity (2); the upper end of a feeding channel (6) is hermetically connected with a feeding mouth (22) and the lower end (61) thereof is positioned in the dust removal cavity (5) on which an air vent (7) is also arranged; an air duct (8) is arranged in the dust removal cavity (5); the lower end (61) of the feeding channel (6) is staggered with the upper end (81) of the air duct (8) in the horizontal direction; the bottom surface of the dust removal cavity (5) is provided with an outlet (51); a dust absorption component is hermetically connected with the lower end (82) of the air duct (8) or the air vent (7) after passing through the outlet (51). The invention also provides a method for drying sand making simultaneously. By adopting the dry sand maker, the drying sand making can have the advantages of high production efficiency and low environmental pollution.

Owner:吴核明

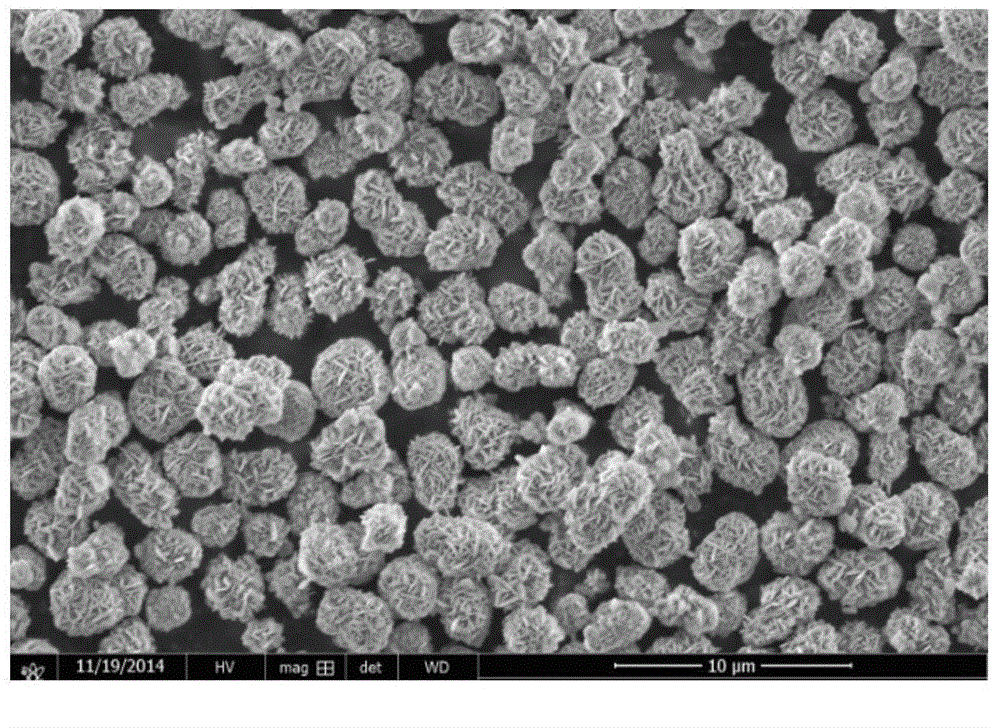

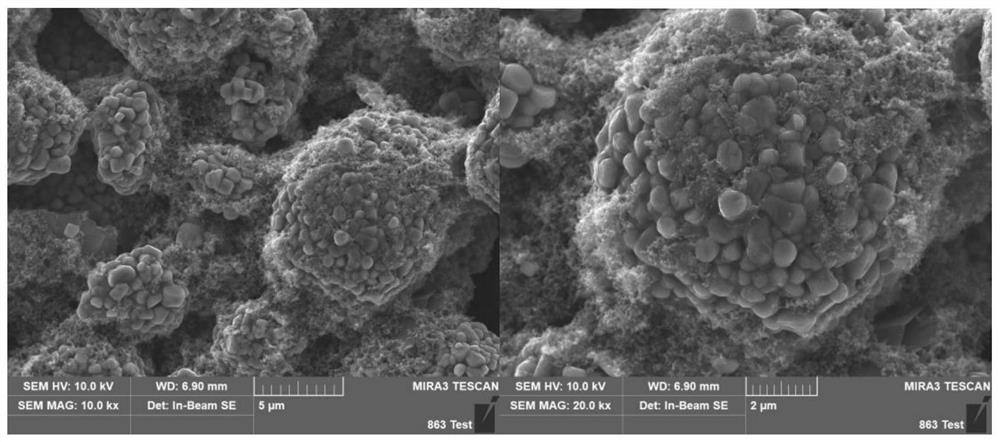

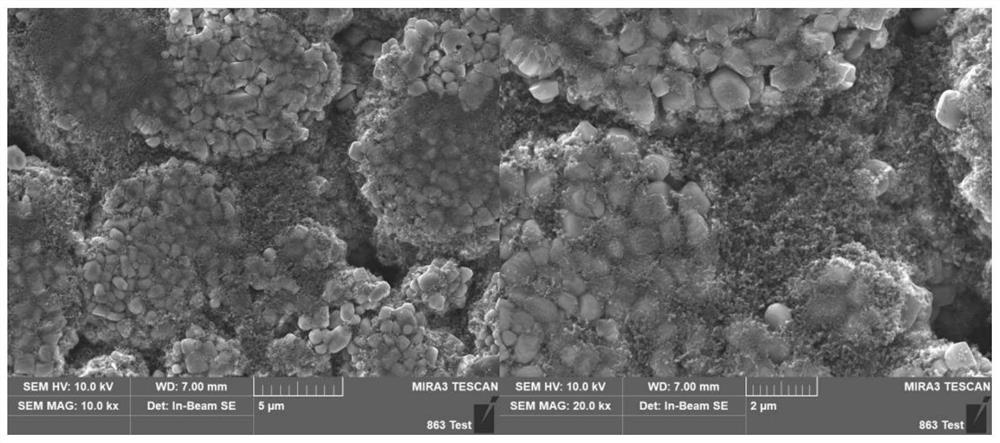

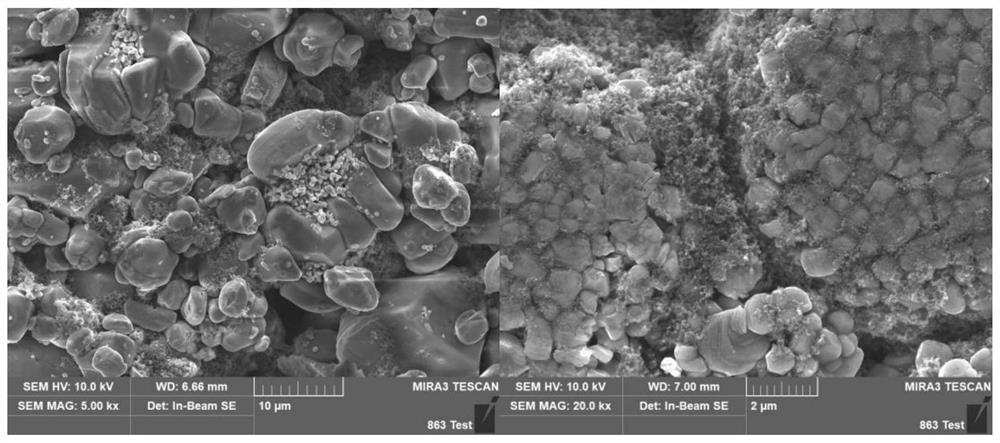

Small-particle-size nickel-cobalt-aluminum oxide and preparation method thereof

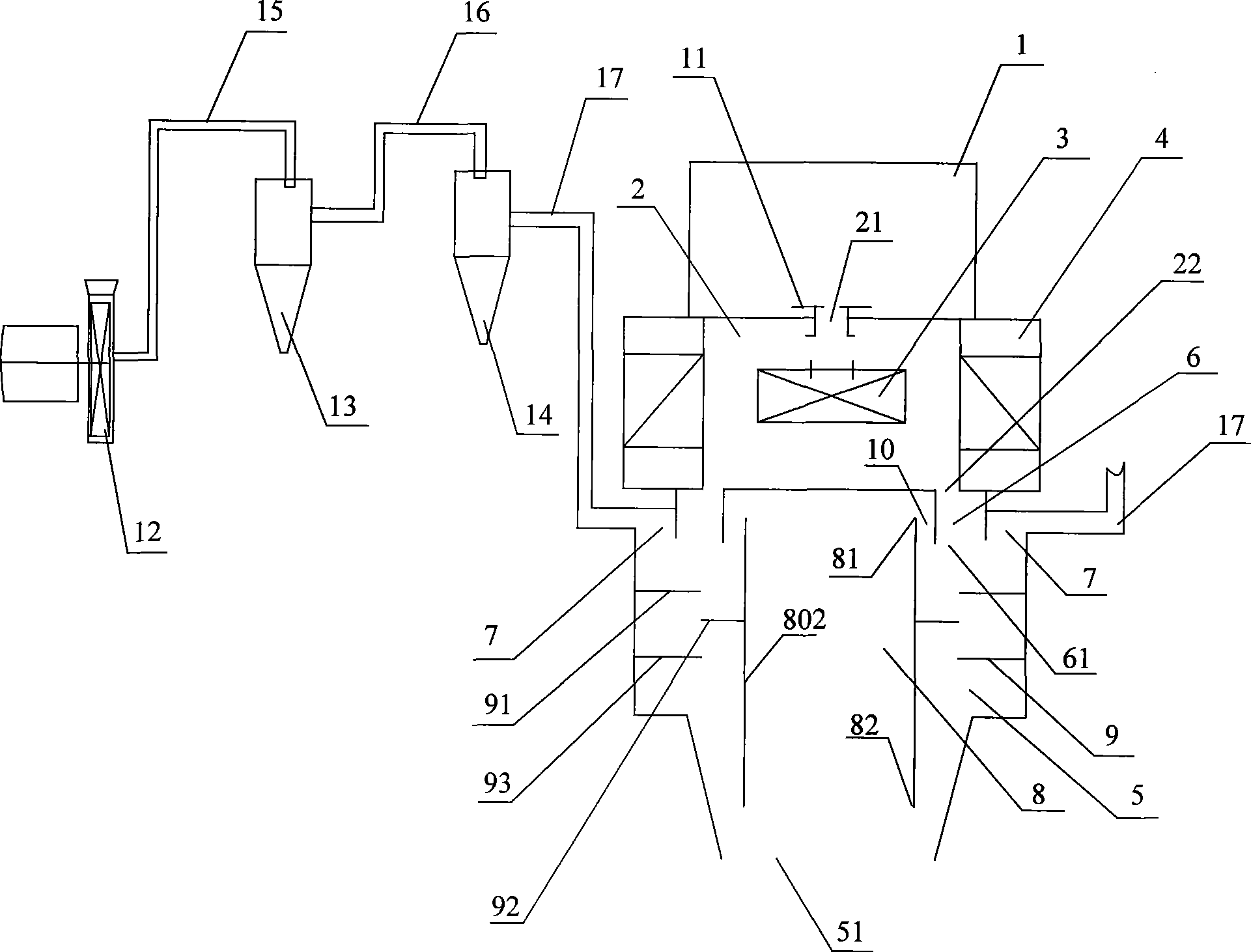

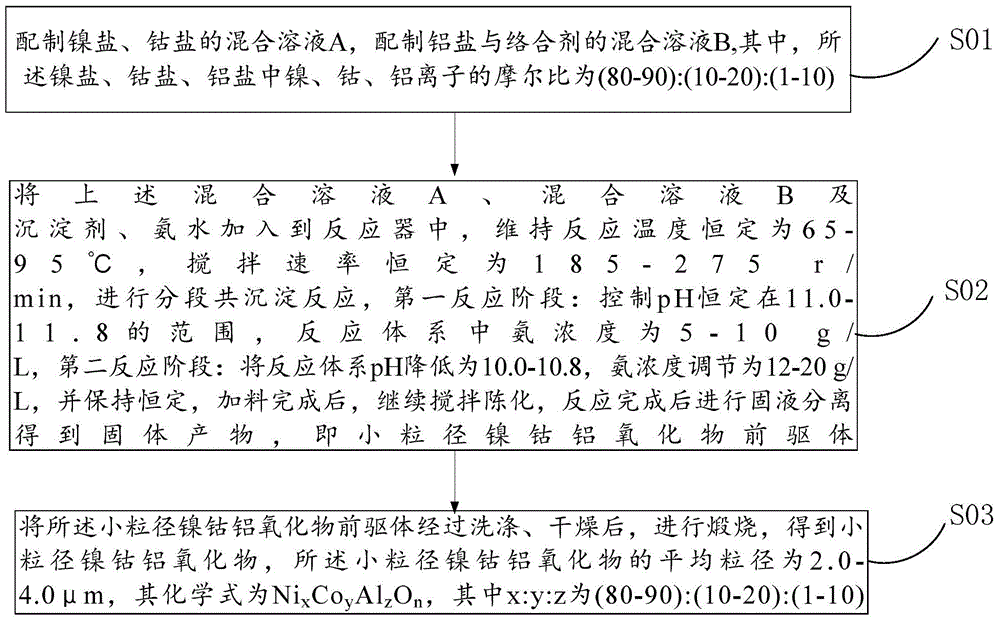

The invention provides a small-particle-size nickel-cobalt-aluminum oxide which is regular spherical, relatively good in sphericity degree and uniform in particle size distribution and has the average particle size of 2.0-4.0 [mu]m; the bulk density is greater than 0.8 g / cm<3>, the tap density is greater than 1.2 g / cm<3>, and the small-particle-size nickel-cobalt-aluminum oxide can be used for stacking and filling with a large-particle-size nickel-cobalt-aluminum oxide, so as to solve the application problem of low tap density of a positive electrode material. The invention also provides a preparation method of the small-particle-size nickel-cobalt-aluminum oxide, wherein the preparation method comprises the steps: adding a nickel and cobalt mixed solution, an aluminum-complexing agent mixed solution, a precipitating agent and ammonia water into a reactor in a parallel flow manner, and controlling conditions of high pH and low ammonia concentration during an initial stage of a reaction; in the reaction process, under conditions of low pH and high ammonia concentration, making nucleation and growth of a nickel-cobalt-aluminum precursor implemented separately, preparing a small-particle-size nickel-cobalt-aluminum oxide precursor, and calcining to obtain the small-particle-size nickel-cobalt-aluminum oxide with good sphericity degree and high tap density. The preparation method has the advantages of simple process, high controllability and low cost.

Owner:格林爱科(荆门)新能源材料有限公司

Method for preparing nano zinc oxide

InactiveCN1415545AUniform particle size distributionFully contactedZinc oxides/hydroxidesLiquid-liquid reaction processesGranularityNano zinc oxide

Owner:BEIJING UNIV OF CHEM TECH

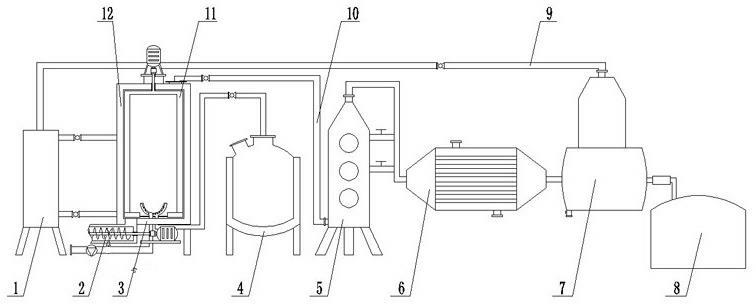

High-temperature steam jetting type oil sand and oil sludge treatment device

InactiveCN102140360AHeat directlyEvenly heatedSludge treatment by pyrolysisLiquid hydrocarbon mixture productionHeating oilSlag

The invention relates to oil sludge treatment equipment for oil producing regions of oil fields, in particular to a high-temperature steam jetting type oil sand and oil sludge treatment device which comprises a cracking evaporation pot, a fractionating tower, a condenser and an oil and water separating pot, wherein the cracking evaporation pot is a vertical pot body on which a heat exchange sandwich layer is arranged, heat conducting oil communicated with a heating oil furnace is arranged in the sandwich layer, an evaporation disc is arranged at the lower part in the pot, high-temperature steam nozzles connected with an superheated steam boiler are uniformly distributed at the bottom of the evaporation disc, a feeding spray pipe connected with a raw material pump is arranged at the side of the evaporation disc, a rotary scraper is arranged at the upper part of the evaporation disc, an air vent which is connected with the fractionating tower through an air pipeline is arranged at the top of the pot, and a spiral slag discharging device is arranged at the bottom of the pot. The high-temperature steam jetting type oil sand and oil sludge treatment device enables oil sludge and high-temperature steam to fully contact and collide with each other and has large treatment capacity; the cracking evaporation pot provides an auxiliary heating function for raw materials to be beneficial for the materials to effectively absorb heat to evaporate oil water; and the cracking evaporation pot is heated by circulating heat conducting oil so that the high-temperature steam jetting type oil sand and oil sludge treatment device has safety and is easy to control.

Owner:NANGUANG YANSHAN LIGHT STEEL STRUCTURE ENG TANGSHAN

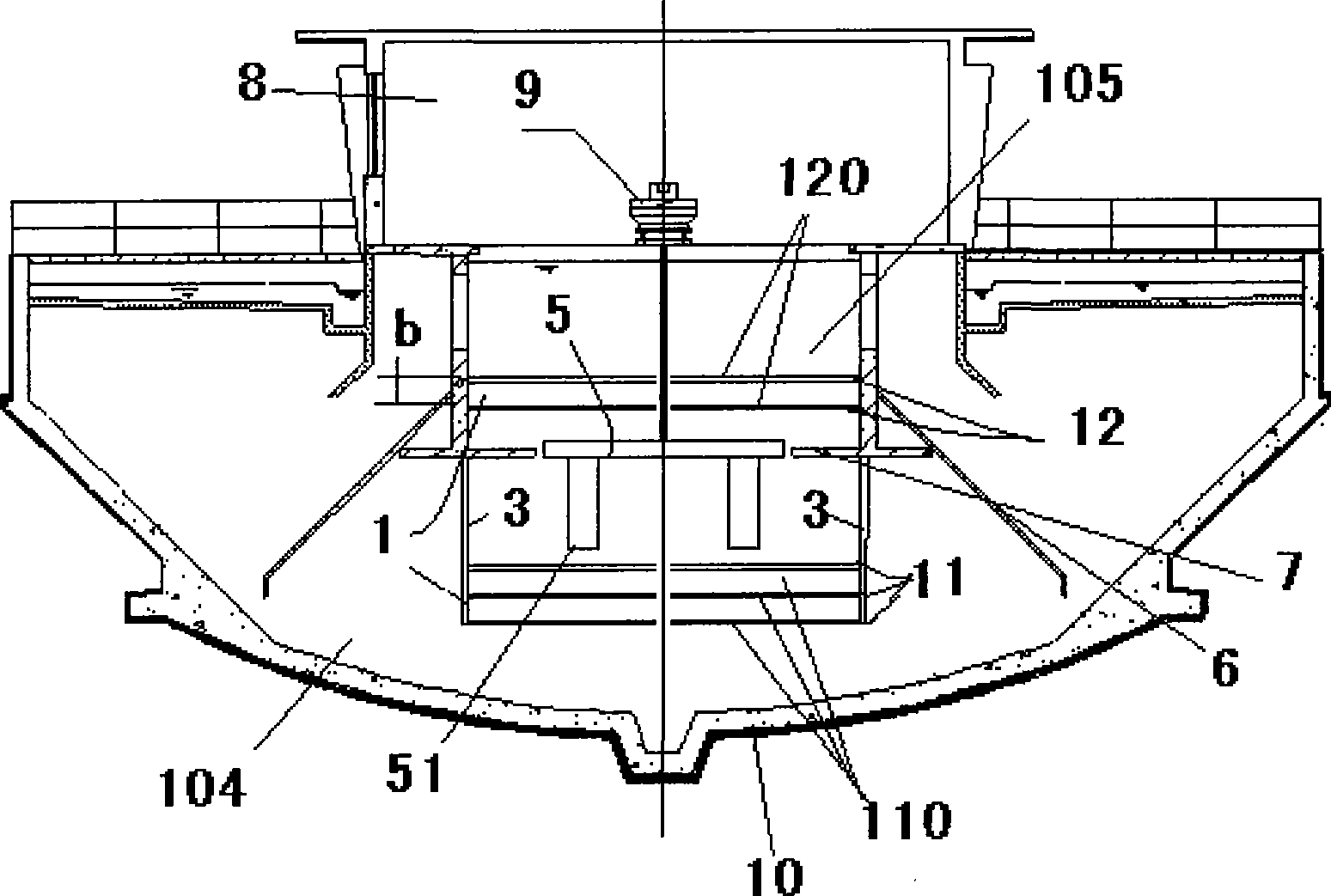

Seawater clarifier turbulence construction and clarifier thereof

InactiveCN101530681AOptimize structural configurationImprove processing efficiencySettling tanks feed/dischargeSedimentation settling tanksFlocculationColloid

The invention provides a seawater clarifier turbulence construction and a clarifier thereof, relating to the technical field of seawater purifying treatment, in particular to the clarifier which improves the turbulence construction. The clarifier comprises a clarifier body composed of a first reaction chamber and a second reaction chamber and an agitating vane, wherein, the turbulence construction comprises a first turbulence unit and a second turbulence unit, the first turbulence unit is arranged in the first reaction chamber of the clarifier, and the second turbulence unit is arranged in the second reaction chamber of the clarifier. The seawater clarifier of the invention can improve flocculation condition effectively and improve the collision probability of destabilized small colloid in seawater, and the formed alumen ustum has better effect in size and settling property, thus achieving the purpose of improving the efficiency of water treatment.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Reaction promoter for flue gas purification treatment

InactiveCN101199916AGuaranteed working conditionsExtended service lifeDispersed particle filtrationOther chemical processesPorositySufficient time

The invention discloses a reaction promoter used for purifying flue gas, which is made by combining diatomite and activated clay, with diatomite accounting for 75-85% of the total weight and activated clay accounting for 15-25% of the total weight. The invention can integrate with hydrated lime to form a membrane of certain thickness (a pre-spray reaction membrane) on the surface of a filter bag, so that hydrated lime and the flue gas can get enough time for colliding and contacting to promote sufficient reaction and adsorption of the harmful substances in the flue gas, which means the reaction and the adsorption occur on the filter bag surface, and which requires the reaction promoter to have such properties as porosity, low density and large specific surface area to ensure the sufficient time and intensity for the reaction and the adsorption; the mighty adsorption to dioxin and heavy metals require the reaction promoter to have strong adsorbing ability to ensure the sufficient and effective absorption; strong permeability and easy stripping ensures the continuity and reliability of the adsorption; absorbing the moisture together with hydrated lime ensures the working condition of the filter bag so as to prolong the service life of the filter bag; the purifying effect is good and the preparation method is simple.

Owner:GUANGDONG CHANT GRP

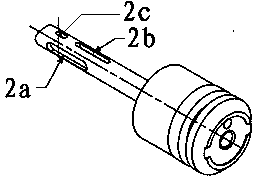

Electromagnetic heating assembly and smoking set using the same

PendingCN110049586AImprove conversion efficiencySave installation spaceCoil arrangementsTobacco devicesEngineeringMetal sheet

The invention discloses an electromagnetic heating assembly and smoking set using the same, wherein the electromagnetic heating assembly comprises a hollow planar coil, an induction metal sheet penetrating through the hollow planar coil and a fixed base for fixing the induction metal sheet; and the smoking set comprises a shell, an electronic assembly, an electromagnetic heating assembly and a cigarette limiting cylinder, wherein the electronic assembly is fixed within the shell, and the electronic assembly is electrically connected with the electromagnetic heating assembly, the cigarette limiting cylinder is clamped and fixed by the shell, the bottom of the cigarette limiting cylinder is provided with a through hole, and the induction metal sheet of the electromagnetic heating assembly extends into the cigarette limiting cylinder. The electromagnetic heating assembly adopting the structure has the advantages of high heat energy conversion efficiency, easy heat dissipation and installation space saving; and the electronic cigarette heating assembly has the advantages of simple structure, low cost and convenient assembly and disassembly besides the advantages described above.

Owner:CHINA TOBACCO HUNAN INDAL CORP

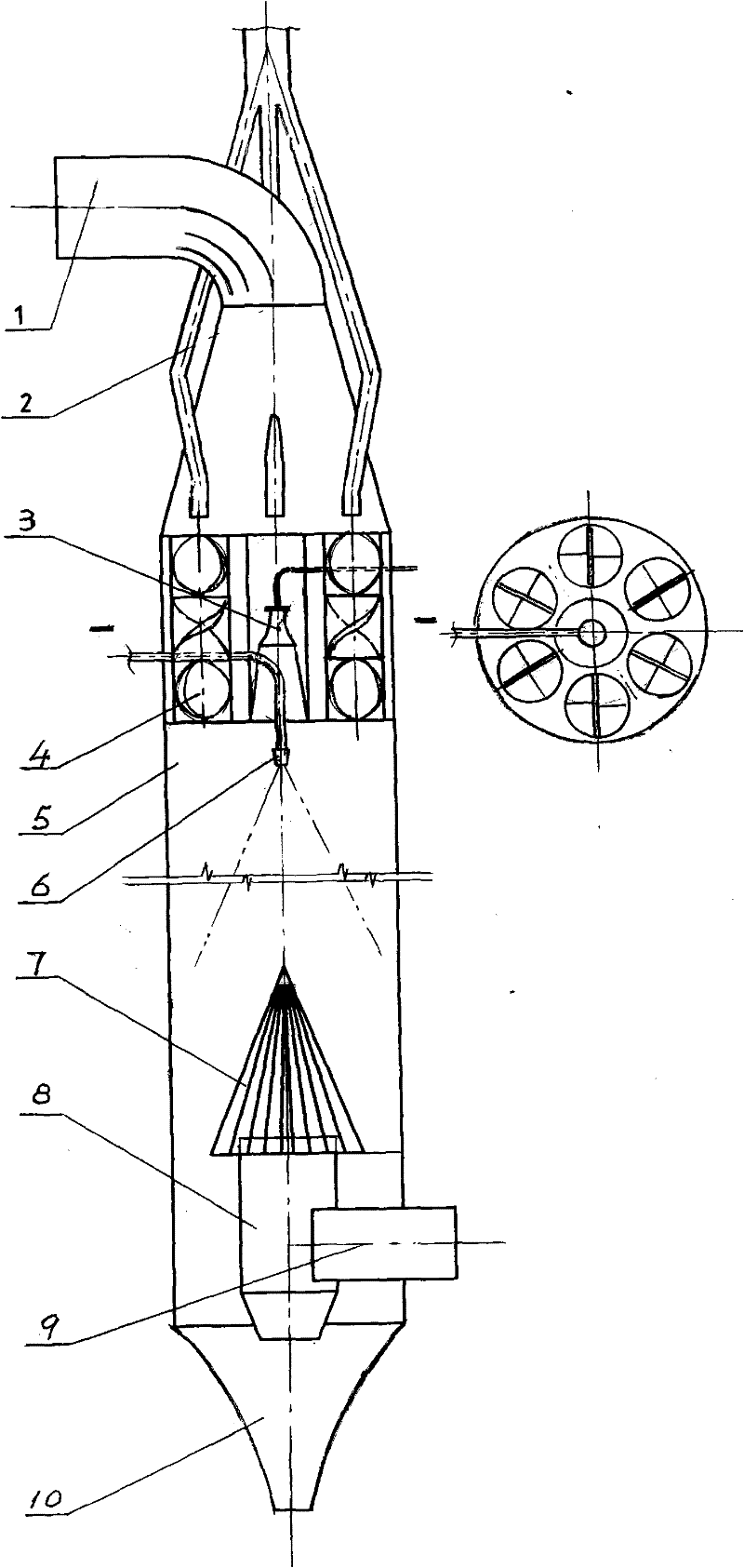

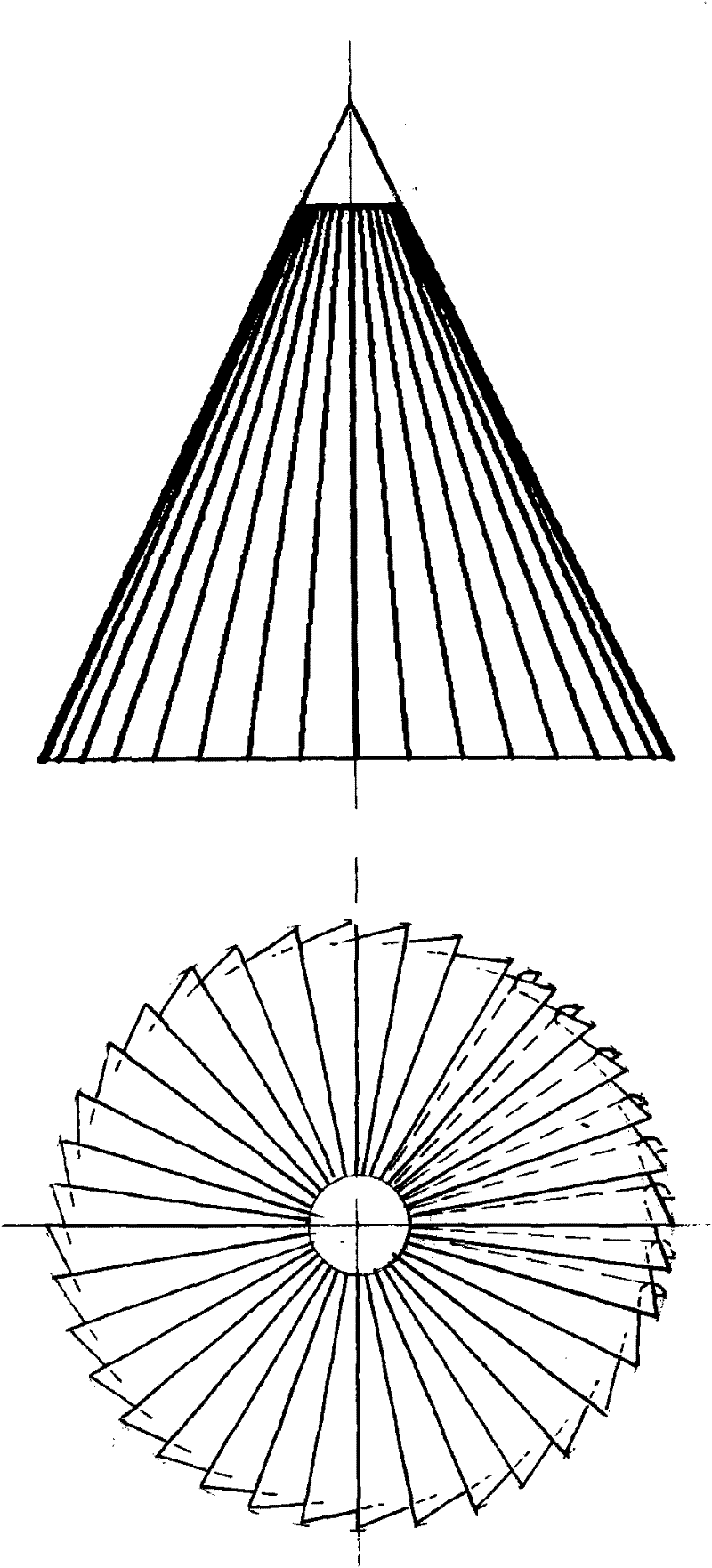

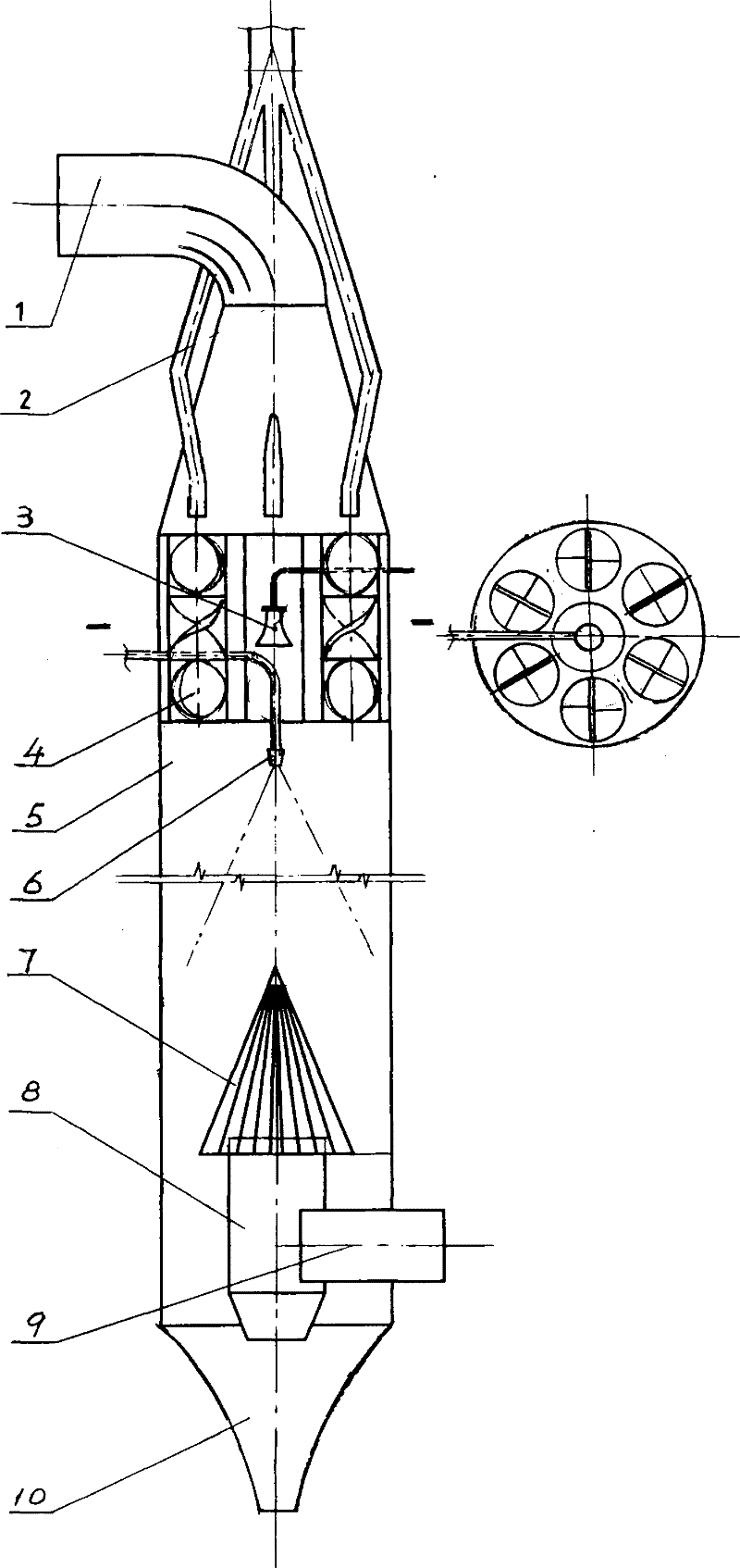

Flue gas desulfurization reactor for descending circulating fluidized bed

InactiveCN102441324AGood effectFull collisionGas treatmentDispersed particle separationNuclear engineeringFlue gas

The invention relates to a flue gas desulfurization technique for a descending circulating fluidized bed. The core equipment of the reactor is a reactor structure, which comprises a straight-flow streamline inlet flue, an absorbent distributor, a sound-wave soot blower, a static mixer, a reaction shell, a humidifying and activating nozzle, a tapered swirl-board gas-solid separator, a gas-solid separation guide cylinder, a desulphurized-gas outlet flue and a hyperbolic ash hopper. The reactor has a rational configuration which enables the smoke in the reactor to be fully collided and mixed with the absorbent so as to obtain a stable and even flow field, a temperature field and a pressure field. Besides, the reactor enables the absorbent to obtain with higher circulation ratio and use ratio. The invention is out of any problems such as sticking wall, scaling and bed collapsing; meanwhile, the reactor reduces the dust load of the exit flue gas obviously and also lowers the load of the bag-type dust remover at the back part greatly, thereby guaranteeing the safe, reliable and long-term operation and solving the technical problem in the semidry method flue gas desulfurization effectively.

Owner:北京博朗环境工程技术股份有限公司 +2

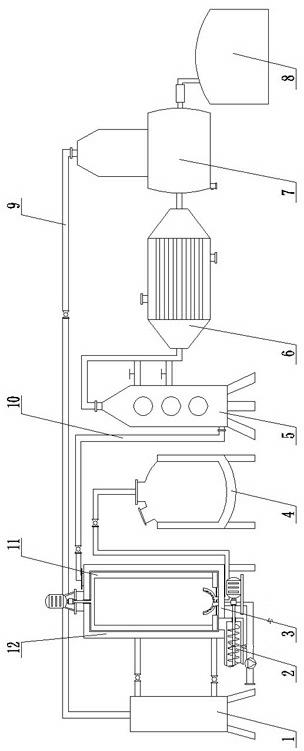

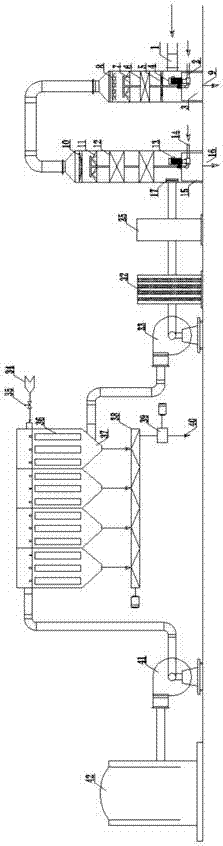

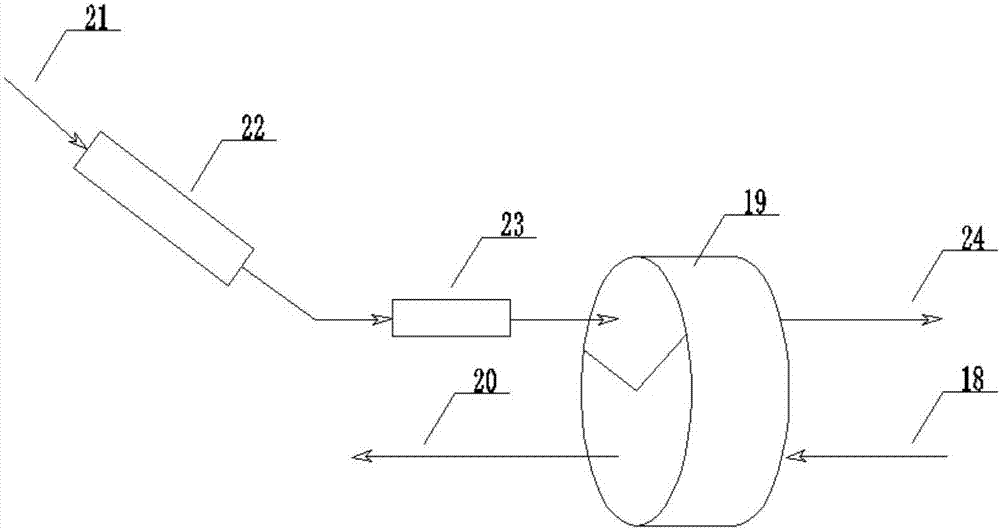

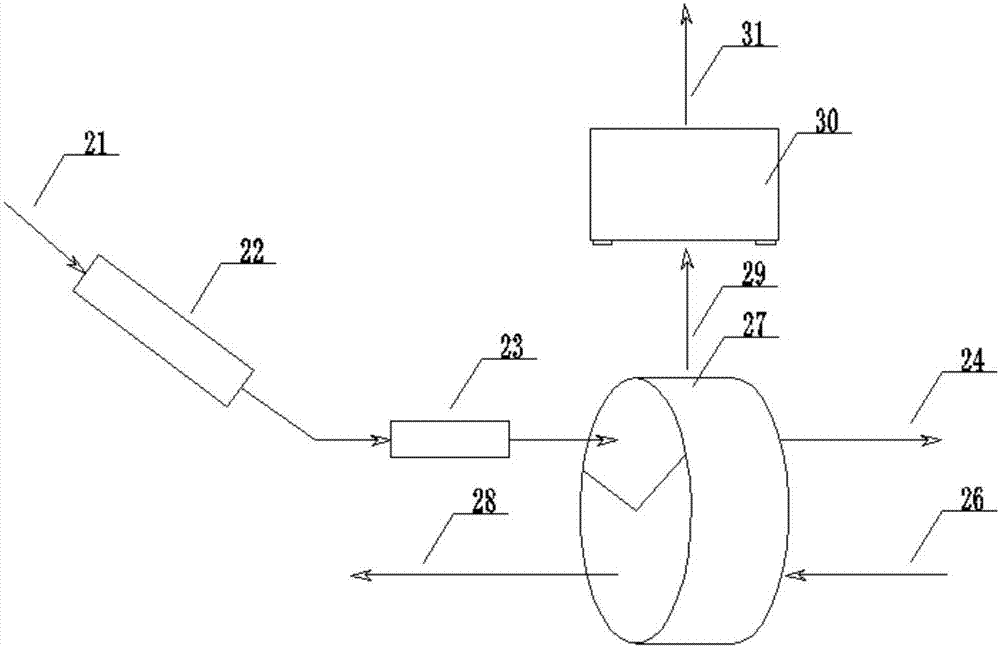

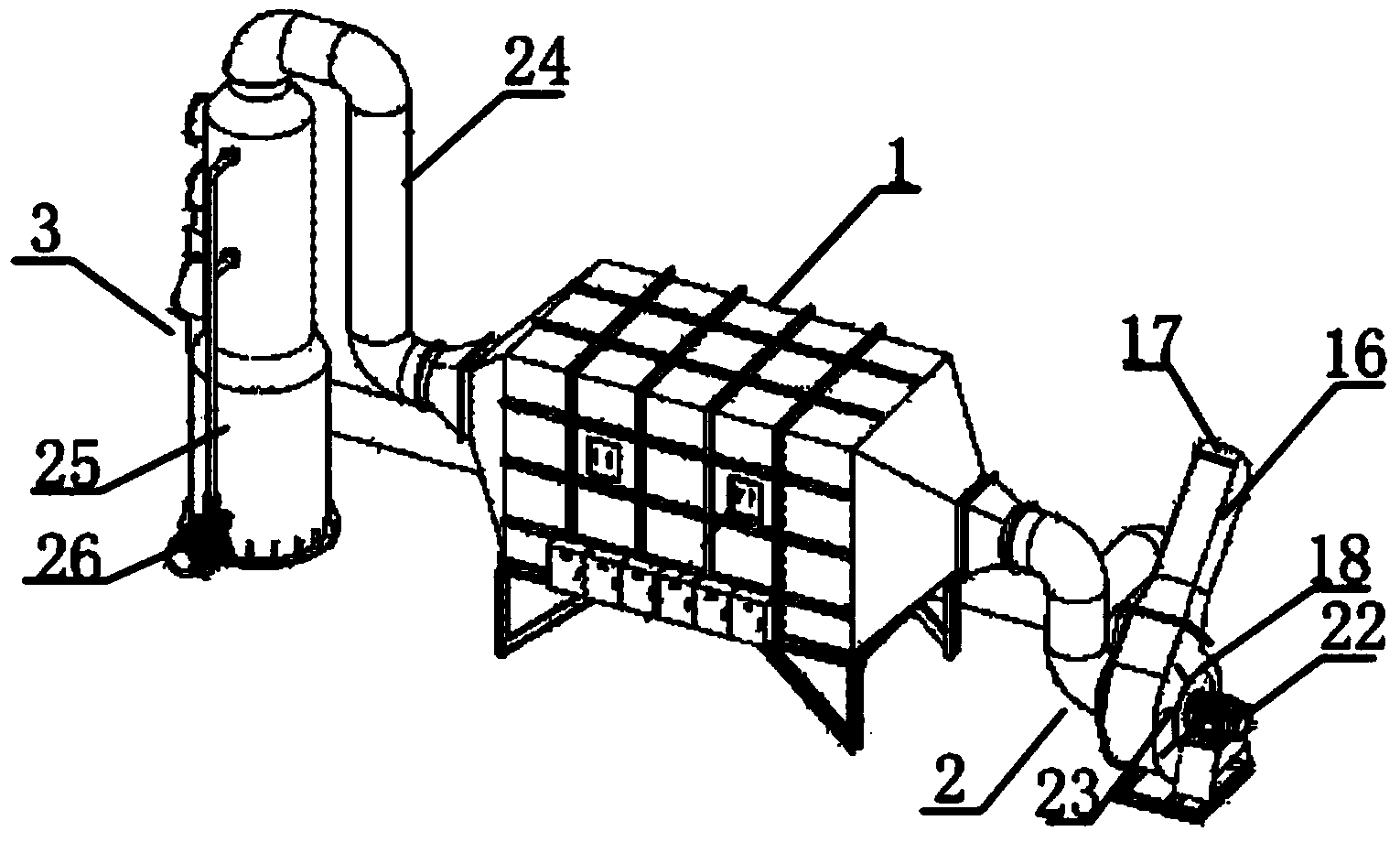

Deodorization and purification treatment system of biological sludge pyrolysis synthesis gas

InactiveCN107297112AReduce pressure drop resistanceIncreased number of spinsCombination devicesGas treatmentCycloneSludge

The invention relates to a deodorization and purification treatment system of biological sludge pyrolysis synthesis gas. The system comprises a cyclone plate water spraying tower module, a spraying reaction acid removal tower module, a solar energy-rotary wheel dehumidification module, a sludge base activated carbon absorption module and a pulse bag type dust remover module in sequential connection, wherein the cyclone plate water spraying tower module comprises a pyrolysis tail gas inlet, a cyclone plate, a filling material layer, a circulation water pump, a water supplementing opening, a first sedimentation pool, a clean water spray head, a first screen defogging device and a sludge outlet; the spraying reaction acid removal tower module comprises a cyclone device, an atomization device, a two-stage filling material layer, a metering circulation pump, a second sedimentation pool, a liquid supplementing pipe and a second screen defogging device; the sludge base activated carbon absorption module consists of a solar heat collector, an electric heater, a sludge base activated carbon rotary wheel, a photocatalysis waste gas treatment device and the like. The deodorization and purification treatment system has the advantages that the structure is reasonable; fetor gas in the pyrolysis tail gas can be controlled in a national standard range; in addition, the pyrolysis synthesis gas is purified; the synthesis gas fuel gas quality is improved.

Owner:ZHEJIANG UNIV OF TECH

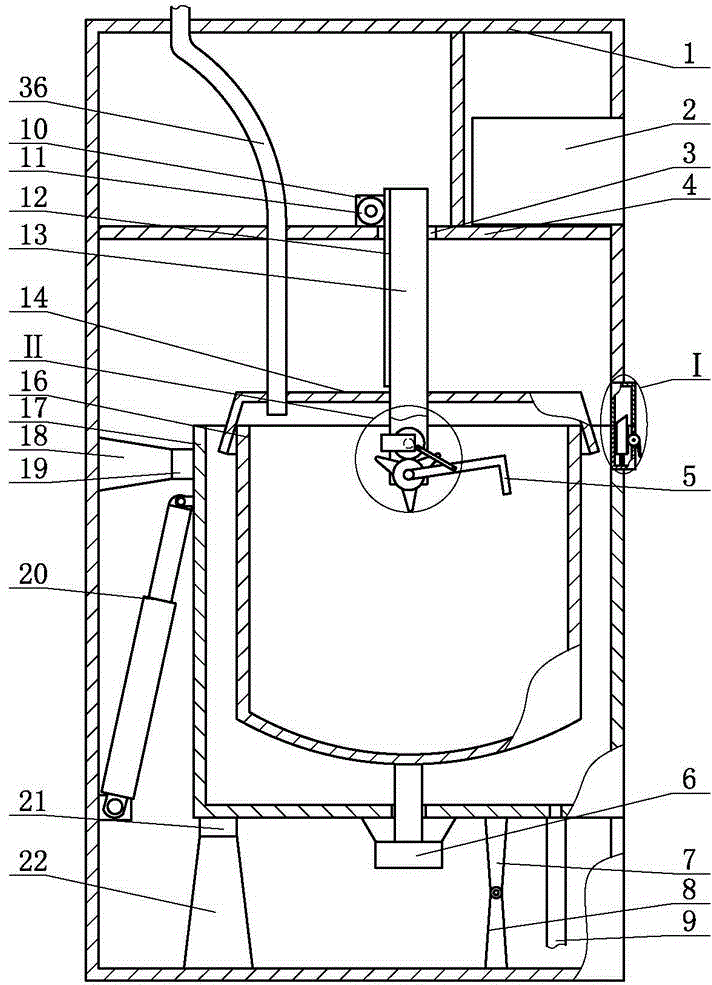

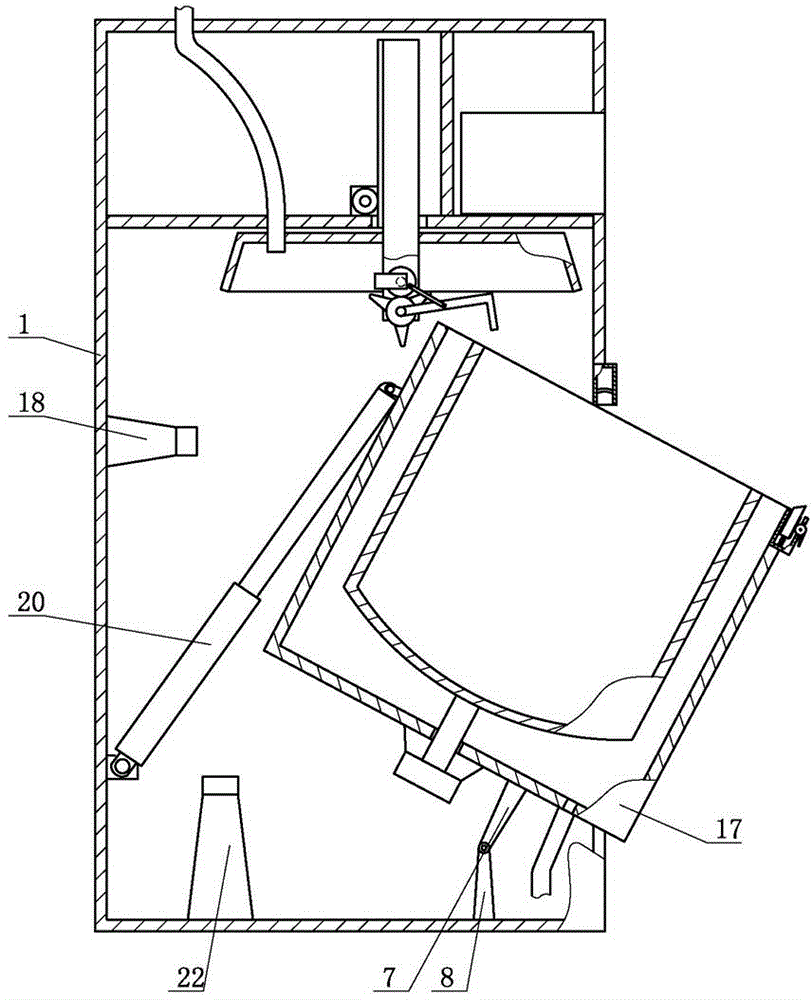

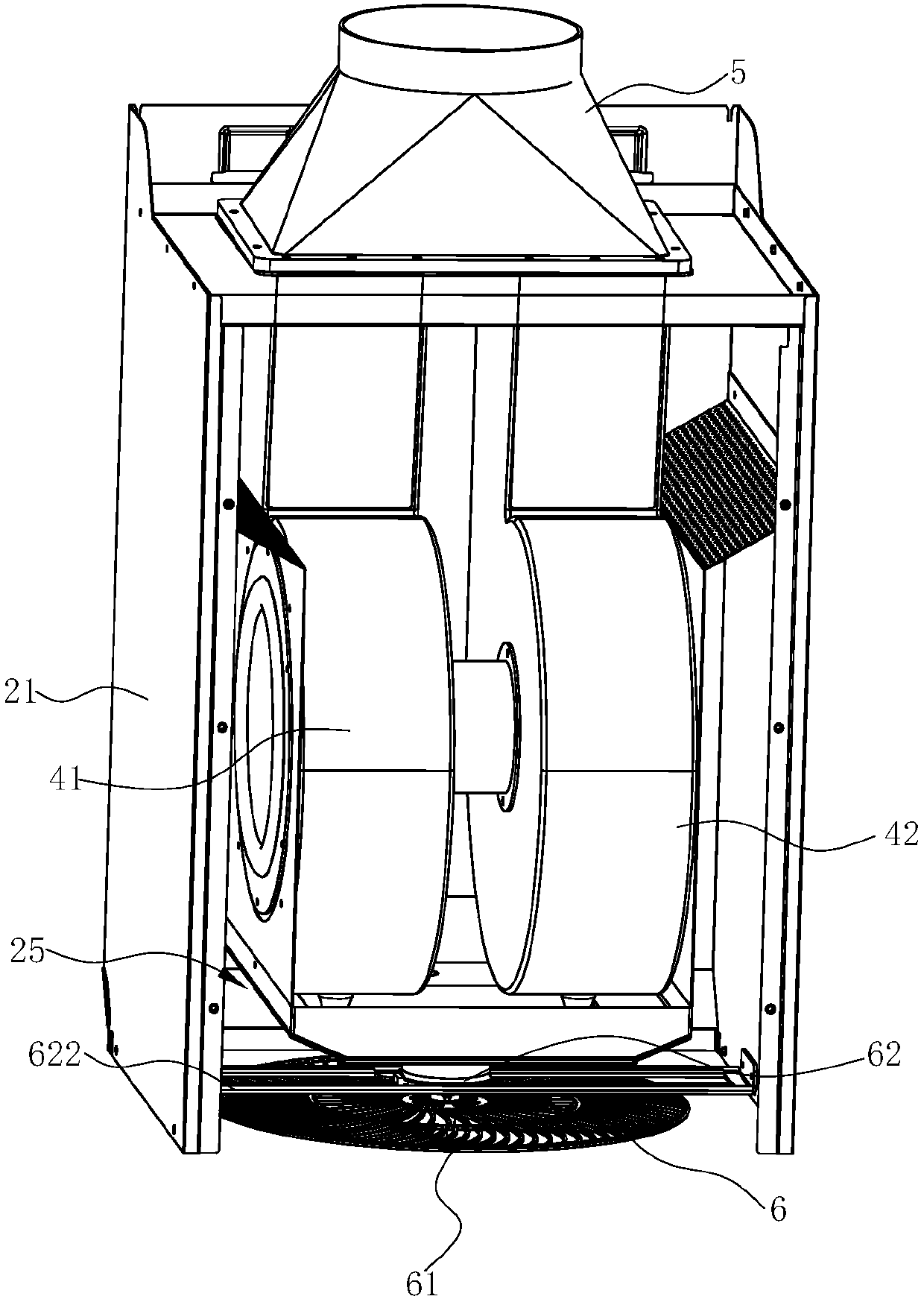

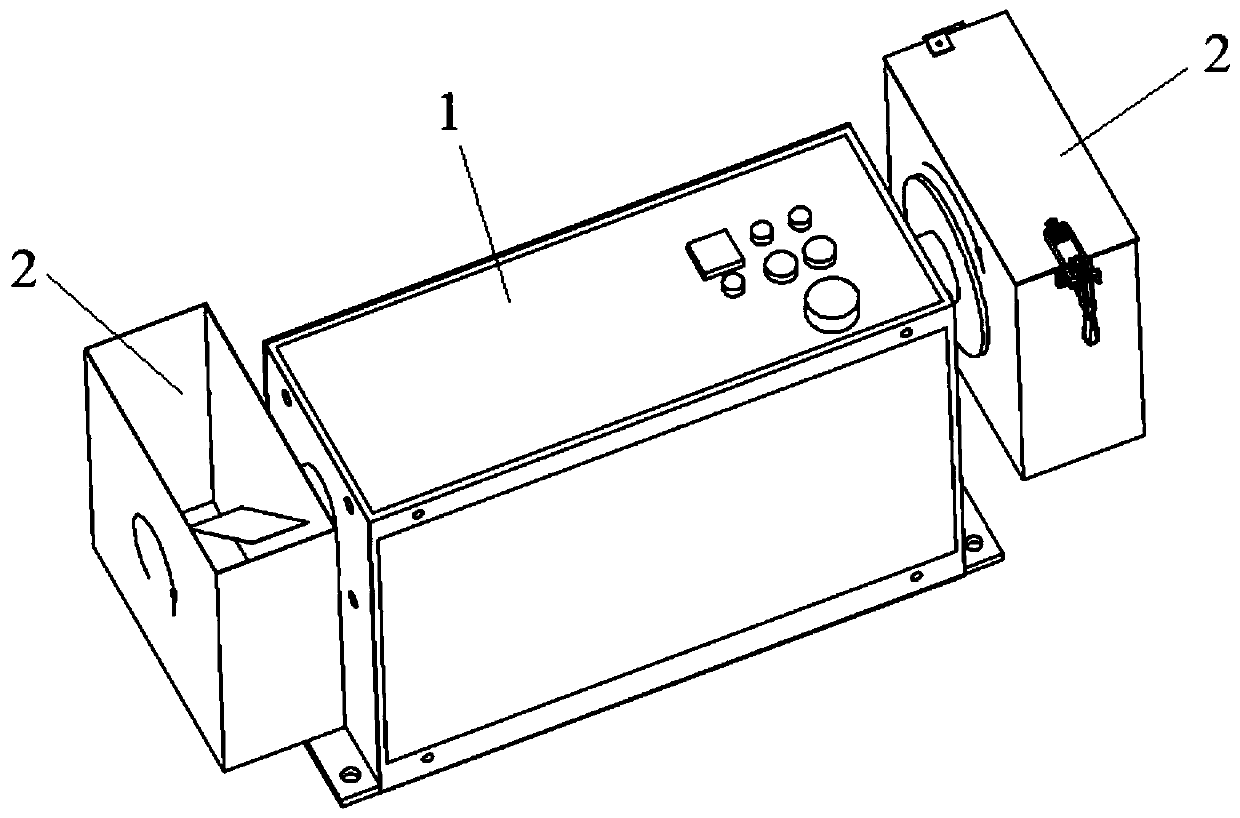

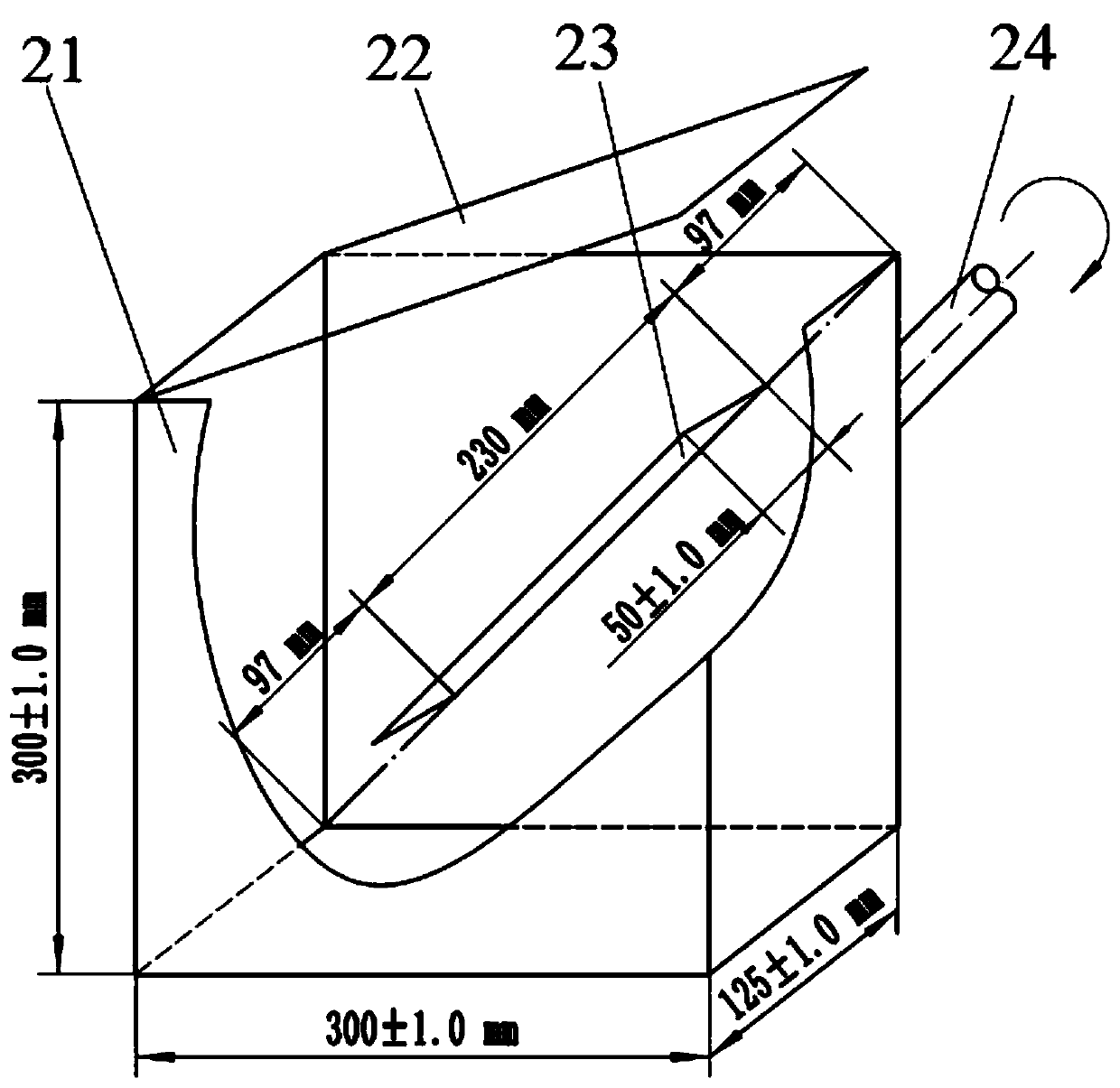

Vertical roller washing machine

InactiveCN104631029AFull collisionShorten the timeOther washing machinesWashing machine with receptaclesWaste management

A vertical roller washing machine comprises a wash bucket and a shell, and is characterized in that the wash bucket is located in the shell, a stirring and washing device support is arranged in the wash bucket, a stirring and washing shaft is installed on the stirring and washing device support and located in the wash bucket, the stirring and washing shaft is connected with a rotating motor, stirring and washing blades are arranged on the stirring and washing shaft, the lower portion of the wash bucket is hinged to the shell, an opening is formed in one side of the shell, and the upper portion of the wash bucket can extend out of the opening of the shell. The vertical roller washing machine has the advantages that in the vertical roller washing machine, a washing power device stirs clothes to be turned and flapped, clothes are turned and circulated from top to bottom in the wash bucket, actions are exerted on clothes of all layers in the wash bucket, clothes fully collide with the stirring and washing blades, and therefore the washing effect is improved, and the clothes washing time is shortened; the lower portion of the wash bucket is hinged to the shell, when clothes are taken out and put in, the wash bucket can be controlled to turn, the upper portion of the wash bucket inclines and extends out of the shell, the occupied space is small, and clothes are convenient to take out and put in.

Owner:李懿

Low-temperature plasma exhaust gas purification device

InactiveCN104107622AImprove air purification efficiencyImprove impactDispersed particle separationProduct gasEngineering

The invention relates to a low-temperature plasma exhaust gas purification device. The low-temperature plasma exhaust gas purification device comprises a low-temperature plasma reaction chamber, two ends of the low-temperature plasma reaction chamber are respectively provided with a gas inlet mechanism and a gas outlet mechanism, and several free radical emitters are arranged in the cavity of the low-temperature plasma reaction chamber. The low-temperature plasma exhaust gas purification device has optimal gas purification effects and improves gas purification efficiency.

Owner:宁波东方盛大环保科技有限公司

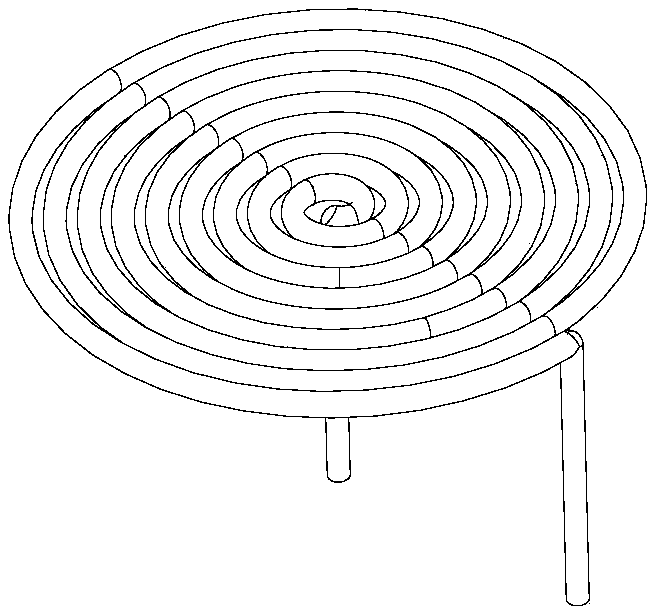

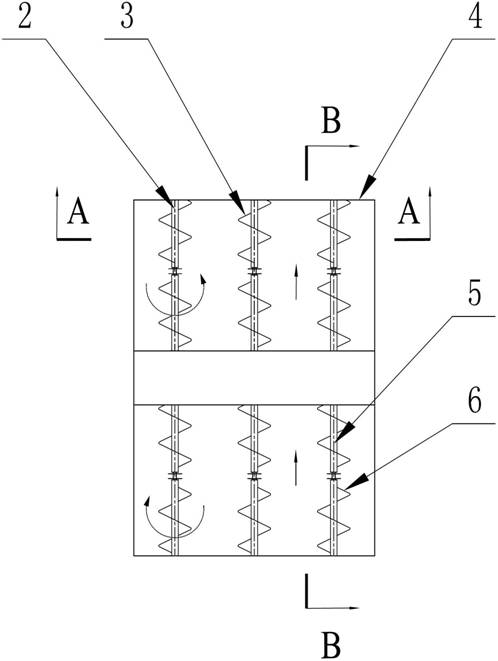

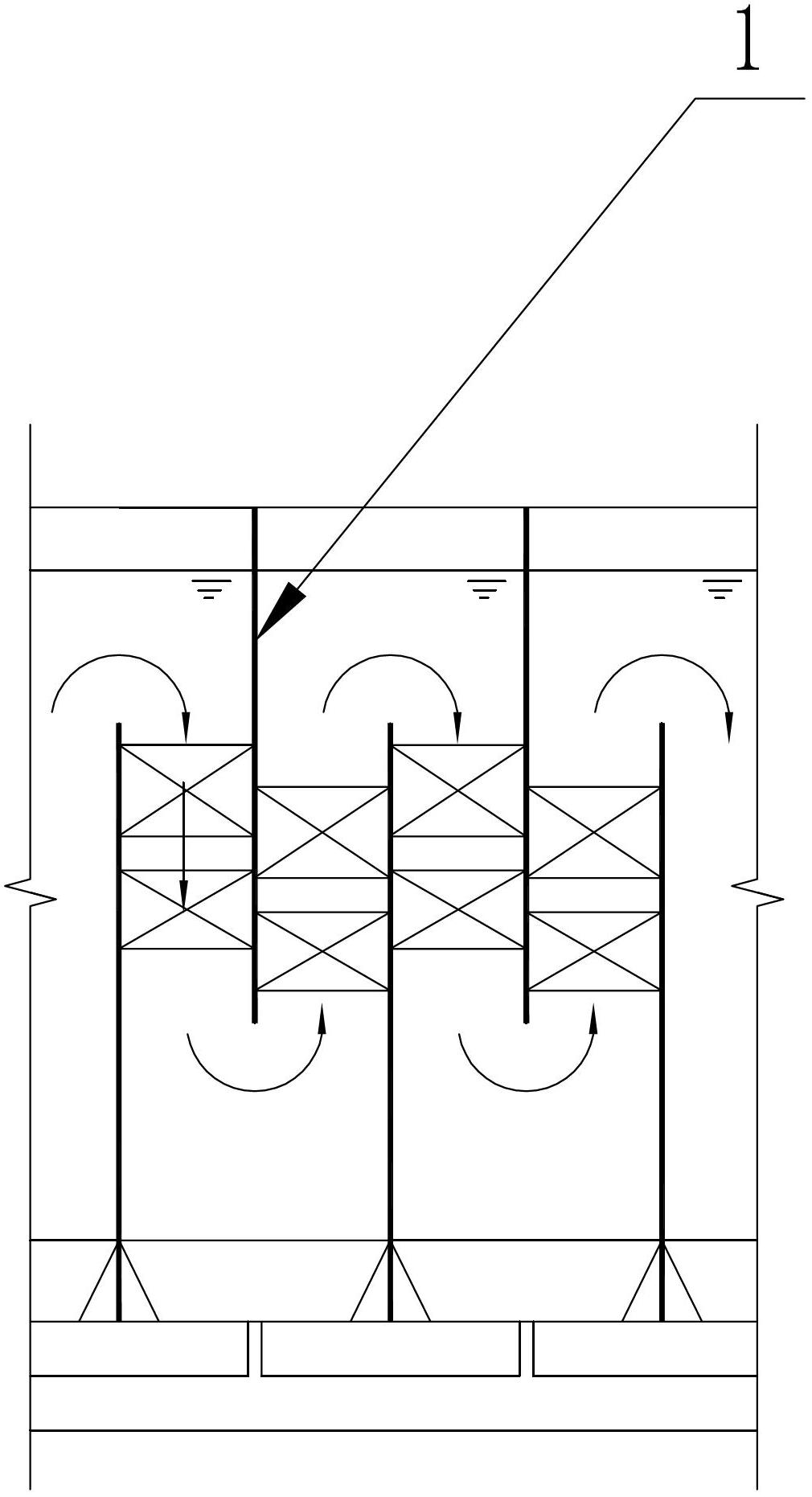

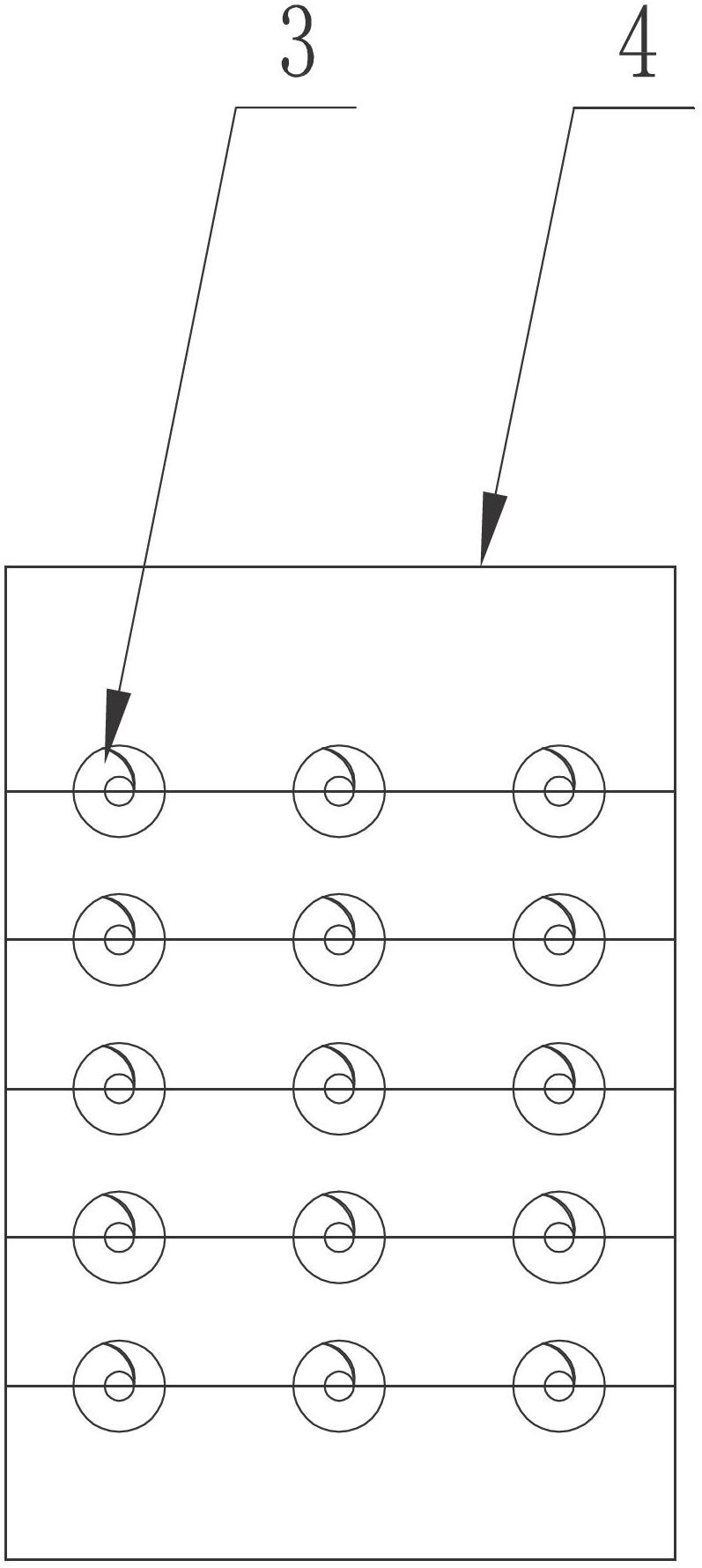

Spiral flocculator and application to folded plate type flocculation reaction tank

ActiveCN102674518AFully disturbedIncrease mixing intensityWater/sewage treatment by flocculation/precipitationSedimentation settling tanksFlocculationWater flow

The invention belongs to water treatment equipment, and particularly relates to a spiral flocculator which comprises a support. At least two spiral plates with opposite turning directions are longitudinally arranged on the support at intervals, the upper end and the lower end of each spiral plate are rotationally assembled on the support, and strip-shaped blades are radially fixed onto outer edges of the spiral plates. The spiral flocculator is mounted between two adjacent partition boards in a folded plate type flocculation reaction tank when applied to the folded plate type flocculation reaction tank. The spiral flocculator solves problems of large application limitation, poor flocculation effect and large occupied area of an existing reaction tank in the prior art, and has the advantages that a disturbance effect to water flow is good, the occupied area of the reaction tank is small, installation is simple, energy is saved, and the like.

Owner:JIACHENG ENVIRONMENTAL PROTECTION ENG CO LTD

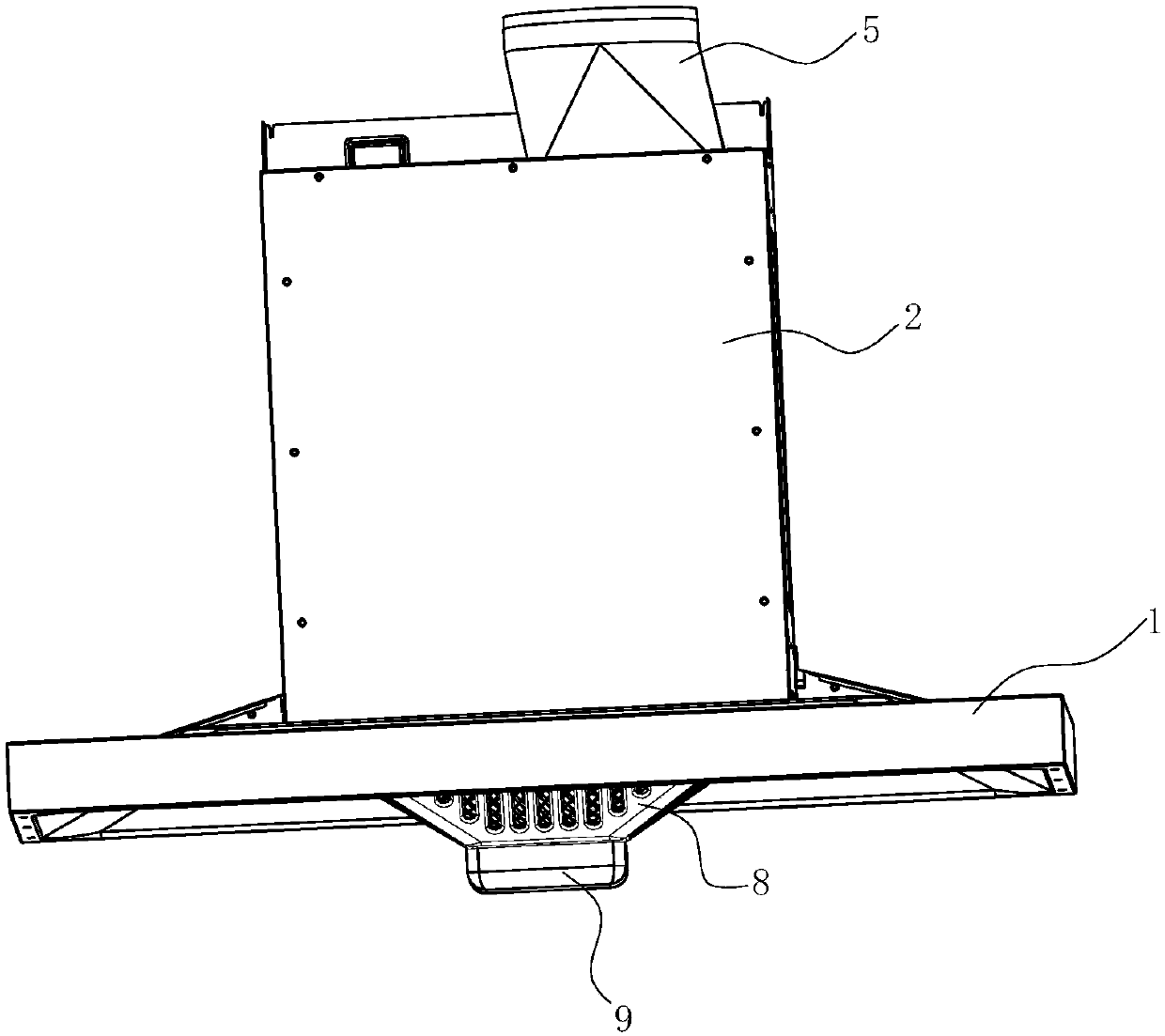

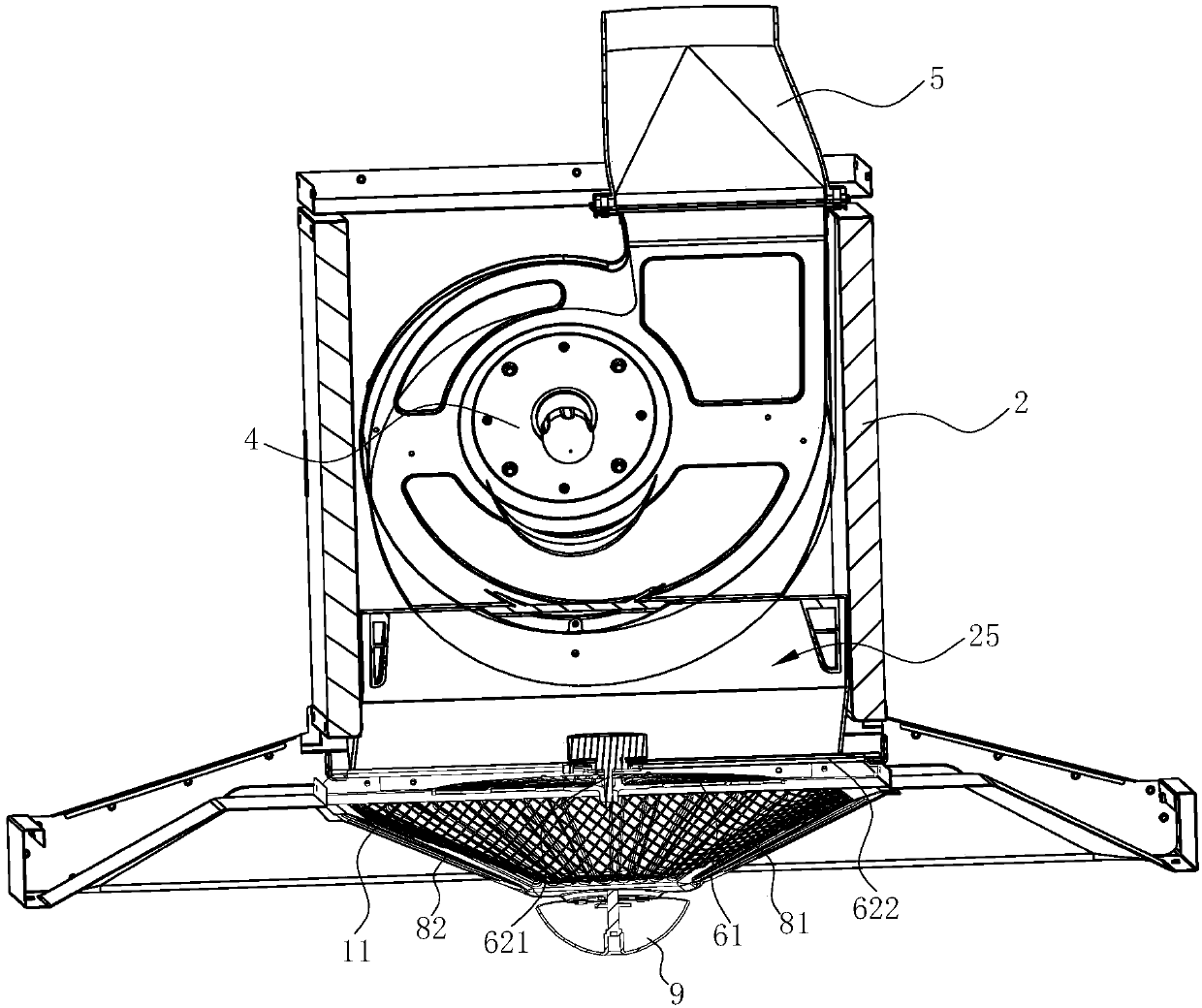

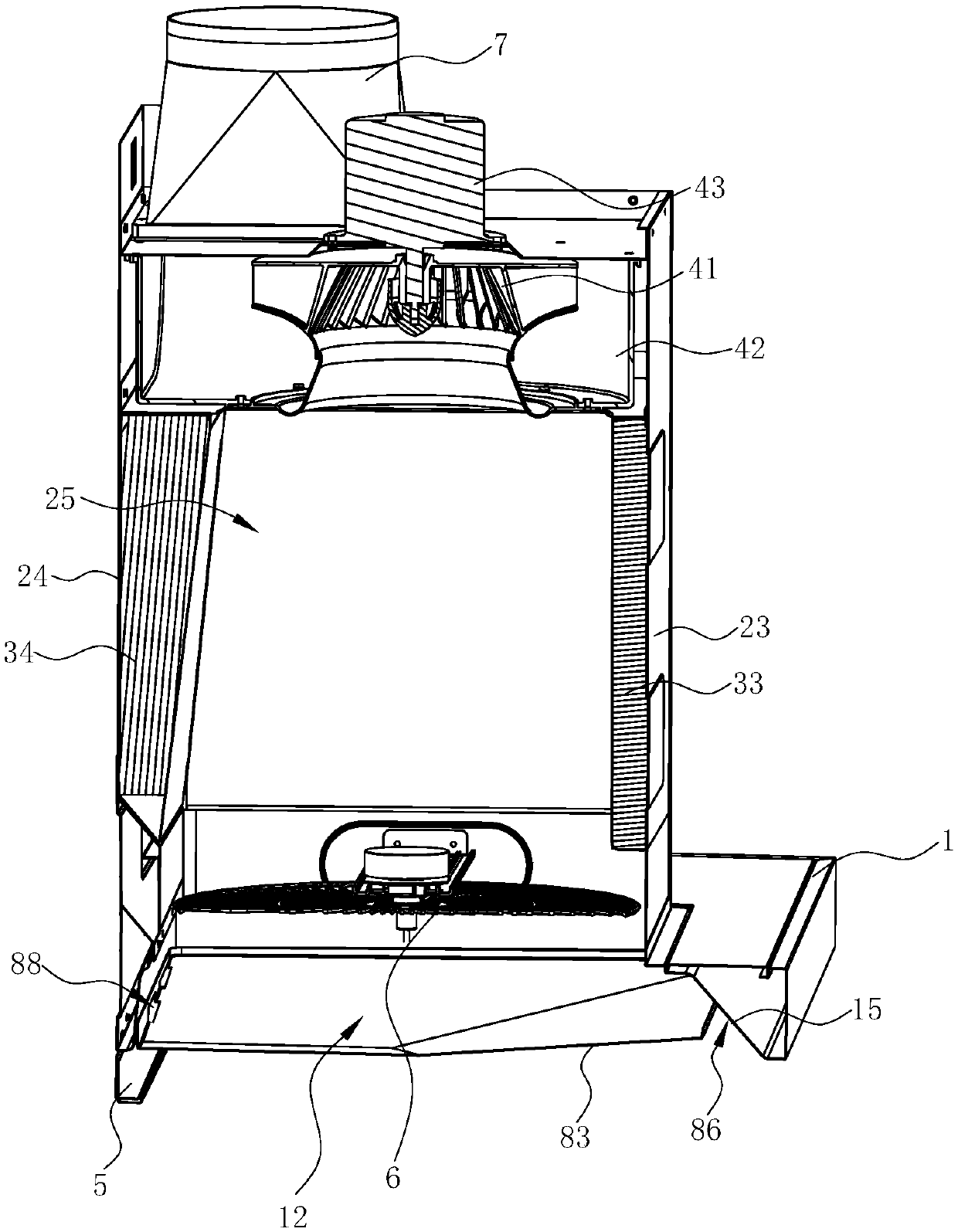

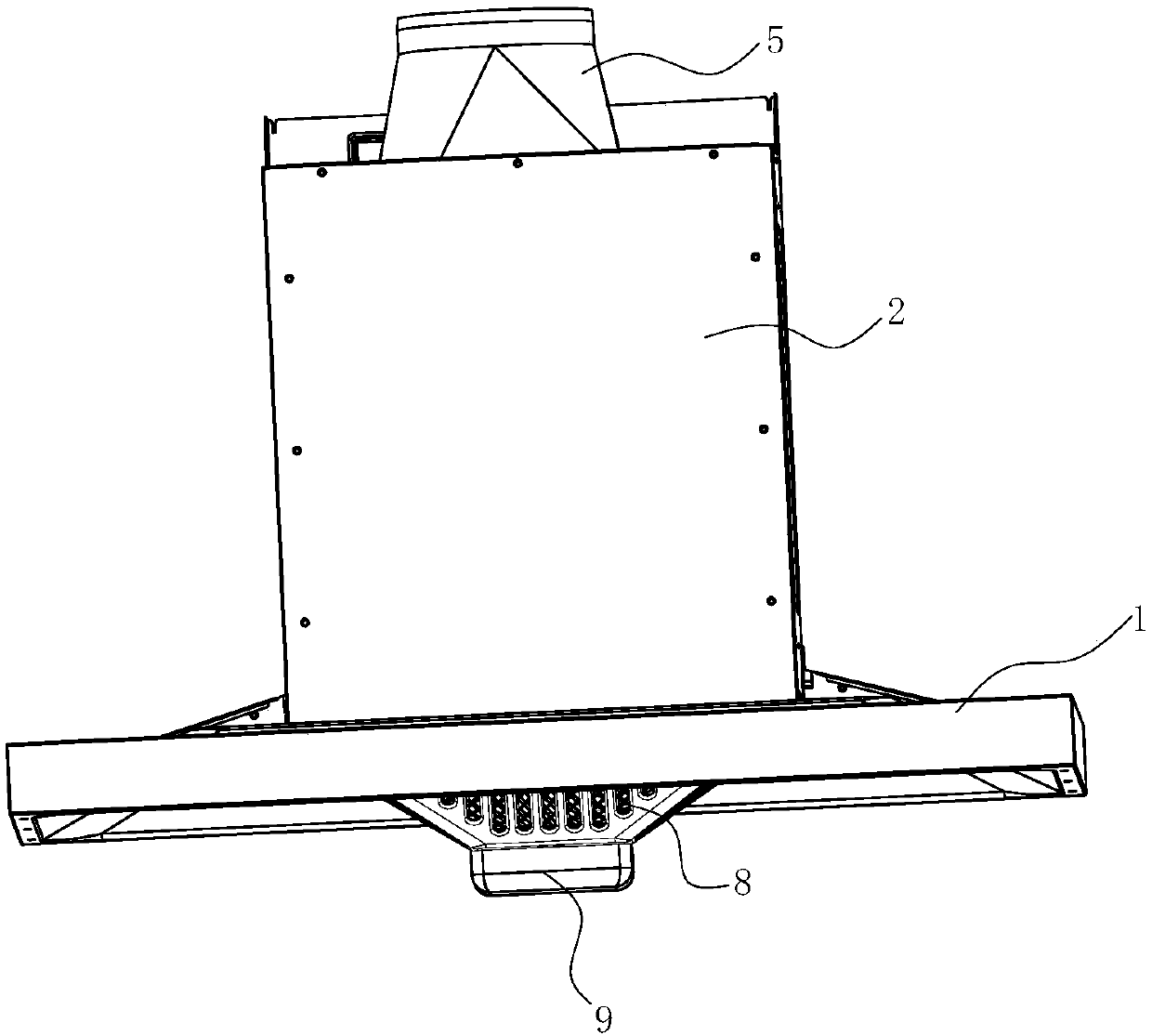

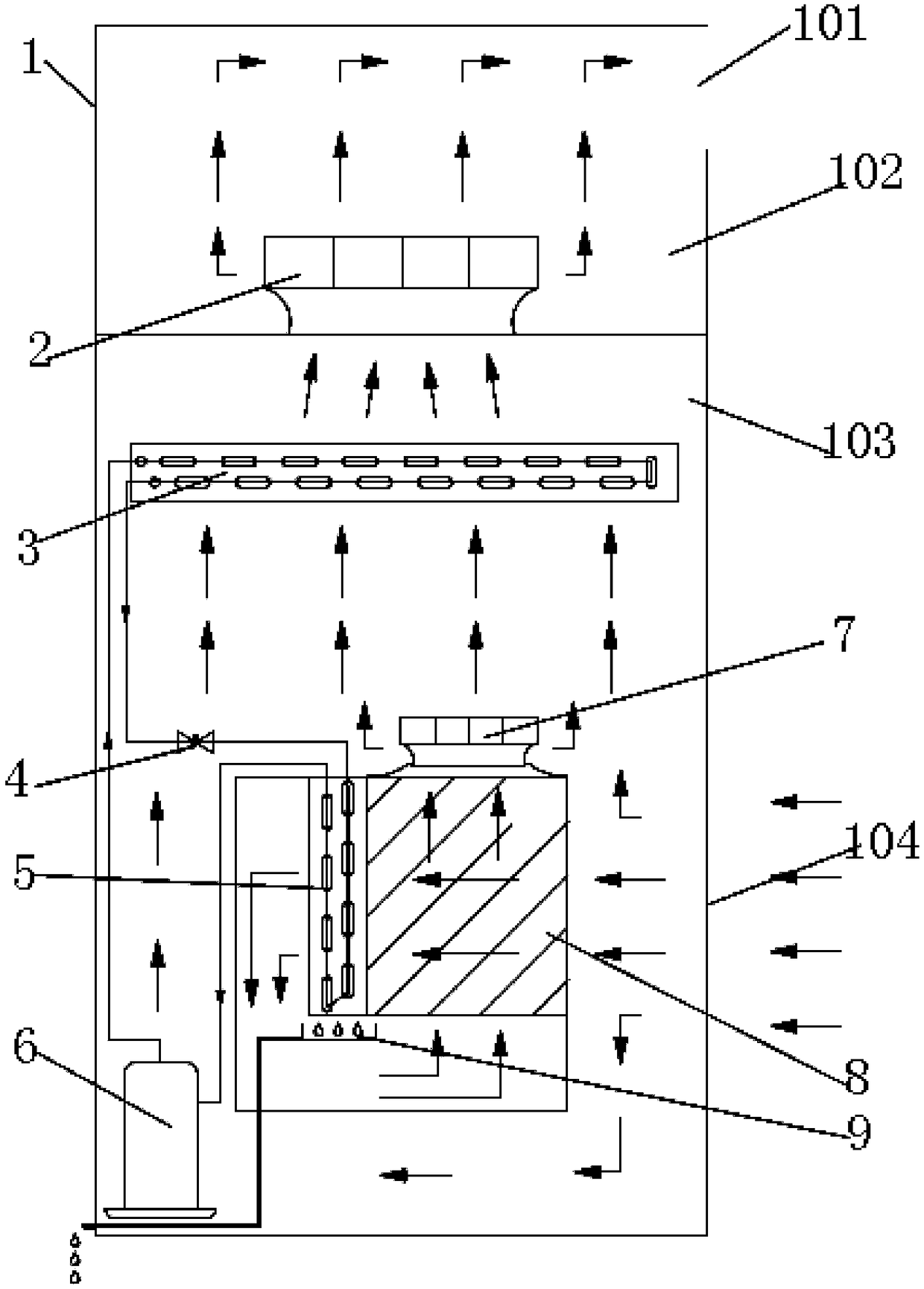

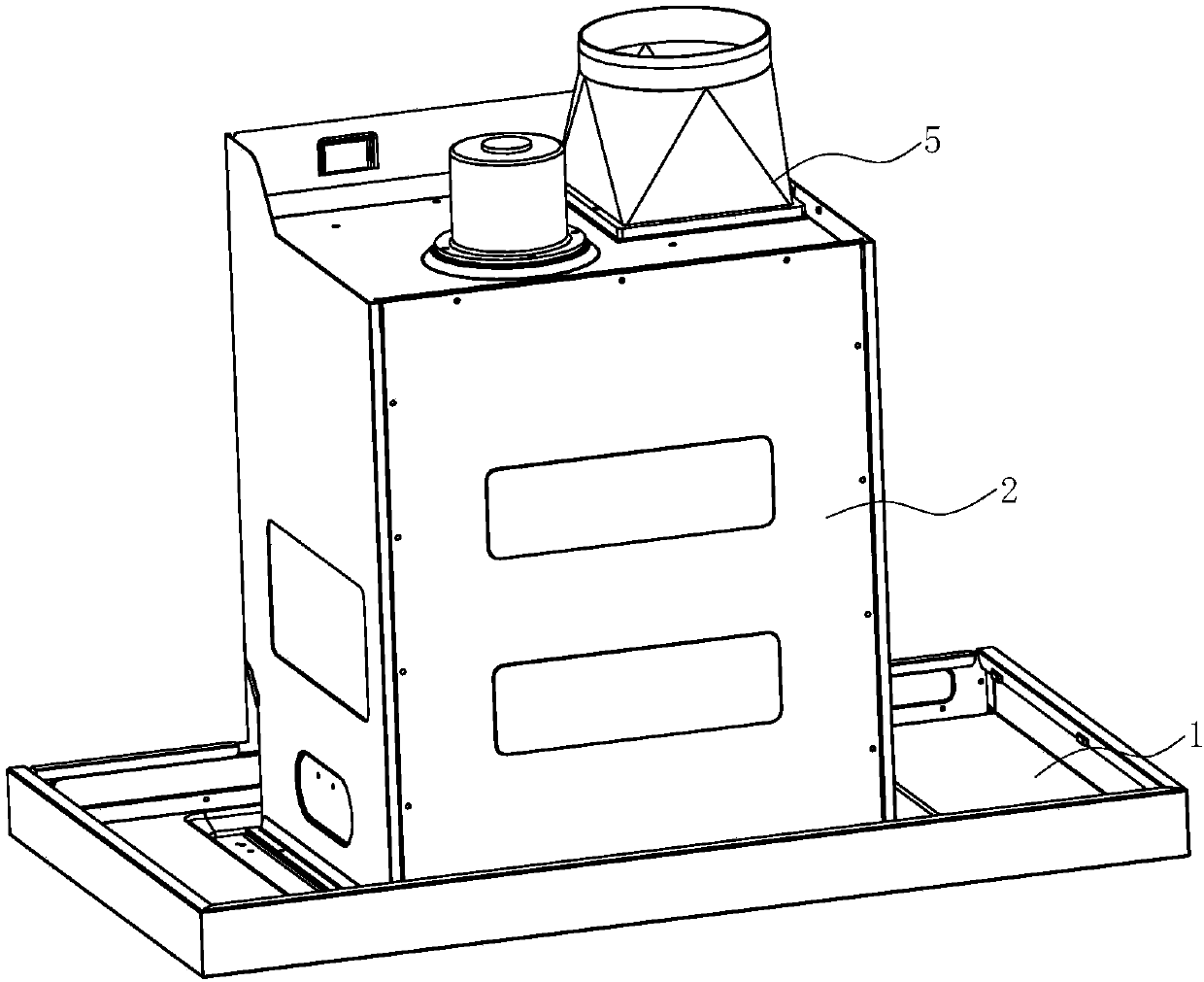

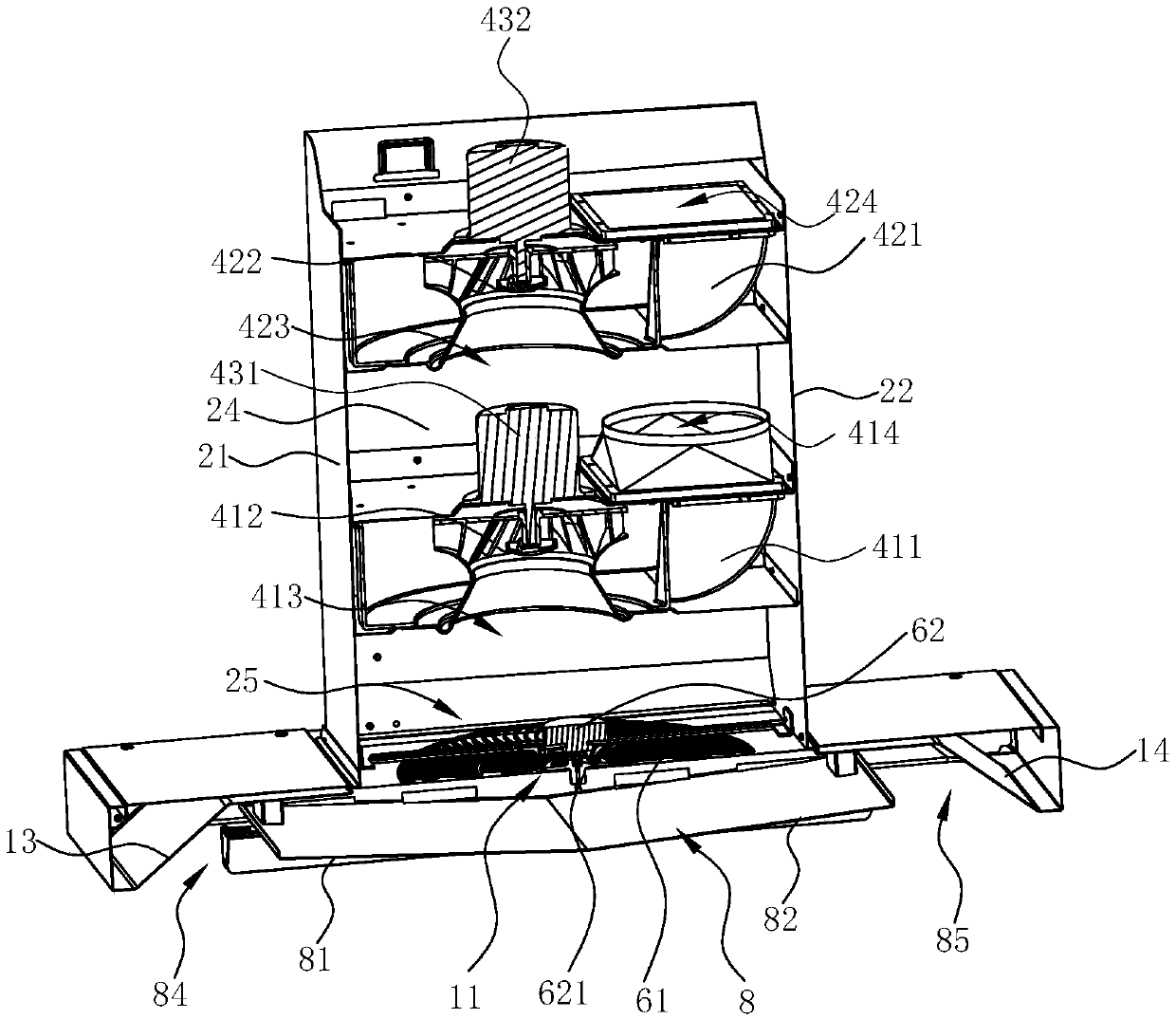

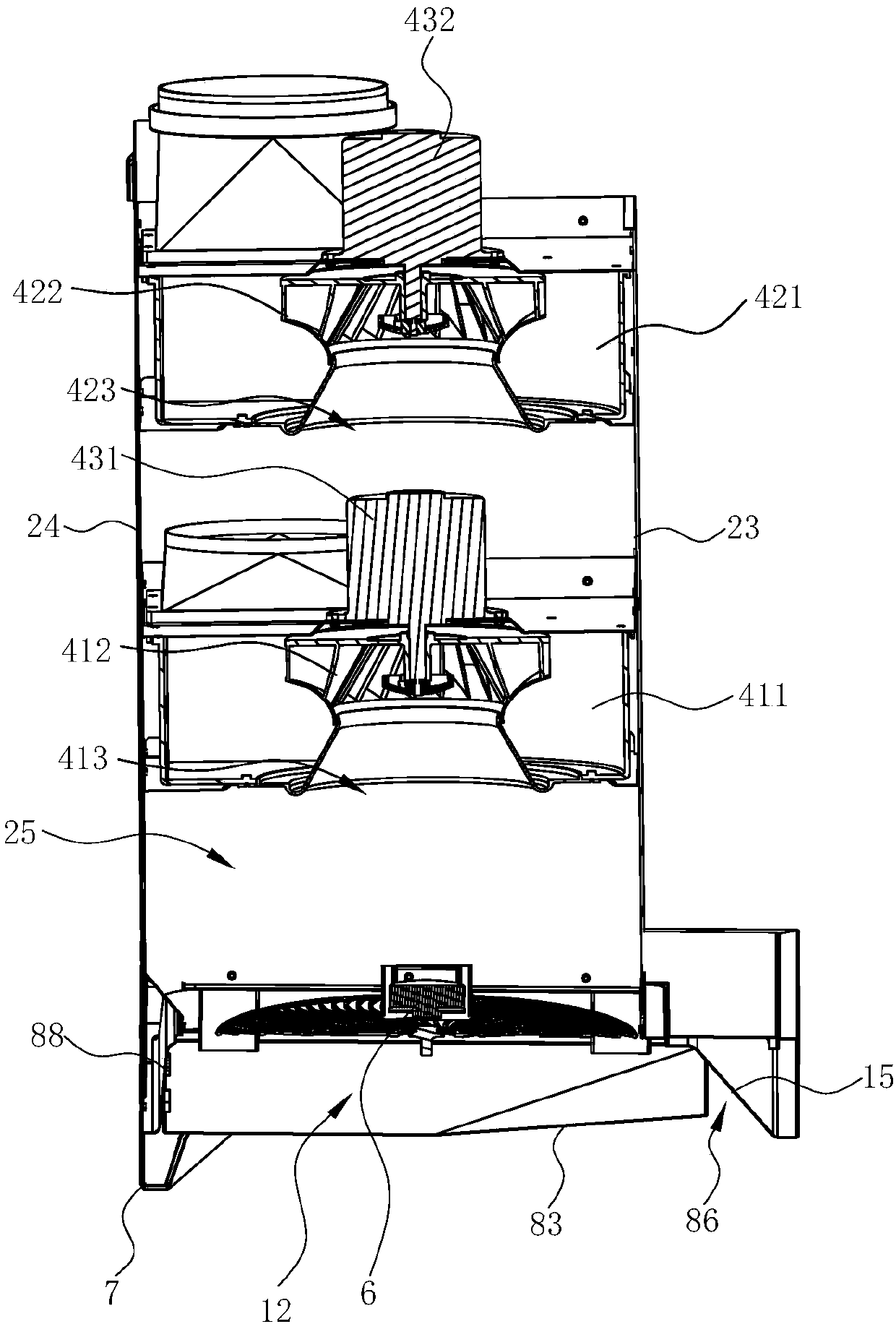

Range hood

PendingCN109780598AGuaranteed air intake areaImprove distributionDomestic stoves or rangesLighting and heating apparatusWaste managementAirflow

The invention discloses a range hood. The range hood comprises a cooking fume collection hood, a case arranged above the cooking fume collection hood, and a cooking fume filter device. An air inlet isformed in the cooking fume collection hood. A duct is formed in the case. The cooking fume filter device comprises an oil screen arranged at the air inlet. The whole oil screen is in the shape of a cone which becomes smaller from top to bottom and extends downwards from the air inlet. The range hood is characterized in that the cooking fume filter device further comprises a rotary filter screen arranged in the case and located at an inlet of the duct. The oil screen and the rotary filter screen are arranged, the oil screen can rectify and guide the air flow, and the air flow can evenly distributed at the air inlet through the rotary filter screen; and through the combination of the oil screen and the rotary filter screen, effective rectification and guidance of the air flow can be achieved, turbulent currents and disordered currents in the air flow are reduced, the air flow is made smooth, and vortexes formed before the air flow enters a fan system are reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Combined type deep purification device for desulfurized wet flue gas

ActiveCN106310911AEasy to filter and purifyEffective annihilationCombination devicesGas treatmentFlue gasEngineering

The invention provides a combined type deep purification device for desulfurized wet flue gas. The device comprises a venturi negative absorption demisting layer, an efficient demisting layer, a condensation demisting layer and a hyperfine demisting layer from bottom to top, wherein a cross beam I is arranged between the vacuum negative absorption demisting layer and the efficient demisting layer; hanging plates I are arranged at left and right ends of the cross beam I; support square steel I is arranged at the lower ends of the hanging plates I; a collecting tank is arranged in the middle of the support square steel I; the vacuum negative absorption demisting layer is provided with venturi blades; the efficient demisting layer is provided with efficient demisting layer blades; a cross beam II is arranged between the condensation demisting layer and the hyperfine demisting layer; the condensation demisting layer is provided with condensation demisting layer blades; the hyperfine demisting layer is provided with hyperfine demisting layer blades; and support plates are arranged at left and right ends of the cross beam II. The combined type deep purification device for desulfurized wet flue gas provided by the invention is favorable in purification effect and reliable in operation.

Owner:SHANDONG GUOSHUN CONSTR GRP

Lithium ion battery positive electrode slurry and preparation method thereof

InactiveCN112786864AImprove stabilityNo agglomerationCell electrodesSecondary cellsPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses a lithium ion battery positive electrode slurry. The positive electrode slurry comprises, by weight, 93.5-97.95% of a positive electrode active material, 1-3% of a conductive agent, 1-3% of a binder A, and 0.05-0.5% of a binder B. The binder A is one of polyvinylidene fluoride or polytetrafluoroethylene, and the viscosity of the binder B is 500 to 2500 mPas; and the positive electrode slurry further comprises a solvent, the positive electrode active material, the conductive agent, the binder A and the binder B are uniformly mixed by the solvent, the solid content of the obtained positive electrode slurry is 70-75%, and the viscosity of the obtained positive electrode slurry is 6000-15000 mPa.s. According to the invention, the dispersion uniformity of the conductive agent can be improved, the stability of the viscosity of the positive electrode slurry can be improved, and the processing efficiency of the positive plate can be improved.

Owner:深圳好电科技有限公司

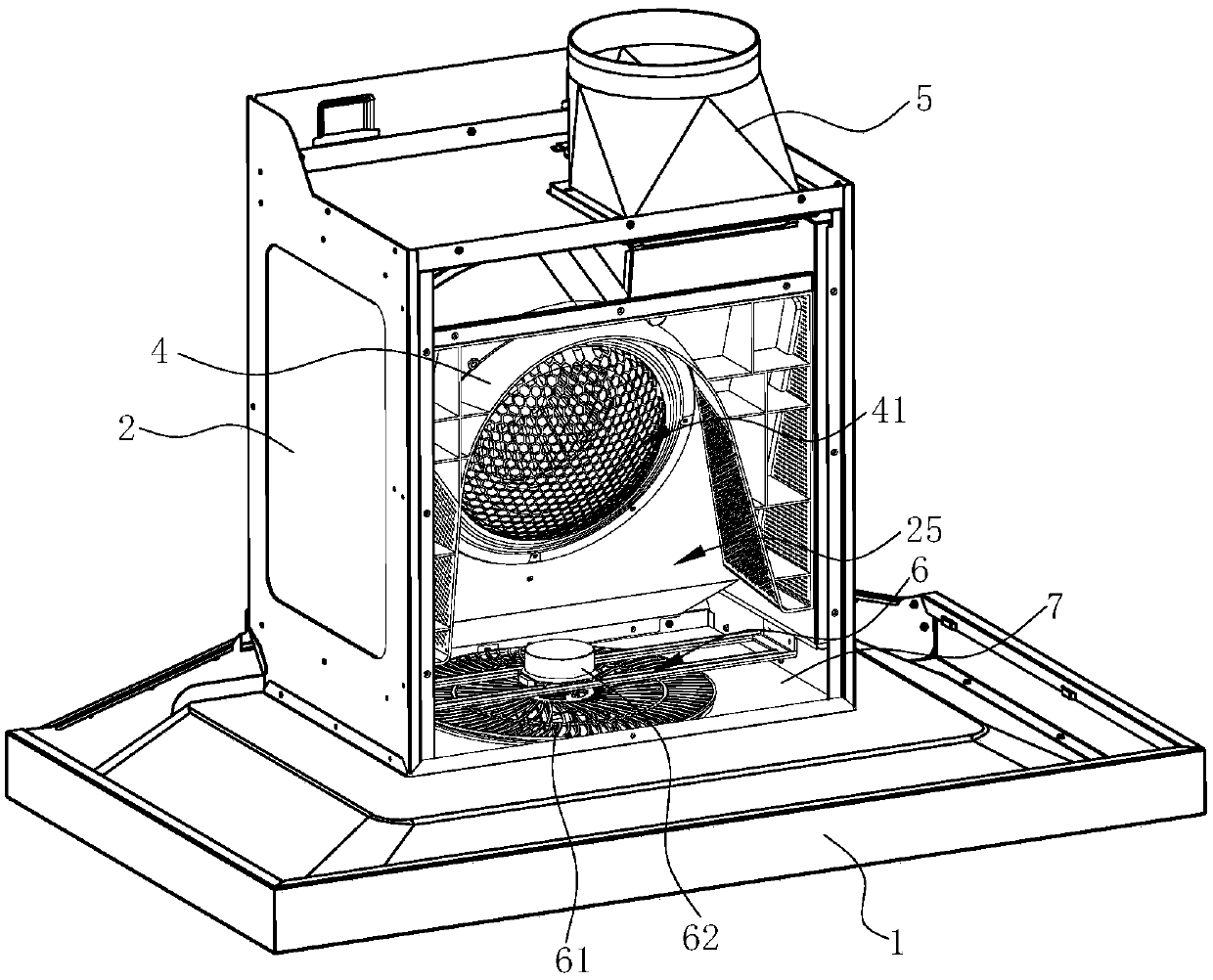

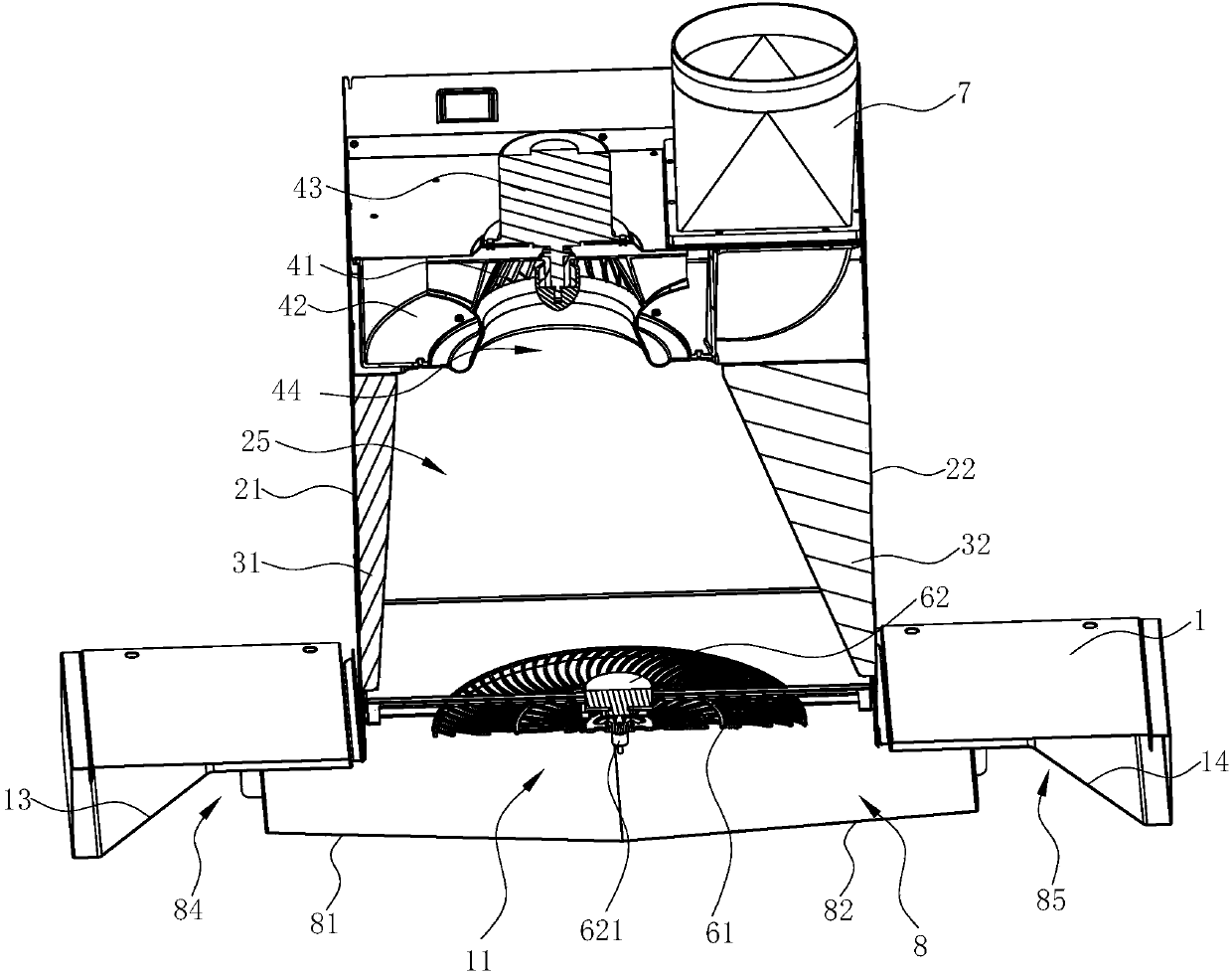

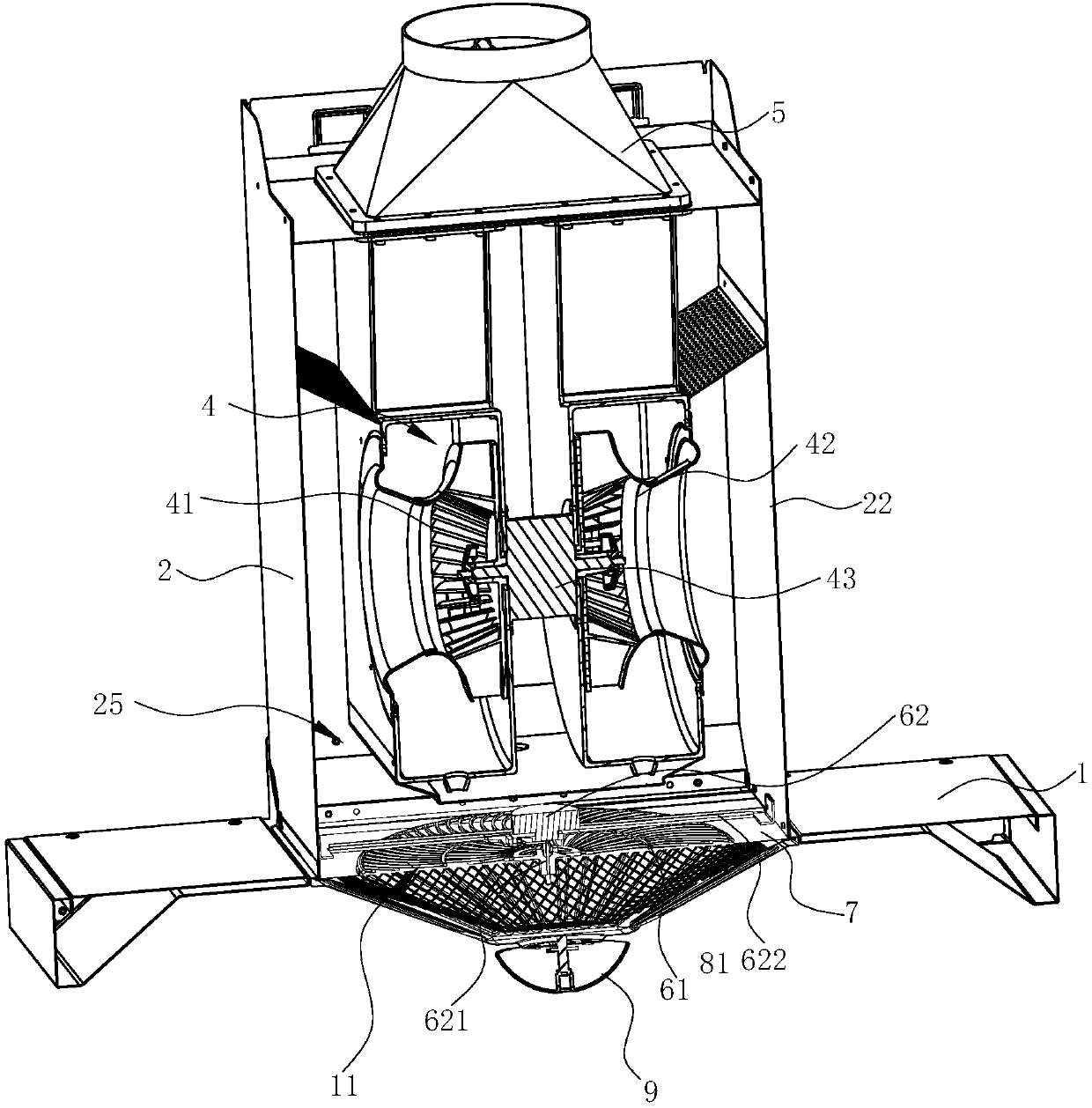

Range hood

PendingCN109595630ASmooth entryPlay a role in rectificationDomestic stoves or rangesLighting and heating apparatusContact timeMechanical engineering

The invention discloses a range hood. The range hood comprises a smoke collecting cover, a machine box arranged above the smoke collecting cover and a fan arranged in the machine box, an air inlet isformed in the smoke collecting cover, a smoke guide plate is arranged below the air inlet, the fan is a three-dimensional fan, at least a part of the lower surface of the smoke guide plate is gradually inclined upwards from the middle to the edge so as to cooperate with the corresponding wall surface of the smoke collecting cover to define an acceleration flow channel with the cross section gradually reduced from bottom to top. The amount of oil smoke entering the range hood per unit time can be increased through the acceleration flow channel, so that the oil smoke suction effect is improved;and through the horizontal three-dimensional fan and a rotary filter screen arranged at an inlet of an air duct, the oil smoke can pass through the rotary filter screen at a relatively low flow rate before not being accelerated through the air duct, then the mutual contact time between the oil smoke and the rotary filter screen is relatively long so that the oil smoke can be fully collided with the rotary filter screen.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

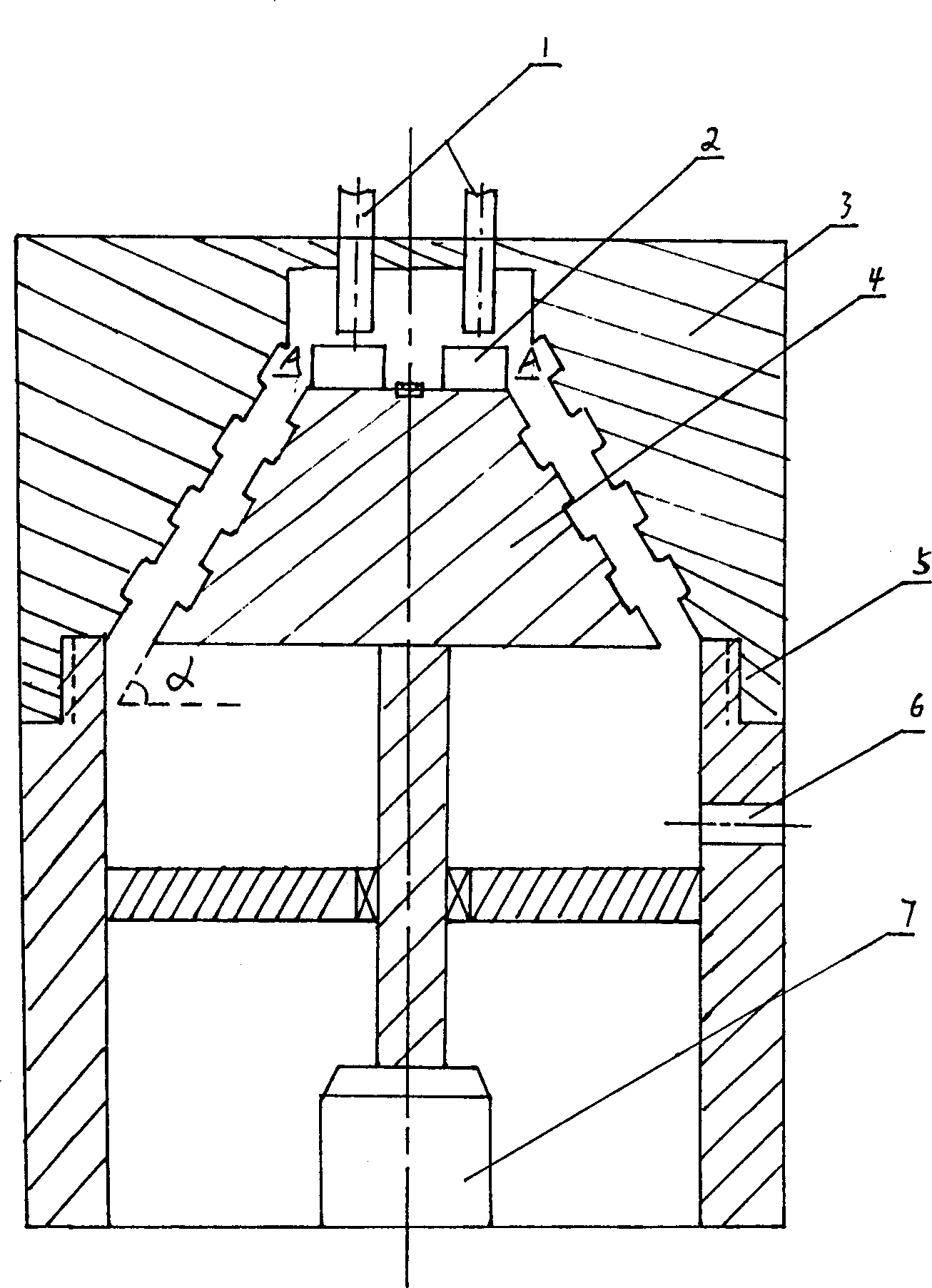

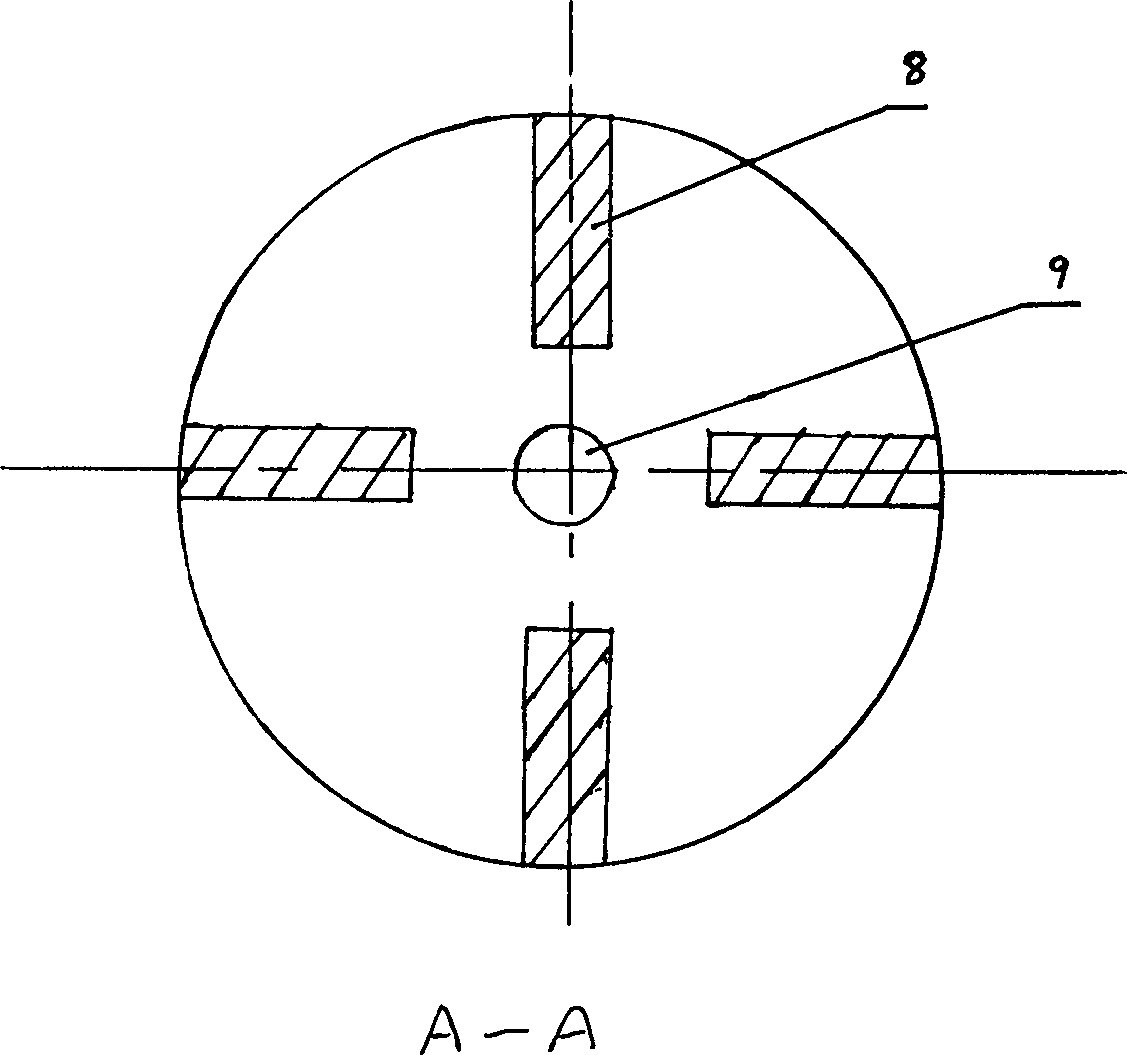

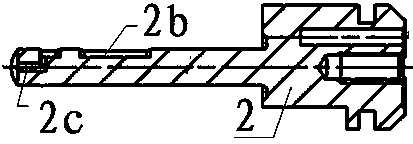

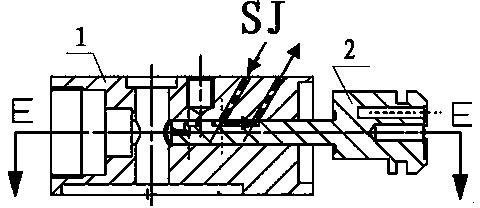

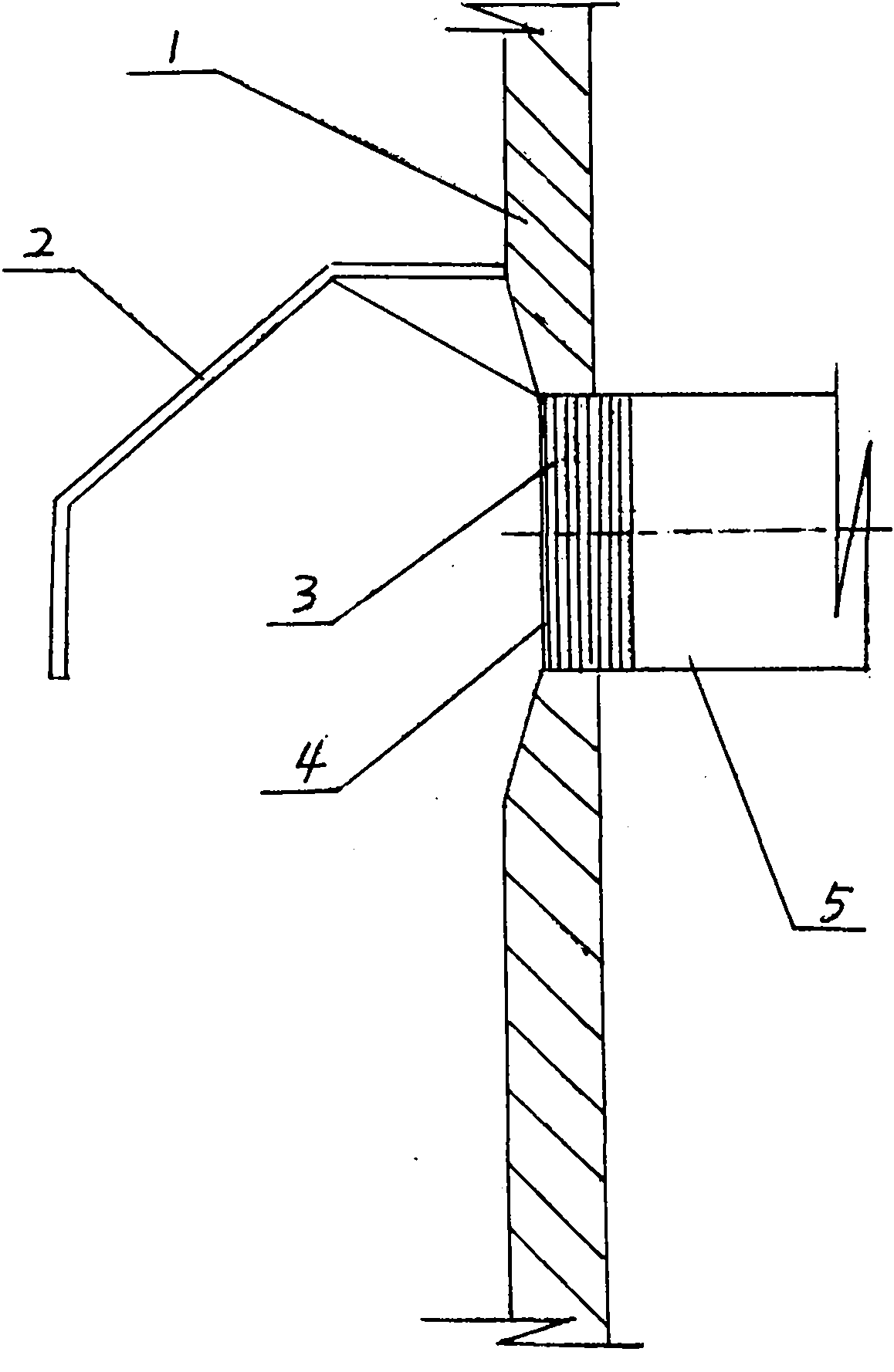

Three-component mixing head for injection molding

The invention discloses a three-component mixing head for injection molding. The mixing head comprises a pressure regulating core block and a small piston. The pressure regulating core block comprises a small piston push rod installing hole, a color paste feeding hole, a color paste discharging hole, an ISO feeding hole, an ISO discharging hole, a POL feeding hole, a POL discharging hole, a horizontal mixing and injecting zone and a mixture discharging. An included angle is formed between the color paste feeding hole and the horizontal mixing and injecting zone. The push rod of the small piston is provided with a first high pressure circulating groove, a second high pressure circulating groove and a color paste circulating groove, wherein the first high pressure circulating groove and the second high pressure circulating groove are symmetrically arranged, and the color paste circulating groove is located on the symmetrical center line of the first high pressure circulating groove and the second high pressure circulating groove. The push rod of the small piston is slidably mounted in the small piston push rod installing hole in the pressure regulating core block through clearance fit and can carry out linear reciprocating motion along the small piston push rod installing hole. The three-component mixing head has the following advantages: sufficient bumping of three components is realized, a good mixing effect is obtained; ISO and POL do not flow backward relative to the center hole of the small piston during pouring, the color paste injection center hole of the small piston does not have obstruction fault, production efficiency is improved, processing time and maintenance time are saved, and cost for spare parts is reduced.

Owner:TIANHE FUAO AUTO SAFETY SYST CHANGCHUN

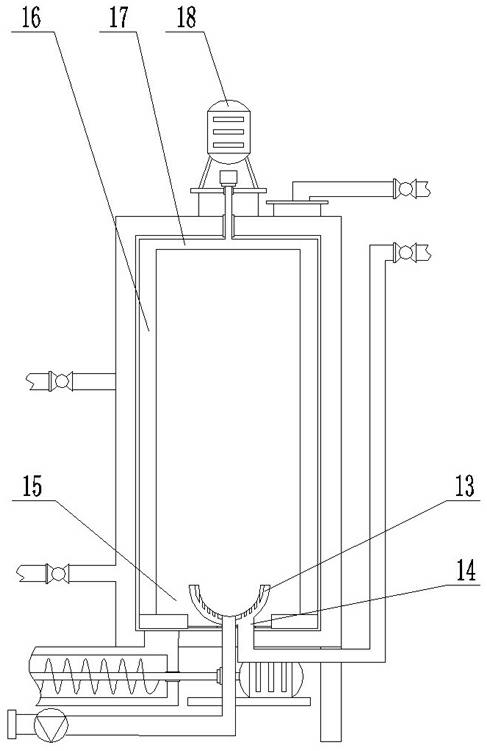

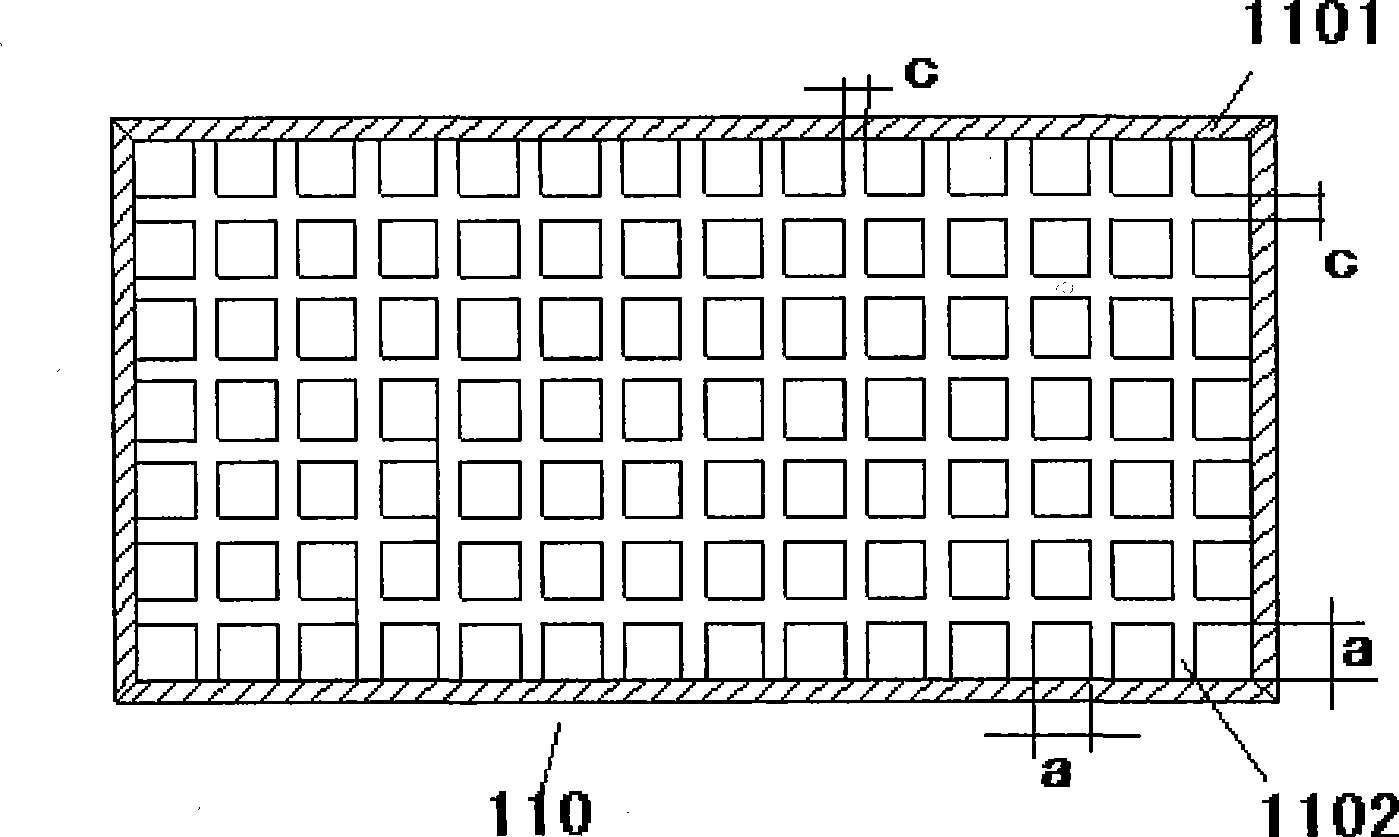

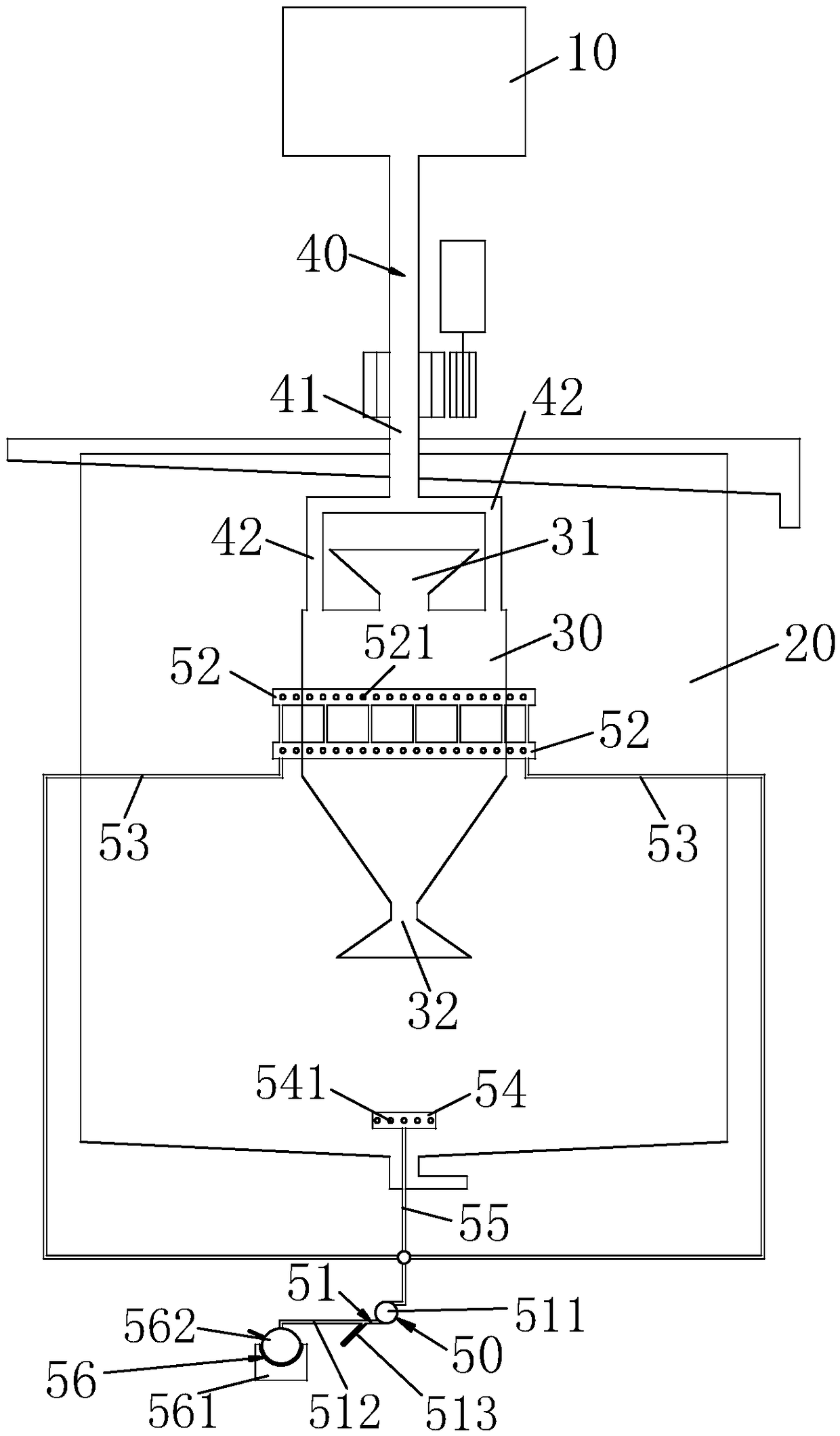

Extracting pot with homogenization baffle plate

The invention discloses an extracting pot with a homogenization baffle plate. The extracting pot with the homogenization baffle plate comprises a baffle plate, liquid spraying pipes and gas passing pipes, wherein a baffle plate which separates an inner cavity of a pot body into an upper part and a lower part is horizontally arranged close to a material inlet and in the pot body; the downward liquid spraying pipes are distributed circumferentially on the baffle plate; the rest part of the baffle plate is provided with upward gas passing pipes, and the upper edges of the gas passing pipes are higher than the material inlet; the upper ends of the liquid spraying pipes are provided with inlets and the lower ends of the liquid spraying pipes are provided with outlets, and the inner diameters of the liquid spraying pipes reduce gradually from the inlets to the outlets; the outlets of the liquid spraying pipes are oblique downwards, and each outlet of the liquid spraying pipes forms a 45-degree angle with the direction of the tangential speed in the clockwise rotation of the liquid spraying pipes on the circumference, or each outlet of the liquid spraying pipes forms a 45-degree angle with the direction of the tangential speed in the anticlockwise rotation of the liquid spraying pipes on the circumference; and the inner diameters of the gas passing pipes are greater than the inner diameters of the inlets of the liquid spraying pipes. Liquid and solid medicinal materials in the extraction pot are mixed uniformly; effective active components in medicinal materials can be extracted rapidly and fully; and the extraction efficiency of the extraction pot is improved.

Owner:汪振朴

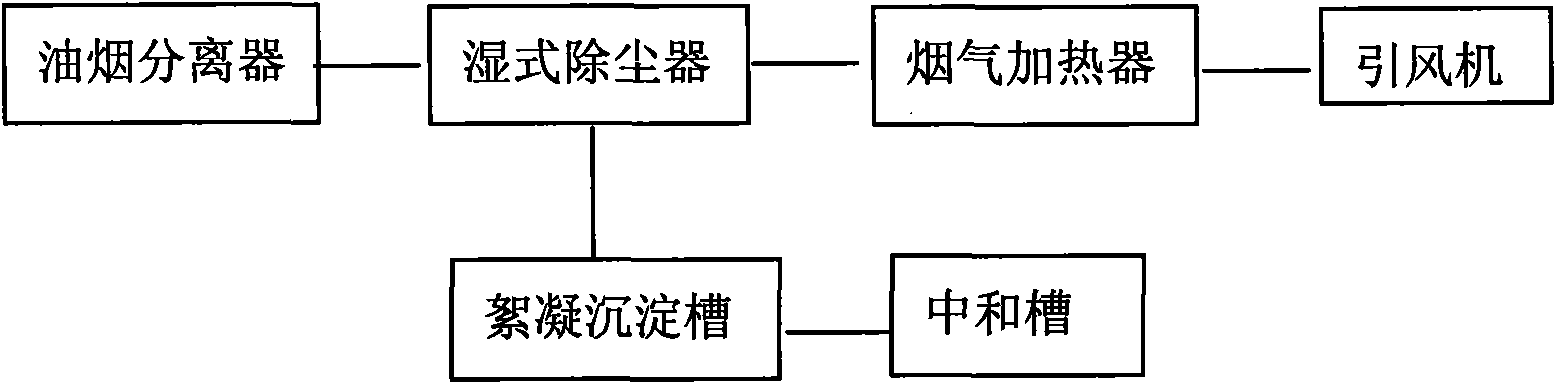

Purifying method and system of kitchen lampblack and lampblack separator

The invention discloses purifying method and system of kitchen lampblack and a lampblack separator and aims to provide a method and a system capable of purifying lampblack generated in kitchens to ensure a clean atmospheric environment and ensure that people obtain clean air. The method comprises the following steps of: collecting the lampblack generated by kitchens into a lampblack separator for lampblack separation with a collision cooling method; and cleaning and dedusting by using a wet dust remover after the lampblack is collected, wherein the cleaning and dedusting processes in the wet dust remover are as follows: an adsorption solution is ejected by using a circulating pump into a high-pressure nozzle arranged above the wet dust remover and sprays downwards into the wet dust remover; the absorption solution is in fully contact and collides with the catadromous lampblack and the lampblack is in secondarily contact with the absorption solution at the bottom of the wet dust remover for further absorbing; the lampblack is heated to 150-160 DEG C; and then the lampblack is discharged into the atmosphere through a chimney by using a draught fan.

Owner:广州博旺环保科技发展有限公司

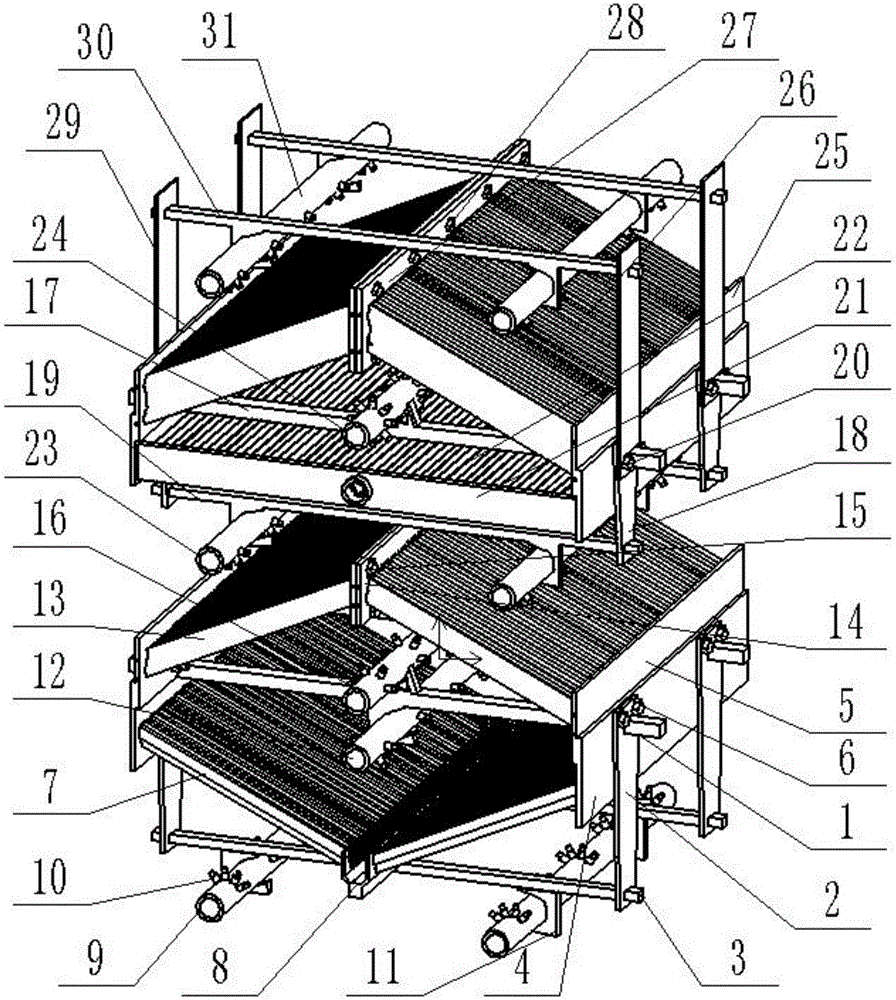

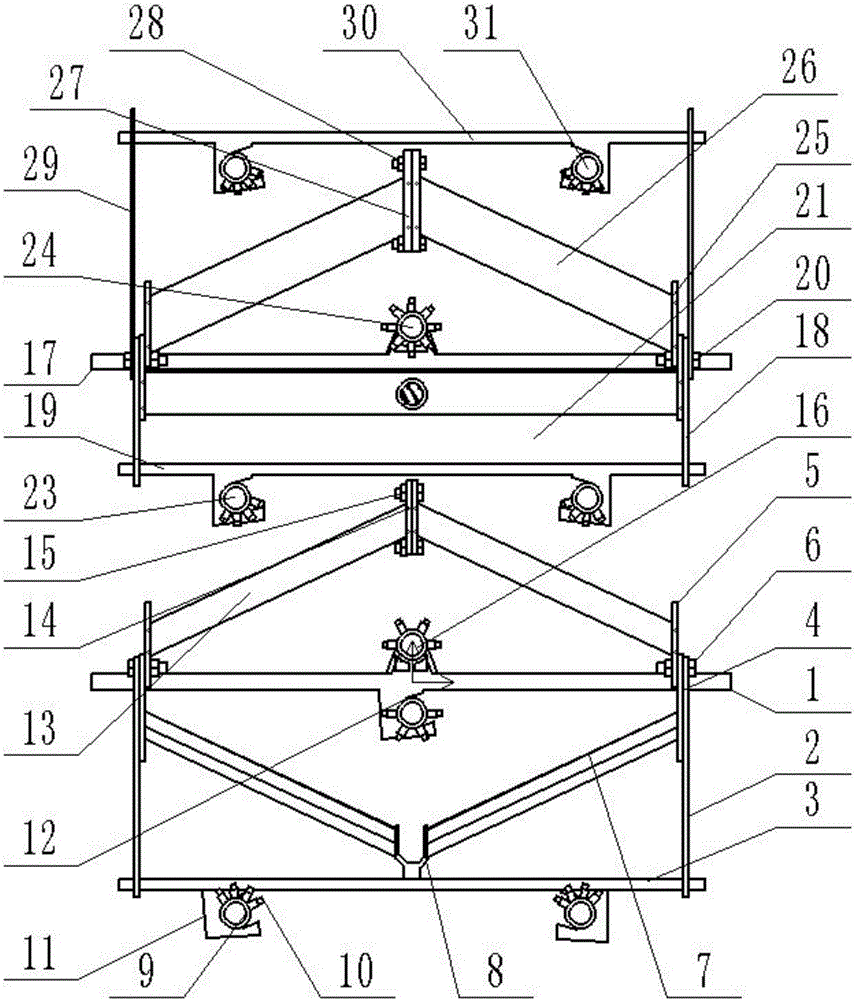

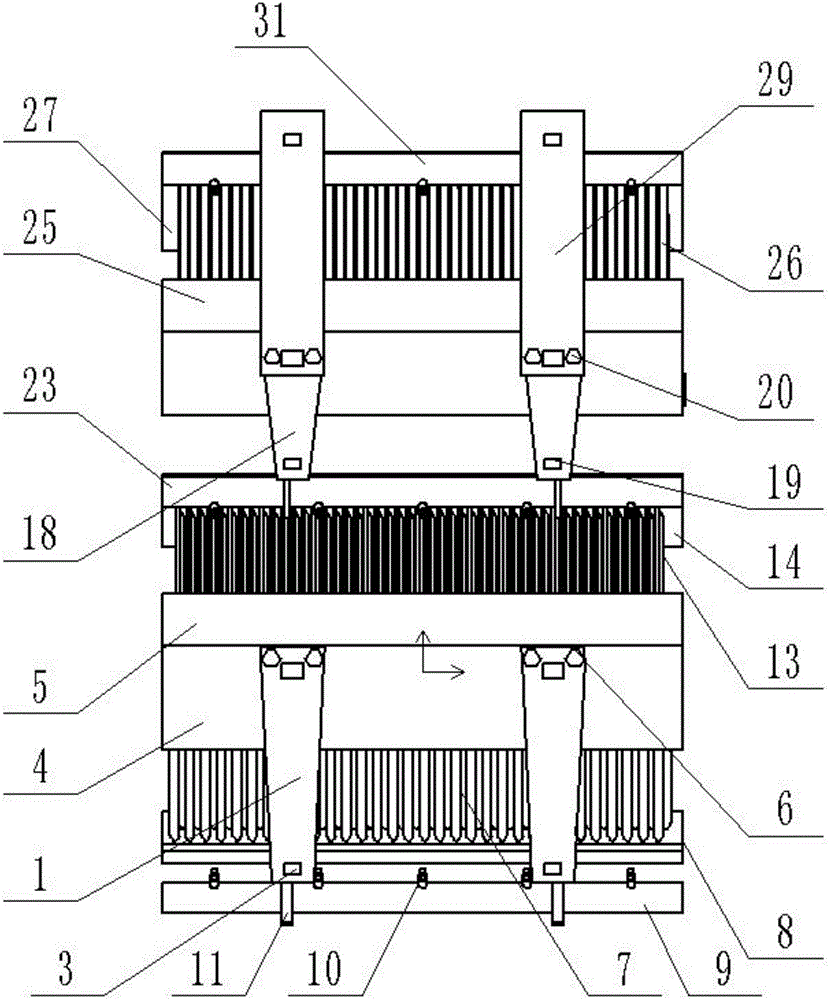

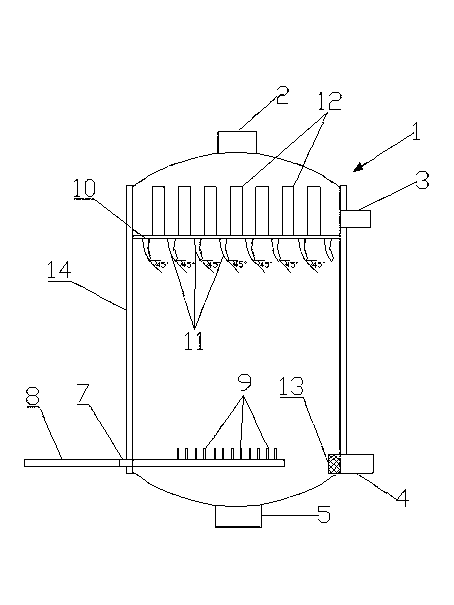

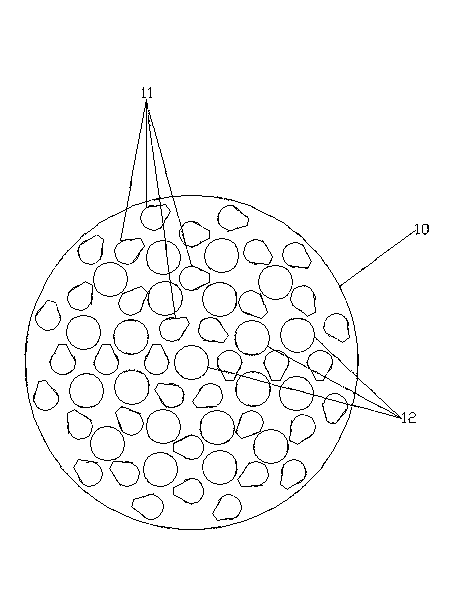

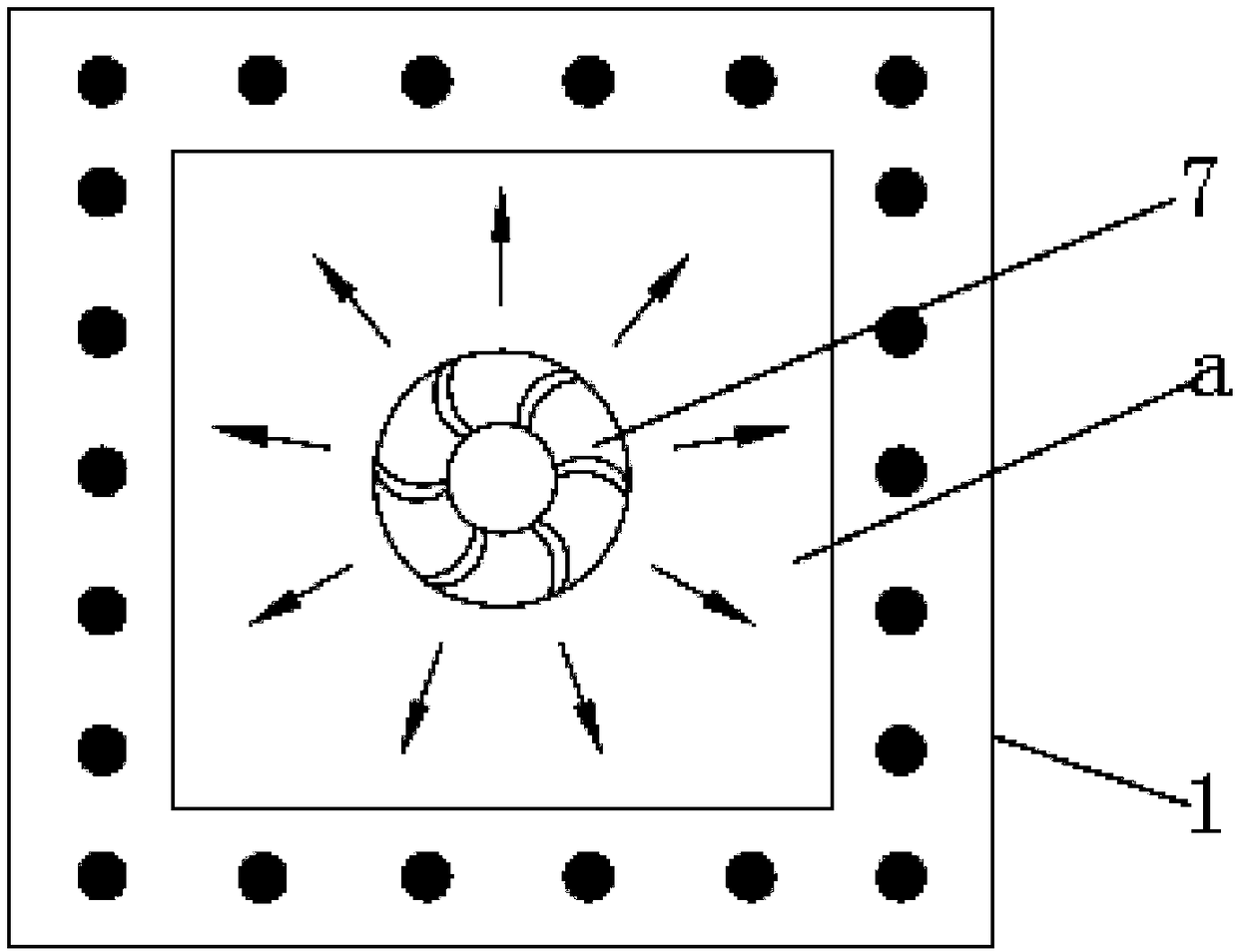

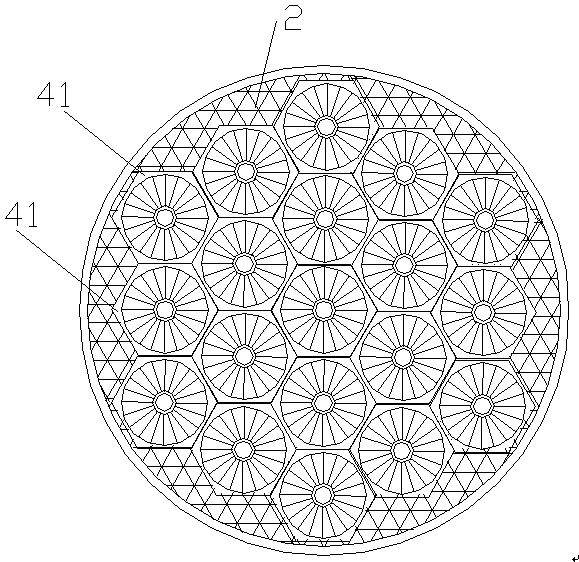

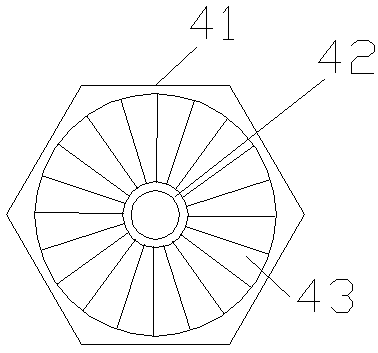

Mineral flotation system

ActiveCN109046793AReduce the difficulty of collisionIncrease the probability of collisionFlotationMaceralEngineering

The invention belongs to the technical field of mineral flotation, and particularly relates to a mineral flotation system. The device comprises a rotatable ore pulp barrel, a flotation groove communicated with the ore pulp barrel, a rotating barrel capable of rotating is arranged in the flotation groove in a sleeved mode, the rotating barrel is communicated with the ore pulp barrel through a pipeline, one end, connected with the rotating barrel, of the pipeline is located at the upper end of the barrel wall of the rotating barrel or close to the barrel wall of the rotating barrel, the rotatingbarrel and the ore pulp barrel rotate synchronously, the lower part of the rotating barrel is of a cone structure and is in a reduced diameter shape from top to bottom, an upper overflow port and a lower underflow port are formed in the upper end and the lower end of the rotating barrel respectively, the flotation groove is communicated with the ore pulp barrel through the rotating barrel and thepipeline; the system further comprises a bubble generation device, and the bubble generation device is communicated with the flotation groove. According to the mineral flotation system, the effectivecollision rate of the bubbles can be improved when the mineral flotation work is carried out, so that the collision probability between the bubbles and the mineral particles to be recovered is increased, and then the flotation efficiency is improved.

Owner:ANHUI UNIV OF SCI & TECH

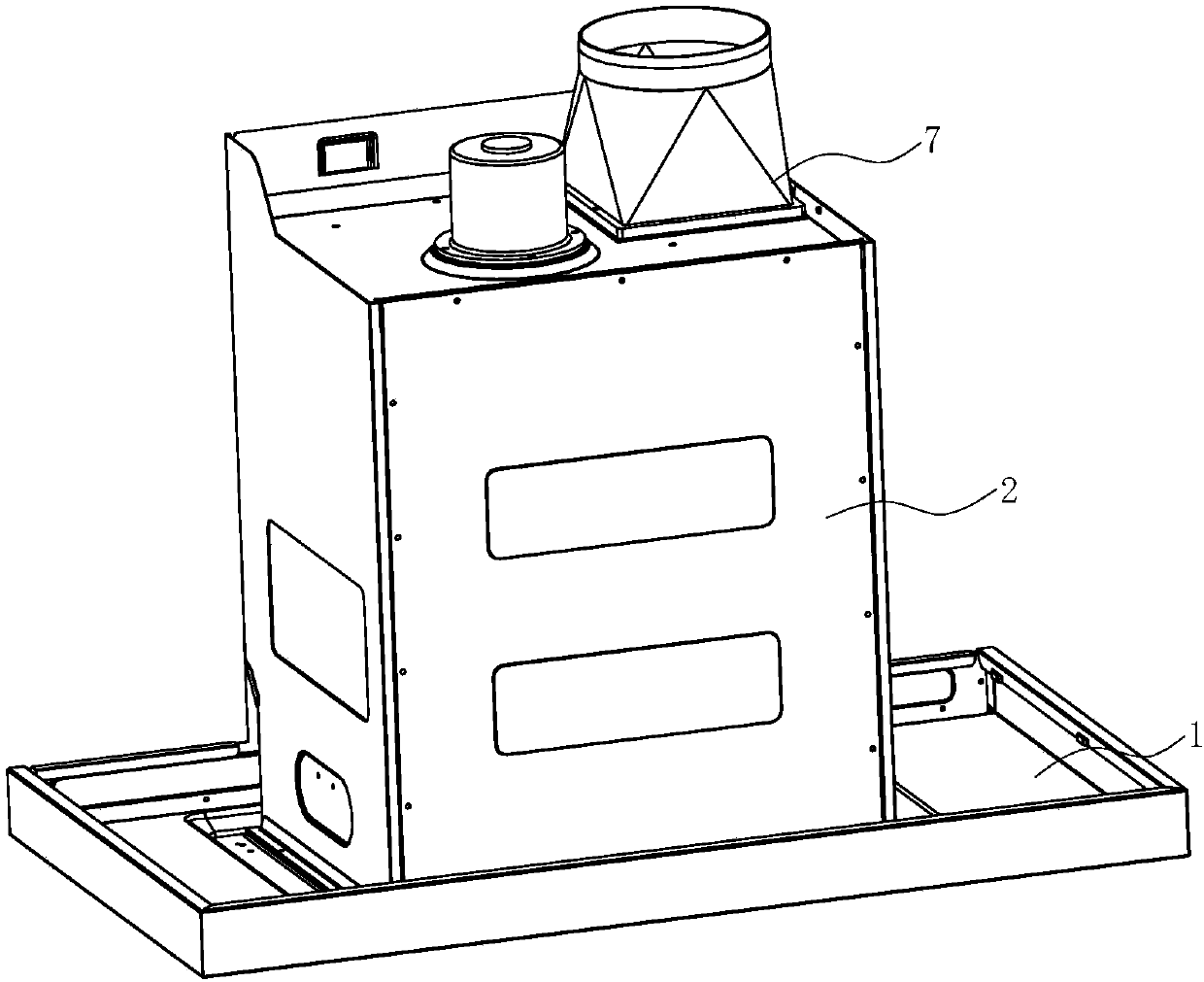

Range hood

PendingCN109780595AGuaranteed air intake areaSmooth entryDomestic stoves or rangesLighting and heating apparatusAir volumeExhaust fumes

The invention discloses a range hood. The range hood comprises an exhaust fume collecting hood, a machine box and an oil fume filtering device. The machine box is arranged on the top of the exhaust fume collecting hood. An air inlet is formed in the exhaust fume collecting hood. An air channel is formed in the machine box. The oil fume filtering device comprises an oil screen, wherein the oil screen is arranged in the air inlet. The whole oil screen is in a shape of a big-end-up cone which downwards extends from the air inlet. A fan system is arranged in the machine box and comprises a first ternary fan and a second ternary fan, wherein the first ternary fan and the second ternary fan are arranged in parallel. The oil fume filtering device further comprises a rotary filtering screen, wherein the rotary filtering screen is arranged in the machine box and located in an inlet of the air channel. The oil screen and the rotary filtering screen are arranged, the oil screen can conduct rectification and guide on the airflow, the rotary filtering screen facilitates the purpose that the airflow is uniformly distributed in the air inlet, and therefore oil fumes which enter the air channel can enter corresponding air inlet cavities of the corresponding fans, the gas independently flows in each air inlet cavity, the phenomenon that air inlets of the two adjacent fans seize the air is avoided, and then the air quantities in the air inlets of the double fans can be uniform.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Method for testing mechanical durability of biomass granular fuel

InactiveCN111426598ASufficient mechanical durabilityImplement testWeighing by removing componentComposite materialProcess engineering

The invention discloses a method for testing the mechanical durability of biomass granular fuel. The method comprises the following steps: (1) preparing a sample; (2) carrying out fine material screening on the sample in a mechanical rocking sieve; (3) weighing the mass ME of the biomass granular fuel retained on a test sieve by using a balance, and putting the biomass granular fuel into a rotating box of a mechanical durability tester; (4) starting a mechanical durability tester such that the rotating box rotates, wherein the rotating time of the rotating box is determined according to the type of the biomass fuel; (5) taking out the biomass granular fuel in the mechanical durability tester, and putting the biomass granular fuel into the mechanical rocking sieve again for fine material screening; (6) weighing the mass MA of the biomass granular fuel retained on the test sieve by using the balance; (7) calculating the mechanical durability DU of the biomass granular fuel by using a formula DU = 100 * MA / ME (%); and (8) repeating the steps (2)-(7) for more than 6 times, and calculating the average value of results to be accurate to 1.0%. According to the invention, the testing of the mechanical durability of the biomass granular fuel is realized.

Owner:INT CENT FOR BAMBOO & RATTAN

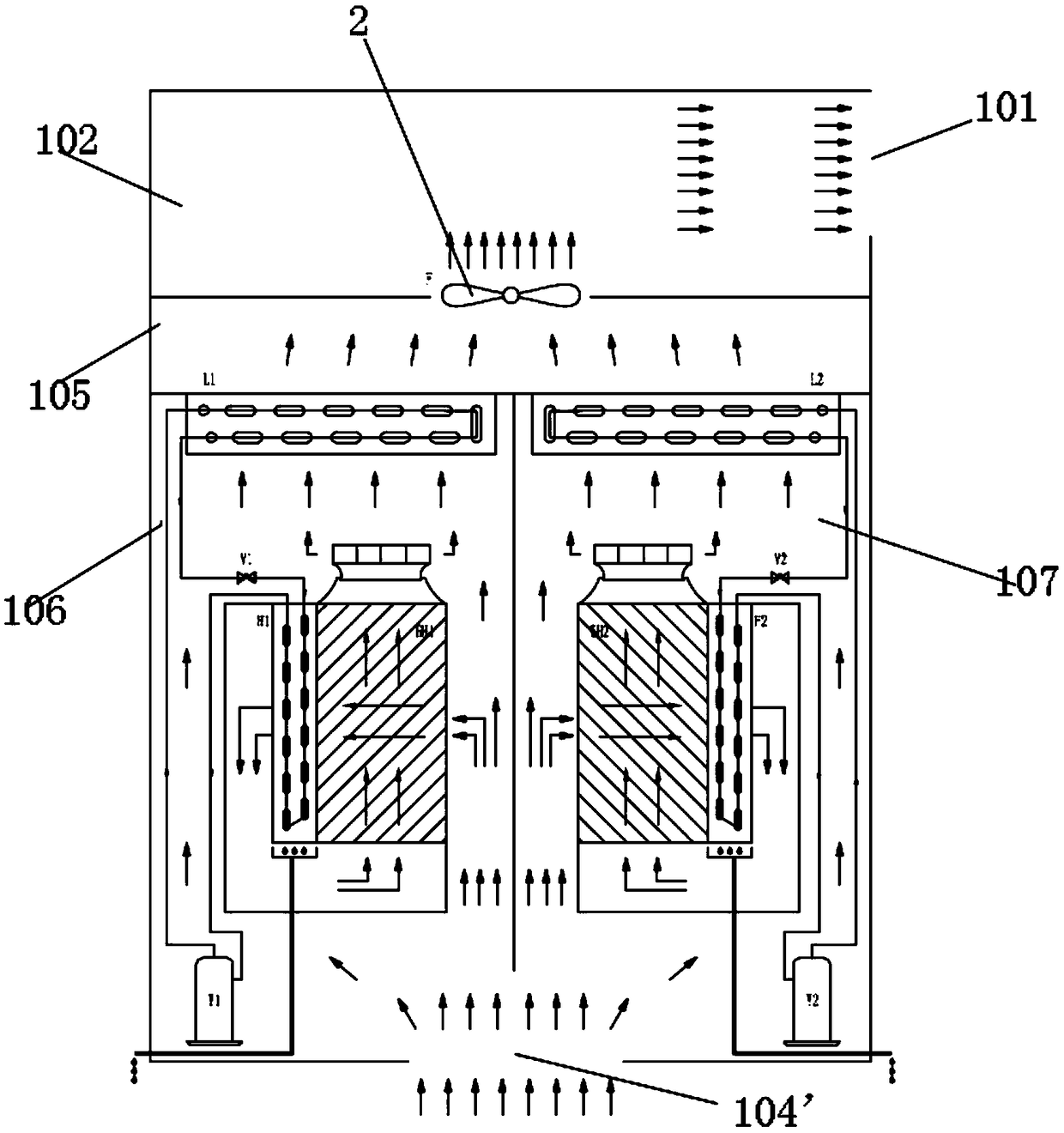

Dehumidifying and drying machine with homogenized temperature and humidity of air outlet section of condenser

PendingCN109341317AReduce condensing pressureReduce power consumptionDrying gas arrangementsEngineeringRefrigerant

The invention discloses a dehumidifying and drying machine with homogenized temperature and humidity of an air outlet section of a condenser. The machine comprises a shell body which is provided withan air outlet and an air inlet, a first fan is arranged at the air outlet, and at least one set of dehumidification system is arranged in the shell body; the dehumidification system comprises a compressor, the condenser, a throttling device and an evaporator, wherein the compressor, the condenser, the throttling device and the evaporator are sequentially connected to form a loop for refrigerant circulation; and a cross-flow heat exchanger is arranged on one side of the evaporator, inlet air and outlet air of the evaporator pass through a hot fluid channel and a cold fluid channel of the cross-flow heat exchanger respectively, a second fan is arranged at the air outlet position of the top of the cross-flow heat exchanger, so that an air inlet pre-cooling efficient dehumidification uniform air distribution module is formed. According to the machine, wet air enters the shell body, part of the wet air sequentially flows through the hot fluid channel of the cross-flow heat exchanger, the evaporator and the cold fluid channel of the cross-flow heat exchanger to be changed into dry air, then the dry air is mixed uniformly with the other part of the wet air directly from the air inlet under the action of the second fan, and then the mixed air flows through the condenser to be heated and finally discharged out of the air outlet.

Owner:HANGZHOU PREAIR ELECTRICAL APPLIANCE IND

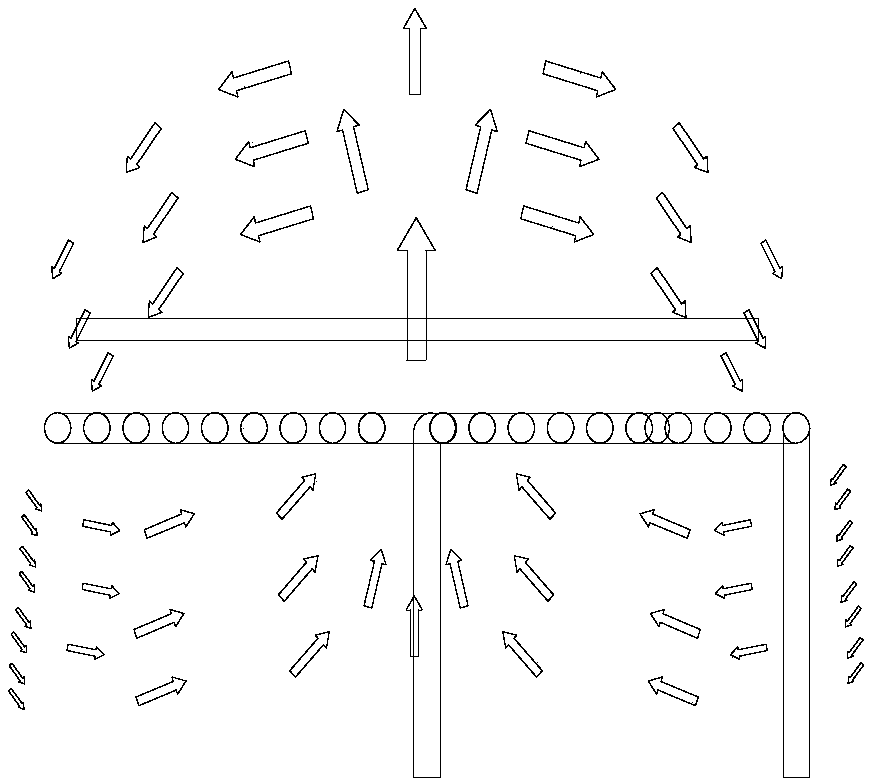

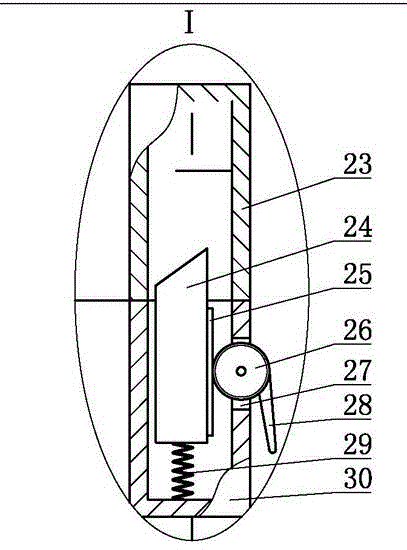

Combined type ion lens ion wind generation device

PendingCN107335544AFull collisionGather and fullyElectrode constructionsElectrodes cleaningIon windEngineering

The invention provides a combined type ion lens ion wind generation device. The combined type ion lens ion wind generation device comprises an emitting electrode, wherein the emitting electrode comprises a plurality of electrode plates made of a conducting material; plate surfaces of the plurality of electrode plates are located in the front-back vertical direction; a row of discharging needles are uniformly arrayed on a backward side face of each electrode plate along the vertical direction; each discharging needle backward stretches out along the horizontal direction; a front lens plate is arranged behind the emitting electrode; a plate surface of the front lens plate is located in the left-back vertical direction; a plurality of grades of circular front lens through holes are uniformly arrayed on the a plate surface of the front lens plate along the vertical direction; the backward side face of each electrode plate faces one row of the front lens through holes; and a needle point of each discharging needle points to the middle part of one front lens through hole. The invention aims at providing the combined type ion lens ion wind generation device, which can be applied to an outdoor open space system, can be used for reducing the concentration of particulate matters at the periphery of a region of the device can be reduced within relatively short time, does not need to be driven by utilizing a draught fan in a purification process and has extremely low power consumption.

Owner:北京中和锦程科技有限公司

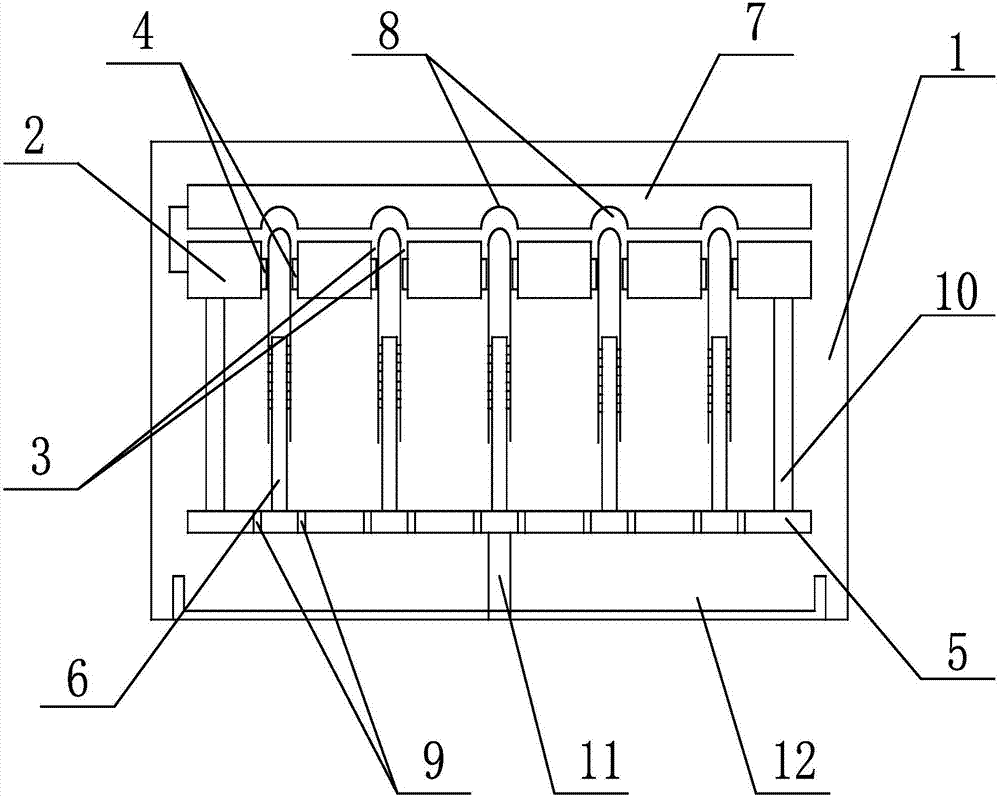

Asphalt high-temperature cleaning machine for test pipe bottle

The invention discloses an asphalt high-temperature cleaning machine for a test pipe bottle. The asphalt high-temperature cleaning machine comprises a cleaning box body; a test pipe storage plate is arranged in the cleaning box body; a plurality of test pipe inserting holes are formed in the test pipe storage plate; fixing sliding blocks are arranged on the inner walls of the test pipe inserting holes; a cleaning plate is arranged below the test pipe storage plate; a plurality of self-rotating cleaning nozzles are vertically arranged on the cleaning plate and located under the test pipe inserting holes; a test pipe heating plate is arranged above the test pipe storage plate; a plurality of upwards-convex heating grooves are formed in the bottom surface of the test pipe heating plate; heating wires are arranged in the heating grooves; and the heating grooves are located over the test pipe inserting holes. According to the asphalt cleaning machine, the bottoms of test pipes are heated, asphalt can be softened, then the test pipes are rinsed, thus asphalt quick cleaning can be achieved, the asphalt cleaning efficiency is improved, and excessive consumption of a solvent and heat energy is reduced.

Owner:四川宝利沥青有限公司

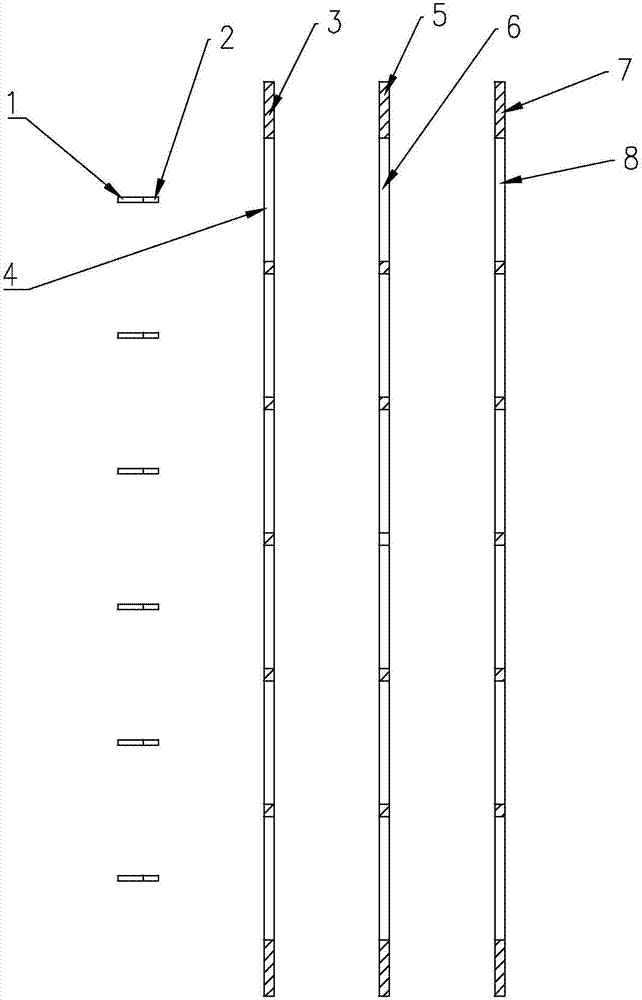

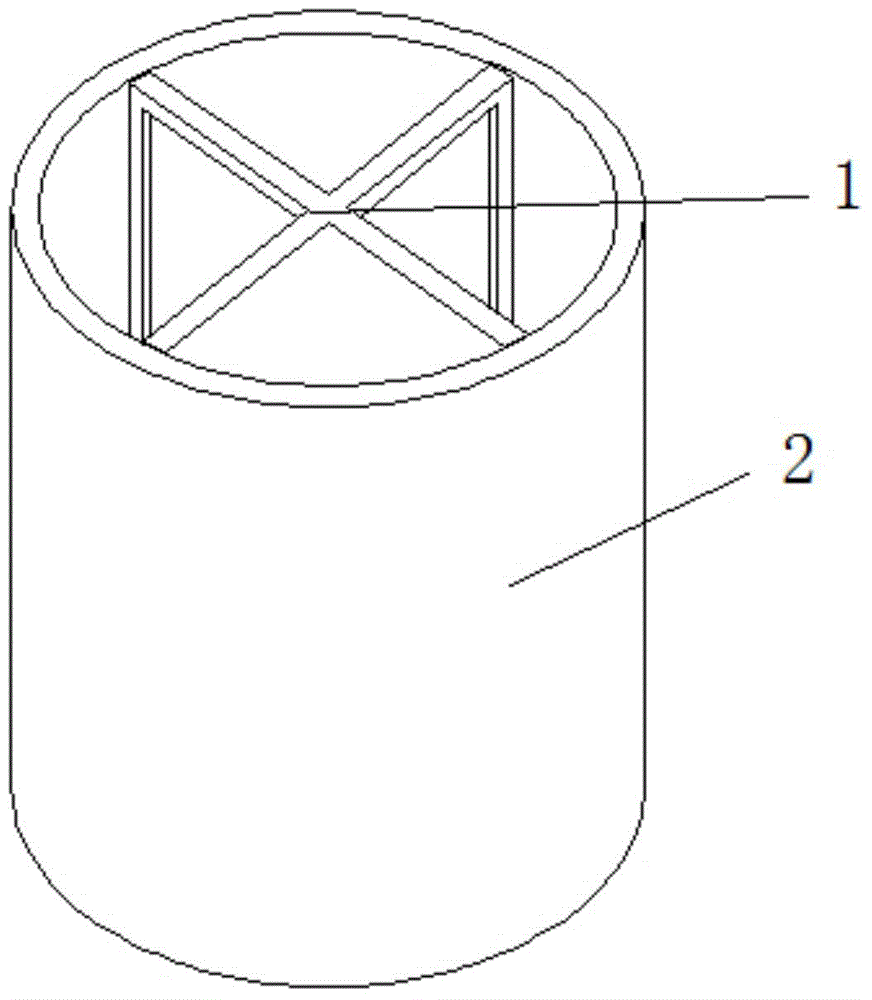

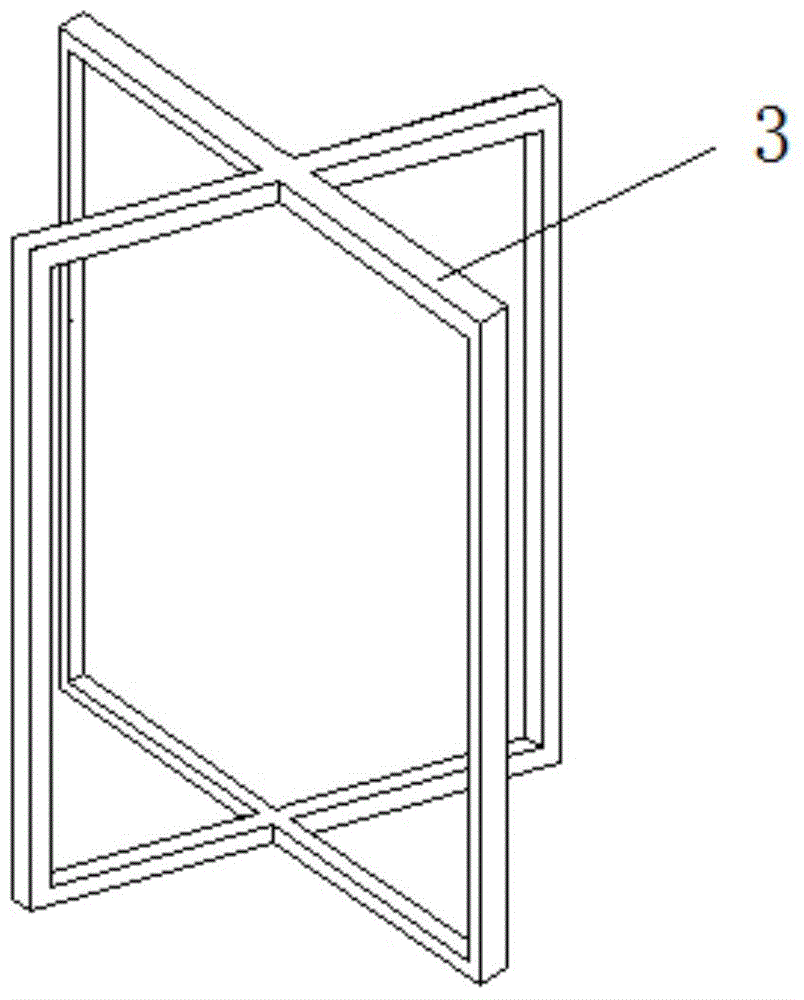

Scraper for planetary ball mill

InactiveCN105312123ASolve the bottom of the tankSolve the international problem of tank wall agglomerationGrain treatmentsEngineeringBall mill

The invention provides a scraper for a planetary ball mill. The scraper comprises a body, wherein the body is provided with a frame structure; and the body is built in a ball milling tank and is close to an inner wall of the ball milling tank. The scraper disclosed by the invention is applied to various planetary ball mills, the special scraper is arranged in the used ball milling tank, and the international problem that materials are agglomerated at the tank bottom and on the tank wall of the ball milling tank in the ball milling process of the ball mill is solved, so that the materials are always dispersed in the ball milling tank, milling balls and the materials can be fully collided and milled in the ball milling tank, and the ball milling effect is greatly improved.

Owner:南京南大仪器有限公司

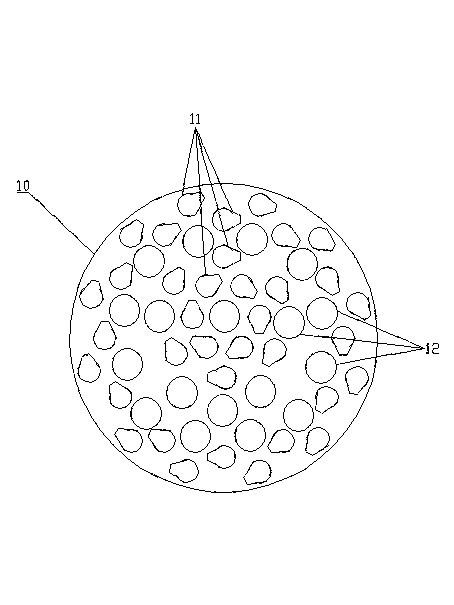

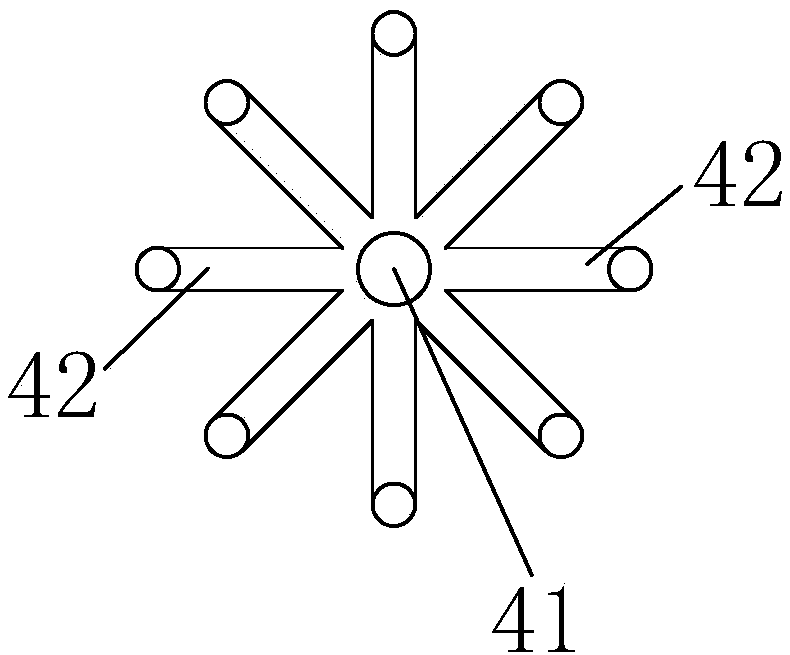

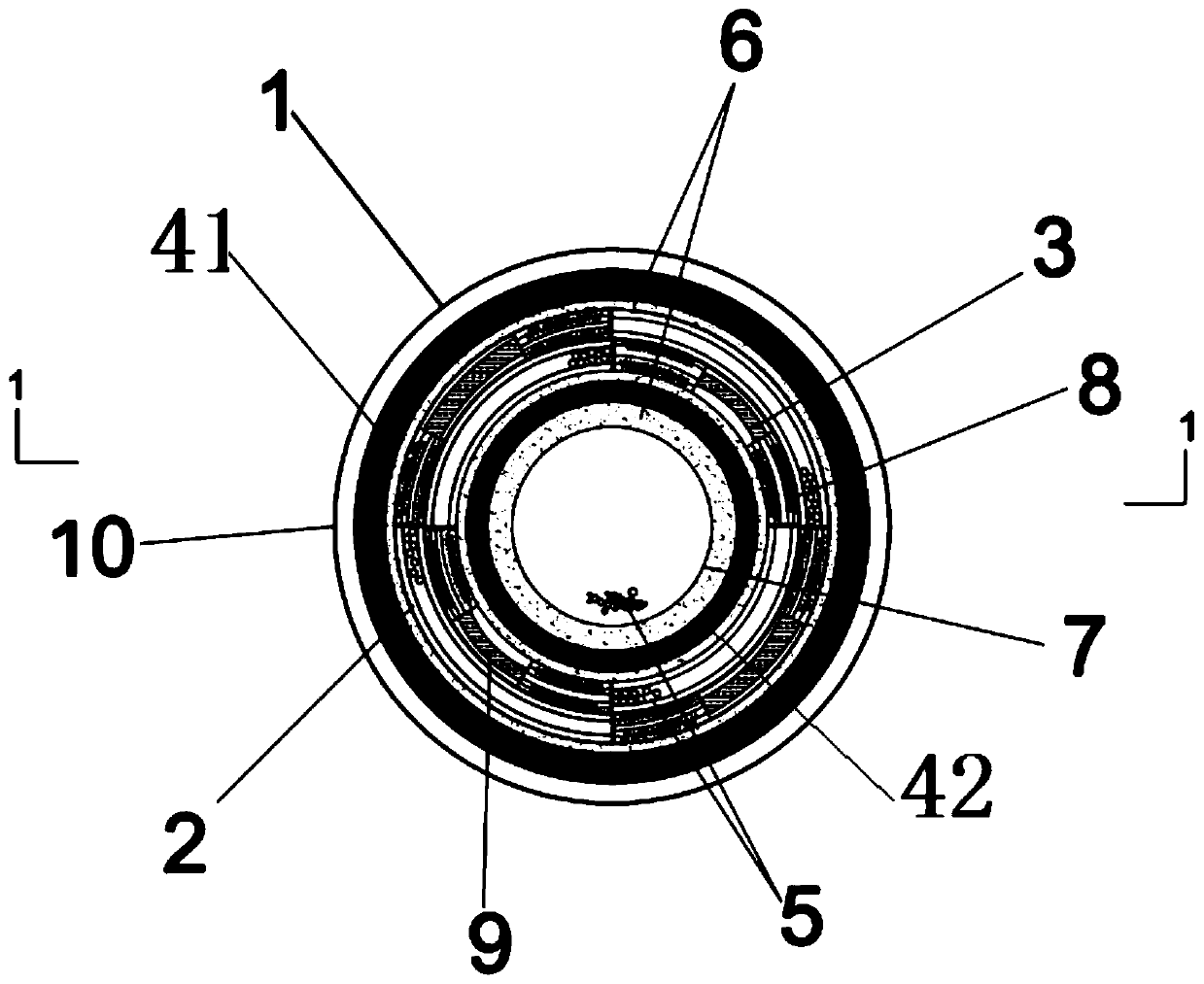

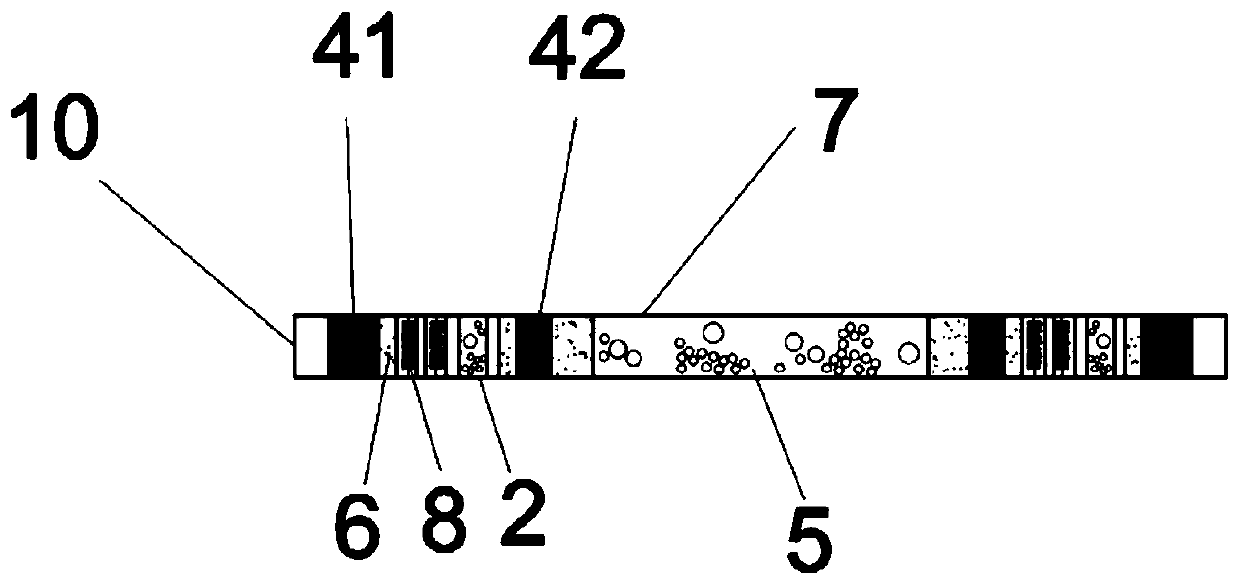

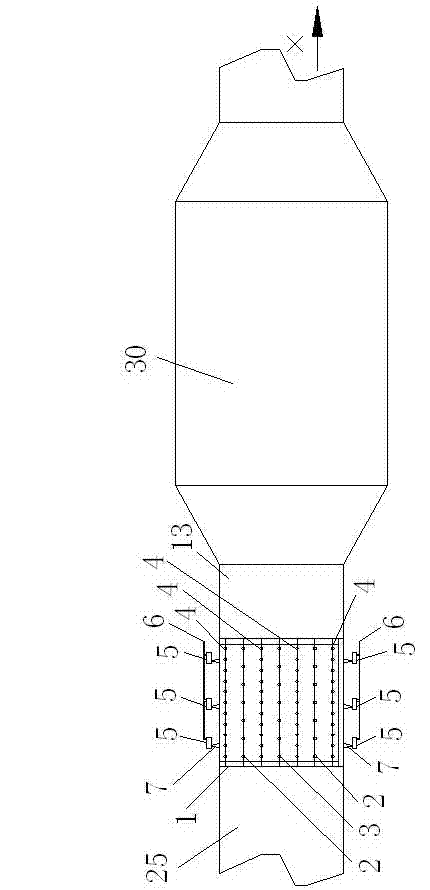

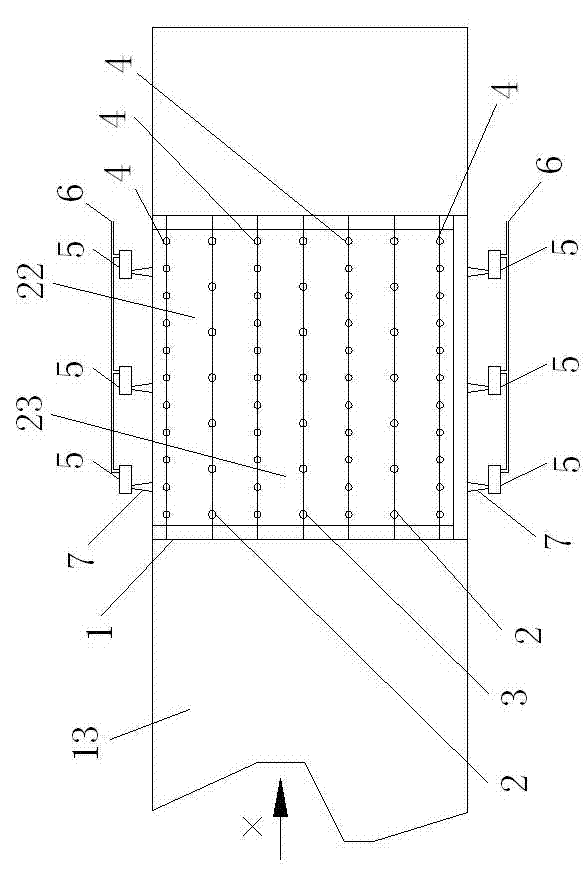

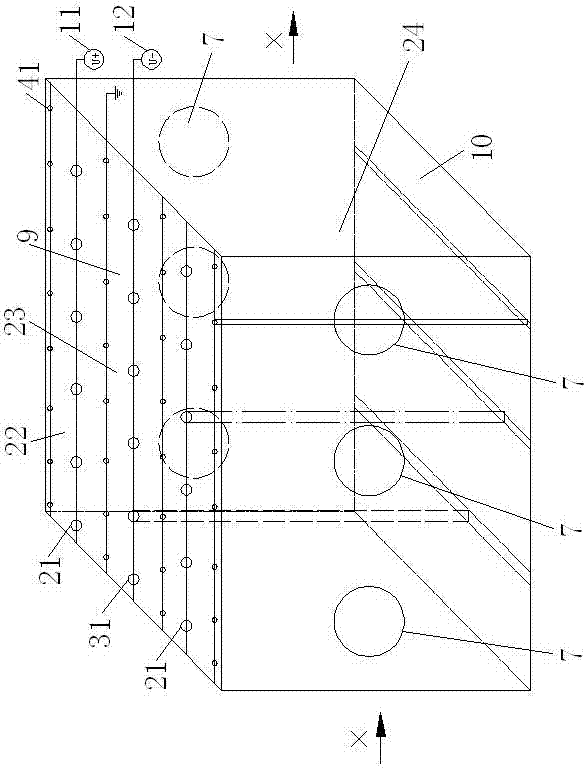

Nonlinear electromagnetic particle damper

ActiveCN110685485AFull collisionAdequate exerciseProtective buildings/sheltersShock proofingEngineeringMixed mode

The invention relates to a nonlinear electromagnetic particle damper. The damper is integrally of a cylindrical or spherical damper cavity structure (1) of a multilayer structure and sequentially comprises a shell (10), a large permanent magnet (41), a small permanent magnet (42) and an inner cavity (7) from outside to inside; the inner cavity (7) is provided with a particle group (5); and a multi-layer electromagnetic particle damping mechanism is arranged between the large permanent magnet (41) and the small permanent magnet (42). Compared with the prior art, for the nonlinear electromagnetic particle damper, by combining the advantages of a particle damper and electromagnetic energy consumption, energy dissipation in a mixed mode is realized with reaching complementary advantages, a novel damper, having the advantages of convenience in mounting, good energy consumption effect, wide damping frequency, capability of being used for multiple times and the like, is formed, and the nonlinear electromagnetic particle damper has engineering practical significance.

Owner:TONGJI UNIV

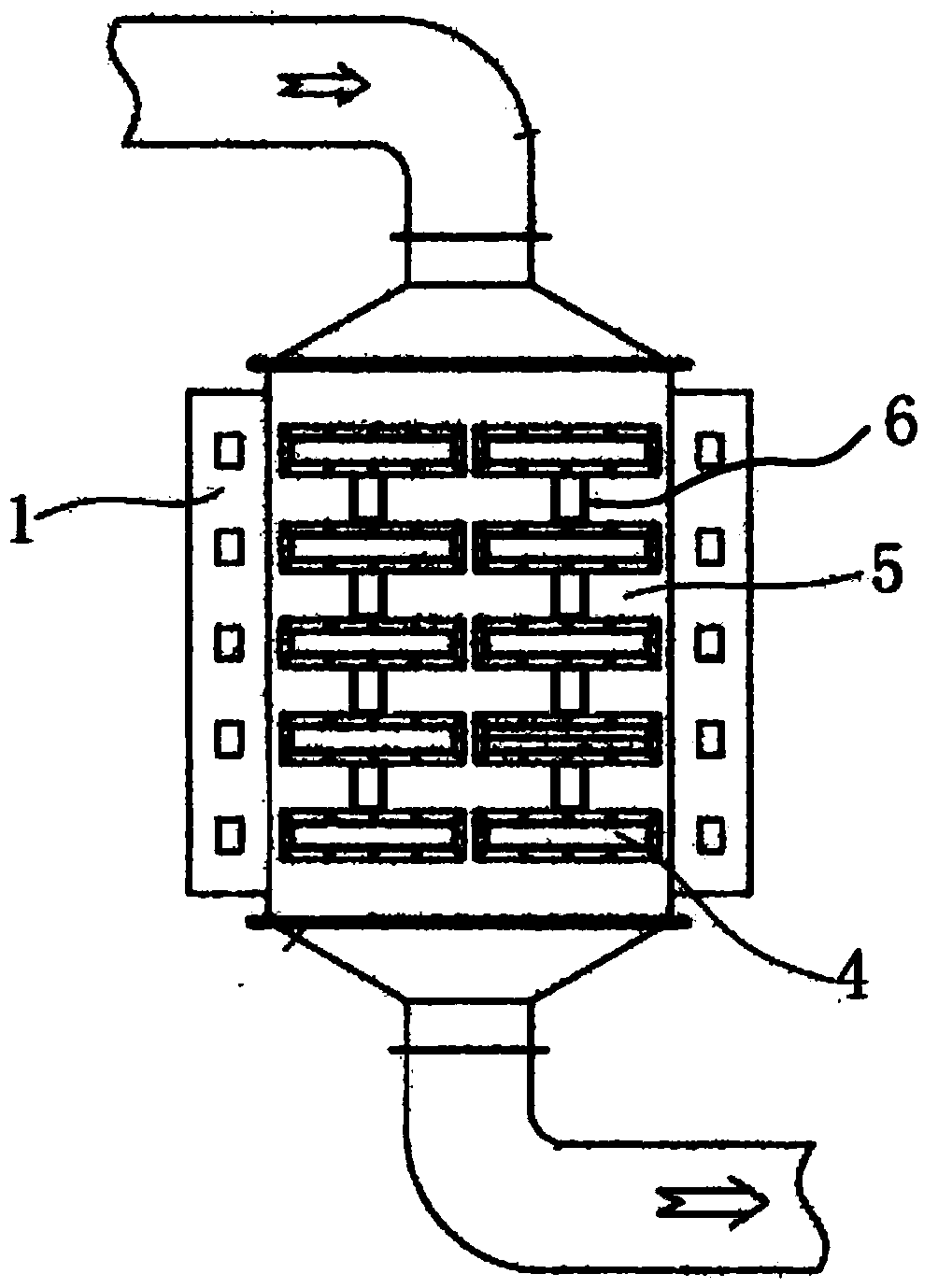

Flue embedded acoustic-electric joint condenser

ActiveCN103047669AAvoid hard collisionGood for collision condensationLighting and heating apparatusExternal electric electrostatic seperatorElectricityFlue gas

The invention relates to a flue embedded acoustic-electric joint condenser. At present, existing acoustic-electric joint condensers cannot achieve acoustic coagulation effects. The flue embedded acoustic-electric joint condenser is characterized by comprising a positive high-voltage power supply, a negative high-voltage power supply, a plurality of rows of positive discharge electrode wire groups, a plurality of rows of negative discharge electrode wire groups, a plurality of rows of grounding electrode wire groups and a metal module, the metal module is provided with a metal top cover and a metal bottom plate, a flue gas channel is formed between the metal top cover and the metal bottom plate, each row of positive discharge electrode wire groups includes a plurality of positive discharge electrode wires, each row of negative discharge electrode wire groups includes a plurality of negative discharge electrode wires, each row of grounding electrode wire groups includes a plurality of grounding electrode wires, one row of grounding electrode wire groups is arranged between one row of positive discharge electrode wire groups and one row of negative discharge electrode wire groups which are adjacent, a positive discharge channel is formed between one row of positive discharge electrode wire groups and one row of grounding electrode wire groups which are adjacent, and a negative discharge channel is formed between one row of negative discharge electrode wire groups and one row of grounding electrode wire groups which are adjacent. The flue embedded acoustic-electric joint condenser is small in occupied space and can achieve the acoustic coagulation effects.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Extractor hood

PendingCN109595647APlay a role in rectificationCompact structureDomestic stoves or rangesLighting and heating apparatusContact timeEngineering

The invention discloses an extractor hood. The extractor hood comprises a fume collecting hood, a machine case arranged above the fume collecting hood, and a draught fan system arranged in the machinecase. The fume collecting hood is provided with an air inlet, a fume guiding plate is arranged below the air inlet, and the draught fan system comprises a first ternary draught fan and a second ternary draught fan which are connected in series. At least one part of the lower surface of the fume guiding plate gradually inclines upwards from the middle to the edge and is matched with the corresponding wall face of the fume collecting hood accordingly so that an acceleration runner with the cross section gradually reduced from bottom to top can be defined. Through the acceleration runner, the volume of the cooking fume entering the extractor hood within the unit time can be increased, and the cooking fume suction effect is enhanced; and through a rotation filter net arranged at the positionof an air flue inlet, the cooking fume passes through the rotation filter net with the low flow speed before being accelerated by the air flue, the mutual contact time of the cooking fume and the rotation filter net is long, and sufficient collisions between the cooking fume and the rotation filter net can be achieved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

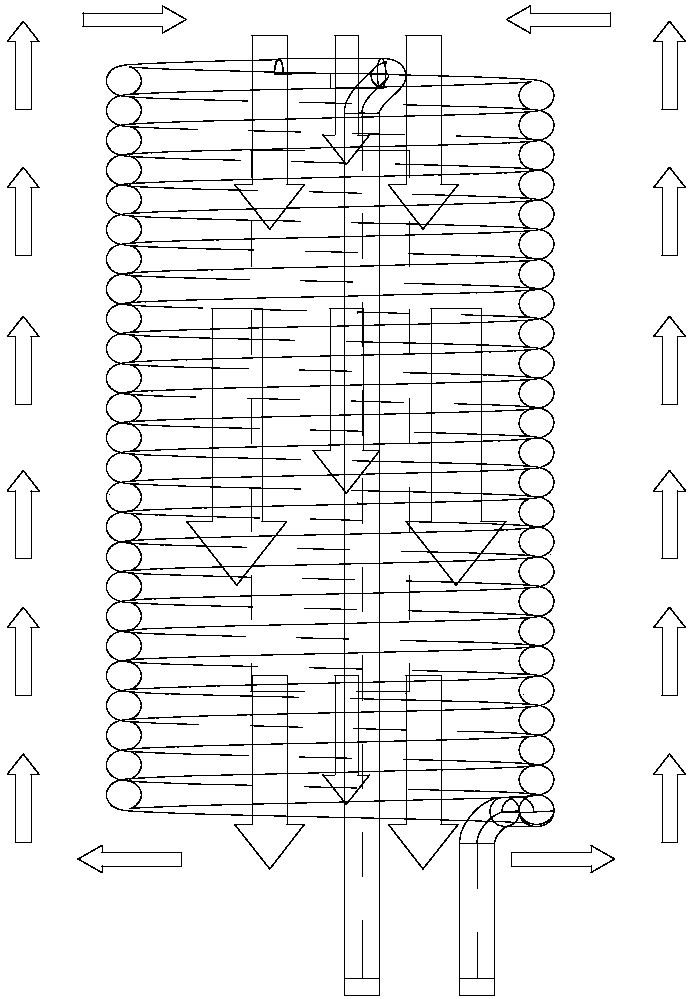

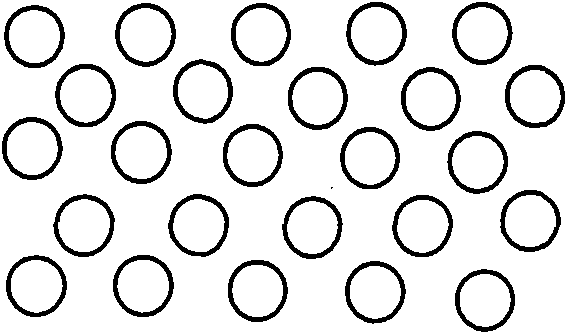

Wet honeycomb type desulfurization and dust removal device

The invention discloses a wet honeycomb type desulfurization and dust removal device, which comprises a tower body. A lower sieve plate and an upper sieve plate are arranged in the middle of the towerbody, a turbulent flow chamber is formed between the lower sieve plate and the upper sieve plate, a water film duster is arranged below the lower sieve plate, a spray mechanism is arranged above theupper sieve plate, a demister is arranged above the tower body, and the top of the tower body is connected with a chimney. The technical solution adopted to solve the technical problem is characterized in that a plurality of honeycomb type turbulent flow cabins with round inner walls are placed in the turbulent flow chamber, a fixed hollow shaft is arranged in the middle of each honeycomb type turbulent flow cabin, a plurality of fan blades are connected to the bottom of the fixed hollow shafts, and a plurality of lightweight hollow balls are placed in the honeycomb type turbulent flow cabins.A honeycomb type floating ball turbulent motion structure is creatively adopted in the turbulent flow tower, so that the lightweight balls can fully move and collide to achieve the best spherical surface capturing effect, and the centrifugal dust removal is combined into a turbulent-flow dust removal link, thereby greatly improving the dust removing effect.

Owner:德州名将工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com