Purifying method and system of kitchen lampblack and lampblack separator

A technology of fume separator and fume purification, which is applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve problems such as sewer blockage, no purification device, secondary pollution, etc., and achieve environmental protection, easy realization, and elimination The effect of pollution sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

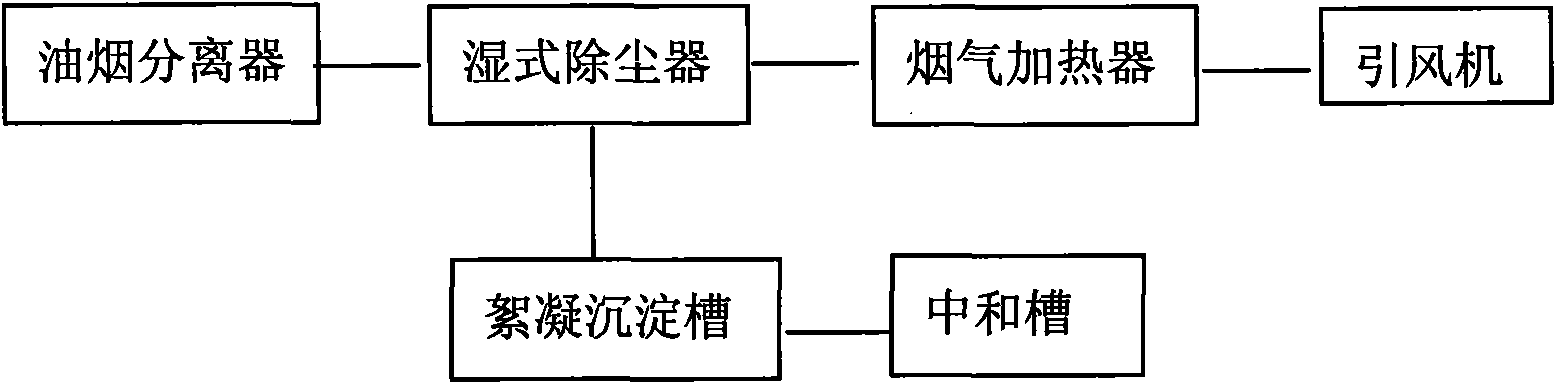

[0028] The purification method of cooking oil fume of the present invention comprises the following steps:

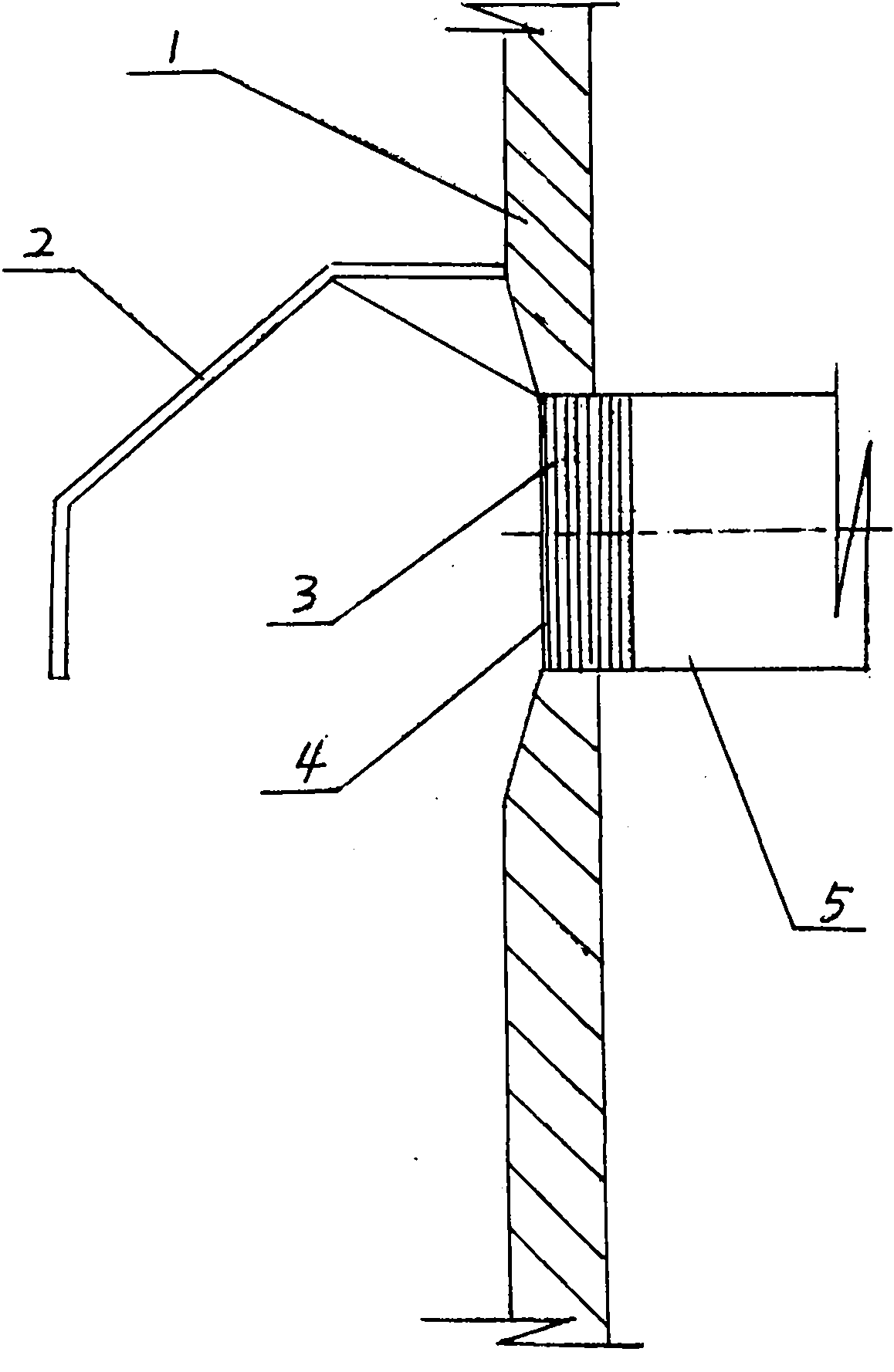

[0029] (1) Collect the oil fume generated in the kitchen into the oil fume separator, separate the oil fume by collision cooling, and recover the separated residual oil. The recovered residual oil accounts for about 30%-45% of the oil fume. The residual oil and the unedible fat of fried food can be collected as a source of raw material for making biodiesel, and the utilization of waste regeneration resources can be carried out.

[0030] (2) The flue gas after oil fume separation is collected and then washed and dedusted by the wet dust collector. The washing and dust removal process in the wet dust collector is as follows: the adsorption liquid is pumped into the high-pressure nozzle above the wet dust collector with a circulating pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com