Dehumidifying and drying machine with homogenized temperature and humidity of air outlet section of condenser

A condenser and homogenization technology, applied in the direction of dryer, drying, drying gas arrangement, etc., can solve the problems of low air velocity, uneven temperature and humidity, low Reynolds number, etc., to reduce pressure difference and improve dehumidification The effect of energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

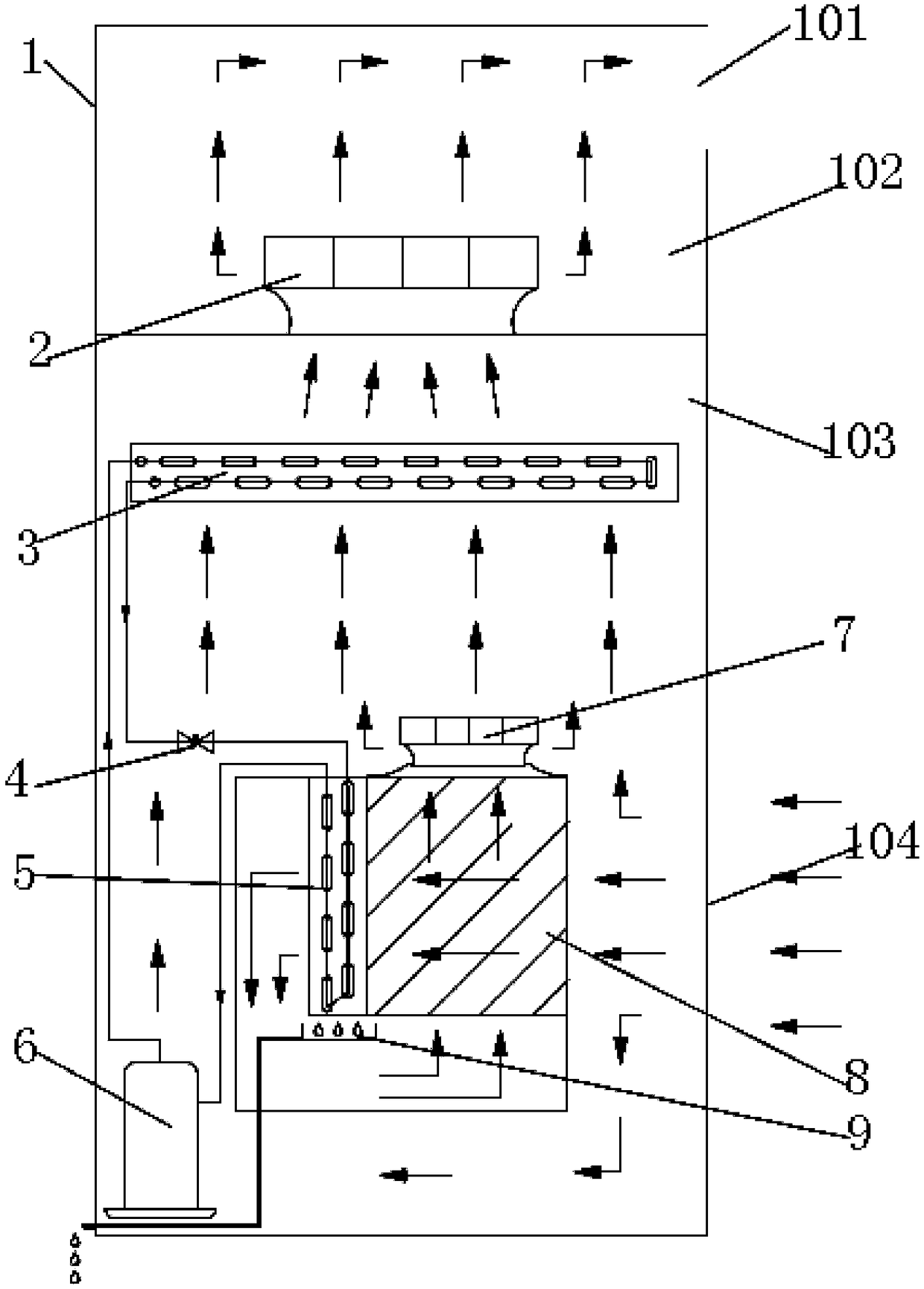

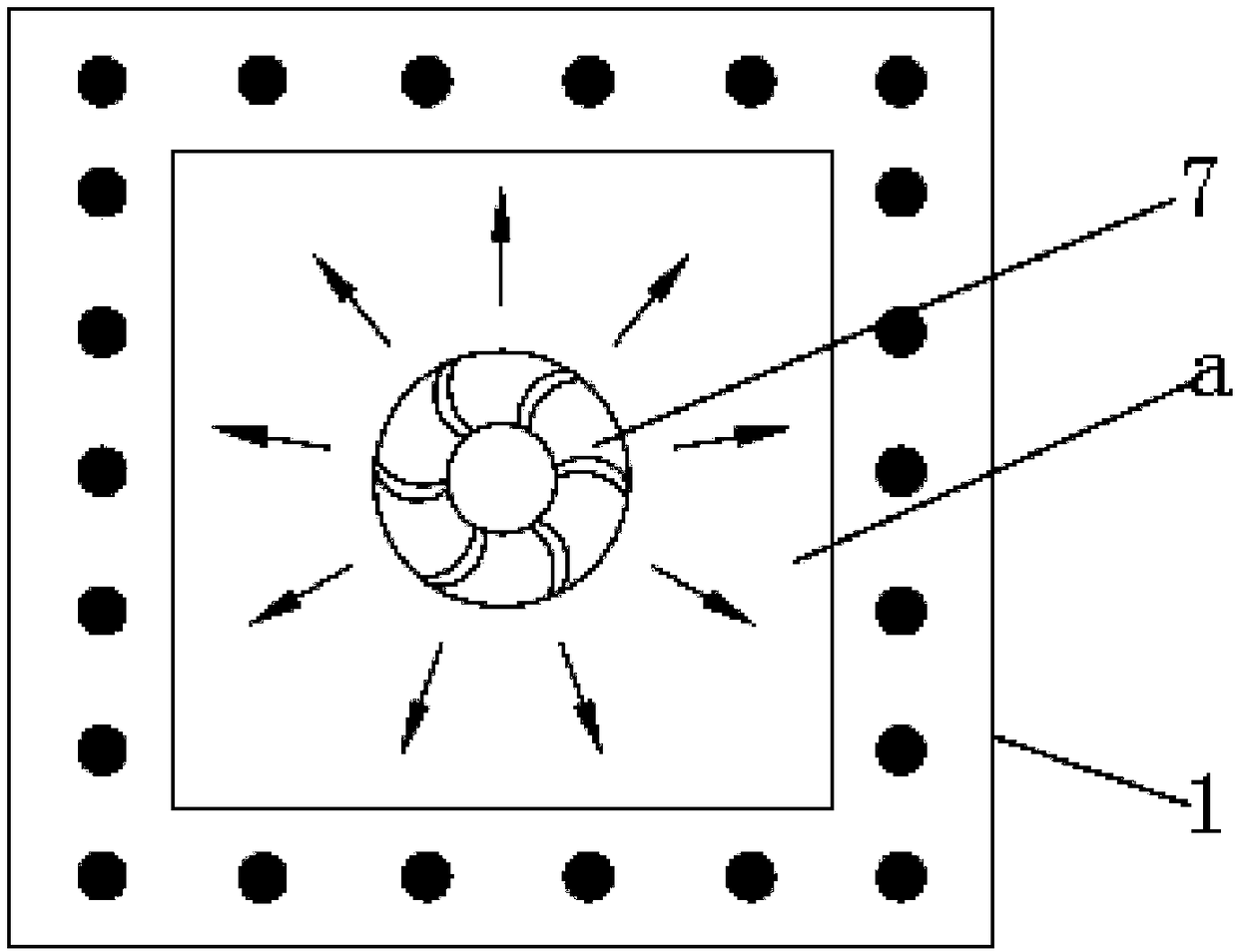

[0031] refer to Figure 1-2 In this embodiment, the dehumidification dryer with uniform temperature and humidity at the air outlet section of the condenser provided in this embodiment has only one set of dehumidification system in the housing 1; The air outlet channel 102 communicates with the dehumidification air channel 103, the air outlet 101 is arranged on the side wall of the air outlet channel 102, and the air inlet 104 is arranged on the side wall of the dehumidification air channel 103; the first blower fan 2 is arranged in the air outlet channel 102. Under the action of the first blower 2 , the humid air enters the dehumidification air channel from the air inlet 103 , enters the air outlet channel 102 after being dehumidified by the dehumidification system, and finally is discharged from the air outlet 101 .

[0032] In this embodiment, the dehumidification system includes a sequentially connected compressor 6, evaporator 5, throttling device 4, and condenser 3; the a...

Embodiment 2

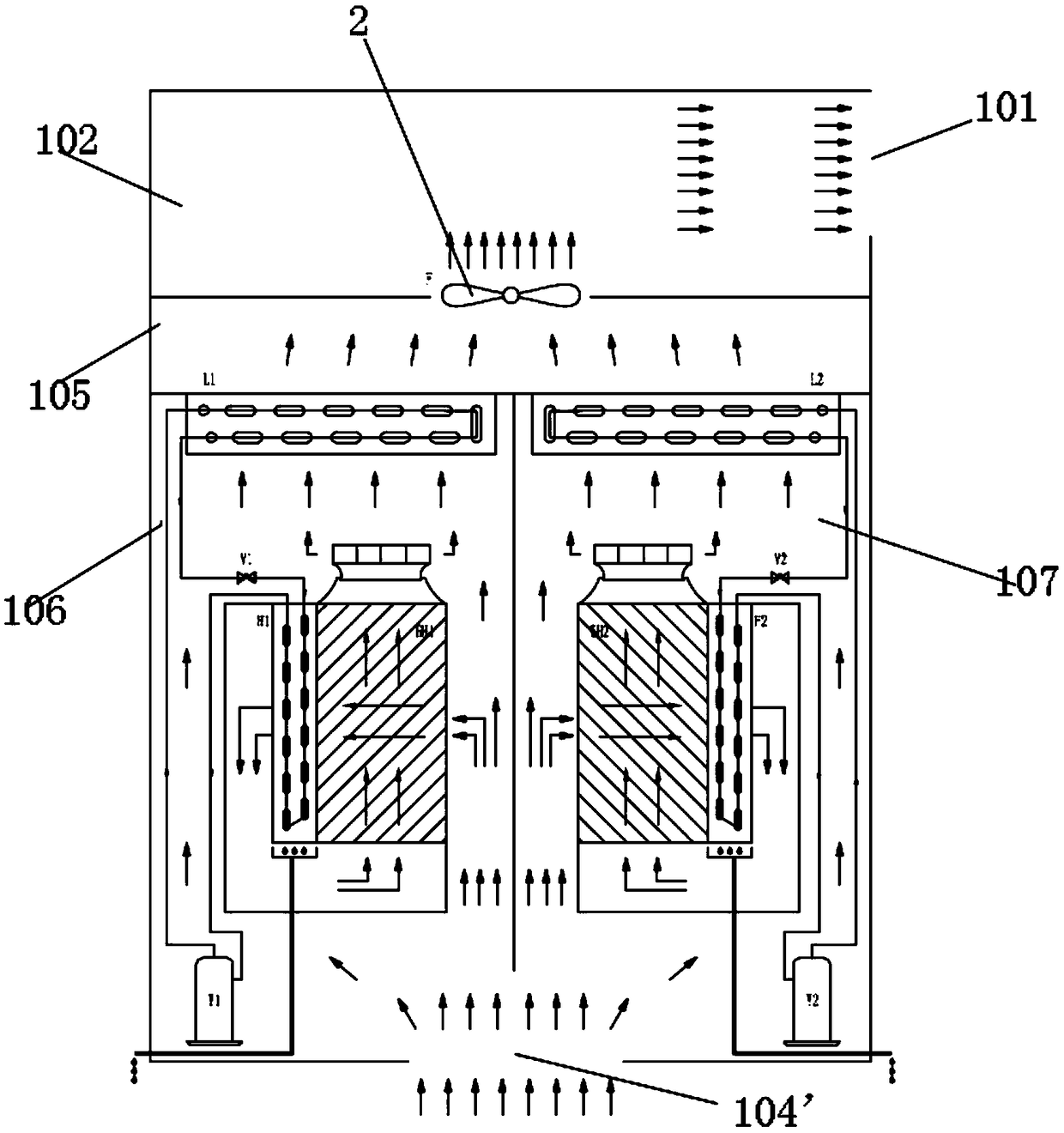

[0043] refer to Figure 3-4 , this embodiment is an adjustment made on the basis of embodiment 1.

[0044] Specifically, the shell 1 is divided into exhaust air passage 102, mixing passage 105 and dehumidification air passage from top to bottom; wherein the dehumidification air passage is divided into two left and right dehumidification air passages 106 and right dehumidification air passage 107 arranged side by side. The dehumidification air duct 106 and the right dehumidification air duct 107 are respectively provided with a set of dehumidification systems. The specific structure and installation methods of the dehumidification systems can refer to the description in Embodiment 1, and there is no limitation here.

[0045] Further, the air inlet 104' is arranged at the bottom of the housing 1, and is divided into two airflows to enter the left dehumidification air duct 106 and the right dehumidification air duct 107 respectively.

[0046] In this embodiment, two sets of dehu...

Embodiment 3

[0048] refer to Figure 5 , the present embodiment provides a heat pump flue-cured tobacco room, including a smoke room 10 and a dehumidification dryer for uniform temperature and humidity of the condenser air outlet section arranged on one side of the smoke room 10; wherein, the temperature and humidity of the condenser air outlet section The homogenized dehumidification dryer adopts the dehumidification dryer with uniform temperature and humidity at the air outlet section of the condenser described in Embodiment 1 or Embodiment 2.

[0049] Further, several tobacco curing racks 11 are arranged in the smoking room 10, and the tobacco leaves are hung on the tobacco curing racks 11 in sequence.

[0050] Further, the air outlet on the smoke room 10 communicates with the air inlet of the dehumidification dryer, and the air inlet on the smoke room 10 communicates with the air outlet of the dehumidification dryer.

[0051] Of course, in other embodiments, the dehumidification dryer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com