Direct-evaporating type ice cold accumulation refrigerating system and refrigerating method thereof

A refrigeration system, evaporative technology, applied in the directions of refrigerators, air conditioning systems, refrigeration components, etc., can solve the problems of large compression ratio, complex control and high cost of air-cooled ice-making units, to improve heat exchange efficiency, reduce costs, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

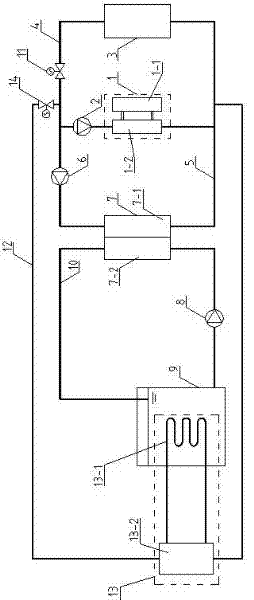

[0058] Such as figure 1 As shown, the present invention includes a refrigeration unit 1, a terminal device 3, a first chilled water pump 2, and the first chilled water pump 2, the evaporator 1-2 of the refrigeration unit 1, and the terminal device 3 are sequentially connected in a loop through a first pipeline 4.

[0059] The third pipeline 5 is bypassed on the first pipeline 4 between the terminal device 3 and the first chilled water pump 2, and the other end of the third pipeline 5 is bypassed on the first pipeline 4 between the terminal device 3 and the refrigeration unit 1 , the second chilled water pump 6 and the thermal fluid passage 7-1 of the heat exchange device 7 are connected in series on the third pipeline 5 .

[0060] The cold fluid channel 7 - 2 of the heat exchange device 7 , the (variable flow type) third chilled water pump 8 and the ice storage tank 9 are connected in a loop through a second pipeline 10 .

[0061] The evaporator 13 - 1 of the ice making unit ...

Embodiment 2

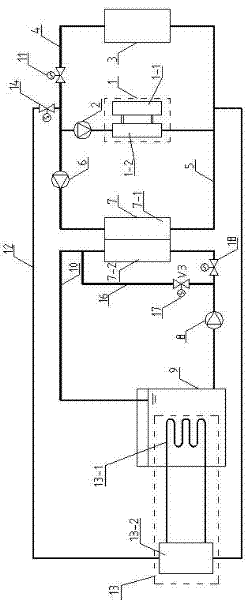

[0099] Such as figure 2 As shown, the others are the same as those in Embodiment 1, but the third chilled water pump 8 is a common chilled water pump.

[0100] In addition, the fifth pipeline 16 is connected between the second pipeline 10 at both ends of the cold fluid passage 7-2 of the heat exchange device 7, and the third valve 17 is connected in series on the fifth pipeline 16. A fourth valve 18 is connected in series on the second pipeline 10 between the cold fluid channels 7-2 of the device 7 .

[0101] The flow rate of the primary chilled water entering the cold fluid channel 7-2 of the heat exchange device 7 is adjusted through the valve 17 and the valve 18 to adjust the temperature of the secondary chilled water in the hot fluid channel 7-1 of the heat exchange device 7.

Embodiment 3

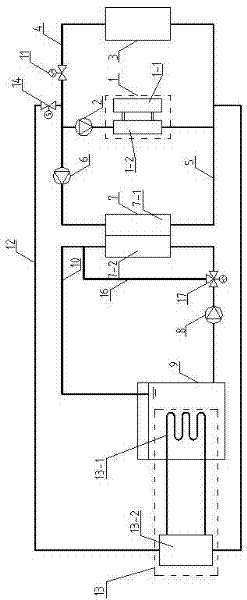

[0103] Such as image 3 As shown, the others are the same as those in Embodiment 1, but the third chilled water pump 8 is a common chilled water pump.

[0104] In addition, a fifth pipeline 16 is connected between the second pipeline 10 connecting both ends of the cold fluid channel 7 - 2 of the heat exchange device 7 , and a three-way valve 17 is connected in series at the intersection of the fifth pipeline 16 and the second pipeline 10 .

[0105] The flow rate of the primary chilled water entering the cold fluid channel 7 - 2 of the heat exchange device 7 is adjusted through the three-way valve 17 to adjust the temperature of the secondary chilled water in the hot fluid channel 7 - 1 of the heat exchange device 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com