Patents

Literature

289 results about "Vapor-compression refrigeration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

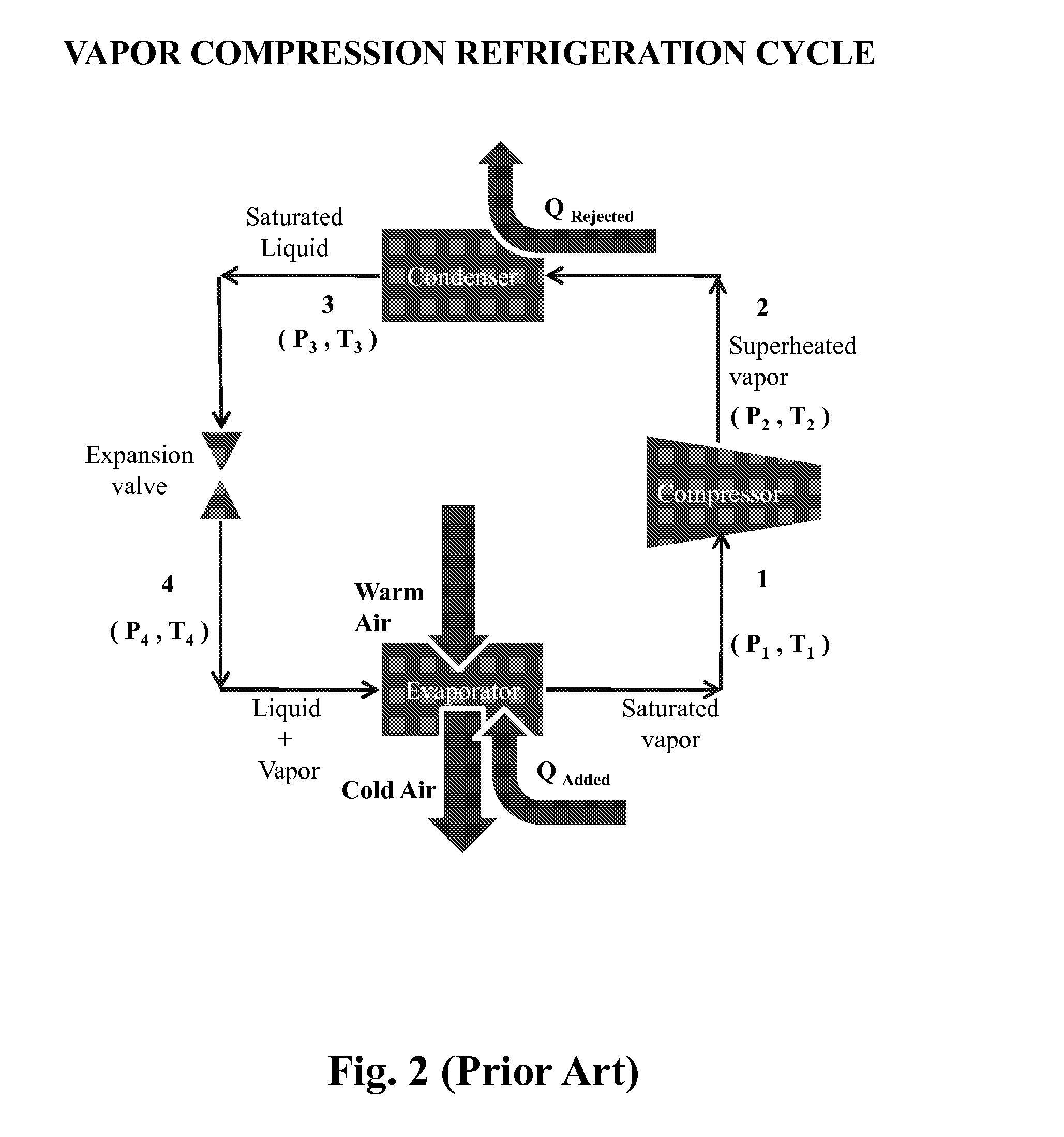

Vapour-compression refrigeration or vapor-compression refrigeration system (VCRS), in which the refrigerant undergoes phase changes, is one of the many refrigeration cycles and is the most widely used method for air-conditioning of buildings and automobiles. It is also used in domestic and commercial refrigerators, large-scale warehouses for chilled or frozen storage of foods and meats, refrigerated trucks and railroad cars, and a host of other commercial and industrial services. Oil refineries, petrochemical and chemical processing plants, and natural gas processing plants are among the many types of industrial plants that often utilize large vapor-compression refrigeration systems.

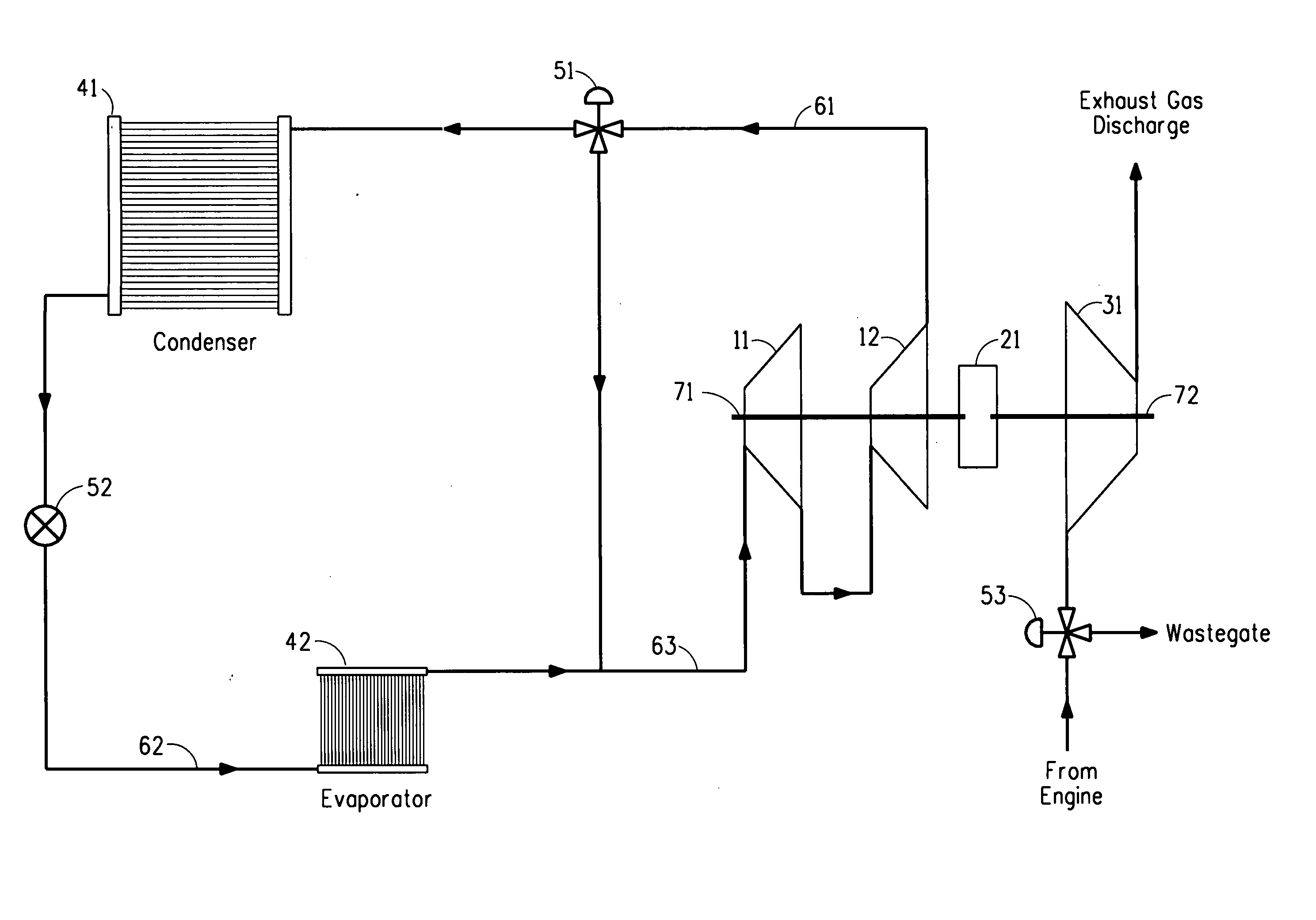

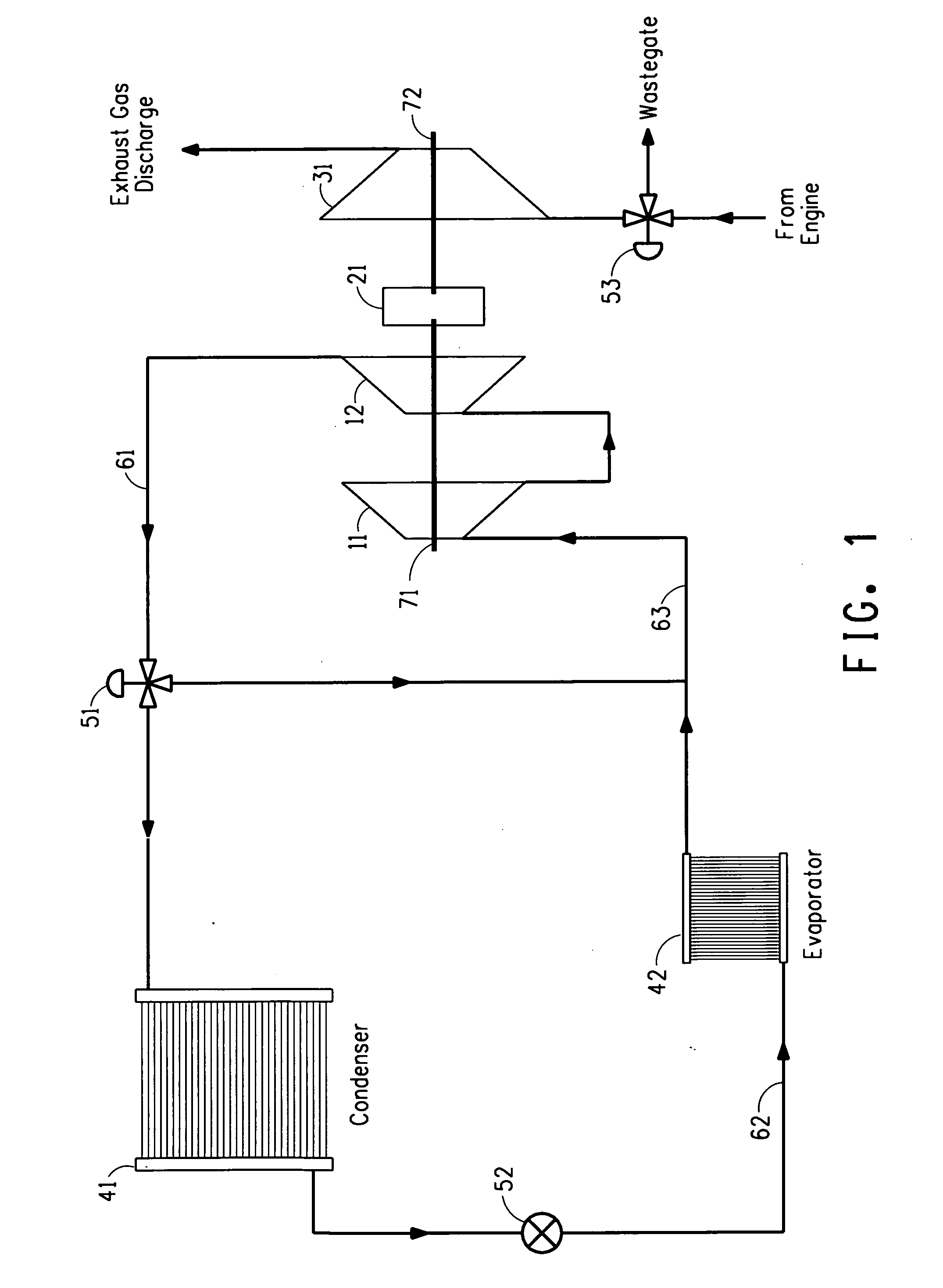

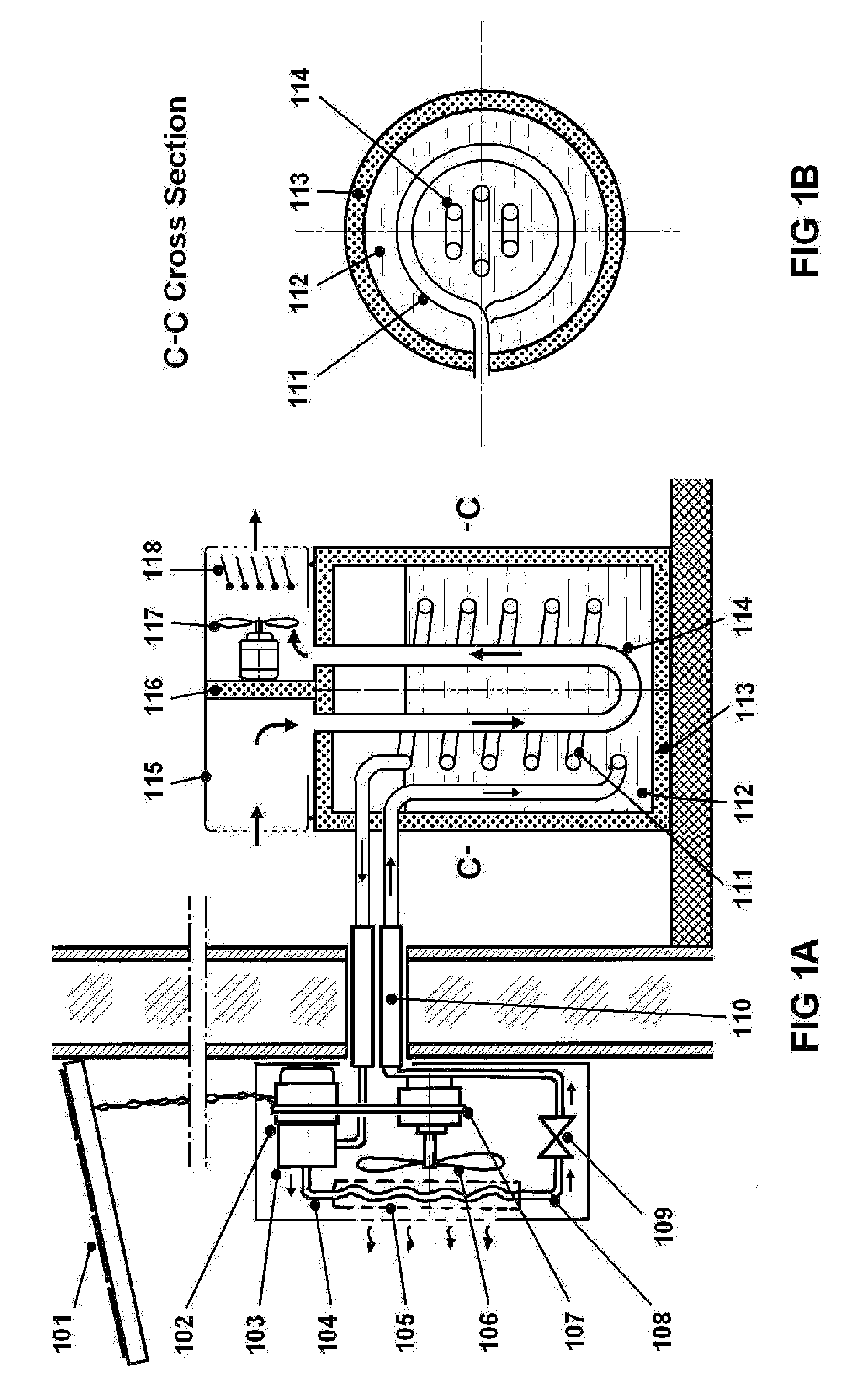

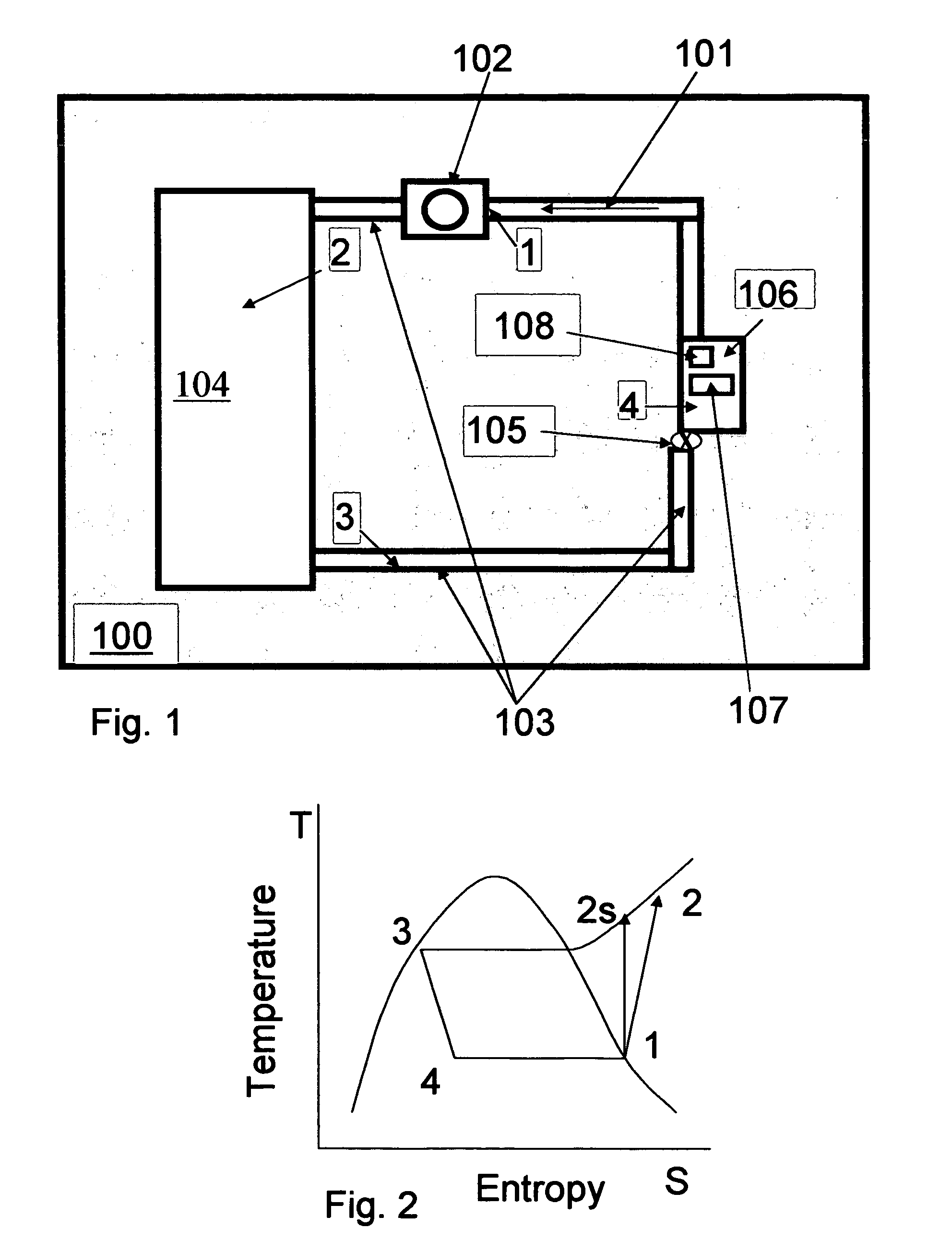

Refrigeration/air-conditioning apparatus powered by an engine exhaust gas driven turbine

InactiveUS20060242985A1Vary amountClimate change adaptationCompression machines with non-reversible cycleAir conditioningRefrigeration

Owner:EI DU PONT DE NEMOURS & CO

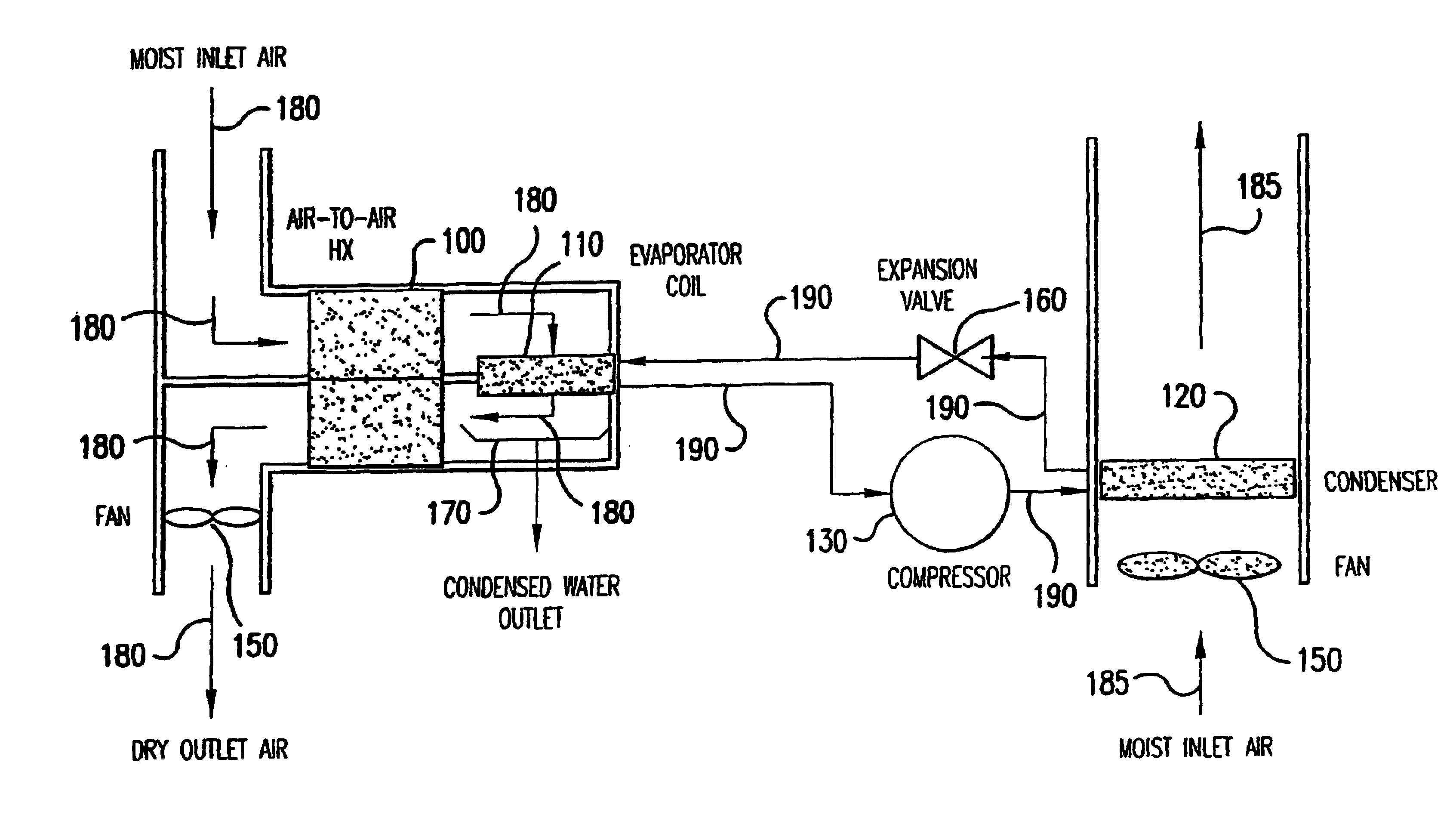

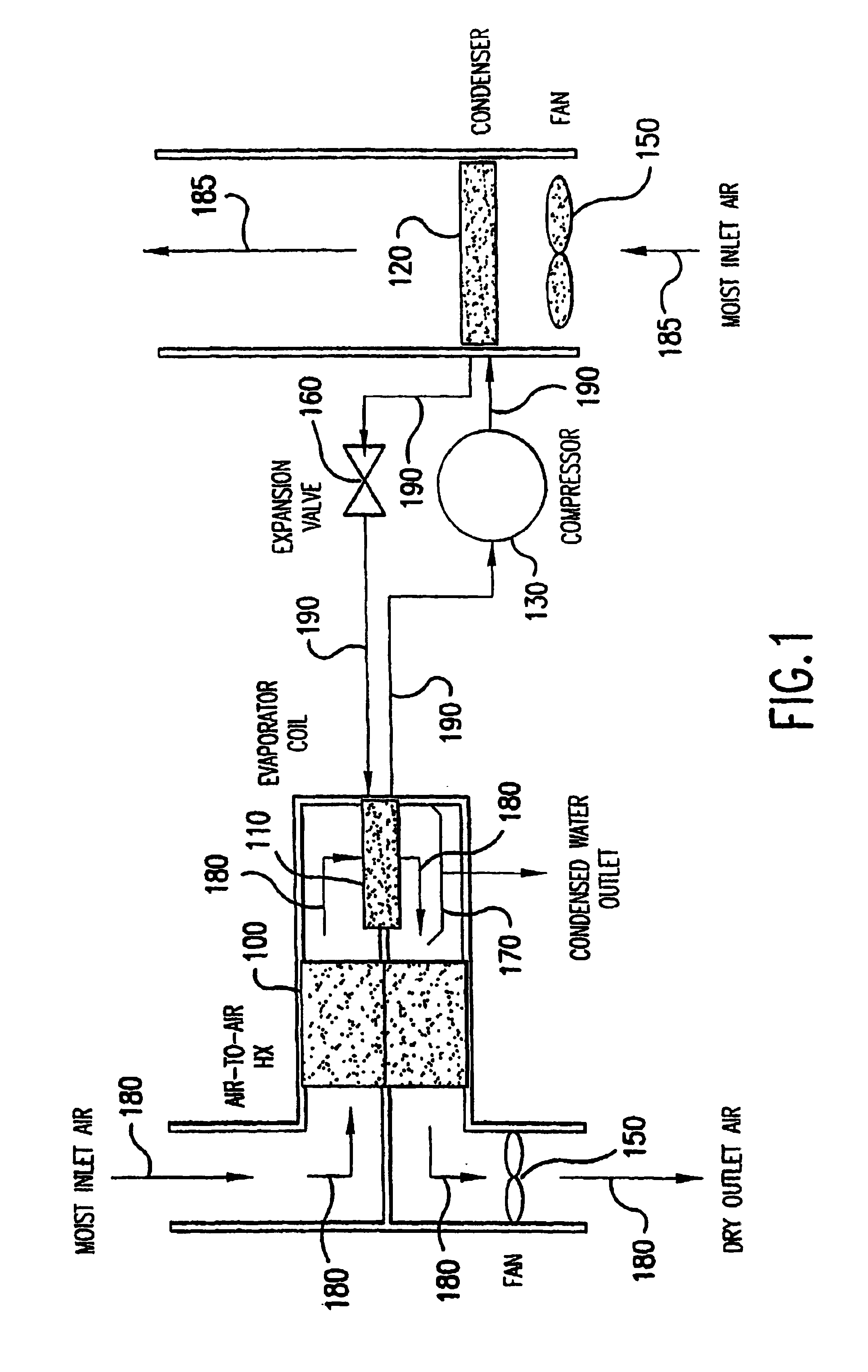

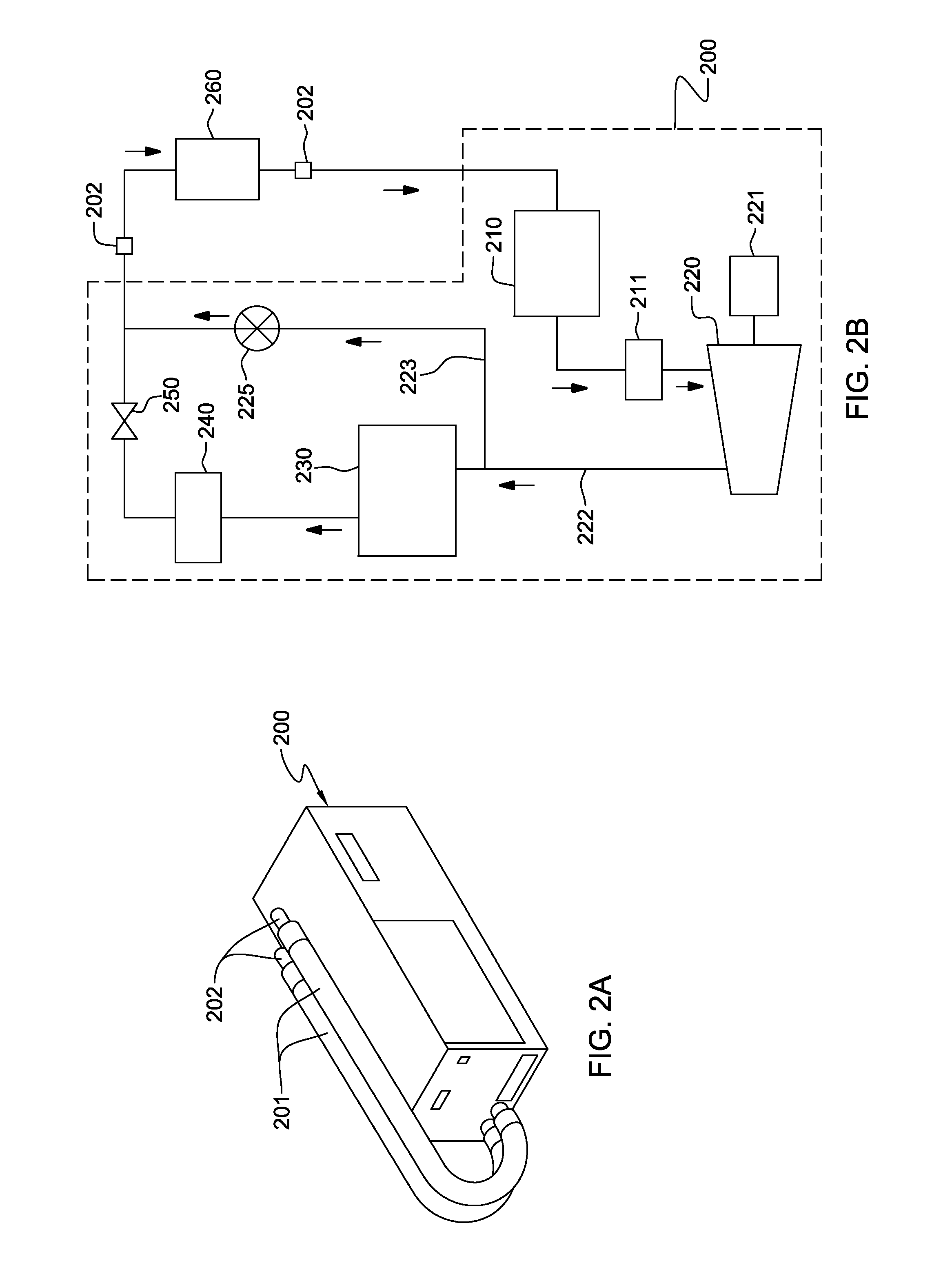

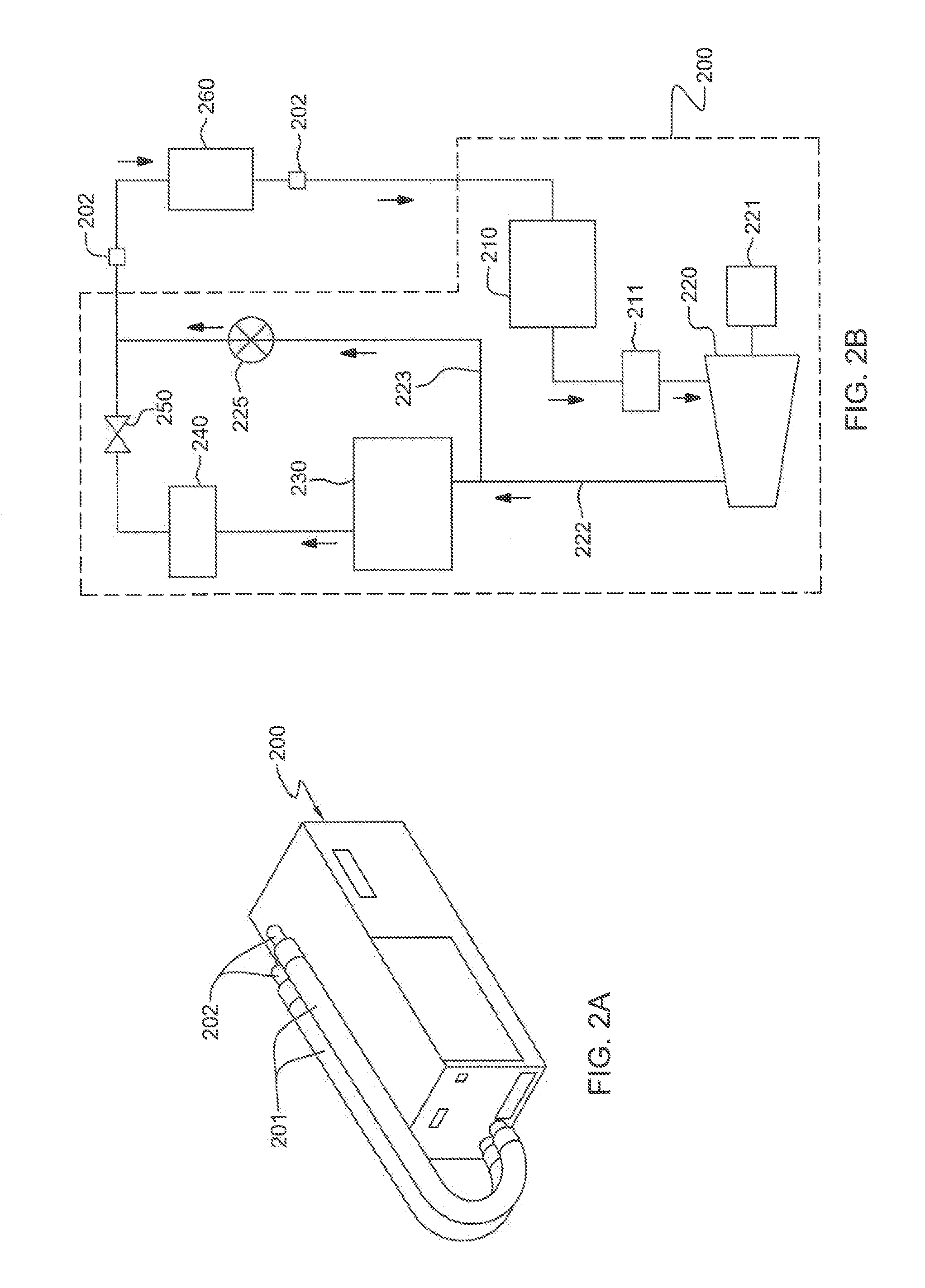

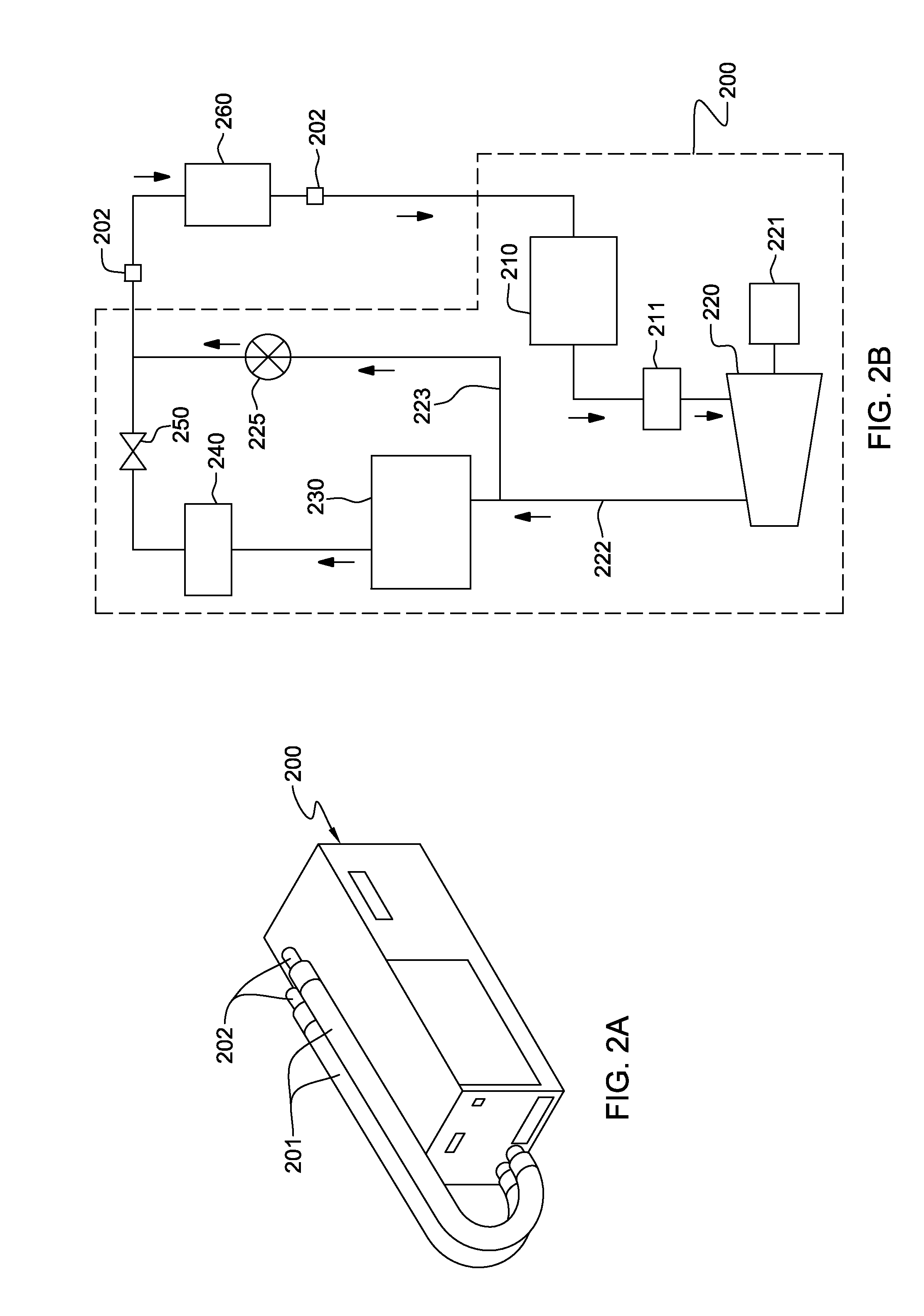

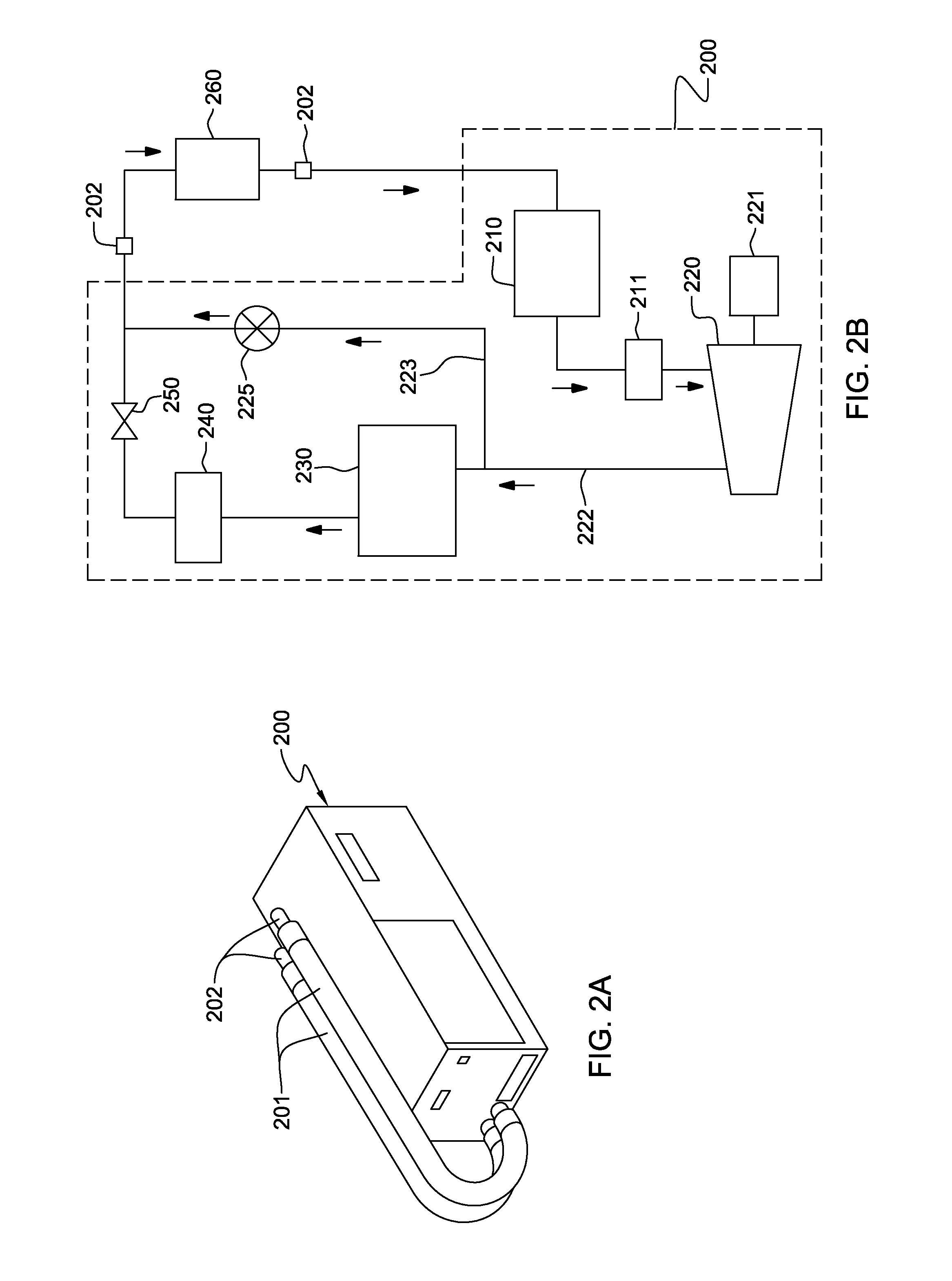

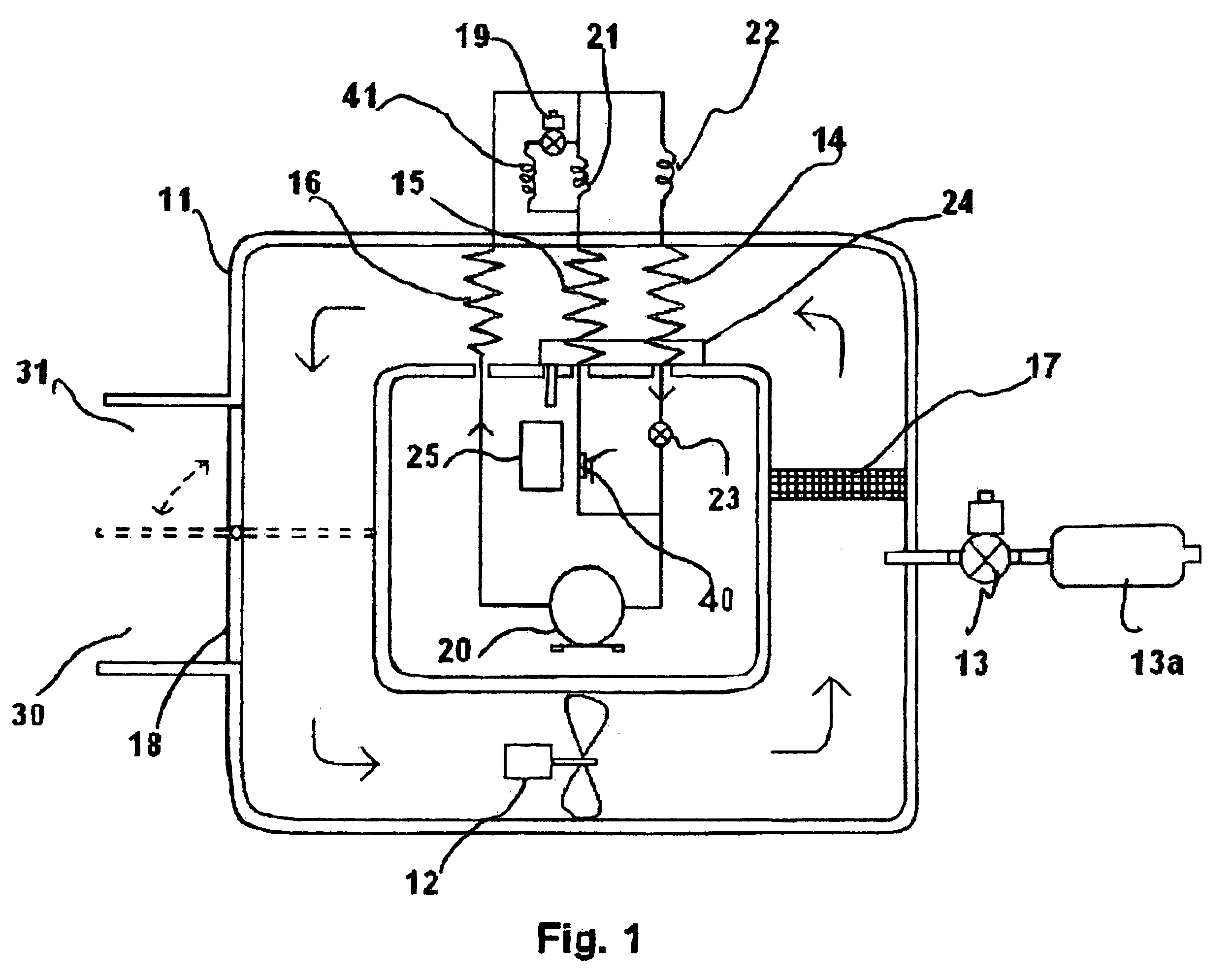

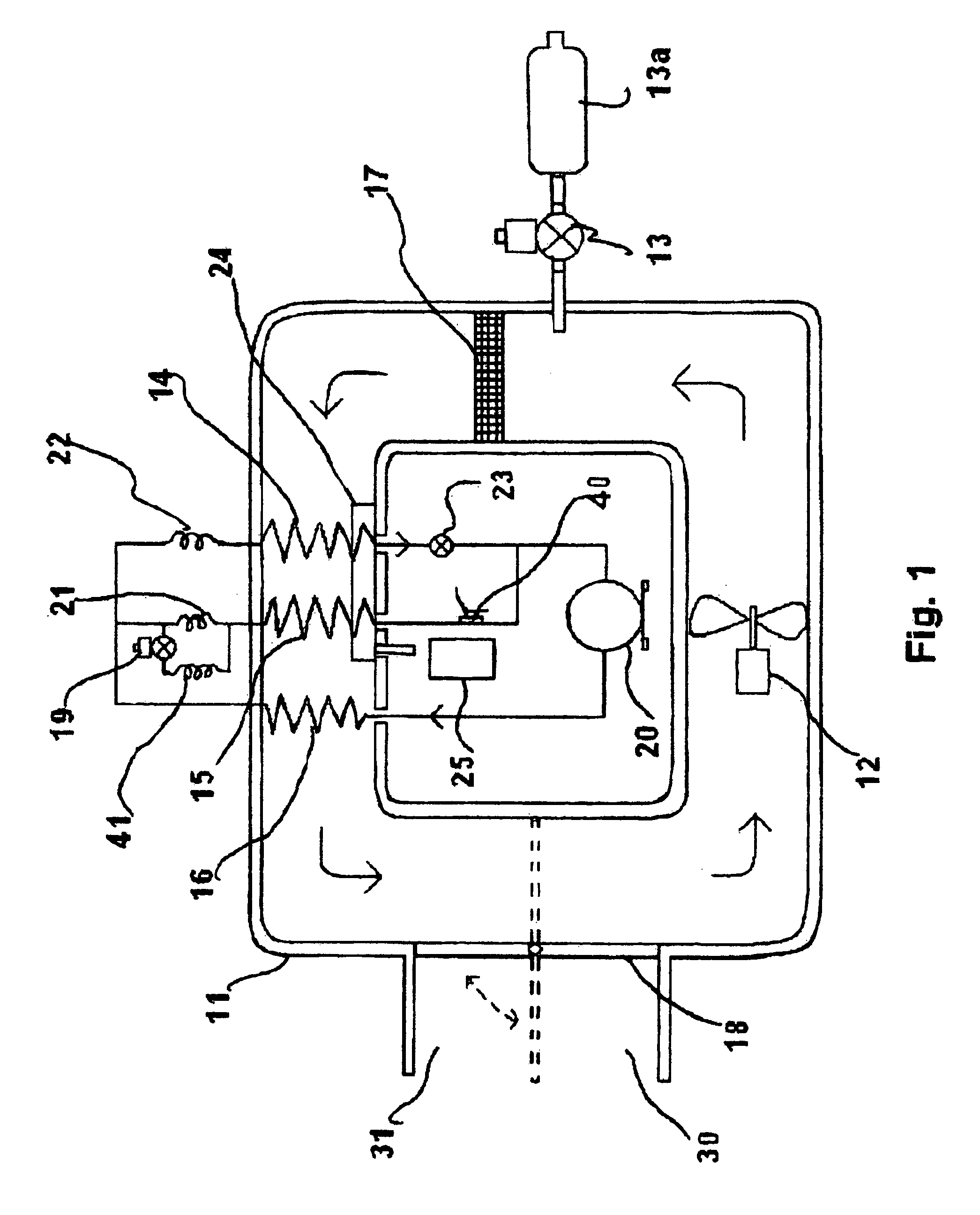

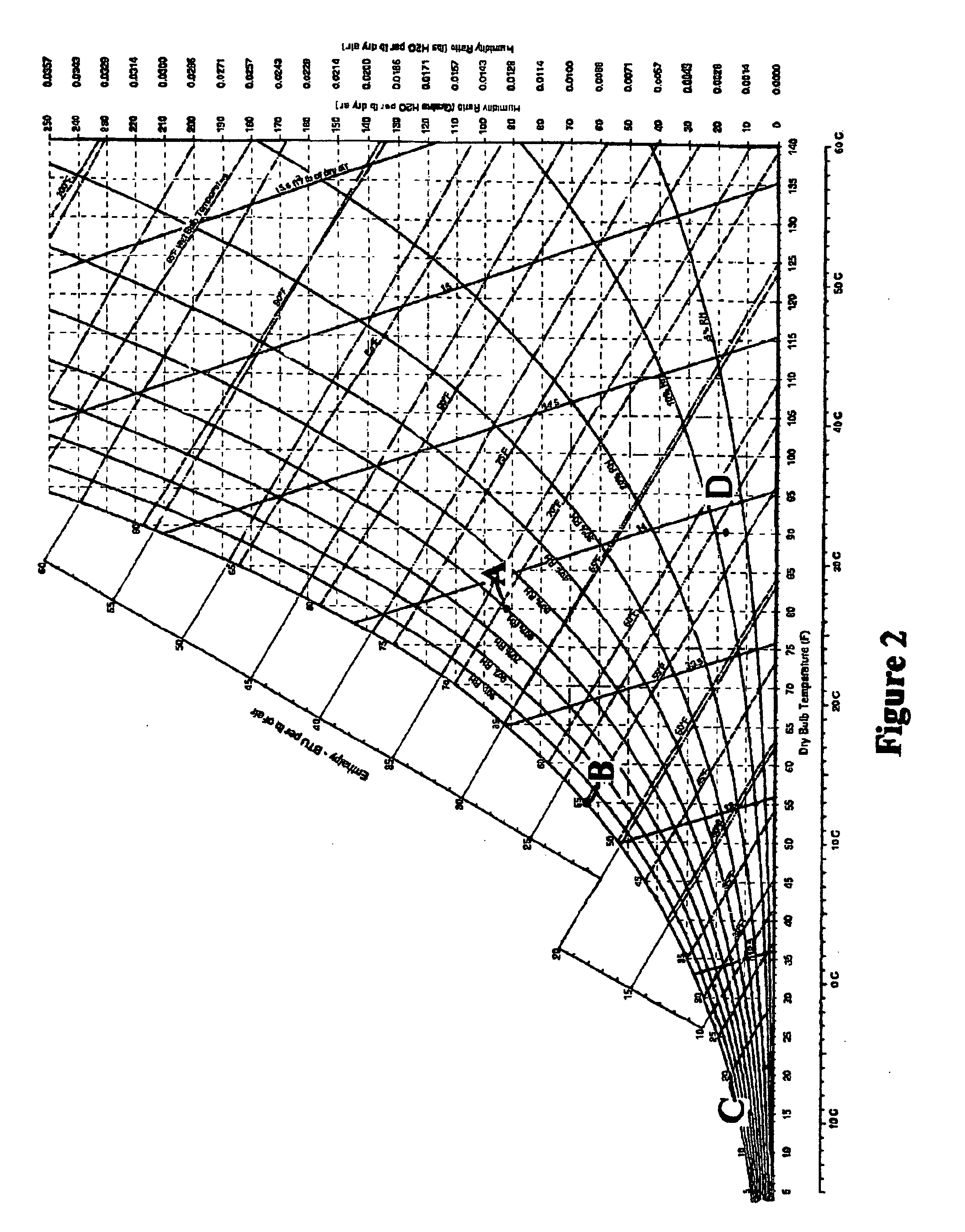

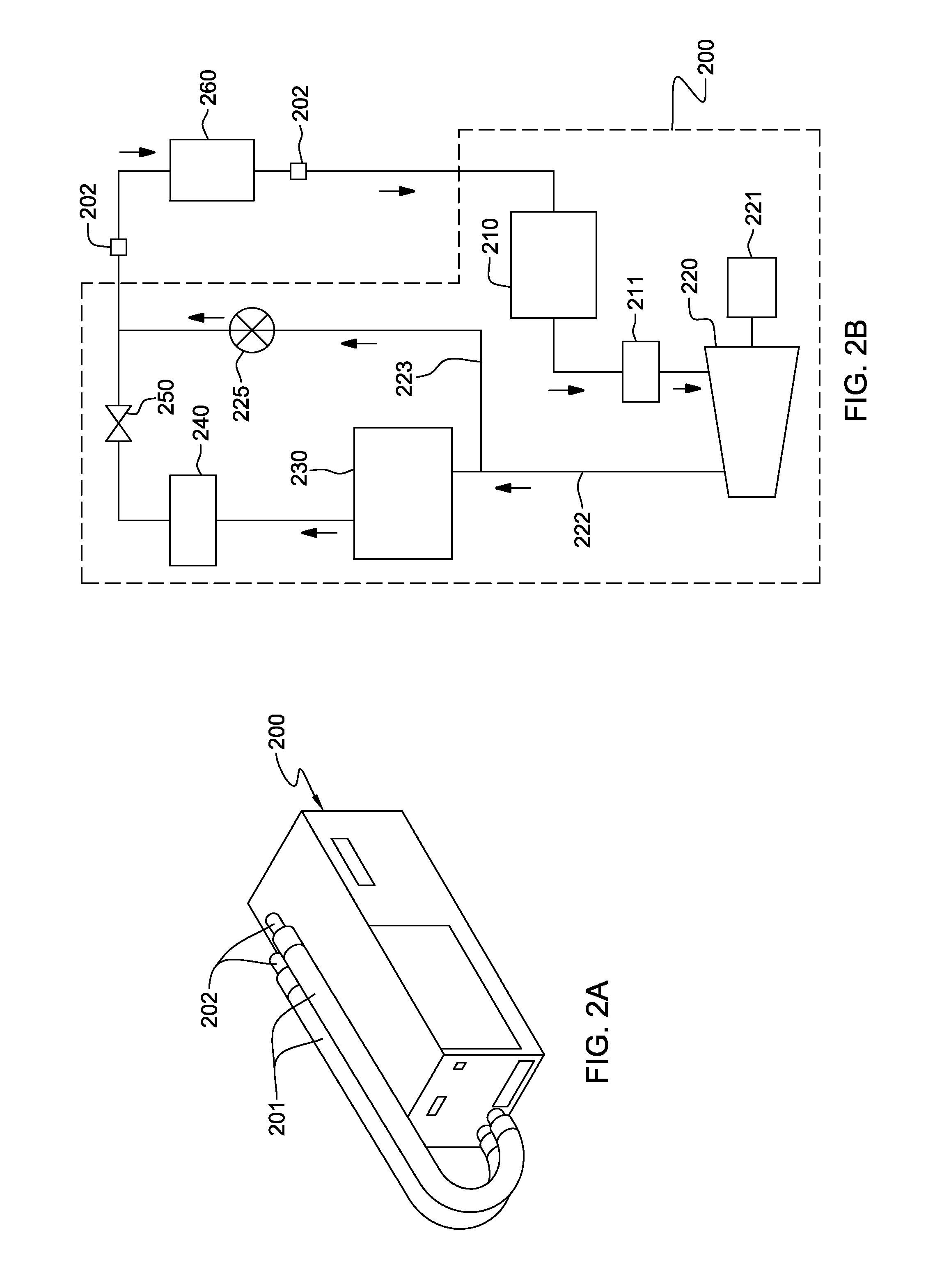

Device for collecting water from air

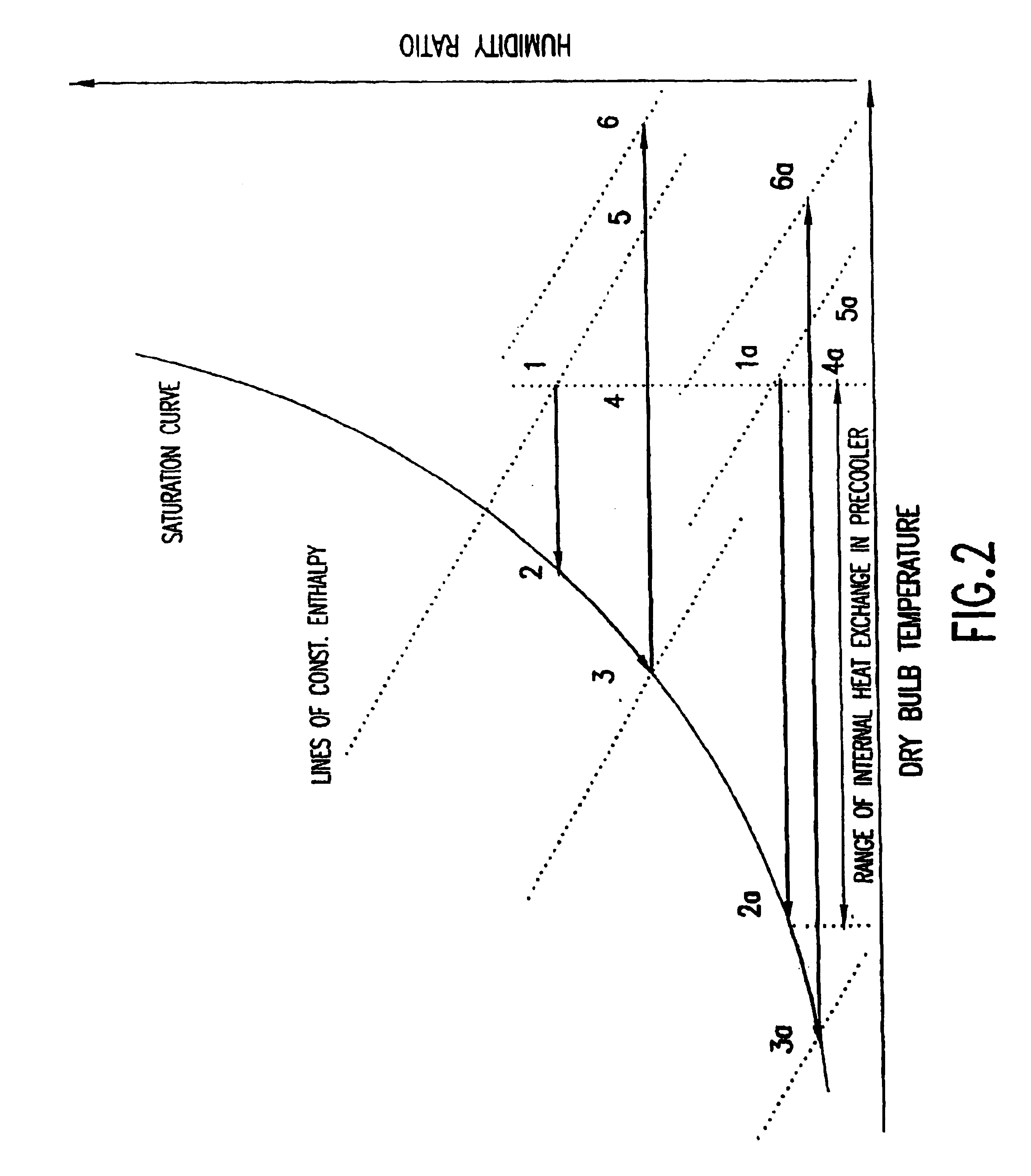

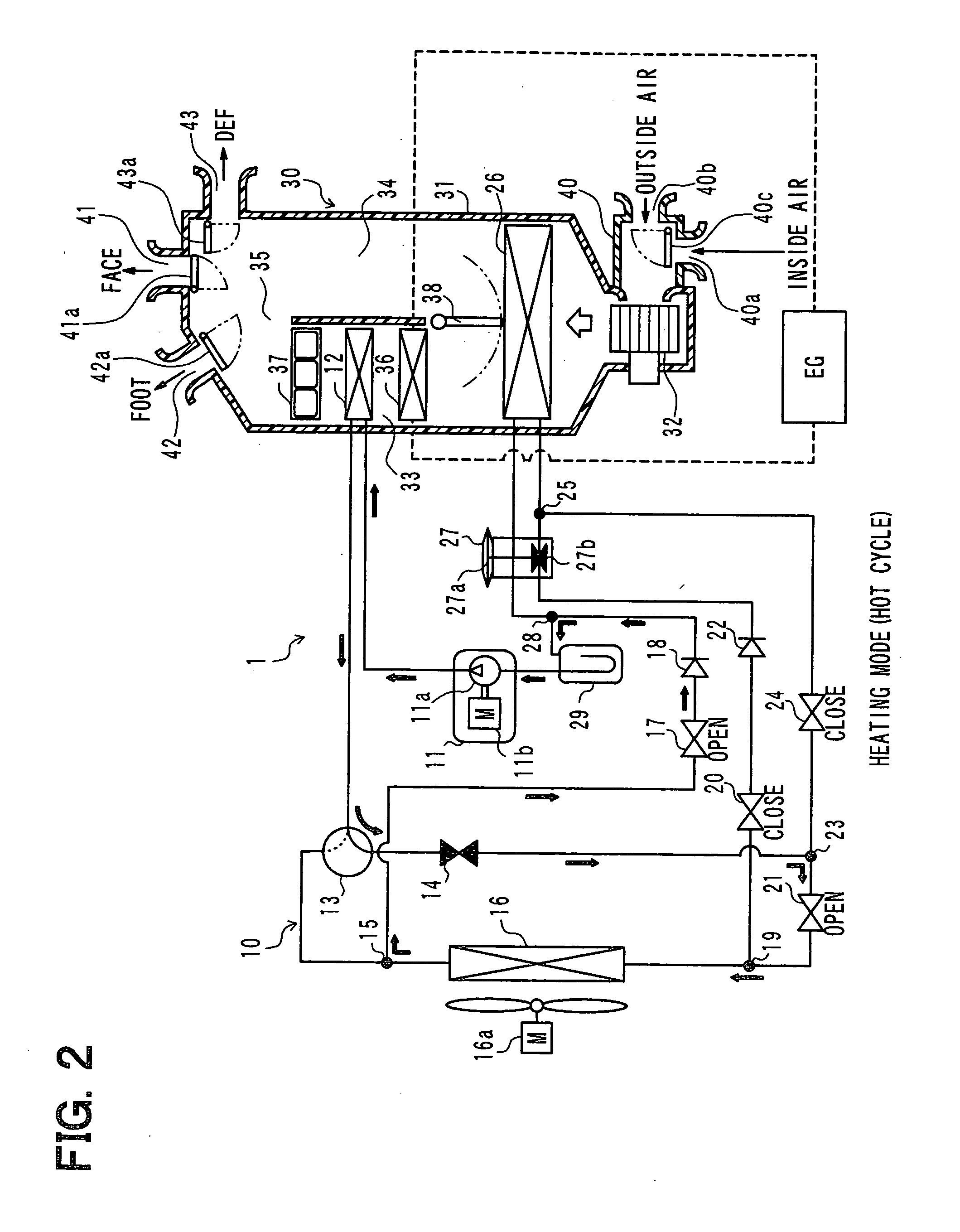

The present invention is directed to a water making device that collects the moisture contained in the atmosphere and condenses it into high purity water. In one embodiment, moist air entering the water making / water cooling system flows across an air filter, then a precooler heat exchanger (where the air stream is cooled to or close to its dew point) and then a water extraction heat exchanger, where the air stream is cooled further and water is extracted. The water that leaves water extraction heat exchanger is collected in a water collection device and passes from there through a primary water filter into a water storage tank. The air stream then passes across a reheat heat exchanger and exhausted to the outside. A water circulation pump extracts water from the water storage tank and circulates the water stream through an evaporator of a vapor compression refrigeration system, where the water stream is chilled, then through the water extraction heat exchanger and precooler, where the incoming air stream is chilled by removing heat to the water stream. The water stream is then circulated through the reheat heat exchanger, where the water stream is again cooled by removing heat to the cool dry air exiting the water extraction heat exchanger. Finally, the cooled water stream is circulated through the water filter to a three way valve, that directs water flow either to a dispenser or back to the water storage tank.

Owner:UNIV OF MARYLAND

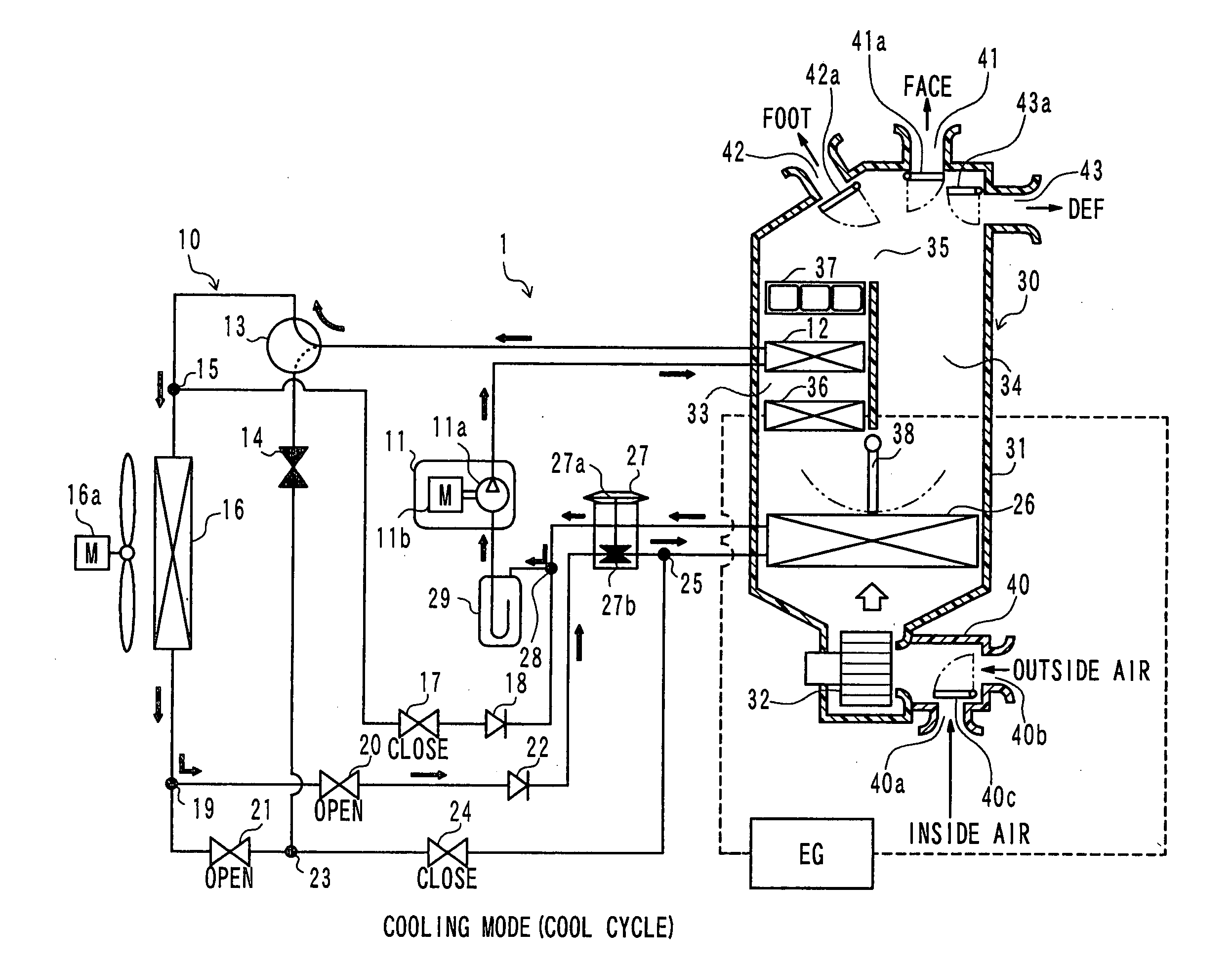

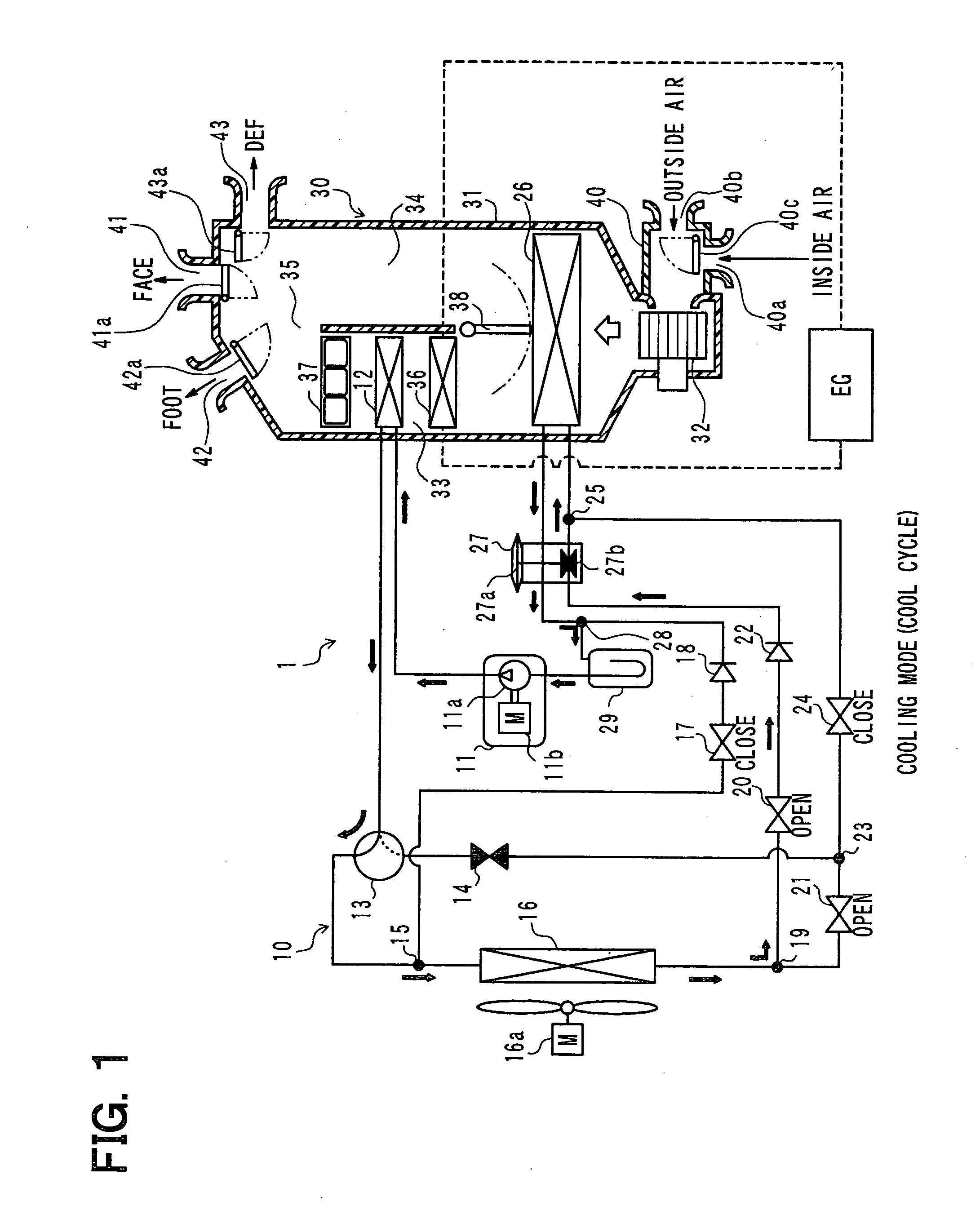

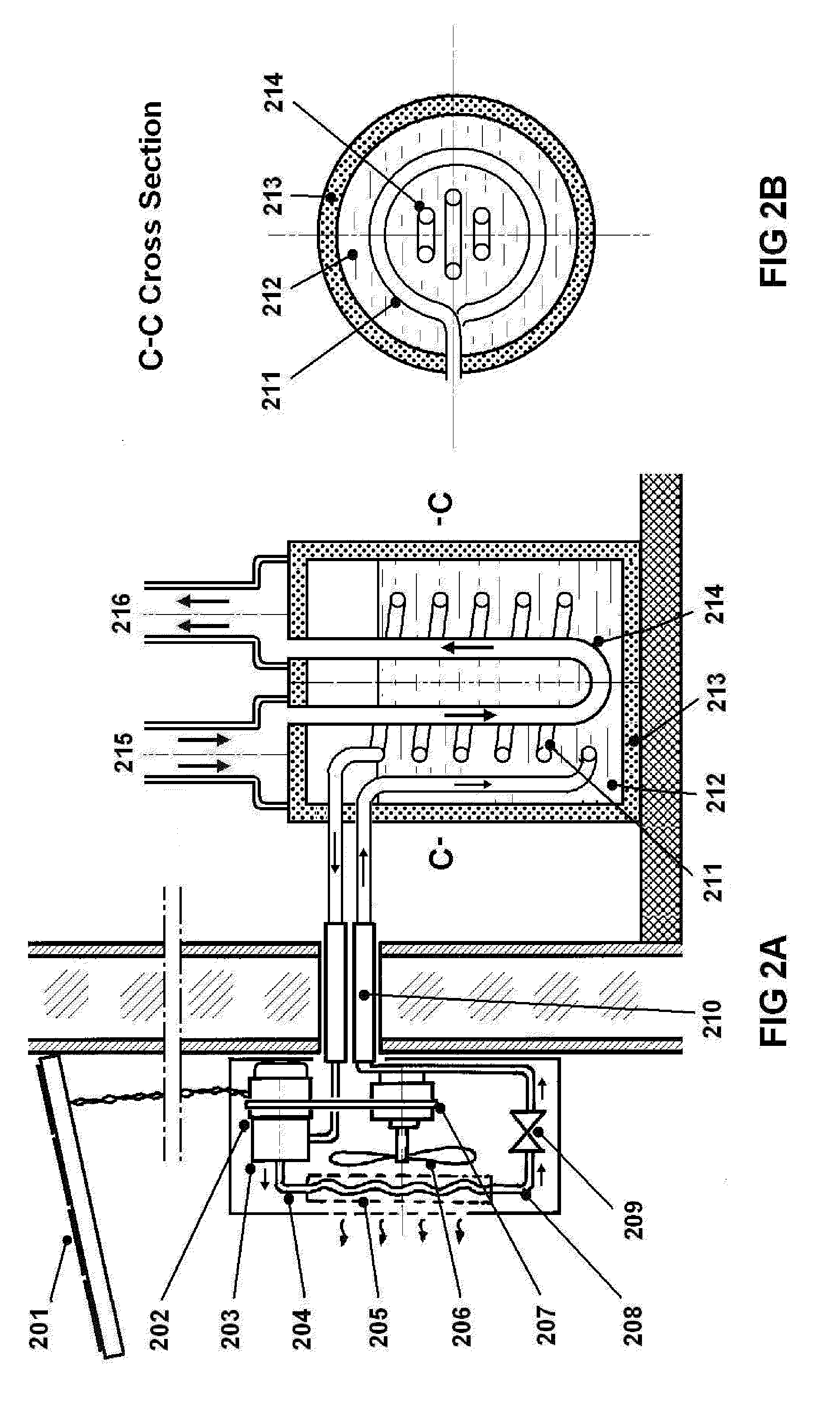

Air conditioner for vehicle with heat pump cycle

InactiveUS20100326127A1Effectively reducing fuel consumptionPrevent heating capacity being excessiveMechanical apparatusCompression machines with non-reversible cycleEngineeringInternal combustion engine

An air conditioner for a vehicle includes a vapor compression refrigeration cycle configured to have a heat pump cycle for heating air to be blown into an interior of a vehicle compartment, and a heating member for heating the air using a coolant of an internal combustion engine of the vehicle as a heat source. In the air conditioner, an operation request signal is output by an air conditioning controller to the internal combustion engine when an outside air temperature is lower than a predetermined threshold.

Owner:DENSO CORP

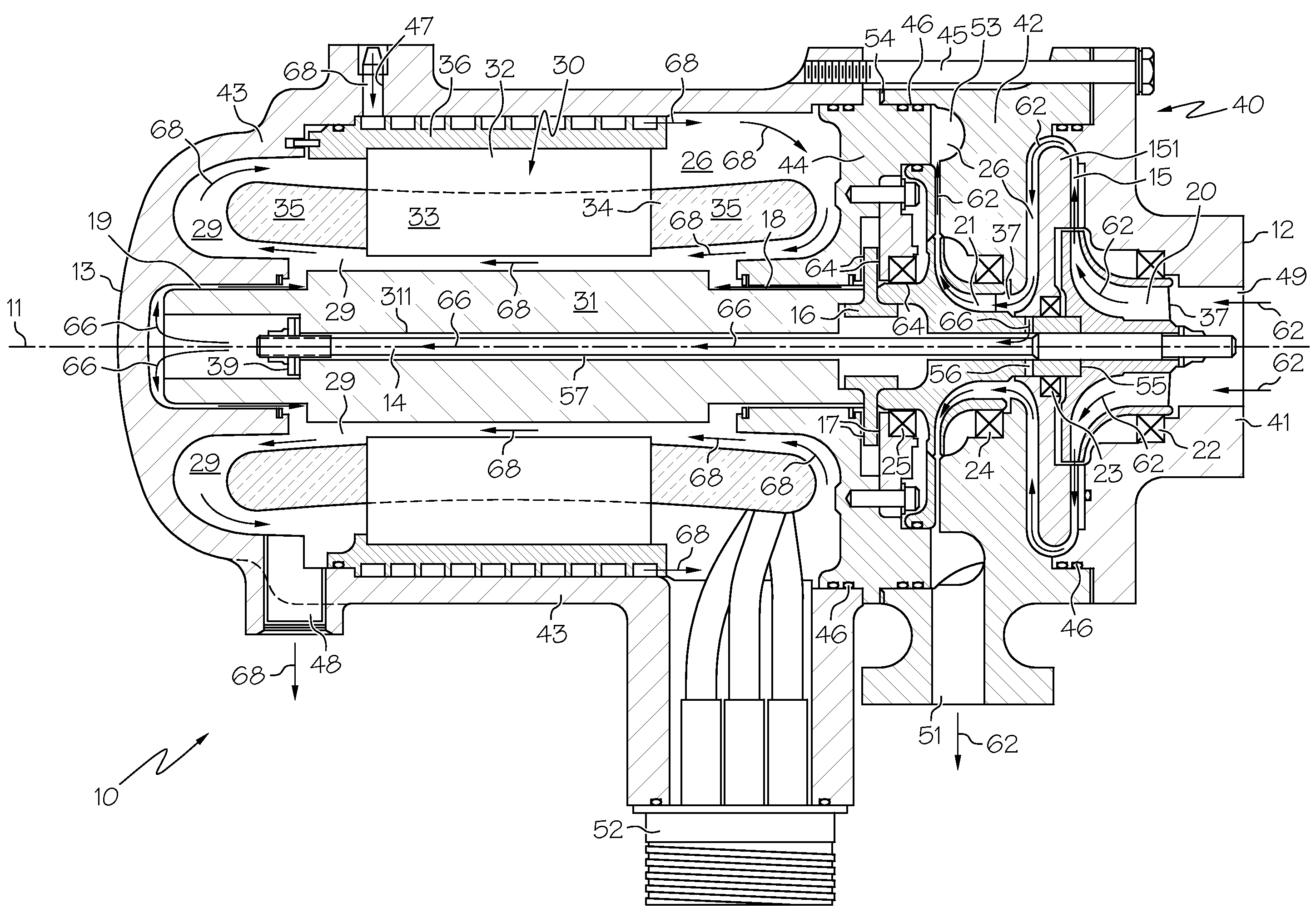

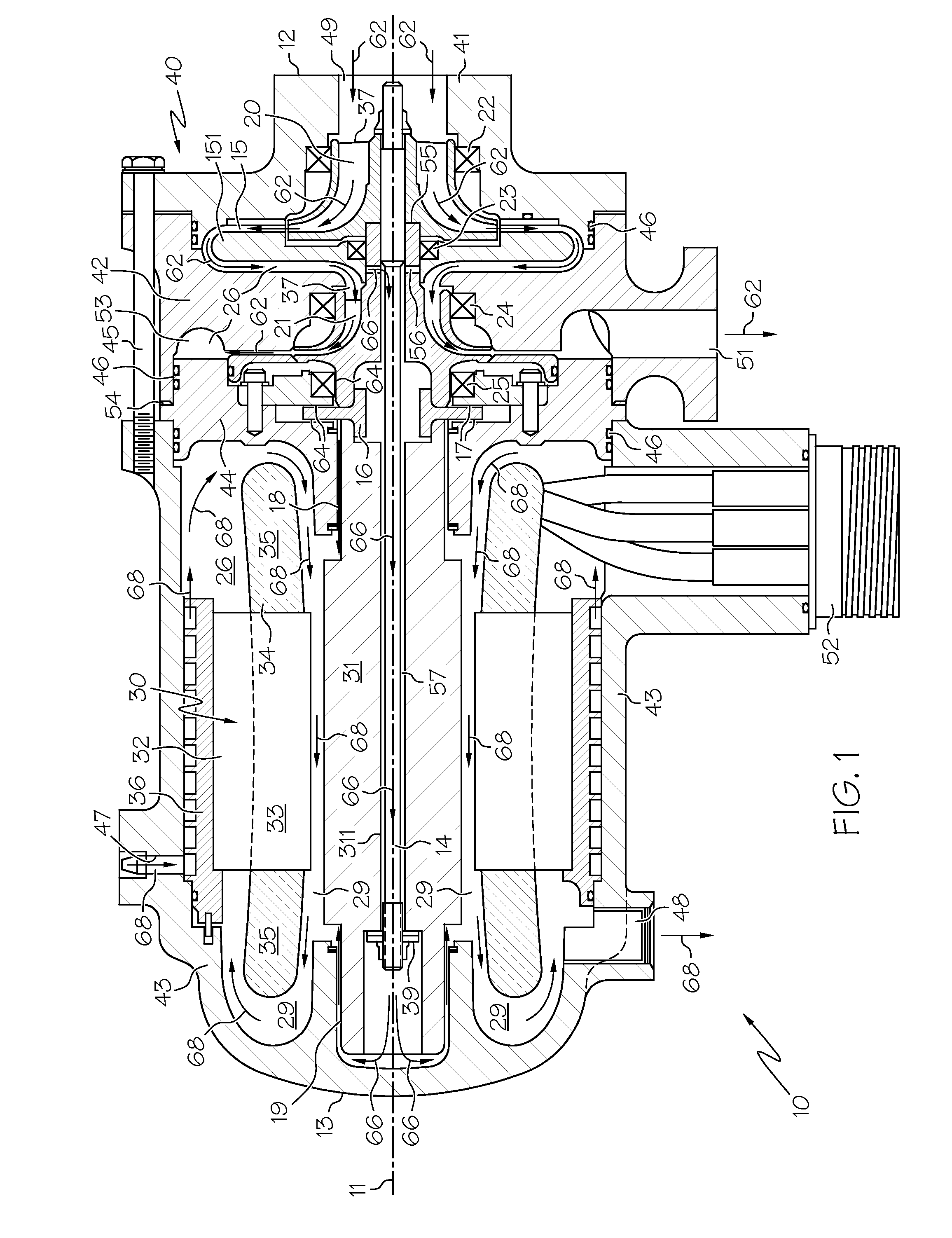

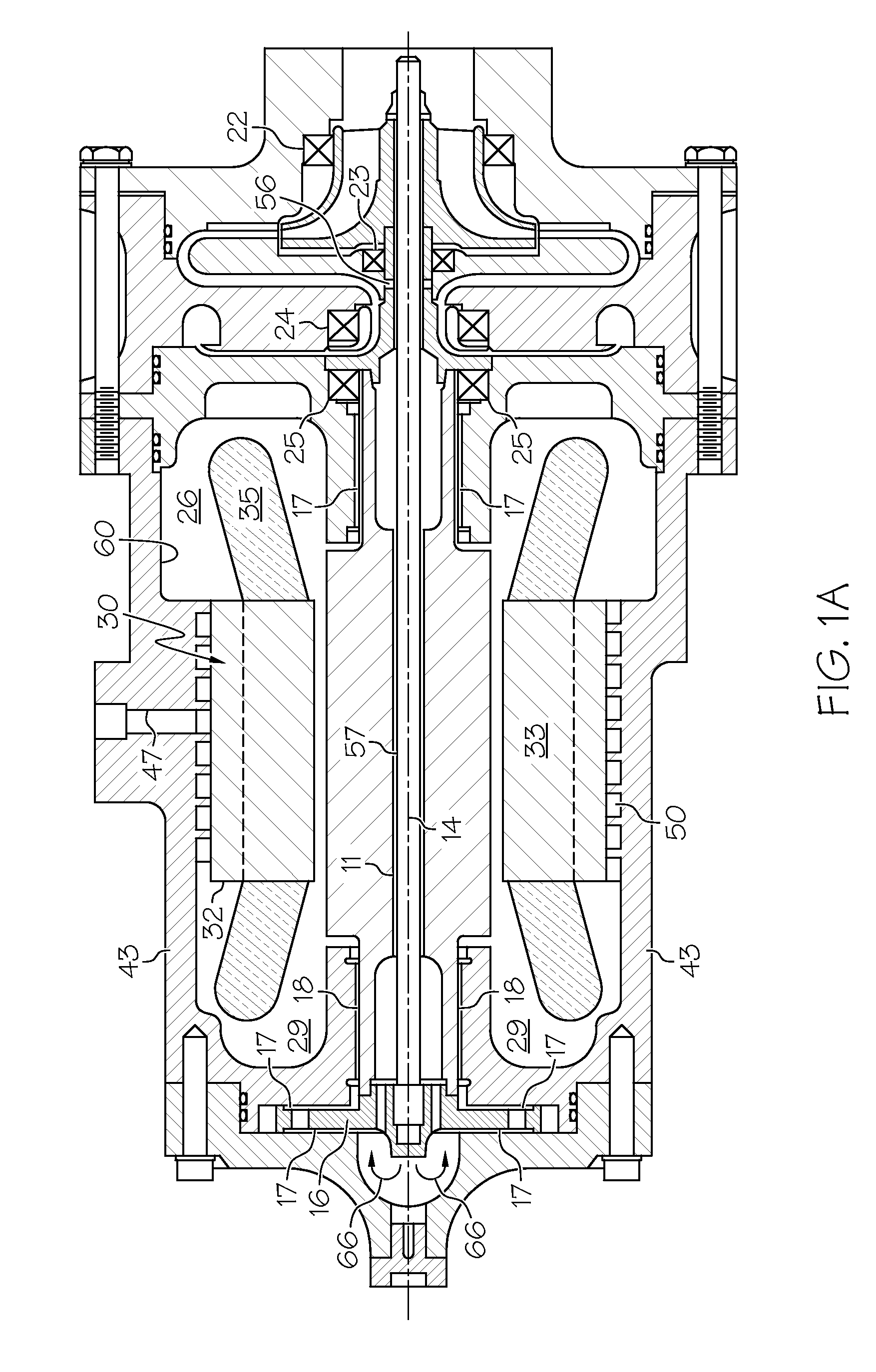

Two-stage vapor cycle compressor

A two-stage vapor cycle compressor includes a first stage impeller, a second stage impeller situated adjacent to the first stage impeller, an electric motor running on a pair of foil bearings, a thrust disk including two foil bearings and being positioned between the second stage impeller and the electric motor, and a compressor housing enclosing the first and second stage impeller and the electric motor. A refrigerant vapor compressed by the first stage and second stage impeller flows through an internal passageway formed by the compressor housing and cools the foil bearings and the electric motor. The compressor may be a gravity insensitive, small, and lightweight machine that may be easily assembled at low manufacturing costs. The two-stage vapor cycle compressor may be suitable for, but not limited to, applications in vapor compression refrigeration systems, such as air-conditioning systems, for example, in the aircraft and aerospace industries.

Owner:HONEYWELL INT INC

Detectable refrigerant compositions and uses thereof

InactiveUS20050211949A1Easy to detectDetection of fluid at leakage pointHeat-exchange elementsInfraredCorona discharge

Disclosed herein are detectable refrigerant compositions, comprising from about 0.001 to about 5 weight percent tracer compositions, which are useful to identify leaking in a vapor compression refrigeration and / or air conditioning system. The presence of the tracers make the refrigerant compositions detectable by chemo / electro-active array, corona discharge, heated diode, electrochemical, photoionization, infra red, ultrasonic and electron capture detectors.

Owner:EI DU PONT DE NEMOURS & CO

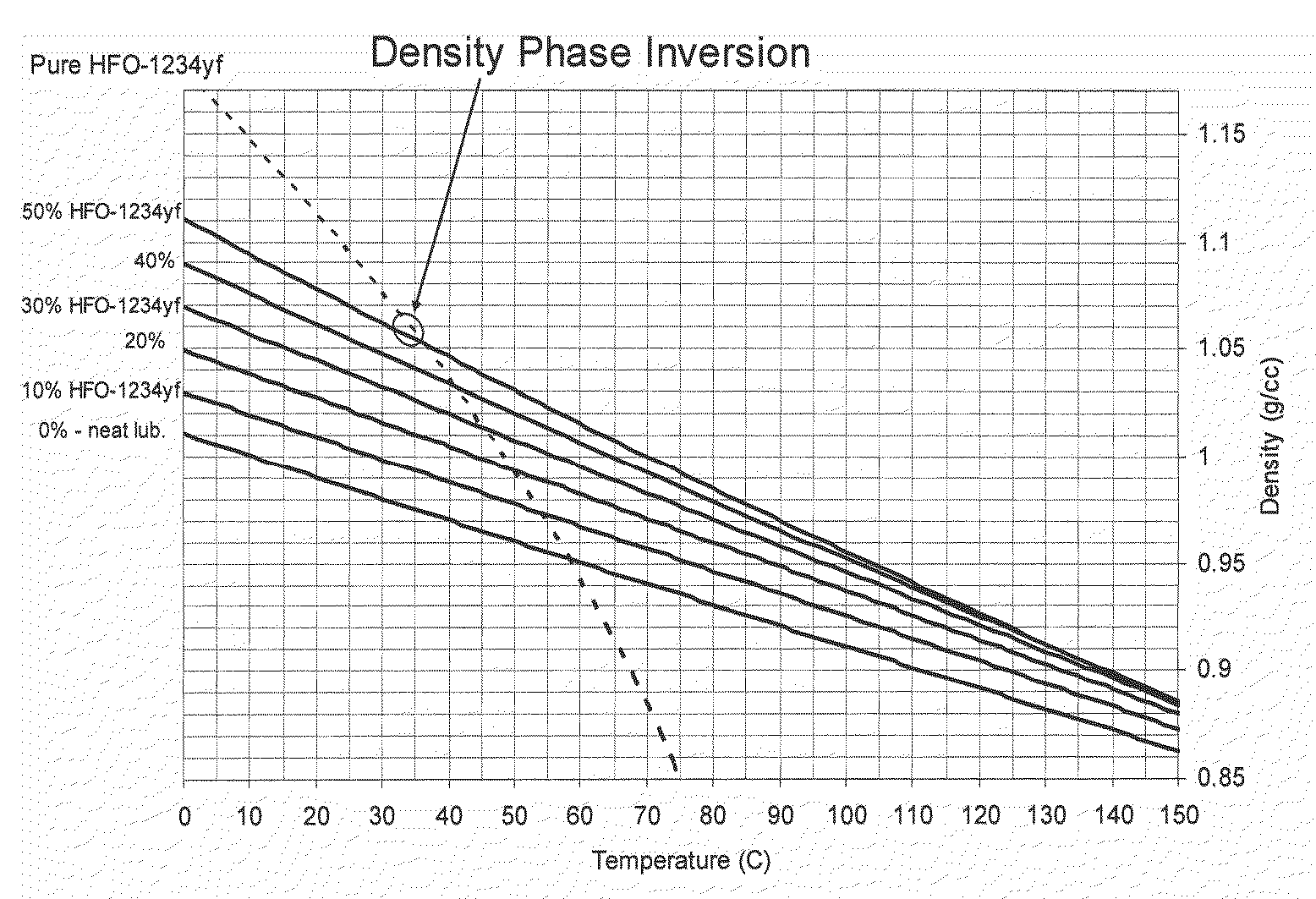

Method for selecting lubricants for heat pumps

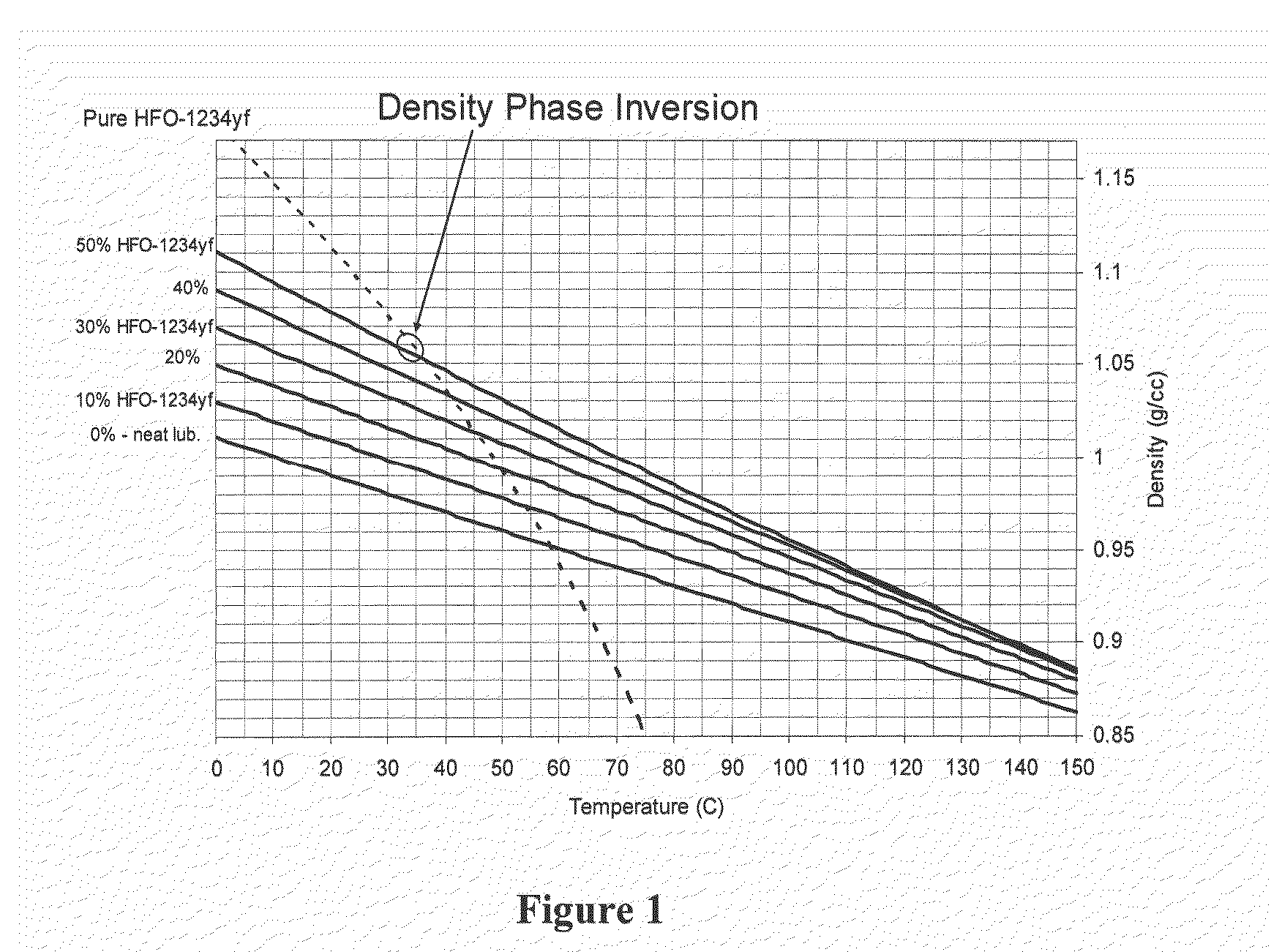

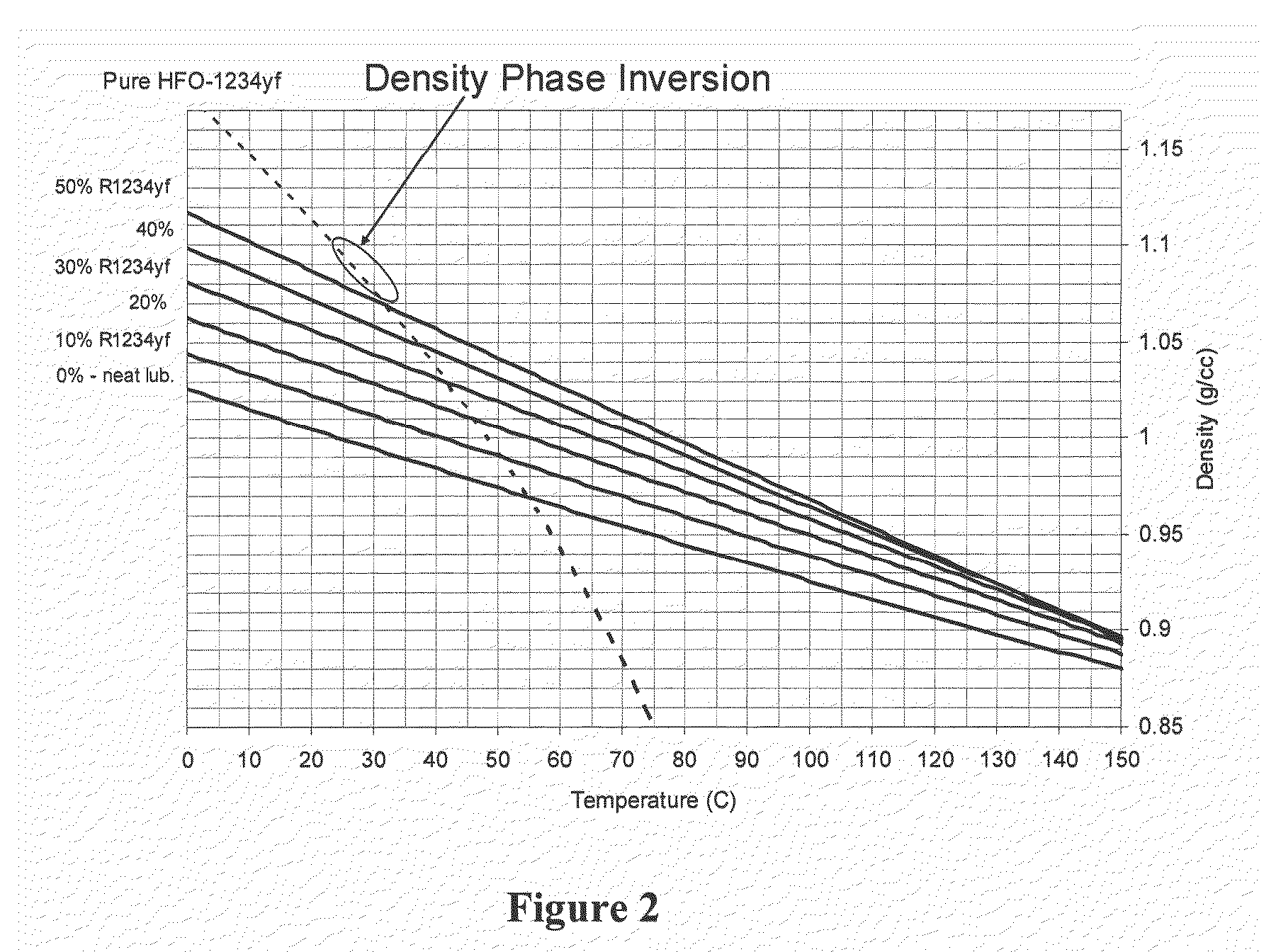

ActiveUS20090241562A1Reduce frictionImprove efficiencyCompressorHeat-exchange elementsEngineeringVapor-compression refrigeration

Provided is a method for selecting a lubricant and a refrigerant for use in a vapor-compression refrigeration device such that the combination of the lubricant and refrigerant produces a fluid system having a lubricant-rich phase and a refrigerant-rich phase, yet exhibits miscible-type properties.

Owner:HONEYWELL INT INC

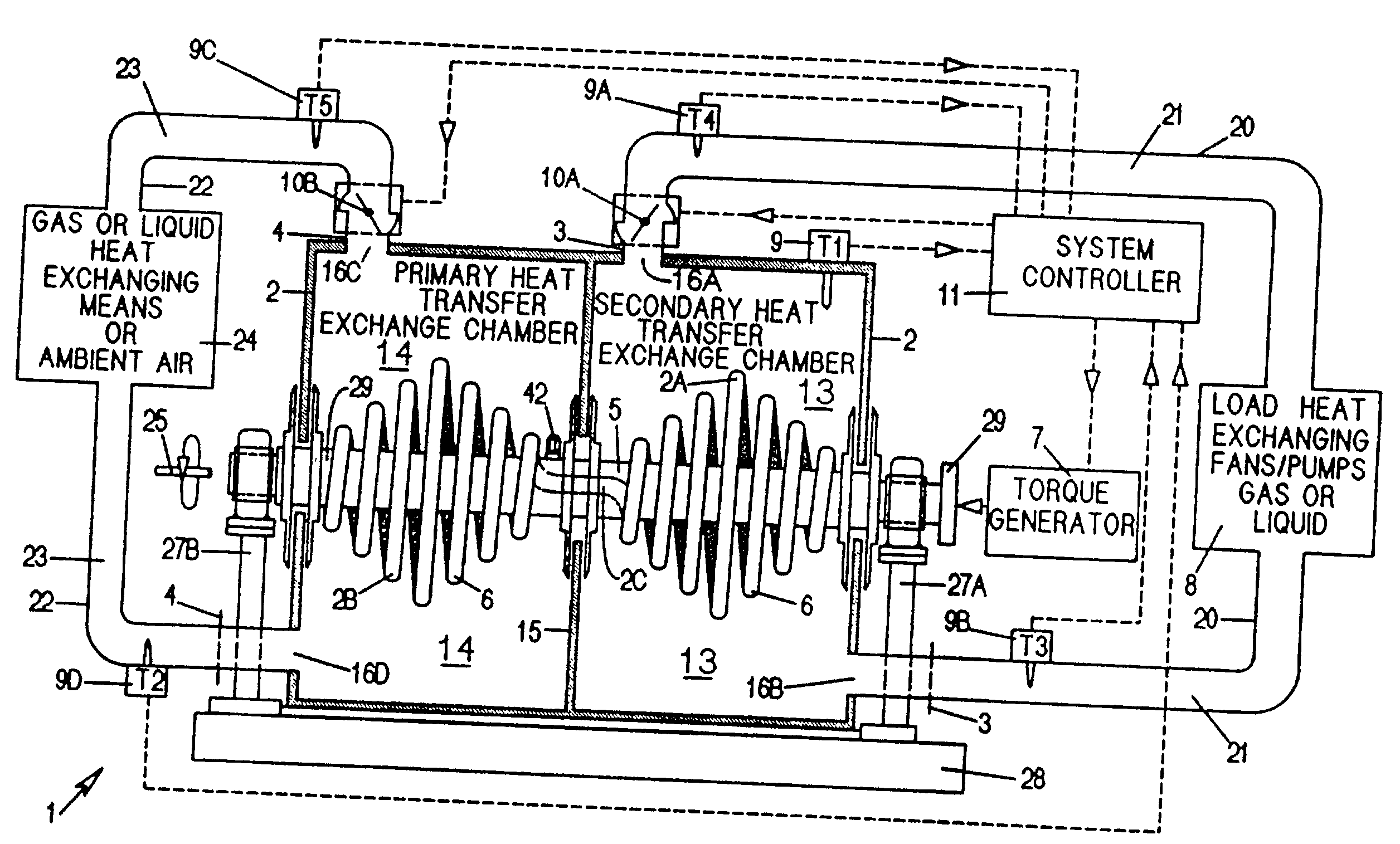

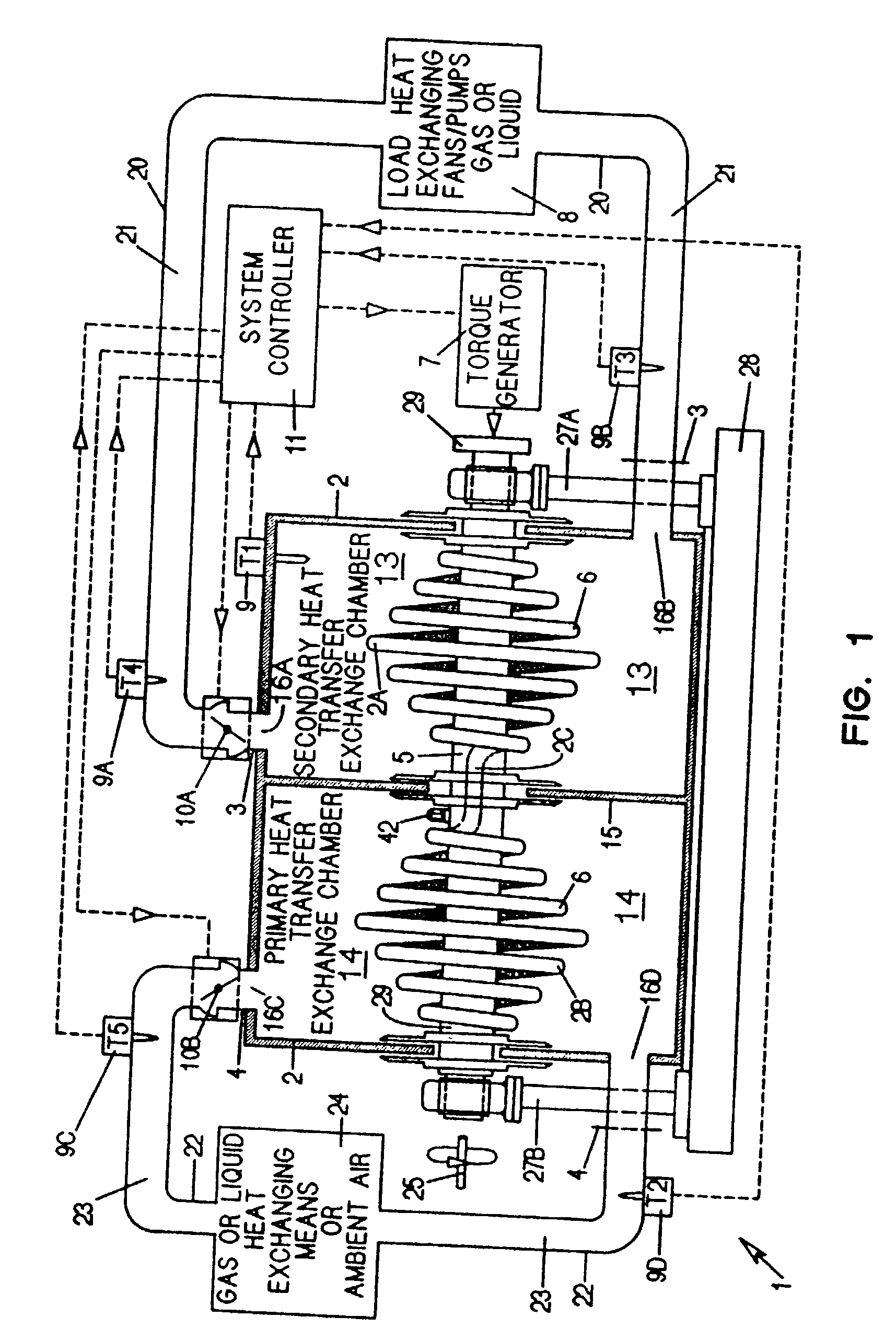

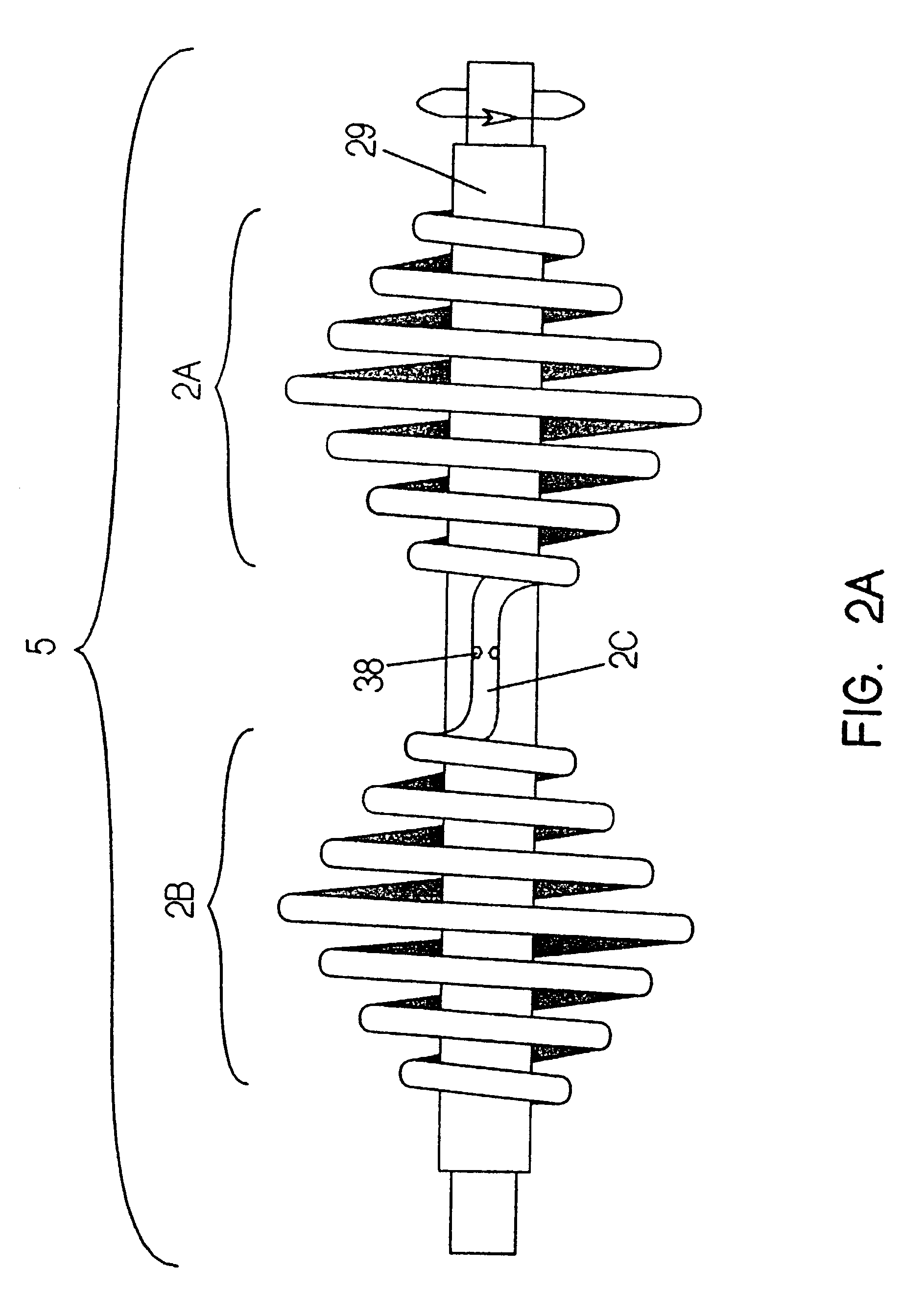

Centrifugal heat transfer engine and heat transfer systems embodying the same

InactiveUS20030145621A1Simple methodReduce the introductionSelf-contained rotary compression machinesCompression machines with non-reversible cycleRotational axisThermal isolation

A heat transfer engine having cooling and heating modes of reversible operation, in which heat can be effectively transferred within diverse user environments for cooling, heating and dehumidification applications. The heat transfer engine of the present invention includes a rotor structure which is rotatably supported within a stator structure. The stator has primary and secondary heat exchanging chambers in thermal isolation from each other. The rotor has primary and secondary heat transferring portions within which a closed fluid flow circuit is embodied. The closed fluid flow circuit within the rotor has a spiraled fluid-return passageway extending along its rotary shaft, and is charged with a refrigerant which is automatically circulated between the primary and secondary heat transferring portions of the rotor when the rotor is rotated within an optimized angular velocity range under the control of a temperature-responsive system controller. During the cooling mode of operation, the primary heat transfer portion of the rotor carries out an evaporation function within the primary heat exchanging chamber of the stator structure, while the secondary heat transfer portion of the rotor carries out a condenser function within the secondary heat exchanging chamber of the stator. During the cooling mode of operation, a vapor-compression refrigeration process is realized by the primary heat transfer portion of the rotor performing an evaporation function within the primary heat exchanging chamber of the stator structure, while the secondary heat transfer portion of the rotor performs a condenser function within the secondary heat exchanging chamber of the stator. During the heating mode of operation, a vapor-compression refrigeration process is realized by the primary heat transfer portion of the rotor performing a condenser function within the primary heat exchanging chamber of the stator structure, while the secondary heat transfer portion of the rotor performs an evaporation function within the secondary heat exchanging chamber of the stator. By virtue of the present invention, a technically feasible heat transfer engine is provided which avoids the need for conventional external compressors, while allowing the use of environmentally safe refrigerants. Various embodiments of the heat transfer engine are disclosed, in addition to methods of manufacture and fields and applications of use.

Owner:KELIX HEAT TRANSFER SYST

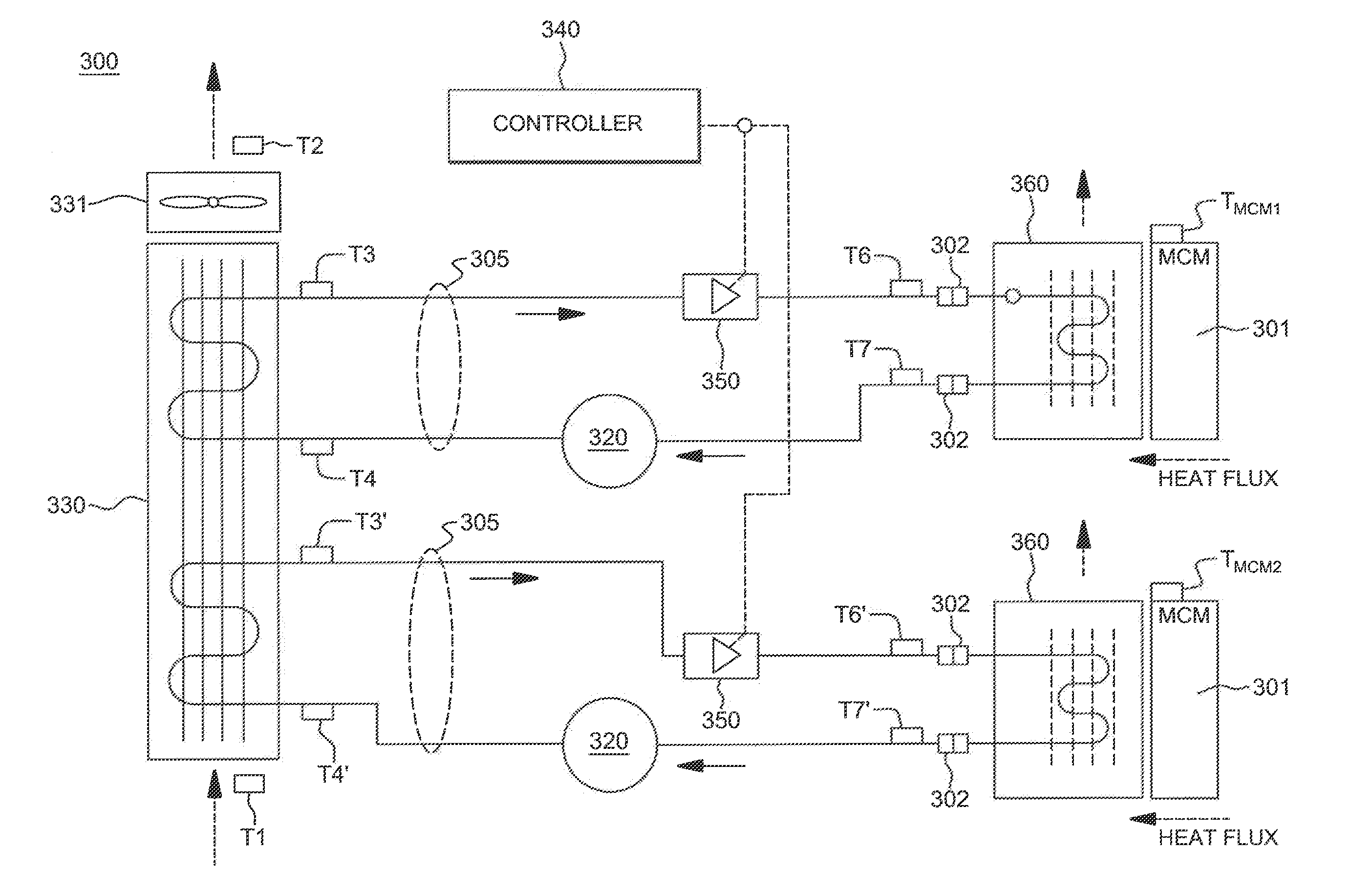

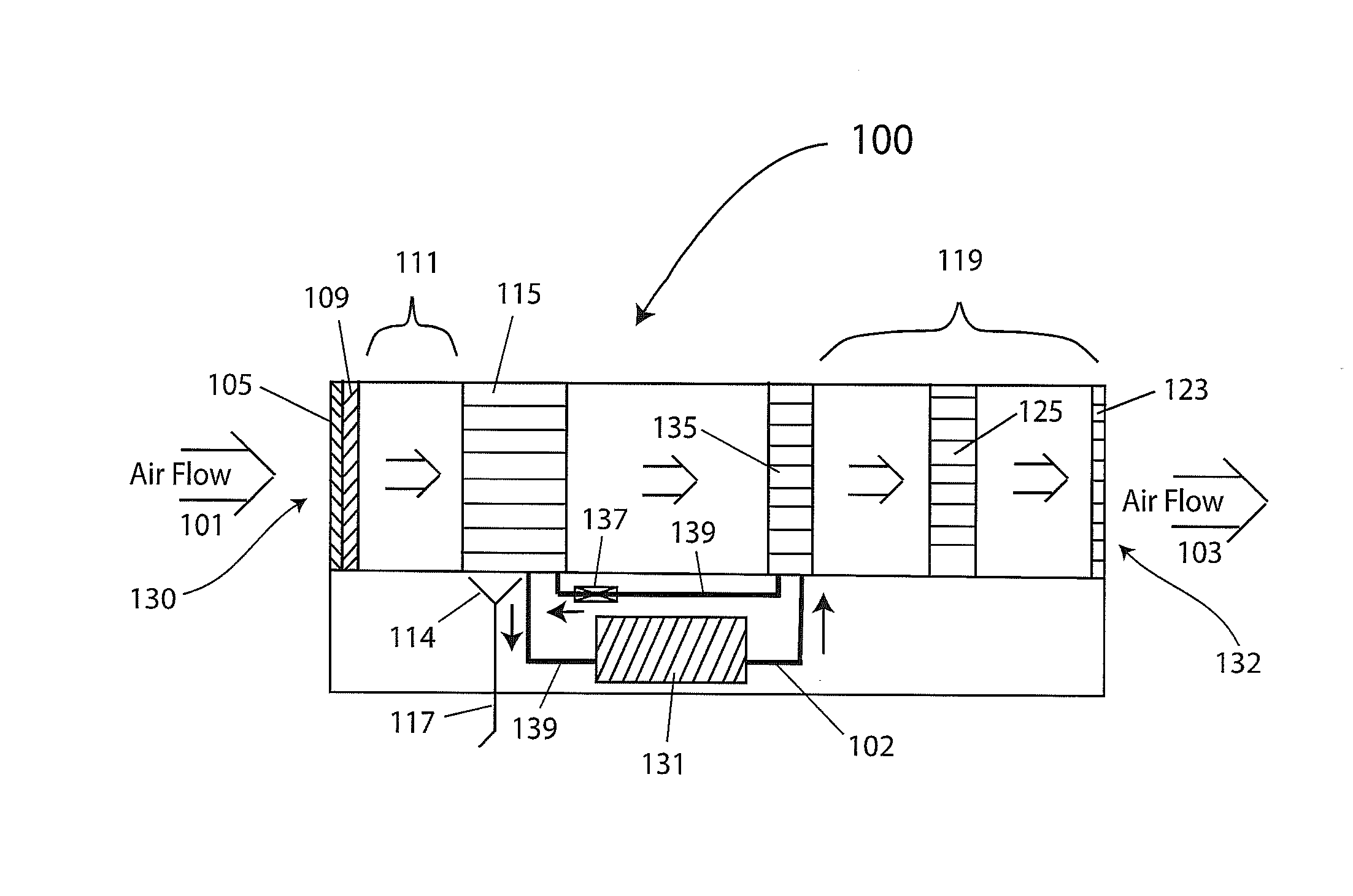

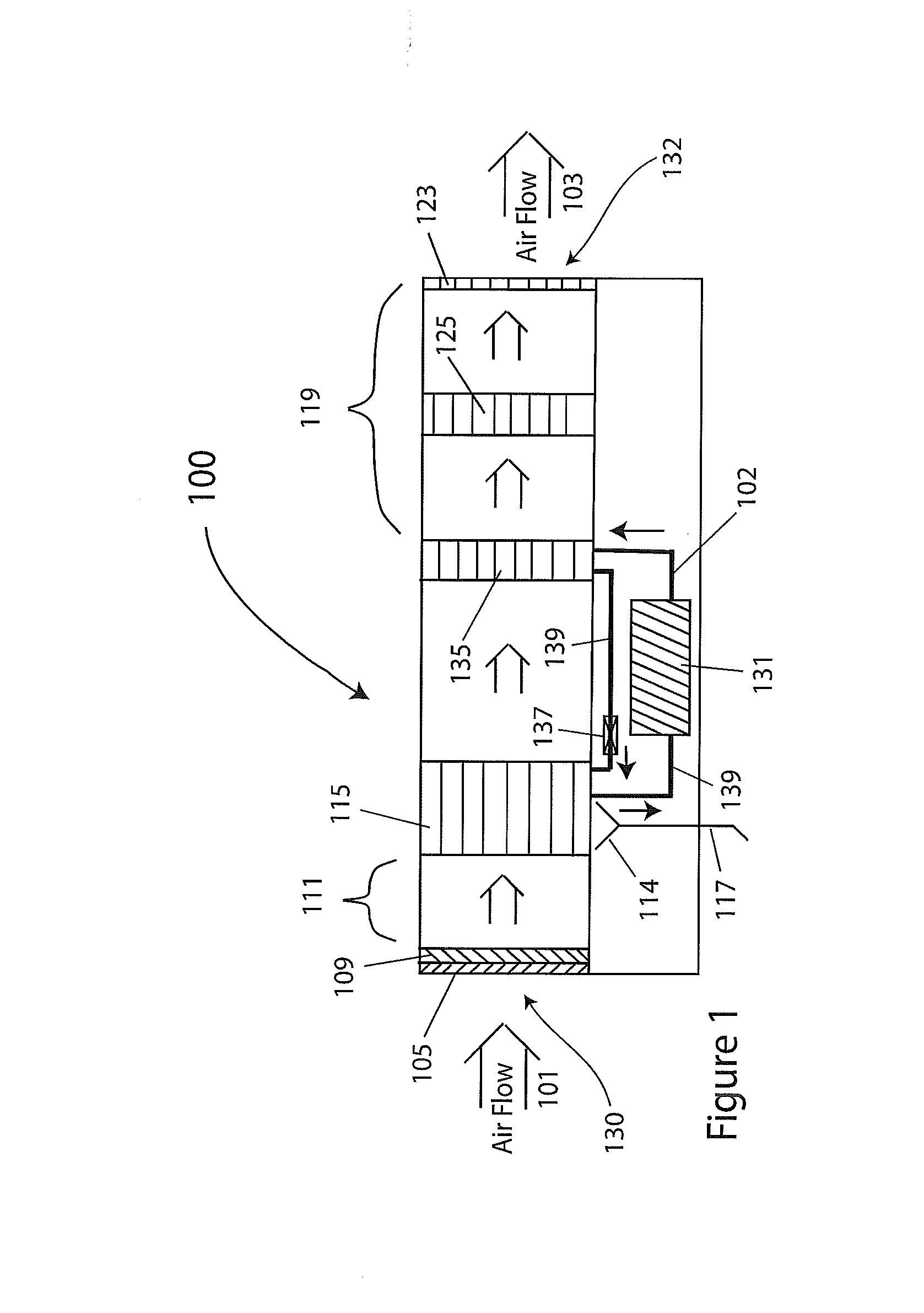

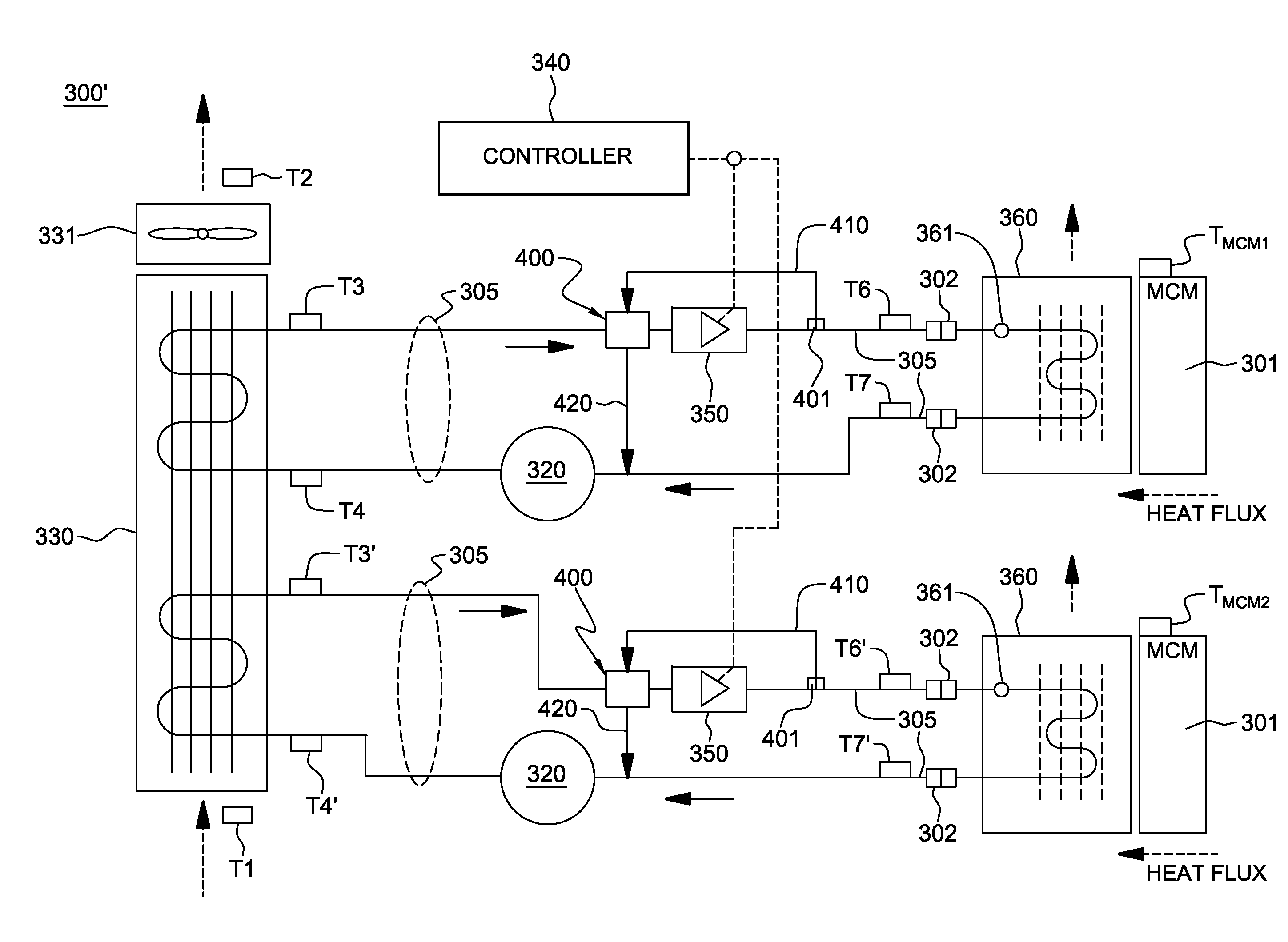

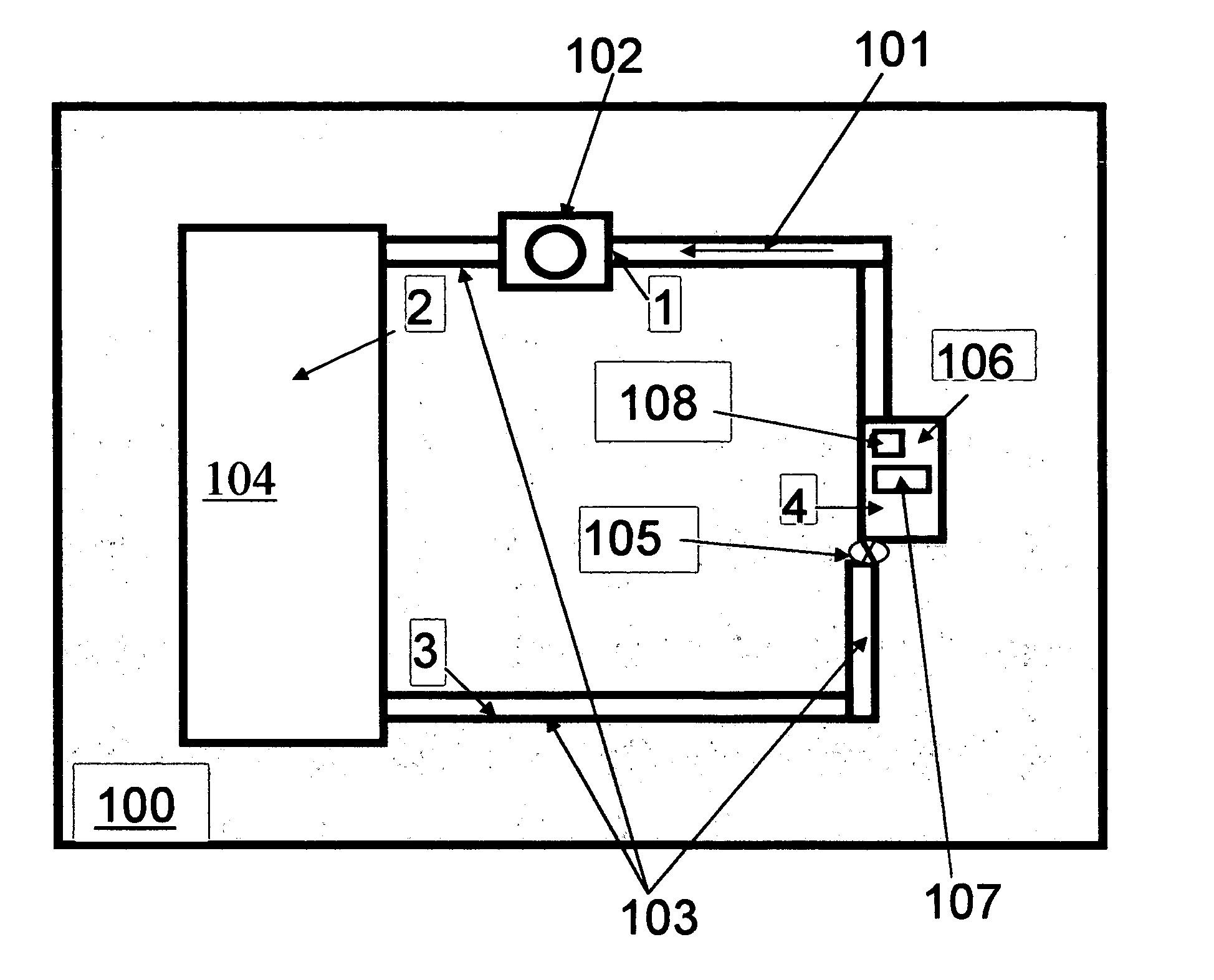

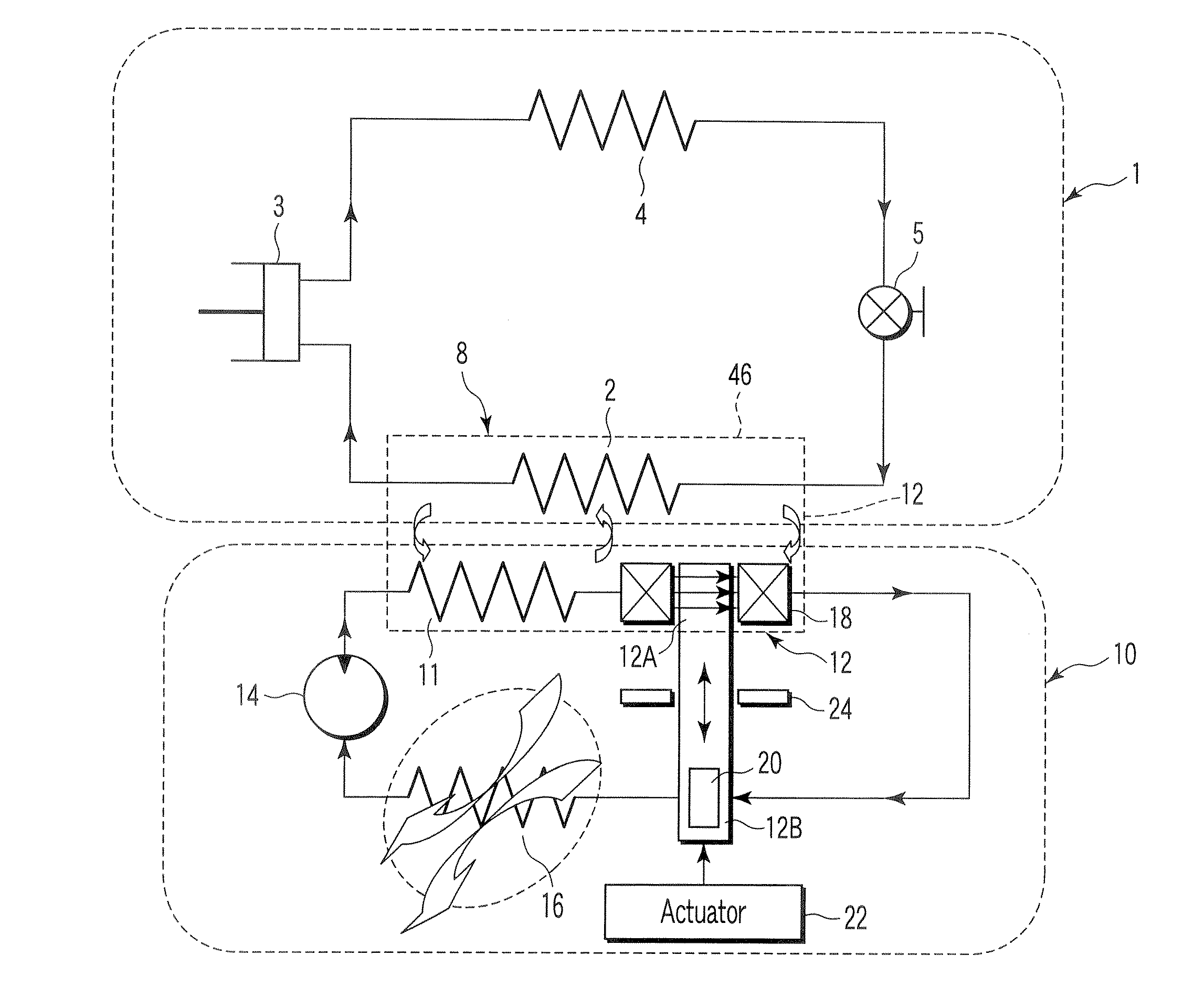

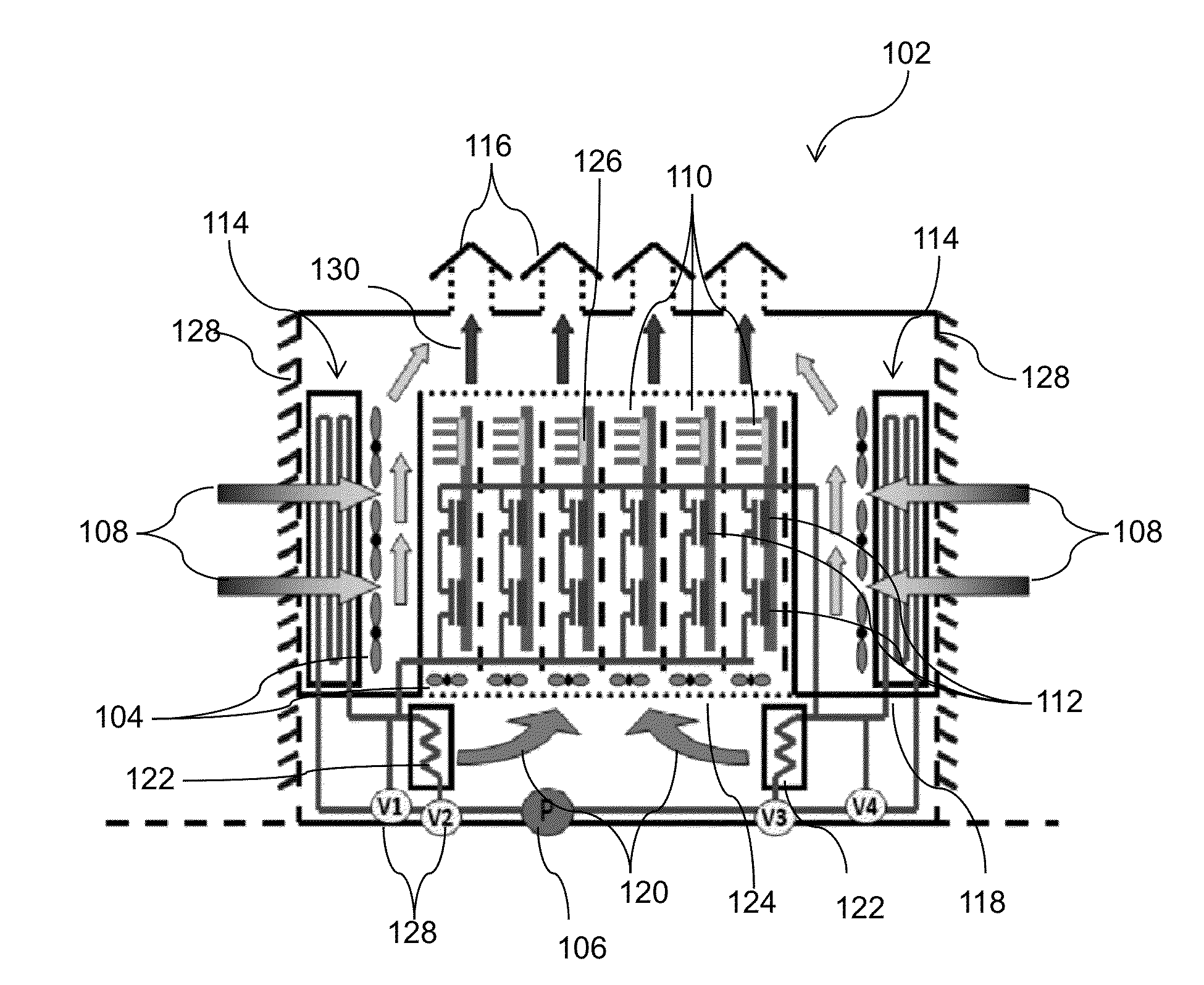

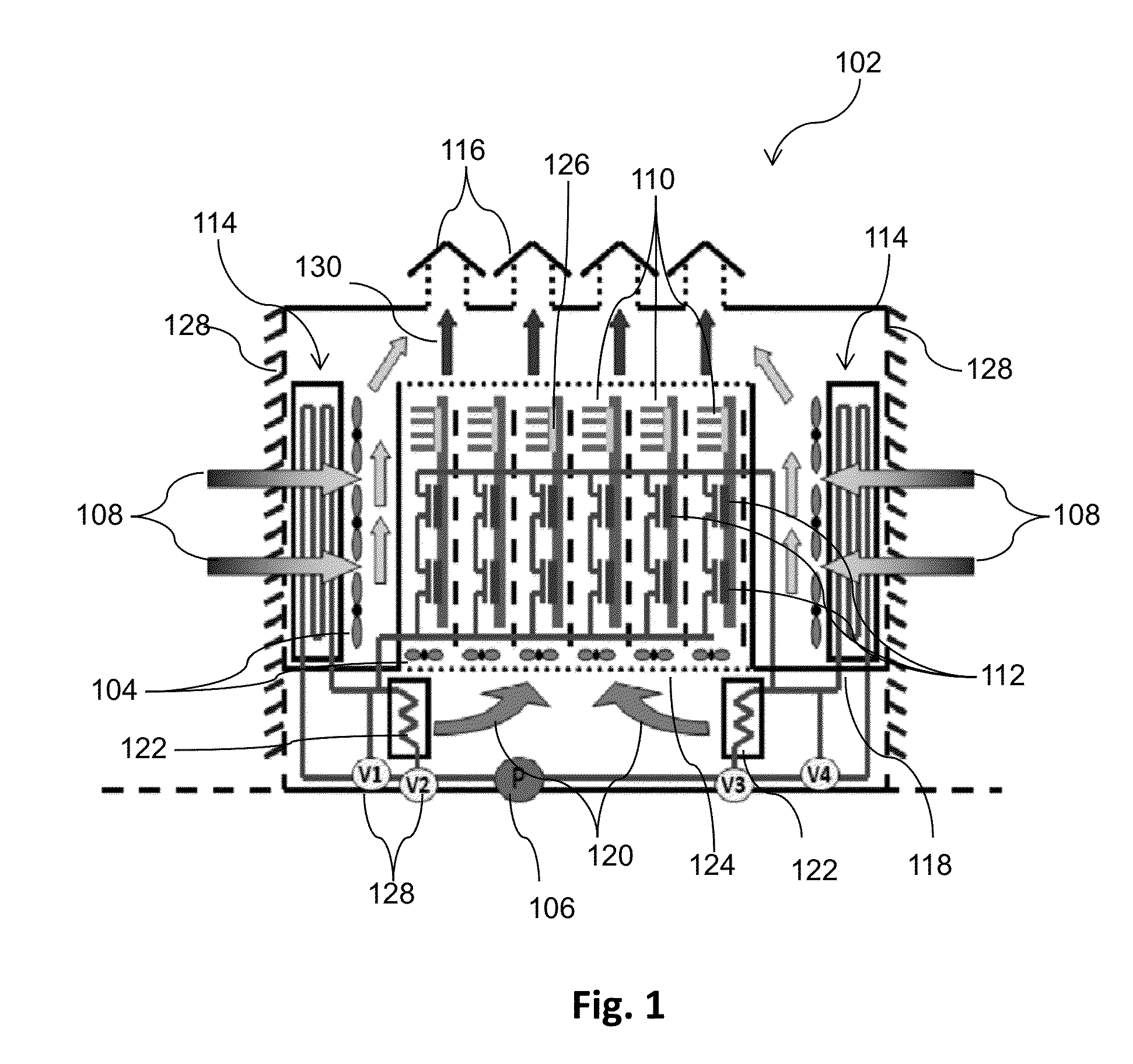

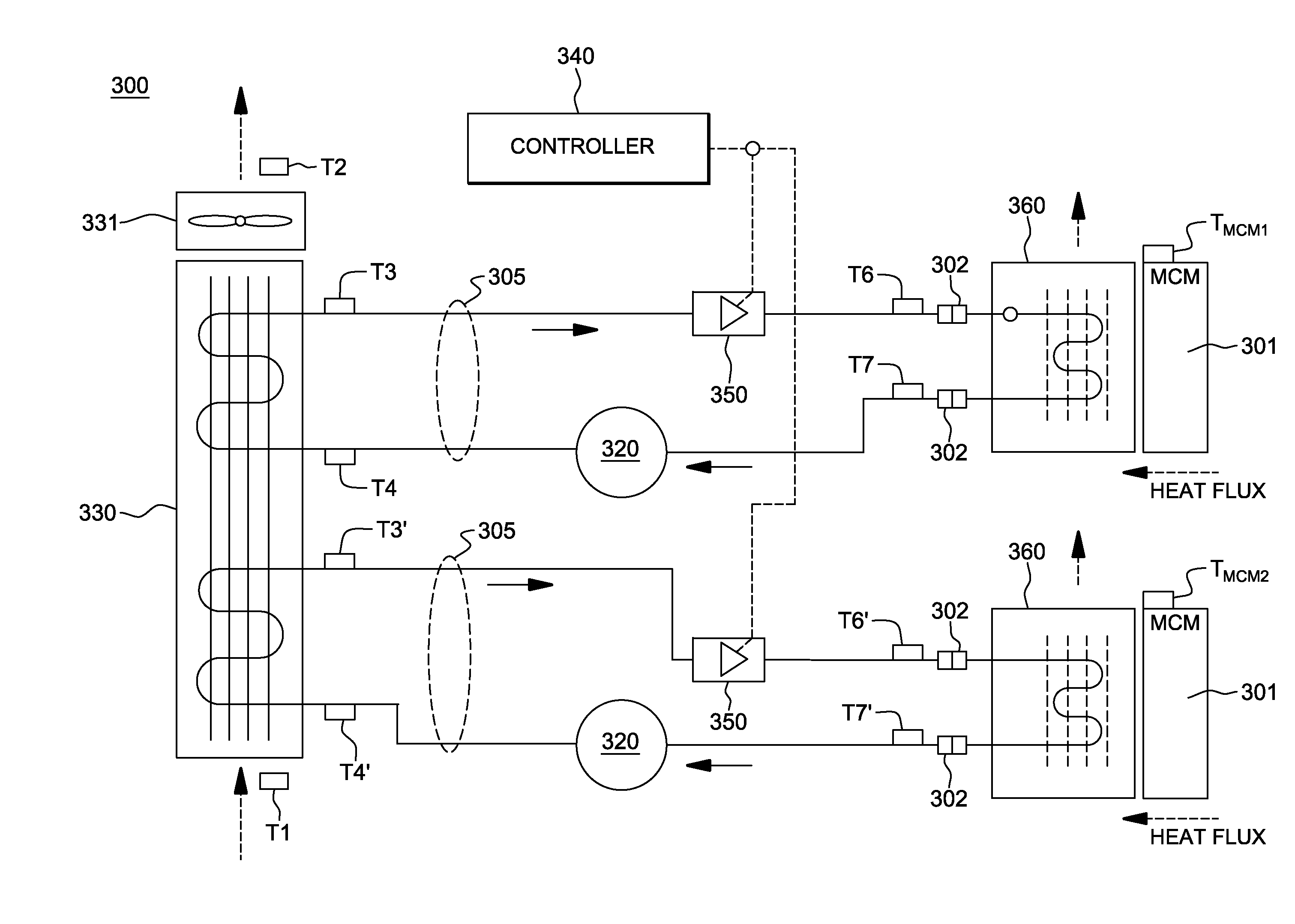

Coolant-buffered, vapor-compression refrigeration with thermal storage and compressor cycling

ActiveUS20120111036A1Improve cooling effectSuppress swingHeat storage plantsCompression machines with non-reversible cycleThermal energy storageEngineering

Owner:IBM CORP

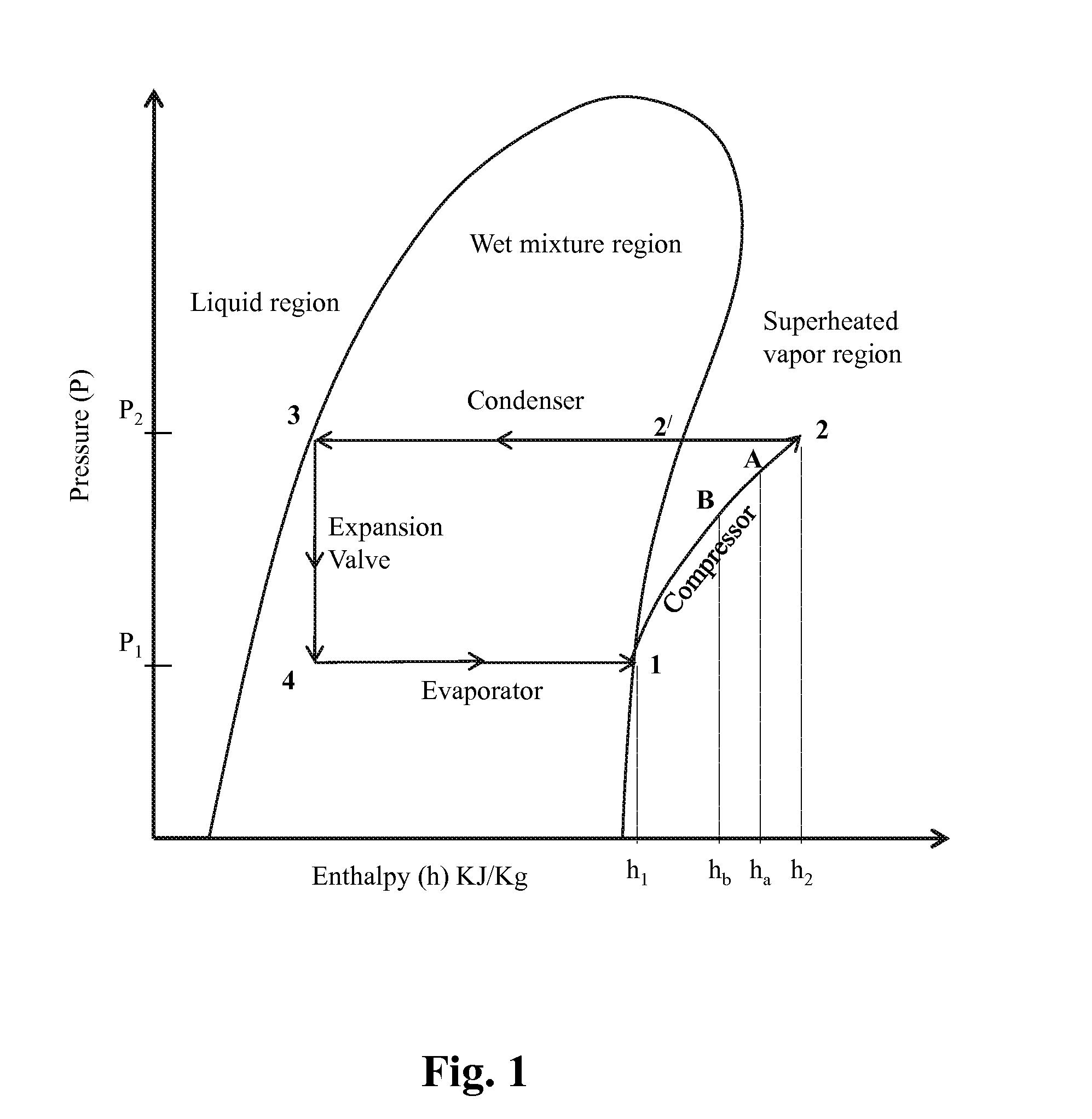

Thermoelectric-enhanced, vapor-compression refrigeration apparatus facilitating cooling of an electronic component

InactiveUS20120111027A1Improve cooling effectOvercomes shortcomingDomestic cooling apparatusMachines using electric/magnetic effectsEngineeringThermodynamic state

Apparatus and method are provided for facilitating cooling of an electronic component. The apparatus includes a refrigerant loop, a compressor coupled to the refrigerant loop, and a controllable thermoelectric array disposed in thermal communication with the refrigerant loop. Refrigerant flowing through the refrigerant loop facilitates dissipation of heat from the electronic component, and the thermoelectric array is disposed with a first portion of the refrigerant loop, residing upstream of the compressor, in thermal contact with a first side of the array, and a second portion of the refrigerant loop, residing downstream of the compressor, in thermal contact with a second side of the array. The thermoelectric array ensures that refrigerant in the refrigerant loop entering the compressor is in a superheated thermodynamic state by transferring heat from refrigerant passing through the second portion to refrigerant passing through the first portion of the refrigerant loop.

Owner:IBM CORP

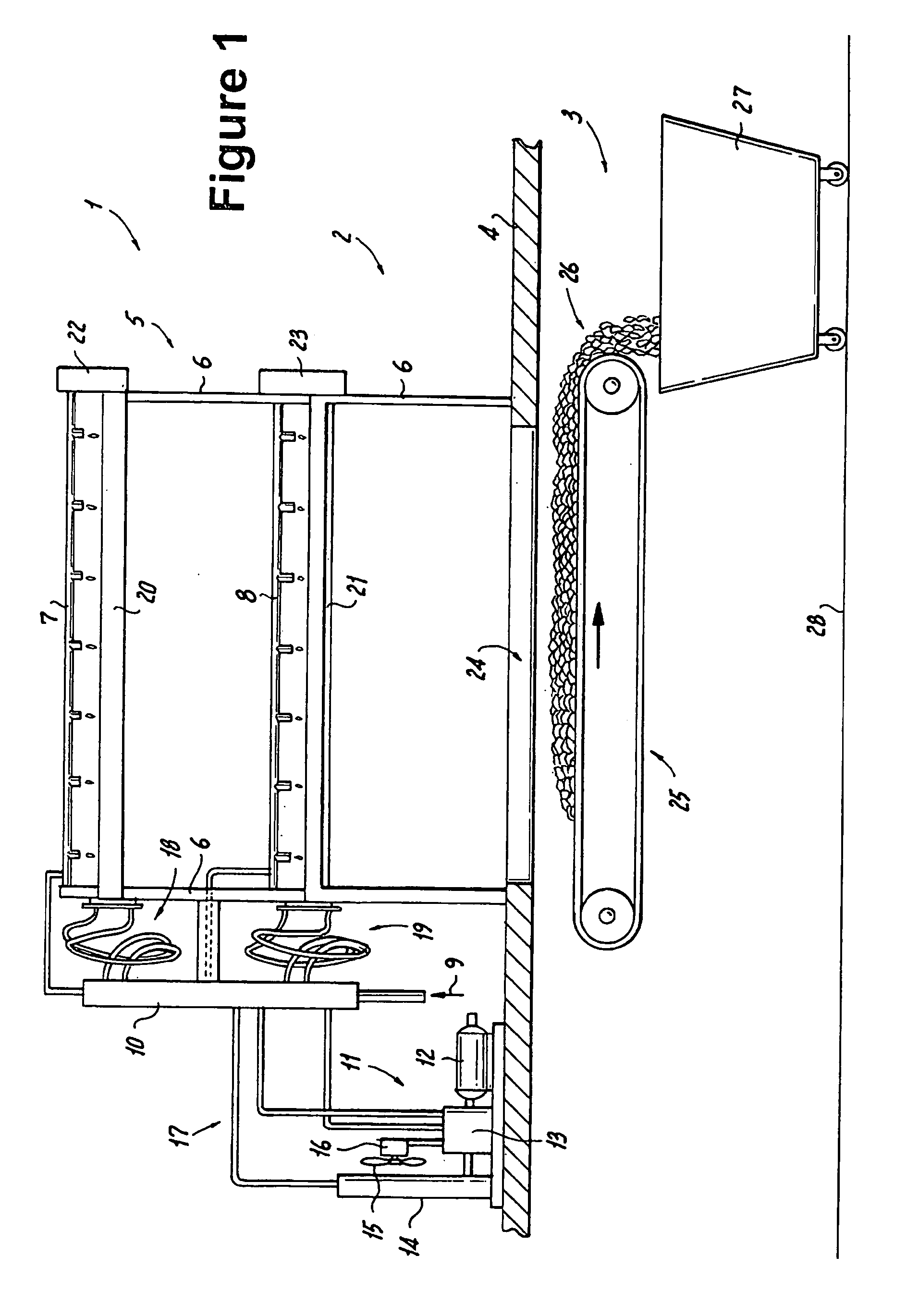

Liquid milk freeze/thaw apparatus and method

InactiveUS7059140B2Extended shelf lifeImprove disadvantagesLighting and heating apparatusIce productionSaline waterSuper cooling

A high throughput, short batch cycle commercial ice making machine produces salt containing, milk containing or beverage containing commercial ice, which resists melting in convenient sizes for mobile food carts, market produce, or fish displays. The machine introduces super-cooled liquid, that is in a liquid state while exposed to a temperature below freezing, into a batch of pre-formed hollow molds of one or more horizontally oriented ice forming freezing trays oriented horizontally. Using vapor compression refrigeration, the machine produces a plurality of supercooled ice segments in pockets within the freezing tray. The supercooled ice segments are rapidly subjected to a short, temporary contact with a high heat source from a sleeve integral with the freezing tray compartments, along a peripheral bottom surface of the ice segment accommodating freezing tray molds. This temporarily melts a bottom surface of each ice segment, lubricating it and loosening it. Then the machine rotates the freezing tray containing the batch of ice segments about its horizontally oriented axis to a vertically oriented dump position, thereby dumping the temporarily heated ice segments into the freezing tray. The ice cubes thus formed may be fresh water, salt water or beverage containing ice cubes.

Owner:ZEVLAKIS ANASTASSIA

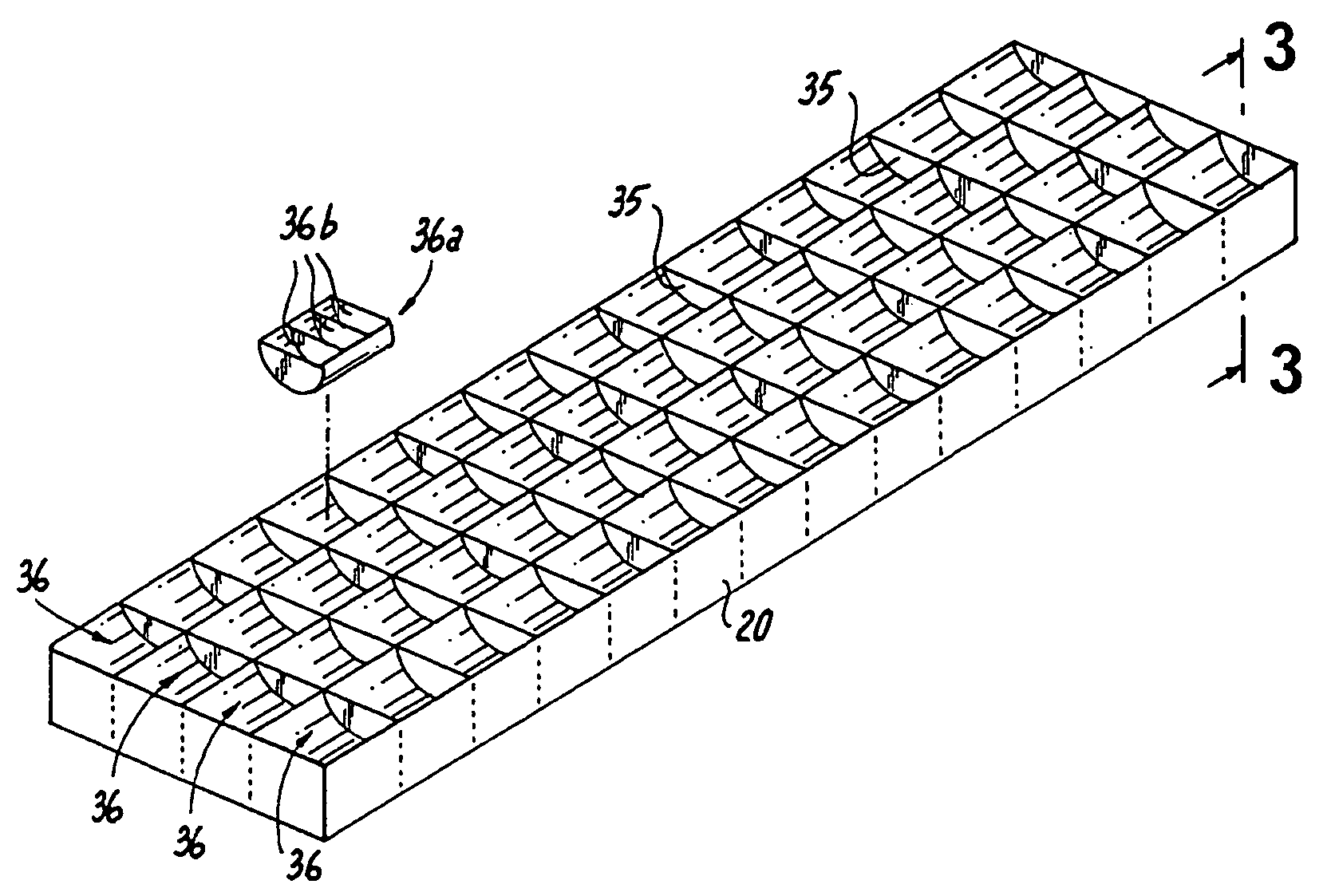

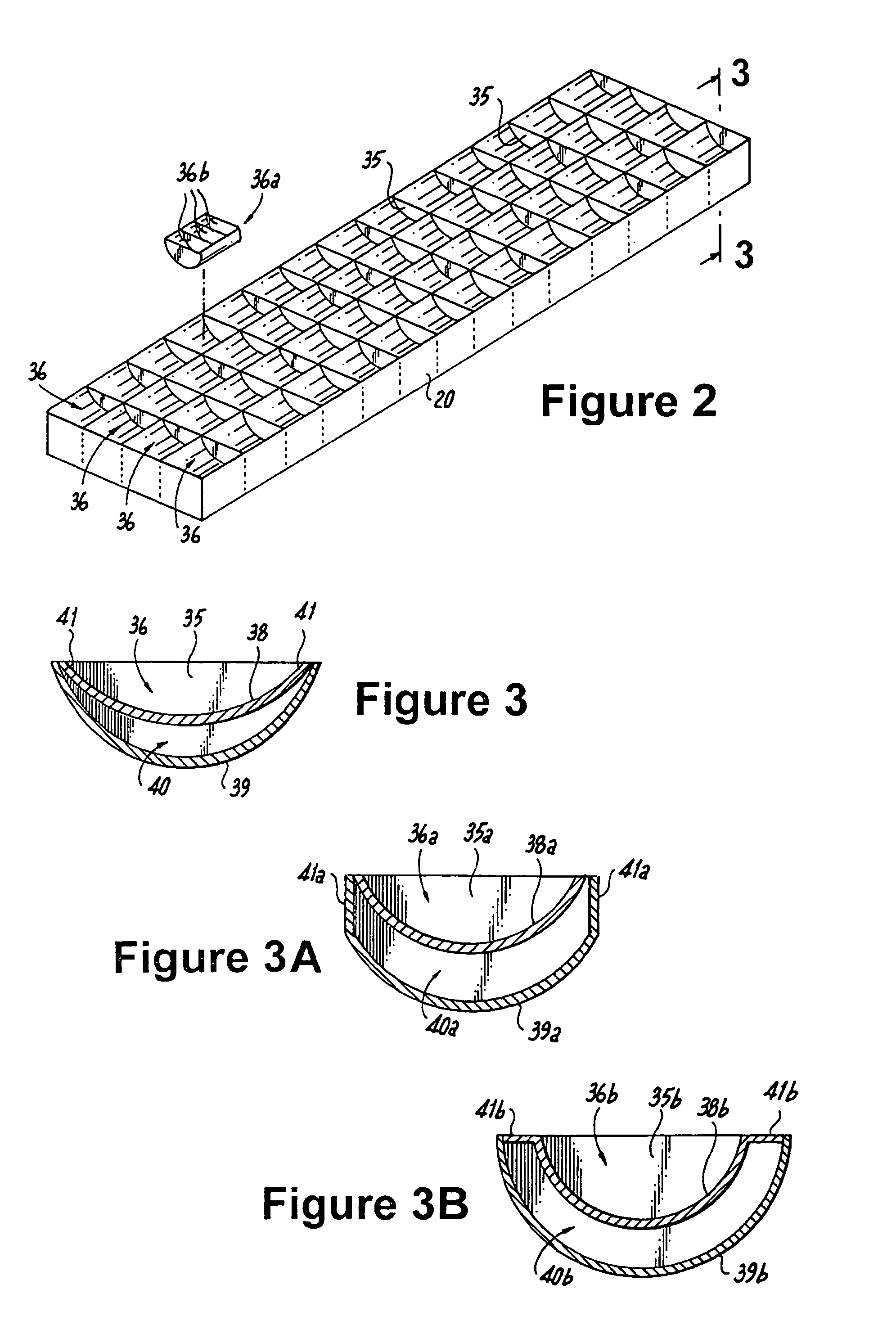

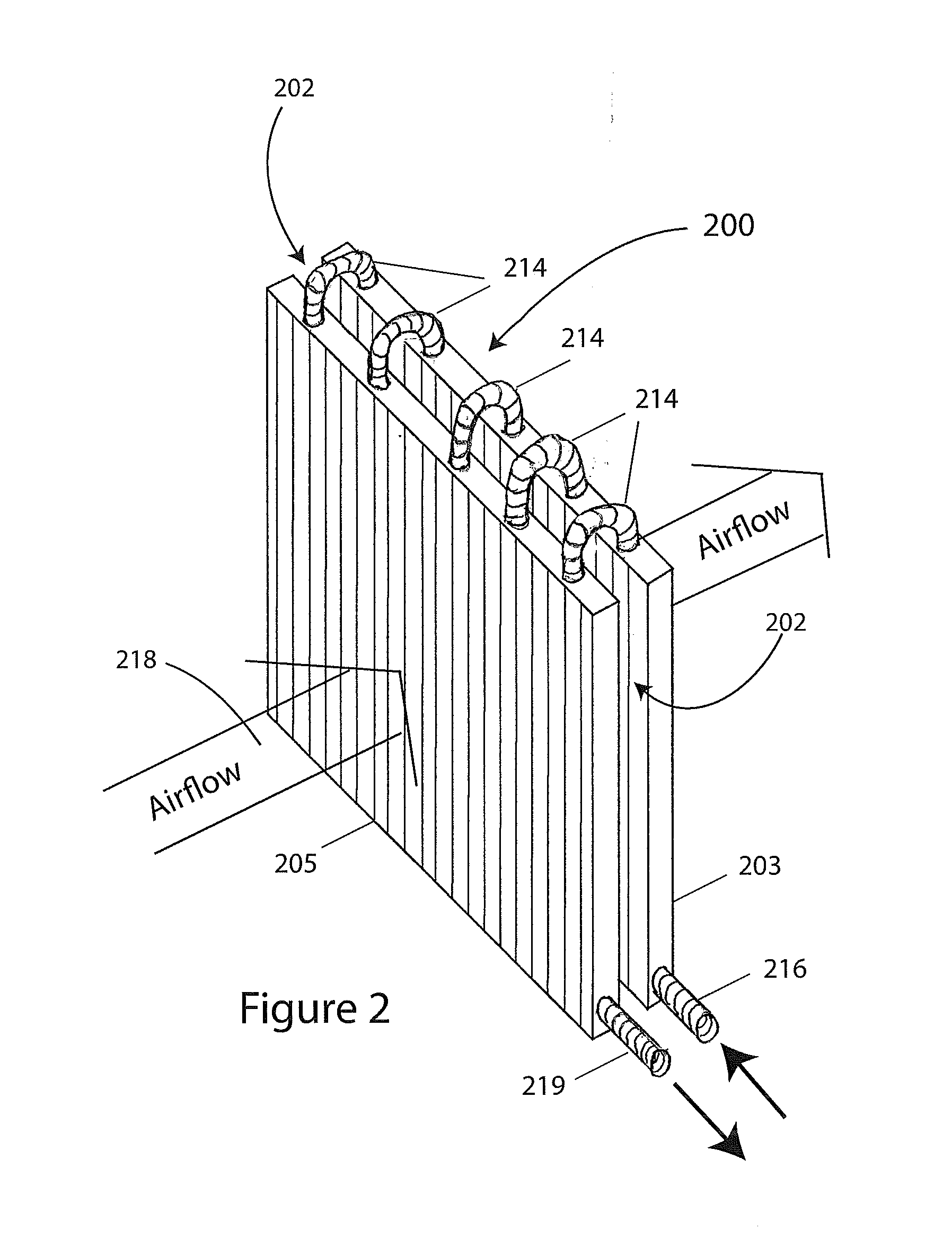

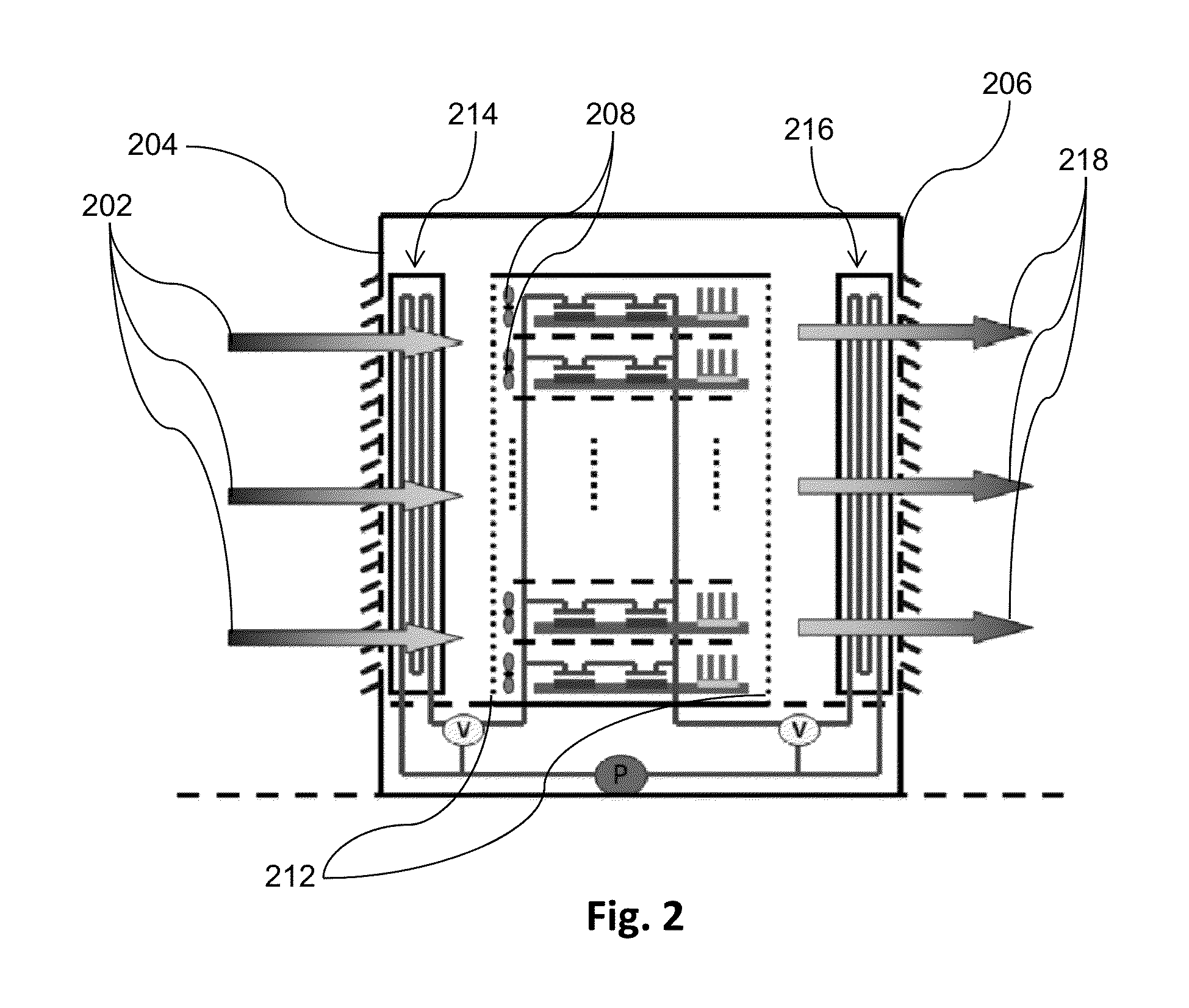

Multiple Panel Heat Exchanger

InactiveUS20130312451A1Easy to controlSimple processCompression machines with non-reversible cycleEvaporators/condensersEngineeringVapor-compression refrigeration

A multiple panel heat exchanger and atmospheric water harvester using the same is provided. The multiple panel heat exchanger includes two or more heat exchange panels arranged in side-by-side series with their major cross sectional areas normal to airflow across the heat exchanger. The heat exchange panels are fluidically connected in series and with a first heat exchange panel in the series having a heat exchange fluid inlet into the heat exchanger and a last heat exchange panel in the series having a heat exchange fluid outlet from the heat exchanger. The multiple panel heat exchanger is suited for a heat exchanger in a refrigeration circuit, such as an evaporator in a vapor-compression refrigeration circuit. An atmospheric water harvester including the multiple panel heat exchanger is also provided.

Owner:MAX MICHAEL D

Contaminant separator for a vapor-compression refrigeration apparatus

InactiveUS20130091867A1Facilitate depositionFacilitates componentMetal-working apparatusMachines using electric/magnetic effectsEngineeringElectronic component

Apparatuses and methods are provided for facilitating cooling of an electronic component. The apparatus includes a vapor-compression refrigeration system, which includes an expansion component, an evaporator, a compressor and a condenser coupled in fluid communication. The evaporator is coupled to and cools the electronic component. The apparatus further includes a contaminant separator coupled in fluid communication with the refrigerant flow path. The separator includes a refrigerant cold filter and a thermoelectric array. At least a portion of refrigerant passing through the refrigerant flow path passes through the cold filter, and the thermoelectric array provides cooling to the cold filter to cool refrigerant passing through the filter. By cooling refrigerant passing through the filter, contaminants solidify from the refrigerant, and are deposited in the cold filter. The separator may further include a refrigerant hot filter coupled to a hot side of the thermoelectric array for further filtering the refrigerant.

Owner:IBM CORP

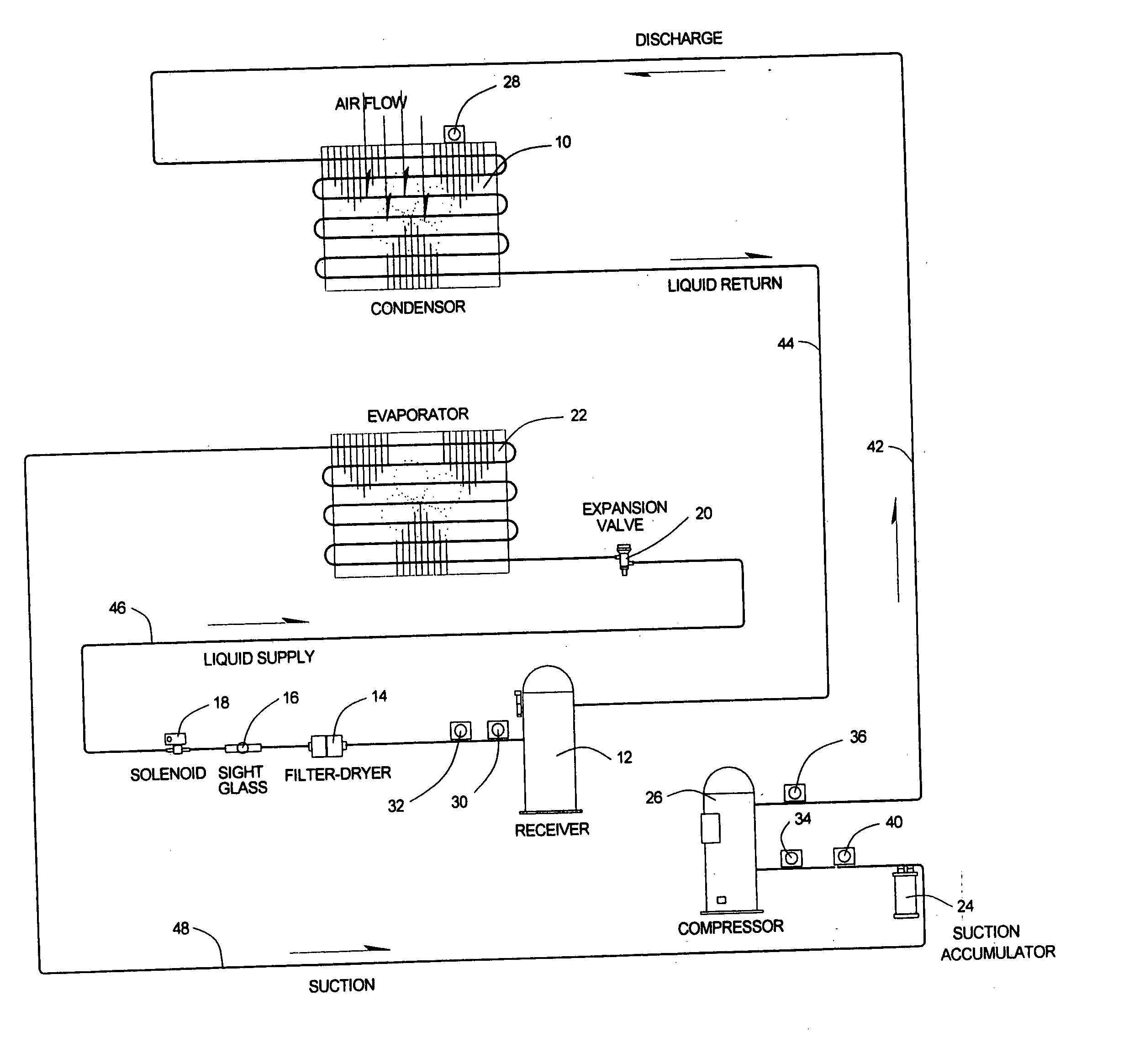

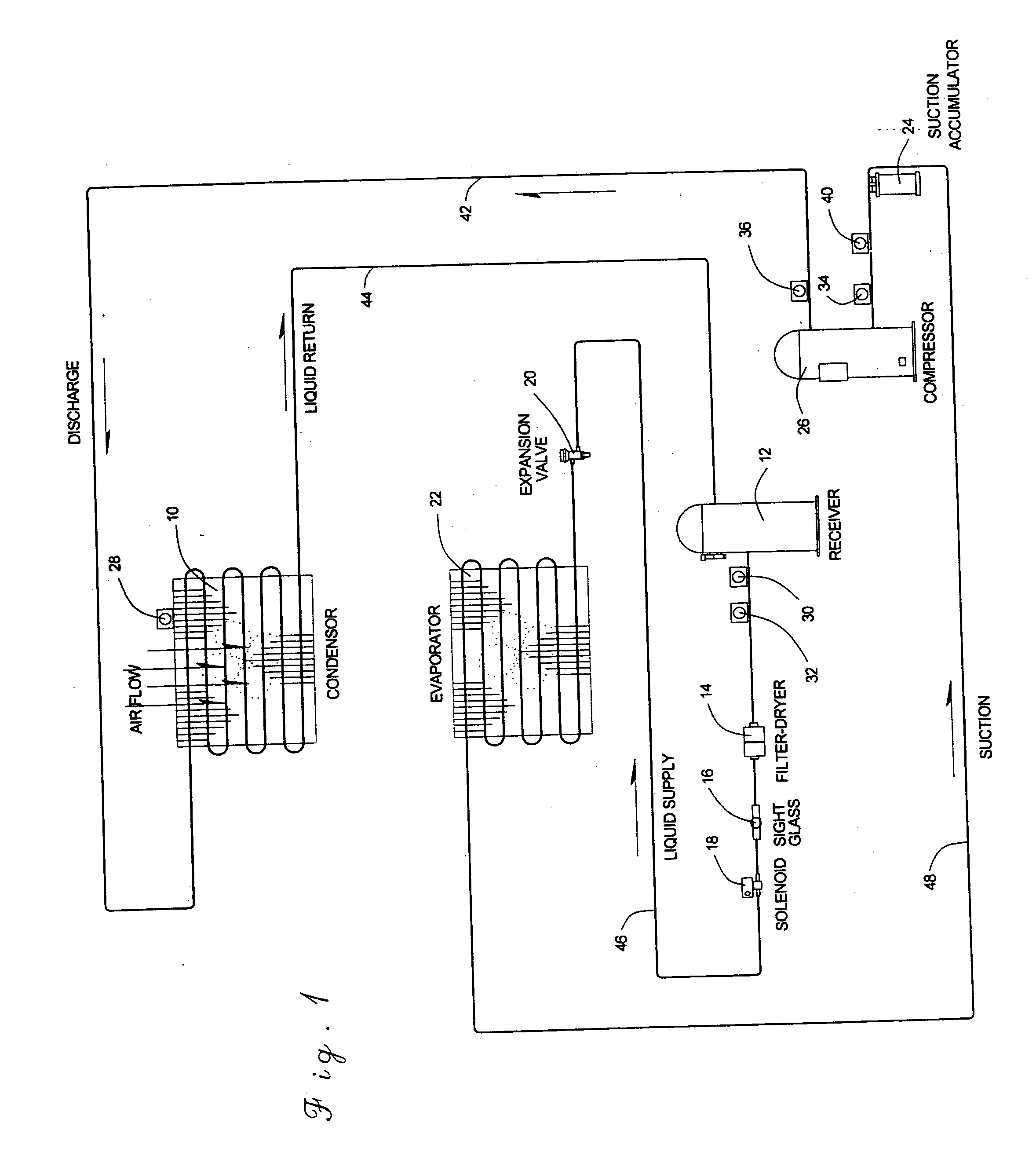

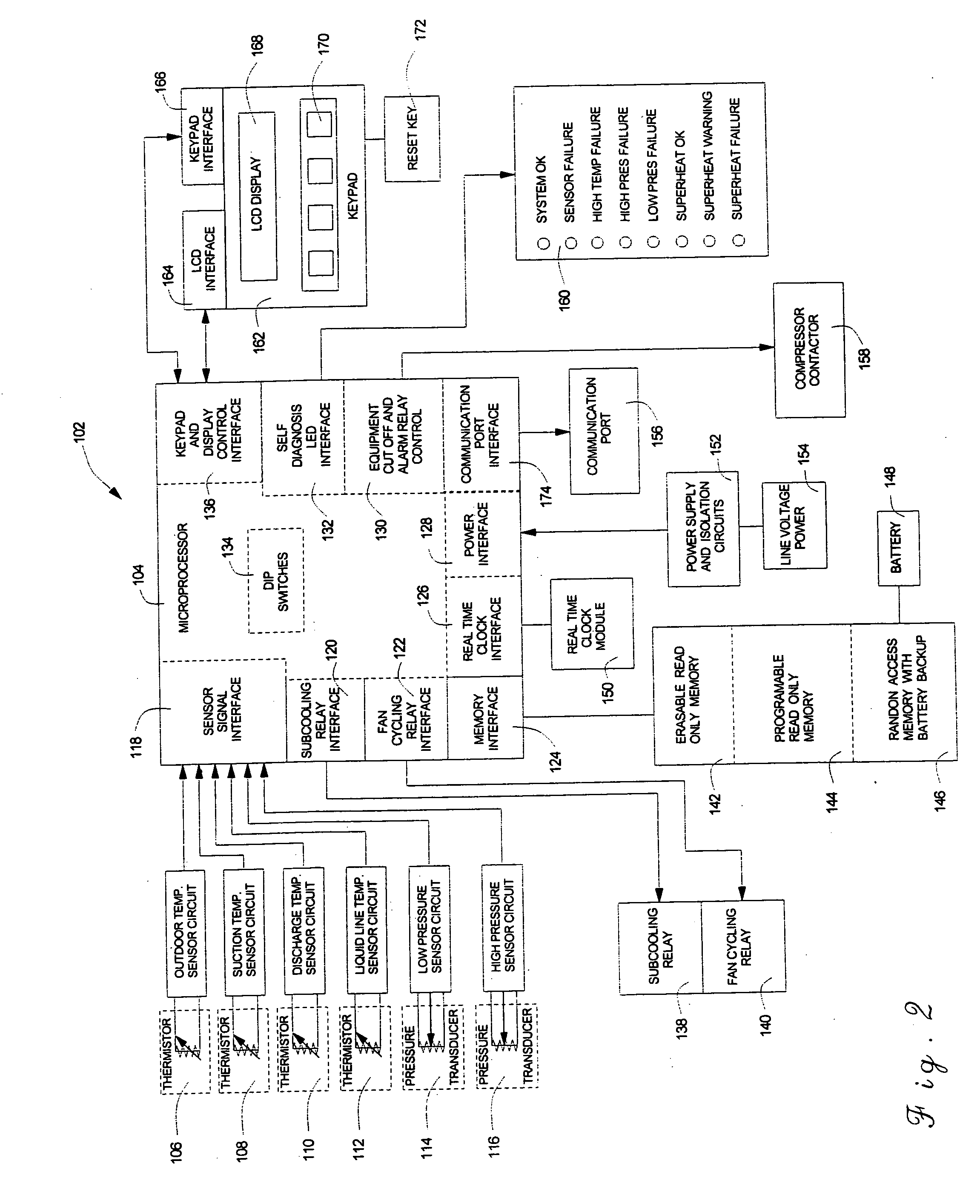

Refrigeration mechanical diagnostic protection and control device

InactiveUS20060075771A1Improve system efficiencyIncrease subcoolingCompression machines with non-reversible cycleEvaporators/condensersService personnelMonitoring system

In vapor compression refrigeration systems a mechanism and method are provided for protecting a compressor from failures related to lack of superheat, loss of lubricating oil and other system malfunctions. Also provided is a mean of monitoring system conditions and providing service personnel with a quick manner of diagnosing problems.

Owner:TRACEY GEORGE R JR +2

Solar-Powered Air Conditioner Using a Mixture of Glycerin, Alcohol and Water to Store Energy

A solar-powered air conditioning system comprising an energy-storage medium made of a mixture of 5%-20% glycerin, 2.5%-10% alcohol and water in a thermally insulated container is disclosed. While frozen, the said energy storage medium becomes slurry of thin sheets of ice dispersed in liquid, which will not damage the container and the heat-exchange pipes. The system uses a solar photovoltaic panel to directly drive a vapor-compression refrigeration unit to freeze the said energy storage medium. A ventilation system forces air through a heat-exchange coil in the said energy-storage medium, to generate chilled air to cool the space. In the absence of sunlight, the energy-storage medium can keep frozen for days. With or without sunlight, the flowing air chilled by the frozen energy-storage medium continues to cool the room or the entire building.

Owner:CHEN CHENGJUN JULIAN

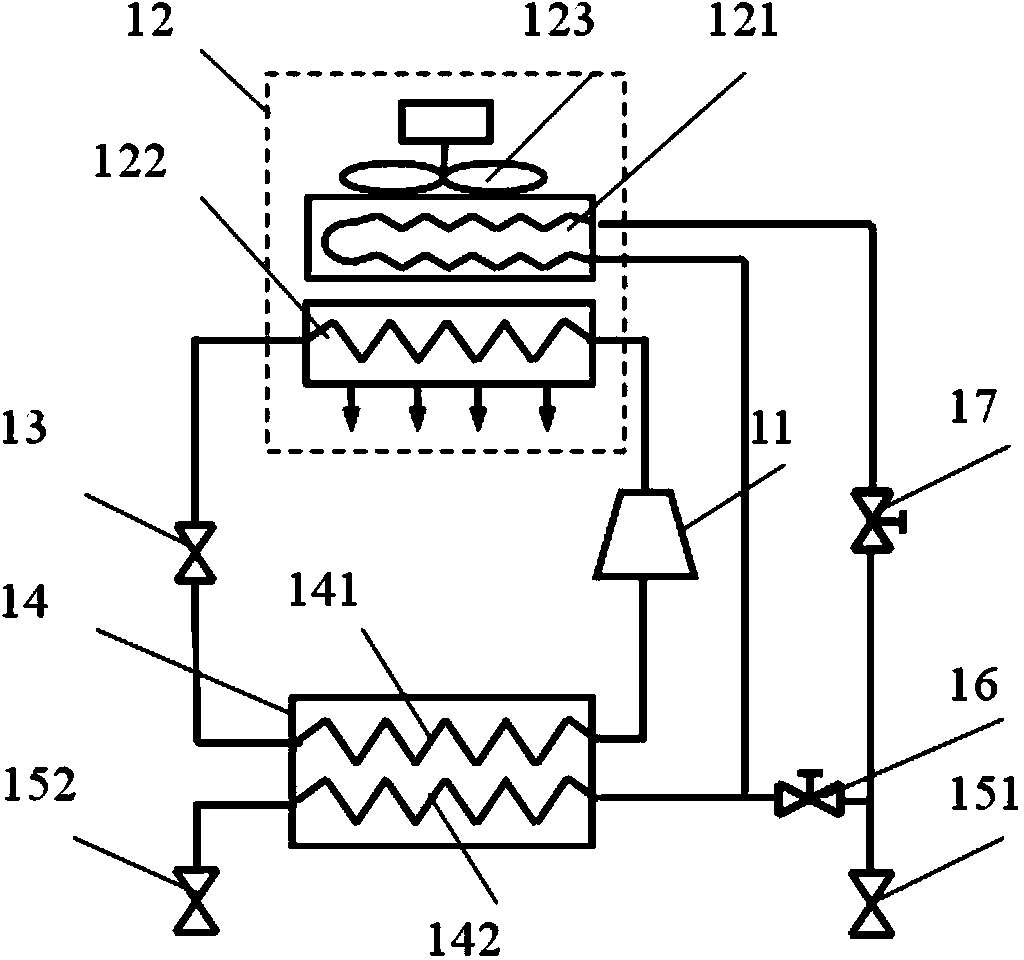

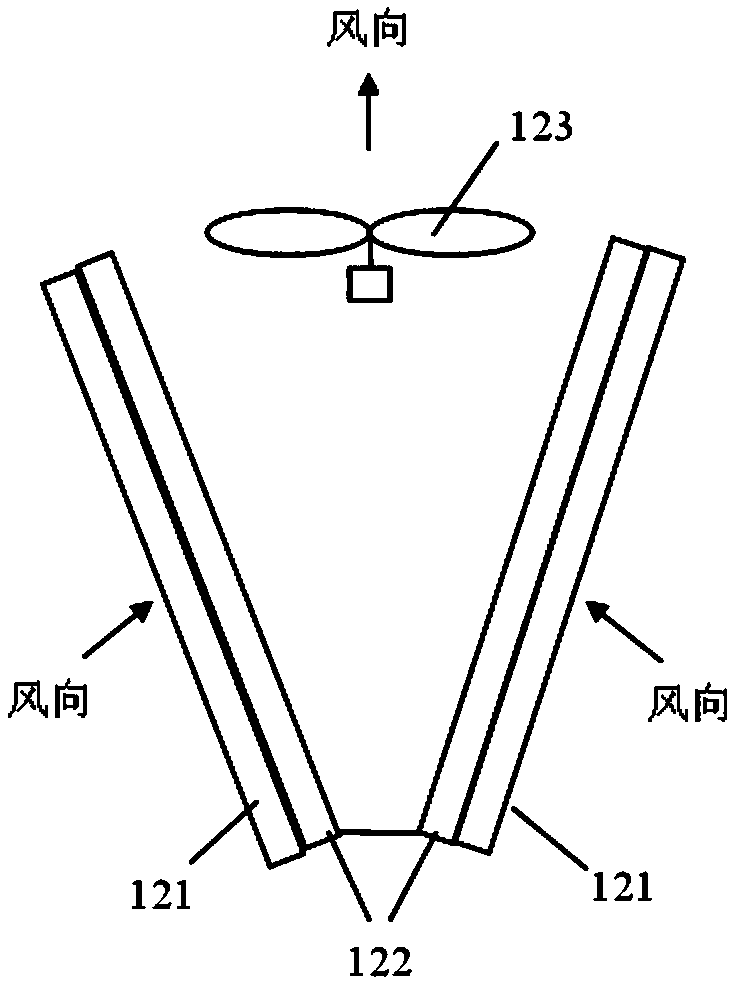

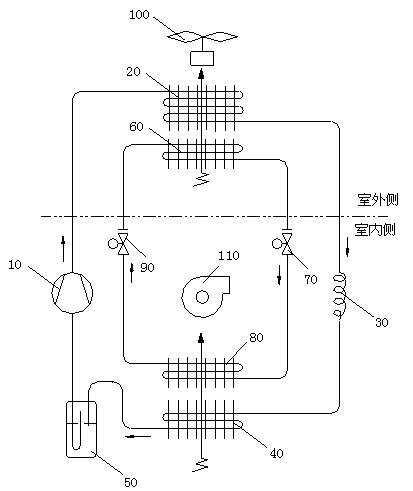

Split type refrigeration and heat pipe heat exchanging cycle coupling apparatus and cycle method

InactiveCN101457999AExtended service lifeGuaranteed cleanlinessCompression machines with non-reversible cycleIndirect heat exchangersAtmospheric airCoupling

The invention provides a split refrigeration and thermo tube heat exchange cycle coupling device and a cycling method thereof and relates to a coupling method of vapor-compression refrigeration cycle and thermo tube heat exchange cycle. The split refrigeration and thermo tube heat exchange cycle coupling device can discharge heat energy in an enclosed environment with an inner heat source into outdoor atmosphere all the year round. When the temperature difference between the enclosed environment and the outdoor atmosphere is larger than 10 DEG C, the device can also switch the cycle of the invention into a thermo tube heat exchange cycle mode and discharge the heat energy in the enclosed environment with the inner heat source into the atmosphere by a split outdoor condenser (as a condensing segment of the thermo tube) and an indoor evaporator (as an evaporating segment of the thermo tube). At the time, only indoor and outdoor fan motor power is consumed, and the refrigeration cycle compressor is not required to be operated. When the temperature difference between the enclosed environment and the outdoor atmosphere is less than 10 DEG C, the split refrigeration and thermo tube heat exchange cycle coupling device switches the thermo tube heat exchange cycle into a vapor compression refrigeration cycle mode and discharge the heat energy in the enclosed environment with the inner heat source into the atmosphere from the refrigeration cycle.

Owner:SOUTHEAST UNIV

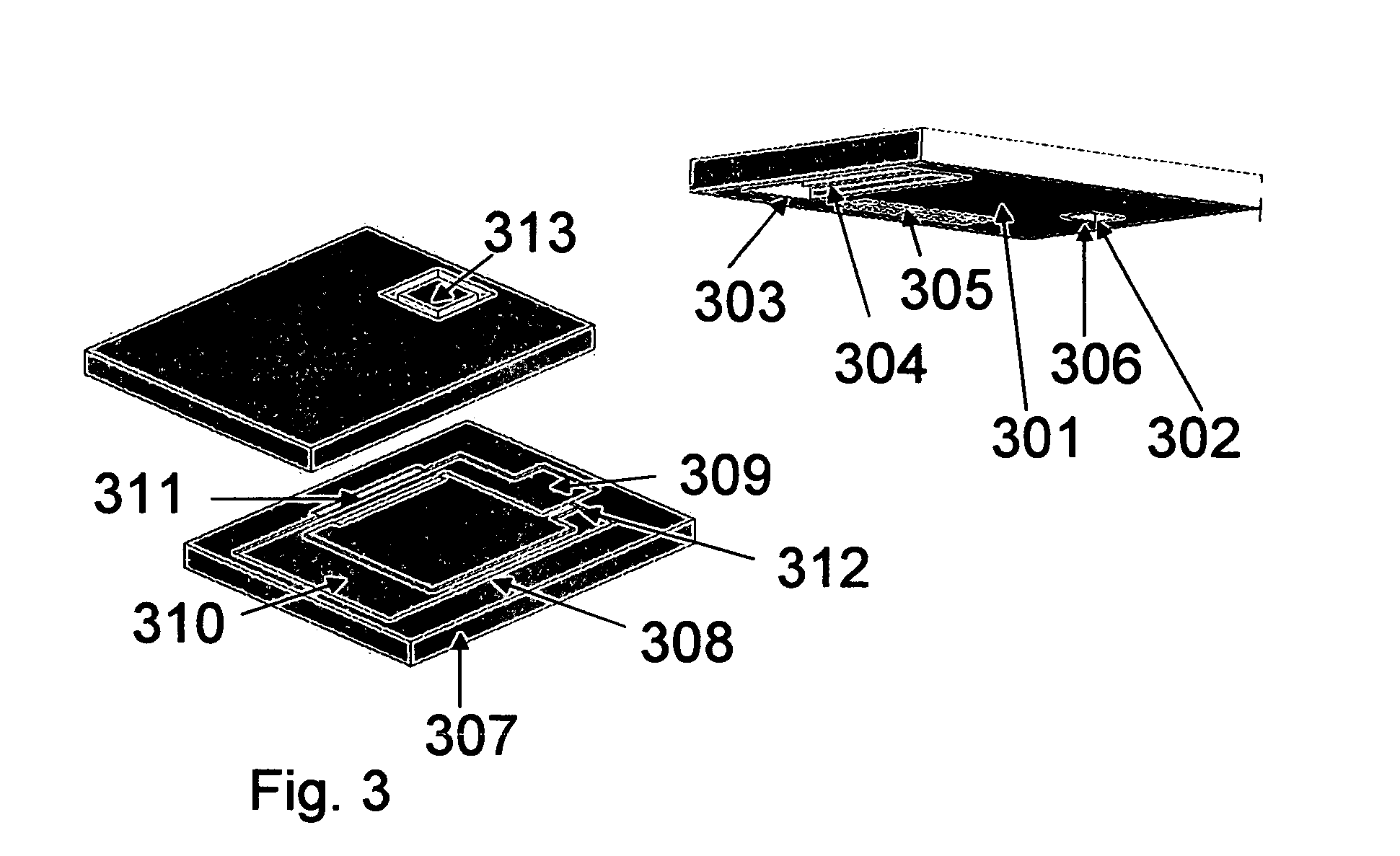

MEMS based micro vapor compression refrigeration system for microelectronic and photonic thermal control

InactiveUS20050144968A1Compression machines with non-reversible cycleRefrigeration devicesThermoelectric coolingVolumetric Mass Density

A micro-refrigerator is fabricated using Micro-Electro Mechanical Systems processing and is used to thermally control photonic or microelectronic circuits. Temperatures below local ambient are possible due to the refrigeration capability of the device and unwanted parasitic heat such as from the walls or lid of an enclosure is minimized due to the small size of the cooled mounting area for the integrated circuit. Localized cooling is provided by jets of vapor droplet mixture controlled to impinge directly onto the hottest regions of a microelectronic or photonic integrated circuit allowing greater circuit density and thermal dissipation at isolated regions within the integrated circuit and advantageously improving performance. Methods of manufacturing micro-scale refrigerator elements including the compressor, evaporator and condenser are defined. This device is a direct improvement over the commonly used thermoelectric cooler for thermal control of microelectronic or photonic devices.

Owner:SHAKESPEARE WALTER JEFFREY

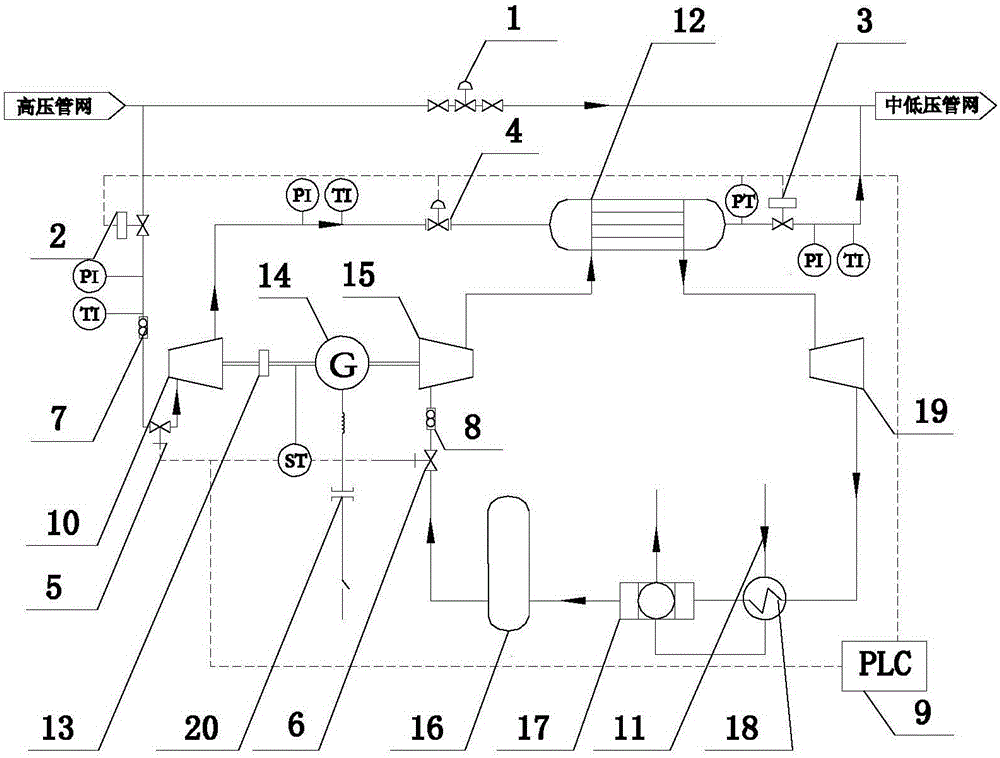

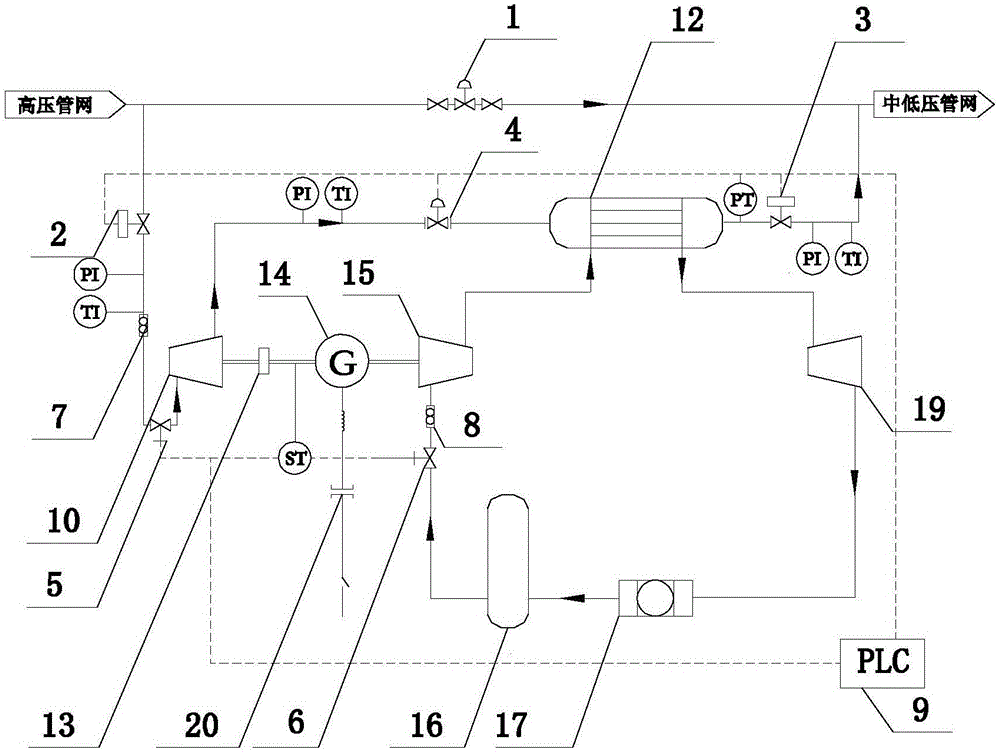

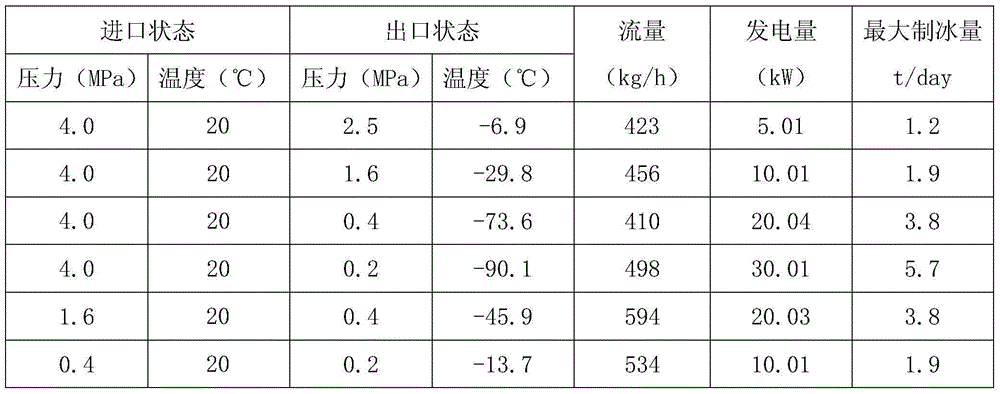

Integrated device capable of achieving expansion power generation and compression refrigeration through natural gas pressure

InactiveCN105114131AReduce volumeReduce weightIce productionEfficient regulation technologiesControl systemElectric power system

Owner:BEIJING GAS GRP +1

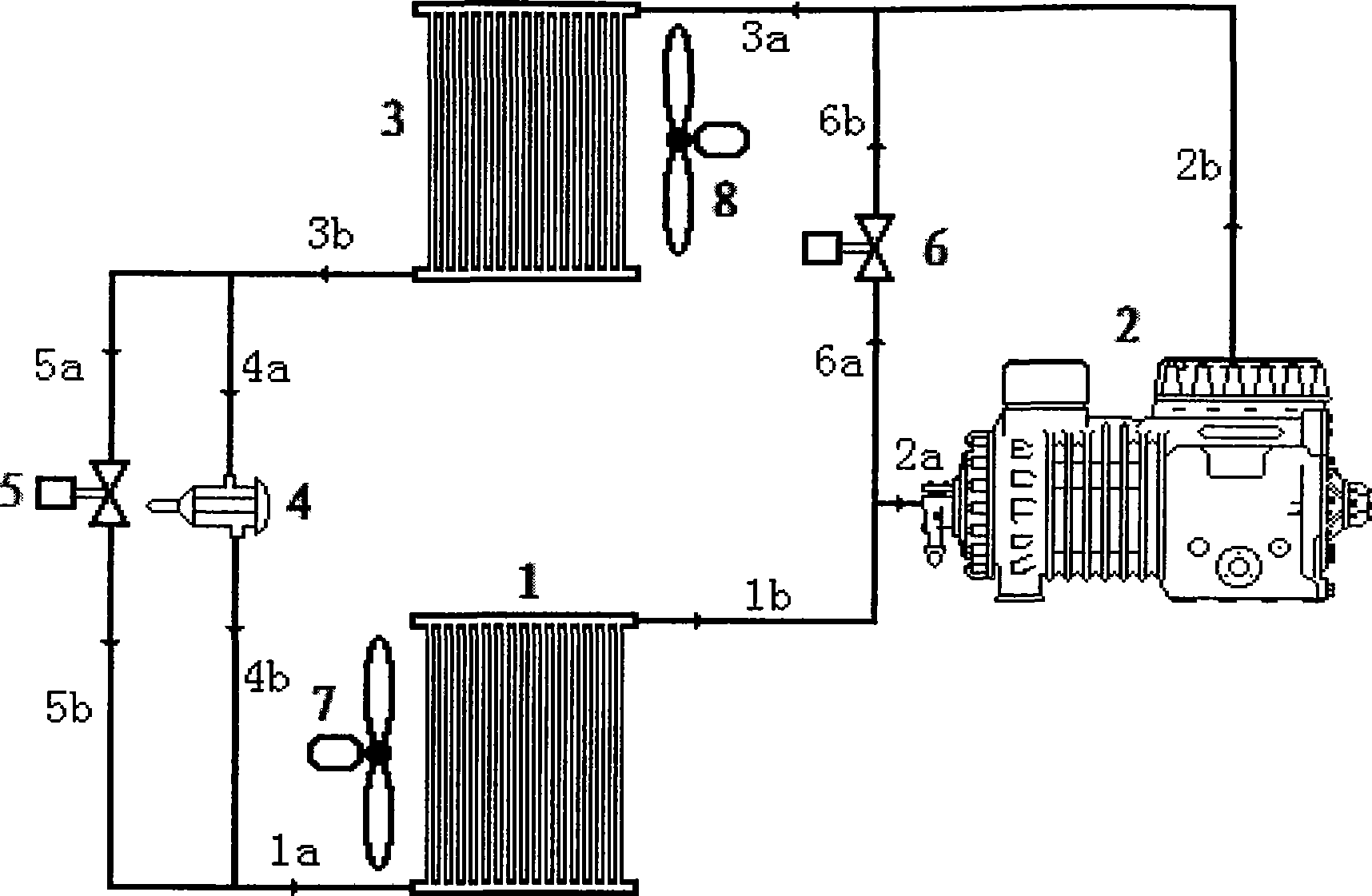

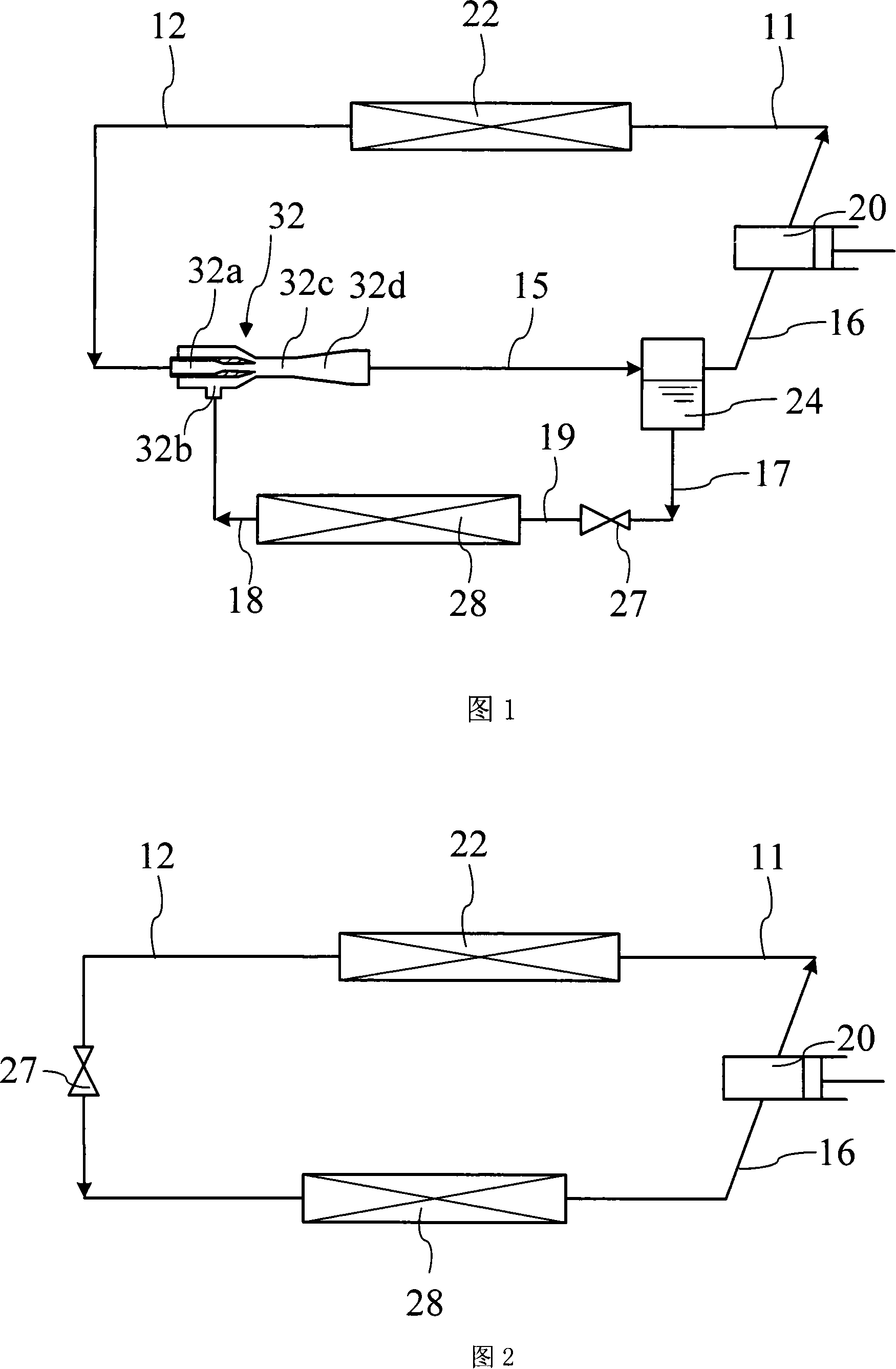

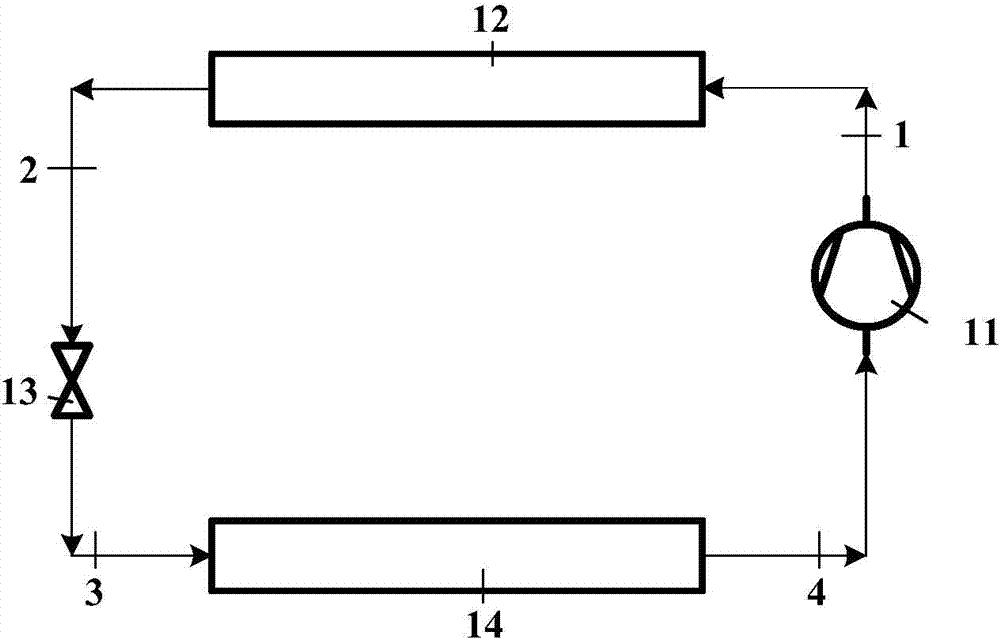

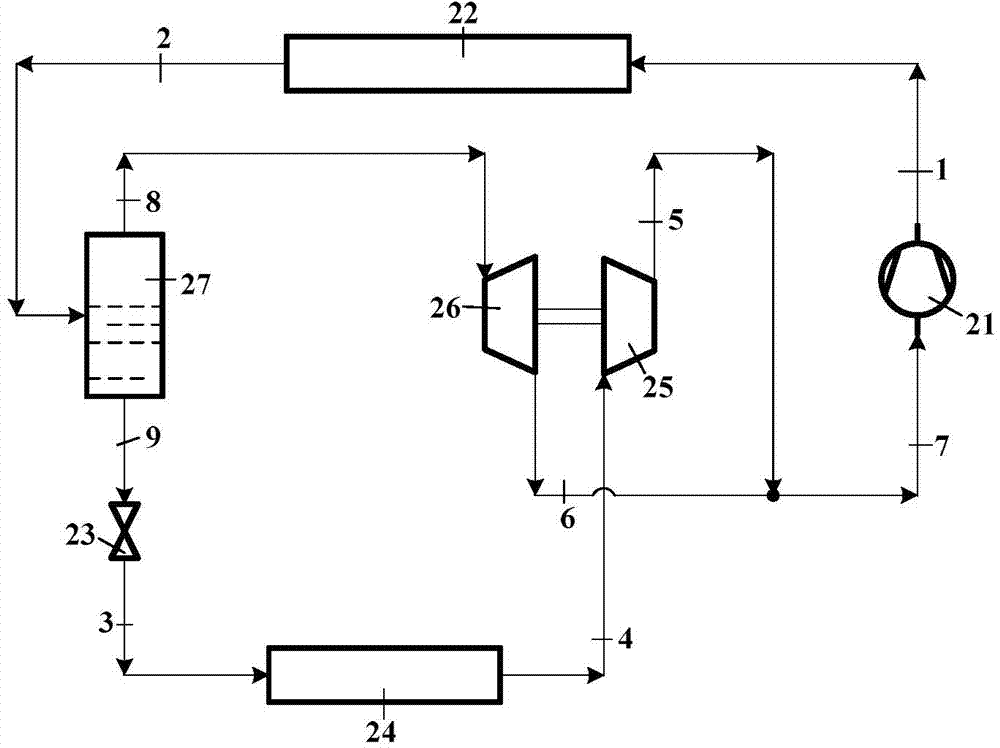

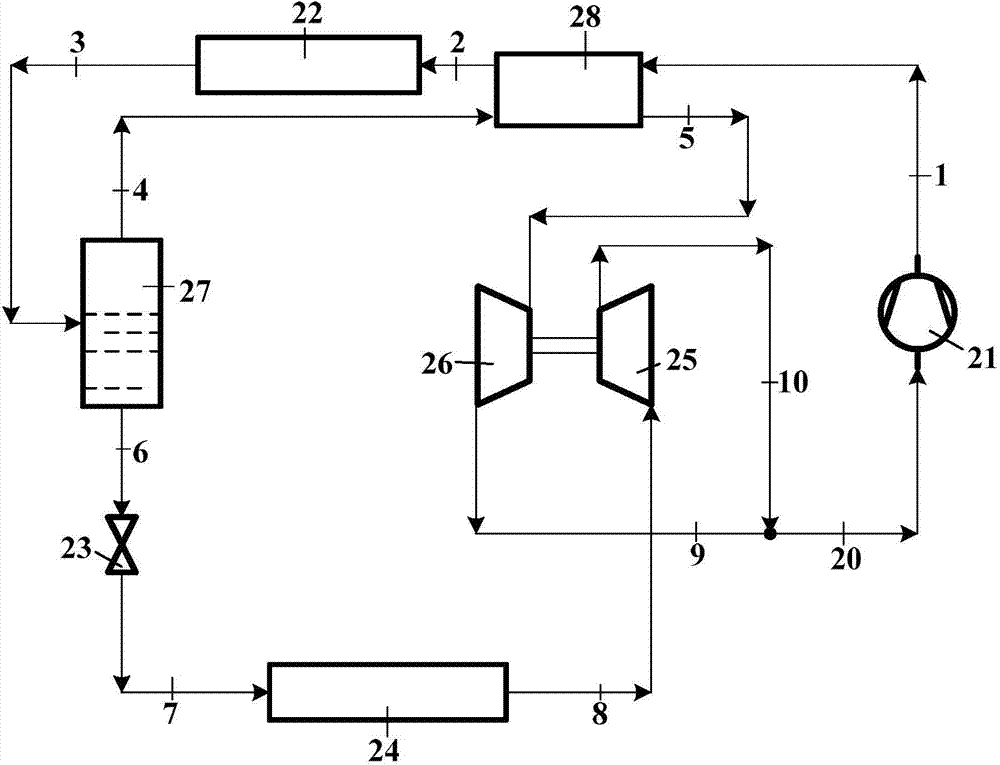

Device and method for combined ejection refrigeration and vapor compression refrigeration cycle

InactiveCN101825372AImprove the cooling factorImprove energy savingRefrigeration machinesEngineeringRefrigeration

The invention relates to a device and a method for the combined ejection refrigeration and vapor compression refrigeration cycle, aiming at improving the running efficiency of the refrigeration system and solving the problems that the unit power and the unit condensation rate of the compressor increase and the air transmission rate and the refrigeration coefficient decrease due to the regenerative cycle adopted in the vapor compression refrigeration cycle to make the refrigerant have a certain supercooling degree. On the vapor compression refrigeration cycle side, the air exhaust opening of a compressor (2) is connected with the refrigerant inlet of a generator (5), the refrigerant inlet of the generator (5) is connected with the inlet of a first condenser (3), the outlet of the first condenser (3) is connected with the refrigerant inlet of a supercooler (6), the refrigerant outlet of the supercooler (6) is connected with the refrigerant inlet of an evaporator (1) through a throttle valve (4), and the outlet of the evaporator (1) is communicated with the air suction opening of the compressor (2). The ejection refrigeration cycle and the vapor compression refrigeration cycle are combined in the device, and two refrigeration systems are connected through one generator and one supercooler.

Owner:SOUTHEAST UNIV

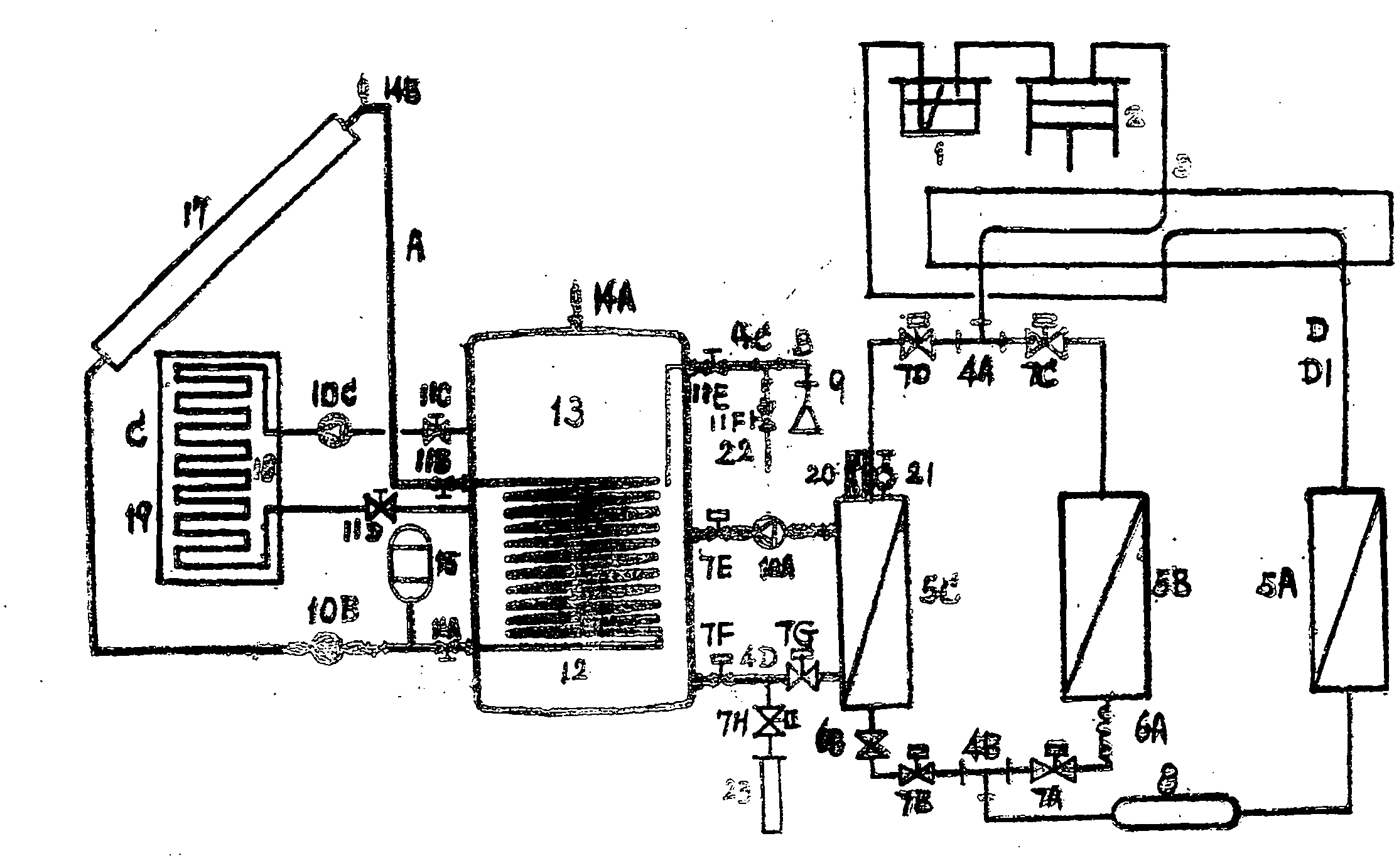

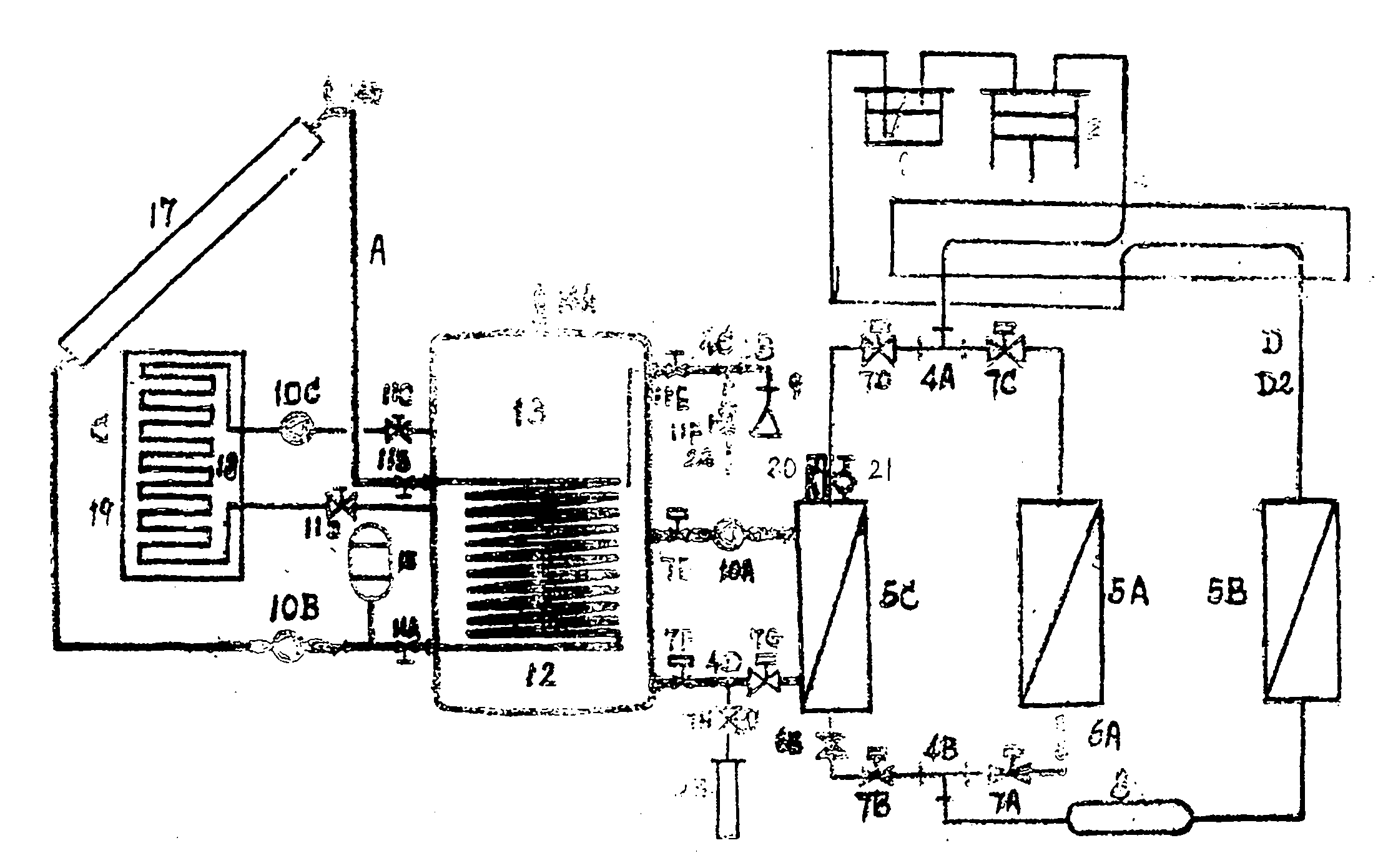

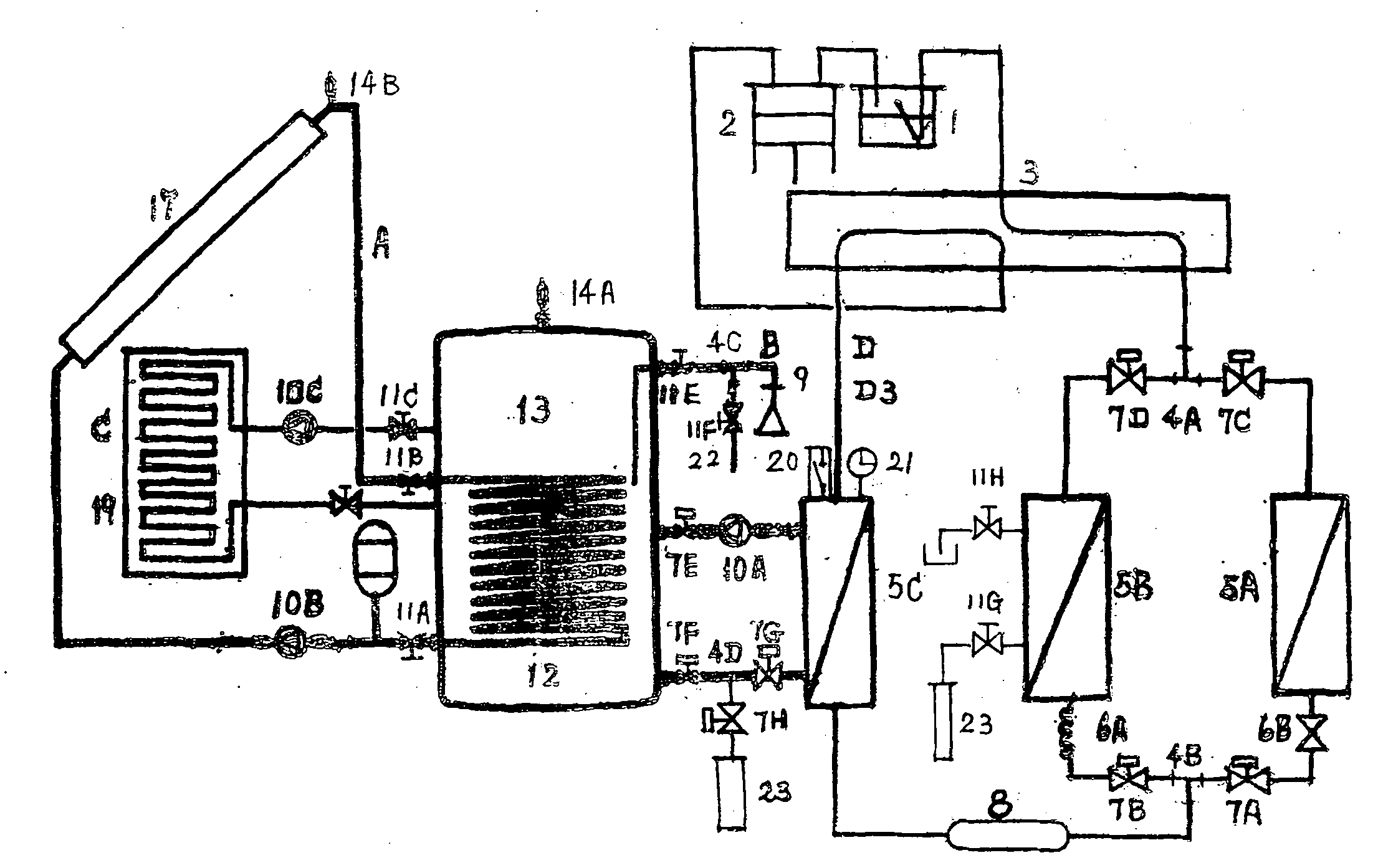

Shower, heating and air conditioning complex system device for producing hot water by using solar energy, air source and low power

The invention relates to a shower, heating and air conditioning complex system device for producing hot water by using solar energy, air source and low power. The device is formed by grafting and compounding a solar water heating system, a shower system, a floor heating system and an auxiliary heating system, and is provided with a control system; the auxiliary heating system is formed by grafting and compounding an air source pump and an air conditioner; in a steam compression refrigeration system of the air conditioner, a third heat exchanger which takes water as a heat exchange medium and one of a first heat exchanger and a second heat exchanger which takes air as the heat exchange medium in the system are connected with each other in parallel by using a pair of tee joints and two pairs of electromagnetic valves; and the third heat exchanger is provided with a temperature controller, is connected with a solar hot water storage tank by using a water inlet pipe and a water outlet pipe in a sealing way, and is connected with a hot water pump and an electromagnetic valve. The device has the advantages of saving electricity by 70 percent compared with an electric heater and saving a host compared with a special air-source heat pump, can be used for heating in winter and used for conditioning air in summer, recovers waste heat discharged from an original outdoor unit for producing hot water used for shower without reducing an energy efficiency ratio, acquires two gains by using one part of power, saves energy and reduces emission.

Owner:罗桂荣

Coolant-buffered, vapor-compression refrigeration with thermal storage and compressor cycling

ActiveUS8783052B2Improve cooling effectSuppress swingHeat storage plantsCompression machines with non-reversible cycleThermal energy storageEngineering

Owner:INT BUSINESS MASCH CORP

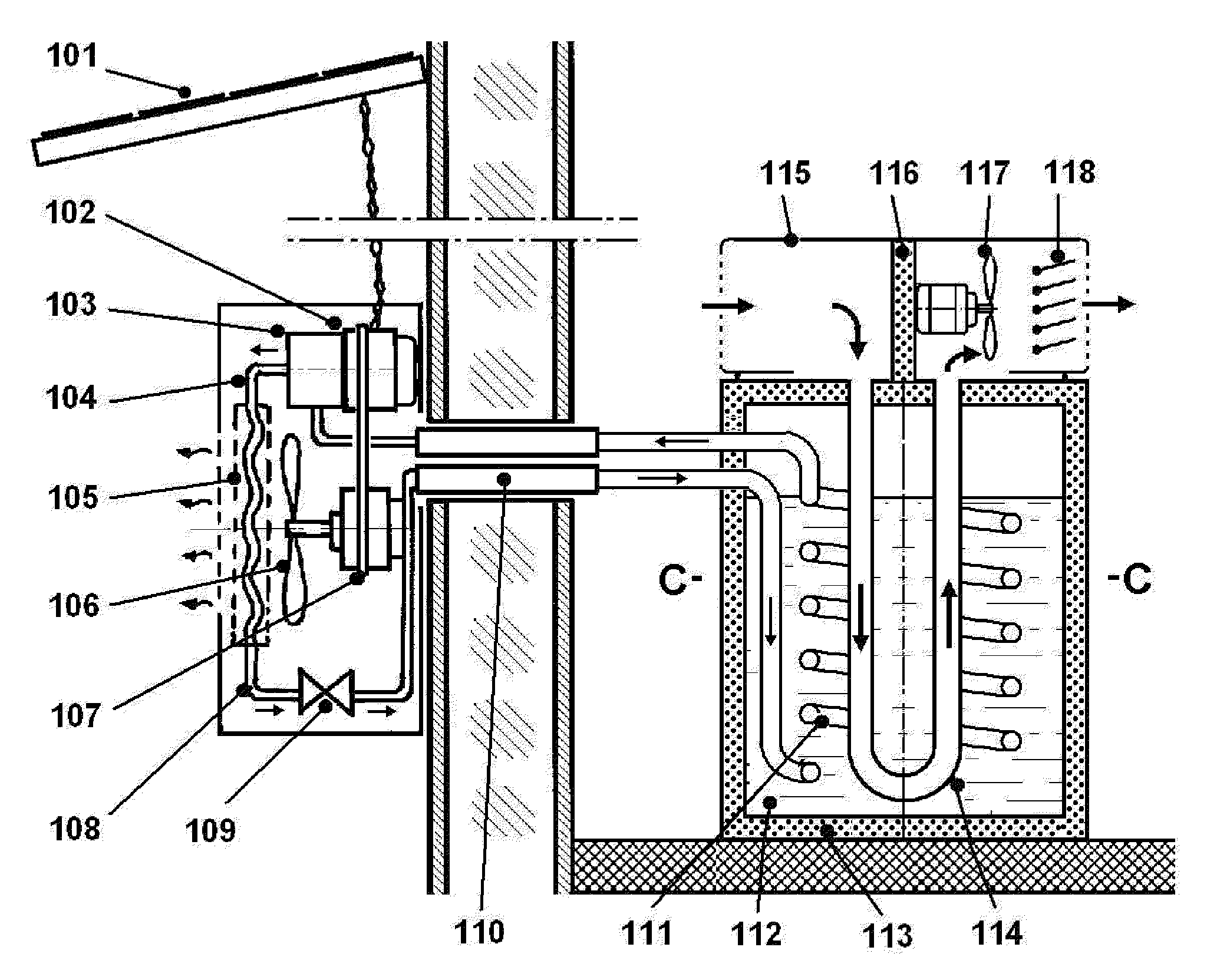

Multipurpose adiabatic potable water production apparatus and method

ActiveUS7121101B2Safe to drinkReduce energy costsMechanical apparatusGeneral water supply conservationAir cycleWater vapor

Apparatus and methods for transforming water vapor into potable water by using a vapor compression refrigeration system which includes first and second cooling elements disposed in a closed loop air passage duct that provides a continuous air circulation pattern driven by a fan or similar device. Water is introduced into the circulating air and undergoes adiabatic cooling followed by two stage cooling, first at a temperature below the dew point and then at a lower temperature at or below freezing. Water is collected from the air in each step and the air is thereafter heated back up by the condensing element of the refrigeration system enabling it to absorb more water vapor at the point of introduction. The air is recirculated and processed as above to permit cyclical water recovery.

Owner:SKYWATER INT LLC

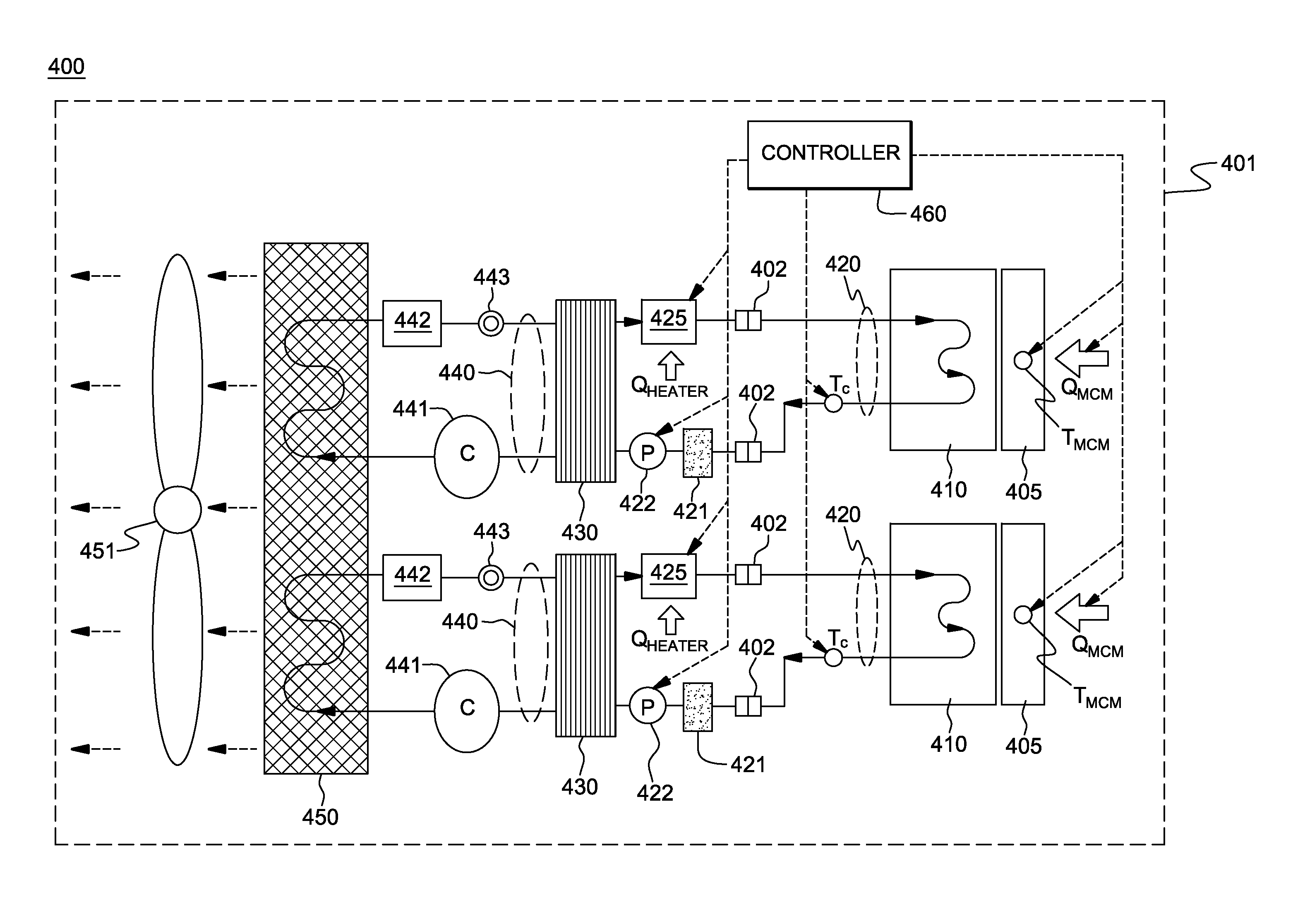

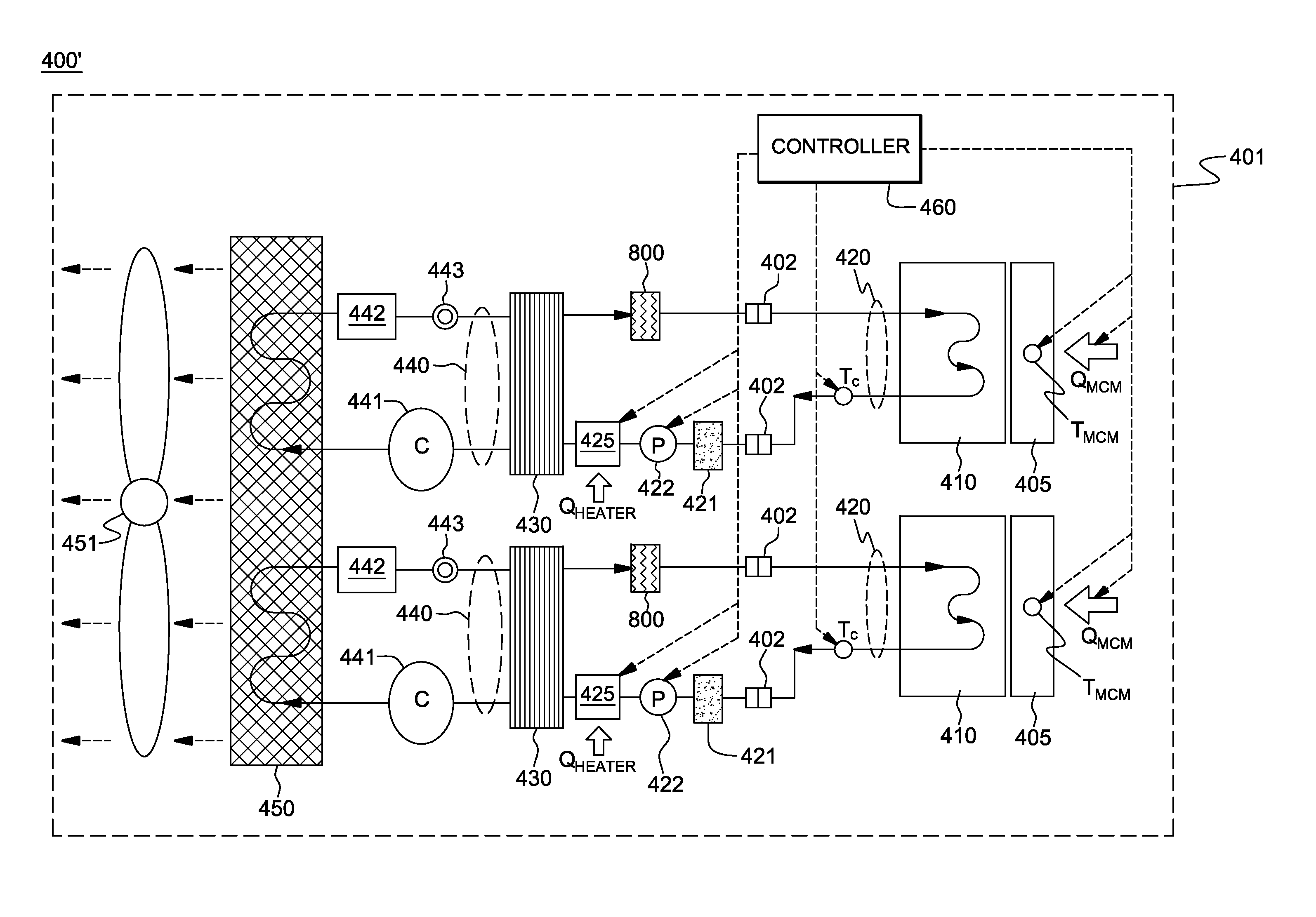

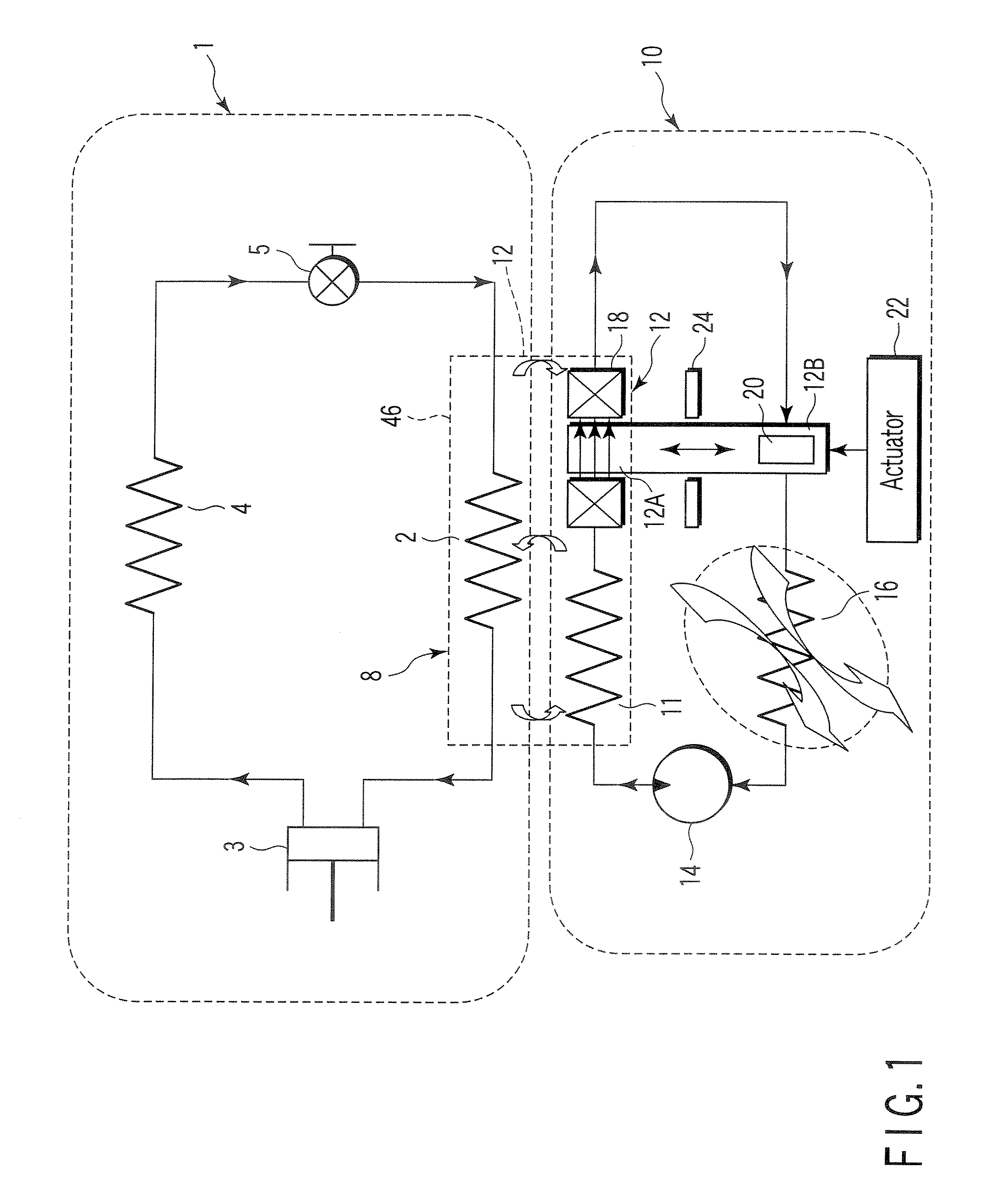

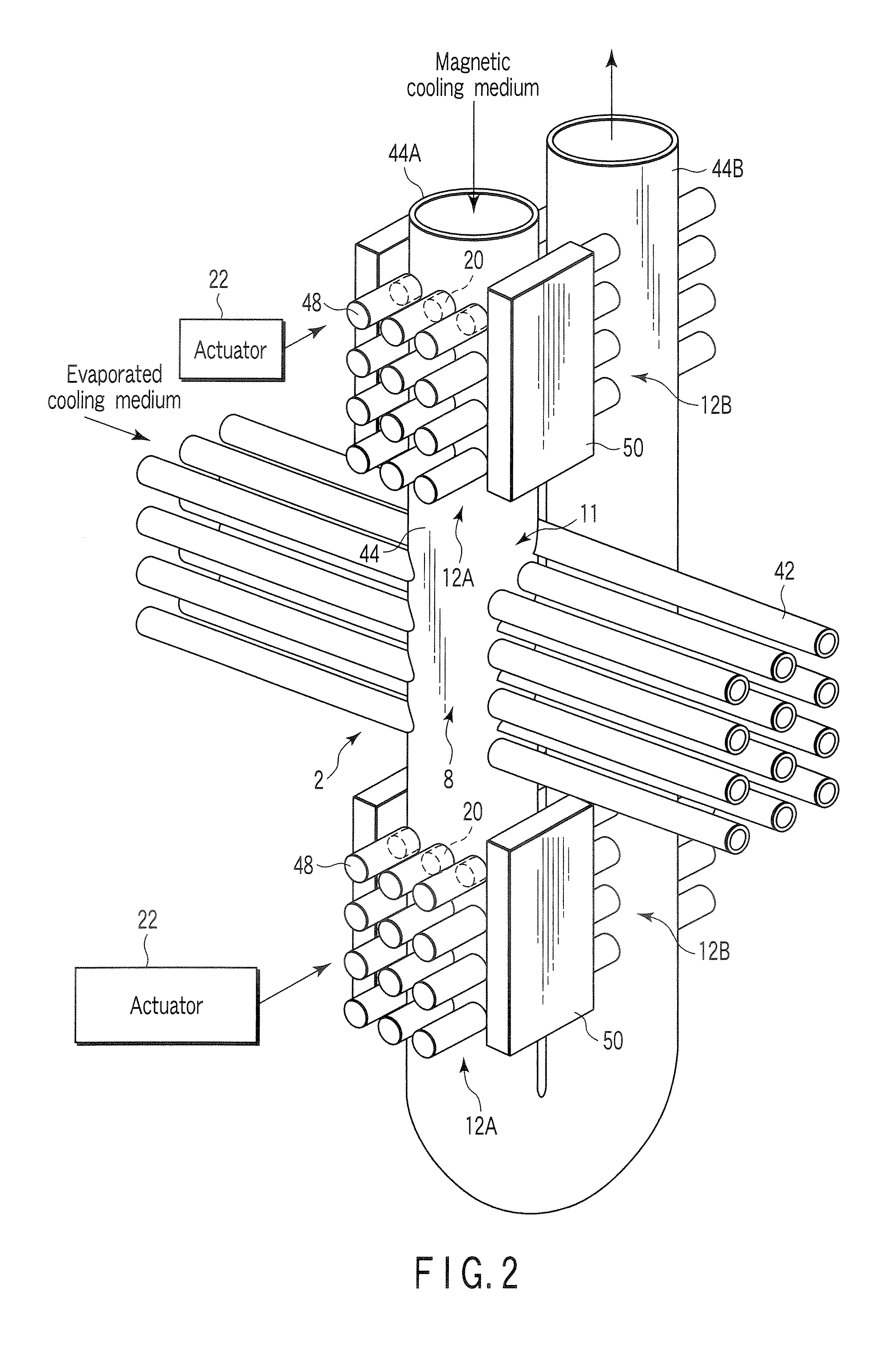

Hybrid magnetic refrigerator

InactiveUS20070240428A1Energy efficient heating/coolingCompression machines with cascade operationNuclear engineeringMagnetic refrigeration

A compact and highly efficient hybrid magnetic refrigerator includes a hybrid refrigerating apparatus wherein an evaporator of a vapor compression refrigeration cycle and a heat exchanger of a magnetic refrigeration cycle are thermally connected. The magnetic refrigeration cycle is provided with a magnetic refrigeration unit in which a magnetic substance dissipates and absorbs heat according to the increase and decrease of a magnetic field in order to heat and cool a refrigerant circulating in its vicinity. The heated refrigerant is cooled by the evaporator of the vapor compression refrigeration cycle and the cooled refrigerant is supplied to the heat exchanger cooling the outside air.

Owner:KK TOSHIBA

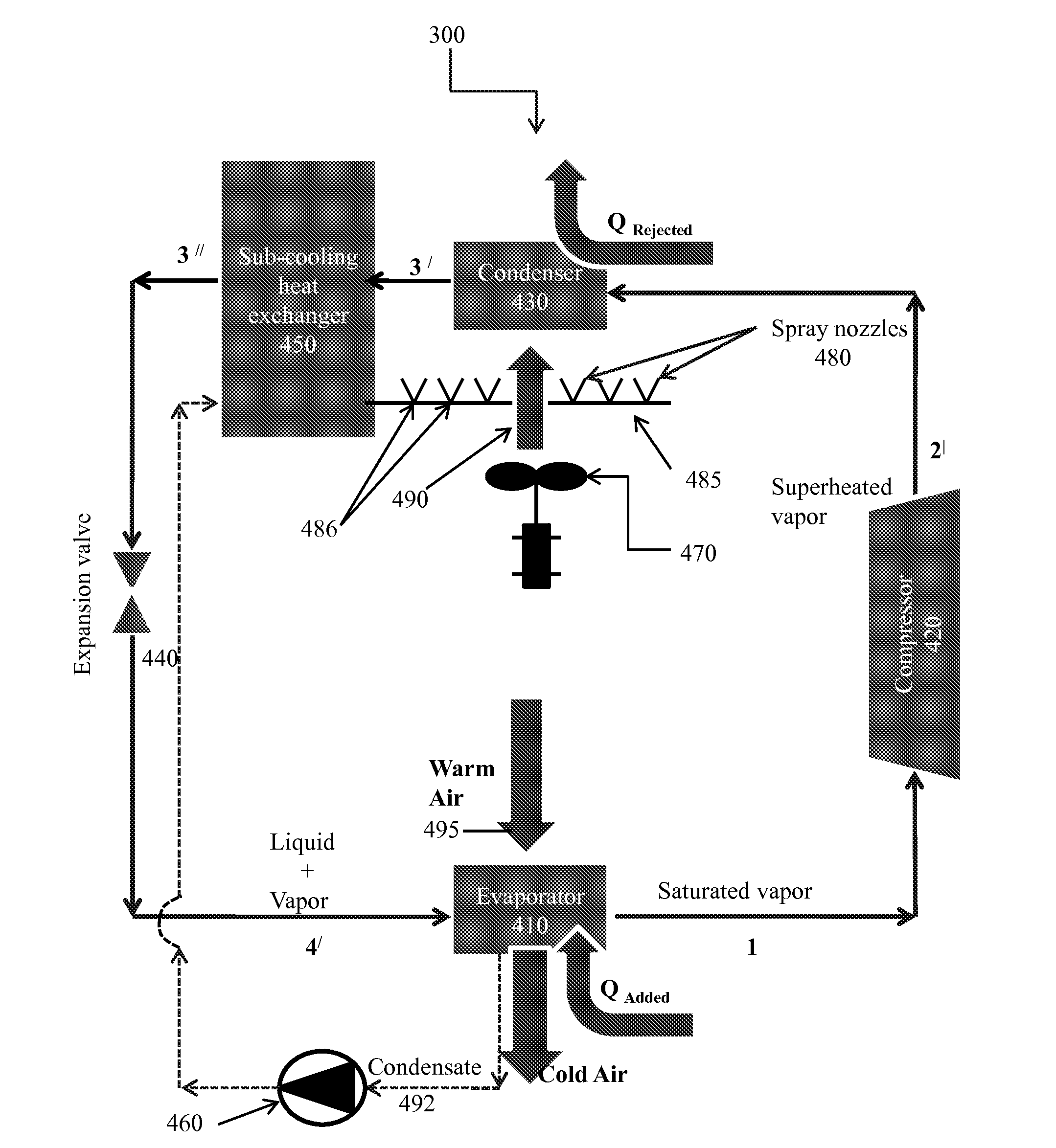

Condensate-free outdoor air cooling unit

InactiveUS20130061615A1Highly advantageousHighly effectiveEvaporators/condensersFree-cooling systemsSpray nozzleFree cooling

A highly efficient condensate-free cooling unit functionally based on vapor-compression refrigeration cycle has been described. The condensate collected from the evaporator of the cooling unit is routed through a sub-cooling heat exchanger where it exchanges heat with the primary heat exchange medium emerging through the condenser of the cooling unit, thus, sub-cooling the primary heat exchange medium to a lower temperature before it enters the expansion valve. Emerging from the sub-cooling heat exchanger, the condensate flows through a condensate outlet pipe into multiple spray nozzles disposed over the condensate outlet pipe. The spray nozzles sprinkle the condensate over the hot air blown into the condenser to reduce its temperature. The cooling unit has a substantially higher coefficient of performance compared to the conventional cooling units utilizing vapor-compression refrigeration cycle, and eliminates the problems of condensate removal persistent in the art.

Owner:ADVANCED TECHN SOLUTIONS

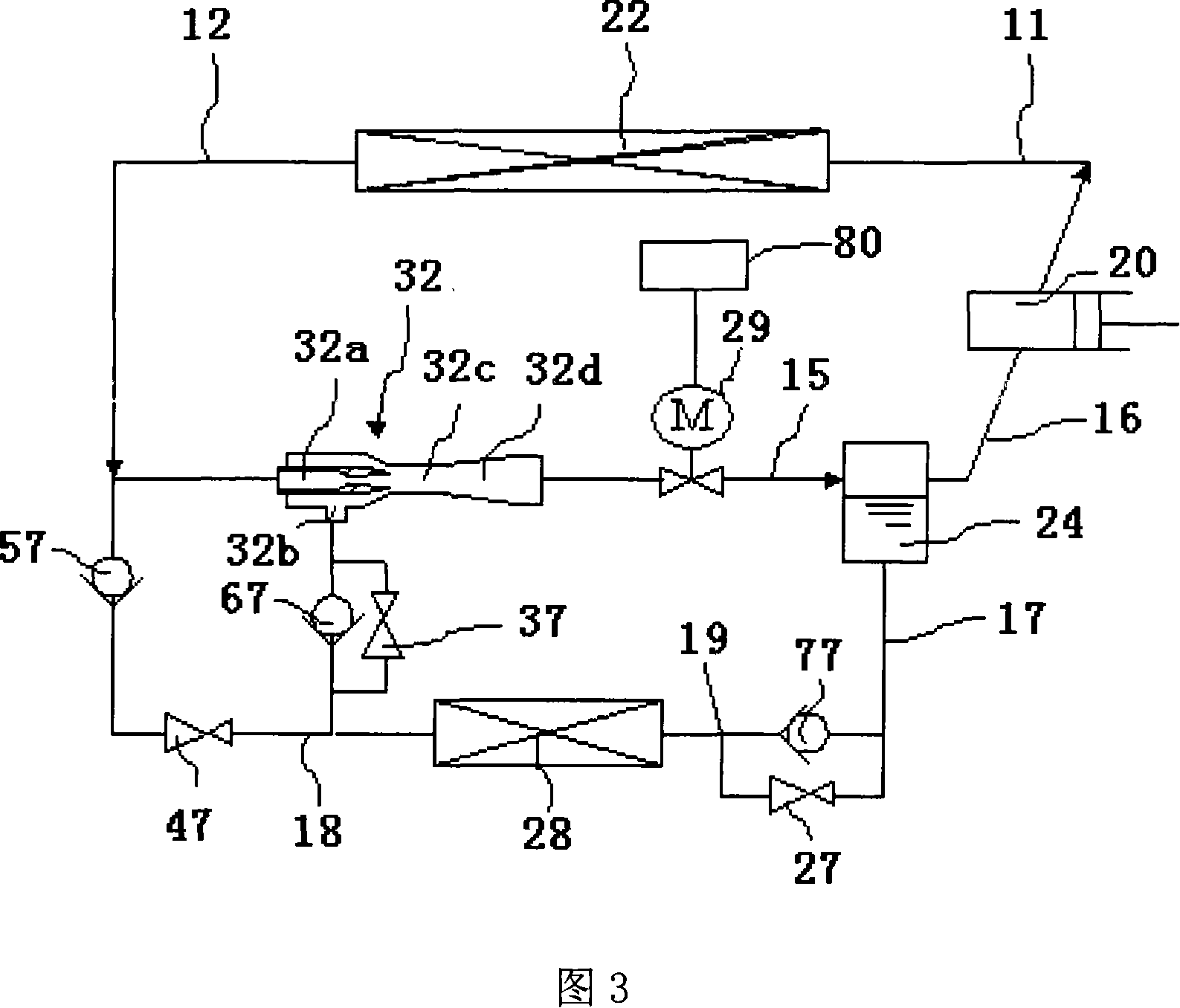

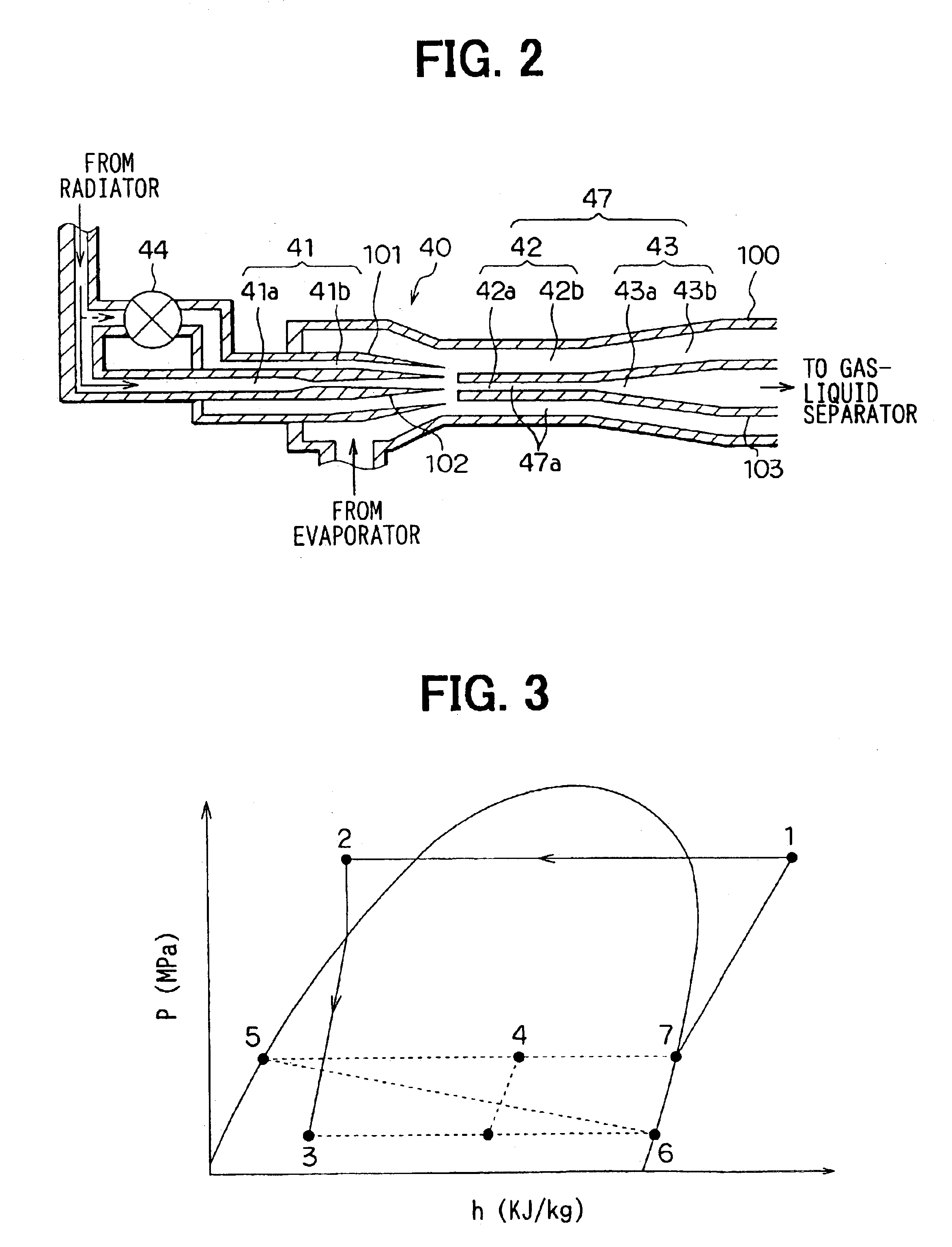

Vapour compressing refrigeration system including injector

InactiveCN101135505AImprove cooling effectDefrost operation is simple and practicalCompression machines with non-reversible cycleVapor–liquid separatorEngineering

The invention discloses a vapor compression refrigerating system with ejector. It includes compressor, air-liquid separator, radiator, ejector and evaporator. The compressor outlet is connected with the radiator, the compressor inlet is connected with the air-liquid separator; the air-liquid separator is connected with diffusing section of the ejector via a valve; the valve is connected with controller; the radiator is connected with ejector nozzle via pipeline and is connected with first throttling element via the pipeline; the first throttling element is connected with the evaporator through pipeline and is connected with secondary throttling element and secondary one-way valve paralleled with the secondary throttling element to ejector suction chamber by pipeline; the evaporator is connected with the liquid end of air-liquid separator; the air end of air-liquid separator is connected with the compressor via pipeline.

Owner:XI AN JIAOTONG UNIV

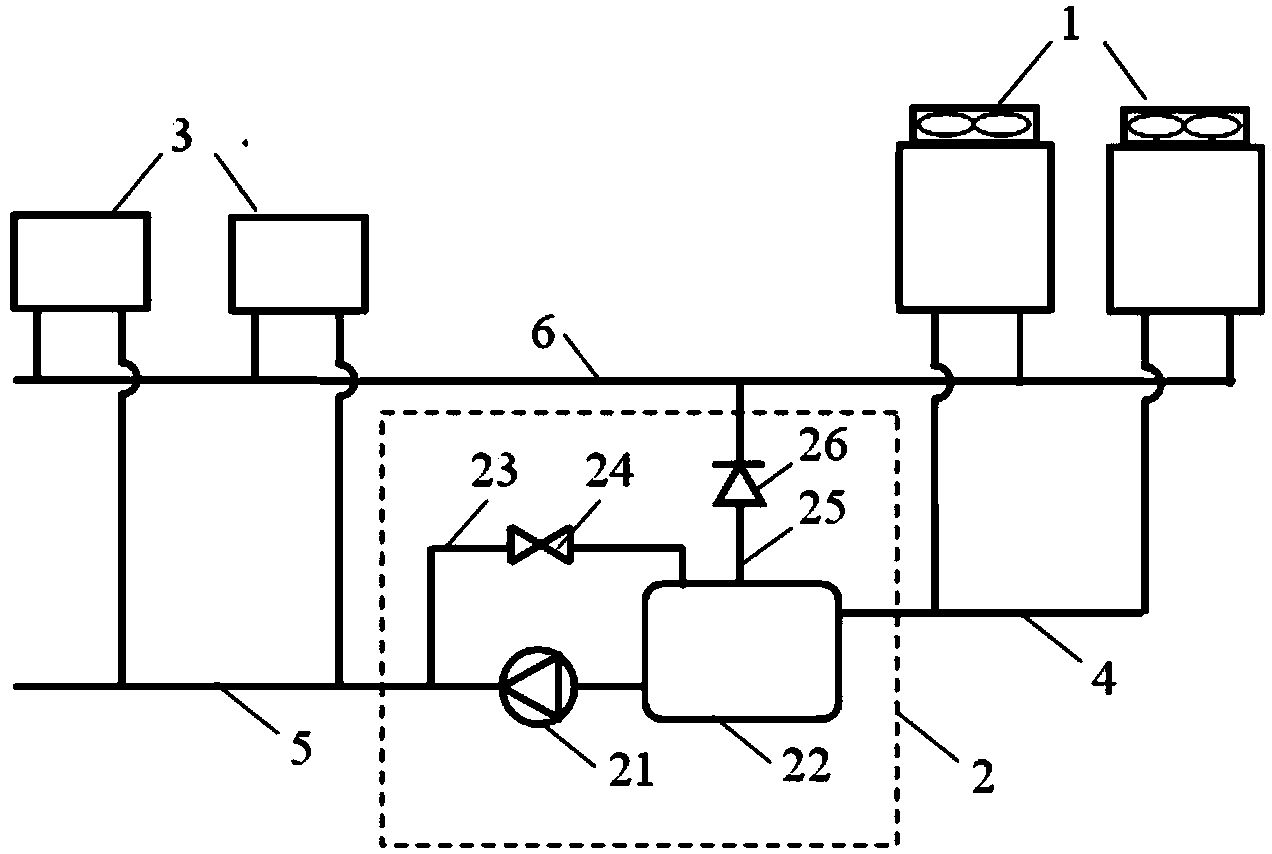

Combined type refrigeration and multi-connected air conditioning system

ActiveCN104251529ALarge working temperature zoneMaximize utilizationMechanical apparatusSpace heating and ventilation safety systemsEngineeringTransition season

The invention discloses a combined refrigeration and multi-connected air conditioning system which is characterized in that a cold source system of the multi-connected air conditioning system, which is composed of two or more than two outdoor composite refrigeration modules is arranged outdoors; each outdoor combined refrigeration module is formed by compositing a first refrigerant vapor compression refrigeration cycle loop and a second refrigerant cycle loop; one or more direct evaporative indoor air cooler modules are arranged indoors, and a refrigerant storage and transmission unit is connected between each outdoor composite refrigeration module and the corresponding indoor air cooler module to form a closed cycle system through a liquid collecting pipe, a liquid supply main pipe and a return air main pipe. According to the combined refrigeration and multi-connected air conditioning system, the number of the indoor and outdoor modules is set according to the design heating loads of air conditioning objects, refrigerating capacity is precisely regulated, the thermal control demands of various all-weather running data rooms and electronic devices are met, and natural cold sources in days and nights, transition seasons and winters can be used to the maximum extent to realize energy conservation and emission reduction of the air conditioning system.

Owner:CHINA YANGZI GRP CHUZHOU YANGZI AIR CONDITIONERCO

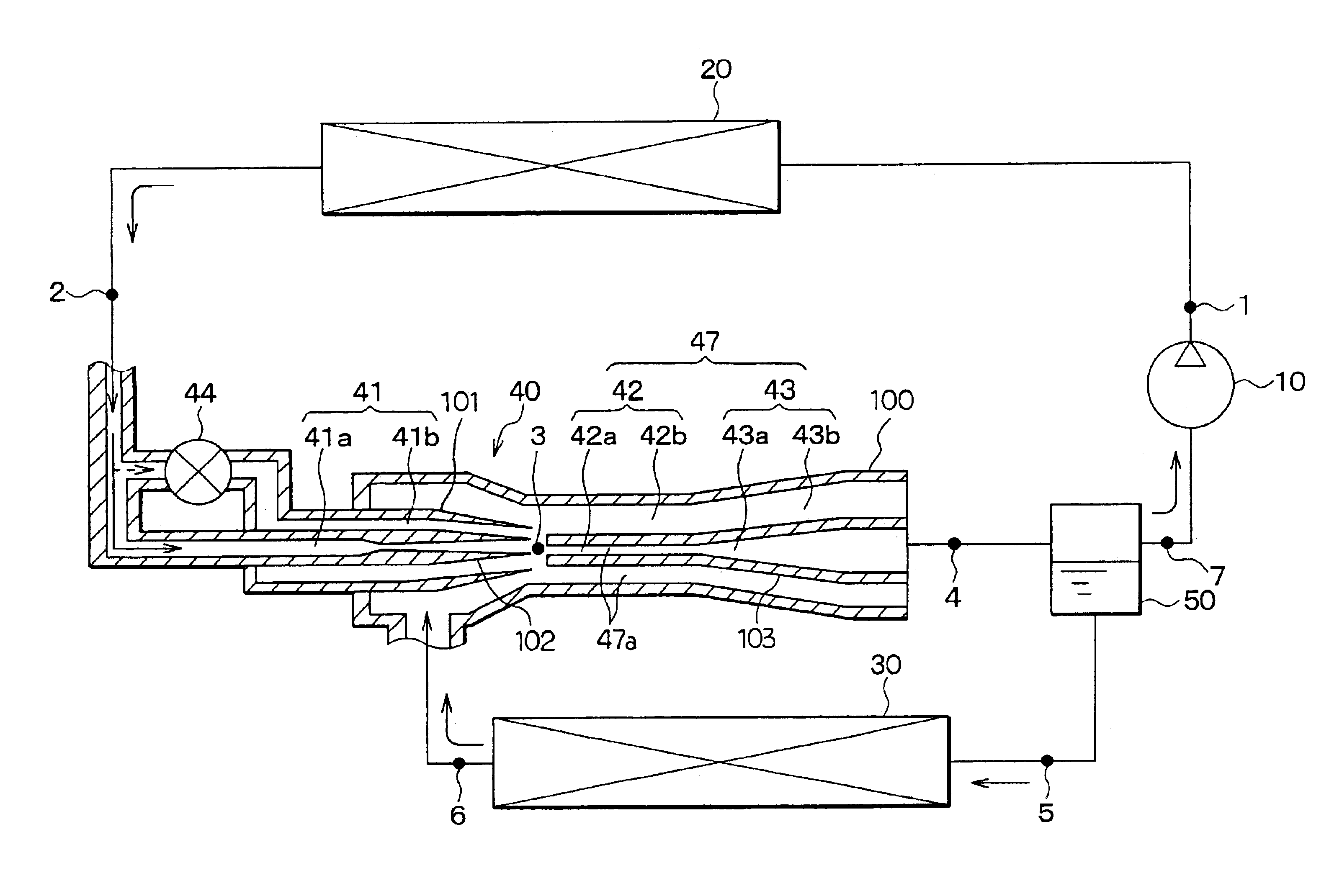

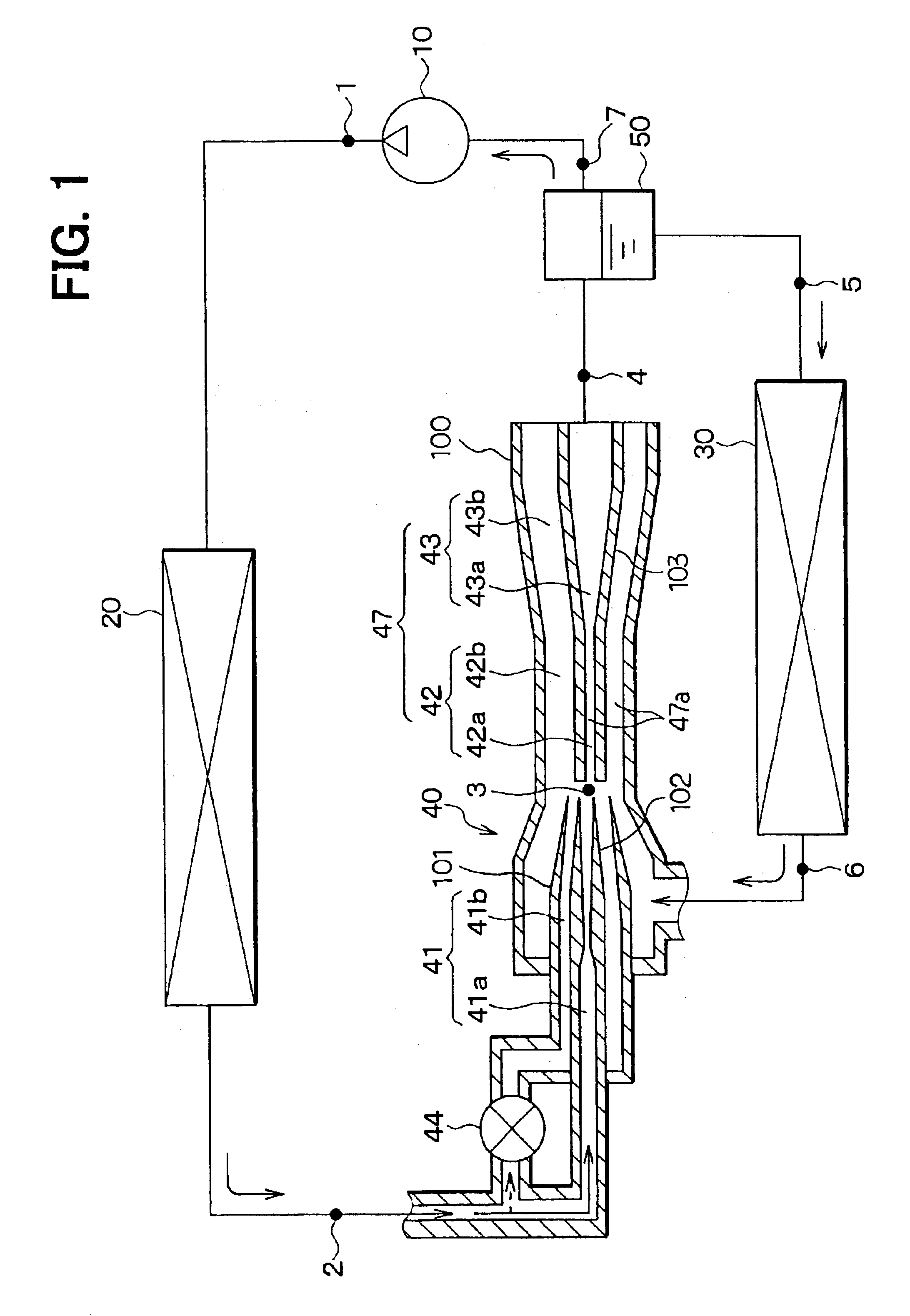

Ejector-type depressurizer for vapor compression refrigeration system

InactiveUS6904769B2Improve injection efficiencyIncrease pressureCompression machines with non-reversible cycleJet pumpsEngineeringVapor-compression refrigeration

In an ejector-type depressurizer, a nozzle arrangement converts pressure energy of refrigerant supplied from a radiator into velocity energy to depressurize and expand the refrigerant, and a pressurizer arrangement mixes the refrigerant discharged from the nozzle arrangement with the refrigerant drawn from an evaporator and converts the velocity energy of the refrigerant discharged from the nozzle arrangement into pressure energy to increase the pressure of the mixed refrigerant discharged from the pressurizer arrangement. The pressurizer arrangement includes a refrigerant passage that conducts the refrigerant supplied from the nozzle arrangement and the refrigerant supplied from the evaporator, and the refrigerant passage includes a refrigerant passing zone, through which the refrigerant from the nozzle arrangement and the refrigerant from the evaporator mainly pass during operation of the ejector-type depressurizer. A cross sectional size of the refrigerant passing zone of the refrigerant passage is variable.

Owner:DENSO CORP

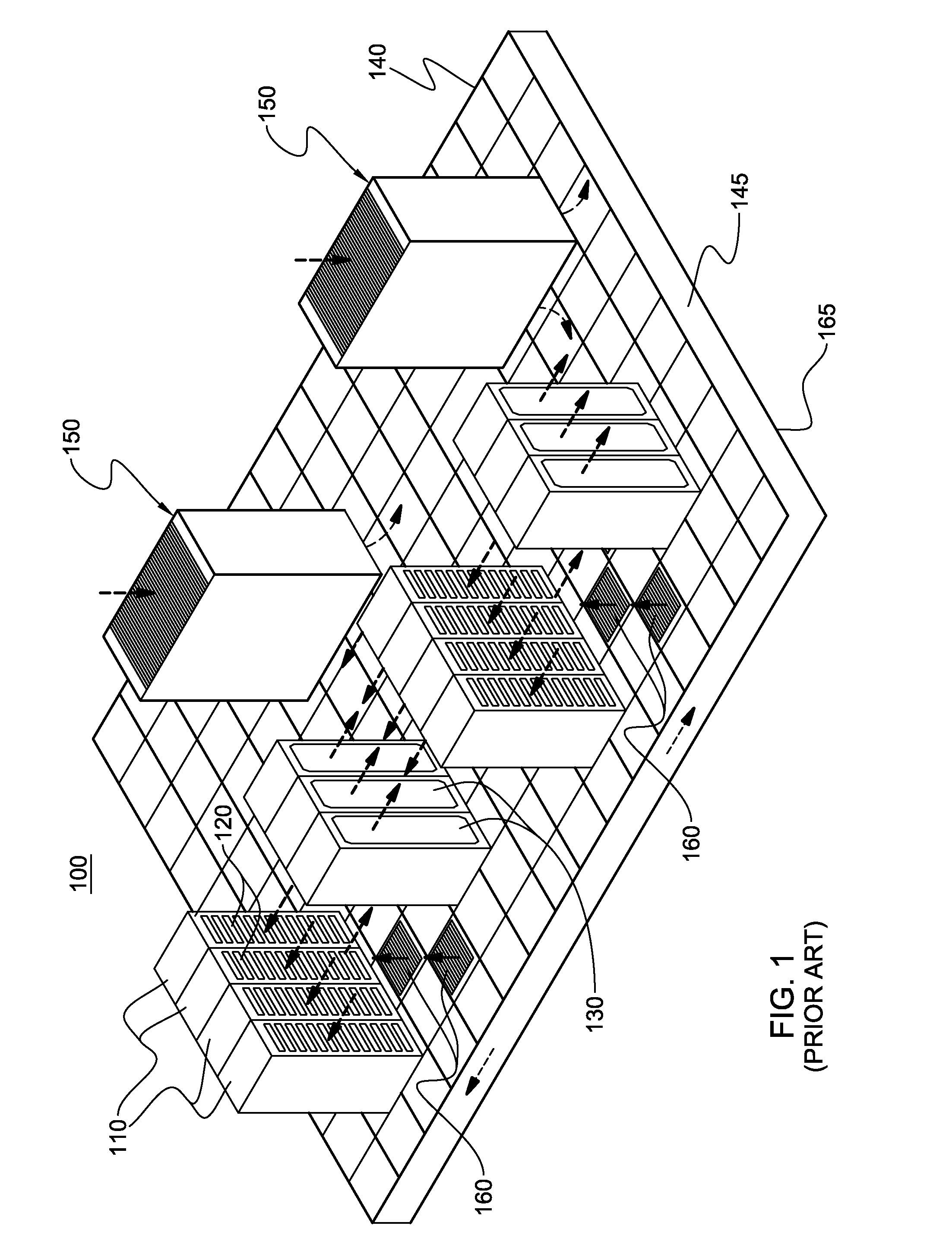

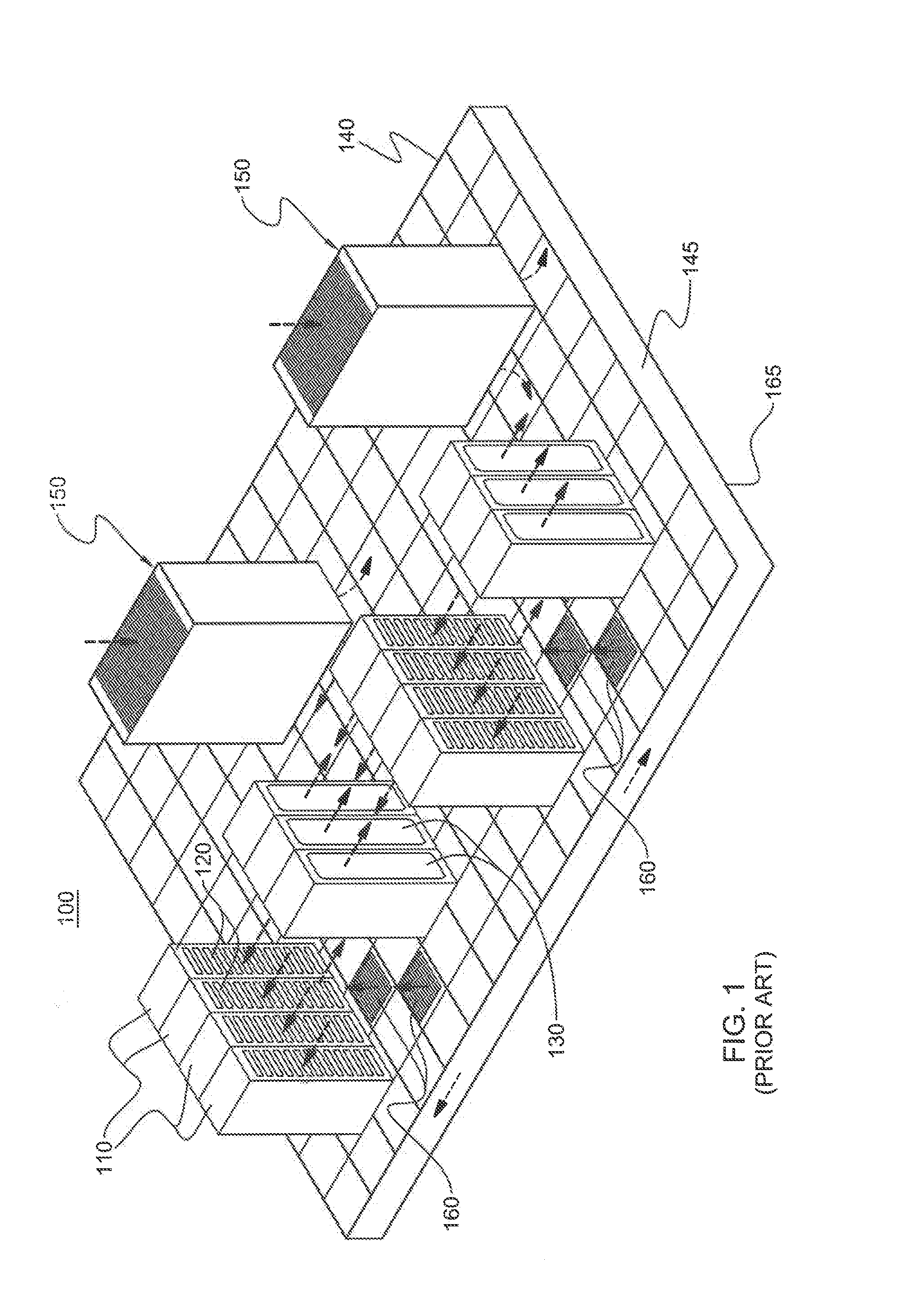

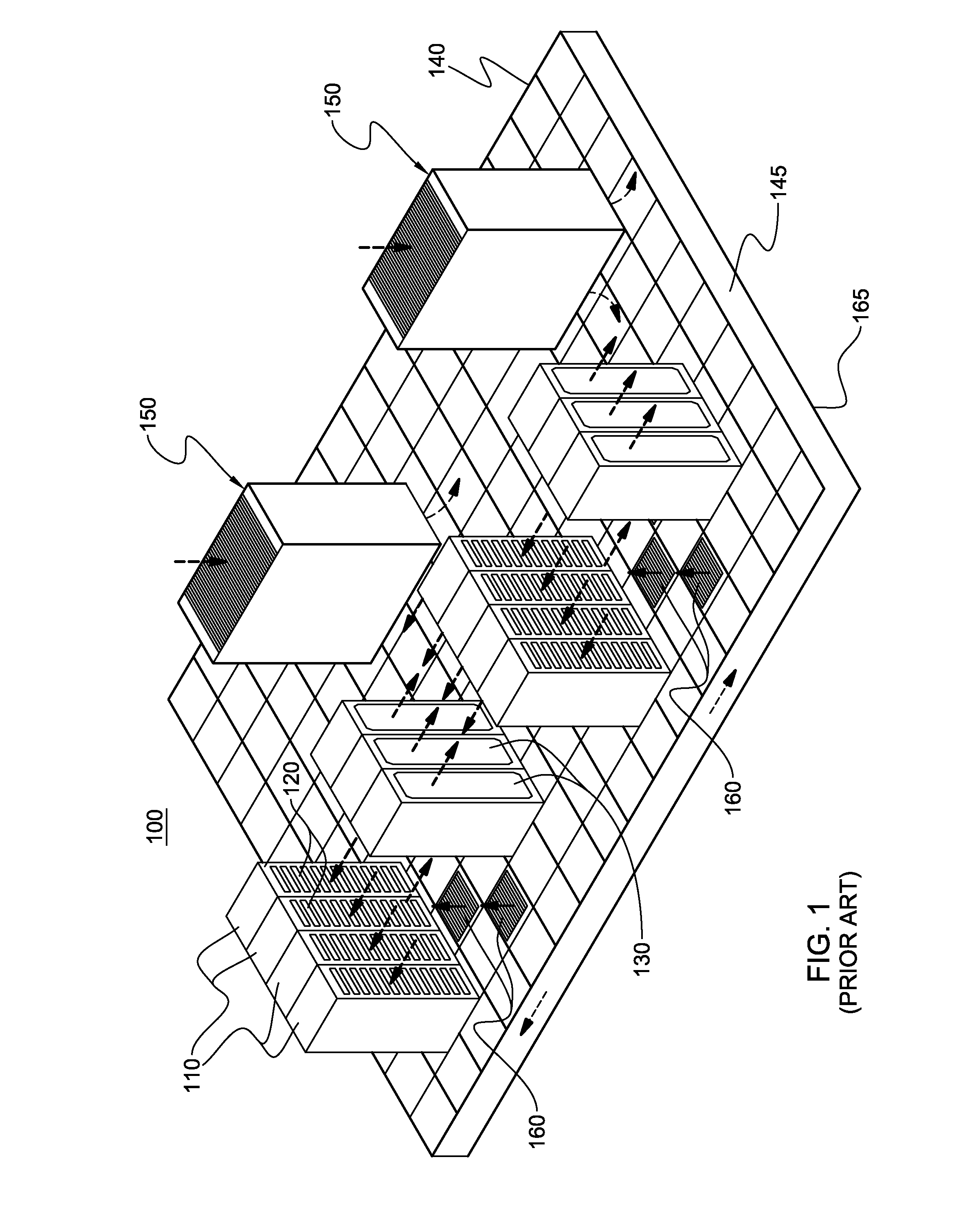

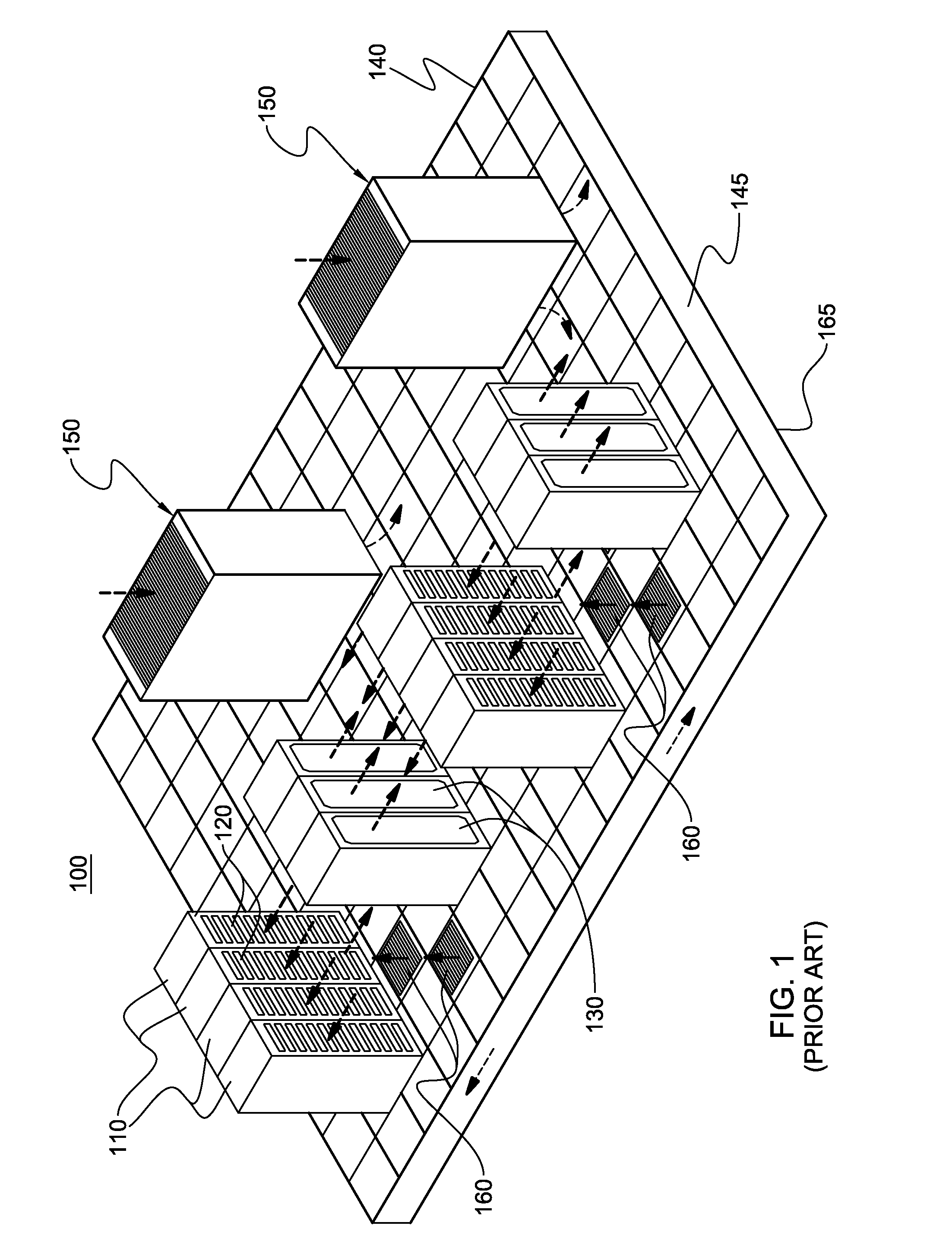

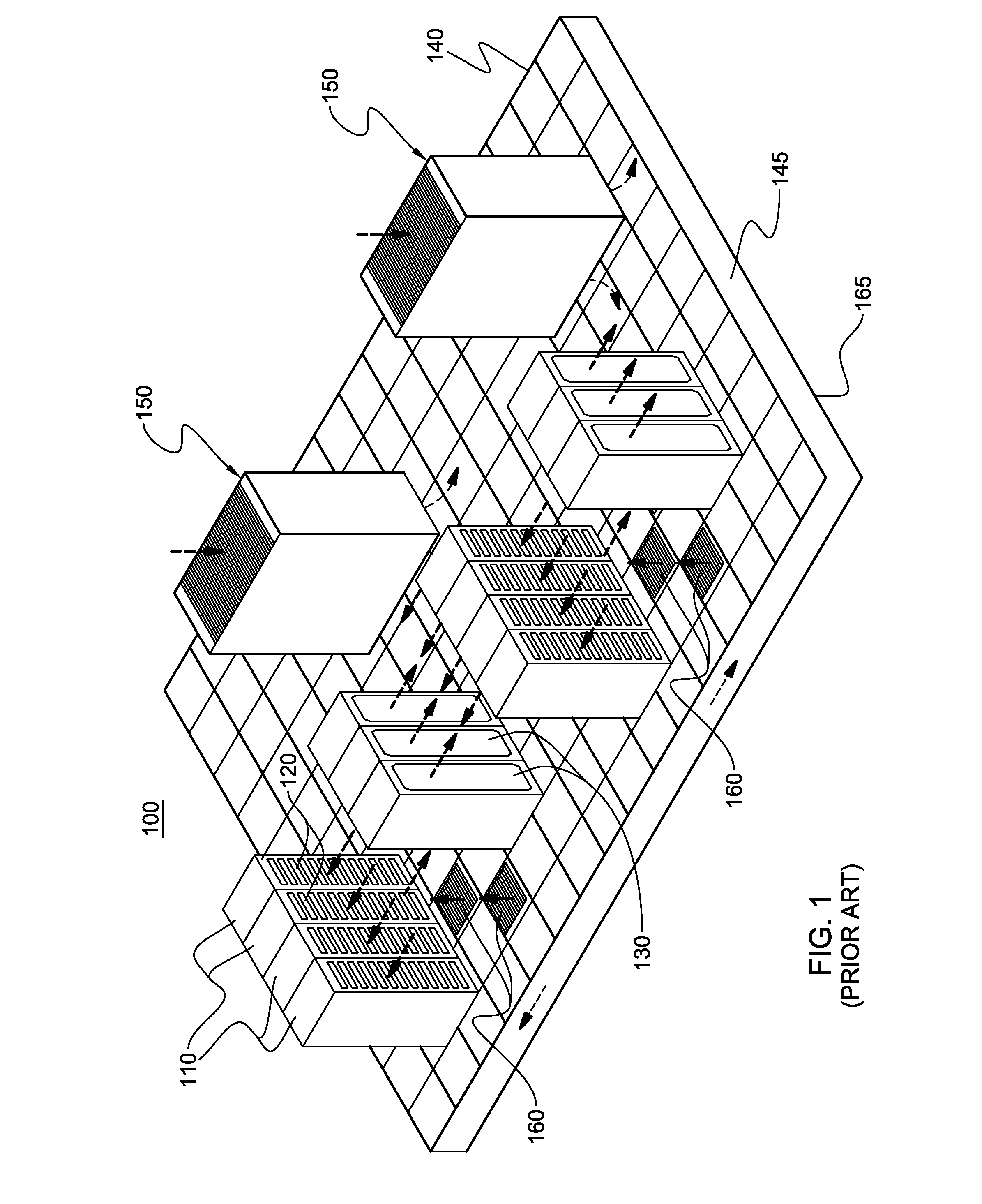

Server cooling system without the use of vapor compression refrigeration

ActiveUS20140301036A1Digital data processing detailsCooling/ventilation/heating modificationsNuclear engineeringVapor-compression refrigeration

A system, method, and computer product for cooling a server center without the use of vapor compression refrigeration. An example embodiment involves using outdoor ambient air to cool first server components directly and to cool heat exchanges containing liquid used to cool second server components.

Owner:IBM CORP

Vapor-compression refrigeration apparatus with refrgierant bypass and controlled heat load

InactiveUS20120111037A1Easy to moveEasy to maintain temperatureCompression machines with non-reversible cycleRefrigeration devicesThermodynamic stateEngineering

Apparatus and method are provided for cooling an electronic component. The apparatus includes a refrigerant evaporator in thermal communication with the component(s) to be cooled, and a refrigerant loop coupled in fluid communication with the evaporator for facilitating flow of refrigerant through the evaporator. The apparatus further includes a compressor in fluid communication with the refrigerant loop, a refrigerant bypass pipe coupled to the refrigerant loop in parallel fluid communication with the evaporator, and a control valve for controlling refrigerant flow through the evaporator. The control valve is controlled to maintain temperature of the component(s) within a specified temperature range. The apparatus further includes a controllable refrigerant heater associated with the refrigerant bypass pipe for providing an adjustable heat load on refrigerant in the bypass pipe to ensure that refrigerant entering the compressor is in a superheated thermodynamic state.

Owner:IBM CORP

Vapor compression refrigeration cycle expansion work recovery system

ActiveCN103940134AExhaust temperature controlGuaranteed efficiencyCompression machines with non-reversible cycleVapor–liquid separatorGas phase

The invention discloses a vapor compression refrigeration cycle expansion work recovery system. The system comprises a main compressor (i), a condenser (ii), a gas and liquid separator (iii), a gas expander (iv), an expansion valve (v), an evaporator (vi) and an auxiliary compressor (vii), wherein the condenser (ii) is connected with the main compressor (i) and cools gaseous working mediums from the main compressor into a gas and liquid two-phase mixture; the gas and liquid separator (iii) is connected with the condenser and performs phase separation on the gas and liquid two-phase mixture from the condenser; the gas expander (iv) is connected with a gas phase working medium outlet of the gas and liquid separator; the expansion valve (v) is connected with a liquid phase working medium outlet of the gas and liquid separator; the evaporator (vi) is connected with the expansion valve; the auxiliary compressor (vii) is connected with the evaporator; a gaseous working medium outlet of the gas expander and a gaseous working medium outlet of the auxiliary compressor are jointly communicated with a gaseous working medium inlet of the main compressor through a pipeline. Due to stage compression of the system, the compression ratio in each compression process is decreased, the efficiency of the compressors is guaranteed, and the circulation COP is improved.

Owner:TIANJIN UNIV

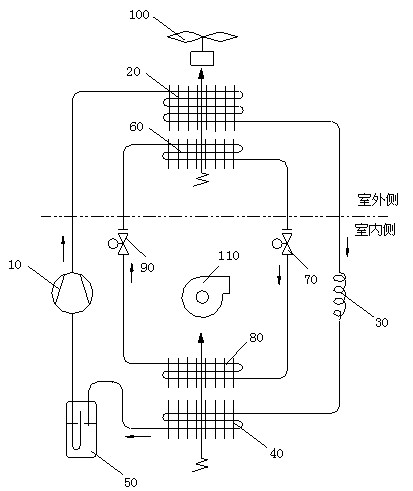

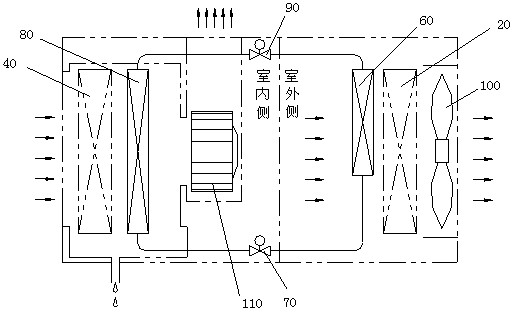

Integral heat pipe composite air conditioner

InactiveCN102155769AFunction increaseRealize low-temperature refrigeration and heat exchangeSpace heating and ventilation safety systemsLighting and heating apparatusCondenser (heat transfer)Engineering

The invention relates to an integral heat pipe composite air conditioner. A heat pipe device is a loop which is formed by sequentially connecting a heat pipe condenser and a heat pipe evaporator through pipelines, wherein the heat pipe condenser is arranged above the heat pipe evaporator; the heat pipe condenser and a condenser share a fan; the heat pipe evaporator and an evaporator share a centrifugal fan; a first temperature sensor is arranged at an air inlet of the condenser; a second temperature sensor is arranged at an air inlet of the evaporator; and the first temperature sensor, the second temperature sensor, a compressor, the fan and the centrifugal fan are respectively connected with a controller. The technical scheme shows that the integral heat pipe composite air conditioner combines a traditional steam compression refrigeration technology with a heat pipe technology, the air conditioner is used for refrigeration at a normal condition, when an indoor and outdoor temperature difference reaches a set temperature, the controller switches off signals of the compressor, at the moment, the compressor stops working, the heat pipe device begins working, the heat pipe is used for exchanging heat so as to realize the low temperature refrigeration and heat transfer and increase the function of the air conditioner under the condition that the appearance of the air conditioner is not changed.

Owner:合肥天鹅制冷科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com