Integral heat pipe composite air conditioner

A composite air-conditioning and integrated technology, which is applied in the direction of air-conditioning systems, household heating, heating methods, etc., can solve the problems of limited use, achieve the effect of adding functions, convenient maintenance, and realizing low-temperature refrigeration and heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

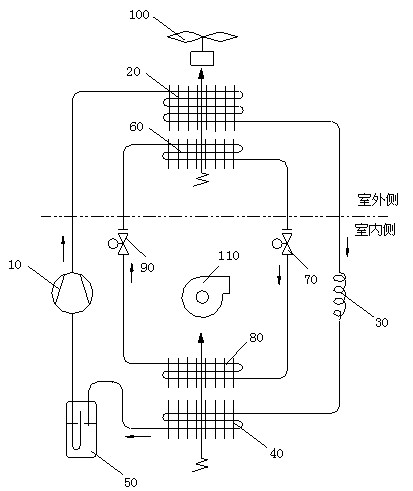

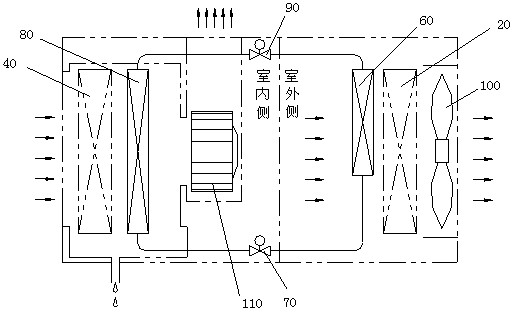

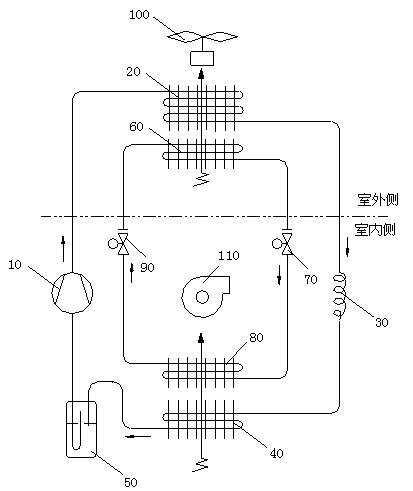

[0012] Such as figure 1 , figure 2 The shown integrated heat pipe composite air conditioner includes an air conditioner and a heat pipe device. The air conditioner is composed of a compressor 10, a condenser 20, capillaries 30, an evaporator 40, and a gas-liquid separator 50. The device is connected into a circuit by a heat pipe condenser 60 and a heat pipe evaporator 80 sequentially through pipelines, wherein the heat pipe condenser 60 is located above the heat pipe evaporator 80, and the heat pipe condenser 60 and the condenser share a fan 100, and the heat pipe evaporator 80 and the evaporator The device 40 shares a centrifugal fan 110, the air inlet of the condenser 20 is provided with a first temperature sensor, the air inlet of the evaporator 40 is provided with a second temperature sensor, the first temperature sensor, the second temperature sensor, the compressor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com