Patents

Literature

82results about How to "Easy to maintain temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

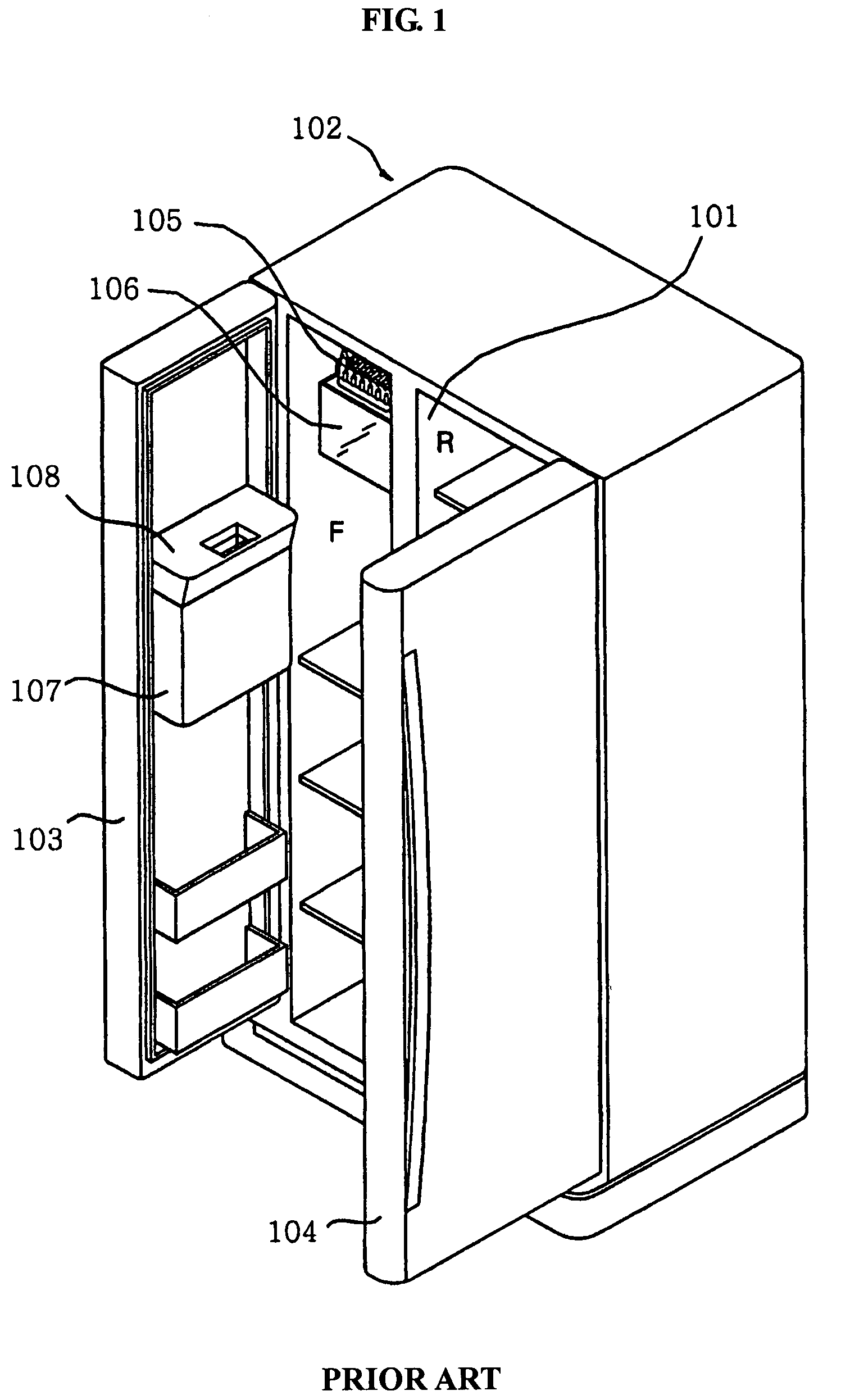

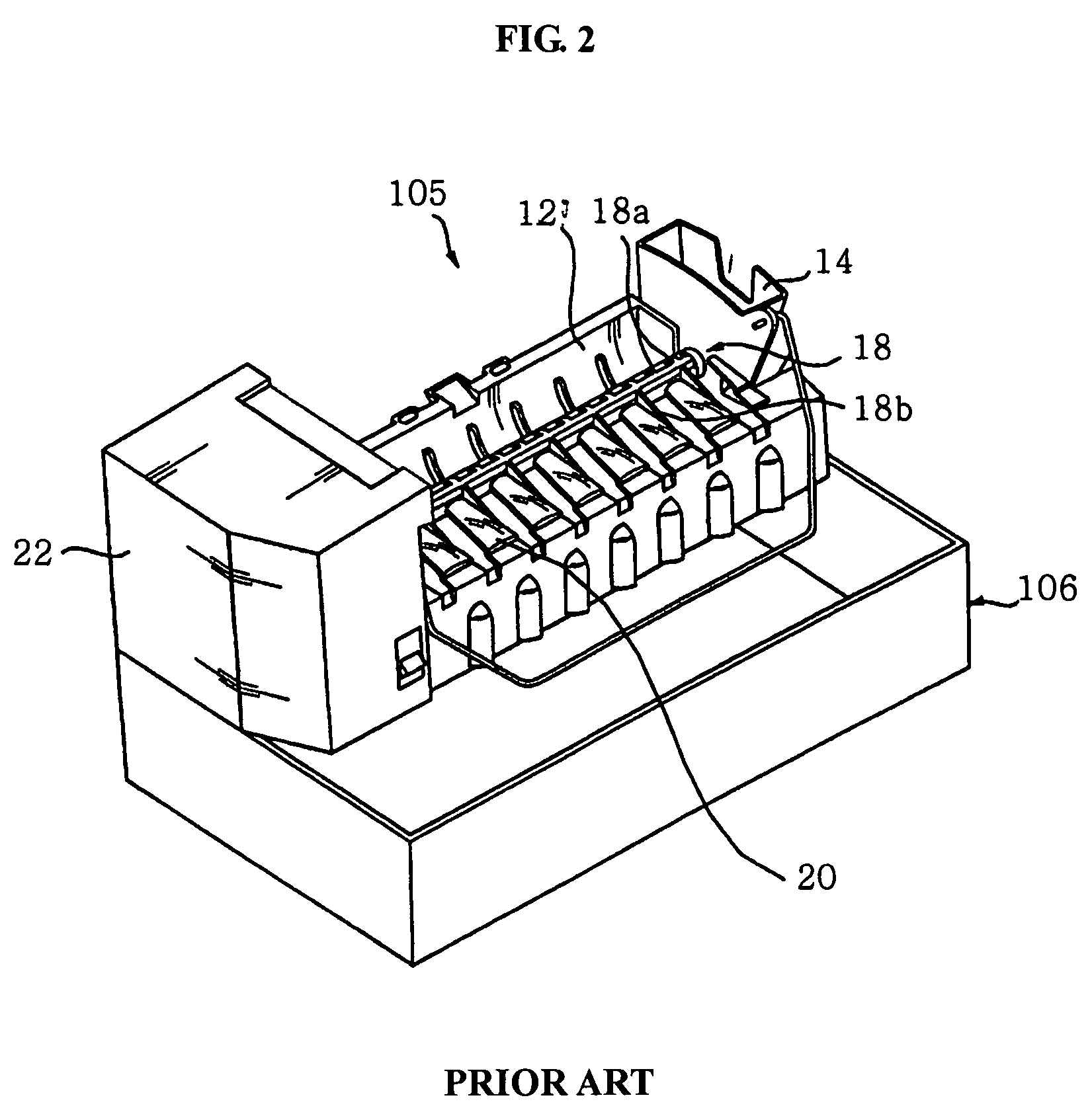

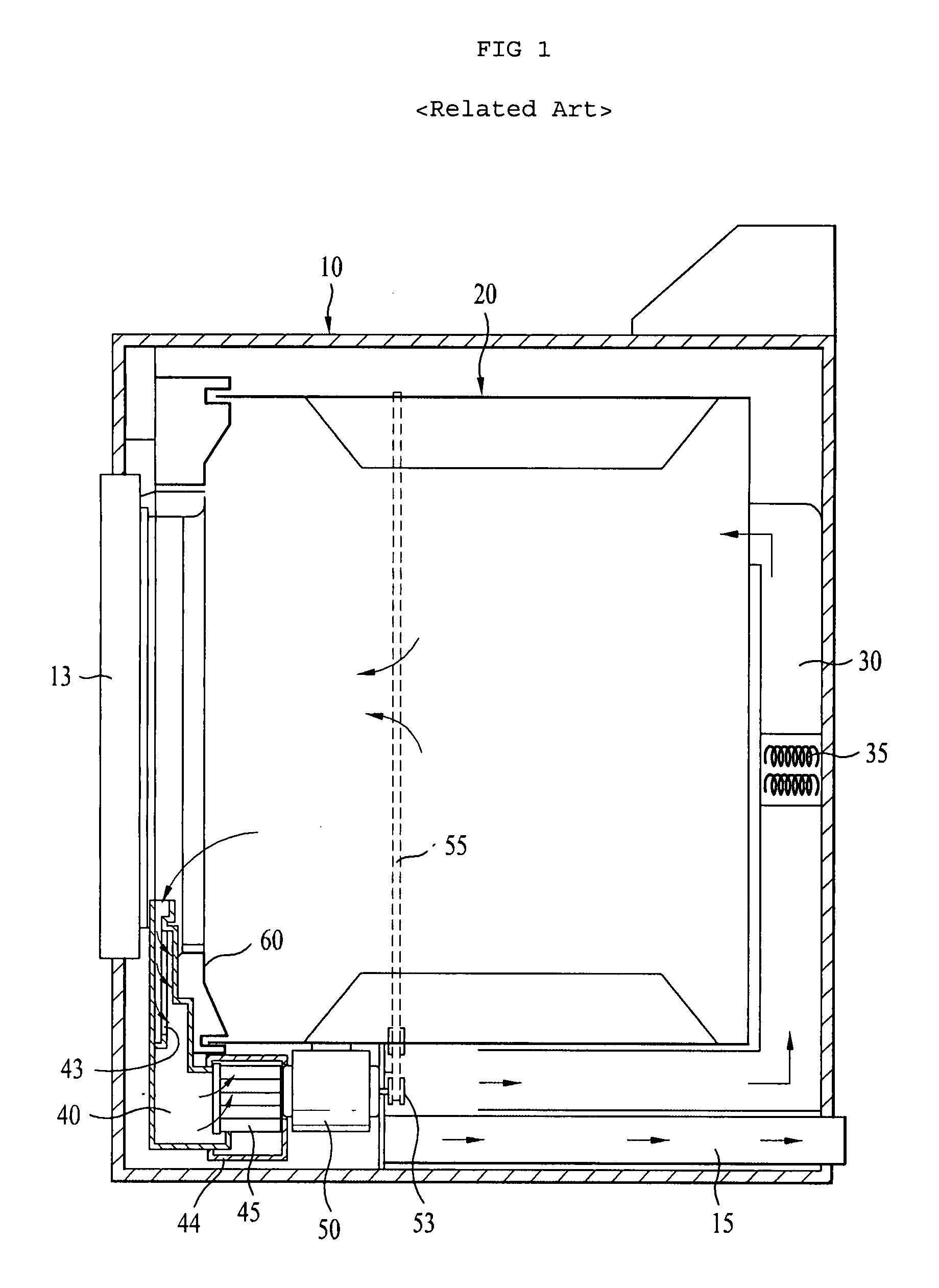

Rotary type ice maker and method for making ice using the same

InactiveUS7210299B2Price competitivenessSimple structureLighting and heating apparatusIce productionEngineeringPosition fixing

Disclosed are a rotary type ice maker and a method for making ice using the same. The rotary type ice maker comprises an ice making mold having ice making cavities in upper and lower sides thereof, respectively, a rotating shaft for supporting the ice making mold so that the ice making mold is rotated by its own weight or by the weight of ice cubes in the ice making cavities, and a mold position fixing device for fixing or releasing the ice making mold by engaging with the ice making mold or separating from the ice making mold.

Owner:LG ELECTRONICS INC

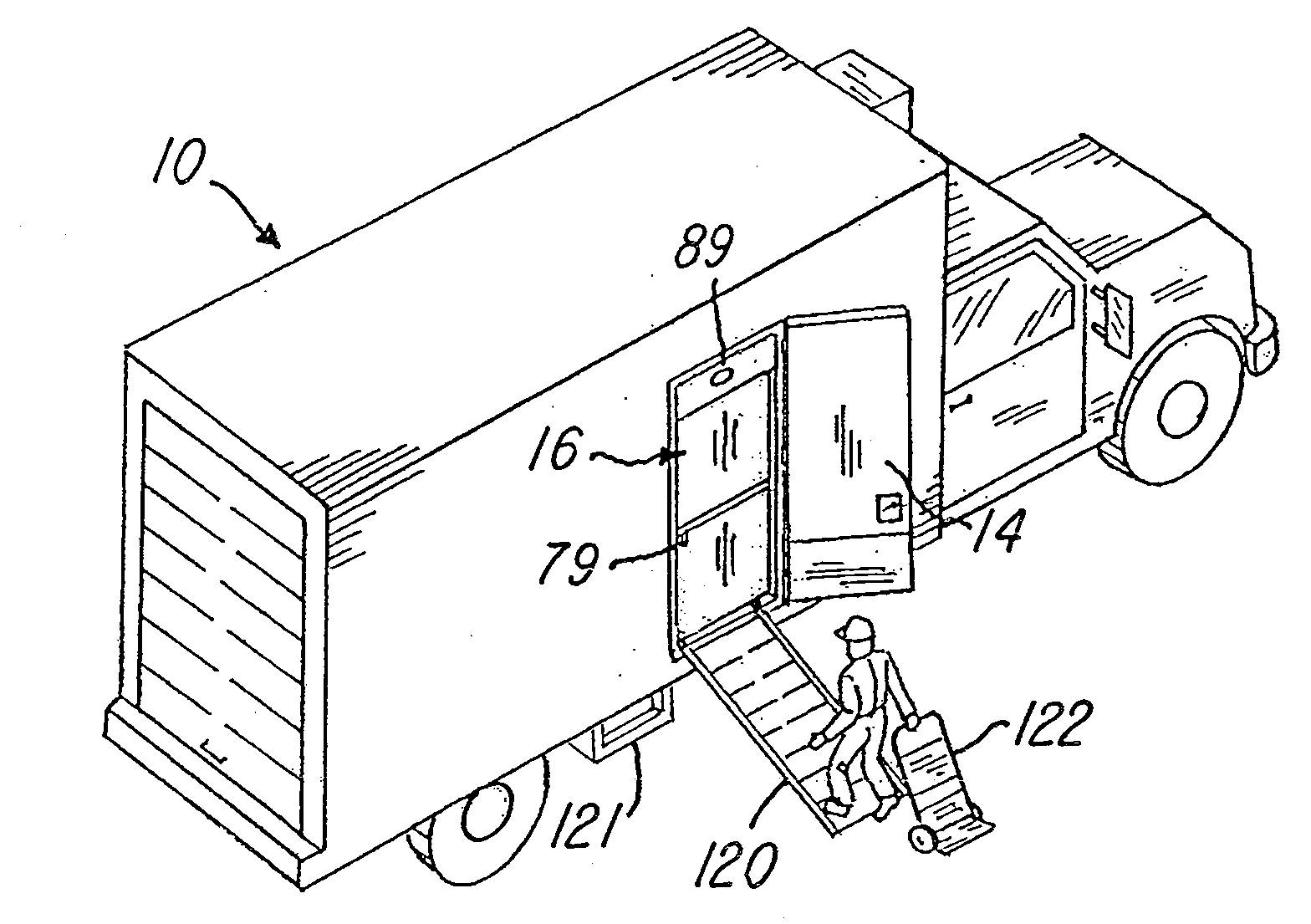

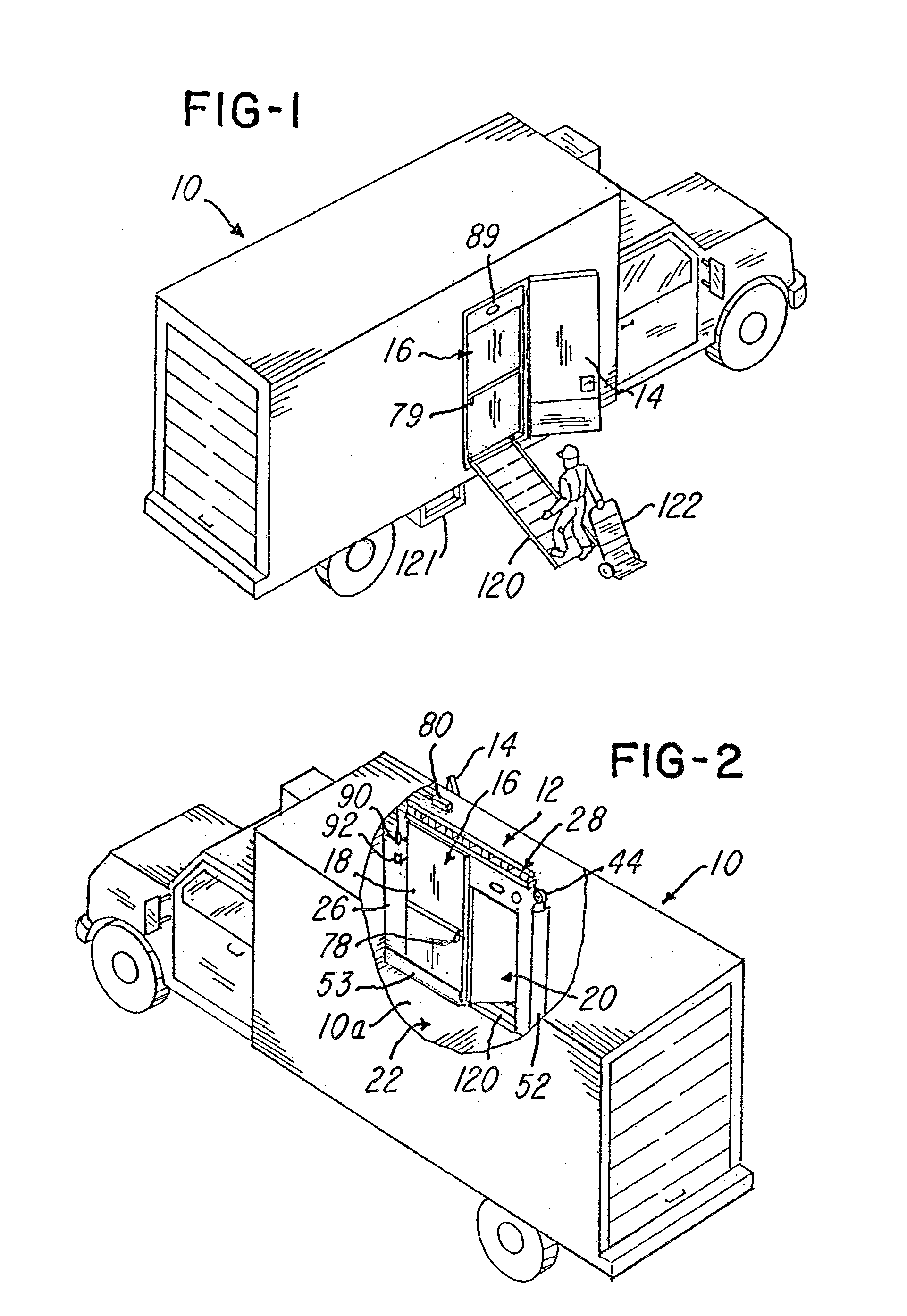

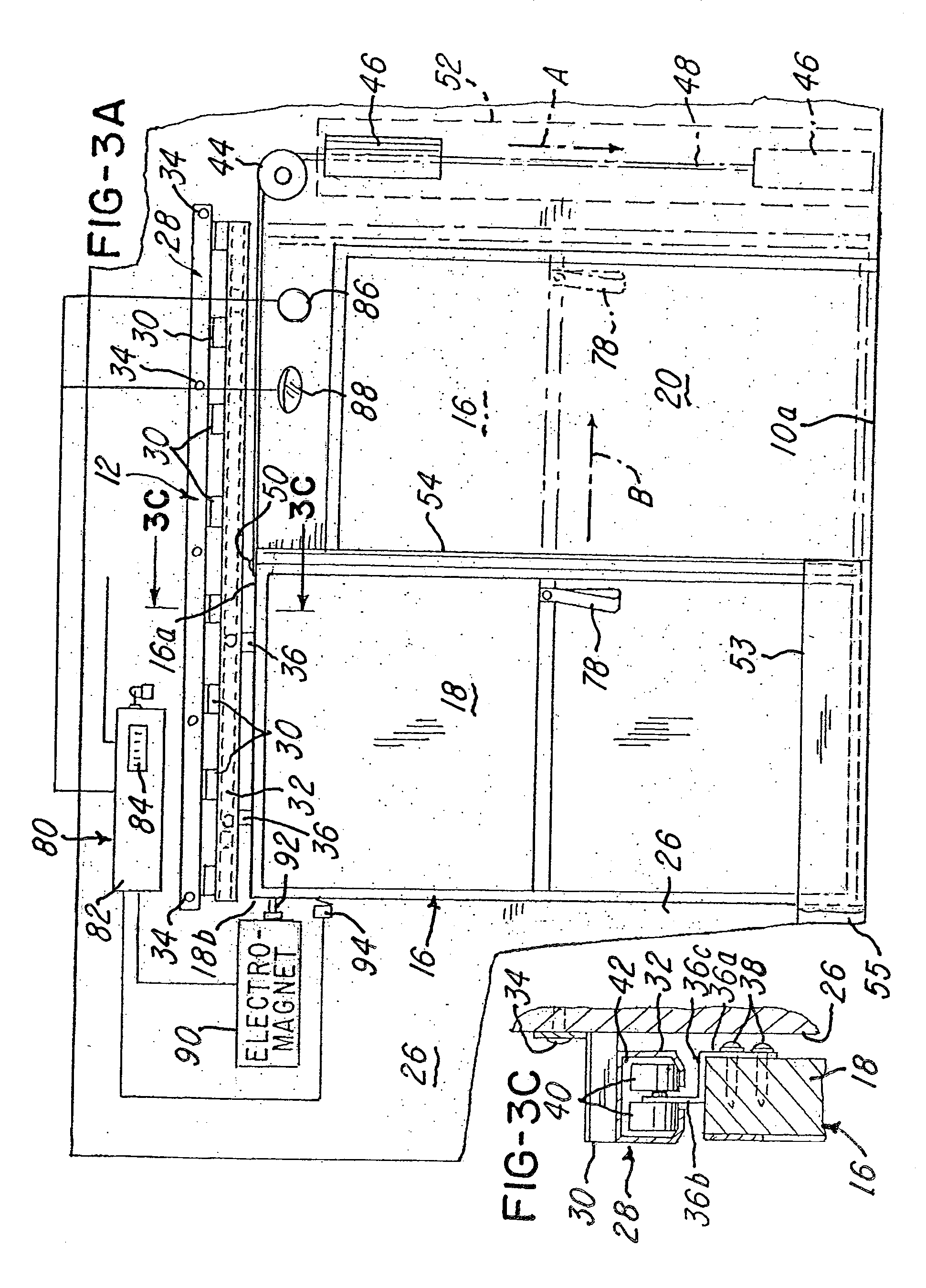

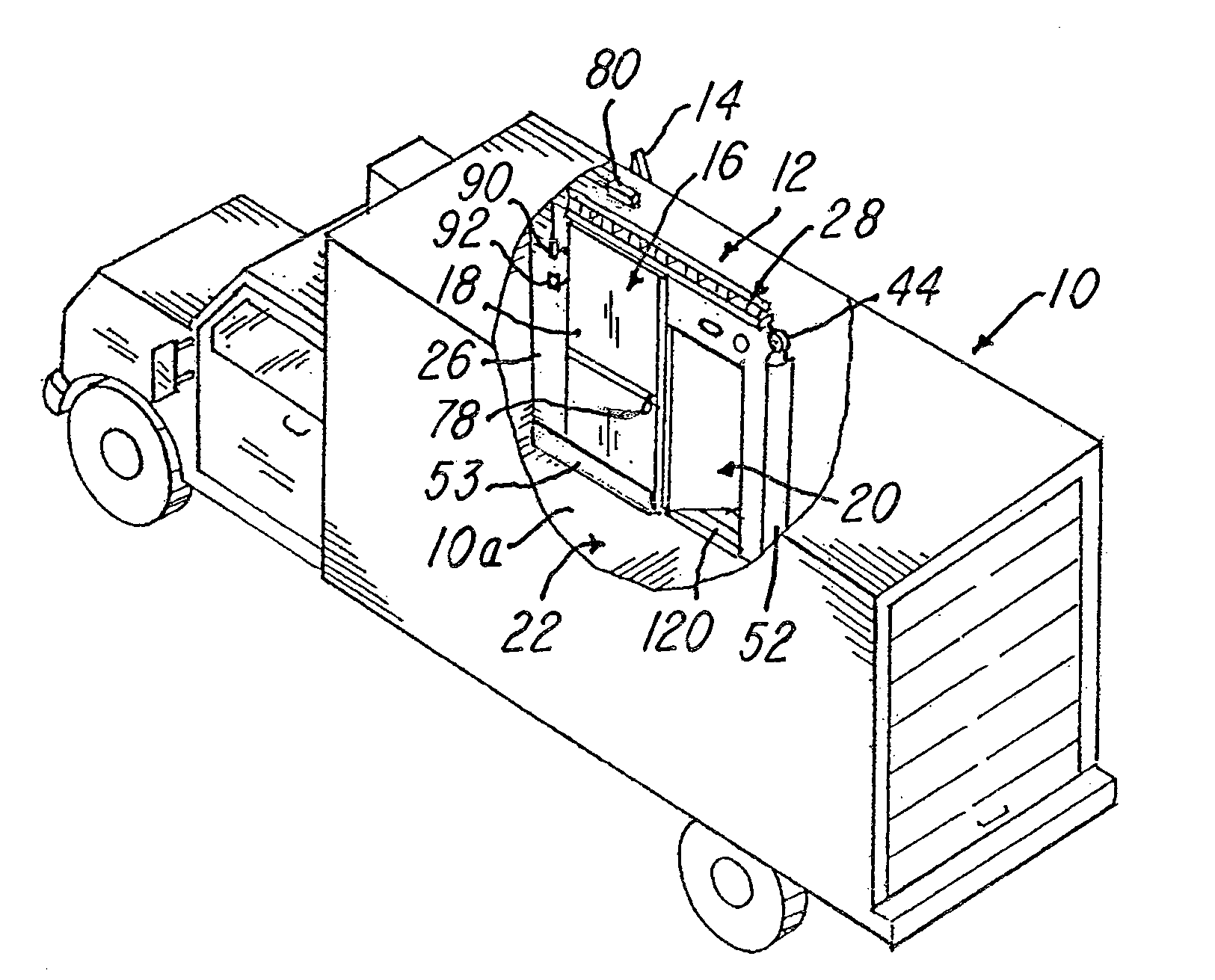

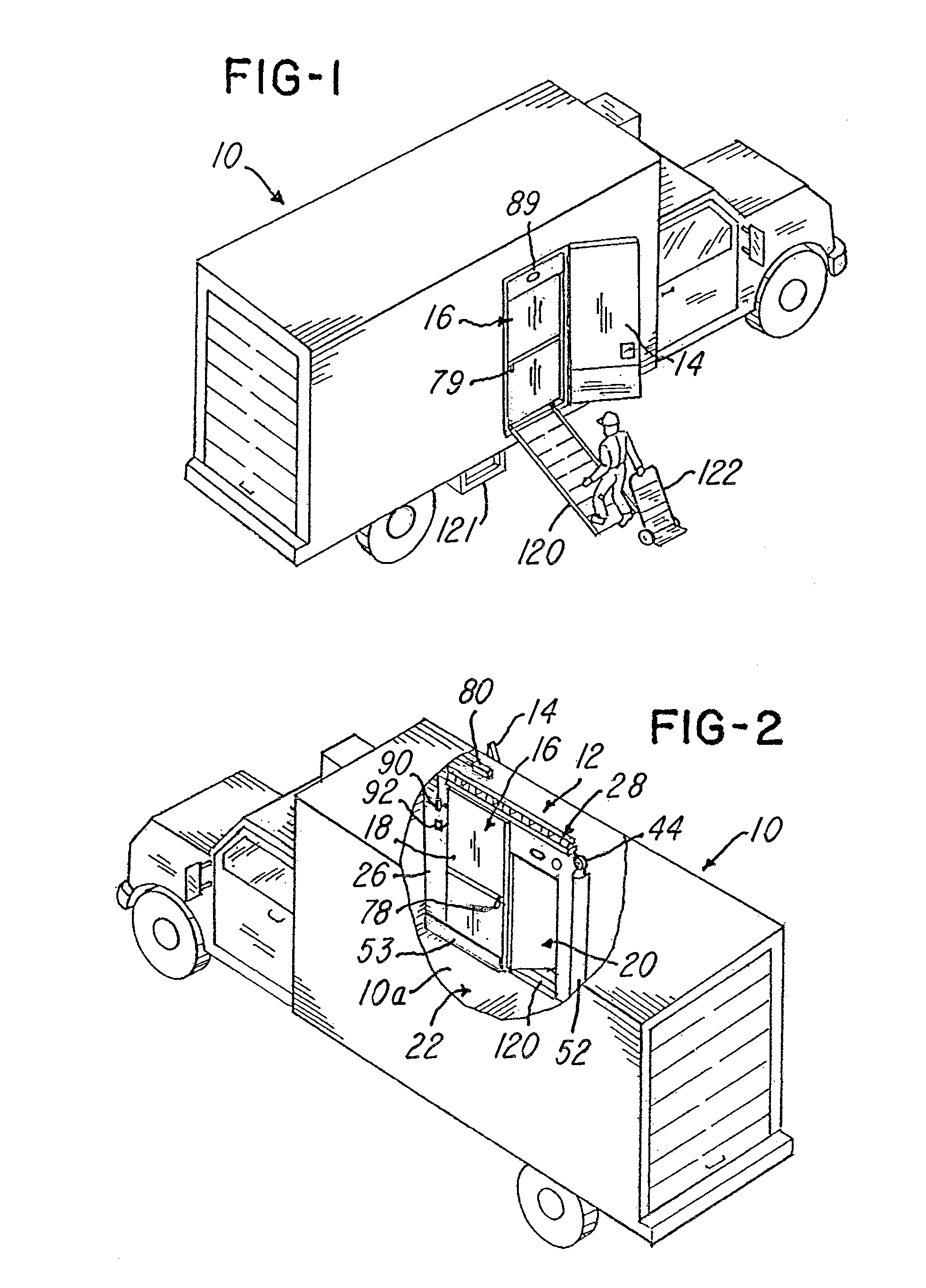

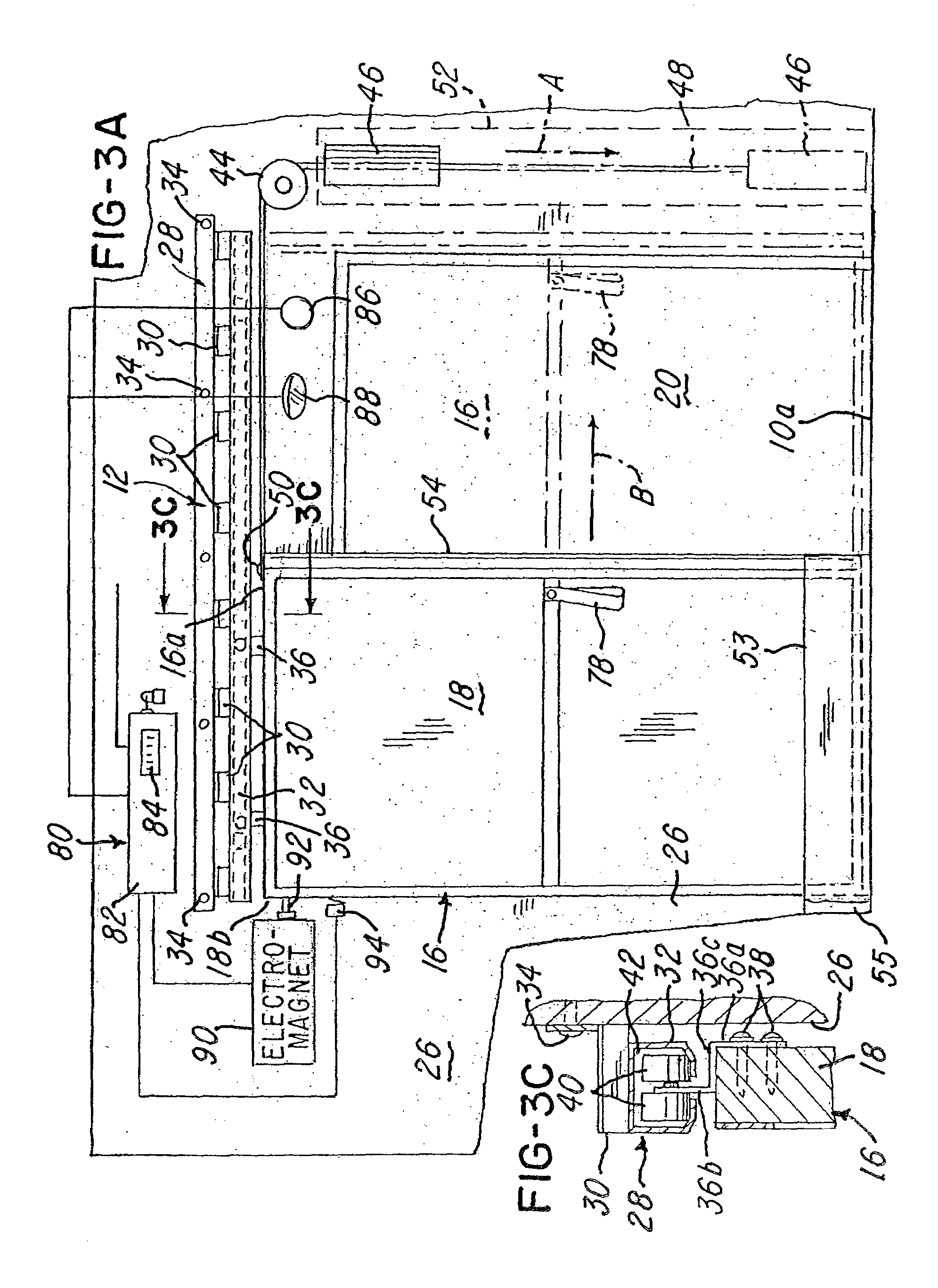

Secondary door and temperature control system and method

InactiveUS20080036238A1Reduce riskEasy to maintain temperatureWindowsWindscreensEntrywayTemperature control

An inner or secondary door and temperature control system for use on a vehicle or trailer having a storage compartment and a first or primary door associated with a first entry or entryway into the storage compartment. The secondary door provides a moveable barrier or door that is situated in operative relationship to the first entry or entryway associated with the first door in order to prevent thermal loss from the storage compartment area during deliveries or at times when the first door is open.

Owner:WEEDA DEWEY J +1

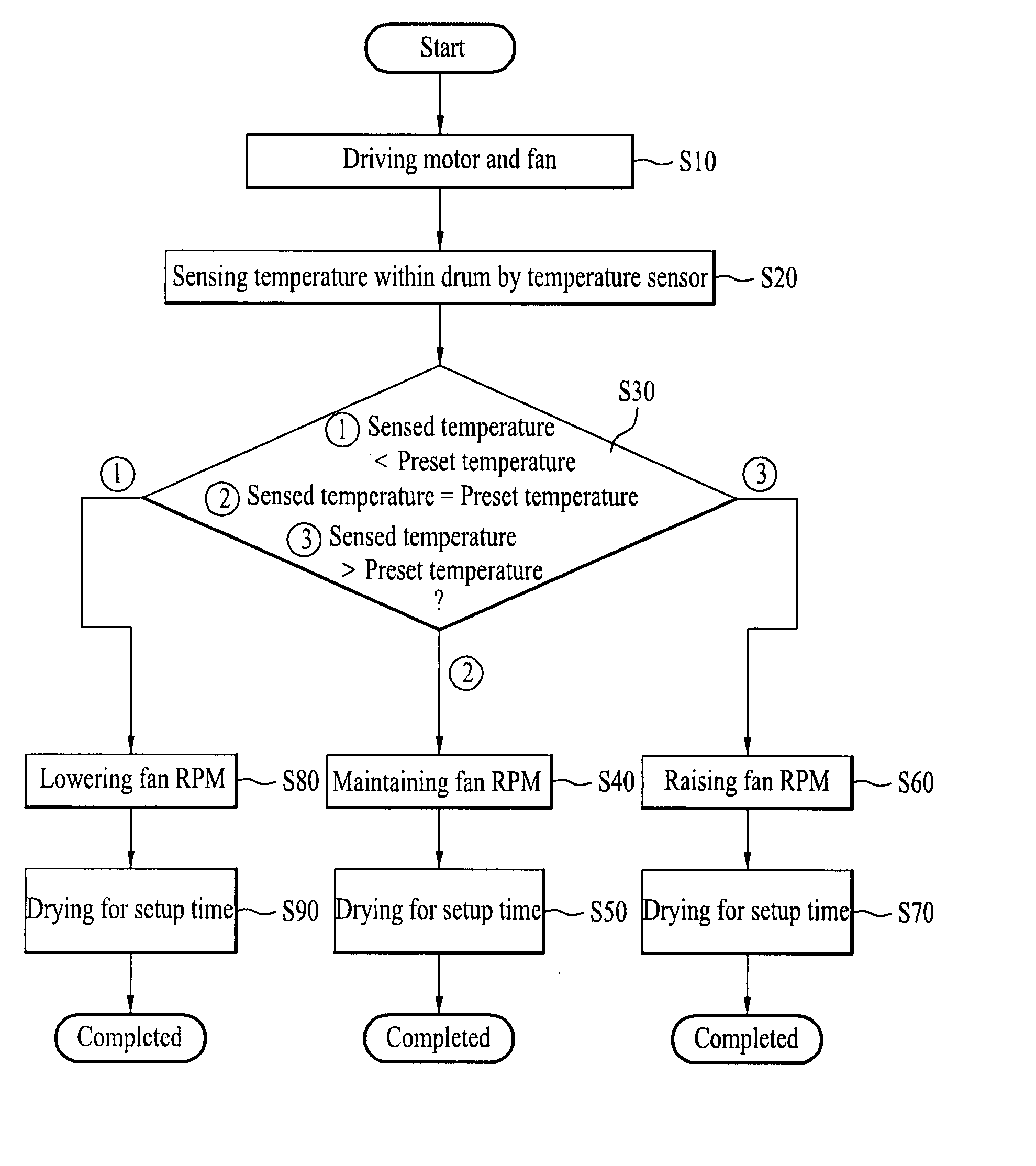

Dryer and control method thereof

InactiveUS20070251119A1Energy saveOptimal temperature maintenanceDrying gas arrangementsLaundry dryer apparatusRevolutions per minuteDrive motor

A dryer and control method thereof are disclosed, by which energy saving and optimal temperature maintenance within a drying drum are enabled in a manner of diversifying a heater temperature by varying a rotational speed of a blowing fan used for the dryer. The present invention includes a drying drum for accommodating an object to be dried therein, a blowing fan provided to enable an air to pass through the drying drum, a heater heating an air supplied to the drying drum, a temperature sensor sensing a temperature within the drying drum, a driving motor generating a driving force to rotate the drying drum and the blowing fan, and a control unit controlling an RPM (revolutions per minute) of the driving motor to be varied according to a sensing result of the temperature sensor.

Owner:LG ELECTRONICS INC

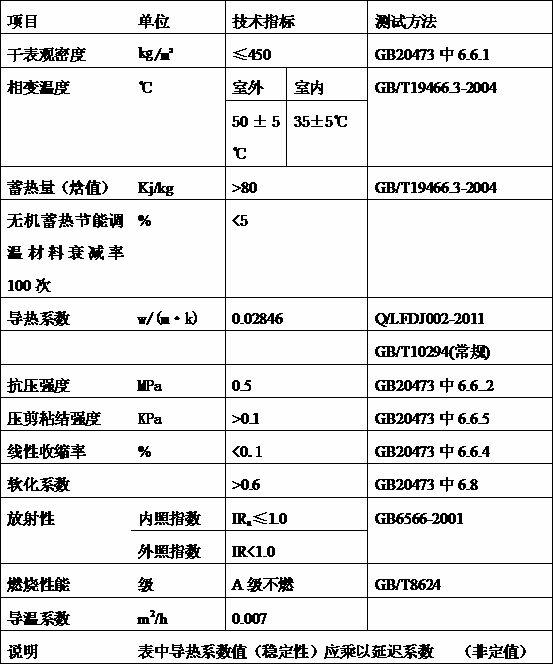

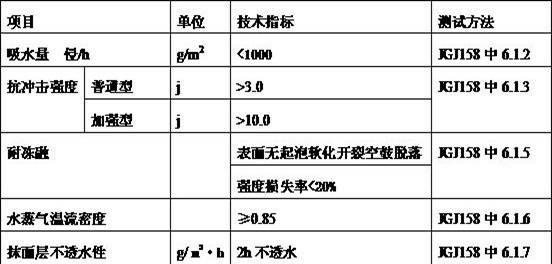

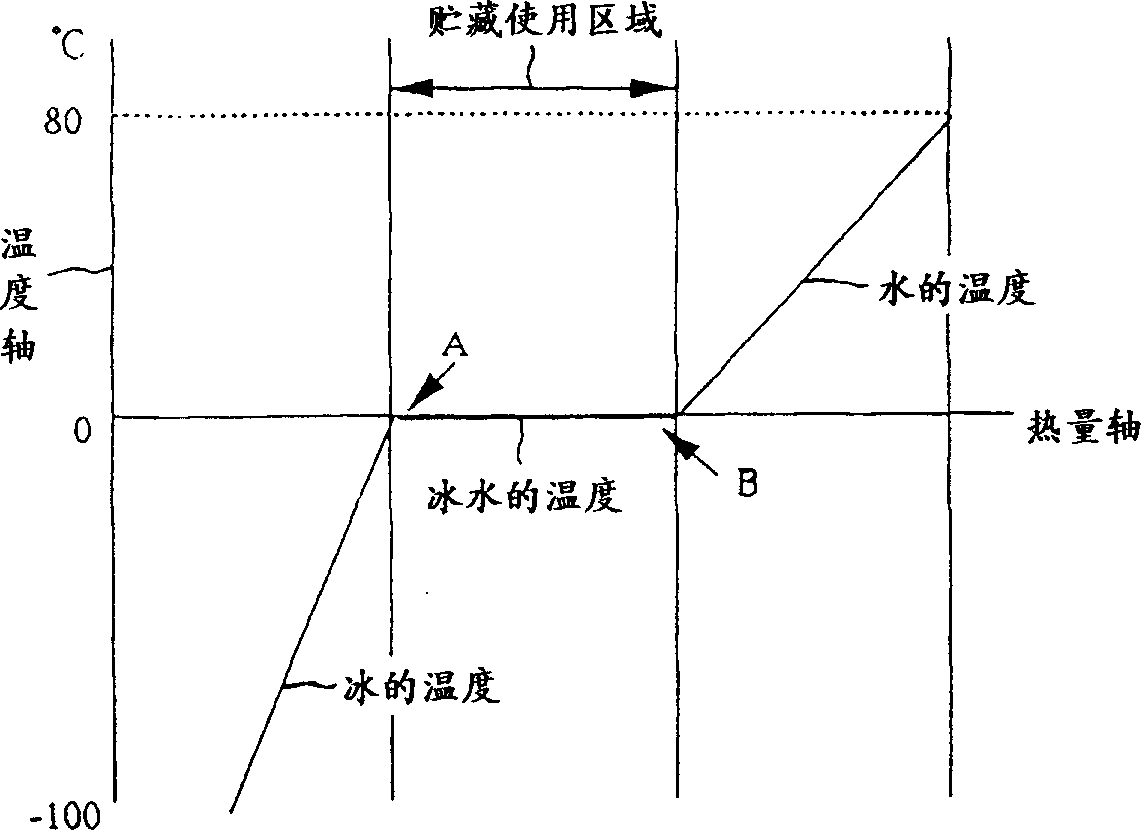

Phase-change and heat-storage heat preservation material and production method thereof

ActiveCN101613592ALow thermal conductivityLarge heat storage energyHeat-exchange elementsThermal energyParaffin wax

The invention relates to a phase-change and heat-storage heat preservation material and a production method thereof. The production method comprises the following steps: mixing paraffin wax, synthetic fatty acid, adipic acid, montan wax, crystal wax of heat storage materials accounting for 60 percent of the total weight in stirring and heating conditions according to a certain weight part ratio; raising the temperature to a certain value in atmospheric pressure; sequentially adding fire retardant, moisture repel, pour point depressant, stain control agent, mildew preventive and cement enhancer of adjustment materials accounting for 40 percent of the total weight under continuously stirring for reaction in a certain time; and keeping the temperature for 3 to 6 hours under continuously stirring, raising the temperature to 300 to 320 DEG C, keeping the temperature for few minutes, coating the materials to be finished goods when the temperature drops to be suitable for coating. The phase-change and heat-storage heat preservation material can become liquid phase so as to store heat energy when being heated (heat sources of sunlight, and the like) to achieve the saturation temperature; and when external temperature is lower than a set temperature, the phase-change and heat-storage material releases the heat energy, the phase-change material becomes solid phase from the liquid phase when the heat energy release is completed, and the process is repeated again and again for cycle.

Owner:阿尔派新能源(广东)集团有限公司 +1

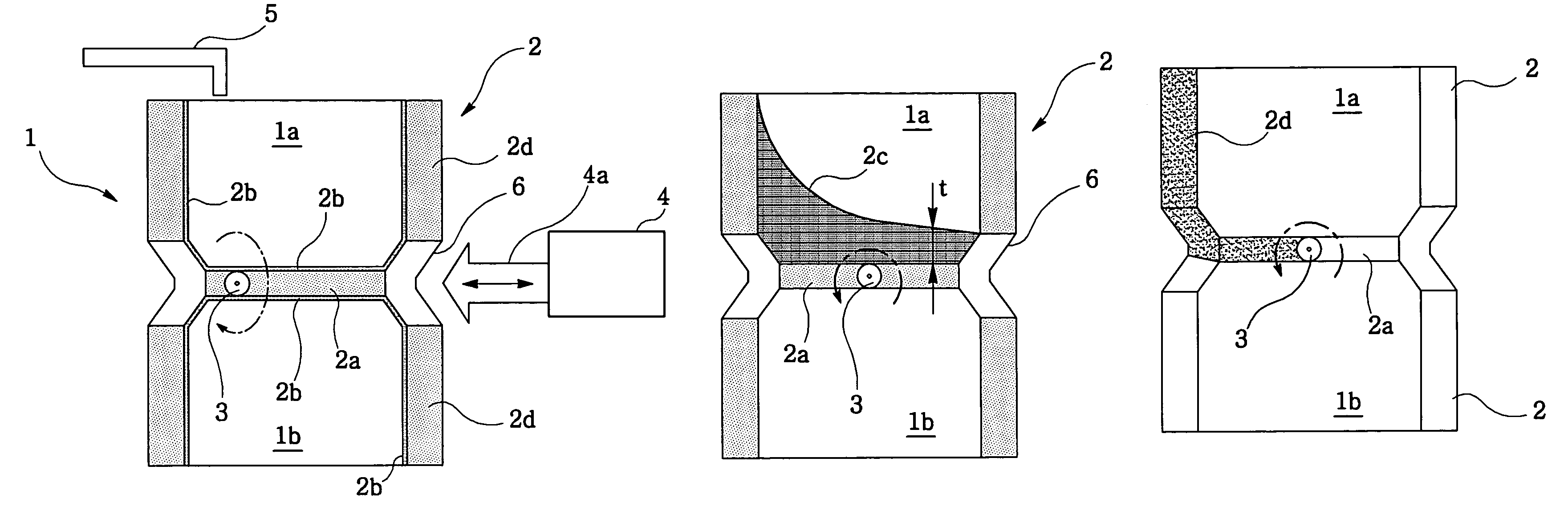

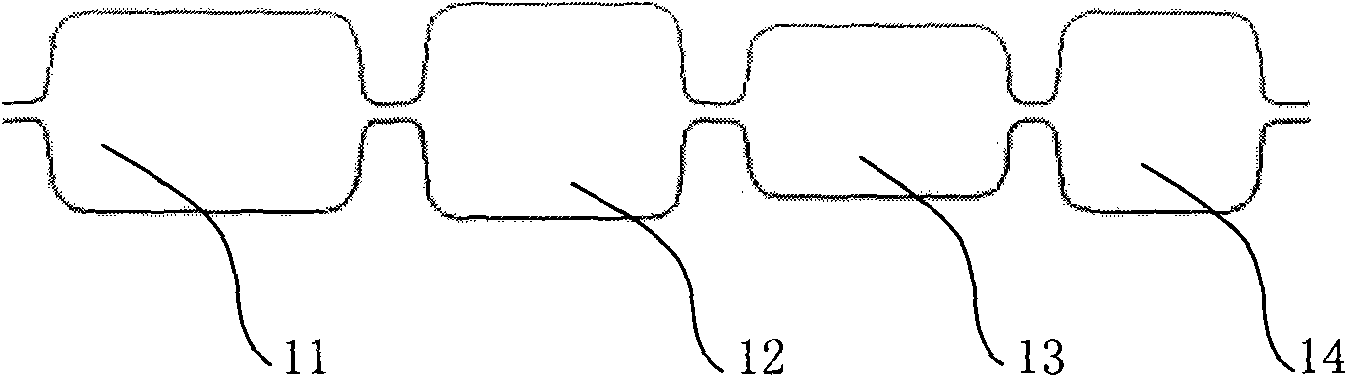

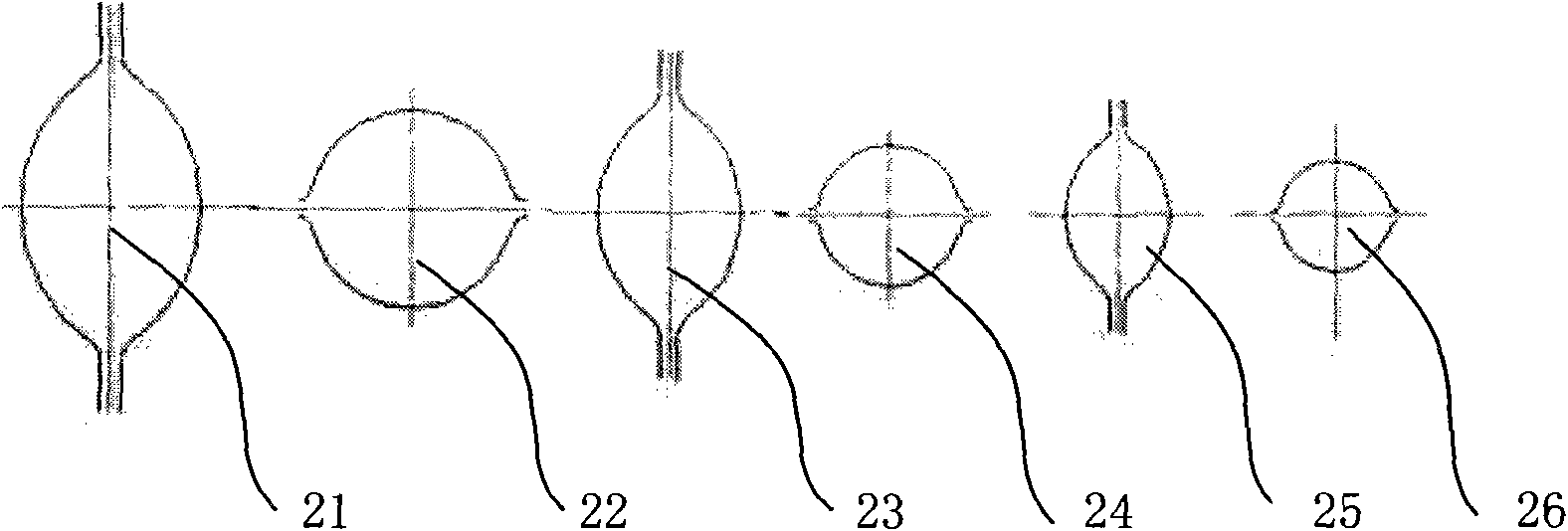

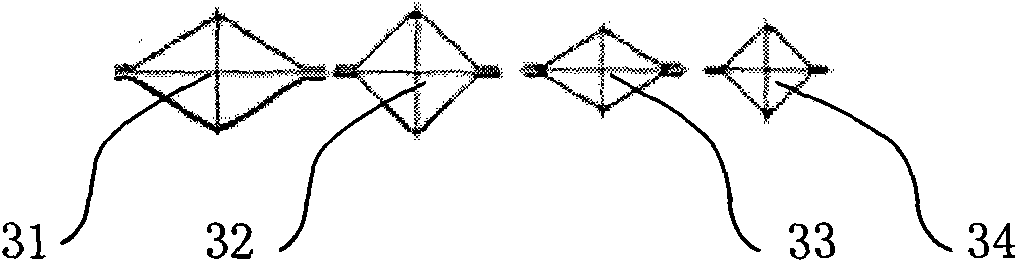

Method for rolling square steel

InactiveCN102039307AIncrease profitReduce consumptionMetal rolling arrangementsStress concentrationContinuous rolling

The invention relates to a method for rolling square steel. A frame is at least provided with a frame group consisting of an elliptical hole frame and a round hole frame, and a diamond hole frame and a square hole frame are connected behind the frame group. By the method for rolling the square steel, for steel rolling manufacturers which are put into operation, when square steel and round steel products are collinearly rolled by the same set of continuous rolling unit, the phenomenon of round steel hole pattern accompanying turning caused by nonuniform rolling yield can be effectively avoided, the utilization rate of a roller can be effectively improved, the consumption of the roller is reduced, and times for changing the roller can be reduced; the types of hole patterns are reduced, the sharing performance of on-line hole patterns is greatly improved, the times for changing the roller in a rolling line are reduced, and the roller is fully utilized; fishtail at the tail of a rolled piece, which is formed due to nonuniform deformation, has small length, so that the yield of the rolled piece is improved; the stress concentration of the roller is relatively small, so that risk that the roller is broken is reduced; and a tilting gear in front of a continuous rolling machine is saved, so that equipment investment is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Secondary door and temperature control system and method

InactiveUS7703835B2Reduce riskEasy to maintain temperatureWindowsWindscreensEntrywayTemperature control

An inner or secondary door and temperature control system for use on a vehicle or trailer having a storage compartment and a first or primary door associated with a first entry or entryway into the storage compartment. The secondary door provides a moveable barrier or door that is situated in operative relationship to the first entry or entryway associated with the first door in order to prevent thermal loss from the storage compartment area during deliveries or at times when the first door is open.

Owner:WEEDA DEWEY J +1

Inorganic heat-storage, energy-saving and temperature-regulating wall material

Disclosed is an inorganic heat-storage, energy-saving and temperature-regulating wall material. The technical scheme includes that a certain quantity of high alumina cement, vitreous beads, aluminum silicate powder, bentonite, redispersible polymer powder, hydroxypropyl methyl cellulose, polypropylene fibers, starch ether 6200, gray calcium powder, water repellent or waterproofing agent, air-entraining agent and asbestos wool are mixed, and are sufficiently mixed in a cyclone separation manner and packaged to form a finished product. When heated (by heat sources such as sunlight and the like), the low-carbon heat-storage, energy-saving and automatic temperature-regulating wall material becomes liquid when reaching saturated temperature, and heat energy is stored; and when external temperature is lower than set temperature, the heat-storage material begins to release heat, after the heat is released thoroughly, the phase-change material becomes solid from the liquid, and the process runs in circle. The inorganic heat-storage, energy-saving and temperature-regulating wall material can be made into a section, a plate, mortar and a perforated brick, can absorb sound wave, is elastic, and vibrates, rebounds and reversely absorbs under sound wave impact, frequencies of the material are different, structural vibration is relieved, and the purpose of eliminating noise is achieved.

Owner:吉林益冠无机相变科技有限公司

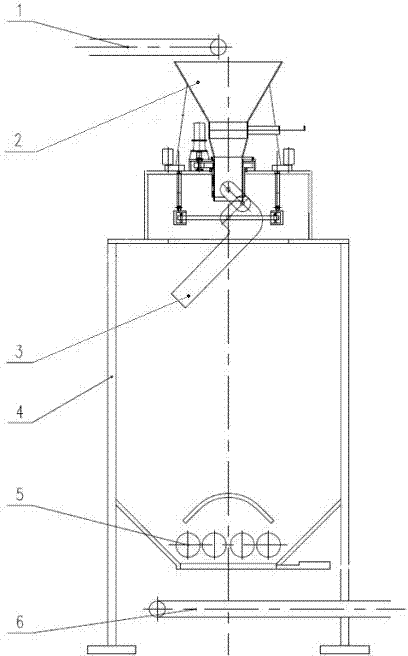

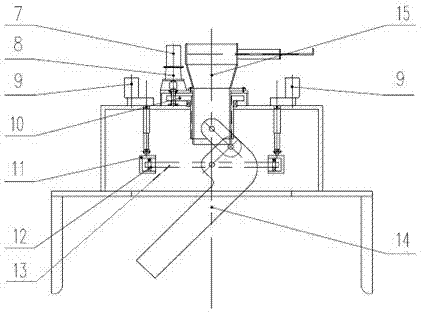

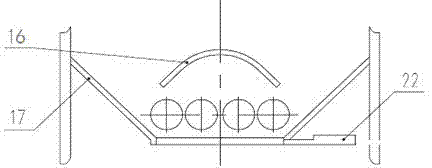

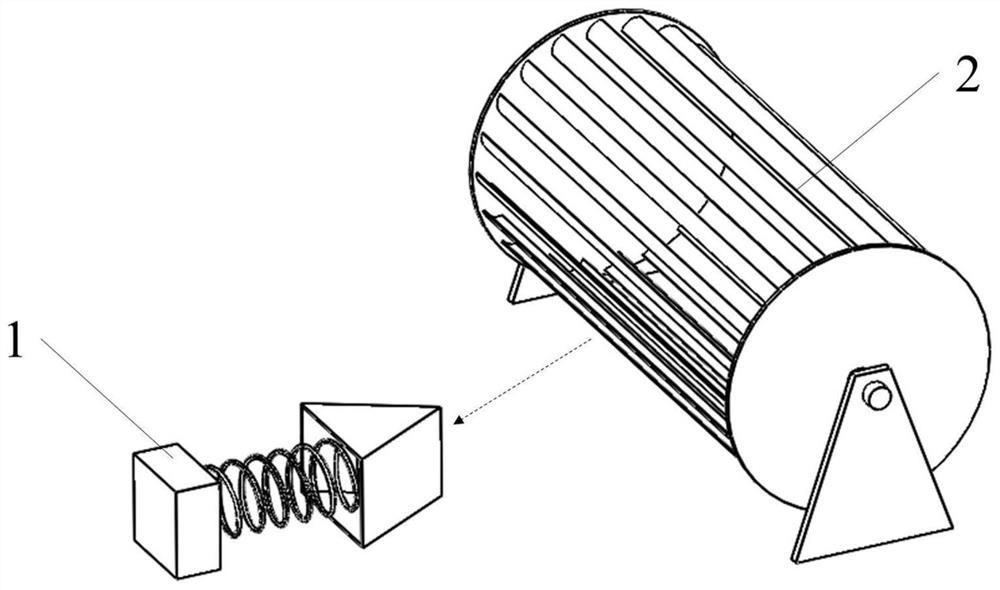

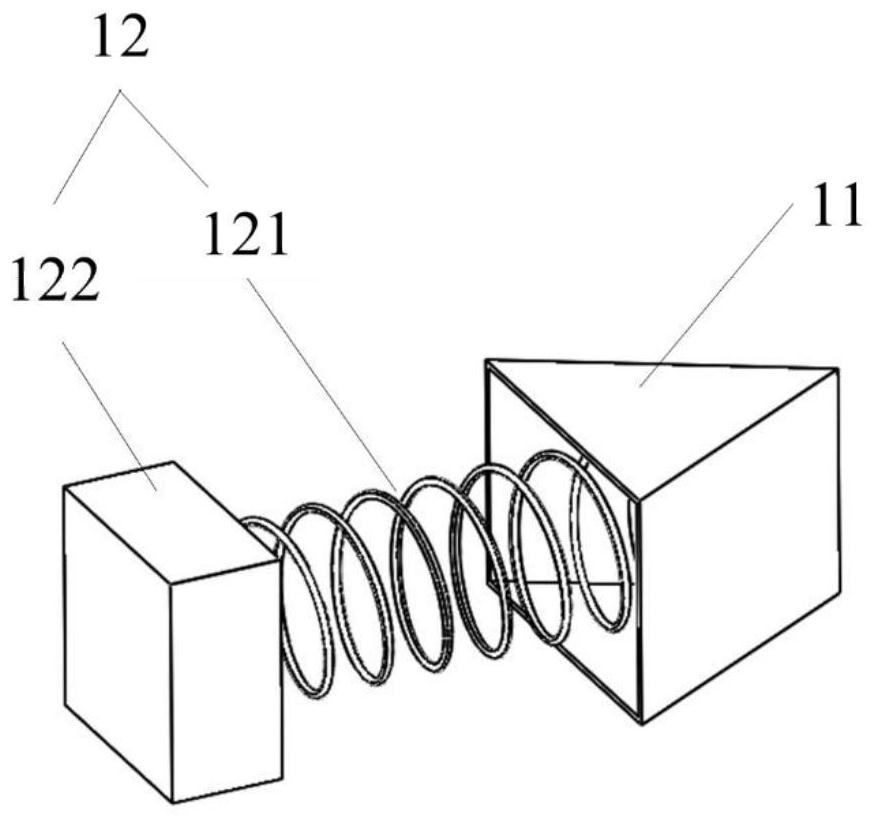

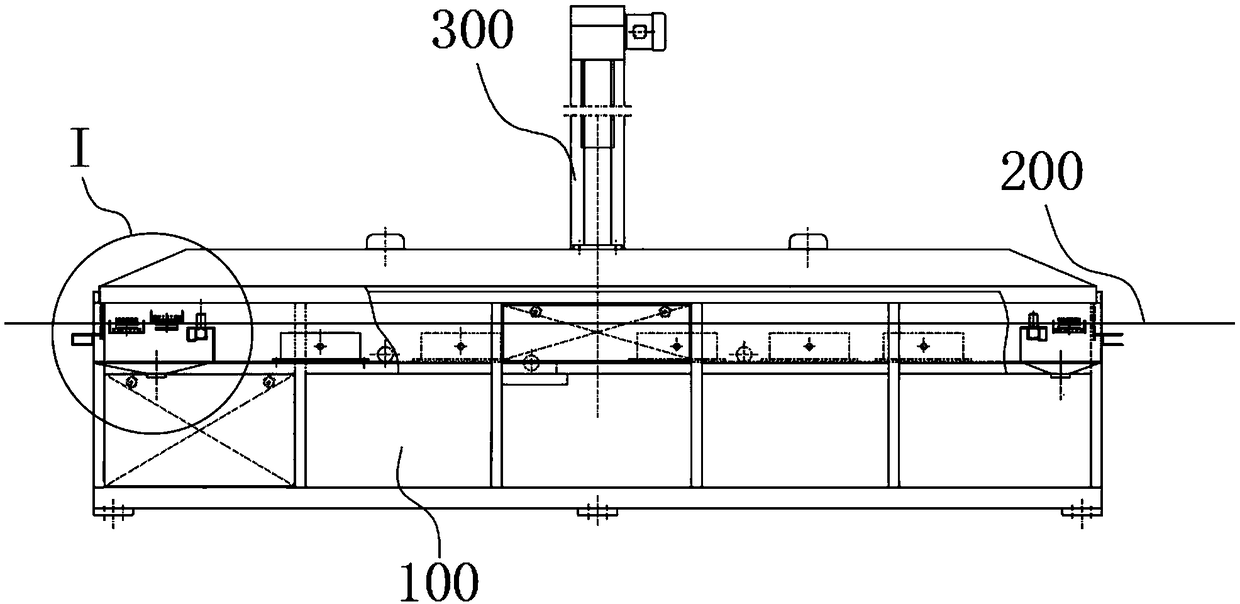

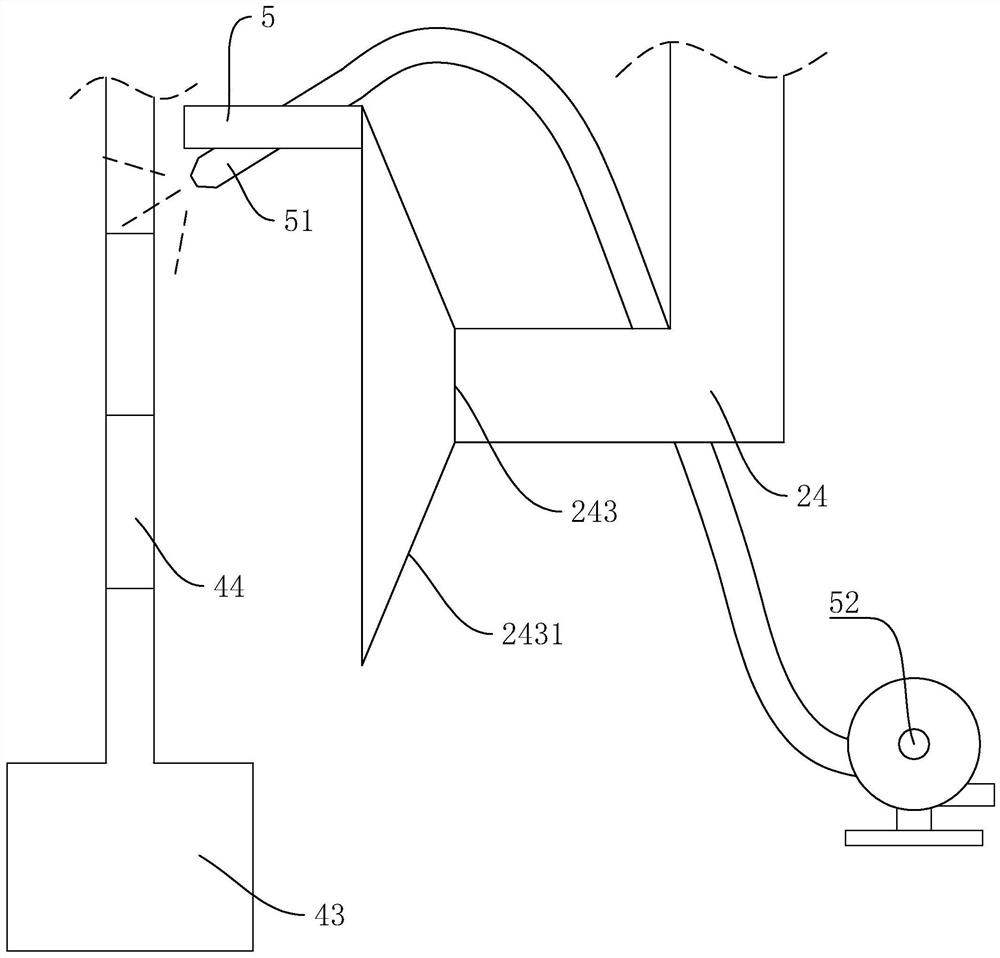

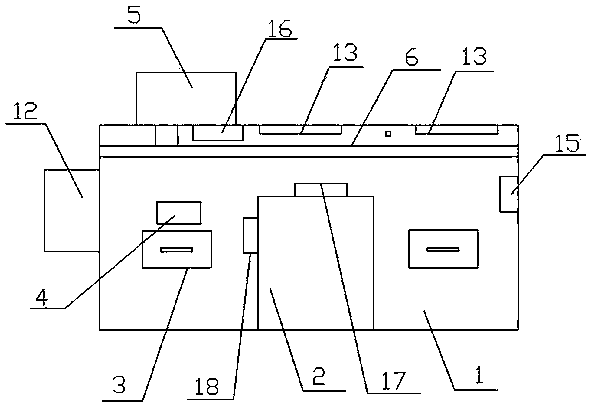

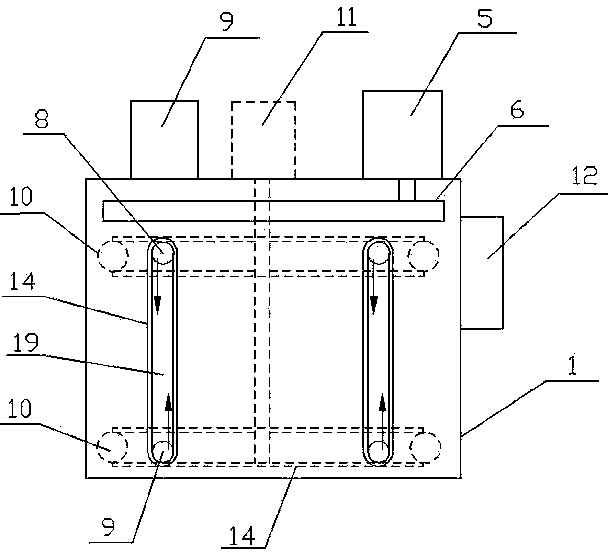

Cylindrical ageing storehouse capable of automatically distributing and discharging

ActiveCN103569689AEasy to keep hydratedEasy to maintain temperatureLoading/unloadingGear wheelReducer

The invention relates to a cylindrical ageing storehouse capable of automatically distributing and discharging. The cylindrical ageing storehouse is characterized by comprising a feeding belt conveyor, a silo, a distributing system, a storehouse body, a roller-type discharge device and a blanking belt conveyor which are sequentially connected, wherein the distributing system comprises a first motor, a first speed reducer, electric cylinders, a bull and pinion, moving blocks, pulleys, a connecting rod, a distributing chute and a blanking pipe; the first motor, the first speed reducer, the bull and pinion and the distributing chute are sequentially connected; the electric cylinders, the moving blocks and the connecting rod are sequentially connected; a supporting point of the distributing chute is arranged on the connecting rod; the blanking pipe is arranged at the upper end of the distributing chute; the upper end of the blanking pipe is connected with the silo; the feeding belt conveyor is arranged above the silo; and the distributing chute extends into the storehouse body. The cylindrical ageing storehouse has the advantages that feeding and distributing are uniform; moisture and temperature of a raw material are easy to keep; the raw material can achieve first in first out; raised dust is easy to collect and dispose; a space utilization ratio is high; and mechanization and automation degrees are high.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

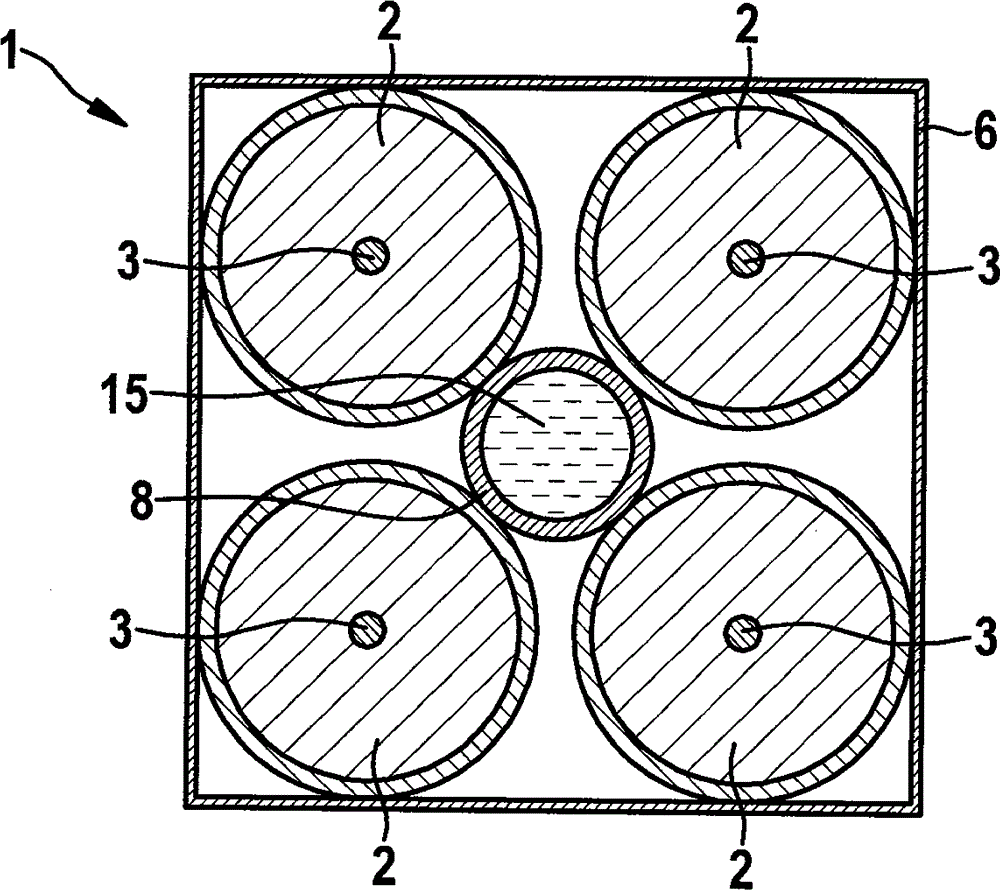

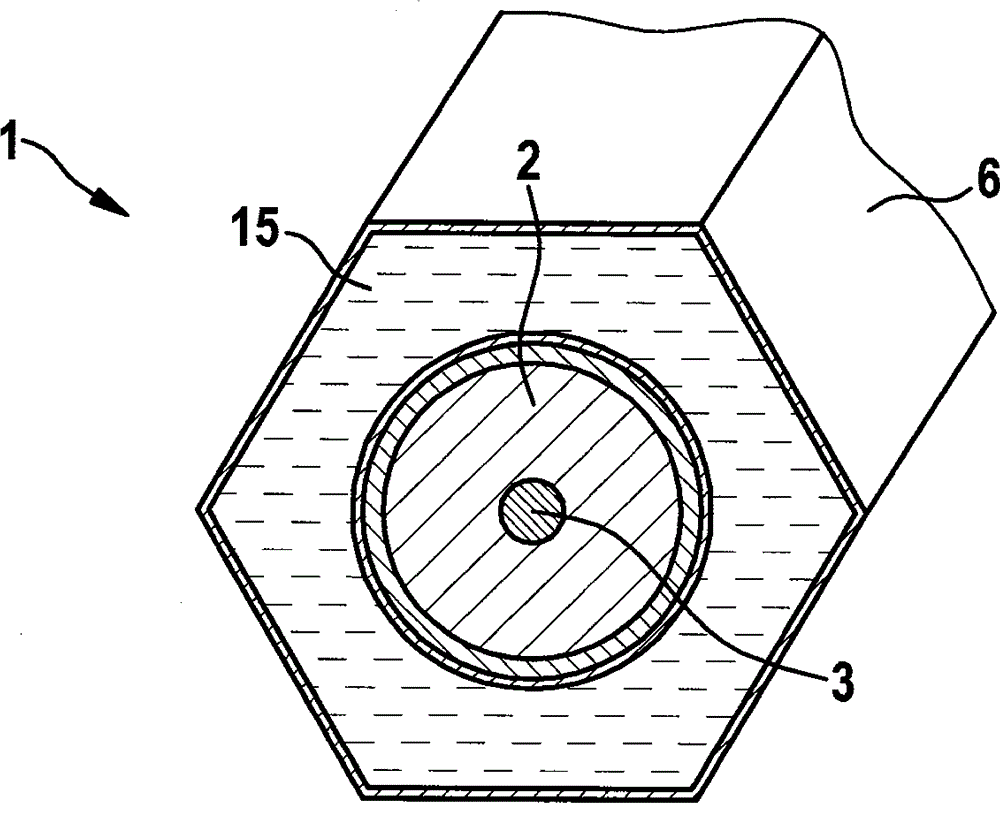

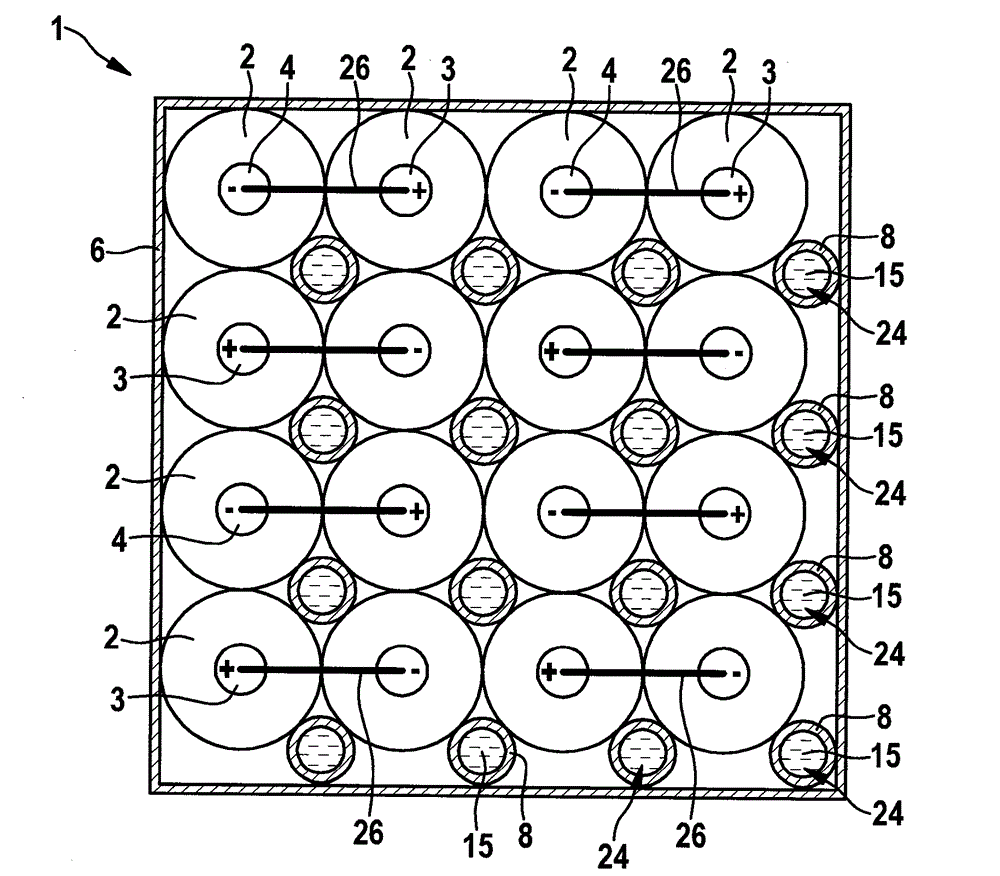

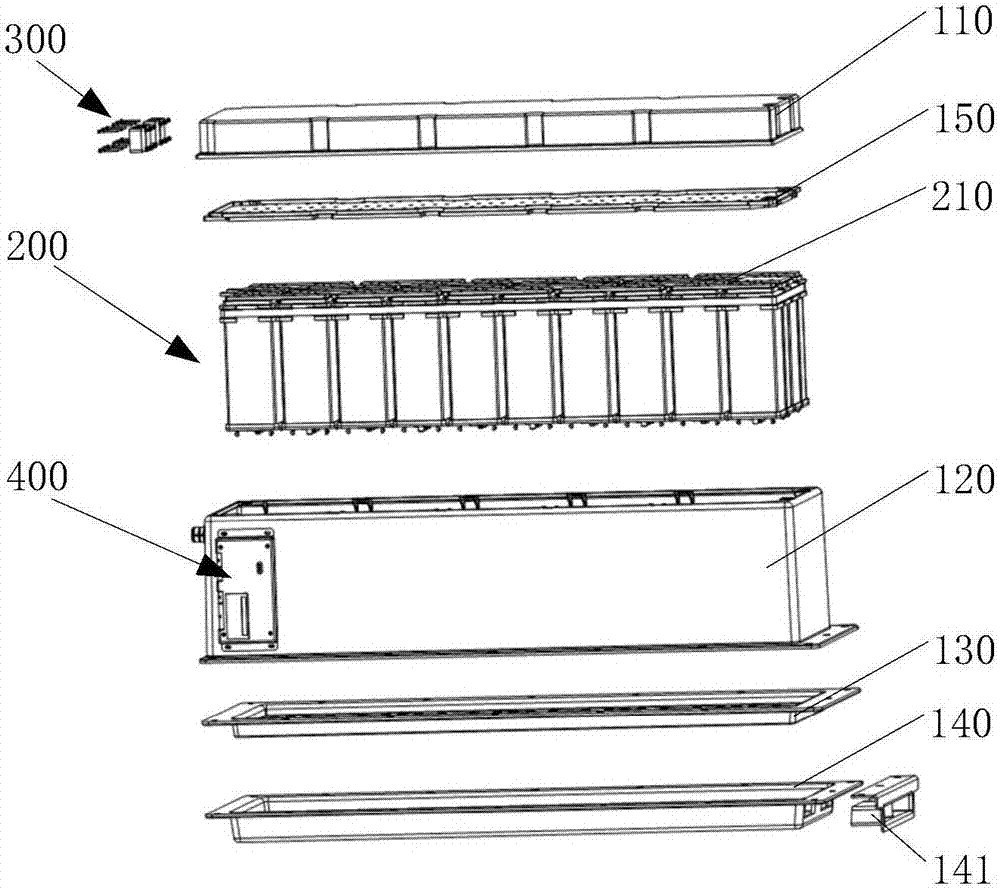

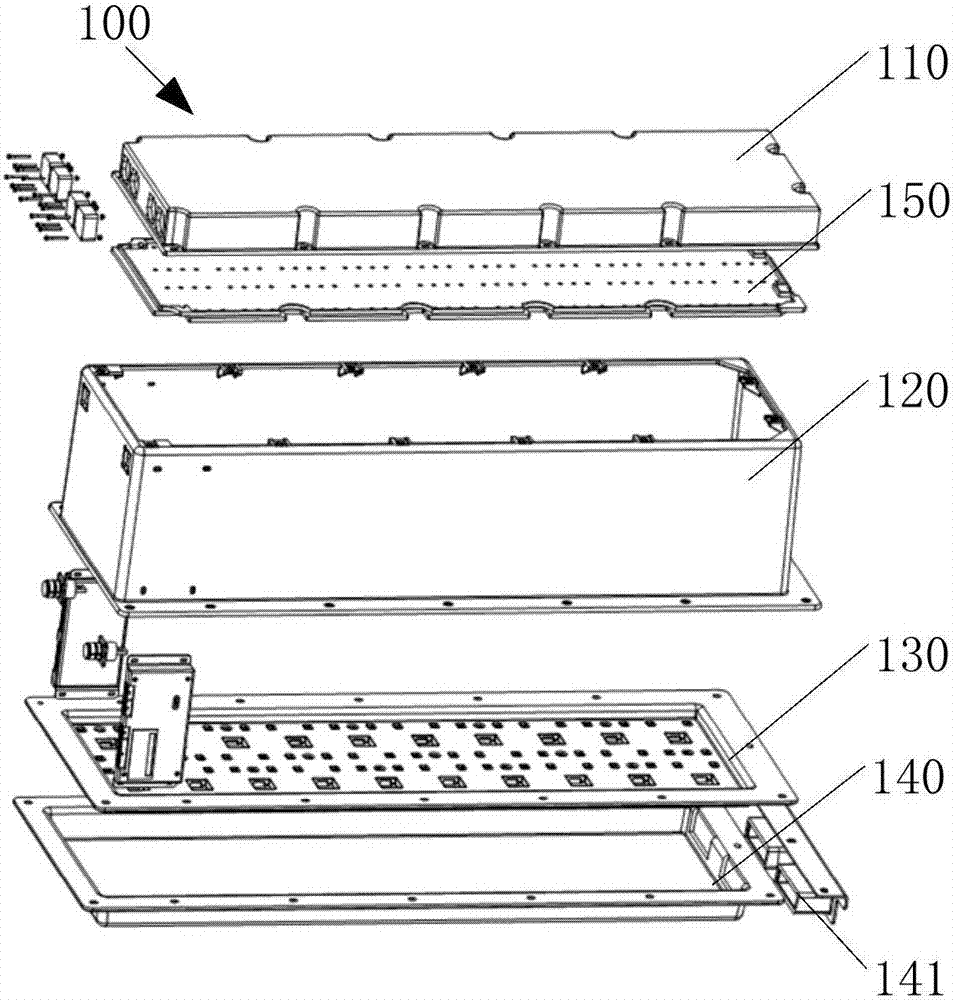

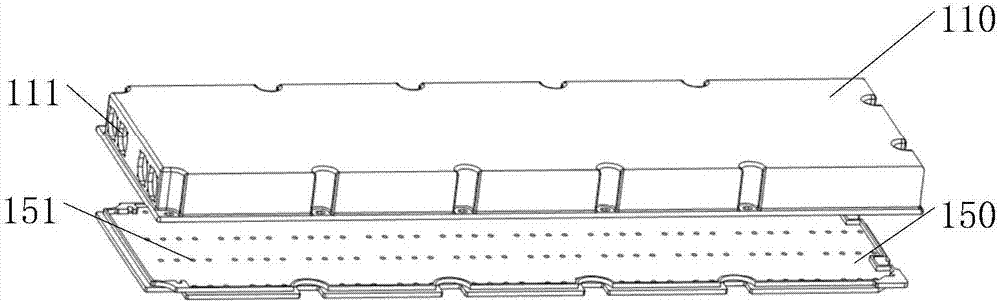

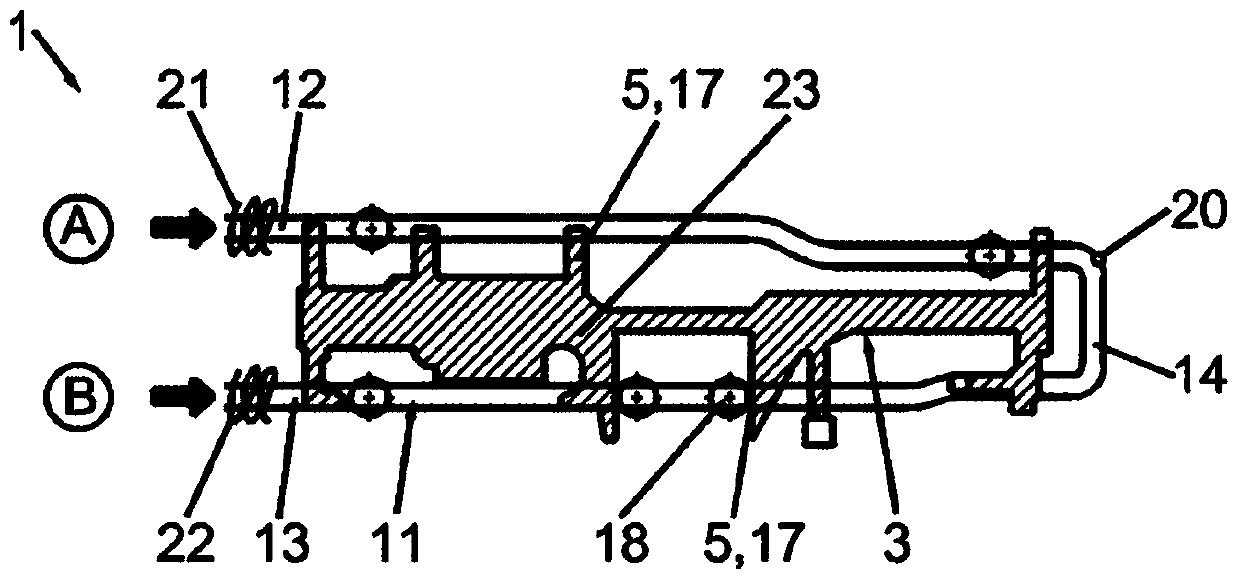

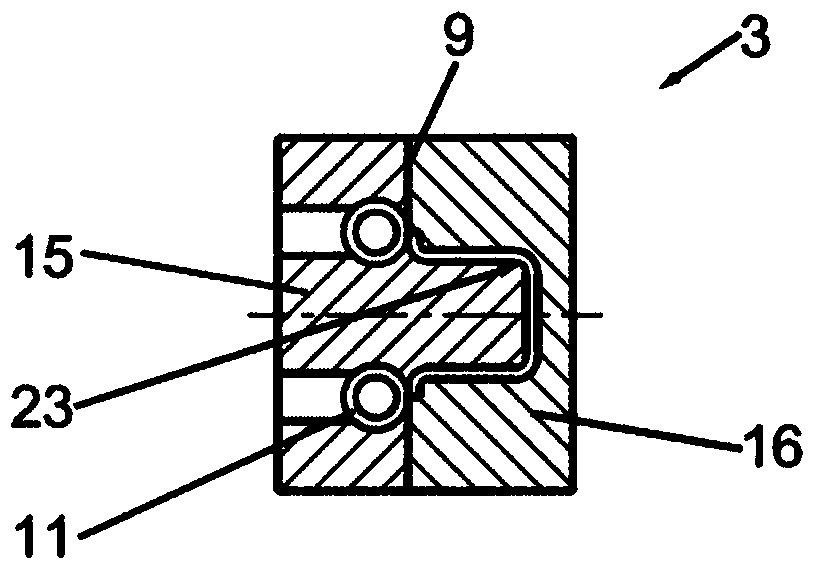

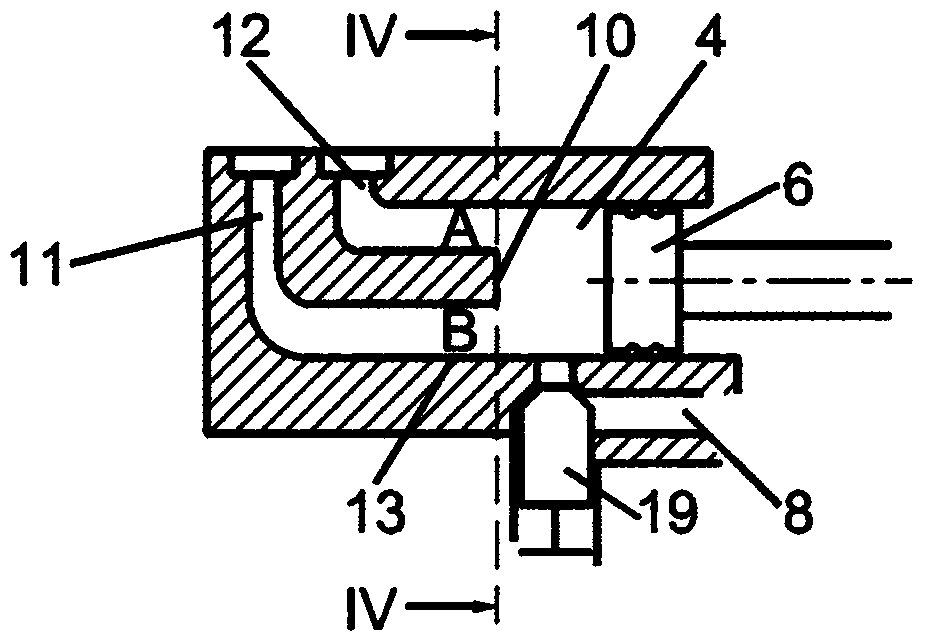

Battery unit with a plurality of battery cells and battery module with a plurality of such battery units

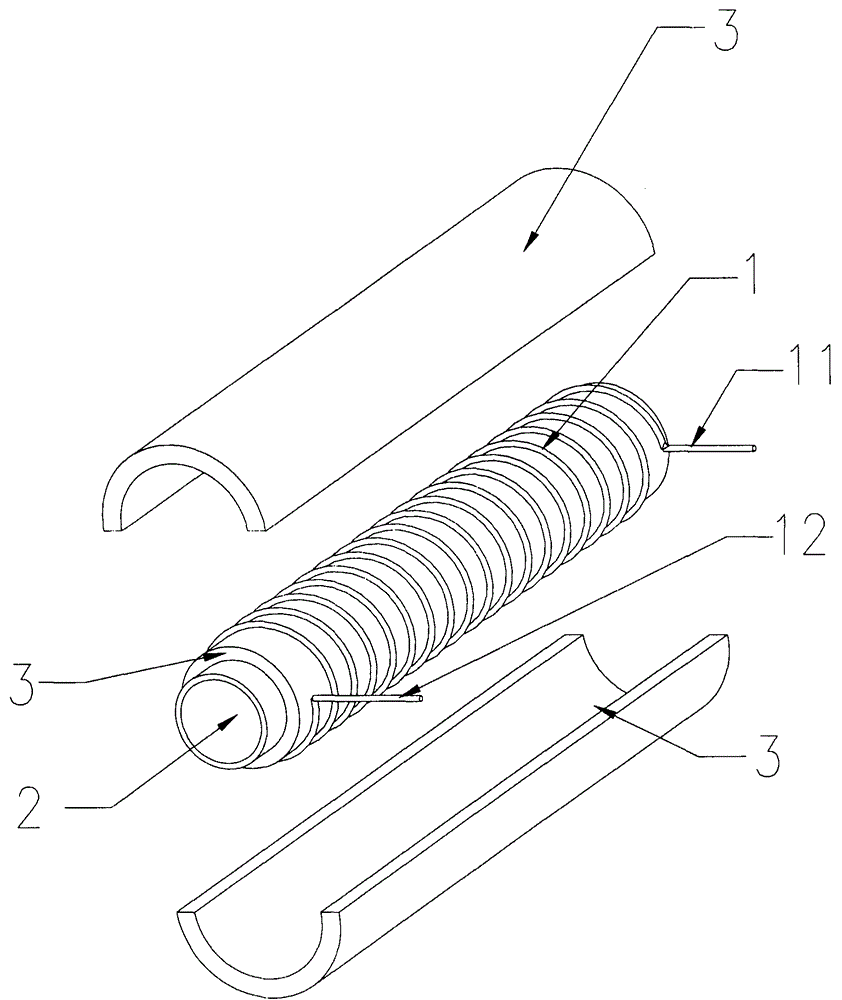

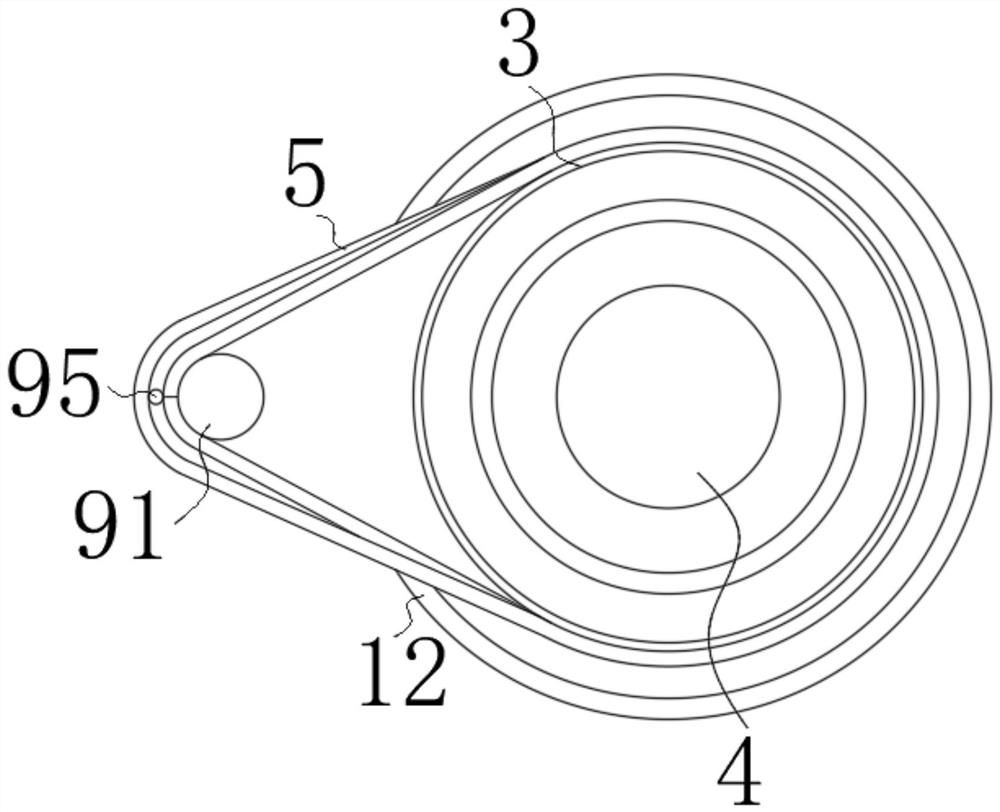

ActiveCN105280870AImproved deformabilityGood weight distributionSmall-sized cells cases/jacketsSecondary cellsEngineeringElectrical and Electronics engineering

The present invention relates to a battery unit (1) comprising a plurality of battery cells (2) each having a first electrode (3) and a second electrode (4) for electrically contacting the respective battery cell (2), wherein the battery cells (2) through cell connectors (5) are electrically connected to each other and the interconnected battery cells (2) are enclosed by an outer casing (6) integrating the battery cells (2) together, the cell connectors (5) comprise at least one flexible molded portion and the outer casing (6) at least partially is flexible, such that the battery unit (1) is deformable according to the change of the relative structure of the battery cells (2). Furthermore, the invention relates to a battery module having a plurality of electrically connected battery units (1).

Owner:ROBERT BOSCH GMBH

Honeycomb vacuum hole heat insulating ceramic tile and technique for producing the same

InactiveCN101412614AImprove insulation performanceEasy to maintain temperatureCeramicwareClaywaresBrickKaolin clay

The invention discloses a honeycomb vacuum hole heat insulating ceramic tile and a process for producing the same. The raw materials for the unburned brick of the heat insulating ceramic tile in weight percentage are: (1) 60 to 70 percent of kaolin, (2) 1 to 5 percent of plastic foam particle, and (3) 20 to 30 percent of water; the raw materials for a glistening white glaze by weight percentages are: (1) 50 to 65 percent of silicon oxide, (2) 13 to 18 percent of aluminum oxide, (3) 12 to 17 percent of calcium oxide, (4) 0.5 to 1.5 percent of magnesium oxide, (5) 3 to 4 percent of sodium oxide, and (6) 1 to 1.5 percent of potassium oxide; and the plastic foam comprises but is not limited to polyurethane plastic particle the diameter of which is between 6 and 7 millimeters. The process for producing the ceramic tile comprises the following steps: mixing and pressing various raw materials of the heat insulating ceramic tile into specified unburned bricks, naturally drying the specified unburned bricks completely, spraying the glistening white glaze on the specified unburned bricks, airing and then firing the specified unburned bricks to obtain the finished product. When the ceramic tile is fired into the finished product, a plurality of honeycomb vacuum holes appear in the brick body, the vacuum holes are not connected with each other and are kept at a constant temperature, thus the honeycomb vacuum hole heat insulating ceramic tile has good heat insulating effect.

Owner:周凤华

Buoyancy-type liquid level meter

InactiveCN103644954AEliminate water ingressReduce manufacturing costLevel indicators by floatsMeasuring instrumentTransducer

The invention relates to a buoyancy-type liquid level meter for measuring the liquid level by applying a buoyancy, gravity and equilibrant balancing method, aiming at mainly solving the problem of influence of the temperature, pressure, vaporization and coagulation of a measured medium on measurement and overcoming the defects of an existing related measuring instrument. The method is not limited by the situation that the specific gravity of a floater is less than the specific gravity of measured liquid and can be used for measuring the liquid level by using a solid or hollow floater. The measuring meter suitable for multiple environments and multiple liquid levels can be manufactured according to specific conditions. The invention relates to a steam dome water level switch for measuring the steam dome water level inside an industrial boiler. The steam dome water level switch disclosed by the invention has high accuracy, high reliability and less drifting without frequent verification adjustment. Compared with a transducer, the steam dome water level switch disclosed by the invention has the advantages that intermediate conversion links are few, access of a computer system is not needed, an independent protective signal output is realized, complex electronic software and hardware are omitted, steam-water density compensation calculation is avoided, and the influence of steam-water density change and the influence of fast boiler load change are basically eliminated.

Owner:冯振宇

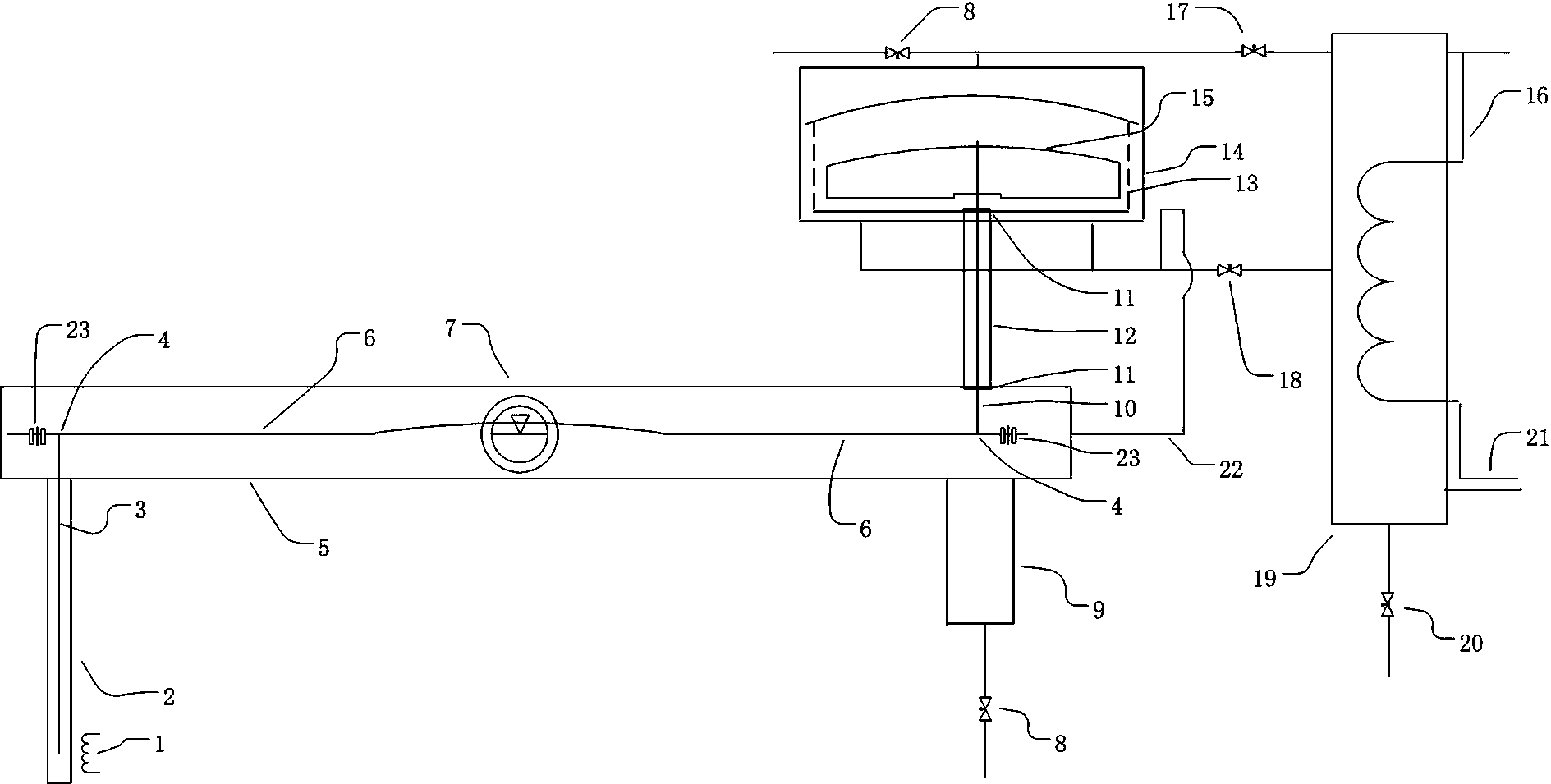

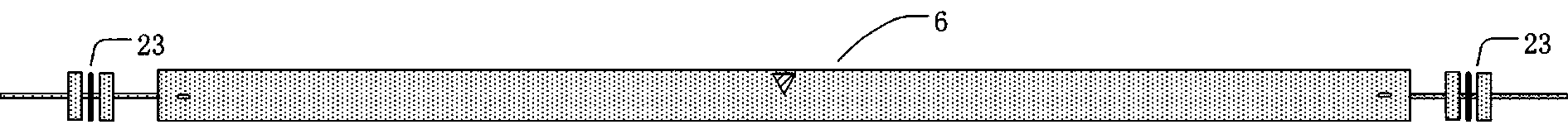

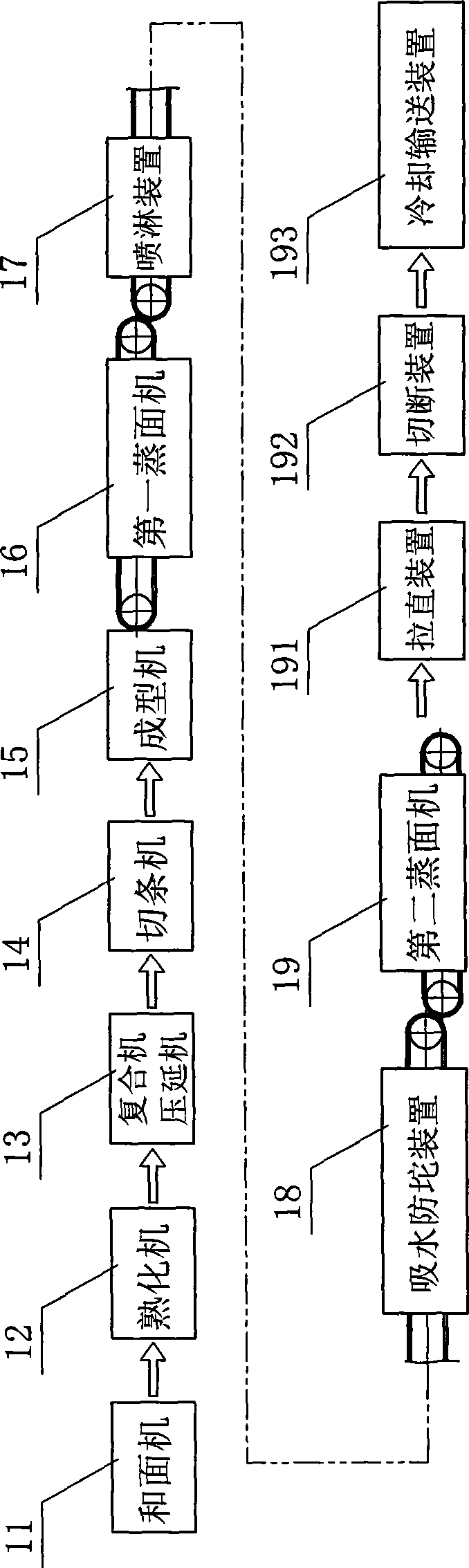

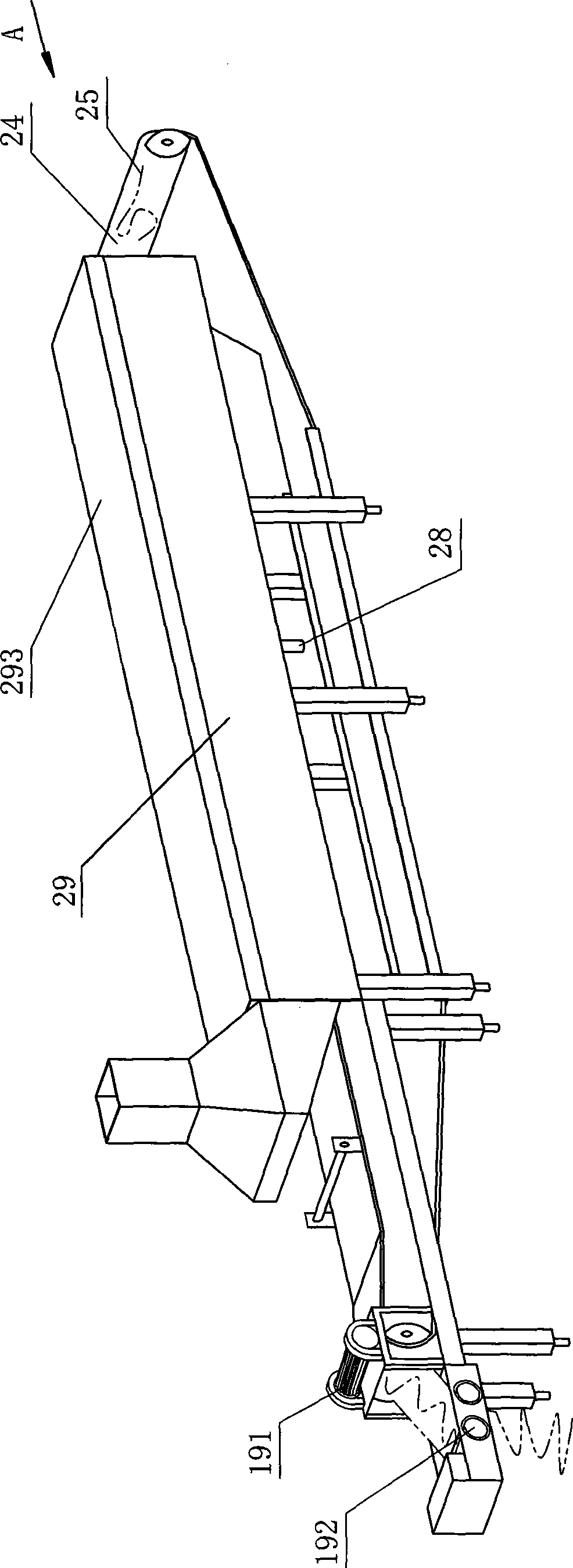

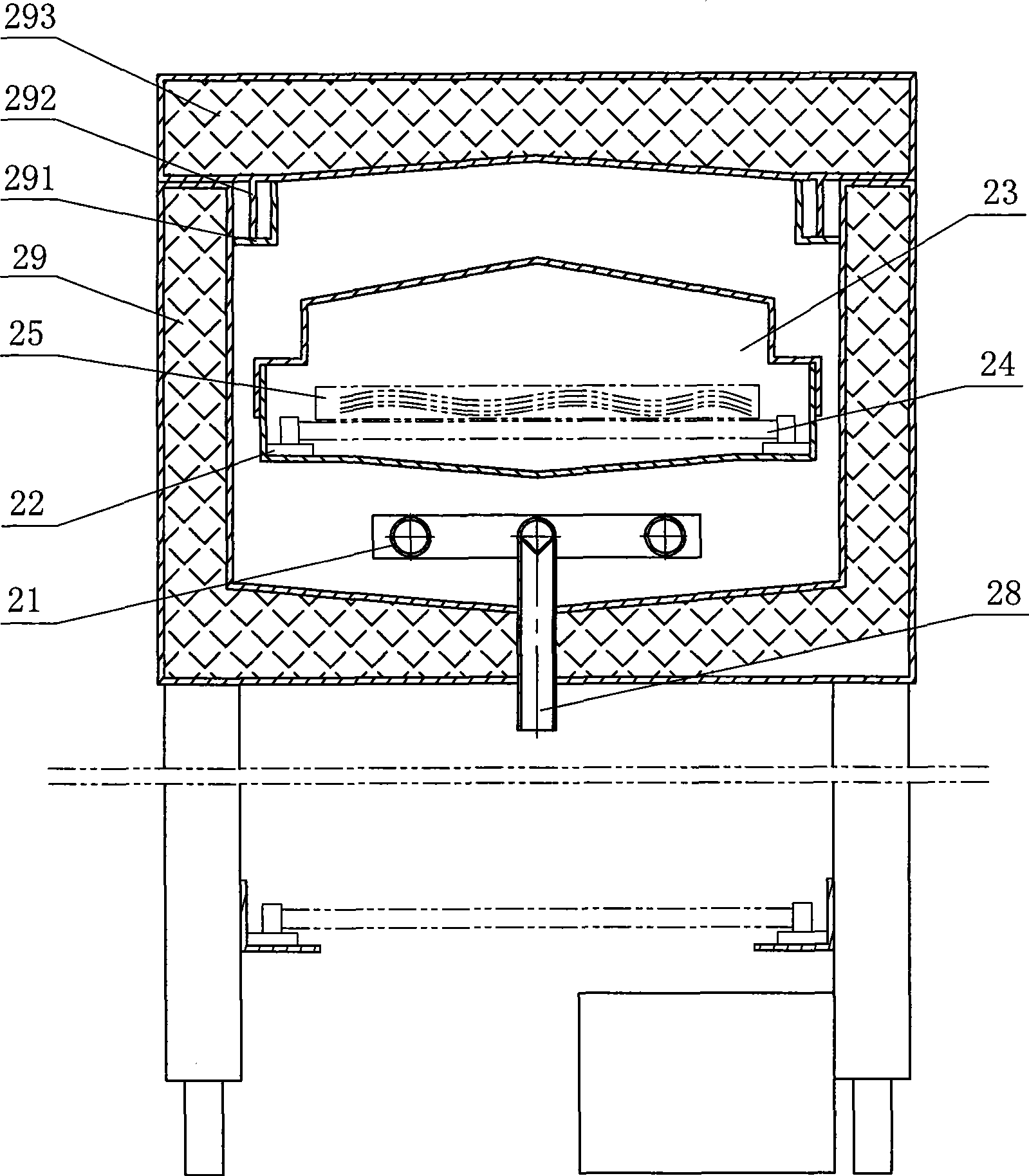

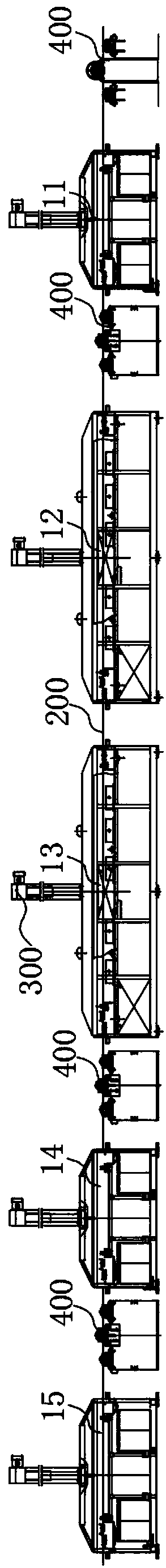

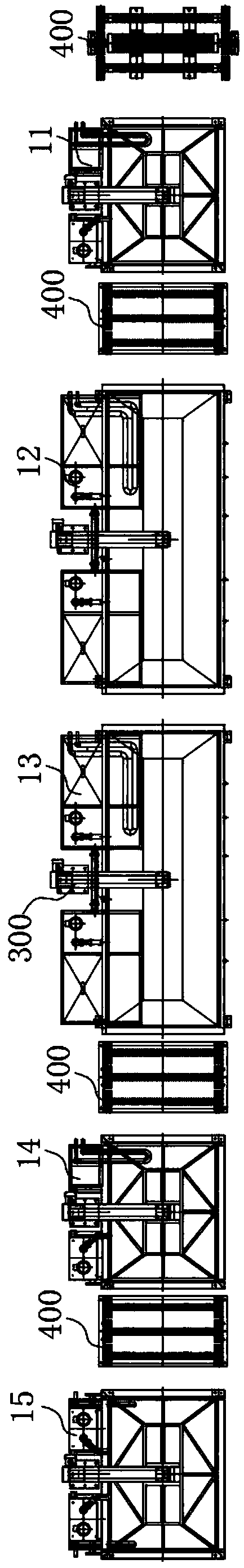

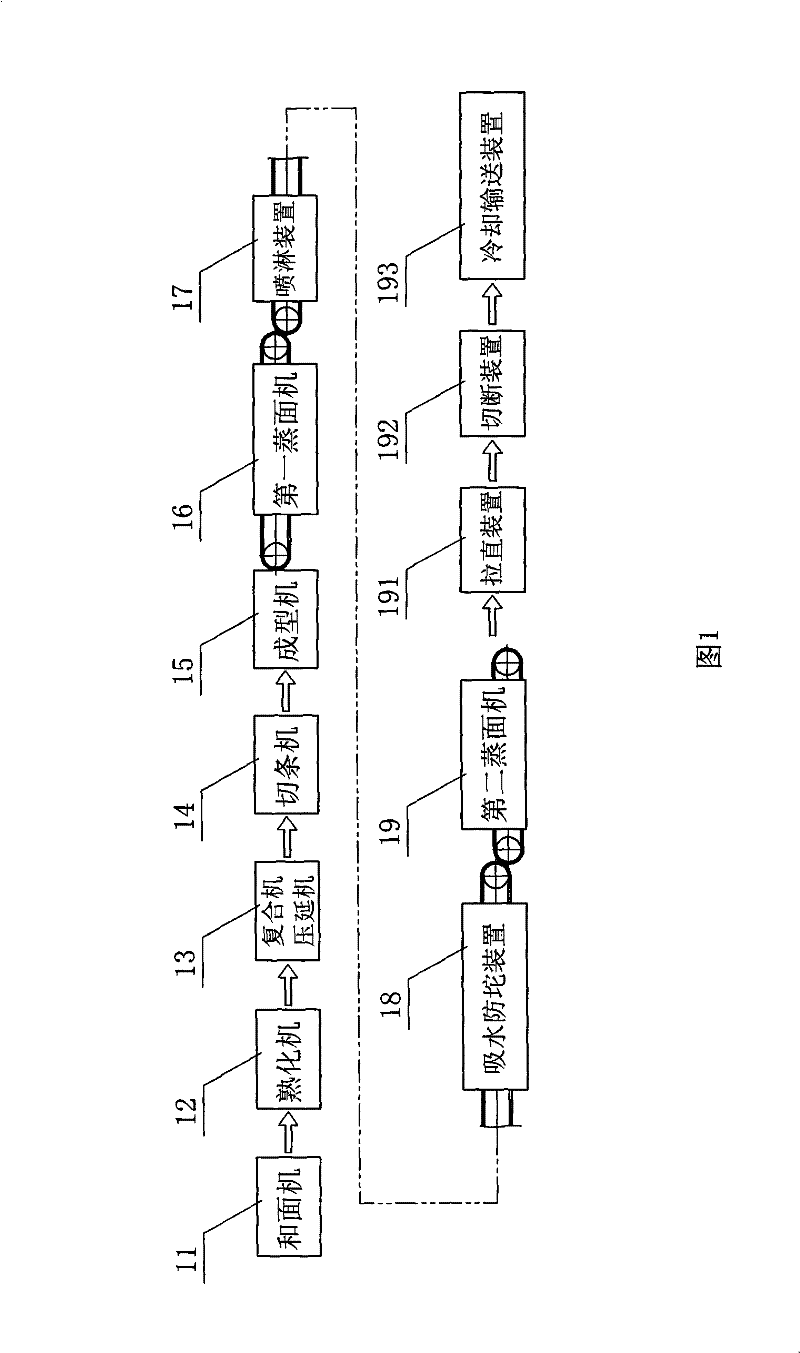

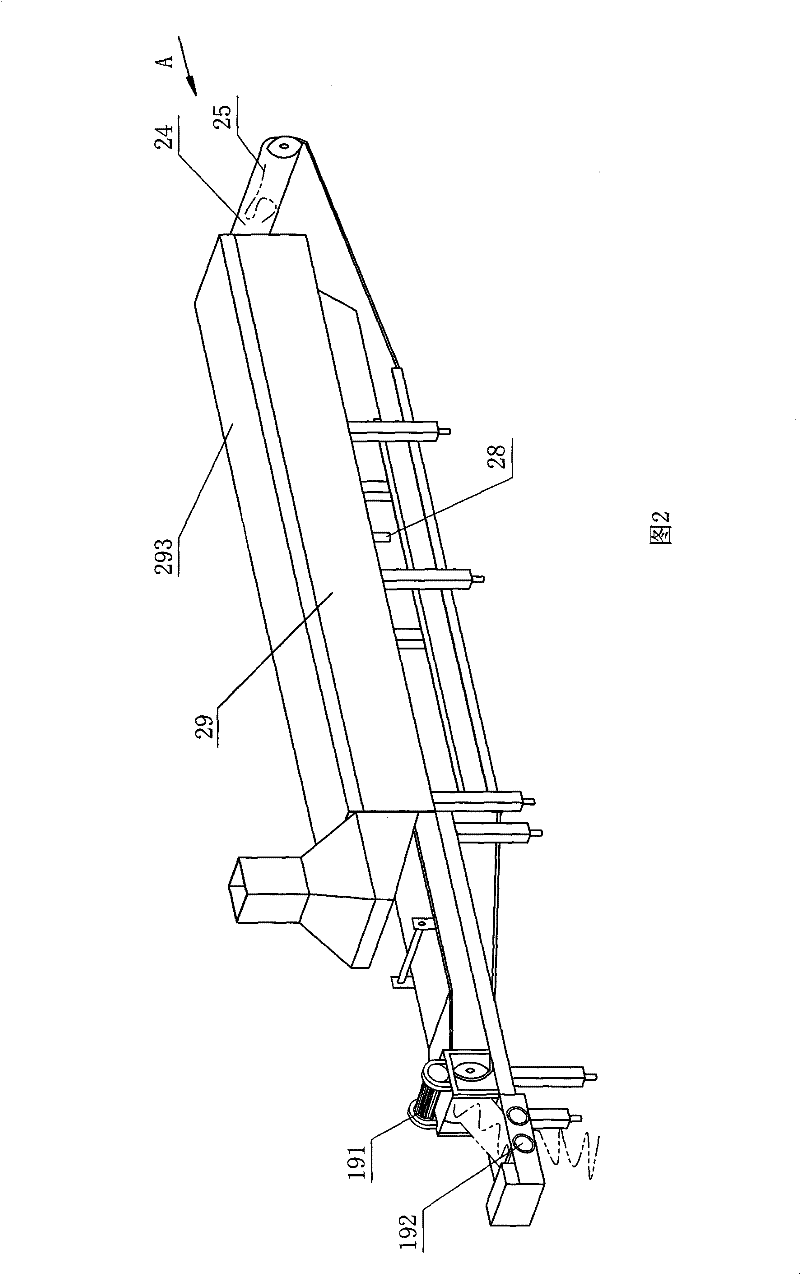

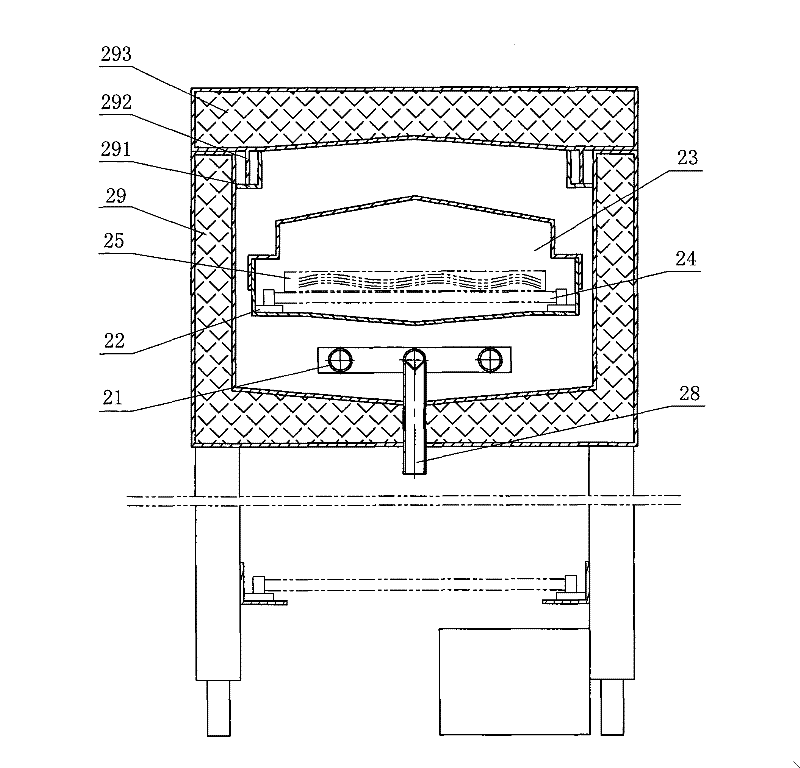

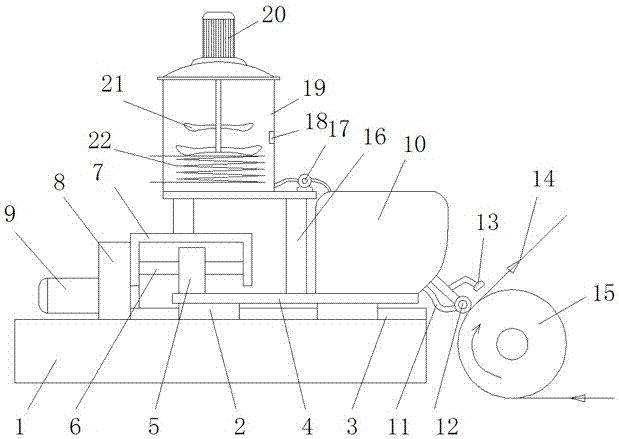

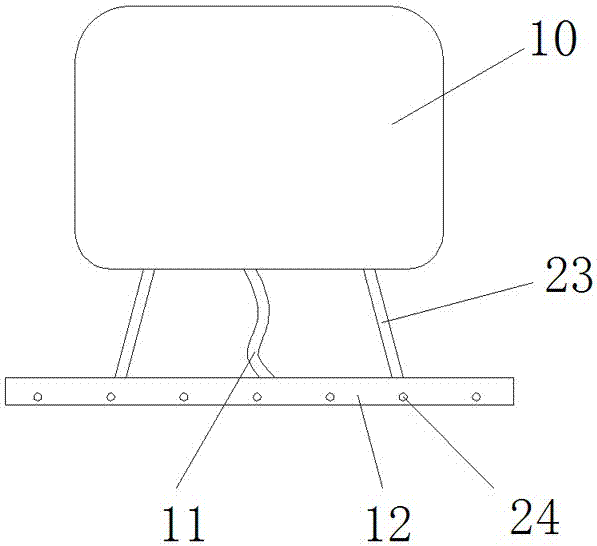

Steamed noodle production line and noodle steaming machine thereof

InactiveCN101530181AIncrease moisture contentGreat tasteFood preparationEngineeringHigh water content

The invention relates to a steamed noodle production line and a noodle steaming machine thereof. The steamed noodle production line comprises a raw noodle processing device and a steaming machine. The steaming device comprises a first noodle steaming machine, a water-absorbing and anti-lumping device and a second noodle steaming machine, which are arranged sequentially and are all provided with an independent net belt conveying mechanism. A noodle input end and a noodle output end of adjacent net belt conveying mechanisms are jointed with each other. A spraying device which sprays towards a conveying net belt is erected between the first noodle steaming machine and the water-absorbing and anti-lumping device. The first noodle steaming machine and the second noodle steaming machine are all provided with a steam box and at least one liner arranged in the steam box. Two ends of each liner are all provided with openings used for penetrating the conveying net belt. The inner cavity of the liner is a transmission passage of the conveying net belt. Input edge net belts of the net belt conveying mechanisms of the first noodle steaming machine and the second noodle steaming machine respectively pass through the transmission passages of the conveying net belts of respective liners. The space of the steam box outside the liner is a steam chamber. Steamed noodle produced by the steamed noodle production line and the noodle steaming machine thereof has high water content, is soft and pliable and has good taste.

Owner:陈 东亮

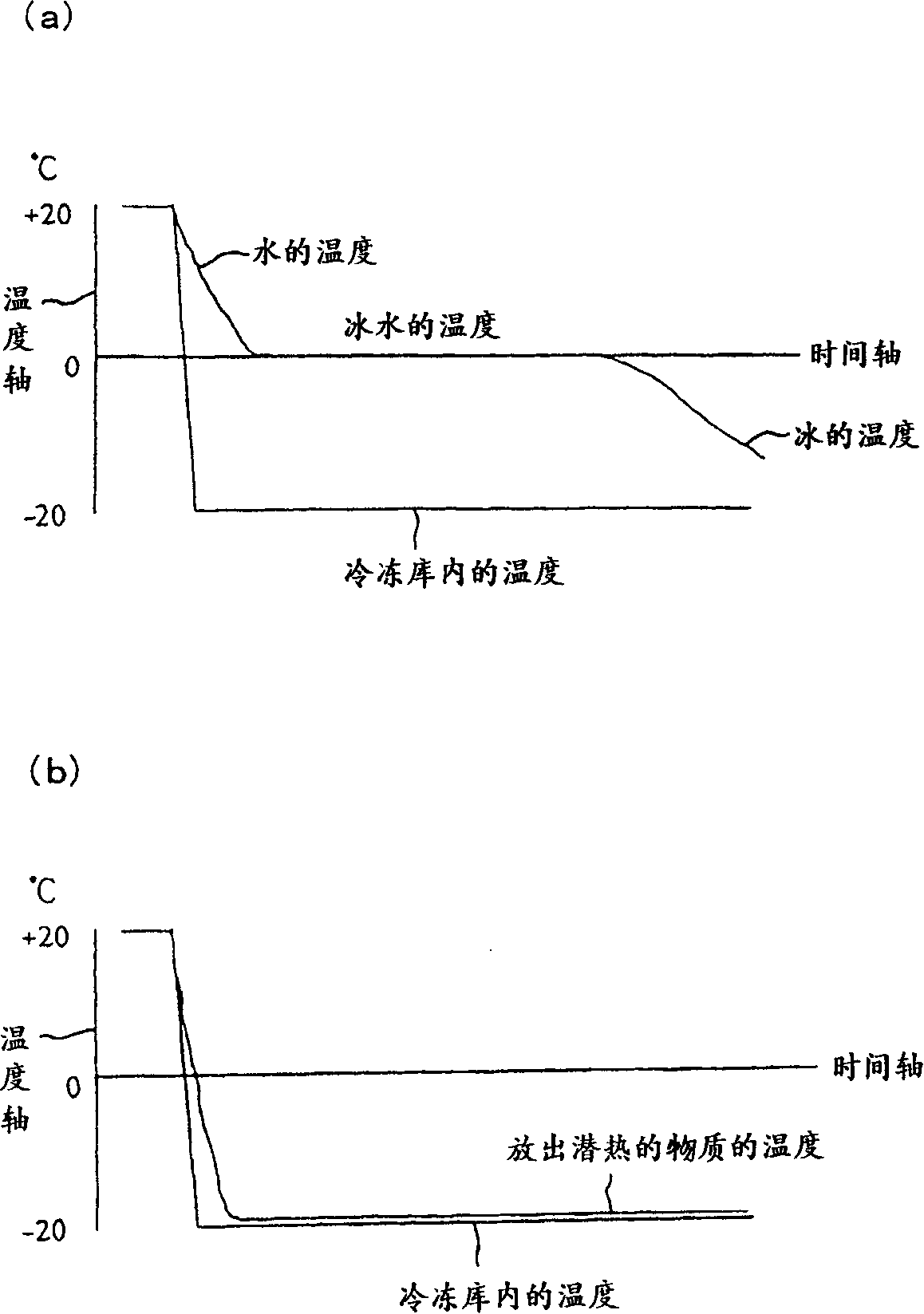

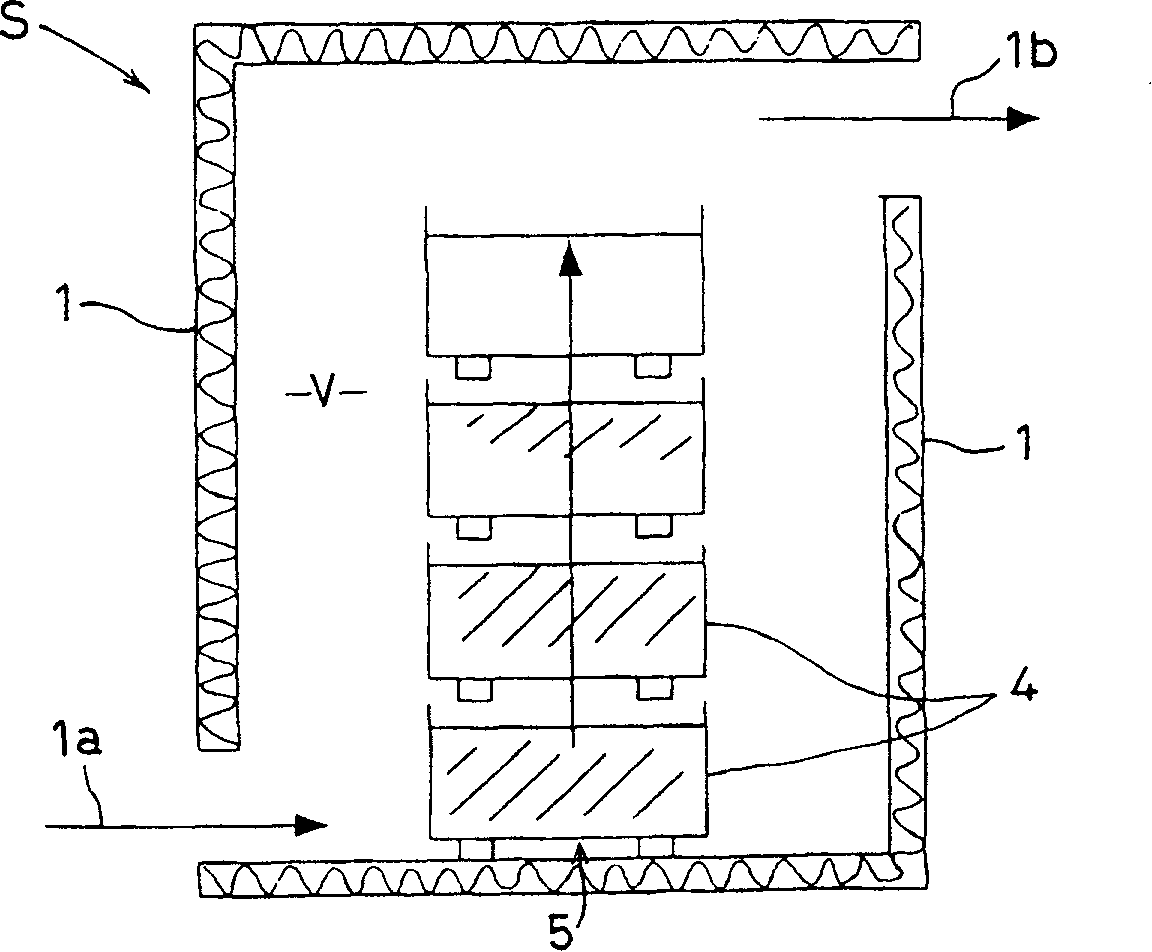

Storage equipment and storage method

InactiveCN1293748AStorage realizedEasy to maintain temperatureDomestic cooling apparatusLighting and heating apparatusInterior spaceIce water

A storage equipment comprising a heat insulating shell capable of insulating an inner space, a water storage tank capable of storing water disposed in an ice water storage tank arrangement space formed in the inner space of the heat insulating shell, a fresh air inlet capable of taking fresh air into the inner space of the heat insulating shell provided at the lower part of the heat insulating shell, and an inner outlet capable of exhausting inner air from the inner space of the heat insulating shell to the outside provided at the upper part of the heat insulating shell.

Owner:TSUCHIYA DAIRY EQUIP MFG +2

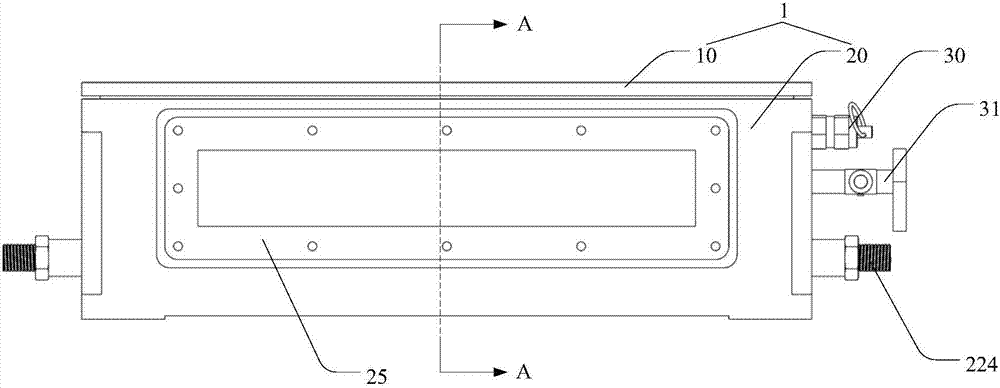

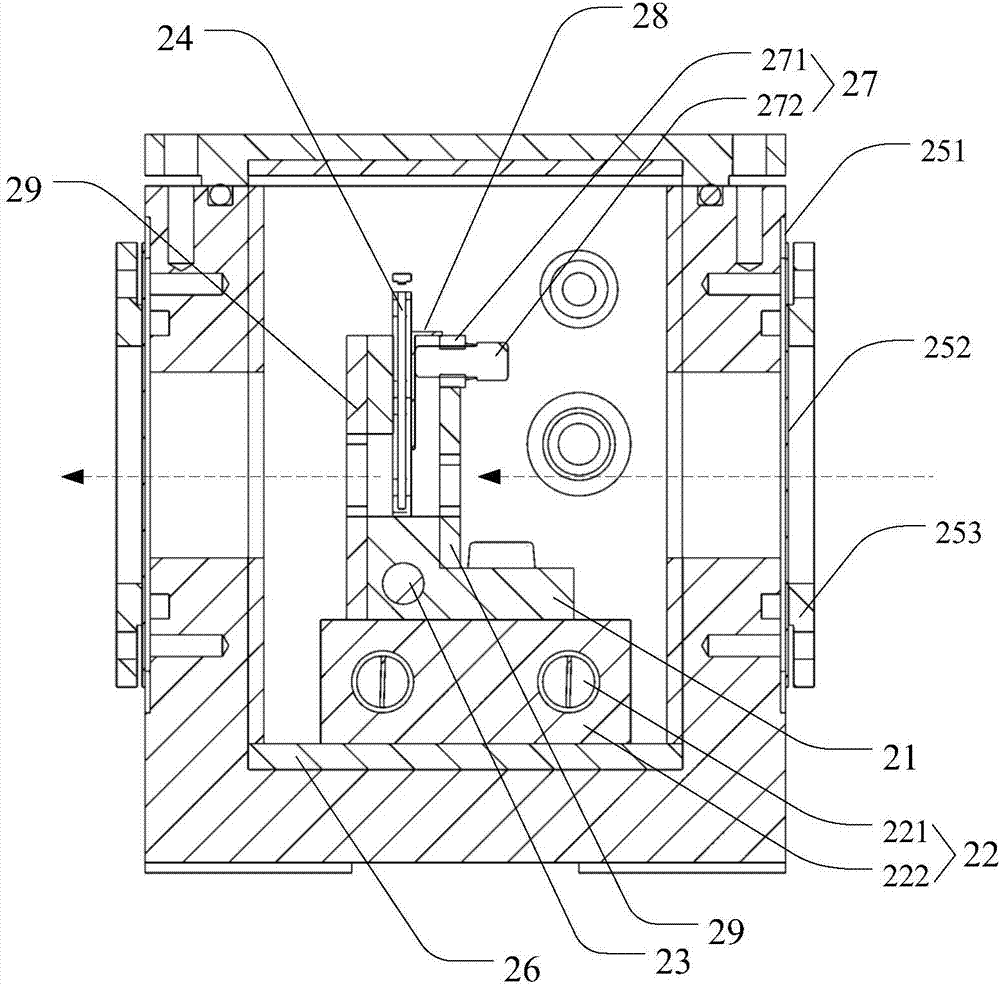

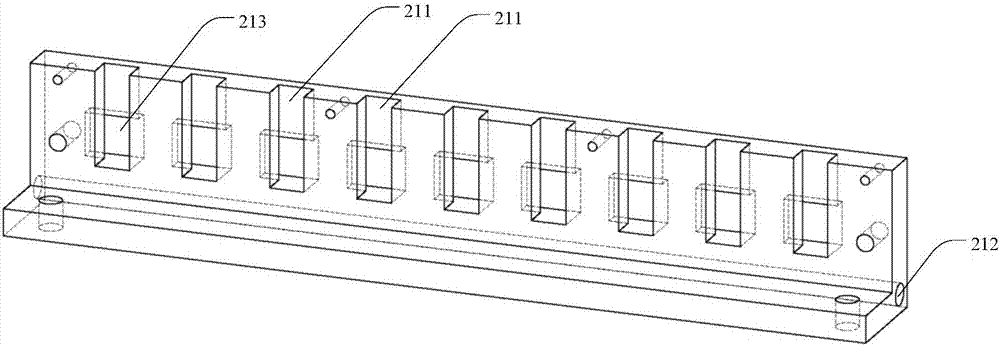

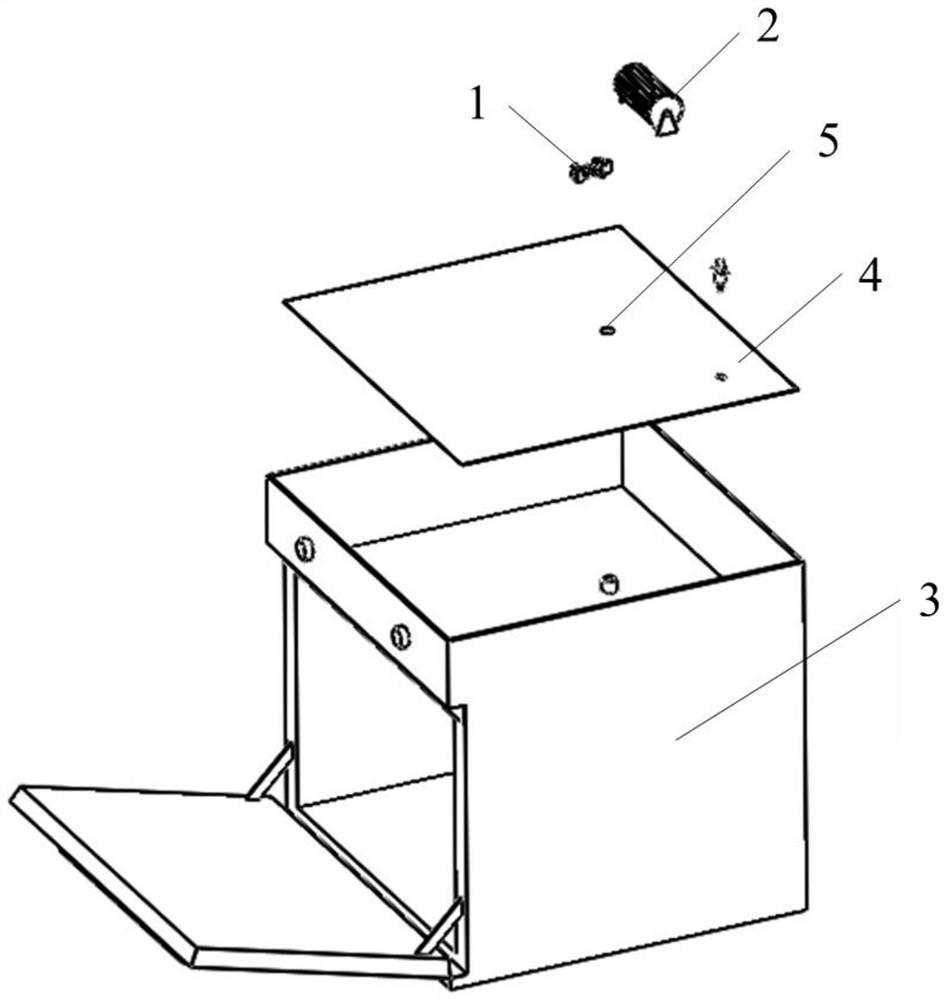

Multi-sample thermostat for small-angle scattering experiment

ActiveCN107213932AImprove experimental efficiencySmall temperature differenceHeating or cooling apparatusSupporting apparatusEngineeringSample temperature

The invention discloses a multi-sample thermostat for a small-angle scattering experiment. The multi-sample thermostat comprises a cavity shell, and a sample holder, a fluid heat exchanger and a heating device which are arranged in the cavity shell, wherein the sample holder is provided with a plurality of sample cells for placing sample boxes; through coupling of the fluid heat exchanger and the heating device, the temperatures of a plurality of samples are kept constant; the plurality of sample cells are distributed in the length direction of the sample holder, i.e. the plurality of sample cells are placed side by side, thereby improving the experiment efficiency; the temperature difference among the plurality of sample cells is very little; and a heat insulating layer is arranged on the inner wall of the cavity shell, thereby being beneficial to constant temperature keeping.

Owner:DONGGUAN NEUTRON SCI CENT

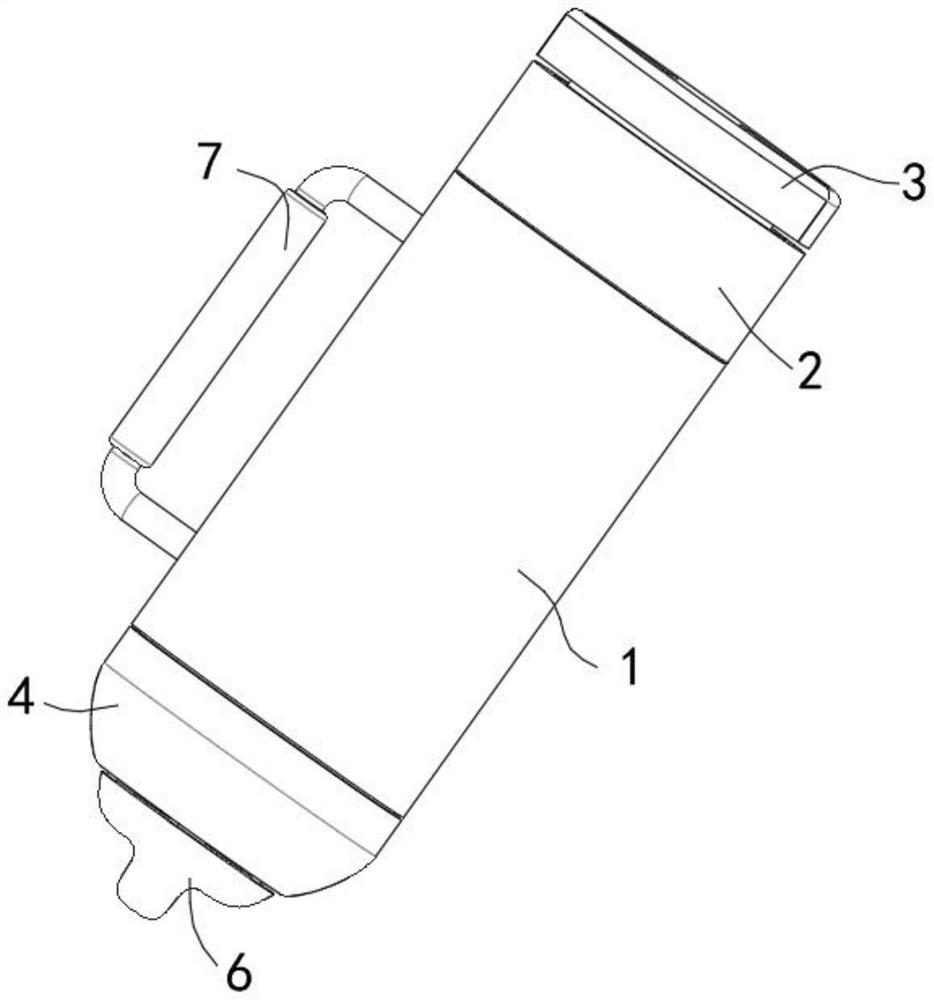

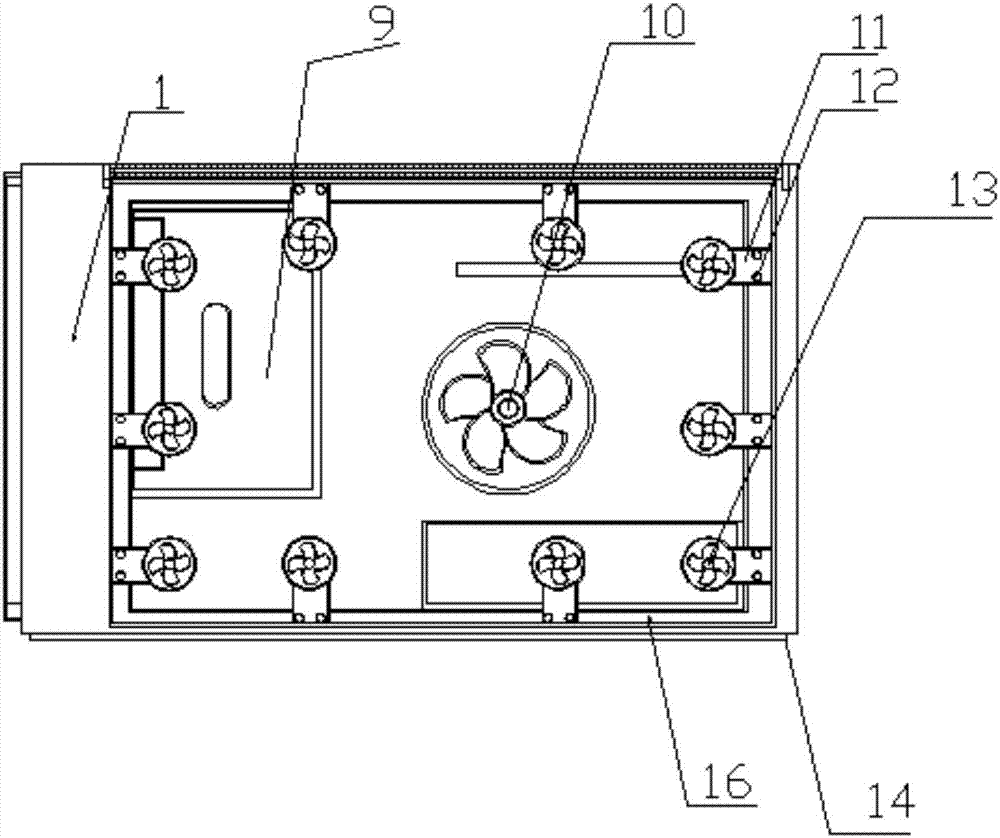

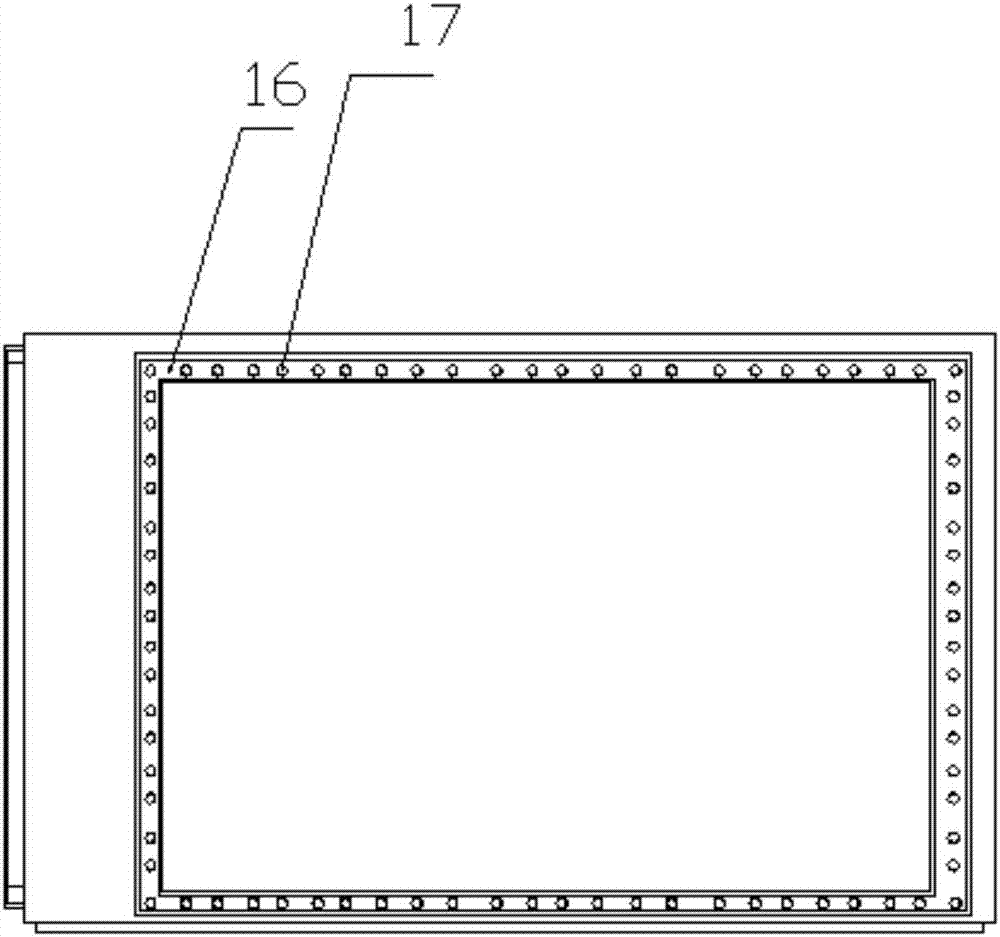

Automatic heat dissipation battery and power supply system of electric vehicle

ActiveCN107464903AEasy to maintain temperatureRealize the cooling effectCell temperature controlCell component detailsElectricityWorking environment

The invention provides an automatic heat dissipation battery and a power supply system of an electric vehicle, and relates to the technical field of energy storage. The automatic heat dissipation battery comprises a battery box main body, a battery module, a heat dissipation component and a monitoring unit, wherein the battery module is arranged in the battery box main body, a gap is formed between the battery module and the battery box main body, a first ventilation passage is formed in the top of the battery box main body, a second ventilation passage is formed in the bottom of the battery box main body, the heat dissipation component is arranged at one end of the first ventilation passage, and the monitoring unit is arranged on the battery box main body and is electrically connected with the heat dissipation component. The power supply system of the electric vehicle comprises the automatic heat dissipation battery. The invention aims to provide the automatic heat dissipation battery and the power supply system of the electric vehicle, which are used for solving the problem that the battery in the prior art is low in heat dissipation efficiency to cause relatively high temperature in the battery box and the problem that a severe working environment cannot be met due to the adoption of a shuttle window heat dissipation structure.

Owner:NORTHERN ALTAIR NANOTECH CO LTD

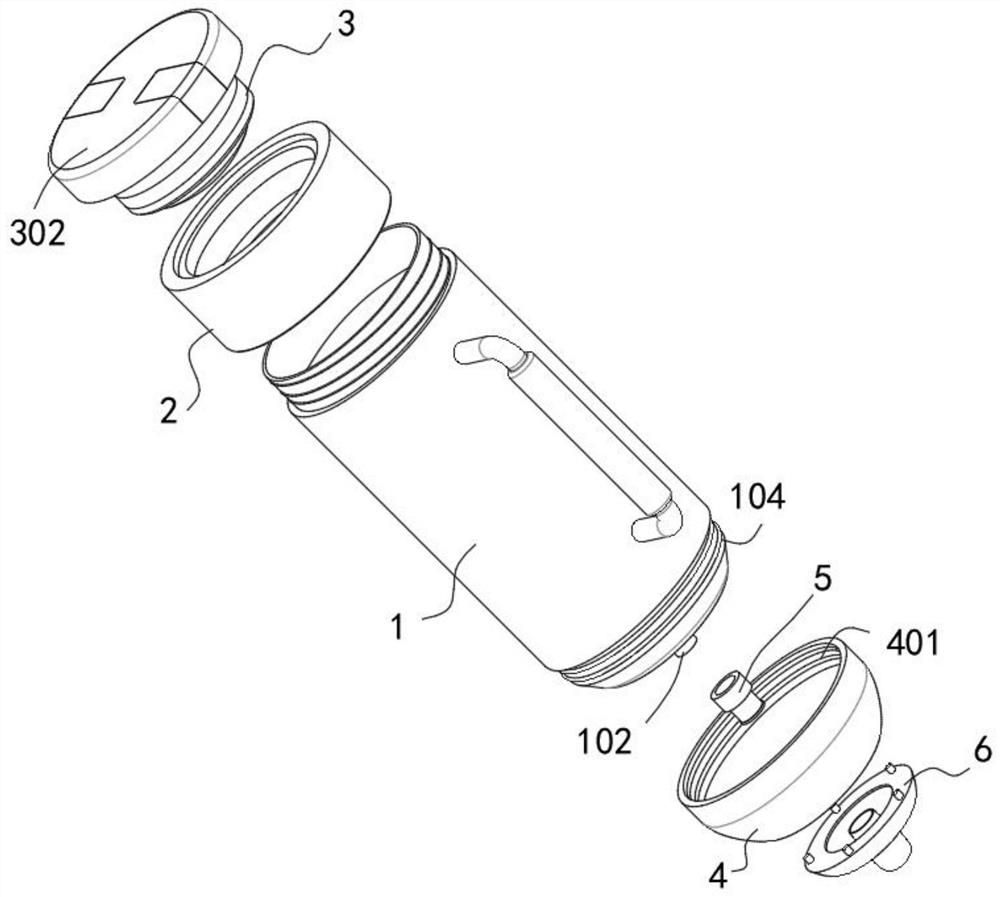

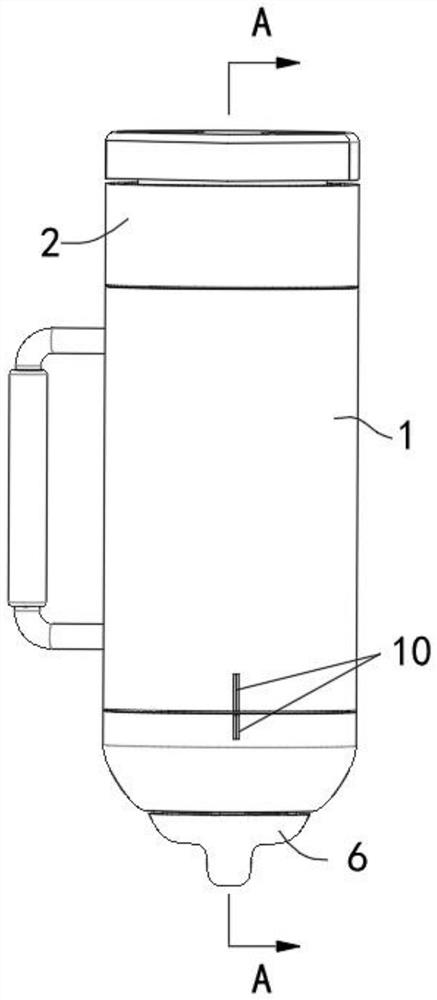

Medicine feeder for pediatric internal medicine department

InactiveCN111631958AEasy to maintain temperatureEasy to operateOral administration deviceFeeding-bottlesPharmacy medicineSurgery

The invention relates to the technical field of medicine feeding tools, and provides a medicine feeder for the pediatric internal medicine department. The medicine feeder comprises a bottle body and asmashing assembly, wherein an accommodating cavity is formed in the bottle body, an opening which communicates with the accommodating cavity is formed in the upper end of the bottle body, a needle nozzle which communicates with the accommodating cavity is fixed to the lower end of the bottle body, and a blocking body is arranged in the needle nozzle; the smashing assembly comprises a supporting piece and a pressing connection piece, the supporting piece comprises a connecting shell and a groove body, the groove body is arranged in the middle of the connecting shell, the periphery of the groove body is fixedly connected with the inner wall of the connecting shell to divide the connecting shell into an upper cavity and a lower cavity, the lower cavity communicates with the accommodating cavity, and a communicated notch is formed between the upper cavity and the lower cavity; the pressing connection piece is in threaded connection with the interior of the upper cavity, and an arc-shapedprotrusion matched with the upper surface of the groove body is arranged on the bottom of the pressing connection piece; and the connecting shell is in threaded connection with the opening. By the medicine feeder, the problems that an existing medicine feeding mode of smashing blocky medicines is troublesome in whole process, the time and labor are wasted, and the temperature of liquid medicine isreduced fast are solved.

Owner:周春清

Energy saving heat preserving tile

The invention relates to an energy saving heat preserving tile. The semis of the energy saving heat preserving tile comprises the following raw materials: 30 to 40 percent of kaolin, 15 to 25 percent of calcite powder, 8 to 15 percent of talcum powder, 10 to 20 percent of hollow microspheres, 5 to 15 percent of titanium white, 10 to 15 percent of fluoro-silicon resin, and 10 to 15 percent of water. The thickness of the tile is 8 to 12 mm. The tile is also added with sodium nitrate accounting for 0.5 to 0.7 percent. The energy saving heat preserving tile provided by the invention can endure long time exposing to the weather of complex environment without pulverization, delaminating and changing of color, is resistant to abrasion and water, and has excellent performance of heat insulating, temperature maintaining and energy saving.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

Dampness removing structure, steam cooking device and humidity control method

ActiveCN112056920AEasy dischargeStable internal environmentSteam cooking vesselsTime-controlled ignitorsThermodynamicsSteam cooking

The invention discloses a dampness removing structure, a steam cooking device and a humidity control method. The dampness removing structure is used for the steam cooking device and comprises an air blocking module and a driving module; the air blocking module is arranged above the exterior of an exhaust port of the steam cooking device and used for adjusting the opening degree of the exhaust port, and the driving module is arranged on the steam cooking device; and the driving module is started to drive the air blocking module to move, the opening degree of the exhaust port is changed, and thegas discharge amount is adjusted. Accordingly, by arranging the dampness removing structure, the driving module is started to drive the air blocking module to change the opening degree of the exhaustport, then the gas discharge amount is adjusted, and the rapid dampness removing effect is achieved; and meanwhile, by obtaining the real-time oxygen concentration controllable range according to thereal-time temperature of an inner container, the preset humidity and the controllable humidity corresponding to the cooking mode, finally, whether humidification and / or dampness removing is conductedor not is determined according to the comparison relation between the real-time oxygen concentration and the real-time oxygen concentration controllable range, and the problem that humidity control is not precise due to real-time temperature change of the inner container is effectively avoided.

Owner:VATTI CORP LTD

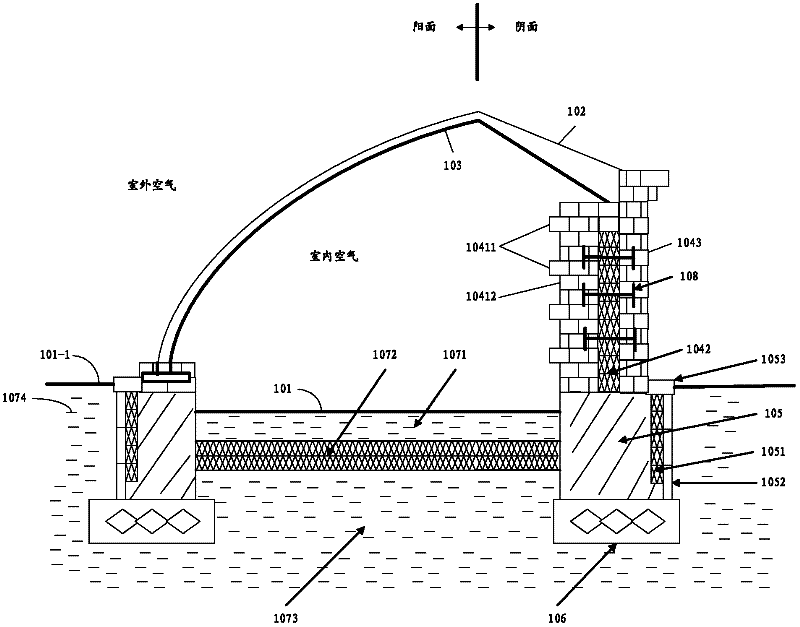

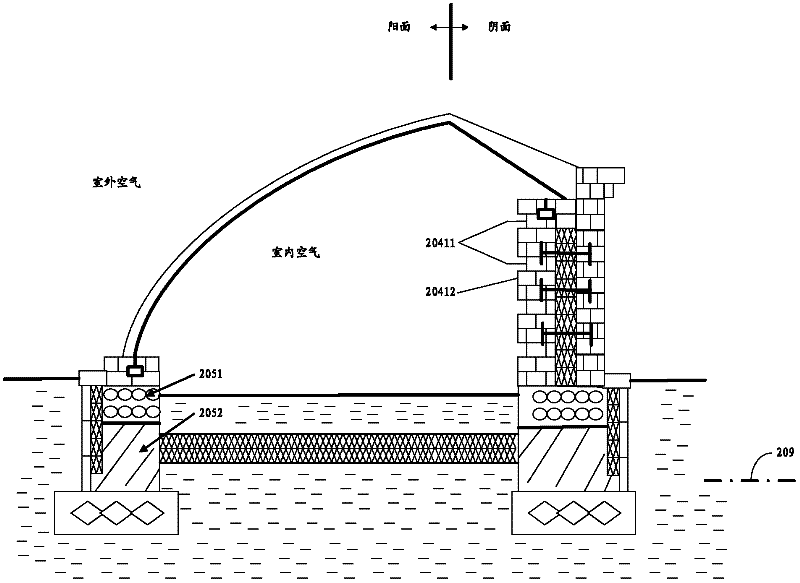

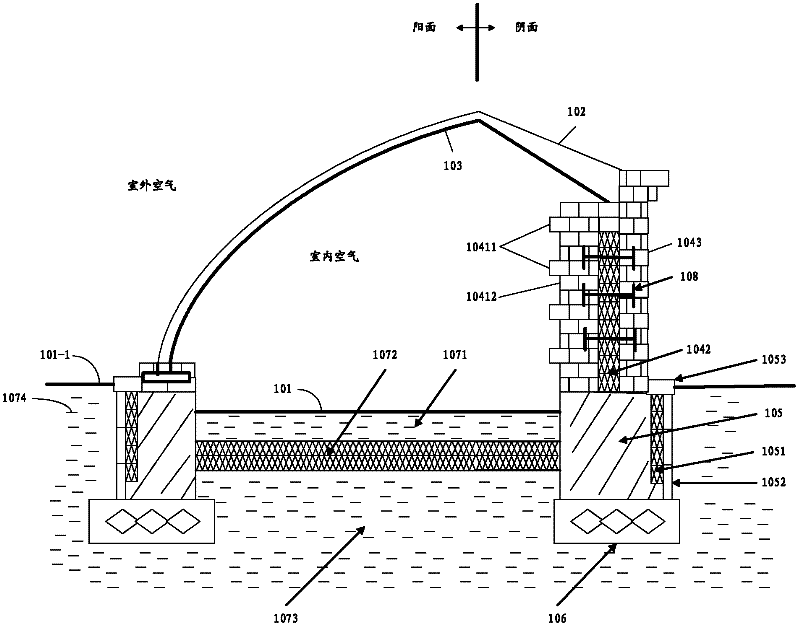

Floor-heating type high thermal insulating daylight energy-saving greenhouse

InactiveCN102239792AHelps growEasy to maintain temperatureClimate change adaptationSaving energy measuresGreenhouseDaylight

The invention relates to a floor-heating type high thermal insulating daylight energy-saving greenhouse which comprises greenhouse heat insulation soil, a roof mulch, an arch centering, a wall, a wall footing and a ground base, wherein the greenhouse heat insulation soil is arranged under an indoor ground line; the arch centering is arranged under the roof mulch and has a supporting effect; the wall is arranged under the arch centering for supporting and fixing the arch centering; the wall footing is arranged under the ground line and is connected with the bottom of the wall for supporting the wall; the ground bas is arranged under the wall footing and has the effects of supporting and collapse prevention; the greenhouse heat insulation soil comprises upper layer soil, a thermal insulating layer and lower layer soil; crops are planted in the upper layer soil; the upper surface of the upper layer soil is in contact with indoor air; the side surface of the upper layer soil is in contact with the wall footing; the lower layer soil is connected with outside soil; a part of the side surface of the lower layer soil is in contact with the wall footing; and in the vertical direction, the thermal insulating layer is arranged between the upper layer soil and the lower layer soil, and the side surface of the thermal insulating layer is in contact with the wall footing. By using the technical scheme of the invention, the temperature of the upper layer soil can be kept and increased more rapidly.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Steel wire galvanized surface pretreatment system and process

ActiveCN109487189ACleaning wire is efficient and cleanReduce replacement frequencyHot-dipping/immersion processesProcess efficiency improvementMegasonic cleaningEngineering

The invention relates to the technical field of metal material processing. The steel wire galvanized surface pretreatment system and process is characterized in that the processing system comprises afirst washing tank, a first ultrasonic cleaning tank, a second ultrasonic cleaning tank, a second washing tank and a plating assisting tank which are sequentially arranged; the inner rear end of the first ultrasonic cleaning tank, the inner rear end of the first ultrasonic cleaning tank and the inner rear end of the second ultrasonic cleaning tank are correspondingly provided with an upper part rubber wire wiping assembly and a lower part rubber wire wiping assembly; each of the upper part rubber assembly and the lower part rubber assembly comprises fixed supports, a rubber strip fixing plateand rubber strips; the rubber strip fixing plate is densely and fixedly connected to the rubber strips, the two sides of the rubber strip fixing plate are connected to the side wall of a groove body through the fixing supports, and steel wires penetrate through the dense rubber strips on the rubber strip fixing plate; and the process comprises the steps of one-time water washing, one-time ultrasonic cleaning, secondary ultrasonic cleaning, secondary water washing and plating assisting, and the steel wire galvanized surface pretreatment system is adopted. According to the system and the process, the wire wiping rubber strips are added, the cleaning is clean, and the efficiency is high.

Owner:巩义市恒星金属制品有限公司

Casting device with an annular duct and a casting method

InactiveCN104174830AReduce shareReduce cooling powerFoundry mouldsFoundry coresMetallurgyAnnular duct

A casting device includes a mold cavity configured to form a hollow space for a cast part, a casting chamber for a metal melt, a gating system, an annular duct for the metal melt, and at least two annular duct connections configured to connect the casting chamber to the annular duct. The annular duct is configured to be connectable with the mold cavity via the gating system.

Owner:舒乐绞扭机有限责任公司

Steamed noodle production line and noodle steaming machine thereof

InactiveCN101530181BIncrease moisture contentGreat tasteDough processingEngineeringHigh water content

The invention relates to a steamed noodle production line and a noodle steaming machine thereof. The steamed noodle production line comprises a raw noodle processing device and a steaming machine. The steaming device comprises a first noodle steaming machine, a water-absorbing and anti-lumping device and a second noodle steaming machine, which are arranged sequentially and are all provided with an independent net belt conveying mechanism. A noodle input end and a noodle output end of adjacent net belt conveying mechanisms are jointed with each other. A spraying device which sprays towards a conveying net belt is erected between the first noodle steaming machine and the water-absorbing and anti-lumping device. The first noodle steaming machine and the second noodle steaming machine are allprovided with a steam box and at least one liner arranged in the steam box. Two ends of each liner are all provided with openings used for penetrating the conveying net belt. The inner cavity of the liner is a transmission passage of the conveying net belt. Input edge net belts of the net belt conveying mechanisms of the first noodle steaming machine and the second noodle steaming machine respectively pass through the transmission passages of the conveying net belts of respective liners. The space of the steam box outside the liner is a steam chamber. Steamed noodle produced by the steamed noodle production line and the noodle steaming machine thereof has high water content, is soft and pliable and has good taste.

Owner:陈 东亮

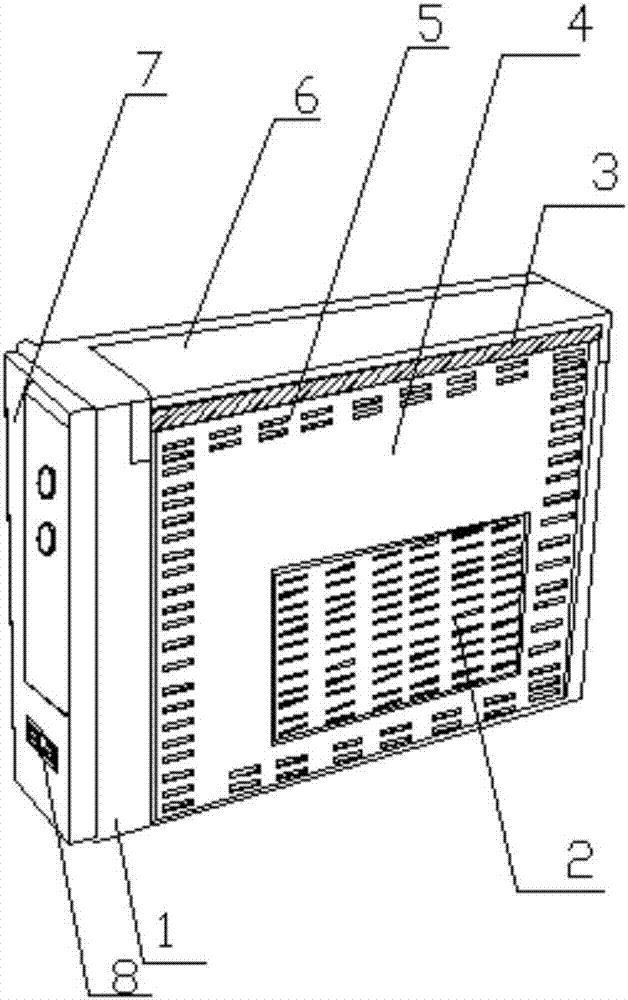

Host case convenient to cool

InactiveCN107092326AEasy to openEasy to cleanDigital processing power distributionDrive motorEngineering

The invention discloses a host case convenient to cool. A control button is arranged at one end of a case body, a USB connecting hole is formed in the bottom of the control button, a baffle is arranged at the other end of the case body, a cooling plate is arranged on the baffle, frame cooling holes are formed in the periphery of the cooling plate, a rotating shaft is arranged at the top of the baffle, a top plate is arranged at the top of the case body, a clamping groove is formed in one end of the baffle, sliding chutes are formed in two ends of the clamping groove, fixing holes are formed in the clamping groove, supporting shafts are arranged on one side of the clamping groove, connecting holes are formed in the supporting shafts, a cooling fan is arranged at one end of each supporting shaft, a driving motor is arranged at one end of each cooling fan, and fan blades are arranged at the other ends of the cooling fans. The host case convenient to cool is novel in structure and simple and convenient to operate, the cooling fans can be conveniently moved by means of connecting blocks and rollers, and the cooling fans correspond to the frame cooling holes, thereby facilitating keeping of the temperature in the case body. The service life of a host is prolonged, meanwhile, the baffles are convenient to open through the rotating shafts, and the inside of the case body is convenient to clear and maintain.

Owner:JIANGSU ZHANBANG INTELLIGENT TECH CO LTD

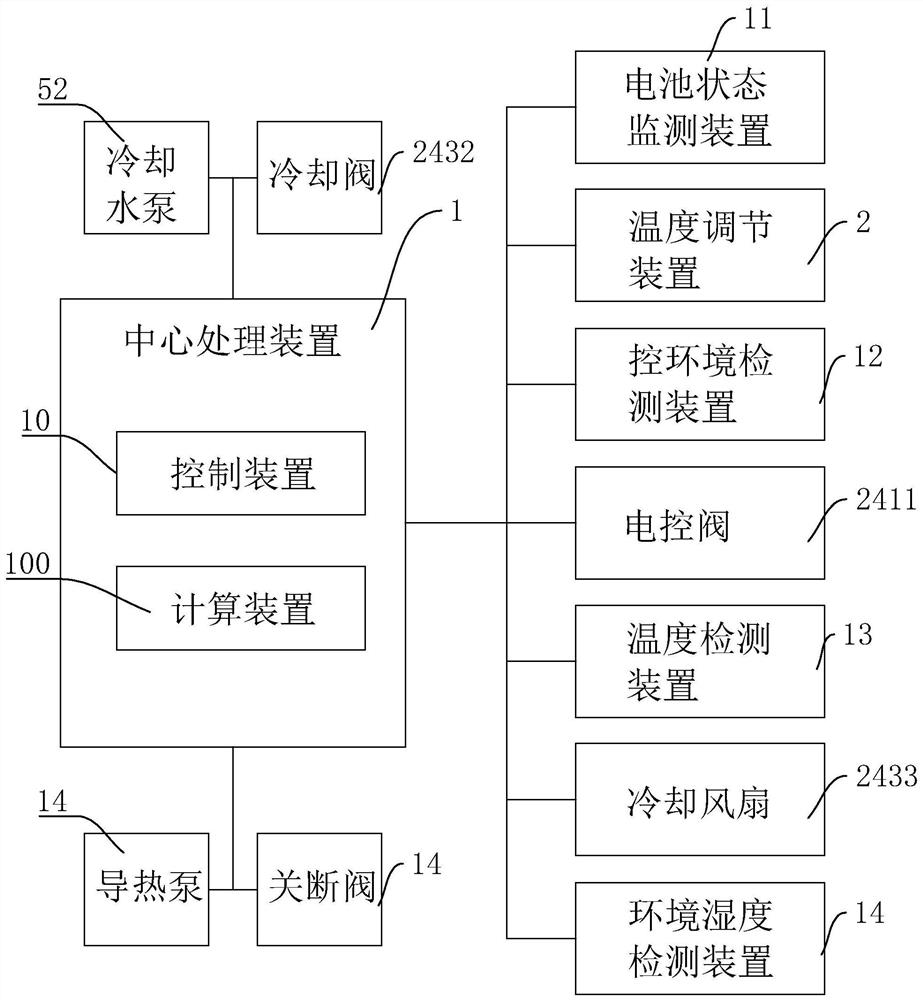

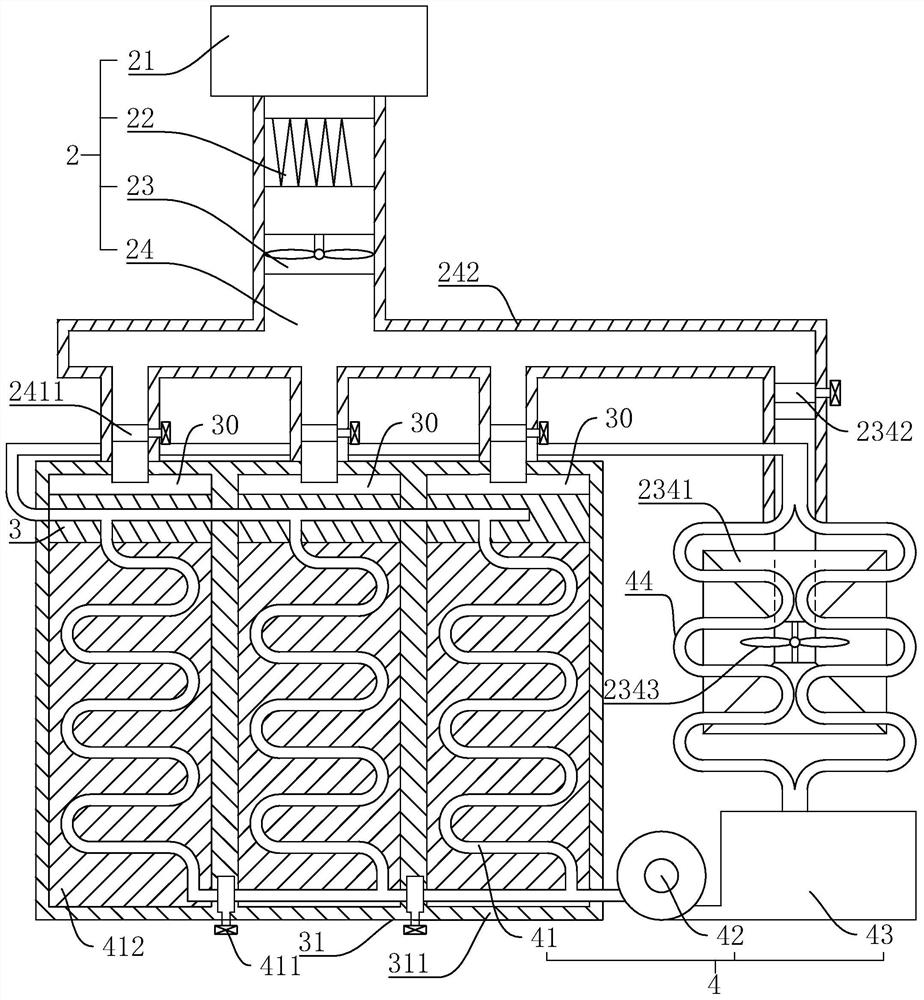

Temperature control device based on energy storage battery temperature difference

ActiveCN111834701AImprove cooling effectPromotes the effect of radiating outwardSecondary cells testingTemperature controlHeat management

The invention discloses a temperature control device based on energy storage battery temperature difference, and relates to the technical field of battery management, and aims to solve technical problems that a fan control mode is mostly adopted for heat management of an existing energy storage system, the temperature of a battery cannot be effectively reduced in time, and if the system works in acold region, a fan control mode does not have a heating function, and the whole system works in an unsuitable temperature range. The technical scheme is characterized in that the device comprises a central processing device, a temperature adjusting device, a battery state monitoring device, an environment detection device and multiple groups of energy storage batteries. The central processing device comprises a control device and a calculating device, the control device is connected with an electric control valve arranged on each adjusting pipe and controls the opening size of the electric control valve, and the calculating device is used for calculating the power of the temperature adjusting device according to the environment temperature and the working voltage and the working current of the energy storage battery. And the effect of conveniently adjusting the temperature of the energy storage system according to the environment is achieved.

Owner:上海快卜新能源科技有限公司

Coating machine head used for coating compound machine and with variable gap

InactiveCN106964519ANothing producedImprove film qualityLiquid surface applicatorsCoatingsEngineeringDistance sensors

The invention discloses a variable gap coating head for a coating compound machine, which comprises a coating frame and a coating cylinder, the coating cylinder is fixed on a base close to the coating roller, the The base is slidingly set above the coating frame, and the left end of the coating frame is equipped with an adjustment motor, which is driven and connected to the base through a screw drive mechanism, and the bottom right side of the coating cylinder is passed through a tube The body support is provided with a coating pipe body extending along the length direction of the coating roller, and a distance sensor facing the substrate on the coating roller is installed on the pipe body support; A plurality of liquid outlet holes are arranged in distribution, and the coating pipe body communicates with the bottom of the coating cylinder body through a hose, and a support platform is fixed on the base. The temperature of the system drops rapidly, the coating is evenly applied, and the quality of the finished product is good.

Owner:JIANGSU JINFENG LIGHT IND EQUIP CO LTD

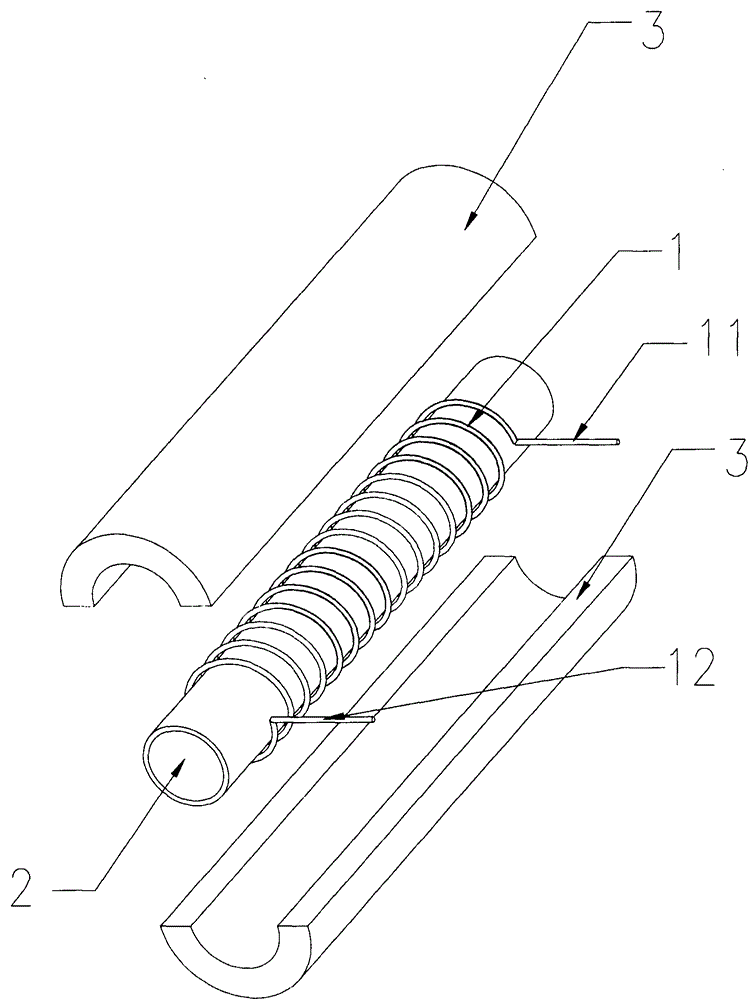

Active compensation heat preservation method and pipeline heat preserving structure

InactiveCN104141855AReduce temperature dropEasy to maintain temperaturePipe heating/coolingHeat lossesHeat balance

The invention provides an active compensation heat preservation method and a pipeline heat preserving structure for implementing the method, wherein the method and the structure are mainly used for heat preservation of hot gas conveying pipelines. An electromagnetic induction coil is arranged between the surface of a pipeline and a heat-preserving layer or in the heat-preserving layer of the pipeline, the pipeline serves as an electromagnetic induction heating body, pipeline heat preservation heat loss is calculated or measured, electromagnetic induction heating capacity compensates 10-90% of the pipeline heat preservation heat loss, the method and the structure are suitable for pipeline heat preservation when temperature of fluid in the pipeline ranges from 200 DEG C to 1000 DEG C, and the defects that an existing hot gas conveying pipeline is high in heat preserving cost, long in heat balance time, large in hot gas secondary heating investment, low in reliability and high in operation cost are overcome.

Owner:聂红军

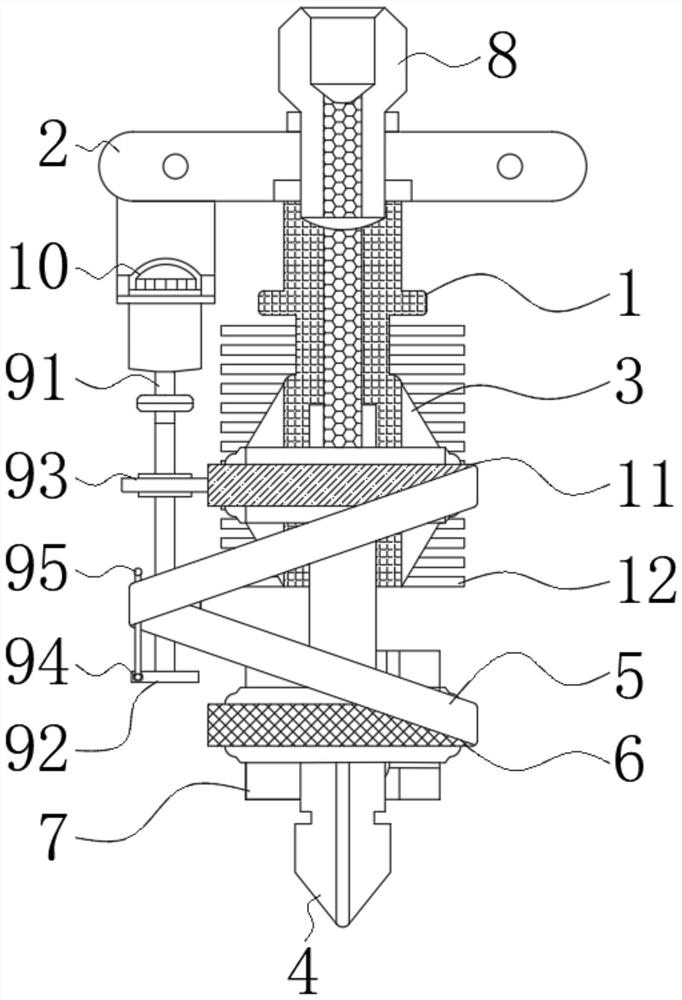

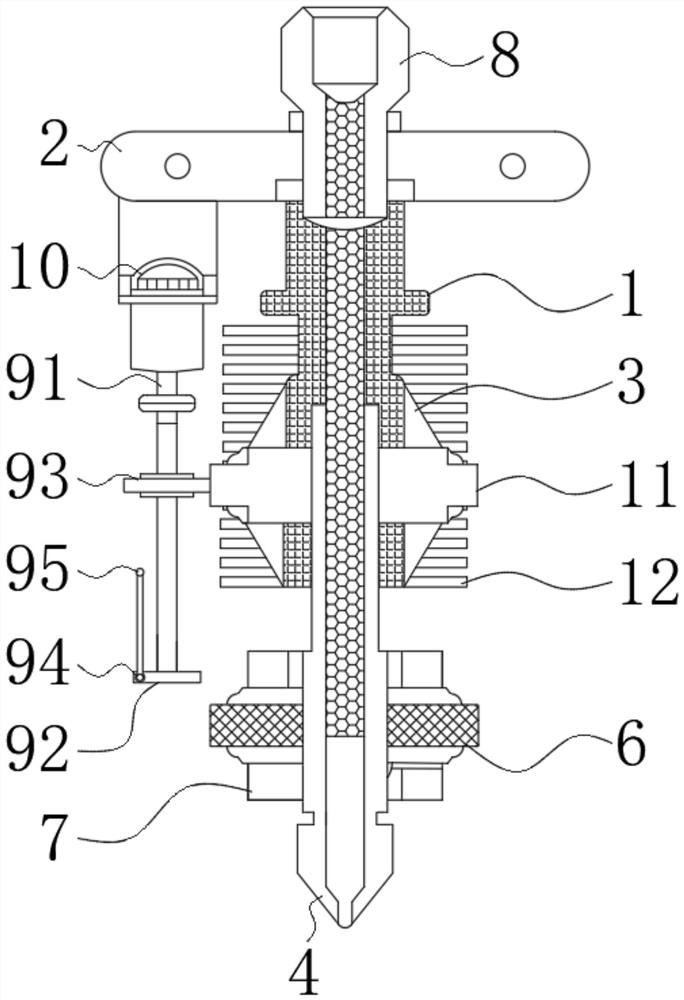

Spray head device for three-dimensional printing

The invention relates to the technical field of Internet of Things identification, and discloses a spray head device for three-dimensional printing. The spray head device comprises a feeding through pipe, the top of the feeding through pipe is fixedly connected with a feeding hopper, a discharging port of the feeding hopper is in sealed connection with a feeding port of the feeding through pipe, the outer surface of the feeding hopper is fixedly connected with a regulation and control platen, the bottom of the regulation and control platen is fixedly connected with the top of a feeding throughpipe, and the back face of the feeding through pipe is fixedly connected with a heat dissipation grid. According to the spray head device for three-dimensional printing, heat of the feeding through pipe inside a heat dissipation conical ring is cooled, so that the situations that a raw material begins to expand after being heated when not located in a heat preservation ring area and consequentlythe resistance of raw material sliding is increased are effectively reduced, meanwhile heat is transmitted to the outer side of a heat preservation ring to facilitate keeping of the temperature of theouter side of a heating ring, the situation that the energy loss is increased due to continuous heating of the heating ring is avoided, effective utilization of surplus heat on the spray head devicefor three-dimensional printing is improved, energy loss is reduced, and the printing cost is reduced.

Owner:罗凡

LED lamp aging test room

InactiveCN104198957AEasy to maintain temperatureEven air distributionLamps testingEngineeringLED lamp

The invention provides an LED lamp aging test room. The LED lamp aging test room is provided with a material pass box, operators do not need to open doors during operation and can pass needed materials directly through the material pass box, and thus a purified indoor environment is achieved. Indoor constant temperature is realized by means of heating of a heating pipe arranged in the LED lamp aging test room. Circulating ventilation is achieved through an air supply port and an air return port according to the working principle of bottom supply and top return, so that air distribution is uniform. Since the LED lamp aging test room is provided with an exhaust pipeline, an exhaust fan is started to exhaust air outwards when indoor temperature exceeds a limit, and indoor hot air is exhausted outwards to reduce the indoor temperature.

Owner:SUZHOU CHENGTENG ELECTRONICS TECH

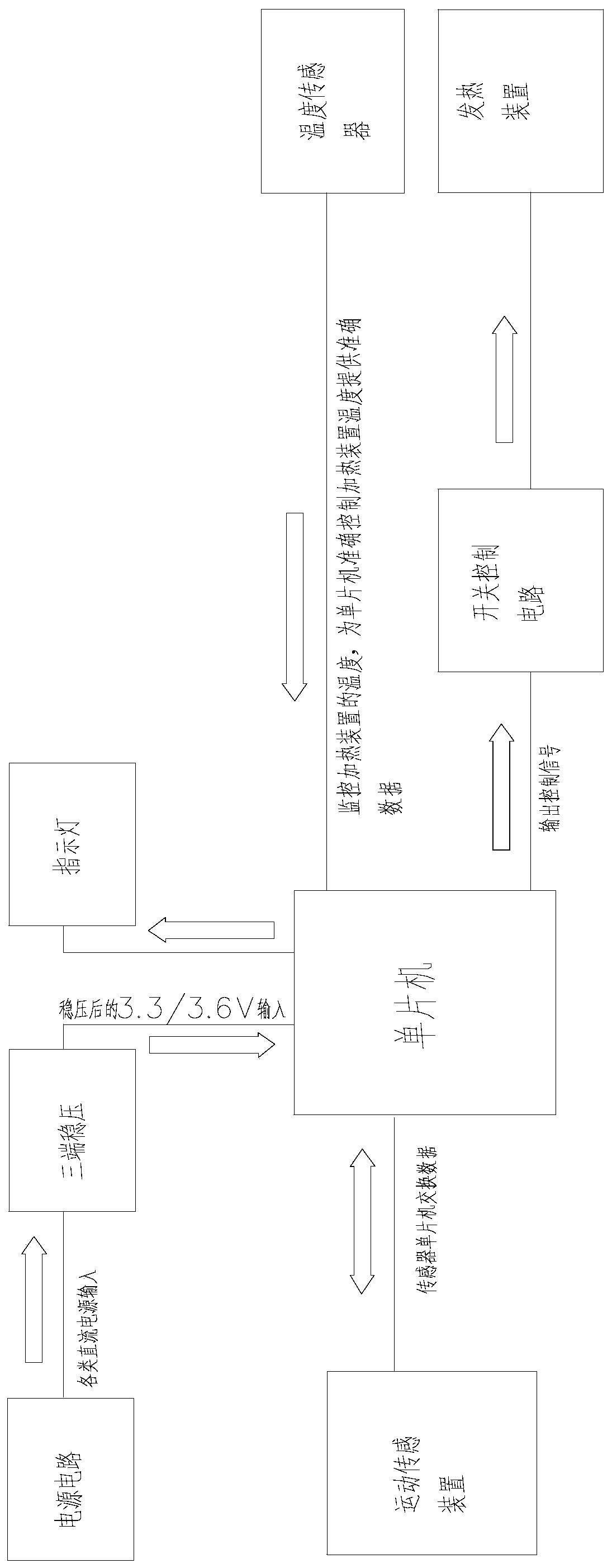

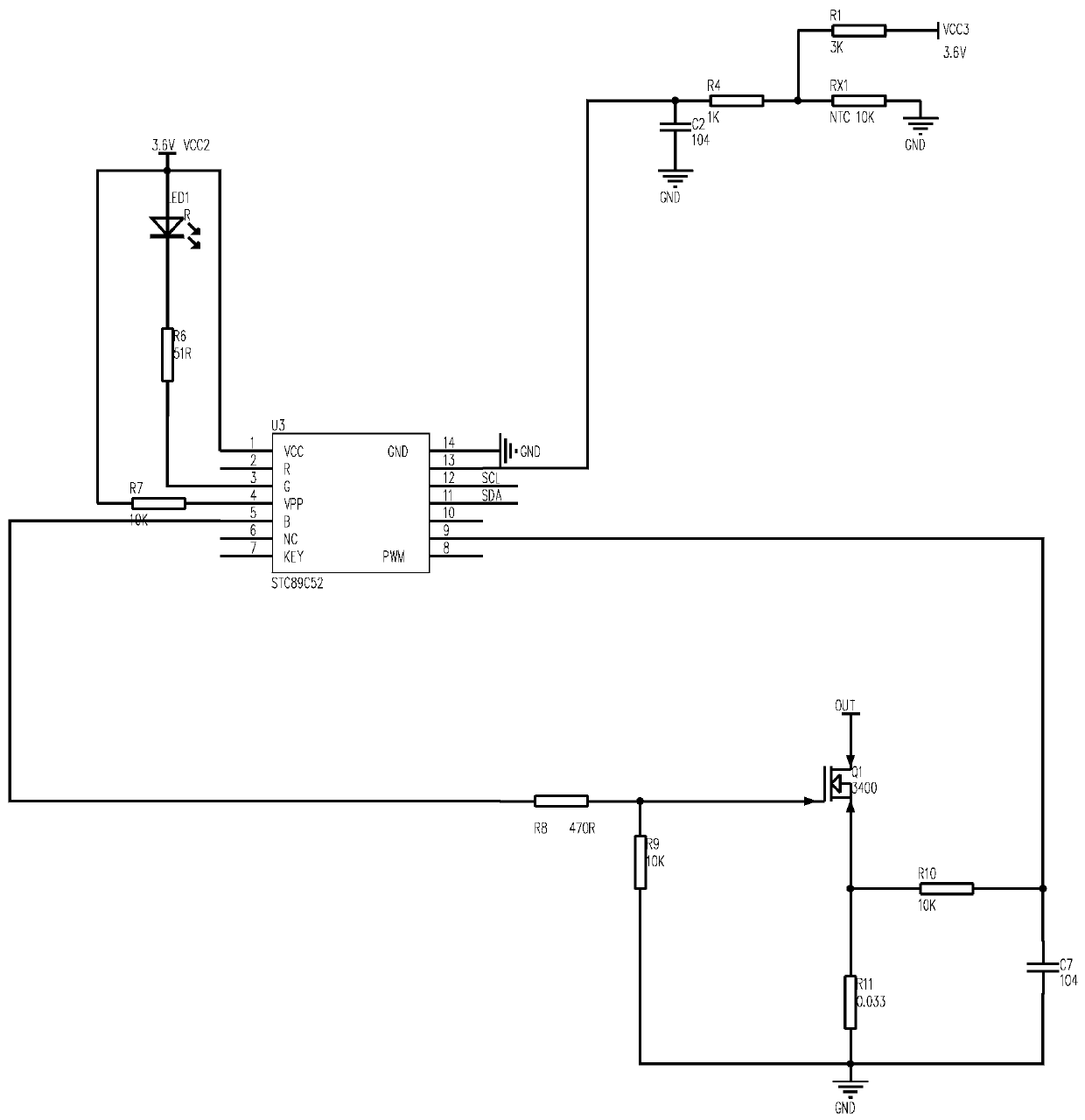

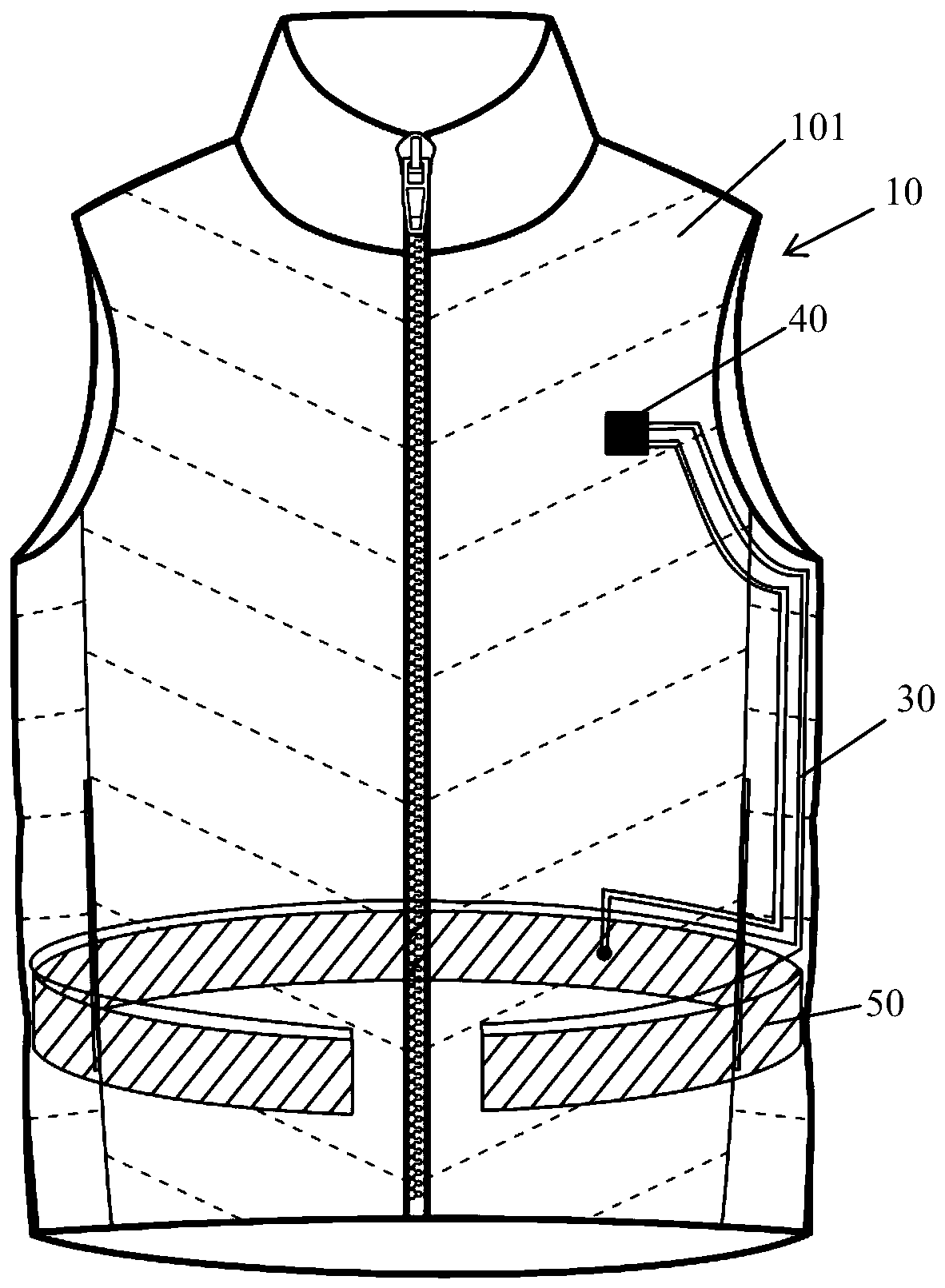

Motion sensing circuit and heating garment with motion sensing circuit

PendingCN109820261AImprove real-time performanceEasy to maintain temperatureTemperature control using electric meansProtective garmentElectricityTemperature control

The invention discloses a motion sensing circuit which comprises a power circuit, a controller, a switch control circuit, a motion sensing device for sensing human motions, and a heating device for heating. The controller is electrically connected with the switch control circuit and the motion sensing device. The switch control circuit is electrically connected with the heating device. The power circuit is used for supplying power to the controller, the switch control circuit, the motion sensing device and the heating device. The motion sensing device output sensing data to the controller. A temperature sensor is used for detecting the temperature of the heating device and feeding a temperature signal to the controller. The controller sends out a control signal to the switch control circuit after comparing and judging the sensing data and temperature signal and the temperature control command preset by the controller, and the heating on and off operations of the heating device are executed by the switch control circuit. The invention further discloses an intelligent heating garment with the motion sensing circuit. The heating on and off operations of the heating device are controlled in time through motion sensing, and a garment body more easily tends to be constant in temperature.

Owner:深圳市开芃智能科技有限公司

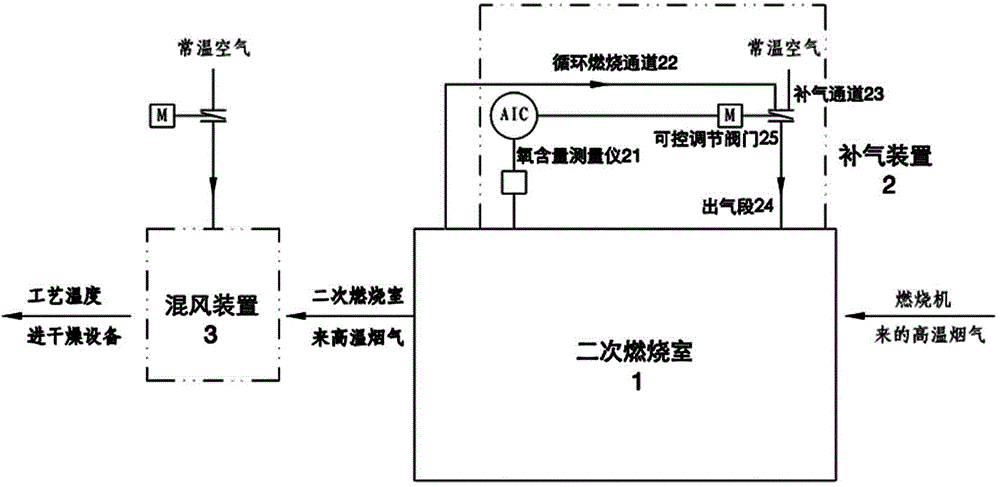

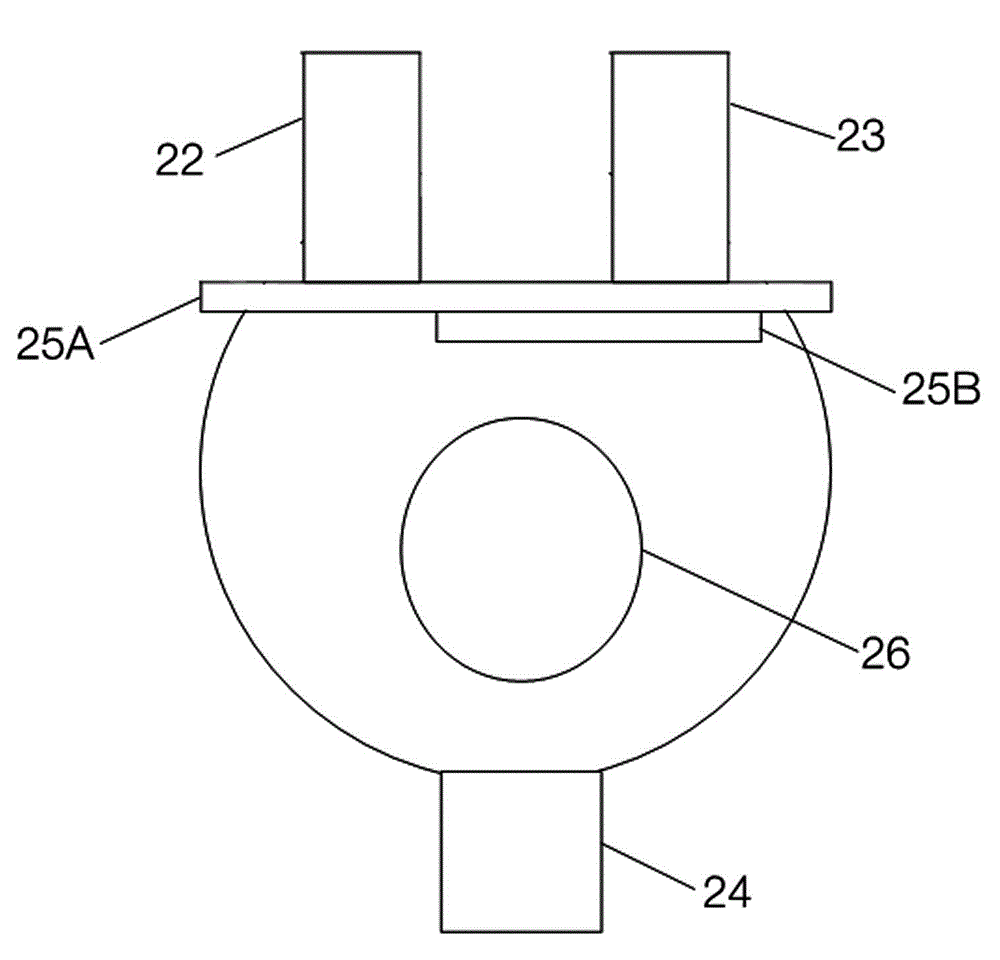

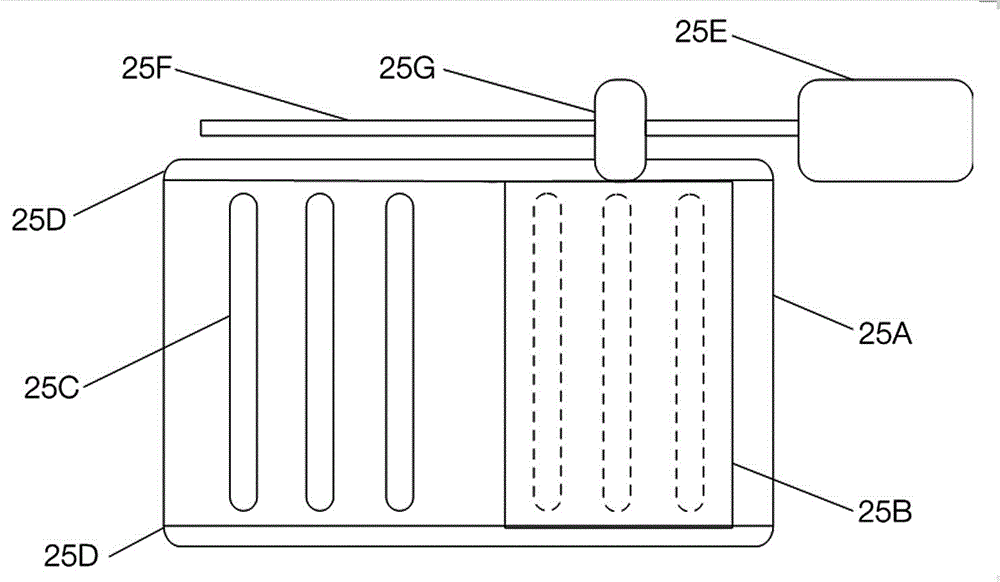

Secondary combustion air supplementation device for biofuel combustion furnace

ActiveCN104676578AMaintain flue gas temperatureImprovement effectDamper arrangementSolid fuel combustionProcess engineeringCombustion chamber

The invention discloses a secondary combustion air supplementation device for a biofuel combustion furnace. In order to completely combust a fuel and reduce harmful ingredients in flue gas produced by combustion to minimum values, an air supplementation device is additionally arranged at the front end of a secondary combustion chamber, and a high-accuracy oxygen content measurer is arranged at the tail end of the secondary combustion chamber. According to the device, an air supply passage and the opening of each passage valve can be automatically regulated according to oxygen content measured by the oxygen content measurer by the air supplementation device, so that the oxygen content in the flue gas can reach a reasonable control range.

Owner:浙江美宝工业科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com