Inorganic heat-storage, energy-saving and temperature-regulating wall material

A wall material and heat storage technology, applied in the field of natural inorganic heat storage building materials, can solve the problems of easy combustion, poor bonding strength, easy slippage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Take 1000 kg of 42.5 grade high alumina cement, 700 kg of vitrified microspheres with a closed cell rate ≥ 50%, 420 kg of aluminum silicate powder, 240 kg of bentonite, 25 kg of redispersible latex powder F2805, and 7 kg of hydroxyl Propyl methyl cellulose, 16 kg of polypropylene fiber (FC-05), 15 kg of starch ether 6200, 200 kg of lime calcium powder, 15 kg of 206 silicone water repellent, 10 kg of alkane as an air-entraining agent Phenol ethylene oxide and 80 kg of asbestos wool are added into the mixing tank, and after being thoroughly mixed by cyclone separation, after being fully mixed and packaged, it becomes the finished product of the inorganic heat storage energy-saving temperature-regulating wall material of the present invention.

[0023] Method of use: After packing the product of the present invention into bags and transporting it to the construction site, there is no need to add any substances, just add an appropriate amount of water to stir evenly, and the...

example 2

[0026] Take 1,000 kg of 42.5 grade high alumina cement, 550 kg of vitrified microspheres with a closed cell rate ≥ 50%, 450 kg of aluminum silicate powder, 200 kg of bentonite, 20 kg of redispersible latex powder F2805, and 8 kg of hydroxyl Propyl methyl cellulose, 15 kg of polypropylene fiber (FC-05), 10 kg of starch ether 6200, 150 kg of lime calcium powder, 15 kg of 206 silicone water repellent, 11 kg of alkane as an air-entraining agent Phenol ethylene oxide and 100 kg of asbestos wool are added to the mixing tank and fully mixed by cyclone separation. After fully mixed and packaged, it becomes the finished product of the inorganic thermal storage energy-saving temperature-regulating wall material of the present invention.

[0027] Method of use: After packing the product of the present invention into bags and transporting it to the construction site, there is no need to add any substances, just add an appropriate amount of water to stir evenly, and then directly apply it t...

example 3

[0030] Take 1000 kg of 42.5 grade high alumina cement, 800 kg of vitrified microspheres with a closed cell rate ≥ 50%, 300 kg of aluminum silicate powder, 150 kg of bentonite, 25 kg of redispersible latex powder F2805, and 5 kg of hydroxyl Propyl methyl cellulose, 13 kg of polypropylene fiber (FC-05), 18 kg of starch ether 6200, 100 kg of ash calcium powder, 16 kg of 206 silicone water repellent, 8 kg of alkane as an air-entraining agent Phenylphenol ethylene oxide, 110 kilograms of asbestos wool, are added in the mixing tank, and after being thoroughly mixed by cyclone separation, after fully mixing and packaging, it becomes the finished product of the inorganic thermal storage energy-saving temperature-regulating wall material of the present invention.

[0031] The using method and scope of application of the present invention are identical with example 1.

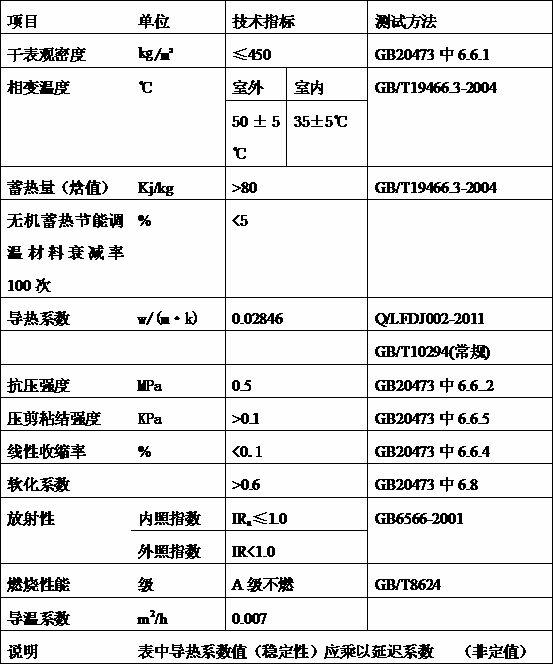

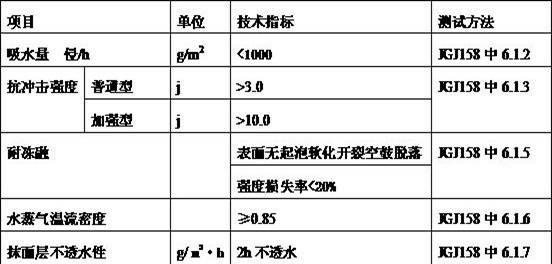

[0032] After testing, its physical and mechanical performance indicators are also within the range of Table 1 and Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com