Casting device with an annular duct and a casting method

A technology of annular pipes and molds, applied in the direction of casting molds, casting mold components, manufacturing tools, etc., can solve problems such as complex structures of casting devices, and achieve the effect of low cost and low quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

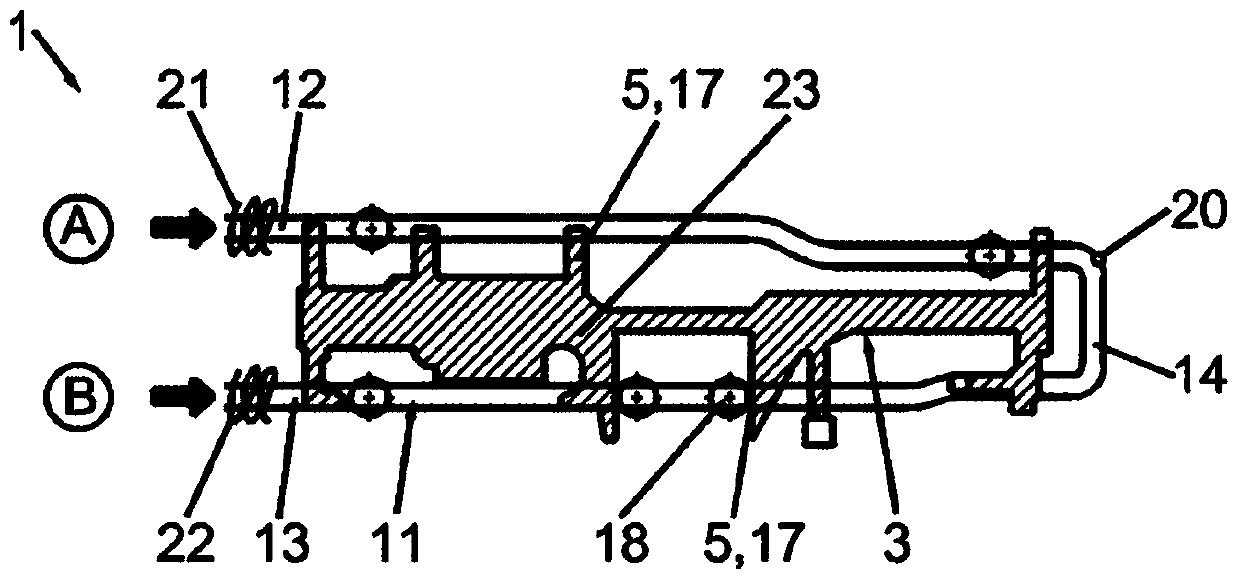

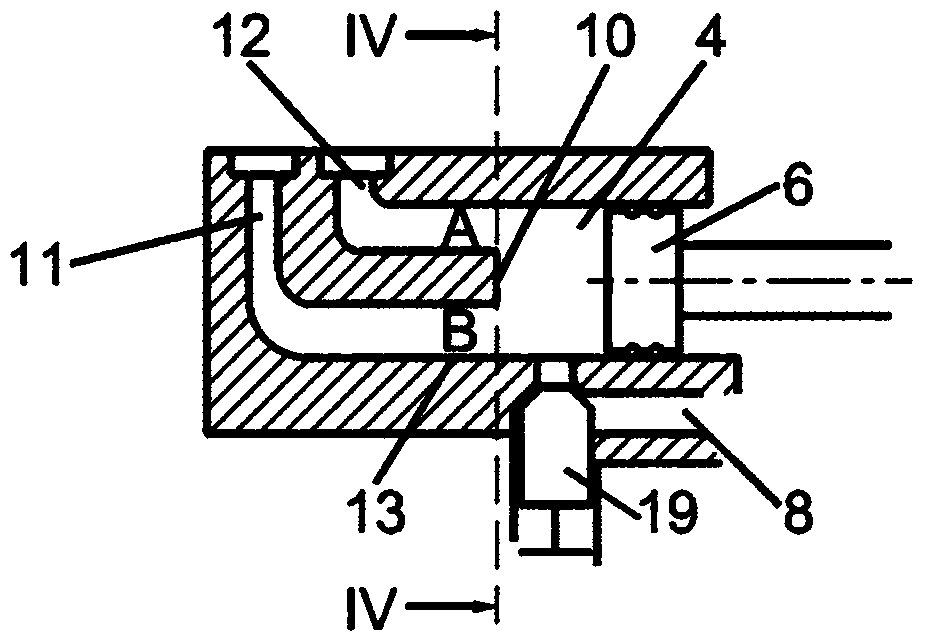

[0049] Figure 4 A part of a casting device 1 for die-casting molten metals such as molten magnesium or molten aluminum is shown. The melt 2 is guided from a melt reservoir 7 via a supply line 8 which can be blocked by means of a melt valve 19 into a casting chamber 4 . The casting chamber 4 is oriented horizontally and can be moved by a hydraulically moved casting piston 6 ( image 3 ) pressure loading. On the end side 10 opposite the casting piston 6 , the casting chamber 4 has exactly two annular line connections A and B, which form the ends of the annular line 11 .

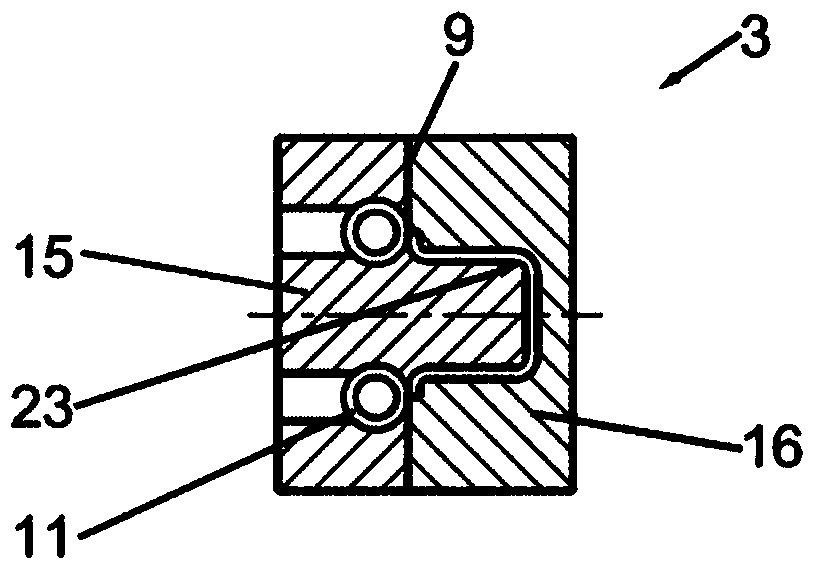

[0050] Such as figure 1 As shown, the annular duct 11 is guided in the vicinity of the tool cavity 3 and is formed by two essentially parallel, pressure-resistant connecting channels 12 , 13 . The connecting channels 12 , 13 open into the casting chamber 4 in annular line connections A and B, wherein the annular line connection A is arranged above the annular line connection B. The connecting channels 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com