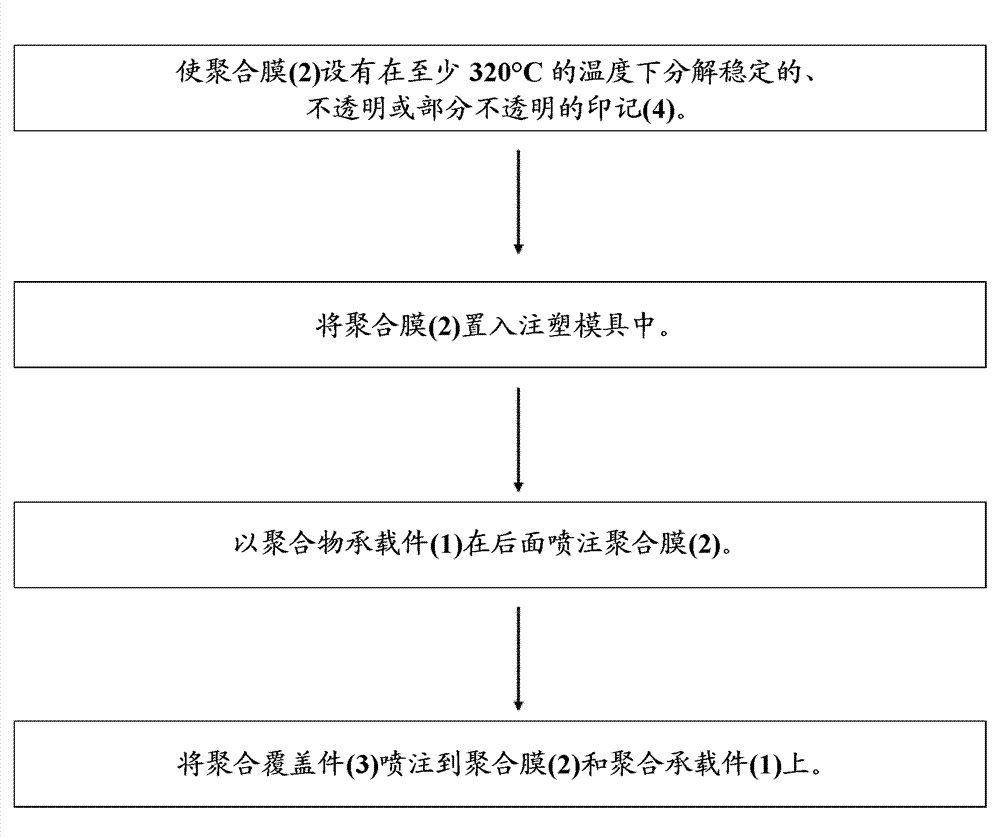

Method for producing a plastic trim part

A technology for decorative parts and plastics, applied in the field of plastic decorative parts, can solve the problem of not allowing targeted modification of materials in the polymer phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

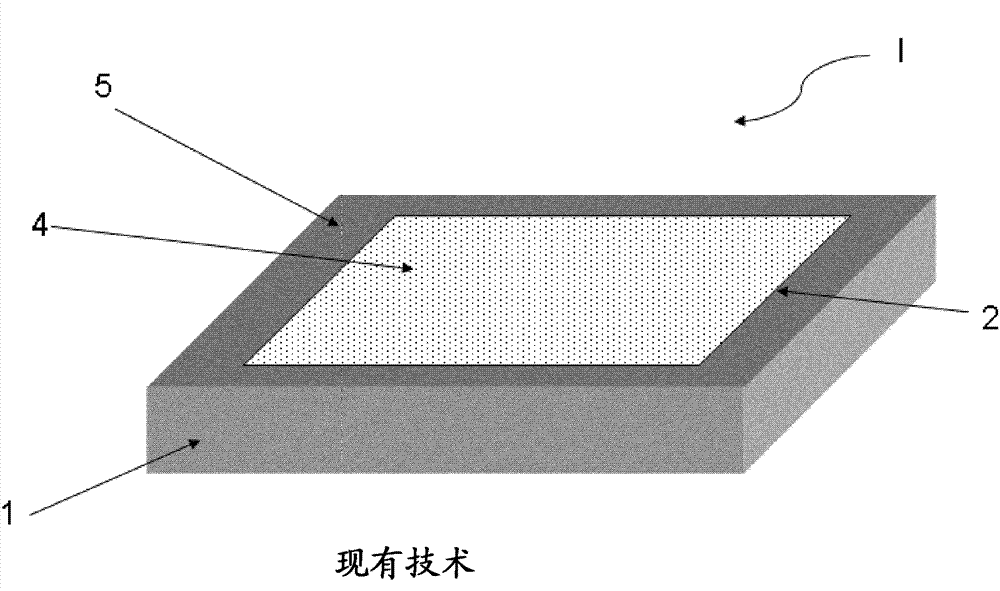

[0035] figure 1 A schematic view of a plastic trim part (I) according to the prior art is shown. A polymer film (2) with a decorative print (4) is arranged on a section of a polymer carrier (1), for example a dashboard of a motor vehicle. The edge region ( 5 ) can be designed not only in the same color as the polymer carrier ( 1 ), but also in a different color.

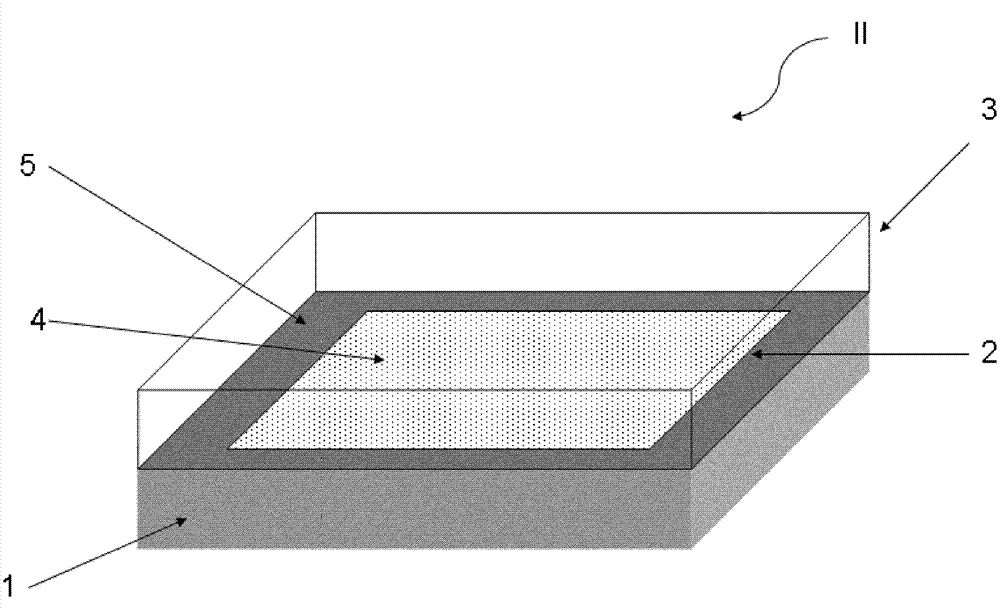

[0036] figure 2 A schematic view of a plastic trim part (II) according to the invention is shown. A transparent polymer cover ( 3 ) of PC or PMMA is arranged on an opaque polymer carrier ( 1 ) of acrylonitrile-butadiene-styrene (ABS). A polymer film (2) with a decorative print (4) is arranged between the polymer carrier (1) and the polymer cover (3). The transparent polymeric cover (3) protects the polymeric film (2) from UV radiation, abrasion and damage and at the same time makes a decorative imprint (4) on the polymeric film (for example, Kremer Pigmente GmbH & Unlimited GmbH & Co. KG, Aichstetten, Germany, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com