Patents

Literature

98 results about "Steam dome" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The steam dome is a vessel fitted to the top of the boiler of a steam engine. It contains the opening to the main steam pipe and its purpose is to allow this opening to be kept well above the water level in the boiler. This arrangement acts as a simple steam separator and minimises the risk that water will be carried over to the cylinders where it might cause a hydraulic lock, also known as priming.

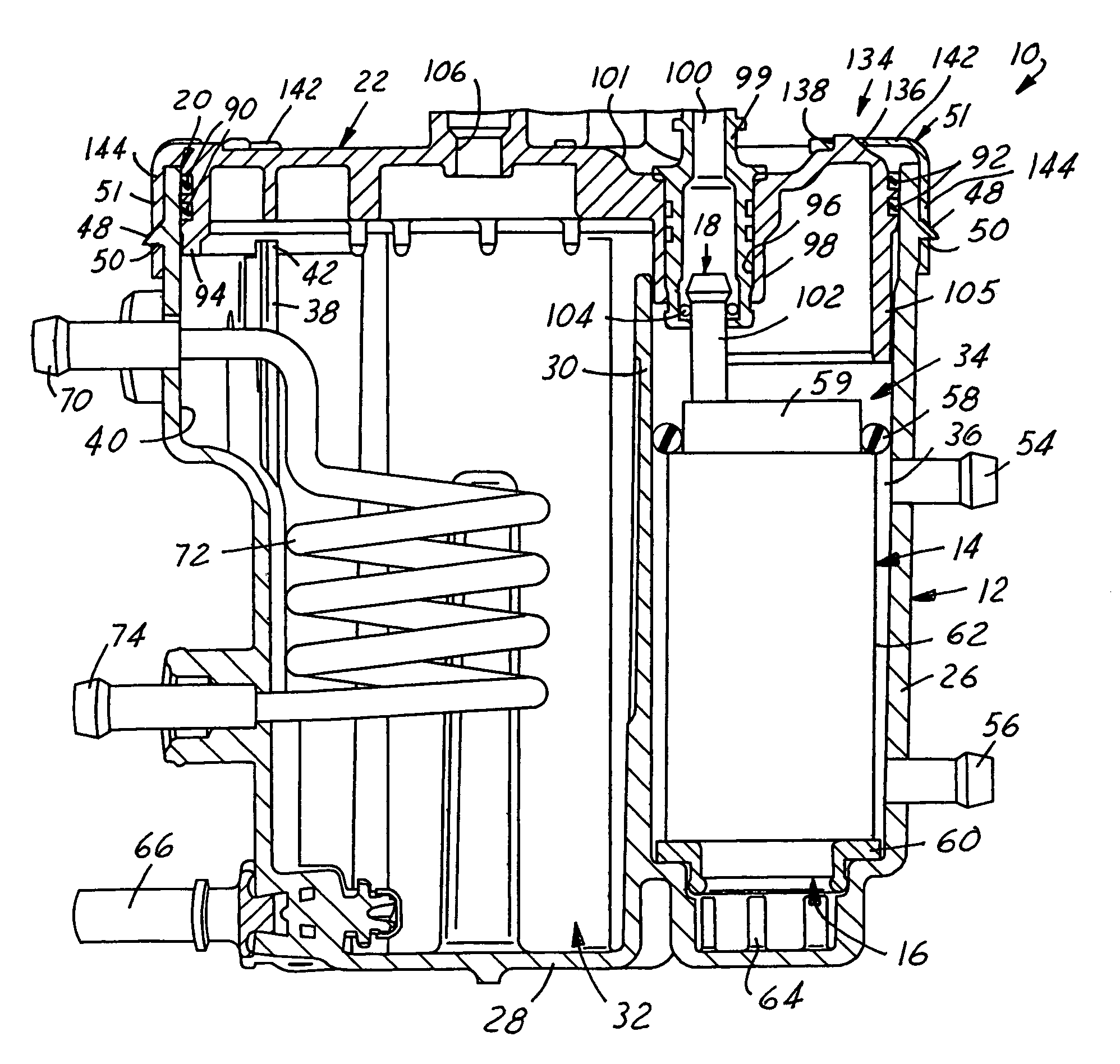

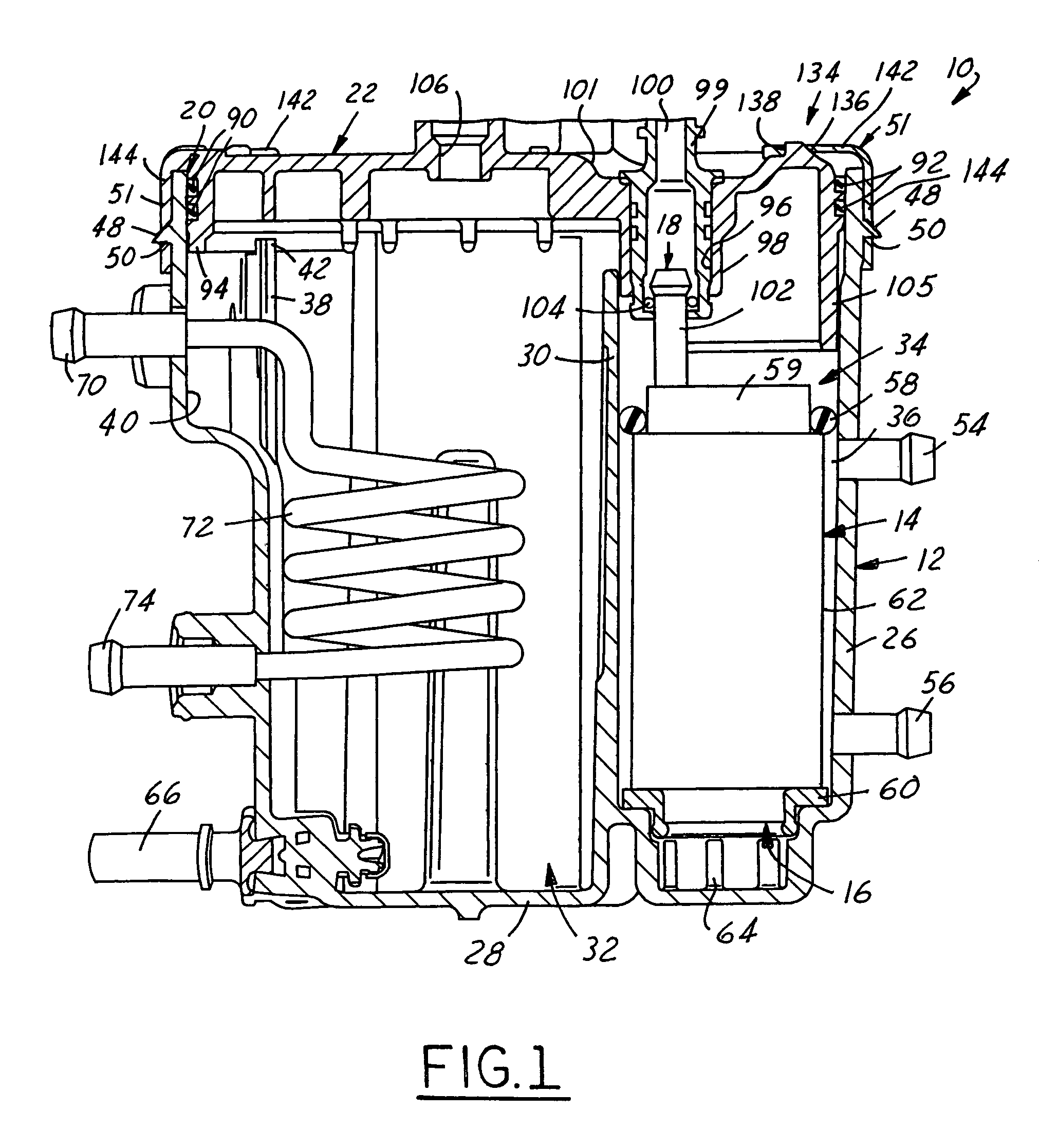

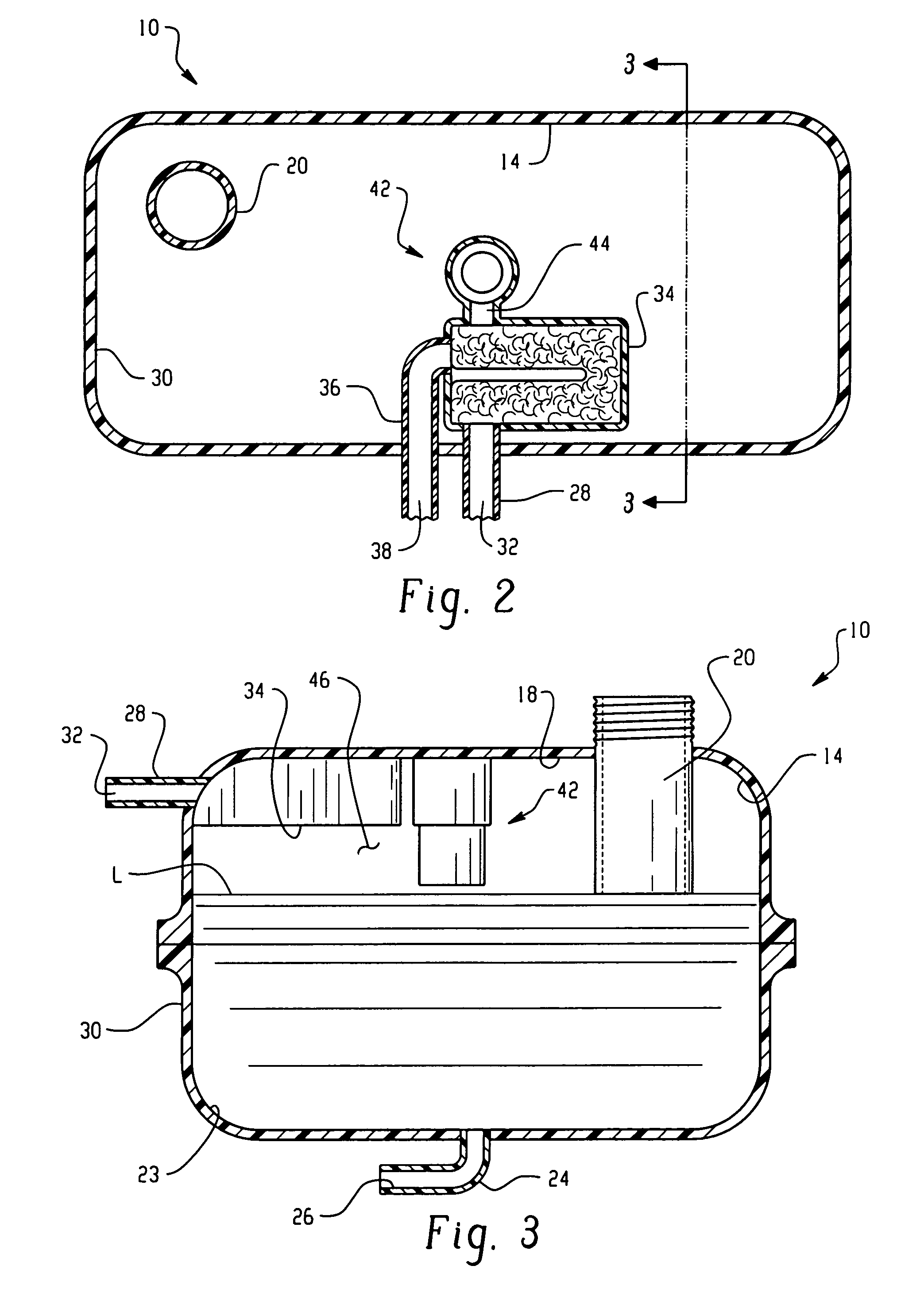

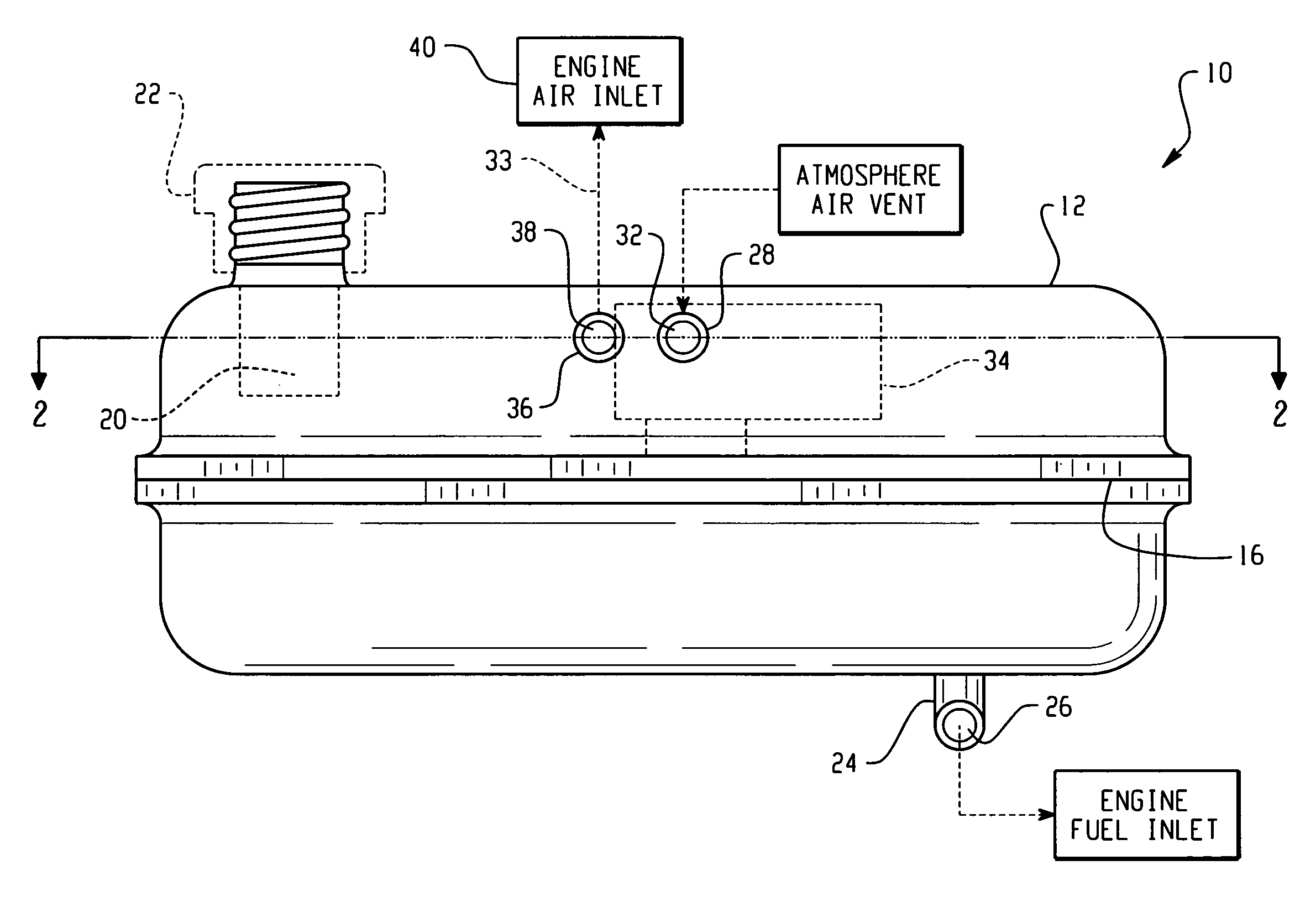

Fuel vapor separator

InactiveUS7013878B1Reliable exhaustReduce eliminateAir coolingMachines/enginesExhaust valveNuclear engineering

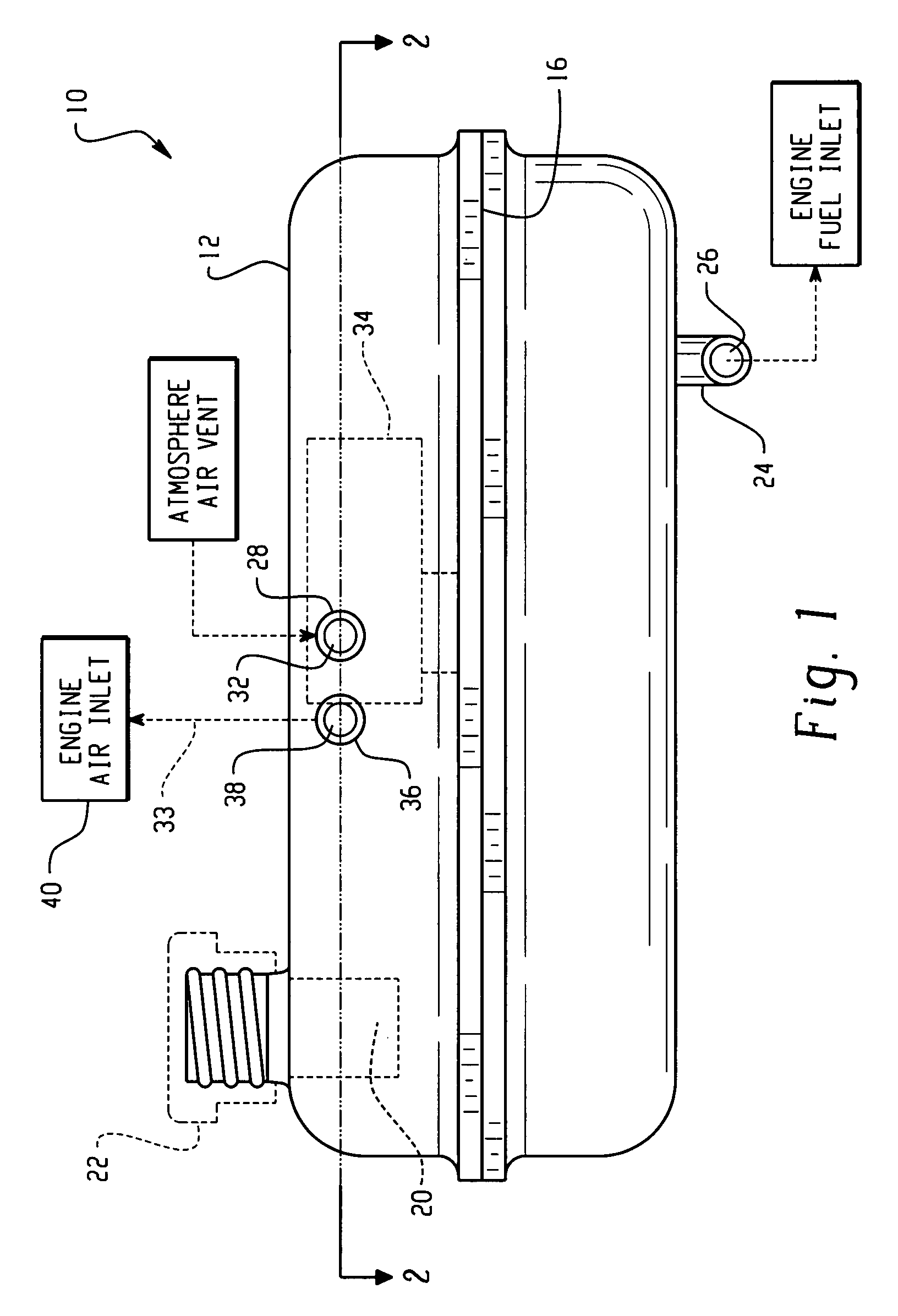

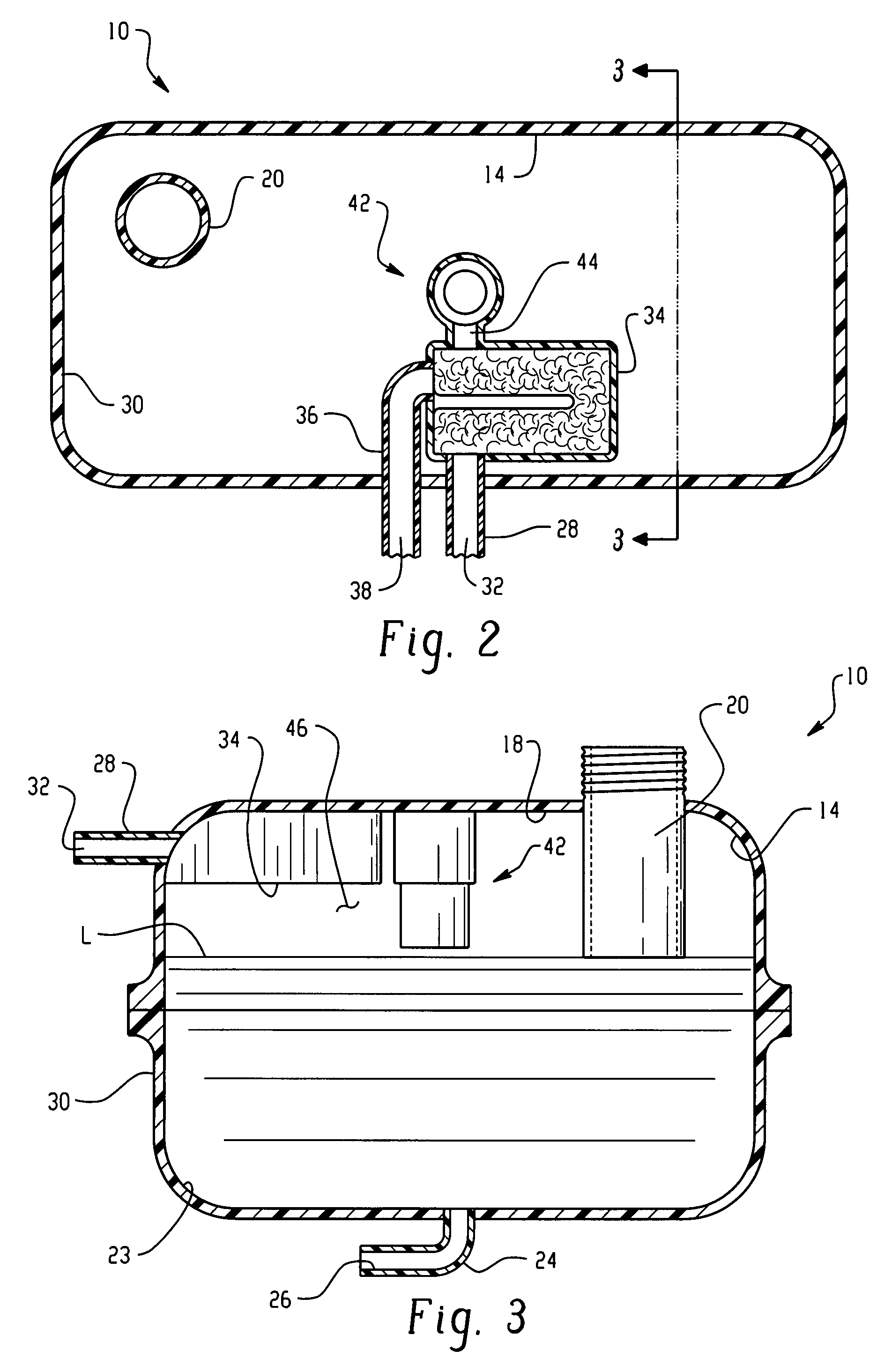

A fuel vapor separator includes a polymeric body that preferably has a polymeric canister and a polymeric lid secured to the canister to define a liquid tight enclosure. The enclosure is preferably divided into at least two chambers. One chamber preferably receives liquid fuel and communicates with a heat exchanger to cool the supply of liquid fuel therein. Vapor is trapped in a vapor dome area above the liquid fuel and is vented through a vent valve carried by the fuel vapor separator. The other chamber of the enclosure preferably receives a high pressure fuel pump adapted to receive liquid fuel from the first chamber, and to deliver liquid fuel under pressure to the engine. Preferably, the chamber in which the fuel pump is received is communicated with a coolant to facilitate cooling the fuel pump in use.

Owner:WALBRO ENGINE MANAGEMENT

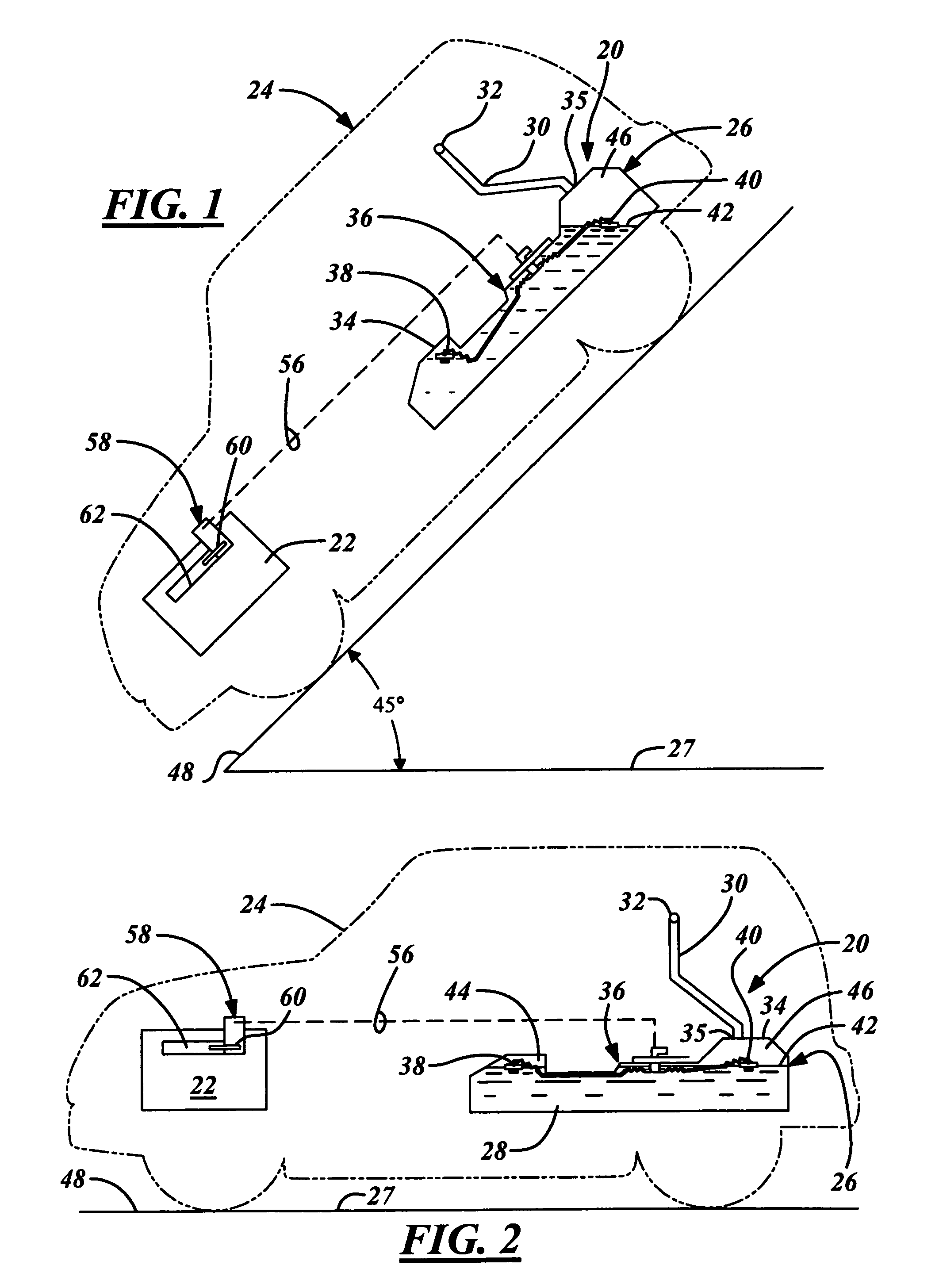

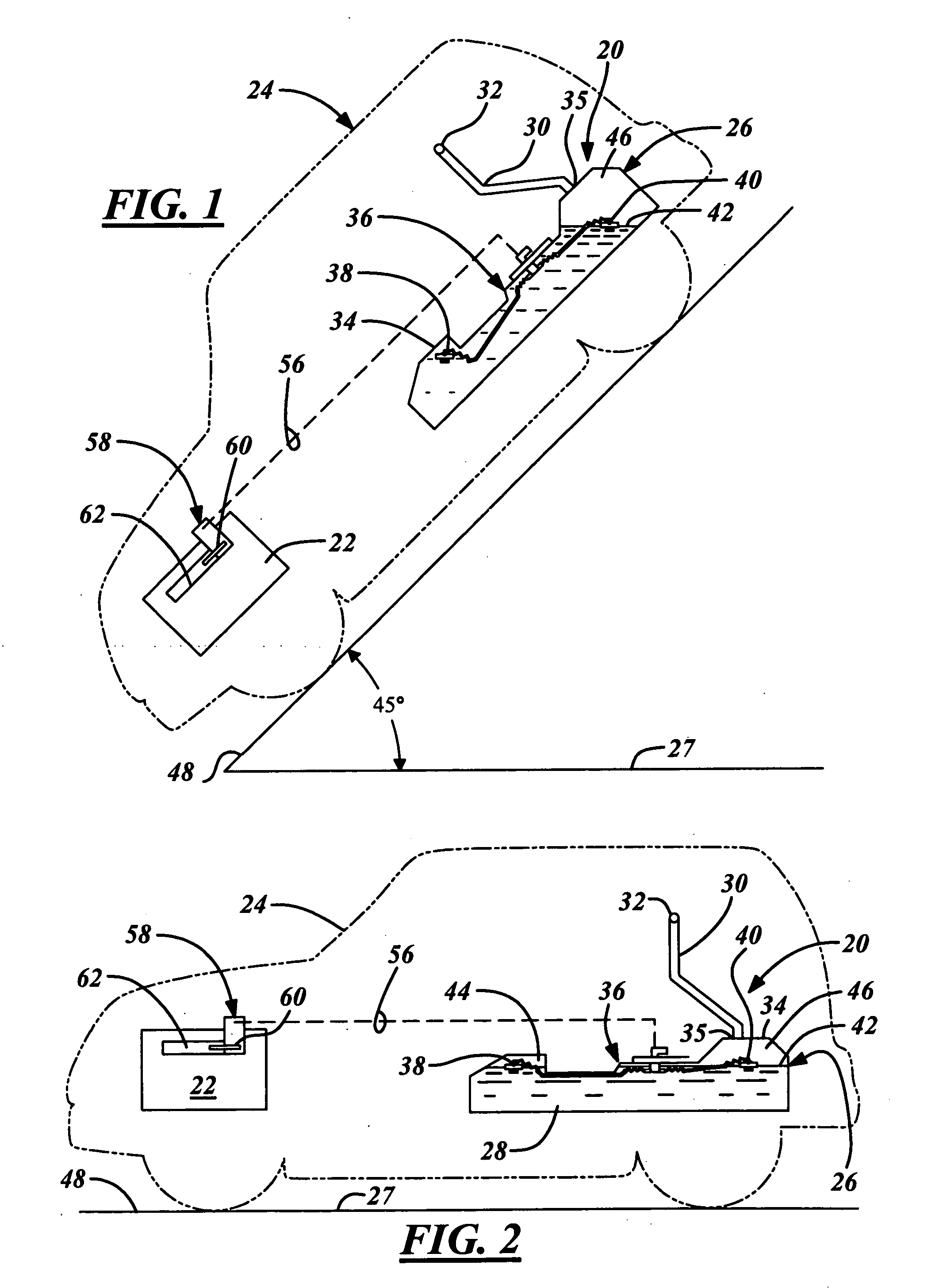

Fuel storage system for a vehicle

InactiveUS7520293B2Good flexibilityLight weightOperating means/releasing devices for valvesLarge containersExhaust valveSurface level

A fuel storage system for a transportation or recreational vehicle has a fuel tank that carries a vapor assembly that seeks out vapor pockets and controllably removes fuel vapor from the tank without releasing hydrocarbons to the surrounding environment. Preferably, a vent manifold attaches to a flange that sealably covers an access hole of the tank. At least one flexible tentacle extends from the manifold in the tank to a respective vapor vent valve that floats upon the surface of fuel at a vapor dome. When freely floating, the vent valve is open thus communicates the vapor dome through the tentacle and preferably with a filtering carbon canister. As fuel surface levels change or the vehicle tilts, changing the vapor dome size or location in the tank, the floating vapor vent valve is free to move generally with the vapor dome and as permitted by the flexibility of the trailing tentacle. With tank orientations where the vapor vent valve falls below the surface of fuel, the vent valve automatically closes to prevent flooding of the respective tentacle and remote vapor canister.

Owner:TI GRP AUTOMOTIVE SYST LLC

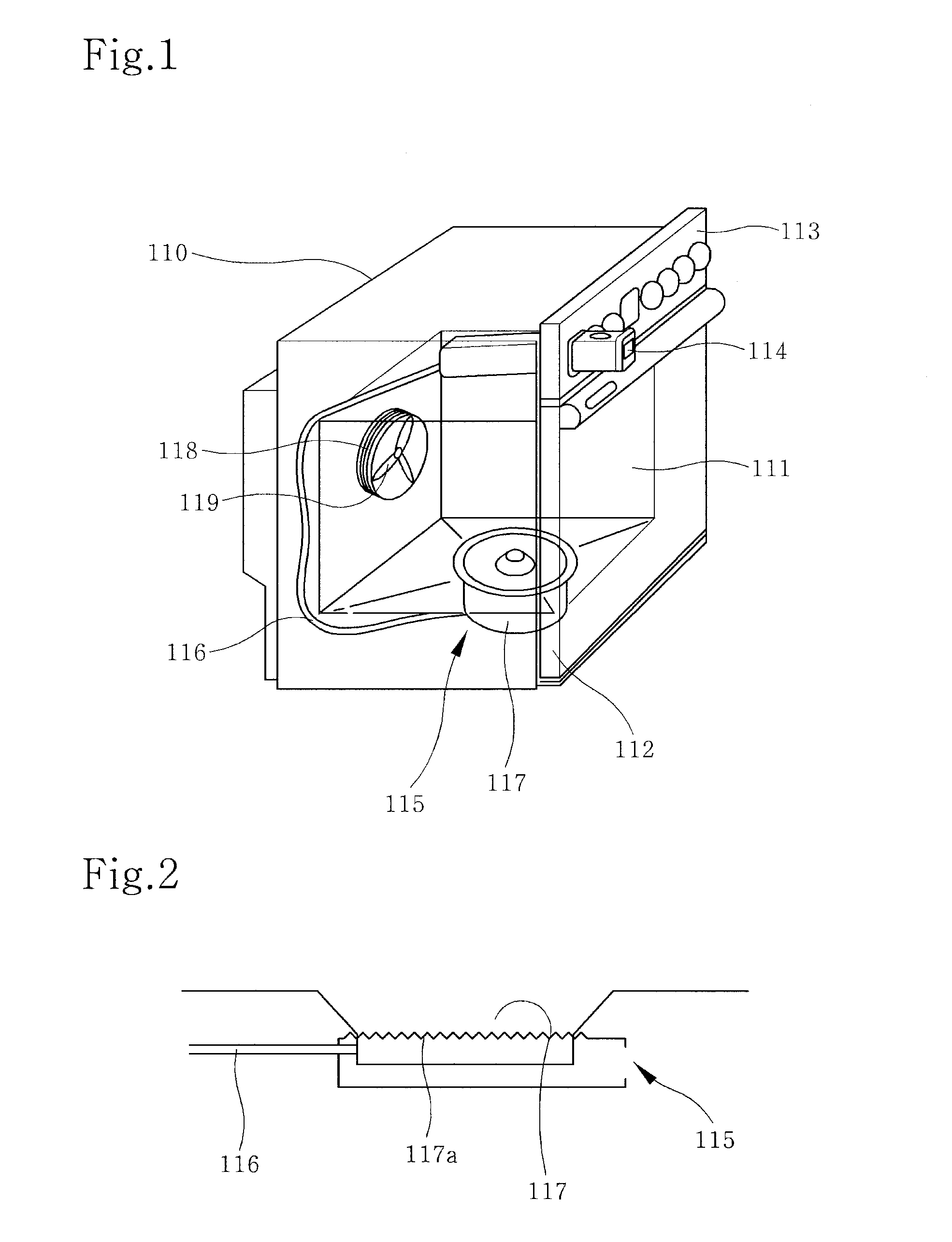

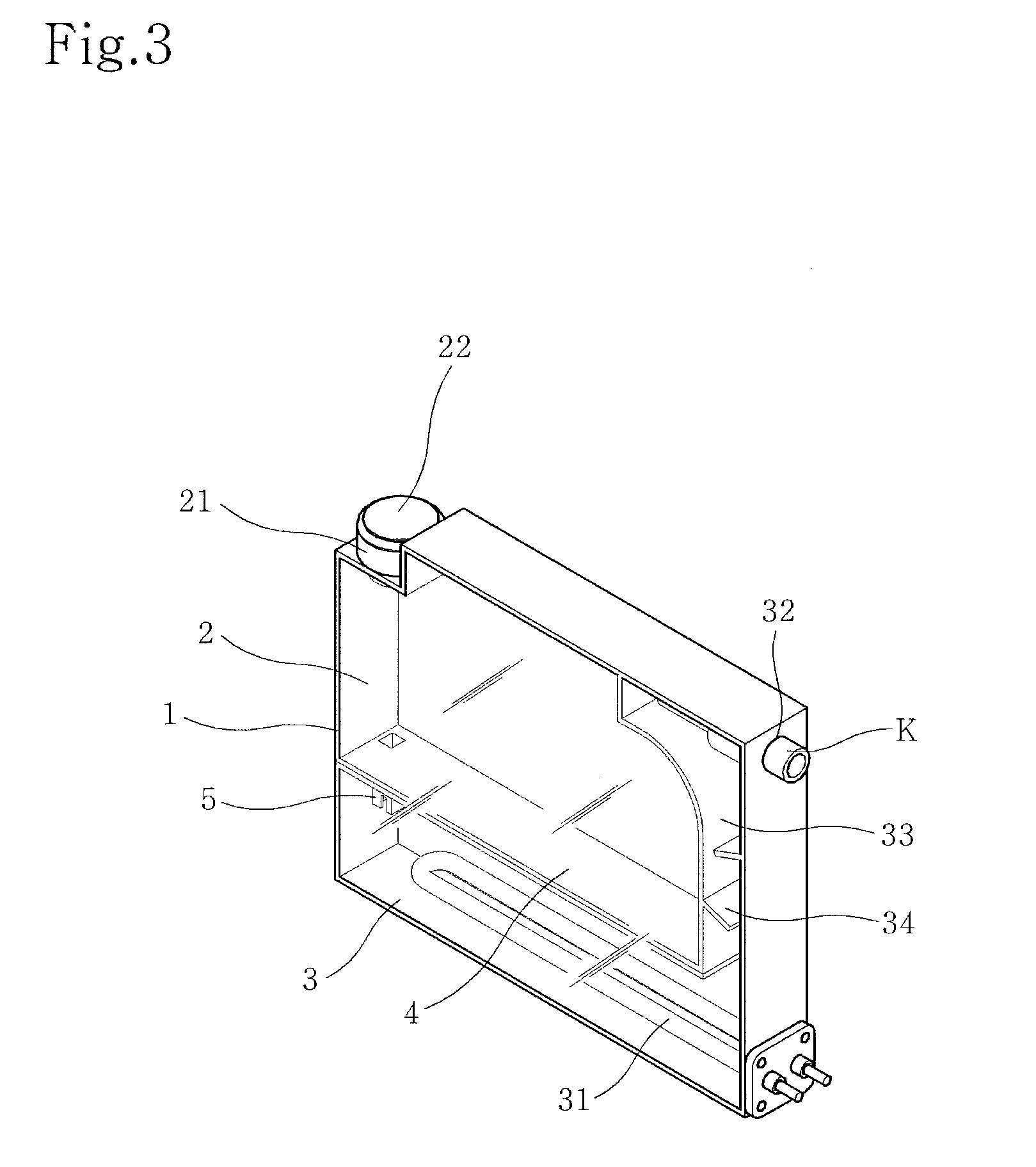

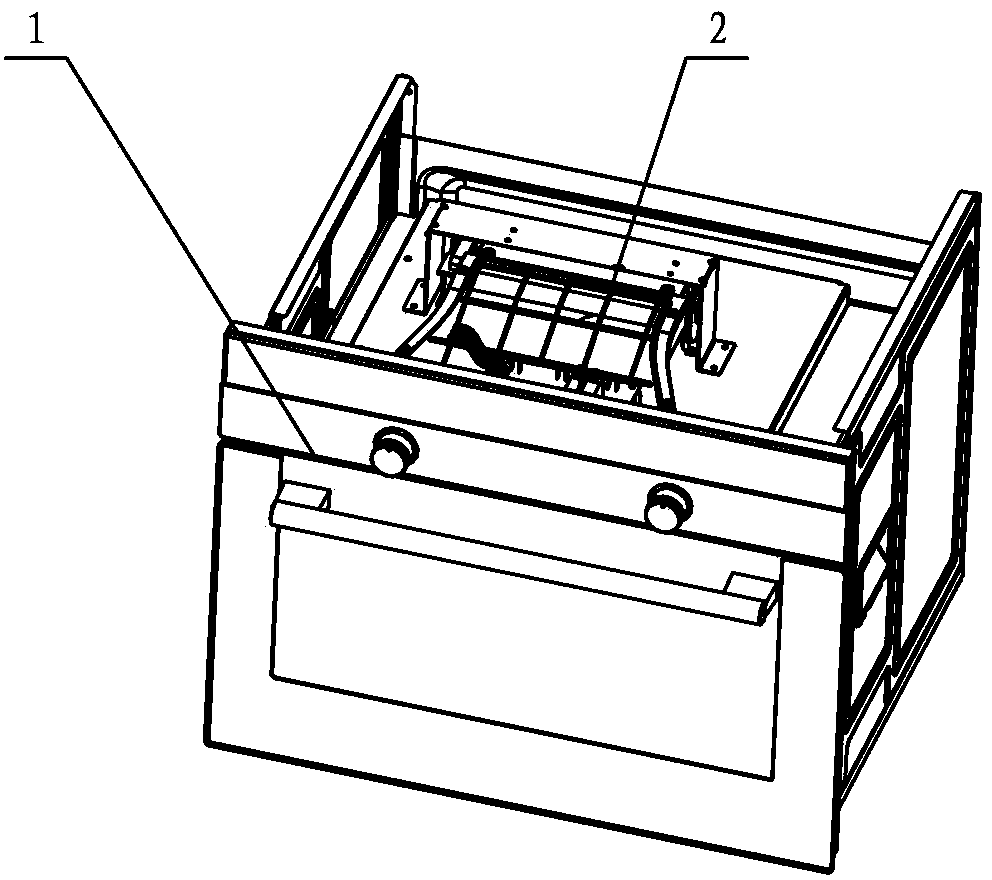

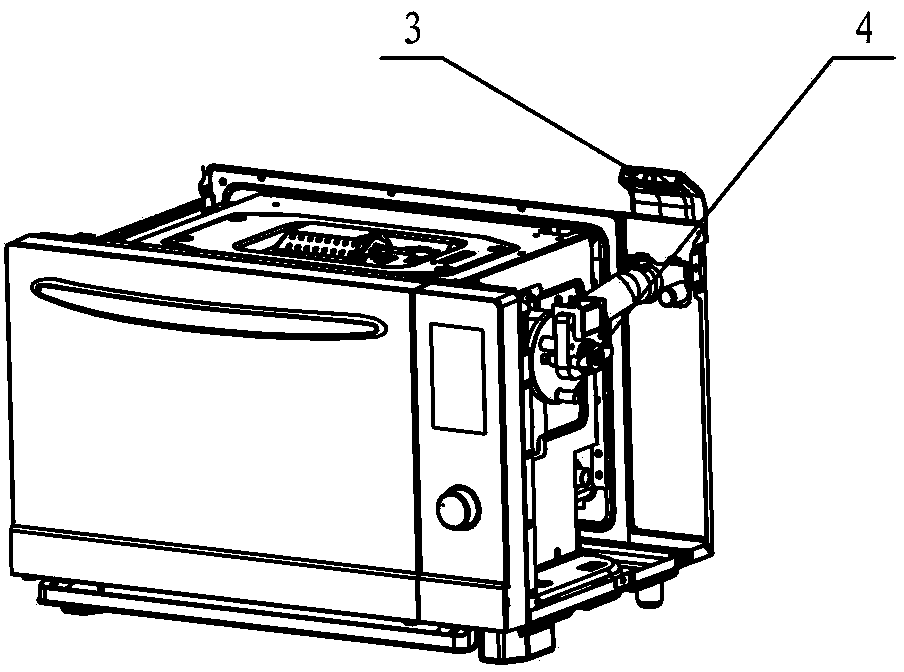

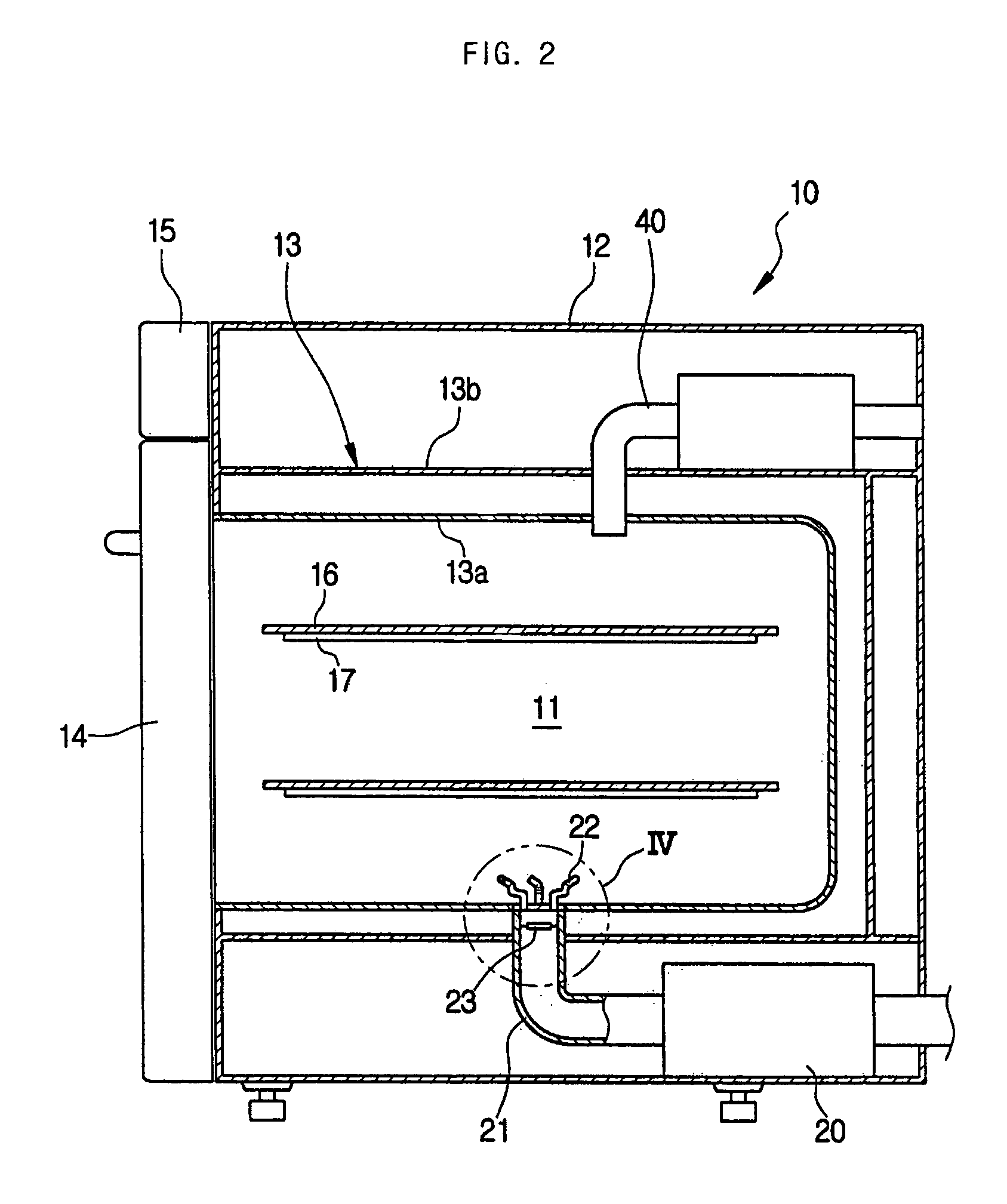

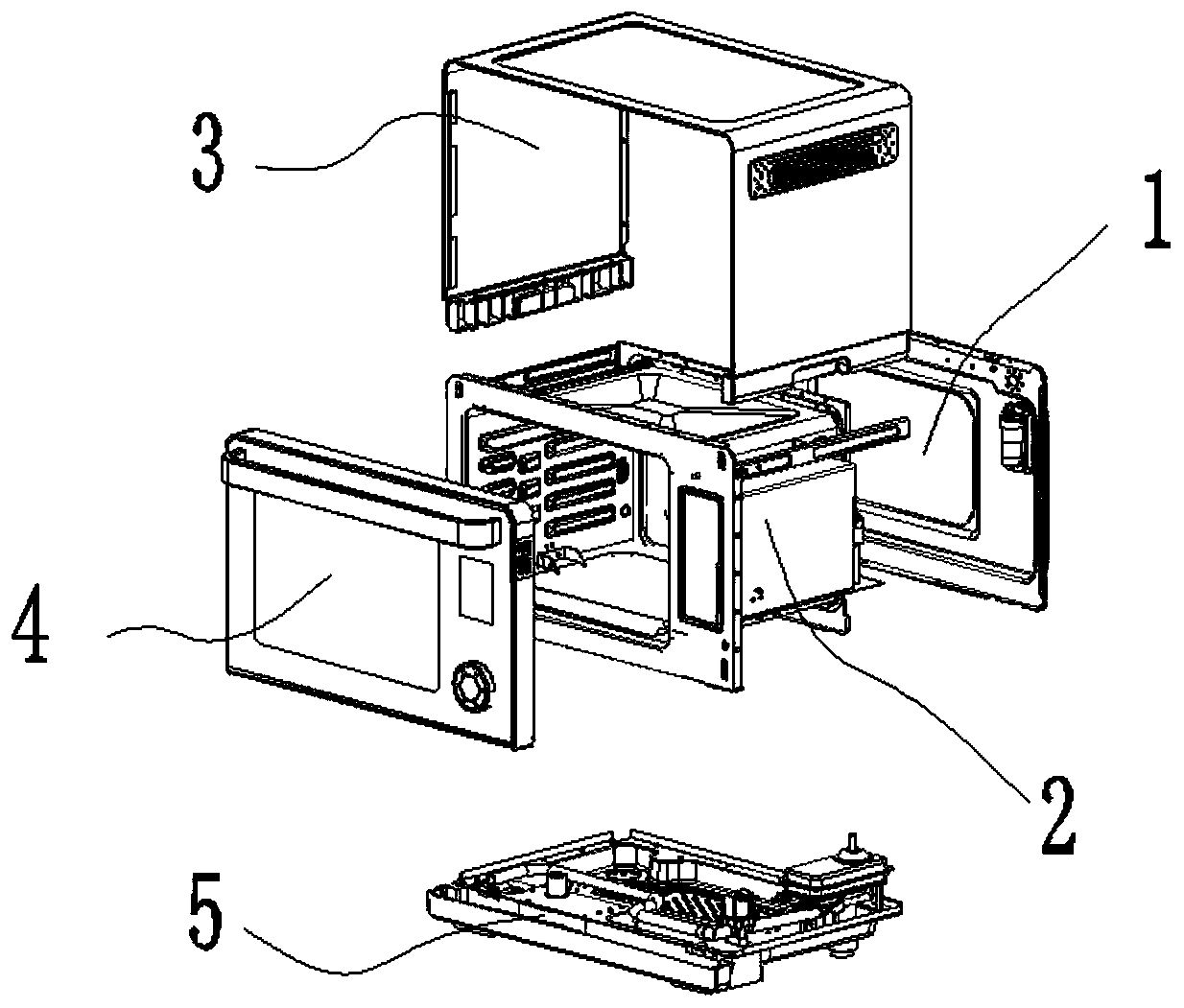

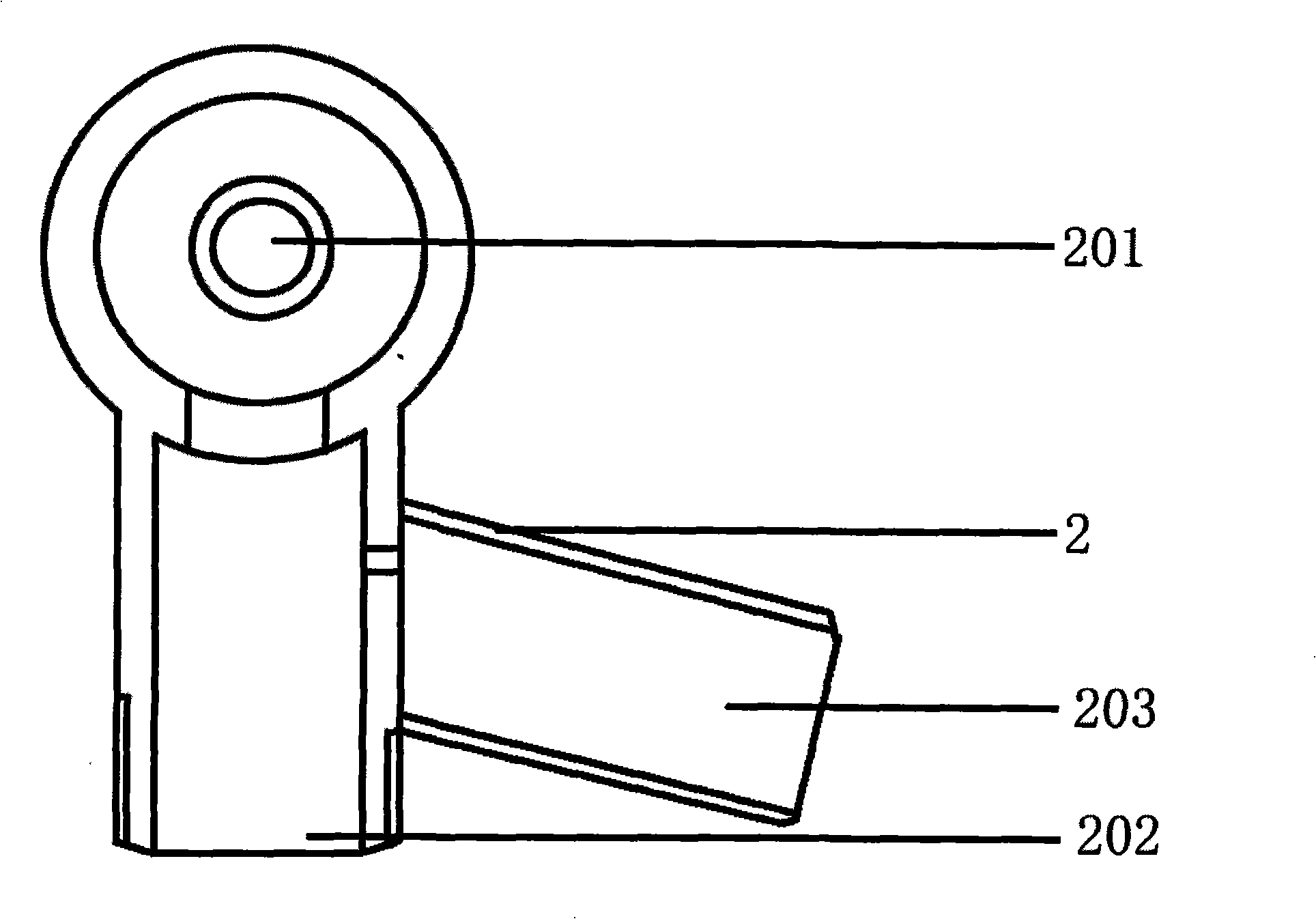

Steam generator of steam oven

ActiveUS20100054717A1Simplify device configurationEasy to cleanDomestic stoves or rangesOven air-treatment devicesEngineeringSteam dome

Disclosed is a steam oven to cook food in a cooking chamber by use of steam. More particularly, disclosed is a steam generator of a steam oven, which can simplify the configuration of a device required to generate steam and is detachably attached to a cabinet to assure easy cleaning and washing thereof. The steam generator includes a single body having an inner space divided into a water supply compartment and a boiler compartment by a partition, the water supply compartment having a water pouring hole, and the boiler compartment having a heater and a steam discharge hole. Also, a water supply passage is defined between the water supply compartment and the boiler compartment. This configuration has the effects of achieving improved workability and reduced manufacturing costs of the steam generator and also, of overcoming a limit in the inner volume of a cooking chamber of the steam oven.

Owner:LG ELECTRONICS INC

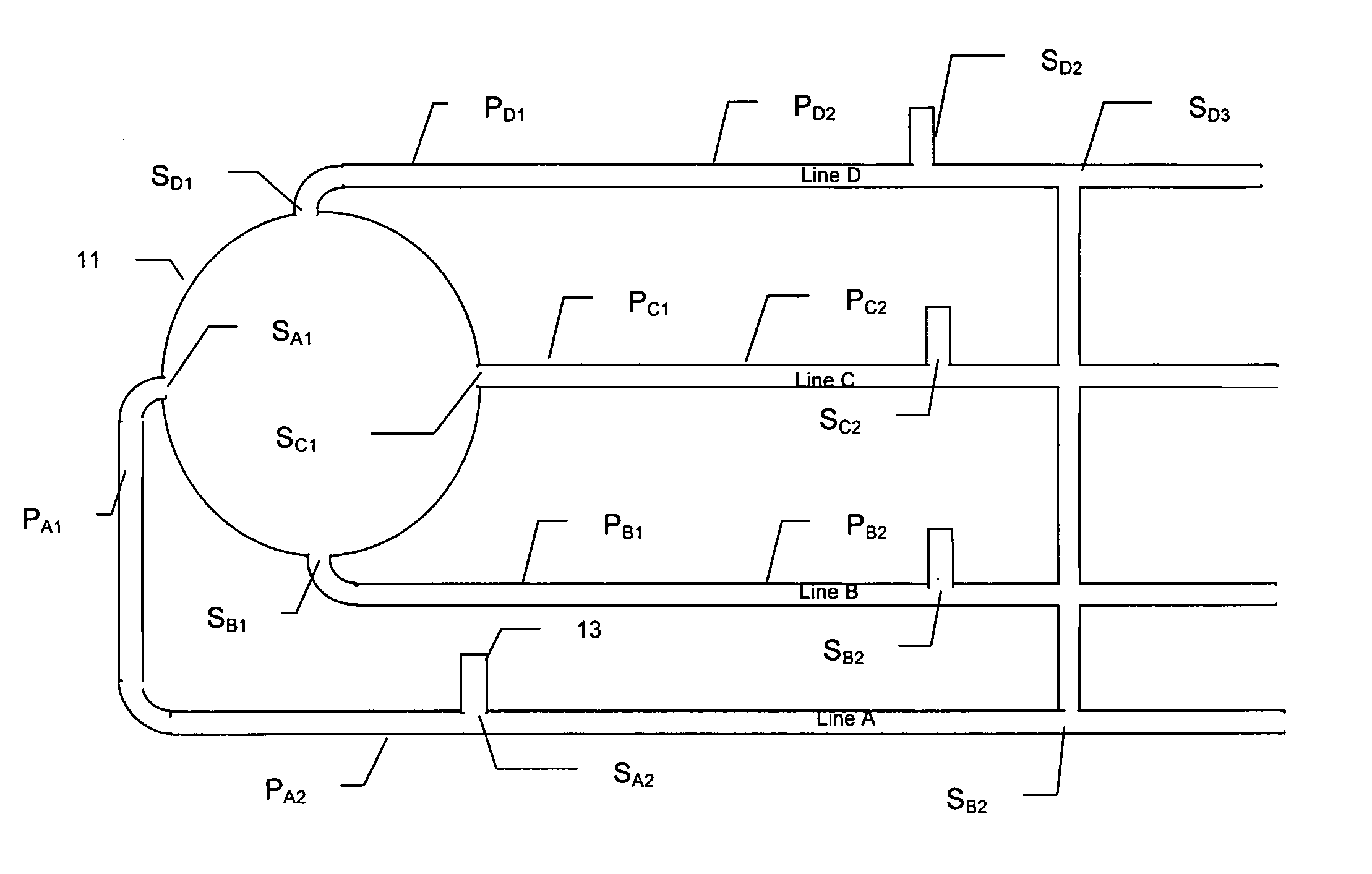

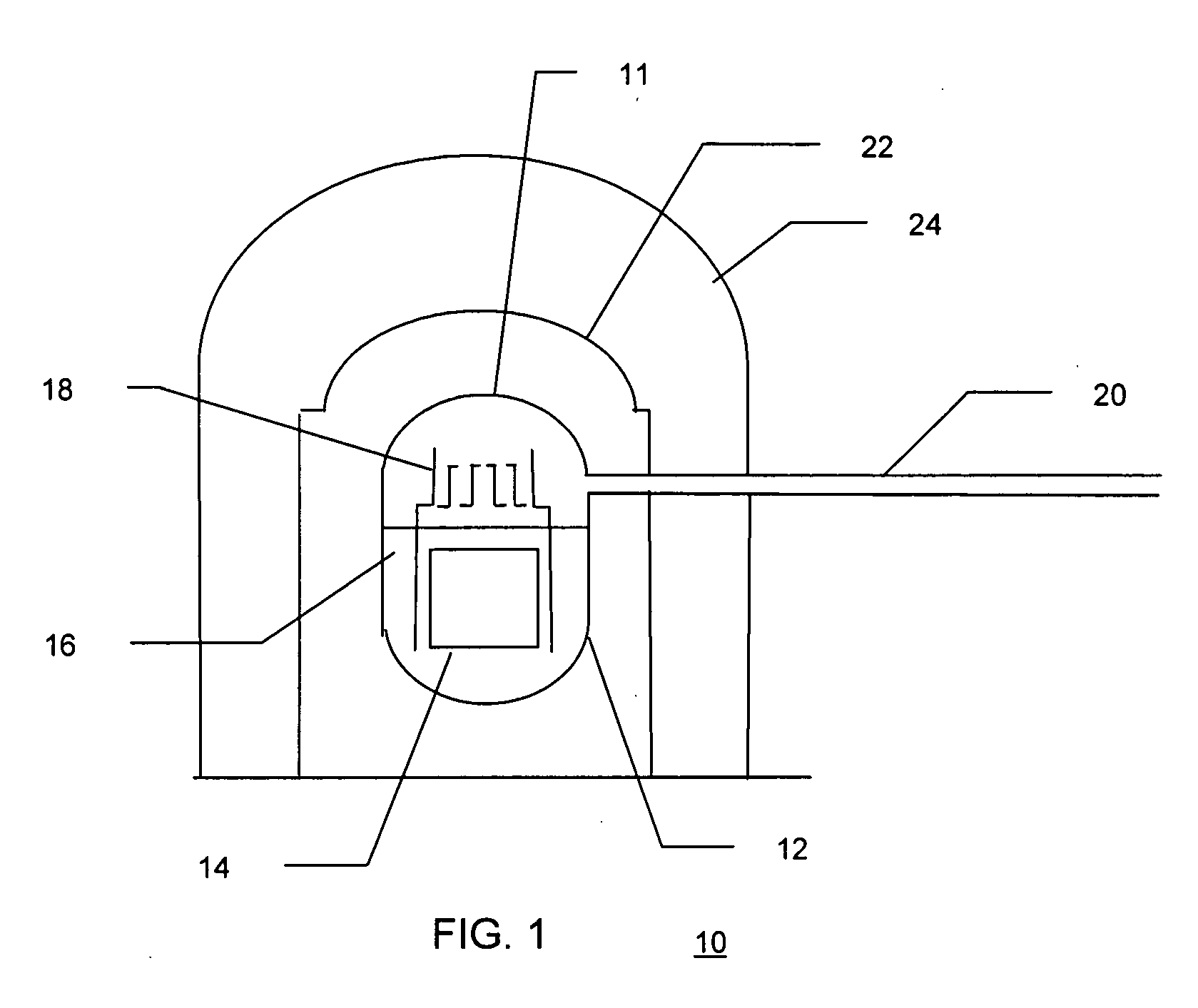

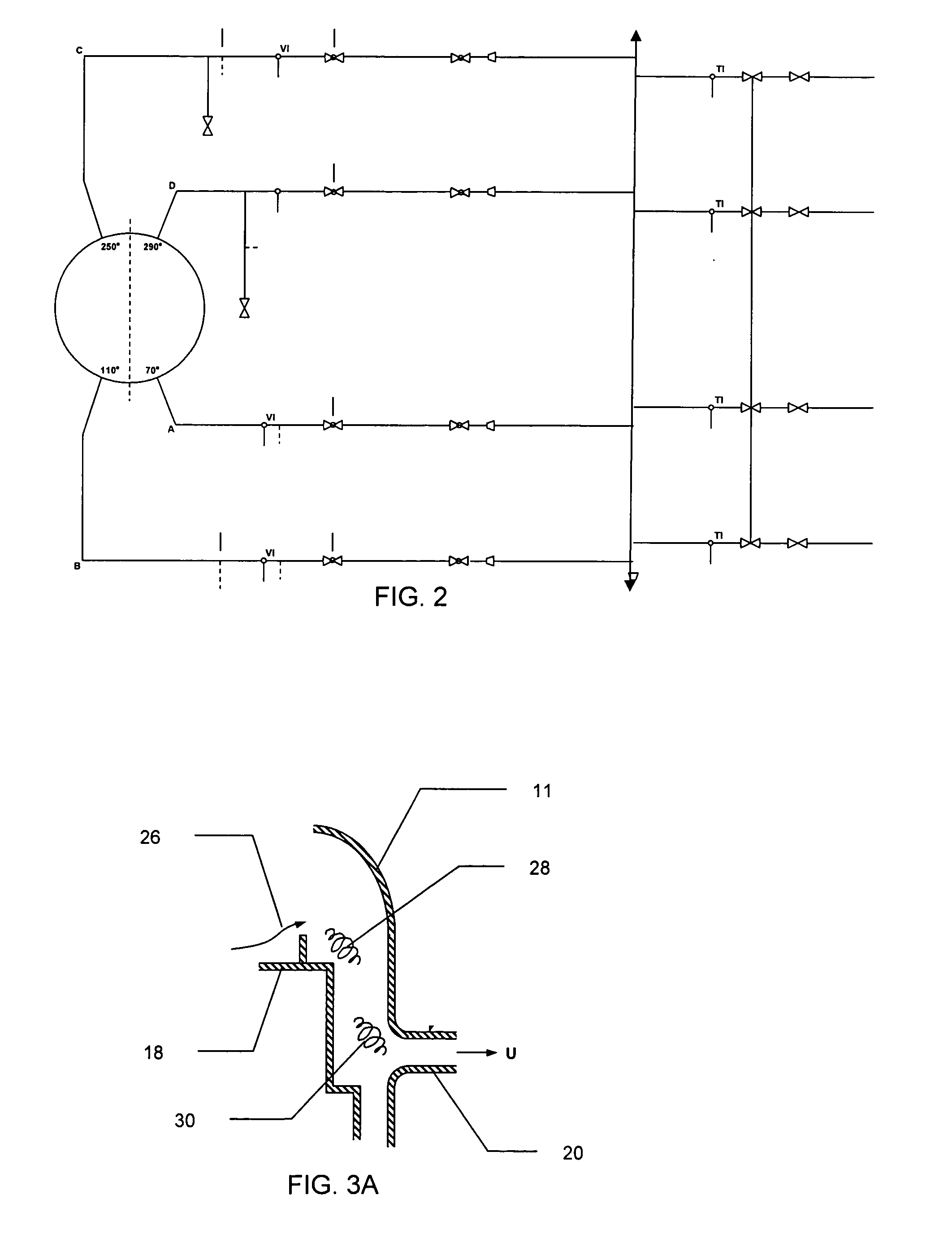

System and method for determining fluctuating pressure loading on a component in a reactor steam dome

ActiveUS20060078081A1Accurate estimateAccurate measurementTesting/calibration apparatusFlow propertiesSound sourcesEngineering

A system and method for accurately estimating the fluctuating pressure loads on components, such as steam dryers, within a BWR steam dome using pressure time history measurements made on components of the BWR facility external to the steam dome. The method uses existing sensors to obtain the pressure time histories. An accurate determination of the fluctuating pressure loads within the steam dome may be obtained by modeling and analyzing the steam delivery system external to the steam dome, including all possible acoustic sources, using acoustic circuit methodology and pressure time histories, and then coupling these results, essentially as part of the boundary conditions, to the solutions for Helmholtz equation within the steam dome.

Owner:WESTINGHOUSE ELECTRIC CORP

Production method of steam chest rubber diaphram

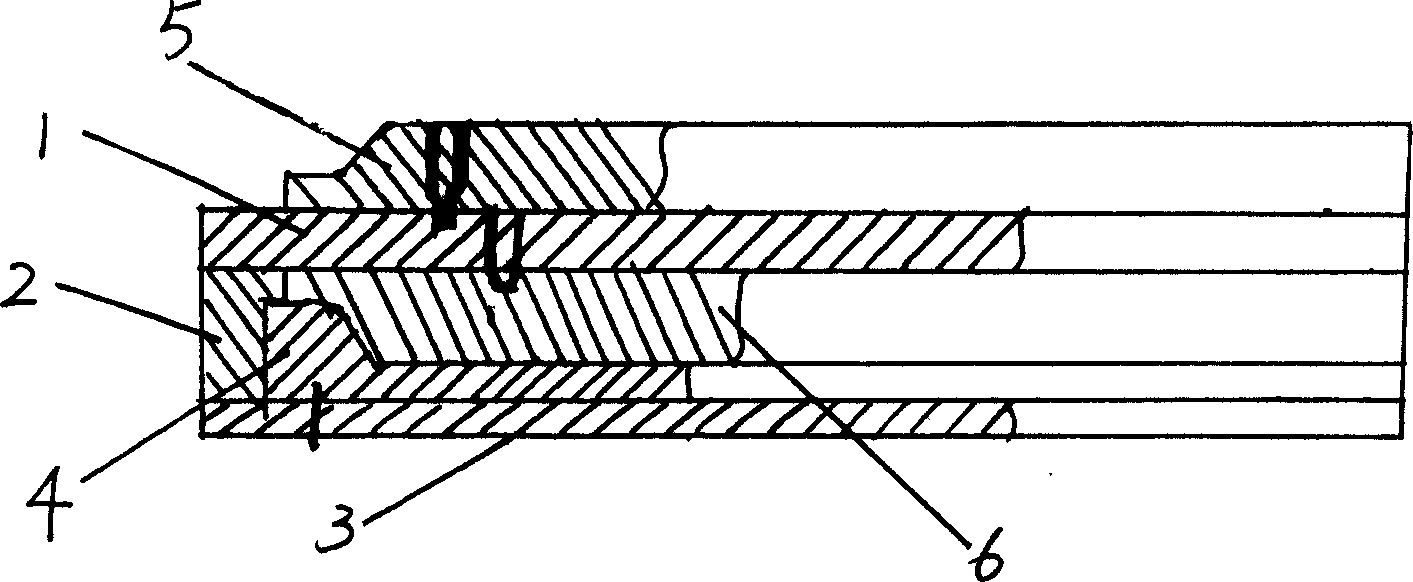

ActiveCN1911628ASolve the centering problemSolve the requestBraking action transmissionWork in processEngineering

The production process of rubber diaphragm for steam dome includes the steps of preparing material, the first vulcanizing, the second vulcanizing, etc. Each of the vulcanizing steps has mold cavity temperature of 148 deg.c+ / -3 deg.c, pressure of 18 Mpa and pressurized vulcanizing time of 2.5 min, and is performed after vacuumizing and pressurizing for three times. The upper mold for the first vulcanizing and the second vulcanizing has two acting surfaces in the opposite sides and is turned once after each vulcanizing. The present invention has simplified technological process, low production cost and high product quality.

Owner:NINGGUO HAI TIAN LI IND DEV

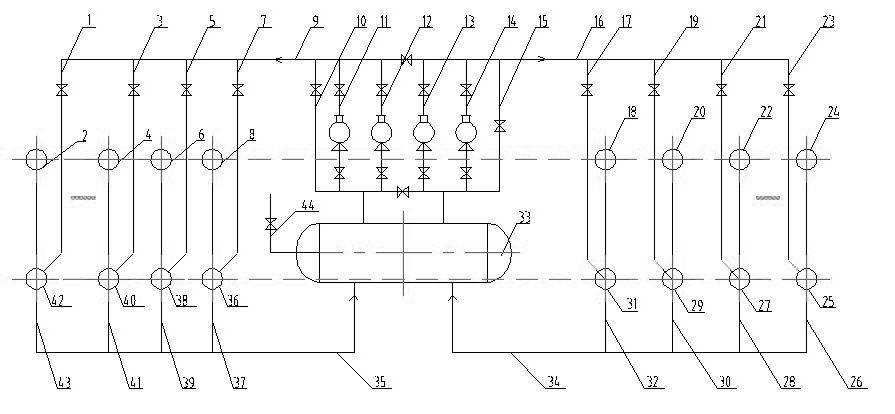

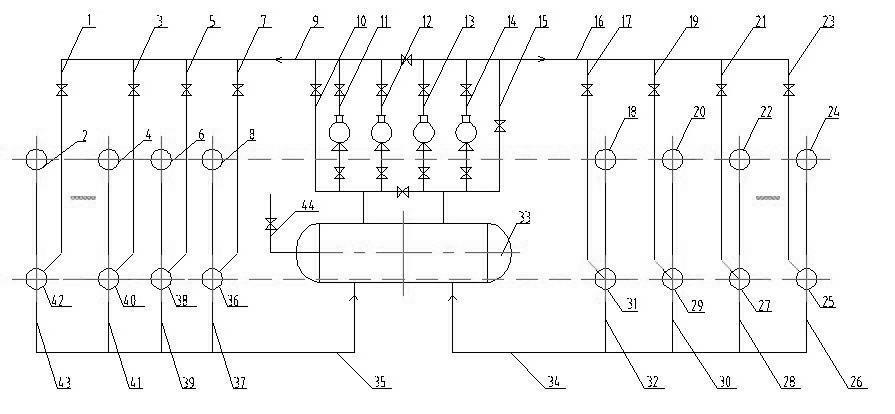

Multi-tower binary-working-medium solar high-temperature heat power generation system

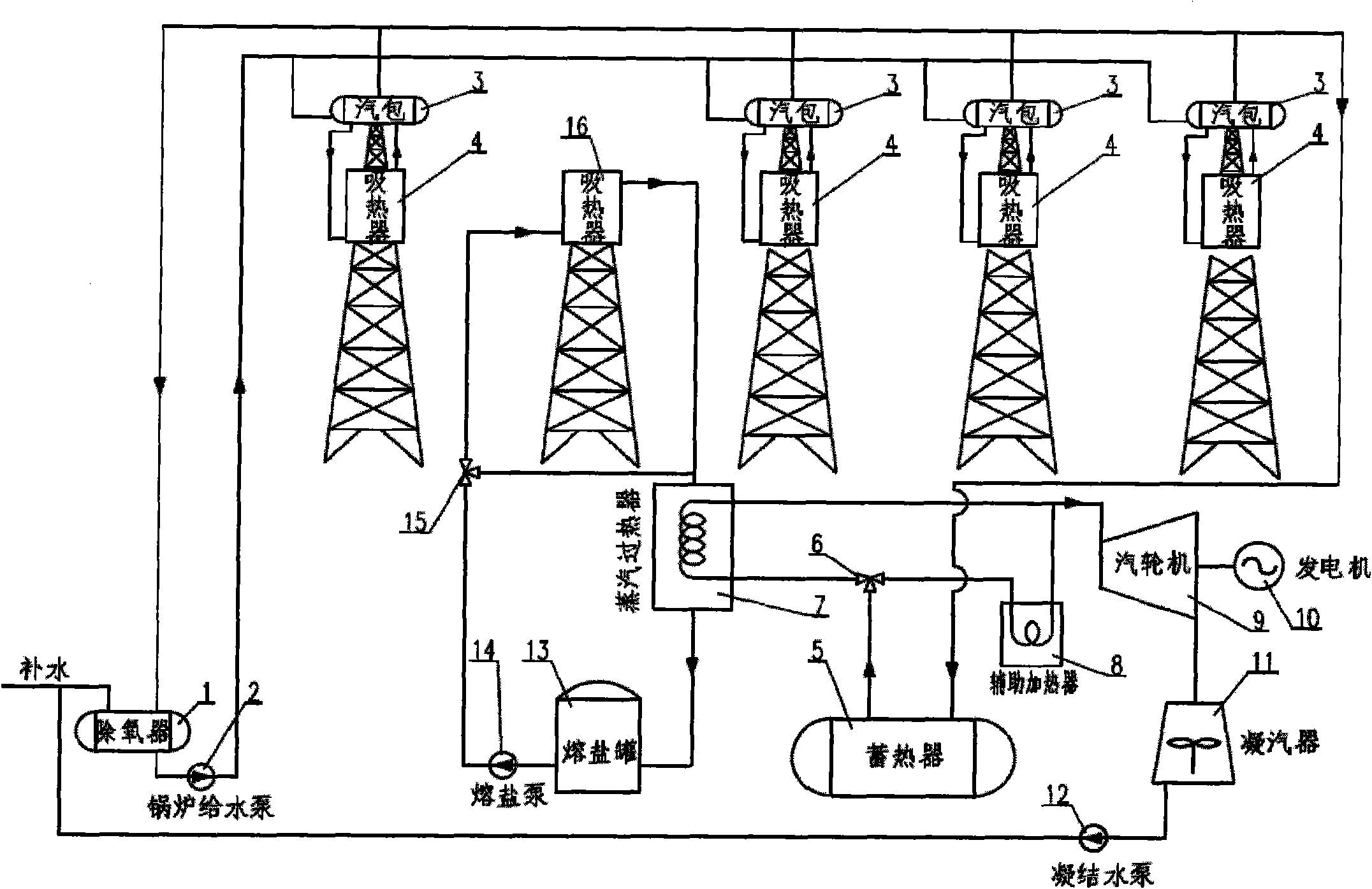

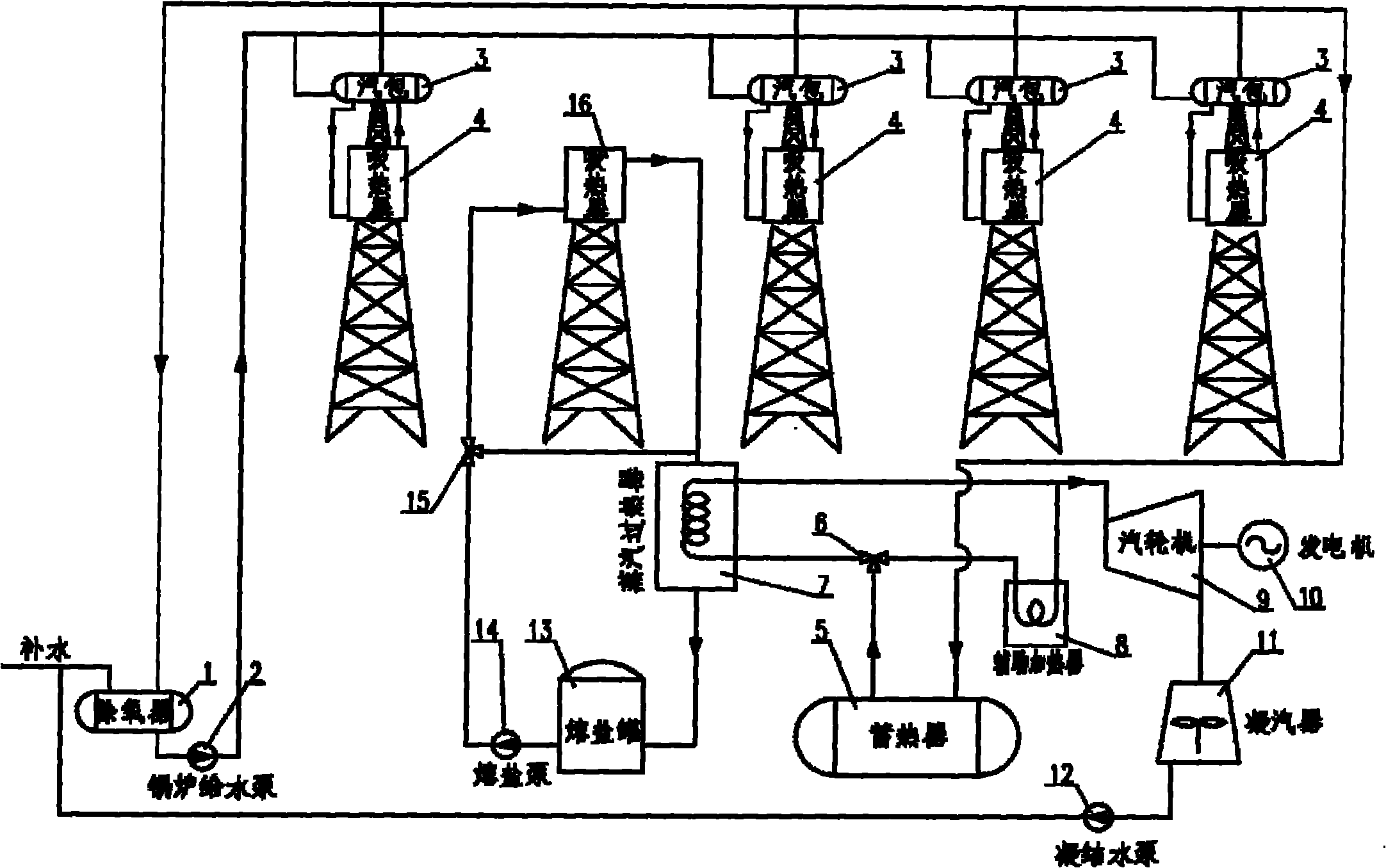

ActiveCN102146899AIncrease heating capacityExtended operating temperature rangeFrom solar energyMachines/enginesDeaeratorEngineering

The invention relates to a multi-tower binary-working-medium solar high-temperature heat power generation system which comprises a water working-medium heat absorber, a steam dome, a molten salt heat absorber, a water feeding pump, a saturated heat accumulator, a molten salt pump, a molten salt tank, a steam overheater, an auxiliary heater, a deaerator, a steam turbine, a condenser and a condensate pump; water in the steam dome enters the water medium heat absorber in a natural circulation way to finish the preheating and evaporating process of water; after steam-water separation, saturated steam is introduced to the saturated heat accumulator; molten salt is heated in the molten salt heat absorber and is subjected to heat release in the steam overheater so that the saturated steam is heated to reach required overheat parameter parameters, and finally, the heated saturated steam is introduced to the steam turbine to work; and the steam subjected to expansion working is condensed into condensed water in the condenser, the condensed water is conveyed to the steam-type deaerator through the condensate pump, and the deaerated water is conveyed to the steam dome on the heat absorber through the water feeding pump, thereby a circulation process is finished. The multi-tower binary-working-medium solar high-temperature heat power generation system has the characteristics of high safety, saved investment, simpleness in operation and maintenance, and the like at the same time of improving the efficiency of the solar heat power generation system.

Owner:HANGZHOU BOILER GRP CO LTD

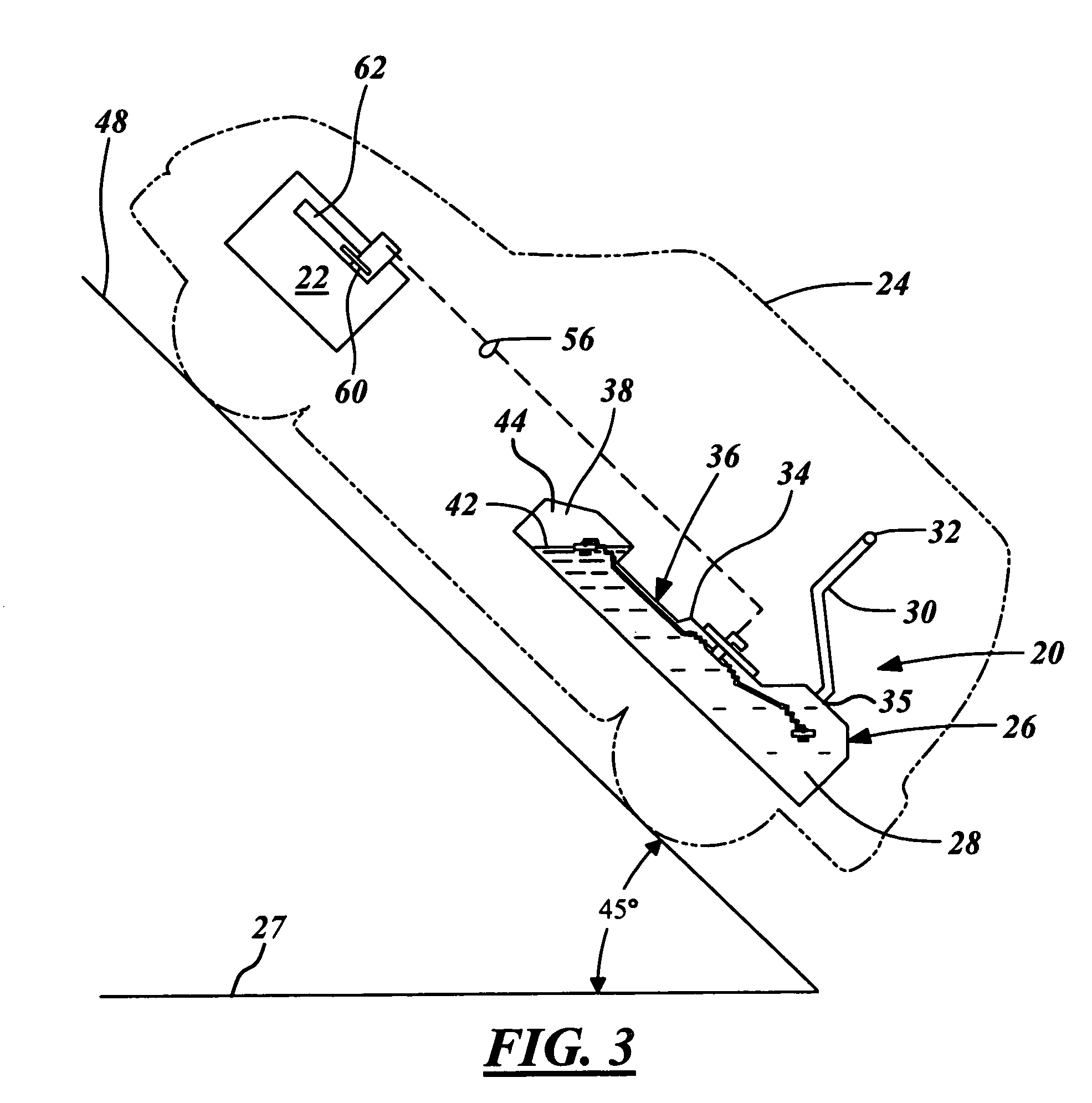

Flue gas heater by evaporative cooling

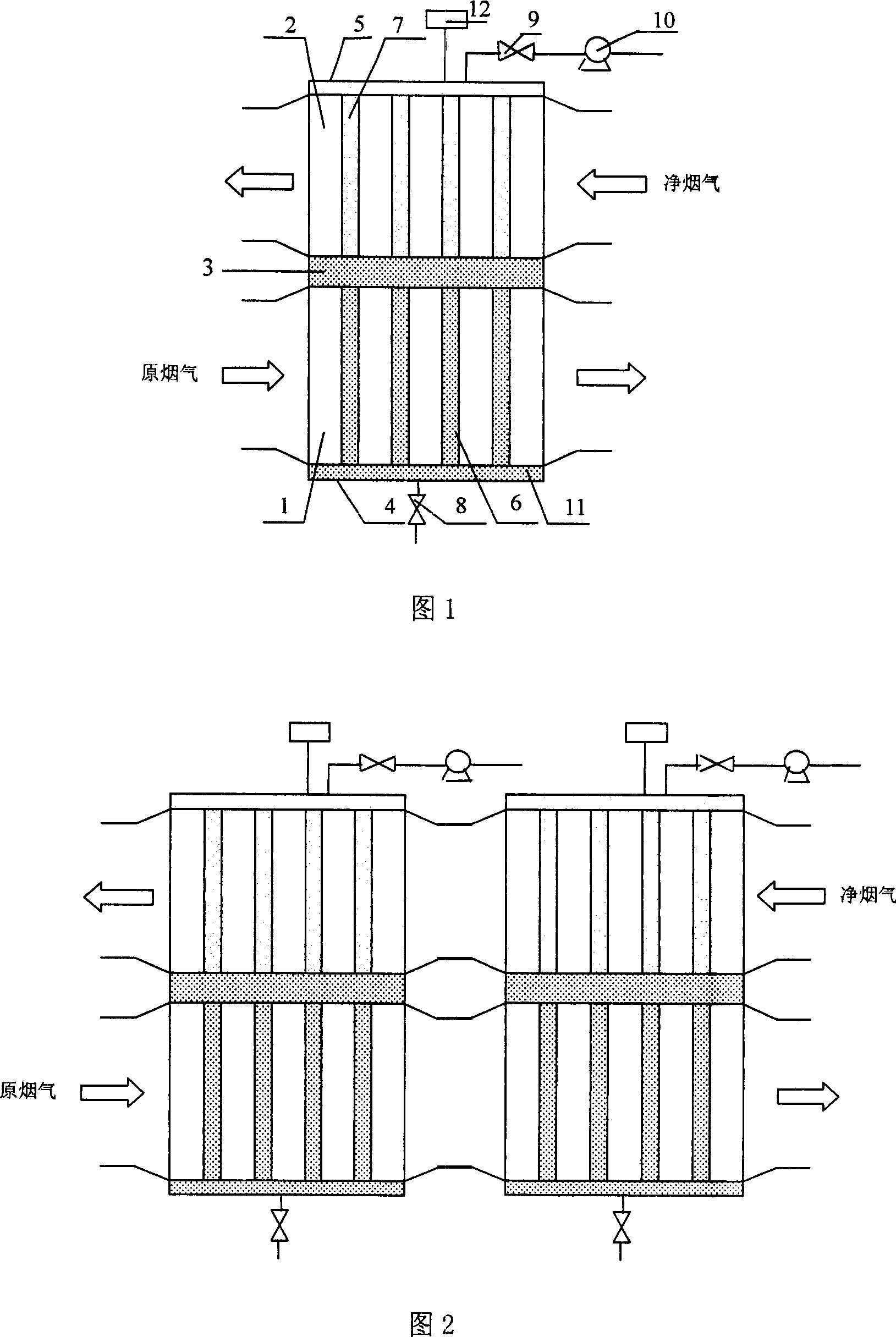

InactiveCN1995823AImprove heat transfer efficiencyLighting and heating apparatusEvaporative coolerLiquid medium

The invention relates to an evaporation and cooling gas heater, comprising original smoke heat exchanger (1) and purified smoke heat exchanger (2), steam dome (3), by which two heat exchangers are connected. At the side of original smoke heat exchanger (1), the quantity of heat of original smoke is transferred to the cycling medium (11) in heat exchanging pipe (6) at original smoke side. The cycling medium (11) is evaporated by heating and formed steam enters in heat exchanging pipe (7) at purified smoke side. In the heat exchanging pipe (7), the quantity of heat of steam is transferred to the purified smoke and the purified smoke is condensed into liquid. Under the effect of gravity, liquid medium returns into the heat exchanging pipe (6) at the original smoke side through steam dome (3). By the cycling, the purpose that the quantity of heat of original is used to heat the purified smoke is realized. Steam even-pressure room (5) at the purified smoke side is connected with vacuum pump (10) outside so as to control the pressure in evaporating and cooling system and the boiling point of cycling medium. The invention can adopt multiple groups of smoke heater in parallel. By controlling the pressure in each heat exchanger, multi-step temperature difference heat exchanger is realized. The invention is provided with no leakage of smoke, strong applicable ability to load variety of mainframe, and no operation consumption.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Preparation technique of automobile brake steam chamber separator

The invention is a process for manufacturing the steam dome diaphragm of an automobile brake, which includes the steps of measuring and cutting the raw materials of film and canvas; conducting first shaping on a vulcanizing machine using a steam dome diaphragm mold; putting the film and the canvas into a lower mold cavity during the shaping; closing up a ferrule locating canvas and then an upper shaping diaphragm; pushing the film and the canvas into the hotplate center of the vulcanizing machine; keeping the pressure and shaping for 30 to 40 seconds at the set temperature ranging from 152 to 157 DEG C for first shaping and under the pressure of 16 to 18MPa; carrying out automatic gas emission or vacuumizing according to different vulcanizing machines; dismantling the upper diaphragm after the first shaping; putting a second film into the mold cavity and closing the vulcanized upper diaphragm through the second shaping; pushing the mold into the hotplate center of the vulcanizing machine again for the second shaping and vulcanizing at the same set temperature and under the same pressure for 5 to 5.5 minutes; and finally stripping the mold, and cooling and trimming the diaphragm. Compared with prior art, the process has higher adhesiveness and burst strength, improves the quality and service life of the product, changes wearing parts into permanent parts, enhances productivity and reduces production cost.

Owner:NINGBO QIAOSHI RUBBER PLASTIC CO LTD

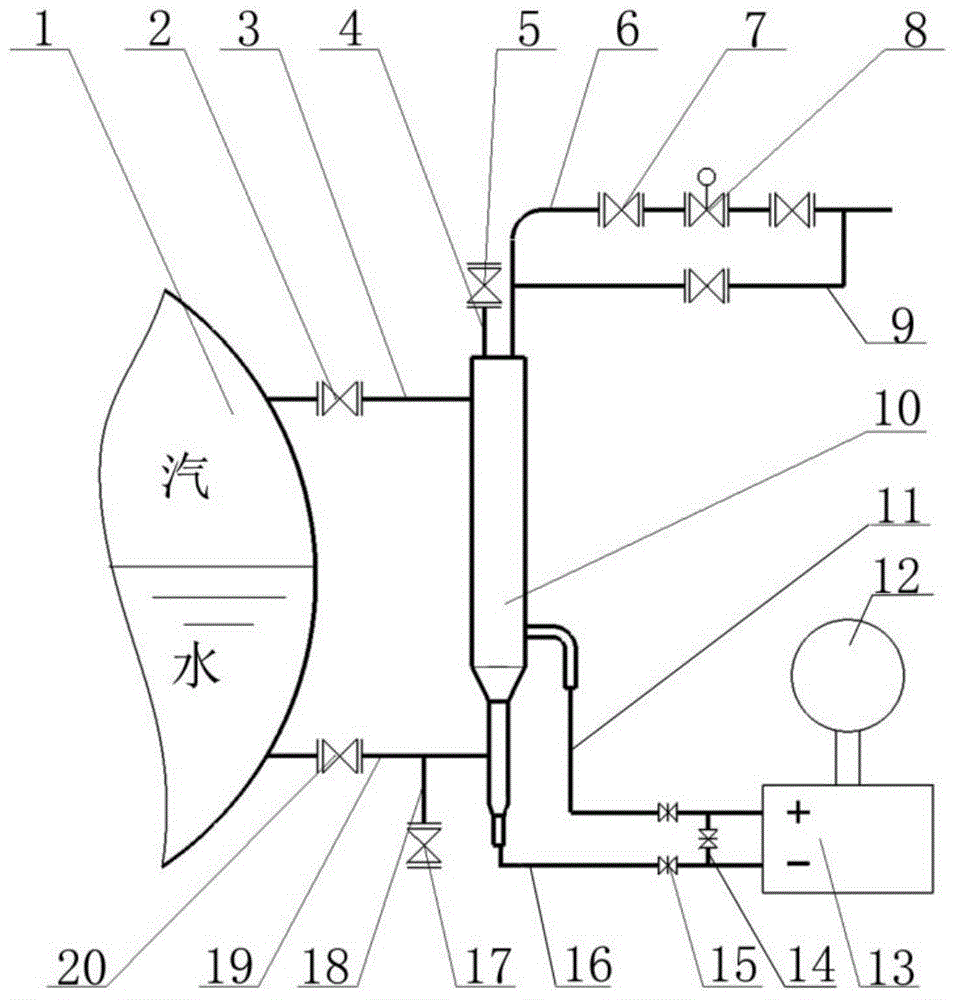

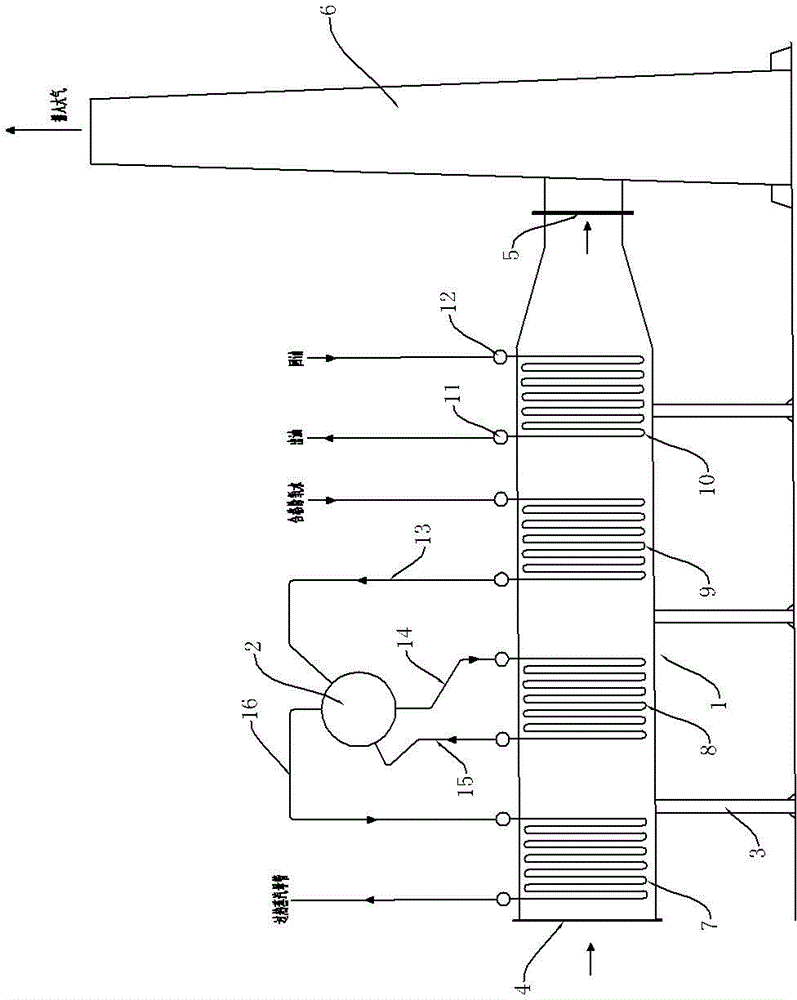

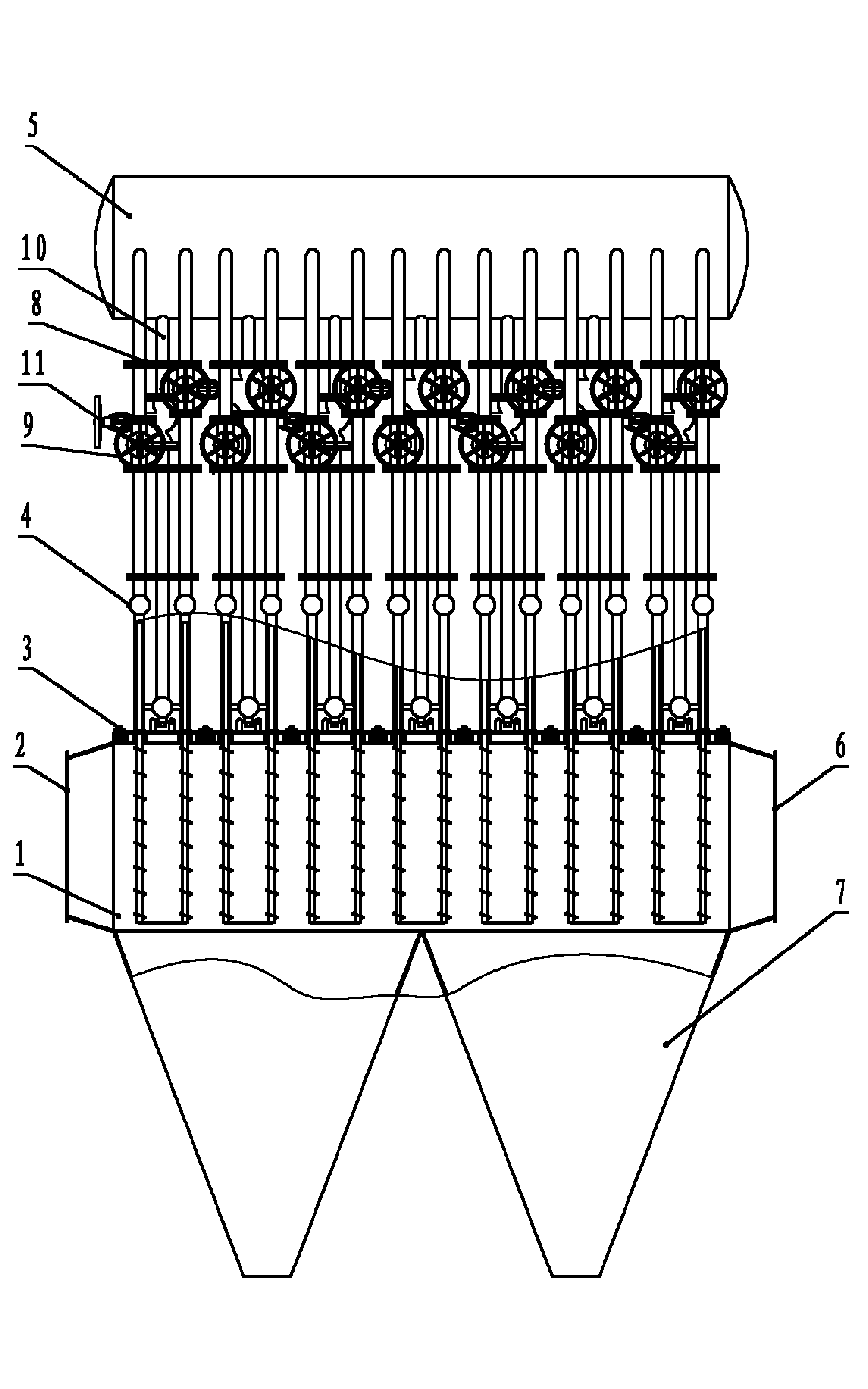

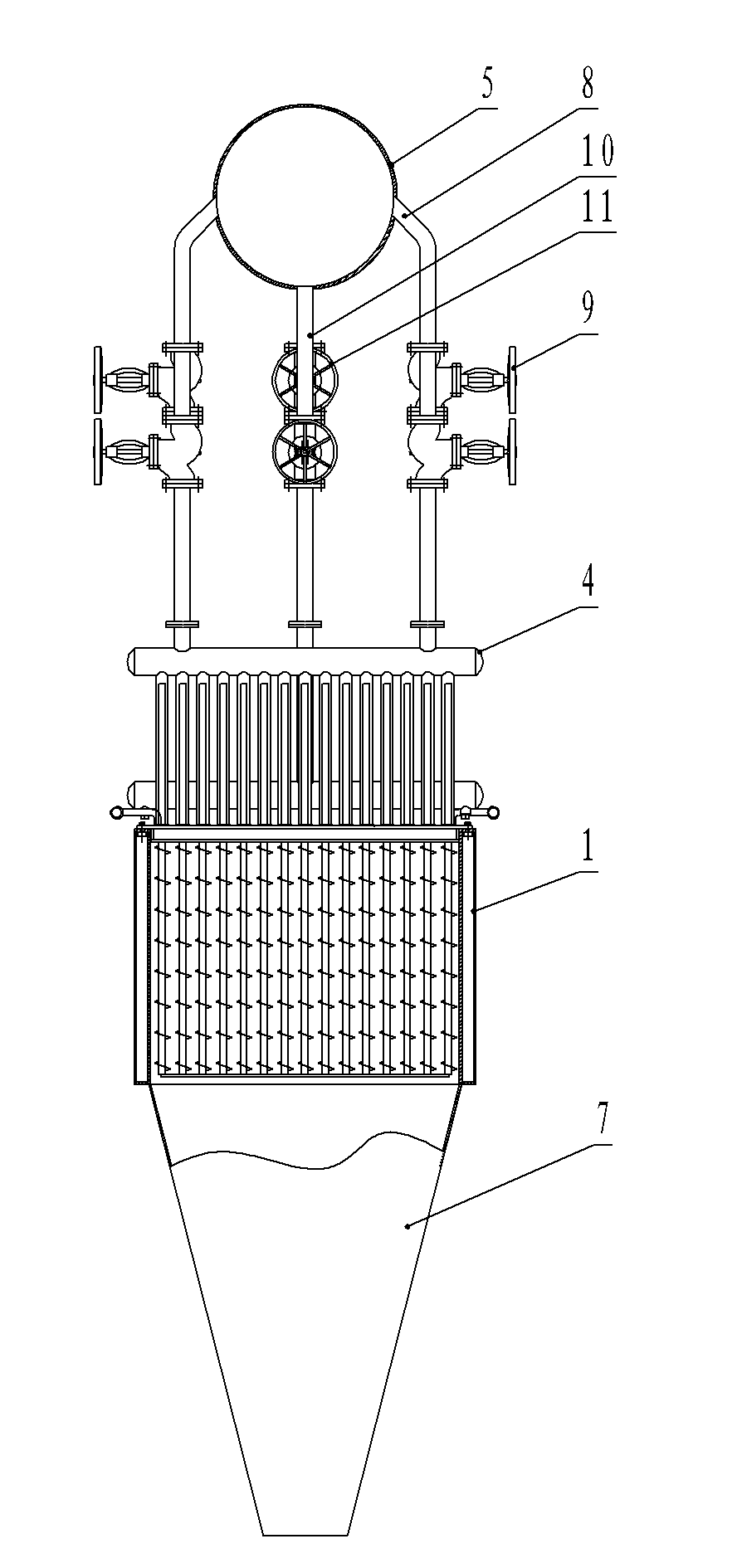

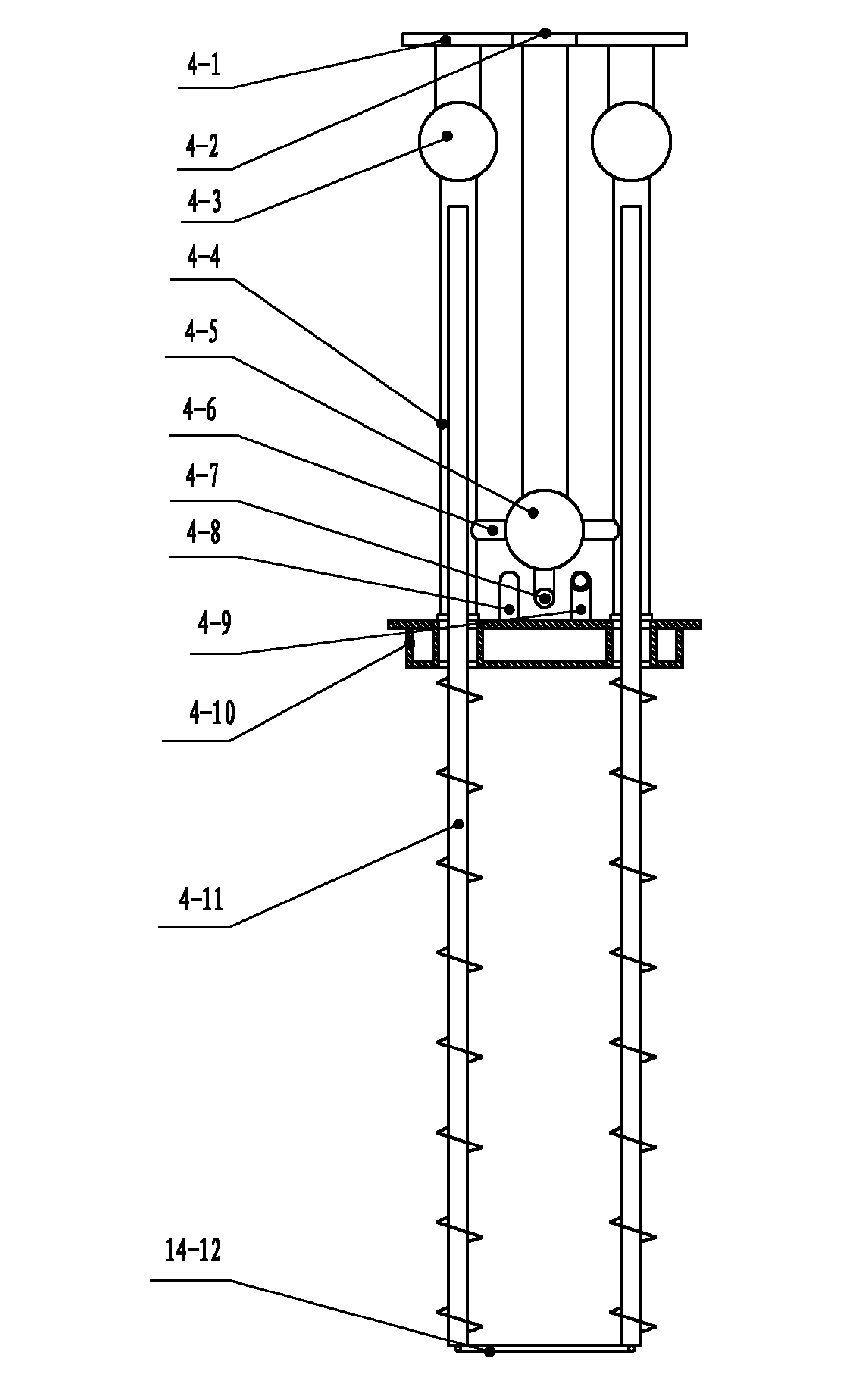

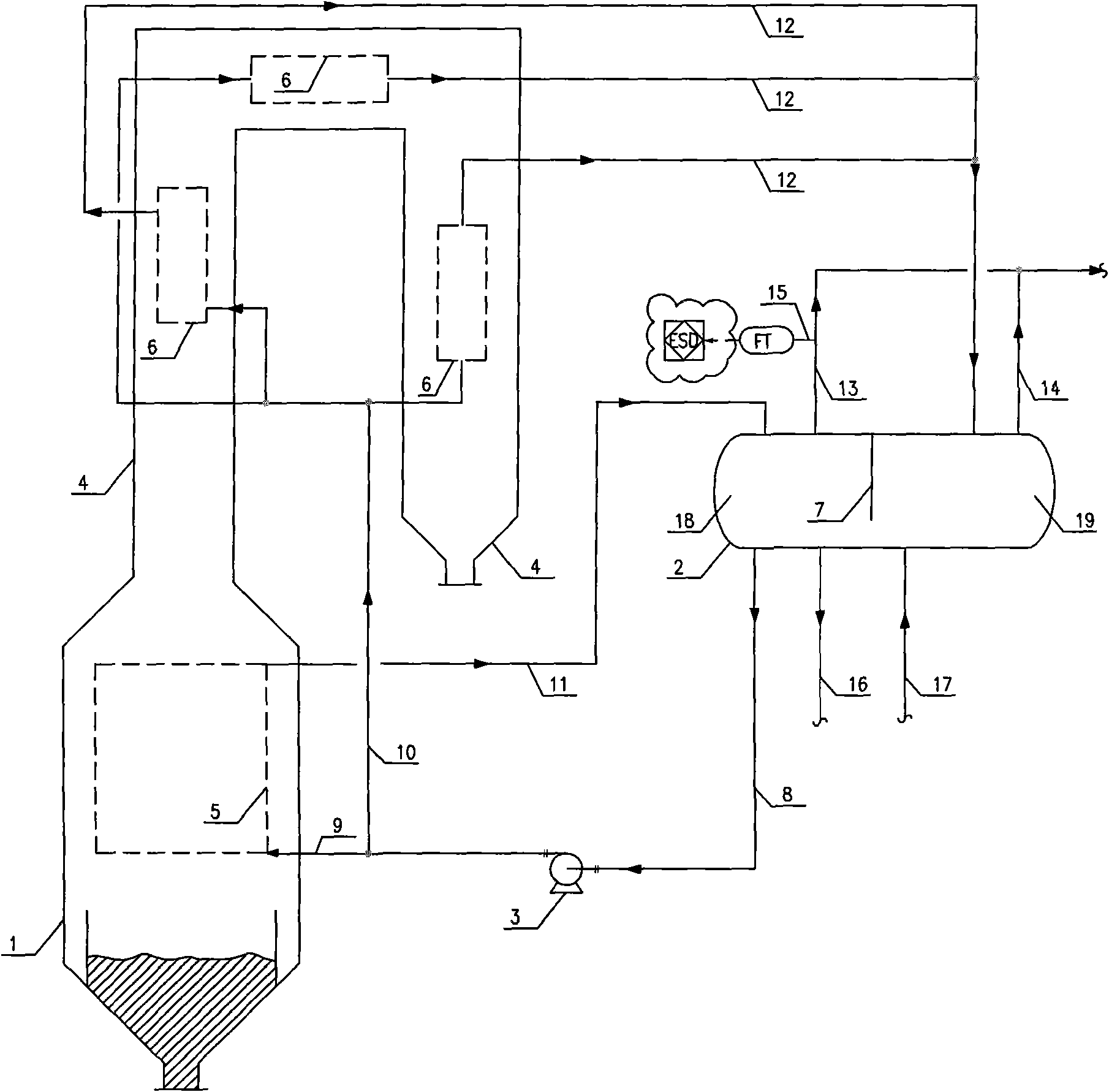

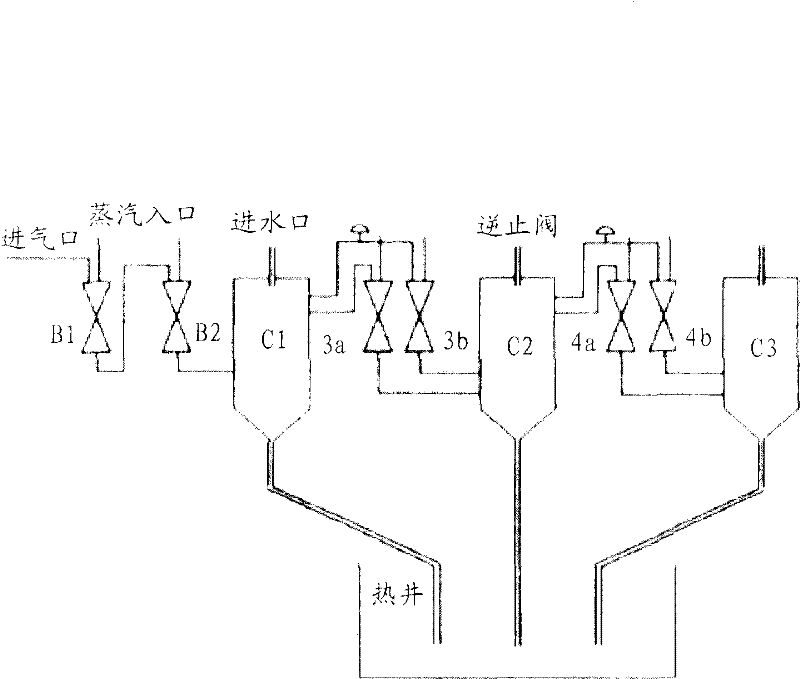

Coke oven crude gas sensible heat recycling system

InactiveCN105255503ASensible heat is stable and efficientSensible heat recovery is stable and efficientLiquid degasificationSteam generation using hot heat carriersWorking environmentProcess engineering

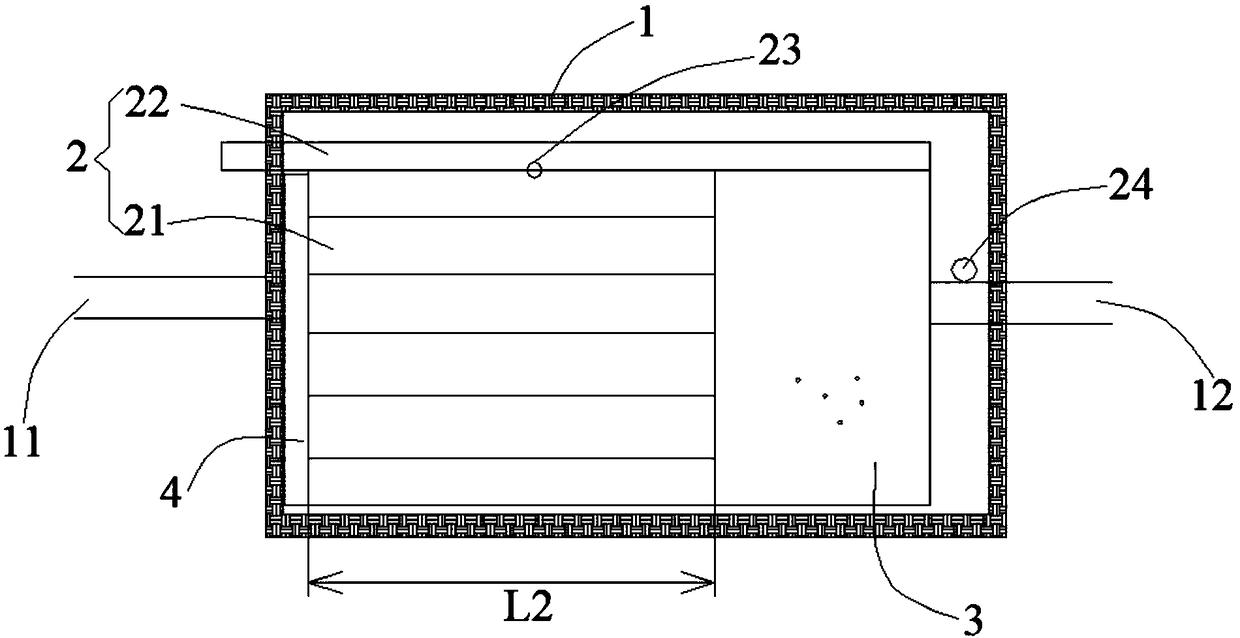

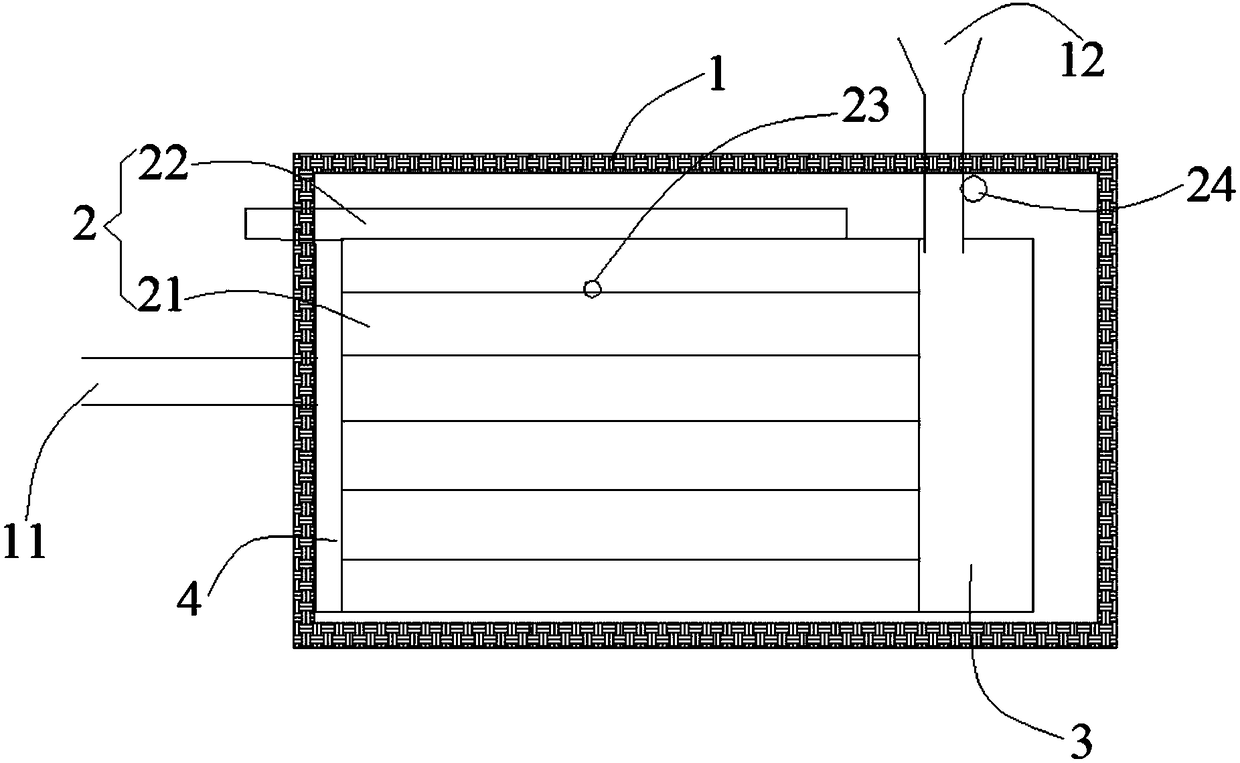

The invention discloses a coke oven crude gas sensible heat recycling system. The coke oven crude gas sensible heat recycling system comprises an oxygen removing device, a steam dome and one or more sets of ascending tube heat exchanger units, and each ascending tube heat exchanger unit is formed by connecting multiple ascending tube heat exchangers in parallel; supplied water is connected with the steam dome through the oxygen removing device, and the steam dome is connected with the ascending tube heat exchangers to form a steam-water loop; the supplied water is conveyed into the steam dome after oxygen in the supplied water is removed through the oxygen removing device, the supplied water in the steam dome is divided into multiple branches to flow through supplied water channels of all ascending tube heat exchangers, the supplied water in the supplied water channels is heated to form a steam-water mixture to be sent back to the steam dome, steam-water separation is conducted on the steam-water mixture in the steam dome, and separated steam is output for use. By means of coke oven crude gas sensible heat recycling system, the defect that the coke oven crude gas working environment is bad is overcome, the defects of a past coke oven crude gas sensible heat recycling technology are overcome, and the sensible heat recycling device and system which are compact in structure, good in effect, stable in operation and convenient to install are provided.

Owner:SHANGHAI BAOSTEEL ENERGY TECH

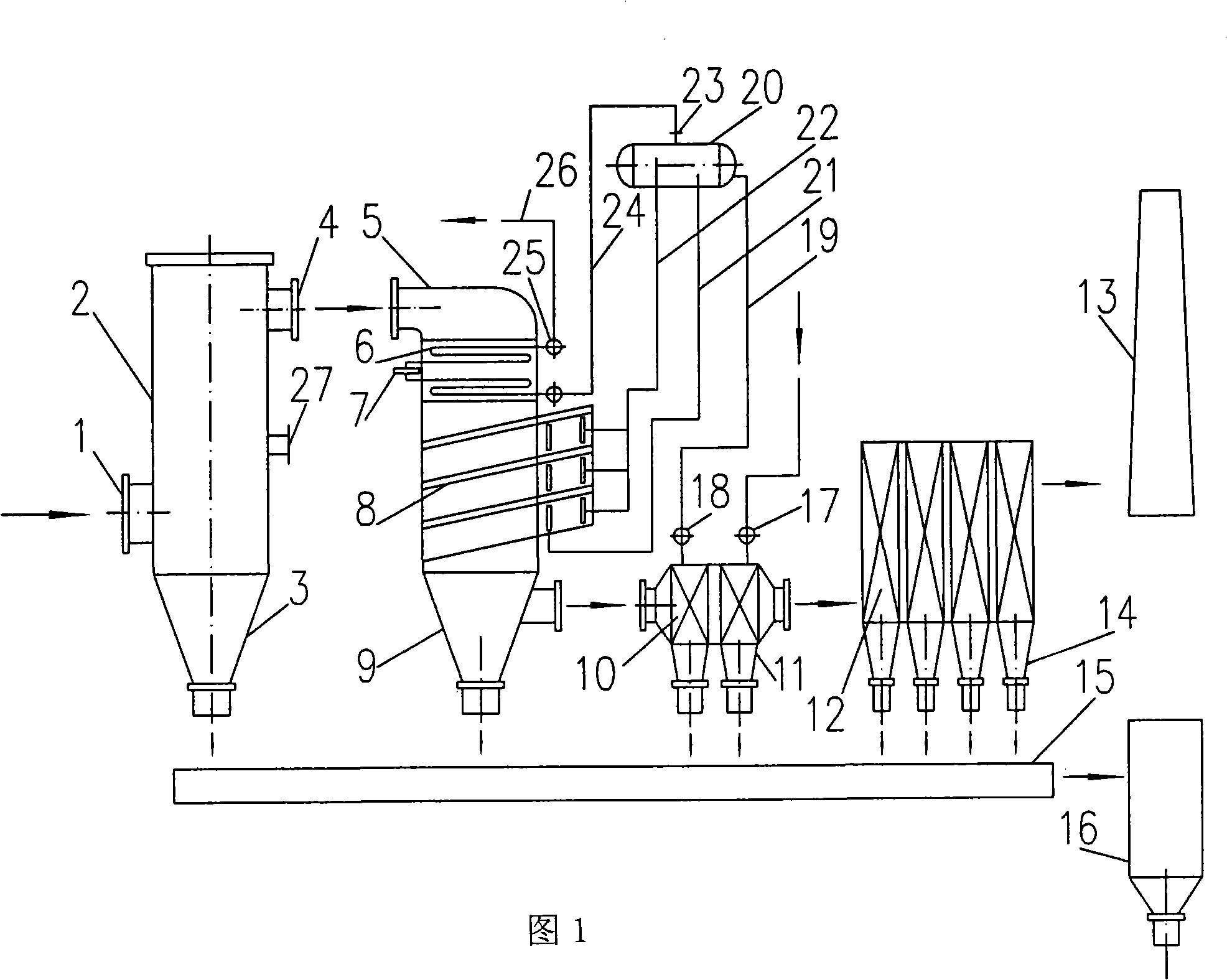

Waste heat recovery from smelting reduction ironmaking in heat pipe type rotary hearth furnace and steam production apparatus

ActiveCN101358259ALess consumablesImprove heat transfer efficiencyRotary drum furnacesIncreasing energy efficiencyHeat conductingSuperheater

A heat pipe type rotary hearth furnace melting reducing iron-making waste heat recovery and steam producing device is composed of a secondary combustion setting chamber (2), a steam superheater (6), a heat pipe steam generator (8), a heat pipe feed water preheater (10), a bag type dust collector (12), a chimney (13) and a steam dome (20). The waste heat recovery and steam producing device is characterized in that one side of the outer wall of the secondary combustion setting chamber (2) is provided with an inlet (1), and the other side is connected with an outlet (4) which is connected with a high-temperature flue (5); the steam superheater (6) and the heat pipe steam generator (8) are arranged on the high-temperature flue (8); the heat pipe steam generator (8) adopts heat pipes to be as the heat conducting elements; the bottom end of the high-temperature flue (5) is provided with an ash discharge tee (9); the horizontal outlet of the ash discharge tee (9) is orderly connected with the heat pipe feed water preheater (10), the bag type dust collector (12) and the chimney (13). The device has high heat conducting efficiency, safety, reliability, small volume of the equipment and convenient dismounting.

Owner:NANJING SHENGNUO HEAT PIPE

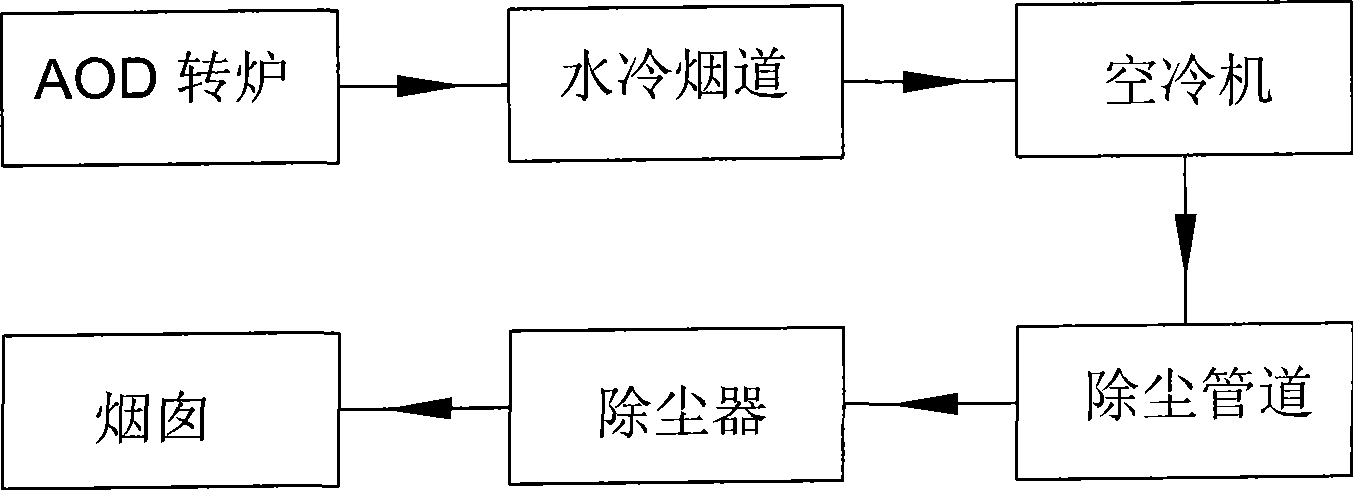

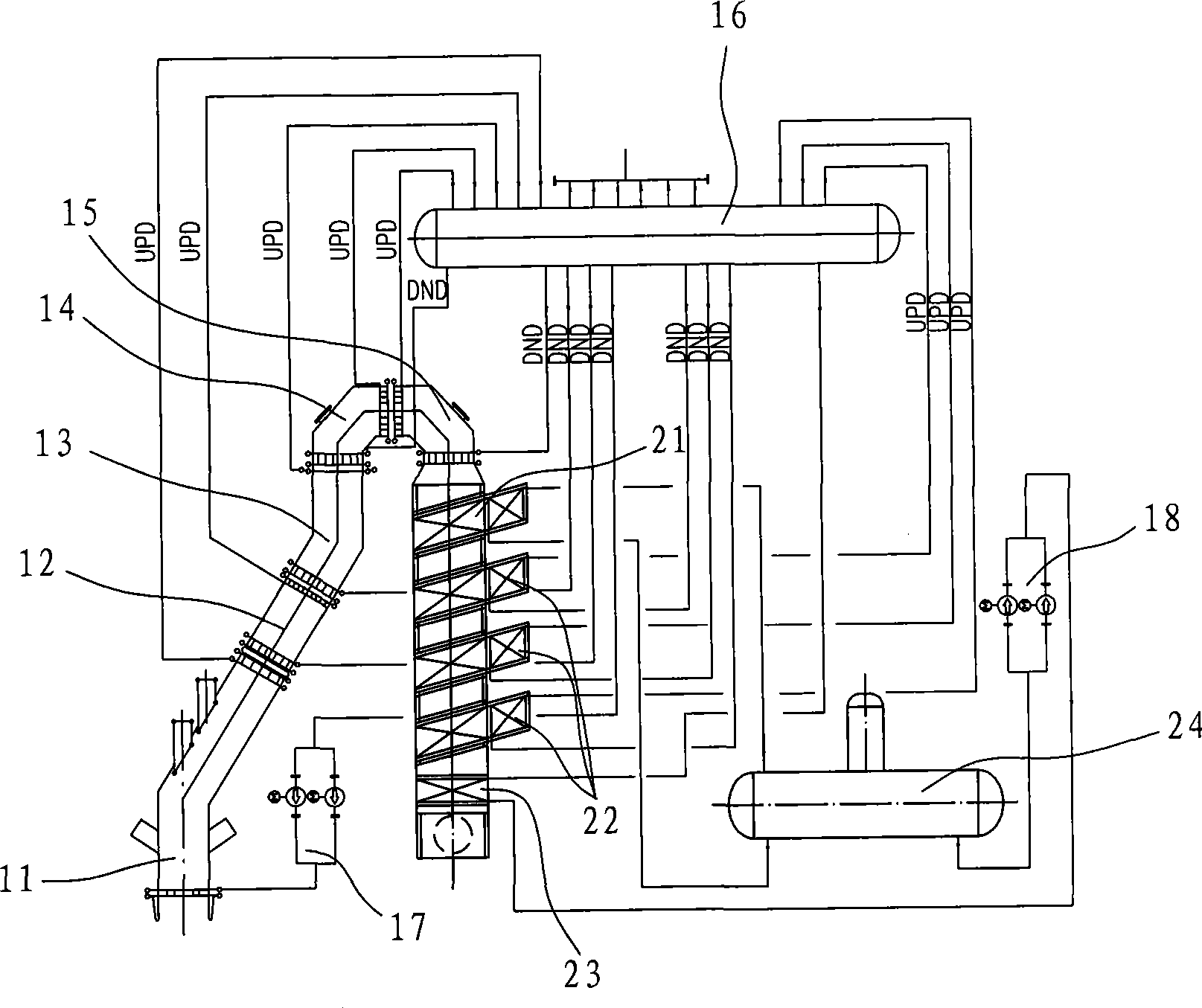

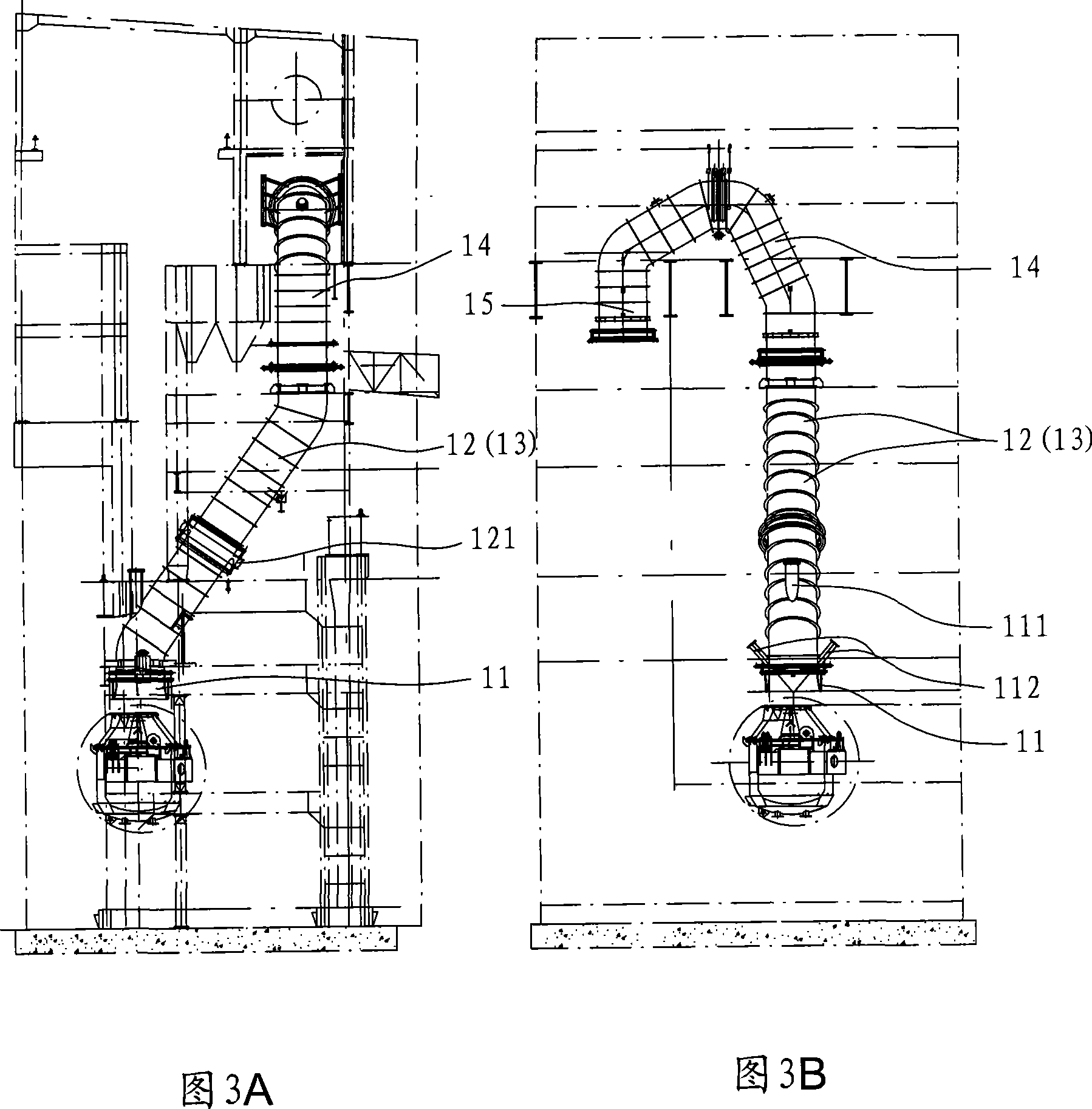

AOD converter flue gas waste heat recovery apparatus

ActiveCN101476015AReduce the temperatureAvoid pipe burstsManufacturing convertersEvaporationDeaerator

The invention provides an AOD convertor flue gas waste heat recovery apparatus comprising a high-temperature flue gas evaporation cooling part and a low-temperature flue gas waste heat recovery part. The high-temperature flue gas evaporation cooling part comprises a fire hole fixed segment smoke canal, a middle I segment smoke canal, a middle II segment smoke canal, a middle III segment smoke canal, an end segment smoke canal and a steam dome which are communicated one by one, and the middle I segment smoke canal, the middle II segment smoke canal, the middle III segment smoke canal, the end segment smoke canal, the steam dome and the ascending pipe and the corresponding descending pipe which are communicated with the upper side thereof together form a natural cycle system; the low-temperature flue gas waste heat recovery part comprises a pre-heater, a heat exchanger, a coal economizer, a deaerator and a water supply pump, wherein, the pre-heater and the deaerator form a natural loop through the connected ascending pipe and descending pipe for heating and deoxidizing the water in the deaerator and saving the steam consumption, the deoxidized water is then pumped by the water supply pump to the steam dome through the coal economizer, therefore, smoke temperature can be reduced sufficiently and heat can be recovered, in addition, because no recirculating pump is added to the heat exchanger singly, the electrical energy is saved.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

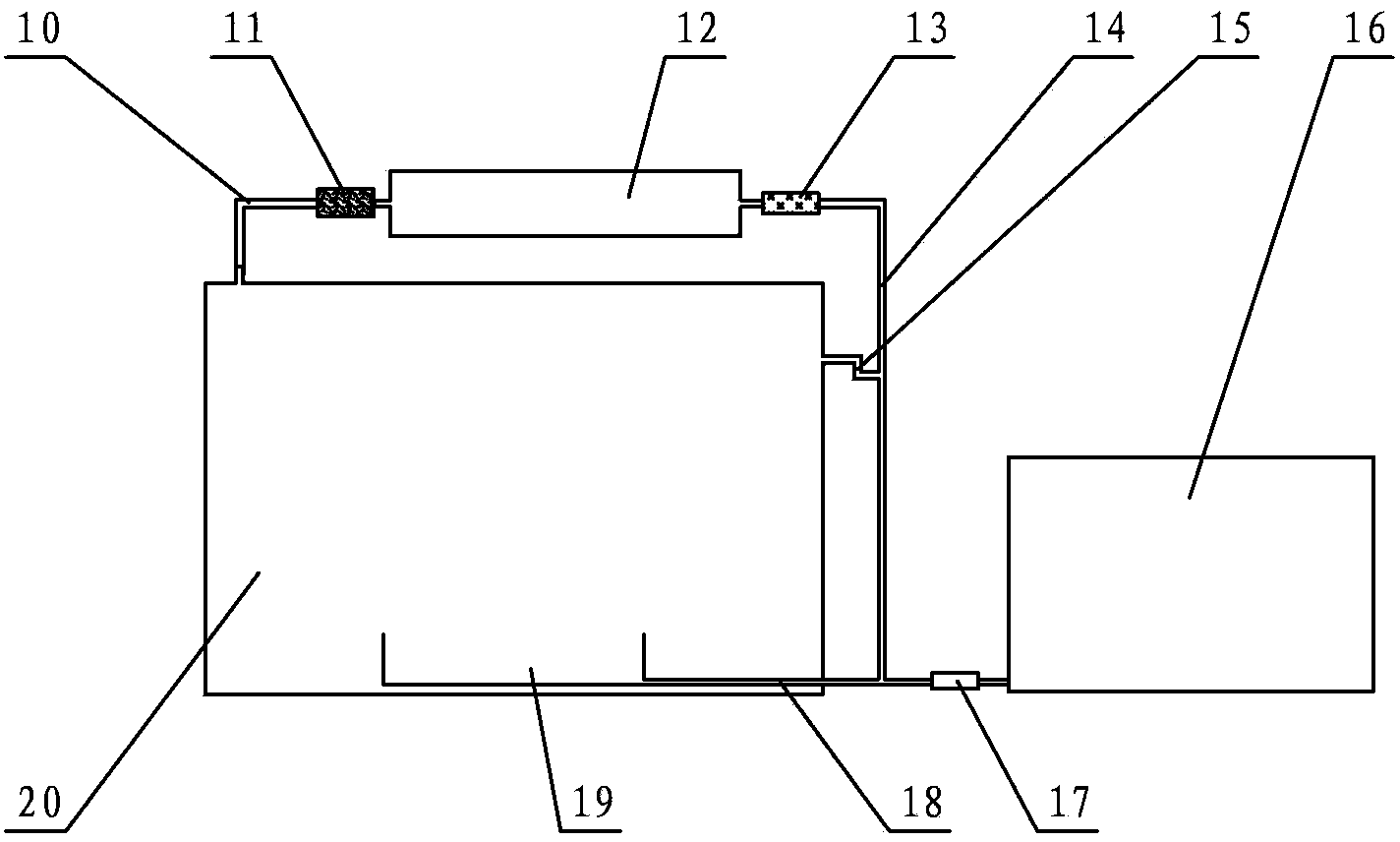

Steam oven and operation method thereof

ActiveCN103349496AAdd recovery and recycling functionsSolve the hazardSteam cooking vesselsEngineeringGuide tube

The invention relates to a steam oven and an operation method thereof. The steam oven comprises an evaporating disk arranged in an oven cavity, a steam recovery device and leakage pipe, wherein one end of a water inlet pipe is communicated with the evaporating disk or a steam generator, and the other end of the water inlet pipe is communicated with a water tank; the steam recovery device is used for recovering steam discharged out from the oven cavity, and comprises a steam guide pipe; one end of the steam guide pipe is communicated with the interior of the oven cavity, and the other end of the steam guide pipe is communicated with an inlet of a steam cooling mechanism; an outlet of the steam cooling mechanism is communicated with the water inlet pipe or the water tank through a water outlet pipe; the other end of the steam guide pipe is communicated with the inlet of the steam cooling mechanism through a steam filter; the outlet of the steam cooling mechanism is communicated with the water outlet pipe through an air channel of a forced exhaust fan; an opening in one end of the leakage pipe is formed in the inner wall of the oven cavity, and the other end of the leakage pipe is communicated with the water outlet pipe. The steam oven has the characteristics of being simple and reasonable in structure, flexible to operate, safe and reliable, and wide in application range.

Owner:GUANGDONG GALANZ MICROWAVE OVEN & ELECTRICAL APPLIANCES MFG

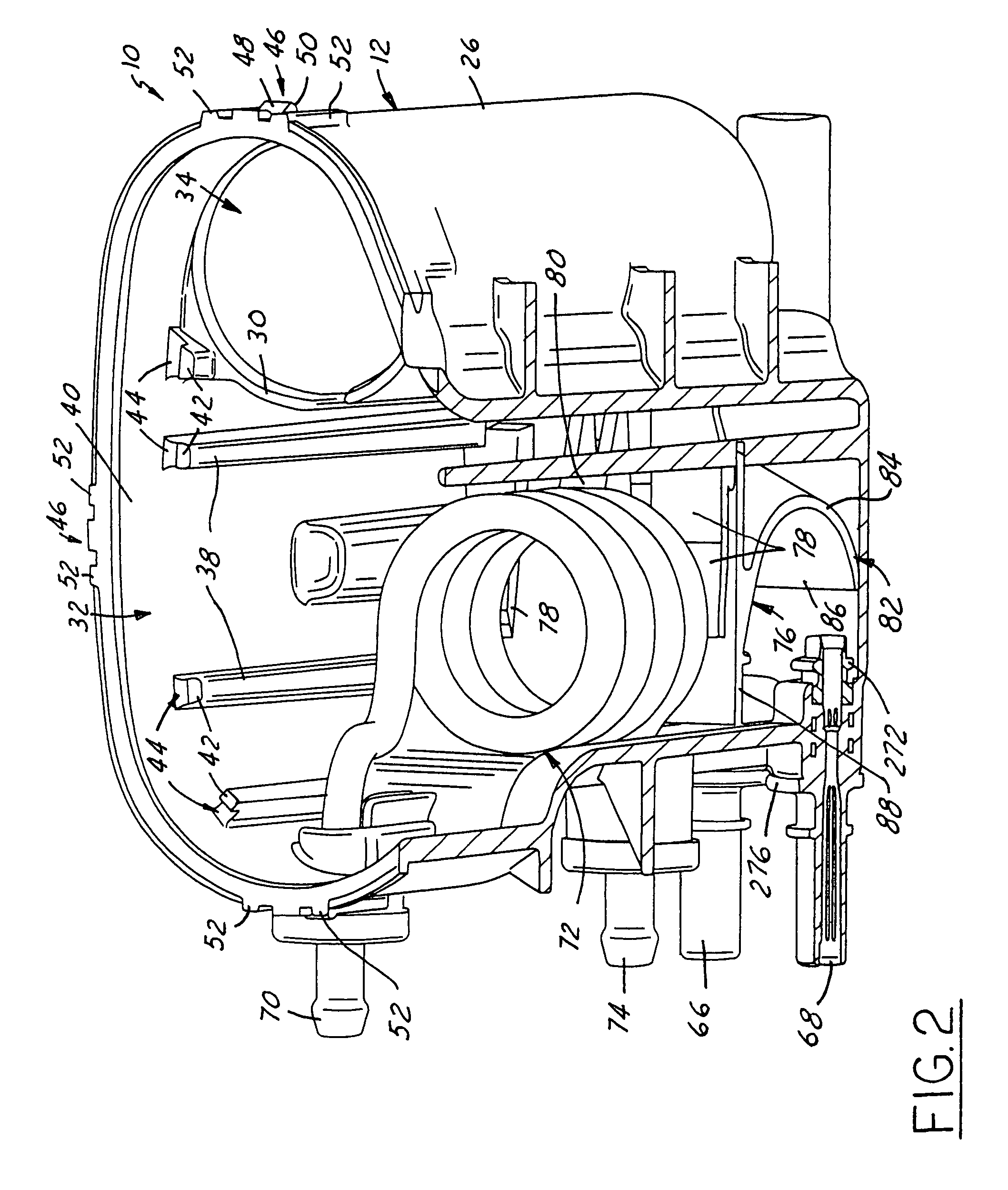

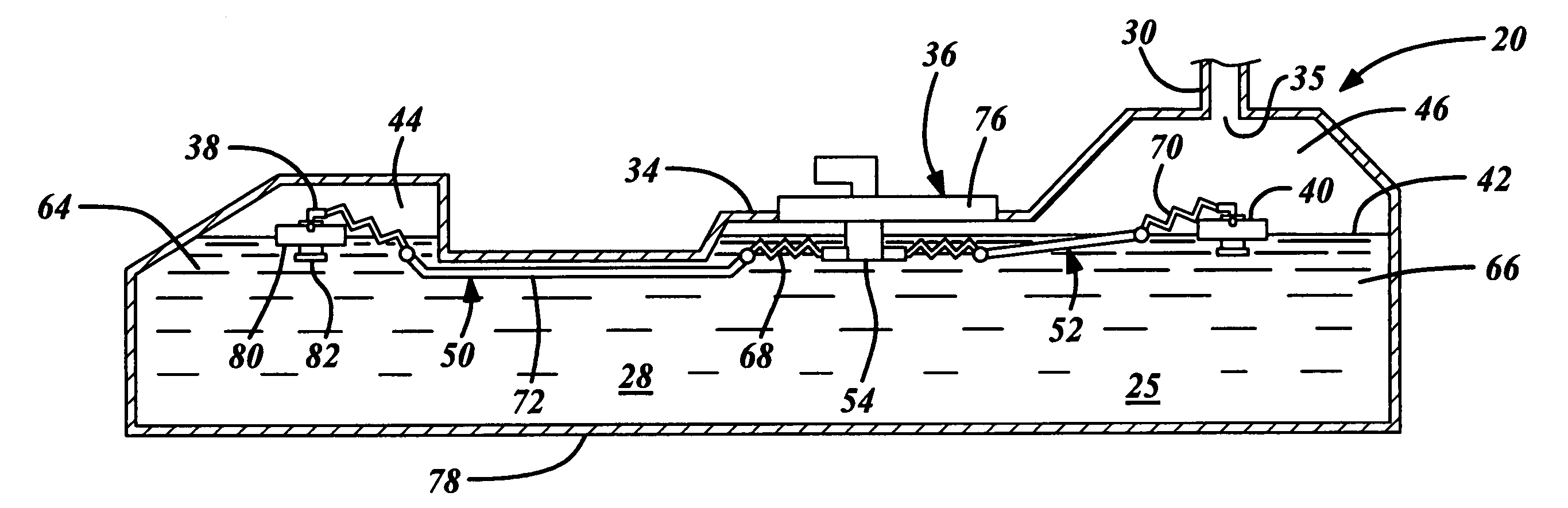

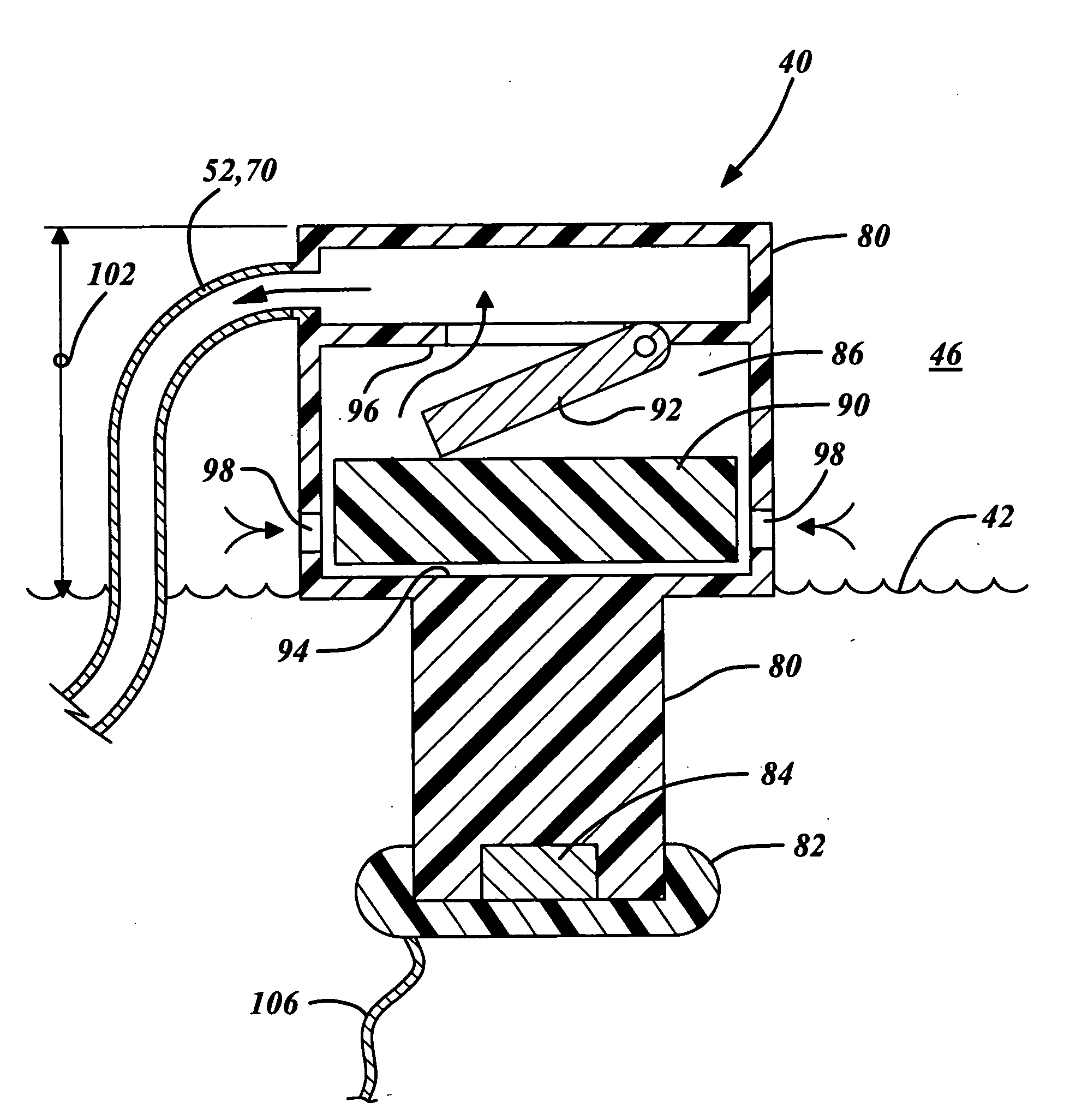

Fuel storage system for a vehicle

InactiveUS20070186976A1Good flexibilityImproved fuel tank pressure controlLarge containersPipeline systemsHydrocotyle bowlesioidesSurface level

A fuel storage system for a transportation or recreational vehicle has a fuel tank that carries a vapor assembly that seeks out vapor pockets and controllably removes fuel vapor from the tank without releasing hydrocarbons to the surrounding environment. Preferably, a vent manifold attaches to a flange that sealably covers an access hole of the tank. At least one flexible tentacle extends from the manifold in the tank to a respective vapor vent valve that floats upon the surface of fuel at a vapor dome. When freely floating, the vent valve is open thus communicates the vapor dome through the tentacle and preferably with a filtering carbon canister. As fuel surface levels change or the vehicle tilts, changing the vapor dome size or location in the tank, the floating vapor vent valve is free to move generally with the vapor dome and as permitted by the flexibility of the trailing tentacle. With tank orientations where the vapor vent valve falls below the surface of fuel, the vent valve automatically closes to prevent flooding of the respective tentacle and remote vapor canister.

Owner:TI GRP AUTOMOTIVE SYST LLC

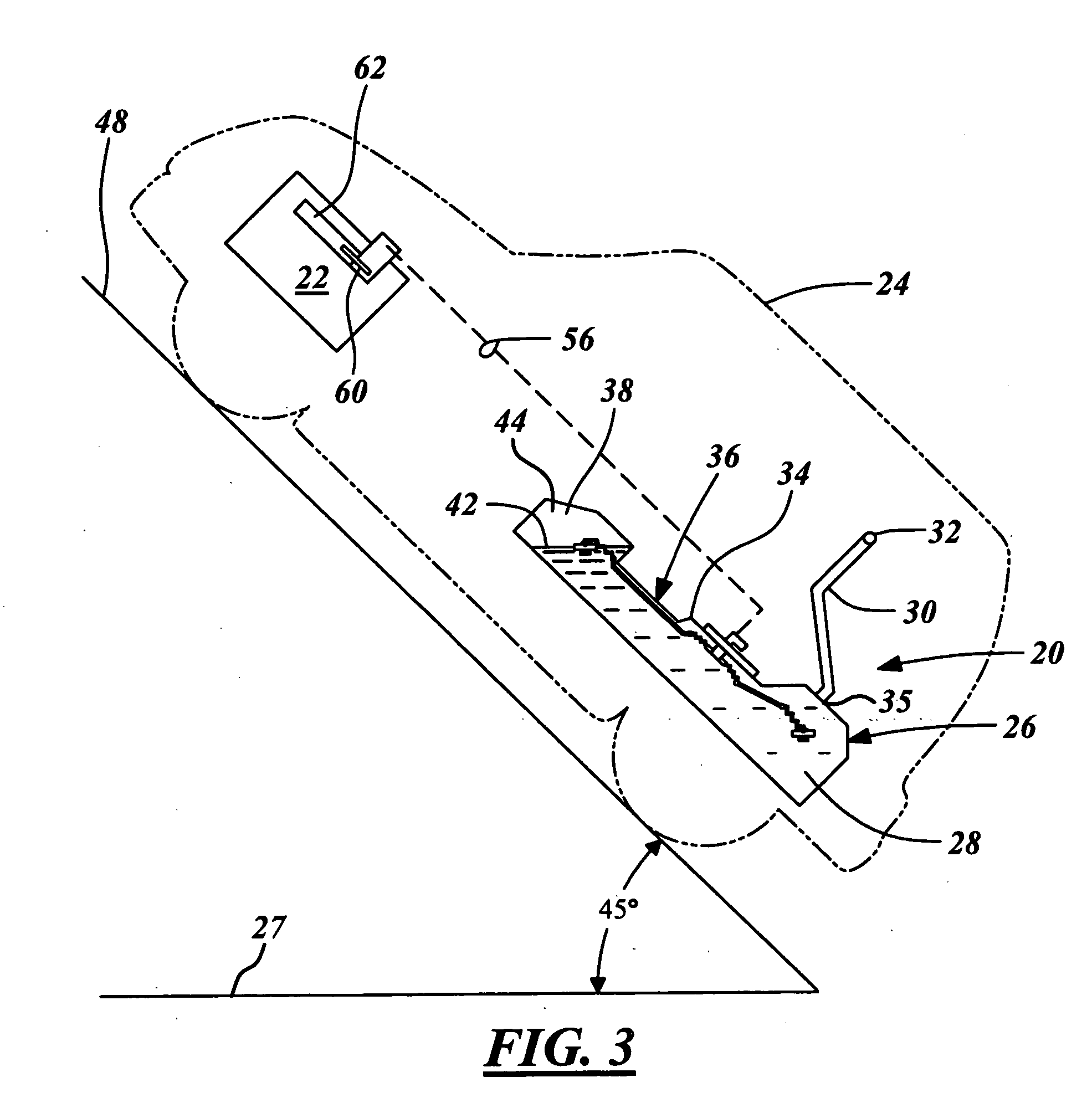

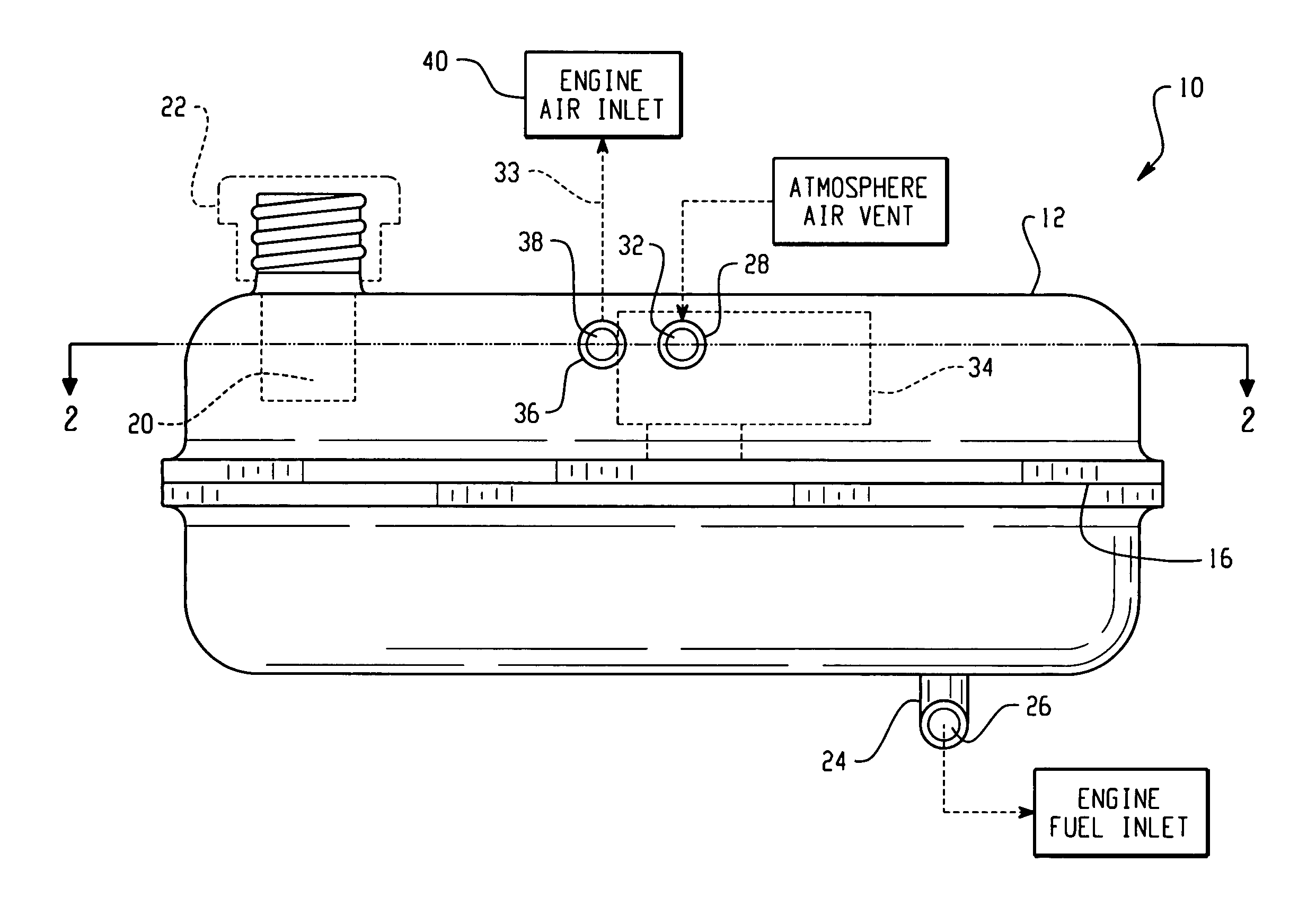

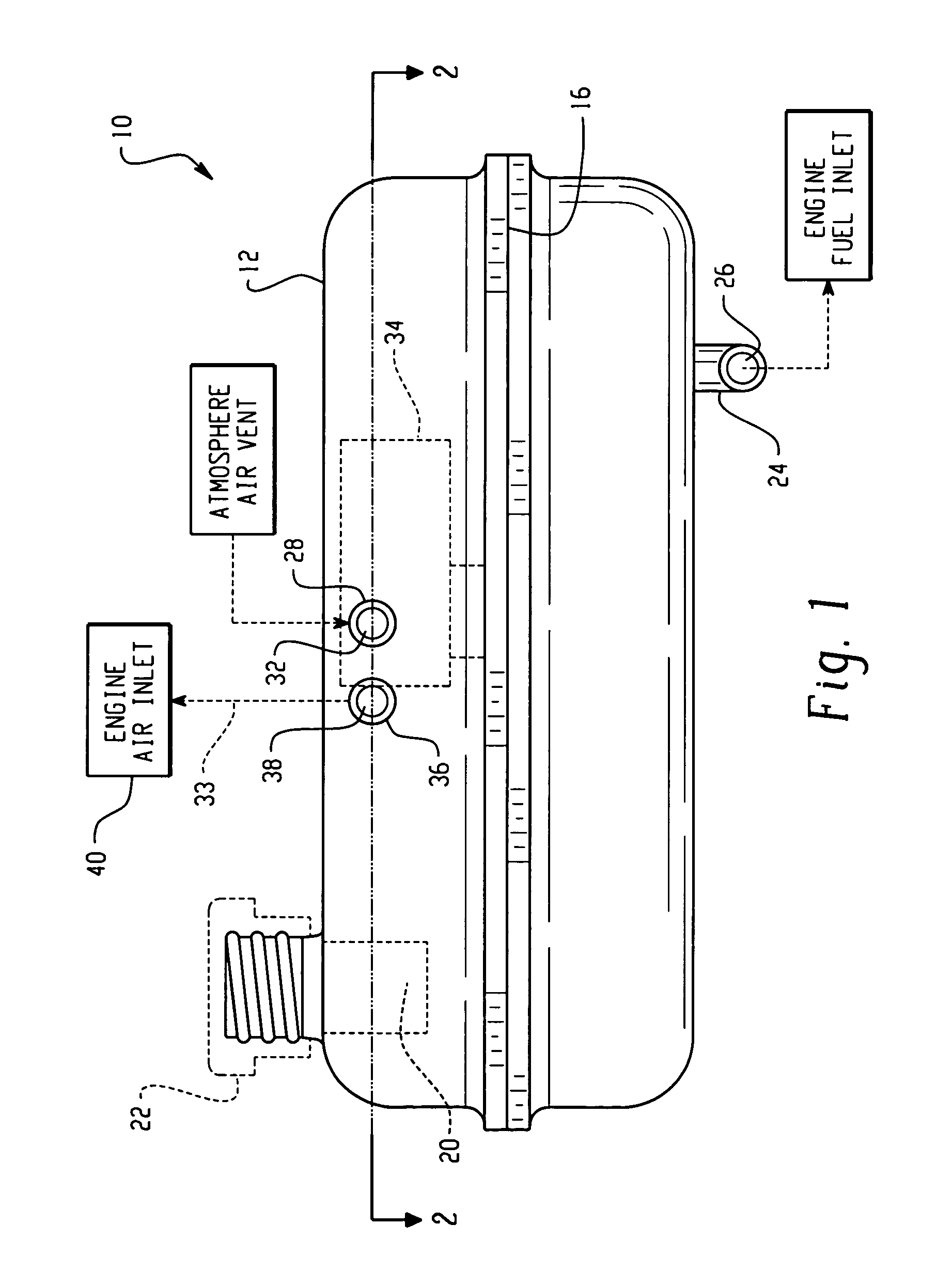

Small engine fuel tank with integrated evaporative controls

ActiveUS7213583B2Easy to installAddressing Insufficient ControlNon-fuel substance addition to fuelFuel injection apparatusExhaust valveAtmospheric air

Owner:EATON INTELLIGENT POWER LTD

Balance container system capable of performing online setting check and online setting check method based on balance container system

ActiveCN104879739ARealize disassembly-free online setting and verificationReliable performanceBoiler indication operationsSteam boilersLower limitDifferential pressure

The invention relates to a balance container system capable of performing online setting check and an online setting check method based on the balance container system. The system comprises a balance container and a differential pressure transmitter connected with the balance container, wherein the balance container is connected with steam space and water space of a steam dome through a steam connection pipe and a water connection pipe respectively, and the differential pressure transmitter is connected with a boiler control system; a water supplementing pipe and an emptying pipe are vertically arranged at the upper part of a balance container barrel, the water connection pipe is vertically downwards provided with a water check pipe through a tee joint, the lower end surface of the water supplementing pipe is set as high as the water level detection upper limit position, and the upper end surface of the water check pipe is set as high as the water level detection lower limit position. The system is simple in structure and convenient to use and adjust, and can realize non-dismantling online setting check of the balance container; the online setting check method based on the balance container system comprises three adjusting modes including manual setting during initial assembly of a boiler, manual compensation setting during operation and automatic compensation setting, the setting is rapid and effective, stable and reliable working performance of the balance container can be guaranteed, and the time for setting check of the balance container can be greatly saved.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

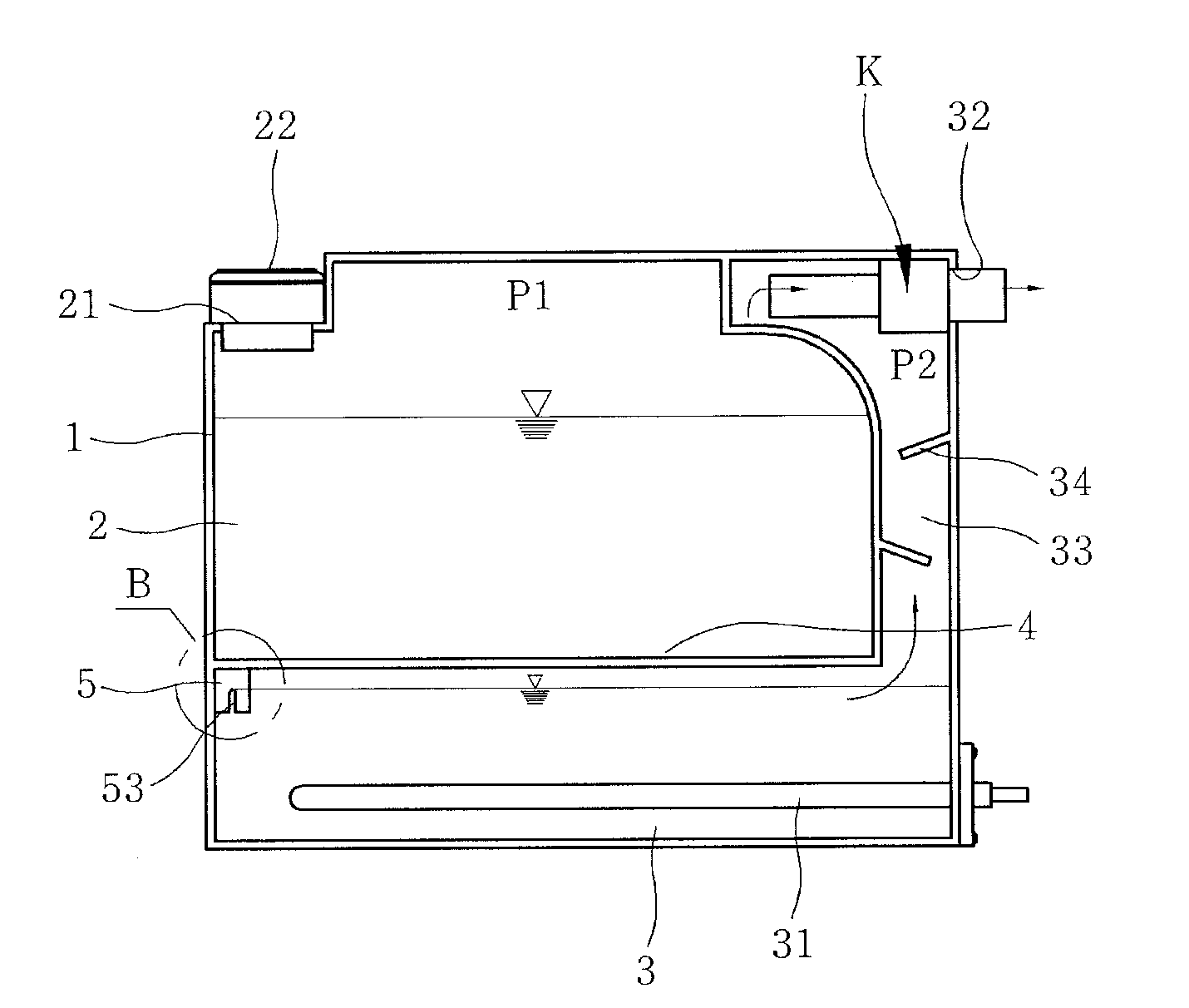

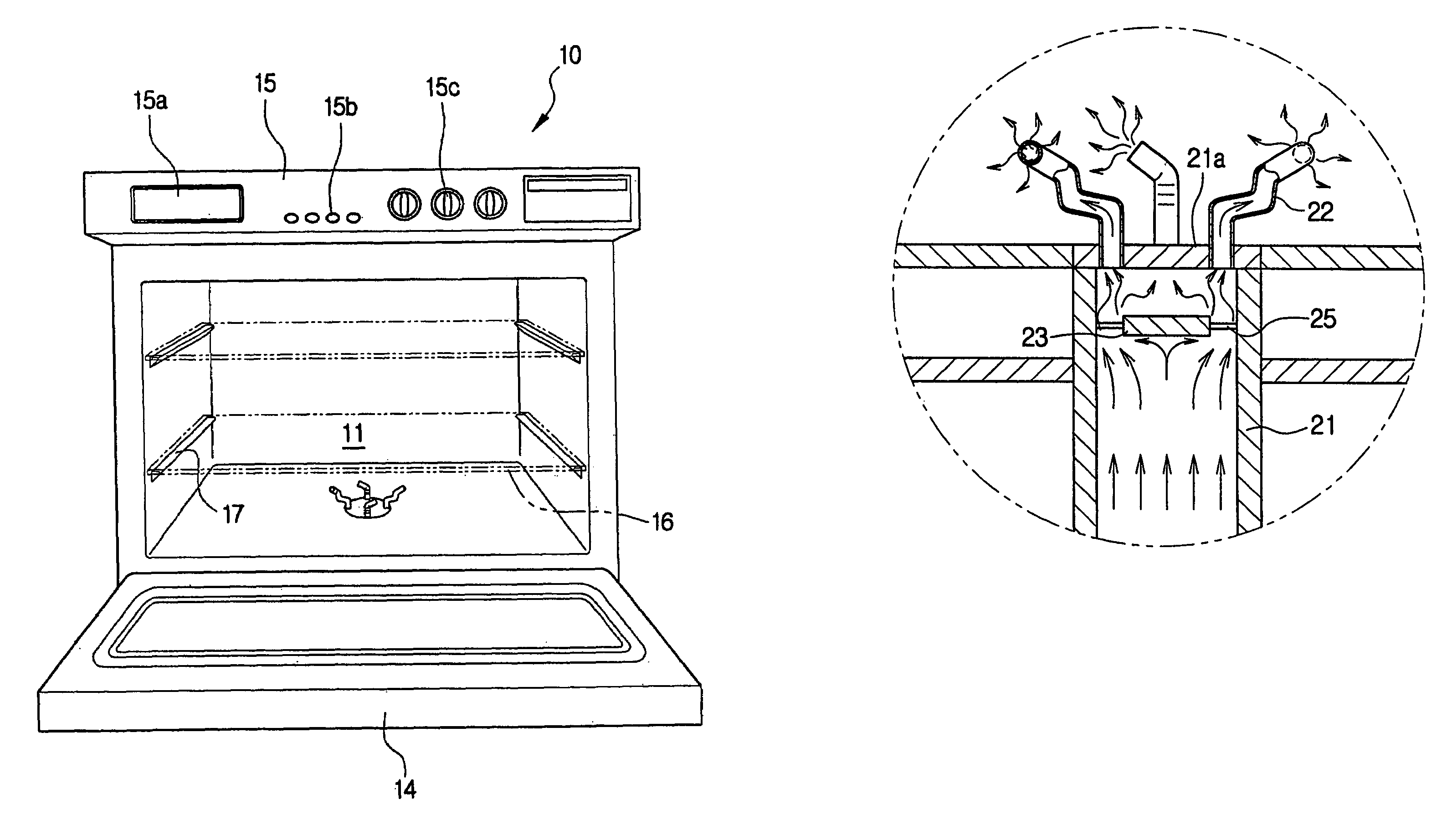

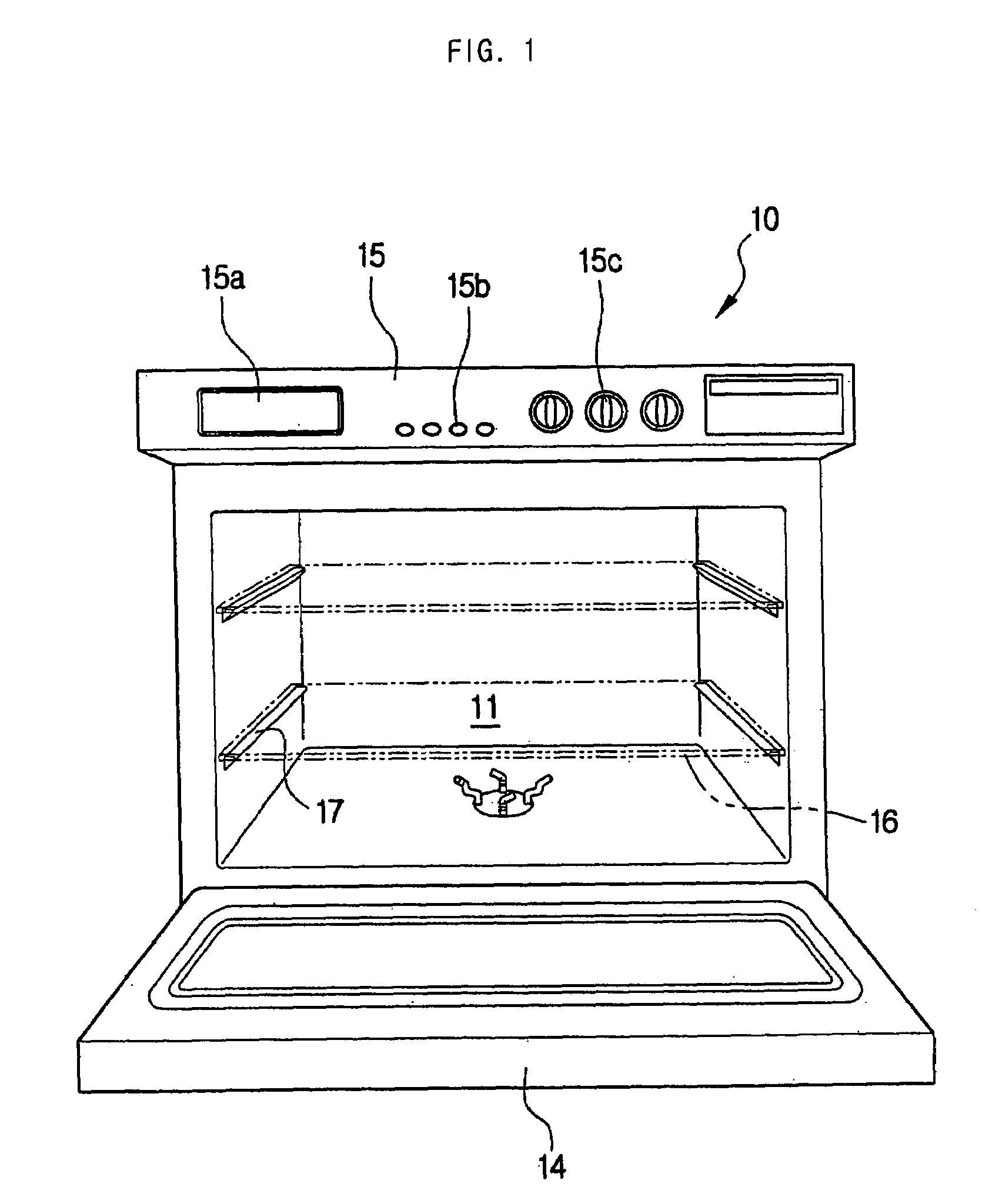

Steam oven

InactiveUS7093592B2Equally distributedDomestic stoves or rangesLiquid heating fuelEngineeringSteam dome

A steam oven having a steam distributing unit which is installed in the steam oven and evenly distributes steam generated by a steam generator into a cooking cavity, which is defined in a cabinet of the steam oven. The steam oven has the steam generator, the cooking cavity, a steam feed pipe to feed the steam generated by the steam generator into the cooking cavity, and a steam distributing pipe to distribute the steam from the steam feed pipe into the cooking cavity. The steam oven additionally has a sectional area control part provided in the steam feed pipe, to control a flow speed of the steam in the steam feed pipe.

Owner:SAMSUNG ELECTRONICS CO LTD

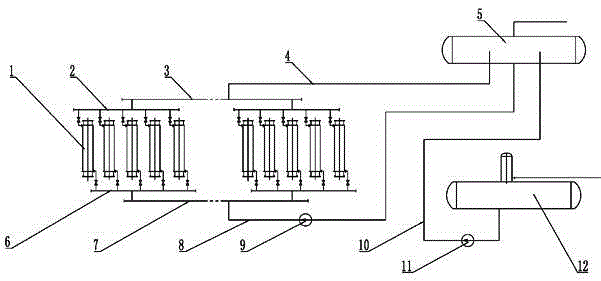

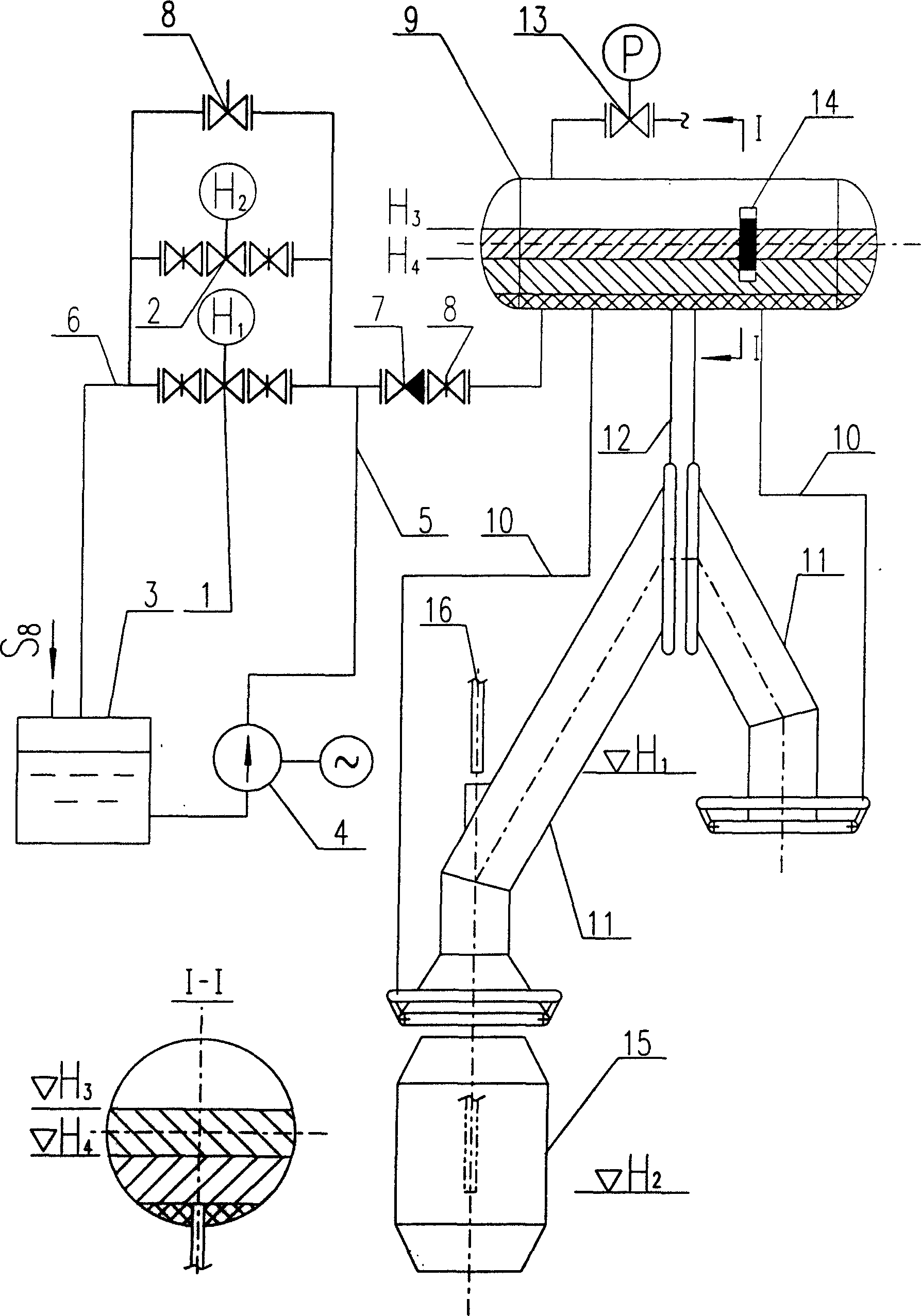

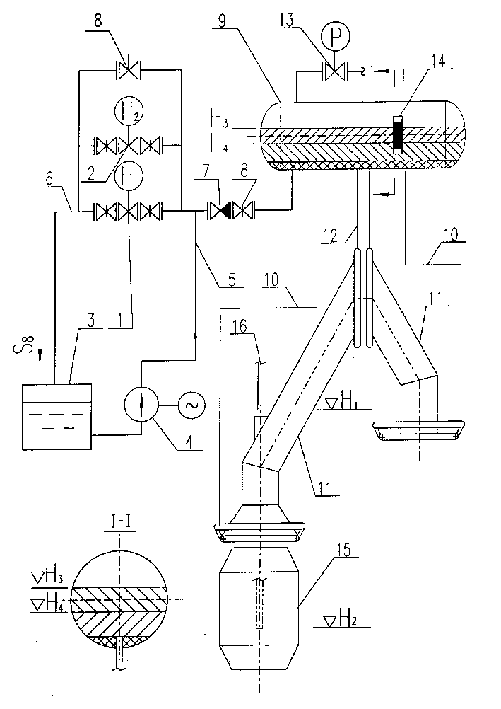

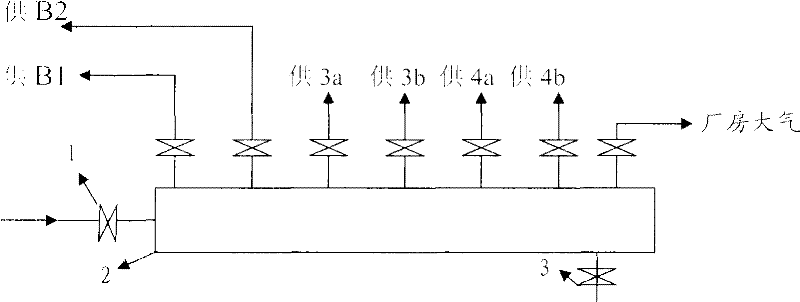

Method and equipment for recycling crude gas waste heat in ascending pipes of coke oven

ActiveCN102494549AEasy to operate and controlEasy to implementIndirect heat exchangersWater flowCoke oven

The invention relates to a method and equipment for recycling crude gas waste heat in ascending pipes of a coke oven, and belongs to the technical field of the recycling of the crude gas waste heat of coke ovens. In the technical scheme, the method comprises the following steps that a centralized steam dome collects and separates steam and water of heat exchangers corresponding to all ascending pipes of the coke oven, and the separated steam is conveyed to the next process to be used from a steam outlet of the centralized steam dome; the separated water is pumped into a water feeding header pipe by a circulating water pump from a water outlet of the centralized steam dome and is distributed to the heat exchangers corresponding to all ascending pipes of the coke oven by each connection pipe, so that the water absorbs heat in the heat exchangers to be vaporized partially and flows into a backwater header pipe by the connection pipes, and the vaporized steam water mixture flows into the centralized steam dome by the backwater header pipe; and steam-water separation is performed, so that the separated steam flows out to be used in the next process, and the separated water flows into the next circulation again. Compared with a mode of controlling dozens of steam domes and hundreds of steam domes, the invention has the advantages that: the method and the equipment are easy and convenient to operate and control, namely only one centralized steam dome is needed to be controlled.

Owner:董洪峰

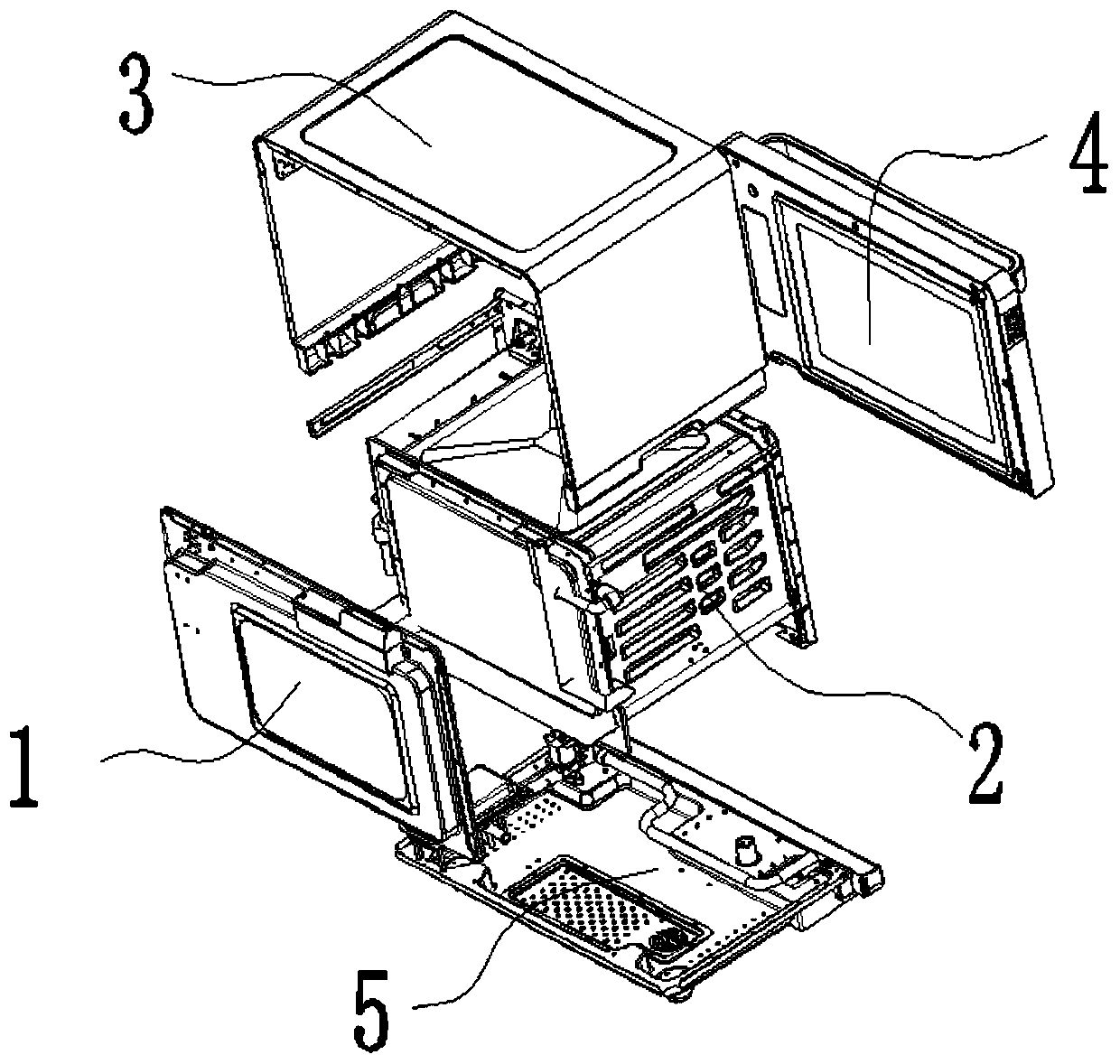

Steam exhaust structure and steam oven adopting same

PendingCN109998387AAchieve airtightShorten the timeSteam cooking vesselsRoasters/grillsEngineeringSteam dome

The invention discloses a steam oven. The steam oven comprises a door body, an accommodating cavity, a shell and a rear cover, wherein a steam exhaust structure is arranged on the rear cover; the steam exhaust structure comprises at least two steam exhaust holes and an automatic switchover closing unit; the steam exhaust holes communicate with the accommodating cavity of the steam oven; and the automatic switchover closing unit is used for closing or opening at least one steam exhaust hole. Compared with the prior art, the technical scheme has the advantages that the structure is simple, the use is convenient, the steaming and baking quality is excellent, etc.

Owner:GUANGDONG KEJIALIN ELECTRICAL APPLIANCE MFG

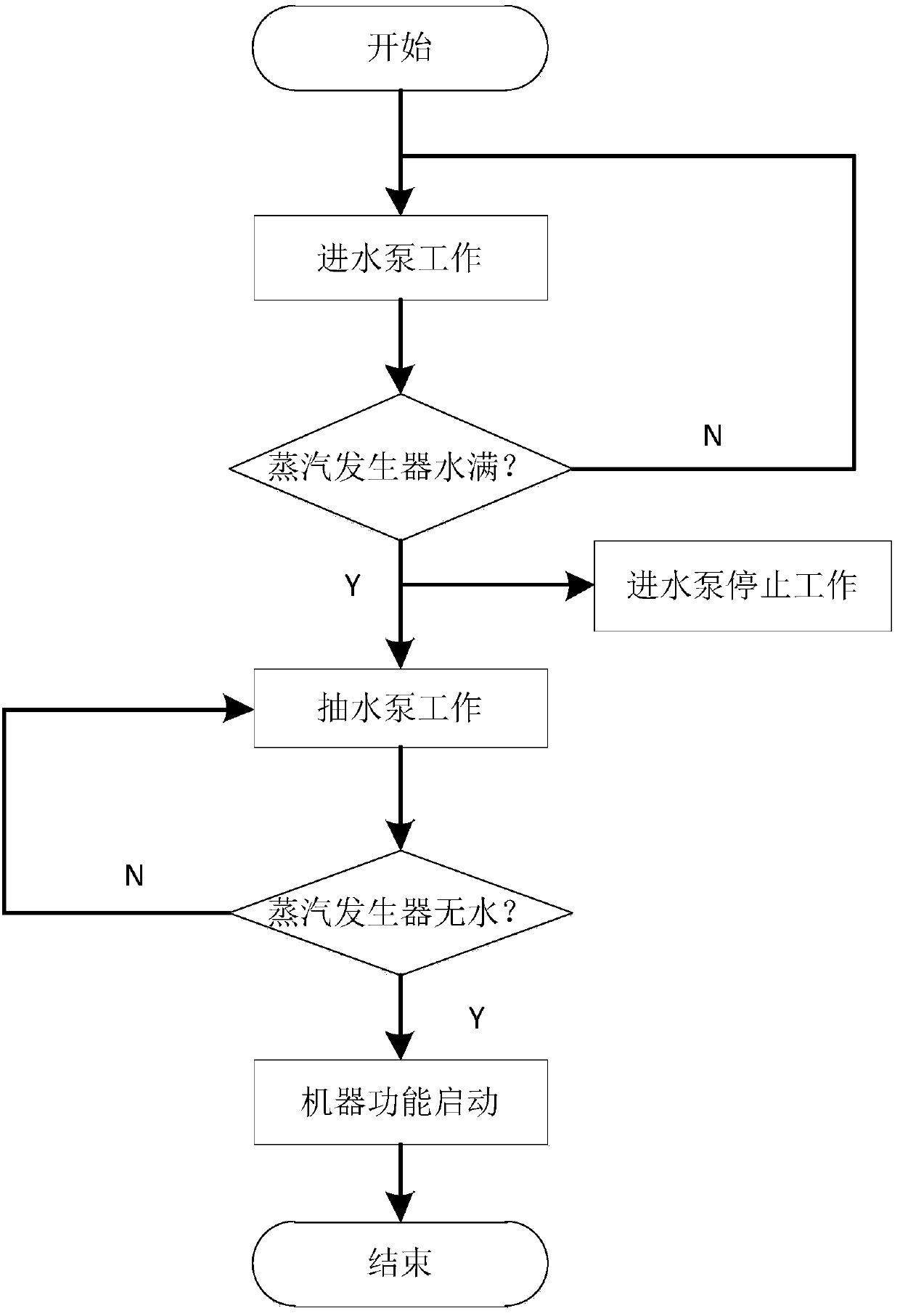

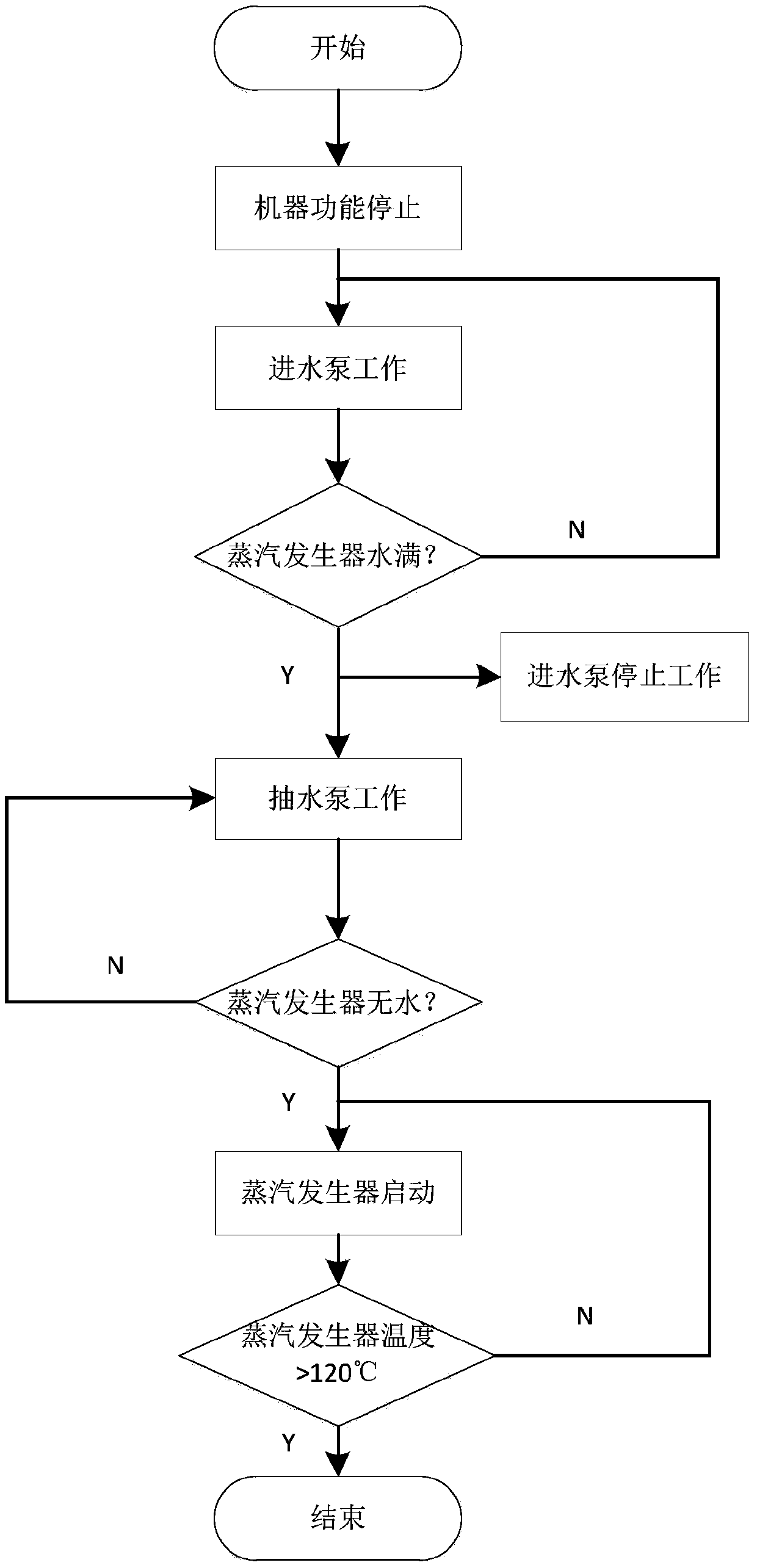

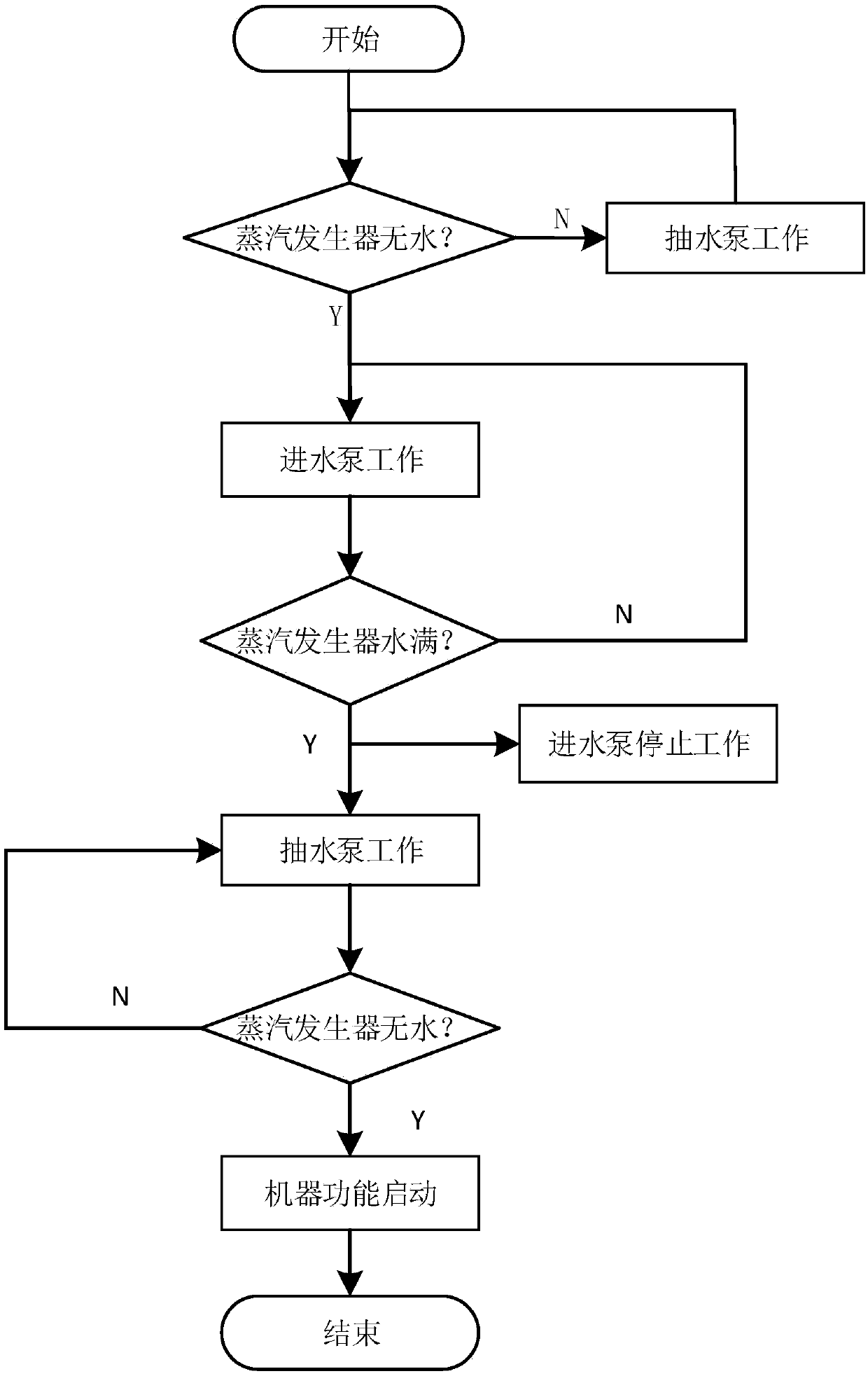

Control method for keeping waterway clean and steam oven

InactiveCN110089926APrevent spoilageFull washSteam cooking vesselsRoasters/grillsEngineeringWater level

The invention discloses a control method for keeping a waterway clean, which comprises the following steps of: before a steam oven executes a working procedure and / or after the steam oven stops executing the working procedure, executing a flushing procedure to ensure that a waterway structure cooperates with a steam generator to work to flush the waterway of the steam oven; the washing procedure comprises the following steps that a water inlet pump adds water into a steam generator, a steam generator water level indicator monitors the water level in the steam generator in real time till the steam generator is filled with water, and a water suction pump empties the water in the steam generator. Before the steam oven executes the working procedure and / or after the steam oven stops executingthe working procedure, water in the waterway structure is actively cleaned, and the health problem caused by deterioration of residual water is avoided.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD

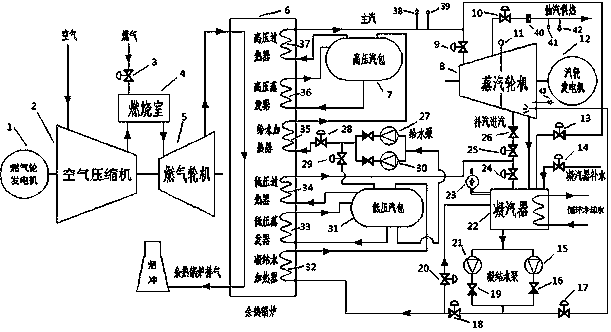

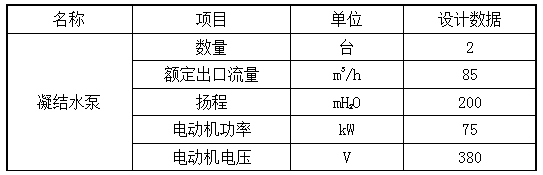

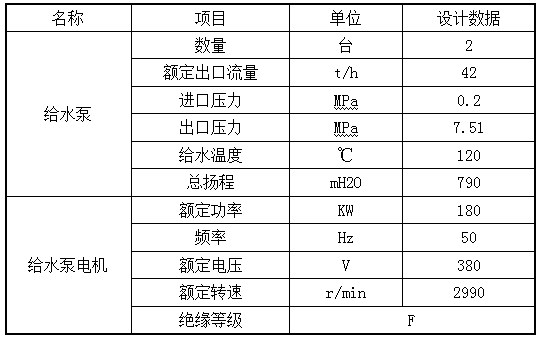

System and method for supplying heat to combined circulation machine group of last stage blades of cooling steam turbine

ActiveCN110486098AReduce the temperatureAvoid damageFeed water supplyBlade accessoriesEngineeringHigh pressure

The invention belongs to the technical field of combined circulation heat supply and control, and particularly relates to a system and a method for supplying heat to a combined circulation machine group of last stage blades of a cooling steam turbine. The system comprises a gas turbine generator group, an exhaust heat boiler, a steamer generator group, a low-pressure steam dome, a high-pressure steam dome, a condensation water pump, a water feeding pump, a pipeline and a valve, wherein steam supplementing is performed on the inner part of a steam turbine cylinder through a steam supplementingregulating valve mounted behind a rotating partition board, so that the last stage blades of the steam turbine are cooled caused by that the steam flow is increased, and the problems that the rotatingpartition board is closed to perform steam extraction for heat supply, and subsequent steam flow is reduced, so that the blasting of the last-stage blades is damaged by high temperature are solved; and when the power of a turbo generator is smaller than 30% of rated load, and the steam source for steam supplementing is insufficient, a steam exhaust cylinder water spray valve is automatically turned on to perform water spraying on a steam exhaust cylinder of the steam turbine, so that the temperature of the last stage blades of the steam turbine is reduced, and the problem that the last stageblades of the steam turbine are damaged is solved.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

Steam generator and steam oven

PendingCN108518665AIncrease the heat exchange areaImprove heat transfer efficiencySteam generation heating methodsSteam cooking vesselsControl systemEngineering

The invention provides a steam generator and a steam oven, and relates to the technical field of kitchen electric appliances. The steam generator comprises a shell body and a steam generation unit, wherein the shell body is provided with a water inlet and an exhaust port, the steam generation unit is arranged in the shell body and comprises a gasification chamber provided with a plurality of micro-channels and a heating bod used for heating the gasification chamber, and the heating body is in thermal contact with the gasification chamber; after the liquid enters the shell body from the water inlet, the liquid is divided by the micro-channels, and can be rapidly gasified in each micro-channel under the action of the heating body; and the exhaust port is used for discharging steam generatedin the steam generation unit. The steam oven comprises a water tank, the steam generator and a water pump used for conveying water in the water tank to the steam generator, wherein the water pump is connected with a control system of the steam oven, and the exhaust port of the steam generator communicates with a cooking cavity of the steam oven. According to the steam generator and the steam oven,the problem that the steam generating speed of a steam generator in an existing steam oven is low is solved.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Double-medium waste heat boiler

InactiveCN104406144AReduce purchase and operation costsReduce consumptionStorage heatersSteam generation using hot heat carriersAtmospheric airSuperheater

The invention provides a double-medium waste heat boiler. The double-medium waste heat boiler provide superheated steam for industrial production and meanwhile can provide hot water for heating, accordingly can effectively reduce the purchase and operation cost of the boiler and greatly reduce energy consumption and pollutant discharge. The double-medium waste heat boiler comprises a waste heat boiler flue and a steam dome, wherein the waste heat boiler flue is horizontally installed on a support, a waste heat high-temperature smoke inlet is formed in one end of the waste heat boiler flue, a smoke outlet is formed in the other end of the waste heat boiler flue and connected with a chimney, a superheater, an evaporator and an economizer are sequentially arranged in the waste heat boiler flue in the smoke flowing direction, and high-temperature smoke flows into the waste heat boiler flue through the waste heat high-temperature smoke inlet, sequentially scours vertical pipe bundles of the superheater, the evaporator and the economizer and then is discharged into the atmosphere through the smoke outlet and the chimney. The double-medium waste heat boiler is characterized in that a convection section of an organic heat carrier boiler is further arranged in the waste heat boiler flue and is arranged at the rear portion of the economizer in the smoke flowing direction.

Owner:JIANGSU TAIHU BOILER

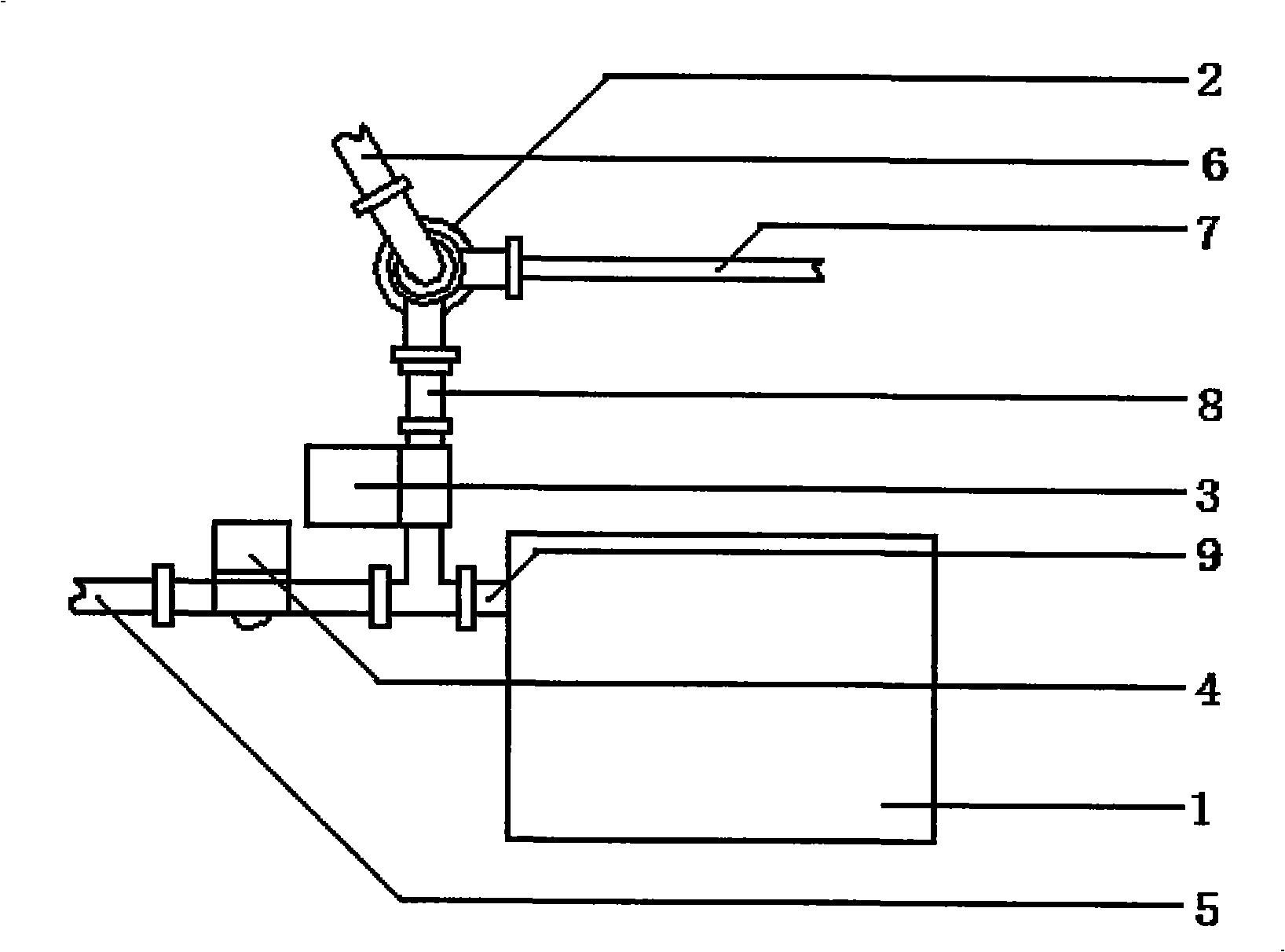

Converter steam dome high/low water level automatic feedwater unit

InactiveCN1566371ANo misuseThe principle system is simpleManufacturing convertersEvaporationEngineering

The invention discloses a converter steam dome high / low water level automatic feedwater unit, wherein two single impact water level adjustable valve are arranged on the backwater pipe of the revolving furnace evaporation cooling supply pipe interlocking with rise and fall of the oxygen guns.

Owner:SHOUGANG CORPORATION

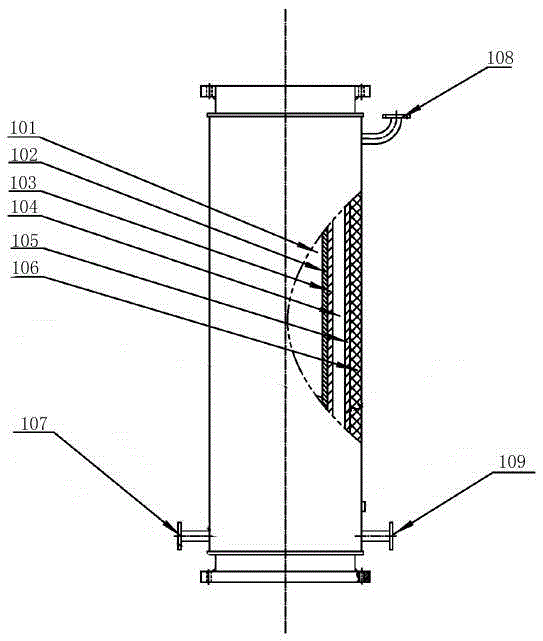

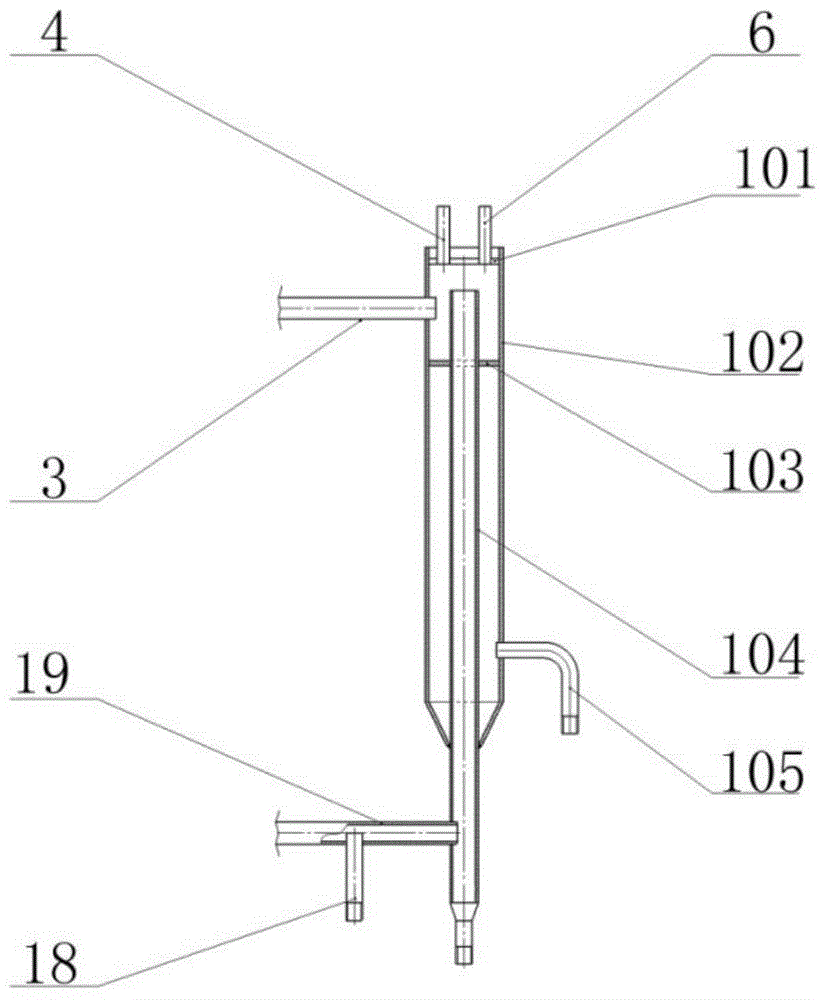

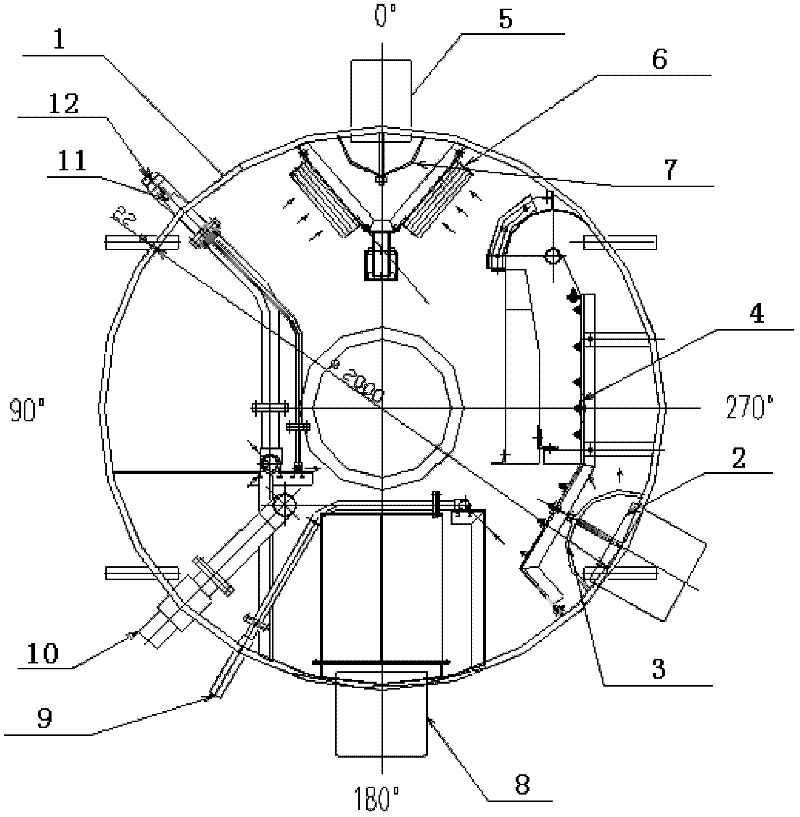

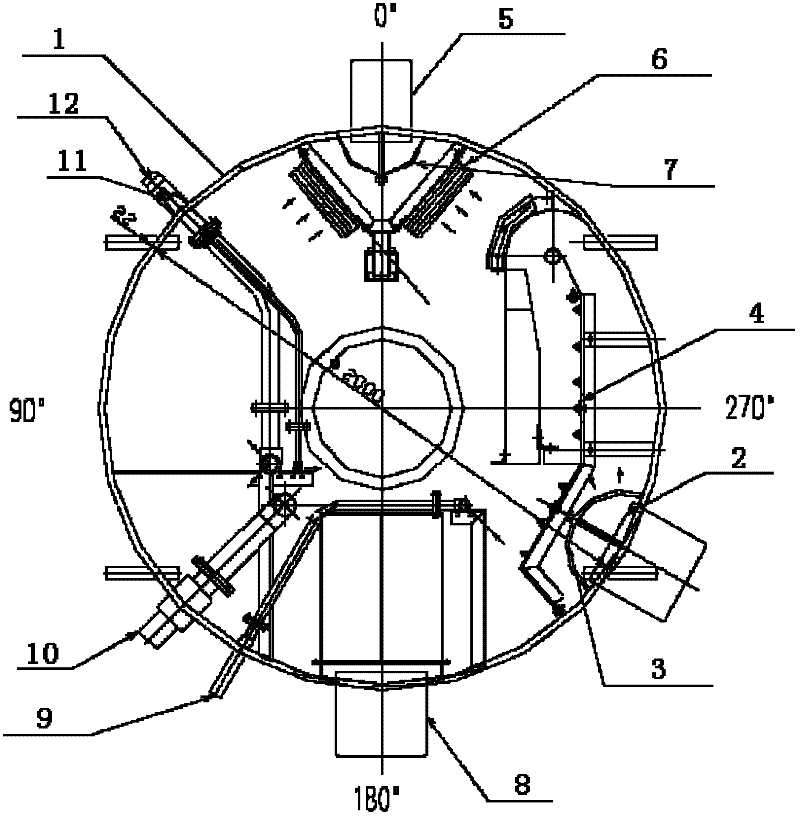

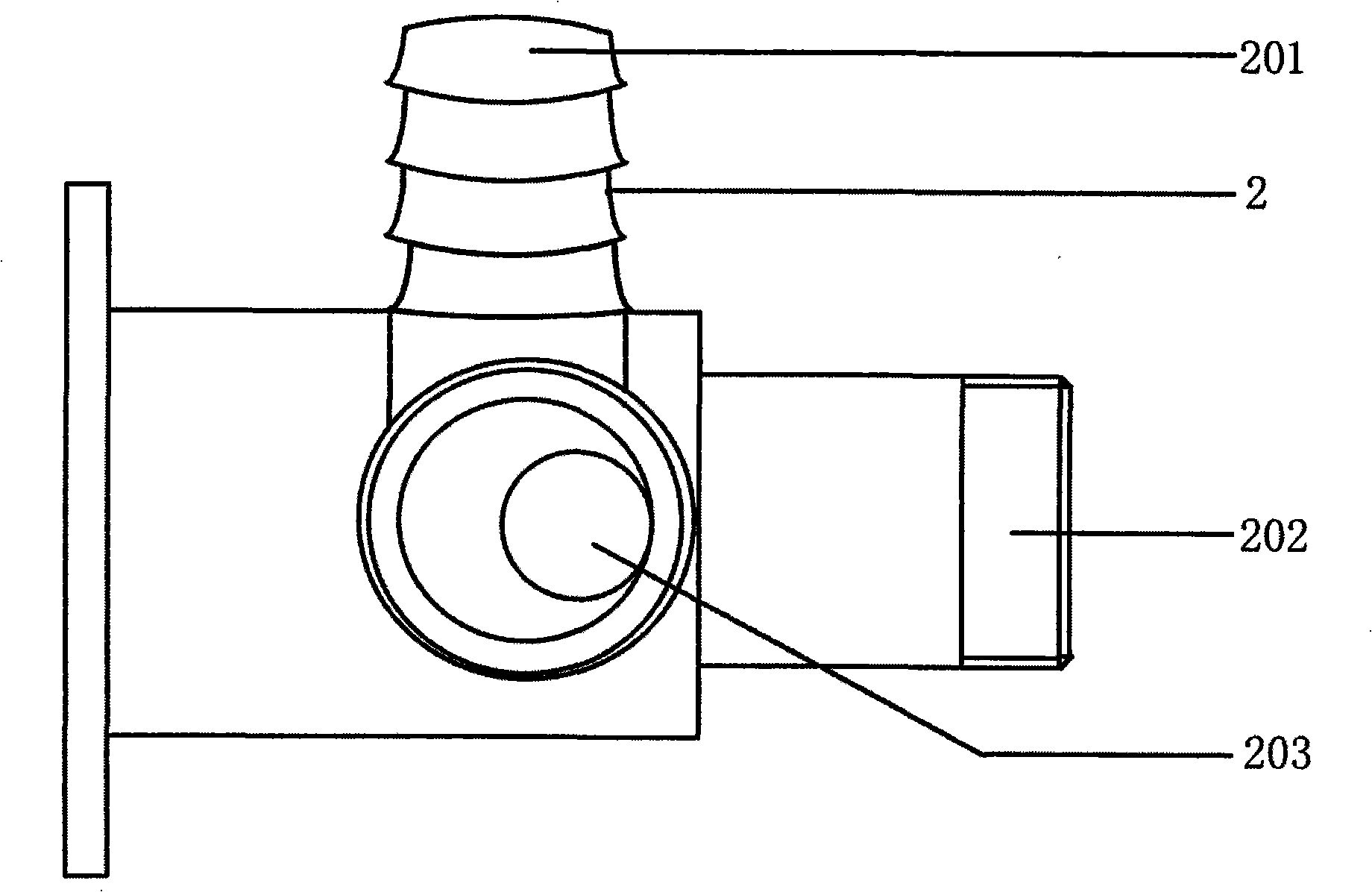

Steam and water separation device for steam dome

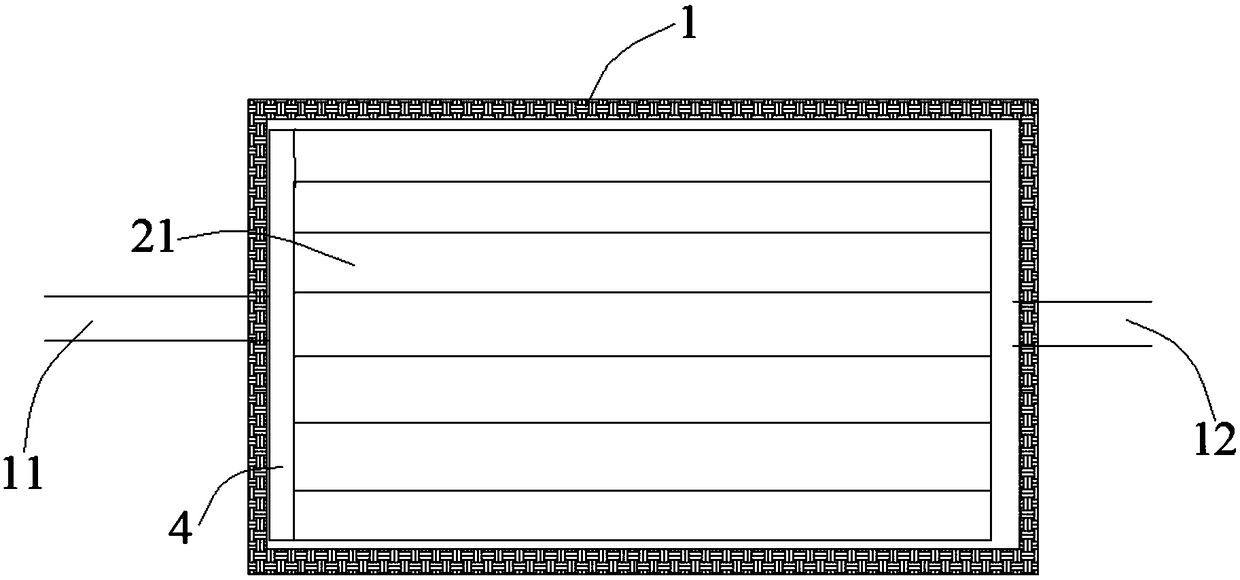

ActiveCN102230613AGood cycle conditionReduced chance of blown pipesSteam separation arrangementsProduct gasEngineering

The invention discloses a steam and water separation device for a steam dome, and the device provided by the invention comprises a primary separation device and a secondary separation device, wherein the primary separation device is arranged on the mouth of an ascending tube used for inputting a steam and water mixture in a steam dome body; and the secondary separation device is arranged on the mouth of a steam extraction tube for outputting gas in the steam dome body. The device has a simple structure and is convenient to manufacture, install and overhaul; meanwhile, good water circulation working condition can be guaranteed, and overlarge circulation resistance can be avoided; and in addition, the device can effectively carry out steam and water separation so as to lower the tube explosion possibility of the superheater, and satisfies the operation reliability of the boiler and user requirements.

Owner:ANHUI CONCH KAWASAKI ENERGY CONSERVATION EQUIP

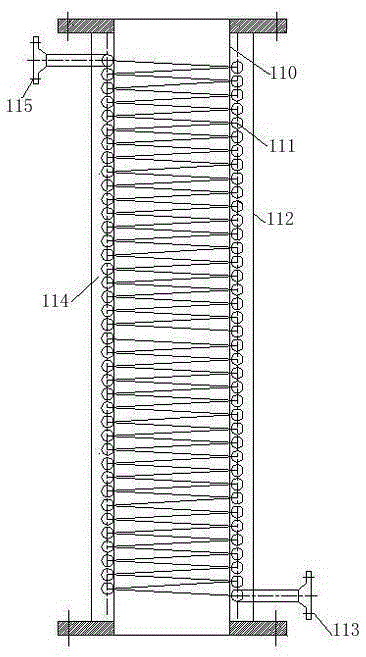

Assembly type heat-pipe steam generator of kiln furnace

InactiveCN102128439AImprove adaptabilitySolve the problem of poor adaptability to fluctuations in working conditionsEnergy industryIncreasing energy efficiencyFlue gasEngineering

The invention discloses an assembly type heat-pipe steam generator of a kiln furnace; a plurality of groups of heat-pipe heat-exchanging assemblies are installed in a smoke box; each group of heat-pipe heat-exchanging assemblies is formed by fixedly connecting a movable top plate of the smoke box as well as a plurality of heat pipes and sleeve assemblies which penetrate on the movable top plate; and each sleeve assembly is formed by connecting sleeves enclosed on the upper part of the heat pipes on the movable top plate; the upper parts of the sleeves are communicated with a steam dome through a connecting pipeline and a gas valve; and the lower parts of the sleeves are communicated with water outlets at the lower part of the steam dome through a connecting pipeline and a water valve. In comparison with the prior art, the assembly type heat-pipe steam generator disclosed by the invention is capable of solving the problems that the traditional heat-pipe steam generator is difficult to repair and replace and has poor adaptability to the fluctuant working conditions of the kiln furnace and high maintenance cost, and is beneficial to improvement of the reliability of the heat-pipe steam generator as well as standardization and normalization of design, production, installation, use, maintenance and other aspects of flue gas waste heat recovery for the kiln furnaces.

Owner:GUANGXI ZHIYUAN ENERGY SAVING & ENVIRONMENTAL PROTECTION EQUIP

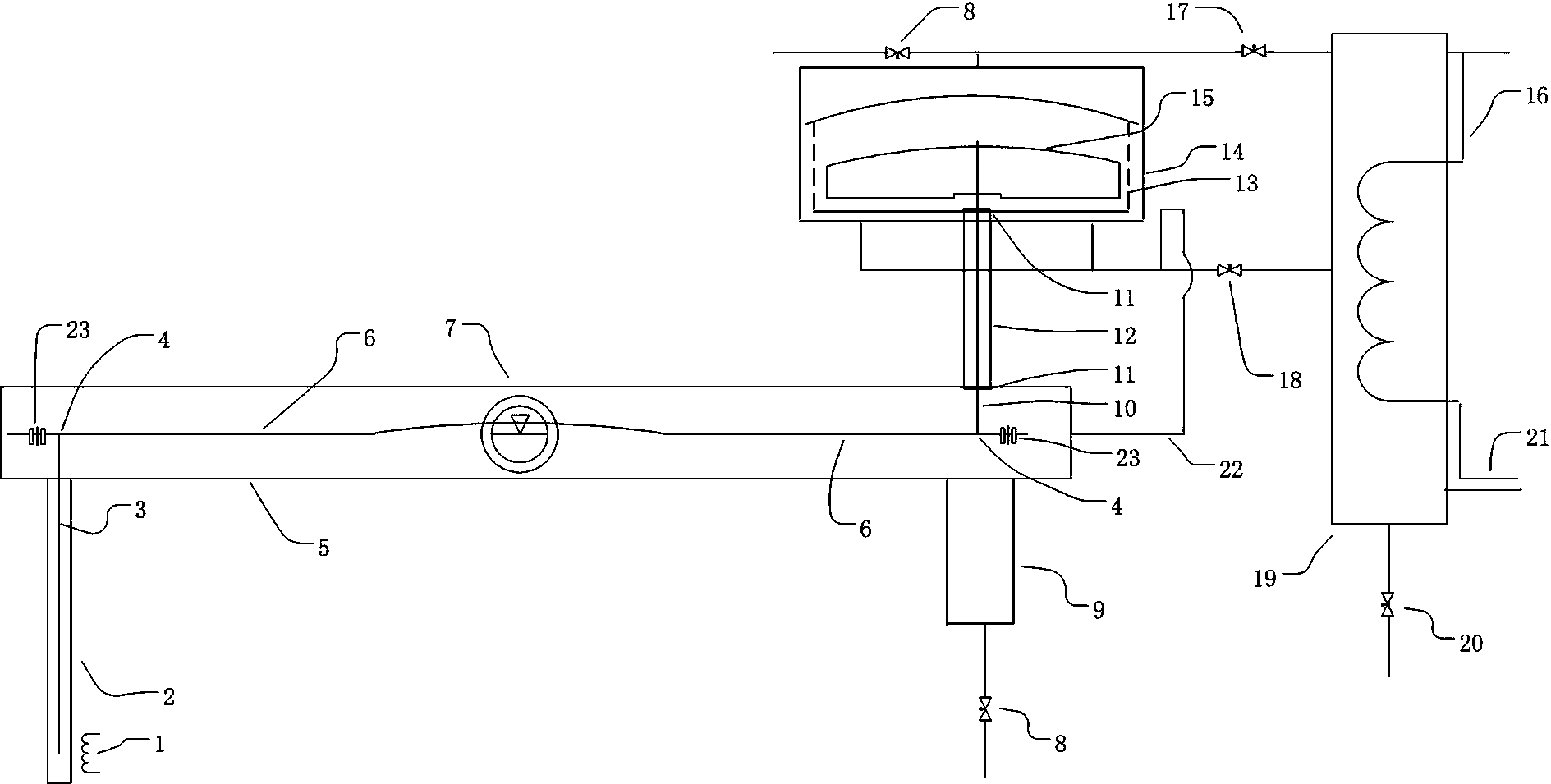

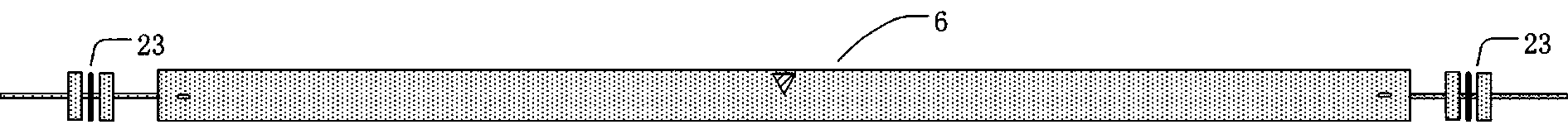

Small engine fuel tank with integrated evaporative controls

ActiveUS7383825B2Easy to installAddressing Insufficient ControlNon-fuel substance addition to fuelMachines/enginesDiscriminatorAtmospheric air

A fuel tank assembly for small engines having a vapor storage canister disposed within the tank in the vapor dome with an atmospheric vent line to the canister through the tank wall and a canister vapor outlet line also through the tank wall. A liquid / vapor discriminator is disposed in the vapor dome of the tank with the discriminator outlet connected to the canister inlet. A fuel filler tube extends through the tank wall to a desired depth to prevent vapor from escaping through the filler tube when the fuel level rises to the lower end of the filler tube and alerts the operator by rapid rise of fuel in the filler tube.

Owner:EATON INTELLIGENT POWER LTD

Buoyancy-type liquid level meter

InactiveCN103644954AEliminate water ingressReduce manufacturing costLevel indicators by floatsMeasuring instrumentTransducer

The invention relates to a buoyancy-type liquid level meter for measuring the liquid level by applying a buoyancy, gravity and equilibrant balancing method, aiming at mainly solving the problem of influence of the temperature, pressure, vaporization and coagulation of a measured medium on measurement and overcoming the defects of an existing related measuring instrument. The method is not limited by the situation that the specific gravity of a floater is less than the specific gravity of measured liquid and can be used for measuring the liquid level by using a solid or hollow floater. The measuring meter suitable for multiple environments and multiple liquid levels can be manufactured according to specific conditions. The invention relates to a steam dome water level switch for measuring the steam dome water level inside an industrial boiler. The steam dome water level switch disclosed by the invention has high accuracy, high reliability and less drifting without frequent verification adjustment. Compared with a transducer, the steam dome water level switch disclosed by the invention has the advantages that intermediate conversion links are few, access of a computer system is not needed, an independent protective signal output is realized, complex electronic software and hardware are omitted, steam-water density compensation calculation is avoided, and the influence of steam-water density change and the influence of fast boiler load change are basically eliminated.

Owner:冯振宇

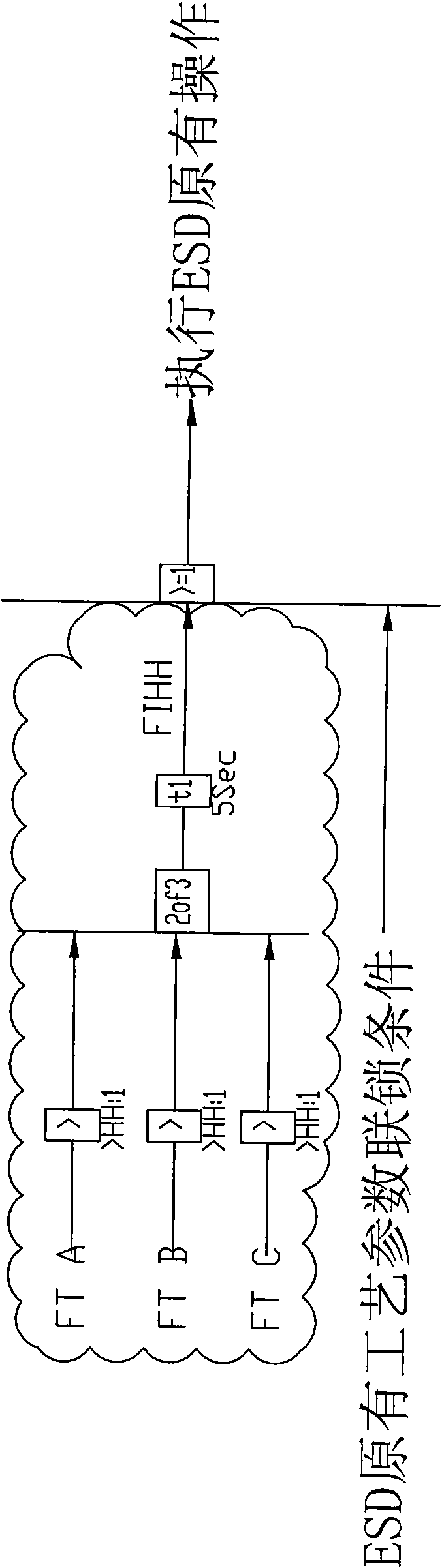

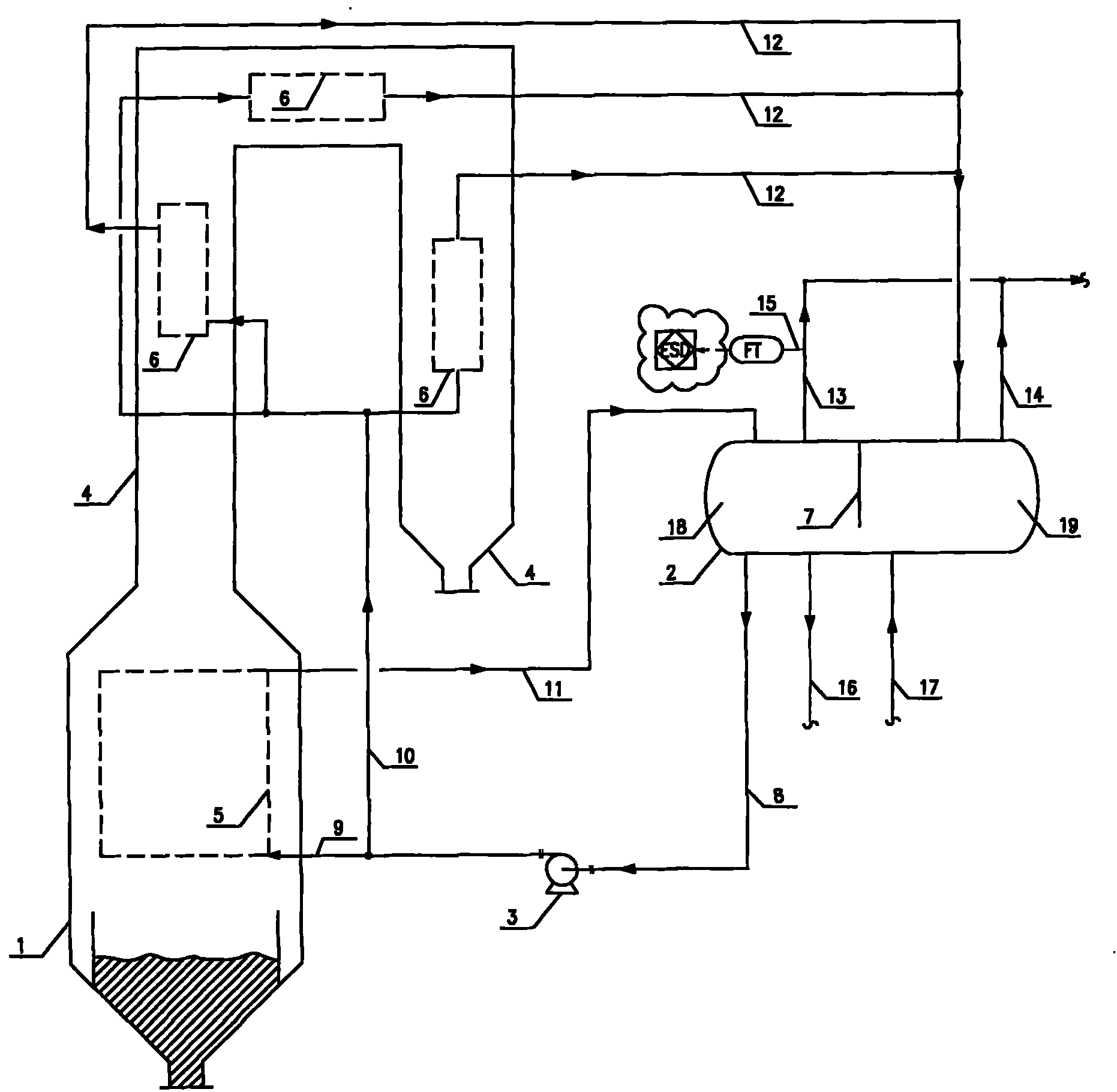

Safety control mechanism for powdered coal gasifier

ActiveCN102041107ADeterioration in operating conditionsRapid responseSteam generation plantsCombustible gas productionSafety controlGas cooler

The invention relates to a safety control mechanism for a powdered coal gasifier, which comprises a gasifier shell, a synthesis gas cooler shell and a steam dome. A gasifier water cooling wall is arranged in the gasifier shell, a synthesis gas cooler steam generator is arranged in the synthesis gas cooler shell, and the steam dome is internally provided with a steam dome separator which separates the steam dome into two chambers, i.e. a steam dome gasifier steam separating chamber and a steam dome synthesis gas cooler steam separating chamber. The safety control mechanism for a powdered coal gasifier is characterized in that a steam pipe from the steam dome gasifier steam separating chamber is equipped with a steam meter used for measuring the steam yield of the gasifier water cooling wall and capable of directly reflecting operating conditions of internal parts in a gasifier, and the steam meter can be connected with a safety interlocking system. Compared with the prior art, the safety control mechanism for a powdered coal gasifier can visually and timely detect the temperature change condition of the gasifier water cooling wall and cut off the supply of reaction material flow in time when steam flow reaches an interlocking value, thereby avoiding the further deterioration of the operating condition of the gasifier.

Owner:CHINA PETROCHEMICAL CORP +2

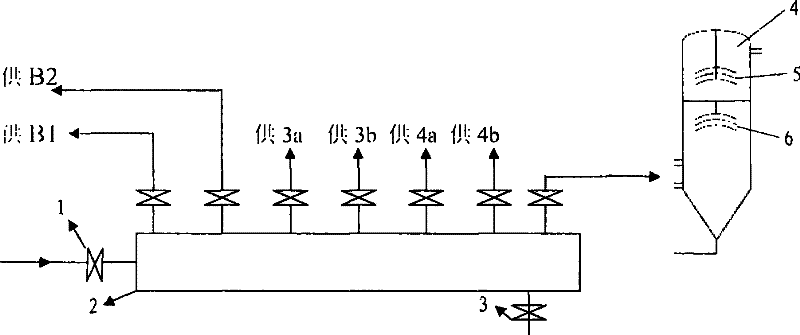

Steam releasing method for RH vacuum pump system steam dome

InactiveCN102392103ANoise Reduction and CancellationSafe and harmlessSteam/vapor condensersSprayerEngineering

The invention provides a steam releasing method for an RH vacuum pump system steam dome. The method is characterized in that the releasing pipe of a steam dome is connected to the lower part of a condenser. When steam is released, the released steam is introduced into the condenser. The condenser is a third-stage condenser (C3 condenser) which is arranged on a platform near the steam dome. The C3 condenser is sealed and is communicated with condensate water. The upper part of the C3 condenser is provided with an upper sprayer; the middle of the C3 condenser is provided with a middle sprayer; and when released steam airflow is introduced into the C3 condenser, the steam airflow carries out heat exchange with the condensate water sprayed from the middle sprayer and the upper sprayer of the C3 condenser to be condensed into water.

Owner:攀钢集团西昌钢钒有限公司

Steam constant temperature pump

InactiveCN101354127AFast heatingEasy to useSteam generation heating methodsBoiler controlElectricitySolenoid valve

The invention provides a steam thermostatic pump which comprises a steam generator, a noise-free three-way steam heating valve and a controlling part. One end of a guide tube is connected with the steam generator while the other end thereof is divided into two parts to form a first guide tube and a second guide tube, wherein, the first guide tube is connected with the noise-free three-way steam heating valve which is hollow and communicated in the middle while the second guide tube is connected with a steam pipe; the controlling part at least consists of a first solenoid valve and a second solenoid valve which can exchange the position with the first solenoid valve; the noise-free three-way steam heating valve at least comprises a first connector connected with a water inlet pipe, a second connector connected with an air inlet pipe and a third connector connected with a steam heating pipe. The steam thermostatic pump can realize the aim of warming up and utilizing the steam by heating and outputting the steam or mixing the steam with water and air, and also completely separates water from electricity; in addition, the thermostatic pump is also fast in heating and has the advantages of convenience, safety and energy conservation, being a novel design which can be widely applied to a variety of bathtubs, steam rooms and water heaters.

Owner:胡建伟

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com