Production method of steam chest rubber diaphram

A technology of rubber diaphragm and production method, which is applied in the direction of brakes, transportation and packaging, and brake transmission devices, can solve the problems of high thickness and dimensional accuracy of semi-finished film, difficult process, and high labor intensity, so as to improve the blasting strength and The effect of service life, reducing process difficulty and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

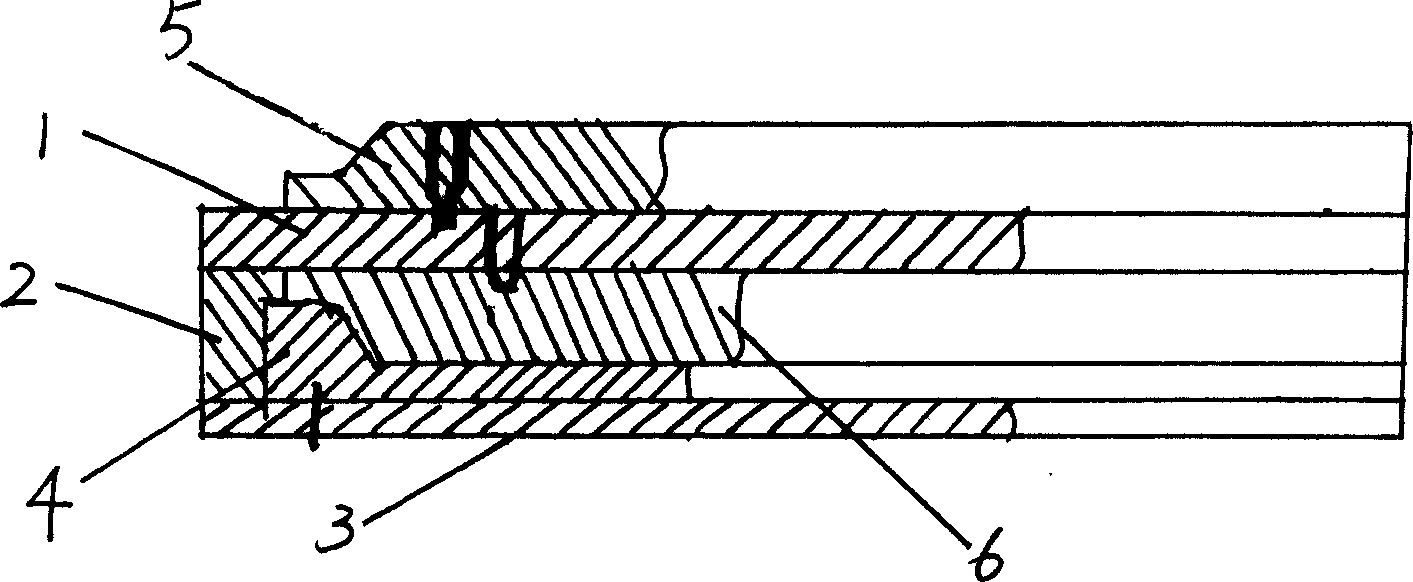

[0019] see figure 1 .

[0020] The steam chamber rubber diaphragm mold includes an upper template 1, a pressure ring 2, and a lower template 3. The lower mold 4 is fixed on the lower template 3. The pressure ring 2 is an annular ring and is set outside the lower mold 4. The front and back sides of the upper template 1 are respectively fixed. There is a mandrel, one side is fixed with a vulcanization molding upper mold 5; the other side is fixed with a secondary vulcanization molding upper mold 6.

[0021] The inner sidewall of the lower mold 4 is an inclined plane, and the inner sidewall is covered with protrusions (welding spots).

[0022] Taking the product specification diameter as 199mm, thickness as 39mm, 1-9 moulds, and a 500T automatic push-out vacuum plate vulcanizing press as an example, the production method of the steam chamber rubber diaphragm of the present invention will be described in detail below:

[0023] Preparation of rubber block and canvas raw materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com