Mould, mould base and process for one-time forming of canvas of air chamber rubber diaphragms

A technology for rubber diaphragms and forming molds, applied in the production field of rubber parts, can solve the problems of high requirements on thickness and dimensional accuracy of semi-finished films, inability to control the center position of canvas well, and difficulty in process control, etc., to save energy and reduce production cycle. Short, easy-to-cut effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The best implementation mode of the present invention will be described in detail below in conjunction with the accompanying drawings, but not limited thereto.

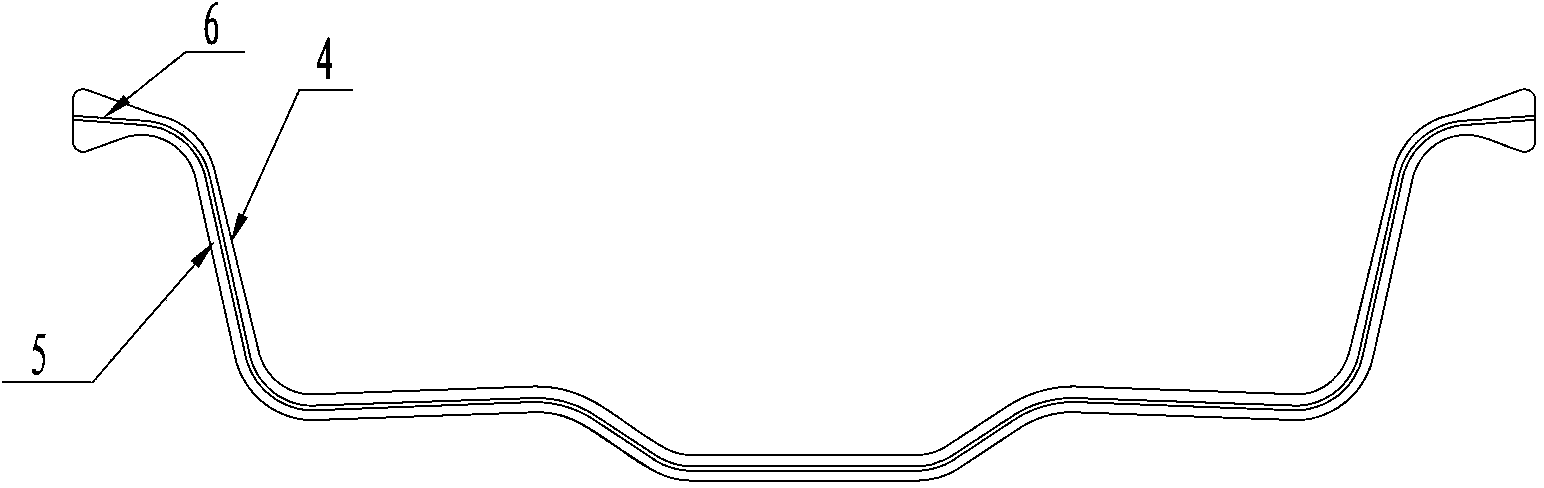

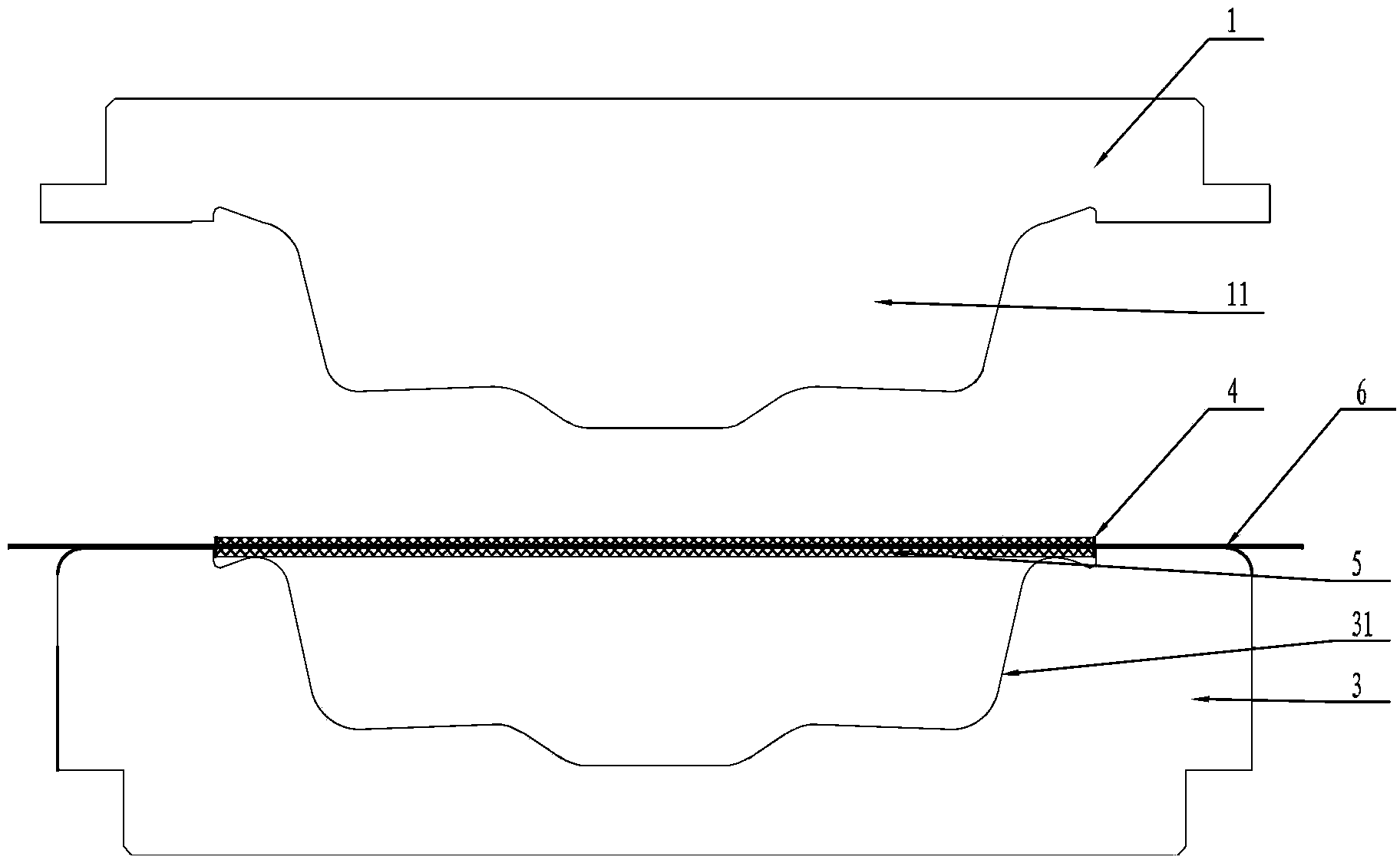

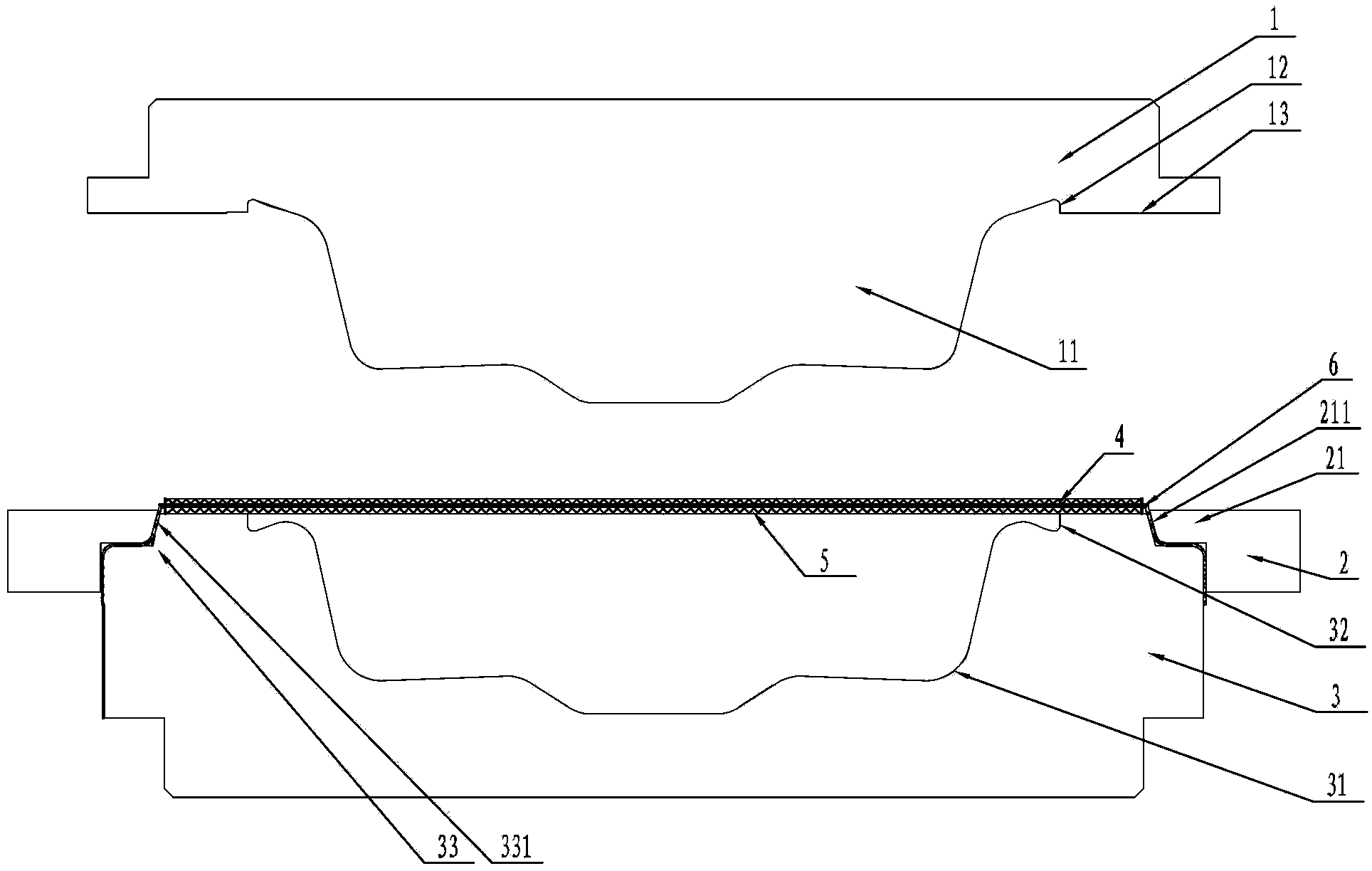

[0036] Such as image 3 , 4 As shown, the present invention provides a canvas shaping mold for an air chamber rubber diaphragm, comprising: an upper mold 1 and a lower mold 3; the lower side of the upper mold 1 is formed with an upper flange 11 corresponding to the shape of the air chamber rubber diaphragm; The upper side of the lower mold 3 corresponds to the shape of the upper flange 11 of the upper mold 1, forming a lower concave cavity 31; it also includes a collar 2 that can pre-tighten the canvas, and the collar 2 can be buckled on the lower mold 3 on the outer edge of the top. Adding ferrule 2 to pre-tighten canvas 6, the requirements for canvas 6 cloth surface are low during molding, and the shape of canvas can be square, which can be convenient for cutting and improve the speed of cutting.

[0037] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com