Patents

Literature

47results about How to "Fast cropping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

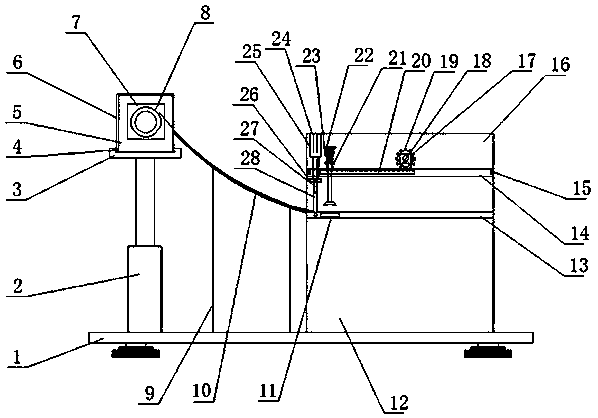

Corrugated paper cutting device

InactiveCN105922315ASimple structureFast croppingMetal working apparatusArticle deliveryEngineeringKnife blades

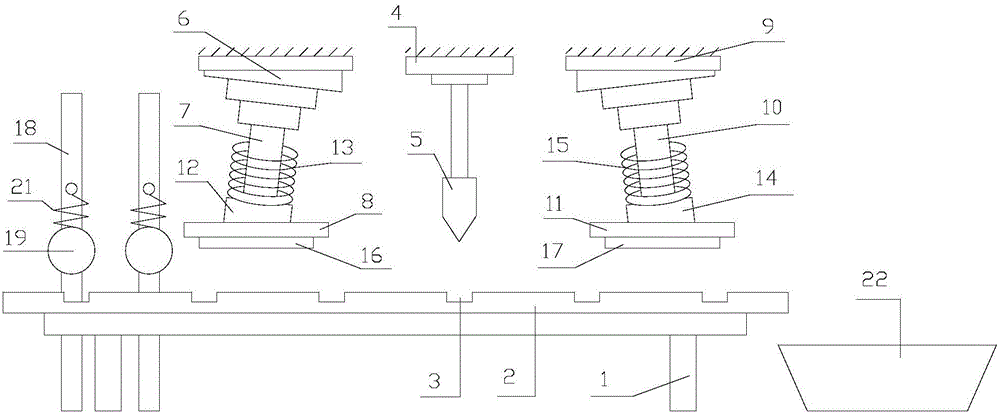

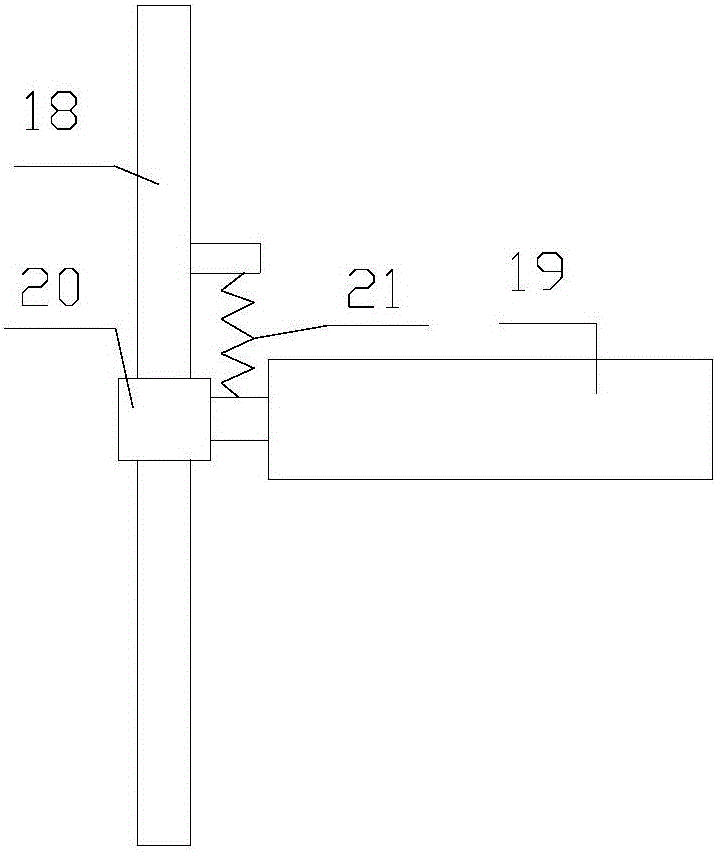

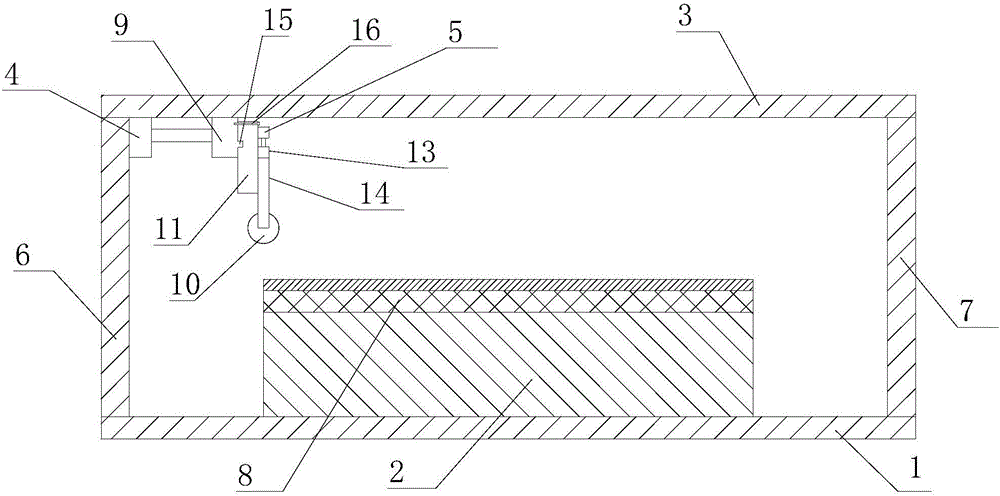

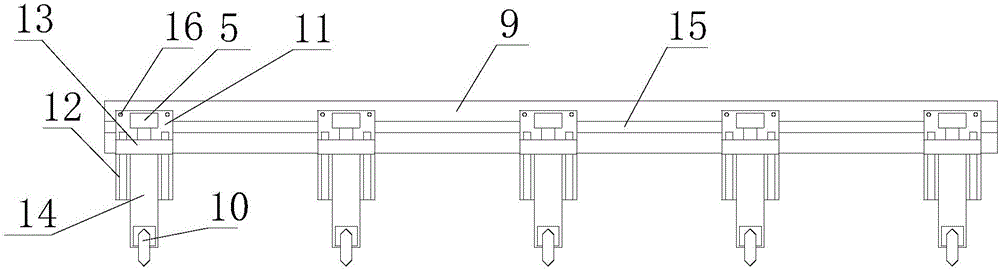

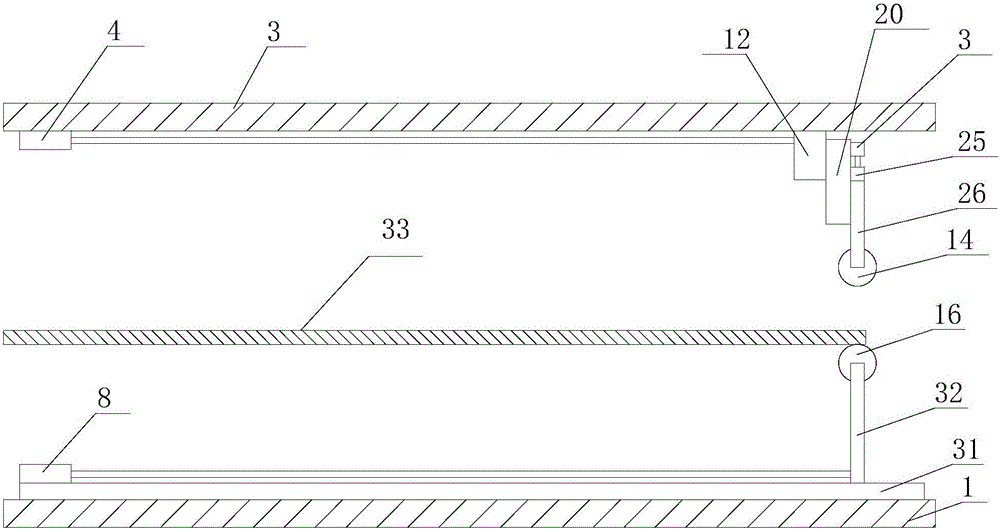

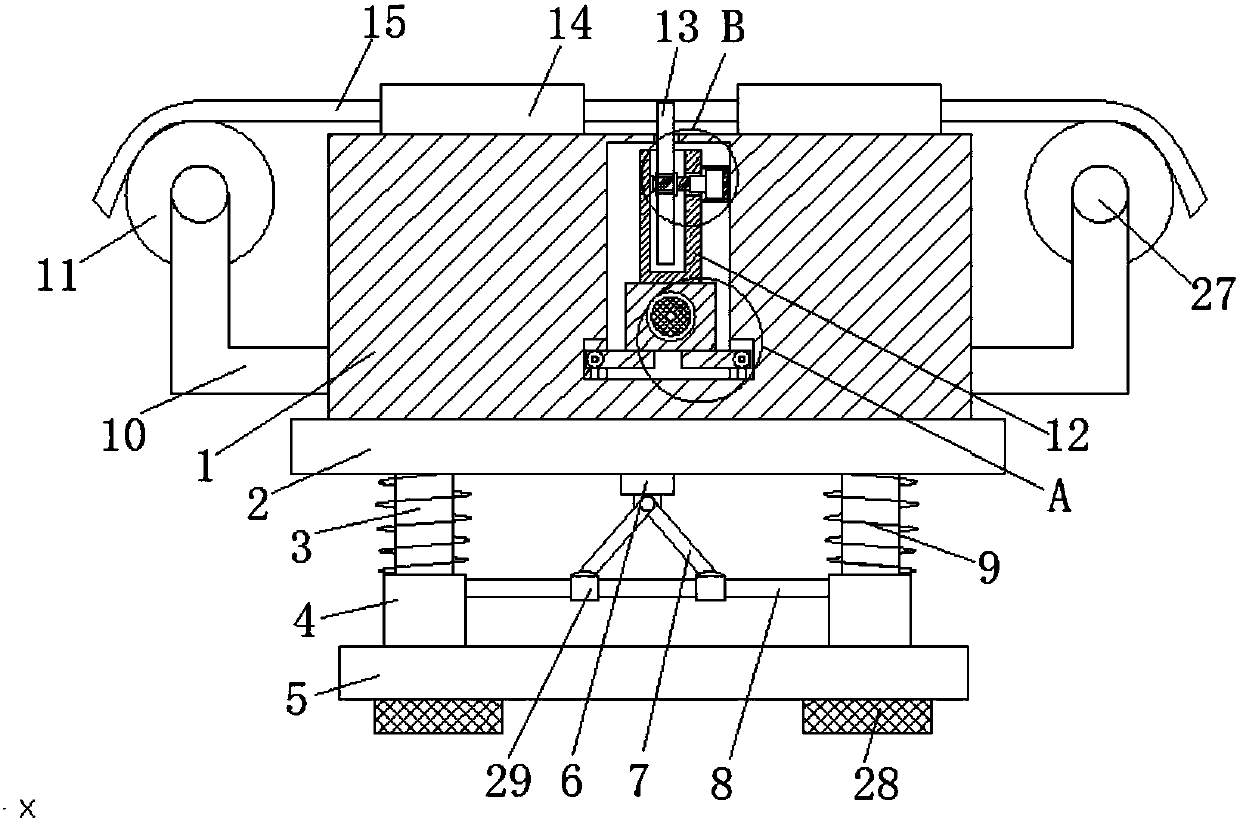

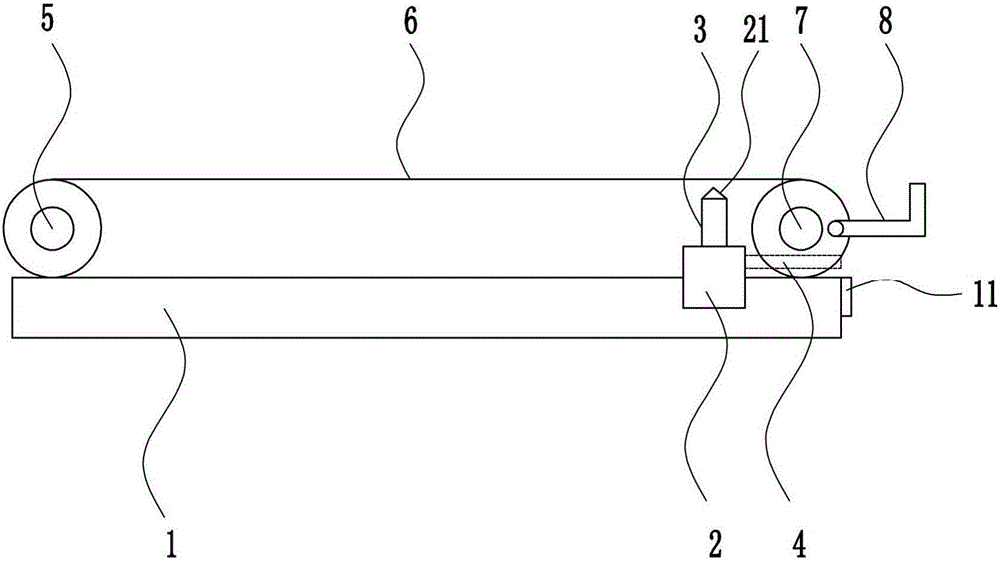

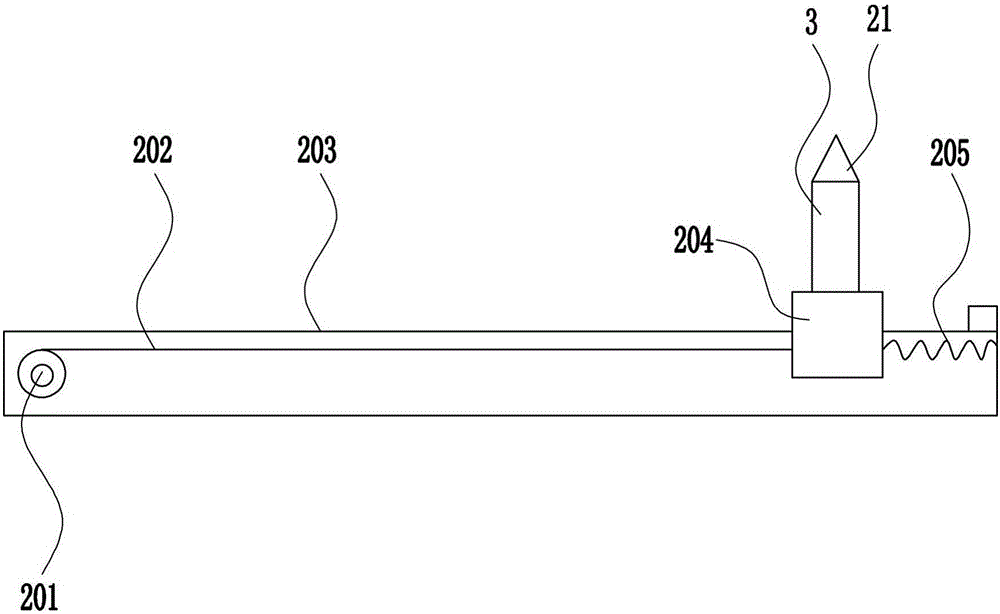

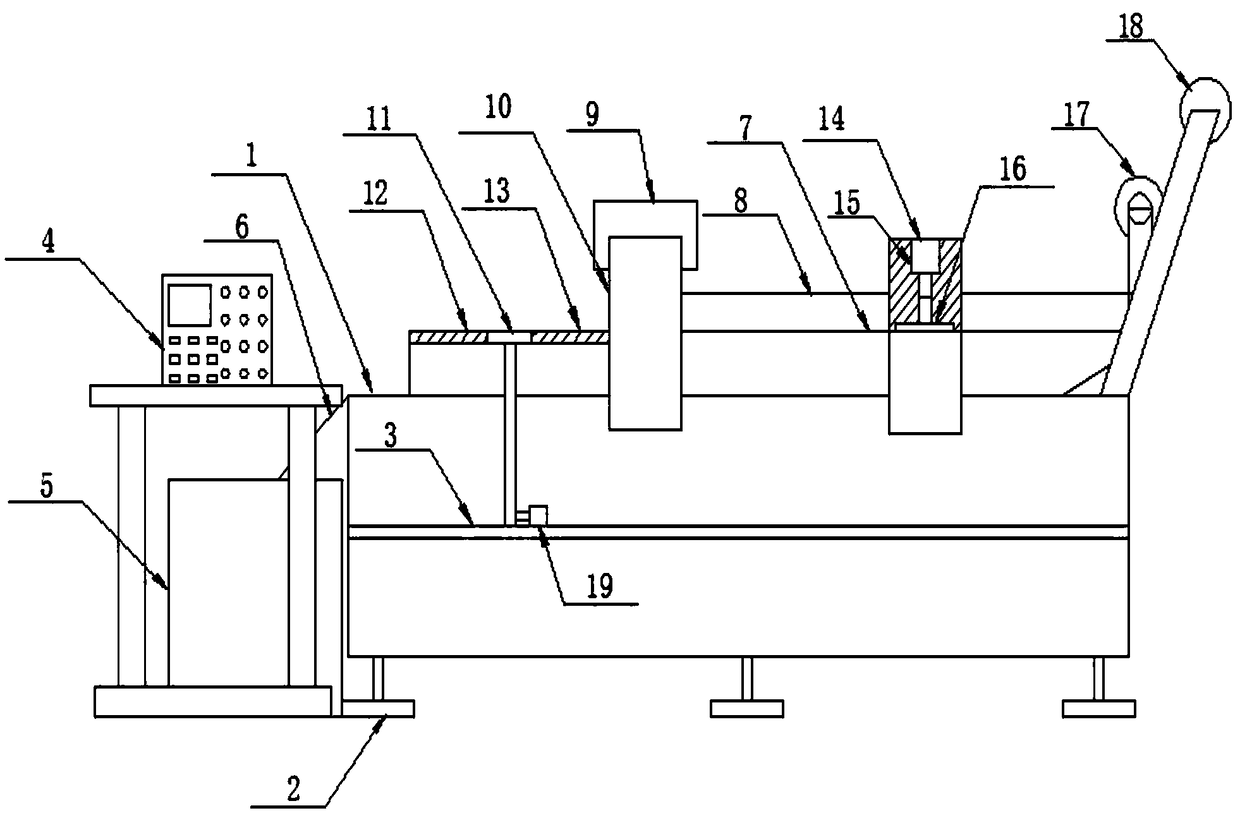

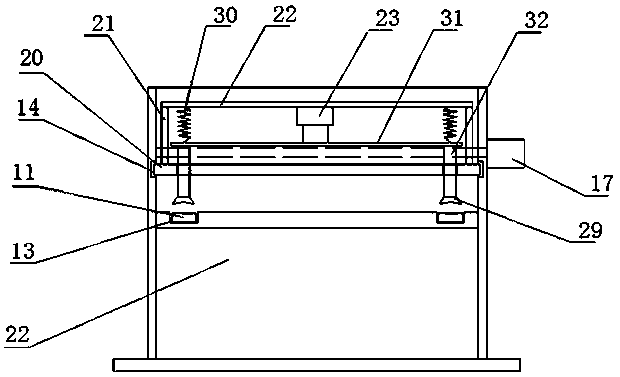

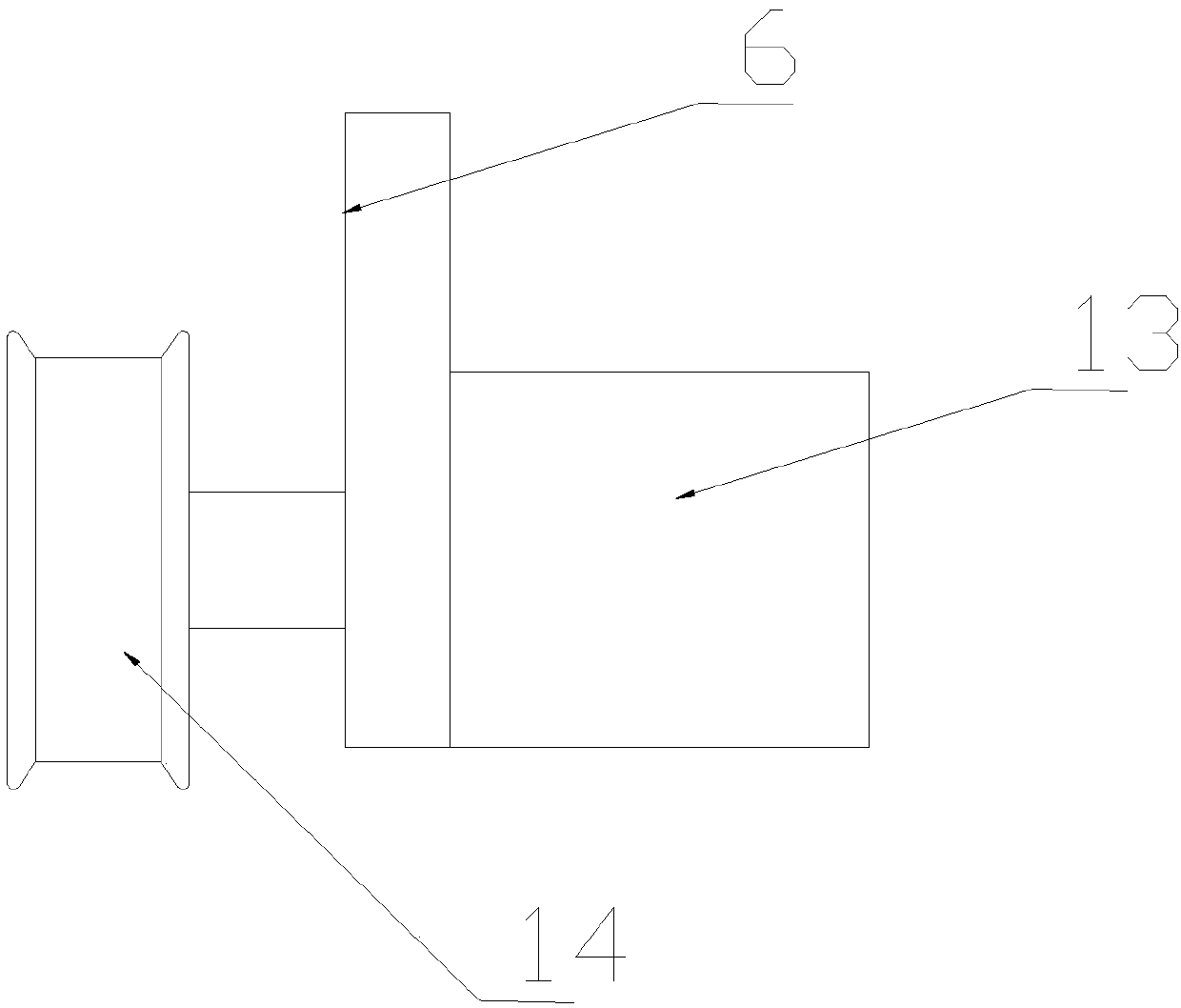

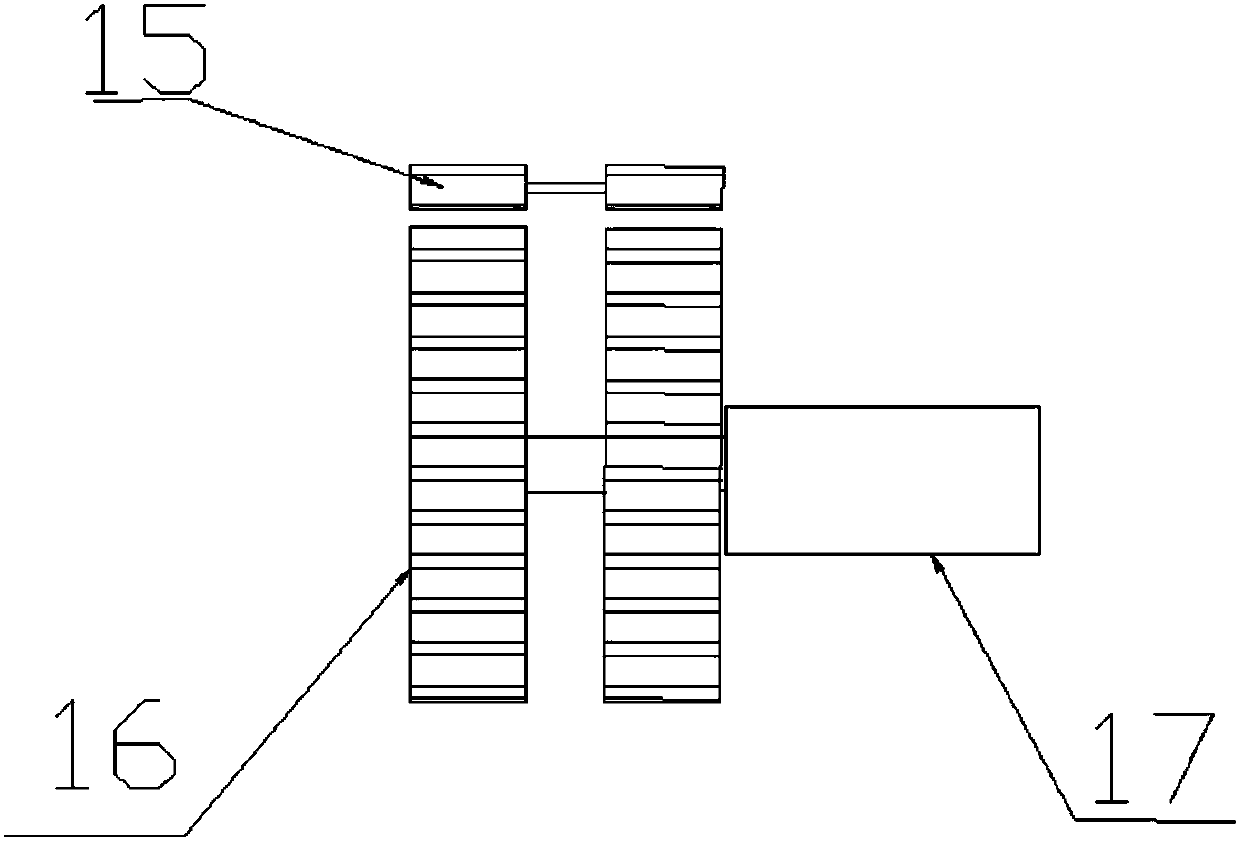

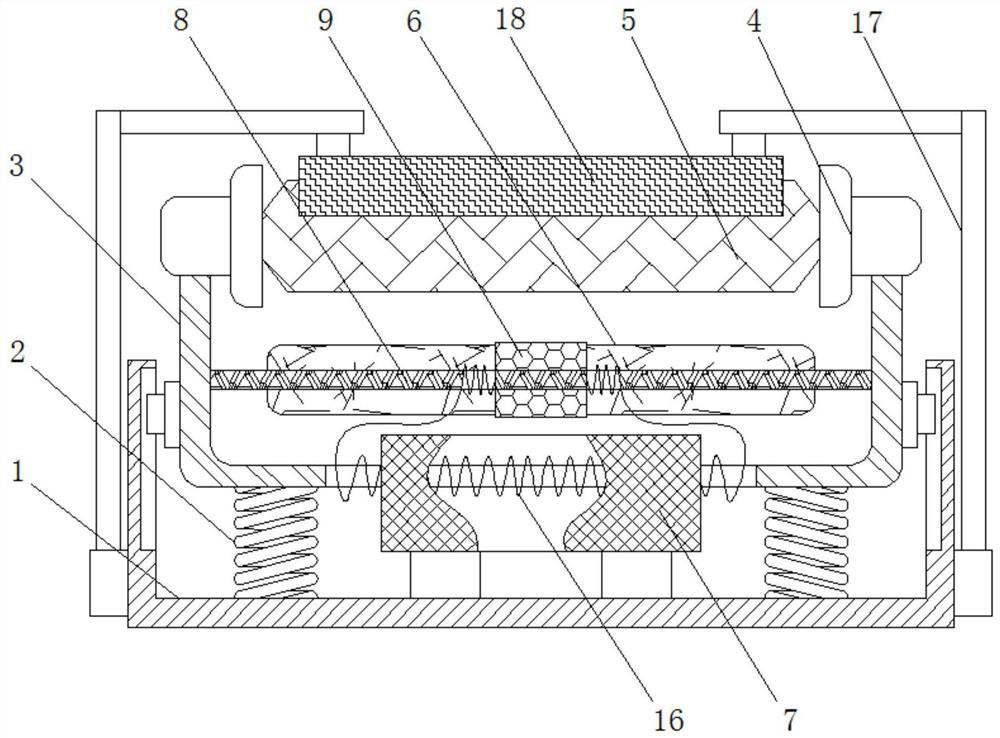

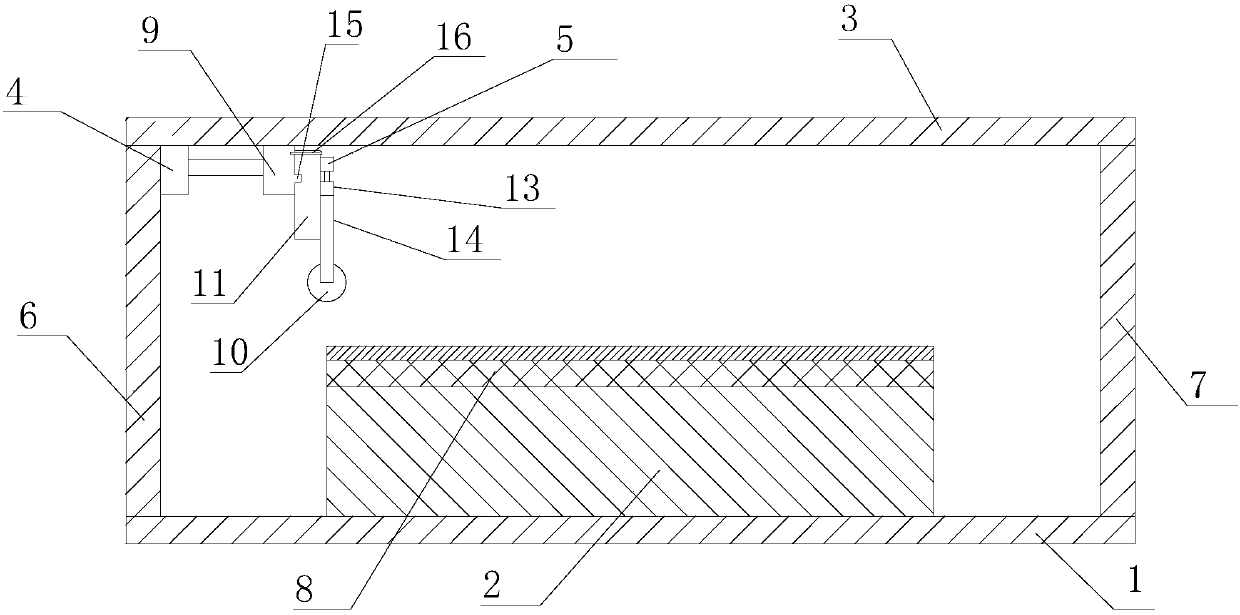

The invention discloses a corrugated paper cutting device. The corrugated paper cutting device comprises a support, a conveying plate, a driving mechanism, a controller, a cutting mechanism, a first pressing and holding mechanism and a second pressing and holding mechanism. Guide rails are arranged on the support. The conveying plate is movably mounted on the guide rails. A plurality of grooves are formed in the conveying plate at intervals and are sequentially arranged in the length direction of the guide rails. The length direction of the grooves is perpendicular to or obliquely crosses with the length direction of the guide rails. The driving mechanism is used for driving the conveying plate to move in the length direction of the guide rails. The driving mechanism is in communication connection with the controller. The cutting mechanism is used for cutting corrugated paper and comprises a driving unit and a blade. The driving unit drives the blade to move close to the grooves or far from the grooves. The corrugated paper cutting device is simple in structure and good in corrugated paper cutting effect.

Owner:BENGBU ZHENHUA PACKING MACHINERY

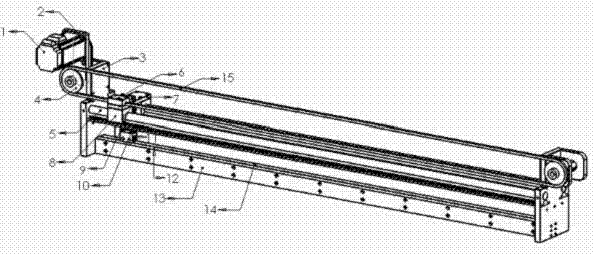

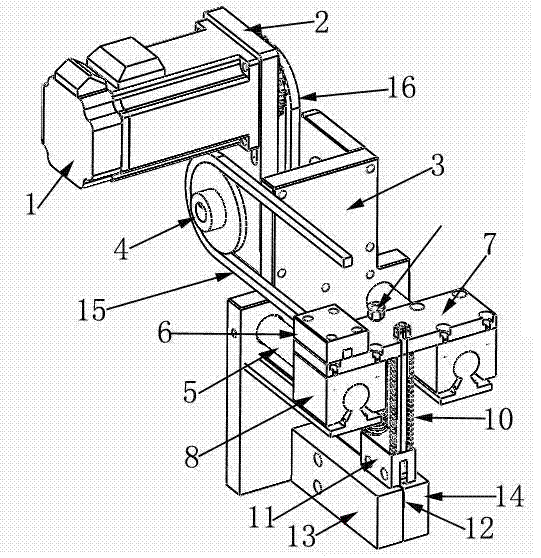

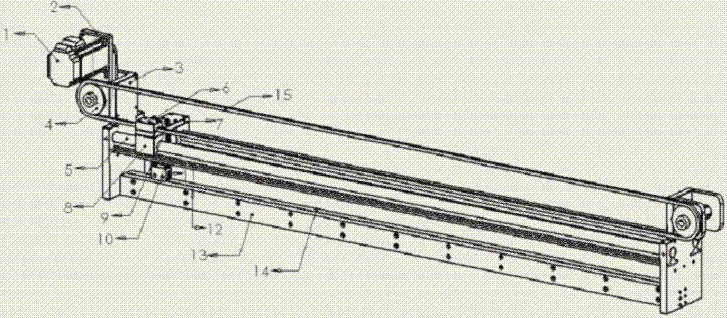

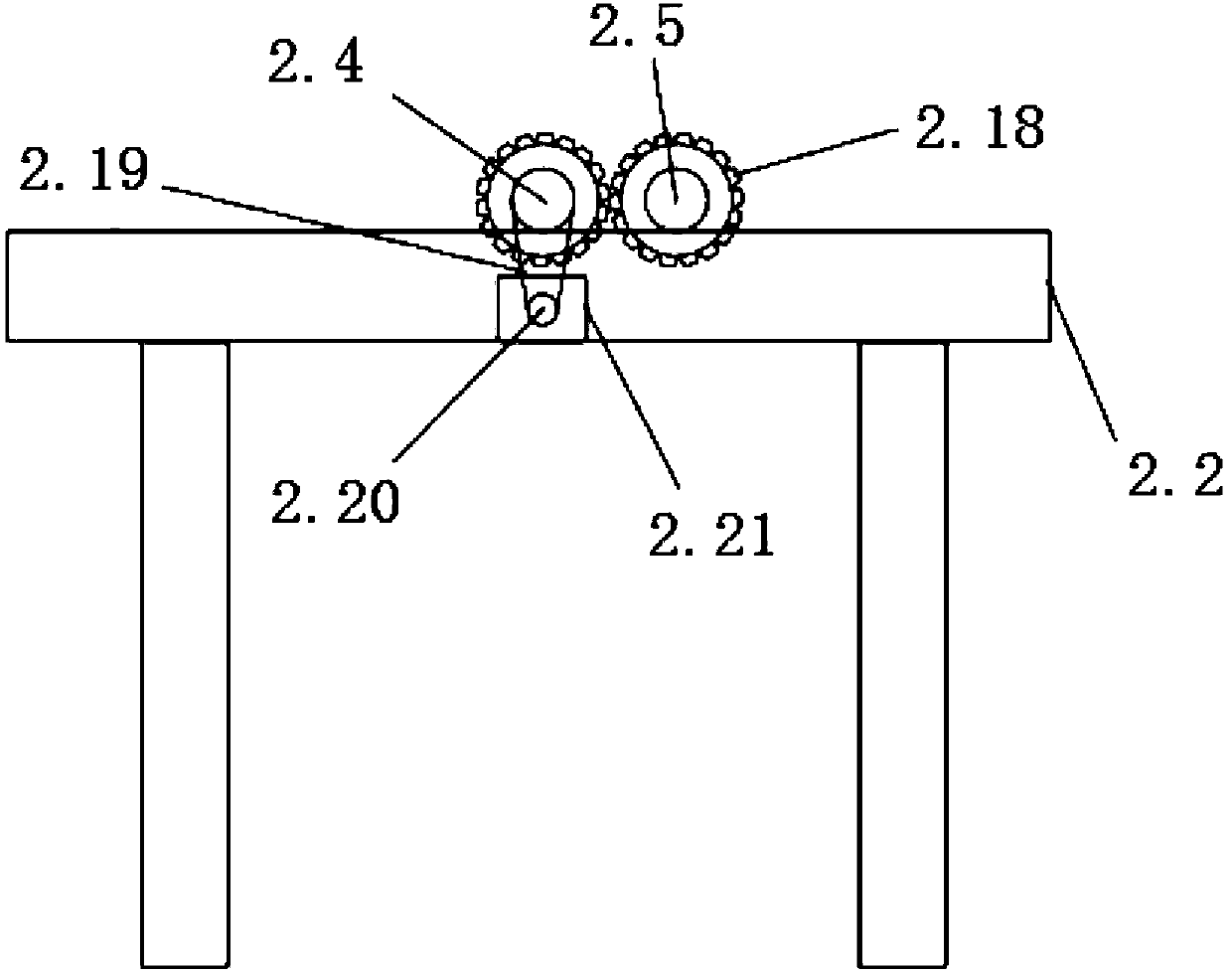

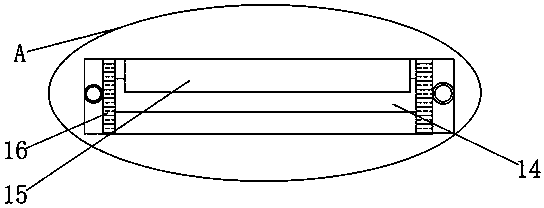

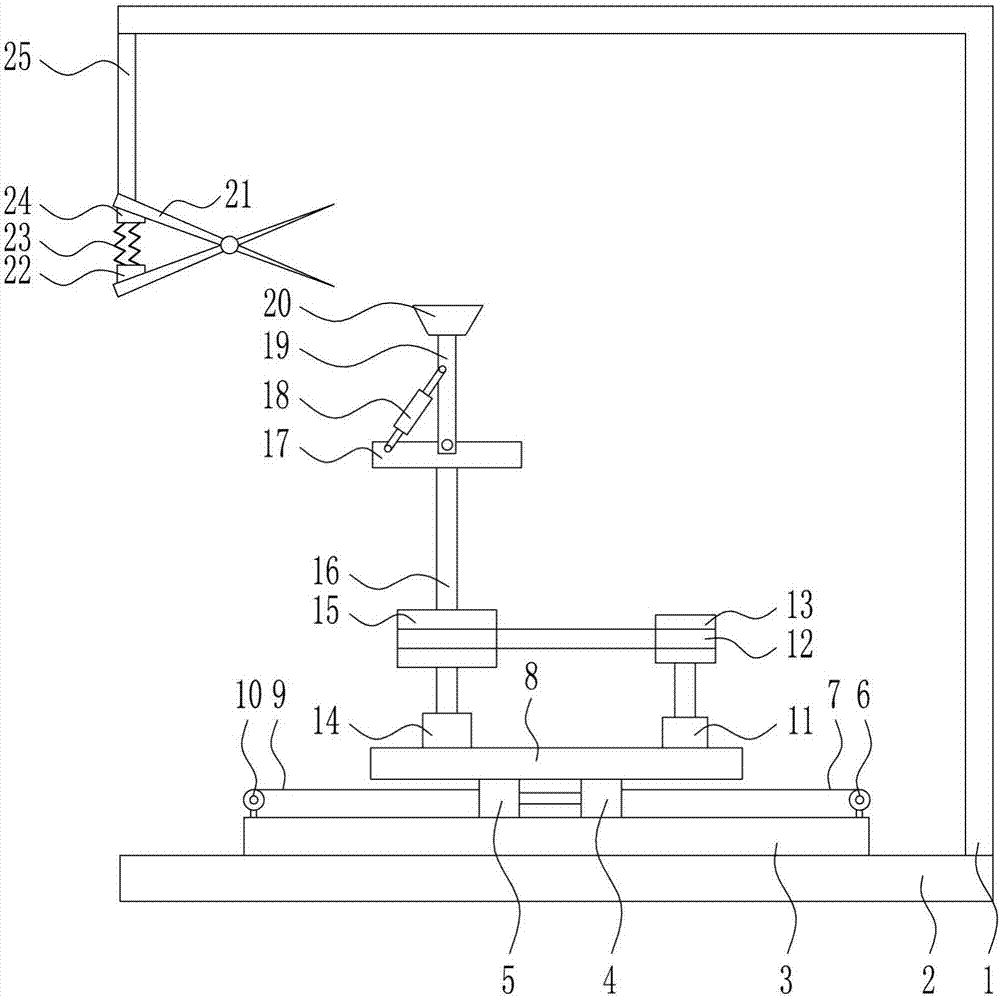

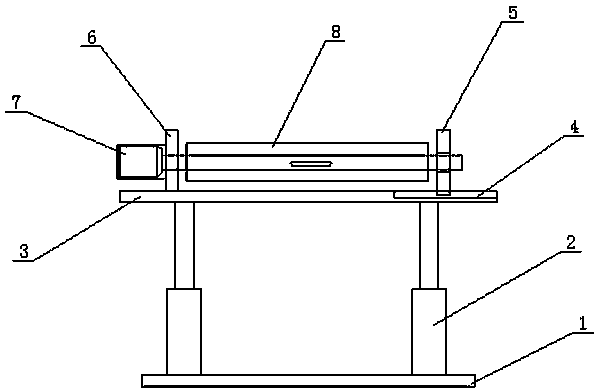

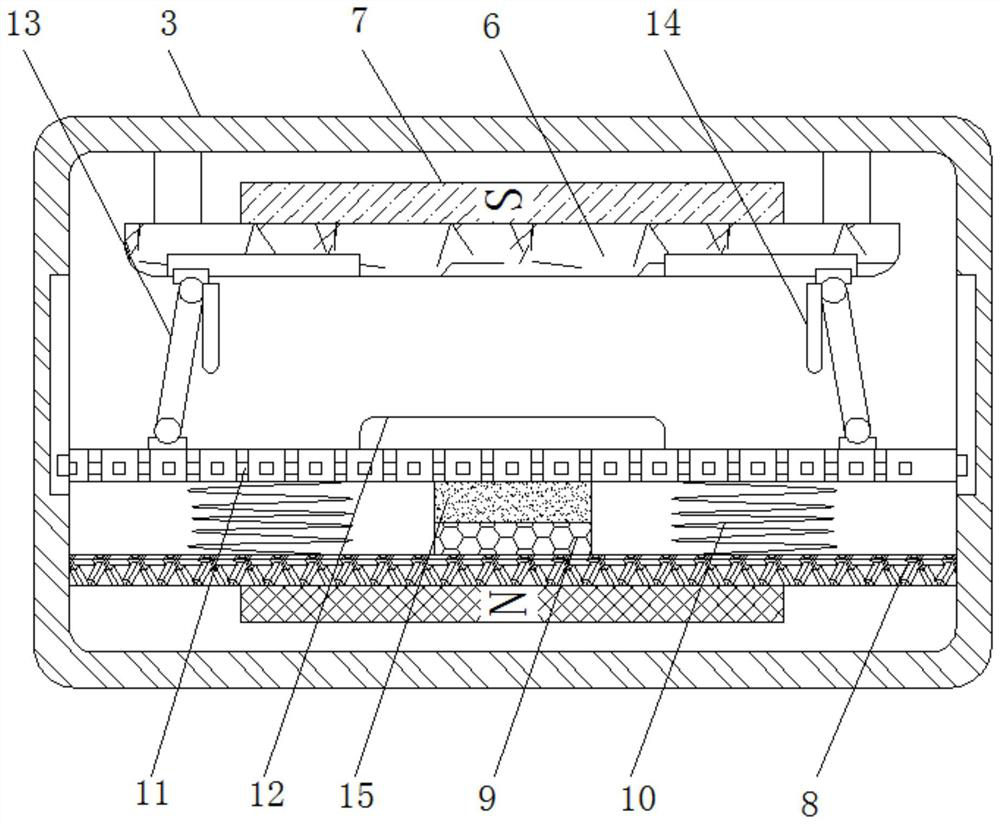

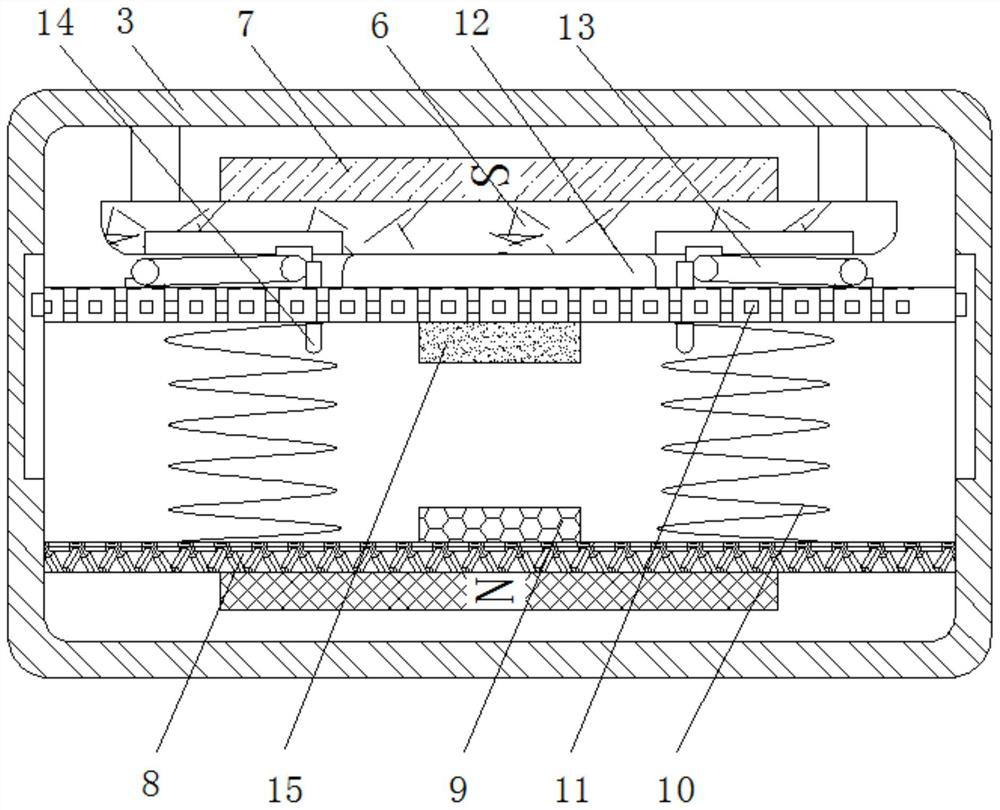

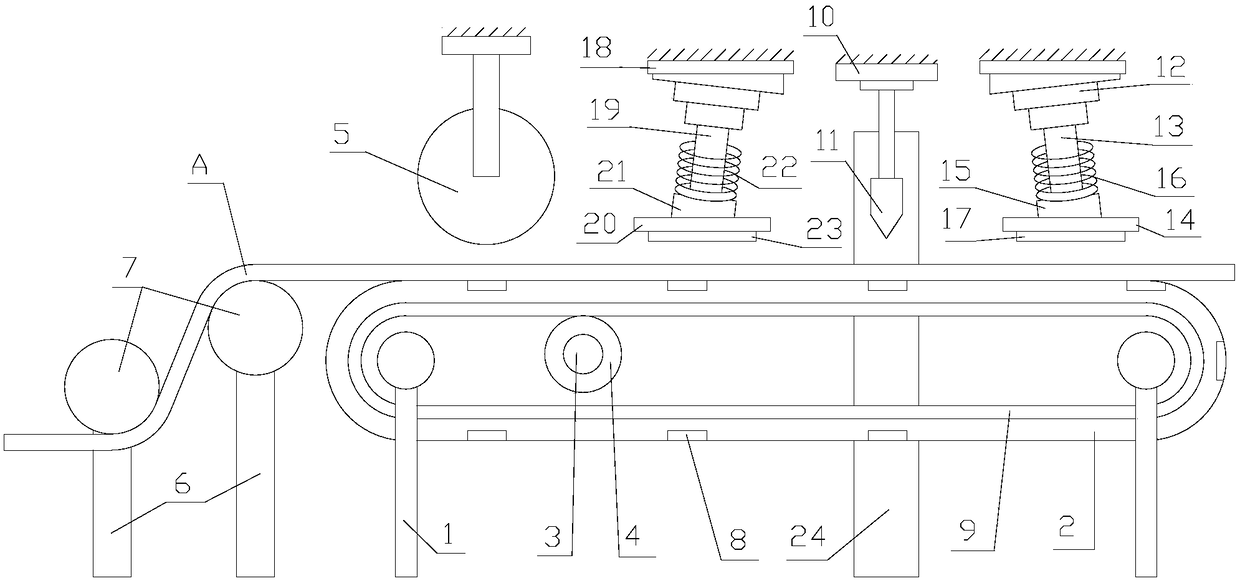

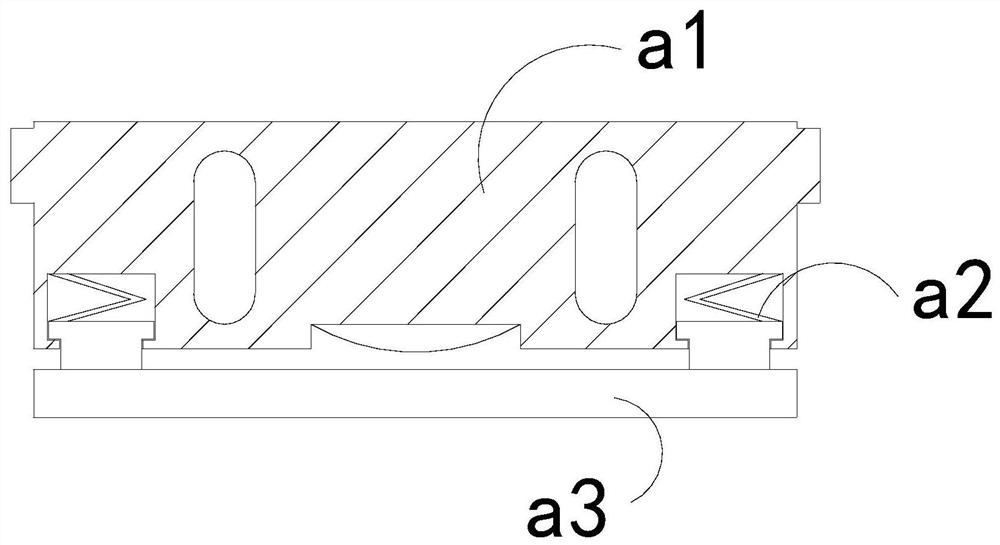

Paperboard cutting and processing equipment

ActiveCN105922331APrevent deviationGuarantee subsequent processing accuracyMetal working apparatusPaperboardEngineering

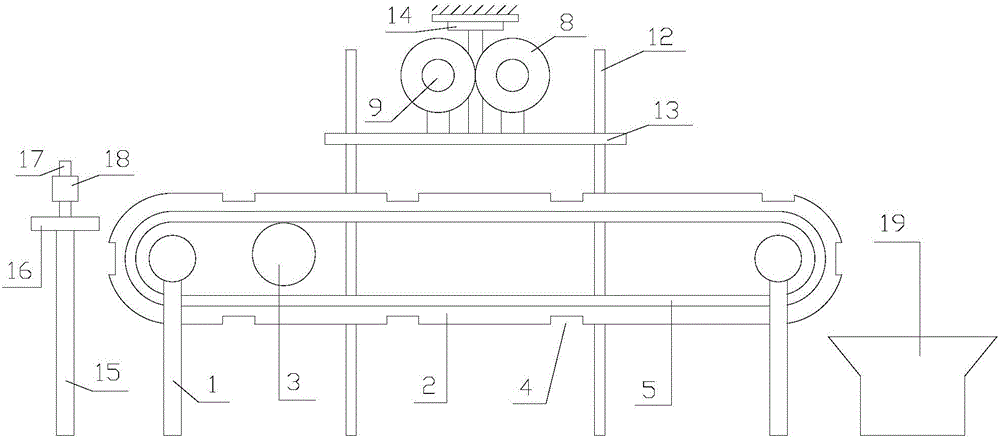

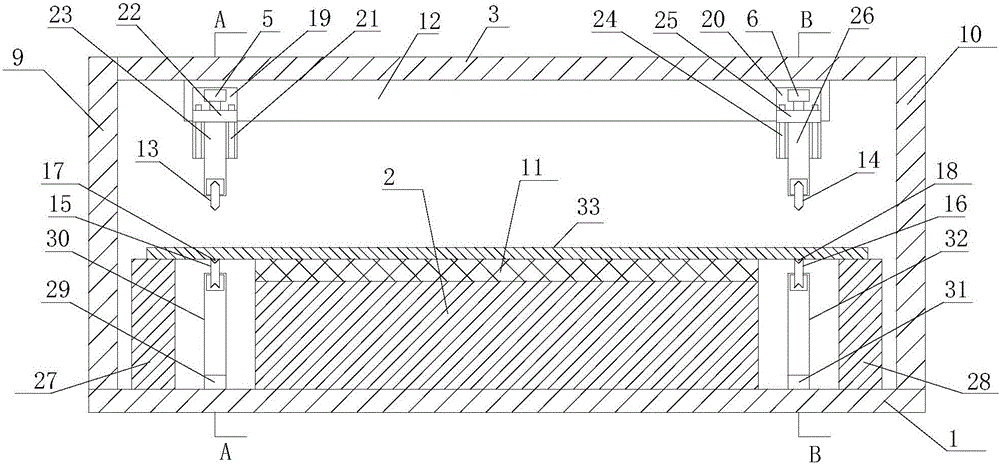

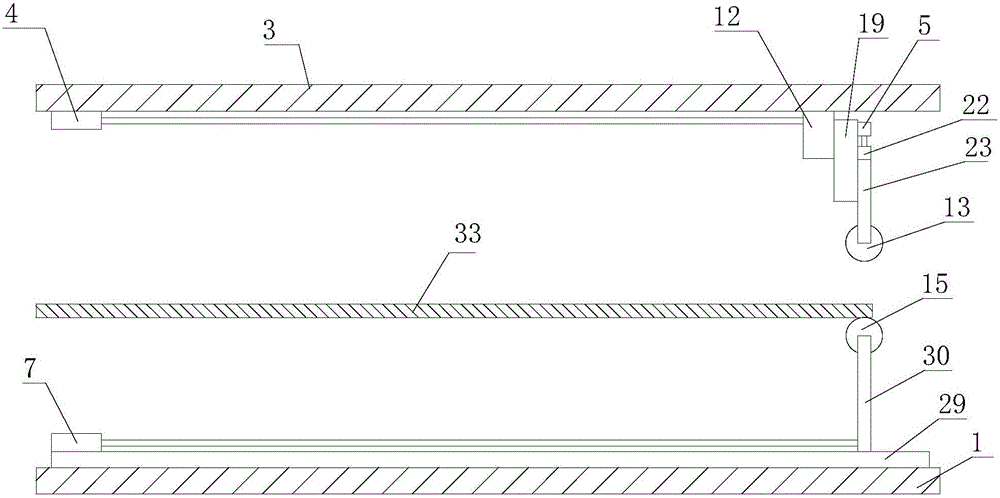

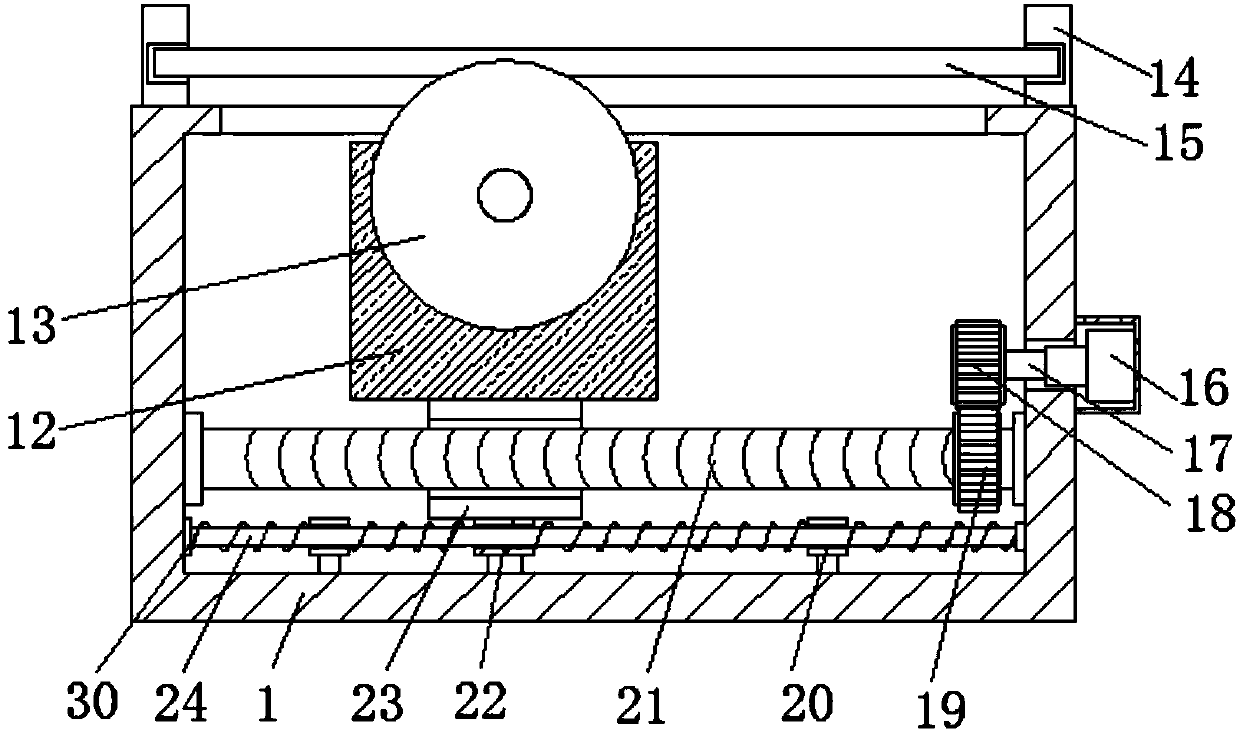

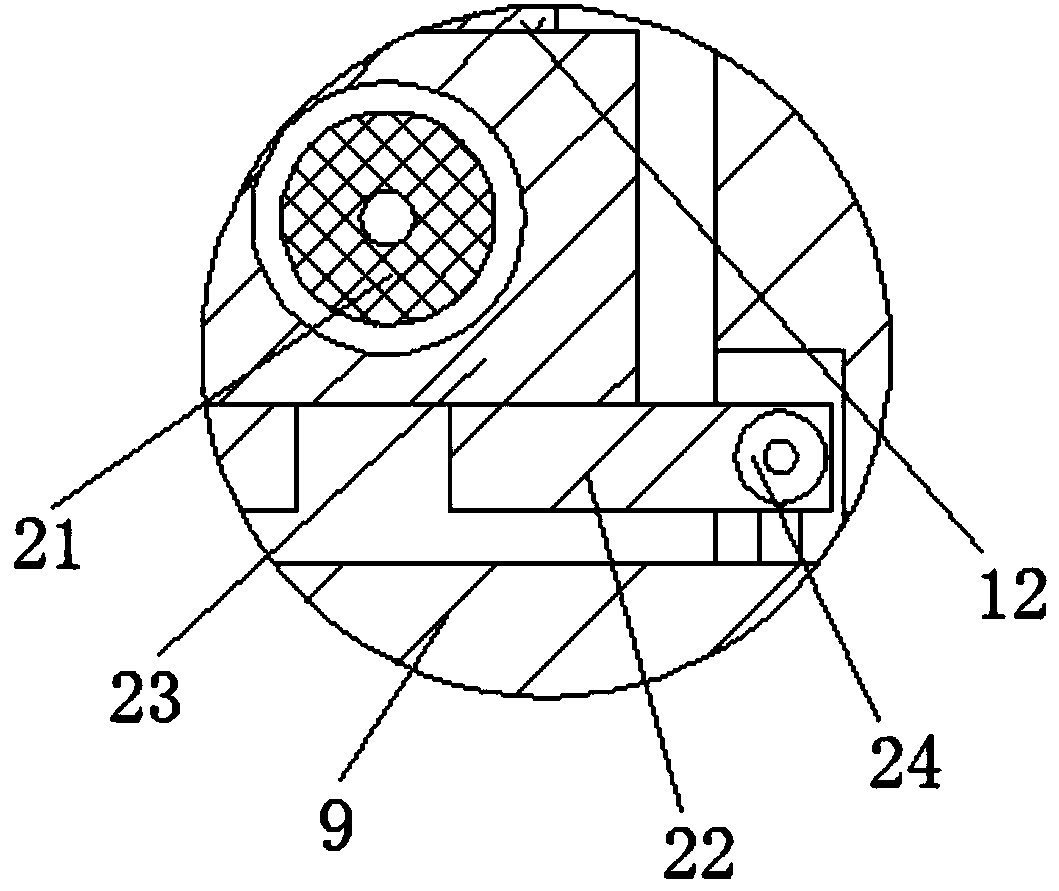

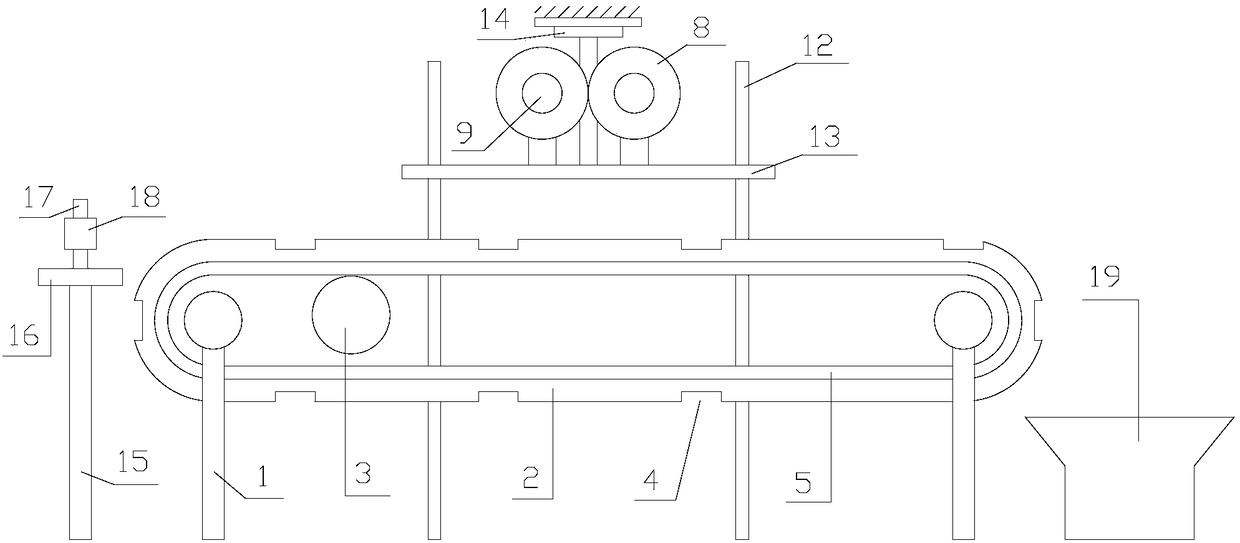

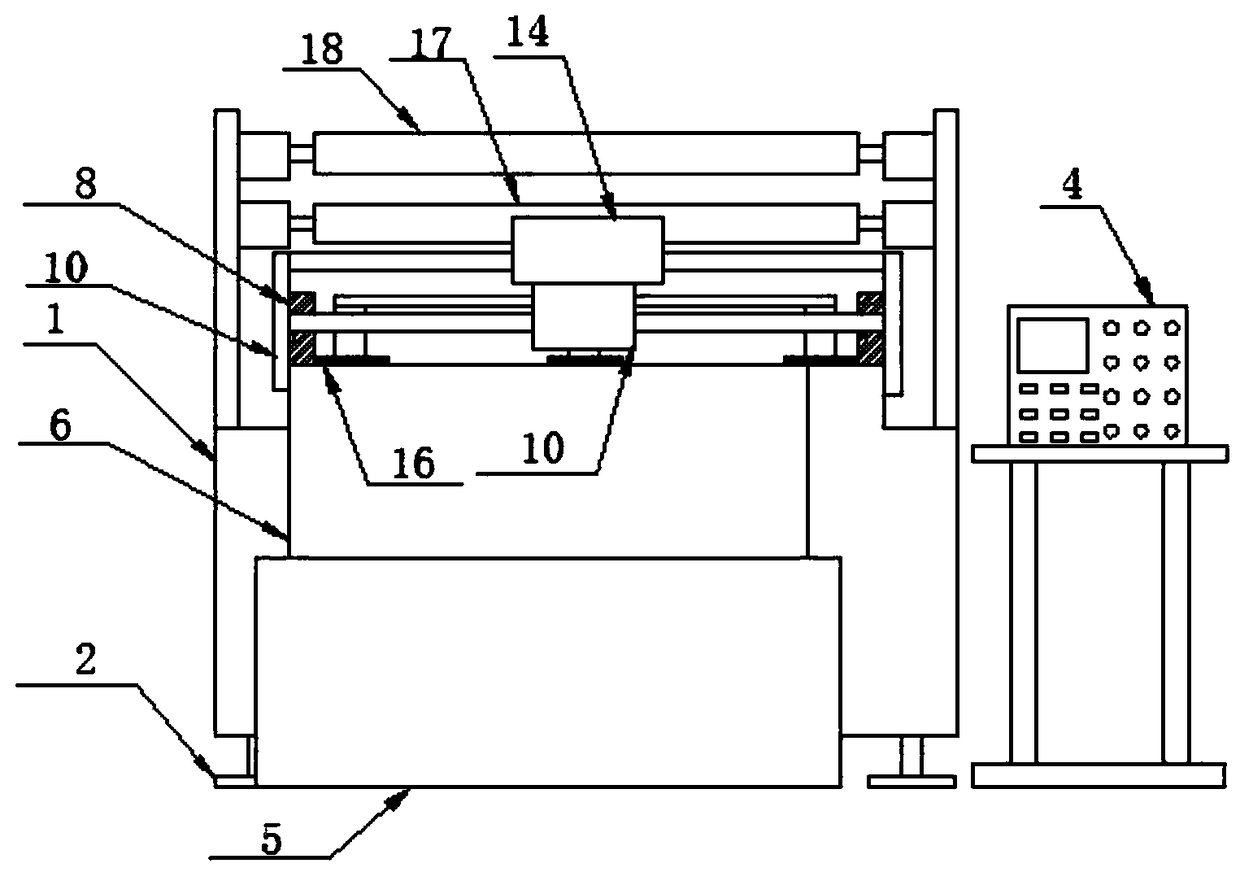

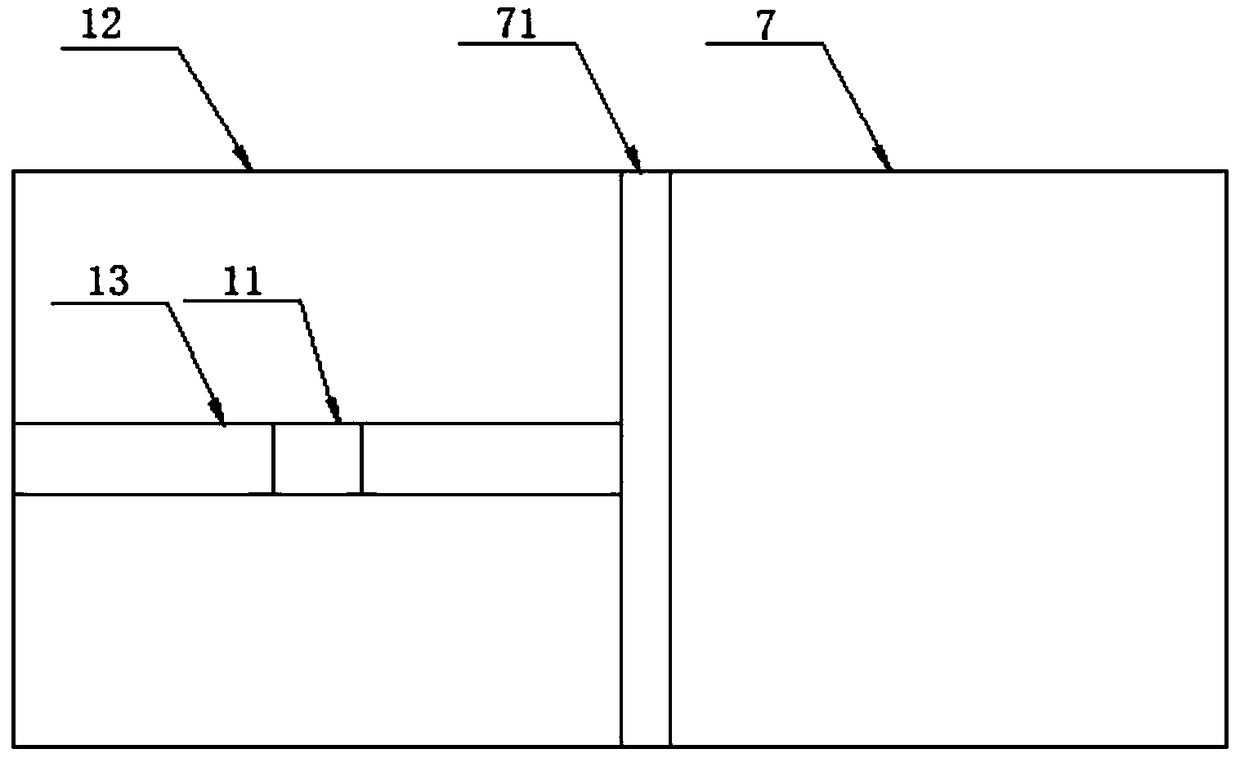

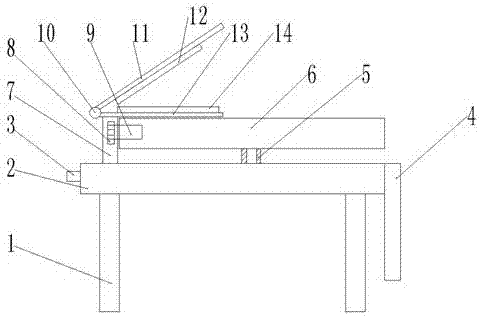

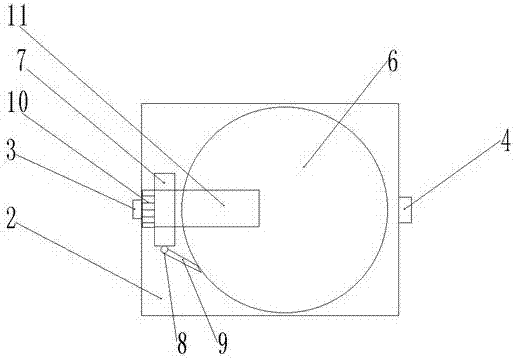

The invention discloses paperboard cutting and processing equipment. The equipment comprises a mounting frame, a conveyor belt, a rotary shaft, a first driving unit, a cutting part and a pressing and holding part. The conveyor belt is mounted on the mounting frame. The upper surface of the conveyor belt is provided with a plurality of accommodating grooves which are evenly distributed in the length direction of the conveyor belt. The length direction of the accommodating grooves is perpendicular to the length direction of the conveyor belt. The lower surface of the conveyor belt is provided with first gears which are distributed in the length direction of the conveyor belt. The rotary shaft is rotatably mounted on the mounting frame. One end of the rotary shaft is arranged in a space defined by the conveyor belt. The local peripheral surface of the rotary shaft is provided with second gears which are distributed in the circumferential direction of the rotary shaft. The second gears are engaged with the first gears. The first driving unit is used for driving the rotary shaft to rotate. The cutting part is used for cutting paperboards and comprises a second driving unit and a blade. The second driving unit is used for driving the blade to move close to the accommodating grooves or far from the accommodating grooves. The paperboard cutting and processing equipment is good in paperboard cutting effect.

Owner:BENGBU ZHENHUA PACKING MACHINERY

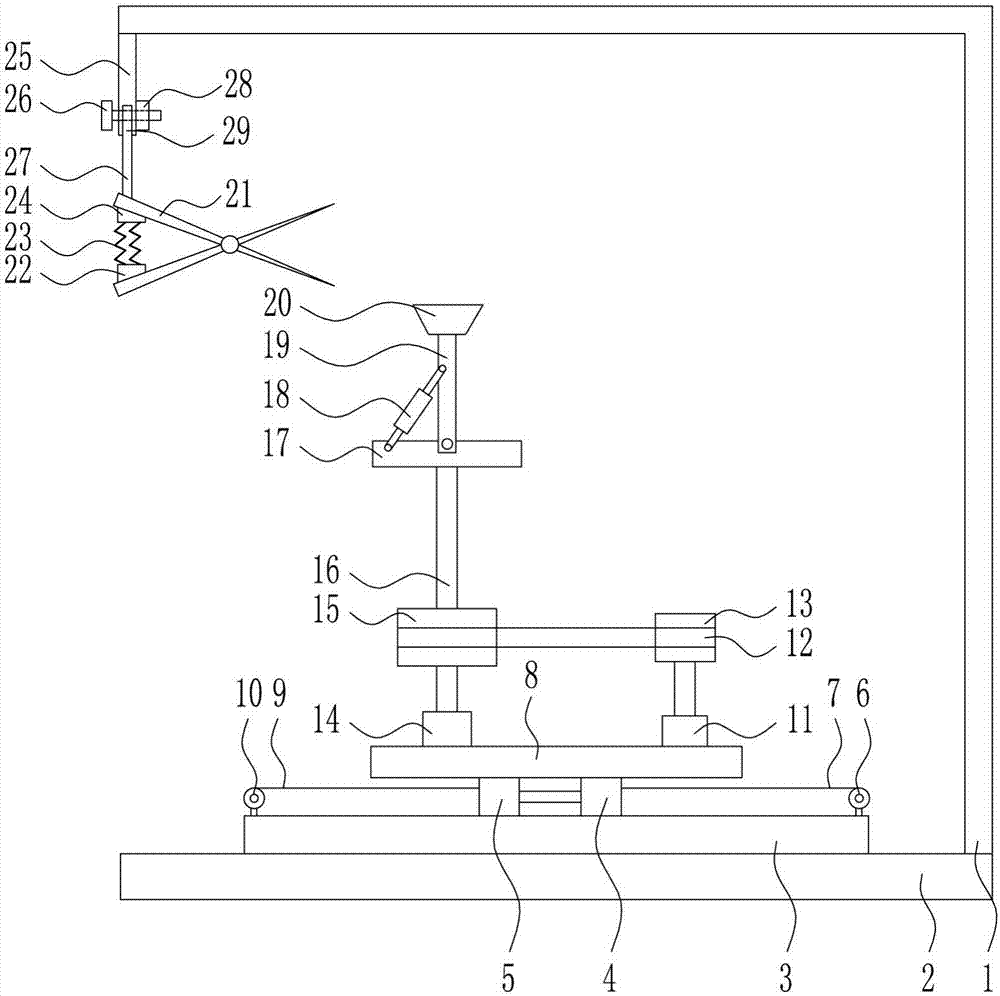

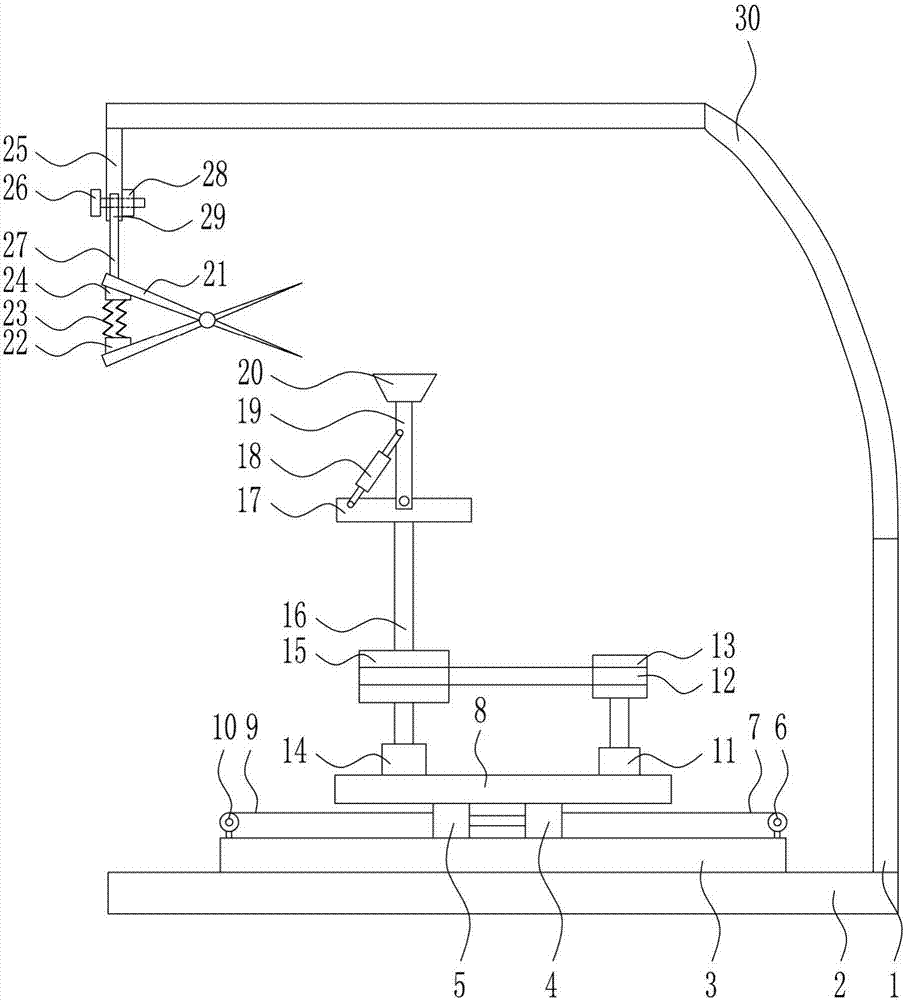

Continuous type printing paperboard clipping processing equipment

ActiveCN106003824AGuaranteed flat and perfectImprove cropping accuracyPaper-makingBox making operationsPaperboardEngineering

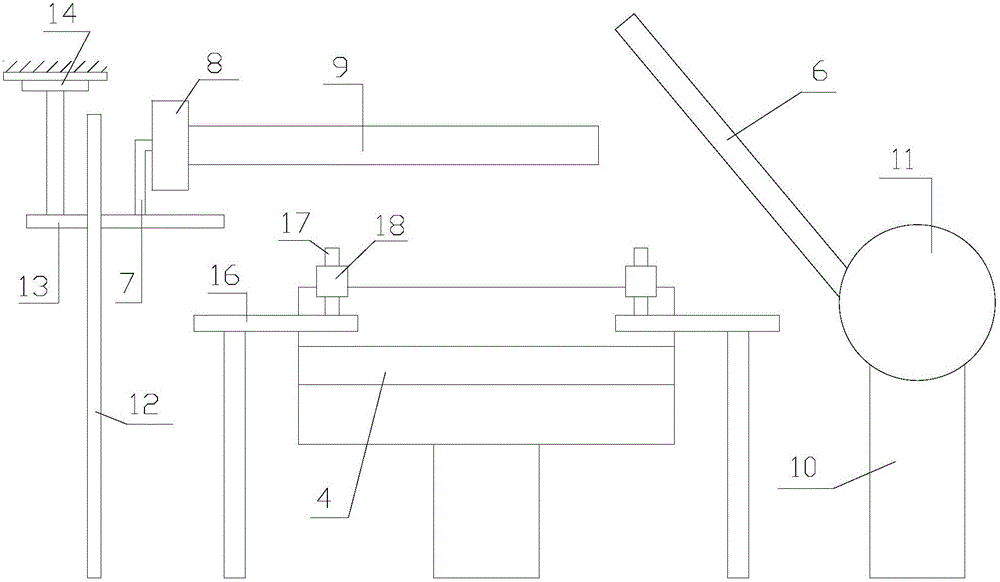

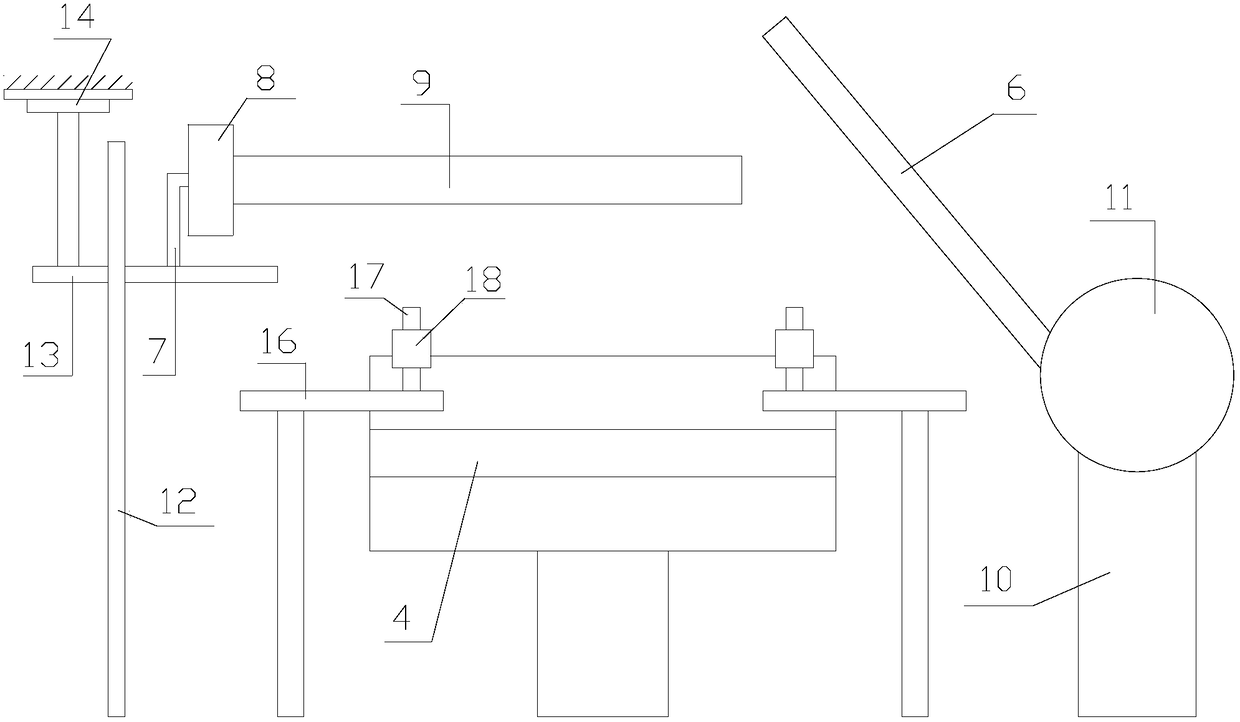

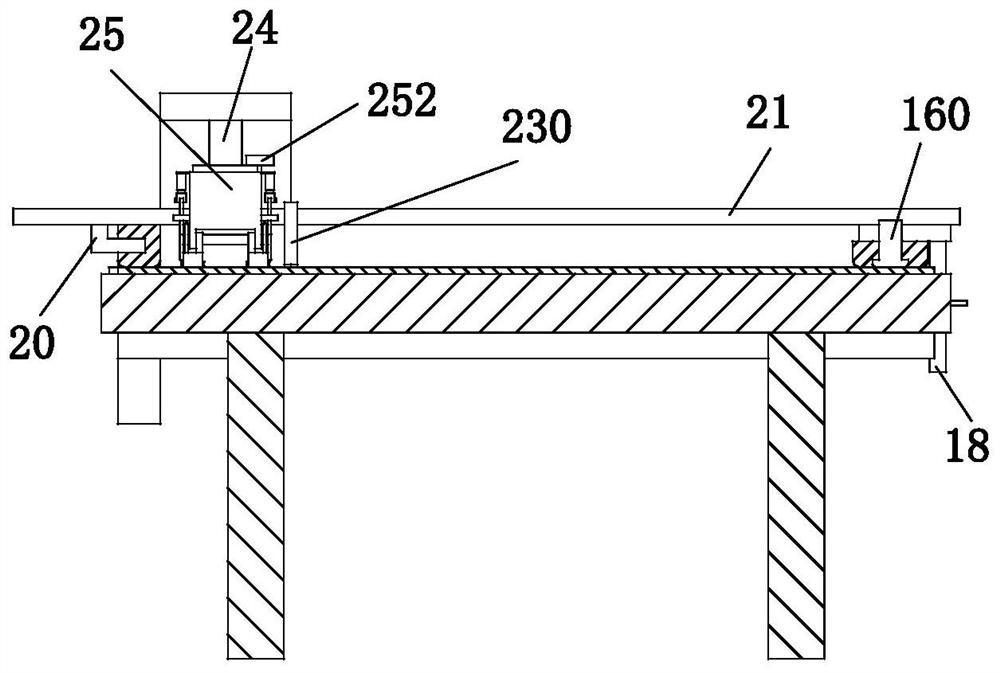

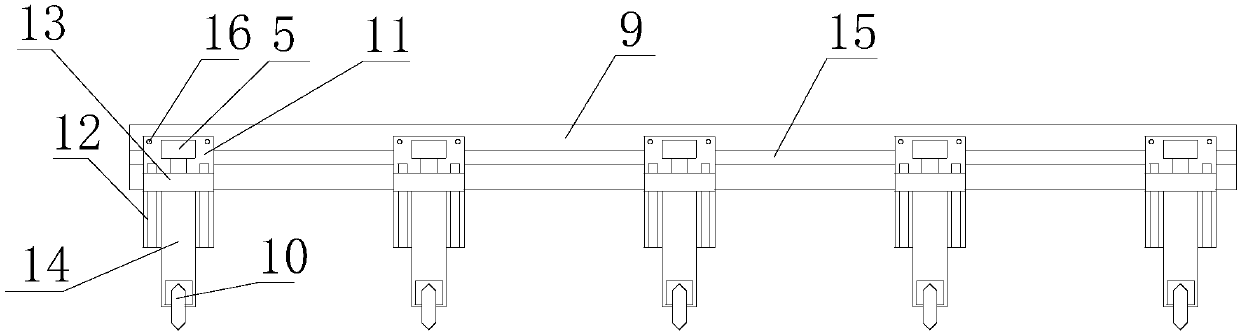

The invention discloses continuous type printing paperboard clipping processing equipment. The continuous type printing paperboard clipping processing equipment comprises a base, a worktable, a first driving mechanism, a mounting frame, a clipping mechanism, a second driving mechanism, third driving mechanisms, a monitor and a control mechanism; a conveying roller group is arranged on the worktable; a detection station is arranged at a discharging end of the conveying roller group; the clipping mechanism comprises a movable plate and a plurality of cutting knives, wherein the movable plate is movably mounted on the mounting frame and is parallel to the base; the movable plate is arranged in the conveying direction of the conveying roller group; in the conveying direction of the conveying roller group, the cutting knives are arranged in parallel on the movable plate; the monitor is used for monitoring whether the paperboard reaches the detection station; the control mechanism is connected with the first driving mechanism, the second driving mechanism, the plurality of third driving mechanisms and the monitor and is used for controlling the first driving mechanism, the second driving mechanism, the third driving mechanisms and the monitor to act. The continuous type printing paperboard clipping processing equipment disclosed by the invention is high in clipping precision, fast in clipping speed and high in processing efficiency; and a clipped paperboard is discharged in time and is fed to the conveying roller group in time, thereby realizing continuous processing of the paperboard.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

Automatic edge cutting equipment for paperboard processing

ActiveCN105799214AGuaranteed flat and perfectImprove trimming accuracyBox making operationsPaper-makingPaperboardEngineering

The invention provides automatic edge cutting equipment for paperboard processing. The automatic edge cutting equipment comprises a base, a workbench, a mounting plate, an edge cutting mechanism, a first driving mechanism, a second driving mechanism, a third driving mechanism, a fourth driving mechanism, a fifth driving mechanism, a sixth driving mechanism, a monitor and a control mechanism, wherein a conveying roller group for conveying a paperboard is arranged between the material feeding end and the material discharging end of the workbench; the edge cutting mechanism comprises a mobile plate, a first edge cutter, a second edge cutter, a first supporting wheel and a second supporting wheel; the projection, on the base, of the first edge cutter is overlapped with the first supporting wheel; the projection, on the base, of the second edge cutter is overlapped with the second supporting wheel; the control mechanism is connected with and controls the actions of the first driving mechanism, the second driving mechanism, the third driving mechanism, the fourth driving mechanism, the fifth driving mechanism, the sixth driving mechanism and the monitor. The automatic edge cutting equipment is high in edge cutting precision and high in cutting speed; during processing, the automatic edge cutting equipment is high in processing efficiency.

Owner:安徽中天电器有限公司

Intelligent cloth cutting system and method

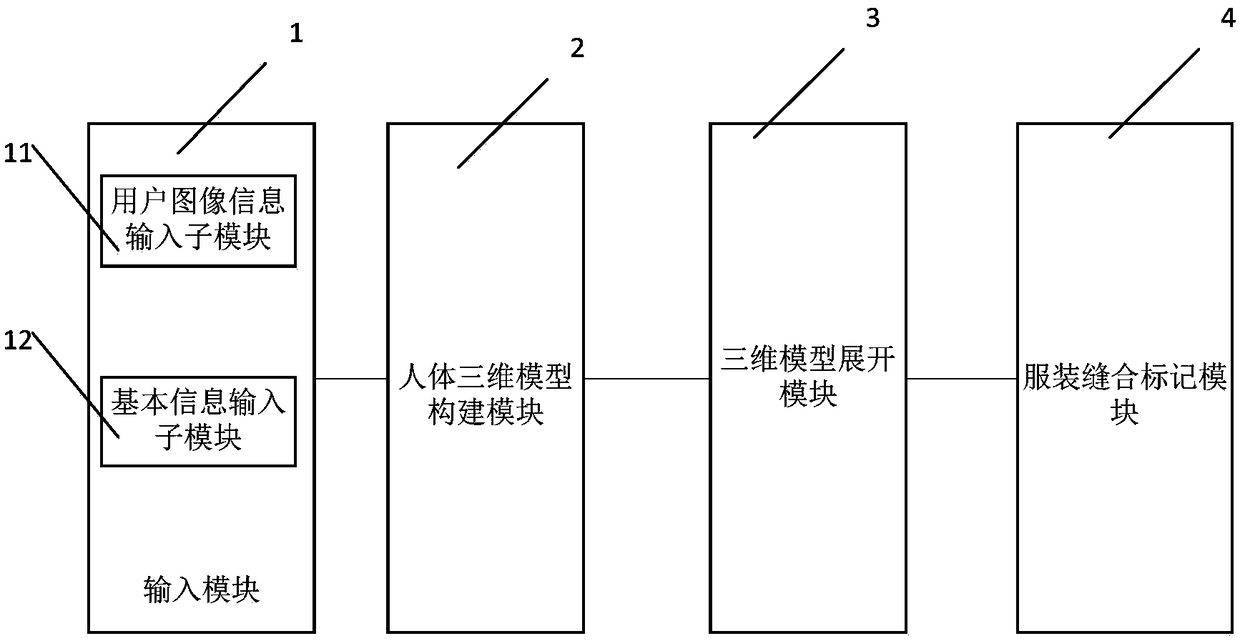

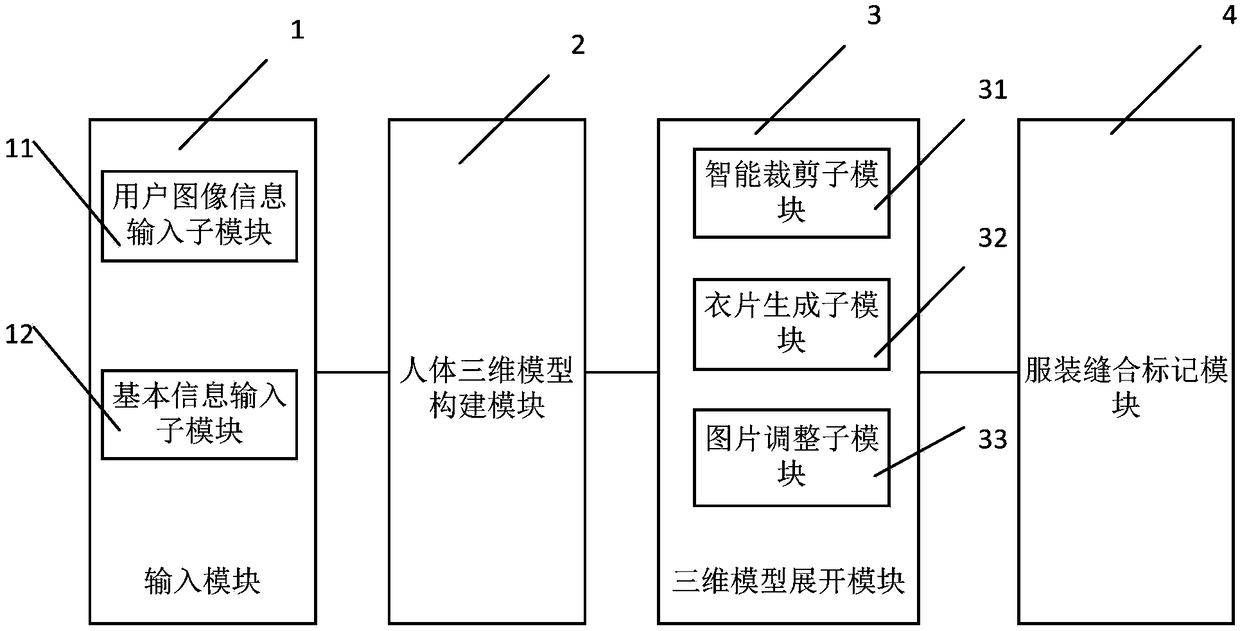

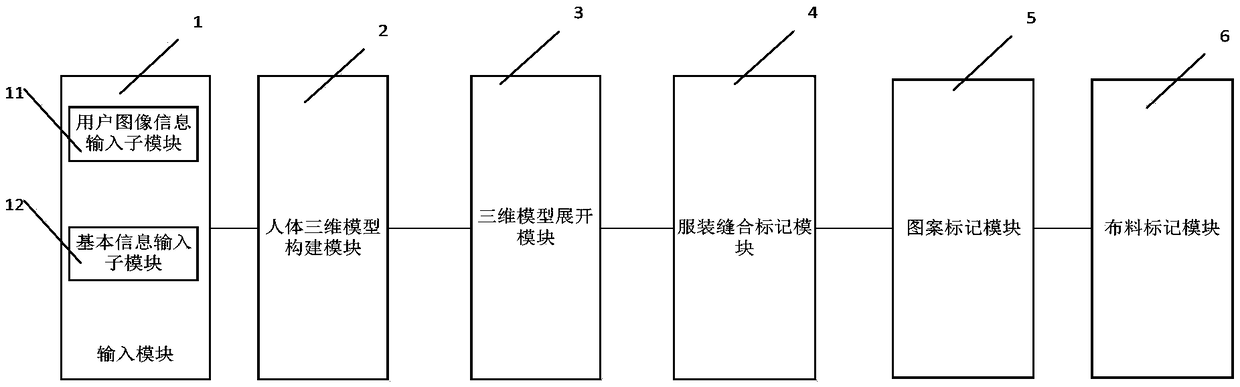

InactiveCN108876913AFor precise cuttingFast croppingImage analysisGeometric image transformationHuman bodyComputer module

The invention discloses an intelligent cloth cutting system comprising an input module, a human body three-dimensional model building module, a three-dimensional model unfolding module and a cloth sewing marking module, wherein the human body three-dimensional model building module is used for building a human body three-dimensional model of a user according to body size information of the user; the three-dimensional model unfolding module is used for cutting and unfolding the human body three-dimensional model according to cutting design of a cloth sample selected by the user, and generatinga two-dimensional cloth cutting and unfolding image which is the same as the design of the cloth sample and matches the body size of the user; the cloth sewing marking module is used for marking cutting lines, cutting and sewing lines, accessories and splicing positions of accessories on the two-dimensional cloth cutting and unfolding image. According to the intelligent cloth cutting system and the method, the two-dimensional cloth cutting and unfolding image can be accurately obtained according to human body three-dimensional model data of the user, clothing factory can cut a cloth sheet according to the two-dimensional cutting and unfolding image, sew cloth according to the sewing lines, thereby clothing efficiency can be improved, sewn cloth is matched with the body size of the user, and effect of cutting cloth to fit the body size can be achieved.

Owner:天门市志远信息科技有限公司

Novel spinning cloth cutting device

The invention discloses a novel spinning cloth cutting device which comprises a workbench. A bearing plate is fixedly connected to the lower end of the workbench, two buffer mechanisms are fixedly connected to the lower end of the bearing plate, the lower ends of the two buffer mechanisms are fixedly connected with a base plate, supporting rods are fixedly connected to the side walls of the two buffer mechanisms, a fixing block is fixedly connected to the lower end of the bearing plate, a sliding mechanism is rotationally connected to the fixing block, the sliding mechanism is connected to thesupporting rod in a sliding mode, a placement groove is formed inside the workbench, a threaded rod is rotationally connected to the interior of the placement groove, the side wall of one end of thethreaded rod is fixedly sleeved with a first gear, and a first driving device is fixedly connected to the side wall of the workbench. The novel spinning cloth cutting device is simple in structure andconvenient to operate, the manufacturing cost is lowered, the production efficiency is improved, the automatic efficiency is high, the workload of operators is relieved, the cutting speed is high, the quality is high, and the using effect is quite good.

Owner:肇庆市高要区同彩服饰有限公司

Method and device for displaying any cross section of geometric body, and electronic device

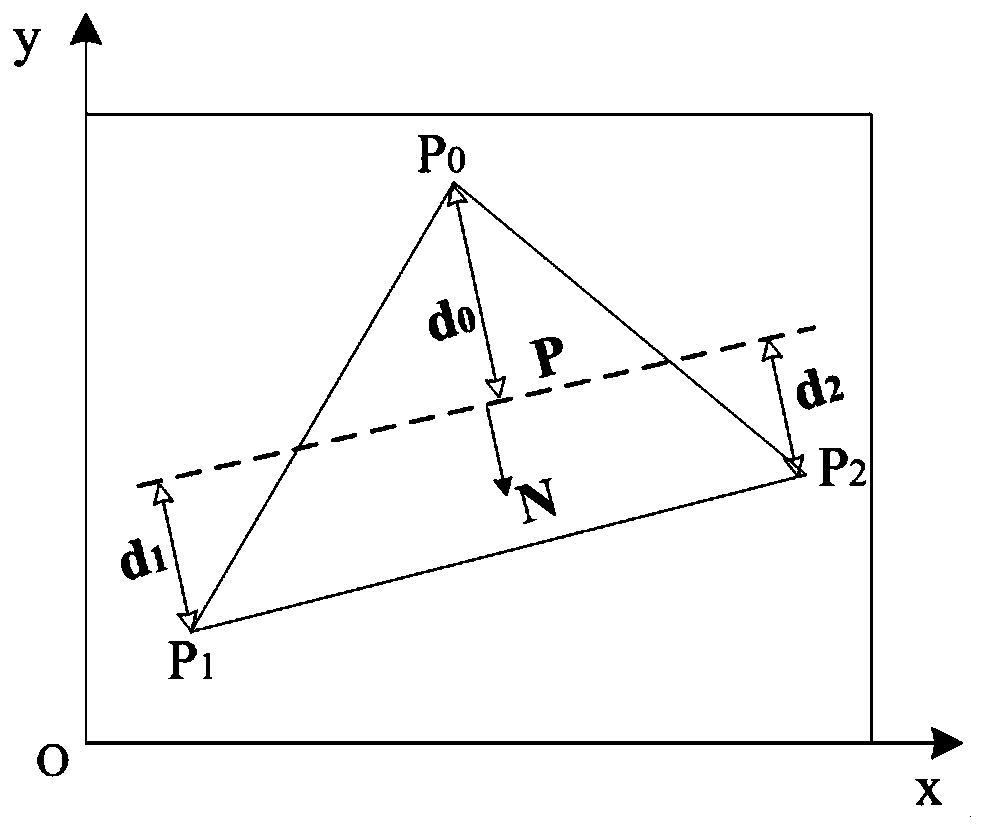

ActiveCN109934893AGet cropped effectReduce computationFilling planer surface with attributes3D-image renderingSection planeComputer graphics (images)

The invention discloses a method and a device for displaying any cross section of a geometric body, which are used for solving the problems of geometric body cutting efficiency and cross section filling flexibility. According to the scheme, the method comprises: the normal vector of a cutting plane is calculated according to input geometry data and cutting plane parameters, the distance between each vertex of each basic primitive of the geometry and the cutting plane is calculated, then rasterization is conducted on the basic primitives, and the distance between each primitive segment and thecutting plane is obtained through linear interpolation; when each basic primitive is colored, a primitive segment with the distance larger than 0 is colored on the front face, then coloring is carriedout on the back face of the basic primitive, and in the back face coloring process, an original normal vector of the basic primitive is replaced with a normal vector of a cut plane. Therefore, profile filling, display of any cross section and profile filling are achieved, and the cutting operation efficiency and the profile filling flexibility are high.

Owner:GLODON CO LTD

Non-woven cloth fixed-width cutting device for non-woven cloth interlayer fence

The invention relates to a cutting device, in particular to a non-woven cloth fixed-width cutting device for a non-woven cloth interlayer fence. The non-woven cloth fixed-width cutting device for the non-woven cloth interlayer fence is high in speed, capable of achieving fixed-width cutting and easy to operate. In order to solve the technical problems, the non-woven cloth fixed-width cutting device for the non-woven cloth interlayer fence is provided and comprises a bottom plate, a forward and backward moving device, a cutter, an indication plate, a cloth winding wheel, cloth, a coiling block, a rocker, a first rubber block, a dividing ruler, a second sliding rail, a second slider and the like. The cloth winding wheel is rotationally connected with the left side of the top of the bottom plate, the cloth is wound on the cloth winding wheel, and the coiling block is rotationally connected with the right side of the top of the bottom plate. The effects of high cutting speed, fixed-width cutting and easy operation are achieved. Besides, the cutting device is reasonable in structure, low in manufacturing cost and easy to maintain because a fixing plate is made of Q235 steel.

Owner:防城港市宝兴工艺品有限公司

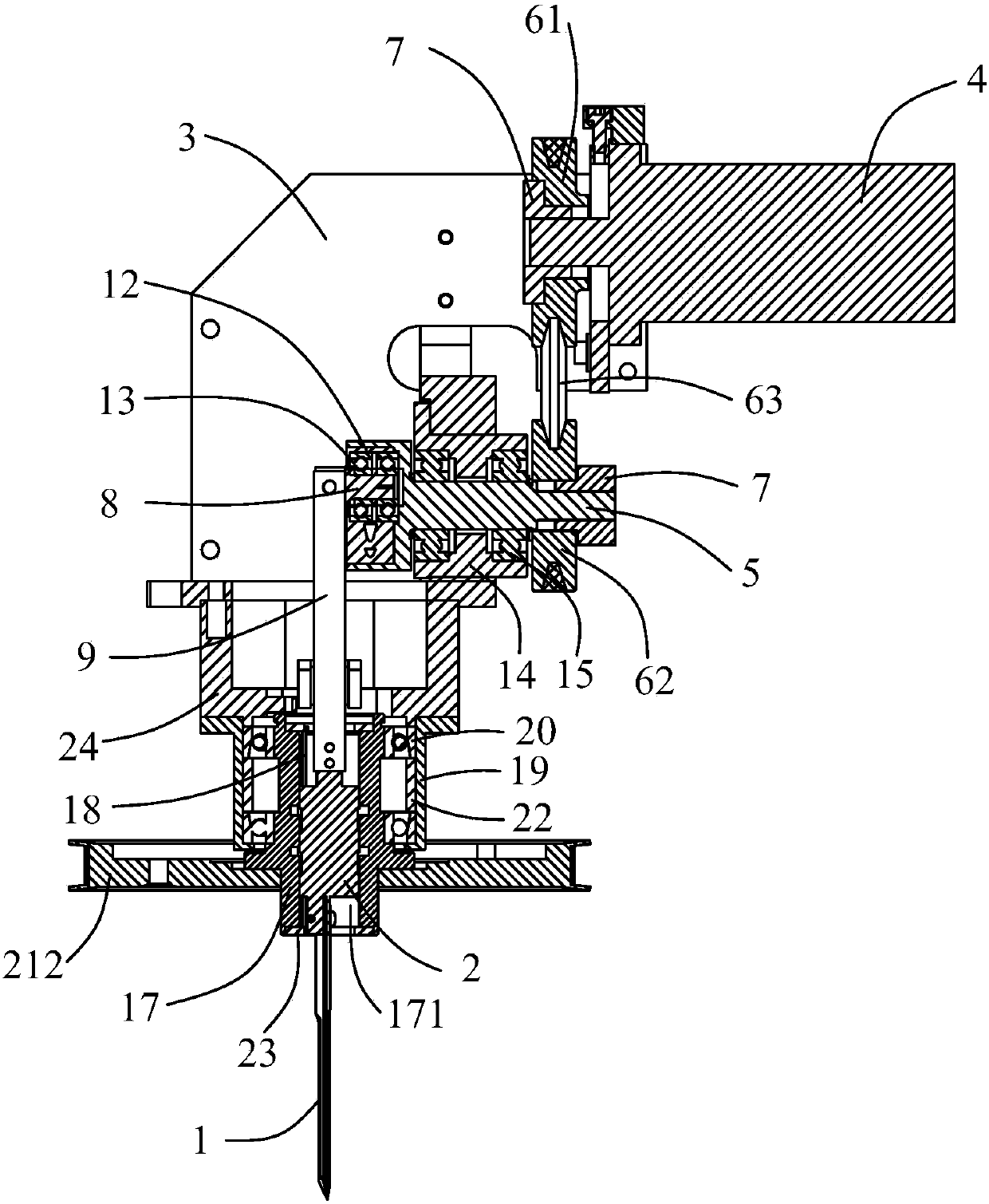

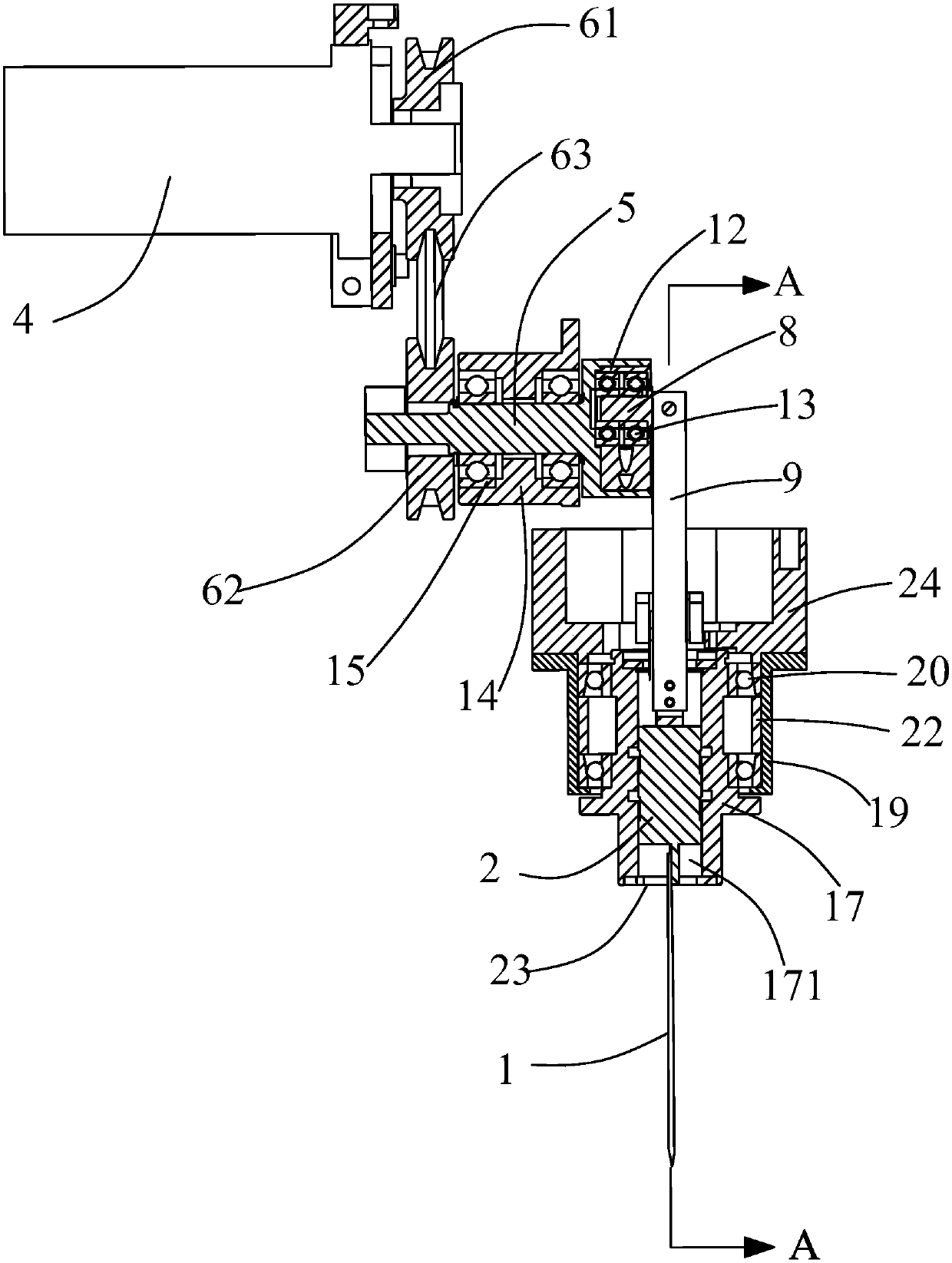

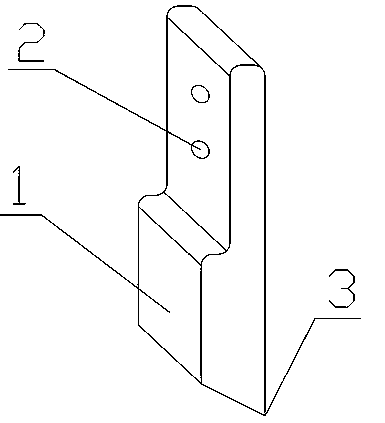

Dedicated electric tailoring cutter for fur

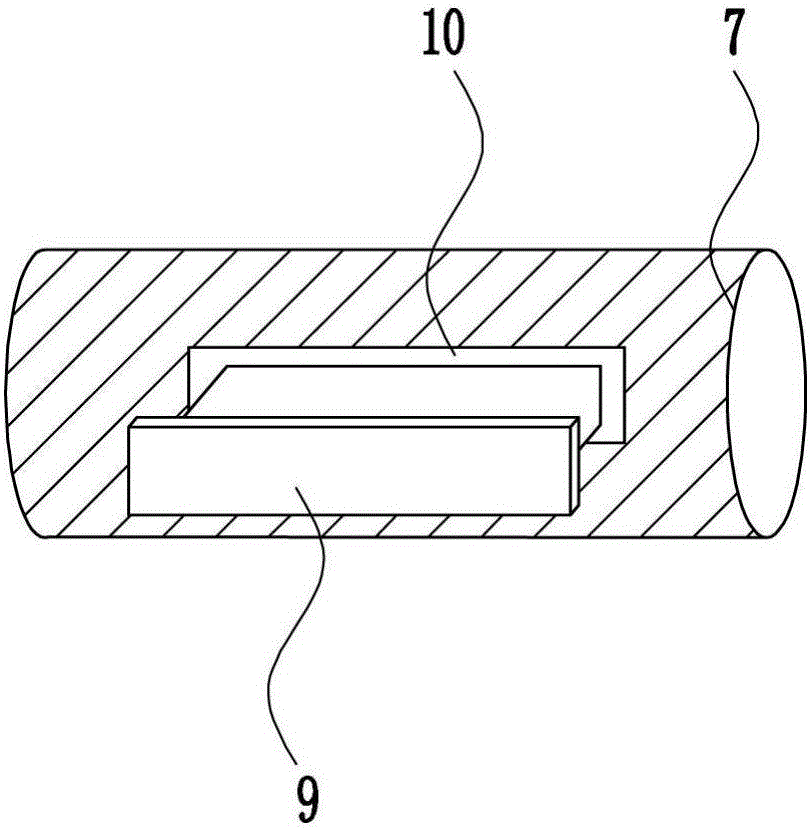

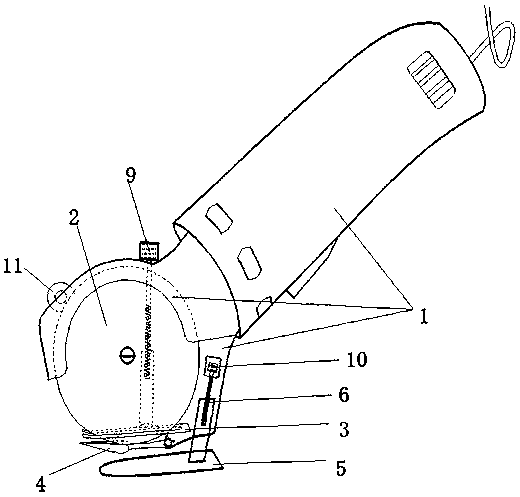

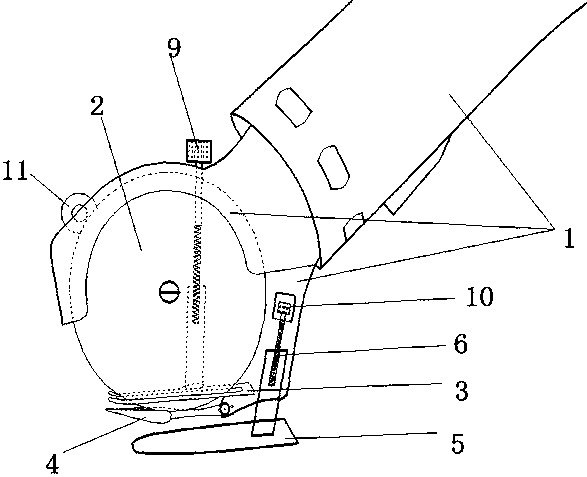

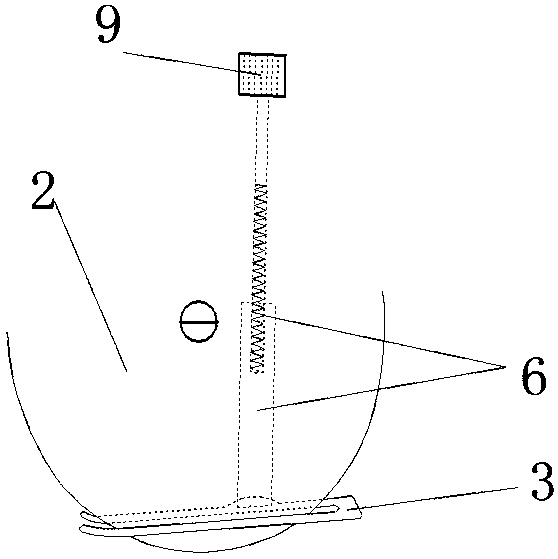

PendingCN108127700AImprove work efficiencyFast croppingLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineeringPRESSURE FEET

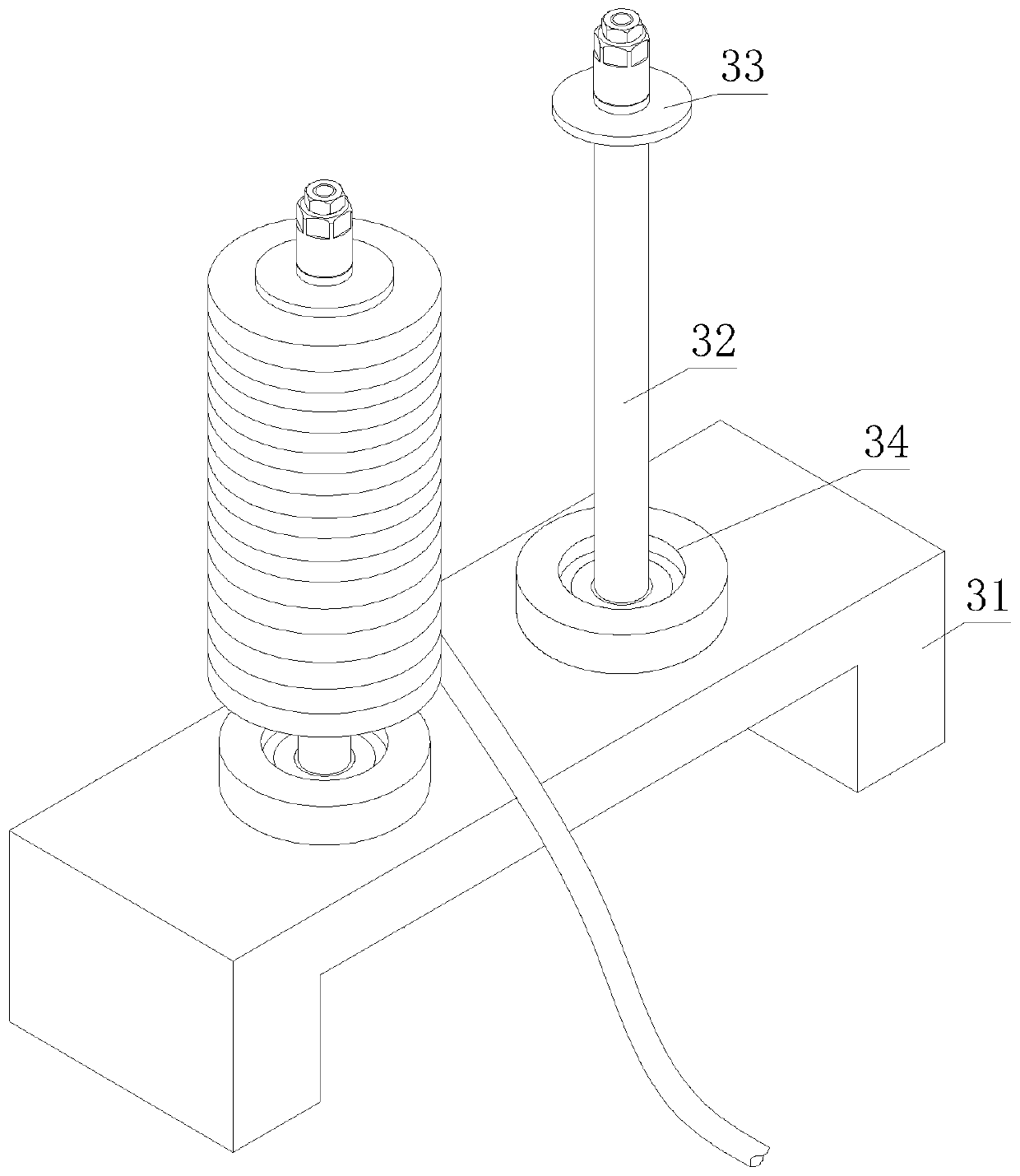

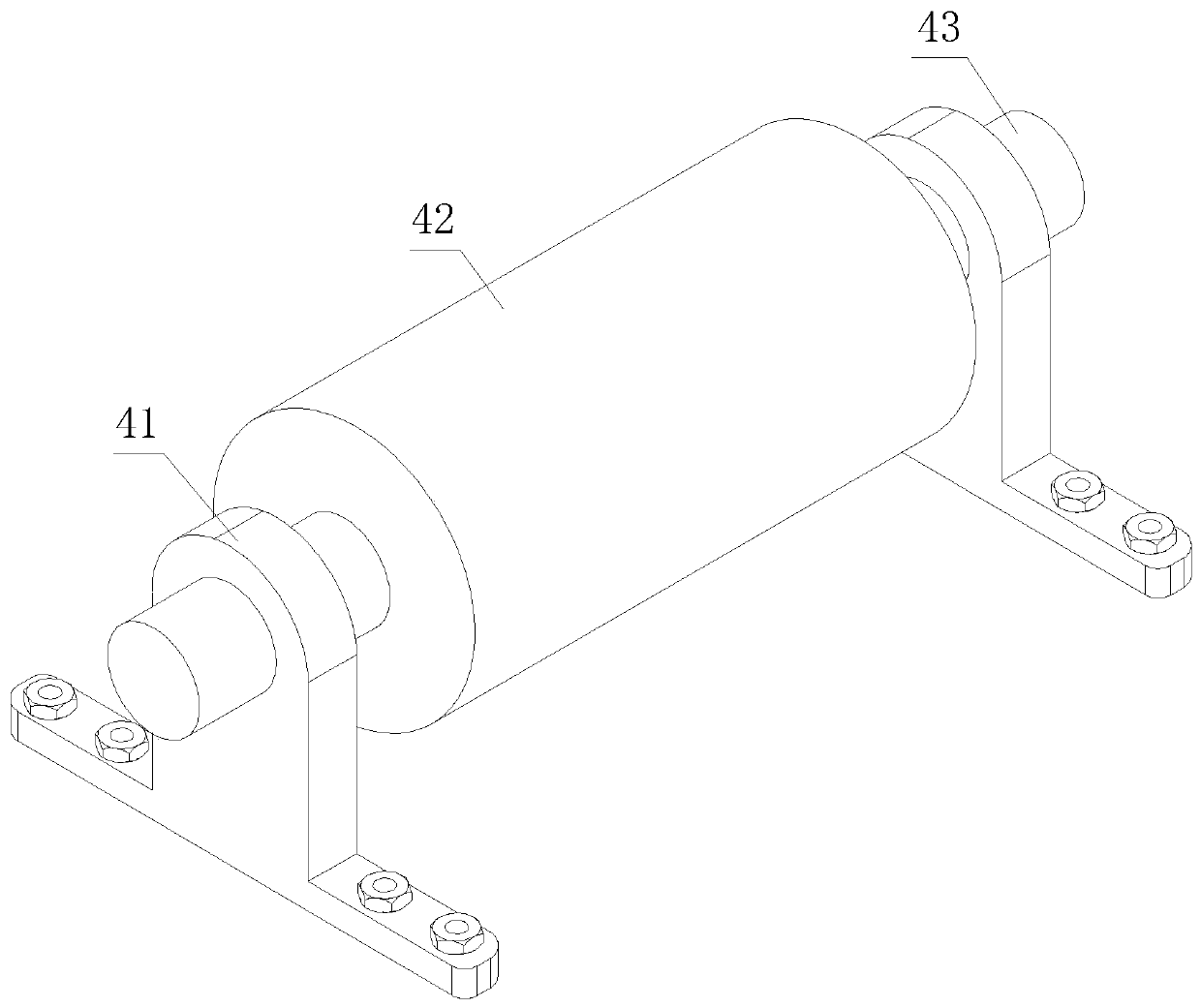

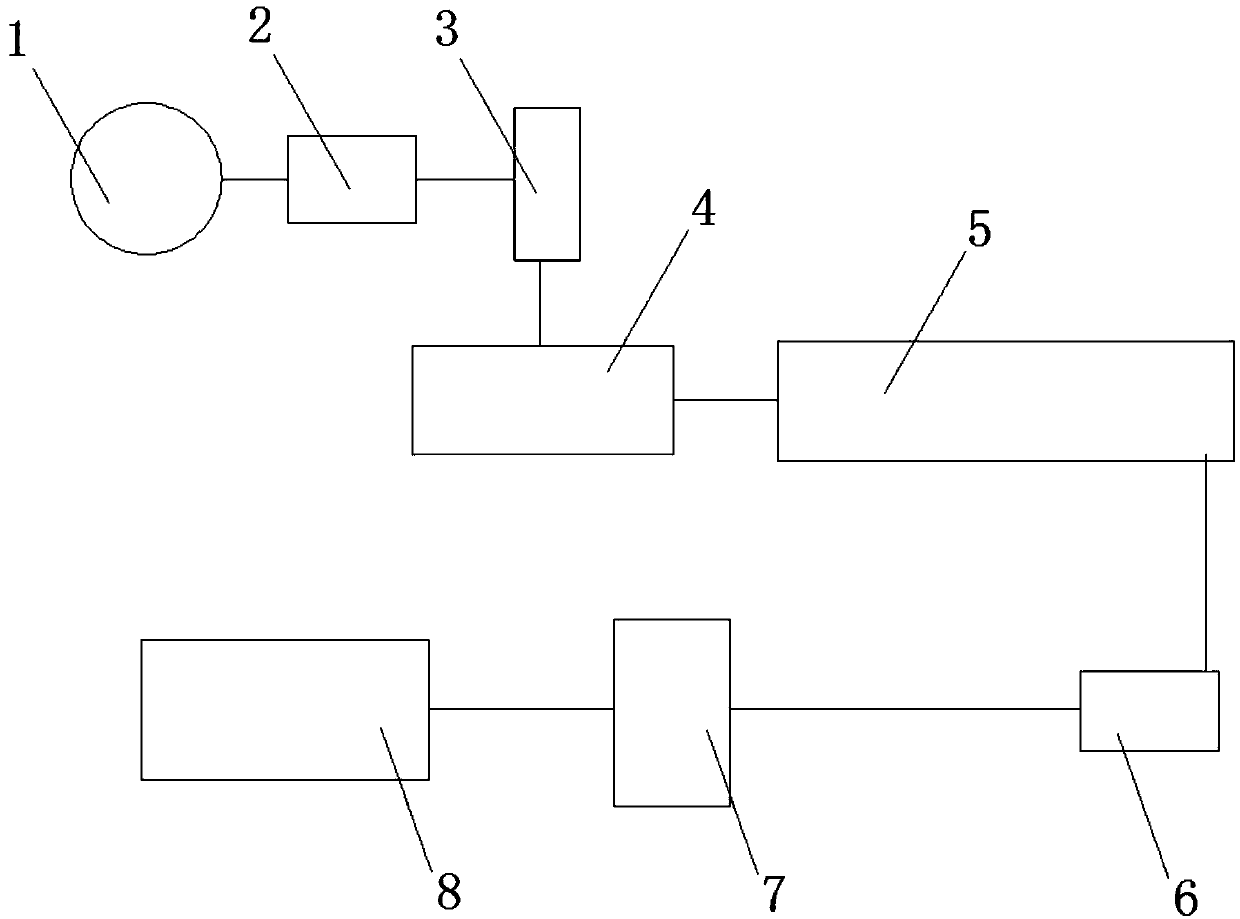

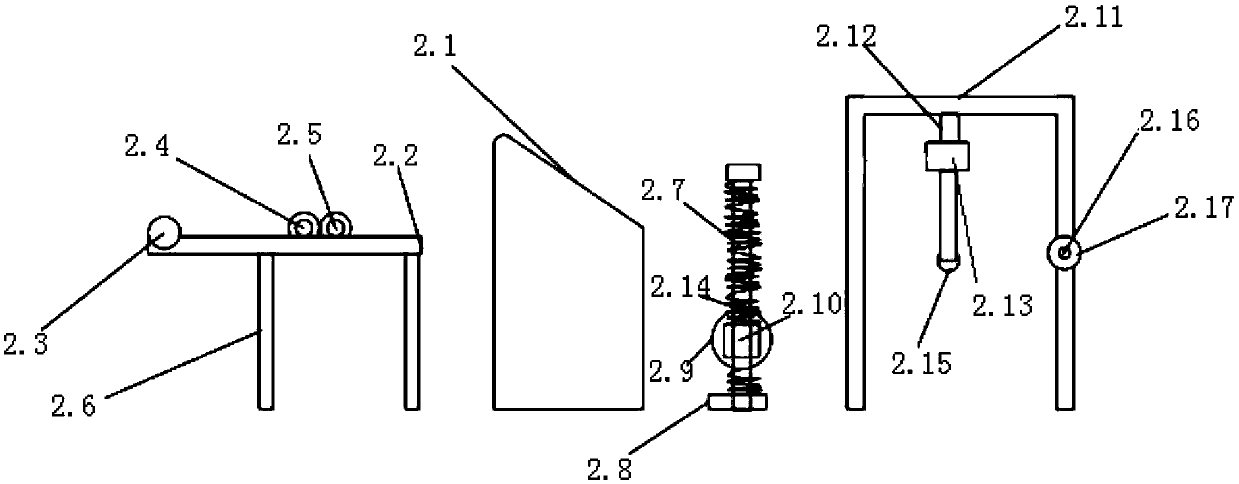

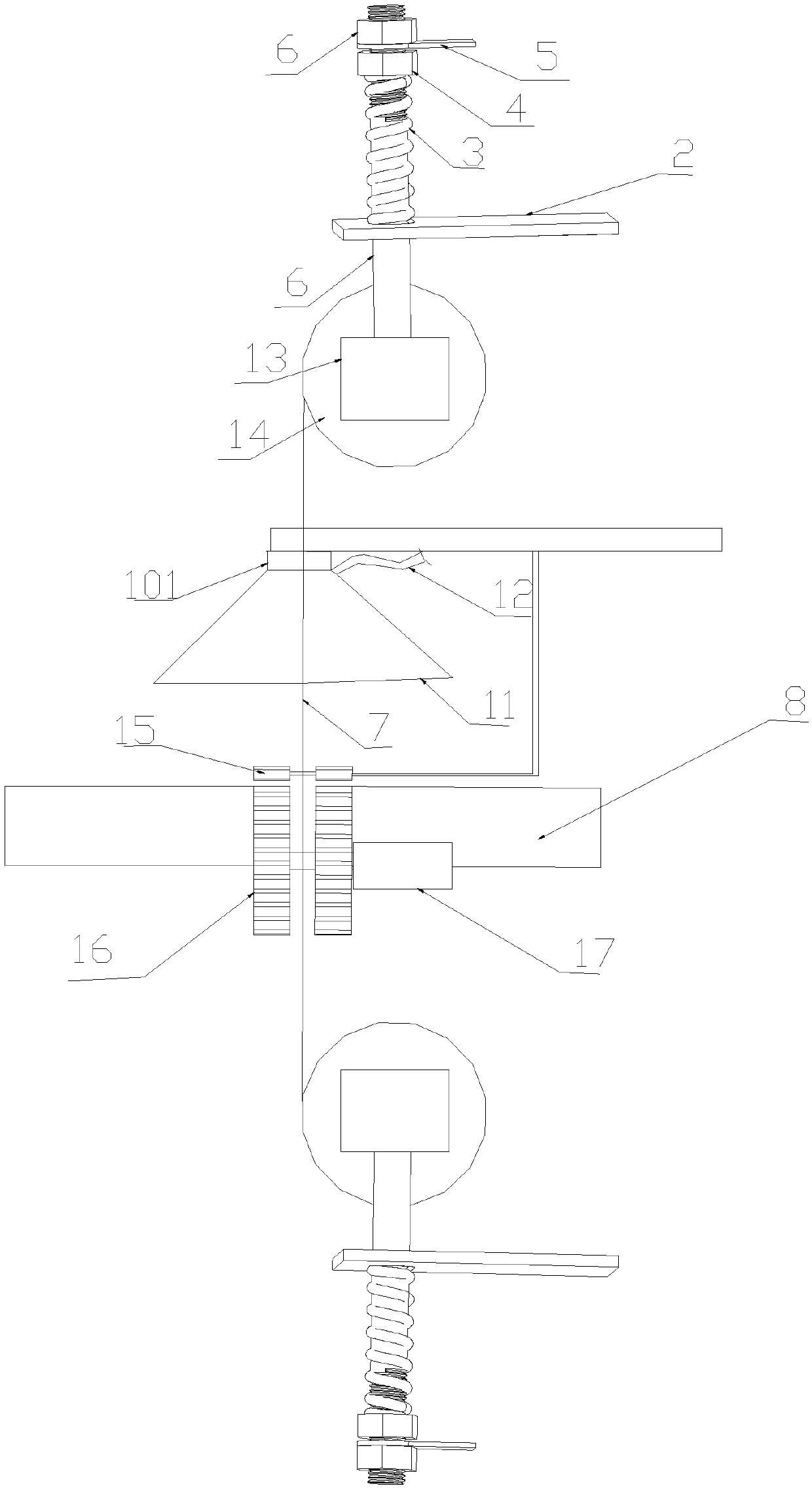

The invention discloses a dedicated electric tailoring cutter for fur. The dedicated electric tailoring cutter comprises a machine body (1), a rotary cutting blade (2), an upper material blocking pressure foot, a lower hair stirring fork (4), a hair stirring fork resilience device (8) and a table attached sliding base (5), wherein the rotary cutting blade (2) is arranged at the machine head end, the upper material blocking pressure foot (3) is fixed to a machine head, the height of the upper material blocking pressure foot (3) is adjustable, the lower hair stirring fork (4) is fixed to the lower end of the machine head, the hair stirring fork resilience device (8) is arranged at the connection point between the hair stirring fork and the machine head, the table attached sliding base (5) isfixed to the machine head, and the height of the table attached sliding base (5) is adjustable. The dedicated electric tailoring cutter disclosed by the invention has the beneficial effects: the depth of a knife edge is controlled by the upper material blocking pressure foot to effectively prevent plush from being damaged by the cutting blade; the lower hair stirring fork can effectively stir theplush to the two sides before the cutting blade to prevent the plush from being damaged by the cutting blade; even if fine-width fur is pruned, section flatness can be also ensured; the table attached sliding base with the adjustable height can be suitable for tailoring and cutting different thicknesses of fur materials; the dedicated electric tailoring cutter has the advantages of quick tailoring speed, neat and identical sections, high work efficiency, safety and reliability.

Owner:郑智

Ultra-wide cutter device for soft films

The invention discloses an ultra-wide cutter device for soft films, which comprises two sliding rail fixing plate. One sliding rail fixing plate is connected with a driving device, two linear guide rods, a front cutter clamp, a rear cutter clamp and a tungsten steel blade are connected between the two sliding rail fixing plates, the tungsten steel blade is clamped between the front cutter clamp and the rear cutter clamp, each of the sliding rail fixing plates is provided with a transmission sprocket, a transmission chain is connected onto the transmission sprockets, two linear sliders are respectively connected with the linear guide rods, a slider pressure plate is connected onto the two linear sliders, a chain pressing block is connected onto the slider pressure plate, the transmission chain penetrates through the chain pressing block and is fixed onto the chain pressing block, two cutter pressing guide rods are further connected to the lower side of the slider pressure block and connected with a cutter pressing box, the cutter pressing box is placed on the tungsten steel blade, and two cutter pressing springs are respectively sleeved on the cutter pressing guide rods. The cutter device is quick in cutting speed, and cuts the soft films neatly, lateral cut edges are smooth after cutting, accordingly, industrial injury accidents are reduced, and the requirement of sufficient cutting width can be met.

Owner:SUZHOU HUARI JINLING MACHINERY

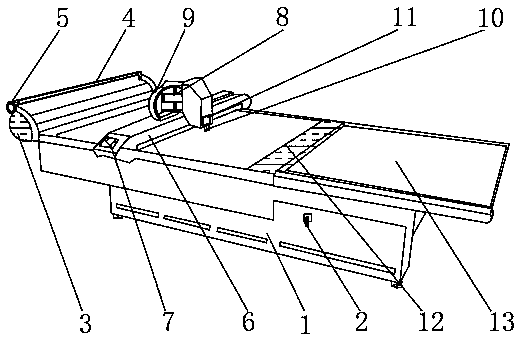

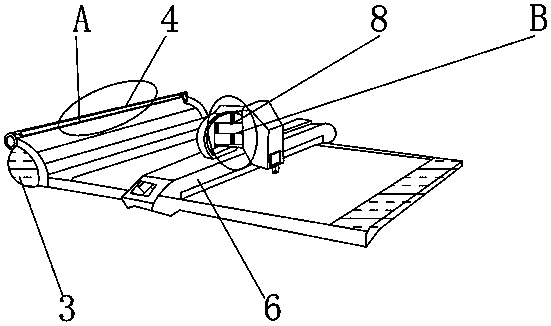

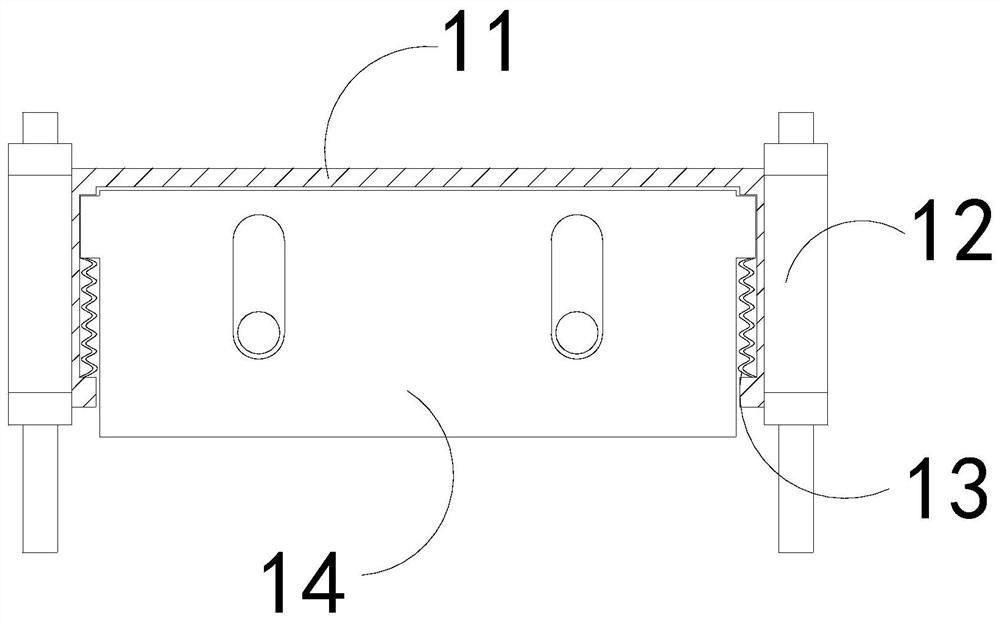

Rolling cutter for conical non-woven fabric gauze mask ear bands and method

ActiveCN111411505AImprove flatnessAvoid wrinklesSevering textilesStructural engineeringNonwoven fabric

The invention discloses a rolling cutter for conical non-woven fabric gauze mask ear bands and a method, and belongs to the technical field of conical gauze mask ear band cutting. The rolling cutter comprises a support. A working table plate is fixed to the upper side of the support. A conveying belt is arranged in the middle of the working table plate. A winding device, a guide device and a rolling cutting device are installed above the working table plate. The guide device is arranged at the side end of the winding device, and the rolling cutting device is arranged at the side end of the guide device. The rolling cutting device comprises a frame plate, a rolling roll, an air cylinder, moving plates and a connecting shaft rod. The moving plates are arranged below the two sides of the frame plate. According to the rolling cutter for the conical non-woven fabric gauze mask ear bands and the method in the invention, the flatness of materials is improved, the materials can be shaped, wrinkling is prevented, subsequent cutting can be facilitated, the length between two blades can be adjusted as required, ear band threads of different lengths can be cut conveniently, the rolling cutteris suitable for different gauze mask threads, and cutting efficiency is improved; and bothway cutting is conducted, the cutting speed is increased and production benefits are also increased.

Owner:MAANSHAN HENGLIDA MACHINE BLADE

Efficient production line for clothes

InactiveCN109527685AEasy to storeReduce work proceduresClothes making applicancesYarnProduction line

The invention discloses an efficient production line for clothes, which sequentially comprises a knitting machine, a cloth inspecting device, a loosening machine, a fabric placing frame, a cutting machine, a sewing machine, an ironing device and a finishing system from front to back, wherein yarns are knitted into a fabric by the knitting machine, after being rolled into a cloth roll, the fabric is sent to the cloth inspecting device for cloth inspecting operation; after the fabric passes through the cloth inspecting device, the fabric is directly sent to the cloth loosening machine for clothloosening; after the cloth loosening is finished, the fabric is placed on the fabric placing frame; after the fabric is stored on the fabric placing frame, when the fabric needs to be cut, the fabricis pushed to the front of the cutting machine, and after the fabric is cut, the fabric is sent to a sewing machine to be sewed to form clothes, then is sent to an ironing device to be ironed, and thenis sent to a finishing system to be finished to finally form the finished clothes. The efficient production line for the clothes can avoid cloth wrinkles and improve the smoothness of the cloth, thefabric placing frame has a larger capacity of, and the cloth is smoothly distributed and conveyed on the cutting machine, the cutting speed is high.

Owner:江阴嘉美针织制衣有限公司

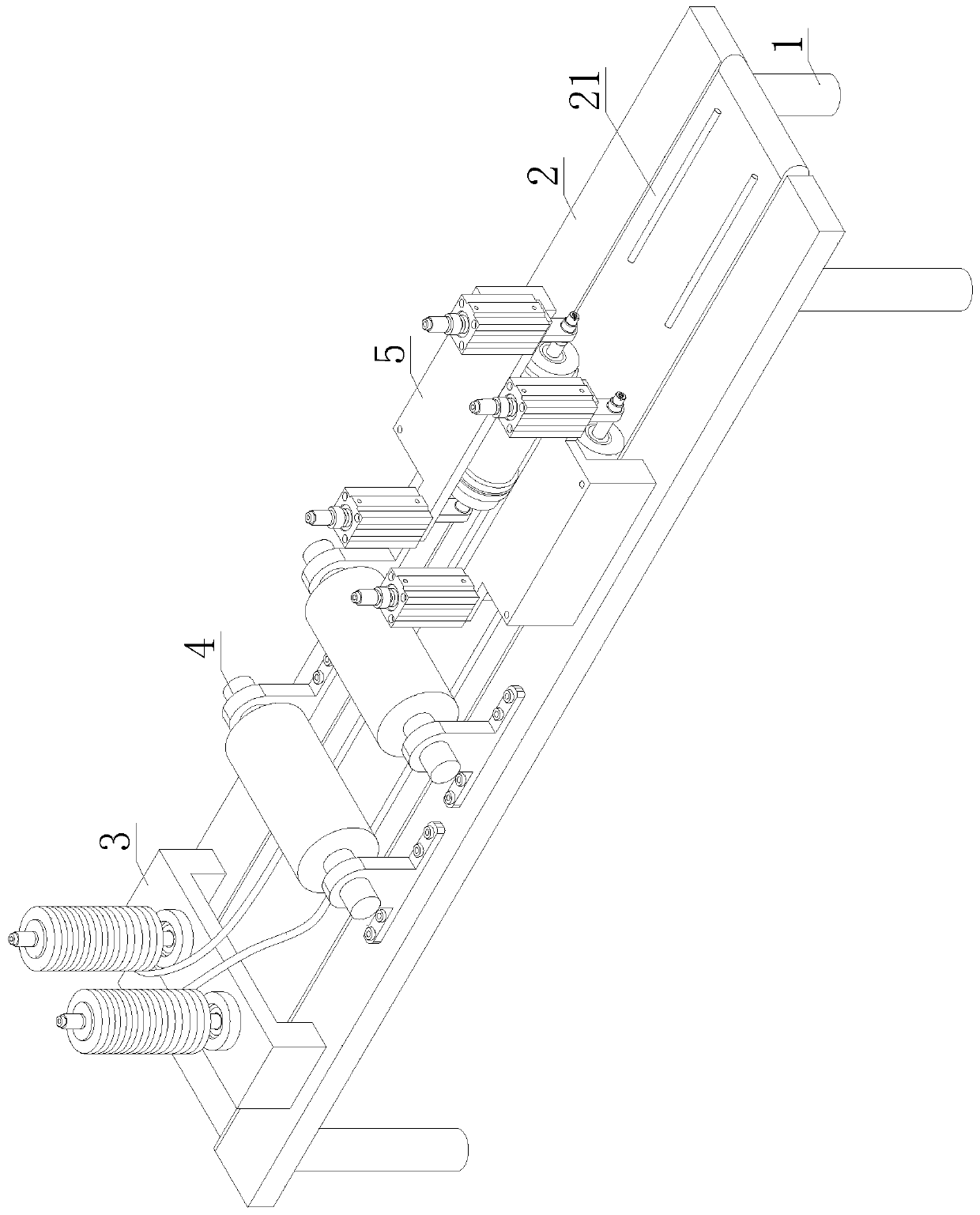

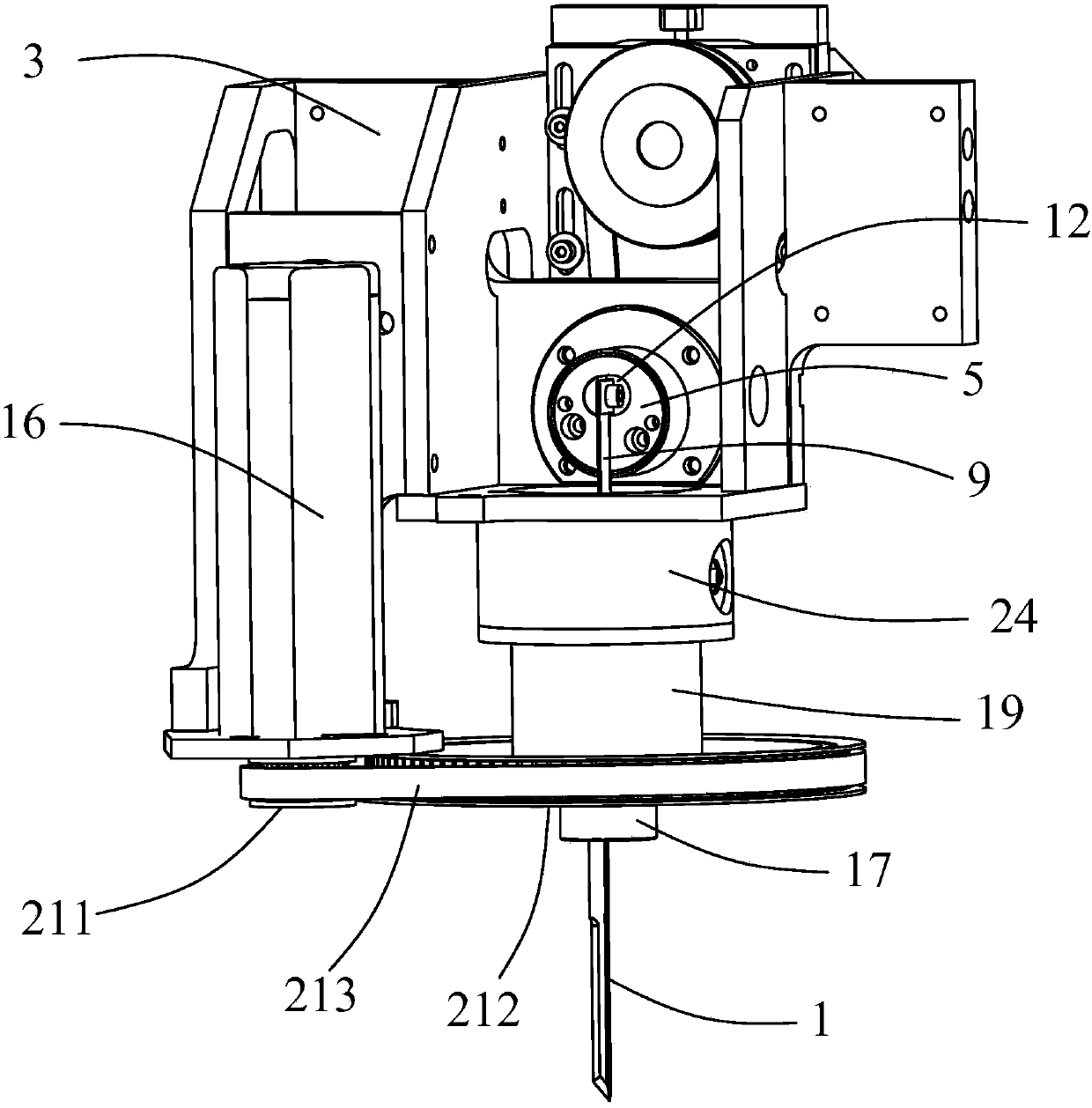

Cutting device for automatic cutting system

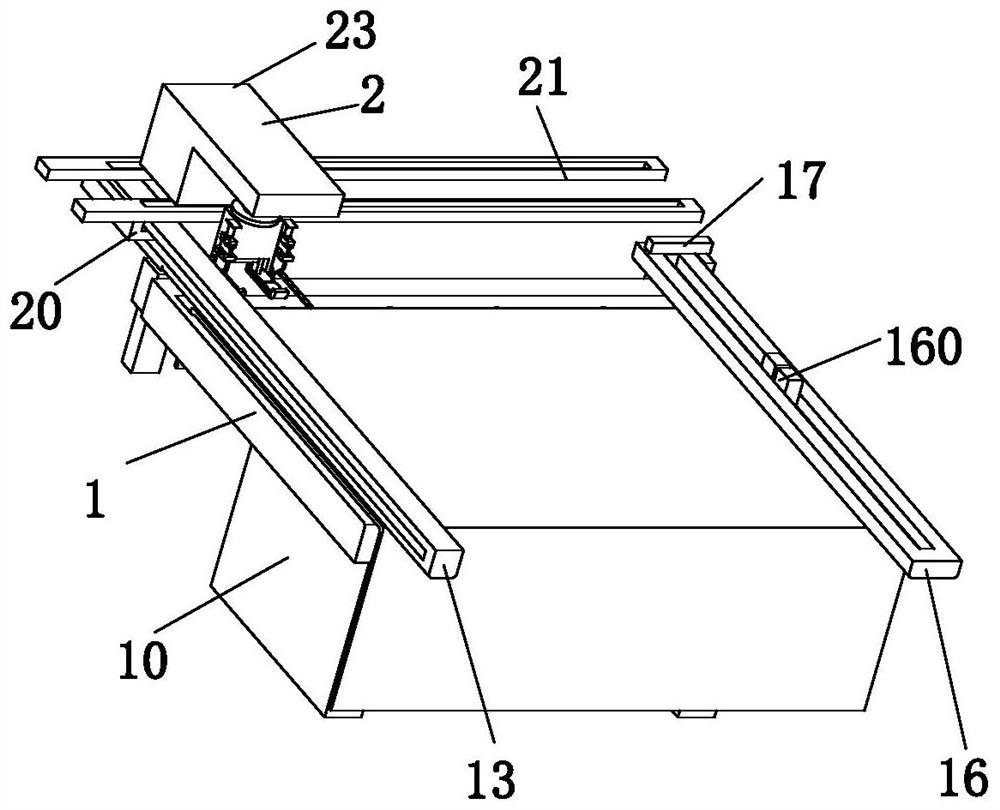

ActiveCN105970590BImprove cropping accuracyImprove cutting efficiencySevering textilesEngineeringUltimate tensile strength

The invention provides a clipping device of an automatic clipping system. The clipping device comprises a rack, a clipping tool extending vertically, an X-direction moving support, a Y-direction moving support and a vertical moving mechanism, wherein the X-direction moving support is mounted on the rack and capable of moving in the front and back direction; the Y-direction moving support is mounted on the X-direction moving support and capable of moving laterally; the vertical moving mechanism is mounted on the Y-direction moving support and provided with a rotatable tool fixing bar capable of reciprocating vertically, and the upper end of the clipping tool is fixedly connected with the lower end of the tool fixing bar. According to the clipping device, the clipping tool can move front and back in the X direction, move laterally in the Y direction, reciprocate vertically in the Z direction and rotate, and accordingly purposes of automatic fabric cutting and clipping are achieved; the clipping device has high clipping precision, high clipping speed, high clipping efficiency and low labor intensity.

Owner:BULLMER ELECTROMECHANICAL TECH

A kind of cardboard cutting and processing equipment

ActiveCN105922331BPrevent deviationGuarantee subsequent processing accuracyMetal working apparatusCardboardConveyor belt

The invention discloses paperboard cutting and processing equipment. The equipment comprises a mounting frame, a conveyor belt, a rotary shaft, a first driving unit, a cutting part and a pressing and holding part. The conveyor belt is mounted on the mounting frame. The upper surface of the conveyor belt is provided with a plurality of accommodating grooves which are evenly distributed in the length direction of the conveyor belt. The length direction of the accommodating grooves is perpendicular to the length direction of the conveyor belt. The lower surface of the conveyor belt is provided with first gears which are distributed in the length direction of the conveyor belt. The rotary shaft is rotatably mounted on the mounting frame. One end of the rotary shaft is arranged in a space defined by the conveyor belt. The local peripheral surface of the rotary shaft is provided with second gears which are distributed in the circumferential direction of the rotary shaft. The second gears are engaged with the first gears. The first driving unit is used for driving the rotary shaft to rotate. The cutting part is used for cutting paperboards and comprises a second driving unit and a blade. The second driving unit is used for driving the blade to move close to the accommodating grooves or far from the accommodating grooves. The paperboard cutting and processing equipment is good in paperboard cutting effect.

Owner:BENGBU ZHENHUA PACKING MACHINERY

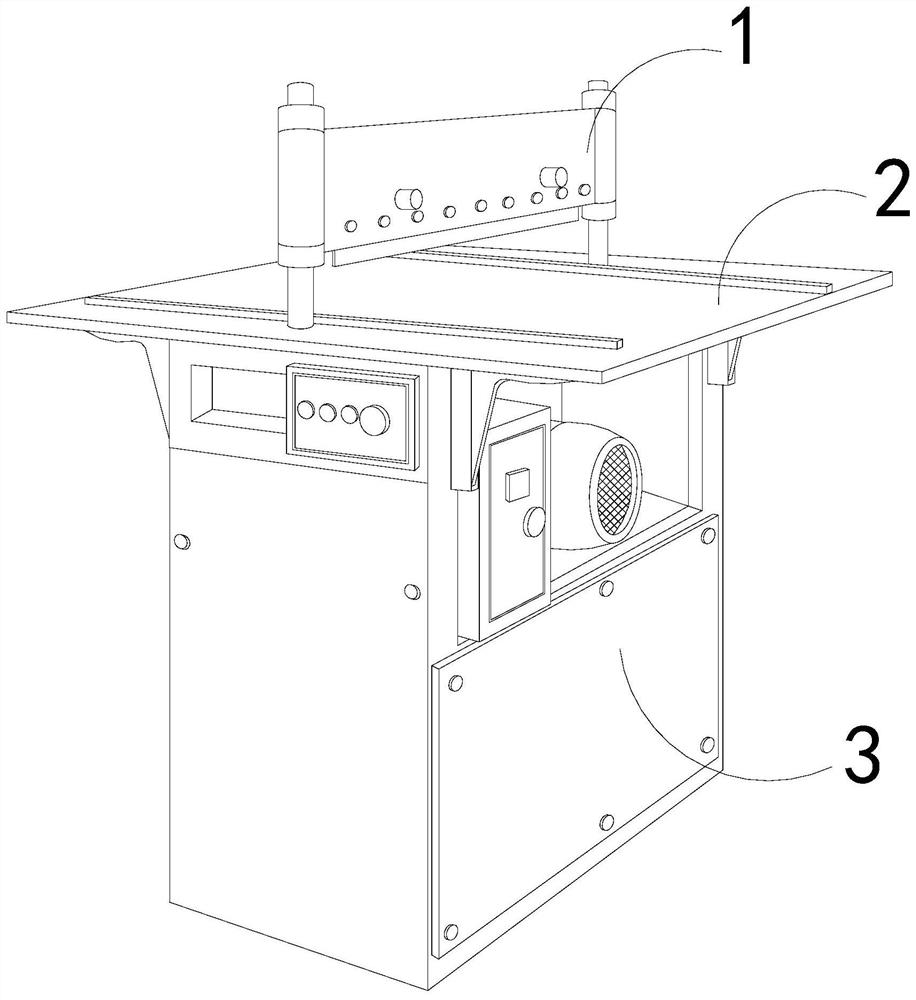

Full-automatic clothes cutting machine

The invention discloses a full-automatic clothes cutting machine which comprises a cutting machine main body. A power switch is arranged on the outer surface of the lower end of the cutting machine main body, a roller is fixedly installed at the front end of the cutting machine main body, a pressure plate is fixedly mounted at the upper end of the roller, fixed knobs are disposed at the two ends of the pressure plate, a movable frame is movably installed on the upper surface of the cutting machine main body, a control panel is fixedly mounted at one end of the movable frame, and a motor is movably mounted on the upper surface of the movable frame. The full-automatic clothes cutting machine is provided with the pressure plate, a ball bearing and a CCD image sensor, it can be ensured that cloth entering the cutting machine is flat and smooth, the cutting speed is improved, a large load can be borne, a rotating friction force is effectively reduced, the work efficiency is improved, imagesduring the cutting can also be clearly seen at a remote distance, the cutting is stopped automatically when the abnormality is found, the error rate is reduced, and a better use prospect is brought about.

Owner:漳州拓奇实业有限公司

A fast cutting device for trousers samples

InactiveCN106473287BFast croppingSimple structureClothes making applicancesEngineeringMechanical engineering

The invention relates to a tailoring apparatus and in particular relates to a trousers sample plate quick tailoring apparatus. The technical problem to be solved is to provide a trousers sample plate quick tailoring apparatus with quick tailoring speed. The trousers sample plate quick tailoring apparatus comprises a rack, a pedestal, a slide rail, a first slide block, a second slide block, a first electric wheel, a first stay rope, a movable plate, a second stay rope, a second electric wheel and a motor, wherein the slide rail is arranged on the left side of the rack; the slide rail is provided with the second slide block and the first slide block; the second slide block is arranged on the left side of the first slide block; the right side of the second slide block is connected with the left side of the first slide block; and the upper ends of the second and first slide blocks are provided with the movable plate. Effects of quick tailoring speed, simple structure and convenient operation can be achieved; the tailoring process can be observed and monitored; and left material after the tailoring can be collected and recovered and reused.

Owner:江苏桓华婴儿用品有限公司

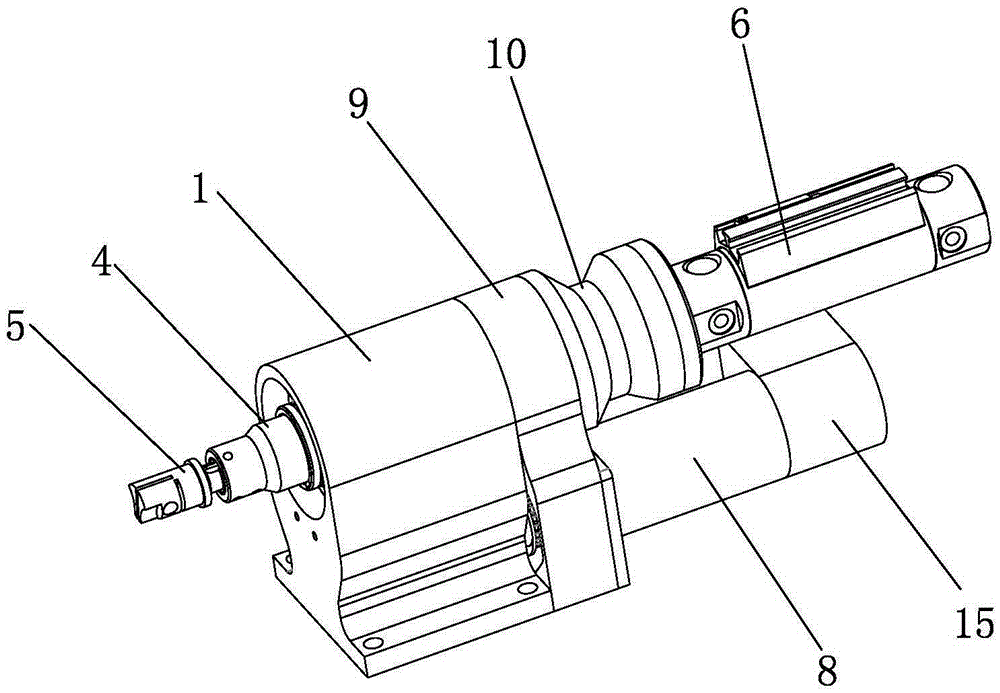

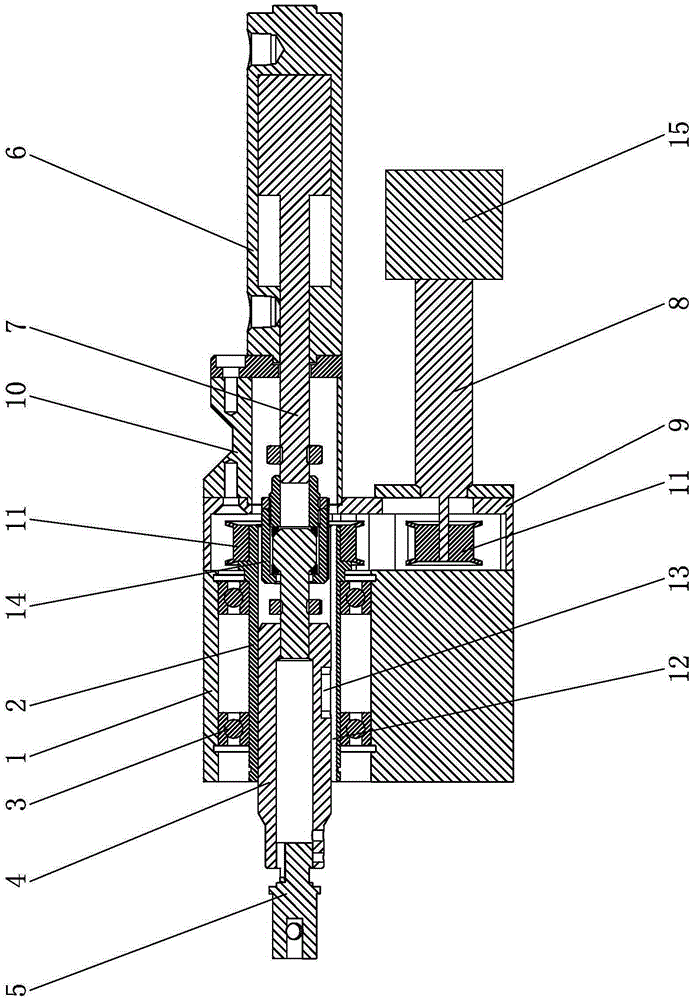

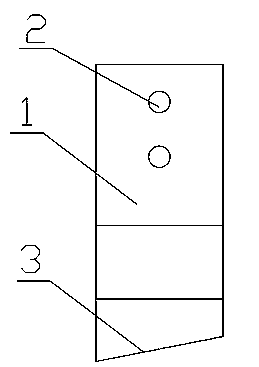

V-shaped corner cutting device for cutting machine tool

InactiveCN105400912AOutstanding and Beneficial Technical EffectsFast croppingLeather clicking/perforating/clickingEngineeringMachine tool

The invention belongs to the technical field of cutting machine tool corner cutting and particularly relates to a V-shaped corner cutting device for a cutting machine tool. The V-shaped corner cutting device comprises a fixing seat. A sleeve is supported in the fixing seat through a bearing. A connecting shaft is sleeved with the sleeve. A cutter chuck is arranged at the front end of the connecting shaft and the rear end of the connecting shaft is connected with an output shaft of a power device fixed to the fixing seat. The power device drives the connecting shaft to move in the sleeve in the axial direction. A servo motor fixed to the fixing seat drives the sleeve to rotate through a transmission mechanism. The sleeve drives the connecting shaft to rotate. The V-shaped corner cutting device has the beneficial effects that when used, the V-shaped corner cutting device is installed on a cutting bit of the cutting machine tool, a V-shaped cutter is installed on the cutter chuck, the angle of the V-shaped cutter is adjusted through the servo motor in the use process, after the V-shaped cutter is orientated, an air cylinder drives the V-shaped cutter to move up and down so that a V-shaped cut notch can be cut on fabric, V-shaped cut notches in different directions can be cut by adjusting the V-shaped cutter through the servo motor at different angles, the cutting speed is high, and efficiency and accuracy are high.

Owner:BULLMER ELECTROMECHANICAL TECH

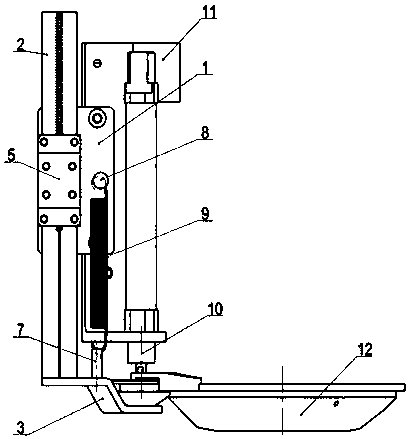

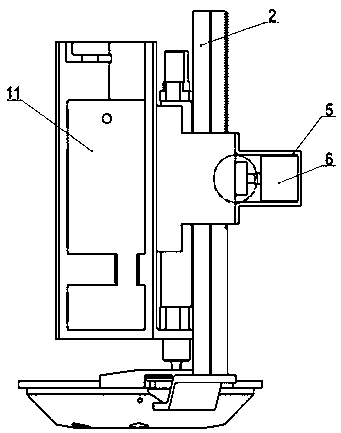

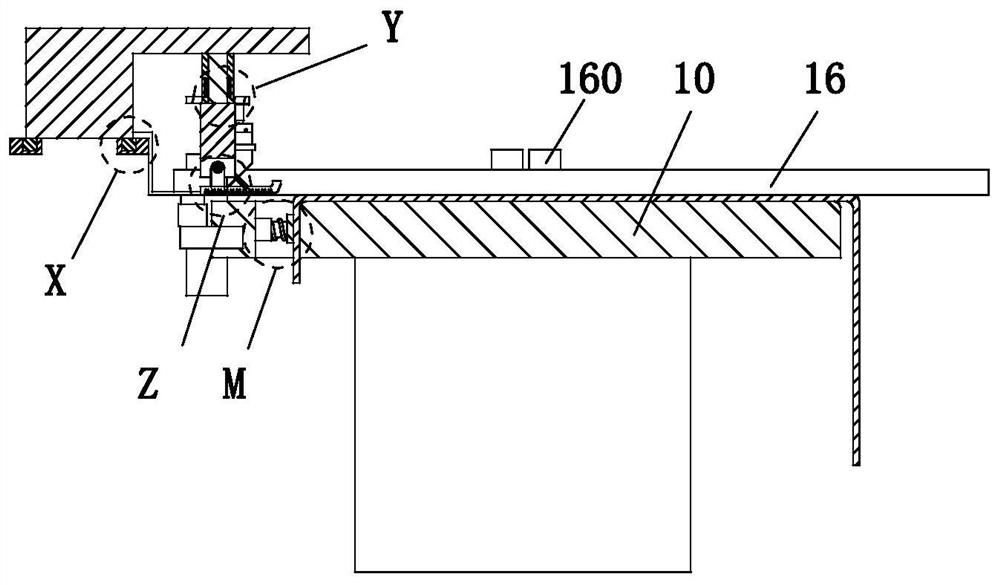

Cutting bed with cutting knife disk positioning device

ActiveCN108149467ASolve the movement problemHigh precisionSevering textilesEngineeringMechanical engineering

The invention discloses a cutting bed with a cutting knife disk positioning device. A fixing seat of the cutting knife disk positioning device is arranged on a clipping machine head rack base of the cutting bed, the fixing seat is provided with a hollow channel, a positioning shaft penetrates through the channel of the fixing seat, the bottom of the positioning shaft is connected with a supportingplate, a saw tooth fixing strip is arranged on a side surface of the positioning shaft and is fixed to a toothed block in an engaged manner, the toothed block is mounted on an outputting shaft of a cylinder, the cylinder is mounted on the fixing seat of the positioning device through a cylinder seat, a knife disk assembly is placed on the supporting plate, the supporting plate supports the knifedisk assembly, and when the knife disk assembly moves back and forth, the bottom of the knife disk assembly is not in contact with a fabric. The cutting bed with the cutting knife disk positioning device has the advantages that the cutting disk assembly is supported, the problem of position running of smooth fabrics is solved, the precision and efficiency are improved, and the clipping speed is increased.

Owner:YYC IND CO LTD CHINA

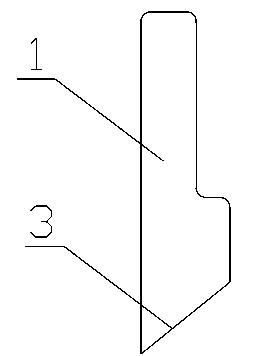

Tailoring tool

The invention relates to an auxiliary device of a sewing machine, in particular to a tailoring tool. The tailoring tool comprises a blade which is provided with an installing hole, the blade is further provided with a cutting edge, and a certain angle is formed between the cutting edge and the horizontal plane in a slant mode. The tailoring tool is installed on a machine head of the sewing machine through the installing hole, and the machine head of the sewing machine drives a tailoring device to tailor cloth. By means of the tailoring tool, the blade is fixed on the machine head of the sewing machine, the sewing machine instead of manual operation drives the blade to tailor the cloth, the tailoring speed is high, labor is saved, and the tailored cloth is attractive in appearance and reliable in quality.

Owner:中江县四海制衣有限责任公司

Cutting mechanism for preventing deviation of cloth and applied to garment production

InactiveCN108774870APrevent deviationImprove cutting efficiencySevering textilesElectric controlCotton material

The invention discloses a cutting mechanism for preventing the deviation of cloth and applied to garment production. The cutting mechanism comprises a machine body, a plurality of supporting bases andan electric control box, the supporting bases are fixedly arranged at the bottom of the machine body and are all of a structure with a narrow upper side and a wide lower side, a bracket is arranged on one side of the machine body, and the electric control box is disposed on the top of the bracket; a transverse bracket is fixedly arranged on the machine body, an electric push rod is arranged on the top of the transverse bracket, a T-shaped sliding block is fixedly arranged on the top of the electric push rod, and a working plate and a conveying plate are arranged on the top of the machine body; a cutting groove is formed in one end of the working plate, an obliquely arranged cloth guiding plate is connected to one end of the conveying plate, a cloth collection box is arranged at one end ofthe bottom of the cloth guiding plate, an obliquely arranged support is welded to one end of the machine body, and a cloth conveying roller is arranged on the top of the support; a stretching rolleris parallelly arranged on one side of the cloth conveying roller. Through arrangement of deviation correcting plates and the cutting groove, the deviation of the cloth is prevented, the efficiency ofcutting the cloth is improved, and the effect of cutting the cloth is ensured.

Owner:东台市天工纺织品有限公司

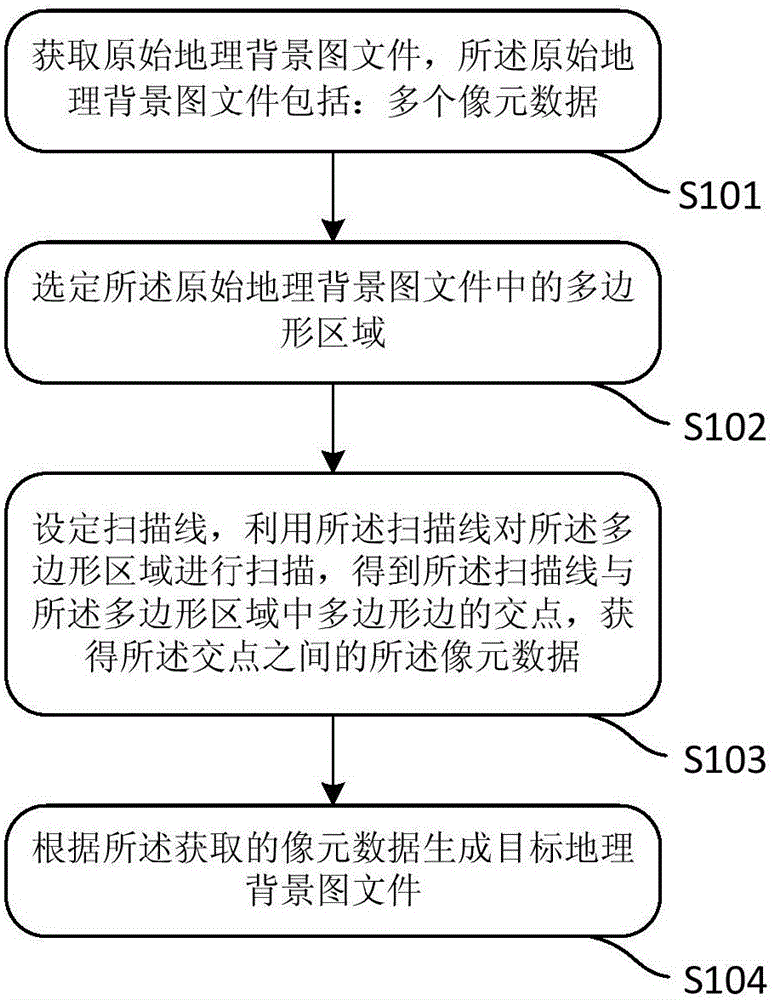

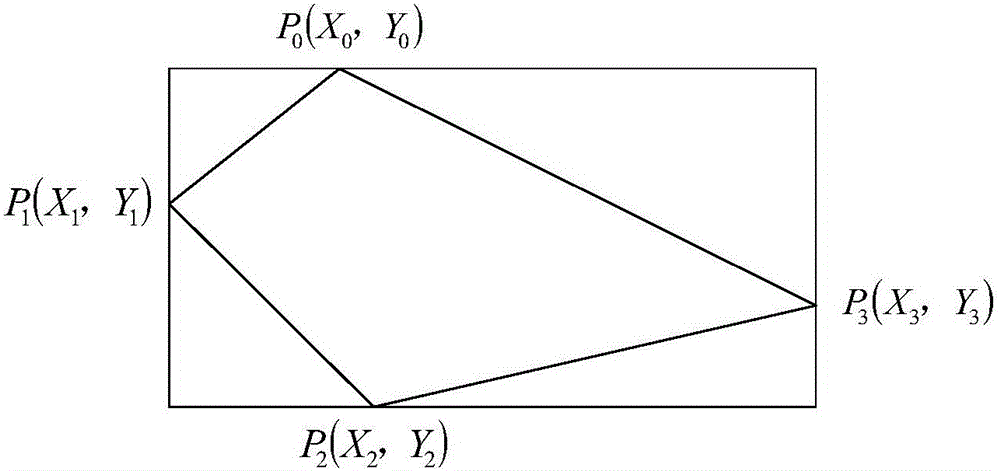

Geographic background image cutting method and system

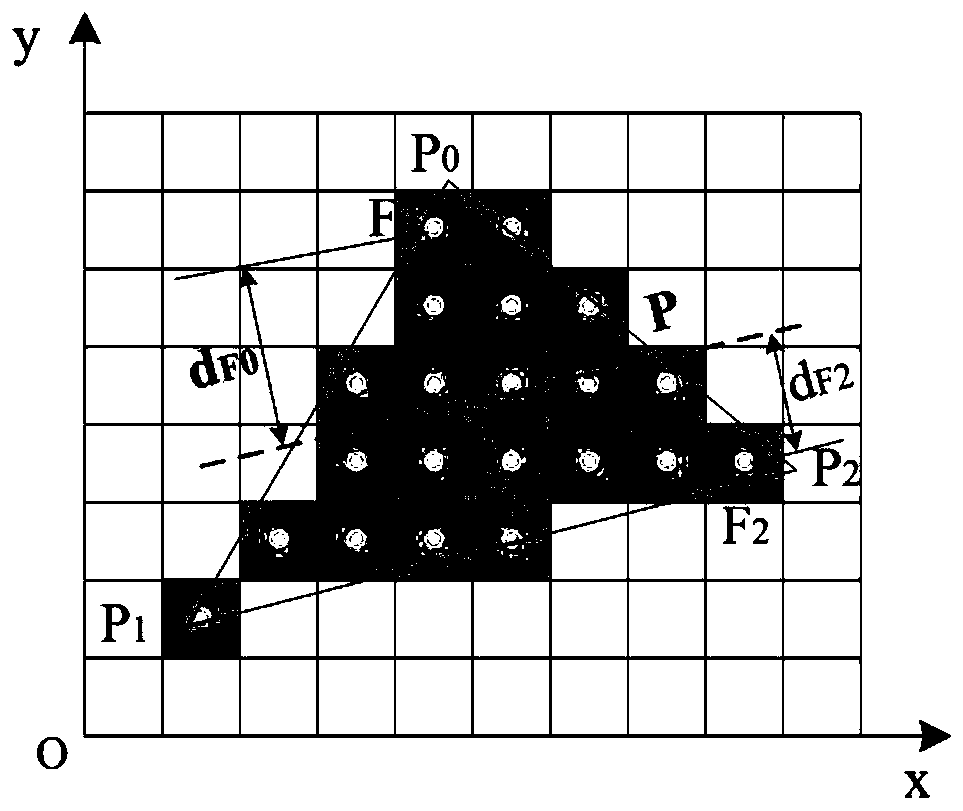

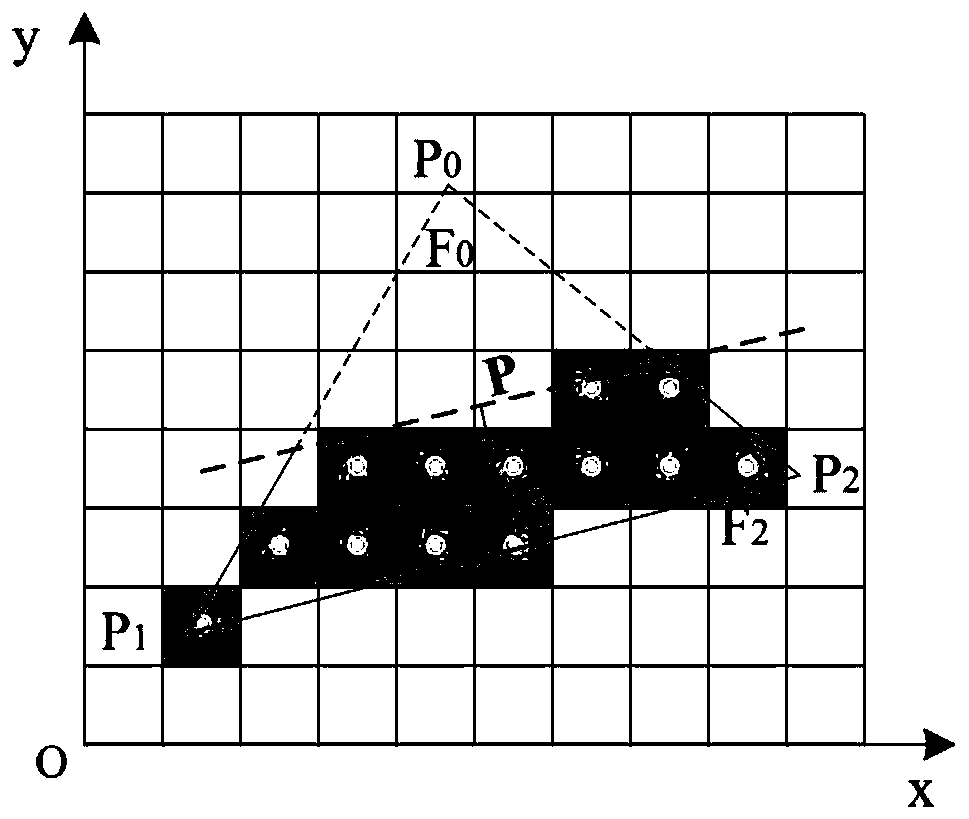

InactiveCN106204606AFast croppingQuick calculationImage enhancementImage analysisIntersection of a polyhedron with a lineBackground image

The embodiment of the invention discloses a geographic background image cutting method and system. The method comprises the steps that an original geographic background image file is acquired, wherein the original geographic background image file includes multiple pixel element data; the polygonal area in the original geographic background image file is selected; a scanning line is set, and the polygonal area is scanned by using the scanning line so that the intersection points of the scanning line and the polygon edges of the polygonal area are obtained, and the pixel element data between the intersection points are acquired; and a target geographic background image file is generated according to the acquired pixel element data. According to the geographic background image cutting method and system, the cutting speed of the geographic background image can be enhanced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Cutting device of non-woven fabric

The invention discloses a cutting device of a non-woven fabric. A wedge-shaped groove is formed in one end of a first transverse plate, a wedge-shaped block is arranged at the bottom of a movable block, the movable block is slidably arranged in the wedge-shaped groove of the first transverse plate through the wedge-shaped block at the bottom, and a fixed block is fixedly arranged at the other endof the first transverse plate; a first motor is arranged on one side of the fixed block through a motor mounting base, the output end of the first motor is provided with a rotating shaft through a coupler, a cloth roller is fixedly arranged on the rotating shaft through a key, and supporting plates are vertically arranged on the two sides of a supporting base respectively; second sliding grooves are formed in the horizontal directions of the supporting plates on the two sides of the supporting base, and a partition plate is slidably connected with the interiors of the second sliding grooves ofthe supporting plates; sliding rods are arranged at the two ends of the other side of a third transverse plate respectively, and through holes allowing the sliding rods to penetrate through are formed in the partition plate; a sucker is fixedly arranged at the other end of each sliding rod.

Owner:HUZHOU PINCHUANG INCUBATOR

Fabric cutting platform

InactiveCN107234647AFast croppingAvoid Cropping Quality LossMetal working apparatusArm lengthsEngineering

The invention discloses a fabric cutting platform, which comprises a support rod, a desktop is welded on the top outer wall of the support rod, a scissor frame is connected to one side outer wall of the desktop through bolts, and a storage box is welded on the other side outer wall of the desktop. The top of the storage box is provided with an opening, the top outer wall of the desktop is welded with a bearing, the end of the bearing away from the desktop is welded with an operating table, the outer wall of the top of the desktop is welded with a connecting rod, and the outer wall of the connecting rod is welded with a connecting block, And the connecting rod is welded with a buckle through the connecting block, the end of the buckle away from the connecting block is slidably connected with the outer wall of the console, the end of the connecting rod far away from the desktop is welded with a bottom knife rest, and the outer wall of the top of the bottom knife rest is welded With bottom knife. The operating table of the present invention is connected with the desktop through bearings, so the operating table can be rotated, and it is necessary to cut the place where the length of the arm cannot reach, and only need to rotate the operating table without tilting the body or rotating the cloth.

Owner:徐广俊

Cloth cutting machine

The invention belongs to the technical field of cloth processors, and particularly relates to a cloth cutting machine. The problems such as complex structure, high cost and low working efficiency of an existing cloth cutting machine can be solved. The machine comprises a workbench, a current regulator and a switch, two knife rest plates are arranged on the workbench, and conducting rods are arranged at the upper ends of the knife rest plates; the conducting rods can slide relative to the knife rest plates, an elastic part provides elasticity for the conducting rods, and the conducting rods arearranged above and below the workbench respectively; a motor and a rolling wheel are arranged at the corresponding ends of the conducting rods respectively, and a heating wire winds the rolling wheel. The cloth cutting machine can cut raw edges of mass cloth, can cut long cloth continuously and be easy and convenient to operate, and can effectively reduce the device cost and labor cost.

Owner:湖州凯尔服饰有限公司

Presser foot positioning device for garment tailoring

Owner:池州市卓尔服饰有限公司

Automatic cutting device for graphene textile material winding

InactiveCN112173796AFor precise cuttingAvoid disorderSevering textilesWebs handlingStructural engineeringGraphene

The invention relates to the technical field of graphene textile winding and cutting, and discloses an automatic cutting device for graphene textile material winding. The automatic cutting device comprises a box body, wherein first springs are welded to the two sides of the inner bottom wall of the box body, and moving boxes slidably connected with the inner walls of the two sides of the box bodyare welded to the tops of the first springs. According to the automatic cutting device for graphene textile material winding, by mounting the box body, the moving boxes, closing coils, magnet sets, electromagnets, magnets and other structures, when rotating rollers receive materials, the weight of the rotating rollers can be increased, the closing coils are driven to do magnetic induction line cutting motion in the magnet sets, when the weight of the material receiving rollers reach a certain degree, the electromagnets are non-magnetic, cutting blades cut off the rolled graphene cloth under the action of second springs, the cloth can be cut off quickly and accurately, the cutting speed is high, the precision is high, materials are saved, operation is flexible and convenient, the working time of workers is shortened, and the production efficiency is improved.

Owner:唐天玲

A device for processing corrugated paper

Owner:BENGBU ZHENHUA PACKING MACHINERY

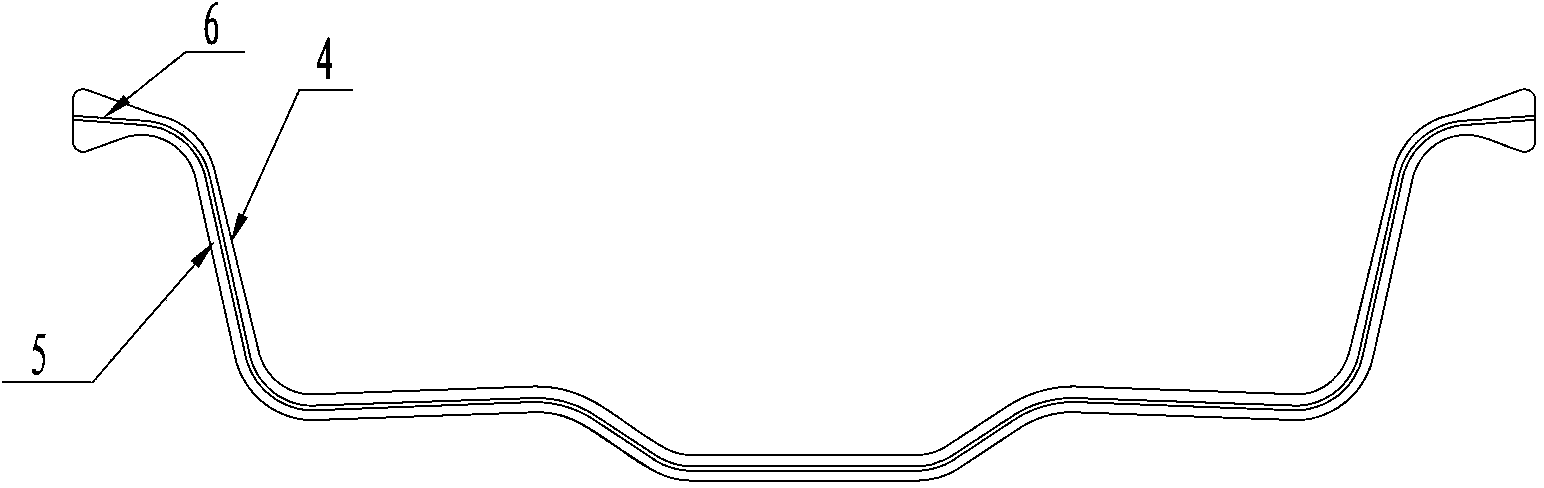

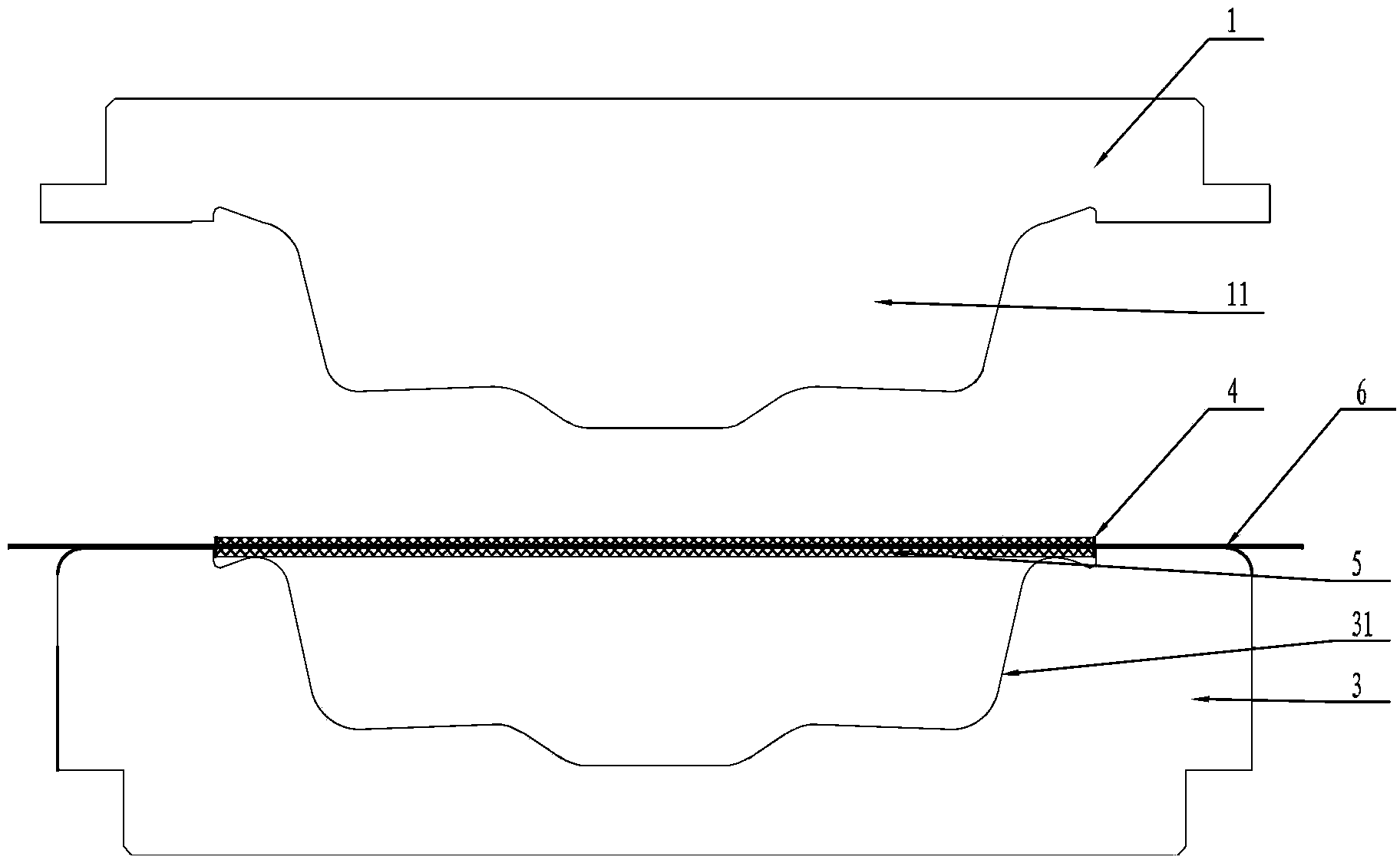

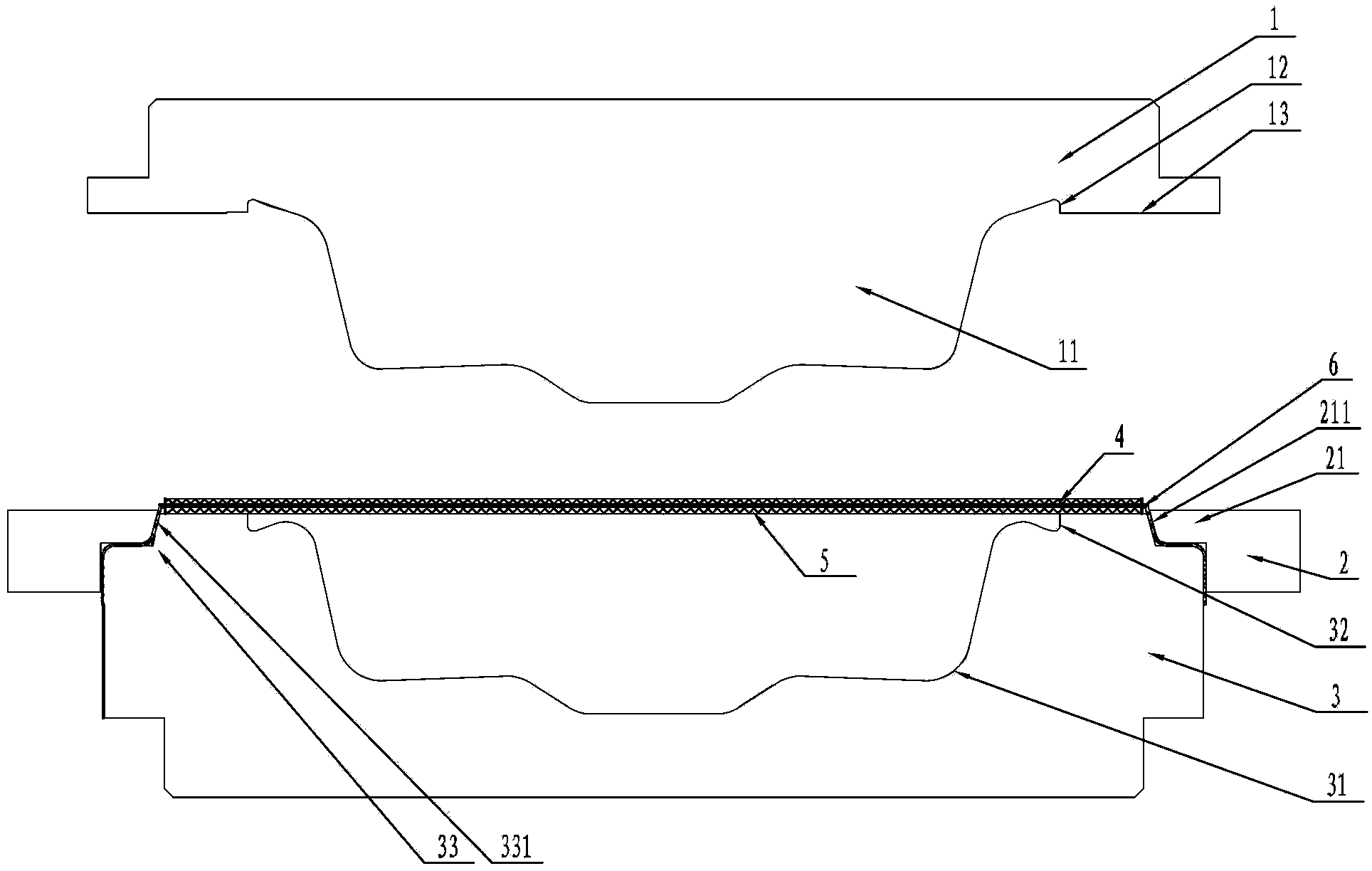

Mould, mould base and process for one-time forming of canvas of air chamber rubber diaphragms

The invention discloses a mould, a mould base and a process for one-time forming of canvas of air chamber rubber diaphragms. The mould comprises an upper mould and a lower mould, an upper flange corresponding to an air chamber rubber diaphragm in shape is formed on the lower side of the upper mould, and a lower concave cavity corresponding to the upper flange of the upper mould in shape is formed on the upper side of the lower mould. The mould is characterized by further comprising a sleeve ring which can be used for pre-tightening of canvas, and the sleeve ring can be pressed and fastened to the upper outer edge of the lower mould. The sleeve ring is added for pre-tightening of the canvas, so that the requirement on canvas face in forming is low. The canvas can be square selectively, and tailoring is facilitated while tailoring speed can be increased. In addition, the problem of centering in one-time forming of the canvas is well solved, and problems of small inclination and exposure of the canvas are further solved.

Owner:宁波乔士橡塑有限公司

A continuous printing cardboard cutting processing equipment

ActiveCN106003824BGuaranteed flat and perfectImprove cropping accuracyBox making operationsPaper-makingCardboardEngineering

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

Medical fiber material preparation machine

InactiveCN113338020AFast croppingEasy to bring up the situationSevering textilesMetal working apparatusFiberStructural engineering

The invention discloses a medical fiber material preparation machine. The medical fiber material preparation machine structurally comprises a cutting mechanism, an operating floor and a base, the bottom of the operating floor is welded to the top of the base, the cutting mechanism is installed at the top position of the operating floor, and a movable ball can rotate through friction generated by the tangent plane of medical fiber cotton cloth to the movable ball, so that a cutting blade can smoothly cut off medical fiber cotton cloth; then an external expansion plate can extend outwards through thrust generated by a boosting blade to the external expansion plate, and therefore the section of the medical fiber cotton cloth can be pushed away from the surface of a knife switch; and the cutting blade contracts upwards to extrude the stress block, the stress block can be contracted upwards along a bearing plate, so that the contracted stress block can be buffered by a buffer plate, and then the cutting blade can be pressed by a lower pressing plate, so that the medical fiber cotton cloth can be better cut off by the cutting blade.

Owner:蔡彬彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com