Patents

Literature

93results about How to "Quick crop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

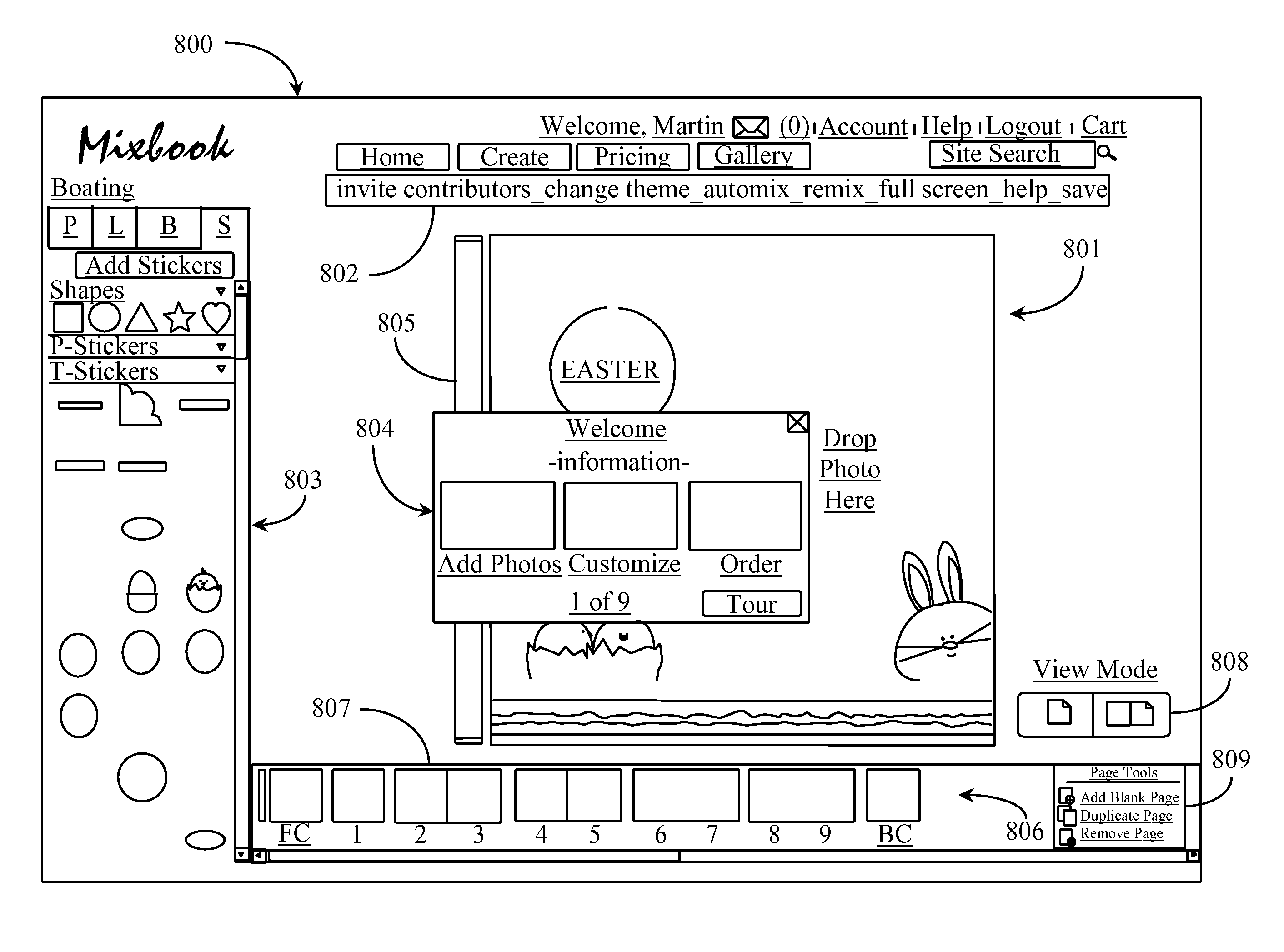

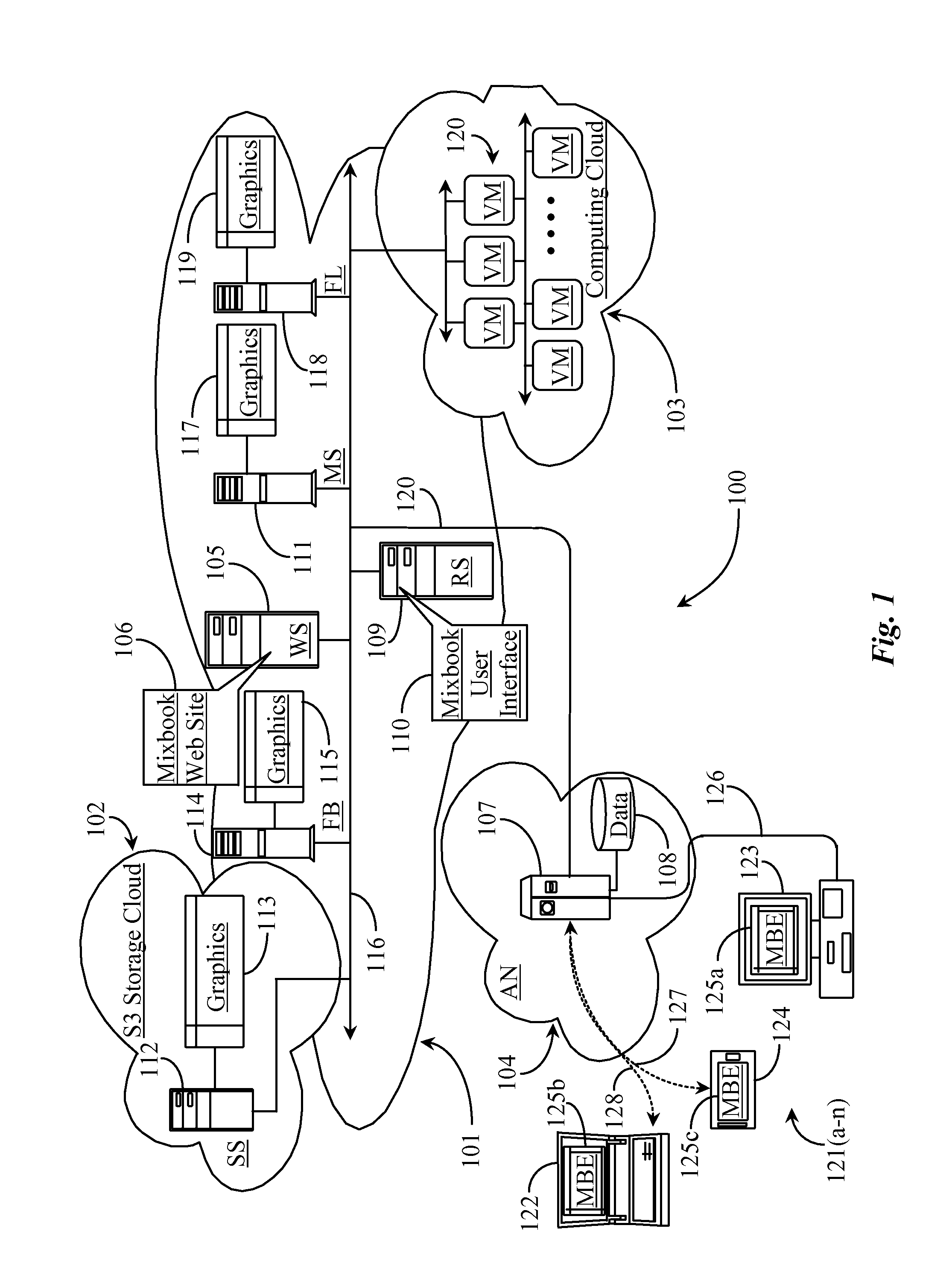

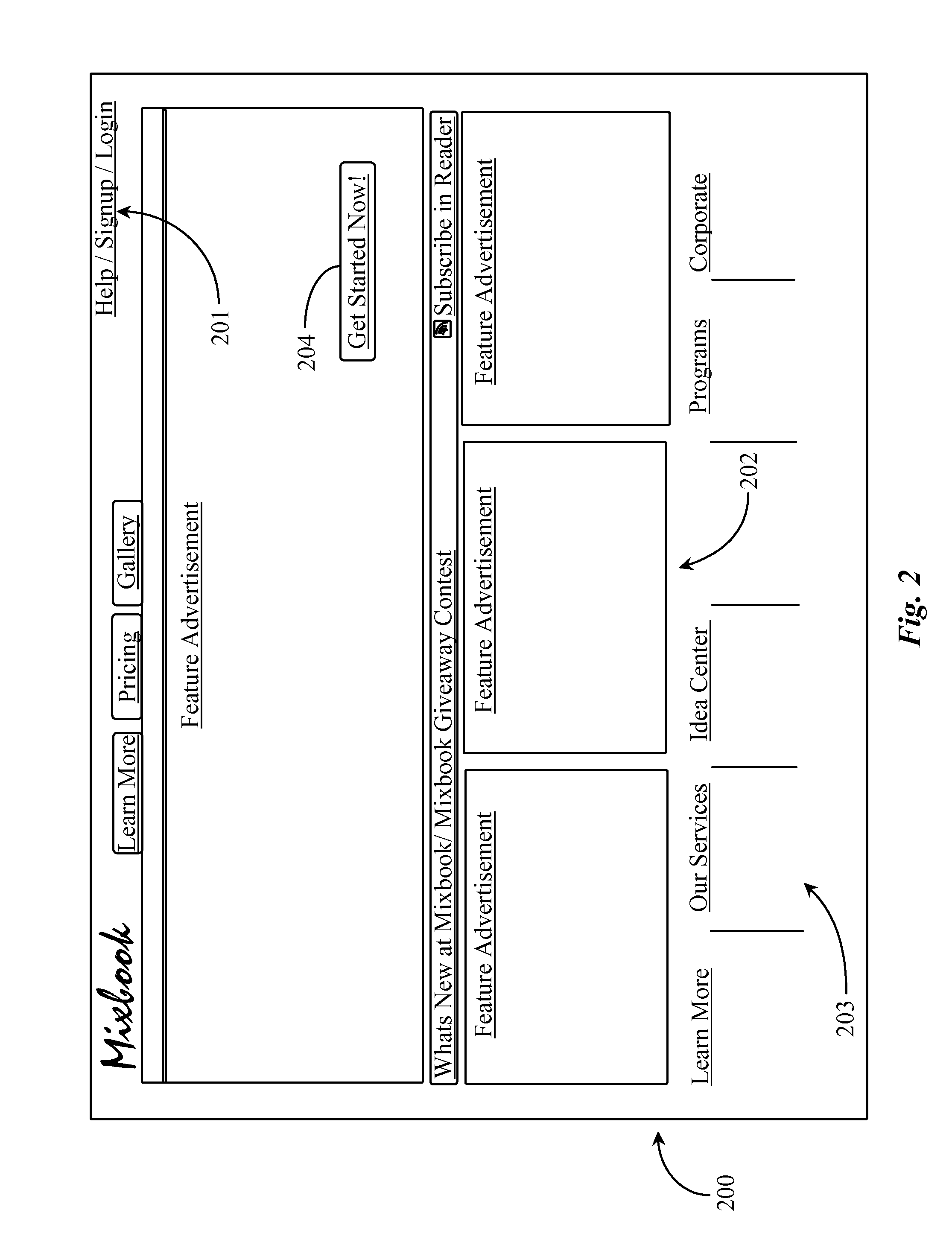

Interactive Image Container Integrated as an Image or Photo Cropping Tool in an Online Collage-Based Editor

InactiveUS20110016419A1Quick cropImprove efficiencyCharacter and pattern recognitionStill image data indexingGraphical user interfaceImage processing

In a system for creating and editing image and or text-based projects including a server connected to a data network, the server having access to a digital medium containing an executable graphics user interface (GUI) for contributing and for editing content, the GUI accessible by computer browser, an interactive image container integrated as an image or photo cropping tool in the GUI includes an image display window of a predefined geometric configuration disposed on a project page for containing and displaying an image that has been placed thereon, and an image handle associated with the image container, the image handle visible on highlight or selection of the image within the image container.

Owner:INTERACTIVE MEMORIES

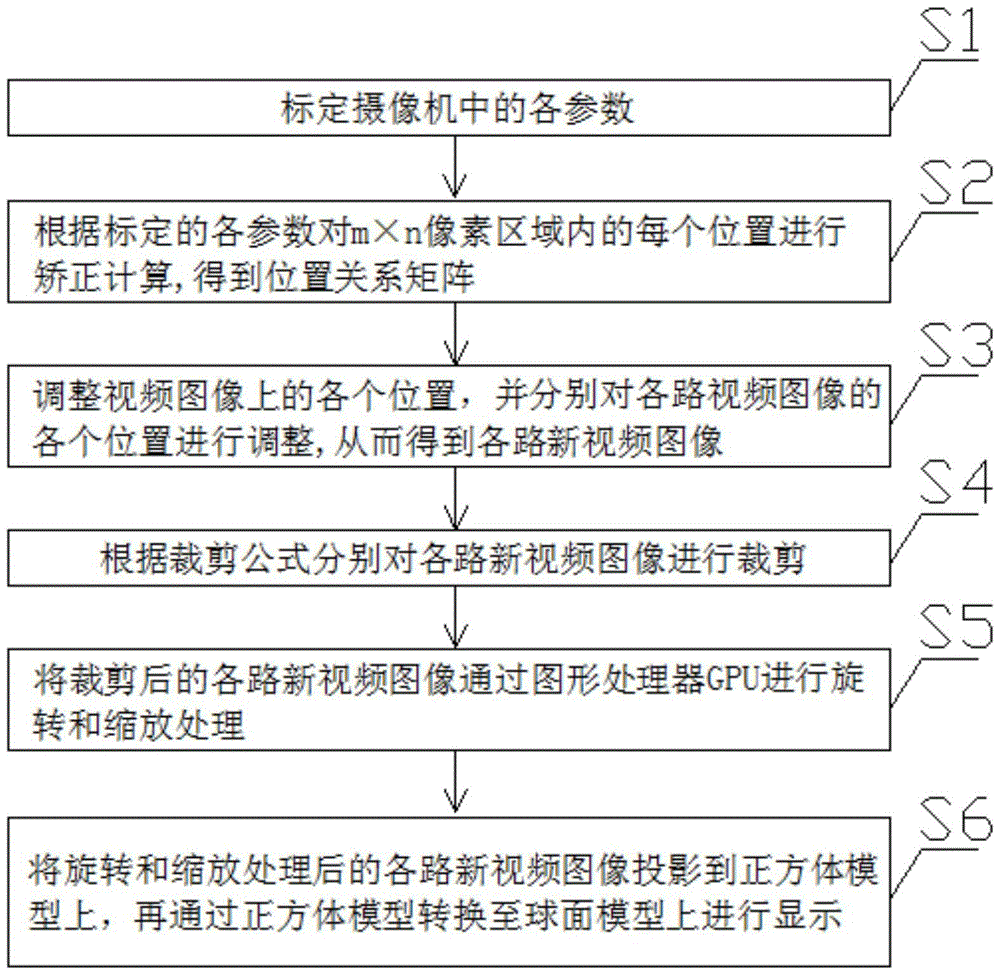

Spherical mosaic method and system of video image

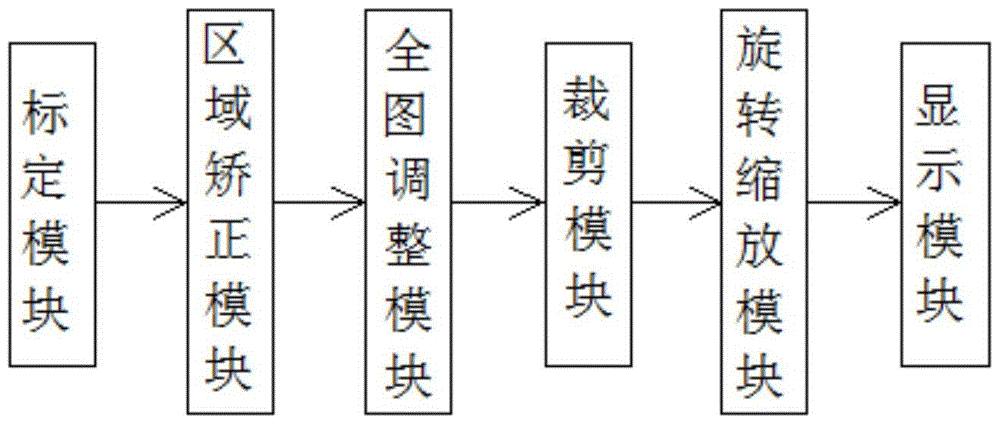

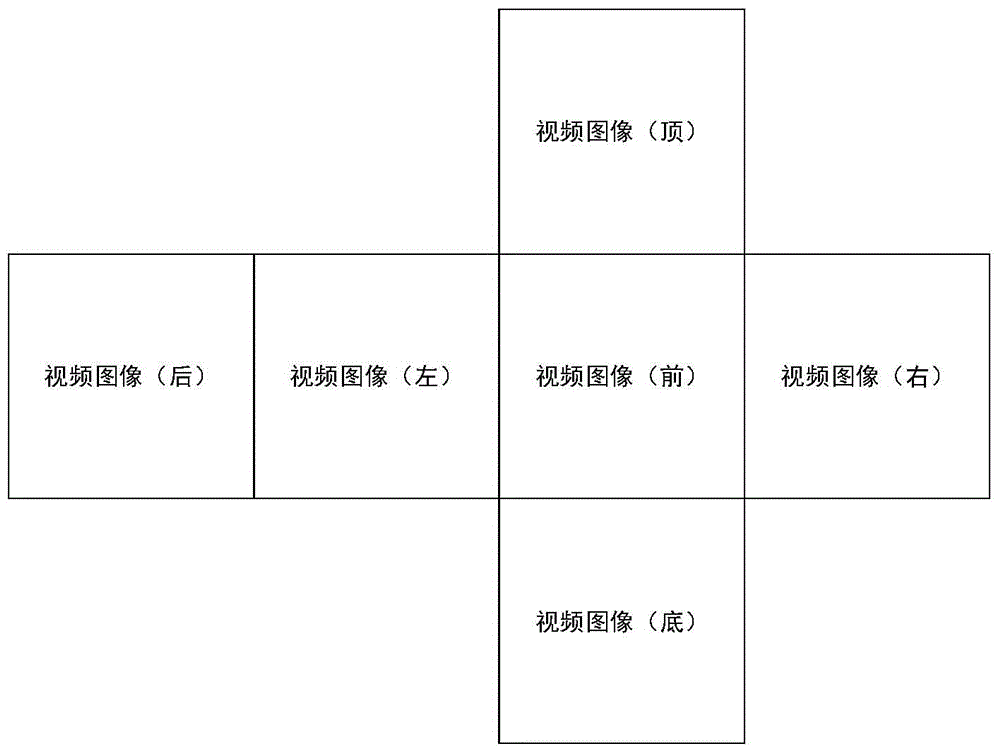

ActiveCN105741233ARequires low configurationSpherical splicing method is simpleGeometric image transformationGraphicsVideo image

The invention provides a spherical mosaic method and system of a video image. The system comprises a calibration module, an area correction module, a total graph regulation module, a cutting module, a rotating and scaling module and a display module, wherein the calibration module is used for calibrating each parameter in a camera; the area correction module is used for correcting each position in a set area; the total graph regulation module is used for regulating each position in each path of video image; the cutting module is sued for cutting each path of video image; the rotating and scaling module is used for rotating and scaling each path of video image; and the display module is used for displaying on a spherical model. The spherical mosaic method realized by the invention is simple and is low in configuration required by a computer, each path of video image is independently processed and does not mutually interfere, and therefore, processing speed is high. High instantaneity still can be obtained under the mosaic of multiple paths of high-resolution cameras. The system can be applied to real-time video mosaic and is combined with an OpenGL (Graphics Library) graphic program interface to project each path of image to be displayed on the spherical model to achieve a good display effect; and meanwhile, the system is suitable for the mosaic of a wide angle camera and has the advantages of small blind point area and high practicality.

Owner:GUILIN CHANGHAI DEV

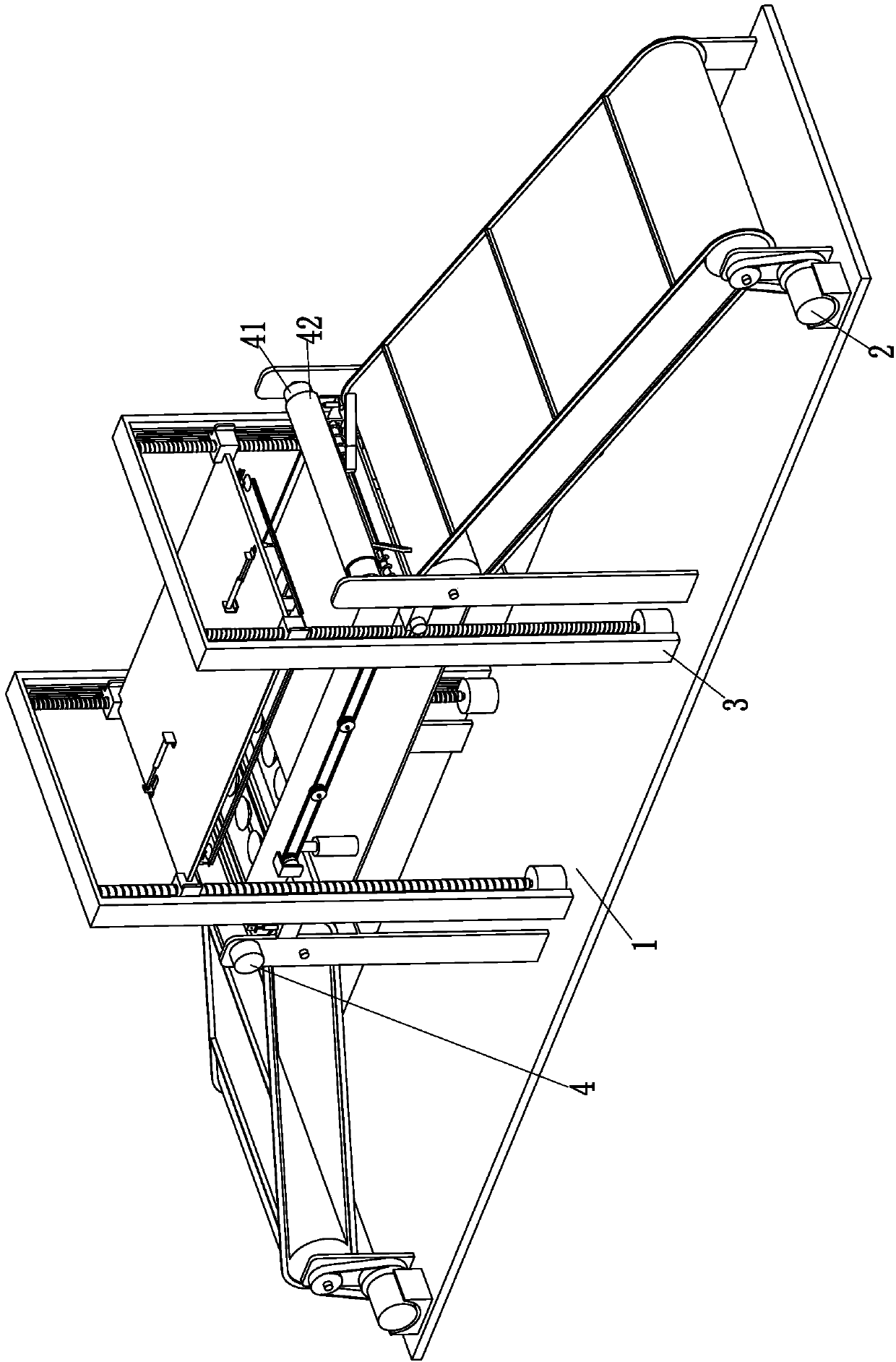

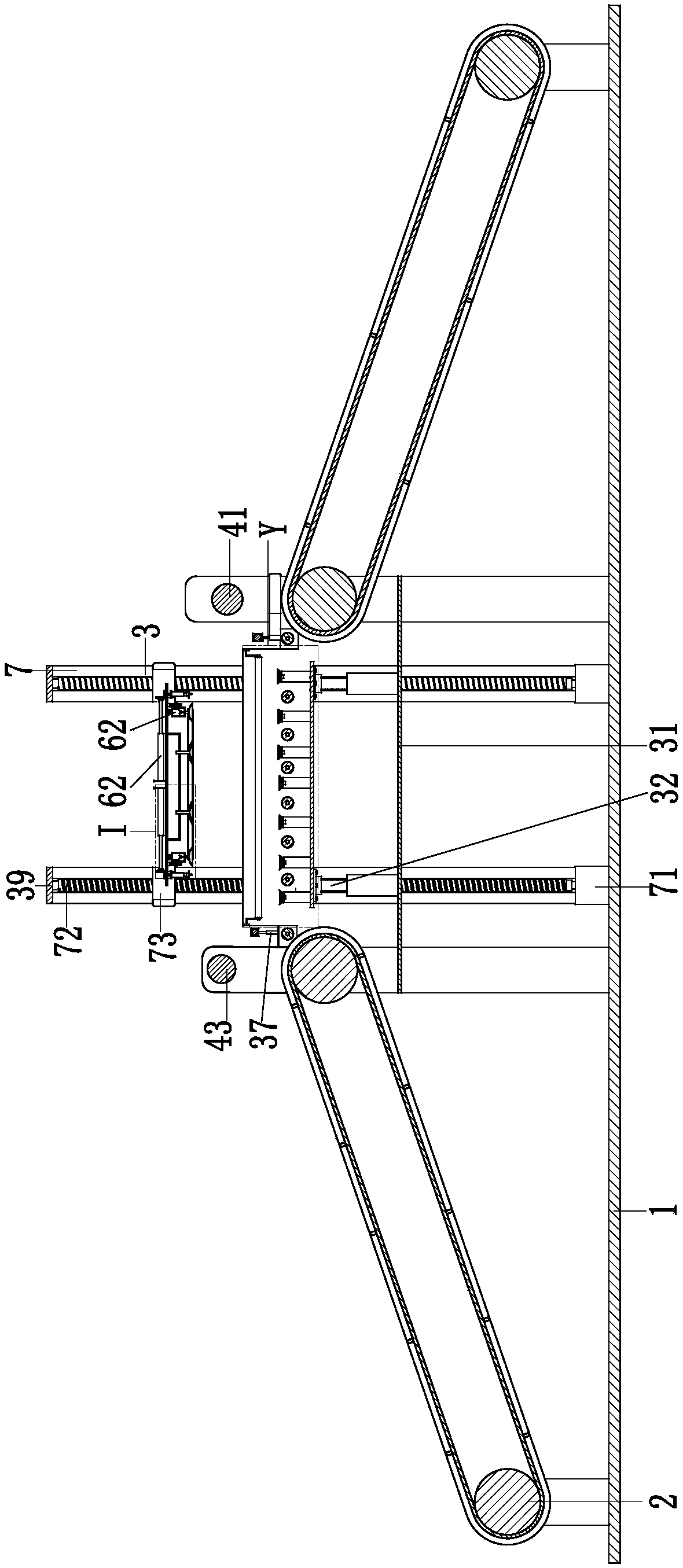

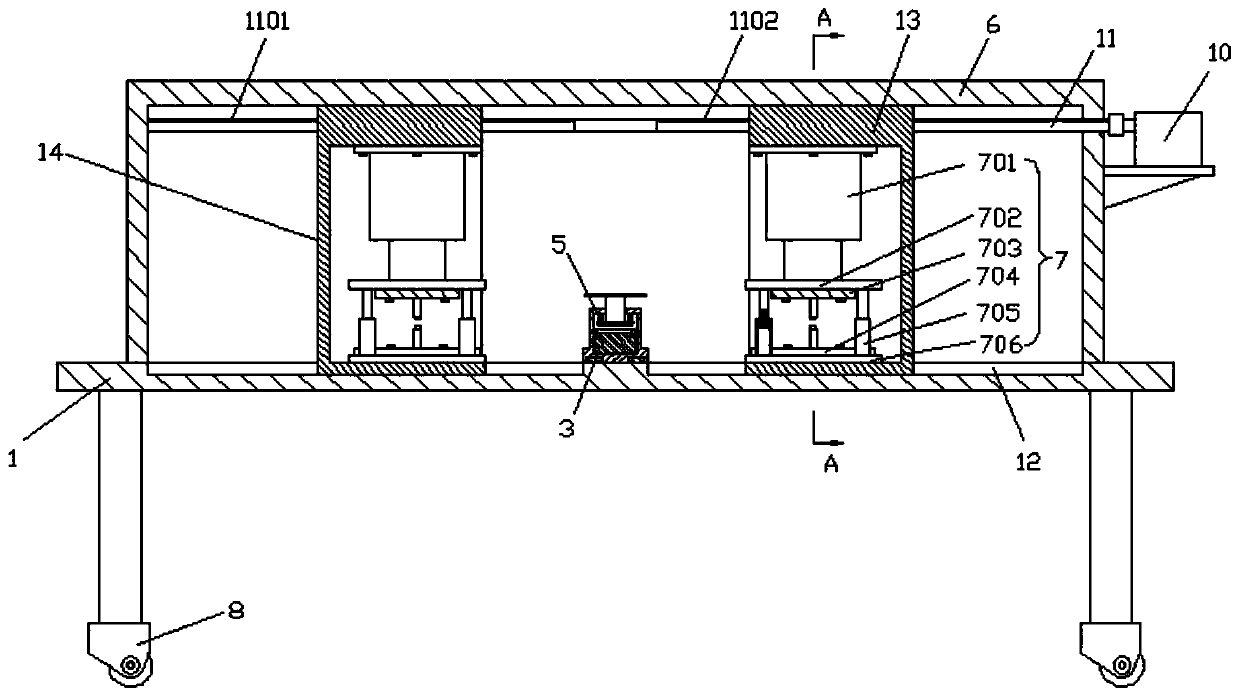

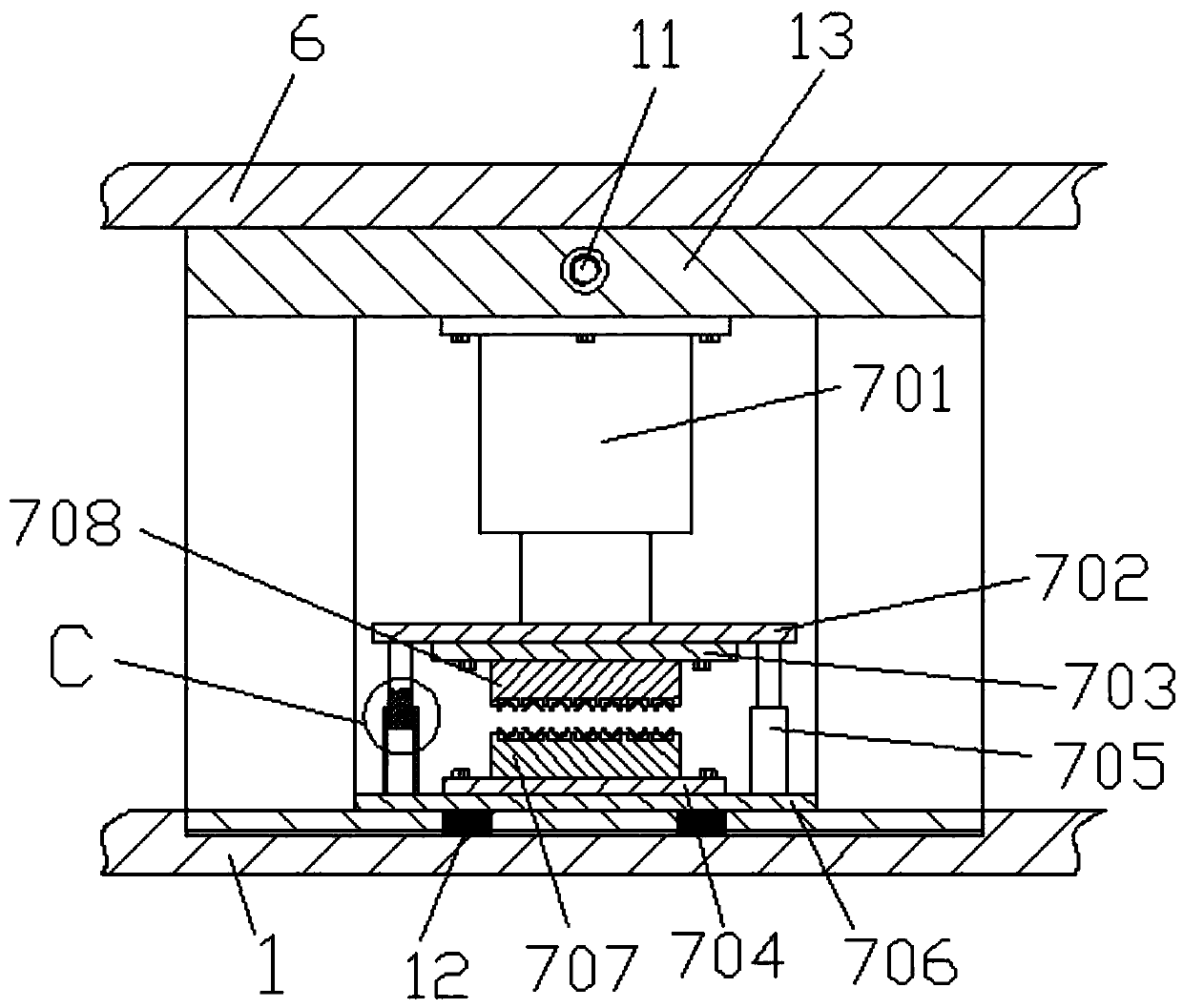

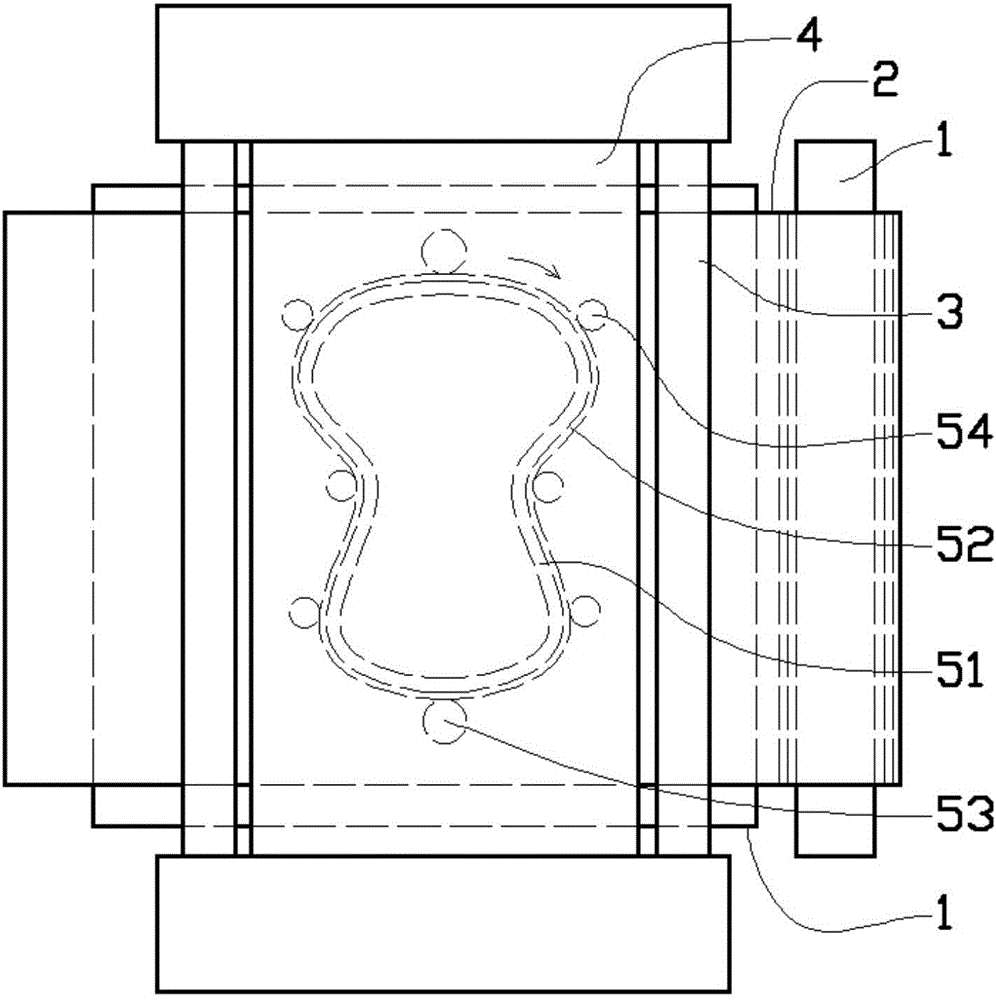

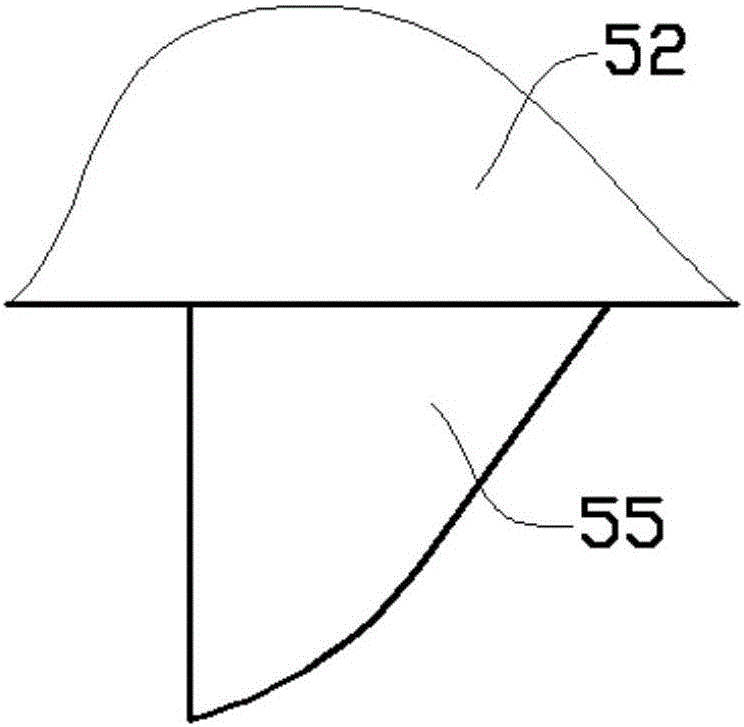

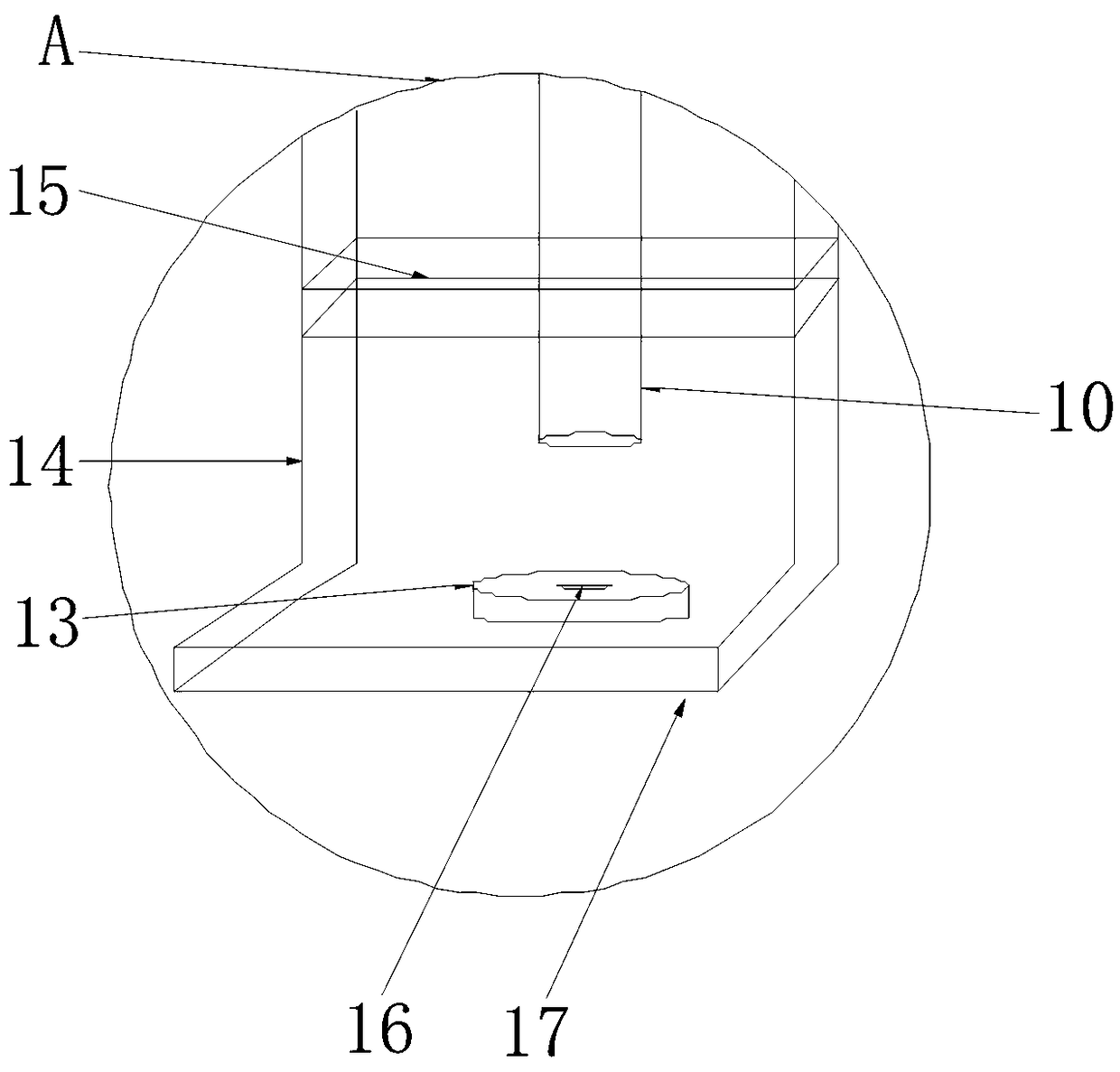

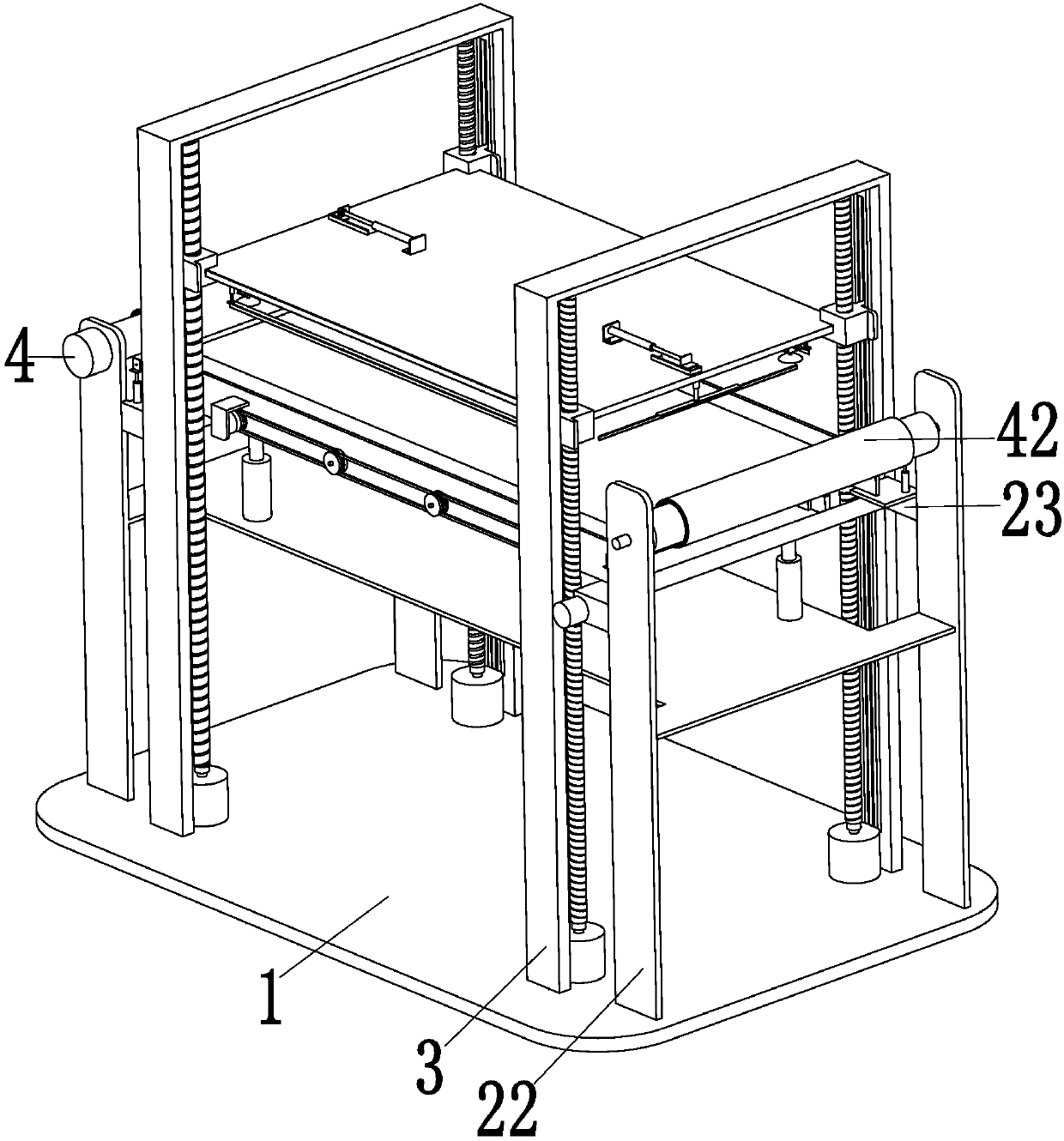

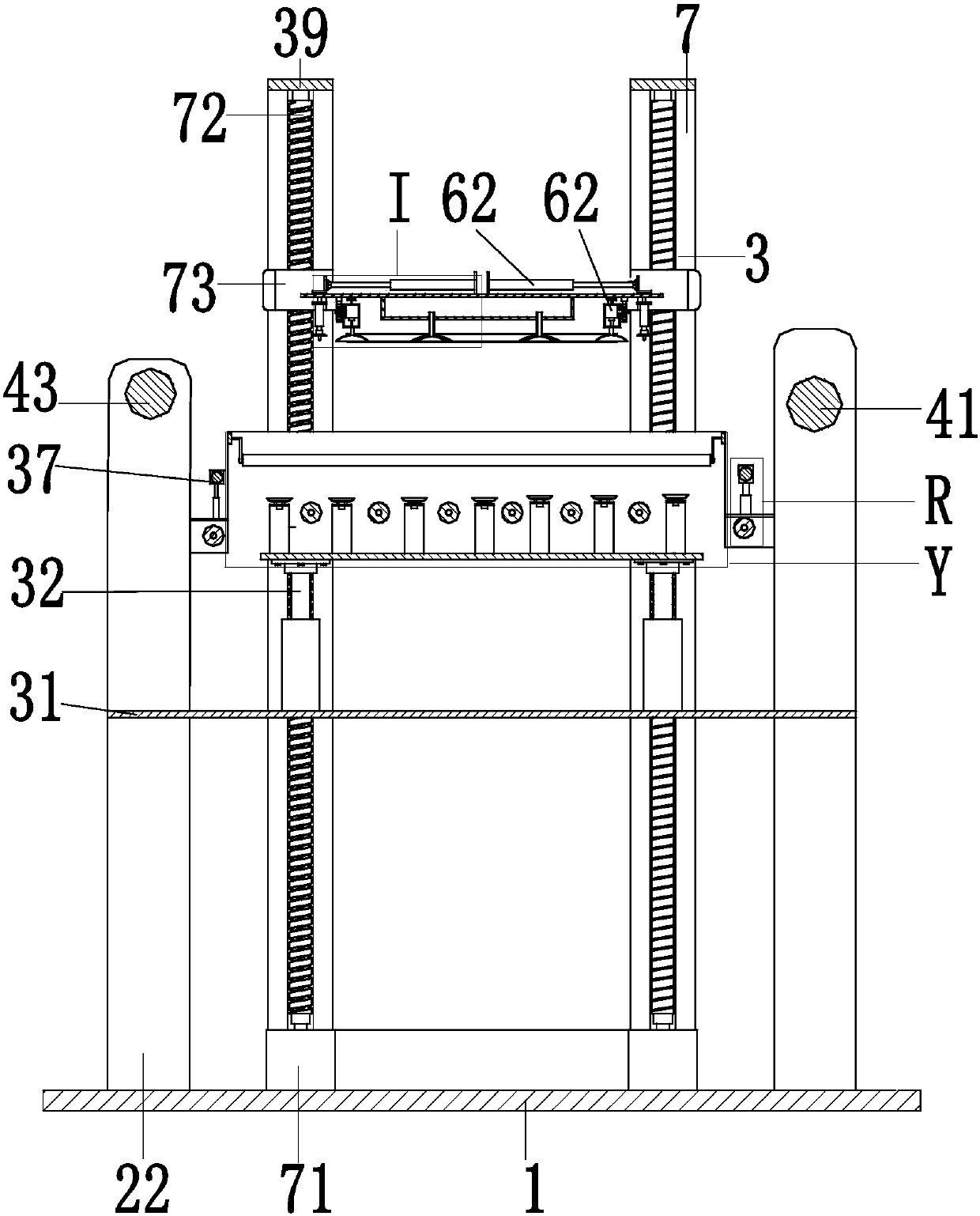

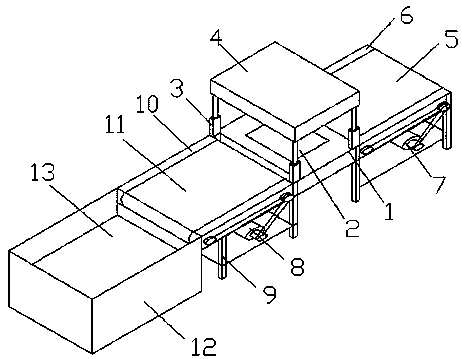

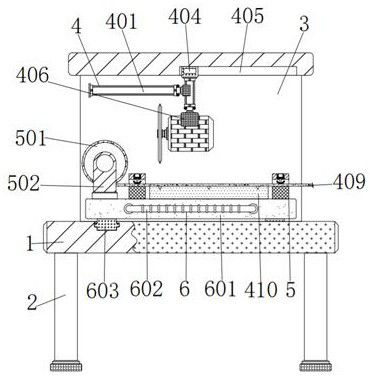

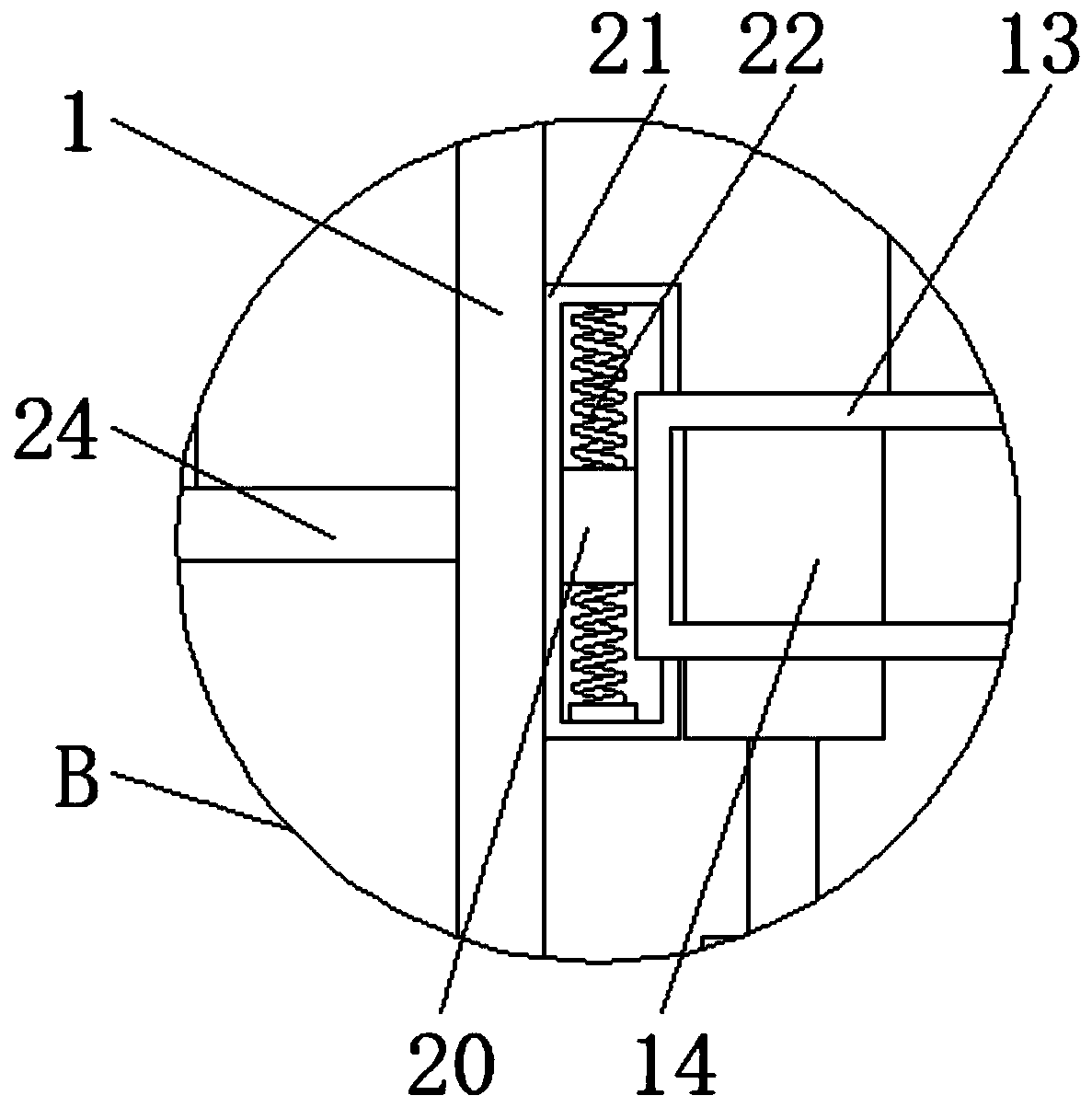

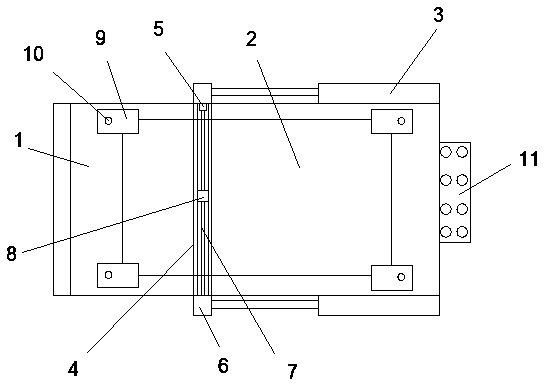

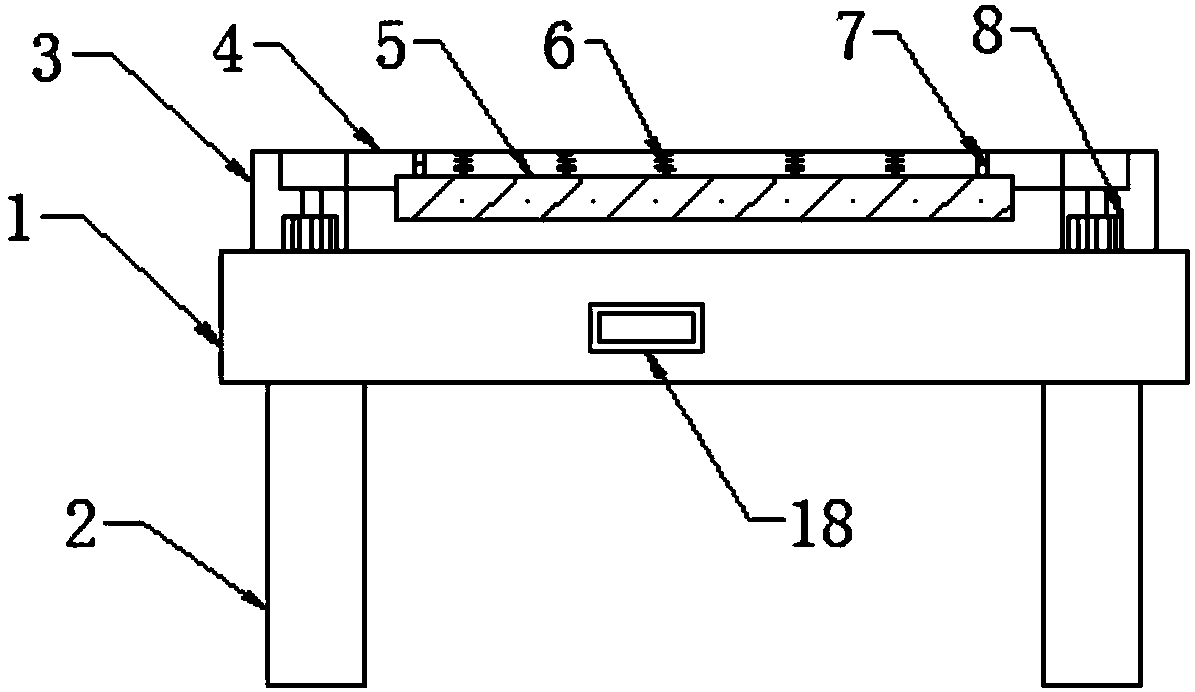

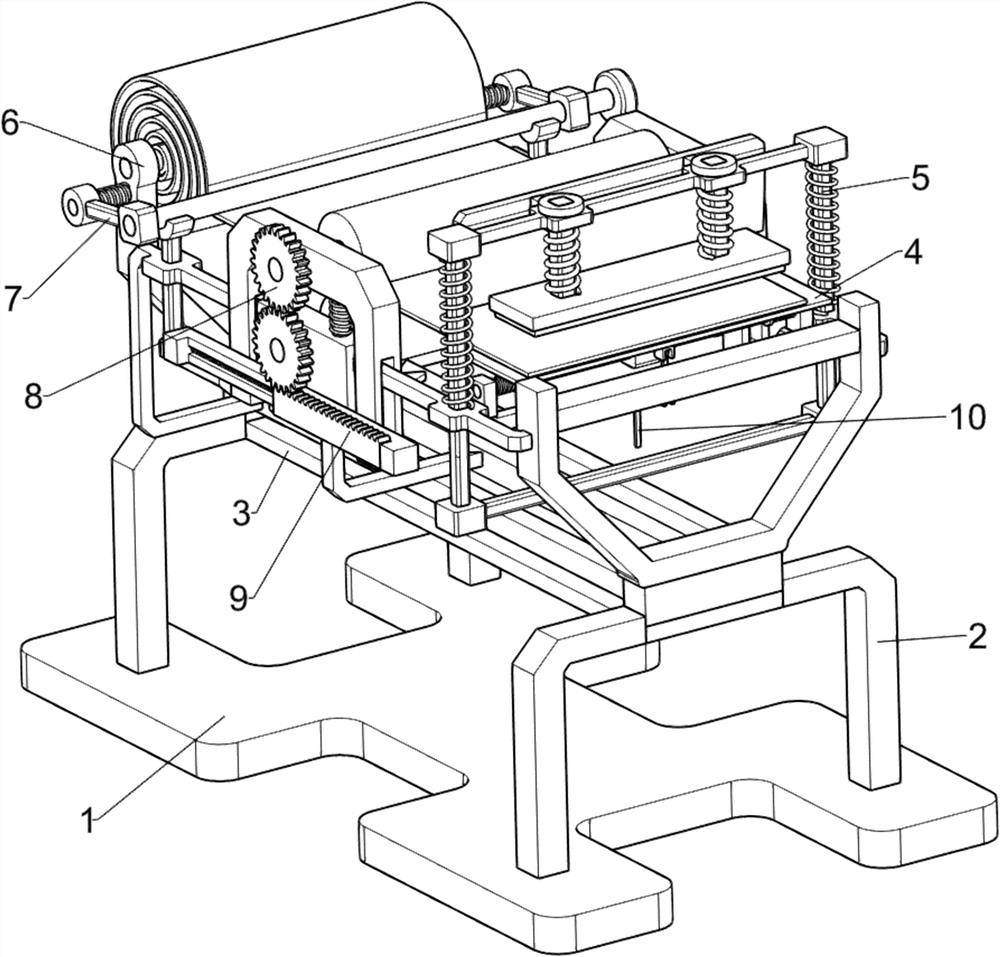

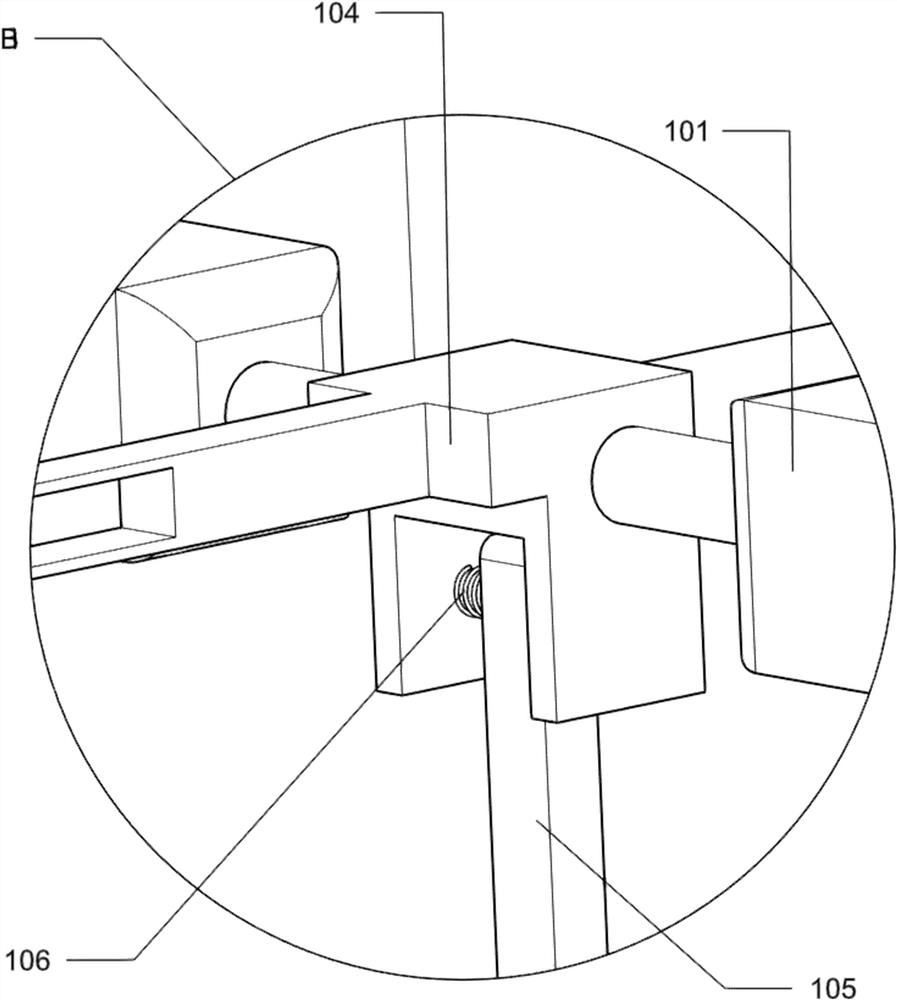

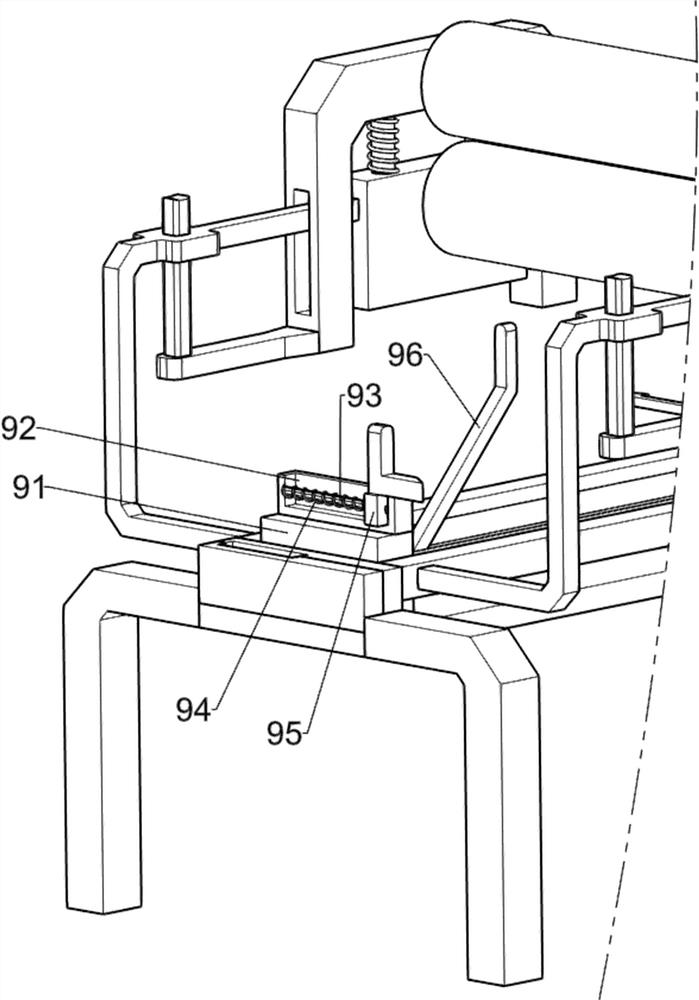

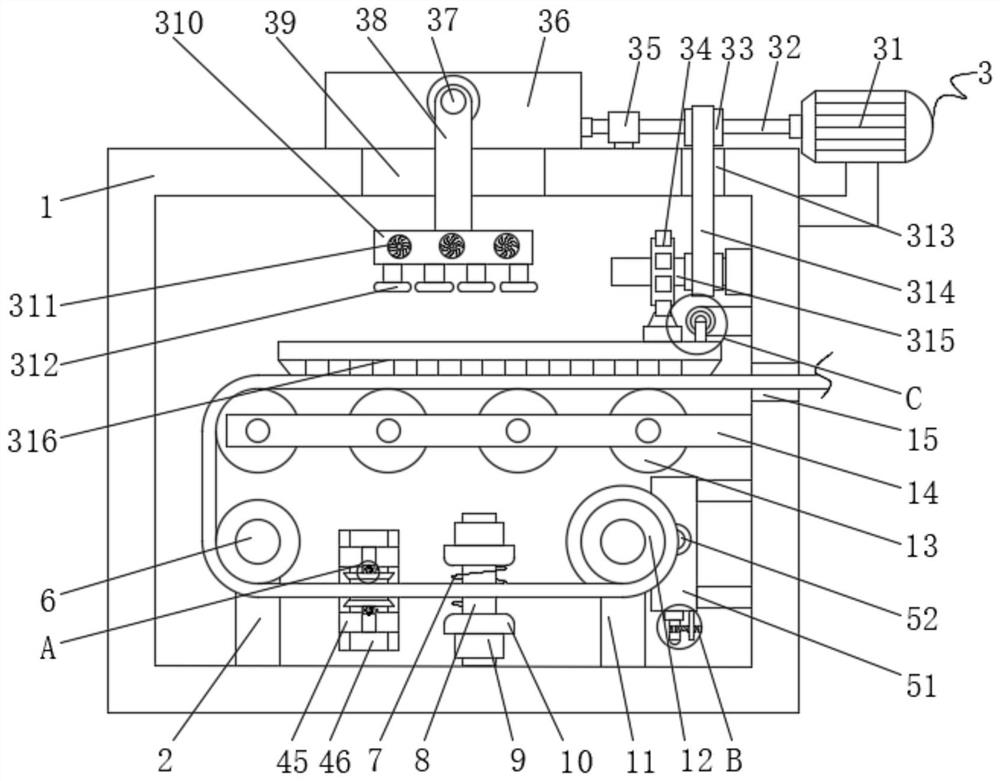

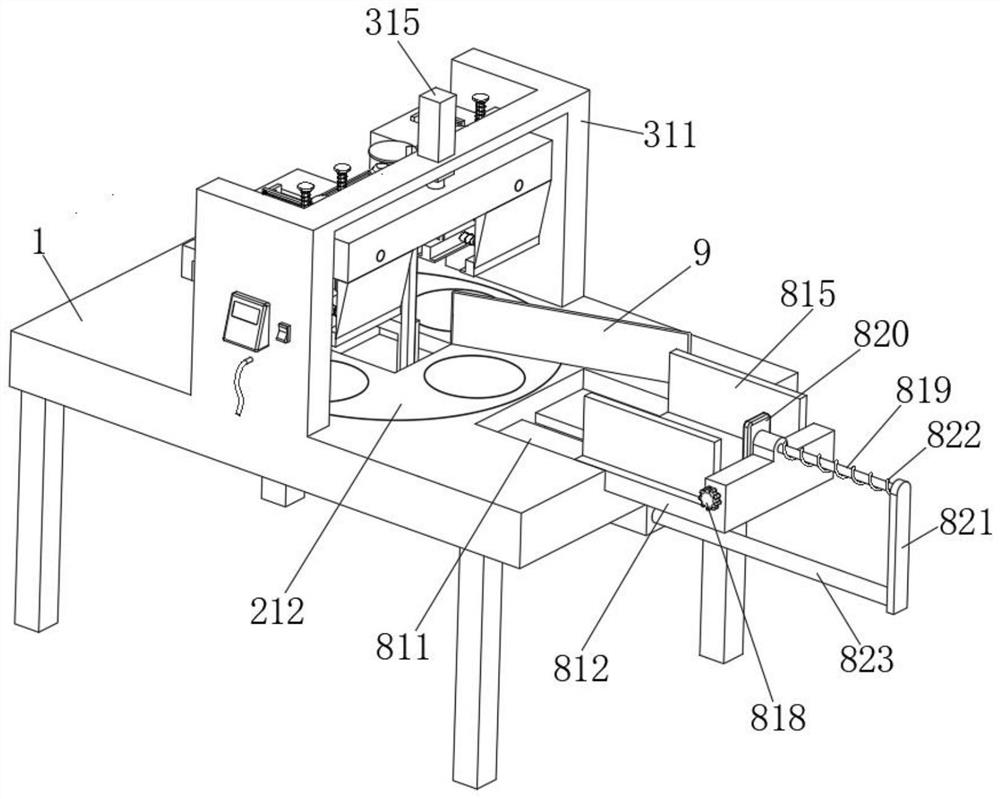

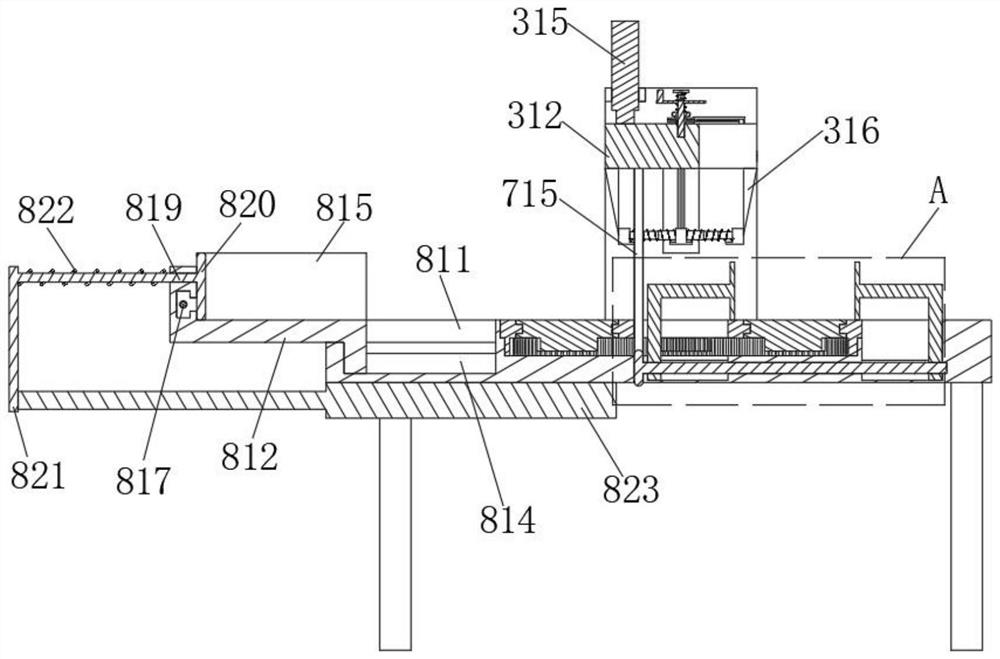

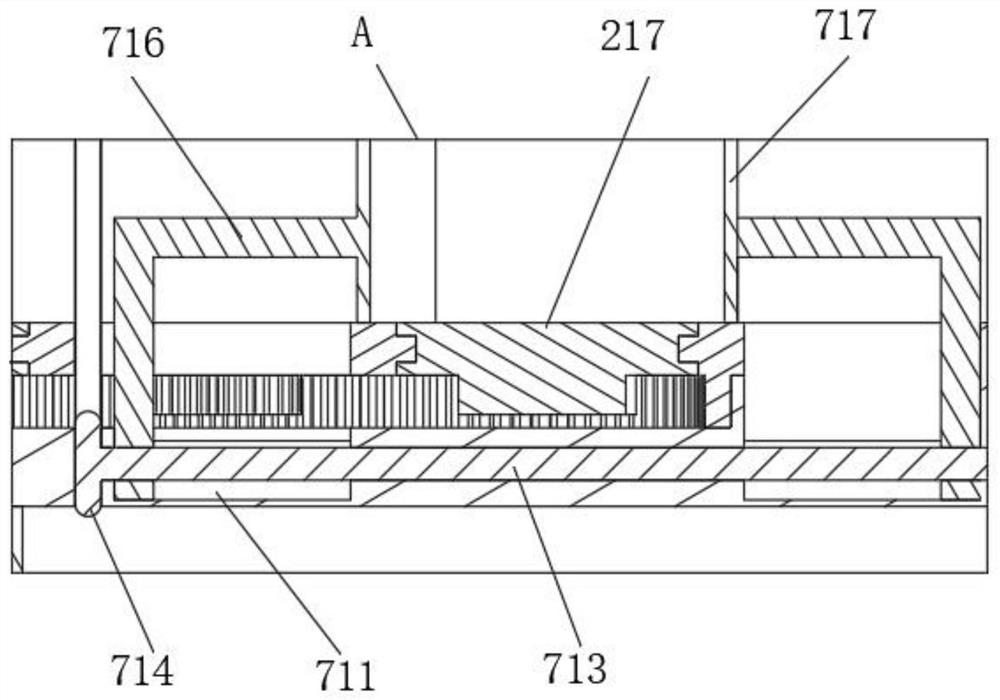

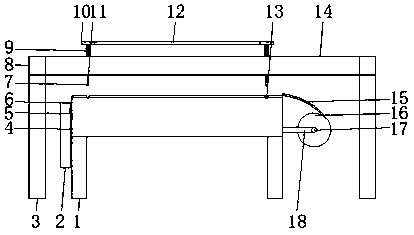

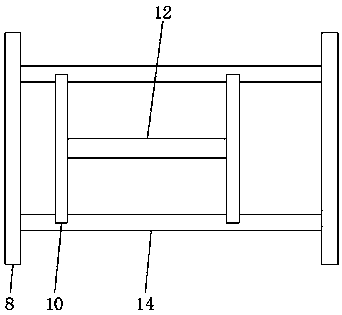

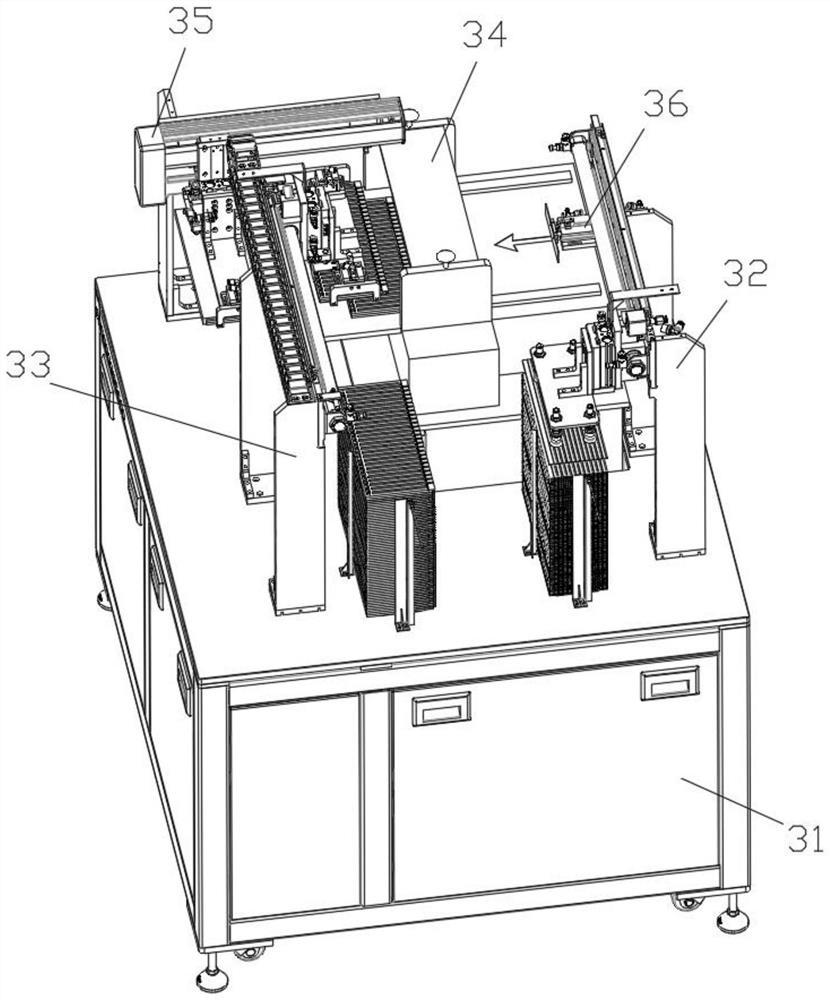

Automatic laminating processing equipment of container house flat color steel plate

ActiveCN107757045AHigh precisionImprove stabilityLamination ancillary operationsLaminationSteel platesEngineering

The invention relates to automatic laminating processing equipment of a container house flat color steel plate. The automatic laminating processing equipment of the container house flat color steel plate comprises a bottom plate; two conveying devices are symmetrically arranged on the bottom plate; a winding device is arranged between the two conveying devices; a conveying and laminating device isarranged between the two conveying devices; and the two conveying devices, the winding device and the conveying and laminating device are cooperatively used to finish the automatic laminating processof the color steel plate. The automatic laminating processing equipment of the container house flat color steel plate can solve the problems that the existing flat color steel plate laminating equipment cannot laminate the upper end and the lower end of the flat color steel plate in the laminating process of the existing flat color steel plate, the flat color steel plate is liable to move under the action of an external force in laminating processing process of the existing laminating processing equipment by the flat color steel plate laminating equipment, the flat color steel plates with different sizes need to be adjusted manually during laminating processing, the precision degree is slow, the labor intensity is large, the time consumption is high, the stability is low, the working efficiency is low and the like, and can realize the function of automatically laminating the container house flat color steel plate.

Owner:新沂市新南环保产业技术研究院有限公司

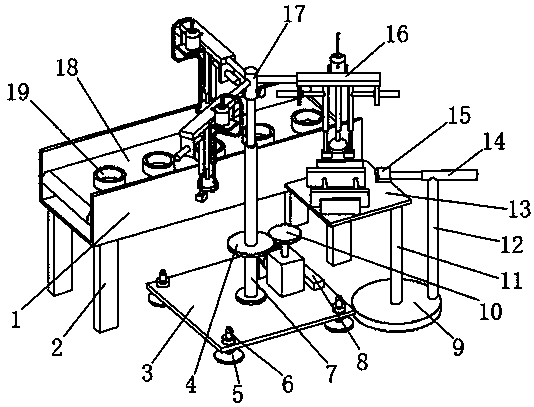

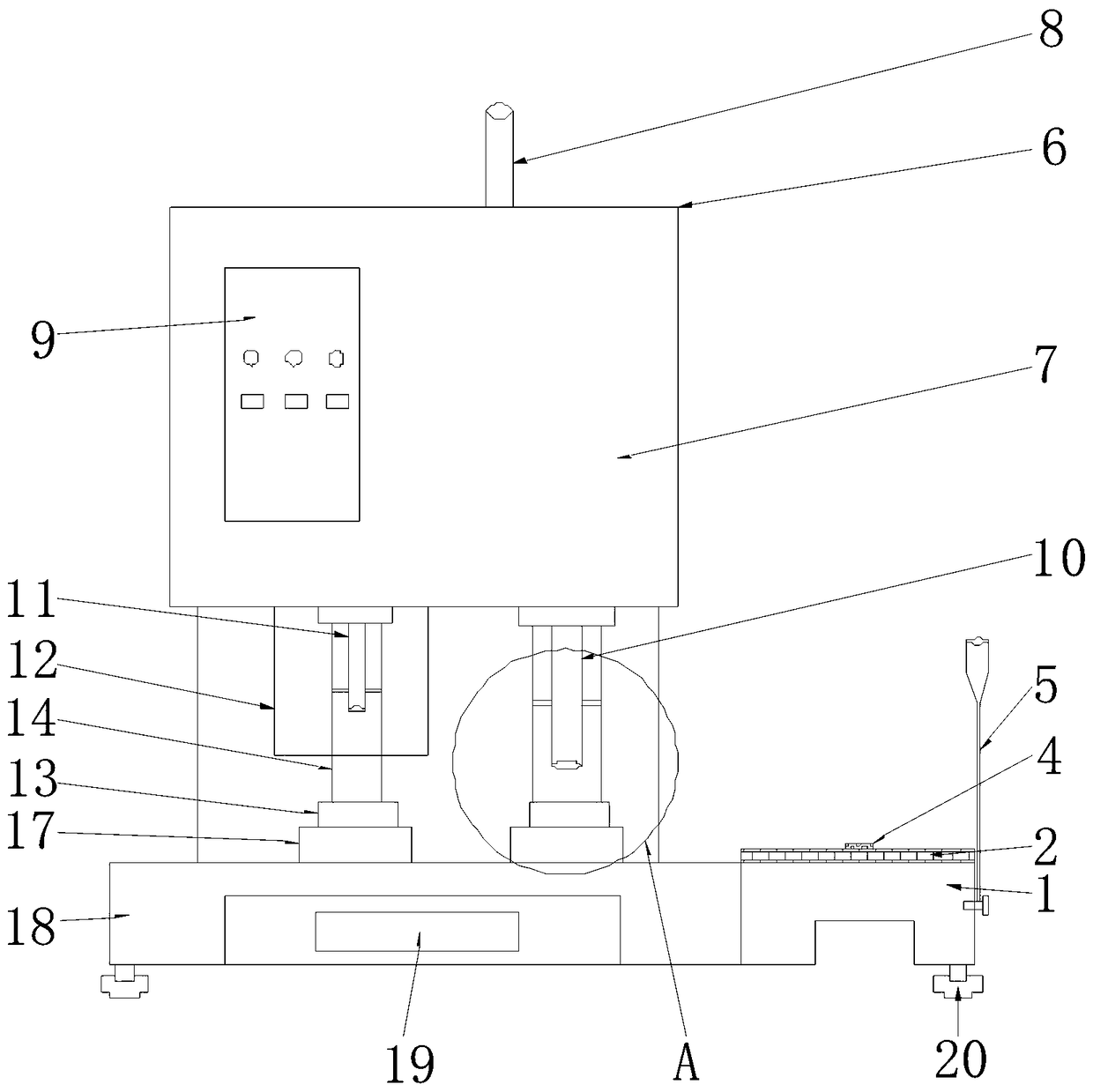

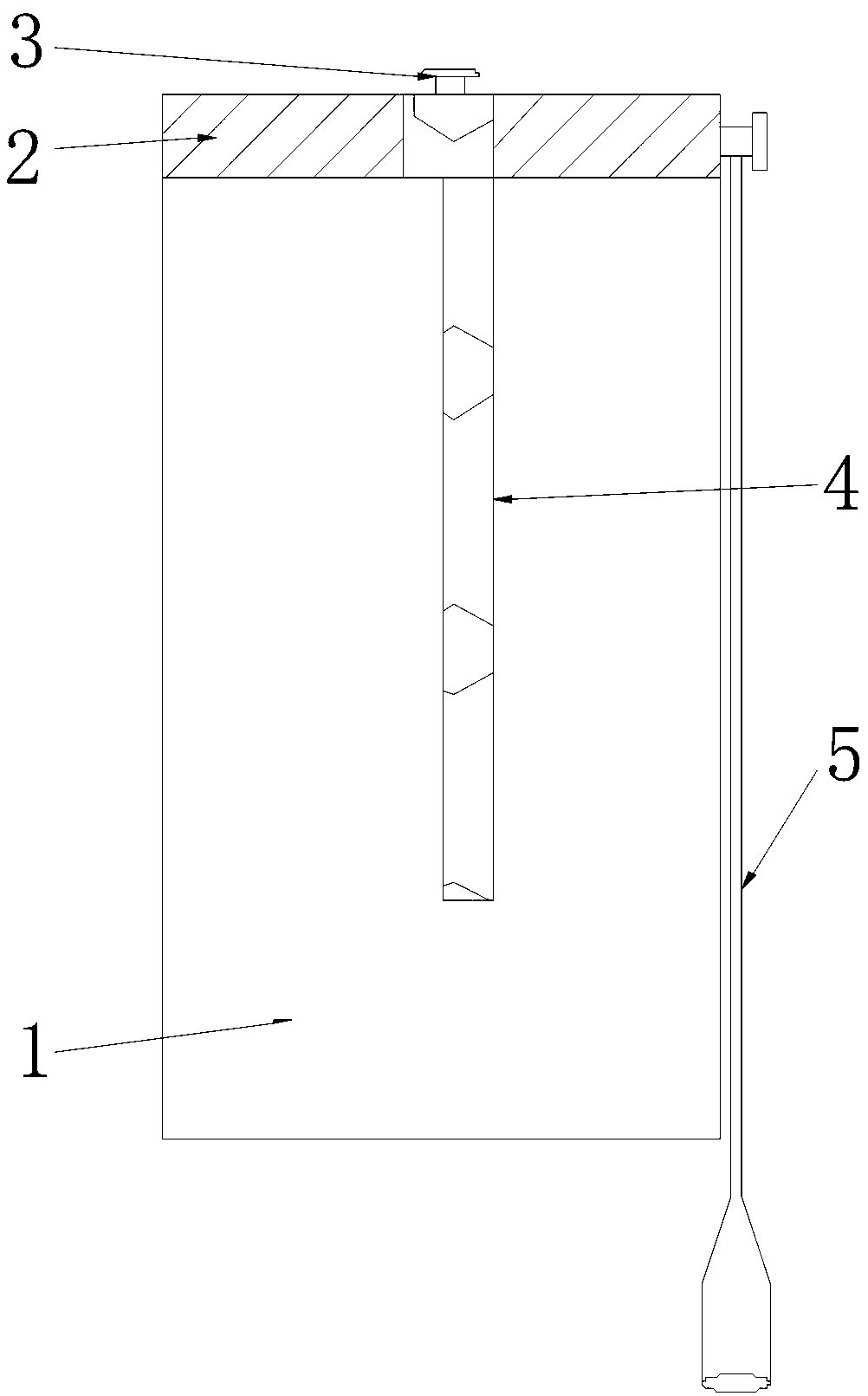

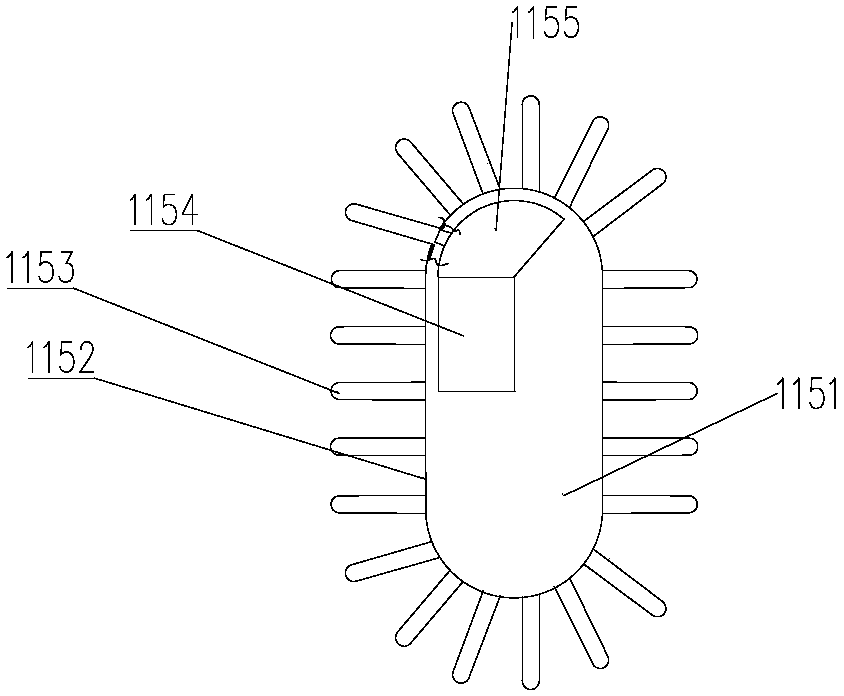

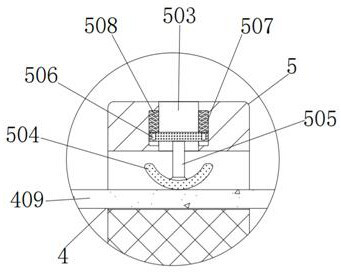

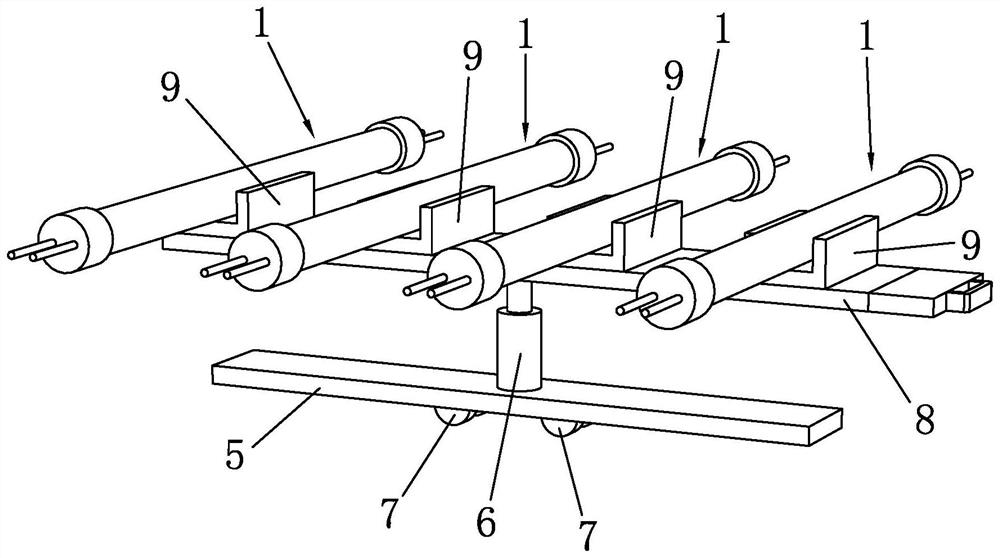

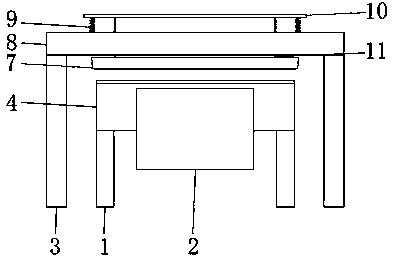

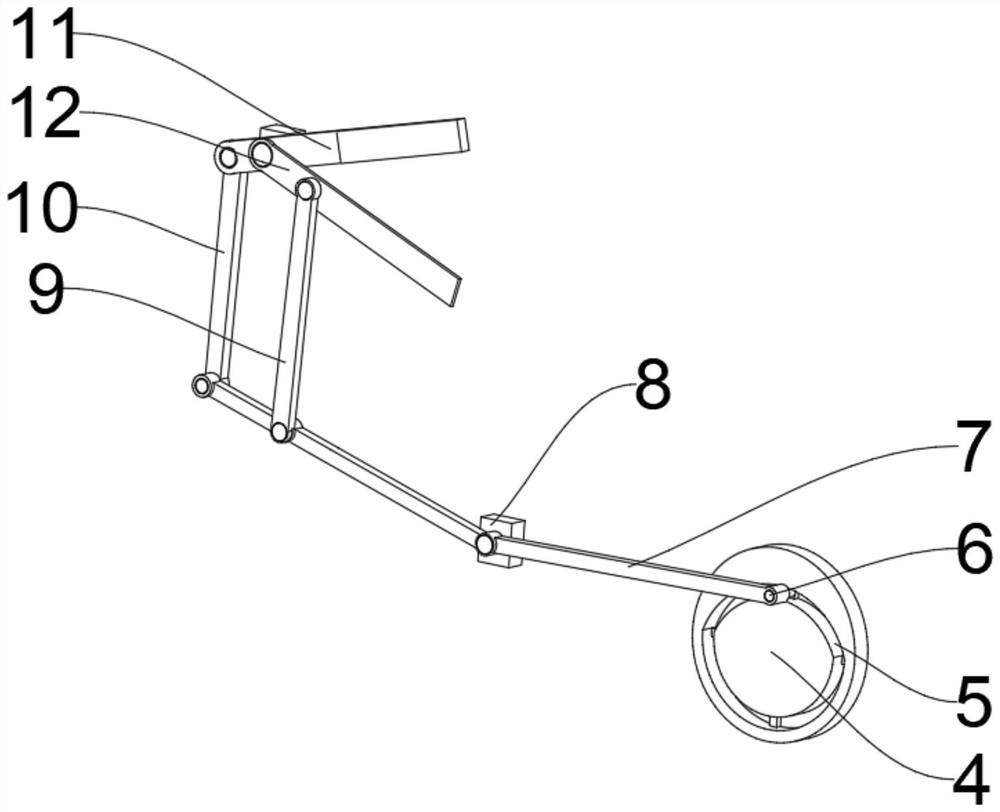

Semi-automatic pearl wool net sleeving device for fruits and vegetables

InactiveCN110053800ACompact structureEasy to operateMetal working apparatusPackaging fruits/vegetablesSemi automaticEngineering

The invention discloses a semi-automatic pearl wool net sleeving device for fruits and vegetables. The semi-automatic pearl wool net sleeving device for the fruits and vegetables comprises a base. According to the semi-automatic pearl wool net sleeving device for the fruits and vegetables, the structure is compact, operation is convenient, the occupation space is small in the using process, and the outer surfaces of the fruits and vegetables can be quickly and efficiently sleeved with pearl wool nets; fruit and vegetable positioning grooves are formed, therefore, the fruits and vegetables canbe clamped and fixed, and positioning in the fruit and vegetable sleeving process is convenient; a sleeve is arranged, and therefore lifting adjusting of U-shaped positioning plates is convenient; anair pump and an umbrella-shaped air bag are arranged, therefore, the pearl wool nets can be quickly opened, and sleeving connection of the pearl wool nets is convenient; a third electric telescopic rod is arranged, and therefore lifting adjusting of the umbrella-shaped air bag is convenient; electric fixtures are arranged, and therefore clamping and positioning of the pearl wool nets are convenient; the pearl wool nets can be automatically connected in a sleeving mode through fourth electric telescopic rods; upper-end openings of the pearl wool nets can be quickly opened through fifth electrictelescopic rods; and positioning studs are arranged, and therefore lifting adjusting of anti-skid blocks is convenient.

Owner:李占福

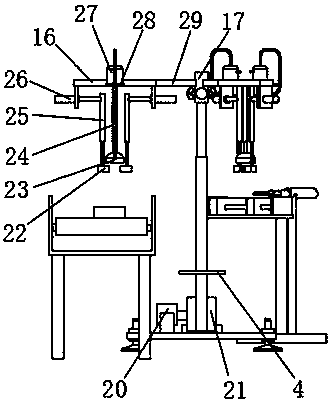

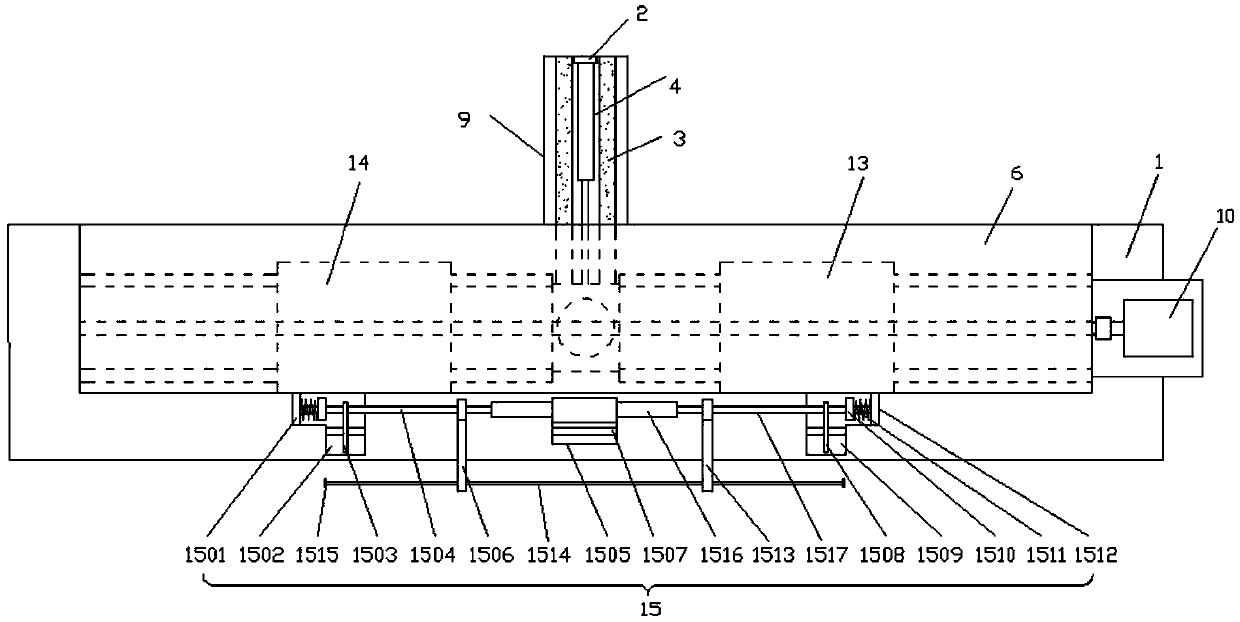

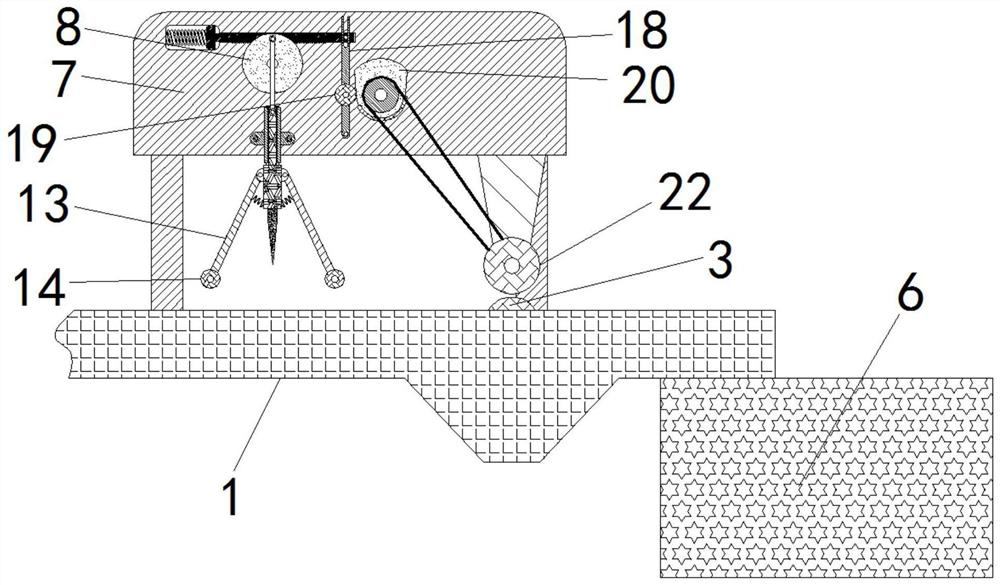

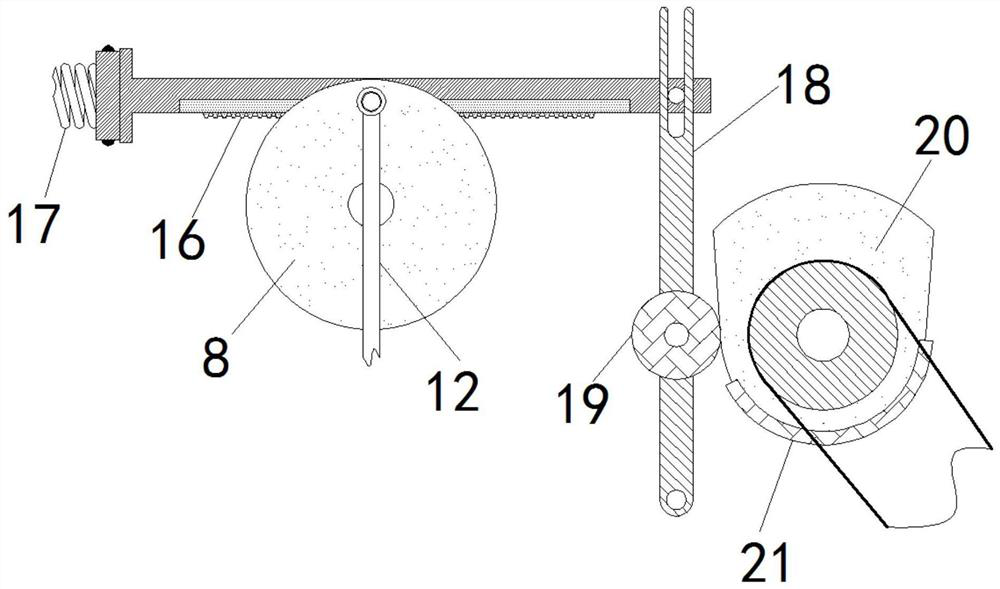

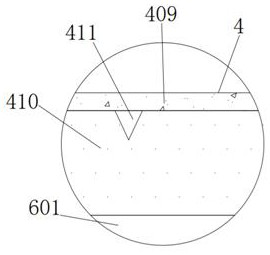

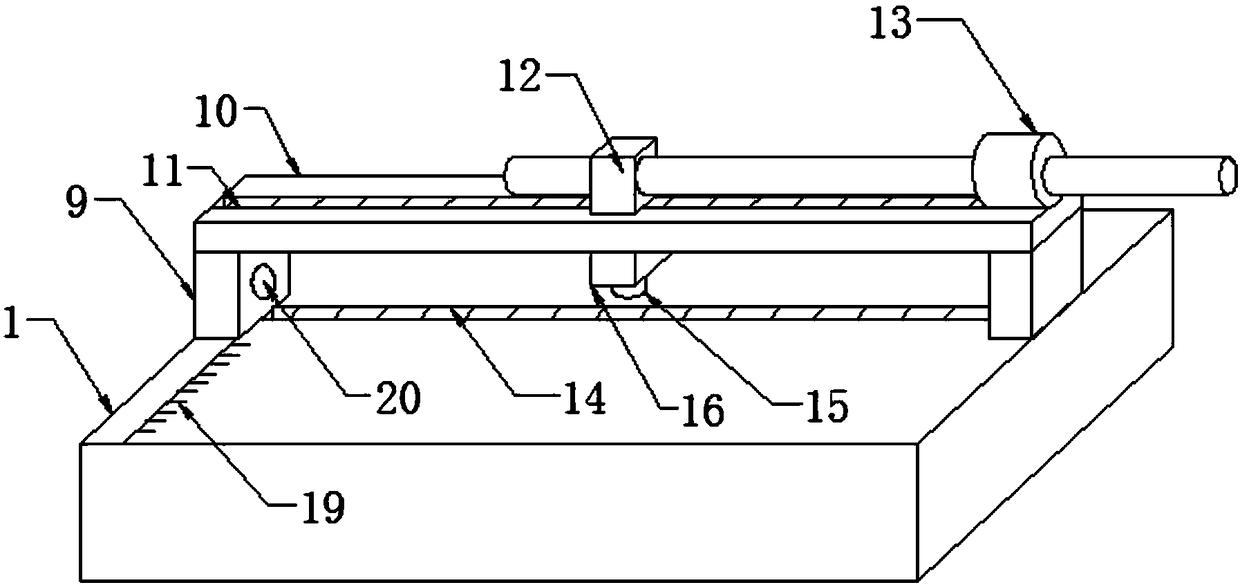

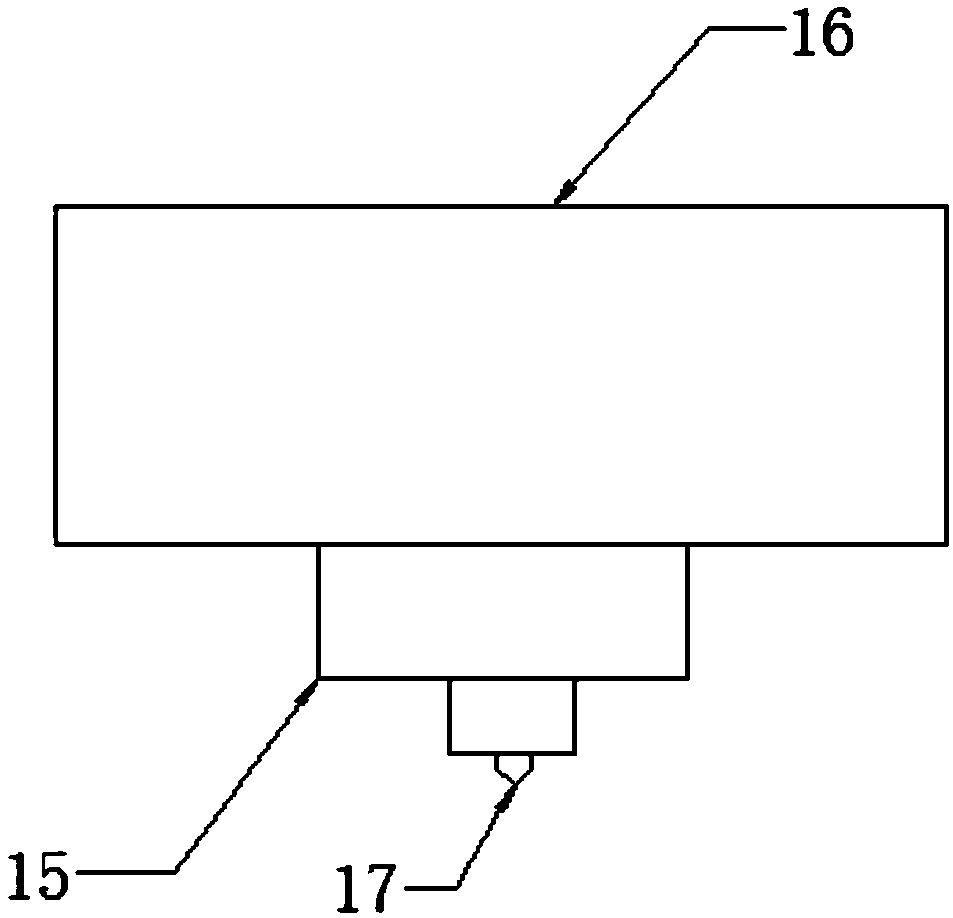

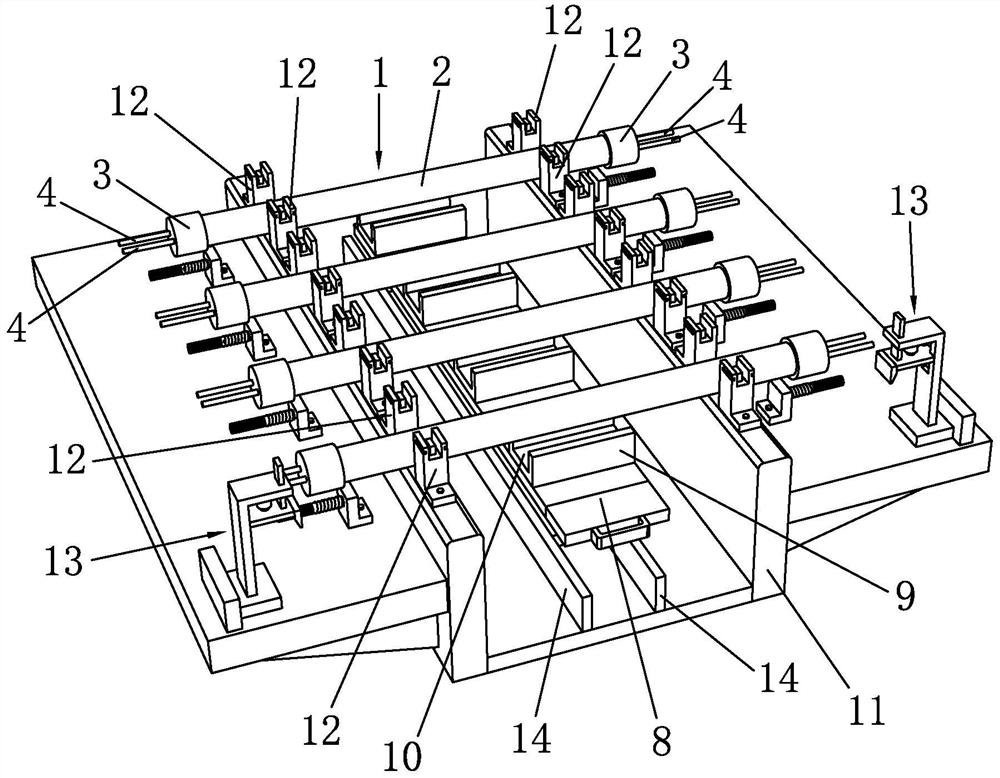

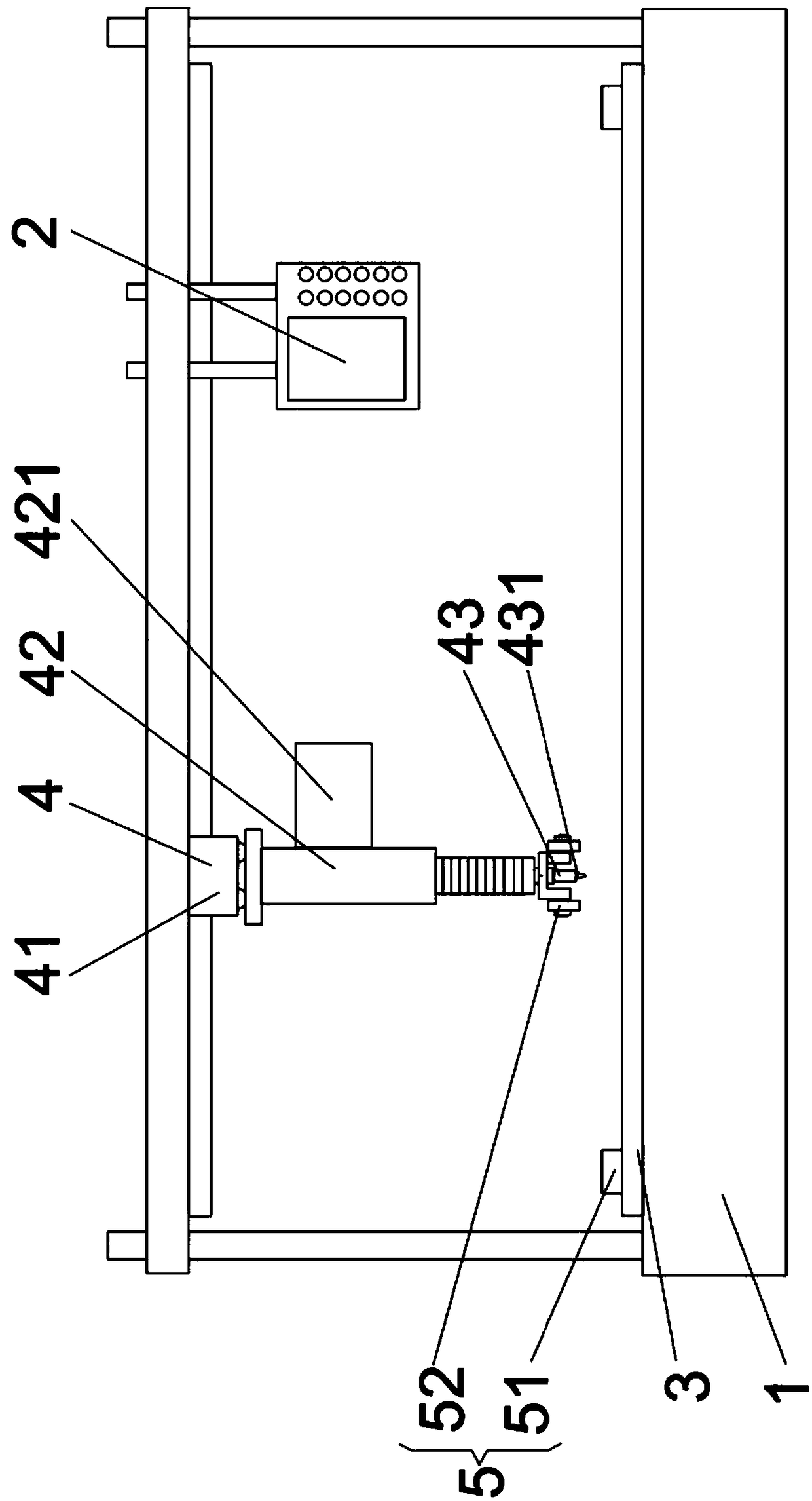

Bidirectional skin stripping device with adjustable length can having cutting function for data line

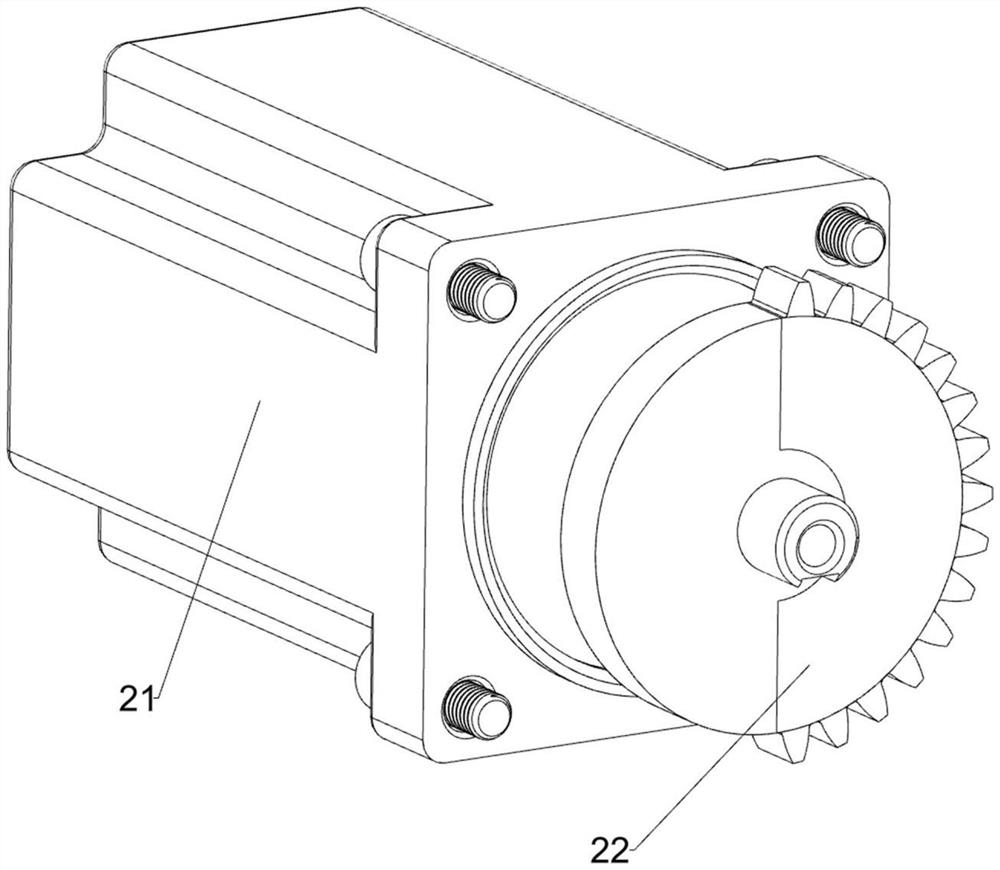

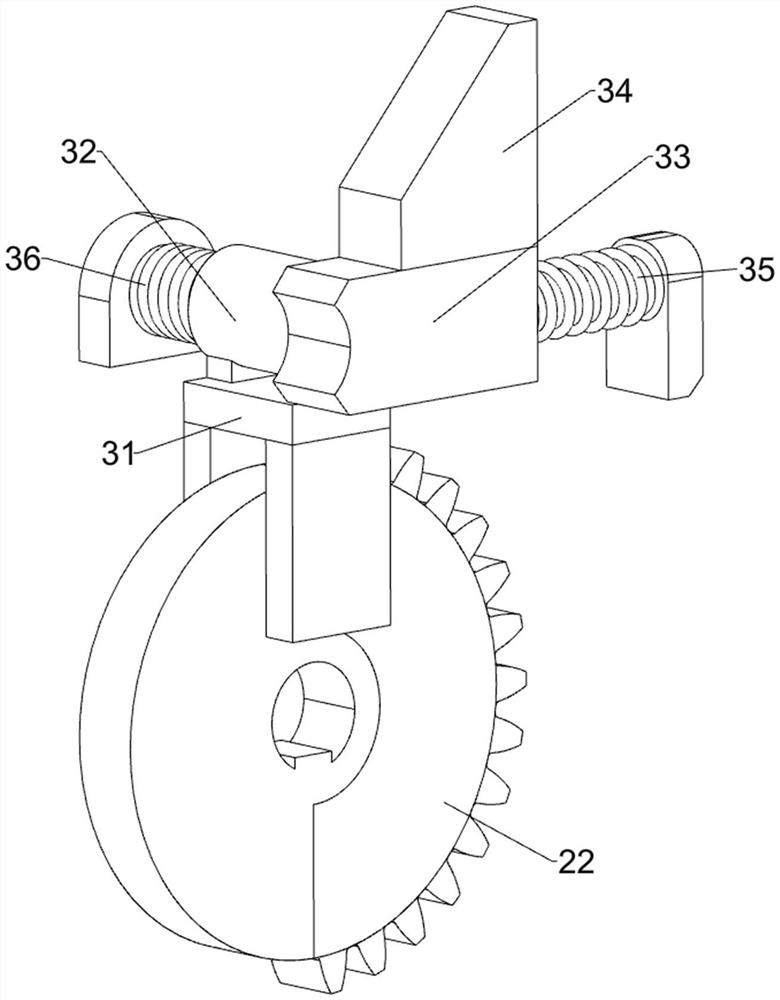

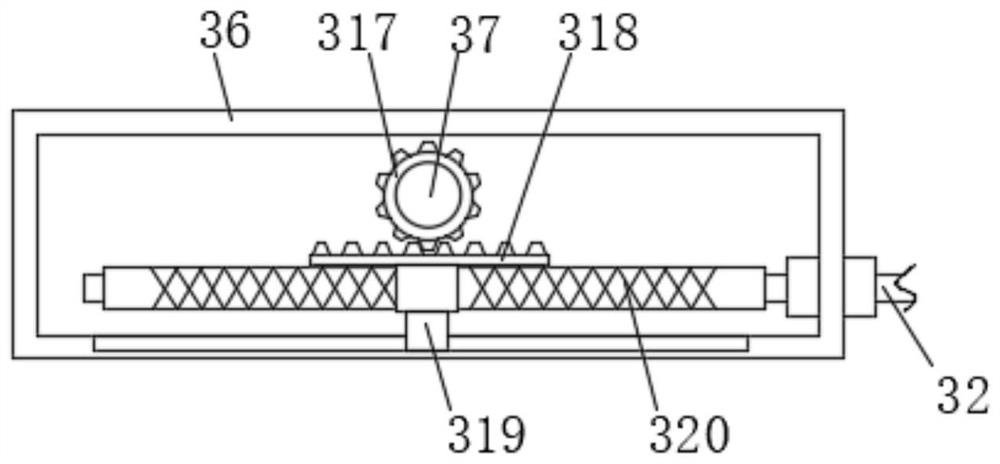

ActiveCN109616853AAdjustable lengthImprove processing efficiencyLine/current collector detailsElectronic waste recyclingBall screwEngineering

A bidirectional skin stripping device with adjustable length can having a cutting function for a data line comprises a rack, a cutting mechanism and a support rack, wherein a guide rail base and two linear guide rails are arranged at an upper end of the rack, a clamping mechanism is arranged on the guide rail base and is connected with an extension end of an electric push rod, skin stripping mechanisms are arranged at the upper end of the rack and are respectively fixed on a first seat and a second seat, upper ends of the first seat and the second seat are respectively arranged at a left-handthread end and a right-hand thread end in a bidirectional ball screw, and a tail end of the bidirectional ball screw is connected with an output shaft of a stepping motor. By the bidirectional skin stripping device, bidirectional skin stripping can be performed on two heads of the data line, the data line can be rapidly cut, the bidirectional skin stripping can be performed on the two heads of thedata line, the required length of the data line can be adjusted, and the processing efficiency of the data line is improved; and meanwhile, skin stripping operation can be simultaneously performed onthe data lines with different thickness, no damage to a data line core is generated during skin stripping, and the bidirectional skin stripping device has the characteristics of safety, reliability and the like and is simple to operate.

Owner:湖南九耀科技有限公司

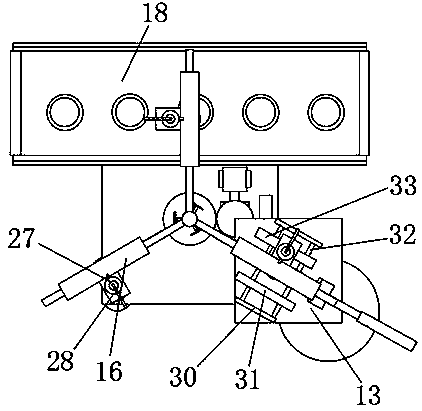

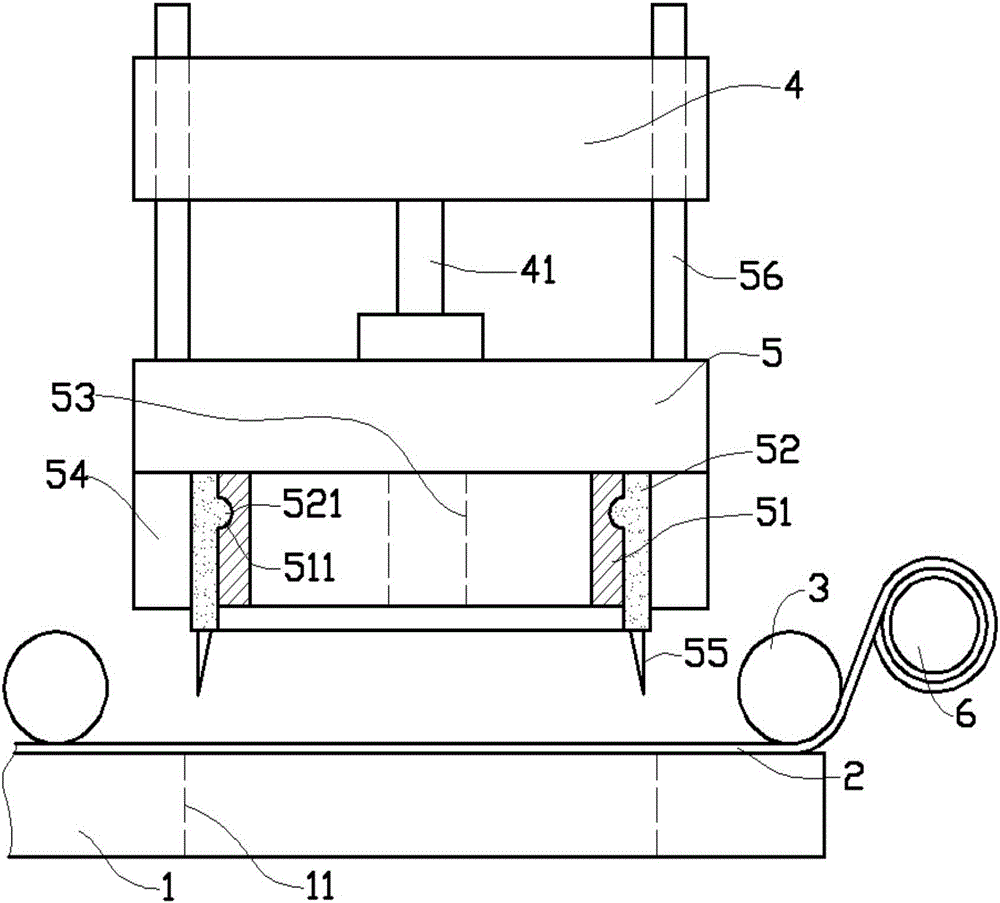

Cutting device realizing rapid forming

The invention provides a cutting device realizing rapid forming. The cutting device comprises a cutting table, wherein the upper plane of the cutting table adopts a horizontal design; cloth passes from the upper part of the cutting table in a tightly attached manner; pressure rollers are designed at upper parts of the front position and the rear position of the cutting table; a fixedly assembled mounting module is designed at the upper part of the cutting table; a lifting module is arranged between the mounting module and the cutting table; the lifting module and the mounting module are assembled in a vertical siding manner; a horizontal shaping track is designed at the lower part of the lifting module; a tensioning synchronous belt winds around the outer side of the shaping track; more than two cutting knives extending vertically downwards are designed at the lower part of the synchronous belt. When the device is used for cutting the cloth, the cutting knives rapidly move with the synchronous belt, multiple blades at the lower part of the synchronous belt cut the cloth simultaneously, so that cutting of the cloth can be finished rapidly, and the production efficiency is higher.

Owner:仙桃市兴荣防护用品有限公司

Hospital accounting voucher arranging device

InactiveCN109228724AQuick cropSolve efficiency problemsMetal working apparatusSheet bindingEngineeringVoucher

According to the technical scheme, the invention provides a hospital accounting voucher arranging device which comprises a cutting table and a drilling and bookbinding machine. An aligning rod is installed on the upper rear side of the cutting table and connected with a pressing rod through a rotating screw. A paper cutter is installed on the right side of the cutting table. A box body is installed at the upper portion of the drilling and bookbinding machine. A feed port is formed in the top of the box body. A touch key plate is installed right on the front side of the box body. A pressing rivet pipe and a drill are installed on the lower side of the box body. A transparent protection cover is arranged on the upper side of the drill. Bottom plates are arranged on the lower side of the pressing rivet pipe and the lower side of the drill. Baffles are installed on the two sides of the bottom plates respectively. Positioning plates are formed in the positions, between the inner walls of the baffles, of the pressing rivet pipe and the drill. Positioning holes are formed in the upper ends of the bottom plates. Supporting plates are installed on the lower sides of the bottom plates. Basesare installed on the lower sides of the supporting plates. Chipping boxes are arranged in the bases. Antiskid rubber cushions are installed at the bottoms of the bases.

Owner:徐州宇飞电力科技有限公司

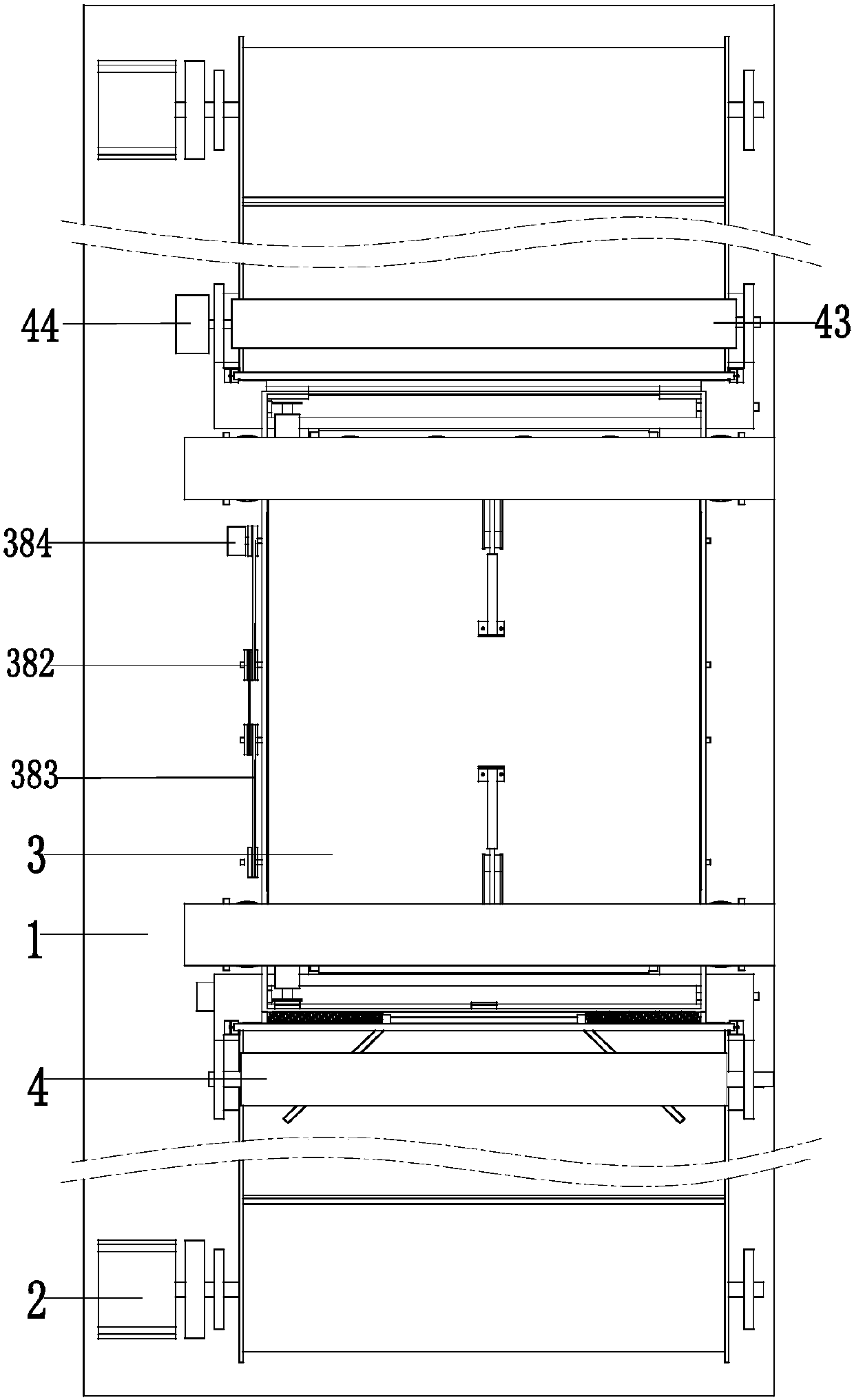

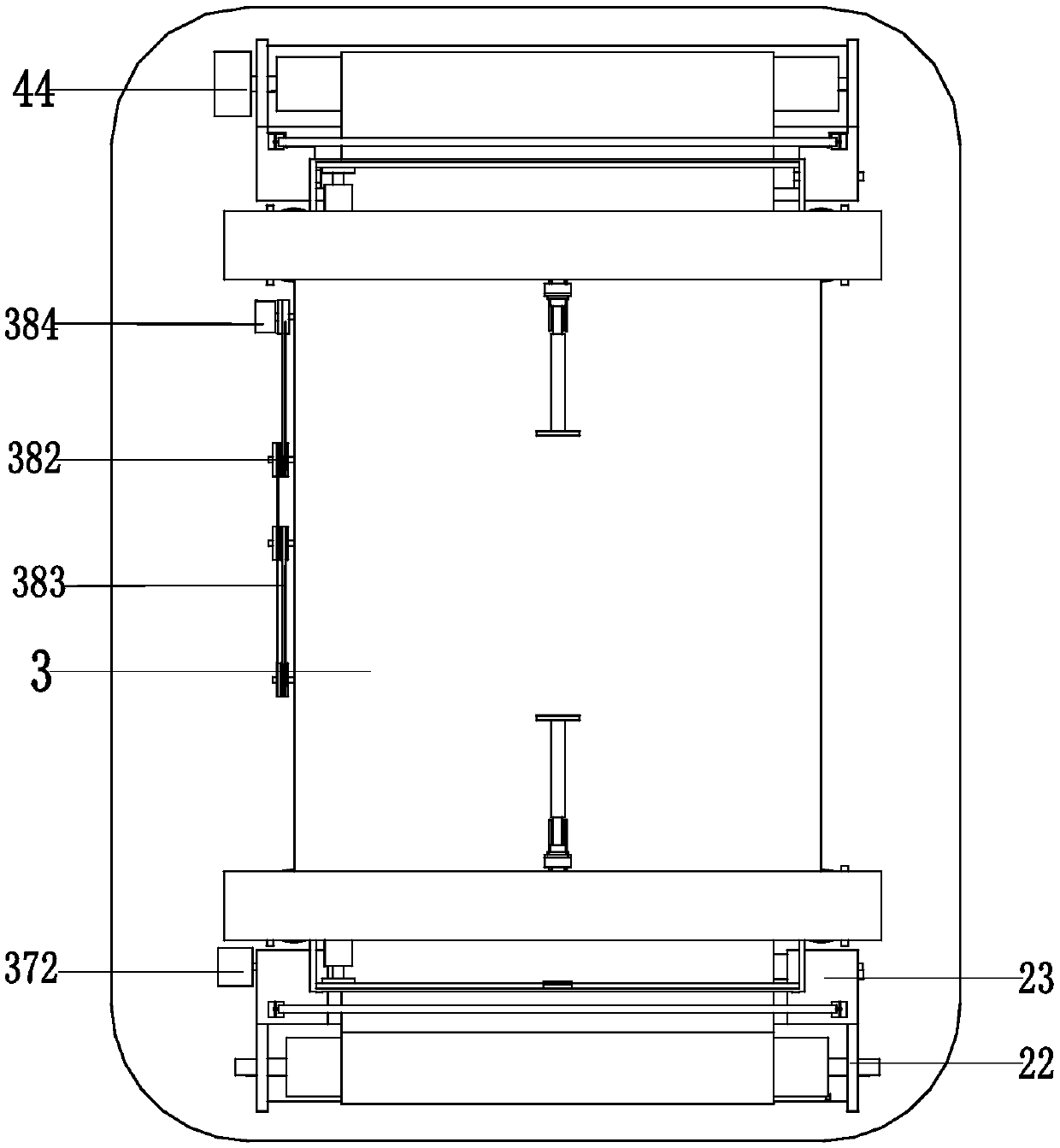

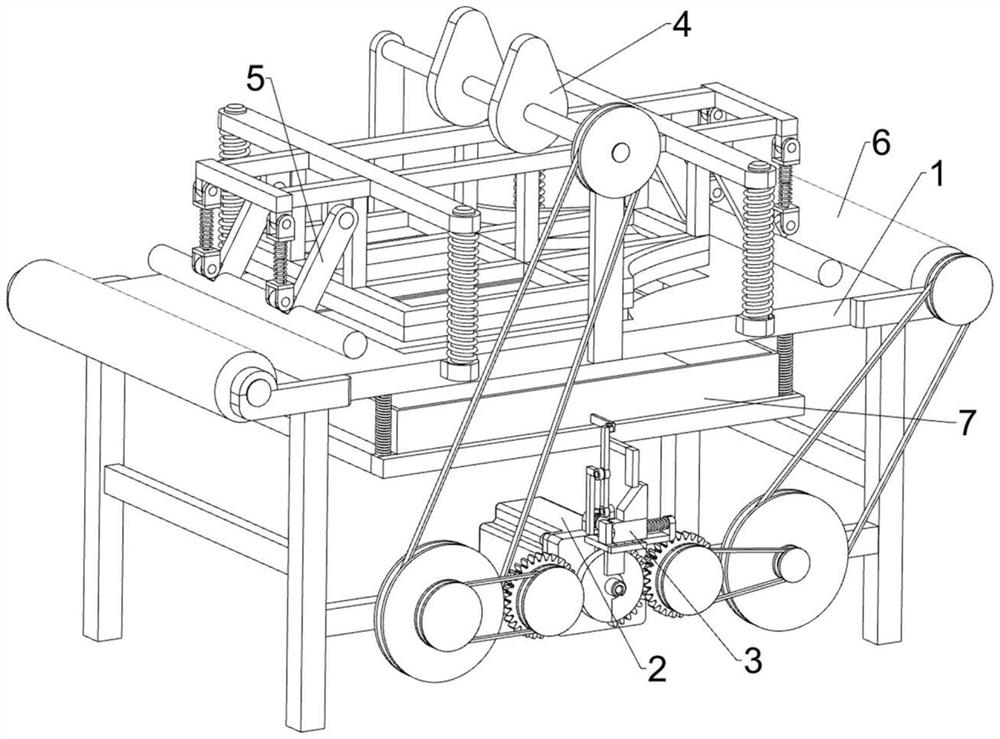

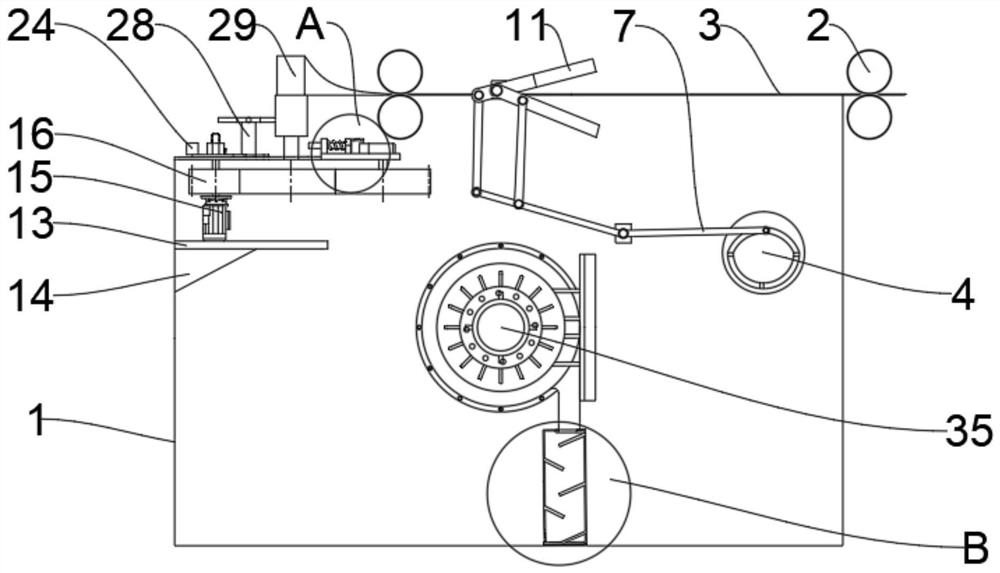

High-efficiency automatic coating device for flat color steel plate

ActiveCN107776948AReduce labor intensityNo manual operationPackagingEngineeringUltimate tensile strength

The invention relates to a high-efficiency automatic coating device for a flat color steel plate. The high-efficiency automatic coating device comprises a bottom plate, wherein two pairs of baffles IIare symmetrically mounted on the front and rear sides of the bottom plate, winding devices are arranged between upper sides of the two pairs of baffles II, a coating conveying device is mounted at the lower ends of the two pairs of baffles II, and an automatic coating process of the flat color steel plate is finished under matched use of the winding devices and the coating conveying device. The high-efficiency automatic coating device can solve the problems that the upper and lower ends of the flat color steel plate cannot be coated by the existing flat color steel plate coating equipment, the flat color steel plate is easy to move under the action of external force in the flat color steel plate coating process by the existing coating equipment, manual adjustment is needed when flat colorsteel plates in different sizes are coated, the precision is low, the labor intensity is high, long time is consumed, the stability and the working efficiency are low and the like in the coating process of the existing flat color steel plate, and high-efficiency automatic coating of the flat color steel plate can be realized.

Owner:唐山海德林纳新型建材有限公司

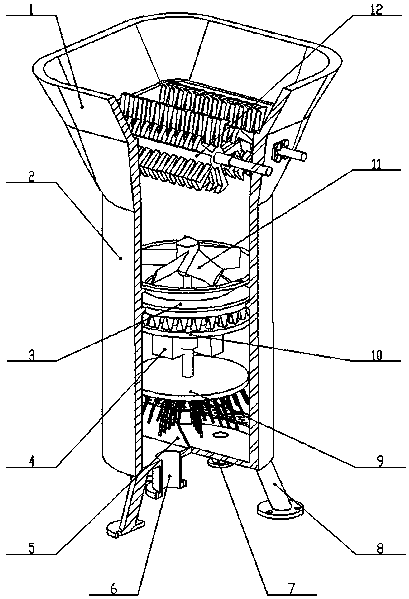

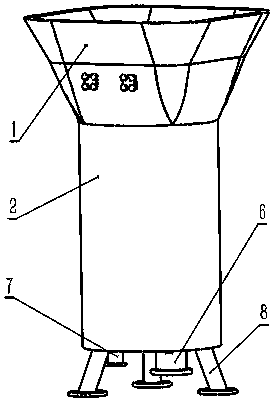

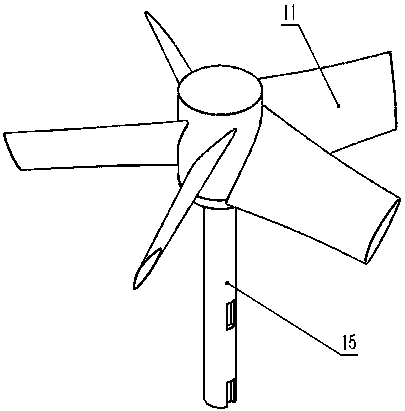

Powdering and then grinding type pulping equipment

PendingCN107604725AQuick cropImprove efficiencyPulp beating/refining methodsRaw material divisionLiquid waterSlurry

The invention provides powdering and then grinding type pulping equipment. The equipment mainly comprises a conical feeding inlet device, a rectangular tooth-shaped roller device, a stirring device, aconical grinding roller device, a bevel gear drive device and an inclined filter device. The equipment is characterized in that paper sheets are smashed and recycled through rectangular tooth-shapedrollers, and then slurry grinding is performed through a conical grinding roller. The recycled paper sheets are smashed in advance through shear force formed by the rectangular tooth-shaped roller device; the paper sheets and liquid water are stirred through rotation of the stirring device, and feed liquid soaking stirring and accelerated downward flowing are achieved; slurry is ground through thehigh-speed rotating conical grinding roller, and fine grinding of the paper sheets is achieved; due to rotation of the inclined filter device, liquid water and slurry separation is achieved.

Owner:UNIV OF JINAN

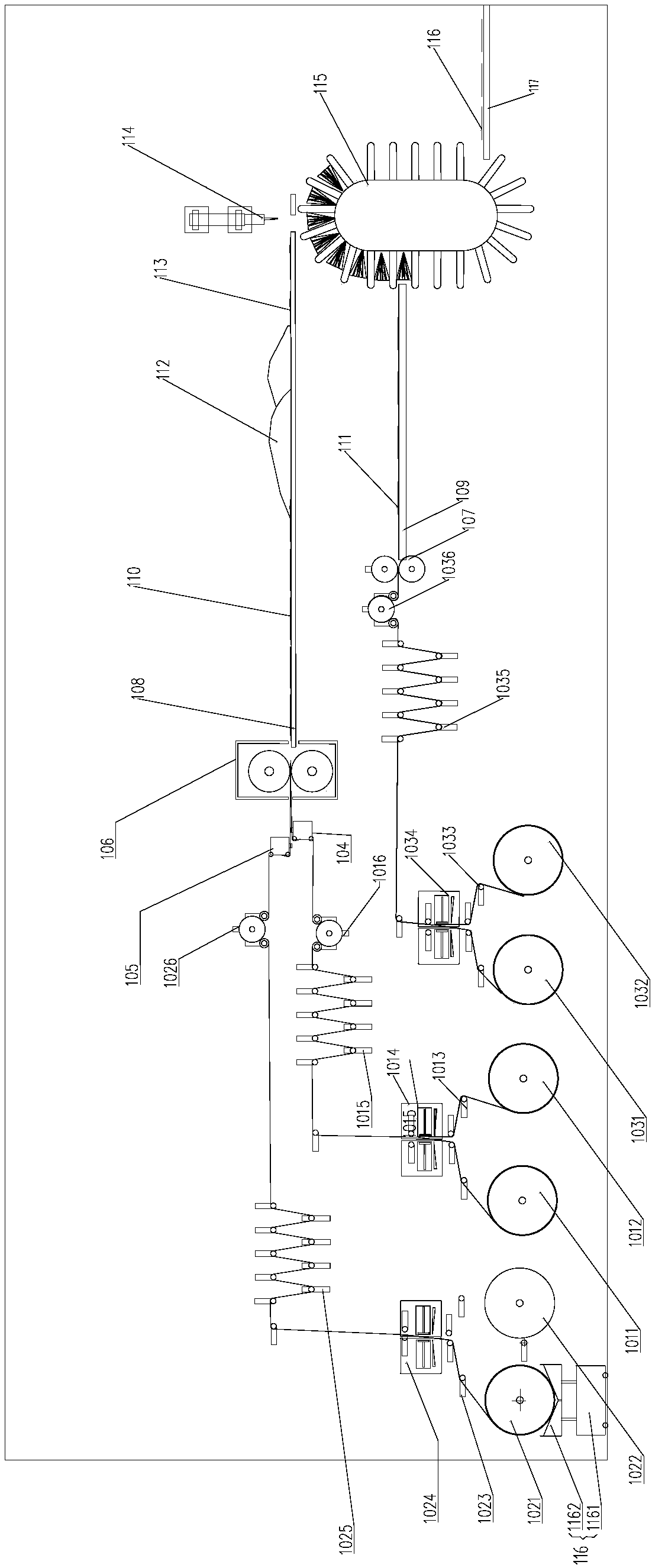

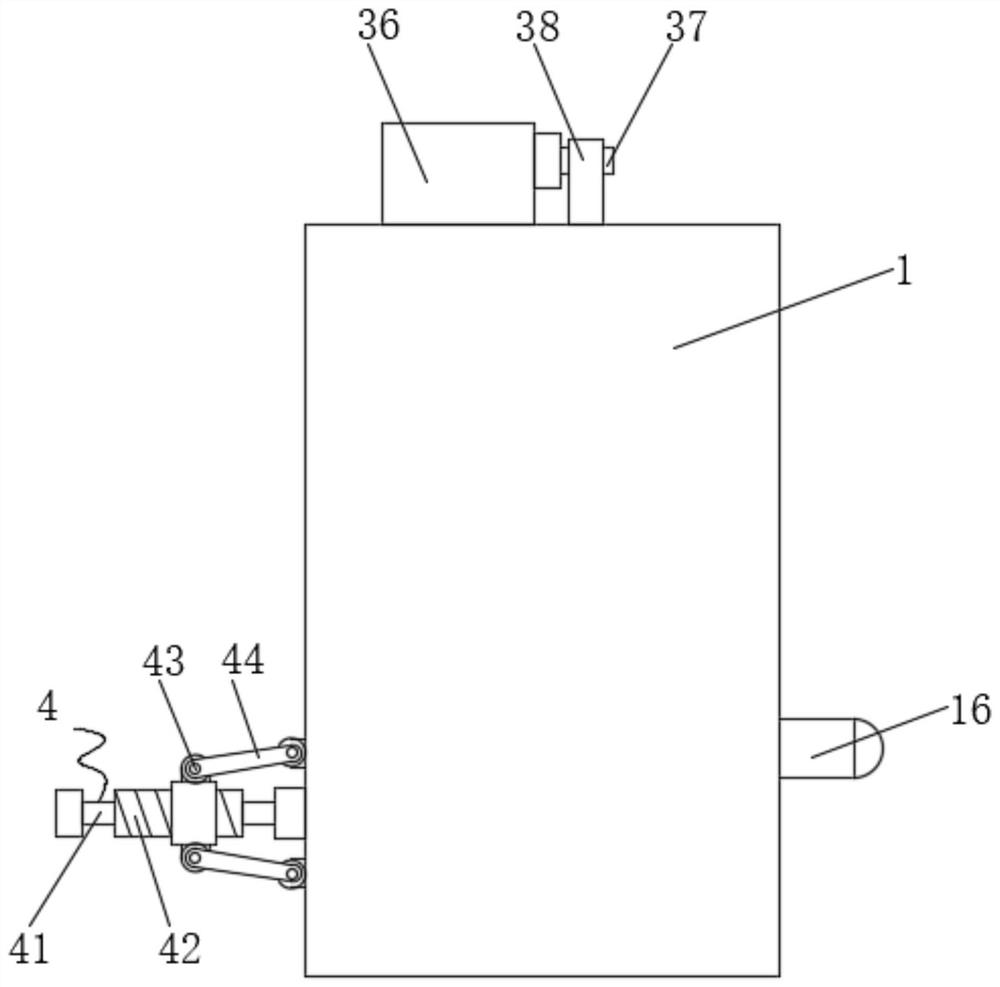

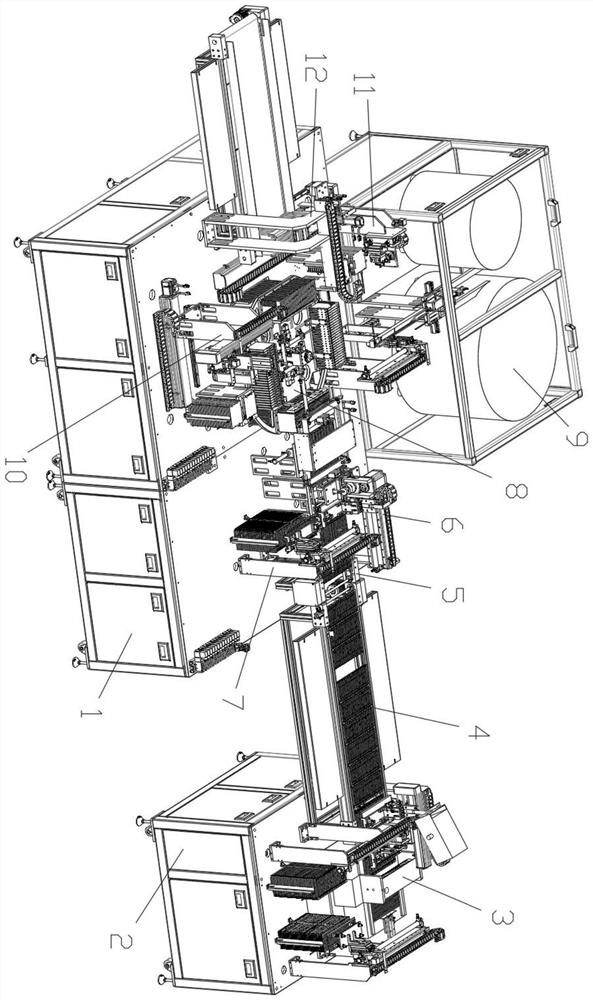

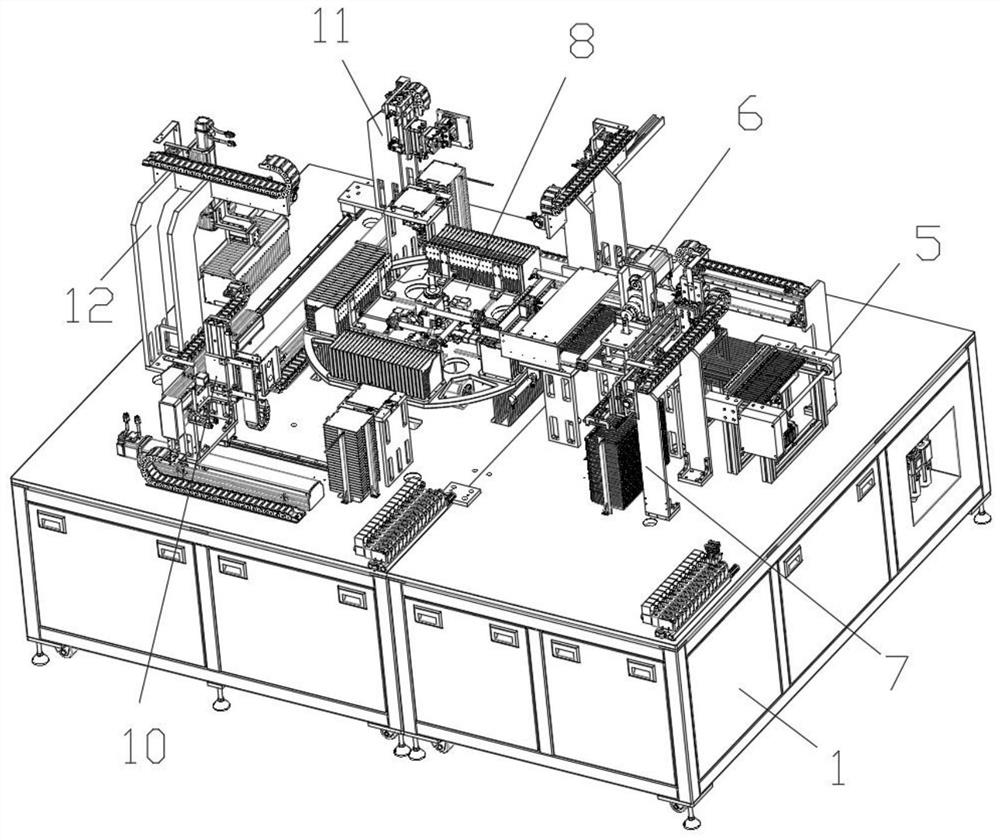

Full-automatic mask production line

PendingCN108100737AQuick cropQuick baggingWrapping material feeding apparatusArticle deliveryProduction lineEngineering

The invention belongs to the technical field of mask production, and particularly relates to a full-automatic mask production line. Materials of a mask unwinding device and a mask film-covering unwinding device are superimposed through a deviation rectifying device and then enter a first roller die-cutting machine so as to form mask structures on a first belt conveying line; a mask packaging bag unwinding device is connected with a second roller die-cutting machine so as to form mask packaging bags on a second belt conveying line; the mask structures are left-right folded through a mask left-right folding seat and then form folded mask structures; and the mask packaging bags are opened after entering a bag opening device, and an air cylinder telescopic arm is arranged on the first belt conveying line, so that the folded mask structures fall into the mask packaging bags after being stamped and folded through the air cylinder telescopic arm, and meanwhile, the mask packaging bags on thesecond belt conveying line are continuously opened through the bag opening device. The functions of quick cutting, quick folding and quick bagging of masks are realized accordingly, and meanwhile, thefull-automatic mask production line realizes uninterrupted feeding by arranging an AGV trolley and an automatic splicing device.

Owner:上海德辉供应链有限公司

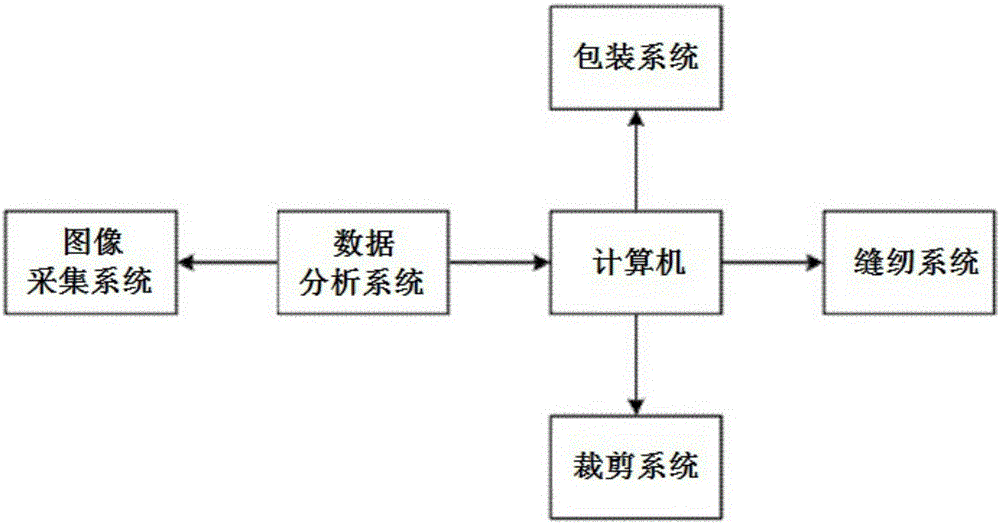

Automatic garment-customizing system

The invention relates to an automatic garment-customizing system comprising a computer, an image acquisition system, a data analysis system, a cutting system and a sewing system. The computer is connected with the data analysis system, the cutting system and the sewing system, and the computer is used for controlling the working states of the data analysis system, the cutting system and the sewing system. The data analysis system is connected with the image acquisition system, and the image acquisition system is used for acquiring stature information of a user and forms a three dimensional image; the data analysis system carries out data analysis to the three dimensional image and transmits analysis data to the computer; the computer controls the cutting system to cut the cloth; and the sewing system sews the cut cloths, and the cloths form a ready-made garment. The computer is also connected with a packaging system, and the packaging system pastes marks on the ready-made garments and packages the ready-made garments.

Owner:安徽东锦服饰有限公司

Cloth cutting device for garment production

InactiveCN112011993AQuick cropImprove crop qualitySevering textilesArticle deliveryEngineeringMechanical engineering

The invention relates to the technical field of cloth cutting devices, and discloses a cloth cutting device for garment production. The device includes a tailoring table, and a through groove is formed in the right part of the cutting table; an inner cavity of the through groove is connected with a first conveying roller in a sliding manner; a first spring is fixedly connected between the first conveying roller and the side wall of the inner cavity of the through groove; an electromagnet is fixedly installed at the bottom of the inner cavity of the through groove; a storage box is fixedly connected to the lower end of the right portion of the cutting table; a loading block is fixedly installed at the upper end of the cutting table; and a transmission disc is rotatably connected to the front end of the loading block. According to the cloth cutting device for garment production, a cam rotates to extrude a rotating roller, a guide strip pushes a rack to move leftwards, then the rack enables the transmission disc to drive a connecting rod and a pushing sliding strip to fall, and when the cam rotates in the later period, a second conveying roller is driven to rotate, so that the cuttingquality of cloth is improved, and the problem that the cut cloth needs to be manually collected is solved.

Owner:聂伟成

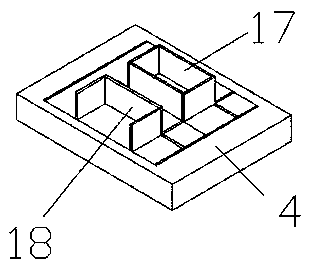

Paper box automatic forming device used for automatic labelling and boxing assembly line

The invention discloses a paper box automatic forming device used for an automatic labelling and boxing assembly line. The device comprises a device body. A paperboard storage box is arranged at one end of the device body. A paperboard holding plate is arranged inside the paperboard storage box. A second electric telescopic rod is arranged at the bottom end of the paperboard holding plate. A workbench is arranged in the middle of the device body. A discharging conveying belt fixing frame is arranged on one side of the workbench. A discharging conveying belt is arranged on the discharging conveying belt fixing frame. A discharging conveying belt motor is arranged at the bottom end of the discharging conveying belt. A feeding conveying belt fixing frame is arranged on the other side of the workbench. A feeding conveying belt is arranged on the feeding conveying belt fixing frame. By means of the device, paper boxes can be fast fed, conveyed, cut, notched and folding formed, the paper boxes are primarily processed, the forming efficiency is improved, time is saved, in addition, cut waste can be recovered, the structure is simple, and popularization is facilitated.

Owner:YANCHENG INST OF TECH

Textile fabric rapid automatic cutting device

InactiveCN112030528AAvoid accumulationSolve the unevennessSevering textilesHydraulic cylinderElectric machinery

The invention discloses a textile fabric rapid automatic cutting device. The textile fabric rapid automatic cutting device comprises a bottom plate, wherein the middle of the top end of the bottom plate is fixedly connected with the bottom end of a first supporting plate, and a cutting mechanism is installed on the inner side of the upper portion of the first supporting plate. According to the textile fabric rapid automatic cutting device, an output shaft of a motor drives a cutter to rotate, the output end of a second hydraulic cylinder drives the cutter on the motor to move downwards througha second clamping plate, so that the cutter is inserted into cutter grooves in a rubber pad to cut textile fabric, meanwhile, the output end of the right side of the first hydraulic cylinder drives the second hydraulic cylinder through a first clamping plate to slide left and right in a first sliding groove in the first supporting plate through a first sliding block, the cutter moves left and right to be matched in three cutter grooves in different positions in the rubber pad, textile cloth can be cut into different sizes, the application range is wide, and the problems that an existing textile fabric rapid automatic cutting device cannot change the cutting size, and the use range is single are solved.

Owner:常胜男

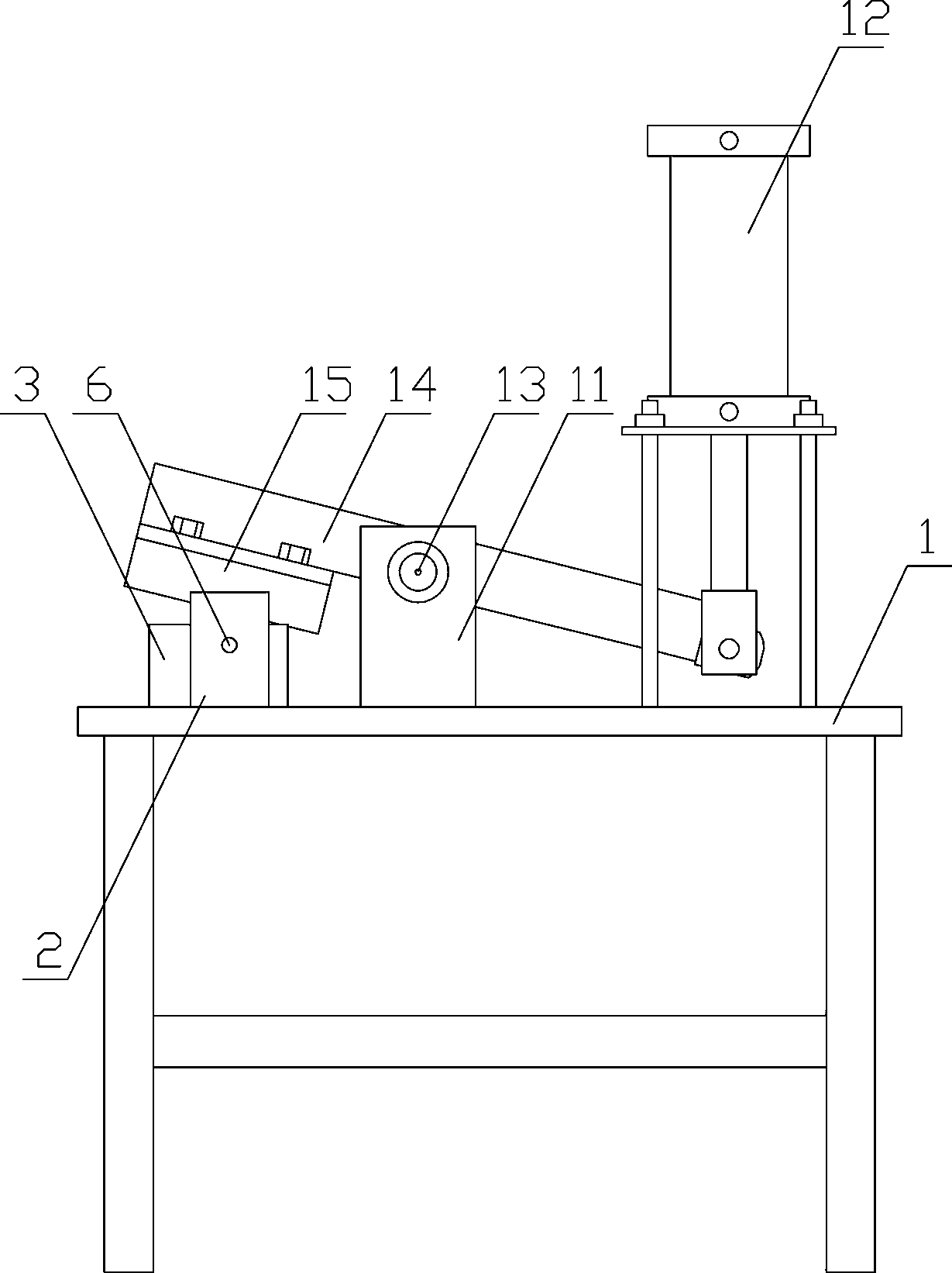

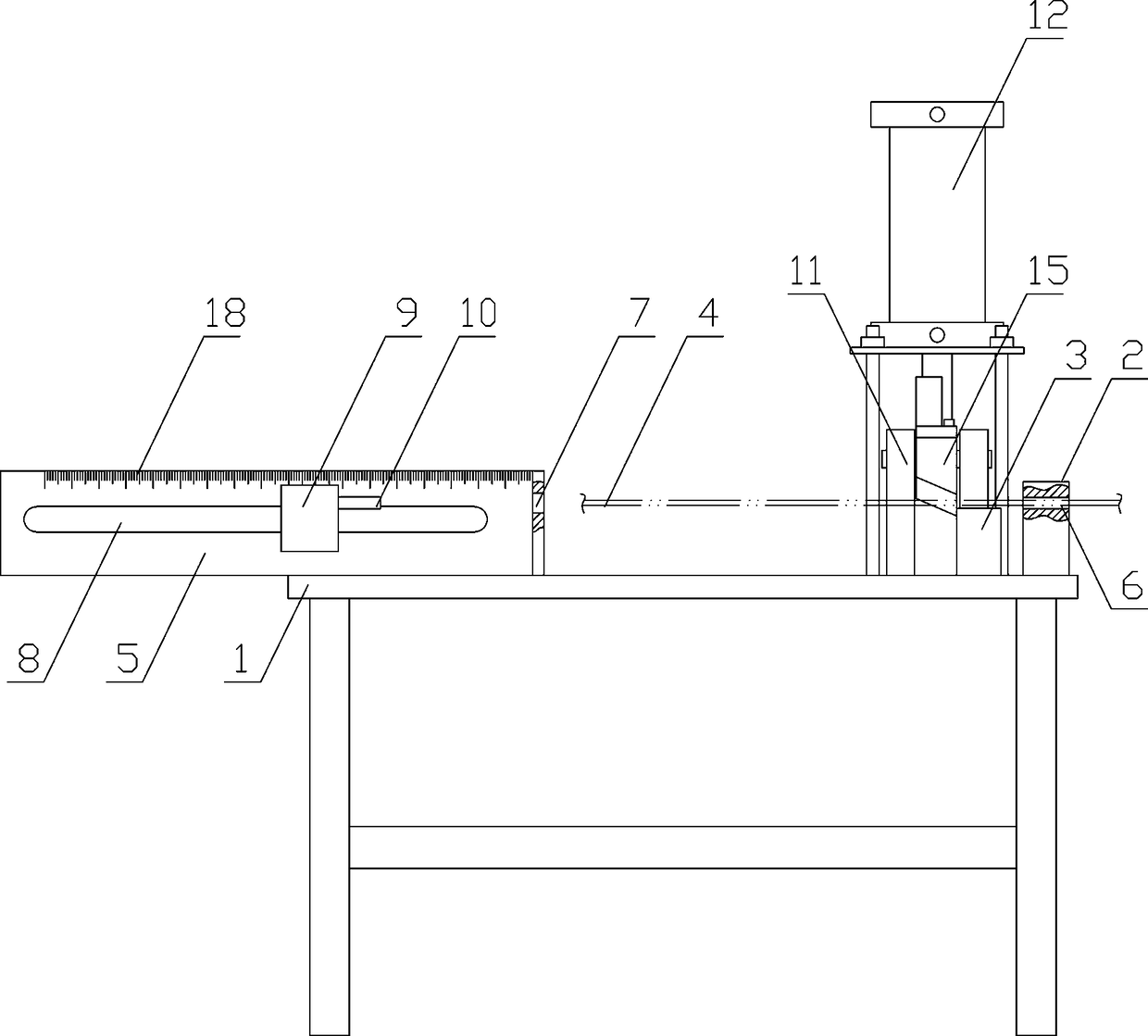

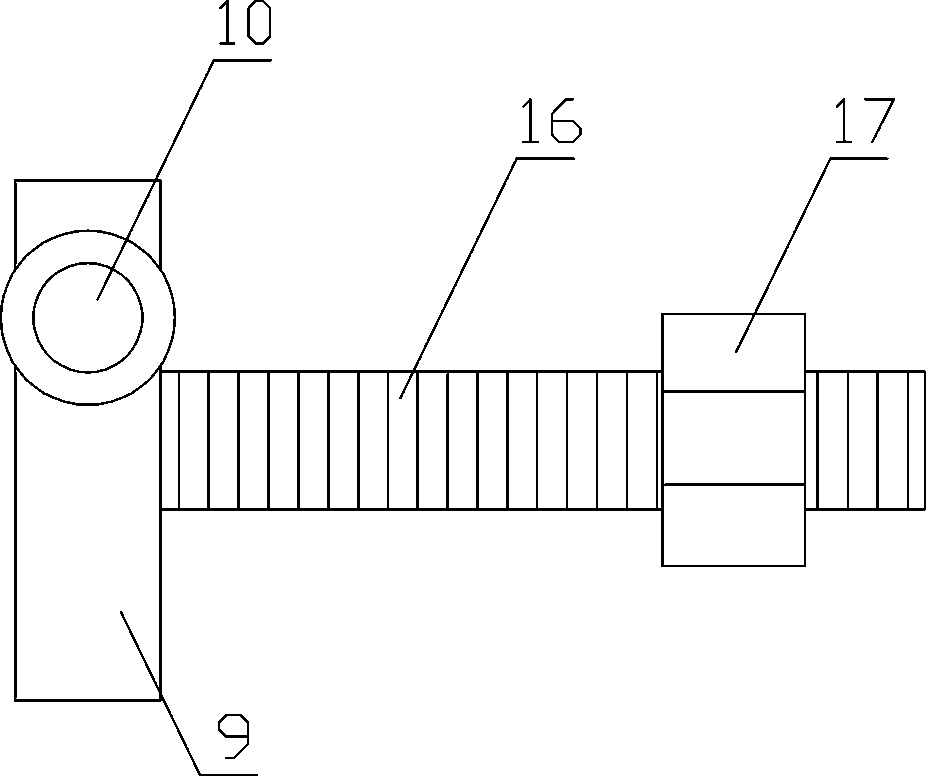

Steel wire shearing machine

InactiveCN108213558AQuick cropEasy to adjustNibbling shearing machinesShearing machine accessoriesEngineeringMachining

The invention relates to the technical field of machining, in particular to a steel wire shearing machine. The steel wire shearing machine is provided with a work platform. The work platform is sequentially provided with a guiding block, a profiling die and a length adjusting device in the transverse direction. The guiding block is provided with an input hole. The length adjusting device is provided with an L-shaped support, the short edge of the L-shaped support is provided with an output hole, and the long edge of the L-shaped support is provided with an adjusting hole in the transverse direction. A contactor capable of being transversely adjusted is arranged in the adjusting hole and provided with a proximity switch. The longitudinal side, along the profiling die, of the work platform is sequentially and fixedly provided with a supporting block and a vertically-arranged air cylinder, the supporting block is provided with a fixing shaft hinged to the middle portion of a swing arm, one end of the swing arm is hinged to the telescopic end of the air cylinder, and the other end of the swing arm is provided with a tool matched with the profiling die. The steel wire shearing machine is simple in structure and convenient to operate, rapid and continuous steel wire tailing is achieved, the tailoring efficiency is high, and it is ensured that the tailored end face of the steel wire is smooth and tidy.

Owner:湖北兴洋科技有限公司

Hand-held branch pruning machine for garden maintenance

InactiveCN109041872ATo achieve the effect of isolationEasy to holdCuttersMotor driven pruning sawsArchitectural engineeringHand held

The invention relates to the technical field of garden maintenance equipment, and discloses a hand-held branch pruning machine for garden maintenance. The pruning machine comprises an installing box I, a handle fixedly sleeves one side of an inner cavity of the installing box I, and one side of the handle extends to the outer portion of one side of the installing box I; the outer wall of the handle is fixedly sleeved with a sleeve pipe located on one side of the installing box I, one end of the handle is fixedly connected with an installing plate located in the installing box I, and the top ofone side of the installing plate is fixedly connected with one end of a telescopic upper rod. According to the hand-held branch pruning machine for garden maintenance, by arranging the installing boxI, the handle, the sleeve pipe, the installing plate, the telescopic upper rod, a fixed box, a movable plate, a spring I and a partition plate, noises generated in the working process of a motor canbe isolated, by arranging the sleeve pipe, a user can conveniently hold the pruning machine by hand, and the user can be protected to avoid that the noises make the ears of the user uncomfortable.

Owner:杭州真树园林设计工程有限公司

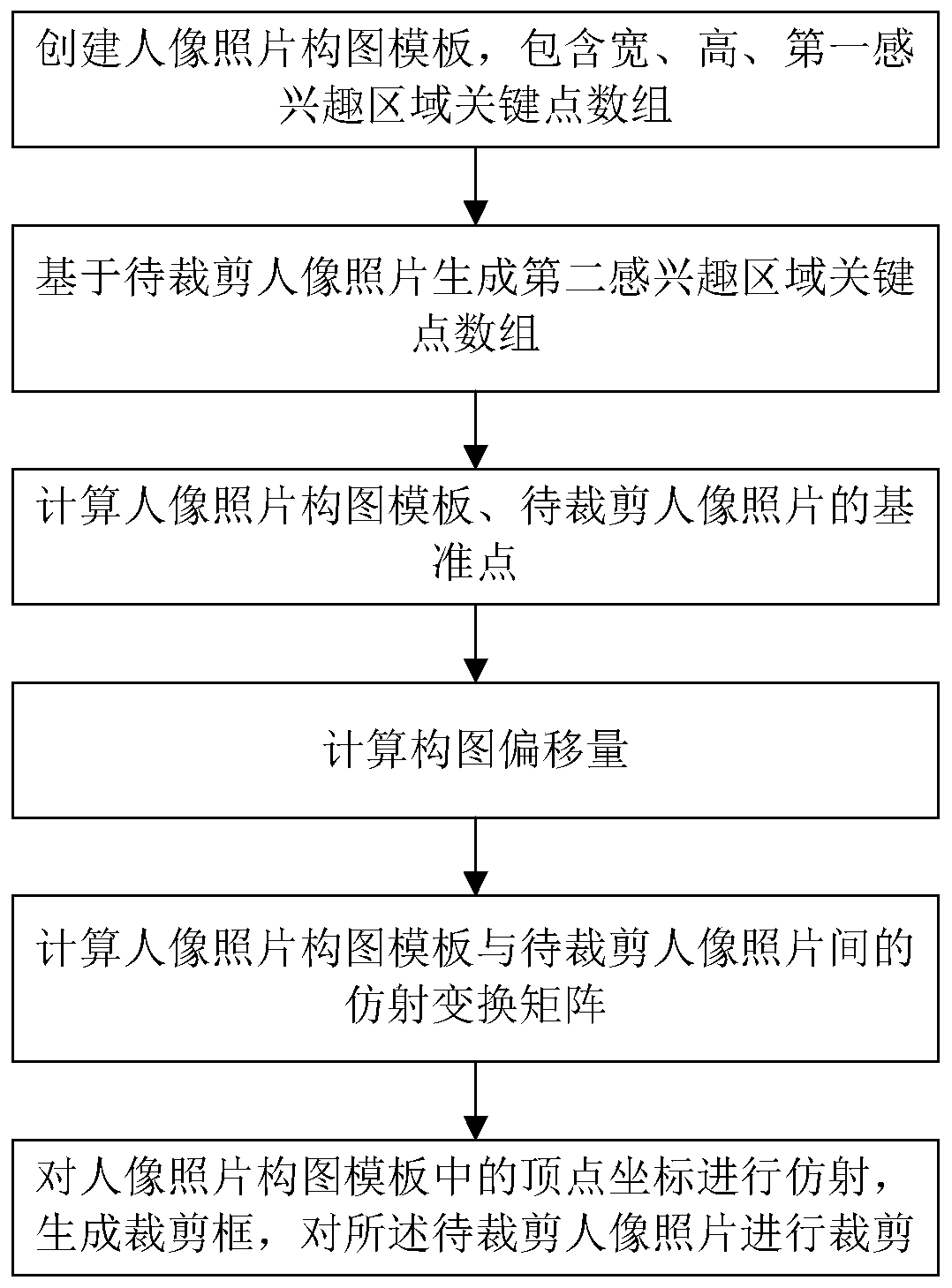

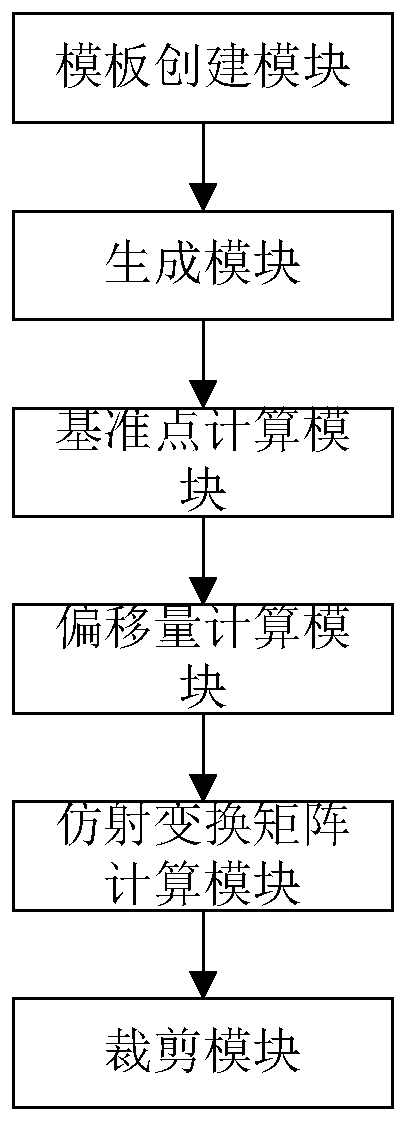

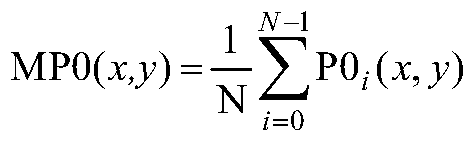

Automatic composition cutting method and system for quick portrait photo

ActiveCN111080667AQuick cropIn line with aesthetic meaningImage analysisGeometric image transformationComputer graphics (images)Engineering

The invention discloses an automatic composition cutting method and system for a quick portrait photo, and the method comprises the following steps: S1, building a portrait photograph composition template which comprises a wide region key point array, a high region key point array and a first region-of-interest key point array; S2, extracting corresponding key points in the portrait photo to be cut, and generating a second region-of-interest key point array; S3, calculating a portrait picture composition template and a reference point of the portrait picture to be cut; S4, calculating composition offset based on the portrait picture composition template and the portrait picture to be cut; S5, calculating an affine transformation matrix between the portrait picture composition template andthe portrait picture to be cut; and S6, performing affine on vertex coordinates in the portrait picture composition template based on the affine transformation matrix to generate a cutting frame, andcutting the to-be-cut portrait picture. According to the invention, automatic cutting of portrait photos is realized, the workload is reduced, and the cutting processing efficiency is improved.

Owner:HANGZHOU QUWEI SCI & TECH

Garment tailoring device

The invention discloses a garment tailoring device. The garment tailoring device comprises a working table, a fabric fixing plate, first electric telescopic rods, a cutting frame, a bearing, a motor,a lead screw, a sliding block, fabric securing plates, fixing nuts and power switches. The fabric fixing plate is mounted on the top of the working table. The fabric securing plates are mounted at thefour corners of the fabric fixing plate. The fixing nuts are mounted on the fabric securing plates. The first electric telescopic rods are mounted on the two sides of the working table. The cutting frame is mounted at one ends of the first electric telescopic rods. The lead screw is arranged in the middle of the cutting frame. The bearing is mounted at one end of the lead screw, and the motor ismounted at the other end of the lead screw. The sliding block is mounted on the lead screw. The power switches are mounted at one end of the working table. The garment tailoring device can cut garments quickly, can cut different parts of the garments, can quickly fix the garments and is high in flexibility, high in speed and efficiency, strong in overall stability, simple in structure and convenient to popularize.

Owner:东安县雅姿服装有限责任公司

Textile machine cutting device

InactiveCN108316001AAccurate croppingImprove cutting efficiencySevering textilesHydraulic cylinderEngineering

The invention discloses a textile machine cutting device which comprises an operation desk. The top end of one side of the operation desk is fixedly connected with two first supporting plates, first hydraulic cylinders are fixedly connected into the first supporting plates, hydraulic rods of the two first hydraulic cylinders are in transmission connection with cross rods, the bottoms of the crossrods are movably connected with pressing plates, the top ends of the pressing plates are fixedly connected with a plurality of springs, the top ends of the springs are fixedly connected with the innertop ends of the cross rods, the top end of the other side of the operation desk is fixedly connected with two second supporting plates, the top ends of the two second supporting plates are fixedly connected with fixing plates, and one side of the top end of each fixing plate is fixedly connected with a linear reciprocating motor. The device is provided with a cutter capable of cutting in a reciprocating manner, textile fabrics can be rapidly and accurately cut, the cut textile fabrics are more uniform in specification, the pressing plates can perform elastic pressing, so that pressing of thetextile fabrics by a worker is omitted, and cutting efficiency is improved.

Owner:湖州南浔富龙纺织有限公司

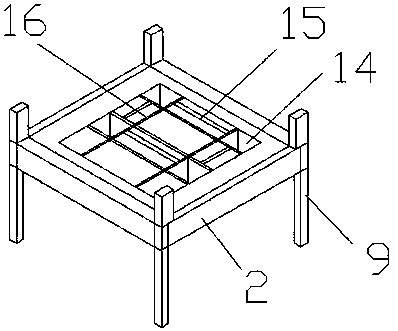

Couplet finished product cutting equipment for couplet production

PendingCN113734861AQuick cropEasy to placeOverturning articlesMetal working apparatusWorkbenchIndustrial engineering

The invention relates to cutting equipment, in particular to couplet finished product cutting equipment for couplet production. According to the couplet finished product cutting equipment for couplet production, the couplet cutting efficiency is high, transportation is convenient, and material returning is easy. The couplet finished product cutting equipment for couplet production comprises a bottom plate, two machine frames, a workbench, a bearing mechanism and a cutting mechanism, and the two machine frames are arranged on the bottom plate; the workbench is connected between the two machine frames; the bearing mechanism is arranged on the workbench; and the cutting mechanism is arranged on the bearing mechanism. Through cooperation of the bearing mechanism, the cutting mechanism, an opening and closing mechanism and a smoothening mechanism, the effect of rapidly cutting couplets is achieved, after the couplets are placed on the bearing mechanism, the couplets are cut into strips through the cutting mechanism, people can take down the couplets from the bearing mechanism, meanwhile, the couplets can be conveniently placed, and through cooperation of a horizontal conveying mechanism and an intermittent conveying mechanism, the effect of automatically and indirectly conveying the couplets is achieved.

Owner:朱坤昌

Cutting device for aprons

The invention relates to a cutting device, and in particular relates to a cutting device for aprons. The invention aims to provide the cutting device for the aprons, which can be used for quickly cutting cloth without damaging the cloth. The cutting device for aprons comprises a support; a power assembly, mounted on the bracket and powered by a motor to work; a control assembly, installed on the support and conducting control in a sliding mode; and a cutting assembly, installed on the support and used for cutting the cloth in a sliding mode. Through cooperation of the power assembly, the control assembly and the cutting assembly, the effect of rapidly cutting the cloth needed for manufacturing the apron is achieved; by means of a pressing assembly, when the cloth is cut, the cloth can be automatically fixed, the cloth cutting quality is improved, and meanwhile the device is safer to use; and by means of a waste winding assembly, the cut cloth can be automatically wound, and the deviceis more convenient to use.

Owner:江西诺捷科技股份有限公司

Automatic fabric cutting machine

The invention discloses an automatic fabric cutting machine which includes an underframe, a conveying table, a dividing mechanism, a clamping mechanism, a cutting mechanism and a stacking mechanism. The underframe is provided with the conveying table, and the conveying table is provided with the dividing mechanism, the clamping mechanism and the cutting mechanism. The dividing mechanism includes adividing connecting rod and a dividing roller. The dividing connecting rod is connected with the underframe and provided with the dividing roller, and cloth is disposed on the dividing roller. The conveying table includes a flat conveying table and an inclined conveying table which are connected with each other. The inclined conveying table is connected with a supporting frame. The stacking mechanism is disposed below the inclined conveying table and includes a stacking table, a sliding groove, a sliding rod, a fixed rod, a hand grab and a power mechanism. According to the automatic fabric cutting machine, the cut cloth is effectively stacked, the automatic fabric cutting machine saves time and labor and reduces working strength, and the cut cloth is stacked tidily without wrinkle or folding.

Owner:盐城市寻球远志科技有限公司

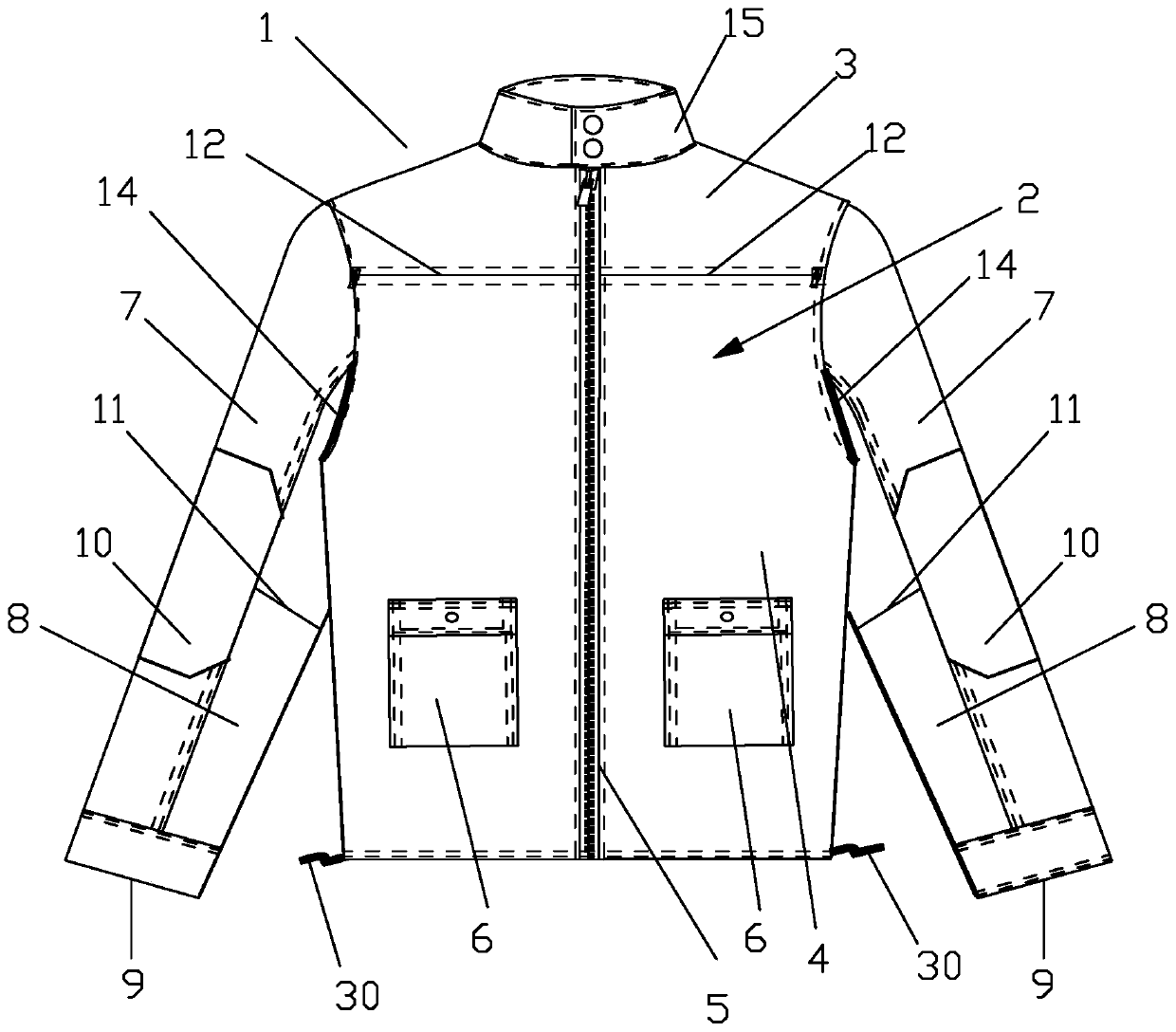

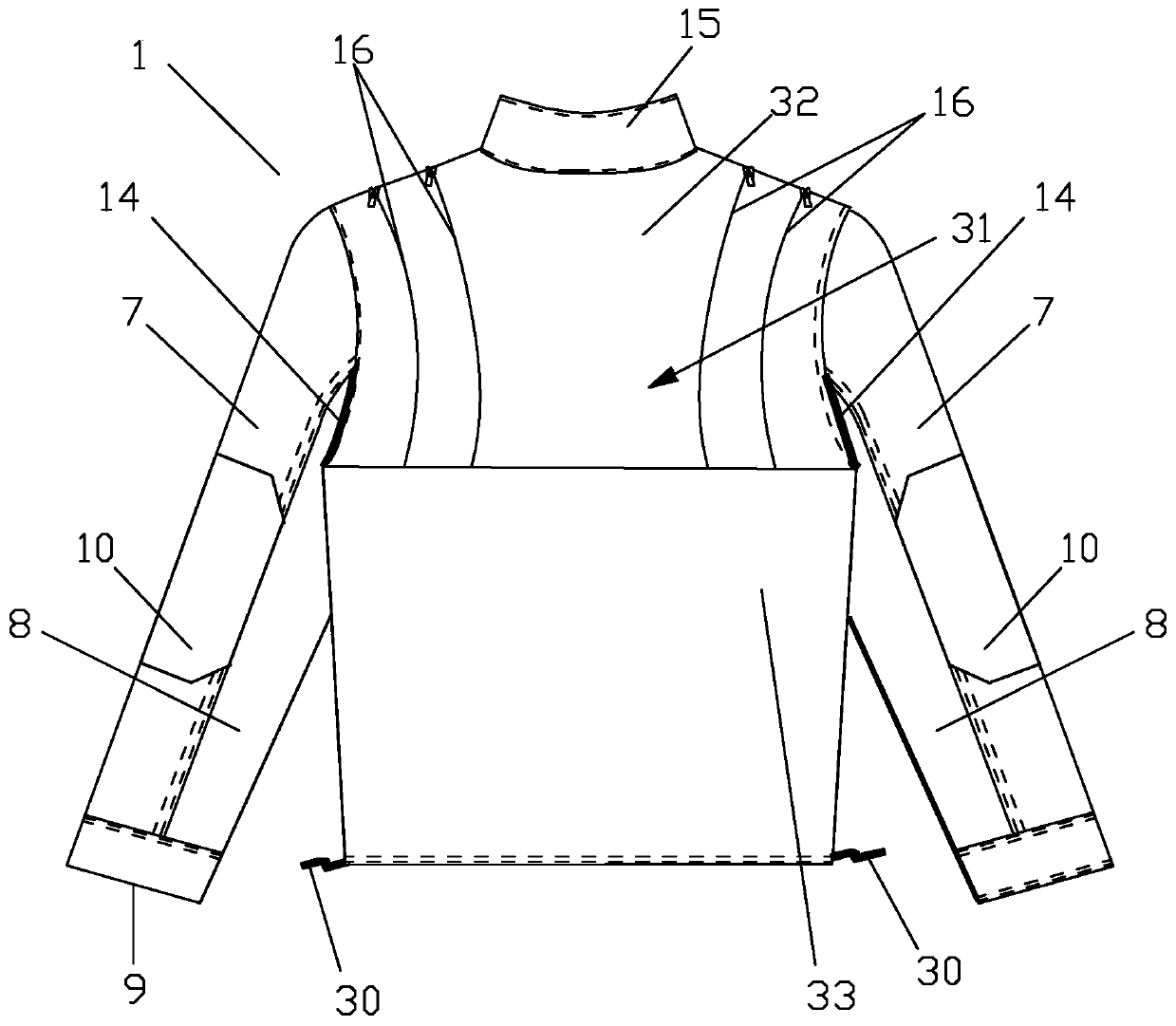

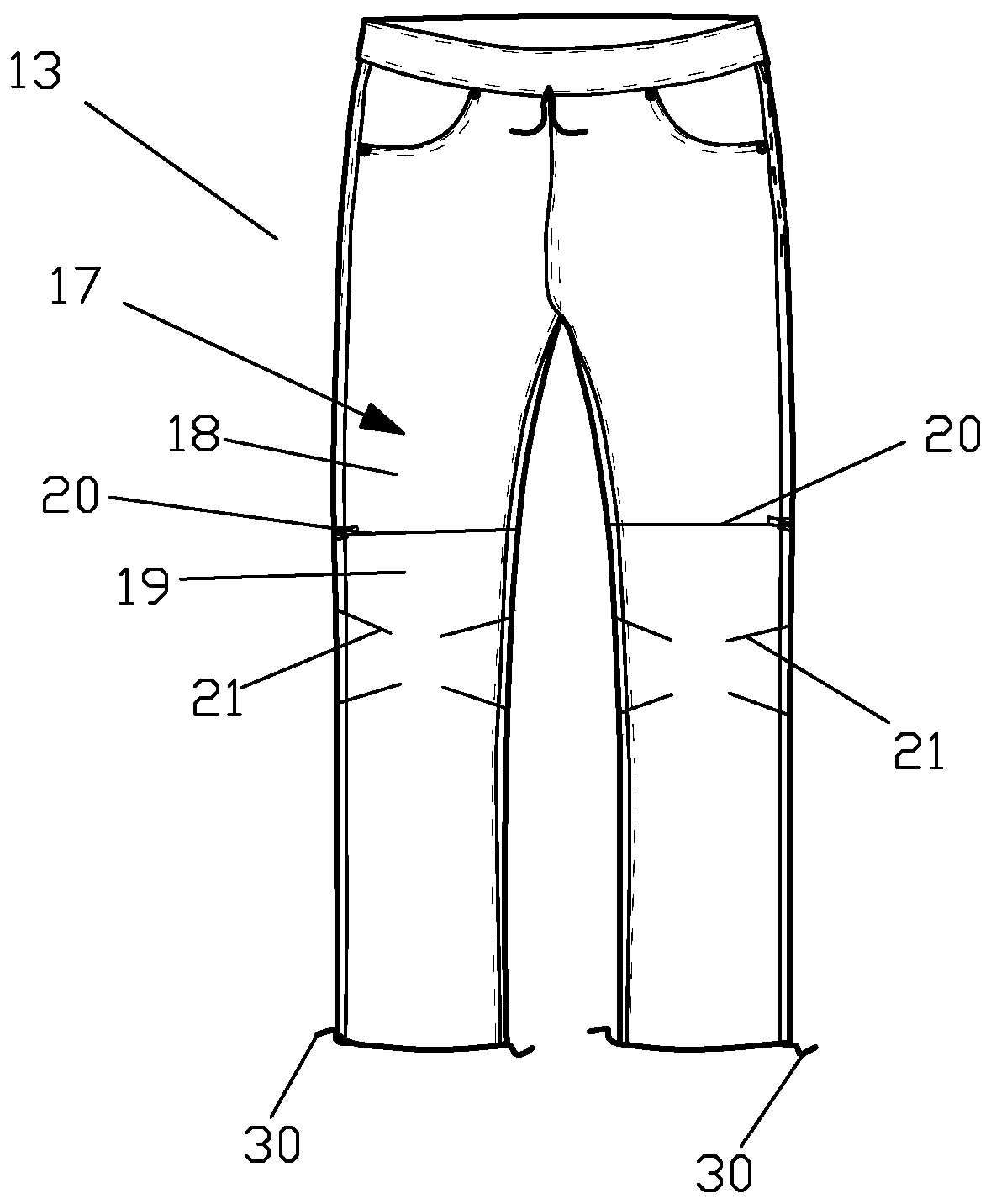

Protective clothing structure for operation at high temperature and constructing method of protective clothing structure for operation at high temperature

ActiveCN110638121AGuaranteed wearing comfortReduce heat radiationProtective garmentSpecial outerwear garmentsInfraredHuman body

The invention discloses a protective clothing structure for operation at high temperature and a constructing method of the protective clothing structure for operation at high temperature. The protective clothing structure for operation at high temperature includes a top and a pair of trousers, invisible zippers are arranged on both the top and the trousers, meshed cloth pieces are arranged on thepositions of the inner sides of the invisible zippers, and the top and the trousers are opened by the invisible zippers; and the fabric of the top and the trousers include a first thermal insulating layer, a second thermal insulating layer and a moisture transmission layer from outside to inside. By opening the invisible zippers, the air in the protective clothing can exchange with the external environment by forced convection, which can effectively accelerate the loss of the heat produced by a human body. The first thermal insulating layer can reduce thermal radiation to the human body at high temperature by using the ability of a nanomaterial to reflect near-infrared rays; the second thermal insulating layer uses an immobile air layer in an aerogel porous structure to isolate the external high-temperature environment from the human body, phase change microcapsules absorb the heat produced by the human body during a phase change process, and the microcapsule structures can prevent leakage of a phase change material; and the moisture transmission layer has good effect of single-way moisture transmission, moisture absorption and fast drying. The protective clothing is convenient touse and comfortable to wear with good protective performance.

Owner:浙江蓝天制衣有限公司

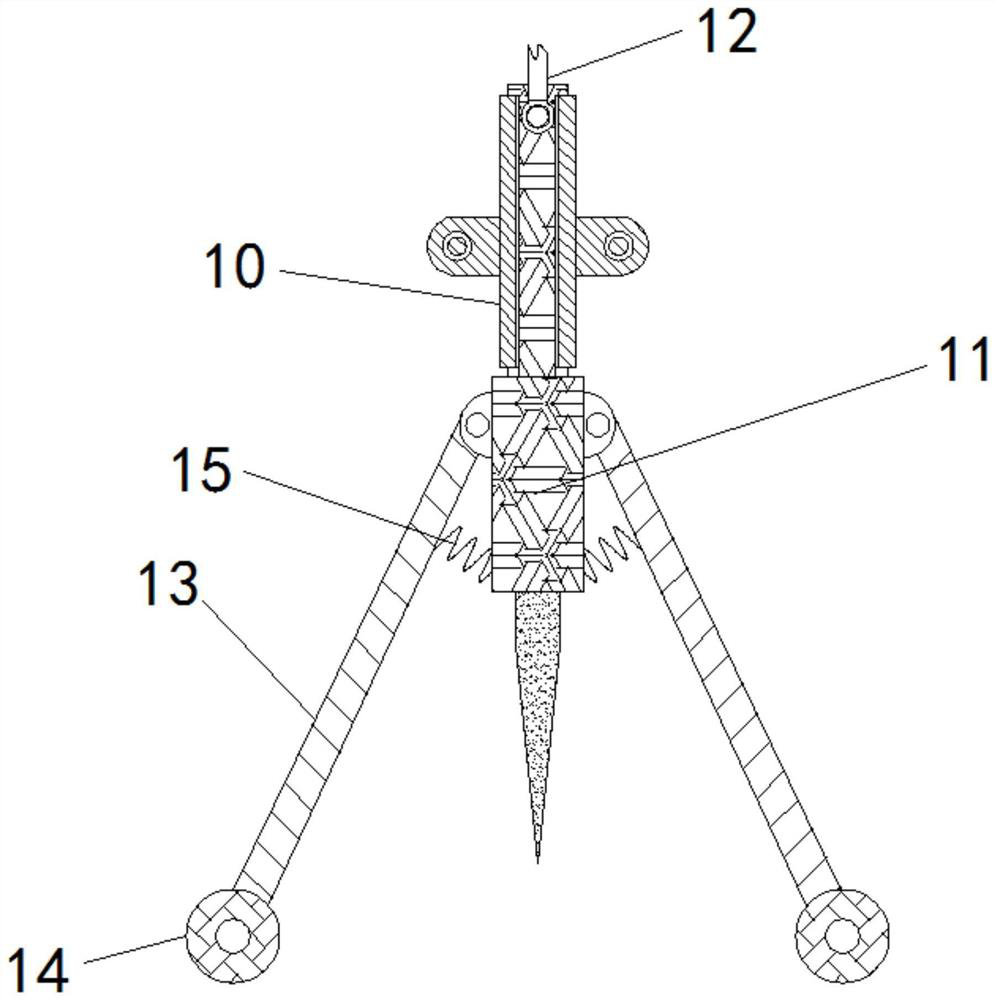

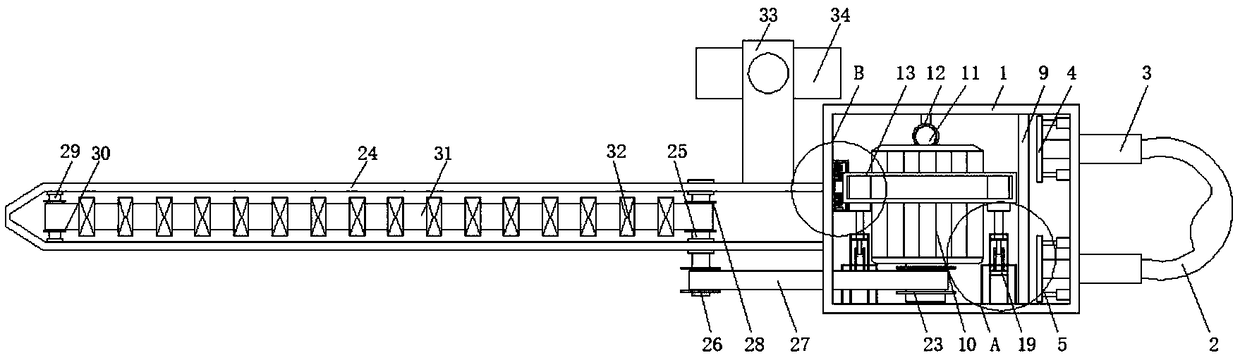

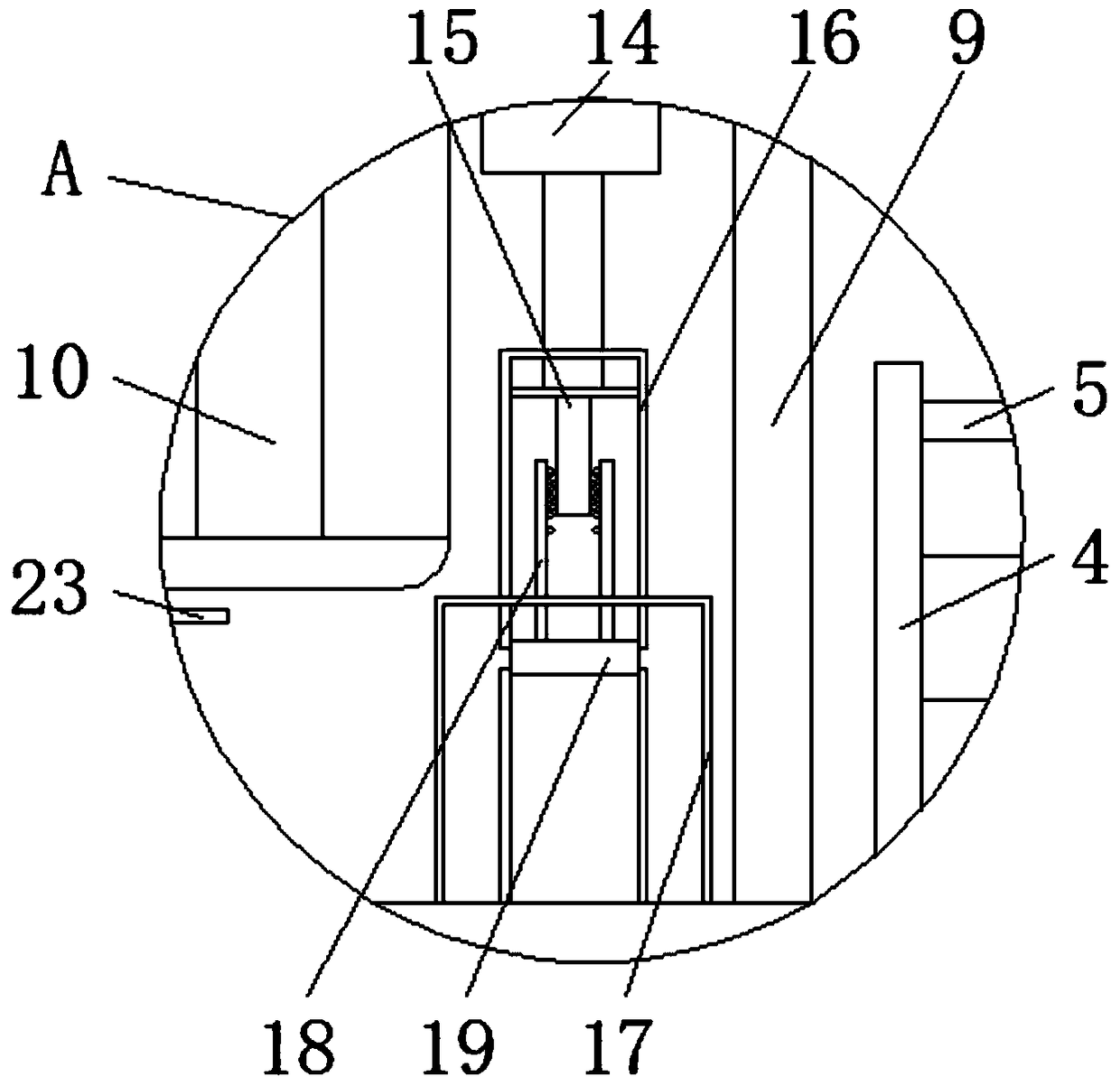

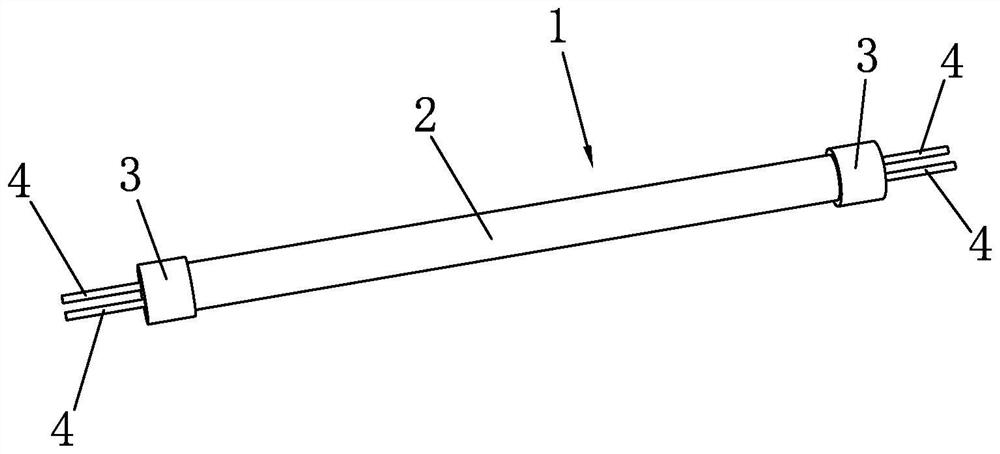

Cutting method for LED lamp tube pins

The invention discloses a cutting method for LED lamp tube pins. The cutting method comprises the following steps that a, a mounting base is fixed; b, LED lamp tube limiting units are installed; c, arranging the LED lamp tube on a trimming table; d, limiting the tube body of the LED lamp tube; e, determining the cutting positions of the pins of the LED lamp tube; f, cutting the pins of the LED lamp tube; g, the limiting structure is disassembled; h, the connecting pipe sleeve is taken out; and i, taking out the cut LED lamp tube. The LED lamp tube can be limited, the LED lamp tube is prevented from moving when pins are cut, the pin cutting quality is improved, meanwhile, force borne by a tube head of the LED lamp tube can be transmitted to the wire cutting table through the connecting tube sleeve and the supporting plate, the tube head is supported, the LED lamp tube is prevented from being damaged when the pins are cut, the pin cutting position of the LED lamp tube can be determined, and the LED lamp tube cutting efficiency is improved. The pin cutting accuracy is improved, it is guaranteed that the cut pins keep the same length, and meanwhile the cut positions of the pins can be flat.

Owner:嵊州市三九灯具有限公司

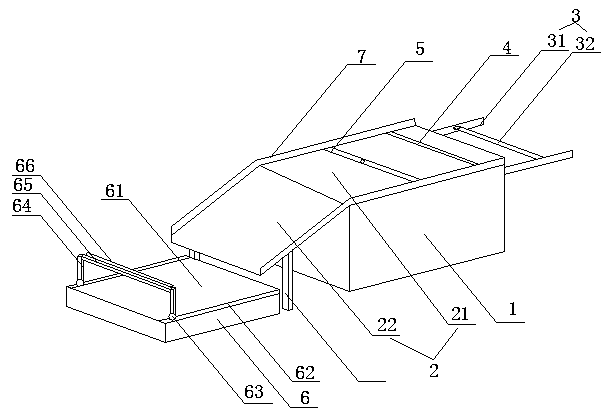

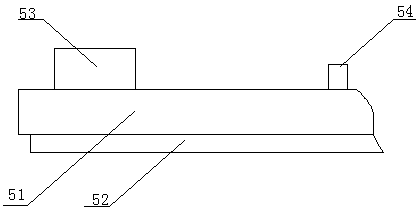

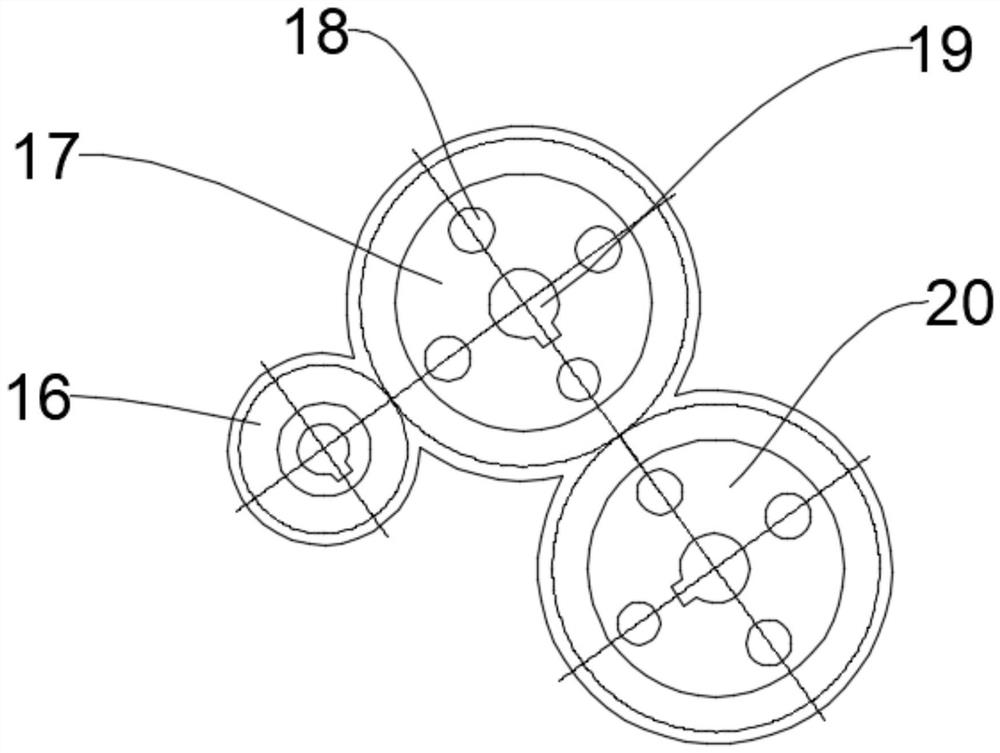

Waterproof material rolling device with precise cutting function

PendingCN112875357AEasy to cleanQuick clean upDrying solid materials without heatCleaning using toolsGear driveGear wheel

The invention discloses a waterproof material rolling device with a precise cutting function, and relates to the technical field of waterproof material processing devices. The waterproof material rolling device comprises a fixing cover, a drying mechanism is fixedly connected to the upper surface of the fixing cover, a straight plate is fixedly connected to the right side face of the inner wall of the fixing cover, and a plurality of transmission rollers are rotationally connected to one side face of the straight plate. By arranging the drying mechanism, air can be blown to a processed film through an air outlet by starting a fan, so that residual moisture on the film is blow-dried, a third rotating shaft rotates, a half-tooth gear drives a second rack to move, a second rack drives a cleaning plate to move left and right on the film under the elastic action of a first telescopic rod and a first spring, so that accumulated water is spread and dust is swept, the drying of residual water is further improved, the cleaning efficiency of the rolling device on the residual water and dust on the film is improved, the cleaning effect is improved, and people can quickly clean the film.

Owner:安徽金川防水防腐新型材料有限公司

High-efficiency printing cutting device capable of rapidly cutting in batches for paper printing

InactiveCN113001610AEasy to slide frictionEasy to operateMetal working apparatusProcess engineeringIndustrial engineering

The invention relates to the technical field of cutting devices, in particular to a high-efficiency printing cutting device capable of rapidly cutting in batches for paper printing. The device comprises a mounting table, a servo motor, a first electric push rod and a second electric push rod, wherein a rotating mechanism is arranged in the middle of the upper end of the mounting table, and comprises a first clamping groove, a rotating table, an inner gear, a first gear, a first transmission shaft, a servo motor, a cutting table and a second gear, the first clamping groove is formed in the middle of the upper end of the mounting table, and the rotating table is rotationally connected into the first clamping groove. The device is easy to operate, the size of paper needing to be cut is set in advance, the paper can be rapidly cut into the needed size, the device is suitable for cutting the paper of the same size in batches, the situation that the cutting size needs to be frequently adjusted during cutting is avoided, and the cutting efficiency is greatly improved; and the paper does not need to be manually pushed into the cutting device during cutting each time, so that the safety of the device is also improved.

Owner:陈万林

Medical first-aid-blanket cutting device

The invention discloses a medical first-aid-blanket cutting device. The medical first-aid-blanket cutting device comprises a collecting box, second support columns, a placing table and second supportsand is characterized in that first support columns are welded to the four corners of the bottom end of the placing table, hooks are fixedly connected to one side of the placing table, the collectingbox is movably connected with the hooks through hook grooves, positioning rods are welded to the other end of the placing table, rotary shafts are mounted at the front ends of the positioning rods, atransverse rod is rotatably mounted on the rotary shafts, a cylinder sleeves the surface of the transverse rod, the top end face of the placing table is provided with grooves, first supports are welded to the top end faces of the second support columns, third supports are welded to the inner sides of the first supports, the second supports are elastically connected to the tops of the third supports through springs, pressing plates are welded to the middles of the second supports, connecting rods are welded to the bottom end faces of the second supports, and cutting blades are welded to the bottom ends of the connecting rods. The medical first-aid-blanket cutting device is capable of achieving fast cutting and waste collecting and is better than a traditional product.

Owner:王回芳

Automatic screening and packaging process for medical test paper

InactiveCN113306811ARealize automatic handling and deliveryRealize pressingPaper article packagingPackaging automatic controlMolecular sieveProcess engineering

The invention discloses an automatic screening and packaging process for medical test paper. The automatic screening and packaging process comprises the following specific screening and packaging steps that S1, carrying out a test paper sheet and test paper groove feeding process; S2, cutting, separating and boxing the test paper sheets; S3, carrying and conveying test paper groove plates and screening test paper sheets; S4, carrying out a test paper box feeding and conveying process; S5, carrying out a test paper groove plate recycling process; S6, carrying out a test paper sheet pressing process; S7, carrying out a test paper box shifting and moving process; S8, carrying out a test paper box upper cover feeding process; S9, carrying out a test paper box packing process; S10, assembling a molecular sieve bag and a sieve box; S11, carrying out a molecular sieve box feeding and conveying process; S12, carrying out a test paper box lower cover feeding and assembling process; S13, carrying out a test paper outer packaging box discharging process; The automatic screening and packaging process is high in automation degree, the overall screening and packaging efficiency is improved, the labor cost is reduced, and the good market application value is achieved.

Owner:深圳中科智美科技有限公司

Front part shaping device

The invention provides a front part shaping device. The front part shaping device comprises a frame, a controller, a cutting platform, a cutting mechanism and a compressing mechanism and is characterized in that the controller is a computer, and the controller is connected with and controls the cutting platform, the cutting mechanism and the compressing mechanism; the cutting platform, the cuttingmechanism and the compressing mechanism are mounted on the frame; suit shaping software is installed in the computer, a user measures the body size of a consumer and inputs the data into the computer, the suit shaping software automatically builds and sets the overall size and front part size of a suit, sets the appearance and size of the suit by selecting a suit style, and converts the set parameters into the sizes of cloth, which needs to be cut, of various parts, and automatic cutting is performed. The front part shaping device has the advantages that automatic and fast cutting is achieved, the suit can be shaped automatically, traditional pure manual cutting can be replaced, the device is low in dependence on personal experience, low in error rate and capable of saving cloth, and thecustomized suit produced by the device is fit.

Owner:银川滨河如意服装有限公司

Textile fabric edge cutting device

InactiveCN112048901AQuick cropReasonable structural designSevering textilesMetal working apparatusGear wheelEngineering

The invention discloses a textile fabric edge cutting device. The device comprises a frame body and a movable rod, wherein a roller shaft is installed at the top of the frame body, fabric is arrangedin the middle of the roller shaft, a cutting mechanism is installed in the middle of the frame body, a guide mechanism is arranged on the left side of the cutting mechanism, the guide mechanism is connected with a conveying mechanism through a gear, and a recycling mechanism is arranged under the cutting mechanism. The device is reasonable in overall structural design, convenient to assemble, highin automation degree and extremely convenient to use, the cutting mechanism can rapidly cut textile fabric, a roller can roll up the cut fabric, the guide mechanism pushes the barrel-shaped fabric forwards, the conveying mechanism conveys the barrel-shaped fabric out, and the recycling mechanism can recycle and reuse waste materials generated in the cutting process.

Owner:蒋秀兰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com