Cutting device for aprons

A cutting device and apron technology, applied in the cutting of textile materials, textiles and papermaking, etc., can solve problems such as easily damaged fabrics, and achieve the effects of improving quality, convenient use of equipment, and speeding up efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

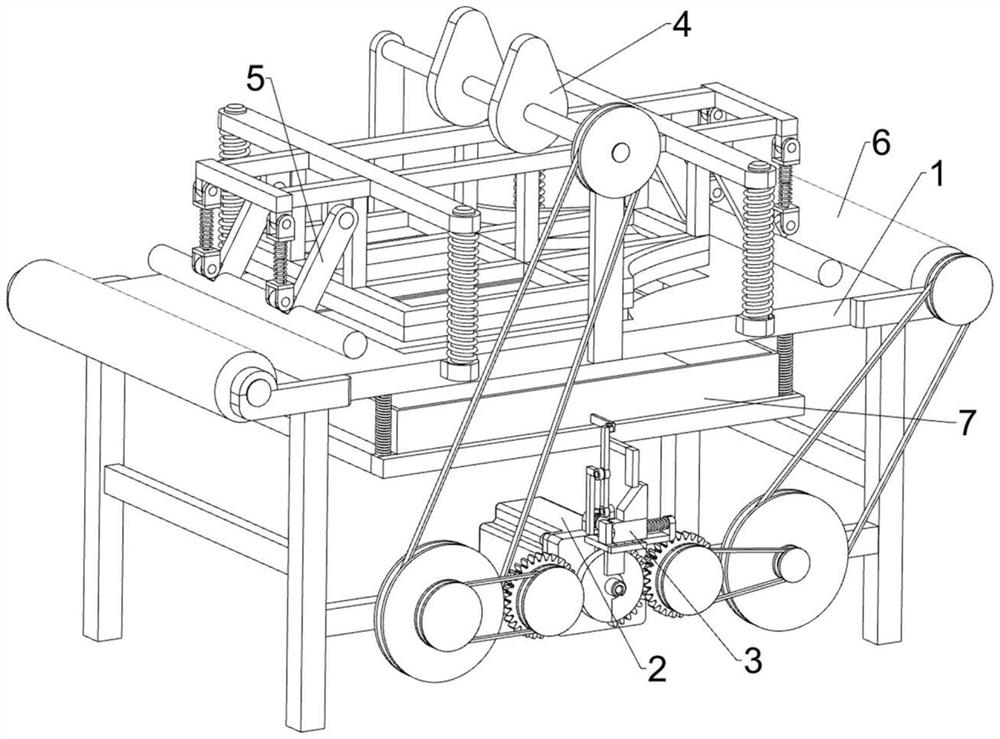

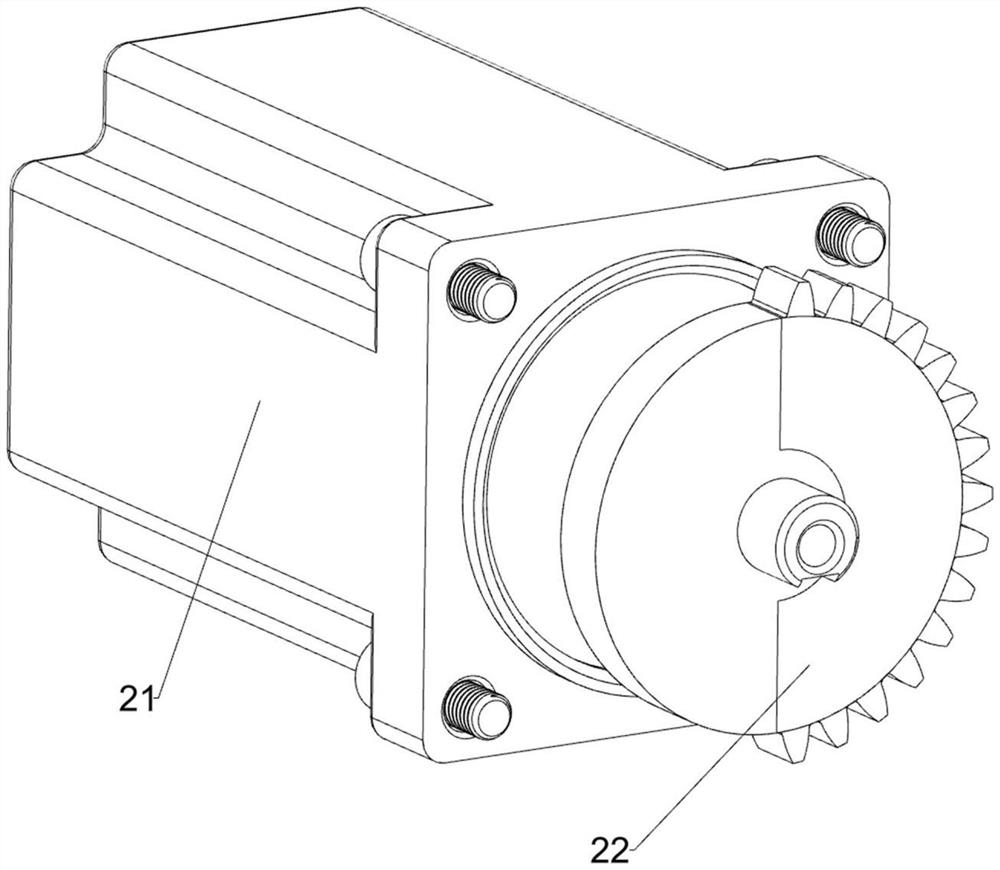

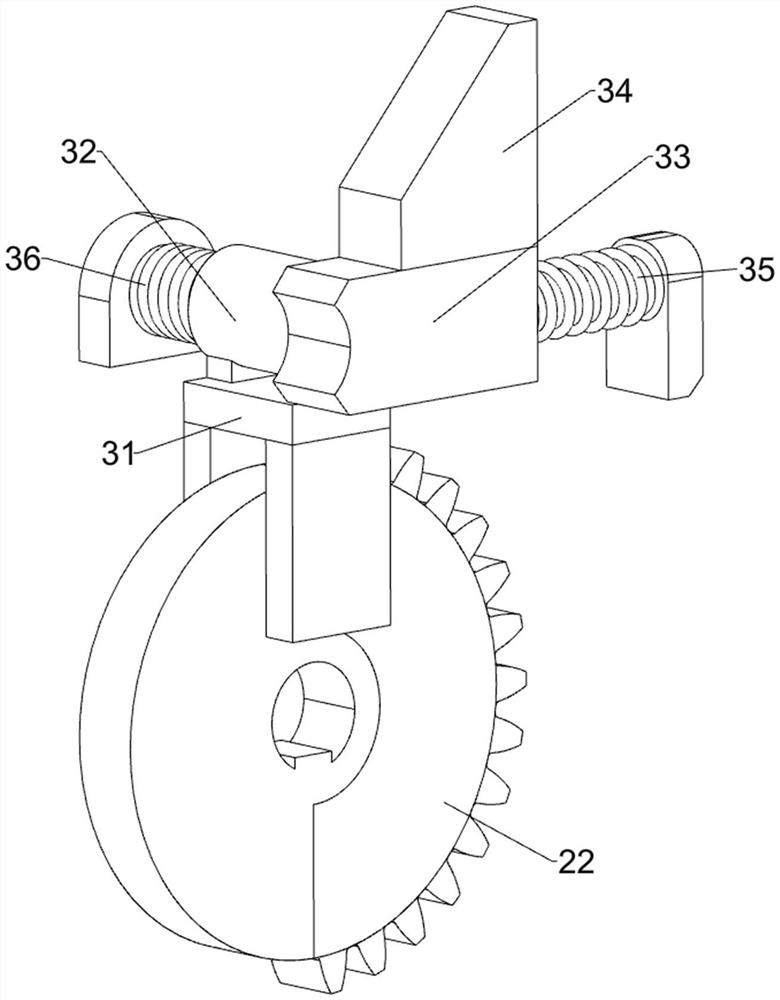

[0027] A cutting device for an apron, such as Figure 1-Figure 4 As shown, it includes a bracket 1, a power component 2, a control component 3 and a cutting component 4. The power component 2 powered by a motor is installed in the front middle of the bracket 1, and the upper middle of the front side of the bracket 1 is installed by sliding. The control assembly 3 of the control is provided with a cutting assembly 4 that cuts the cloth by sliding between the front side and the top of the support 1 .

[0028] When it is necessary to use the device to cut the apron fabric, the fabric is first placed on the top of the support 1, and then the power component 2 is controlled to start working, and the power component 2 drives the cutting component 4 to cut the fabric. In the process of cutting the fabric, workers are required Fix the fabric, after the piece of fabric is cut, disconnect the cutting component 4 from the power component 2 through the control component 3, then re-place t...

Embodiment 2

[0036] On the basis of Example 1, such as figure 1 , Figure 5 , Figure 6 and Figure 7 As shown, it also includes a compression assembly 5, and the left and right sides of the sliding frame 41 are equipped with a compression assembly 5. The compression assembly 5 includes a pole 51, a telescopic rod 52, a swing rod 53, a second concave block 54, Pressing roller 55 and the 4th spring 56, sliding frame 41 left and right sides all are welded with support rod 51, and the support rod 51 outer sides of left and right sides are all rotationally provided with telescopic rod 52, and telescopic rod 52 bottom ends are all welded with The second concave block 54, the fourth spring 56 is connected between the second concave block 54 and the top of the telescopic rod 52, and a fork 53 is provided in a rotating manner between the bottom of the second concave block 54 and the pole 51. All rotation type is provided with pressure roller 55 between the fork 53 bottom ends of the right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com