Patents

Literature

37results about How to "Auto fix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

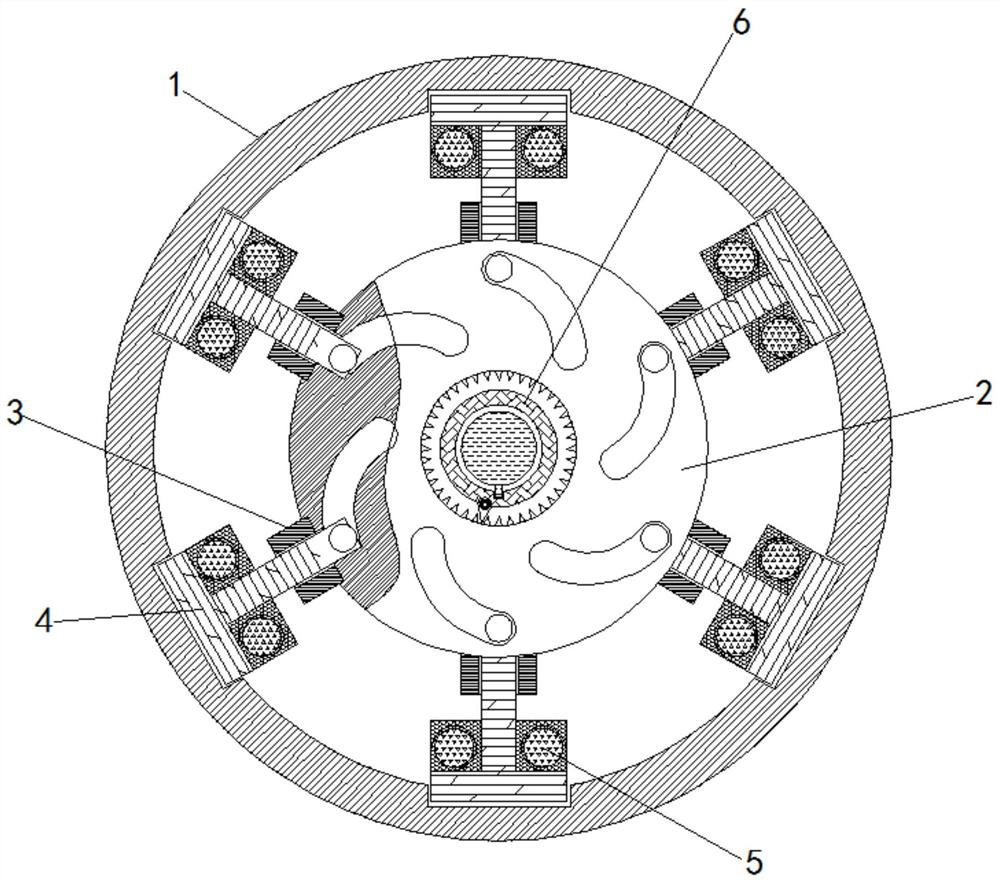

Arm fixing and medicine applying equipment for hospital surgery

ActiveCN112603709AAchieve fixationWork lessMedical devicesMedical applicatorsEngineeringMechanical engineering

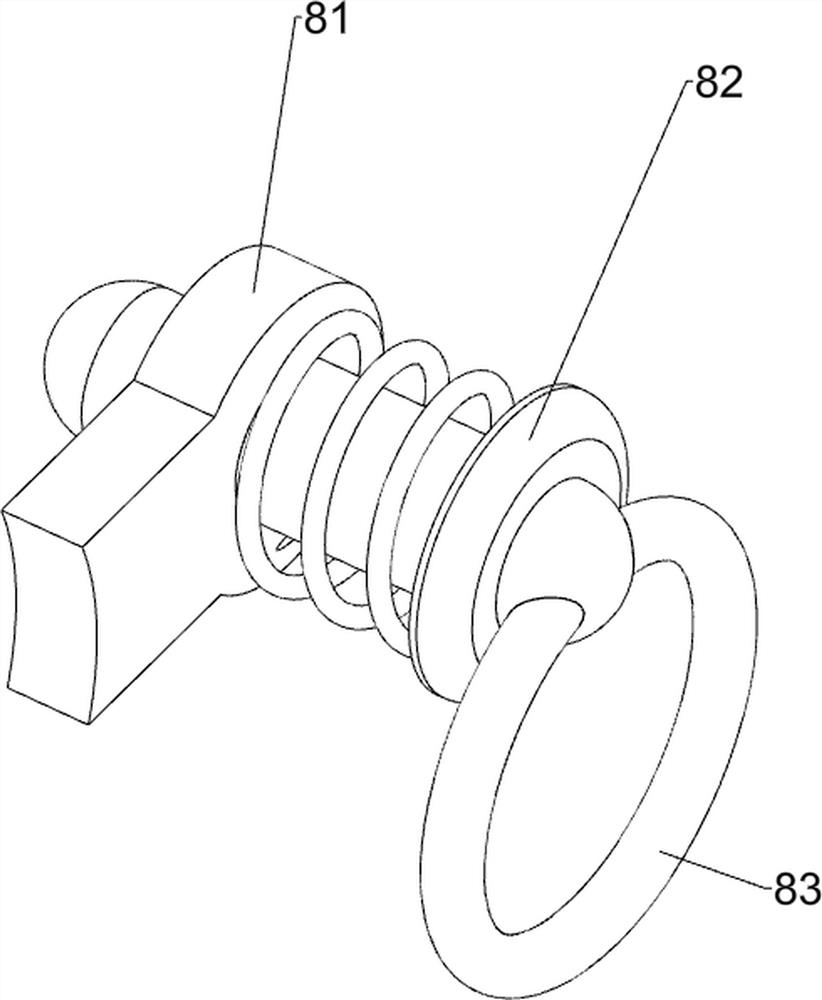

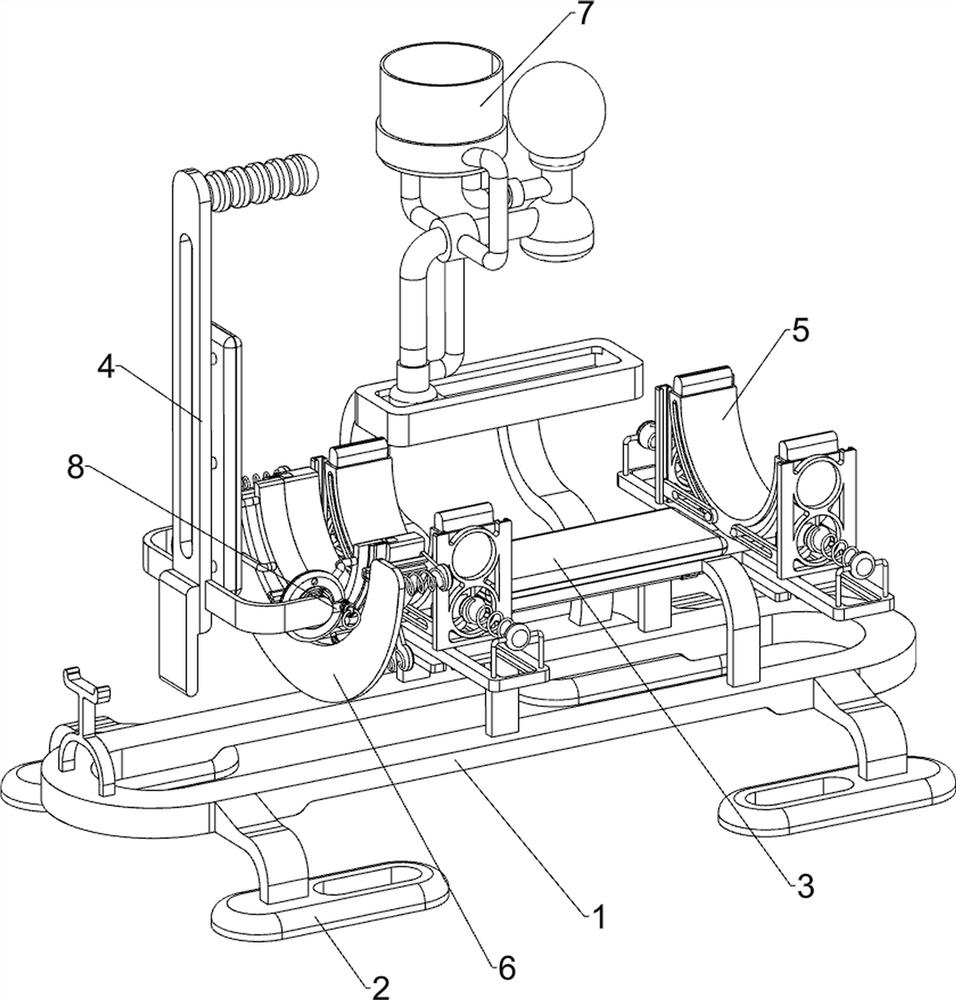

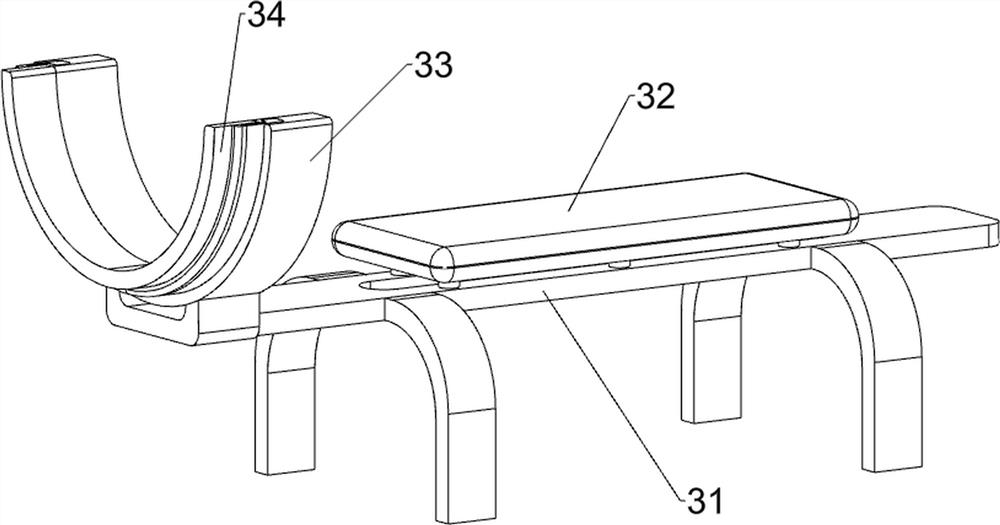

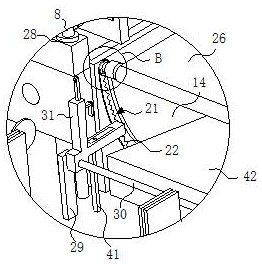

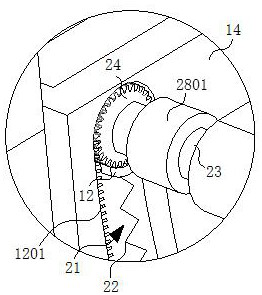

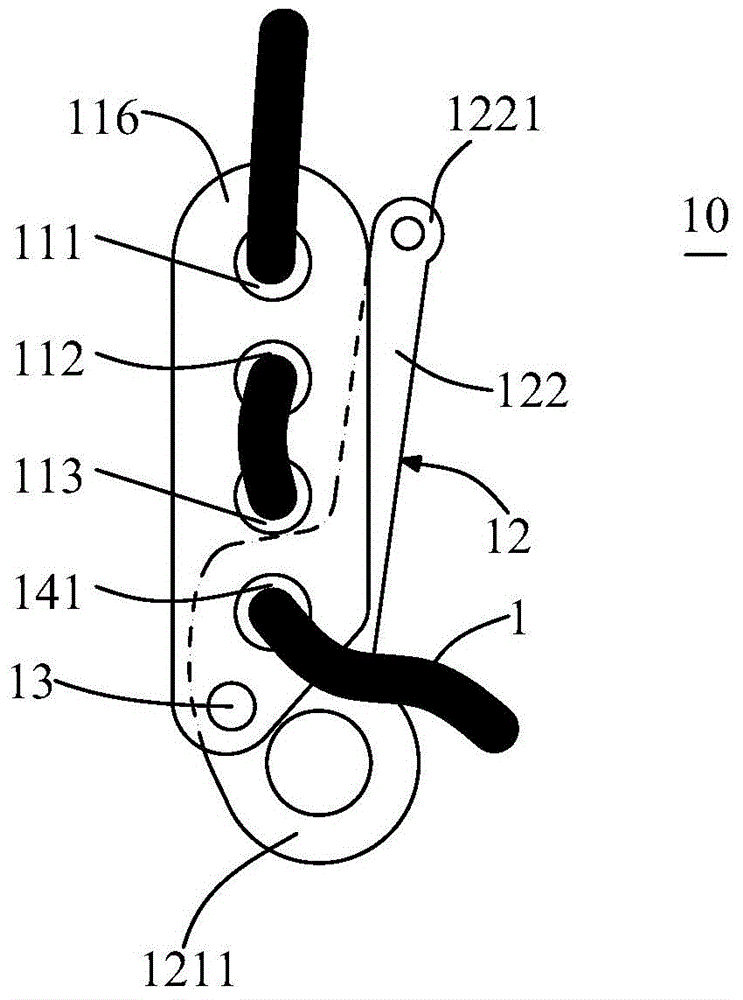

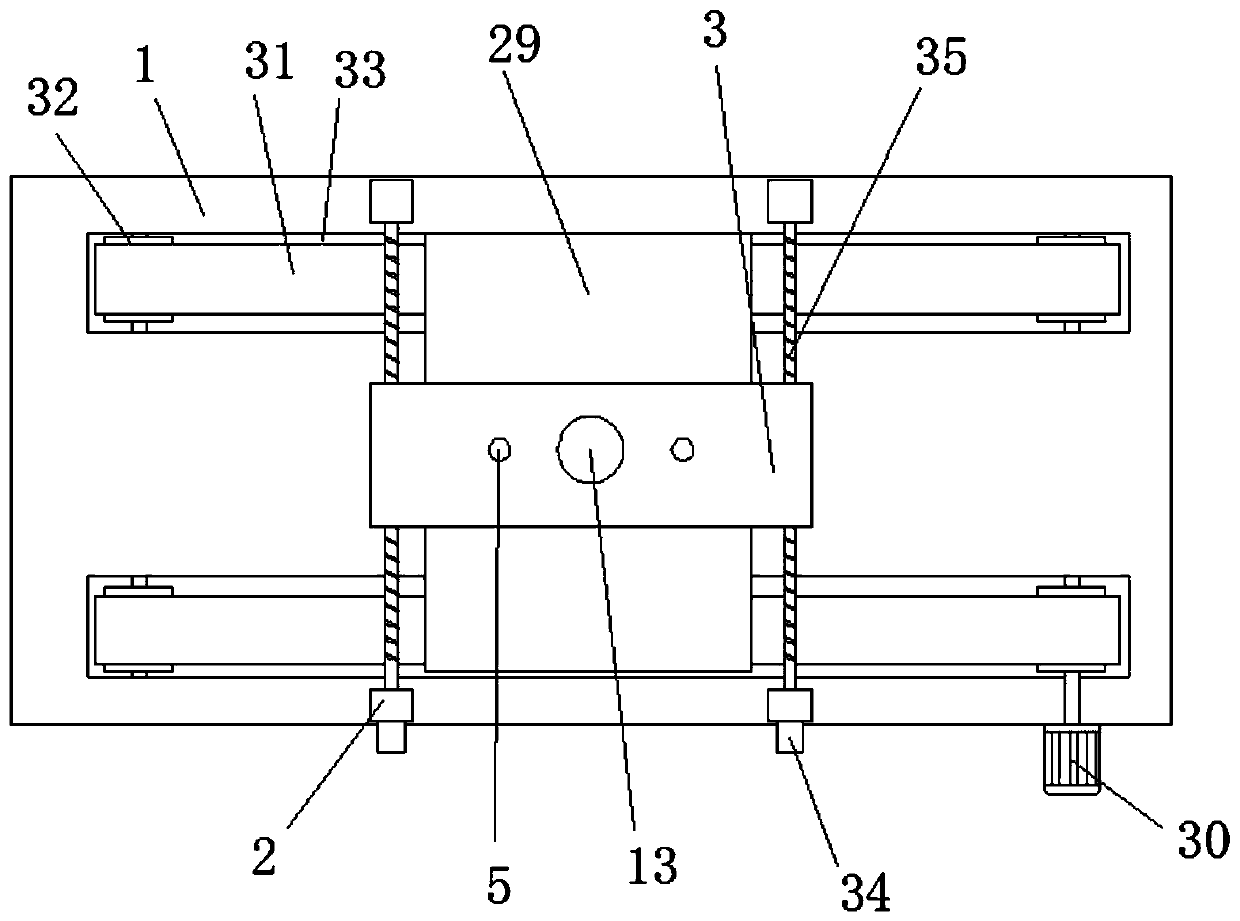

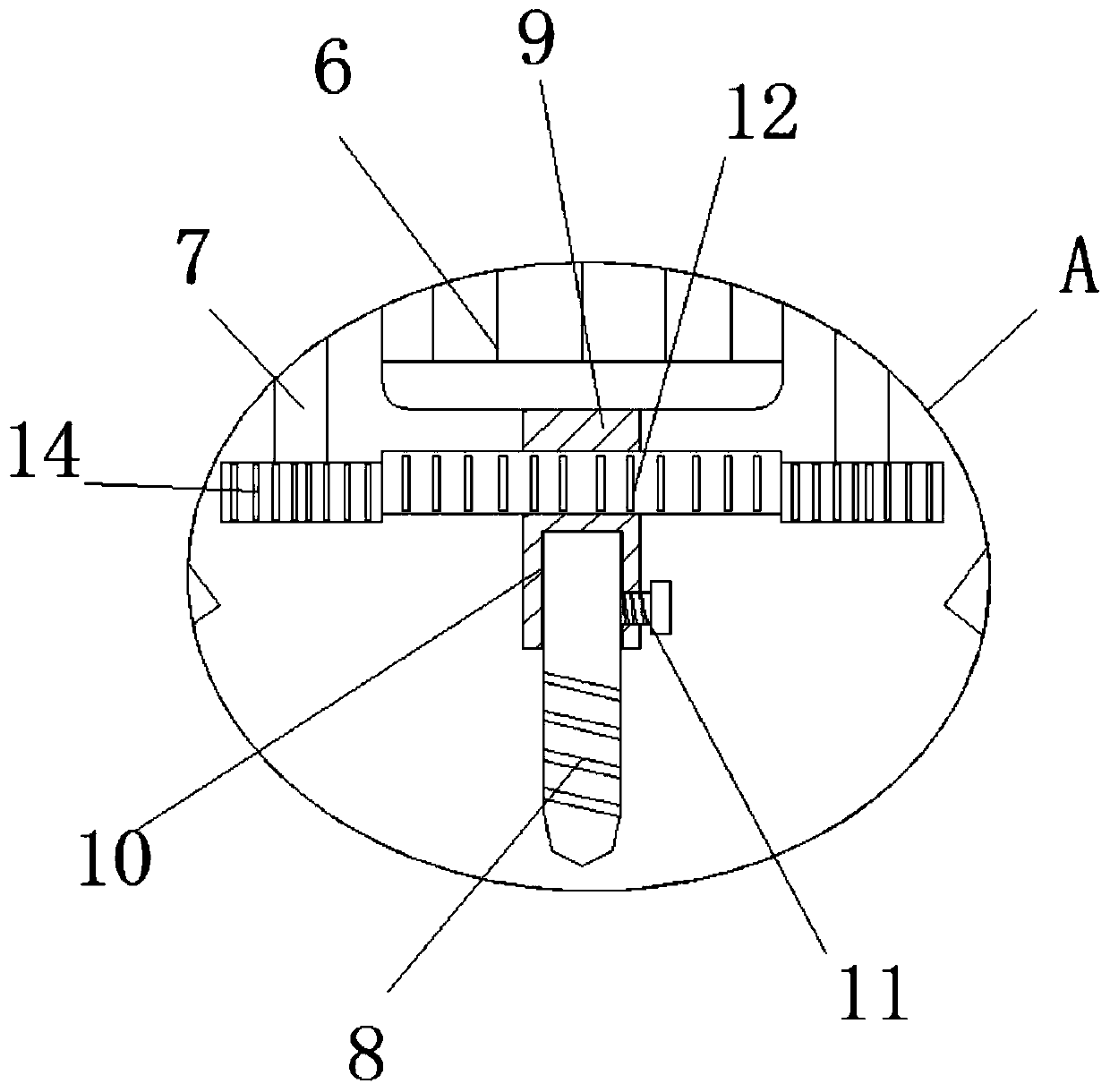

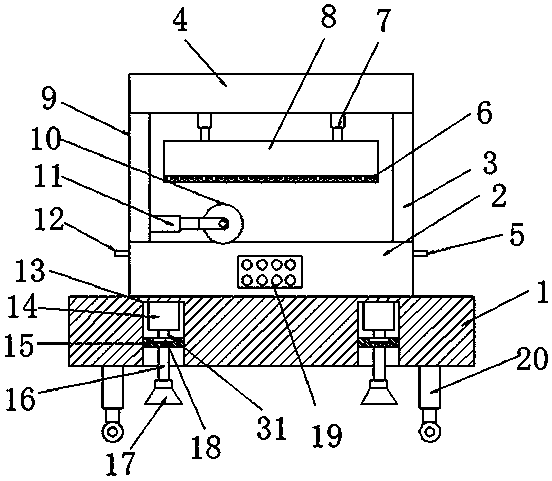

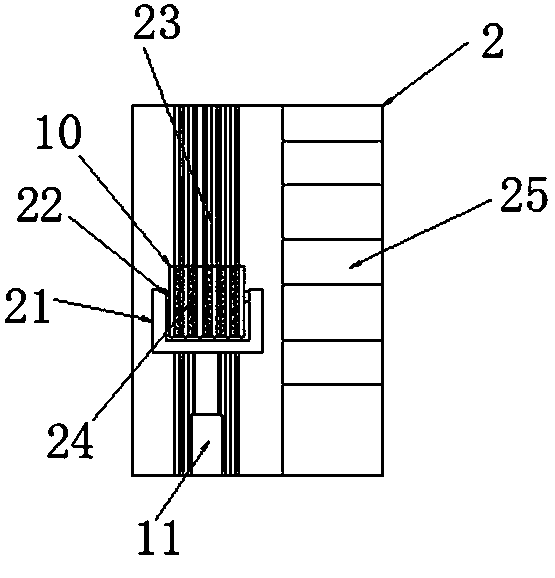

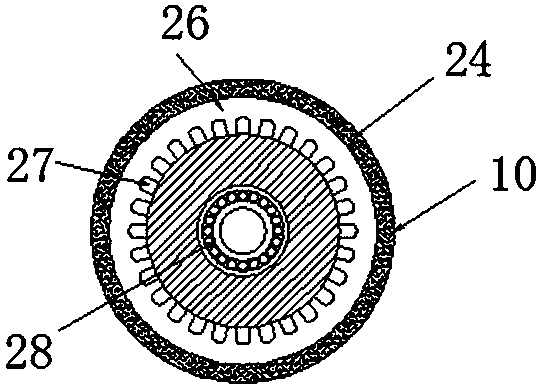

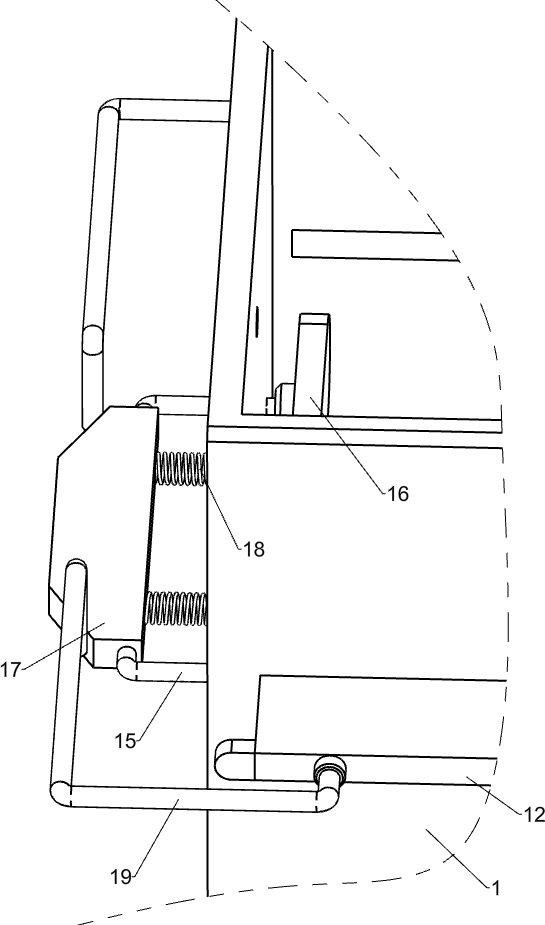

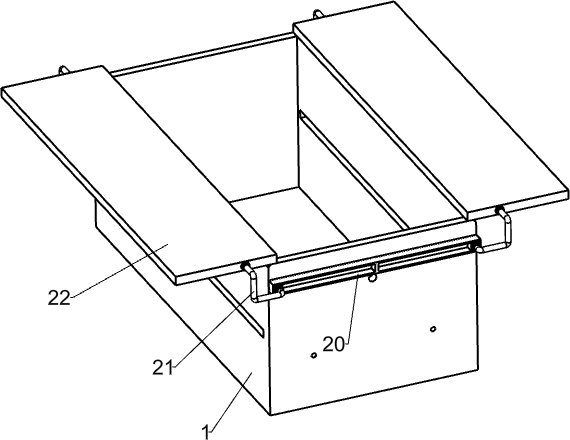

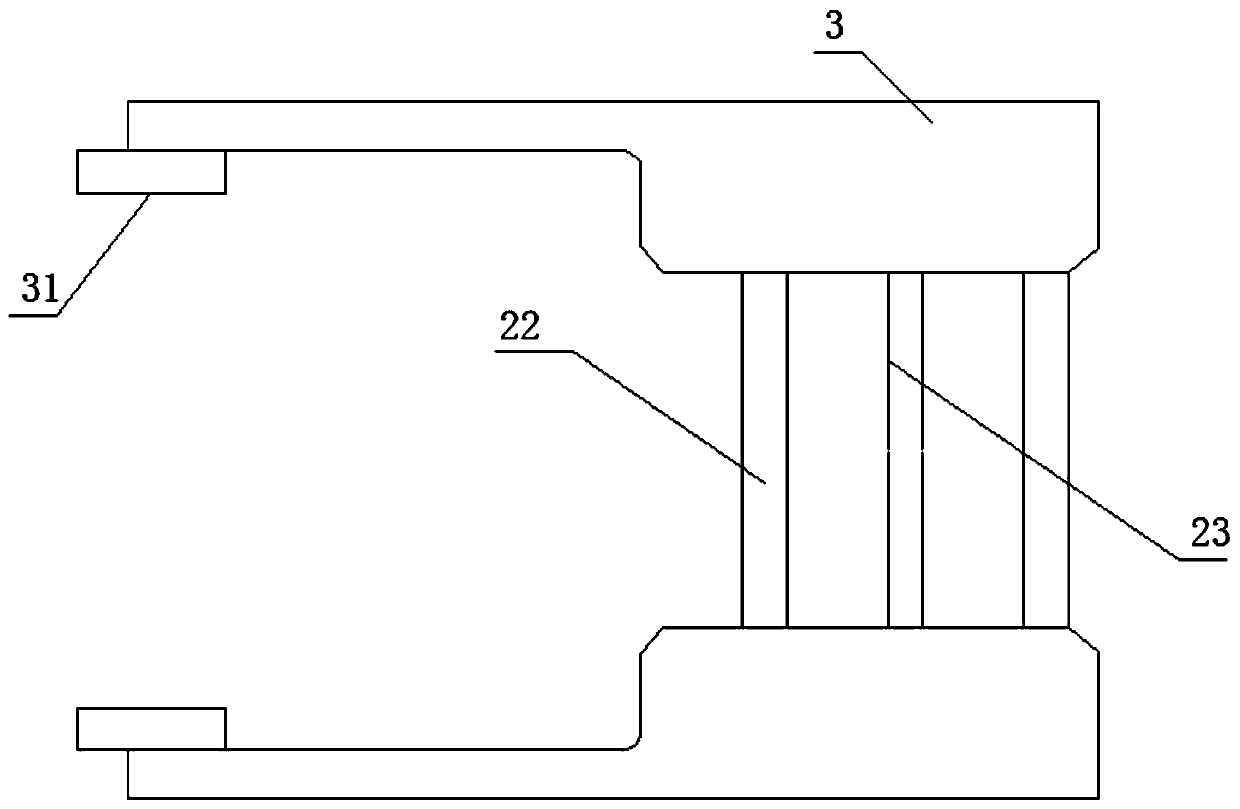

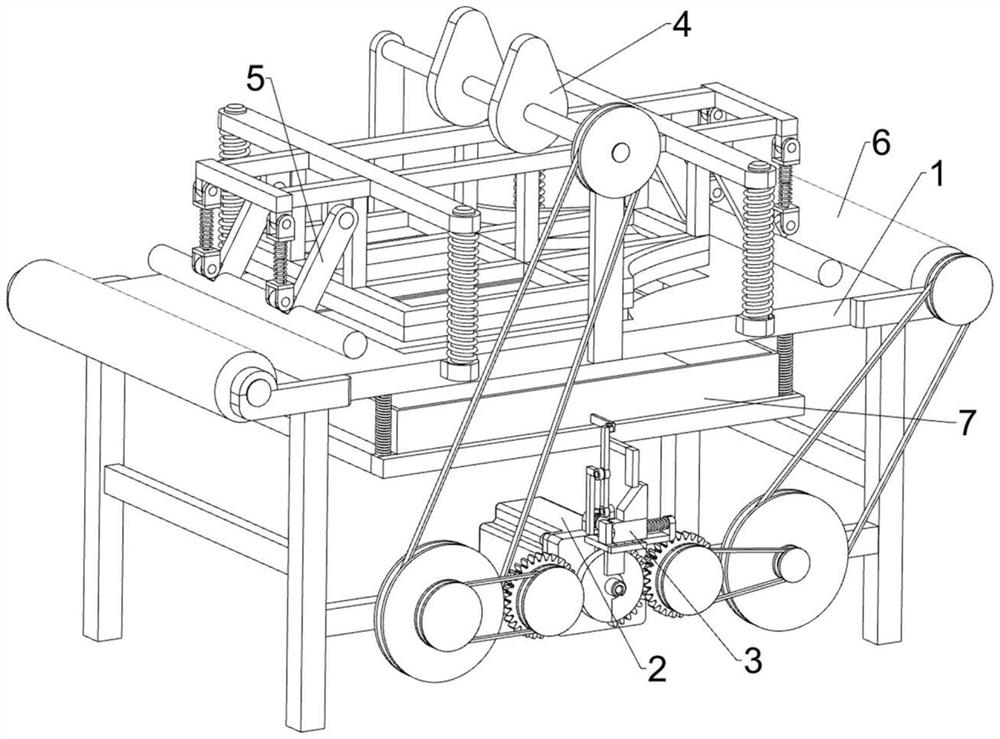

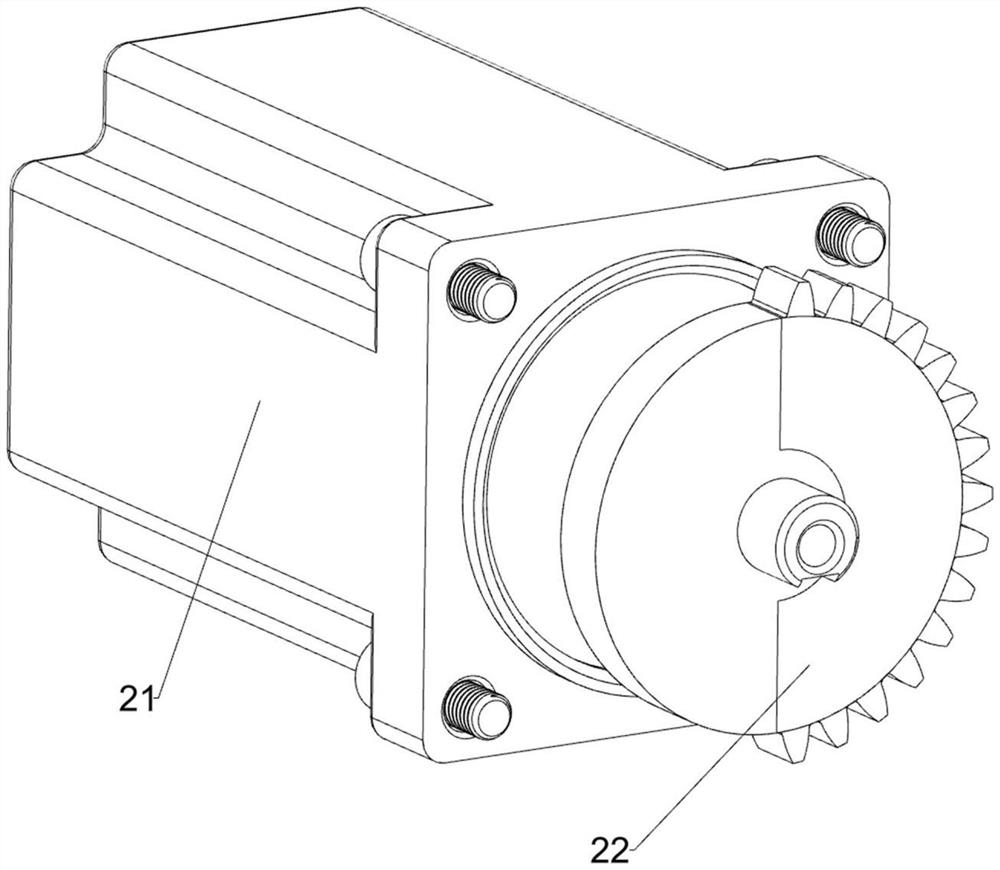

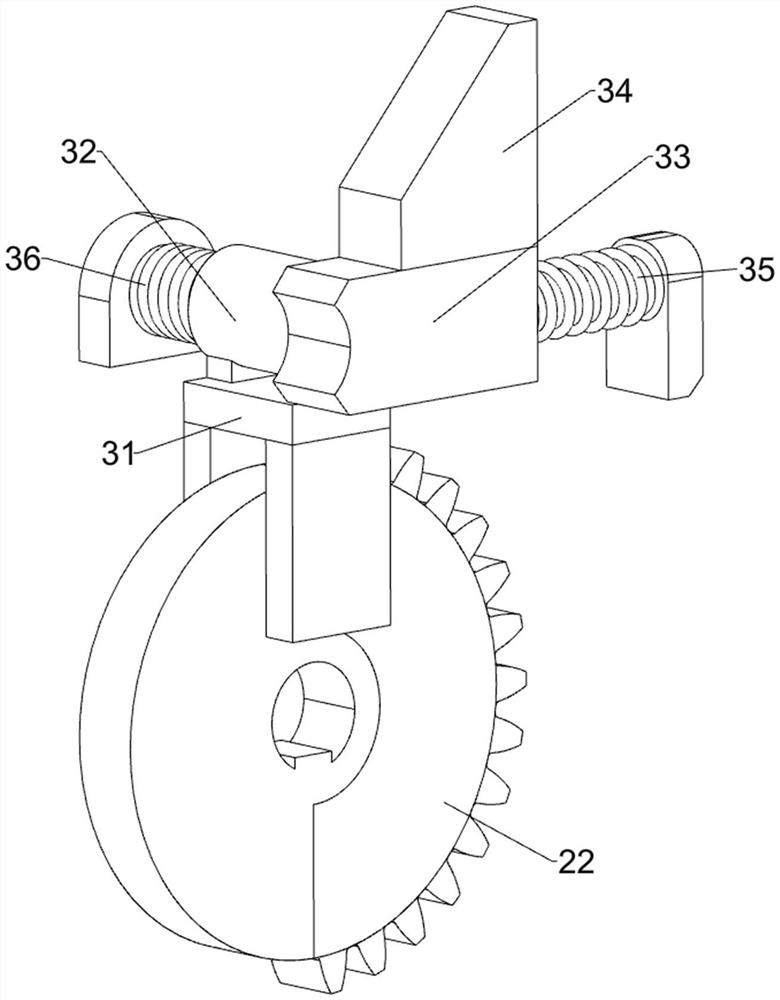

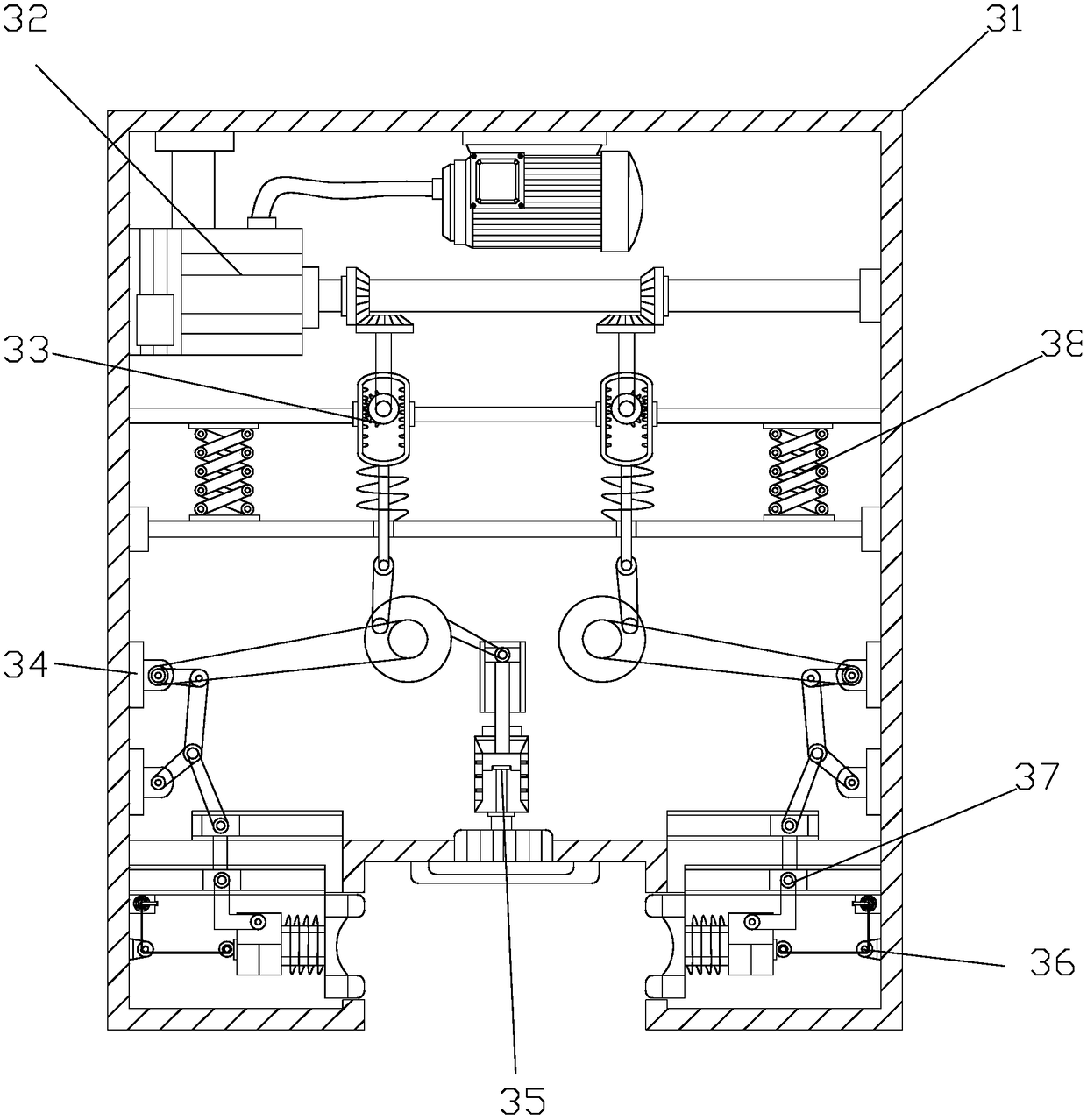

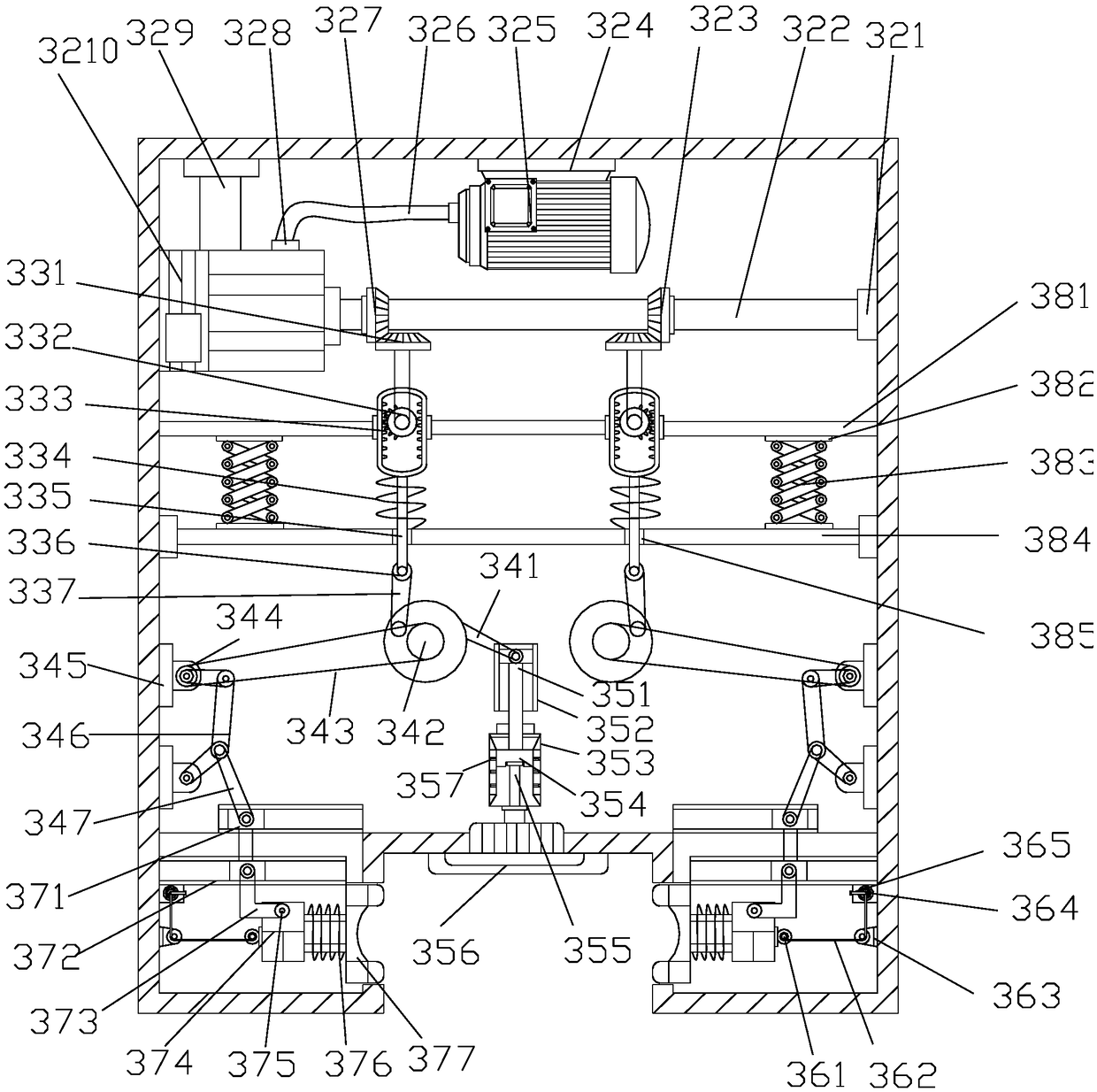

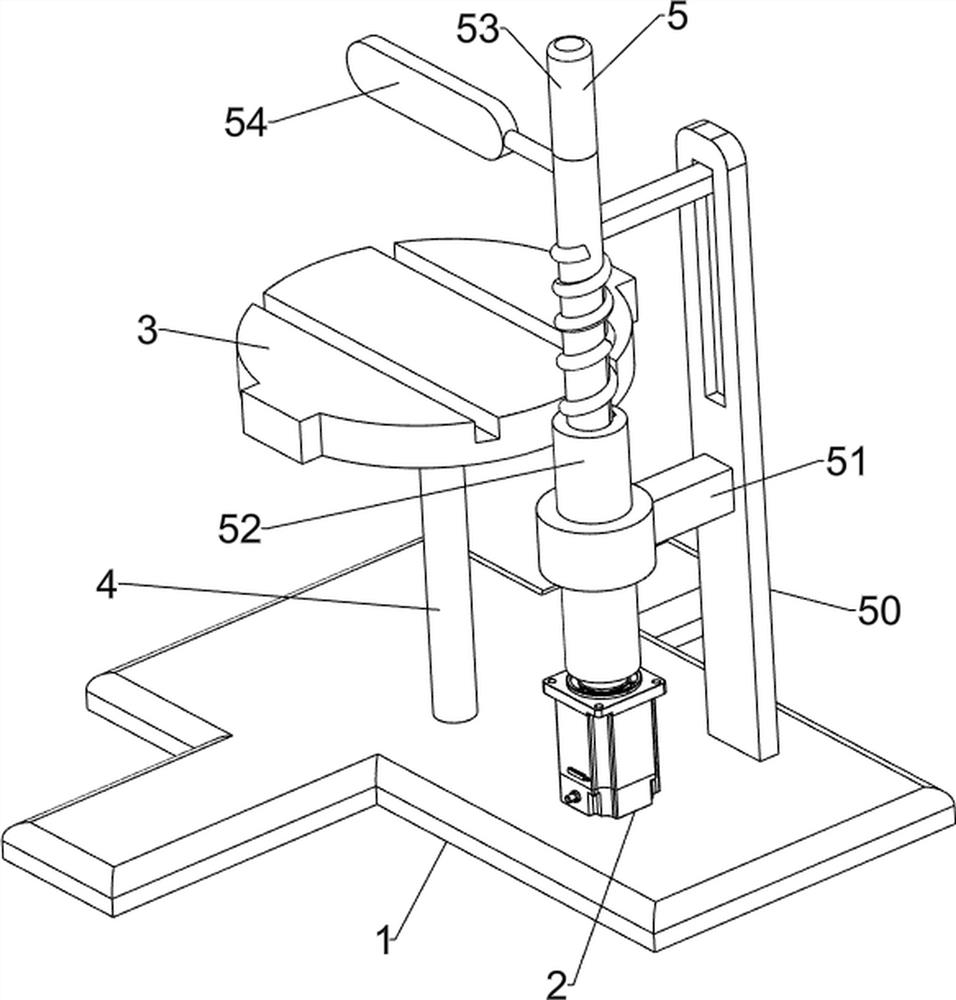

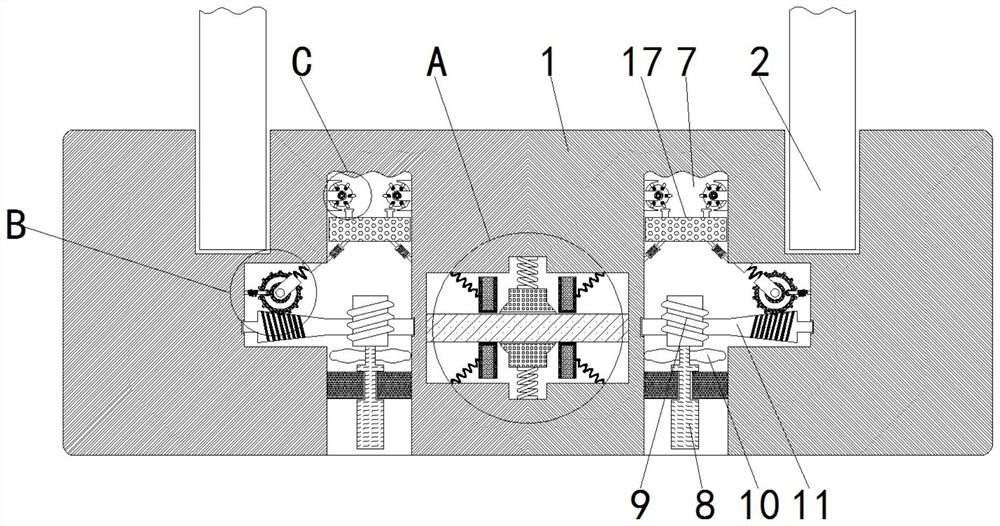

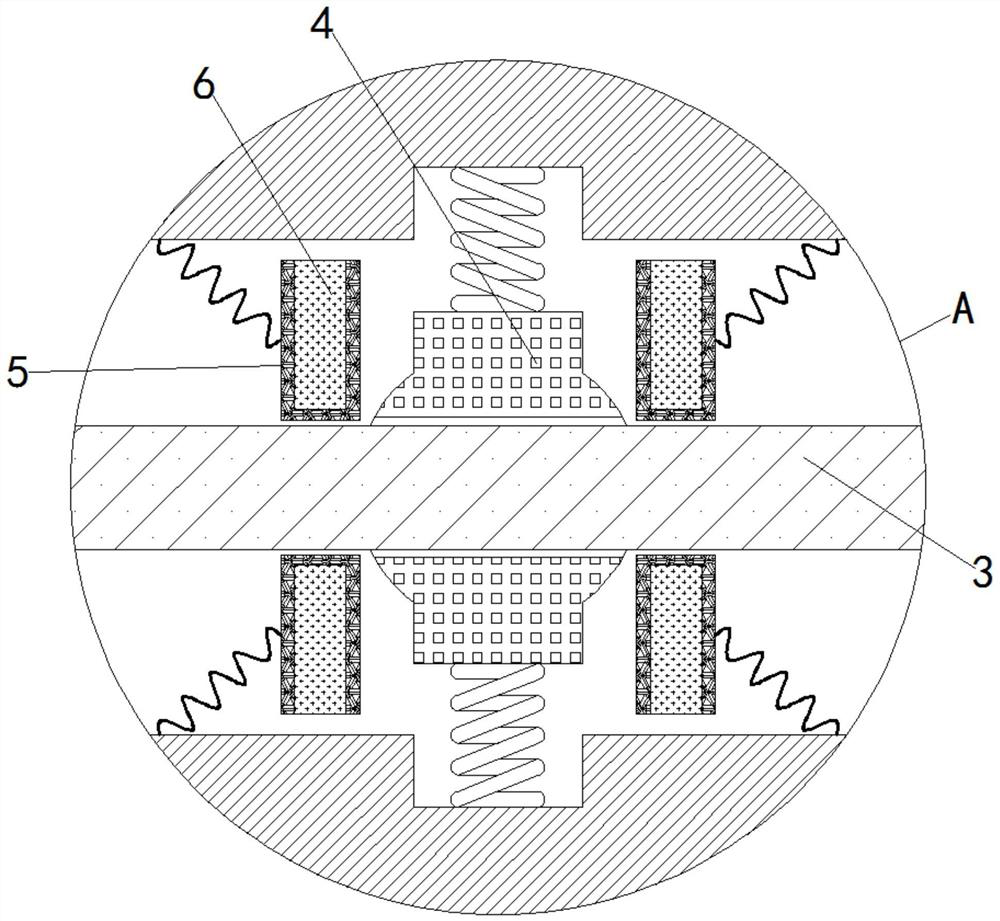

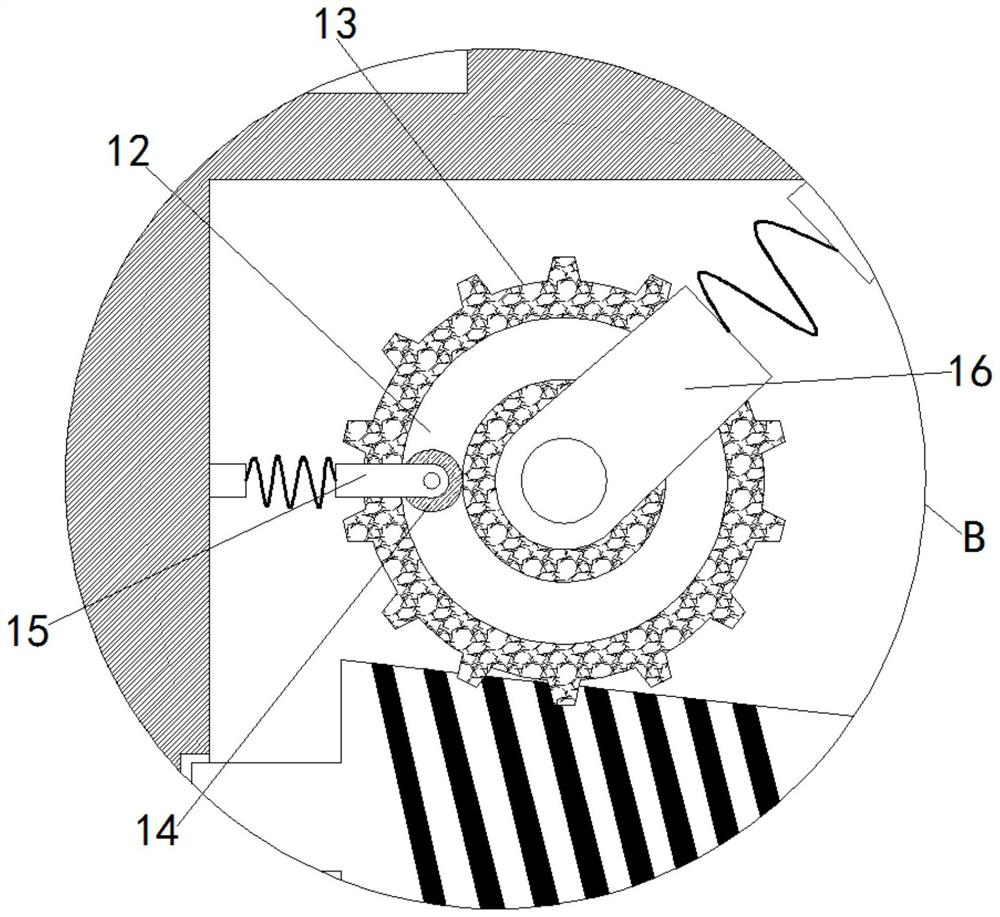

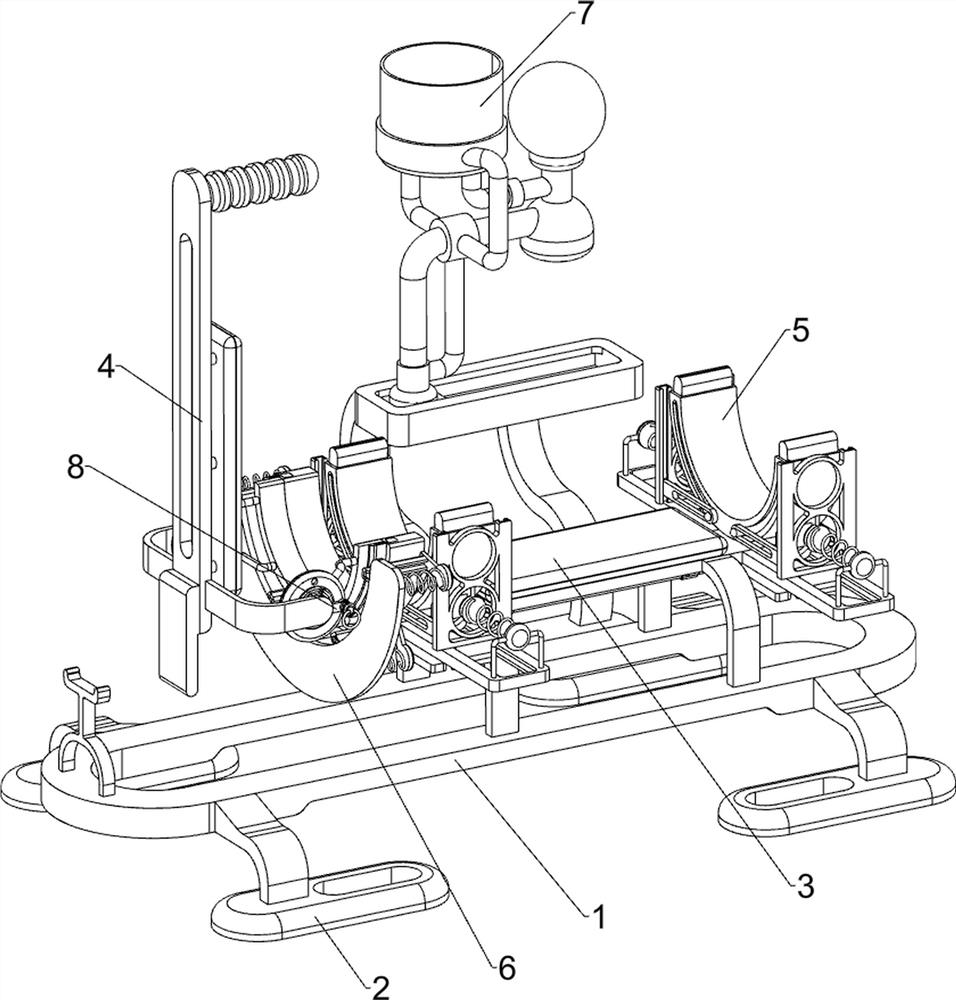

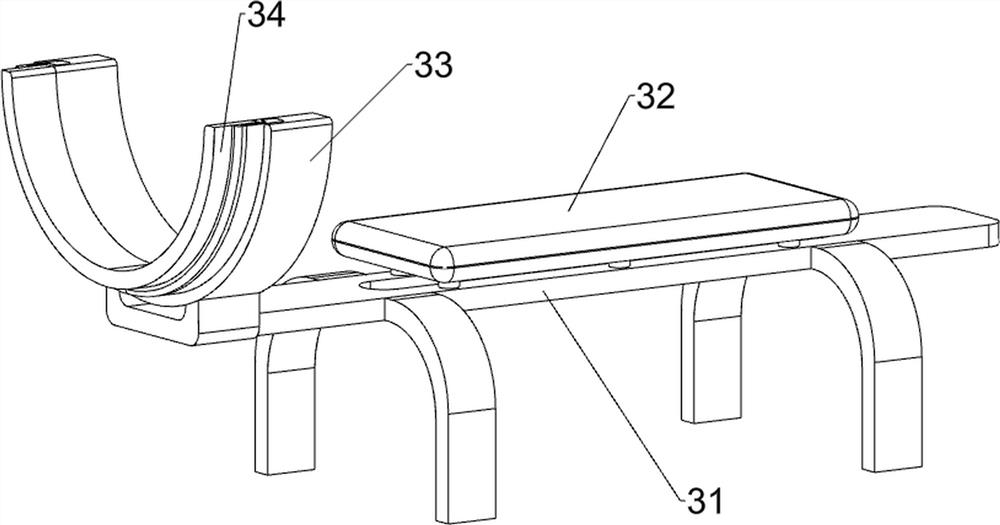

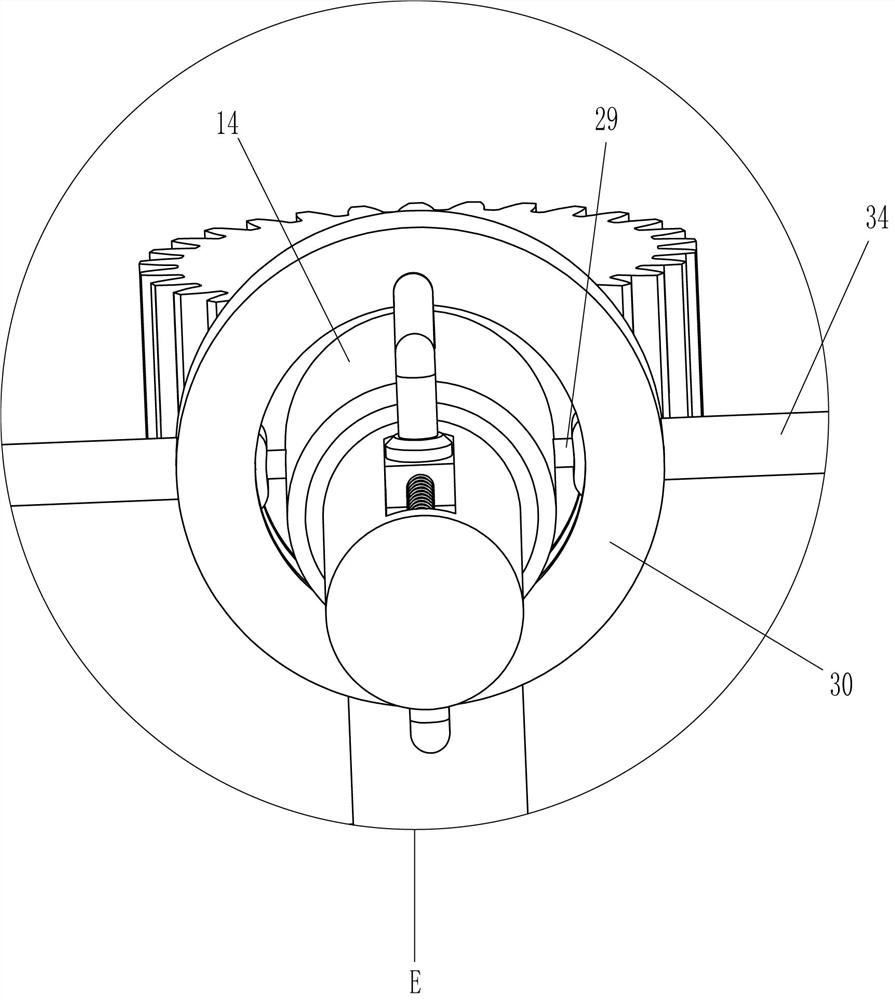

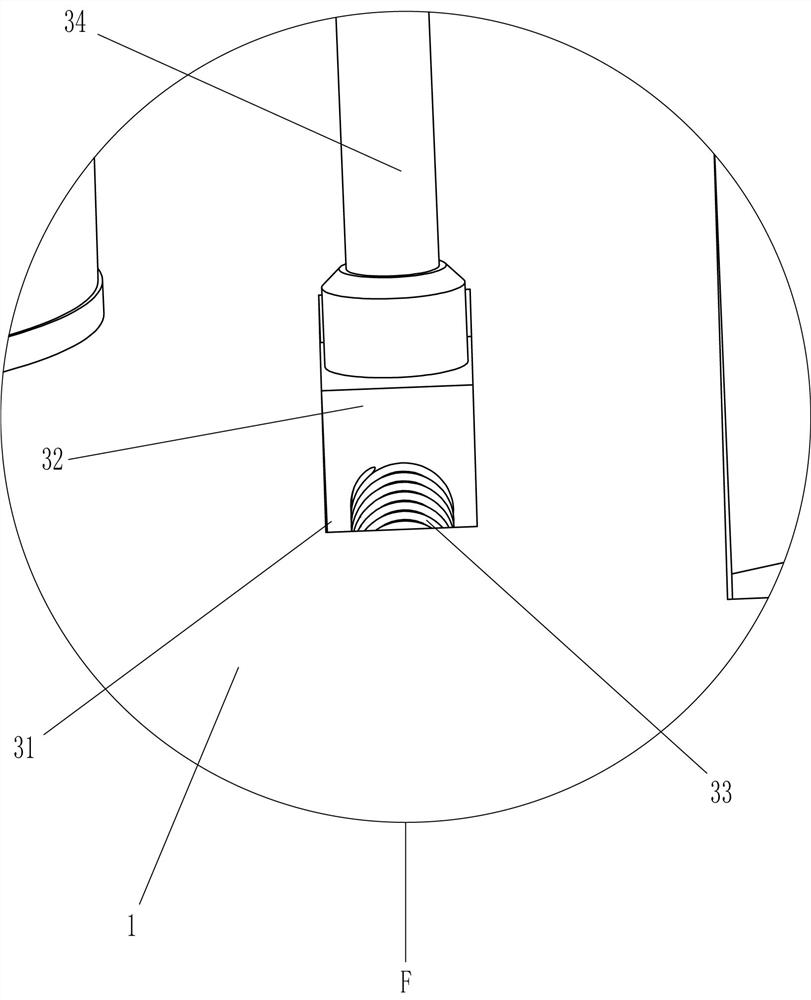

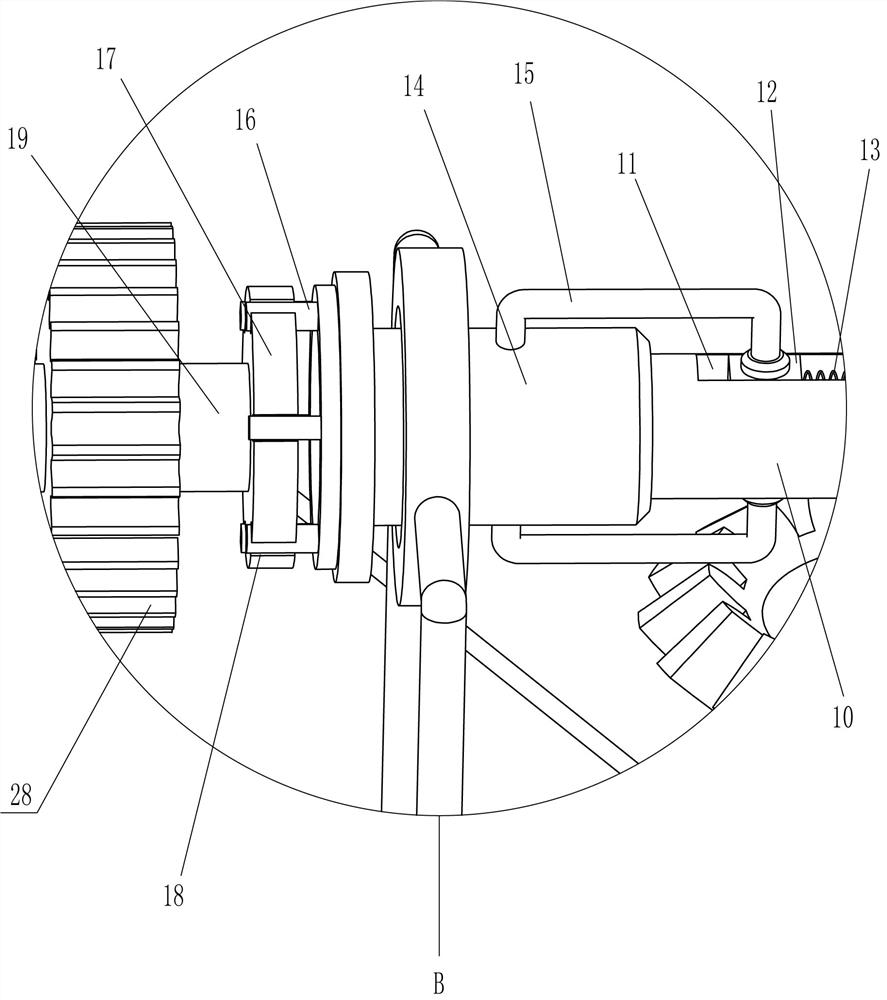

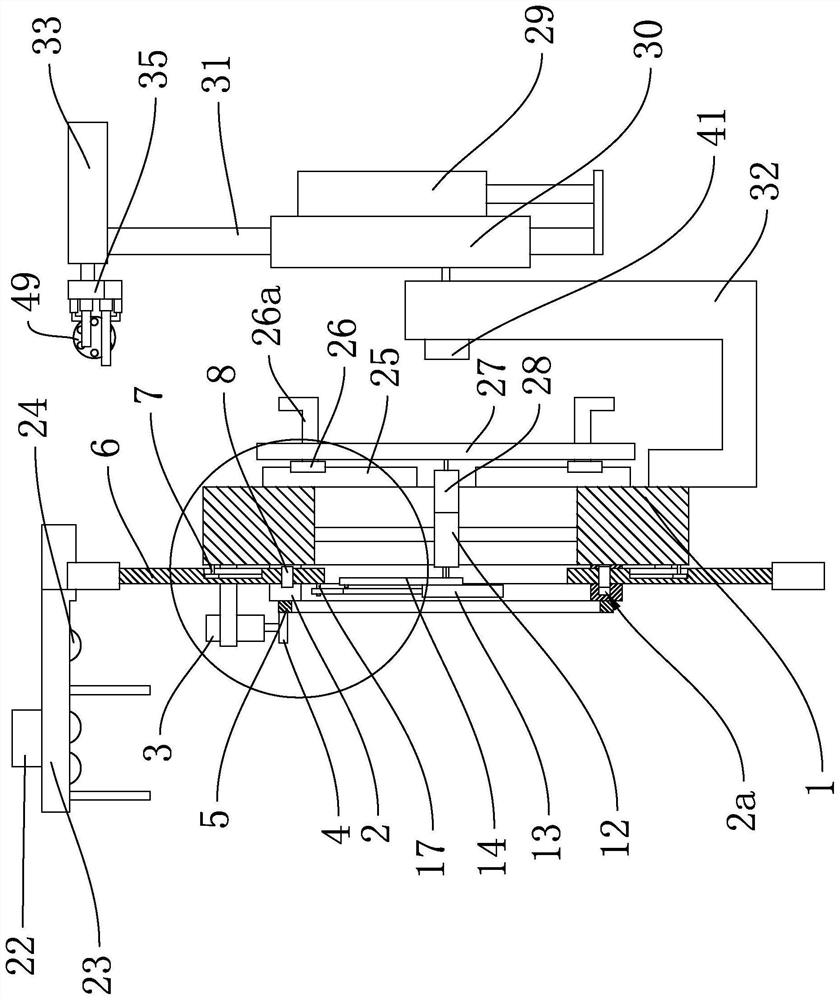

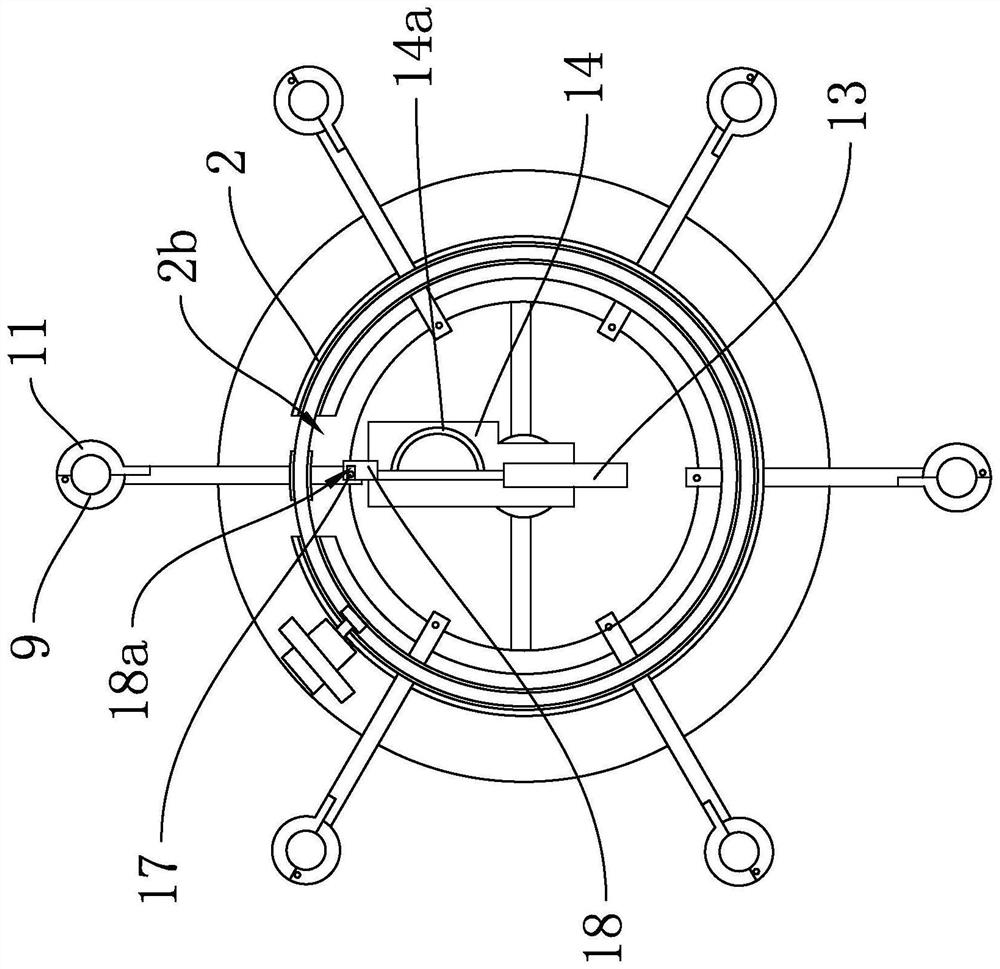

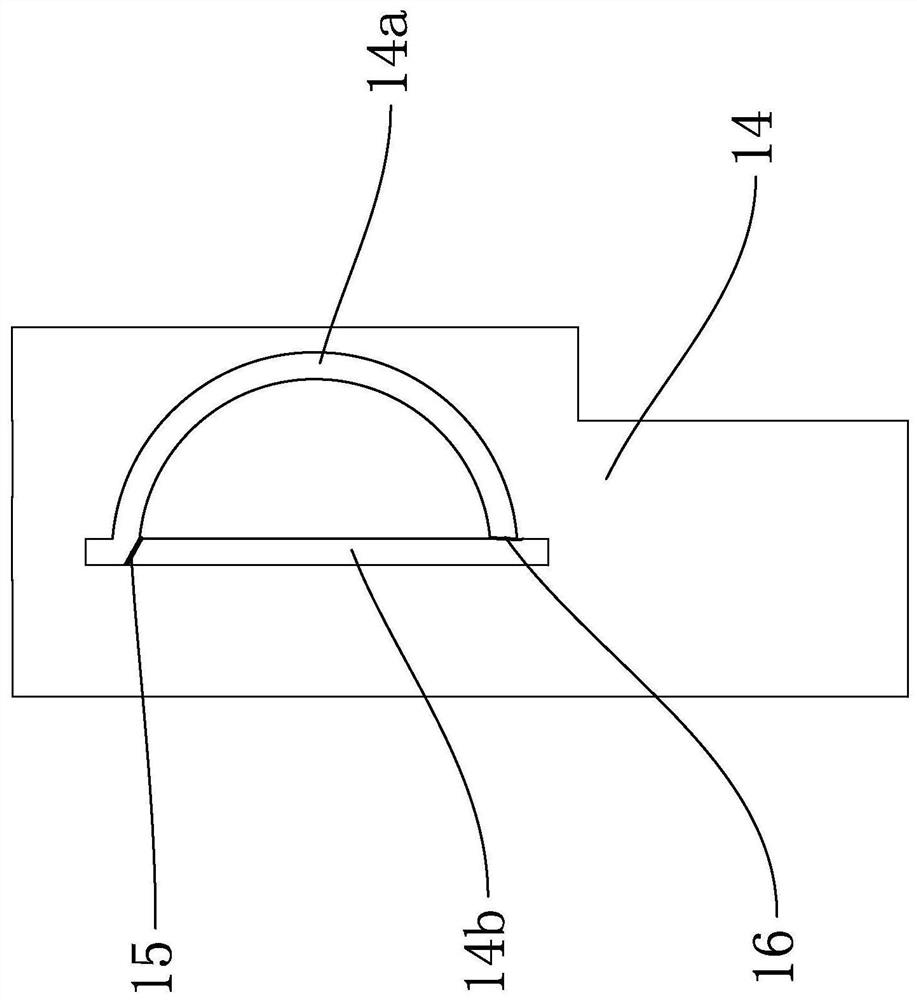

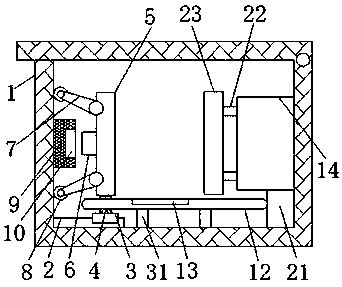

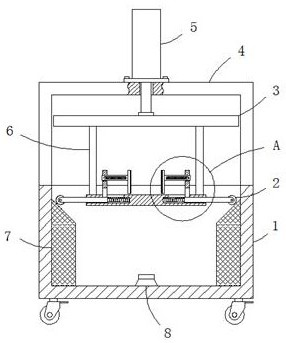

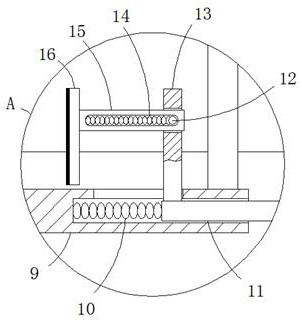

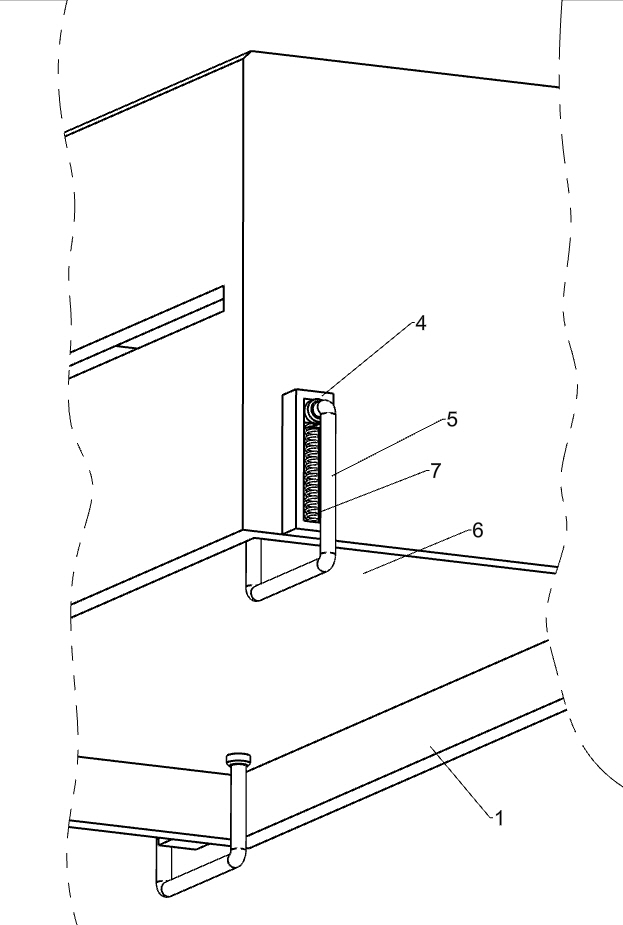

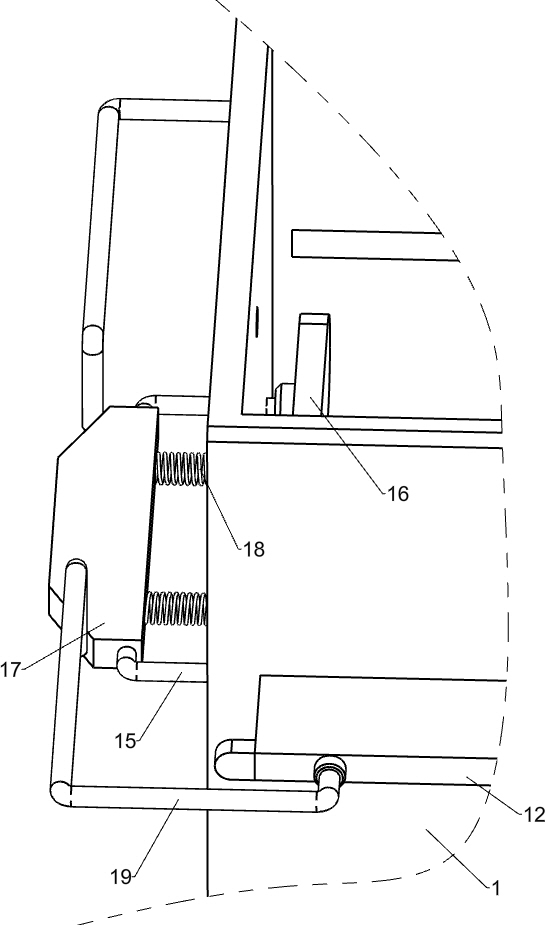

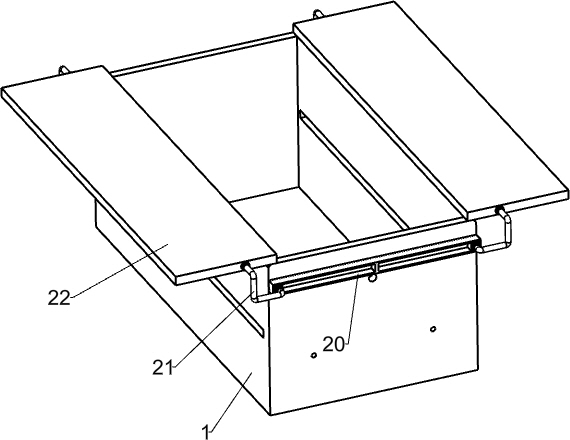

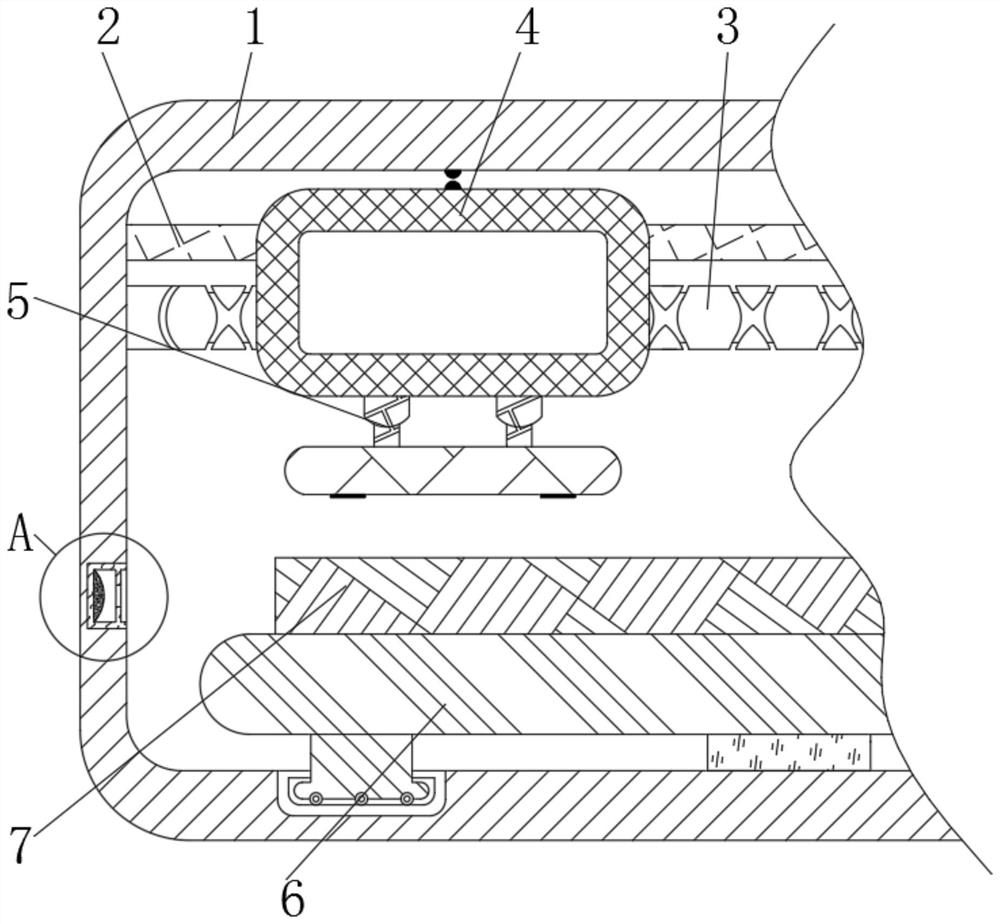

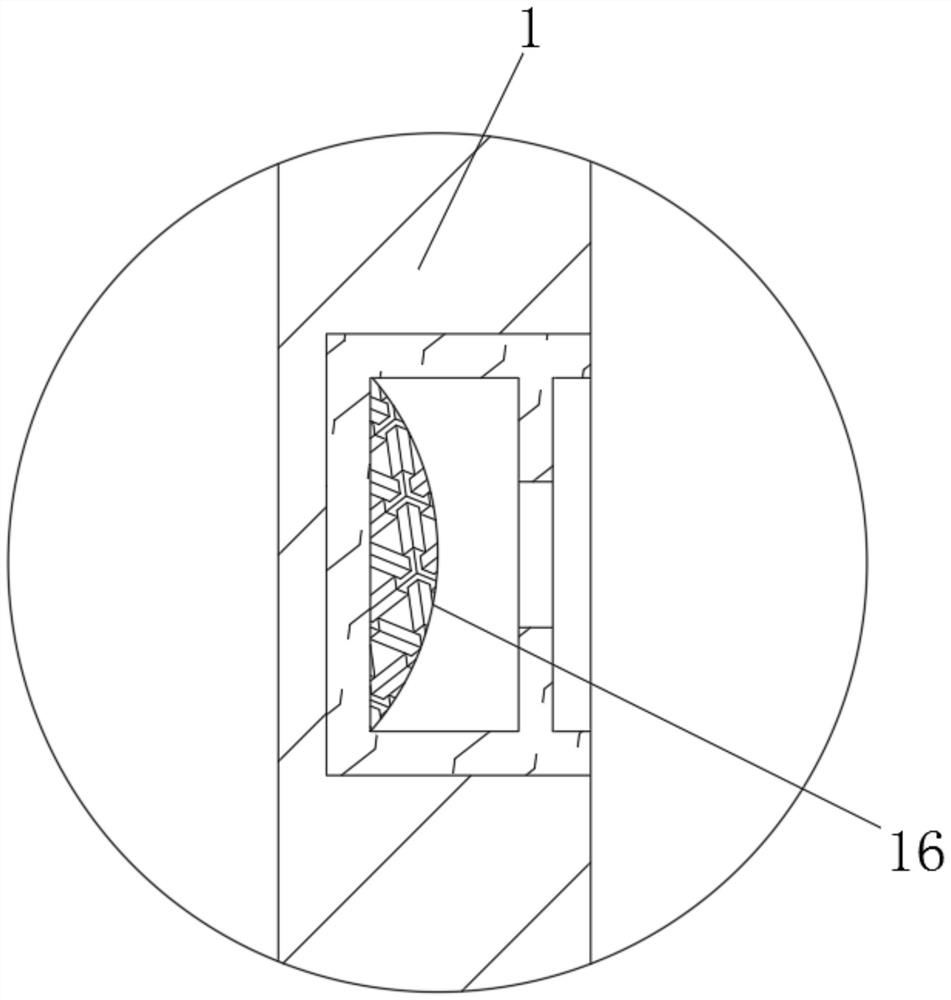

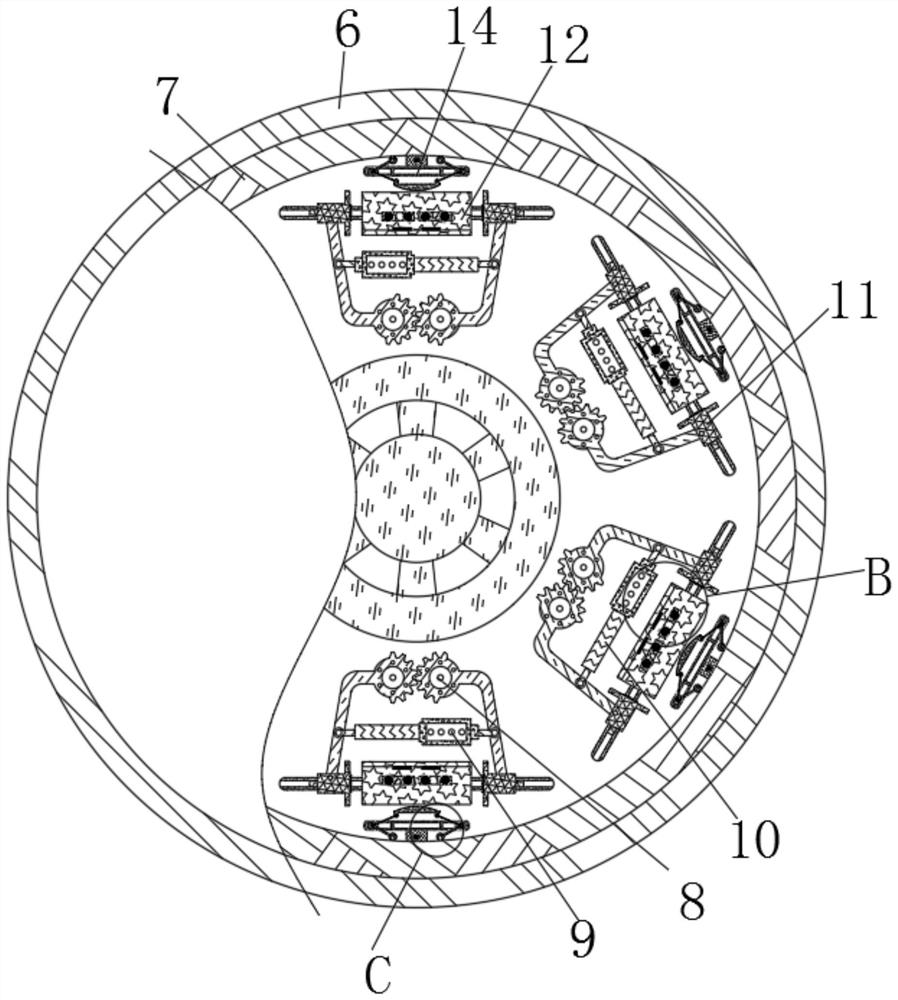

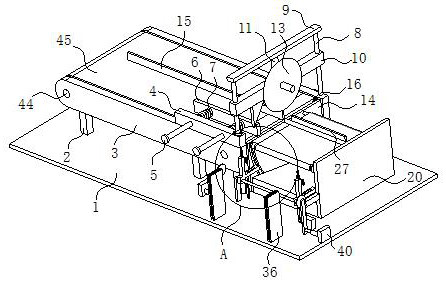

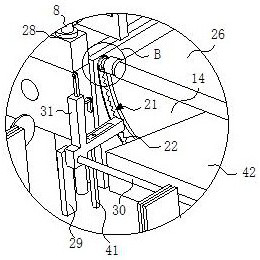

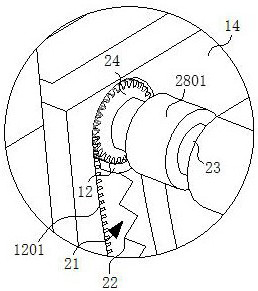

The invention relates to medicine applying equipment, in particular to arm fixing medicine applying equipment for hospital surgery. According to the arm fixing and medicine applying equipment for the hospital surgery, automatic fixing, position changing and automatic medicine applying can be achieved. According to the technical scheme, the arm fixing and medicine applying equipment for the hospital surgery comprises a bottom plate frame and supporting foot frames, and the supporting foot frames are arranged on the four sides of the bottom plate frame; a big arm placing mechanism is arranged on one side of the top of the bottom plate frame; and a forearm placing mechanism and the big arm placing mechanism are connected with the forearm placing mechanism. Through the cooperation of the big arm placing mechanism, the forearm placing mechanism and the fixing mechanism, the arms of people can be fixed, and the parts can be automatically turned over according to the medicine applying parts of people.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

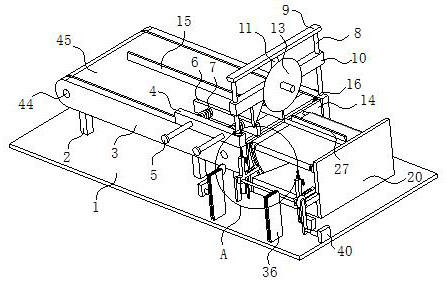

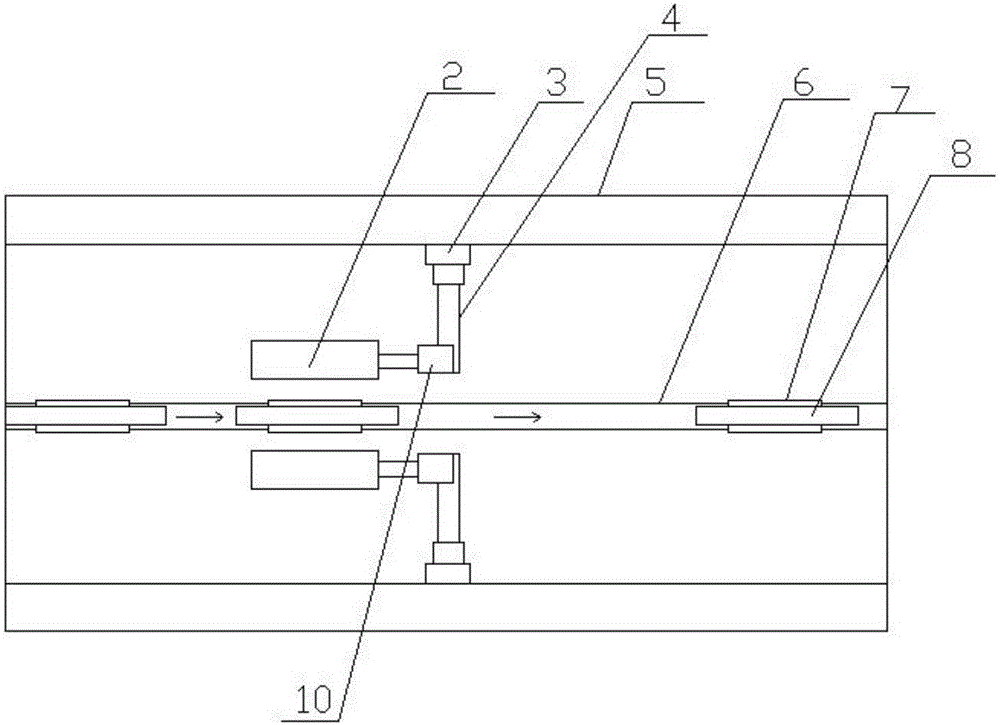

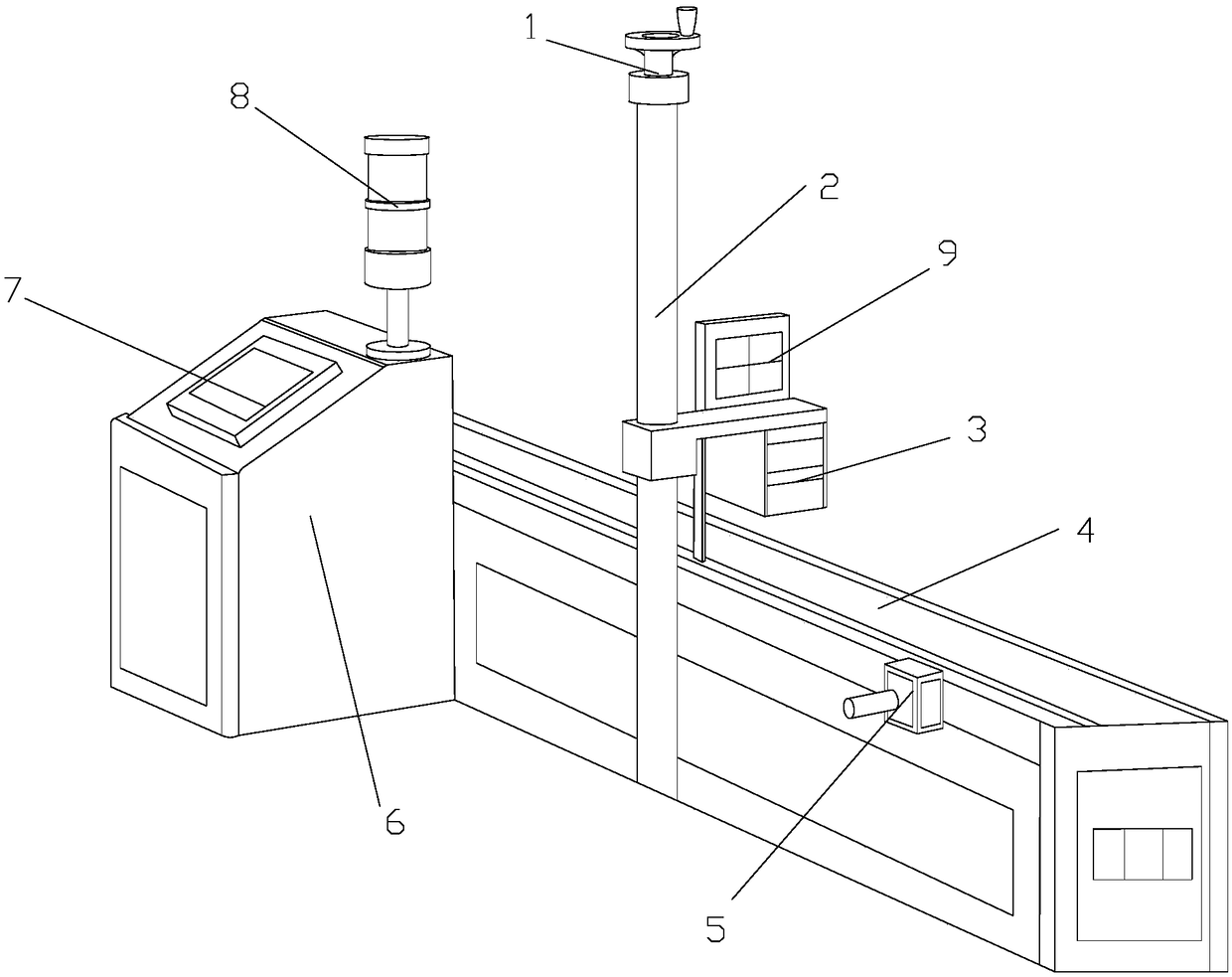

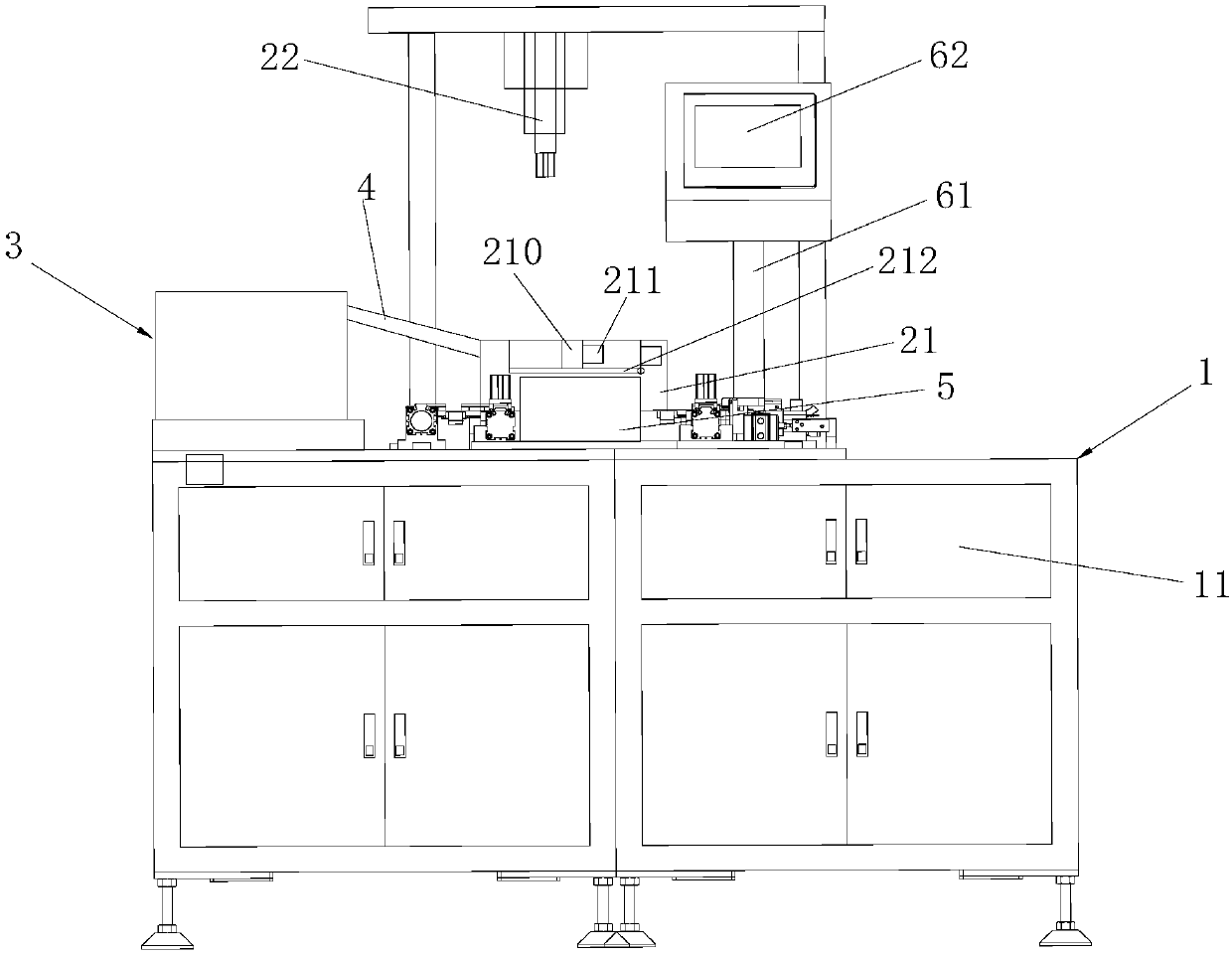

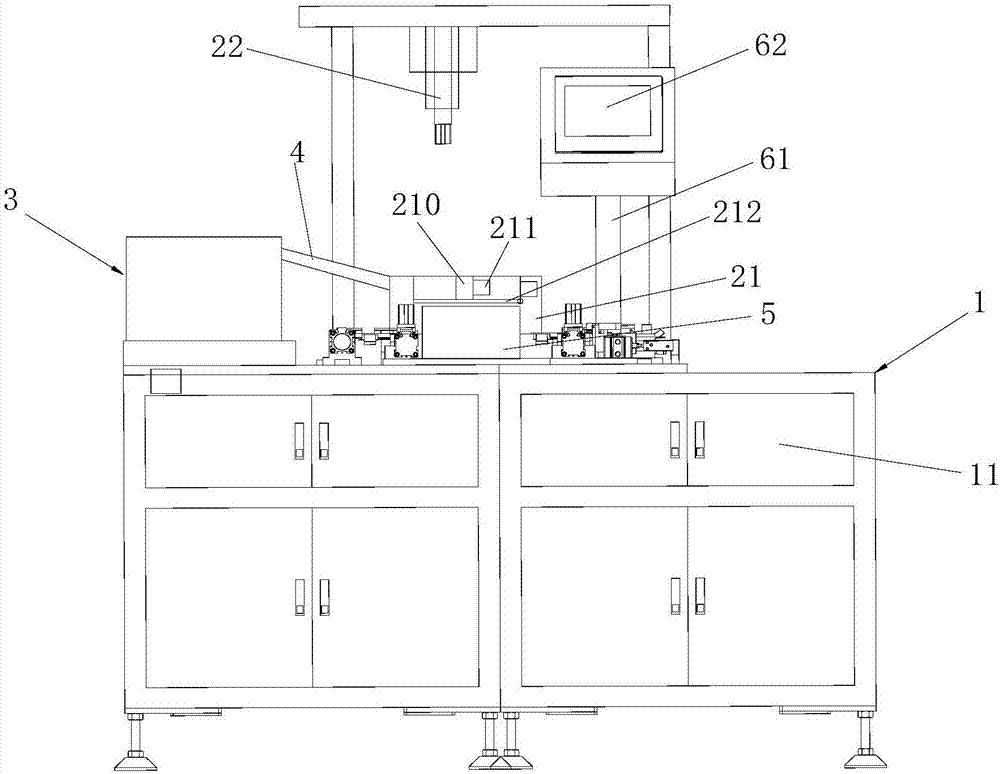

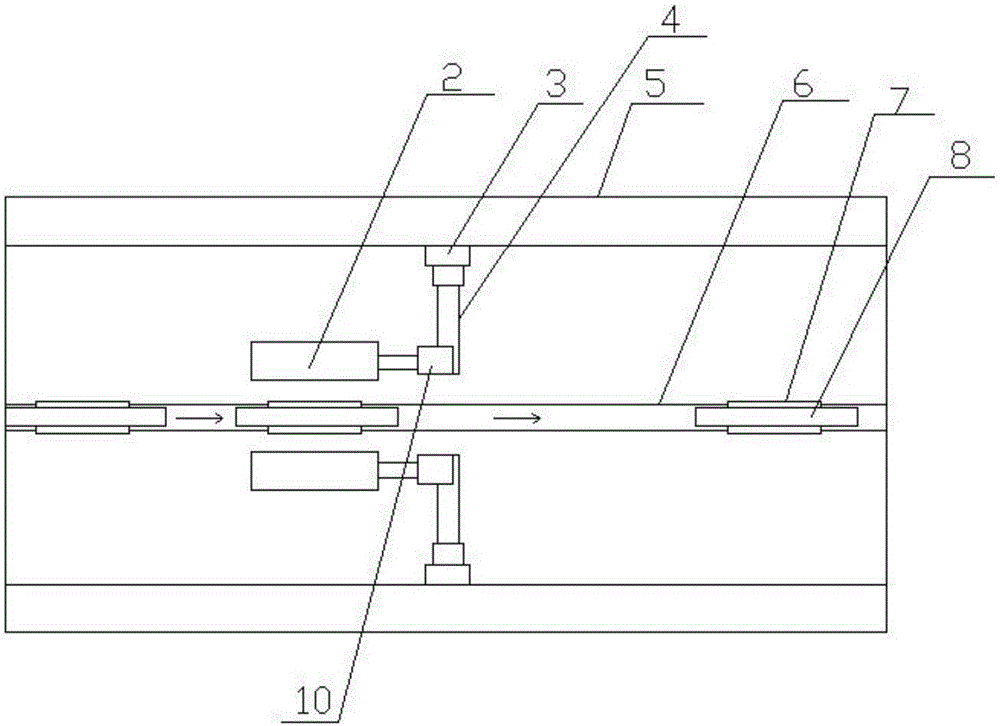

High-pressure-resistant stainless steel pipe full-automatic production line

ActiveCN112171295AMovement precisionAuto fixEdge grinding machinesOther manufacturing equipments/toolsStructural engineeringSS - Stainless steel

The invention discloses a high-pressure-resistant stainless steel pipe full-automatic production line in the technical field of stainless steel pipe production. The high-pressure-resistant stainless steel pipe full-automatic production line comprises a bottom plate, two sets of supporting columns are fixedly connected to the top of the bottom plate, each supporting column comprises two supportingrods, first mounting plates are fixedly connected to the tops of the two sets of supporting columns, a transmission mechanism is arranged between the two first mounting plates, a grinding device is arranged in front of the top of the bottom plate, and a grinding positioning mechanism is arranged at the top of the bottom plate; and the polishing positioning mechanism comprises a second mounting plate fixedly connected to the top of the first mounting plate, and first sliding rods which are symmetrically arranged are slidably connected to the left side wall and the right side wall of the secondmounting plate located on the right side. And through the arrangement of the grinding positioning mechanism, the cut stainless steel pipe can accurately move to the grinding position, meanwhile, the stainless steel pipe can be automatically fixed, a worker can easily take the stainless steel pipe, and the machining efficiency is improved.

Owner:江西康腾卫浴有限公司

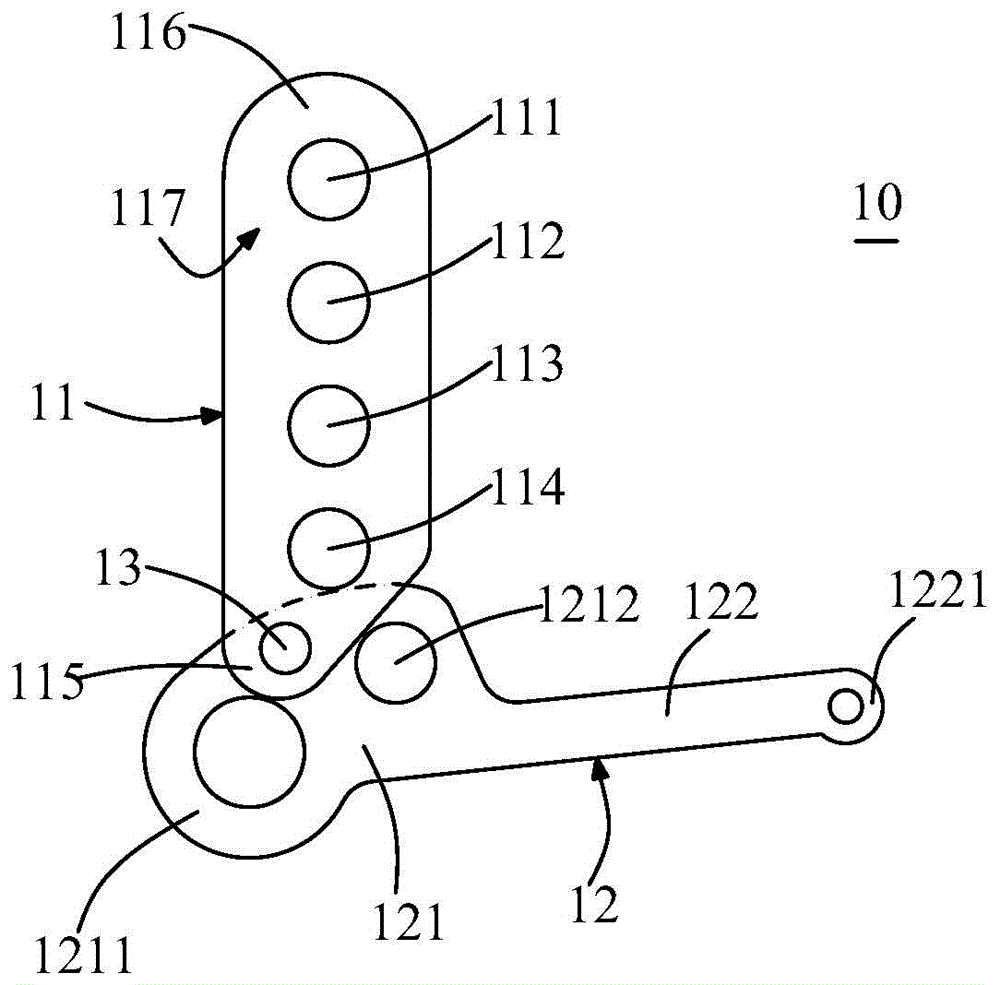

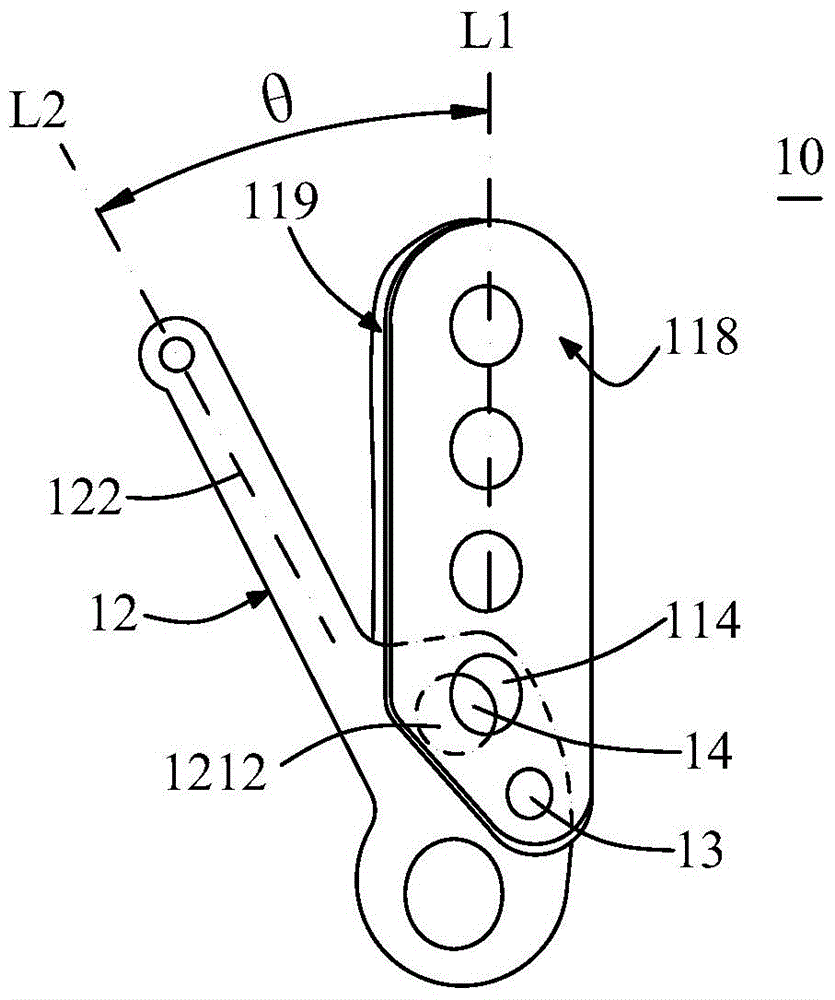

Adjustable descending device

The invention provides an adjustable descending device. The adjustable descending device comprises a descending body, a hinged connection pin shaft and a rotating handle. The descending body comprises a hinged end and a descending free end which are oppositely arranged. The descending body is provided with a first limiting hole and at least three rope threading hole. The rotating handle comprises a rotating part and a handle operating part connected with the rotating part. The rotating part is provided with a hanging buckle ring and a second limiting hole. The rotating part is hinged to the hinged end through the hinged connection pin shaft. The first limiting hole and the second limiting hole can at least partially overlap to form an adjustable overlapped region used for containing a rope. When the rope is arranged in the overlapped region in a penetrating manner, tensile force which is exerted on the hanging buckle ring and equal to the gravity of a descending person applies torque to the hinged connection pin shaft, and the torque is increased while the area of the overlapped region is increased and is decreased while the area of the overlapped region is decreased. The adjustable descending device can adjust friction force between the rope and the descending device, fix a human body at high altitude and liberate the two hands.

Owner:步兵

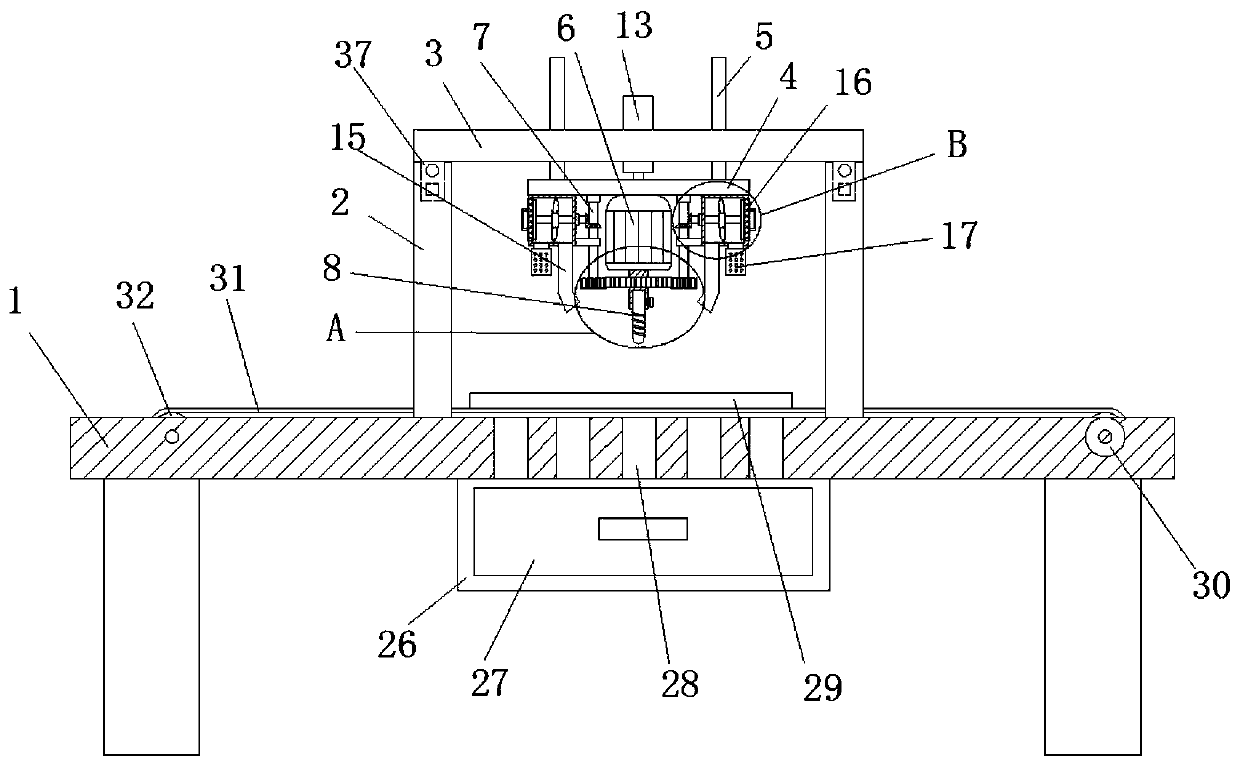

Mechanical component machining forming system

InactiveCN106041673ASimple structureEasy to useGrinding carriagesGrinding feed controlCylindrical grindingEngineering

The invention discloses a mechanical component machining forming system. The mechanical component machining forming system comprises a shell, a fixing device and a machined component. Each of the two ends in the shell is fixedly provided with a hydraulic telescopic rod. The telescopic end of each hydraulic telescopic rod is fixedly connected with an installing block through a universal joint with a servo device. The two installing blocks are oppositely arranged. Each installing block is fixedly provided with a first motor. A cylindrical grinding block is fixedly arranged at the rotating shaft end of each first motor. The two cylindrical grinding blocks are arranged in a parallel structure manner, and a gap exists between the two cylindrical grinding blocks. A sliding groove is formed in the inner wall of the shell and transversely arranged, one or more sliding blocks are movably arranged in the sliding groove, and the ends, located in the sliding groove, of the sliding blocks are each fixedly provided with one or more wheels. The wheels are driven by a drive device which is a stepping motor. The mechanical component machining forming system is simple in structure, convenient to use and capable of automatically fixing a component needing to be ground, and the grinding speed and efficiency are greatly improved.

Owner:XIAN TECHNOLOGICAL UNIV

Sheet material punching structure for buildings and bridges

InactiveCN111558739ADrilling position can be adjustedAvoid cloggingCleaning using toolsPositioning apparatusPunchingArchitectural engineering

The invention belongs to the technical field of sheet material punching, particularly relates to a sheet material punching structure for buildings and bridges. Aiming at solving the problems that an existing punching device is single in function, sheet materials need to be manually moved, the sheet materials cannot be automatically fixed, and chippings cannot be collected, the following scheme isprovided. According to the scheme, the device comprises a working plate, a conveying mechanism is arranged at the top of the working plate, the sheet materials are placed on the conveying mechanism, four supporting rods are fixedly connected to the top of the working plate, the four supporting rods are movably connected with the same top plate, the supporting rods located on the same horizontal transverse lines are connected with driving mechanisms, the top plate is matched with the two driving mechanisms, a propelling motor is embedded in the working plate, a lifting plate is fixedly connected to an output shaft of the propelling motor, and a motor is fixedly connected to the bottom of the lifting plate. According to the device, the operation is convenient, the sheet materials can be automatically moved, the sheet materials can be automatically fixed, and the chippings can be collected.

Owner:顾轩波

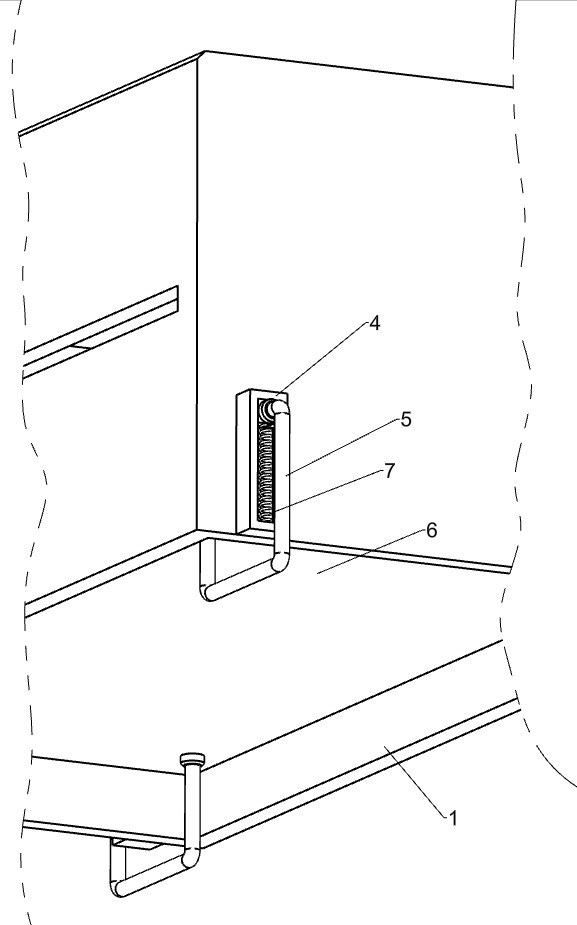

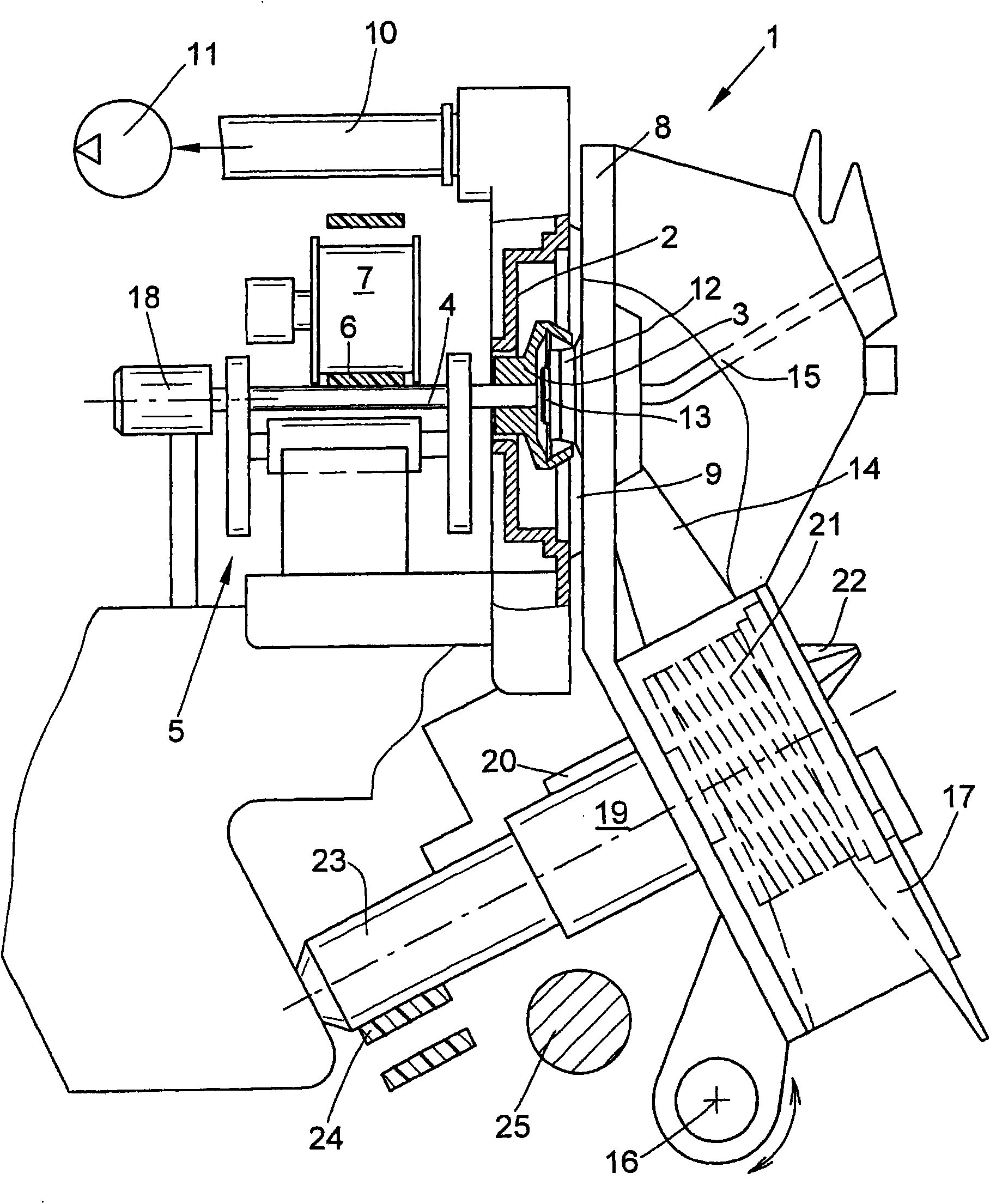

Display element for displaying information on a push handle

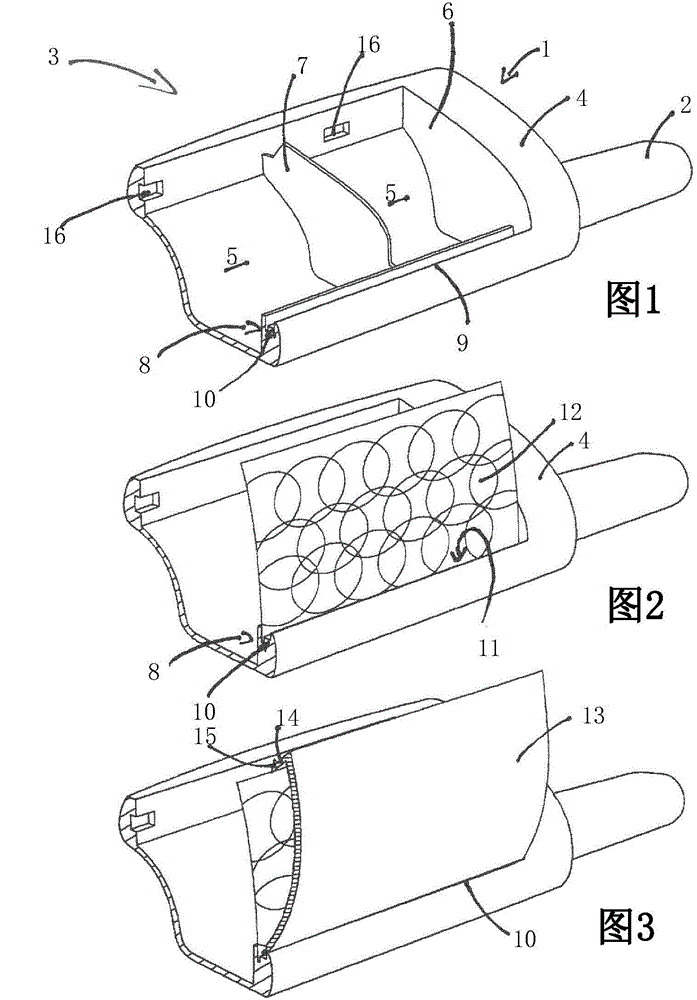

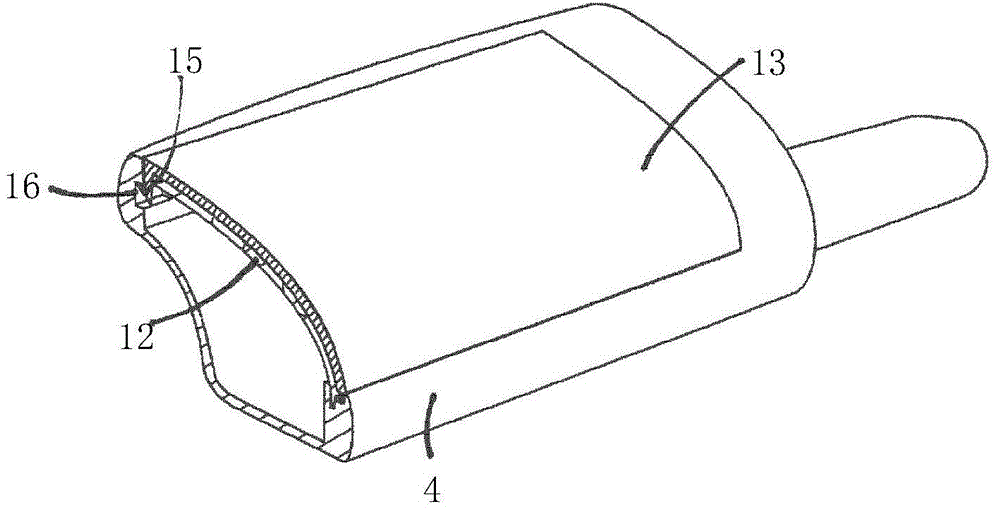

ActiveCN104903950AAssembly precisionAuto fixArticle advertisingMobile visual advertisingEngineeringSupermarket trolley

The invention relates to a display element (1) for displaying information on a push handle (3) of a supermarket trolley that can be pushed by hand. The display element (1) comprises a main body (4) having a region (5) which is covered by a transparent cover separably mounted on the main body (4). A two-dimensional information medium (12) can be arranged between the main body (4) and the cover, wherein the main body (4) comprises a groove (8) into which one end edge (11) of the information medium (12) can be inserted and the inserted end edge (11) is retained in the groove (8) by friction locking.

Owner:弗朗茨.维特 +1

Sealing structure of food packaging machine

InactiveCN107758004AIncrease productivityEffective sealingWrapper twisting/gatheringEngineeringFood packaging

The invention discloses a sealing structure of a food packaging machine. The sealing structure comprises a base. A working table is fixedly connected to the top of the base. A water storage cavity isformed in the working table. The bottom of the water storage cavity is fixedly connected with a water pump. The upper surface of the working table is provided with tooth grooves distributed uniformlyin the length direction of the working table. Containing grooves distributed uniformly are formed in the side, close to the tooth grooves, of the upper surface of the working table. A first supportingplate and a second supporting plate which are distributed symmetrically are fixedly and perpendicularly connected to the upper surface of the working table. A first electric push rod is fixedly connected to the sidewall, opposite to the second supporting plate, of the first supporting plate. The end, far from the first supporting plate, of the first electric push rod is fixedly connected with a U-shaped fixing plate. The sealing structure is convenient to operate, capable of sealing food bags effectively, capable of preventing the food bags from being obliquely sealed and capable of cooling the food bags sealed through heating. Working staff can move the packaging machine conveniently. The production efficiency of food packaging is improved.

Owner:广州小造电子商务有限公司

Cloth storage device for cloth processing

The invention relates to a storage device, and particularly relates to a cloth storage device for cloth processing. The cloth storage device for cloth processing can store more cloth, can fix the cloth and enables the cloth not to be scattered easily. The cloth storage device for cloth processing comprises a frame body, rollers symmetrically mounted on the frame body, a grip mounted on the frame body, a placement assembly mounted on the frame body, a layering assembly mounted on the frame body and a fixing assembly mounted on the frame body. According to the cloth storage device for cloth processing, the cloth storage work for cloth processing can be completed on the placement assembly, when the cloth on the placement assembly reaches a certain degree, the layering assembly can be triggered to divide the frame body into an upper layer and a lower layer, when the layering assembly conducts layering, the lower layer of cloth can be automatically fixed, then the cloth is placed in the upper layer of space, the frame body can be closed after the cloth is placed, and when the frame body is closed, the upper layer of cloth can be automatically fixed.

Owner:湖北新宇纺服饰有限责任公司

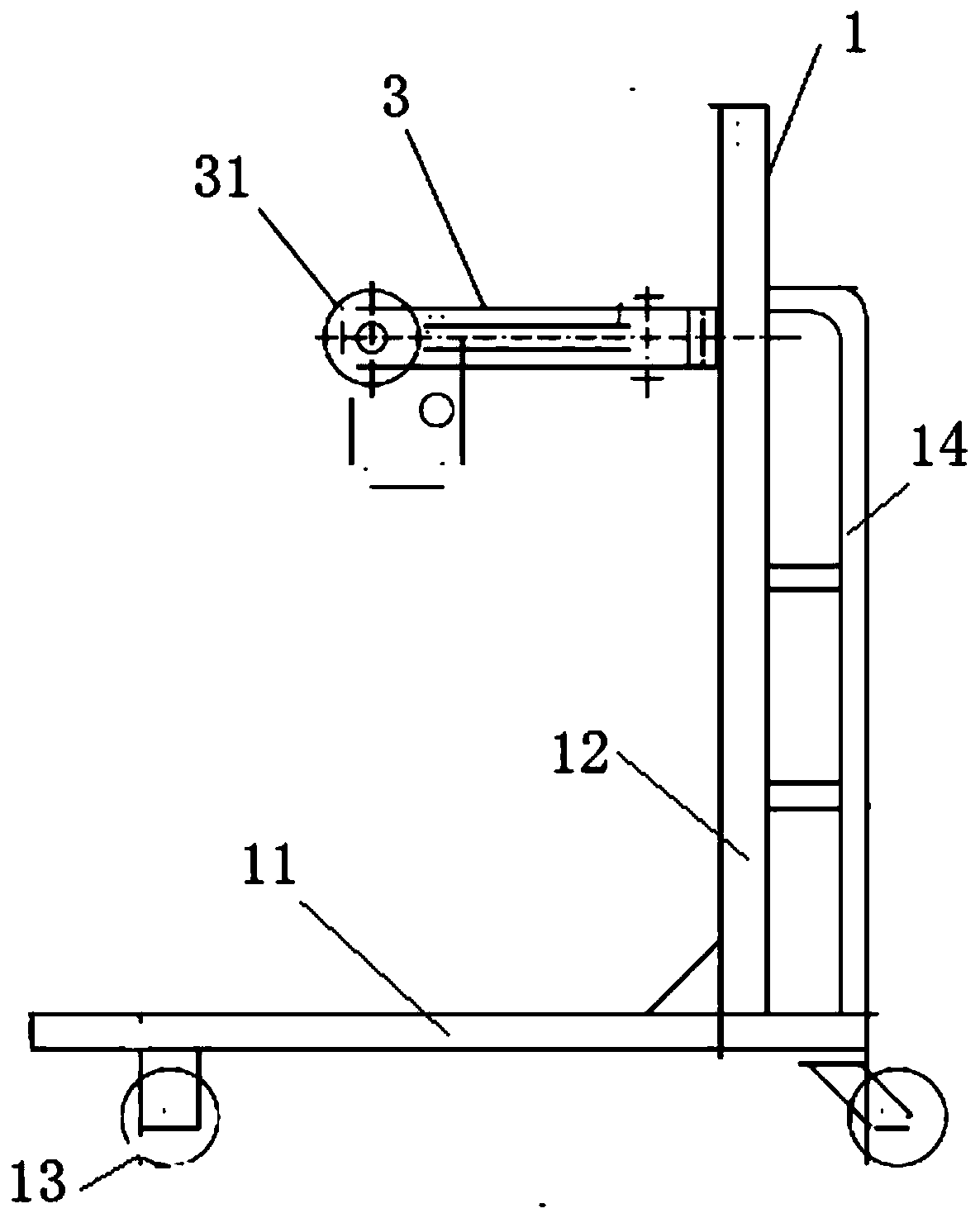

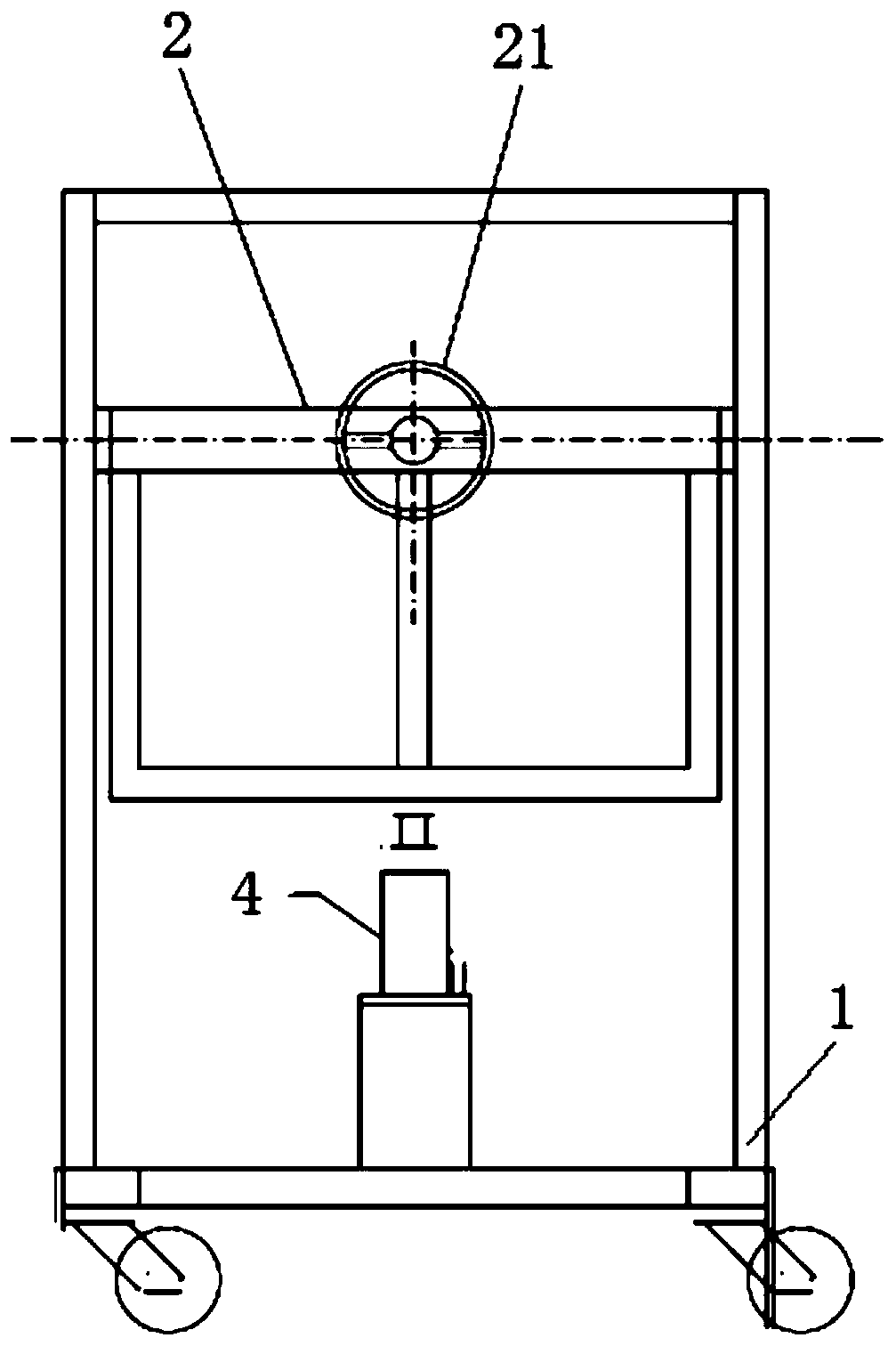

Maintenance-assistant device with liftable and overturning circuit breaker base plate

The present invention discloses a maintenance-assistant device with a liftable and overturning circuit breaker base plate. The device comprises a lifting support, the lifting support is provided withcross slide rails, the cross slide rails are connected with a clamping arm module, the clamping arm module comprises a left side clamping arm and a right side clamping arm separately arranged at leftand right sides side by side, the inner sides of the front ends of the left side clamping arm and the right side clamping arm are hinged with an overturning support, the left side clamping arm and theright side clamping arm are connected with a horizontal ball screw respectively through a left nut and a right nut, the horizontal ball screw is connected with a clamping motor, the clamping motor drives the horizontal ball screw, the horizontal ball screw drives movement of the left and right nuts, and the left and right nuts respectively drive the movement of the left side clamping arm and theright side clamping arm along the cross slide rails. The maintenance-assistant device can achieve lifting and overturning functions, is convenient to maintain, low in cost, good in safety performanceand high in operability.

Owner:STATE GRID ZHEJIANG XINCHANG POWER SUPPLY +3

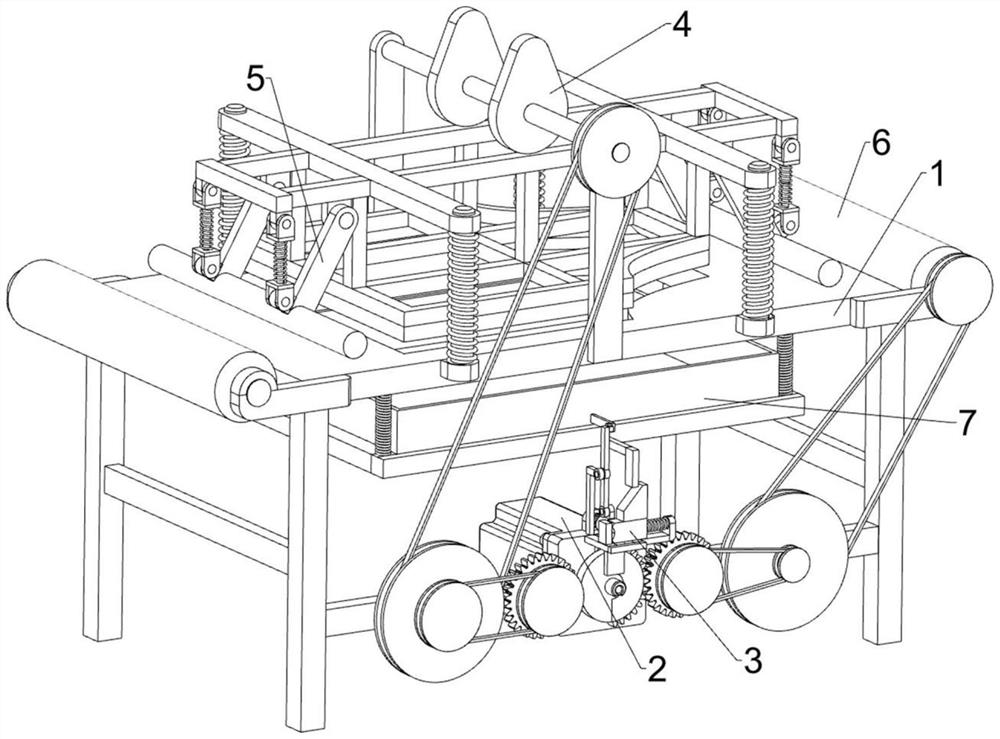

Cutting device for aprons

The invention relates to a cutting device, and in particular relates to a cutting device for aprons. The invention aims to provide the cutting device for the aprons, which can be used for quickly cutting cloth without damaging the cloth. The cutting device for aprons comprises a support; a power assembly, mounted on the bracket and powered by a motor to work; a control assembly, installed on the support and conducting control in a sliding mode; and a cutting assembly, installed on the support and used for cutting the cloth in a sliding mode. Through cooperation of the power assembly, the control assembly and the cutting assembly, the effect of rapidly cutting the cloth needed for manufacturing the apron is achieved; by means of a pressing assembly, when the cloth is cut, the cloth can be automatically fixed, the cloth cutting quality is improved, and meanwhile the device is safer to use; and by means of a waste winding assembly, the cut cloth can be automatically wound, and the deviceis more convenient to use.

Owner:江西诺捷科技股份有限公司

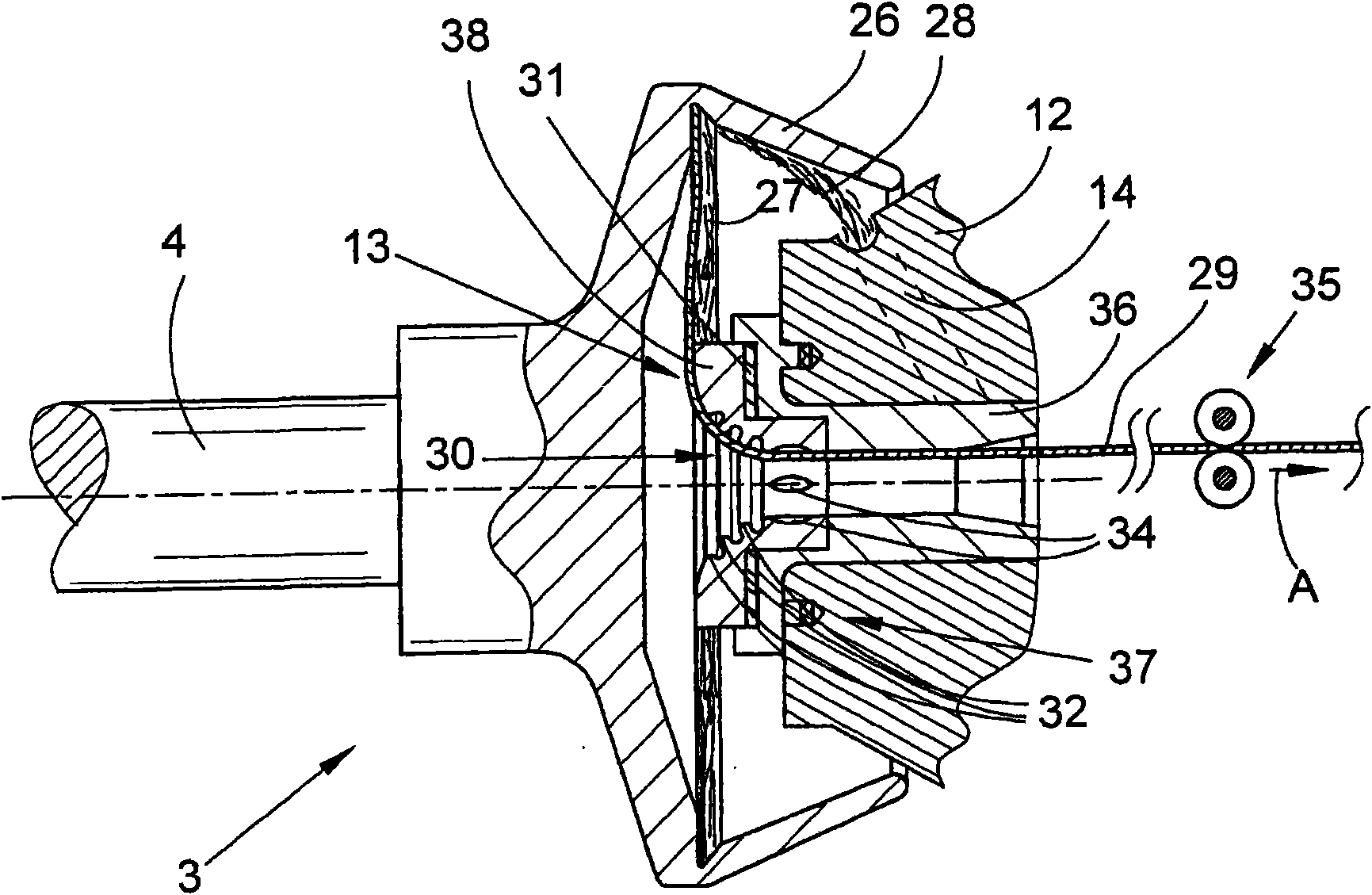

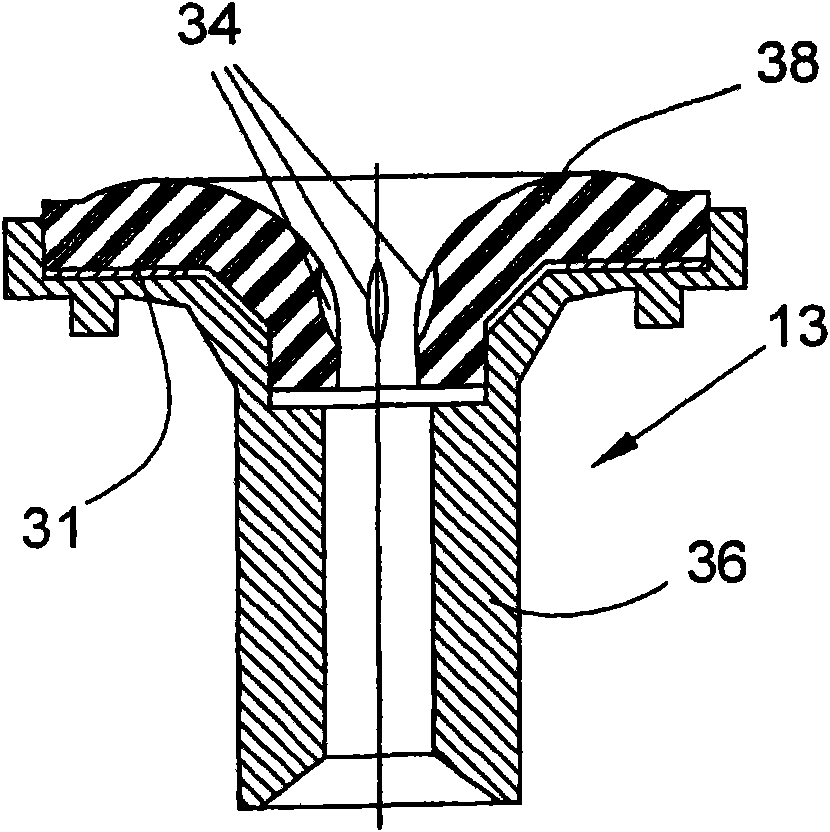

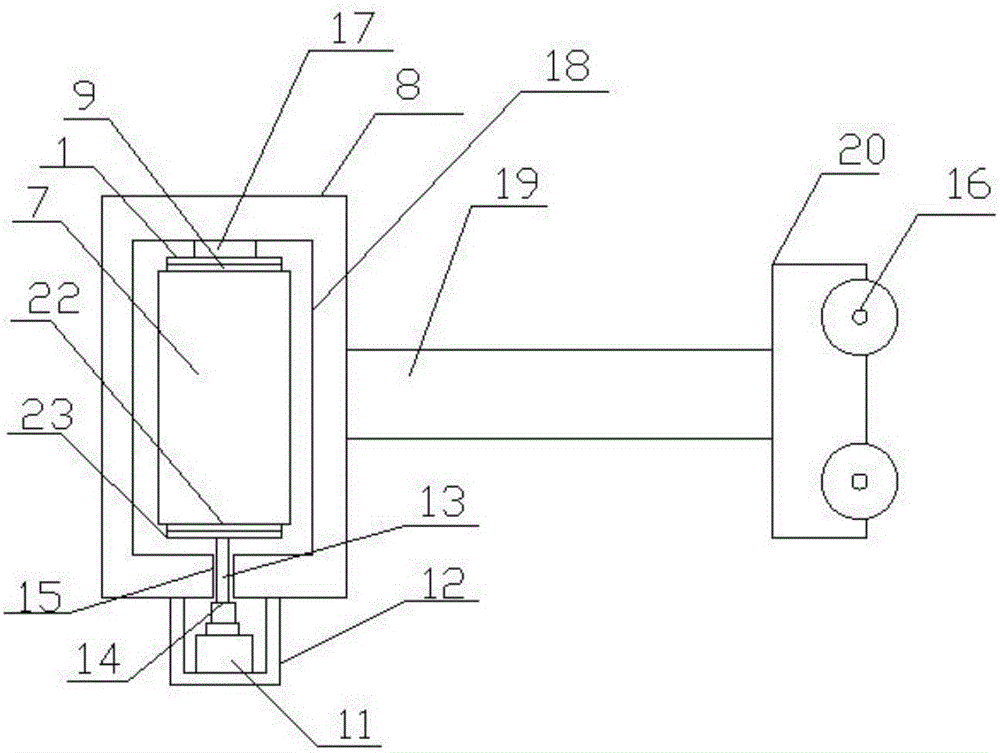

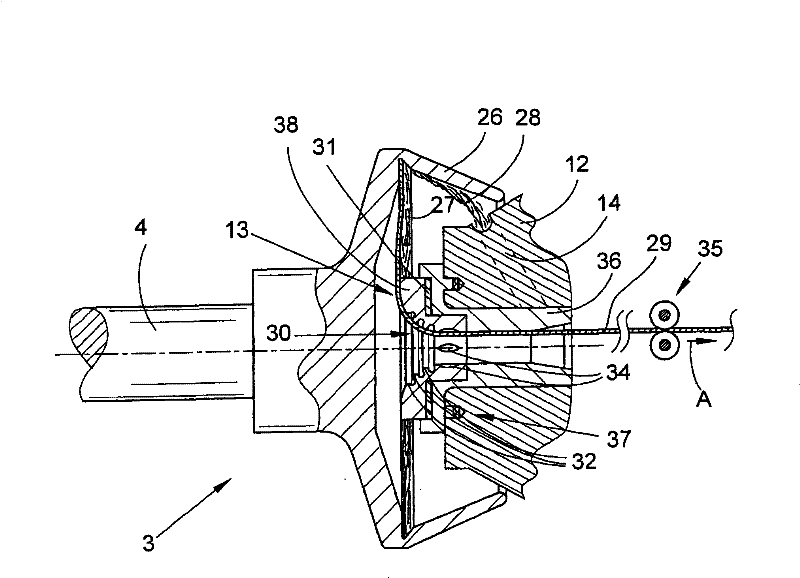

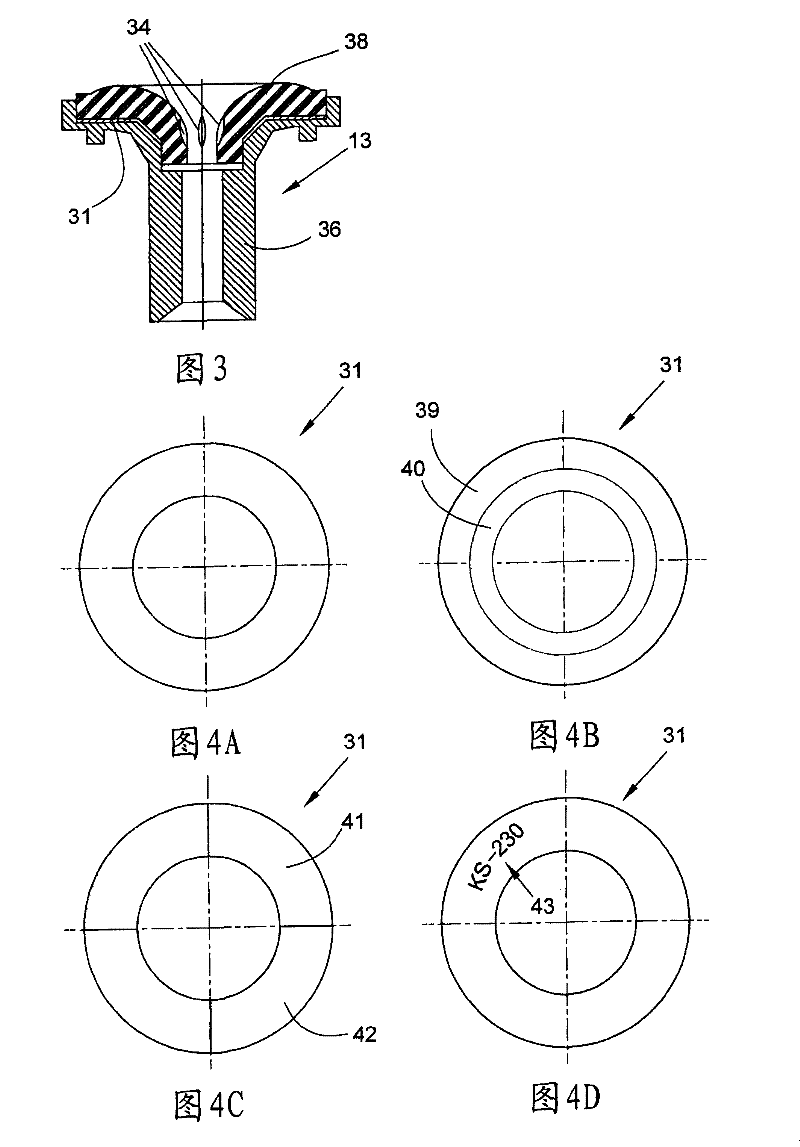

Yarn extraction nozzle

InactiveCN101560706AReduce wearService life exceedsContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The present invention relates to a yarn extraction nozzle of a free end rotor spinning device, comprising a nozzle base and a optically distinguished mark, which is used for distinguishing type of the yarn extraction nozzle, a nozzle insert made of ceramic is fixed on the nozzle base. According to the invention, the nozzle insert (38) is made of transparent sub-micron ceramic.

Owner:SAURER GERMANY GMBH & CO KG

Can body seal detection device

PendingCN108820361APrevent movementAvoid fixationWrapper twisting/gatheringPackaging automatic controlEngineeringAtmospheric pressure

The invention discloses a can body seal detection device. The device structurally comprises a lifting adjusting disc, a lifting rod, a secondary seal device, a conveying way, a driver, a control electric box, a control panel, an alarm device, a seal detection instrument, a seal cover shell, a power starting device, a gear transmission mechanism, a lever transmission mechanism, an air pressure sealmechanism, an auxiliary fixing mechanism, a fixing stabilizing mechanism and a balance buffer mechanism. According to the can body seal detection device, when the device detects a non-seal product, acan body can be fixed and stabilized automatically, secondary seal is carried out, manual treatment by a worker is not needed, the device is easy and convenient, labor force of a worker is effectively saved, the inner structure is stable, the device is more intelligent, and product production efficiency is greatly improved.

Owner:刘晨钟

Round timber pier slitting equipment

PendingCN112318628AEasy to cleanEasy to collectGripping devicesClamping devicesEngineeringStructural engineering

The invention relates to slitting equipment, in particular to round timber pier slitting equipment. The round timber pier slitting equipment can fix round timber piers, slit the round timber piers andconveniently clean chippings generated in a slitting process, the round timber pier slitting equipment comprises a base, a servo motor is arranged on the rear side of the top of the base, a supporting rod arranged in the middle of the top of the base, a workbench arranged at the top of the supporting rod, a slitting mechanism arranged on the side, close to the servo motor, of the top of the base,parts of the slitting mechanism are connected with an output shaft of the servo motor, and a clamping mechanism connected between the two sides of the top of the base, and parts of the clamping mechanism are connected with parts of the slitting mechanism. Under the cooperation of the servo motor, the slitting mechanism, the clamping mechanism and a push plate, the round timber piers can be automatically fixed, the round timber piers can be automatically slit, and the chippings generated during slitting of the round timber piers can be conveniently cleared and collected.

Owner:李江英

Windproof movable merchant advertising board base based on intelligent manufacturing

InactiveCN112927635AAuto fixAvoid leaningDispersed particle filtrationTransportation and packagingDrive wheelSmart manufacturing

The invention relates to the technical field of advertising boards, and discloses a windproof movable merchant advertising board base based on intelligent manufacturing, which comprises a base, an advertising rod is arranged at the top of the base in a penetrating manner, a horizontal rod is arranged in the base, and a gravity block is slidably connected to the surface of the horizontal rod. Pressure sensing switches are slidably connected to the side face of the horizontal rod and located on the two sides of the gravity block, a driving wheel is connected to the side face of the conical shaft in a meshed mode, a pull rod is rotatably connected to the surface of a pulley, a limiting rod is rotatably connected to the surface of the driving wheel, and a filtering plate is slidably connected to the interior of the ventilation cavity. The top of the filtering plate is fixedly connected with a bearing plate, and a wind blocking wheel is arranged above the bearing plate. According to the windproof type movable merchant advertising board base based on intelligent manufacturing, through cooperative use of the gravity block and the exhaust fan, the effect that an advertising board is automatically fixed when strong wind occurs, and toppling is prevented is achieved.

Owner:刘光东

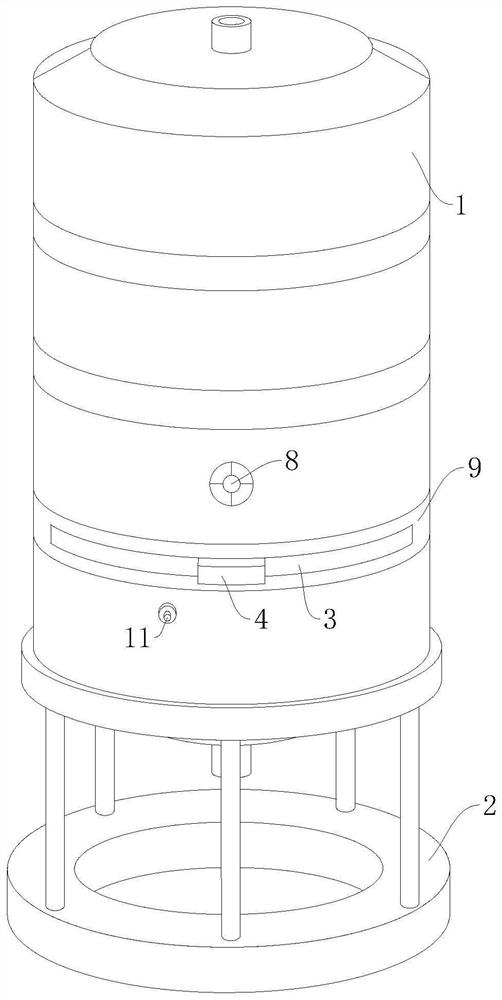

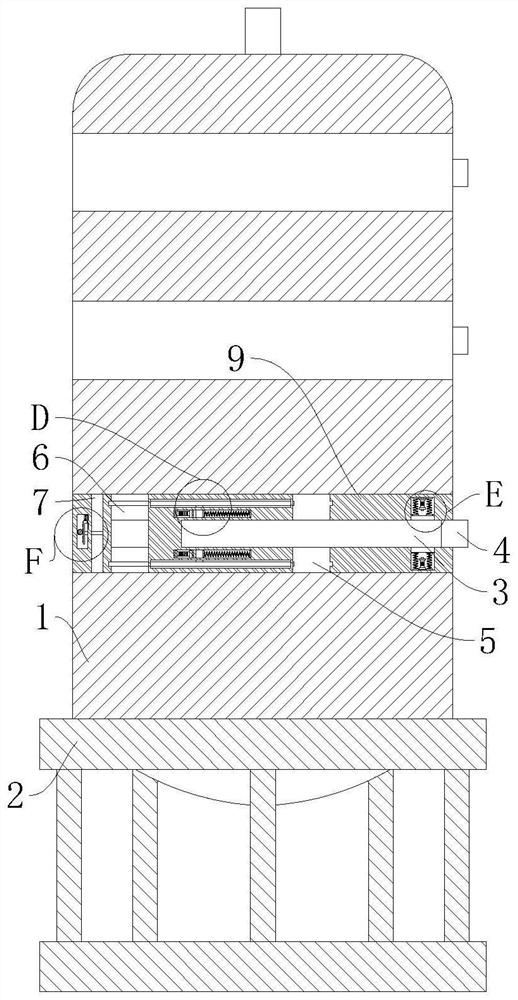

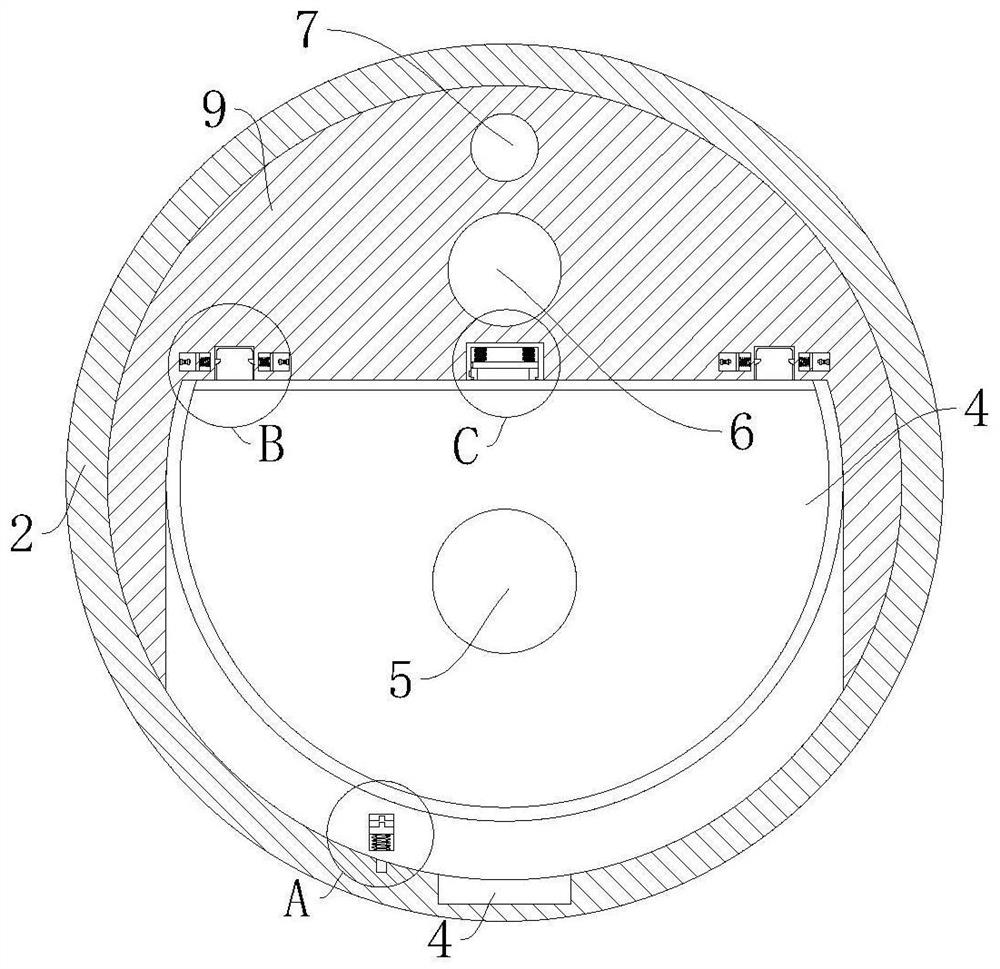

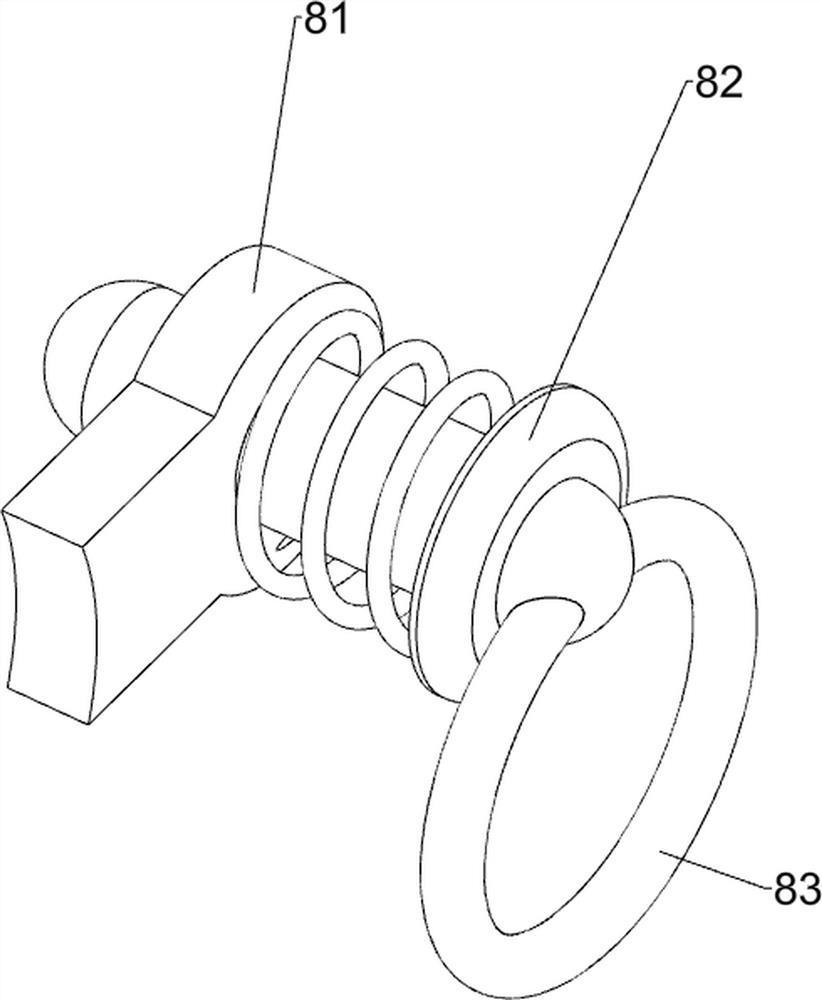

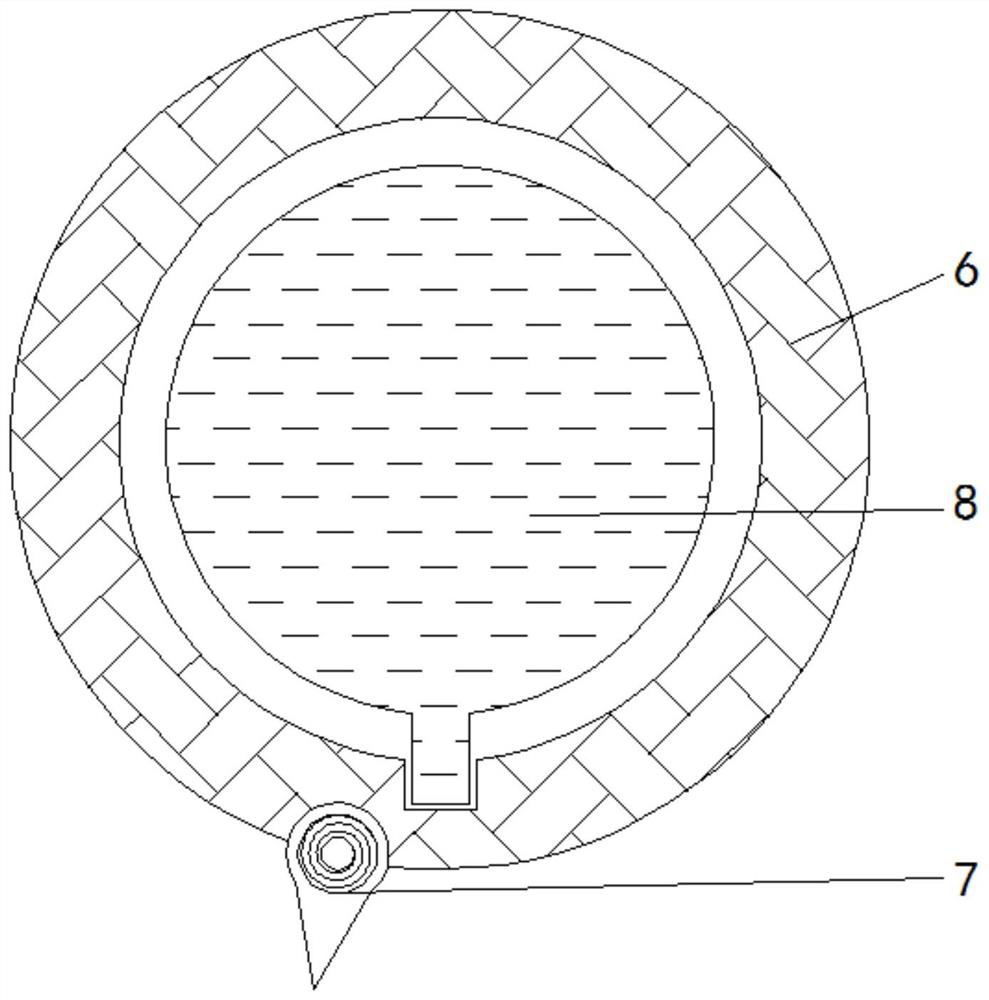

Separating tower for coal chemical industry

PendingCN114870786AEasy to disassembleEasy to installChemical industryChemical/physical/physico-chemical stationary reactorsThermodynamicsTower

The invention relates to the technical field of coal chemical industry, in particular to a coal chemical industry separation tower which comprises a separation tower body, a base is mounted at the lower end of the separation tower body, a filler layer is arranged in the separation tower body, and a filler plate for filtering is arranged in the filler layer. A first exhaust hole for ventilation is formed in the packing layer, a second exhaust hole for temporary exhaust is formed in the side, away from the packing plate, of the packing layer, a fixing block is fixedly installed at the rear end of the packing plate, and a pressing block is fixedly installed at the rear end of the fixing block; and when the filler plate and the handle are completely inserted, the sealing assembly seals the second exhaust hole and opens the first exhaust hole. According to the separation tower, the filler layer can be directly extracted and then replaced, and the temporary filler layer beside can be used for working during replacement, so that the working time of the separation tower can be prolonged, and the working efficiency of the separation tower can be improved.

Owner:陈琪

A hospital surgical arm fixed medicine application equipment

ActiveCN112603709BAchieve fixationWork lessMedical devicesMedical applicatorsPhysical medicine and rehabilitationEngineering

The invention relates to a medicine application equipment, in particular to a hospital surgical arm fixed medicine application equipment. The technical problem to be solved is: to provide a hospital surgical arm fixation and medicine application device capable of automatically fixing and changing positions and automatically applying medicine. The technical scheme is as follows: a hospital surgical arm fixing medicine application equipment, including a base plate frame and a foot frame, the base frame is provided with the foot frame on four sides; a large arm placement mechanism, and a large arm placement mechanism is arranged on one side of the top of the base plate frame ; Forearm placement mechanism, the forearm placement mechanism is connected to the big arm placement mechanism. Through the cooperation between the big arm placing mechanism, the forearm placing mechanism and the fixing mechanism, people's arms can be fixed, and the parts can be automatically turned over according to the parts where people apply medicine.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

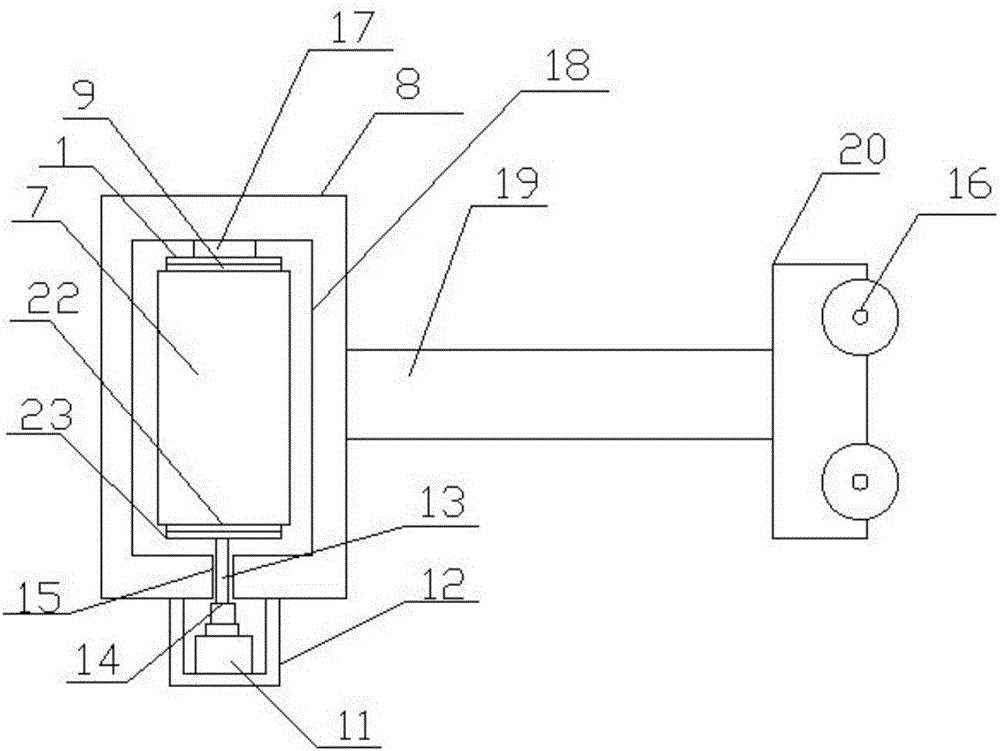

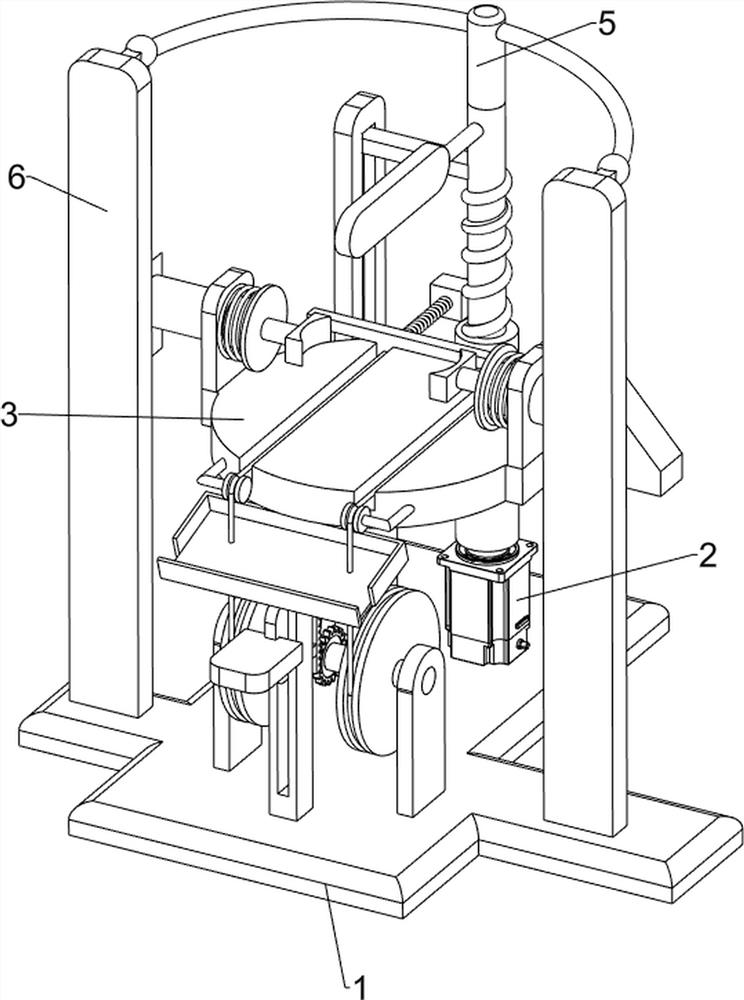

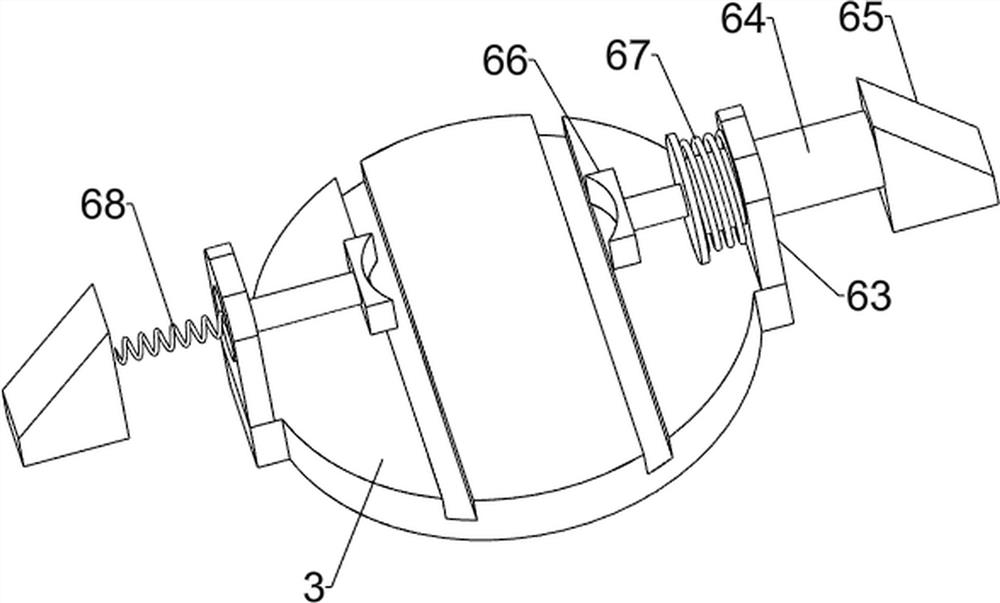

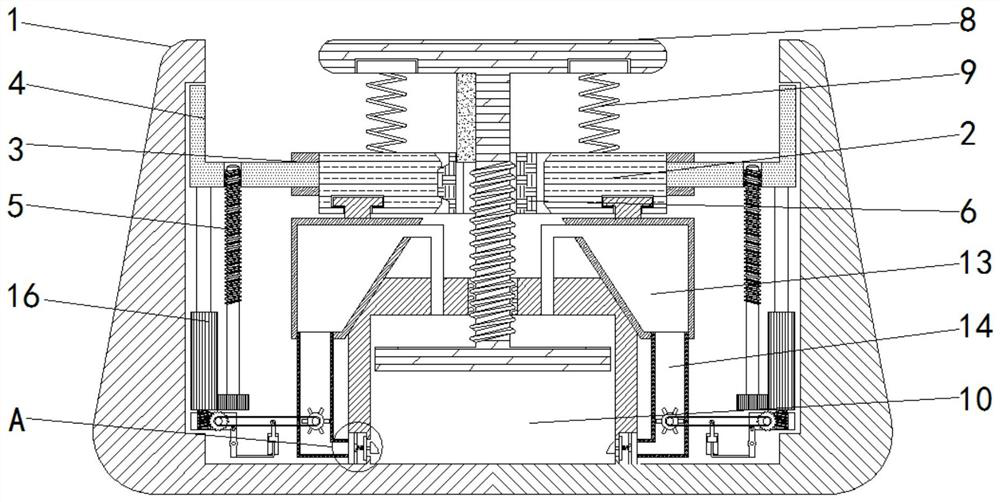

Leg stretching device for orthopedics

ActiveCN111449910BAuto fixQuick fixChiropractic devicesPhysical medicine and rehabilitationOrthopedic department

The invention relates to a leg stretching device, in particular to a leg stretching device for orthopedics. The technical problem to be solved by the present invention is to provide an orthopedic leg stretching device which stably fixes the leg and can change the direction of stretching. A leg stretching device for orthopedics, comprising a base for installing the whole device; a support plate mounted on the base; a first slide rail rotatably mounted on the support plate; a drive assembly mounted on the base, Power is provided by a motor; the clamping component is installed on the first slide rail and fixed by rotation. The invention can automatically stretch the legs through the guiding cylinder and the circular shaft, which is convenient and fast. Through the cooperation of the horizontal plate and the snap ring, the legs can be quickly fixed to prevent the displacement of the legs when they are stretched. The bevel gear cooperates with the second bevel gear to transmit power when changing directions and stretching the legs.

Owner:李进梅

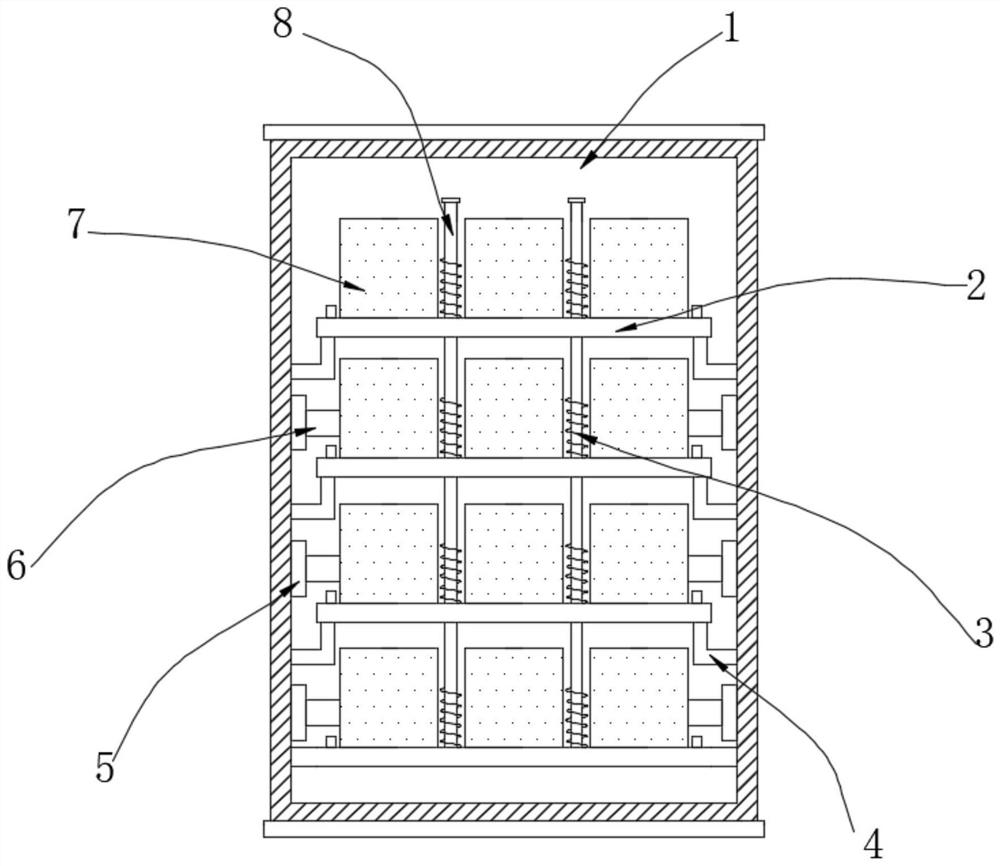

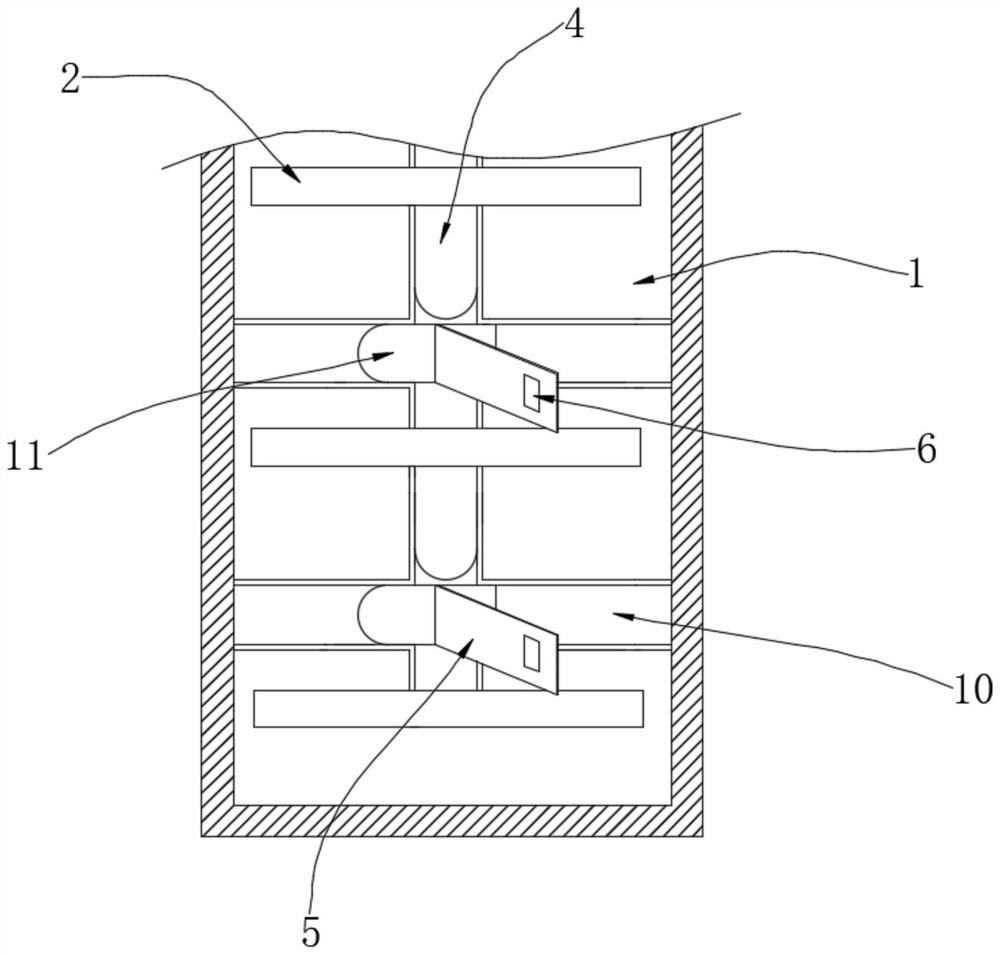

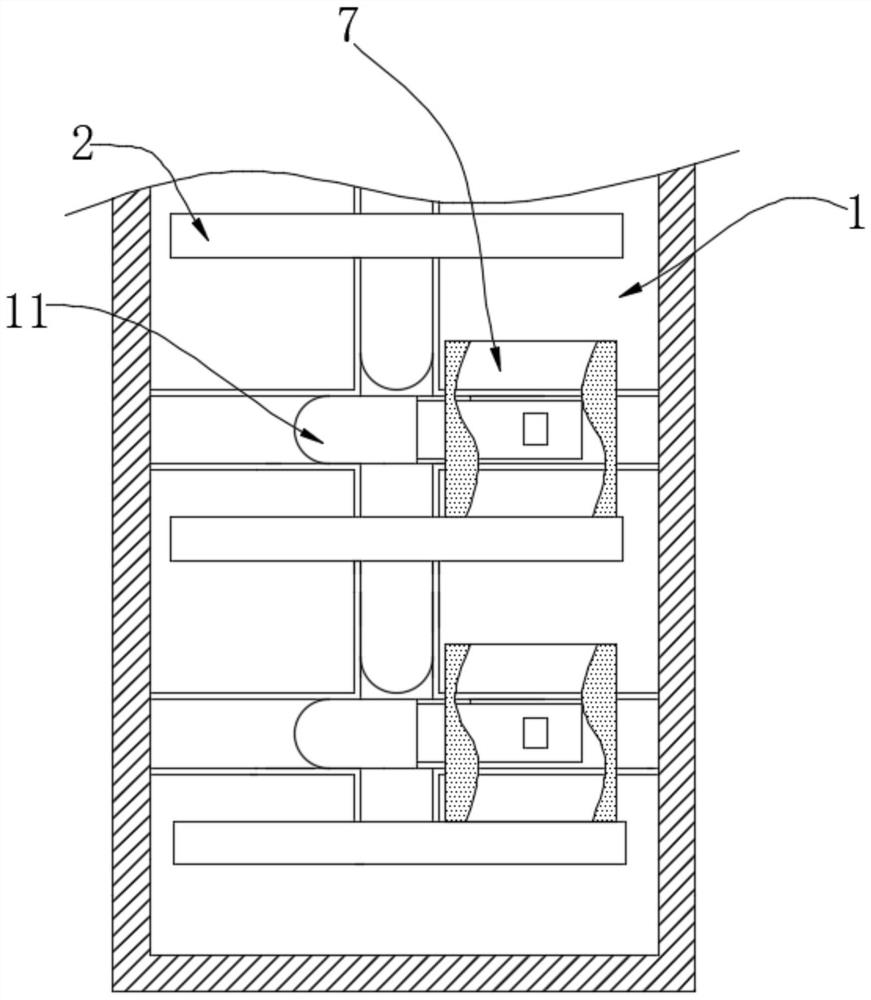

Battery cabinet for base station

InactiveCN114069076AEasy to carryAvoid damageBatteries circuit arrangementsSecondary cells charging/dischargingStructural engineeringMechanical engineering

The invention relates to the technical field of battery cabinets, and discloses a battery cabinet for a base station. The battery cabinet comprises a cabinet body and batteries, a plurality of support plates are sequentially mounted in the cabinet body from top to bottom at intervals, the batteries are placed on the support plates, support legs are fixedly connected to two sides of the bottom of each support plate, and cross-shaped sliding grooves are formed in two sides of the inner wall of the cabinet body. A sliding block capable of sliding is arranged in the transverse sliding groove, a pressing plate is hinged to the outer surface of the sliding groove, and a connecting rod is fixedly connected to the surface of one side of the pressing plate. By arranging damping springs, the bottoms of the supporting plates make contact with the bottoms of the damping springs during descending, height descending is stopped, buffering protection can be conducted on the batteries which are not completely unloaded on the surfaces of the supporting plates, and the situation that the batteries are damaged due to too large vibration force during descending is avoided; the batteries can be separated, while the heat dissipation effect is improved, the left-right overturning of the batteries can be limited when the cabinet body is carried, so the situation that strong short-circuit current is generated after the exposed batteries collide with poles is avoided.

Owner:董武昌

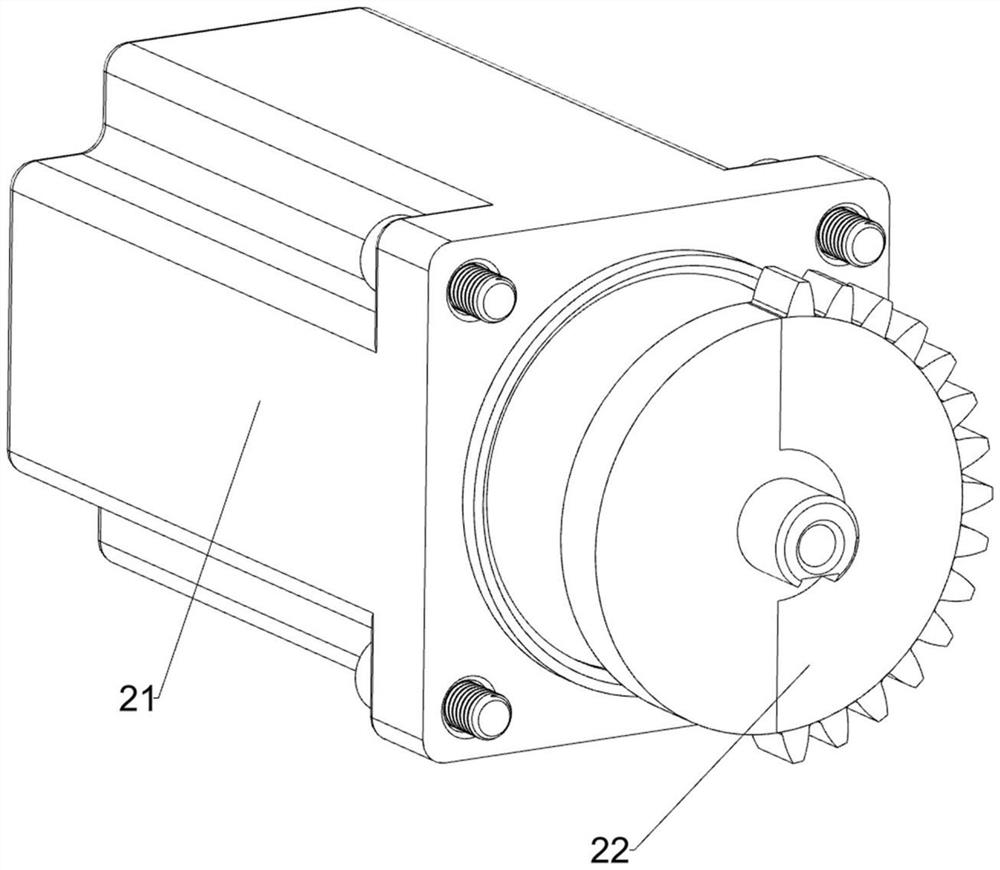

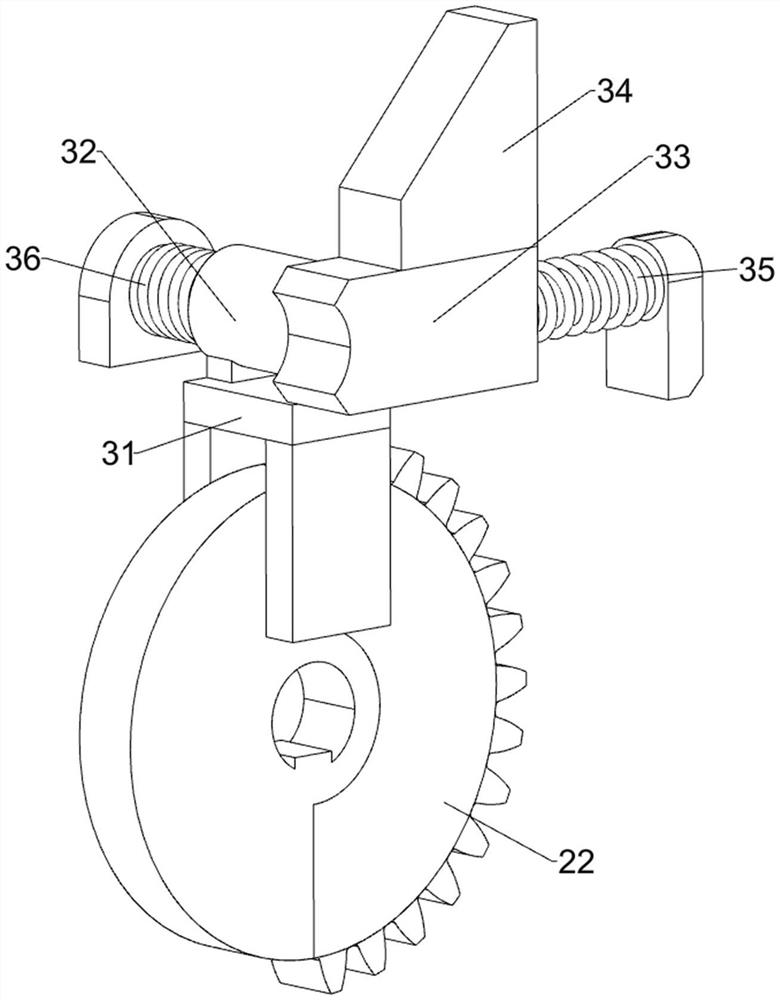

A six-wire high-voltage line sub-coil installation device

ActiveCN112003225BAuto fixReduce riskSpatial arrangements/dispositions of cablesElectric machineGear wheel

The invention provides a six-wire high-voltage line sub-coil installation device, which belongs to the field of mechanical technology. An installation device for a six-wire high-voltage line sub-coil, including a fixed ring, a rotating ring is arranged on the fixed ring, an annular chute is arranged on the rotating ring, a gap connected with the chute is provided on the rotating ring, and a The first motor, a gear is fixed on the output shaft of the first motor, a gear ring is fixed on the rotating ring, and the gear meshes with the gear ring; six swing arms are arranged in a circumferential array on the fixed ring, and a first guide is provided on the swing arm The fixed ring is fixed with six positioning pins, the positioning pins extend into the first guide groove, the swing arm can rotate around the positioning pin and the swing arm can move along the positioning pin through the first guide groove, and the swing arm is fixed with The slider is slidably arranged in the chute, after the notch on the rotating ring rotates to one of the sliders. The invention has the advantages of convenience for workers to install sub-coils and high safety.

Owner:海宁金都新能源有限公司

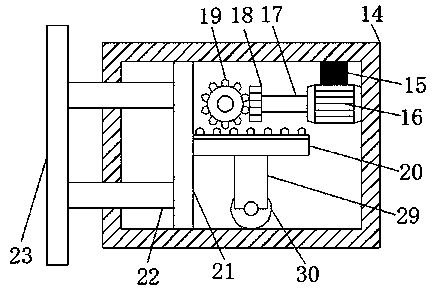

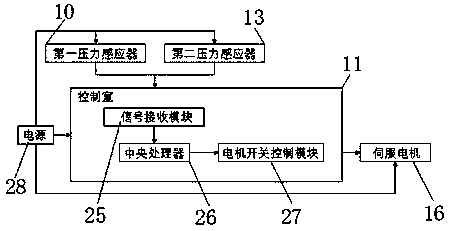

Intelligent express box based on unmanned receiving and delivering

The invention discloses an intelligent express box based on unmanned receiving and delivering, and relates to the technical field of express boxes. The express box comprises an express box body, wherein the middle of the inner wall of one side of the express box body is fixedly connected with a first fixing block, a first pressure sensor is fixedly arranged on one side of the first fixing block, acontroller is fixedly arranged on the other side of the inner wall of the bottom end of the express box body, a supporting plate is arranged at the bottom end of the express box body, and a second pressure sensor is fixedly arranged in the middle of the upper surface of the supporting plate. According to the intelligent express box based on unmanned receiving and delivering, a first rotary shaftcan drive a first gear to rotate, the first gear can drive a second gear to rotate, the second gear drives a transverse plate to move left and right through a gear rack, the transverse plate drives aright clamping plate to move left and right through a transverse rod, the right clamping plate moves left and right, so that a left clamping plate and the right clamping plate can fix objects with different sizes, and the situation that the objects shake in the transportation process can be avoided.

Owner:罗海洋

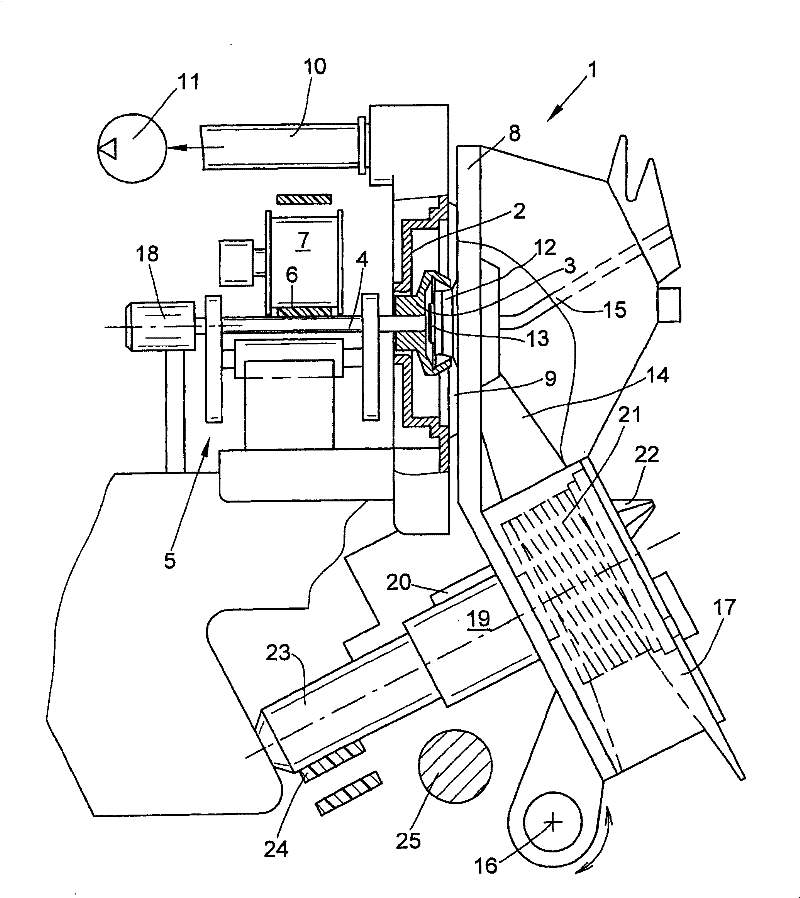

A motor rotor plane cutting machine

InactiveCN106992638BFlat cutting is convenientAuto fixManufacturing stator/rotor bodiesMilling equipment detailsEngineeringMechanical engineering

The invention belongs to the technical field of motor rotor production devices, and provides a plane cutting machine of a motor rotor. The plane cutting machine comprises a device rack and a plane cutting device. A power supply box is arranged under the device rack. The plane cutting device comprises a positioning die fixedly connected to the device rack and a cutting tool arranged on the positioning die. A vibration loading disc is arranged on one side of the positioning die and is connected with the positioning die through a sliding groove body. A material sending sliding groove is arranged in the sliding groove body. The width of the material sending sliding groove is equal to the external diameter of the motor rotor. An accommodation groove used for accommodating the motor rotor is arranged in the positioning die. One end of the material sending sliding groove communicates with the accommodation groove. The other end of the material sending sliding groove communicates with a discharging opening of the vibration loading disc. An electromagnet used for absorbing the motor rotor is arranged on the side face of the accommodation groove. The production efficiency of the plane cutting machine is high.

Owner:柳州众赢机械有限公司

Plane cutting machine of motor rotor

InactiveCN106992638AFlat cutting is convenientAuto fixManufacturing stator/rotor bodiesMilling equipment detailsEngineeringMechanical engineering

The invention belongs to the technical field of motor rotor production devices, and provides a plane cutting machine of a motor rotor. The plane cutting machine comprises a device rack and a plane cutting device. A power supply box is arranged under the device rack. The plane cutting device comprises a positioning die fixedly connected to the device rack and a cutting tool arranged on the positioning die. A vibration loading disc is arranged on one side of the positioning die and is connected with the positioning die through a sliding groove body. A material sending sliding groove is arranged in the sliding groove body. The width of the material sending sliding groove is equal to the external diameter of the motor rotor. An accommodation groove used for accommodating the motor rotor is arranged in the positioning die. One end of the material sending sliding groove communicates with the accommodation groove. The other end of the material sending sliding groove communicates with a discharging opening of the vibration loading disc. An electromagnet used for absorbing the motor rotor is arranged on the side face of the accommodation groove. The production efficiency of the plane cutting machine is high.

Owner:柳州众赢机械有限公司

Automatically-resized mounting base for industrial robot

The invention relates to the technical field of industrial robots, and discloses an automatically-resized mounting base for an industrial robot. The mounting base comprises a mounting seat, a rotatingwheel is fixedly connected to the top of the mounting seat, a water pipe is inserted into the bottom of a water tank, a water wheel is fixedly connected to the interior of the water pipe, and a driving wheel is fixedly connected to the bottom of a clamping rod. A belt wheel is meshed with the bottom of the driving wheel, a sliding block is fixedly connected to the back face of the belt wheel, a connecting rod is movably connected to the bottom of the sliding block, and a tensioning rod is slidably connected into the mounting seat. According to the automatically-resized mounting base for the industrial robot, the robot presses a pressing rod to descend, the pressing rod rotates under the action of a pressing cavity, the pressing rod drives a transmission wheel to rotate, the transmission wheel drives the rotating wheel to rotate, the rotating wheel drives the clamping rod to move, and then the clamping rod and a guide rail are used in cooperation, so that the effect of automatically adjusting the size according to the robot is achieved.

Owner:广州尚开科技有限公司

Cutting device for apron

ActiveCN112252015BAuto fixQuality improvementSevering textilesAgricultural scienceAgricultural engineering

The invention relates to a cutting device, in particular to a cutting device for an apron. The object of the present invention is to provide a cutting device for an apron that can quickly cut cloth without damaging the cloth. A cutting device for an apron, comprising: a bracket; a power component installed on the bracket, powered by a motor to work; a control component installed on the bracket, controlled by sliding; a cutting component installed on the bracket, through Swipe to cut fabric. Through the cooperation of power components, control components and cutting components, the present invention achieves the effect of quickly cutting out the cloth required for making aprons; the present invention can automatically fix the cloth when cutting the cloth through the pressing component, improving the cutting of the cloth. At the same time, the equipment is safer to use; the invention can automatically wind up the cut cloth through the waste material winding component, and the equipment is more convenient to use.

Owner:江西诺捷科技股份有限公司

Ultrasonic cleaning equipment with high safety

InactiveCN112170372AImprove securityEasy accessCleaning using liquidsMegasonic cleaningStructural engineering

Owner:陕西诺盈自动化仪表有限公司

A fabric storage device for fabric processing

Owner:湖北新宇纺服饰有限责任公司

Screen printing machine protection device capable of automatically positioning and fixing square aluminum plate

InactiveCN113459649AEasy to processImprove work efficiencyScreen printersScreen printingPhysicsEngineering

The invention relates to the technical field of screen printing machines, and discloses a screen printing machine protection device capable of automatically positioning and fixing a square aluminum plate. The screen printing machine protection device comprises a shell, a polished rod is fixedly connected to the interior of the shell, a lead screw is rotatably connected to the interior of the shell, a moving block is movably connected to the exterior of the lead screw, and a telescopic rod is movably connected to the exterior of the moving block. A rotating disc is movably connected to the interior of the shell, a fixing shell is fixedly connected to the exterior of the rotating disc, a half gear is fixedly connected to the inner side of the fixing shell, a pushing air cylinder is movably connected to the outer portion of the half gear, through the interaction between all the structures of the device, the square aluminum plate can be clamped in time through a clamping rod after being placed into the device, the square aluminum plate is positioned under the action of a pushing assembly, so that the effects of fixing the square aluminum plate and automatically positioning the square aluminum plate are achieved, the machining effect is guaranteed, and the production efficiency is improved.

Owner:兰宗选

A fully automatic production line for high-pressure stainless steel pipes

ActiveCN112171295BMovement precisionAuto fixEdge grinding machinesOther manufacturing equipments/toolsProduction lineSS - Stainless steel

The invention discloses a full-automatic production line for high-pressure stainless steel pipes in the technical field of stainless steel pipe production. The tops of the support columns are fixedly connected with a first mounting plate, a transmission mechanism is provided between the two first mounting plates, a grinding device is provided in front of the top of the bottom plate, and a grinding, conveying and positioning mechanism is provided at the top of the bottom plate ; The grinding and conveying positioning mechanism includes a second mounting plate fixedly connected to the top of the first mounting plate, and the second mounting plate slides through a symmetrically arranged first slide bar; through the setting of the grinding and conveying positioning mechanism, it can The cut stainless steel tube can be accurately moved to the grinding position, and the stainless steel tube can be automatically fixed at the same time, so that the staff can easily take it and improve the processing efficiency.

Owner:江西康腾卫浴有限公司

Mechanical parts processing and forming system

InactiveCN106041673BAuto fixReduce damage rateGrinding carriagesGrinding feed controlMechanical componentsMachine parts

Owner:XIAN TECH UNIV

Yarn extraction nozzle

InactiveCN101560706BReduce wearService life exceedsContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The present invention relates to a yarn extraction nozzle of a free end rotor spinning device, comprising a nozzle base and a optically distinguished mark, which is used for distinguishing type of theyarn extraction nozzle, a nozzle insert made of ceramic is fixed on the nozzle base. According to the invention, the nozzle insert (38) is made of transparent sub-micron ceramic.

Owner:SAURER GERMANY GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com