Patents

Literature

150results about How to "Adjust friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

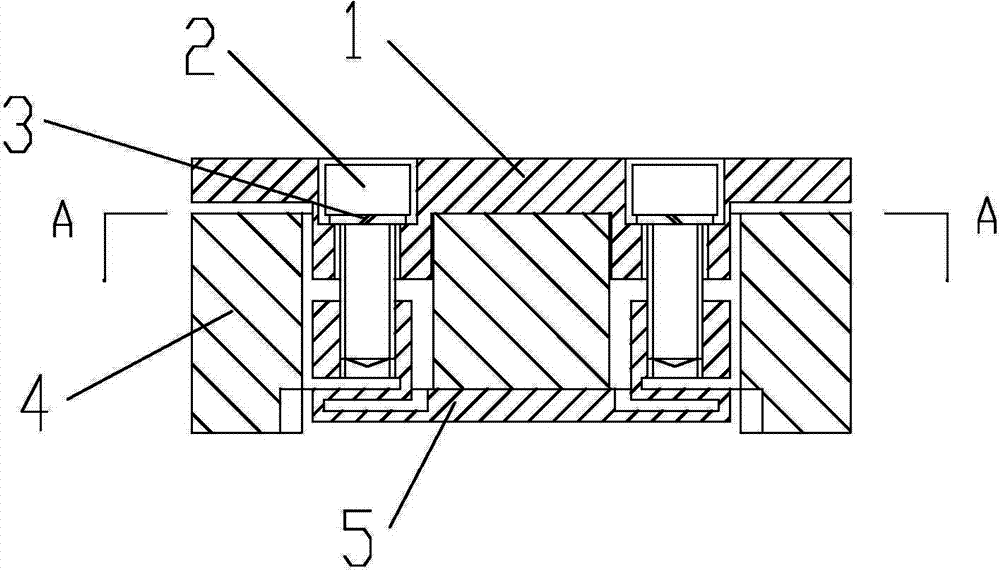

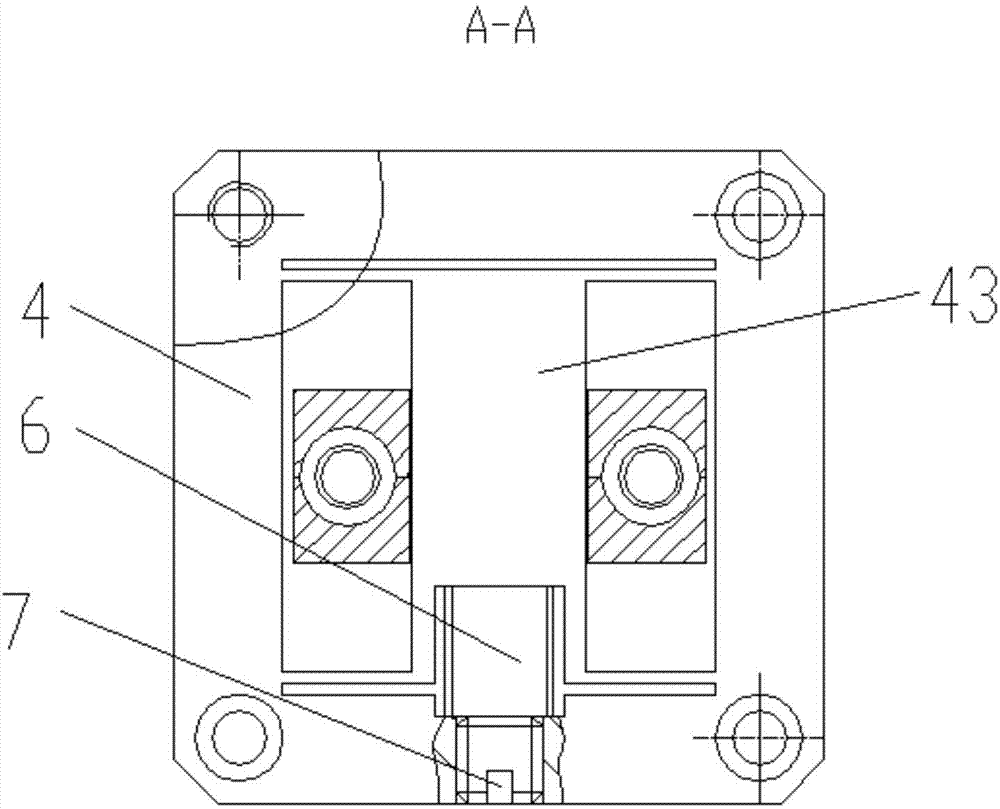

Bottom pre-tensioning type stick-slip driving cross-scale precision motion platform

ActiveCN103580532AAdjust frictionEasy to adjustPiezoelectric/electrostriction/magnetostriction machinesBatch productionEngineering

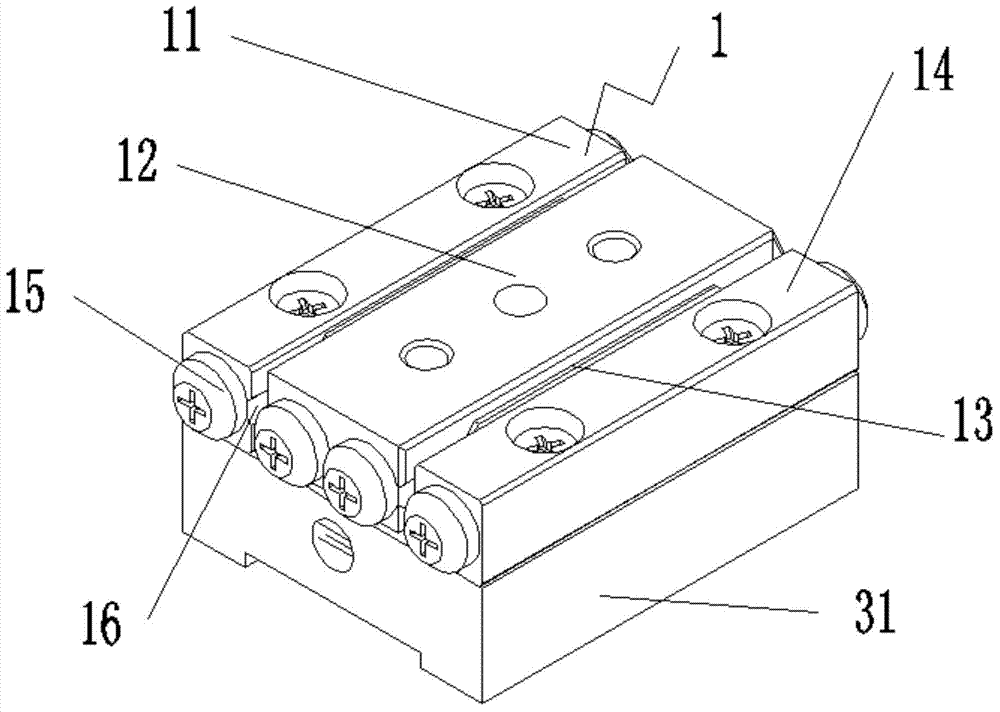

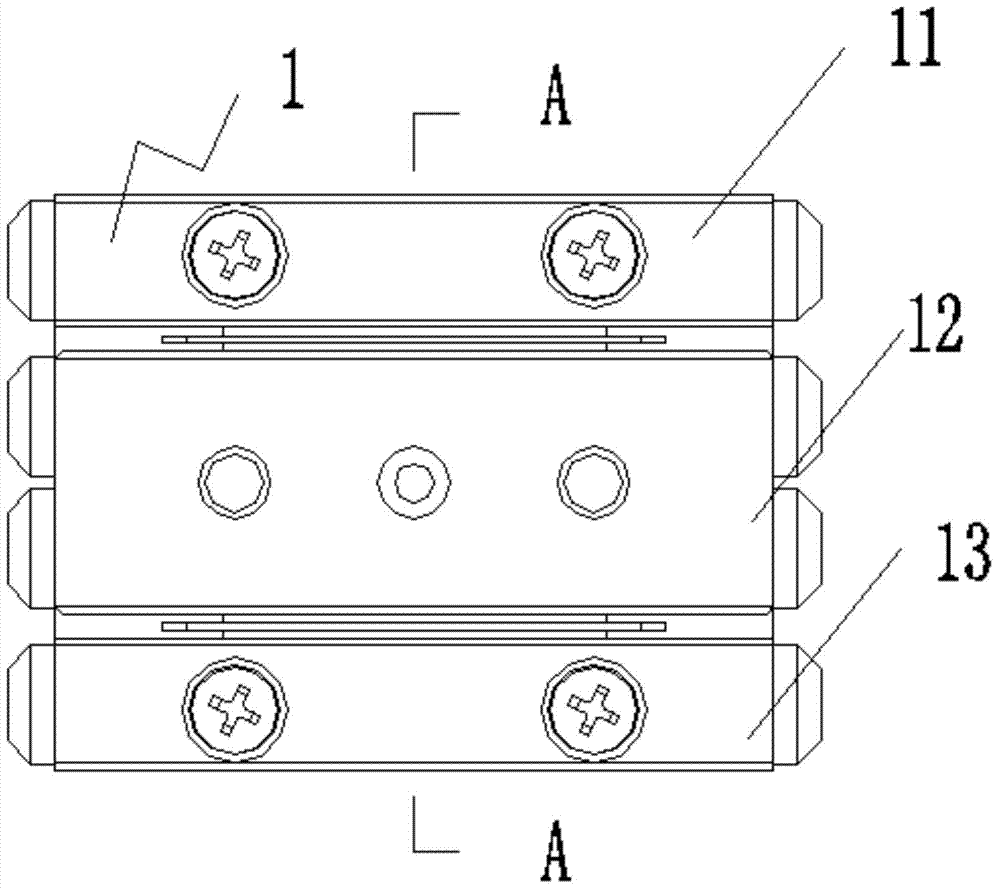

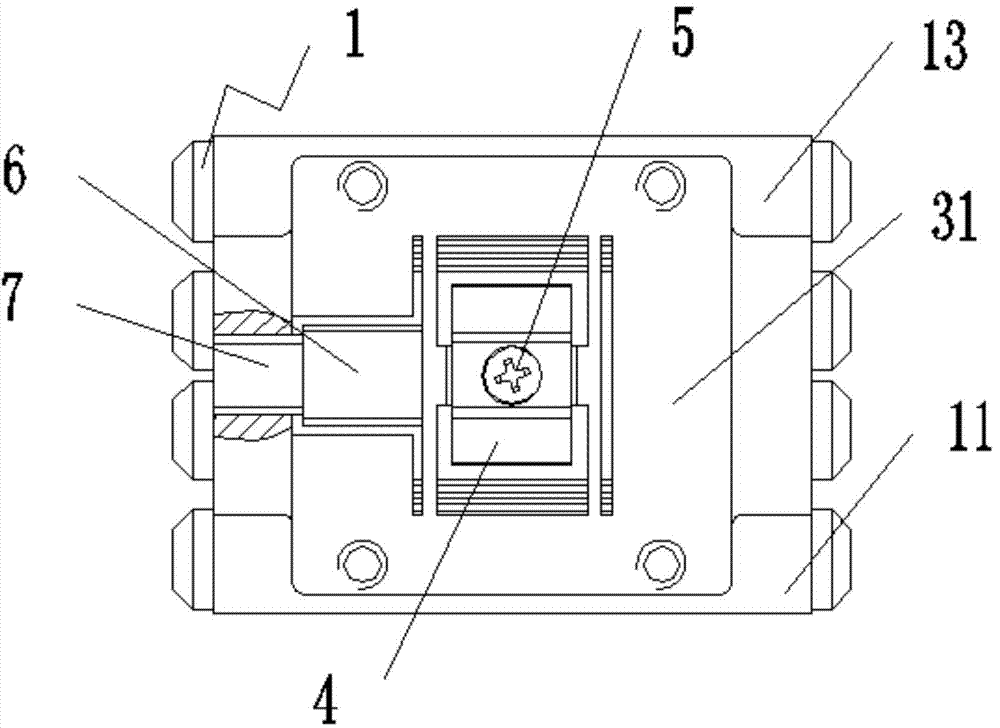

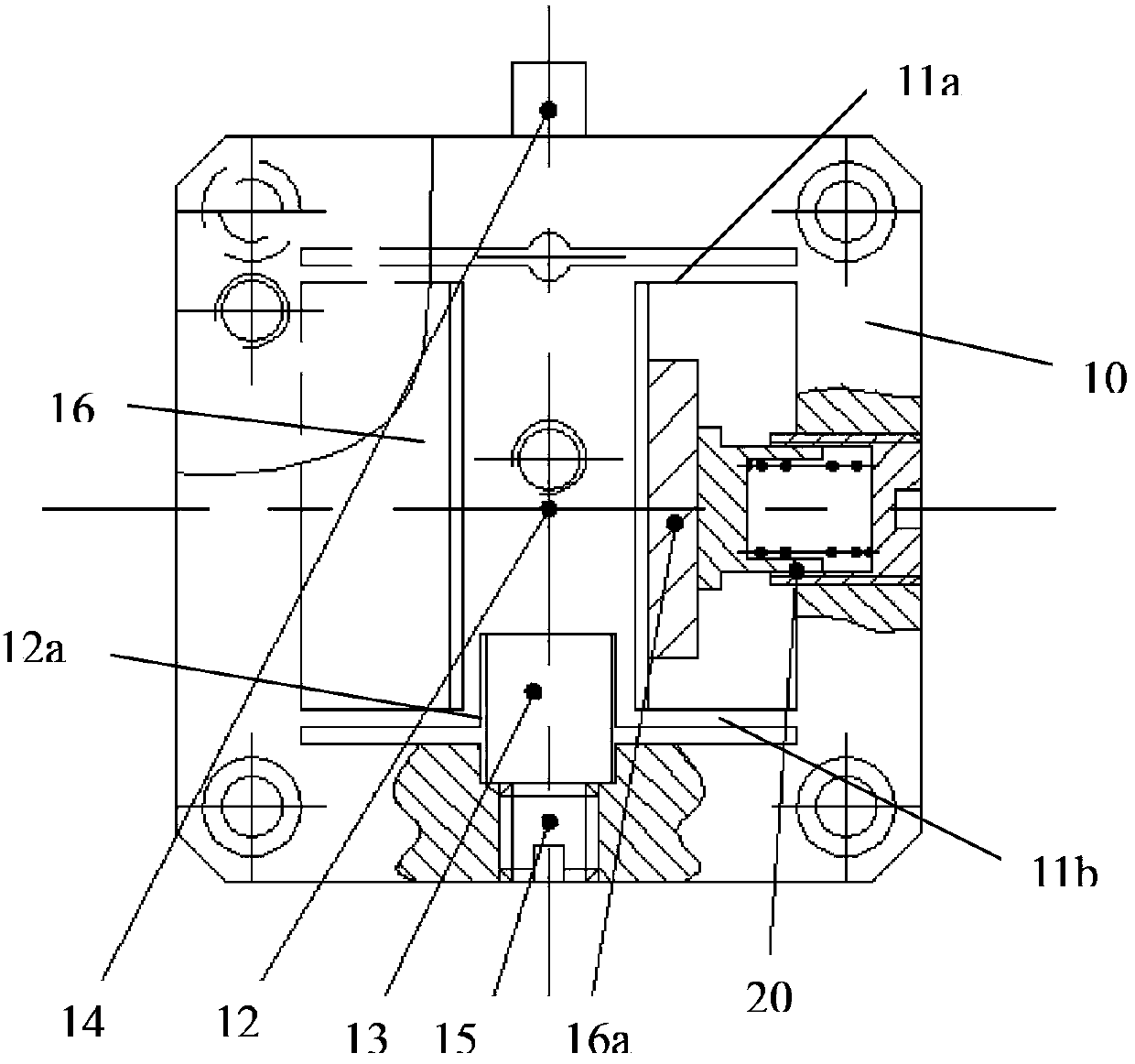

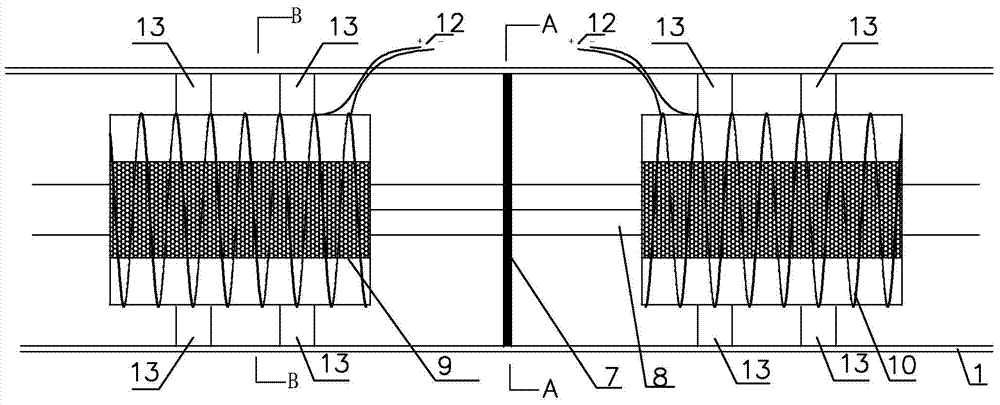

The invention discloses a bottom pre-tensioning type stick-slip driving cross-scale precision motion platform which comprises a base, a friction oscillator, an oscillator driving source and a sliding block, wherein a pre-tensioning force adjustment structure for providing pre-tensioning force is arranged between the bottom of the sliding block and the base; the pre-tensioning force adjustment structure comprises a V-shaped spring for providing the pre-tensioning force and an adjustment screw used for adjusting the V-shaped spring; the V-shaped spring is mounted on the base in a compression and deformation manner through the adjustment screw; the pre-tensioning force adjustment structure is used for adjusting the pre-tensioning force; a stick-slip effect occurs between the sliding block and the friction oscillator; and the sliding block performs cross-scale precision motion. According to the bottom pre-tensioning type stick-slip driving cross-scale precision motion platform, an adjustment manner of the pre-tensioning force of the motion platform is greatly simplified, and processing and assembly are facilitated, so that the output performance of the stick-slip driving cross-scale precision motion platform is effectively improved, the motion precision and consistency of the stick-slip driving cross-scale precision motion platform can be guaranteed simply and effectively, and the motion platform is suitable for batch production.

Owner:SUZHOU UNIV

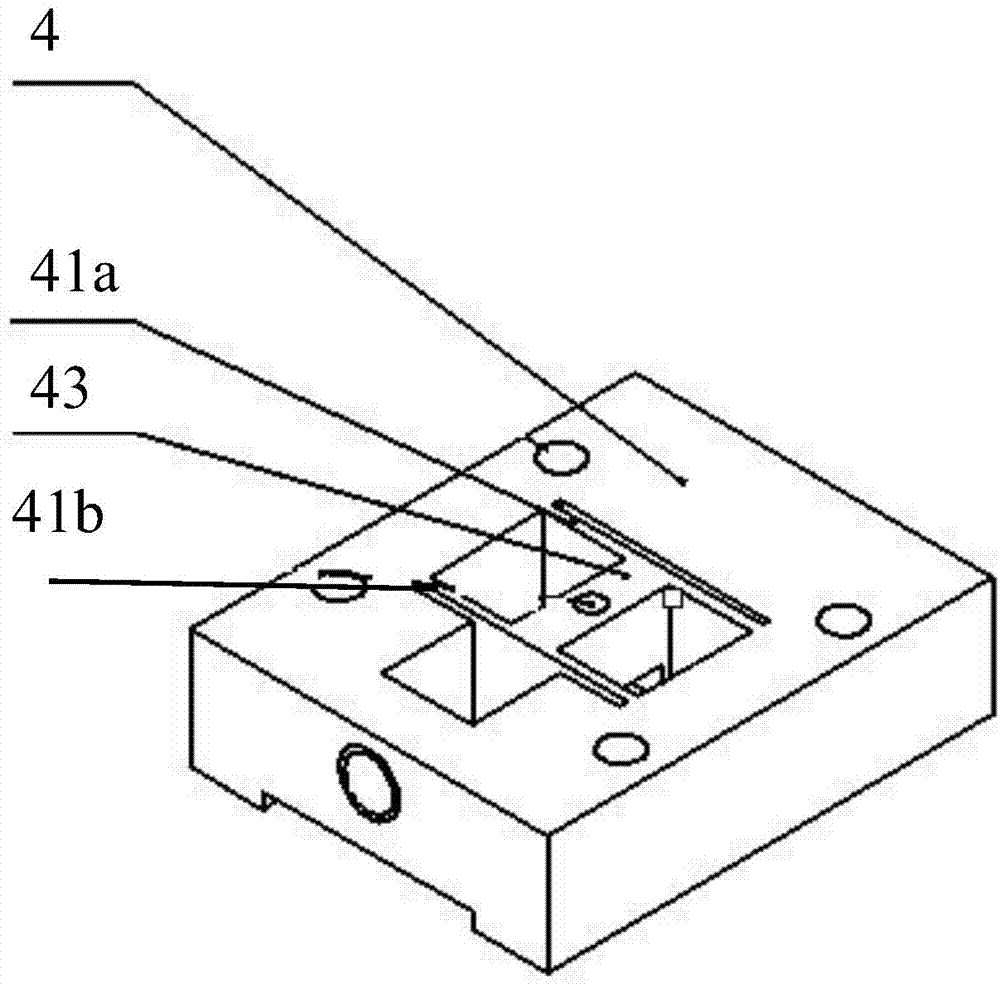

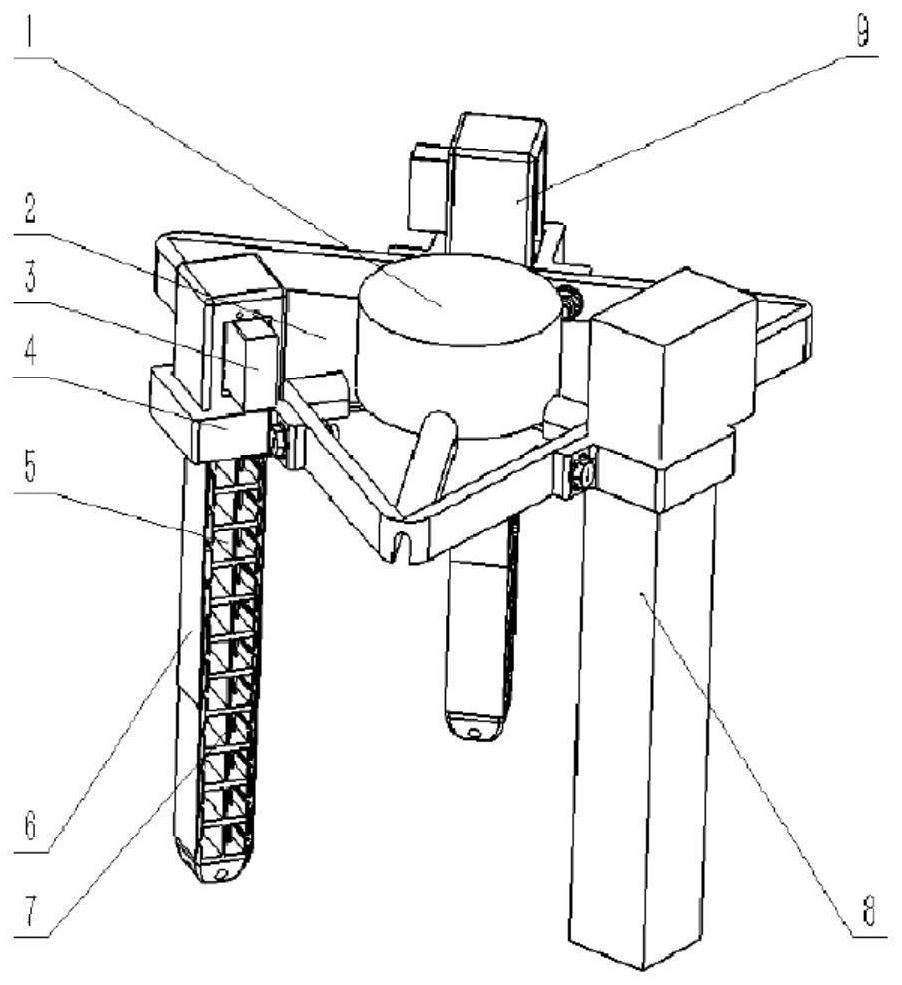

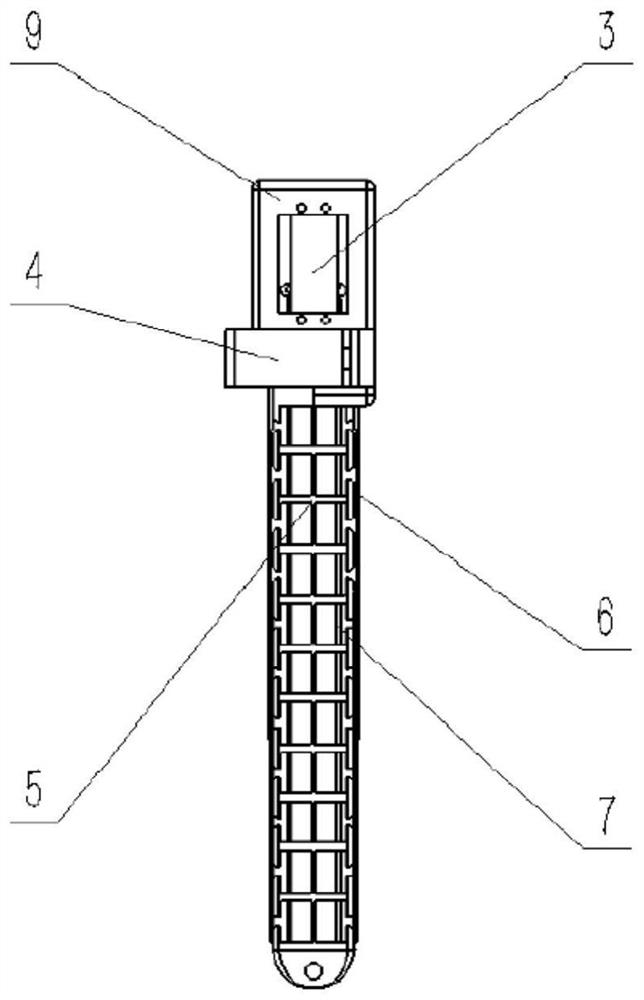

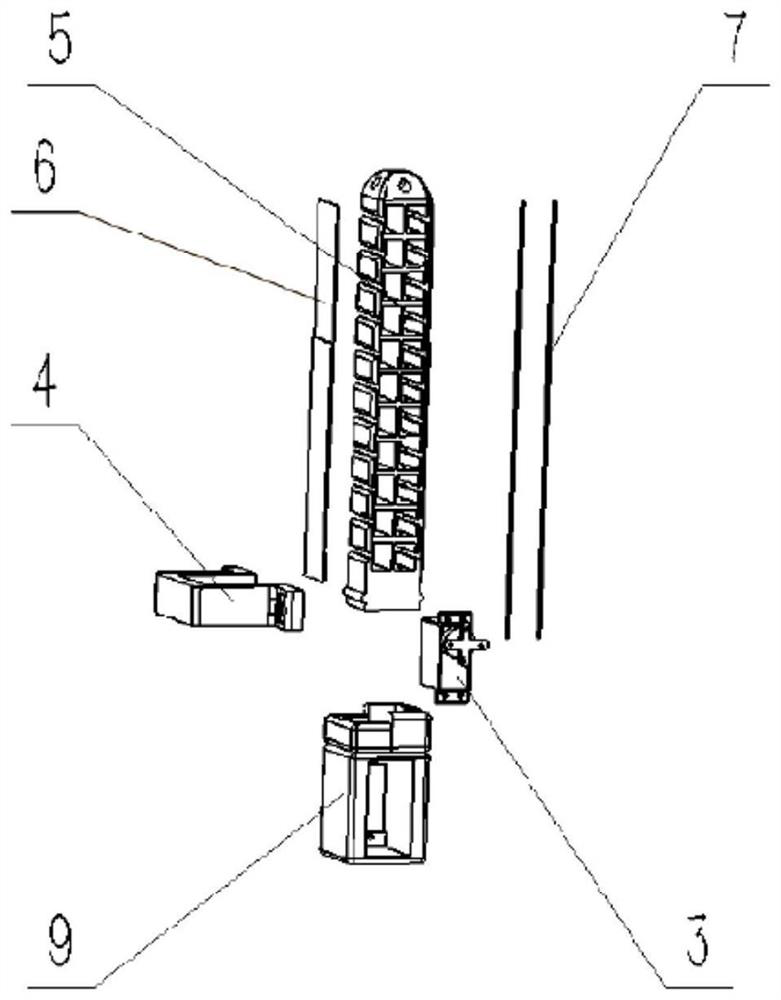

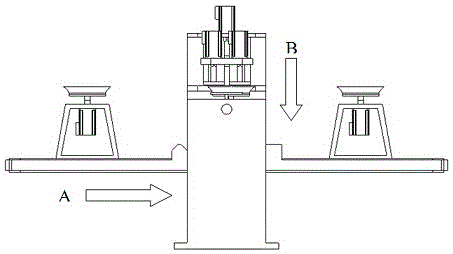

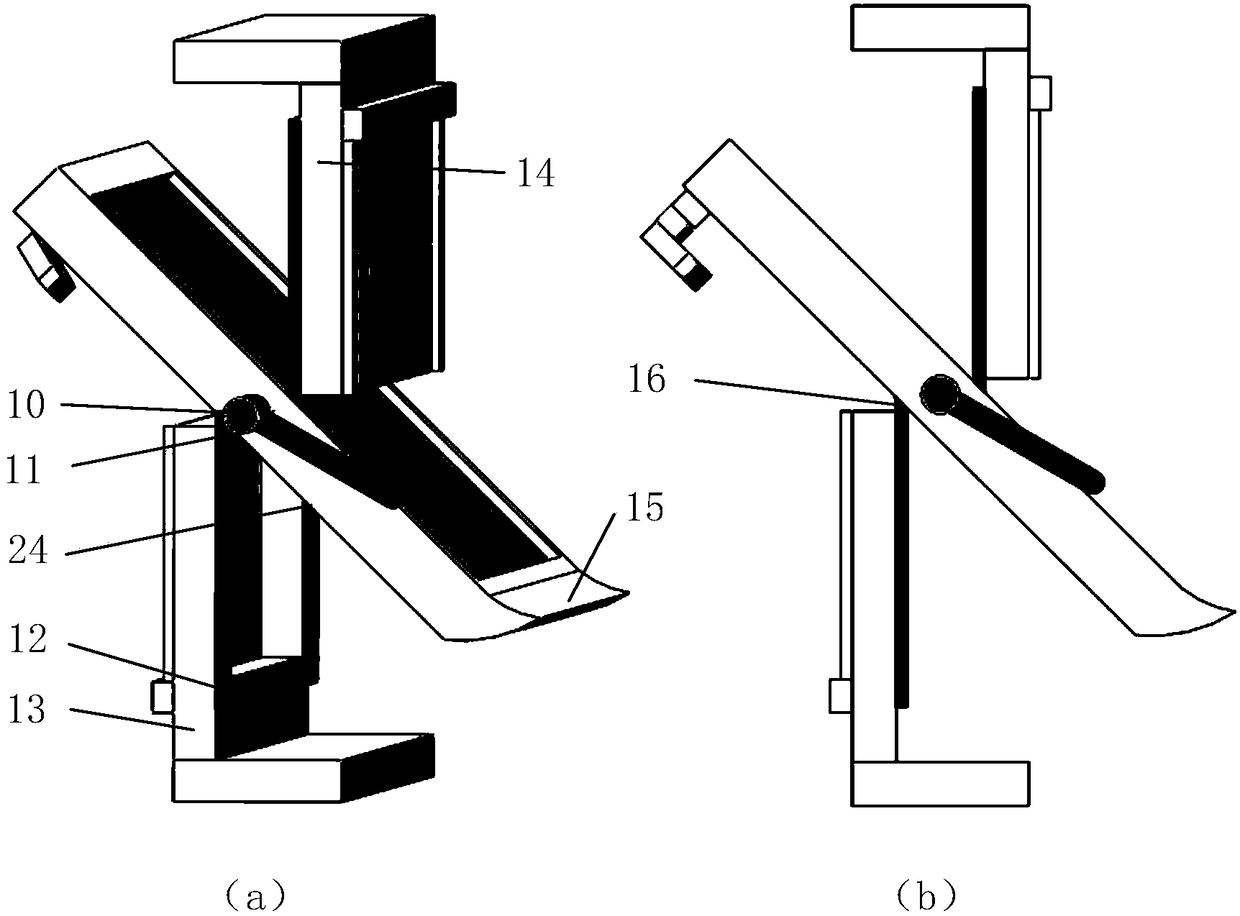

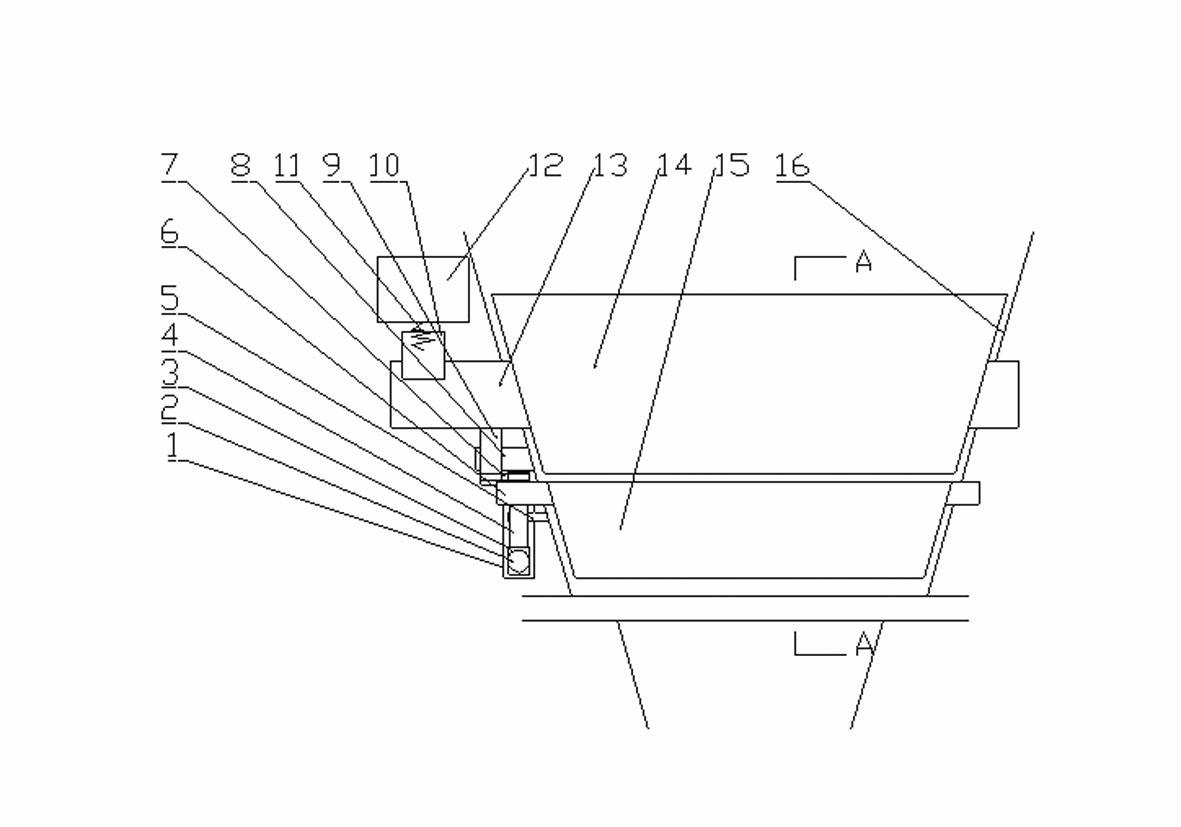

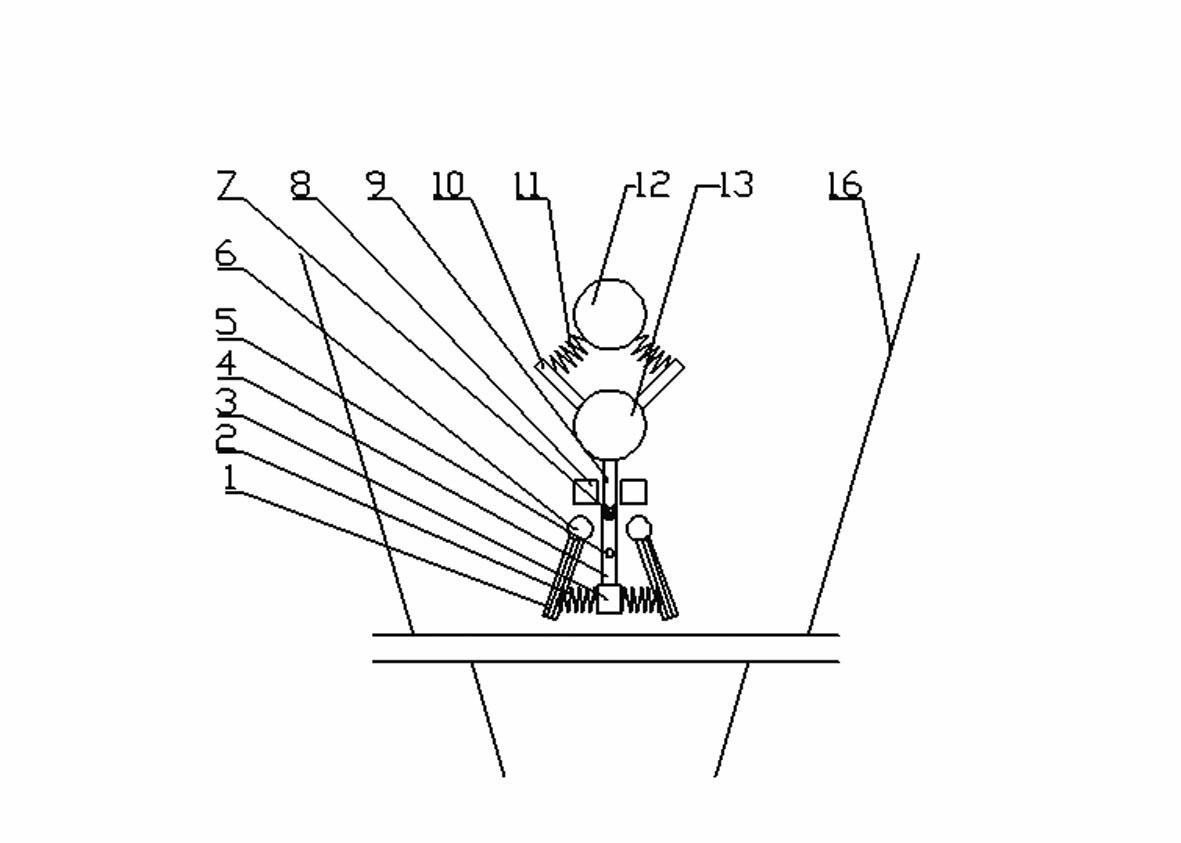

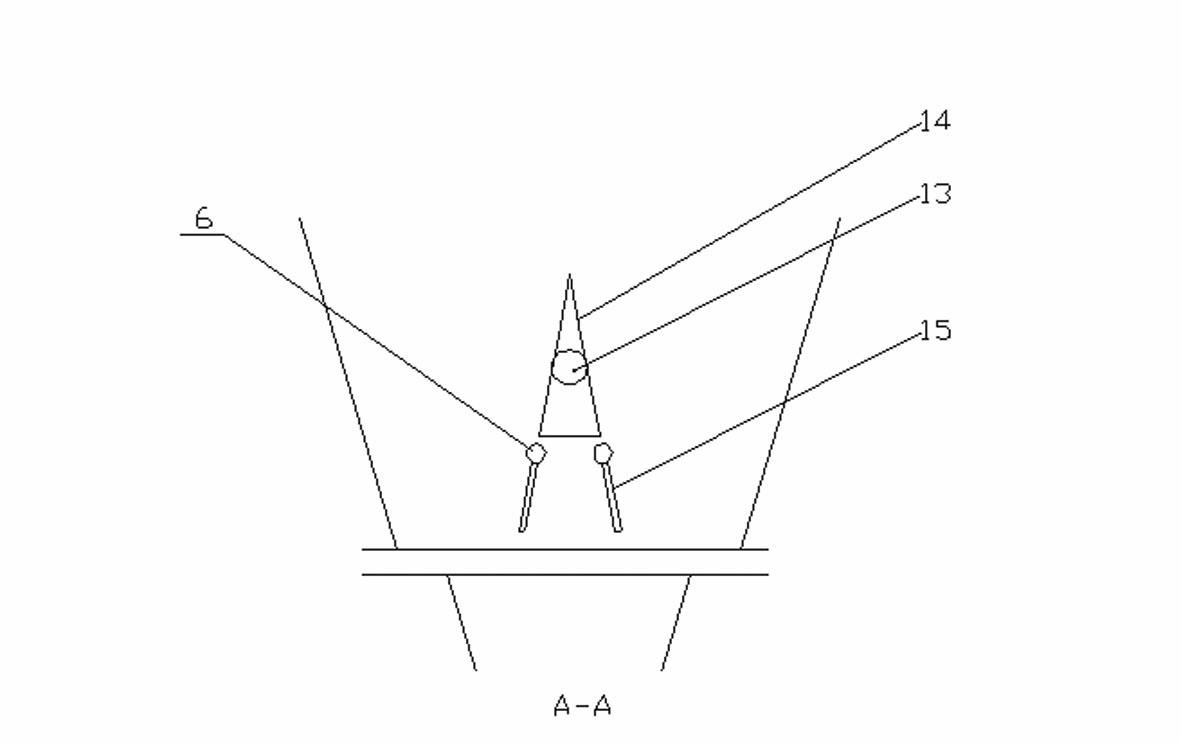

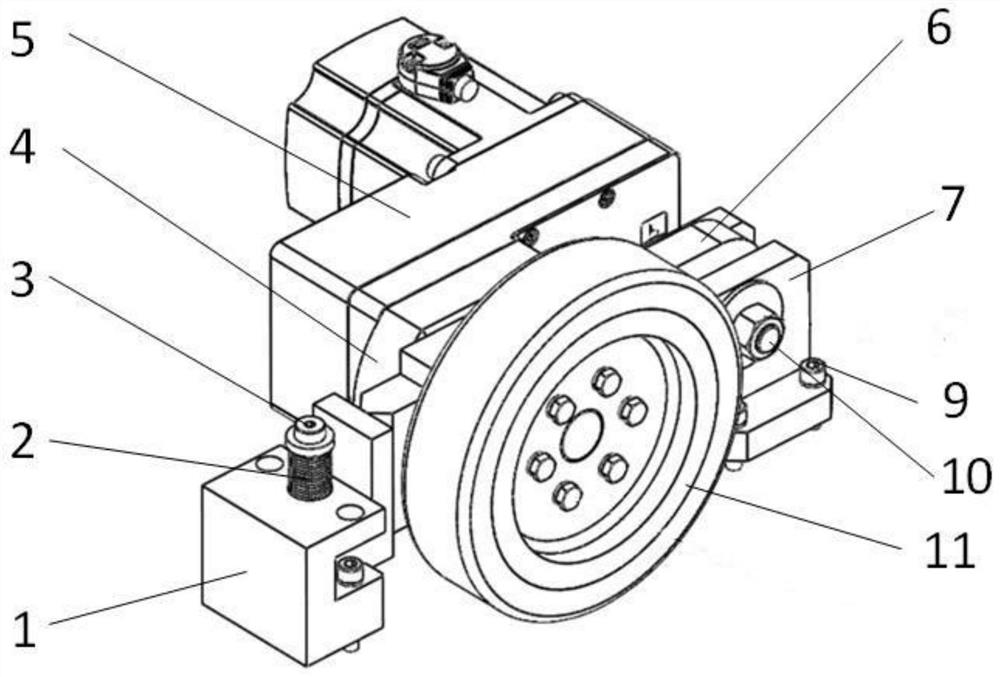

Stick-slip driving cross-scale precise motion platform

InactiveCN103391023AAdjust frictionEasy to adjustPiezoelectric/electrostriction/magnetostriction machinesEngineeringFriction force

The invention discloses a stick-slip driving cross-scale precise motion platform which comprises a base, a friction vibrator, a vibrator driving source and a sliding block, wherein the friction vibrator is mounted on the base; the vibrator driving source is mounted between the friction vibrator and the base and provides a driving force for the friction vibrator; the sliding block is connected with the friction vibrator in a sleeving manner, and contacted with the friction vibrator to generate a friction force; a pretightening force adjustment structure for providing a pretightening force is arranged between the side surface of the sliding block and the base, and used for adjusting the magnitude of the friction force; a stick-slip effect is generated between the sliding block and the friction vibrator; and the sliding block makes cross-scale precise motion. According to the stick-slip driving cross-scale precise motion platform, an adjustment mode of the pretightening force of the motion platform is simplified greatly; processing and assembling are facilitated; the output performance of the stick-slip driving cross-scale precise motion platform is further improved effectively; the motion precision and the consistency of the stick-slip driving cross-scale precise motion platform can be guaranteed simply and effectively; and the stick-slip driving cross-scale precise motion platform is suitable for mass production.

Owner:SUZHOU UNIV

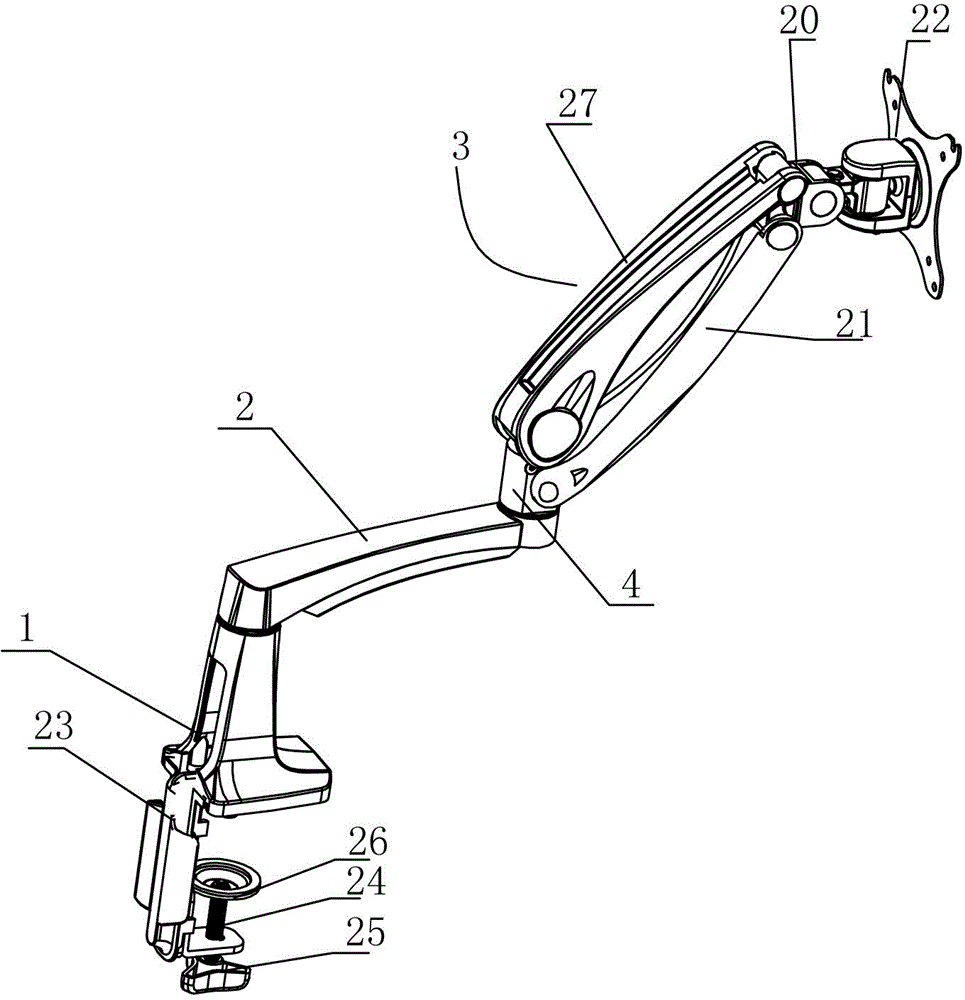

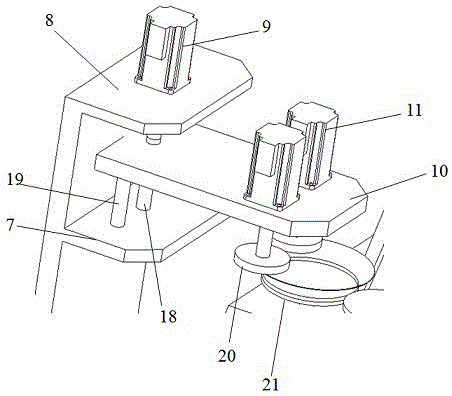

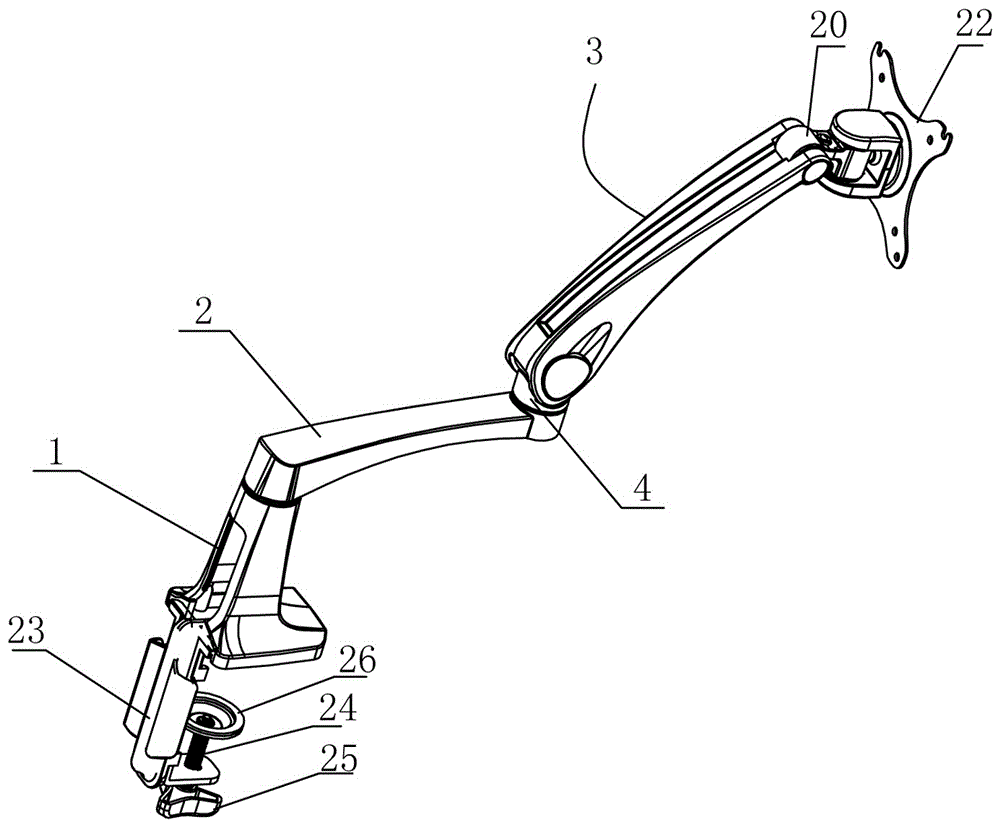

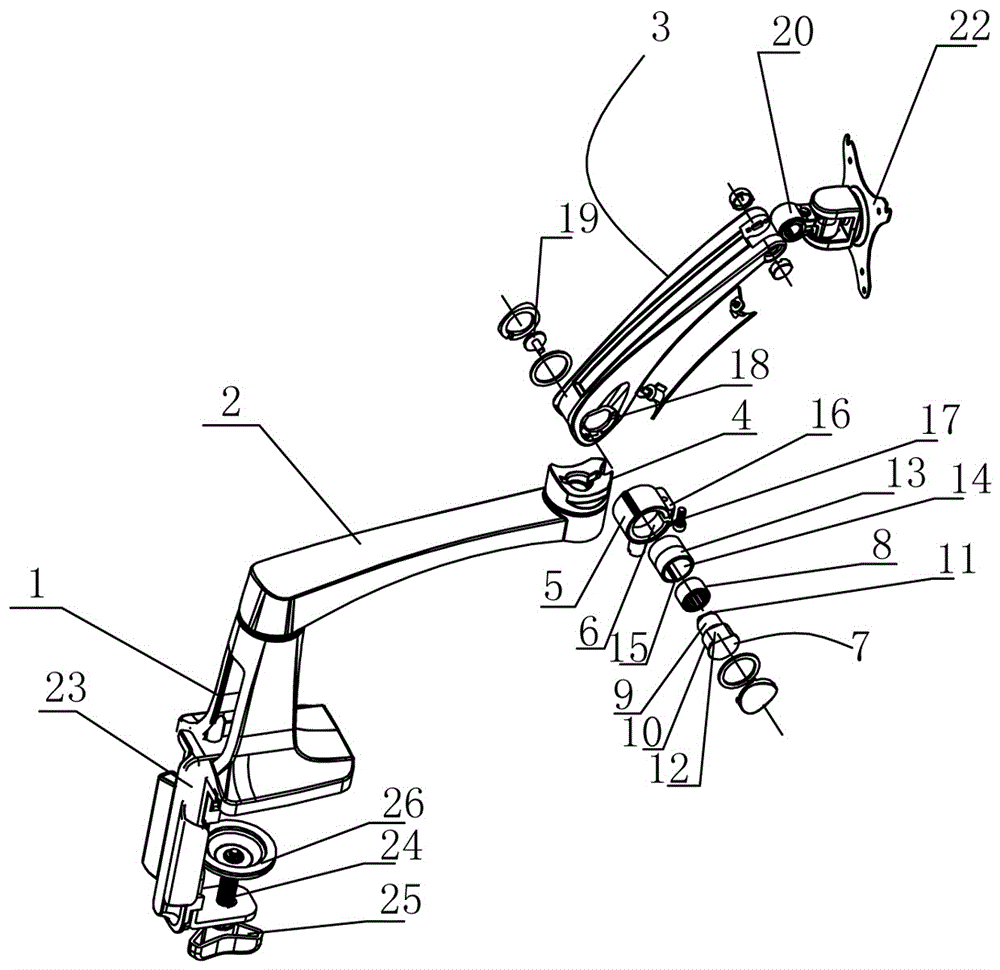

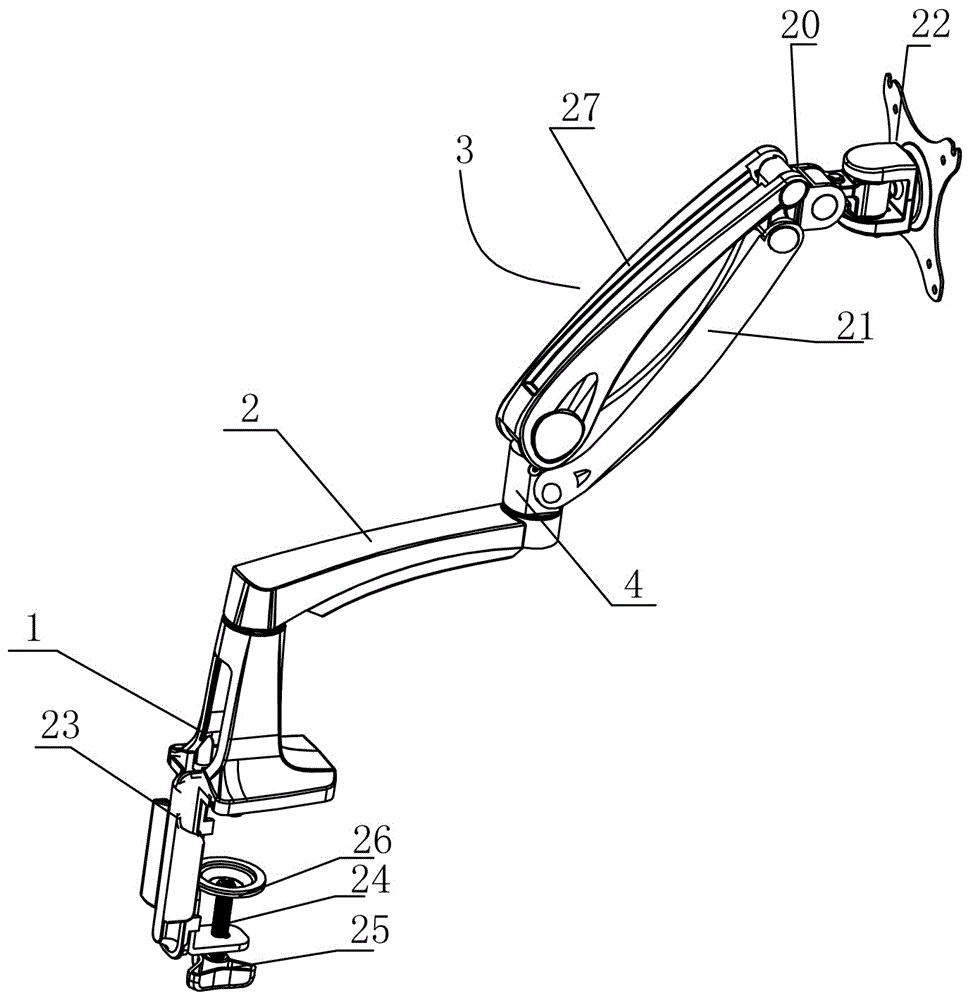

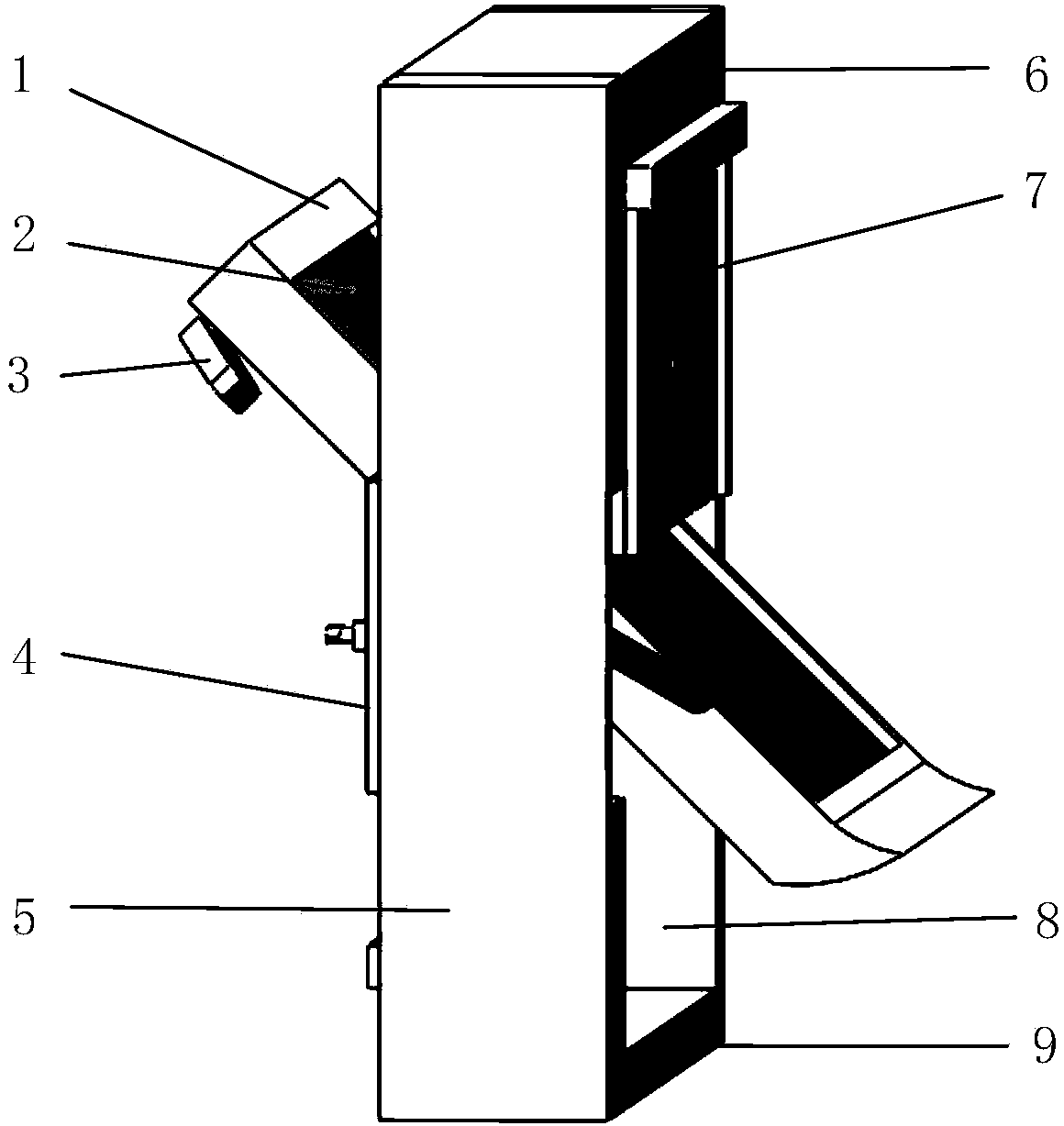

Flat-panel display bracket

ActiveCN103953829AStable frictional resistanceLow rotational resistanceStands/trestlesDisplay deviceEngineering

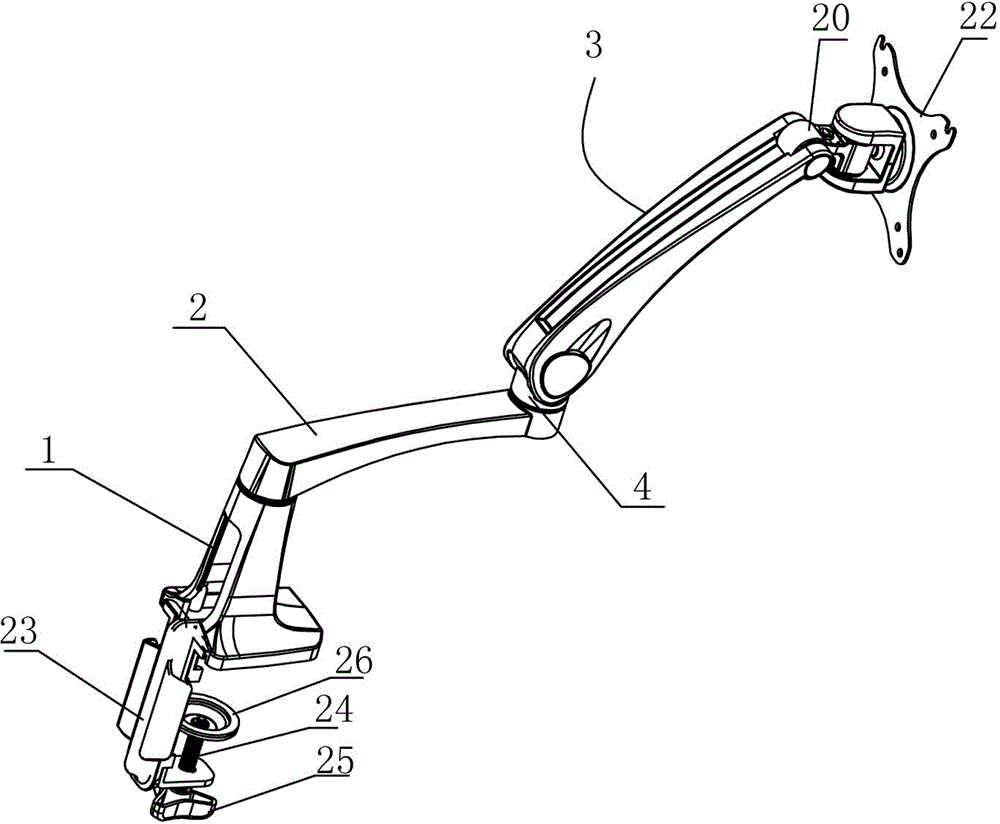

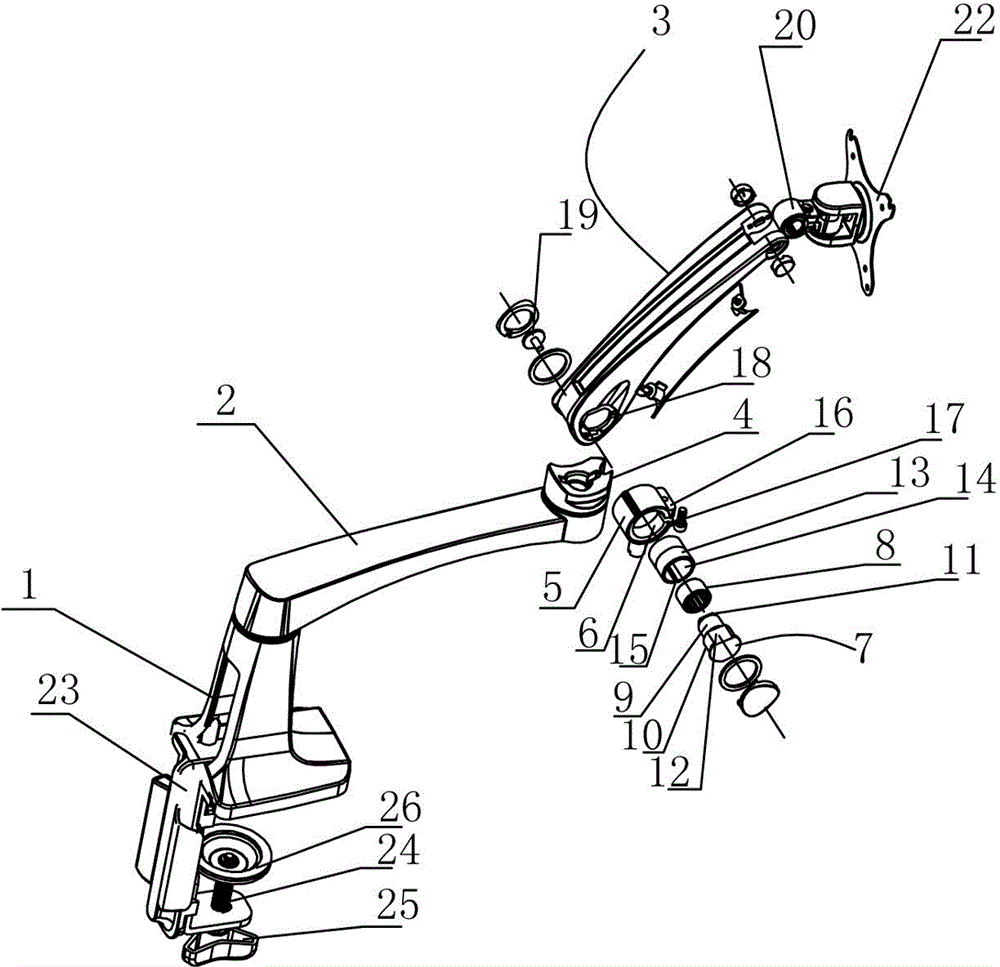

The invention discloses a flat-panel display bracket, comprising a base, a first rocker arm and a second rocker arm, wherein one end of the first rocker arm is rotatably connected with a rotary shaft of the base, and the other end of the first rocker arm is rotatably connected with one end of the second rocker arm. The flat-panel display bracket further comprises a hanging plate and a connection block, wherein one end of the connection block is articulated with the second rocker arm, the other end of the connection block is articulated with the hanging plate, a rotary seat is arranged between the first rocker arm and the second rocker arm, the lower end of the rotary seat is rotatably connected with the first rocker arm, the second rocker arm is articulated with the rotary seat through a rotary shaft, a one-way bearing is connected with the rotary shaft, the outer circumference wall of the one-way bearing is clung with the inner wall of a mounting hole of the rotary shaft of the rotary seat, and the two ends of the rotary shaft are fixedly arranged on the two side walls of the second rocker arm. According to the flat-panel display bracket, downward inclination of the hanging plate caused by the self weight of the second rocker arm is prevented, and the angle regulation of the hanging plate is labor-saving and convenient.

Owner:LOCTEK ERGONOMIC TECH CORP

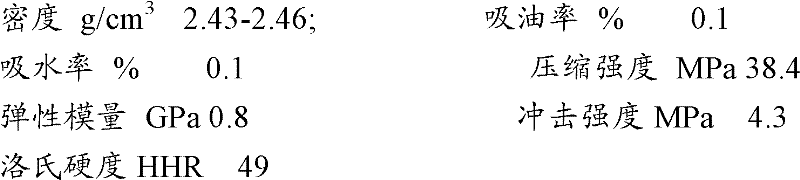

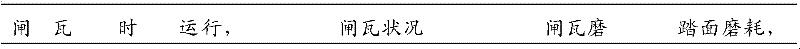

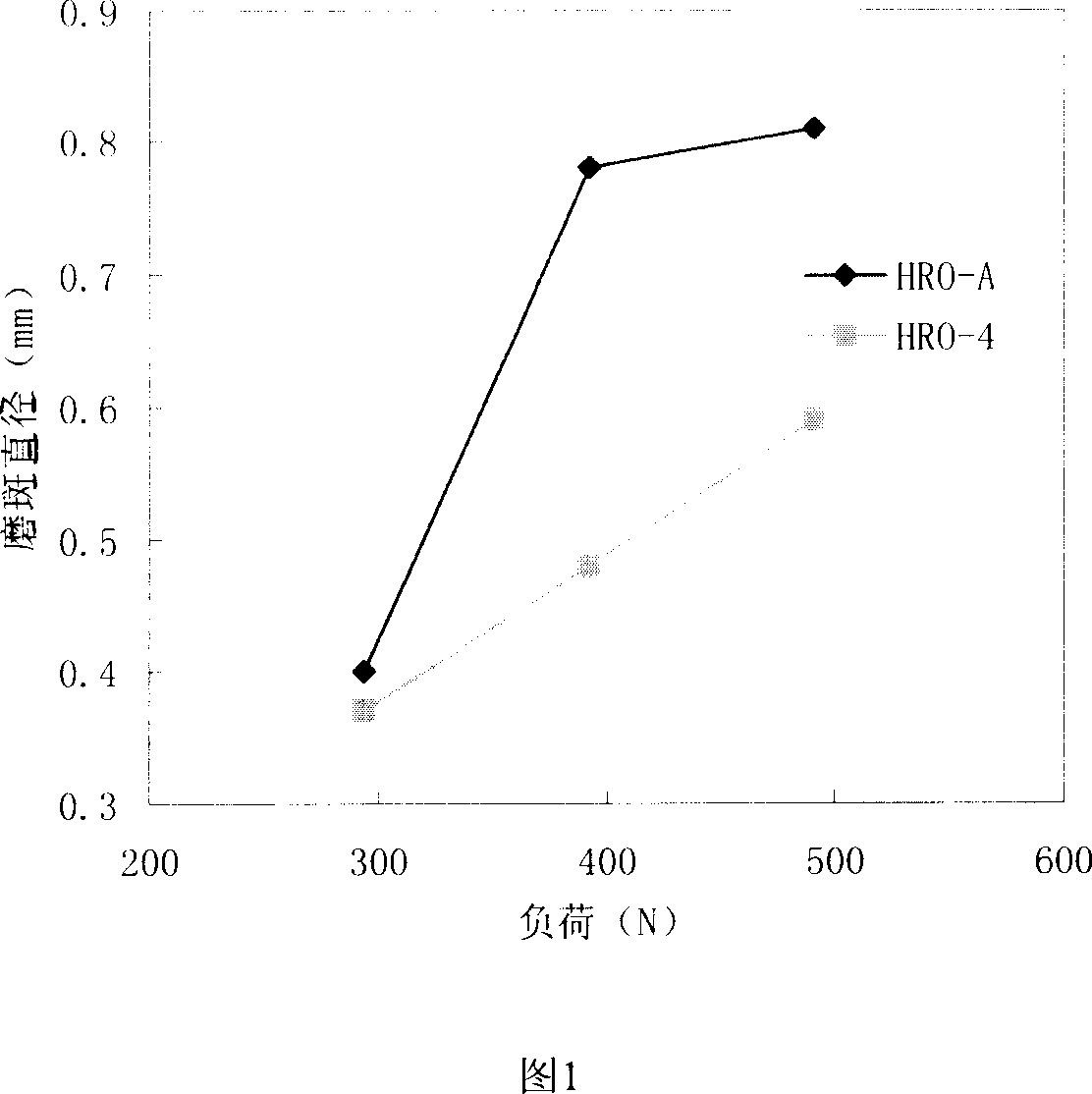

Synthetic brake shoe and preparation method thereof

The invention provides a synthetic brake shoe which comprises the following raw materials in parts by weight: 3-5 parts of phenol formaldehyde resin, 1.5-3.5 parts of nitrile-butadiene rubber, 1.5-3.5 parts of graphite, 3.5-5.5 parts of reduced iron powder, 4.5-6.5 parts of steel fiber, 1.5-3.5 parts of wollastonite, 2.5-4.5 parts of meerschaum, 3.5-5.5 parts of potash feldspar, 0.05-0.20 part ofaluminum oxide, 0.15-0.40 part of sulfur and 0.05-0.20 part of accelerator. The invention selects preferable raw materials and formula to develop the synthetic brake shoe which has the advantages of long service life, low abrasion mating plate and high friction factor. The car loading examination proves that the synthetic brake shoe satisfies the design requirements, does not generate harmful damascene, and does not generate thermal damage on the wheels; the service life is apparently longer than the currently universal synthetic brake shoe with high friction factor, reaching 0.2-0.24 millionkilometers per year; and the application and maintenance cost is lowered, the operation time for replacing the brake shoe is shortened, and the conveying efficiency is enhanced.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

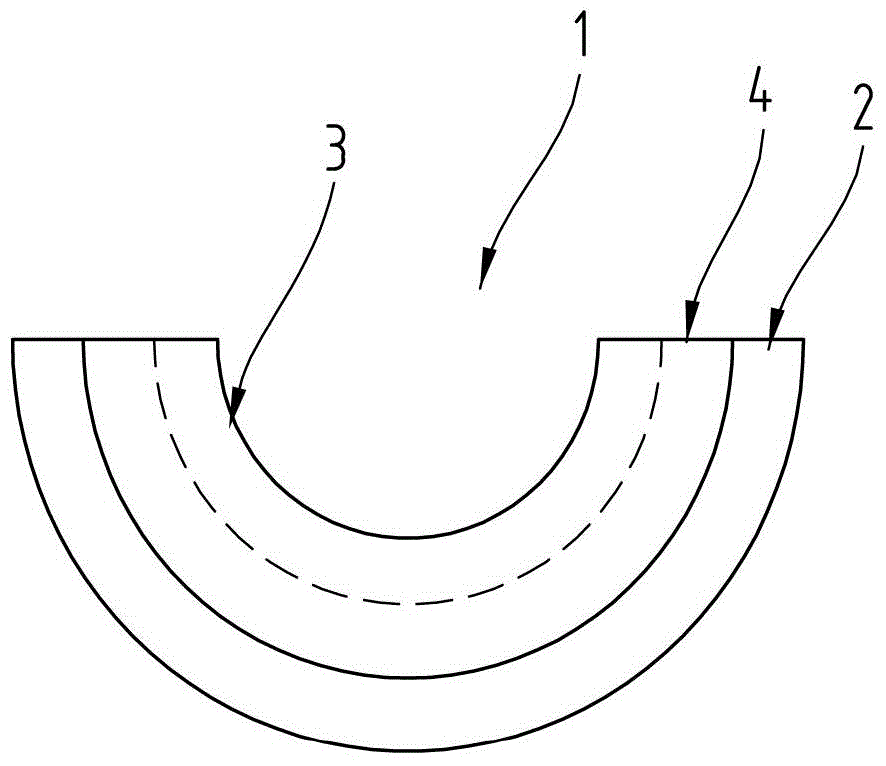

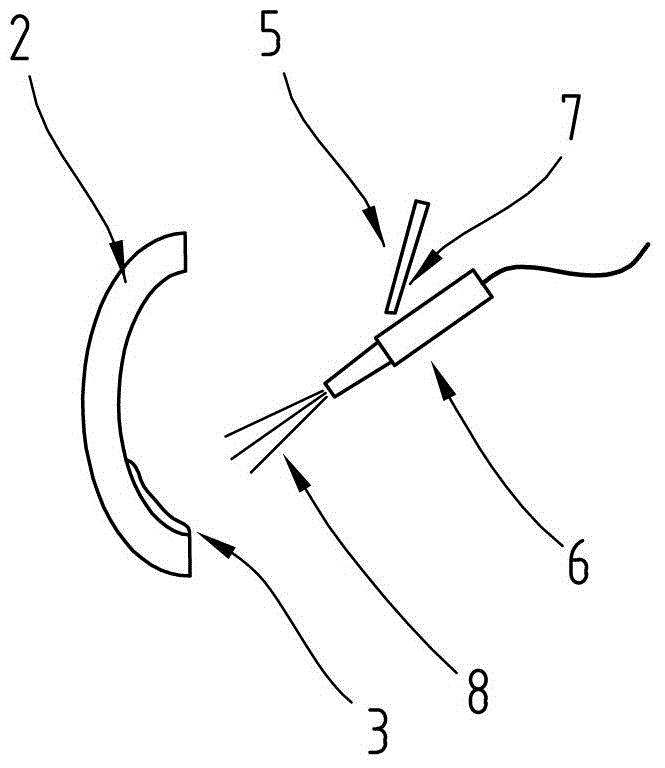

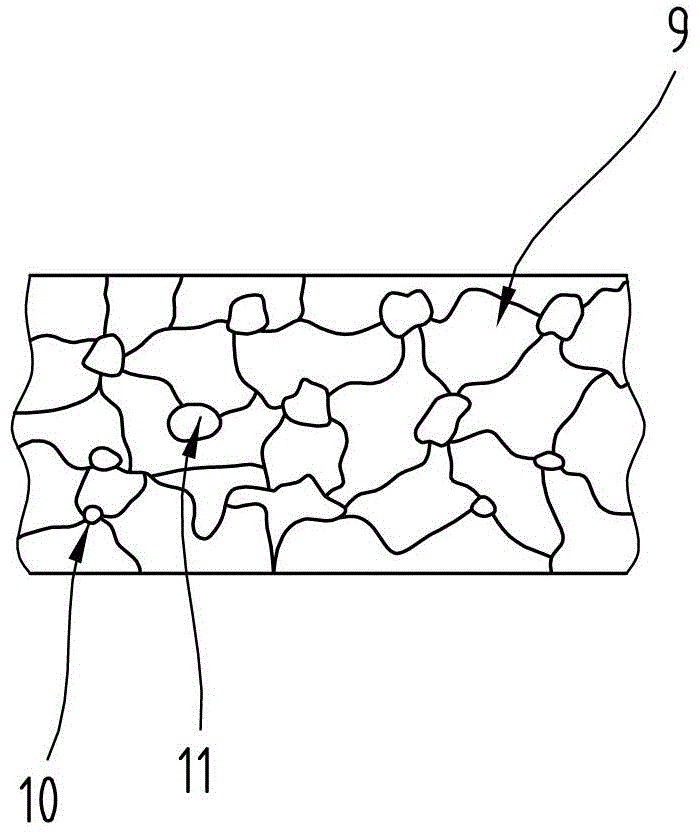

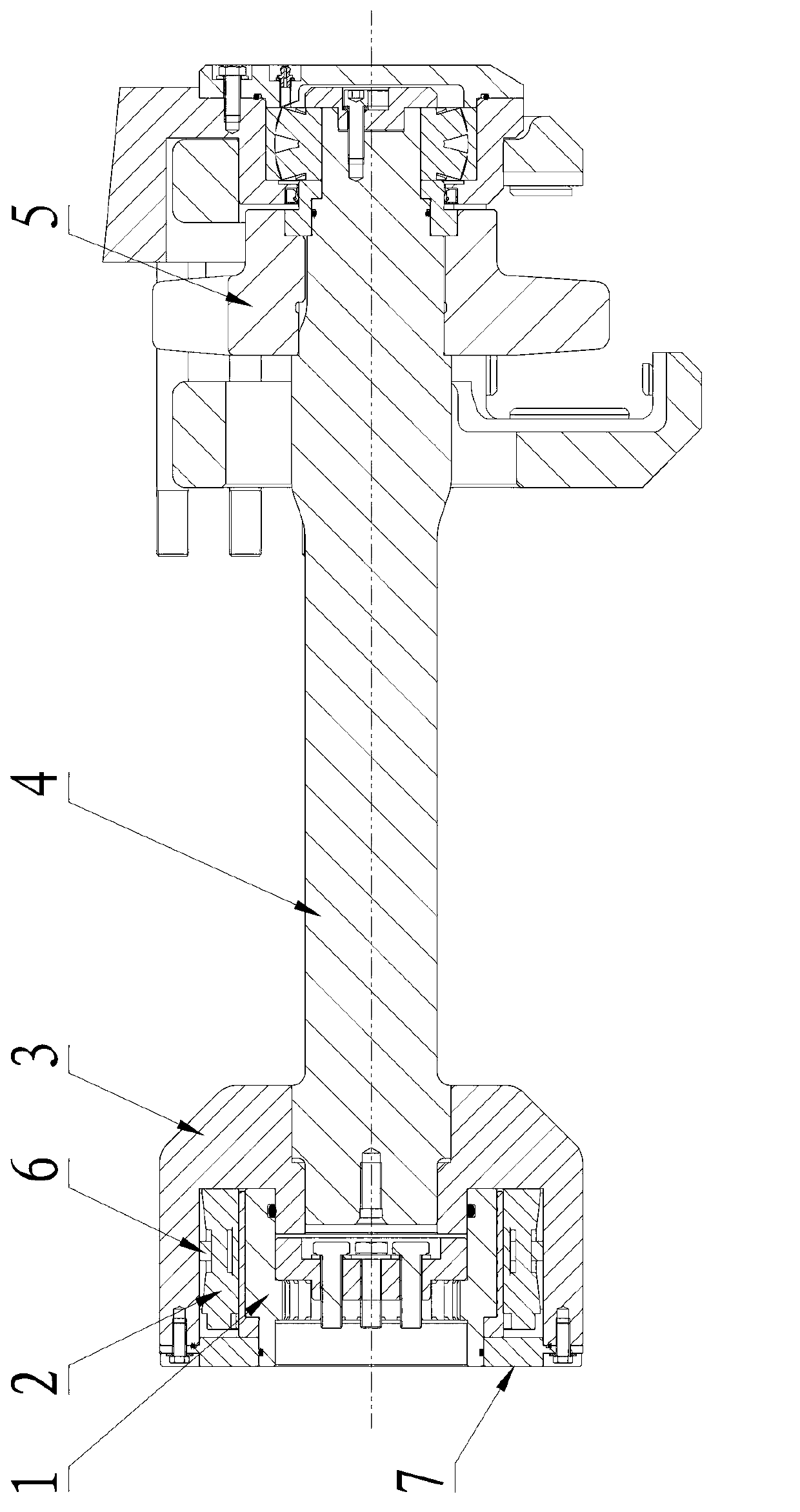

Method for manufacturing sliding bearing

The invention discloses a method for manufacturing a sliding bearing (1). The method includes the following steps that a metal supporting layer (2) is provided, and an additional metal layer made of a spraying material is directly sprayed on the metal supporting layer (2) or sprayed on the metal supporting layer (2) through at least one metal interlayer, wherein the additional metal layer is made of a tin base alloy provided with a tin-rich substrate in which hard particles (10) and / or soft particles (11) are added, the hard particles (10) are harder than the substrate and / or the soft particles (11) are softer than the substrate; and the spraying material (5) is adopted, under the condition that the spraying material (5) contains the hard particles (10), the additional metal layer with the hard particles (10) is formed, and / or under the condition that the spraying material (5) contains the soft particles (11), the additional metal layer with the soft particles (11) is formed, wherein the hard particles (10) and / or the soft particles (11) maintain a solid form in the spraying process.

Owner:MIBA PRECISION COMPONENTS CHINA

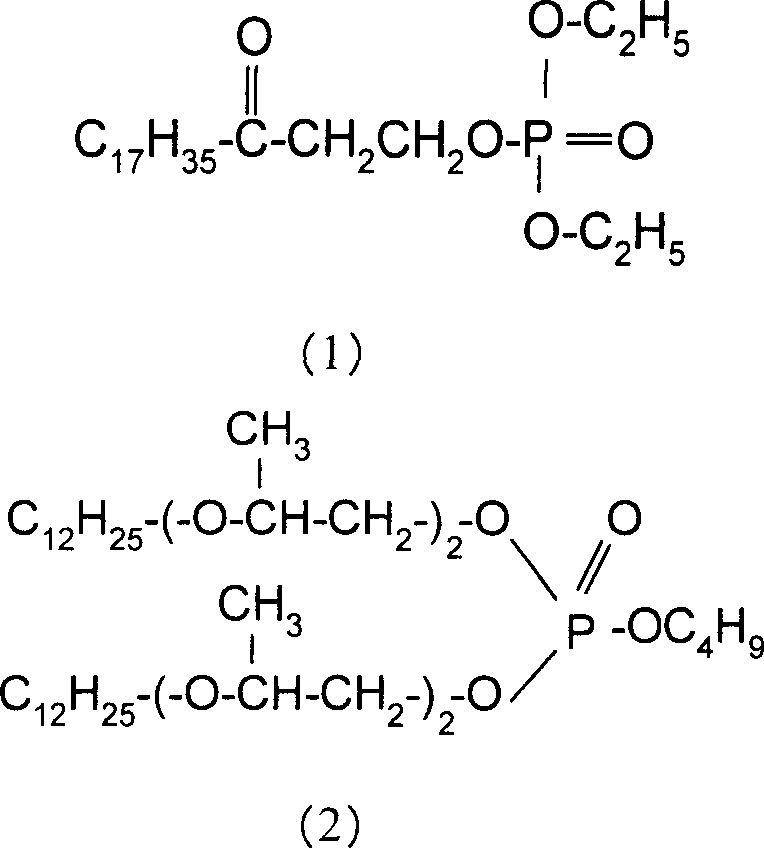

Hot-rolled oil composition containing organosilicon antiwear slip-proofing agent

The invention discloses a hot-rolled composition with organic silicon anti-friction antilubricant, which comprises the following parts: (I) lubricant basic oil with viscosity at 5-300mm2 / s at 40 deg.c, (II) 0.1-20wt% sulphur extreme pressure agent with one or more material from alkyl polysulfide, sulfur ore oil and sulfur polyol ester, (III) 0.05-15wt% phosphorus antiwear agent with one or more material from phosphate, phosphonate, phosphite ester, acid phosphate ester, phosphite ester amine salt, phosphamide ester, dialkyl dithiophosphate, dimercaptothiodiazole dithiophosphate ester and acid phosphate imidazoline salt, (IV) 0.001-25% organosilicon abrasion resistance antilubricant with silicon chloride, C2-16 aliphatic amine, disperser and non-ionic surface activator.

Owner:CHINA PETROLEUM & CHEM CORP +1

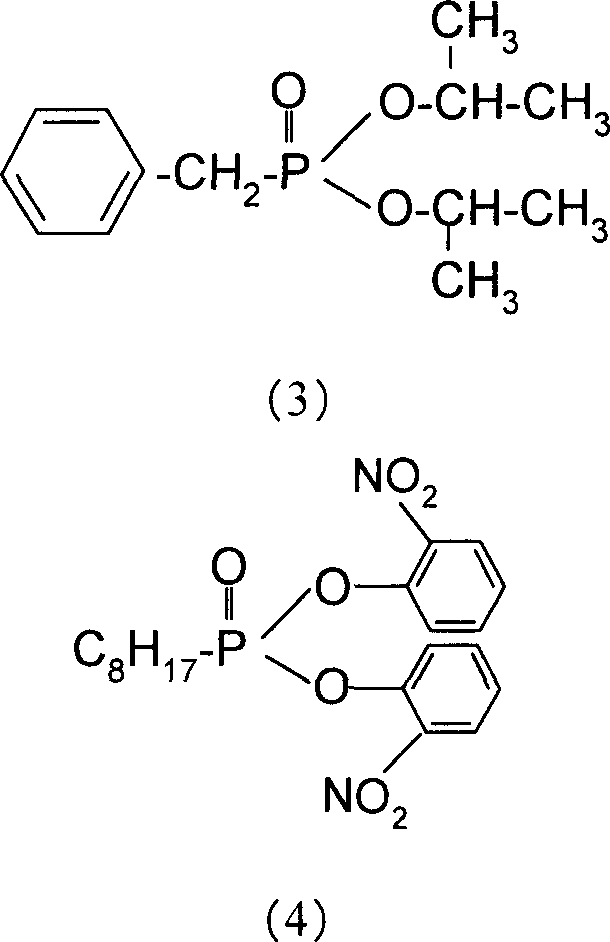

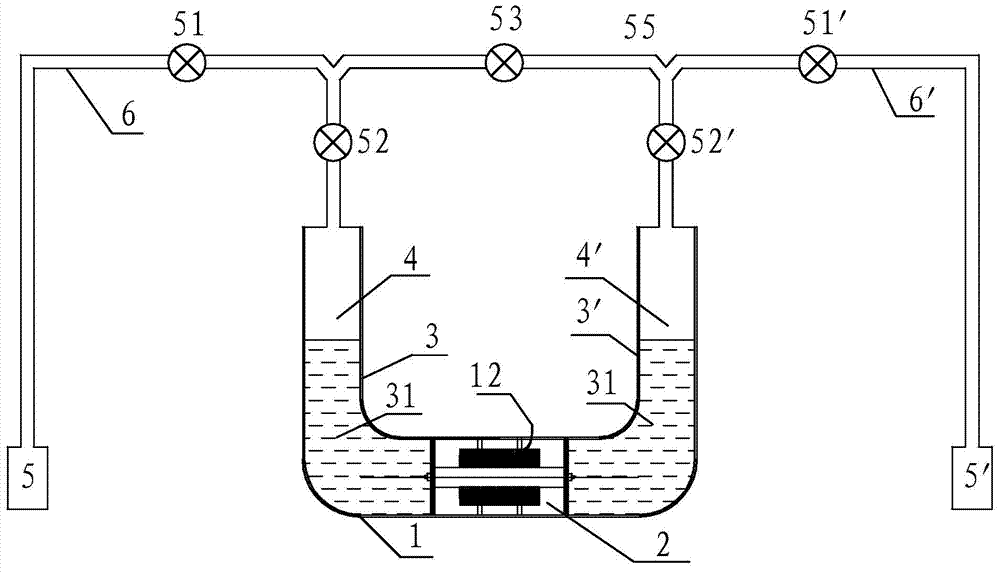

Novel tuning gas-liquid column damper with damping and frequency dual regulation function and structural vibration control system

ActiveCN103669631AThe model is simple and preciseEasy and precise operationShock proofingControl systemLiquid column

The invention discloses a novel tuning gas-liquid column damper with a damping and frequency dual regulation function and a structural vibration control system. The damper can be used for regulating damping and frequency conveniently, thereby achieving the optimal vibration / shock reduction effect on a controlled structural object in different construction phases under different intensities of loads. The novel damper has two characteristics, wherein one characteristic is that a damper valve which can regulate damping force is arranged on a horizontal section of a U-shaped pipe, and the damper valve is a magneto-rheological friction-type damper valve or an electromagnet friction-type damper valve; the other characteristic is that a gas column is further closed at vertical sections on the two sides of the U-shaped pipe, an air pressure regulation device is also installed, and the frequency of the damper is changed by means of regulating air pressure. The structural vibration control system is composed of at least one damper, at least one sensor used for measuring a structural vibration state and at least one controller, and can achieve the optimal vibration control effect on a structure in different construction phases under different use conditions and different intensities of imposed loads.

Owner:杭州健而控科技有限公司

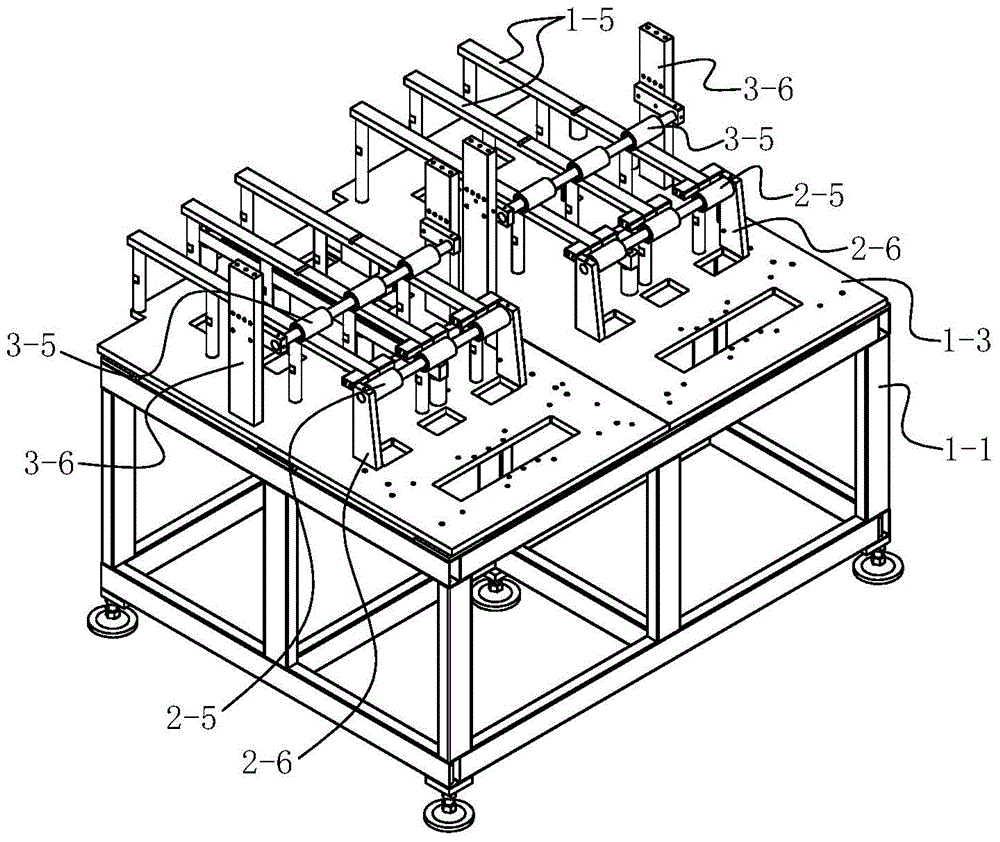

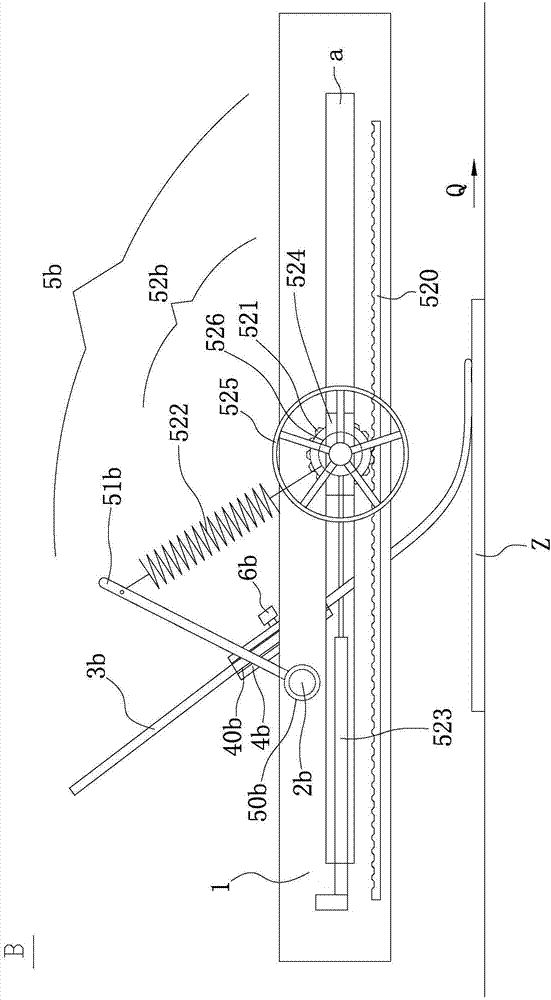

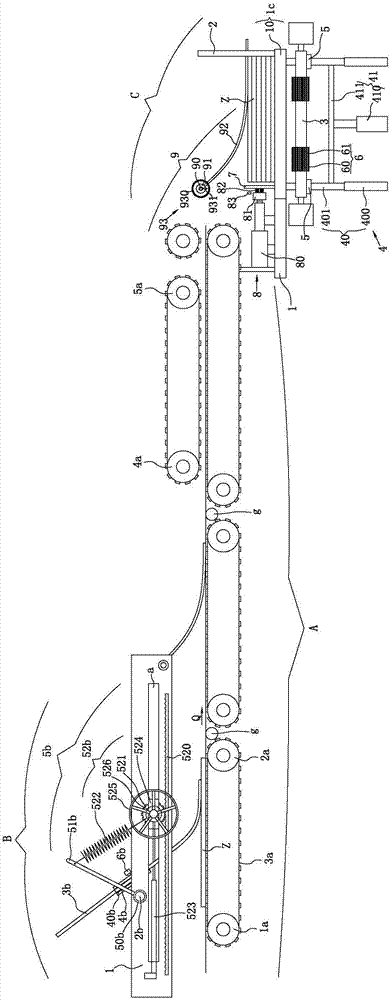

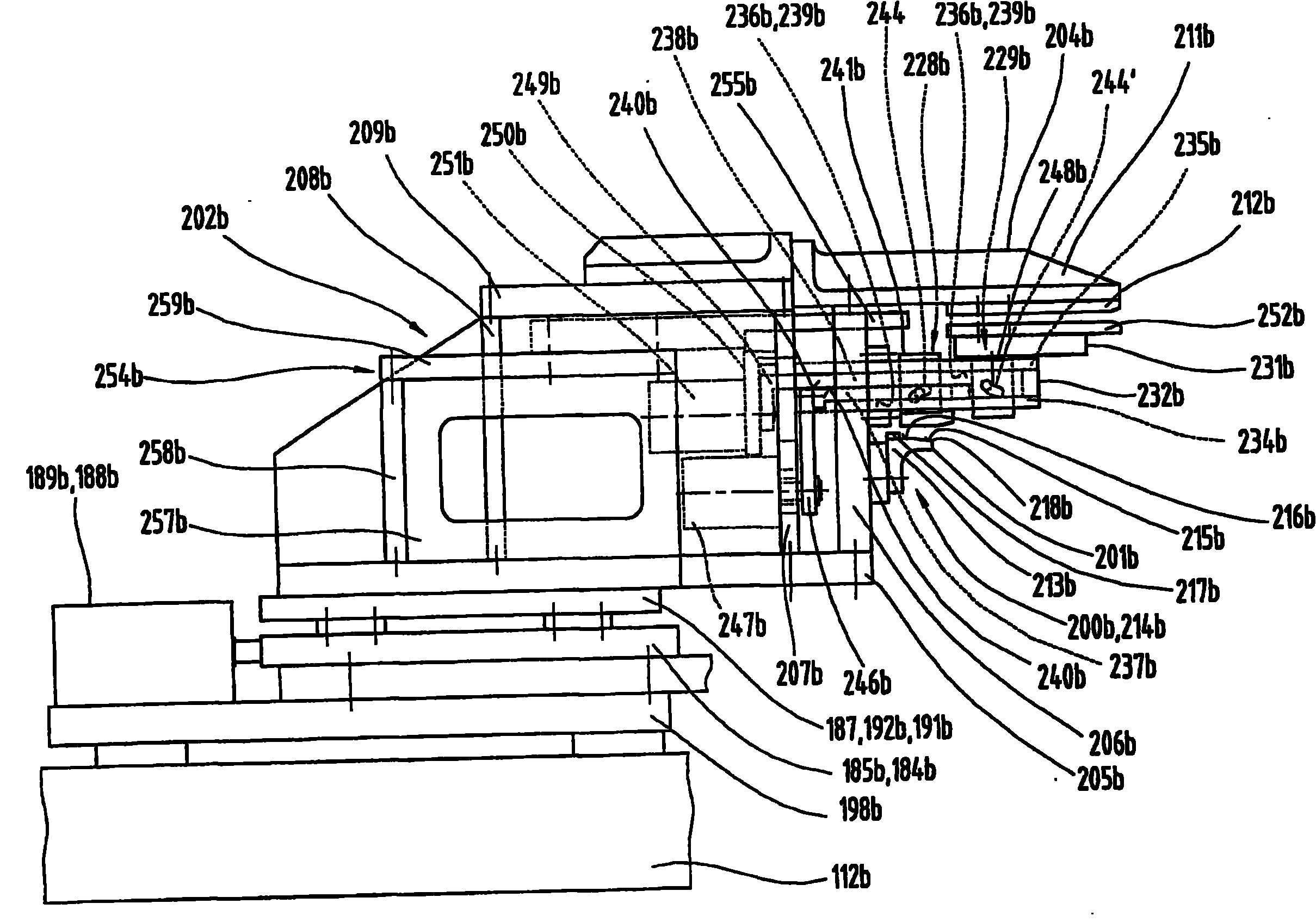

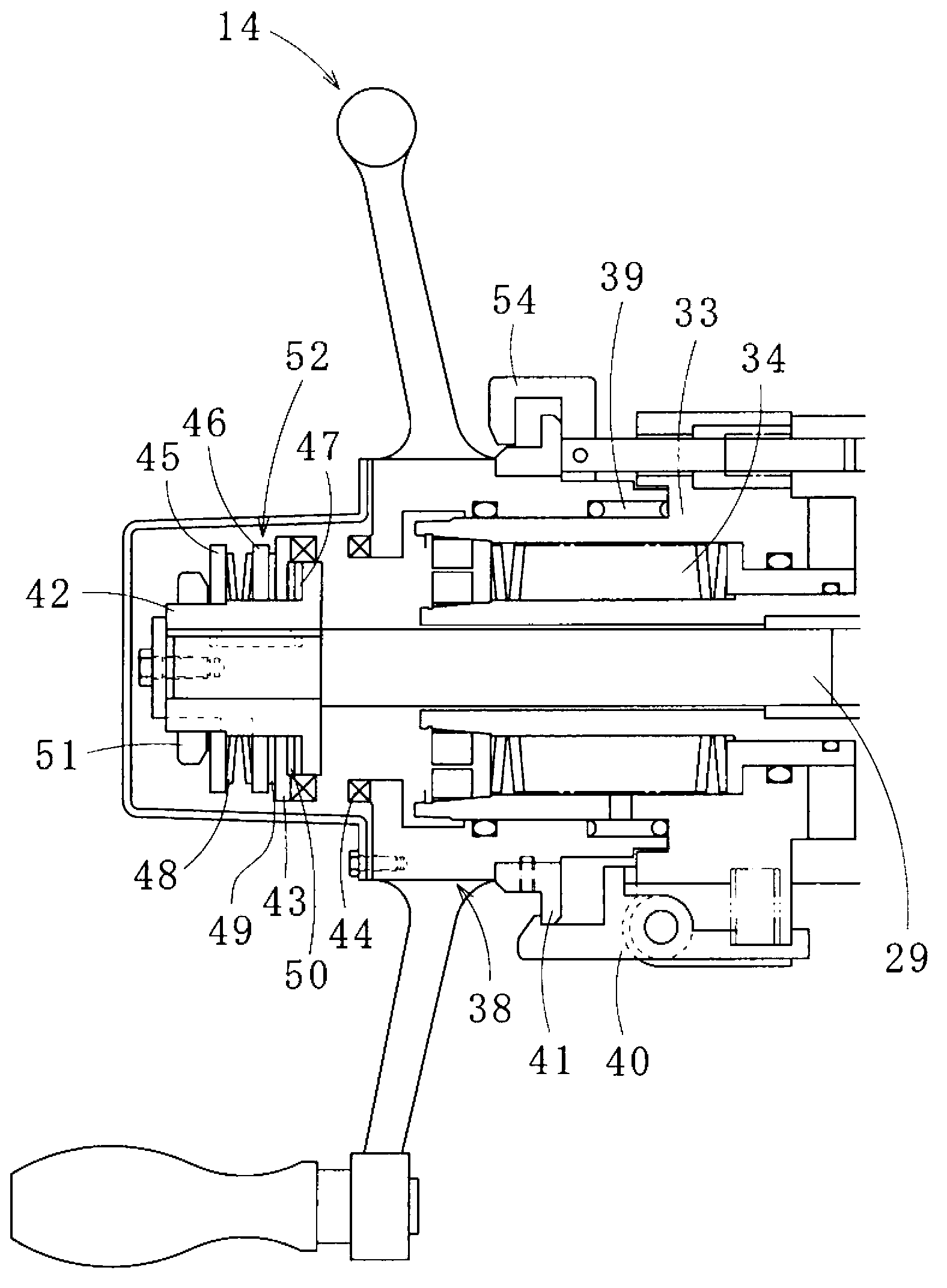

Installation for producing and method for assembling parts

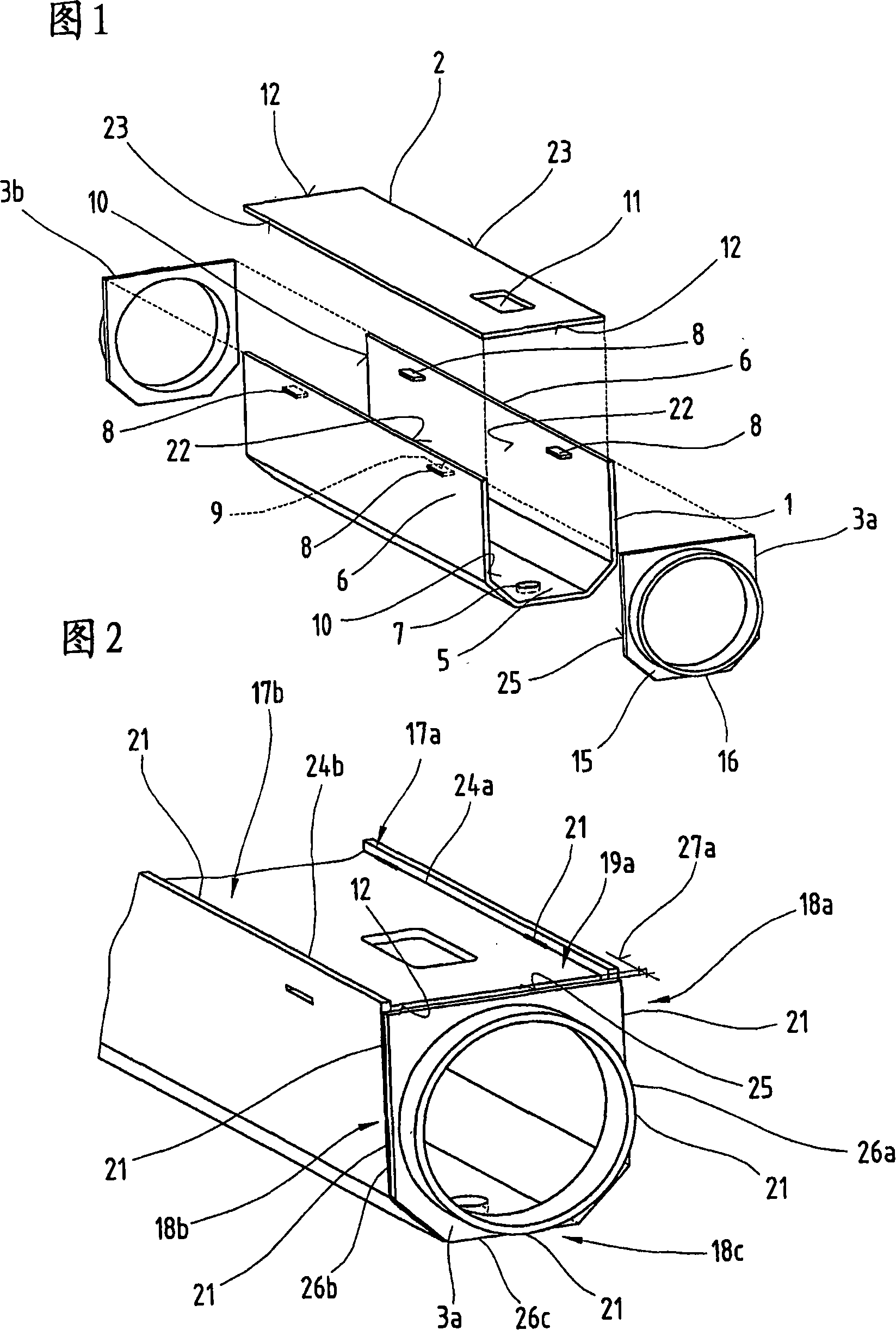

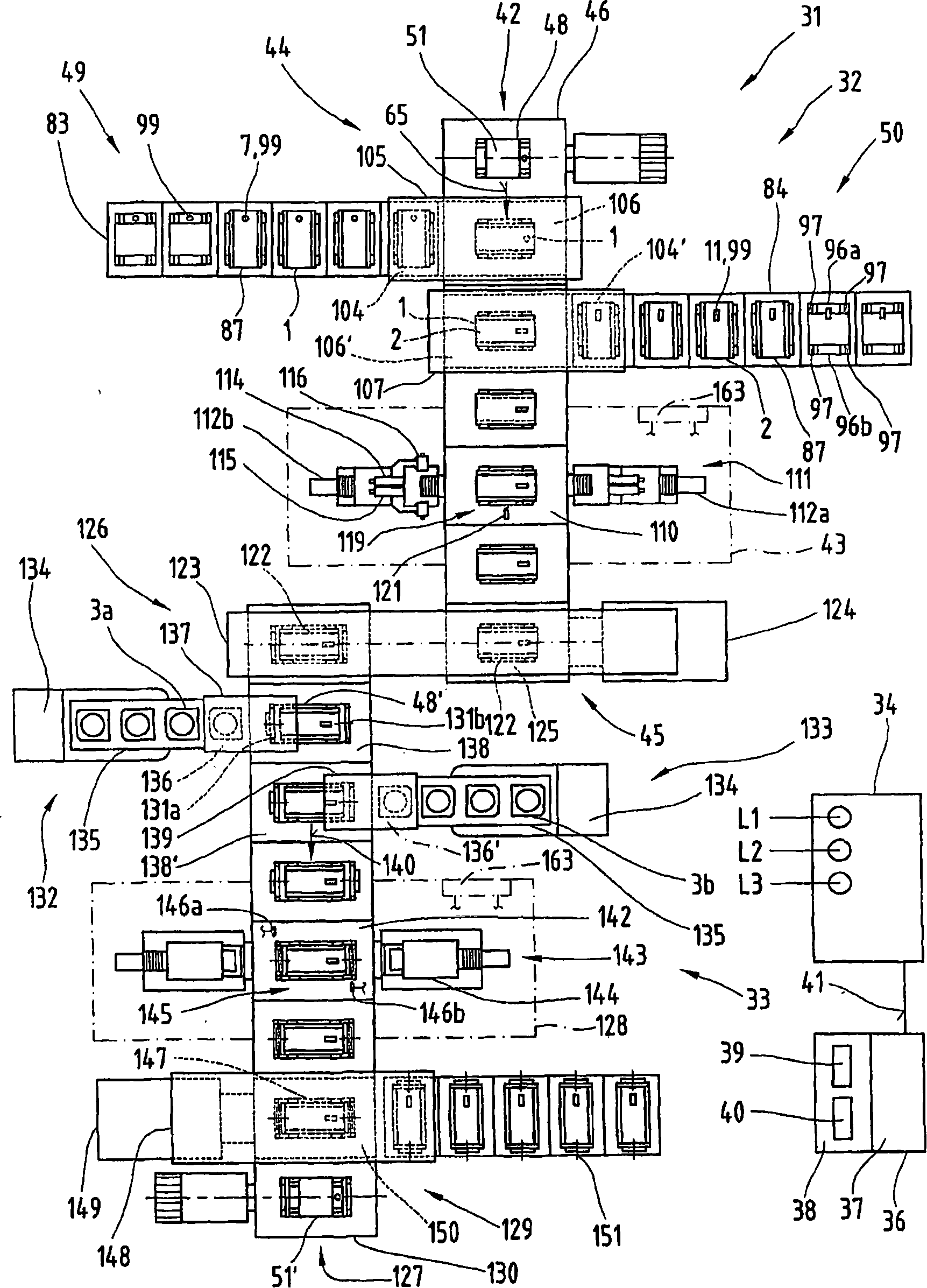

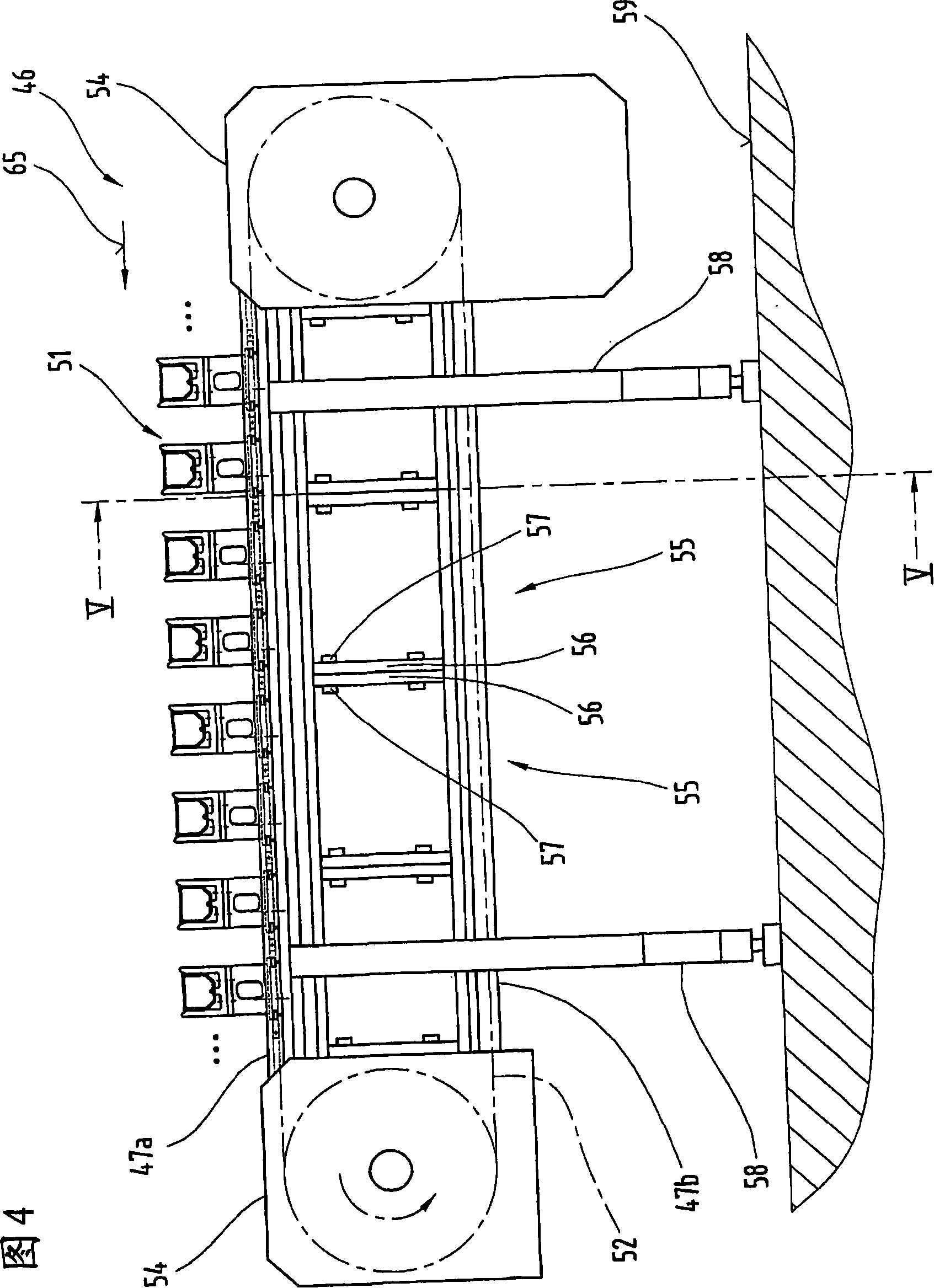

InactiveCN101163567ATakt time optimizationEasy to controlConveyorsWelding/cutting auxillary devicesLocation EquipmentSupport surface

The invention concerns a method and an installation for producing a component consisting of several assembled parts. The first part (1) and the second part (2) are taken from a part delivery site proximate the conveying device and set in mutually oriented position on part conveying supports of the conveying device then conveyed with the part conveying supports to an assembling station. The part conveying device is maintained in a retaining position in the assembling station, the mutually oriented parts (1, 2) are moved by means of a heightwise positioning device (200a, 200b) and simultaneously moved from a conveying position on the part conveying support to a delivering position. Then the parts are positioned relative to each other, fixed and finally assembled to form the component. The assembled component is then set on a part conveying support and carried with said support. The part conveying supports comprise a housing exclusively provided with positioning means for holding a part (1) during its transport and, in the advancing direction of this positioning means, spaced apart supporting lateral guiding surfaces as well as support surfaces for one part (1) resting on the preceding surfaces.

Owner:STIWA HLDG

Fixing and rust-removing equipment for steel tubes of different tube diameters

ActiveCN110815006AImprove grinding efficiencyReduce workloadGrinding carriagesGrinding machinesSteel tubeManufacturing engineering

The invention discloses fixing and rust-removing equipment for steel tubes of different tube diameters. The fixing and rust-removing equipment comprises a triangular clamping assembly, a drive assembly and a grinding rust-removing assembly, wherein the triangular clamping assembly comprises a bottom supporting regulating assembly and a top pressing assembly; the bottom supporting regulating assembly and the top pressing assembly can perform position regulation according to diameters of the steel tubes and can clamp the steel tubes in a triangular mode; the drive assembly is used for driving aroller body in the triangular clamping assembly to rotate, so that the steel tubes are driven to rotate; the horizontal plane on which the lowest position of a guide roller I and the lowest position of a guide roller II are located is slightly higher than the horizontal plane on which the lowest position of a supporting transmission roller I; after position regulation is performed on the supporting transmission roller I and a supporting transmission roller II, a transmission belt still can drive the supporting transmission roller I and the supporting transmission roller II to rotate; and the grinding rust-removing assembly is arranged at one side of the triangular clamping assembly for grinding the surfaces of the steel tubes. The equipment can replace labor power to grind, improves grinding efficiency and relieves workload of a worker.

Owner:慈溪市诚和管业有限公司

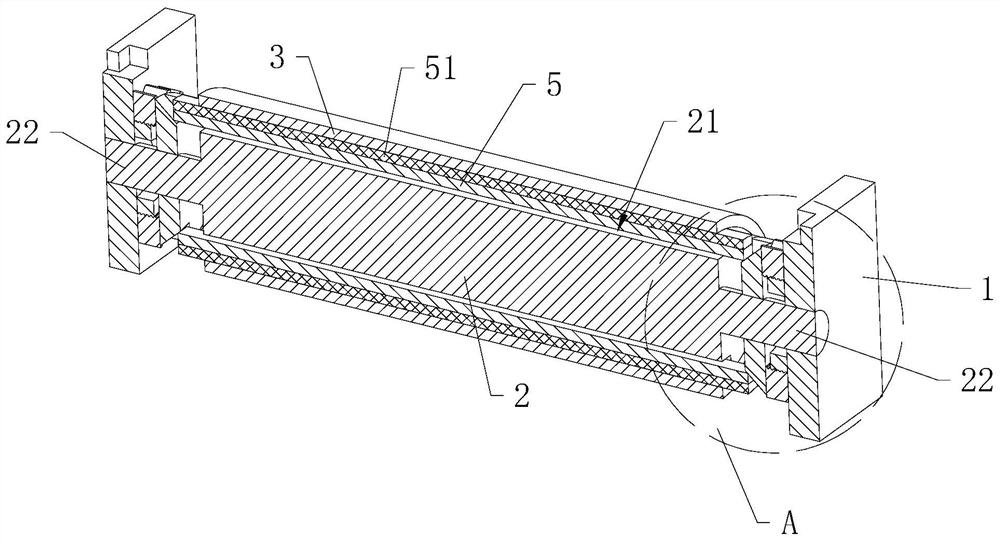

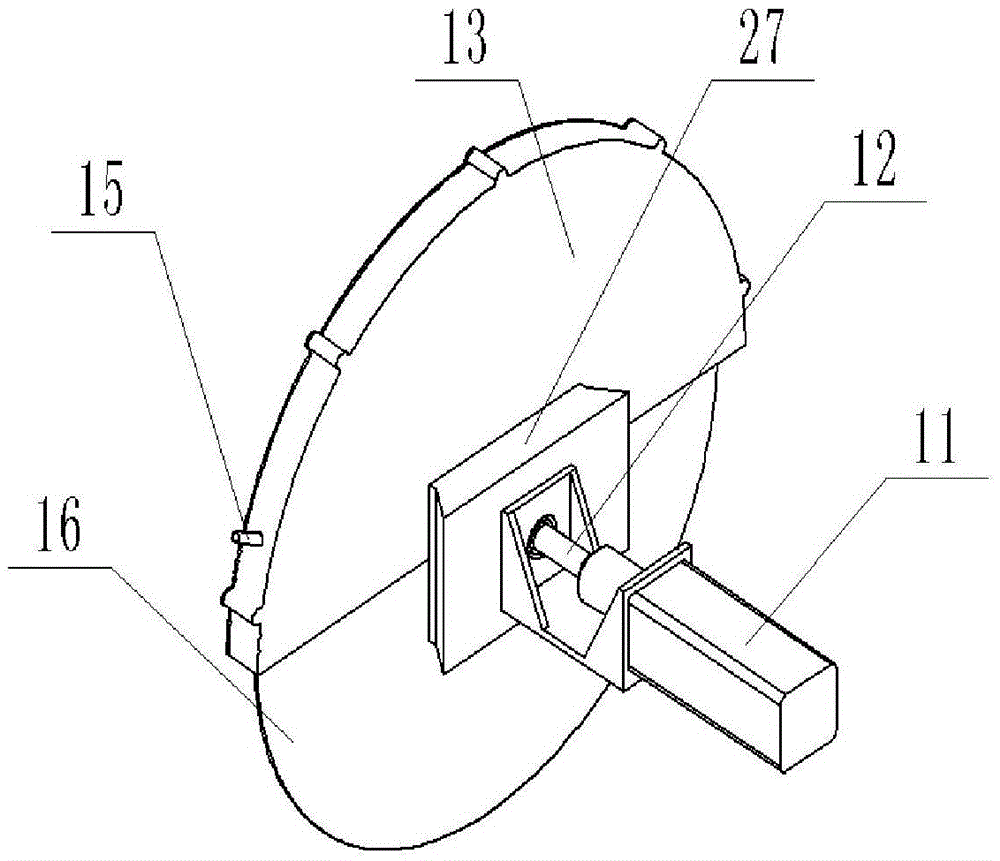

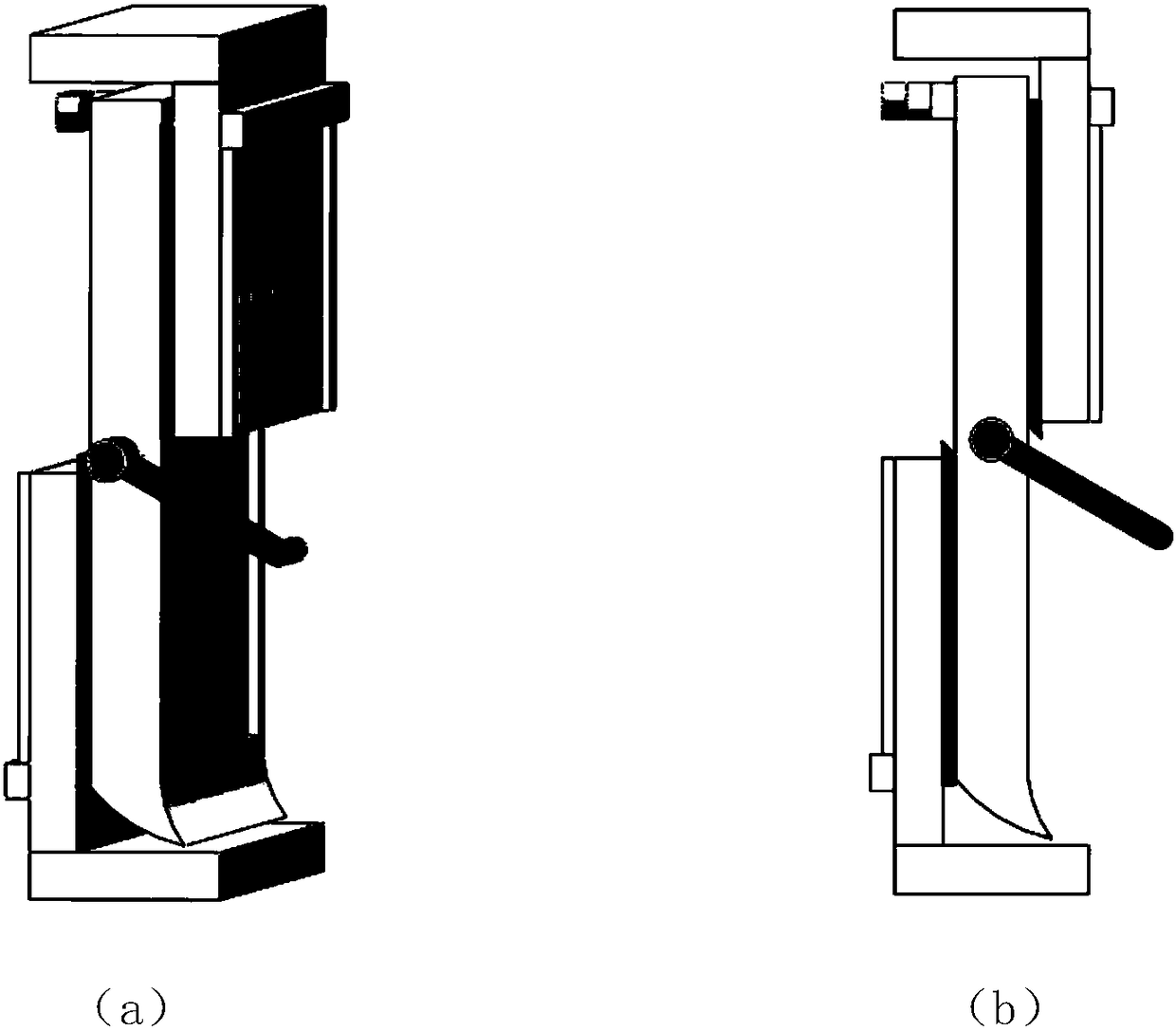

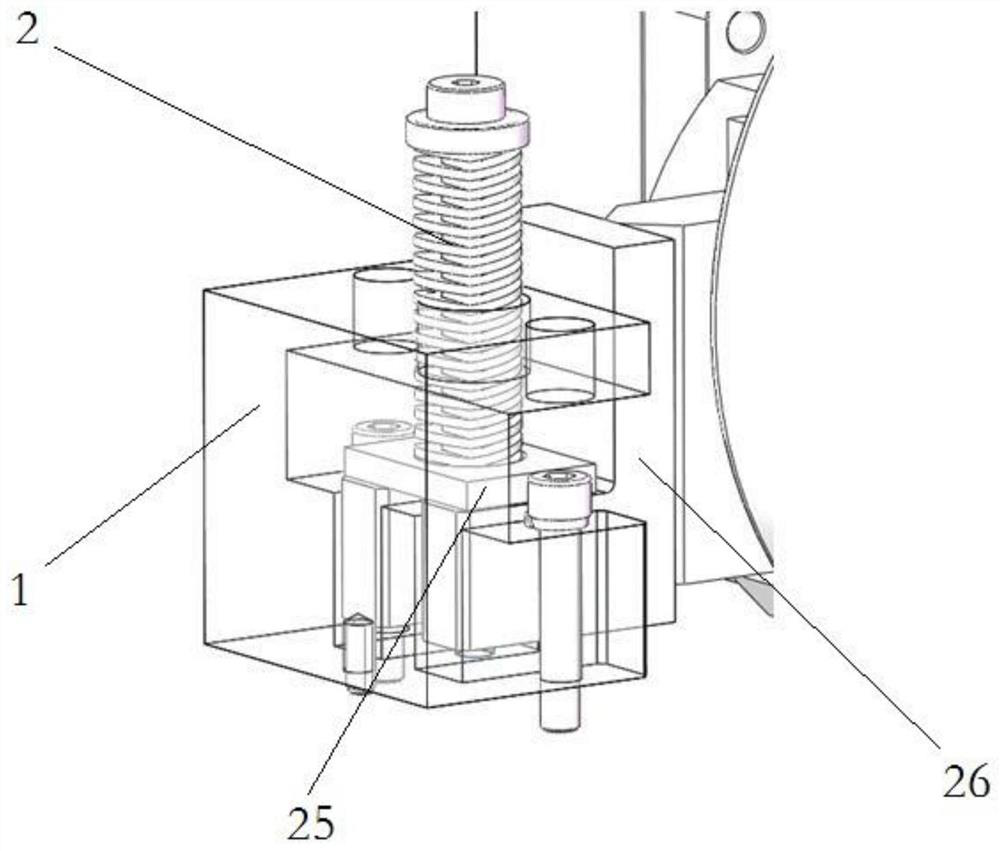

Vertical pre-tightening type stick-slip drive cross-scale precise motion platform

ActiveCN103618473AAdjust frictionEasy to adjustPiezoelectric/electrostriction/magnetostriction machinesEngineeringMechanical engineering

The invention discloses a vertical pre-tightening type stick-slip drive cross-scale precise motion platform which comprises a base plate, a base, a friction oscillator, an oscillator drive source and a sliding block. A pre-tightening force adjusting structure for providing pre-tightening force is arranged between the sliding block and the base plate and comprises adjusting screws used for providing the pre-tightening force, the adjusting screws penetrate through the sliding block and the base and then are connected with the base plate, and the pre-tightening force can be adjusted by adjusting the threaded connection length of the adjusting screws and the base plate. The pre-tightening force adjusting method of the motion platform is greatly simplified, machining and assembling are facilitated, the output performance of the stick-slip drive cross-scale precise motion platform is effectively improved, motion precision and consistency of the stick-slip drive cross-scale precise motion platform are simply and effectively ensured, and volume production is facilitated.

Owner:SUZHOU UNIV

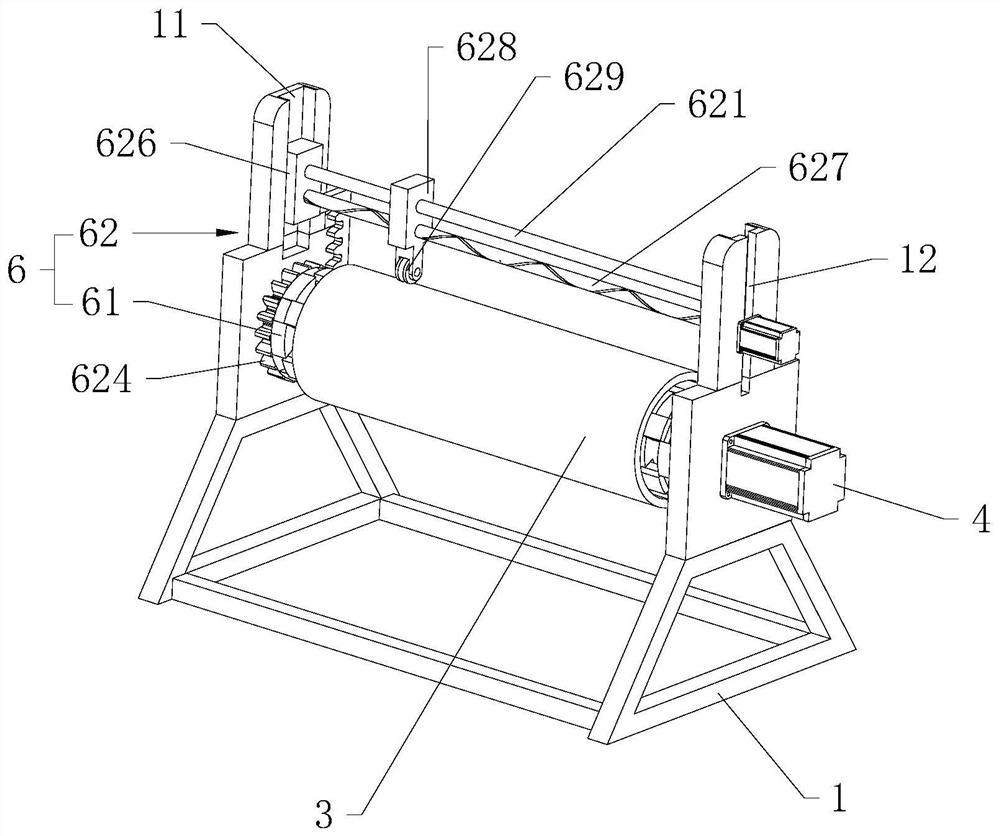

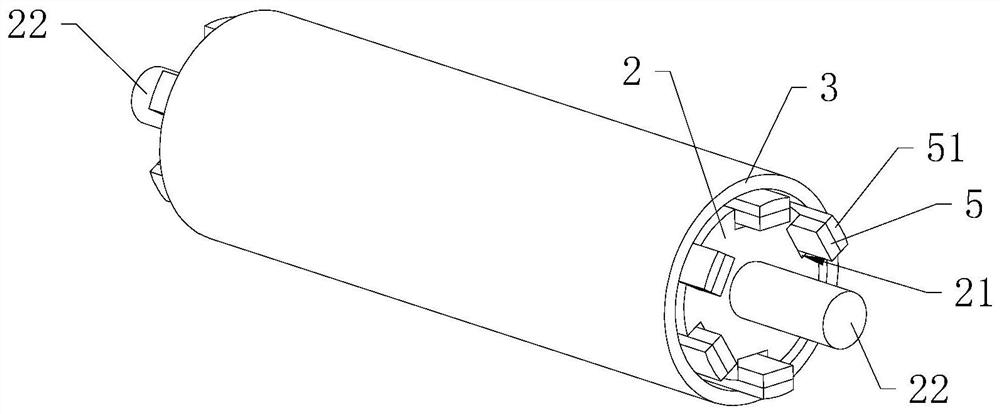

Tubular product rolling device

ActiveCN111620188AAvoid deformationImprove product qualityFilament handlingElectric machineStructural engineering

The invention relates to a tubular product rolling device. The tubular product rolling device comprises a rack, a motor arranged on the rack and a rotating shaft rotatably arranged on the rack. The motor drives the rotating shaft to rotate at a uniform speed, a sleeve is further rotatably connected on the rotating shaft in a sleeving manner, and a friction pair is formed between the inner circumference of the sleeve and the rotating shaft. With a tubular product being rolled, the actual rolling radius of the tubular product is increased gradually, the tubular product blocks rotation of the sleeve, and the sleeve and an elastic part slide relatively, that is, the rotating speed of the sleeve is lower than that of the rotating shaft, so that the rolling linear speed of the tubular product isconstant. The rolling linear speed of the tubular product is equal to an output speed of a first extruder, the tubular product is prevented from being deforming as a result of a too large tensile force, and follow-up normal production is guaranteed, so that a product part is relatively high in production quality.

Owner:台州巨壹塑业有限公司

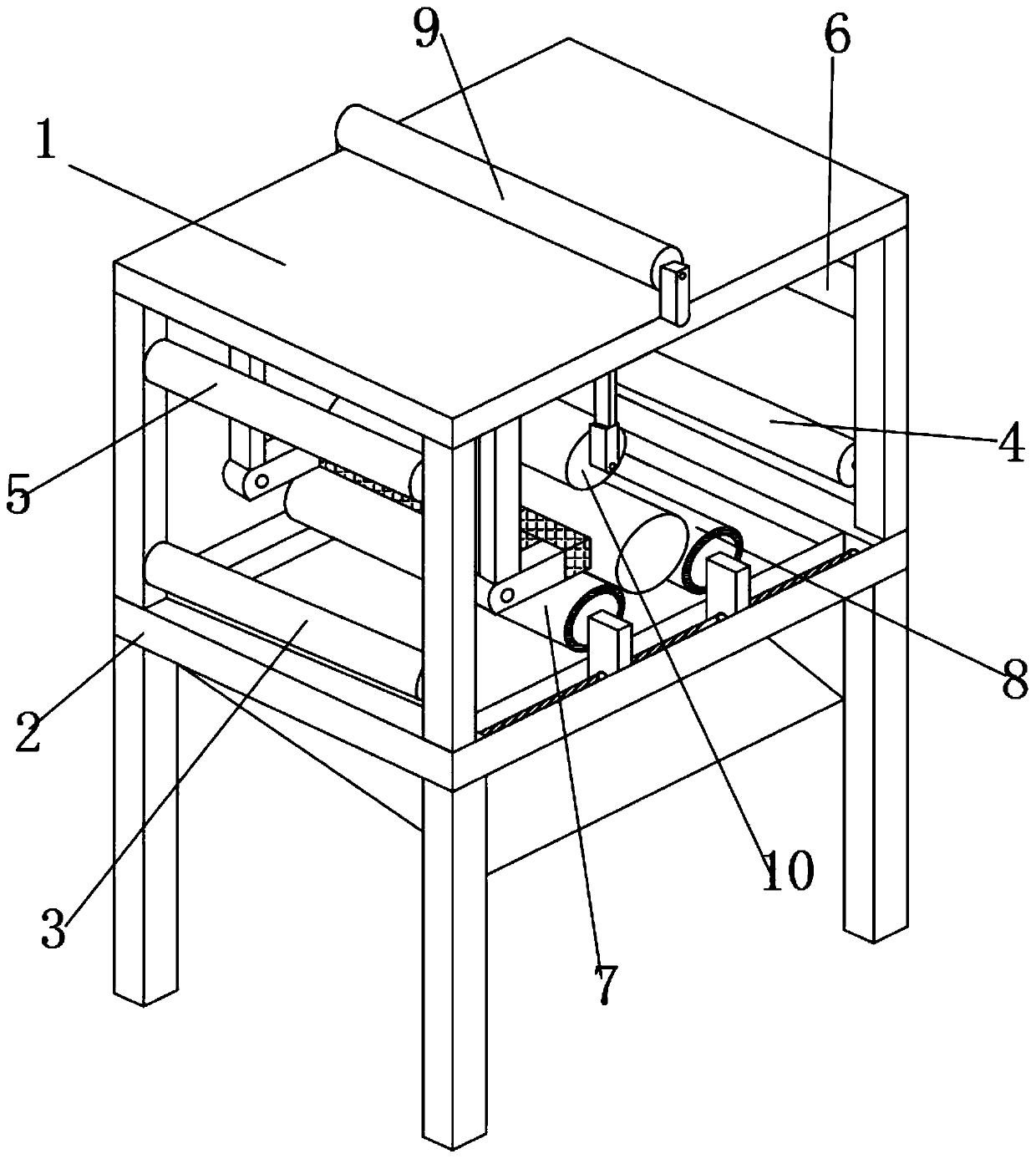

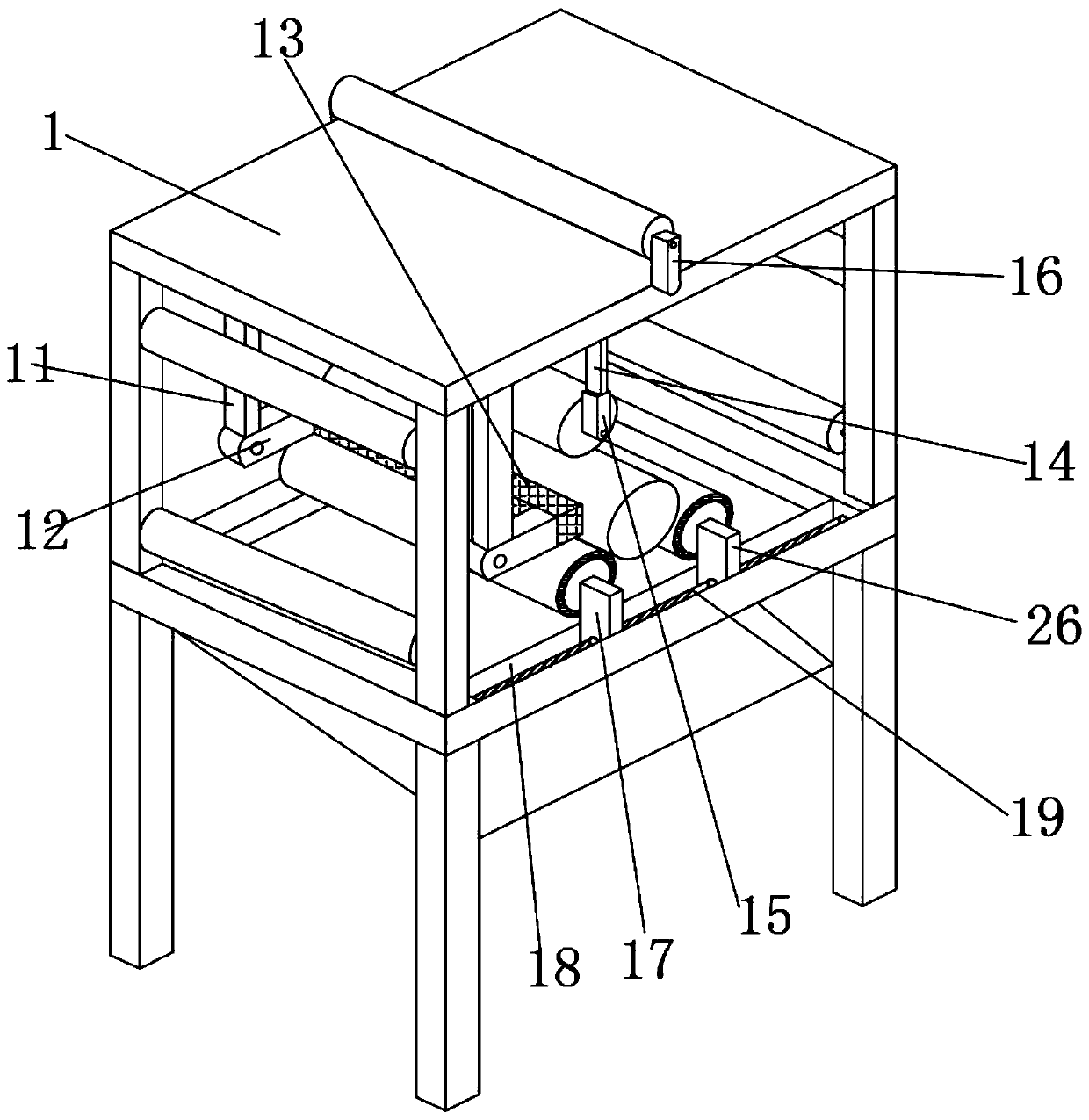

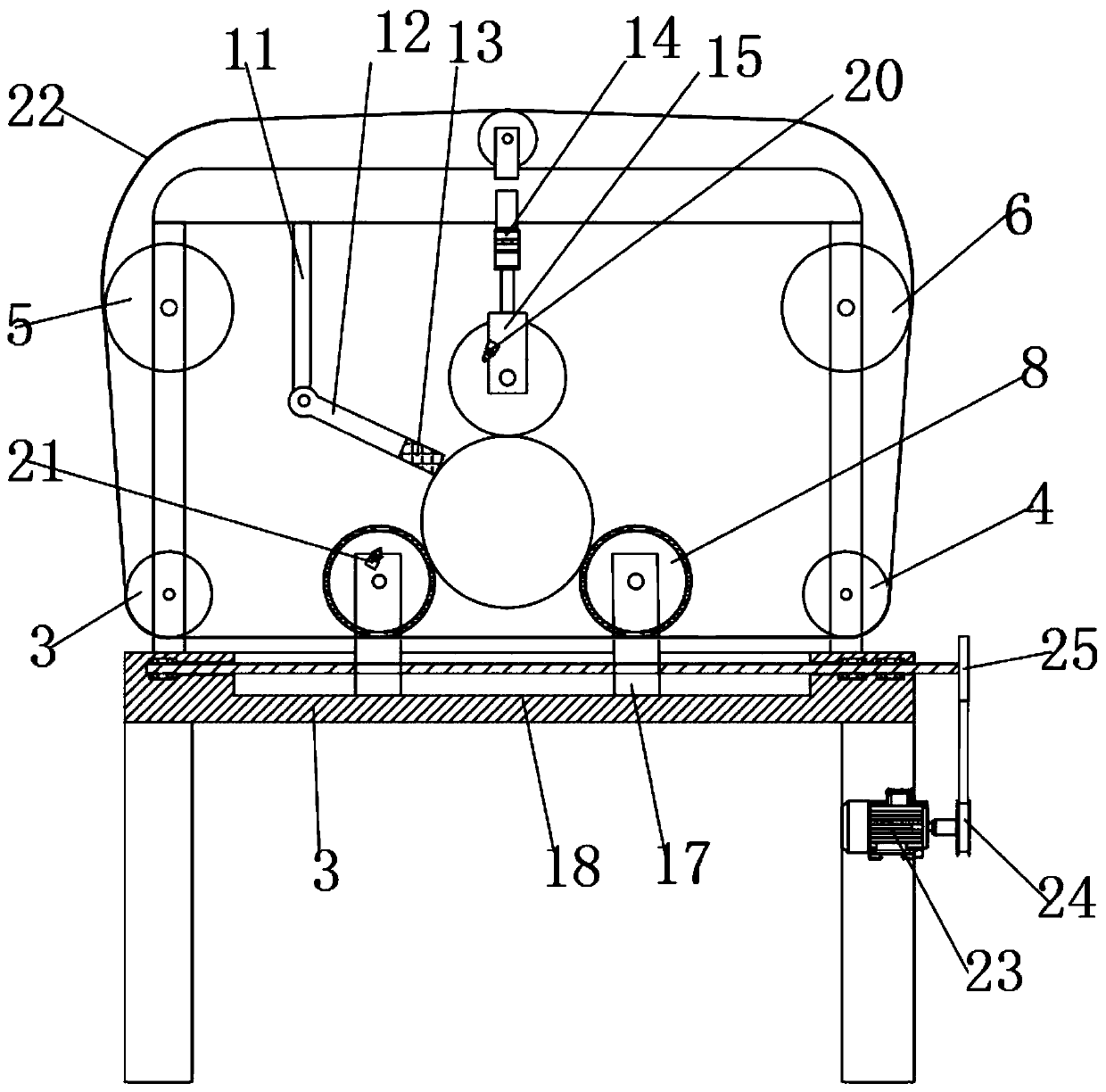

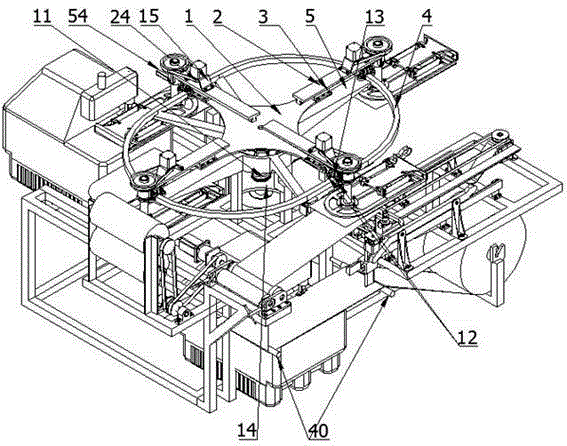

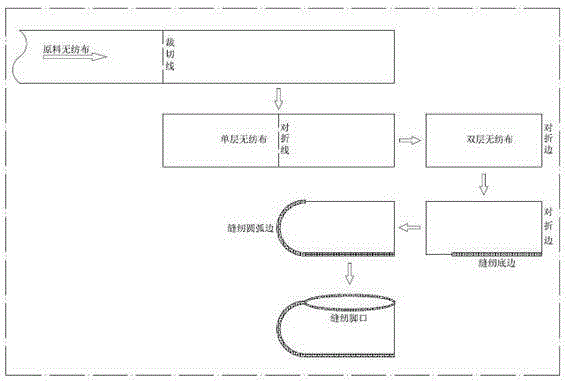

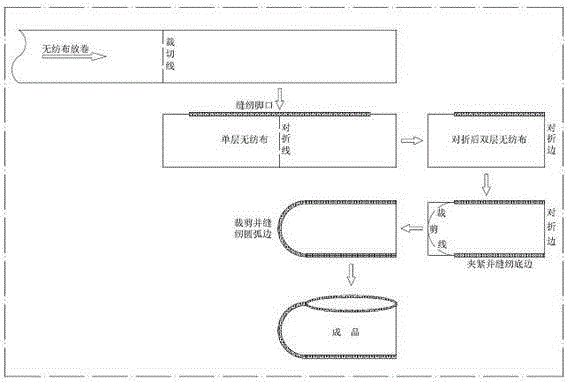

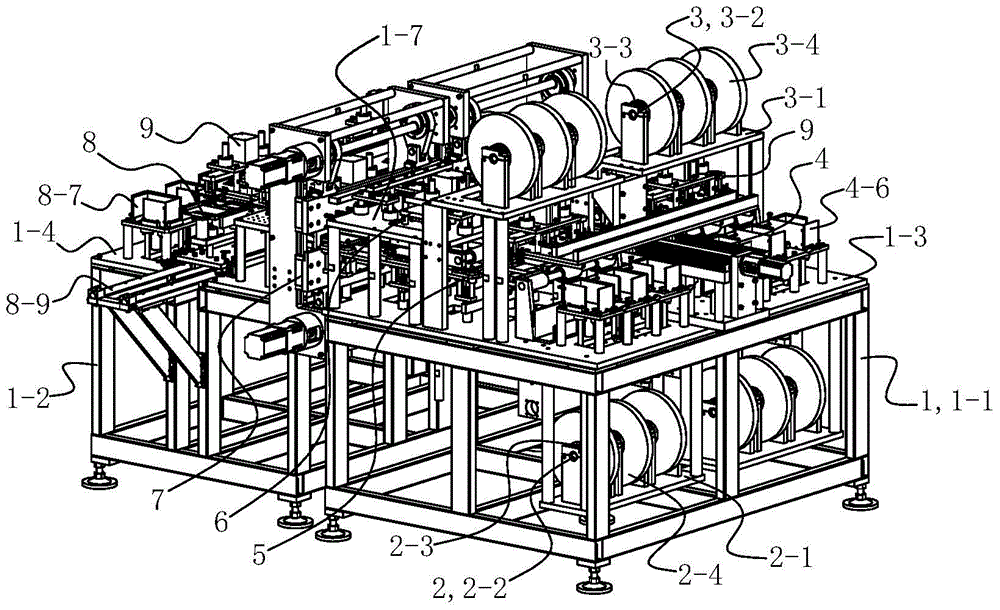

Full-automatic non-woven fabric shoe cover overlock machine

InactiveCN104082910ASmart structural designImprove efficiencyLip-settingShoe trimmingEngineeringMechanical engineering

The invention discloses a full-automatic non-woven fabric shoe cover overlock machine. A roll non-woven fabric shoe cover raw material is subjected to processes of automatic feeding, folding, tailoring, sewing, discharging and the like by the machine, and automatic production of a shoe cover is completed; the sewing process comprises steps as follows: sewing of a shoe cover opening, folding, sewing of a shoe sole opening, tailoring and sewing of a circular arc edge; straight line and circular arc combined guide tracks are designed, the production time of a single shoe cover is shorter than or equal to 3 seconds; the overlock machine commonly used in the market is used for sewing an elastic band onto the shoe cover; a folding mechanism is always in a horizontal state in the folding process and matched with a conveying speed; the semi-circular arc edge is sewn through self-rotation of a clamp, and the circular arc is at the front end of the made shoe cover and is attractive and fit for a foot; a special tailoring mechanism is designed, and fusing is not required; non-woven fabric coated with anti-slip coating can be used, an anti-slip strip is not required to be pressed, and a product is anti-static, breathable and wear-resisting; and the machine occupies little space, the stations are smoothly connected, a small long strip is not required to be folded for wrapping the elastic band, the noise is low, and the folding mechanism is simple, flexible and stable in folding and cannot tear the raw material.

Owner:WUHAN TEXTILE UNIV

Linearly driven flexible gripper with variable rigidity and variable rigidity control method thereof

The invention discloses a linearly driven flexible gripper with variable rigidity based on a layer interference technology and a variable rigidity control method thereof. The gripper comprises a pedestal, wherein a plurality of flexible fingers and a motor are mounted at the edge of the pedestal, each flexible finger is externally coated with a vacuum bag, a vacuum pump is mounted in the middle ofthe pedestal, and the vacuum pump is connected to the vacuum bags; each flexible finger comprises a flexible finger framework, the middle of the flexible finger framework is of a sheet structure, a series of T-shaped block structures are arranged on two sides, a round hole is formed in the middle of each T-shaped block structure, a tendon rope penetrates the round hole, the upper end of the tendon rope is connected to the motor, and the lower end of the tendon rope is connected to the top end of the flexible finger framework; and the outer ends of the T-shaped block structures are connected to flexible sheets. The motor rotates to drive the tendon ropes, so that the fingers bend. Rigidity variation of the gripper is controlled by externally connecting a negative pressure pump, so that itis safe to drive bending and variable rigidity. The linearly driven flexible gripper is easy and controllable to operate and relatively large in grabbing space, can achieve a variable rigidity effect,and is suitable for relatively more occasions.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

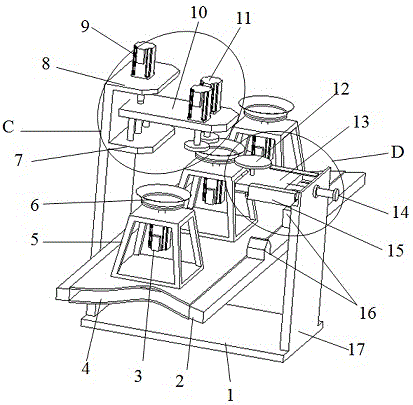

Vertical two-station composited fettling device

ActiveCN105033808AReduce the numberCompact structureEdge grinding machinesGrinding drivesProduction lineMotor drive

The invention discloses a vertical two-station composited fettling device. Before working, a perpendicular moving motor drives a suspension plate to move upward; a driving air cylinder allows a horizontal moving plate to move backward to allow bowl bottom fettling sponge to be far away from a bowl blank; the perpendicular moving motor acts to allow the suspension plate to move down; bowl top fettling sponges are contacted with a top edge of the bowl blank to fettle; a piston rod of the driving air cylinder stretches out to allow the horizontal moving plate to move forward at the same time; the bowl bottom fettling sponge is contacted with a bottom edge of the bowl blank; a bowl bottom fettling motor rotates to fettle the bottom edge of the bowl blank; after the fettling, the bowl bottom fettling sponge and the bowl top fettling sponges leave the bowl blank; and a conveying belt drives brackets to move forward to allow a next bowl blank to enter a fettling station. The device solves the problems that the traditional fettling equipment is low in fettling efficiency, high in labor intensity and low in automation degree. The device facilitates assembling an automatic production line, and has the advantages of simplicity in operation and good fettling quality.

Owner:江苏盛世盈泰智能设备科技有限公司

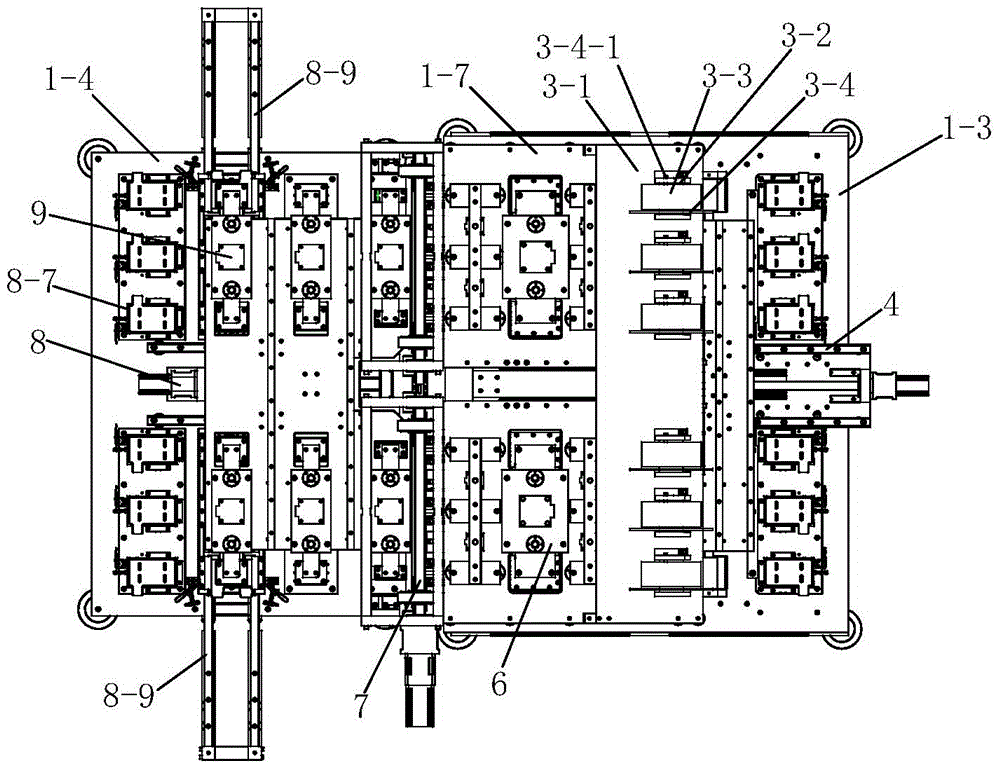

Automatic film-enveloping and piece-laminating machine

ActiveCN104064813ANo relative displacementHigh coating precisionAssembling battery machinesFinal product manufactureEngineeringAutomation

The invention relates to an automatic film-enveloping and piece-laminating machine. The machine comprises a stander, a lower diaphragm unreeling device, an upper diaphragm unreeling device, a piece-feeding device, a piece-moving device, a sealing-pressing device, a shearing device and a piece-laminating device, wherein long-strip-shaped piece-moving platforms are arranged on the stander; the piece-feeding device comprises sucking disc piece-fetching mechanisms and a piece-feeding translation mechanism; the piece-moving device comprises a clamp plate translation mechanism, piece-moving substrates, clamp plate air cylinders, base plates and clamp plates; the sealing-pressing device comprises a heat-seal assembly and a heat-seal lifting mechanism, the heat-seal assembly is located above the piece-moving platforms, and the heat-seal lifting mechanism is used for driving the rising and the falling of the heat-seal assembly; the piece-laminating device comprises sucking disc piece-fetching mechanisms, a piece-laminating translation mechanism and piece-collecting mechanisms, and the piece-laminating translation mechanism is used for driving the sucking disc piece-fetching mechanisms to carry out translational motion. According to the automatic film-enveloping and piece-laminating machine, the full automation is realized during film-enveloping, heat-seal, shearing and piece-laminating processes, the film-enveloping precision is high, the film-enveloping speed is high, and the film-enveloping effect is good.

Owner:上海恒动新能源有限公司

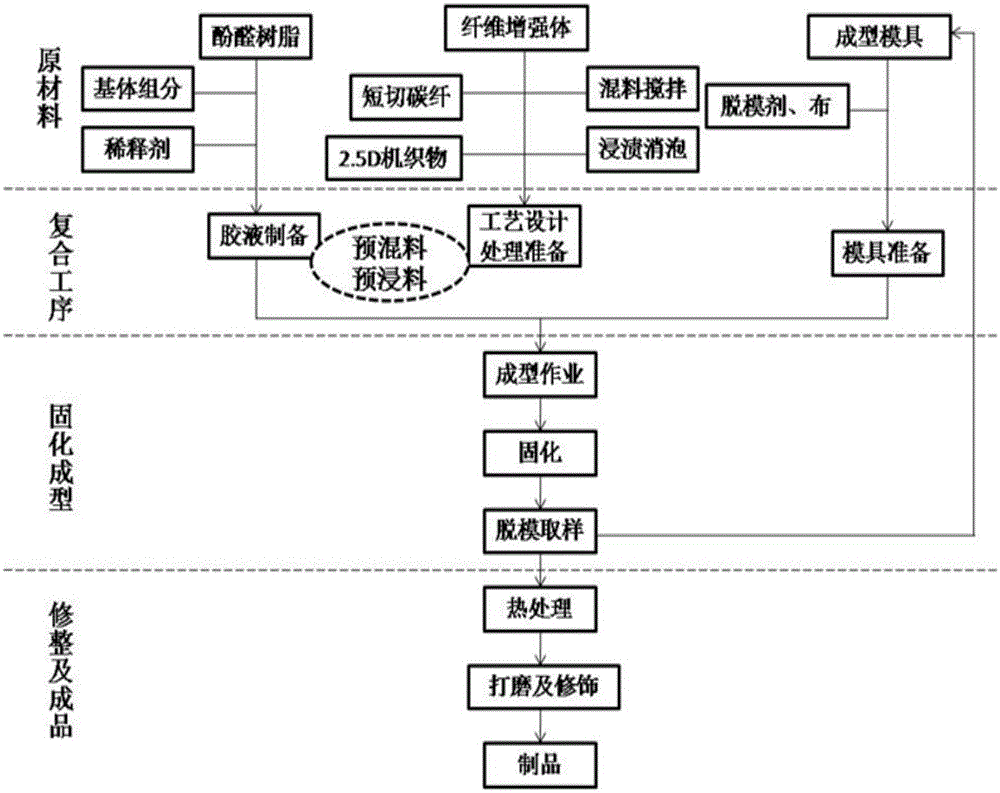

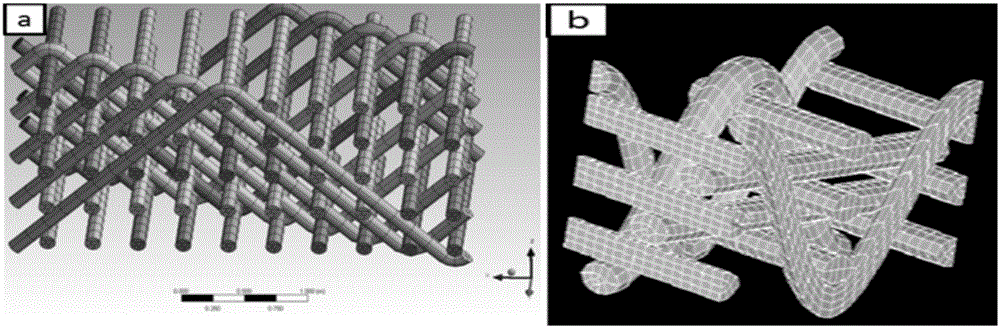

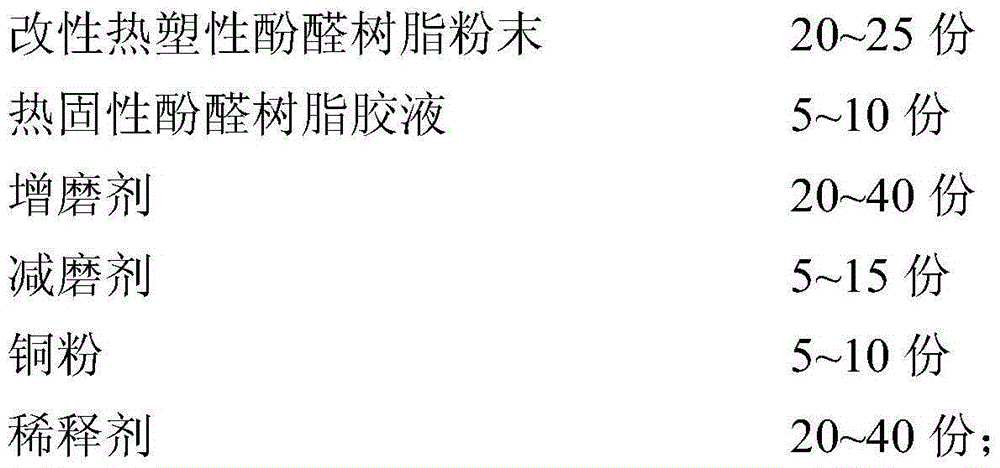

Deep-crosslinked-structure carbon-fiber-reinforced phenolic-resin-base friction material and preparation method thereof

ActiveCN105038116AImprove flexural strengthIncreased shear strengthOther chemical processesInterlaminar shearUltimate tensile strength

The invention discloses a deep-crosslinked-structure carbon-fiber-reinforced phenolic-resin-base friction material. The preparation method of the friction material comprises the following steps: preparing a deep-crosslinked-structure carbon fiber prefabricated body, preparing a matrix colloidal liquid, and preparing the friction material, wherein the friction materials is prepared by immersing the deep-crosslinked-structure carbon fiber prefabricated body in the colloidal liquid and carrying out die pressing treatment. The stitching warp penetrates through the friction material in the whole thickness direction to form the three-dimensional structure, thereby overcoming the defect of delamination and increasing the interlaminar shear strength. The friction material has the advantages of excellent structural designability, excellent integral impact resistance and excellent fatigue resistance. The preparation method has the advantages of simple technique and low production cost, and is convenient for popularization.

Owner:JIANGNAN UNIV

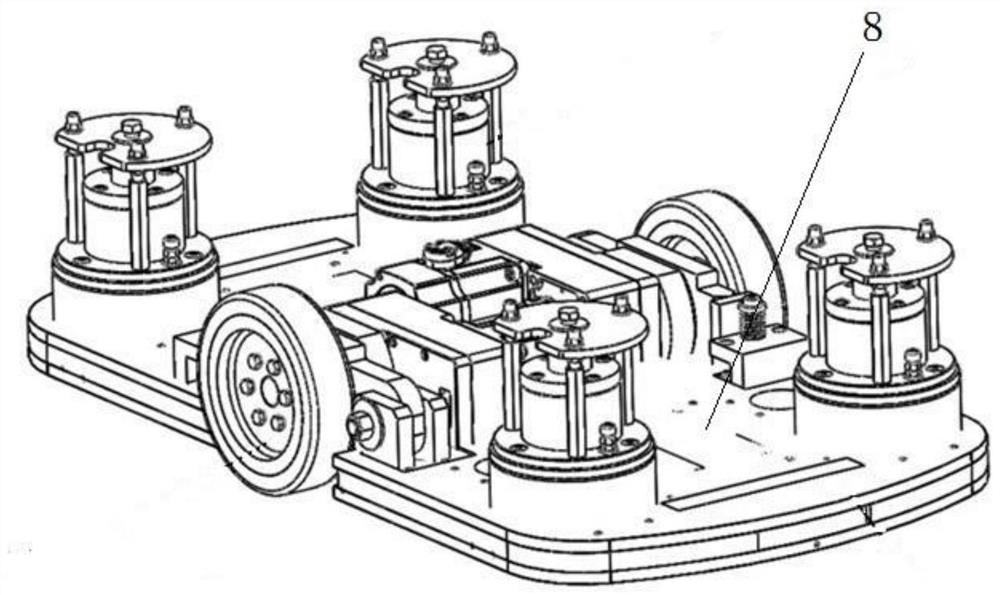

Flat Panel Monitor Stand

ActiveCN103953829BStable frictional resistanceLow rotational resistanceStands/trestlesDisplay deviceEngineering

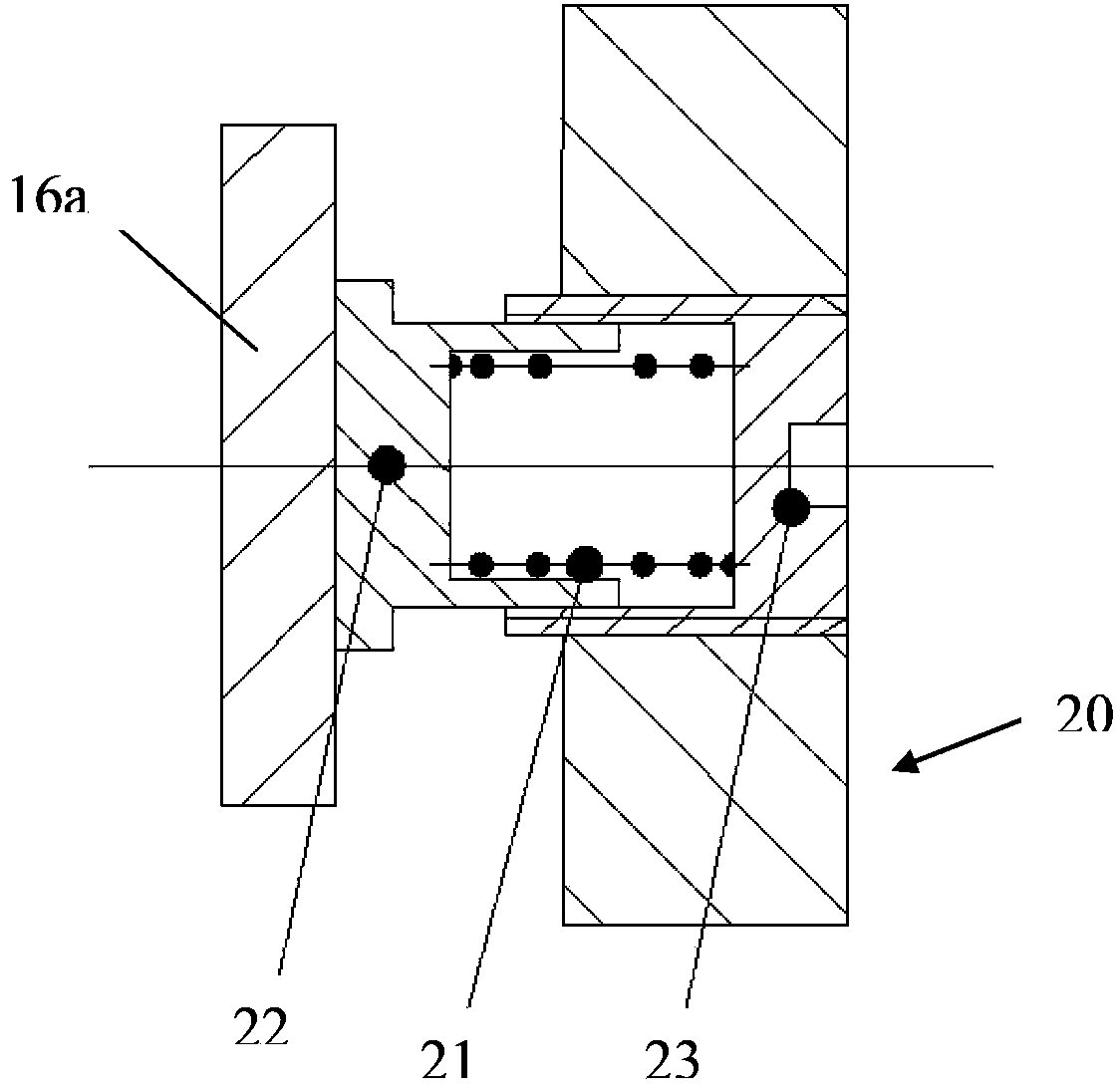

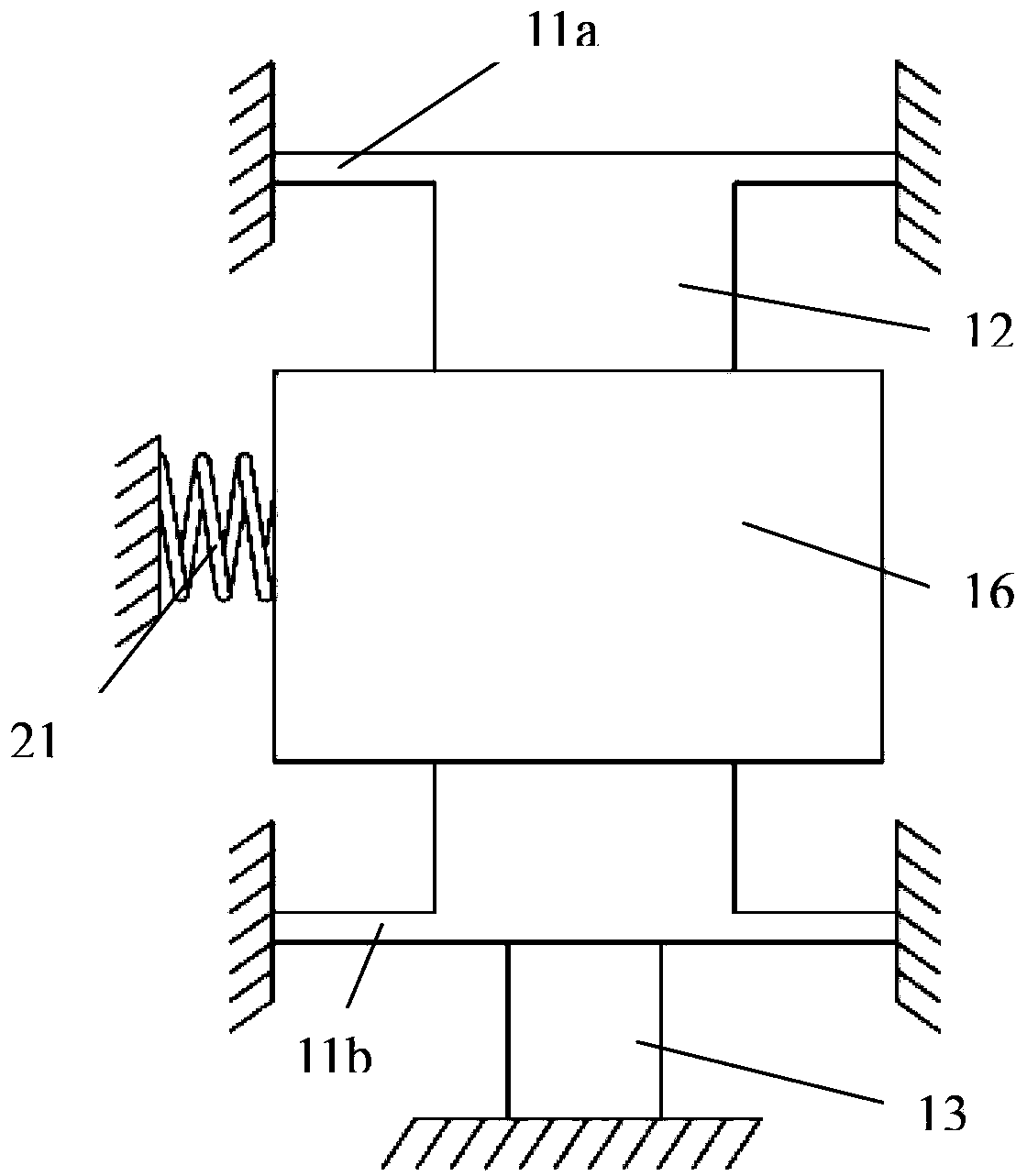

Disclosed is a flat panel display stand, comprising a base (1), a first rocker arm (2) and a second rocker arm (3), wherein one end of the first rocker arm (2) is rotatably connected to a rotary shaft (7) on the base (1), the other end of the first rocker arm (2) is rotatably connected to one end of the second rocker arm (3); and further comprising a hanging plate (22) and a connecting block (20), wherein one end of the connecting block (20) is hinged with the second rocker arm (3), the other end of the connecting block (20) is hinged with the hanging plate (22), a rotating base (4) is provided between the first rocker arm (2) and the second rocker arm (3), a lower end of the rotating base (4) is rotatably connected to the first rocker arm (2), the second rocker arm (3) is hinged with the rotating base (4) via the rotary shaft (7), a one-way bearing (8) is connected on the rotary shaft (7), an outer peripheral wall of the one-way bearing (8) is tightly fitted with an inner wall of a mounting hole of the rotary shaft (7) on the rotating base (4), and two ends of the rotary shaft (7) are fixedly mounted on two side walls of the second rocker arm (3). The flat panel display stand prevents the dead-weight of the second rocker arm (3) causing the hanging plate (22) to tilt downwards, while making adjustment of the angle of the hanging plate (22) economical on labour and convenient.

Owner:LOCTEK ERGONOMIC TECH CORP

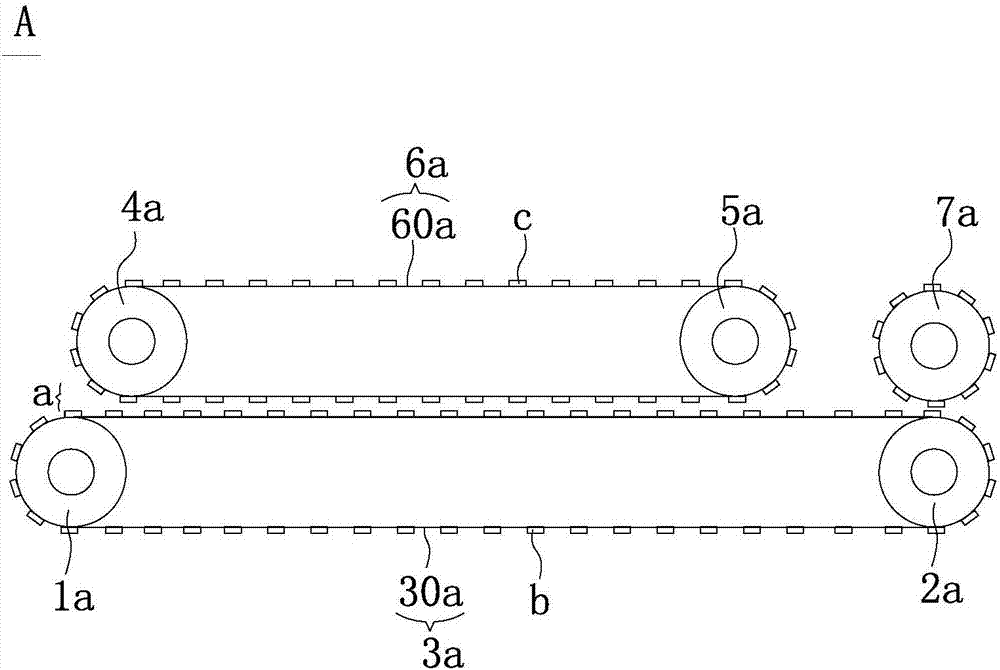

Paperboard collecting machine

ActiveCN106956956AAdjust frictionPrevent slippingPile receiversArticle deliveryPaperboardEngineering

The invention relates to a paperboard collecting machine. The paperboard collecting machine comprises first driving roller, second driving rollers and annular driving belts, wherein each first driving roller and each second driving roller horizontally extend in the direction perpendicular to the paperboard conveyance direction of the corresponding annular driving belt, each annular driving belt comprises multiple first annular partitioned belts arranged in the length direction of the corresponding first driving roller and the corresponding second driving roller at intervals. A conveying device further comprises a first compression roller, a second compression roller and an annular pressing belt, wherein the first compression roller and the second compression roller are arranged between the corresponding first driving roller and the corresponding second driving roller and located above the corresponding first driving roller and the corresponding second driving roller, and the corresponding first driving roller and the first compression roller rotate oppositely so that paperboards can move in the conveyance direction. The annular pressing belt comprises multiple second annular partitioned belts which are arranged in the length direction of the first compression roller and the second compression roller at intervals, wherein the first annular partitioned belts and the second annular partitioned belts are mutually parallel, a conveyance channel is formed, and the height of the conveyance channel can be adjusted. According to the paperboard collecting machine, the multiple vertically-corresponding annular partitioned belts clamp the top and bottom of the sequentially-stacked paperboards, so that the paperboards move relatively stable, cost is low, and the conveyance efficiency is high.

Owner:苏州庆丰包装材料有限公司

Coal mining machine and travel unit overload protective device thereof

The invention provides a coal mining machine and a travel unit overload protective device thereof. The travel unit overload protective device of the coal mining machine comprises a first connecting piece, a second connecting piece and a friction piece, wherein the first connecting piece is connected with a low-speed end of a transmission system of a traction unit of the coal mining machine; the second connecting piece is connected with a travelling wheel of the travel unit of the of the coal mining machine; and friction surfaces of the friction piece are respectively tightly pressed on the first connecting piece and the second connecting piece, so that the first connecting piece and the second connecting piece can be in overload slipped connection with each other. The travel unit overload protective device of the coal mining machine has the beneficial effects that when the overload phenomenon occurs, the first connecting piece and the second connecting piece can slip to realize overload protection, so that overload protection parts can not be damaged; and as the first connecting piece is connected with the low-speed end of the transmission system of the traction unit of the coal mining machine, the overload protection effect can be played within the shortest time, so that damage to transmission parts and components due to overload can be avoided.

Owner:SANY HEAVY EQUIP

Installation for producing and method for assembling parts

InactiveCN101804539AMobile do not wantEliminate errorsWelding/cutting auxillary devicesAssembly machinesEngineeringLocation Equipment

Owner:STIWA HLDG

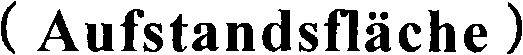

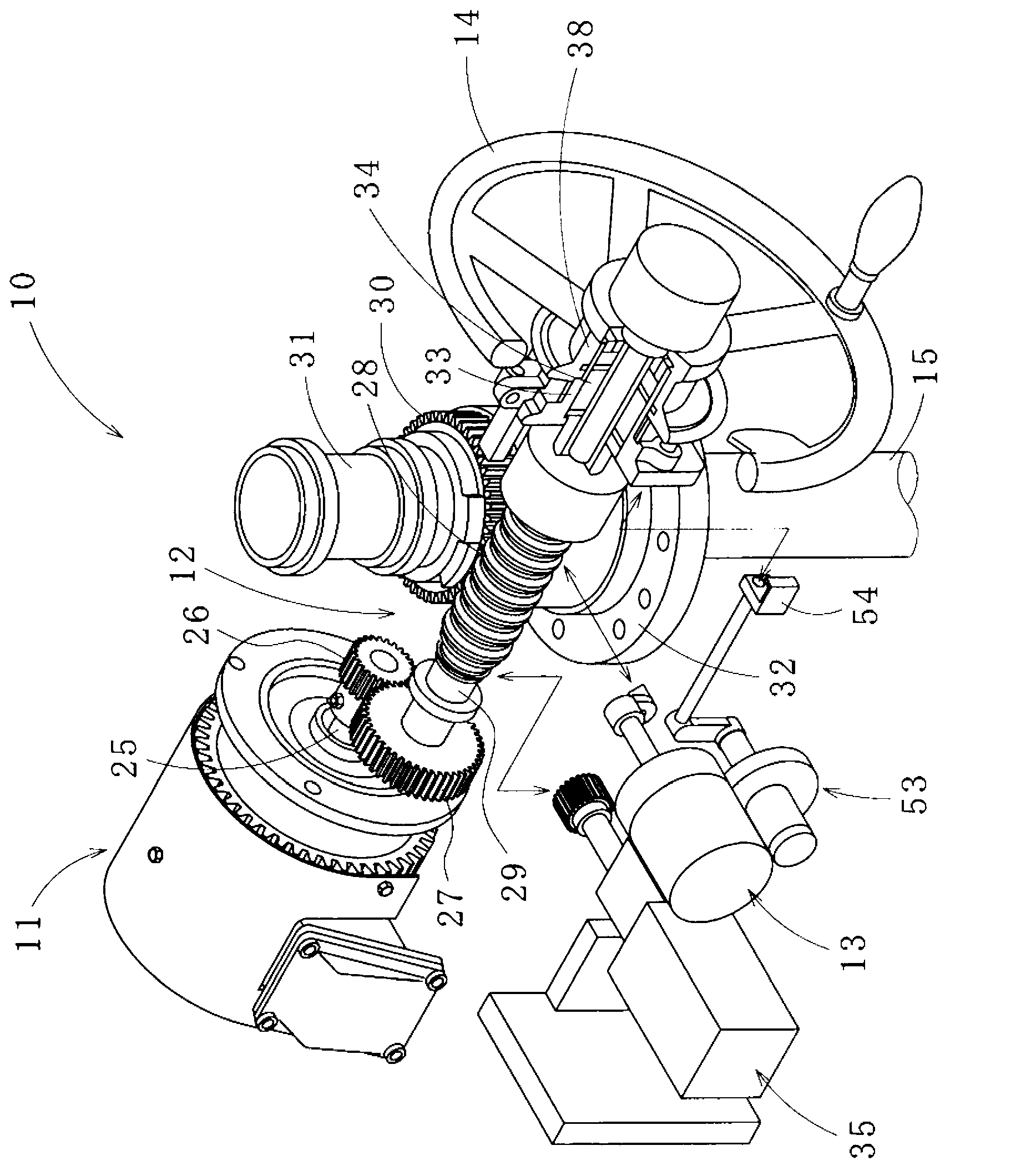

Valve controller, electric gate valve and electric valve

ActiveCN103256420ALimit loadAvoid damageOperating means/releasing devices for valvesWhole bodyElectric machine

Provided are a valve controller, an electric gate valve and an electric valve. The valve controller (10) comprises a motor (11); a power transmission unit (12) that transmits driving power of the motor to an external machine; a torque limiter (13) that makes the motor stop when the power transmission unit generates certain load during running of the motor; and a hand-operated handle (14) that applies power onto the external machine through the power transmission unit. The hand-operated handle has a rotatable body that is connected with the hand-operated handle to be a whole body to rotate; a torque drive part that is connected with the power transmission unit; and a friction generation part that enables friction to be generated between the rotatable body and the torque drive part. When torque applied by the hand-operated handle onto the rotatable body exceeds the friction between the rotatable body and the torque drive part, the torque drive part is separated from the power transmission unit and the rotatable body. Therefore, power of transmission to the external machine is limited via operation of the handle when load with the prescribed amount is generated.

Owner:WEST ELECTRIC CO LTD

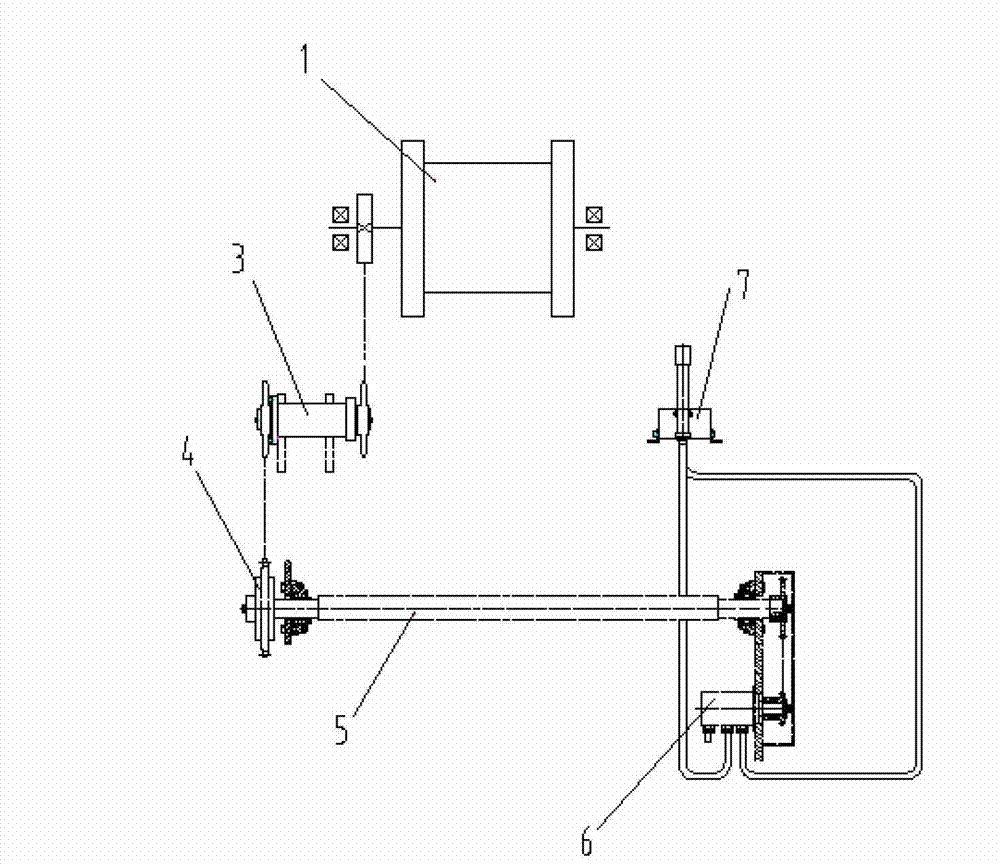

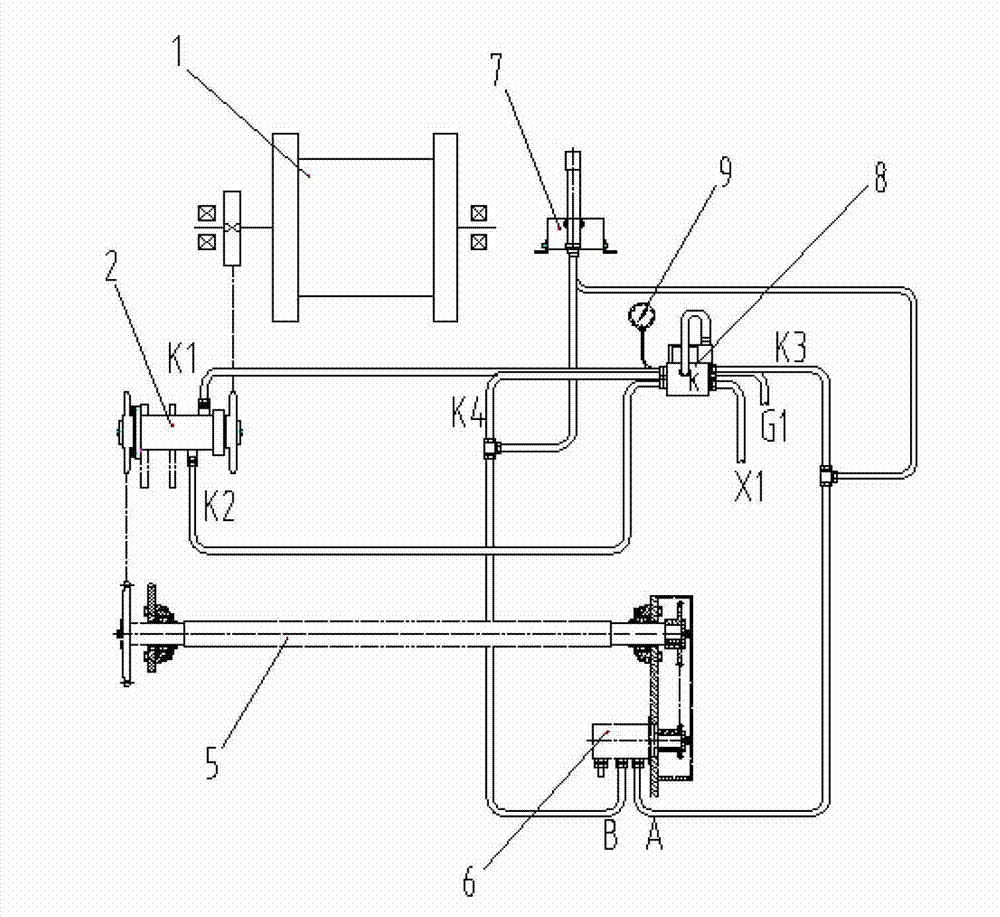

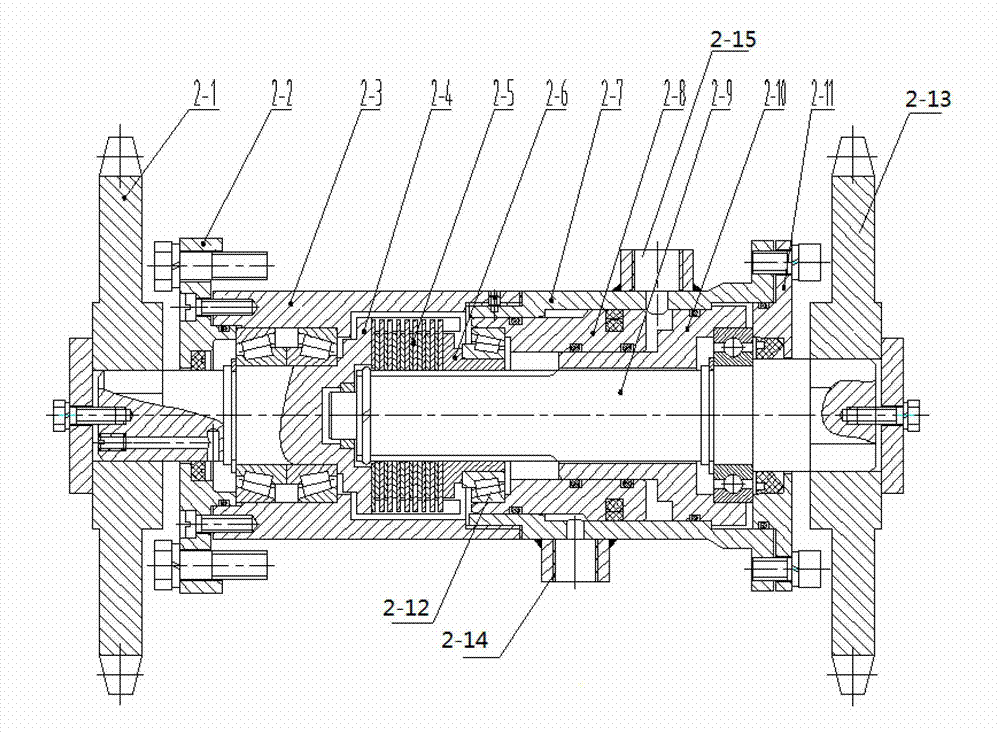

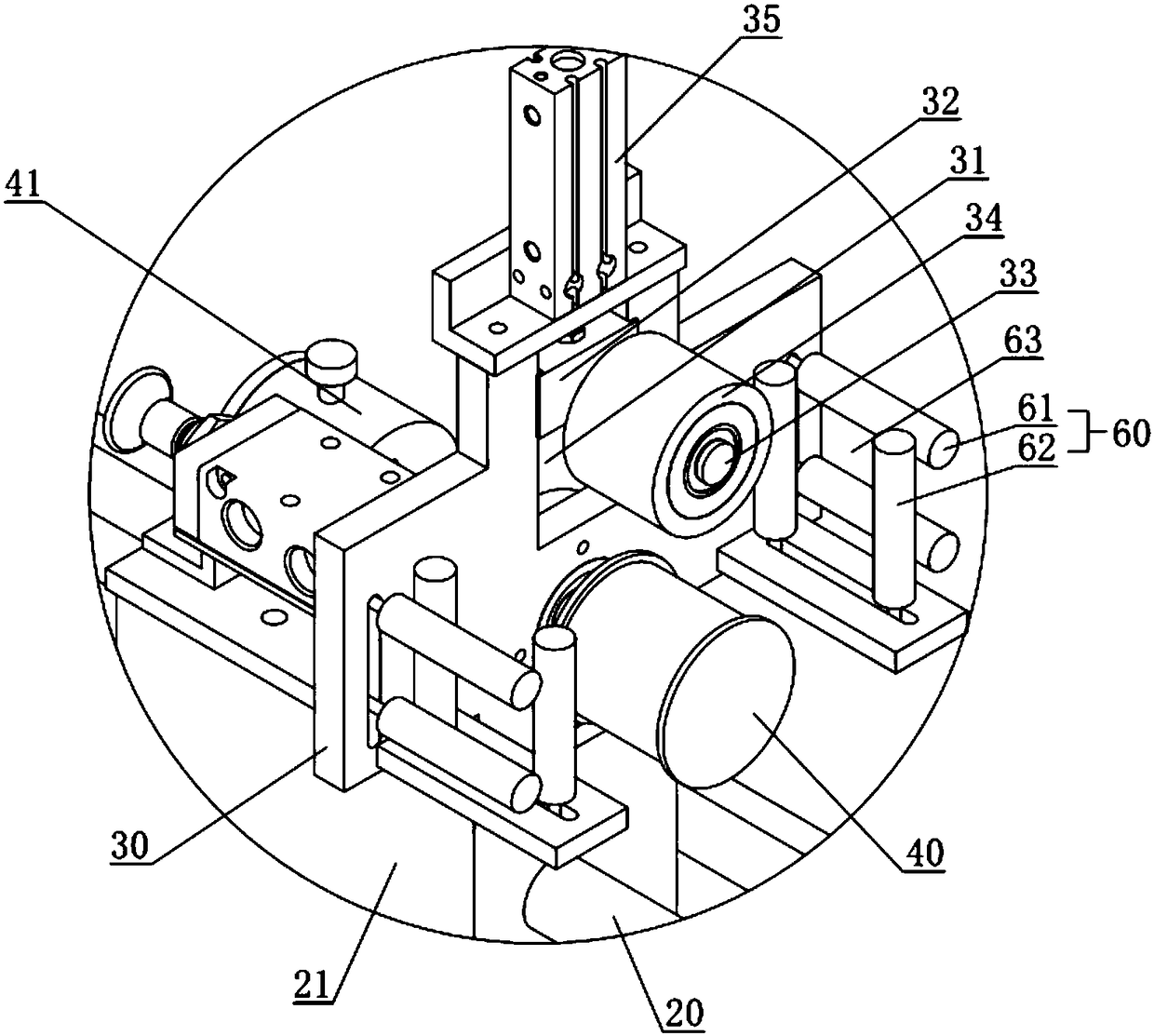

Tubing arrangement switch device of drum of coiled tubing operation machine and control system of tubing arrangement switch device

ActiveCN103711448AExtended service lifeImprove field operation safety and work efficiencyDrilling rodsDrilling casingsClutchConductor Coil

The invention discloses tubing arrangement switch device of a drum of a coiled tubing operation machine and a control system of the tubing arrangement switch device. The tubing arrangement switch device comprises a driving unit, a driven unit and a clutch unit. The clutch unit is arranged between the driving unit and the driven unit. The driving unit is provided with a hydraulic adapter joint used for controlling connection states of the clutch unit. The control system comprises the drum, a two-way lead screw, a hydraulic control system and the tubing arrangement switch device; the tubing arrangement switch device is mounted between the drum for coiled tubing winding and the two-way lead-screw, the hydraulic adapter joint is connected with a corresponding control interface of the hydraulic control system, and the hydraulic control system controls connection states of the tubing arrangement switch device through switching under the hydraulic effects. By the aid of the tubing arrangement switch device and the hydraulic control system, quick switching between automatic tubing arrangement and manually forced tubing arrangement can be realized by operators in an operation room, running torque of a forced tubing arrangement motor of the drum for coiled tubing winding is reduced, and service lives of the forced tubing arrangement motor and the tubing arrangement switch device are prolonged.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

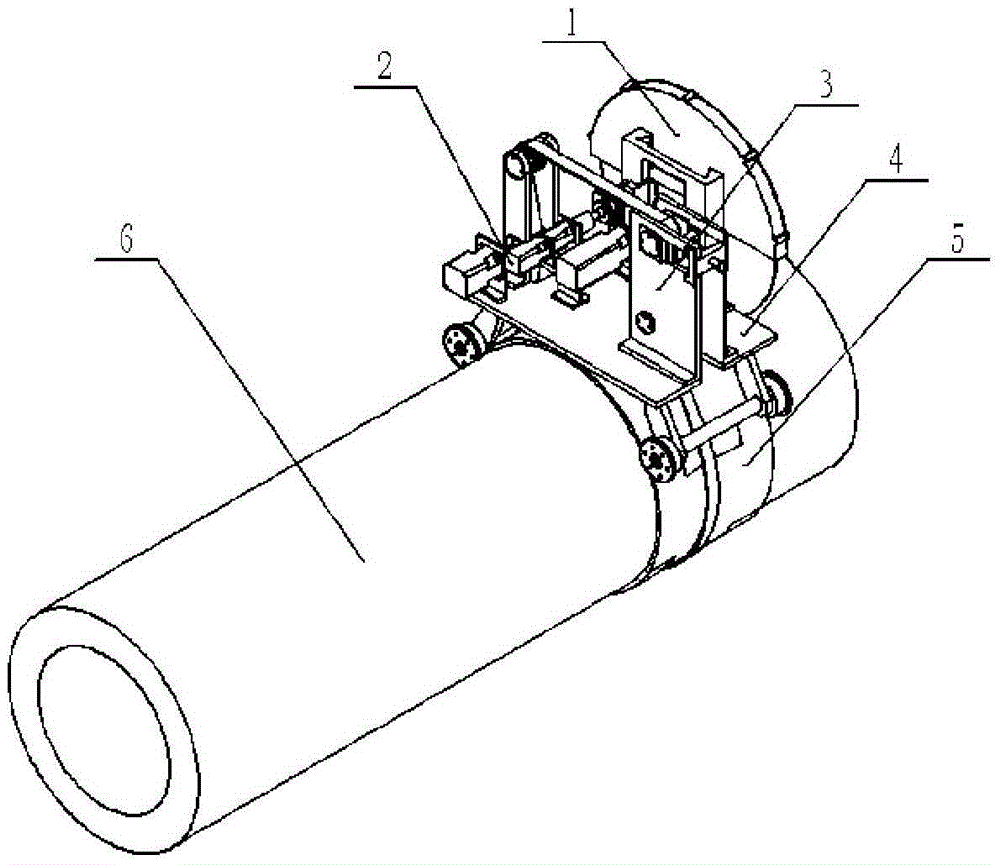

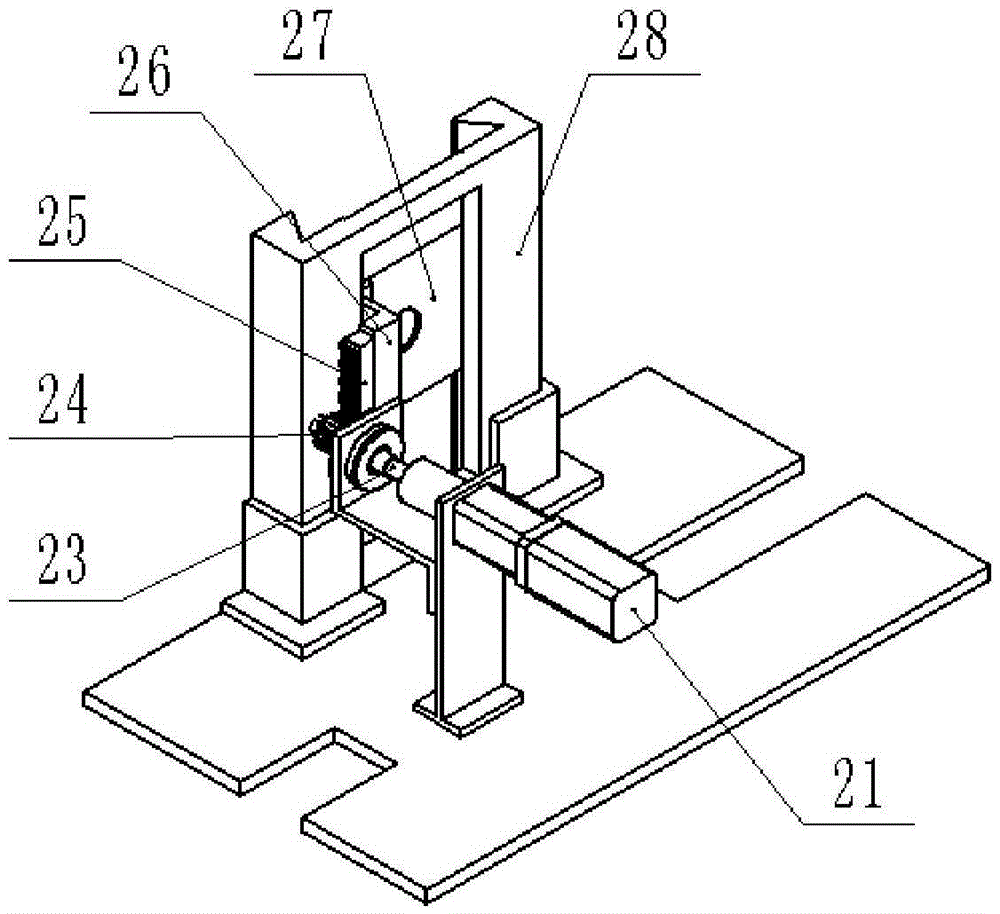

Automatic large pipeline cutting machine

InactiveCN105562818ABasic requirements for realizing radial cuttingAdjust frictionMetal sawing devicesEngineeringMechanical engineering

An automatic large pipeline cutting machine is characterized by comprising a cutting mechanism, a lifting mechanism, a circumference walking mechanism, an installing bottom plate and a circumference rail; the circumference walking mechanism and the lifting mechanism are both installed on the installing bottom plate, the circumference rail is installed around the circumference of a pipeline to be cut, the circumference walking mechanism moves along the circumference rail and drives the installing bottom plate to move along the circumference of the pipeline to be cut; and the cutting mechanism is arranged at the tail end of the lifting mechanism.

Owner:HEBEI UNIV OF TECH

Air volume adjustable powerless air window

ActiveCN108222732AStable ventilationNo direct energy consumptionBuilding braking devicesVentilation arrangementAir volumeWindow opening

The invention discloses an air volume adjustable powerless air window. The gravity center of the air window is located at the upper portion of a rotation shaft of the air window. When the air window is opened and used through a handle, due to the joint action of gravity torque and a reset torsion spring, the air window is in an open state when no air or breeze blows outdoors, and air can be led into a room. Due to the fact that the area of the part, at the lower portion of the rotation shaft, of the air window is larger than the area of the part, at the upper portion of the rotation shaft, ofthe air window, an upper screen window is externally arranged and a lower screen window is internally arranged, torque generated due to the outdoor air pressure is reverse to the gravity torque, the larger the outdoor air speed is, the smaller the aperture of the air window becomes, and vice versa. A window frame at the lower portion of the air window is a wing-shaped lower edge, and the acting torque of the outdoor air pressure can be increased. Through an air window limiting mechanism, the air window rotation range can be adjusted according to different requirements for the air volume. Air window opening and closing damping and noise lowering are conducted through the torsion spring and a sealing device. The device is simple and reliable, a power device and a sensor are not needed, and the air volume adjustable powerless air window is suitable for being used on a large scale in different areas in China.

Owner:DALIAN UNIV OF TECH

Compound brake pad and preparation method thereof

InactiveCN108167358AFree from corrosionStrong oxidation abilityOther chemical processesFriction liningCalcium hydroxideWhiskers

The invention relates to a compound brake pad, a preparation method and an application thereof. The compound brake pad is prepared from the following raw materials in parts by weight: 2-20 parts of potassium titanate whiskers, 5-20 parts of zinc powder, 1-15 parts of calcium hydroxide, 0.5-10 parts of friction powder, 1-15 parts of aramid fibers, 2-18 parts of resin, 5-20 parts of copper wool and5-30 parts of ceramic fibers. By combining the zinc powder with calcium hydroxide, the zinc powder is high in oxidizing property and can be used as a protecting pole of the brake pad in a braking process, and all the charges are transferred to the brake pad while the zinc powder and calcium hydroxide are reacted, so that a brake disc is prevented from being corroded, and the condition that the brake disc and the brake pad are adhered due to rusting of the brake disc is avoided.

Owner:QINGDAO JIHONG AUTO PARTS

Material bin feeding dredging method and device

The invention discloses a material bin feeding dredging method and a material bin feeding dredging device. The invention comprises: 1) a tapered central guiding body, a control rotary plate and the wall of a material bin are jointly support material weight to prevent or eliminate arching at a discharge hole; 2) the control rotary plate swings to destroy the balance of an arching part support force system to prevent or eliminate the arching at the central guiding body and / or the control rotary plate; 3) a transmission device connects the central guiding body and the control rotary plate, and the control rotary plate drives the central guiding body to swing so as to prevent or eliminate the arching at the central guiding body; 4) a vibration device connected with the central guiding body is arranged outside the material bin, and drives the central guiding body and the control rotary plate to vibrate so as to prevent or eliminate the arching at the central guiding body and / or the control rotary plate; and 5) a limit block is arranged beside the transmission device, and when the transmission device moves, the transmission device impacts the limit block to vibrate the material bin so as to prevent or eliminate the arching in the material bin. The problem of feeding blockage of the material bin is solved by a feeding and dredging control combined method, and the anti-blockage dredging effect is better.

Owner:SHANXI SANHESHENG IND TECH +1

Light-load AGV suspension adjusting device and working method

PendingCN112297740AAdaptableBest Suspension ParametersResilient suspensionsVehiclesGround pressureStructural engineering

The invention discloses a light-load AGV suspension adjusting device and a working method. The light-load AGV suspension adjusting device comprises an AGV bottom plate, a driving wheel suspension device and a universal wheel suspension device. The universal wheel suspension device is arranged on the AGV bottom plate, the driving wheel suspension device is further arranged on the AGV bottom plate;the driving suspension device comprises a suspension support and a fork opening plate; an inserting plate groove is formed in the lower side face of the suspension support; an inserting plate matchedwith the inserting plate groove is arranged on the fork opening plate, and a fork opening plate cover plate is arranged on the upper side of the inserting plate. A threaded hole is formed in the suspension support, an adjusting screw is connected into the threaded hole through threads, a spring sleeve is arranged on the outer side of the adjusting screw in a sleeving mode, a limiting nut is arranged at the upper end of the spring sleeve, and the fork opening plate is connected with one end of the driving support. When an AGV runs to an uneven road surface, the driving wheel can drive a drivingbracket to rotate and float by taking a pin shaft as the center, and meanwhile, the spring sleeve can stretch or contract, so that the adjustment of the driving wheel on the ground pressure is realized, and the friction force between the driving wheel and the ground is further adjusted.

Owner:SHANDONG UNIV +1

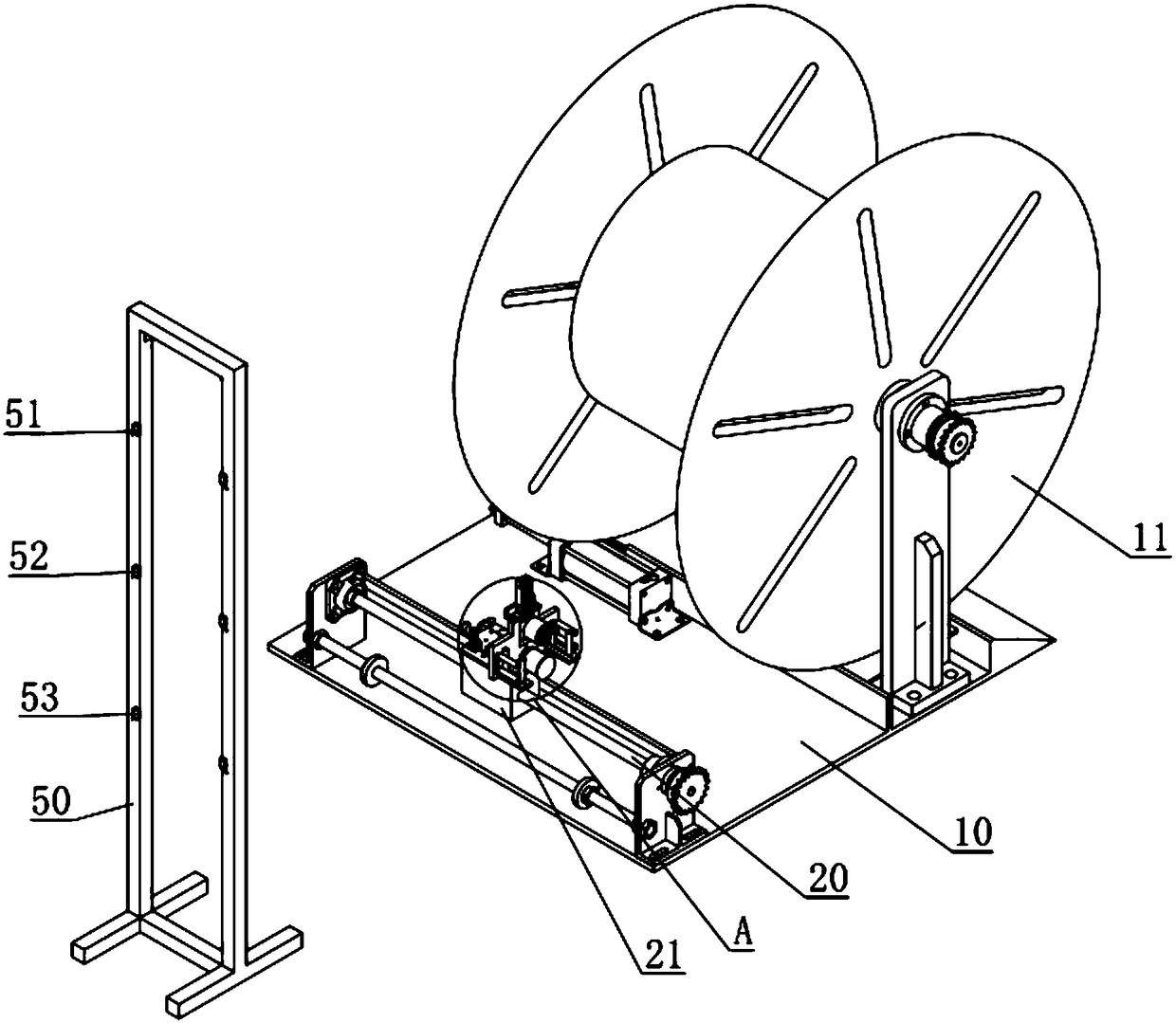

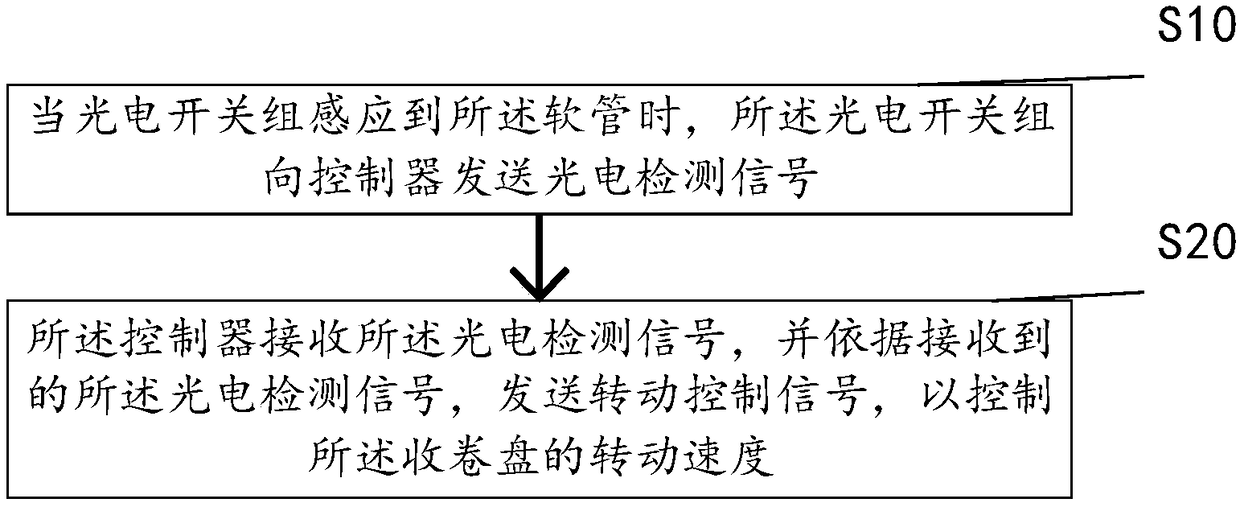

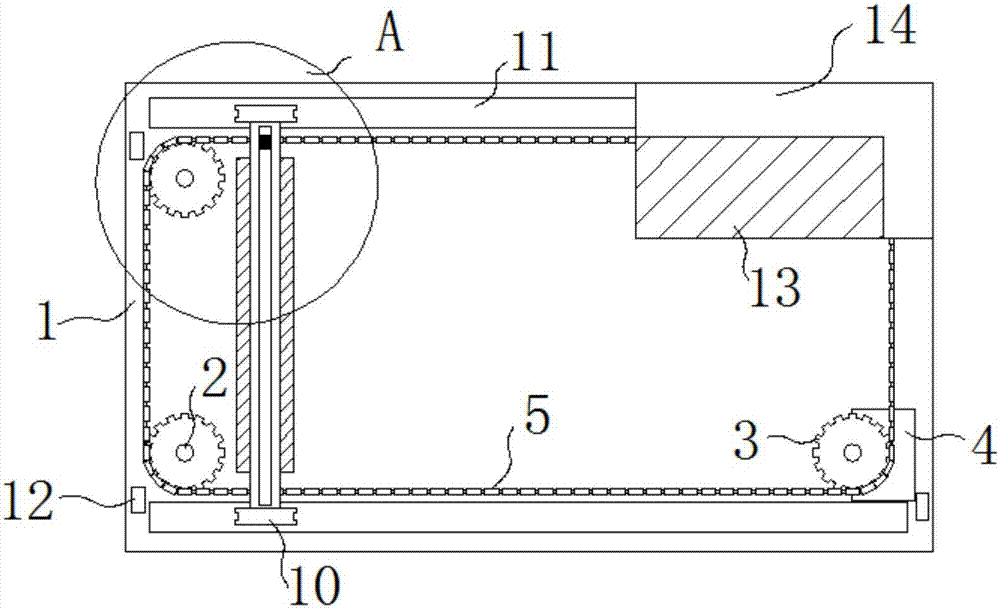

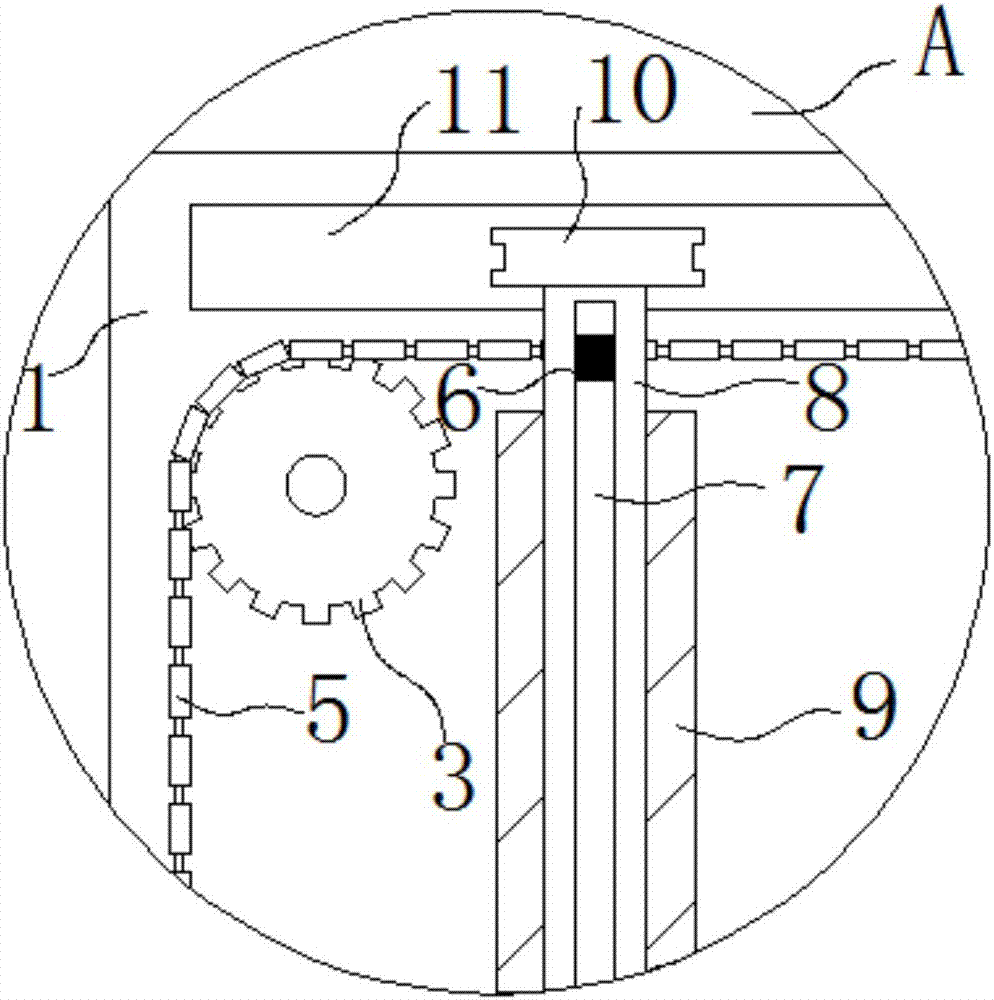

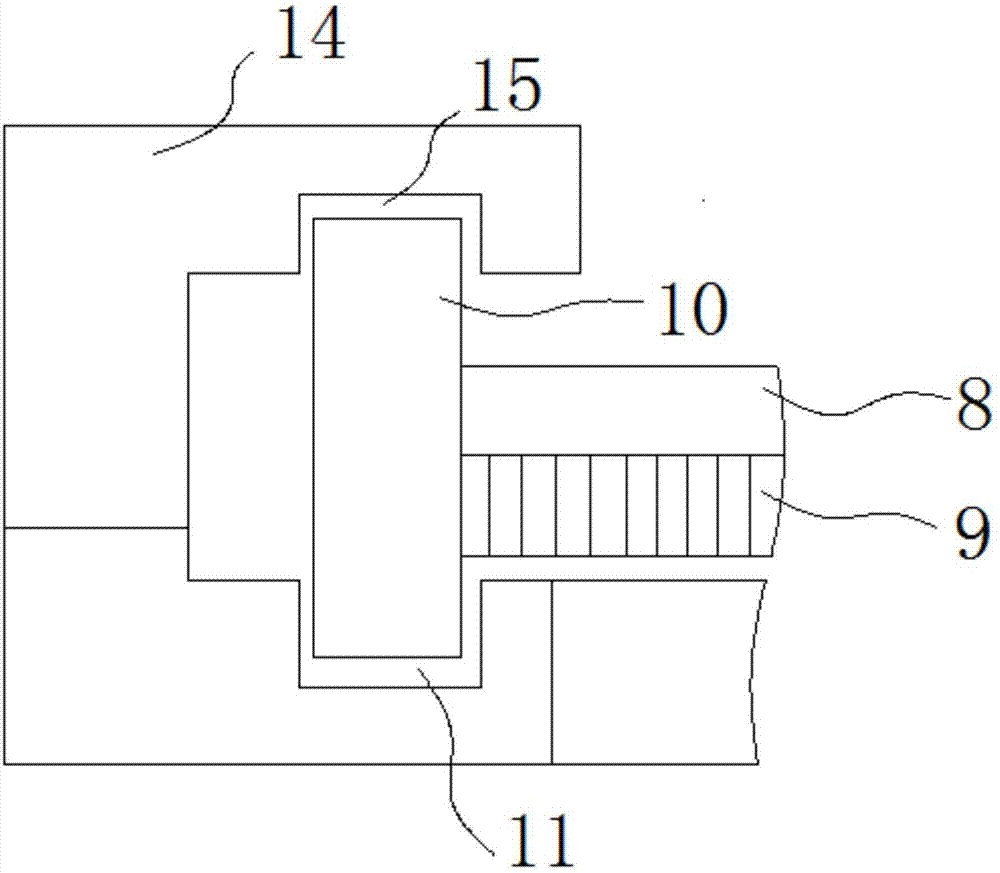

Hose winding device and winding method

The invention discloses a hose winding device and a winding method. The hose winding device comprises a bottom plate, a detection mechanism, a wire arranging mechanism and a controller, wherein a winding mechanism is arranged on the bottom plate, and the winding mechanism comprises a winding disc arranged on the bottom plate and a motor for driving the winding disc to rotate; the detection mechanism is arranged in the radial direction of the winding disc, the detection mechanism comprises a detection support and a photoelectric switch set, and the height of a hose in the detection support is detected; the wire arranging mechanism is arranged on the bottom plate, and the wire arranging mechanism is arranged between the detection mechanism and the winding disc; and the controller is electrically connected with the photoelectric switch set, when the photoelectric switch set senses the hose, the photoelectric switch set sends a photoelectric detection signal to the controller, the controller sends a rotation control signal to the receiver according to the received photoelectric detection signal so as to control the rotation speed of the winding disc. According to the hose winding device and the winding method, the rotating signal can be sent to the controller according to the detected height, so that the possibility that the hose is folded or laminated is reduced, the possibility that the hose is pulled off is reduced, and the hose winding device can be stably rolled.

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL

Electric blackboard chalk dust erasing device

Owner:TAICANG CENTURY BRIDGE IND & COMMERCIAL OFFICE

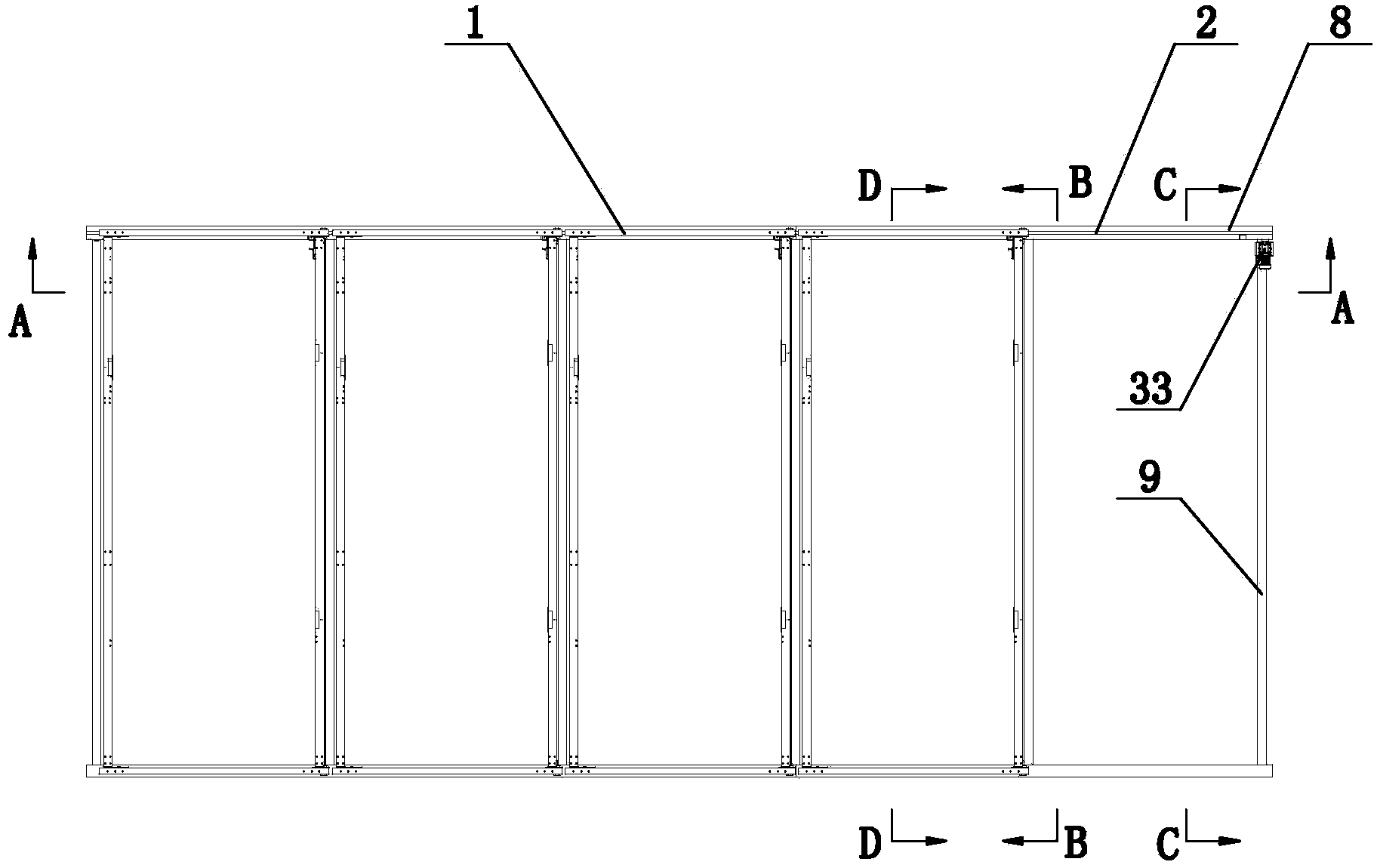

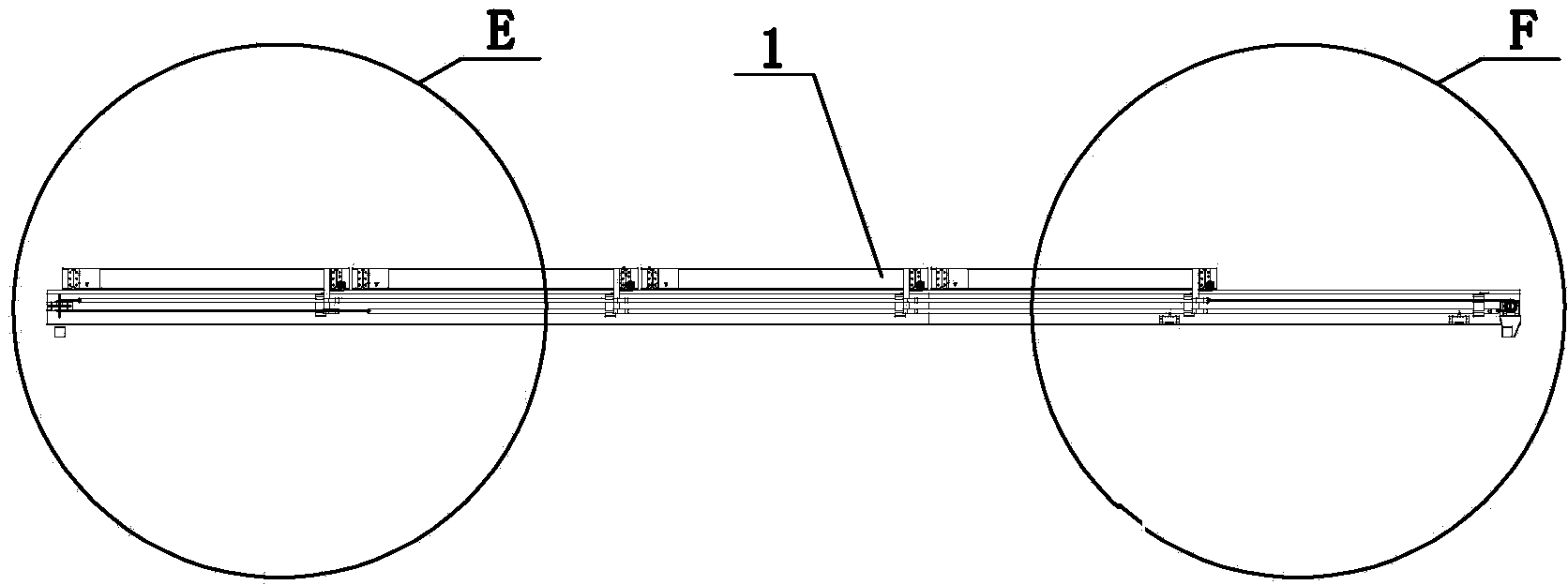

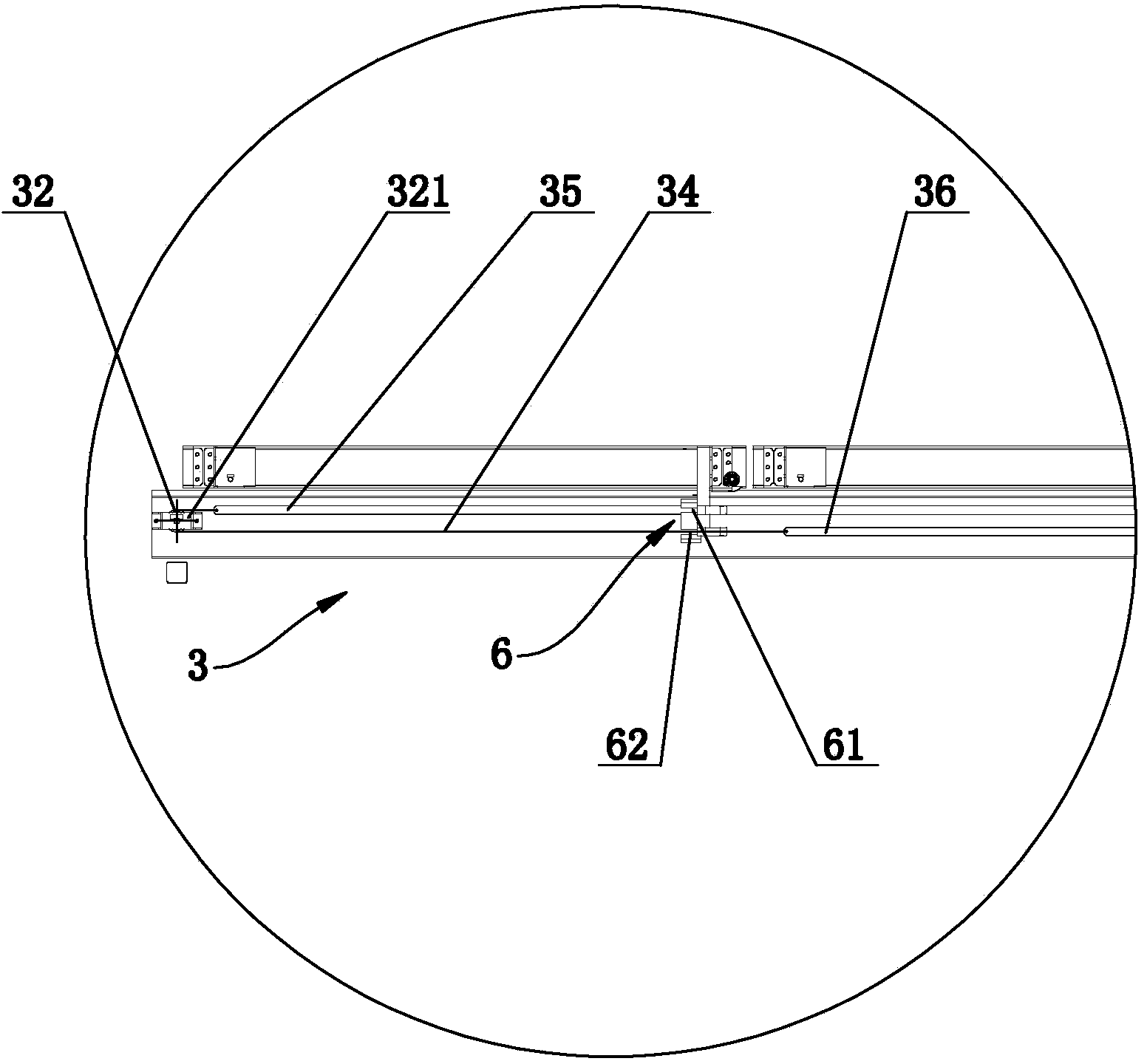

Transverse moving transmission system with motor matched with multiple plates and lifting transverse moving type parking equipment

ActiveCN103924804AReduce the number of control pointsSave travel switchParkingsElectric machineControl theory

The invention discloses a transverse moving transmission system with a motor matched with multiple plates, and belongs to the technical field of three-dimensional parking equipment. The system comprises transverse moving frames, a transverse moving guide rail, a dragging device used for enabling the transverse moving frames to move along the transverse moving guide rail transversely and a control device used for controlling the transverse moving frames to move along the transverse moving guide rail transversely. The control device comprises a bolt control device and a stroke control device. The four corners of each transverse moving frame are respectively provided with a walking wheel, and the walking wheels are installed on the transverse moving guide rail in a restricted mode. The invention further discloses lifting transverse moving parking equipment which comprises the transverse moving transmission system with the motor matched with the multiple plates. Each layer is only provided with only one power device and the transverse moving frames on the corresponding layer can be dragged, a large number of motors can be saved, resource waste is reduced, cost is reduced, each layer only needs to be provided with two stroke switches, a large quantity of stroke switches can be saved, control procedures are simplified, PLC control points are reduced, and control cost is reduced.

Owner:DAYANG PARKING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com