Bottom pre-tensioning type stick-slip driving cross-scale precision motion platform

A precision motion, bottom preload technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of small adjustment range of friction preload and friction adjustment Restricted, small friction adjustment range, etc., to ensure the accuracy and consistency of motion, facilitate processing and assembly, and improve output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

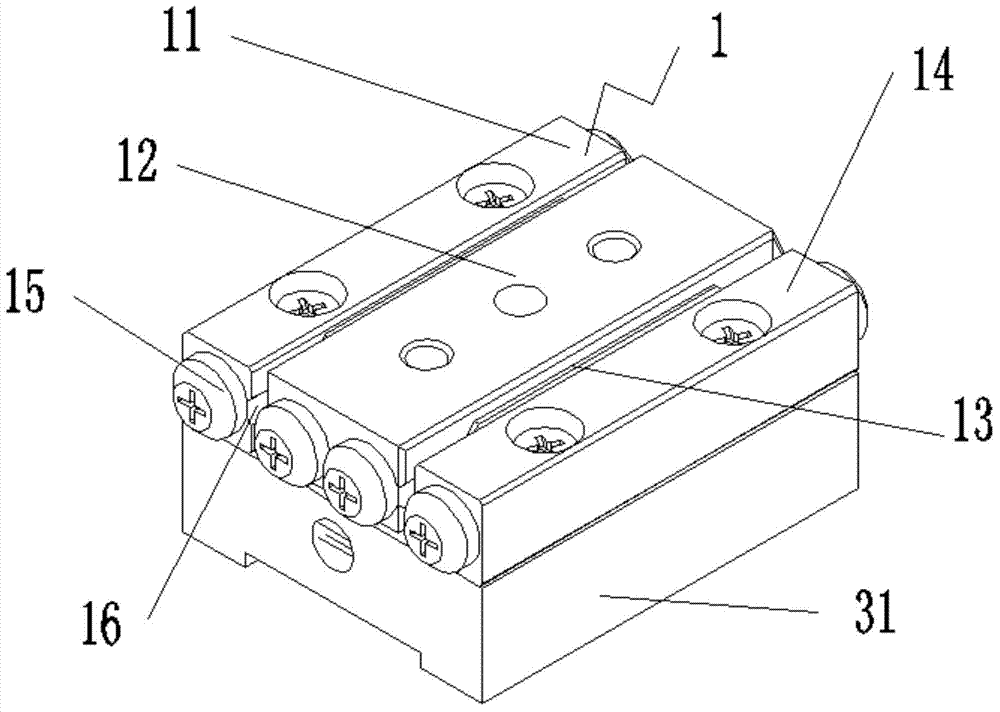

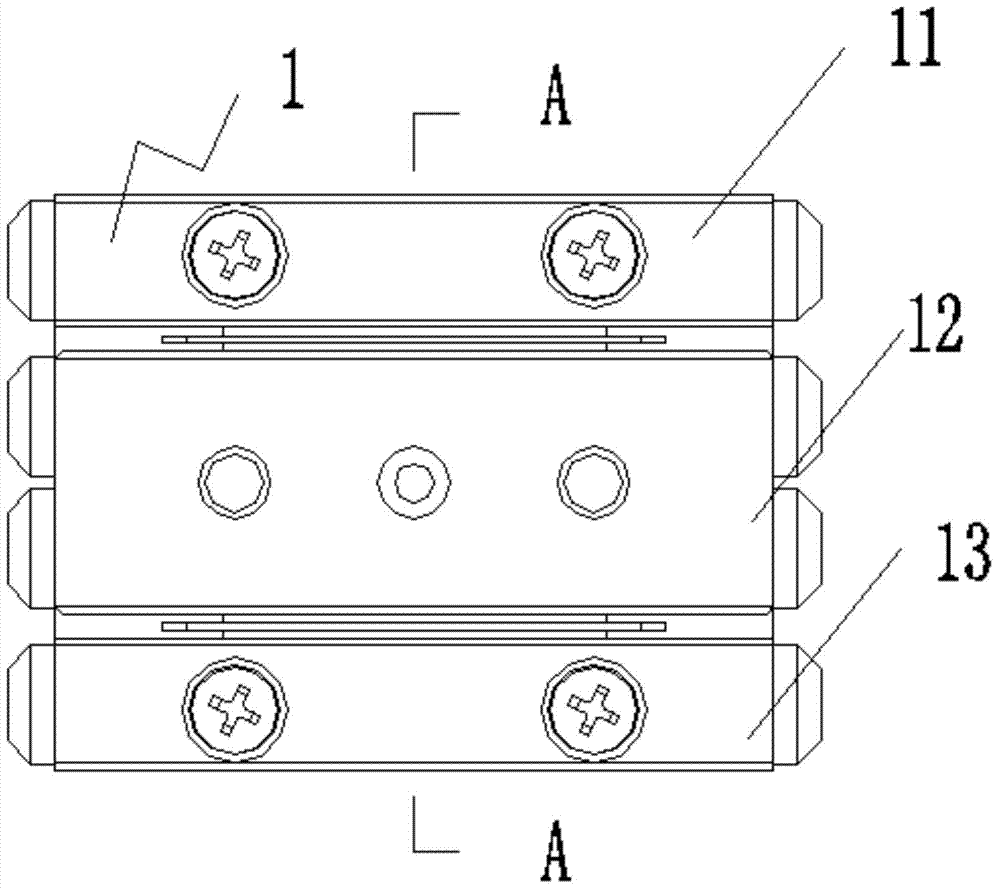

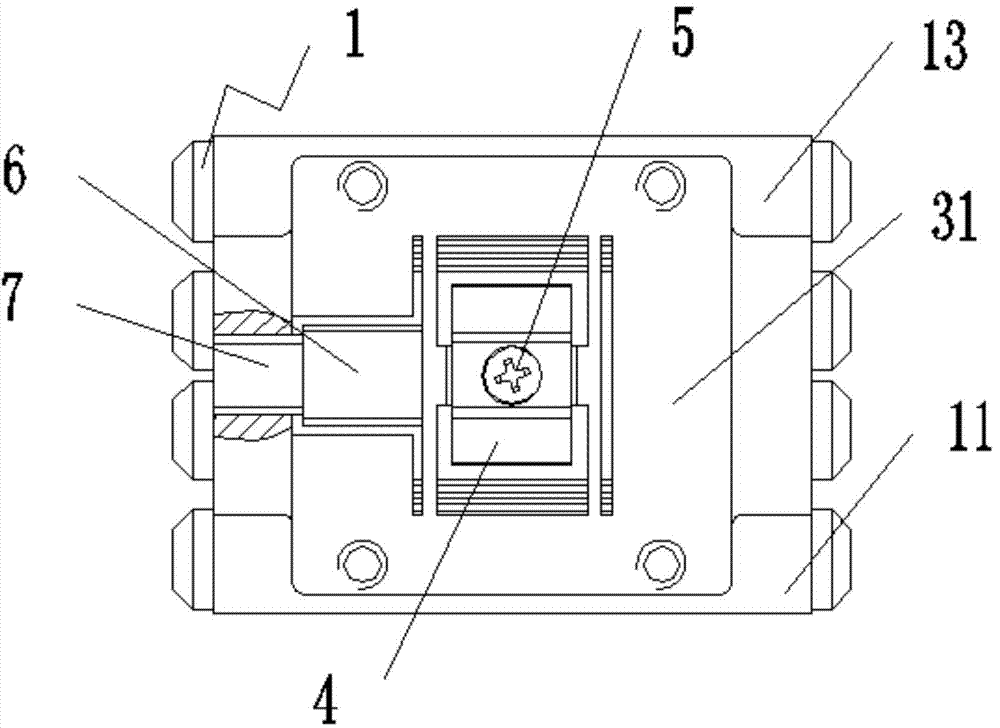

[0031] The embodiment of the present invention discloses a bottom-pretensioned stick-slip driving cross-scale precision motion platform, including:

[0032] base;

[0033] a friction vibrator, the friction vibrator is installed on the base;

[0034] A vibrator drive source, the vibrator drive source is installed between the friction vibrator and the base to provide driving force to the friction vibrator;

[0035]The slider is arranged above the friction vibrator, and contacts with the friction vibrator to generate friction force;

[0036] A preload adjustment structure providing preload is provided between the bottom of the slider and the base, and the preload adjustment structure includes a V-shaped spring that provides the preload and is used for adjusting The adjustment screw of the V-shaped spring, the V-shaped spring is installed on the base in a compressed and deformed manner through the adjustment screw, and the pre-tightening force adjustment structure is used to adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com