Material bin feeding dredging method and device

A material silo and material technology, applied in the direction of transportation and packaging, packaging, containers, etc., can solve problems such as blocking materials, and achieve the effects of avoiding blocking, reducing friction, and smoothing unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

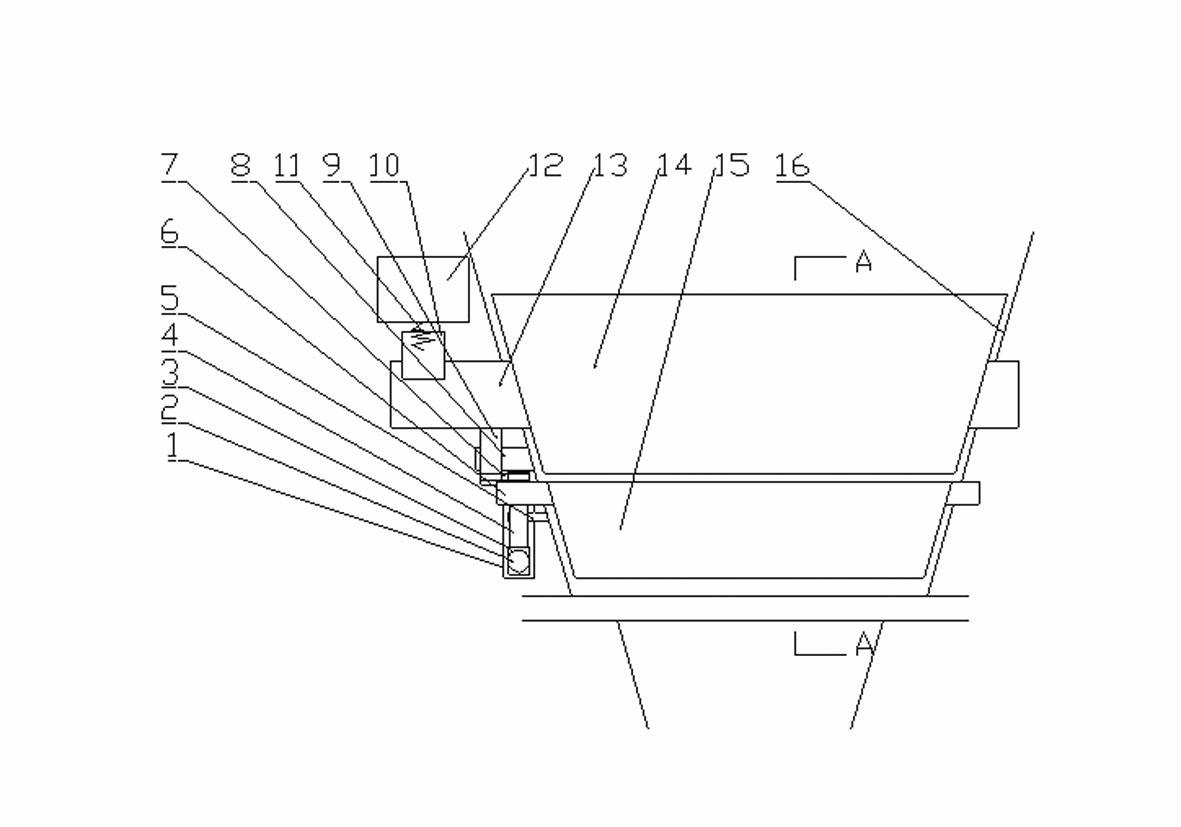

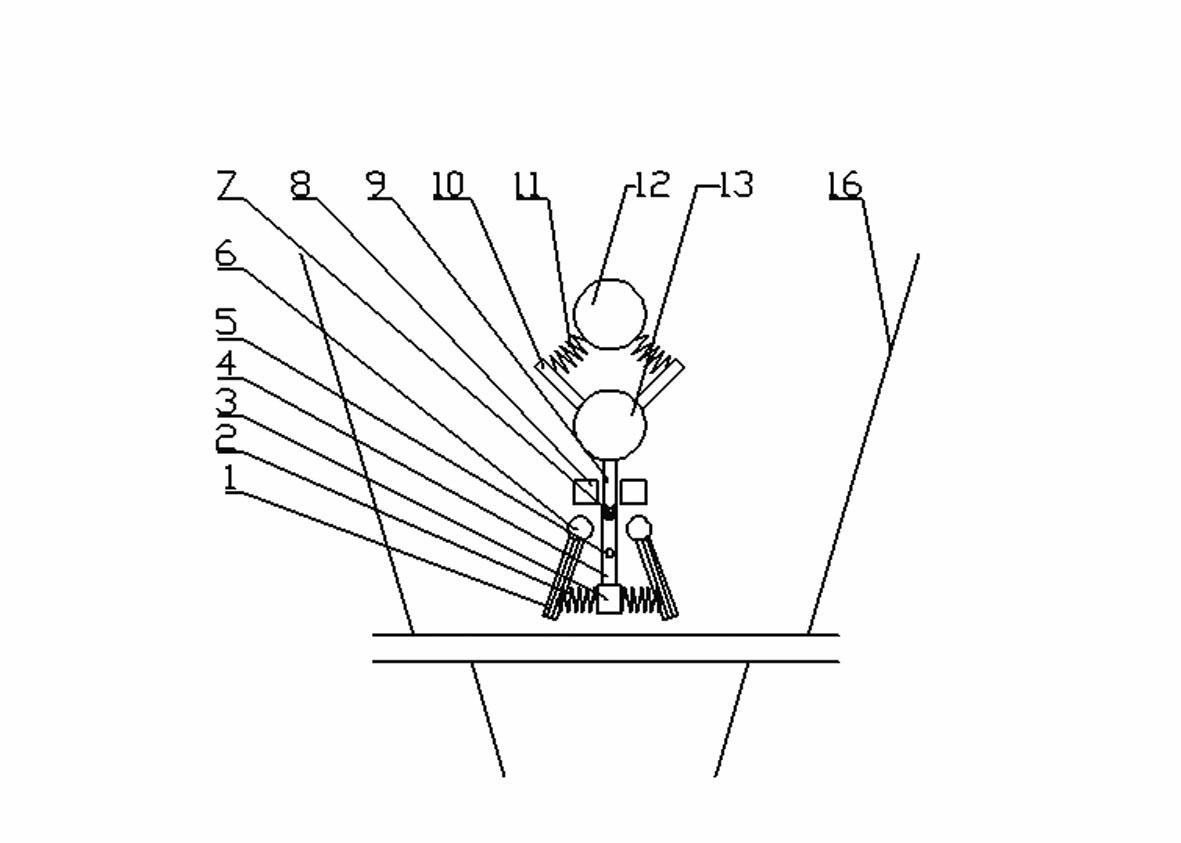

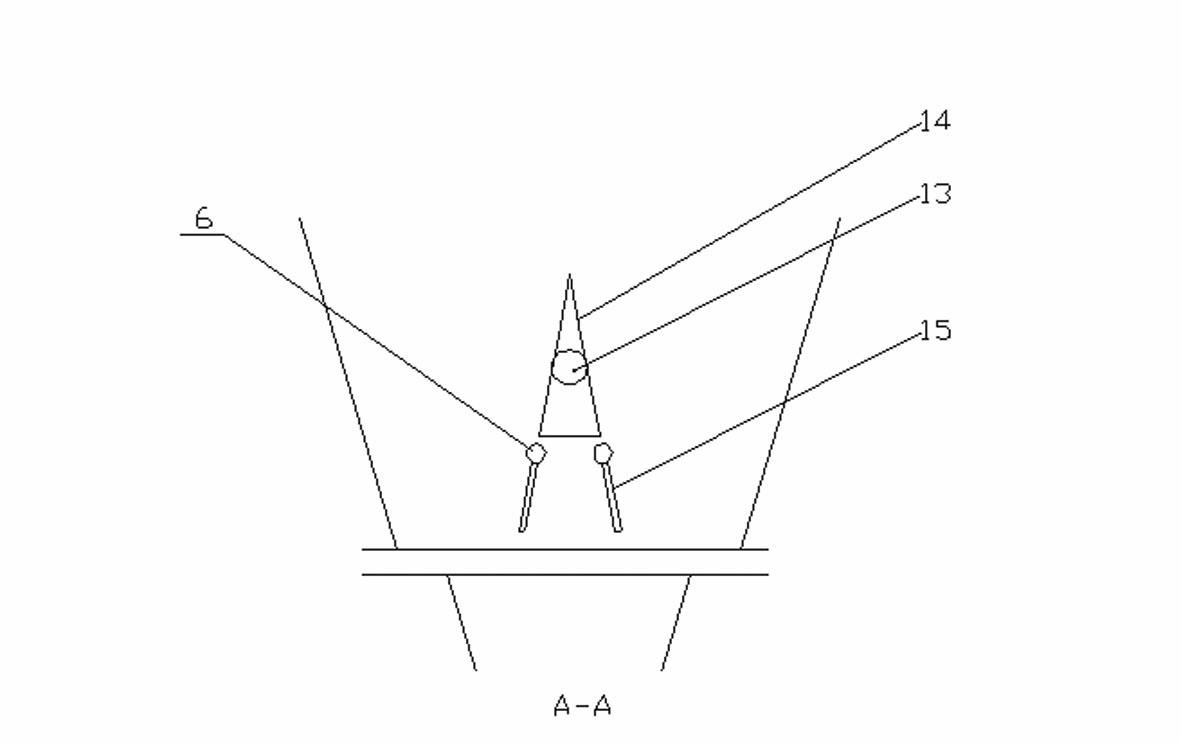

[0036] The structure of the material bin unloading transportation device of the present invention is as follows: figure 1 , figure 2 As shown, a central guide body 14, a control rotating plate 15 and a vibrator 12 are included. Center guide body 14 is installed in material bin 16, and the longitudinal section of center guide body 14 is triangular, and center guide body coupling shaft 13 is fixed on center guide body 14 with perpendicular to longitudinal section direction, and the bin of two ends and material bin 16 The body is hinged, and two control rotating plates 15 are installed symmetrically along the inclined plane of the central guiding body 14 below the center guiding body 14. The control rotating plates 15 are movably installed on the material bin 16 through the control rotating plate coupling shaft 6 fixed on its upper end. See the installation position of guide body 14 and control rotating plate 15 in material bin 16 image 3 .

[0037] An active swing rod 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com