Patents

Literature

73results about How to "Unobstructed feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

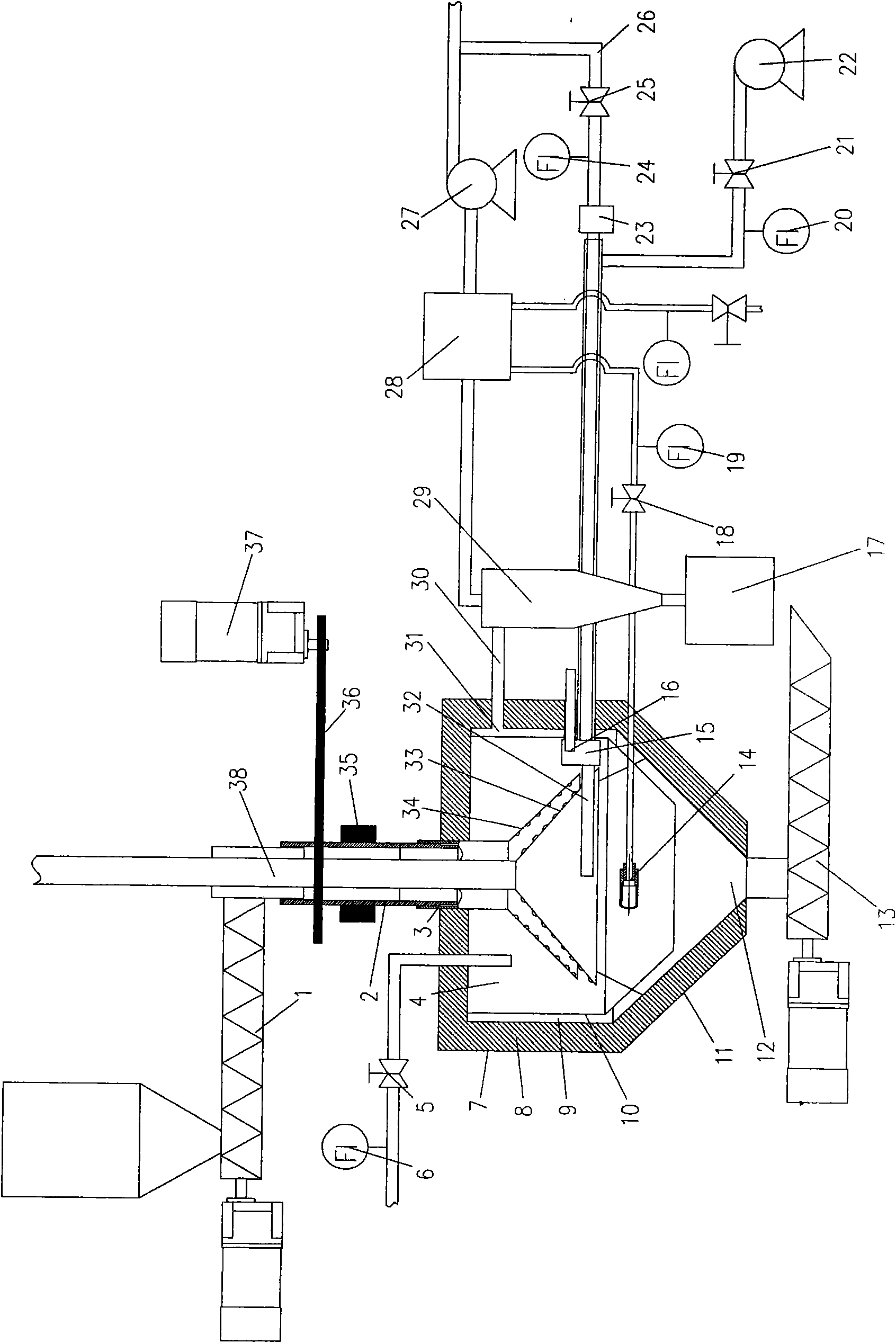

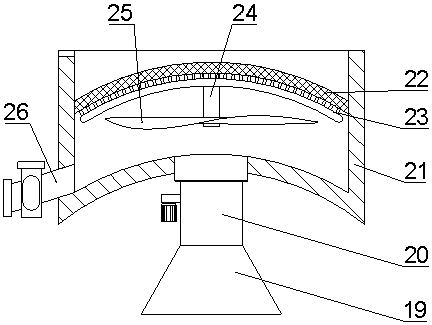

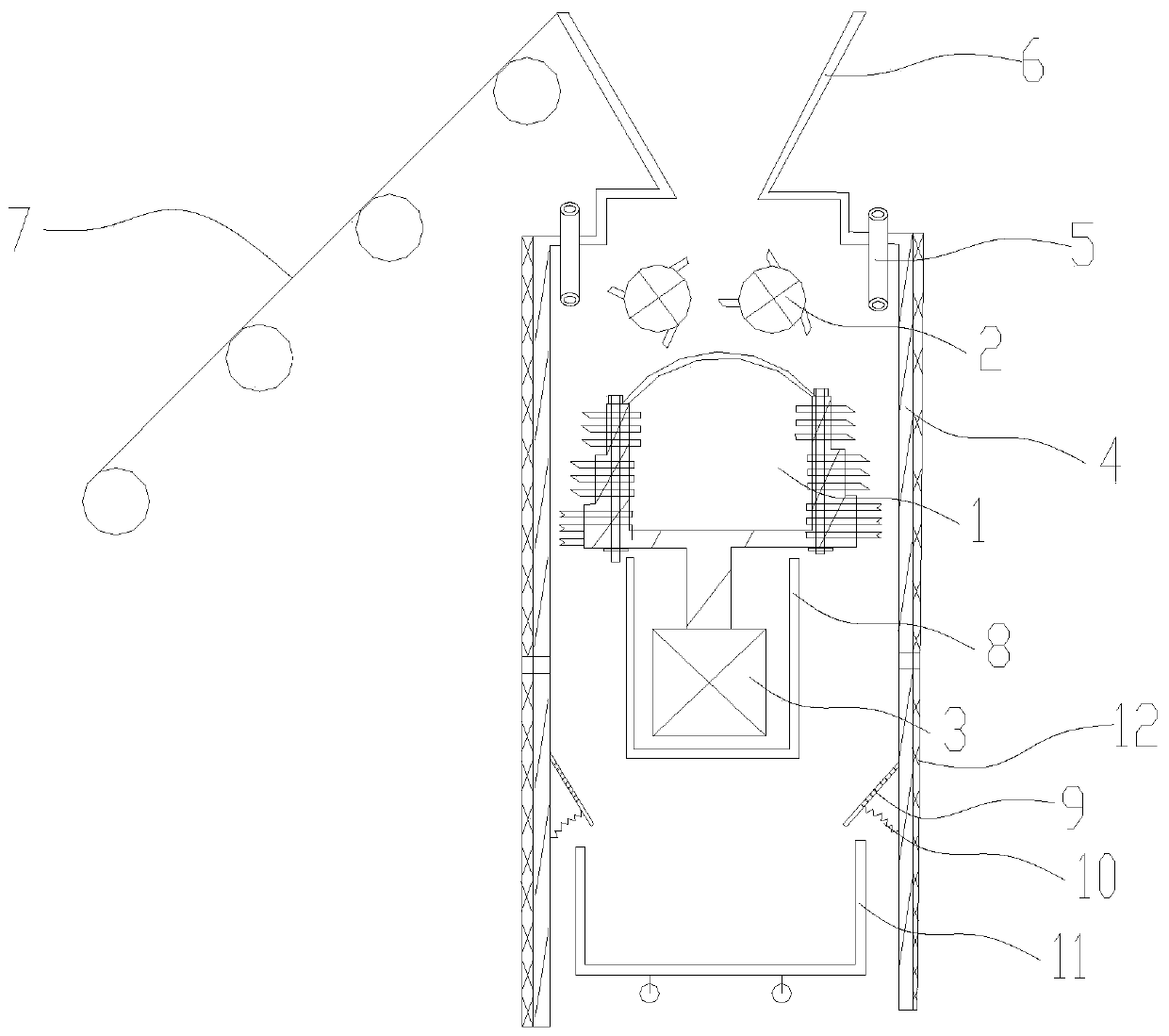

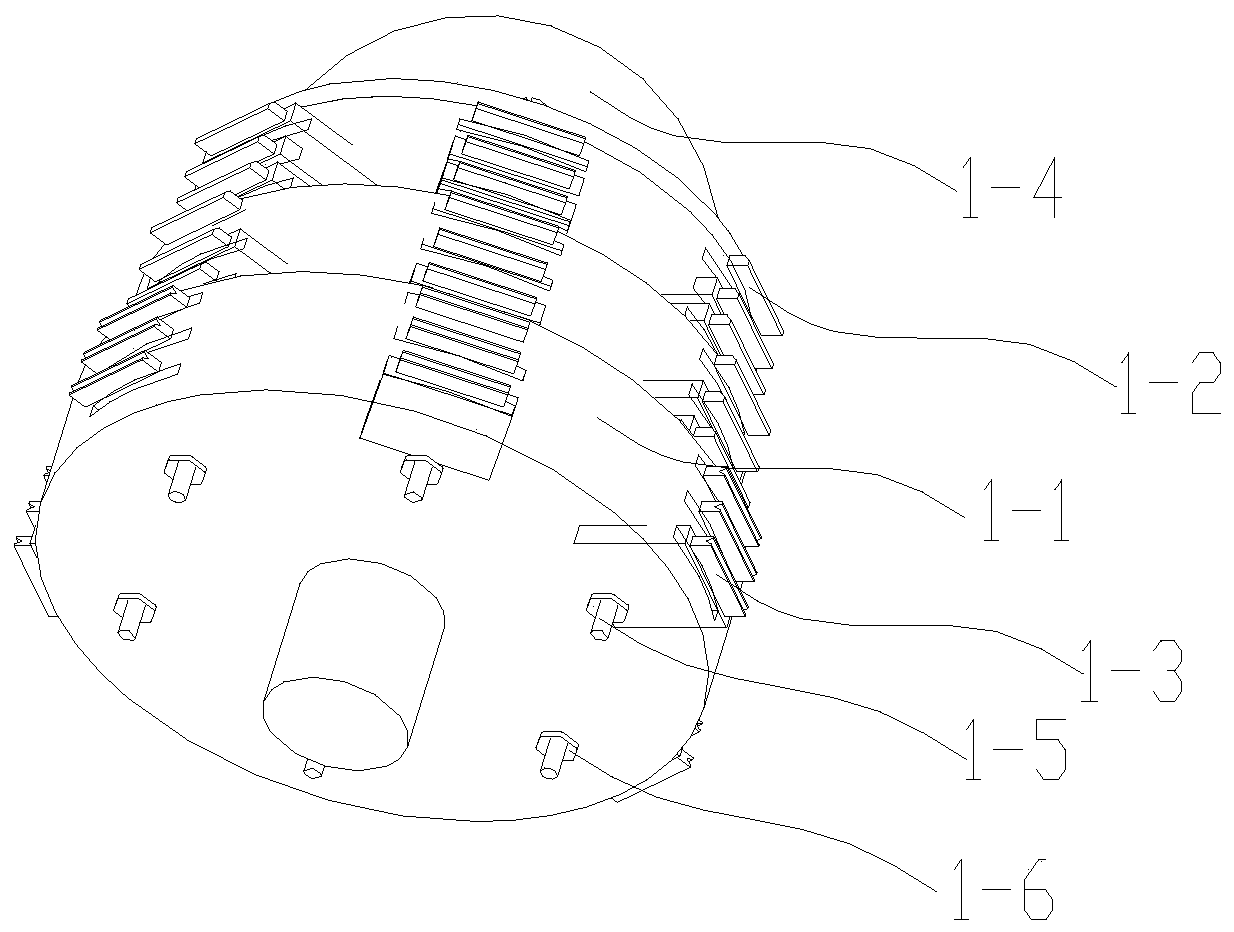

Internal combustion type heating rotating cone type biomass pyrolysis liquefaction device

ActiveCN101445737ARealize inverse motionImprove heat transfer effectBiofuelsSpecial form destructive distillationFlue gasFuel tank

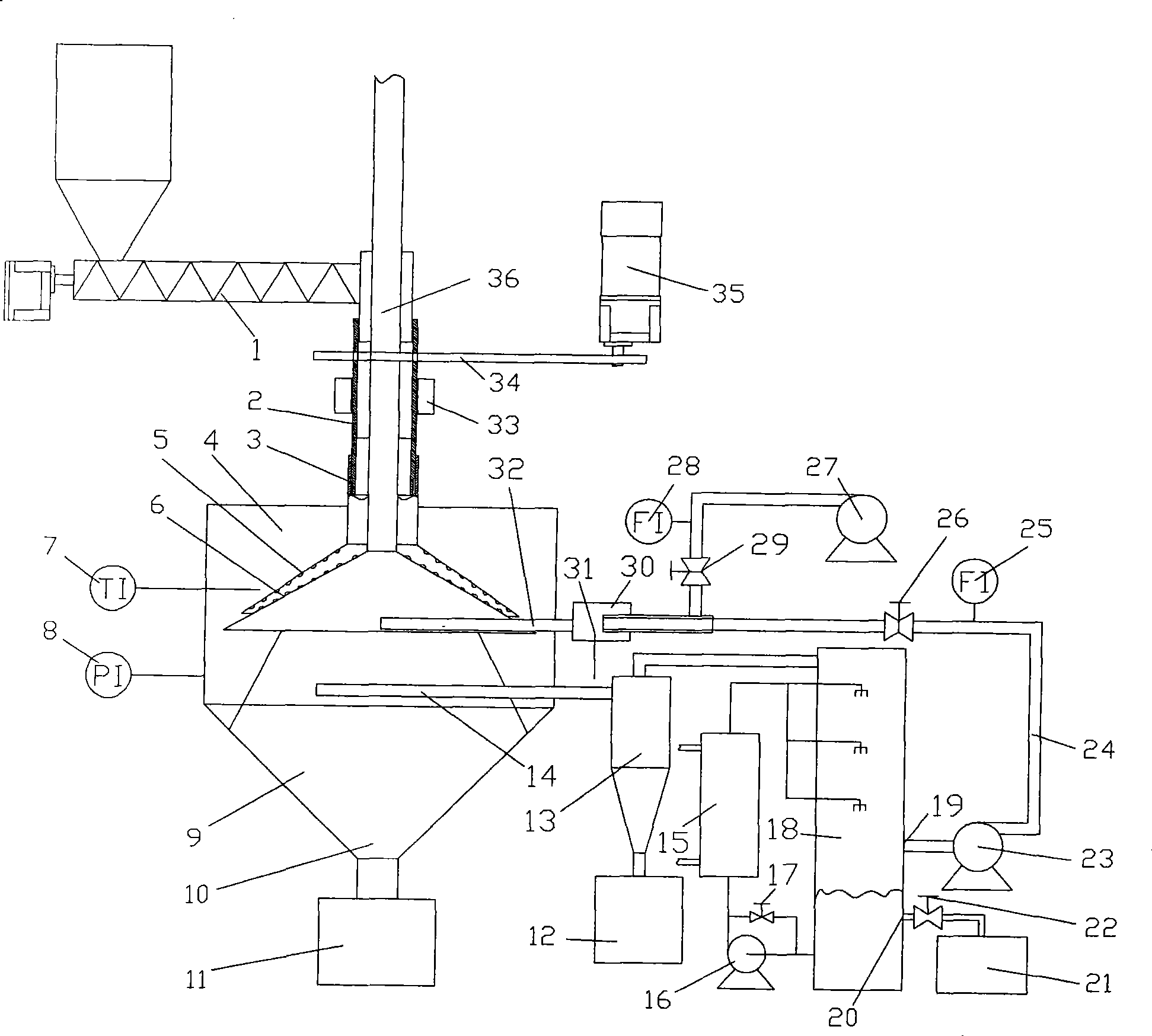

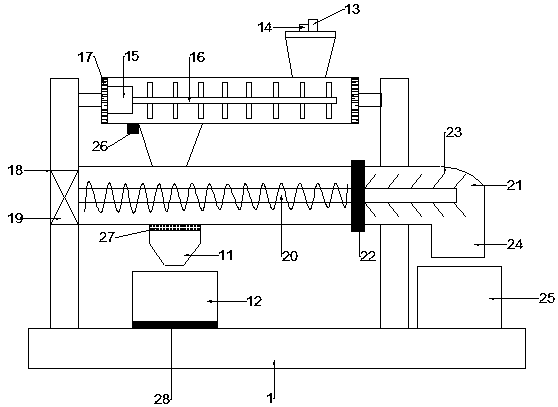

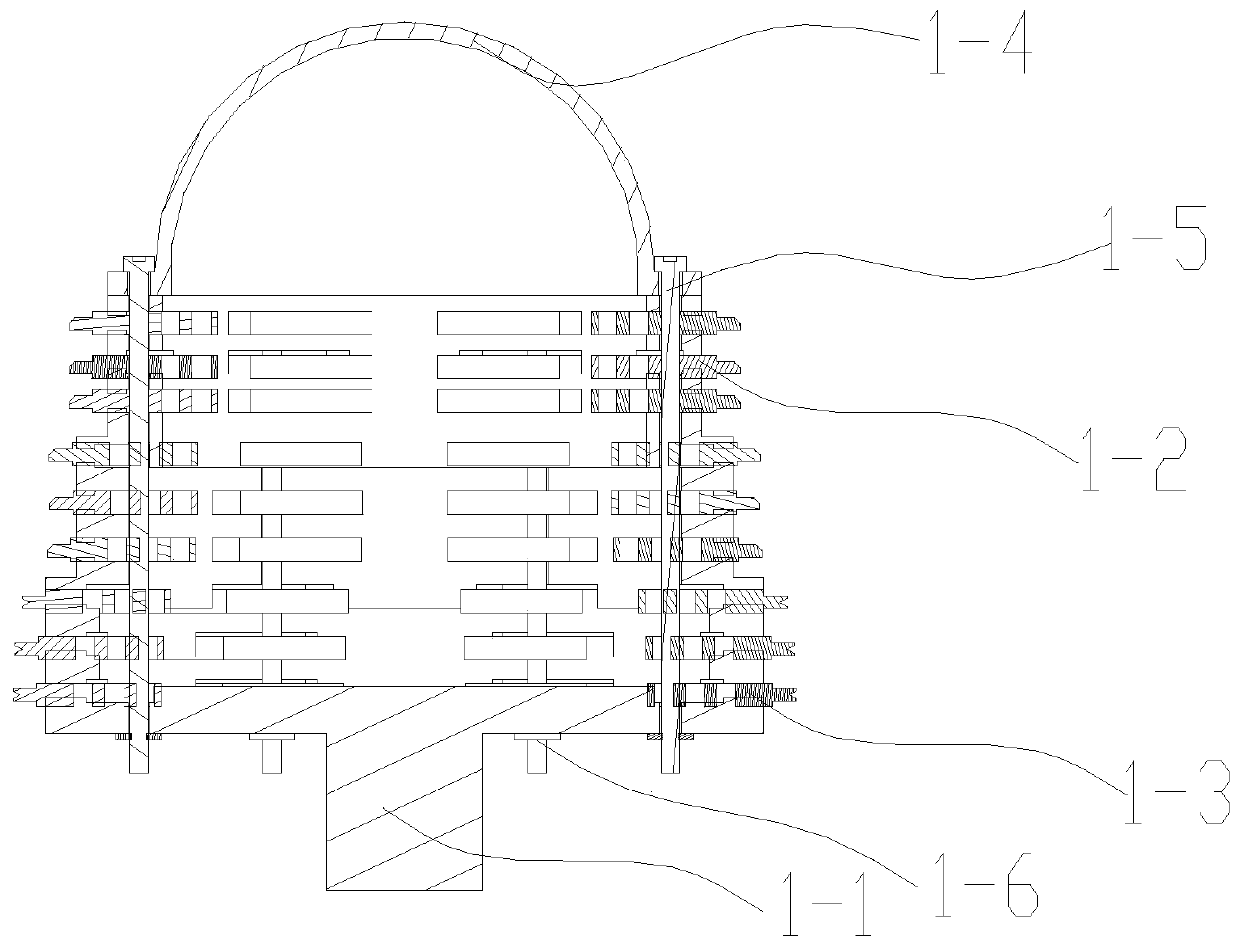

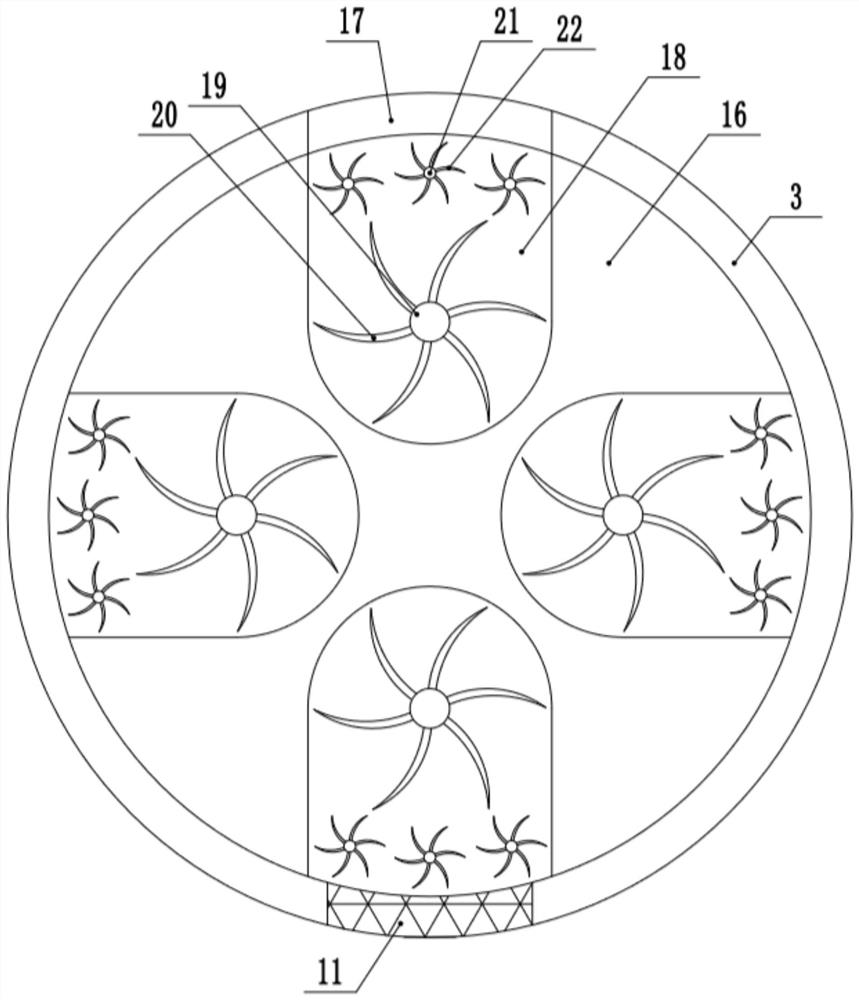

The invention relates to an internal combustion type heating rotating cone type biomass pyrolysis liquefaction device. The device is characterized in that two concentric cones are arranged in a reactor, the outer cone is a rotating cone, and the inner cone is a fixed cone; a charging barrel is sectionally arranged into an upper section charging barrel and a lower section charging barrel, the upper part of the rotating cone is connected with the lower section charging barrel, and the upper section charging barrel is communicated with a spiral feeding mechanism; the upper part of the fixed cone is communicated with a flue gas pipeline; the end surface at the bottom part of the fixed cone is closed, and the lower part of the fixed cone is tangentially connected with a burning pipeline; a porous filter tube is arranged in the reactor, a reactor is led out form the other end of the porous filter tube, and the reactor is communicated with a cyclone dust collector positioned outside the reactor, the output end of the bottom part of the cyclone dust collector is connected with a carbon collecting box, and a gas outlet opening at the top part is connected with a condenser through a pyrolysis gas pipeline; an oil outlet opening on the condenser is communicated with an oil collecting tank, the air outlet opening of the condenser is accessed into a pyrolysis gas burner through a pyrolysis gas return pipeline. The invention realizes biomass self-heating type pyrolysis liquefaction, effectively improves the utilization ratio of the pyrolysis byproduct and reduces the total cost for biomass liquefaction.

Owner:ANHUI WEIDA ENVIRONMENTAL PROTECTION TECH

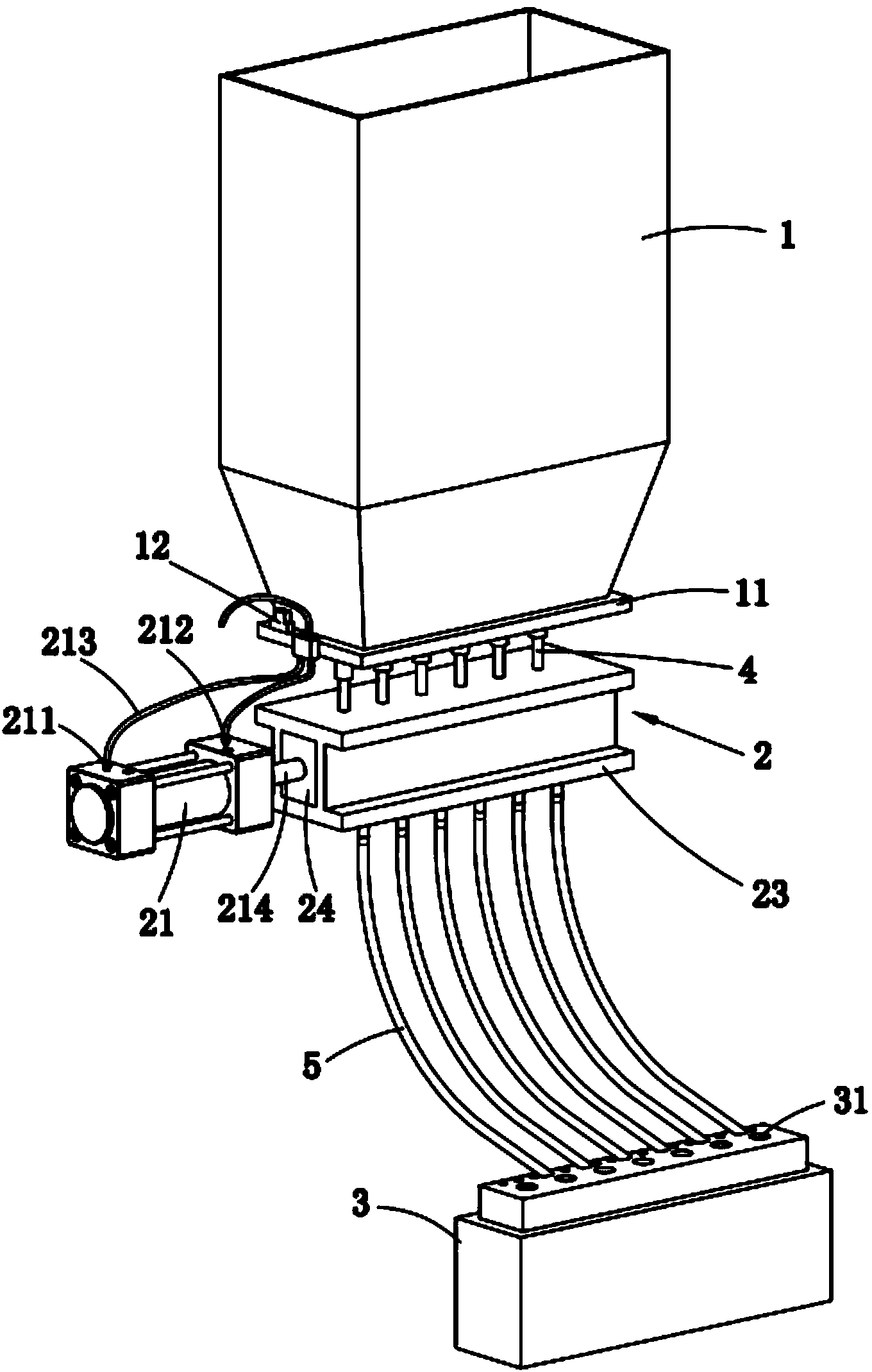

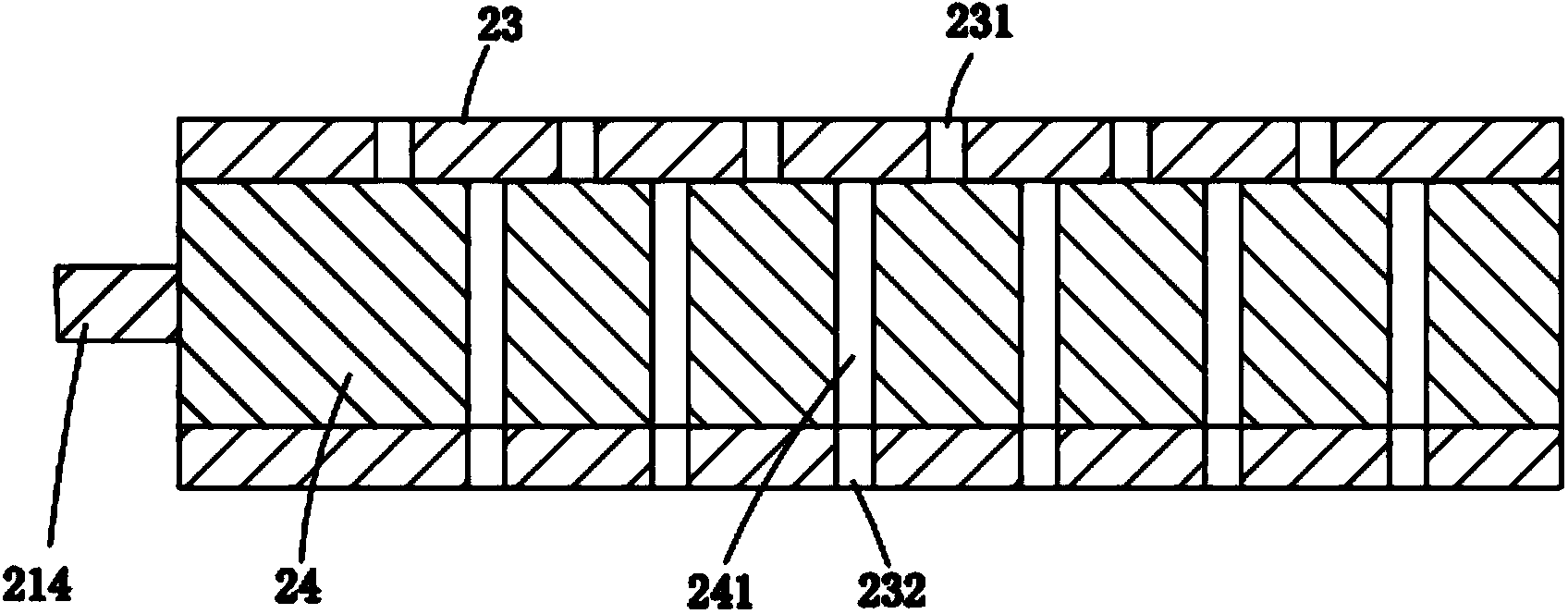

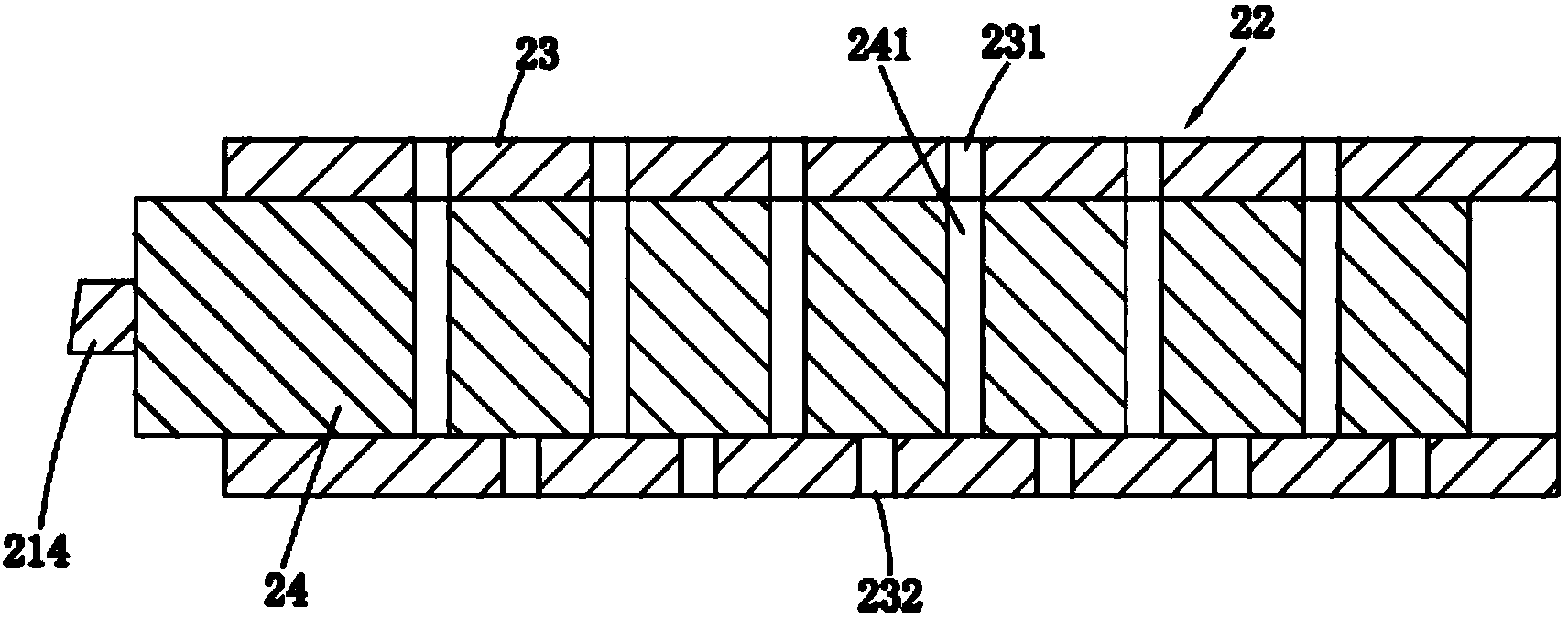

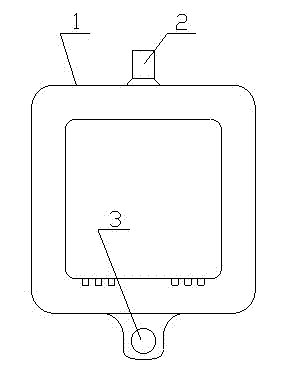

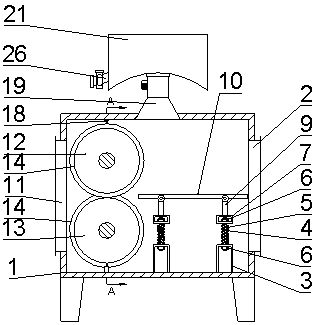

Quantitative material injection device of mould

The invention relates to a quantitative material injection device of a mould. The quantitative material injection device comprises a hopper, a feeding device and a lower mould body, wherein the hopper is further provided with a material level detection sensor connected with a main controller and an opening sealing plate is arranged at the bottom of the hopper; a plurality of outlets are uniformly formed in the opening sealing plate; each outlet is provided with a material guide pipe; the feeding device comprises an air cylinder and a material injection mechanism; a plurality of material injection openings corresponding to the outlets of the opening sealing plate are formed in the upper surface of the material injection mechanism; a plurality of discharging holes are formed in the lower surface of the material injection mechanism; a plurality of cavities are vertically formed in the lower mould body; the front side of each cavity is obliquely provided with a material injection pipe communicated with the cavity; the tops of the material injection pipes are correspondingly connected with the discharging holes respectively. The quantitative material injection device can be used for rapidly feeding back the volume of raw materials in the hopper in time through the material level detection sensor so that a certain pressure value is maintained in the hopper; the feeding device is driven by the air cylinder to automatically and quantitatively feed and discharge the materials at intervals, and furthermore, the feeding amount in the mould is controlled; the quantitative material injection device is reasonable in structure and high in production efficiency and can be used for continuously and smoothly discharging the materials.

Owner:东莞市宜曼洲电子科技有限公司

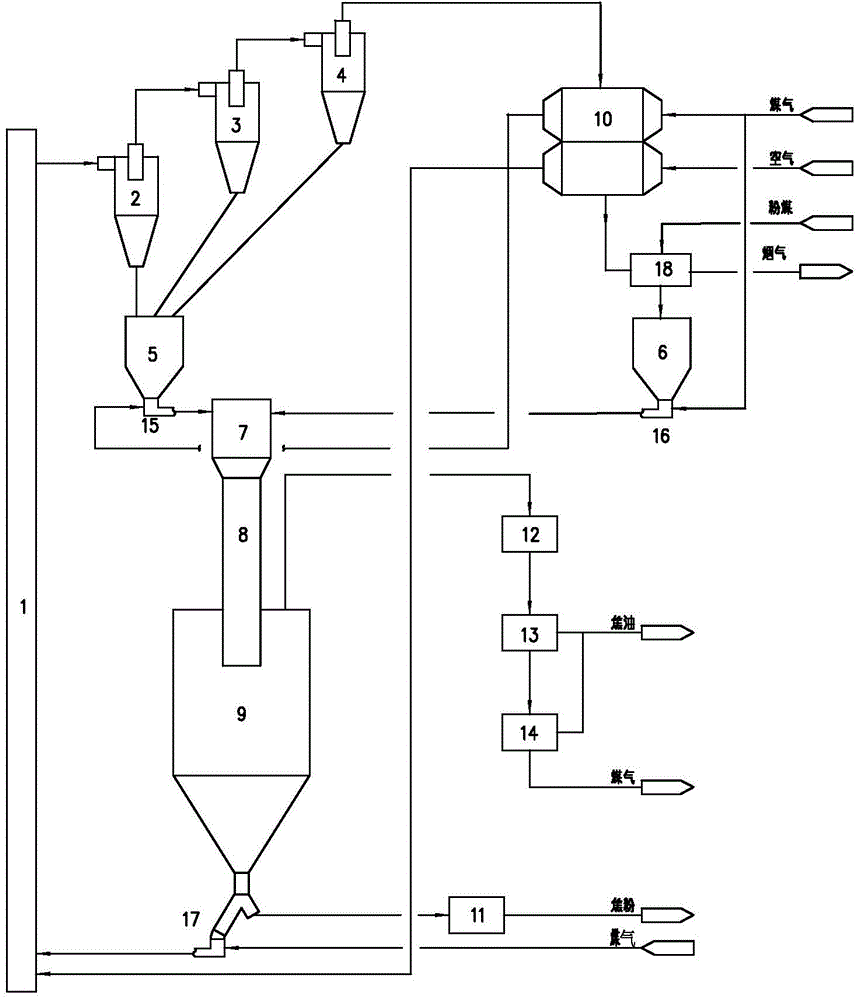

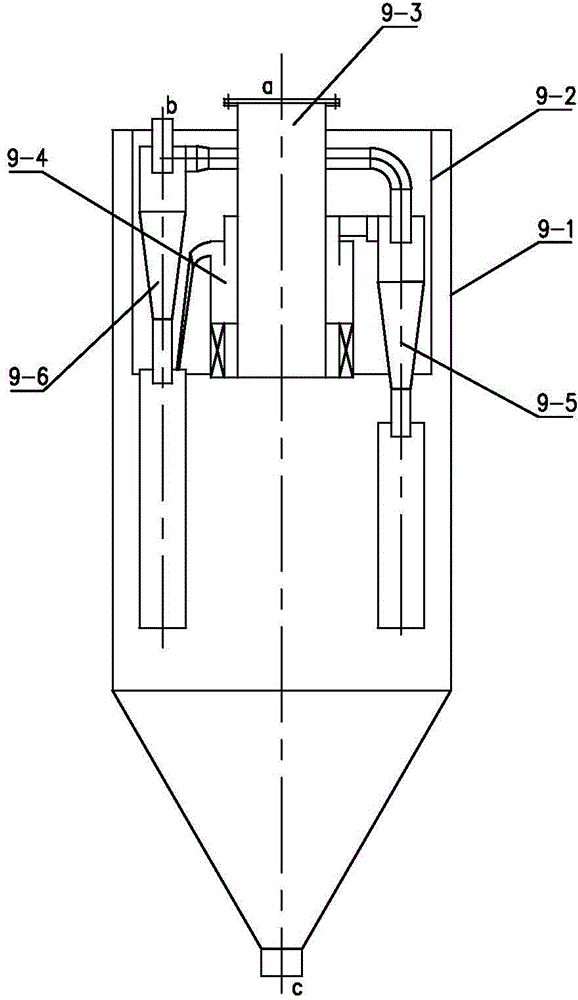

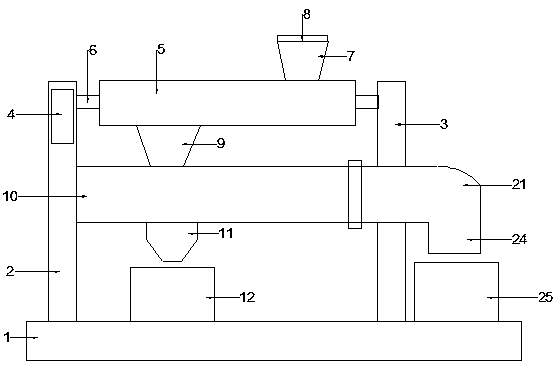

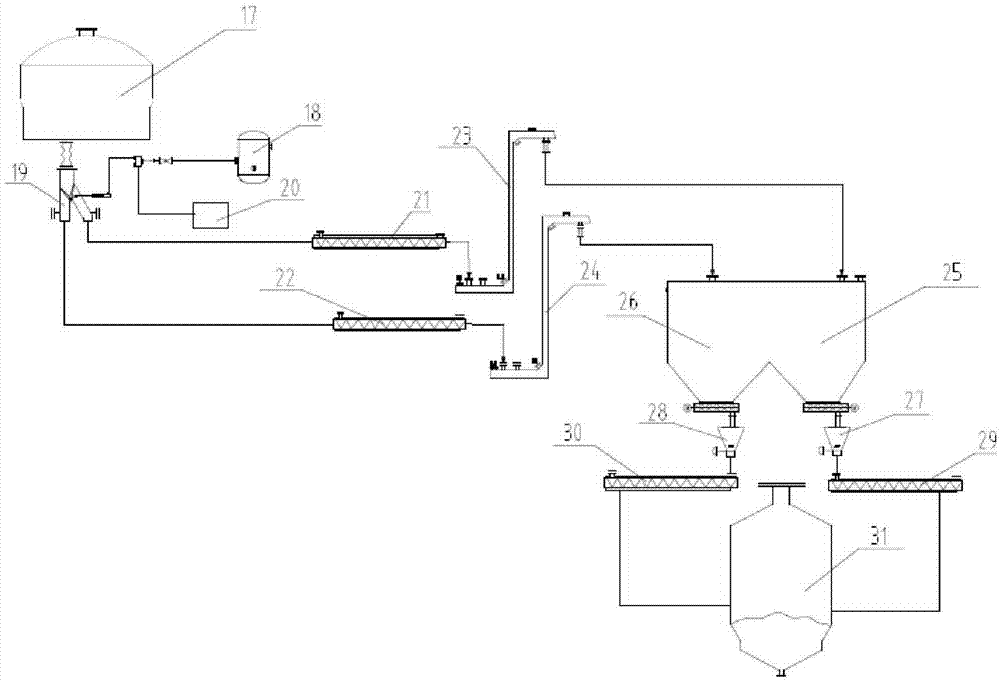

Down-flow gas semi-coke activated pulverized coal pyrolysis system and method

ActiveCN104449774AImprove pyrolysis efficiencyImprove dust removal efficiencyDirect heating destructive distillationGasification processes detailsCycloneFlue gas

The invention relates to a down-flow gas semi-coke activated pulverized coal pyrolysis system and method. The system is characterized in that a high-temperature flue gas heat exchanger is communicated with a second L-shaped valve, a first L-shaped valve, a vertical mill and an upward heating riser; the vertical mill is communicated with a dry pulverized coal surge bin; a cyclone mixer is communicated with a high-temperature semi-coke surge bin, the high-temperature flue gas heat exchanger, the dry pulverized coal surge bin and a downer reaction pipe; the downer reaction pipe is communicated with an oil-gas cyclone dust collector; the oil-gas cyclone dust collector is communicated with a semi-coke cooler and the upward heating riser; the upward heating riser is communicated with a primary cyclone dust collector; the primary cyclone dust collector is communicated with a secondary cyclone dust collector; the secondary cyclone dust collector is communicated with a ternary cyclone dust collector; the ternary cyclone dust collector is communicated with the high-temperature flue gas heat exchanger; and the primary cyclone dust collector, the secondary cyclone dust collector and the ternary cyclone dust collector are communicated with the high-temperature semi-coke surge bin. The system and the method can be used for improving the yield of coal tar and reducing the consumption of energy, the dust collectors discharge materials smoothly, and subsequent fine dust removal is carried out stably.

Owner:王树宽

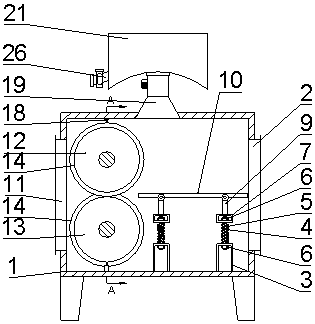

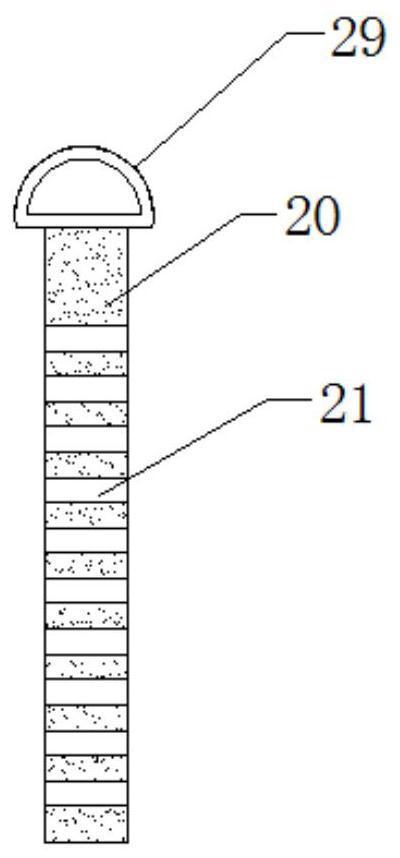

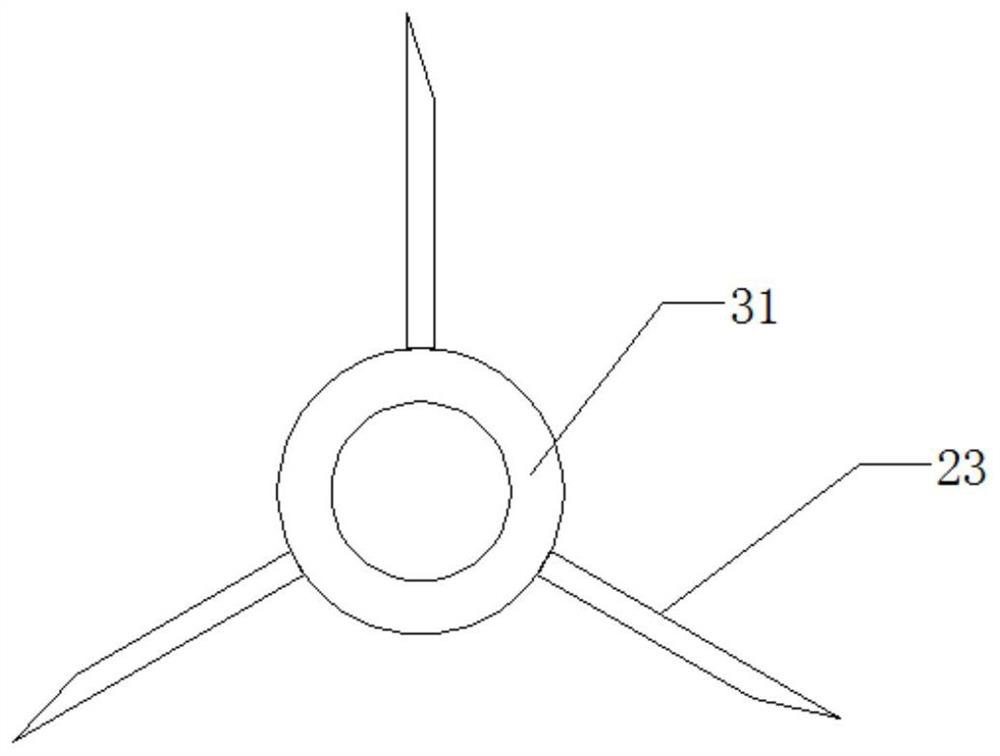

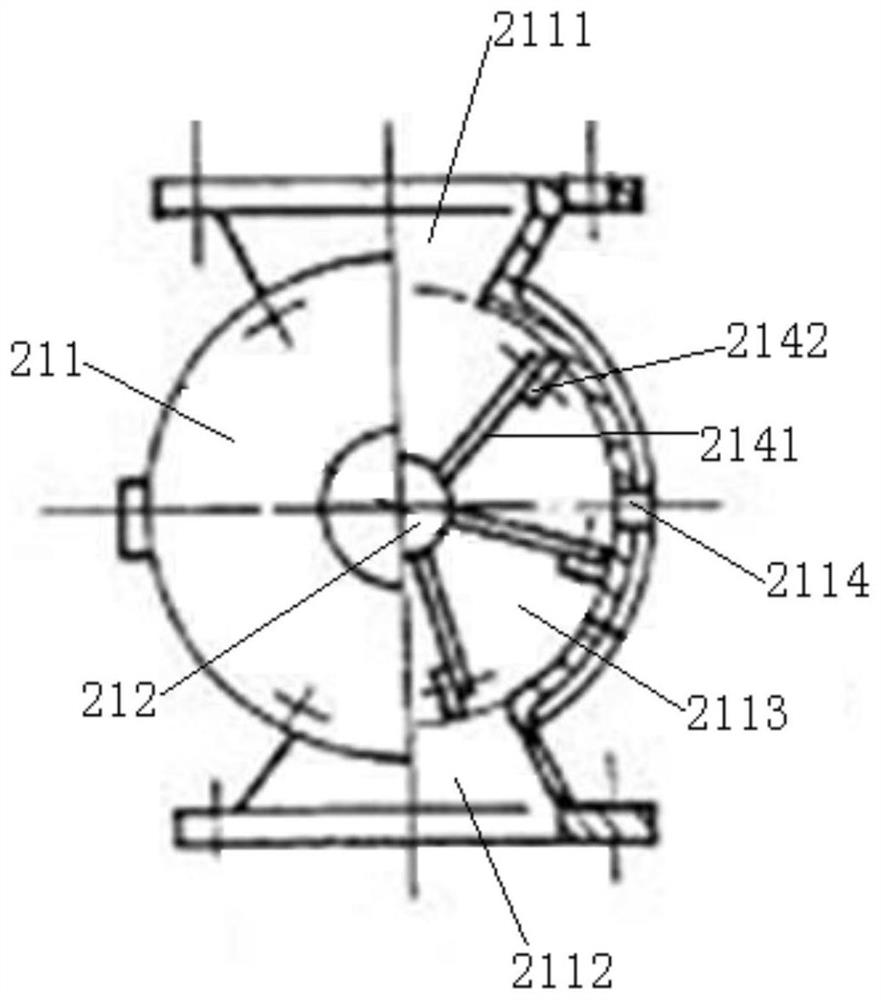

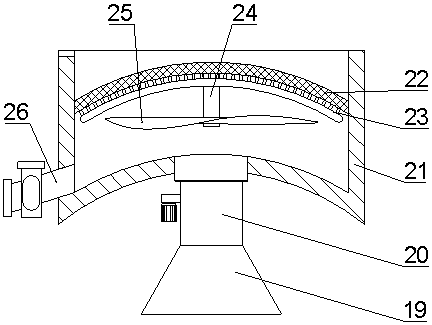

Internal combustion heating rotation conical biomass gasification furnace

InactiveCN101538484AIncrease temperatureImprove efficiencyCombined combustion mitigationCombustible gas productionProcess engineeringBiomass gasifier

The invention provides an internal combustion heating rotation conical biomass gasification furnace which is characterized in that the furnace body is internally provided with two concentric cones, wherein the external cone is a rotation cone and the internal cone is a fixed cone; the top of the rotation cone is connected with a material cylinder at the lower section; the top of the fixed cone is communicated with a smoke gas pipeline; the bottom end surface of the fixed cone is closed and the lower part thereof is tangentially connected with a combustion pipeline; the side wall of the furnace body is arranged as jacket structure; the jacket comprises a high-temperature resistance furnace wall, a combustion gas pipeline, a heat preservation layer and an external wall of the gasification furnace sequentially from inside to outside; the airflow passage in which the combustion gas is led out from the gasification furnace is that the combustion gas is led to the bottom port of the combustion gas pipeline from the bottom of the gasification furnace along the inclined surface of the conical furnace bottom; the delivery outlet of the combustion gas is arranged at the upper part of the combustion gas passage; and a gas transmission pipeline connected on the delivery outlet of the combustion gas outside the gasification furnace is connected with a gas storage cabinet by an induced draft fan. The gasification furnace greatly improves the biomass gasification rate and the heat value of the combustion gas.

Owner:HEFEI UNIV OF TECH

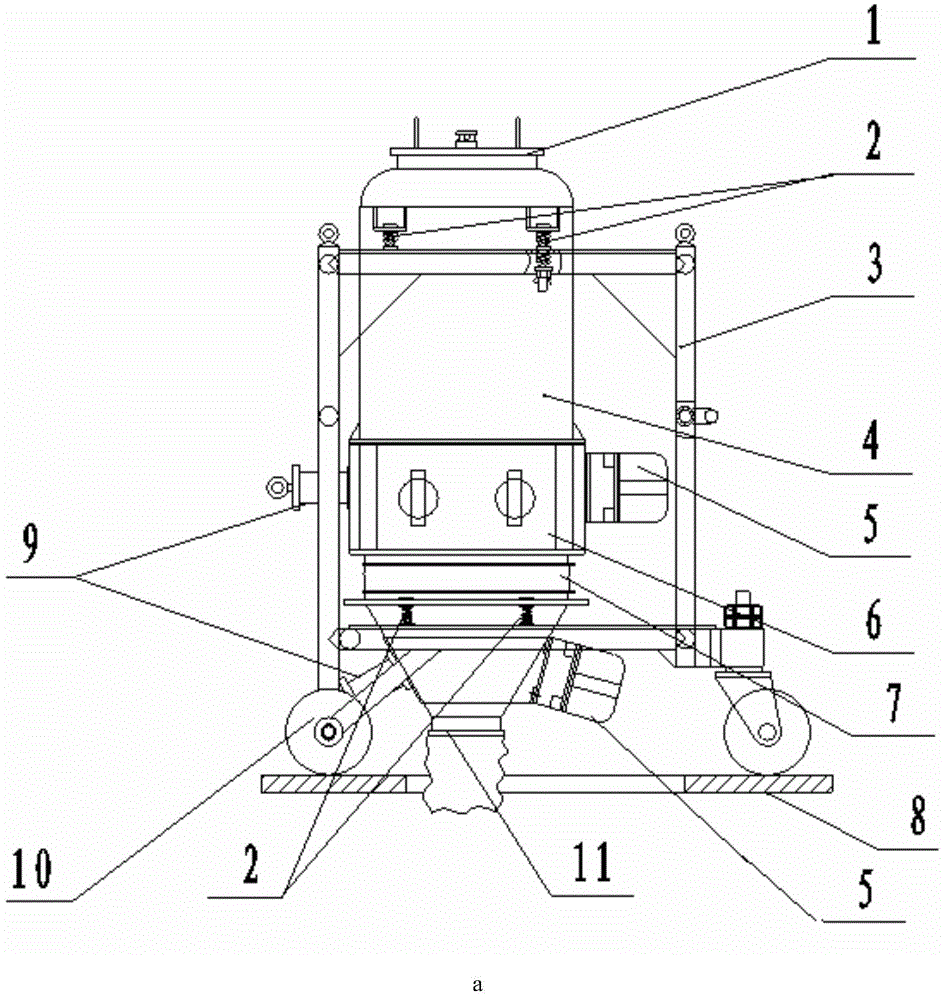

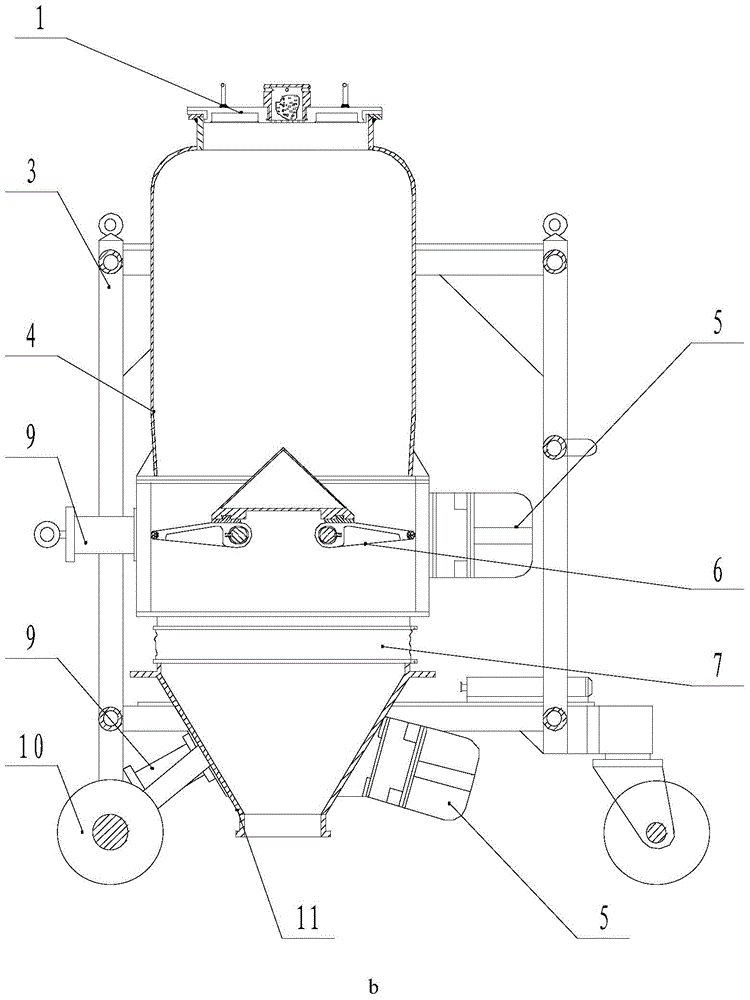

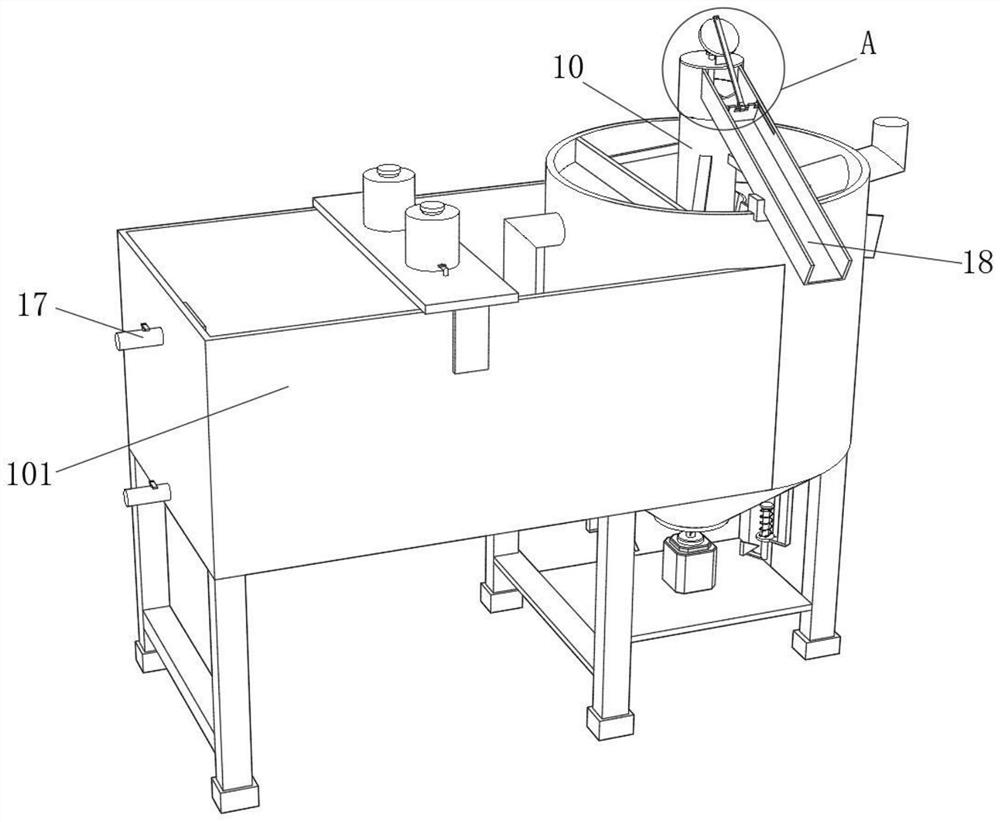

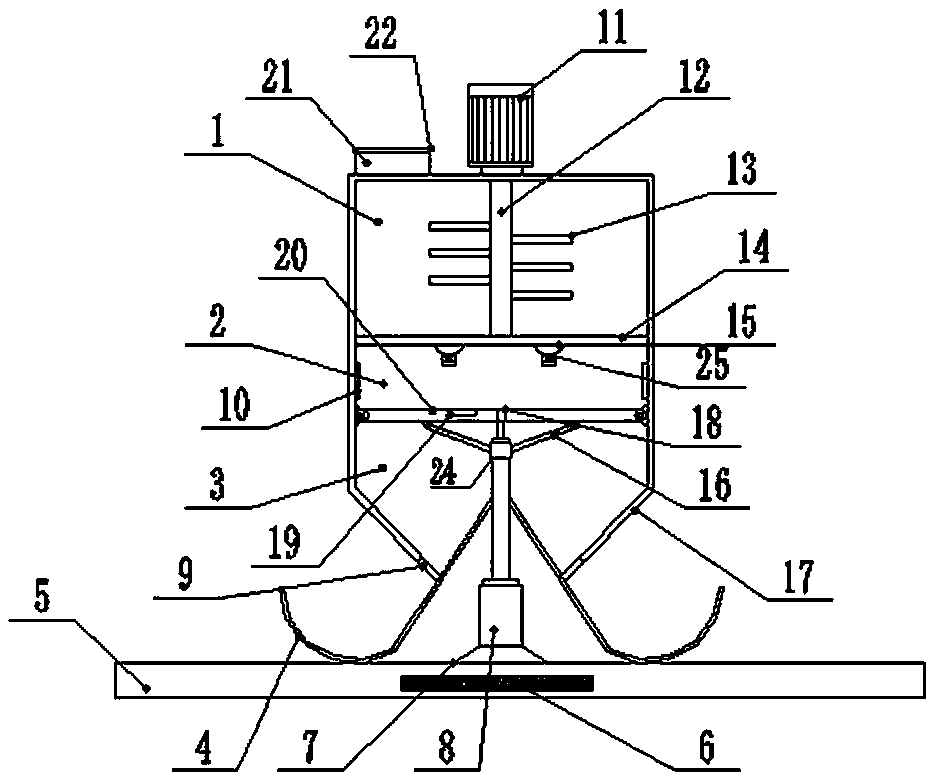

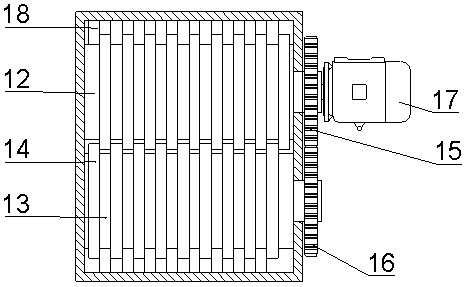

Powder storage device with quantitative discharging function

ActiveCN104309956APrevent blocking phenomenonUniform feedingLarge containersMechanical engineeringEngineering

The invention relates to a powder storage device with a quantitative discharging function. The powder storage device is characterized in that a material containing barrel is mounted on an upper cross beam of a frame through a flexible connector; a quantitative discharging device is fixedly arranged below the material containing barrel; a discharging hopper is fixedly arranged below the quantitative discharging device; a dustproof cover is arranged on the discharging hopper in a sleeving way; the number of explosion-proof electromagnetic vibrators is two, the two explosion-proof electromagnetic vibrators are respectively mounted on a supporting base of the quantitative discharging device and a connecting base of the discharging hopper; the number of air hammers is two, one of the air hammers is mounted on the supporting base of the quantitative discharging device, and the other air hammer is mounted on a connecting plate of the discharging hopper. The powder storage device has the benefits that the powder storage device can be used for automatic quantitative discharging, transportation and storage of a lot of power stored; through the design of the structure and the adjustment of the vibration frequency of the explosion-proof electromagnetic vibrators, the arching and agglomeration phenomenon of the powder in the blanking process can be greatly reduced, so that smooth blanking is ensured; the power quantitative discharging is realized through real-time monitoring of power weight in the discharging process.

Owner:XIAN AEROSPACE CHEM PROPULTION PLANT

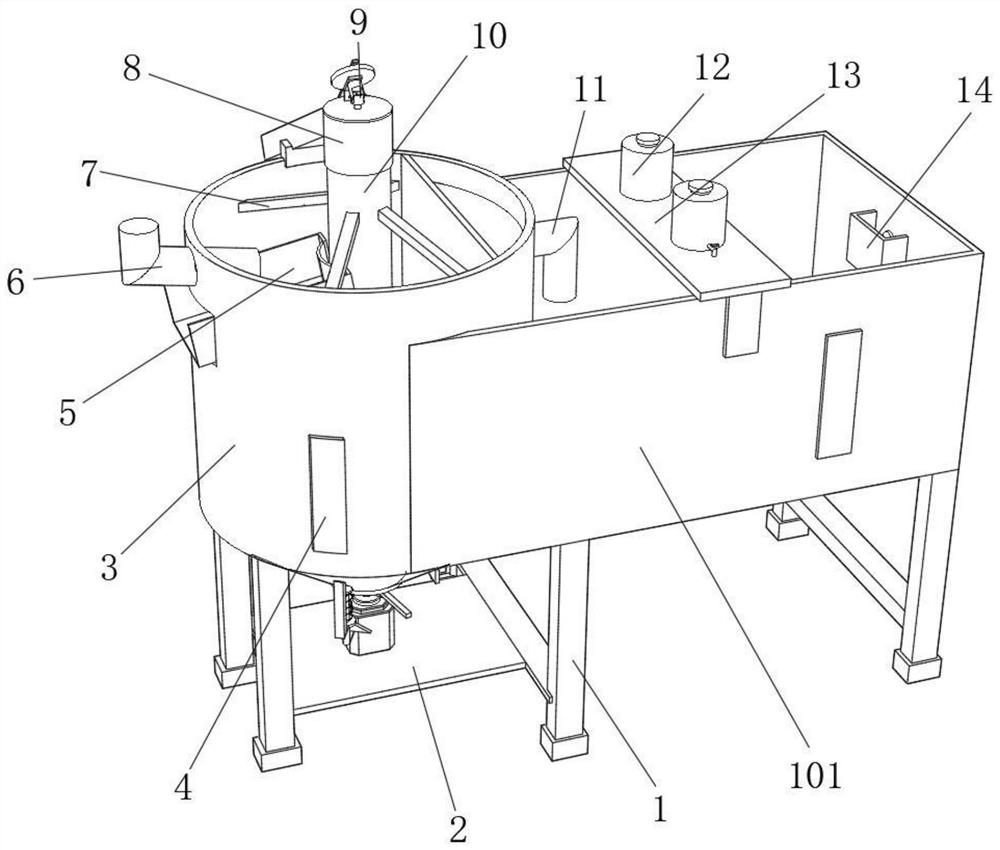

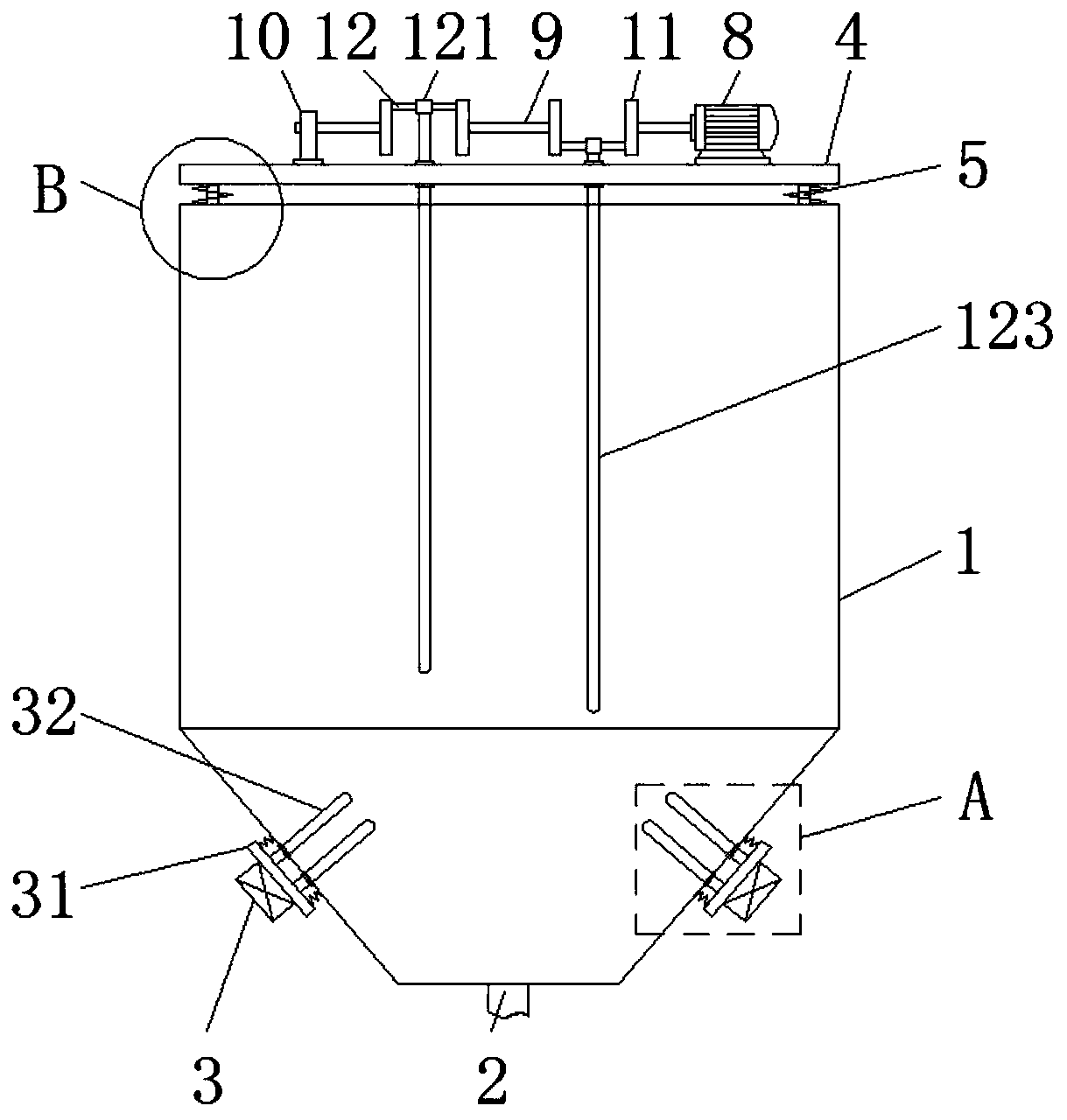

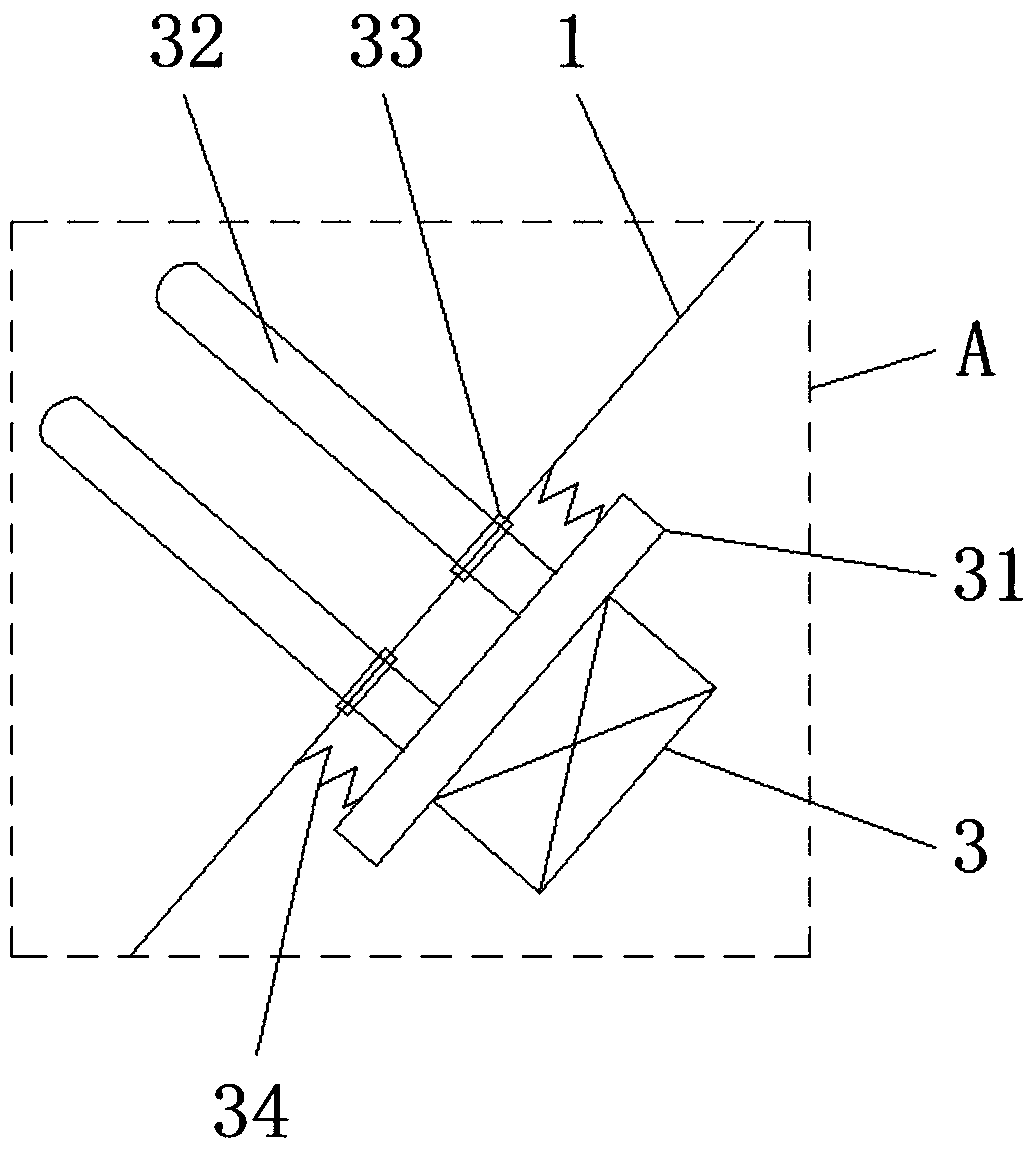

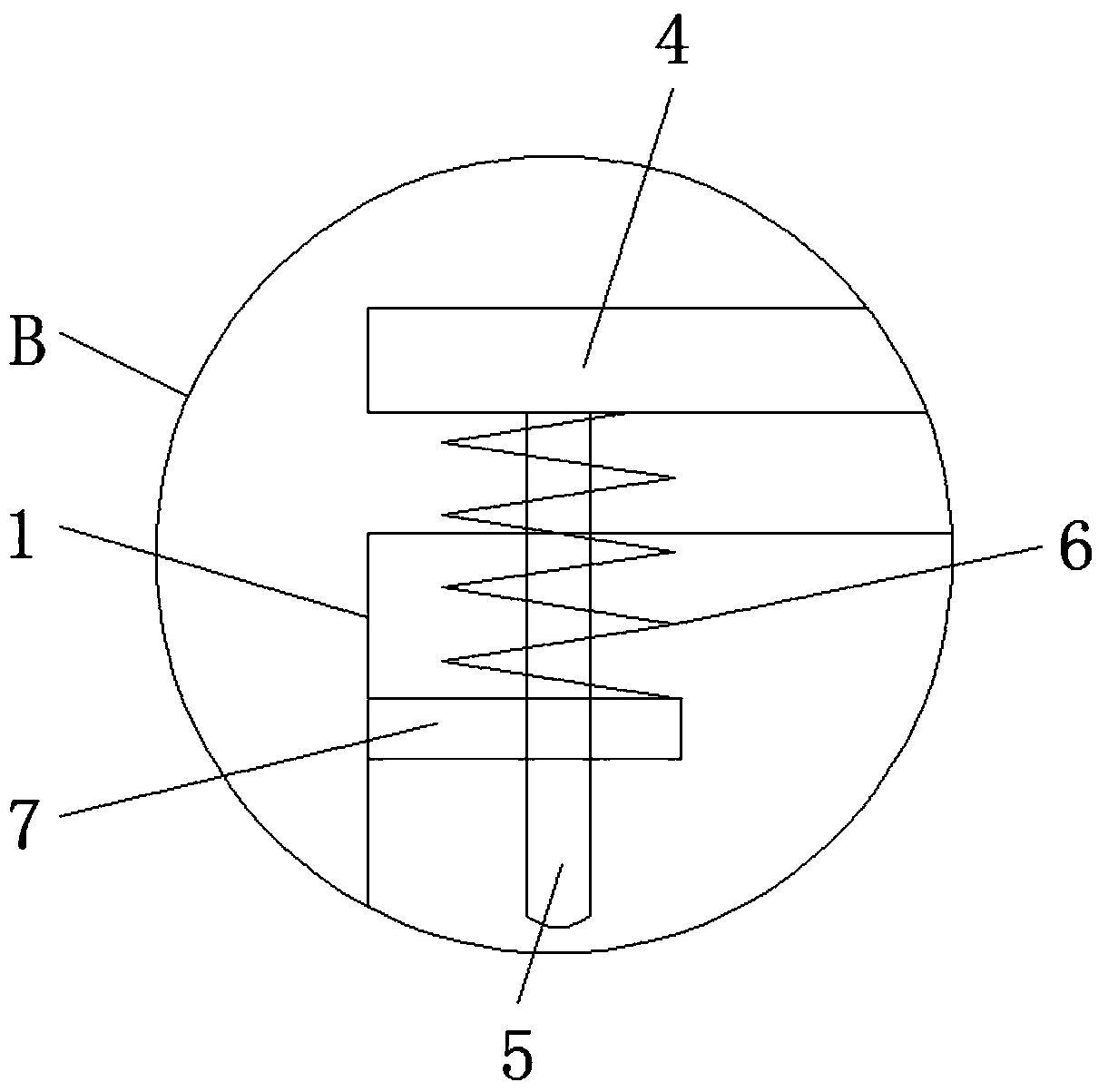

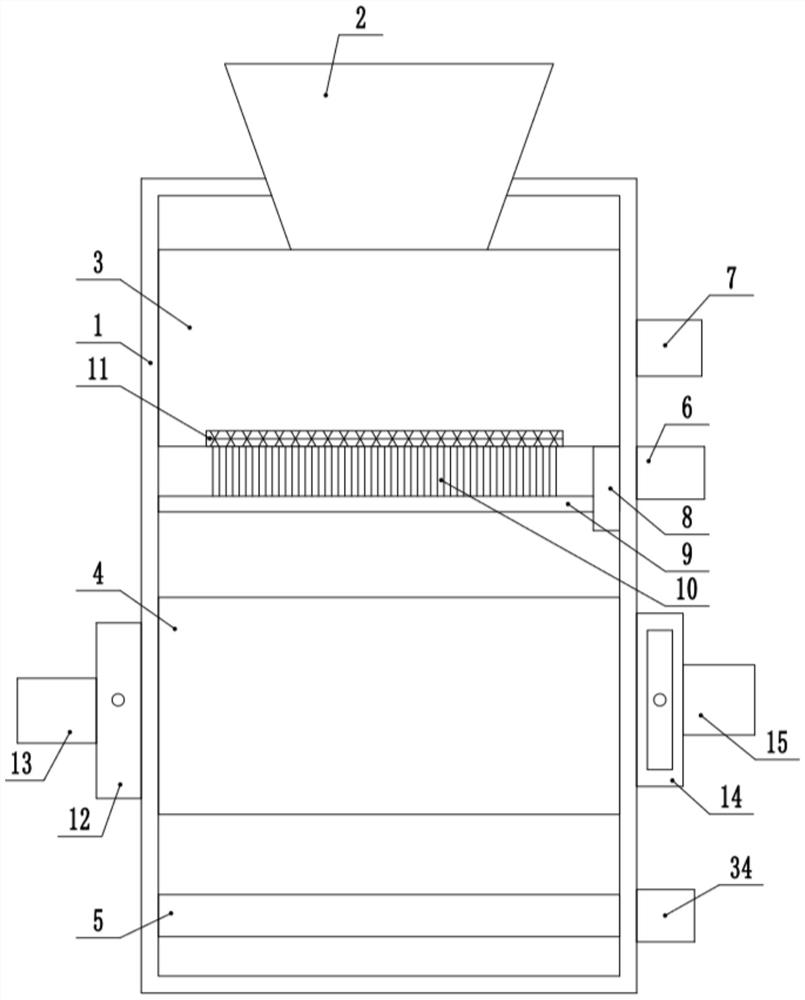

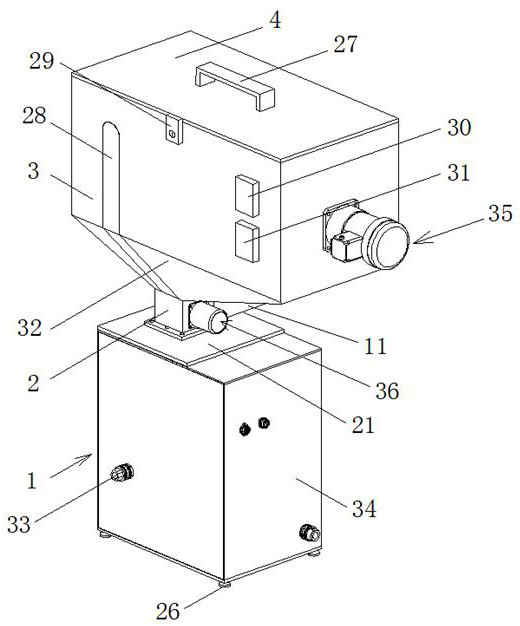

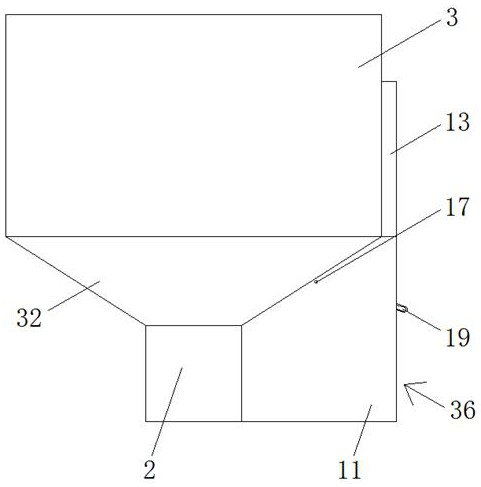

Iron furnace slag and coal cinder ash autoclaved brick production device

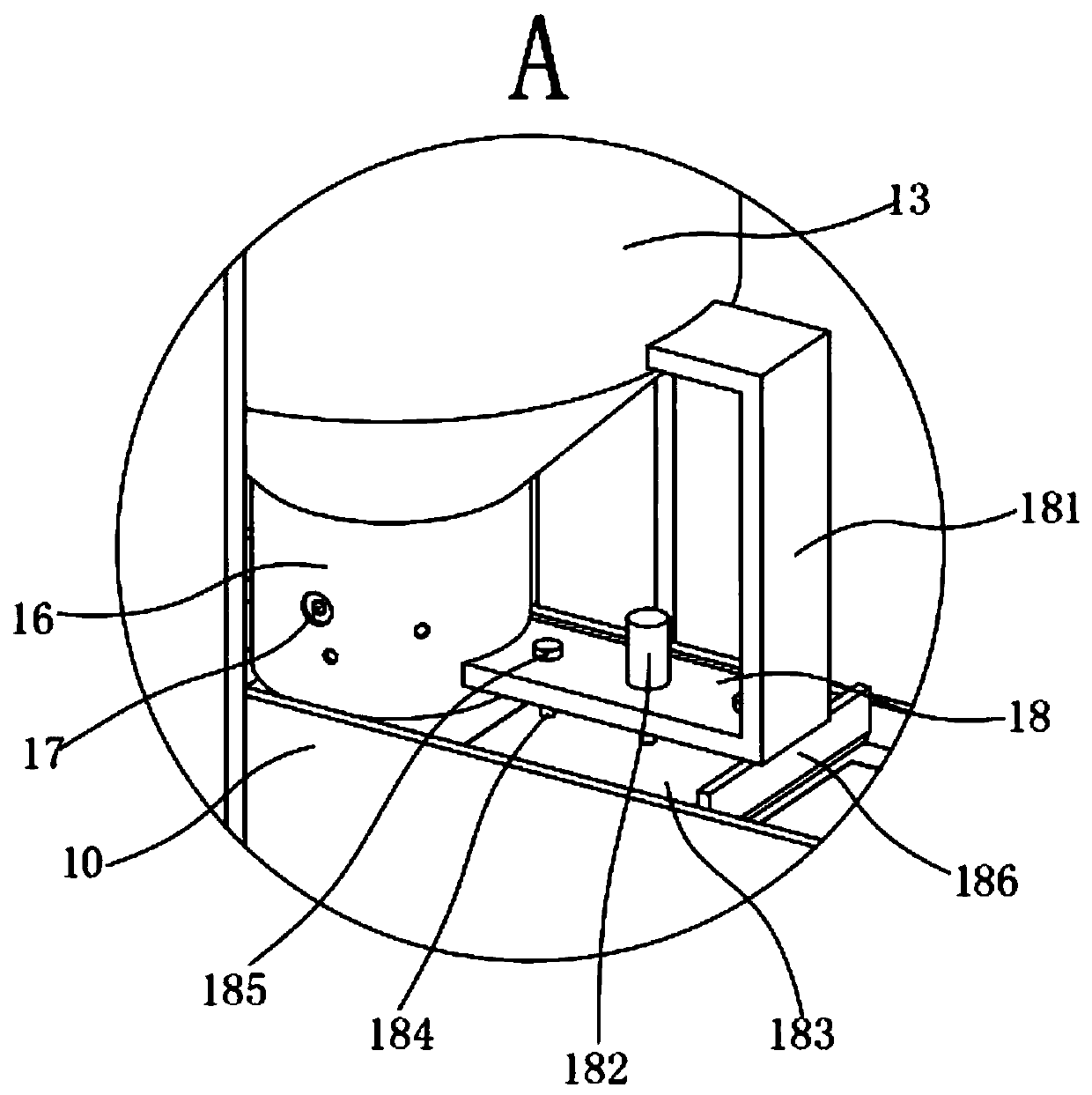

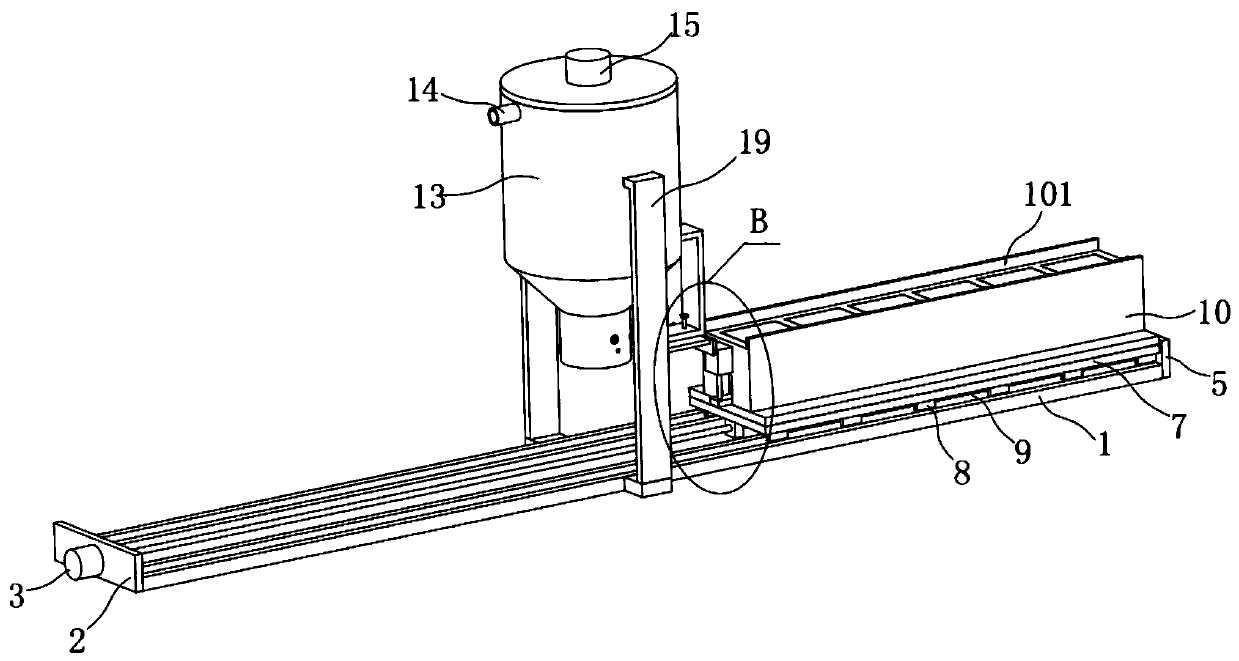

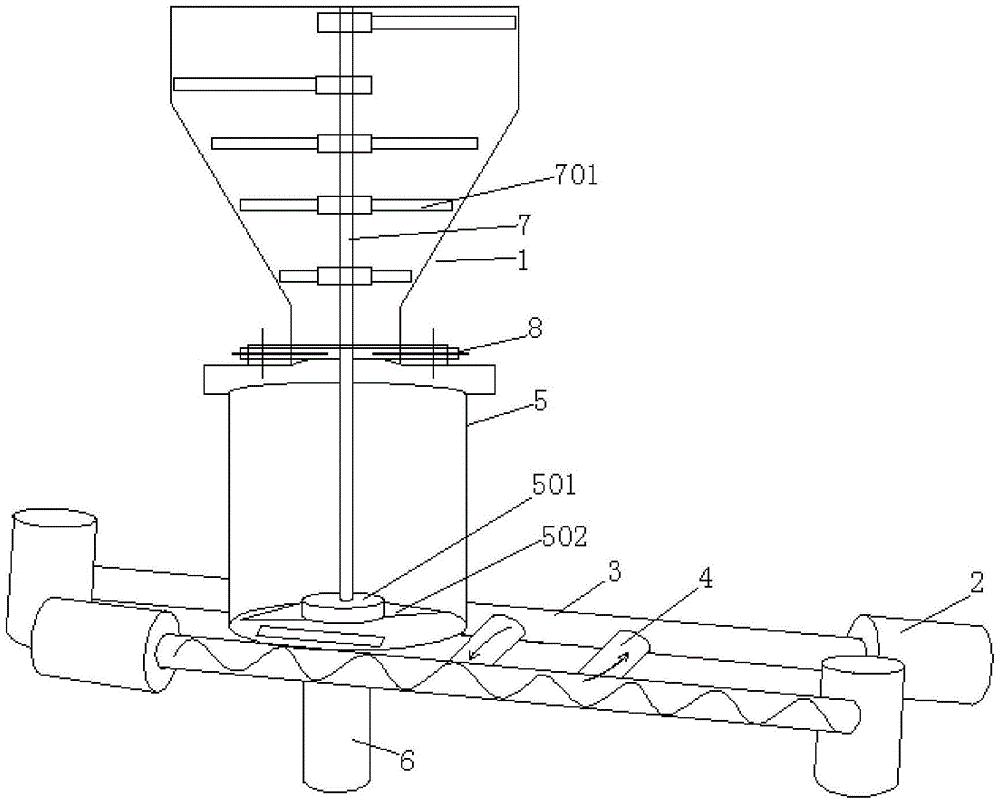

ActiveCN111216217APrevent solidificationUnobstructed feedingDischarging arrangementFeeding arrangmentsBrickSlag

The invention discloses an iron furnace slag and coal cinder ash autoclaved brick production device. The iron furnace slag and coal cinder ash autoclaved brick production device comprises a mounting seat, wherein a first mounting plate is fixed at one end of the mounting seat; a first servo motor is fixed on the first mounting plate; a screw rod is fixed on an output shaft of the first servo motor; the screw rod is in threaded connection with a movable block; a movable seat is welded to the movable block; a forming die is mounted on the movable seat; a plurality of forming cavities are formedin the forming die; a material ejection mechanism is arranged in each forming cavity; a material storage barrel is arranged in the middle of the mounting seat; the material storage barrel is welded tothe mounting seat through a supporting frame; the upper end of the material storage barrel communicates with a feeding pipe; a stirring mechanism is arranged in the material storage barrel; the bottom end of the material storage barrel communicates with a discharging pipe; a discharging switch mechanism is arranged in the discharging pipe; a material pressing mechanism is arranged on one side ofthe lower end of the discharging pipe; and the forming die is located below the discharging pipe and the material pressing mechanism. By adopting the iron furnace slag and coal cinder ash autoclaved brick production device, raw materials are stirred and the flowability is improved; and automatic discharging, material pressing, material scraping and material ejection are realized, and the working efficiency is high.

Owner:淮北市恒兴新型建材科技有限公司

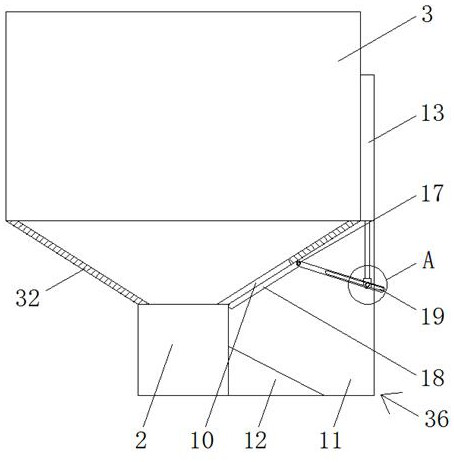

Anti-blocking device for accurately feeding materials

InactiveCN104003206AUnobstructed feedingPrecise cuttingLarge containersLoading/unloadingReturn channelEngineering

The invention discloses an anti-blocking device for accurately feeding materials. The anti-blocking device comprises a material receiving hopper, a conveying motor and a pair of fixed-quantity conveying machines, the conveying motor is fixedly installed at the back ends of the fixed-quantity conveying machines, material discharging openings are oppositely formed, a material returning channel is formed between two fixed-quantity conveying machine channels, the upper ends of the fixed-quantity conveying machine channels are communicated with a material discharging barrel, the upper end of the material discharging barrel is connected with the material receiving hopper, a rotary motor is fixedly installed on the lower end face of the material discharging barrel, an arc breaking shaft is connected to the rotary motor, and a plurality of breaking scraping blocks are arranged on the arc breaking shaft; a rotary flange is arranged on the lower end face of the material discharging barrel, and rotary blades are symmetrically arranged on the two sides of the rotary flange. By means of the anti-blocking device, the problem that powder cannot be accurately controlled to be fed is solved, the design structure is reasonable, and the materials are accurately and smoothly conveyed; when material blocking occurs at the material discharging openings, buffering can be achieved, and non-halt adjustment is achieved.

Owner:TONGLING QIANYI CHEM EQUIP

Vacuumizing device of sauce bag

InactiveCN108263654AUnobstructed feedingEvenly distributedPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringPlastic film

The invention discloses a vacuumizing device of a sauce bag. The vacuumizing device comprises a machine frame, a plastic film guiding assembly arranged on the machine frame, and a sauce conveying device. A side sealing device, a horizontal sealing device, a bag drawing device and a cutting device are sequentially arranged in the machine frame from top to bottom. The sauce conveying device comprises a conveying charging barrel, a charging hopper, a conveying motor and a conveying screw blade. The conveying screw blade is rotationally arranged in the conveying charging barrel. The input shaft end of the conveying screw blade penetrates through the end of the conveying charging barrel to be in drive connection with the output end of the conveying motor. A charging inlet of the conveying charging barrel is connected with the conical charging hopper. A transverse frame is mounted on the charging hopper. An anti-blockage motor is mounted on the transverse frame. A charging screw blade matched with the charging hopper is arranged in the charging hopper. The vacuumizing device is reasonable in structure design and capable of preventing discharging blockage effectively, thus, sauce is distributed evenly, air in the sauce bag can be pumped out, and the shelf life of the sauce bag is prolonged.

Owner:ANHUI SANXIONGDI POTATO IND

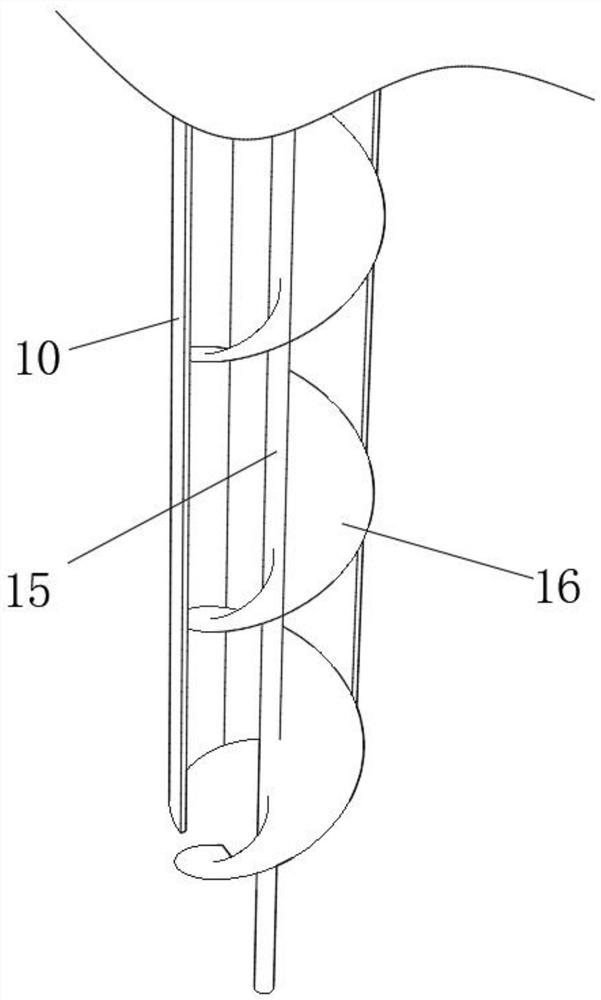

Sewage treatment device convenient for sludge cleaning

InactiveCN113651450AAutomate cleaningImprove processing efficiencyWater treatment parameter controlSpecific water treatment objectivesSludgeSewage

The invention relates to the technical field of sewage treatment, and discloses a sewage treatment device convenient for sludge cleaning. The sewage treatment device comprises a bottom frame; the top of the bottom frame is fixedly connected with a treatment tank; one side of the treatment tank is fixedly connected with a sludge discharge cylinder, and the sludge discharge cylinder is fixed to the bottom frame; the inner wall of one side of the sludge discharge cylinder is fixedly connected with a plurality of fixing rods; bottom frame; a lifting pipe is fixedly connected between the multiple fixing rods; a sludge discharging pipe is fixedly connected to the top of the lifting pipe; a lifting shaft is movably connected to one side of the lifting pipe and one side of the sludge discharging pipe; and a spiral blade is fixedly connected to one side of the lifting shaft. According to the sewage treatment device, sludge in sewage can be automatically cleaned through the spiral blade, and the sewage treatment efficiency of the device is improved; meanwhile, the sludge can be smoothly discharged through a sludge pushing mechanism, and the discharging effect of a sludge pouring hopper is improved; and the sewage in the treatment tank can be deodorized through a deodorization mechanism, and the deodorization effect of the device is improved.

Owner:秦文燕

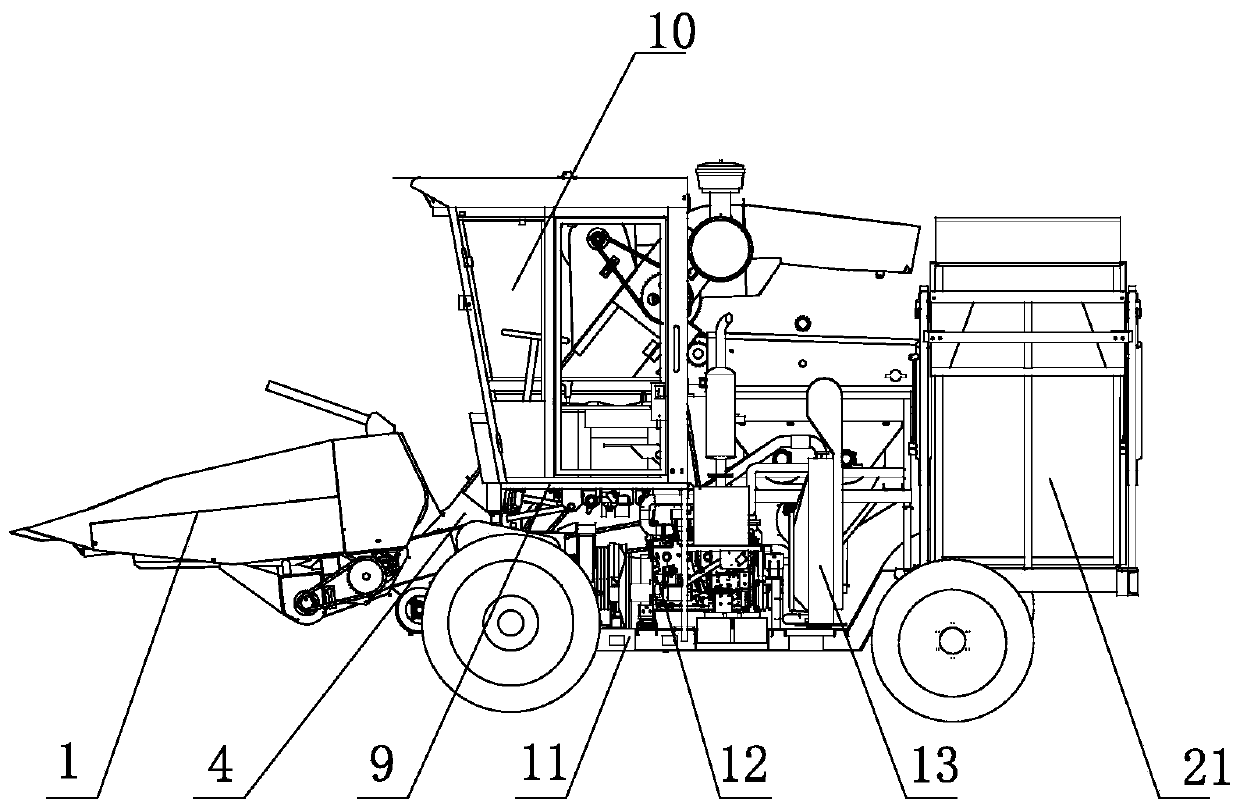

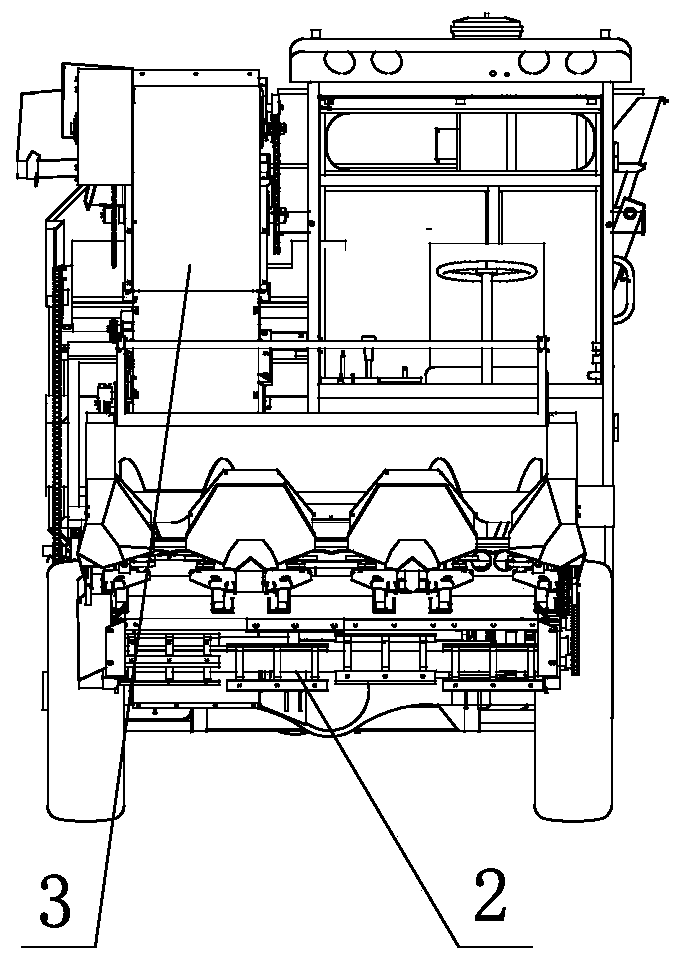

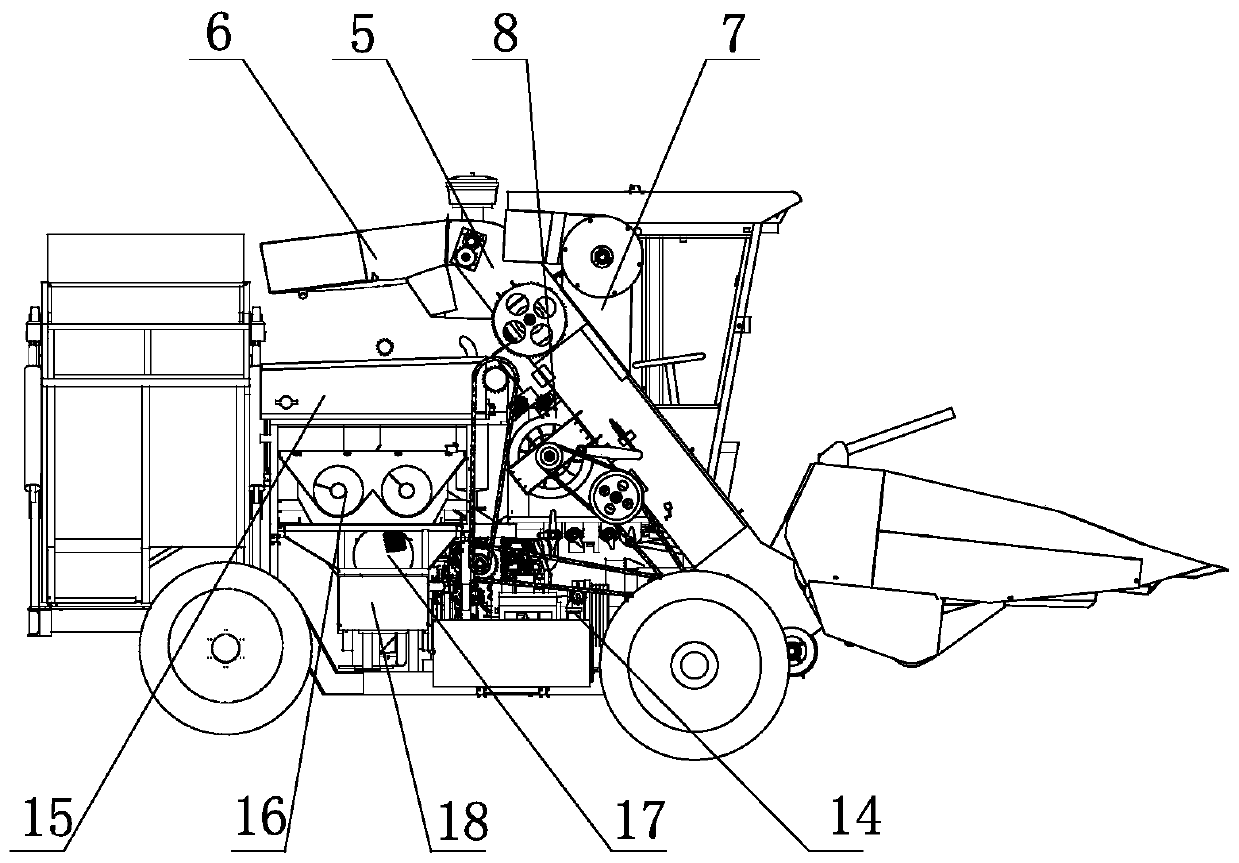

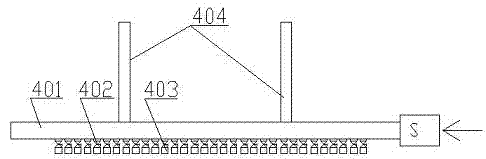

Three-row time-sharing four-wheel-drive hill corn harvester

PendingCN111034460ACompact structureImprove stabilityMowersAgricultural undercarriagesDrive shaftAgricultural engineering

The invention belongs to the field of agricultural machinery, and specifically relates to a three-row time-sharing four-wheel-drive hill corn harvester. The three-row time-sharing four-wheel-drive hill corn harvester comprises a chassis assembly which comprises a power system, a walking chassis system and a driving system, wherein the power system is connected with a gearbox; the first end of thegearbox is connected with front wheels through a front drive transmission shaft; the second end of the gearbox is connected with rear wheels through a rear drive transmission shaft; a clutch is connected with and arranged between the gearbox and the rear drive transmission shaft; the rear drive transmission shaft obtains transmission force output by the gearbox according to the clutch state of theclutch; and the front drive transmission shaft obtains transmission force output by the gearbox all the time. The three-row time-sharing four-wheel-drive hill corn harvester provided by the inventionis compact in overall structure, ultralow in gravity center, good in stability, high in climbing capacity, comfortable in operation environment, high in harvesting efficiency, capable of achieving time-sharing four-wheel-drive operation and applicable to operation in large hilly land parcels.

Owner:SHANDONG JUMING MASCH CO LTD

Device for solving powder material coking arch

InactiveCN109353704AImprove arch breaking effectGood for arch breakingLarge containersDevice PlateEngineering

The invention discloses a device for solving powder material coking arch. The device comprises a material bin, shaking devices and a driving motor, wherein the bottom end of the material bin is provided with a material outlet, the shaking devices are arranged on the edge sides of the material bin, the top of the material bin is provided with device plates horizontally distributed, the inner wall of the top end of the material bin is provided with horizontal plates horizontally distributed in a welded manner, the driving motor is installed on the upper end faces of the device plates and connected with a rotating shaft, round plates connected with the rotating shaft are arranged above the device plates, and every two adjacent round plates are connected through horizontal rods. According to the device for solving the powder material coking arch, by means of redesign on the top structure of an existing material bin, arch breaking operations on middle-lower portion materials inside the material bin are facilitated, by means of use of the shaking devices and related structures, the use of a traditional fluidization device is replaced, the bottom arch breaking effect of the material bin can be made to be better, and meanwhile, the material unloading process is made to be more unobstructed.

Owner:HUNAN CHUANGYUAN NEW MATERIALS

Discarded fungus package disposal device for edible fungus production

ActiveCN109229676AEasy to collectSmall footprintPlastic recyclingGrain treatmentsEngineeringPollution

The invention discloses a discarded fungus package disposal device for edible fungus production, which comprises: a bracket; a feeding shell fixed on the top of the inner wall of the bracket; a feeding motor, which is fixed on the top of the inner wall of the bracket; a decelerator, which is connected on the bottom of the feeding motor by an output shaft; a screw feeding shaft, which is connectedby the output shaft on one side of the decelerator; and one end of the screw feeding shaft away from the decelerator runs through the feeding shell and extends to the inside of the feeding shell. Thediscarded fungus package disposal device relates to the technical field of the fungus package disposal techniques. According to the discarded fungus package disposal device for edible fungus production, the goal of stripping the discarded fungus package, collecting the discarded fungus package conveniently, and preventing the clogging of the discarded fungus package feed can be achieved, the spaceoccupied by the discarded fungus package is saved, the transportation of the discarded fungus material and the next processing to the discarded fungus material are convenient, thereby working continuously, not leaking the materials, avoiding the pollution to the environment, being convenient for the people to concentrate the processing to the plastics, preventing the fungus package to clog, making the feed material more unobstructed, and enhancing the work efficiency.

Owner:JIANGSU YUGUAN MODERN AGRI S AND T CO LTD

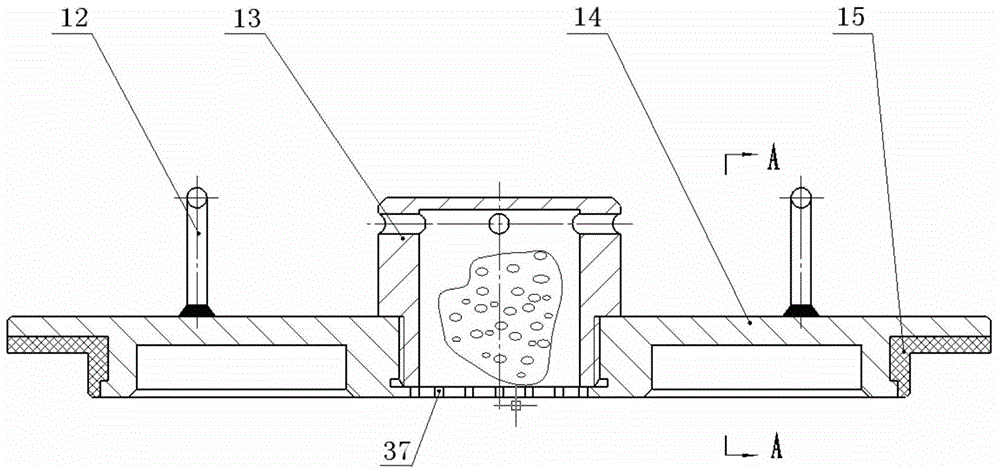

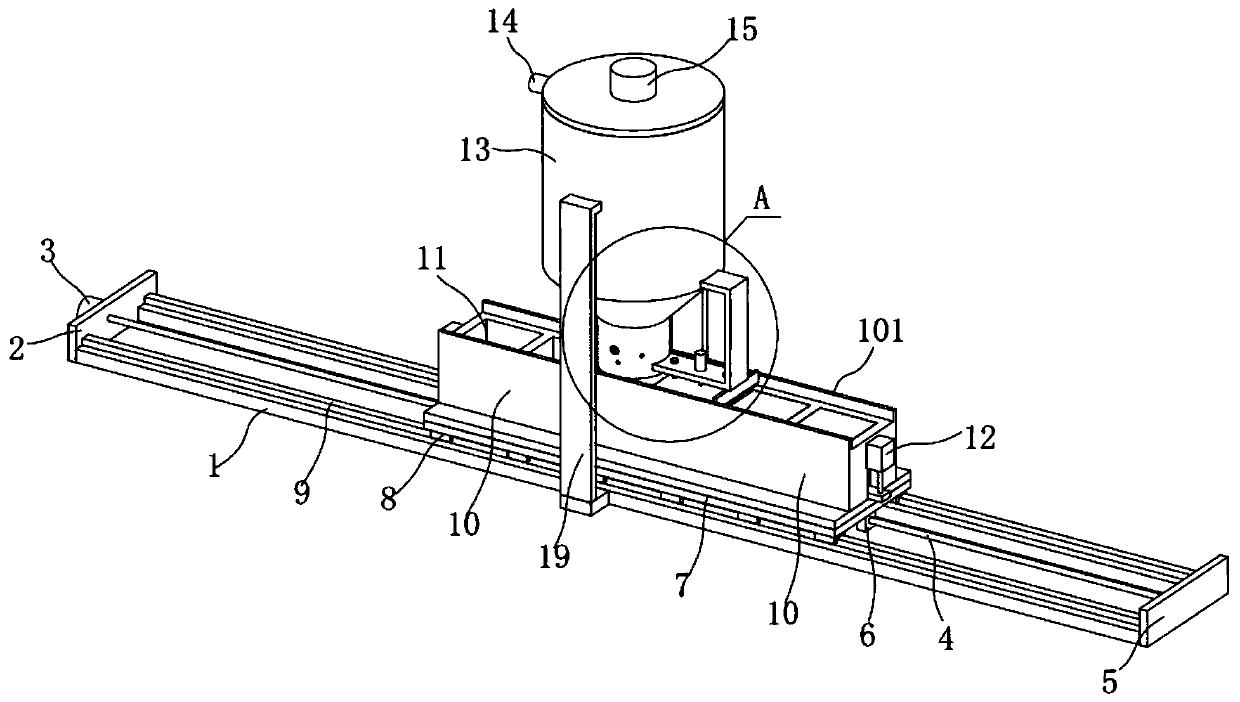

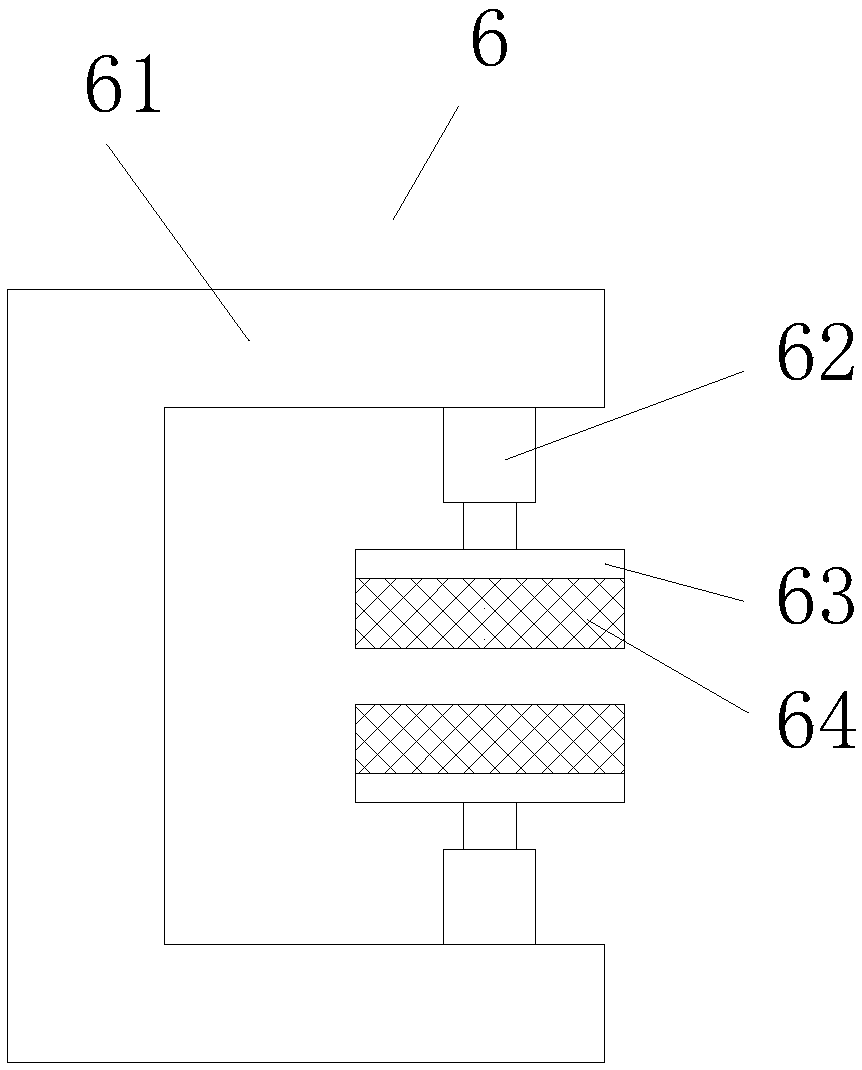

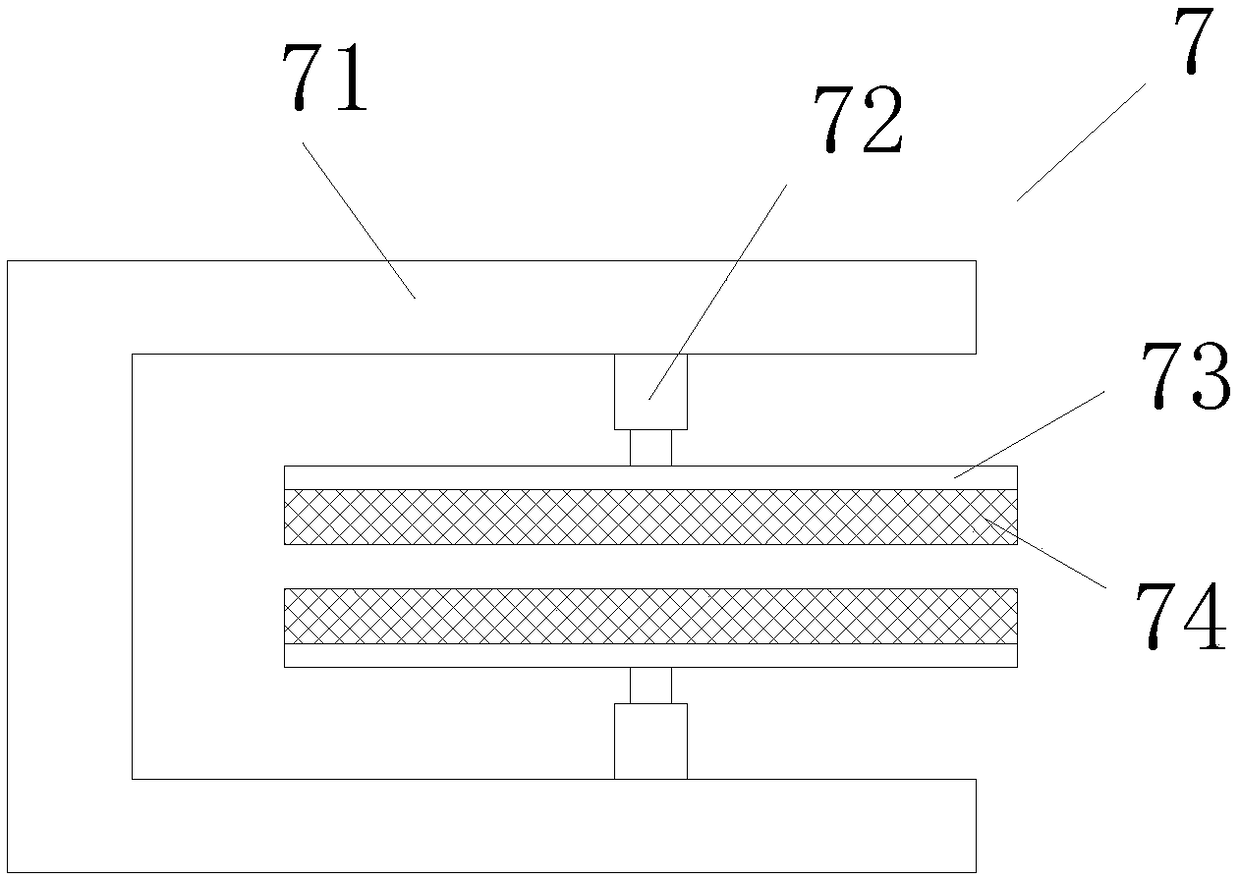

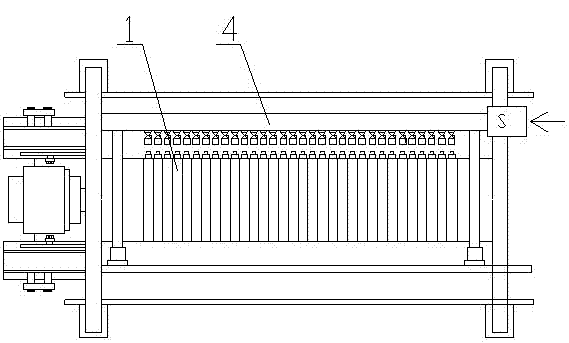

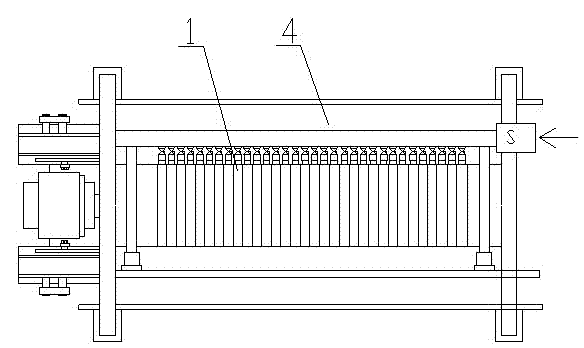

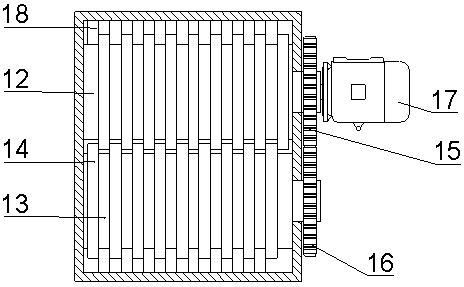

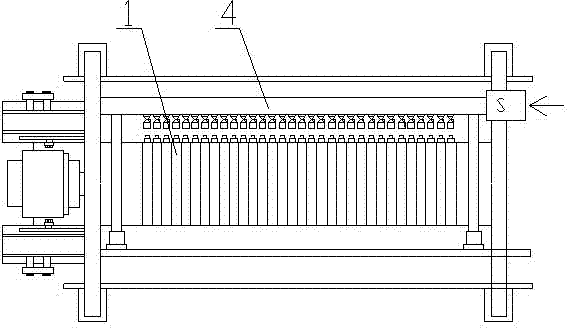

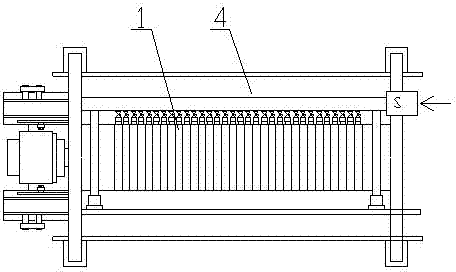

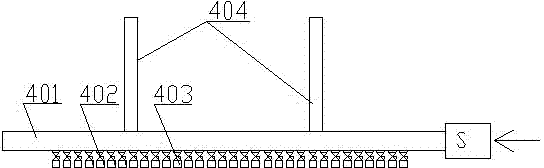

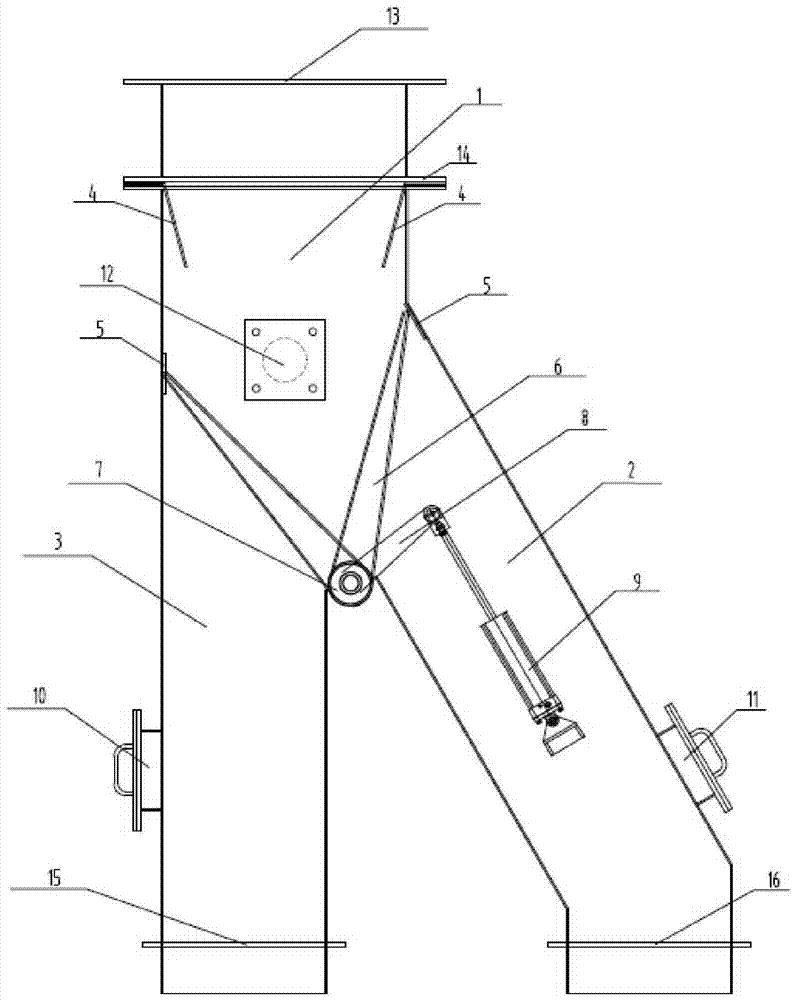

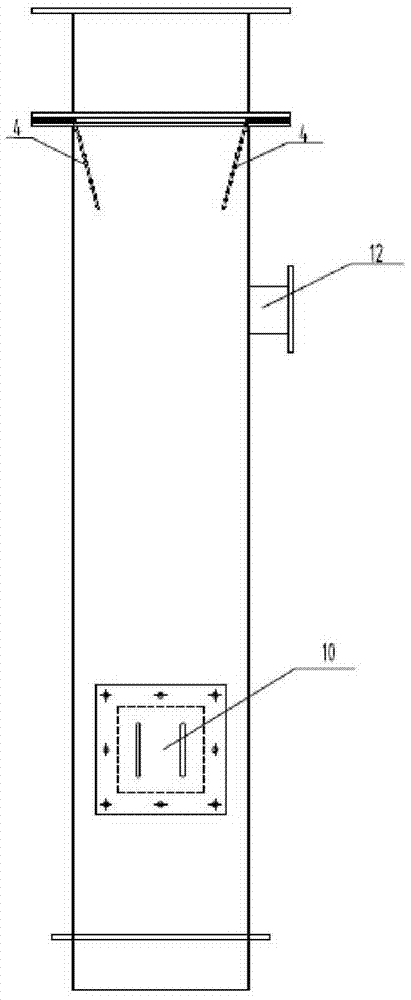

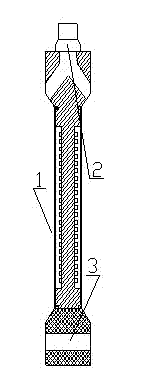

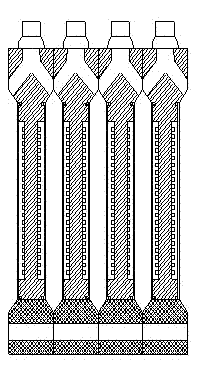

FIFO (Fast-In Fast-Out) efficient filter-cloth filter-plate pressure filter and high-speed feeding method

InactiveCN102527112AMeet the pressing requirementsImprove feeding efficiencyFiltration separationPlate pressureEngineering

The invention relates to a FIFO (Fast-In Fast-Out) efficient filter-cloth filter-plate pressure filter capable of speedily feeding and speedily discharging and a high-speed feeding method. The FIFO efficient filter-cloth filter-plate pressure filter comprises a filter-cloth filter-plate pressure filter. In the filter-cloth filter-plate pressure filter, feeding ports are arranged at the upper ends of a plurality of filter-cloth filter-plates in a filter-cloth filter-plate set while discharging ports are arranged at the lower ends of the filter-cloth filter-plates; a vertical lifting feeding assembly is located above the feeding ports of the filter-cloth filter-plate set; and a plurality of feeding nozzles which are communicated with the part below the vertical lifting feeding assembly are respectively matched with the feeding ports of the filter-cloth filter-plates in the filter-cloth filter-plate set. The FIFO efficient filter-cloth filter-plate pressure filter has the advantages that: 1) the precedent of directly feeding through the filter-cloth filter-plates is created, the feeding efficiency is high, the feeding is smooth and the energy consumption is low; 2) a check valve is served as a valve of the feeding ports, the demand on high-speed feeding is met, the valve can be automatically locked and closed after the feeding is ended, and the squeezing demand of the filter-cloth filter-plates is met; and 3) the discharging ports are arranged at the lower ends of the filter-cloth filter-plates, so that the discharging speed is high and no energy is consumed.

Owner:青岛易兴源环保科技有限公司

Blanking unit structure in rotary type packaging machine

The invention discloses a blanking unit structure in a rotary type packaging machine. The blanking unit structure comprises a fixing seat, wherein a guide sleeve is arranged on one side of the fixing seat; a movable guide rod is matched in the guide sleeve in a guide manner; a transversely straight fixing plate is mounted at the upper end part of the movable guide rod; a tapered hopper is mounted on the fixing plate; a connecting rod is mounted at the lower end part of the movable guide rod; the other end of the connecting rod is rotationally mounted on a crank arm below the connecting rod; the middle of the crank arm is rotationally mounted on a mounted bearing; the other end of the crank arm is connected with the connecting rod; the other end of the connecting rod is connected with the lower end of a swing arm above the connecting rod; a spring is arranged between the lower end of the swing arm and a limit baffle below the swing arm; and a roller is mounted in the middle of the swing arm and matched with a blanking cam on one side of the roller in a rolling manner. The blanking unit structure is reasonable in structural design, and the cam indirectly drive the tapered hopper to move up and down, so that the tapered hopper moves slowly by the aid of the driving of the cam for blanking along with charging, a material can be blanked smoothly at the same time, and the completeness of a whole blanking process is guaranteed.

Owner:ANHUI ZENGRAN PACKAGING SCI & TECH

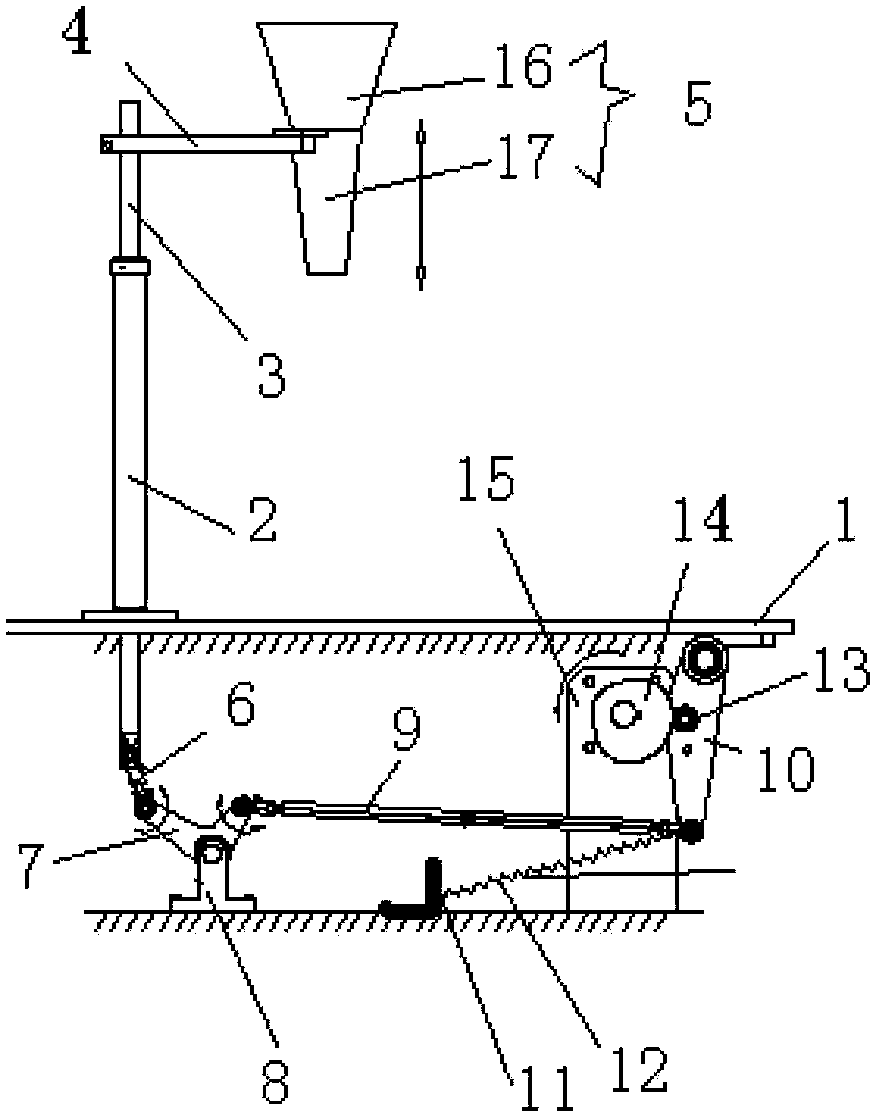

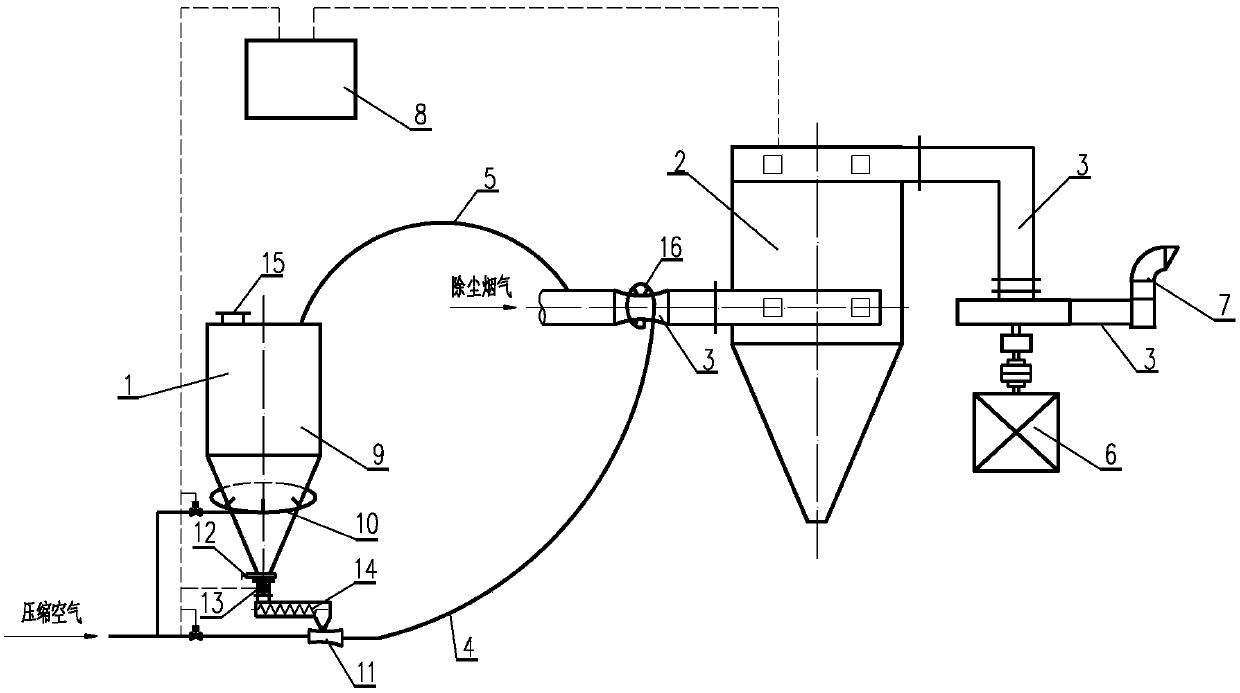

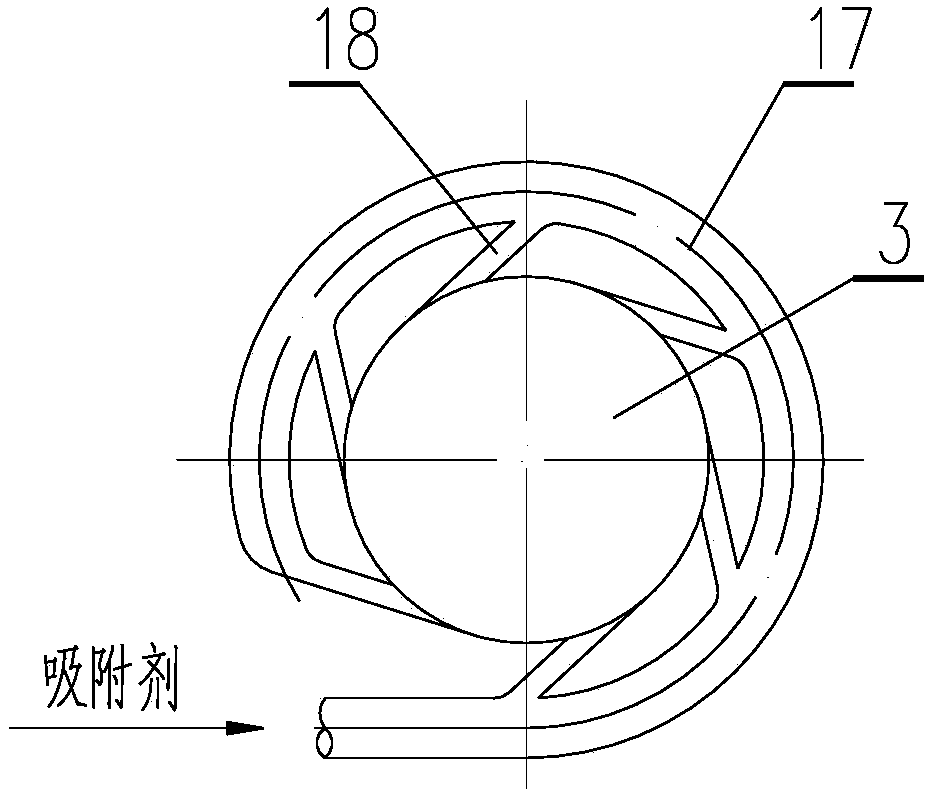

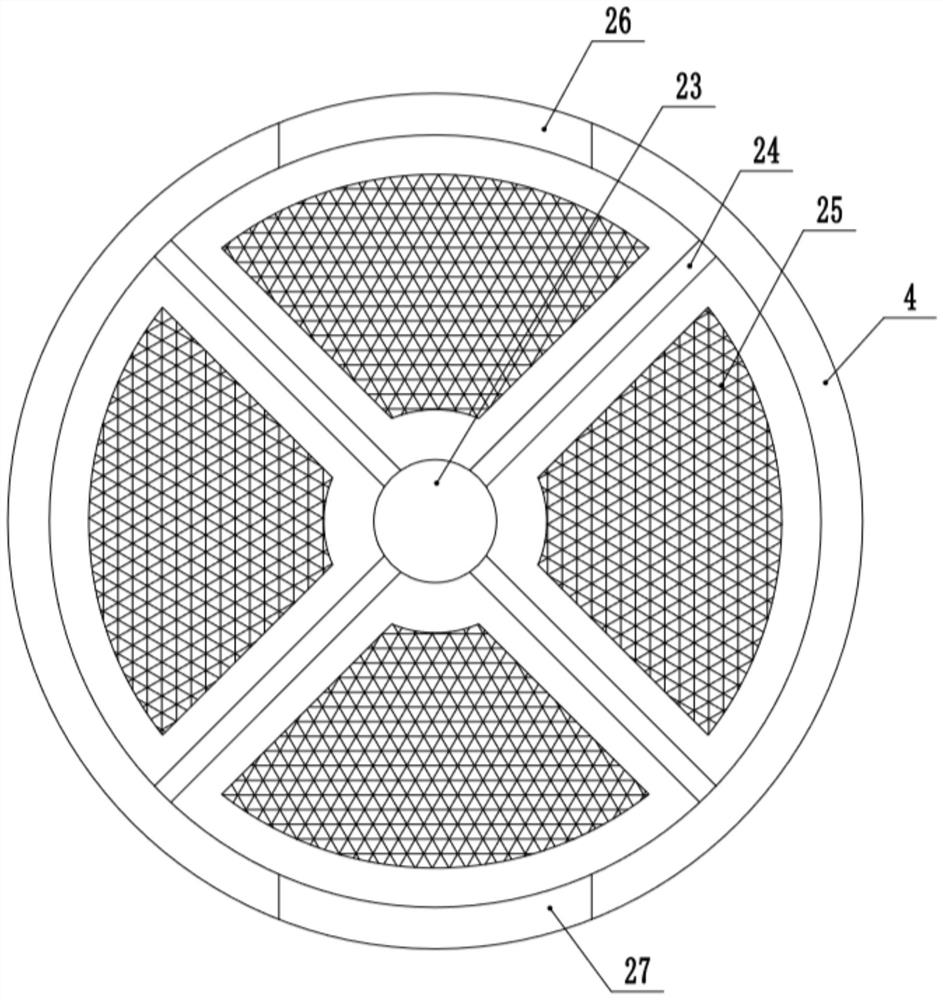

Device and method for carrying out adsorption purification treatment on sticky or moisture-containing dust smoke

The invention relates to a device and a method for carrying out adsorption purification treatment on sticky or moisture-containing dust smoke. The device comprises an adsorbent storage unit, a smoke purification unit, a pipeline unit, an adsorbent conveying unit, an air pressure balance unit, a fan unit, a chimney and a control unit, wherein the bottom of the adsorbent storage unit is connected with the adsorbent conveying unit, a feeding hole of the adsorbent conveying unit is connected with the pipeline unit at an entrance of the smoke purification unit, and an exit of the smoke purificationunit, the fan unit and the chimney are connected by virtue of the pipeline unit; the air pressure balance unit is arranged at the top of the adsorbent storage unit, and the other end of the air pressure balance unit is connected with the pipeline unit at the entrance of the smoke purification unit; and the control unit controls the whole adsorption purification technological process. Compared with the prior art, the invention has the beneficial effects that the device and the method have good purification effect on sticky or moisture-containing dust smoke and have the characteristics of low investment cost, simple structure, high purification efficiency and long service life.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

PP or PET spunbond spunlace non-woven fabric splitting machine

InactiveCN108547137AUnobstructed feedingImprove environmental qualitySevering textilesSuspended particlesImpeller

The invention discloses a PP or PET spunbond spunlace non-woven fabric splitting machine, and relates to the technical field of non-woven fabric processing. The position of a material sliding plate isadjusted by rotating adjusting nuts, the inclination angle of the material sliding plate can be adjusted, non-woven fabric raw materials can slide on the material sliding plate with a certain inclination angle, and the feeding smoothness is kept. Due to the arrangement of multiple annular cutters, the non-woven fabric raw materials can be split into multiple strips at the same time, and the splitting efficiency is improved. Suspended particles generated in the splitting process enter a filtering barrel under the effect of an axial flow fan, the suspended particles are intercepted through theeffect of an arc-shaped filter net, and the environment quality of a processing region is improved. A wind power impeller rotates by wind at a certain flow rate, an arc-shaped brush plate is driven bya rotary shaft to rotate, the particles on the arc-shaped filter net are brushed away, finally the particles are conveniently discharged through an impurity discharge pipe, the filtering effect of the annular filter net is guaranteed, and cleaning is convenient.

Owner:JIAN CITY SANJIANG SUPERFINE FIBER NONWOVEN

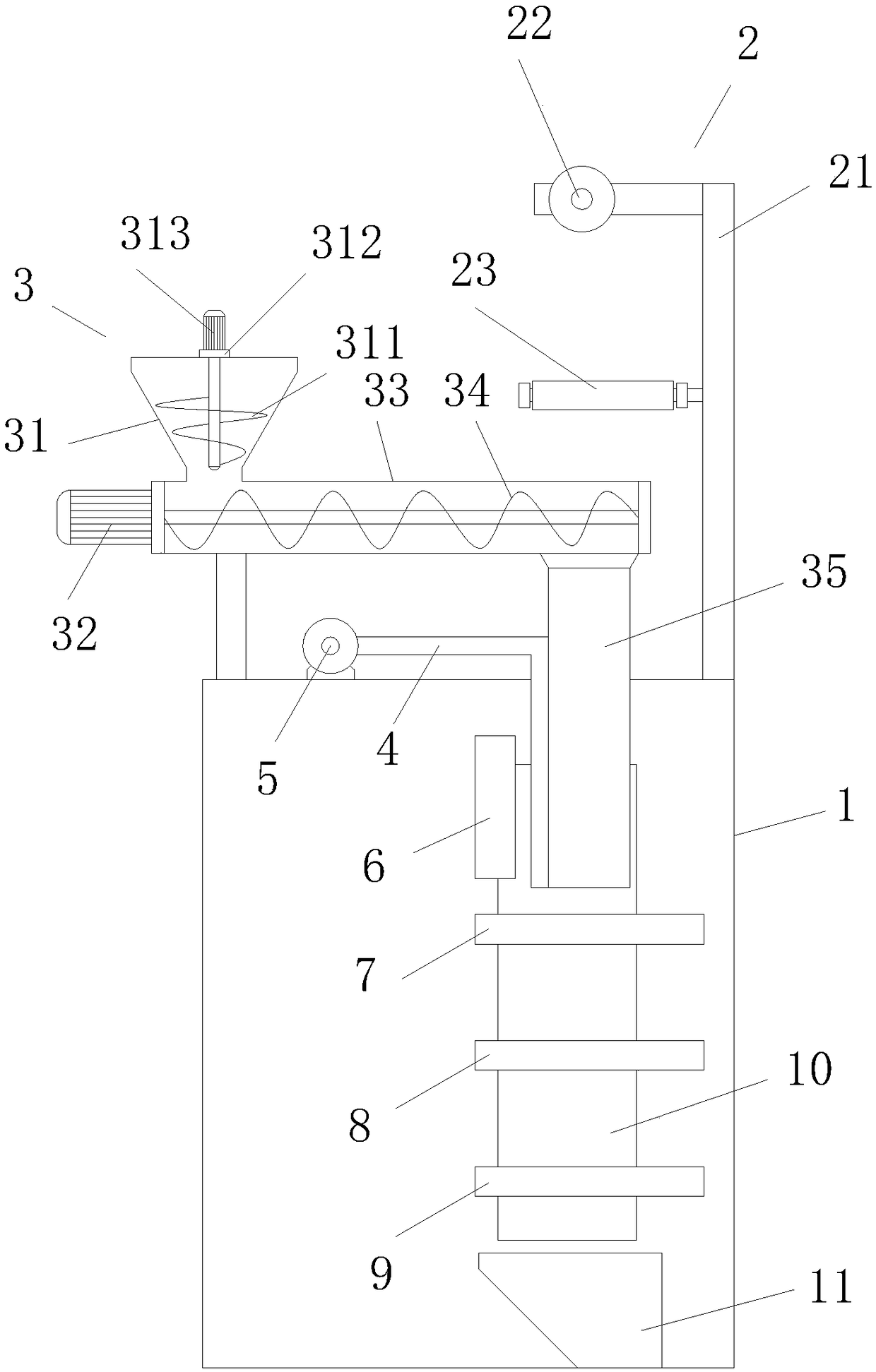

Home-use oil press

InactiveCN109225532AUnobstructed feedingEvenly heatedRotary stirring mixersTransportation and packagingSlagOil storage

The invention discloses a home-use oil press, which comprises a base, wherein a left support frame and a right support frame are arranged above the base; the left support frame and the right support frame are fixedly welded with the base; the left support frame is provided with a control device; a baking chamber is arranged between the left support frame and the right support frame; the two sidesof the baking chamber are connected with the left support frame and the right support frame through connecting blocks; the top end of one side of the baking chamber is provided with a feeding opening;the feeding opening is communicated with the baking chamber; the upper end of the feeding opening is provided with a material cover; a blanking hopper is arranged under the drying chamber; a pressingcavity is arranged under the blanking hopper; the baking chamber is connected with the pressing cavity through the blanking hopper; the lower end of the pressing cavity is provided with an oil outlet; an oil storage barrel is arranged under the oil outlet; the oil storage barrel is arranged on the base. The home-use oil press has the effects that the structure is reasonable; the use is convenient; a slag outlet and a slag collecting barrel are installed, so that the cleaning of oil slag is convenient; the effect of ensuring the work efficiency of the oil press is achieved.

Owner:高金飞

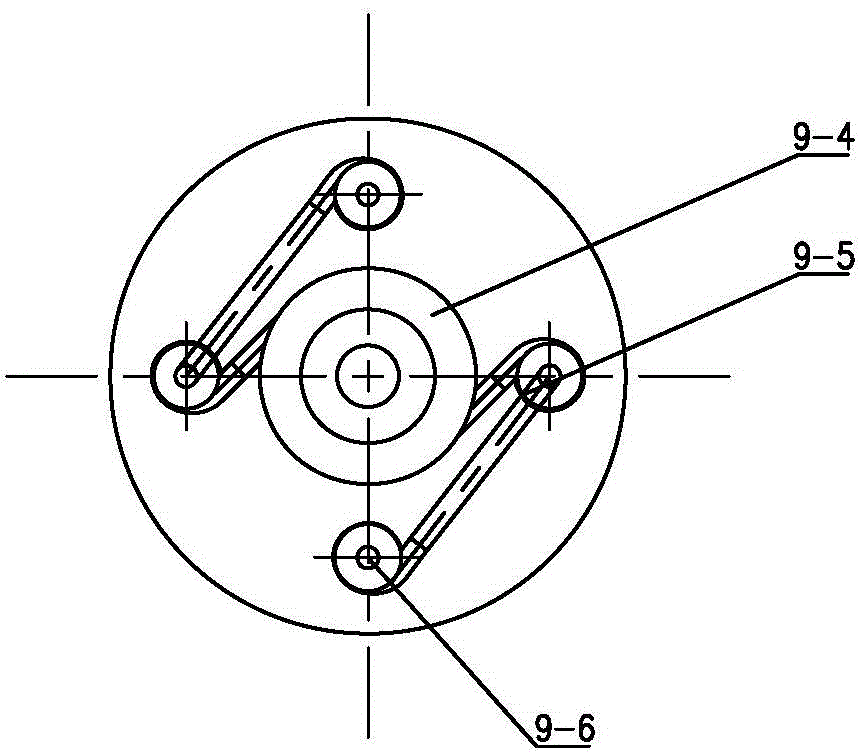

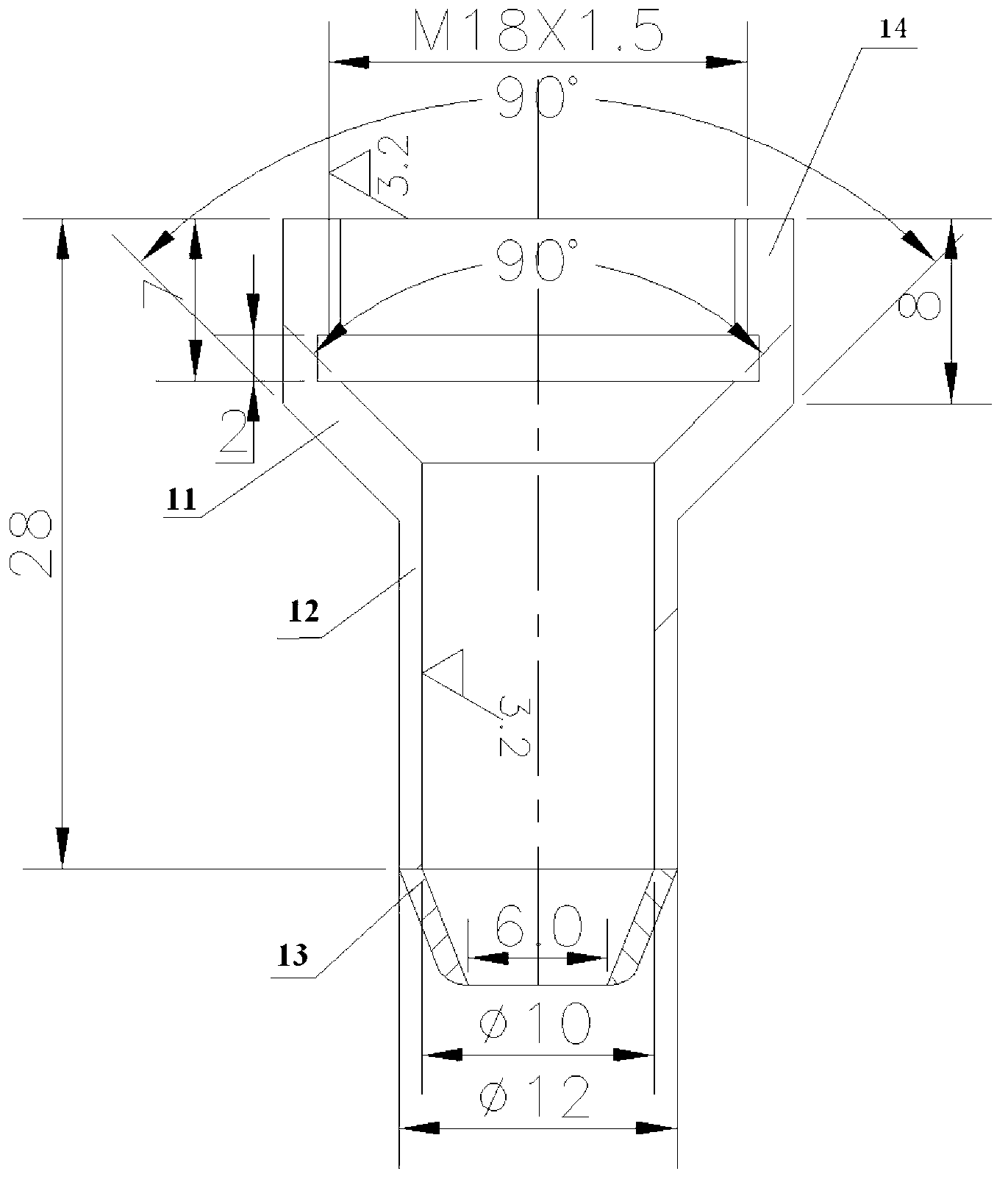

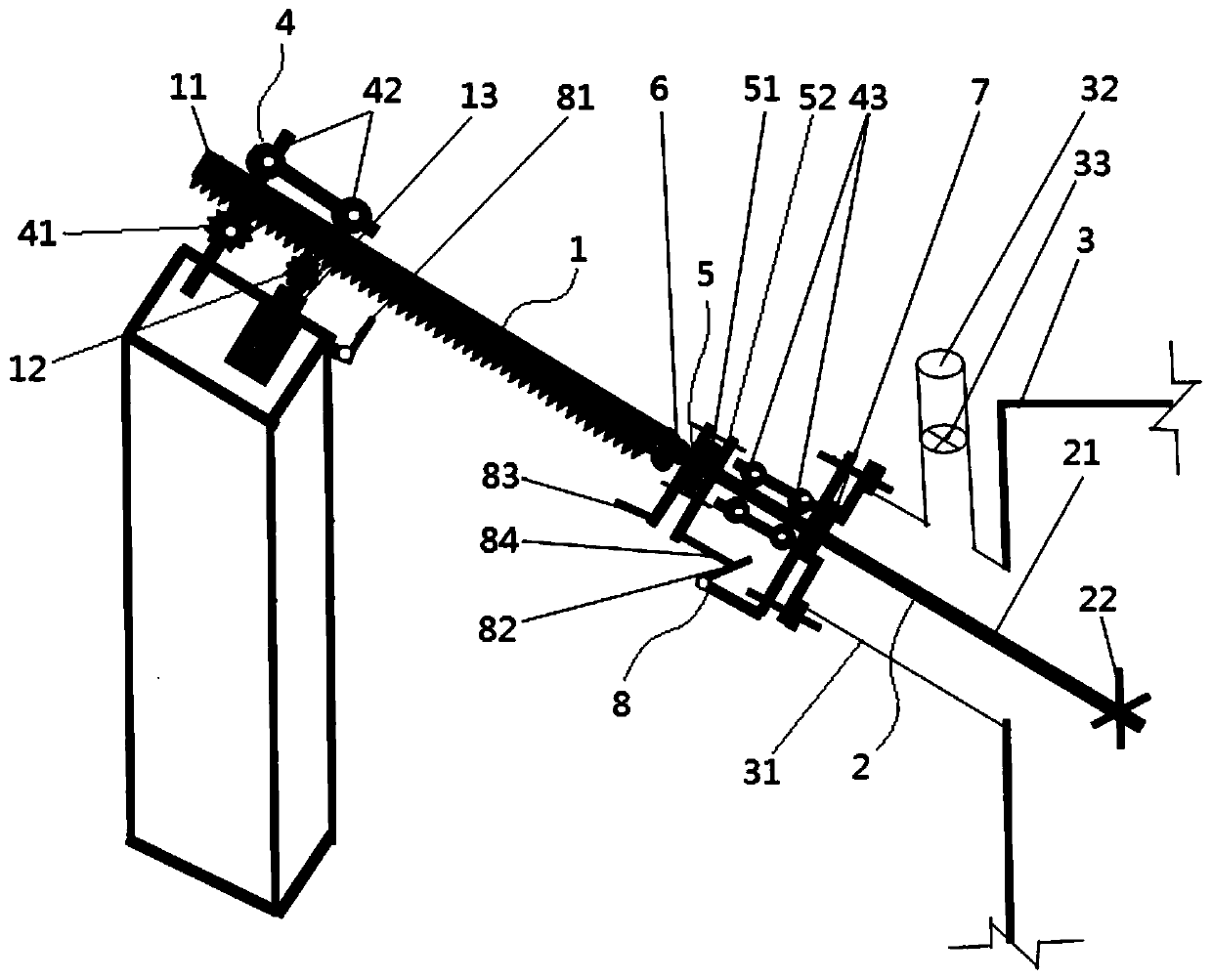

Automatic and intelligent primer gating system and working method thereof

ActiveCN103196338AReduce the number of peopleRealize the purpose of automatic pouringBlastingProgrammable logic controllerSafety coefficient

The invention relates to an automatic and intelligent primer gating system which comprises a control module and a gating module, wherein the control module monitors the working state of the gating module in real time via a sensor and controls the gating module to work according to regulation on the monitored working state so as to realize closed-loop control work. The automatic and intelligent primer gating system adopts PLC (programmable logic controller) control, thereby realizing the purpose of automatic gating and greatly improving the production efficiency while reducing the labor intensity; operators are reduced, and the safety in production is improved; and the gating system is safe and reliable in design, and is matched with a safety interlocking control monitoring system, thereby increasing the safety coefficient of production. The medicine injection structure adopted by the gating system is reasonable, is unlikely to cause remaining medicines, and is smooth in blanking, thereby reducing the manual maintenance cost of the system.

Owner:SHANDONG TIANBAO CHEM

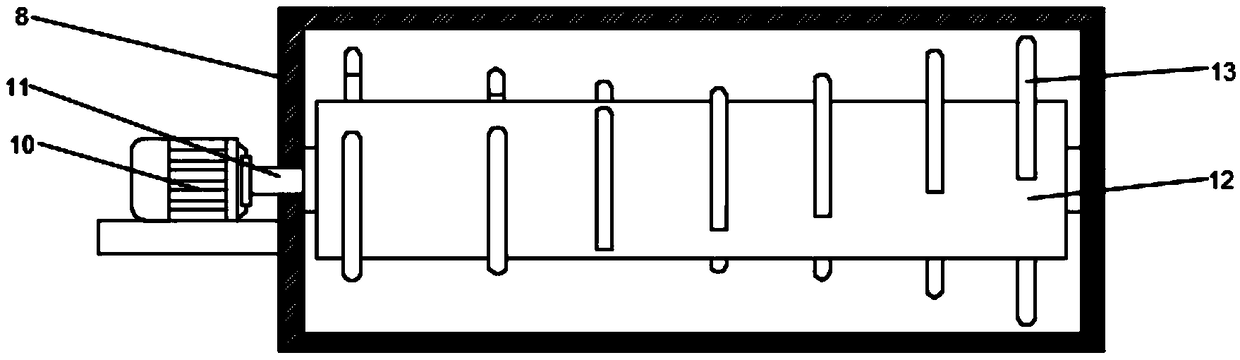

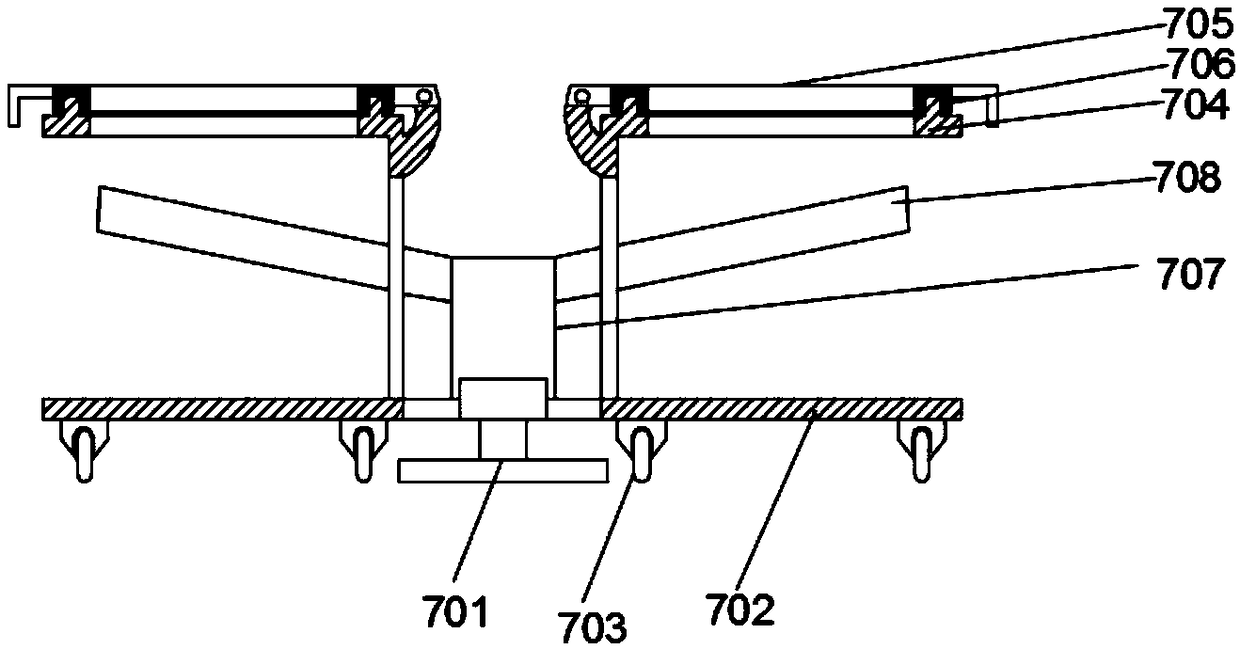

Efficient High-speed charging and fast discharging membrane filter board pressure filter and high-speed charging method

ActiveCN102553312AMeet the pressing requirementsImprove feeding efficiencyFiltration separationEngineeringFilter press

The invention relates to an efficient high-speed charging and fast discharging membrane filter board pressure filter which has the functions of high-speed charging and fast discharging and a high-speed charging method. The efficient high-speed charging and fast discharging membrane filter board pressure filter comprises a membrane filter board pressure filer. In the membrane filter board pressure filter, a charging hole is arranged at the upper end of each of a plurality of membrane filter boards in a membrane filter board group, and a discharging hole is respectively arranged at the lower part of each of a plurality of membrane filter boards in the membrane filter board group; a vertical-lifting feeding assembly is positioned above the charging holes of the membrane filter board group; and a plurality of feeding nozzles communicated with the downside of the feeding assembly respectively match with the charging holes of a plurality of membrane filter boards in the membrane filter board group. The efficient high-speed charging and fast discharging membrane filter board pressure filter provided by the invention has the advantages that: (1) a precedent that direct charging of the membrane filter boards is created, so that the charging operation not only has high efficiency and is smooth, but also the energy consumption is low; (2) single-way valves are adopted as the valves of the charging holes, so that not only requirements on high-speed charging are met, but also the valves can be locked automatically to meet the requirement on the squeezing of the membrane filter boards after the charging ends; and (3) the discharging holes are arranged at the lower parts of the membrane filter boards, so that the discharging speed is not only high, but also no energy is consumed.

Owner:HANGZHOU XINGYUAN FILTER TECH

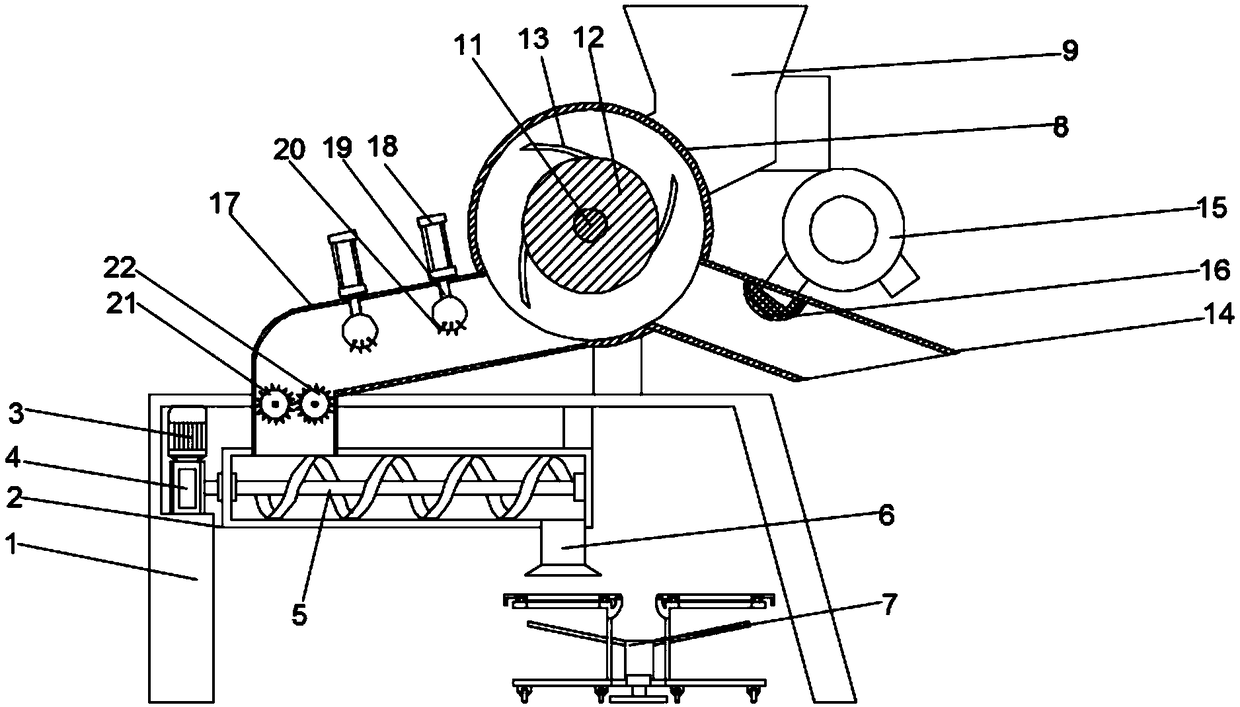

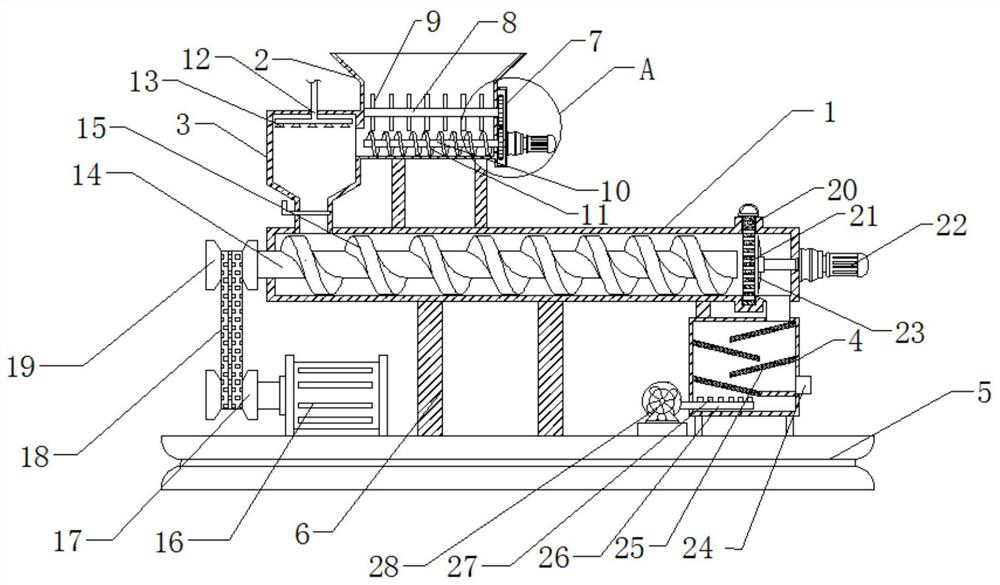

Feed expanding machine

The invention discloses a feed expanding machine, and belongs to the field of machinery. The feed expanding machine comprises a cylinder body, a feeding cylinder is fixed on the top of the cylinder body, a gear box is fixed on one side of the feeding cylinder, a second motor is installed on one side of the gear box, the output end of the second motor is connected with a driving shaft, one end of the driving shaft penetrates through one side of the gear box and extends into the feeding cylinder, a driving gear and a driven gear are arranged in the gear box, the driving gear is meshed with the driven gear, the driving gear drives the driven gear to rotate through rotation of the second motor, the driven gear rotates to enable the rotating shaft to rotate, the rotating shaft drives a crushingcutter to rotate to crush coagulated blocks in feed raw materials, then the driving shaft drives conveying blades to rotate to convey the feed raw materials into a steam heating chamber, and throughcrushing and spiral conveying of the raw materials, the raw materials are fed smoothly, the curing degree is high, and the production efficiency is improved.

Owner:万载县联胜科技有限公司

Vertical plastic crushing machine

PendingCN110171079AImprove sound insulationInhibition flip upPlastic recyclingMechanical material recoveryEngineeringMechanical engineering

The invention discloses a vertical plastic crushing machine, and belongs to the technical field of environmental protection equipment. The vertical plastic crushing machine solves the problems that acutter of an existing plastic crushing device is difficult to replace when damaged, cleaning is inconvenient and the sizes of crushed particles are not uniform. The vertical plastic crushing machine comprises a rotary cutter assembling unit, a primary crushing mechanism, a rotary motor, a shell, air inlet equipment, a feeding hopper, a conveying device, a baffle, a sieve plate, a spring and a trolley. The rotary cutter assembling unit is arranged in the shell, the distance between the cutter on the rotary cutter assembly and the inner wall of the shell is gradually reduced from top to bottom,and multi-stage crushing is carried out; and the primary crushing mechanism can preliminarily crush plastic conveyed into the feeding hopper by the conveying device, the temperature in the shell is effectively reduced due to the arrangement of the air inlet equipment, the plastic adhesion caused by too high temperature rise is prevented, and a cleaning function is also achieved. The vertical plastic crushing machine has the advantages that the cutter is easy to replace, cleaning is facilitated, cutting is uniform and discharging is smooth, and has high practicability.

Owner:孝感森济禾机械设备有限公司

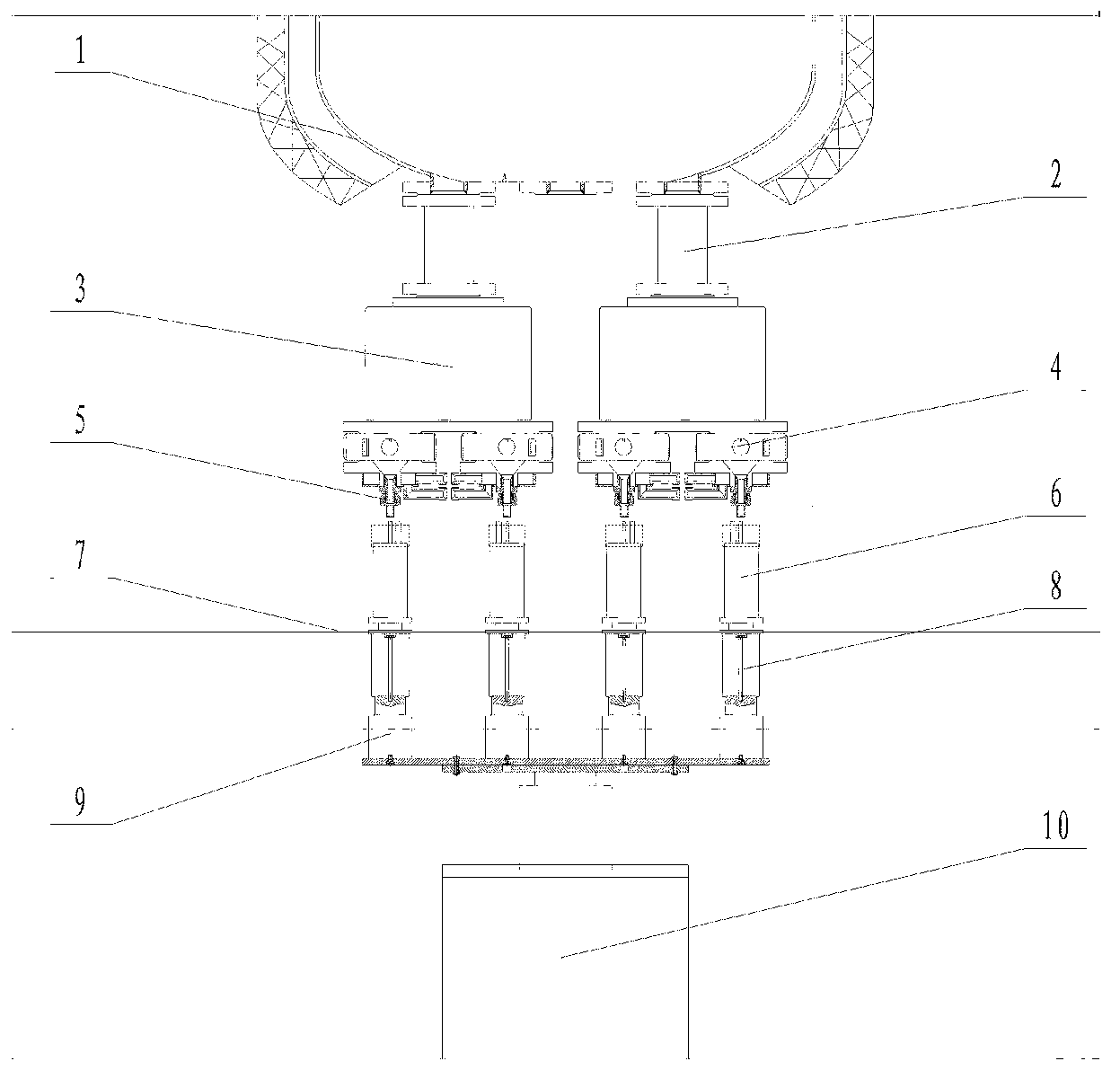

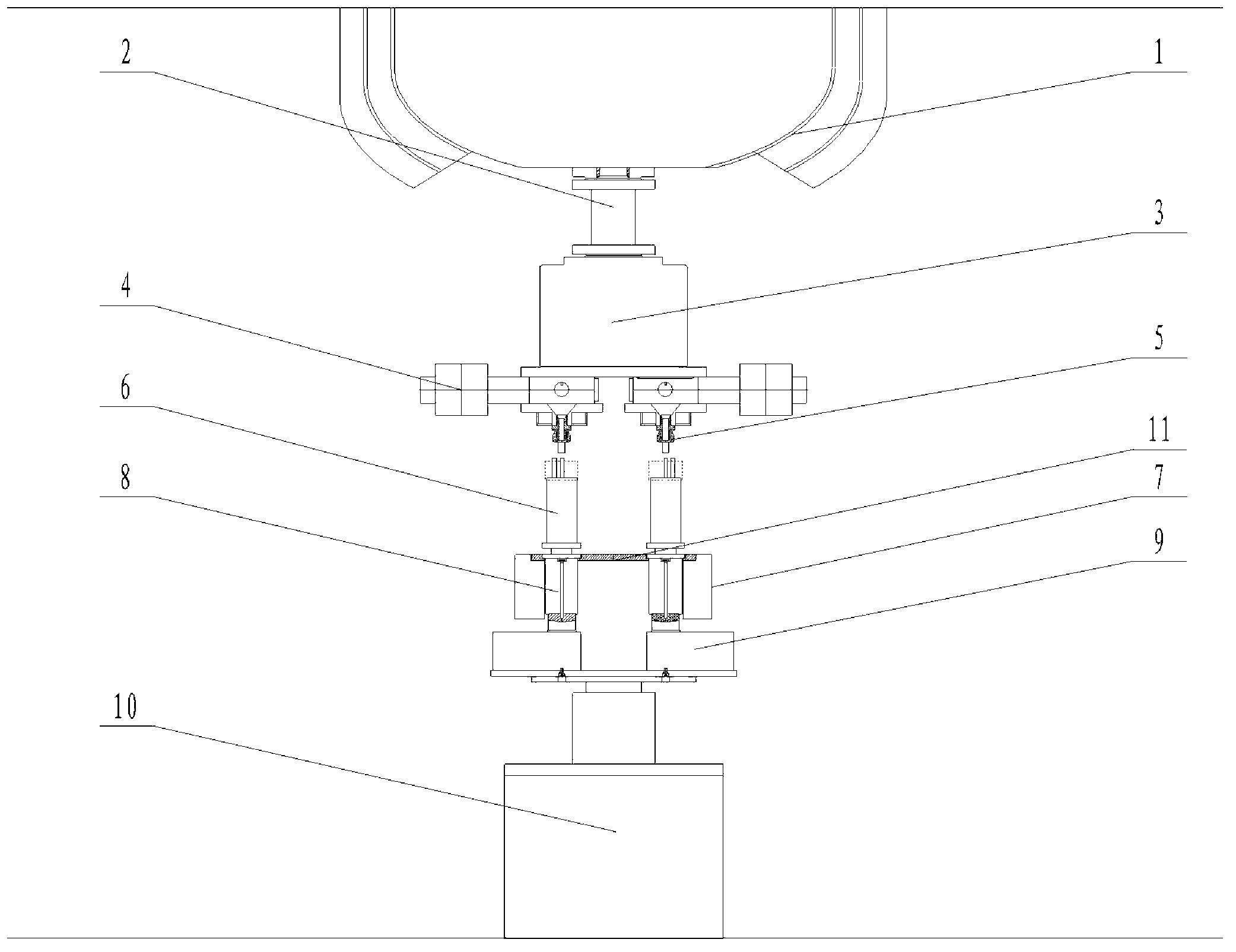

Multi-channel half-dry sludge switching device and sludge conveying system comprising same

The invention provides a multi-channel half-dry sludge switching device and a sludge conveying system comprising the same. The multi-channel half-dry sludge switching device comprises a channel main body and a switching portion; the switching portion is arranged on the channel main body; the channel main body is supported and fixed on an installation base plane through a support; the channel main body comprises a main channel which extends to form a first channel and a second channel; the main channel and the second channel are vertical channels; the first channel is an inclined channel; the switching portion comprises a power cylinder, a rotary shaft and a turning plate; the power cylinder is arranged on the outer wall of the first channel; the power cylinder is connected with the rotary shaft through a connecting rod; the rotary shaft is fixed at the connecting position of the first channel and the second channel; a first end of the turning plate is connected with the rotary shaft; a second end of the turning plate is fixed on the corresponding position of the channel main body. According to the multi-channel half-dry sludge switching device and the sludge conveying system comprising the same, the structure is simple, the feeding and the discharging are smooth, the switching is convenient, and the efficiency of the integral sludge conveying system is improved.

Owner:BMEI

High-in quick-out filter cloth filter plate and high-speed feed method

ActiveCN102527113AMeet the pressing requirementsImprove feeding efficiencyFiltration separationEngineeringCheck valve

The invention relates to a high-in quick-out filter cloth filter plate and a high-speed feed method, which can feed at high speed and discharge quickly. The high-in quick-out filter cloth filter plate comprises a filter cloth filter plate, wherein the filter cloth filter plate is provided with a feed port and a discharge port, the feed port in the filter cloth filter plate is directly communicated with a squeezing cavity, and a feed valve is positioned on the feed port. The high-in quick-out filter cloth filter plate and the high-speed feed method have the advantages that firstly, an example of filter cloth filter plate direct feed is provided, feed efficiency is high, feed is smooth, and energy consumption is low; secondly, a check valve is adopted as a valve of the feed port so as to meet requirements of high-speed feed, and after feed is finished, the valve can be locked automatically so as to meet squeezing requirements of the filter cloth filter plate; and thirdly, the discharge port is arranged at the lower portion of the filter cloth filter plate, thereby being quick in discharge speed and free of energy consumption.

Owner:HANGZHOU XINGYUAN FILTER TECH

Environment-friendly garden waste drying treatment device

InactiveCN112325569APartition shredding implementationEasy to dryDrying gas arrangementsPreliminary solid treatment for dryingEngineeringEnvironmental engineering

The invention discloses an environment-friendly garden waste drying treatment device, and relates to the technical field of environmental protection. A treatment box is included, the top end of the treatment box is fixedly connected with a feeding hopper, the upper part in the treatment box is fixedly connected with a pretreatment cylinder, and the lower part in the treatment box is fixedly connected with a drying cylinder; and a zoned crushing mechanism is arranged in the pretreatment cylinder, a drying mechanism is arranged in the drying cylinder, a sweeping anti-blocking mechanism is arranged below the pretreatment cylinder, air circulation conveying mechanisms are arranged at the two ends of the drying cylinder, and a conveying mechanism is arranged in the treatment box below the drying cylinder. The zoned crushing mechanism is arranged to achieve zoned crushing of waste; by arranging the sweeping anti-blocking mechanism, a filter screen can be swept repeatedly, waste is preventedfrom blocking meshes of the filter screen, discharging is smoother; and rapid zoned drying of the waste can be achieved by arranging the drying mechanism, the treatment effect on garden waste is good,and later recycling is facilitated.

Owner:孙文超

Biological generator set

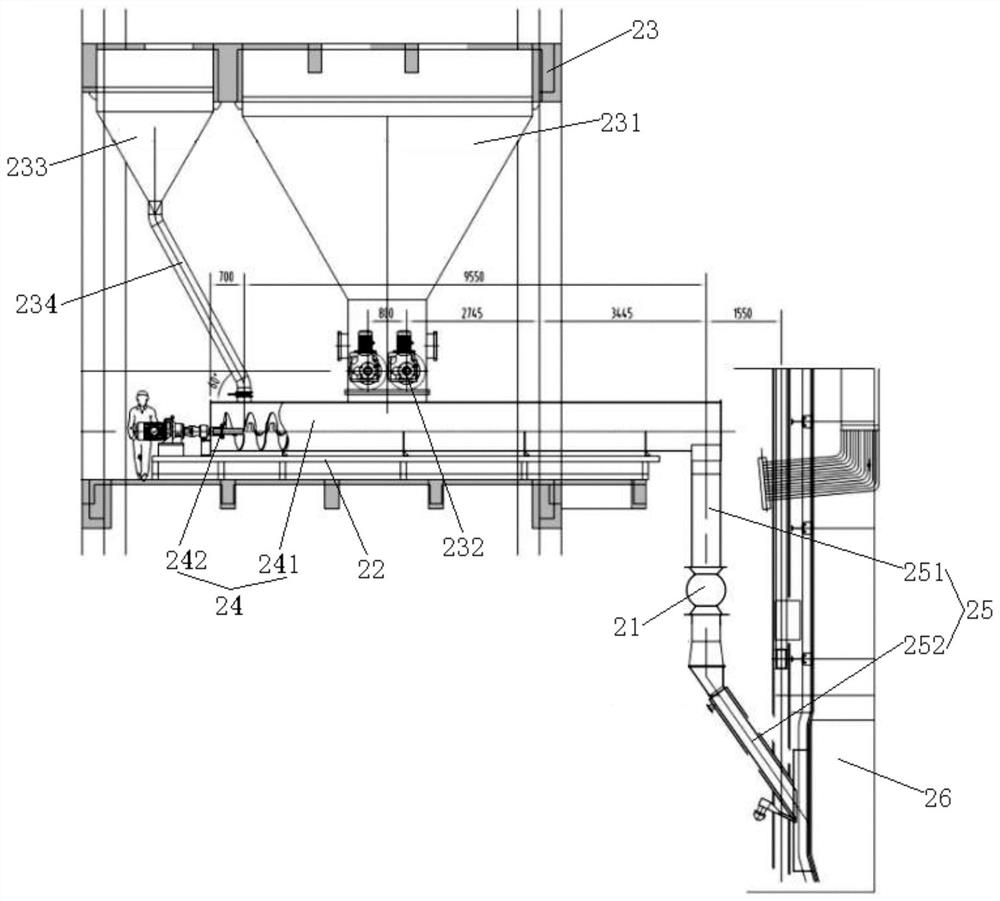

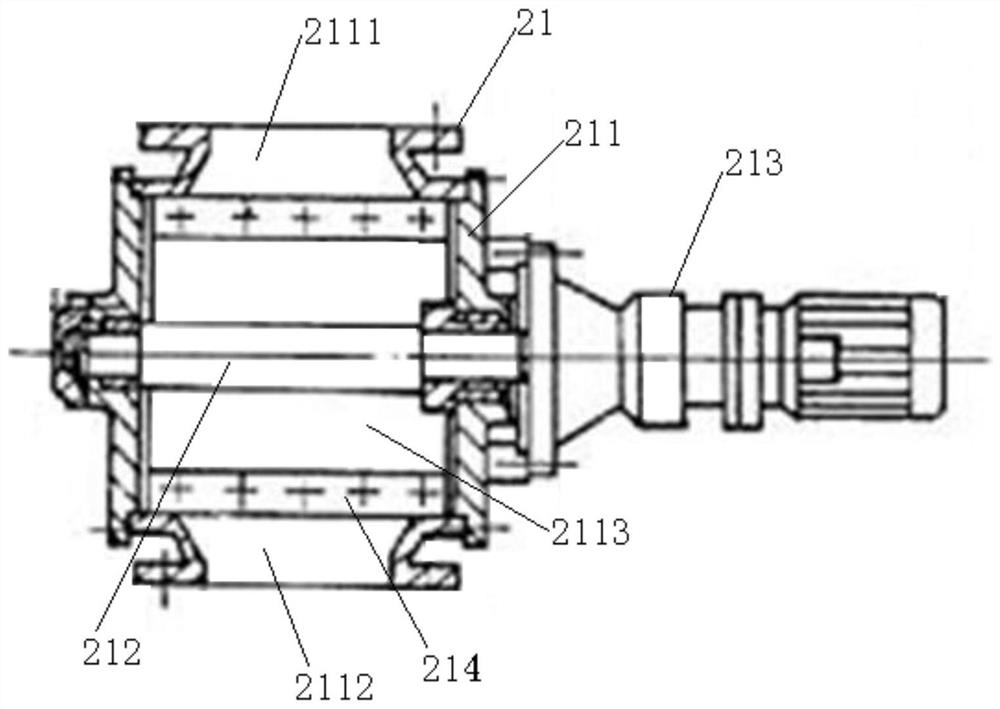

PendingCN112413578AIncrease power generationReduce the risk and pollution of the working environmentFluidized bed combustionIndirect carbon-dioxide mitigationFlueProcess engineering

The invention discloses a biological generator set. The biological generator set comprises a front feeding system used for feeding materials to a boiler, a flue smoke discharging system used for discharging and treating smoke generated by biomass fuel combustion, a smoke separating device used for conducting coarse separation on the smoke in the flue smoke discharging system, and soot blowing equipment used for conducting soot blowing treatment on an air preheater in the flue smoke discharging system; the front feeding system is connected to the feeding end of the boiler; the flue smoke discharging system is arranged in the boiler gas discharging direction; and the smoke separating device and the soot blowing equipment are connected in a smoke discharging path of the flue smoke dischargingsystem. According to the biological generator set, smooth discharging can be guaranteed, the generating capacity of the generator set is improved, and the danger during work and the pollution to theworking environment are effectively reduced; and moreover, bonded ash blocks hardened on the wall surface of the smoke channel can be crushed into return ash, and the smoke can be effectively prevented from being hardened on the wall surface of the smoke channel during separation, so that the formation of the bonded ash blocks is reduced, and the smoke in the smoke channel is discharged smoothly.

Owner:安化华晟生物能源有限责任公司

Automatic feed putting device for chicken farm

InactiveCN109924142AUnobstructed feedingReduce labor intensityRotary stirring mixersAvicultureHydraulic cylinderEngineering

The invention discloses an automatic feed putting device for a chicken farm. The device comprises a storage bin, a disinfecting bin, a discharging chamber, a feeding trough and a bottom plate; a feeding port is formed in the storage bin, and the right side of the feeding port is provided with a stirring motor; the disinfecting bin is arranged below the storage bin; sterilizing lamps are symmetrically arranged at the left and right ends of the sterilizing bins; the lower end of the disinfecting bin is provided with four baffles; each baffle is provided with a pressure sensor B; an electric hydraulic cylinder is arranged at the lower ends of the baffles and sleeved with a fixing ring, and the upper end of the electric hydraulic cylinder is provided with a contact switch; four pull rods are fixedly connected to the fixing ring; the lower end of the discharging chamber is provided with the feeding trough; the lower end of the feeding trough is provided with the bottom plate, and the bottomplate is internally provided with a pressure sensor A. By means of the device, a large amount of feed is stored in the storage bin and can be automatically put, a breeder does not need to regularly put the feed any more, and the labor intensity of the breeder is greatly reduced.

Owner:福州和暄实业有限公司

Kiln feeding dredging device and kiln

PendingCN111426201AStable input powerAvoid hardening and cloggingCharge manipulationAluminium electrolysisAutomatic control

The invention relates to the technical field of innocent treatment, in particular to a kiln feeding dredging device and a kiln. The kiln feeding dredging device comprises a driving assembly and a dredging assembly; the dredging assembly is used for extending into a feeding transition channel of the kiln; the driving assembly is connected with the dredging assembly to drive the dredging assembly toreciprocate along the feeding transition channel, and thus aluminum electrolysis waste cathode particles entering the feeding transition channel are scattered and are uniformly pushed into the kiln according to a fixed angle; the aluminum electrolysis waste cathode particles are prevented from being agglomerated by high-temperature flue gas in the kiln, the blanking repose angle of the aluminum electrolysis waste cathode particles is stabilized, the purposes of smooth feeding and stable material surface in the kiln are achieved, the stable input power of the kiln is ensured, and the reductionof productivity and quality fluctuation is avoided; the direction of the driving assembly is regulated and controlled by a first guide wheel, and the direction of the dredging assembly is regulated and controlled by a second guide wheel; the driving assembly and the dredging assembly are combined and connected through a universal joint and an insulating part; the oxygen isolation function is realized by a sealing assembly; and integral interlocking automatic control can be achieved.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

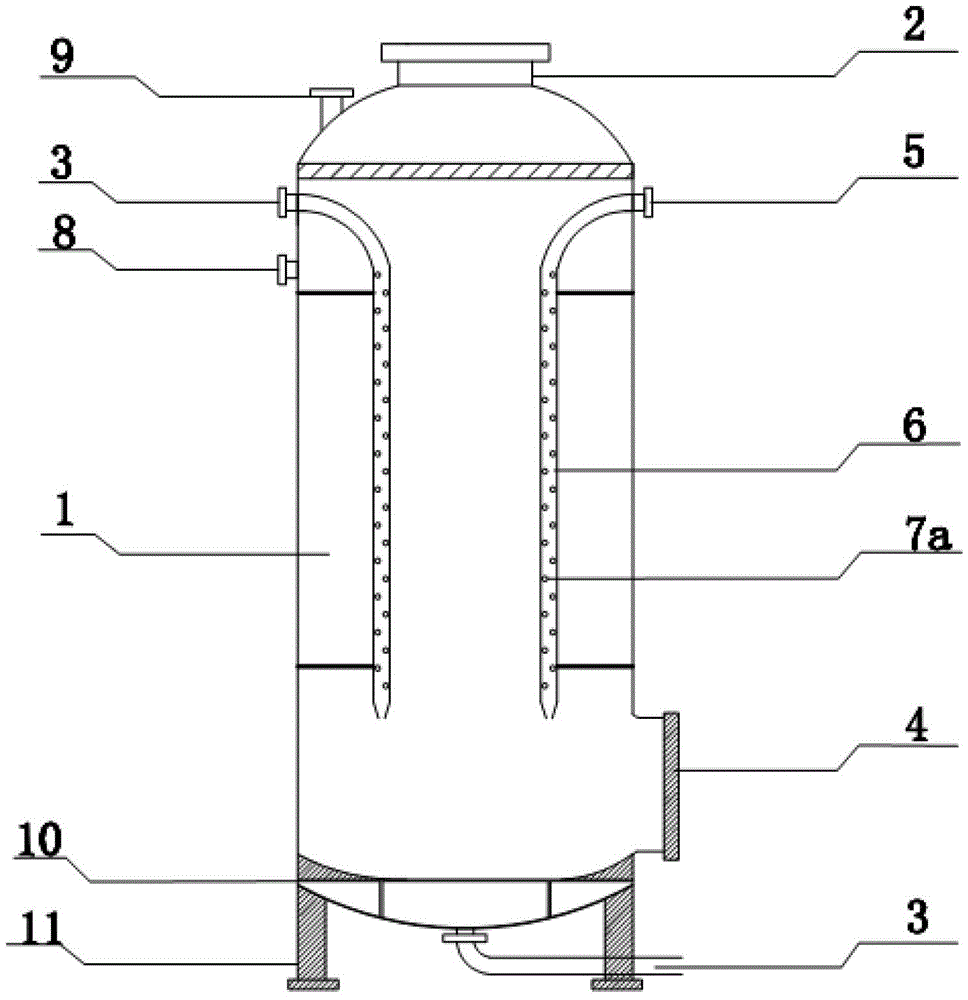

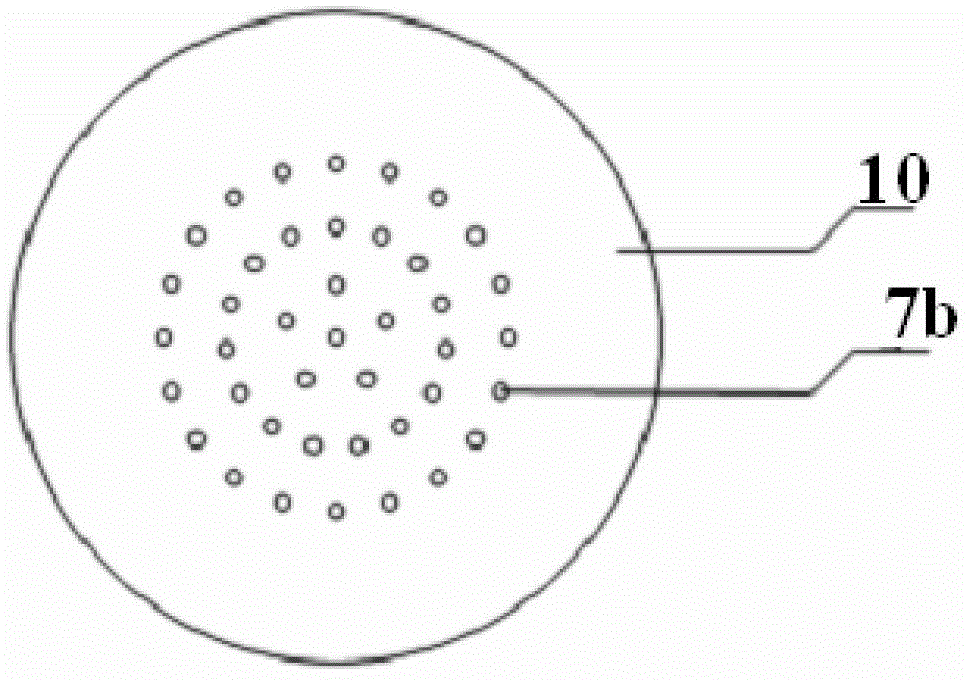

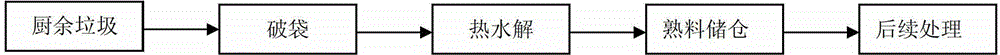

Kitchen garbage pyrohydrolysis method and device thereof

The invention discloses a kitchen garbage pyrohydrolysis method and a device thereof. The device comprises a tank body, wherein the top of the tank body is provided with a feed port, and the bottom of the tank body is communicated with a drain pipe; the lower part of the side wall of the tank body is provided with a discharge hole, the upper part of the side wall of the tank body is provided with at least three steam inlets, and the steam inlets extend to the upper part of the discharge hole along a steam pipeline; and the side wall of the tank body is provided with an exhaust port. The processing method of the kitchen garbage provided by the invention comprises the following steps of: transferring the kitchen garbage to a tank body of a pyrohydrolysis device so as to carry out pyrohydrolysis, after finishing pyrohydrolysis, discharging the materials from the discharge hole, and realizing the treatment on the kitchen garbage; and the treatment process is simple, the device is directly fed so as to carry out pyrohydrolysis after a bag is opened, labor and other sorting process are saved, the failure rate of a processing line is reduced, and the operating efficiency is improved.

Owner:BEIJING JIELV ENVIRONMENTAL TECH CO LTD

A pp or pet spunbond spunlace nonwoven fabric slitting machine

InactiveCN108547137BUnobstructed feedingImprove environmental qualitySevering textilesSuspended particlesEngineering

The invention discloses a PP or PET spunbond spunlace non-woven fabric splitting machine, and relates to the technical field of non-woven fabric processing. The position of a material sliding plate isadjusted by rotating adjusting nuts, the inclination angle of the material sliding plate can be adjusted, non-woven fabric raw materials can slide on the material sliding plate with a certain inclination angle, and the feeding smoothness is kept. Due to the arrangement of multiple annular cutters, the non-woven fabric raw materials can be split into multiple strips at the same time, and the splitting efficiency is improved. Suspended particles generated in the splitting process enter a filtering barrel under the effect of an axial flow fan, the suspended particles are intercepted through theeffect of an arc-shaped filter net, and the environment quality of a processing region is improved. A wind power impeller rotates by wind at a certain flow rate, an arc-shaped brush plate is driven bya rotary shaft to rotate, the particles on the arc-shaped filter net are brushed away, finally the particles are conveniently discharged through an impurity discharge pipe, the filtering effect of the annular filter net is guaranteed, and cleaning is convenient.

Owner:JIAN CITY SANJIANG SUPERFINE FIBER NONWOVEN

Micro-particle cleaning device for disassembled electric energy meter

PendingCN113414190AReduce volatilityReduce the frequency of dry ice refillsCleaning processes and apparatusDry iceMechanical engineering

The invention discloses a micro-particle cleaning device for a disassembled electric energy meter. The micro-particle cleaning device comprises a dry ice cleaning machine, wherein a supporting plate is arranged on the dry ice cleaning machine, a discharging pipe is arranged on the supporting plate, a discharging opening used for communicating the discharging pipe with the supporting plate is formed in the supporting plate, a material box is arranged on the discharging pipe, a first-stage hopper is arranged on the material box, a stirring mechanism used for stirring dry ice in the first-stage hopper is arranged on the first-stage hopper, a turning plate mechanism used for discharging the dry ice is arranged on the discharging pipe, and the box cover, the first-stage hopper and the material box are all made of heat preservation materials. By arranging the first-stage hopper and the material box, much dry ice can be additionally stored, so that the frequency of supplementing the dry ice by workers is reduced, use is facilitated, and the box cover, the first-stage hopper and the material box which are made of the heat preservation materials are adopted, so that the situation that the dry ice absorbs external heat and volatilizes can be reduced.

Owner:YINCHUAN POWER SUPPLY COMPANY OF STATE GRID NINGXIA ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com