Anti-blocking device for accurately feeding materials

A precise feeding and anti-blocking technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problem of difficult to accurately control feeding of powder, and achieve the effect of unobstructed and accurate blanking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

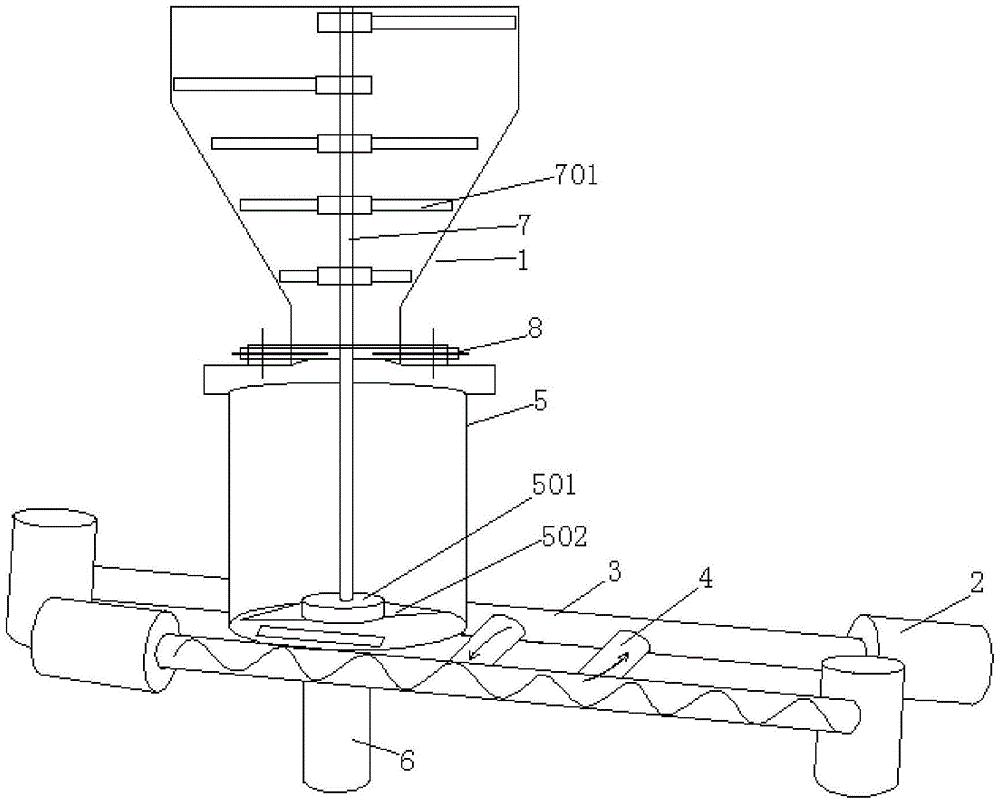

[0010] Referring to the accompanying drawings, an anti-blocking device for precise feeding includes a hopper 1, a conveying motor 2 and a quantitative conveyor 3, the conveying motor 2 is fixed on the rear end of the quantitative conveyor 3, the quantitative conveyor is a pair, and the output The openings are set opposite to each other, and a return channel 4 is provided between the two quantitative conveyor channels. A rotating motor 6 is fixedly installed, and the rotating motor 6 is connected with an arch-breaking shaft 7, and a plurality of crushing scrapers 701 are arranged on the arch-breaking shaft 7; Both sides are provided with symmetrical rotating blades 502, and a sliding gate 8 is provided at the upper port of the discharging cylinder 5, which is convenient for controlling the overall discharging. The lower end of the receiving hopper is set on the discharge cylinder which is equivalent to the buffer function, and the lower end of the discharge cylinder is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com