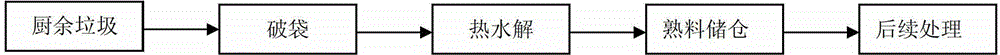

Kitchen garbage pyrohydrolysis method and device thereof

A technology of kitchen waste and thermal hydrolysis, applied in the direction of solid waste removal, etc., can solve problems such as inability to apply, and achieve the effect of reducing failure rate, less impact, and avoiding dead ends of discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0033] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

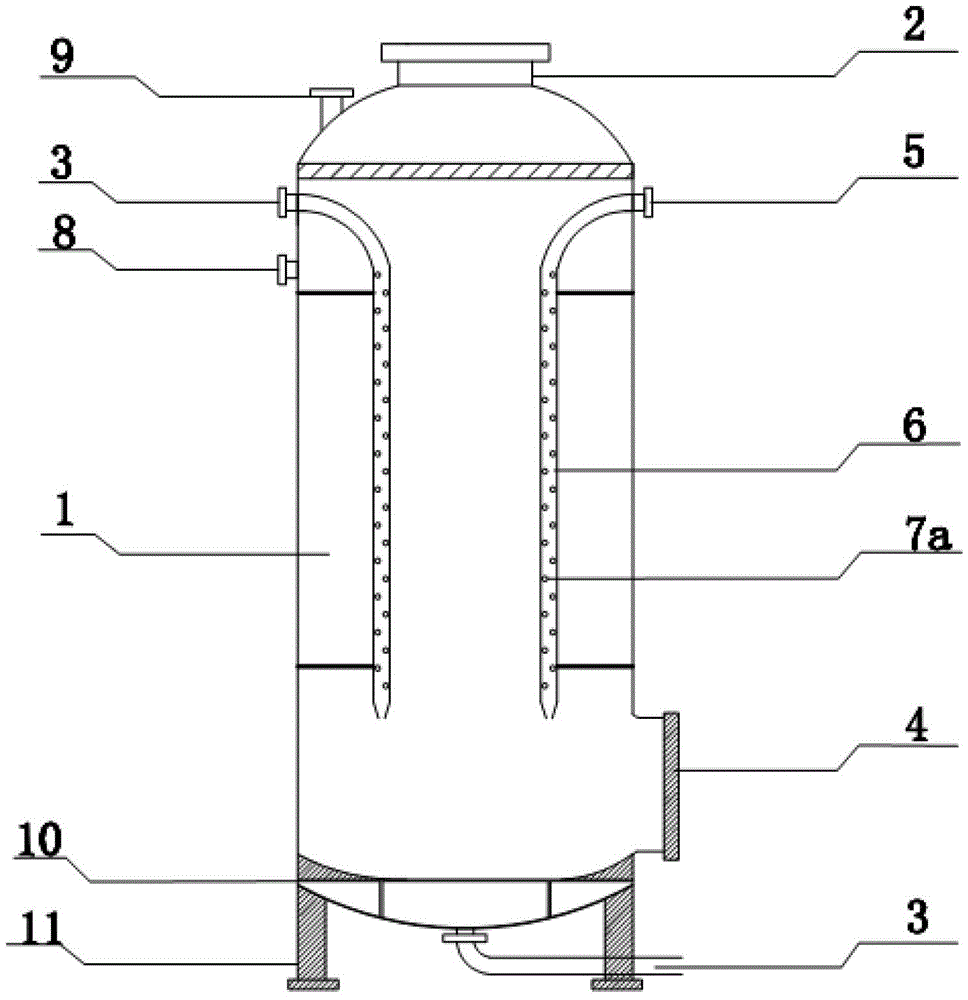

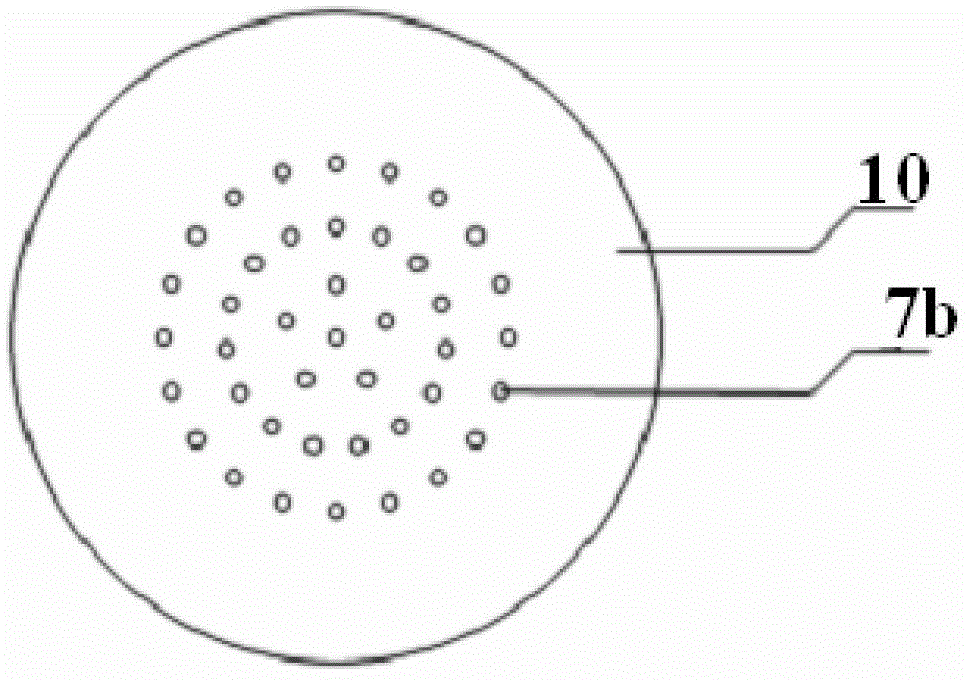

[0034] Such as figure 1 As shown, the kitchen waste thermal hydrolysis device provided by the present invention includes a tank body 1 made of stainless steel; the top of the tank body 1 is provided with a feed port 2, and the bottom of the tank body 1 communicates with a drain pipe 3 ; The lower part of the side wall of the tank 1 is provided with a discharge port 4; the side wall of the tank 1 is provided with an exhaust port 8. The upper part of the side wall of the tank body 1 is provided with three steam inlets 5 for passing steam into the tank body 1; the three steam inlets 5 are evenly arranged along the circumference of the tank body 1, and are supported by two steam pipe supports It is fixed on the side wall of the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com