Blanking unit structure in rotary type packaging machine

A technology of rotary packaging machine and unit structure, applied in the direction of packaging, etc., can solve the problems of affecting normal work, affecting the working environment, flying dust, etc., and achieve the effect of reasonable structure design, integrity assurance and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

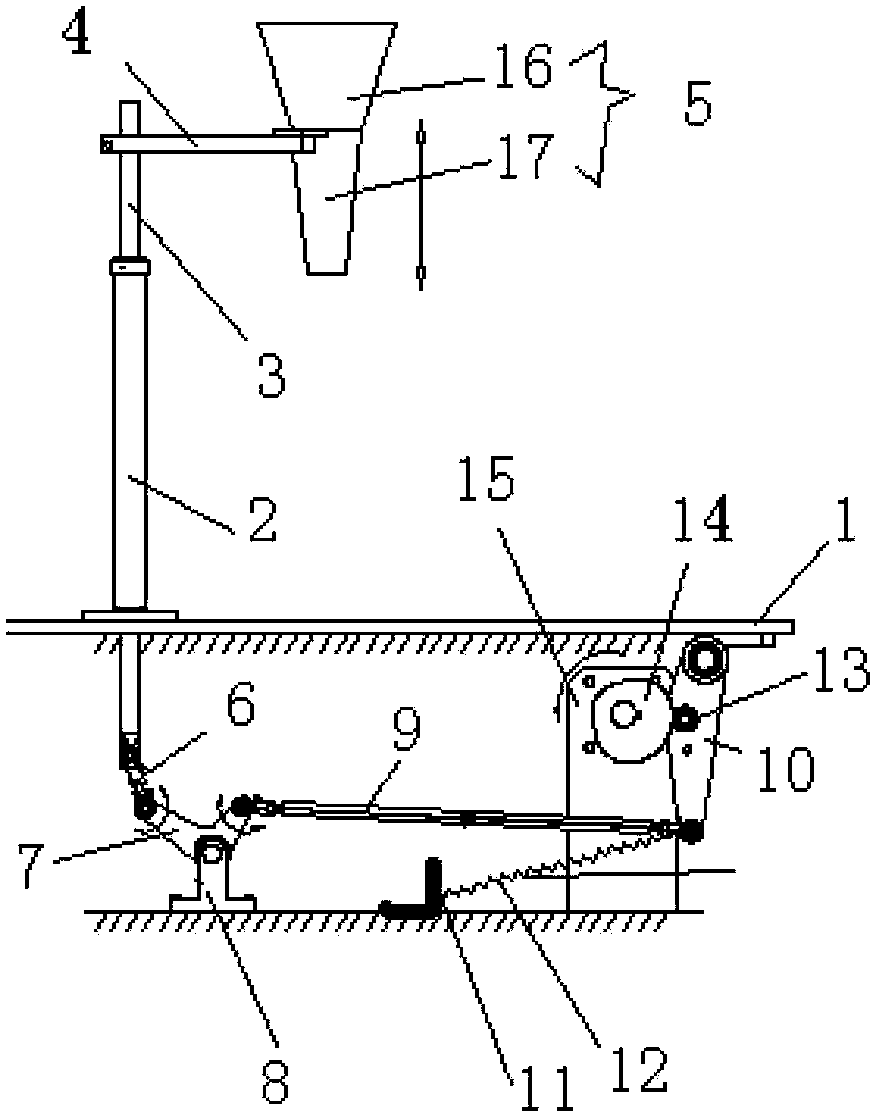

[0012] Referring to the accompanying drawings, a cutting unit structure in a rotary packaging machine includes a fixed seat 1, a guide sleeve 2 is provided on one side of the fixed seat 1, and a moving guide rod 3 is guided in the guide sleeve 2, and the moving guide rod The upper end of 3 is equipped with a horizontal and straight fixed plate 4, and a conical hopper 5 is installed on the fixed plate 4, and a connecting rod 6 is installed on the lower end of the moving guide rod 3, and the other end of the connecting rod 6 is rotated and installed on the turning point below it. On the arm 7, the middle part of the crank arm 7 is rotatably mounted on the belt seat bearing 8, the other end of the crank arm 7 is connected with a connecting rod 9, the other end of the connecting rod 9 is connected with the lower end of the swing arm 10 above it, and the upper end of the swing arm 10 rotates Installed on the fixed seat 1, a spring 12 is provided between the lower end of the swing ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com