Patents

Literature

2619results about "Chutes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

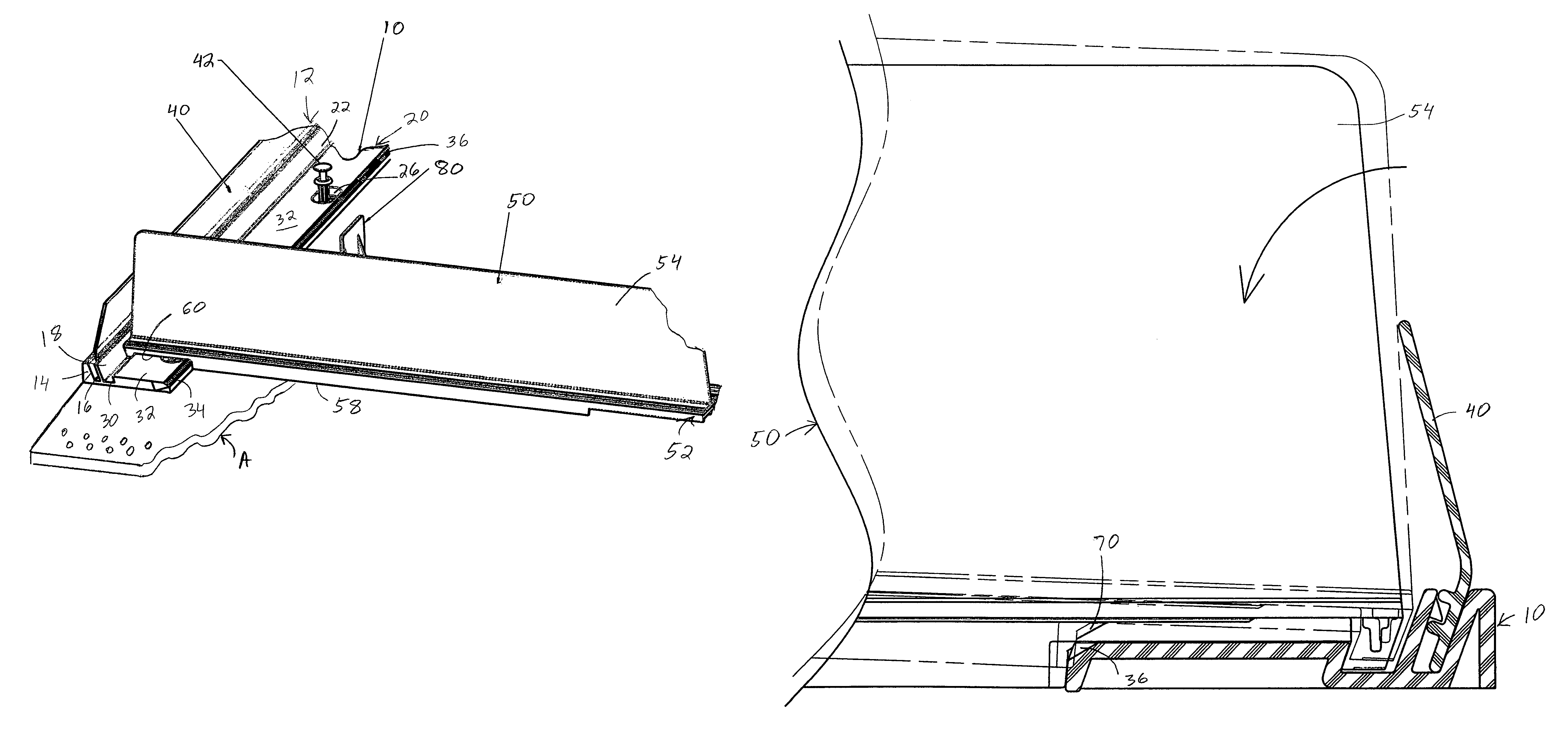

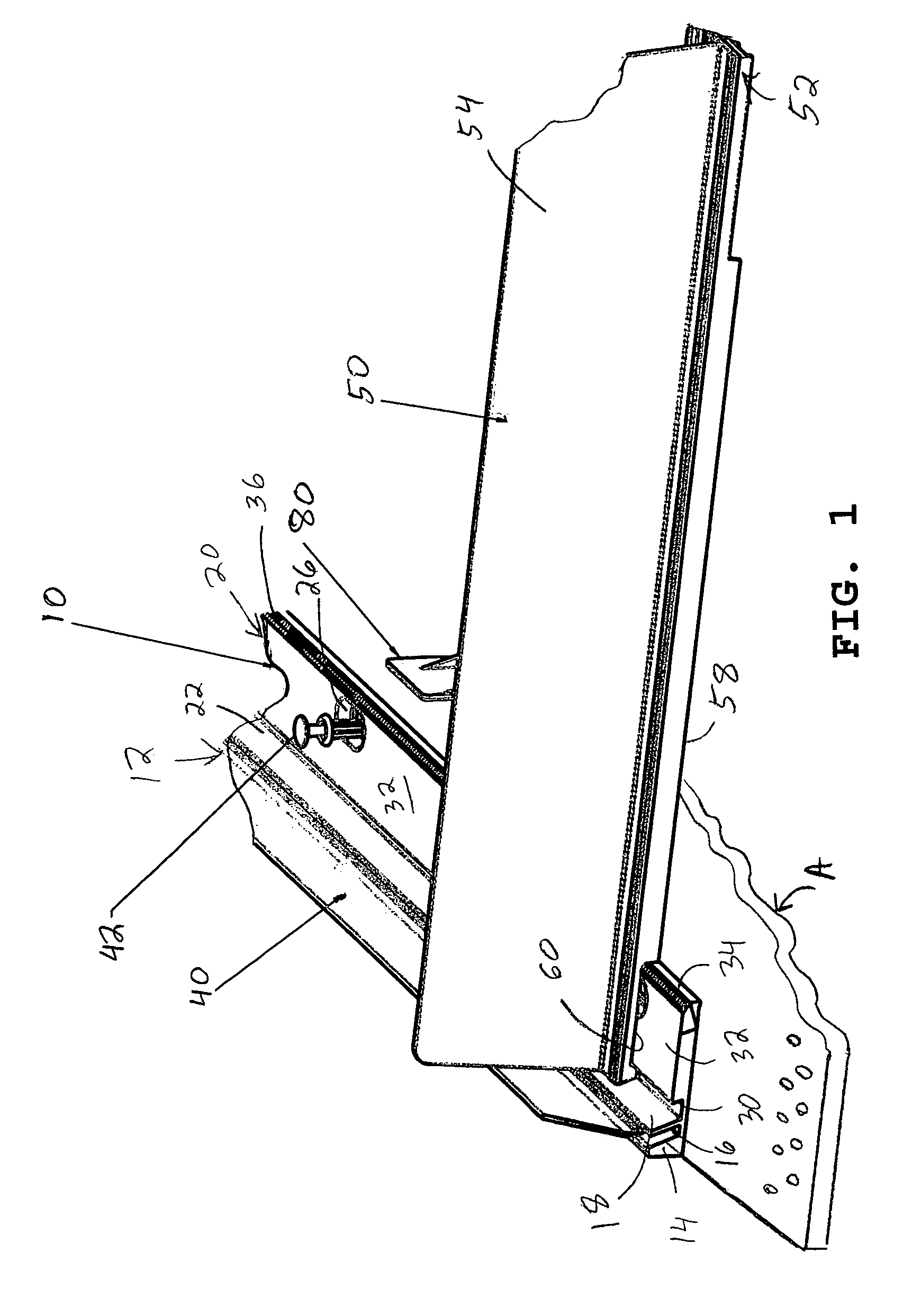

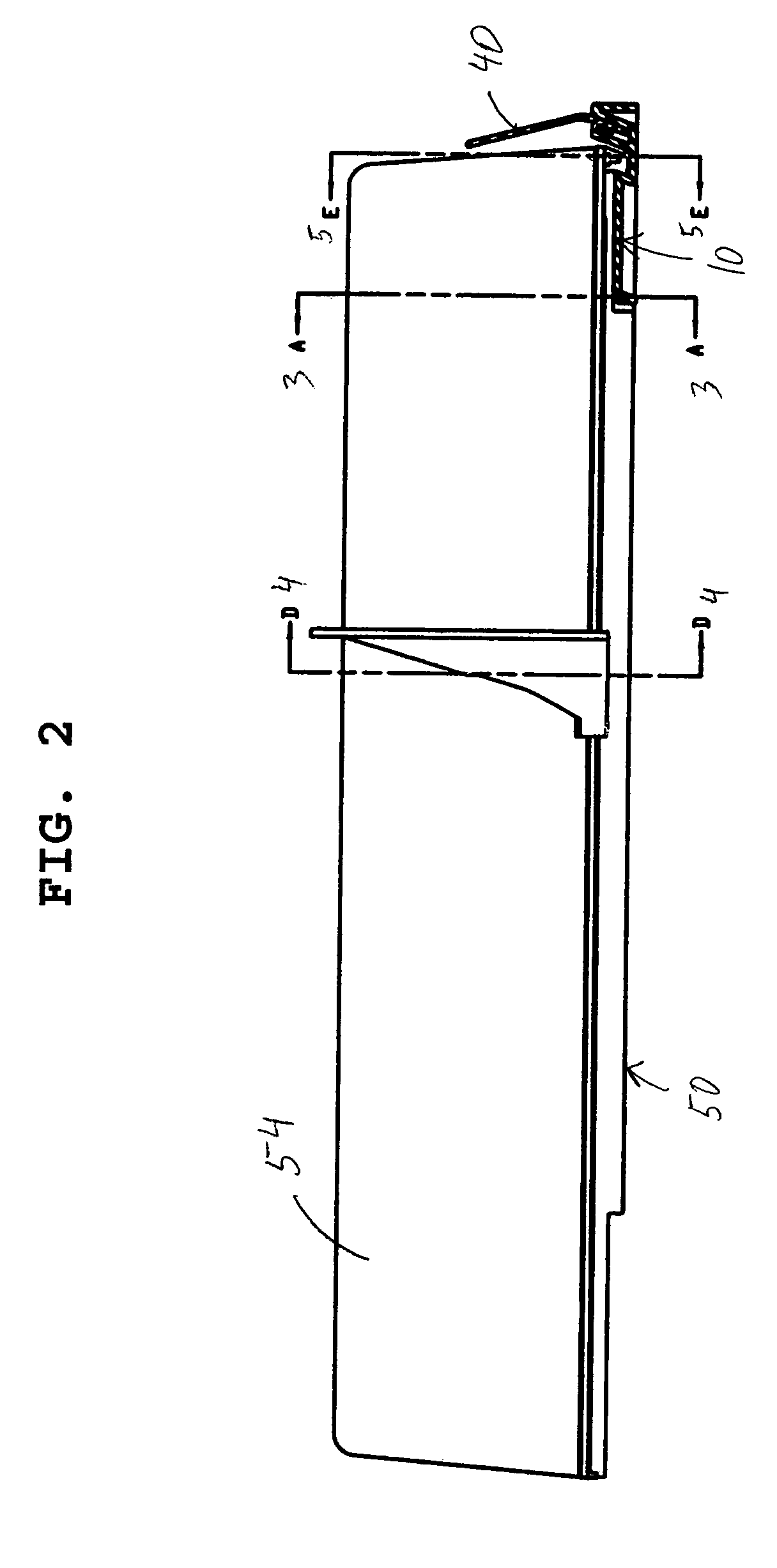

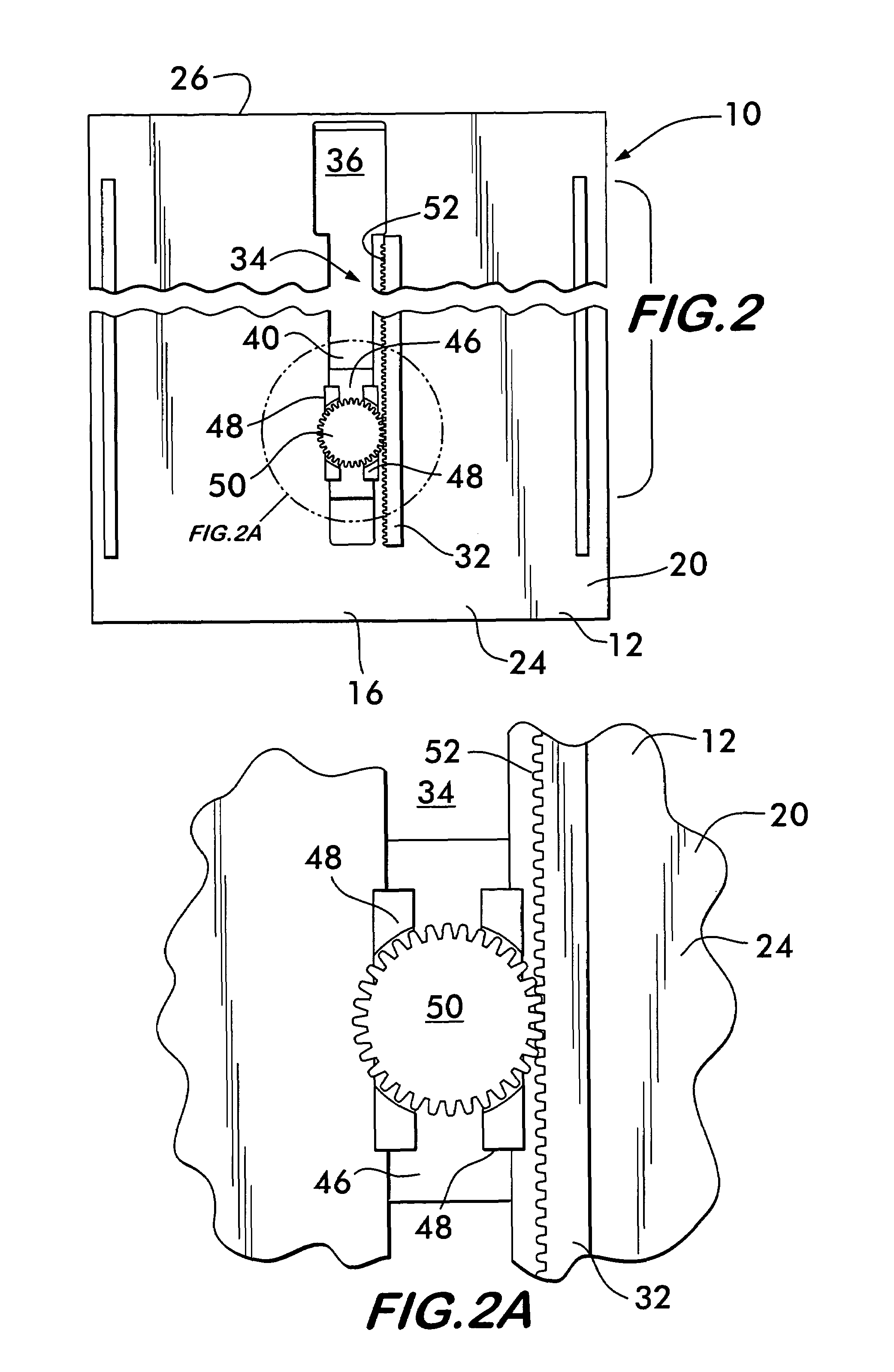

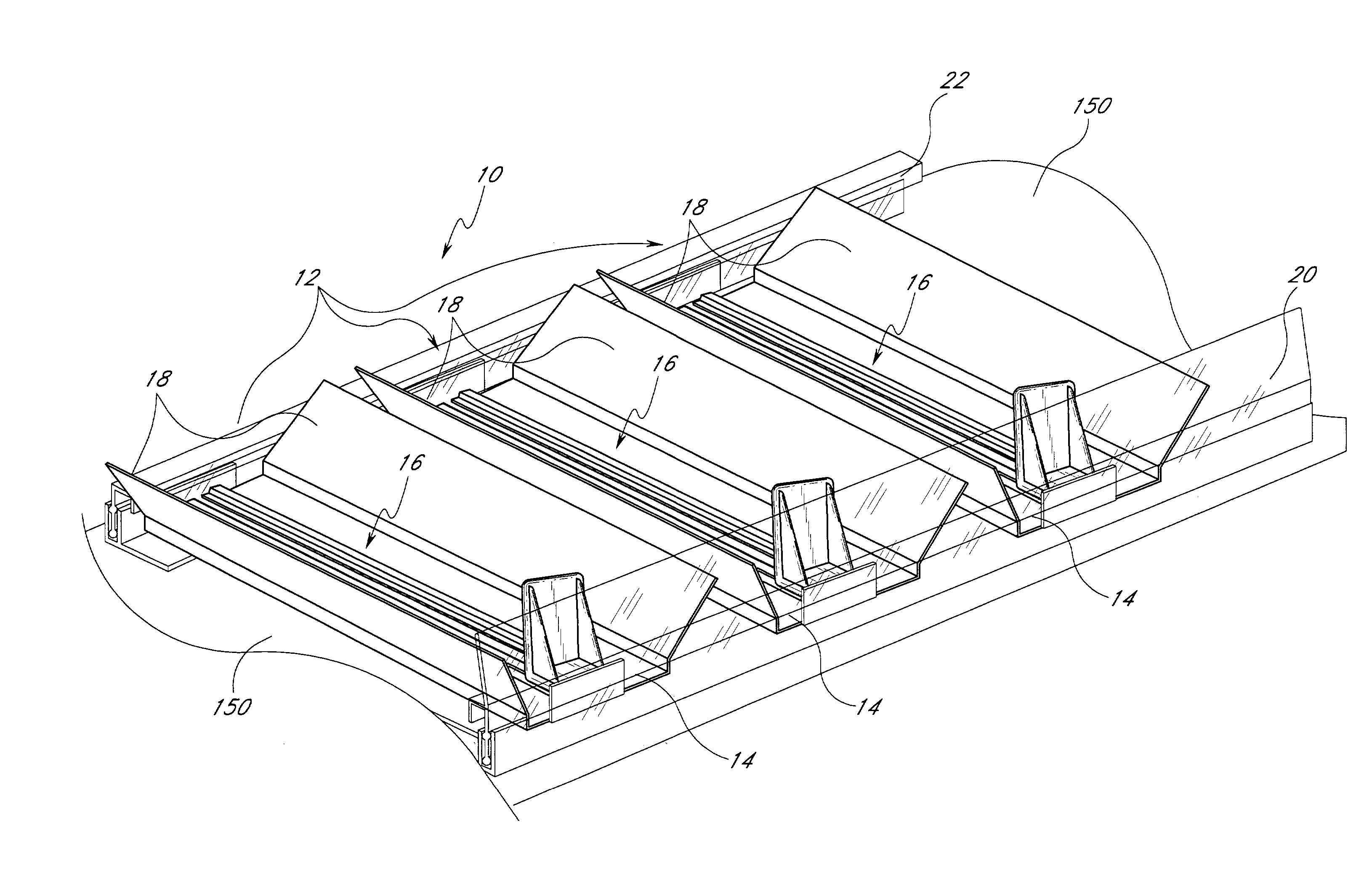

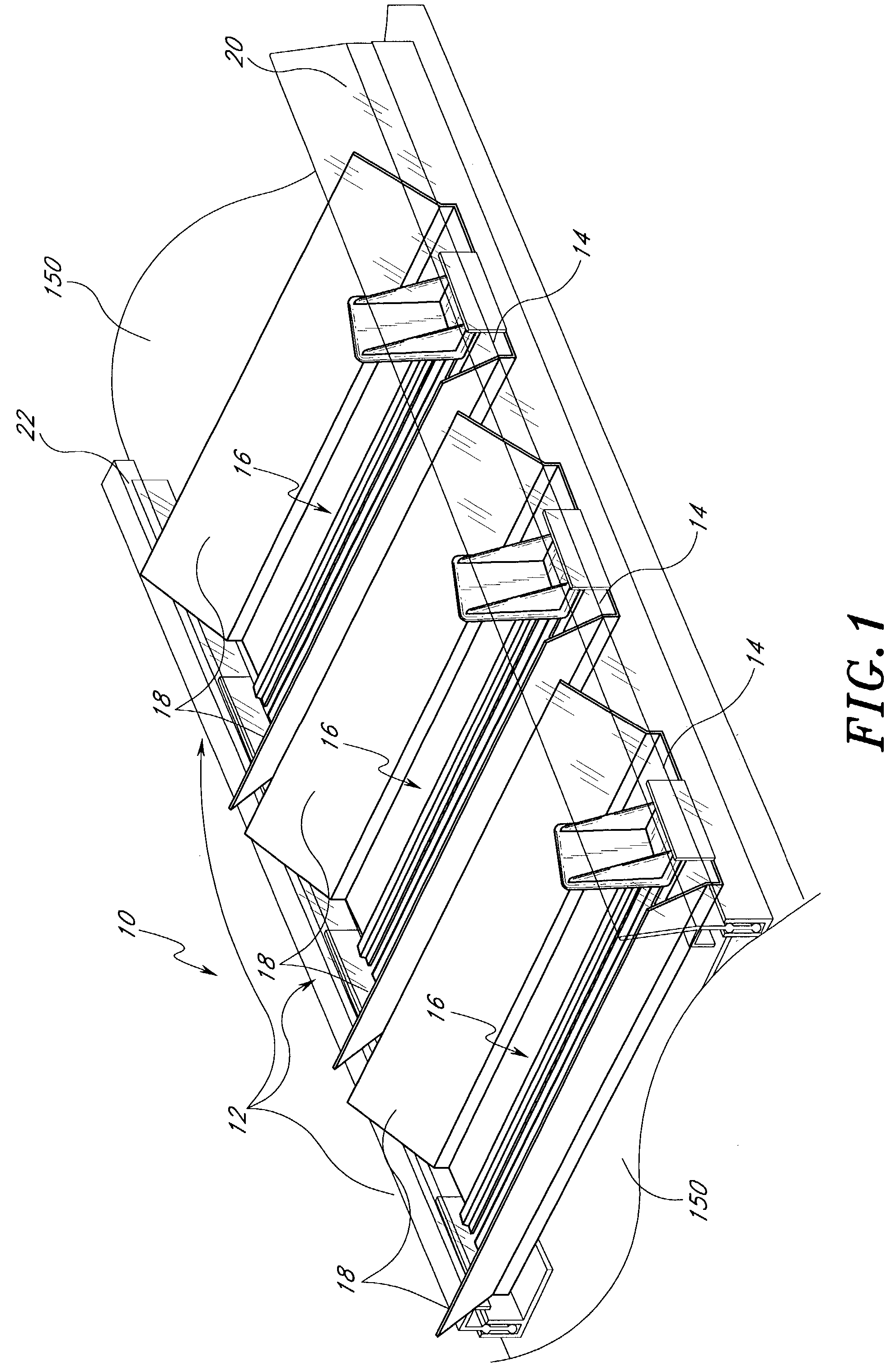

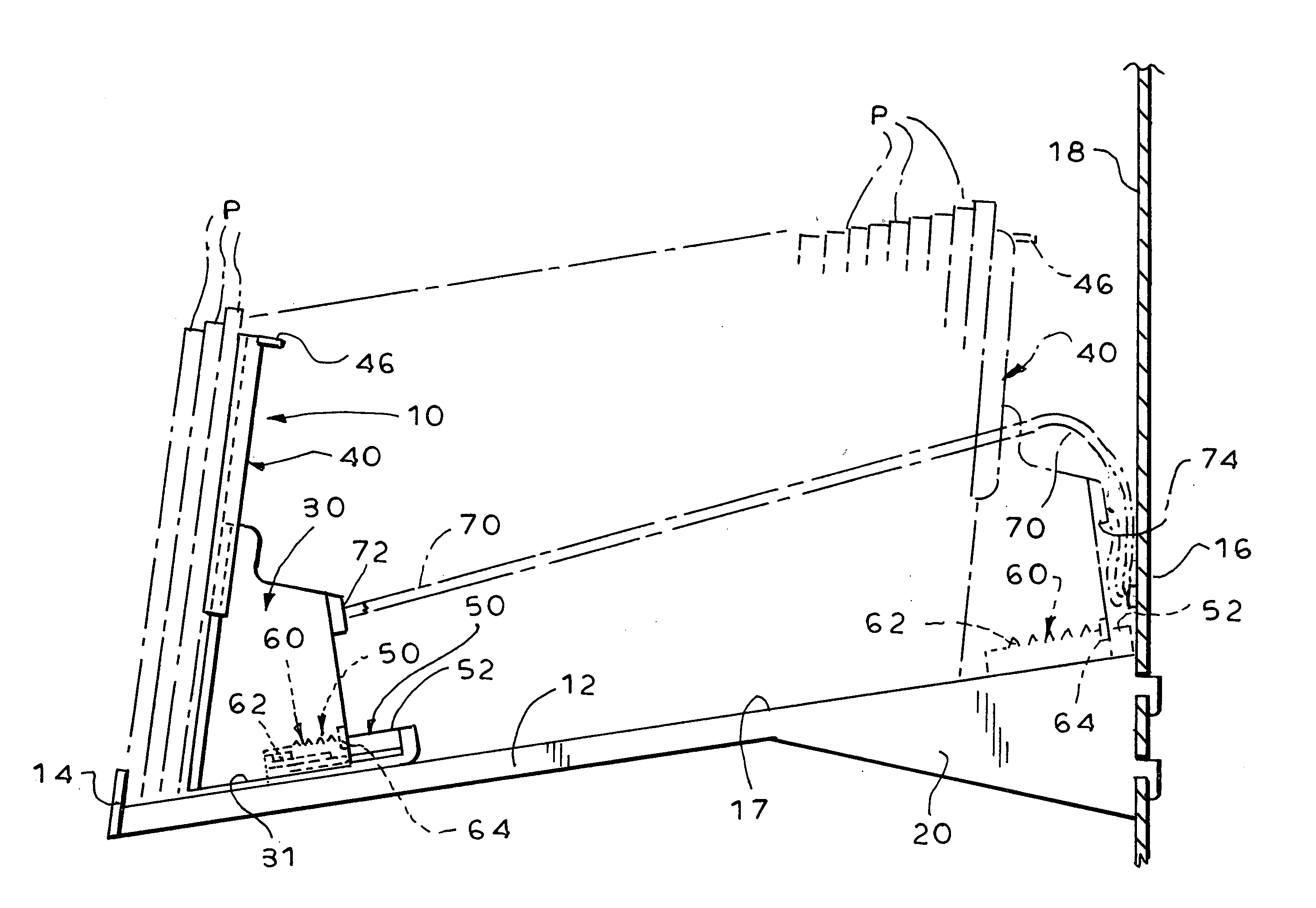

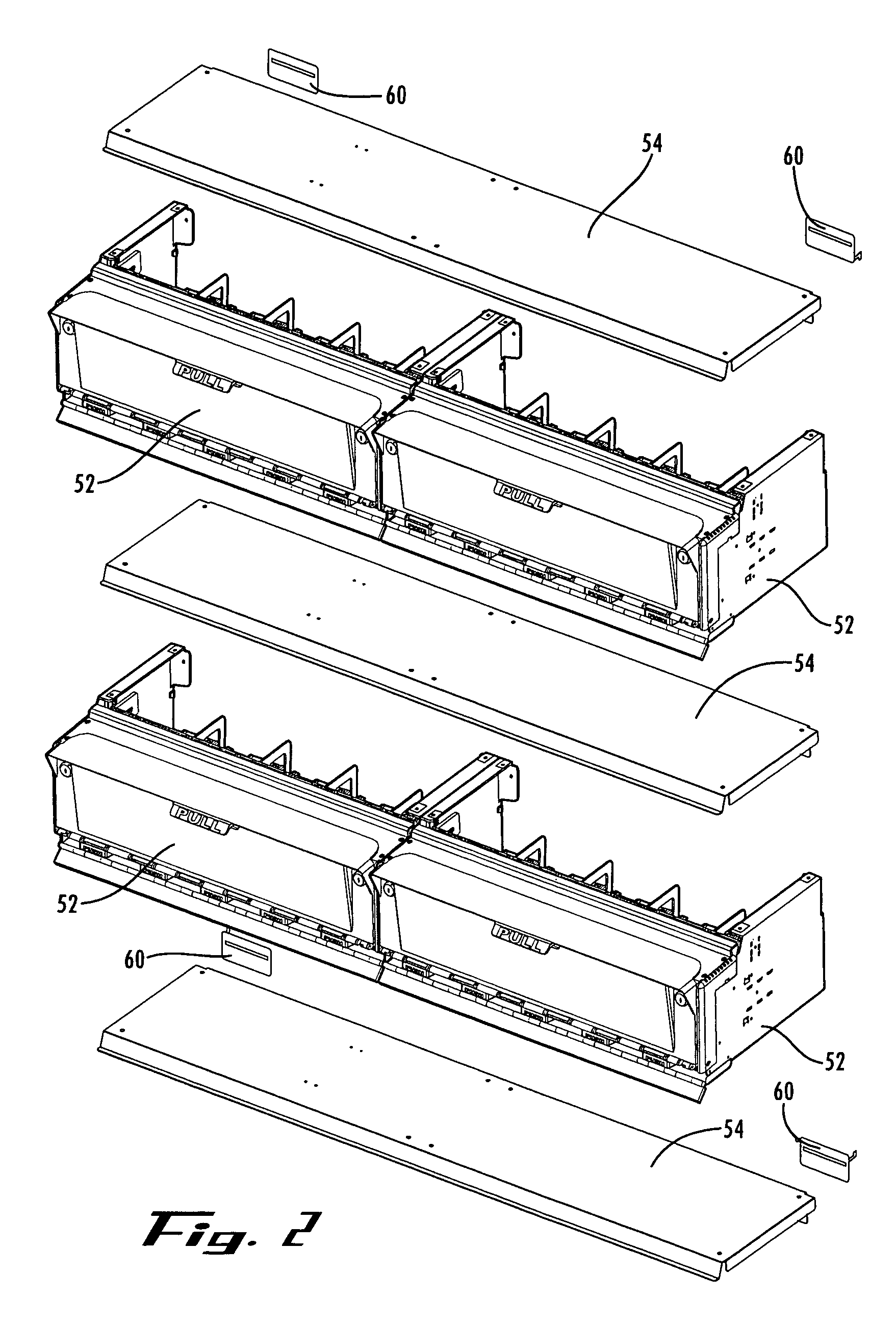

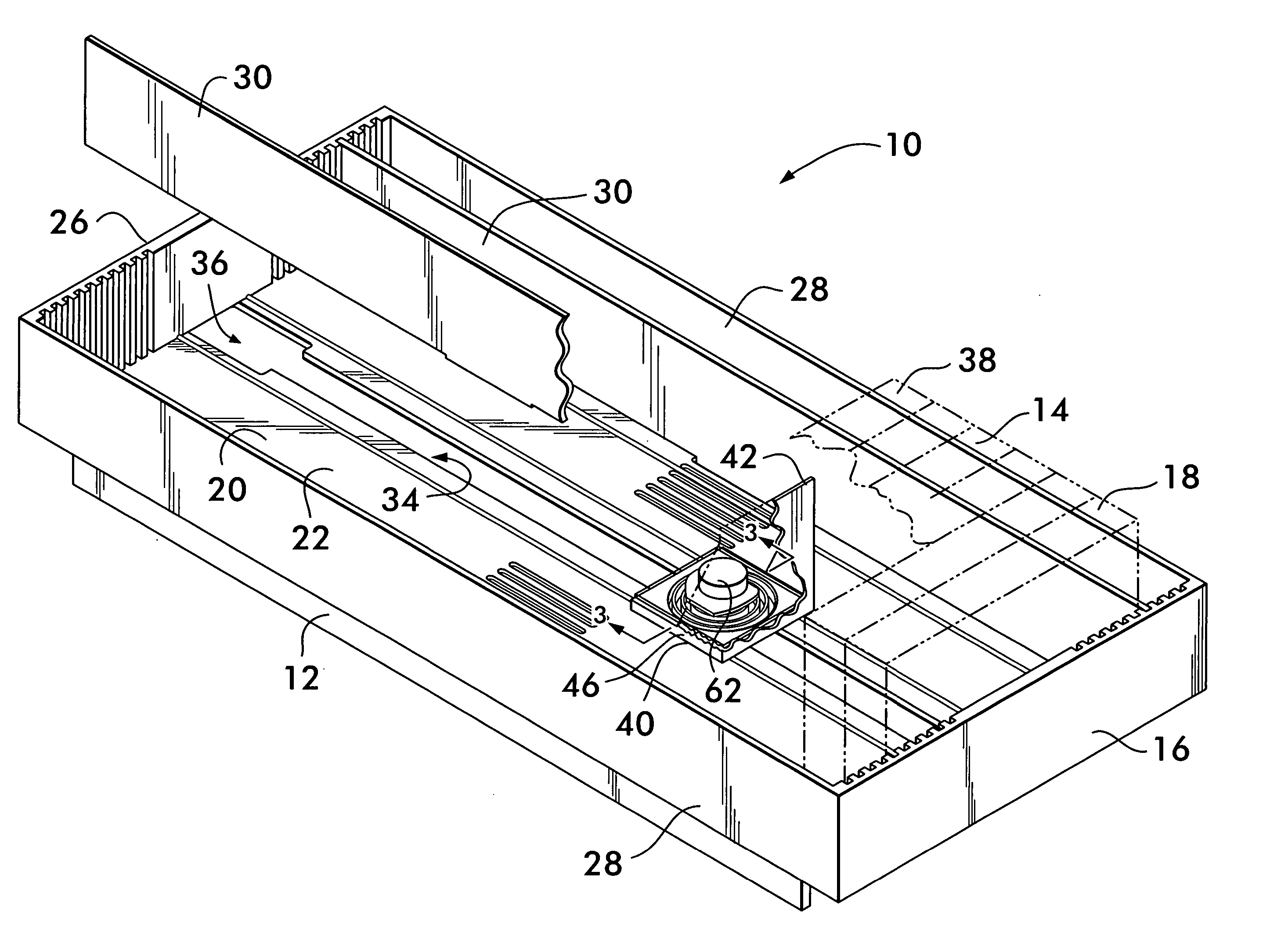

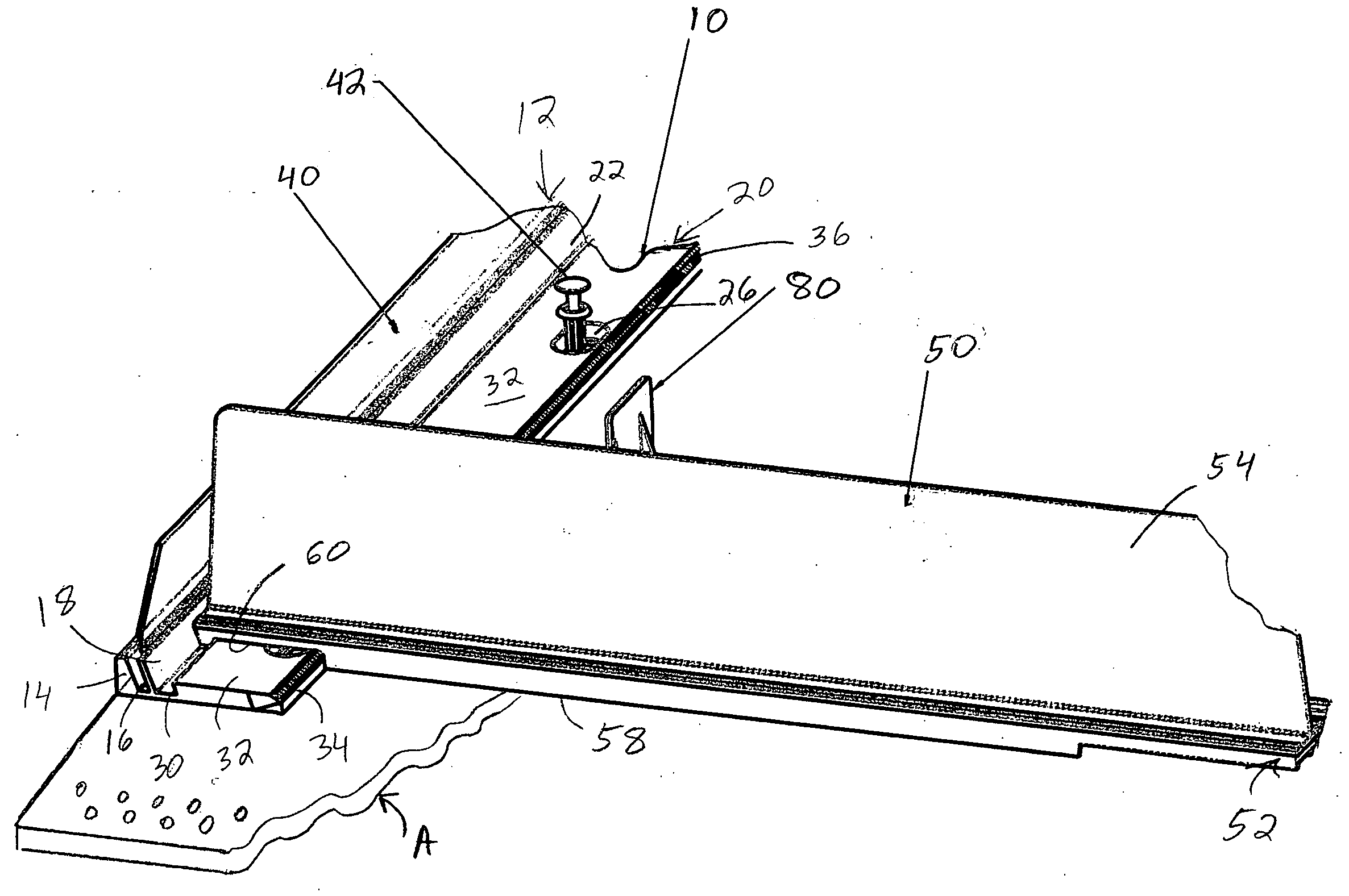

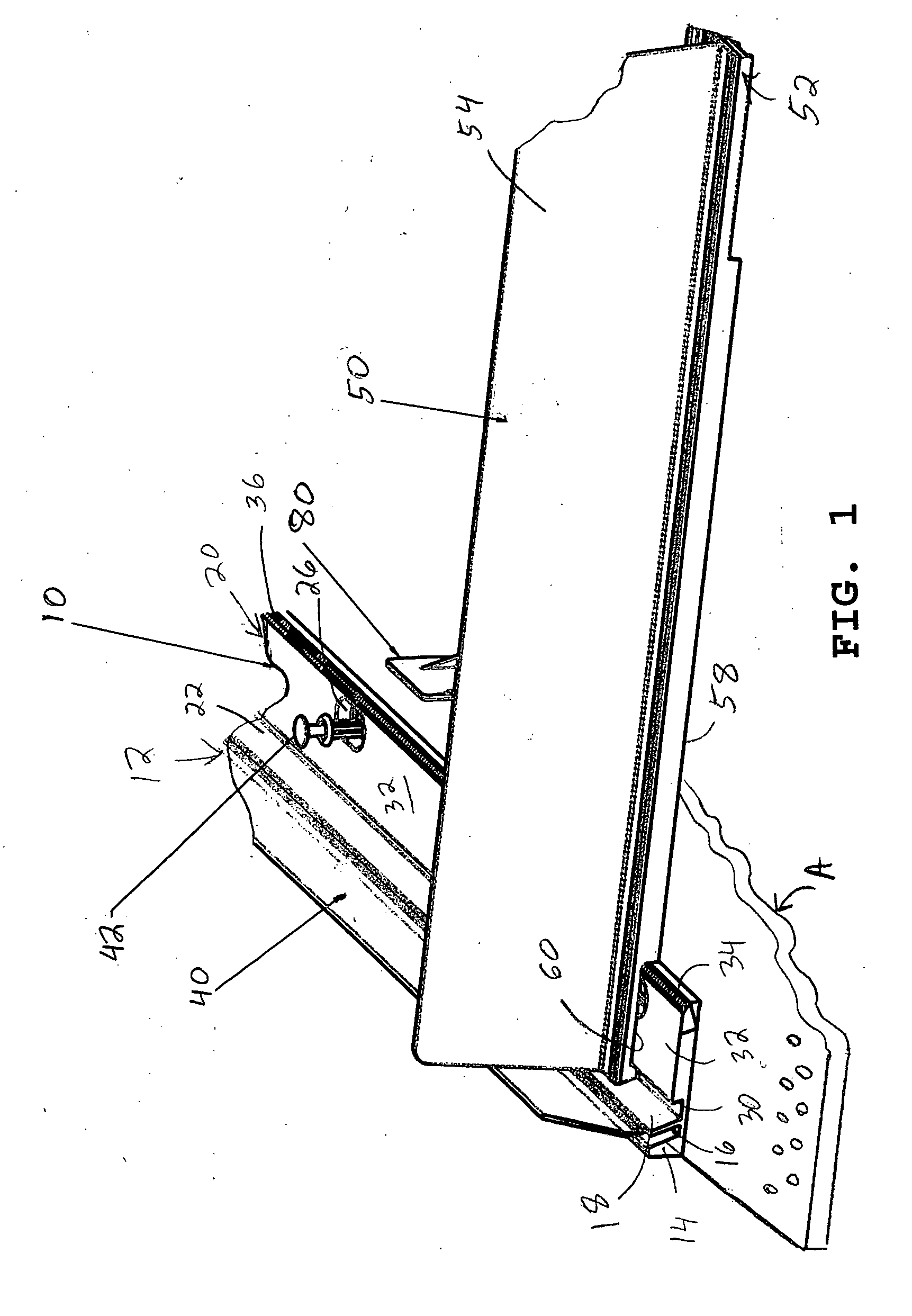

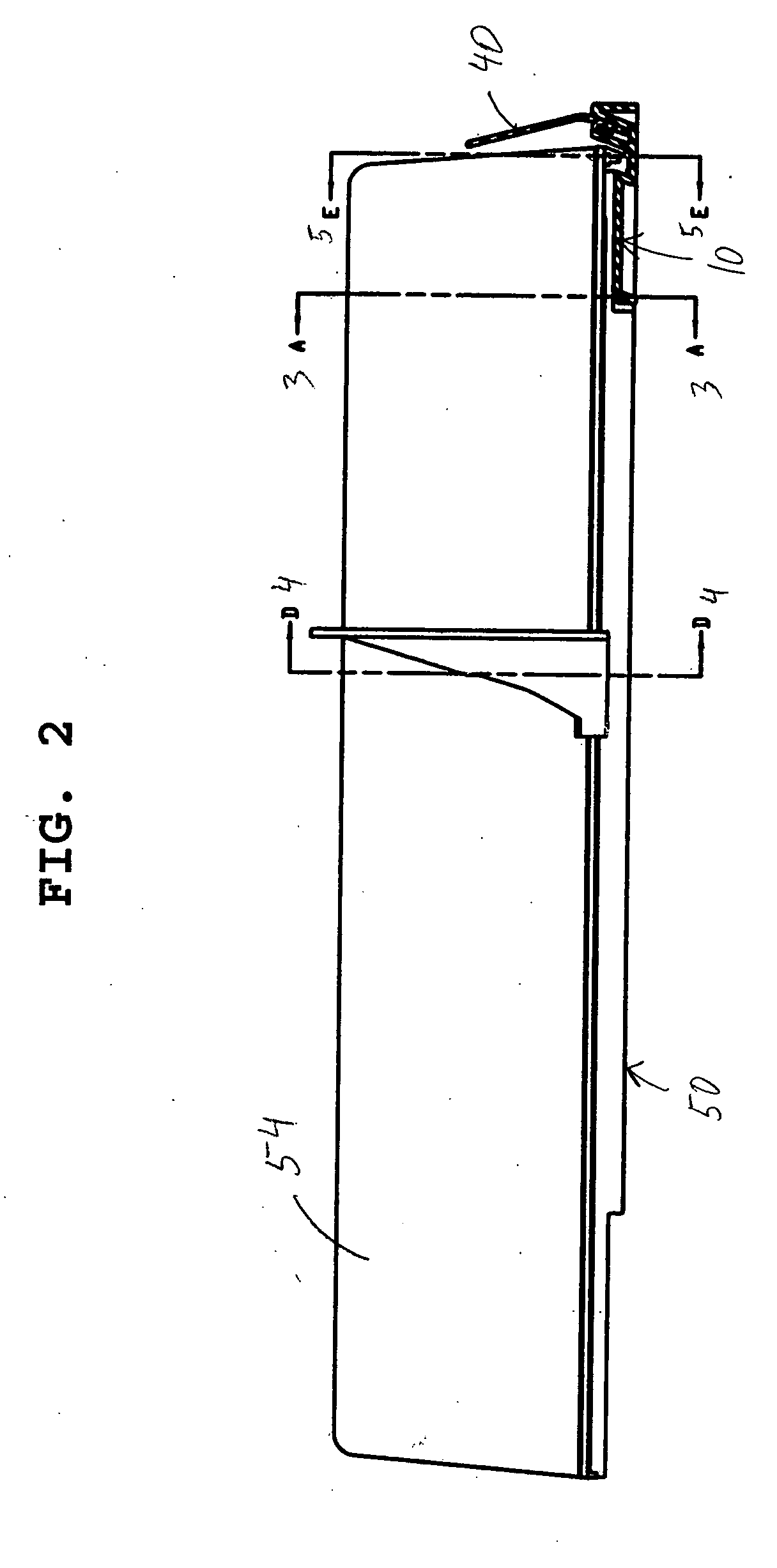

Adjustable shelving system

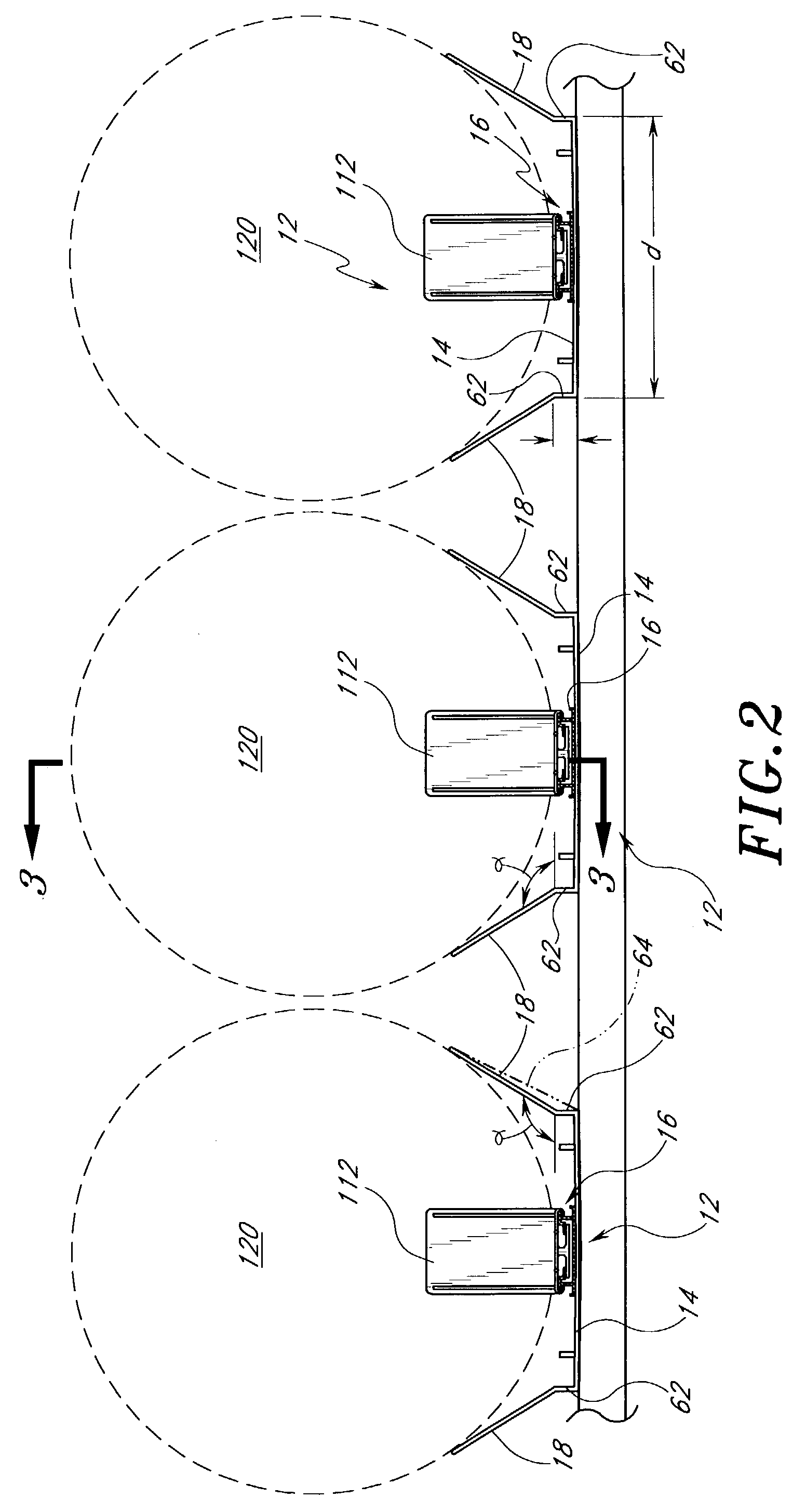

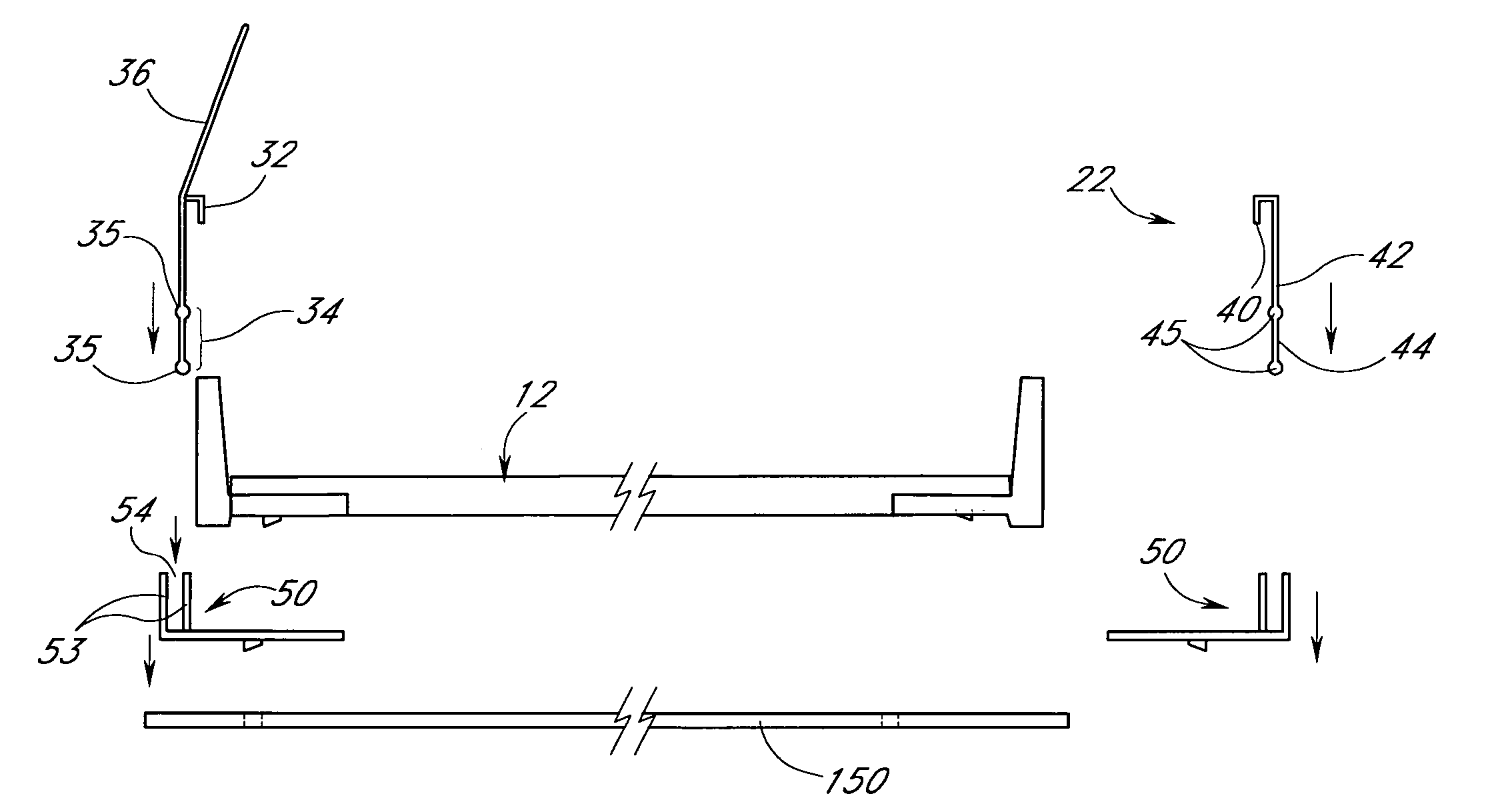

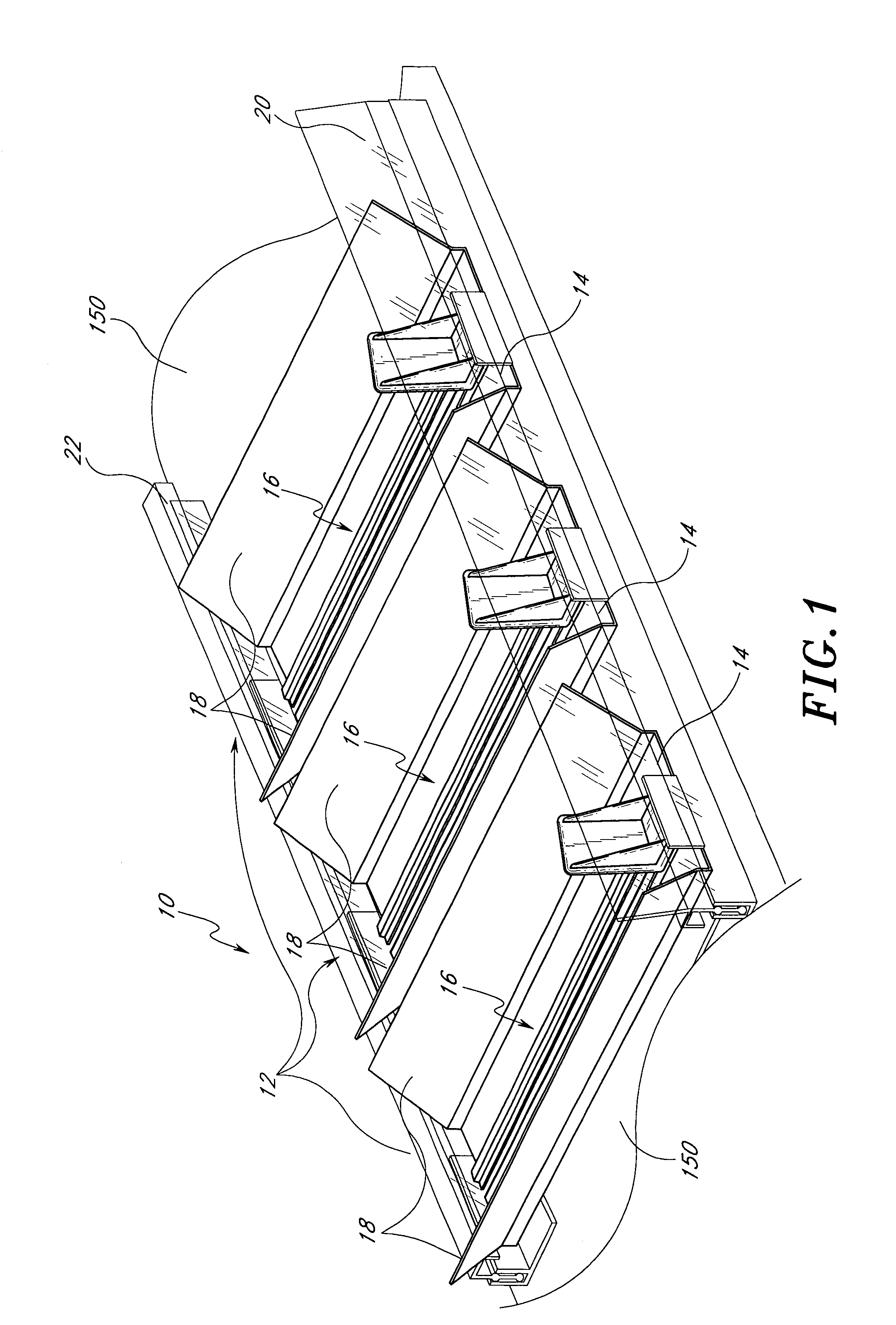

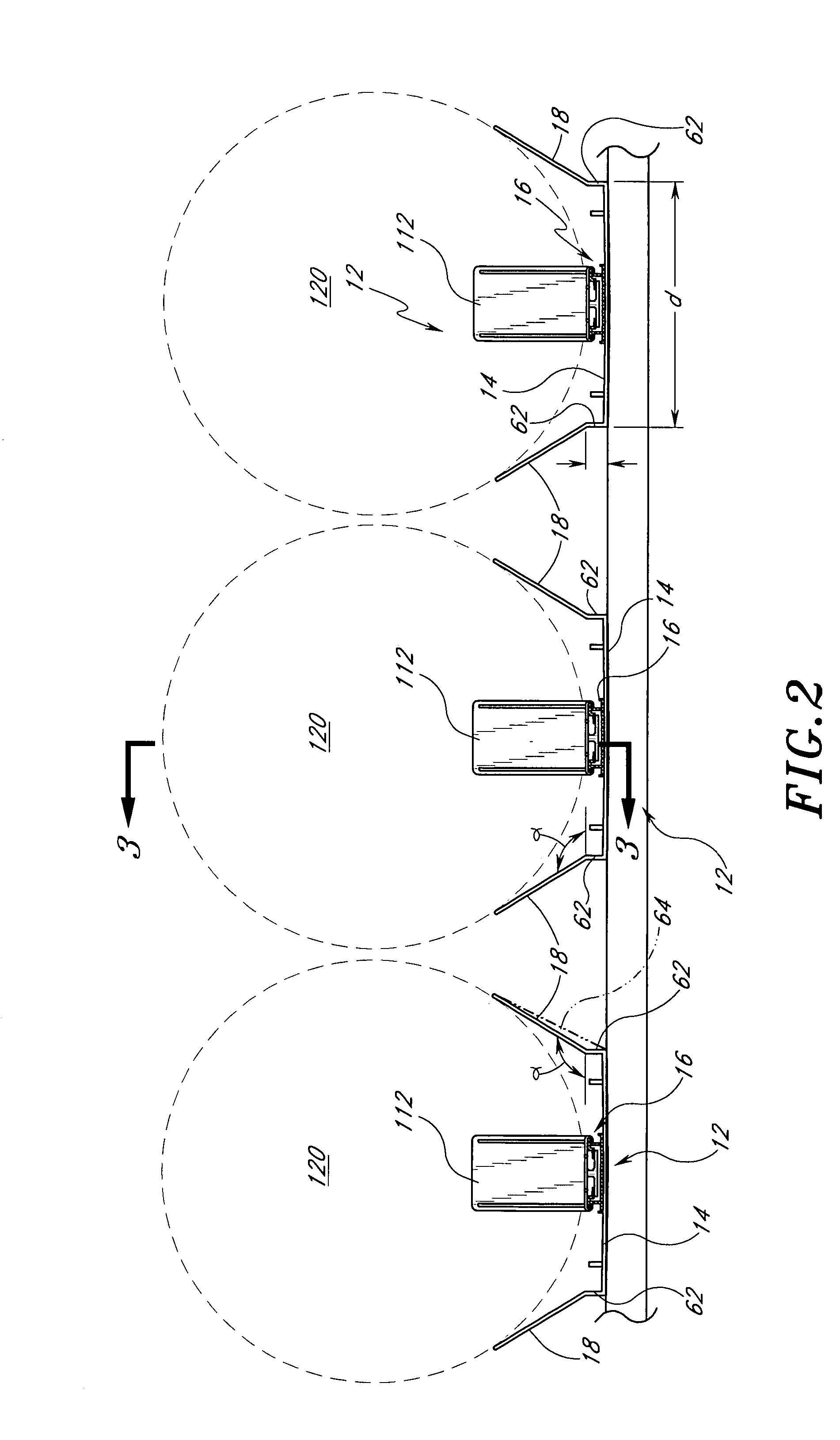

A shelving system includes an elongated mounting member operationally securable to an associated shelf. The mounting member includes an approximately vertically oriented wall and an approximately horizontally oriented wall. A track is received on the mounting member in a non-sliding manner. The track extends transversely to a longitudinal axis of the associated shelf. An elongated rail extends longitudinally along the track. A spring urged pusher is slidably mounted in relation to the rail. A slot extends transversely along a bottom face of the track. A first smooth contact surface is located on the mounting member approximately a horizontally oriented wall. A second smooth contact surface is located on the track adjacent the slot. The second contact surface engages the first contact surface to retard a sideward sliding motion of the track in relation to the mounting member.

Owner:FASTENERS FOR RETAIL

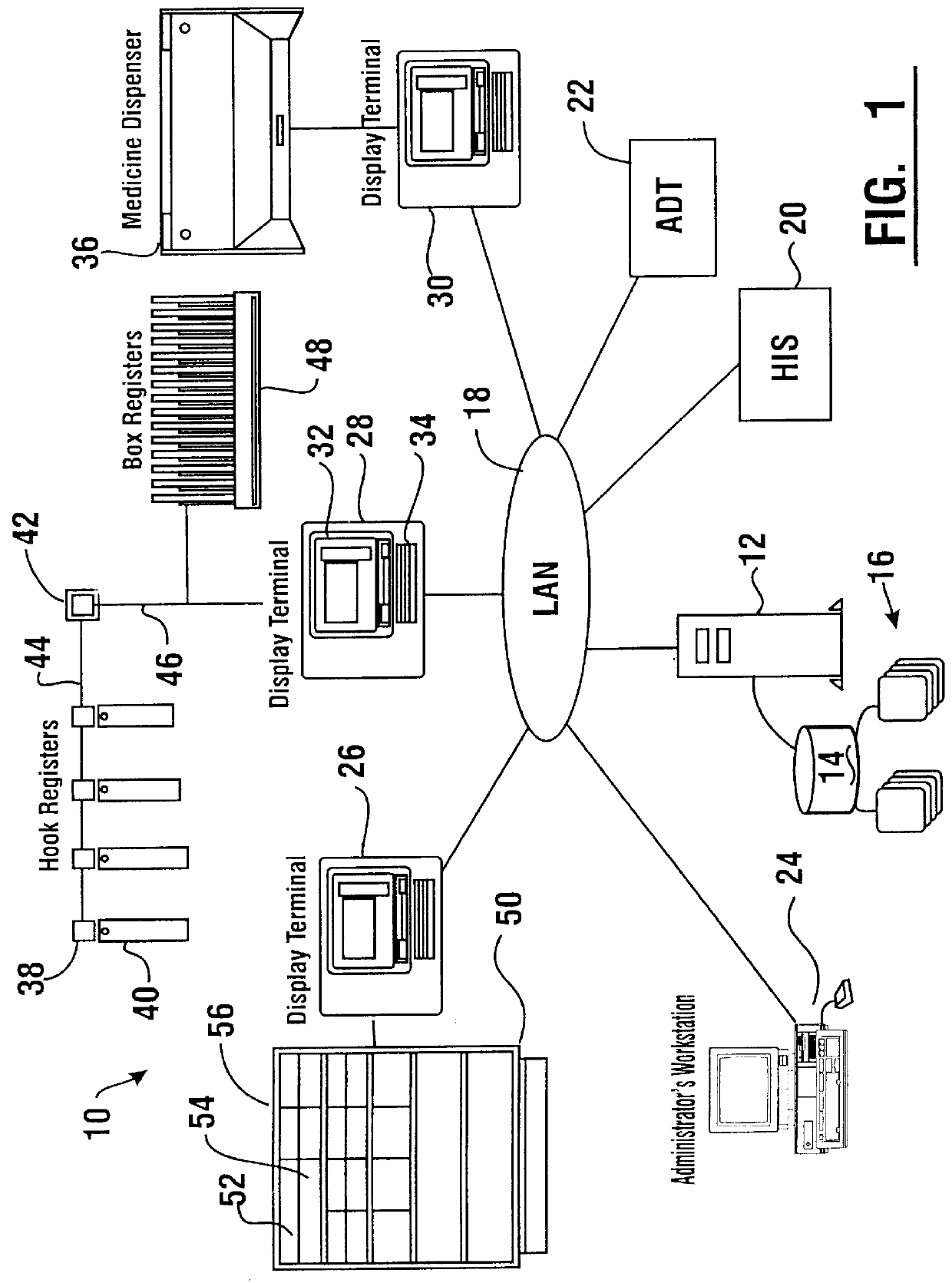

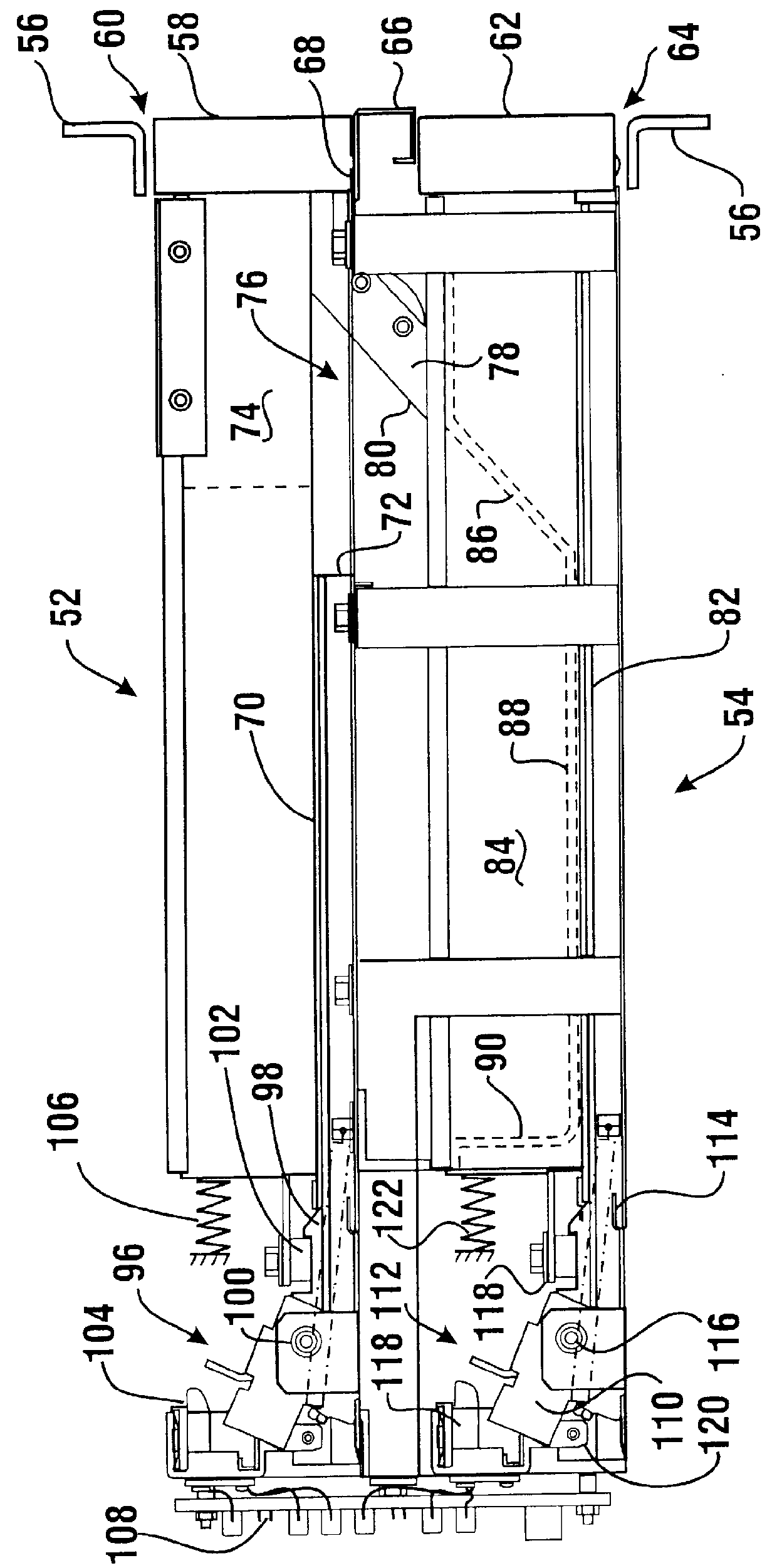

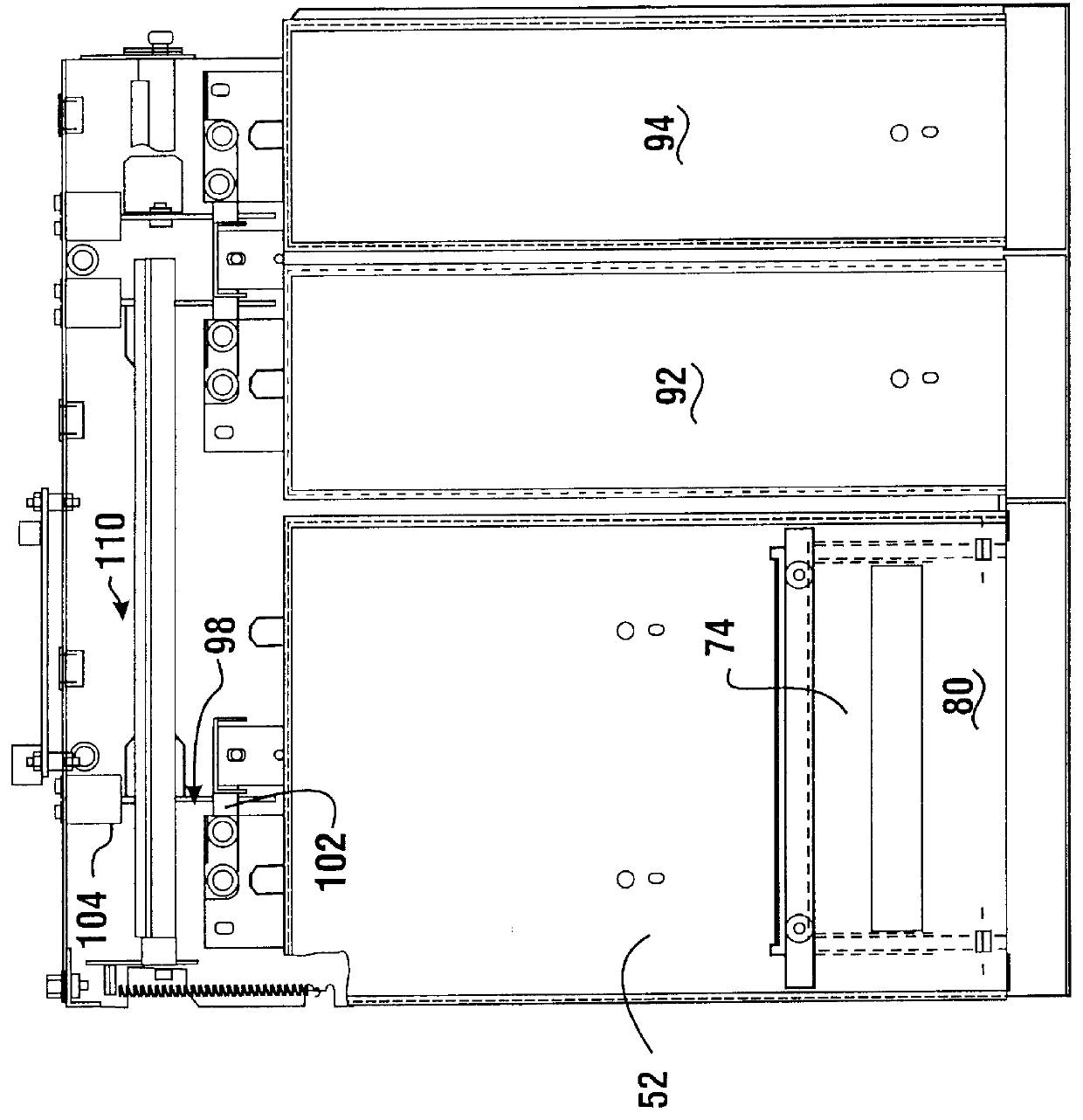

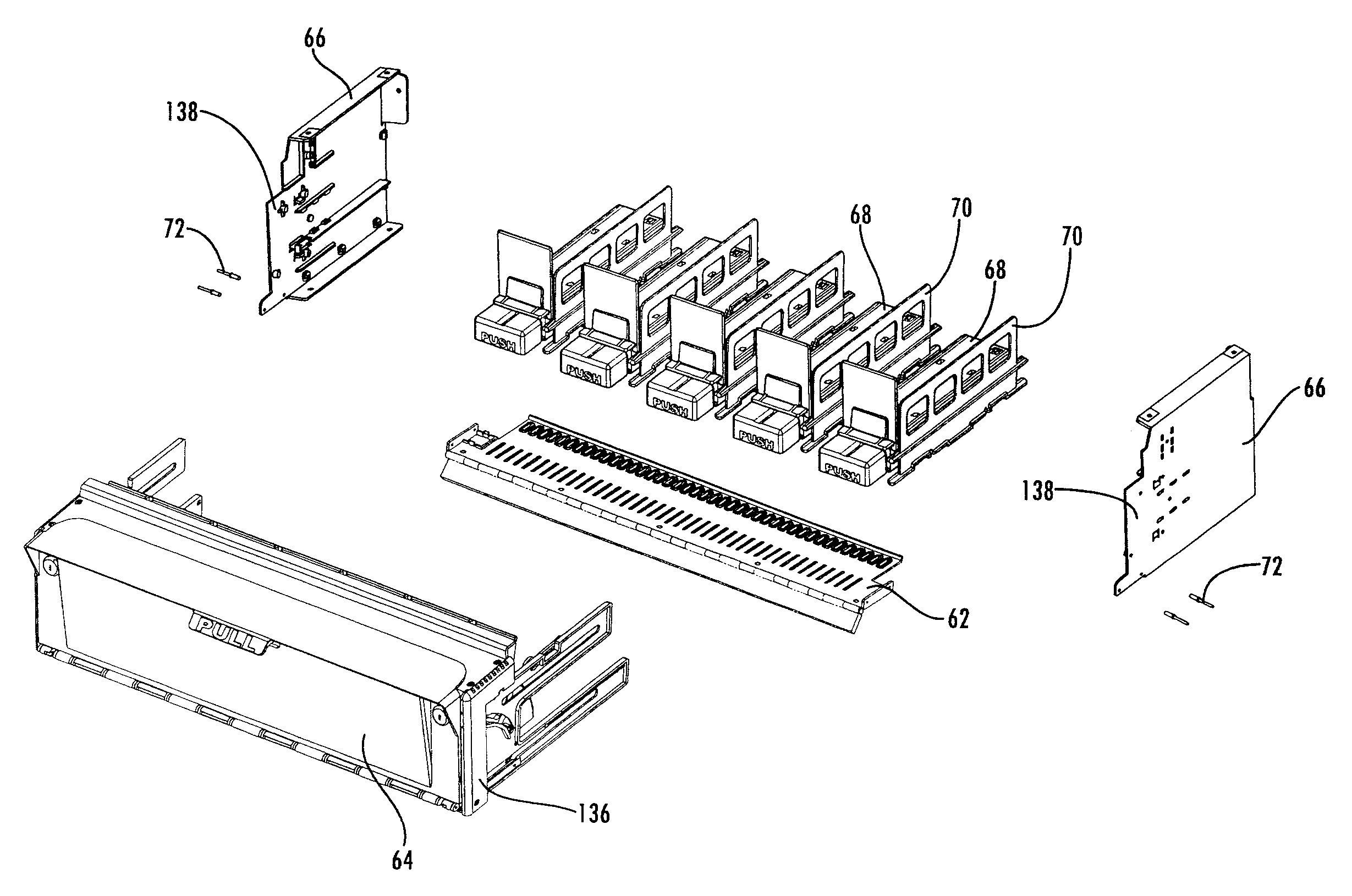

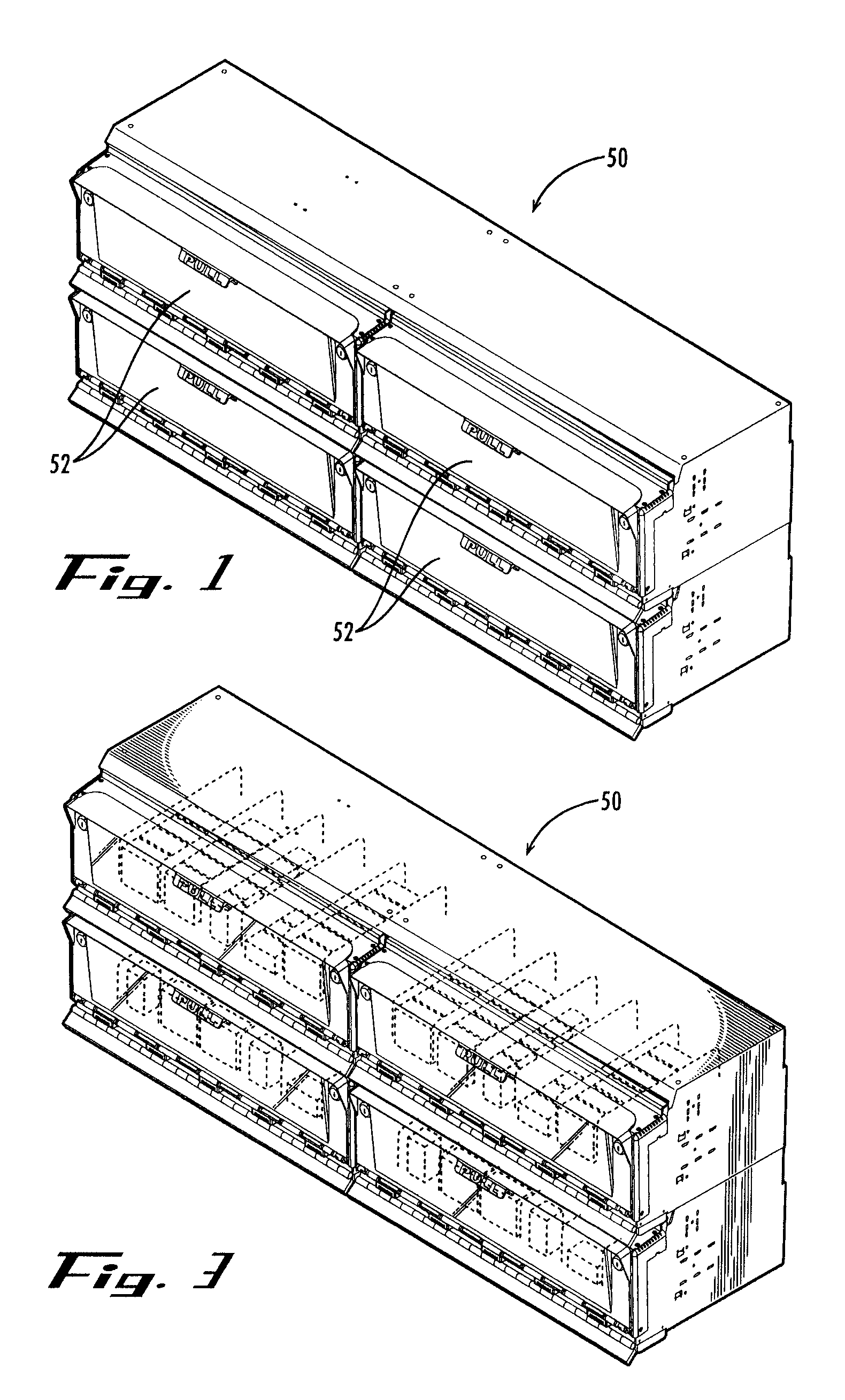

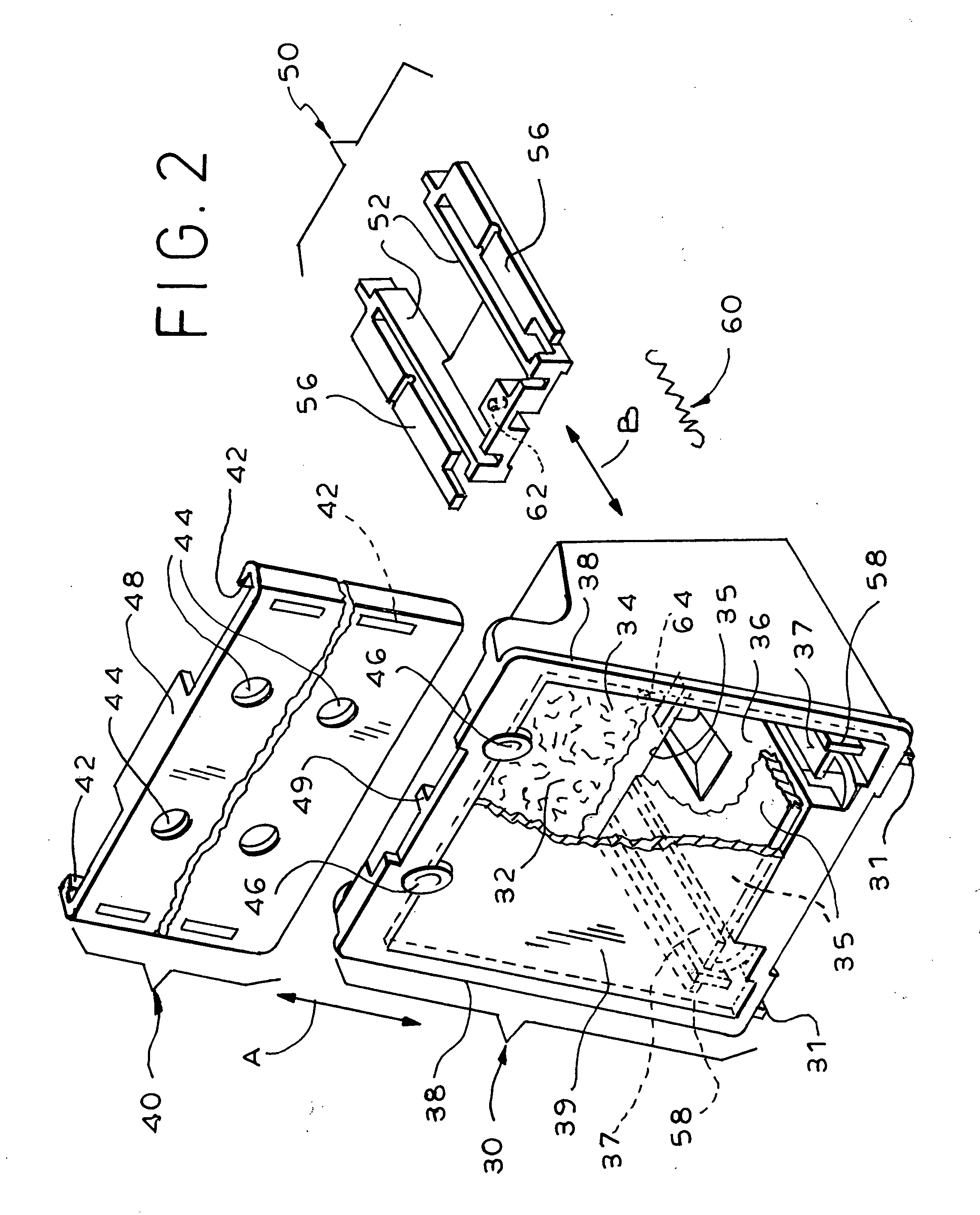

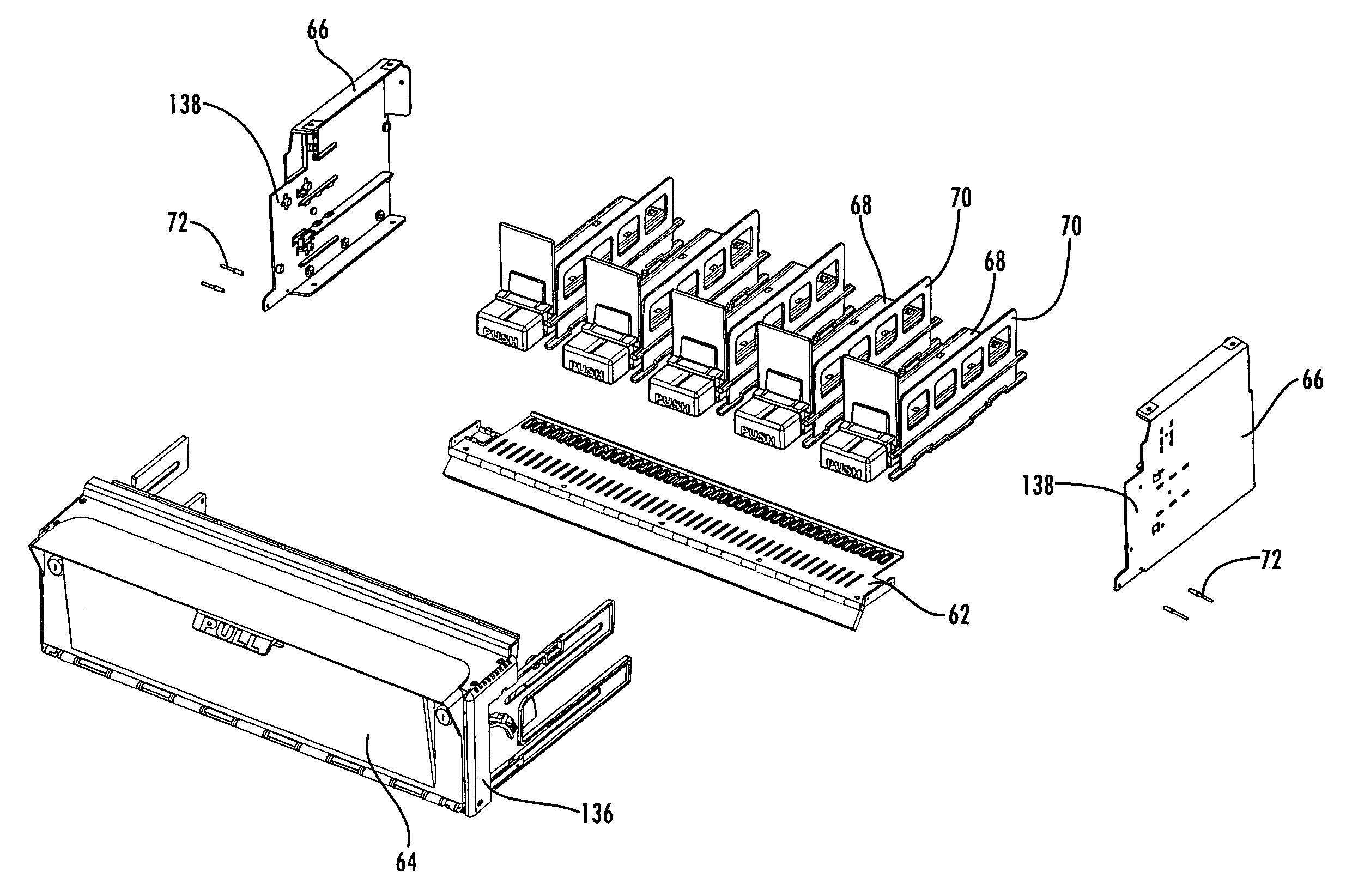

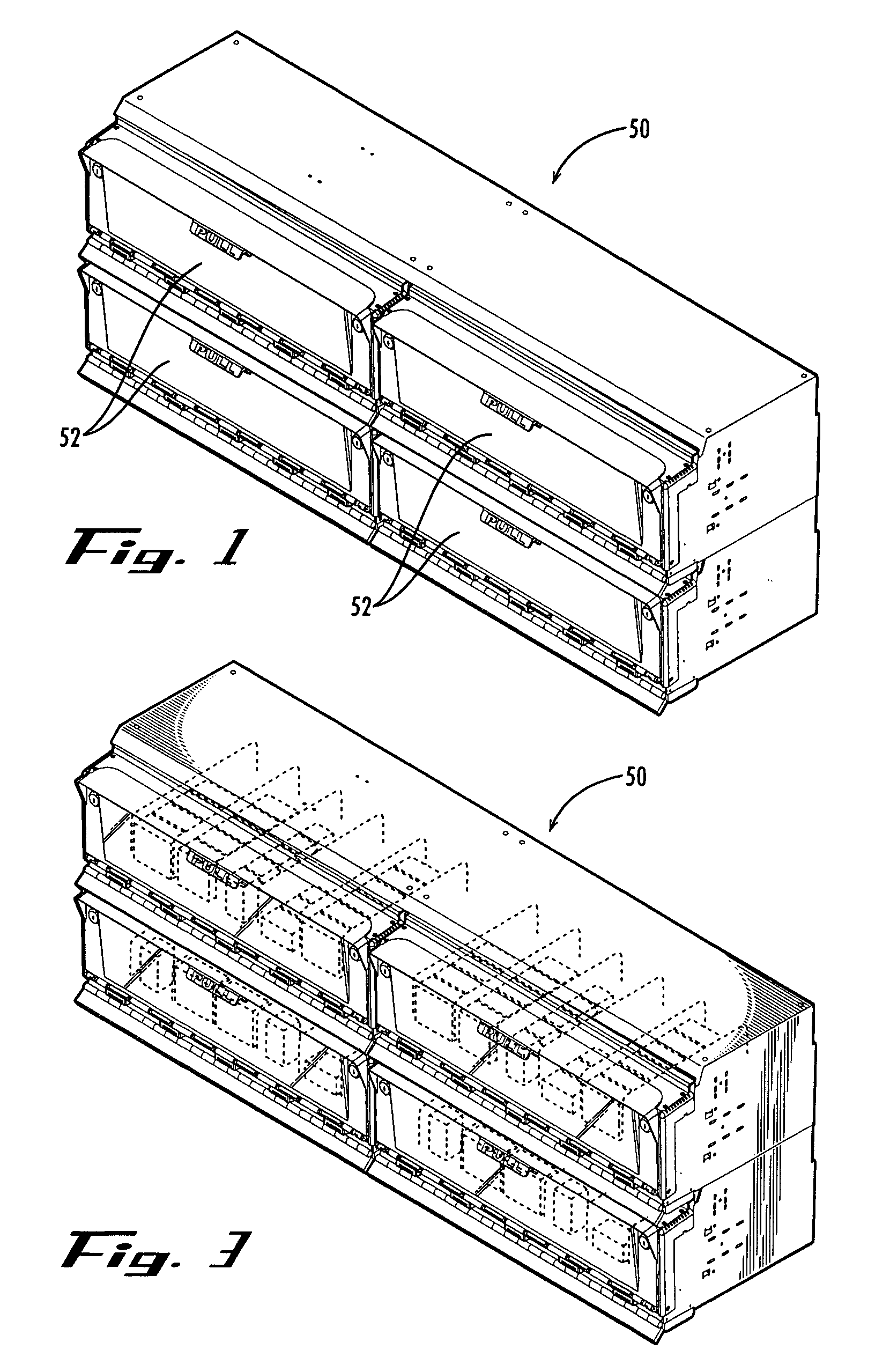

Apparatus and method for accepting return of unused medical items

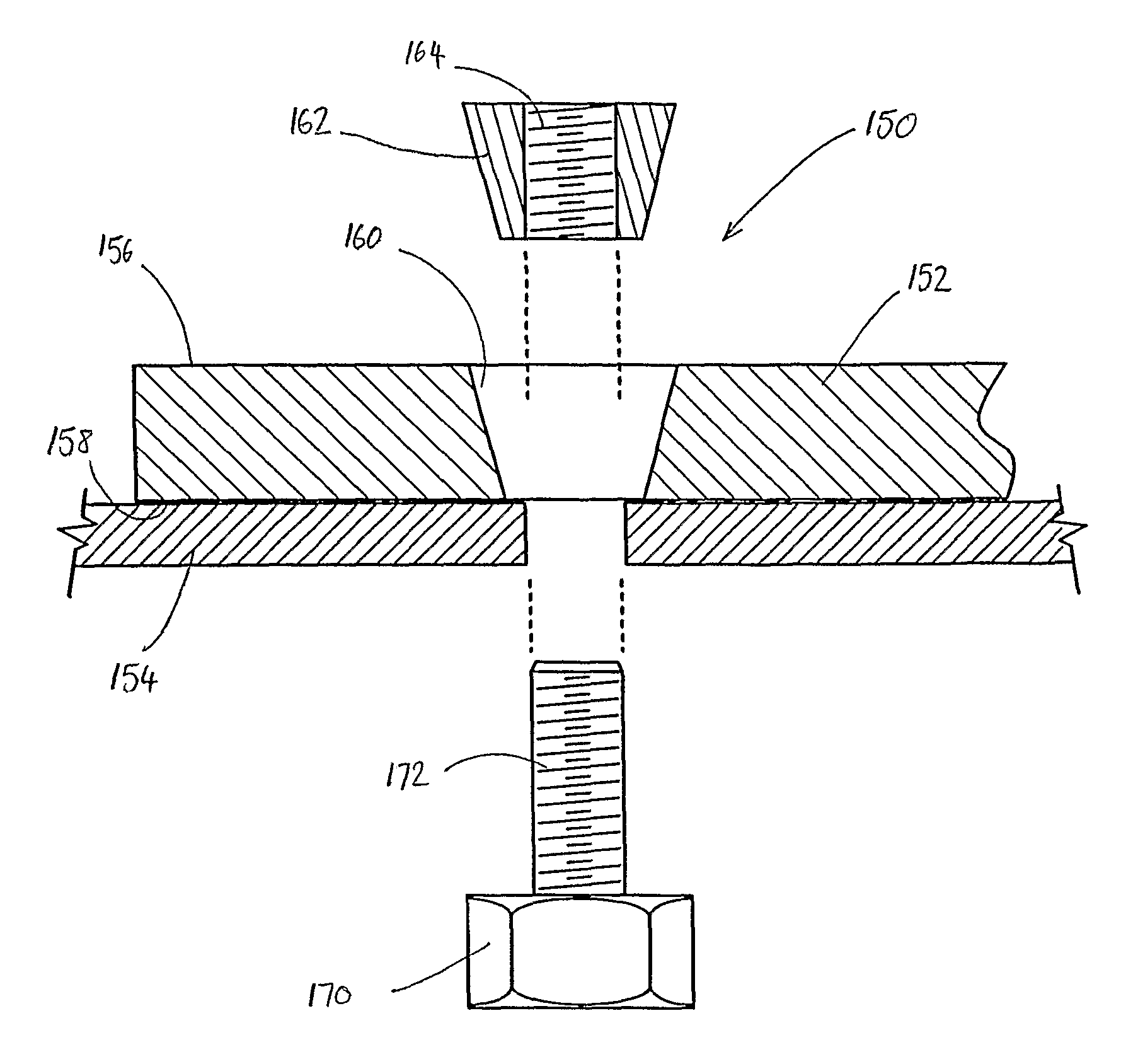

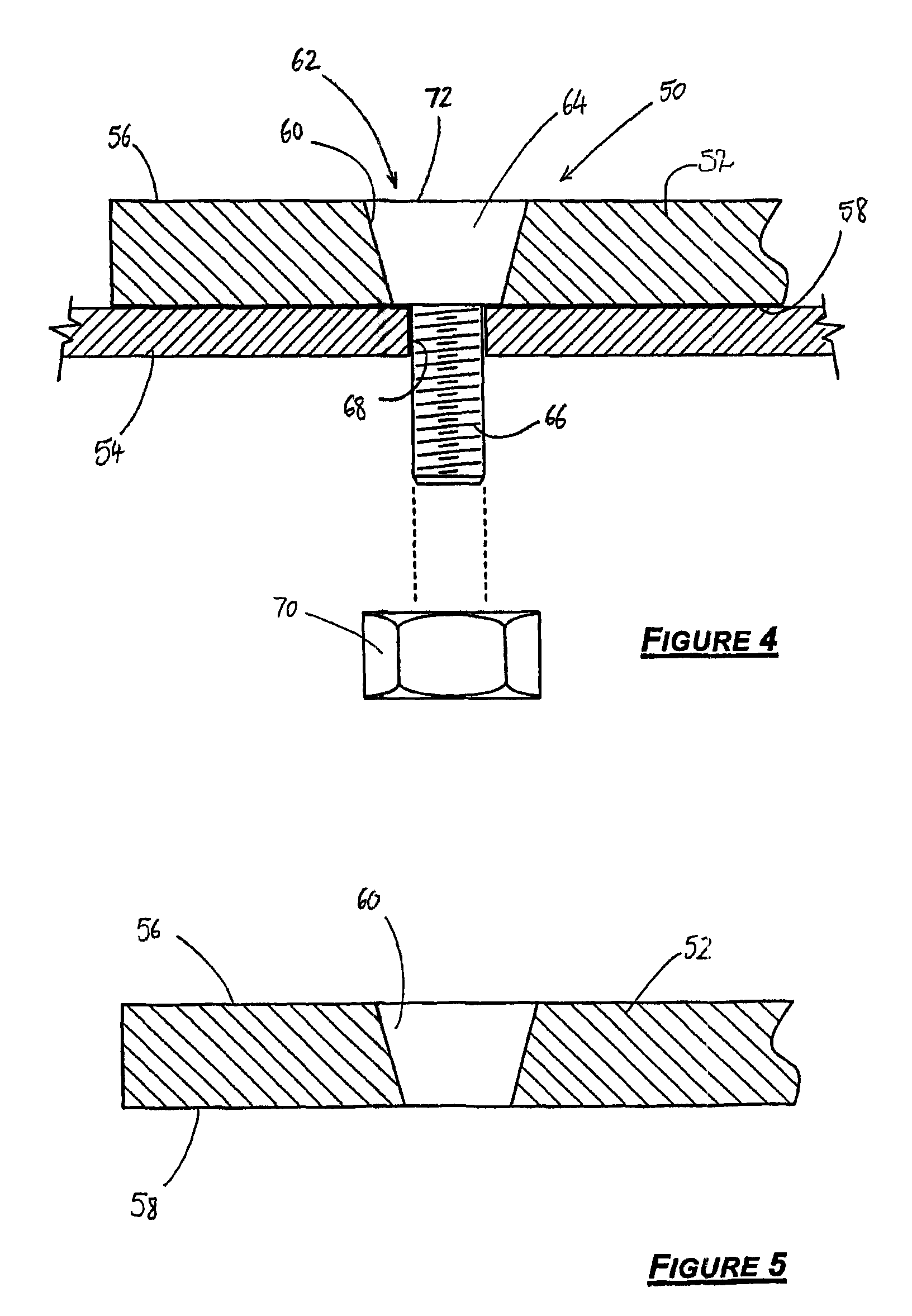

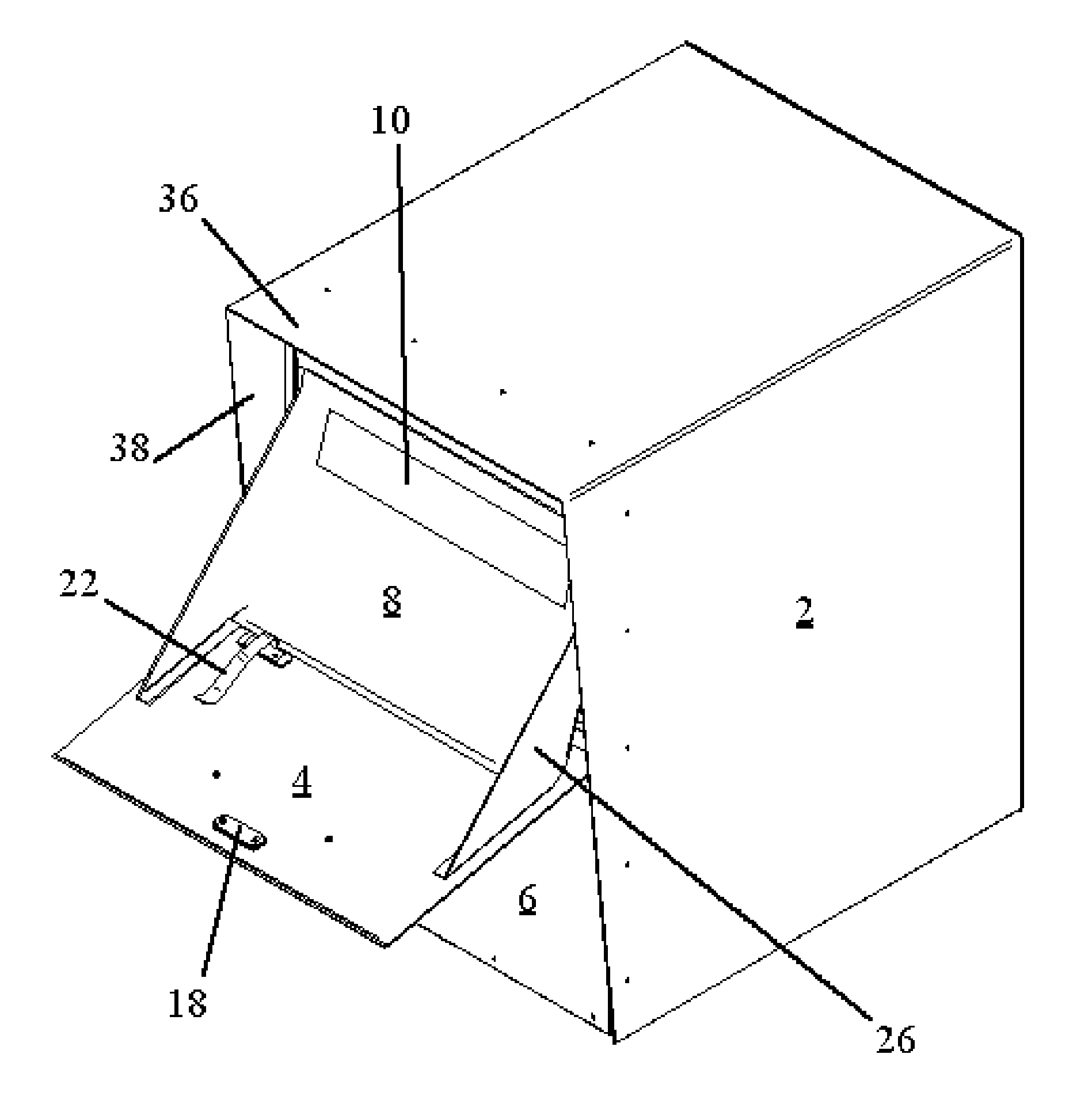

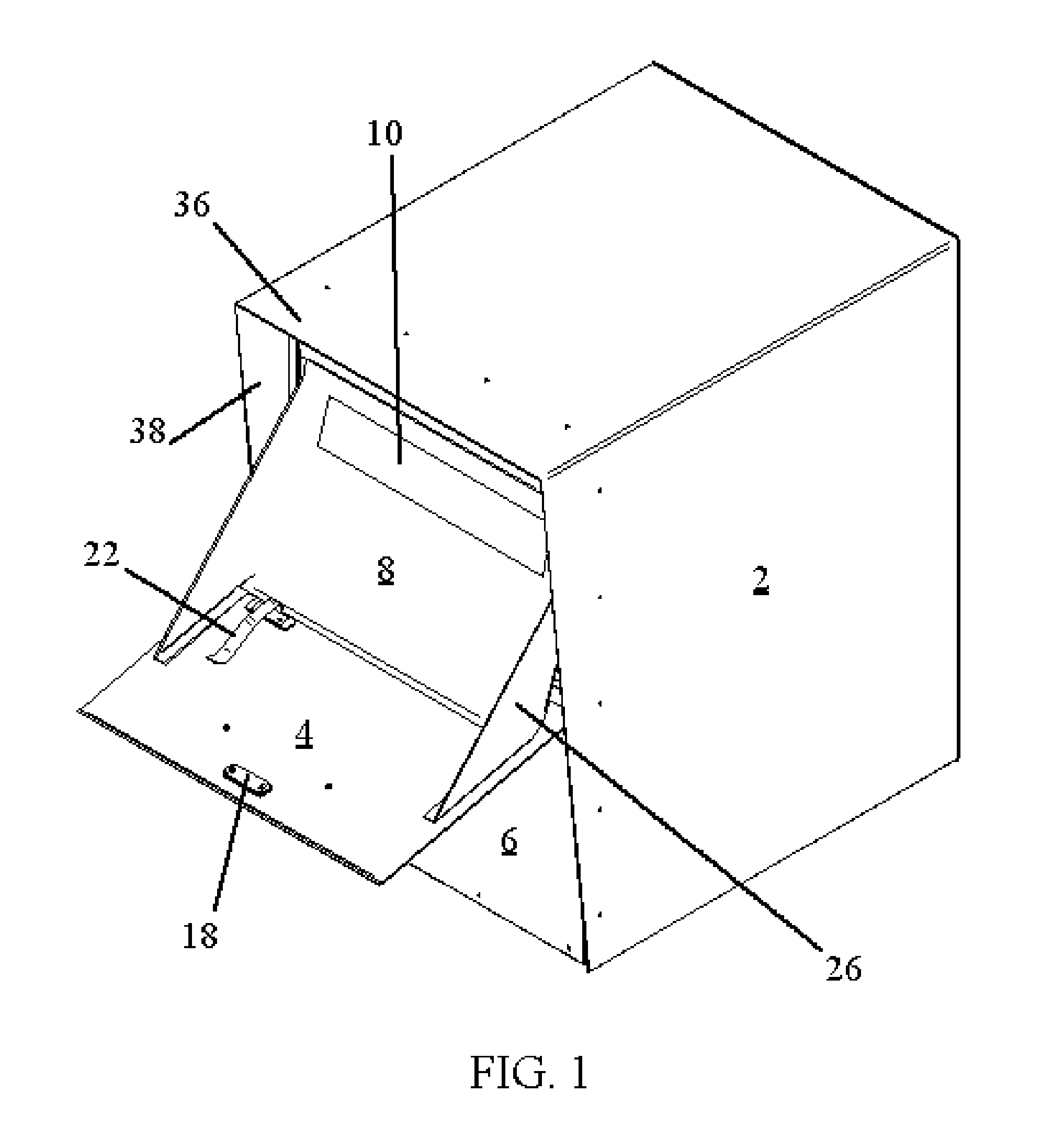

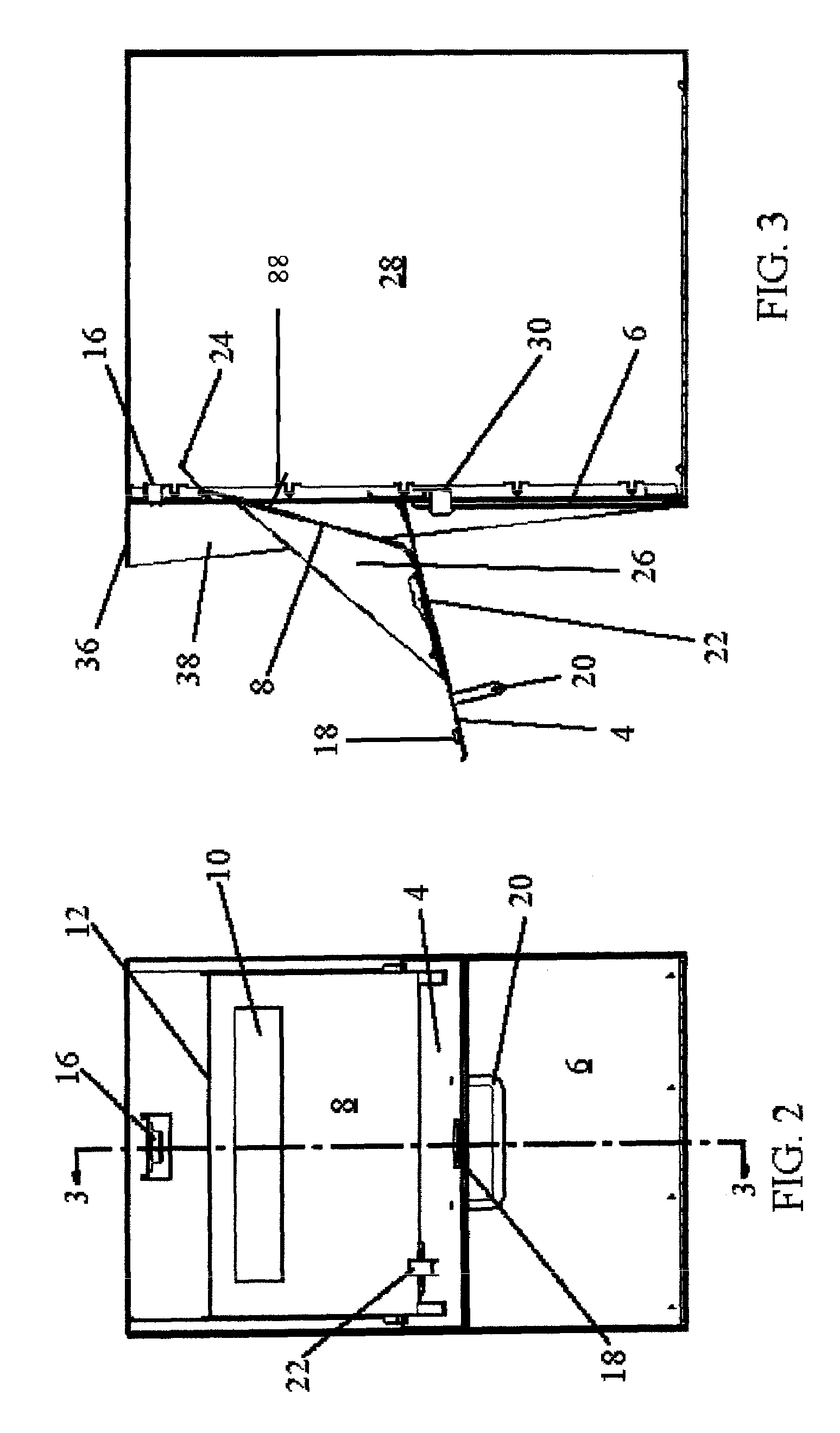

An apparatus for accepting return of unused medical items is part of a system (10) used for automated dispensing and tracking of medical items within a medical facility. The apparatus includes a return drawer (52, 156) and a retrieve drawer (54, 158) which are opened responsive to signals received from a display terminal (26) which is networked with a computer (12) which includes a database (14). The return drawer includes a pocket (74, 160) therein. The pocket is accessible from outside of a housing (56) when the return drawer is moved to an open position. The pocket includes an opening (76, 156). The pocket is closed by a trap door (78, 170) when the return drawer is in the open position. Medical items to be returned (132, 184, 186) are placed in the pocket and the return drawer is closed. Upon the closing of the return drawer the trap door is moved to an open position by an actuator. The returned medical item passes from the pocket to a retrieve area (84, 188) in the retrieve drawer. Medical items are stored in the retrieve area until the retrieve drawer is opened by a user authorized to retrieve items from said retrieve area. The opening of the return and retrieve drawers is controlled responsive to the input of data at the display terminal corresponding to information in records (16) in the database.

Owner:DIEBOLD NIXDORF

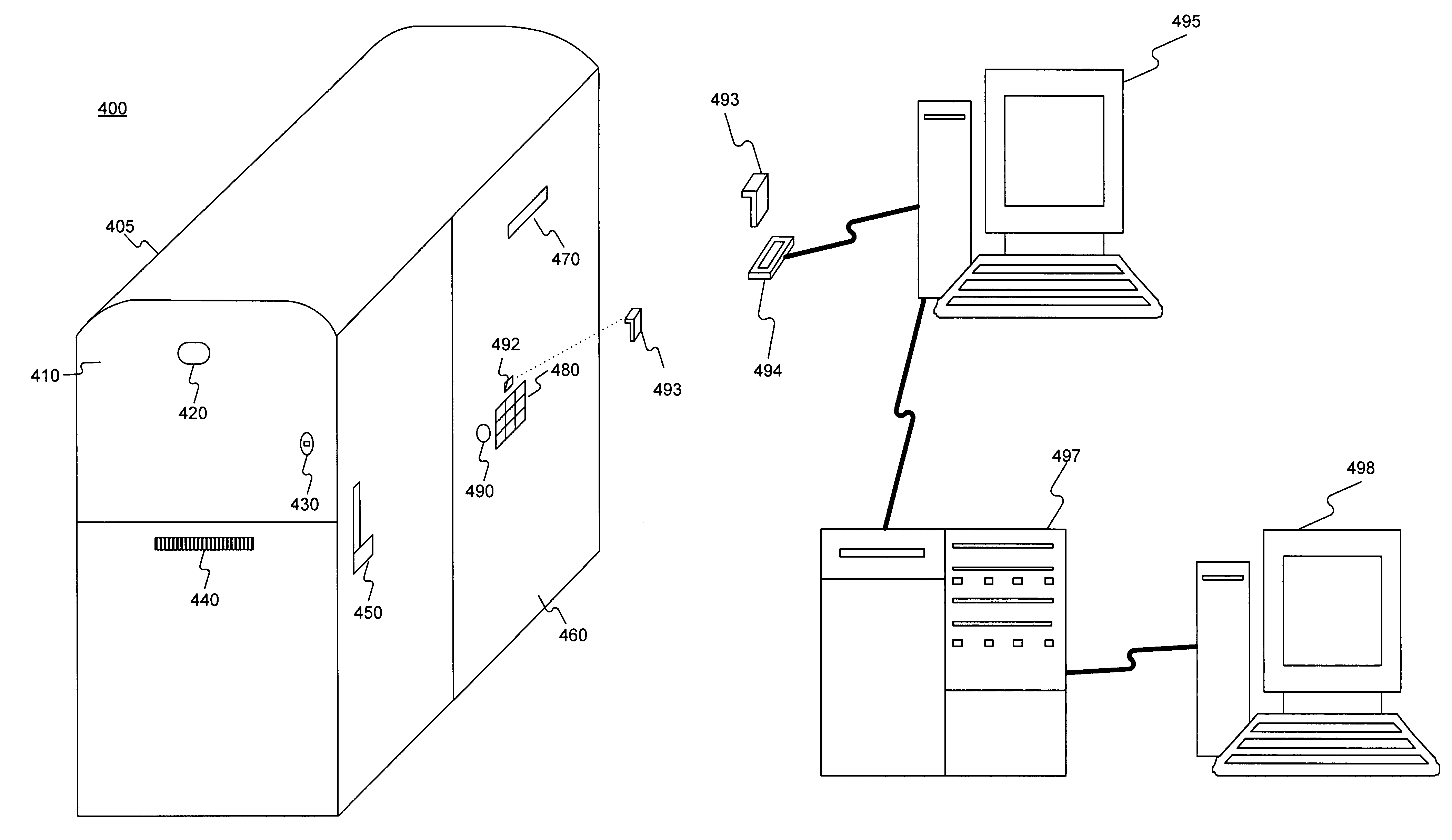

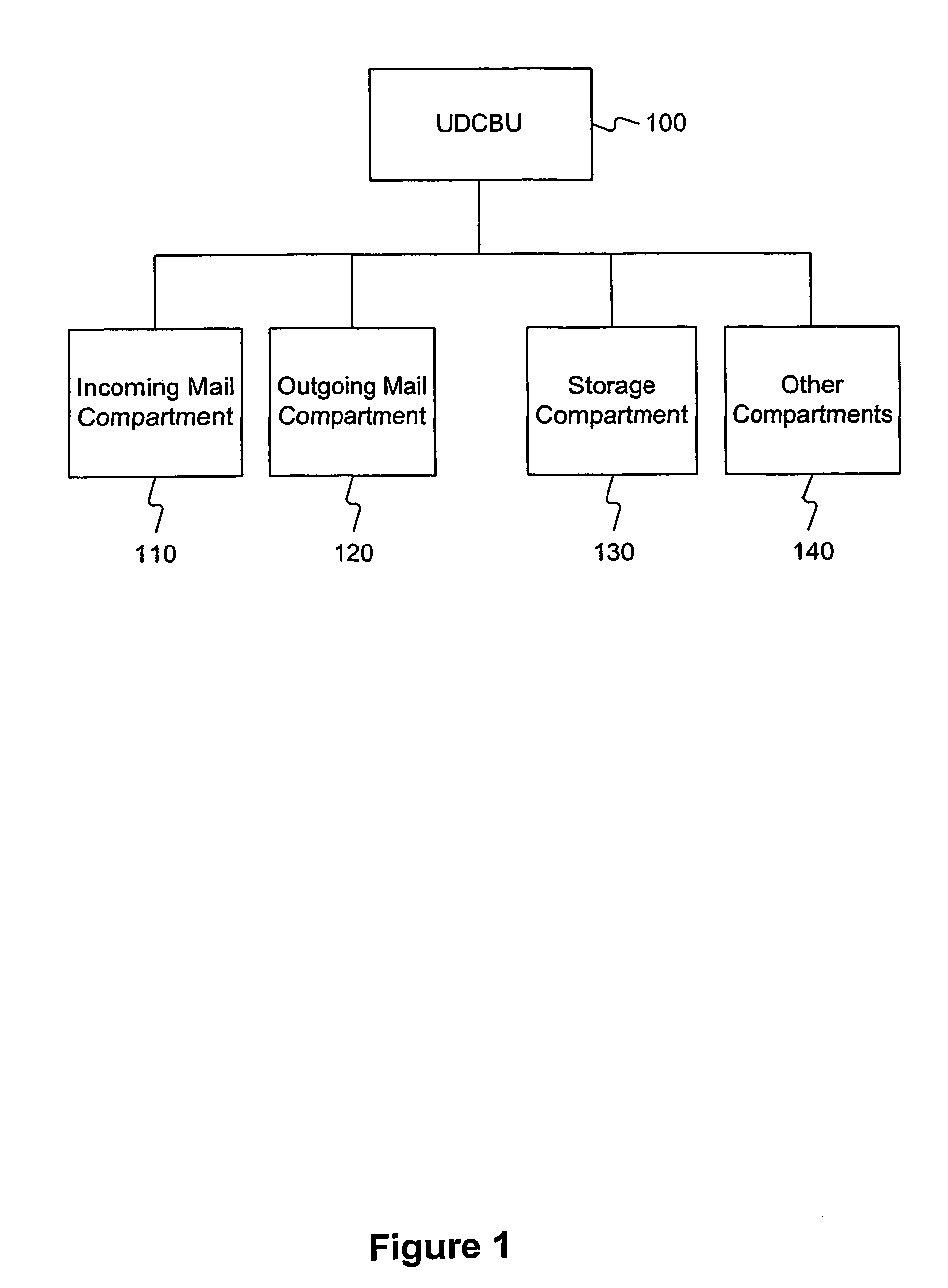

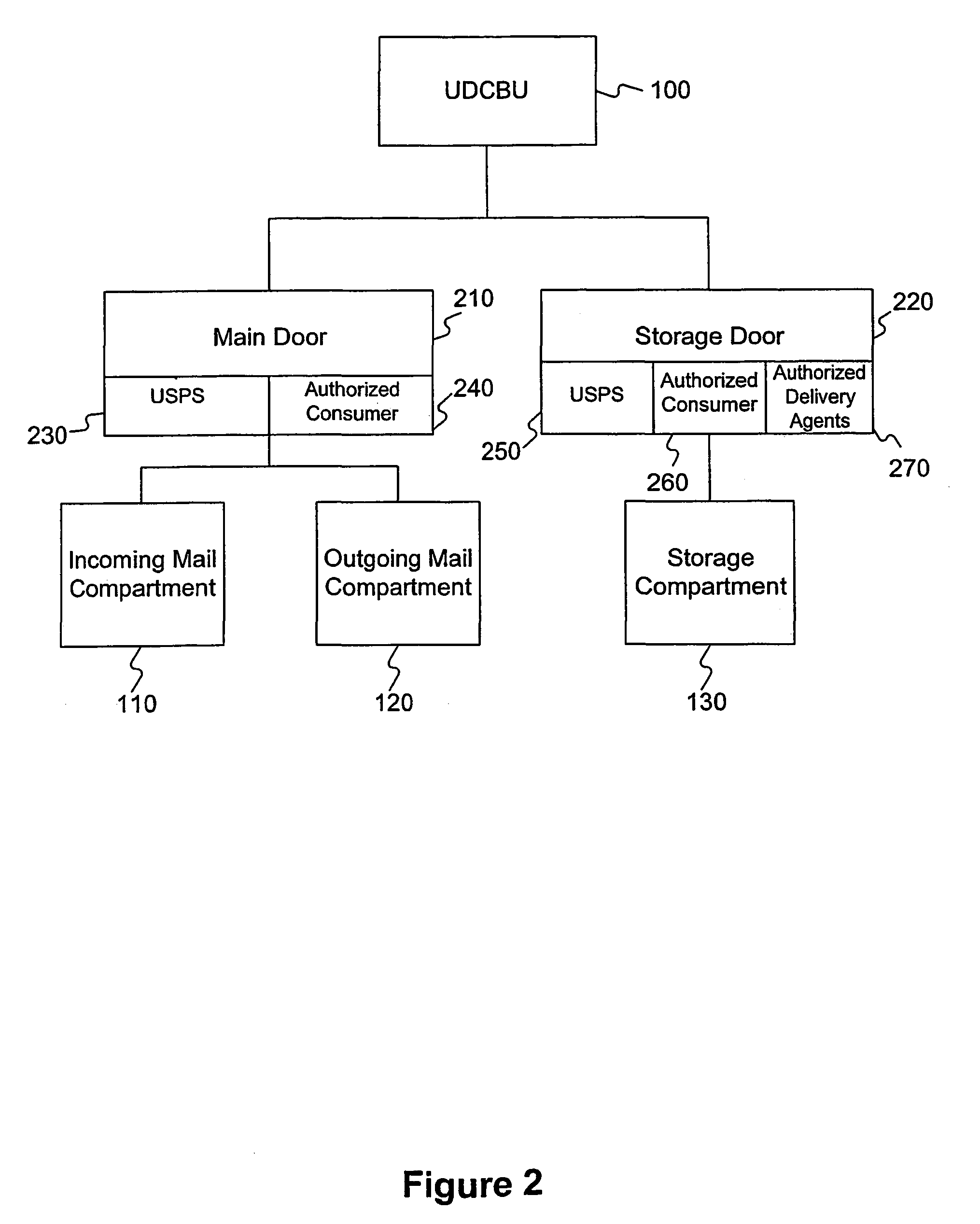

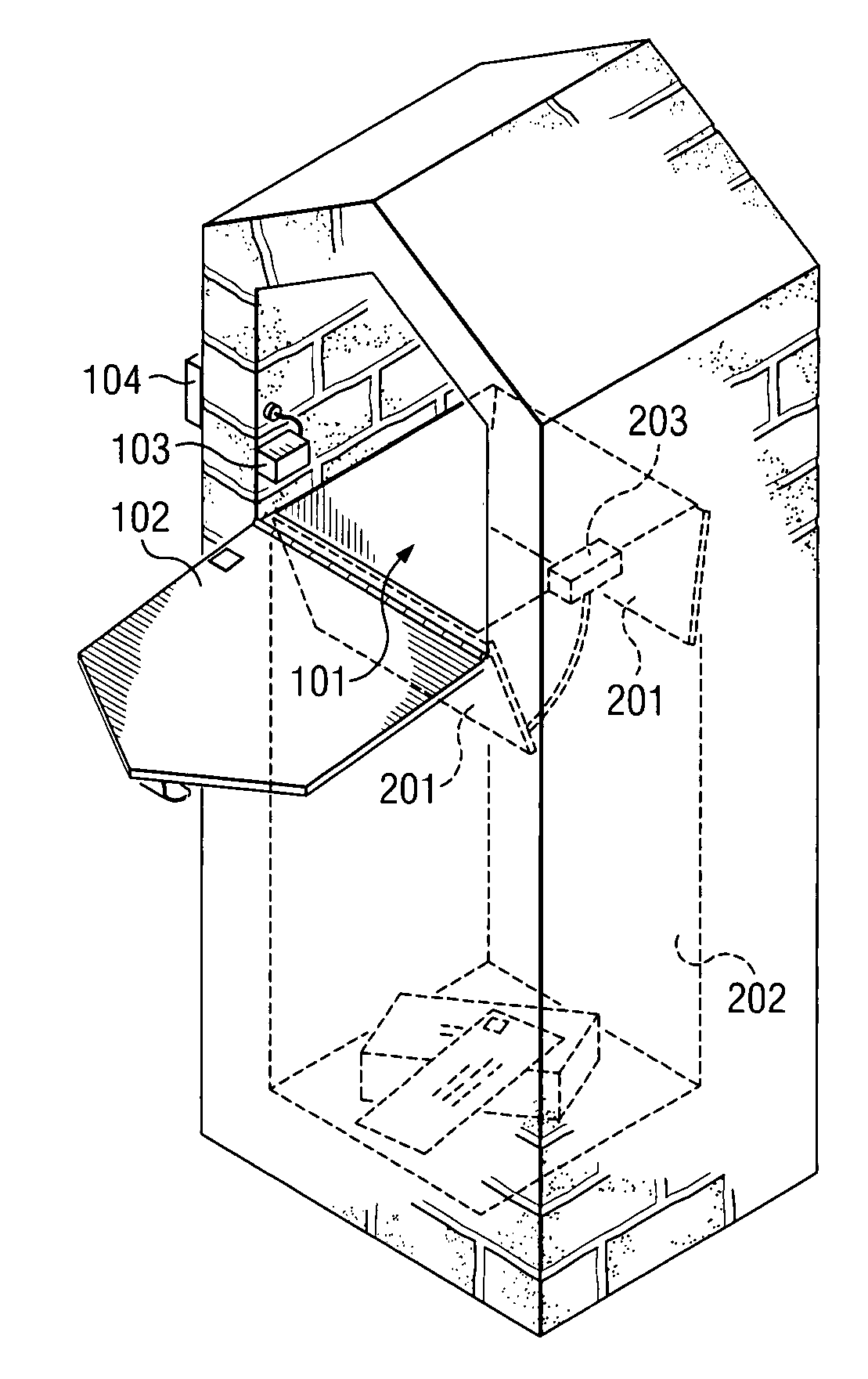

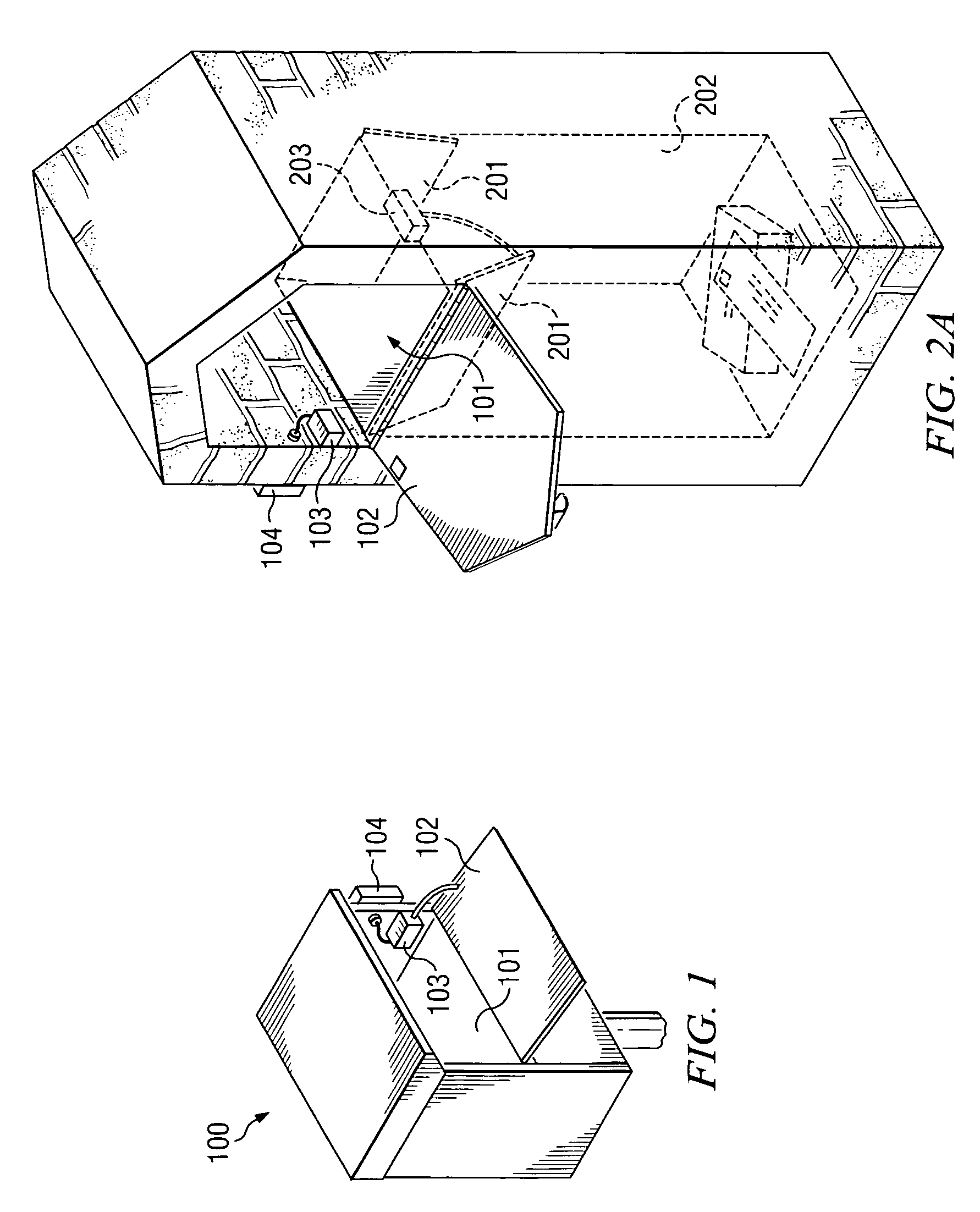

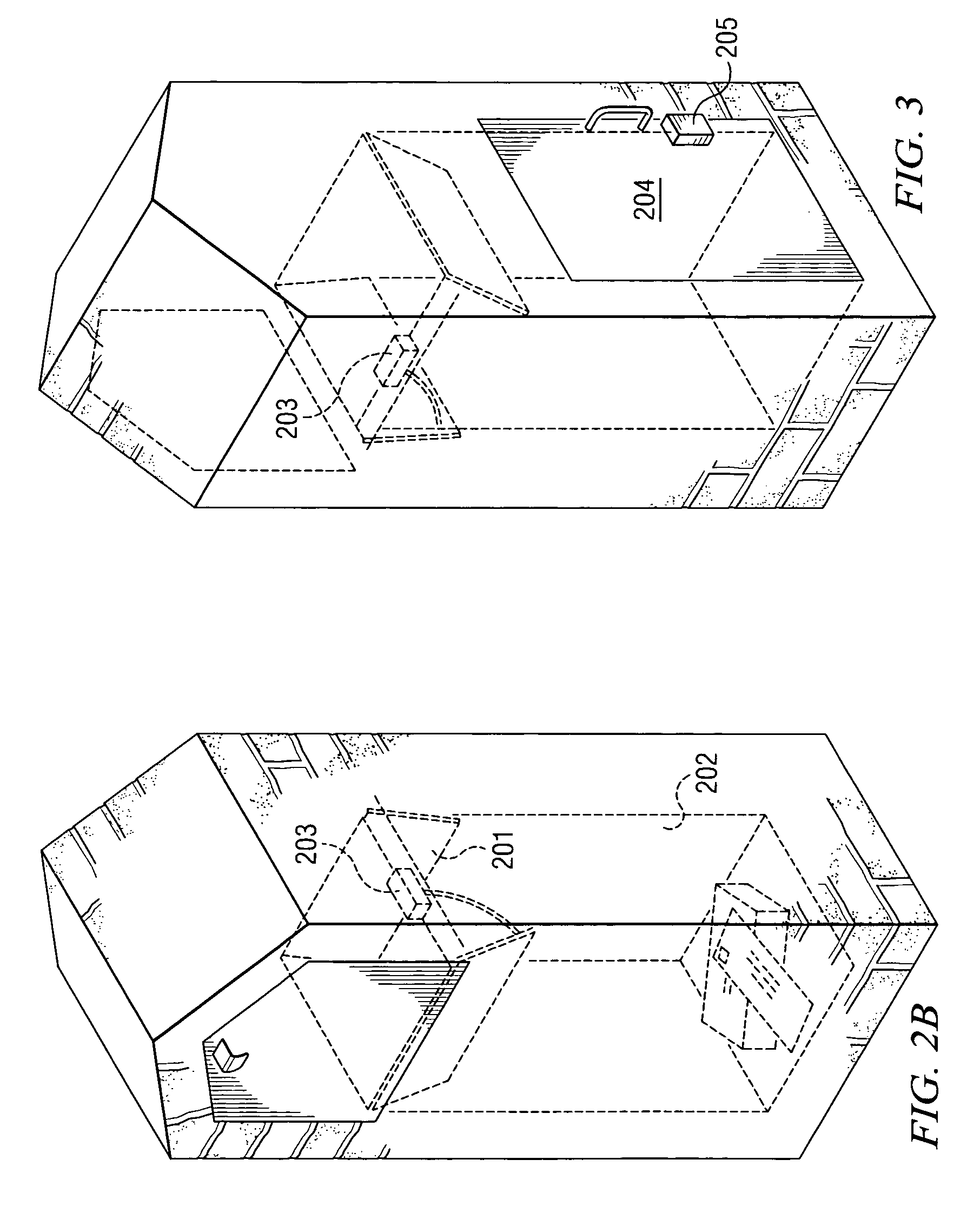

Universal delivery and collection box unit (UDCBU)

InactiveUS7337944B2Apparatus for meter-controlled dispensingKitchen equipmentEngineeringPostal service

The invention relates to a universal delivery and collection box unit (UDCBU). In one implementation, a UDCBU includes a mail compartment (110 / 120) accessible by one door (210) and a storage compartment (130) accessible by a second door (220). The mail compartment allows the postal service to deliver and pickup mail. The storage compartment allows both the postal service and authorized delivery services to deliver larger parcels. In this implementation, information would be recorded regarding access to this storage compartment and transmitted electronically to a consumer.

Owner:US POSTAL SERVICE

Flexible front merchandising display device

Owner:DISPLAY INDS

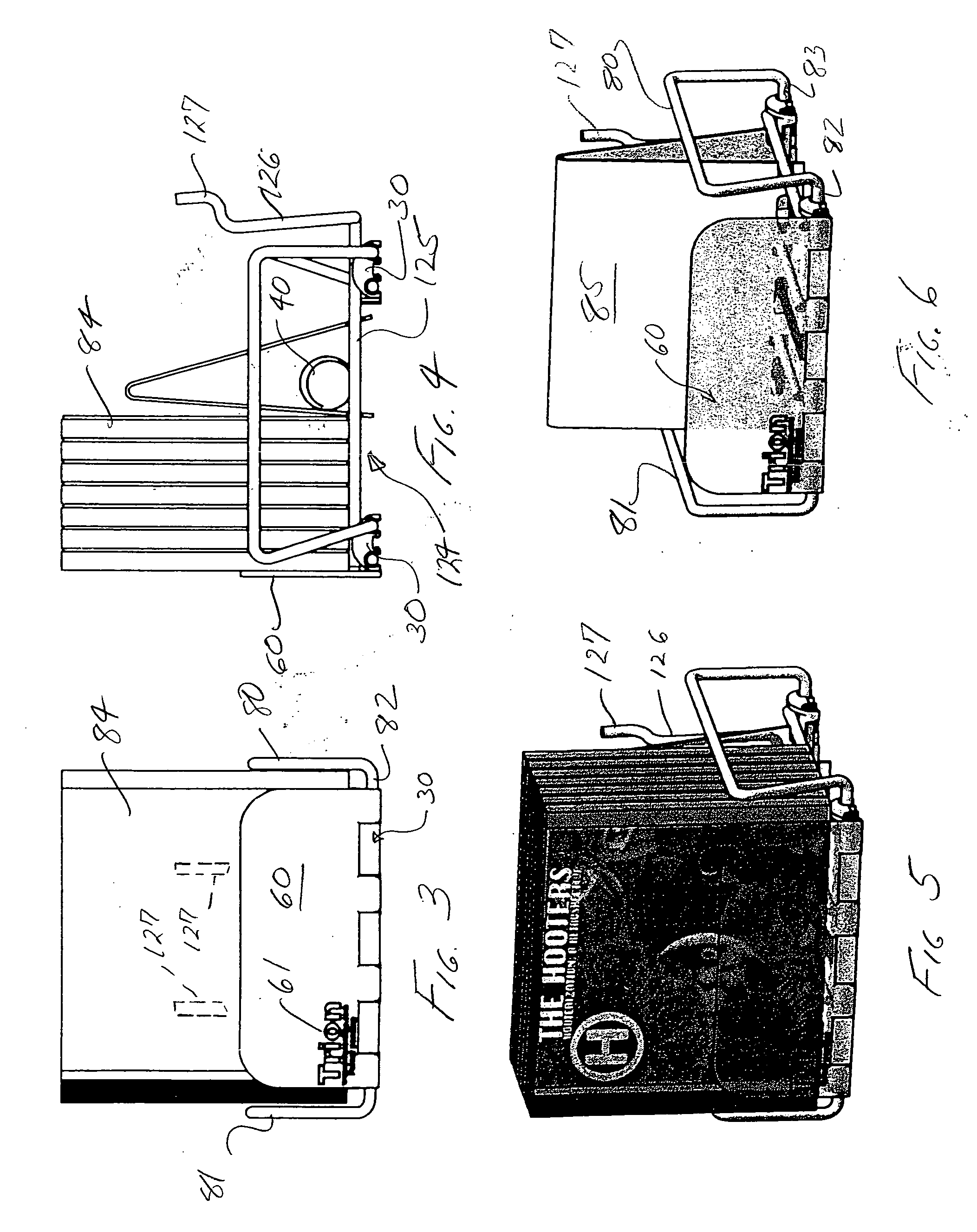

Weighted pusher

InactiveUS6955269B2Preclude product from tipping the pusherRacksCard-filingEngineeringMechanical engineering

Owner:DISPLAY TECHNOLOGIES INC

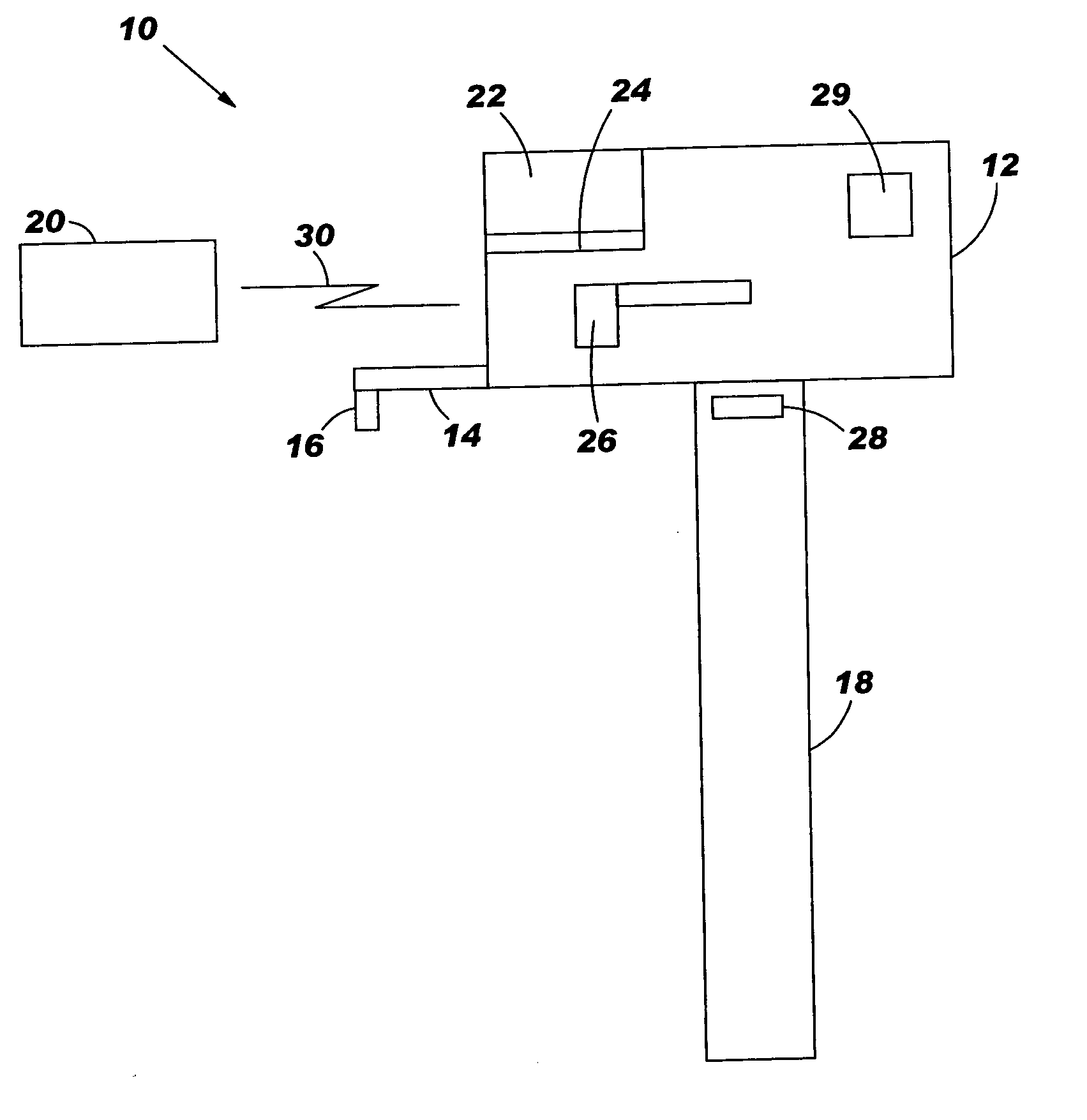

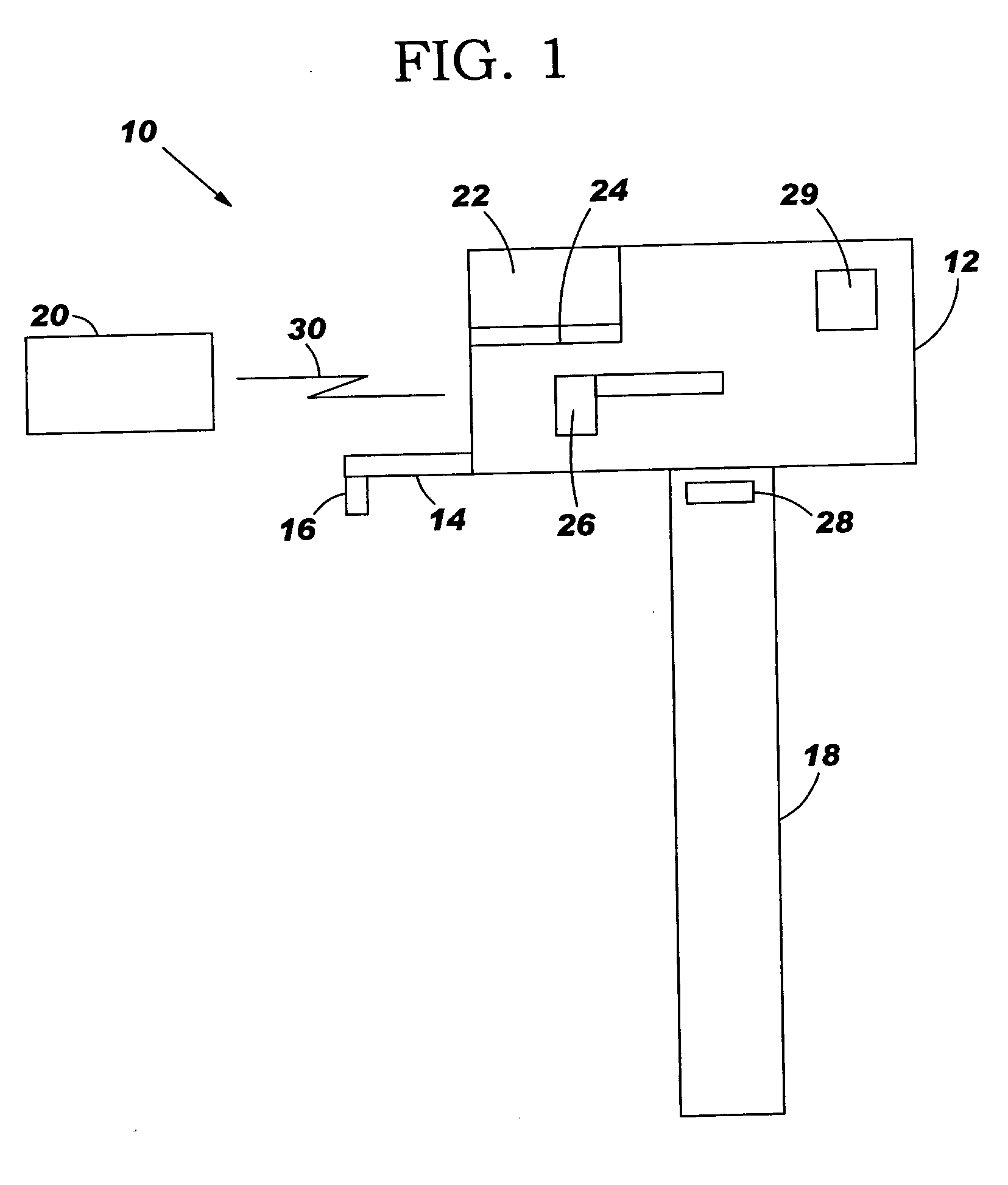

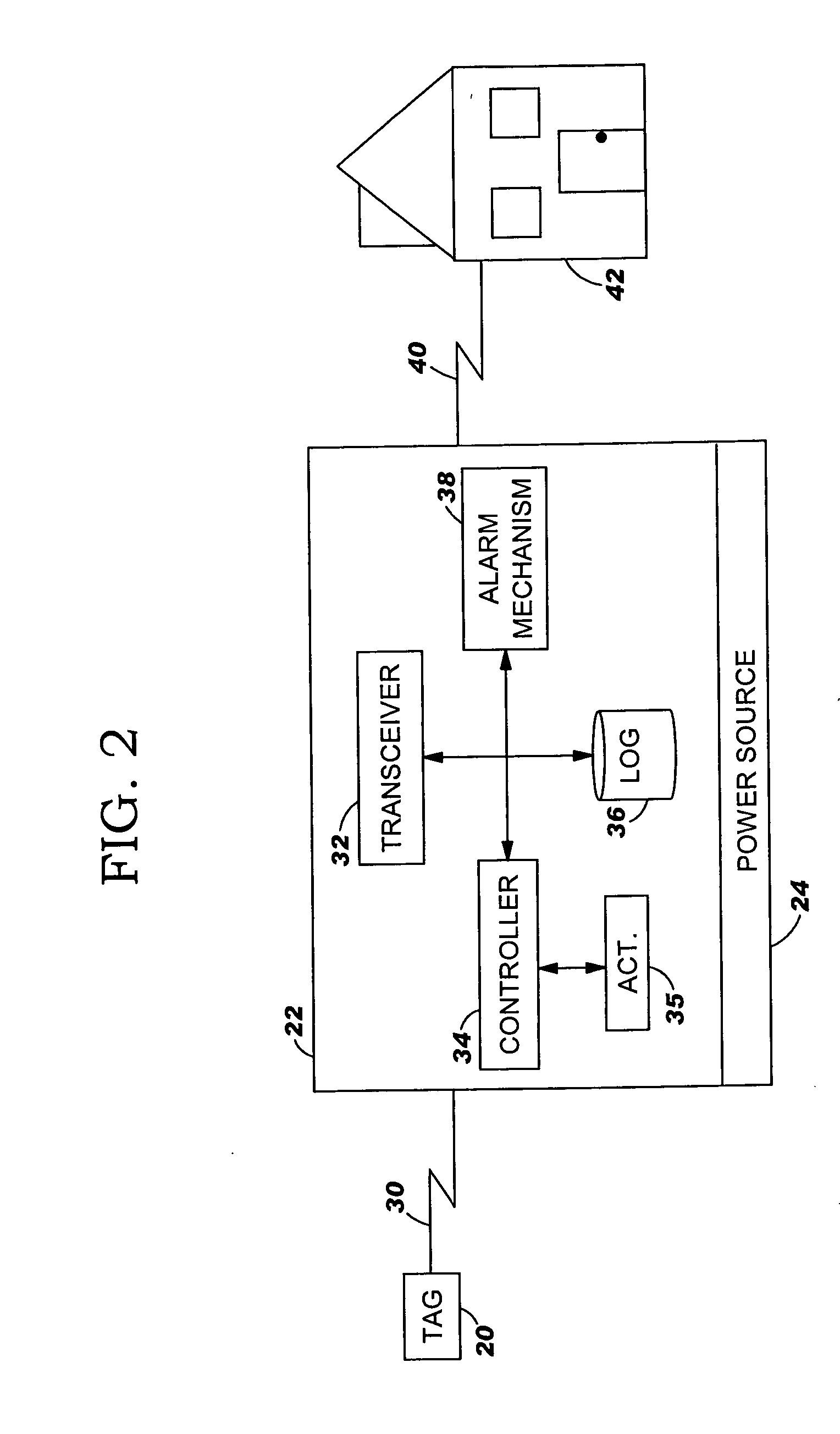

RFID-keyed mailbox, and RFID-based system and method for securing a mailbox

InactiveUS20050006452A1Electric signal transmission systemsDigital data processing detailsComputer science

Under the present invention, a mailbox is equipped with a RFID reader. The RFID reader receives a continuously transmitted signal from an RFID tag that contains an RF identifier. Upon receipt, the RFID reader compares the RF identifier in the signal to an RF identifier assigned to the mailbox. If a match is established, the mailbox is unlocked and access is permitted.

Owner:IBM CORP

Theft deterrent system

InactiveUS8485391B2Easy to useEasy to adjustMechanical apparatusTobacco pipesTime delaysComputer module

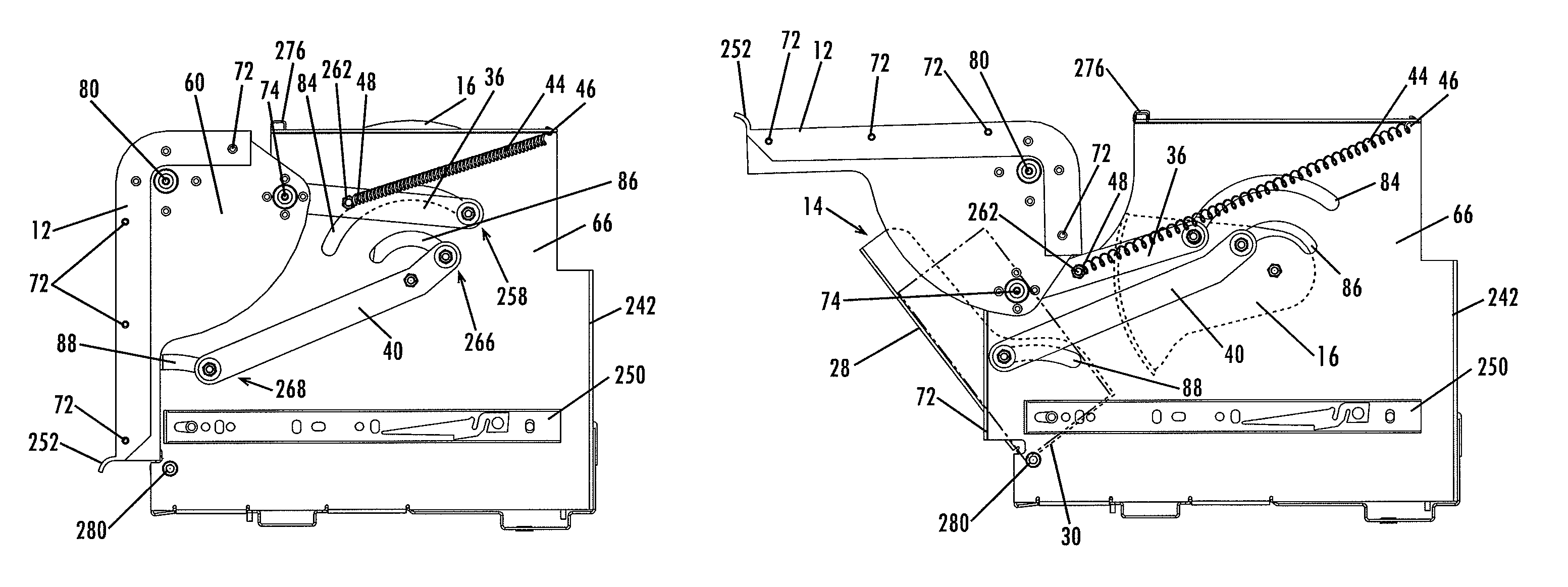

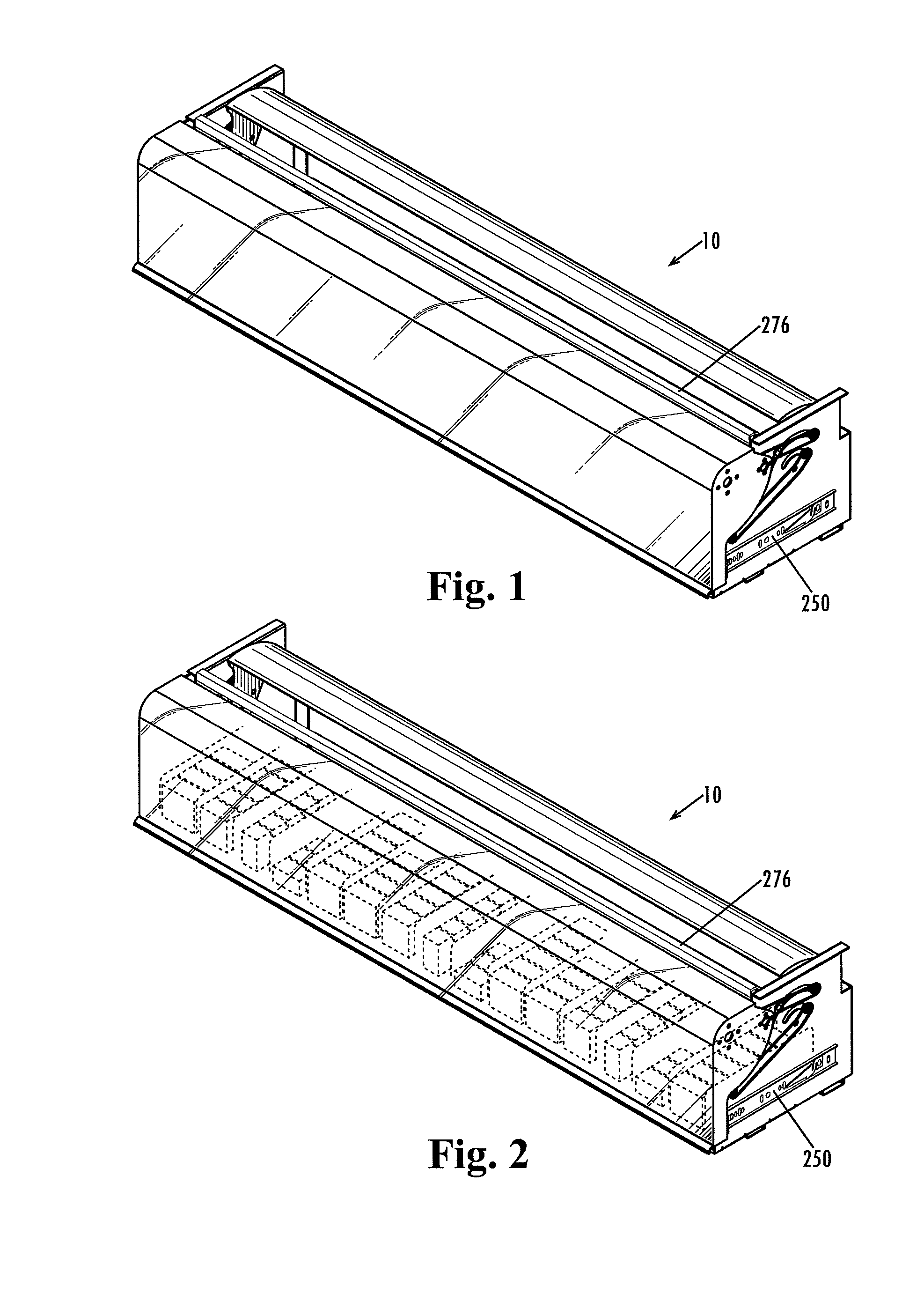

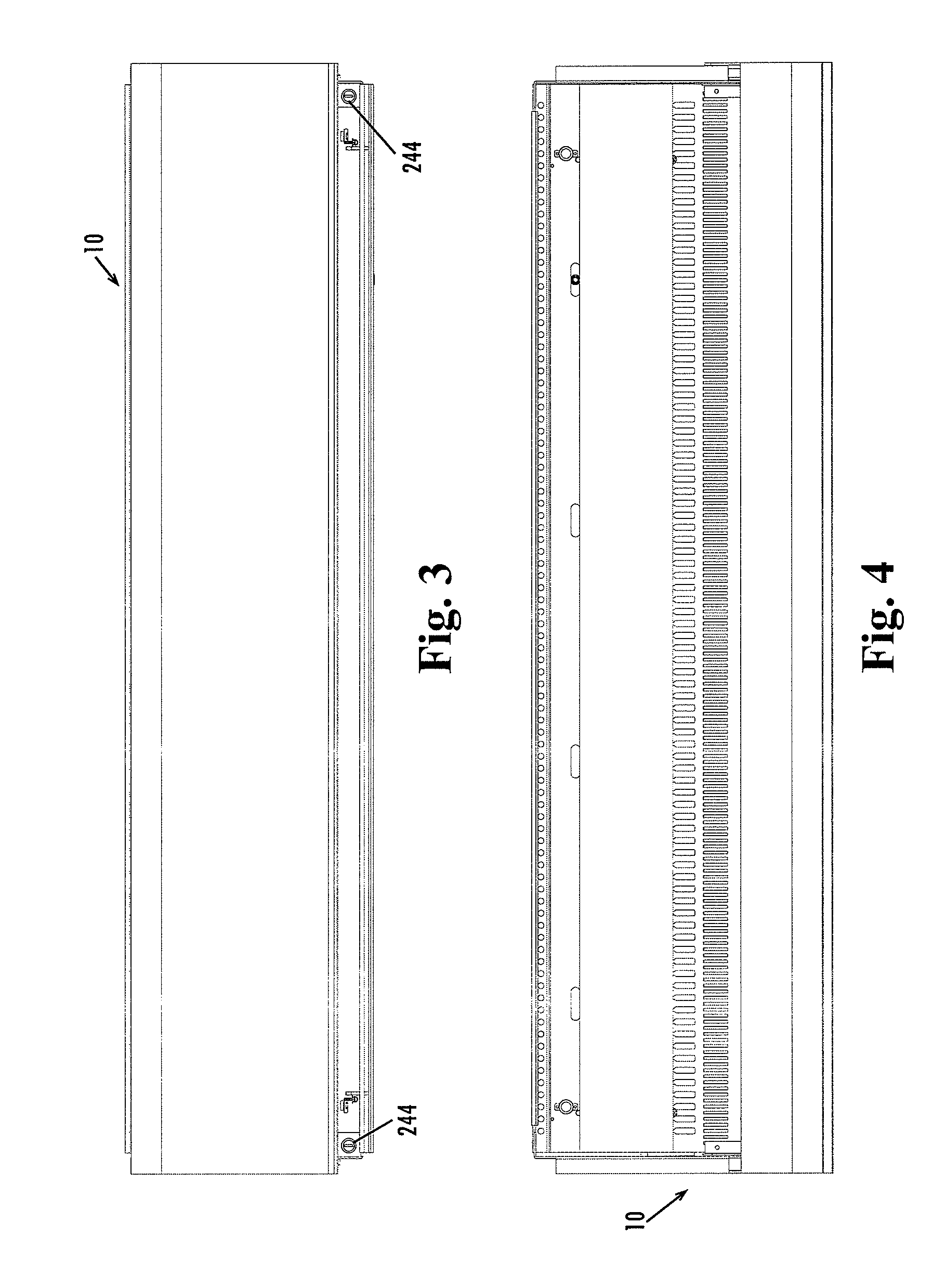

Systems for deterring theft of retail products. Systems of this invention provide theft deterrent dispensing modules for dispensing products and may incorporate theft deterrent measures including mechanical deterrents, time delays and sound. The dispensing modules may include one or more pusher assemblies for dispensing product. Certain systems of this invention may also include a lockout feature, so that only one pusher assembly may be activated to dispense a product at one time.

Owner:WESTROCK SHARED SERVICES LLC

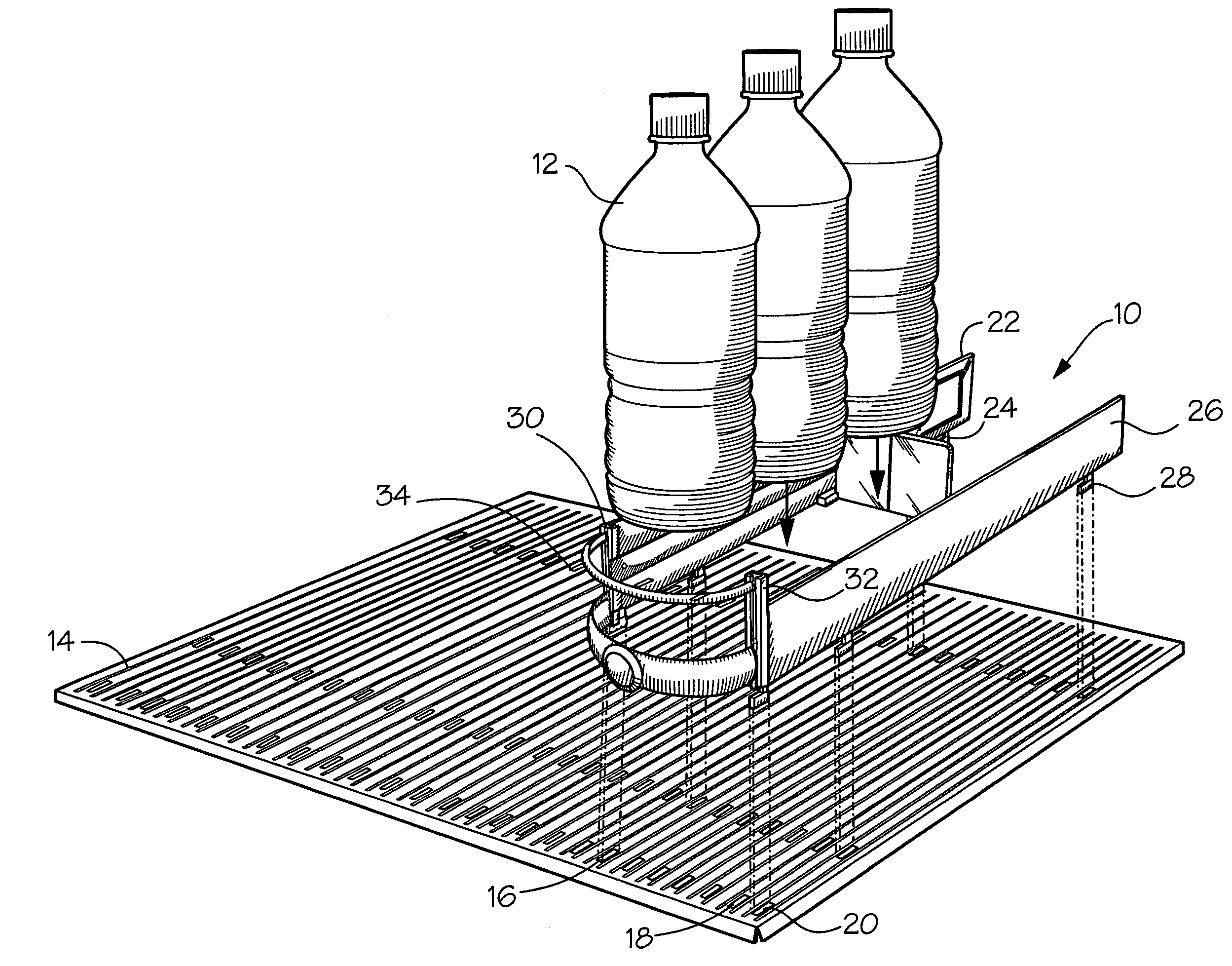

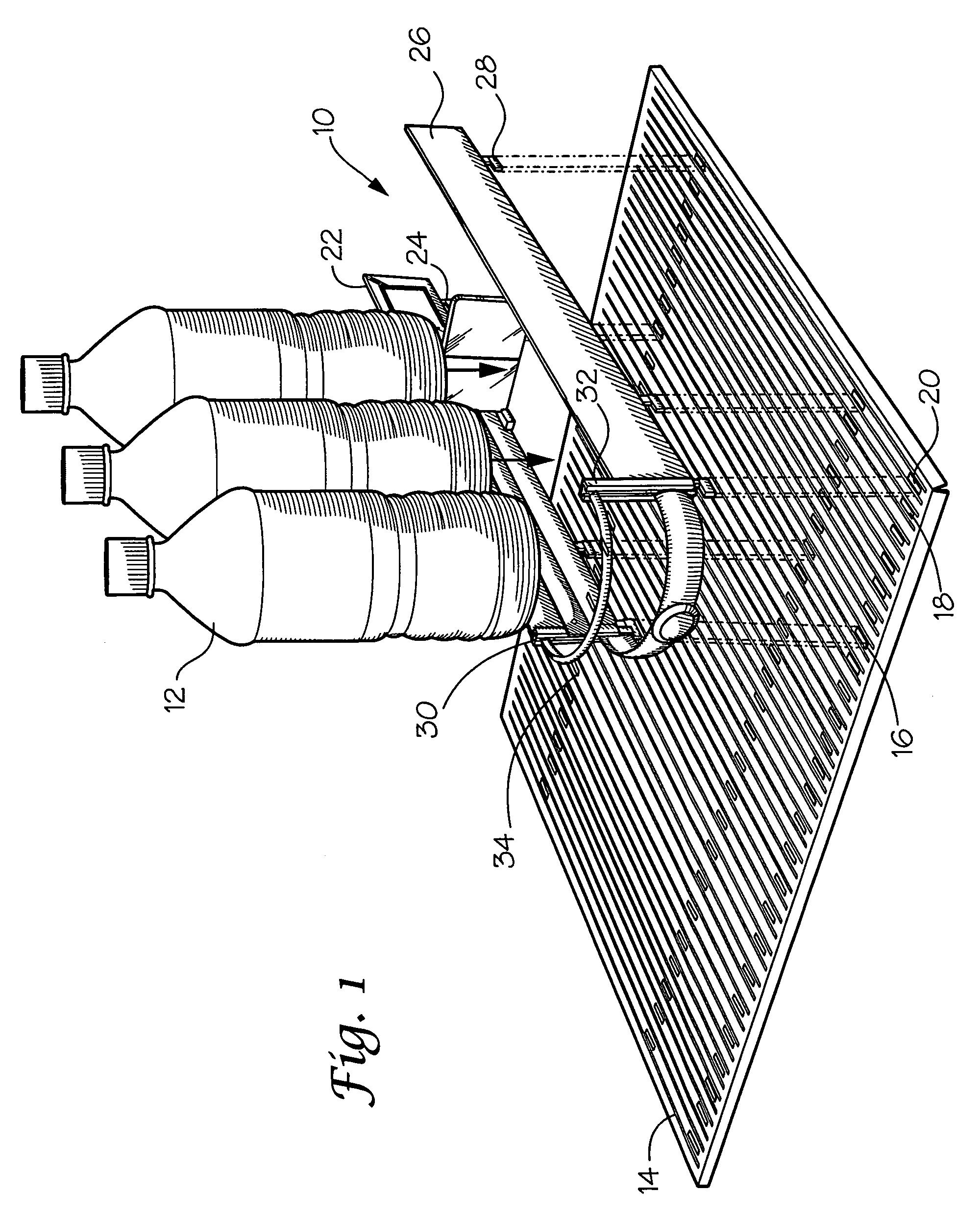

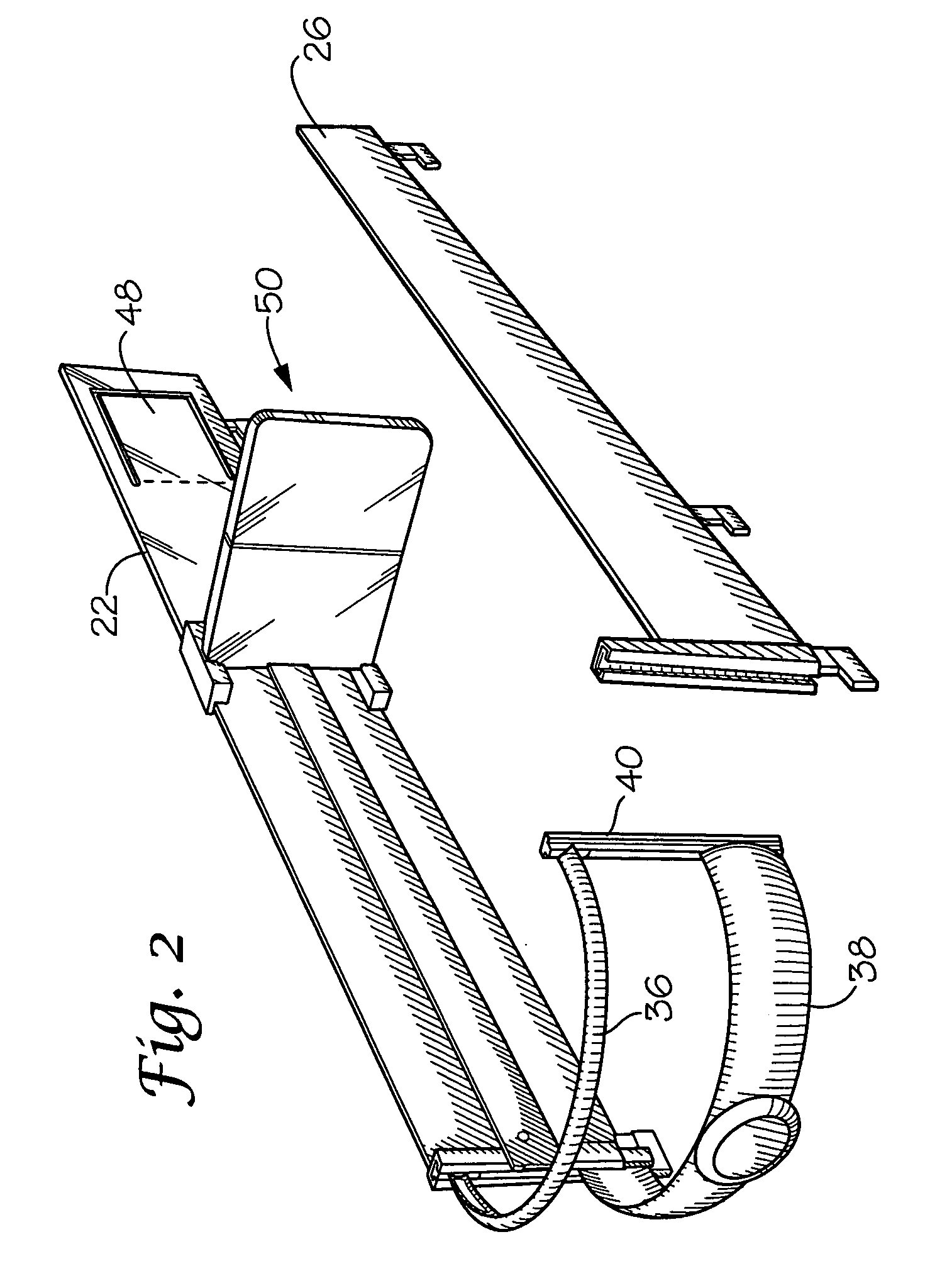

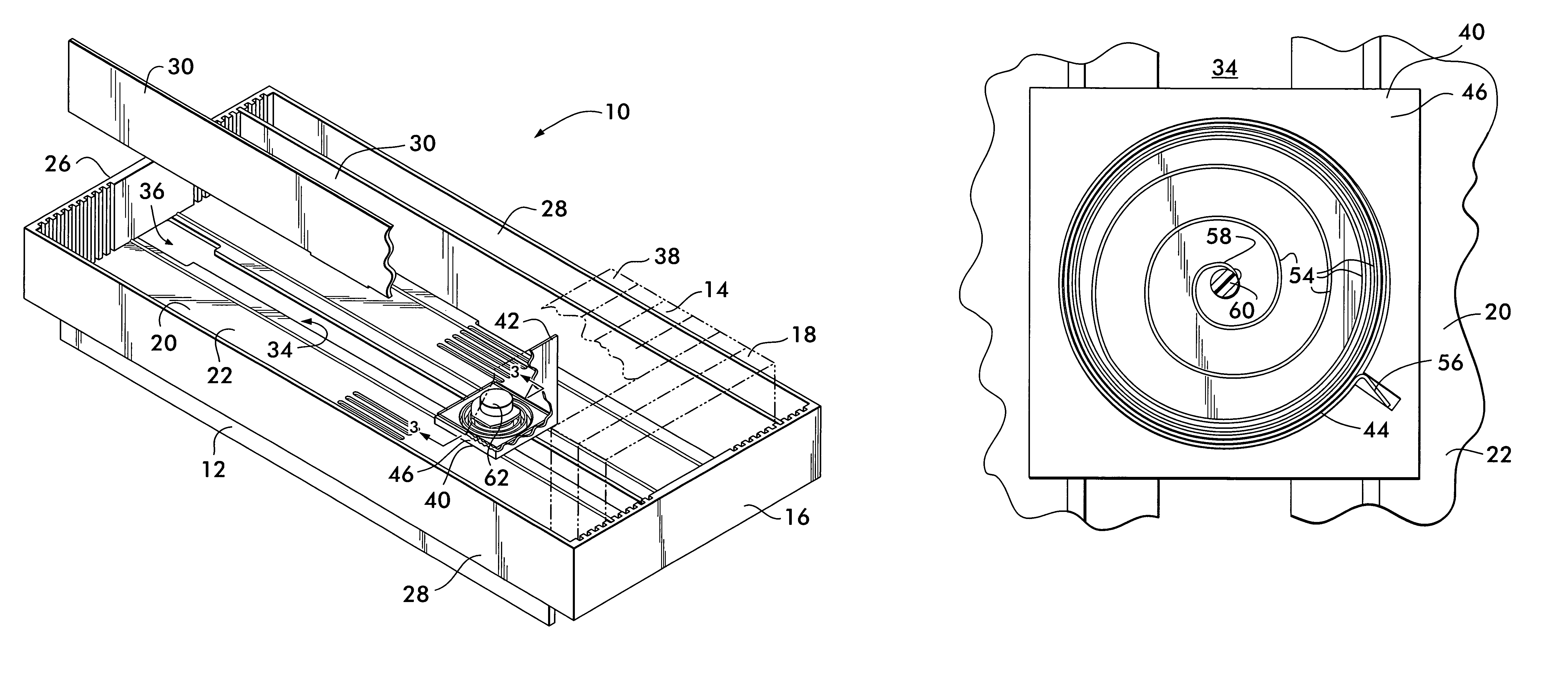

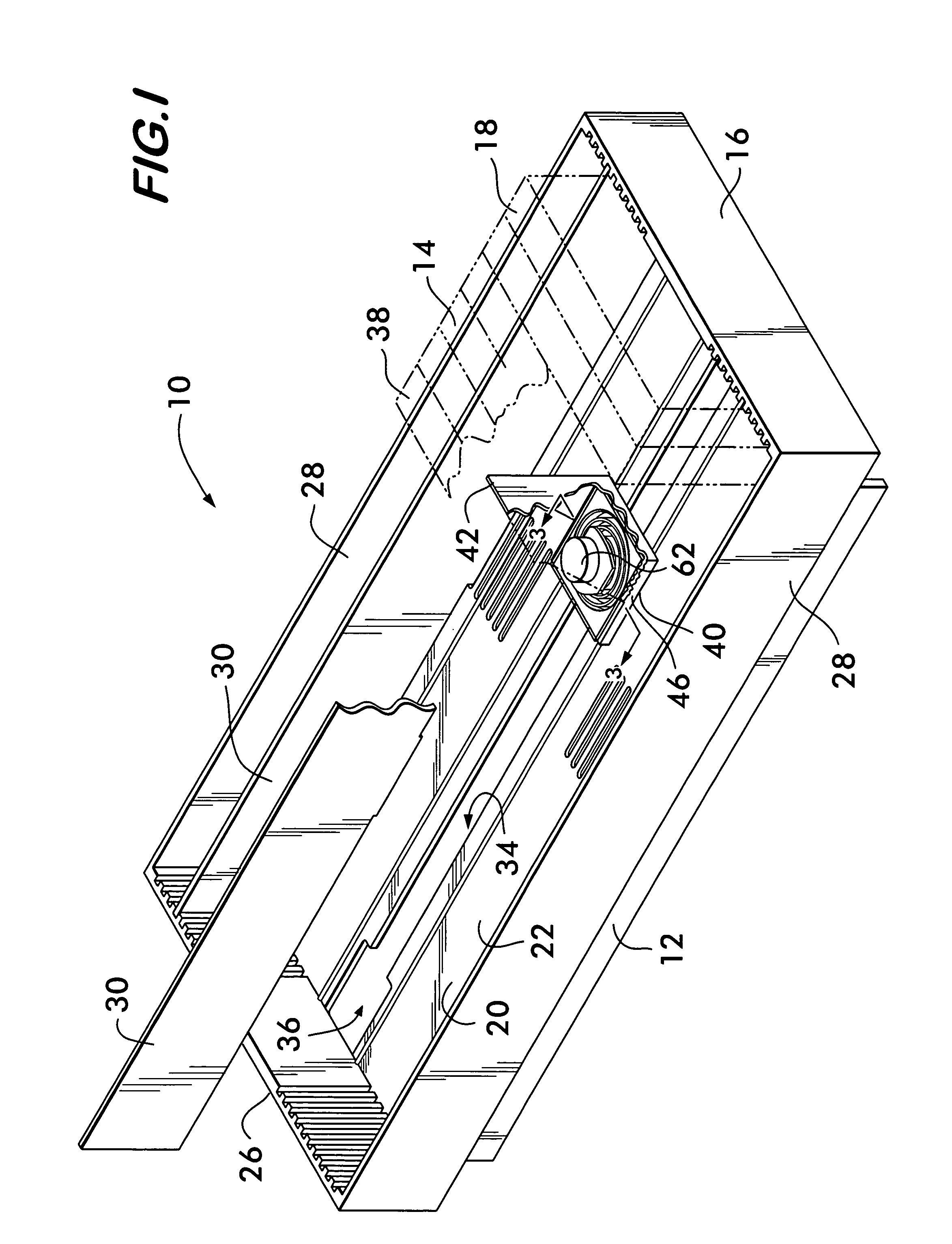

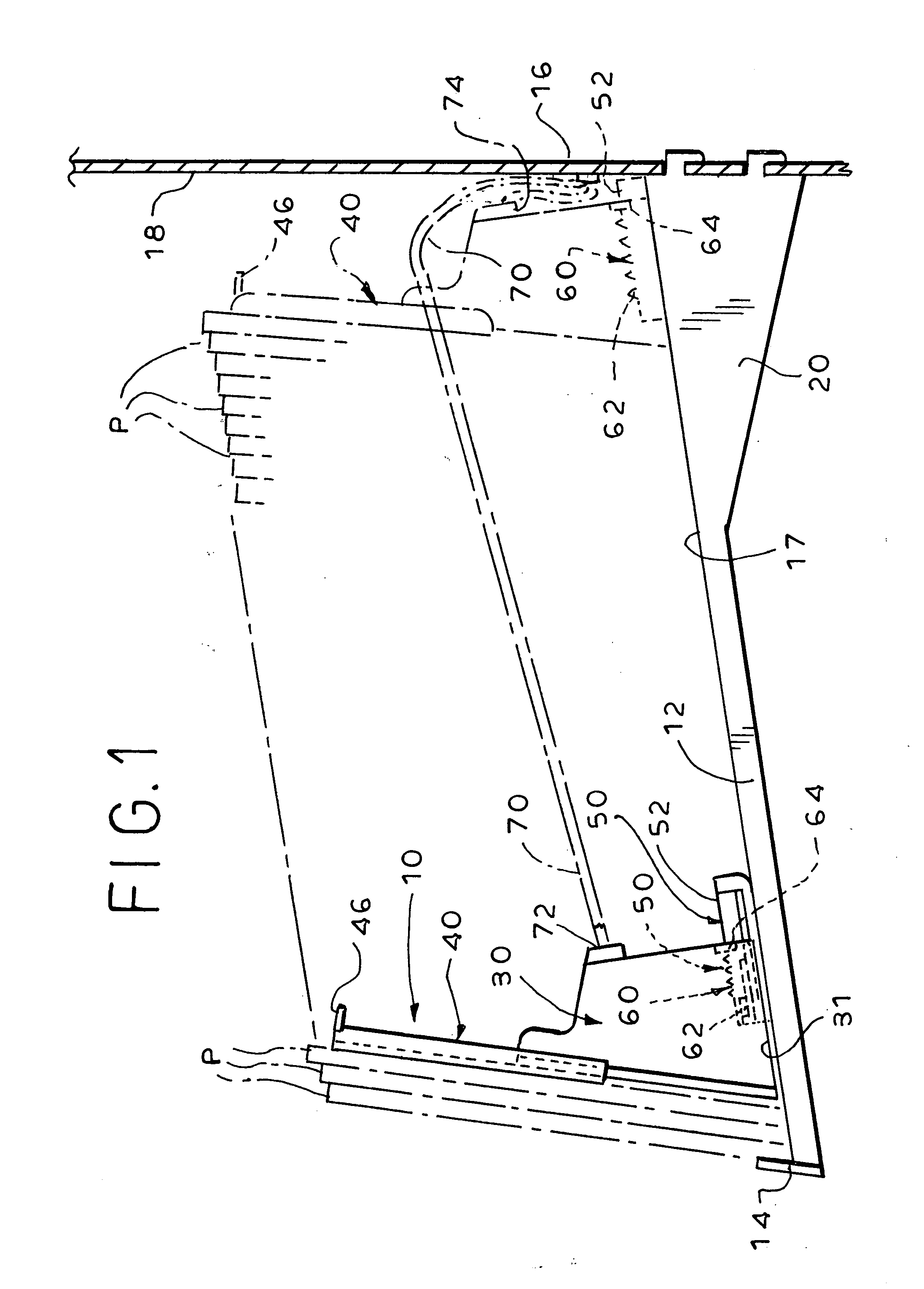

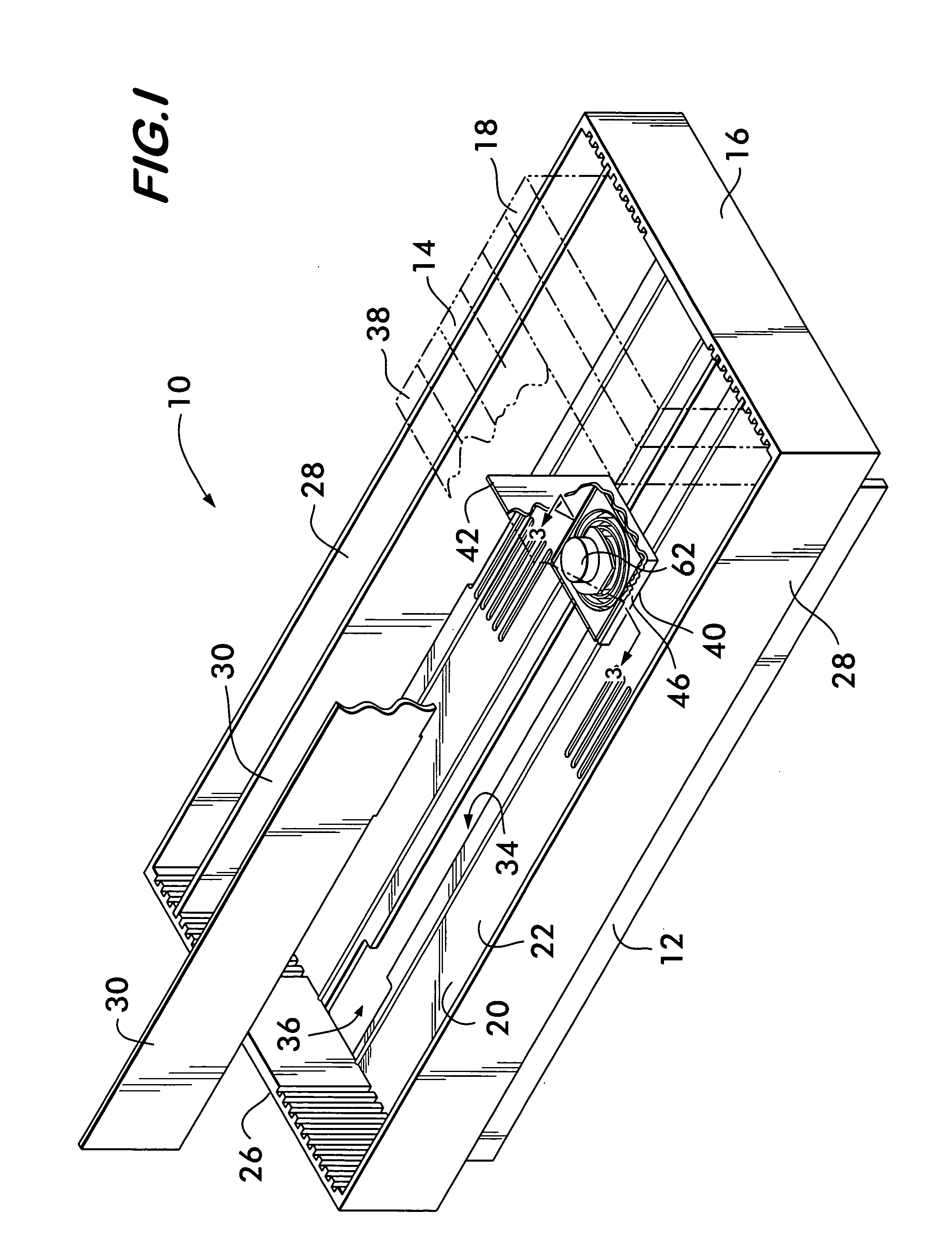

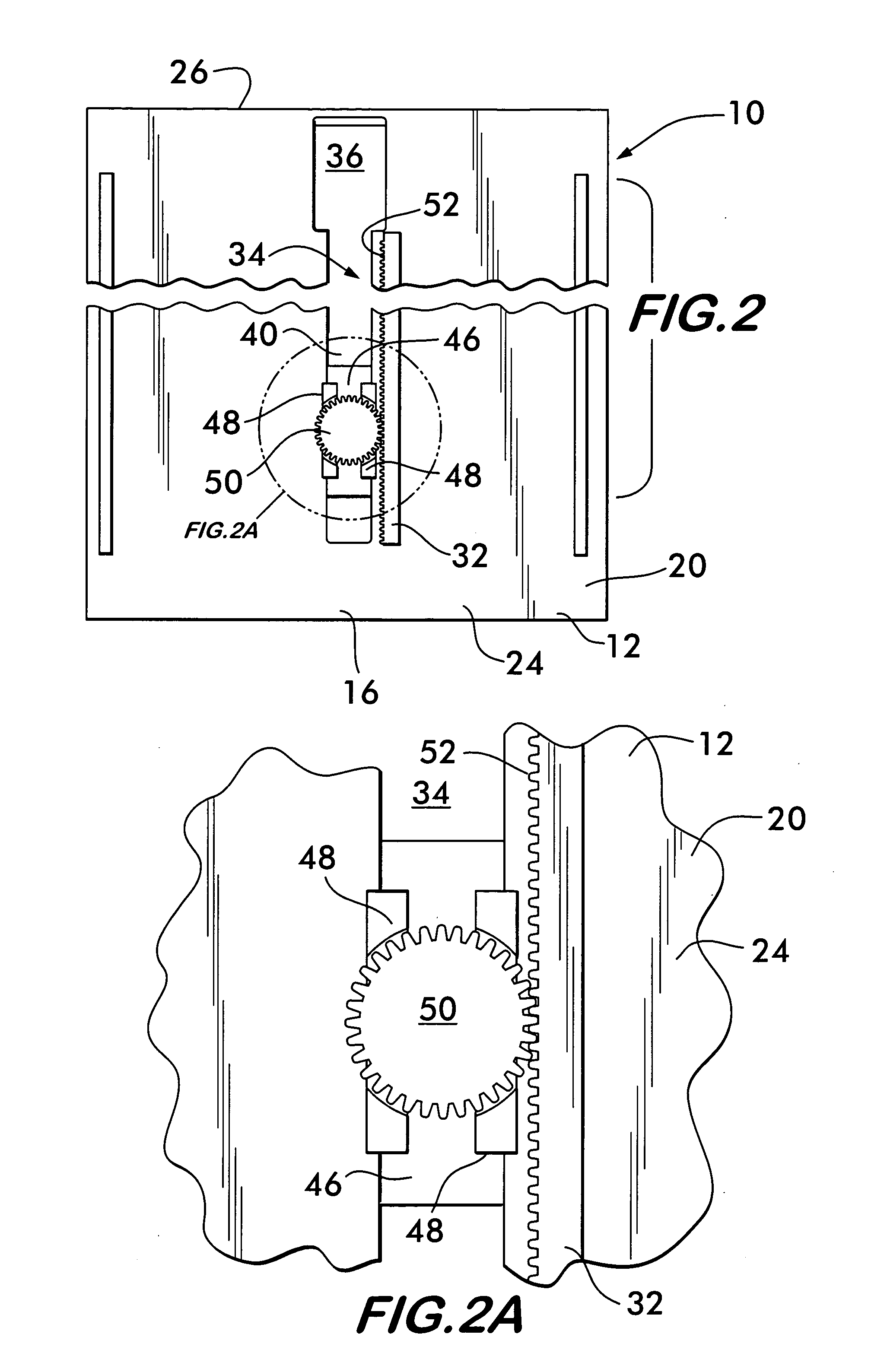

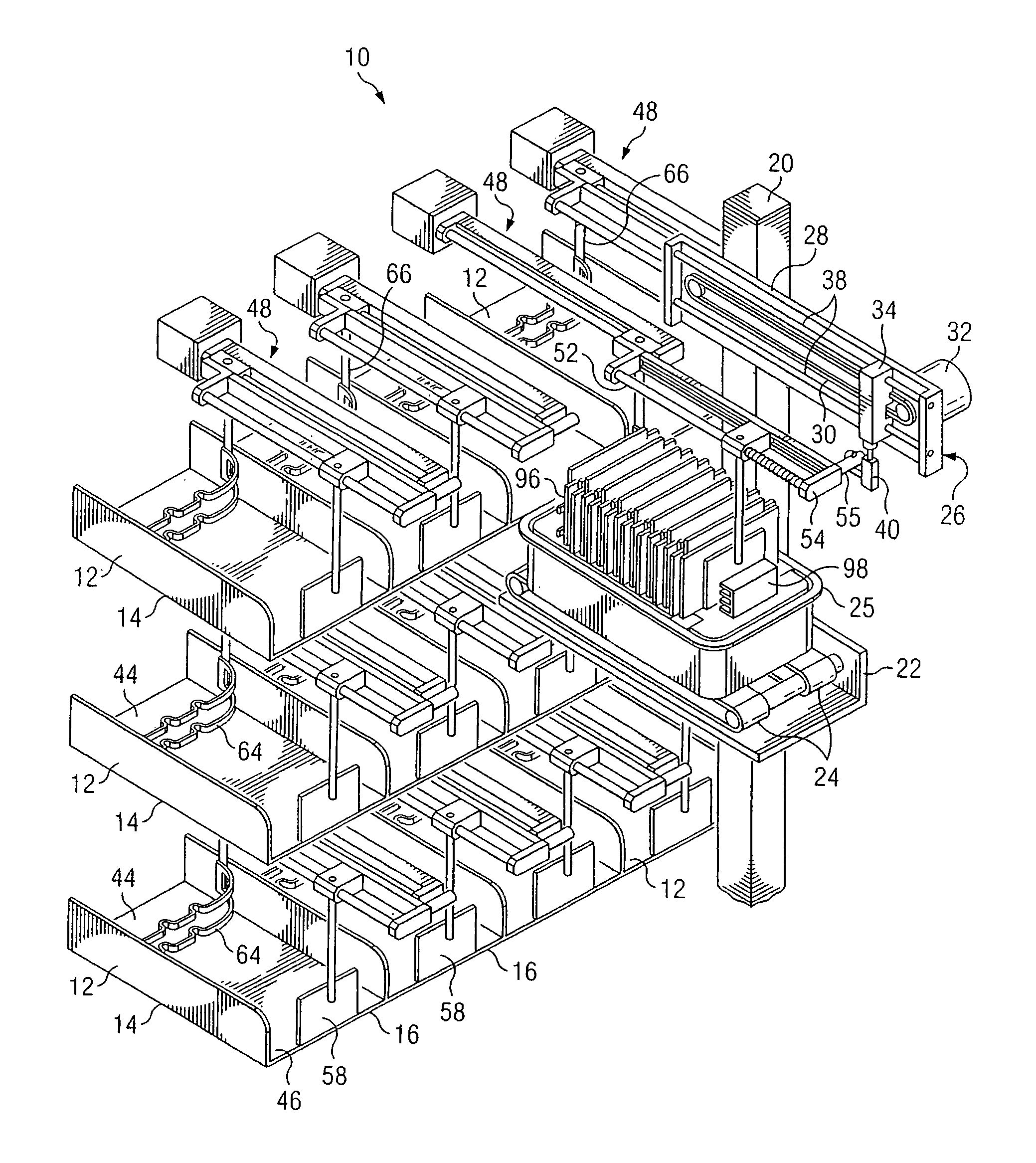

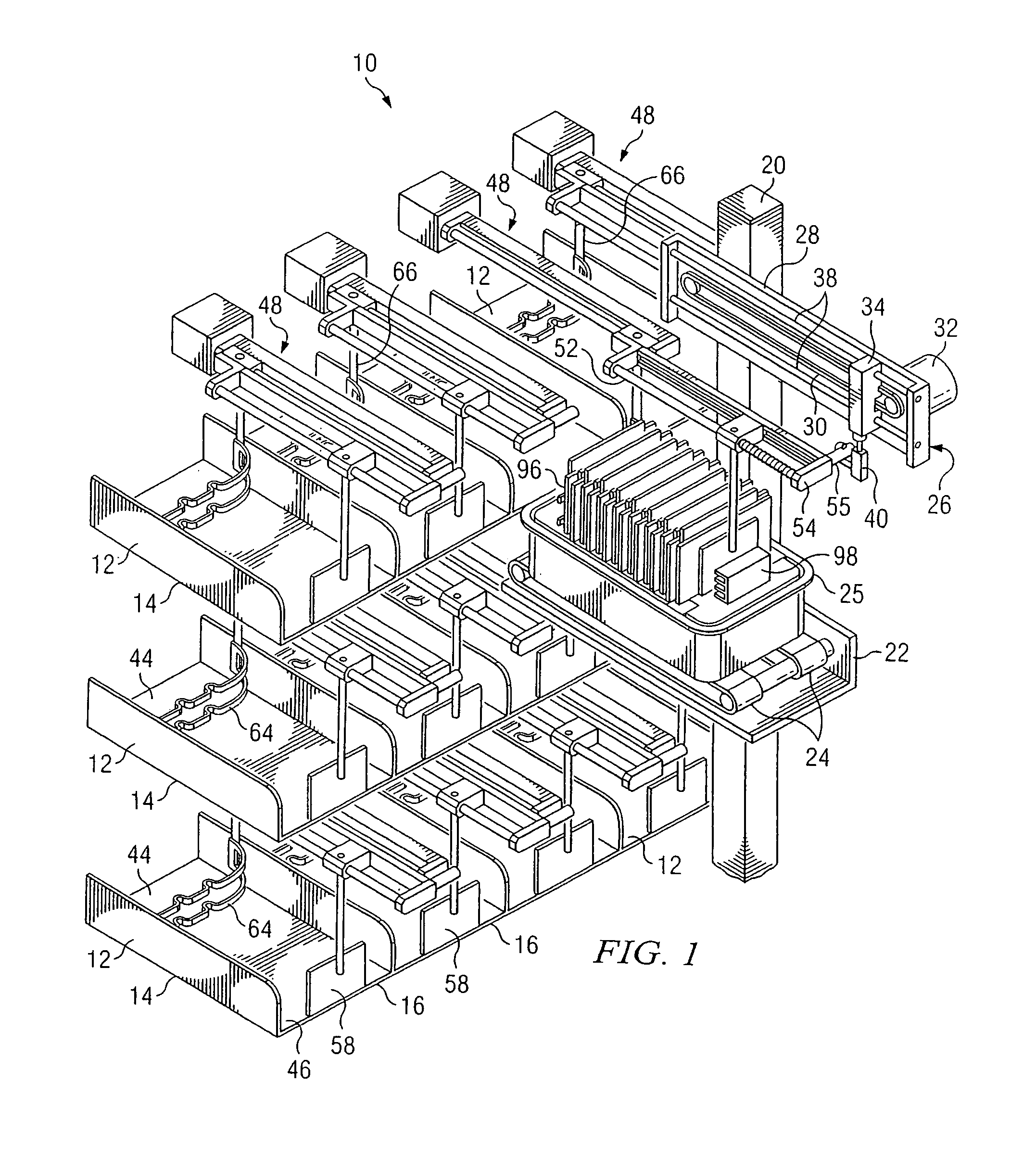

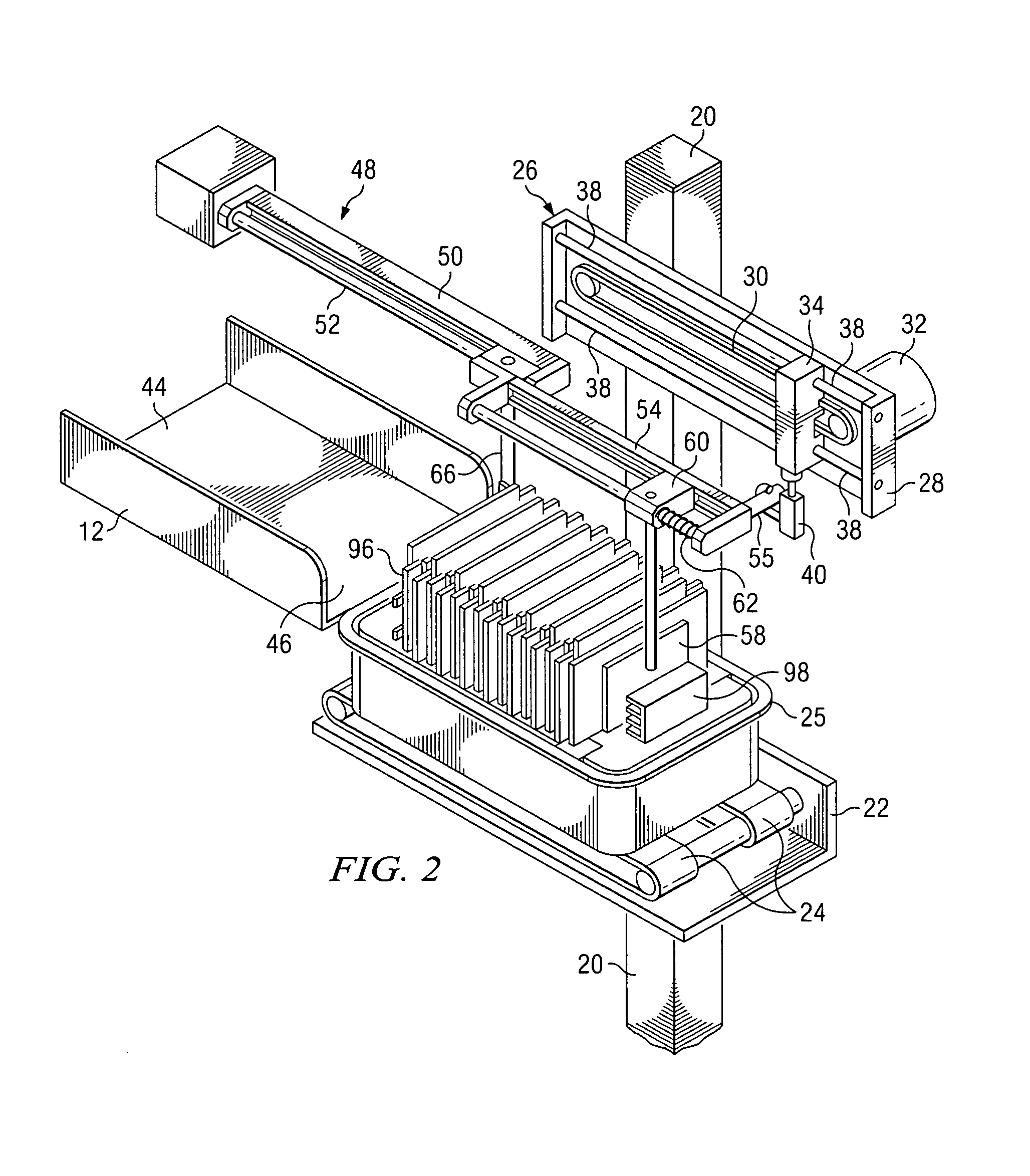

Pusher assembly, merchandise dispenser and method of dispensing merchandise

A spring-driven pusher assembly of a merchandise dispenser in which the spring is carried entirely on the pusher assembly behind the articles being dispensed to thereby eliminate any interference problems with RF signals or the like used for purposes of determining inventories and the like. Preferably, the spring is a spiral spring that rotates a drive wheel when the spring uncoils. The drive wheel cooperatively engages a guide track on the base of the dispenser, and the rotation of the drive wheel causes the pusher assembly to advance along the guide track toward the dispensing end of the dispenser.

Owner:VULCAN SPRING & MFG

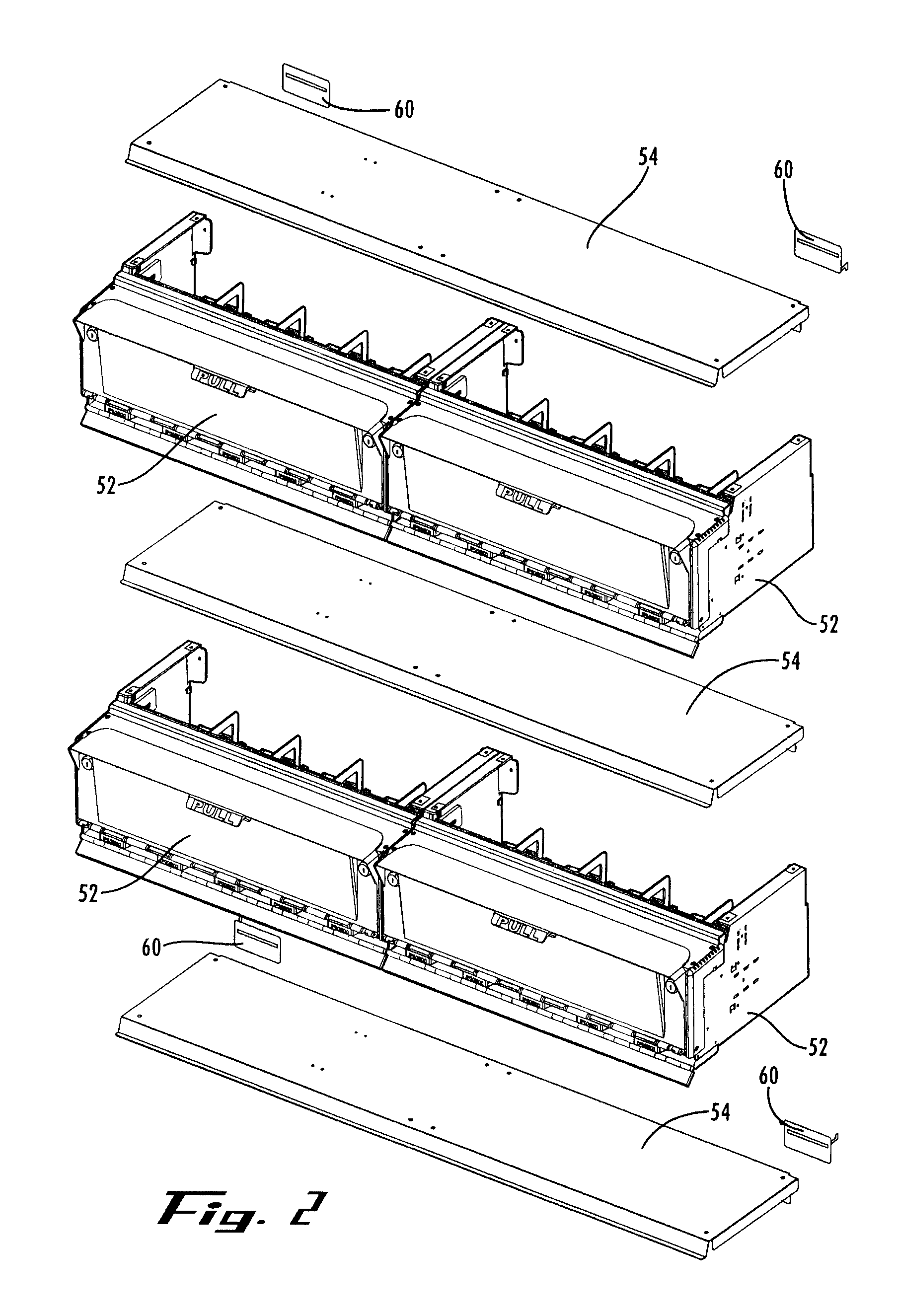

Secure merchandising system

Systems for deterring theft of retail products. Systems of this invention provide theft deterrent dispensing modules for dispensing products and may incorporate theft deterrent measures including mechanical deterrents, time delays and sound. The dispensing modules may include one or more pusher assemblies for dispensing product. Certain systems of this invention may also include a lockout feature, so that one only pusher assembly may be activated to dispense a product at one time. In some embodiments, a door assembly may be provided as an additional theft deterrent mechanism so that access to additional product not yet dispensed by the pusher assembly is restricted.

Owner:WESTROCK SHARED SERVICES LLC

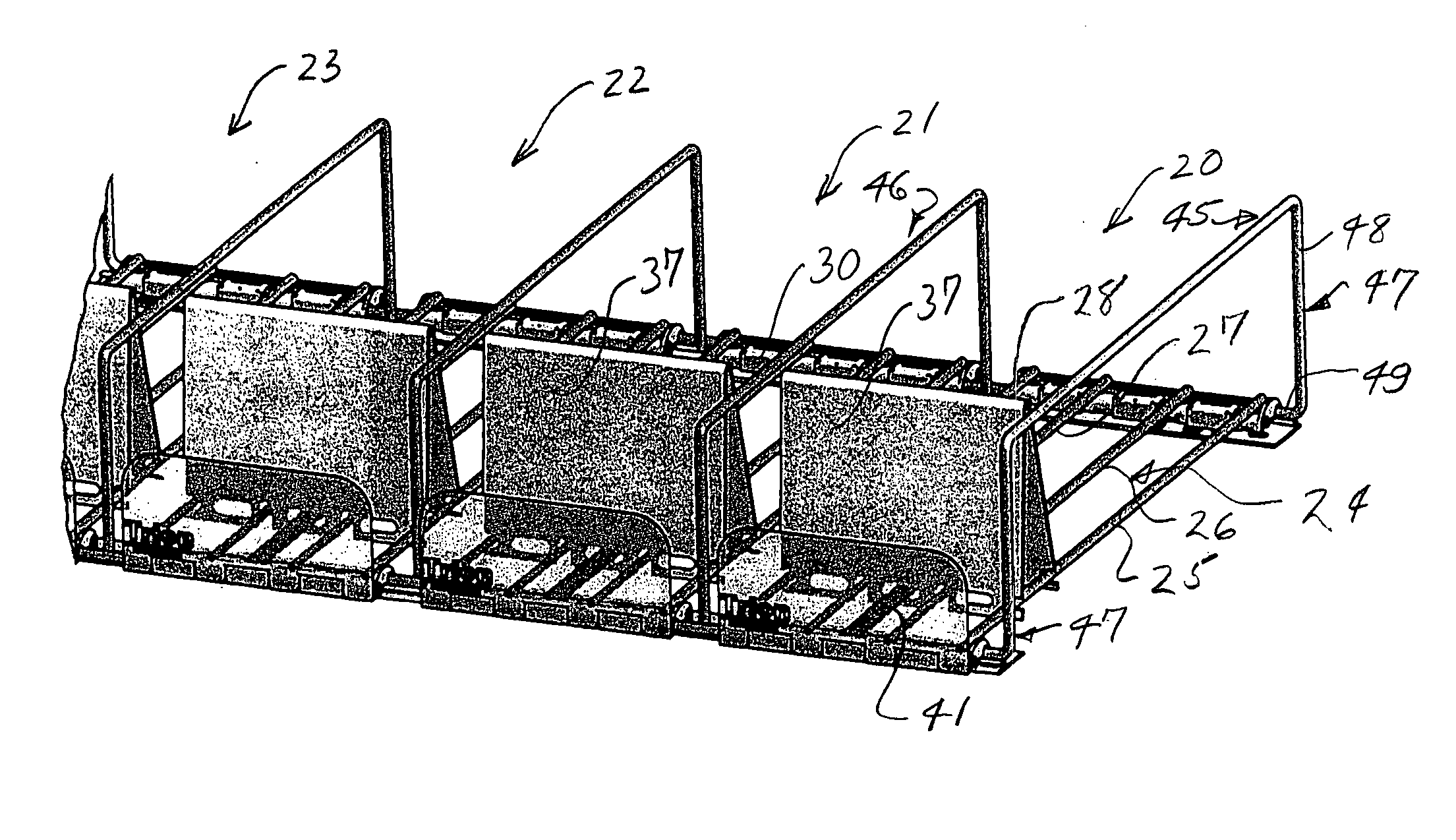

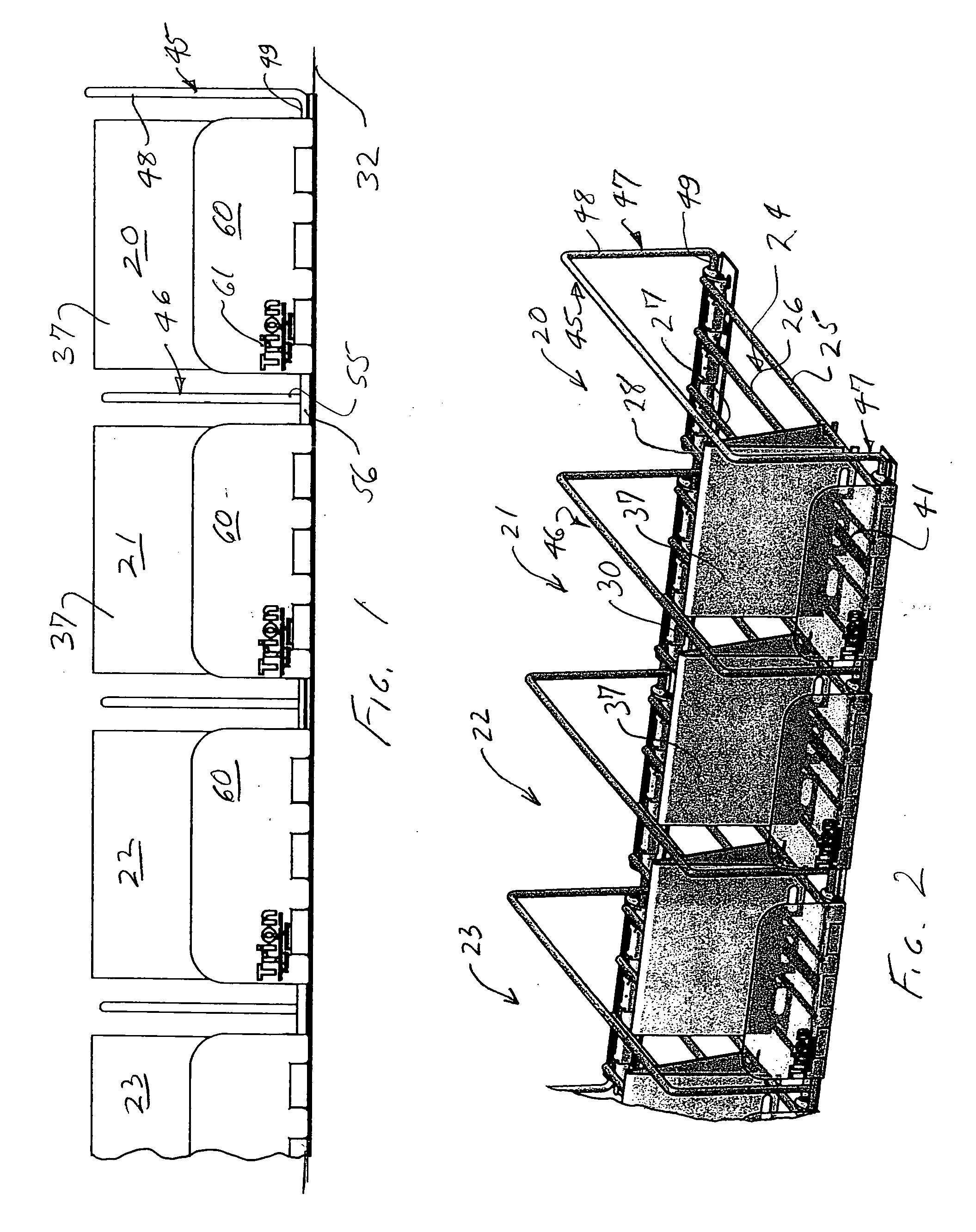

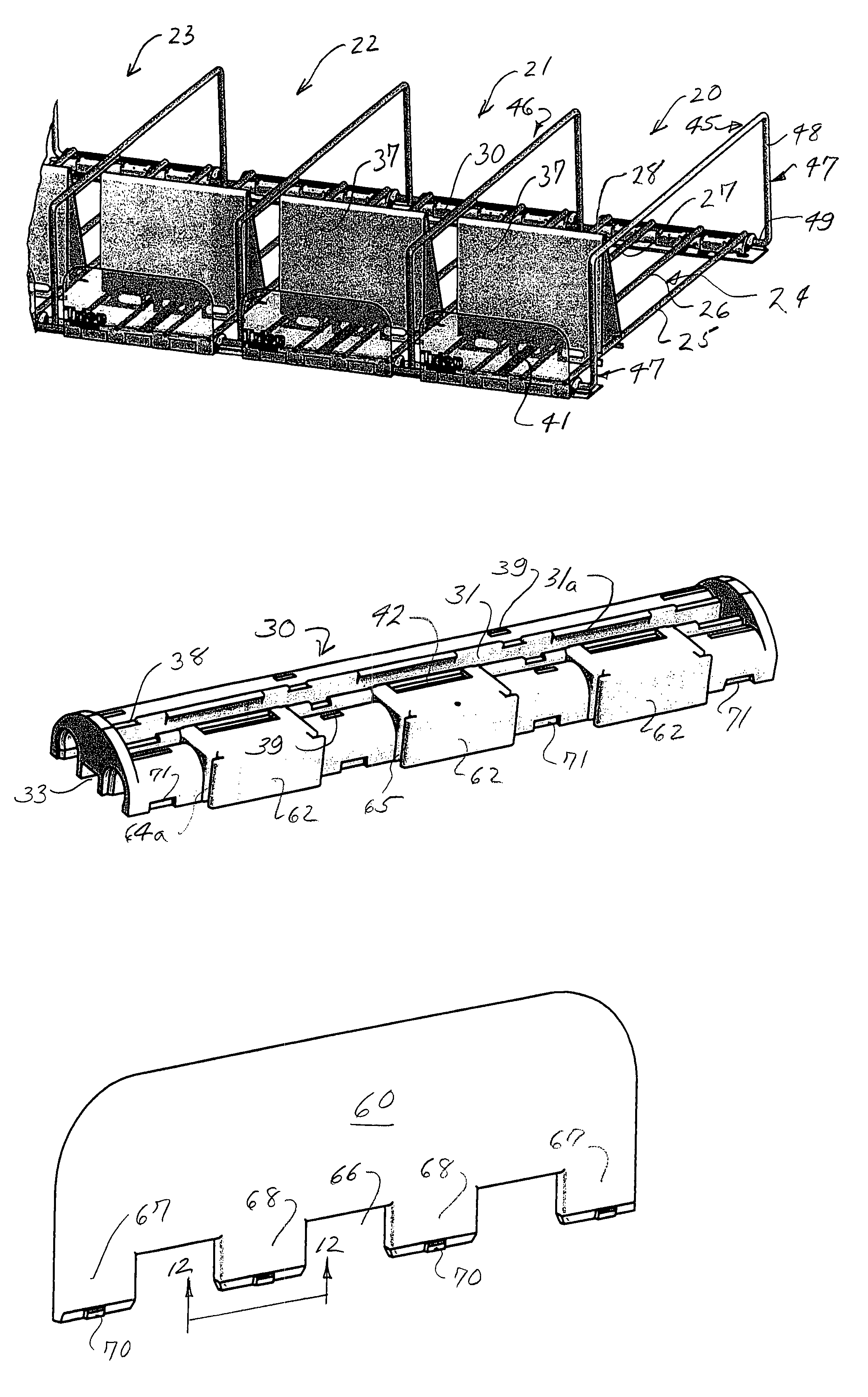

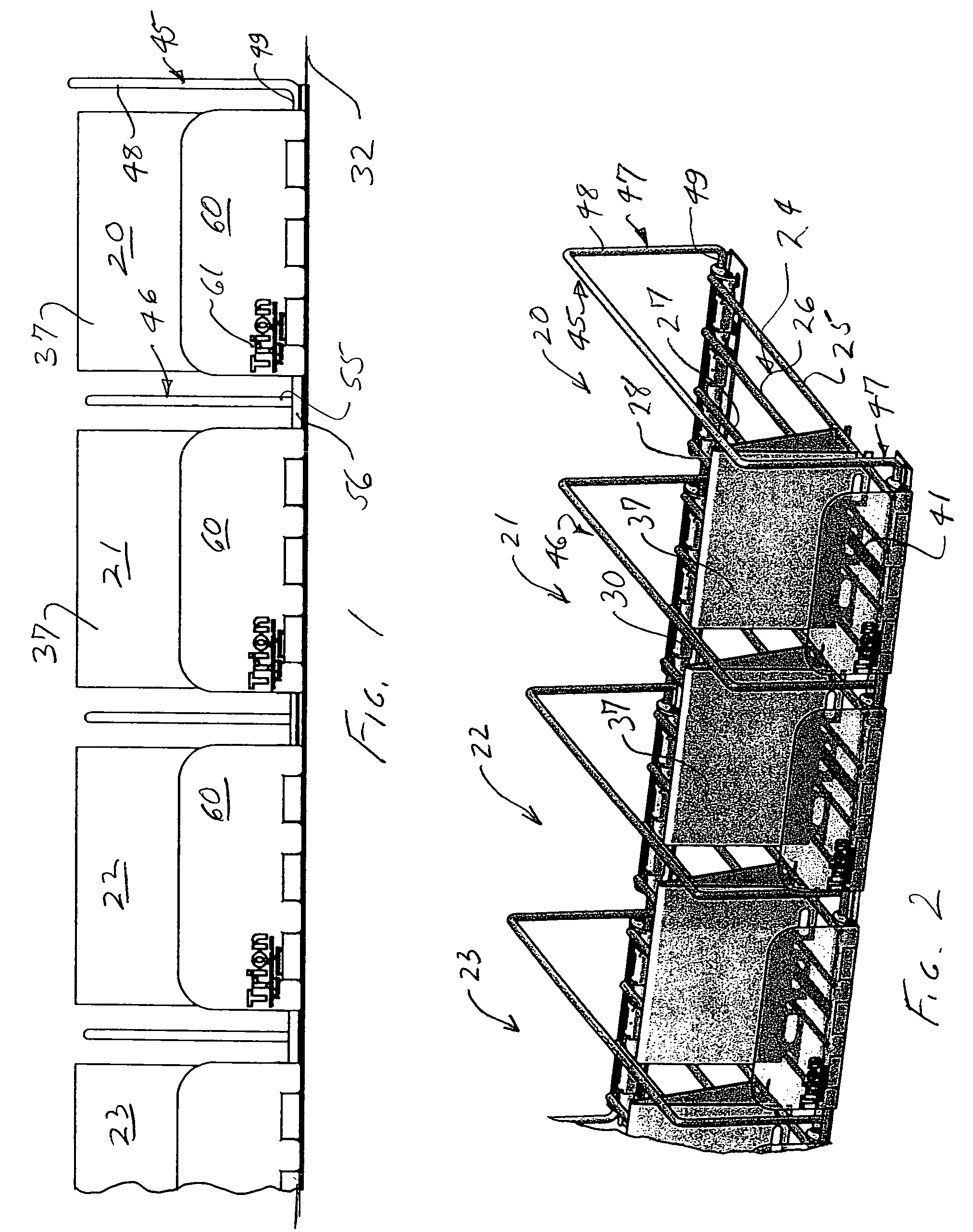

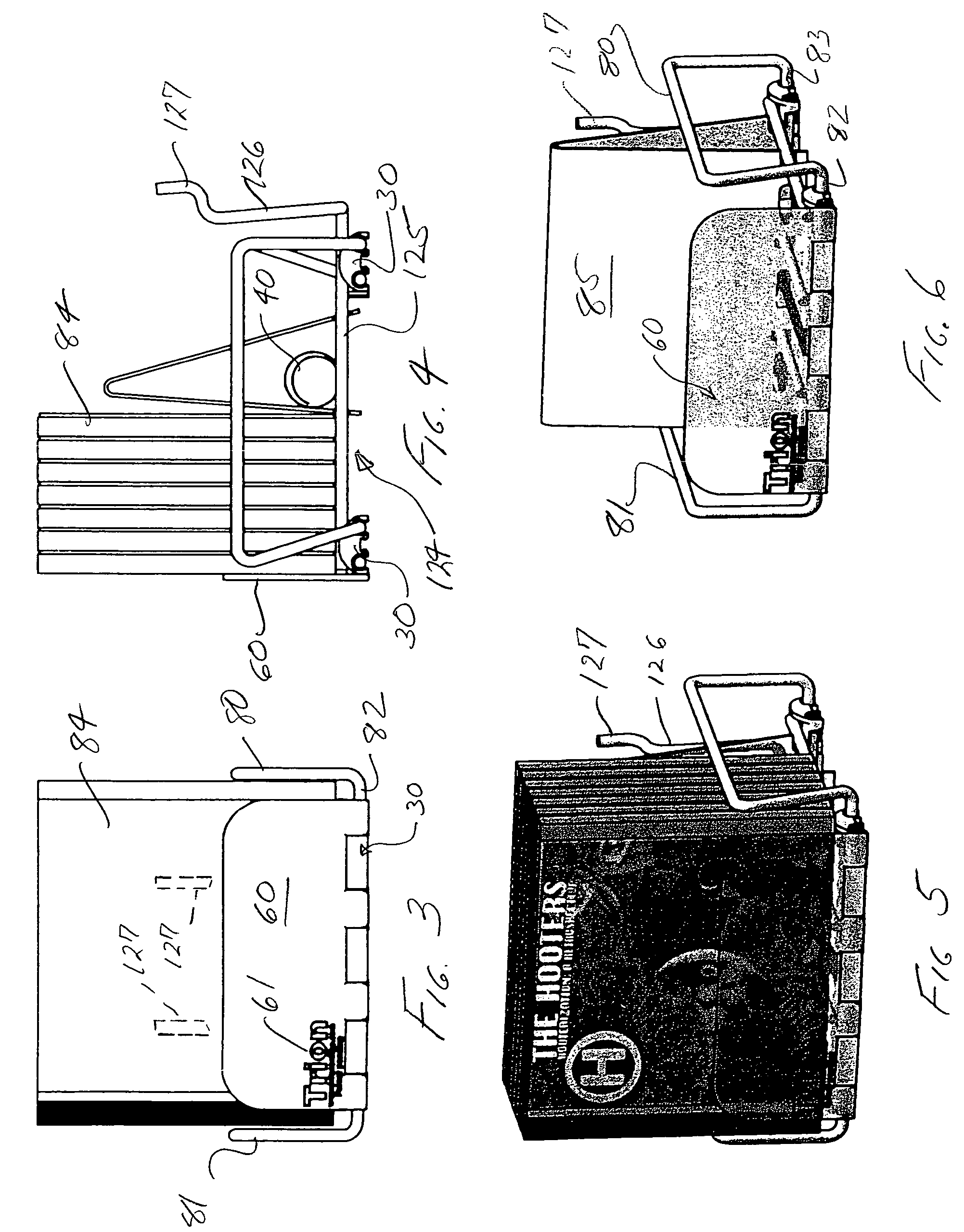

Product display rack with front barrier panel

A product display device is comprised of a wire base structure with a plurality of spaced-apart, straight parallel wire supports extending in a front-to-back direction, and wire cross bars underlying the wire supports adjacent their front and back ends. Plastic base elements are snap-fitted to the cross bars at the front and back ends of the wire base structure, and a pusher means is provided on the base structure for urging displayed product items toward the front. A molded plastic barrier panei is mounted at the front of the front base element by vertical tabs which are received in vertical grooves at the front of the base element. The plastic barrier panel can be made of clear, transparent material for optimum viewing of the product being displayed. The panels can accommodate the presence of product identifying logos, graphics or other special information associated with a particular product.

Owner:TRION IND

Forward feeding modular display rack for rounded articles

Owner:BURKE DISPLAY SYST

Modular display rack having horizontally separable front barrier

Owner:BURKE DISPLAY SYST

Weighted pusher

InactiveUS20050077259A1Small footprintMaximize lengthRacksCard-filingEngineeringMechanical engineering

Owner:DISPLAY TECHNOLOGIES INC

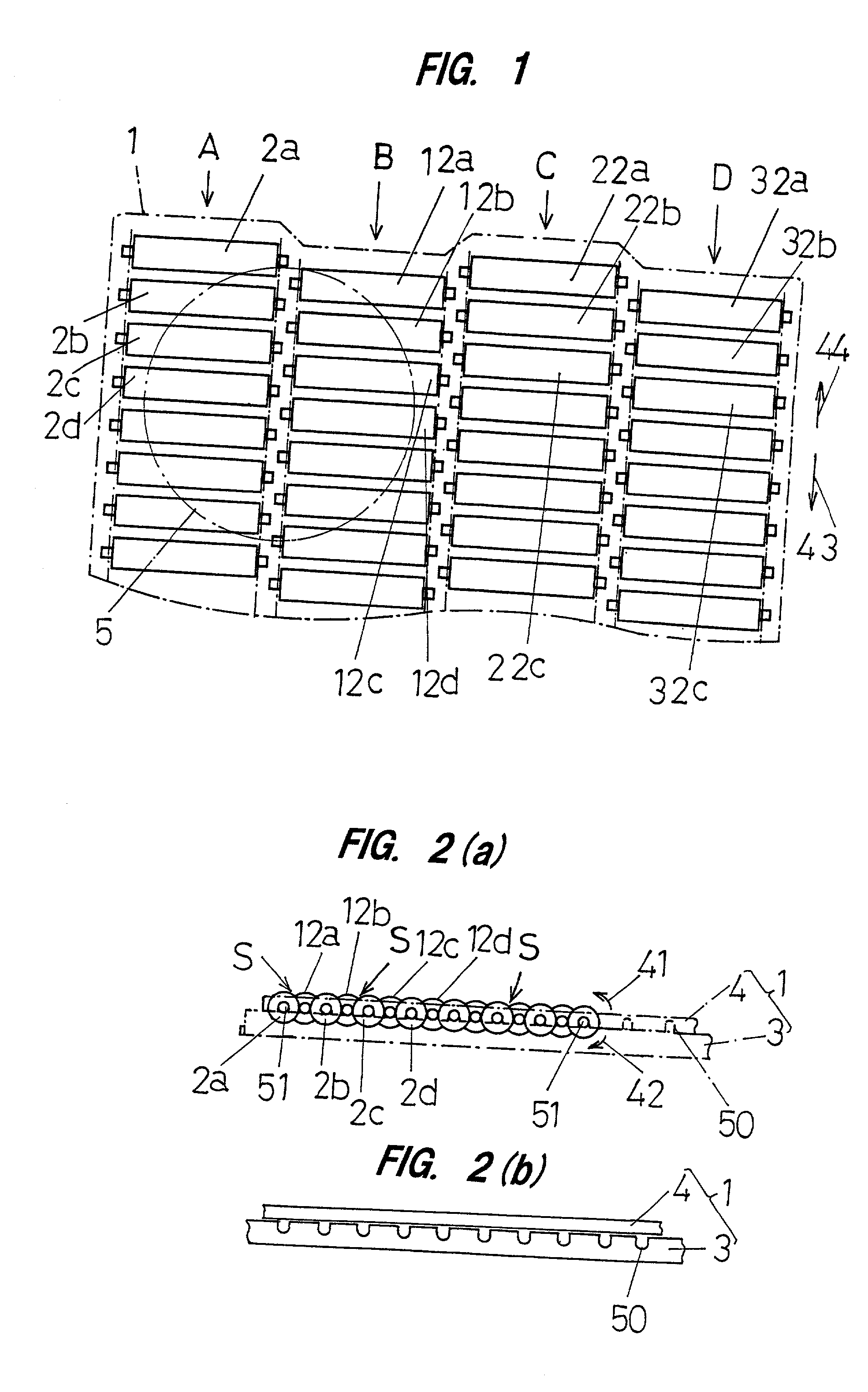

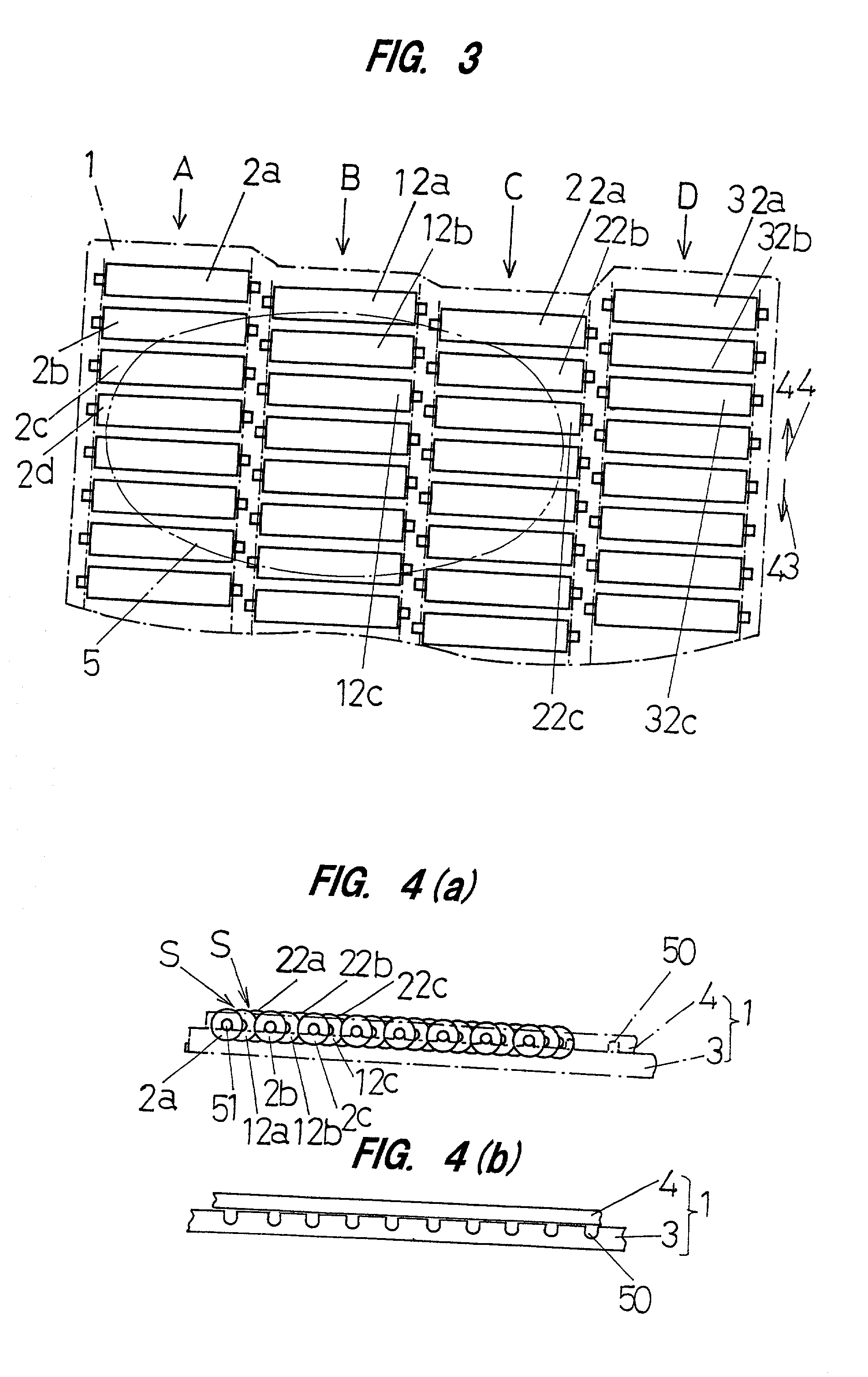

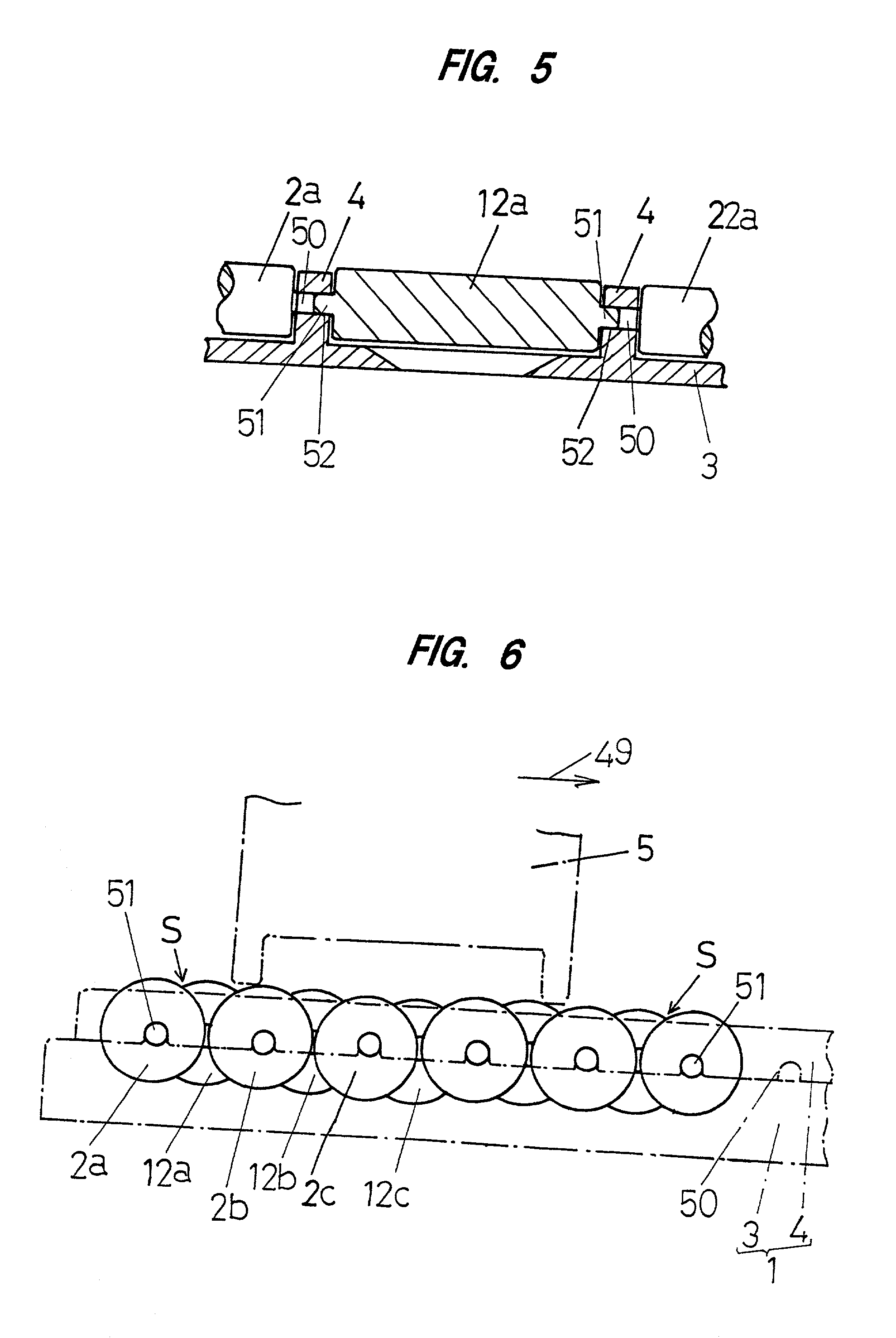

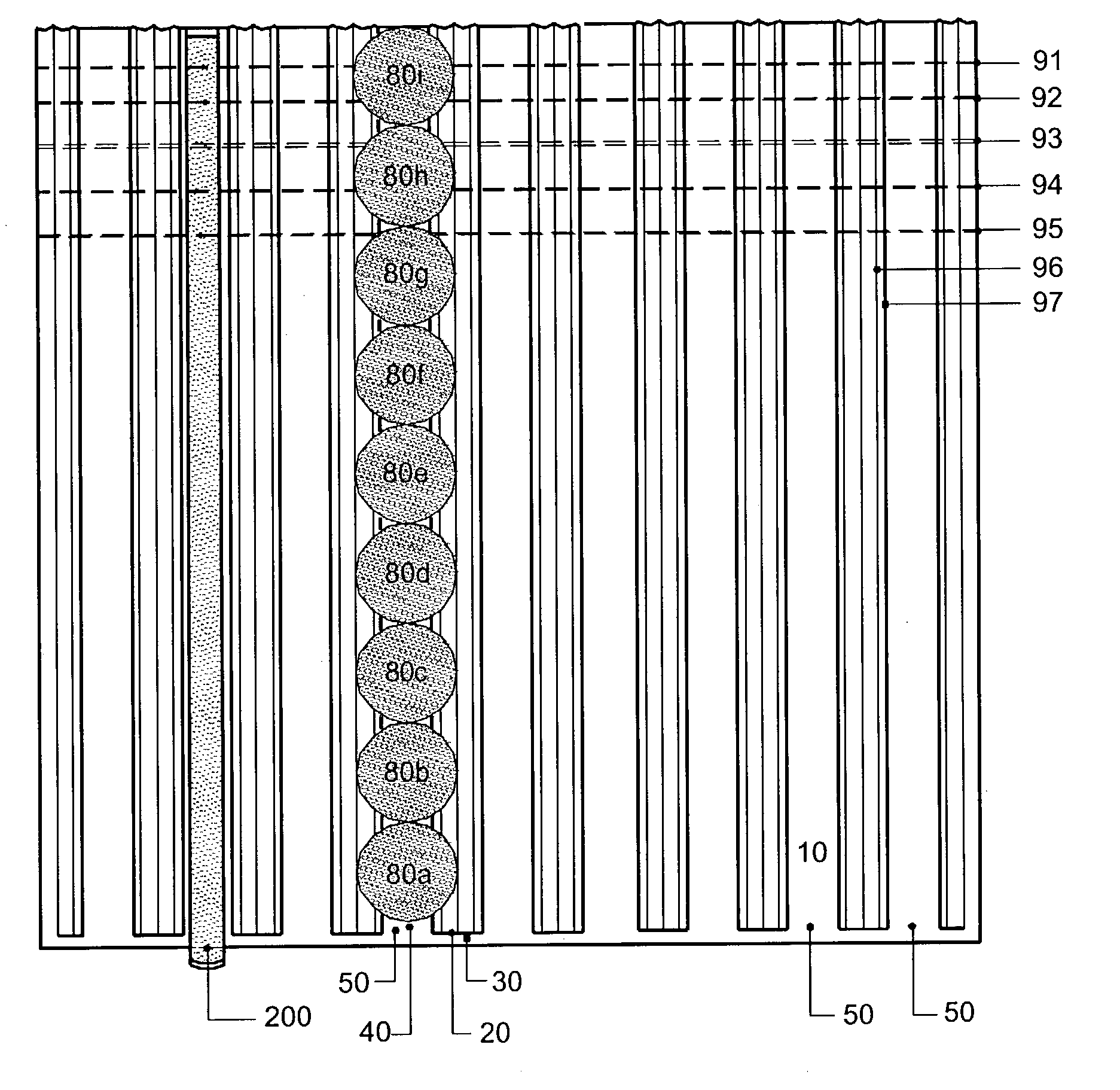

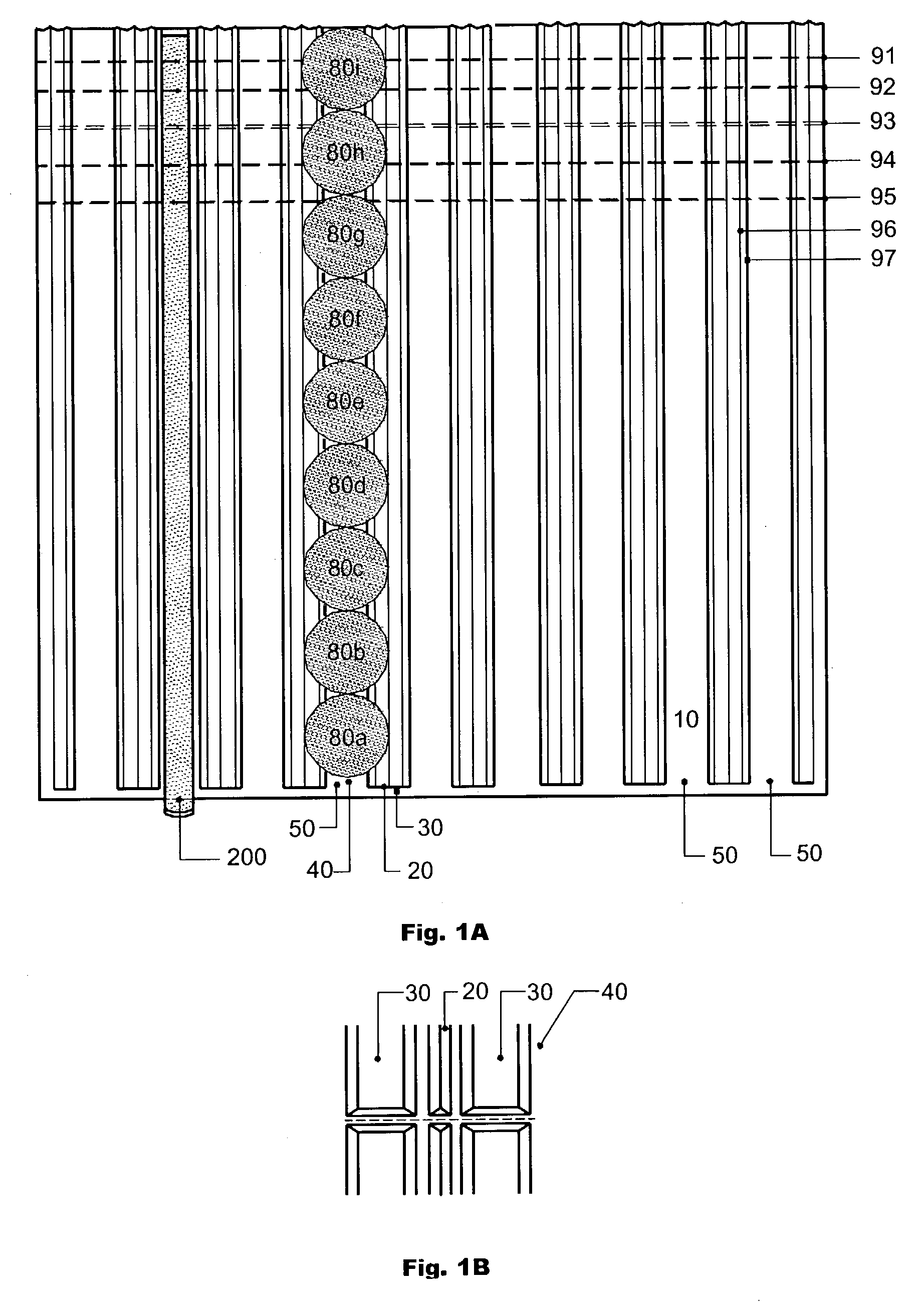

Showcase assembly unit for showcase structure

A showcase assembly unit for the showcase structure is disclosed, which includes a roller support frame and a plurality of parallel sets of rollers mounted on the roller support frame, wherein the rollers in each set of rollers are mounted rotatably and arranged one after another from the rear end toward the front end of the roller support frame, and a plurality of individual articles, such as canned foods or drinks, may be placed across two or more parallel sets of rollers and are capable of moving one by one from the rear end toward the front end of the roller support frame. In the showcase assembly unit for the showcase structure according to the present invention, each roller has a specific width that is smaller than the size of the bottom of a particular article across the roller, and each of the rollers in each set is axially offset relative to each of the rollers in each adjacent set.

Owner:SEKISUI PLASTICS CO LTD

Theft deterrent system

Systems for deterring theft of retail products. Systems of this invention provide theft deterrent cabinets for dispensing products and may incorporate theft deterrent measures including mechanical deterrents, time delays and sound.

Owner:WESTROCK SHARED SERVICES LLC

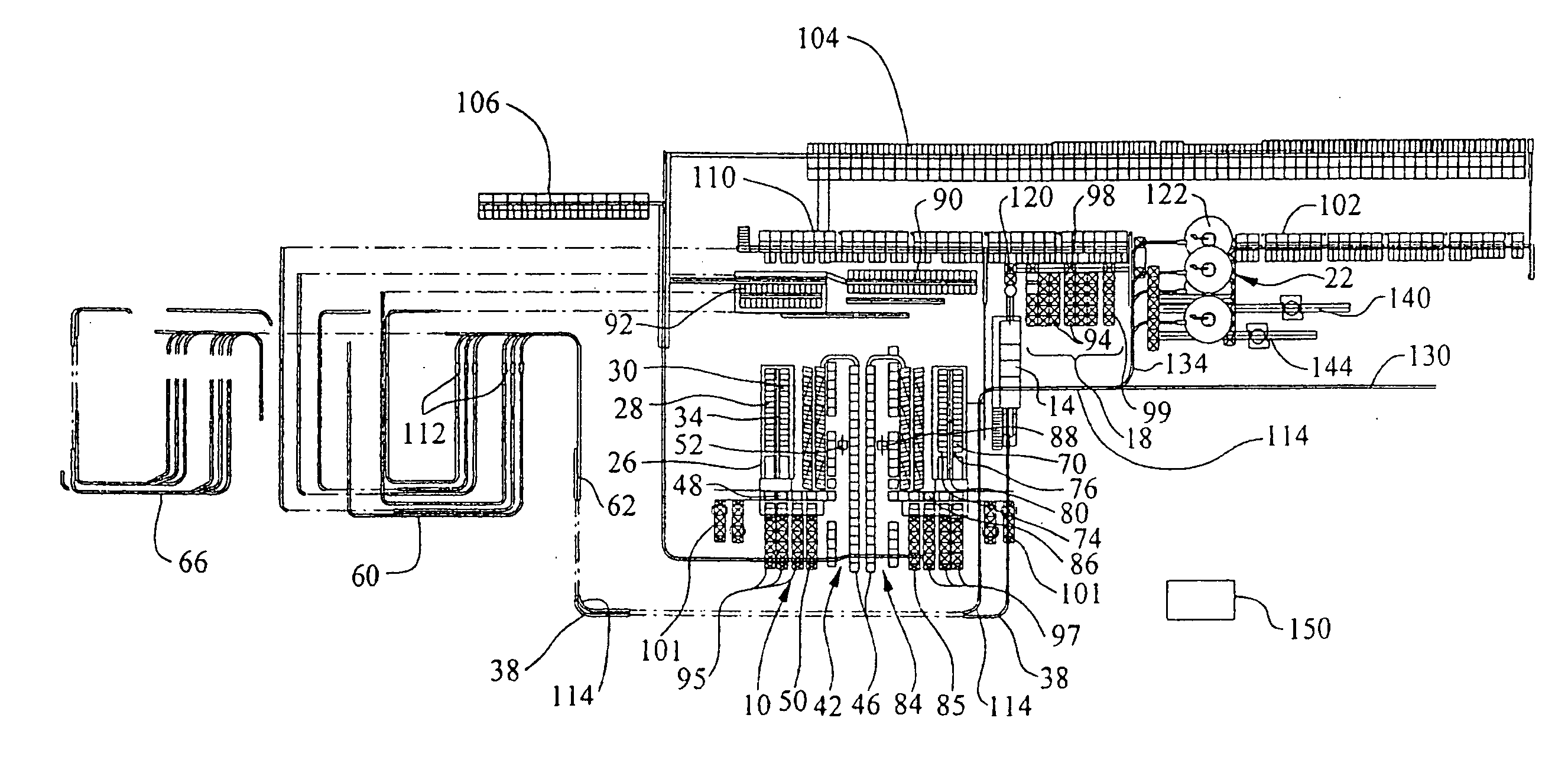

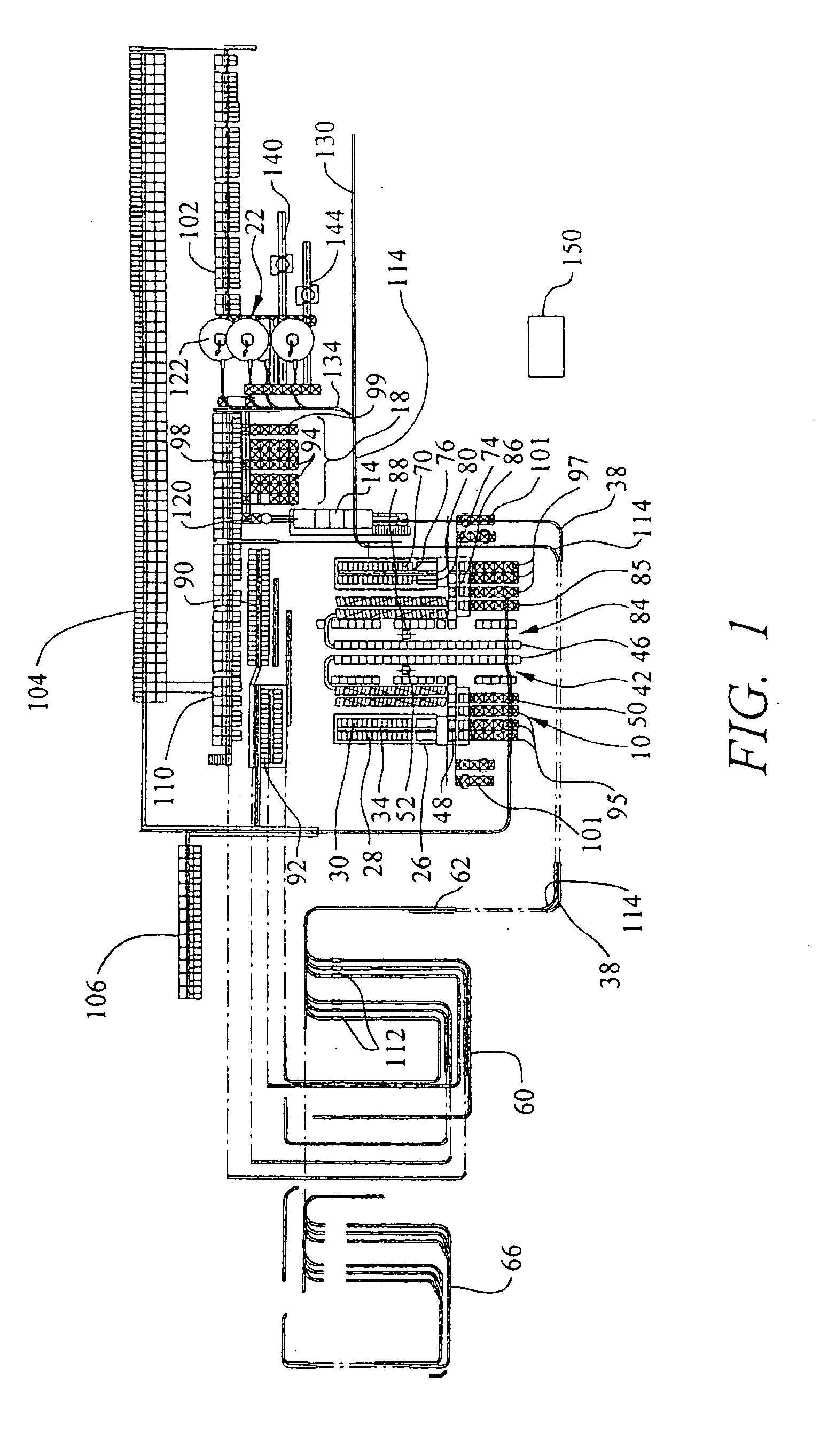

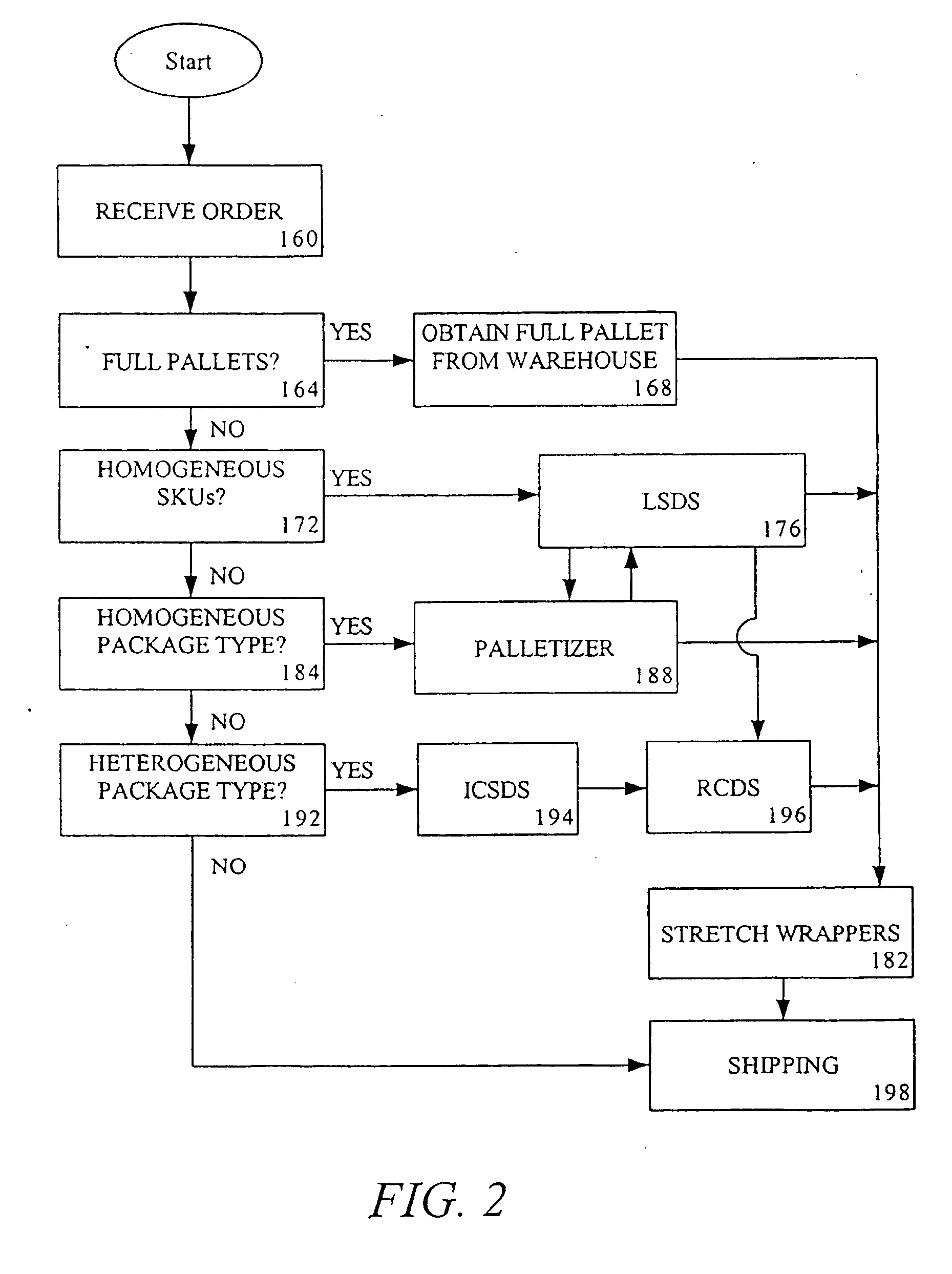

Automated container storage and delivery system

A material storage and delivery system includes an individual container storage and delivery system (ICSDS). A palletizer is provided for placing containers from the ICSDS on a pallet. A layer storage and delivery system (LSDS) places full layers of containers on a pallet. A robotic container delivery system (RCDS) places individual containers on a pallet. A conveyor system conveys containers and pallets between at least two of the ICSDS, the palletizer, the LSDS and the RCDS. A method for storing and delivering containers is also disclosed.

Owner:STINGEL FREDERICK J III +2

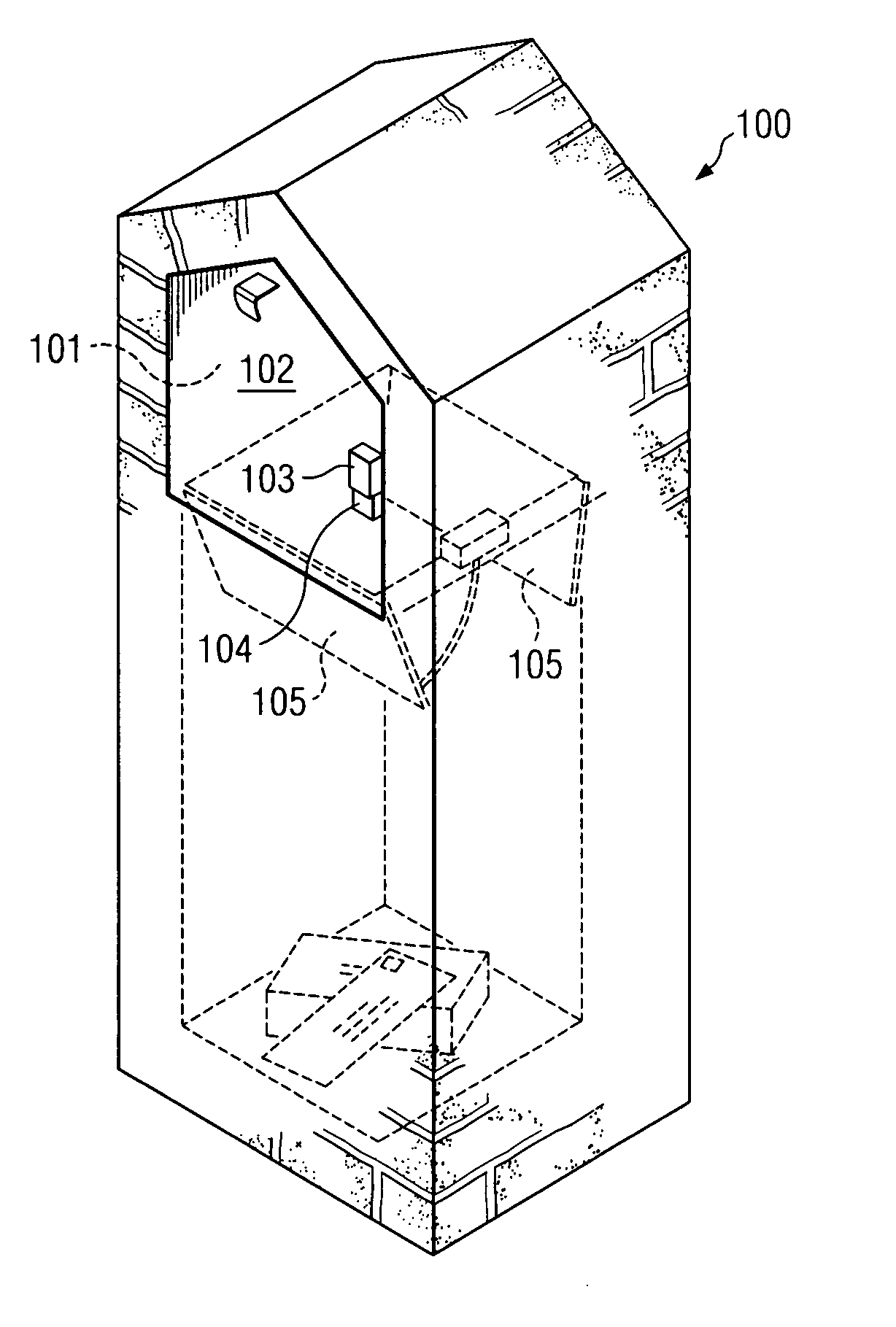

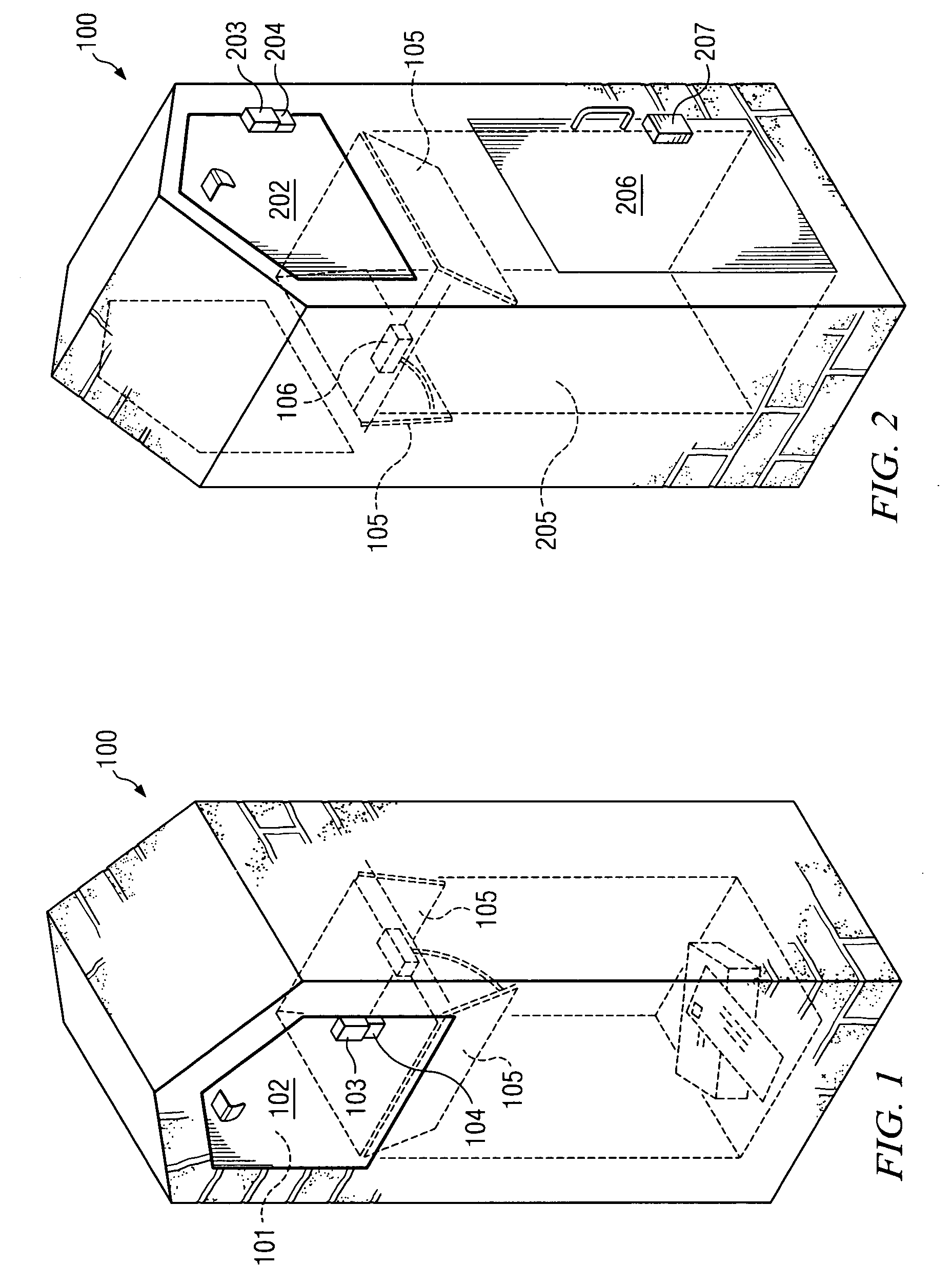

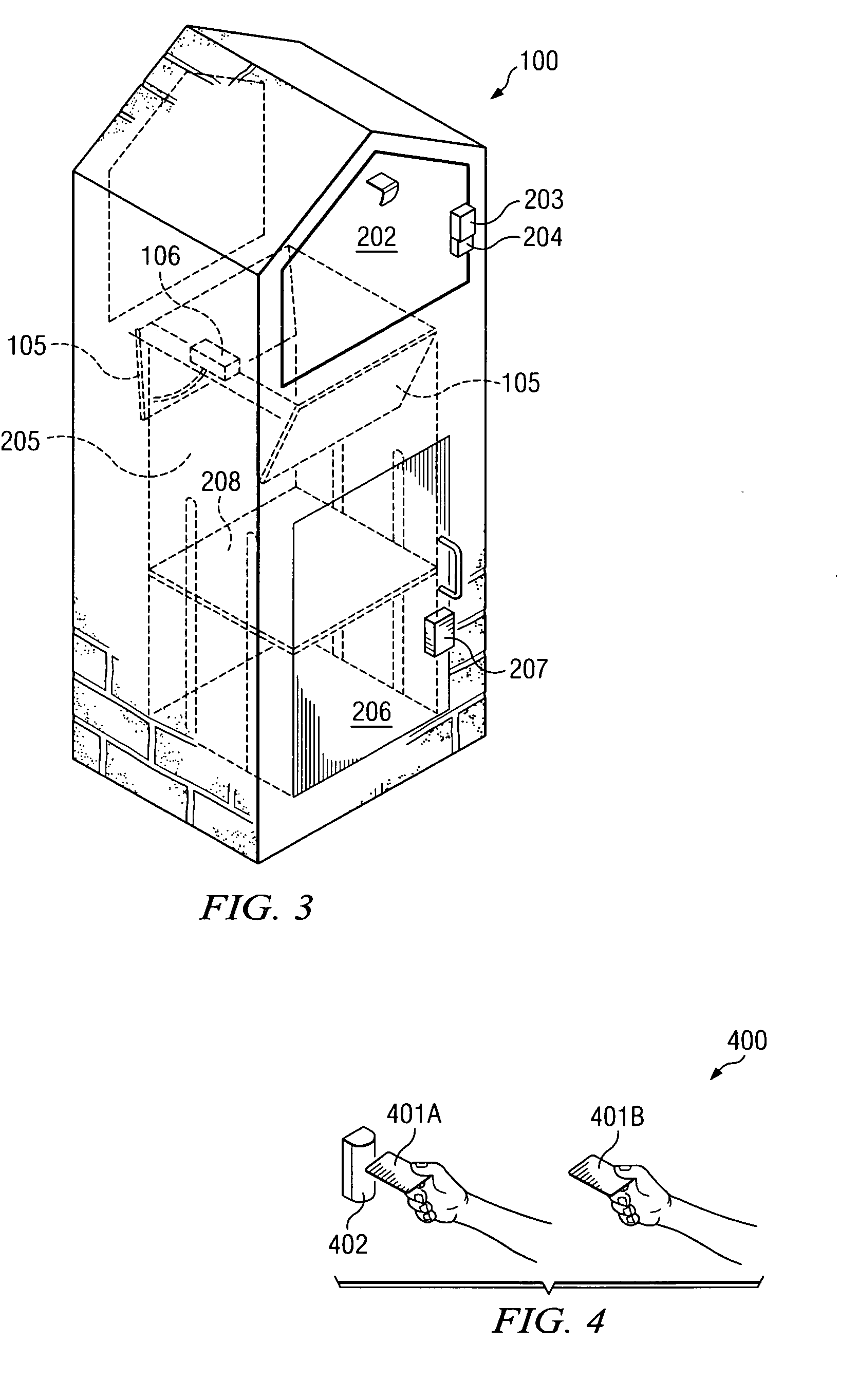

Theft preventative mailbox with rear residential and storage vault door and remote unlocking activation mechanism

InactiveUS20090084836A1Apparent advantageElectric signal transmission systemsDigital data processing detailsFront edgeBiological activation

What is disclosed is a secure mailbox having at least an upper compartment with a plurality of sides, a front mailbox door hinge-ably coupled to a front edge of a side of the upper compartment, a locking and unlocking mechanism being adapted to lock the front mailbox door to the upper compartment and an unlocking activation mechanism coupled to the locking and unlocking mechanism; an upper rear mailbox door hinge-ably coupled to a rear edge of a side of the upper compartment, a locking and unlocking mechanism being adapted to lock the rear mailbox door to the upper compartment and an unlocking activation mechanism coupled to the locking and unlocking mechanism and a lower compartment having a lower, rear mailbox door hinge-ably coupled to a rear edge of a side of the lower compartment, at least one trap door being located between the upper compartment and lower compartment.

Owner:DUDLEY JOSEPH H

Pusher assembly, merchandise dispenser and method of dispensing merchandise

A spring-driven pusher assembly of a merchandise dispenser in which the spring is carried entirely on the pusher assembly behind the articles being dispensed to thereby eliminate any interference problems with RF signals or the like used for purposes of determining inventories and the like. Preferably, the spring is a spiral spring that rotates a drive wheel when the spring uncoils. The drive wheel cooperatively engages a guide track on the base of the dispenser, and the rotation of the drive wheel causes the pusher assembly to advance along the guide track toward the dispensing end of the dispenser. A method of dispensing merchandise is also provided.

Owner:VULCAN SPRING & MFG

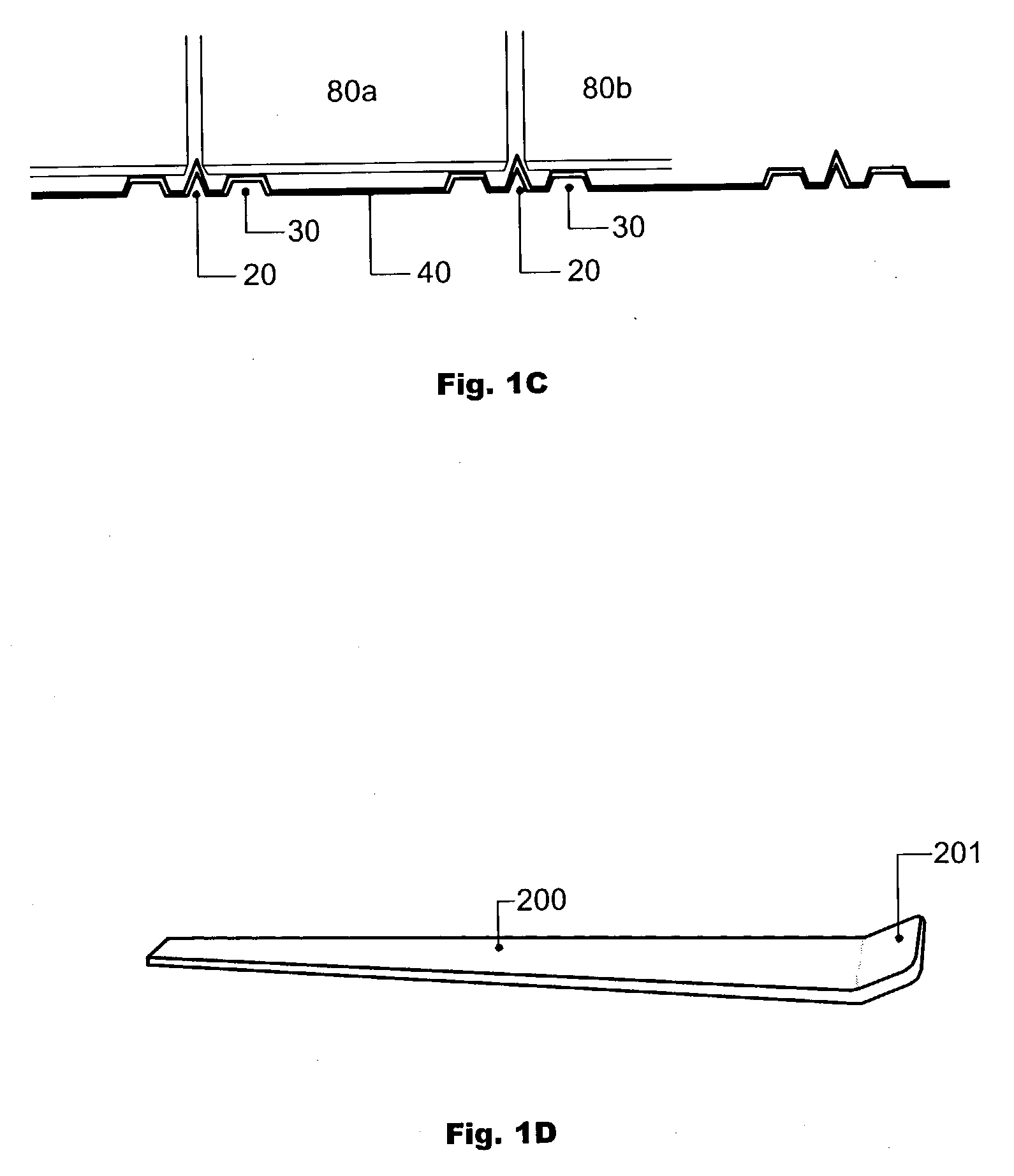

System and method for product display, arrangement and rotation James Garth Close

A device, system, and method for manually arranging products on a display shelf. A plastic ridged base may be cut to a desired display shelf width along preformed notches and then be placed on the display shelf. Excess base width may serve as a rear backing element to support row partitions. The ridges support merchandise and permit a pull member to rest between ridges. The pull member may be manually pulled to bring merchandise to the front of a row. The ridges may be universal, or may be of specific dimensions for items such as soup cans or baby food jars.

Owner:CLOSE JAMES GARTH

Product display rack with front barrier panel

Owner:TRION IND

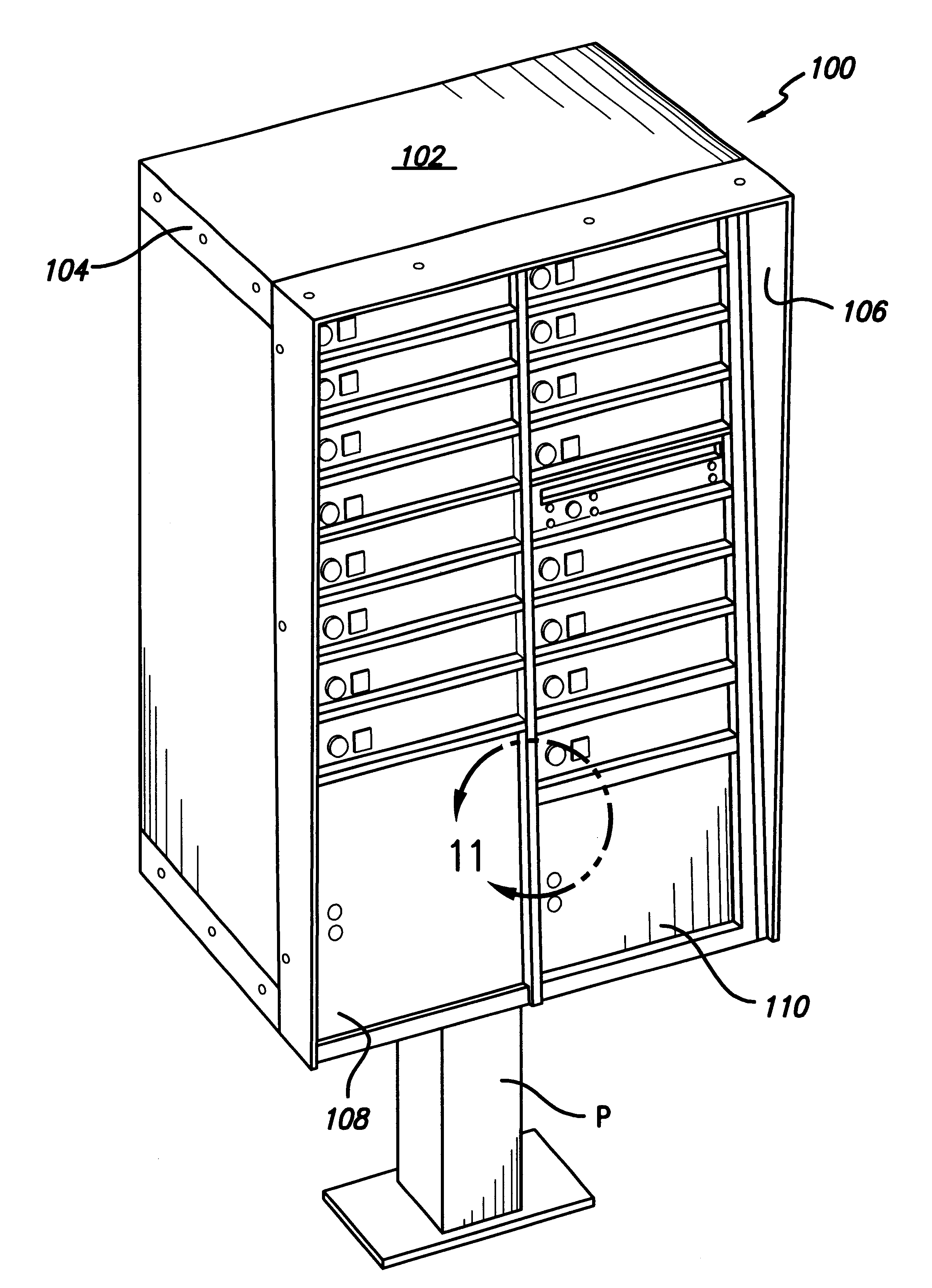

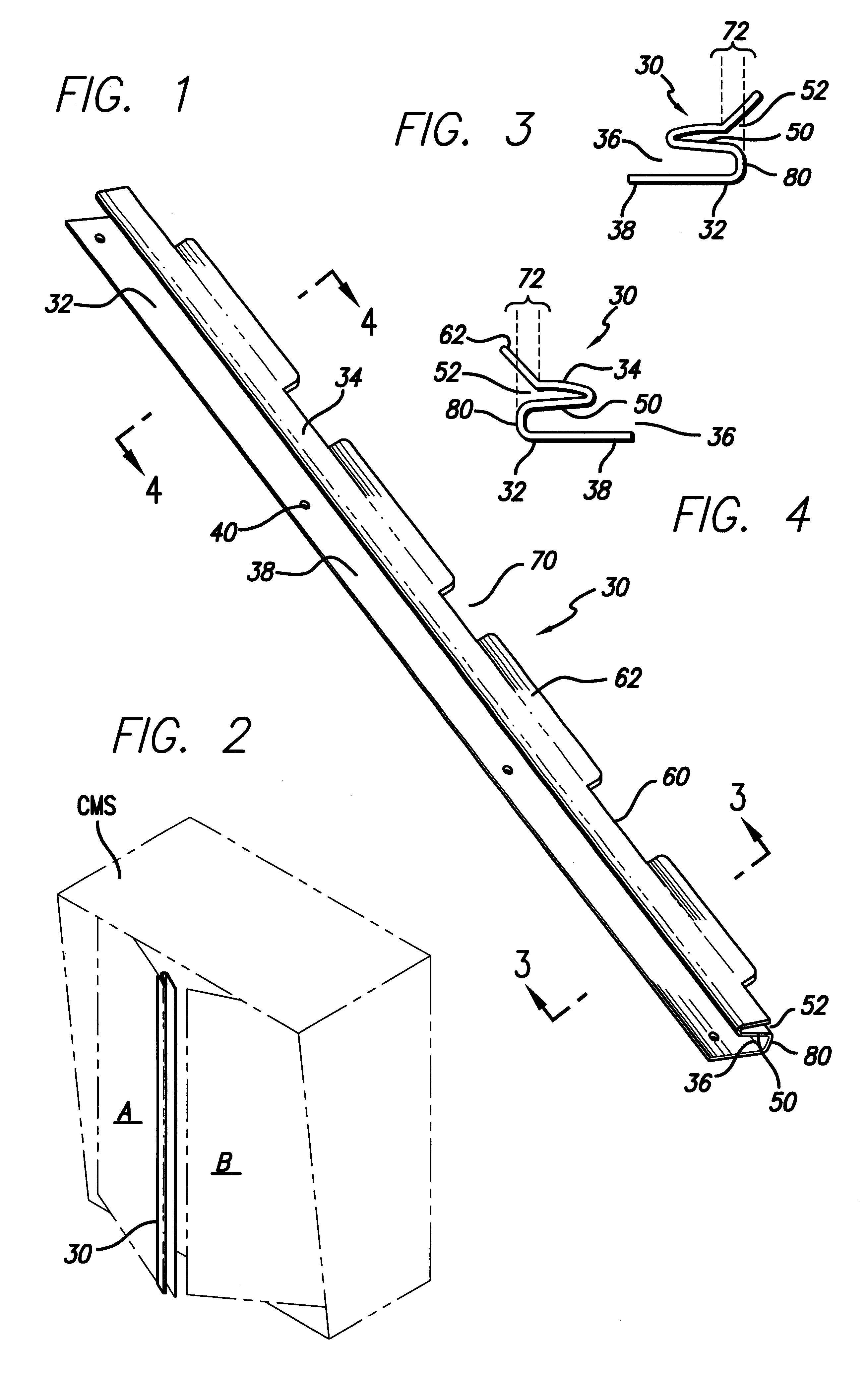

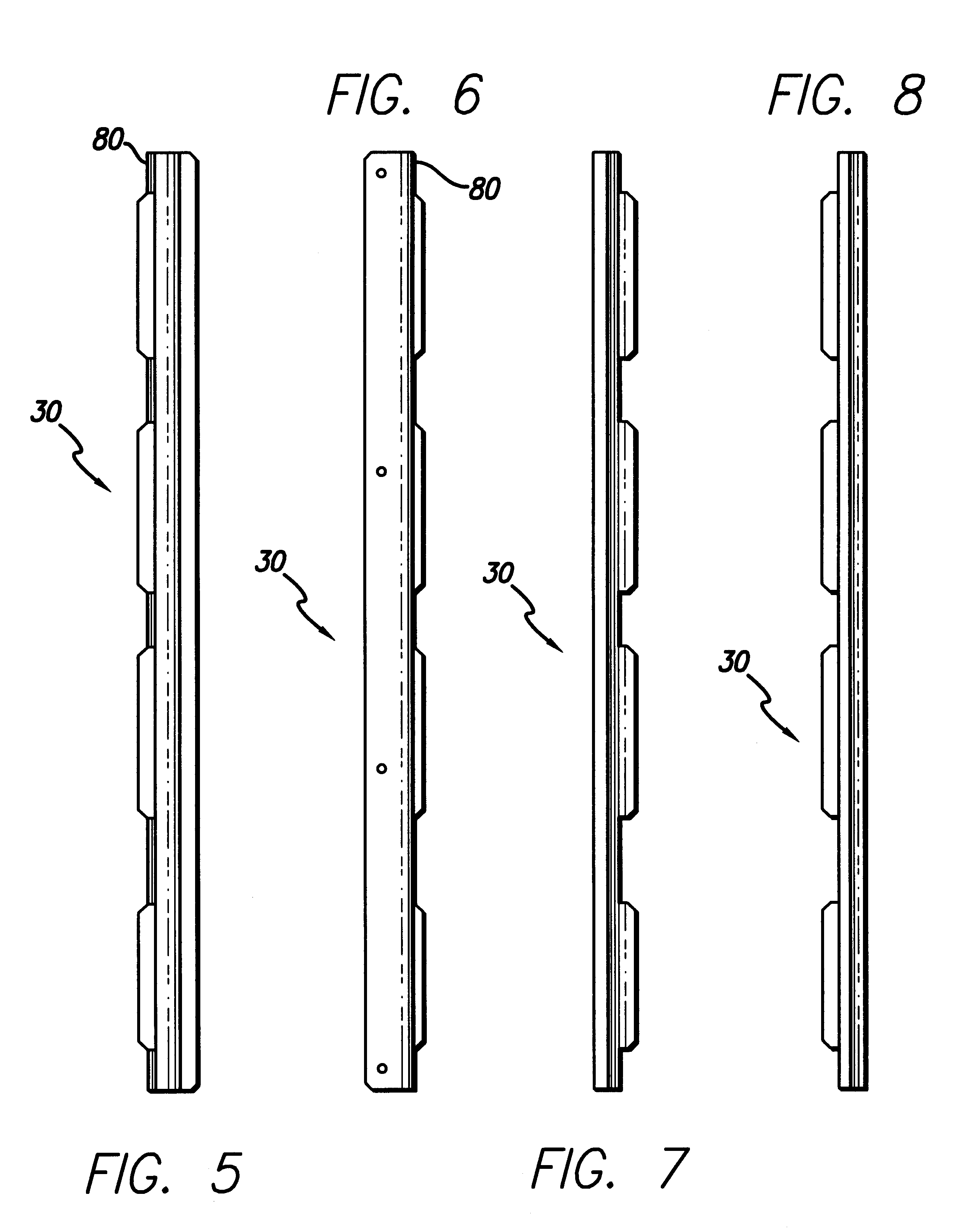

Secure cluster box unit for mail and parcels

An interlocking door seam provides a stronger seam for double doors, making them less subject to attack by prybars and the like. Particularly for central mail stations (CMS) and central box units CBU, double doors present there are subject to attack by prybars and the like that force the locks and allow thieves to rifle the contents of the enclosed mail boxes. Attachment of interlocking door seam to the first edge of the first double doors protects that first edge from prybar attacks. The adjoining edge of the second double door then releasably fits into a convex strip that protects the adjoining edge of the second double door, thereby protecting it from prybar attack. The interlocking door seam allows normal operation of the double doors while decreasing the risk to the central mail station of prybar attack at the seam between the double doors. Flanges present along the free edge of the convex strip provide easy engagement of that free edge. Gaps between such flanges accommodate shelving inside the central mail station. Construction of the interlocking door seam by tempered steel or hard and durable materials provides enhanced protection from prybar attack. Additionally, a main access door bolt bracket may serve to better secure and close the double doors, thwarting forced entry therethrough. The individual mailbox slot doors may have hooked cams to provide fail-safe closure.

Owner:CANAM MARKETING

Adjustable shelving system

A shelving system includes an elongated mounting member operationally securable to an associated shelf. The mounting member includes an approximately vertically oriented wall and an approximately horizontally oriented wall. A track is received on the mounting member in a non-sliding manner. The track extends transversely to a longitudinal axis of the associated shelf. An elongated rail extends longitudinally along the track. A spring urged pusher is slidably mounted in relation to the rail. A slot extends transversely along a bottom face of the track. A first smooth contact surface is located on the mounting member approximately a horizontally oriented wall. A second smooth contact surface is located on the track adjacent the slot. The second contact surface engages the first contact surface to retard a sideward sliding motion of the track in relation to the mounting member.

Owner:FASTENERS FOR RETAIL

Theft preventative mailbox having remote unlocking activation mechanism

InactiveUS7249705B2Electric signal transmission systemsDigital data processing detailsBiological activationElectrical and Electronics engineering

What is disclosed is a secure mailbox having at least a main compartment with a plurality of sides forming the enclosed main compartment, a front mailbox door hingedly coupled to the remainder of the main compartment, a locking and unlocking mechanism being adapted to lock the front mailbox door to the main compartment and an unlocking activation mechanism coupled to the locking and unlocking mechanism comprised of either a card key system, a FOB system or an RFID system.

Owner:DUDLEY JOSEPH

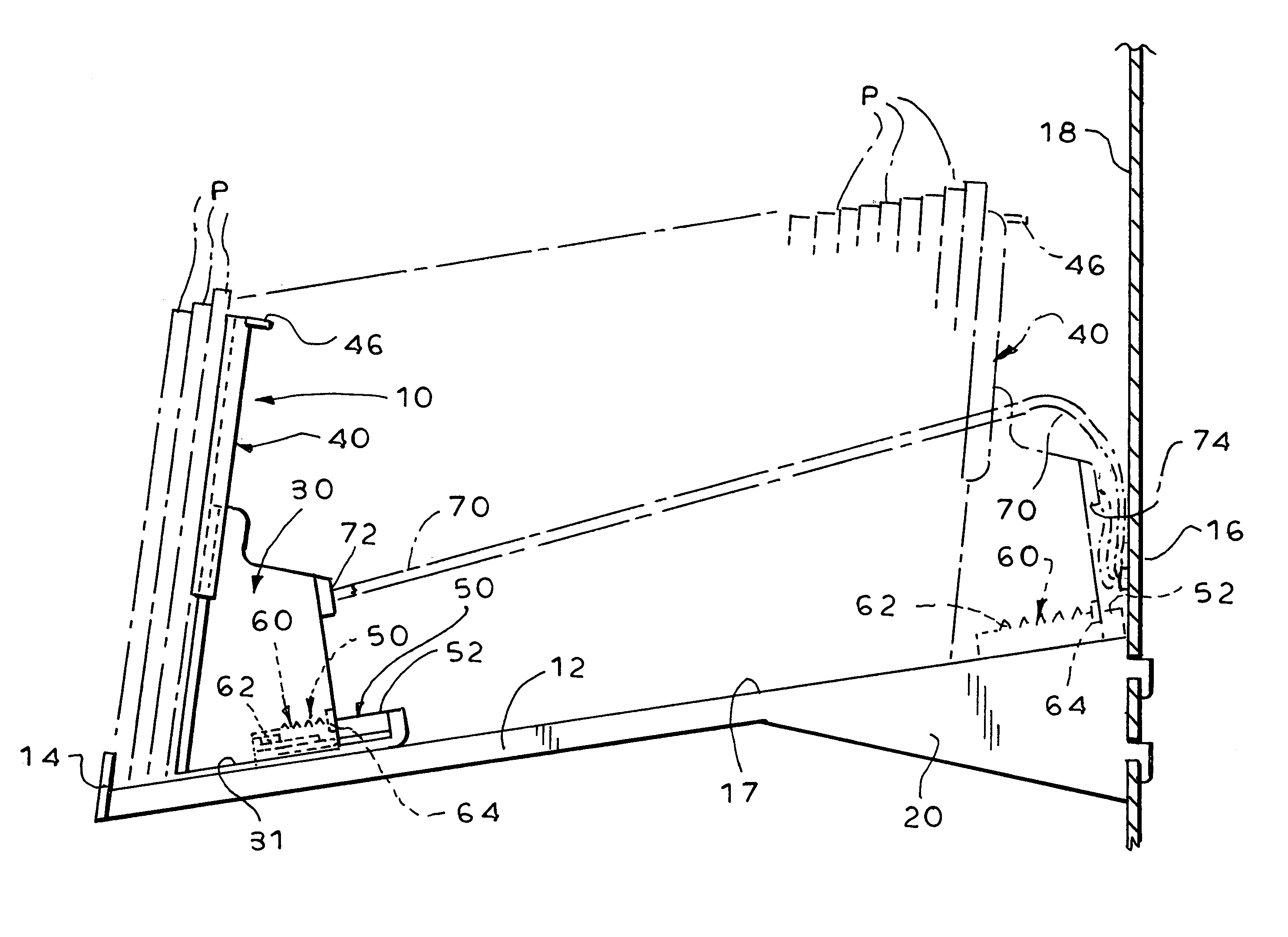

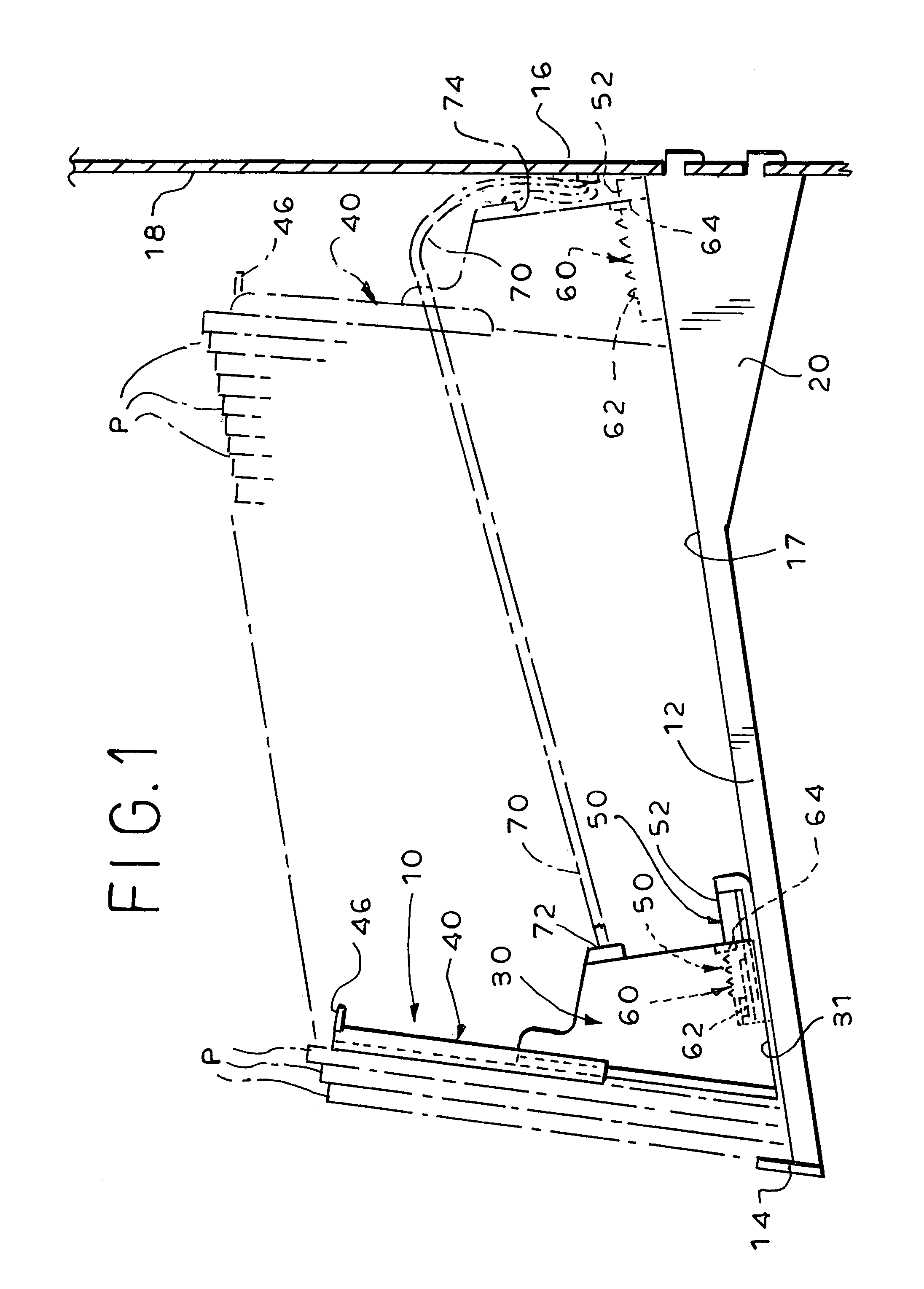

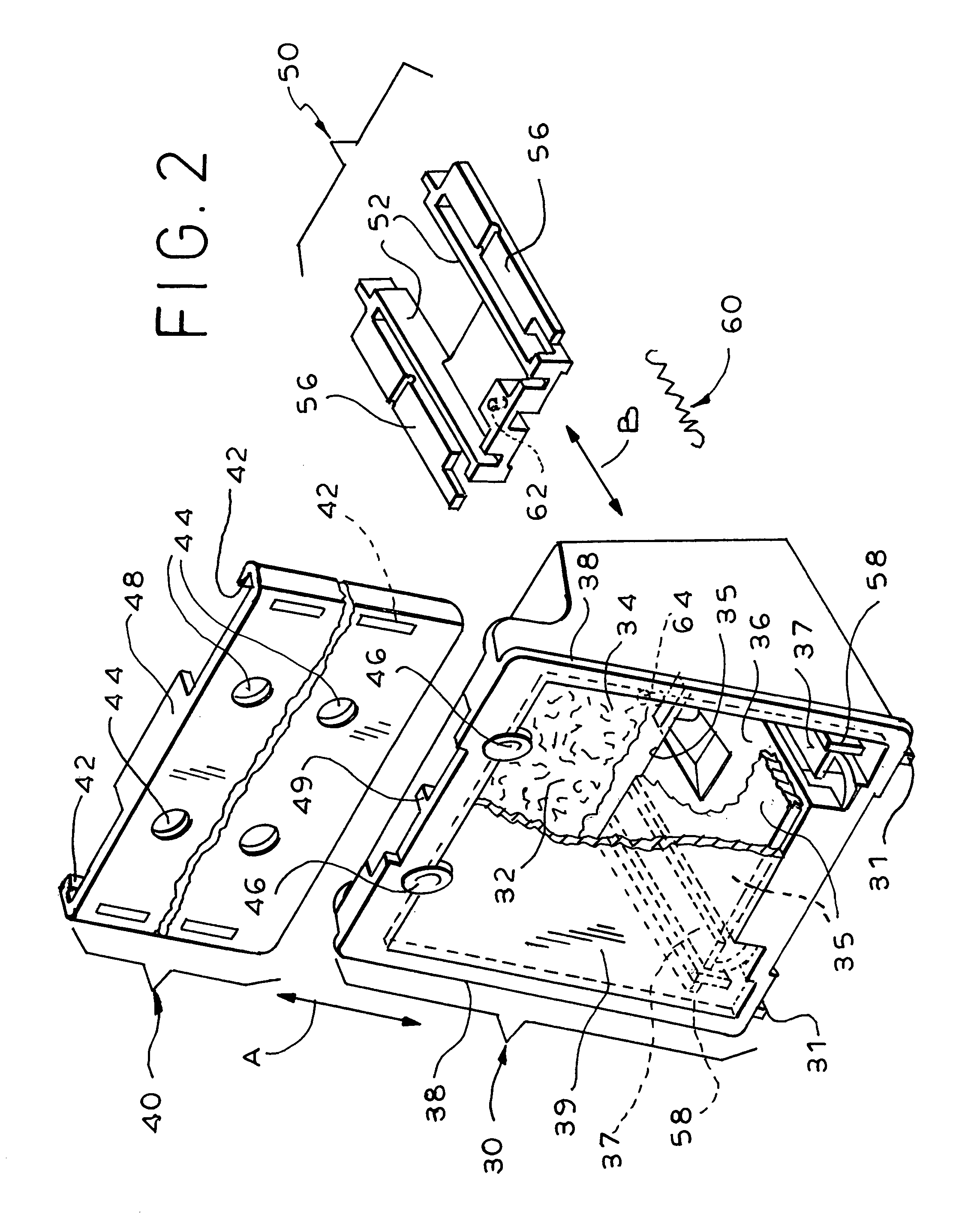

Method and apparatus for mechanized pocket sweeping

InactiveUS7112031B2Separation devicesCharacter and pattern recognitionEngineeringMechanical engineering

A method for sweeping mail pieces from pockets of a sorter including the steps of (1) sorting mail pieces to a plurality of pockets based upon a preselected sorting criteria, (2) positioning an unloading robot adjacent to a selected one of the pockets when the pocket has received a predetermined volume of mail pieces, the robot carrying a tray having upright side walls and bottom wall, (3) engaging the pocket with a sweeping apparatus, (4) removing mail pieces in the pocket with the sweeping apparatus, (5) loading the removed mail pieces into the tray carried by the robot, and (6) carrying the tray containing the removed mail pieces to a destination with the robot. An apparatus for implementing the method is also disclosed.

Owner:KÖRBER SUPPLY CHAIN LLC

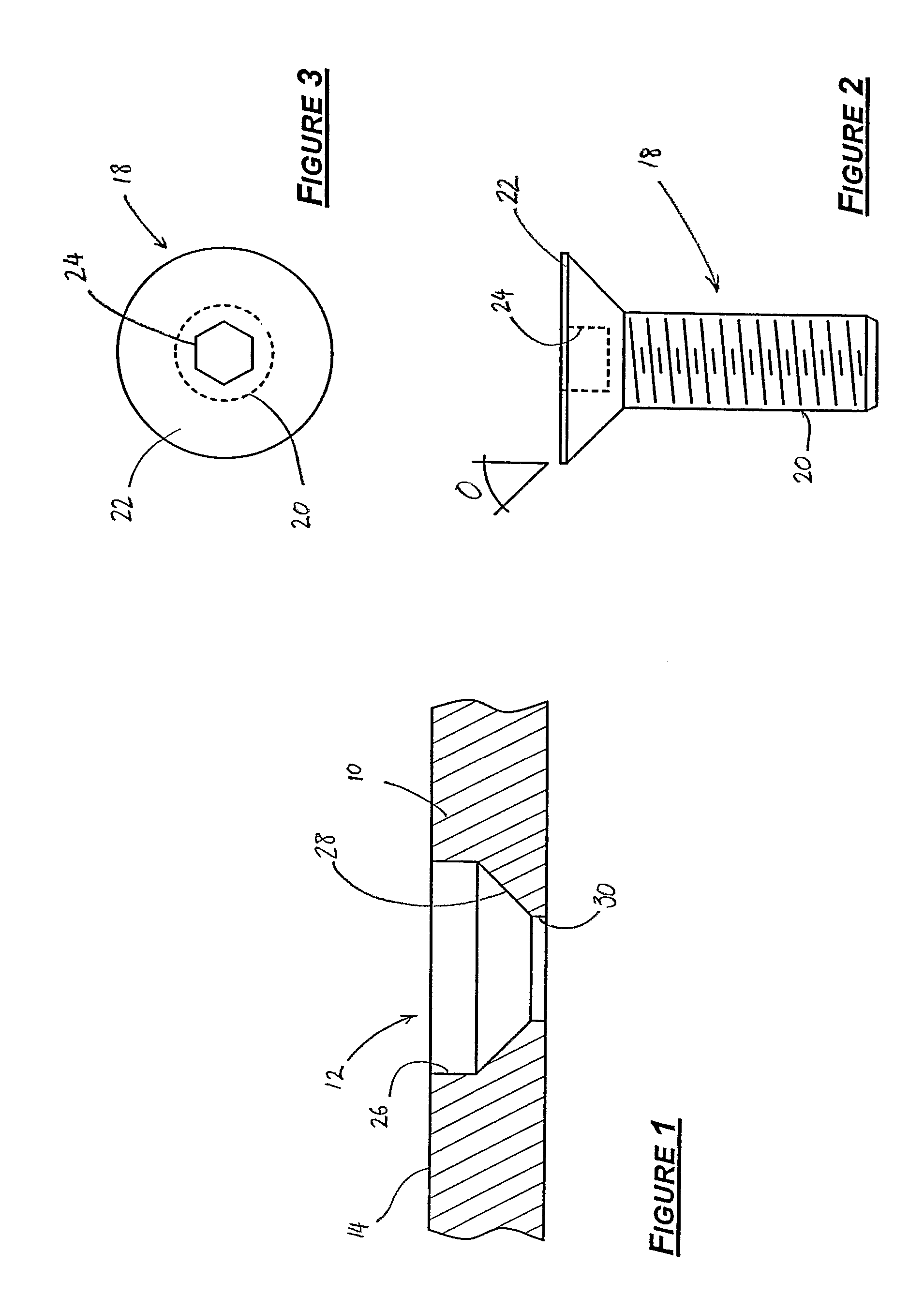

Fastener system for fixing hardened plates

A fastener system for fixing hardened plates includes a fastener element having a frusto-conical head and a threaded shaft portion, wherein a smallest outer diameter of the frusto-conical head is adjacent the threaded shaft, and a largest outer width of the shaft is smaller than a smallest diameter of the head.

Owner:METSO OUTOTEC (FINLAND) OY

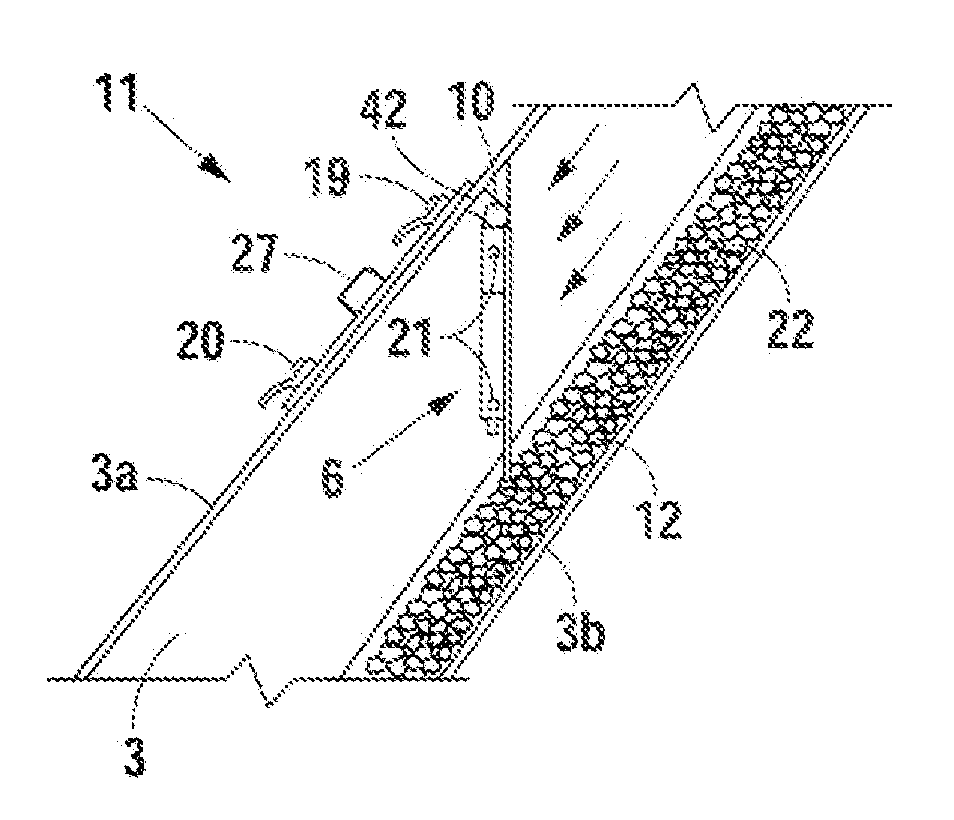

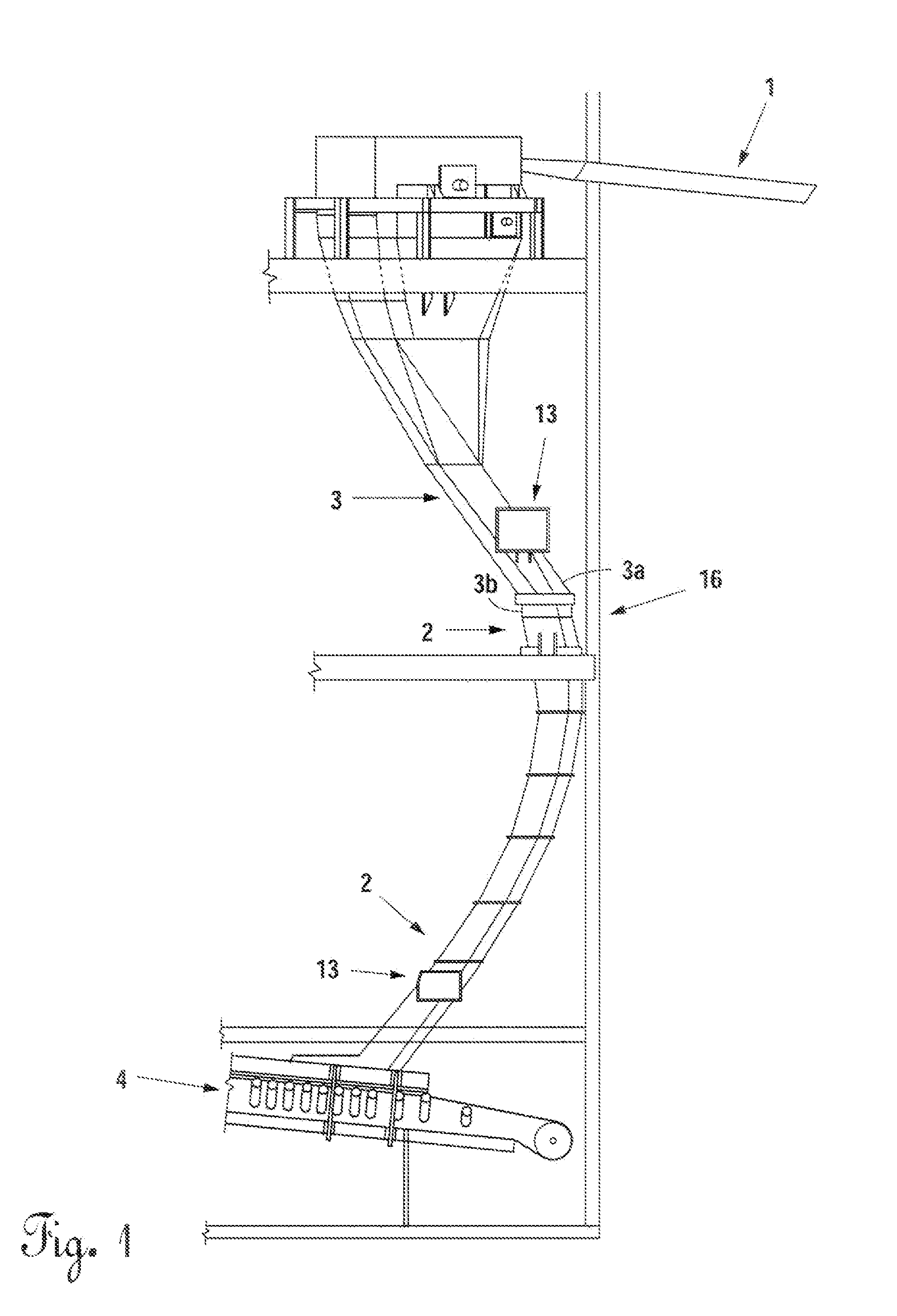

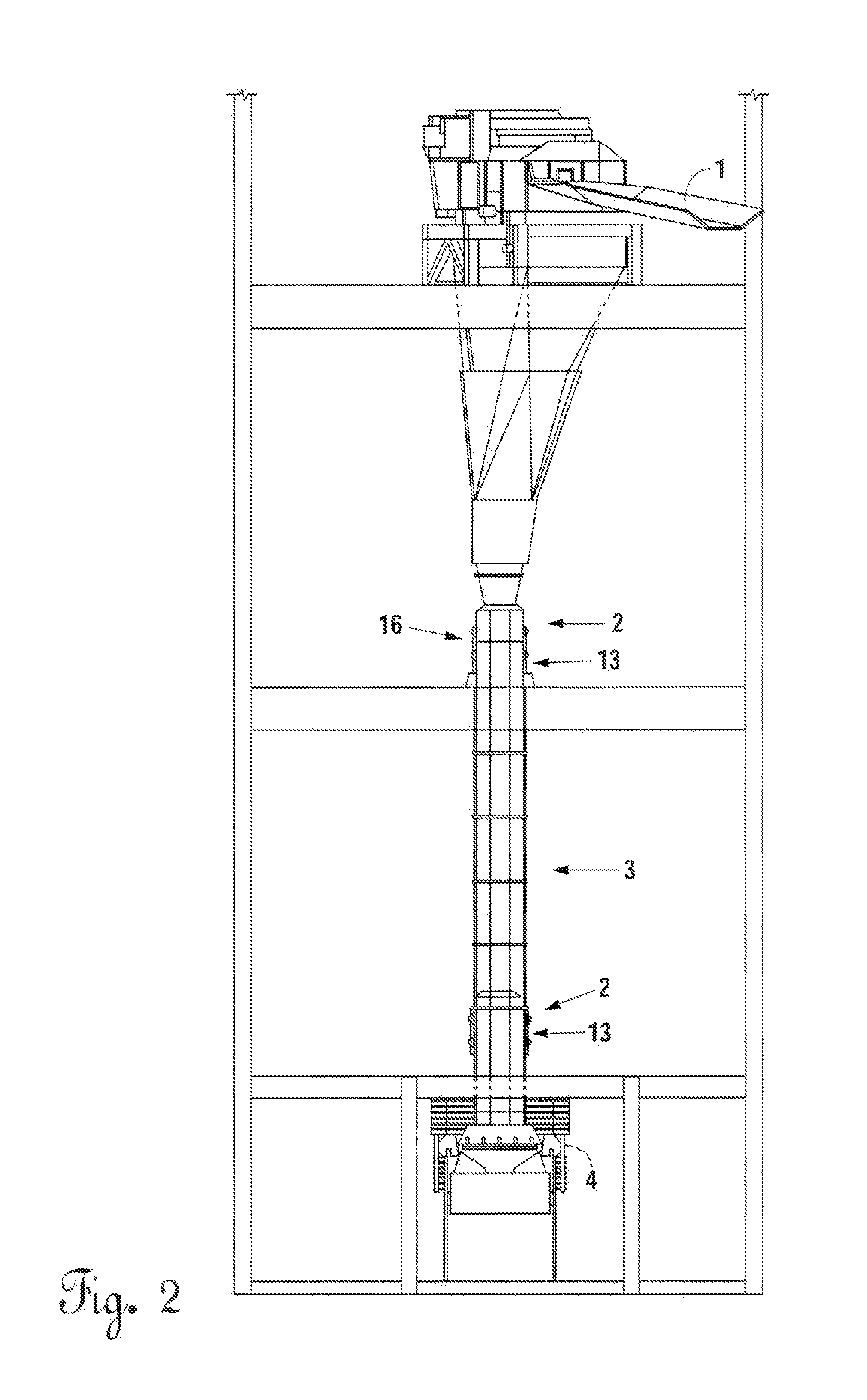

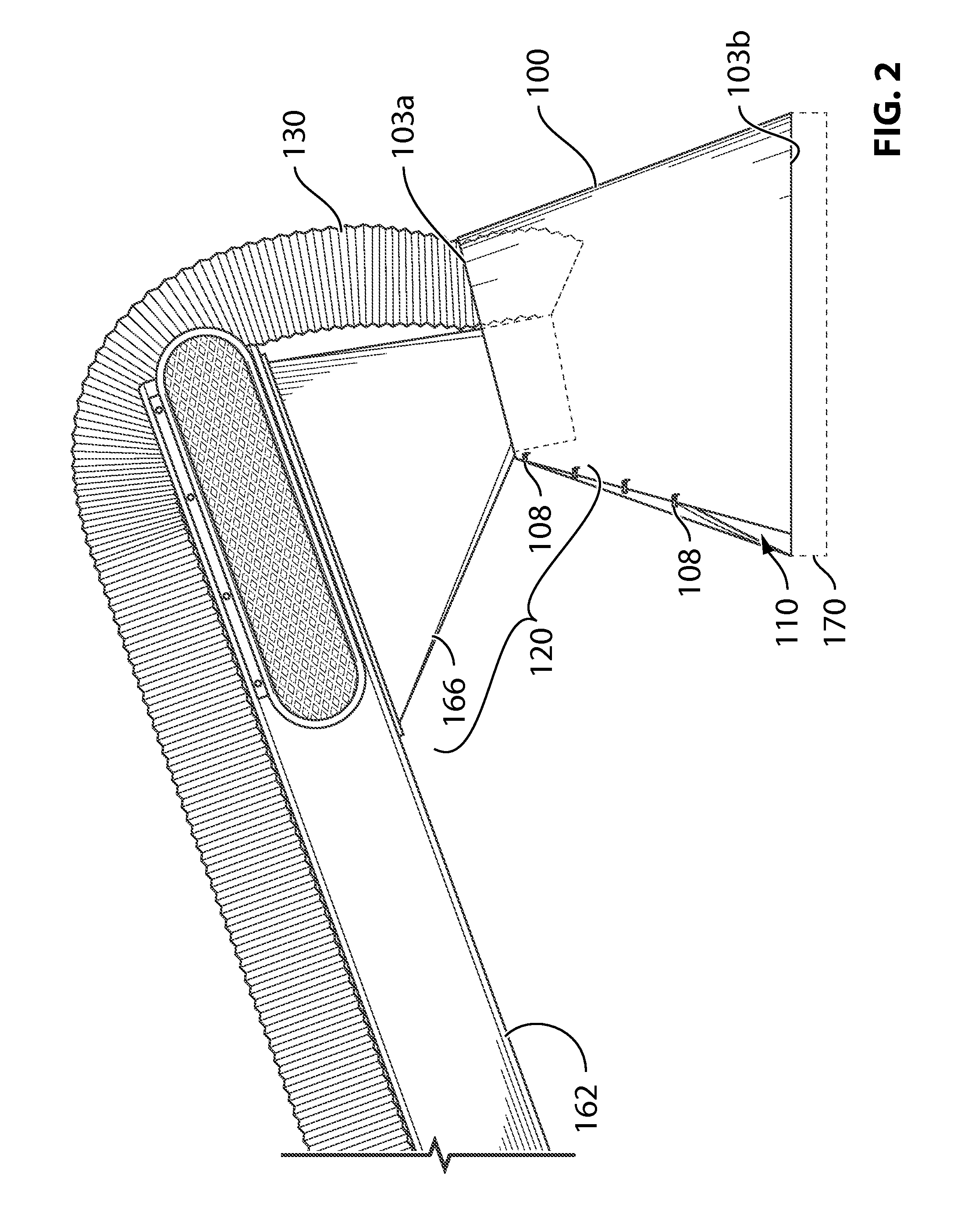

Apparatus and Method for Passive Dust Control in a Transfer Chute

InactiveUS20120090956A1Minimize air flowReduce dust emissionsLoading/unloadingConveyor partsTransfer systemDust control

A dust control apparatus and method for a bulk material handling transfer system having a chute comprising a pathway there through for handling varying volumes of bulk material flowing through the chute using gravity flow. A self-adjusting air restrictor gate is mounted in the chute for engaging the upper surface of flowing bulk material through the chute for restricting the air pathway during material volume flow variations to reduce dust emissions. The gate member contacts the upper surface of flowing bulk material and moves up and down in response to the flow of bulk material through the chute to restrict the flow of air to reduce dust. A counterweight mechanism and a damper helps maintain controlled contact of the air restrictor gate with the upper surface of bulk material flowing through the chute.

Owner:BROBST STEVEN HAYS

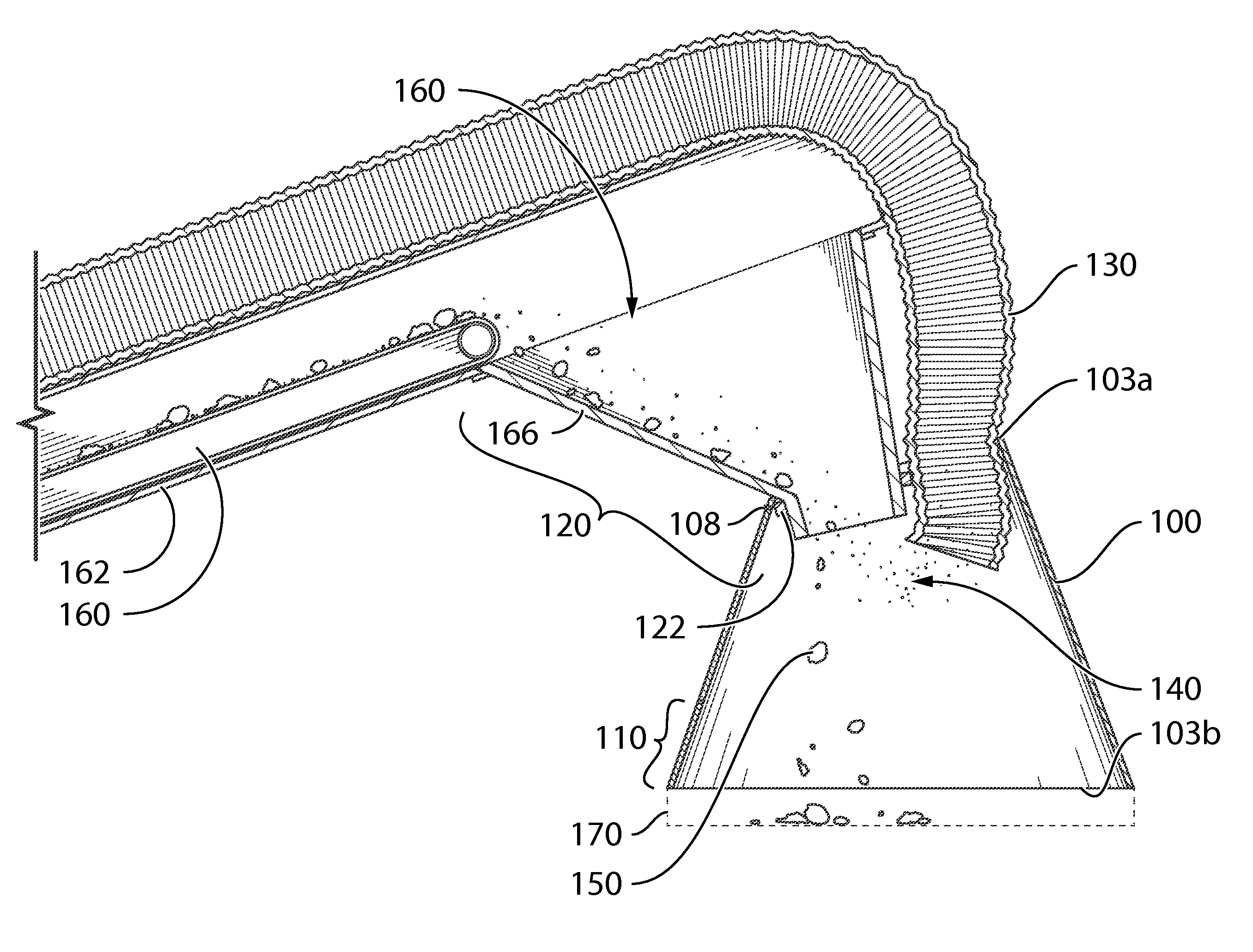

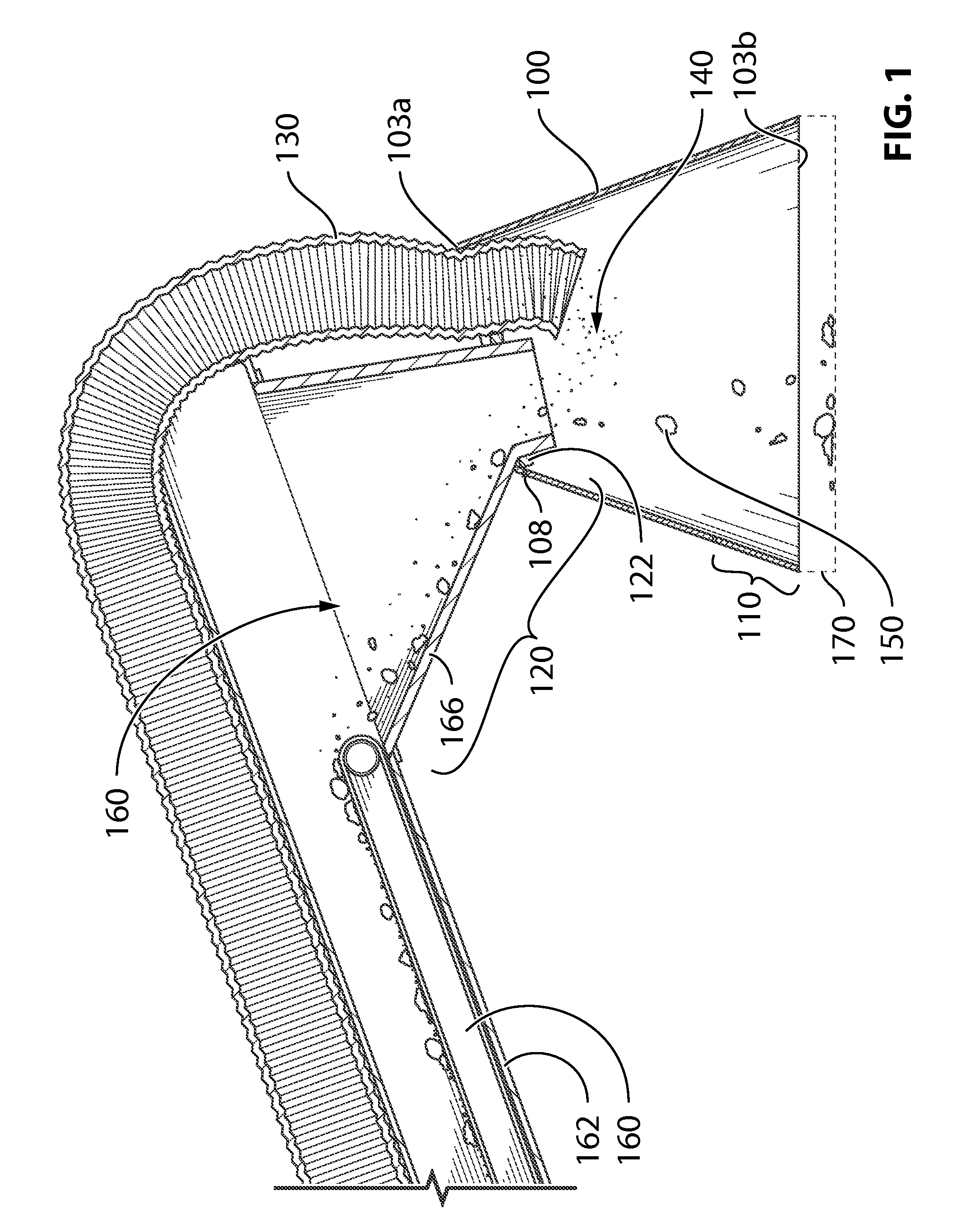

Nose Cone for Dust Control

Preferred nose cones 100 associatable with a tail spout 120 of a sand handler and a vacuum hose 130 of a vacuum system are described herein. A method for containing respirable and / or inhalable particles 140 created in an industrial process is also disclosed herein.

Owner:ASSOC RES - EDC

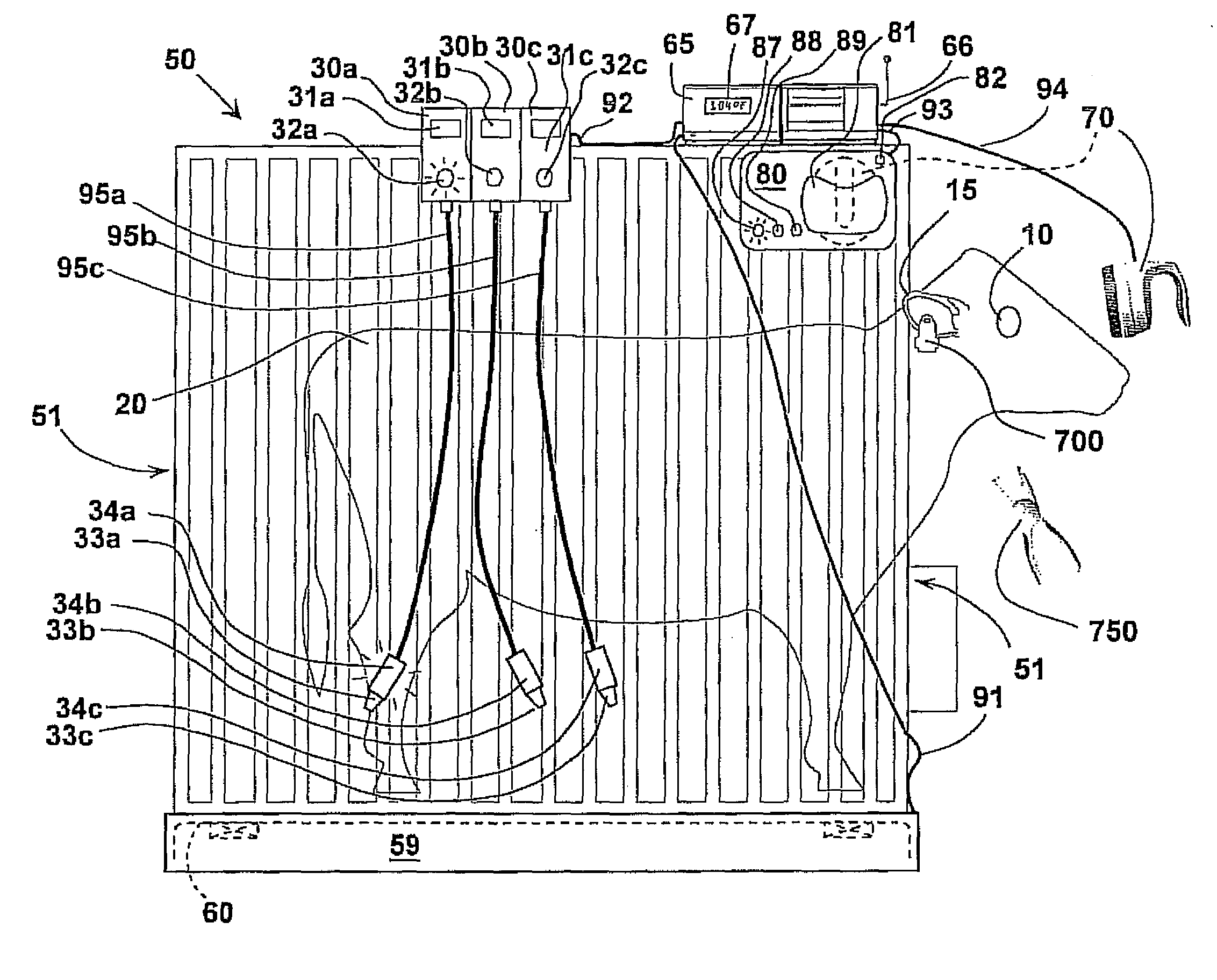

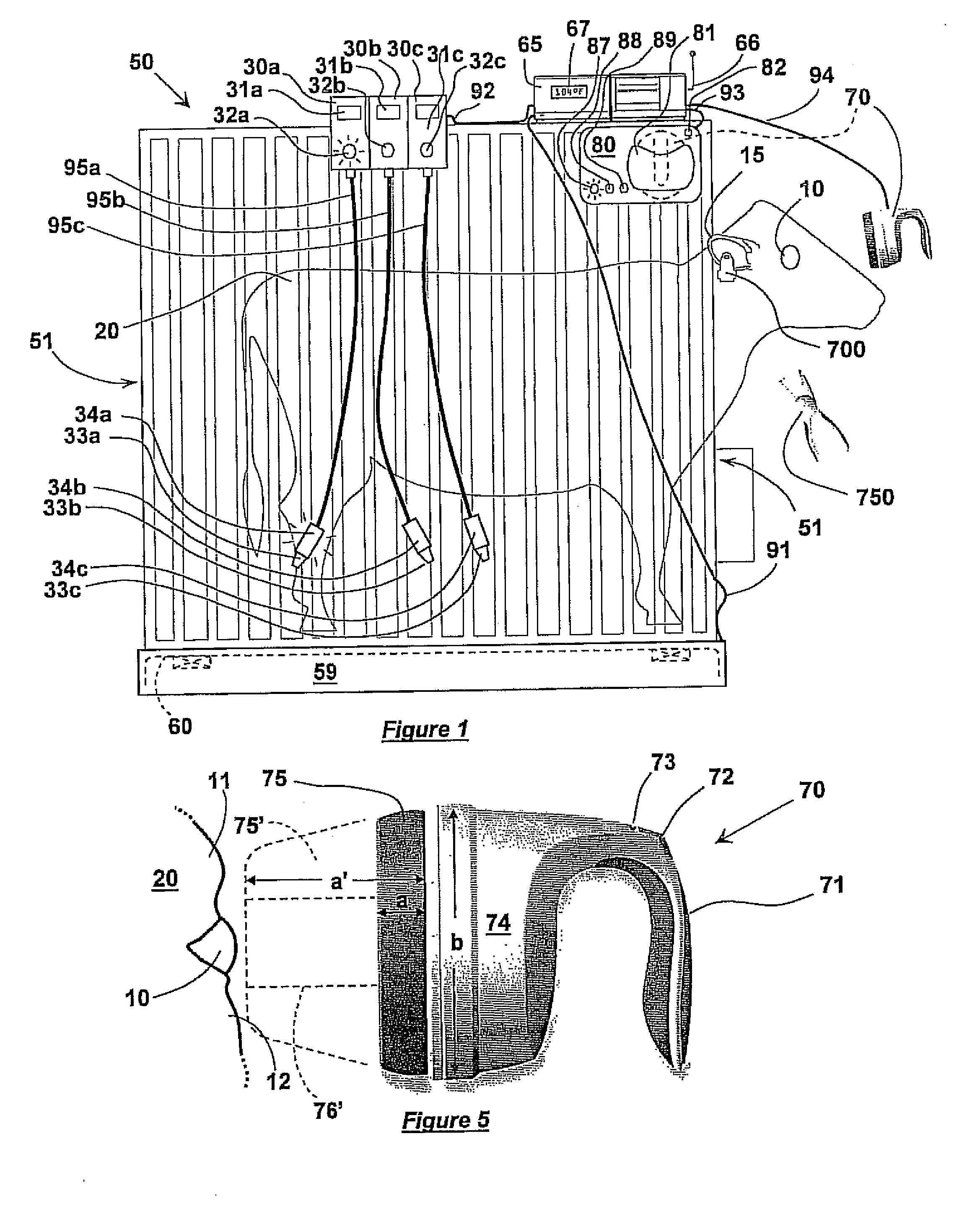

Core-Temperature Based Herd Management System and Method

InactiveUS20100160809A1Increase profitabilityLow costMedical devicesPharmaceutical delivery mechanismCore temperatureHerd management

A system and method for managing a herd of animals possibly requiring medical treatment, such as cows in a feedlot. The animals are herded individually into a chute, where identification data is collected from a tag, and core temperature data is collected using a special non-contacting core temperature sensor. The animal is tagged with a color coded tag representing a range of temperatures into which that animal's temperature falls. The animal is then delivered to a pen corresponding to that range of temperatures, where appropriate medicinal treatment is automatically dosed and applied to the animal.

Owner:HERDX

Mailbox

ActiveUS7320427B2Easy to depositEasy extractionKitchen equipmentDomestic articlesEngineeringCombination Package

The present invention is a security mailbox utilizing a combination package rest and security panel. A mail slot in the security panel prevents easy access to contents of the mailbox. The present invention may be utilized in situations other than mail delivery where security for contents is desired.

Owner:PRESTWICH MATTHEW C

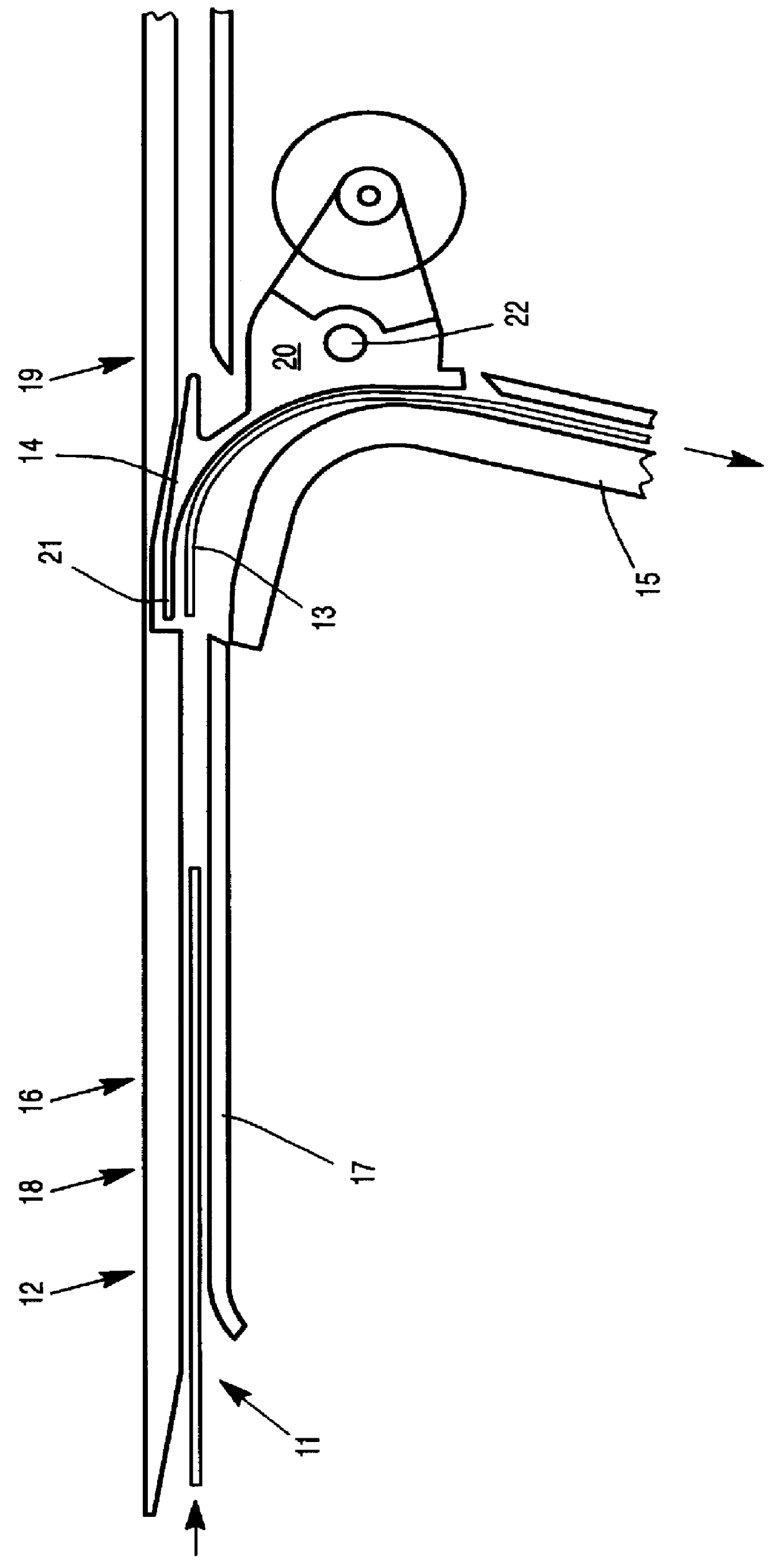

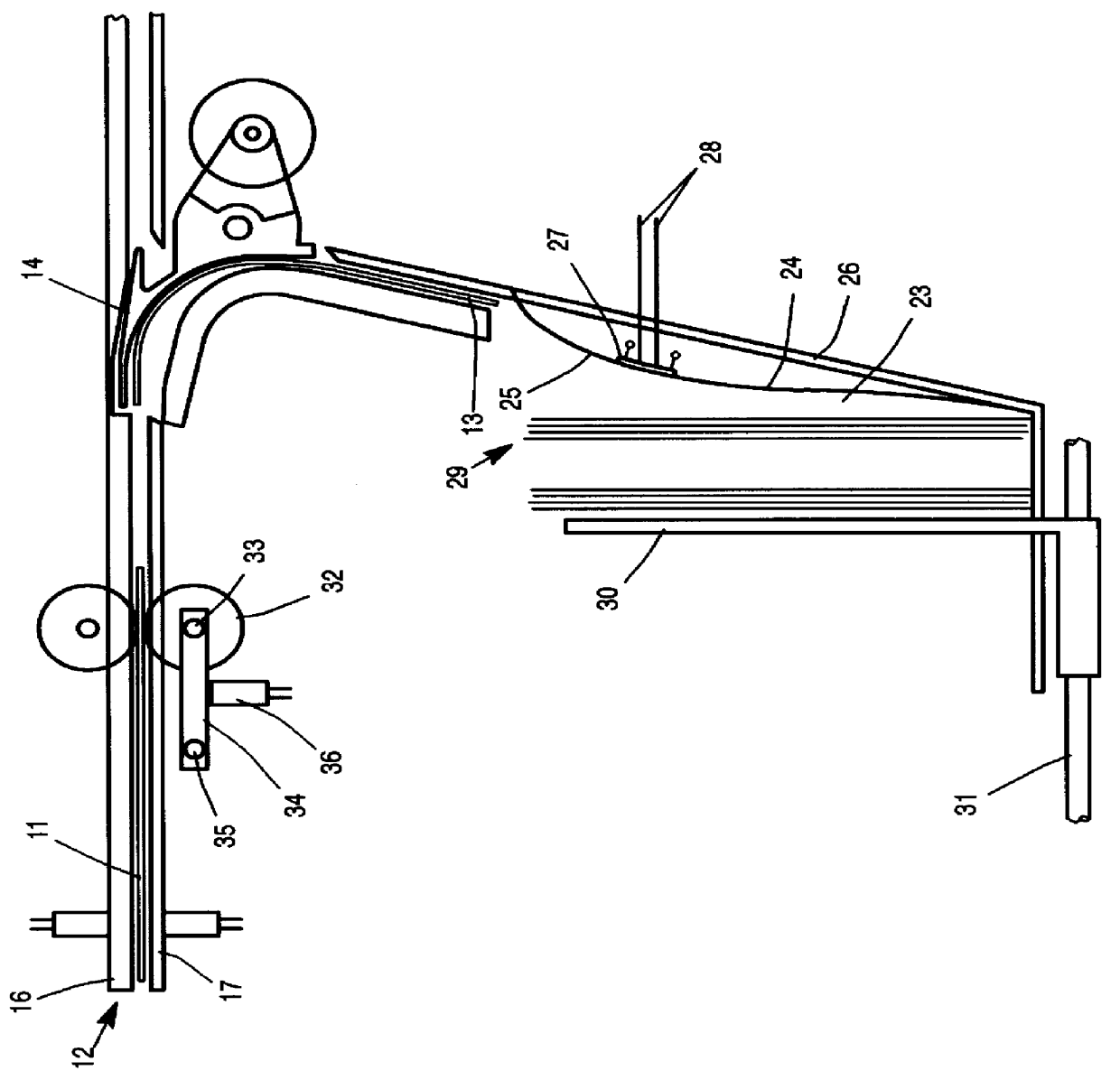

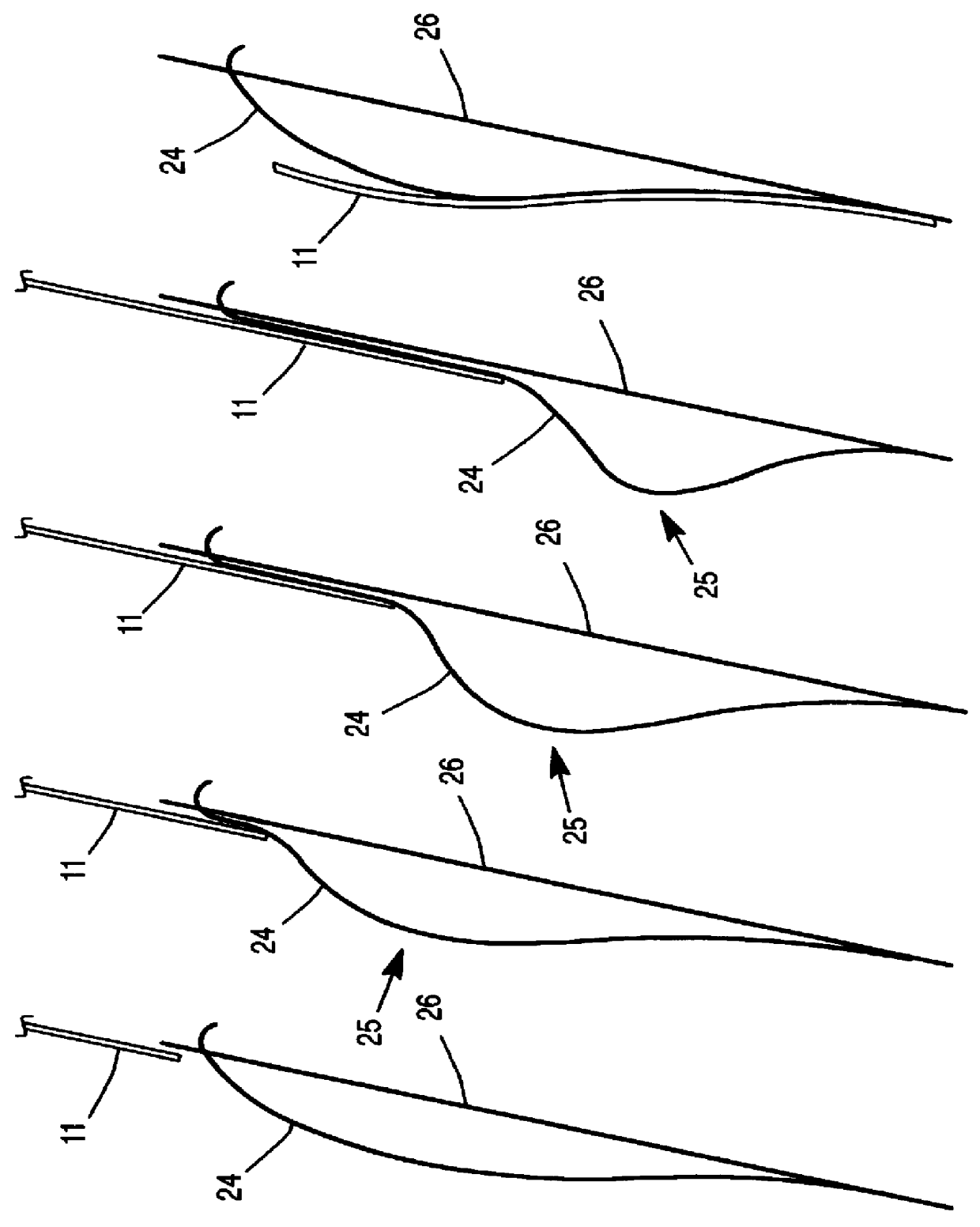

Apparatus and method of automatically adjusting a document deceleration rate

InactiveUS6065746AEnhance simple reliable selective decelerationQuickly and reliably selectively stopFunction indicatorsArticle feedersEngineeringPaper document

Apparatus and method for automatically adjusting a rate at which a document decelerates when entering a sort pocket of a document processing machine. The apparatus includes a track adapted for transporting the document, a guide wall, and a stacker flag spaced away from the guide wall to define the sort pocket therebetween. The sort pocket communicates with the track so that the document exits the track to enter the sort pocket. A wave spring is disposed proximate the guide wall so that the document engages the wave spring and is decelerated by the wave spring when the document enters the sort pocket. The weight of the document is calculated, and a signal is produced that represents the weight of the document. The wave spring is distorted according to this signal to vary a configuration of the wave spring depending on the weight of the document to decelerate the document at an optimal rate.

Owner:BURROUGHS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com