Patents

Literature

49results about How to "Reduce dust emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-absorbing agent and its production process

ActiveUS20060247351A1Less water-soluble component contentImprove water retentionSynthetic resin layered productsCellulosic plastic layered productsAluminium sulfateCross-link

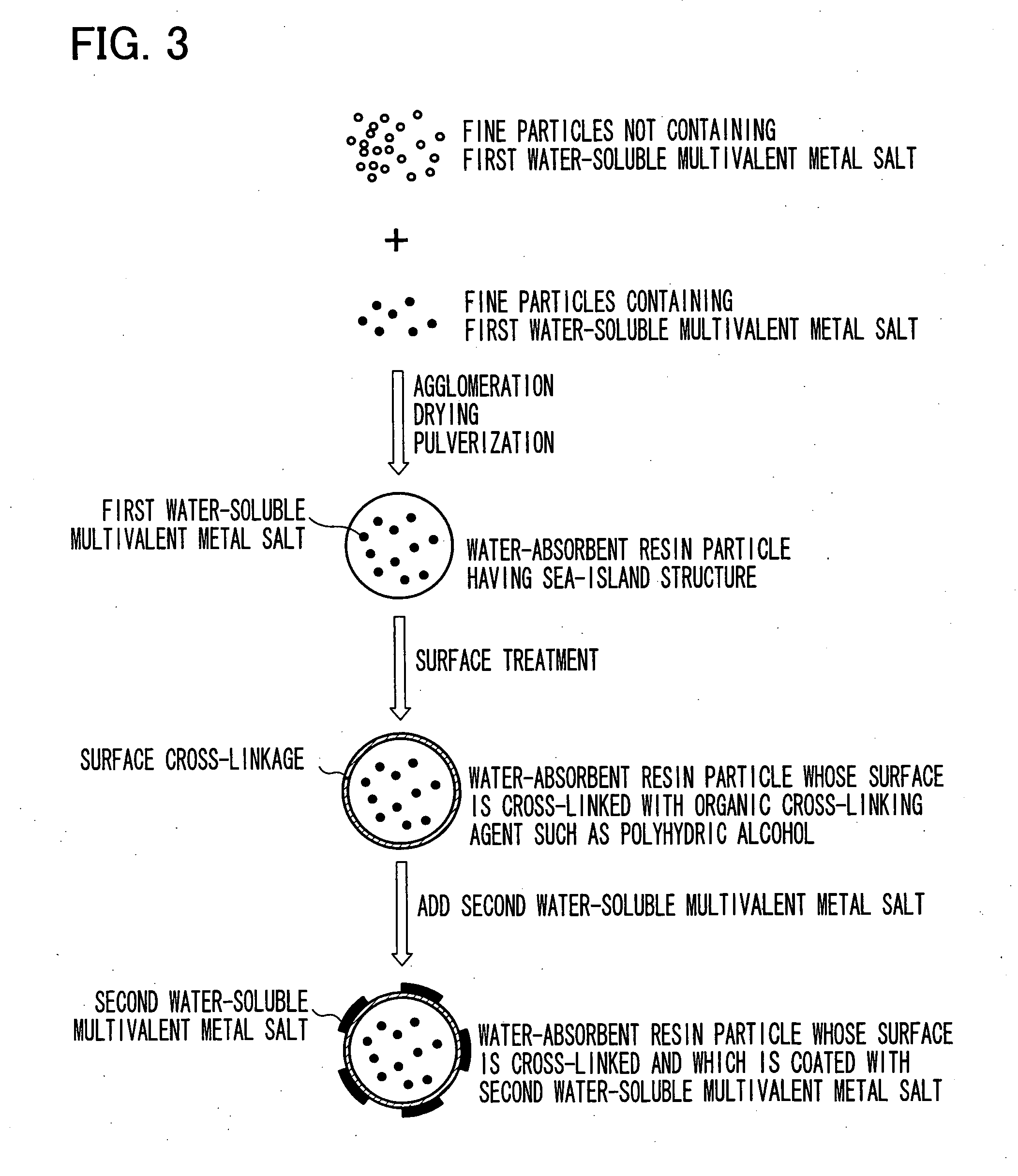

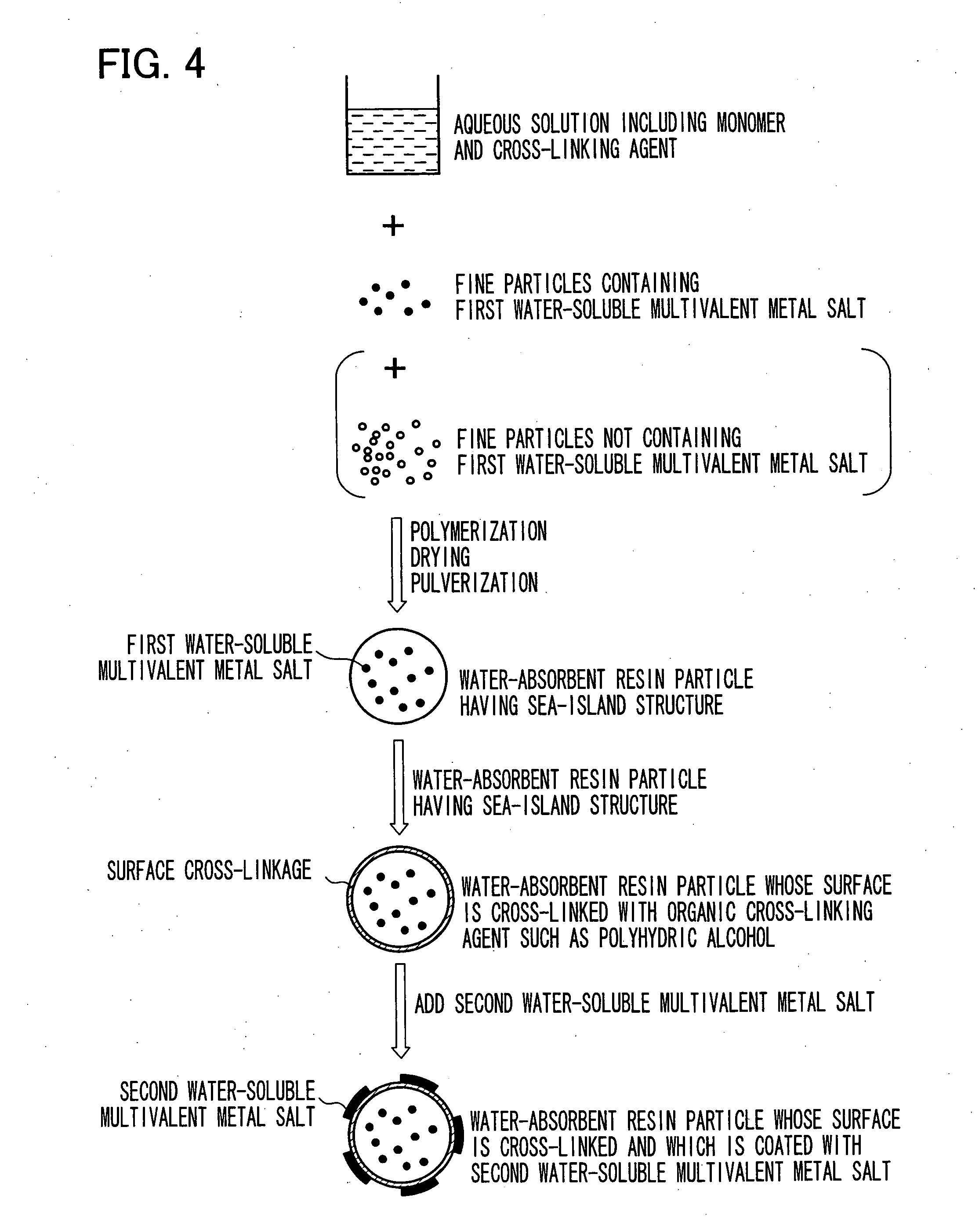

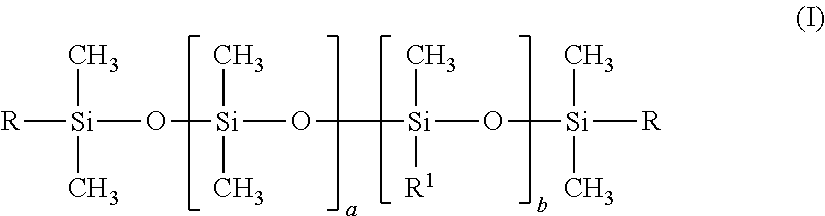

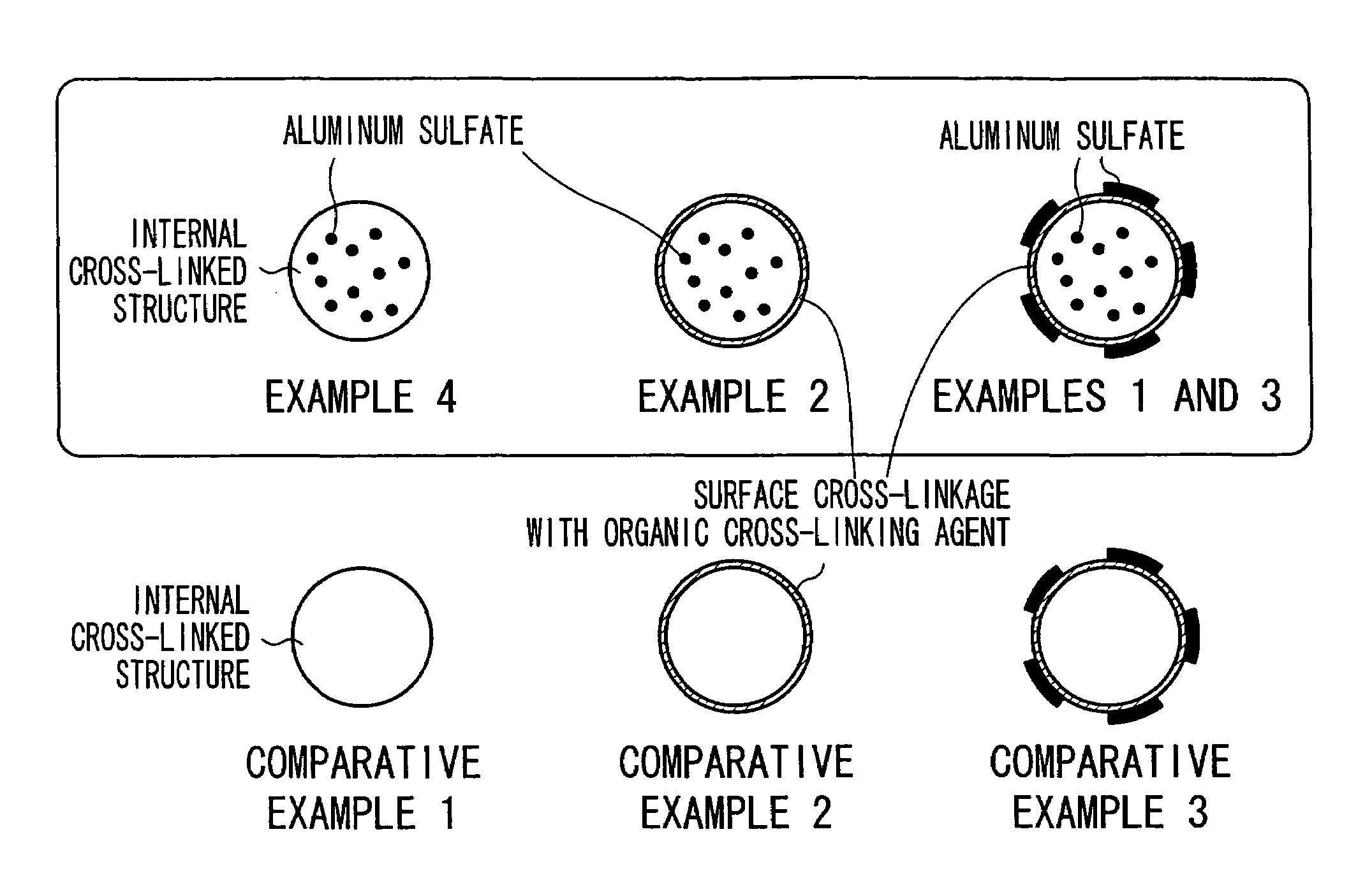

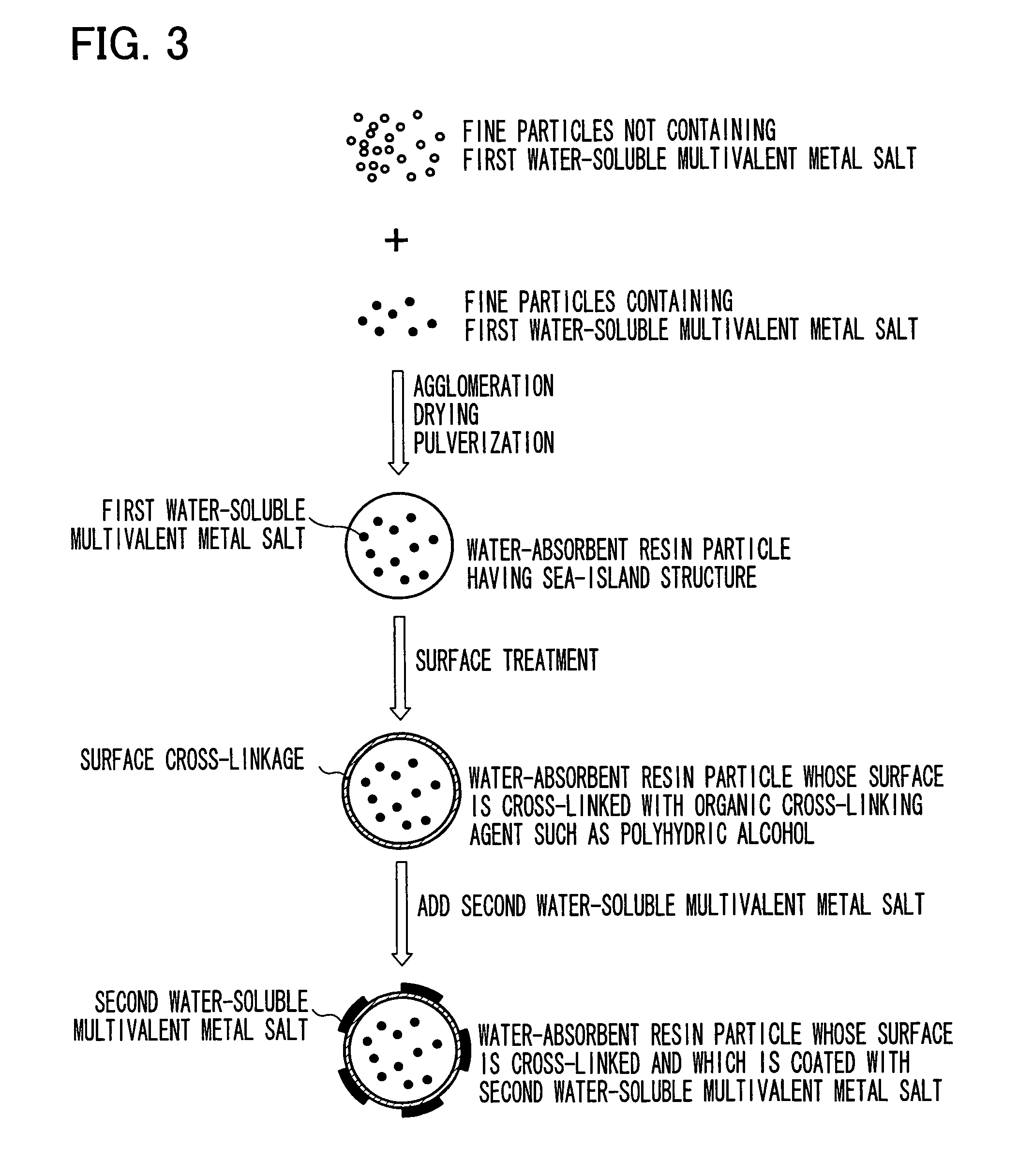

A water-absorbing agent according to the present invention includes water-absorbent resin particles having an internal cross-linked structure,.wherein a vicinity of a surface of the water-absorbent resin particle is cross-linked with a surface cross-linking agent, and the water-absorbent resin particle has therein a sea-island structure having (i) part containing a first water-soluble multivalent metal salt such as aluminum sulfate and (ii) part not containing the first water-soluble multivalent metal salt. With this arrangement, it is possible to provide a water-absorbing agent having less water-soluble component content, more excellent liquid permeability, and more excellent water retention under pressure than the conventional water-absorbing agent.

Owner:NIPPON SHOKUBAI CO LTD

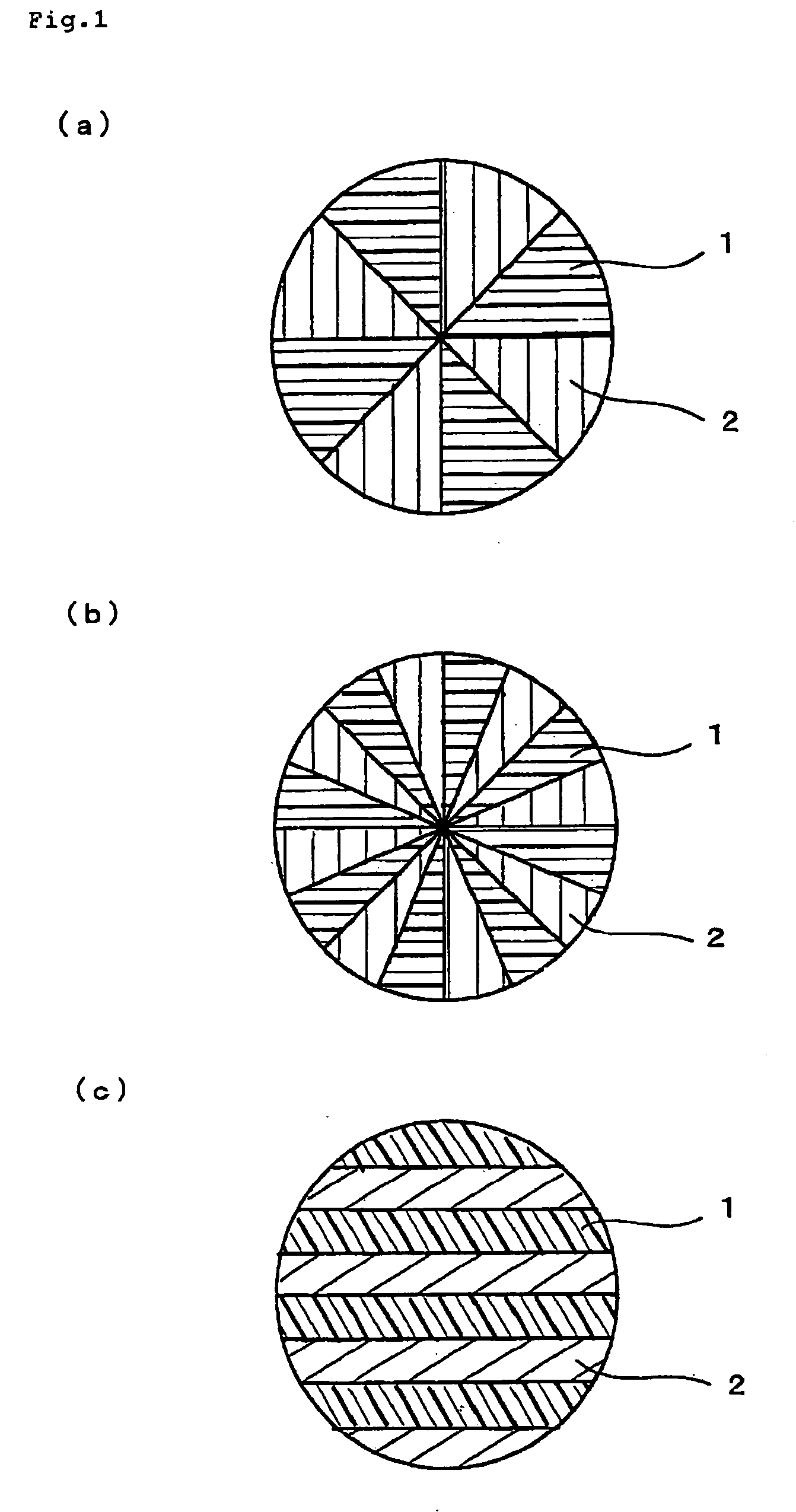

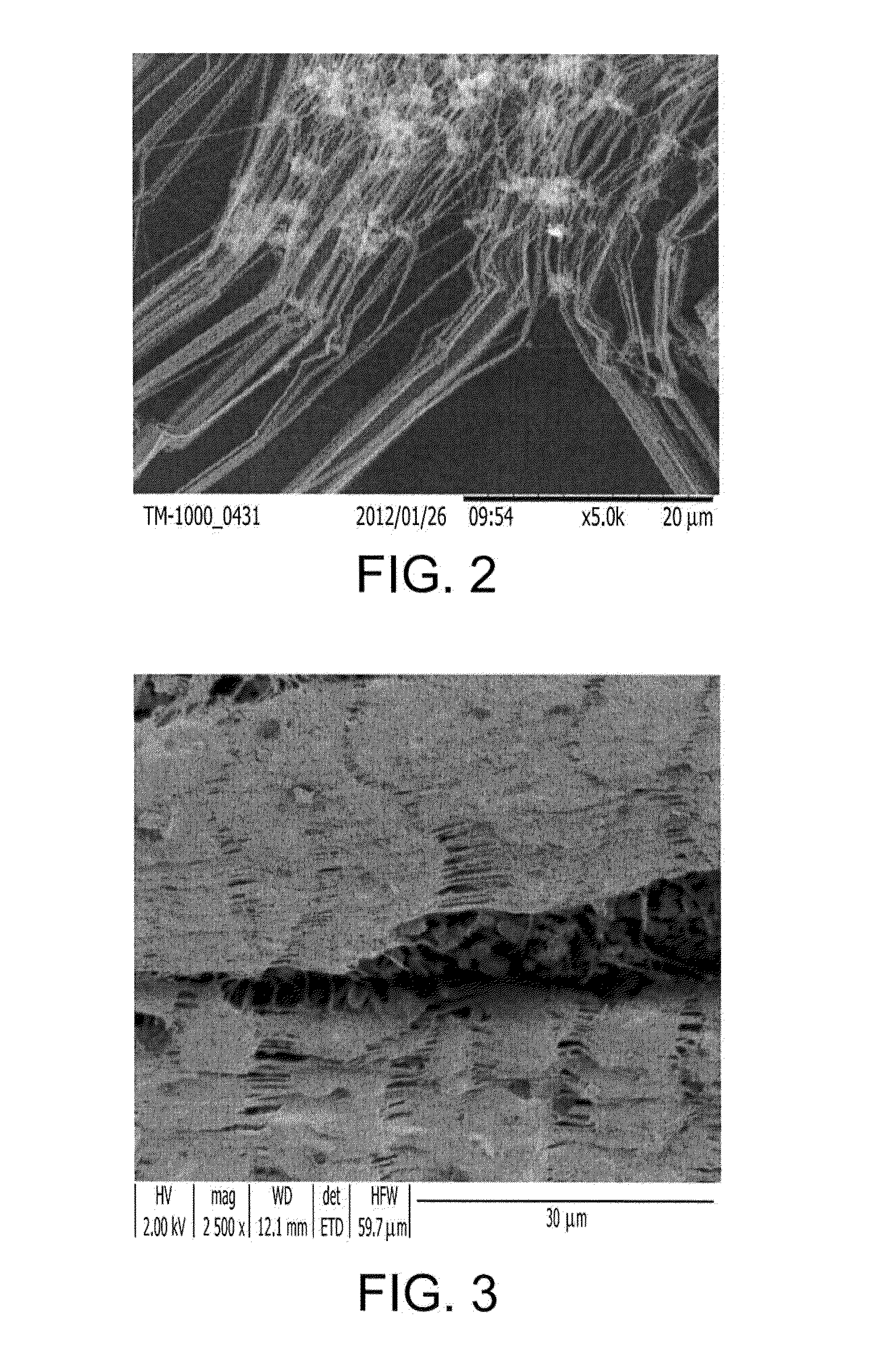

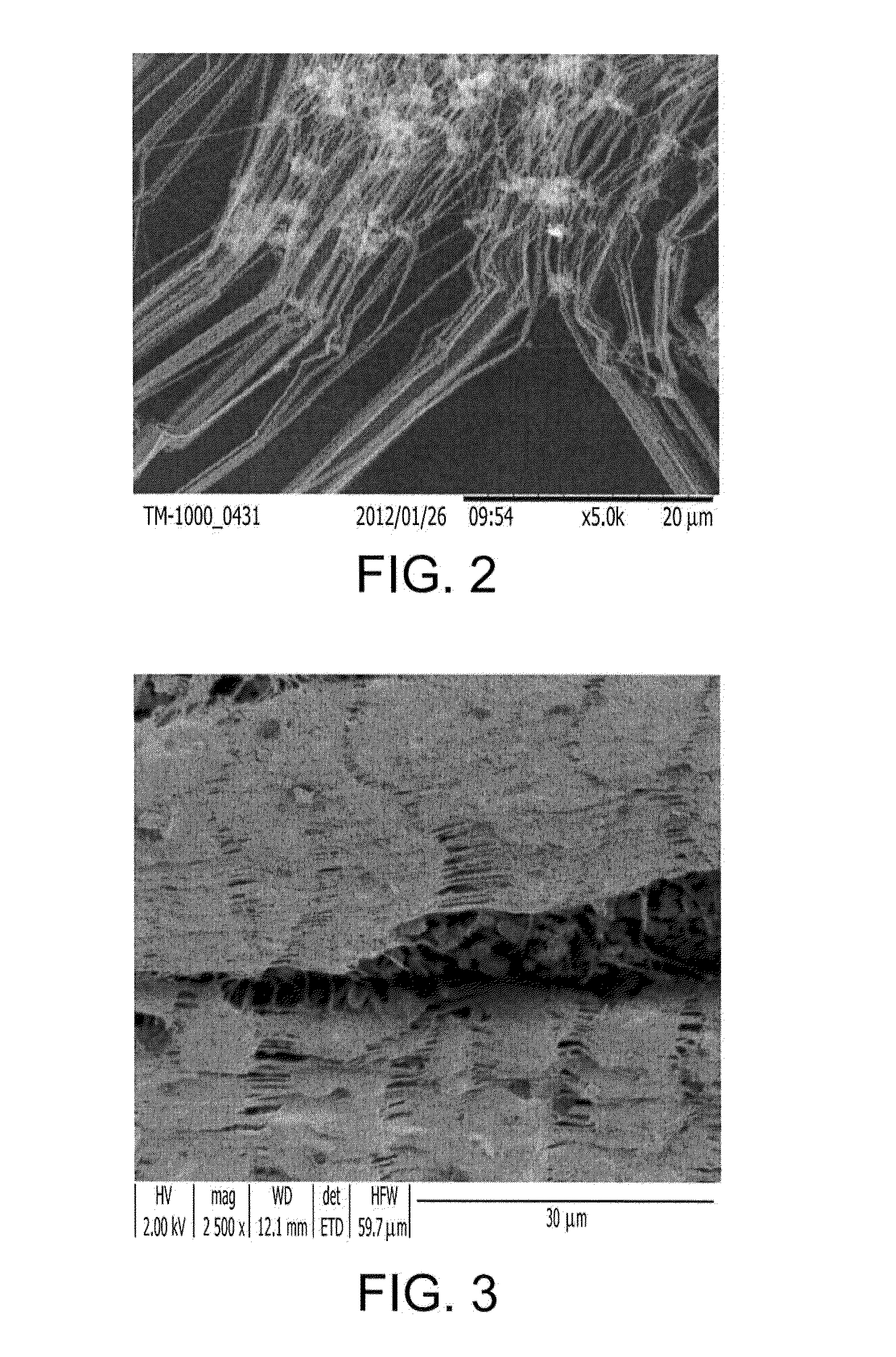

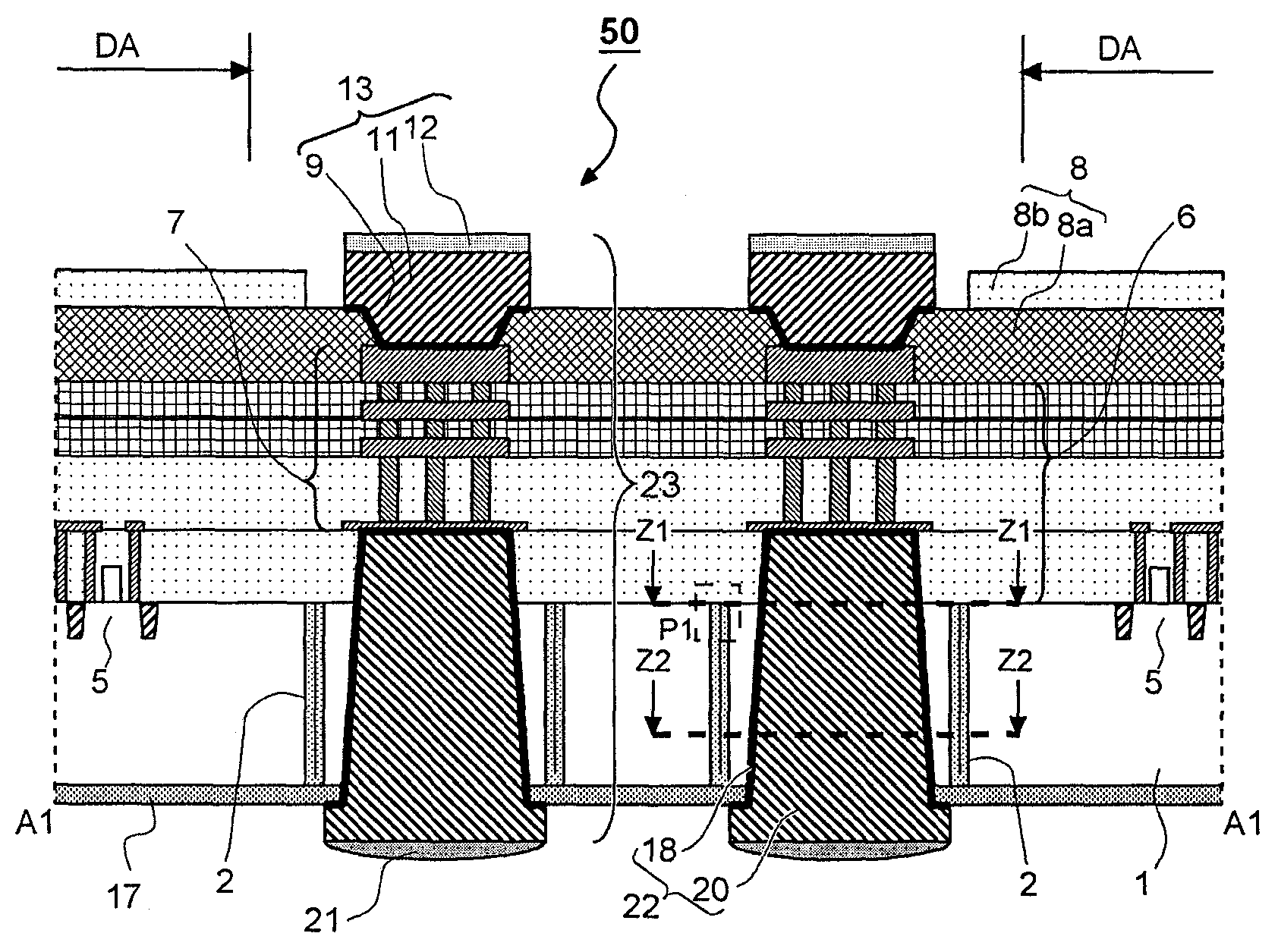

Wiping sheet

InactiveUS20060009106A1Improve wiping effectPromote stratificationCarpet cleanersFloor cleanersNonwoven fabricFiber structure

A wiping sheet is provided, which presents excellent in handling during wiping, high wiping ability for greasy dirt, and less liquid remains on an object after wiping. A wiping sheet having a fiber structure (such as a woven fabric, a knitted fabric and a nonwoven) is obtained, which includes an ultrafine fiber layer containing ultrafine fibers having a fineness of at most 0.9 dtex which result from at least two types of ultrafine fiber-generating conjugate fibers, at least one conjugate fiber giving ultrafine fibers containing a modified vinyl alcohol resin, and the other conjugate fibers giving ultrafine fibers containing another resin(s). The ultrafine fibers can be obtained by a first splittable conjugate fiber including a component containing the modified vinyl alcohol resin and a second splittable conjugate fiber composed of components of other resins. In the ultrafine fiber layer, the fibers are preferably bonded by thermoadhesive resin-containing ultrafine fibers.

Owner:DAIWABO HLDG +1

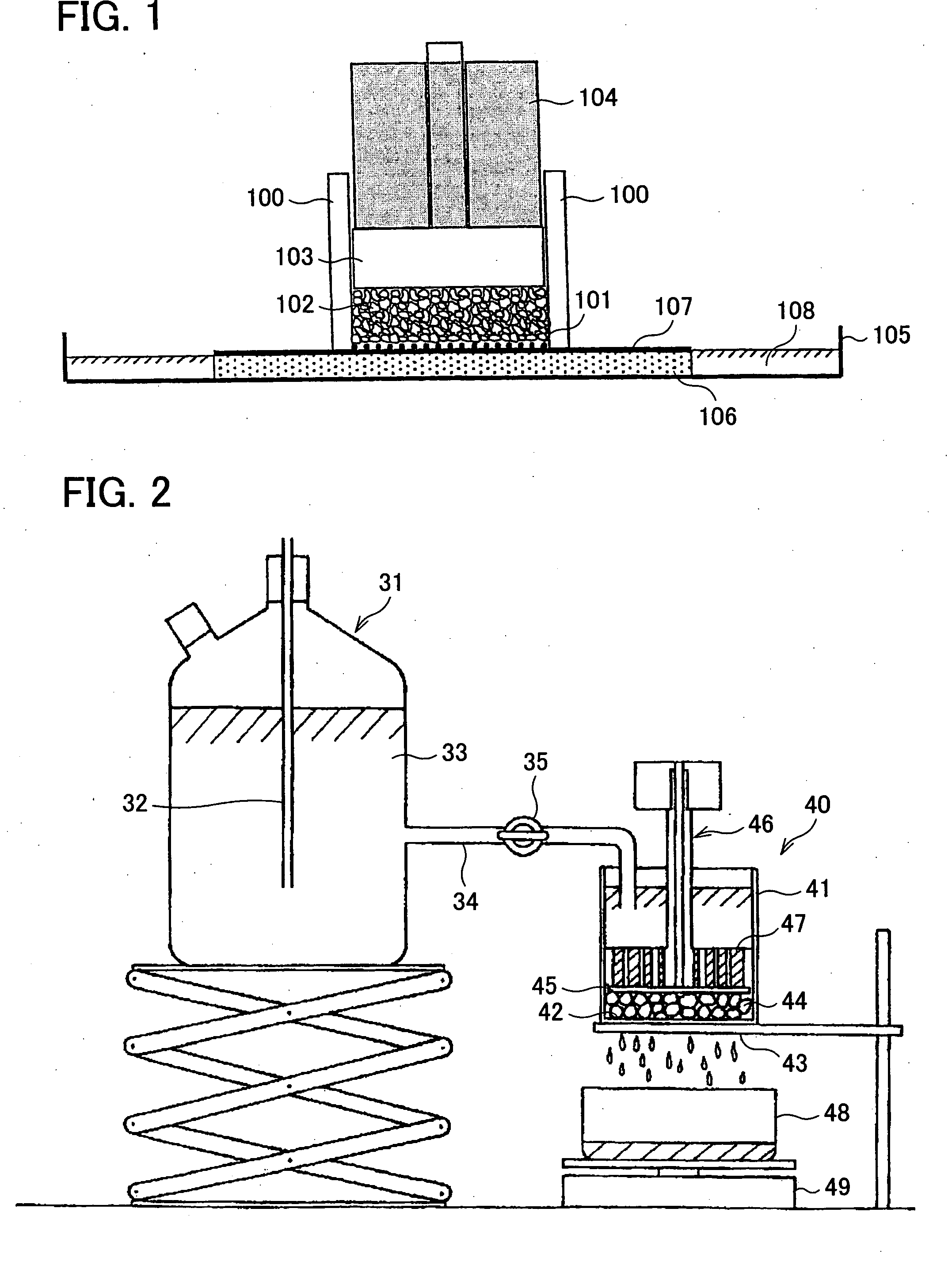

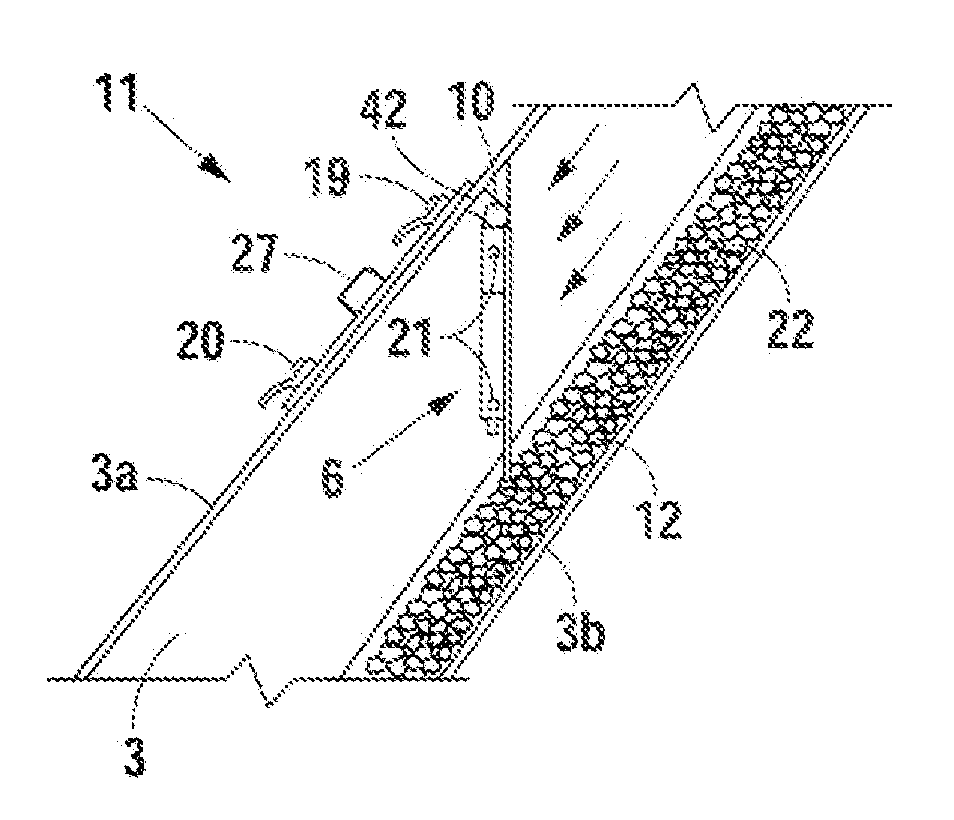

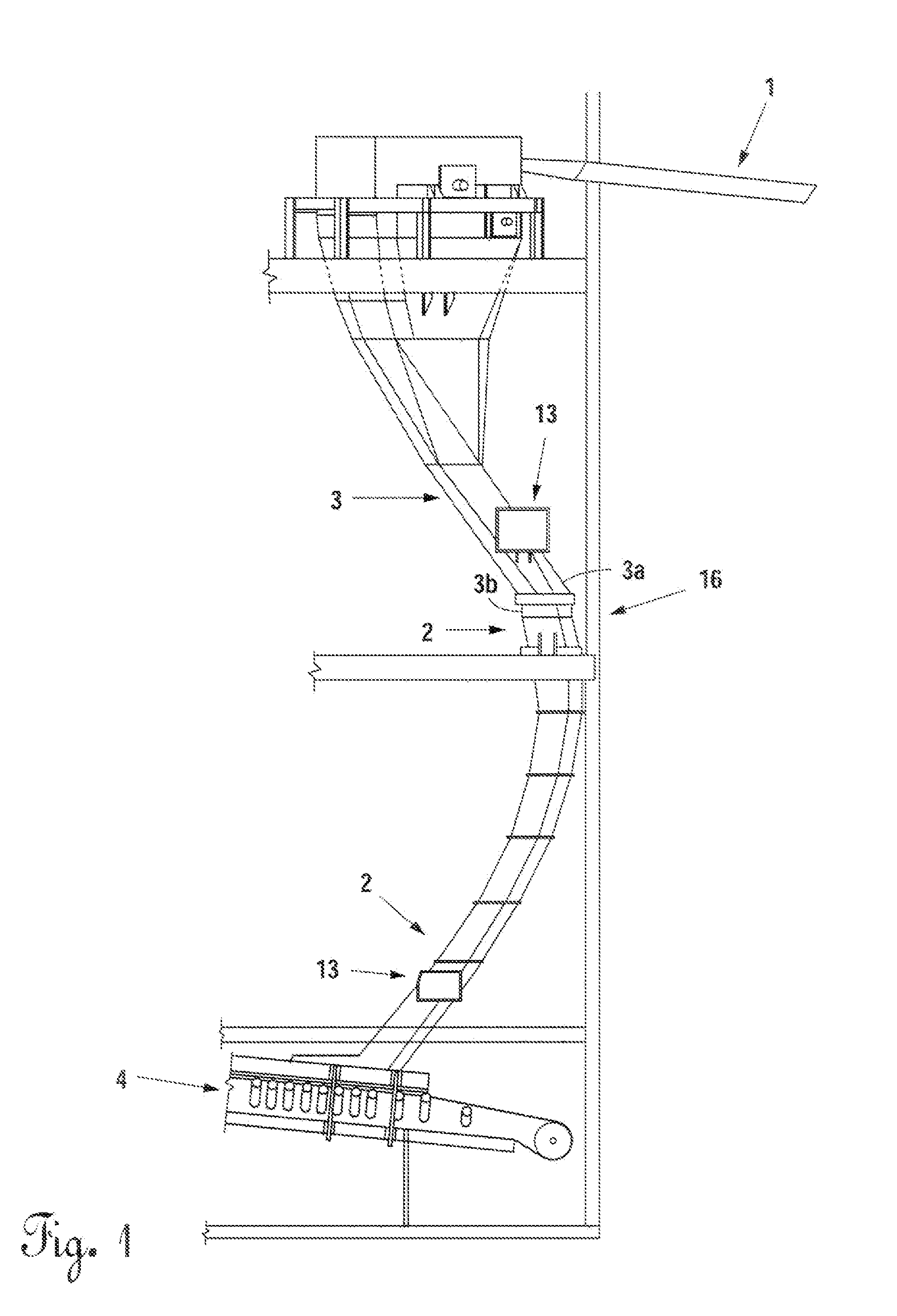

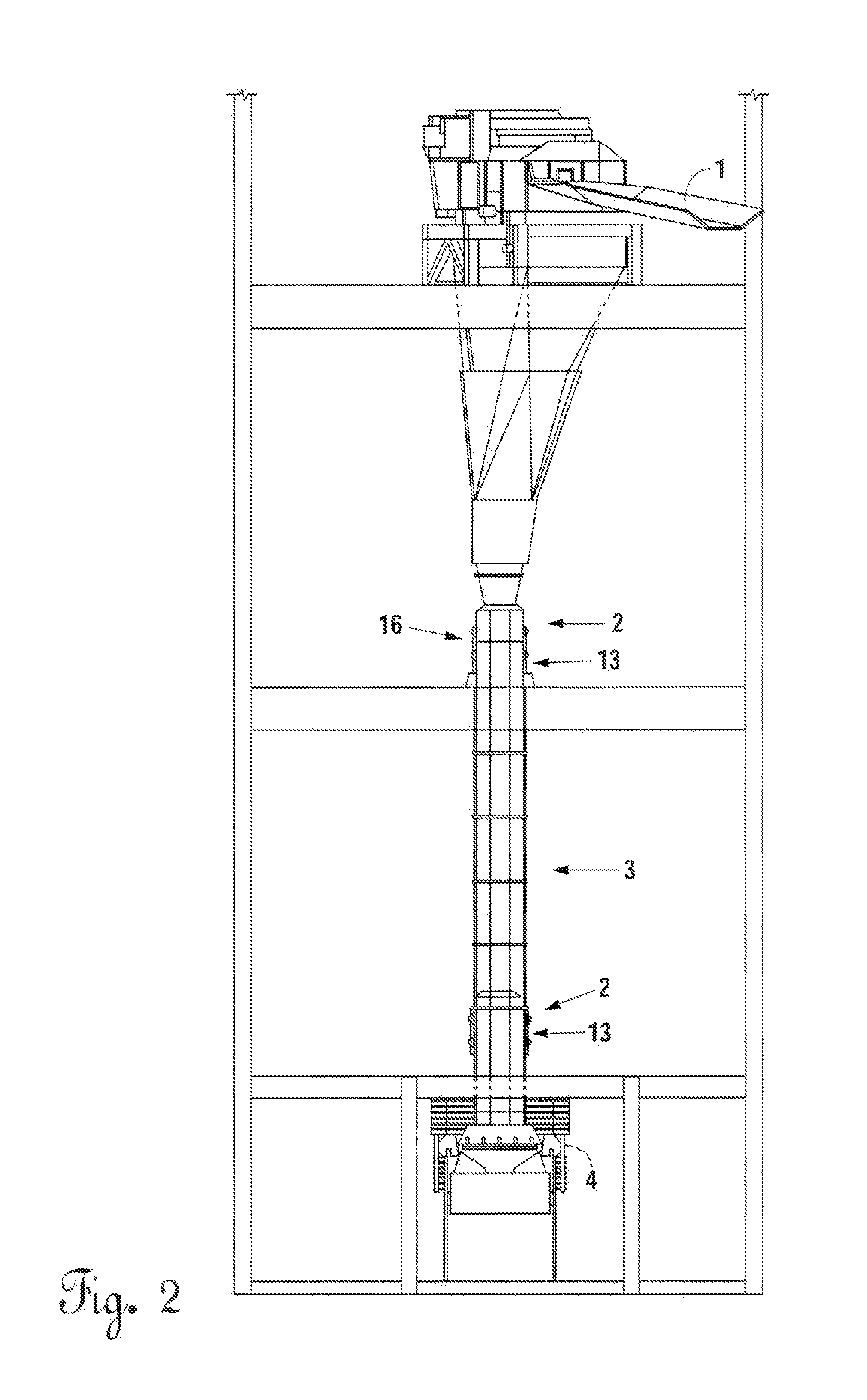

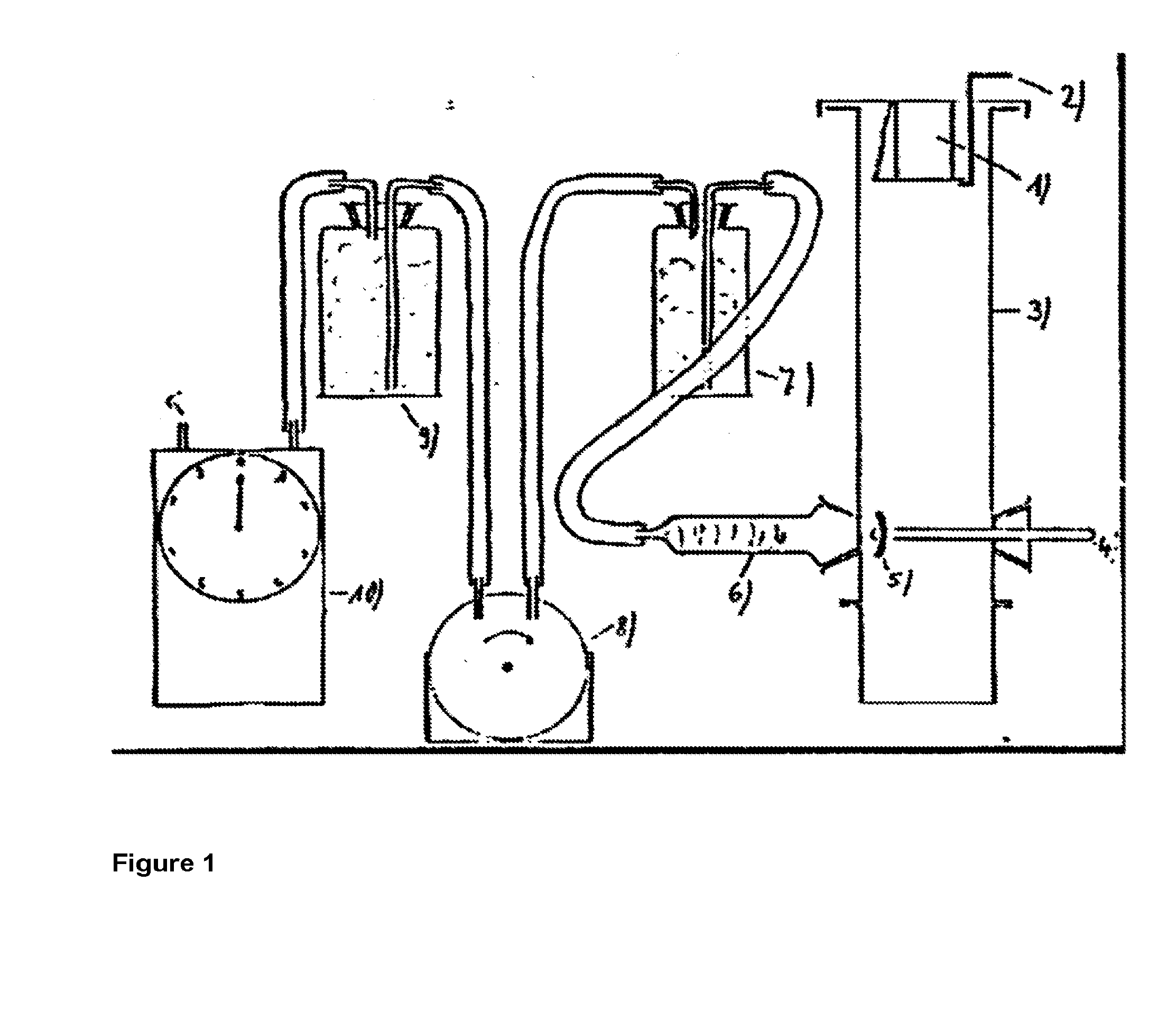

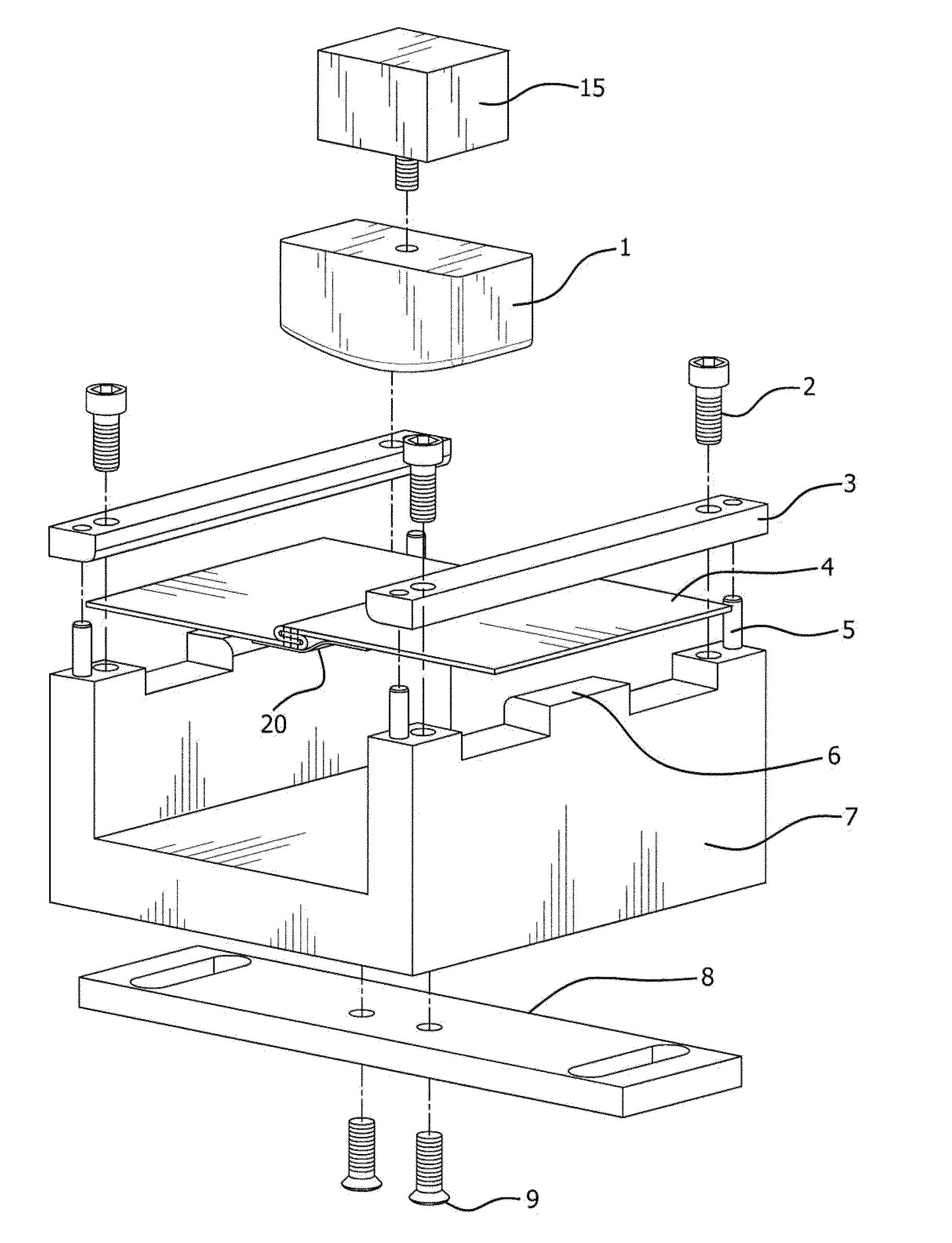

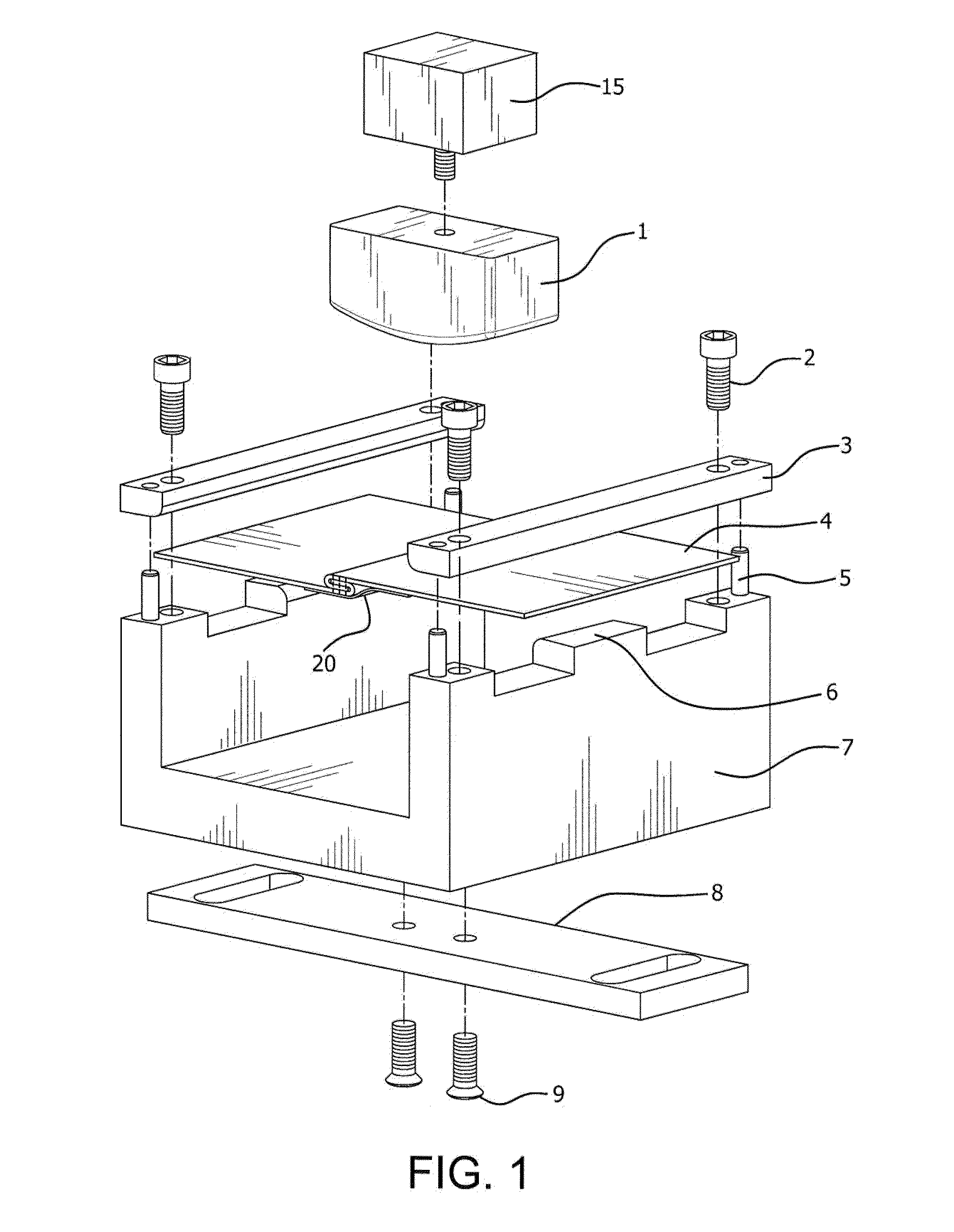

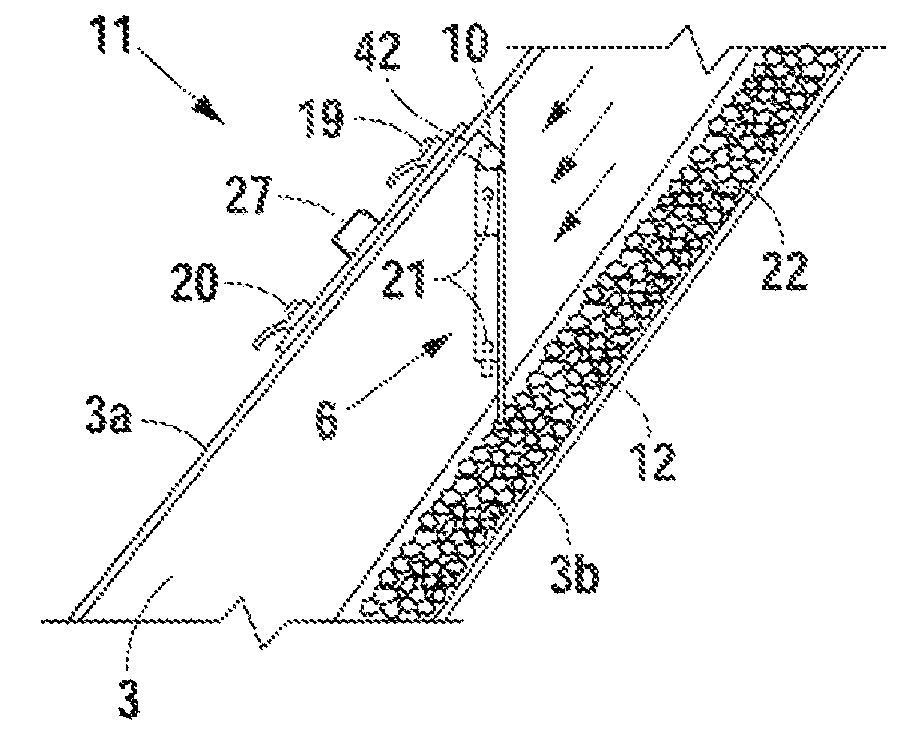

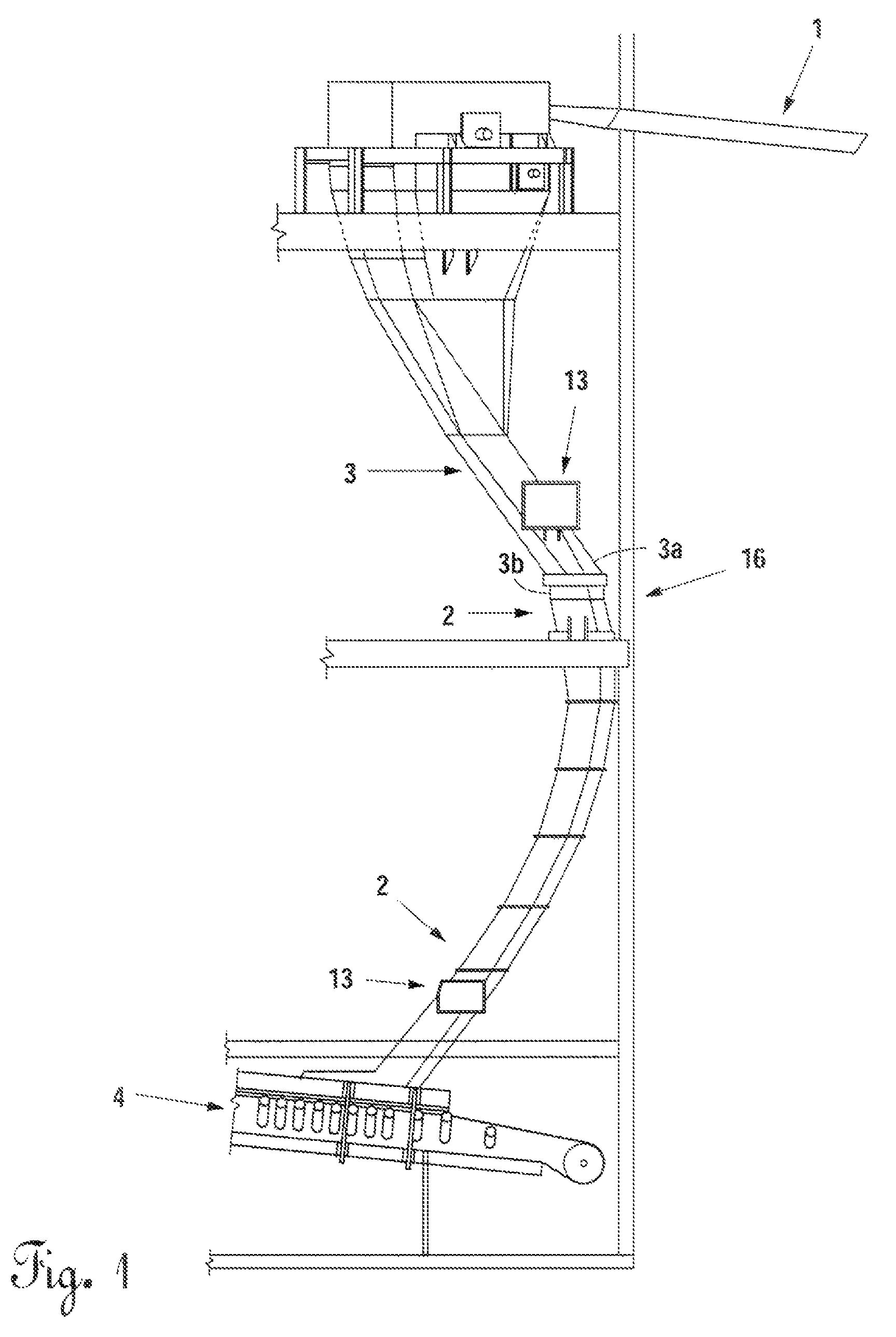

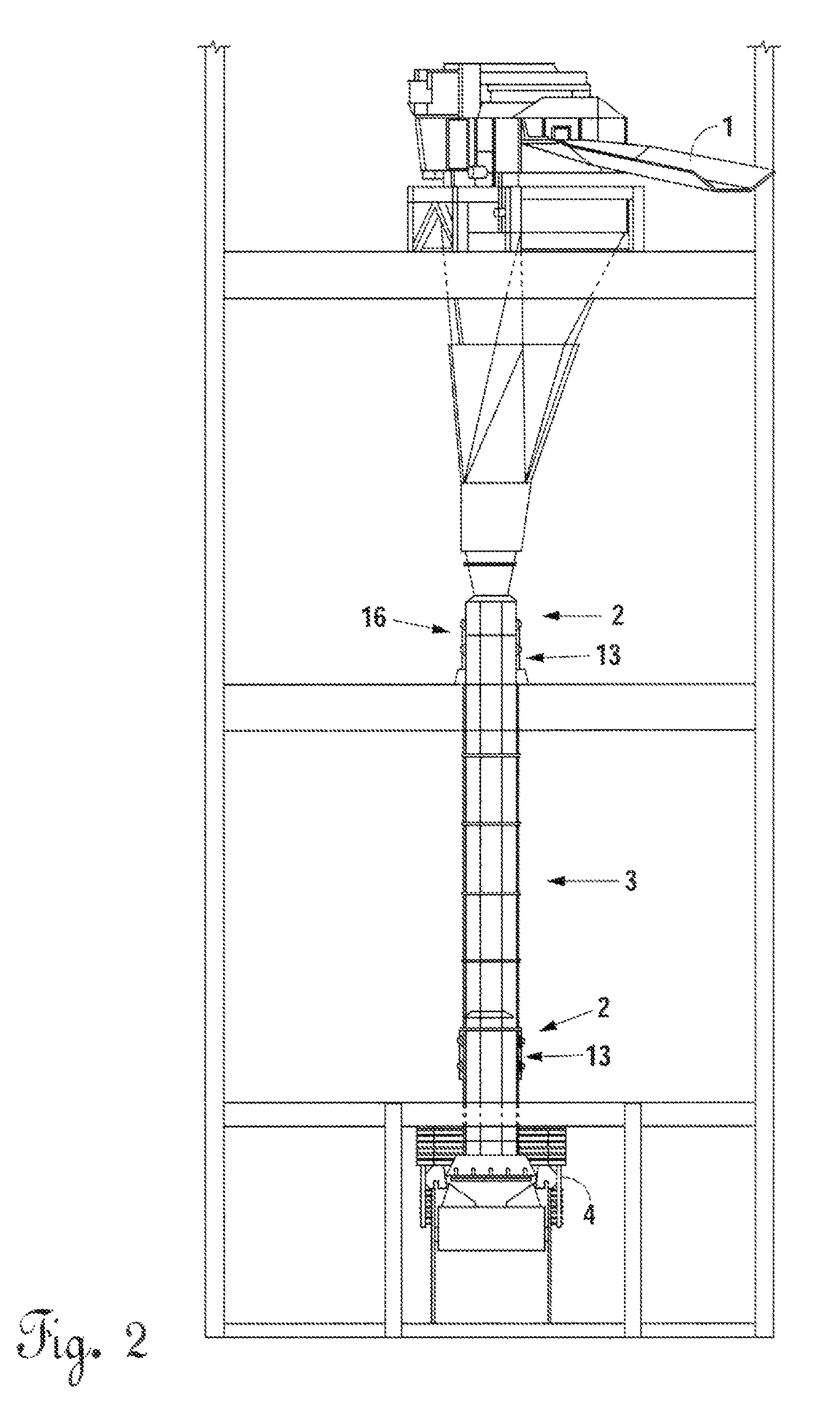

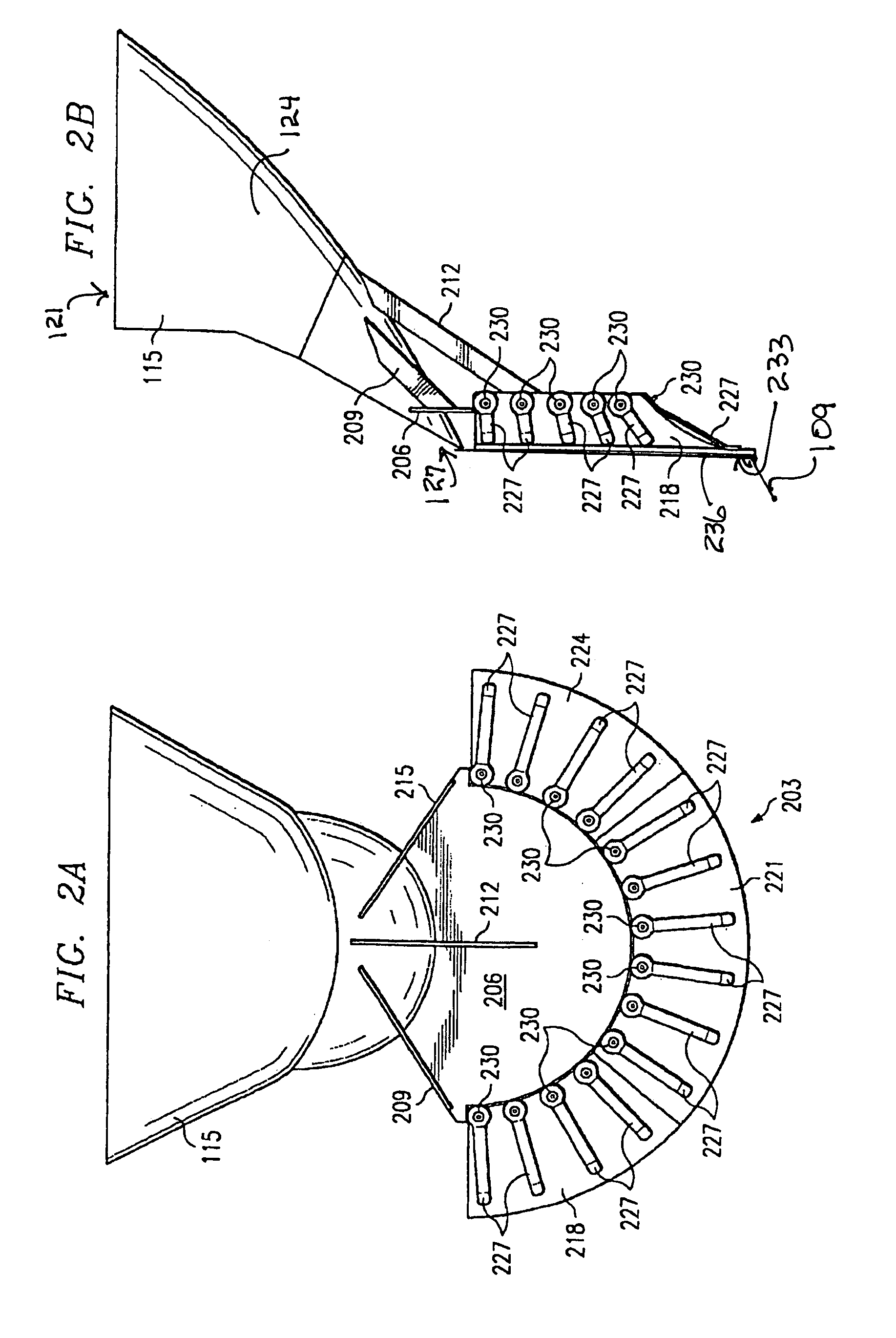

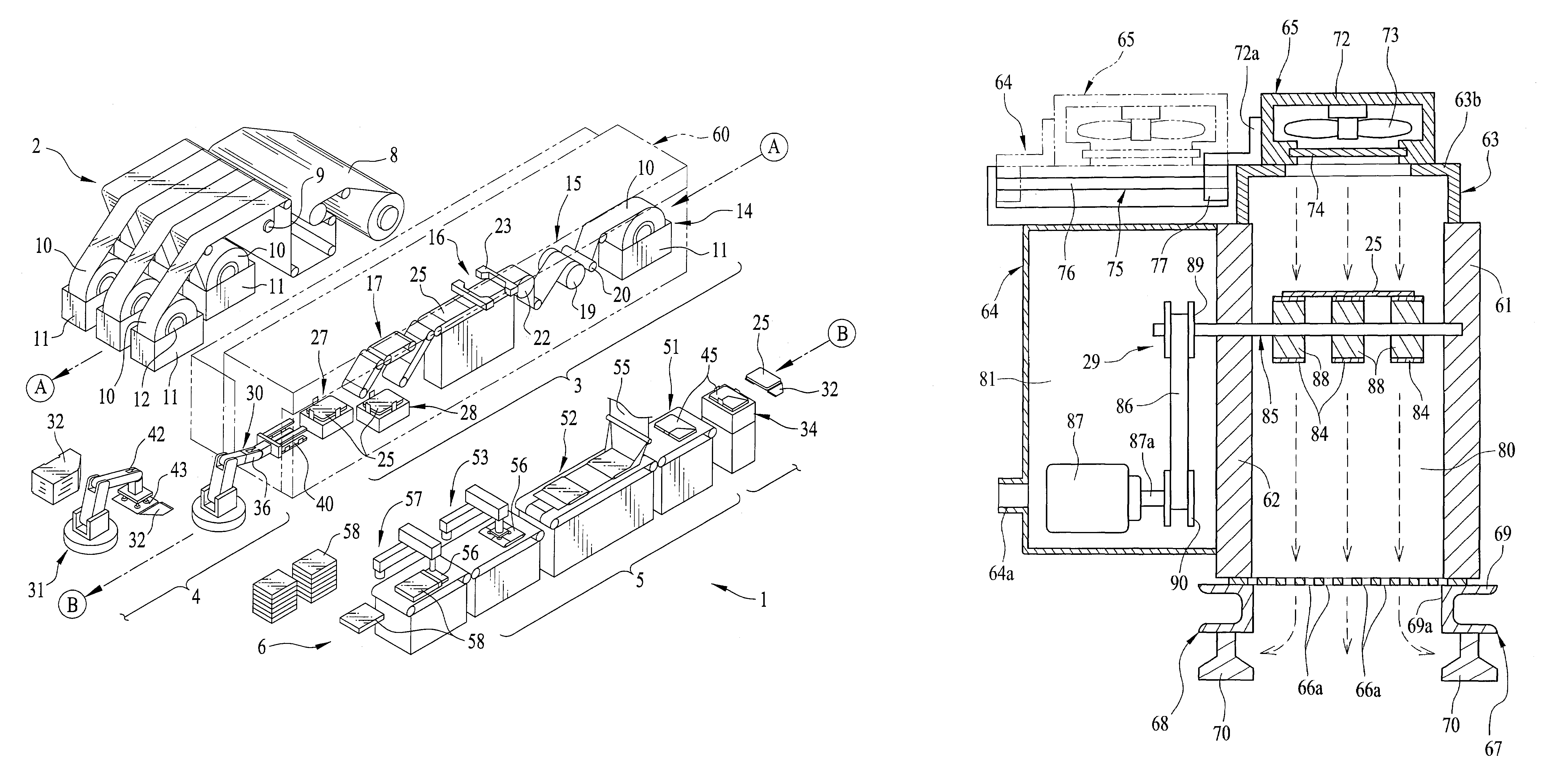

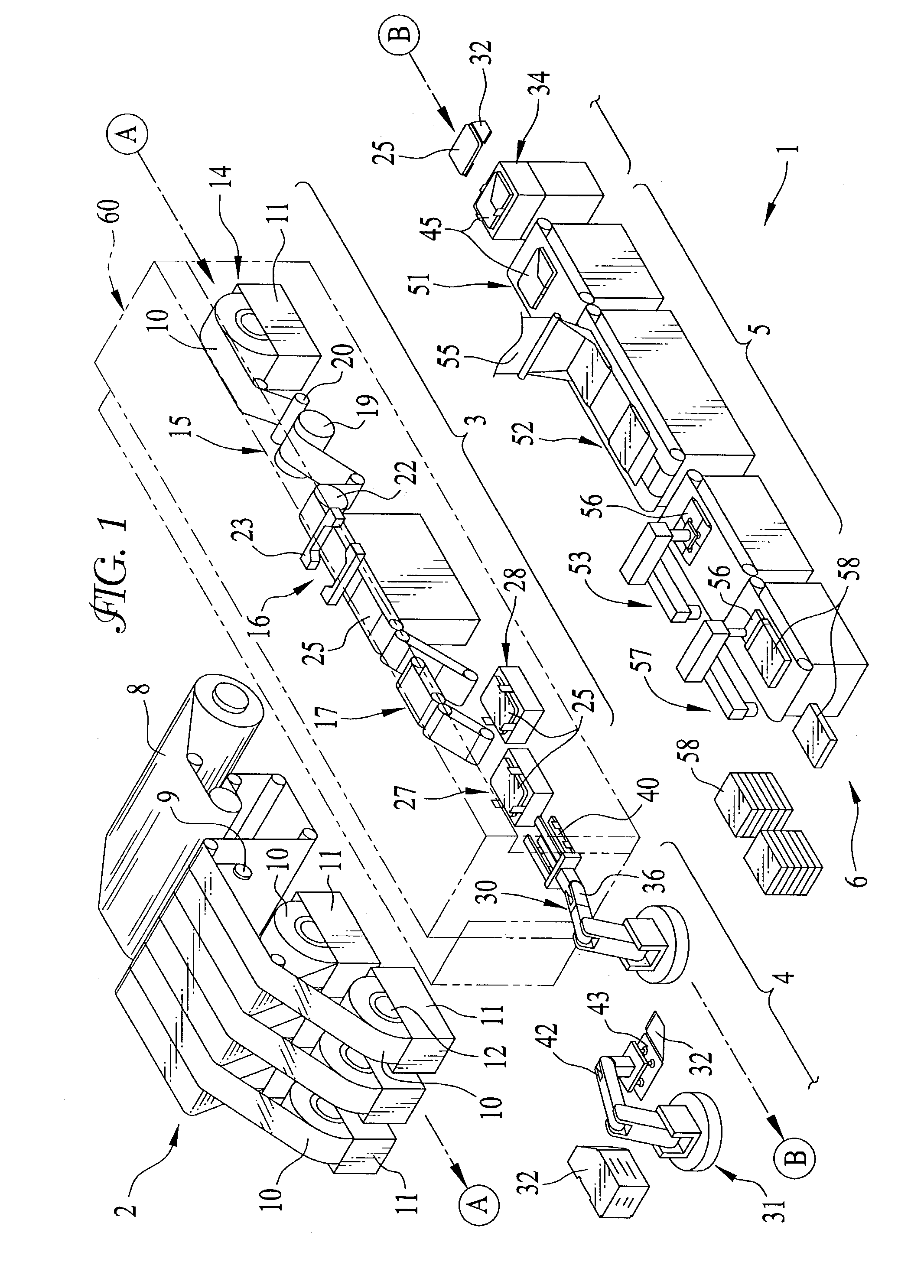

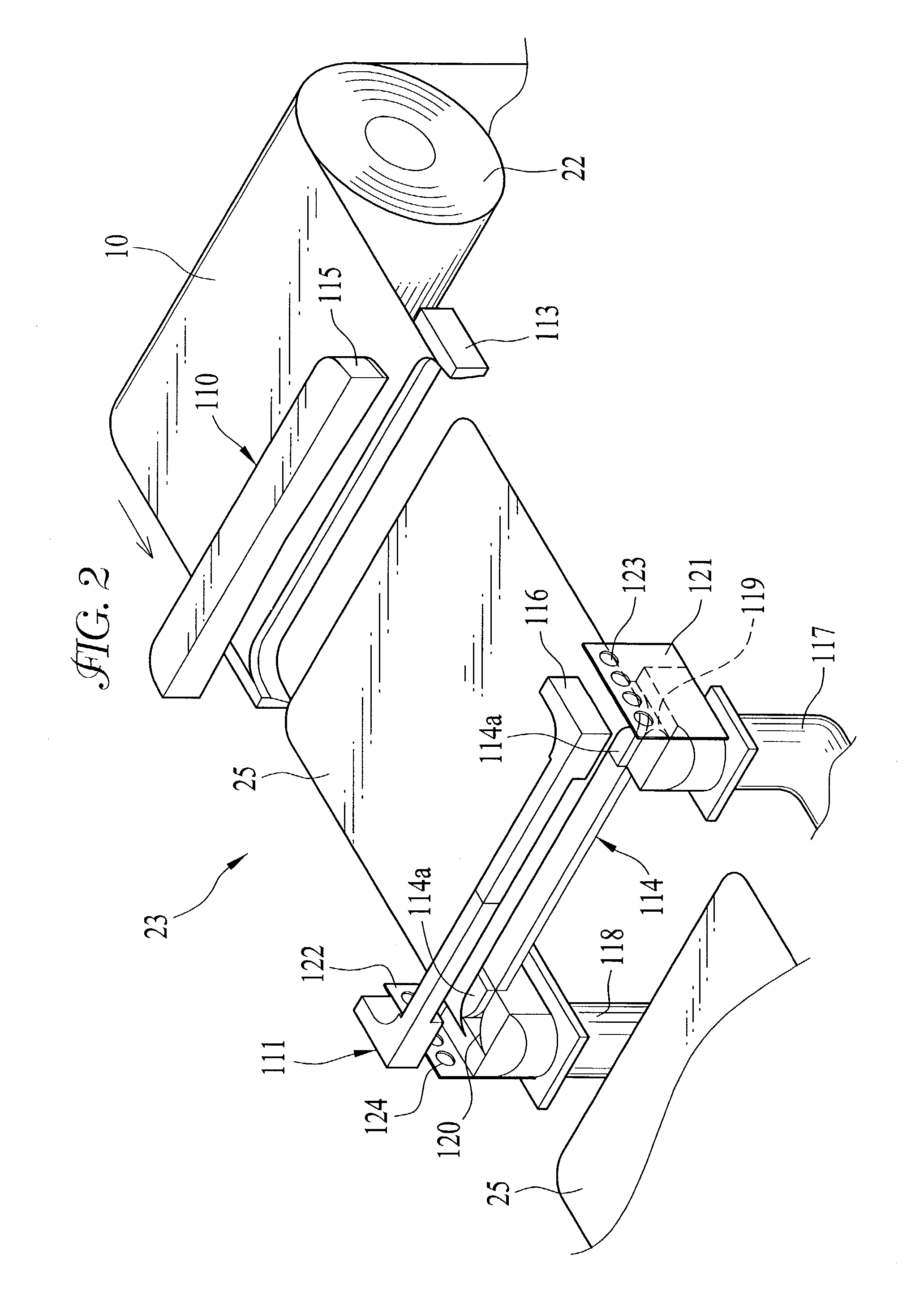

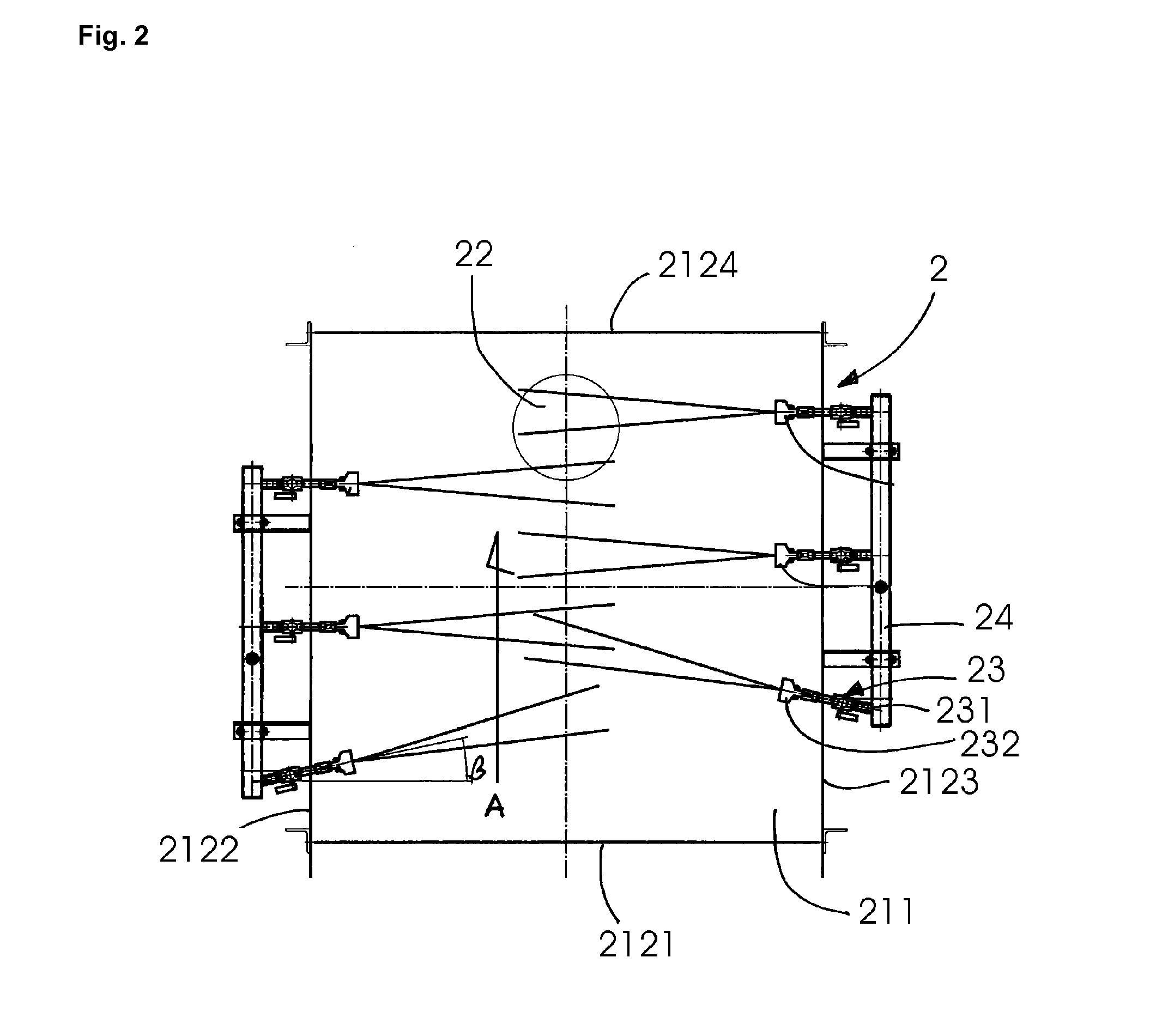

Apparatus and Method for Passive Dust Control in a Transfer Chute

InactiveUS20120090956A1Minimize air flowReduce dust emissionsLoading/unloadingConveyor partsTransfer systemDust control

A dust control apparatus and method for a bulk material handling transfer system having a chute comprising a pathway there through for handling varying volumes of bulk material flowing through the chute using gravity flow. A self-adjusting air restrictor gate is mounted in the chute for engaging the upper surface of flowing bulk material through the chute for restricting the air pathway during material volume flow variations to reduce dust emissions. The gate member contacts the upper surface of flowing bulk material and moves up and down in response to the flow of bulk material through the chute to restrict the flow of air to reduce dust. A counterweight mechanism and a damper helps maintain controlled contact of the air restrictor gate with the upper surface of bulk material flowing through the chute.

Owner:BROBST STEVEN HAYS

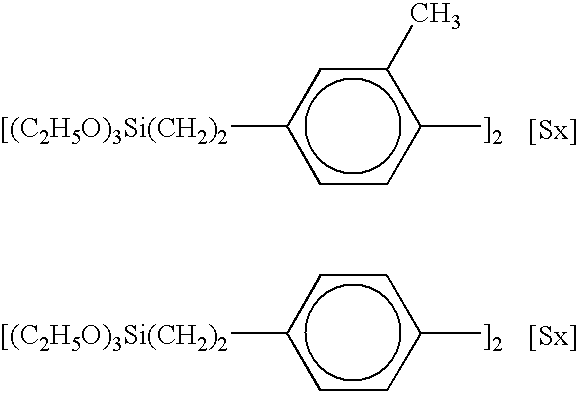

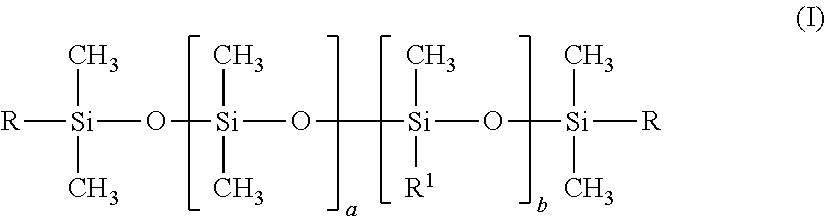

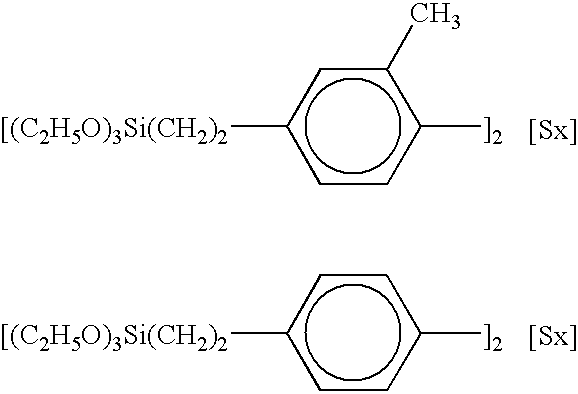

Rubber powders having pulverulent silicatic fillers and prepared from rubbers present in organic solvents, a process for their preparation, and their use

A fine-particle, free-flowing rubber powder containing silicatic fillers, one or more organosilanes having trialkoxysilyl groups, and a rubber prepared by solution polymerization is prepared by a process that starts from a two-phase system: 1) filler in water, and 2) rubber in organic solvent. A rubber / silicatic filler / silane composite is formed during transfer, under gentle conditions, of the various reactants into a single phase. The process features a high degree of freedom in selecting forms of filler and in selecting the organosilane and gives a finished rubber powder in which a silicatic filler and an organosilane have undergone complete chemical reaction.

Owner:PKU PULVERKAUTSCHUK UNION GMBH

Metal impregnated activated carbons and method of making same

InactiveUS20080293565A1Reduce adsorptionReduce manufacturing costOther chemical processesDeodrantsActivated carbonWater soluble

An odor control product is disclosed comprising an activated carbon impregnated with a metal oxide and a salt, wherein the carbon has an activity high enough to compensate for the physical adsorption capacity used by the salt. Methods of making metal-impregnated activated carbon using water-soluble metal salts are provided without need for ammoniacal solvent media. An activated carbon base of higher activity than would be normally employed is impregnated with water-soluble metal salt. The impregnated carbon is impregnated with an aqueous alkaline solution and the resulting hydroxide decomposed to the metal oxide.

Owner:CALGON CARBON

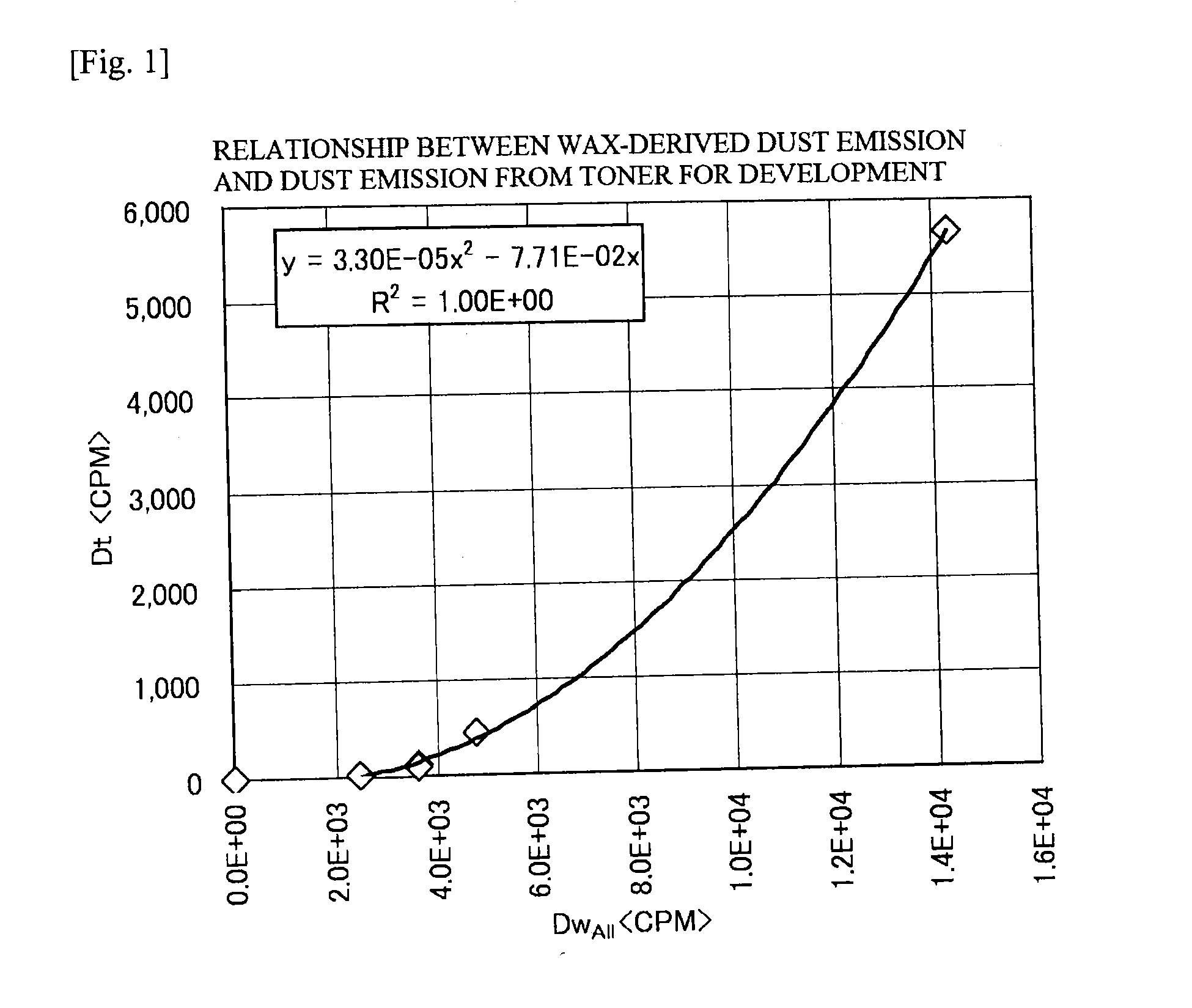

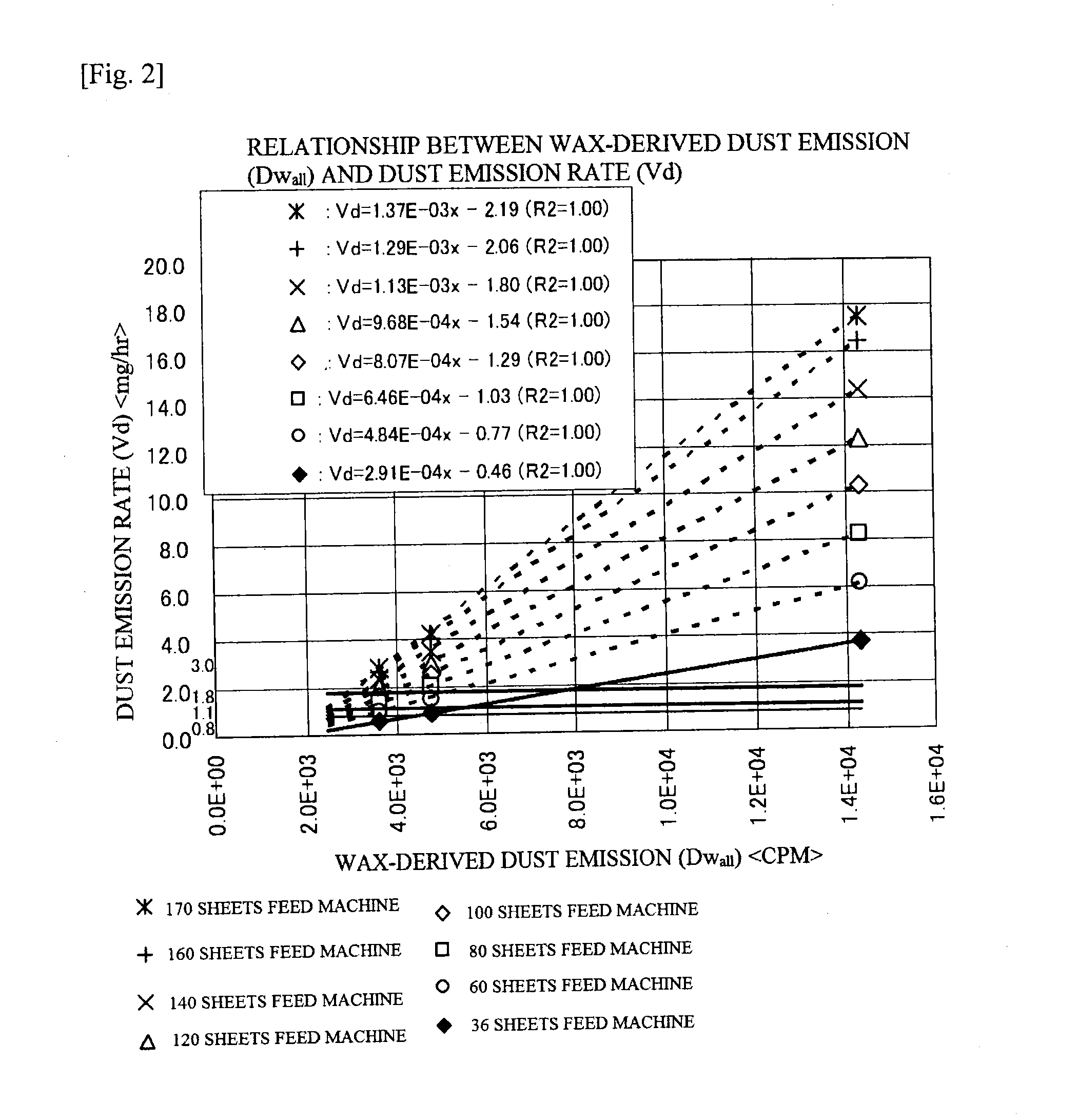

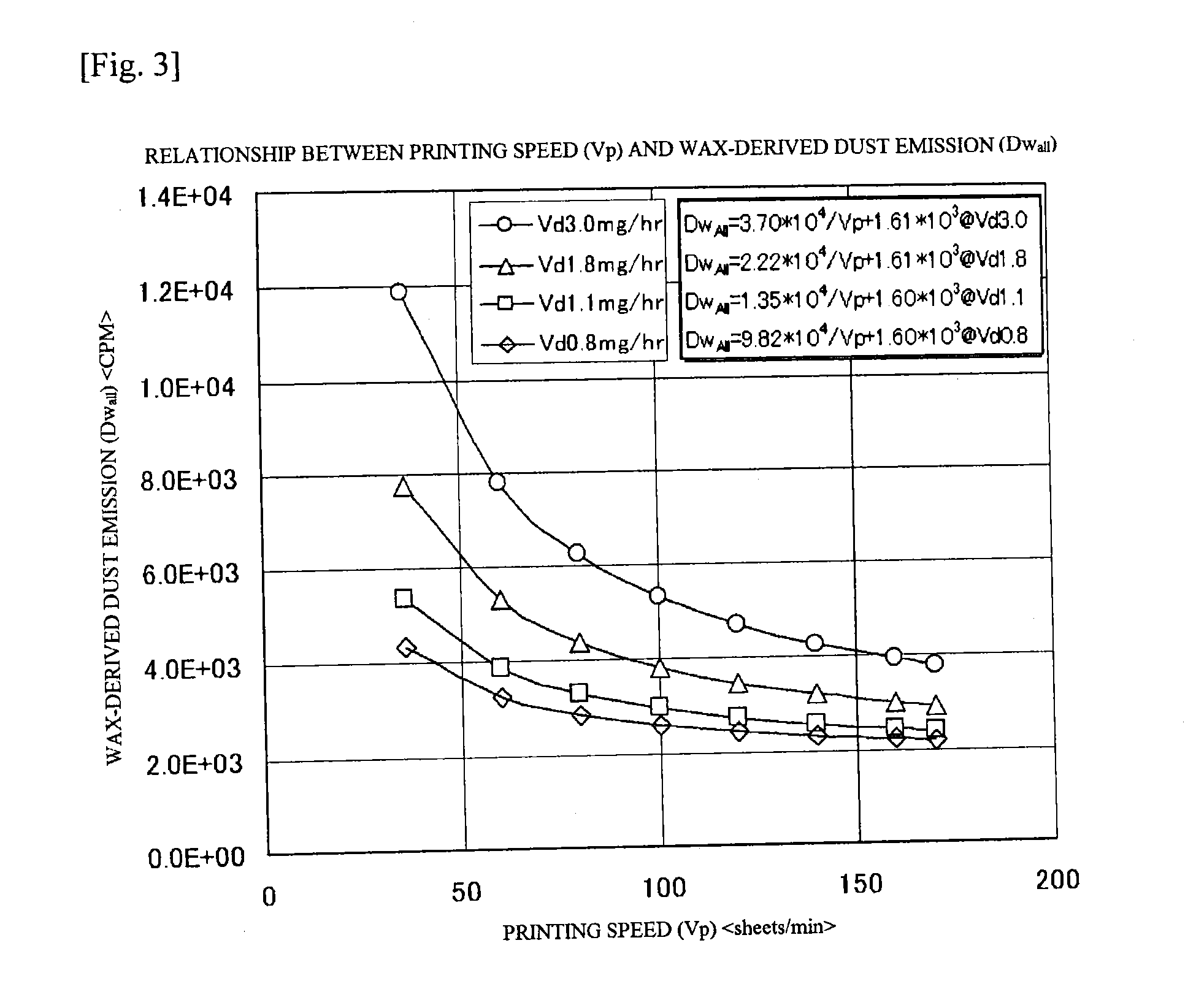

Toner for development of electrostatic images

ActiveUS20150017583A1Reduce dust emissionsHot offset resistance can be improvedElectrographic process apparatusDevelopersWaxEngineering

The object of the present invention is to provide a toner for development of electrostatic images (hereinafter referred to as toner) which, while preventing dust during fixation, secures improved hot offset resistance and is excellent in providing good image quality. The invention relates to the toner that comprises a binder resin, a colorant and a wax, wherein the wax has, while in a state of being contained in the toner, a melting point of from 55° C. to 90° C., and the value Dt of the toner satisfies a specific formula.

Owner:MITSUBISHI CHEM CORP

Surface treatment of particles and their use

ActiveUS20170002181A1Reduced susceptibility to dustingReduce dust emissionsOther chemical processesPigment treatment with organosilicon compoundsZinc sulfideBarium sulfate

Owner:HUNTSMAN P&A GERMANY GMBH +1

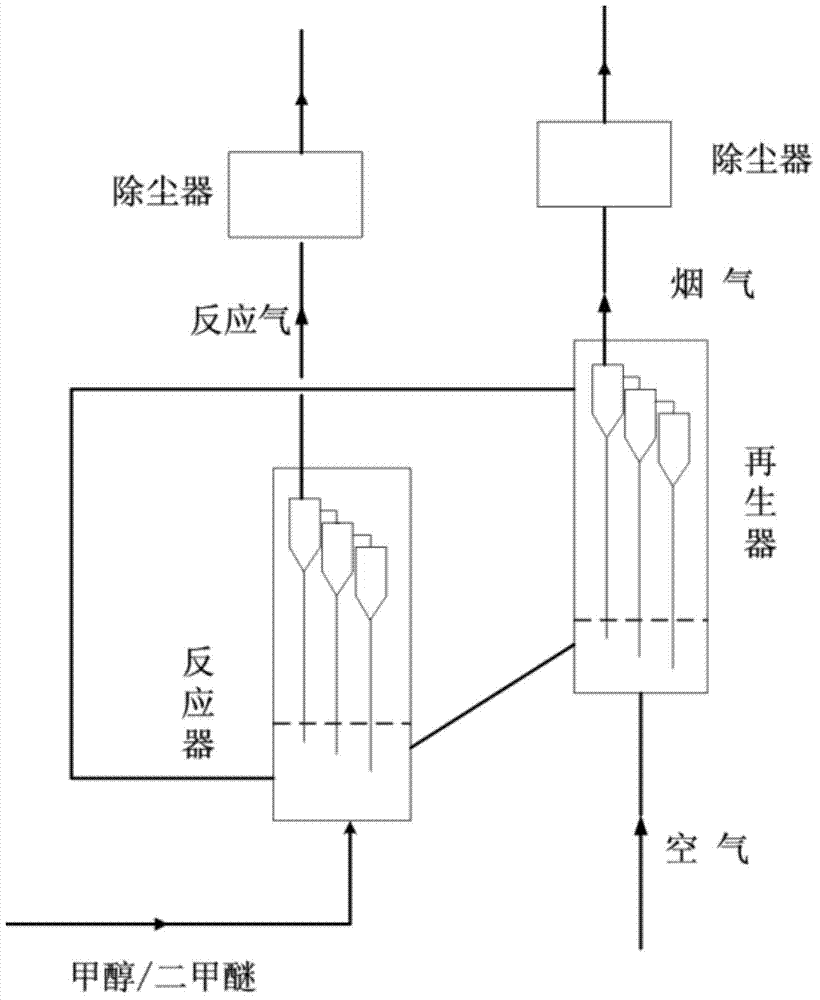

Method for recovering fine catalyst powder to repelletize

ActiveCN103611581AReduce dust emissionsLow costCatalyst regeneration/reactivationHydrocarbon from oxygen organic compoundsPelletizingEther

The invention relates to a method for recovering fine catalyst powder to repelletize. The method is applicable to an alcohol ether-to-olefin fluidized bed system. The method comprises the following steps: collecting the fine catalyst powder from the alcohol ether-to-olefin fluidized bed system by a dust remover inside a fluidized bed reaction system; directly feeding the collected fine catalyst powder to the catalyst pelletizing process; mixing with a fresh catalyst raw material according to any ratio, so as to replace a part of raw materials for pelletizing an alcohol ether-to-olefin catalyst. According to the method disclosed by the invention, the alcohol ether-to-olefin catalyst is recovered by the dust remover after being worn out and broken into a lot of fine powder, and applied to the pelletizing process of a new batch of catalyst. A part of pelletizing material is replaced under the condition of not affecting the performance index of the newly pelletized alcohol ether-to-olefin fluidized bed catalyst, so that dust emission is reduced, the pelletizing raw material cost is reduced, and a part of expenses are saved while the alcohol ether-to-olefin catalyst is friendly to the environment.

Owner:CHINA TIANCHEN ENG +1

Rubber powders having pulverulent silicatic fillers and prepared from rubbers present in organic solvents, a process for their preparation, and their use

A fine-particle, free-flowing rubber powder containing silicatic fillers, one or more organosilanes having trialkoxysilyl groups, and a rubber prepared by solution polymerization is prepared by a process that starts from a two-phase system: 1) filler in water, and 2) rubber in organic solvent. A rubber / silicatic filler / silane composite is formed during transfer, under gentle conditions, of the various reactants into a single phase. The process features a high degree of freedom in selecting forms of filler and in selecting the organosilane and gives a finished rubber powder in which a silicatic filler and an organosilane have undergone complete chemical reaction.

Owner:PKU PULVERKAUTSCHUK UNION GMBH

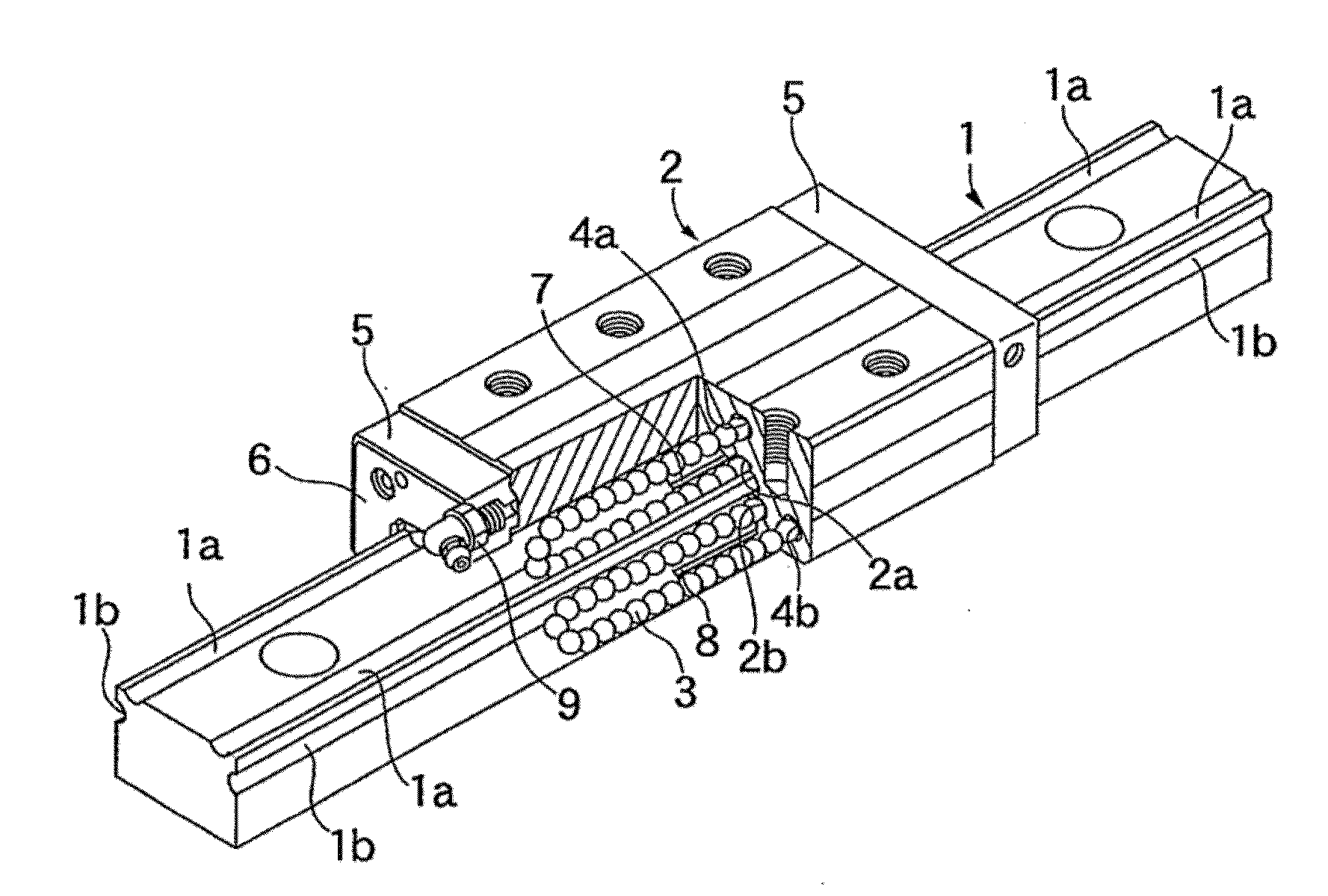

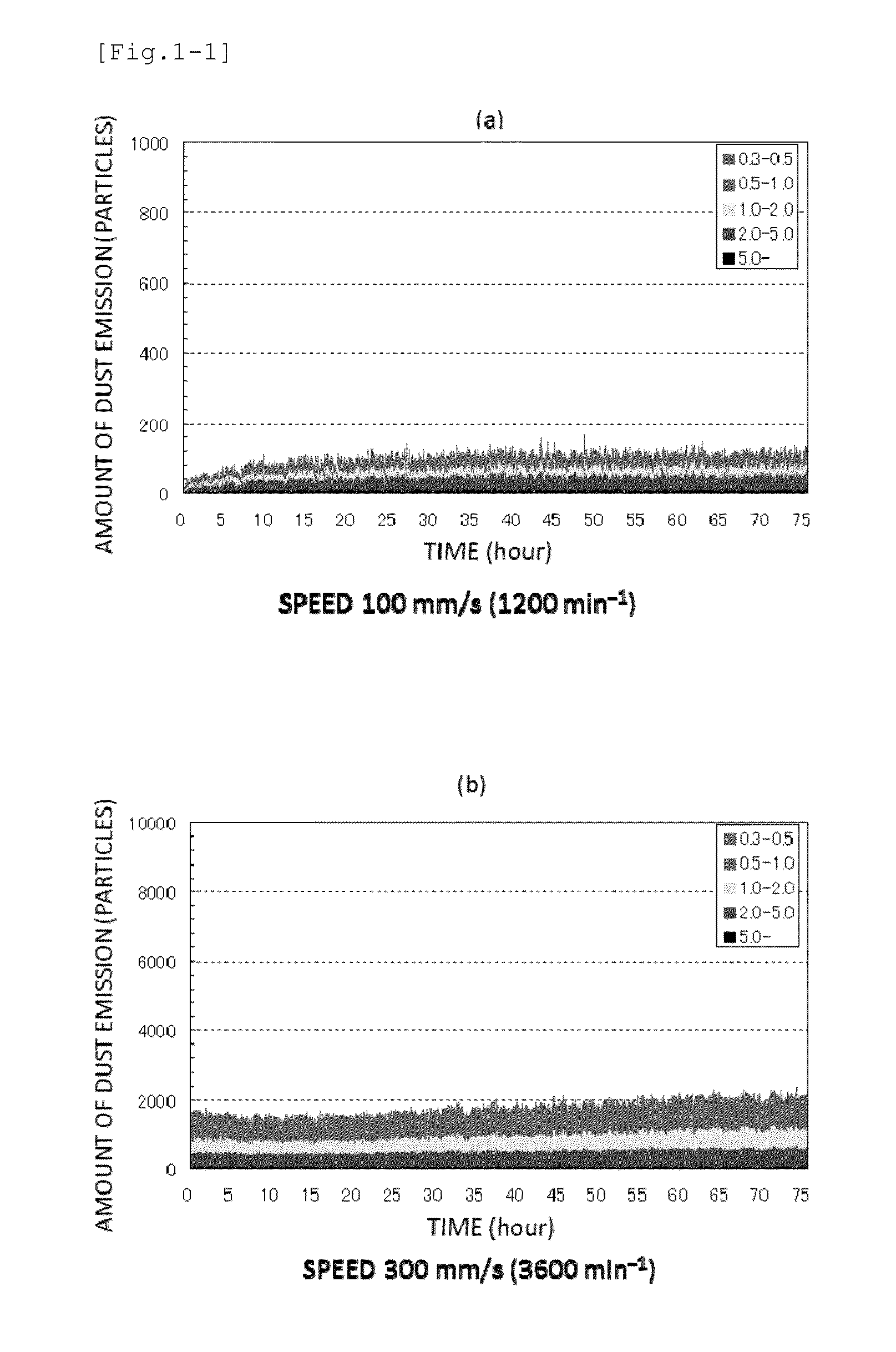

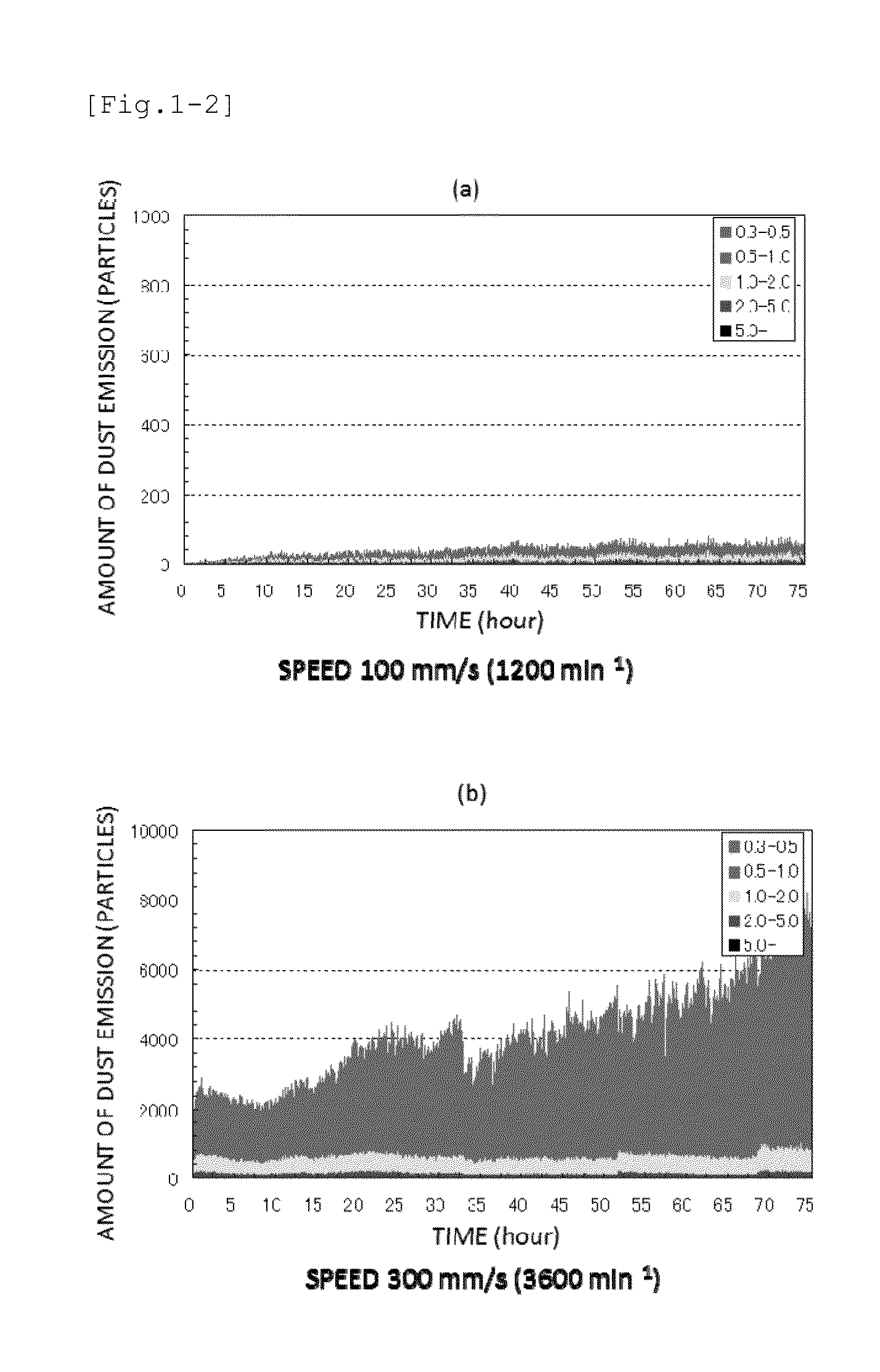

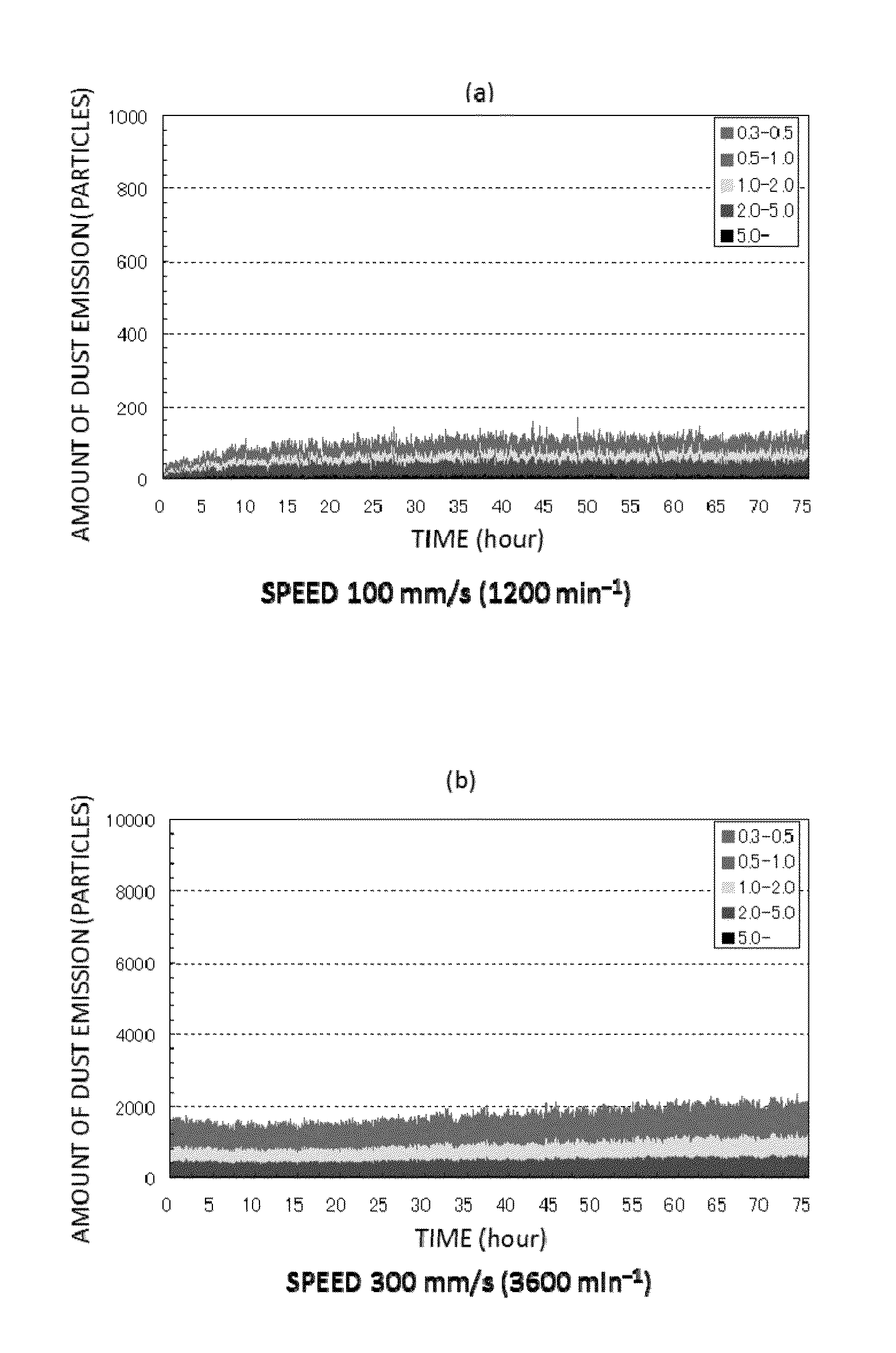

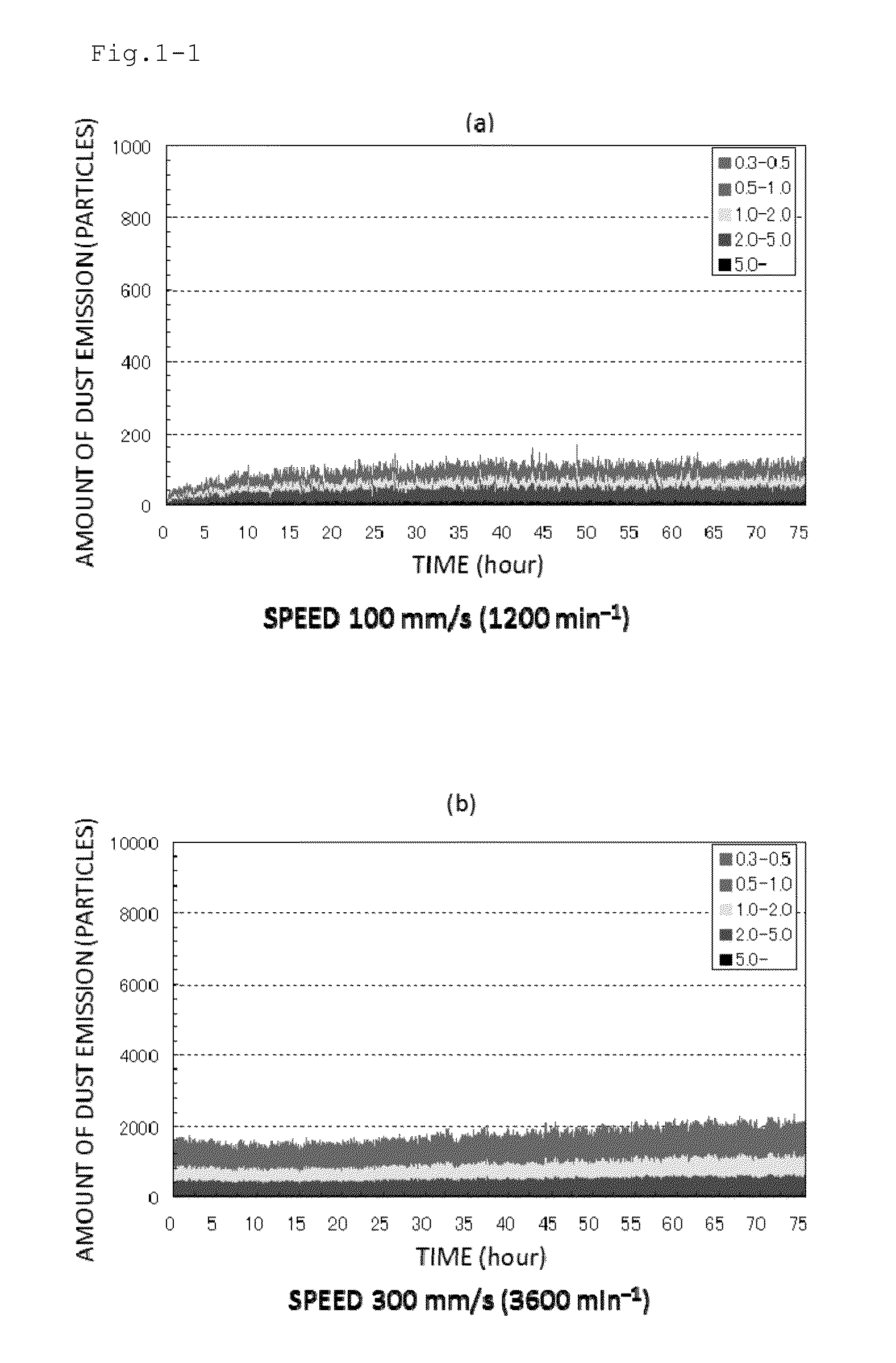

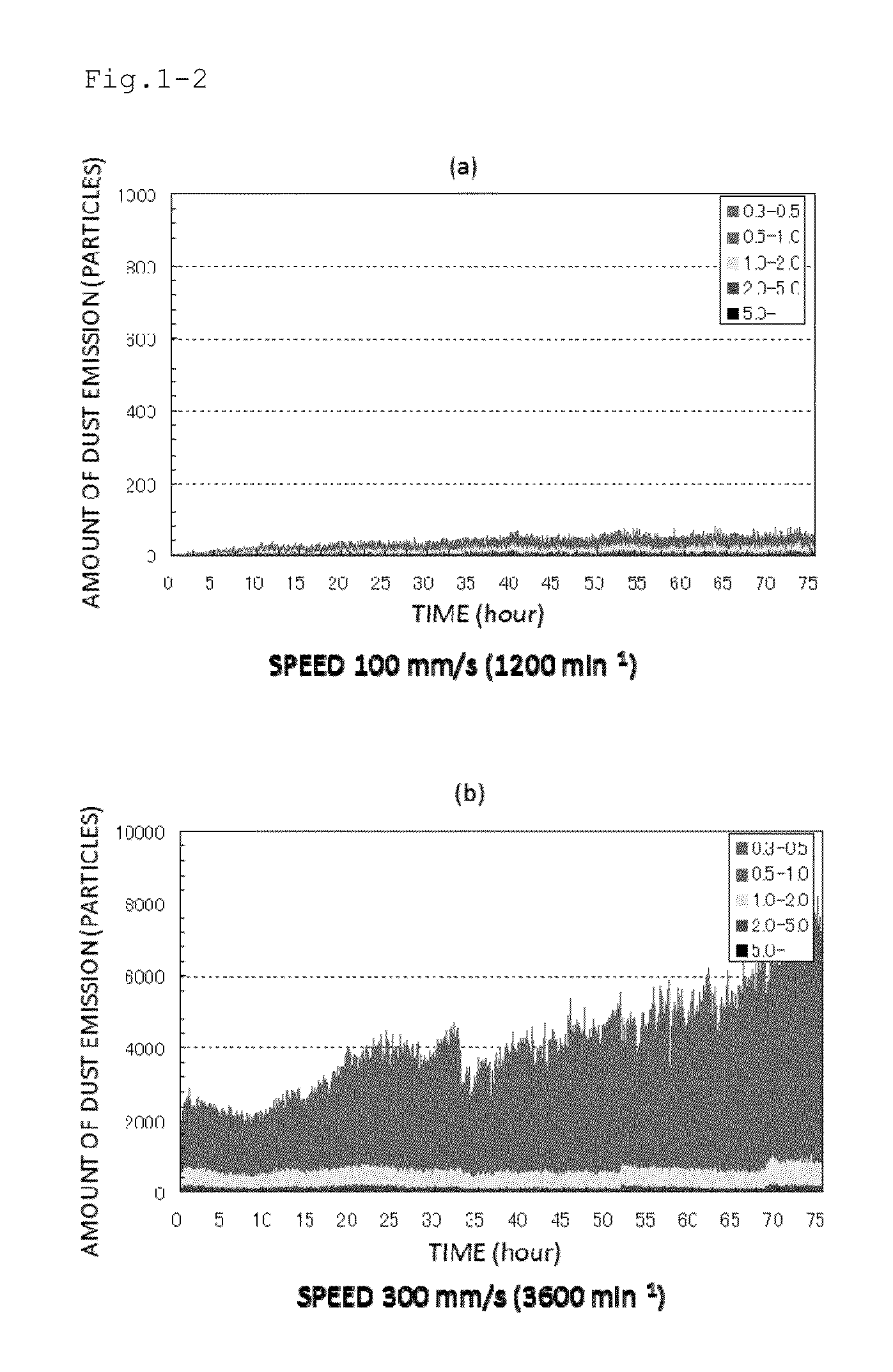

Grease composition and motion guiding device lubricated by grease composition

ActiveUS20140045733A1Improve carrying capacityImprove performanceLinear bearingsRolling contact bearingsClean environmentLithium

The grease composition for a clean environment includes, a base oil, a thickener and a extreme-pressure agent, in which a kinetic viscosity of the base oil at 40° C. is 100˜300 mm2 / s, the thickener comprising a lithium complex soap, a content of the thickener is 10˜40 mass % with respect to the total amount of the grease composition.

Owner:THK CO LTD +1

Surface treatment of particles and their use

ActiveUS9783656B2Reduced susceptibility to dustingReduce dust emissionsOther chemical processesPigment treatment with organosilicon compoundsZinc sulfideBarium sulfate

Owner:HUNTSMAN P&A GERMANY GMBH +1

Water-absorbing agent and its production process

ActiveUS7750085B2Less water-soluble component contentImprove water retentionSynthetic resin layered productsCellulosic plastic layered productsCross-linkAluminium sulfate

A water-absorbing agent according to the present invention includes water-absorbent resin particles having an internal cross-linked structure, wherein a vicinity of a surface of the water-absorbent resin particle is cross-linked with a surface cross-linking agent, and the water-absorbent resin particle has therein a sea-island structure having (i) part containing a first water-soluble multivalent metal salt such as aluminum sulfate and (ii) part not containing the first water-soluble multivalent metal salt. With this arrangement, it is possible to provide a water-absorbing agent having less water-soluble component content, more excellent liquid permeability, and more excellent water retention under pressure than the conventional water-absorbing agent.

Owner:NIPPON SHOKUBAI CO LTD

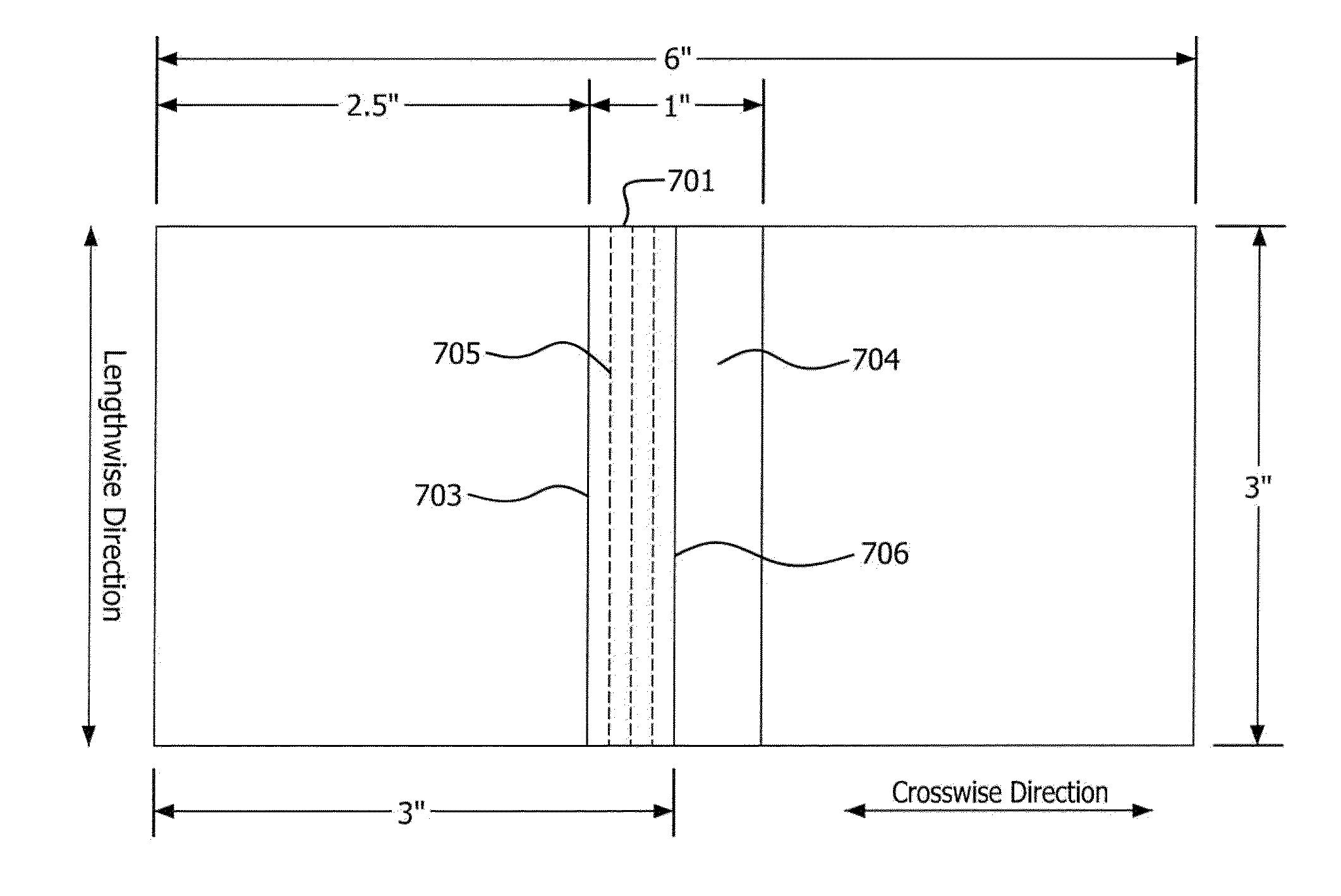

Seam-sealed filters and methods of making thereof

ActiveUS8790432B2Reduce dust emissionsDissipate the static charge from a bagDispersed particle filtrationLoose filtering material filtersBaghouseAir cleaning

A seam-sealed filter in which the seam is sealed with a seam tape comprised of an expanded fluoropolymer, such as ePTFE and copolymers thereof, having a crosswise matrix modulus of greater than 1,950 psi and an enthalpy ratio of less than 0.6 is disclosed. Such seam-sealed filters are capable of undergoing greater than 50,000 pulse-jet or reverse air cleaning cycles without substantial cracking or peeling of the sealed seam. Accordingly, the seam-sealed filters in the form of bags are particularly suitable for use in reducing particulate emissions in cement baghouses and the like.

Owner:WL GORE & ASSOC INC

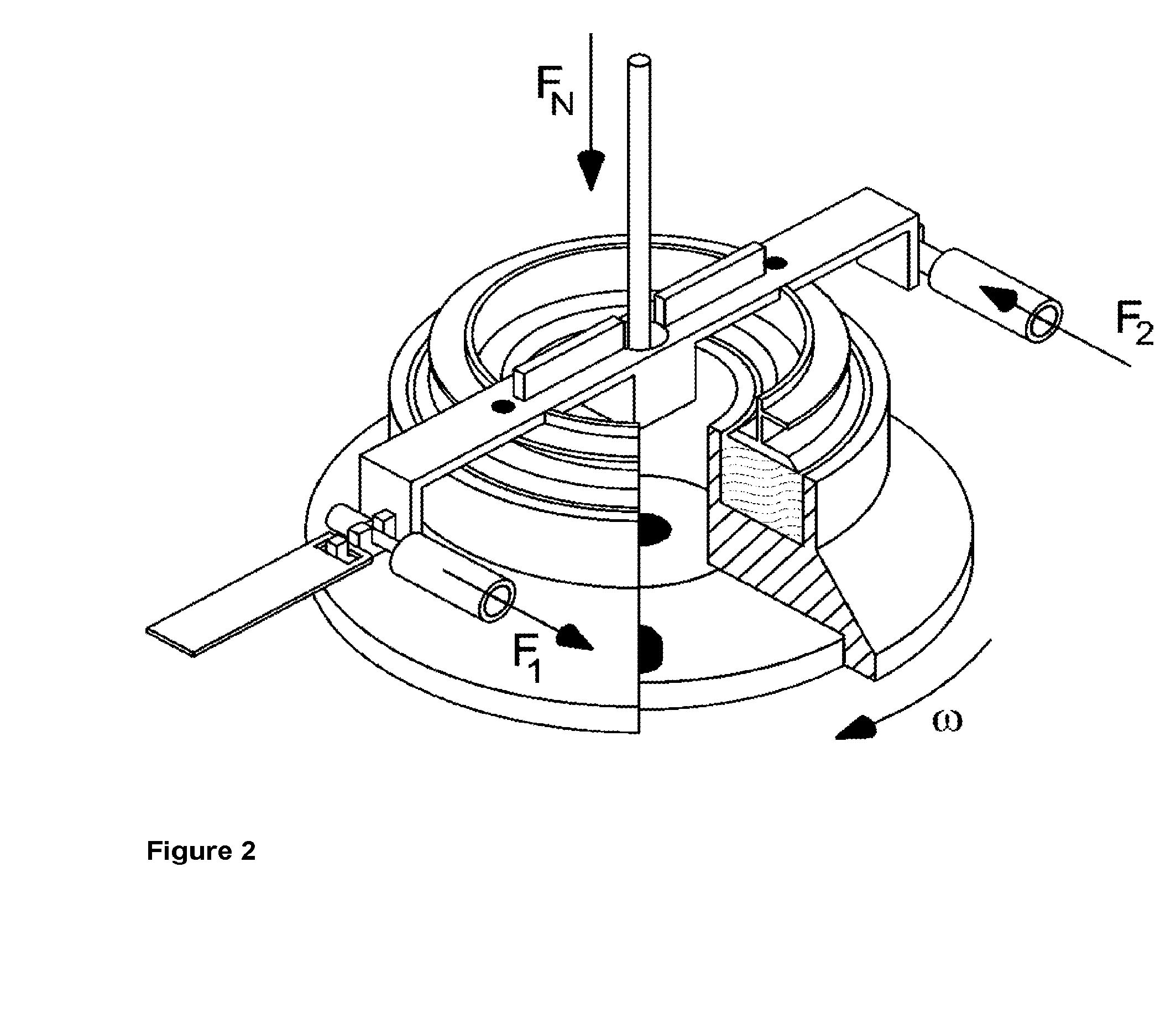

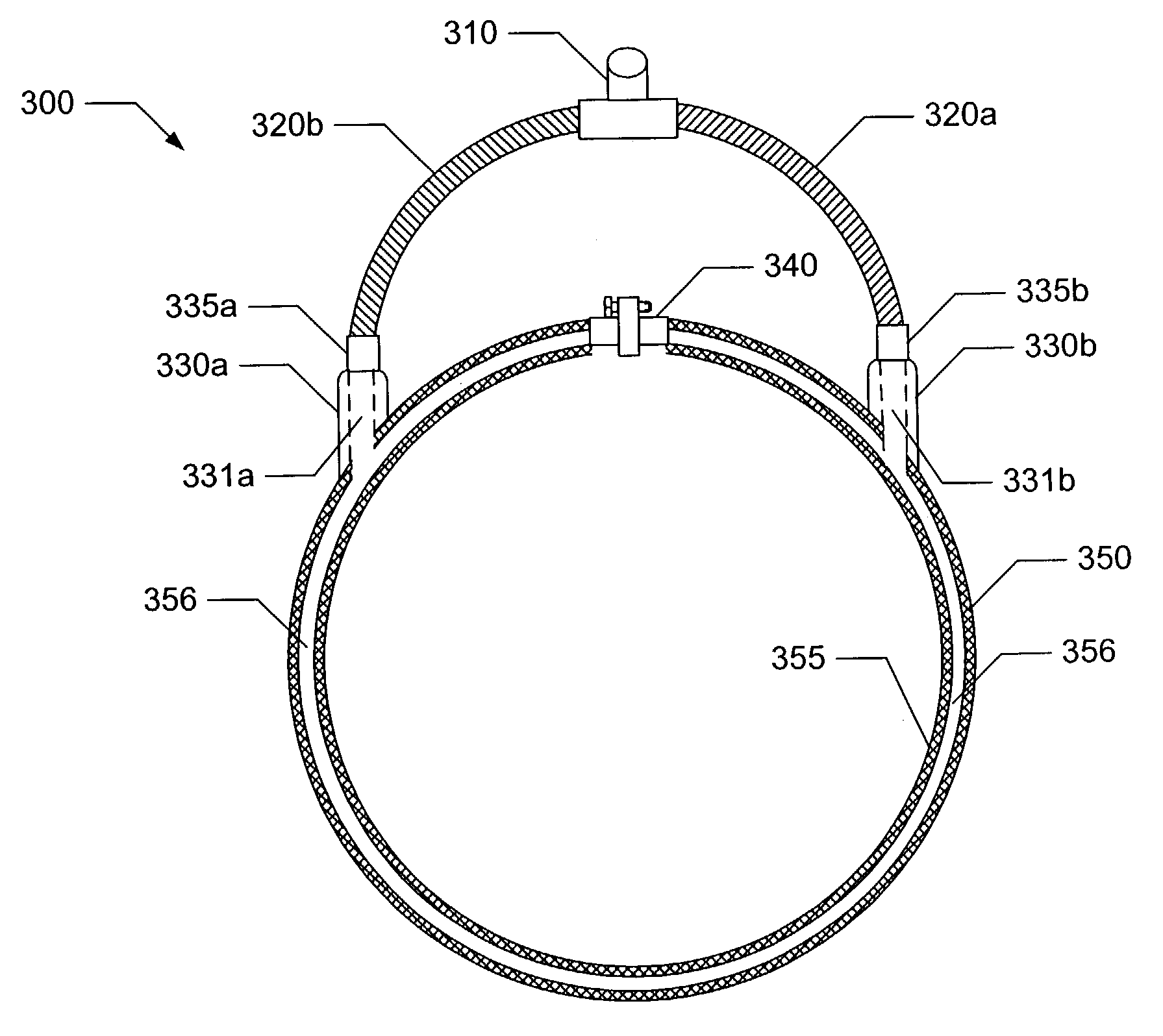

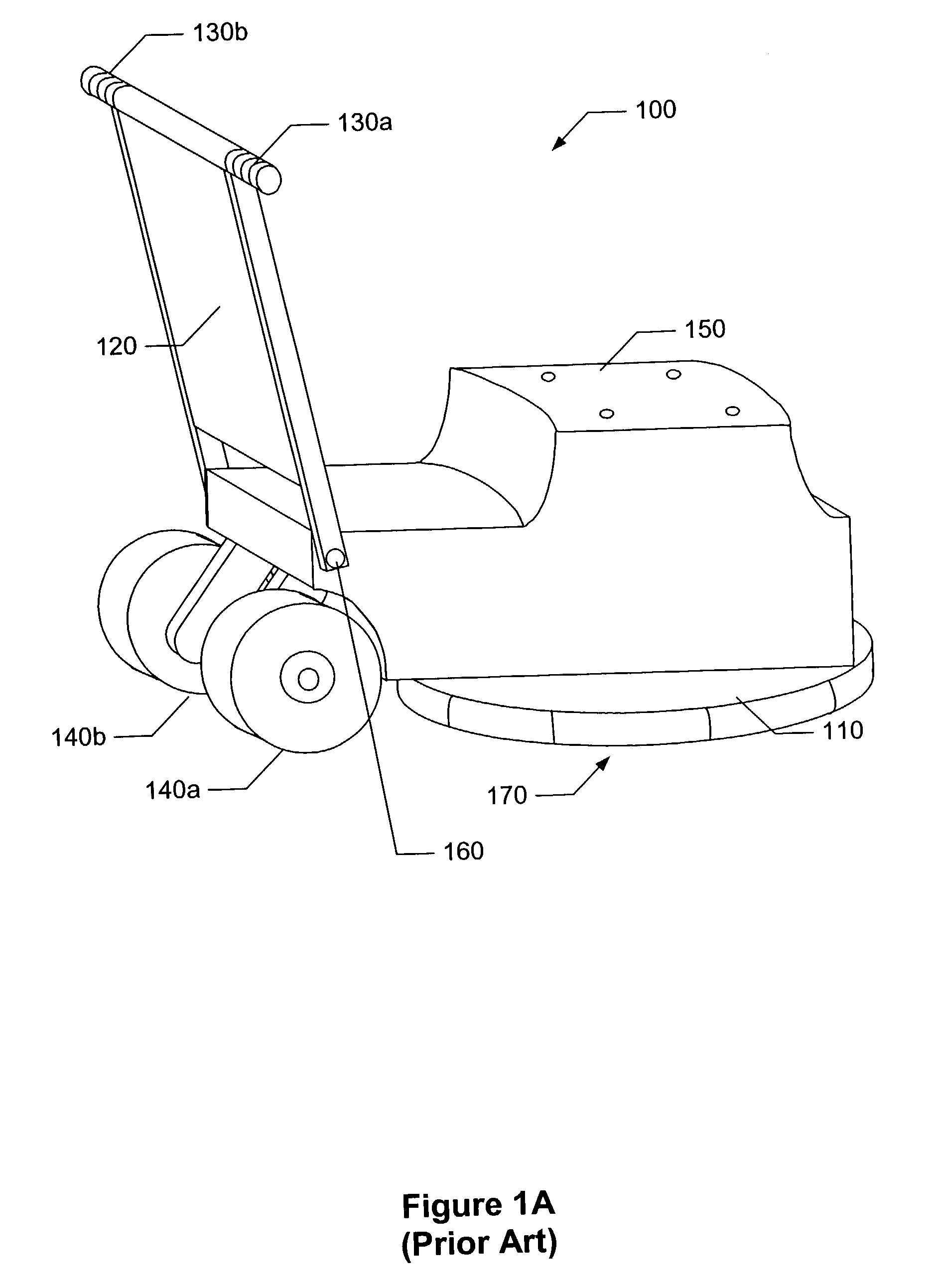

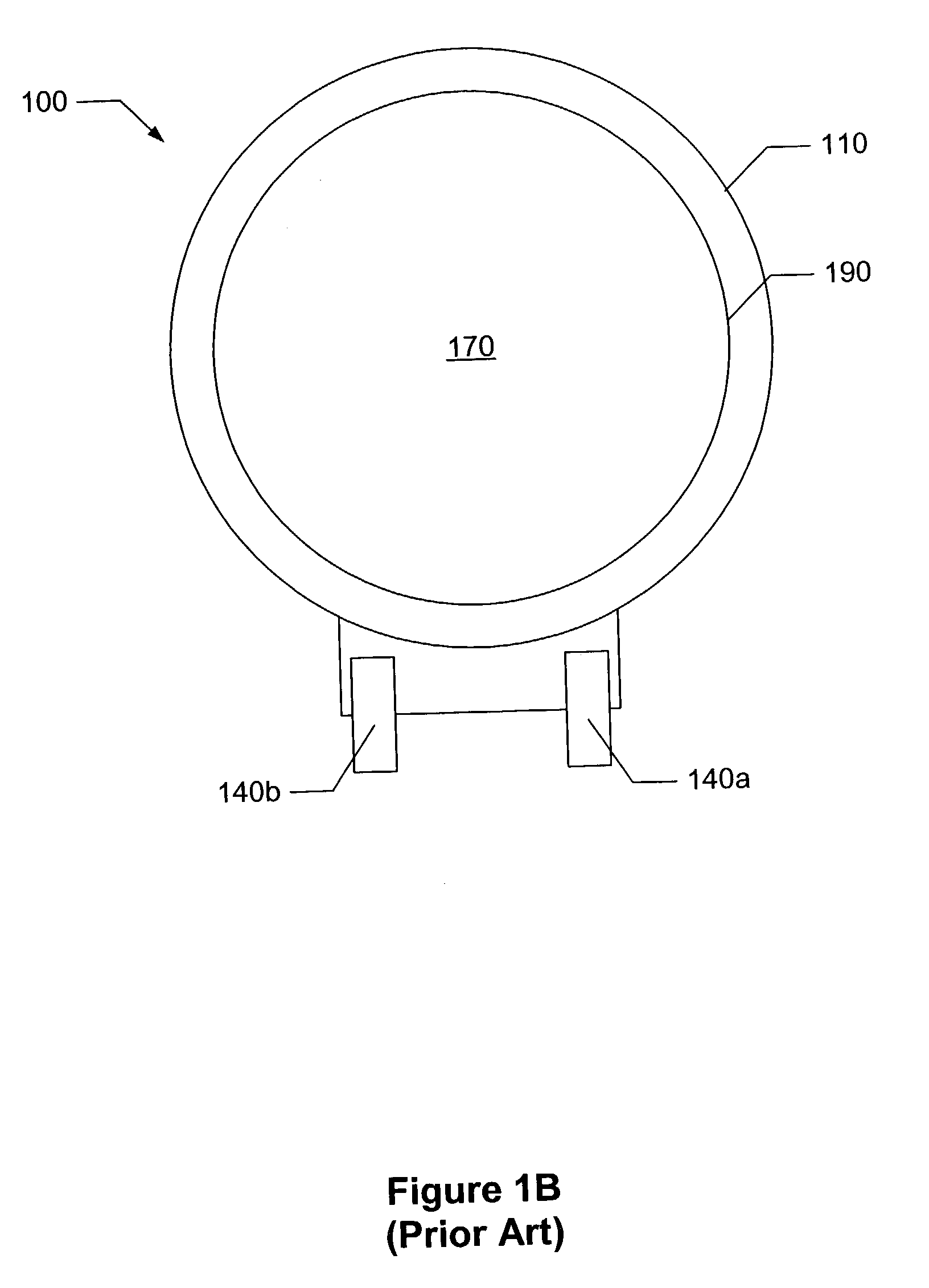

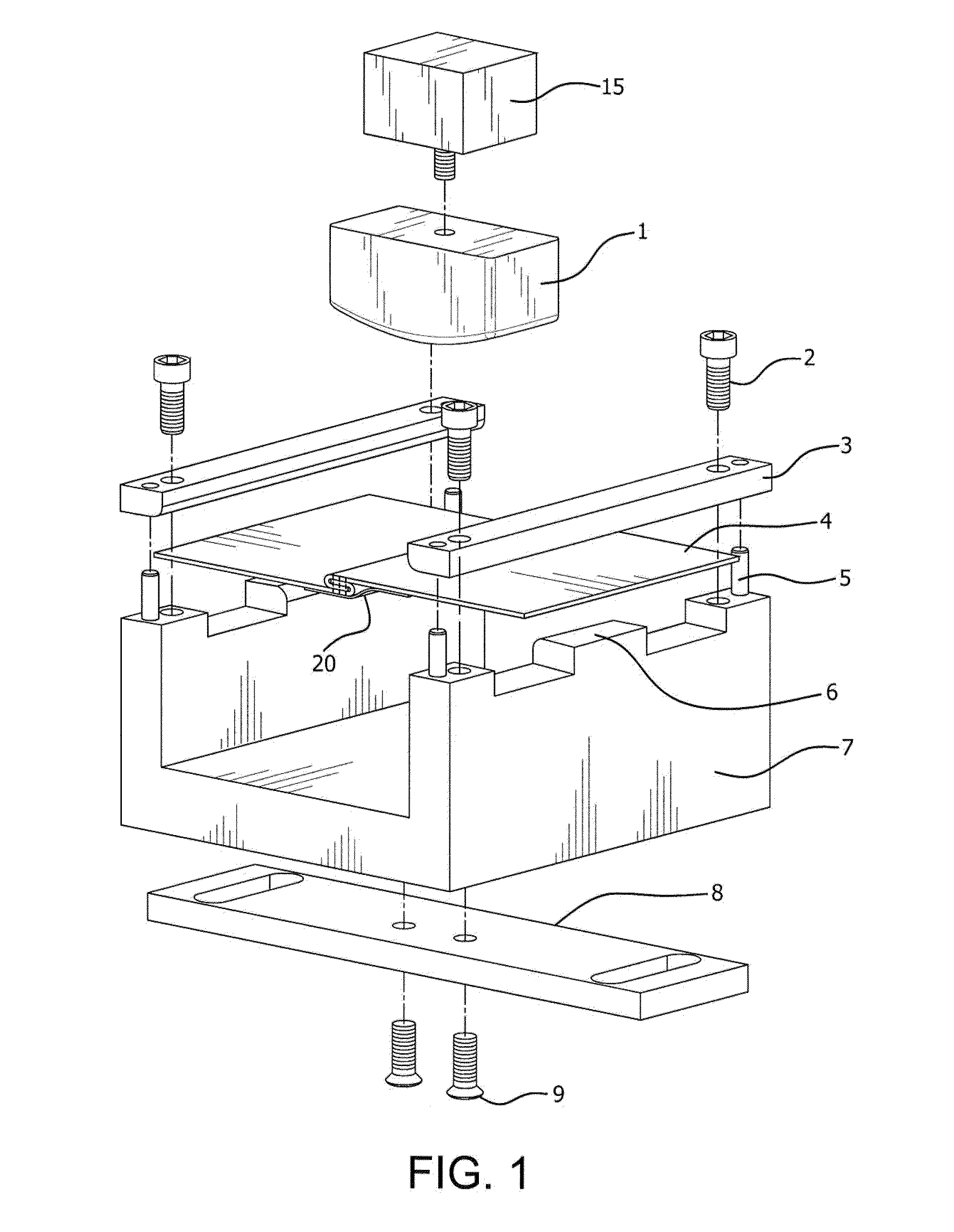

System and methods for reducing dust emissions

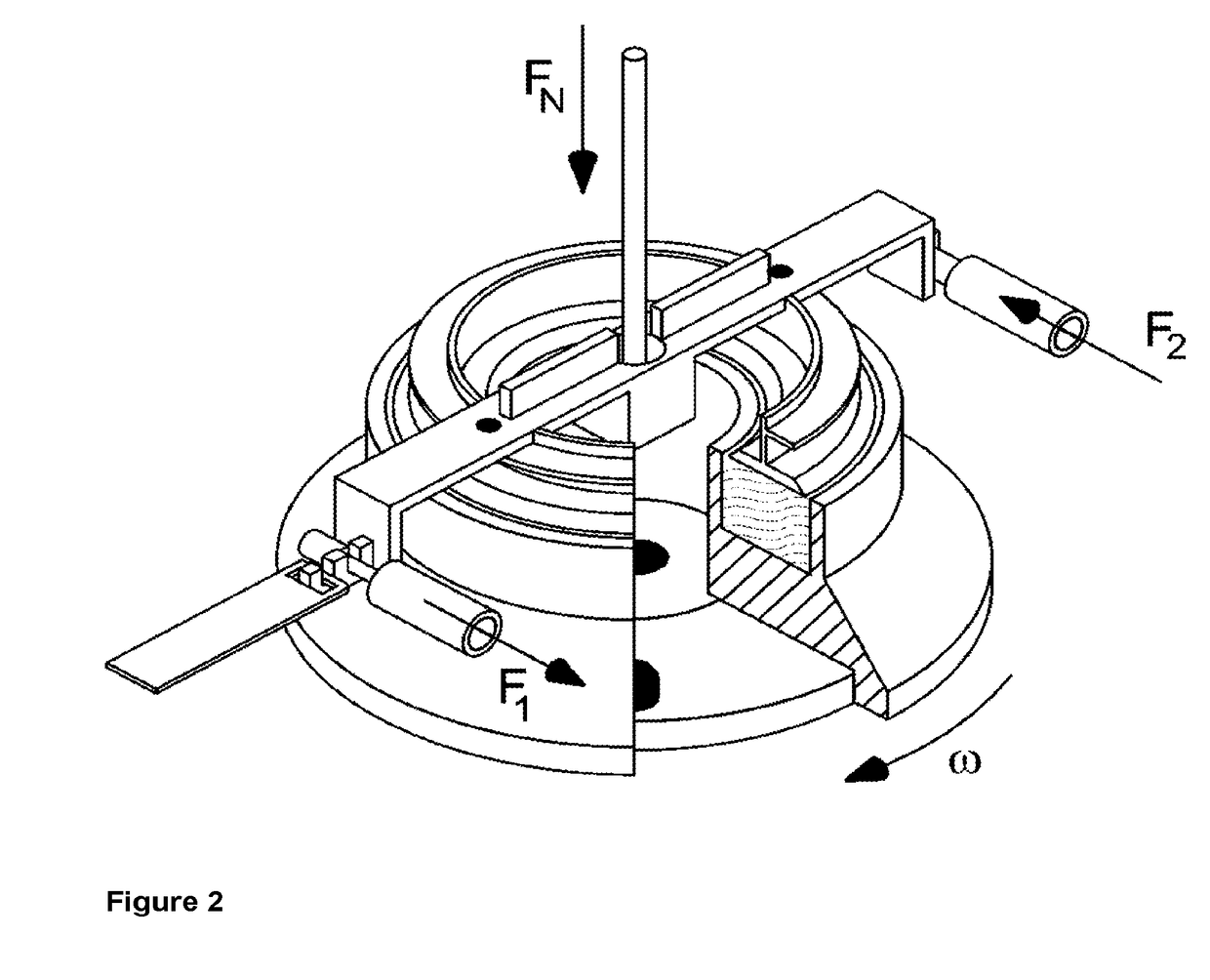

InactiveUS6921320B1Reduce dust emissionsPrevent escapePortable grinding machinesPlane surface grinding machinesSanderEngineering

The systems for reducing dust emissions include a dust catch. In some cases, the dust catch includes an inlet and a discharger. The inlet can be arranged so that it surrounds an abrasive surface of an abrasion device, such as a sander. Dust generated by the abrasion surface can be captured in the inlet and discharged by the discharger. In various cases, the inlet is associated with a skirt including a dust screen. The methods can include attaching a dust catch to an abrasion device such that an inlet of the dust catch encompasses at least a portion of an outer perimeter of an abrasion surface associated with an abrasion device. The abrasion device can then be operated and at least a portion of dust generated by operating the abrasion device is captured by the dust catch.

Owner:NIELSON CHAD J +1

Dust treatment equipment

InactiveCN108355455AImprove dust removal efficiencyReduce dust emissionsCombination devicesDeodrantsElectrostatic precipitatorGas emissions

The invention discloses dust treatment equipment. The equipment comprises a dust lead-in unit, a dust treatment unit, a gas emission unit and a control unit, wherein the dust lead-in unit and the dusttreatment unit are communicated with each other through an air inlet pipeline; the dust lead-in unit comprises an induced draft pipe, an induced draft fan, and a filtering screen arranged at the outlet of the induced draft fan; the dust treatment unit comprises a spraying unit performing spraying treatment on lead-in dust, and a retreatment unit performing retreatment on dust treated by the spraying unit; the gas emission unit comprises a dust concentration sensor for monitoring the concentration of dust in emitted gas, and an air outlet pipeline for emitting gas; the air outlet pipeline is communicated with the air inlet pipeline through a return pipe, so as to ensure that gas returns to the dust treatment unit. The dust treatment unit sequentially performs spraying treatment, dehumidification treatment and electrostatic dust collection treatment on gas containing dust, and is high in dust removal efficiency; the dust concentration sensors monitors the concentration of dust in the treated gas, and the dust emission load is greatly reduced.

Owner:杨建军

Apparatus and method for passive dust control in a transfer chute

InactiveUS8640855B2Minimize air flowReduce dust emissionsLoading/unloadingConveyor partsTransfer systemDust control

A dust control apparatus and method for a bulk material handling transfer system having a chute comprising a pathway there through for handling varying volumes of bulk material flowing through the chute using gravity flow. A self-adjusting air restrictor gate is mounted in the chute for engaging the upper surface of flowing bulk material through the chute for restricting the air pathway during material volume flow variations to reduce dust emissions. The gate member contacts the upper surface of flowing bulk material and moves up and down in response to the flow of bulk material through the chute to restrict the flow of air to reduce dust. A counterweight mechanism and a damper helps maintain controlled contact of the air restrictor gate with the upper surface of bulk material flowing through the chute.

Owner:BROBST STEVEN HAYS

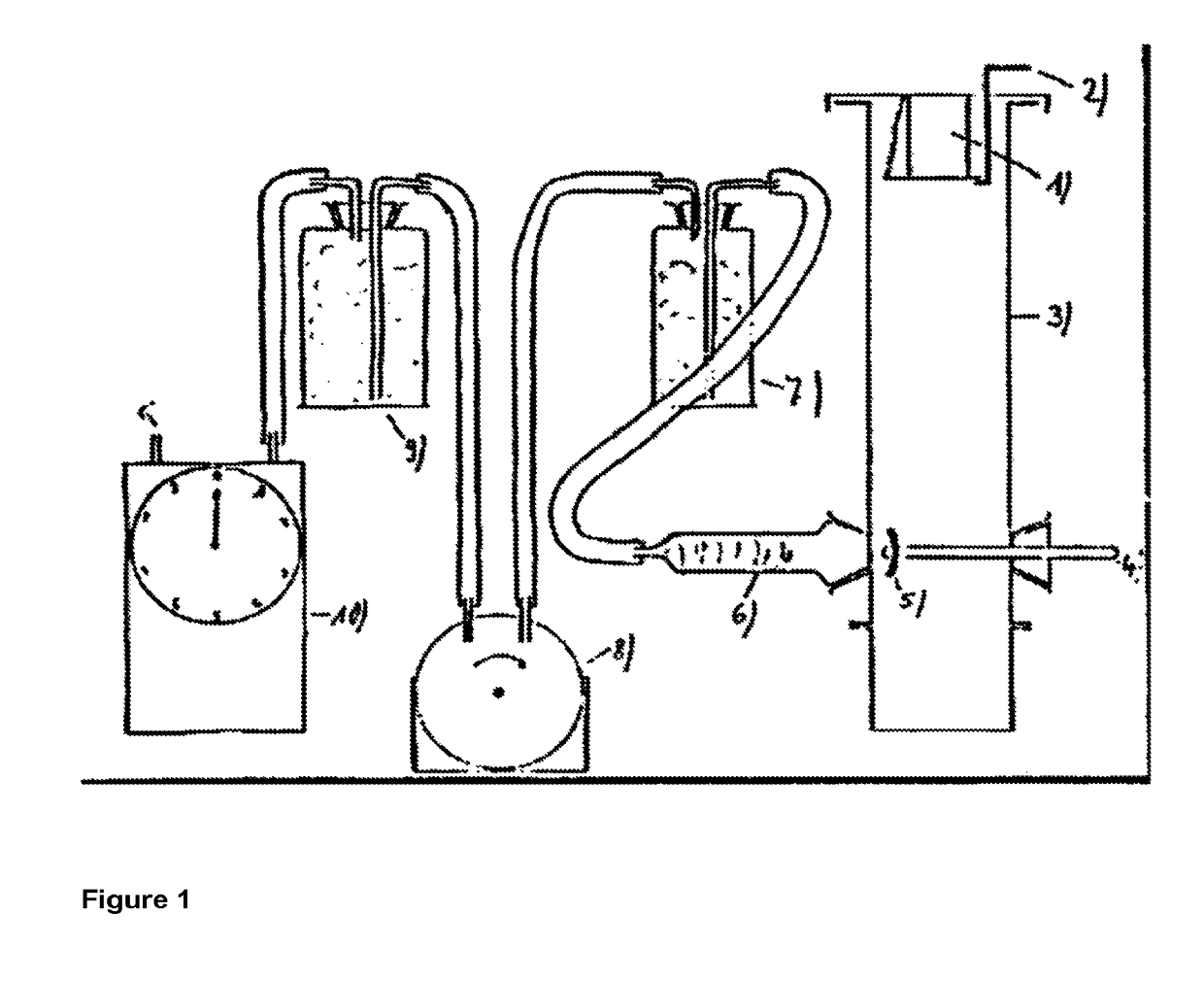

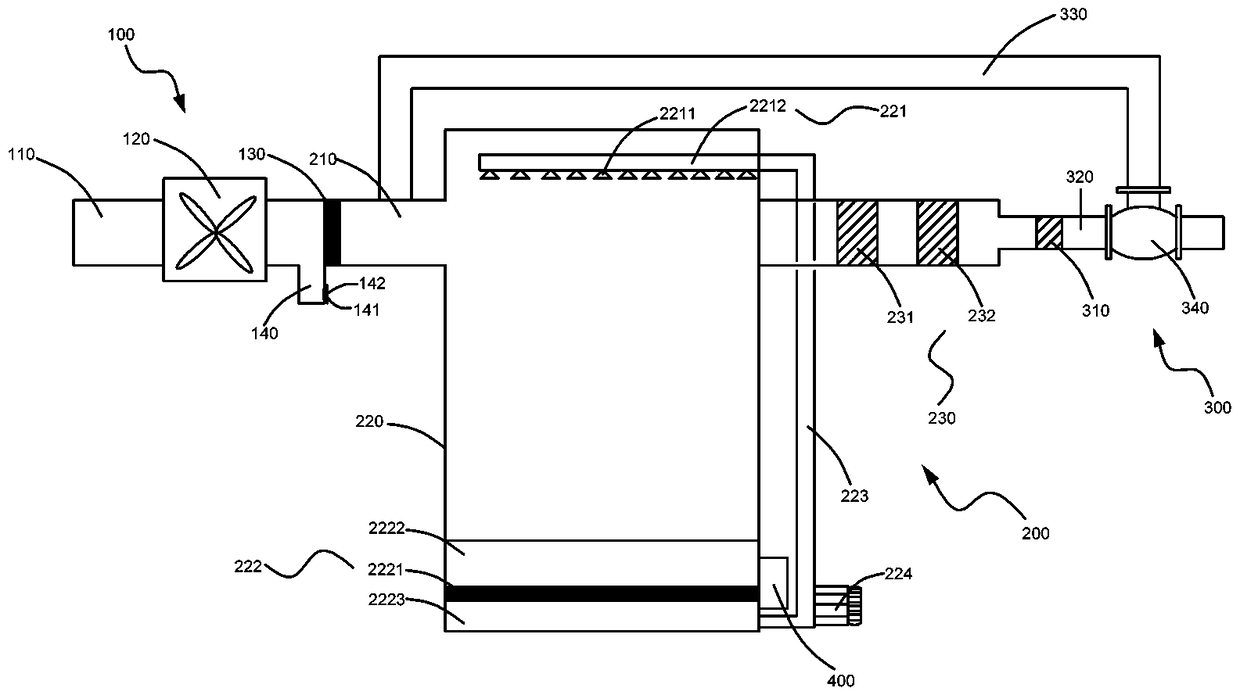

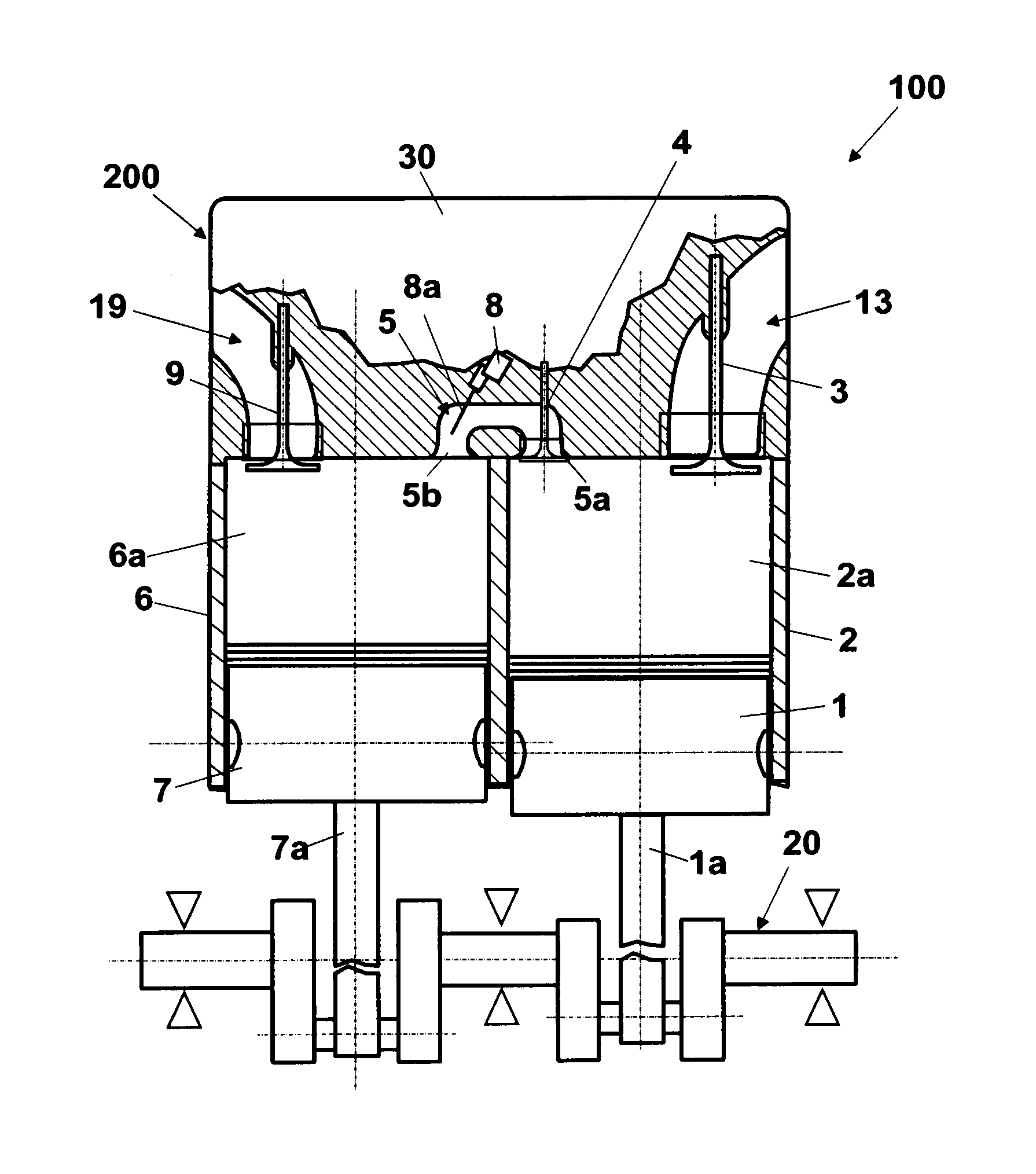

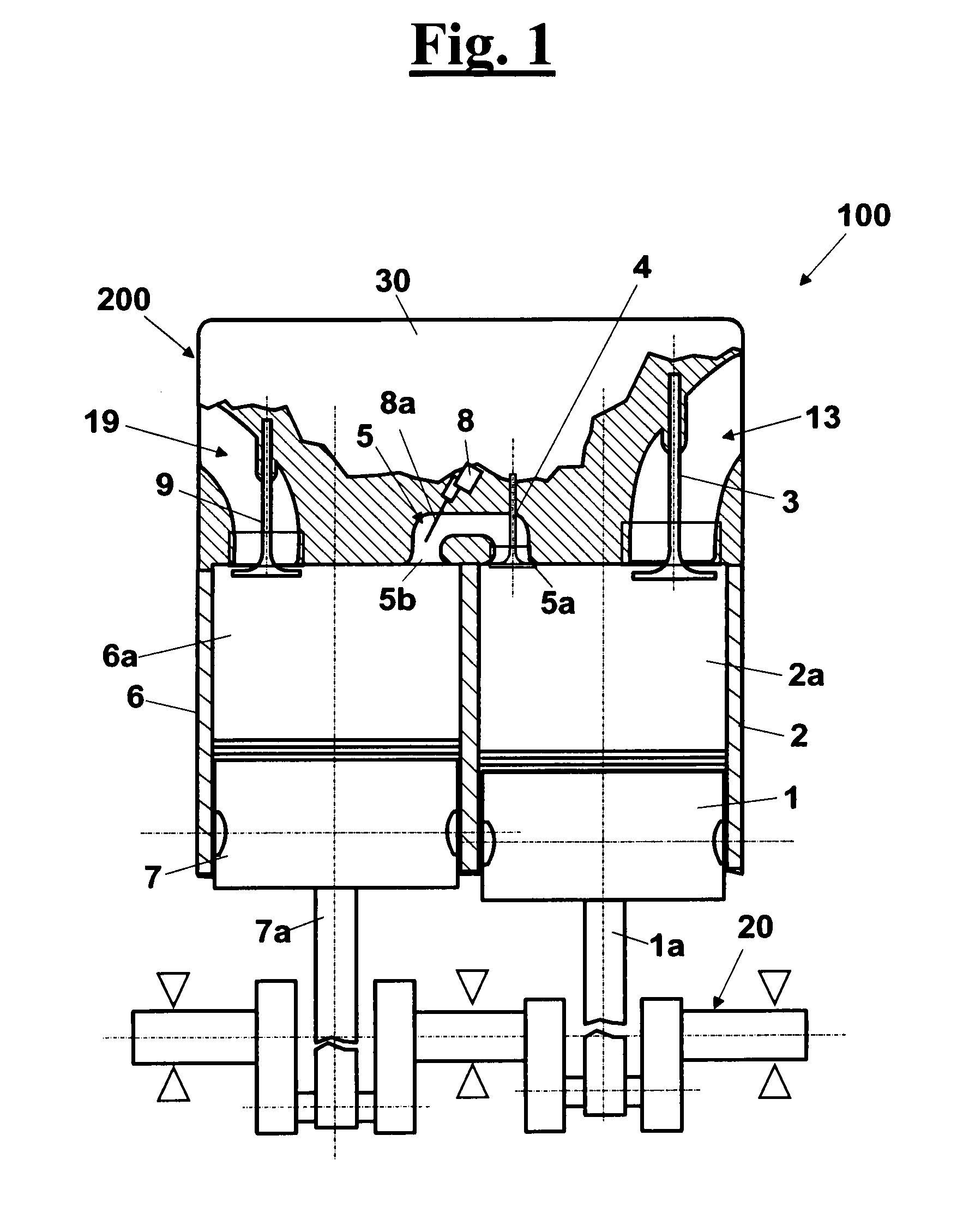

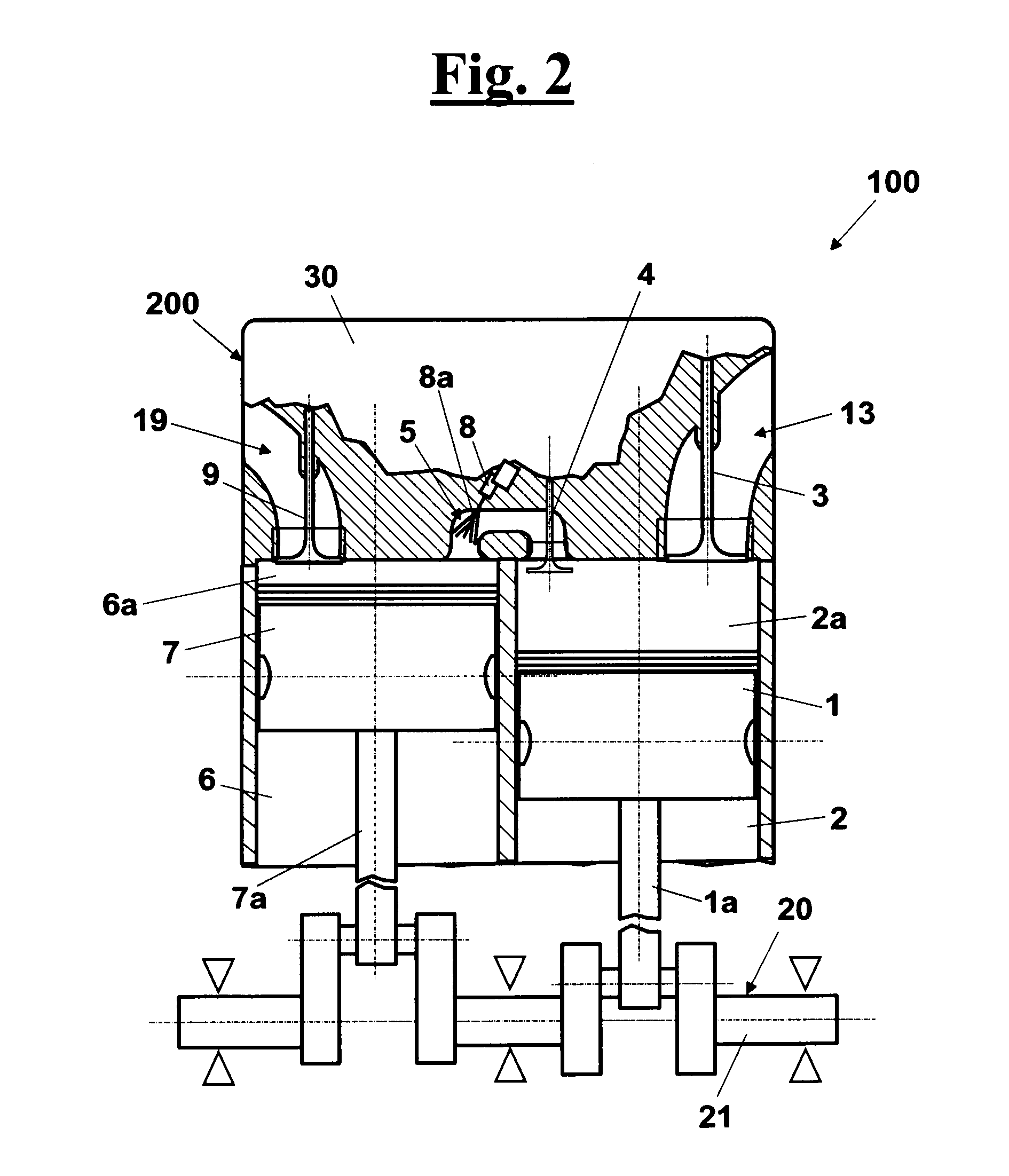

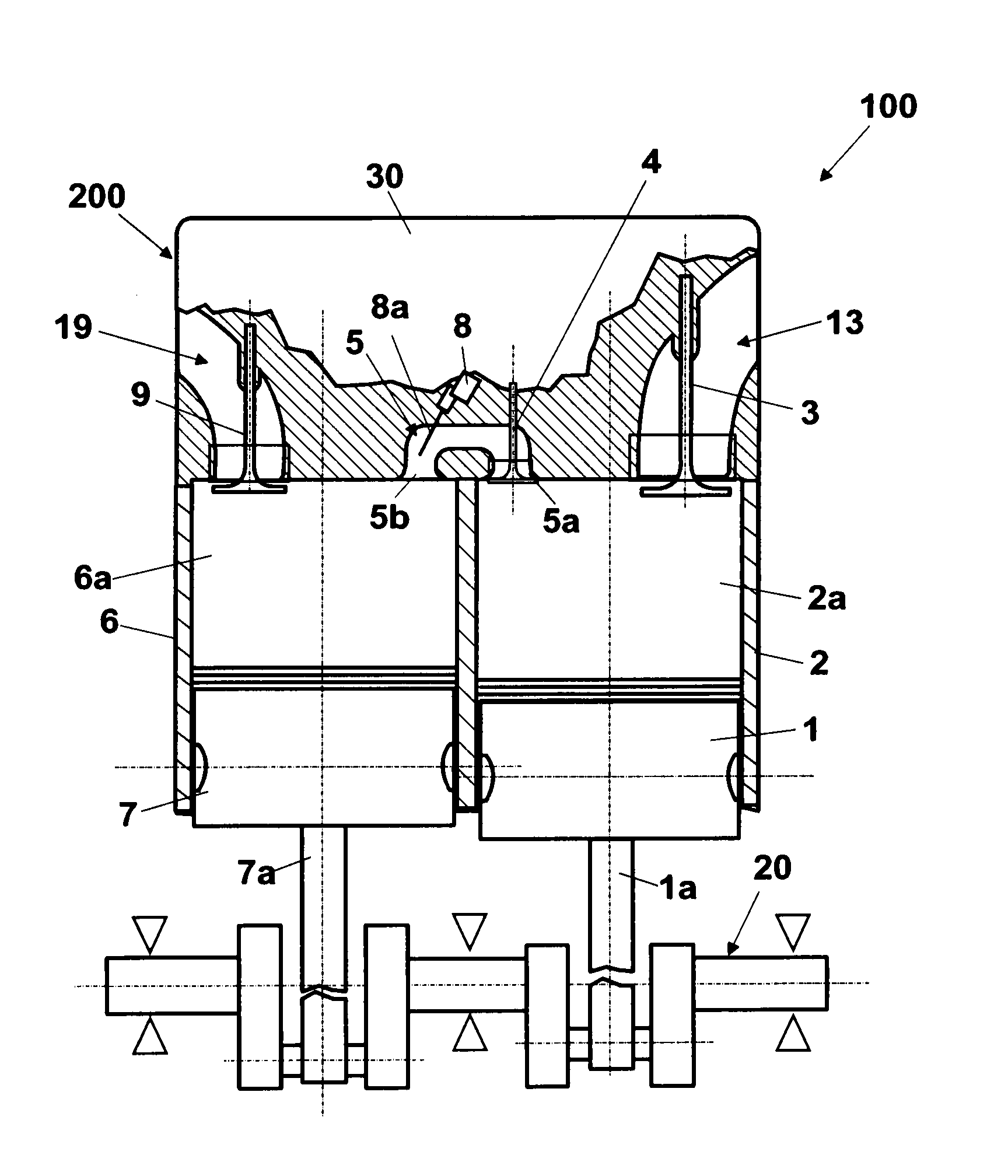

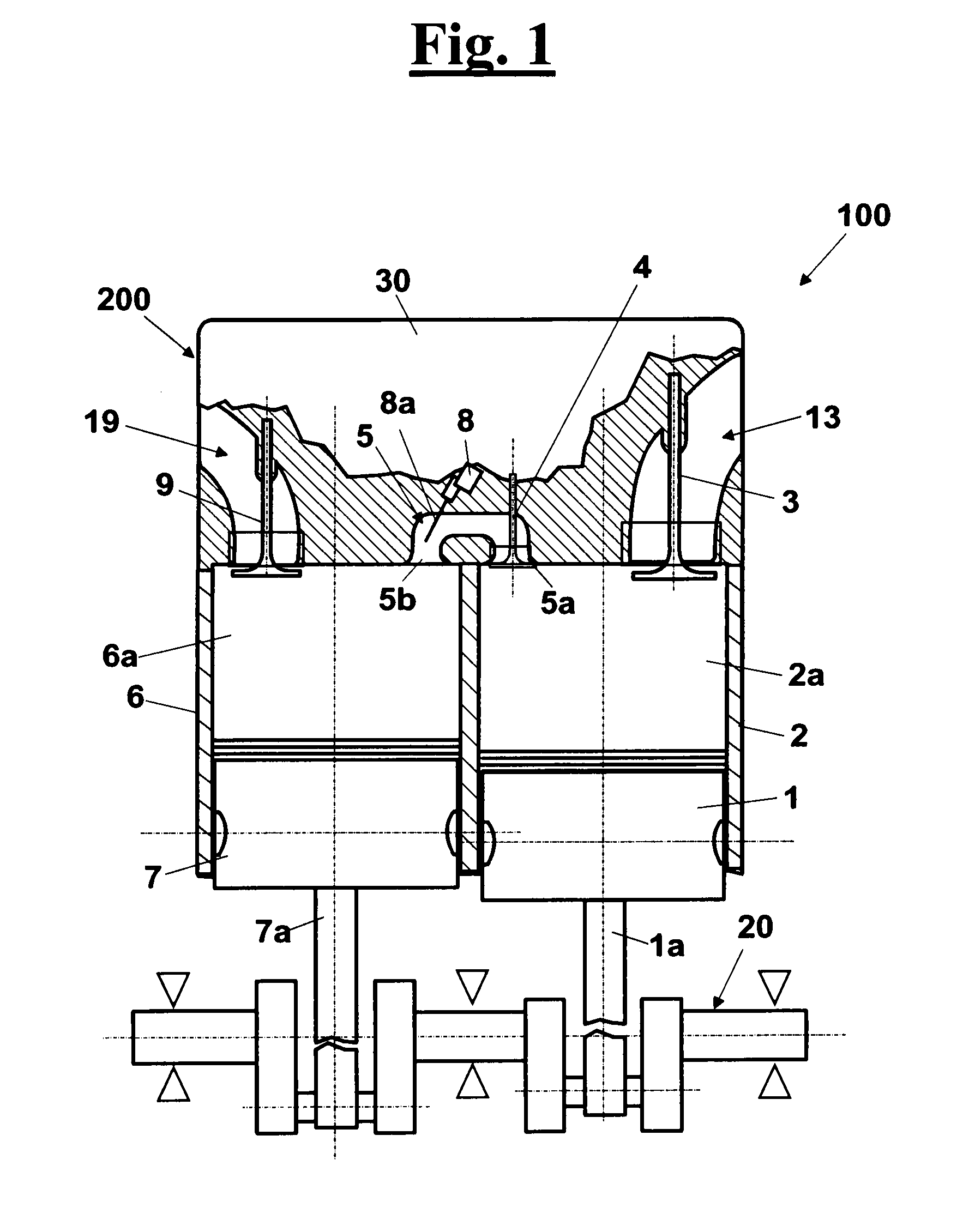

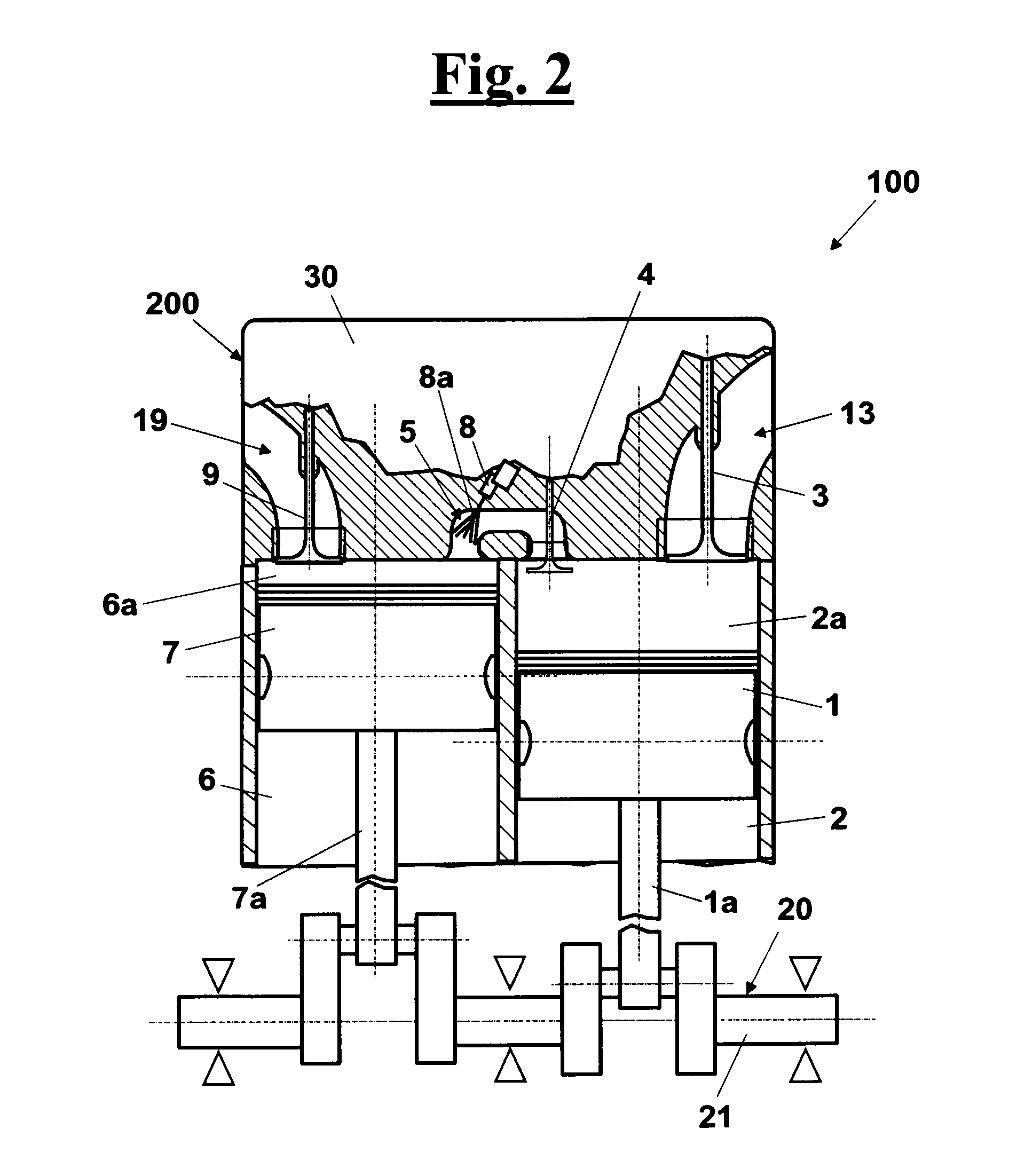

Split-cycle engine

ActiveUS20120167566A1Reduce dust emissionsEmission reductionInternal combustion piston enginesLow pressure fuel injectionExhaust valvePhase shifted

A compression-ignition “split-cycle” engine (100) comprises: a cylinder block (200) with an expansion cylinder (6) having an expansion piston (7) that is adapted to move alternatively between a top dead center (ETDC) and a bottom dead center (EBDC) by a crankshaft mechanism (20) that causes a predetermined position of the expansion piston (7) to correspond to a predetermined crankshaft angle; a compression cylinder (2) having a compression piston (1) that is adapted to move alternatively between a CTDC and a CBDC according to a predetermined angular phase shift in delay to the expansion piston (7); a cylinder head (30) that closes the cylinders and comprises a crossover passageway (5) with an opening (5a) in constant communication towards compression cylinder (2) and an opening (5b) having a transfer valve (4) towards expansion cylinder (6), an intake valve (3) and a exhaust valve (9); a means for opening / closing the transfer valve (4); a means for opening / closing exhaust valve (9) at predetermined moments of the alternative cycle of the pistons, and a fuel injector (8) in the crossover passageway (5). The opening movement of the transfer valve (4) is carried out in advance 20° or more of crankshaft angle with respect to the crankshaft angle of the ETDC, such that from the opening instant up to reaching the ETDC there is a substantial equalization of pressure between the cylinders, such that between the ETDC and the CTDC a transfer occurs of the comburent fluid between the two cylinders, and such that injector (8) injects the fuel (8a) starting from the achievement of the ETDC.

Owner:GREEN ENGINE CONSULTING

Seam-Sealed Filters and Methods of Making Thereof

ActiveUS20130283742A1Sufficiently conductiveReduce dust emissionsDispersed particle filtrationSynthetic resin layered productsBaghouseAir cleaning

A seam-sealed filter in which the seam is sealed with a seam tape comprised of an expanded fluoropolymer, such as ePTFE and copolymers thereof, having a crosswise matrix modulus of greater than 1,950 psi and an enthalpy ratio of less than 0.6 is disclosed. Such seam-sealed filters are capable of undergoing greater than 50,000′pulse-jet or reverse air cleaning cycles without substantial cracking or peeling of the sealed seam. Accordingly, the seam-sealed filters in the form of bags are particularly suitable for use in reducing particulate emissions in cement baghouses and the like.

Owner:WL GORE & ASSOC INC

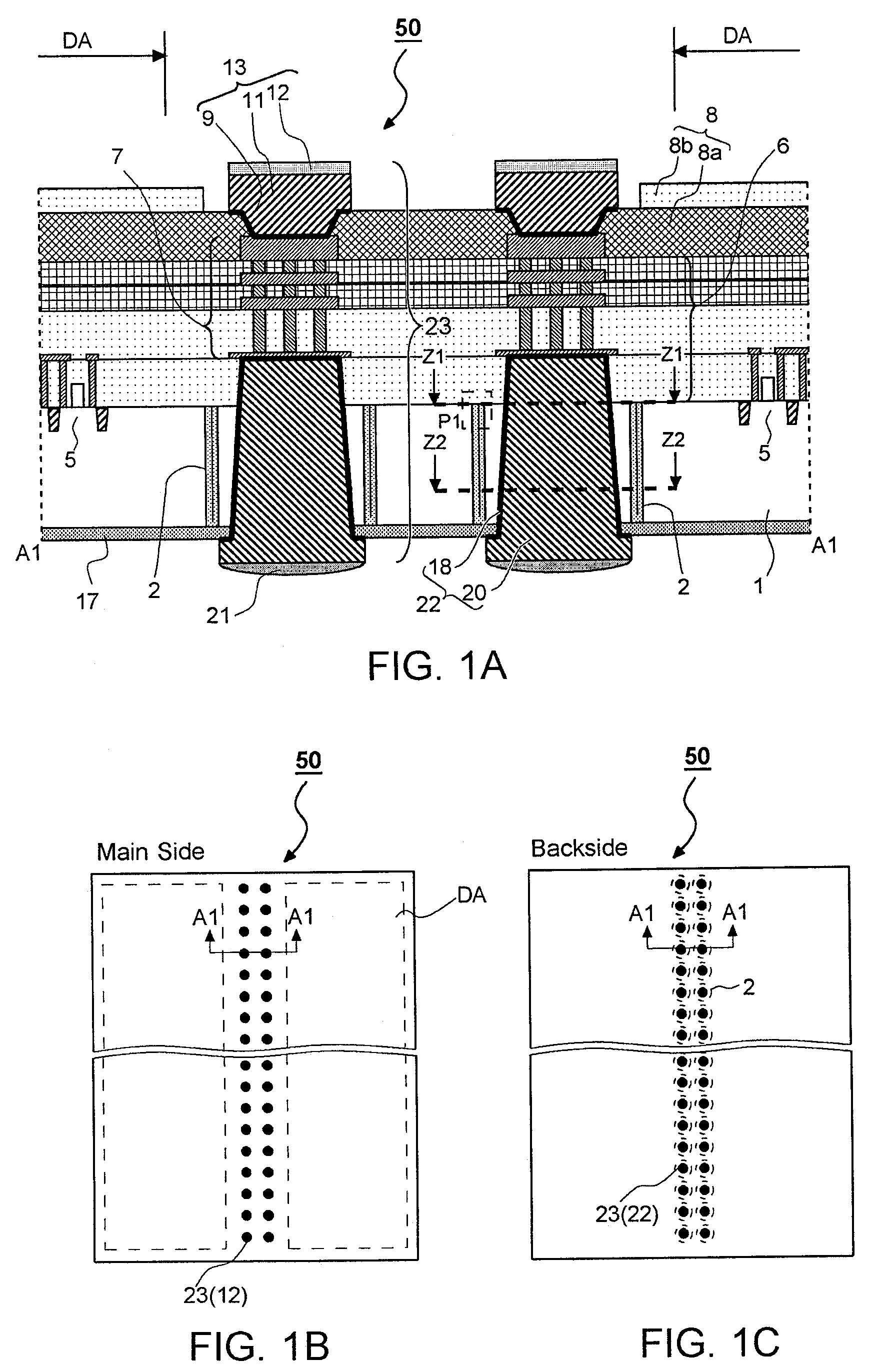

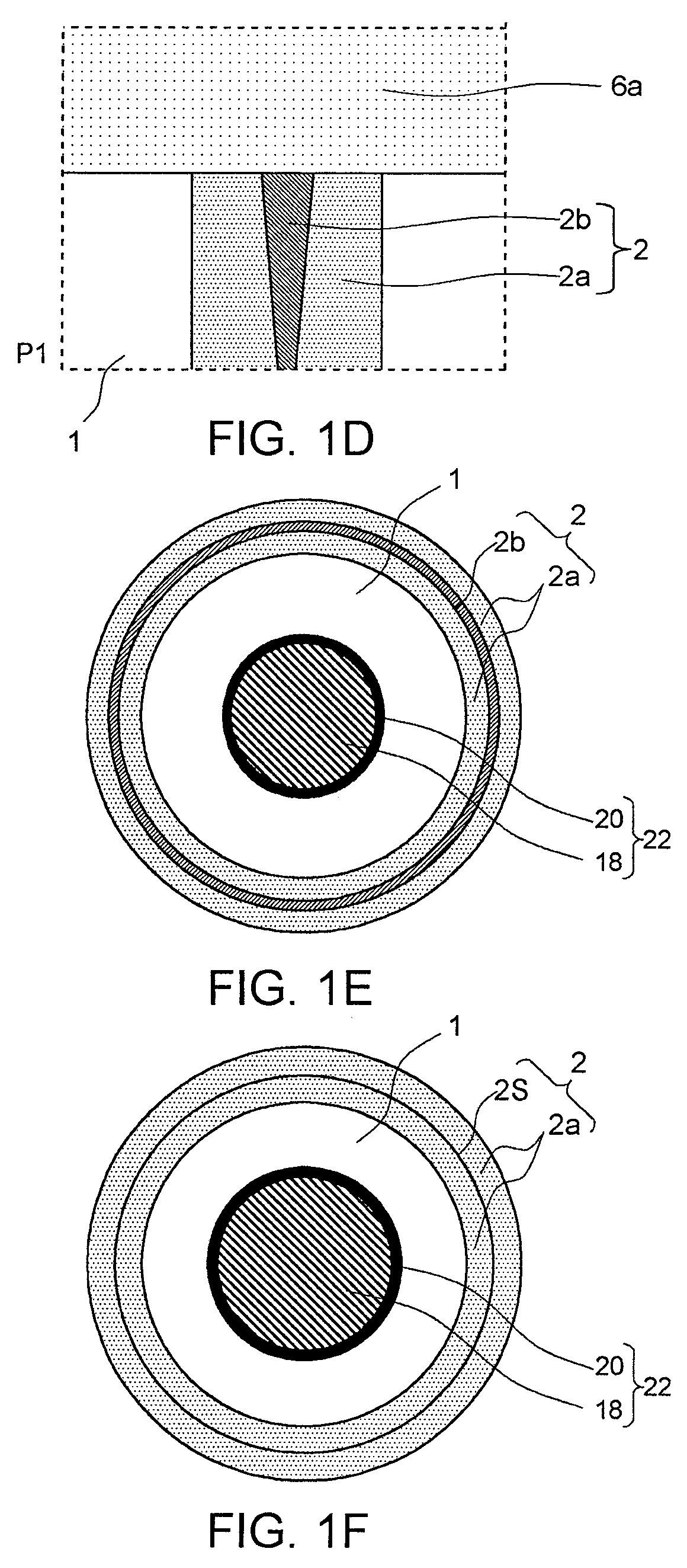

Semiconductor device having through-substrate via with insulating portion

ActiveUS9054081B2Increase productionReduce dust emissionsSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device

A semiconductor device includes an isolation portion penetrating a semiconductor substrate from a first surface to a second surface positioned opposite the first surface. The isolation portion includes a first insulating film and a second insulating film. The first insulating film has a slit portion at a side of the first surface and the slit portion is buried with the second insulating film. The semiconductor device further includes an electrode penetrating the semiconductor substrate that is surrounded by the isolation portion.

Owner:LONGITUDE LICENSING LTD

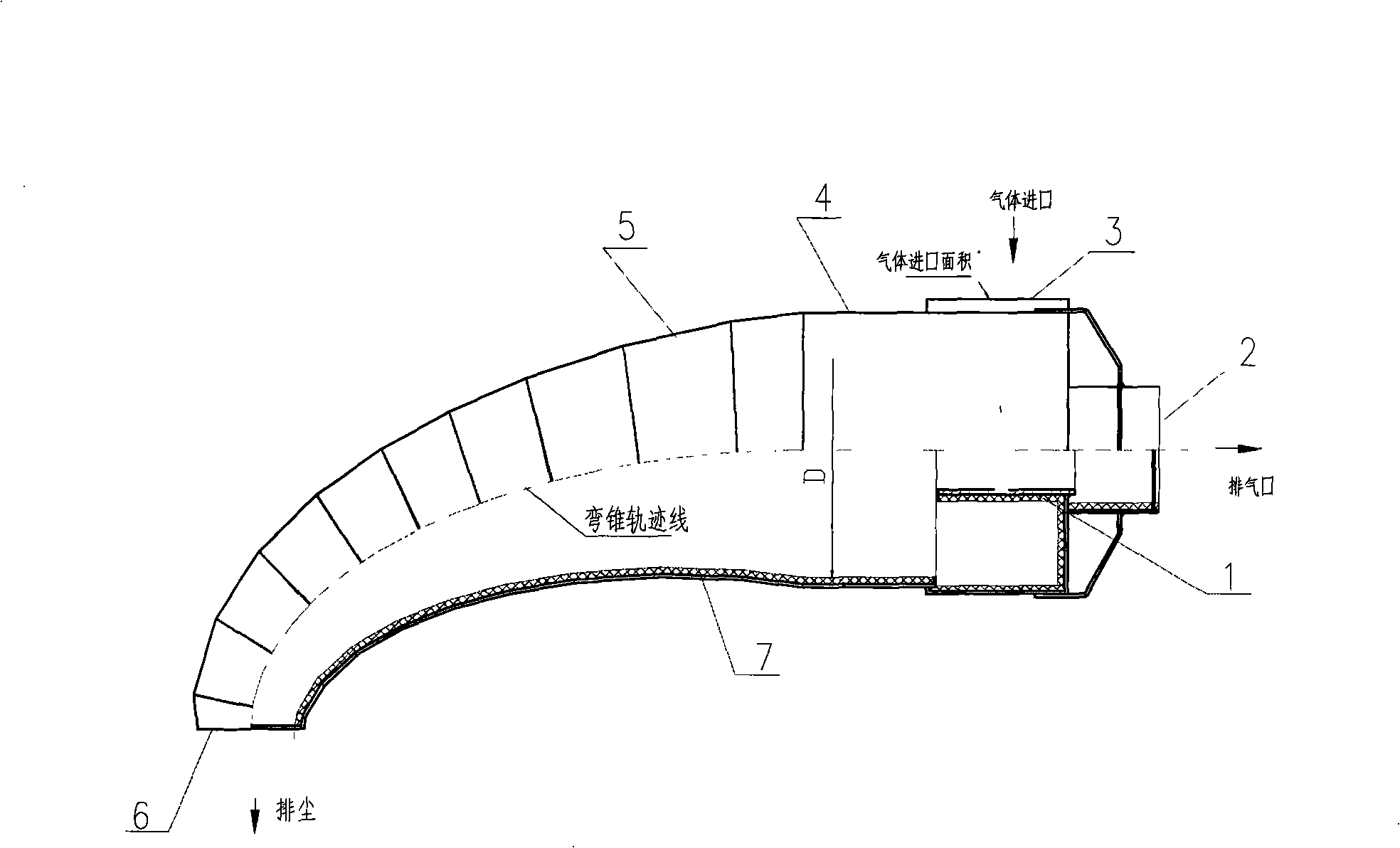

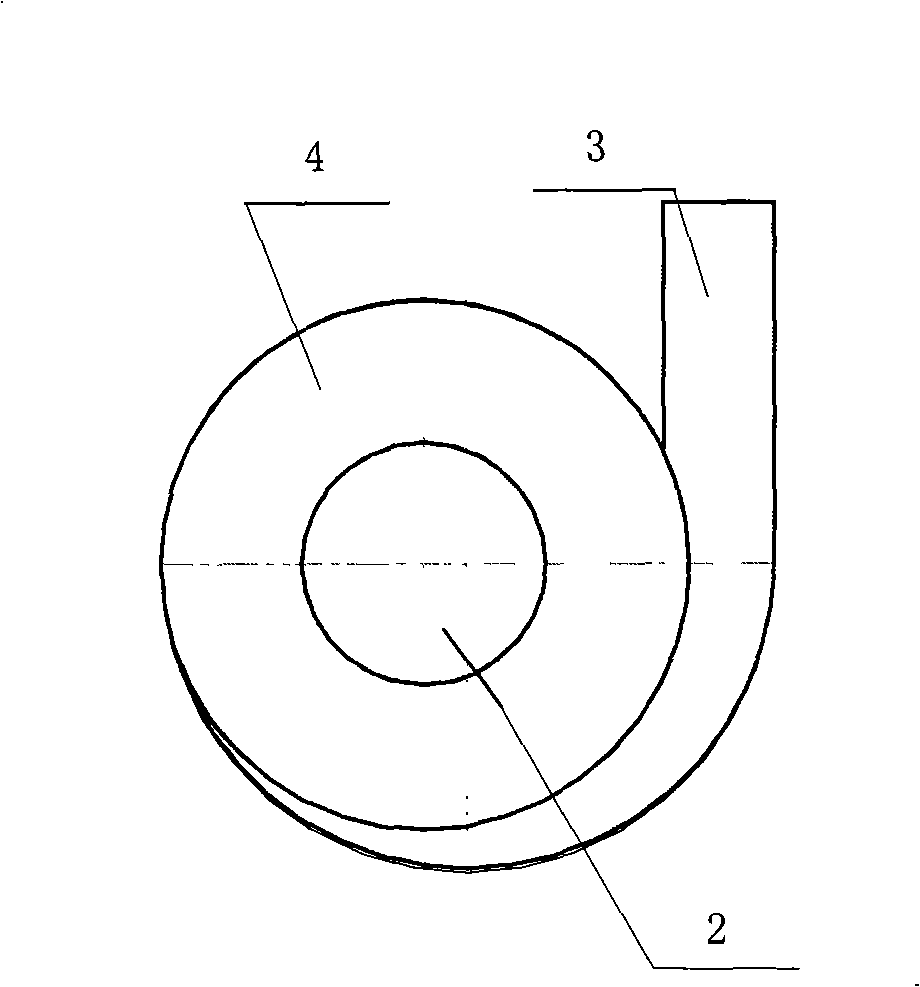

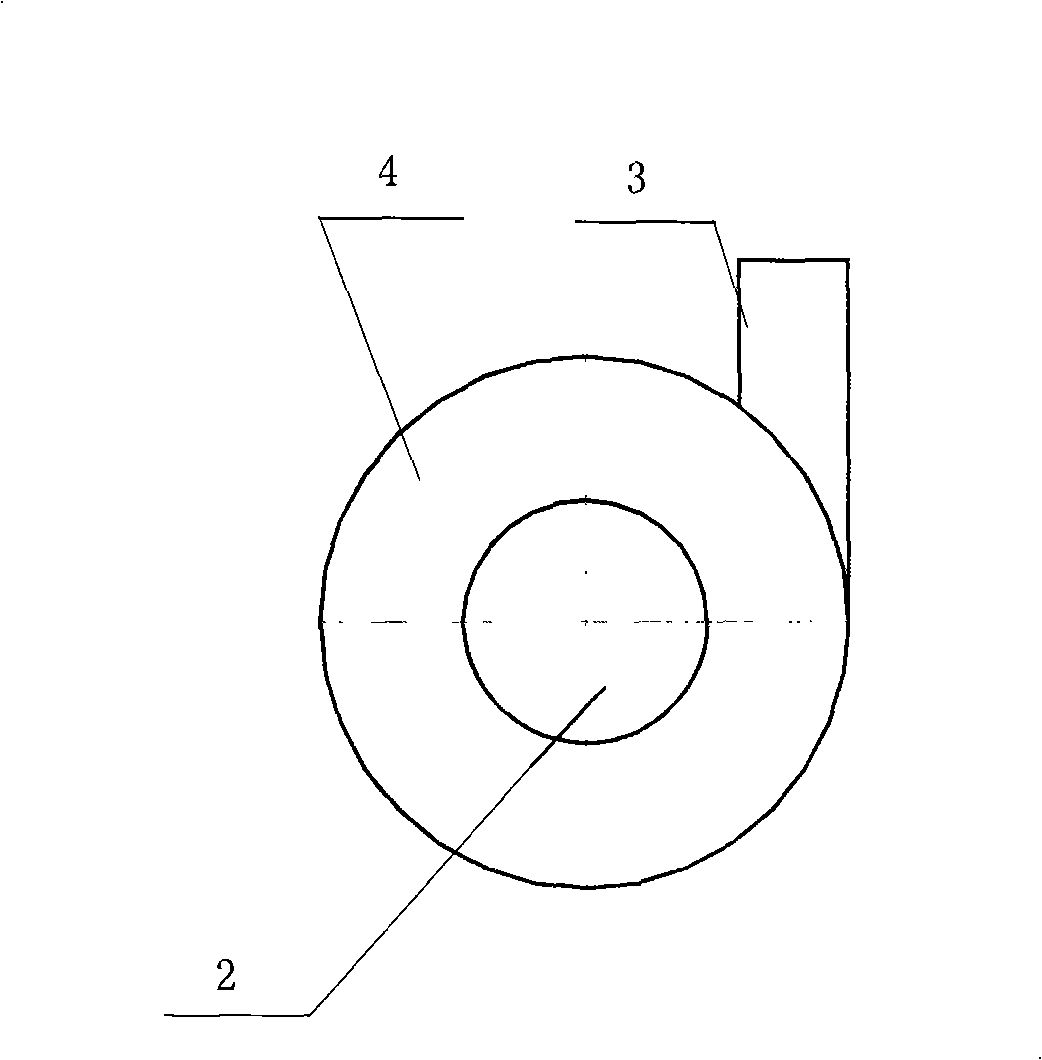

Cyclone separating device and uses thereof

The invention discloses a cyclone separator used for gas-solid or liquid-solid separation, comprising a gas riser, an air outlet, an air inlet, a straight cylinder section, a separation deposition cone section, a dust outlet, and a wearable layer. The cyclone separator is characterized in that the separation deposition cone section adopts a bent cone structure; the axis line track of the bent cone structure is an arc or an ellipse or other smooth transition curved lines. The cyclone separator is mainly used for the separation, recycling and exhaust of the wasted catalyst fine powders in the fourth-class cyclone separation system of a petroleum chemical fluid catalytic cracking device. The cyclone separator with the bent cone structure has installation height which is only one third of the installation height of a vertical cyclone separator, and is applicable to the design and reconstruction of devices with equipment installation space to be restricted; meanwhile, the bent-cone typed cyclone separator has simple structure, large wind disposal quantity and high efficiency; furthermore, as the liner material with high wearability is adopted, the cyclone separator of the invention can be used under high temperature for a long time.

Owner:SINOPEC ENG +1

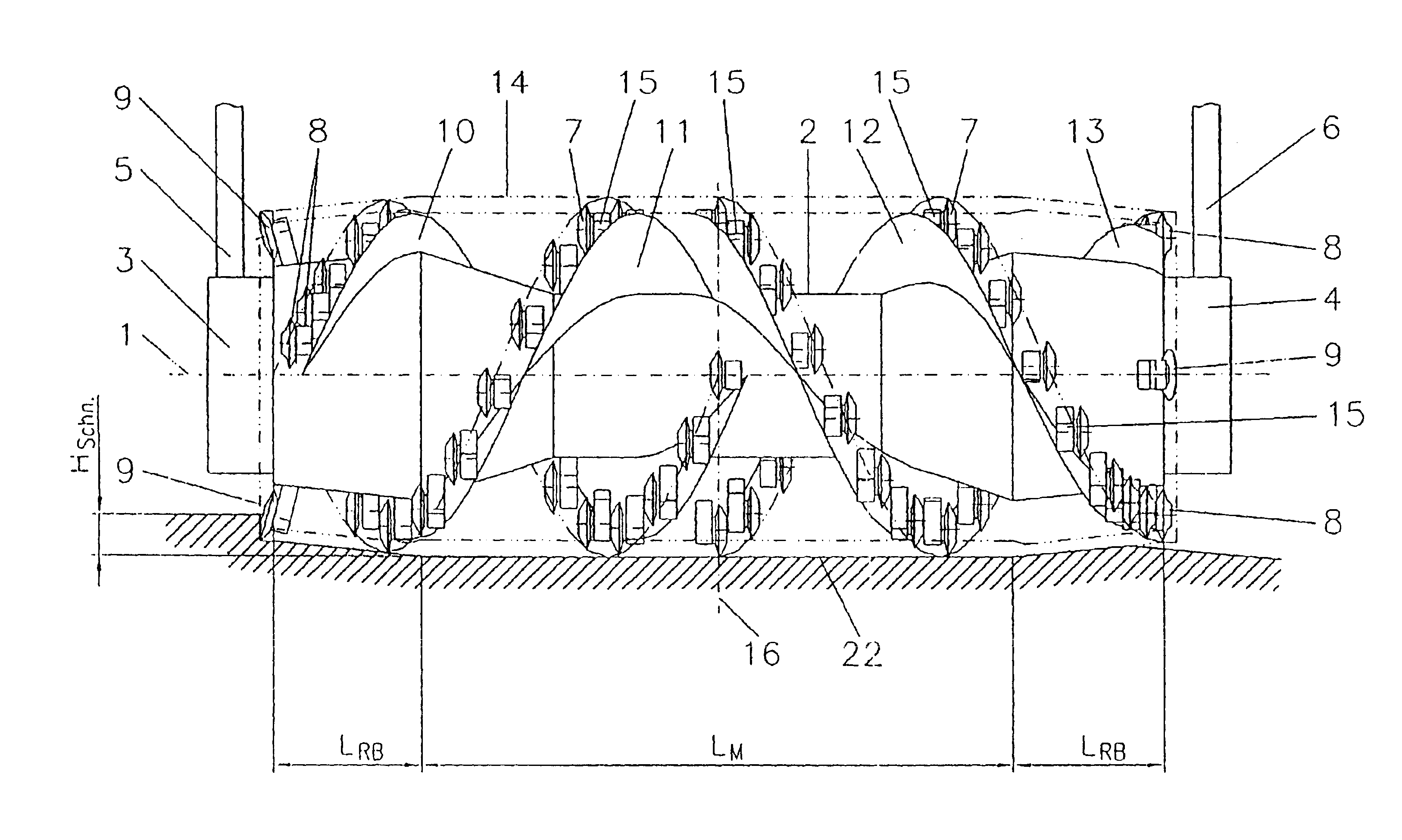

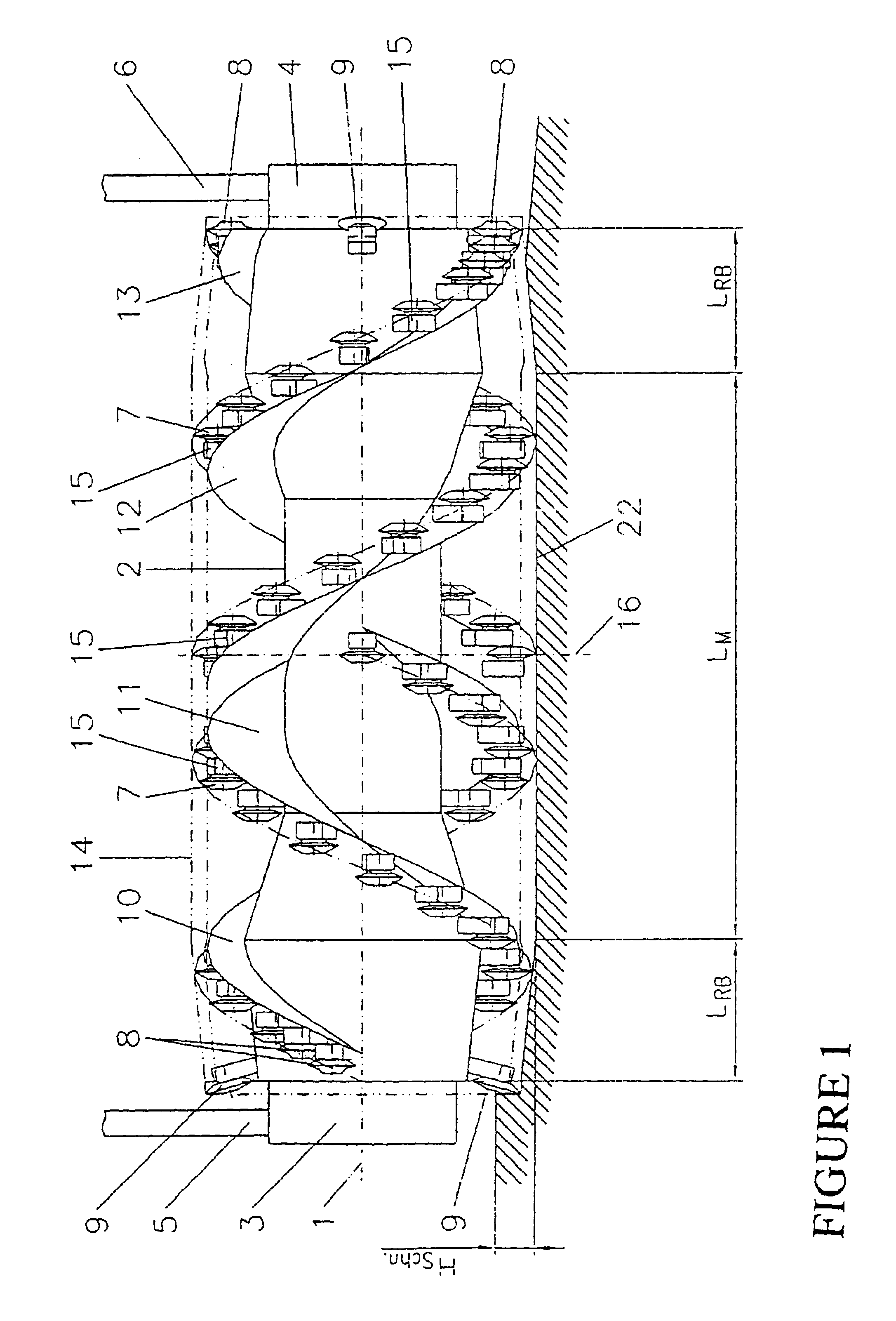

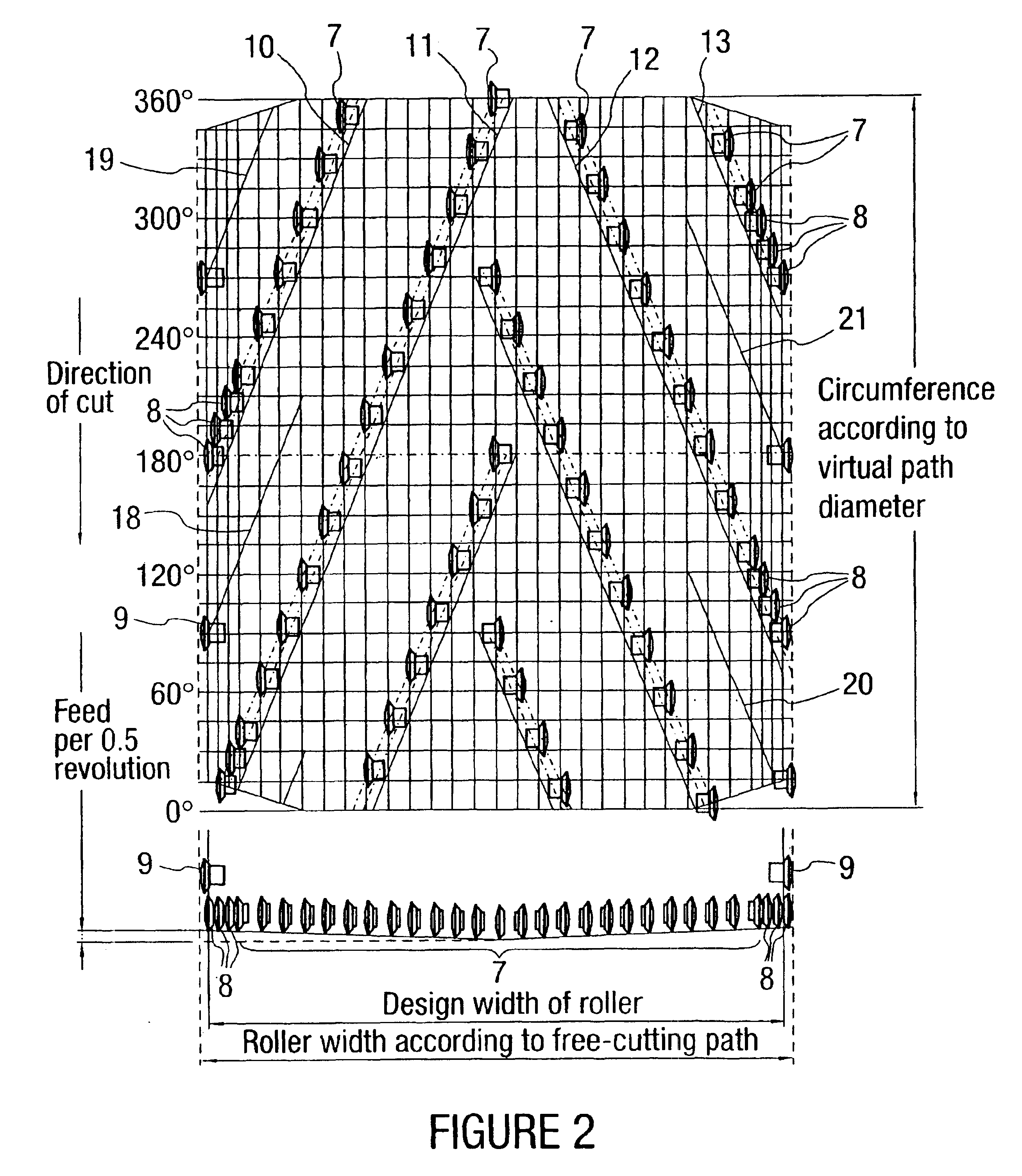

Cutting roller for a continuously operating surface miner

InactiveUS6948779B2Cleanly clearHigh strengthMechanical machines/dredgersOpen-pit miningCircular discHigh intensity

A mining member designed as a cutting roller for a continuously operating surface miner for mining mineral raw materials of high strength. The roller body is equipped for this purpose with mini-disk bits of identical design. Since different conditions occur over the entire width of the roller during the separation of the material from the soil, the roller body is designed correspondingly, and the arrangement of the mini-disk bits is adapted to these conditions. The mini-disk bits in the edge areas are placed at a greater density than are the mini-disk bits (7) in the middle area. In addition, mini-disk bits are directed obliquely toward the outside as free-cutting bits at the two outer edges of the cutting roller. The height of the mini-disk bits is selected to be such that their individual virtual rolling paths together form a virtual cutting roller body, which comprises a middle cylinder, which is joined on both sides by outwardly tapering frusta. This solution is associated with the advantages that more mini-disk bits are available per unit area in the critical edge areas for separating the material and for cutting the roller free, and the cutting height HSchn is smaller there.

Owner:MAN TAKRAF FORDERTECHN

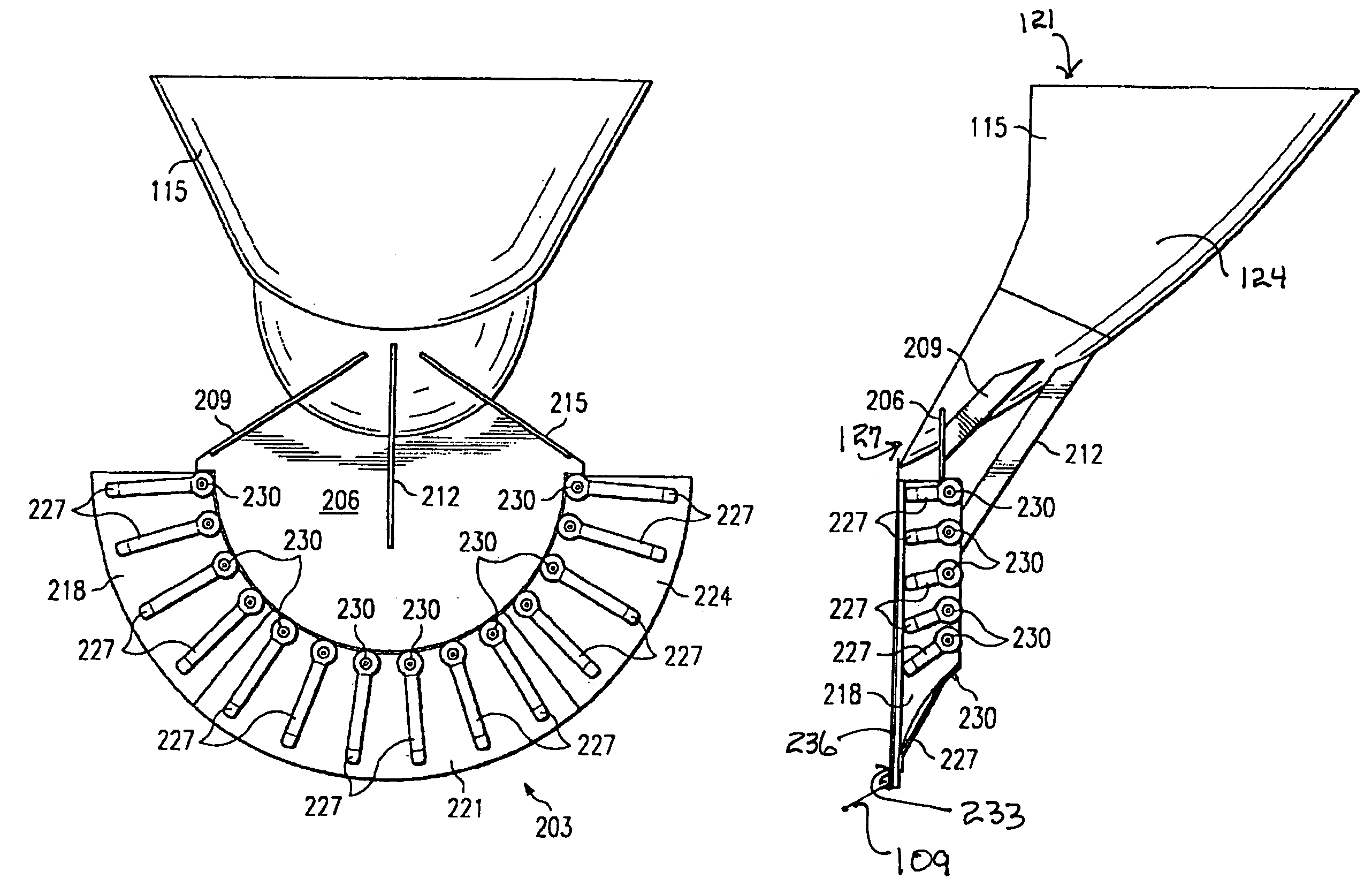

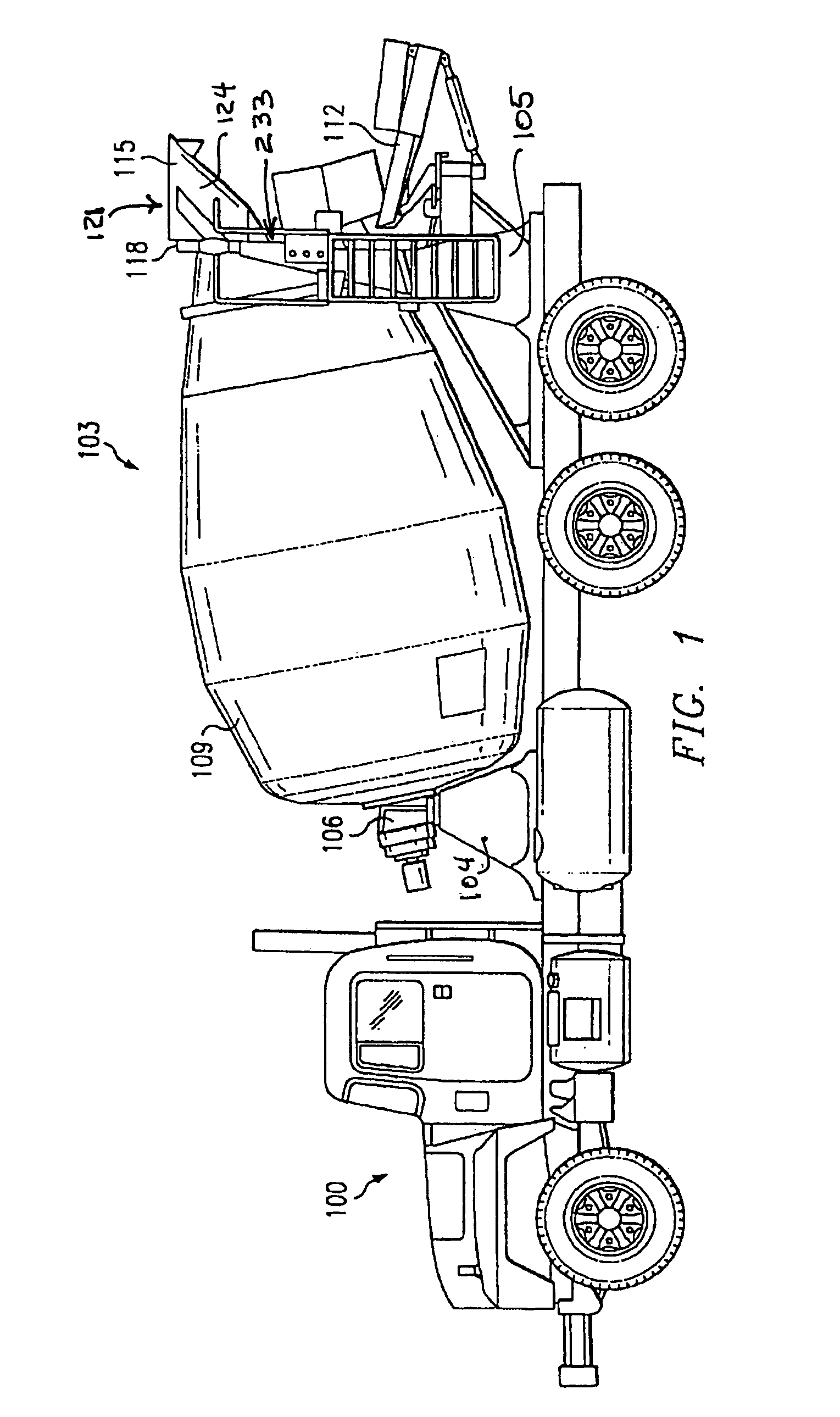

Environmental shield for a truck mounted concrete mixer

InactiveUS6957908B1Reducing and eliminating leakageReduce contentMixing operation control apparatusCement mixing apparatusTerrainEngineering

An environmental shield for reducing or eliminating leakage of materials from transit vehicles, including truck-mounted concrete mixers, is provided. The environmental shield preferably engages at least a portion of an opening on a mixer drum such that the leakage that generally occurs in such situations as travel along hilly or bumpy terrain, surging, etc. may be prevented or minimized. The environmental shield preferably includes a discharge cover and a combination steel / rubber abrasion resistant sealing member and may be preferably coupled to a charging hopper of the transit vehicle.

Owner:OSHKOSH CORPORATION

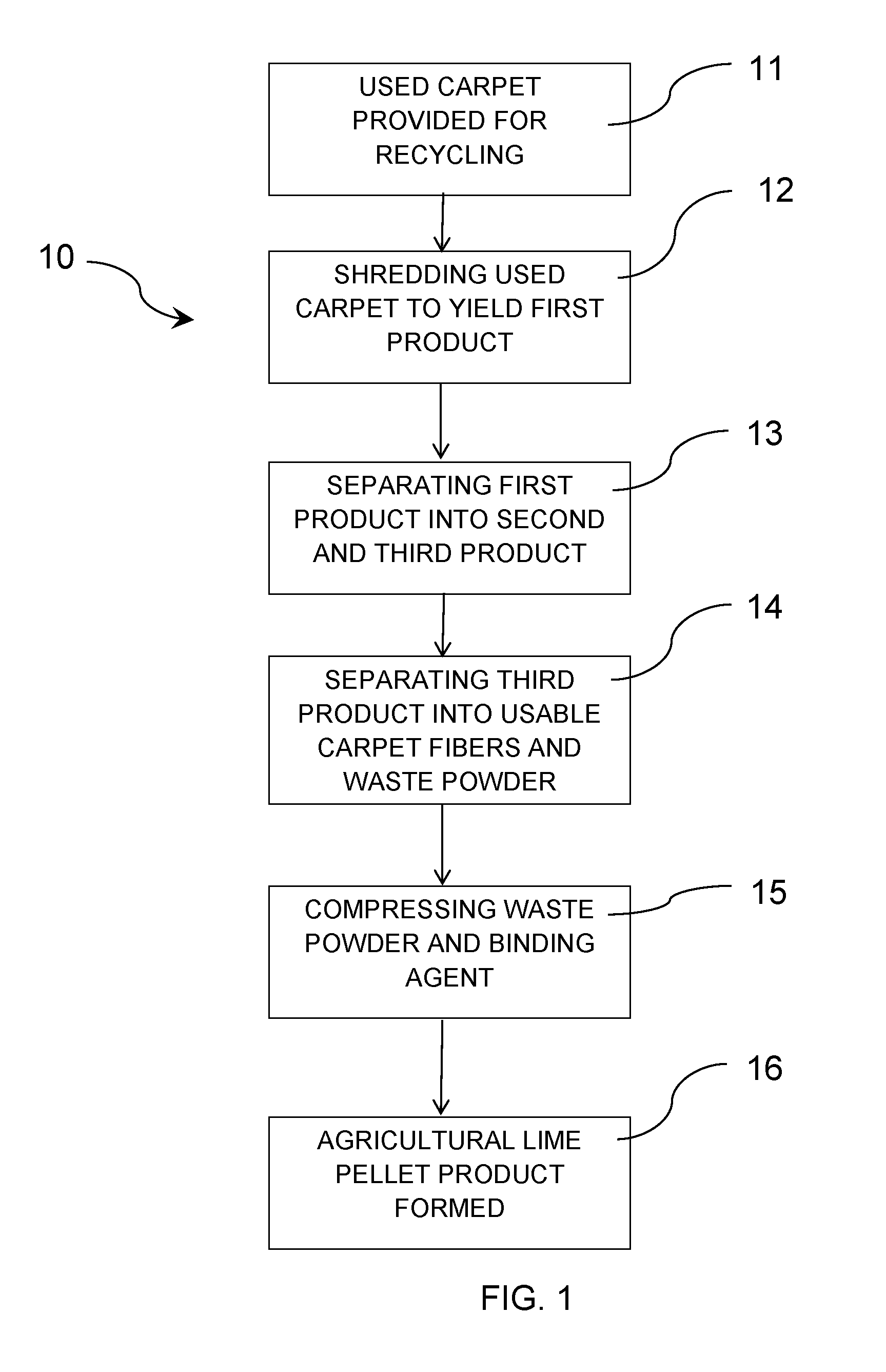

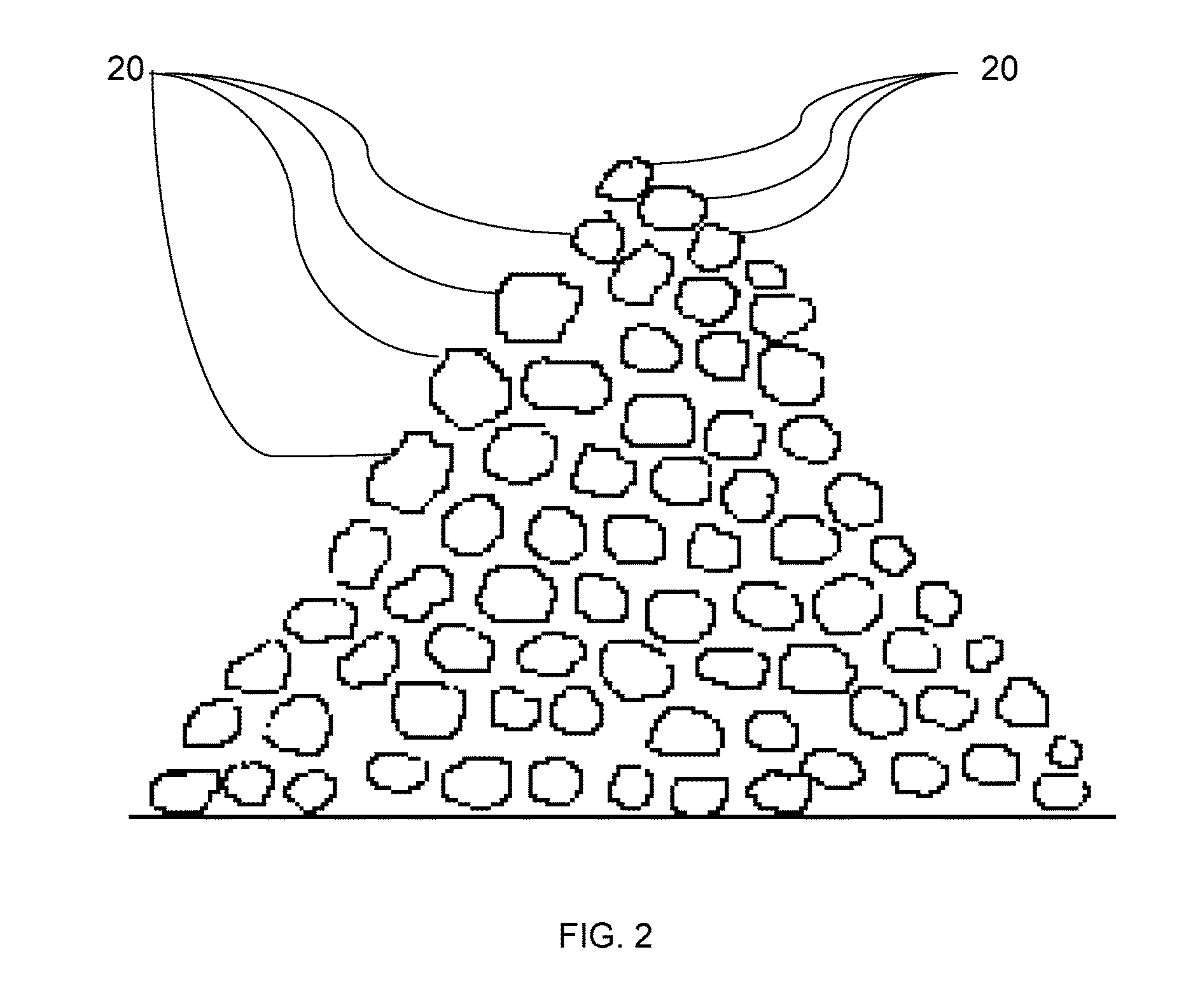

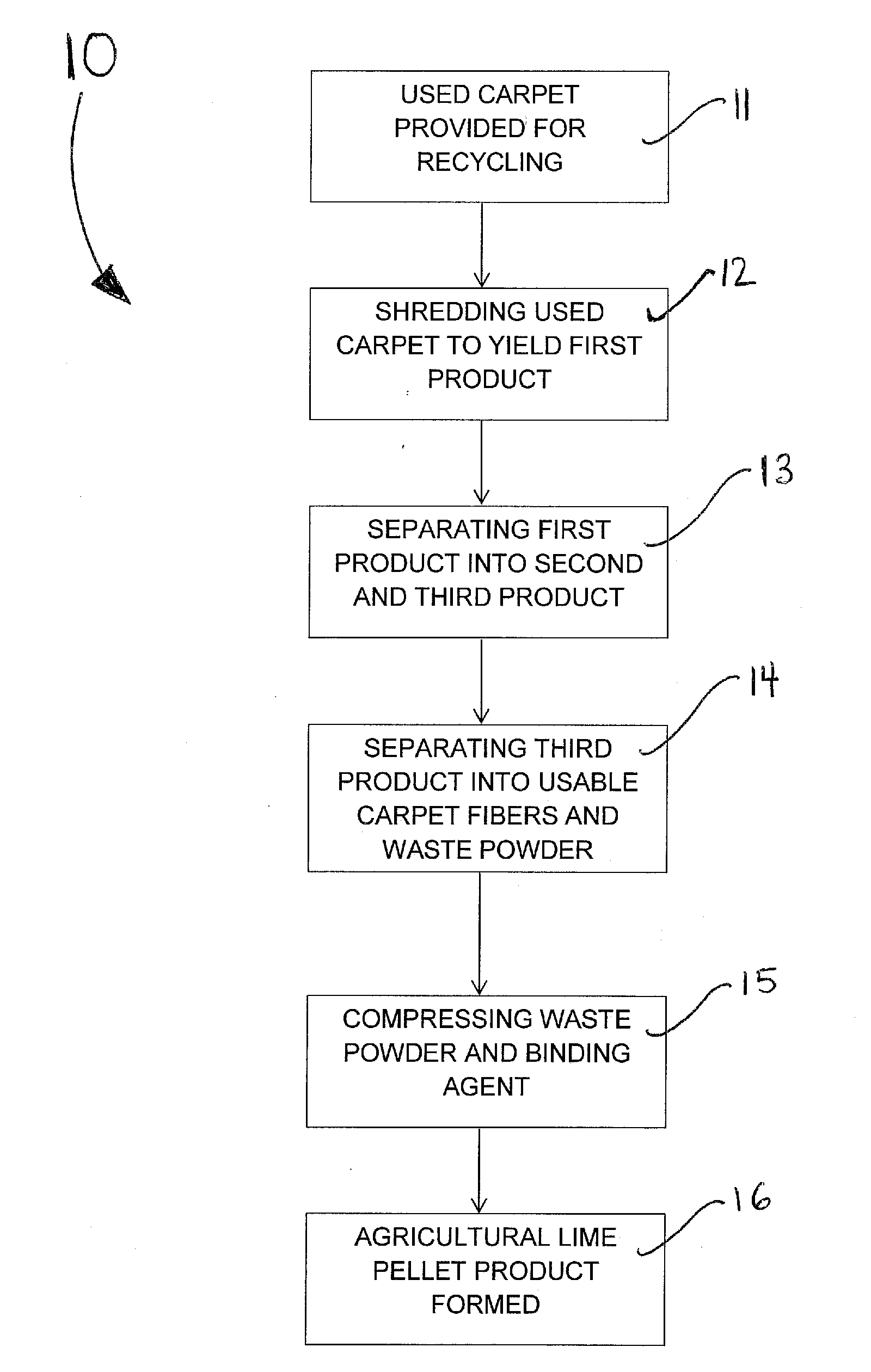

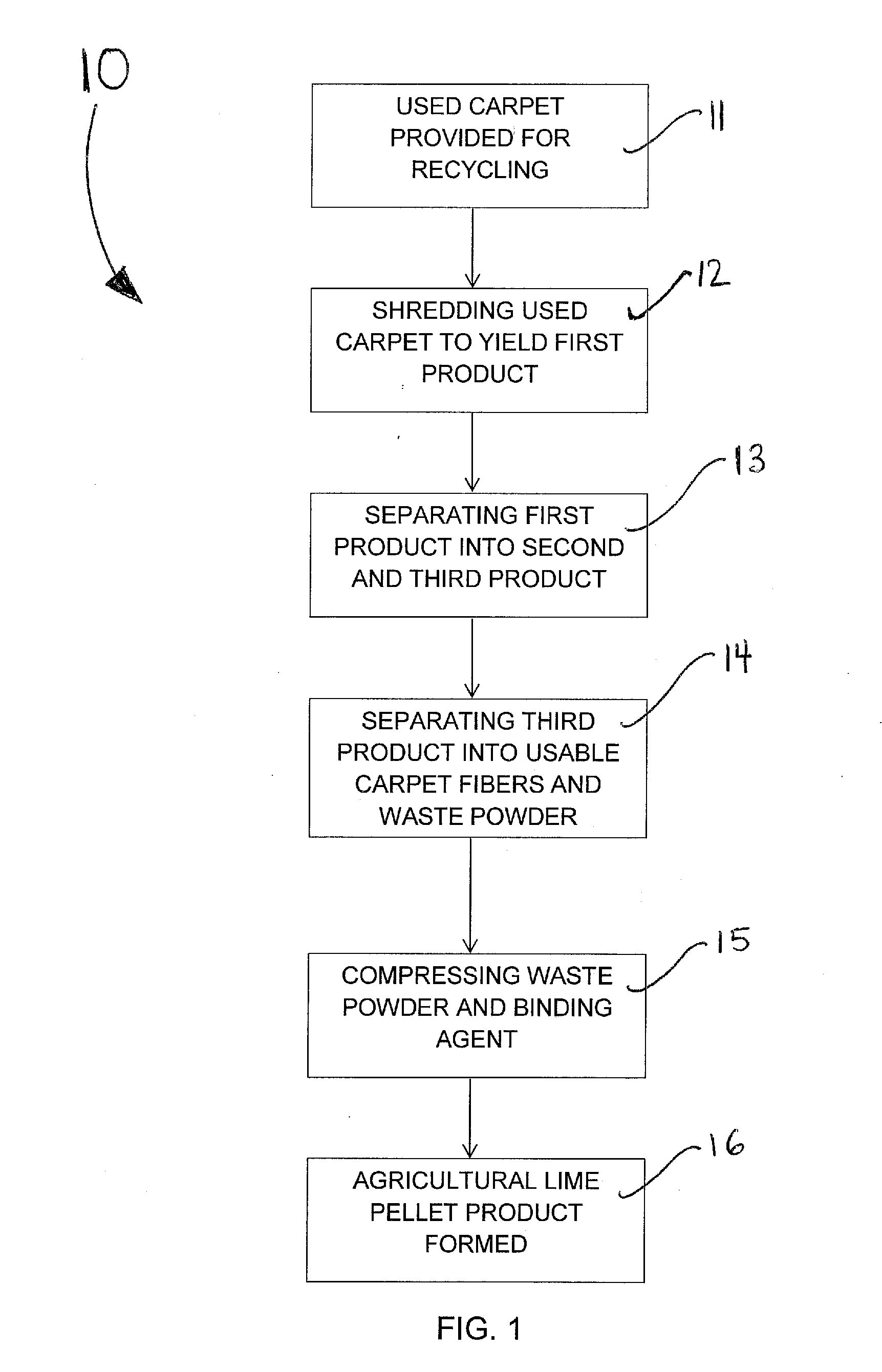

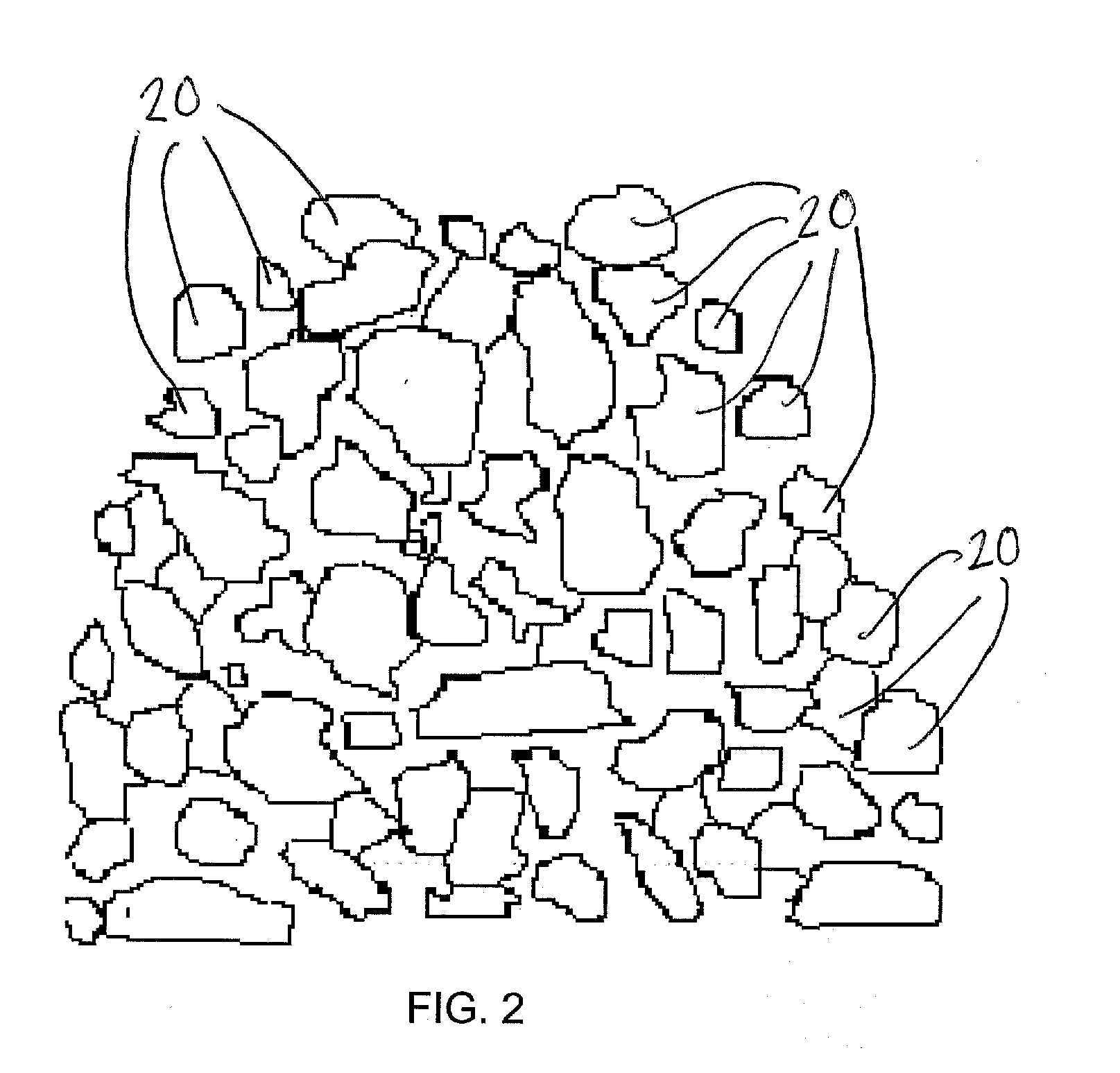

Process for making pellet product for use in soil neutralization and other applications

InactiveUS20170044346A1Reduce dust emissionsEasy to handleOther chemical processesAnimal housingFiberPrill

Recycled carpet mineral filler material is processed to form pellets that can be used in a variety of applications, such as an agricultural lime product, an asphalt paving additive, a loss control material, or cat litter. Used carpet undergoes a shredding process separating valuable resin fibers from the mineral filler and the residual glue. The mineral filler / residual glue undergoes a screening process and then a pelletizing process to produce an agricultural lime product. A liquid or dry adhesive binder can be added to facilitate compaction of the mineral filler in such a manner as to form a pellet, which reduces dust and increases the ease of handling.

Owner:WATERS JOHN HINTON

Soil neutralization product and method of making same

InactiveUS20170044076A1Reduced fugitive dust emissionEasy to handleCalcareous fertilisersMagnesium fertilisersFiberPrill

A process for making an agricultural lime product utilizes recycled carpet mineral filler material. Used carpet undergoes a shredding process separating valuable resin fibers from the mineral filler and the residual glue. The mineral filler / residual glue undergoes a screening process and then a pelletizing process to produce an agricultural lime product. A liquid or dry adhesive binder can be added to facilitate compaction of the mineral filler in such a manner as to form a pellet, which reduces dust and increases the ease of handling.

Owner:WATERS JOHN HINTON

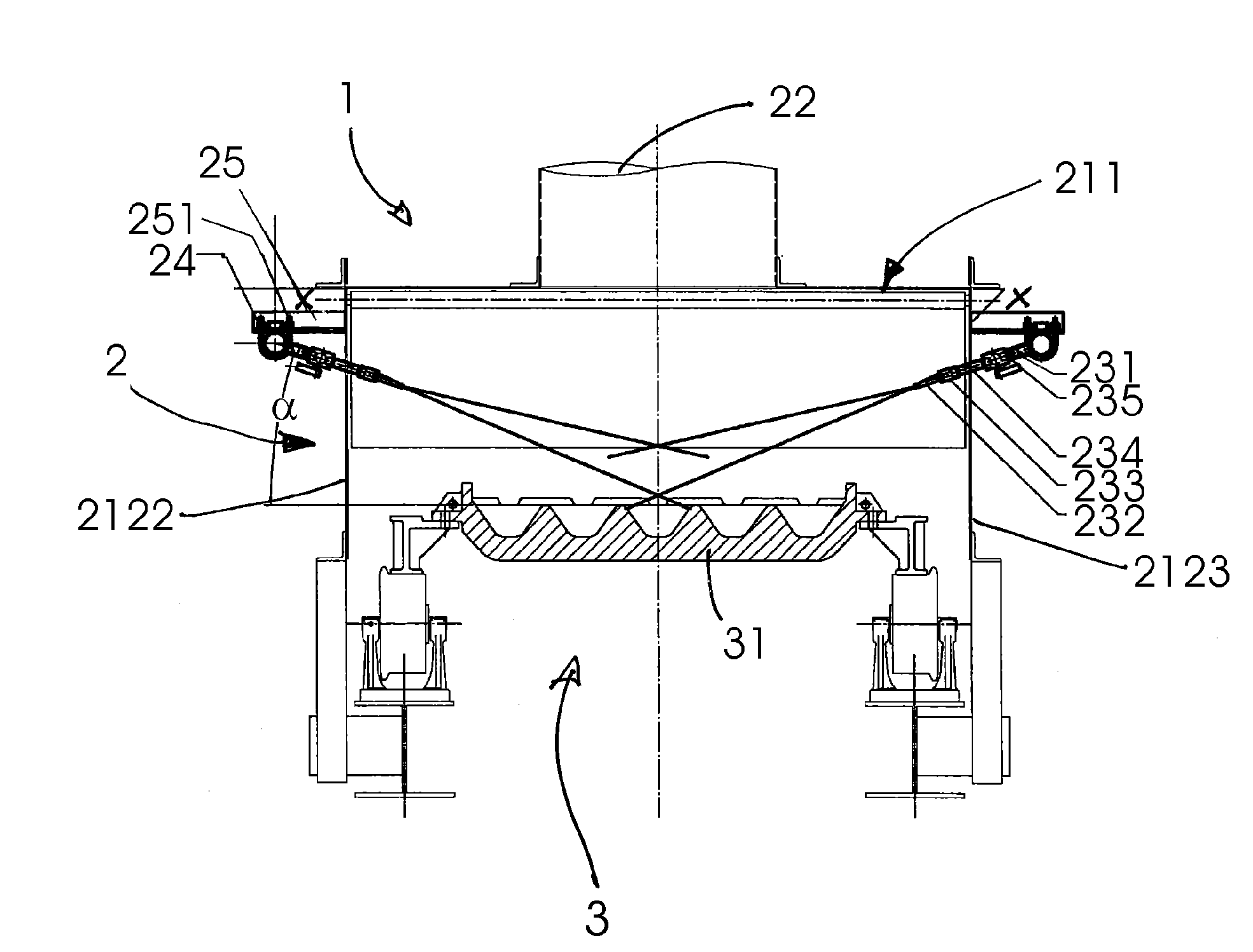

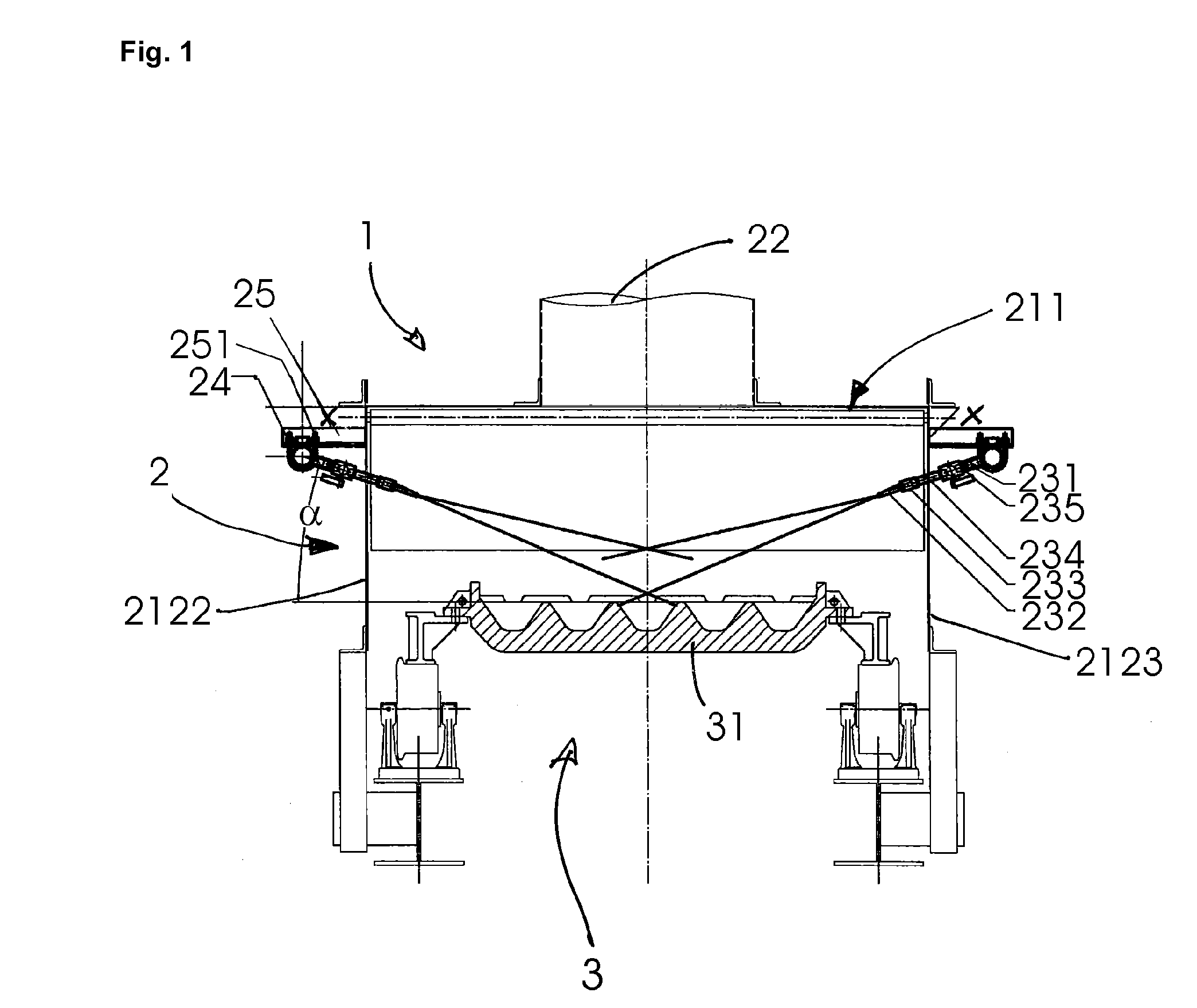

Clean booth and sheet conveyor device

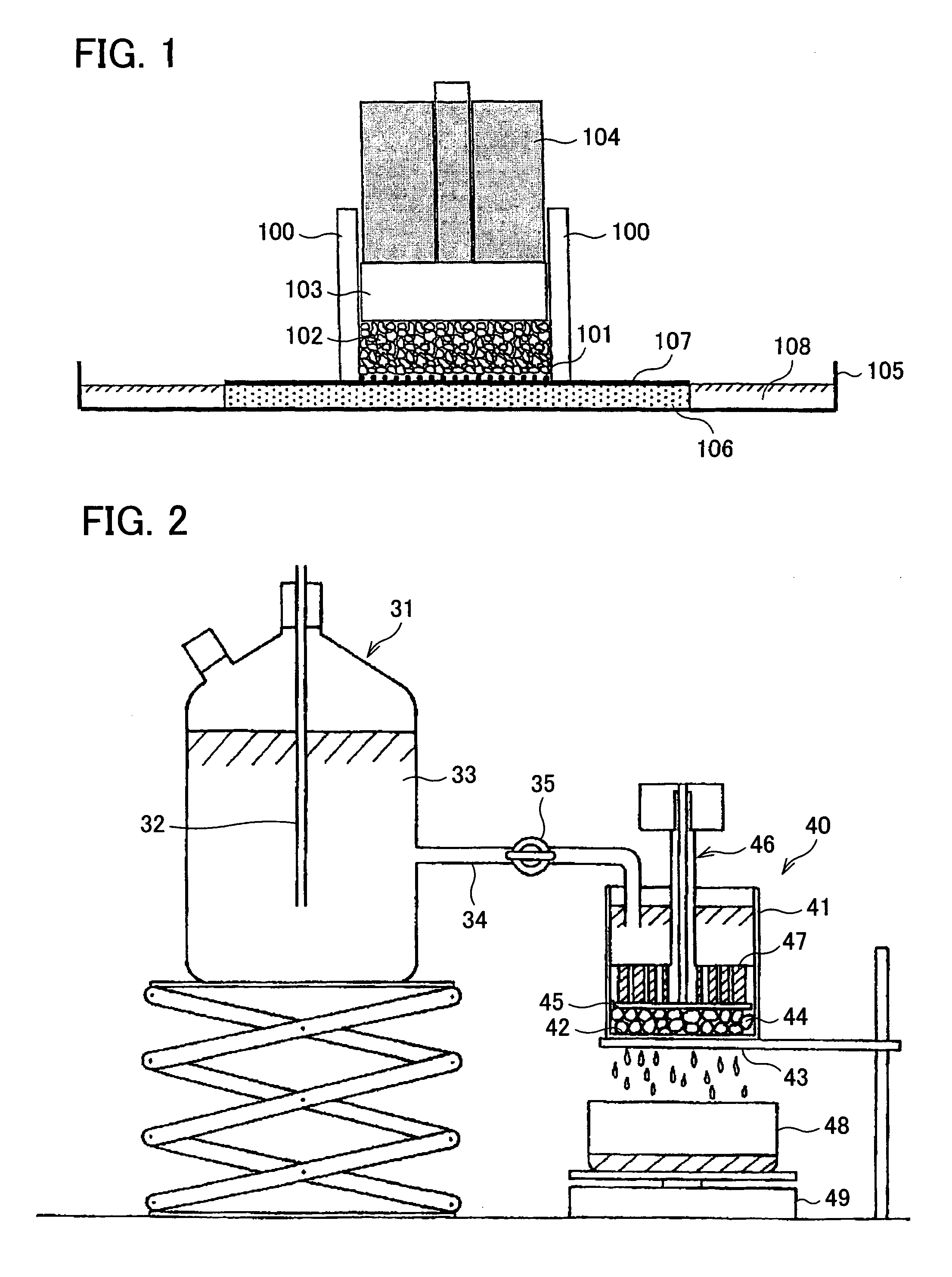

InactiveUS7536940B2Reduce dust emissionsRelieve stressLiquid processingReversal processingMotor driveTransmission belt

Owner:FUJIFILM HLDG CORP +1

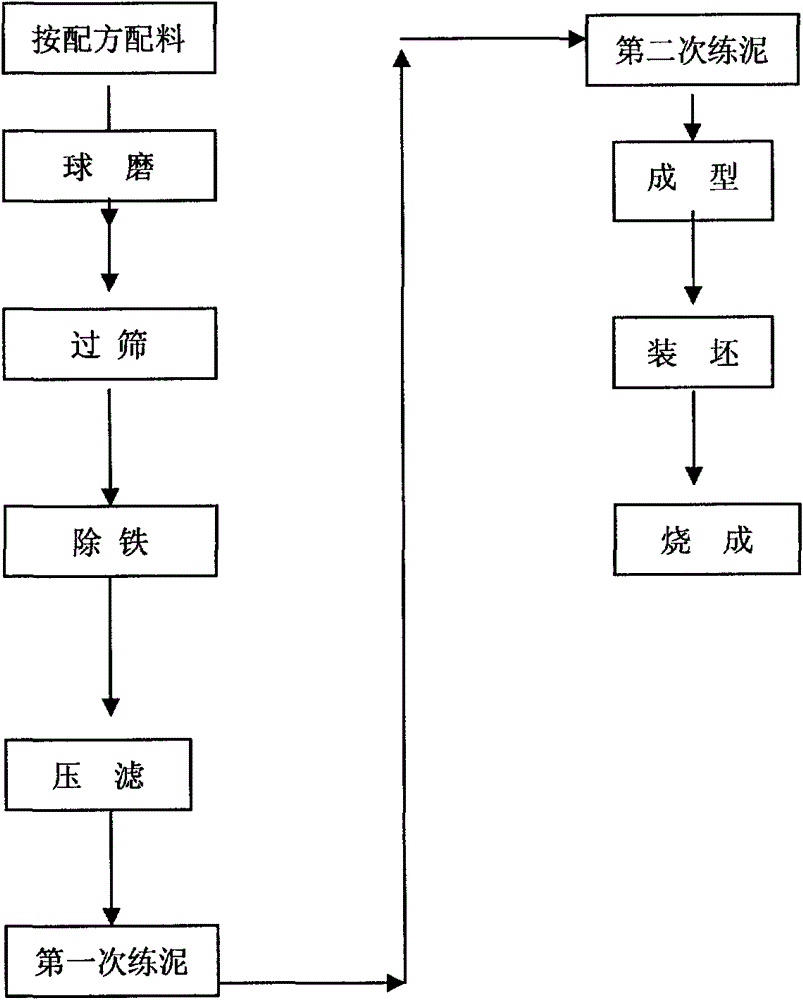

Novel transparent high-level porcelain mud material and porcelain product thereof

The invention relates to a novel transparent high-level porcelain mud material and a porcelain product thereof. The novel porcelain mud material is formed by body and glaze raw materials which are integrally mixed. The formula of the mud material comprises the following raw materials by weight percent: 20-30 percent of kaolin; 10-15 percent of feldspar (potassium feldspar and soda feldspar); 35-45 percent of quartz; 10-20 percent of porous hydroxyl calcium phosphate; 2-3 percent of spodumene and 1-3 percent of talc. In the formula, the porous hydroxyl calcium phosphate is used to substitute for the traditional beef bone ash. Compared with a bone ash porcelain production process flow, the processes of the production process flow of the invention are decreased by half approximately, no 'polishing' process is required and the dust emission is reduced; no 'water washing' process is required and the water resource consumption is reduced; and no 'drying' process is required, the energy is saved because 'double firing' process is changed to 'single firing' process, and the waste saggar is not required to be treated. Compared with the bone ash porcelain manufactured by using a traditionalmethod, the transmittance of the product is higher, the production processes are less, the energy consumption is low, the 'three-waste' is less, the cost is low and the mud material can be used for industries such as household porcelains, display porcelains, decoration porcelains, lamp porcelains and the like.

Owner:福建省玉瓷发展股份有限公司

Dust emission reduction during metal casting

InactiveUS20140331515A1Reduce dust emissionsDrying solid materials with heatPig casting plantsSlagSolid particle

A method for reducing dust emissions in a metal or slag casting apparatus, as well as a metal or slag casting apparatus allowing reducing dust emissions, comprising an endless conveyor having a plurality of casting moulds with upper open tops and which endless conveyor is arranged to move said casting moulds in a first section from a casting station to to the casting station, the method comprising (a) providing a casing forming a bottomless box over at least part of the first section of the endless conveyor, (b) injecting within said casing a gas on the surface of the mould with an angle sufficient to blow off loose, solid particles, such as graphite flakes, formed at the surface of the metal, during early stages of the cooling down and to start the solidification of a superficial layer of metal or slag, (c) extracting the gas and the solid particles by suction from within said casing.

Owner:PAUL WURTH SA

Split-cycle engine

ActiveUS8720396B2Reduce dust emissionsEmission reductionInternal combustion piston enginesLow pressure fuel injectionExhaust valvePhase shifted

Owner:GREEN ENGINE CONSULTING

Grease composition and motion guiding device lubricated by grease composition

The grease composition for a clean environment includes, a base oil, a thickener and a extreme-pressure agent, in which a kinetic viscosity of the base oil at 40° C. is 100˜300 mm2 / s, the thickener comprising a lithium complex soap, a content of the thickener is 10˜40 mass % with respect to the total amount of the grease composition.

Owner:THK CO LTD +1

Mortar composition, method of preparation thereof and use thereof

A mortar composition in the form of a dry powder, ready for use, comprising at least one powdery binder and at least one aggregate, as well as possibly at least one standard additive and / or adjuvant, and formed from particles, at least some of which, referred to as fine particles, are liable to produce an emission of dust, characterized in that it also comprises a fluid additive that consists of least one non-polar hydrocarbon organic substance and that has a capacity for agglomeration of the said fine particles, and in that the dry mortar composition comprises agglomerates of fine particles formed by the fluid additive.

Owner:PAREXGROUP SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com