Patents

Literature

69results about How to "Good under pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-absorbing agent and its production process

ActiveUS20060247351A1Less water-soluble component contentImprove water retentionSynthetic resin layered productsCellulosic plastic layered productsAluminium sulfateCross-link

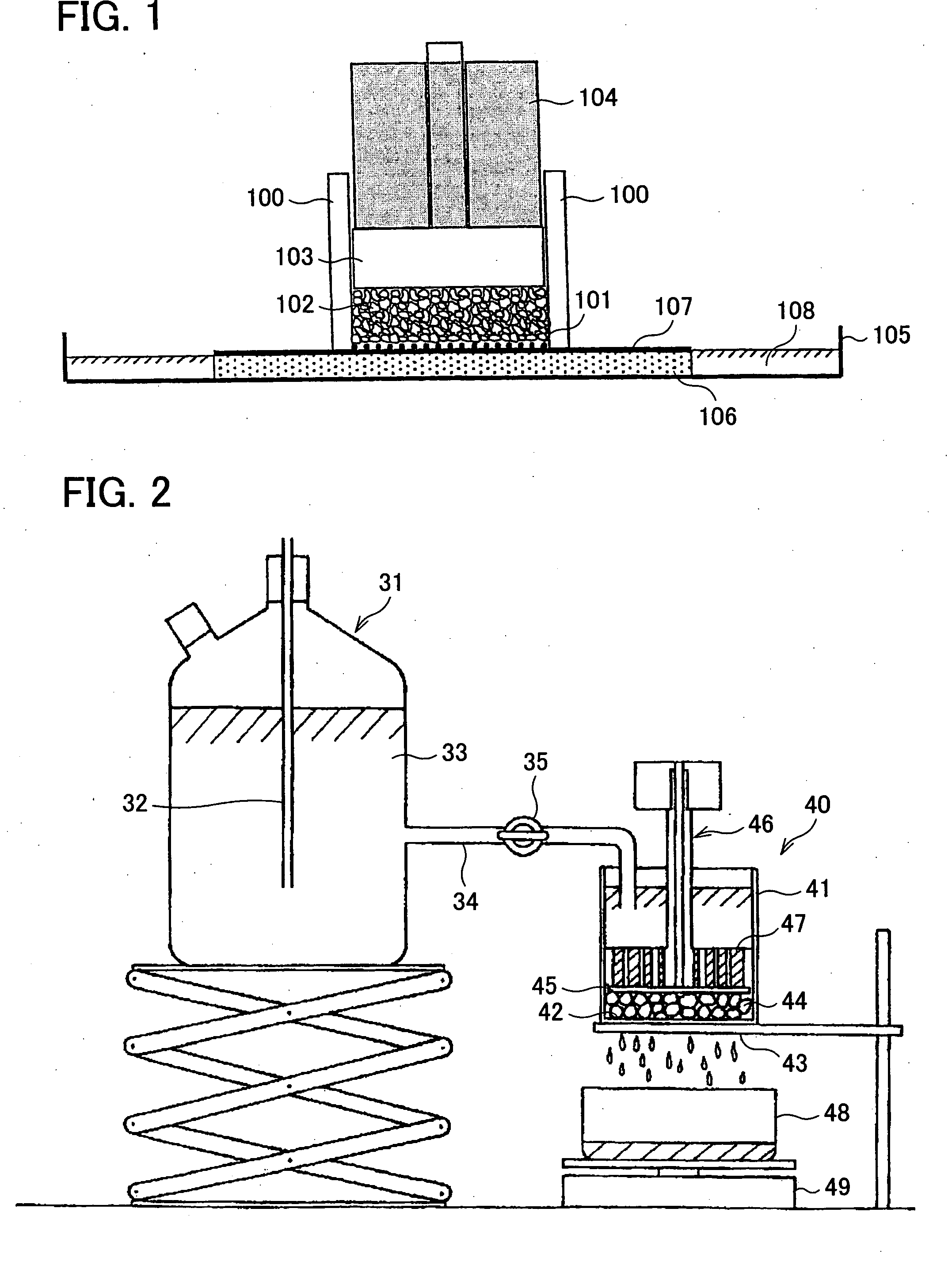

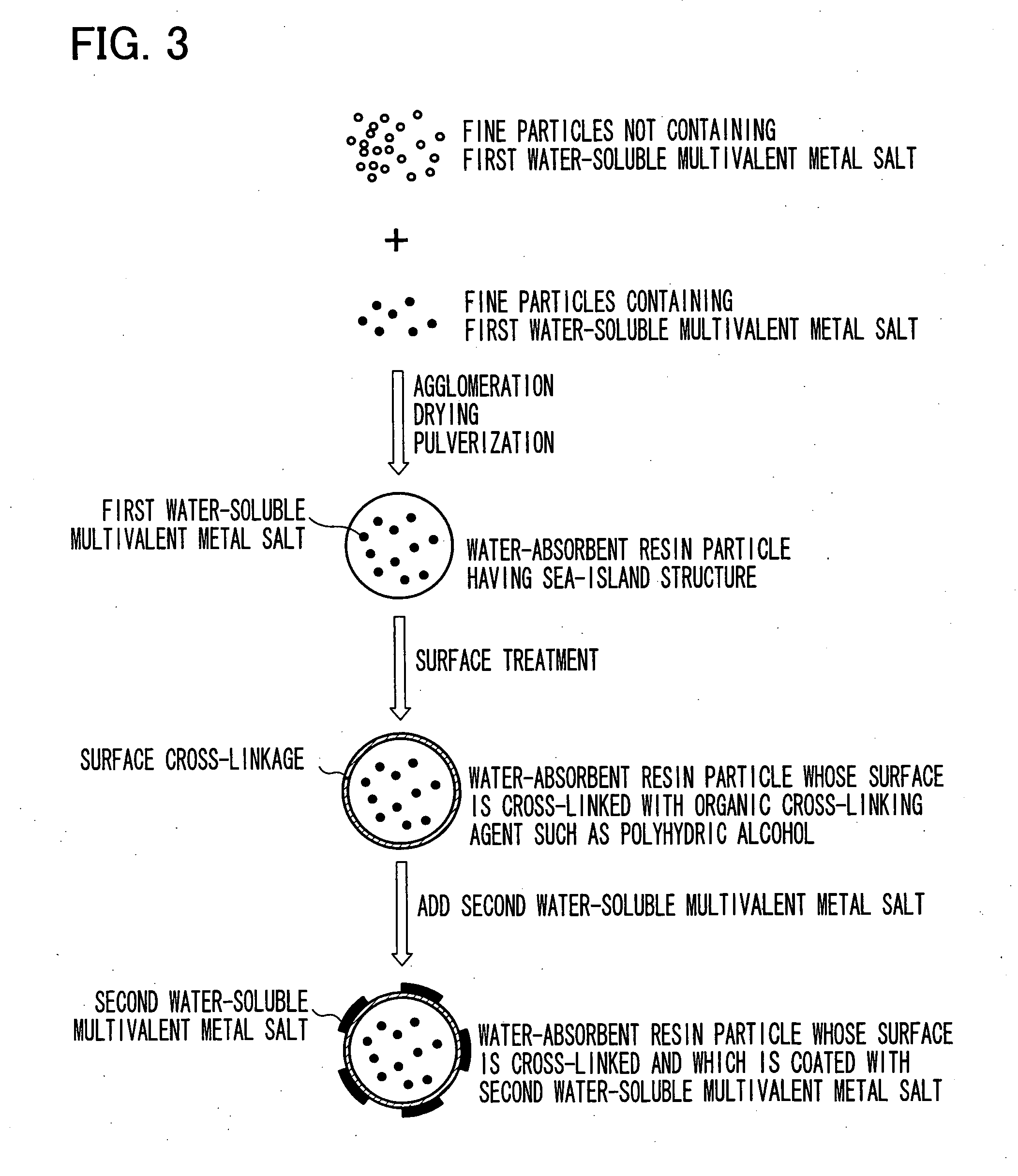

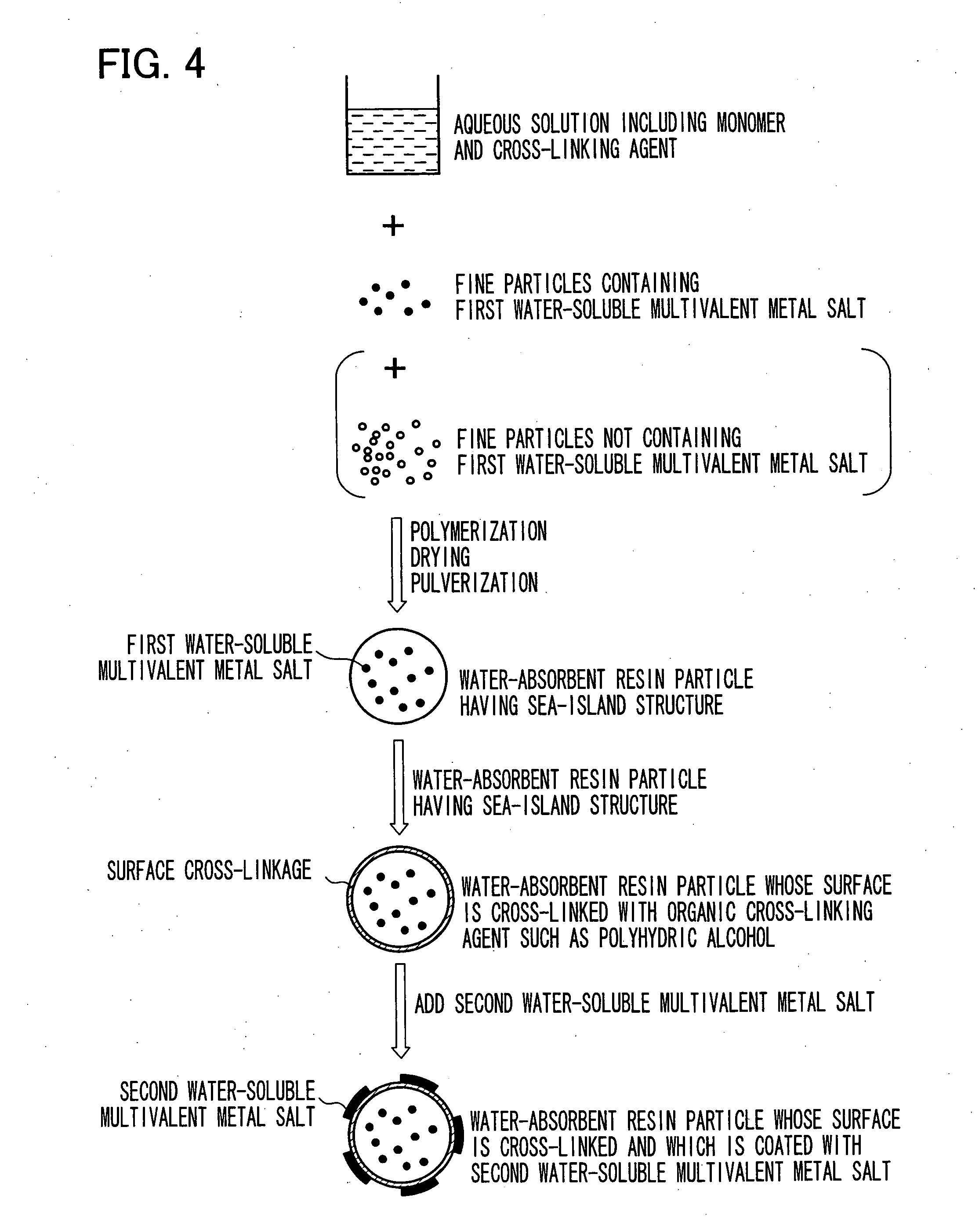

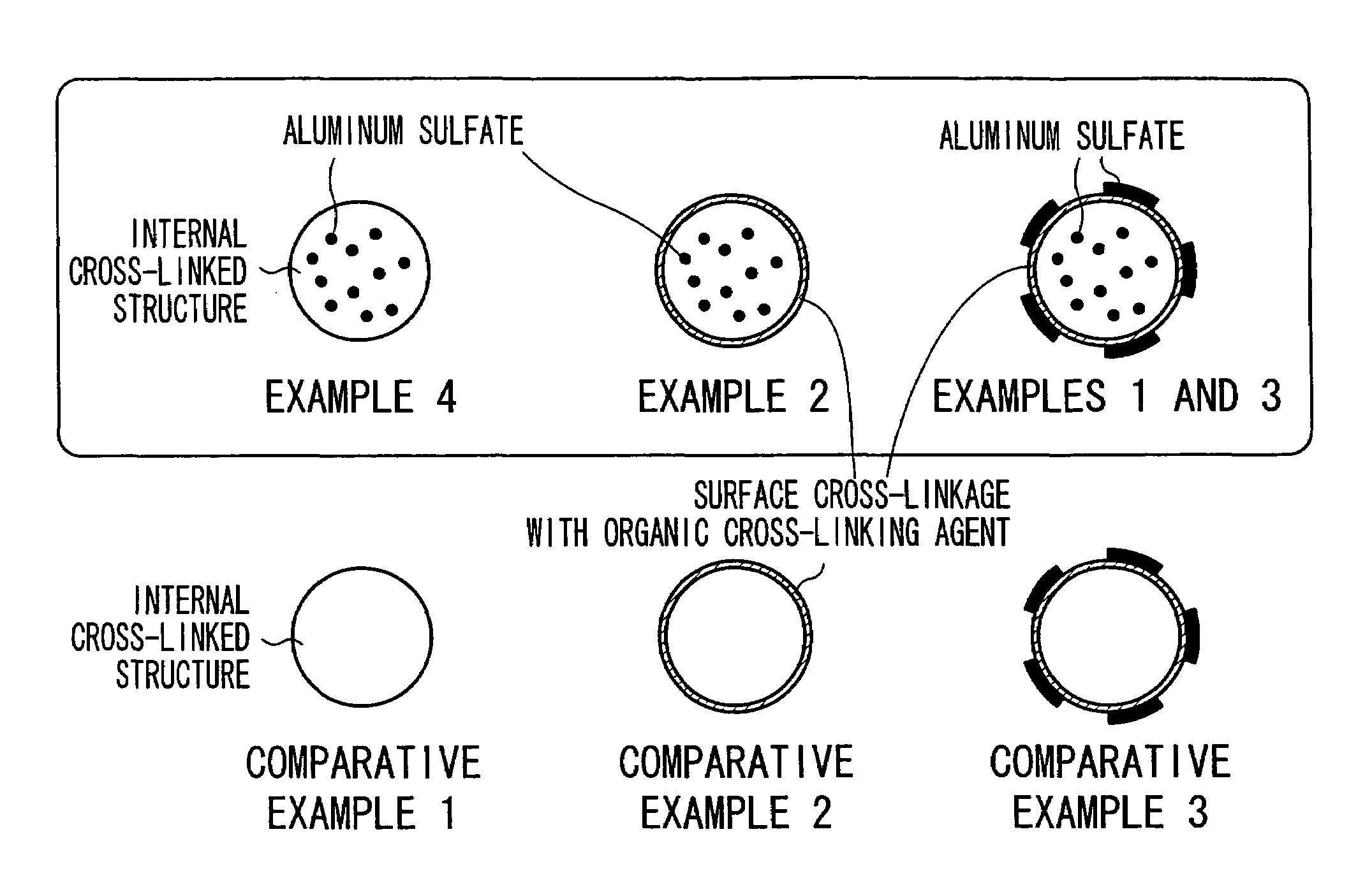

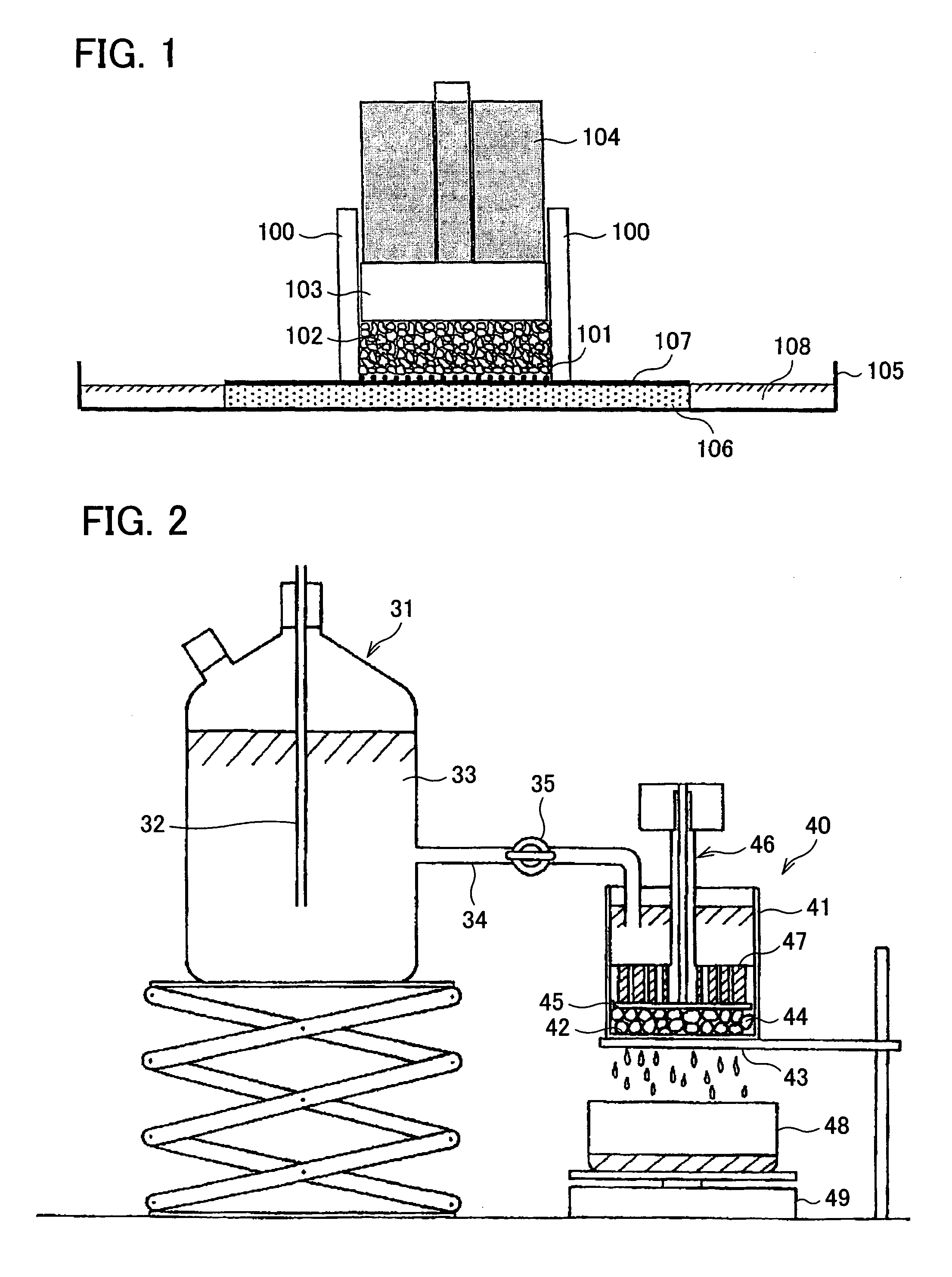

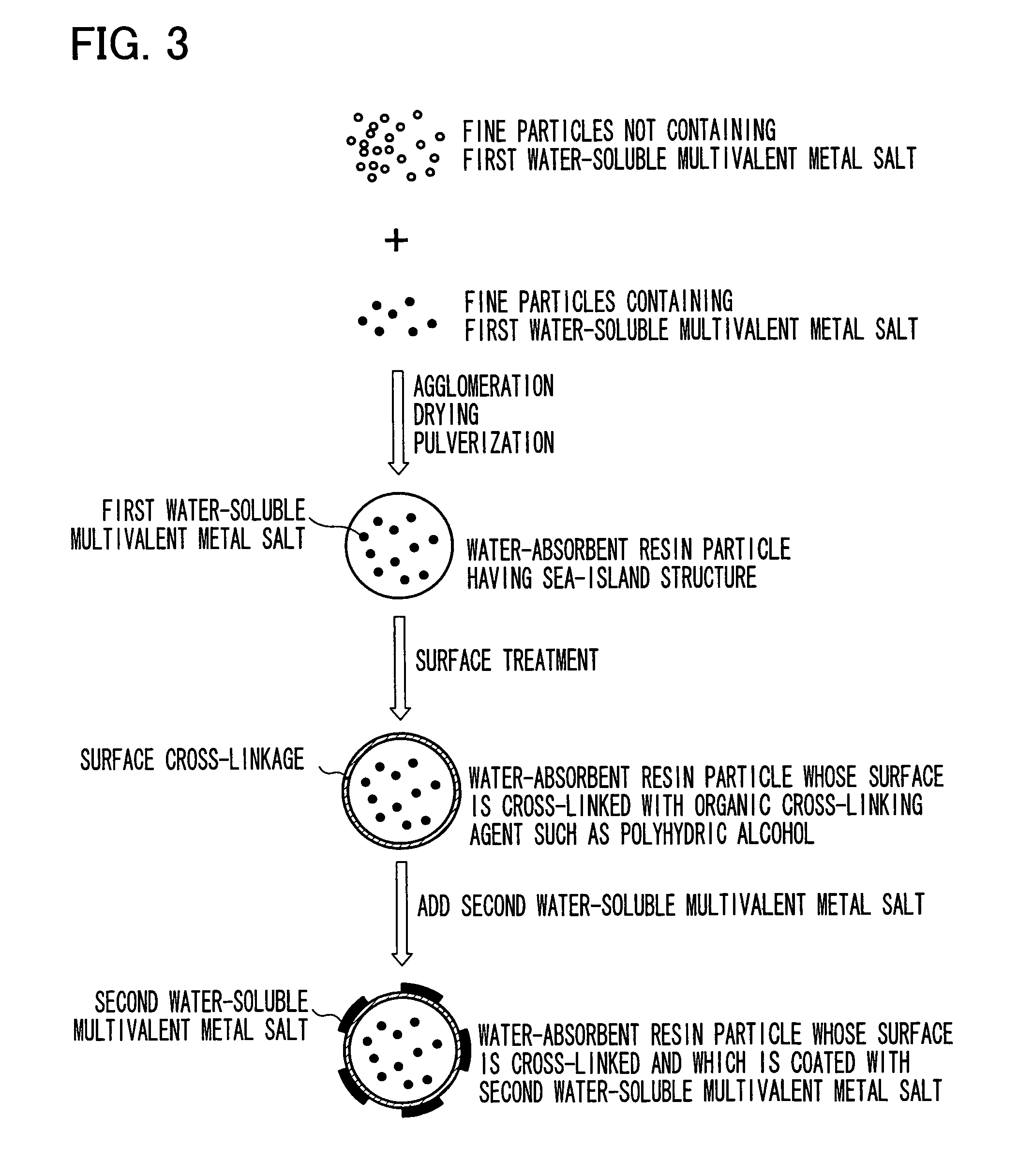

A water-absorbing agent according to the present invention includes water-absorbent resin particles having an internal cross-linked structure,.wherein a vicinity of a surface of the water-absorbent resin particle is cross-linked with a surface cross-linking agent, and the water-absorbent resin particle has therein a sea-island structure having (i) part containing a first water-soluble multivalent metal salt such as aluminum sulfate and (ii) part not containing the first water-soluble multivalent metal salt. With this arrangement, it is possible to provide a water-absorbing agent having less water-soluble component content, more excellent liquid permeability, and more excellent water retention under pressure than the conventional water-absorbing agent.

Owner:NIPPON SHOKUBAI CO LTD

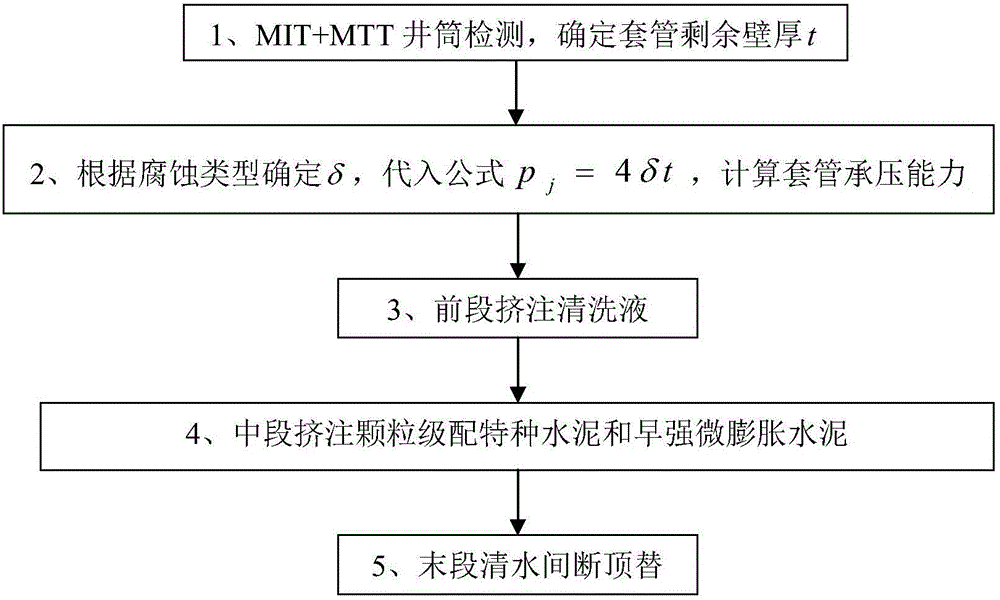

Method for increasing success rate of chemical plugging of leaking casing damage well

ActiveCN106014330AImprove the pressure bearing capacity of the formationImprove plugging success rateProductsSurveyFormation waterEngineering

The invention relates to a method for increasing the success rate of chemical plugging of a leaking casing damage well. A casing pipe horizontal pushing method and a three-slug theory are adopted for the casing damage well with a casing damage part located within 1,000 m, wherein the front section is a washing slug, formation water is replaced, oil dirt and corrosive products on the outer wall of a casing pipe are washed, the wettability is changed, and a good gelling environment is provided for a plugging slug; the middle plugging stratum is a main body cementing section and can effectively prevent leaking and plug the stratum, and a pressure bearing section can be built to isolate the formation water from the casing pipe; the tail section is an intermittent replacement slug, multiple times of replacement are performed intermittently, the main body cementing section can be checked and improved, the plugging success rate is increased, and the validity is prolonged.

Owner:PETROCHINA CO LTD

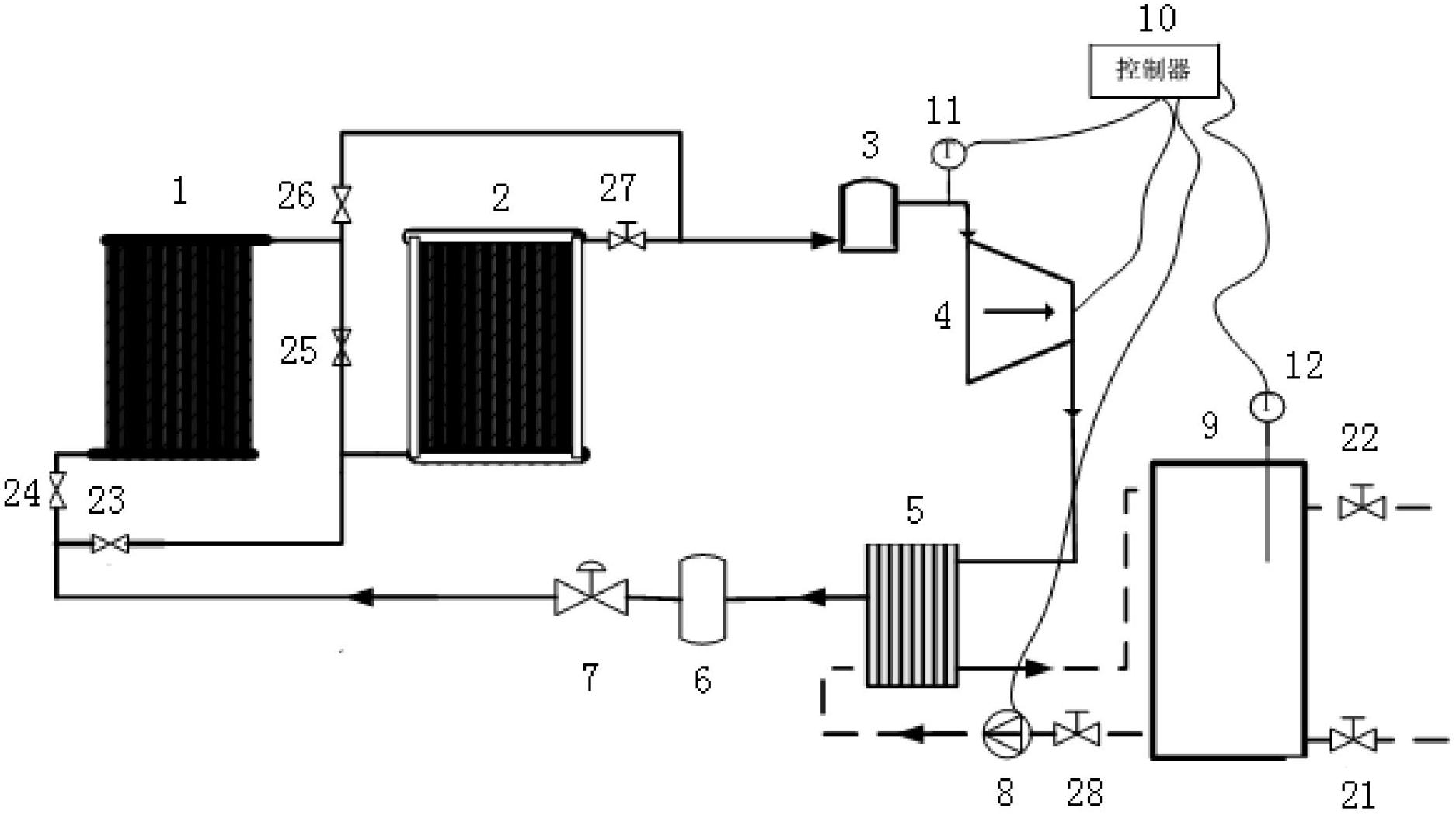

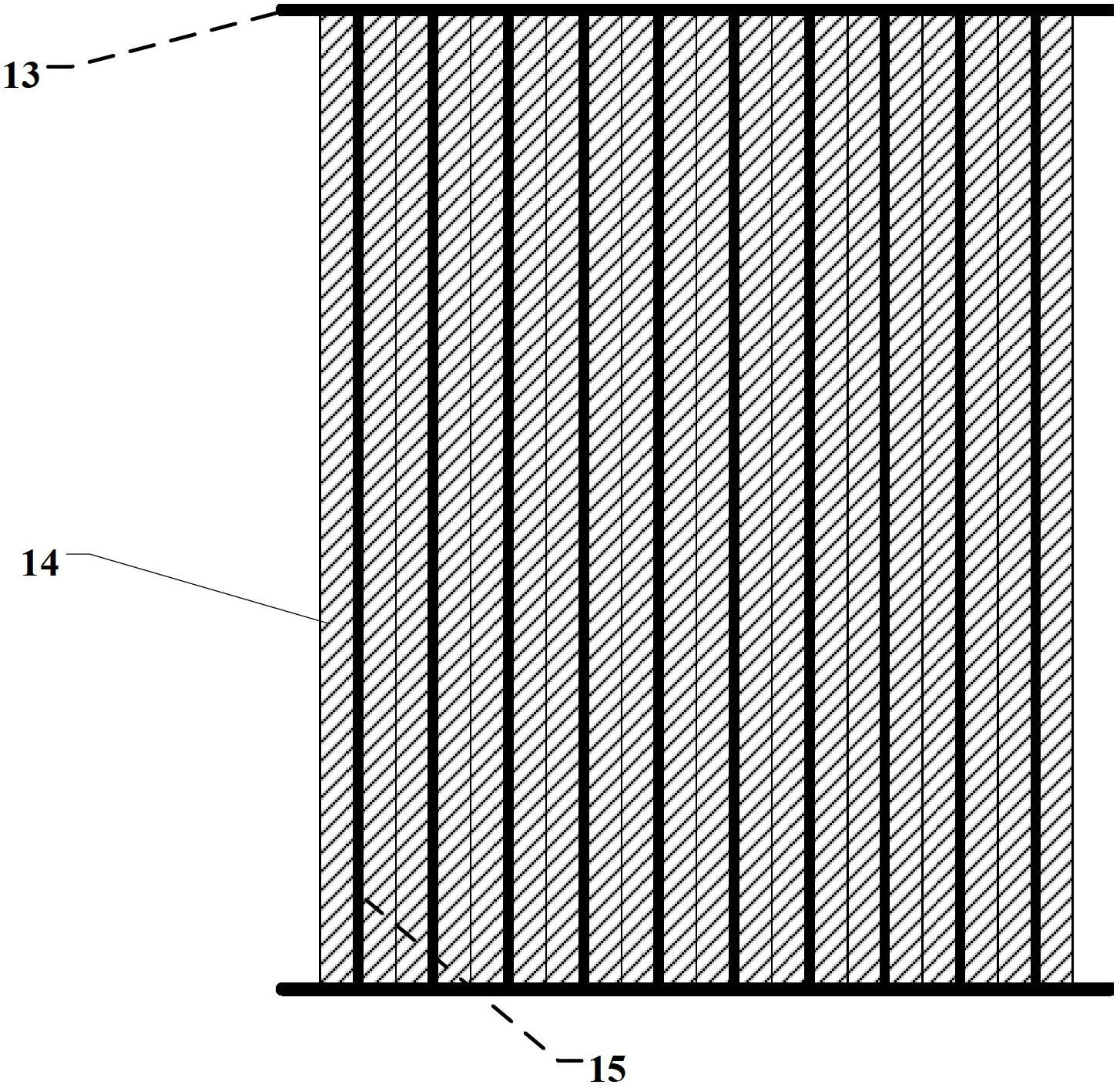

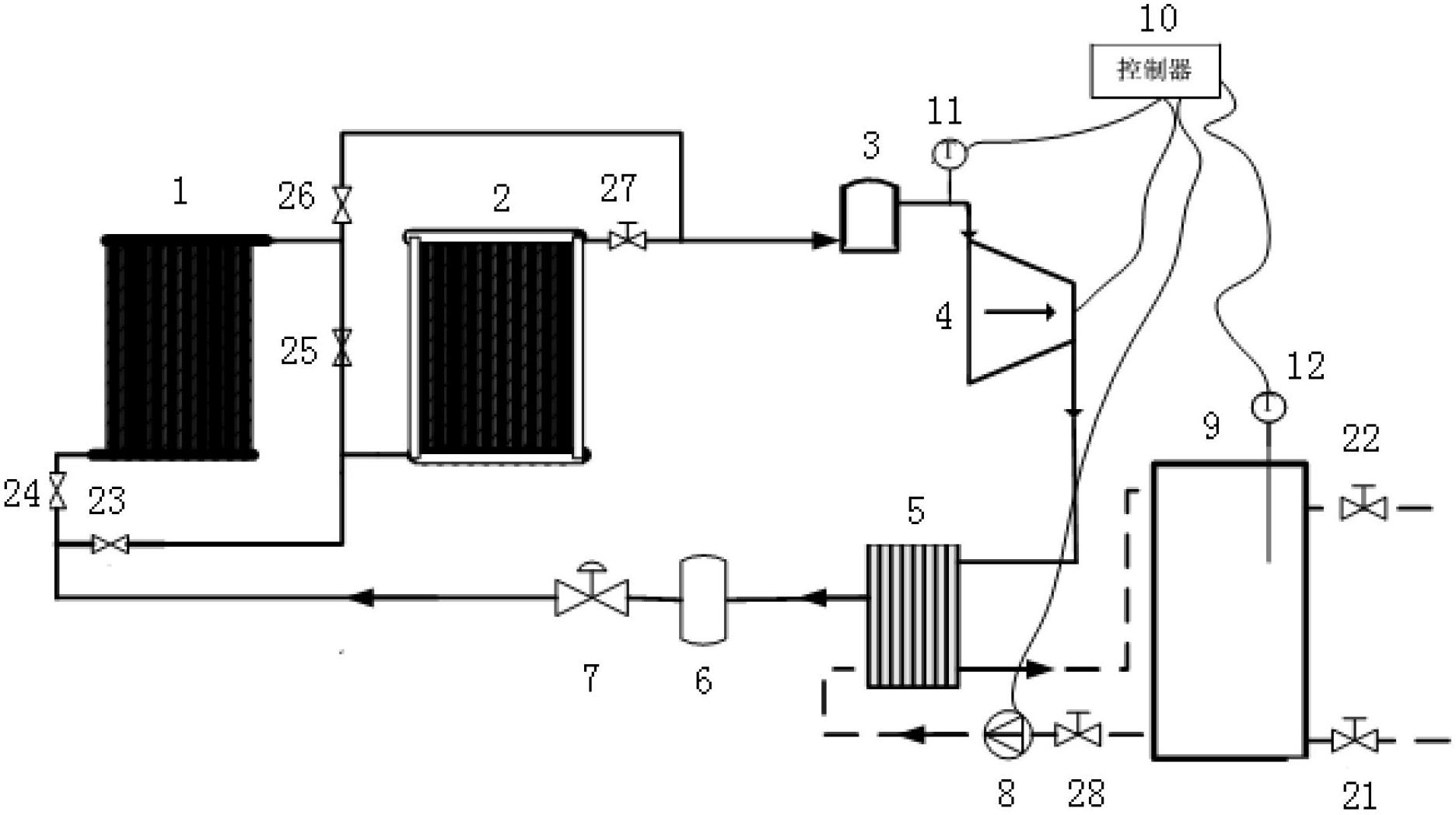

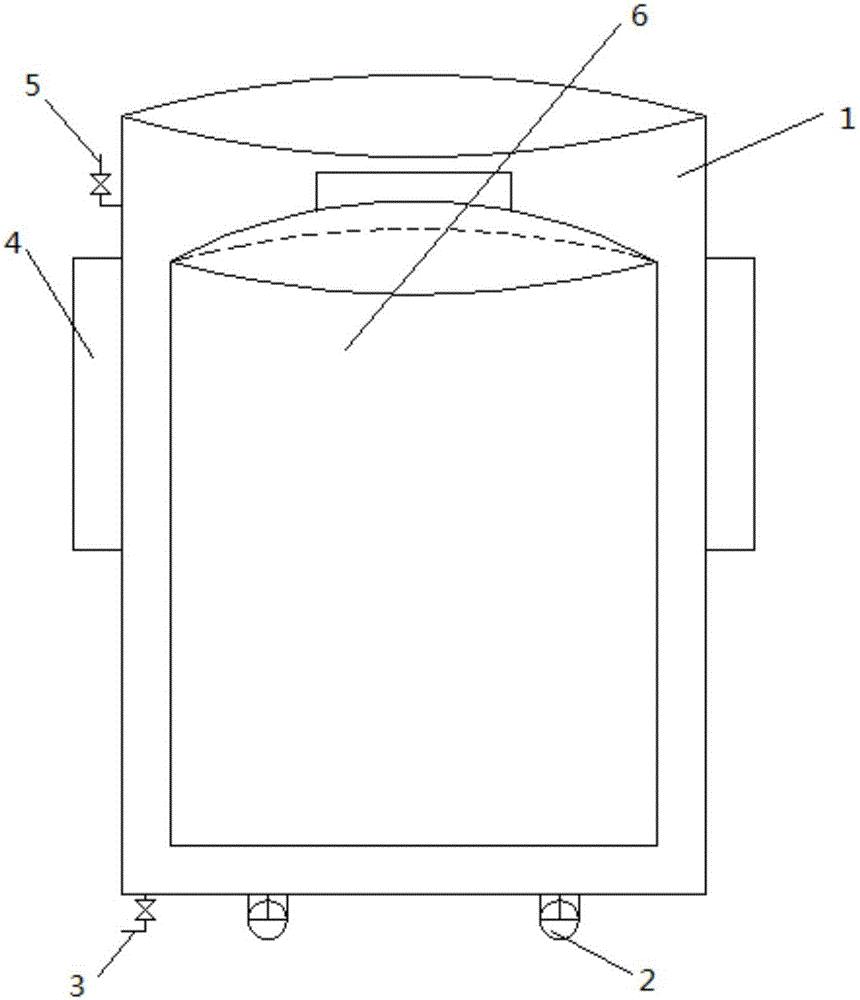

Direct-expansion solar heat pump water heating system

InactiveCN102645044ABalanced utilizationSmall pressure lossSolar heating energySolar heat devicesEnvironmental resistanceGlass cover

The invention discloses a heat absorption core of a collector used for a solar heat pump water heating system, a naked plate type collector, a collector with a glass cover plate as well as a direct-expansion solar heat pump water heating system. The naked plate type collector and collector with the glass cover plate are connected through an electromagnetic valve and a refrigerant copper pipe and, a PLC (Programmable Logic Controller) controls the open and close of the electromagnetic valve according to different external conditions so as to realize the separated operation and series operation of the naked plate type collector and the collector with the glass cover plate. Refrigerant gas through evaporation and compression enters a plate-type heat exchanger so as to carry out countercurrent flow heat exchange with circulating water, hot water temperature is fed back to a controller through a temperature sensor, and the controller controls the open and stop of a compressor. With the structure, the system has the advantages of high energy efficiency ratio, good environmental adaptation, simple structure and the like and is environment-friendly and energy-saving.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

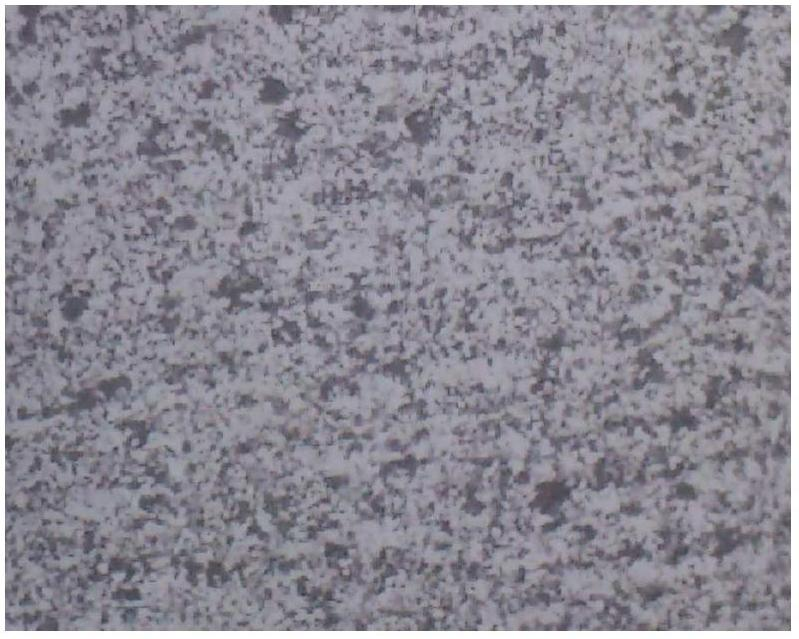

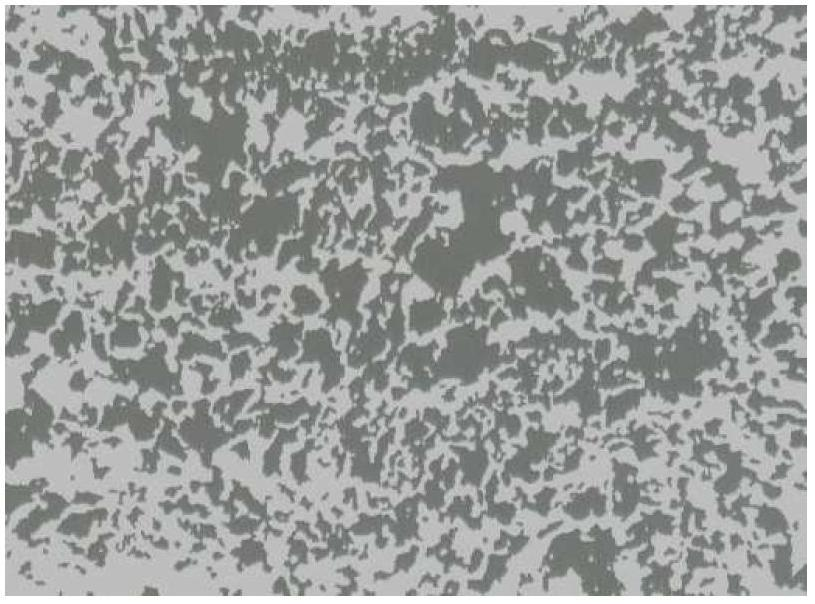

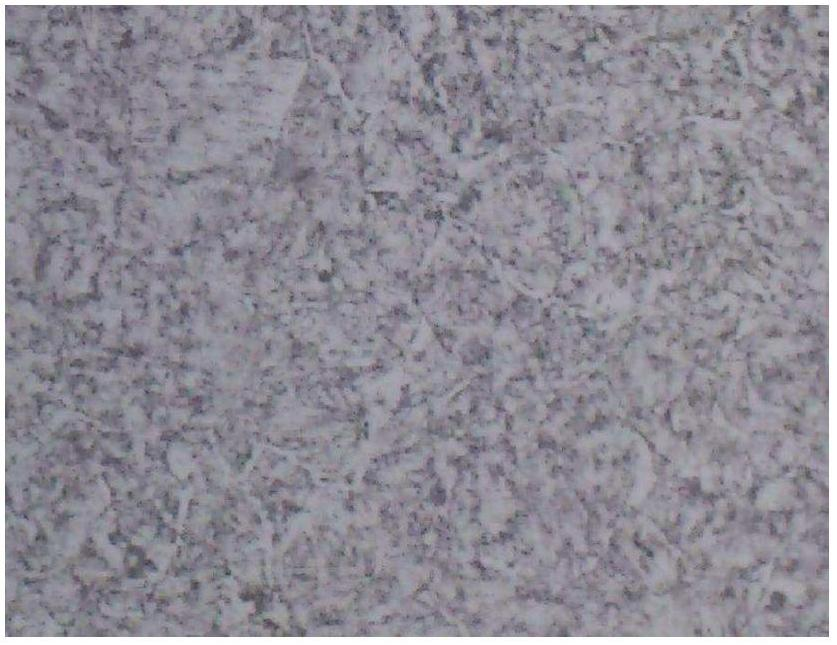

Hardening and tempering technology of alloy-steel tube

ActiveCN102676780AStress reliefUniform internal organizationFurnace typesHeat treatment furnacesHydraulic cylinderFree cooling

The invention discloses a hardening and tempering technology of an alloy-steel tube, and through the technology, the hardened and tempered alloy-steel tube is high in intensity and hardness, has good abrasion resistance and high plasticity, bears great pressure, and has small deformation and less decarburization. The technology comprises the following steps of: (1) annealing treatment: warming to 870-880 DEG C at the speed of 20-25 DEG C / minute, keeping the temperature for 35-40 minutes, and then cooling to 500 DEG C below; (2) quenching treatment: warming to 930-935 DEG C at the speed of 5-10 DEG C / minute, keeping the temperature for 50-60 minutes, then cooling rapidly at the speed of 190-200 DEG C / second to 320-325 DEG C, and cooling naturally to 30-40 DEG C; and (3) tempering treatment: warming to 500-510 DEG C at the speed of 5-10 DEG C / minute, then keeping the temperature for 230-240 minutes, and then cooling naturally to room temperature, thus the hardened and tempered alloy-steel tube is high in intensity and hardness, has good abrasion resistance and high plasticity, bears great pressure, and has small deformation and less decarburization. The hardening and tempering technology of the alloy-steel tube provided by the invention is mainly applied to the hardening and tempering of the alloy-steel tube for a hydraulic cylinder barrel.

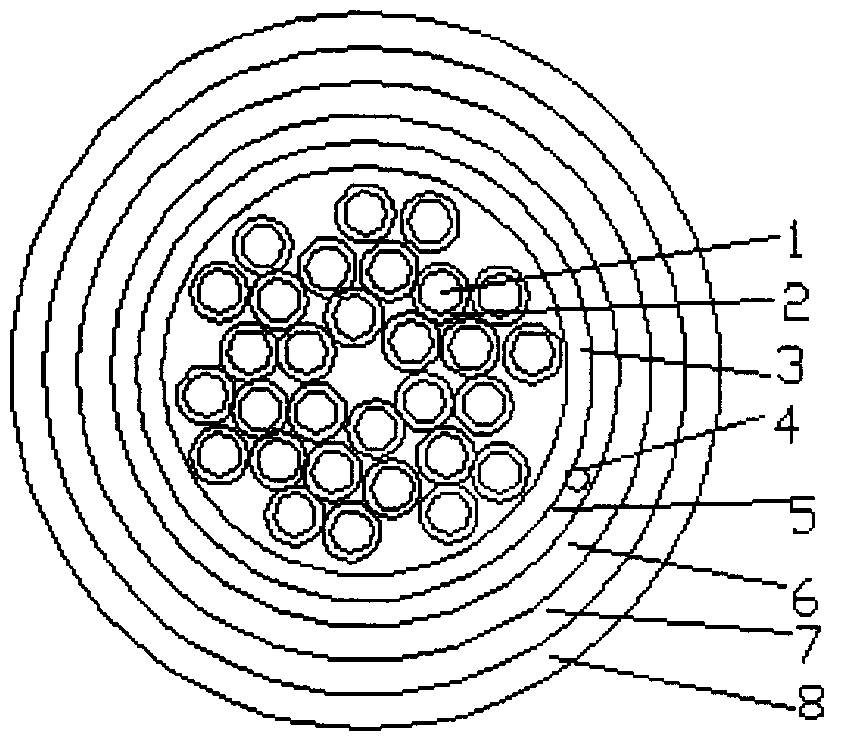

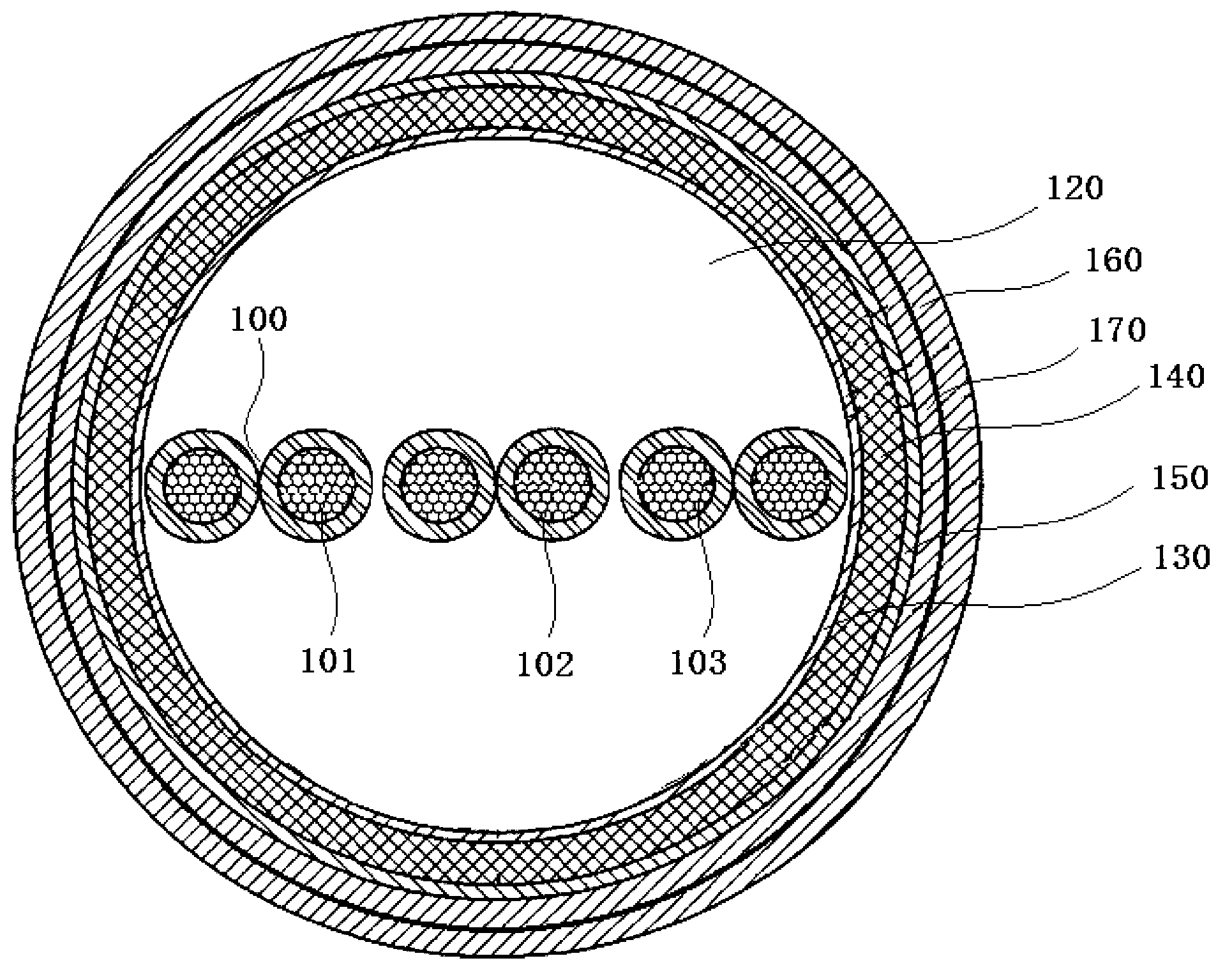

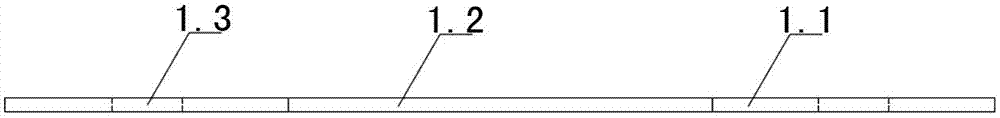

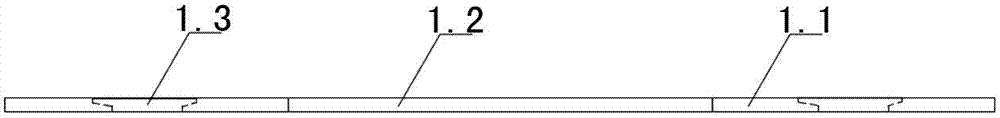

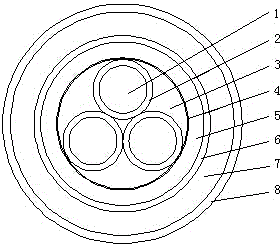

Mining communication cable

InactiveCN103578644AGood under pressureImprove featuresClimate change adaptationCables with twisted pairs/quadsInsulation layerElectrical conductor

The invention provides a mining communication cable. According to the mining communication cable, extruded insulation layers outside a conductor form insulated wire cores, every two insulated wire cores are hinged oppositely to form a single cable core, an electric cable core is formed by hinging multiple cable cores, and an isolating layer, a drainage wire, a copper-polyethylene bonding protective layer, a fire resistant layer, an interlocking armor layer and an outer protective sleeve are arranged outside the electric cable core in sequence. The mining communication cable has the properties of resisting electromagnetic wave interference and being tensile, capable of bearing pressure, dampproof, resistant to fire, resistant to low temperature and resistant to weather, and is especially suitable for communication transmission in various strip mines.

Owner:上海上力电线电缆有限公司

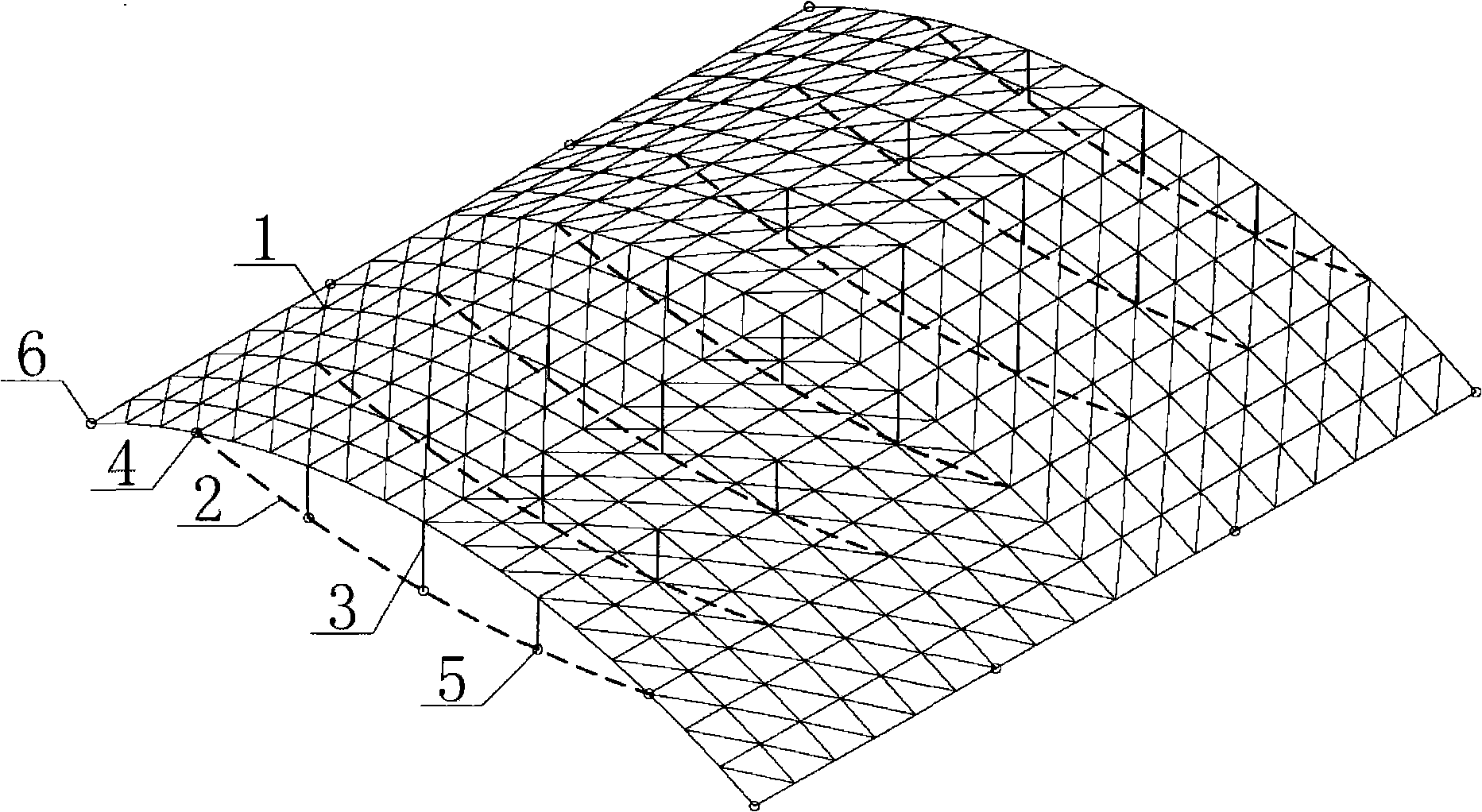

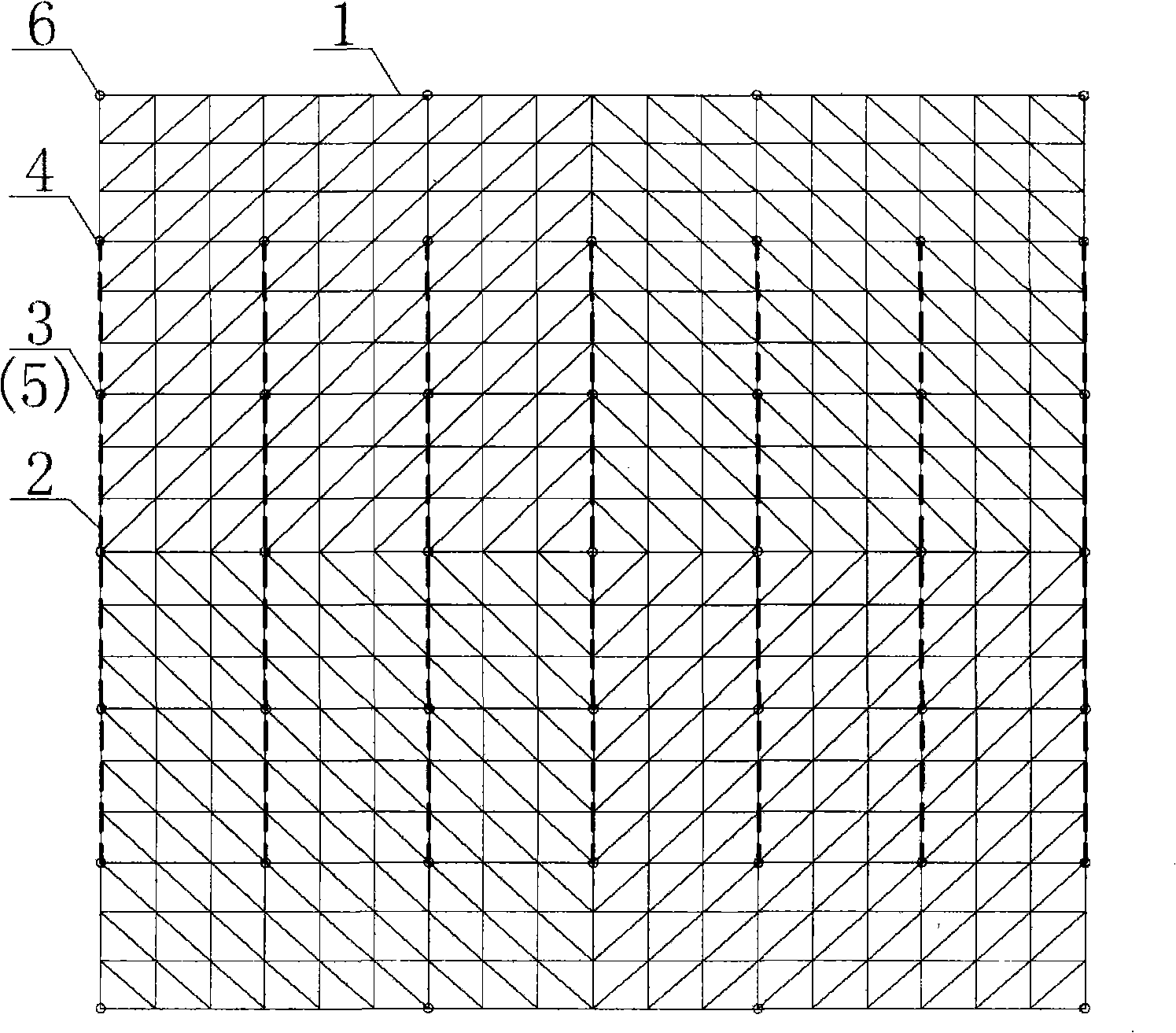

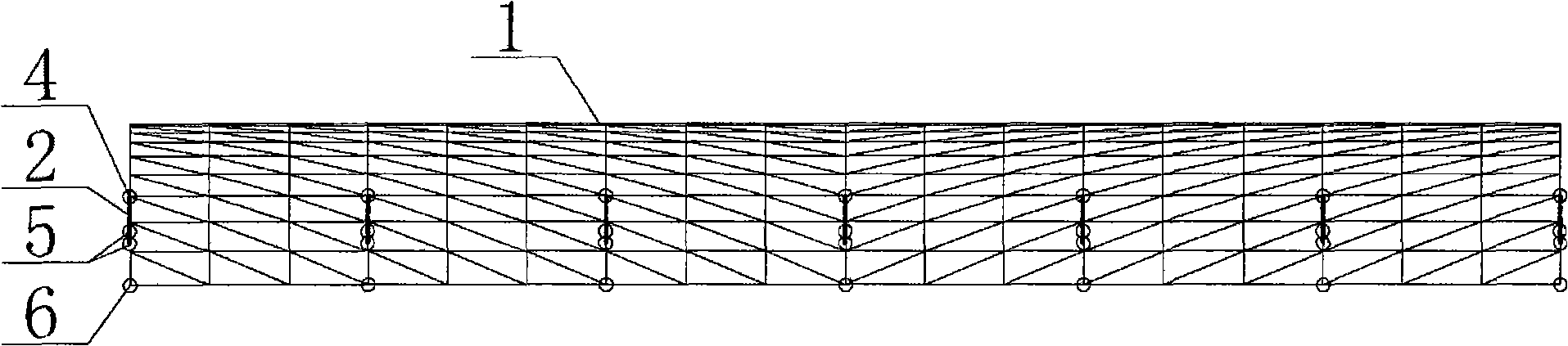

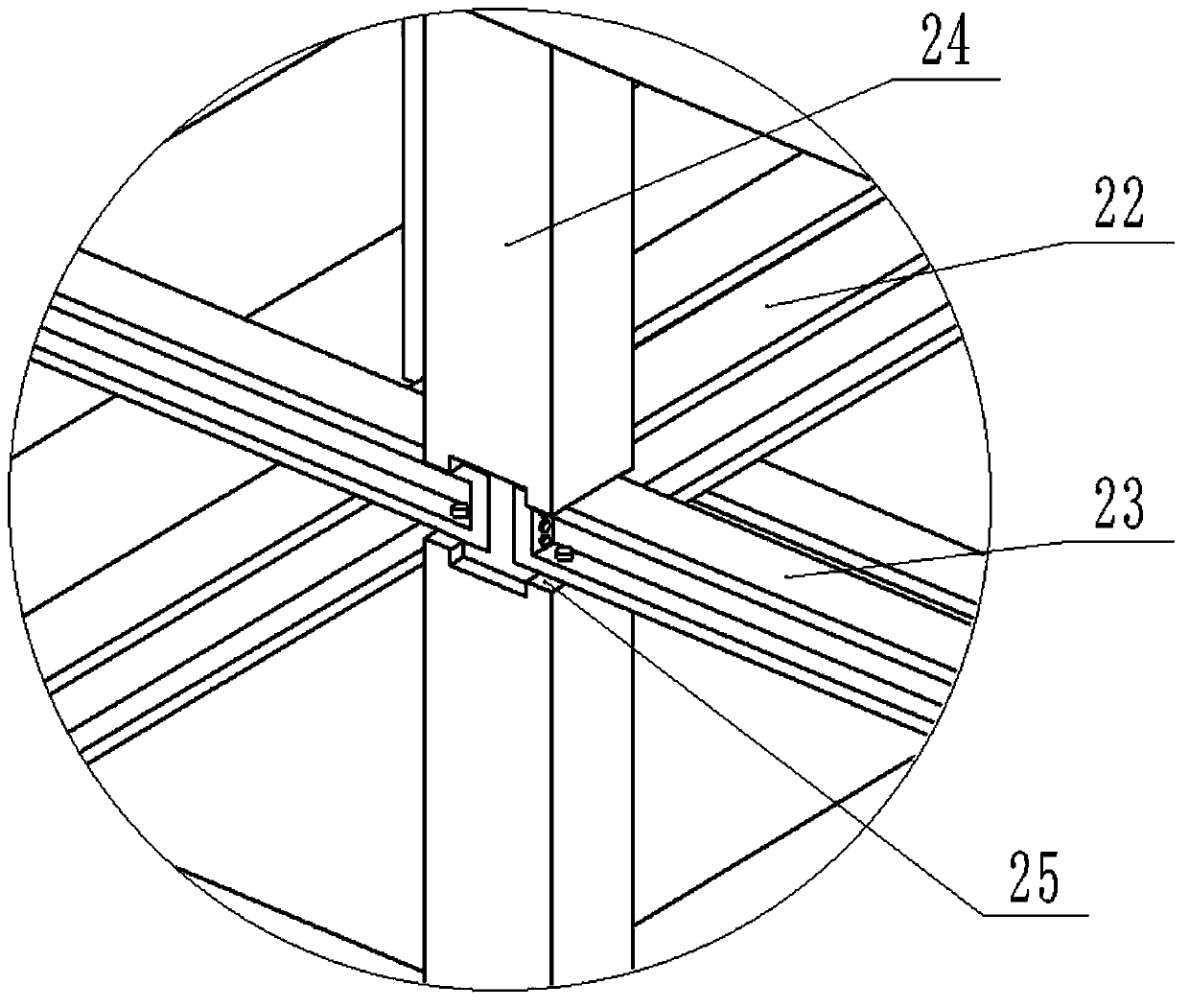

Chord branch barrel shell structure system

InactiveCN101302833AImprove stabilityPoor stability, good leaping abilityBuilding roofsArched structuresEngineeringStructure system

The invention discloses a shell-structure system of a sting-supported cylinder, which comprises a shell, a supporting rod, an inhaul cable, an anchoring node and a turning node. The shell can adopt a net-shell structure with single-layer cylinder surface or with double-layer cylinder surface. The inhaul cable can be connected to the node in the cross cylinder-shell space or to a support. The inhaul cable is connected with the lower part of the supporting rod through the turning rod, and the upper part of the supporting rod is connected to the shell so as to form the shell-structure system of a string-supported cylinder. The shell-structure system of a sting-supported cylinder has the advantages of overcoming the bad stability of single-layer cylinder shell or the thiner double-layer net shell and small striding ability through fully making use of the good compression performance of the shell and high-strength tensile performance of cable material, the shell-structure system of a sting-supported cylinder, being a structure system with large spanning ability, good stability, rationality, economy and convenient application, being universally applied to the common industrial and civil buildings, in particular to the structure system with large span such as convention center and stadium.

Owner:TIANJIN UNIV

Water-absorbing agent and its production process

ActiveUS7750085B2Less water-soluble component contentImprove water retentionSynthetic resin layered productsCellulosic plastic layered productsCross-linkAluminium sulfate

A water-absorbing agent according to the present invention includes water-absorbent resin particles having an internal cross-linked structure, wherein a vicinity of a surface of the water-absorbent resin particle is cross-linked with a surface cross-linking agent, and the water-absorbent resin particle has therein a sea-island structure having (i) part containing a first water-soluble multivalent metal salt such as aluminum sulfate and (ii) part not containing the first water-soluble multivalent metal salt. With this arrangement, it is possible to provide a water-absorbing agent having less water-soluble component content, more excellent liquid permeability, and more excellent water retention under pressure than the conventional water-absorbing agent.

Owner:NIPPON SHOKUBAI CO LTD

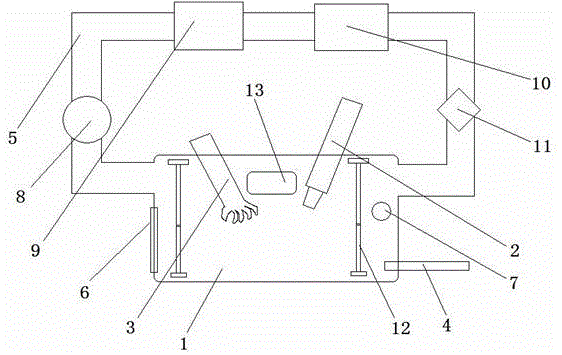

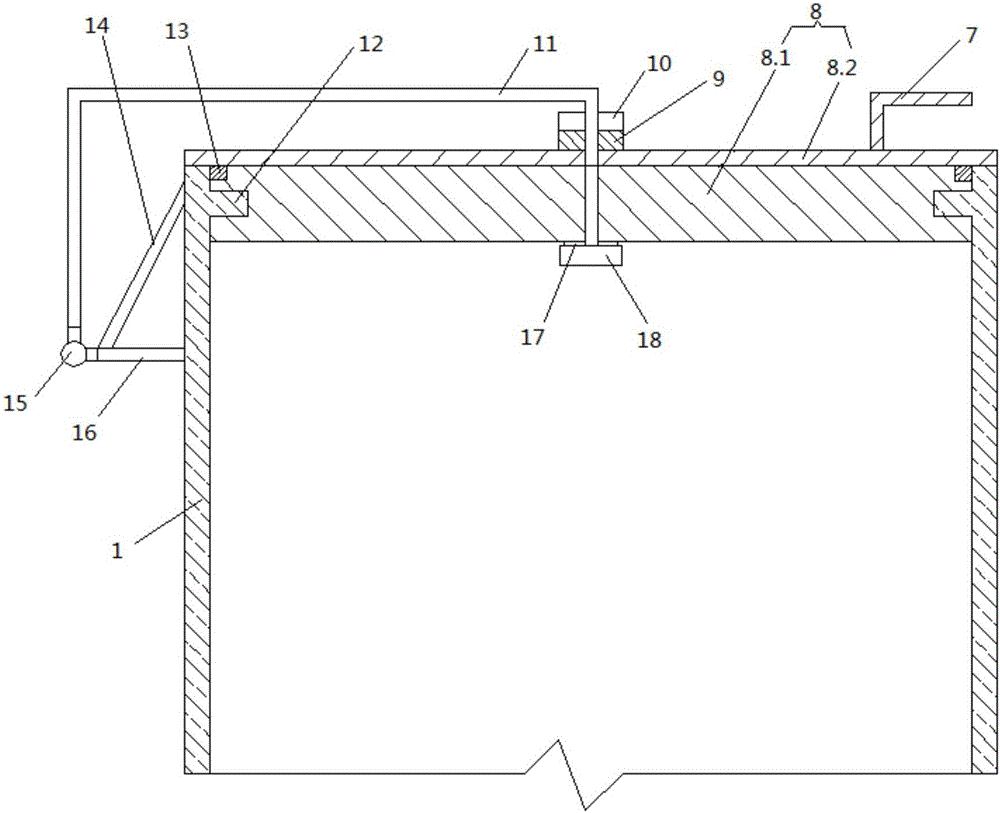

Circulating blowing-type clamping electric welding work box for pipeline operation

InactiveCN105149739AProtection securityReduce usageShielding gas supply/evacuation devicesWelding protection meansExhaust valveEngineering

The invention discloses a circulating blowing-type clamping electric welding work box for pipeline operation. The circulating blowing-type clamping electric welding work box for pipeline operation comprises a folding electric welding box capable of being inflated with gas or deflated. The folding electric welding box is provided with an electric welding nozzle pipe and an inward turning type grabbing glove which penetrate through the folding electric welding box. The folding electric welding box is further provided with an inert gas pipe, a circulating pipe, a workpiece entering closing door and an exhaust valve. The head end and the tail end of the circulating pipe are connected to a set of opposite faces of the folding electric welding box respectively. The circulating pipe is sequentially provided with a circulating gas flow pump, a dust removal link, a gas filter link and a high-temperature heating link in the gas current flowing direction. A clamp mechanism used for clamping a workpiece to be welded is arranged at the bottom in the folding electric welding box. Compared with the prior art, the folding electric welding box is filled with inert gas, an operator carries out operation outside the folding electric welding box, and the internal inert gas is recycled constantly; thus, the use quantity of the rare gas is reduced, and emission of harmful gas is reduced; the environment is protected, and the safety of the operator is protected.

Owner:SUZHOU HUARI JINLING MACHINERY

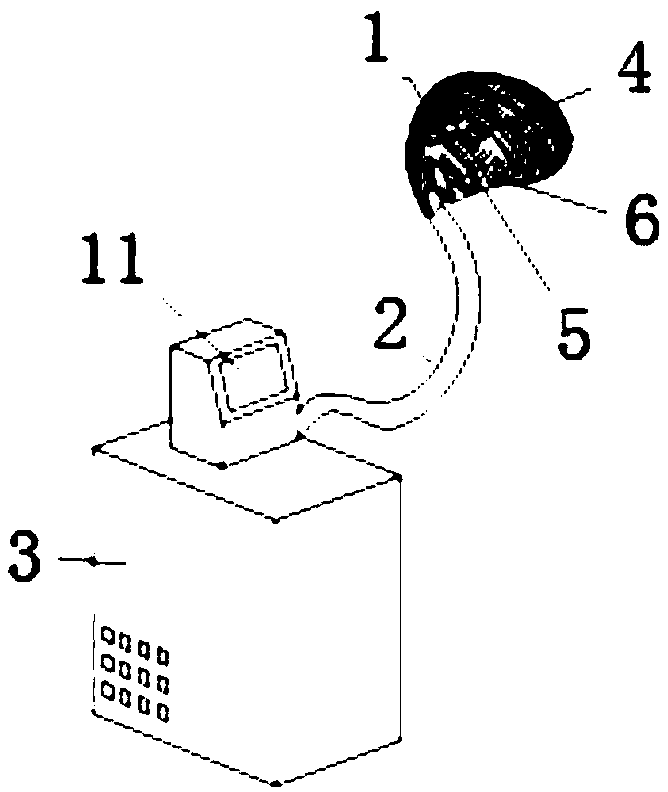

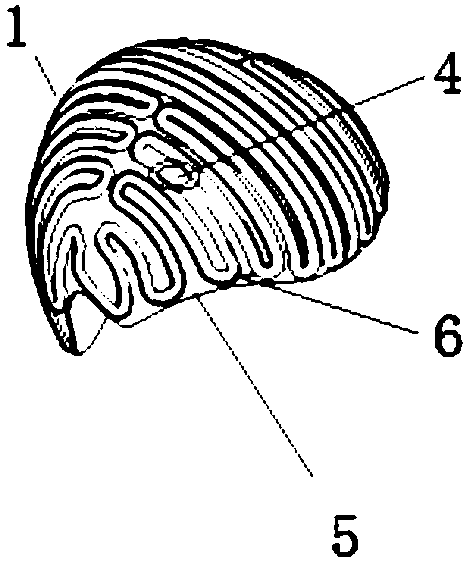

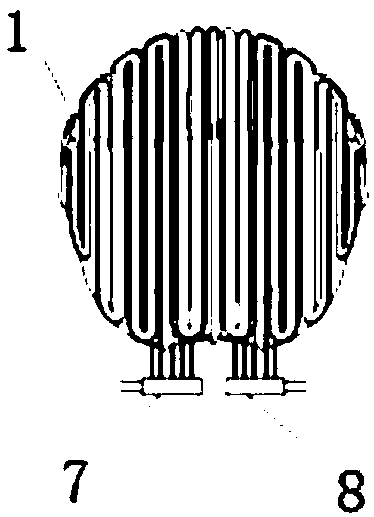

Medical treatment ice cap

InactiveCN107854211AImprove comfortGood treatment effectTherapeutic coolingTherapeutic heatingCapillary networkInsulation layer

The invention relates to a medical treatment ice cap, which comprises an ice cap main body, a connecting channel, and a cooling host machine; the ice cap main body is composed of a soft mat bottom layer, a capillary network cooling layer and an external heat insulation layer; the capillary network cooling layer is fixed on the soft mat bottom layer, and provided with multiple cold media circulating pipelines which are independent to each other; fluid inlet and outlet ends of the multiple cold media circulating pipelines are connected with the cooling host machine through a fluid inlet channeland a fluid outlet channel of a connecting channel by a fluid divider and a fluid collector. By arranging the capillary network cooling layer in the ice cap main body, the capillary network cooling layer is connected with the cooling host machine of an intelligent thermostat; the temperature sensor attached on the capillary network cooling layer can sense the head temperature in real time and transmit the signal to the cooling host; the cooling host machine can control the head temperature through adjusting flow, thus the comfort sense and the treatment effect of a patient are improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

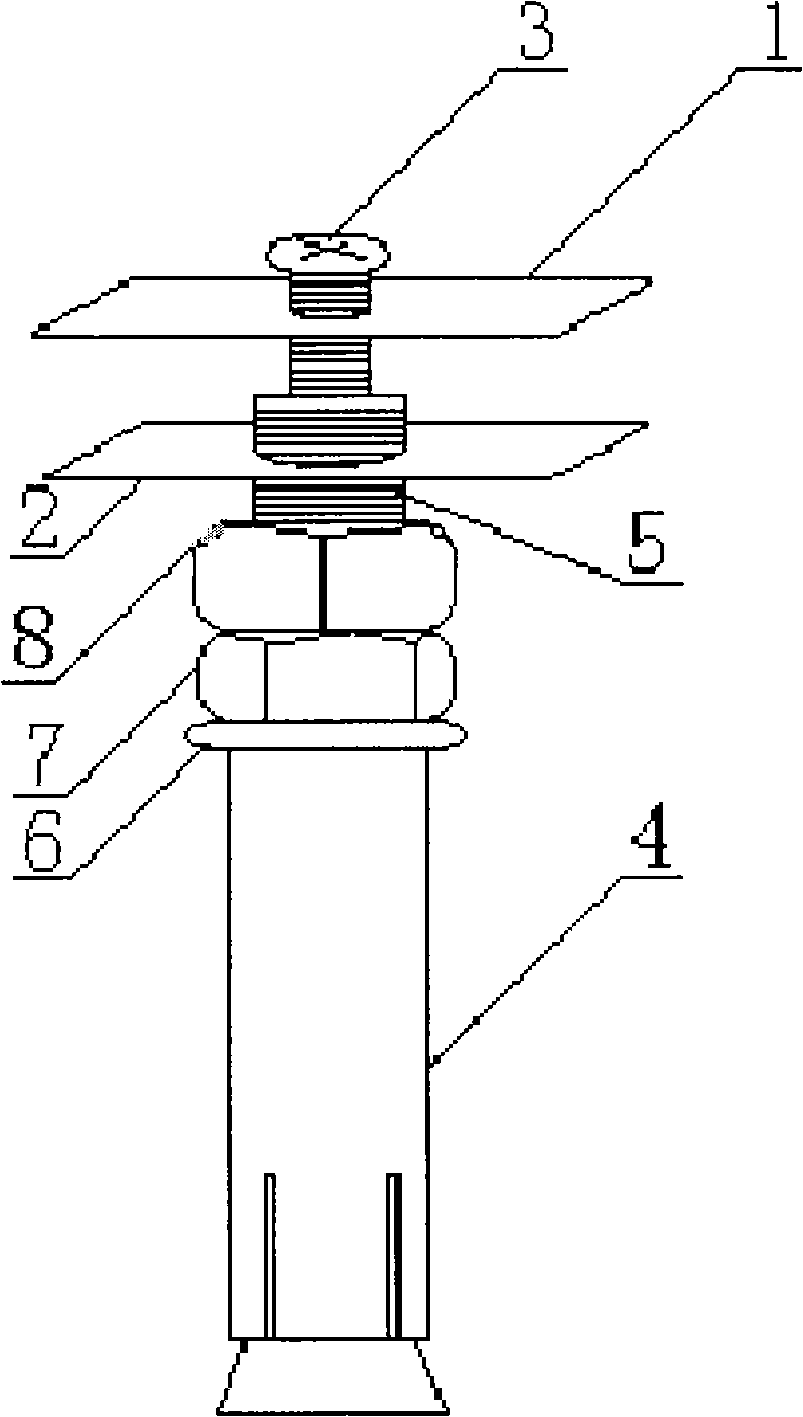

Keel-free direct hanging fastener

The invention relates to a non-keel dry-hanging fastener which belongs to the technical field of parts or structures especially used as fixing material during decorating walls of buildings. The non-keel dry-hanging fastener solves the problem that thermal-insulation decoration plates have no keel dry-hangings and comprises a clip and a fastening piece, wherein, the clip is an expansion bolt, and the center of the threaded rod of the expansion bolt is provided with an inner-threaded round hole; the fastening piece is connected with the threaded rod of the expansion bolt by a screw. The fastening piece consists of a top plate and a base plate which are respectively provided with a round hole. The fastener provided by the invention is made of stainless steel or metal, the surface of which is treated to resist against corrosion, and realizes that thermal-insulation decoration plates have no keel dry-hangings, so that thermal-insulation decoration plates can be perfectly fixed on walls. The fastener is applicable to various wall materials, such as concrete, solid and hollow walls and can make constructions and maintenance convenient and quick. The fastener has high loading capacity, high bearing pressure and good tension-resistance performance; besides, the fastener can prevent the impact damage, reduce the loading of a whole building, provide 3-5 cm horizontal adjustment differences for the distorted surfaces of walls, and provide flat surfaces for wall decoration.

Owner:张俊尧

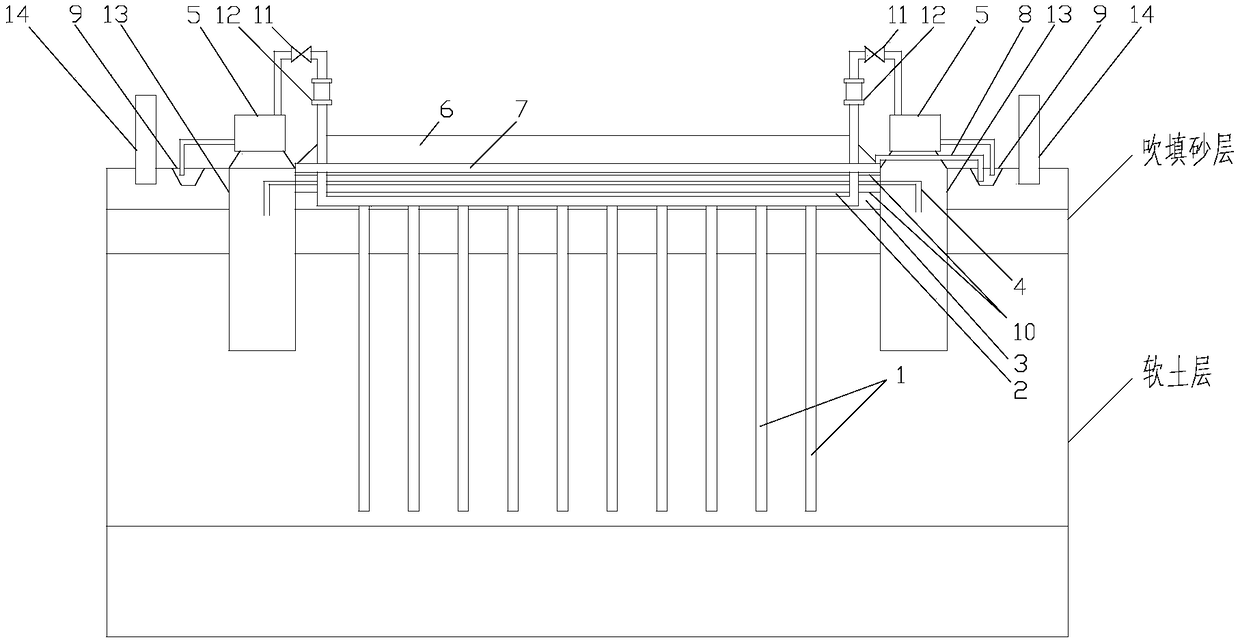

Drainage consolidation system and method for soft soil foundation

PendingCN108691310AProcess Safety for Drain ConsolidationImprove drainage capacitySoil preservationSiphonWater filter

The invention relates to the field of building construction, in particular to a drainage consolidation system and method for a soft soil foundation. A plastic drainage plate is vertically arranged inthe foundation; a horizontal drainage pipe is horizontally arranged and connected with the upper end of the plastic drainage plate; the horizontal drainage pipe is further connected with a vacuum pump, and the vacuum pump is further connected with a drainage trough through a pipeline; the horizontal drainage pipe is embedded through a sand cushion layer; a sealing film is further laid on the sandcushion layer; a pile carrier is arranged above the sealing film, and a water filter pipe is arranged between the sealing film and the pile carrier; one end of a siphon is connected with the water filter pipe; and the other end of the siphon is connected with the drainage trough. By means of the drainage consolidation system for the soft soil foundation, the drainage effect of the foundation is improved, so that the drainage consolidation construction has a better effect and higher efficiency; and with application of the drainage consolidation method for the soft soil foundation, the system iscreated more methodically, and the drainage consolidation process of the soft soil foundation is safer, more efficient and environmentally friendly.

Owner:CHINA HUADIAN ENG

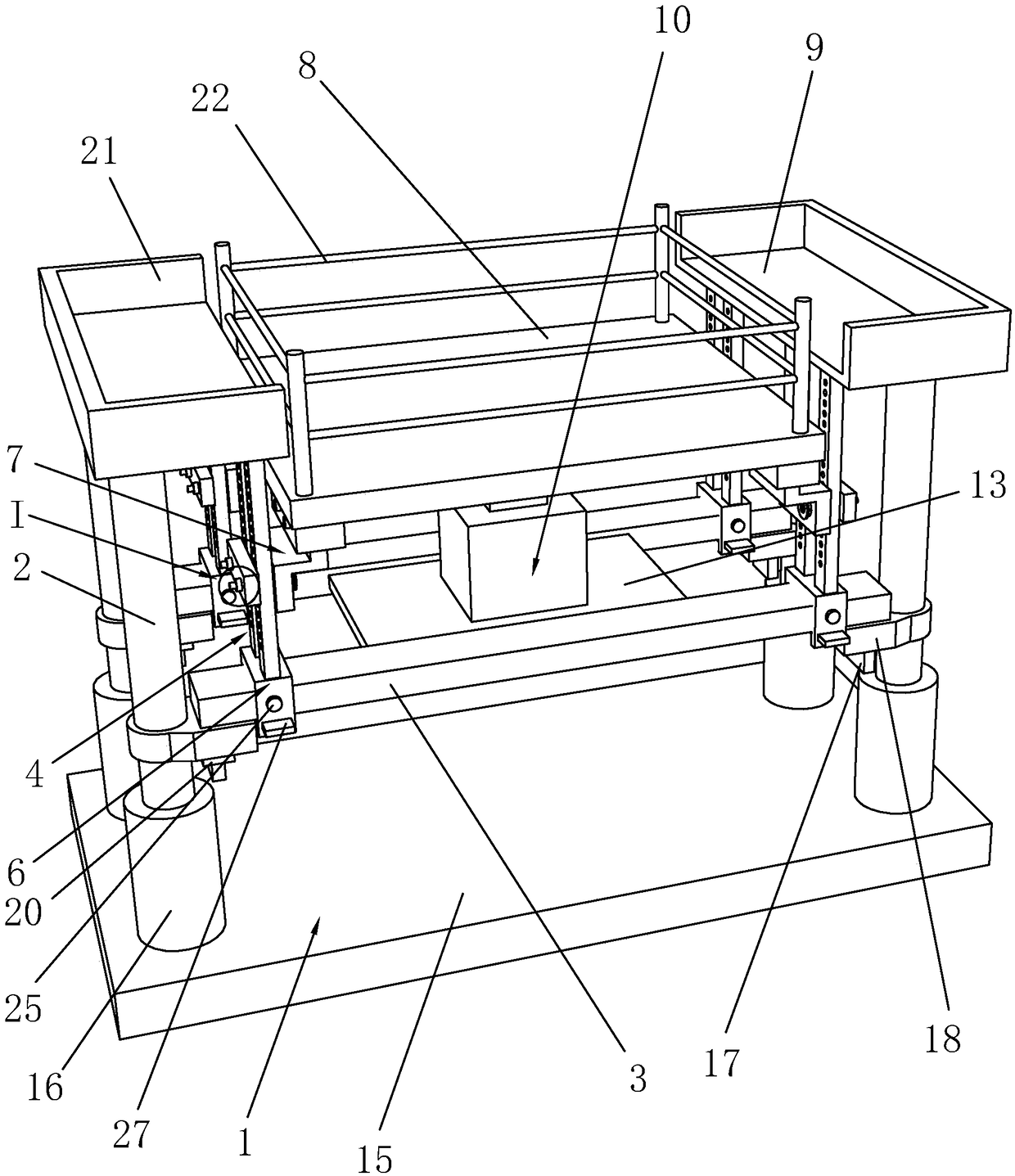

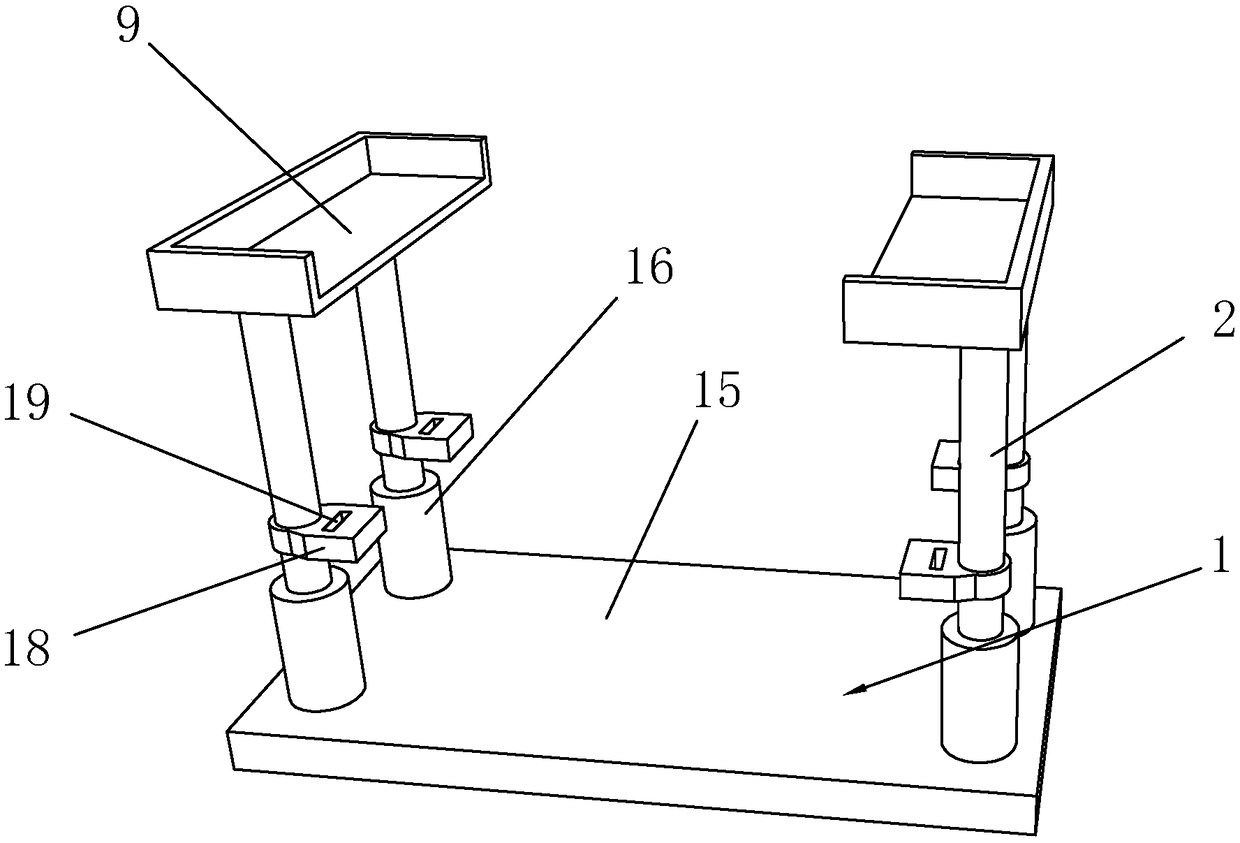

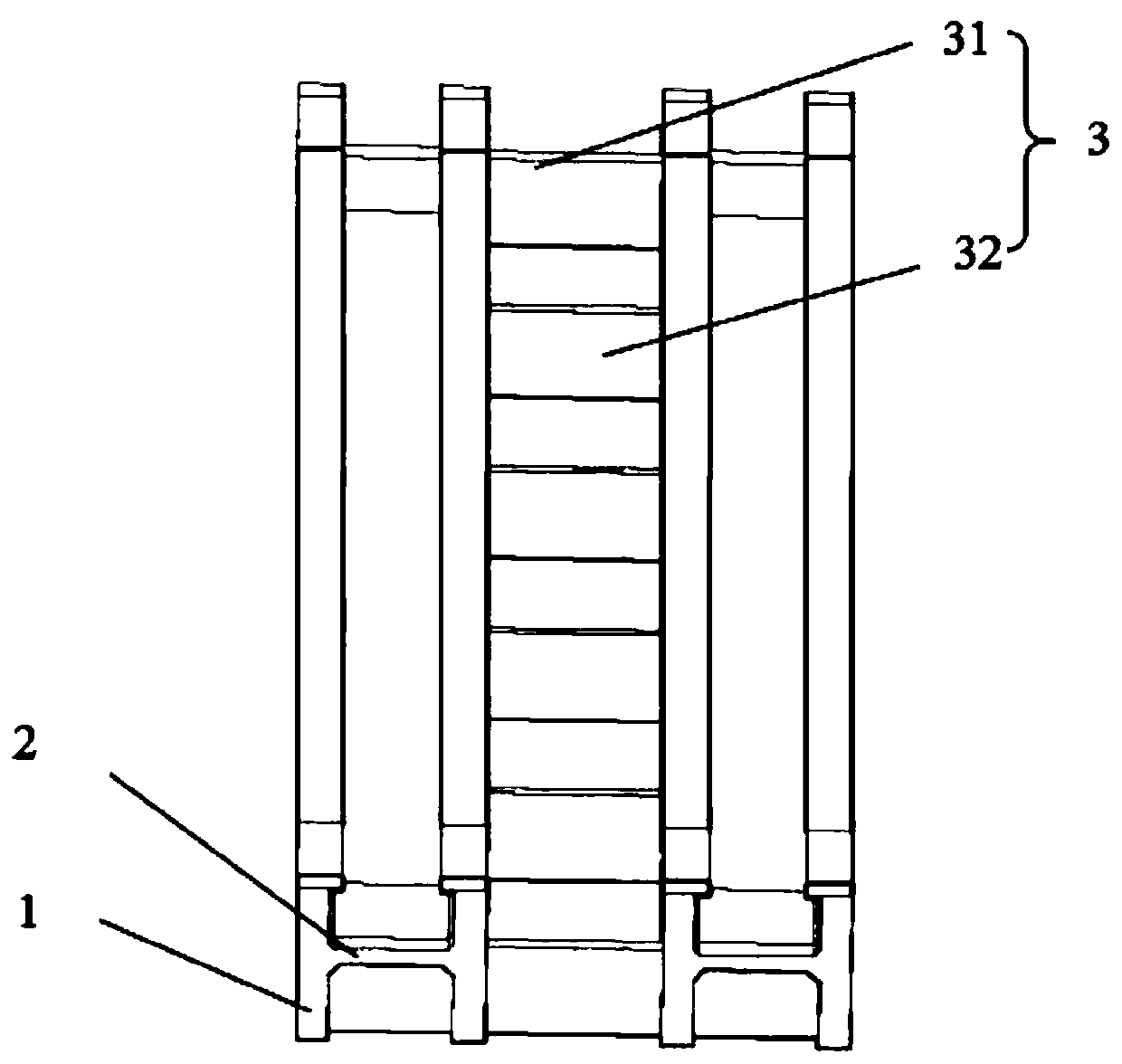

Supporting platform for building construction and installation method of supporting platform

PendingCN109339425ARealize automatic adjustmentImprove structural stabilityScaffold accessoriesUltimate tensile strengthSupport plane

The invention discloses a supporting platform for building construction. The supporting platform includes a supporting frame and a supporting table, the supporting frame comprises a supporting base, supporting columns, connecting rods and an adjusting frame, the supporting columns are uniformly arranged at the corners around the top face of the supporting base, the connecting rods are arranged between the left and right supporting columns correspondingly, the adjusting frame includes a fixing rod piece and an adjusting rod piece, and the supporting table includes a main supporting table and anauxiliary supporting table. An installation method includes the following steps that a, the supporting frame is installed; b, a hydraulic lifting column is installed; c, the supporting table is installed; and d, regular maintenance and overhaul are carried out. According to the supporting platform for building construction and the installation method of the supporting platform, overall design isreasonable, the structure is simple, building and disassembling are convenient, and the overall structural strength and stability of the supporting platform are high; and through design of the main supporting table and the auxiliary supporting table, the functionality and security of the supporting platform are additionally achieved, the main supporting table can facilitate standing of an operator, the auxiliary supporting table can facilitate placement of materials and tools, and meanwhile the height of the main supporting table can be adjusted up and down according to the actual demands.

Owner:ZHEJIANG UNIV OF TECH

Coal gangue sintered brick and preparation method therefor

The present invention discloses a coal gangue sintered brick. The coal gangue sintered brick consists of the following components in proportion by weight: 70-75% of coal gangue; 10-15% of emulsion waste oil; 2-5% of silica fume or cement; and 10-13% of water. The present invention further discloses a method for preparing the coal gangue sintered brick. The method comprises the following steps of: preliminary crushing, smashing, screening, mixing, stirring, aging, secondarily stirring, carrying out vacuum extruding, slitting, carrying out brick-body molding, drying, sintering, and cooling. According to the coal gangue sintered brick and the preparation method therefor disclosed by the invention, the coal gangue and the emulsion waste oil are used as main raw materials for brick preparation, so that not only can cultivated lands and land resources be saved, but also damages to vegetation and river environment can be avoided; and produced bricks have good plasticity, better bearing capability, good water permeability, andare energy-saving and environmentally-friendly.

Owner:贺其宏

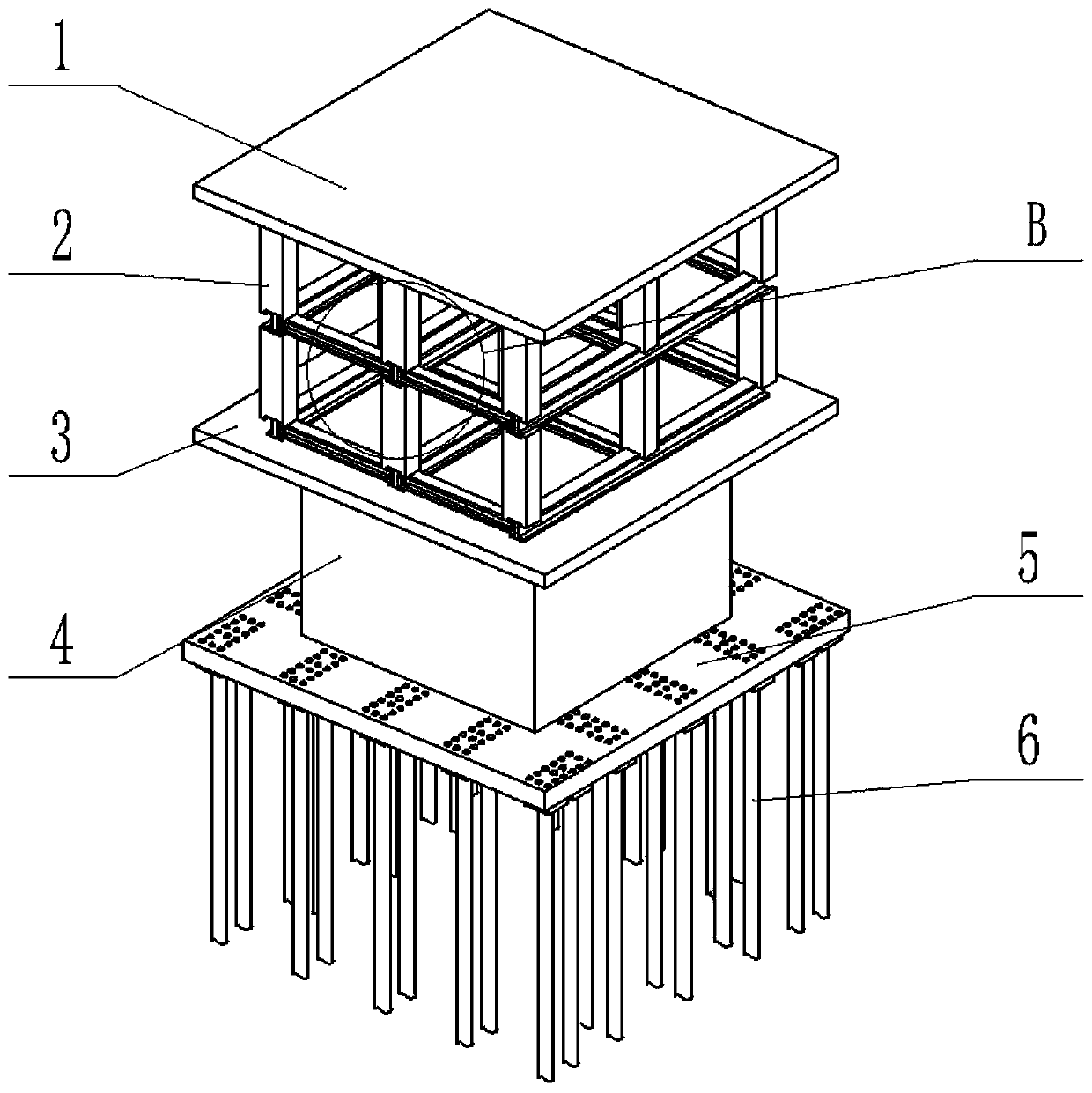

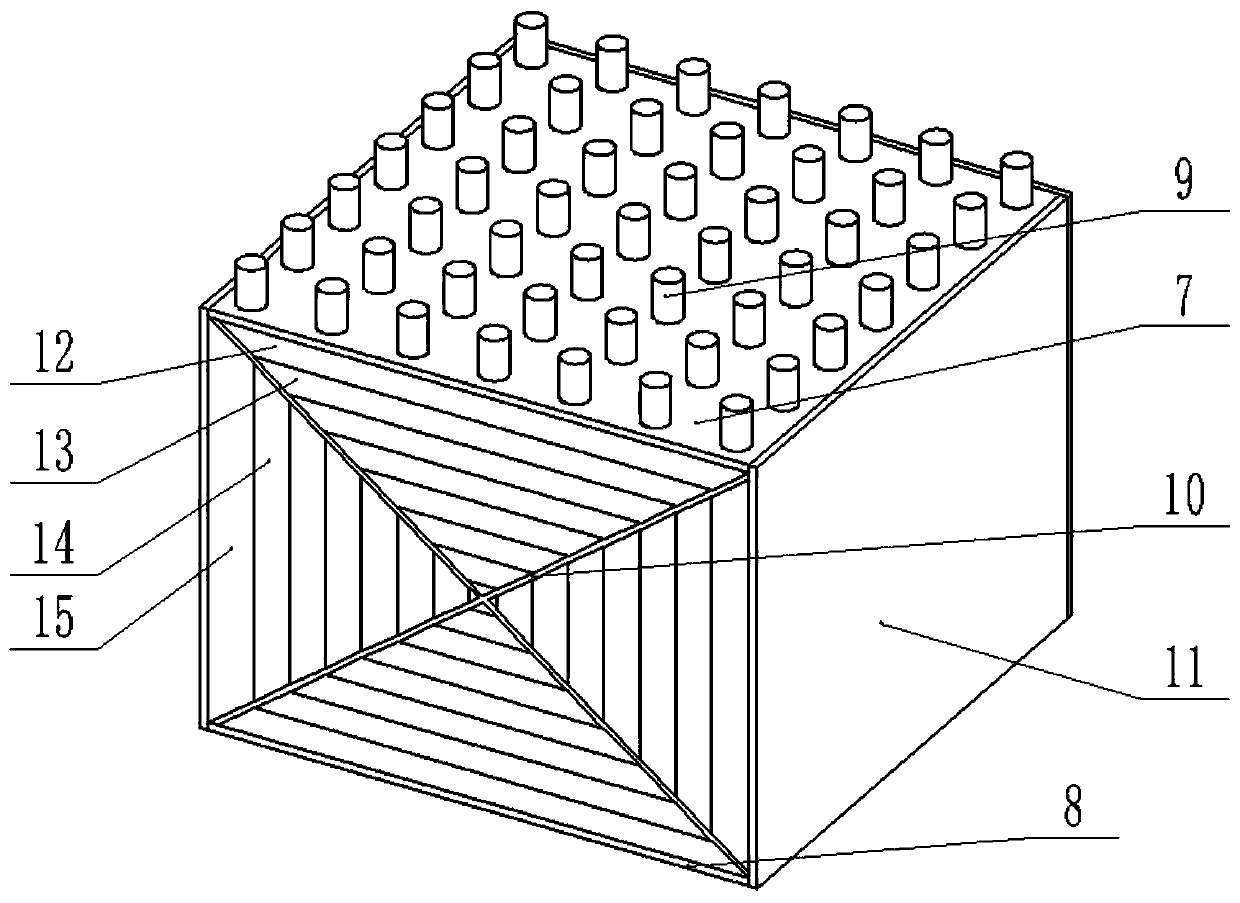

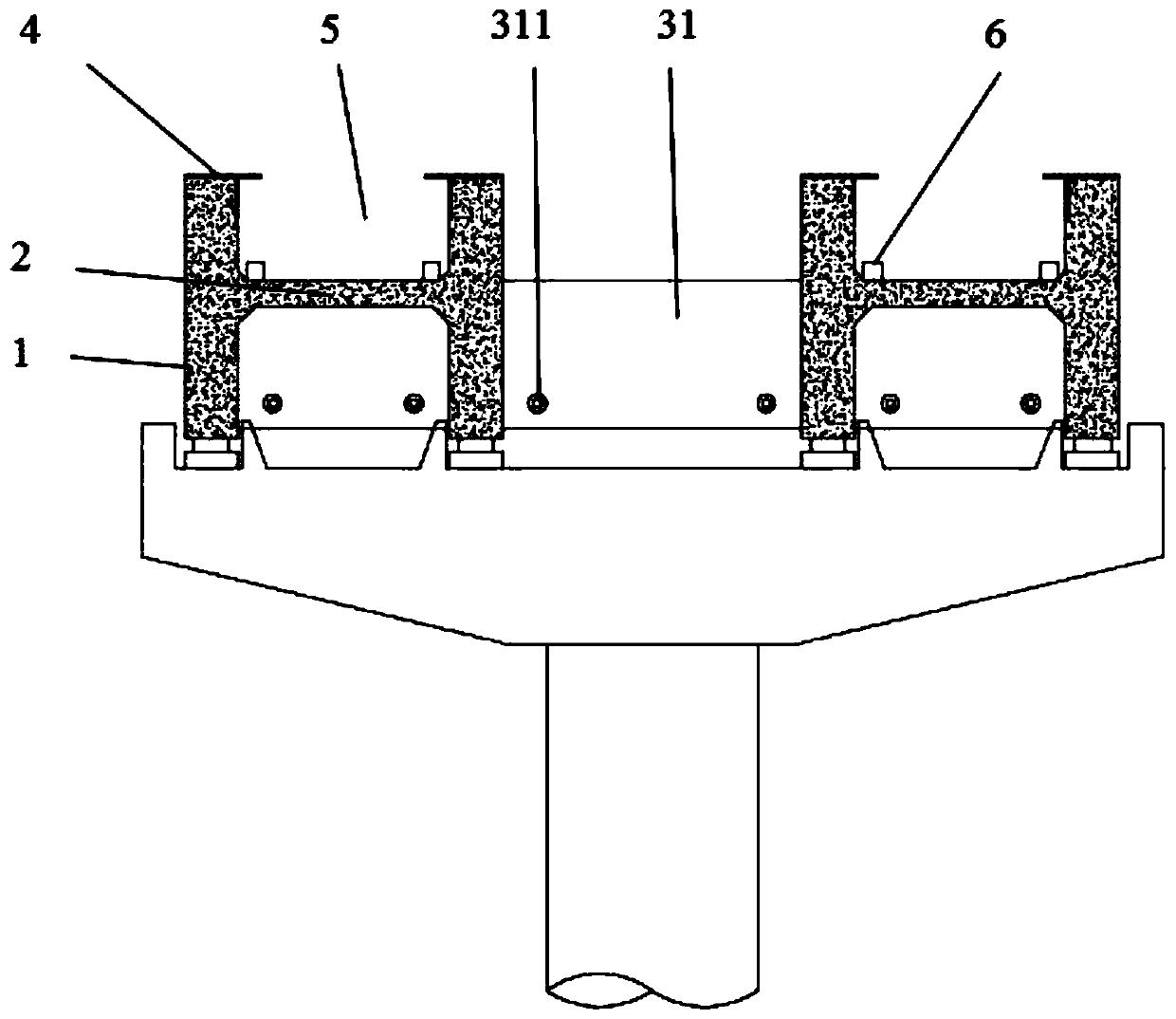

Integral foundation platform for rapid construction

ActiveCN111236287AQuick buildImprove bending resistanceProtective foundationArchitectural engineeringRock bolt

The invention relates to the technical field of buildings, and particularly discloses an integral foundation platform for rapid construction. The integral foundation platform for rapid construction comprises an integral bearing platform and a pressure-bearing type self-rotating anchor rod; the integral bearing platform comprises an upper anchor plate, a middle anchor plate, a lower anchor plate, avibration isolation device and a steel structure bearing platform; the steel structure bearing platform comprises a plurality of transverse steel beams, longitudinal steel beams and vertical steel beams, wherein the transverse steel beams, the longitudinal steel beams and the vertical steel beams are criss-cross and fixed through bolts; the upper anchor plate is arranged at the top of the steel structure bearing platform, the middle anchor plate is arranged at the bottom of the steel structure bearing platform, the vibration isolation device is arranged at the bottom of the middle anchor plate, and the lower anchor plate is arranged at the bottom of the vibration isolation device; and the lower anchor plate is placed on the ground and fixed through the pressure-bearing type self-rotatinganchor rod. The integral foundation platform for rapid construction aims to solve the problems of complex construction process and long construction time.

Owner:CHONGQING UNIV

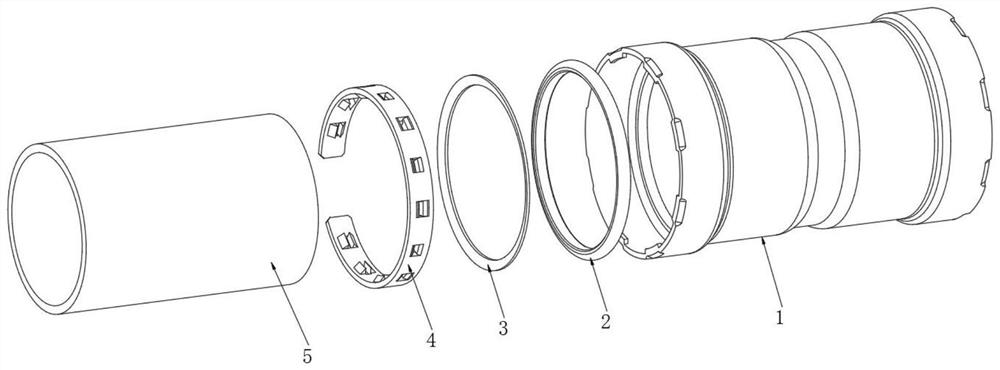

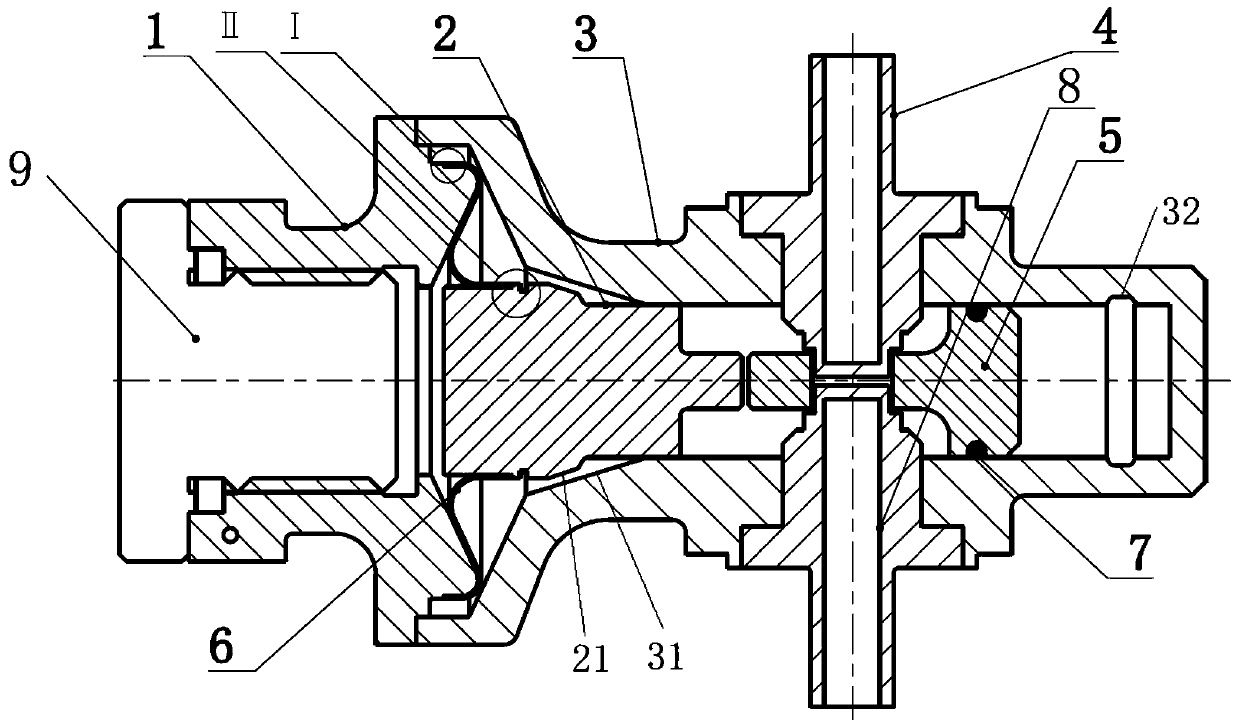

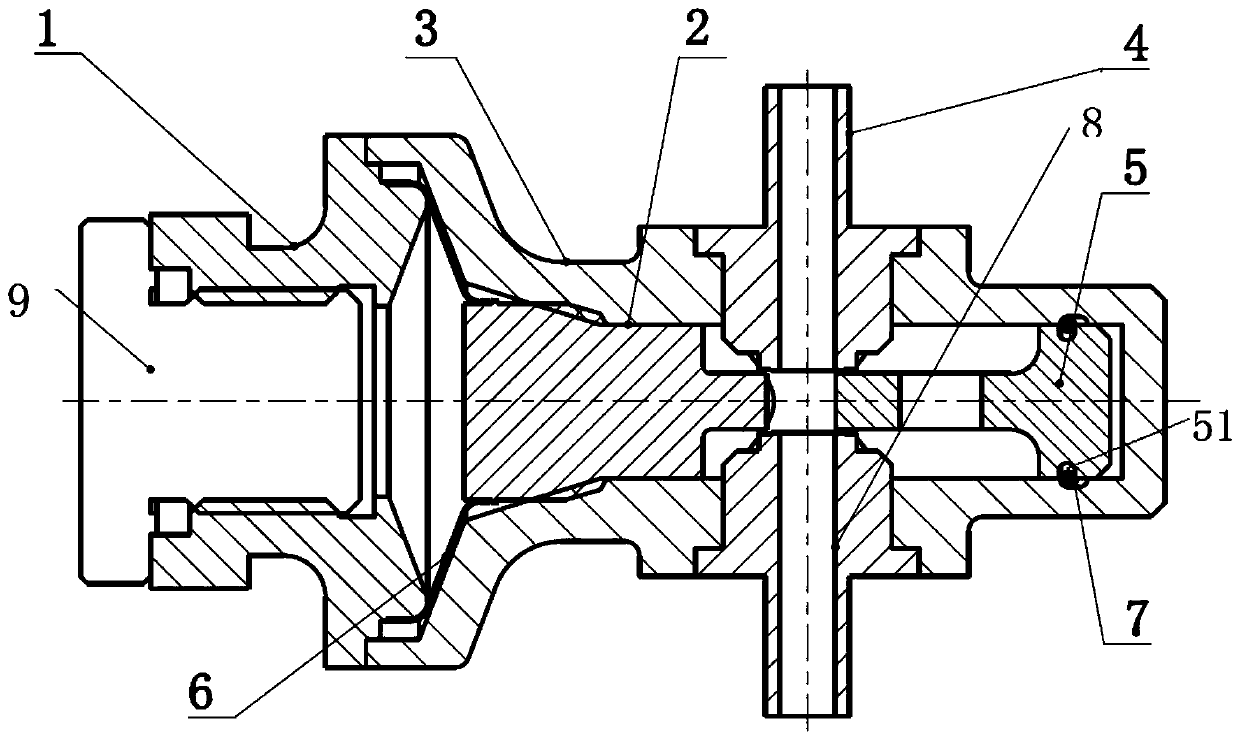

Thick-wall clamping and pressing type pipe fitting

PendingCN112178309APlay a sealing and watertight operationImprove tensile propertiesSleeve/socket jointsCorrosion preventionPipe fittingThick wall

The invention belongs to the technical field of clamping and pressing type pipe fittings, in particular to a thick-wall clamping and pressing type pipe fitting. The thick-wall clamping and pressing type pipe fitting comprises a thick-wall pipe fitting body arranged between two thick-wall steel pipe bodies and used for being connected with the thick-wall steel pipe bodies, and a sealing ring used for sealing, a positioning check ring and a gear ring are installed between the thick-wall pipe fitting body and the thick-wall steel pipe bodies; the thick-wall pipe fitting body comprises a connecting section located in the middle, a first flaring section and a second flaring section, wherein the first flaring section and the second flaring section expand and extend towards the two sides; a thick-wall metal pipe design is adopted, a special tool is used for crimping to deform the pipe fitting, so that the pipe fitting and a steel pipe are connected instantaneously, a crimping tool crimps a socket section of the pipe fitting, the socket section is provided with the sealing ring and the high-strength gear ring, and the sealing ring and the high-strength gear ring are compressed at the sametime to force the sealing ring in a socket section groove to cling to the steel pipe to achieve sealing and water-stopping operation; and the high-strength gear ring shrinks to firmly fasten the steelpipe, so that a good tensile effect is achieved. Due to the adoption of the thick-wall design, and good pressure-bearing performance and impact resistance are achieved.

Owner:国琳(天津)科技有限公司

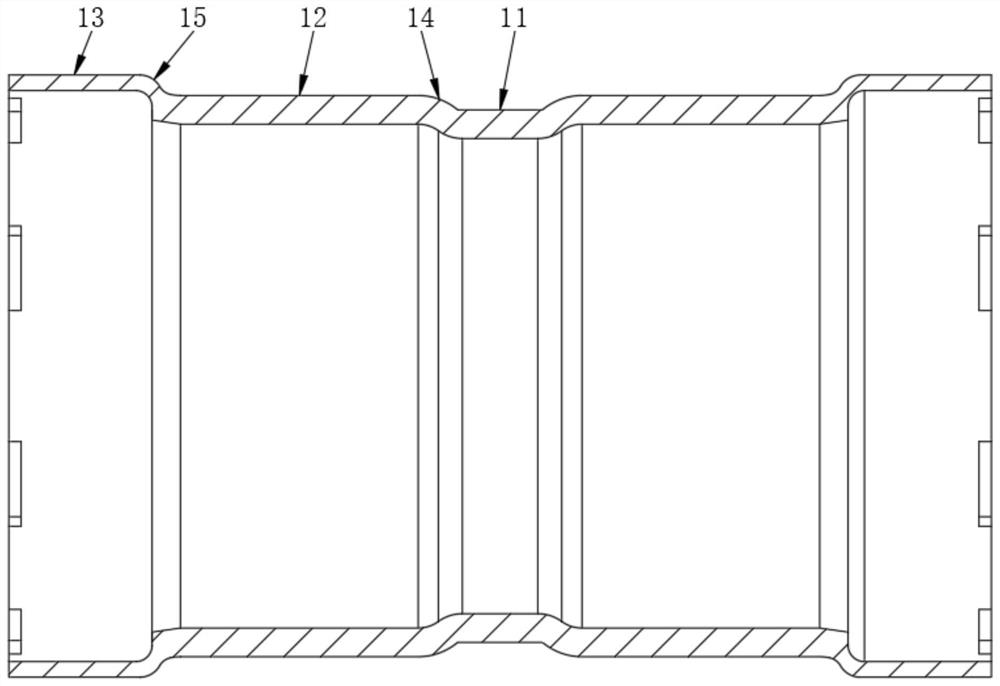

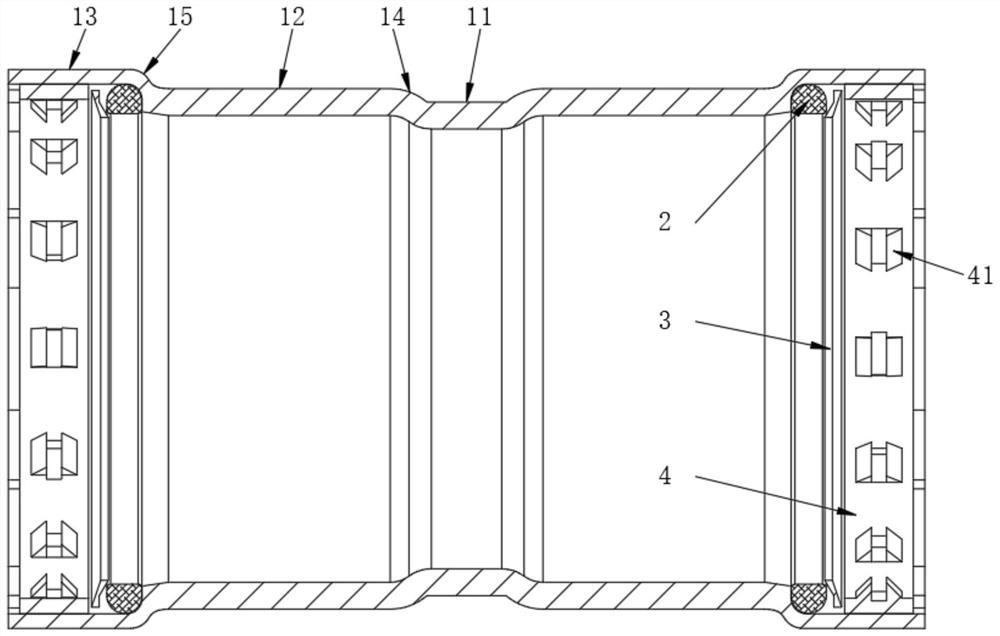

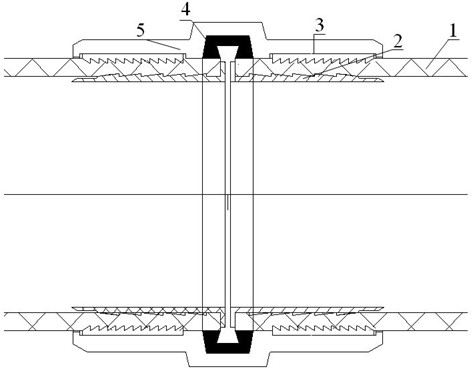

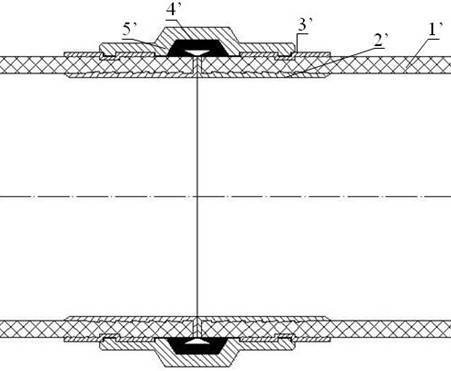

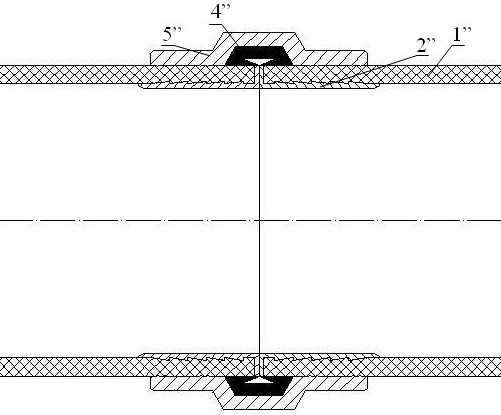

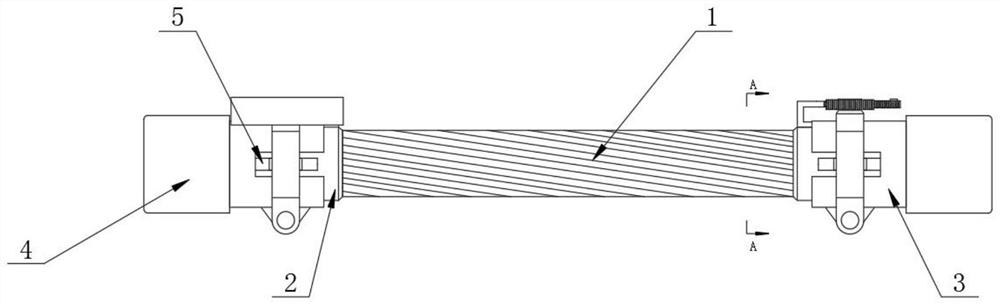

Medium-pressure steel wire reinforced plastic pipeline and pipe fitting connecting method

InactiveCN102322554APrevent leakageResolve connectionPipe connection arrangementsPipe fittingHigh pressure

The invention discloses a medium-pressure steel wire reinforced plastic pipeline and a pipe fitting connecting method. The medium-pressure steel wire reinforced plastic pipeline comprises pipes (1, 1' and 1''), inner bushings (2, 2' and 2''), fastening sleeves (3 and 3'), sealing rings (4, 4' and 4'') and connecting members (5, 5' and 5''), wherein the inner bushings (2, 2' and 2'') are arranged inside ports of the pipes (1, 1' and 1'') for supporting; the fastening sleeves (3 and 3') are fixed on the surfaces of the ports of the pipes (1, 1' and 1'') through a buckling device; the sealing rings (4, 4' and 4'') are sleeved at the ports of the pipes (1, 1' and 1''); and the connecting members (5, 5' and 5'') are connected to the fastening sleeves (3 and 3') or directly used for fastening the pipes (1, 1' and 1''). According to the medium-pressure steel wire reinforced plastic pipeline and the pipe fitting connecting method which are disclosed by the invention, an engineering medium-pressure pipeline and construction connecting scheme is developed, and the problem of pipe fitting connection in the application of the heavy-caliber high-pressure steel wire reinforced plastic pipeline is solved; and the caliber of the pipeline can reach 400mm, and the pressure can reach 10Mpa. The medium-pressure steel wire reinforced plastic pipeline and the pipe fitting connecting method can be better applied to engineering environments with high requirements, such as emergency transportation and the like.

Owner:江苏联冠高新技术有限公司

Construction technology for forming railway crossing by pouring of concrete

Owner:SGIS SONGSHAN CO LTD

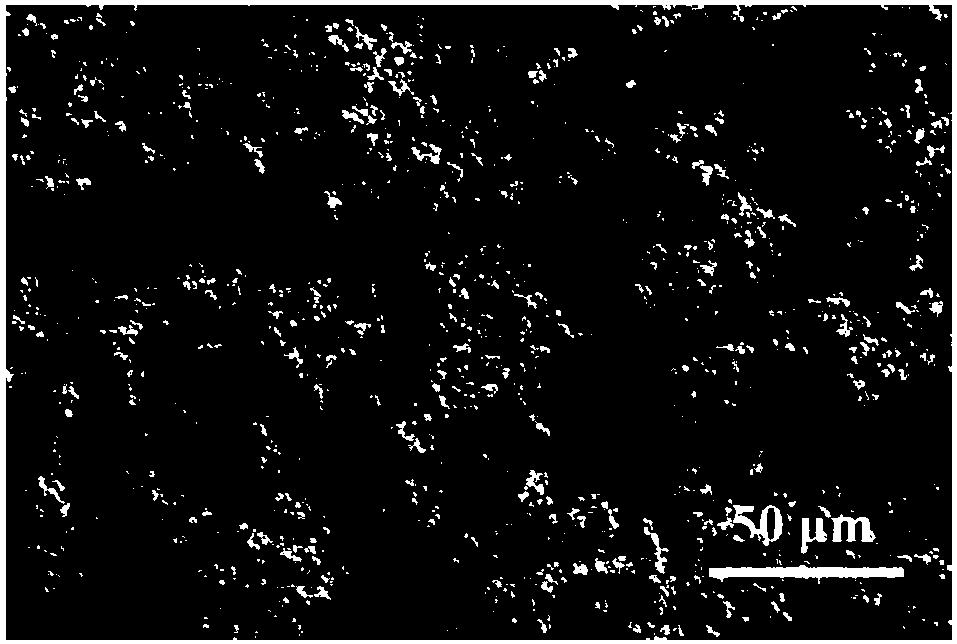

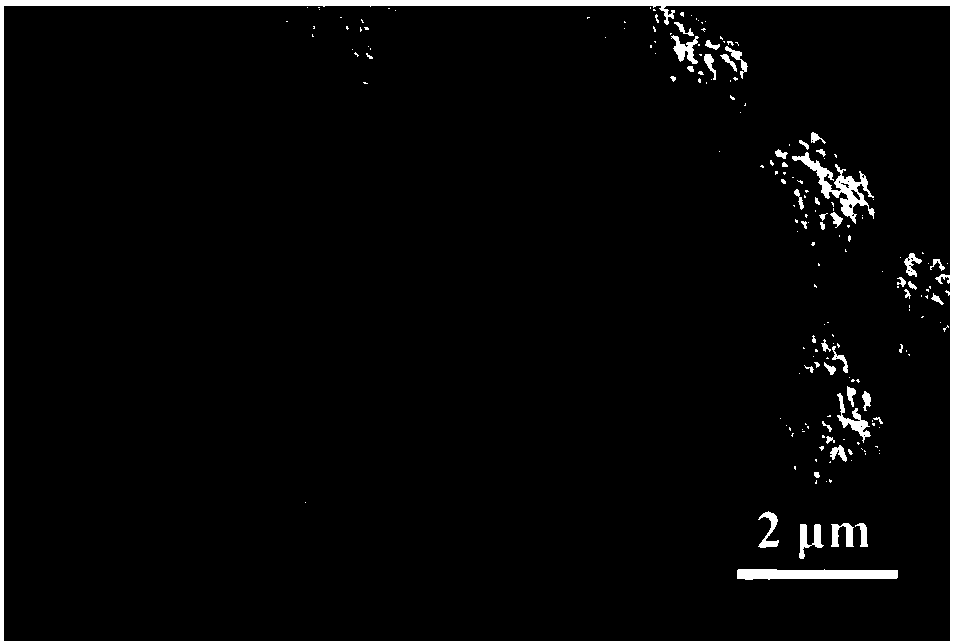

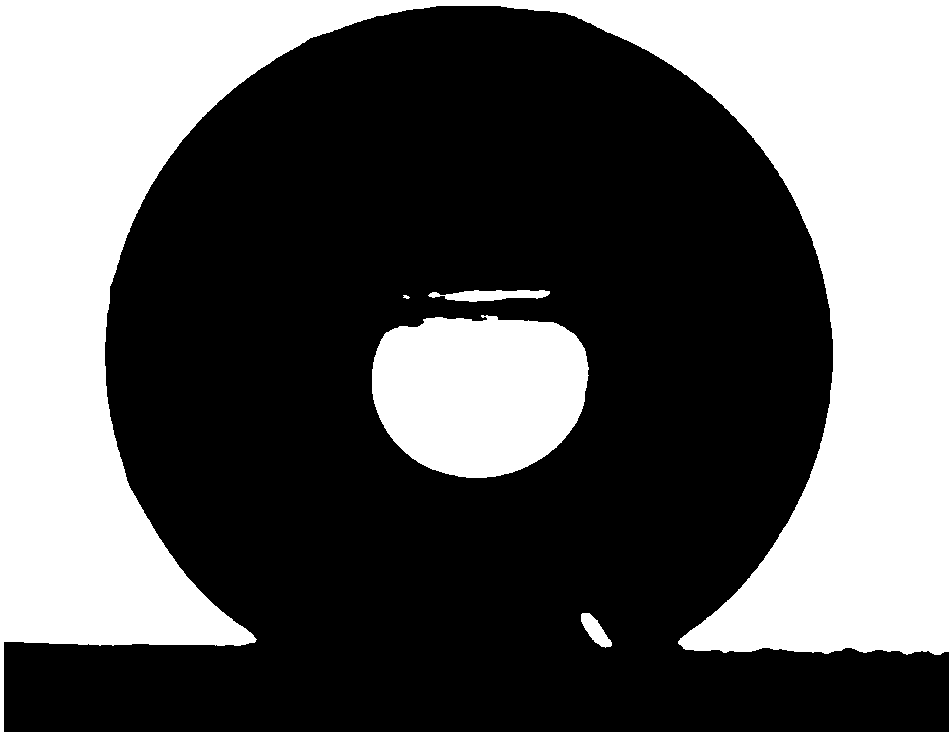

Preparation and application of oil-water separation net membrane with different wettability

InactiveCN107551604ASimple preparation processSimple equipmentFatty/oily/floating substances removal devicesLiquid separationRoom temperatureOil water

The invention discloses preparation and application of an oil-water separation net membrane with different wettability. The method comprises the following steps: (1) ultrasonically cleaning a fabric net and airing; and (2) paving the aired fabric net on a crucible containing liquid polydimethyl siloxane, then putting into a muffle furnace, carrying out high-temperature calcination, cooling to achieve room temperature, and taking out to obtain the oil-water separation net membrane. The oil-water separation net membrane disclosed by the invention has the performances of super-hydrophobic, super-oleophilicity in air and super-hydrophobic in oil. Another oil-water separation net membrane disclosed by the invention has the performances of super-hydrophilicity in air and super-oleophobicity in water. According to the invention, the preparation process is simple, raw materials are easily available, the cost is low, and the oil-water separation net membrane is environmentally friendly and canbe produced and applied in large scale. The two net membranes provided by the invention can be used for separating various types oil-water mixtures, have the advantages of high separation efficiency,quick speed, high bearing pressure, no need for external driving, good stability, multiple times of circulation and the like, and can be applied to the fields of industrial oil-water separation, environment protection and the like.

Owner:SOUTH CHINA UNIV OF TECH

Explosion-proof elevator cable for fire protection

ActiveCN102938265AGood heat insulationRealize video communication functionInsulated cablesInsulated conductorsFire protectionWear resistant

The invention discloses an explosion-proof elevator cable for fire protection, which comprises a cable core, an elastic filling layer, an inner sheath, a tensile and compressive layer, a metal shield layer and an outer sheath, wherein the cable core comprises a plurality of independent control lines, power lines and twisted pair communication conversion video lines; the control lines, power lines and twisted pair communication conversion video lines are provided with the elastic filling layer; the inner sheath is wrapped outside the elastic filling layer and used for protecting the cable core in the inner layer; the outer side of the inner sheath is sequentially provided with the tensile and compressive layer for improving resistance, the metal shield layer for preventing radiation leakage and the outer sheath for preventing physical damages; the metal shield layer is provided with a flame-retardant and explosion-proof layer; and the outer sheath uses wear-resistant, chemical-corrosion-resistant and high-temperature-resistant fluoroplastic for protection.

Owner:上海贝恩科电缆有限公司

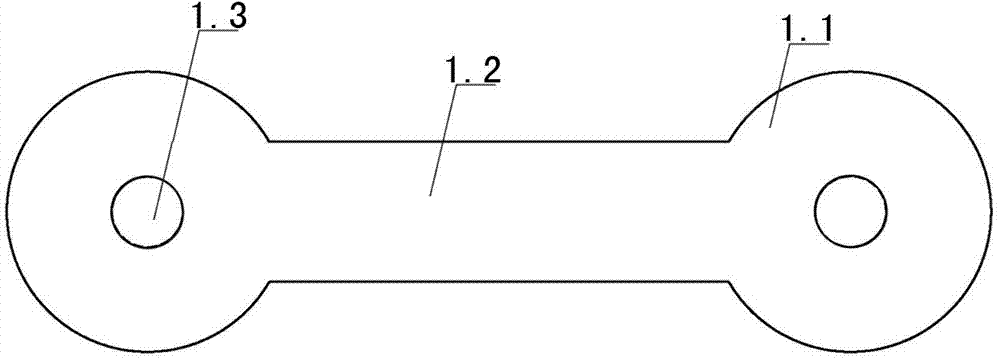

Glass fiber net reinforcement part, exterior wall heat-preservation anti-cracking structure and construction method thereof

ActiveCN104499651AOvercome strengthOvercoming easy crackingHeat proofingBuilding reinforcementsGlass fiberSurface layer

The invention relates to a glass fiber net reinforcement part, an exterior wall heat-preservation anti-cracking structure and a construction method of the exterior wall heat-preservation anti-cracking structure. The glass fiber net reinforcement part is of an integral sheet structure formed by two fixing sheets with the same shape and a connecting bridge connected between the two fixing sheets, and a threaded hole penetrating through a screw is formed at the center position of the fixing sheet. In addition, the glass fiber net reinforcement part is designed to be used for reinforcing the connecting strength of an anti-cracking mortar layer and a heat preservation layer, the glass fiber net reinforcement part has a simple structure, has low cost, can be constructed conveniently, and has a good fixing effect, can compensate the strength loss when the binding power between the anti-cracking mortar layer and the heat preservation layer is low, and can ensure the bonding quality and the construction reliability of the follow-up surface layer, the construction operation is simple, the construction difficulty is not increased, the original construction quality and the construction efficiency are not influenced, the using amount of the anti-cracking mortar can be used to a certain extent, the cost is reduced and the glass fiber net reinforcement part can be widely applied to exterior wall construction.

Owner:BUCG THE EIGHTH CONSTR DEV

Circulating blowing type electric welding work case for pipeline operation

The invention discloses a circulating blowing type electric welding work case for pipeline operation, and the work case comprises a folding electric welding box which can achieve inflation and deflation. An electric welding nozzle pipe and an inwards-turning type grabbing glove are disposed to pass through the folding electric welding box. The folding electric welding box is also provided with an inert gas pipe, a circulating pipe, a workpiece entering closing door, and a gas exhaust door. The head and tail of the circulating pipe are respectively connected to a group of opposite surfaces of the folding electric welding box. The circulating pipe is sequentially provided with a circulating gas flow pump, a dedusting link, a gas filtering link and a high-temperature heating link in the gas flow direction. Compared with the prior art, the interior of the folding electric welding box is filled with inert gas, and an operator carries out operation of the folding electric welding box. The inert gas in the folding electric welding box continuously circulates for use, thereby reducing the consumption of inert gas, reducing the discharge of harmful gas, protecting the environment, and also protecting the safety of an operator.

Owner:SUZHOU HUARI JINLING MACHINERY

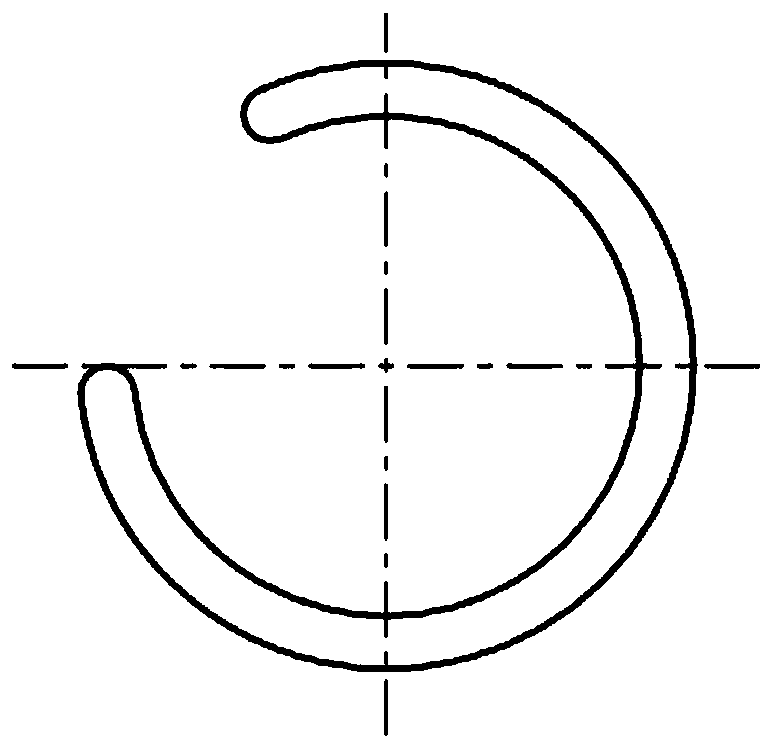

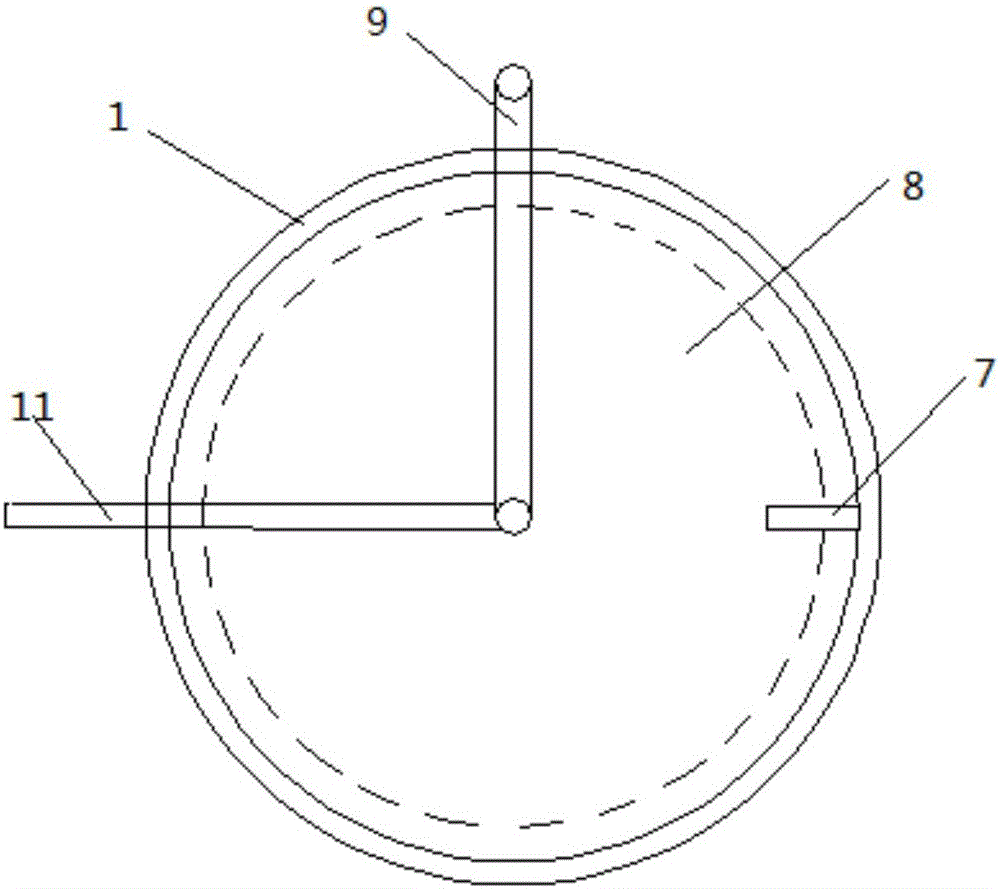

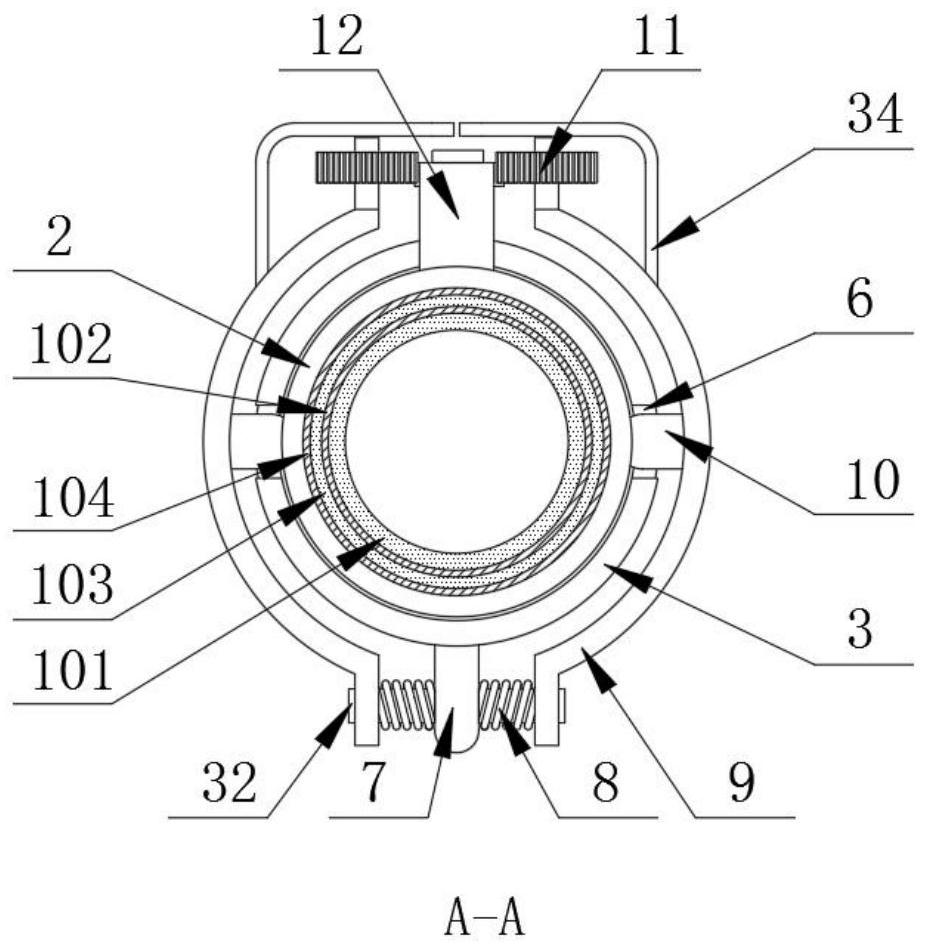

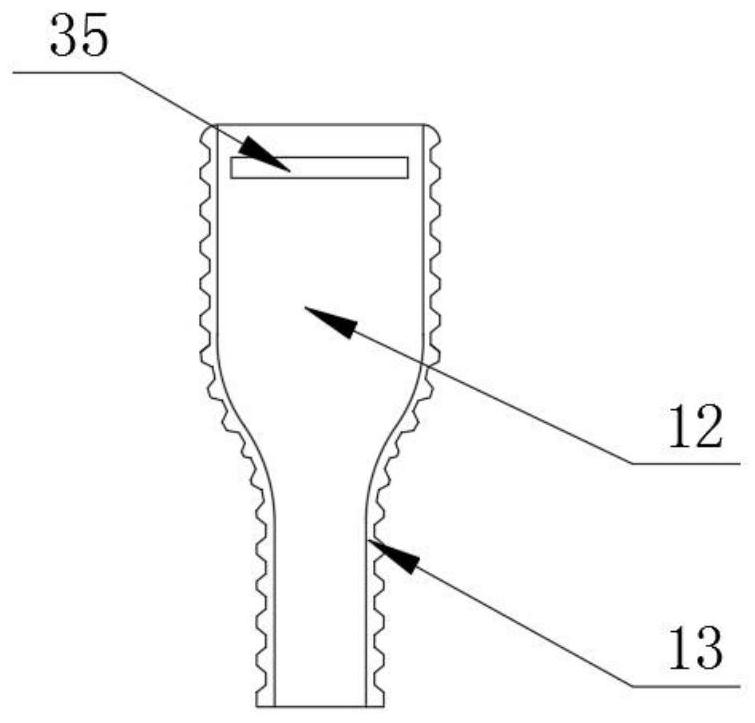

Gas driving membrane turnover type normally closed valve

ActiveCN111022722AGood under pressureEasy flipOperating means/releasing devices for valvesEqualizing valvesCircular discEngineering

The invention relates to a gas driving membrane turnover type normally closed valve. The problems that the sealing performance of an existing gas driving valve cannot meet the requirements, and the size is large are solved. The gas driving membrane turnover type normally closed valve comprises a transfer connection cap, a piston, a shell, an upper valve element, a lower valve element, a cutter, amembrane and a snap ring. An electric explosion pipe is installed at one end of the transfer connection cap, and the other end of the transfer connection cap is fixedly connected with the shell. An inner conical surface is arranged on the inner surface of the shell, an outer conical surface is arranged on the outer surface of the piston, the inner conical surface and the outer conical surface cooperate with each other when the valve is opened, and the sealing operation of the shell and the piston is achieved. The membrane is of a disc-shaped structure, the inner side of the membrane is fixedlyarranged on the outer surface of the piston, and the outer side of the membrane is fixedly arranged on the transfer connection cap. The piston and the cutter are arranged in a cavity of the shell insequence, and a gap is formed between the piston and the cutter. A through notch is formed in the end face of the cutter, a circumferential through hole which is through is formed in the peripheral surface of the shell, and the upper valve element and the lower valve element are arranged in the circumferential through hole and pass through the notch of the cutter.

Owner:XIAN AEROSPACE PROPULSION INST

Safety can for preventing explosion of liquefied petroleum gas cylinder

ActiveCN105757454AIncrease temperatureReduce the likelihood of an explosionVessel geometry/arrangement/sizeContainer filling methodsEngineeringAir tightness

The invention relates to a safety can for preventing an explosion of a liquefied petroleum gas cylinder. The safety can comprises a can body and a can cover, wherein a supporting rod is fixedly arranged on the upper part of the outer side wall of the can body; a connecting rod is vertically rotatably arranged on the middle part of the can cover; the can cover can peripherally rotate around the connecting rod and at a top opening of the can body; the upper end of the connecting rod is bent toward the outer side of the can body and the connecting rod is hinged with the supporting rod through a hinge located at one end, away from the can body, of the supporting rod; an opening handle is fixedly arranged at the top of the can cover; a plurality of fixture blocks are fixedly arranged along the peripheral direction of the inner wall of the top opening of the can body; clamping slots corresponding to the fixture blocks are formed in the peripheral side wall of a plug part of the can cover, respectively; gaps are formed between the adjacent clamping slots and in the peripheral side wall of the plug part of the can cover; after the gaps are rotated along with the can cover till the corresponding fixture blocks are located in the corresponding gaps, the fixture blocks are separated from the plug part of the can cover through the gaps; an airtight handle extending toward the outer side of the can body is arranged at the top of the can cover. The safety can has beneficial effects of simple structure, convenience in operation, quick opening and closing and excellent pressure-bearing and airtight property.

Owner:湖南佳创能源工程设计研究院有限公司

Oil-resisting rubber hose of automobile with good anti-swelling property

ActiveCN112161124AImprove flexibilityGood under pressureJoints with fluid cut-off meansFlexible pipesOperation safetySteel tube

The invention discloses an oil-resisting rubber hose of an automobile with a good anti-swelling property and in particular relates to the technical field of hoses of automobiles. The oil-resisting rubber hose comprises two joining steel pipes, wherein a hose body is fixedly arranged between the two joining steel pipes and an oil inlet joint and an oil outlet joint are separately mounted outside the two joining steel pipes; the hose body, the two joining steel pipes and the oil inlet joint and the oil outlet joint form a hose unit; the oil inlet joint and the oil outlet joint are connected to the two joining steel pipes through clamping structures; connectors are fixedly connected among different hose units, and baffle plate assemblies are arranged in the connectors. In the invention, the whole oil-resisting rubber hose of the automobile has excellent acid and alkali resistance, swelling resistance and aging resistance and is provided with a better disassembling and assembling structure, so that the mounting and detaching flexibility is improved. The oil-resisting rubber hose of the automobile is operated more conveniently. Meanwhile, a quick flow stopping operation can be achievedunder overhauling or accidental conditions, so that the safety coefficient is high.

Owner:昆山伟理塑汽车部件有限公司

0.6kv and 1kv environment-friendly-type ratproof and ant-prevention power cable

InactiveCN105321610AGood under pressureAvoid destructionInsulated cablesPower cablesPolyolefinEngineering

The invention relates to a 0.6kV and 1kV environment-friendly-type ratproof and ant-prevention power cable. The cable comprises three copper conductors. Each copper conductor is provided with an insulating layer so as to form an insulation wire core. A Filling is arranged outside the three insulation wire cores and a low-smoke halogen-free wrapping tape is extruded on an outer portion of the three insulation wire cores so as to form a cable core. A low-smoke halogen-free polyolefin inner sheath is arranged outside the cable core. A steel band armor layer is arranged outside the inner sheath. The steel band armor layer is a double-layer clearance-type galvanized steel strip. A low-smoke halogen-free flame-retardant polyolefin outer sheath is arranged outside the steel band armor layer. A nylon sheath is arranged outside the outer sheath. By using the cable of the invention, the structure is simple, a service life is long, heat resistance performance is good, ultraviolet ray resistance performance, oil resistance performance and chemical property resistance performance are possessed and the cable is safe and environmental-protection.

Owner:JIANGSU HUANENG CABLE

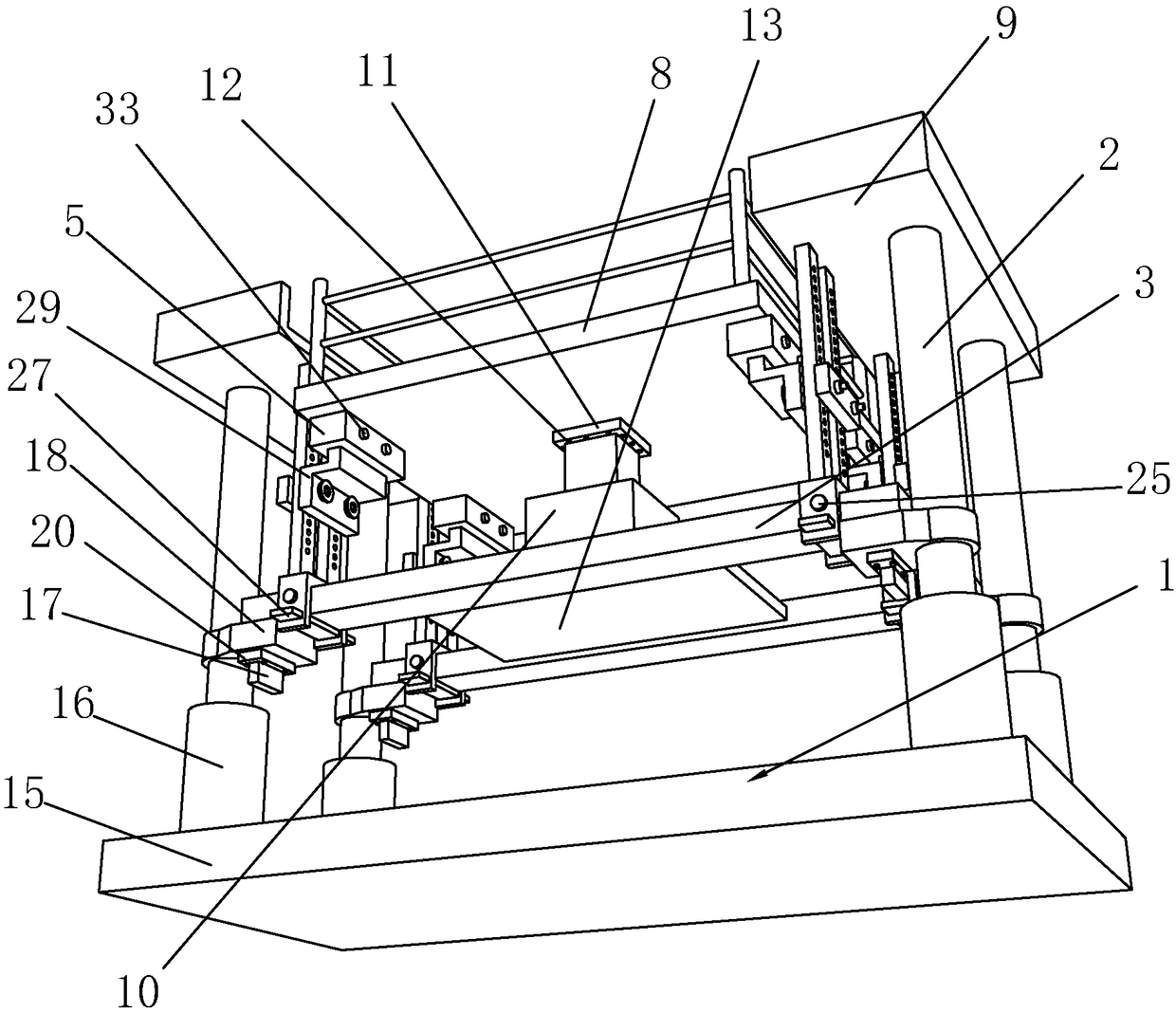

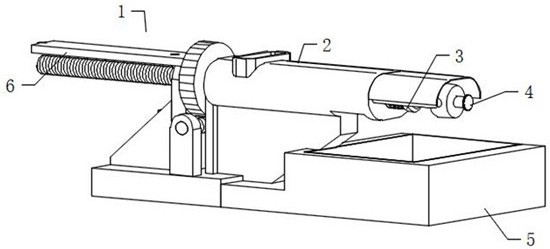

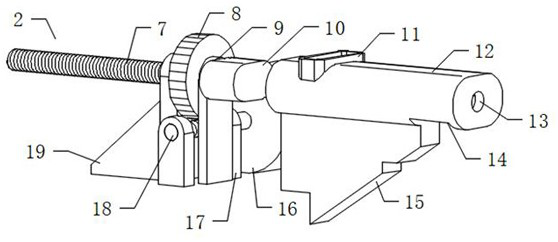

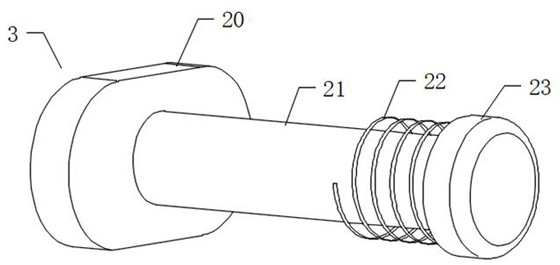

Preparation method for die surface polishing device

PendingCN106737013AReduce replacementReduce the amount of human laborGrinding machinesGrinding work supportsFixed frameEngineering

The invention provides a preparation method for a die surface polishing device. The die surface polishing device comprises a control box, a support device and a polishing device, wherein the support device comprises a fixed frame, a die plate seat and a top plate, the top plate is arranged at one side of the control box, the fixed frame is arranged above the top plate, and the die plate seat is arranged in the fixed frame; and the polishing device comprises an operation frame, a lifting rod and a grinding tool, the operation frame is arranged above the fixed frame and one end of the operation frame is installed on the control box, the lifting rod is arranged on the operation frame, and the grinding tool is arranged at the lower end of the lifting rod. The die plate seat in the invention is capable of rotating in the fixed frame under the driving of a rotary shaft, so that convenience is provided for machining for the other surface, the steps of replacing the die plate seat and overturning are reduced, the machining time is shortened, the labour amount is reduced, and the production efficiency is increased.

Owner:TIANJIN LIDELI TECH DEV CO LTD

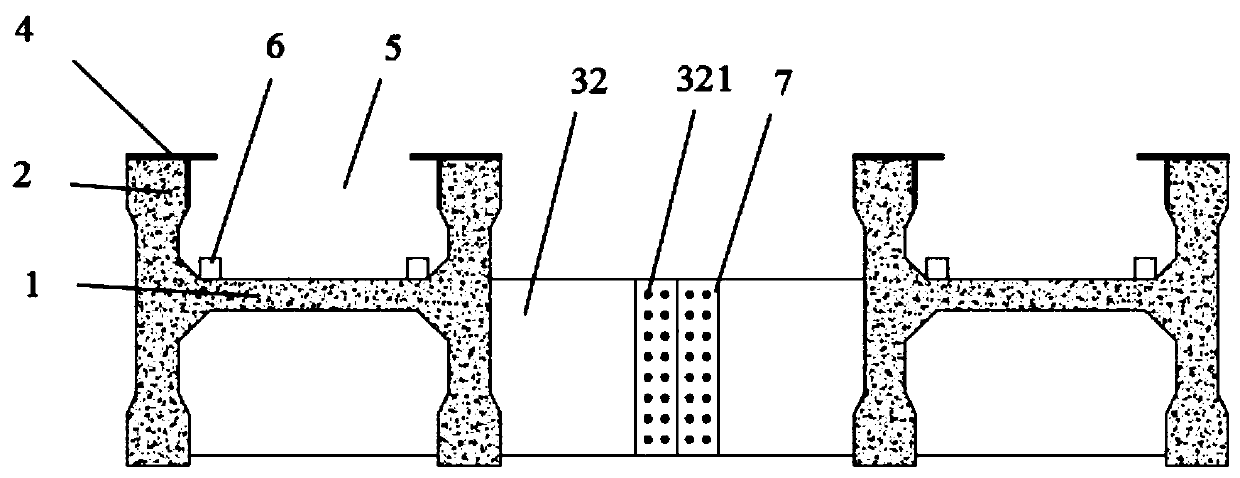

Double-H-shaped concrete rail beam of rubber-tyred tram and construction method thereof

PendingCN111424477AGood driving comfortIncreased durabilityRailway tracksArchitectural engineeringStructural engineering

The invention discloses a double-H-shaped concrete rail beam of a rubber-tyred tram and a construction method threof. The double-H-shaped concrete rail beam is arranged on piers and comprises a plurality of guide rail beam span sections, and every two adjacent guide rail beam span sections are connected in a chaining mode. Each guide rail beam span section comprises four webs, two bottom plates and a transverse partition plate; the four webs and the two bottom plates are combined into a double-H-shaped structure and are connected and combined into an integrated structure through the transversepartition plate; each web plate is of a structure with an I-shaped cross section, and embedded wear-resistant steel plates are arranged at the top end of each web plate and one side end of the top ofeach web plate; each transverse partition plate is located below the bottom plates and comprises two end transverse partition plates and a plurality of middle transverse partition plates. The two endtransverse partition plates are located at the two ends of each guide rail beam span section, and the multiple middle transverse partition plates are sequentially arranged. Compared with an existingsteel guide rail beam, the double-H-shaped concrete rail beam is large in overall rigidity, good in driving comfort, low in noise, good in durability of a concrete structure and small in later maintenance amount.

Owner:中交铁道设计研究总院有限公司

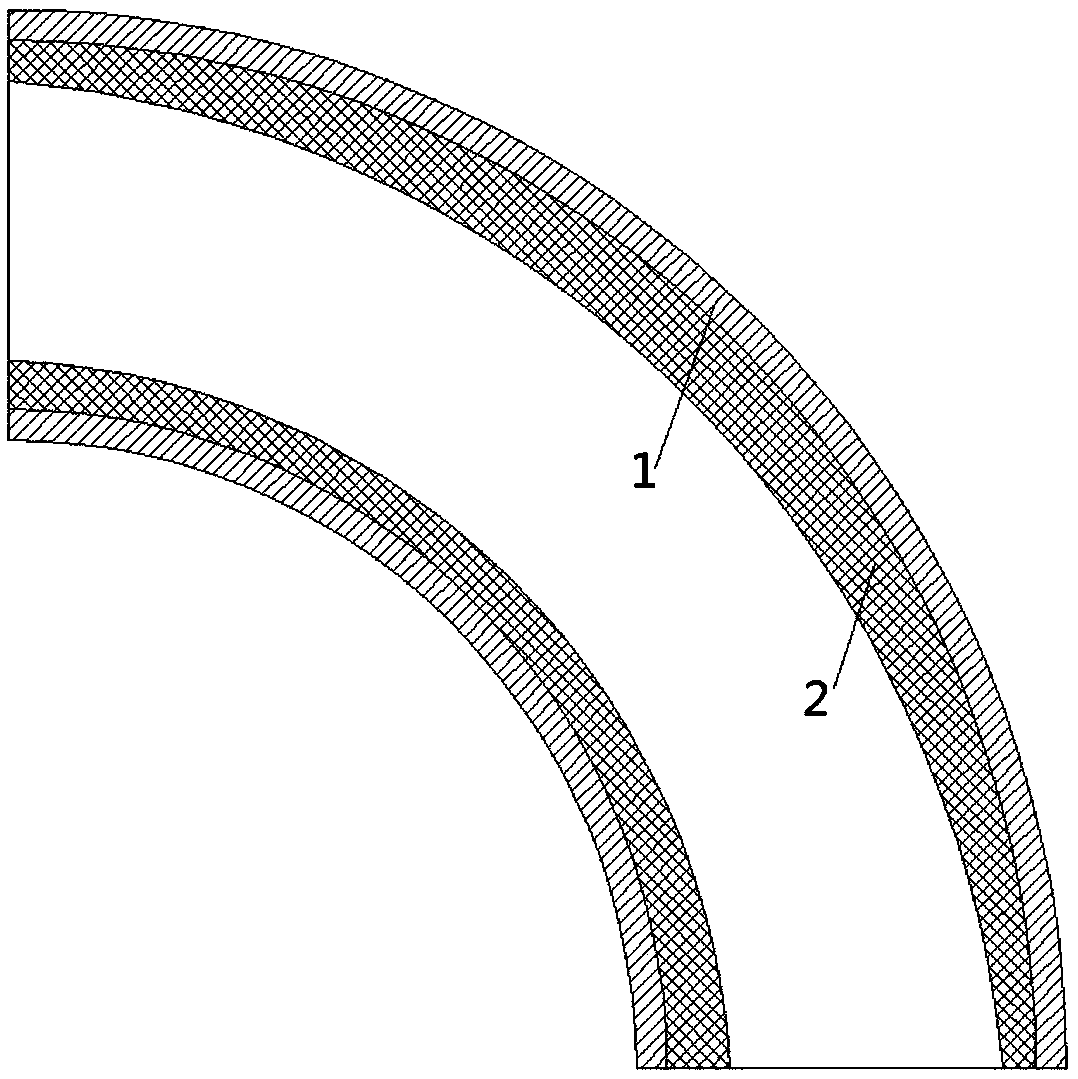

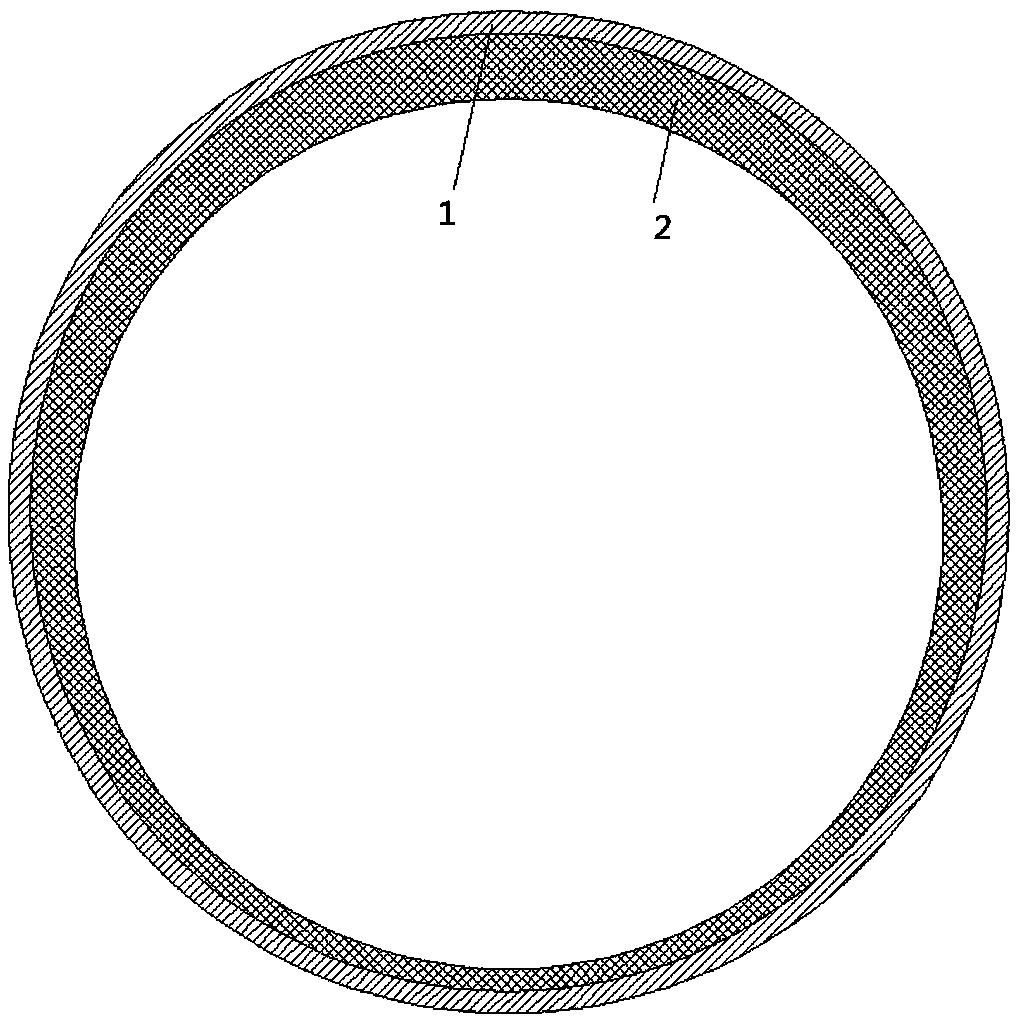

Concrete conveying bent tube and manufacturing method thereof

The invention provides a concrete conveying bent tube. The concrete conveying bent tube comprises a double-layer tube body, wherein the double-layer tube body comprises a tube outer layer made of low-carbon steel and a tube inner layer made of wear-resisting alloy; the thickness of one side of the outer arc of the tube inner layer is gradually reduced from the middle to the two ends; and the thickness of one side of the inner arc of the tube inner layer is gradually increased from the middle to the two ends. The concrete conveying bent tube comprises the double-layer tube body, and the double-layer tube body comprises the tube outer layer made of low-carbon steel and the tube inner layer made of wear-resisting alloy, wherein the structure of the tube inner layer is designed by combining abrasion and a stress working condition of the concrete conveying bent tube in a construction process, the thickness of one side of the outer arc is gradually reduced from the middle to the two ends, and the thickness of one side of the inner arc is gradually increased from the middle to the two ends, so that a weak link of the structure of the concrete conveying bent tube is reinforced, and therefore, the concrete conveying bent tube disclosed by the invention is more reasonable in design, is resistant to wear and impact, is good in pressure bearing, and the service life of the concrete conveying bent tube is prolonged. The invention also provides a manufacturing method for the concrete conveying bent tube.

Owner:SANY AUTOMOBILE MFG CO LTD

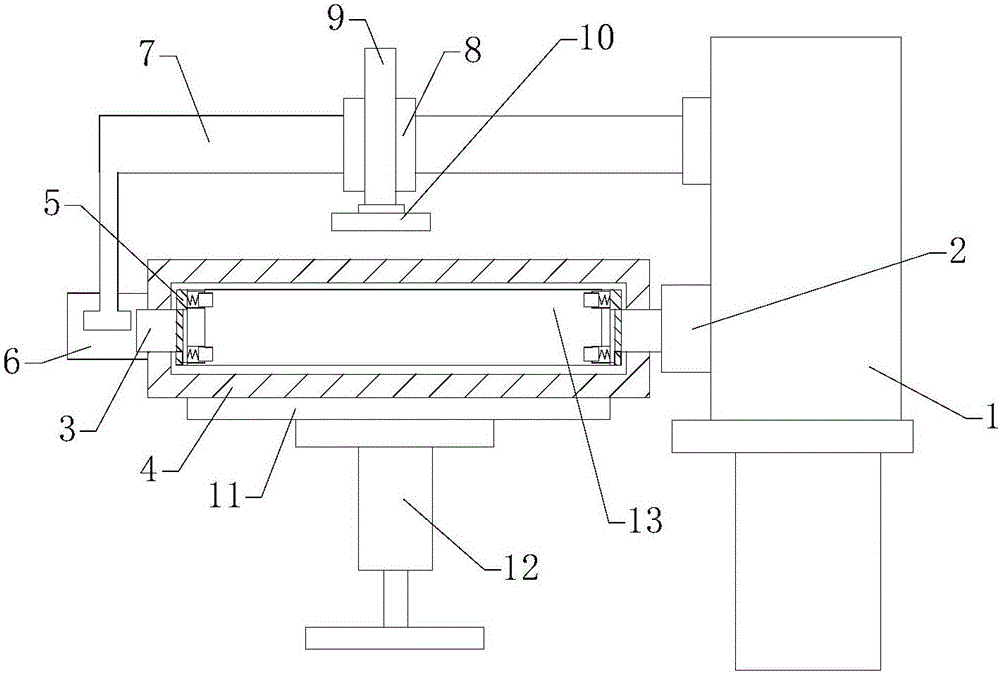

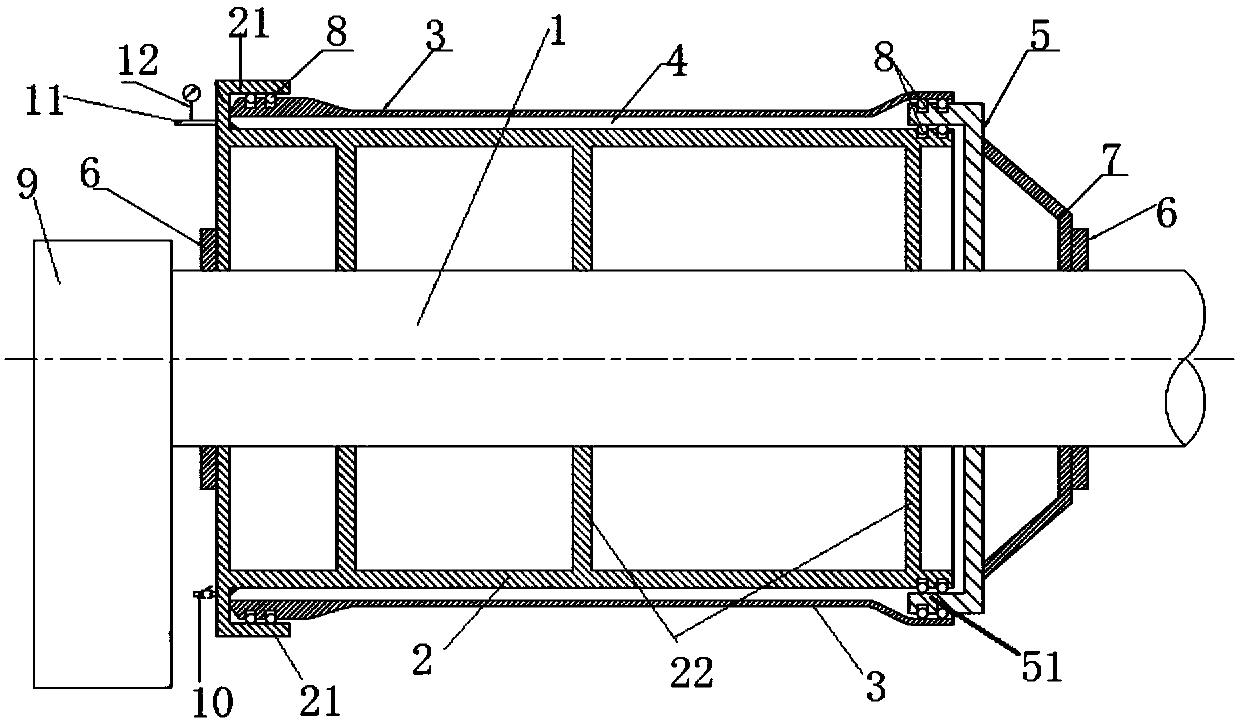

Jacket type water pressure testing device of large-caliber glass steel pipeline

PendingCN107870129AReduce volumeSmall size, interlayer cross-sectional areaMaterial strength using tensile/compressive forcesAxial forceEngineering

The invention discloses a jacket type water pressure testing device of a large-caliber glass steel pipeline. The jacket type water pressure testing device comprises a cantilever arm and a sleeve cylinder, wherein the sleeve cylinder is sheathed on the cantilever arm; a to-be-tested pipeline is sheathed at the exterior of the sleeve cylinder; the sleeve cylinder is in sealed connection with both ends of the to-be-tested pipeline, and a middle section forms a cavity interlayer for water pressure testing. The jacket type water pressure testing device has the advantages that the structural designis reasonable, the installation and detachment are convenient, the time is shortened, and the procedure is simplified; the whole structure is stable, and the bearing pressure is strong; the size of the cavity interlayer for the water pressure testing is small, the cross section of the interlayer is small, and the formed axial force is small; the amount of testing water is small, and the speed of water pressure testing is quick; by adopting different sizes of sleeve cylinders, the jacket type water pressure testing device is suitable for performing the water pressure testing on the multiple sizes of glass steel pipelines, and the application is more flexible and wide.

Owner:NANJING XINHE COMPOSITES CO LTD

A CNC machine tool for processing large transmission gears

ActiveCN113334831BSmall footprintEasy to handleFouling preventionMaintainance and safety accessoriesNumerical controlElectric machine

The invention discloses a CNC machine tool for large-scale transmission gear processing, which includes a CNC machine tool scrap discharge device, the CNC machine tool scrap discharge device includes a scrap compaction body, and the scrap compaction body includes a motor, and the motor passes through Electrically connected to an external power supply, the scrap discharge device of the CNC machine tool also includes a discharge valve, a delay body, a base and a limiter body, the scrap compaction body is fixedly installed with the base, the discharge valve is connected to The solid body is slidably installed together, the delay body is fixedly connected with the crushed material compaction body, the discharge valve is matched with the delay body by a sliding socket, and the crushed material compaction body also includes a threaded rod, a worm wheel, and a first bearing seat , Extrusion slider, feed inlet, compression cylinder, discharge hole, support frame, second bearing seat and worm. The invention relates to the technical field of industrial numerical control machine tool equipment, which can optimize the waste discharge of industrial numerical control machine tools and better meet the needs of use.

Owner:南通润融精密机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com