Patents

Literature

85results about How to "Improve plugging success rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-dehydration hardenable plugging sealing agent

The invention relates to a high-dehydration hardenable plugging sealing agent which comprises the following components by mass percent: 35-50% of solidifying material, 25-35% of composite sealing agent, 5-15% of high-dehydration material, 5-10% of elastic expending material and 10-15% of fiber material, wherein the composite sealing agent is formed by mixing granular husk, mica and cotton seed hull in a mass ratio of 5:2:1; the solidifying material is formed by mixing gypsum, cement, blast furnace slag and sodium phosphate in a mass ratio of 1:1:0.5:0.1; the high-dehydration material is kieselguhr or coal ash; the elastic expending material is formed by mixing coated water-sucking rubber and coated water-sucking resin in a mass ratio of 1:1; and the fiber material is polyacrylonitrile fiber of 9-11mm. The sealing agent integrates with high dehydration, delay expanding, plugging solidification and physical overlap joint; and the formed sealing layer is not easy to destroy in the subsequent drilling process, thereby effectively improving the sealing efficiency.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Plugging flexibilizer

ActiveCN103740346AImprove flexural strengthGood toughening effectDrilling compositionCellulosePetroleum

The invention discloses a plugging flexibilizer, comprising the components in parts by weight: 5-12 parts of polypropylene fiber, 20-30 parts of rubber particles, 1-5 parts of high molecular polyacrylamide, 2-8 parts of toughened nylon, 2-8 parts of asbestos section, 5-12 parts of plant fibers, 4-7 parts of calcium hydroxide, and 0.1-0.4 part of polyanionic cellulose PAC-HV. A preparation method of the plugging flexibilizer comprises the following steps: orderly adding the components in parts by weight to a kneading machine according to a conventional preparation method at constant temperature and constant pressure; evenly mixing and stirring; and crushing into a 0.05-1mm granular product. The plugging flexibilizer has the characteristics of being wide in material source, free of toxicity and pollution, simple and convenient in construction technology, good in rheological property, good in pillar-forming property, strong in tenacity, not easy to fragilely fall off, high in plugging success rate and the like, does not easily generate a rupture and a brittle fracture in the drilling process after plugging, and is widely applied to pressure-loaded plugging engineering of low-pressure fractured formation, large cracks, large caves, subterranean rivers and serious voidage formation in petroleum and geological drilling.

Owner:DONGYING TAIER GASOLINE TECH

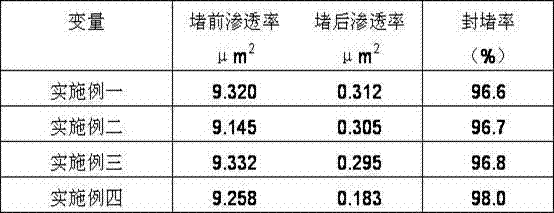

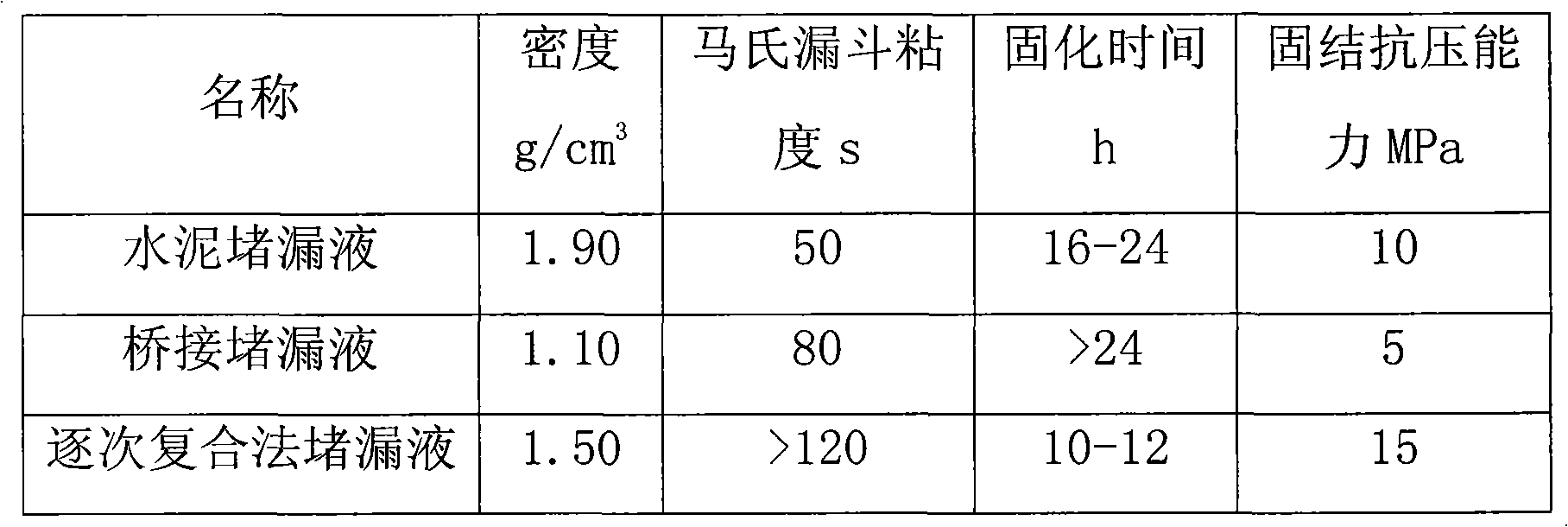

Successive-compounding-process based plugging method for well drilling

InactiveCN102434124AImprove pressure bearing capacitySolve the problem of low plugging success rateDrilling compositionSealing/packingWell drillingPorous medium

The invention discloses a successive-compounding-process based plugging method for well drilling. In the plugging method, a well-cementing cement pump or a mud pump is used for pumping two or more than two kinds of plugging fluids with different components and properties into an underground leakage zone successively in proportion. By means of the plugging method, the applicable range of the plugging fluids can be broadened, the loading capacity of a barefoot interval stratum can also be greatly increased, and the problem of low plugging success rate can be solved. According to the plugging method, a retention layer can be formed in porous media; the purpose of increasing the loading capacity and compressive strength of the stratum can be achieved by compounding the plugging fluids with different components and different properties; in addition, the construction process is simple, the plugging success rate is high, and the well drilling cost is effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hard compound reinforcing bridging agent

ActiveCN101671550AMake sure to enterStrong bridging supportFluid removalDrilling compositionFiberGeological exploration

The invention discloses a hard compound reinforcing bridging agent comprising the following materials in parts by weight: 30-40 parts of shell powder, 15-30 parts of calcium carbonate, 30-40 parts ofnatural hard rubber and 20-30 parts of natural hard fiber. A preparation method comprises the following step: uniformly mixing and stirring the materials in parts by weight at normal temperature and pressure. The hard compound reinforcing bridging agent is prepared by compounding elastic plugging materials with a certain rigidity according to a scientific mixing proportion, and rigid solid granules with different granule diameters enter leaking cracks, leaking pores and leaking passages in the plugging construction process and play bridging and supporting roles in the leaking cracks, the leaking pores and the leaking passages with different sizes. The invention has high supporting capability and plugging characteristic, wide using range, and the like and is widely applied to leakage prevention and plugging technologies of oil and geological exploration.

Owner:DONGYING TAIER GASOLINE TECH

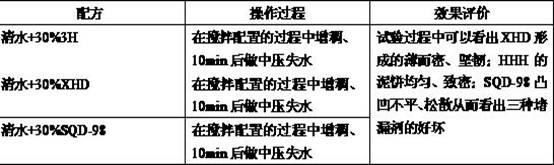

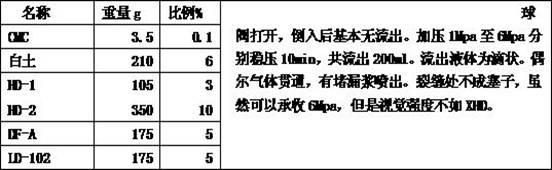

Plugging agent suitable for large leakage, its preparation method and leaking stopping technology

InactiveCN102443382AEnhanced interactionImprove structural strengthDrilling compositionSealing/packingBiologyPetroleum

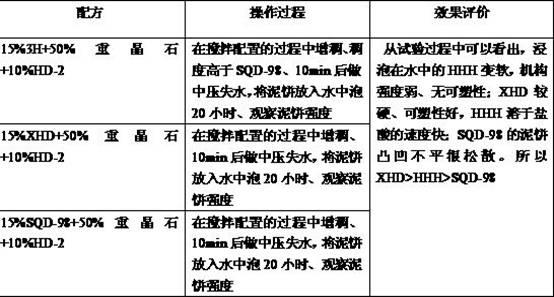

The invention relates to a plugging agent suitable for large leakage, its preparation method and a leaking stopping technology. The invention is suitable for repeatable large leakage, belonging to the field of petroleum drilling. The plugging agent comprises the following ingredients by the following weight ratio: clear water: HSD (HHH): HD-1: HD-2: LD-102: DF-A: barite = 100: 12-15: 4-5: 7-8: 4-5: 30. According to the invention, by reinforcing the interaction among ingredients, maximizing the structural strength of the plugging agent entering a leak layer, maintaining the trend that the leak layer is gradually enhanced with time after injecting the plugging agent in the leak layer, and further increasing the pressure bearing capacity of the leak layer, the leakage problem of a repeatable return-lost large-scale absorption well can be solved, the problem of leaking stopping existing in the prior art can be overcome, and the one-time leak stopping success rate is increased.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

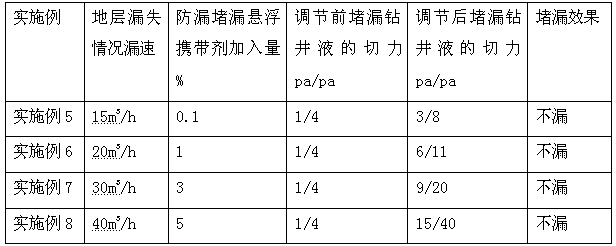

Non-crosslinking special gel leakage stopping method

InactiveCN104563952APrevent wash awayEffective blockingDrilling compositionSealing/packingFiberEngineering

The invention relates to a non-crosslinking special gel leakage stopping method. The method is characterized in the a polishing drilling rod is feed in 20 to 30m the top part of a leaking layer; a drilling tool moves up and down; non-crosslinking special gel leakage stopping slurry is prepared through a clean slurry tank, wherein the non-crosslinking special gel leakage stopping slurry is prepared from water, a special gel ZND-2 leakage stopping agent, a gel fiber leakage stopping agent and a rigid wedging type leakage stopping agent; 0.8 to 1.6 parts by weight of special gel ZND-2 leakage stopping agent, 5 to 8 parts by weight of gel fiber leakage stopping agent and 10 to 15 parts by weight of rigid wedging type leakage stopping agent are added to 100 parts by weight of water; all components are fully agitated and mixed, and then the non-crosslinking special gel leakage stopping slurry is immediately poured into the leaking layer in a well to statically stop the leakage for 4 to 8 hours. The method is simple to construct; the bearing capacity of a plug at the special gel section can be improved; in addition, the bridge-plugged leakage stopping materials can be prevented from being diluted and flushed way by formation fluid, and therefore, the success rate of leakage stopping can be increased.

Owner:CNPC BOHAI DRILLING ENG

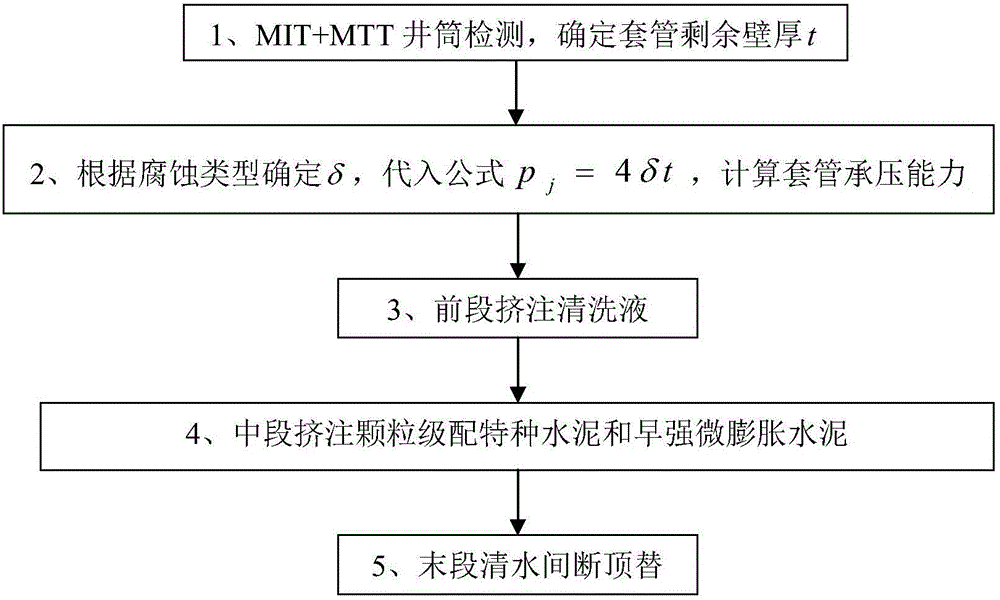

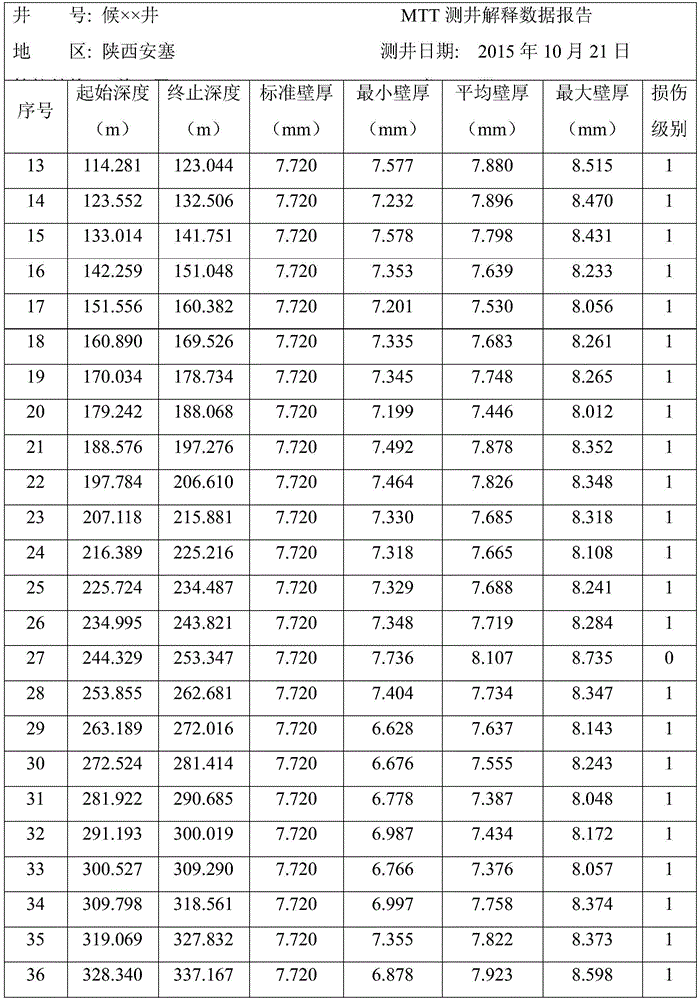

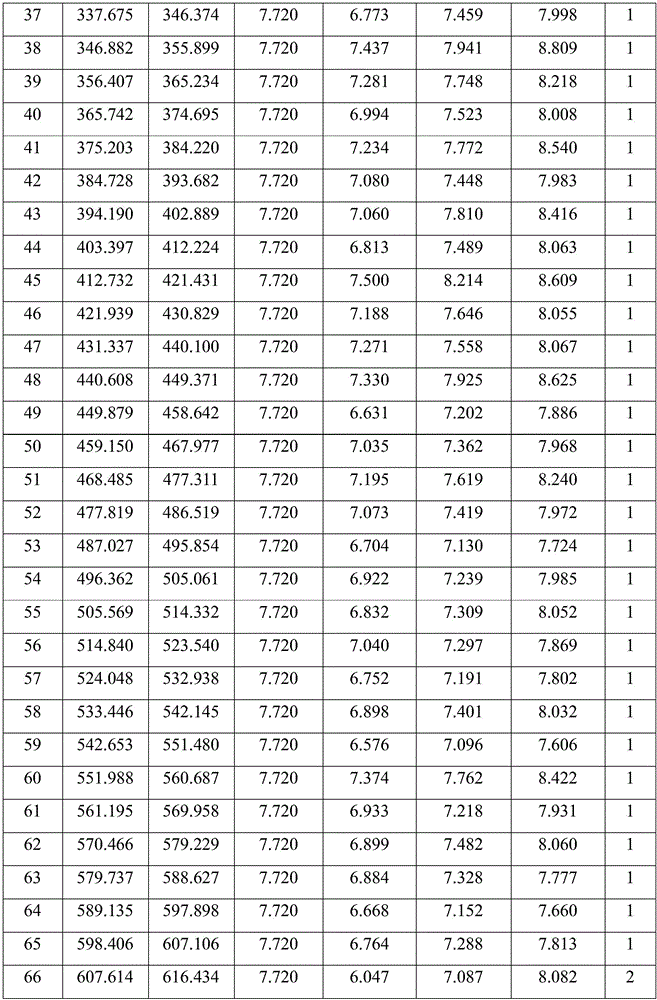

Method for increasing success rate of chemical plugging of leaking casing damage well

ActiveCN106014330AImprove the pressure bearing capacity of the formationImprove plugging success rateProductsSurveyFormation waterEngineering

The invention relates to a method for increasing the success rate of chemical plugging of a leaking casing damage well. A casing pipe horizontal pushing method and a three-slug theory are adopted for the casing damage well with a casing damage part located within 1,000 m, wherein the front section is a washing slug, formation water is replaced, oil dirt and corrosive products on the outer wall of a casing pipe are washed, the wettability is changed, and a good gelling environment is provided for a plugging slug; the middle plugging stratum is a main body cementing section and can effectively prevent leaking and plug the stratum, and a pressure bearing section can be built to isolate the formation water from the casing pipe; the tail section is an intermittent replacement slug, multiple times of replacement are performed intermittently, the main body cementing section can be checked and improved, the plugging success rate is increased, and the validity is prolonged.

Owner:PETROCHINA CO LTD

Expansion and solidification type plugging agent

The invention relates to an expansion and solidification type plugging agent which comprises the following components in parts by weight: 0.5-2 parts of a calcium sulphoaluminate expanding agent, 1-4 parts of polypropylene fibers, 0.1-1 part of a water adsorption expansion type polymer, 1-5 parts of super absorbent resin SAP, 2-6 parts of puffed starch, 2-6 parts of salt-resistant clay, 20-40 parts of calcium carbonate and 0.1-0.5 part of high viscosity polyanionic cellulose PAC-HV. The preparation method comprises the following steps: sequentially adding the components in parts by weight to a kneading machine by a conventional preparation method under normal temperature and pressure; uniformly mixing and stirring; and crushing to a particle product with the grain size of 0.01-0.5mm till being dried. The plugging agent provided by the invention has the characteristics of high expansion rate, viscous flow capacity, plugging capacity, strong salt-resistance, flowability, pumpability, good coagulability, simple process, safe and quick construction, long coagulability, wide source of raw materials, high plugging success rate and the like, and is widely applied to plugging processes of large pore paths, subterranean rivers and great Karst cave leakage strata in petroleum and geological drilling.

Owner:DONGYING TAIER GASOLINE TECH

Lost circulation additive for plugging severe mud loss formation fracture and preparation method of lost circulation additive

ActiveCN107235691ALow costReduce manual labor intensityDrilling compositionGranolithicLost circulation

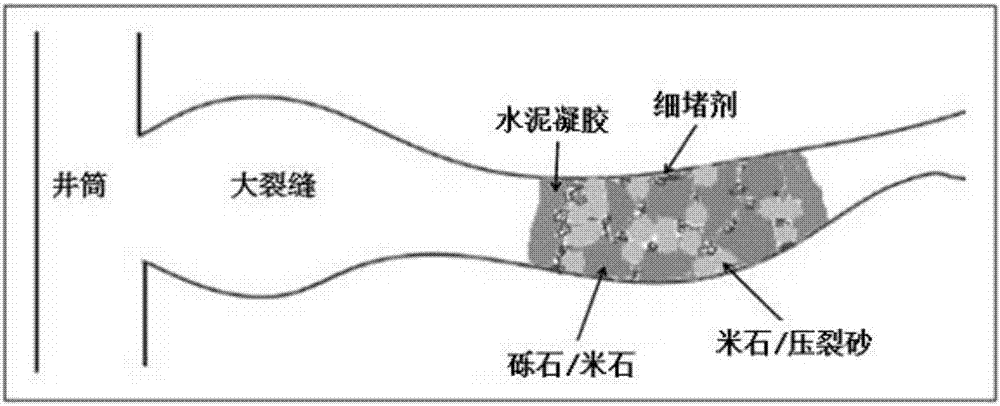

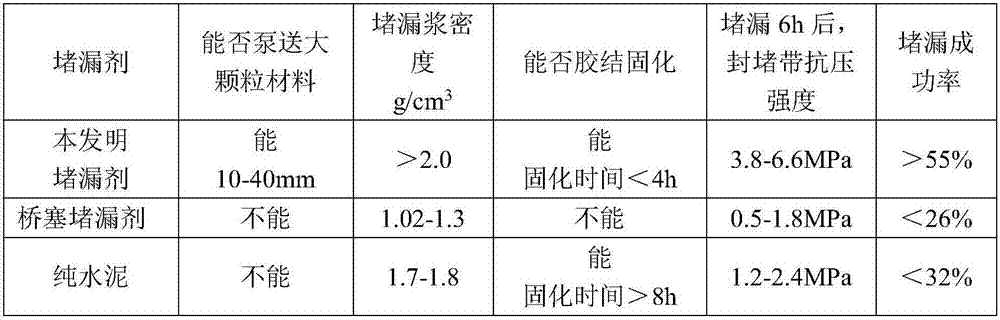

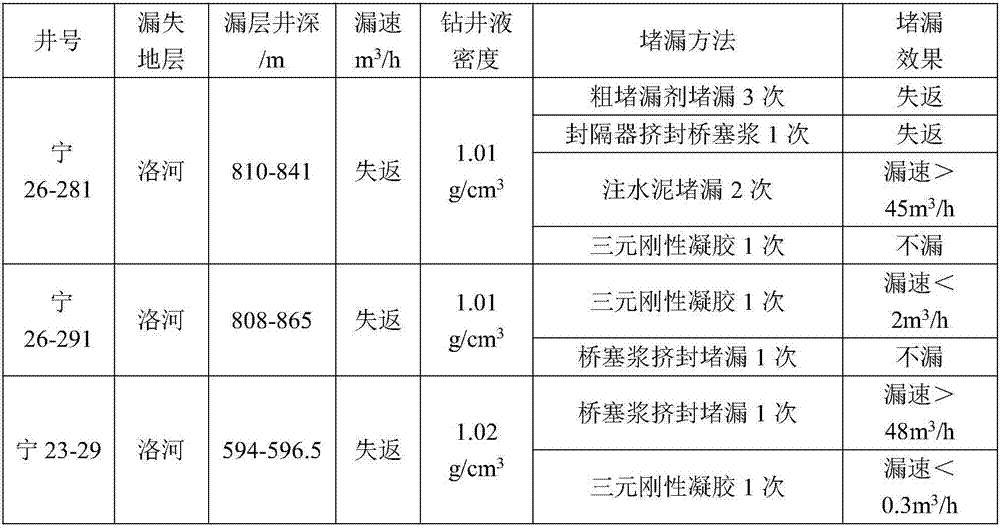

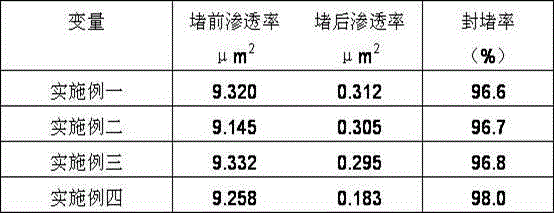

The invention provides a lost circulation additive for plugging severe mud loss formation fracture and a preparation method of the lost circulation additive. The lost circulation additive comprises the following components in percentage by mass: 45-56% of oil well grade-G cement, 8-12% of gravel, 12-15% of granolithic, 15-20% of fracturing sand, 6-9% of a thin plugging agent, 1-2% of a fluid loss agent and 2-4% of an admixture. According to the lost circulation additive disclosed by the invention, large fractures and large holes of the severe mud loss formation can be well plugged, the problem that the plugging agent cannot be bridged, remained, filled and reinforced in the large fractures can be well solved, and the requirements on drilling construction and environment friendliness are met. Moreover, the preparation method is simple, the operability is high, the severe mud loss plugging effect is obvious, the plugging operation cost is effectively reduced, and the plugging operation time is saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-dehydration hardenable plugging sealing agent

ActiveCN102443383BThe preparation method is simple and easyHigh strengthDrilling compositionSodium phosphatesCoal

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

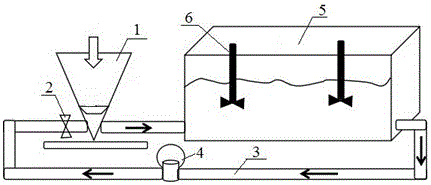

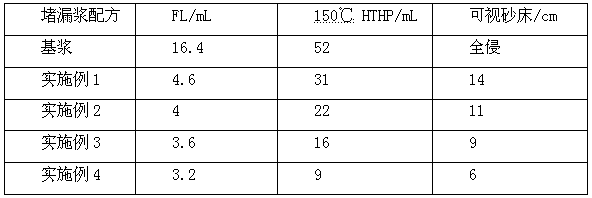

Plugging slurry for enhancing pressure-bearing capacity of leakage formation and preparation method thereof

ActiveCN106566499ASolve the problem of not being able to prepare plugging slurry with drilling team equipmentImprove pressure bearing capacityDrilling compositionSealing/packingFiberWell drilling

The invention provides plugging slurry for enhancing pressure-bearing capacity of leakage formation. The plugging slurry is composed of the following substances (by weight): 55-60% of a curing agent for fiber coagulation, 1-2% of asphalt powder for well drilling, 0.05-0.1% of an oil well cement defoamer and 38-45% of water. The invention also provides a plugging method capable of enhancing pressure-bearing capacity of leakage formation during petroleum drilling process. The method has a good plugging effect on medium and large-scale lost circulation and meets requirements of drilling construction and environmental protection. The plugging technology requires fewer types of chemical materials, and the method for preparation of the plugging slurry is simple. A pressure-bearing squeeze plugging method has strong operationality. The product has a good effect of plugging fractures and pores of a leakage zone and can obviously reduce lost circulation velocity of the leakage zone. Plugging time is greatly shortened and plugging cost is greatly reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

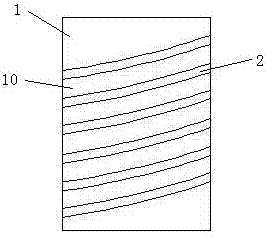

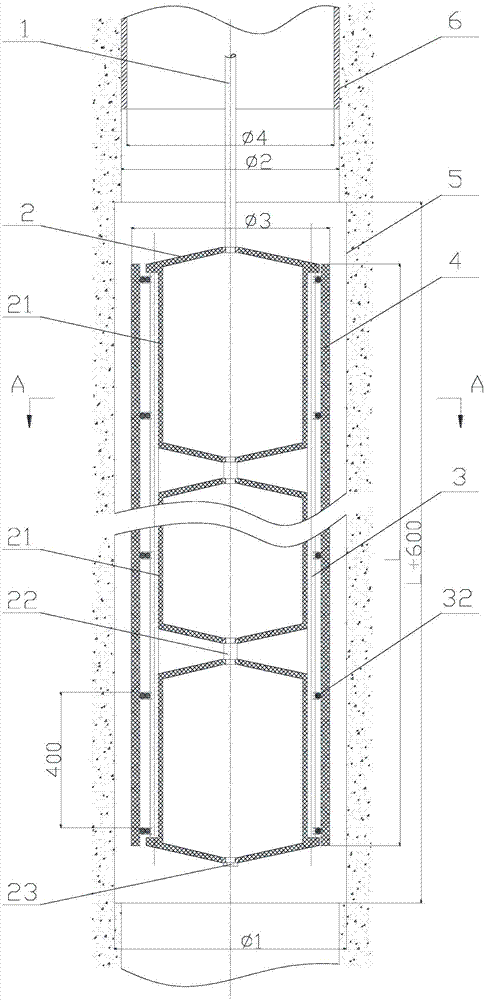

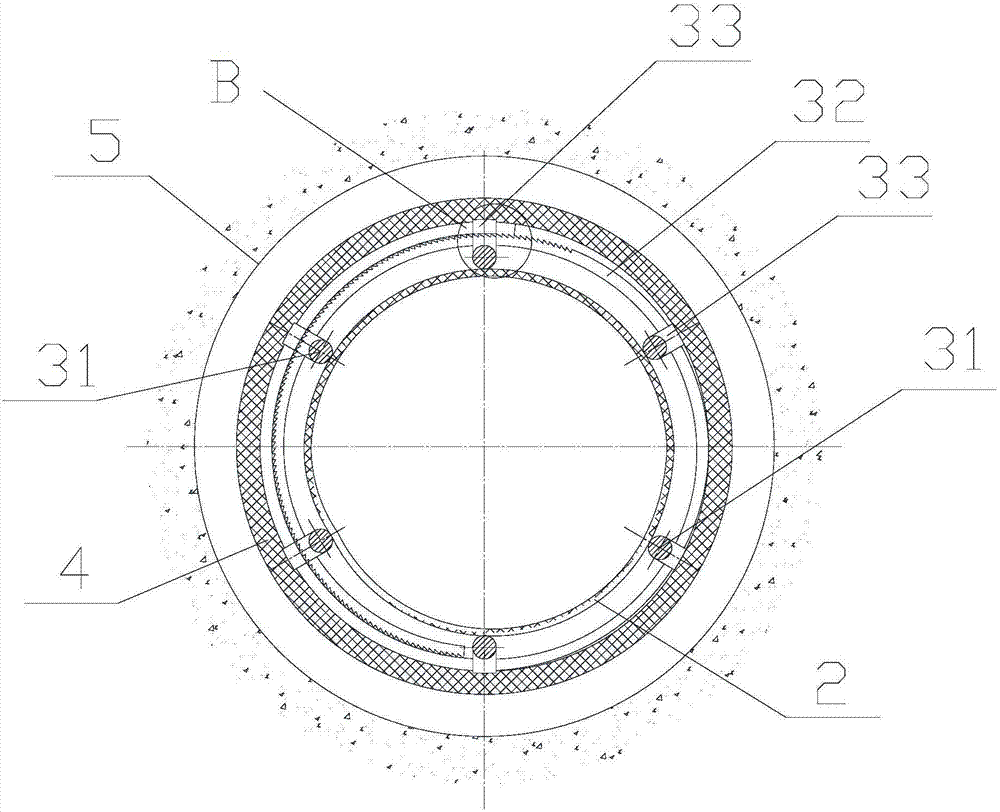

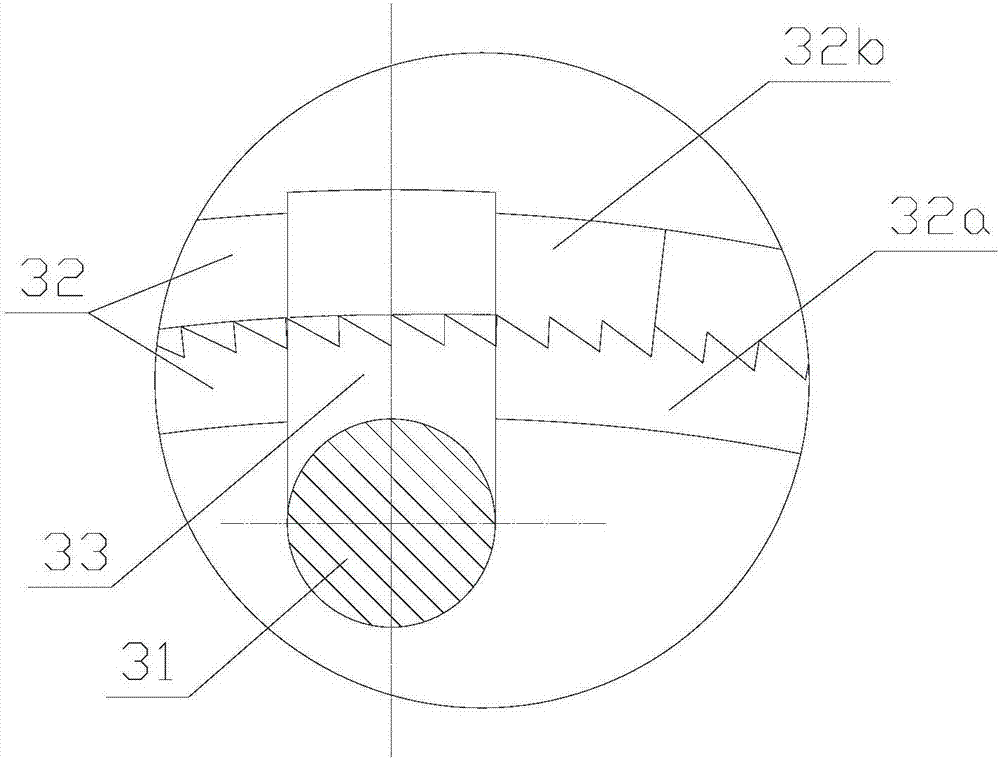

Energy-gathered binding type nidification leaking stoppage wall reinforcing device and application thereof in karst cave leaking stoppage

ActiveCN106930723ASolve the problem of difficult access to the formationImprove plugging success rateBlastingSealing/packingKarstCave

The invention provides an energy-gathered binding type nidification leaking stoppage wall reinforcing device and application thereof in karst cave leaking stoppage and belongs to the technical field of down-hole construction. The device comprises an external slotted metal pipe and an internal nidification blasting tool, spiral seams or straight seams are formed in the pipe wall of the slotted metal pipe in a cut mode, the nidification blasting tool is a core shaft with the surface provided with a plurality of explosive grooves, explosives are placed in the explosive grooves, the slotted metal pipe is arranged on the core shaft in a sleeving mode and fixed, and the core shaft is movably matched with the slotted metal pipe. According to the energy-gathered binding type nidification leaking stoppage wall reinforcing device and the application thereof in karst cave leaking stoppage, the slotted metal pipe can form a bridge frame after explosion, the problem that a leaking stoppage material is not prone to residing to form the bridge frame in a regular leaking stoppage method is solved, and the leaking stoppage success rate of a karst cave stratum can be effectively improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

High pressure-resistant leak stoppage agent and leak stoppage slurry containing same

ActiveCN101955763AHigh plugging capacity and pressure bearing capacityImprove plugging success rateDrilling compositionGramHigh pressure

The invention relates to a high pressure-resistant leak stoppage agent and leak stoppage slurry containing the same. The high pressure-resistant leak stoppage agent consists of the following components in percentage by mass: 25.0 to 27.0 percent of soybean particles, 31.0 to 32.0 percent of walnut shell flour, 7.1 to 7.5 percent of vermiculite, 2.1 to 2.5 percent of peanut hull meal, 22.0 to 22.5percent of cement and 10.0 to 11.0 percent of flocculation coating agent LHB-105 for drilling fluid. The leak stoppage slurry consists of base slurry and the high pressure-resistant leak stoppage agent, wherein 3 to 9 grams of high pressure-resistant leak stoppage agent is added into every 100 milliliters of base slurry. The leak stoppage agent and the leak stoppage slurry stop leaking by combining chemical leak stoppage with particle bridging leak stoppage, so that the technical problems of aperture leak, crack leak and fracture leak under a well can be solved. The leak stoppage agent and the leak stoppage slurry are suitable for severe well leakage caused by a pore formation, a crack formation, a long-section broken formation and the like and can be applied to leak layer construction ofwhich the leak position is difficultly determined.

Owner:北京奥凯立科技发展股份有限公司

Emulsion leaking stopping agent and preparing method thereof

ActiveCN105567189AImprove retentionImprove plugging success rateDrilling compositionFunctional monomerEmulsion

The invention relates to an emulsion leaking stopping agent in oil-and-gas-field well-drilling leaking stopping operation and a preparing method thereof, in particular to a gel-expansion leaking stopping agent with molecules containing functional groups capable of enhancing the interaction with the stratum. The leaking stopping agent is prepared from four monomers in a copolymerized mode; the first monomer supplies hydrophilia to the leaking stopping agent and promotes water expansion of materials; the second monomer is a cationic monomer, supplies groups with positive charges and improves attraction between the charges of the leaking stopping agent and charges of the leakage hole way well wall; the third monomer is a un-saturation organosilicone-coupling-agent monomer and can improve the retention capability of the leaking stopping agent in a leakage layer; the fourth monomer is a polyunsaturated bond functional monomer and enables the leaking stopping agent to form chemical crosslinking. According to the emulsion leaking stopping agent, aqueous solution polymerization is adopted, the technology is simple, and operation is convenient. The prepared leaking stopping agent has the advantages that water expansion capacity is high; as the leaking stopping agent contains the multiple functional groups capable of mechanically interacting with the leakage layer, the retention capability of the leaking stopping materials in the leakage layer can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +2

Cage type well drilling leakage stopping device and well drilling leakage stopping method

ActiveCN107246249AQuality assuranceTo achieve the effect of pluggingGeothermal energy generationSealing/packingRatchetWell drilling

The invention discloses a cage type well drilling leakage stopping device and a well drilling leakage stopping method, and relates to the technical field of petroleum drilling. By the cage type well drilling leakage stopping device and the well drilling leakage stopping method, the well drilling leakage stopping success rate can be increased. According to the technical scheme, the cage type well drilling leakage stopping device comprises a continuous small oil tube, an expansion sleeve, a cage and a sealing sleeve, wherein the continuous small oil tube is connected with the expansion sleeve; the cage comprises cage columns and a locking ring; a ratchet, a pawl and a clamp are respectively arranged at two ends of the locking ring; by the ratchet and the pawl, the locking ring only can be expanded; the sealing sleeve sleeves the outer side of the cage; and the expansion sleeve is positioned in the cage. By gas injection expansion of the expansion sleeve, the whole cage is suspended on the continuous small oil tube, and then is downwards fed to a leakage stopping point for well drilling; the expansion sleeve continues being injected with gas, and the cage and the sealing sleeve are locked on a well wall barrel of a repairing and expanding section; after being exhausted, the expansion sleeve is taken out, finally, a leakage section is stopped with cement, and then the cement is solidified; and the leakage stopping point has been improved, so that the leakage stopping success rate is increased.

Owner:南充西南石油大学设计研究院有限责任公司

High pressure-resistant leak stoppage agent and leak stoppage slurry containing same

The invention relates to a high pressure-resistant leak stoppage agent and leak stoppage slurry containing the same. The high pressure-resistant leak stoppage agent consists of the following components in percentage by mass: 25.0 to 27.0 percent of soybean particles, 31.0 to 32.0 percent of walnut shell flour, 7.1 to 7.5 percent of vermiculite, 2.1 to 2.5 percent of peanut hull meal, 22.0 to 22.5 percent of cement and 10.0 to 11.0 percent of flocculation coating agent LHB-105 for drilling fluid. The leak stoppage slurry consists of base slurry and the high pressure-resistant leak stoppage agent, wherein 3 to 9 grams of high pressure-resistant leak stoppage agent is added into every 100 milliliters of base slurry. The leak stoppage agent and the leak stoppage slurry stop leaking by combining chemical leak stoppage with particle bridging leak stoppage, so that the technical problems of aperture leak, crack leak and fracture leak under a well can be solved. The leak stoppage agent and the leak stoppage slurry are suitable for severe well leakage caused by a pore formation, a crack formation, a long-section broken formation and the like and can be applied to leak layer construction of which the leak position is difficultly determined.

Owner:北京奥凯立科技发展股份有限公司

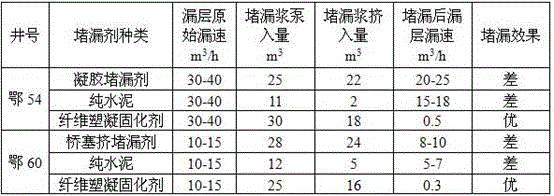

Shell-membrane structure plugging material and preparation method thereof

ActiveCN111826141AImprove water resistanceGood dispersionSolid waste managementDrilling compositionPolymer scienceMeth-

The invention relates to a shell-membrane structure plugging material and a preparation method thereof in the technical field of well drilling plugging. The shell-membrane structure plugging materialis a polymer-coated shell particle plugging material obtained by grafting a hydrophobic group and a water-soluble polymer to the surface of a plant shell. The preparation method of the plugging material with the shell-membrane structure comprises the following steps: grafting a hydrophobic group and a carbon-carbon double bond to the surface of a plant shell, and carrying out emulsion polymerization on the obtained grafted modified shell particle material, acrylamide, 2-acrylamide-2-methylpropanesulfonic acid and a cationic monomer to obtain the shell-membrane structure plugging material. According to the invention, a hydrophobic group and a water-soluble polymer are grafted to the surface of a plant shell, and a hydrophobic protective film is formed on the surface of the shell, so that the water soaking resistance of the shell is greatly improved, the strength of the granular material can be greatly improved during leakage stoppage, and the problem of repeated leakage easily caused byleakage stoppage of plant shell materials is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Coating plugging agent, preparation method thereof, and plugging slurry

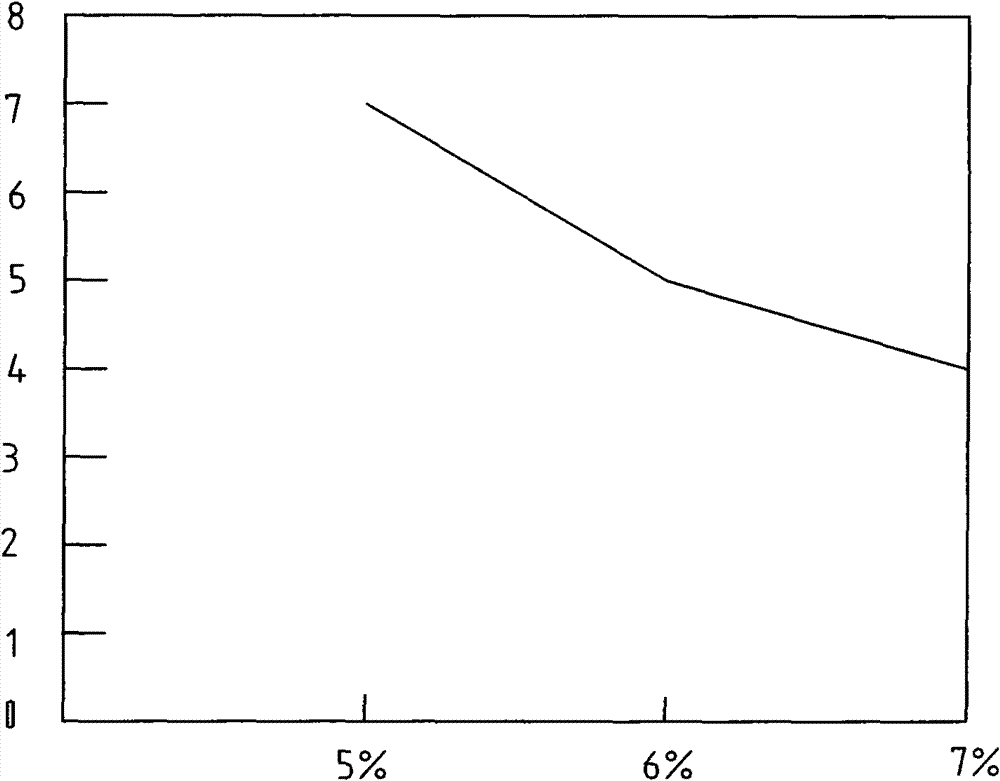

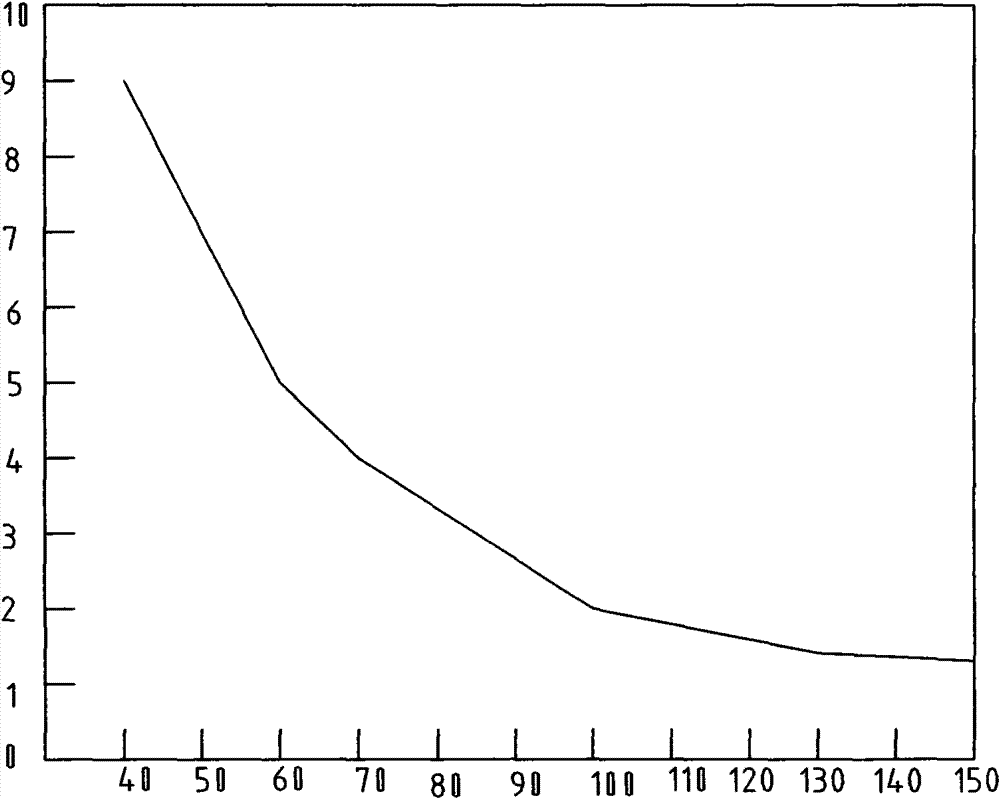

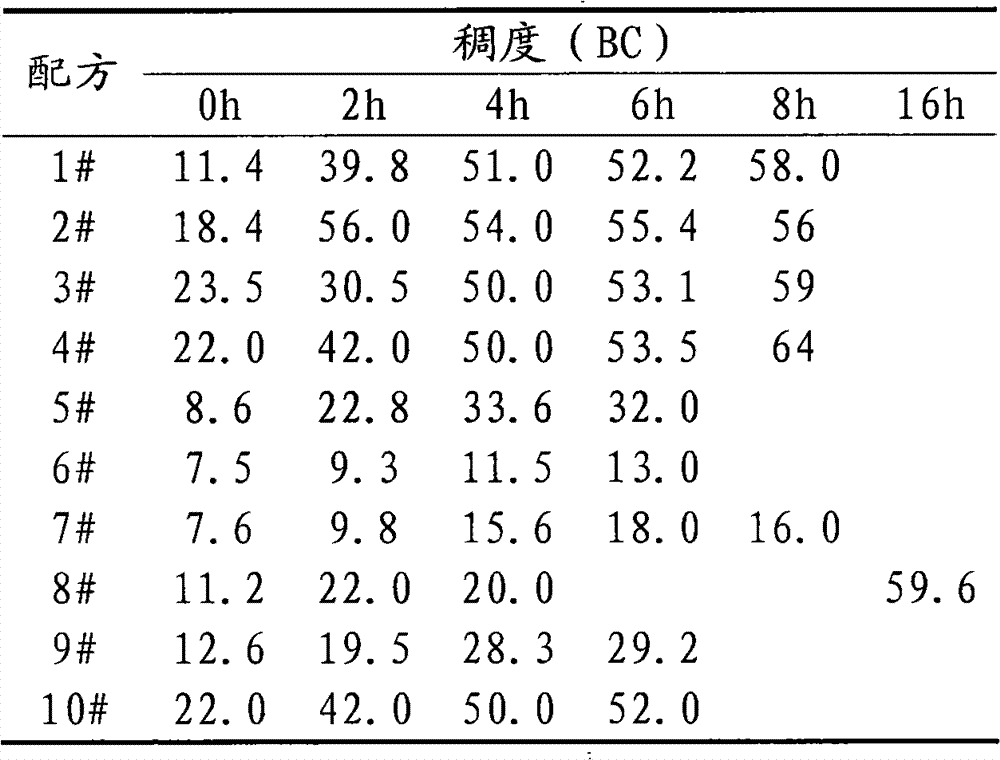

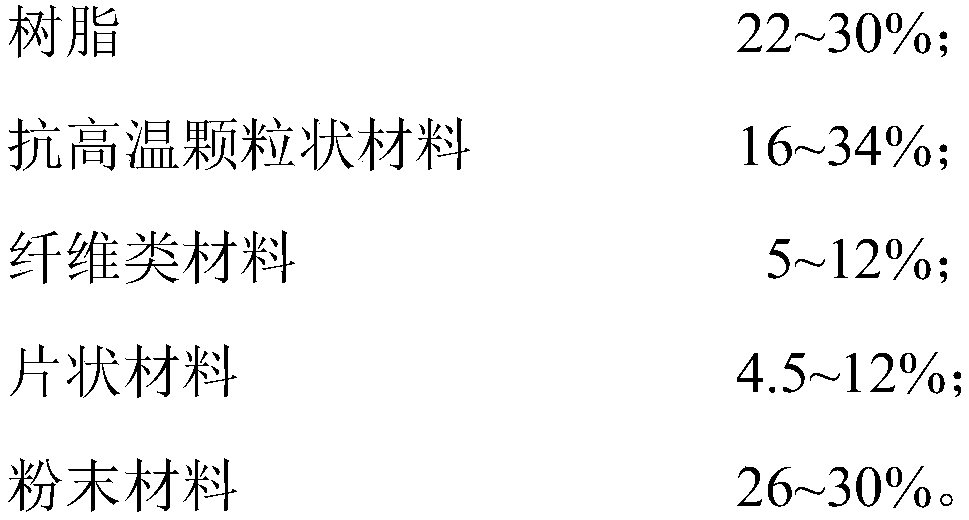

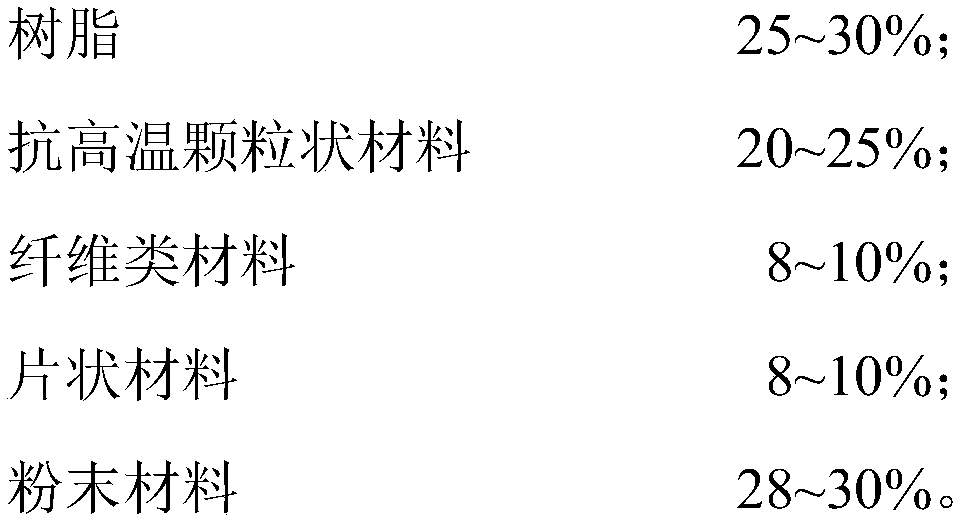

The invention relates to a coating plugging agent, a preparation method thereof and plugging slurry, and belongs to the field of petroleum drilling plugging. The coating plugging agent can comprise the following components in percentage by weight: 22-30% of resin; 16-34% of a high-temperature-resistant granular material; 5-12% of a fibrous material; 4.5-12% of a sheet-like material; and 26-30% ofa powder material. The plugging agent can effectively replace formation fluid, especially asphalt thick oil, at a certain temperature, and can plug cracks of 1-5 mm; the pressure bearing capacity of aformed plugging layer is larger than 10 MPa, and the temperature resistance is larger than 120 DEG C; the coating plugging agent is convenient to transport, simple to prepare plugging slurry on site,convenient to construct and worthy of popularization and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

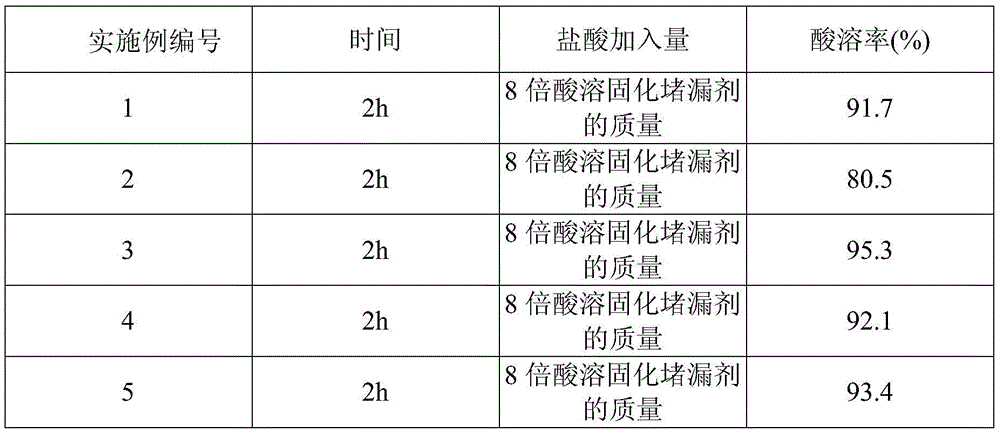

Acid soluble curing plugging agent

InactiveCN105623632AGood acid solubilityHigh strengthDrilling compositionNuclear chemistryRaw material

The invention provides an acid soluble curing plugging agent. The acid soluble curing plugging agent is prepared from, by mass, 30 wt%-60 wt% of G-level oil well cement, 20 wt%-50 wt% of acid soluble superfine calcium carbonate, 5 wt%-15 wt% of sepiolite, 5 wt%-10 wt% of calcium oxide and 10 wt%-20 wt% of diatomite, and the total mass percent of the raw materials is 100%. The acid soluble curing plugging agent can conduct curing plugging when leakage occurs in the drilling process, and acid soluble plugging releasing can be conducted during oil recovery.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method of high-plugging-strength leaking-stopping agent for well drilling

InactiveCN106520092AGood expansion performanceLarge amount of expansionDrilling compositionFiberSwelling capacity

The invention discloses a preparation method of a high-plugging-strength leaking-stopping agent for well drilling, belonging to the technical field of preparation of leaking-stopping agents. The theory of the preparation method comprises the following steps: carrying out graft modification on butyl polyacrylate resin by utilizing oxidized cassava starch and taking methyl ethyl ketone peroxide as an initiator under the catalysis of ethylene glycol antimony, so as to enhance expansibility; then modifying bamboo fibers by virtue of maleic anhydride, and combining the bamboo fibers with modified cassava starch grafted butyl polyacrylate resin by virtue of a coupling agent, so as to enhance strength; and then adding expanded vermiculite, so as to enhance the swell capacity and plugging strength. By utilizing the theory, the defects of existing leaking-stopping agents that the swell capacity is relatively low, the water flushing resistance is relatively weak, the plugging strength is low, and the repeated leakage easily occurs are effectively solved; and by applying the leaking-stopping agent to complex formations with big crevices and multiple caves, the permeability of a blocked layer can be well decreased, and the high strength and pressure resistance of the blocked layer can be obtained.

Owner:常州市鼎升环保科技有限公司

Asphalt layer leakage plugging slurry

The invention discloses asphalt layer leakage plugging slurry which comprises the following components in parts by weight: 100 parts of clear water; 2-8 parts of bentonite; 0.2-0.8 part of sodium carbonate; 0.1-0.6 part of biopolymer XC; 0.1-0.8 part of polyanionic cellulose LV-PAC; 0.1-3 parts of hydroxypropyl guar gum; 0.5-6 parts of a coagulation composite blocking agent; 2-10 parts of a compressible high-elasticity plugging agent; 1-10 parts of a leak-proof plugging filler; 0.1-5 parts of a leakage-proof plugging suspension carrying agent; 1-6 parts of a leakage-proof plugging density regulator; 1-6 parts of a plugging enhancer; 1-6 parts of a high-strength consolidation plugging agent; 2-8 parts of an expansion consolidation type plugging agent; 0.1-6 parts of a leakage prevention andplugging reinforcing agent; 0.1-1 part of dodecyl trimethyl ammonium chloride, 1-5 parts of sorbitan monooleate (SP-80) and 1-3 parts of alkylphenol and ethylene oxide condensates (OP-10). The asphalt layer leakage plugging slurry has the advantages of being resistant to asphalt contamination, high in strength, wide in density adjustable range, high in plugging rate and high in plugging success rate, can be applied to leakage plugging of an asphalt layer, and can also be applied to a high-temperature high-permeability layer, a crack karst cave type stratum, a high-temperature leakage storagesame layer and the like.

Owner:山东华越天成石油技术有限责任公司

High-adaptability temperature-resistant plugging agent and application method thereof

The invention discloses a high-adaptability temperature-resistant plugging agent and application method thereof. The high-adaptability temperature-resistant plugging agent comprises the following components in percentage by weight: 31-34% of activated clay, 30-33% of flexible graphite, 30-31% of mica powder, 2-3% elastomer sponge and 2.5-3.5% of fibers. The invention further provides a preparationmethod of the high-adaptability temperature-resistant plugging agent and application thereof in preparation of plugging working fluid. Based on the base solution per 100milliliters, the addition amount of the high-adaptability temperature-resistant plugging agent is 8-15g. The method comprises the following steps: determining the setting depth of a light drill stem to be the top of a leakage zoneaccording to the leakage condition, accurately replacing the plugging slurry to the required position, rapidly lifting the drilling tool to a safety position, waiting or shutting in and building thepressure for 2-4 hours, and completing the plugging process. The plugging agent is excellent in temperature resistance and high in crack matching degree and can effectively enter the leakage zone to form plugging, the plugging success rate is improved, the plugging formula is single aiming at the leakage zone of different crack width, and convenience is brought to field operations.

Owner:中石化石油工程技术服务有限公司 +2

High-strength consolidation plugging agent

ActiveCN103773340BHas the property of consolidatingHigh strengthDrilling compositionSolubilityCellulose

The invention discloses a high-strength consolidation lost circulation additive, which consists of the following components in parts by weight: 20-40 parts of calcium carbonate, 5-10 parts of silicon dioxide, 1-4 parts of calcium chloride, 0.1-0.4 part of polyanionic cellulose, 0.1-0.2 part of an XC biopolymer, 5-10 parts of aluminum oxide, 3-8 parts of magnesium oxide and 10-16 parts of oil well cement. The lost circulation additive is prepared by carrying out the following steps: adding the components into a kneading machine based on the parts by weight at normal temperature and under normal pressure according to the conventional preparation method; mixing and stirring uniformly; drying; smashing into a powdery product being 0.01-0.2 millimeter in particle size. The high-strength consolidation lost circulation additive has the characteristics of wide raw material source, high strength, strong suspending power, high mobility, high pumpability, condensing and plugging capabilities, high minimum inflation performance, high solubility, high leakage plugging success rate, simple process and safety in construction, is widely applied to petroleum and geological drilling processes, and is particularly to be applied to fractured hard formations and karst cave formations.

Owner:DONGYING TAIER GASOLINE TECH

Deformable plugging block, and preparation method and application thereof

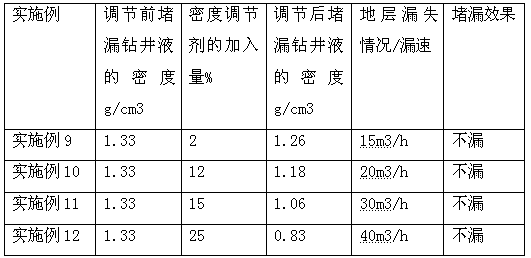

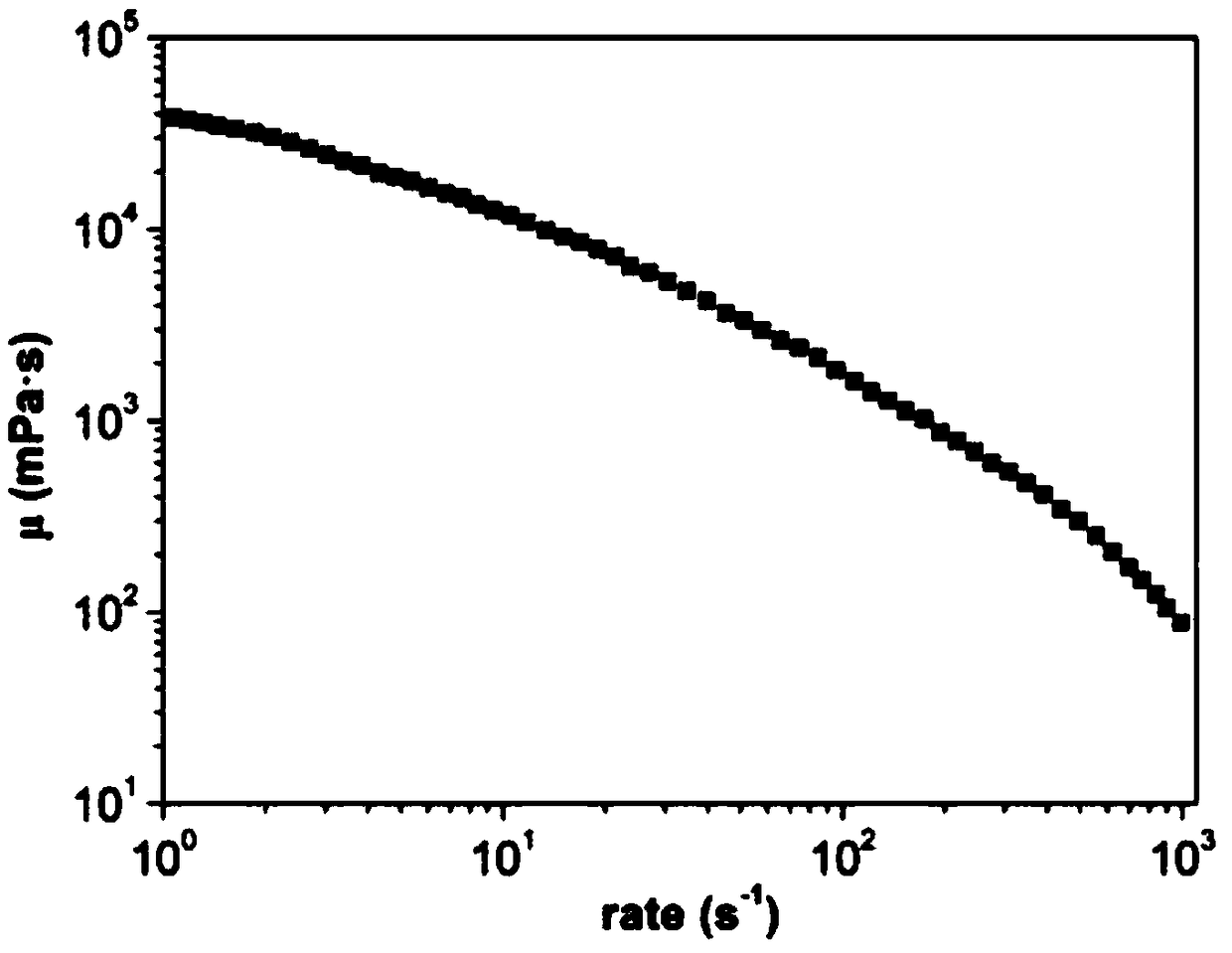

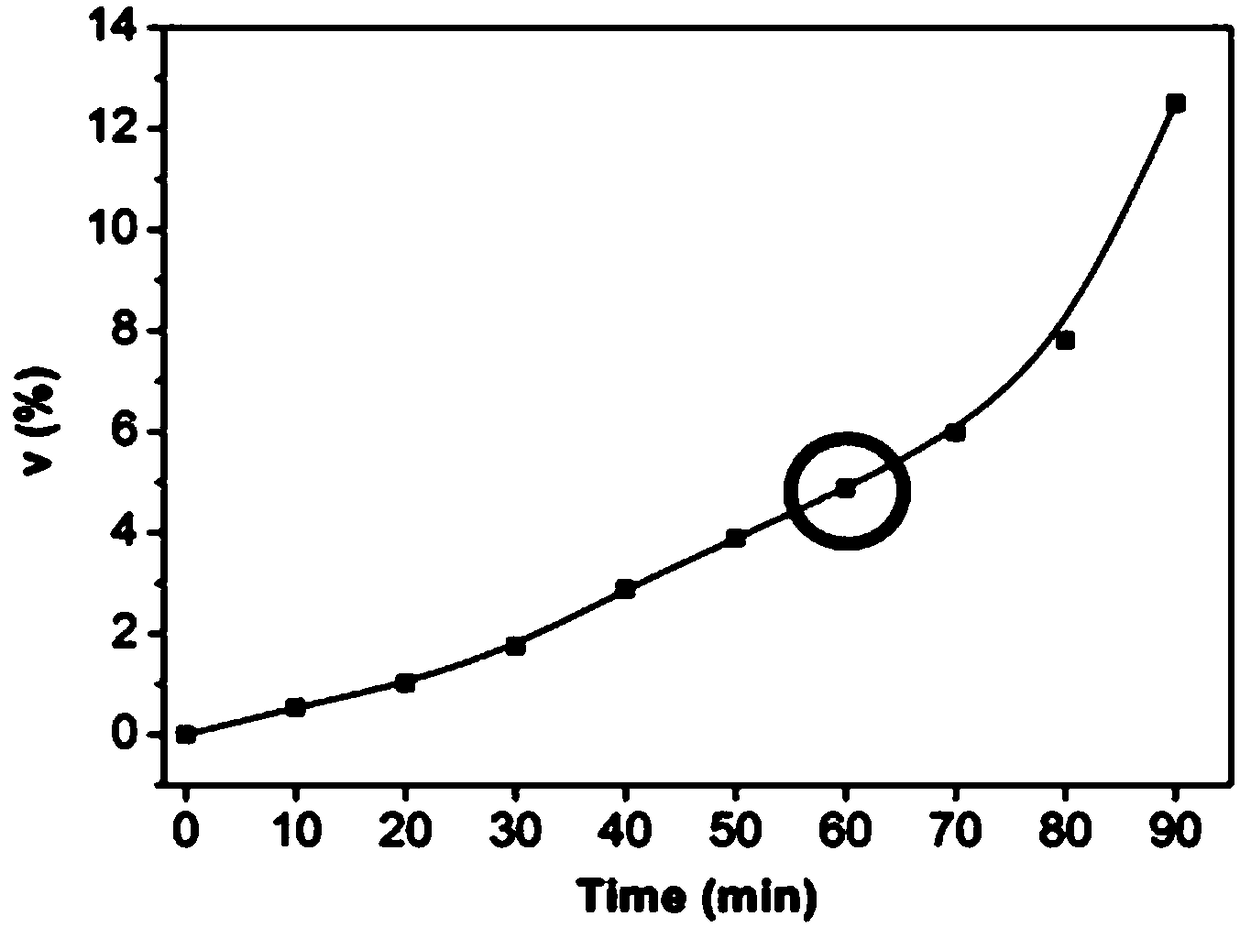

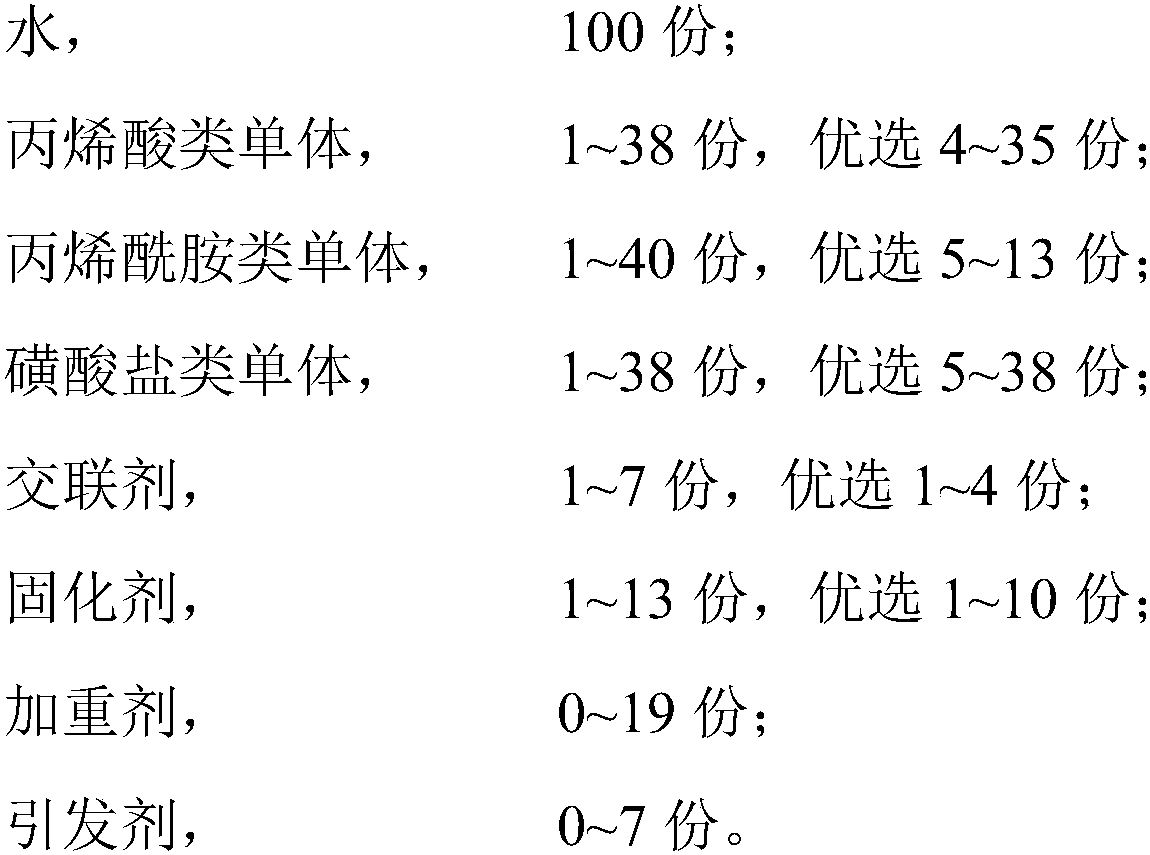

ActiveCN109384879AControllable expansionDeformableDrilling compositionSealing/packingCross-linkKarst

The invention relates to a deformable plugging block, and a preparation method and application thereof, belonging to the field of plugging during petroleum drilling. The deformable plugging block comprises, by weight, 100 parts of water, 1 to 38 parts of acrylic monomers, 1 to 40 parts of acrylamide monomers, 1 to 38 parts of sulfonate monomers, 1 to 7 parts of a cross-linking agent, 1 to 13 partsof a curing agent, 0 to 19 parts of a weighting agent and 0 to 7 parts of an initiator. The deformable plugging block and the preparation method and a construction process thereof in the invention are directed at large-crack and karst-stricken complex formation leakage, particularly have good plugging effect on malignant leakage containing flowing strata and karst-bound formation water, improve plugging effect, reduce the cost of plugging construction, and guarantee the normal operation of drilling construction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil-based cross-linking blocking agent and preparation method thereof

ActiveCN107987810AImprove the blocking effectEnhanced inhibitory effectDrilling compositionCross-linkOil field

The invention relates to the technical field of drilling fluid treatment agent for oil field drilling, in particular to an oil-based cross-linking blocking agent and a preparation method thereof. Theoil-based cross-linking blocking agent comprises the following constitution components in parts by mass: 20 parts of an Al-Fe-Mg nano material and 40-60 parts of alpha-hexadecyl trimethyl glycine betaine. By adopting the oil-based cross-linking blocking agent, a relatively good oil-based cross-linking blocking property is achieved, micro cracks can be effectively blocked when the blocking agent isindependently used, the blocking success rate can be increased when the blocking agent is compounded with other blocking materials, and due to addition of the oil-based cross-linking blocking agent in an oil-based drilling fluid, the API filter loss and the HTHP filter loss of the drilling fluid and the rock core blocking rate are effectively reduced, and the inhibition of the oil-based drillingfluid is further improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Bridging particle containing memory metal

The invention relates to petroleum drilling materials, and particularly relates to a bridging particle for drilling fluid loss. The bridging particle comprises a memory metal frame material, a fibrousbridging material, a filling material, a suspension dispersant, a retaining agent and the like, wherein bridging can be further filled by a fiber material and a filling material based on the reticular structure formed by the memory metal frame material, and a steady bridge plug can be formed and is resistant in fluid soaking. The bridging particle has a long-time bridging effect, and can be usedfor effectively improving the bridging success rate of fractured-vuggy loss.

Owner:中石化石油工程技术服务有限公司 +2

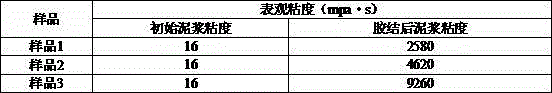

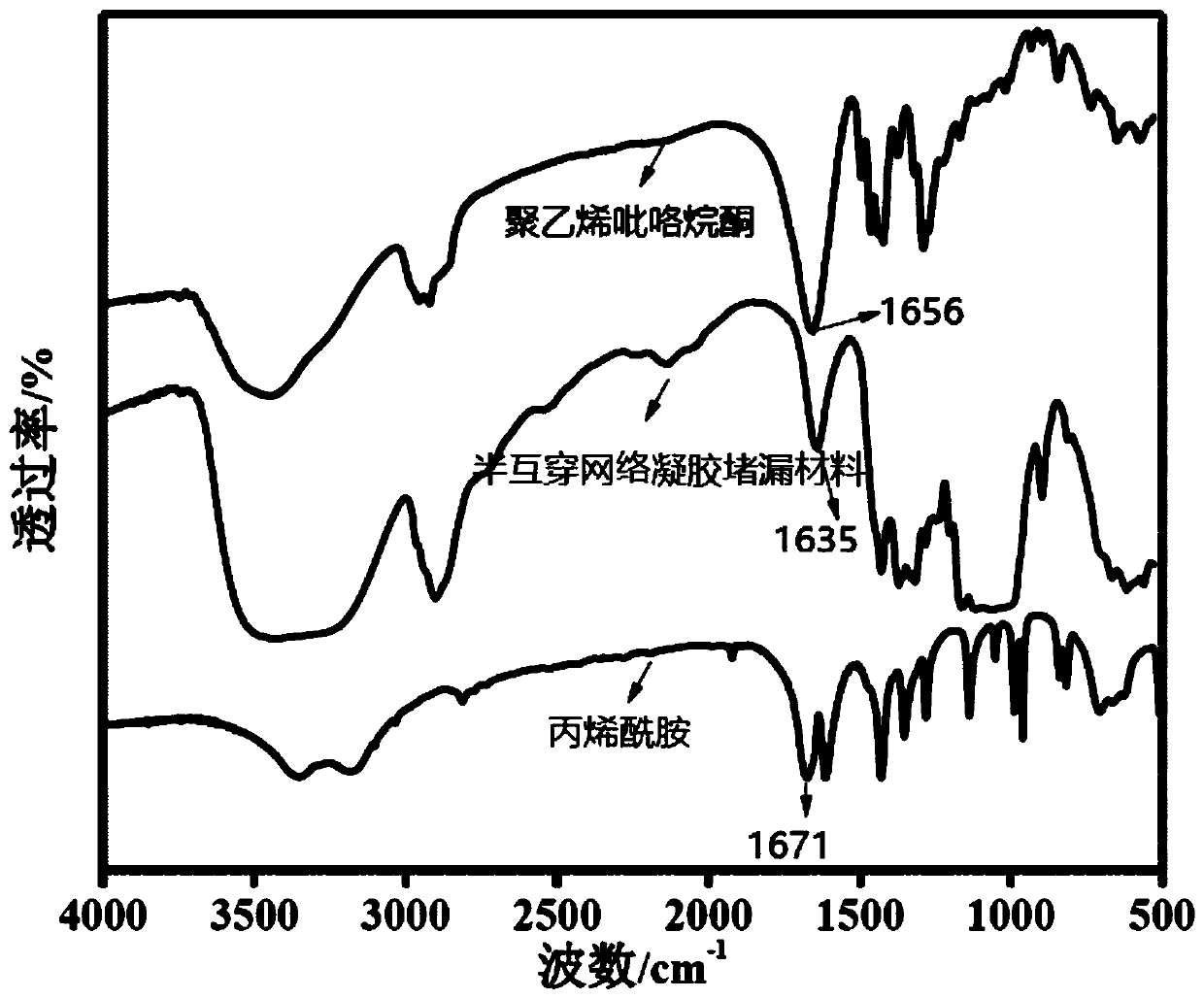

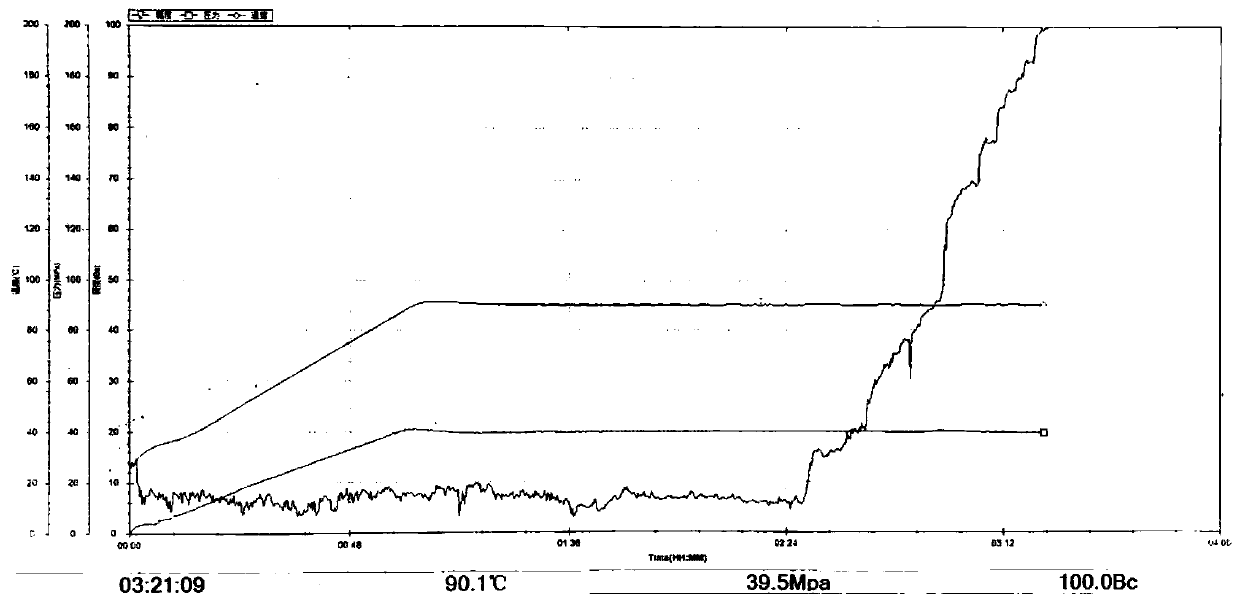

Semi-interpenetrating network gel plugging material for oil and gas fields and preparation method thereof

PendingCN111534292ABase fluid viscosity is lowStrong penetration abilityDrilling compositionChemistryComposite material

The invention discloses a semi-interpenetrating network gel plugging material for oil and gas fields and a preparation method. The plugging material comprises, by weight, 2-5% of a polyacrylamide polymer, 0.1-10% of polyvinylpyrrolidone, 0.1-3% of a cross-linking agent, and 0.1-0.3% of an antioxidant, with the balance being water. The preparation method comprises the following steps: dissolving the antioxidant in water to form a solution A; dispersing the polyacrylamide polymer, the polyvinylpyrrolidone and the cross-linking agent into the solution A according to a ratio, and uniformly mixingto obtain a semi-interpenetrating network gel plugging material base solution; and reacting the semi-interpenetrating network gel plugging material base solution for 8-12 hours, and crosslinking to obtain the semi-interpenetrating network gel plugging material. According to the plugging material disclosed by the invention, a chemical blending network system is formed after the polyvinylpyrrolidoneand a polyacrylamide polymer cross-linked network are interpenetrated or entangled, and the plugging material has high gelatinizing strength and high shear toughness under a high-temperature condition, and has higher pressure-bearing capacity and an excellent plugging effect.

Owner:四川格瑞迪斯石油技术有限公司

Low-pressure leakage layer blocking agent and preparation method thereof

ActiveCN109321218AAvoid pluggingImprove plugging success rateDrilling compositionFiberSodium Bentonite

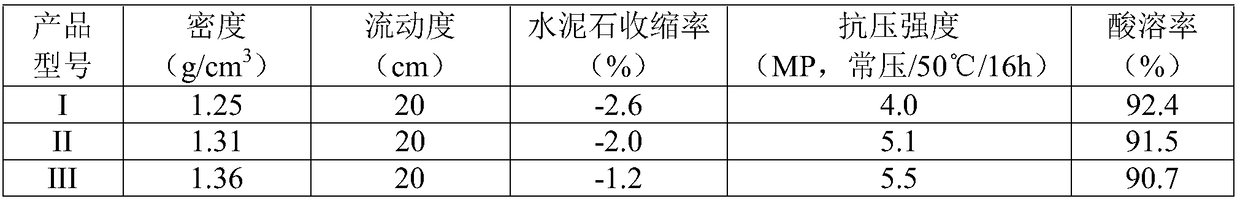

The invention discloses a low-pressure leakage layer blocking agent and a preparation method thereof. The blocking agent is prepared by the following steps: dissolving 8.5 to 10 parts of an activatingagent in water for high-speed stirring and dissolving; weighing 50 to 75 parts of a binding material, 50 to 60 parts of a particle bridging material, 5 to 8 parts of a lightening material, 0.1 to 0.2part of a stabilizer and 1 to 1.5 parts of a slurry modifier; uniformly mixing and pouring the mixture into a slurry cup for uniformly stirring; covering the slurry cup with a cup cover; continuallystirring the mixture at the stirring speed of 12000+ / -500 r / min for 35 seconds, wherein the binding material is a mixture of sodium bentonite and blast furnace slag in the weight ratio of 1 to (7 to 9), the particle bridging material is limestone flour, and the lightening material is sepiolite fiber with the particle size of 1 to 2mm. The low-pressure leakage layer blocking agent is 1.2 to 1.4 g / cm<3> in density, and has the advantages of low density, high thixotropy, minimum inflation and high acid dissociation. By adopting the low-pressure leakage layer blocking agent, the problem of leakagedue to difficulty in lowering the density of ordinary acid-dissolved cement below 1.65 g / cm<3> is solved, so that plugging slurry is effectively prevented from pressing the stratum to cause leakage,and the plugging success rate is improved.

Owner:CNPC BOHAI DRILLING ENG +1

Enhanced plugging gel and preparation method thereof

The invention discloses enhanced plugging gel and a preparation method thereof. The enhanced plugging gel is prepared from, by weight, 0.5%-2% of a polyacrylamide polymer, 2%-5% of a nano enhancer, 1%-3% of a fiber enhancer, 0.1%-5% of a cross-linking agent and 0.1%-0.5% of an antioxidant, with the balance being water. The preparation method comprises the following steps: firstly, dissolving the antioxidant in water; then sequentially dispersing the polyacrylamide polymer, the nano enhancer, the fiber enhancer and the cross-linking agent into water, and uniformly mixing to obtain a reinforcedplugging gel base solution; and carrying out a cross-linking reaction on the enhanced plugging gel base solution for 2-12 hours to obtain the enhanced plugging gel. According to the invention, inorganic nanoparticles and a fiber composite admixture are introduced into a cross-linked polymer network system, and the polymer gel can have the characteristics of high gelatinizing strength, high shear toughness and the like under a high-temperature condition by virtue of the hydrogen-bond interaction formed by the admixture and a gel network, so that the plugging and pressure-bearing capacities of the plugging gel are improved.

Owner:SICHUAN GREDIS PETROLEUM TECH CO LTD

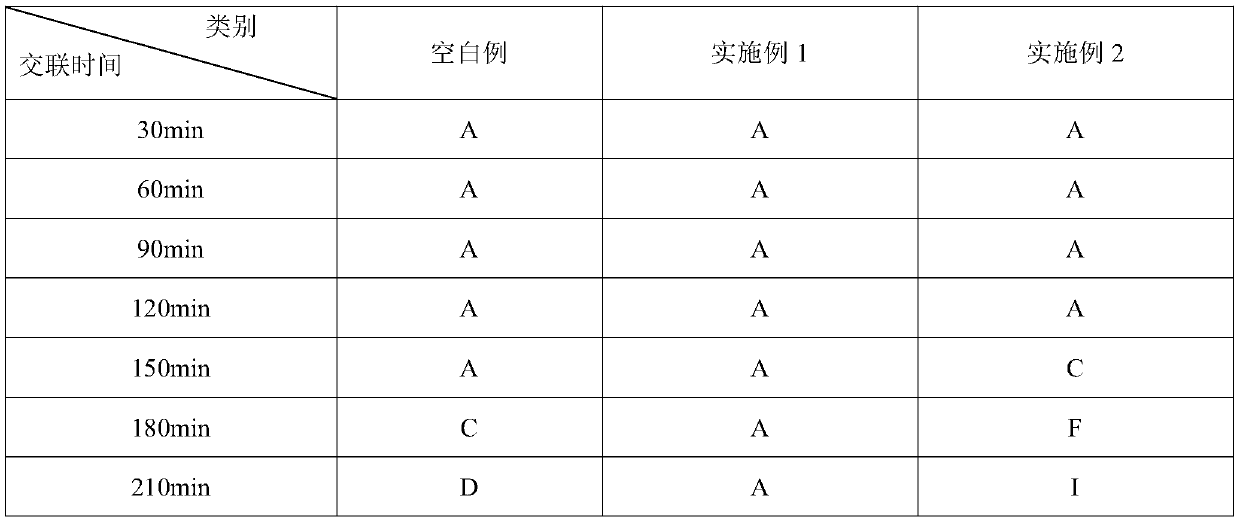

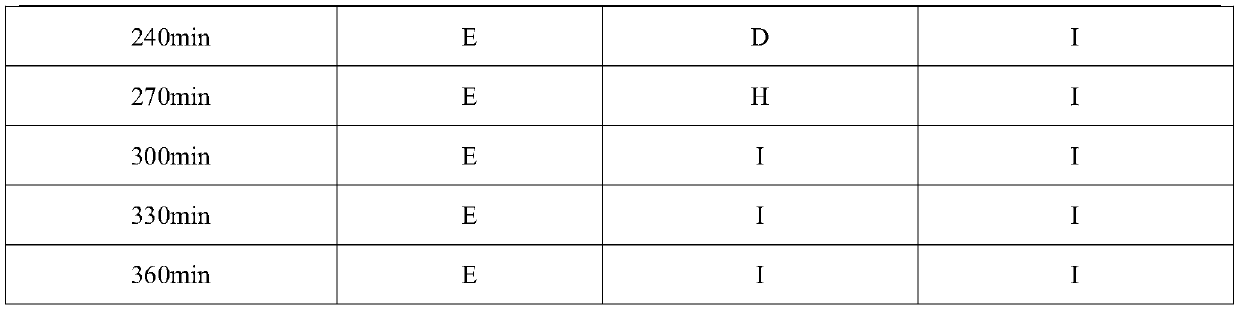

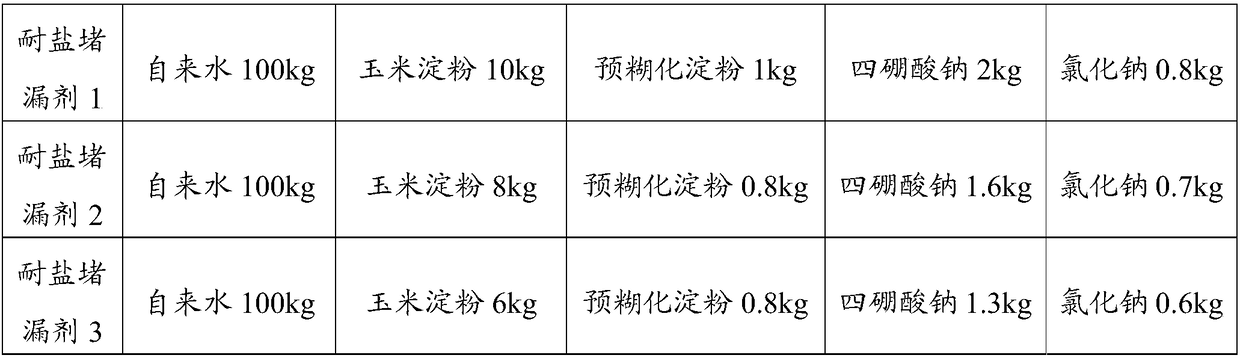

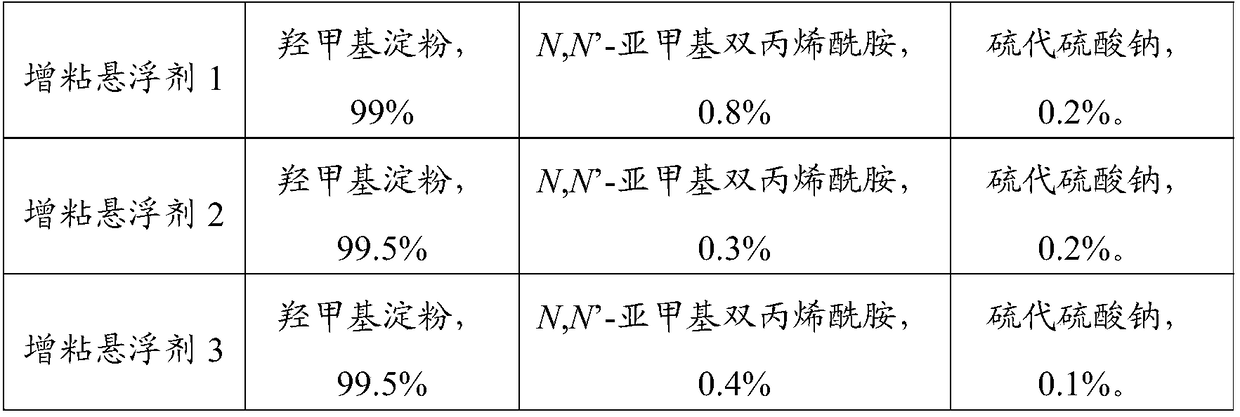

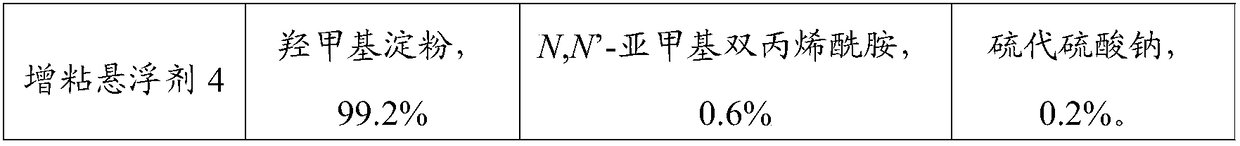

Modified brine workover fluid and preparation method thereof

ActiveCN109385258AEasy to flow backPrevent leakageDrilling compositionSuspending AgentsHydroxymethyl

The invention discloses a modified brine workover fluid and a preparation method thereof, belonging to the technical field of workover fluids for workover during oil-gas field development. The modified brine workover fluid comprises brine, a modifier for preventing brine from fouling, a salt-resistant plugging agent, a tackfying-suspending agent, a unidirectional pressure sealing agent for a drilling fluid and oil-soluble resin. The salt-resistant plugging agent is prepared from the raw materials by mass: 100 parts of water, 8 to 12 parts of natural starch, 0.8 to 2 parts of pregelatinized starch, 1 to 3 parts of sodium tetraborate and 0.7 to 1 part of sodium chloride. The tackifying-suspending agent comprises the following components by mass: 99.0% to 99.5% of hydroxymethyl starch, 0.3% to 0.8% of N,N'-methylenebisacrylamide and 0.1% to 0.2% of thiosulfate. The modified brine workover fluid has the advantages of good plugging effect, a wide plugging range, high salt resistance, easy degradability, etc.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com