Patents

Literature

170results about How to "Easy to flow back" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultra-low resistance acid-type microemulsion plugging removal and stimulation technology for low permeability oil well

ActiveCN101691839AGood dispersionStrong solubilizationFluid removalDrilling compositionSolubilityLiquid surfaces

The invention relates to a plugging removal and stimulation method for a low permeability oil well. The ultra-low resistance acid-type microemulsion is prepared by the following components: 10%-25% of acid, 5%-20% of oil, 5%-25% of alcohol, 0.5%-5% of surfactant, 0.5%-3% of inorganic salt, 0.3-1.5% of corrosion inhibitor and the balance water. The method comprises the following steps: injecting the prepared microemulsion in the oil bearing reservoir of the oil well, closing the oil well to react for 4-10h, cleaning the oil well, flowing the reaction exhaust liquor back, and completing the oilwell to perform normal production. The ultra-low resistance acid-type microemulsion used by the invention has thermodynamic stability, is a high dispersive acid-type microemulsion with good solubilization capacity, has ultra-low surface and interfacial tensions and good solubilization capacity and can increase the dispersive capacity of crude in water and the emulsification and peeling function to oil film; the microemulsion also has good dissolubility in water or oil and good fluidity due to high carrying capability and low seepage resistances so that the oil yield of the oil well is increased and the water content is reduced; the liquid surface tension in oil reservoir is reduced and the flow resistance of the crude is lowered so that the mining rate of the crude is increased and the plugging removal and stimulation of the oil well can be realized.

Owner:陕西中孚石油信息技术有限公司 +1

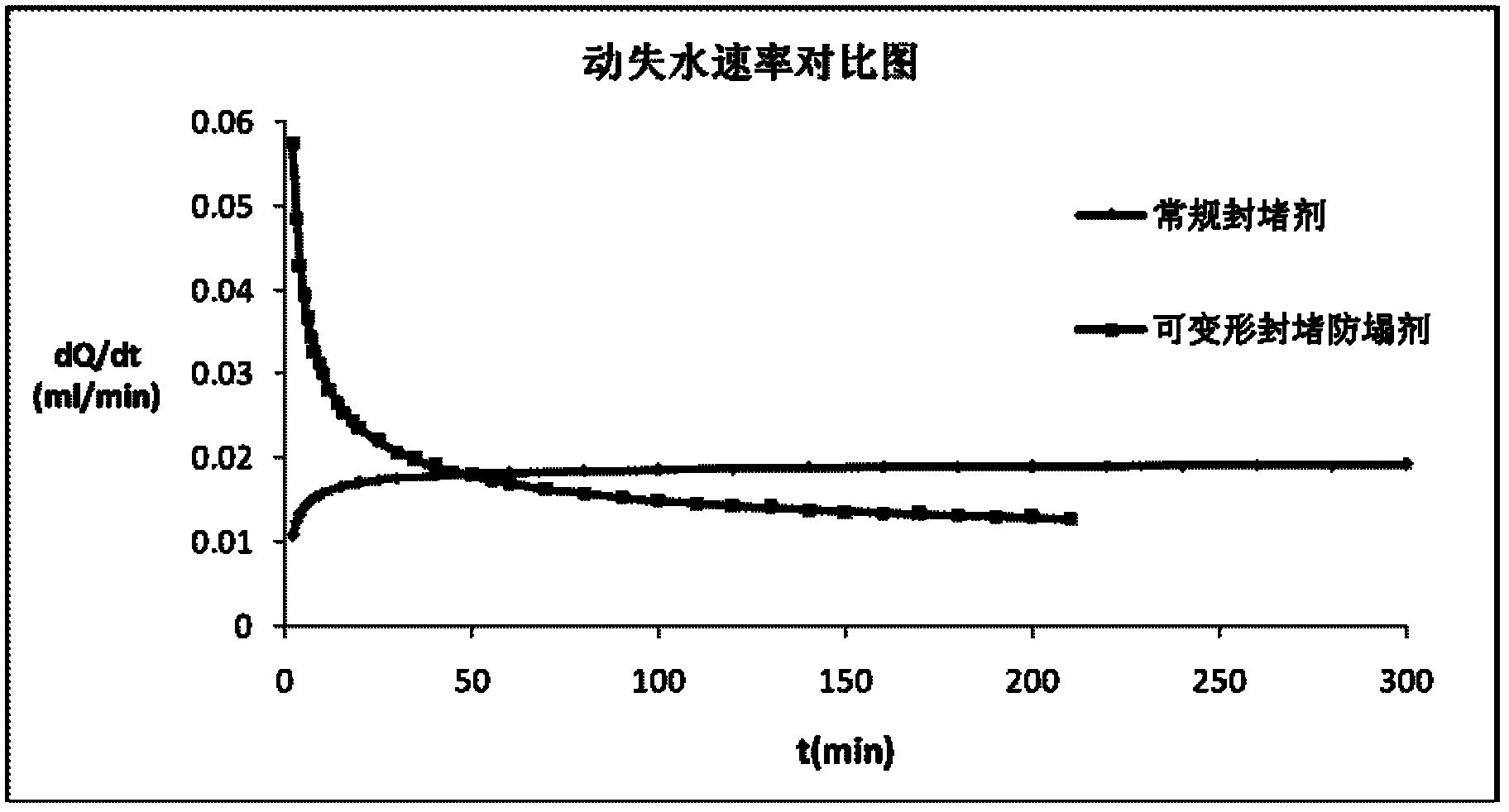

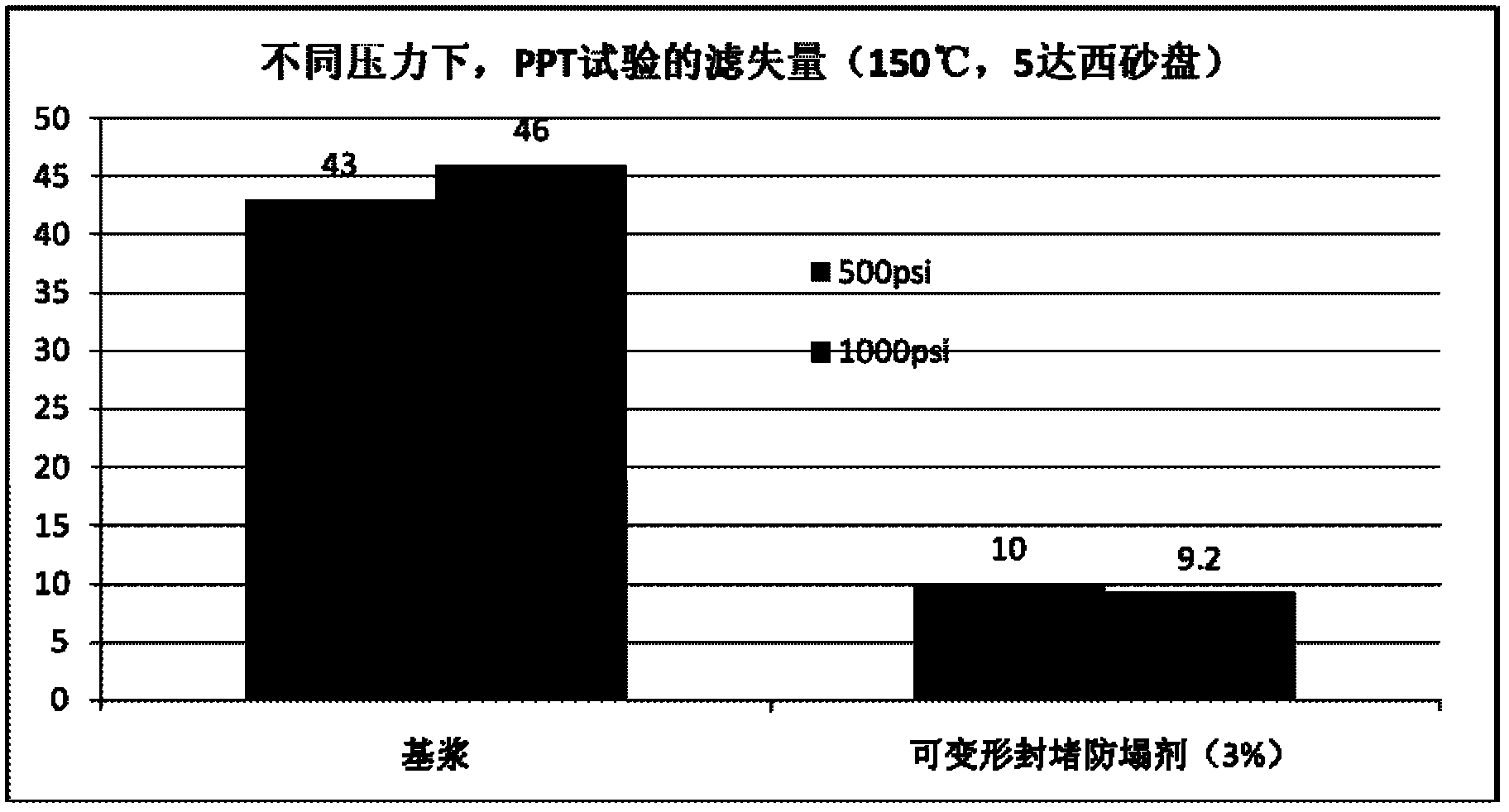

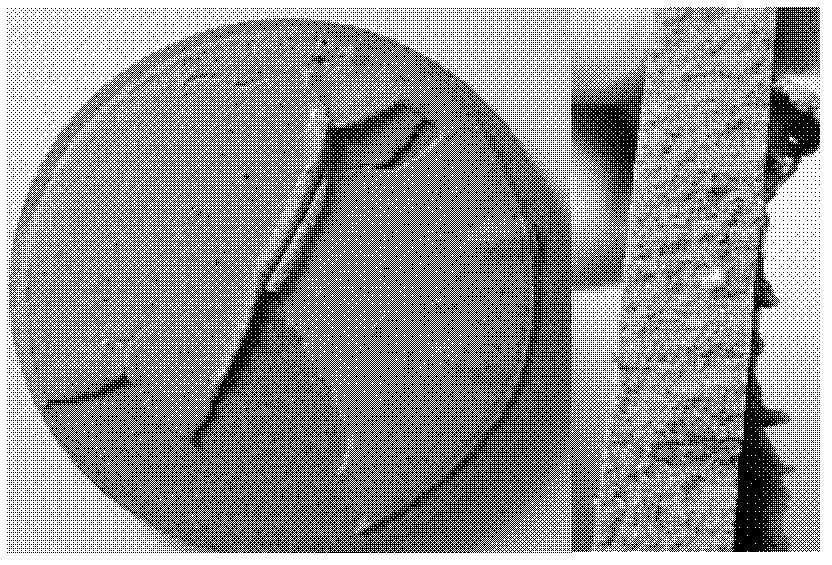

Deformable plugging and anti-sloughing agent for drilling fluid

ActiveCN102676141AImprove the blocking effectImprove compactnessDrilling compositionEngineeringNatural polymers

The invention relates to a deformable plugging and anti-sloughing agent for drilling fluid, and the deformable plugging and anti-sloughing agent comprises 10-90 parts by weight of non-deformable material, 20-80 parts by weight of nano-scale deformable redispersible polymer and 10-60 parts by weight of natural polymer modified material. The invention further relates to a preparation method of the deformable plugging and anti-sloughing agent for the drilling fluid. The preparation method comprises the following steps: mixing all the components according to the corresponding mixture ratio, mixing by virtue of a mixing and stirring machine for 80-120 minutes and screening by virtue of a 100-300 mesh screen, thus obtaining the deformable plugging and anti-sloughing agent.

Owner:CHINA NAT OFFSHORE OIL CORP +1

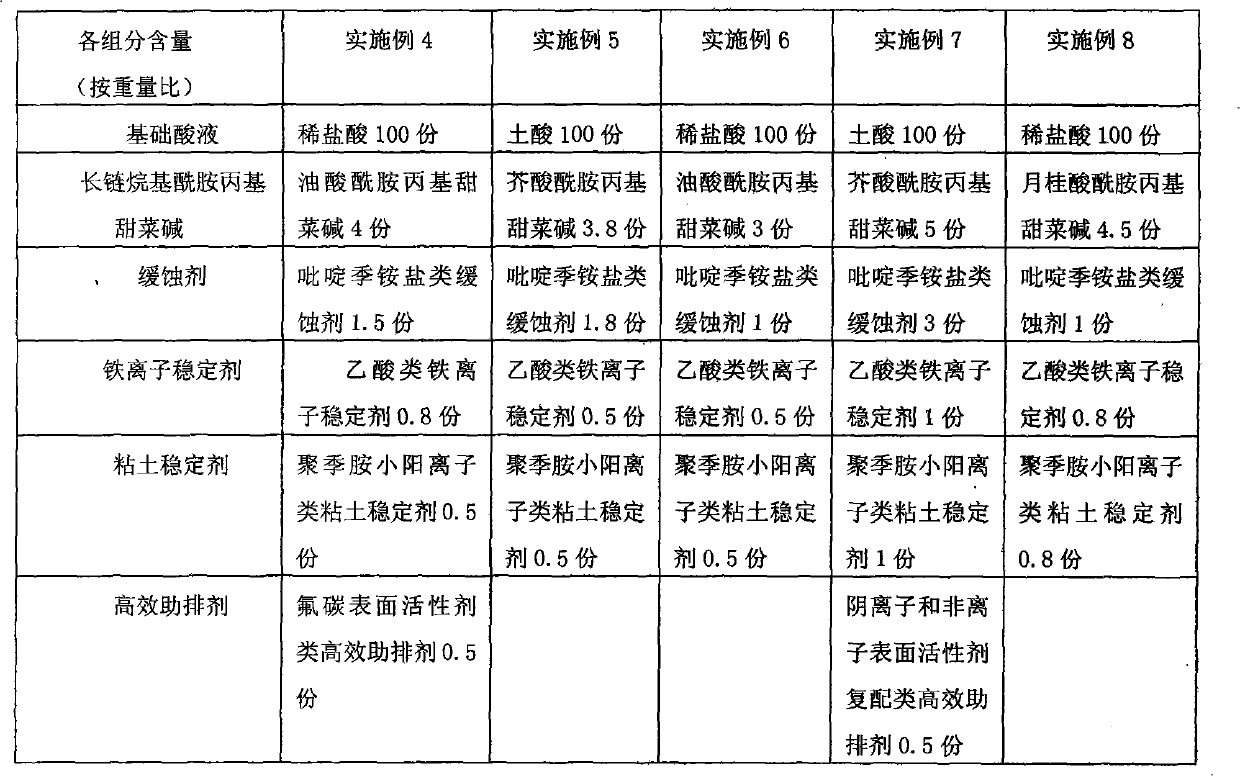

Viscosity-variable diverting acid for improving stratigraphic acidified section

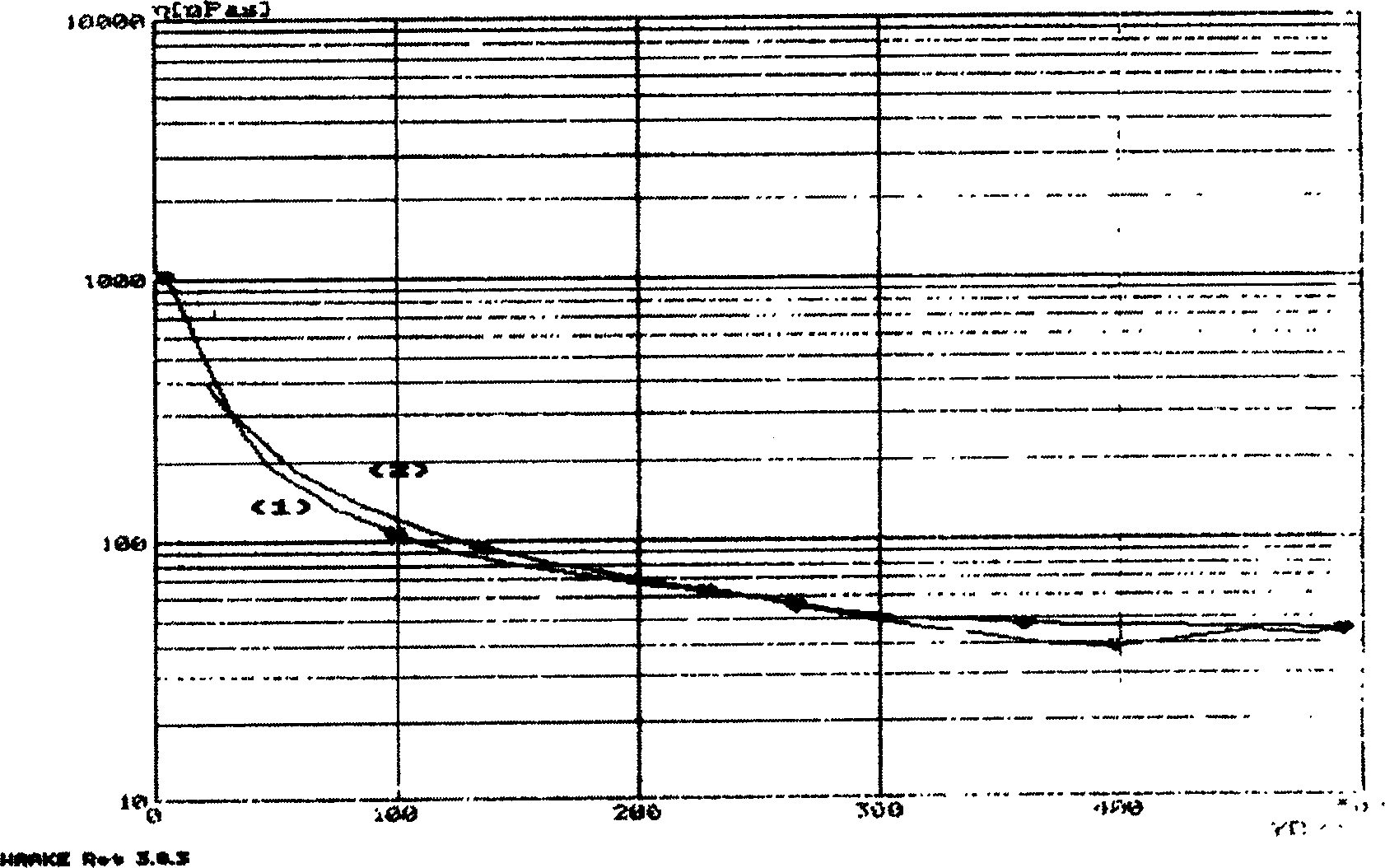

InactiveCN102020983AViscosity auto-increasingConing reductionDrilling compositionBetaineActive agent

The invention discloses viscosity-variable diverting acid for improving a stratigraphic acidified section. An oil layer is uniformly acidified, and the coning of acid liquor in a high permeable stratum is reduced to ensure that part of acid liquor enters middle and low permeable target stratums so as to improve and expand an acidified sweep section. In the viscosity-variable diverting acid, each component is controlled by a pH value, and the viscosity-variable diverting acid mainly comprises the following components in part by weight: 100 parts of basic acid liquor, 3 to 5 parts of long chain alkylamide propyl betaine, 1 to 3 parts of corrosion inhibitors, 0.5 to 1 part of ferrous stabilizer and 0.5 to 1 part of clay stabilizer. The viscosity-variable diverting acid consisting of the components is injected into a target oil layer. In the acidification process, the initial viscosity of the acid liquor is lower, and the initial viscosity at the temperature of 20 DEG C is 10 to 15mPa.s, the acid liquor is easy to enter the high permeable stratum, and subsequent unreacted low-viscosity acid liquor automatically diverts to enter the middle and low permeable stratums. The long chain alkylamide propyl betaine serving as a diverter is an ampholytic surfactant, does not have any macromolecular residues after a gel is broken and does not have any secondary damage to a reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

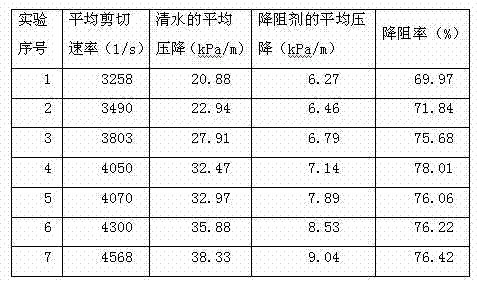

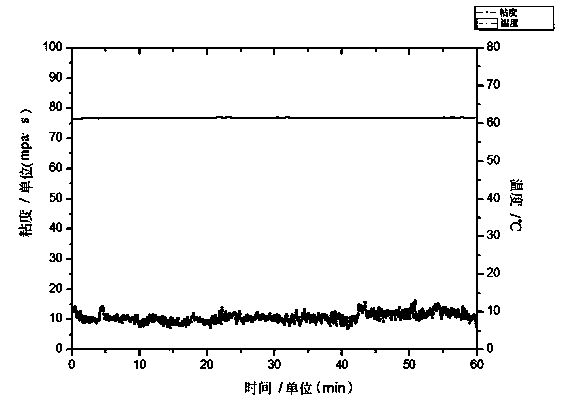

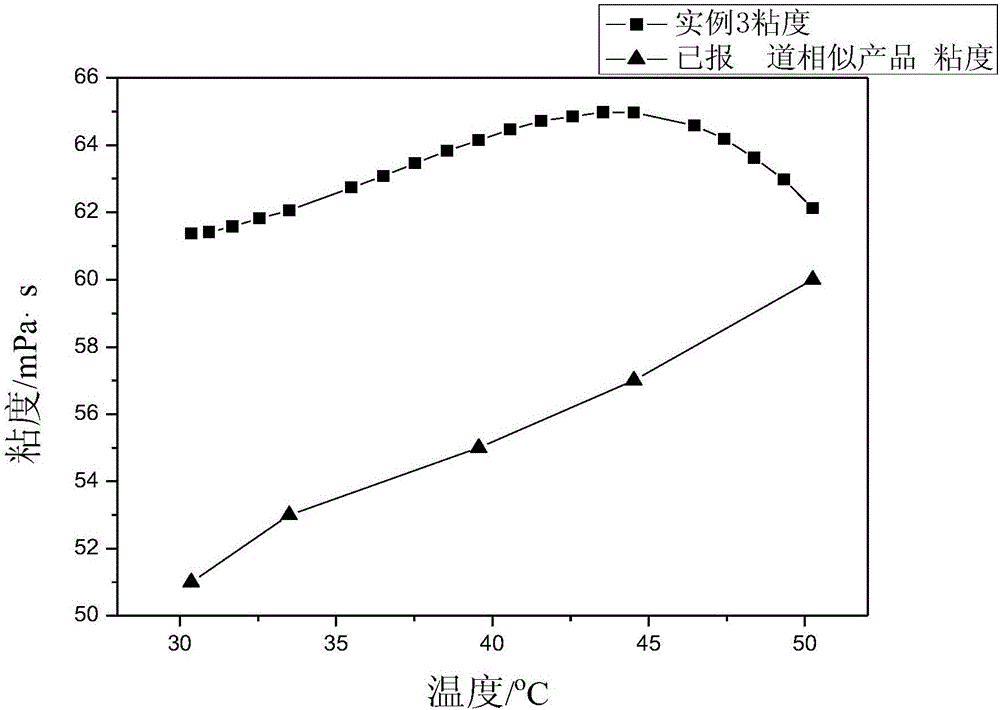

Low-friction recyclable slickwater fracturing fluid suitable for compact oil and gas reservoirs and preparation method thereof

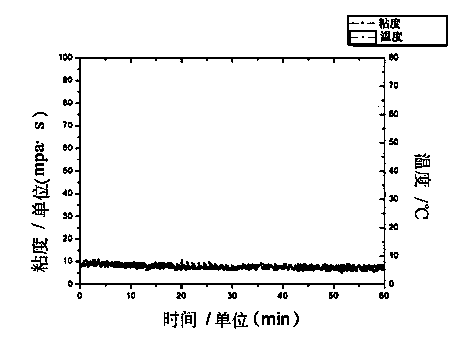

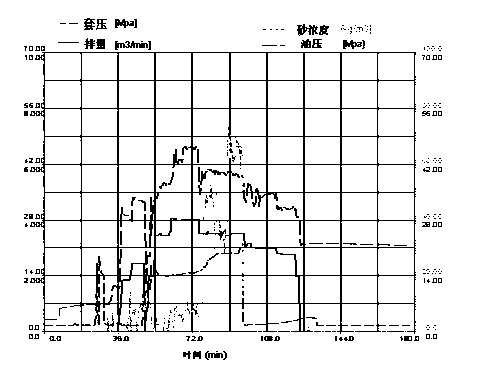

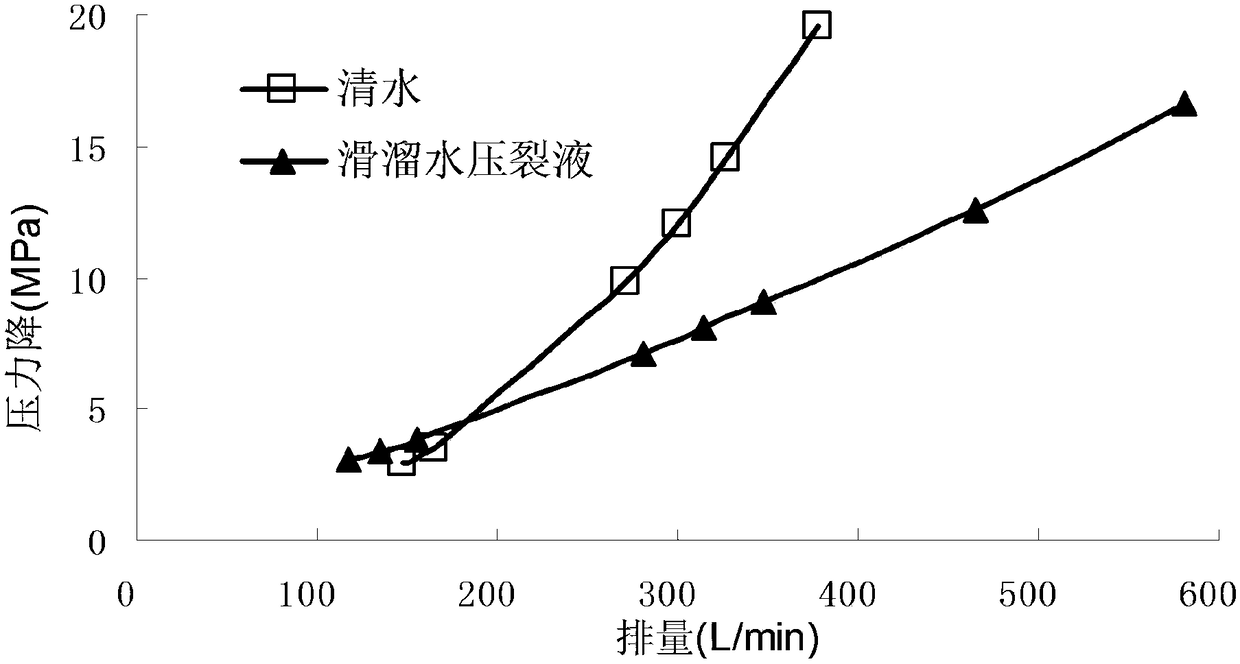

The invention relates to a low-friction recyclable slickwater fracturing fluid system suitable for compact oil and gas reservoirs and a preparation method thereof. Every tonnage of water is added with 0.06-0.25% of a water soluble drag reducer by mass, 0.2-0.5% of a demulsification cleanup additive by mass and 0.5% of a clay stabilizer by mass for evenly mixing to obtain a slickwater fracturing fluid; the prepared slickwater fracturing fluid is a reverse phase micro-emulsion system, and has the characteristics such as low viscosity, thorough gum breaking, easy flowing back, good expansion prevention performance and low friction; the resistance reducing effect is obvious; compared with clear water, the resistance reducing effect can achieve 50-70%; in the scene hydraulic fracturing operation, the resistance reducing rate of the water soluble drag reducer is 42.5% higher than that of the traditional guanidine gum slickwater in the case that the construction displacement is 3.5 m<3> / min.

Owner:PETROCHINA CO LTD

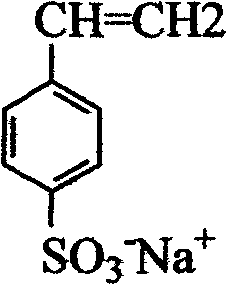

Resistance reducing agent for fracturing quick water of shale gas and preparation method thereof

ActiveCN103755868AHigh temperature resistantReduce frictionDrilling compositionEmulsion polymerizationOil phase

The invention relates to a resistance reducing agent for fracturing quick water of a shale gas and a preparation method thereof. The resistance reducing agent for fracturing quick water of the shale gas is formed by reverse emulsion polymerization by means of combination of a water phase and an oil phase, wherein the weight part ratios of monomers to water in the water phase are sequentially as follows: the ratio of acrylamide: 2-acrylamide-2-methyl propanesulfonic acid: water is (0.7-1.3):(0.7-1.5):1; the weight ratio of monomers to oil in the oil phase is sequentially as follows: the ratio of tween 80:OP-10: white oil is (0.1-0.35):(0.1-0.35):1; and the weight ratio of the water phase to the oil phase is 1:(0.35-0.85). The preparation method comprises the following steps: (1) selecting acrylamide and 2-acrylamide-2-methyl propanesulfonic acid, and dissolving acrylamide and 2-acrylamide-2-methyl propanesulfonic acid in proportion in deionized water to prepare the water phase; (2) selecting tween 80 and white oil and mixing the tween 80 and white oil in a certain proportion to form the oil phase; (3) proportioning the water phase and the oil phase in a certain proportion, and fully mixing to form a stable water-in-oil inverse emulsion base fluid; and (4) catalyzing and initiating by an initiator to synthesize the resistance reducing agent.

Owner:郑州三山石油技术有限公司

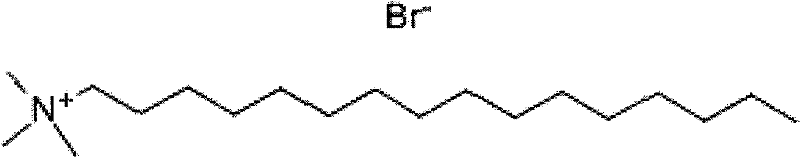

Clean viscous acid for acid fracturing of carbonate reservoir

ActiveCN102453480AGood retarding performanceExtended service lifeDrilling compositionAcid etchingHydrogen-Ion Concentrations

The invention discloses a clean viscous acid for acid fracturing of a carbonate reservoir, which is applied to the technical fields of acidification and acid fracturing of petroleum carbonate reservoirs. The clean viscous acid consists of the following components in percentage by weight: 3-7 percent of hexadecyl trimethyl ammonium bromide, 0.3-0.7 percent of sodium salicylate, 15-28 percent of hydrochloric acid, 0.125-0.25 percent of citric acid or 0.05-0.1 percent of CX-301 or 0.3-0.5 percent of TW-1 serving as an iron ion stabilizing agent, 0.2-0.25 percent of a diimidazoline quaternary ammonium salt and the balance of water. The clean viscous acid has high retardative property, the retarding rate can reach 42-56 percent, the fresh acid viscosity is 25-40 mPa.S, and the acid liquor viscosity rises during acid fracturing of the carbonate reservoir. When the hydrogen ion concentration falls till the pH is more than or equal to 2, the acid liquor viscosity rises for forming viscoelastic gel, the permeation resistance of an acid liquor in a high permeation layer is increased, and the length of an acid etching crack is prolonged. Reacted residual acid gel can undergo gel breaking automatically, is free from residues, is easy for discharging, and has small damage to stratums.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High temperature resistant cleansing emulsion or microemulsion fracturing fluid and preparation method thereof

ActiveCN102838980AIncrease contentReduce apparent viscosityProductsReagentsApparent viscosityPolymer science

The invention relates to a high temperature resistant cleansing emulsion or microemulsion fracturing fluid and a preparation method thereof. The emulsion fracturing fluid is composed of a continuous oil phase, a polymer (I)-containing dispersed water phase and an emulsifier. The preparation method of the emulsion fracturing fluid includes: preparing a mixed solution of the oil phase and the emulsifier, preparing a four-monomer containing water phase, conducting a polymerization reaction in the presence of an initiating agent, and other steps. The product provided in the invention has low apparent viscosity, and can dissolve rapidly. When the emulsion dissolves into gel, the emulsifier can have a synergistic effect with an association polymer, thus further improving and maintaining the viscosity, and helping to prevent leak-off and help flowback. An oxidation gel breaking way is employed for gel breaking, the gel can be completely broken, and the gel breaking solution has low viscosity and contains no residue. The emulsion fracturing fluid is easy to undergo flowback, and has low damage to the stratum.

Owner:CHINA PETROLEUM & CHEM CORP +1

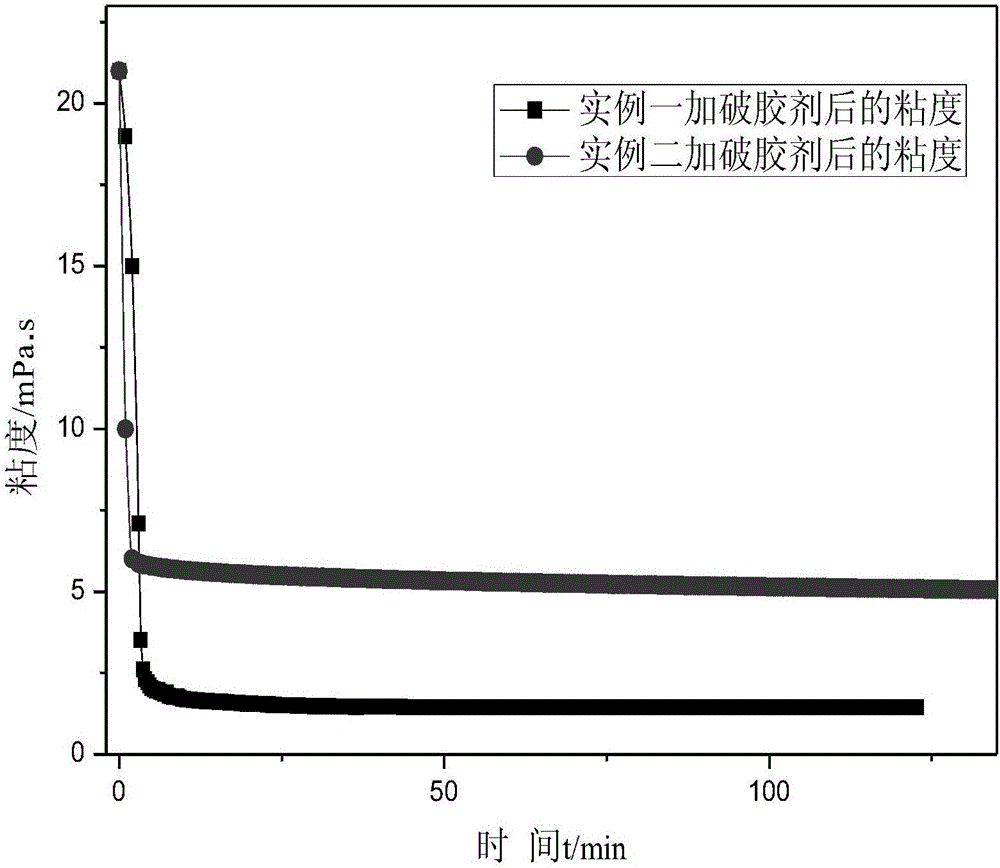

Slippery water fracturing fluid with ultra-low interfacial tension with crude oil after degradation

The invention discloses a slippery water fracturing fluid with ultra-low interfacial tension with crude oil after degradation. The slippery water fracturing fluid is prepared from an ultra-low interfacial tension drag reducer, a demulsify-cleanup additive, a clay stabilizer and a degrading agent. A preparation method of the slippery water fracturing fluid comprises steps as follows: 0.02%-0.10% in percentage by mass of the ultra-low interfacial tension drag reducer, 0.1%-0.2% in percentage by mass of the demulsify-cleanup additive and 0.3% in percentage by mass of the clay stabilizer are added to every ton of water, the agents are mixed to form a homogeneous solution, and 0.08% of the degradation agent is added from a mixing tank of blending equipment during construction. Additives of the slippery water fracturing fluid are all liquid phase, and the slippery water fracturing fluid can be quickly dispersed in water, have good salt tolerance, are not easily affected by the content of bacteria in a fluid preparation solution and have a stable drag reduction effect under the construction displacement of 6-20 m<3> / min; when applied to improvement of low-permeability oil and gas reservoirs, the slippery water fracturing fluid can reduce the interfacial tension between a gel breaking liquid and crude oil and reduce string and construction friction, helps production of the crude oil, increases of the yield of the crude oil and can be prepared repeatedly from backflow fracturing fluids.

Owner:PETROCHINA CO LTD

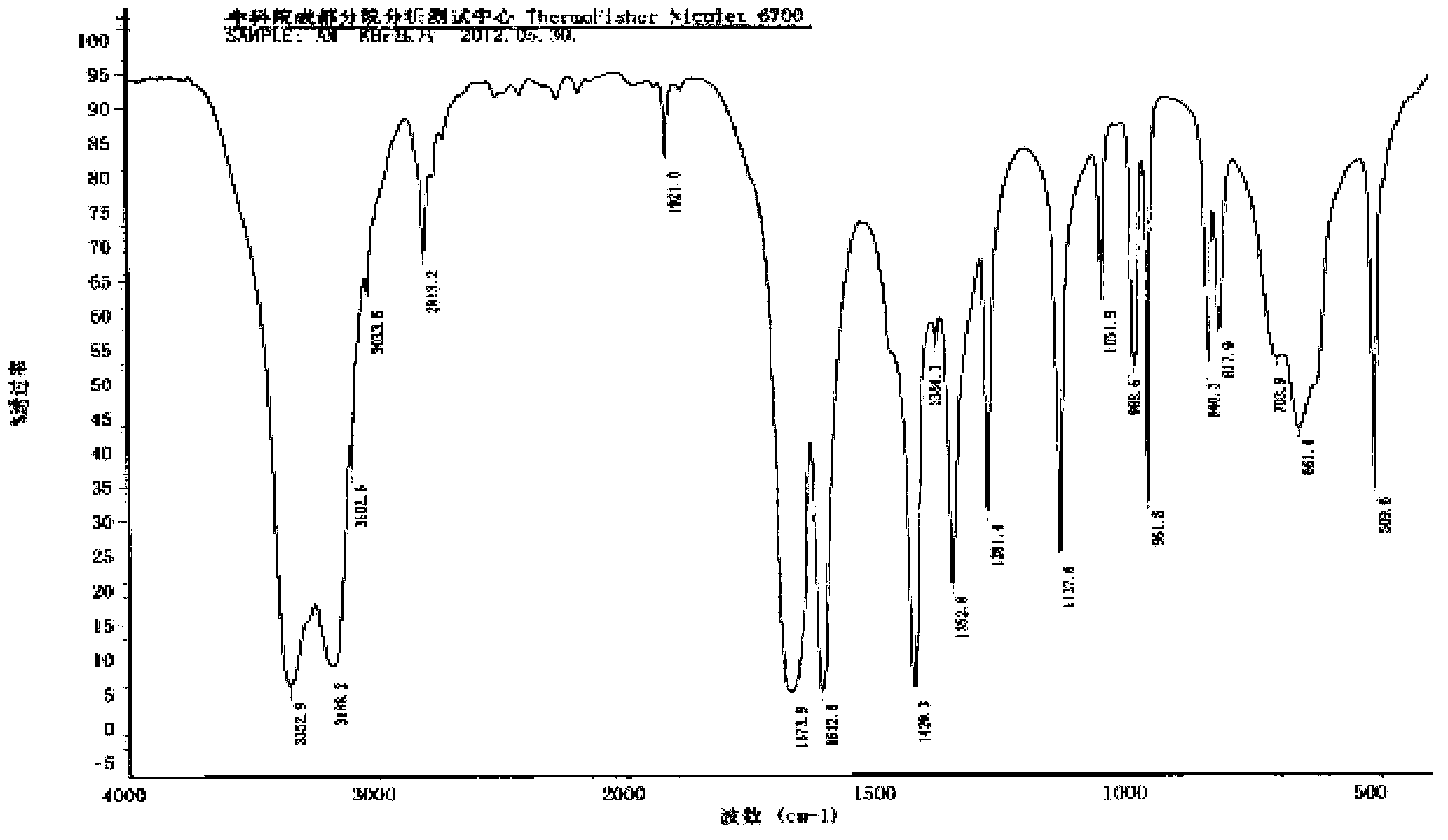

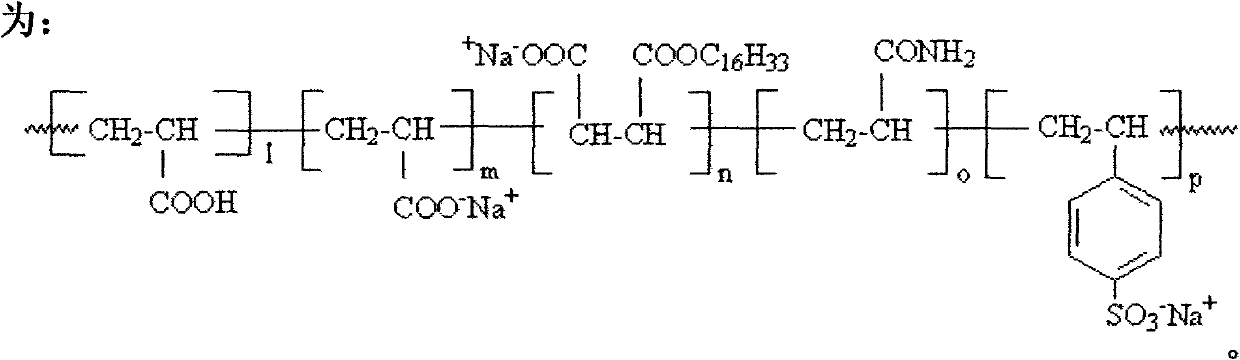

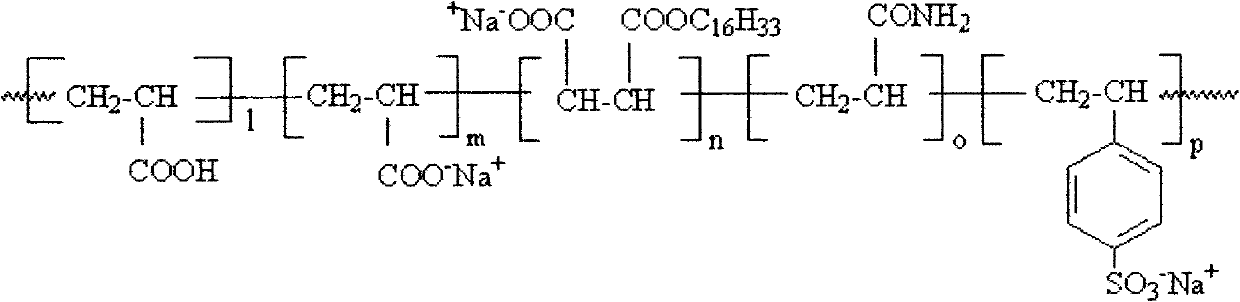

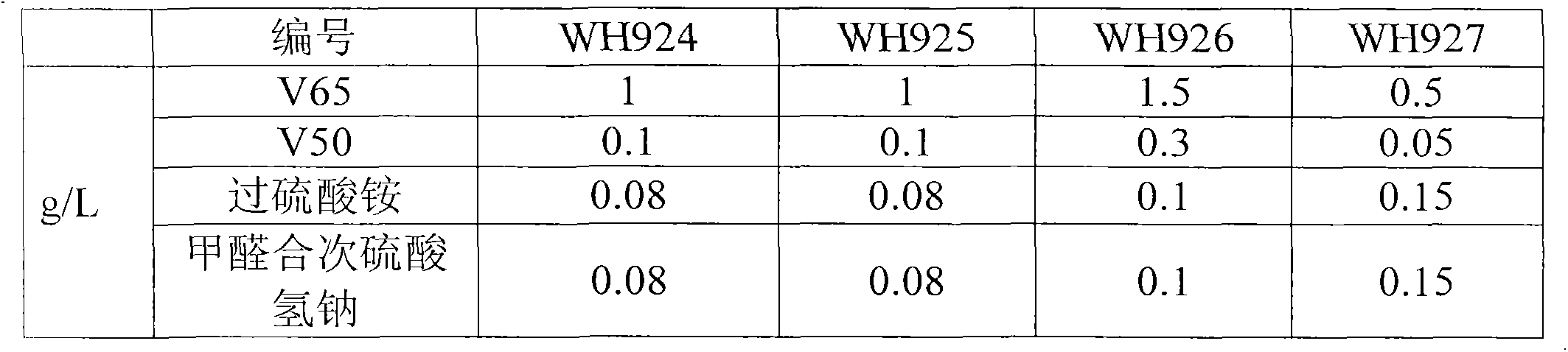

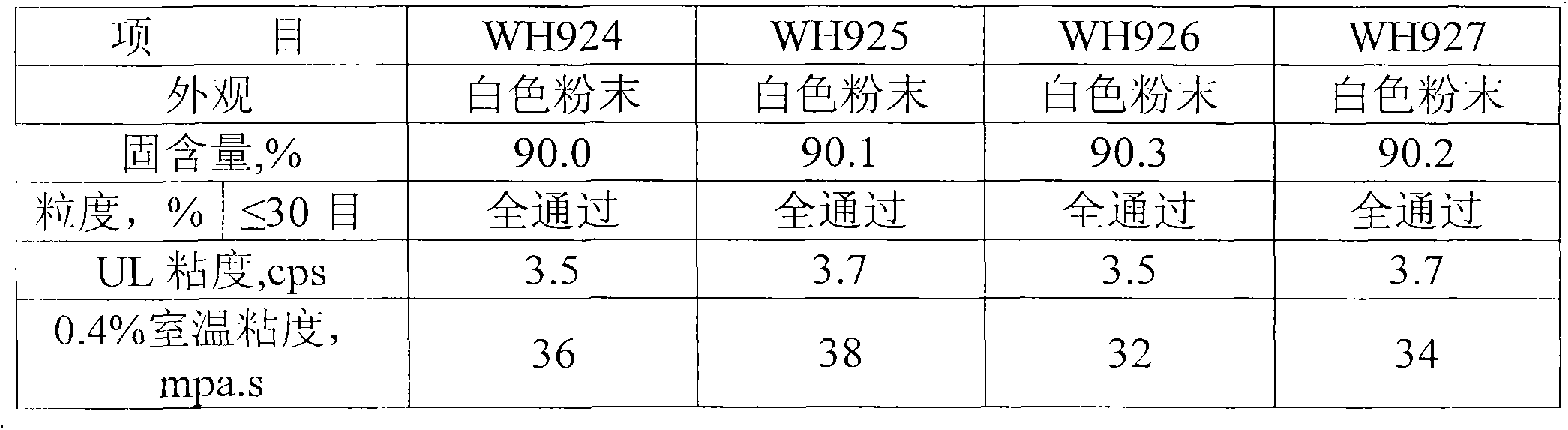

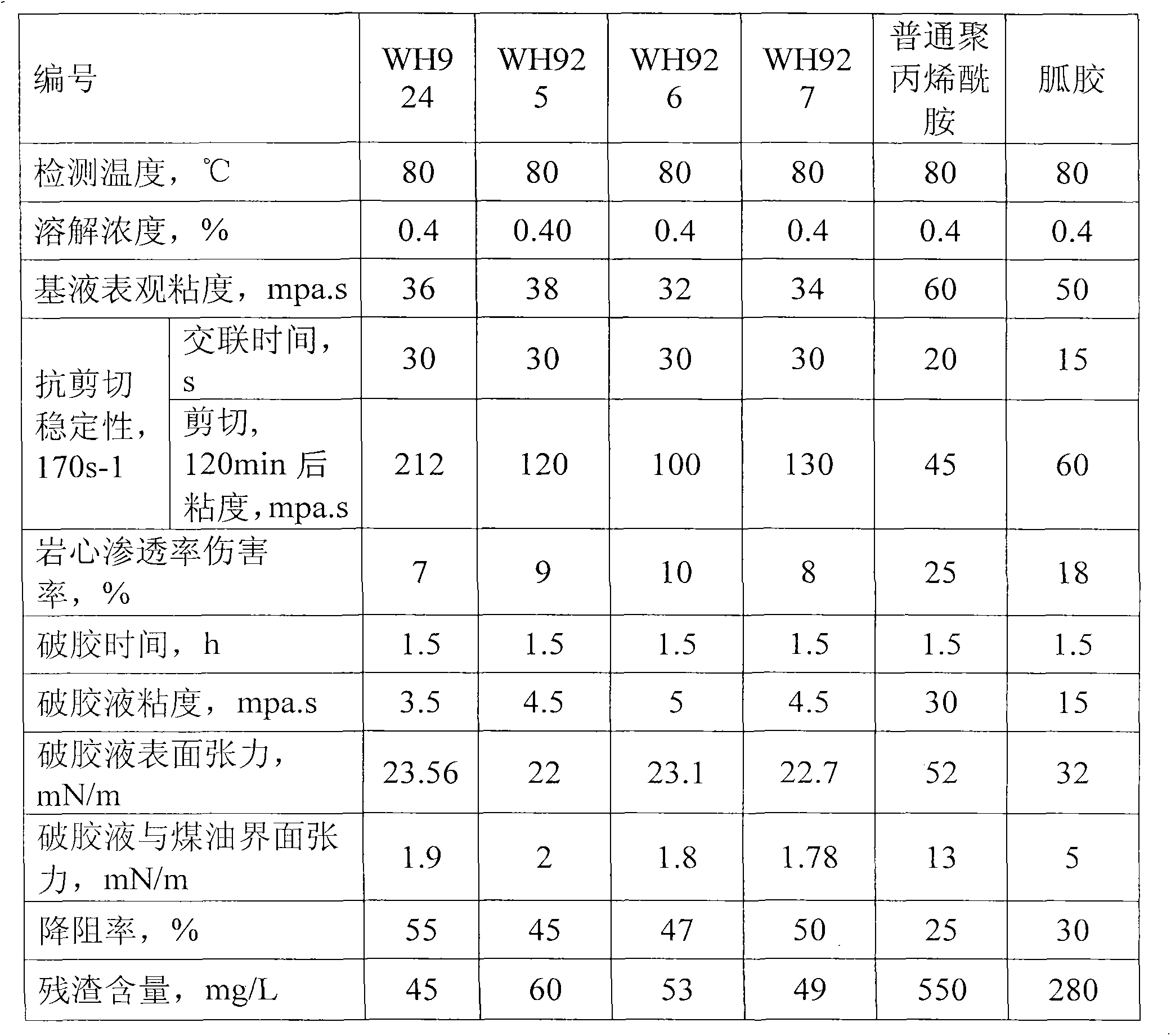

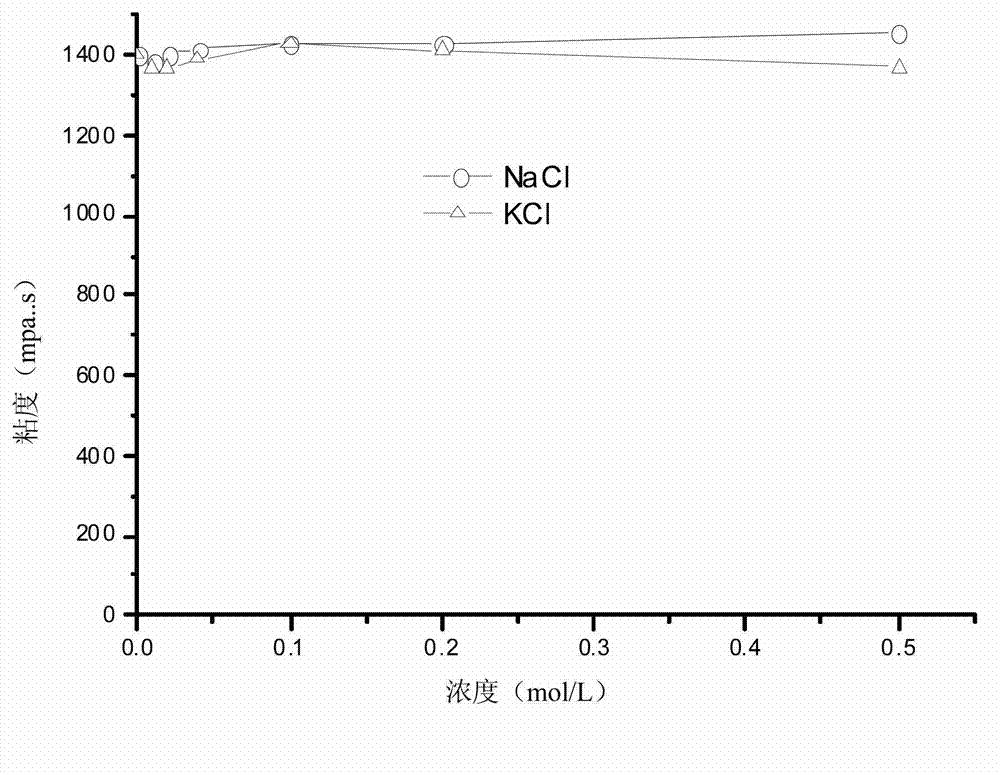

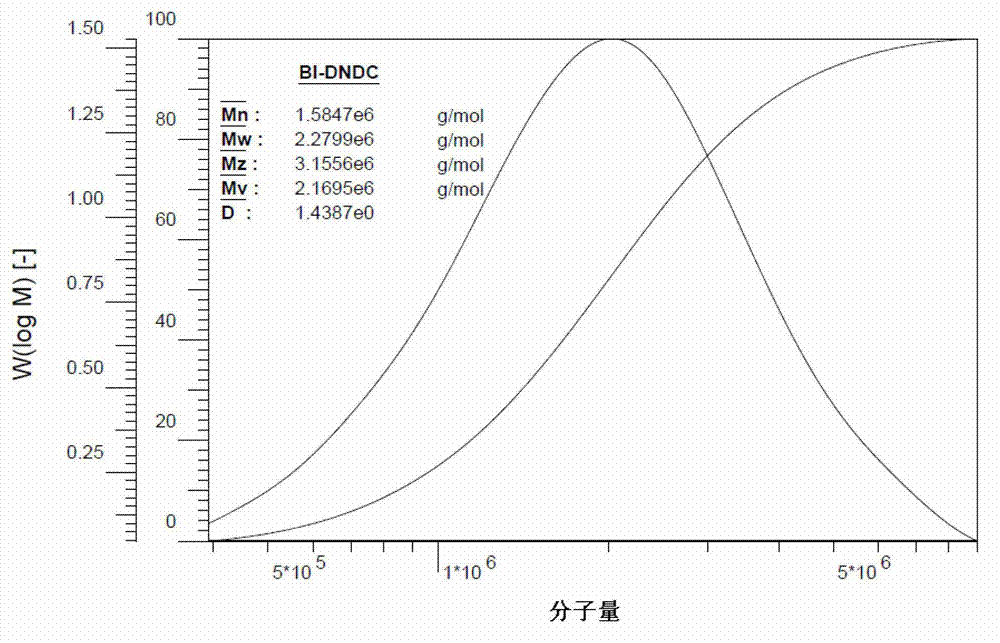

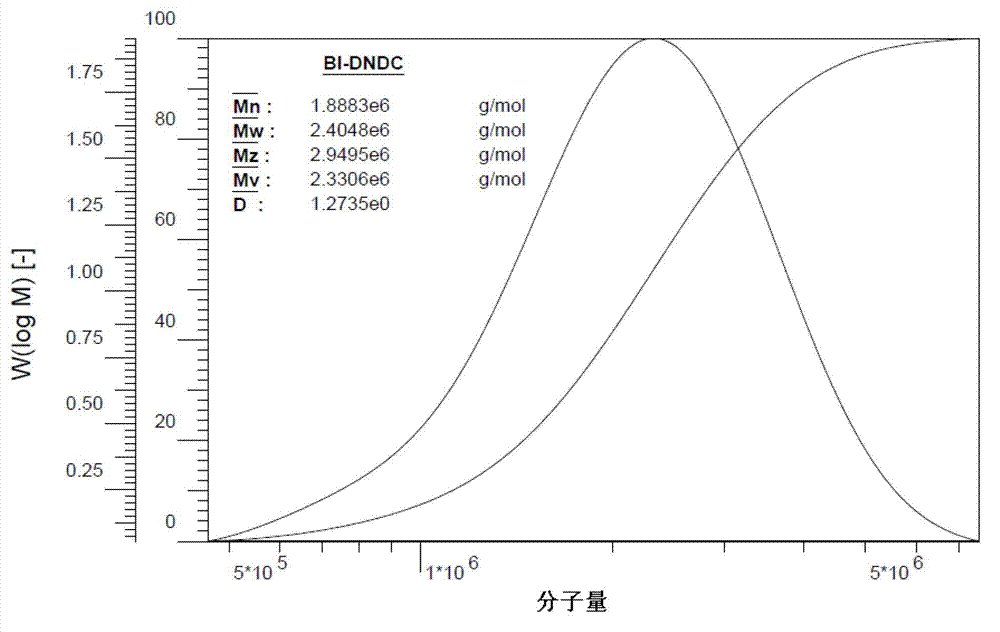

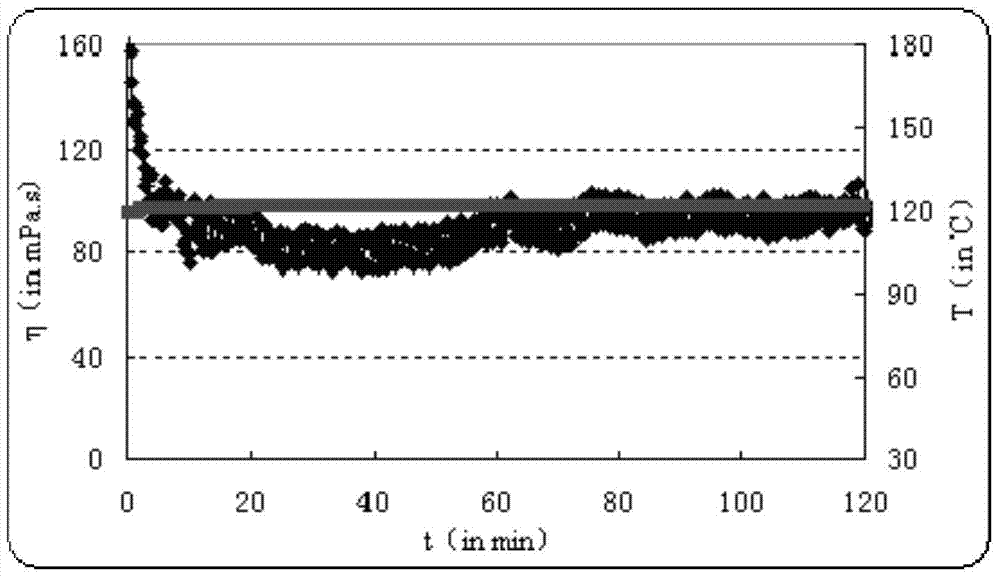

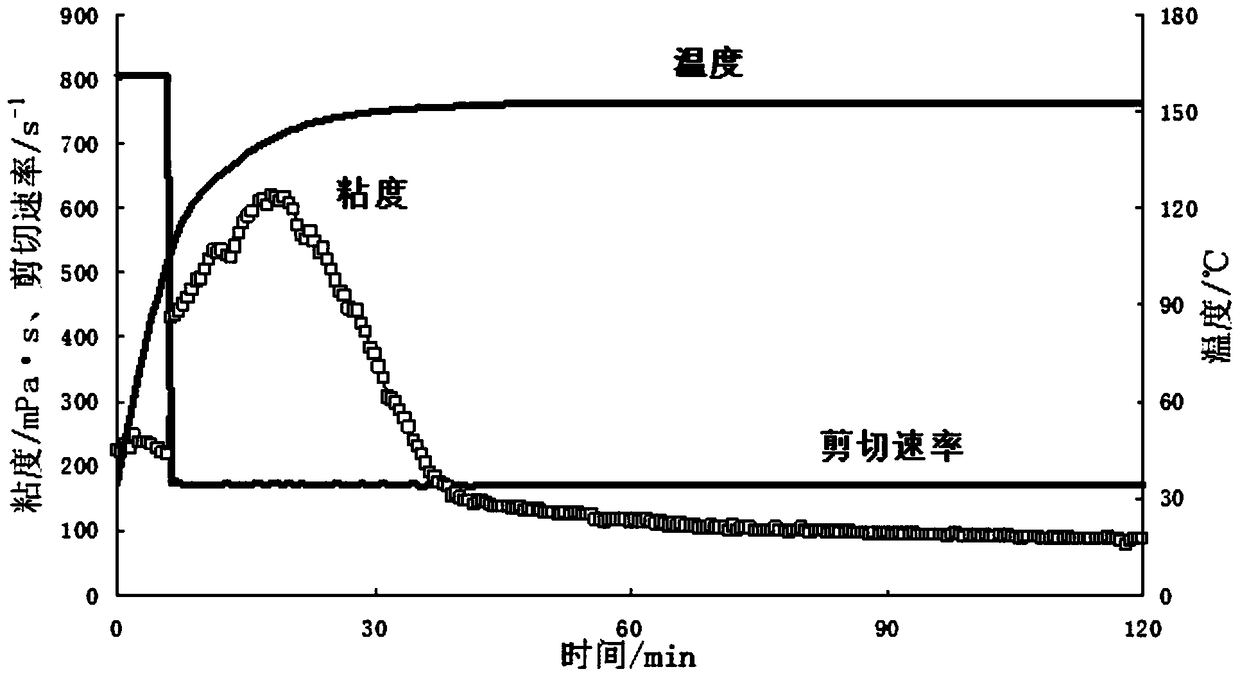

Temperature-resistant and salt-resistant polymer clean fracturing fluid thickening agent and preparation method thereof

The invention provides a temperature-resistant and salt-resistant polymer clean fracturing fluid thickening agent and a preparation method thereof. The temperature-resistant and salt-resistant polymer clean fracturing fluid thickening agent has the advantages of cleanliness, low damage, environmentally friendly characteristics, good viscosity increasing effects, very strong suspension properties,good thermal adaptability allowing a super-wide temperature range of 25 to 240 DEG C, good salt resistance, excellent shear stability, small frictional resistance, obvious fracture effects, long lasting time spent on production after compression, and good cost performance.

Owner:北京爱普聚合科技有限公司

Supercritical carbon dioxide based fracturing liquid system and application thereof

ActiveCN103540308AViscosity value adjustableGood sand carryingFluid removalDrilling compositionEnvironmental resistanceAdhesive

The invention relates to a supercritical carbon dioxide based fracturing liquid system and application thereof. The fracturing liquid system comprises the following components: 0.1%-5% of adhesive, 0.3%-6.5% of conditioner and the rest of supercritical carbon dioxide. The supercritical carbon dioxide based fracturing liquid system provided by the invention can be used for oil field fracturing. In an application field, all components are mixed in certain mass percentage, and a propping agent is pumped into a stratum together with the mixture. The fracturing liquid system provided by the invention has the characteristics of good sand-carrying properties, easy backflow, no residues and no water phase, completely eliminates water-lock and water-sensitive damages, effectively reduces the viscosity of crude oil, inhibits clay swelling, improves the reservoir permeability, greatly saves water resources and can reach the purpose of efficient, environment-friendly and green construction.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

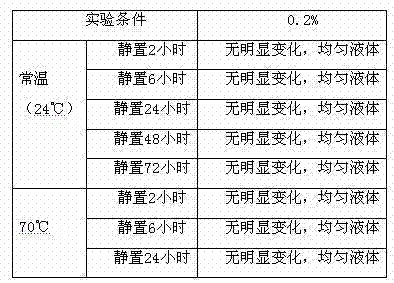

Temperature resistant, non-crosslinked and biodegradable gel leak-stopping agent and preparation method thereof

ActiveCN102358771AImprove temperature resistanceMeet construction requirementsDrilling compositionFluid LeakStructure type

The present invention provides a temperature resistant, non-crosslinked and biodegradable gel leak-stopping agent and a preparation method thereof. The gel leak-stopping agent of the present invention has the following advantages that: the gel leak-stopping agent has extra-wide temperature adaptability, can adapt to a temperature range of 25-180 DEG C, and can meet requirements of oil field construction; the gel leak-stopping agent has rapid dissolution rate, and forms the structure type gel with good shear thinning behavior after dissolving, wherein the structure type gel is the liquid whichcan be pumped and flow; the gel leak-stopping agent does not require cross-linking; the real fluid leak-stopping is realized; the construction is convenient; the product is completely dissolved in water, no precipitate and flocculent insoluble matter are generated during the whole process, no insoluble matter is generated after the product is degraded, such that the flow back is easy or the flow back is not required, the reservoir is not damaged; the product is safe and environmental protection, and is synthesized by the multi-stage initiation, such that the product conversion rate is high, the stability is good, no toxic damage is generated to the stratum, the production layer can be protected.

Owner:北京爱普聚合科技有限公司

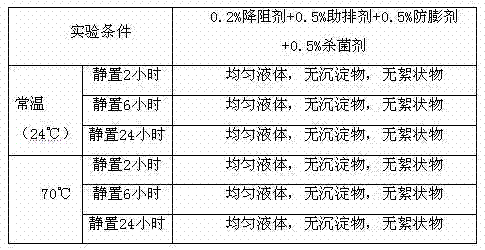

Novel cleaning fracturing fluid system and preparation method thereof

The present invention discloses a novel cleaning fracturing fluid system and a preparation method thereof. The system is characterized in that the fracturing fluid system comprises the following components in percentage by mass: 2%-6% of a cationic surfactant, 1%-5% of a cosurfactant, 0.5%-2% of an organic salt, 2%-7% of an inorganic salt and the balance of water. The preparation method for the cleaning fracturing fluid comprises the steps of: first mixing the cationic surfactant, the cosurfactant and water to obtain a uniform and transparent liquid; and sequentially adding an aqueous solution of the organic salt and the inorganic salt into the uniform and transparent liquid in the case of stirring, and stirring the system for uniform mixing. The preparation method for the cleaning fracturing fluid is simple, convenient in operation, good in viscoelasticity of the system and strong in sand-carrying capability without residues, breaks gels with water or oil automatically, and is easy to return and has small harm to strata.

Owner:CHINA PETROLEUM & CHEM CORP +1

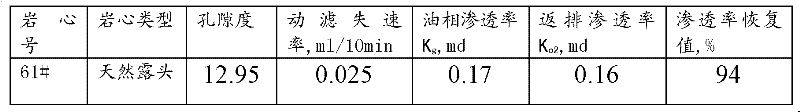

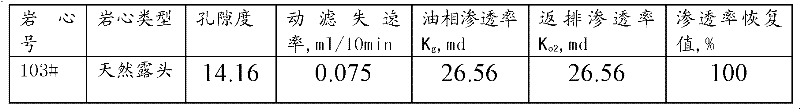

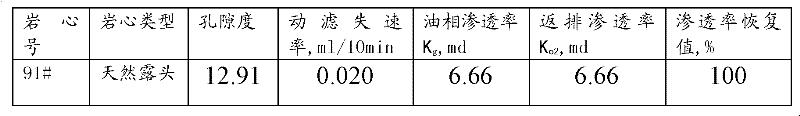

Plugging agent for drilling fluid and protecting low percolation reservoir

The invention discloses a plugging agent for a drilling fluid and protecting a low percolation reservoir, comprising the following components of: 10-40 parts of acid-soluble fiber, 5-10 parts of oil-soluble resin, 30-60 parts of acid-soluble deformed particles, 5-10 parts of high-temperature resistant natural small molecule materials and 10-15 parts of calcium carbonate. The basic component of the plugging agent is the acid-soluble fiber which is swelled and soft, has good tenacity and can expand by adsorbing partial moisture, and the like in the drilling fluid to form a meshy structure so as to form plugging on a hole throat under the action of flowing pressure. In addition, other components in the plugging agent, such as the deformed particles, the natural small molecule materials and the calcium carbonate can combine with the fiber to play a rapid plugging role, and therefore, the plugging agent has low damage depth on the reservoir. The plugging agent can be matched with the radius of the hole throat of the low percolation reservoir according to the regulation on the radius of the hole throat of a low percolation core. A drilling fluid system using the plugging agent as the main plugging material has the dynamic core filtration rate not more than 0.1ml / 10min at high temperature and high pressure.

Owner:CHINA NAT OFFSHORE OIL CORP +1

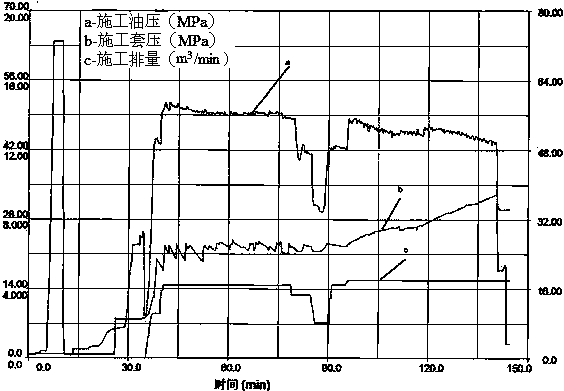

Carbon dioxide-anti-drag water compound fracturing method

InactiveCN105888641ALow flow resistanceInhibit swellingFluid removalDrilling compositionCompound fracturesFracturing fluid

The invention provides a carbon dioxide-anti-drag water compound fracturing method which comprises the following steps of: injecting liquid carbon dioxide fracturing fluid into a stratum; after a period of time, stopping injecting the liquid carbon dioxide fracturing fluid, and then injecting anti-drag water fracturing fluid not added with a propping agent; and after a period of time, stopping injecting the anti-drag water fracturing fluid not added with the propping agent, then injecting anti-drag water compound fracturing fluid carrying the propping agent, and stopping after a period of time. According to the method, different system fracturing fluids are adopted in different injection phases, and special properties of different fracturing fluids are reasonably utilized, so that the effect of enlarging crack network scale, communicating stratum primary fractures, enhancing fracture efficiency, improving the seepage environment of the stratum and improving the reservoir yield; a carbon dioxide-anti-drag water compound fracturing process is applied to a low percolation oil and gas reservoir, so that the per-well yield can be improved, and the problem that traditional fracturing process for low percolation oil and gas reservoirs is poor in productivity improvement effect.

Owner:BEIJING NIUHE RUICHEN ENERGY TECH CO LTD

Clean fracturing fluid and preparation method thereof

InactiveCN105505370AEasy to prepareEasy to operateDrilling compositionFracturing fluidViscoelasticity

The present invention discloses a clean fracturing fluid system and a preparation method thereof, wherein the fracturing fluid system comprises, by mass, 3-6% of a cationic surfactant, 1-4% of a zwitterionic surfactant, 0.5-1.5% of counter ion, 2-5% of an electrolyte, and the balance of water. The clean fracturing fluid preparation method comprises: mixing a cationic surfactant, a zwitterionic surfactant and water to obtain a uniform transparent liquid, adding an aqueous solution of an electrolyte salt and counter ion to the uniform transparent liquid under stirring, and uniformly mixing to obtain the clean fracturing fluid. According to the present invention, the method has characteristics of simpleness and convenient operation, and the clean fracturing fluid system has characteristics of good viscoelasticity, strong sand-carrying ability, no residue, automatic gel breaking with water or oil, easy flowback, and low damage on stratum.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-permeability reservoir water-lock releasing agent and preparation method thereof

ActiveCN102899011ALow cloud pointGood water solubilityDrilling compositionFracturing fluidGlycol ethers

The invention discloses an oil field chemical agent used in petroleum gas oil-pumping operation construction, and particularly relates to a low-permeability reservoir water-lock releasing agent used in working fluid and a preparation method thereof. The low-permeability reservoir water-lock releasing agent consists of the following components in percentage by weight: 1 to 15 percent of glycol ether, 15 to 45 percent of didodecyl dicarboxylic sodium, 15 to 30 percent of ethylene glycol silicon ether and 30 to 60 percent of water. The preparation method comprises the following steps of: adding 30 to 60 percent of water into an enamel reaction kettle, starting a stirrer, and heating to raise the temperature to be between 30 and 40 DEG C; adding 1 to 15 percent of glycol ether and 15 to 45 percent of didodecyl dicarboxylic sodium into the reaction kettle, controlling the temperature and stirring for 1 hour; and adding 15 to 30 percent of ethylene glycol silicon ether into the reaction kettle, controlling the temperature to be between 40 and 80 DEG C, and reacting for 1 to 2 hours to obtain the water-lock releasing agent. The water-lock releasing agent is strong in surface activity and low in use level, can well maintain the permeability of a low-permeability reservoir and release water-lock damages, and is used in the working fluid such as fracturing fluid, perforating fluid, well control fluid and the like.

Owner:唐山冀油瑞丰化工有限公司 +1

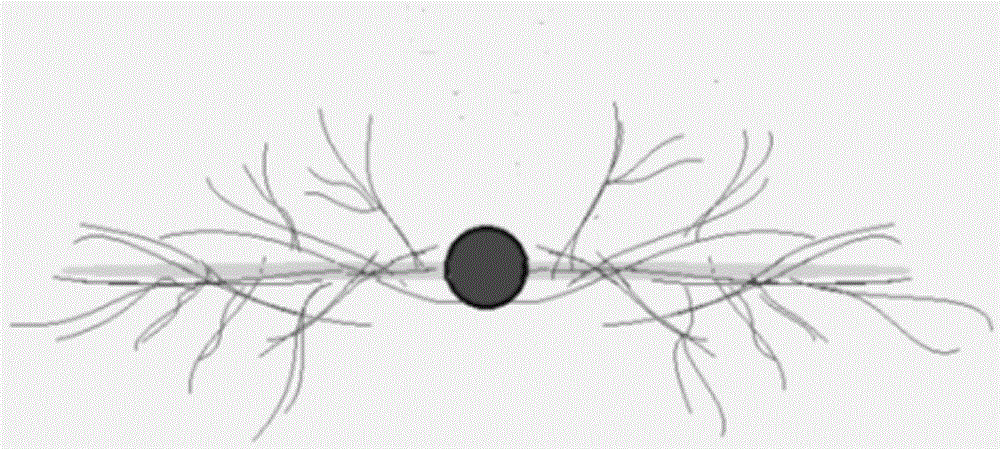

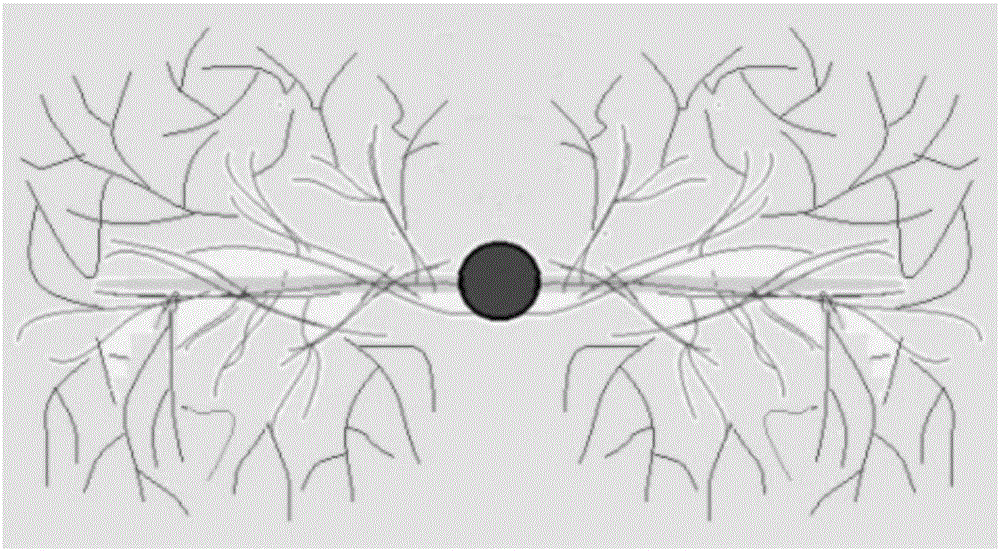

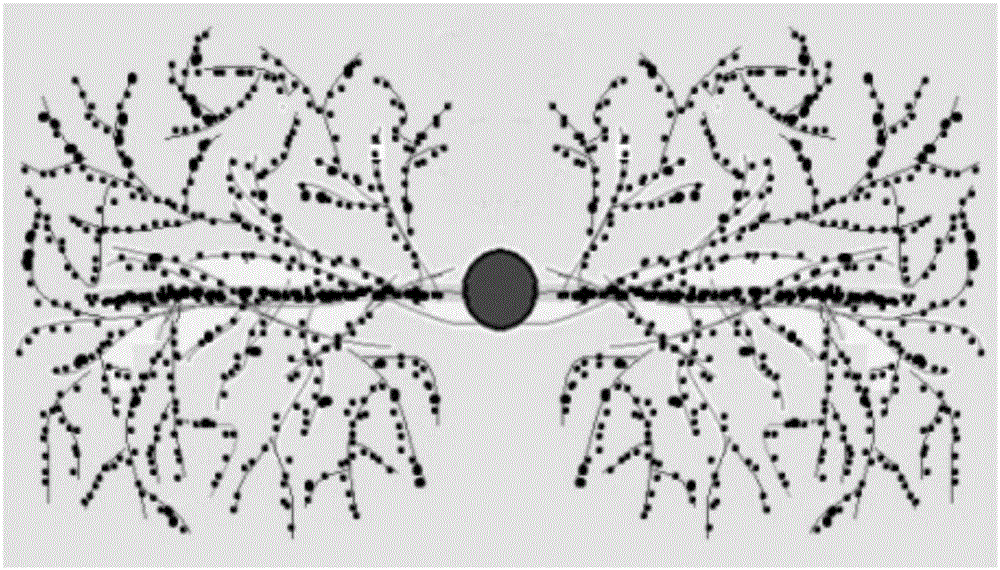

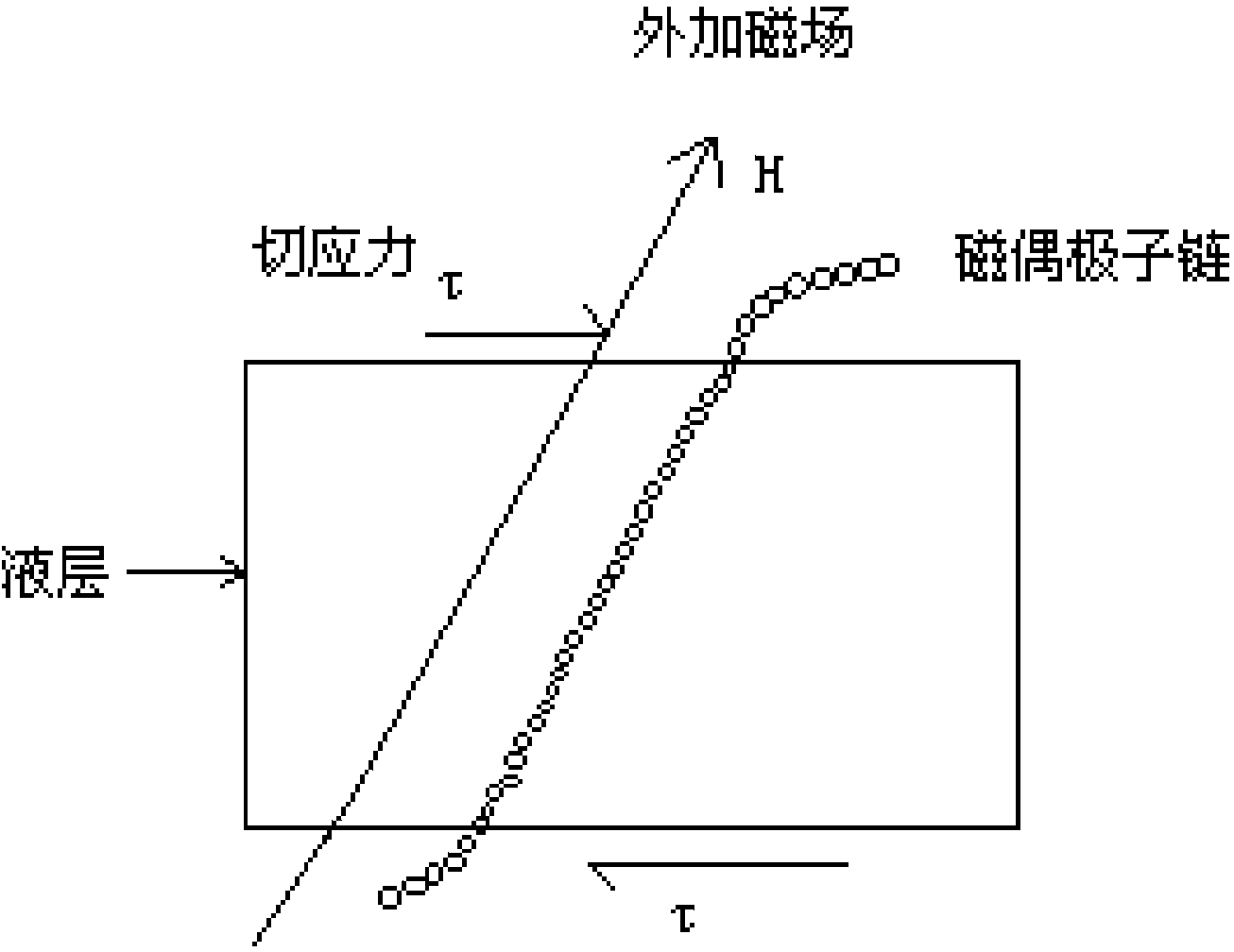

Magnetorheological fluid-based oil-gas well temporary plugging agent as well as preparation method and application thereof

ActiveCN103834375ASimple preparation processEasy to realize industrial productionDrilling compositionSealing/packingMagnetorheological fluidBase oil

The invention relates to a magnetorheological fluid-based oil-gas well temporary plugging agent as well as a preparation method and an application thereof. The temporary plugging agent is prepared from carbonyl iron powder modified by a surface modifier as magnetic particles and white oil as a carrier liquid. The invention also provides a preparation method and an application of the temporary plugging agent. The temporary plugging agent disclosed by the invention is good in stability, friendly to environment, low in raw material, simple in preparation technology, and applicable to industrial production, and can be applied to the temporary plugging occasion in development and production processes of oil and gas fields.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

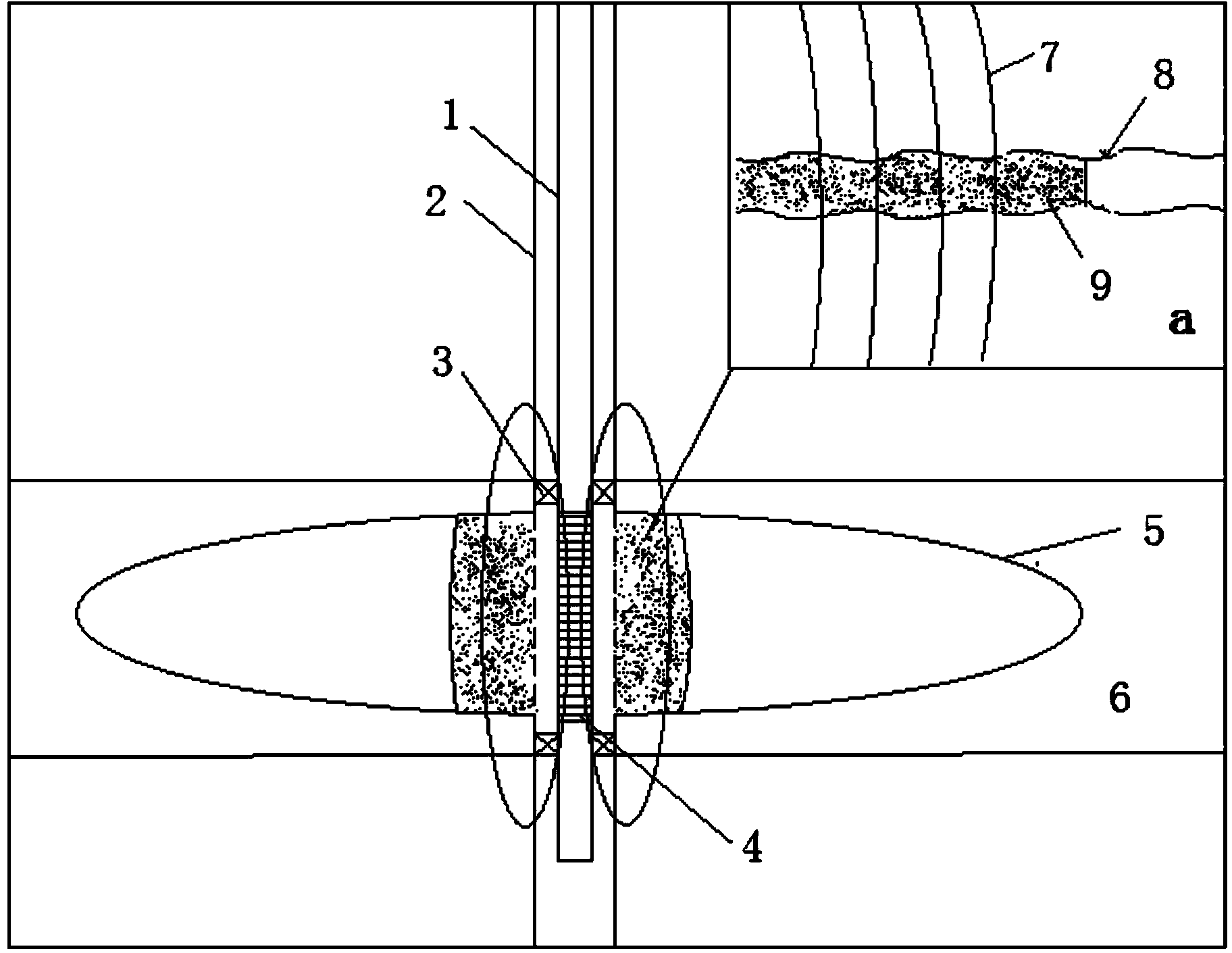

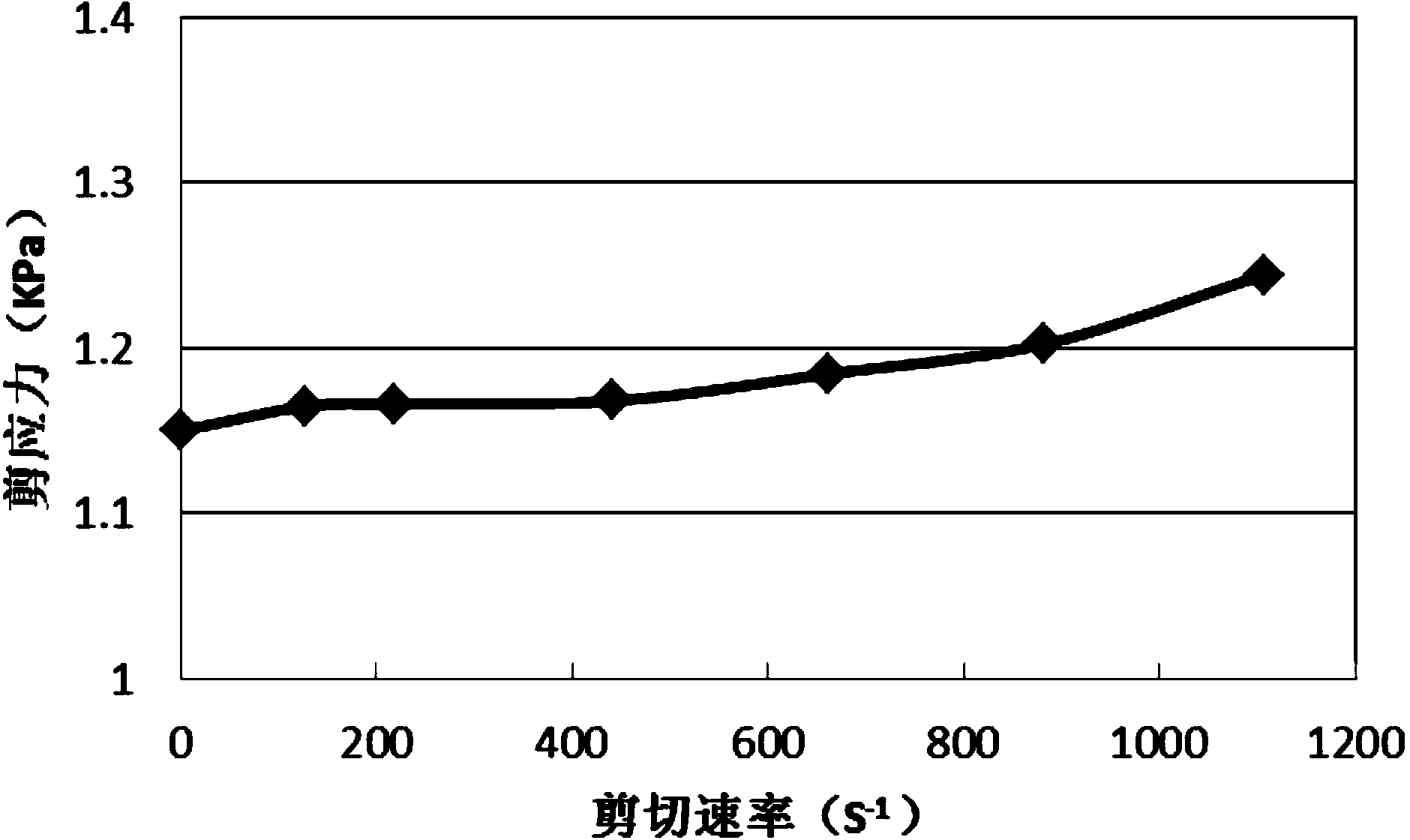

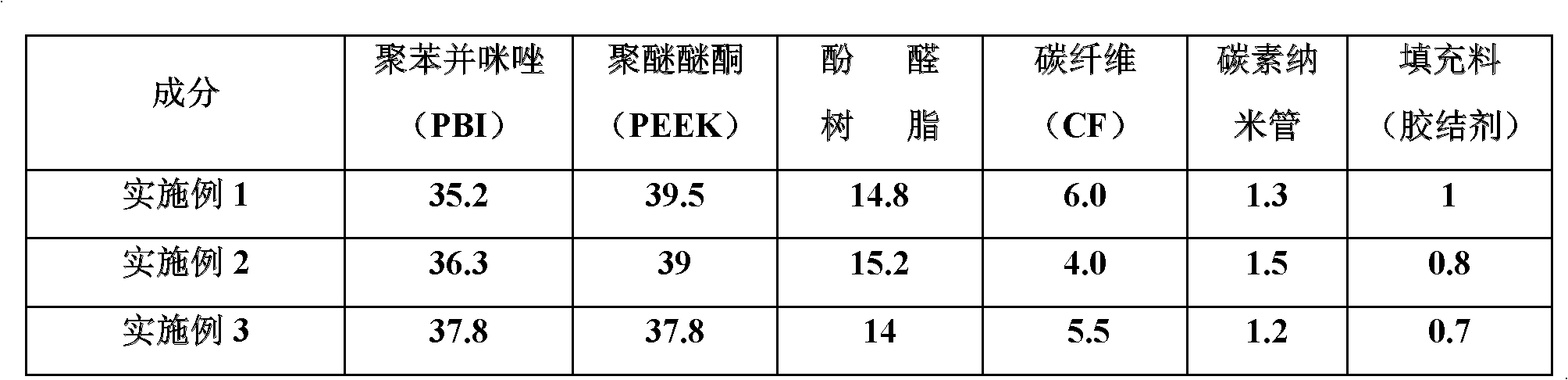

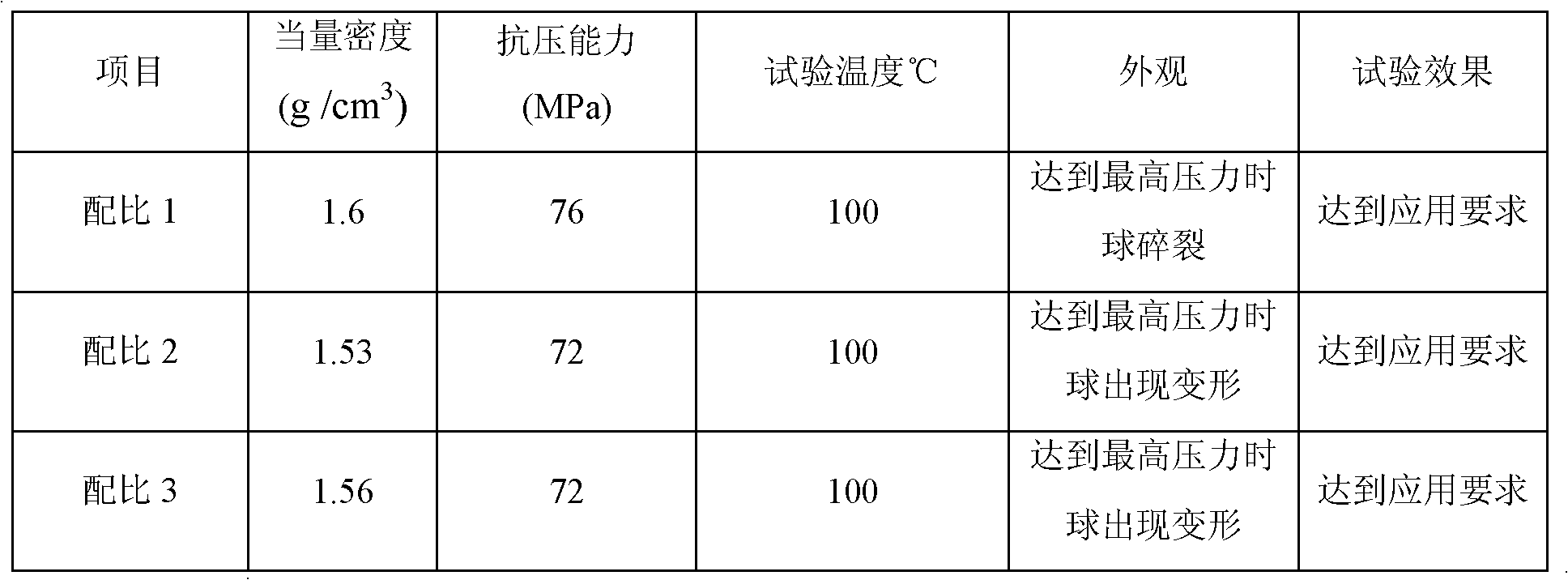

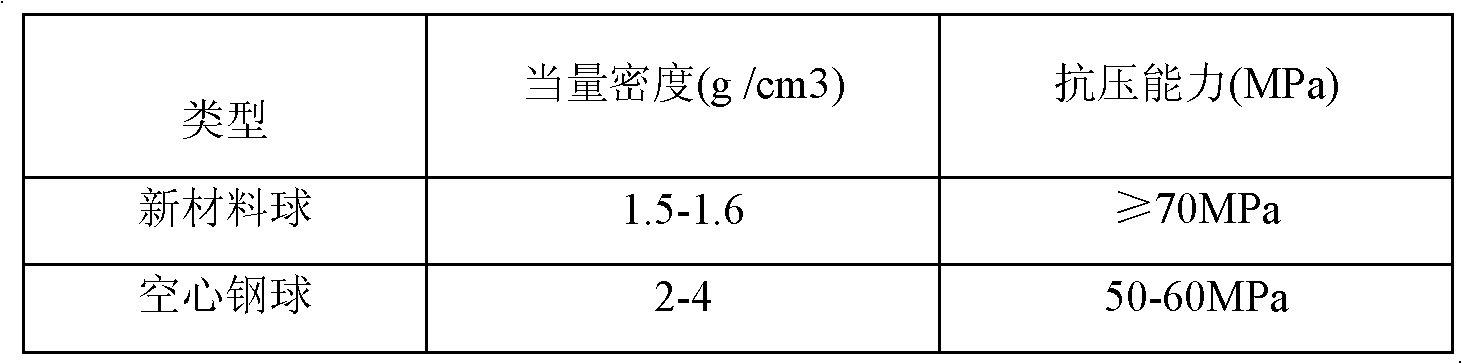

Novel material pressure-out ball used in staged fracturing pitching slide sleeve opening

The invention provides a novel material pressure-out ball for a multi-stage slide sleeve staged fracturing pitching opening-type slide sleeve. The novel material pressure-out ball employs main materials such as polybenzimidazole and polyetheretherketone. The main function of the pressure-out ball is that with the pressure-out ball, pressure-out sealing can be rapidly and reliably realized, pitching slide sleeve can be opened, and fracturing can be realized. The pressure-out ball has substantial characteristics that: (1) the density is low, wherein the density is 1.5-1.6g / cm<3>, such that the capacity of pressure-out ball for rapidly moving forward in a horizontal state can be improved, and backflow is easy; (2) a composite material with main components of polybenzimidazole and polyetheretherketone is adopted, such that a high impact strength is provided, and the abrasion of the pressure-out ball in a forward moving process is small, such that reliable sealing can be realized; (3) a pressure resistance is high, wherein as a result of experiments, no damage is caused under a high pressure of 70MPa; and (4) time is saved, and construction risk is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thickening agent used for water base fracturing fluid and synthetic method thereof

InactiveCN103059828ASuitable for production increase transformationGood sand carrying performanceDrilling compositionWater basedWater insoluble

The invention discloses a thickening agent which is provided with a branched chain structure and used for water base fracture. The thickening agent is composed of six monomers in a copolymerization mode. The six monomers comprise N, N-dimethyl acrylic amide (AAM), dimethyl diallyl ammonium chloride (DADMAC), acrylonitrile (AN), methacrylic acid (AA), 2-acrylic amide-2-methyl propane sulfonate (AMPS) and N-VINYL-2-pyrrolidone (PVN). Further disclosed is a preparation method of the thickening agent with the branched chain structure. Compared with the prior art, the thickening agent has the advantages of being low in residue, temperature resistant, prone to dissolution, anti-shearing and good in sand carrying property. The hyperbranched molecule fracturing fluid thickening agent completely solves the problems that vegetable glue fracturing fluid is high in damage and friction, general polymer fracturing liquid is not resistant to shear and incomplete in gel breaking, and the like. The thickening agent is not like vegetable glue which contains a large amount of water insoluble matters, completely dissolved in a fracturing liquid stock solution, basic zero in the water insoluble matters and free of containing solid phase composition. The obtained fracturing liquid stock solution is glittering, translucent and bright. After gel is broken, compared with a vegetable glue fracturing liquid system, contend of residue is greatly reduced. The thickening agent has the advantages of being less in residue content, low in use viscosity, good in sand carrying property, low in cost, convenient to flow back and the like.

Owner:NANTONG KEYI CHEM

Non-residue polymer fracturing fluid

InactiveCN104710973ABase fluid viscosityEnhanced sand carrying capacityDrilling compositionCross-linkPolymer science

The invention provides a non-residue polymer fracturing fluid. The system of the fracturing fluid comprises 0.15 to 0.45% of a polymer thickening agent, 0.2 to 0.4% of a cleanup additive, 0.01 to 0.08% of a gel breaker and 0.2 to 0.6% of a composite cross-linking agent, with the balance being water with a pH value of 6 to 7. A preparation method for the fracturing fluid comprising the following steps: adding the polymer thickening agent into the water; then adding the cleanup additive, the gel breaker and the composite cross-linking agent; and carrying out uniform mixing under stirring so as to obtain the fracturing fluid. According to the invention, a polymer is used as the thickening agent and is reacted with the composite cross-linking agent to form a gel; the system carries sand in virtue of the gel; after the gel is broken with the gel breaker, the fracturing fluid has a non-residue characteristic similar to the non-residue characteristic of a clean fracturing fluid; and the fracturing fluid is especially applicable to fracturing transformation of low-permeability and ultralow-permeability reservoir strata.

Owner:NORTHWEST UNIV(CN) +1

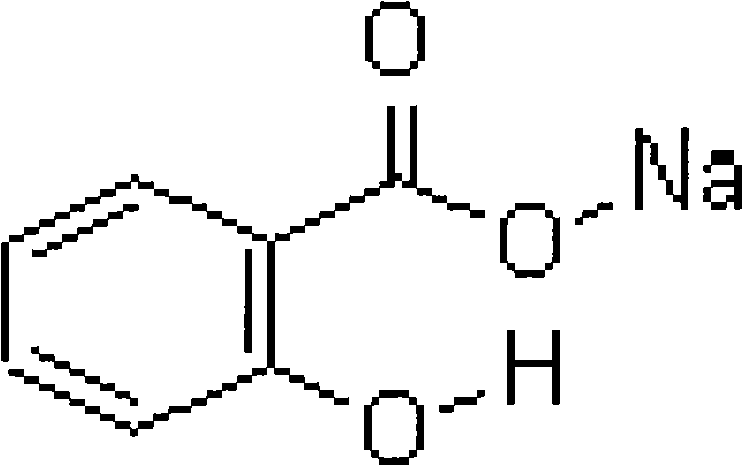

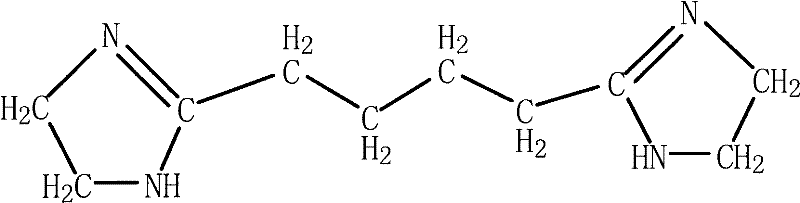

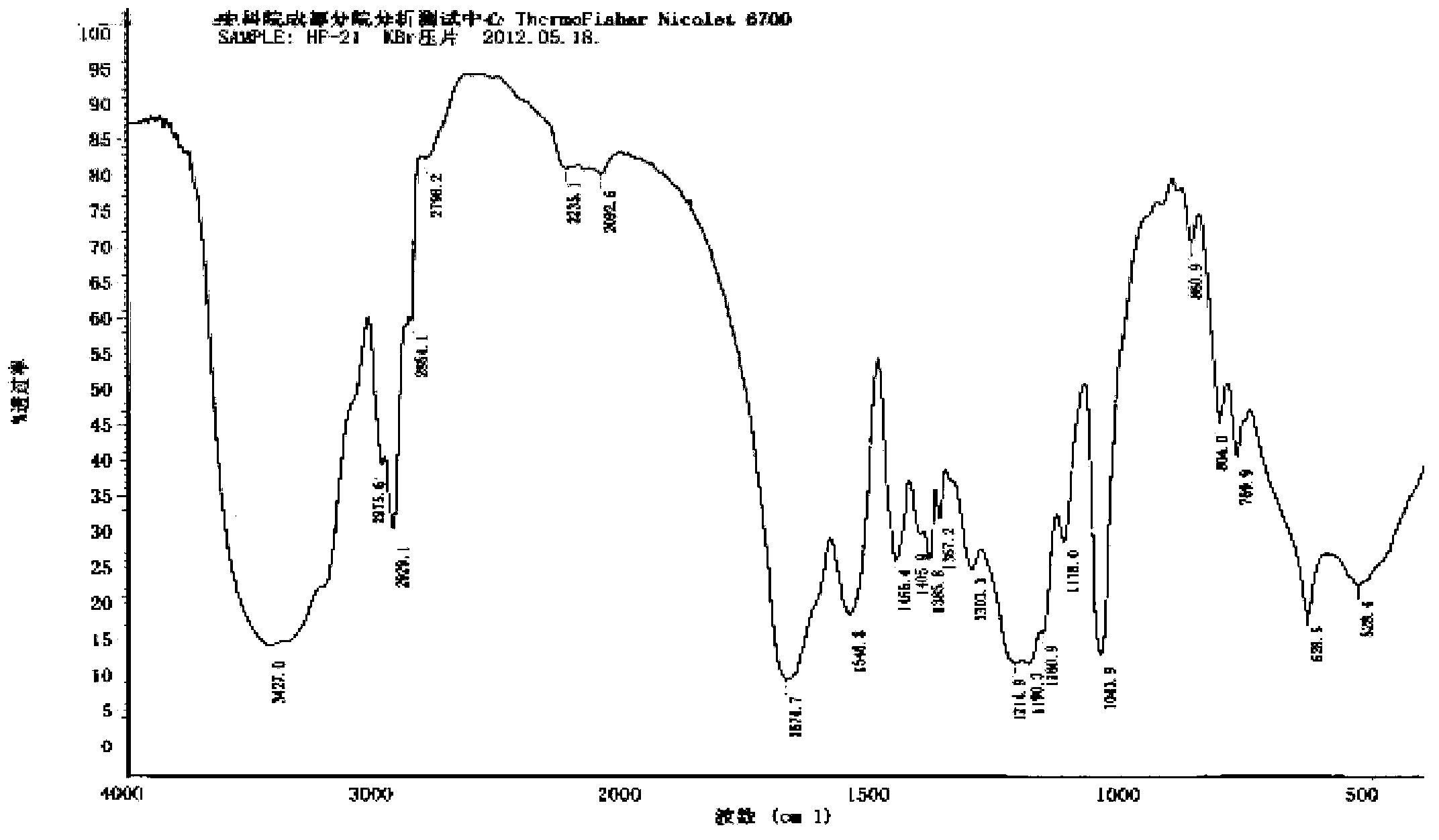

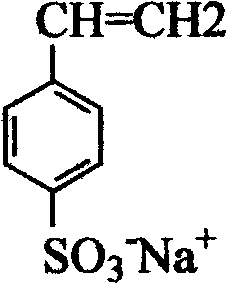

Sulfonic acid modified carboxymethyl hydroxypropyl guar gum, and preparation method and application thereof

ActiveCN103113486AImprove surface activityReduce surface activityDrilling compositionAlcoholAqueous sodium hydroxide

The invention relates to sulfonic acid modified carboxymethyl hydroxypropyl guar gum, and a preparation method and application thereof. The structural formula of the sulfonic acid modified carboxymethyl hydroxypropyl guar gum is shown in the specification, wherein R is H, and n is 0, 1, 2 or 3; or R is OH, and n is 0-6. The preparation method comprises the following steps: adding carboxymethyl hydroxypropyl guar gum into a reaction vessel, and adding an alcohol water solution; in a nitrogen atmosphere, dropwisely adding a sodium hydroxide water solution, heating to 65-80 DEG C while stirring, dropwisely adding a sulfonating agent, and reacting for 3-10 hours; and regulating the pH value of the solution to 7 with acid, filtering, collecting solids, and drying to obtain light yellow powder, namely the sulfonic acid modified carboxymethyl hydroxypropyl guar gum. The prepared sulfonic acid modified carboxymethyl hydroxypropyl guar gum is high in thickening efficiency, low in surface / interface tension, easy to realize viscosity break and beneficial to flowback.

Owner:PETROCHINA CO LTD

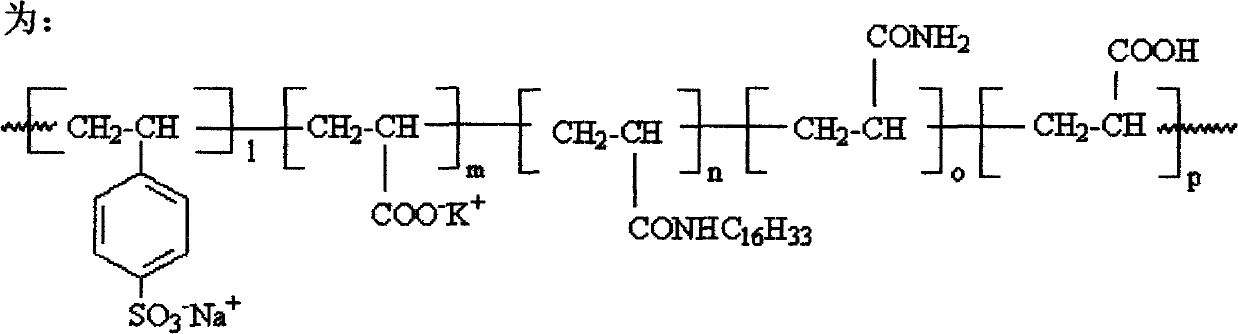

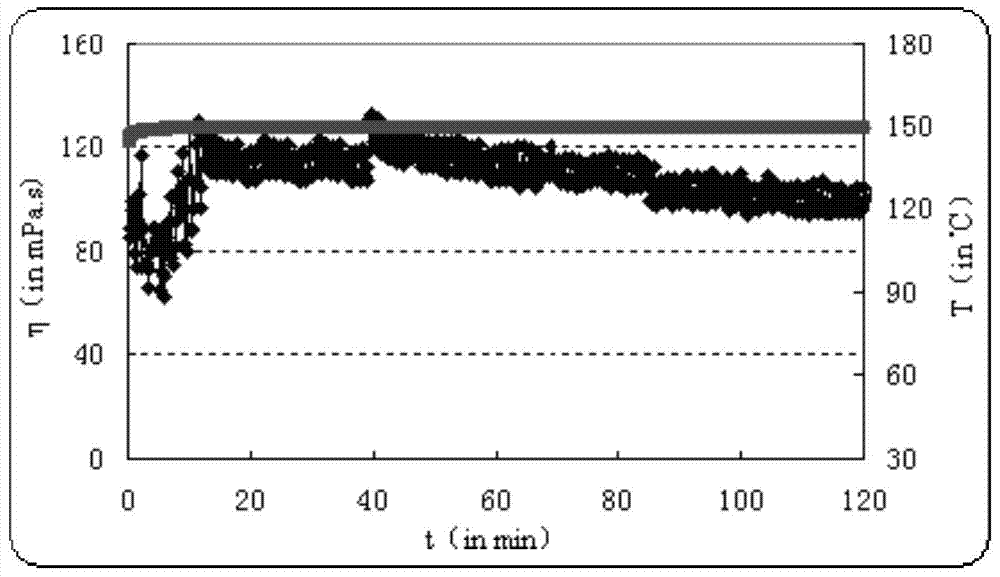

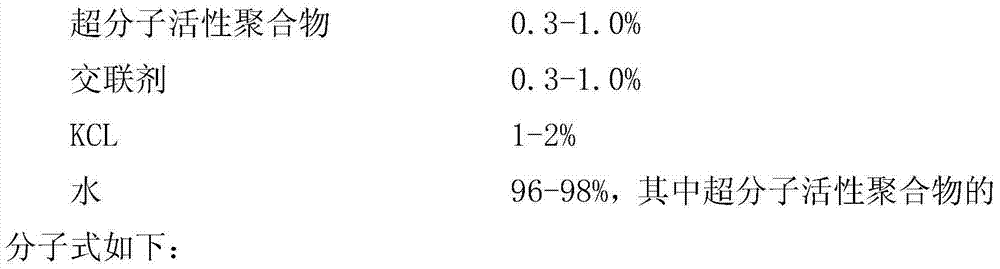

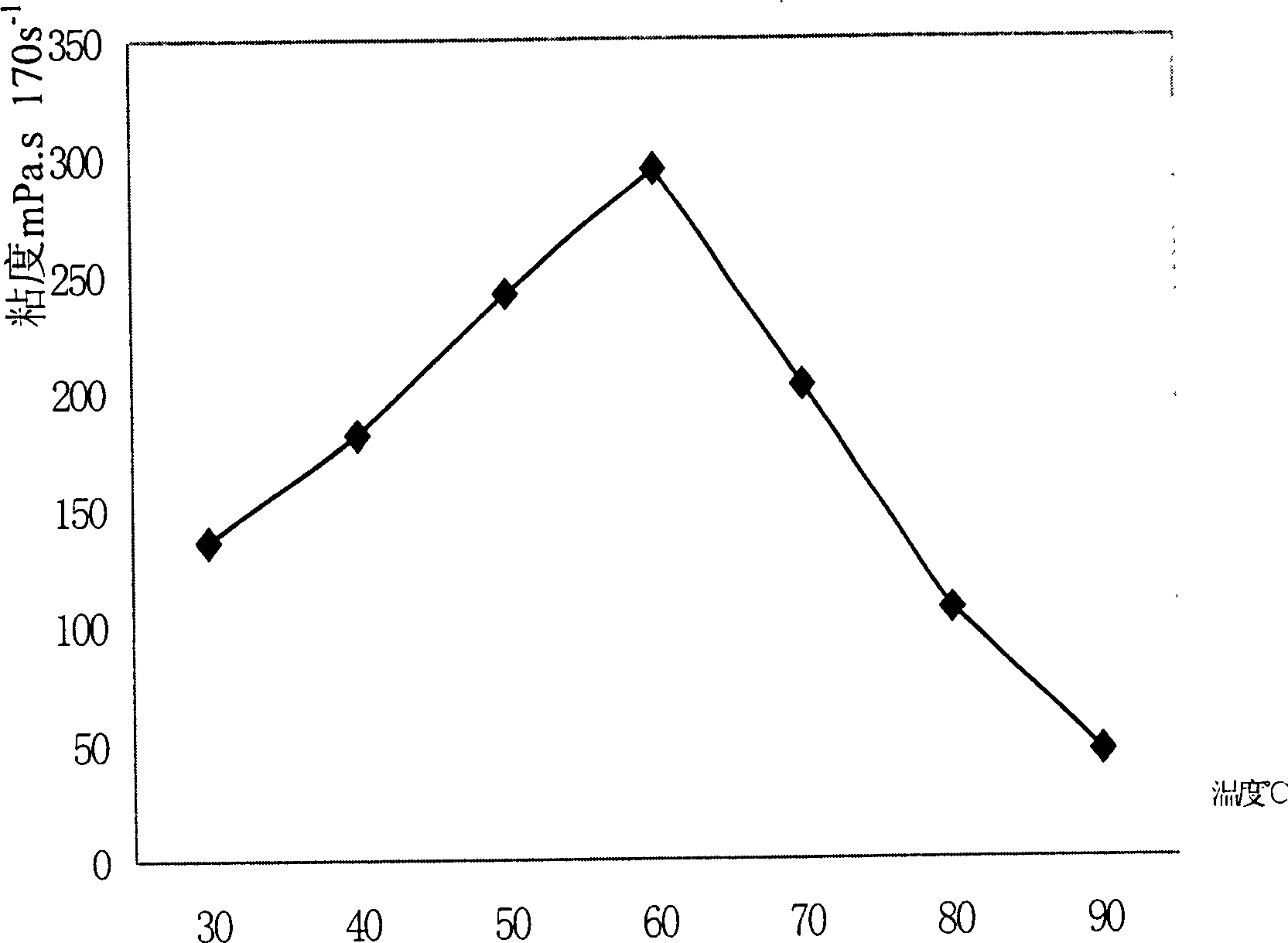

Supramolecular multi-copolymer type clean fracturing fluid

The invention discloses a supramolecular multi-copolymer type clean fracturing fluid. The supramolecular multi-copolymer type clean fracturing fluid comprises the following components in percentage by mass: 0.3-1.0% of supramolecular active polymer, 0.3-1.0% of cross-linking agent, 1-2% of KCL and 96-98% of water, wherein the molecular formula of the supramolecular active polymer is shown in the specification, R is C13-C21 straight chain or branched chain alkyl, n is an integer of 3-6 and p is an integer of 2-4. The fracturing fluid disclosed by the invention has the characteristics of high-temperature resistance, safety and environmental friendliness.

Owner:四川安东油气工程技术服务有限公司

Oil-based liquid-state fracturing fluid thickening agent, and preparation method thereof

ActiveCN103911136ADoes not affect outputDoes not affect structureDrilling compositionLiquid stateFracturing fluid

The invention discloses an oil-based liquid-state fracturing fluid thickening agent, and preparation method thereof. Density of the oil-based liquid-state fracturing fluid thickening agent ranges from 0.9 to 1.2g / cm<3>; gelling time is 20s or less; and viscosity of 1.2% of the oil-based liquid-state fracturing fluid thickening agent after dissolving is 30mPa.s or more. The invention also discloses a preparation method of the oil-based liquid-state fracturing fluid thickening agent.

Owner:北京爱普聚合科技有限公司

Method for preparing residue free fracturing fluid

InactiveCN1285700CMeet the needs of fracturing constructionAvoid harmFluid removalDrilling compositionFluid viscosityFracturing fluid

The present invention relates to a kind of fracturing fluid used in oil and gas field development process, fracturing stimulation measures, the present invention provides an effective method, that is to use unsaturated fatty acid salt with 18 carbon atoms mixed with brine or 18 A fatty acid with 2 carbon atoms, an inorganic base, and brine are mixed. In the brine, the fatty acid salt increases the fluid viscosity and viscoelasticity due to the formation of highly entangled rod-shaped micelles, so as to meet the viscosity requirements of the fracturing fluid. The viscosity of this fracturing fluid depends on the nature of the micelles, which can be disrupted by changing the structure of the micelles. When the fracturing fluid encounters hydrocarbons or is diluted by formation water, it will break the gel without residue, so as to solve the problem of vegetable glue fracturing fluid residues and reduce the impact of residues on the permeability of the fracturing fracture support zone and the formation The damage caused by permeability can improve the stimulation effect of fracturing. At the same time, it provides a new way for fracturing fluid preparation.

Owner:DAGANG OIL FIELD GRP +2

Natural water fracturing construction method

The invention provides a natural water fracturing construction method for petroleum, natural gas, shale gas, water and other fluid mineral products. 5-60 parts by volume of self-suspension fracturing propping agent is added into 100 parts by volume of natural water to form a propping agent suspension fluid, and then the propping agent suspension fluid is delivered into an underground rock formation. According to the natural water fracturing construction method, an expensive fracturing fluid added with organic polymers is not needed in fracturing, and natural water which can be obtained anywhere is directly used for fracturing. Therefore, pollution is reduced, and cost is reduced. The self-suspension fracturing propping agent adopted in the natural water fracturing construction method is long in suspension time in clear water and can better meet the oil or gas extraction demand. The self-suspension fracturing propping agent can reduce the friction of the fracturing fluid, so that a fracturing propping system adopting the natural water fracturing construction method and an existing fracturing fluid have basic same performance, delivery and flow-back are easy.

Owner:BEIJING RECHSAND SCI & TECH GRP

Inverse-phase micro-emulsion polymer fracturing fluid system with online construction function

ActiveCN108559479AGood resistance reduction effectEasy to reuseDrilling compositionMethacrylatePolymer science

The invention discloses an inverse-phase micro-emulsion polymer fracturing fluid system with an online construction function. The inverse-phase micro-emulsion polymer fracturing fluid system comprisesinstant dissolving emulsion thickening agents, functional auxiliaries, a clay stabilizer and fluid preparation water. The instant dissolving emulsion thickening agents are inverse-phase micro-emulsion polymers, and inverse-phase micro-emulsion polymerization is carried out on raw materials including acrylamide, acrylic acid, strong-hydrophilicity monomers, a functional monomer A, a functional monomer B, pH (potential of hydrogen) regulators, solubilizers, composite emulsifiers, oil solvents, initiators and deionized water to obtain the instant dissolving emulsion thickening agents; the functional monomer A is methyl methacrylate or ethyl methacrylate or a mixture of the methyl methacrylate and the ethyl methacrylate; the functional monomer B is vinylphosphonic acid or vinyl sulfonic acid;the functional auxiliaries are non-ionic surfactants; the clay stabilizer is potassium chloride, and the fluid preparation water is clear water or high-mineralization water or treated stratum flow-back fluid. The inverse-phase micro-emulsion polymer fracturing fluid system has the advantages that the inverse-phase micro-emulsion polymer fracturing fluid system is high in dispersing and swelling speed and can be prepared in a batch manner or can be continuously mixed, 'online construction' requirements even can be completely met by the inverse-phase micro-emulsion polymer fracturing fluid system, processes for constructing the inverse-phase micro-emulsion polymer fracturing fluid system are simple, and the fracturing cost can be reduced.

Owner:SOUTHWEST PETROLEUM UNIV +1

Preparation and application of anionic clean fracturing liquid and gel breaker thereof

InactiveCN106566521AGood effectGood sand carryingFluid removalDrilling compositionFracturing fluidSURFACTANT BLEND

The invention relates to the technical field of oil filed fracturing, and specifically relates to an anionic clean fracturing liquid, which is composed of 0.5 to 10% of anionic surfactant, 5 to 20% of counter-ion salts, and the balance being water. The provided clean fracturing liquid preserves all advantages of conventional clean fracturing liquids. The species of additives can be reduced and the requirements on liquid blending equipment can be lowered by using the clean fracturing liquid. The fracturing liquid can be used in oil fields with a high mineralization degree. The gel breaking time can be well controlled by using a gel breaker and the cost is reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

Carbon dioxide anhydrous sand fracturing method

ActiveCN108825194AHigh viscosityImprove sand carrying capacityFluid removalFracturing fluidPressure balance

The invention provides a carbon dioxide anhydrous sand fracturing method. The method comprises the following steps that (1) a gas well and a reservoir which are subjected to carbon dioxide anhydrous sand fracturing are selected; (2) fracturing for fracture forming is carried out, specifically, carbon dioxide is injected into an oil pipe and oil sleeve annulus at the same time, wherein the injection displacement of carbon dioxide prepad is greater than the injection displacement of carbon dioxide in the oil pipe; (3) a gap of a fracturing crack is filled, specifically, a carbon dioxide sand-carrying solution and a viscosity increasing agent are injected into the oil sleeve annulus; and (4) sand stopping and displacing are carried out. Carbon dioxide is simultaneously injected into the oil pipe and the oil sleeve annulus, and pressure balance is achieved; the viscosity increasing agent is added, so that the viscosity and the sand carrying performance of the carbon dioxide are improved, carbon dioxide anhydrous sand fracturing is realized, and the method has the characteristics of small damage to the reservoir, crack filling with a propping agent, and good crack morphology and stability. According to the method, few additives are used, so that the damage and pollution to the environment and the stratum are reduced, and the cost of fracturing fluid is greatly reduced; and carbon dioxide can adsorb and replace natural gas on rock walls, so that the yield of natural gas is improved.

Owner:PETROCHINA CO LTD

Gelled fracturing fluid being applicable to coalbed methane reservoir

ActiveCN101805600ALow priceFast cross-linking at low temperatureDrilling compositionSulfite saltMass ratio

The invention discloses a gelled fracturing fluid being applicable to coalbed methane reservoir, which consists of 0.3 to 0.5 percent of non-ionic polyacrylamide and 0.014 to 0.04 percent of zirconium oxychloride (ZrOCl12) which are used as cross-linking agent, 0.01 to 0.12 percent of hydrochloric acid which is used as pH adjusting agent, 0.06 to 0.12 percent of gelbreaker and surplus water, wherein the gelbreaker is of a redox system which is formed by ammonium persulfate and sodium sulfite according to the mass ratio of (1.0 to 3.0): 1. With the gelbreaker, the gel can be broken under the low-temperature condition. The gelation time and the gel-breaking time of the gelled fracturing fluid are adjustable. The gelled fracturing fluid has the advantages of fast low-temperature cross-linking sped, large viscosity, low filter loss, thorough breaking, no residual slag of gelled fracturing liquid and easy flowback, and can effectively improve the yield of the coalbed methane.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Oil and water well polyacid blocking remover

InactiveCN105482801AFix damagePrevent contamination from cloggingDrilling compositionCalcium in biologySilicic acid

The invention relates to an oil and water well polyacid blocking remover. The blocking remover comprises 10-15% of hydrochloric acid, 6-8% of fluoroboric acid, 12-15% of modified silicic acid, 1-2% of anti-swelling agent, 1-2% of an iron ion stabilizer, 1-2% of a demulsifying cleanup additive, 1-2% of a water damage treatment agent, 2-4% of a corrosion inhibitor, 6-8% of a precipitation inhibitor, and the balance of water. Inorganic acids in the blocking remover are hydrochloric acid and fluoroboric acid, and hydrochloric acid can corrode the calcareous components of reservoir; and fluoroboric acid can corrode solid phase components, and has a loose sandstone bonding effect. An organic acid in the blocking remover is modified silicic acid, and can solve organic obstruction in a drilling fluid. The blocking remover can solve the problems of loose sandstone reservoir mud and drilling fluid pollution and obstruction and low corrosion rate of low-permeability reservoir acid solution blocking removers of present oil wells, and also has a low skeleton corrosion effect.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com