Patents

Literature

83 results about "Vinylphosphonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vinylphosphonic acid is an organophosphorus compound with the formula C₂H₃PO₃H₂. It is a colorless, low-melting solid although commercial samples are often yellowish viscous liquids. It is used to prepare adhesives. As in other phosphonic acids, the phosphorus center is tetrahedral, being bonded to an organic group (vinyl in this case), two OH groups, and an oxygen.

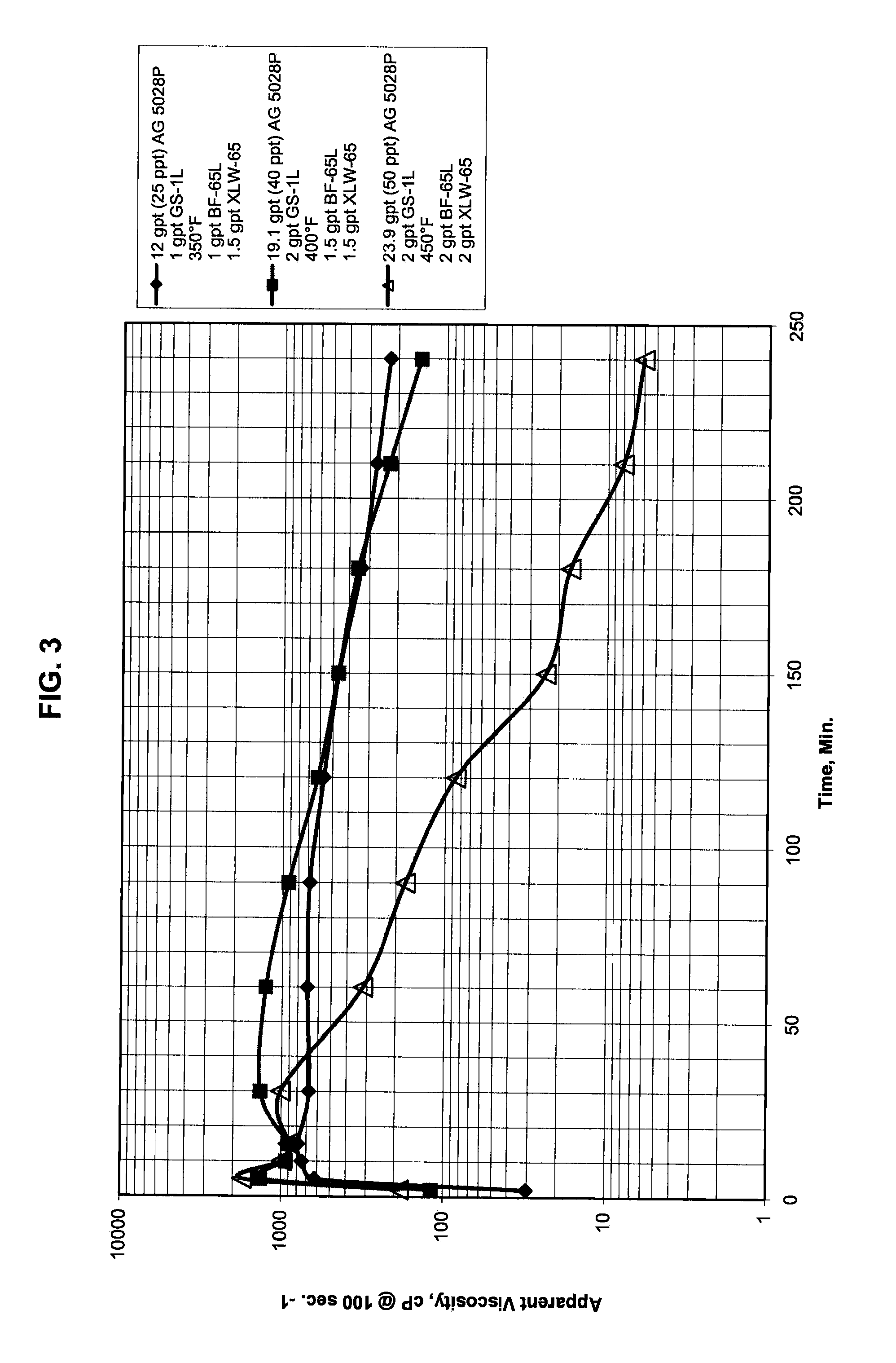

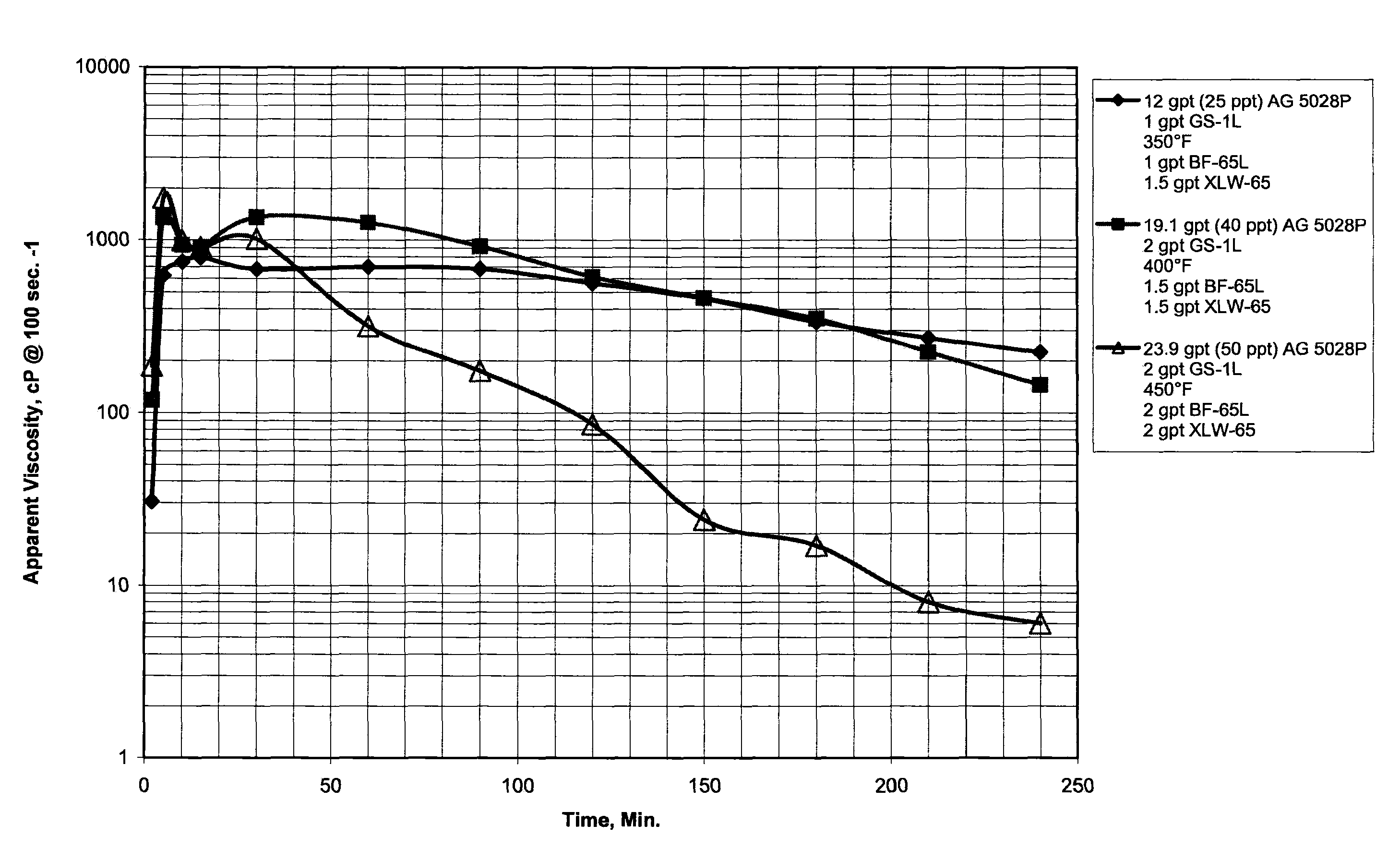

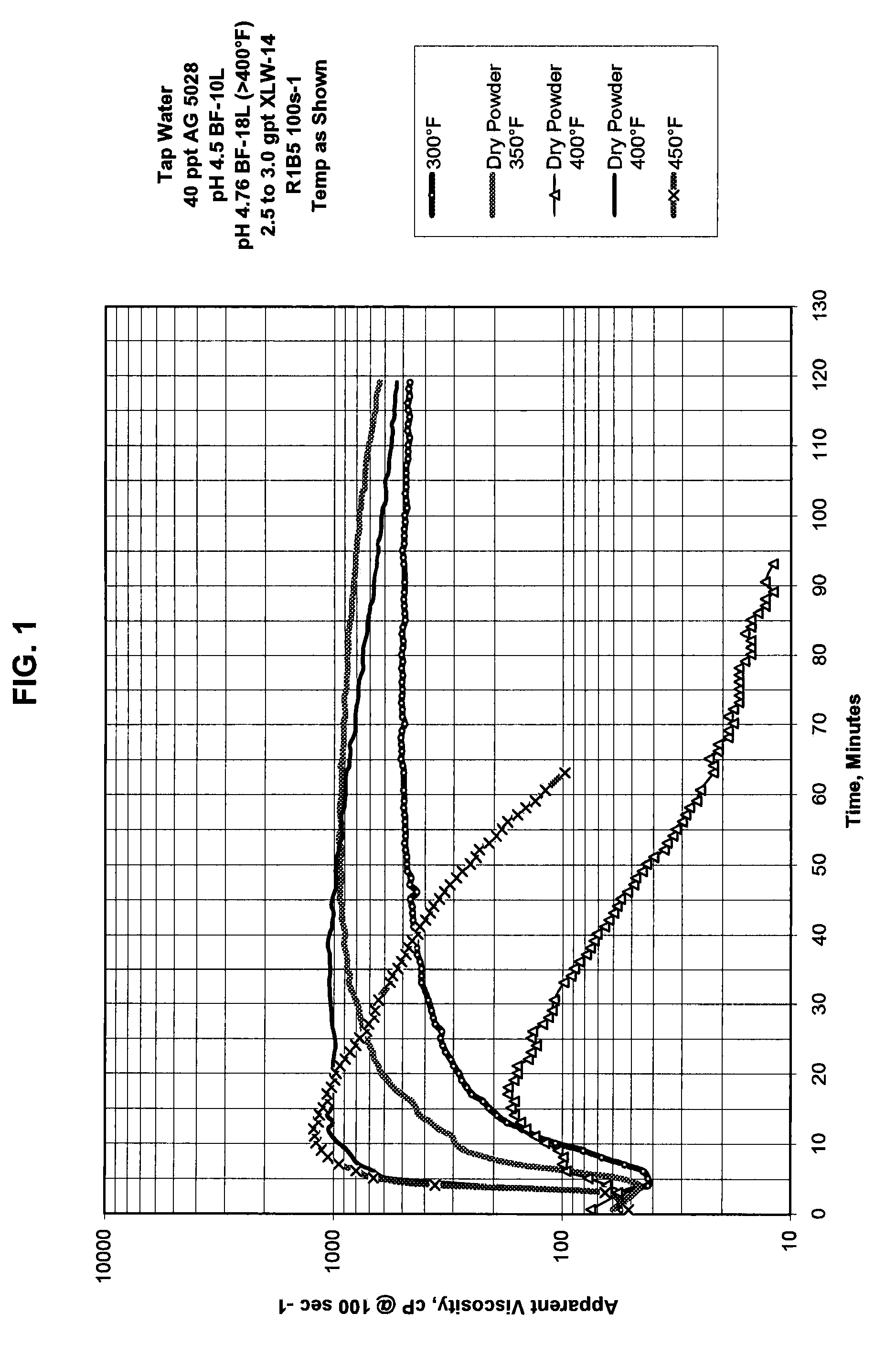

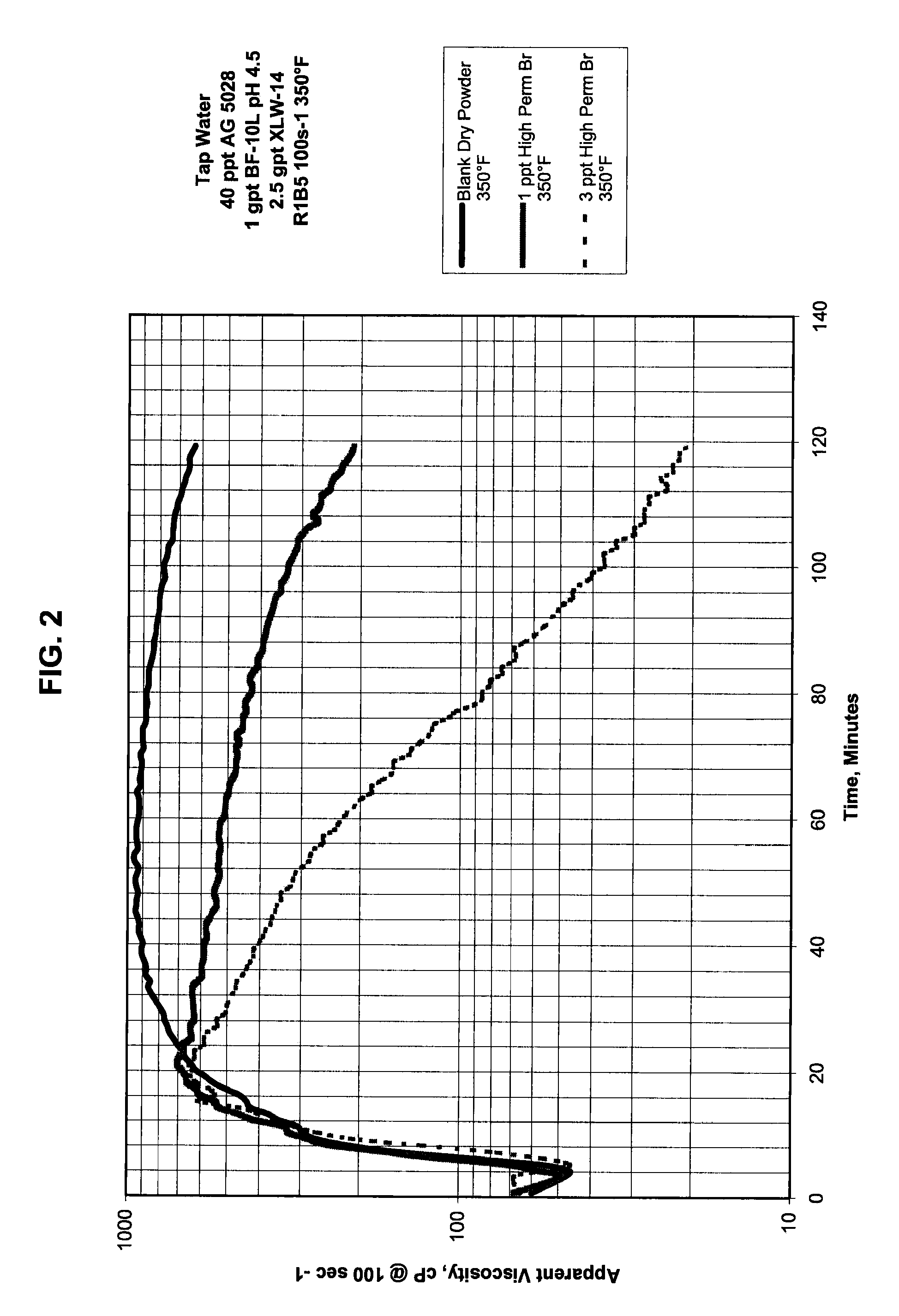

Compositions and Methods of Treating High Temperature Subterranean Formations

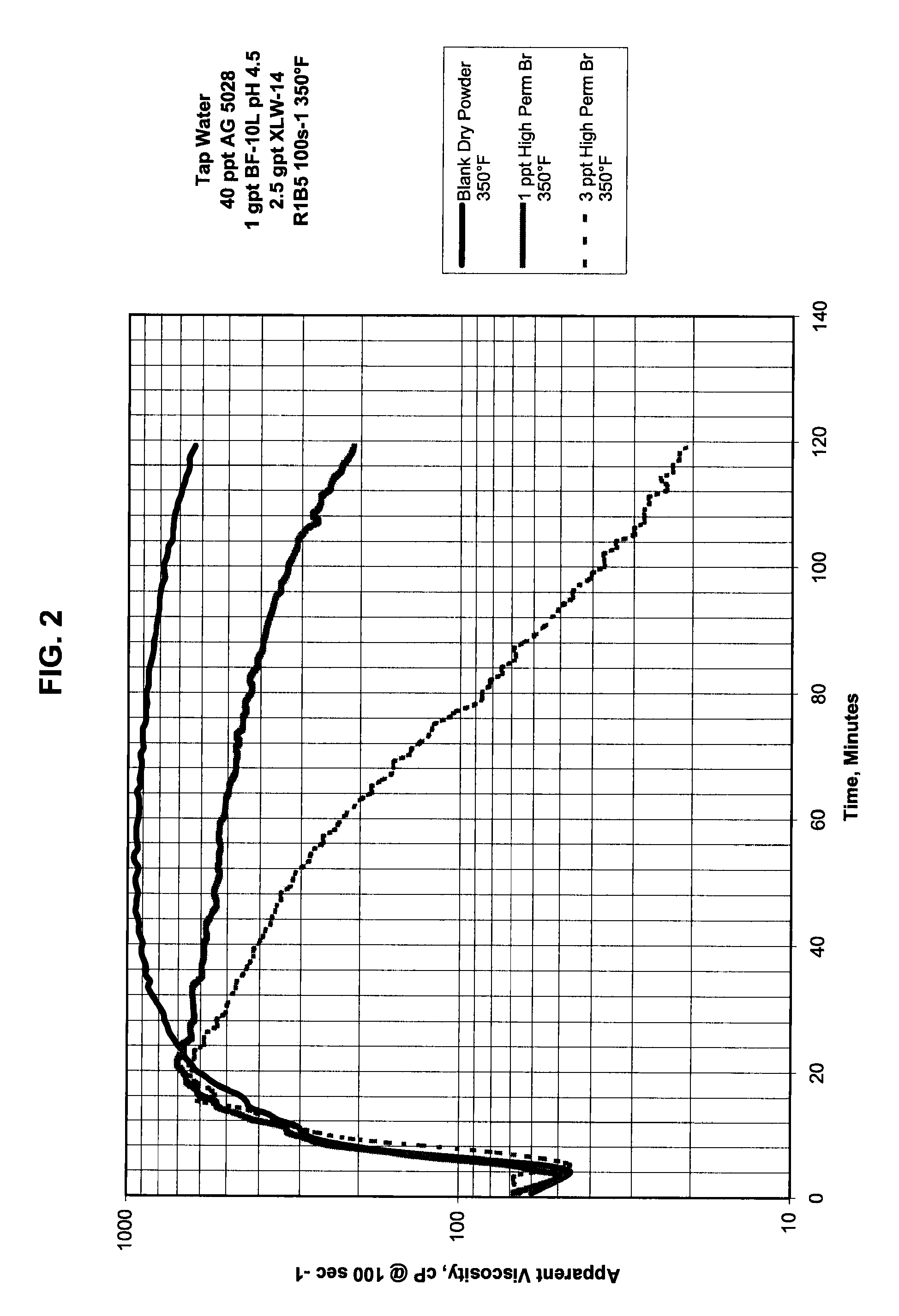

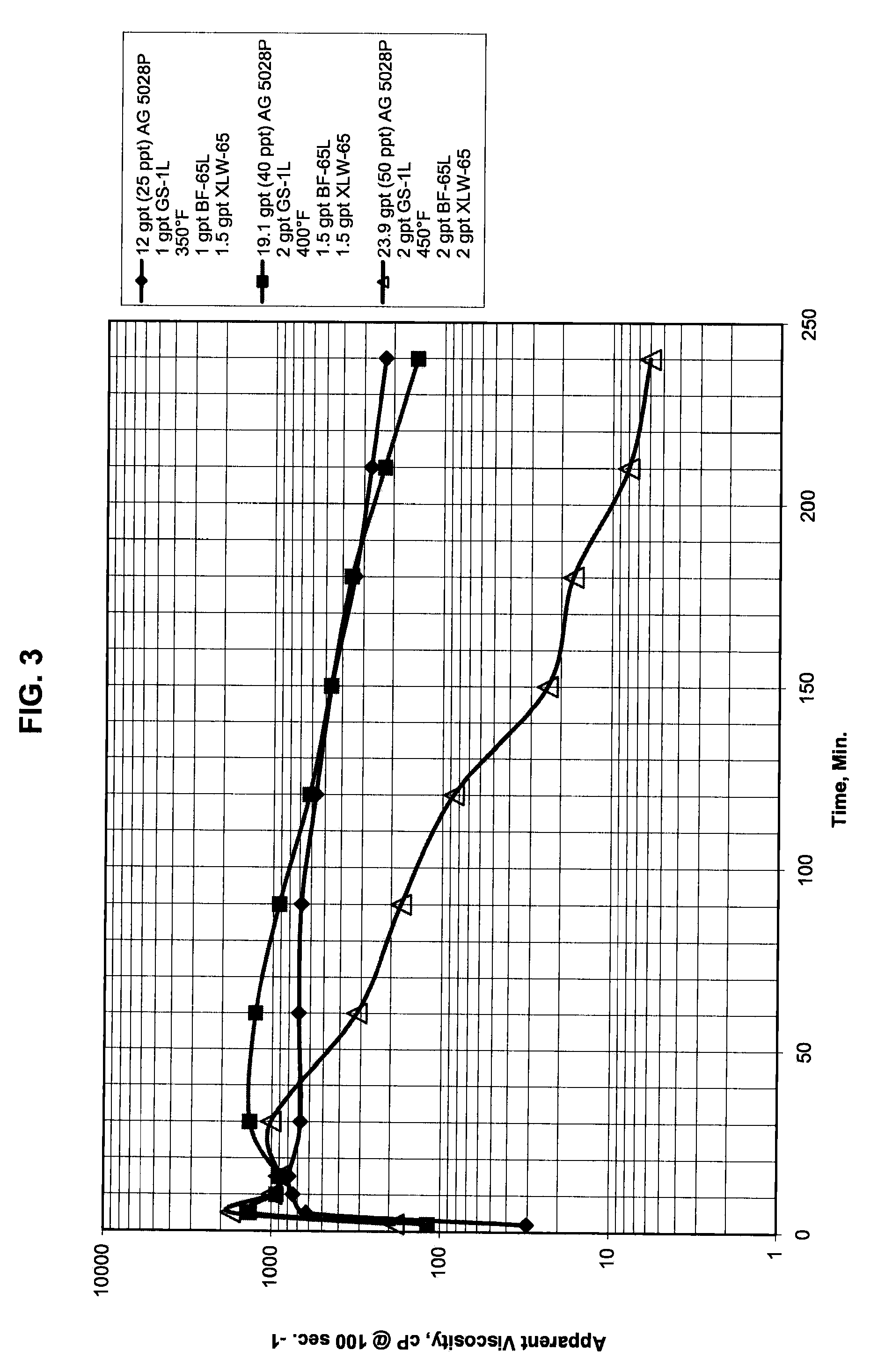

Well treatment fluids and methods of treating high temperature subterranean formations of up to about 500° F. (260° C.) are provided. The well treatment fluids and methods utilize a high molecular weight synthetic copolymer and a pH buffer than maintains a pH in a range of about 4.5 to about 5.25 for the fluids. The high molecular weight synthetic copolymer is derived from acrylamide, acrylamidomethylpropanesulfonic acid, and vinyl phosphonates. The well treatment fluids may be energized or foamed.

Owner:BAKER HUGHES INC

Methods for treating a subterranean formation with a treatment fluid containing a gelling agent and subsequently breaking the gel with an oxidizer

A method is provided for treating a zone of a subterranean formation penetrated by a wellbore. The method includes a step of introducing a treatment fluid into a zone of a subterranean formation through the wellbore, wherein the treatment fluid comprises: (i) water; (ii) a gelling agent comprising a polymer grafted with a vinyl phosphonic acid or derivative thereof; and (iii) a crosslinking agent, and the step of subsequently introducing an oxidizer into a zone of a subterranean formation through the wellbore. According to another aspect the method includes a step of introducing a treatment fluid into a zone of a subterranean formation through the wellbore, wherein the treatment fluid comprises: (i) water; (ii) a gelling agent comprising a polymer grafted with a vinyl phosphonic acid or derivative thereof; and (iii) a magnesium oxide; and the step of: introducing an acid into the zone through the wellbore.

Owner:HALLIBURTON ENERGY SERVICES INC

Method of fracturing with phenothiazine stabilizer

Owner:BAKER HUGHES HLDG LLC

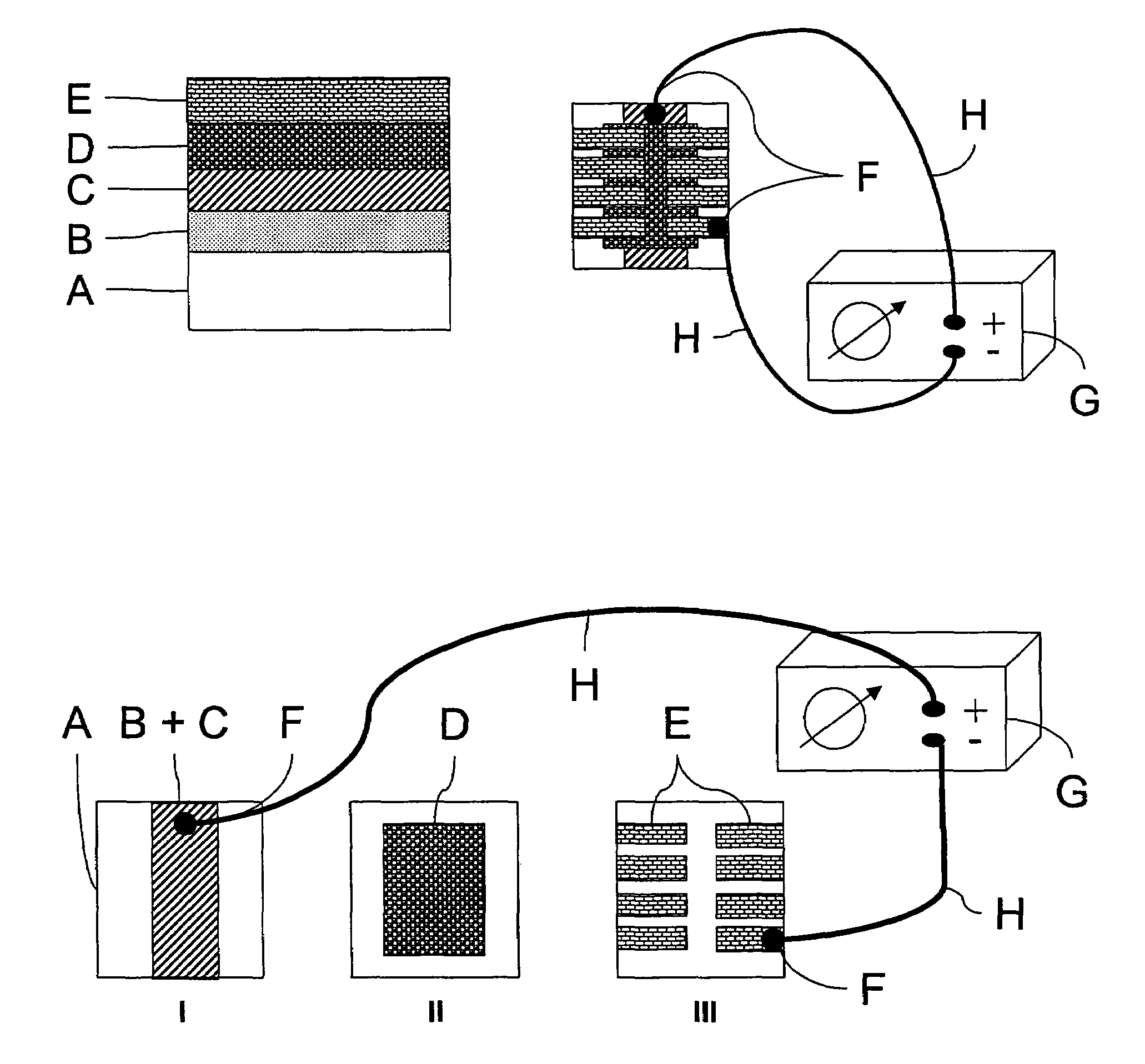

Layer configuration comprising an electron-blocking element

InactiveUS7307276B2Improve device performanceExtended service lifePV power plantsElectroluminescent light sourcesElectronBiomedical engineering

A layer configuration on a support, the layer configuration comprising a non-photoactive element exclusive of unsubstituted poly(3,4-alkylenedioxythiophene)s, the element containing at least one polymer selected from the group consisting of polycarboxy-polymers, optionally quaternized polyamine-polymers and poly(vinylphosphonic acid), the surface of one side of the element being contiguous with a positive electrode and the surface on the opposite side of the element being contiguous with a material capable of transporting holes.

Owner:AGFA GEVAERT AG

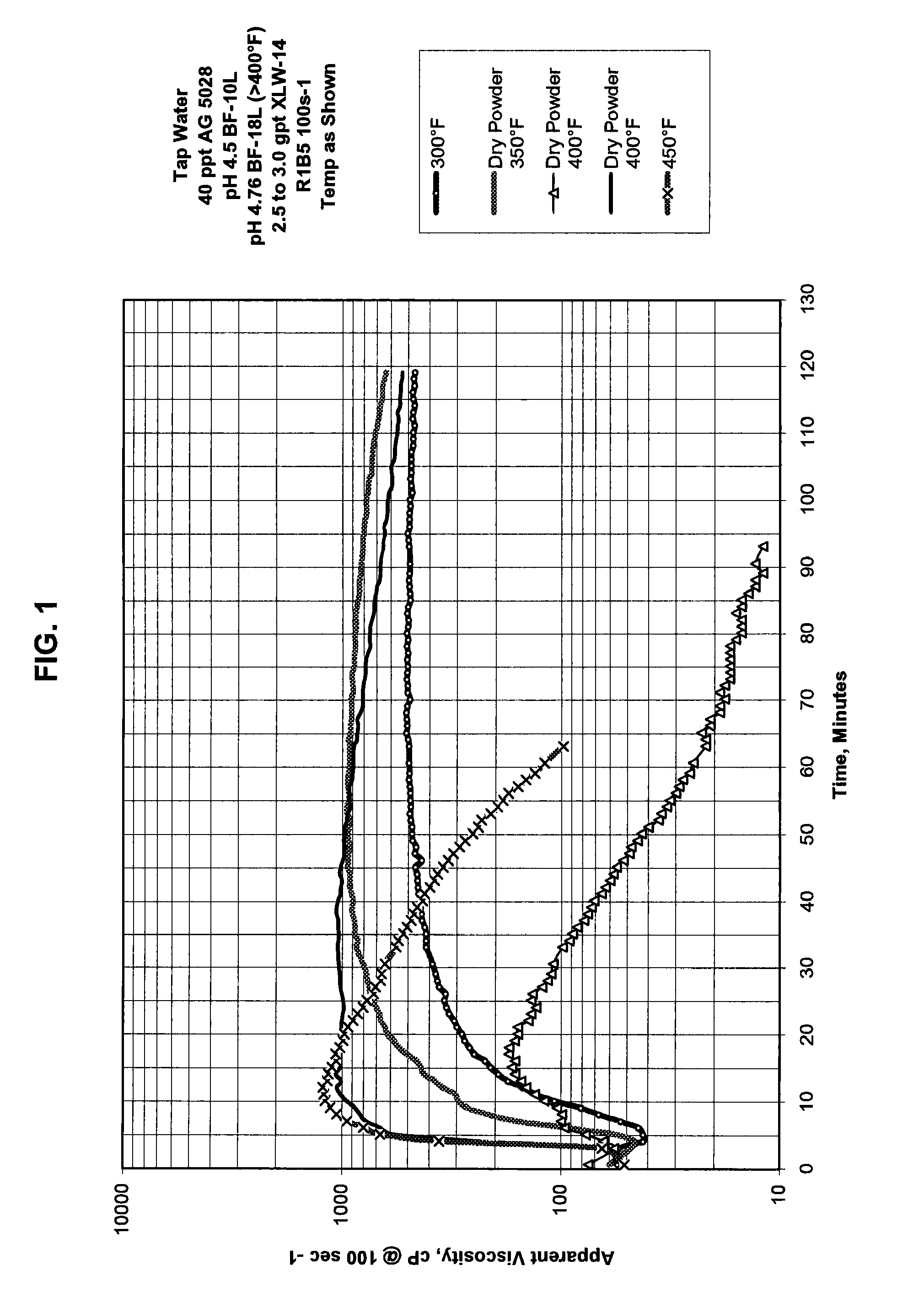

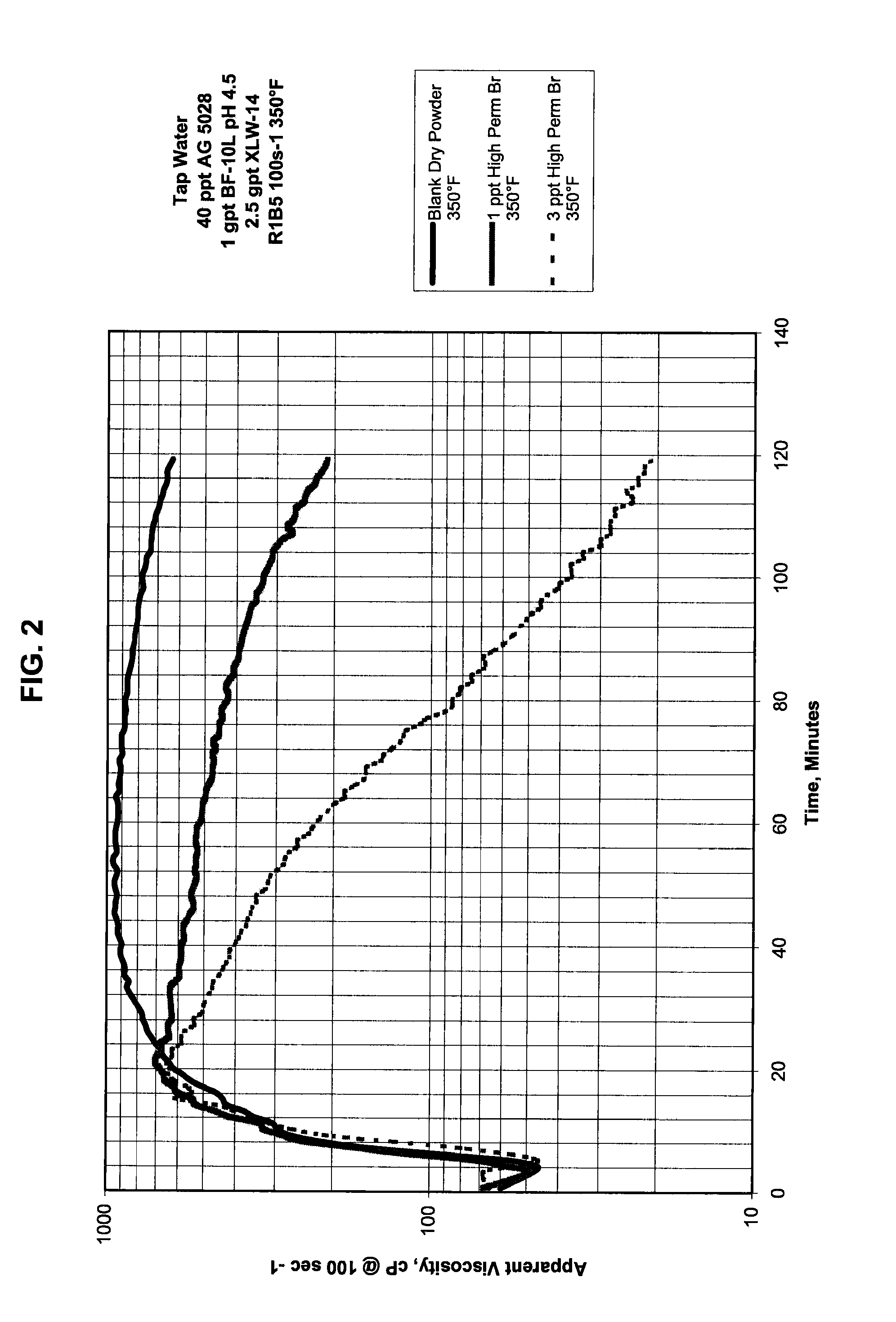

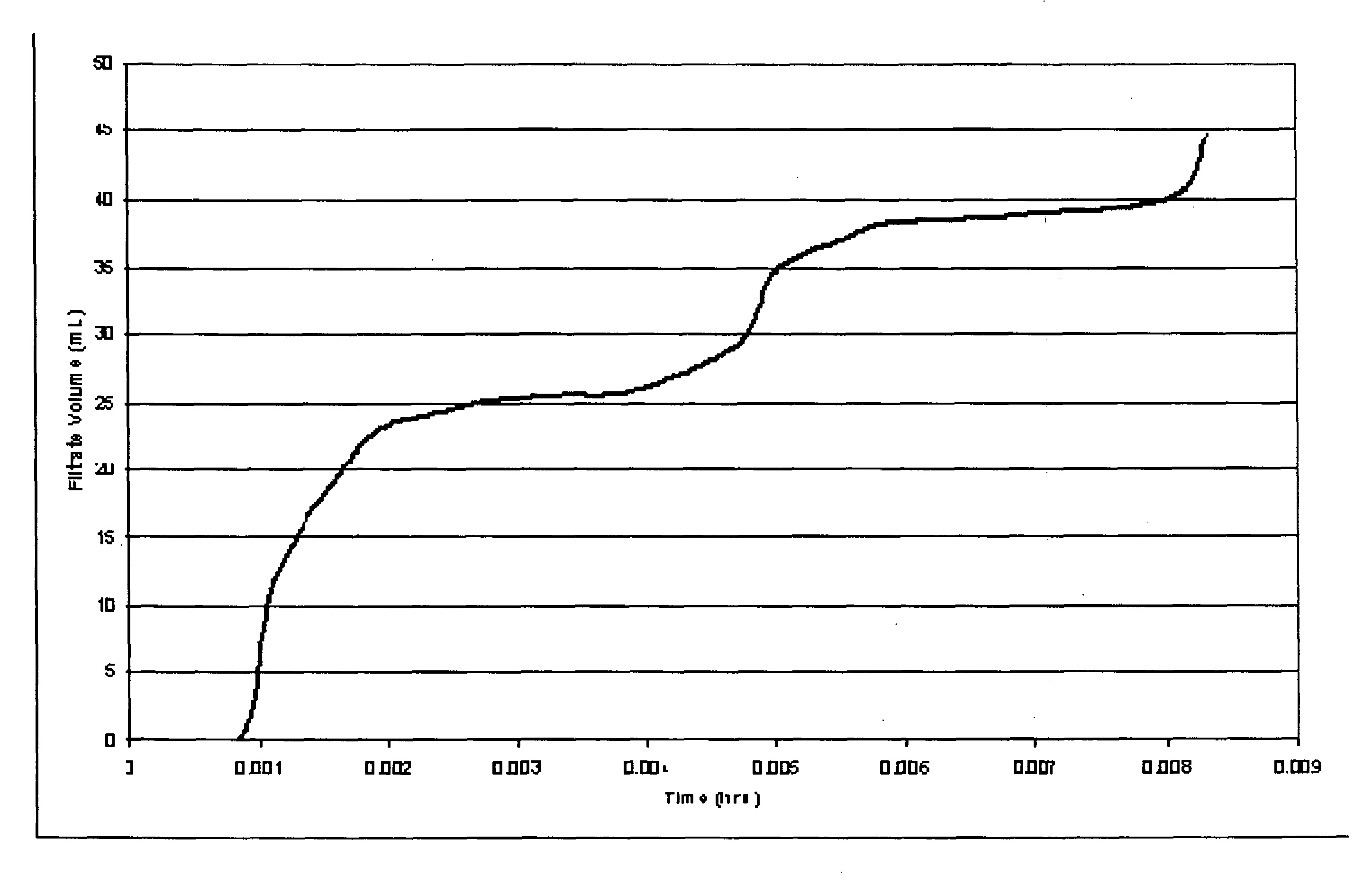

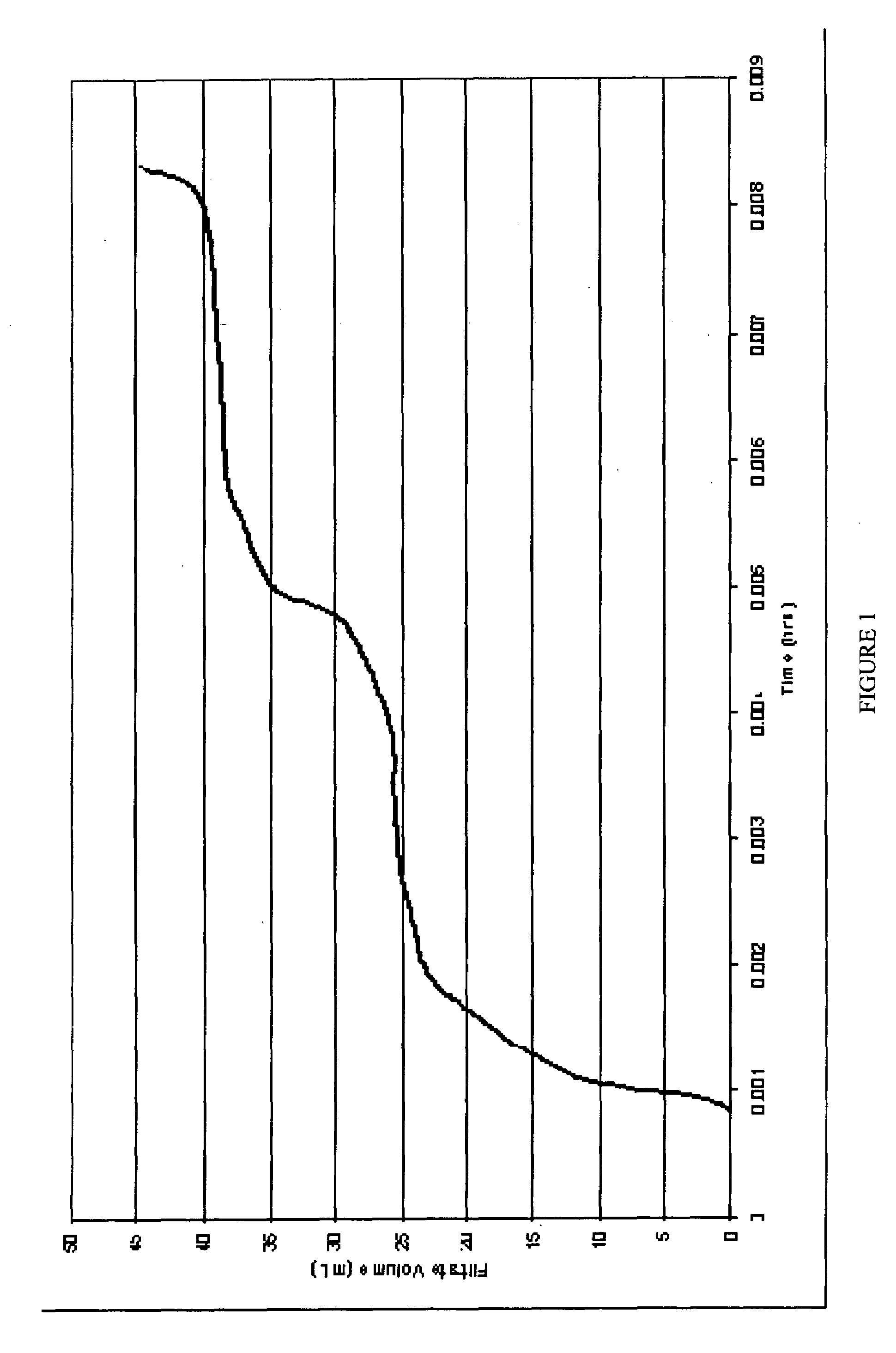

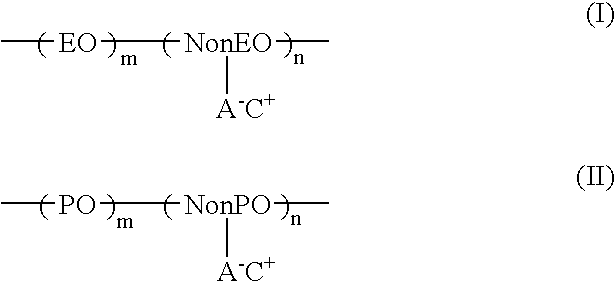

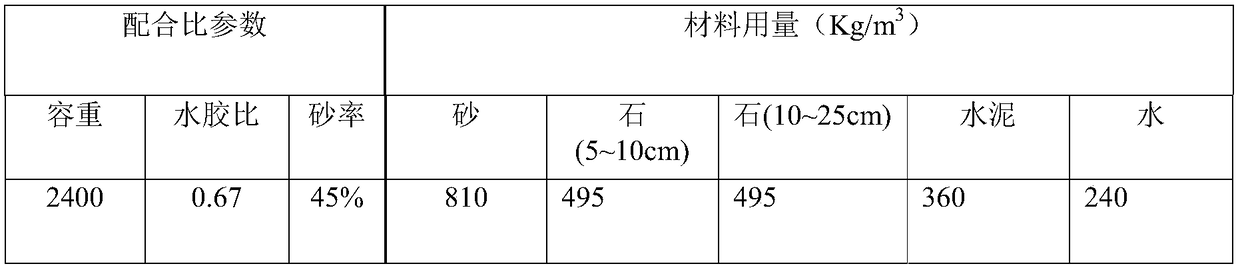

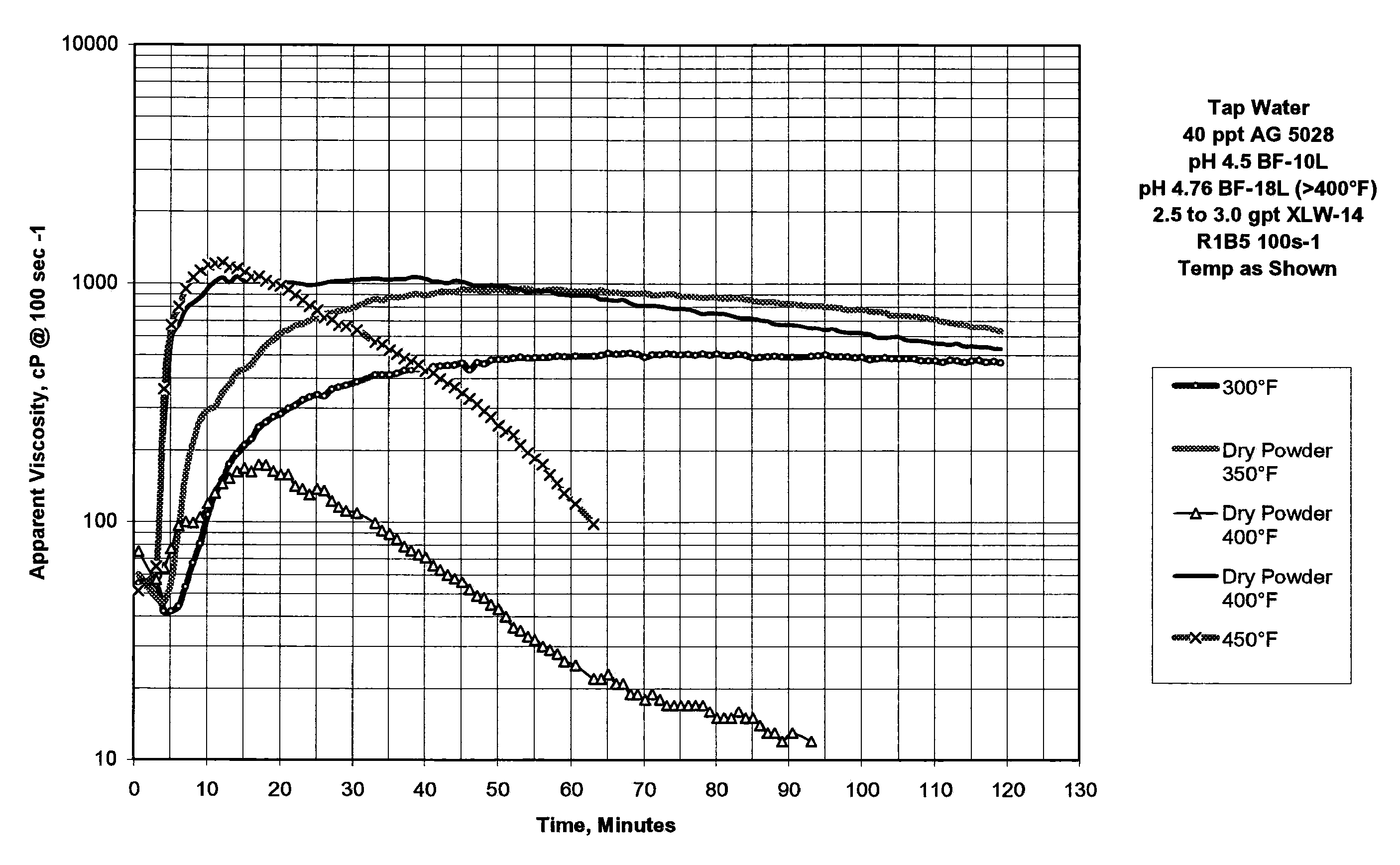

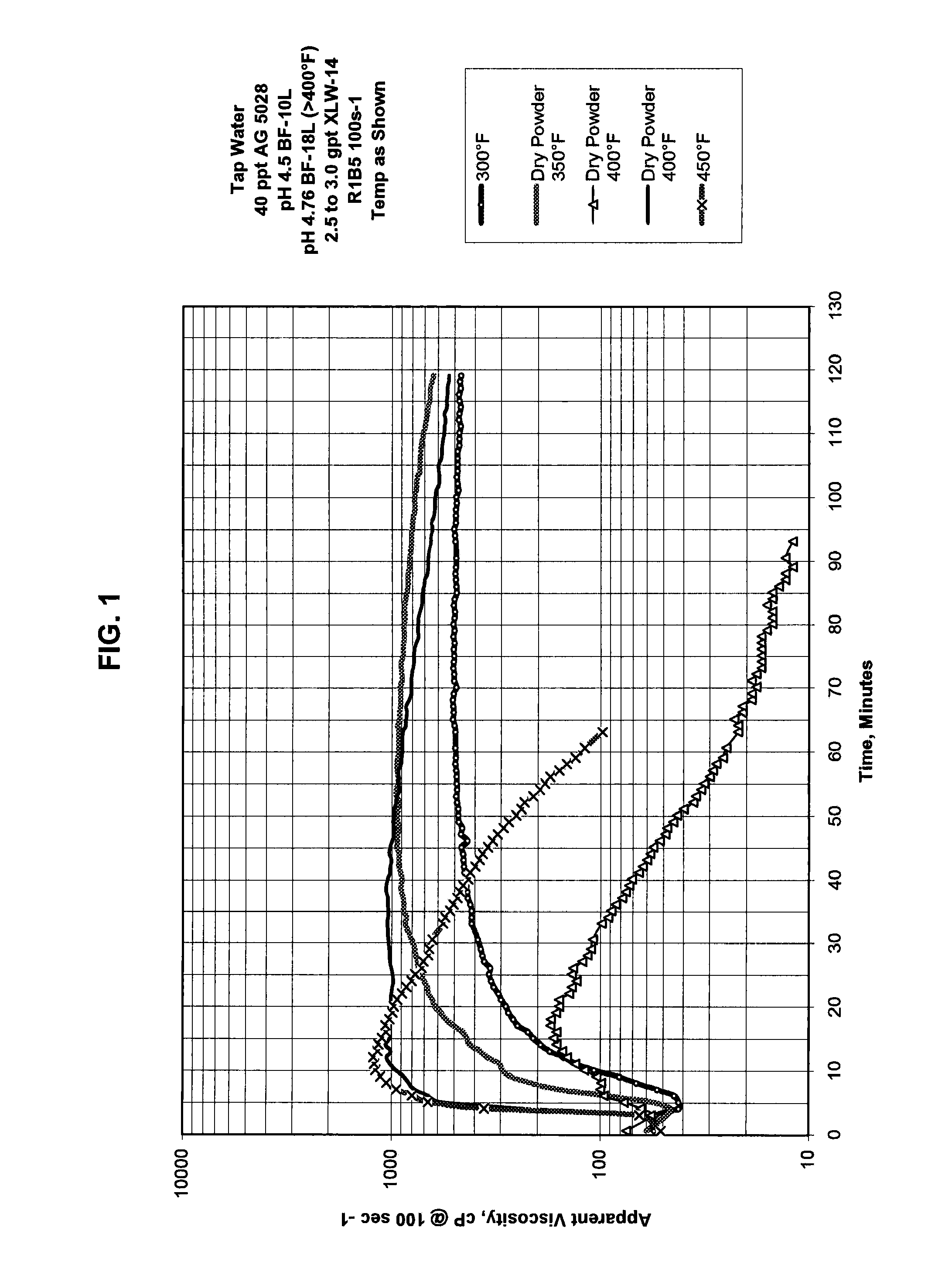

Compositions and methods of treating high temperature subterranean formations

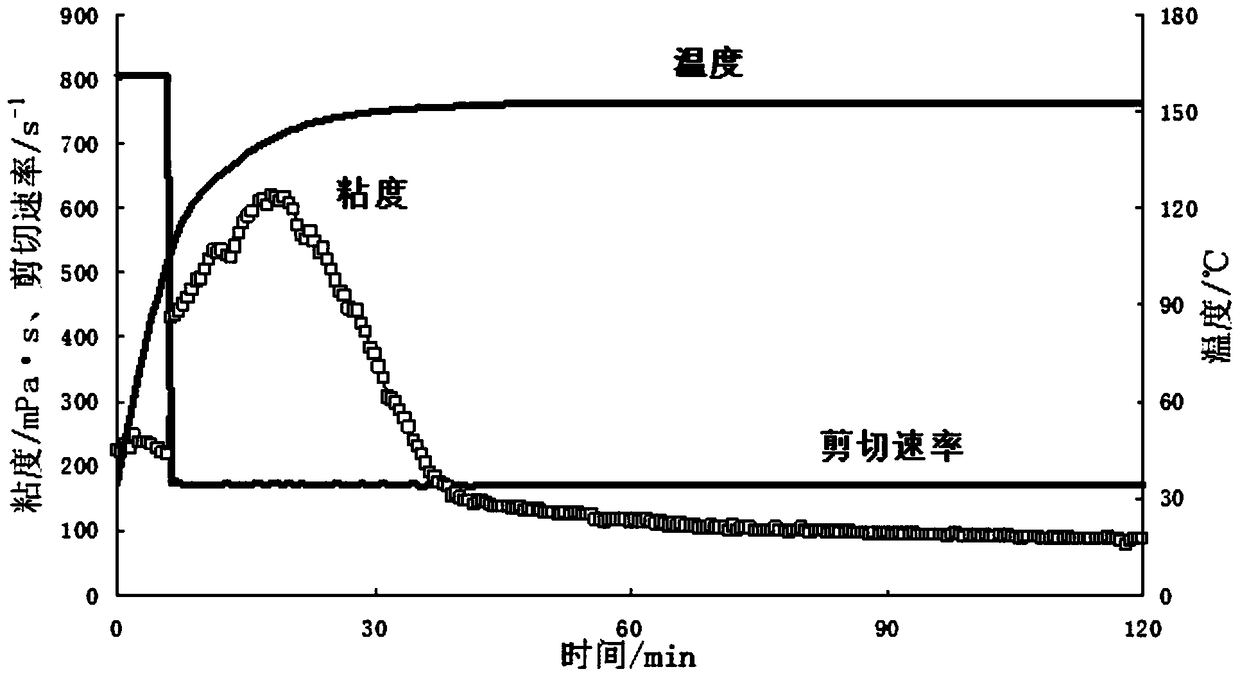

ActiveUS20090192058A1High viscosityPromote hydrationFluid removalFlushingVinylphosphonic acidSynthetic copolymer

Compositions and methods of treating high temperature subterranean formations of up to about 500° F. (260° C.) are provided. The compositions and methods utilize a high molecular weight synthetic copolymer and a pH buffer than maintains a pH in a range of about 4.5 to about 5.25 for the compositions. The high molecular weight synthetic copolymer is derived from acrylamide, acrylamidomethylpropanesulfonic acid, and vinyl phosphonate,

Owner:BAKER HUGHES INC

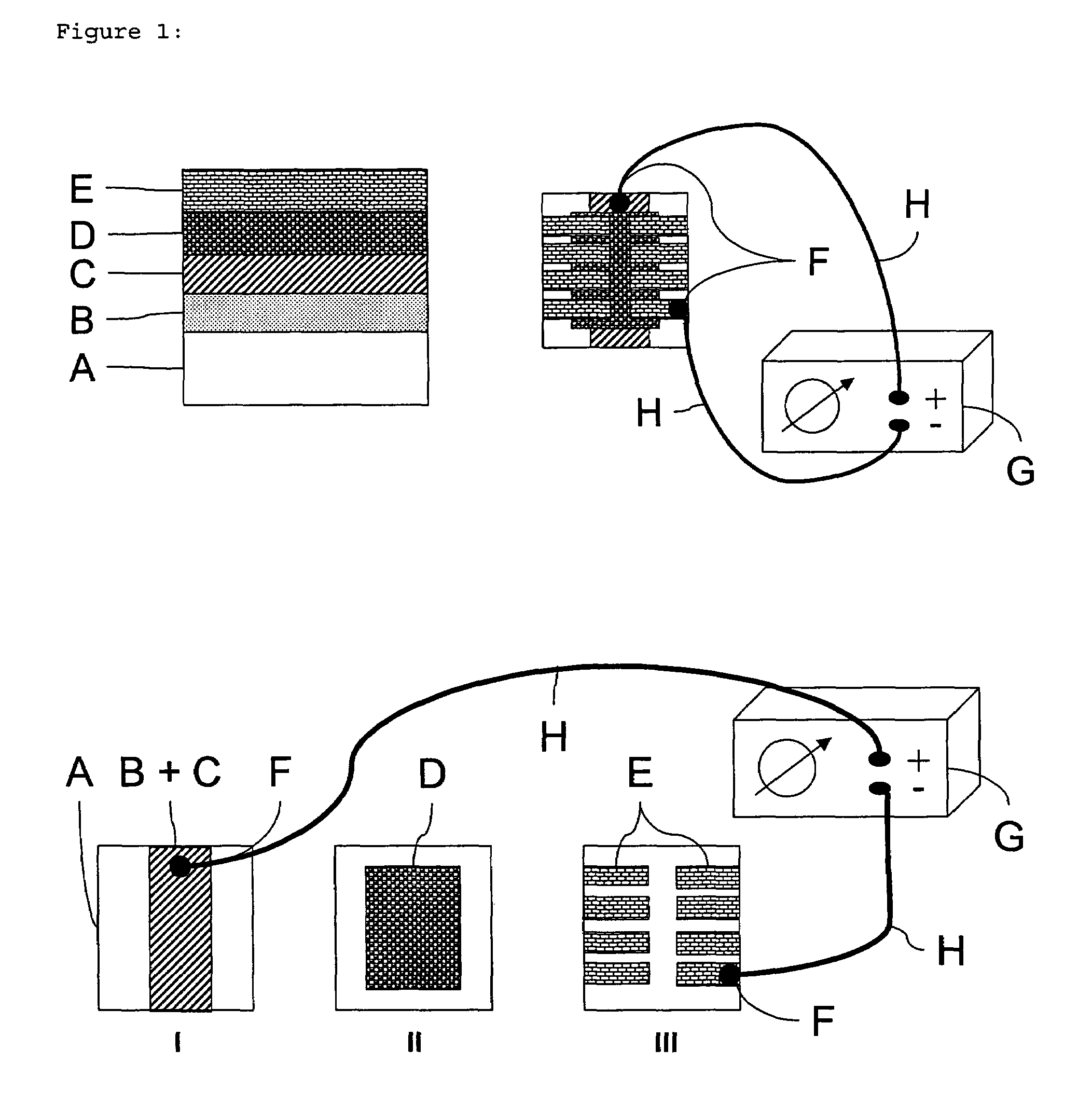

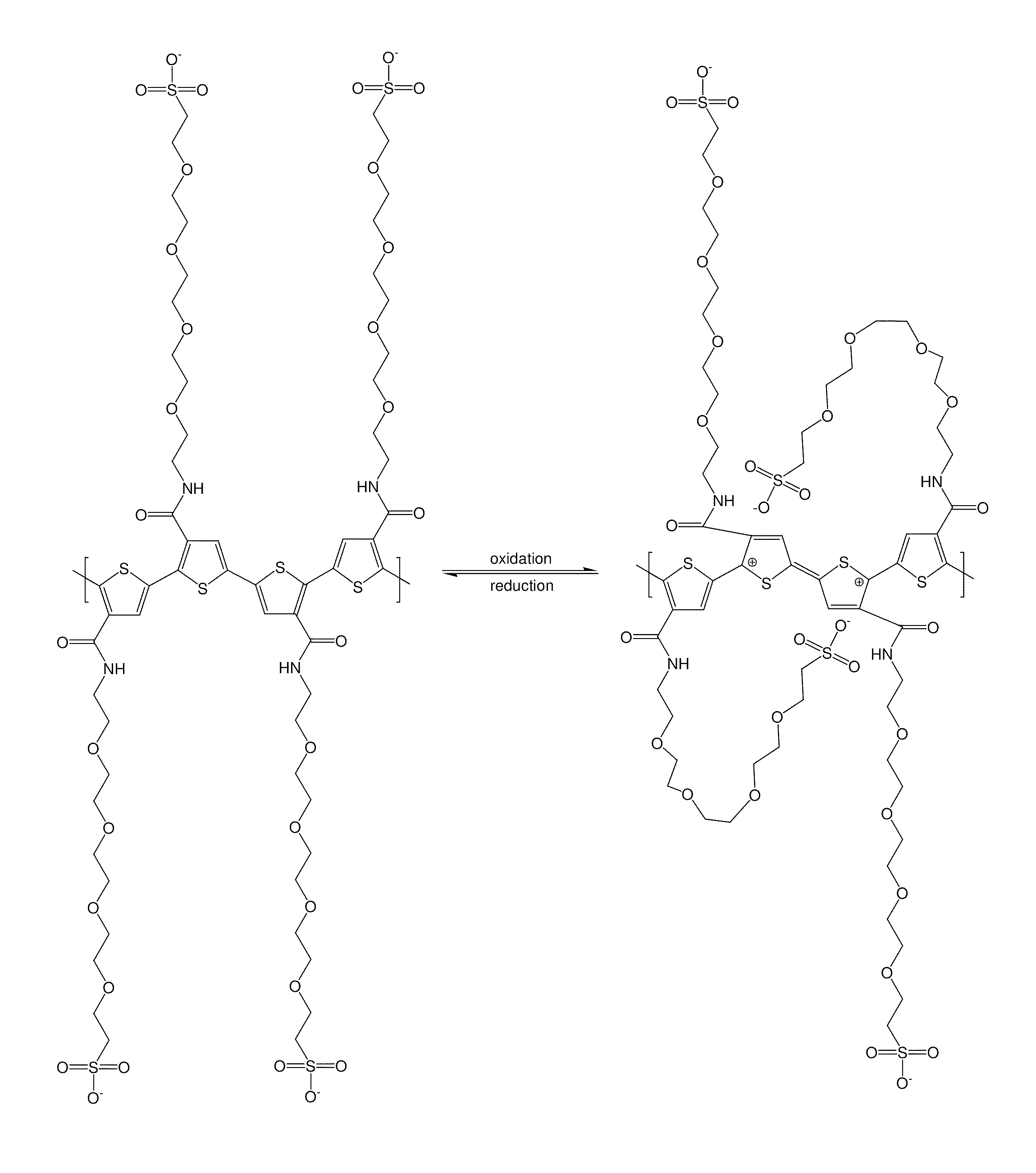

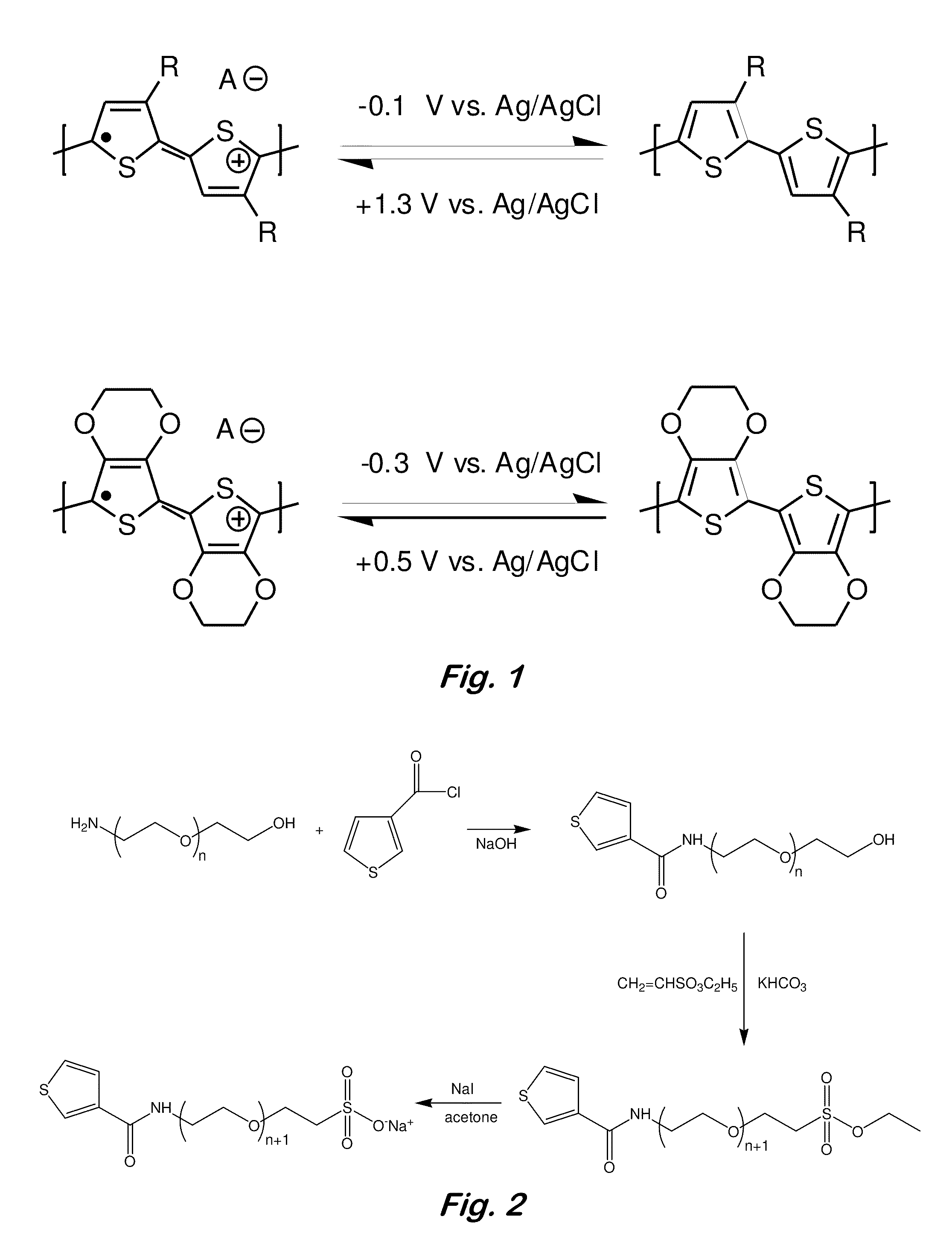

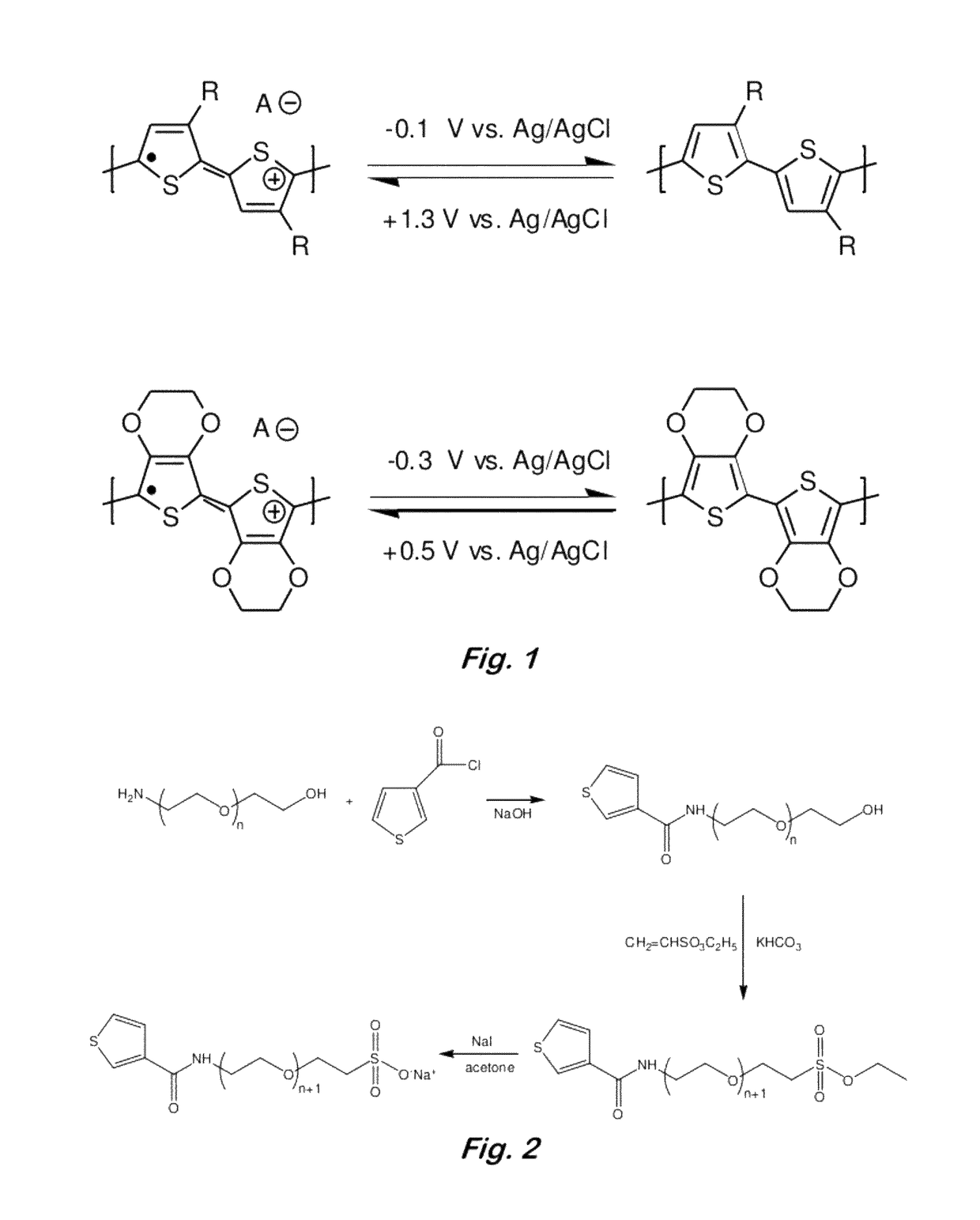

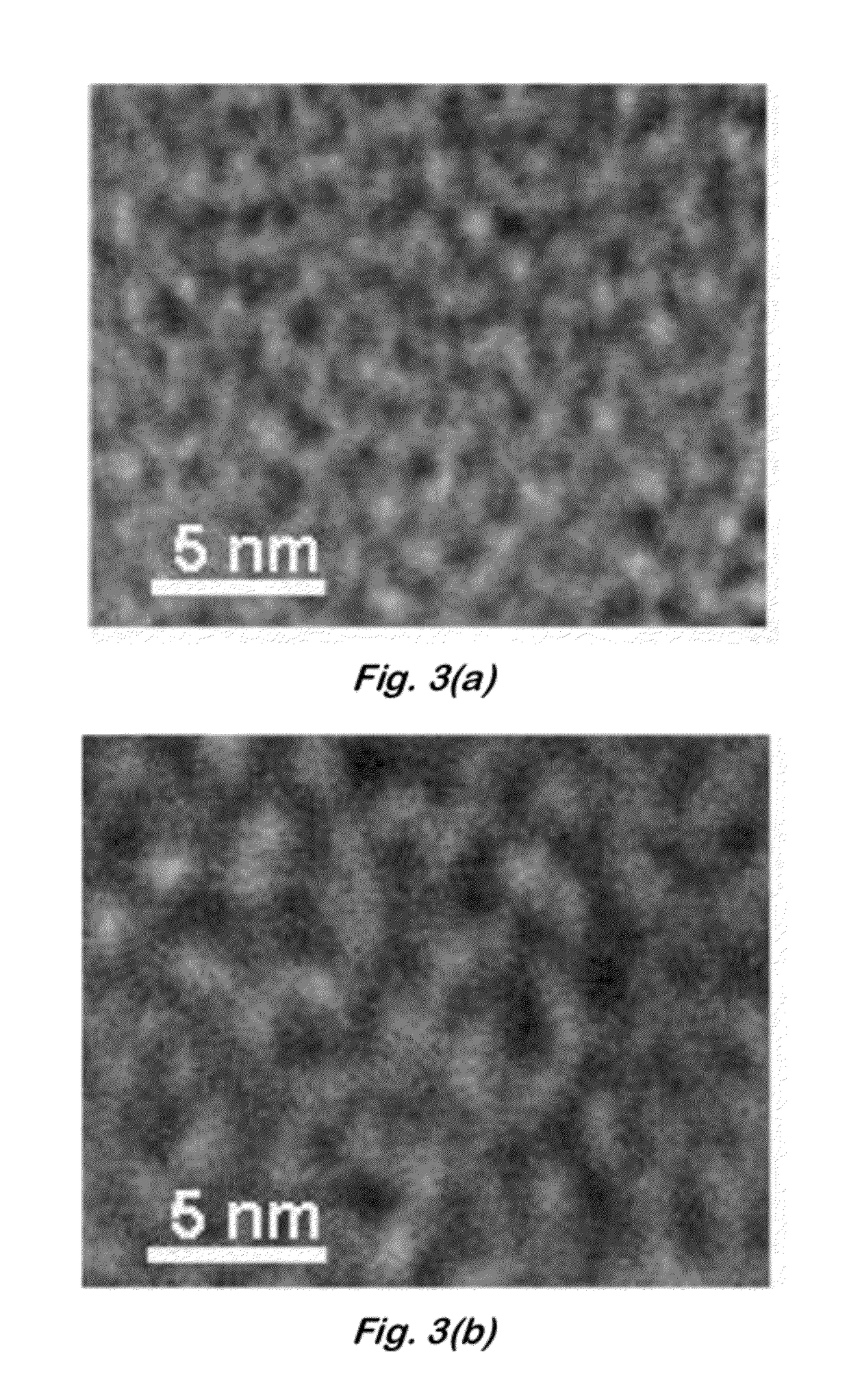

Tether-containing conducting polymers

A compound having the formula below. X is hydroxyl, a sulfonic ester or salt thereof, a phosphonate or salt thereof, a carboxylate or salt thereof, or a boronic ester or salt thereof. The value n is an integer greater than or equal to 2. A polymer made by polymerizing the compound. A method of: reacting NH2—(CH2—CH2—O)n—CH2—CH2—OH with thiophene acid chloride to form a (SC4H3)—CO—NH—(CH2—CH2—O)n—CH2—CH2—OH amide; reacting the amide with a vinyl sulfonic ester, a vinyl phosphonate, a vinyl carboxylate, or a vinyl boronic ester to form an intermediate; and converting the intermediate to a salt form.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Proton Conducting Polymer membrane, Method for Production Thereof and Fuel Cell Therewith

InactiveUS20090136818A1Improve proton conductivityImprove machinabilitySemi-permeable membranesSolid electrolytesStructural formulaAcid group

There are provided a novel proton-conducting polymer membrane that shows good workability in a fuel cell assembling process and good proton conductivity and durability even under high-temperature, non-humidified conditions, a method for production thereof, and a fuel cell therewith. The proton-conducting polymer membrane includes: a polymer membrane containing a polybenzimidazole compound having a sulfonic acid group and / or a phosphonic acid group; and vinylphosphonic acid contained in the polymer membrane. The fuel cell uses the proton-conducting polymer membrane. The polybenzimidazole compound preferably includes a sulfonic and / or phosphonic acid group-containing component represented by Structural Formula (1):wherein n represents an integer of 1 to 4, R1 represents a tetravalent aromatic linking unit capable of forming an imidazole ring, R2 represents a bivalent aromatic linking unit, and Z represents a sulfonic acid group and / or a phosphonic acid group.

Owner:TOYO TOYOBO CO LTD

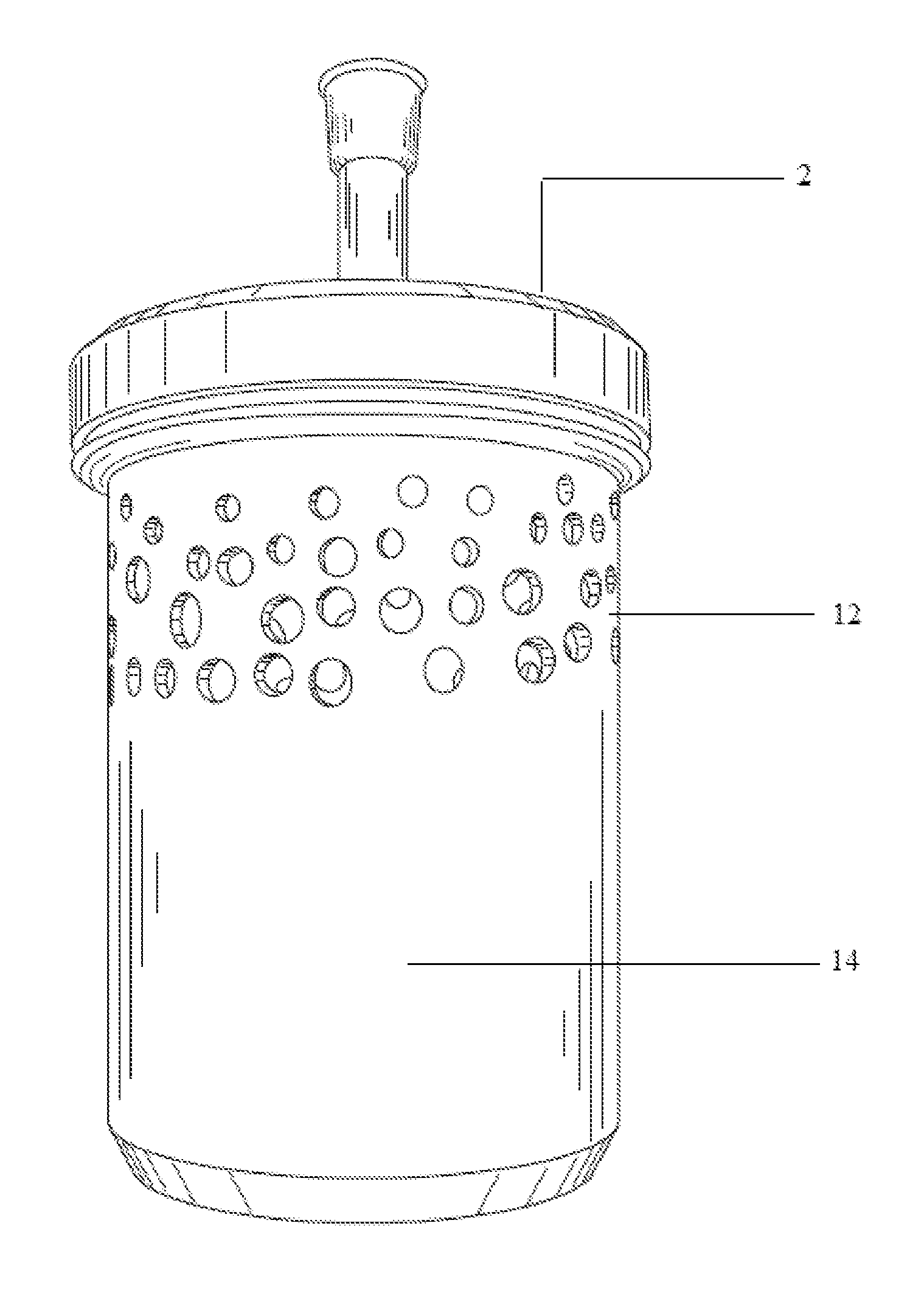

Preparation method of magnetic immobilized enzyme for producing plant sterol ester

ActiveCN102250869AWide applicabilityThe size is easy to controlChemical industryOn/in organic carrierChemical synthesisDouble bond

The invention relates to a preparation method of a magnetic immobilized enzyme for producing a plant sterol ester, belonging to the field of catalytic materials and chemical synthesis. The preparation method of the magnetic immobilized enzyme for producing the plant sterol ester is characterized by comprising the following steps: 1) carrying out chemical modification on a magnetic substrate with vinylphosphonic acid to introduce a carbon-carbon double bond with reactivity onto the surface of the magnetic substrate; 2) wrapping the surfaces of the modified magnetic particles with polymer layers containing epoxy or sulfonate radical groups to obtain magnetic polymer microspheres; and 3) in a buffer solution, immobilizing an enzyme on the surfaces of the magnetic polymer microspheres by an epoxy ring-opening or electrostatic adsorption method to obtain the magnetic immobilized enzyme for producing the plant sterol ester. The obtained magnetic immobilized enzyme has the characteristics of high catalytic activity, good reuse performance and is simple in separation and recovery.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Pressure-sensitive flame retardant adhesive

InactiveCN1282360ANon-macromolecular adhesive additivesEster polymer adhesivesPolymer scienceEmulsion

The present invention discloses a pressure-sensitive, flame-retardant adhesive comprising a composition fabricated with the polymerization of acrylic esters, dibromostyrene, and vinyl phosphonic acid, with or without acrylic acid, mixed with dispersions of antimony trioxide. The adhesive composition preferably is an emulsion polymer fabricated with dibromostyrene, 2-ethylhexyl acrylate, nbutyl acrylate, and vinyl phospohonic acid, mixed with Sb2O3 in an approximate ratio of 100 parts polymer per about 8-12 parts Sb2O3. Preferred polymers are those containing at least about 11.6 % to 15.6 % bromine and from 0.25 % to 2.5 % phosphorous. The adhesive is particularly advantageous in fabricating optical circuit devices.

Owner:ASHLAND LICENSING & INTPROP LLC

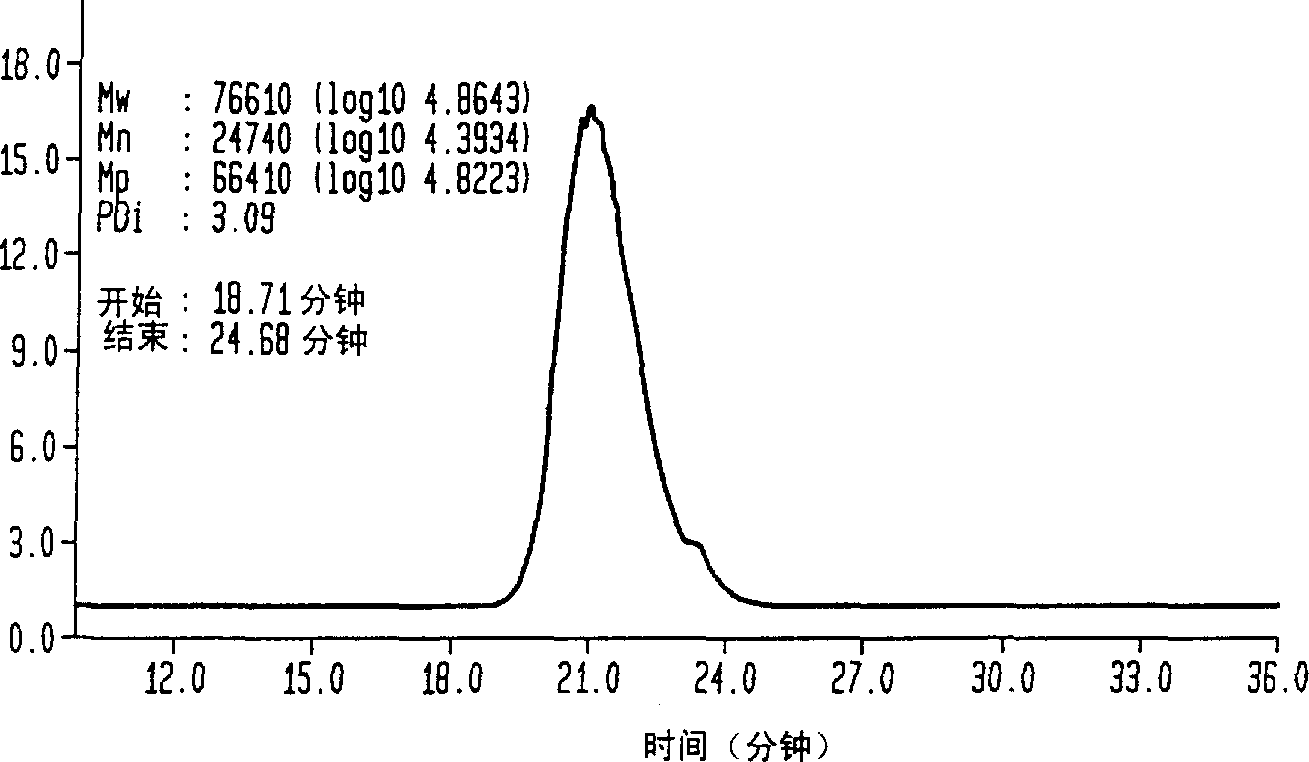

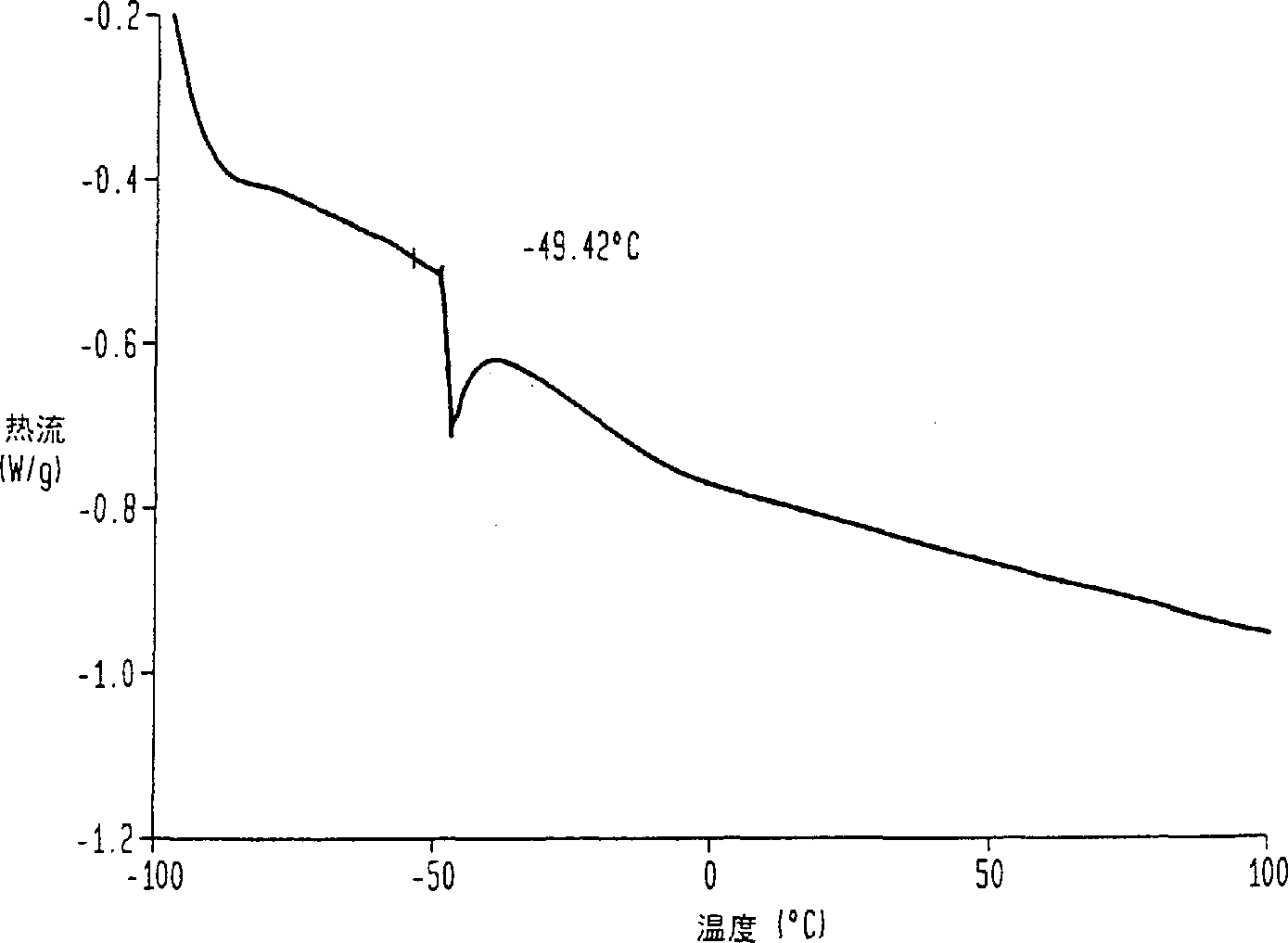

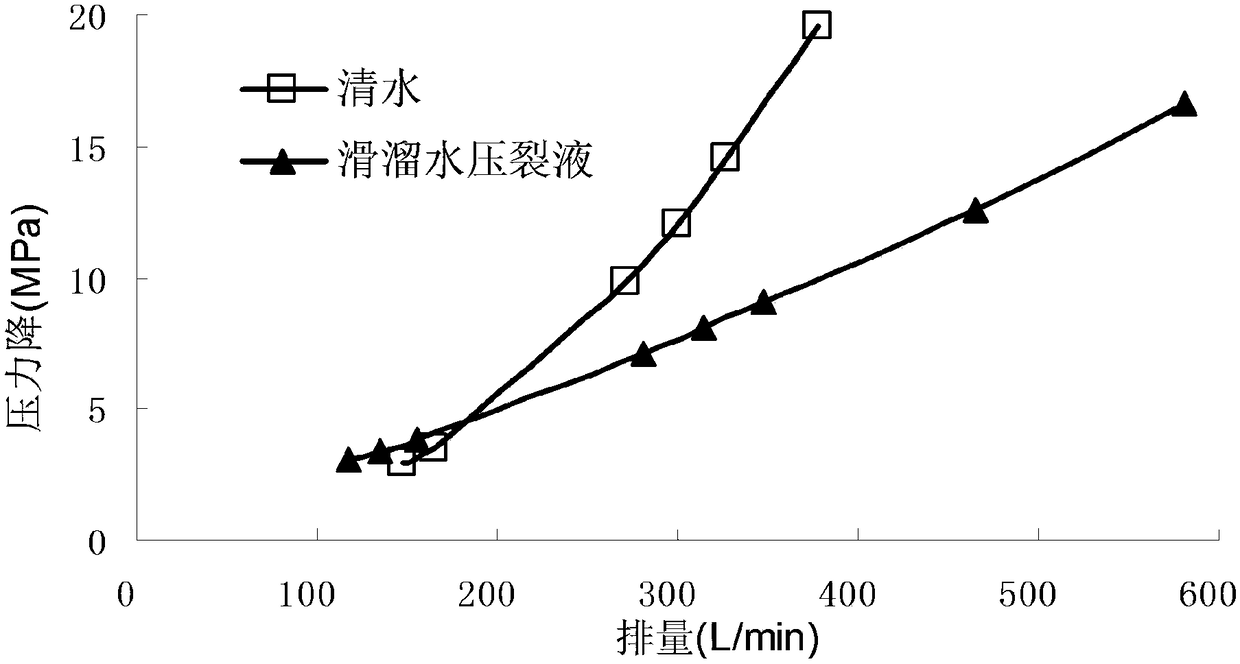

Inverse-phase micro-emulsion polymer fracturing fluid system with online construction function

ActiveCN108559479AGood resistance reduction effectEasy to reuseDrilling compositionMethacrylatePolymer science

The invention discloses an inverse-phase micro-emulsion polymer fracturing fluid system with an online construction function. The inverse-phase micro-emulsion polymer fracturing fluid system comprisesinstant dissolving emulsion thickening agents, functional auxiliaries, a clay stabilizer and fluid preparation water. The instant dissolving emulsion thickening agents are inverse-phase micro-emulsion polymers, and inverse-phase micro-emulsion polymerization is carried out on raw materials including acrylamide, acrylic acid, strong-hydrophilicity monomers, a functional monomer A, a functional monomer B, pH (potential of hydrogen) regulators, solubilizers, composite emulsifiers, oil solvents, initiators and deionized water to obtain the instant dissolving emulsion thickening agents; the functional monomer A is methyl methacrylate or ethyl methacrylate or a mixture of the methyl methacrylate and the ethyl methacrylate; the functional monomer B is vinylphosphonic acid or vinyl sulfonic acid;the functional auxiliaries are non-ionic surfactants; the clay stabilizer is potassium chloride, and the fluid preparation water is clear water or high-mineralization water or treated stratum flow-back fluid. The inverse-phase micro-emulsion polymer fracturing fluid system has the advantages that the inverse-phase micro-emulsion polymer fracturing fluid system is high in dispersing and swelling speed and can be prepared in a batch manner or can be continuously mixed, 'online construction' requirements even can be completely met by the inverse-phase micro-emulsion polymer fracturing fluid system, processes for constructing the inverse-phase micro-emulsion polymer fracturing fluid system are simple, and the fracturing cost can be reduced.

Owner:SOUTHWEST PETROLEUM UNIV +1

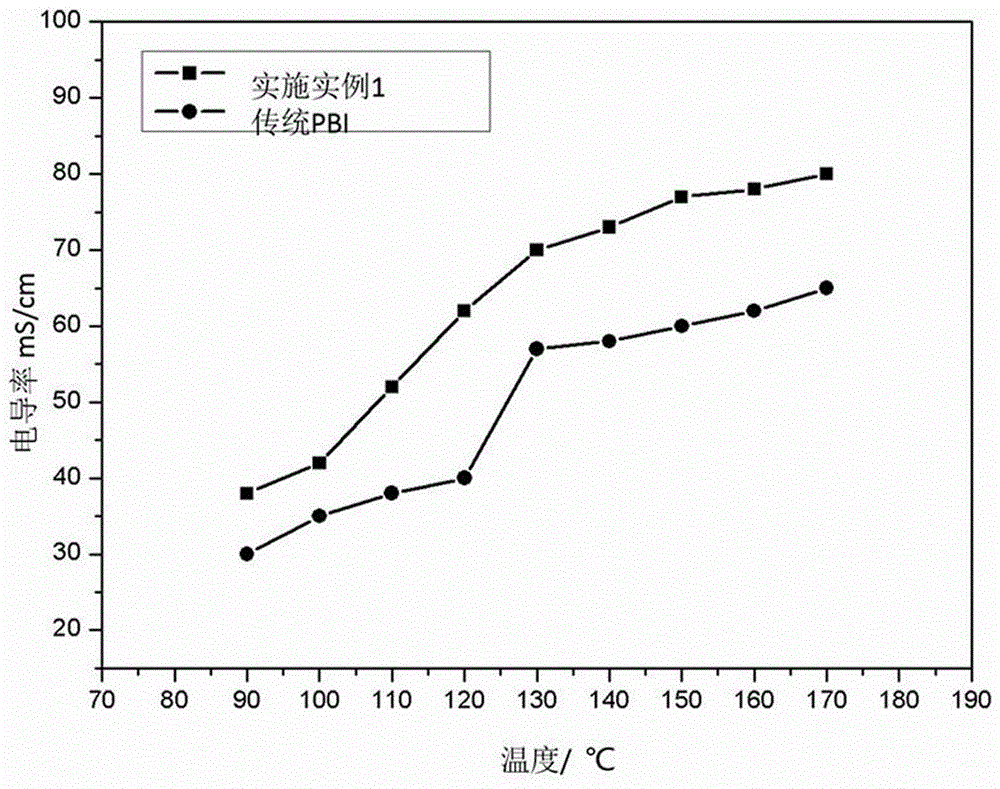

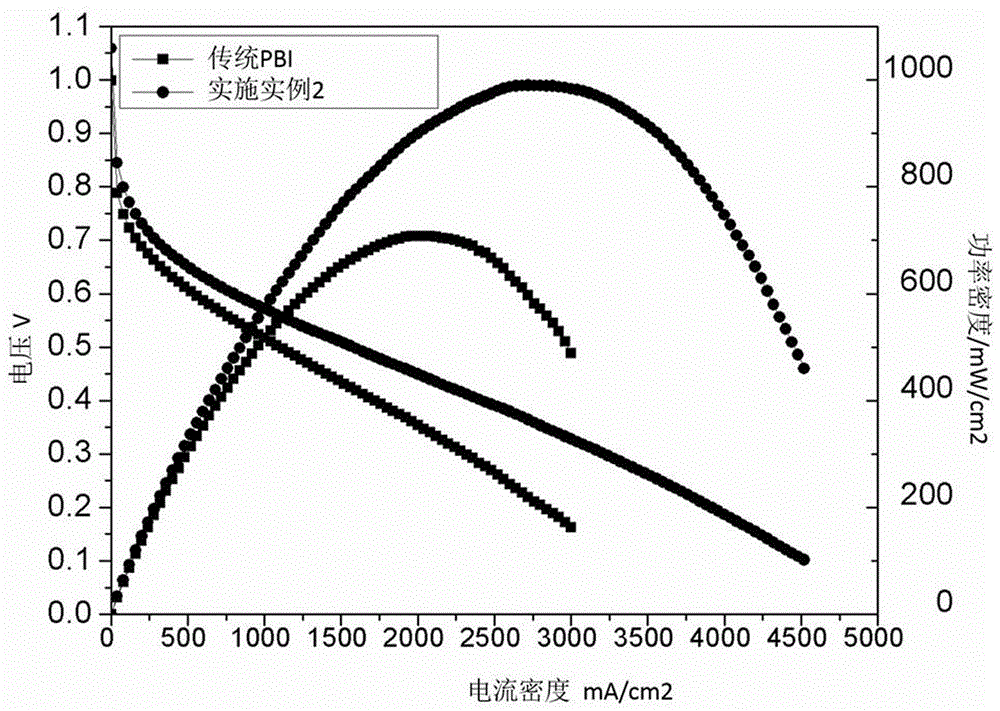

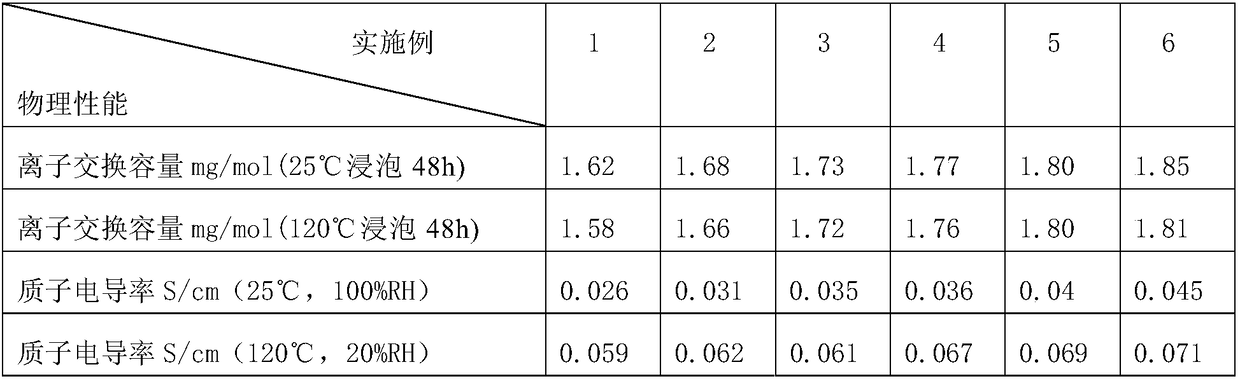

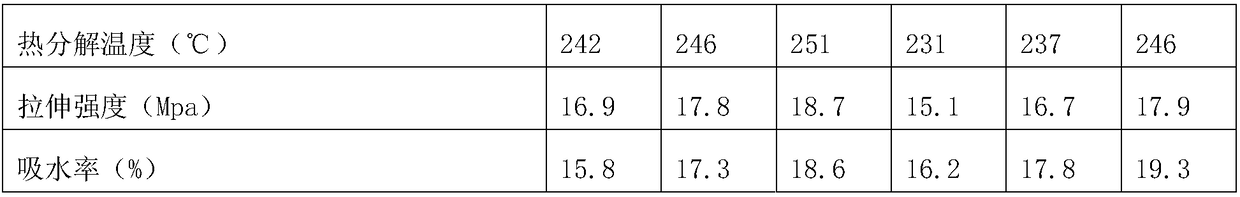

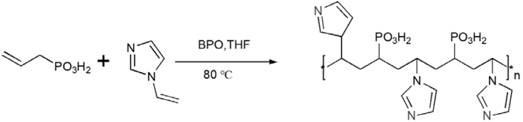

High-oxidization-resistance and high-conductivity crosslinked type polybenzimidazole high-temperature proton exchange membrane and preparation method therefor

ActiveCN106549171AUniform structureImprove antioxidant capacityFuel cell detailsPhosphoric acidElectrochemistry

The invention discloses a high-oxidization-resistance and high-conductivity crosslinked type polybenzimidazole high-temperature proton exchange membrane and a preparation method therefor. The crosslinked membrane takes polybenzimidazole as a polymer framework; through polymerization, a crosslinked net-shaped structure is formed in the membrane by taking vinyl phosphonic acid and vinyl triazole as a crosslinking agent; and a free radical quenching agent which can improve the oxidization resistance of the membrane is doped in the membrane to prepare the high-oxidization-resistance and high-conductivity high-temperature proton exchange membrane. The crosslinked high-temperature proton exchange membrane disclosed by the invention has relatively high proton conductivity and excellent dimensional stability in a non-humidifying condition, and has high oxidization resistance, so that the problem of phosphoric acid loss of a polybenzimidazole / phosphoric acid membrane is completely solved, and the bottleneck that the polymer membrane is degraded under attack of free radicals is overcome; and therefore, the proton exchange membrane can be applied to a high-temperature proton exchange membrane fuel cell, a direct alcohol type fuel cell, an electrochemical sensor or other electrochemical apparatuses as the proton exchange membrane.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI

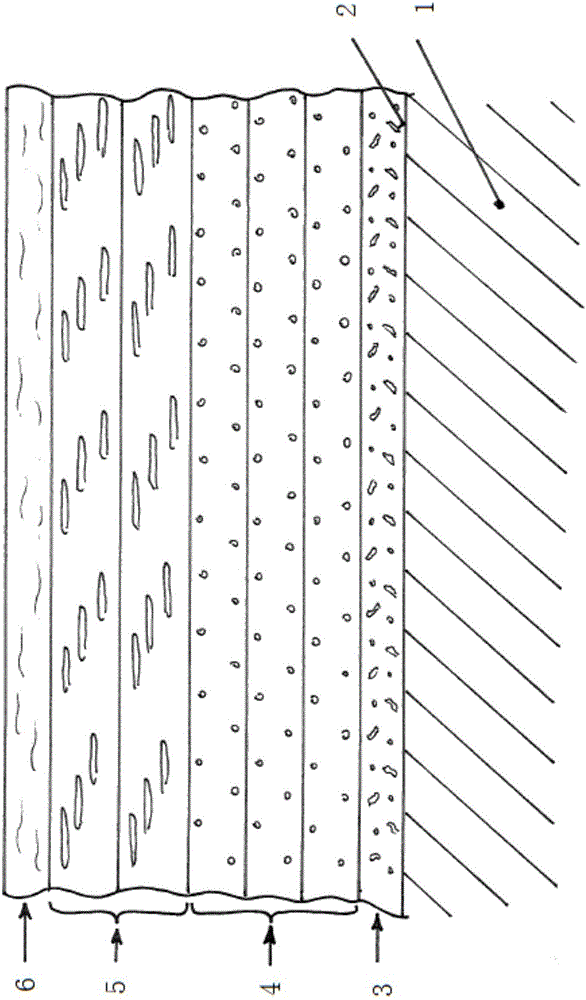

Corrosion protective layer system, corrosion protective bearing component and method for protecting a bearing component from corrosion

ActiveCN106133076AHighly effective against corrosionLow costShaftsBearing componentsInter layerSilanes

The invention relates to a corrosion protective layer system comprising a base layer (3) which contains polyurethane, zinc and vinylphosphonic acid or silane. An intermediate layer (4) which contains polyurethane and zinc is formed on the base layer (3). A cover layer (5) which contains polyurethane and iron mica is formed on the intermediate layer (4). A sealing layer (6) which contains polyurethane is formed on the cover layer (5).

Owner:AB SKF

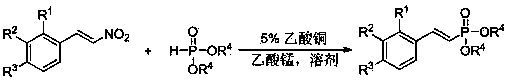

Method for preparing (E)-2-aryl vinyl phosphonate derivatives

ActiveCN104277072ARich typeRaw materials are easy to getGroup 5/15 element organic compoundsMANGANESE ACETATEAccelerant

The invention discloses method for preparing (E)-2-aryl vinyl phosphonate derivatives. The method comprises the specific following steps of dissolving 1-nitro-2-aryl-vinyl derivatives, a phosphorus reagent, an accelerator manganese acetate and a catalyst copper acetate in a solvent and reacting at 20-100 DEG C to obtain the (E)-2-aryl vinyl phosphonate derivatives. According to the method disclosed by the invention, the 1-nitro-2-aryl-vinyl derivatives are adopted as starting materials, the raw materials are easily available and have multiple varieties; the products obtained by the method disclosed by the invention are multiple and can be directly applied and can be also used for other further reaction; according to the method, the use of precious metal reagents and other additives is avoided; and meanwhile, the synthetic route is short, reaction conditions are mild, the reaction operation and post-treatment process are simple, the yield is high and the method is suitable for scale production.

Owner:江苏强盛功能化学股份有限公司

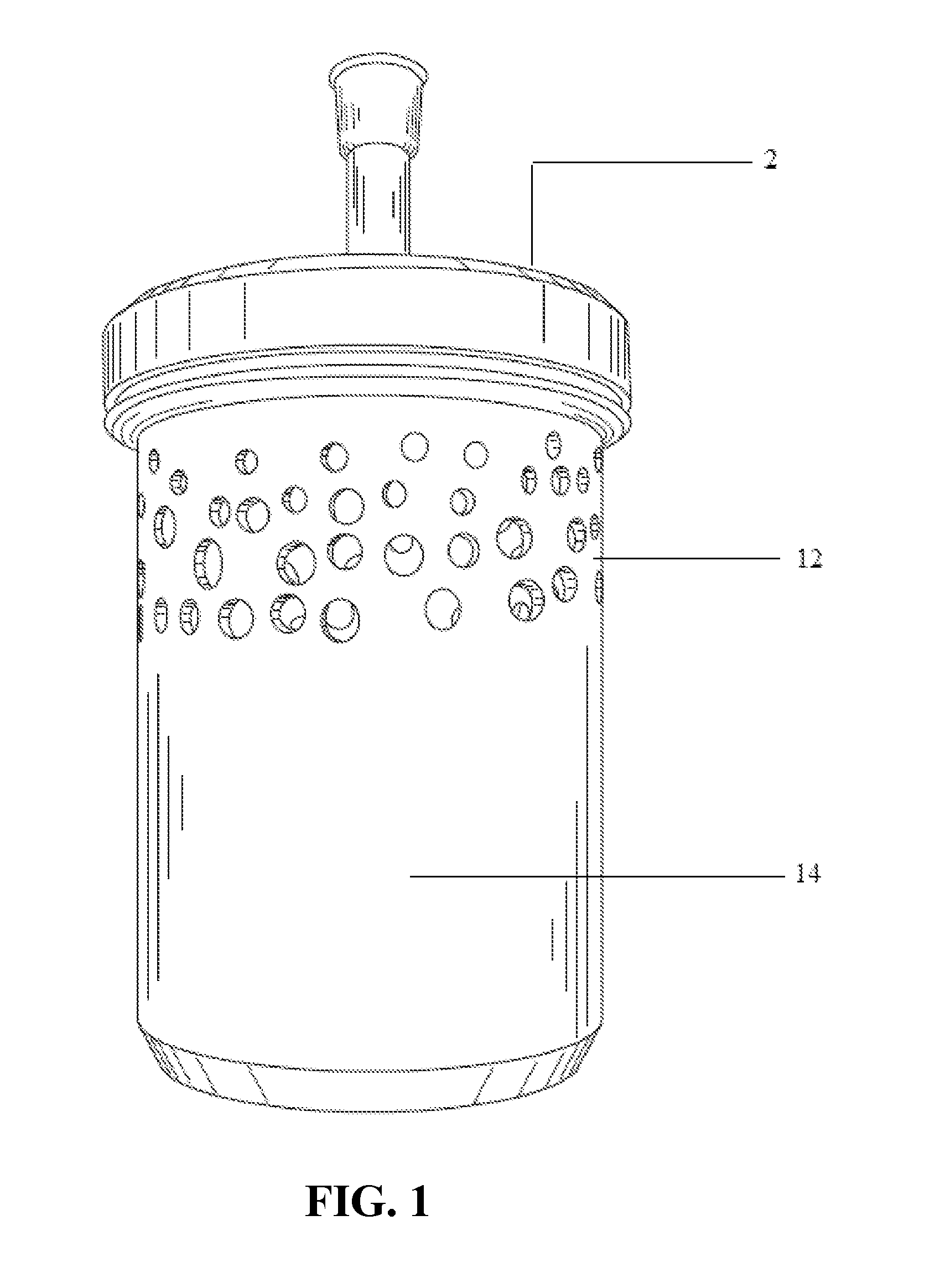

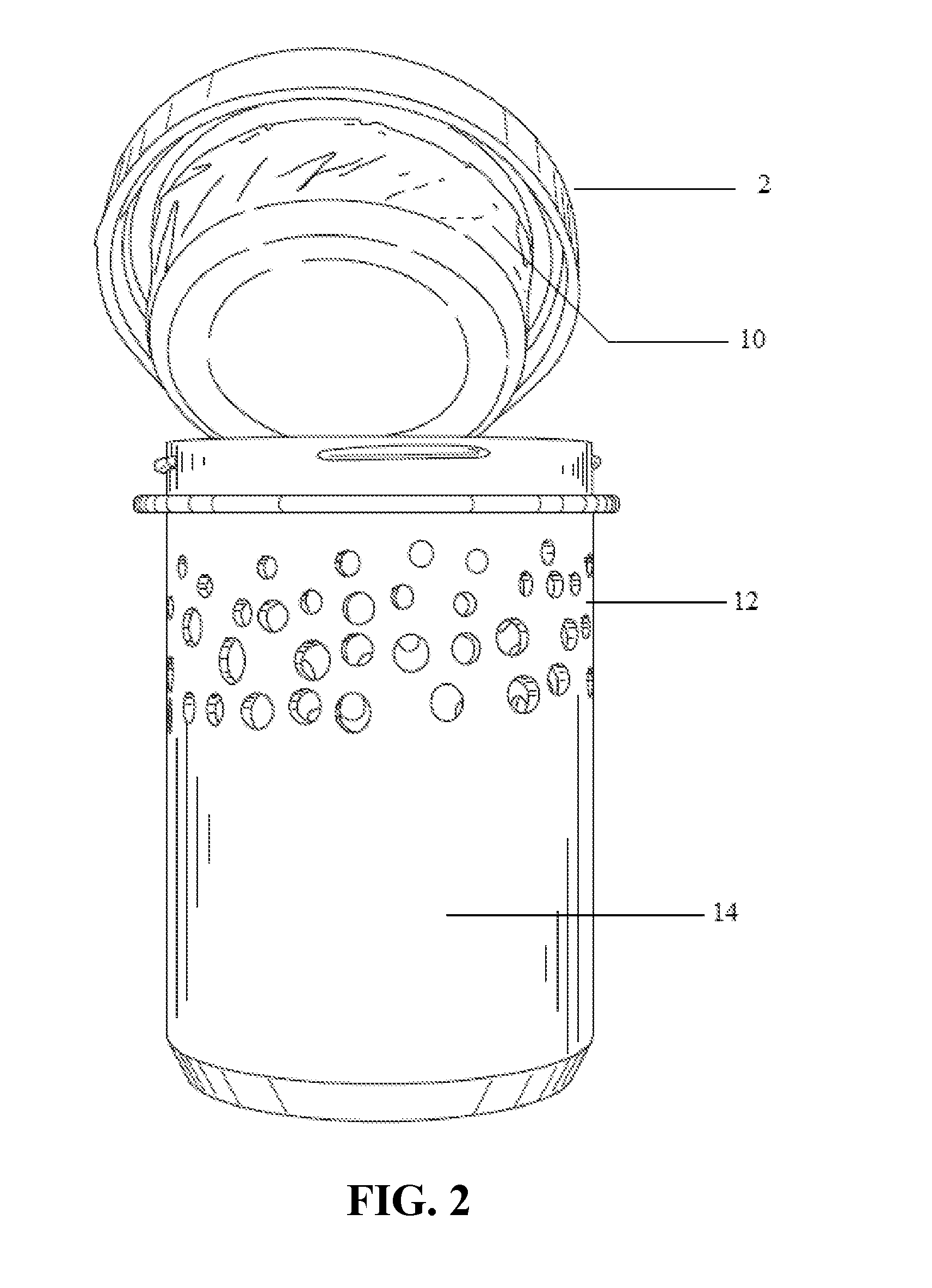

Device for Water Collection from Atmospheric Moisture

ActiveUS20150020687A1Improve efficiencyEasy to useIsotope separationWater conservationAtmospheric airPoly(N-isopropylacrylamide)

A device for collecting water from atmospheric moisture comprises water absorbing material, a protection wall and a water container. The protection wall is in a porous form. The water absorbing material is made of the temperature responsive polymer with a phase separation temperature, including Poly(N-isopropylacrylamide) (PNIPAM), Poly(vinylphosphonate) and etc. when its temperature is below phase separation temperature, the temperature responsive polymer is in a swollen hydrated state, forming hydrogen bond with water molecules; so as to absorb water from the air. When its temperature is above said phase separation temperature, the temperature responsive polymer is in a shrunken dehydrated state, forming hydrogen bond with other temperature responsive polymer molecules; so as to expel the water to the water container.

Owner:KHALIFA UNIV OF SCI & TECH

Diproton-conductor-containing organic-inorganic composite proton exchange membrane and preparation method thereof

InactiveCN108376791AHigh proton conductivityImprove mechanical propertiesFuel cellsElectrical conductorSilanes

The invention relates to a diproton-conductor-containing organic-inorganic composite proton exchange membrane and a preparation method thereof. The preparation method of the proton exchange membrane includes the steps: firstly, performing addition reaction on octavinyl-polyhedral oligomeric silsesquioxane and diethyl vinylphosphonate to obtain phosphoric acid silane; secondly, mixing the phosphoric acid silane and solution containing sulfonated polyetheretherketone to form a membrane by a sol-gel method; thirdly, soaking the membrane into excessive hydrochloric acid solution to perform replacement reaction to obtain the composite proton exchange membrane. According to the membrane, free radical reaction between the octavinyl-polyhedral oligomeric silsesquioxane and the diethyl vinylphosphonate is performed, so that phosphonic acid is firmly combined into the proton exchange membrane in a C-P chemical bond manner, the proton exchange membrane has good dielectric properties and optical properties by a polyhedral frame structure of the polyhedral oligomeric silsesquioxane, the sulfonated polyetheretherketone servers as a substrate material of the proton exchange membrane, the proton conductivity of the proton exchange membrane is greatly improved, and the prepared proton exchange membrane not only has excellent mechanical properties and heat chemical stability, but also has a widetemperature use range.

Owner:WUHAN UNIV OF TECH

High-strength mineralized hydrogel and applications of high-strength mineralized hydrogel in bone repair

InactiveCN108690309AImprove mineralizationImprove bindingTissue regenerationProsthesisCross-linkOsseointegration

The invention discloses a high-strength mineralized hydrogel and applications of the high-strength mineralized hydrogel in bone repair. According to the present invention, N-acryloyl glycinamide and vinylphosphonic acid are used as raw materials and are co-polymerized in the presence of an initiator to prepare a hydrogel, calcium ions and phosphorus ions are deposited in situ in the gel to form hydroxyapatite, the mineralized hydrogel pipe has good tensile performance and good compressive performance due to the physical cross-linking effect of the hydrogen bond and the ion cross-linking effectof the hydroxyapatite and the gel matrix in the gel structure, and due to the presence of hydroxyapatite, the osseointegration and bone repair ability of the gel pipe is improved.

Owner:TIANJIN UNIV

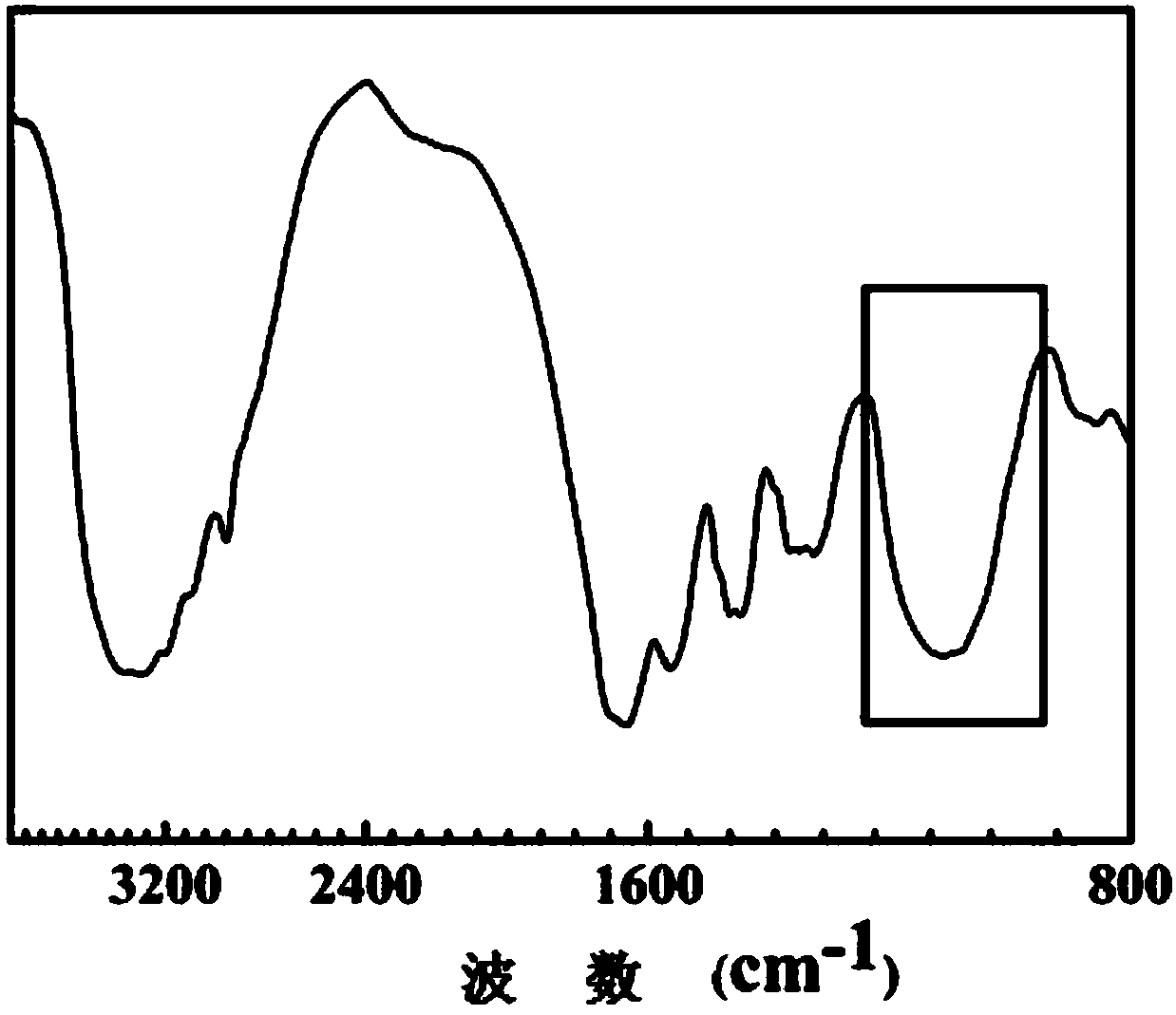

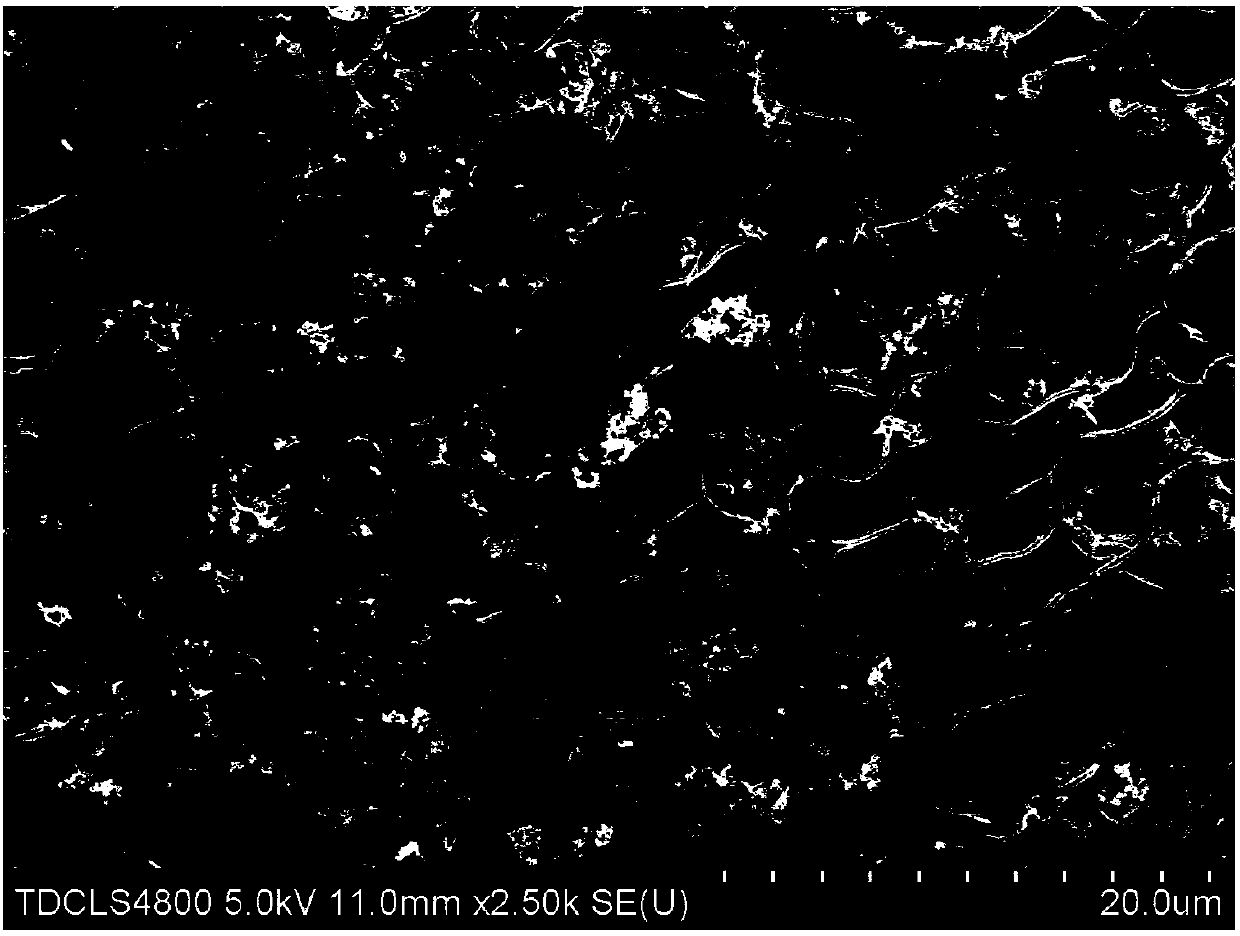

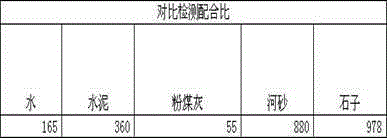

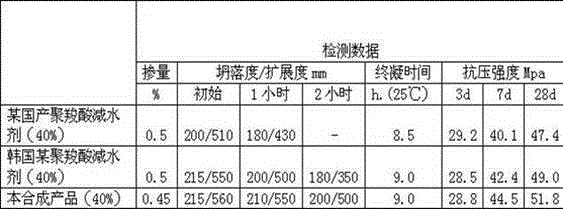

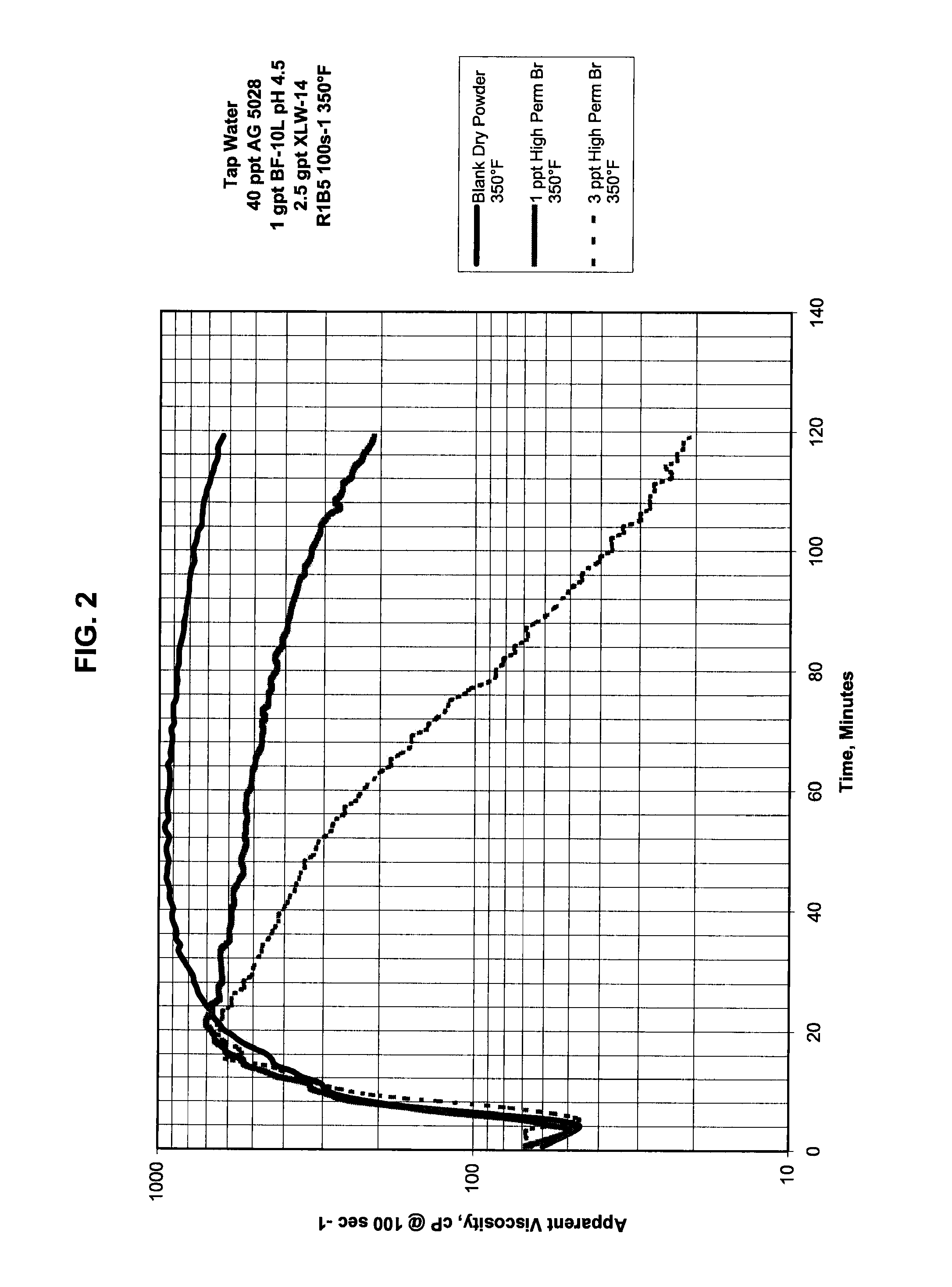

Polyphosphonic acid type water reducing agents and synthesis method thereof

The invention discloses polyphosphonic acid type water reducing agents. The polyphosphonic acid type water reducing agents are prepared from raw materials as follows: a, methyl allyl polyethenoxy ether; b, acrylic acid or methylacrylic acid; c, vinylphosphonic acid; d, ammonium persulfate; e, mercaptoacetic acid or mercaptopropionic acid; f, trisodium phosphate. The mole ratio of a to b to c to f is 1:(3-4):(0.2-1):(2-3); the material d accounts for 0.2%-0.5% of the total weight of all the materials; the material e accounts for 0.1%-0.3% of the total weight of all the materials. Besides, the invention further discloses a synthesis method of the polyphosphonic acid type water reducing agents. Compared with common polycarboxylate superplasticizers, the phosphonic acid and carboxylic acid copolymerized water reducing agent has a better water reducing effect and a slump keeping effect and has a certain delayed coagulation function on concrete.

Owner:吉林众鑫化工集团有限公司

Trivalent chromium passivator concentrated solution and preparation method

ActiveCN105603402AFast film formationUniform film formationMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a trivalent chromium passivator concentrated solution which is prepared from 15-30 parts of chromium dihydrogen phosphate, 5-10 parts of phosphoric acid, 3-10 parts of acidic silica sol, 2-8 parts of low-carbon alcohol, 1-3 parts of sodium nitrate. 0.01-0.2 part of a silane coupling agent, 0.5-2 parts of cobalt nitrate, 0.01-0.2 part of closed synergist vinyl phosphonic acid-acrylic acid copolymer and 30-60 parts of deionized water. A trivalent chromium passivator can be used on the surface of a galvanized steel plate for an automobile so that the surface of the galvanized steel plate can be continuously passivated and form a film, passivation reaction time is short, salt fog resistance time of the film is long, and the trivalent chromium passivator is suitable for dipping of the galvanized steel plate for the automobile and roller painting treatment of workpieces. The trivalent chromium passivator concentrated solution is particularly suitable for the continuous passivation technology.

Owner:CHINA THREE GORGES UNIV

Brightening agent for composite copper plating

ActiveCN108265317AImprove densification performanceGood dispersionCopper platingGlycidyl methacrylate

The invention relates to a brightening agent for composite copper plating and belongs to the technical field of electroplating additives. According to the brightening agent, firstly, maleic anhydrideand acrylic acid are used as raw materials; under the action of ammonium persulfate, polymerization is carried out to form a copolymer; in a polymerization process, sodium valproate and vinylphosphonic acid are added, and are grafted into the copolymer under the catalysis effect of strong acidic styrene cation exchange resin; then N,N-dimethylformamide, anisole, glycidyl methacrylate and the likeare used as raw materials to carry out polymerization; two polymers have good dispersion performance, and copper ions can be uniformly dispersed on the surface of a matrix to carry out copper plating;added benzalacetone and salicylaldehyde can slow down the growth speed of a crystal, a crystal nucleus formation speed is improved and the compactness of crystal grains of a copper plated layer is improved; a surfactant is added and the generation of needle holes is reduced under the action of an auxiliary agent; meanwhile, the binding performance of the plated layer and the matrix is reinforcedby utilizing the effect of the auxiliary agent.

Owner:连云港市赣榆金成镍业有限公司

High-adaptability solid polycarboxylate superplasticizer and polymerization preparation method of body of high-adaptability solid polycarboxylate superplasticizer

The invention relates to a high-adaptability solid polycarboxylate superplasticizer and a polymerization preparation method of a body of the high-adaptability solid polycarboxylate superplasticizer. The solid polycarboxylate superplasticizer is prepared from the following raw materials in parts by mass: 100 to 150 parts of allyl polyethylene glycol APEG monomers with polymerization degree being 33, 21.6 to 32.3 parts of one of acrylic acid and methacrylic acid, 16.5 to 29.6 parts of one of maleic anhydride and diallyl maleate, 2.5 to 6.6 parts of one of styrene and sodium p-styrenesulfonate, 7.5 to 9.6 parts of unsaturated phosphonate monomers, and initiator which accounts for 1 to 3 percent of total mass of all monomers. The unsaturated phosphonate monomer is 2-hydroxyethyl methacrylate phosphate and vinyl diethyl phosphonate; and the initiator is azodiisobutyronitrile and the like. The invention also provides the polymerization preparation method of the body of the solid polycarboxylate superplasticizer. The polycarboxylate superplasticizer has high-performance water reduction effect and also has wide adaptability, and the preparation process of the polycarboxylate superplasticizer is simple and green and environmentally friendly.

Owner:刘翠芬

Method of fracturing with phenothiazine stabilizer

Well treatment fluids and methods of treating high temperature subterranean formations of up to about 500° F. (260° C.) are provided. The well treatment fluids and methods utilize a high molecular weight synthetic copolymer and a pH buffer than maintains a pH in a range of about 4.5 to about 5.25 for the fluids. The high molecular weight synthetic copolymer is derived from acrylamide, acrylamidomethylpropanesulfonic acid, and vinyl phosphonates. The well treatment fluids may be energized or foamed.

Owner:BAKER HUGHES HLDG LLC

Method for metal surface passivation

The invention discloses a method for metal surface passivation, and the method comprises the following steps: 1) mixing, by mass, 1-2 parts of quaternized polyethylenimine, 1-2 parts of hydroxypropyl methyl cellulose, 1-2 parts of polyethyleneimine, 1-2 parts of quaternized polyvinylamine, 1-2 parts of alkoxylated polyethyleneimine, 1-2 parts of polyvinyl imidazole, 80 parts of water, 1-2 parts of fatty alcohol-polyoxyethylene ether and 2-3 parts of polyglycerol monostearate, then adding 20-60 parts of a copolymer synthesized by acrylic acid, vinyl phosphonic acid and hydroxyethyl acrylate to produce a conditioning fluid with the pH value of 2.3 - 2.5; and 2) applying a metal surface with the conditioning fluid in a manner of a wet film. By the method for the metal surface passivation, a fully crosslinkedstable passivation film coating layer is formed on the metal surface.

Owner:常熟市大康汽车座垫有限责任公司

Phosphonic acid-functionalized polymer/graphene nanobelt composite aerogel and preparation method and application thereof

InactiveCN111450808AOvercoming Gel DifficultiesImprove mechanical propertiesOther chemical processesWater contaminantsMethacrylateGraphene nanoribbons

The invention discloses phosphonic acid-functionalized polymer / graphene nanobelt composite aerogel and a preparation method and application thereof, belonging to the field of preparation methods and application of graphene nanobelt composite aerogel. The invention aims to solve the technical problem of low adsorption capacity of an existing graphene aerogel adsorption material. The phosphonic acid-functionalized polymer / graphene nanobelt composite aerogel is aerogel which takes a graphene oxide nanobelt as a matrix that is grafted with a polymer using phosphonic acid as a functional group. Thepreparation method comprises the following steps: 1, preparing a graphene oxide nanobelt; 2, adding trimethylolpropane trimethacrylate, vinylphosphonic acid, azodiisobutyronitrile and the graphene oxide nanobelt into an organic solvent, and carrying out a solvothermal reaction to obtain a solid; and 3, successively carrying out washing, freezing and drying to obtain the composite aerogel, whereinthe grafting rate of phosphorus in the aerogel is 15-25%. The aerogel can be used as an adsorbent for treating thorium-containing wastewater, the adsorption capacity of the aerogel is 300-380 mg / g, and the aerogel can be used in the field of nuclear wastewater treatment.

Owner:EAST CHINA UNIV OF TECH

Preparation method of cement retarder

The invention discloses a preparation method of a cement retarder, and belongs to the technical field of preparation of oil well cement admixtures. The preparation method comprises the following steps of firstly, composting stalk to produce humus; using a sodium pyrophosphate alkaline solution to extract the humus, so as to obtain water-soluble humic acid; quickly degrading the humic acid under the visible light, and enabling the humic acid to complex with calcium ions to form insoluble precipitate to adsorb onto the surface of hydrate, thereby blocking contact with water; using aspartic acid as a raw material, performing amidation, and introducing itaconic acid into the aspartic acid; using the itaconic acid-modified aspartic acid and vinyl phosphonic acid as monomers to polymerize, so as to obtain the polymer, wherein the polymer contains hydroxy and phosphonic acid groups, the hydroxy and phosphonic acid groups has stronger activating effect on the surfaces of cement particles and hydrolyzed products, and can adsorb onto the surface of the solid particle, and the formation of cement and slurry structure is delayed. The prepared cement retarder has the advantages that the good retarding effect and degrading property are realized, and the mixing amount is small in use.

Owner:常州五荣化工有限公司

Wool fabric flame retardation finishing method

InactiveCN103981707AImprove flame retardant performanceGood shrink resistanceFibre treatmentEmulsionGraft reaction

The invention provides a wool fabric flame retardation finishing method, which comprises the following steps: A)pre-treating fabric, performing ultrasonic treatment for 30-60 minutes with frequency of 30-40 KHz; B)pre-emulsifying on a monomer: emulsifying a vinylphosphonic acid monomer by an emulsifier to form an emulsion, adjusting pH value of 3-4; C)performing a grafting reaction: heating a rolling groove filled with the monomer emulsion to the temperature of 80-90 DEG C, continuously heating to the temperature of 90-100 DEG C and reacting for 1-2 hours; D)washing; and E)drying. According to the wool fabric through the flame retardation finishing, the limited oxygen index after washing for 30 times is still at more than 27%, the wool fabric enables self-extinguishing while meeting fire, and has good perdurable flame resistance performance; the ultrasonic treatment is used for pretreatment, and is in favor of subsequent chemical grafting; simultaneously, the wool fabric through ultrasonic treatment has good shrinkproof performance and fluffy degree.

Owner:TONGXIANG PUYUAN WOOLEN KNITTING TECH SERVICE CENT

Method for preparing high-temperature-resistant and salt-resistant retarders for oil well cement

InactiveCN106811183ANot prone to degradationStrong salt resistanceDrilling compositionCis-Butenedioic AcidAcid group

The invention relates to a method for preparing high-temperature-resistant and salt-resistant retarders for oil well cement, and belongs to the field of technologies for preparing retarders. The method includes polymerizing maleic acid which is used as a raw material, and then grafting vinyl phosphonic acid on the maleic acid; hydrolyzing the maleic acid under alkaline conditions to obtain hydrolyzed and modified poly-maleic acid; carrying out reaction on 2-acrylamide-2-methylpropanesulfonic acid and the hydrolyzed and modified poly-maleic acid to obtain reaction products; mixing the reaction products, sodium humate and the like with one another to obtain mixtures and heating the mixtures. The hydrolyzed and modified poly-maleic acid contains a carboxyl group and a phosphonic acid group which are adjacent to each other, accordingly, calcium chelation can be enhanced, and hydrate formation can be reduced. Large quantities of active groups can be led into the reaction products and can be adsorbed on the surfaces of hydrate, accordingly, water contact can be inhibited, impervious layers can be formed around cement particles, hydration effects can be retarded, and the high-temperature stability and the salt resistance can be improved. The method has the advantages that the high-temperature-resistant and salt-resistant retarders for the oil well cement are excellent in high-temperature-resistant property and salt-resistant property and are difficult to degrade under high-temperature conditions, accordingly, influence on the comprehensive properties of cement slurry can be prevented, and the method has a broad application prospect.

Owner:戴琪

Heat-insulating chemical filament and preparation method thereof

InactiveCN107419359AStable chemical and physical propertiesSimple preparation processConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsRutileMaterials science

The invention relates to a heat-insulating chemical filament. The heat-insulating chemical filament comprises, by weight, 17-22 parts of natural ceiba fibers, 5-8 parts of electric mountain flour, 6-10 parts of rutile powder, 2-4 parts of vinylphosphonic acid, 12-18 parts of silks, 10-15 parts of nano silicon oxide, 12-15 parts of polyimide powder, 13-20 parts of wool, 9-14 parts of zinc oxide and 14-19 parts of polylactic acid fibers. The obtained heat-insulating chemical filament has the advantages that the chemical filament produced according to the special raw material formula has circular cross section and stable chemical and physical performance, the heat insulation temperature is larger than or equal to 250 DEG C, the water solution temperature is 80-90 DEG C, the breaking strength is larger than or equal to 3.5cN / dtex, and the monofilament fineness is 2-10dtex; the manufacture process is simple and beneficial to large-scale popularization and application.

Owner:湖州力行纺织有限公司

Tether-containing conducting polymers

A compound having the formula below. X is hydroxyl, a sulfonic ester or salt thereof, a phosphonate or salt thereof, a carboxylate or salt thereof, or a boronic ester or salt thereof. The value n is an integer greater than or equal to 2. A polymer made by polymerizing the compound. A method of: reacting NH2—(CH2—CH2—O)n—CH2—CH2—OH with thiophene acid chloride to form a (SC4H3)—CO—NH—(CH2—CH2—O)n—CH2—CH2—OH amide; reacting the amide with a vinyl sulfonic ester, a vinyl phosphonate, a vinyl carboxylate, or a vinyl boronic ester to form an intermediate; and converting the intermediate to a salt form.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

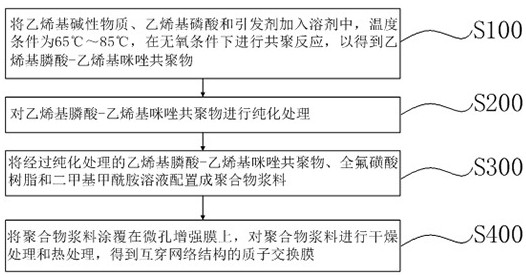

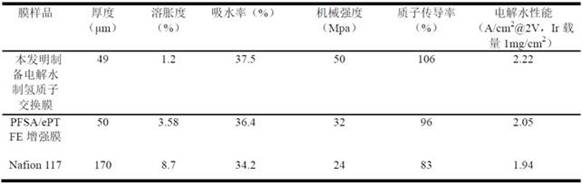

Water electrolysis hydrogen production proton exchange membrane and preparation method thereof

ActiveCN114108006AImprove proton conductivityImprove performanceOrganic diaphragmsPhosphoric acidEngineering

The invention discloses a water electrolysis hydrogen production proton exchange membrane and a preparation method thereof.The preparation method of the water electrolysis hydrogen production proton exchange membrane comprises the steps that a vinyl alkaline substance, vinyl phosphoric acid and an initiator are added into a solvent, the temperature condition is 65-85 DEG C, a copolymerization reaction is carried out under the anaerobic condition, and the water electrolysis hydrogen production proton exchange membrane is obtained; the vinyl phosphonic acid and vinyl imidazole copolymer is obtained; carrying out purification treatment on the vinyl phosphonic acid-vinyl imidazole copolymer; the vinylphosphonic acid-vinyl imidazole copolymer, perfluorinated sulfonic acid resin and a dimethylformamide solution which are subjected to purification treatment are prepared into polymer slurry; and coating a microporous reinforced membrane with the polymer slurry, and carrying out drying treatment and heat treatment on the polymer slurry to obtain the proton exchange membrane with the interpenetrating network structure for hydrogen production by electrolysis of water. According to the method, the proton conduction capability of the water electrolysis hydrogen production proton exchange membrane is enhanced, and the performance of the water electrolysis hydrogen production proton exchange membrane on the water electrolysis membrane electrode is improved.

Owner:SHENZHEN GENERAL HYDROGEN ENERGY TECH CORP LTD

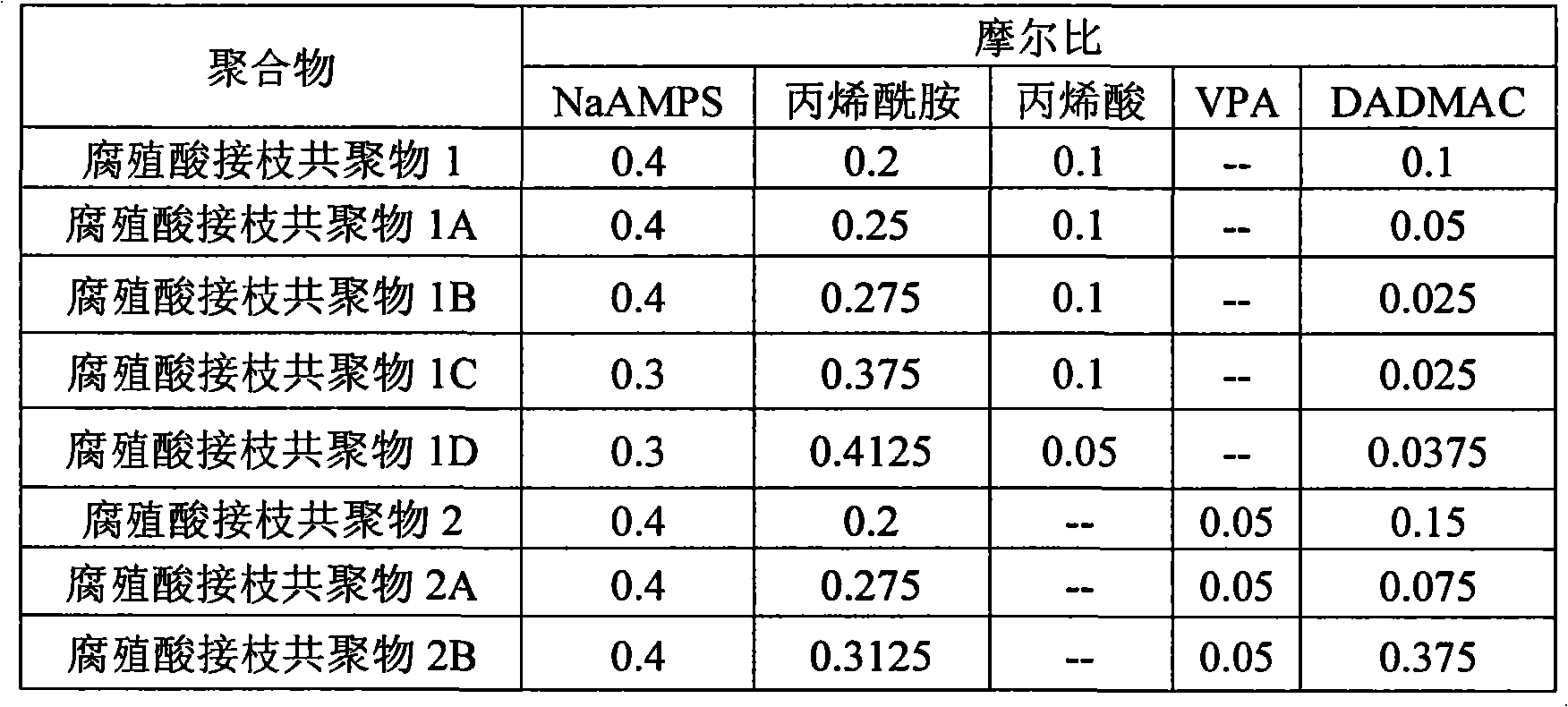

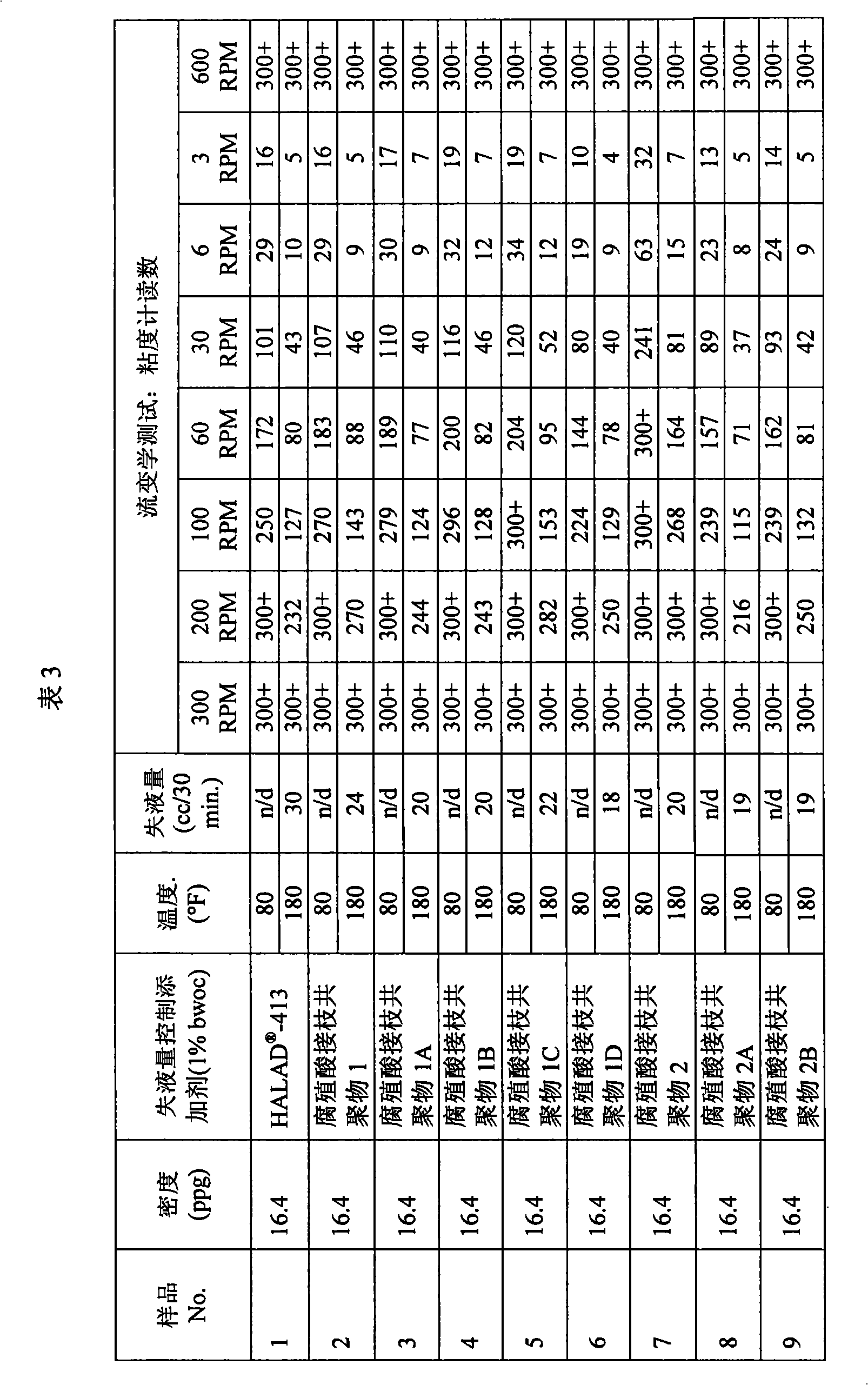

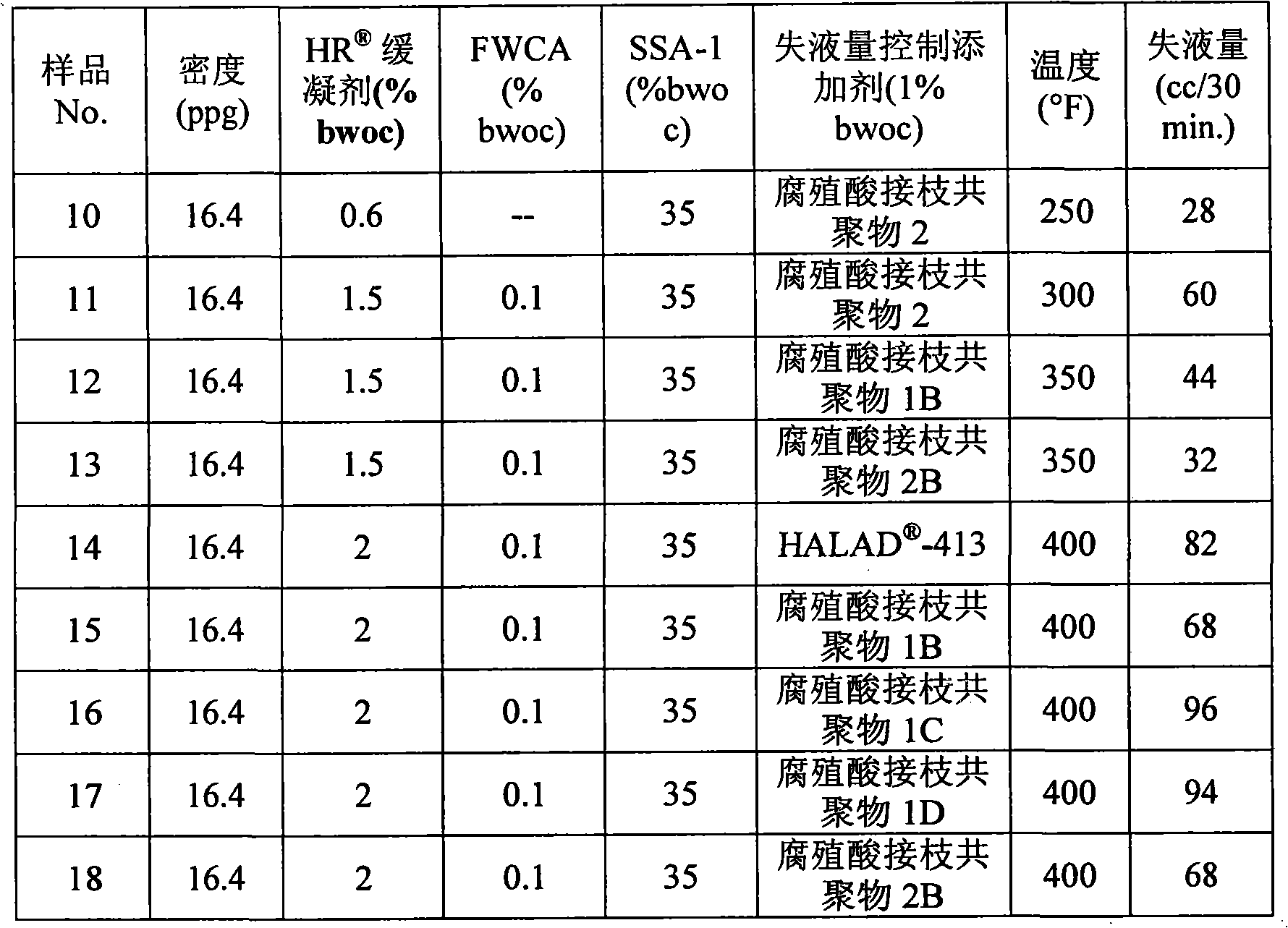

Cement compositions comprising humic acid grafted fluid loss control additives and methods of using them

A cement composition comprising water, a cement, and a fluid loss control additive, the fluid loss control additive comprising a graft copolymer. The graft copolymer comprises a backbone and at least four grafted monomers selected from the group consisting of 2-acrylamido-2-methylpropanesulfonic acid, acrylamide, acrylic acid, vinylphosphonic acid, diallyldimethylammonium chloride, and salts thereof. The backbone of the graft copolymer comprises a humic acid salt. The cement compositions may be used in cementing operations.

Owner:HALLIBURTON ENERGY SERVICES INC

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com