Patents

Literature

162results about How to "Fully crosslinked" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet crosslinked expansion type flame-retardant polyolefin cable insulation sheath material and preparation thereof

ActiveCN101481475AAdd lessHigh flame retardant efficiencyPlastic/resin/waxes insulatorsInsulated cablesPolyolefinProcedure Agents

The invention discloses an insulating and sheathing material of ultraviolet light crosslinking expanding type phosphorus nitrogen flaming resistance polyolefine cables and a preparation method thereof. The invention is characterized in that polyethylene / PEMA and / or ethylene vinyl acetate or maleic anhydride grafted ethylene vinyl acetate or acid amide grafted ethylene vinyl acetate copolymer are taken as base, added with expanding type phosphorus nitrogen halogen-free flame retardants, light trigger, polyfunctional group cross linker and chemical inhibitor and matched with flaming retardant synergistic agent, antismoke agent and processing aid, and then squeezed out and pelleted into photo-crosslinking flame retardant cable materials; and then the flame retardant cable materials are melted and extruded on a cable conductor wire core and clad into an insulating layer and a sheathing layer; hereupon the ultraviolet light irradiation crosslinking is carried on the insulating layer or the sheathing layer. Via detecting, the oxygen index of the insulating layer or the sheathing layer is larger than 30%, the vertical flaming experiment passes through UL-94 V0 level, the tensile strength is larger than 12Mpa, the elongation at break is larger than 350%, and the electric volume resistivity is larger than 8*10 omega.cm.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

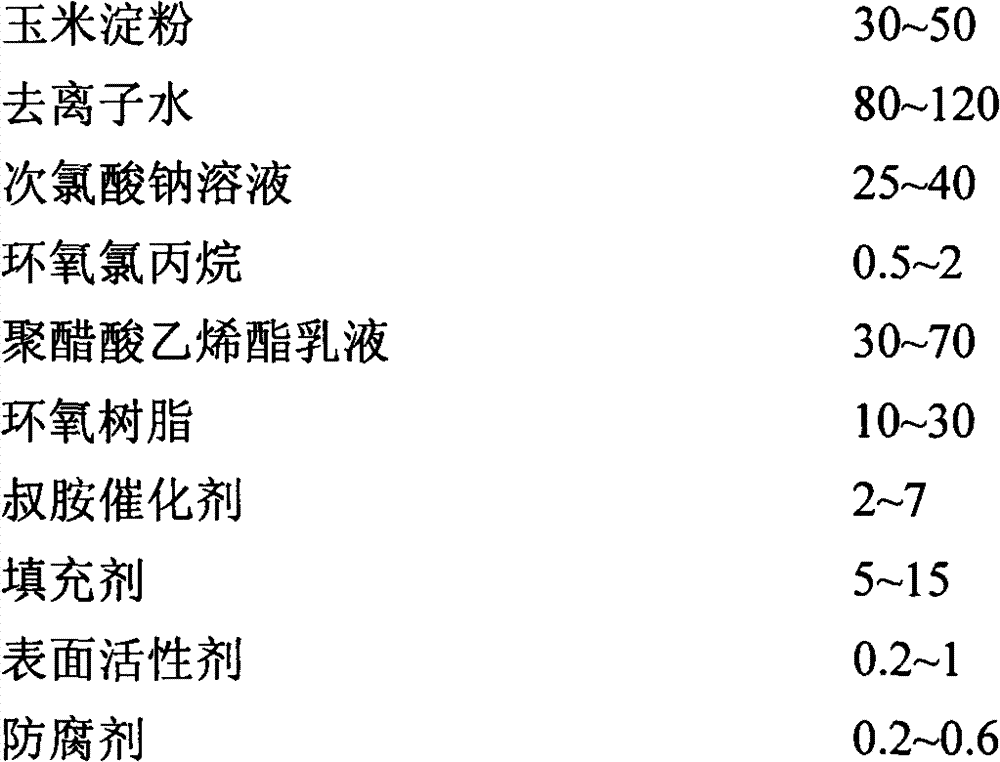

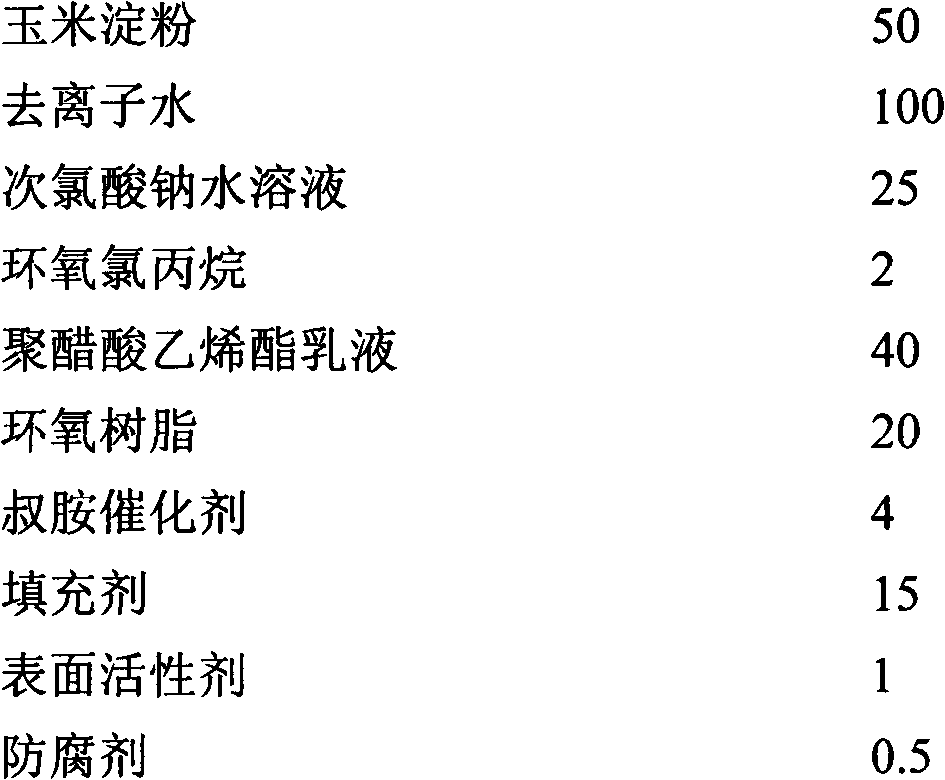

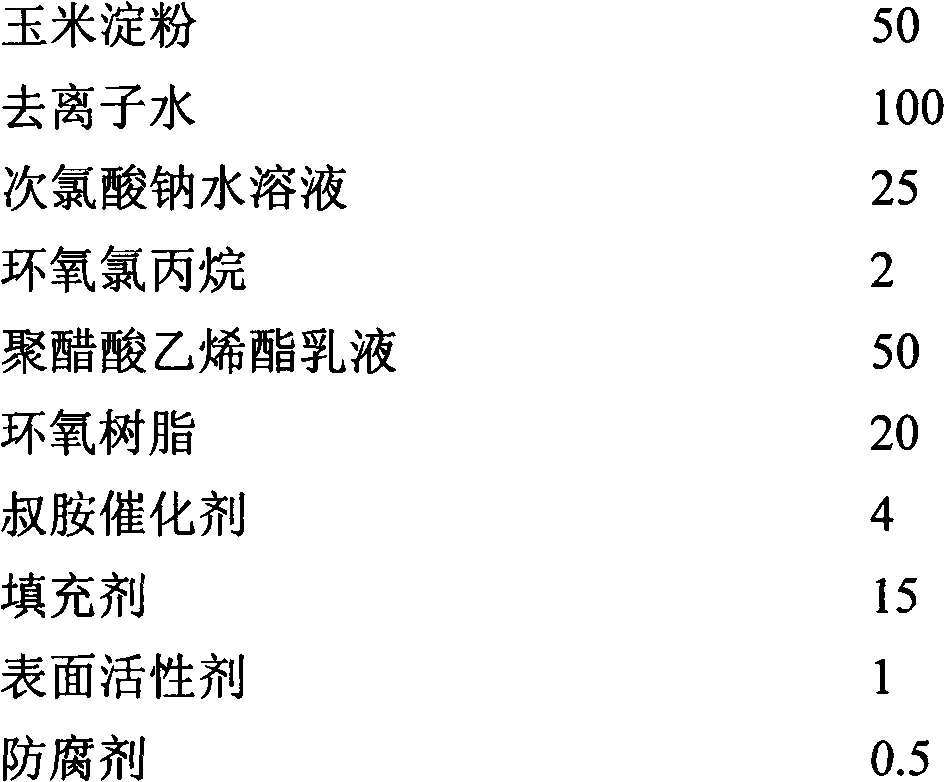

Modified starch adhesive and method for preparing same

InactiveCN102732186AGood compatibilityRaw materials are cheap and easy to getMonocarboxylic acid ester polymer adhesivesStarch derivtive adhesivesEpoxyAdhesive

The invention discloses a modified starch adhesive and a method for preparing the same. The modified starch adhesive comprises the following components by weight: 30-50 parts of corn starch, 80-120 parts of deionized water, 25-40 parts of sodium hypochlorite solution, 0.5-2 parts of epichlorohydrin, 30-70 parts of polyvinyl acetate emulsion, 10-30 parts of epoxy resin, 2-7 parts of tertiary amine catalyst, 5-15 parts of filler, 0.2-1 part of surfactant, and 0.2-0.6 part of preservative, wherein the sodium hypochlorite solution serves as the oxidant, the polyvinyl acetate emulsion serves as the high-cohesive-energy reinforcement component, and the epoxy resin servers as the water-tolerant modified component. The method for preparing the modified starch adhesive comprises the following steps: mixing the oxidized starch emulsion prepared in advance, the polyvinyl acetate emulsion and the epoxy resin according to proportion uniformly, adding the catalyst, the filler and the preservative, and stirring quickly and uniformly. The modified starch adhesive disclosed by the invention has the advantages of high shear strength, high water-tolerant shear strength, moderate viscosity, good liquidity, moderate primary drying time, low cost and excellent integrated performance.

Owner:EAST CHINA UNIV OF SCI & TECH

Composite material prepreg for restoring ultraviolet light curing structure and preparation method thereof

InactiveCN104312192AImprove light curing efficiencyMeet curing requirementsGlass fiberUltraviolet lights

The invention provides a composite material prepreg for quickly ultraviolet light curing a resin base structure reinforced by glass fibers with certain thickness and a preparation method thereof. In the method, a common free radical curing resin as a matrix, a proper photoinitiator, a thermal initiator and other assistants are preferably selected to form a light-thermal composite initiation system, a glass fiber textile is used as a reinforcement material, and the composite material prepreg with a certain thickness is prepared by a proper compound process. The prepreg can be cured by irradiating ultraviolet light on a single surface for 10 minutes, and the light curing thickness at one time can be higher than 15 mm. By adopting the invention, the existing technical problem that the ultraviolet light cannot be used for curing composite material structural members with large thicknesses (10-15 mm and larger) at one time is solved, the composite material prepreg is cured more conveniently and efficiently. The light-cured resin and the composite material thereof express huge application prospect and market potential in some special fields, for example, trenchless repair of municipal drainage pipelines.

Owner:WUHAN UNIV OF TECH

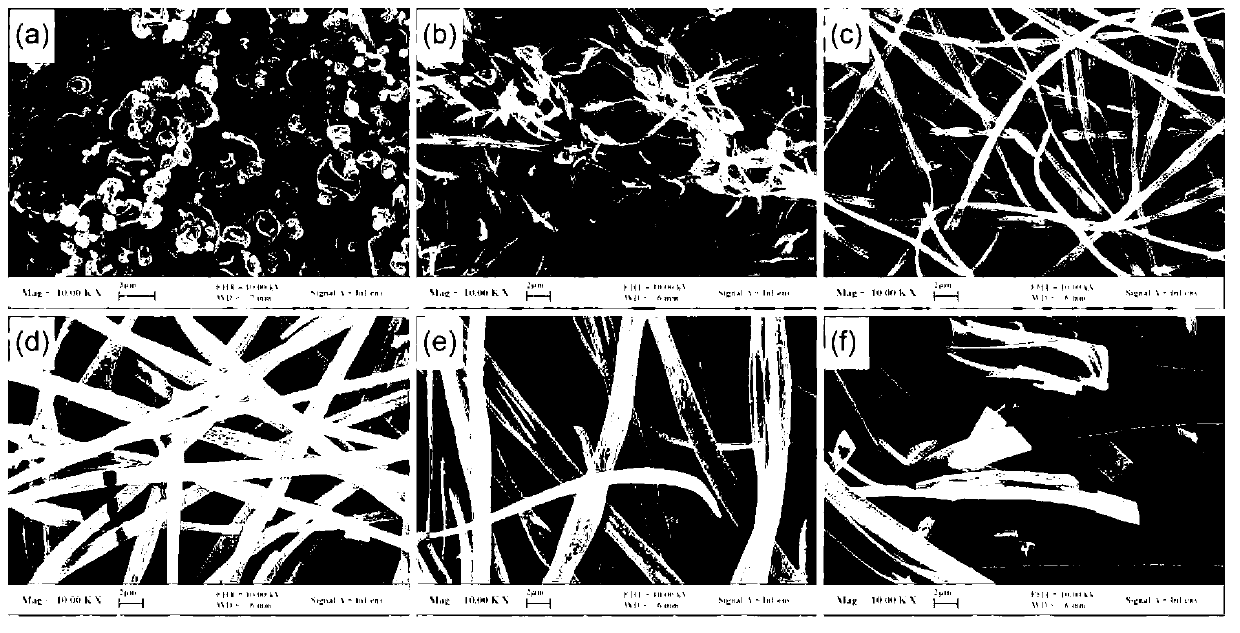

Method for preparing superfine phenolic fibre

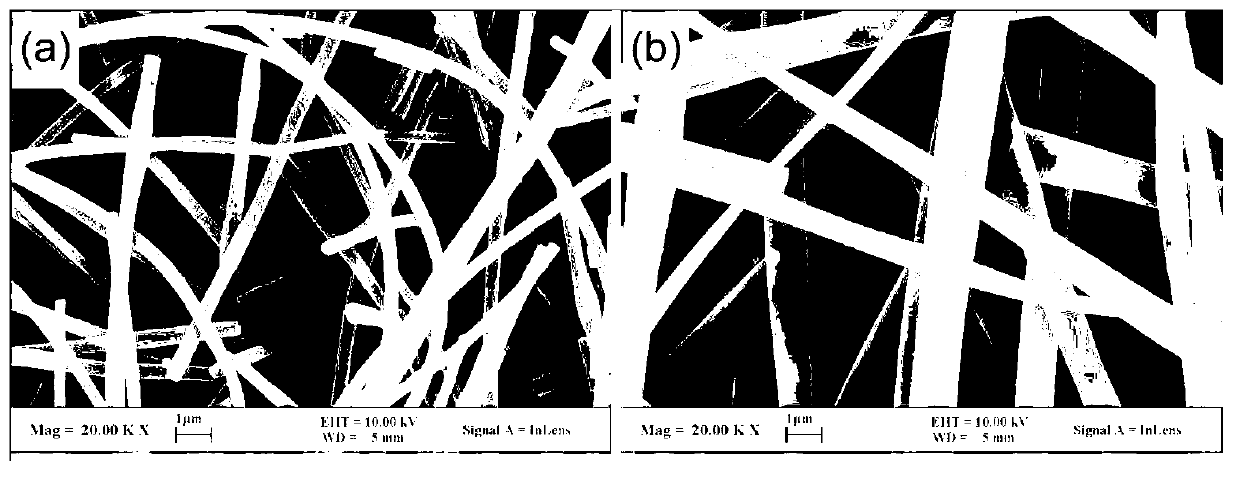

ActiveCN102899738AIncrease the degree of cross-linkingFully crosslinkedMonocomponent synthetic polymer artificial filamentNon-woven fabricsFiberElectrospinning

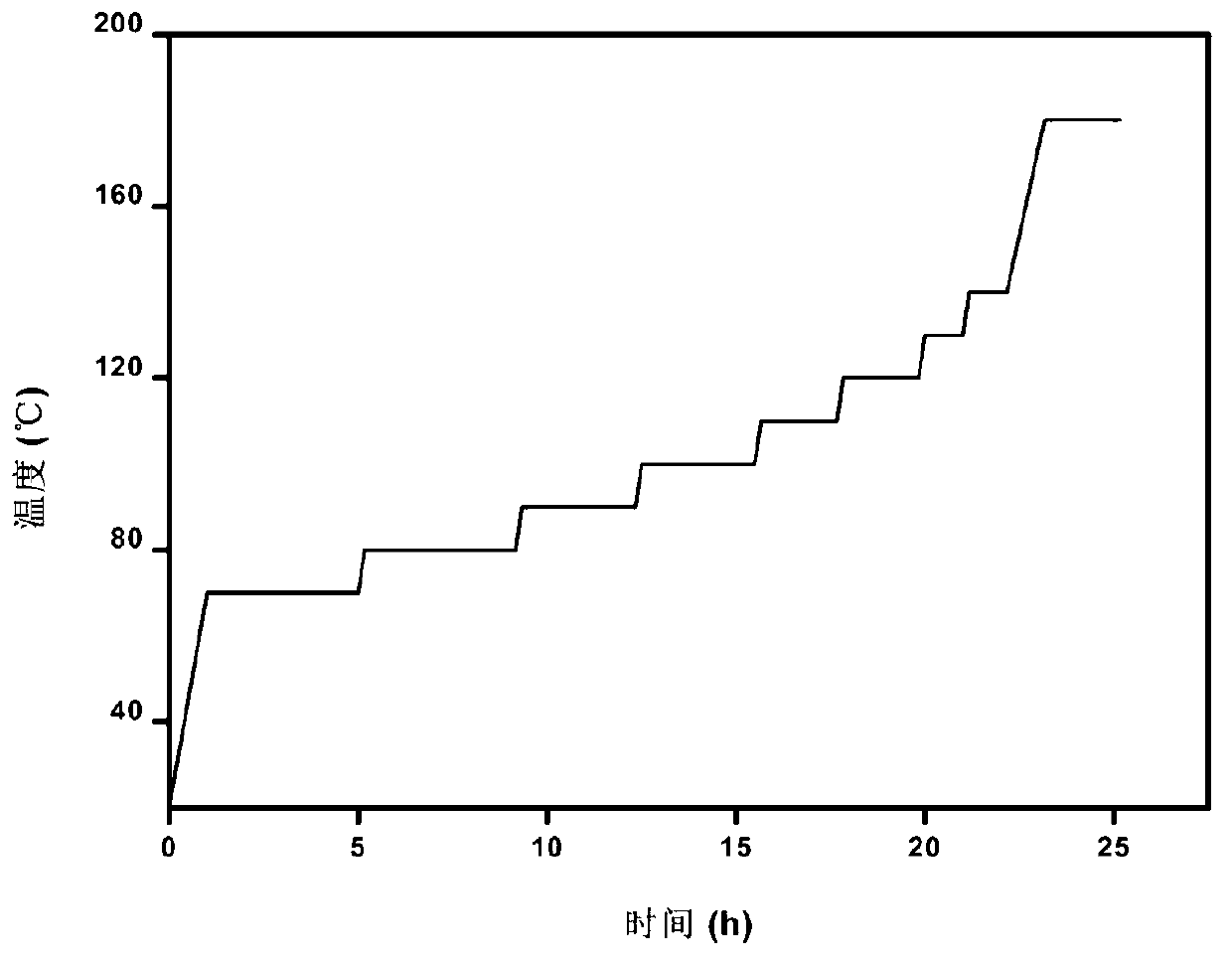

The invention relates to a method for preparing superfine phenolic fibre, comprising the following steps of: firstly, preparing commercially available soluble phenolic resin with low molecular weight (Mw)of 500-3000 into organic solution containing 10-40wt% of soluble phenolic resin; secondly, adding high molecular weight linear polymer into the solution and stirring until the high molecular weight linear polymer is completely dissolved, wherein mass ratio of the high molecular weight linear polymer to the soluble phenolic resin is 1: (20-100); and thirdly, carrying out electrostatic spinning on the solution to obtain the superfine phenolic fibre and a phenolic fiber felt, wherein relative humidity RH of an electrostatic spinning experiment is 15-55%, and the obtained superfine phenolic fibres can be cylindrical, elliptic cylinder-shaped and belt-shaped. Aiming at the characteristic that low-molecular-weight phenolic resin can be easily melted, the invention provides a non-constant-speed stepped heating and curing process, and curing time is shortened under the condition that the fibers are fully crosslinked and are not melted.

Owner:TSINGHUA UNIV

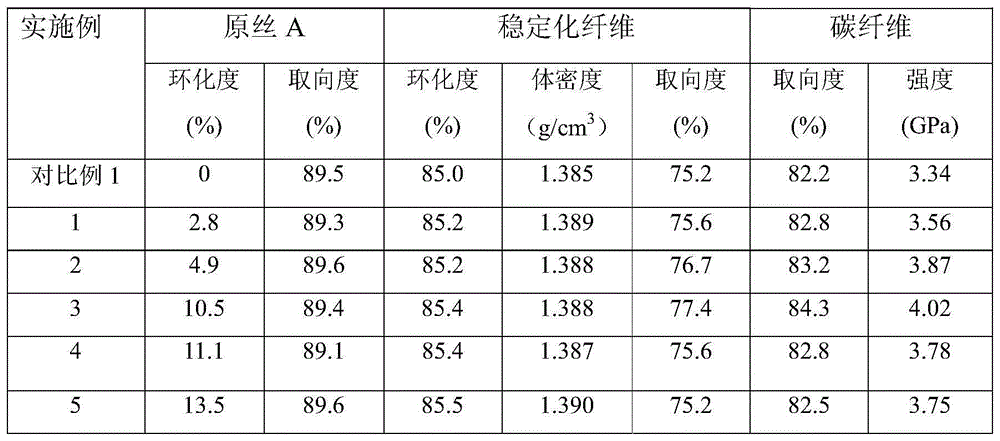

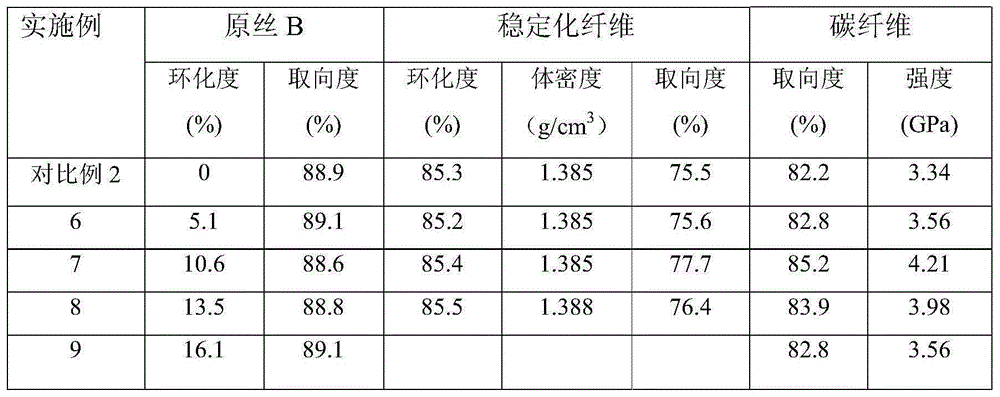

Method for preparing polyacrylonitrile carbon fiber with gamma ray irradiation

InactiveCN104790070AShorten the stabilization timeIncrease productivityPhysical treatmentFibre chemical featuresAir atmospherePre irradiation

The invention relates to a method for preparing polyacrylonitrile carbon fiber with gamma ray irradiation. The method comprises the following steps: carrying out appropriate doses of gamma ray irradiation for polyacrylonitrile fiber in air, vacuum or inert atmosphere, and thus generating part of cyclization and crosslinking structure; carrying out thermal oxidation stabilization for 0-100 min in air atmosphere to achieve full cyclization and crosslinking; carrying out low-temperature carbonization and high-temperature carbonization so as to prepare the high-performance carbon fiber. The method carries out pre-irradiation treatment before thermal stabilization, so that the thermal stabilization time can be shortened, the production efficiency can be improved, and polyacrylonitrile molecules can form a rigid structure with a regular structure and strong heat resistance. Higher rigid drafting can be applied in the thermal stabilization process, the orientation degree graphite-like sheets in the carbon fiber is facilitated, and the high-performance carbon fiber is prepared.

Owner:DONGHUA UNIV

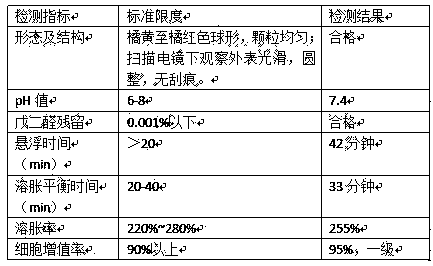

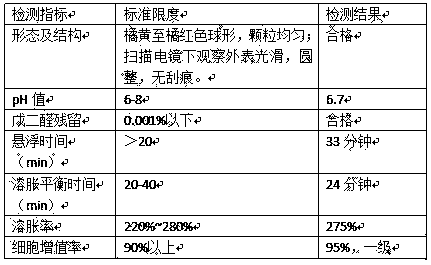

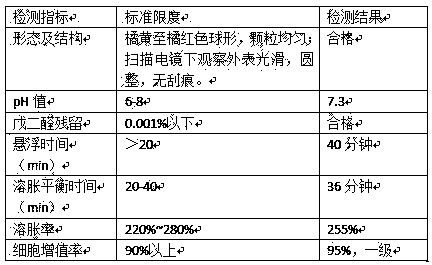

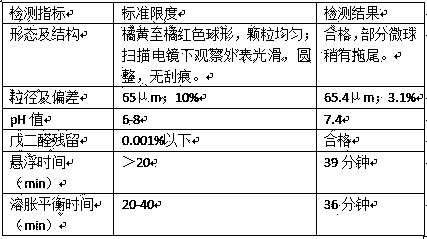

Carboxymethyl chitosan microsphere embolization agent and preparation method thereof

The invention relates to a carboxymethyl chitosan microsphere embolization agent. The embolization agent takes carboxymethyl chitosan as raw materials; the carboxymethyl chitosan is subjected to pretreatment, emulsification, cross-linking and dehydration drying to prepare microspheres with three-dimensional network structures. After the microspheres absorb water, the microspheres are smooth in surface and are rich in elasticity, have good biocompatibility and biodegradablity and is suitable for non-permanent vascular embolization.

Owner:SHIJIAZHUANG YISHENGTANG MEDICAL SUPPLIES

Visible-light-curing vinyl ester resin composite prepreg, and preparation method and application method thereof

The invention particularly provides a visible-light-quick-curing vinyl ester resin composite prepreg, and a preparation method and application method thereof, belonging to the field of repair of a fiber-reinforced resin-base structure with certain thickness. A special vinyl ester resin is used as a matrix; the proper visible light initiator, thermal initiator and other aids are selected to constitute the light-thermal composite initiation system; magnesium oxide is used as a thickener; different types of fabrics are selected as fiber-reinforcing materials according to performance requirements; and a proper composite technique is utilized to prepare the composite prepreg with certain thickness. The visible-light-curing prepreg material can be cured within 5 minutes under the single-side irradiation of visible light, and the once-time photocuring thickness can reach 10mm or above, thereby basically solving the problems of poor operability, poor safety and insufficient film thickness under ultraviolet light. The visible-light-curing prepreg can be subjected to mass application in the field of structure repair.

Owner:四川远鸣科技有限公司

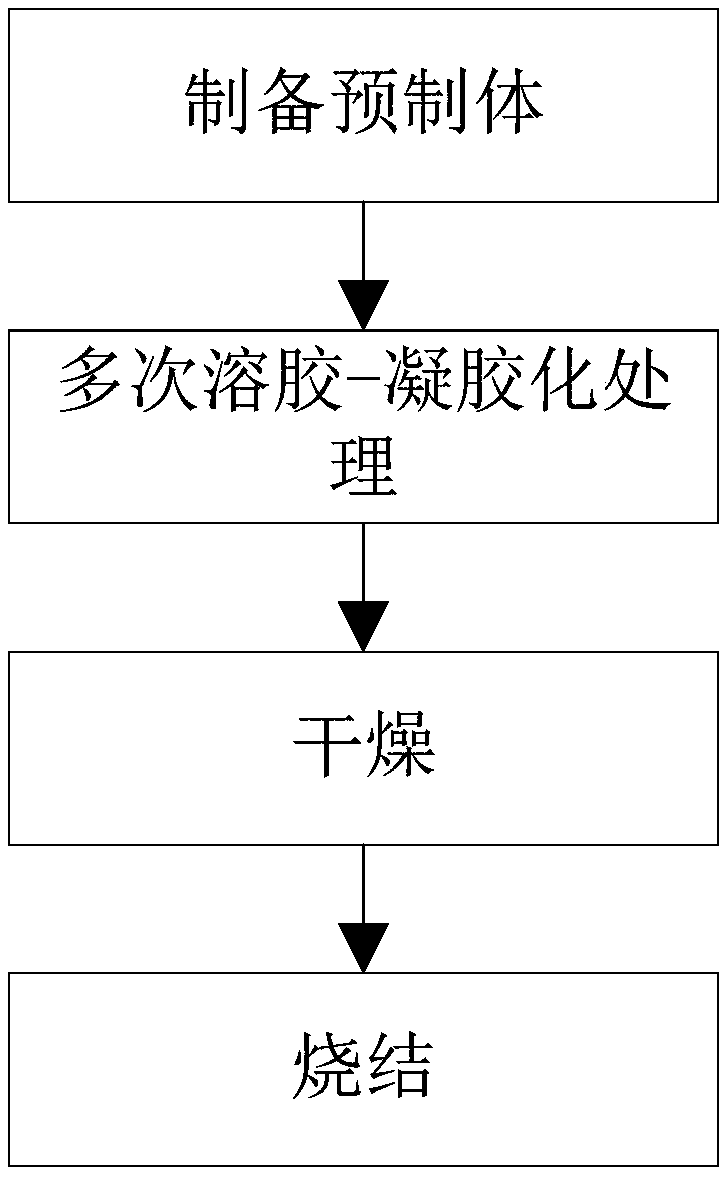

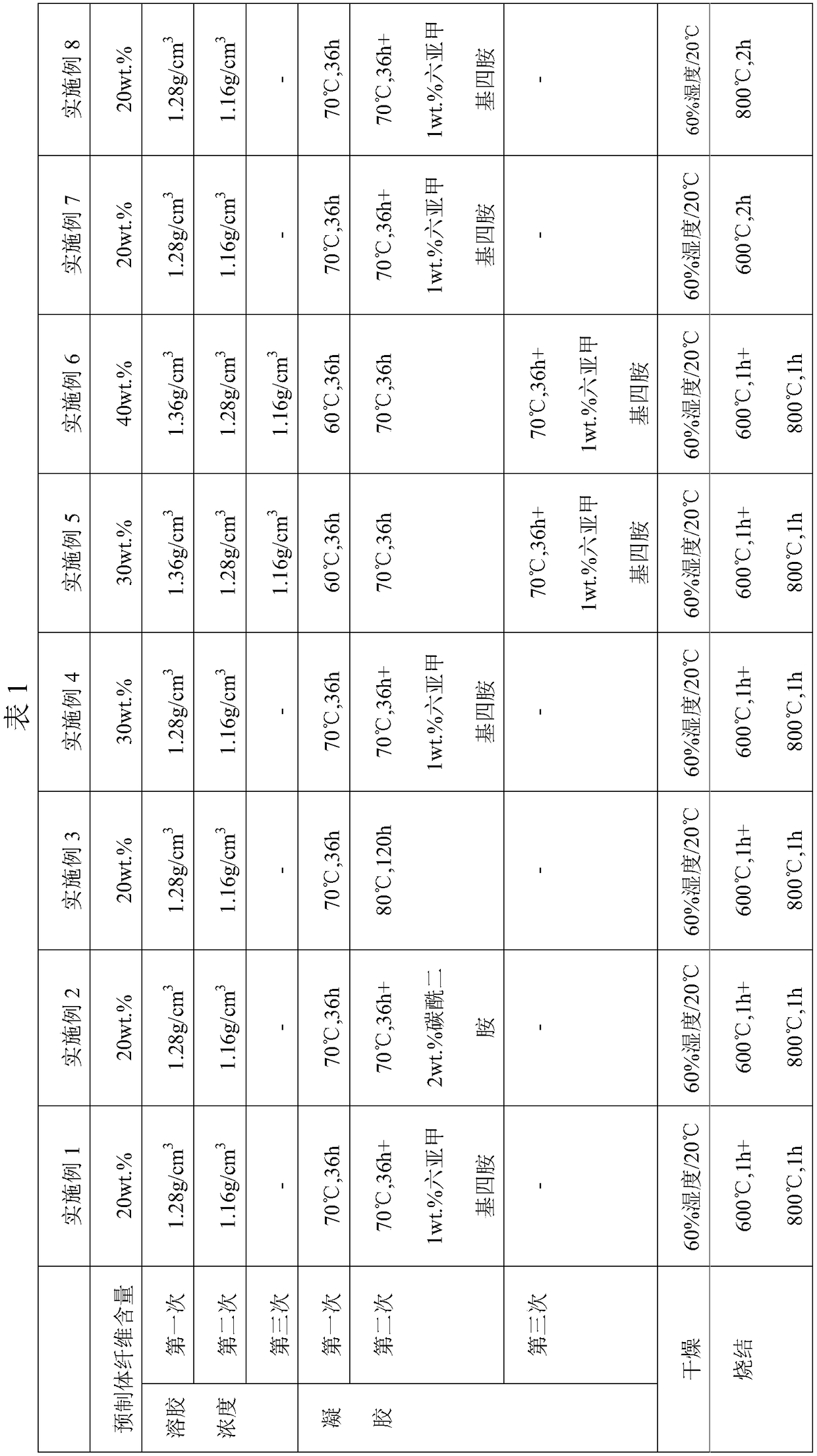

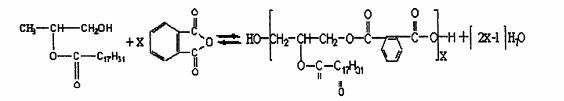

Fiber-reinforced silicon dioxide heat-insulating ceramic material and preparation method and application thereof

The invention relates to a fiber-reinforced silicon dioxide heat-insulating ceramic material and a preparation method and application thereof. The preparation method comprises the following steps: (1), preparing a preform; (2), performing multiple sol-gelation treatment: impregnating the preform with silica sol, then gelating to complete once sol-gelation treatment, repeating the sol-gelation treatment for multiple times, and sequentially reducing the density of the silica sol for impregnation to form gradient impregnation; (3), drying a material treated in the step (2) to obtain a blank; (4),sintering the blank to obtain the fiber-reinforced silicon dioxide heat-insulating ceramic material. By the preparation method, the heat-insulating ceramic material with high compressive strength andlow heat conductivity can be prepared; the heat-insulating ceramic material can be applied to an aircraft heat insulating system.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Curable resin composition for convering a fingernail or artificial fingernail

ActiveUS20120276028A1Good lookingSuperior property in waterCosmetic preparationsToilet preparationsEmulsionPolyethylene glycol

The present invention provides a curable resin composition for coating natural or artificial nails, which in particular exhibits an excellent appearance after coating, high water and scratch resistances, and low levels of odor, damage to nails, and dermal irritancy, resulting in a high level of safety to human bodies and superior storage stability. The curable resin composition for coating a natural or artificial nail of the present invention comprises (A) an aqueous emulsion of a polymer having functional groups polymerizable by exposure to active energy radiation, (B) polyethylene glycol, and (C) a photo radical initiator containing no nitrogen atom in its molecule.

Owner:THREEBOND FINE CHEM CO LTD

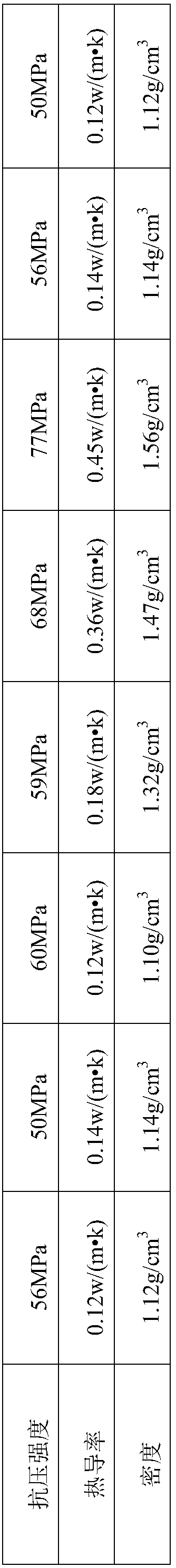

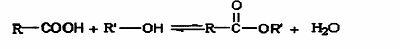

Quick-drying alkyd resin for double-component polyurethane primer

ActiveCN102311542ALow in Vegetable Oleic AcidShort oilPolyurea/polyurethane coatingsBenzoic acidVegetable oil

The invention discloses a quick-drying alkyd resin for a double-component polyurethane primer for a wooden ware compatible with a polyurethane curing agent. The quick-drying alkyd resin comprises the following raw materials in parts by weight: 8-10 parts of monoacid, 9-11 parts of semidry vegetable oil acid, 0.5-1 part of maleic anhydride, 22-28 parts of phthalic anhydride, 4-6 parts of benzoic acid, 11-15 parts of pentaerythritol, 2-5 parts of trimethylolpropane, 6-9 parts of diglycol, 20-25 parts of dimethyl benzene and 5-8 parts of toluene. The quick-drying alkyd resin for the double-component polyurethane primer for the wooden ware has the characteristics of high drying speed, superior transparency, excellent rubbing property, high cost performance and the like, and also has high intermiscibility with the dimethyl benzene.

Owner:SKSHU PAINT

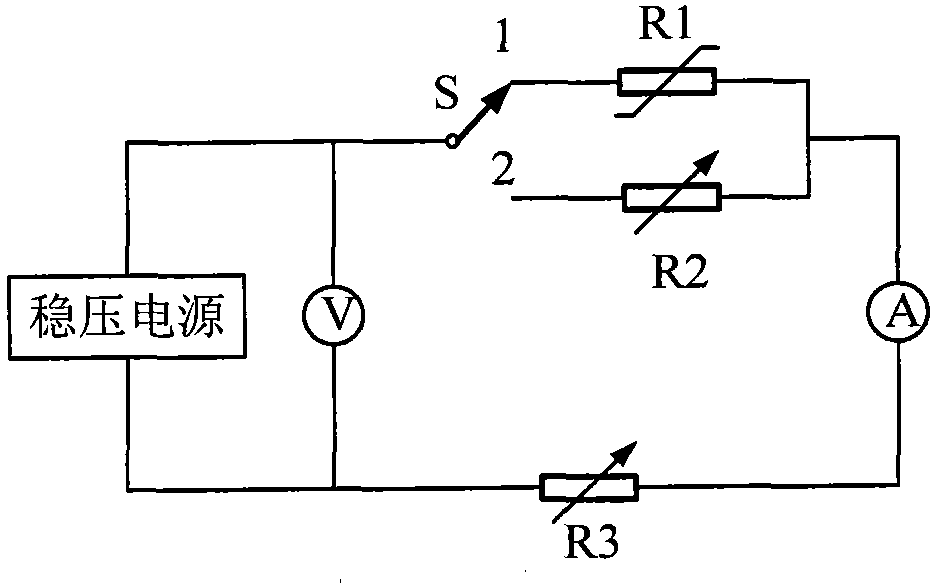

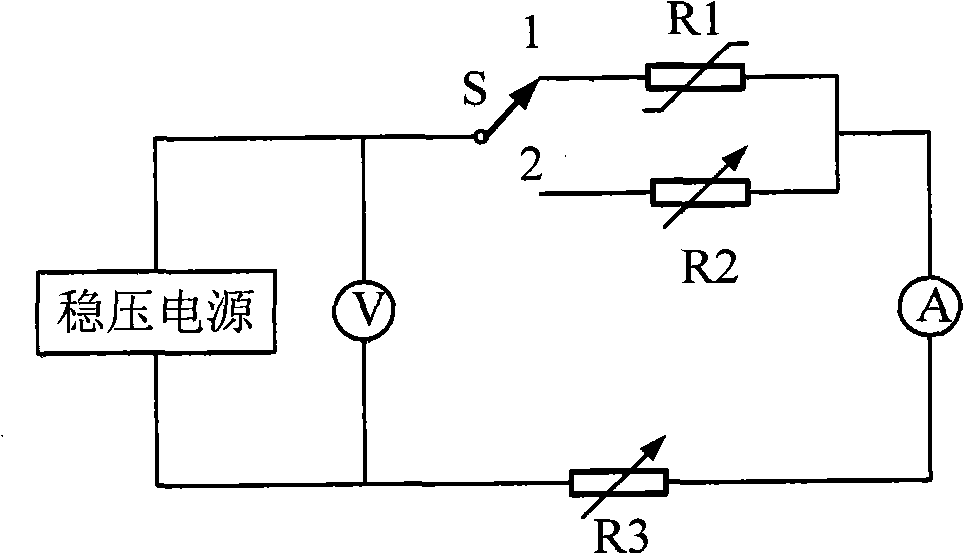

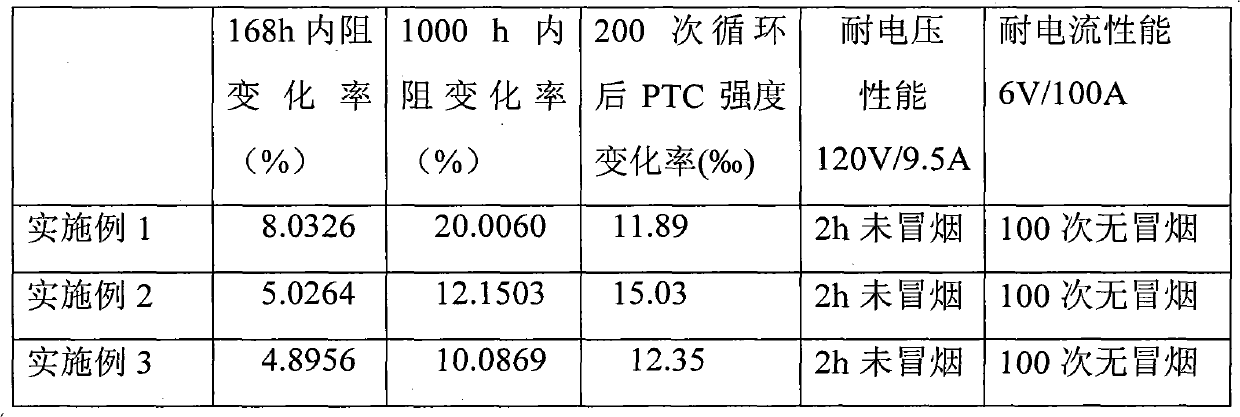

Positive temperature coefficient material, preparation method thereof and thermistor containing positive temperature coefficient material

ActiveCN102558638AIncrease contentIncrease the amount addedPositive temperature coefficient thermistorsAging resistanceThermistor

The invention provides a positive temperature coefficient material. The material is formed by melting a mixture, and the mixture comprises a polymer, a conductive filler, a nucleating agent, an additive, a flame retardant and a lubricant; through considering the total weight of a mixture as a reference, the components by weight percent are 0.5 to 10 wt% additive, 5 to 15 wt% polymer, 0.5 to 10 wt% nucleating agent, and 0.5 to 3 wt% lubricant, 80 to 90 wt% conductive filling material, and 1 to 6 wt% flame retardant; the additive is ethylene-propylene-diene rubber; the conductive filling material is titanate modified conductive filling material; and the flame retardant is titanate modified flame retardant. The invention further provides a preparation method of the material and a thermistor containing the material. The positive temperature coefficient material has good ageing-resistance and pressure resistant and current resistance.

Owner:BYD CO LTD

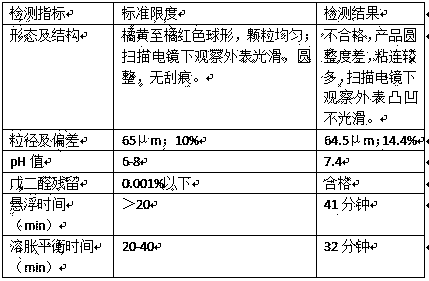

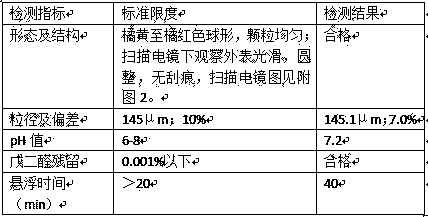

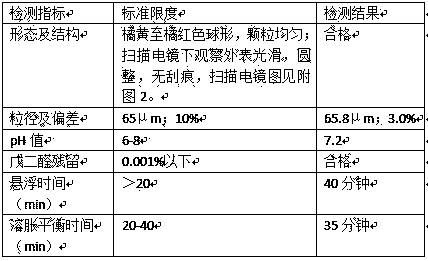

Preparation method of chitosan microsphere

The invention relates to a preparation method of a chitosan microsphere. The preparation method of the chitosan microsphere comprises the following concrete steps: causing an oil phase to flow at a certain flow rate in an oil phase pipeline; vertically injecting a chitosan aqueous phase into the oil phase pipeline from an aqueous phase pipeline at a low speed; separating the chitosan aqueous phase into liquid drops with uniform size by virtue of a shearing force of an oil phase fluid, wherein the liquid drops flow into a container filled with crosslinking agent emulsion along with an oil phase; crosslinking and solidifying to obtain microspheres while stirring; and separating and drying, so that the chitosan microsphere is obtained. The chitosan microsphere prepared by adopting the preparation method has the characteristics of small particle size and high uniformity, safety and effectiveness of embolism in an interventional therapy can be improved, clinical operability can be enhanced, the clinical safety accident rate can be reduced, excessive screening is not needed to be carried out on the chitosan microsphere product to remove microspheres which are not in target particle size, the production cost is reduced, and the production efficiency is improved.

Owner:SHIJIAZHUANG YISHENGTANG MEDICAL SUPPLIES

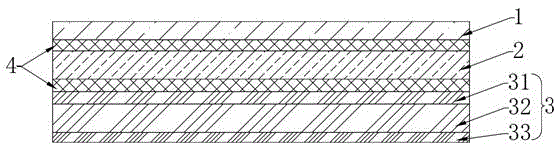

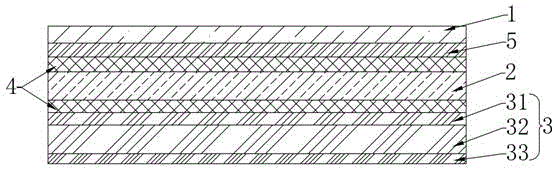

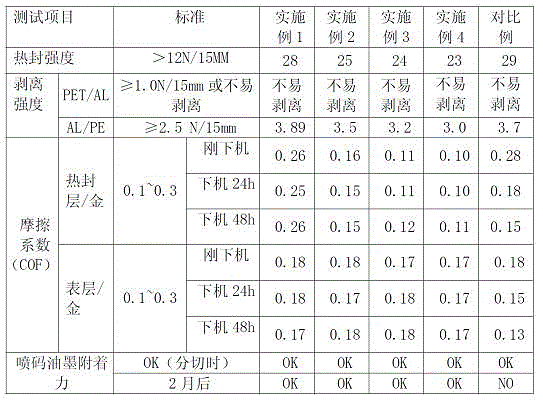

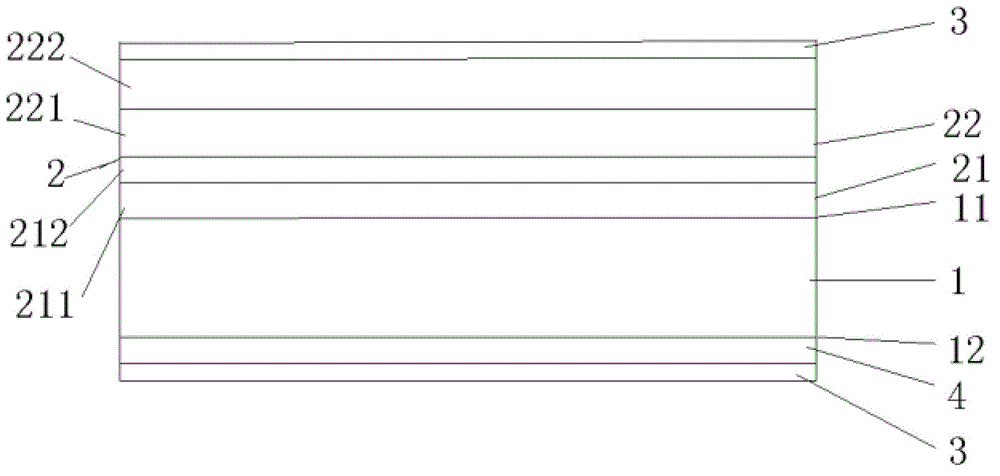

Composite membrane having stable friction coefficient and capable of being spurted with codes and preparation method of composite membrane

InactiveCN105667011AReduce coefficient of frictionImprove stabilityLamination ancillary operationsSynthetic resin layered productsSurface energySilicone resin

The invention discloses a composite film with a stable friction coefficient and which can be coded. It includes an outer layer, a barrier layer and a polyethylene co-extrusion film layer from the outside to the inside, and the polyethylene co-extrusion film layer includes a corona treatment layer from the outside to the inside. , a core layer and a heat-sealing layer. The material composition of the heat-sealing layer mainly includes polyethylene resin and a slip agent. The slip agent is a silicone slip agent masterbatch with polyethylene as a carrier. In the present invention, silicone slippery agent is added to the polyethylene co-extrusion film heat-sealing layer located inside the film, and it is extruded to the surface and evenly distributed during processing by utilizing its incompatibility with the main material to achieve The purpose of reducing the friction coefficient, and the molecular weight is large. Under the high temperature conditions during the film aging, storage and use, the silicone resin with low surface energy will not migrate and precipitate, and improve the stability of the friction coefficient of the inner surface of the film. Unwinding The speed meets the requirements of high-speed packaging machines. The invention discloses a method for preparing a composite film suitable for stable friction coefficient and capable of coding.

Owner:JIANGYIN SHENLONG PACKAGING MATERIALS CO LTD

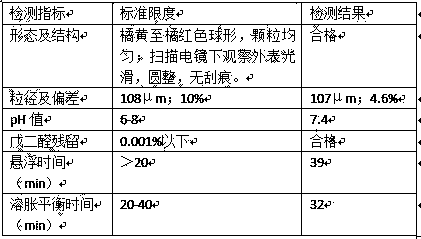

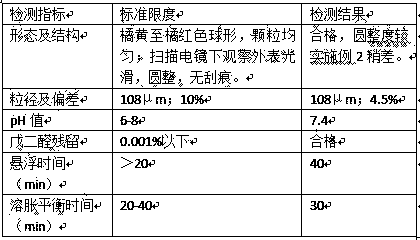

Chitosan microspheres and preparation method thereof

The invention relates to chitosan microspheres. The microspheres are solid spheres which have smooth surface and uniform granularity and are formed by crosslinking of chitosan and a crosslinking agent, wherein the grain diameter of each microsphere is 50-1200 mu m, preferably 50-600mu m, and further preferably 150-300mu m; and the grain diameter difference is not more than 20 percent, and preferably not more than 10 percent. The microspheres provided by the invention have the characteristics of small grain diameters and high uniformity, and are capable of improving the safety effectiveness of embolism in interventional therapy, reinforcing the clinical operability, reducing the clinical safety accident rate and reducing the production cost.

Owner:SHIJIAZHUANG YISHENGTANG MEDICAL SUPPLIES

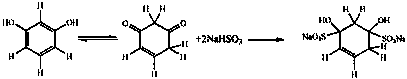

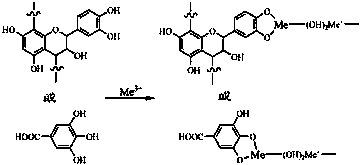

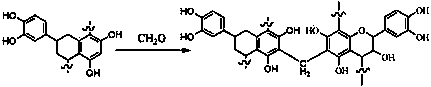

Regeneration plant tanning agent and preparation method thereof

The invention discloses a regeneration plant tanning agent. The regeneration plant tanning agent is prepared according to the following steps: enabling macromolecular tannin precipitation in vegetable tanning liquid waste to be properly degraded and sufficiently peptized through sulfonated processing, at the same time, controlling reaction conditions and maintaining the completeness of the structure of small molecule phenolics; then, utilizing cross-linking treatment to enable the small molecule phenolics to be linked sufficiently in a cross mode, increasing the average molecular weight of the small molecule phenolics, and enabling the molecular weight of the tannin to be distributed in a most proper range in the vegetable tanning process; finally, utilizing peptizing agents to adjust the Zeta electric potential and the grain size of the regeneration tanning agent to stable states. The regeneration plant tanning agent can sufficiently tan naked leather sufficiently. Obtained finished leather can be compared with merchandise industrial tannin extracts in heat stability and mechanical performance. The invention relates to a preparation method of the regeneration plant tanning agent. Vegetable tanning liquid waste is used as basic materials, and the influence of vegetable tanning on the environment can be effectively reduced.

Owner:SICHUAN UNIV

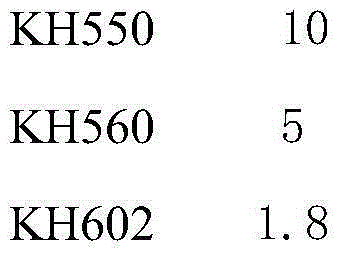

Good caking property two-component hollow glass silicone sealant

InactiveCN105018020AImprove adhesionGood storage stabilityNon-macromolecular adhesive additivesFour componentCaking

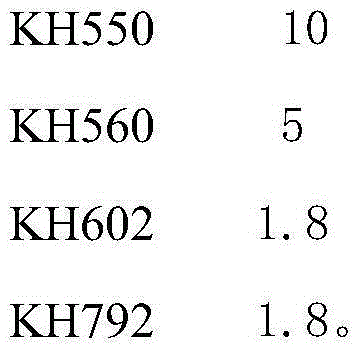

The present invention relates to a good caking property two-component hollow glass silicone sealant which is prepared by mixing A and B components, the weight ratio of A and B components is 10 ~ : 1; an adhesion promoter is added into the B component, the adhesion promoter comprises KH550, KH560, KH602 and KH792, the four components are mixedly placed for cross-linking, the calculated weight ratio of KH550: KH560 is 2: 1, the calculated weight ratio of KH602: KH792 is 1: 1, and the calculated weight ratio of KH550: KH602 is 5-6: 1. The silicone rubber two-component sealant uses the bran-new adhesion promoter to overcome the disadvantages of single use of KH550 and KH560, inherits the dual advantages of good adhesion and process performance stability, and has excellent overall performance.

Owner:TIANJIN HONGTAI GLASS CO LTD

Plastic foamed sheet with antistatic and flame-retardant functions and manufacturing technique thereof

The invention relates to an environment-friendly plastic foamed sheet with antistatic and flame-retardant functions and a manufacturing technique thereof. The manufacturing technique comprises the following steps: preparing bamboo carbon powder, kaolin, plastic, antistatic agent, flame retardant and other chemical assistants, banburying, mixing, discharging from a guillotine to obtain a sheet semi-finished product, and foaming to form with a foaming machine. The plastic foamed sheet is prepared from the following raw materials in parts by mass: 5.5-6 parts of plastic, 1.0-1.5 parts of bamboo carbon powder, 1.5-3.5 parts of kaolin, 1.0-2.5 parts of antistatic agent, 1.5-3.5 parts of flame retardant and 0.5-1.0 part of chemical assistants. The manufacturing technique produces the plastic foamed sheet with high-standard antistatic and flame-retardant functions, overcomes the defects and shortcomings in the prior art, has important and profound significance for solving the problems above, and has very wide market potential.

Owner:冼冰

Softening technology of wool keratin-modified pure cotton fabric

ActiveCN105648741AHigh grafting rateImprove completenessUltrasonic/sonic fibre treatmentGrip property fibresProcess efficiencyKeratin

The invention discloses a softening technology of wool keratin-modified pure cotton fabric. The technology comprises the following steps: (1) carrying out ultrasonic treatment on the pure cotton fabric at 75-85 DEG C and 235-245W for 0.5-0.8 hour to obtain the pure cotton fabric subjected to ultrasonic treatment; (2) dipping the pure cotton fabric subjected to ultrasonic treatment into a wool keratin solution for modified treatment, and taking out and drying the pure cotton fabric to obtain the modified pure cotton fabric; and (3) dipping the modified pure cotton fabric into a mixed solution of a softening agent and a penetrant for softening finishing, and taking out and drying the pure cotton fabric to obtain the soft wool keratin-modified pure cotton fabric. The obtained wool keratin-modified pure cotton fabric is soft; the softness is not reduced after long-term use; and the softening technology is simple and high in process efficiency.

Owner:ZHEJIANG MENGSEN CLOTHING CO LTD

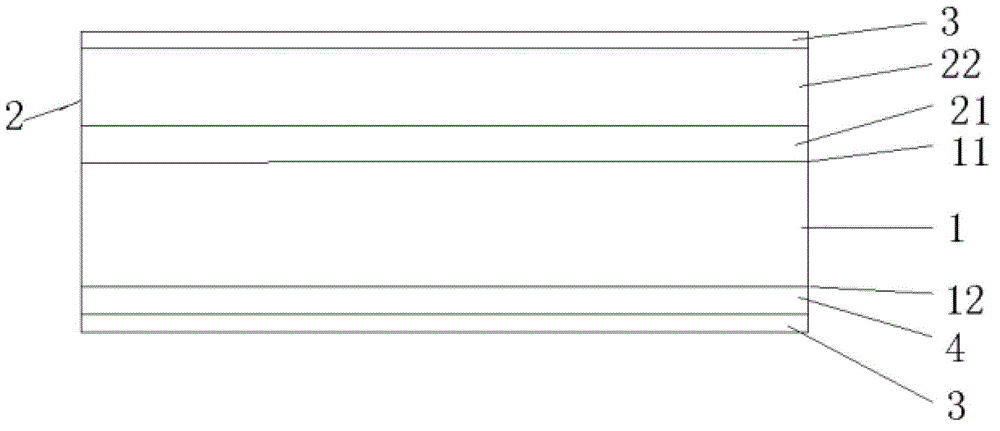

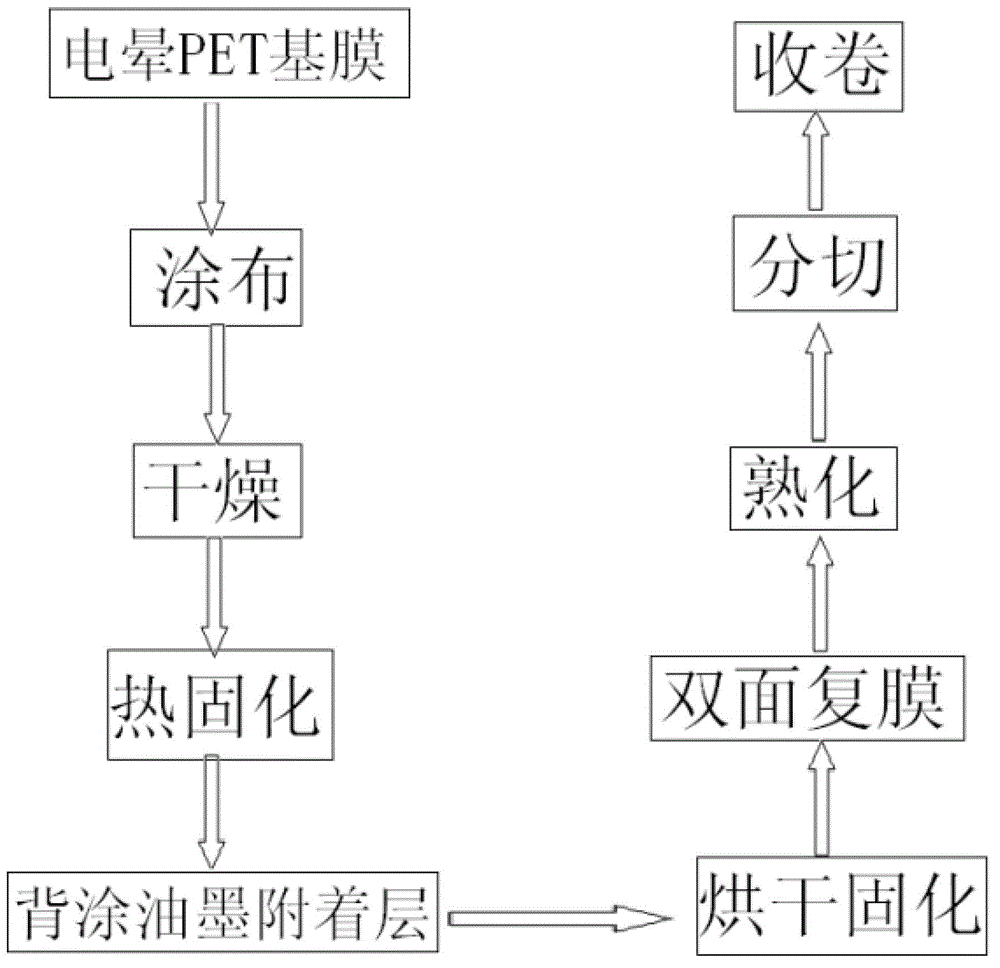

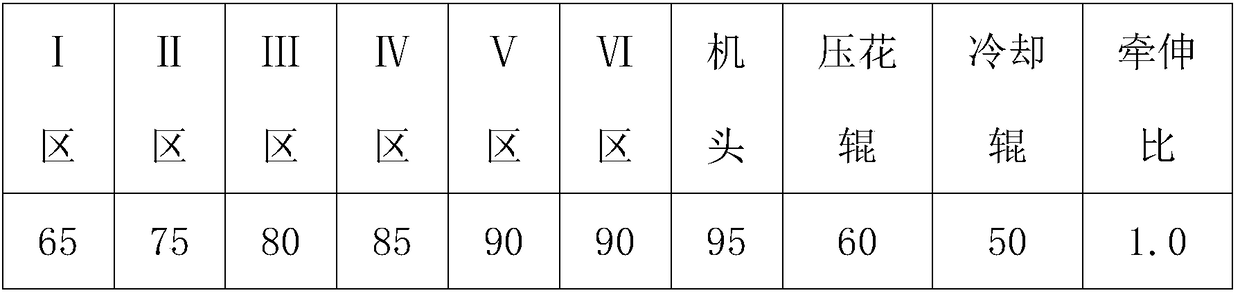

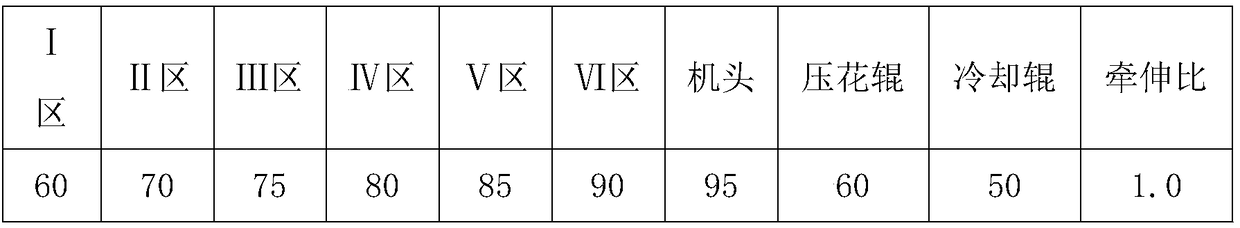

Thermosetting type IMD film and preparation method thereof

InactiveCN102744939AGood light transmissionGood flexibilitySynthetic resin layered productsPolyesterEngineering

The invention provides a thermosetting type IMD film and a preparation method thereof. The IMD film comprises a PET (polyester) base film, wherein an anti-scraping coating layer is arranged on the upper surface of the PET base film; a film layer is arranged on the anti-scraping coating layer; an ink adhesion layer is arranged on the lower surface of the PET base film; the film layer is arranged on the ink adhesion layer; and the anti-scraping coating layer is a thermosetting coating layer. The preparation method comprises the following steps of performing corona on the PET base film; coating the PET base film; drying the coated PET base film; drying and curing the dried PET base film; coating the ink adhesion layer on the back of the thermoset PET base film; and drying and curing the PET base film of which the back is coated with the ink adhesion layer, coating the film on the two surfaces, and curing, rolling and cutting the film. The thermosetting type IMD film has the characteristics of high transmittance, flexibility and adhesion. The process of strengthening the coating is a progressive temperature raising process, the cross-linking of the coating is fuller, and the requirements of high transmittance, flexibility and adhesion are met.

Owner:南京市江亚数码科技有限公司

Preparation method of high-performance fluoride rubber/silicone rubber cable sheath material

InactiveCN105802090AGood weather resistanceAccelerated corrosionRubber insulatorsInsulated cablesElastomerCalcium silicate

The invention discloses a preparation method of a high-performance fluoride rubber / silicone rubber cable sheath material. The preparation method comprises the following steps of performing primary mixing on fluoride rubber, silicone rubber, epoxy acrylate elastomer, hydrogenated butadiene-acrylonitrile rubber, maleic anhydride grafted polyethylene and methyl vinyl silicone rubber grafted methacrylic acid-2,2,2-trifluoroethyl to obtain a primary rubber compound; adding carbon nanotubes, stearic acid modified diatomite, calcium silicate, polyaniline nanofibers, sepiolite fibers and calcium hydroxide, and mixing for 1 to 5 minutes; adding 2,6-di-tert-butyl paraaminophenol, 2,5-di-tert-butylhydroquinone, nitrosodiphenylamine, butylmercaptooxo stannane, 5,5'- dimethyl-5,10-dihydracridine, and mixing for 3 to 8 minutes; adding stearic acid, inositol hexaphosphate, epoxidized linseed oil, active magnesium oxide, bisphenol AF, benzyl triphenyl phosphorus chloride, N,N'-meta phenylene bismaleimide, phenolic resin and an accelerator, mixing for 5 to 10 minutes and then vulcanizing for two times.

Owner:ANHUI HUAYU CABLE GRP

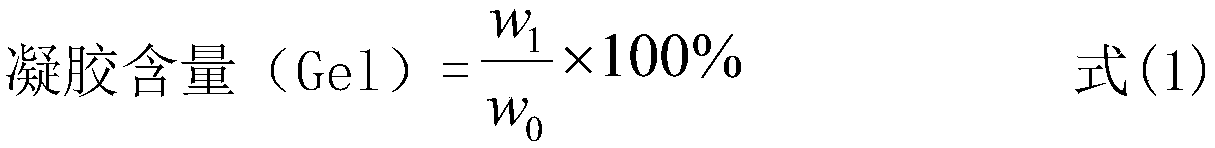

Composite packaging adhesive film for solar packaging material and preparation method of composite packaging adhesive film

ActiveCN109294455AInhibitionAchieving high efficiency of cross-linking and curingNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveElastomerCross-link

The invention discloses a composite packaging adhesive film for a solar packaging material. The composite packaging adhesive film is composed of an ethylene vinyl acetate (EVA) adhesive film layer anda polyolefin elastomer (POE) adhesive film layer, and the EVA adhesive film layer is prepared from the following raw materials in parts by weight: 100 parts of EVA resin, 0.5-1.6 parts of a compositecross-linking agent, 0.5-1 part of a co-crosslinking agent, 0.05-0.2 part of an ultraviolet absorbent, 0.03-0.1 part of an antioxidant and 0.1-0.5 part of a tackifier, wherein the composite cross-linking agent comprises a peroxide and an crosslinking control agent. The invention further discloses a preparation method of the composite packaging adhesive film for the solar packaging material, and the preparation method comprises the following steps: melt extrusion of POE resin, melt extrusion of EVA resin and co-extrusion. According to the composite packaging adhesive film disclosed by the invention, the problems of bubbles and too low gel content of a cured film are solved, and meanwhile, the composite packaging adhesive film has the characteristics of good light transmittance and high glass strength. The preparation method can meet the requirements of process stability, laminating process stability and cross-linking curing efficiency during film preparation by casting at a same time.

Owner:JIANGSU LUSHAN PHOTOVOLTAIC TECH +1

Method for preparing reverse osmosis membrane by utilizing ethyl silicate as oil-phase cosolvent

The invention relates to a method for preparing a reverse osmosis membrane by utilizing ethyl silicate as an oil-phase cosolvent. The method comprises the following steps: infiltrating a supporting film into a water-phase solution to sufficiently infiltrate the supporting film by the water-phase solution; infiltrating the film into an Isopar G solution containing the ethyl silicate and trimesoyl chloride to initiate interfacial polymerization to form an aromatic polyamide separation layer; and performing thermal treatment on the film at 70-90 DEG C to obtain the aromatic polyamide composite reverse osmosis membrane. The method provided by the invention has a simple preparation process and low costs, and is easy to implement, and the prepared aromatic polyamide composite reverse osmosis membrane has high flux of >=3L*m<-2>*h<-1>*bar<-1> and a high rejection rate of >=99.00%; and in addition, the method can also provide reference for preparation of other high-performance aromatic polyamide composite separation membranes.

Owner:TIANJIN UNIV

Two-step method for preparing silane naturally crosslinked polyethylene

The invention discloses a two-step method for preparing silane naturally crosslinked polyethylene. The method comprises the following steps: step one, carrying out twin-screw extrusion pelletization on a silane grafted polyethylene material at the temperature of 180 to 240 DEG C; step two, carrying out twin-screw extrusion pelletization on a catalyzed polyethylene material at the temperature of 150 to 200 DEG C; and step three, preparing the silane grafted polyethylene material and the catalyzed polyethylene material through extrusion, wherein the silane grafted polyethylene material comprisessilane and polyethylene, and the catalyzed polyethylene material comprises a catalyst and polyethylene. The invention aims to provide a preparation method of the silane naturally crosslinked polyethylene with thorough reaction and high crosslinking uniformity.

Owner:GUANGDONG JUHANG INST FOR ADVANCED MATERIALS CO LTD +1

Method for preparing graphene-based biodegradable composite film used in parks

The invention discloses a method for preparing a graphene-based biodegradable composite film used in parks. The method comprises the following steps: compounding graphene oxide twice so as to comprehensively transforming a film in a graphene manner, adding the following components into 50-100 parts by weight of a caprolactam phenylsulfonic acid ionic liquids: 10-20 parts of refined starch, 20-30 parts of cellulose and 5-10 parts of graphene oxide suspension, and further dropping 30-40 parts of a polylactic acid solution which is dissolved in chloroform so as to obtain a film material. The film material has the advantages of good mechanical property, high thermal stability, high degradability, good biocompatibility and the like, and can be used in the field of parks.

Owner:王秋芹

High-hydrophobicity fluorocarbon composition as well as preparation method and application thereof

PendingCN111944364AImprove hydrophobicityGood practical application valueFireproof paintsAntifouling/underwater paintsFluorocarbon ResinsFlame resistance

The invention provides a high-hydrophobicity fluorocarbon composition as well as a preparation method and application thereof, and belongs to the technical field of polymer insulating materials. The high-hydrophobicity fluorocarbon composition is prepared from the following raw materials in parts by weight: 60 parts of fluorocarbon resin; 10 to 25 parts of a reinforcing filler; 50 to 100 parts ofan inorganic flame retardant; 0.2-1 part of a dispersing agent; 12-20 parts of curing agent. The composition can resist electric corrosion and high-temperature damage caused by the electric corrosion,has high hydrophobicity, excellent tracking resistance and flame retardance compared with common silicone rubber coating, and can expand the application field of fluorocarbon coating in the aspect ofelectrical equipment insulation, so that the high-hydrophobicity fluorocarbon composition has a good practical application value.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Black ethylene vinyl acetate (EVA) material for packaging solar cell modules

InactiveCN103131075AReduce temperature differenceImprove thermal conductivityPhotovoltaic energy generationSemiconductor devicesSolar cellEthylene-vinyl acetate

The invention discloses a black ethylene vinyl acetate (EVA) material for packaging solar cell modules. 0.5%-5% of insulativity carbon black is added in components of convention EVA film products. The preparative black EVA material can be applied in cell surfaces, double-face glass components and the like and has an excellent volume resistivity.

Owner:JIANGSU SVECK NEW MATERIAL

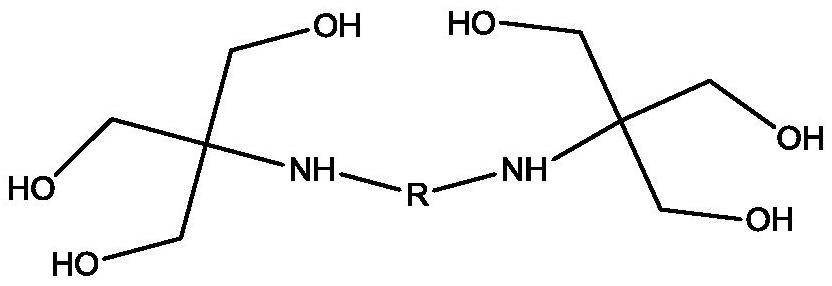

Self-extinction waterborne polyurethane resin as well as preparation method and application thereof

ActiveCN112851898ASimple production processEasy to operatePolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses self-extinction waterborne polyurethane resin as well as a preparation method and application thereof. The self-extinction waterborne polyurethane resin is prepared by mixing and reacting raw materials comprising the following components in the presence of a catalyst: S1, isocyanate; S2, diamine with a plurality of hydroxyl groups; S3, preparing macromolecular polyol; S4, monohydric alcohol and / or dihydric alcohol with a main chain and / or a side chain containing a polyoxyethylene chain segment; S5, a micromolecular polyol chain extender; S6, a hydrophilic compound or a compound with hydrophilic potential; S7, a neutralizer; and S8, a small molecule diamine chain extender. The side chain of the resin provided by the invention has a plurality of hydroxyl groups, and can be fully crosslinked with an isocyanate curing agent-form a net-shaped macromolecular chain, so that the self-extinction polyurethane resin with large molecular weight is obtained while the particle size of emulsion particles is increased, and the chemical resistance and scratch resistance are excellent.

Owner:WANHUA CHEM GRP CO LTD

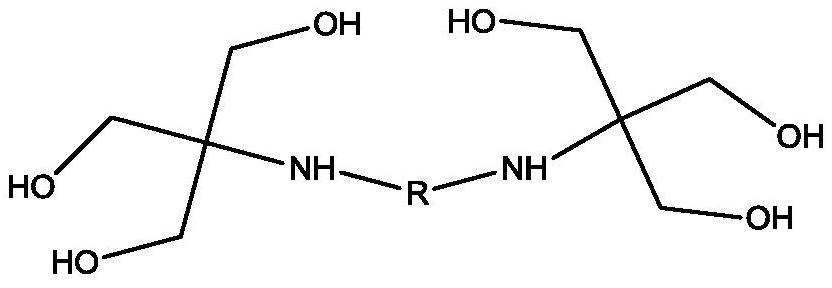

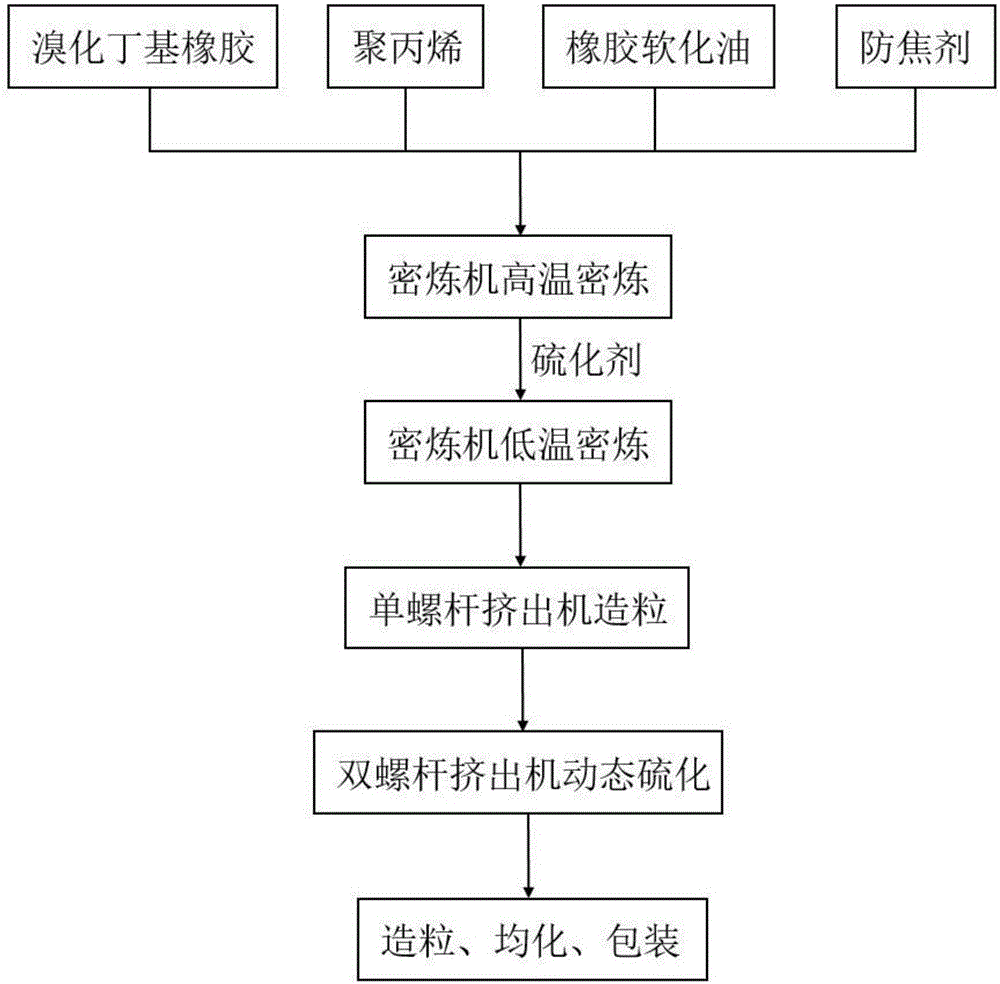

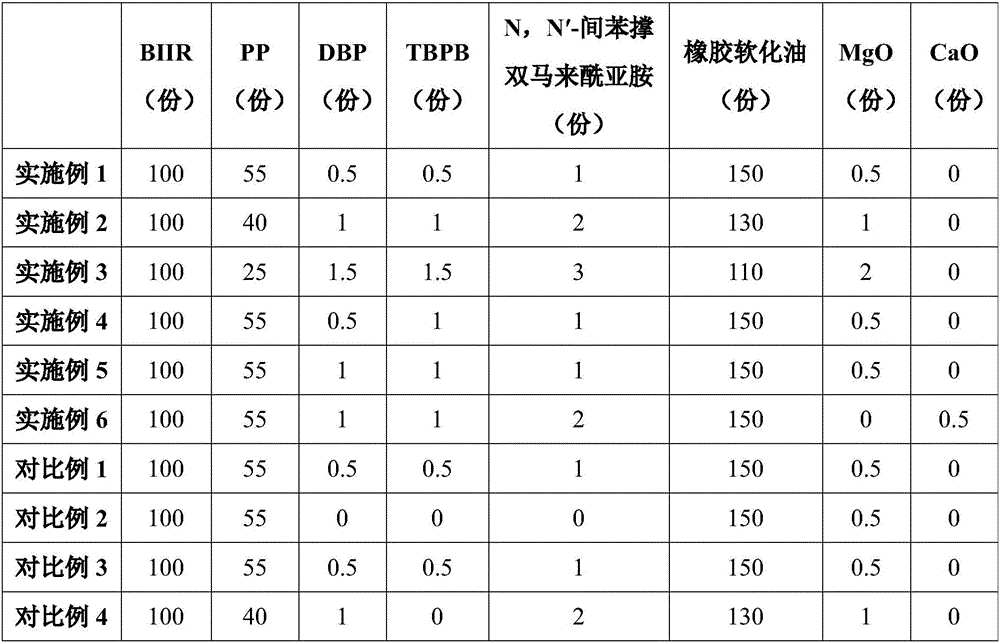

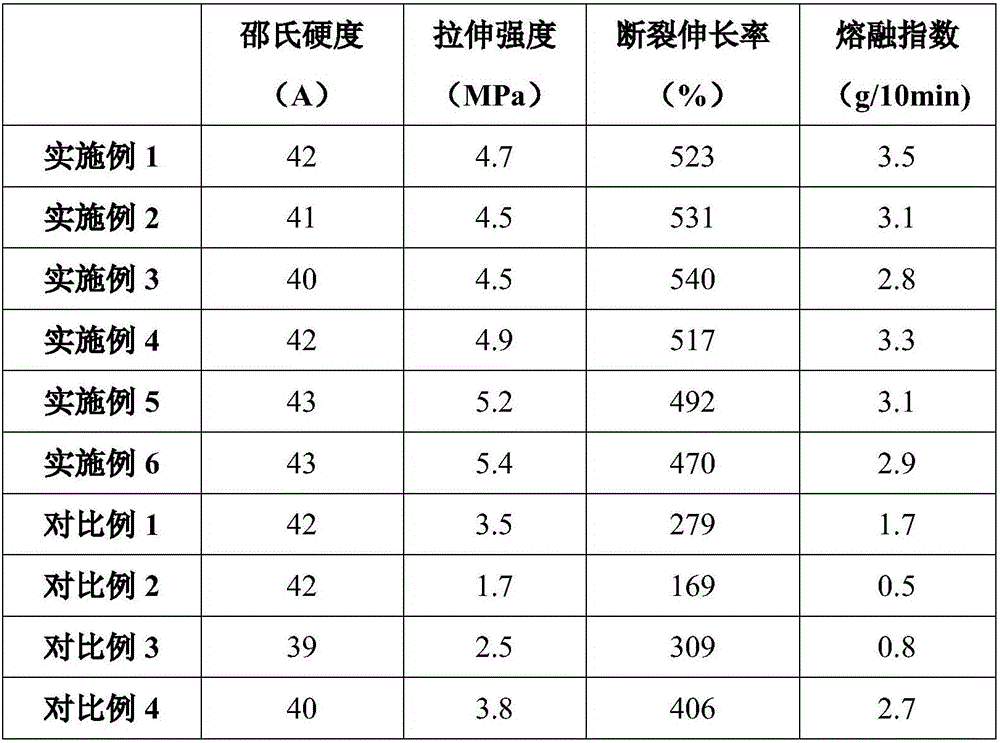

Thermoplastic dynamic vulcanized brominated butyl rubber/polypropylene composition and preparation method thereof

The invention discloses a thermoplastic dynamic vulcanized brominated butyl rubber / polypropylene composition and a preparation method thereof. The thermoplastic dynamic vulcanized brominated butyl rubber / polypropylene composition is prepared from brominated butyl rubber, polypropylene, dialkyl peroxide, peroxyacidester, N,N-m-phenylenedimaleimide, rubber softening oil and a scorch retarder. The preparation method comprises the following steps: 1) performing internal mixing smelting on the brominated butyl rubber, polypropylene and rubber softening oil; 2) further adding a vulcanizing agent, and uniformly mixing; 3) transferring the commixture obtained in the step 2) into a single screw extruder, and performing extrusion pelleting; 4) transferring the commixture obtained in the step 3) into a parallel intermeshing co-rotating twin screw, performing dynamic vulcanization, and performing extrusion pelleting. The thermoplastic dynamic vulcanized brominated butyl rubber / polypropylene composition disclosed by the invention is good in air tightness and barrier property, excellent in mechanical property, feasible in direct injection molding, simple in production process, high in production efficiency, low in cost and easy to popularize and use.

Owner:广东金柏新材料科技股份有限公司

Radiation-crosslinking flame retardant polyolefin material for car thin-wall electric wire and preparation method of material

The invention relates to a radiation-crosslinking flame retardant polyolefin material for a car thin-wall electric wire and a preparation method of the material. The radiation-crosslinking flame retardant polyolefin material for the car thin-wall electric wire is formed by extruding through an extruder after mixing and mulling the materials including ethylene-propylene copolymer resin, ethylene vinyl acetate resin, cyanoacrylate rubber, a flame retardant, an antioxidant, a cross-linking agent, a beta ray-resistant degradation agent, a lubricant and the like through a muller. The car thin-wall electric wire which is manufactured by the radiation-crosslinking flame retardant polyolefin material has high temperature resistance and low temperature resistance, is unlimited in applicable range, has better aging resistance, scraping resistance and processing performance, and is quick in extruding speed, so that the requirements of the car thin-wall electric wire with a temperature-resistant level of 125 DEG C can be satisfied. Moreover, the radiation-crosslinking flame retardant polyolefin material can be used as the material for manufacturing the car thin-wall electric wire with a higher temperature-resistant level (125 DEG C).

Owner:WUXI JAKE PLASTIC

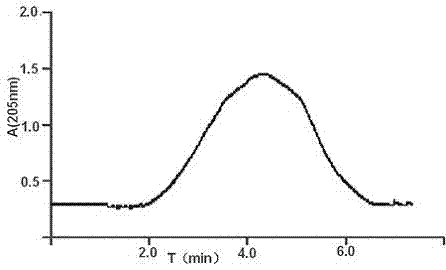

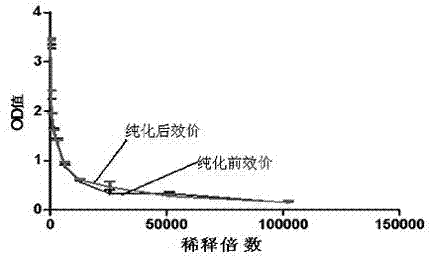

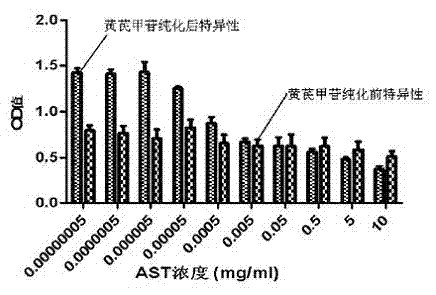

Immunoaffinity chromatographic column adopting astragaloside IV as ligand and application of immunoaffinity chromatographic column

InactiveCN105435758AFully crosslinkedImprove purification efficiencyOther chemical processesSolid sorbent liquid separationAcetic acidSorbent

The invention discloses a technical scheme of an immunoaffinity chromatographic column adopting astragaloside IV as a ligand and an application of the immunoaffinity chromatographic column. The immunoaffinity chromatographic column adopts the astragaloside IV as the ligand and is prepared through specific steps as follows: an astragaloside IV hapten is prepared; an immunoaffinity adsorbent is prepared from the astragaloside IV hapten and a solid-phase carrier through cross-linking; the immunoaffinity adsorbent is taken as packing to be charged into a chromatographic column; the packing is washed alternately with an acetic acid buffer solution and a Tris-HCl buffer solution for three times, and the immunoaffinity chromatographic column is obtained. A method adopting the prepared immunoaffinity chromatographic column to purify an astragaloside IV antibody comprises steps as follows: a to-be-purified sample is added to the immunoaffinity chromatographic column and is eluted by an eluent and neutralized by a neutralization solution and the like. According to the invention, the purification efficiency of the astragaloside IV monoclonal antibody is effectively improved, the purity can be higher than 99%, besides, the operation is simple, the cost is low, and the pollution is low.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com