Preparation method of chitosan microsphere

A chitosan microsphere and chitosan technology, applied in the field of medical devices, can solve the problems of uneven particle size of microspheres, lack of chitosan microspheres, poor safety, etc., and achieve moderate density, stable and uniform product quality, The effect of small material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

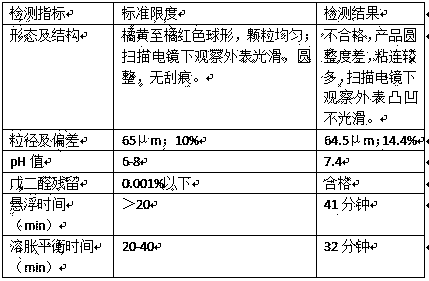

Embodiment 1

[0036] 1. Material preparation: Weigh 0.5 g of chitosan and dissolve it in 50 mL of 1% hydrochloric acid by mass, add 0.45 g of NaCl to make the chitosan aqueous phase; measure according to the volume ratio of 8:2:0.2 Mix liquid paraffin, soybean oil and laureth sulfate to prepare 1 L of oil phase (recyclable); measure 40 mL of 50% by volume glutaraldehyde aqueous solution and dissolve it in 160 mL of normal saline, add 4ml soybean lecithin is made into glutaraldehyde solution, mixed with 200mL prepared oil phase, stirred and emulsified to make glutaraldehyde emulsion, and set aside;

[0037] 2. Preparation process: Use the BT100-2J peristaltic pump produced by Baoding Lange Constant Flow Pump Co., Ltd. to pump the oil phase in the oil storage tank into a transparent silicone tube with a diameter of 800 μm. figure 1 As shown, the tip of the syringe (water phase pipeline 2) filled with chitosan aqueous phase solution is inserted vertically from the side of the transparent silic...

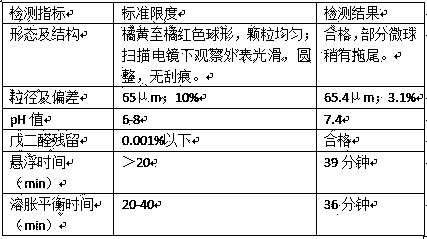

Embodiment 2

[0042] 1. Material preparation: Weigh 0.75 g of chitosan and dissolve it in 50 mL of 1% acetic acid by mass, add 0.45 g of NaCl to make the chitosan aqueous phase, and measure it at a volume ratio of 5:5:0.2 Mix liquid paraffin, aviation kerosene and Span 80 to prepare 1 L of oil phase (recyclable), take 40 mL of 50% glutaraldehyde aqueous solution and dissolve it in 160 mL of normal saline, add 4 mL of Tween 20. Mix with 200mL prepared oil phase, stir and emulsify to make glutaraldehyde emulsion;

[0043] 2. Preparation process: Use the BT100-2J peristaltic pump produced by Baoding Lange Constant Flow Pump Co., Ltd. to pump the oil phase in the oil storage tank into a transparent silicone tube with a diameter of 1000 μm. figure 1 As shown, the tip of the syringe (water phase pipeline 2) filled with chitosan aqueous phase solution is inserted vertically from the side of the transparent silicone tube (oil phase pipeline 1), and a syringe pump is connected behind the syringe, an...

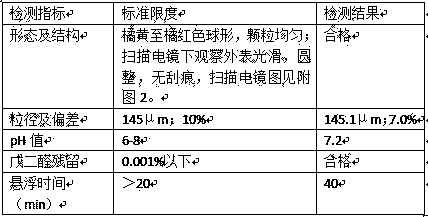

Embodiment 3

[0048] 1. Material preparation: Weigh 1.5 g of chitosan and dissolve it in 50 mL of citric acid with a mass percentage of 1%, add 0.45 g of NaCl to make the chitosan aqueous phase, and measure the liquid at a volume ratio of 10:0.2 Mix paraffin and sodium dodecylbenzenesulfonate to prepare 1 L of oil phase (recyclable), measure 40 mL of glutaraldehyde aqueous solution with a volume percentage of 50% and dissolve it in 160 mL of normal saline, add 4 mL Lecithin, mixed with 200mL oil, stirred and emulsified to make glutaraldehyde emulsion;

[0049] 2. Preparation process: Use the BT100-2J peristaltic pump produced by Baoding Lange Constant Flow Pump Co., Ltd. to pump the oil phase in the oil storage tank into a transparent silicone tube with a diameter of 500 μm. figure 1 As shown, the tip of the syringe (water phase pipeline 2) filled with chitosan aqueous phase solution is inserted vertically from the side of the transparent silicone tube (oil phase pipeline 1), and a syringe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com