Two-step method for preparing silane naturally crosslinked polyethylene

A technology of natural cross-linking and polyethylene, which is applied in the field of preparation of cross-linked polyethylene, can solve problems such as uneven cross-linking, slow diffusion rate, and limited cross-linking rate, so as to reduce production costs, increase recycling rate, and enhance The effect of mechanical properties and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

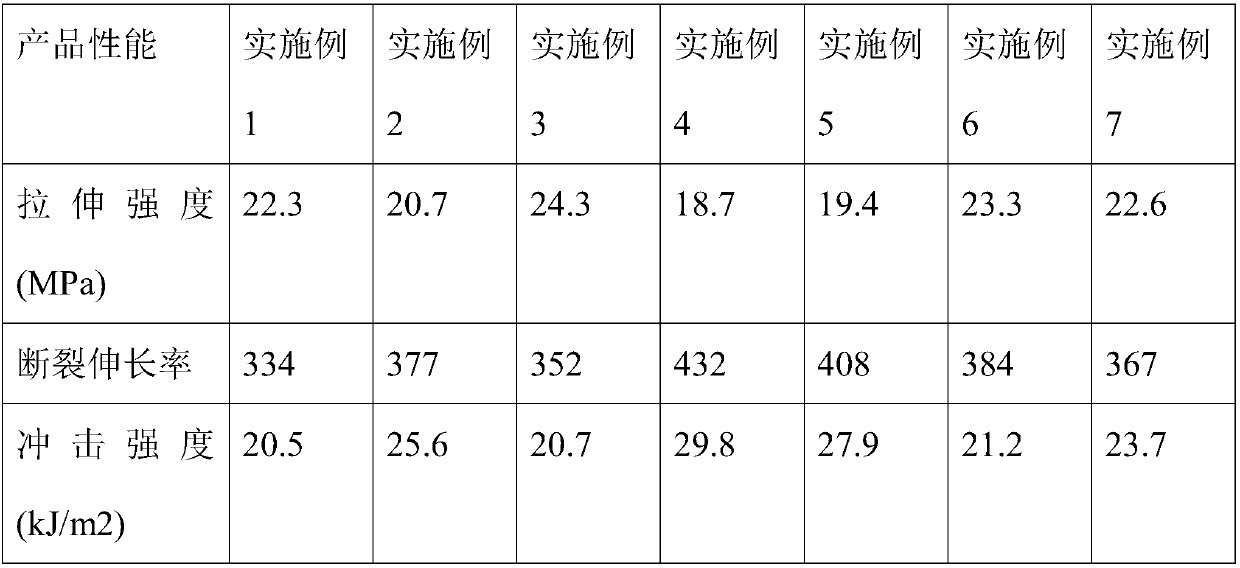

Examples

Embodiment 1

[0042] A silane naturally crosslinked polyethylene disclosed by the invention comprises 95 parts by weight of material A and 5 parts by weight of material B:

[0043] A material component and the weight ratio of each component are:

[0044] Polyethylene plastic 100 parts;

[0045] The polyethylene plastic is composed of 80 parts of HDPE material and 20 parts of LDPE material.

[0046] 5 parts of alkenyltrimethoxysilane;

[0047] 0.03 parts of benzoyl peroxide;

[0048] B material component name and component weight ratio are:

[0049] Polyethylene plastic 100 parts;

[0050] The polyethylene plastic is composed of 80 parts of HDPE material and 20 parts of LDPE material.

[0051] Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester 10 parts;

[0052] Mesylated acetyl 0.3 parts.

Embodiment 2

[0054] A silane natural cross-linked polyethylene disclosed by the invention comprises 85 parts by weight of material A and 15 parts by weight of material B:

[0055] A material component and the weight ratio of each component are:

[0056] Polyethylene plastic 100 parts;

[0057] 0.3 parts of vinyltriethoxysilane;

[0058] 0.2 parts of tert-butyl peroxide;

[0059] The polyethylene plastic is composed of 90 parts of HDPE material and 10 parts of LDPE material.

[0060] B material component name and component weight ratio are:

[0061] Polyethylene plastic 100 parts;

[0062] 2 parts of tris(2,4-di-tert-butylphenyl)phosphite;

Embodiment 3

[0065] A silane naturally cross-linked polyethylene disclosed by the invention comprises 88 parts by weight of material A and 12 parts by weight of material B:

[0066] A material component and the weight ratio of each component are:

[0067] Polyethylene plastic 100 parts;

[0068] The polyethylene plastic is 100 parts HDPE material.

[0069] 2 parts of vinyl trichlorosilane;

[0070] 0.03 parts of tert-butyl peroxybenzoate;

[0071] B material component name and component weight ratio are:

[0072]Polyethylene plastic 100 parts;

[0073] Described polyethylene plastic is made of 100 parts HDPE material.

[0074] 5 parts of tris(2,4-di-tert-butylphenyl)phosphite;

[0075] 5 parts of dodecylbenzenesulfonic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com