Patents

Literature

309results about How to "Small volume expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

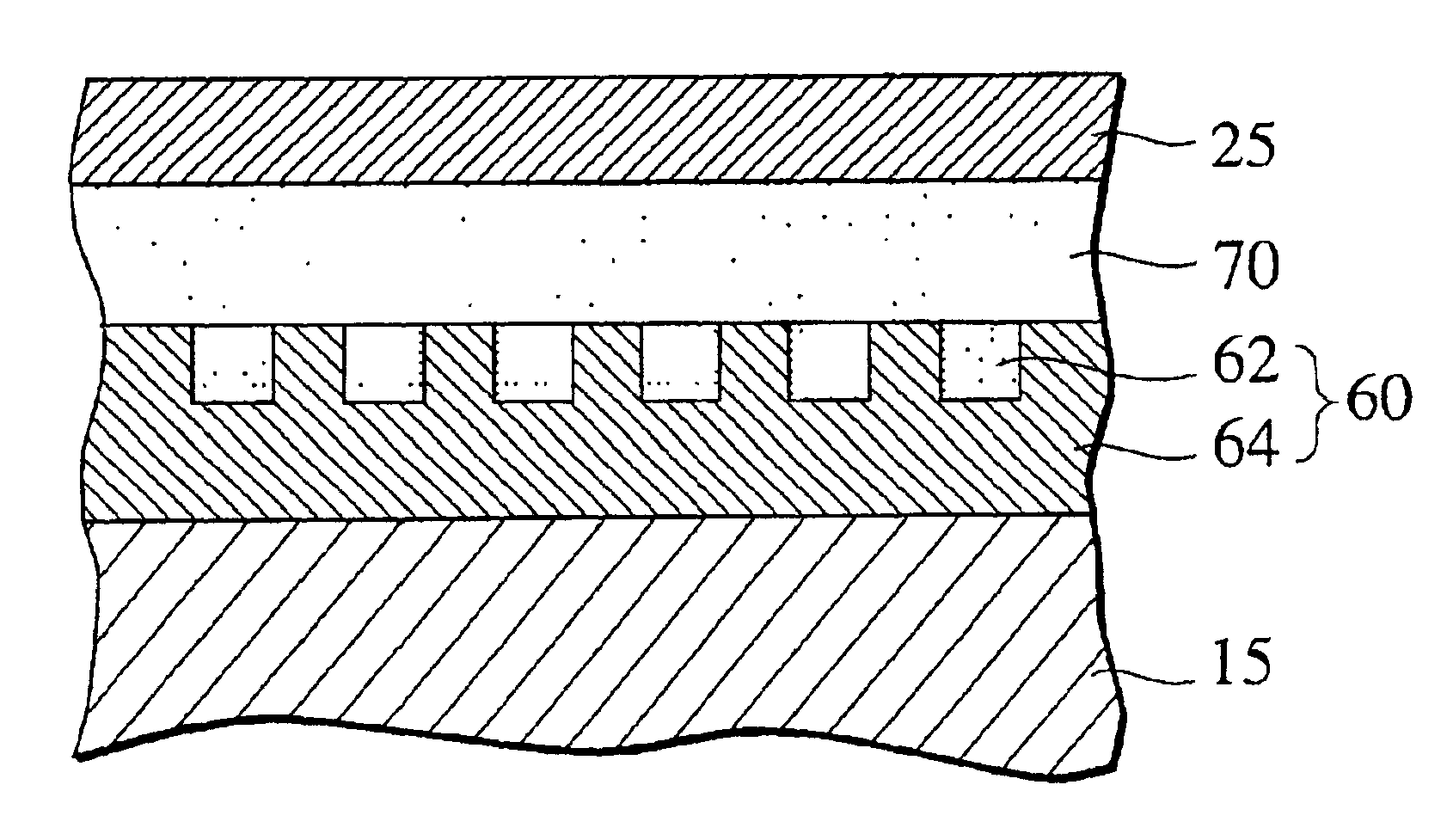

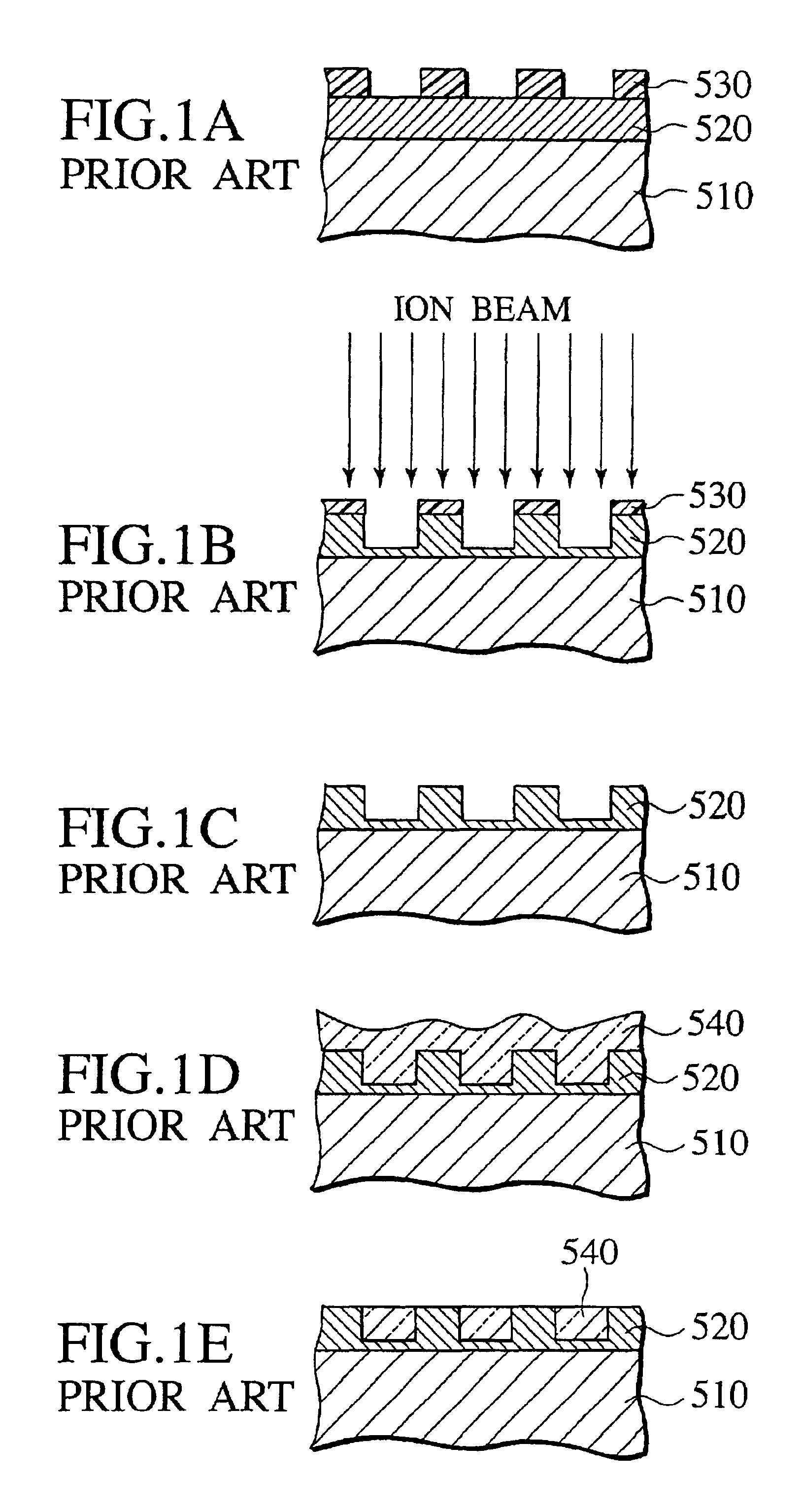

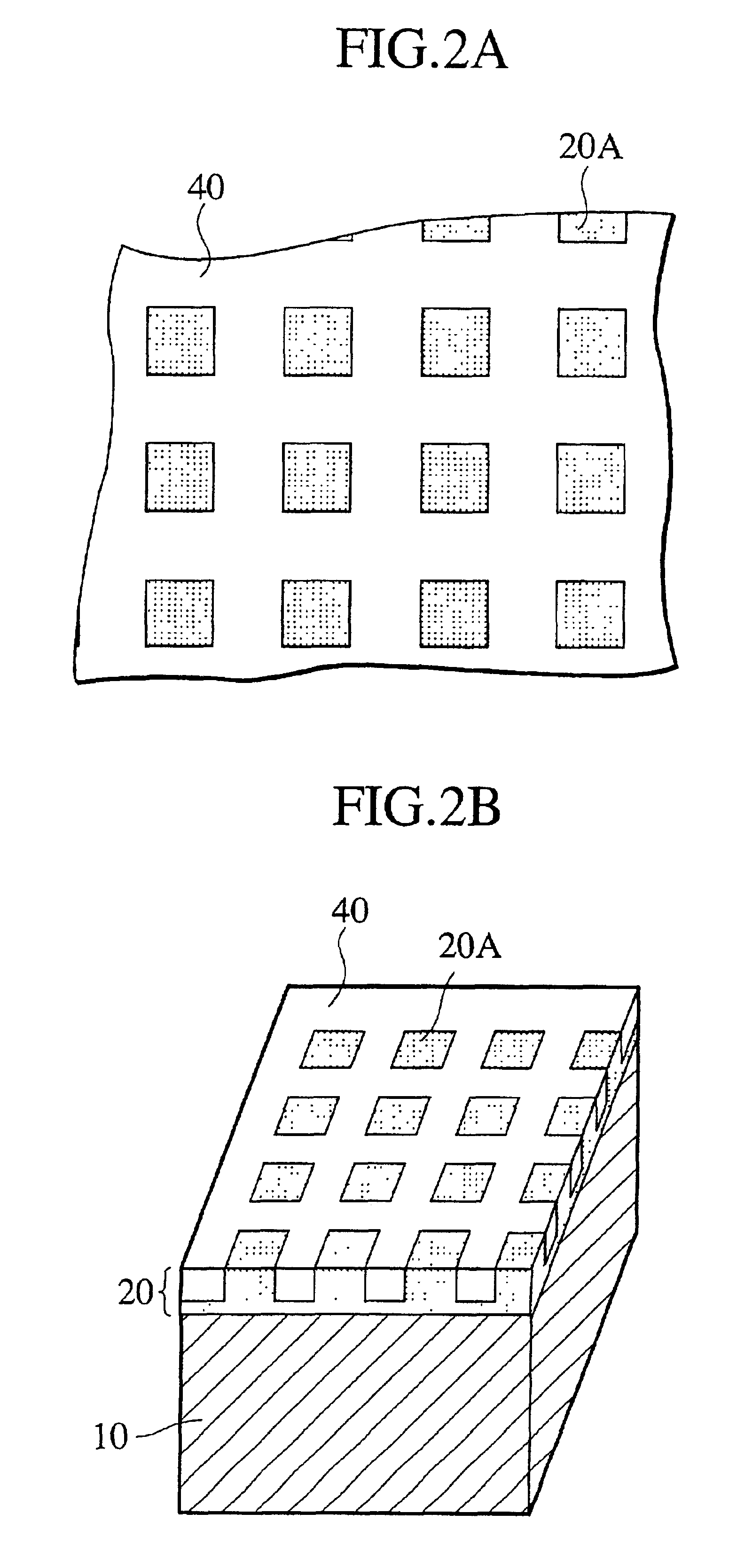

Method of patterning magnetic products using chemical reactions

InactiveUS6841224B2Improve productivityFlat surfaceNanoinformaticsSolid-state devicesHalogenChemical reaction

A method of patterning magnetic material includes forming a ferromagnetic material layer containing one element selected from the group consisting of Fe, Co and Ni on a substrate, selectively masking a surface of the ferromagnetic material layer, and making nonferromagnetic. The making nonferromagnetic step includes exposing an exposed portion in halogen-containing reaction gas, changing magnetism of the exposed portion and a lower layer thereof by chemical reaction, and making the exposed portion a nonferromagnetic material region. A magnetic recording medium is fabricated by using the magnetic material patterning method and includes a plurality of recording regions made of ferromagnetic materials, each containing at least one element selected from the group consisting of Fe, Co and Ni, and a nonferromagnetic material region for separating the recording regions from each other. The nonferromagnetic material region is a compound region of the ferromagnetic material and halogen.

Owner:KK TOSHIBA

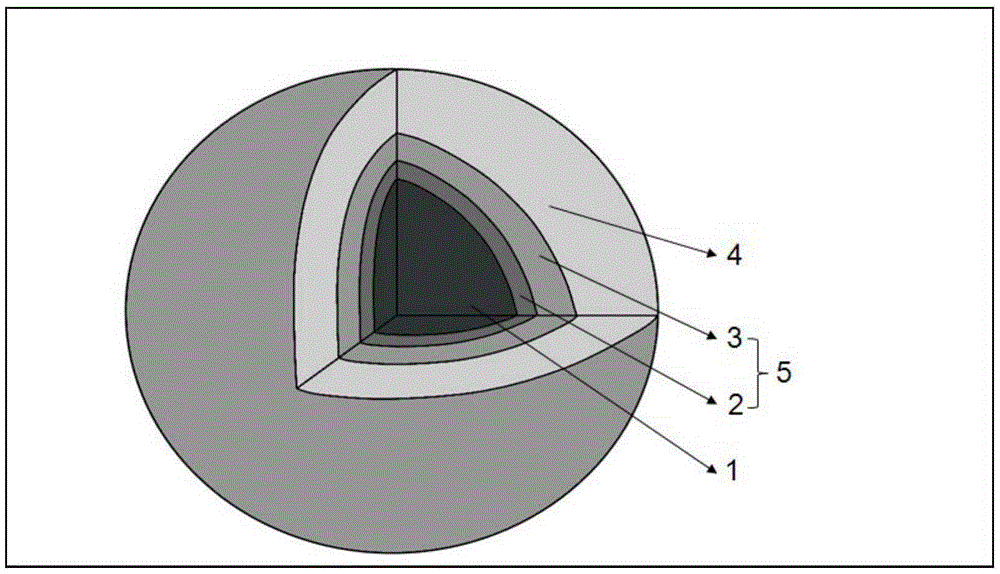

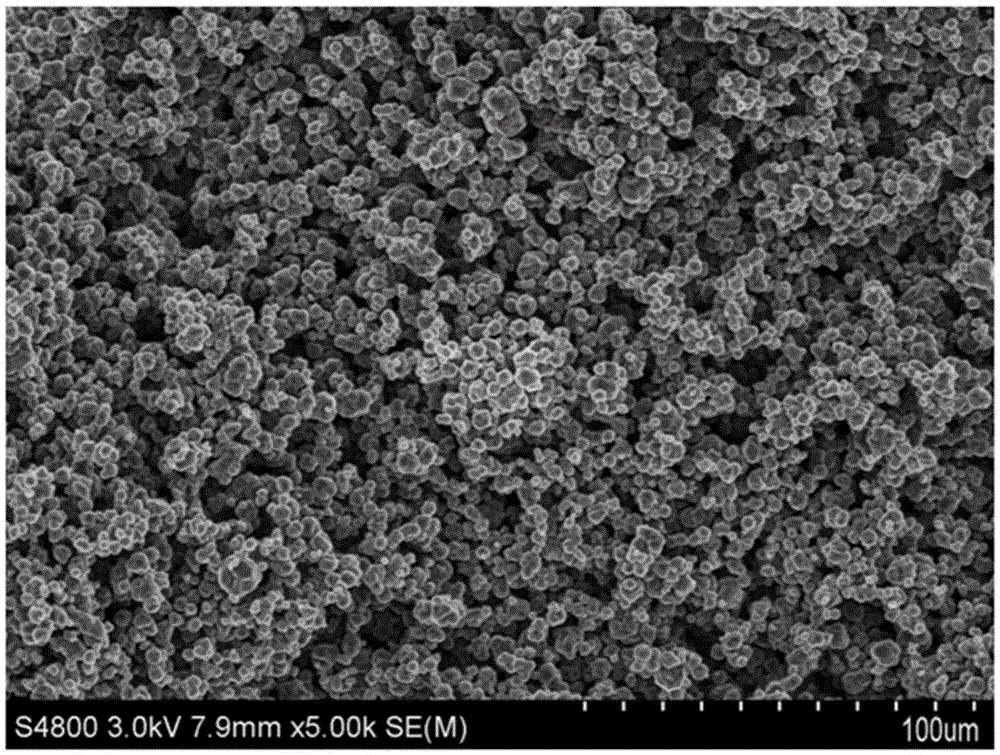

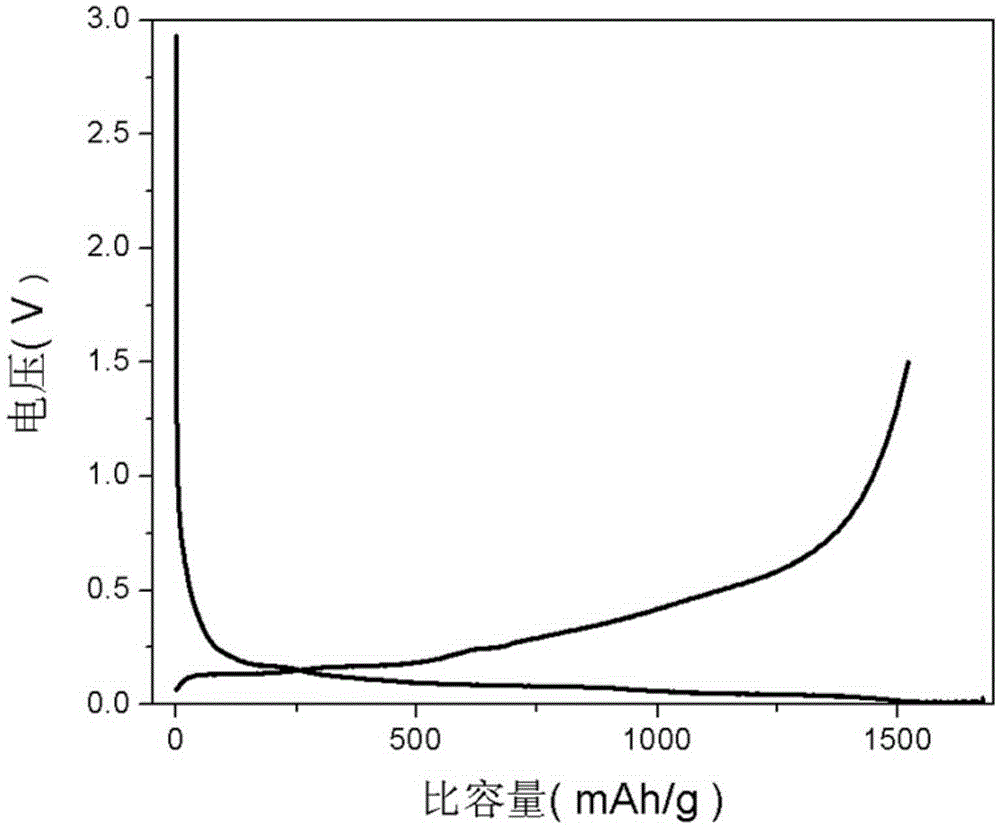

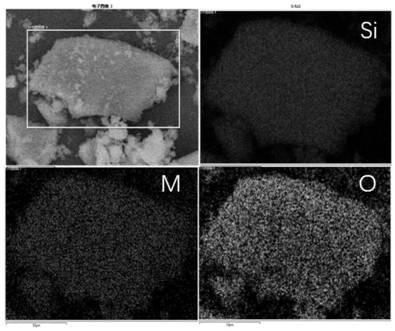

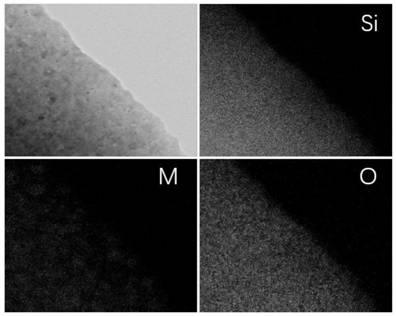

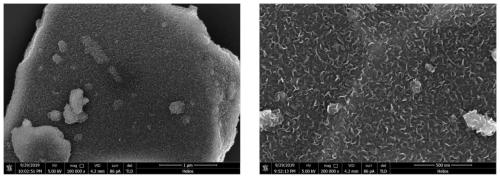

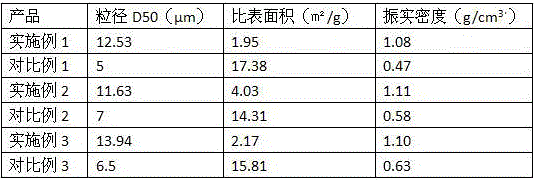

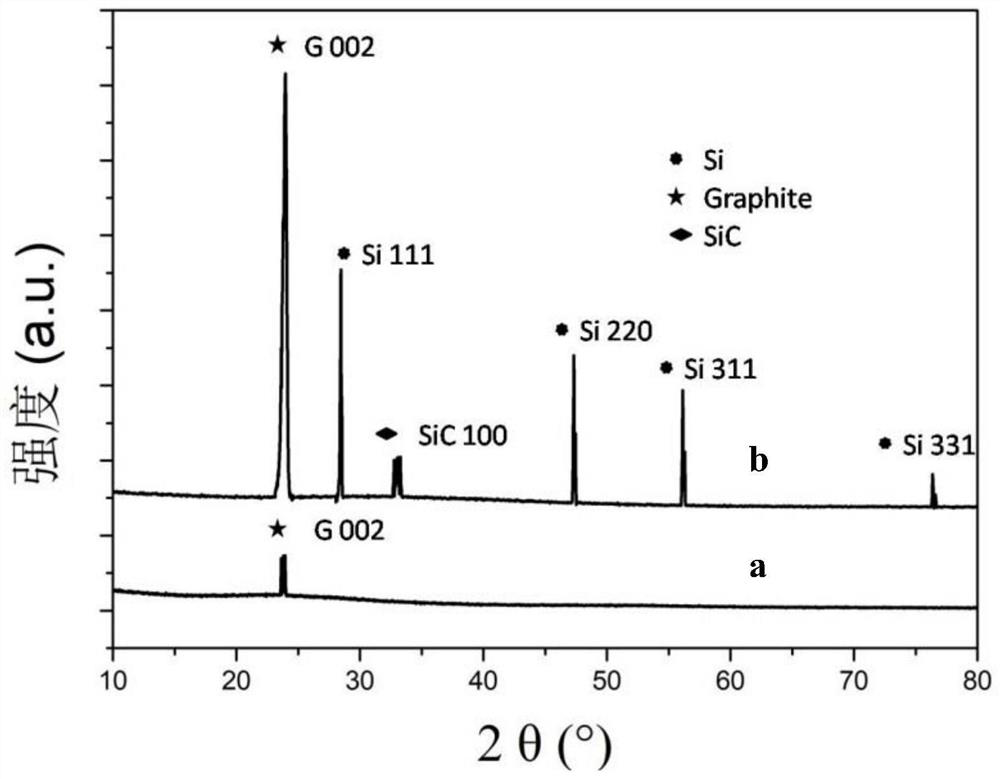

Composite silicon negative electrode material, and preparation method and application thereof

ActiveCN105406050AGood electrical conductivityIncrease capacitySiliconElectrode thermal treatmentCarbon layerLithium

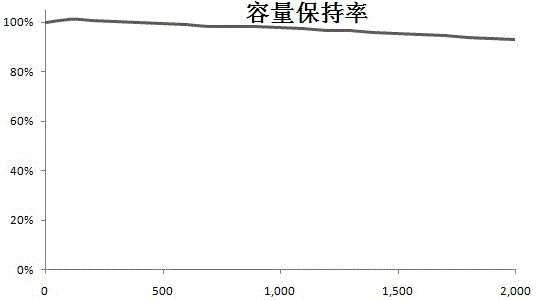

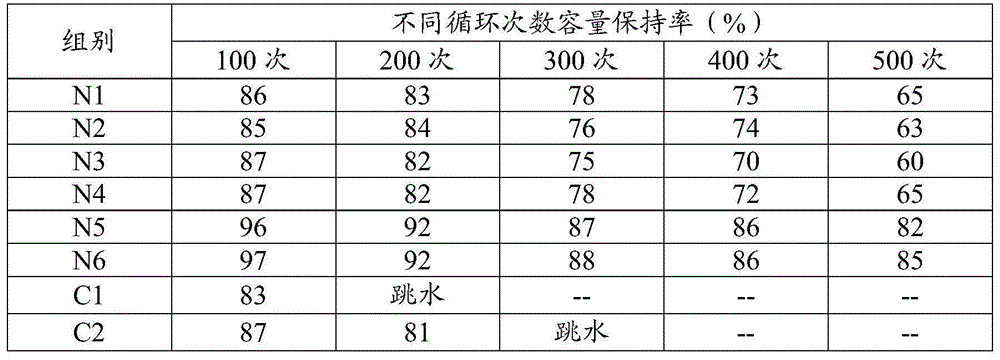

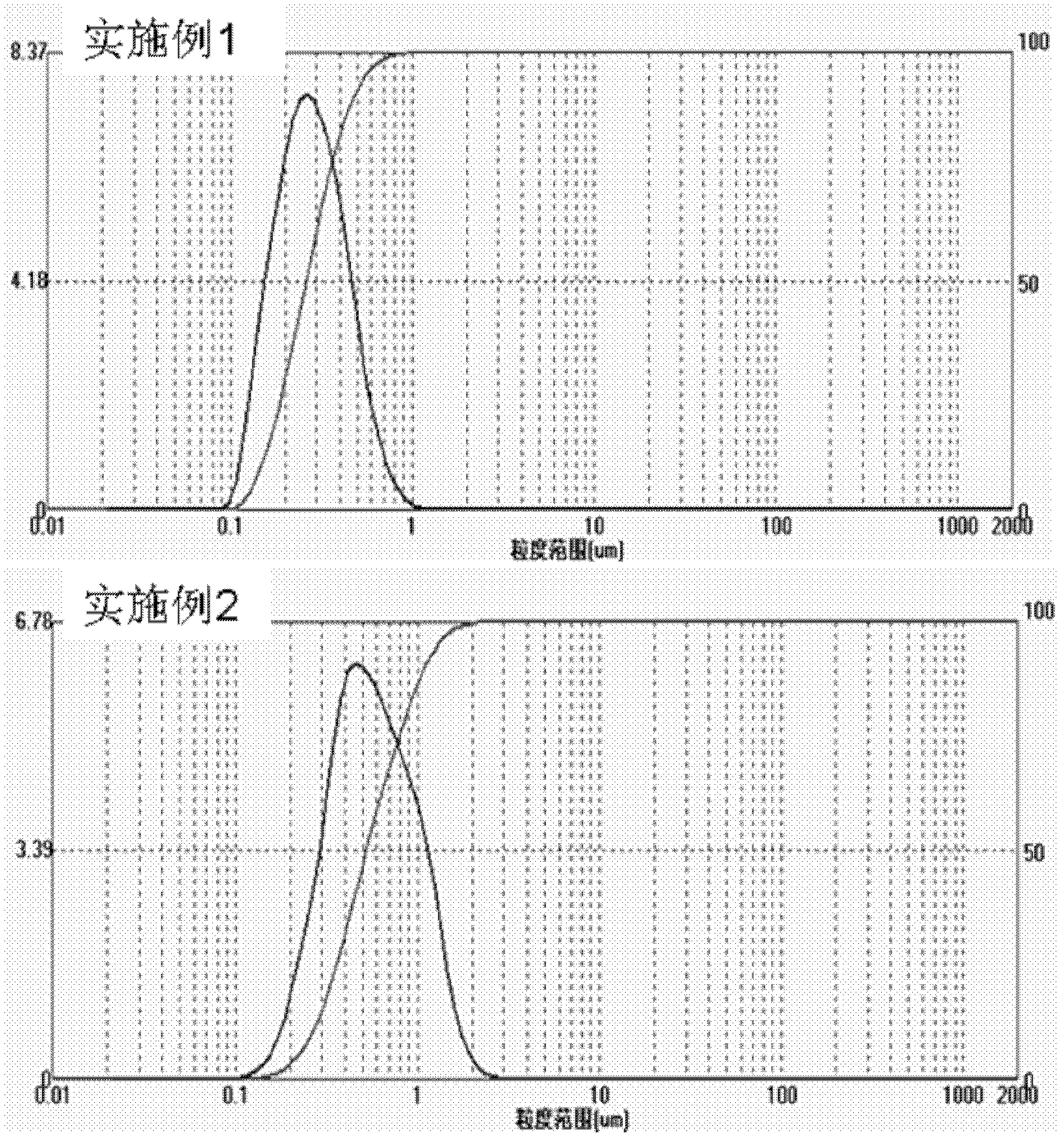

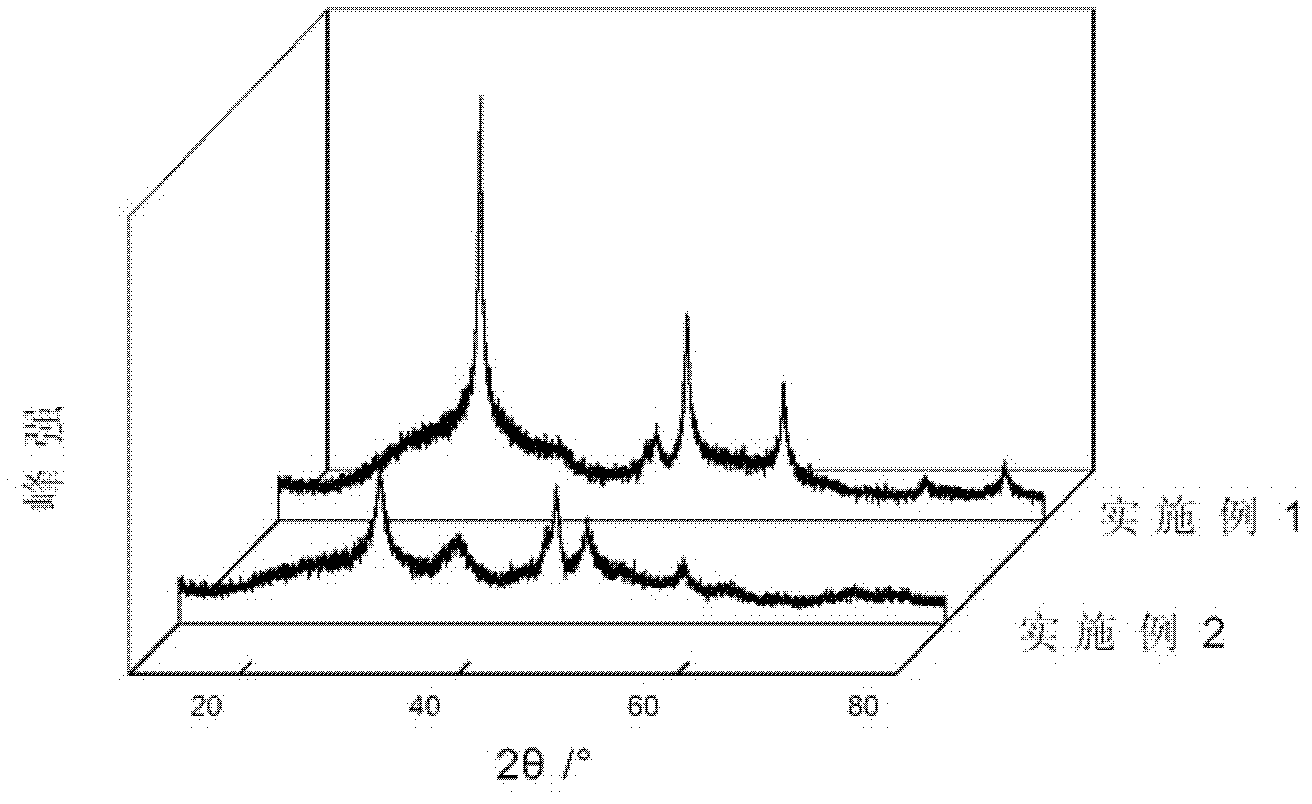

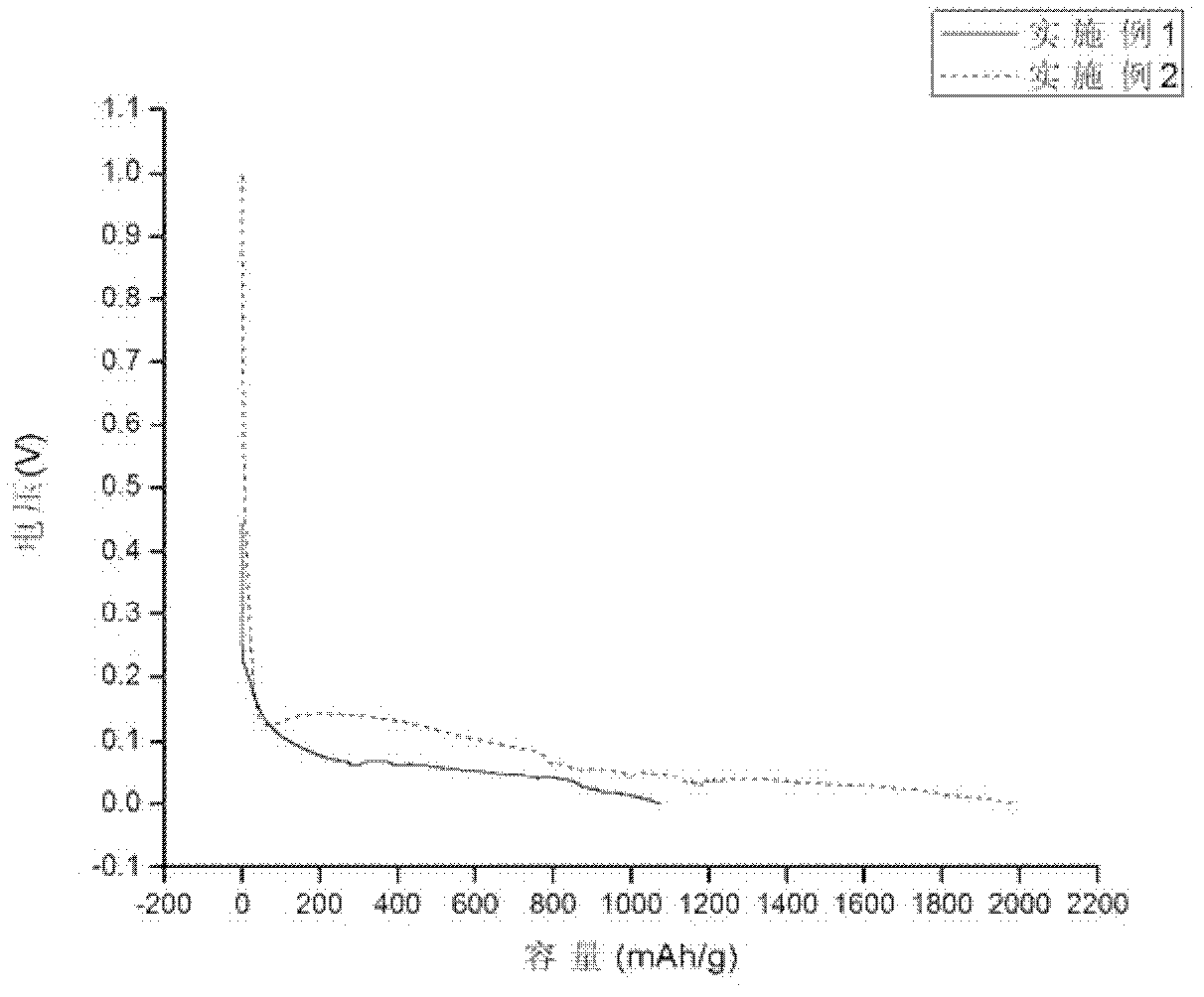

The invention relates to a composite silicon negative electrode material. The composite silicon negative electrode material comprises nanometer silicon, a nanometer composite layer coating the surface of nanometer silicon and a conductive carbon layer uniformly coating the nanometer composite layer, wherein the nanometer composite layer is silicon oxide and metal alloy. According to the composite silicon negative electrode material with a three-layer structure, the nanometer composite layer composed of the silicon oxide and the metal alloy coating the surface of the silicon oxide effectively reduces volume expansion of the nanometer silicon, maintains the characteristic of high conductivity of the silicon material, improves mobility of lithium ions, prevents direct contact between a silicon negative electrode and an electrolyte, and can form a hard SEI film on the surface of the composite silicon negative electrode material, thereby allowing the cycle performance of the material to be substantially enhanced. The composite silicon negative electrode material has the characteristics of high capacity (greater than 1500 mAh / g), long cycle life (with a capacity retention ratio of more than 90% after 300 cycles) and high conductivity. The preparation method for the composite silicon negative electrode material is simple, easily controllable, and applicable to industrial production.

Owner:DINGYUAN NEW ENERGY TECH CO LTD

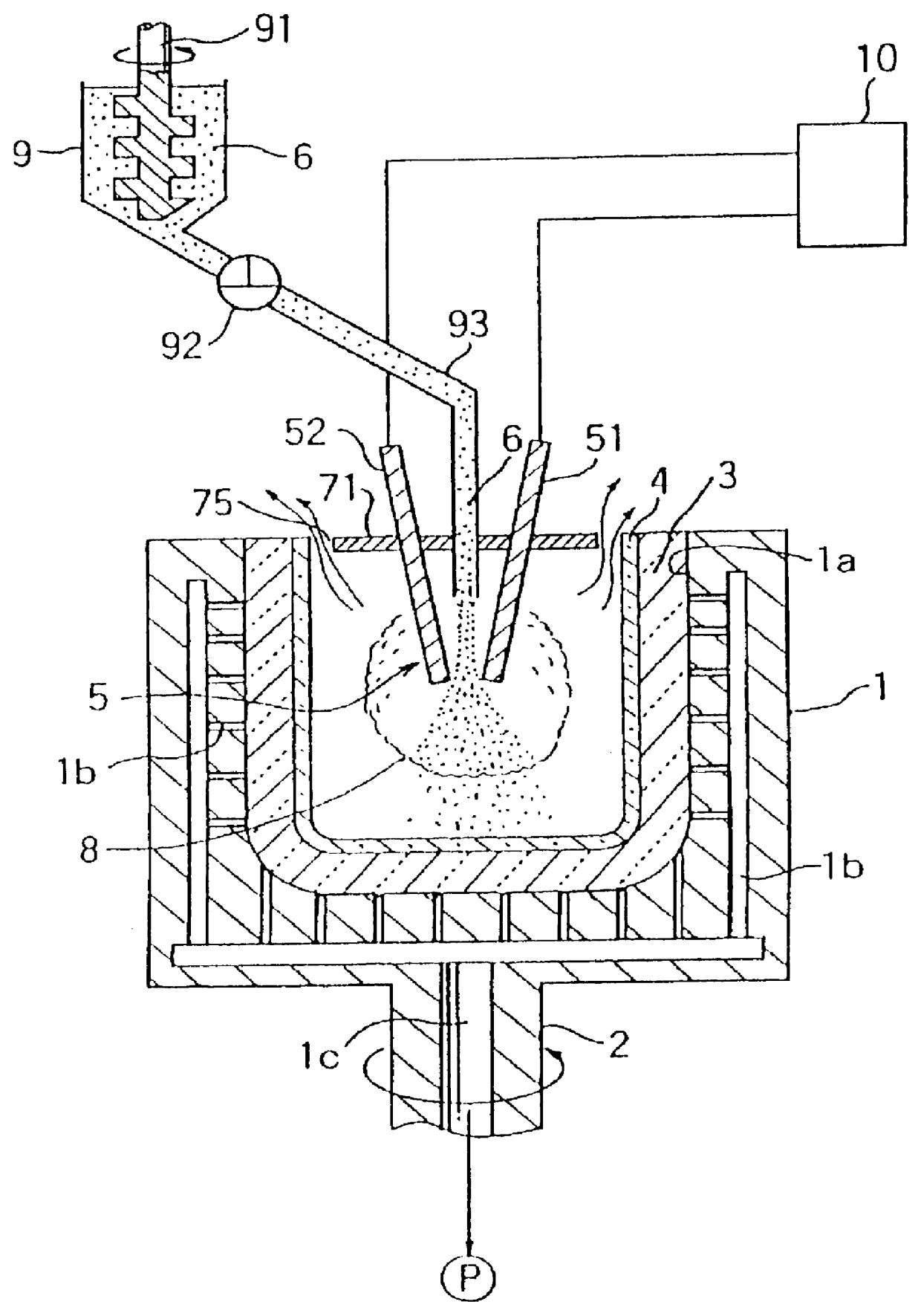

Quart crucible with large diameter for pulling single crystal and method of producing the same

InactiveUS6136092ASmall volume expansionAvoid deformationLayered productsBy pulling from meltCrucibleSingle crystal

Owner:SHIN ETABU QUARTZ PRODS

Nano metal fluid with high heat-transfer performance

ActiveCN1955252AImprove thermal conductivityFast absorption and deliveryDigital data processing detailsSemiconductor/solid-state device detailsLiquid metalSolvent

This invention provides a high heat transfer performance liquid nano-metal. It relates to cooling fluid working medium, and especially it can be used under high rush density condition which need high intensity cooling fluid working medium for heat exchanging and cooling, such as computer array and reactor. The solvent of this invention is liquid metal, and the soluble of this invention is nanometer particle. This invention solve the problem of high price of present metal liquid cooling working medium and the limited performance of common metal liquid, leaking out easily taken place using common liquid and easy forming sediment of present nanometer cooling agent.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Hollow silicon-based composite material, preparation method and lithium ion battery comprising composite material

ActiveCN106129411AHigh strengthSmall volume expansionCell electrodesSecondary cellsLithium electrodeThermal treatment

The invention relates to a hollow silicon-based composite material, a preparation method and a lithium ion battery. The hollow silicon-based composite material disclosed by the invention comprises hollow cavities, a carbon-silicon composite layer and a cladding carbon layer in sequence from inside to outside, wherein the carbon-silicon composite layer comprises a secondary particle silicon layer and a deposited carbon layer. The preparation method comprises the following steps: firstly bonding silicon oxide and / or silicon on the surface of graphite uniformly, then removing the graphite through oxidizing heat treatment to obtain a hollow structure, then obtaining nanometer silicon through reduction by using a reducing agent, obtaining hollow particles consisting of the hollow cavities and the secondary particle silicon layer, then carrying out in-situ cladding on the surface of the secondary particle silicon layer, and then finally carrying out cladding of the cladding carbon layer to obtain the hollow silicon-based composite material. The battery prepared by using the composite material as an anode material has high cycle performance and rate capability, the first-time reversible capacity is more than 1453.2 mAh / g, the first-time coulomb efficiency is more than 87.8%, and the hundred-time cycle capacity retention ratio is more than 95.2%.

Owner:BTR NEW MATERIAL GRP CO LTD

Non-aqueous electrolyte secondary battery, negative electrode material, and making method

ActiveCN101567438ASmall volume expansionImprove initial efficiencyElectrode manufacturing processesSiliconSilicon oxideSilicon particle

A negative electrode material comprising an active material and 1-20 wt% of a polyimide resin binder is suitable for use in non-aqueous electrolyte secondary batteries. The active material comprises silicon oxide particles and 1-50 wt% of silicon particles. The negative electrode exhibits improved cycle performance while maintaining the high battery capacity and low volume expansion of silicon oxide. The non-aqueous electrolyte secondary battery has a high initial efficiency and maintains improved performance and efficiency over repeated charge / discharge cycles by virtue of mitigated volumetric changes during charge / discharge cycles.

Owner:SHIN ETSU CHEM IND CO LTD

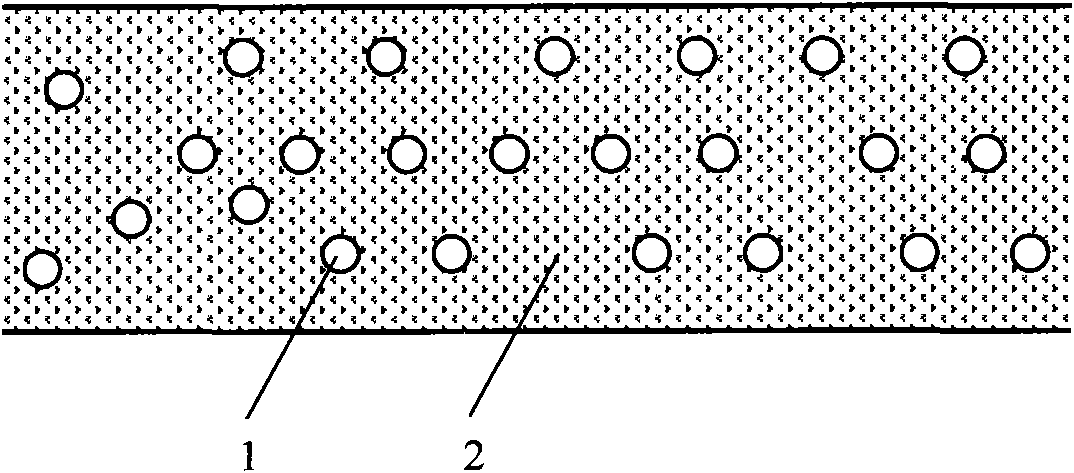

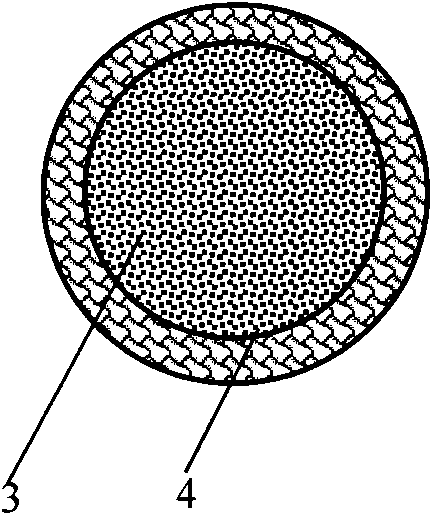

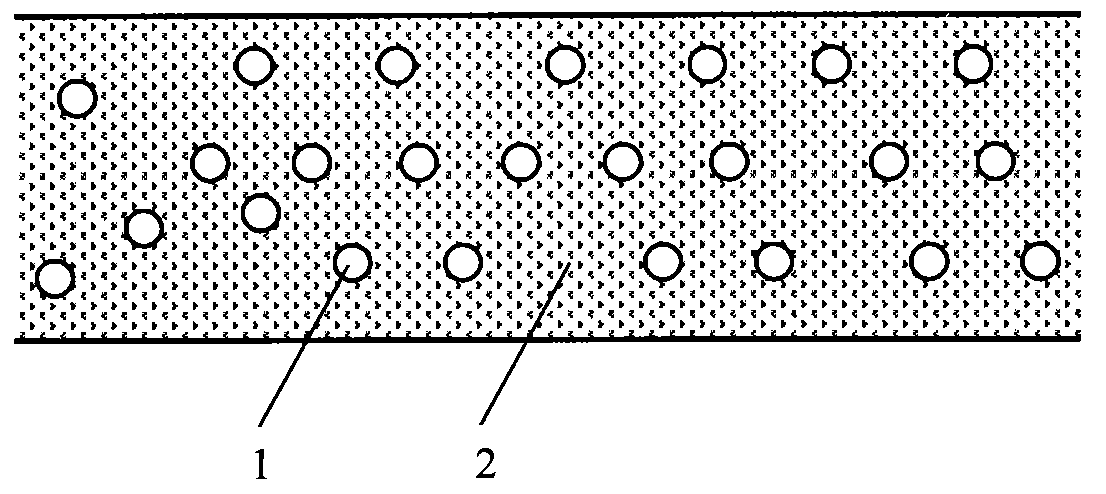

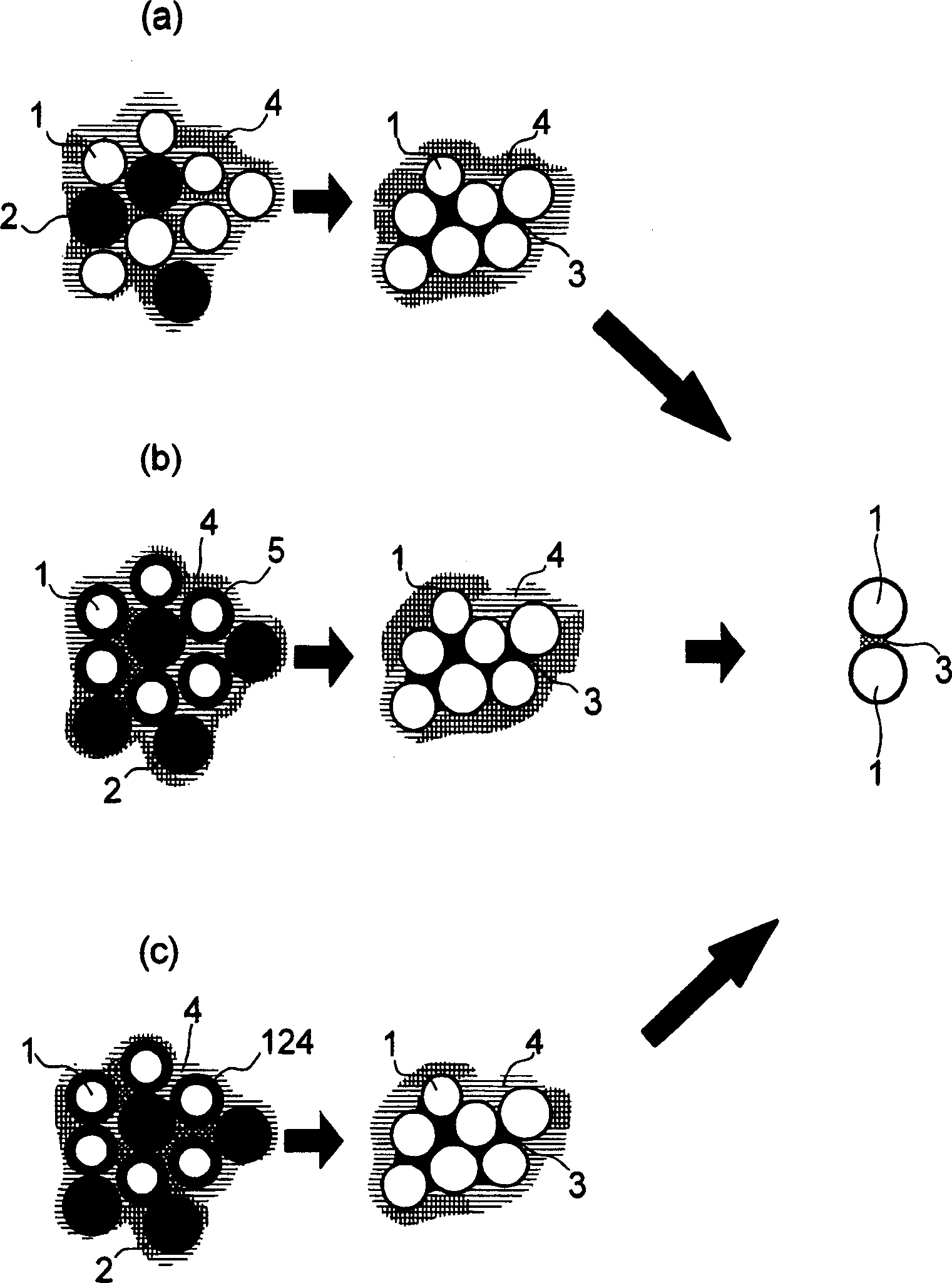

Liquid metal fluid containing phase-change microcapsules

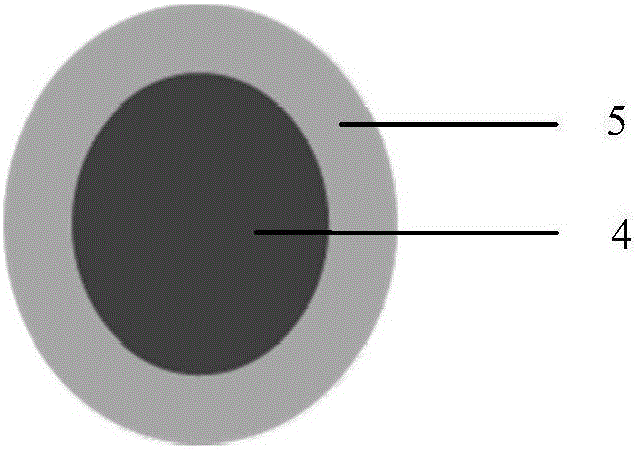

InactiveCN101775270AHigh apparent specific heatIncrease surface tensionHeat-exchange elementsMicroballoon preparationIndiumIn situ polymerization

The invention discloses a liquid metal fluid containing phase-change microcapsules, which adopts phase-change microcapsules (1) as a solute and liquid metal (2) as a solvent, wherein the phase-change microcapsules (1), which are prepared by using an in-situ polymerization method or other methods to embed a phase-change material (3) into an outer casing (4), are spherical and has the diameter of 1nm-1mm; and the liquid metal (2) can be mercury, gallium, gallium-indium alloy or gallium-indium-tin alloy. The invention has the advantages that the liquid metal fluid containing the phase-change microcapsules has a large apparent ratio in the phase-change temperature area of a phase-change material, the phase-change microcapsules (1) are difficult to be deposited or aggregated, the liquid metal fluid has favorable performances in the aspects of calorifics, electrics, magnetics, and the like, and the thermal properties of traditional liquid metals can be enhanced greatly. The liquid metal fluid is a cooling medium suitable for various heat radiating occasions with high heat flux density, and can be widely applied to the fields of computer chips, satellites, rocket propulsion booster and lasers.

Owner:CHONGQING UNIV

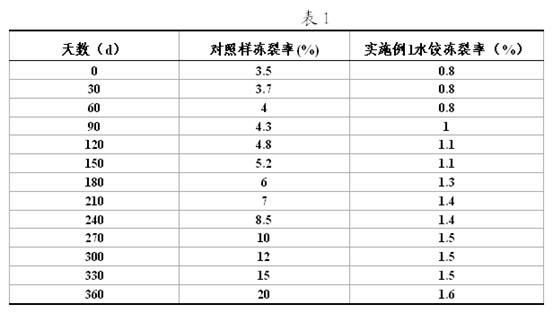

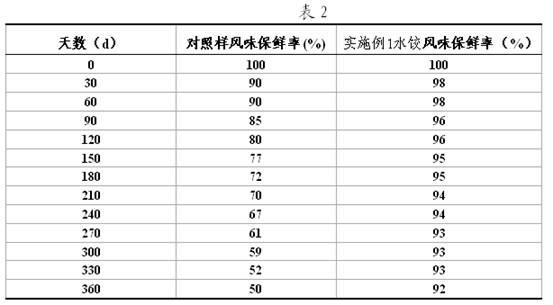

Novel quick-frozen dumpling and preparation method thereof

InactiveCN102125226ASmall volume expansionReduce frost crackingFood preparationAnti freezingAntifreeze protein

The invention belongs to the industrial field of quick-frozen foods, and in particular relates to a quick-frozen dumpling and a preparation method thereof. The novel quick-frozen dumpling comprises a dumpling wrapper and dumpling stuffing, wherein the dumpling wrapper is made from flour, coarse cereals flour, vegetable protein powder, anti-freezing protein, modified starch, an enzyme preparation, vegetable polysaccharide and water; and the dumpling stuffing is made from meat, vegetables, a seasoner, modified starch, vegetable proteins and water. The quick-frozen dumpling is even and reasonable in nutrition collocation, abundant in nutrition, and delicious in taste. The novel quick-frozen dumpling is fresh in taste and good in color and luster under the freezing status, can notbe frozen to be cracked, and can not degrade the dumpling wrapper, the electric energy can be saved by more than 20% during producing, and the multiple effects for improving the high quality, saving the energy, and reducing the consumption are realized.

Owner:河南省食品工业科学研究所

Silicon-carbon composite material and preparation method thereof

InactiveCN109802120AAvoid chalkingImprove cycle performanceMaterial nanotechnologyCell electrodesCyclic processCarbon coating

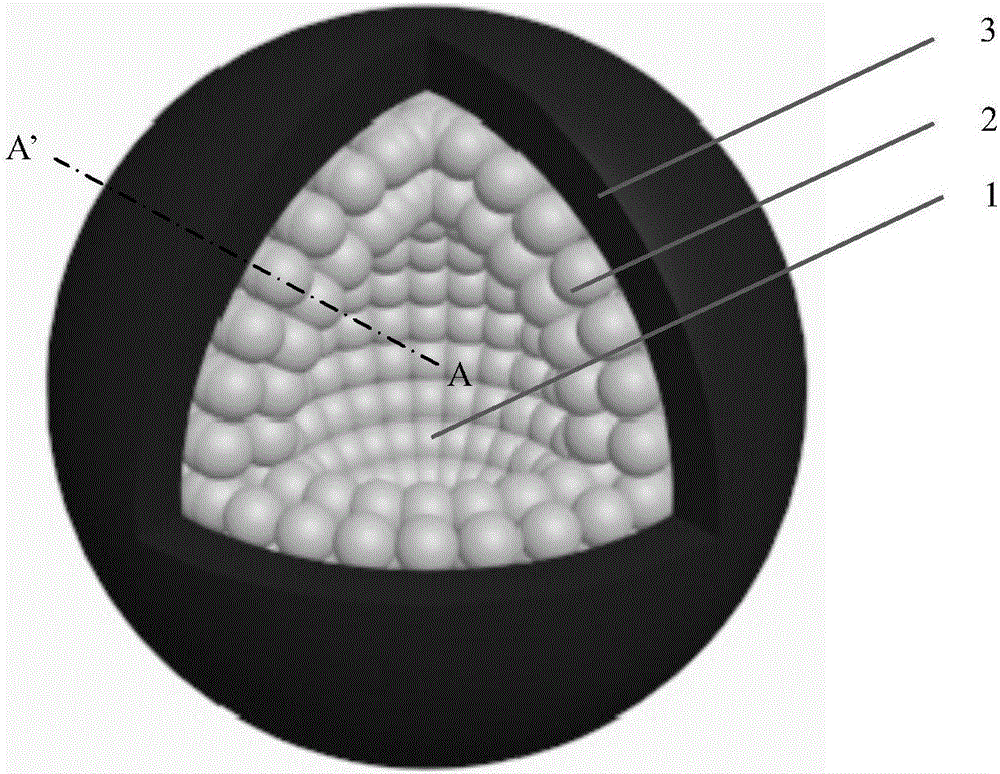

The invention discloses a silicon-carbon composite material which is a composite material similar to a dragon fruit structure. The silicon-carbon composite material comprises a base core, a silicon-carbon composite housing and a coating layer. The silicon-carbon composite housing is formed by uniformly dispersing a plurality of nano silicon particles in conductive carbon. The nano silicon particles are formed by pyrolysis of a silicon source. The conductive carbon is formed by pyrolysis of an organic carbon source. The coating layer is a carbon coating layer. At least one carbon coating layeris provided. The thickness of a single carbon coating layer is 0.2 to 3[mu]m. Compared with the prior art, a silicon-carbon composite material precursor is formed by using vapor phase synchronous deposition, and carbon coating is performed to form the silicon-carbon composite material similar to the dragon fruit structure. The silicon-carbon composite material has a high first effect, low expansion and long circulation, slows down the silicon material grain growth during the heat treatment process, avoids the powdering of the material during the cycle, alleviates the volume expansion effect ofthe silicon-based material, and is improved in the cycle performance, the electrical conductivity and the rate performance.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Preparation method of molybdenum carbide/nitrogen-sulfur codoped spongy graphene cathode composite for sodium-ion battery

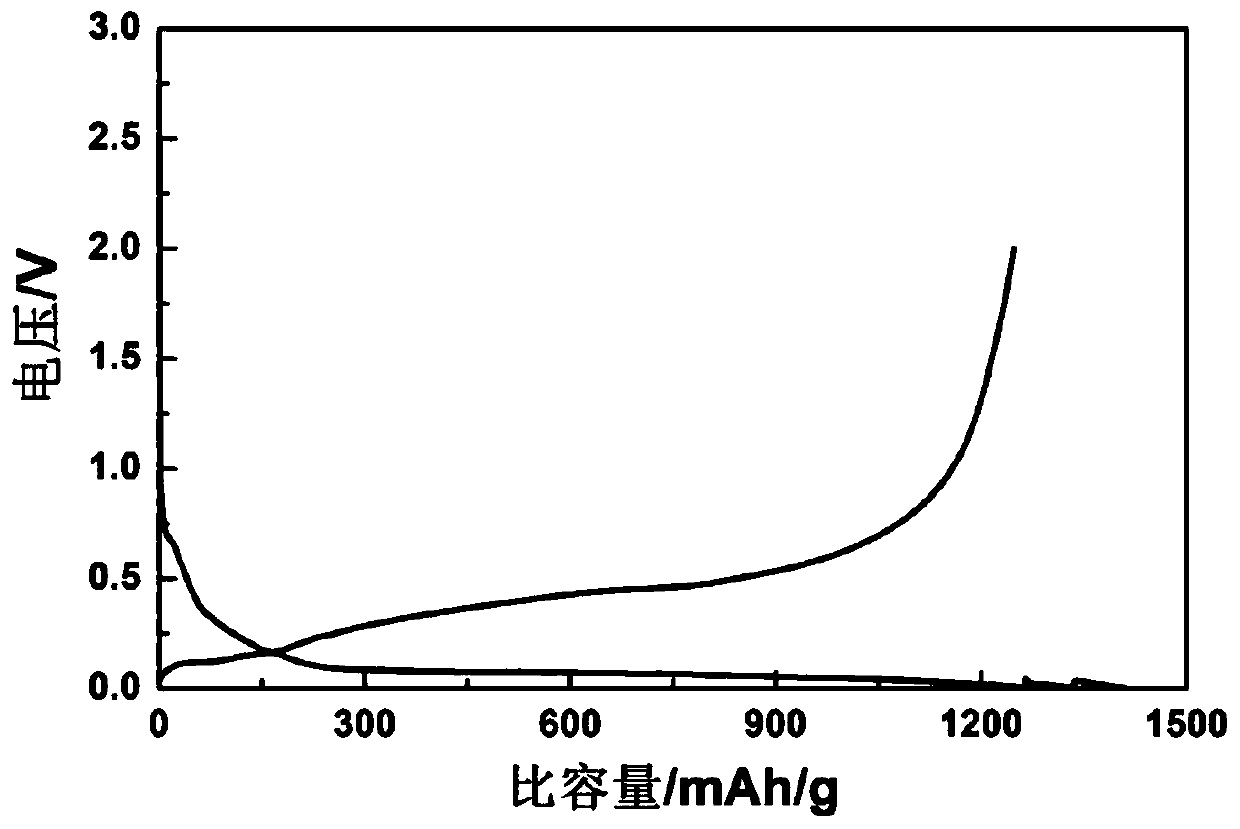

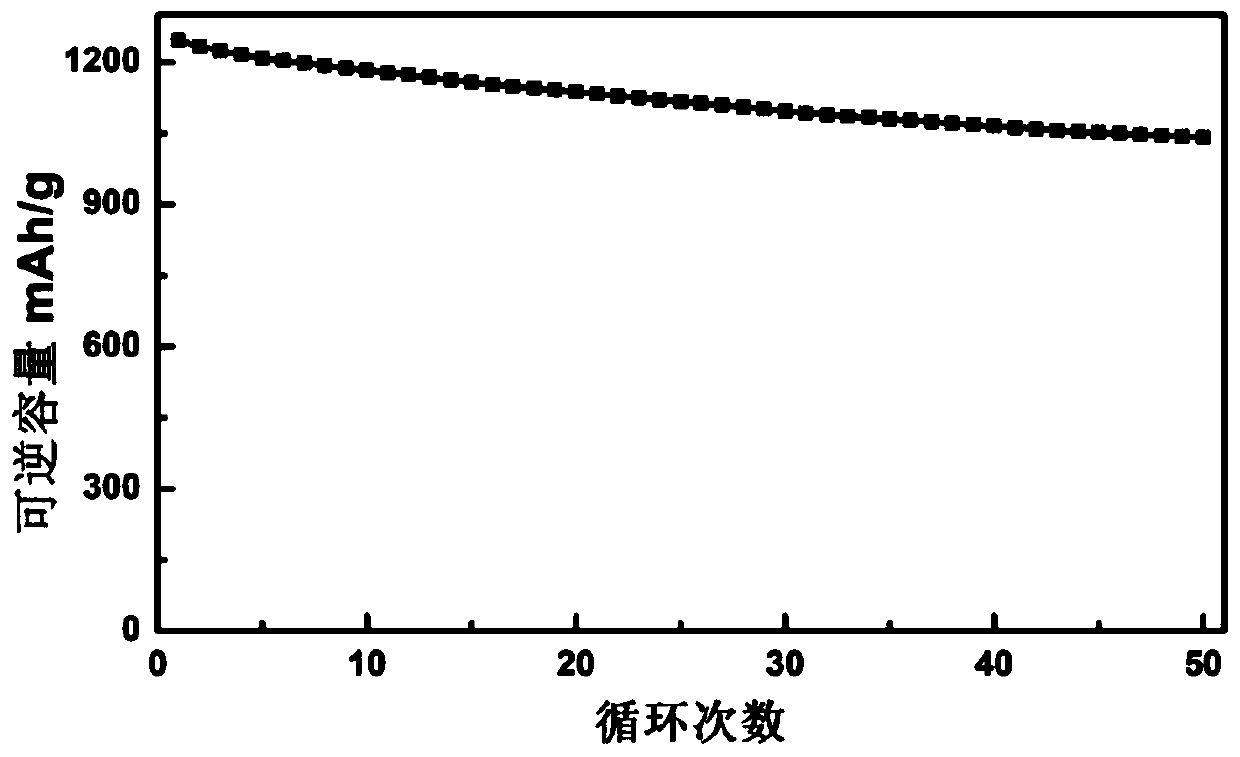

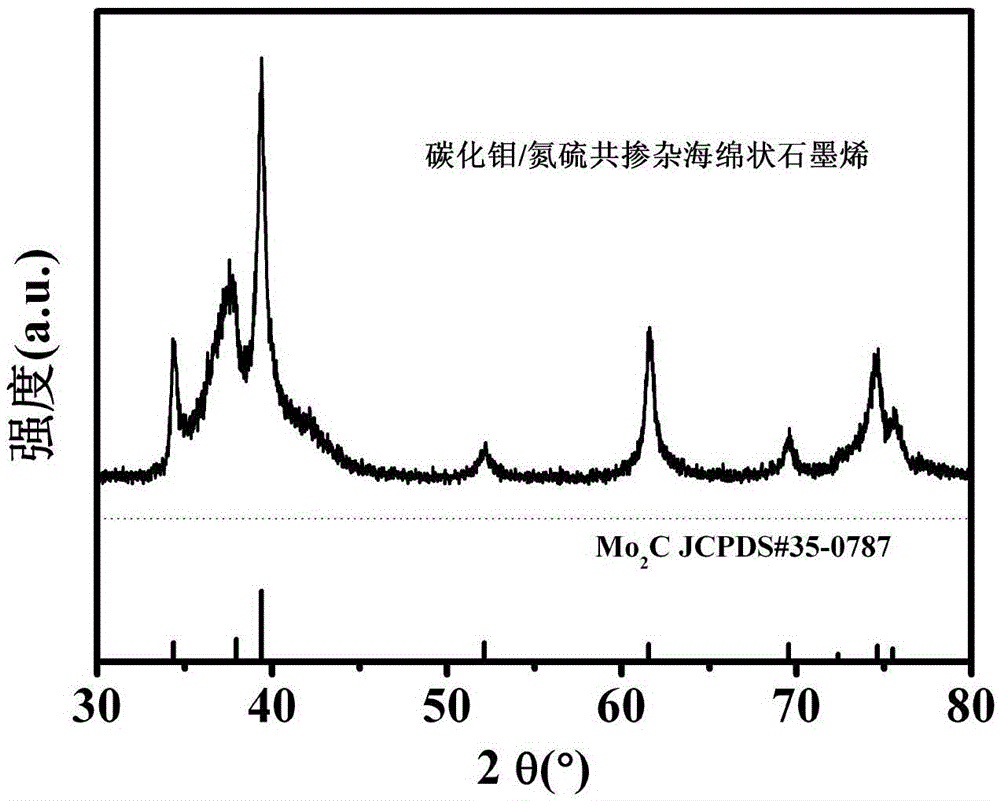

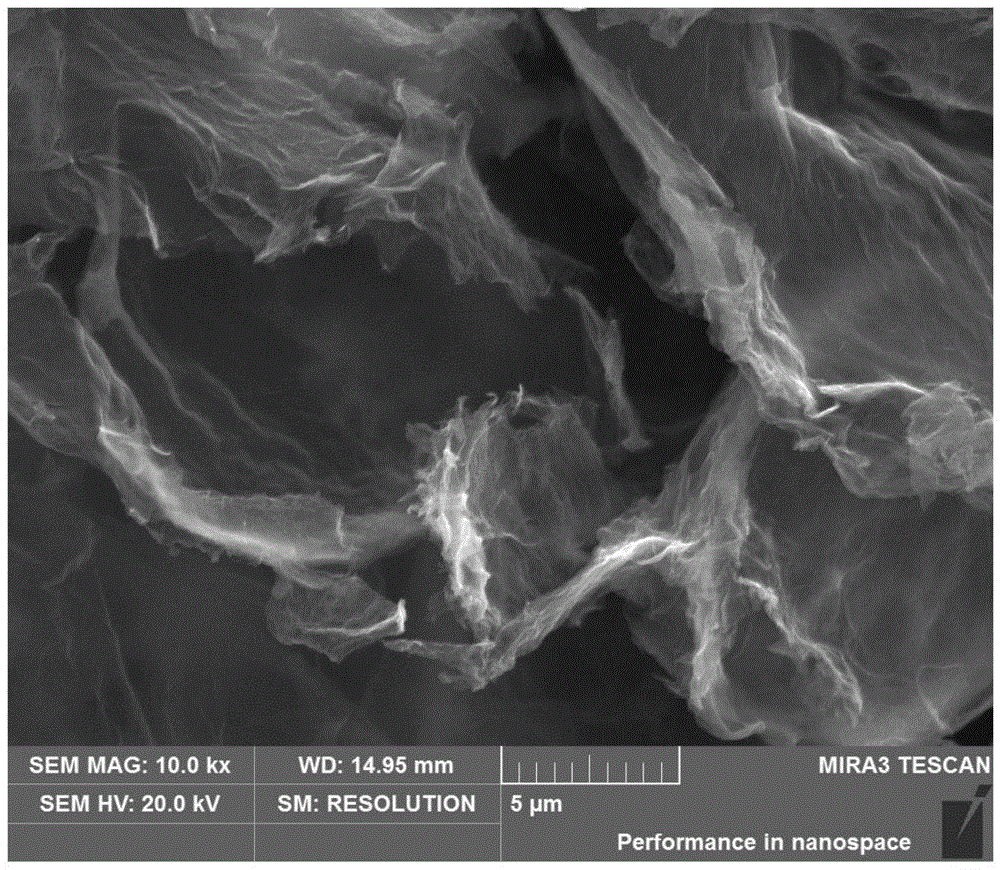

ActiveCN105591077ASmall volume expansionImproved magnification performanceCell electrodesSecondary cellsDoped grapheneFreeze-drying

The invention discloses a preparation method of a molybdenum carbide / nitrogen-sulfur codoped spongy graphene cathode composite for a sodium-ion battery. According to the molybdenum carbide / nitrogen-sulfur codoped spongy graphene cathode composite prepared through the preparation method, molybdenum carbide particles are uniformly distributed in carbide / nitrogen-sulfur codoped spongy graphene which has a great number of surface folds, has a great number of active sites and is of a three-dimensional structure. The preparation method comprises the steps of dissolving a molybdenum source and a carbon source into a graphene oxide solution, adding a nitrogen source and a sulfur source, adjusting ph value, then conducting a hydrothermal reaction on an obtained mixed solution, conducting freeze-drying on a product, then putting the product in a quartz crucible for high temperature heat treatment, and conducting natural cooling after a reaction is ended, so that the composite is obtained. In the hydrothermal reaction process, graphene doping and reduction, formation of a precursor and composition of the precursor and doped graphene are conducted synchronously. The composite can be obtained by combining the hydrothermal method with the subsequent heat treatment process, and the preparation method is simple in process and low in cost and has good research prospect.

Owner:CENT SOUTH UNIV

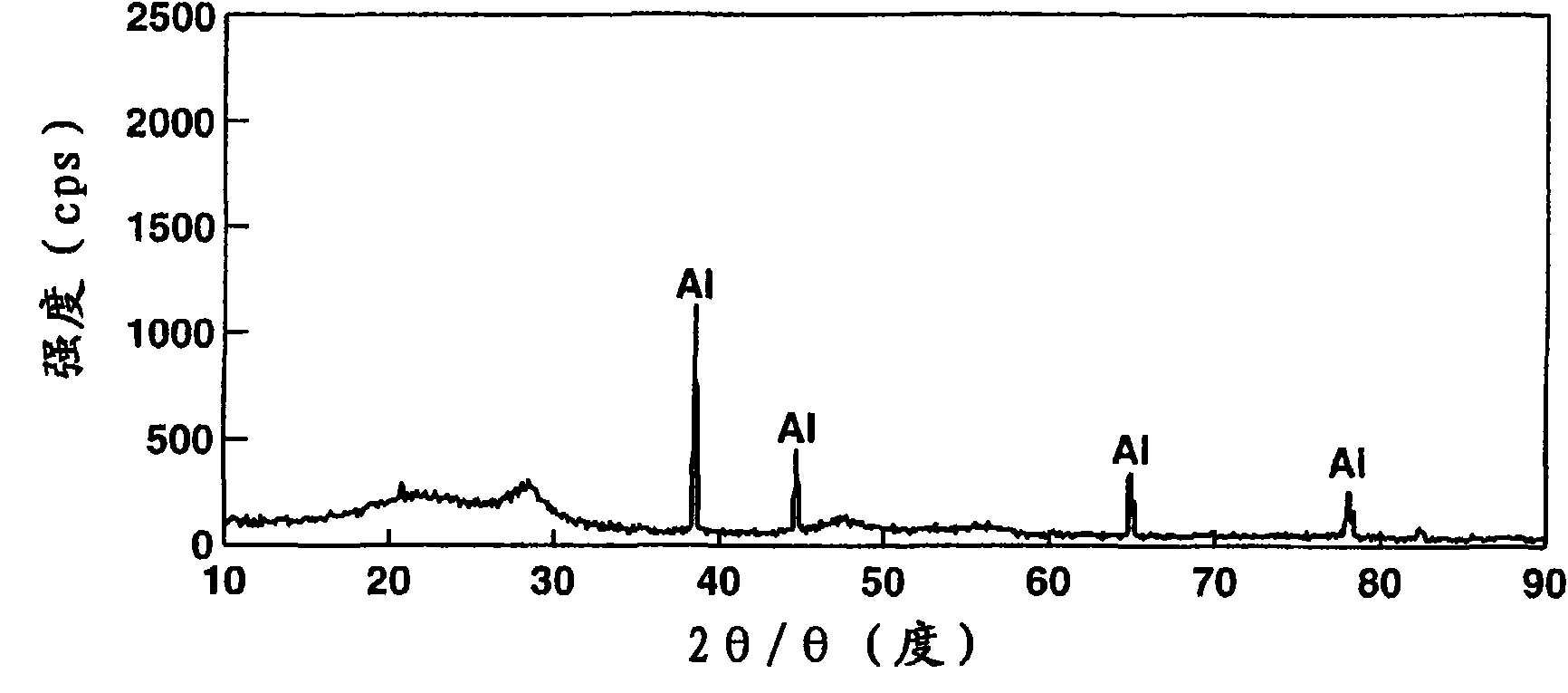

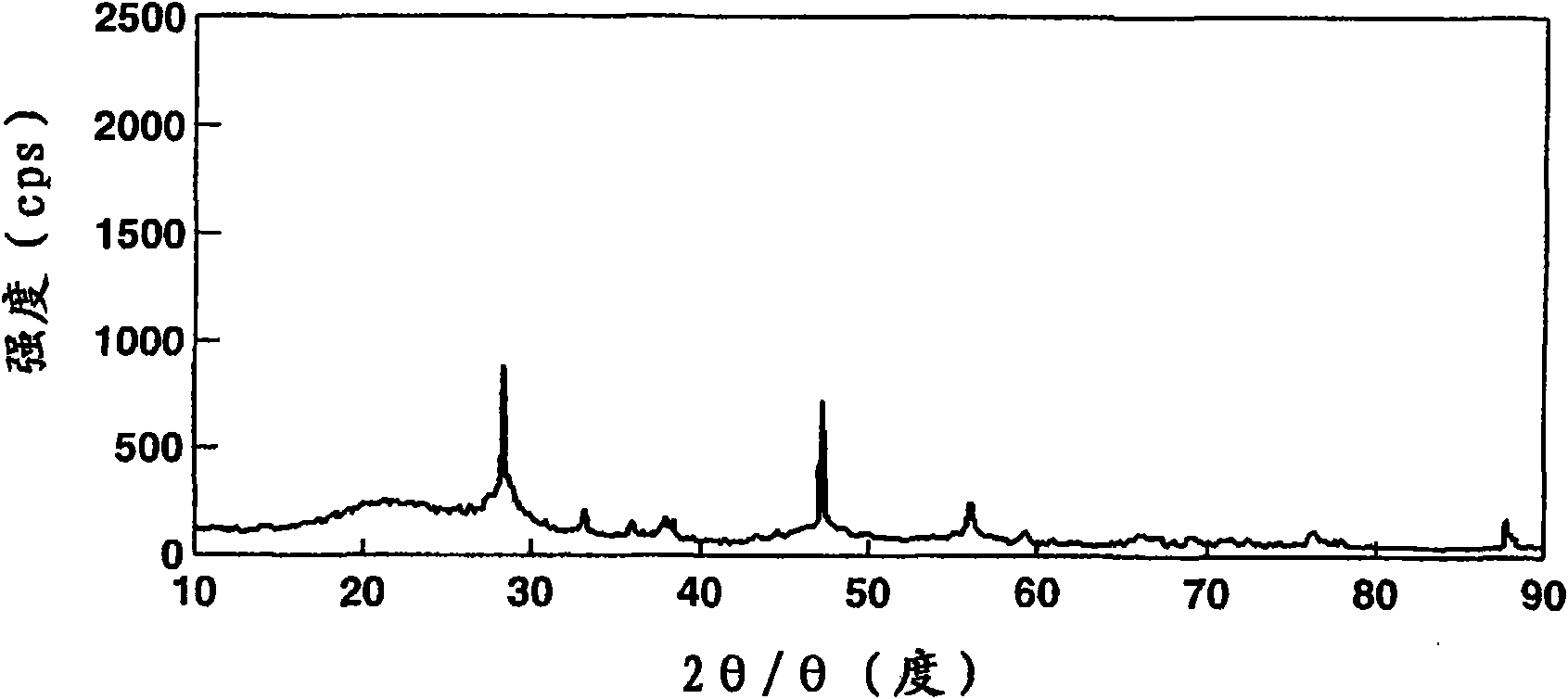

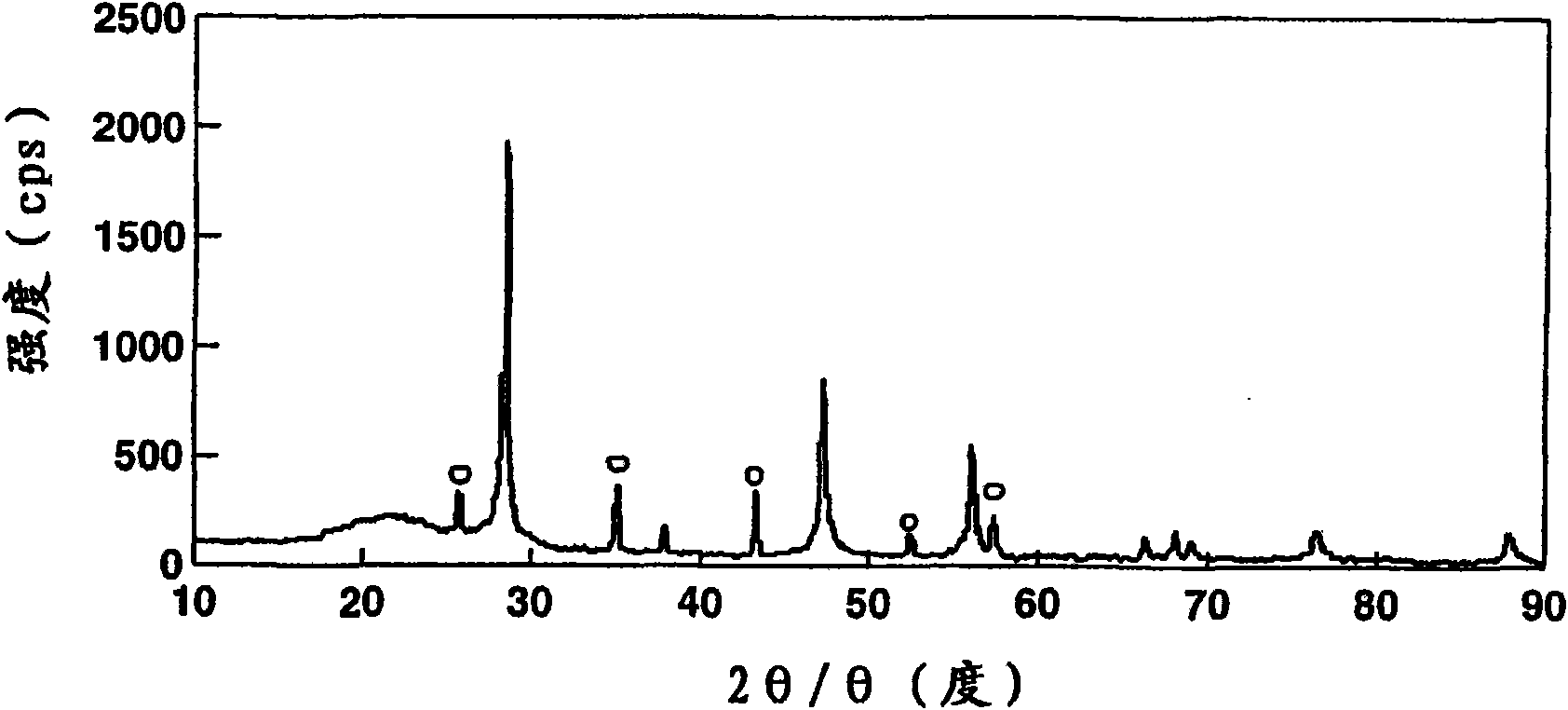

Non-aqueous electrolyte secondary battery, negative electrode, negative electrode material, and preparation of si-o-al composite

InactiveCN101662013AHigh 1st cycle charge/discharge efficiencyImprove cycle performanceElectrode manufacturing processesActive material electrodesDischarge efficiencyElectrical battery

The invention relates to a non-aqueous electrolyte secondary battery, a negative electrode, a negative electrode material and a preparation of Si-O-Al composite. An Si-O-Al composite comprising silicon, silicon oxide, and aluminum oxide exhibits a powder XRD spectrum in which the intensity of a signal of silicon at 28.3 DEG is 1-9 times the intensity of a signal near 21 DEG. A negative electrode material comprising the Si-O-Al composite is used to construct a non-aqueous electrolyte secondary battery which is improved in 1st cycle charge / discharge efficiency and cycle performance while maintaining the high battery capacity and low volume expansion upon charging of silicon oxide.

Owner:SHIN ETSU CHEM CO LTD

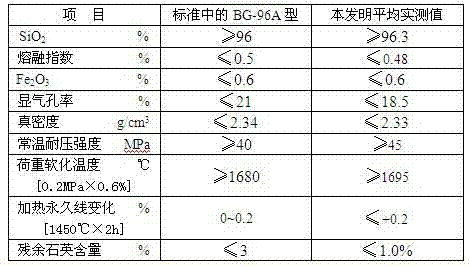

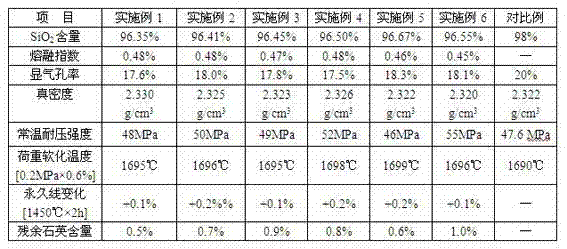

Silica brick for glass furnace

ActiveCN102515801ASmall volume expansionReduce crackingGlass furnace apparatusGlass productionPorosityBrick

The invention discloses a silica brick for a glass furnace, and belongs to the technical field of refractory materials. The silica brick for a glass furnace comprises: by weight, 30 to 45% of silica having particle sizes of 3 to 1.0mm, 5 to 25% of silica having particle sizes of 1.0 to 0.5mm, 30 to 50% of silica having particle sizes less than 0.5mm, an additive and a composite additive, wherein the weight of the additive is 5 to 15% of the total weight of the silica and the weight of the composite additive is 2 to 10% of the total weight of the silica. SiO2 content of the silica is great than or equal to 99%. Al2O3 content of the silica is less than or equal to 0.25%. Fe2O3 content of the silica is less than or equal to 0.45%. The additive is a waste silica material having SiO2 content great than or equal to 96%. The composite additive is a mixture of lime milk, mill scales and calcium lignosulphonate. The silica brick for a glass furnace has high SiO2 content, a high yield, low impurity content, low apparent porosity, good high-temperature performances and a long service life. A preparation technology of the silica brick for a glass furnace is simple and is suitable for large-scale production.

Owner:ZHEJIANG ZHAOSHAN SILICEOUS REFRACTORY MATERIAL

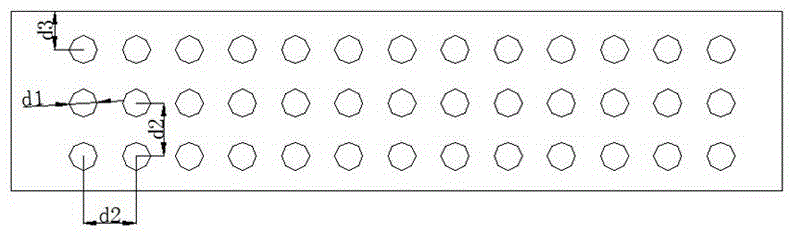

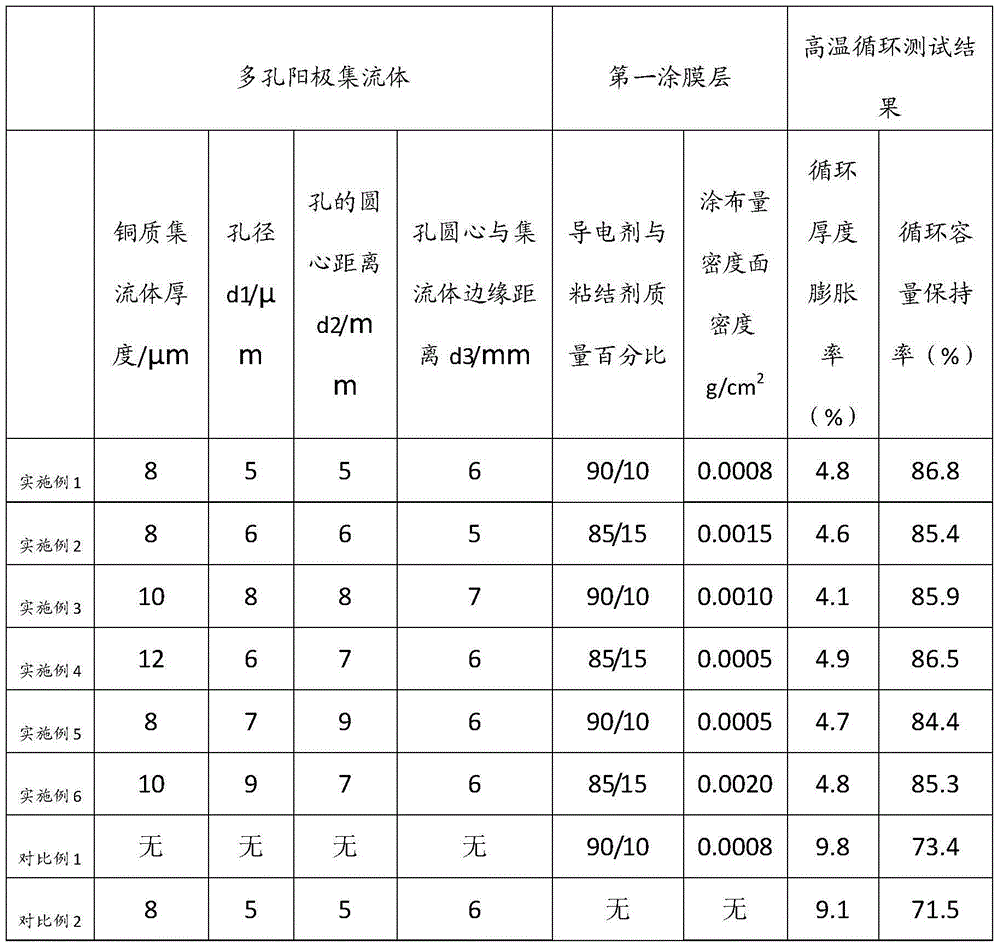

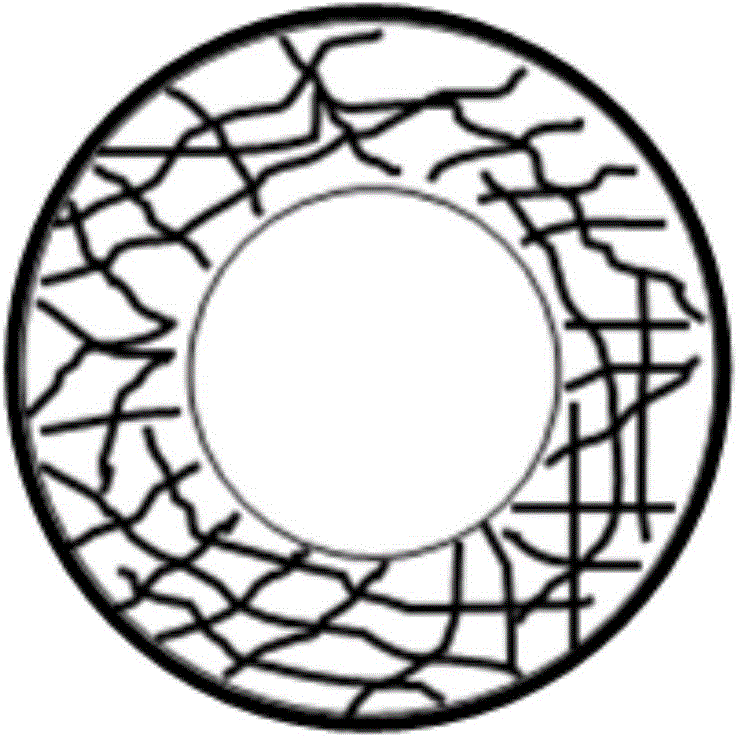

Porous silicon and carbon mixed anode plate and lithium ion secondary battery comprising same

InactiveCN104091921ASmall volume expansionReduce adhesionElectrode carriers/collectorsSecondary cellsCyclic processRetention ratio

The invention discloses a porous silicon and carbon mixed anode plate and a lithium ion secondary battery comprising the same. The porous silicon and carbon mixed anode plate comprises a porous anode current collector, and two coating layers coating the porous anode current collector, wherein a first layer which is close to the porous anode current collector is made of a mixture of a bonding agent and a conductive agent, a second layer is made of a mixture of a silicon and carbon mixture, the bonding agent and the conductive agent, and the second layer coats the first layer; the lithium ion secondary battery comprises a cathode plate, the porous silicon and carbon mixed anode plate, and an isolating membrane and electrolyte which are arranged between the cathode plate and the porous silicon and carbon mixed anode plate. The porous silicon and carbon mixed anode plate provided by the invention overcomes the defect that the silicon and carbon mixed anode lithium ion secondary battery prepared by adopting a traditional technology is large in volume in the cyclic process, and is capable of increasing the circulation capacity retention ratio of the silicon and carbon mixed anode lithium ion secondary battery, reducing the thickness swelling rate of the lithium ion battery in the cyclic process and increasing the energy density of the lithium ion secondary battery.

Owner:XIAMEN SHOUNENG TECH

Preparation method for graphite anode material of lithium ion battery

InactiveCN105932281AReduce turnoverReduce lossesElectrode manufacturing processesSodium-ion batteryLithium-ion battery

The invention discloses a preparation method for a graphite anode material of a lithium ion battery. Fine graphite powder with a small particle size and an organic carbon source are taken as raw materials; through adoption of processes such as mixing, high temperature processing, graphitizing and sieving and through mixing of the fine powder and the organic carbon source in a heating environment, coating, kneading and secondary granulating effects can be realized; and under the adhering effect of the organic carbon source, the fine powder with the small particle size forms secondary particles. The anisotropy problem of the materials is solved, and the tap density of the materials is improved. According to the method, the turnover and device residual loss of the materials are reduced, the yield is high, the processes are simple, the energy consumption is low, the environment is protected, the surface coating effects of the materials are even, and the consistency is high. The prepared anode material is characterized in anisotropy, low iron impurity content, low initial irreversible capacity, low volume expansion, high liquid absorbency, high cycle performance, high cost performance and high comprehensive performance.

Owner:田东

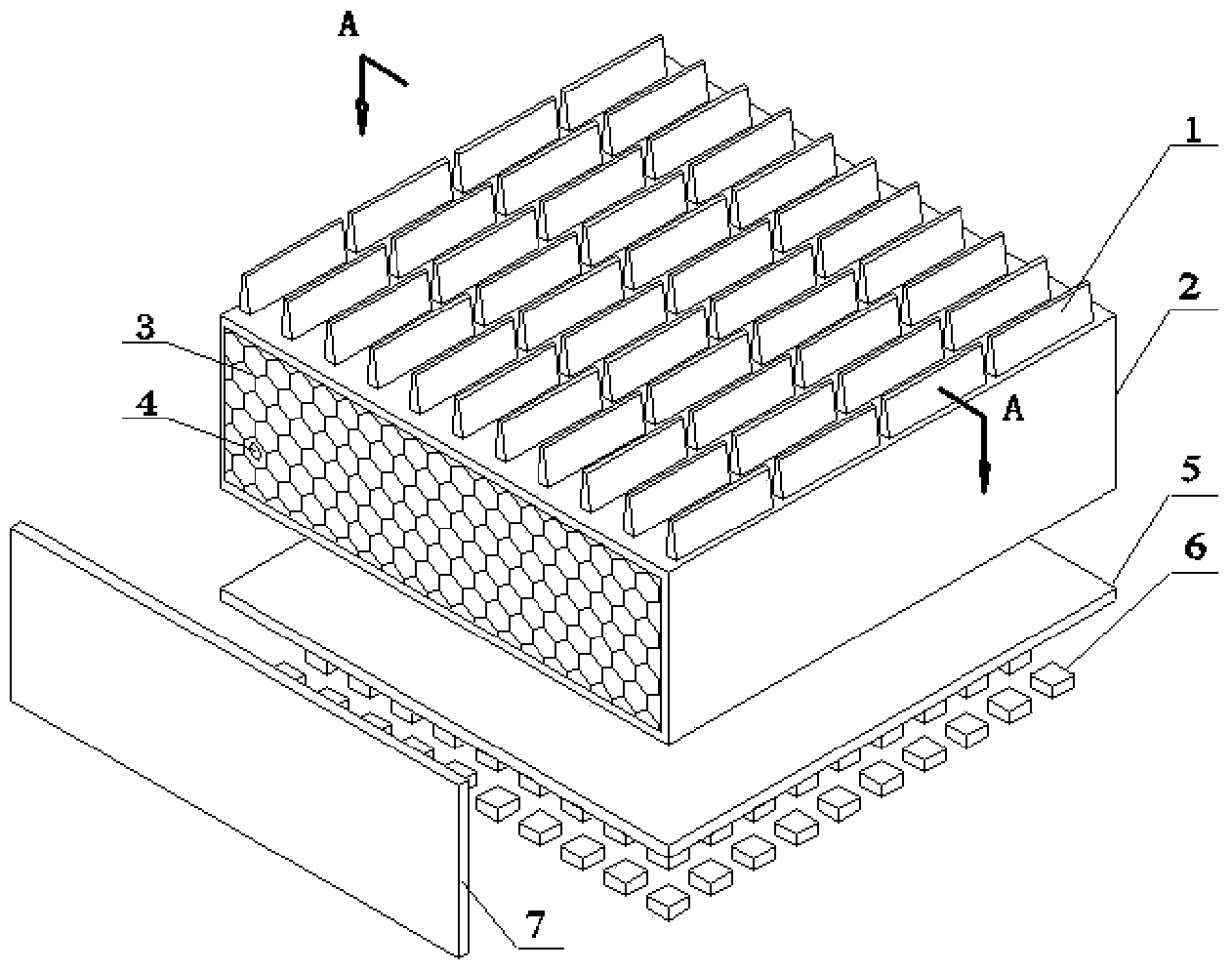

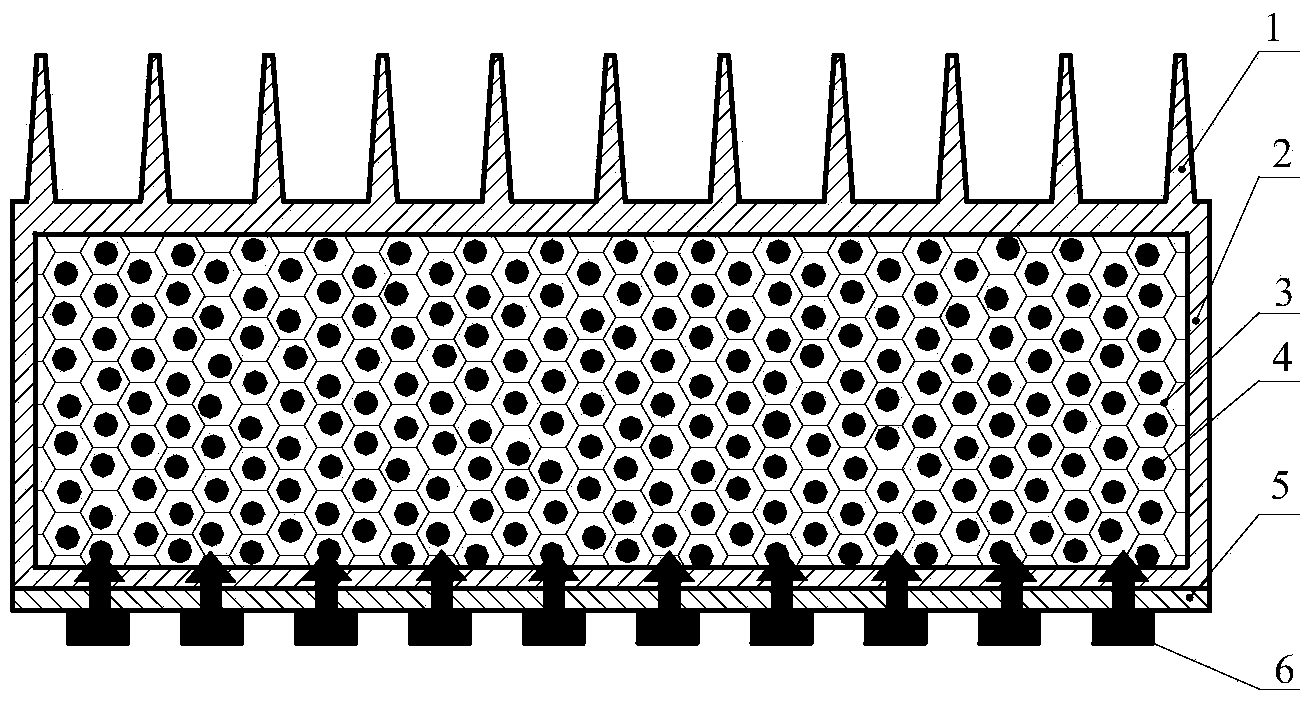

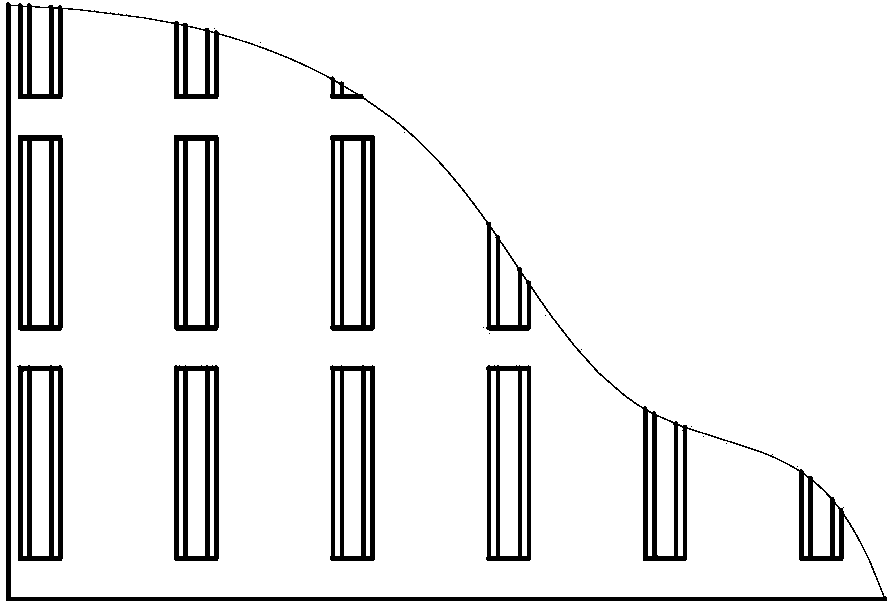

High-power LED multi-hole phase-changing heat sink structure

InactiveCN104241513AReduce dependenceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesExternal energyWorking temperature

A high-power LED multi-hole phase-changing heat sink structure comprises a radiator inner cavity. A plurality of radiator fins are arranged on the top face of the radiator inner cavity. A metal multi-hole structure is arranged in the radiator inner cavity in a sintering mode. Holes of the metal multi-hole structure are filled with phase-changing materials. An LED electronic chip is arranged on the bottom face of the radiator inner cavity. The melting point of the phase-changing materials is lower than the normal working temperature of the LED electronic chip. The response speed of phase-changing latent heat storing can be increased, the weight and the cost of an LED radiating structure are lowered, a part of heat emitted by the chip during LED working is dissipated in a natural-convection mode, a large part is stored by latent heat absorbed during a phase-changing material melting process, meanwhile, the temperature of the LED chip is controlled through the melting point of the phase-changing materials, and radiating performance is improved. The high-power LED multi-hole phase-changing heat sink structure has the advantages of being simple in structure, light in weight, small in size, good in adjusting performance, good in radiating effect, long in service life, free from external energy loss and environment pollution and the like.

Owner:XI AN JIAOTONG UNIV

Modified silicon monoxide material for lithium ion battery negative electrode and preparation method thereof

ActiveCN111072038ASmall volume expansionReduce consumptionSilicaSecondary cellsSilicon monoxideSilicon oxide

The invention discloses a modified silicon monoxide material and a preparation method thereof. The modified silicon monoxide material is the modified silicon monoxide material used for a lithium battery negative electrode. The modified silicon monoxide material is prepared by the following steps: reacting raw materials silicon, silicon dioxide and metal silicate under high-temperature and vacuum conditions to prepare silicon monoxide, and reacting metal steam with silicon monoxide in the preparation process to form metal silicate in situ; wherein the metal silicate is uniformly dispersed around the silicon and the silicon monoxide to form silicon-containing particles, and the carbon material is coated on the surfaces of the silicon-containing particles. The silicate in the modified siliconmonoxide material is uniformly dispersed, the carbon material is uniformly coated, and the modified silicon monoxide material shows high specific capacity, high initial coulombic efficiency, excellent cycle performance and rate capability when used as the lithium ion battery negative electrode material. Moreover, the preparation method disclosed by the invention is low in raw material price and beneficial to industrial implementation, so that the modified silicon monoxide has a very wide application prospect.

Owner:JIANGXI IAMETAL NEW ENERGY TECH CO LTD

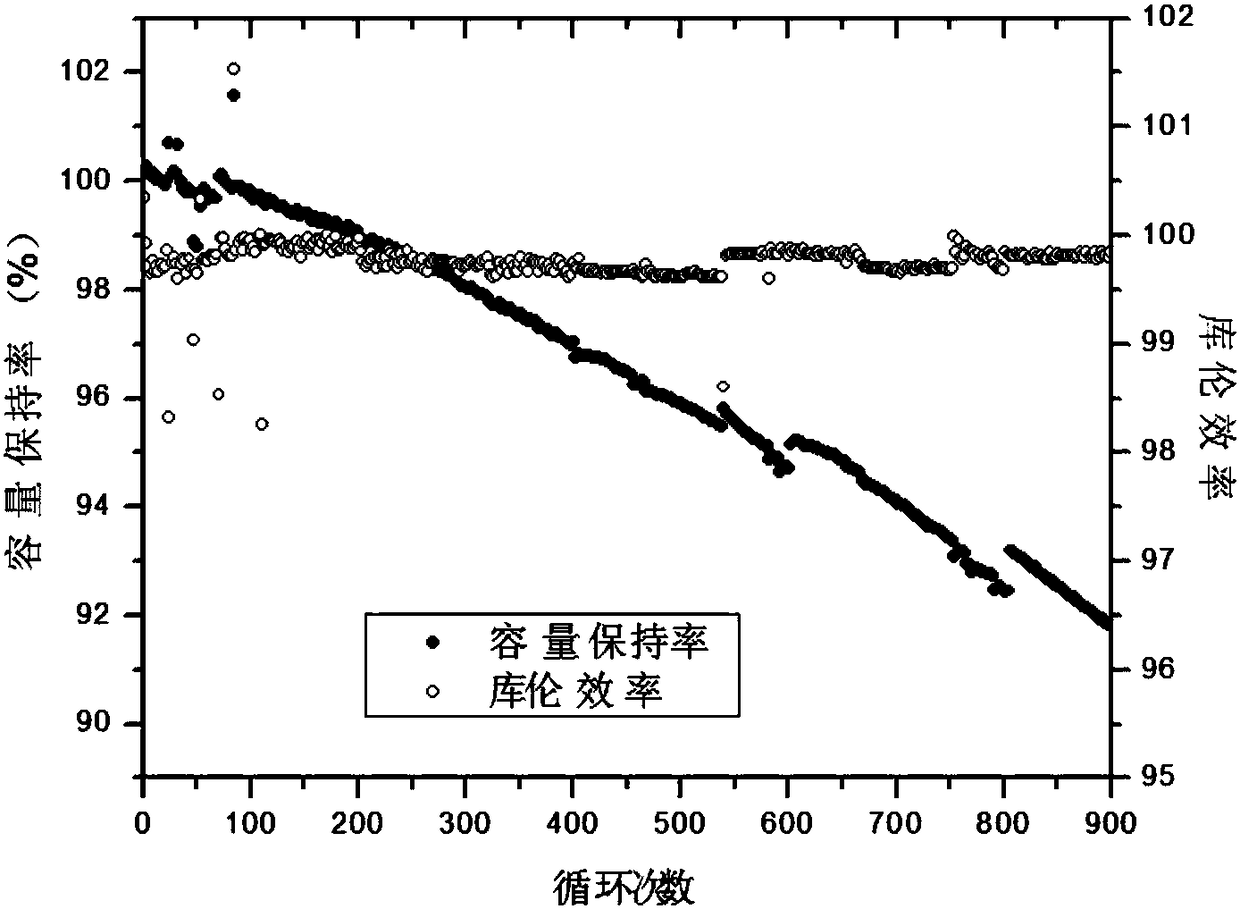

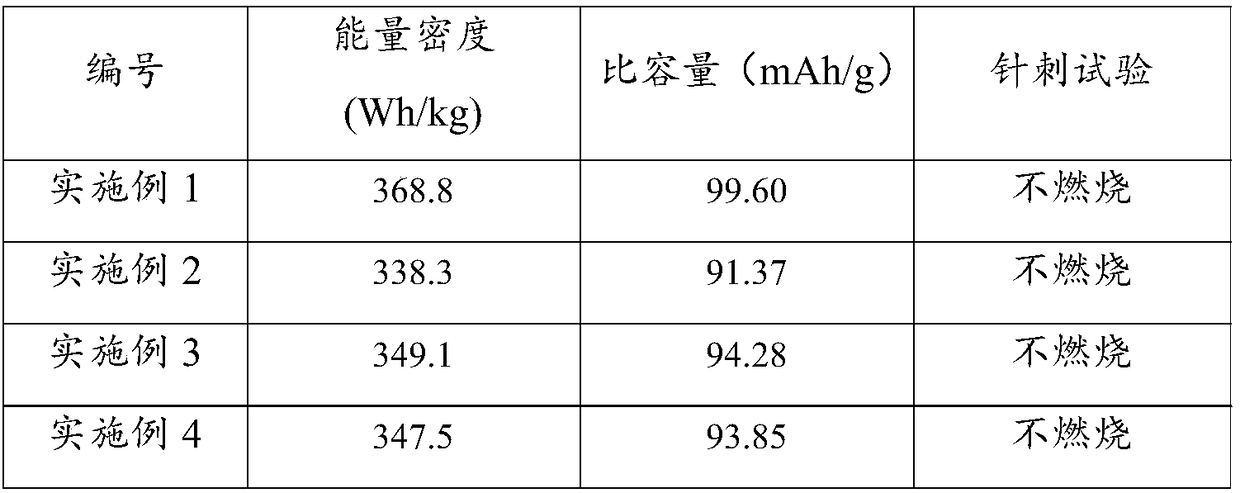

Lithium-rich manganese material, positive electrode material for lithium-ion battery, positive plate for lithium-ion battery, lithium-ion battery and preparation method of lithium-ion battery

ActiveCN108172823AIncrease capacityHigh Capacity FeaturesFinal product manufacturePositive electrodesElectrical batteryLithium-ion battery

The invention discloses a lithium-rich manganese material, a positive electrode material for a lithium-ion battery, a positive plate for the lithium-ion battery, the lithium-ion battery and a preparation method of the lithium-ion battery and relates to the technical field of lithium-ion batteries. The molecular formula of the lithium-rich manganese material is aLi2MnO3.(1-a)LiNi0.5Mn1.5O4.(1-a)LiNi0.5Mn0.5O2, wherein a is smaller than or equal to 0.3 and greater than or equal to 0.01. The positive electrode material comprises the lithium-rich manganese material; the positive plate is coated with the positive electrode material; an active material of the positive electrode material for the lithium-ion battery is the lithium-rich manganese material; and the active material of a negative electrode material is a SiO / C composite material. According to the lithium-rich manganese material, the defects that an existing positive electrode material is in low specific capacity and low in initialefficiency and an existing negative electrode material is low in coulombic efficiency and poor in cycle performance are relieved. Through the cooperation of the positive electrode material and the negative electrode material, the obtained lithium-ion battery has high specific energy and high security, and the energy density of the battery is greater than 320Wh / kg.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Preparation method for artificial graphite negative electrode material for lithium ion battery

InactiveCN105958070ALow tap densityHigh tap densityCell electrodesSecondary cellsEnvironmental resistanceLithium-ion battery

Disclosed is a preparation method for an artificial graphite negative electrode material for a lithium ion battery. Artificial graphite coke powder with small grain diameter and an organic carbon source are taken as the raw materials; the raw materials are subjected to procedures of mixing, high-temperature treatment, graphitization treatment, sieving and the like; the coke powder and the organic carbon source are mixed in a heating environment, and the effects of coating, mixing and holding, secondary pelleting and the like can be achieved; the small-particle coke powder can form secondary particles under the cohesive action of the organic carbon source; therefore, the problem of anisotropy of the material is solved, and the tap density of the material is improved; meanwhile, the artificial graphite negative electrode material is capable of lowering the material turnover and equipment residual loss, high in yield, simple in procedures, low in energy consumption, environment-friendly, uniform in the coating effect on the surface of the material, and high in consistency; and in addition, the prepared negative electrode material has the characteristics of isotropy, low iron impurity content, low initial irreversible capacity, small volume expansion, high absorbency, high circulation performance, high performance cost ratio, excellent comprehensive performance and the like.

Owner:田东

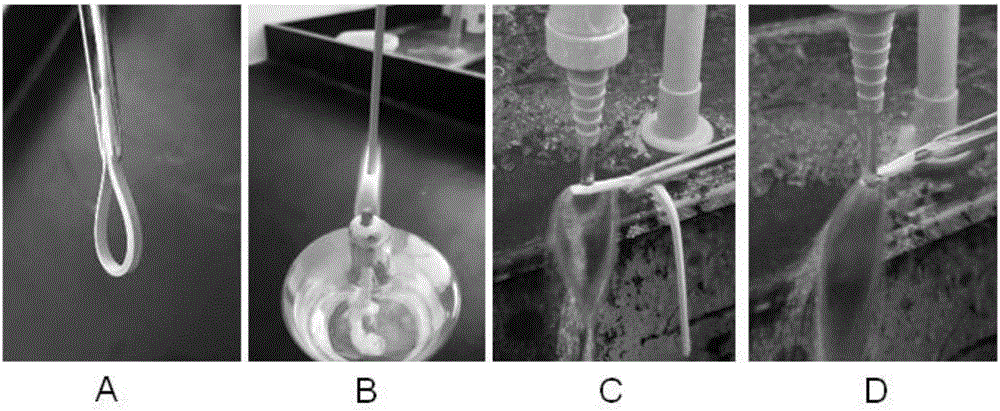

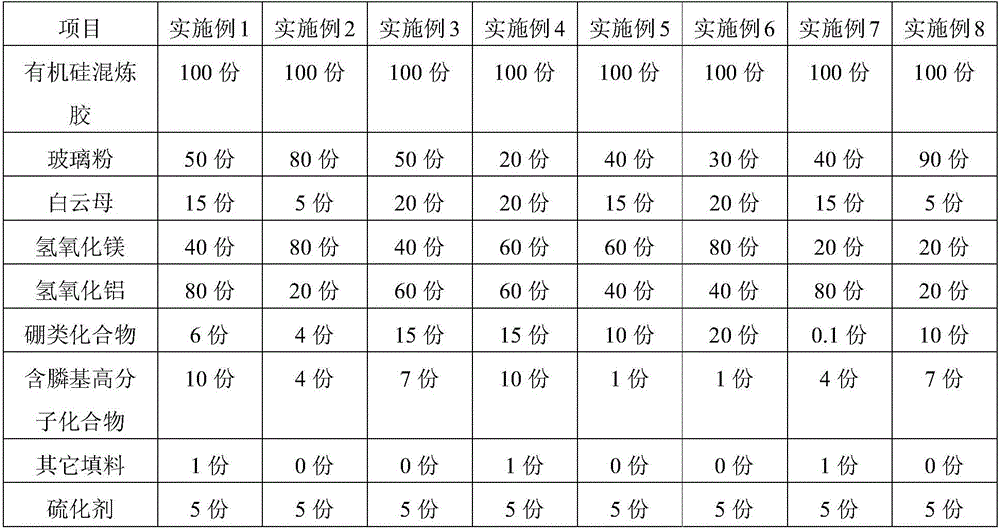

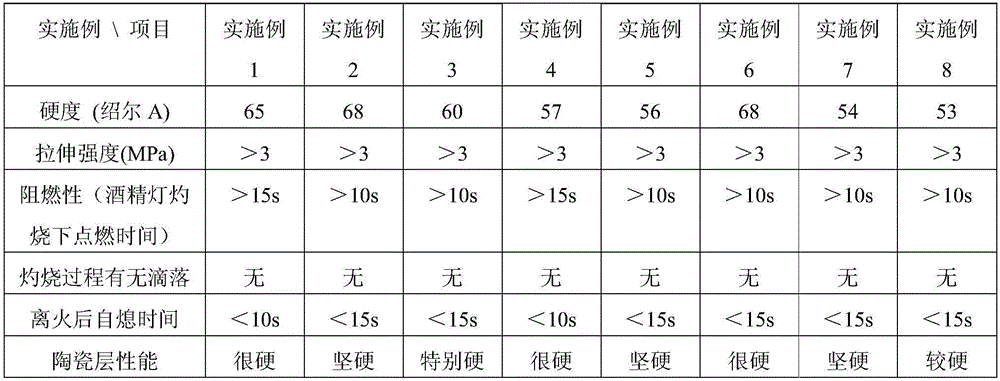

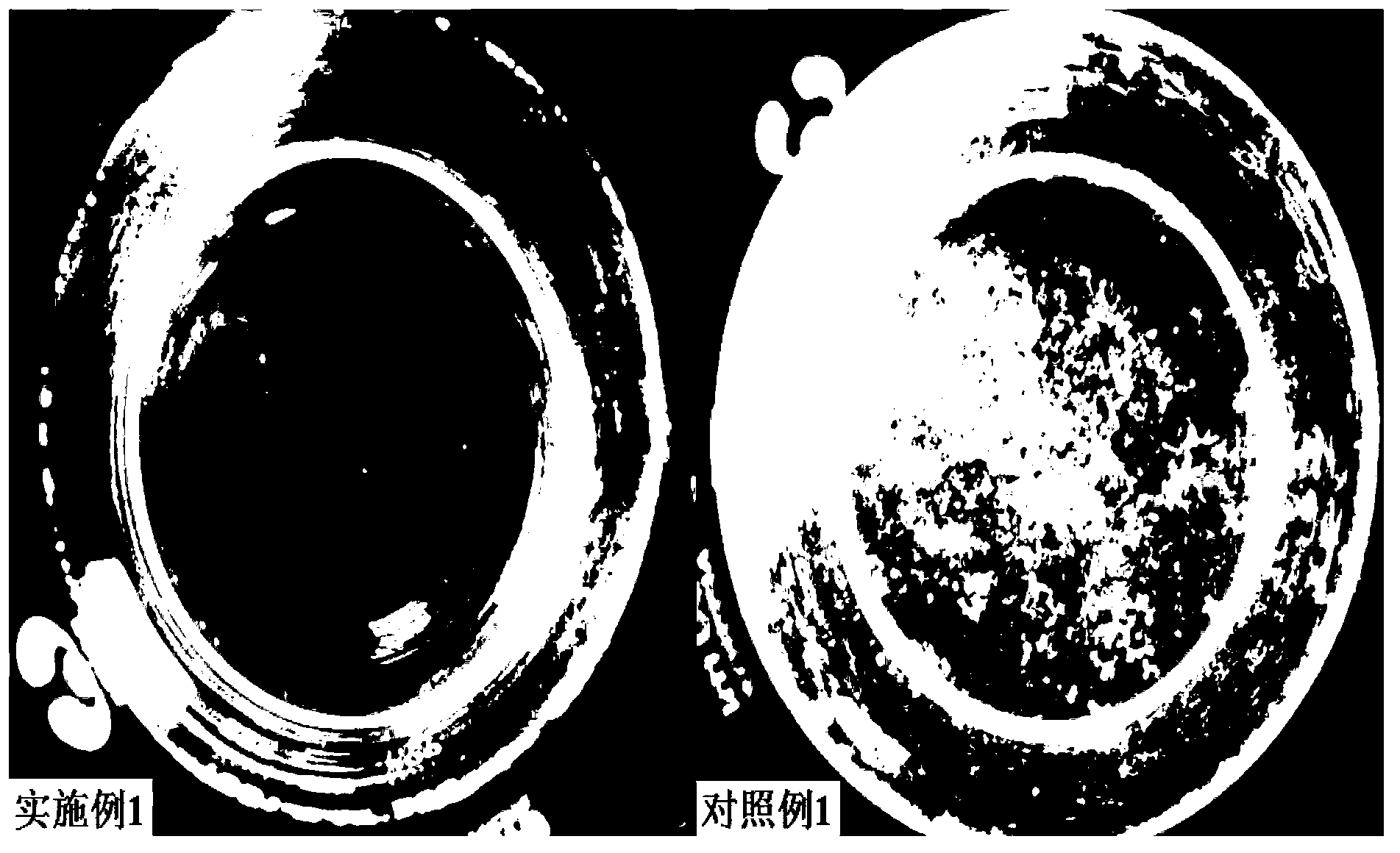

Flame-retardant and drippage-free ceramization silicon rubber and preparation method thereof

ActiveCN105884267AGood physical and mechanical propertiesThe process is simple and easy to controlAluminium hydroxideEconomic benefits

The invention relates to flame-retardant and drippage-free ceramization silicon rubber and a preparation method thereof. The silicon rubber is prepared from components in parts by weight as follows: 100 parts of organic silicon rubber compounds, 1 part to 10 parts of a vulcanizing agent, 100 parts to 150 parts of ceramization powder and 0 to 100 parts of other filler or auxiliaries, wherein the ceramization powder is prepared from raw materials in parts by weight as follows: 1 part to 120 parts of glass powder, 1 part to 20 parts of muscovite, 1 part to 200 parts of magnesium hydroxide, 1 part to 200 parts of aluminum hydroxide, 0.1 parts to 50 parts of boron compounds and 0.1 parts to 20 parts of phosphono-containing polymer compounds. The ceramization silicon rubber prepared with the method has advantages of good flame retardance and self-extinguishment performance; a ceramic layer formed after firing has good compactness and insulativity, external force resistance and the like. The preparation process is simple, raw materials are cheap, and accordingly the silicon rubber is expected to be applied to fields such as wires and cables, the electronic and electrical technology, aerospace engineering and the like and has quite good economic benefits and popularization value.

Owner:SHANDONG UNIV

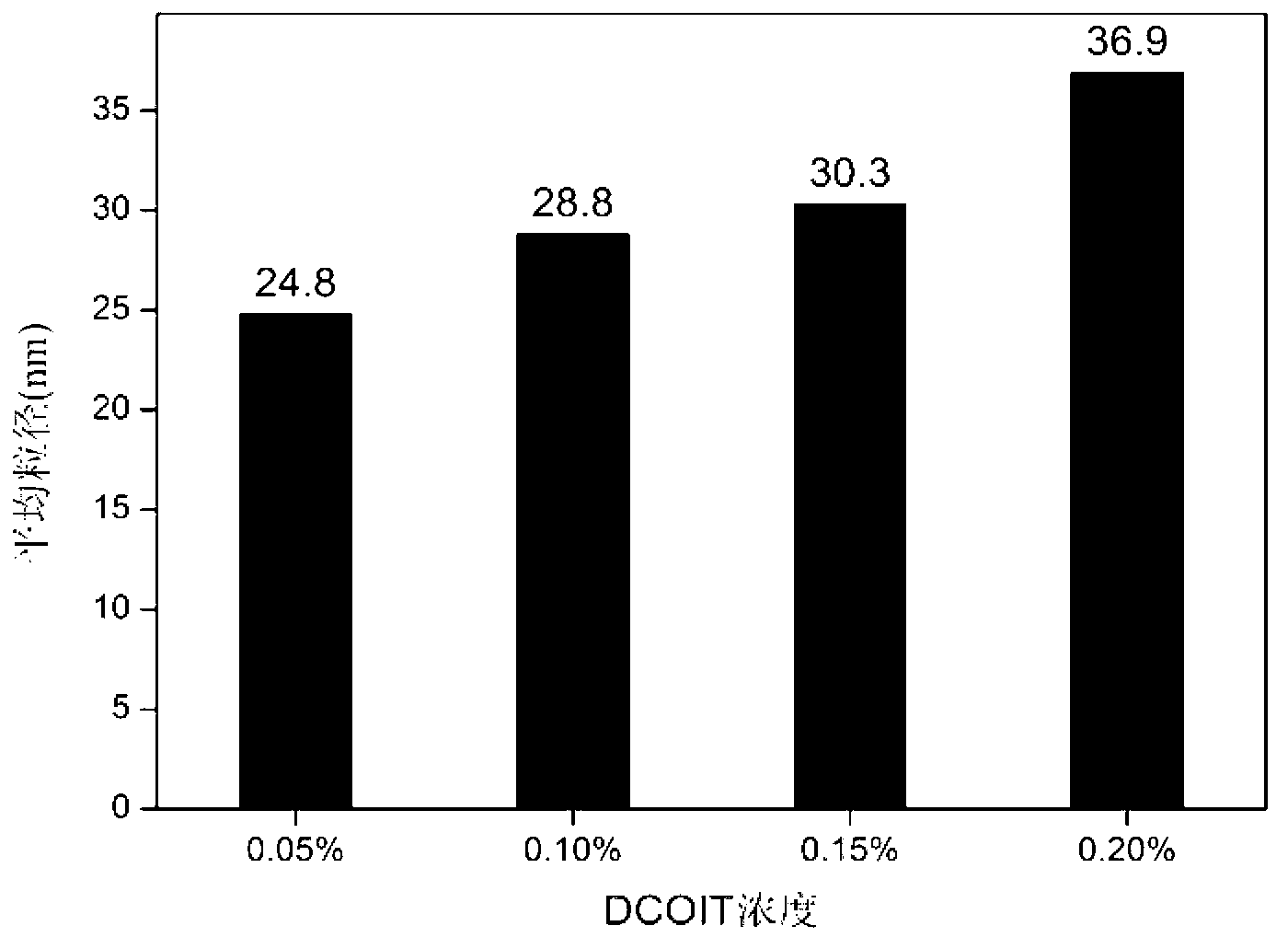

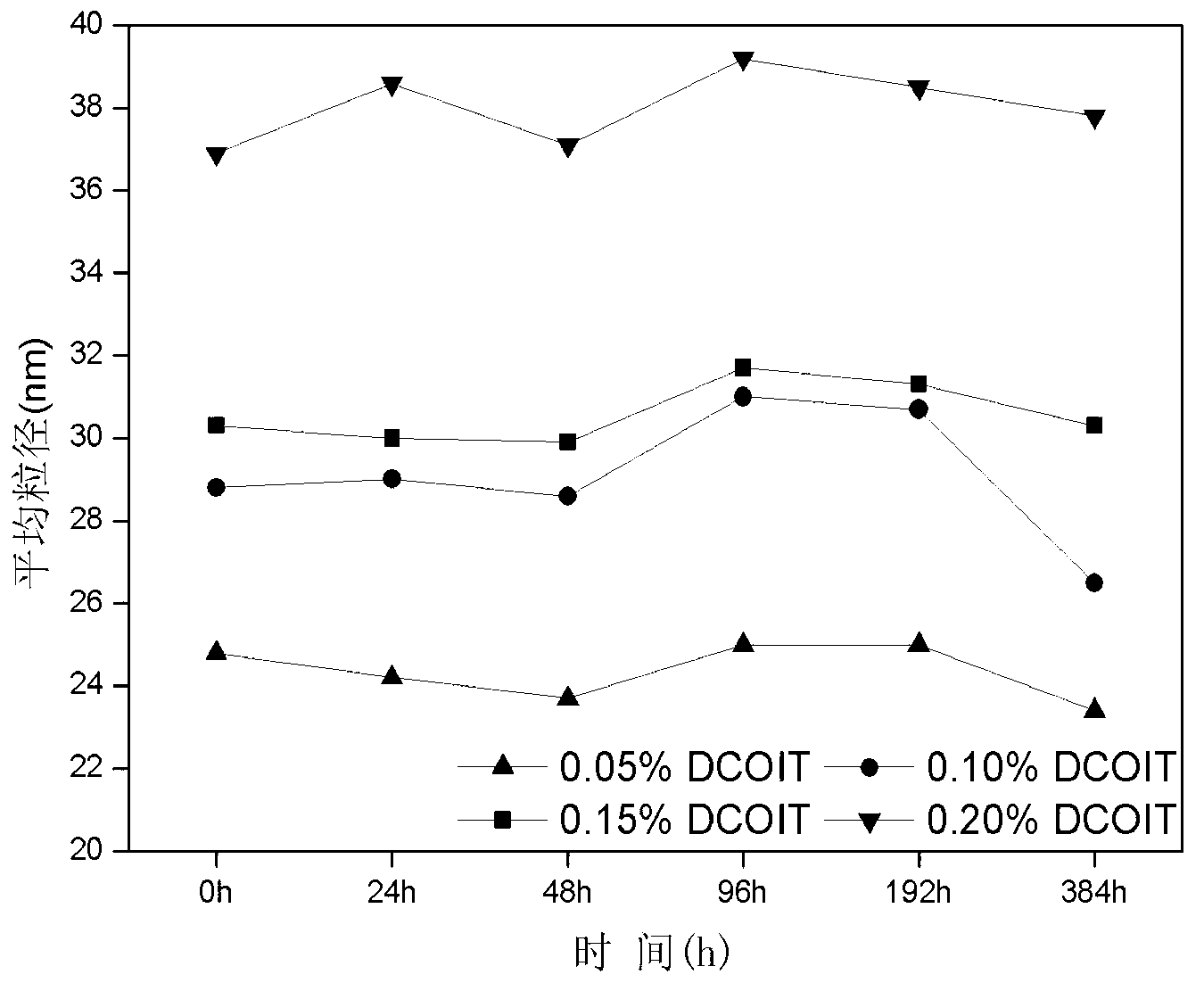

Micro-emulsion-type wood and bamboo mould-proof agent, as well as preparation method and application thereof

ActiveCN103317566AImprove timelinessBroad-spectrum killing activityWood impregnation detailsEnvironmental resistanceCarboxylic acid

The invention relates to a micro-emulsion-type wood and bamboo mould-proof agent, as well as a preparation method and application thereof. The micro-emulsion-type wood and bamboo mould-proof agent comprises the following components in parts by weight: 1 to 200 parts of isothiazolinone original medicaments, 1 to 1,000 parts of ester solvents, 1 to 500 parts of alcohol or ester cosolvents, 1 to 1,500 parts of polyoxyethylene non-ionic surfactants, 1 to 150 parts of succinate or polyoxyethylene ether salt non-ionic surfactants, 1 to 100 parts of long-chain carboxylic acid additives, and 1 to 1,000,000 parts of water. The micro-emulsion-type wood and bamboo mould-proof agent disclosed by the invention has the advantages that the chemical agents meet the requirements on environment friendliness and no toxicity; the preparation process is simple; the crystallization degree is low; the stability is high; the particle size is small; the permeability and the mould-proof performance are high; the volume expansibility of the processed bamboo and wood is reduced and the like; the micro-emulsion-type wood and bamboo mould-proof agent is stable, effective and environmentally-friendly, and is much better than that in the prior art.

Owner:BEIJING FORESTRY UNIVERSITY

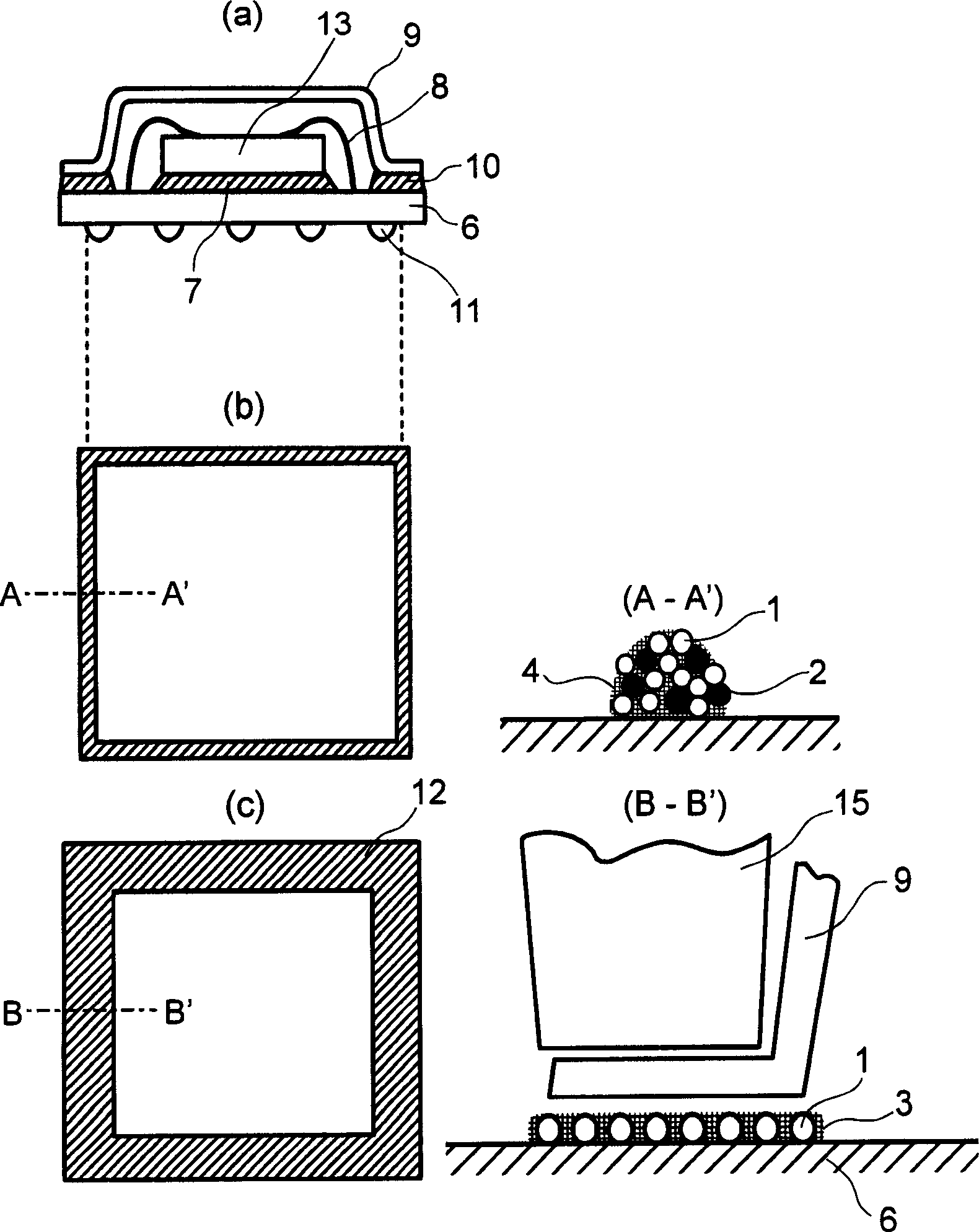

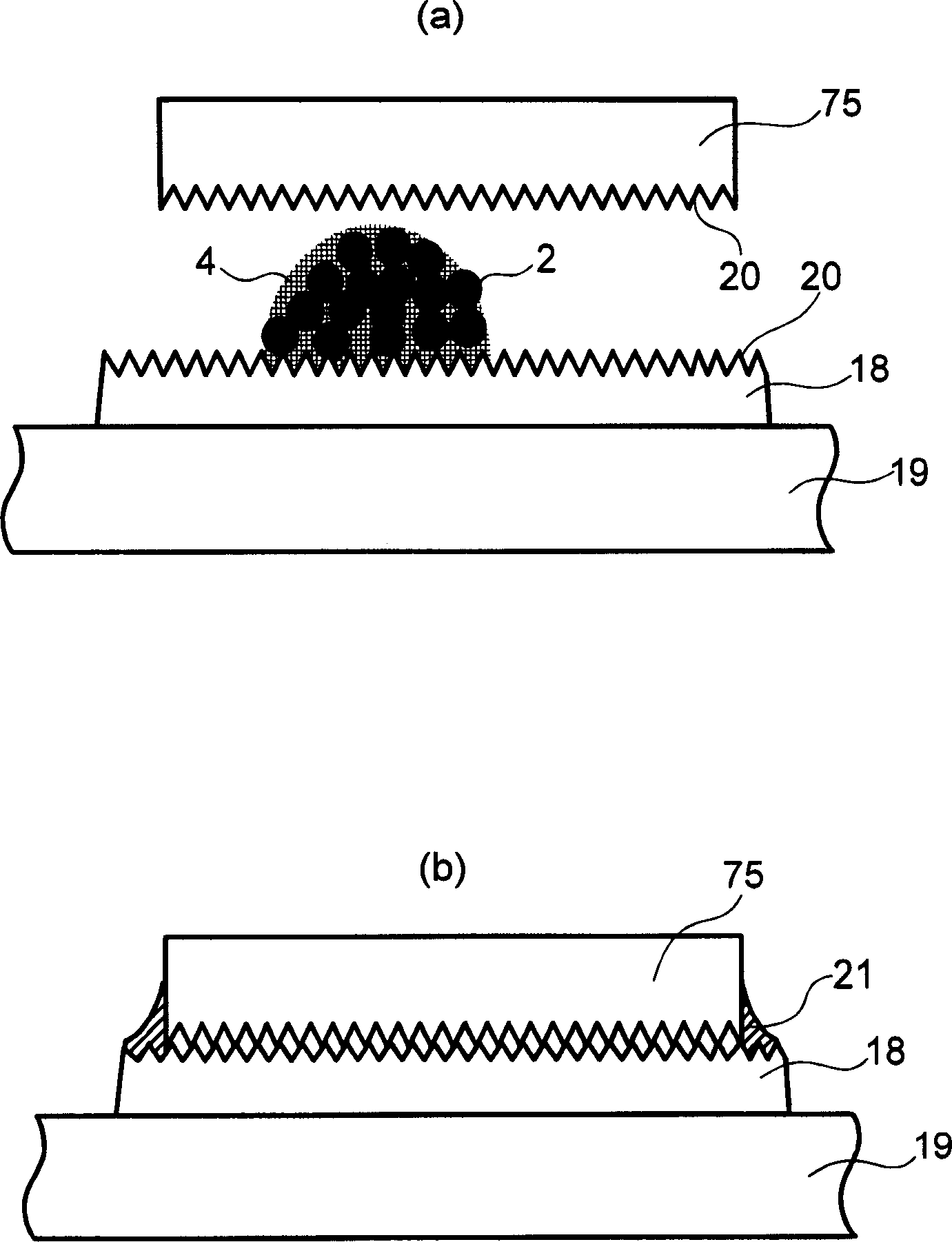

Electronic device

InactiveCN1444273ACut wellSmall volume expansionPrinted circuit assemblingFinal product manufactureMetallurgyElectron

In an electronic device realizing high-temperature terminal solder bonding in temperature-level bonding, the bonding portion between the semiconductor device and the substrate is formed by metal balls composed of Cu or the like and a compound composed of the metal balls and Sn, and Metal balls are held together by compounds.

Owner:RENESAS ELECTRONICS CORP

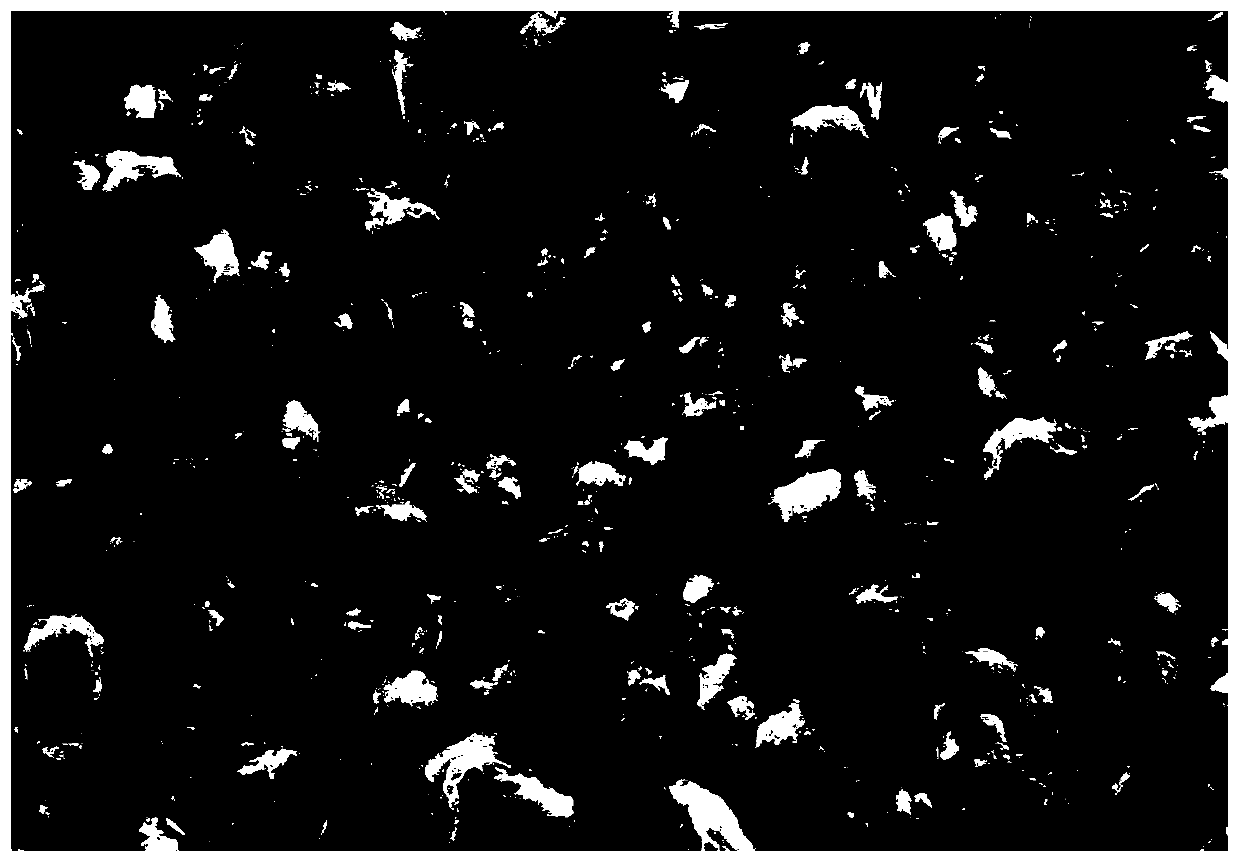

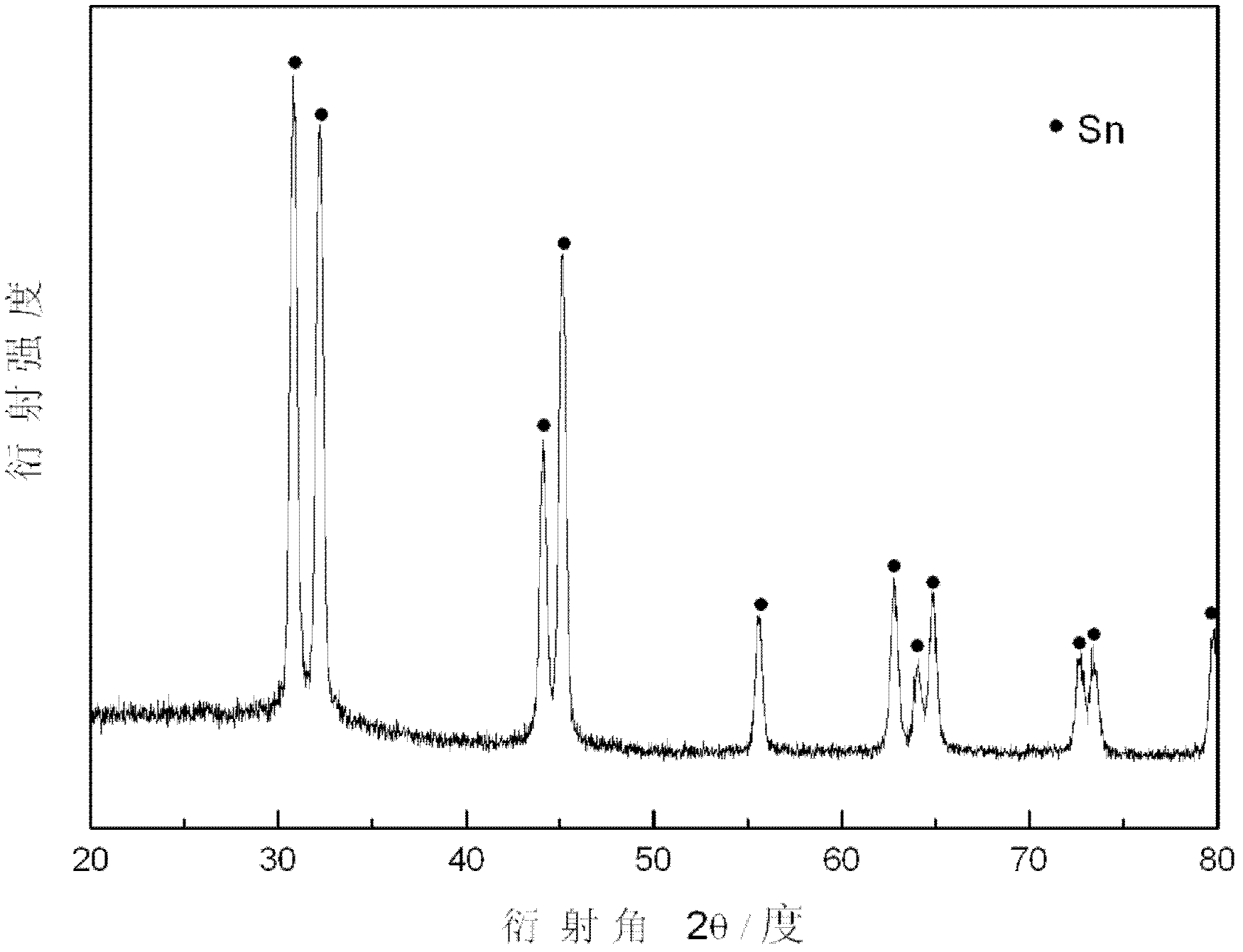

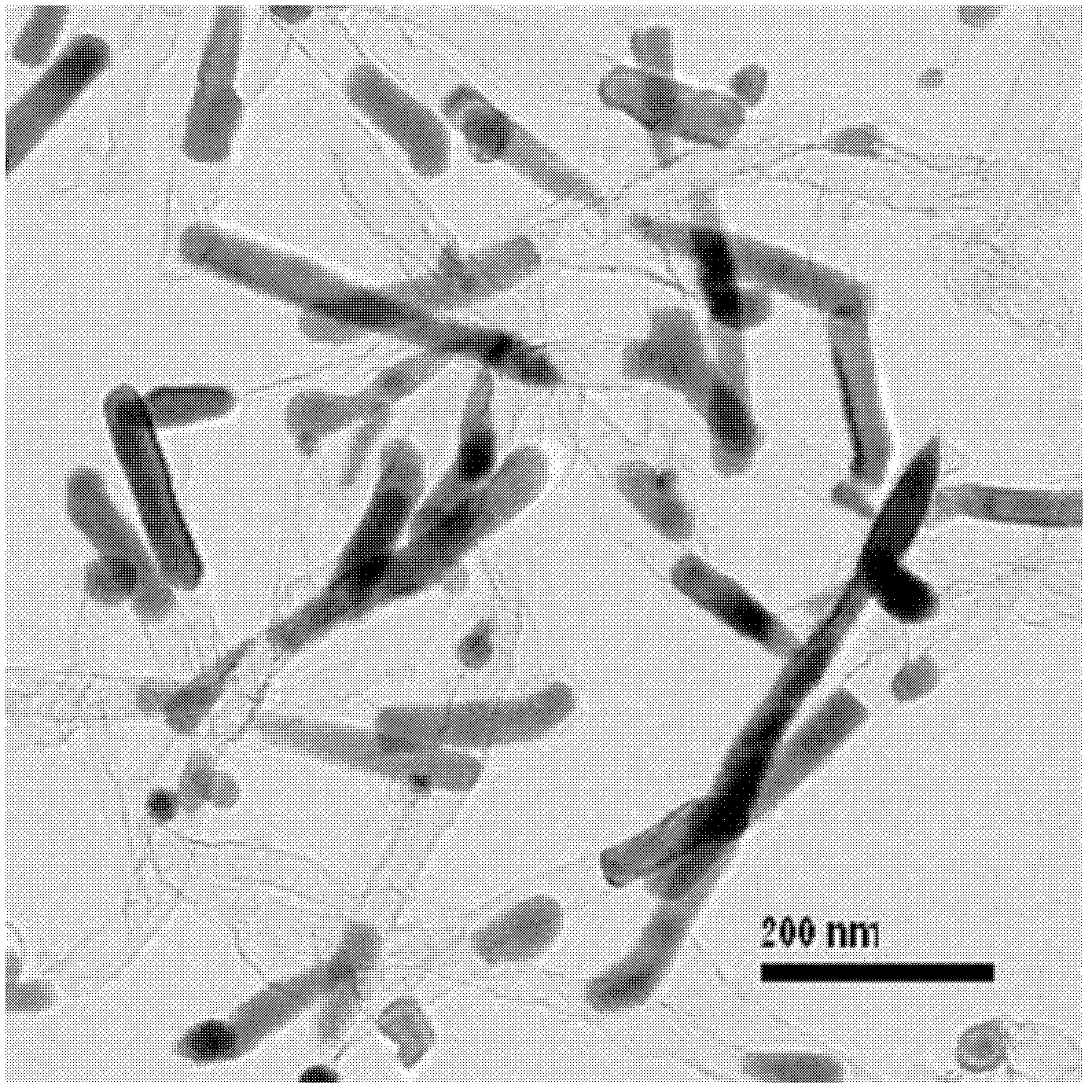

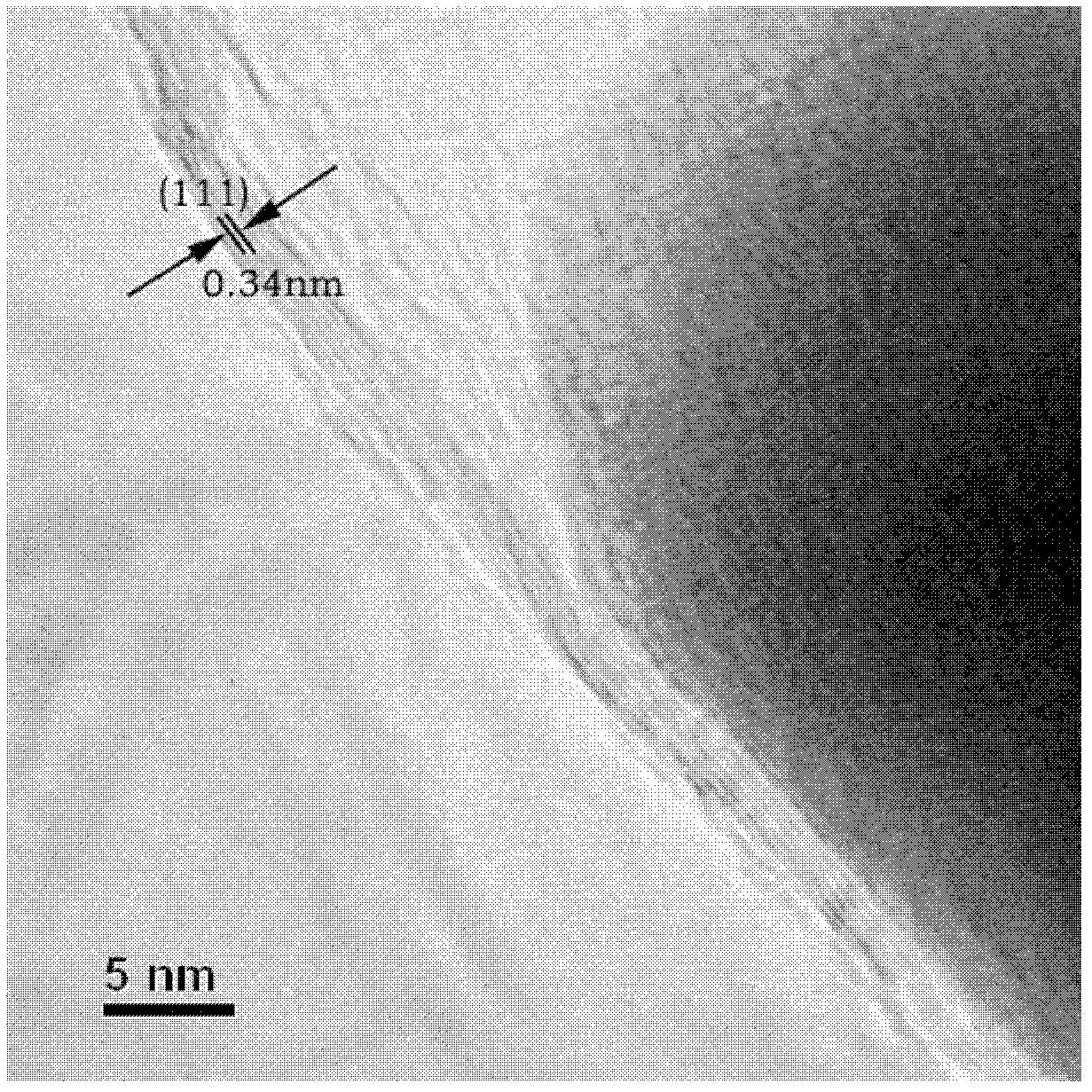

Preparation method and application of carbon tin nanometer composite powder

InactiveCN102623669ASmall volume expansionHigh reversible lithium storage capacityMaterial nanotechnologyElectrode manufacturing processesAutomatic controlCarbon nanotube

The invention provides a preparation method of carbon tin nanometer composite powder of a negative electrode material of a lithium ion battery, and belongs to the field of preparation technologies and the application of nanometer materials. The technical solution scheme of the preparation method is that by utilizing automatic control direct current arc plasma equipment, block-shaped metallic tin or micron-size tin powder is pressed into a block to serve as an anode; a graphite rod is used as a cathode; a certain proportion of carbon-containing gas, active gas and inert gas are introduced a reaction chamber; and after a block-shaped target material is evaporated, carbon-coated tin nanometer composite particles are obtained. The powder material is used as an active substance to manufacture a negative electrode of the lithium ion battery, and the first reversible specific capacity of the powder material can reach 620mAh / g. The preparation method has the advantages that the carbon-coated tin nanometer particles synthesized in situ are provided with structures of multi-wall carbon nanometer tubes partially filled with the metallic tin, and the material used as the negative electrode material of the lithium ion battery has high intercalation / deintercalation lithium capacity density and high cycle stability; and besides, the costs of raw materials are low, the process is simple and large scale preparation can be conducted, so that the preparation method satisfies the requirements of industrial production.

Owner:DALIAN UNIV OF TECH

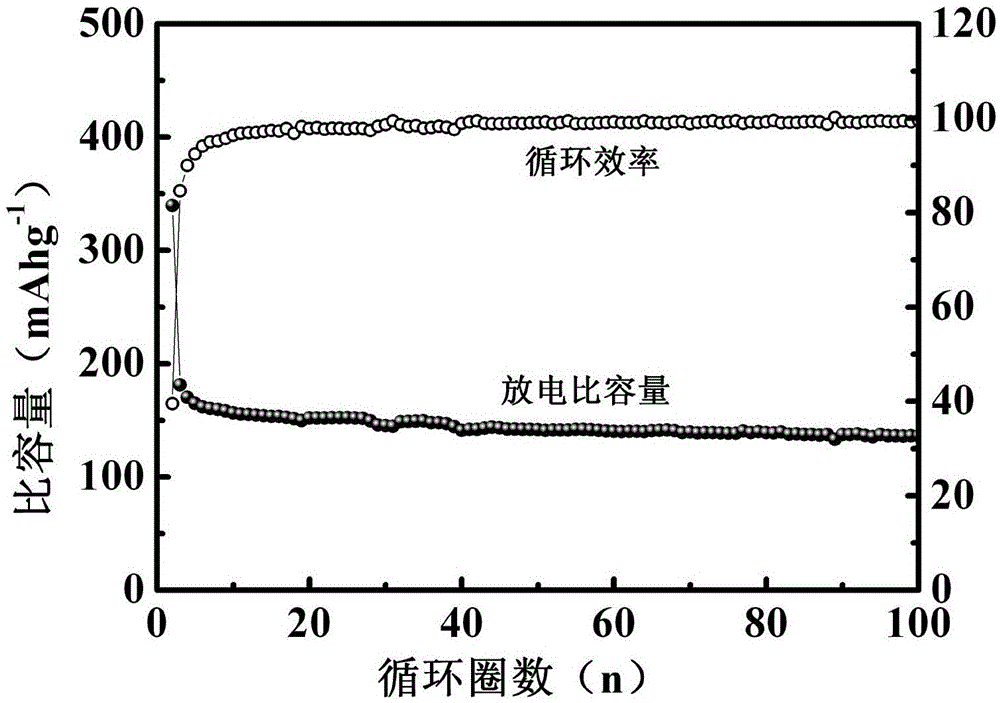

Negative active material for lithium secondary battery and lithium secondary battery comprising same

ActiveCN102511094ALarge capacityHigh capacity retentionNegative electrodesLi-accumulatorsSilicon alloyLithium-ion battery

The present invention relates to a negative active material for a lithium secondary battery and the lithium secondary battery comprising the same. The negative active material for the lithium secondary battery of the present invention comprises: silicon; and a silicon alloy which includes at least one kind of metal except the silicon, and is capable of being alloyed with lithium, wherein the volume of an inactive region that does not react to lithium contained within the silicon alloy is 50% to 75% relative to the entire volume of the active material. The negative active material of the present invention has a higher capacity than a carbon-based negative active material, embodies a small volume expansion after being charged and discharged, and shows a high capacity maintenance rate, thereby expressing an excellent cycle property.

Owner:LG ENERGY SOLUTION LTD

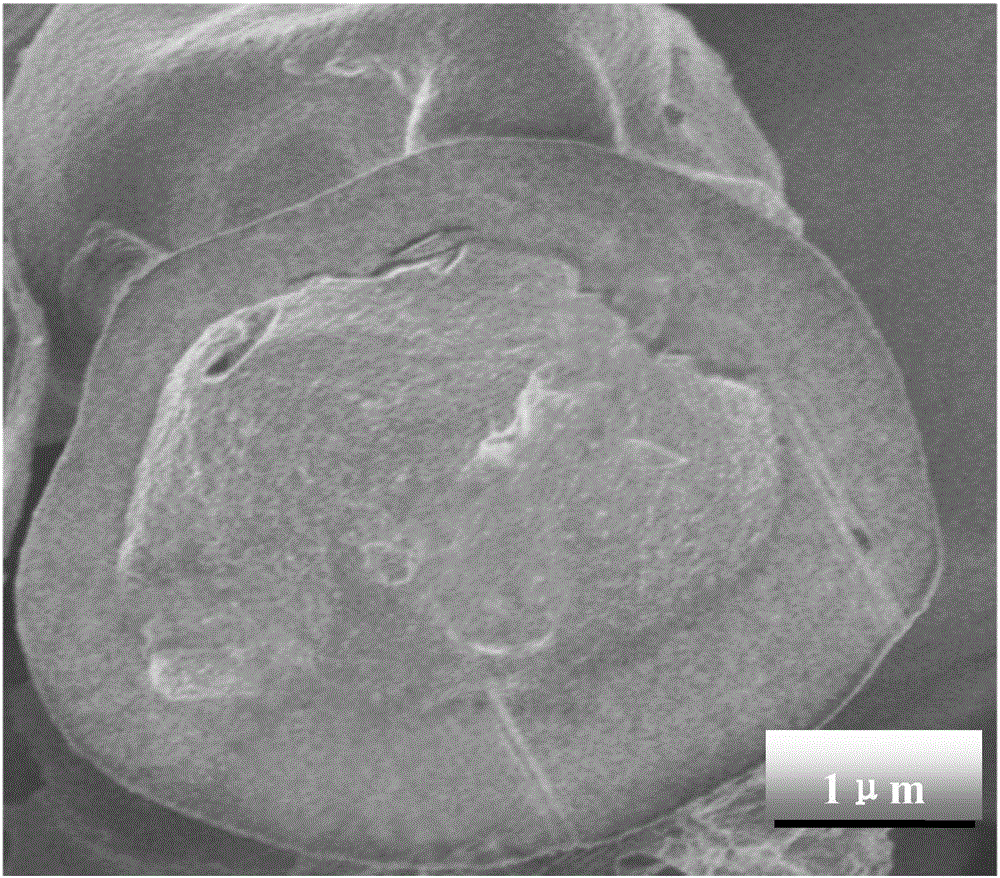

Preparation method of silicon monoxide composite negative electrode material and product thereof

ActiveCN112086630ASmall volume expansionInhibit sheddingSecondary cellsNegative electrodesCarbon coatingCarbon layer

The invention discloses a preparation method of a silicon monoxide composite negative electrode material, which comprises the following steps: by using elemental silicon and silicon dioxide as initialraw materials, carrying out a neutralization reaction to generate silicon monoxide; vaporizing silicon monoxide, introducing the vaporized silicon monoxide into a chemical vapor deposition furnace filled with a carbon material, and carrying out chemical vapor deposition to obtain a primary product; and finally, carrying out carbon coating to obtain the silicon monoxide composite negative electrode material. The prepared composite negative electrode material has a sandwich type sandwich structure, a carbon material is taken as a core, the outer surface of the carbon material is uniformly coated with silicon monoxide, and the outermost layer is coated with a uniform carbon layer. The lithium ion battery assembled by the composite negative electrode material has relatively high capacity andrelatively good cycling stability, and particularly has ultrahigh initial coulombic efficiency, and the highest initial coulombic efficiency can reach 90%.

Owner:云南锂宸新材料科技有限公司

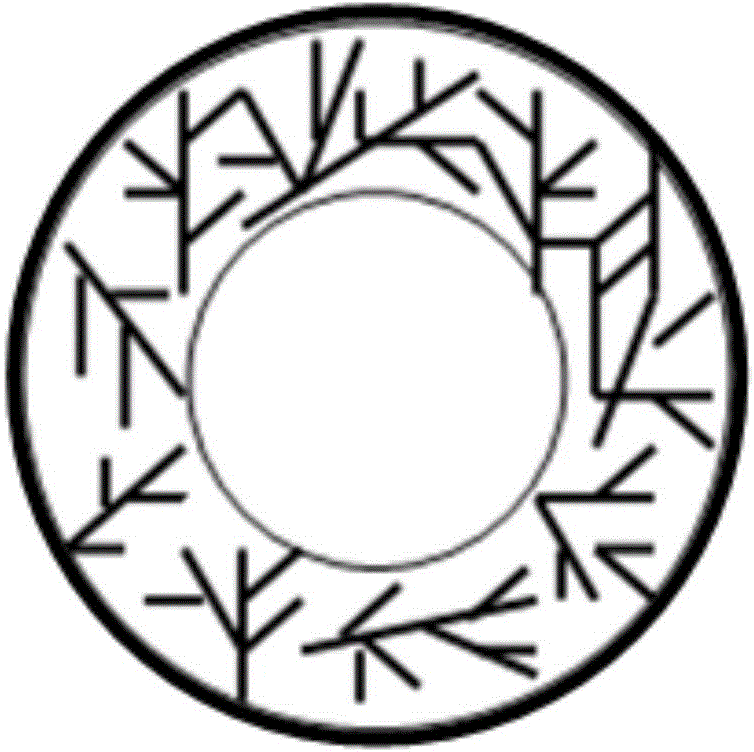

Anode active material of lithium ion battery and preparation method thereof

ActiveCN104979536ASmall volume expansionReduce relative expansionCell electrodesSecondary cellsLithium electrodeElectrochemistry

The invention discloses an anode active material of lithium ion batteries. The anode active material includes silicone alloy particles, wherein the interior of the silicone alloy particles is in a hollow honeycomb-like structure and the outer layer of the silicone alloy particles is coated with an amorphous carbon layer. The anode active material is in the structure that the interior is in the hollow honeycomb-like structure while the outer layer is coated with the amorphous carbon layer, so that not only is volume expansion during charging and discharging process alleviated through the pores in the honeycomb-like structure, but also the relative expansion of the particles can be reduced through the hollow honeycomb-like structure, so that damage on SEI films on the surface of the particle is reduced, and the anode active material can improve electrochemical performances of the lithium ion batteries and prolongs the service life of the lithium ion batteries. In addition, the invention also discloses a preparation method of the anode active material of the lithium ion batteries, and a lithium ion battery anode piece and a lithium ion battery manufactured with the anode active material.

Owner:NINGDE AMPEREX TECH

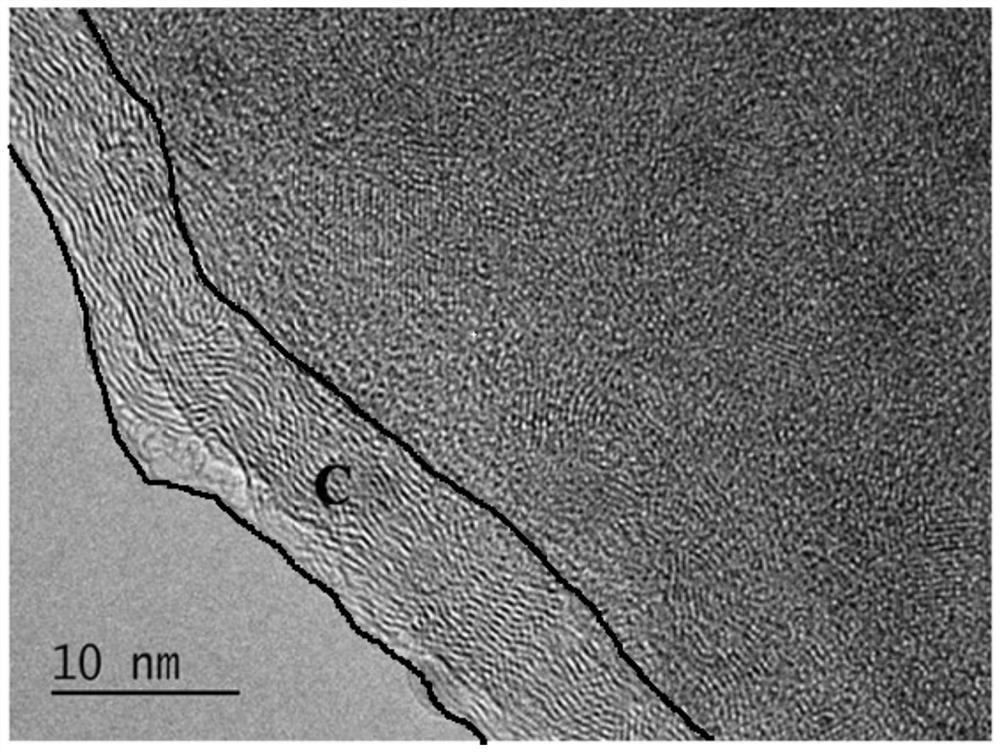

Process for producing silicon-based carbon composite material for lithium ion battery cathode

InactiveCN102623682AImprove lithium storage performanceImprove conductivityElectrode manufacturing processesSilicon matrixCarbon composites

Disclosed is a process for producing a silicon-based composite material for a lithium ion battery cathode. The process comprises that silicon powder serves as a main material, graphite powder or flocculent carbon black serves as an auxiliary material, the main material and the auxiliary material are mixed and placed in a ball-grinding steel tank, argon serves as a shielding gas, the ball-grinding steel tank inflated with the shielding gas is placed in a planetary ball mill, and powder with granularity of less than 20 mum, which is the silicon-based composite material for the lithium ion battery cathode, is obtained after the mixture is subjected to ball milling at 500 revolutions / minute for 80 hours. The process has the advantages that the silicon material having the good lithium-storing capacity is mixed with the carbon material having the good electrical conductivity, atomic-grade mixing of the silicon material and the carbon material is achieved in a mechanical alloying mode, the electrical conductively of the silicon matrix is fully improved, and the inert carbon material can reduce volume expansion caused by the processes of lithium intercalation and lithium deintercalation of the silicon material in the processes of charging and discharging of the inert carbon material, so that the cycle performance of the silicon material is improved, the electrical conductivity and the cycle performance of the carbon-doped material are better than those of the pure silicon material.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Calcined quartz powder casting coating and production method thereof

ActiveCN104493076AGood suspensionHigh coating strengthFoundry mouldsFoundry coresSpecific gravitySolvent

The invention discloses a calcined quartz powder casting coating and a production method thereof. The calcined quartz powder casting coating comprises the following components: 80-100 parts of quartz powder, 0-50 parts of corundum powder, 0-100 parts of mullite powder, 0-30 parts of bauxite powder, 0-100 parts of zircon powder, 0-10 parts of flake graphite, 0-20 parts of earthy graphite, 0-5 parts of red iron oxide, 6-8 parts of a suspension, 5-8 parts of resin and an appropriate amount of a solvent. The production method comprises the following steps: adding the suspension, the resin and the appropriate amount of solvent in a blender to be stirred for 10-30 minutes, then adding quartz powder, alumina powder, mullite powder, bauxite powder, zircon powder, flake graphite, earthy graphite, and red iron oxide to be stirred for 30-60 minutes, adding the appropriate amount of solvent to be adjusted to an appropriate proportion to obtain the casting coating. According to the calcined quartz powder casting coating and the production method thereof provided by the invention, the calcined quartz powder is used as a refractory material to produce the coating, and the resource of quartz powder is rich, so that the problem of lack of resources is solved; the cost is greatly reduced, the product quality is improved, the market competitiveness is strong and the popularization and application value is high.

Owner:昌乐恒昌化工有限公司

High-capacity composite anode material, preparation method, and lithium ion battery containing high-capacity composite anode material

ActiveCN108232151ARich reservesImprove negative electrode capacityMaterial nanotechnologyCell electrodesNew energySodium-ion battery

The invention discloses a high-capacity composite anode material, a preparation method, and a lithium ion battery containing the high-capacity composite anode material, which belong to the technical field of new energy materials. The method comprises the following steps of (1) mixing and ball milling an organic carbon source, nanometer silicon and silicon oxide, mechanical fusing, and obtaining acarbonized precursor; (2) carrying out heat treatment on the carbonized precursor to obtain the composite anode material. According to the method provided by the invention, two high-capacity anodes are synthesized, and the high-performance composite anode material is prepared through a specific process design; the composite anode material is not only high in capacity and energy density, but also greatly improved in contact and electrical conductivity, small in interface resistance, small in volume expansion, and beneficial to reducing of side reaction, ensures the cell volume expansion to be within a reasonable range, and ensures the safety of the cell.

Owner:EVE ENERGY CO LTD

Battery anode material of embedding Sn-based alloy in porous carbon and preparation method of the battery anode material

InactiveCN108695498AImprove intercalation efficiencySmall volume expansionCell electrodesSecondary cellsIonTube furnace

The invention discloses a battery anode material of embedding Sn-based alloy in porous carbon and a preparation method of the battery anode material. The composite material is formed by uniformly embedding nano Sn-based alloy, coated by three-dimensional network porous carbon, into a three-dimensional network carbon structure. The preparation method includes steps of: dissolving NaCl, as a template, with a carbon source, a tin source, and other metal salts, uniformly mixing the components, and freeze-drying the mixture to maintain the cubic structure of NaCl; grinding the mixture, performing thermal treatment in a tubular furnace at certain temperature in an inert gas or reductive atmosphere, and washing the product to remove the NaCl template; drying the product to obtain the composite material. The material, as an anode in lithium ion or sodium ion batteries, is high in capacity, good in cycle performance and excellent in rate capability; the preparation method is simple, is environment-friendly and performance-controllable, and has universality and can be scaled-up.

Owner:东北大学秦皇岛分校

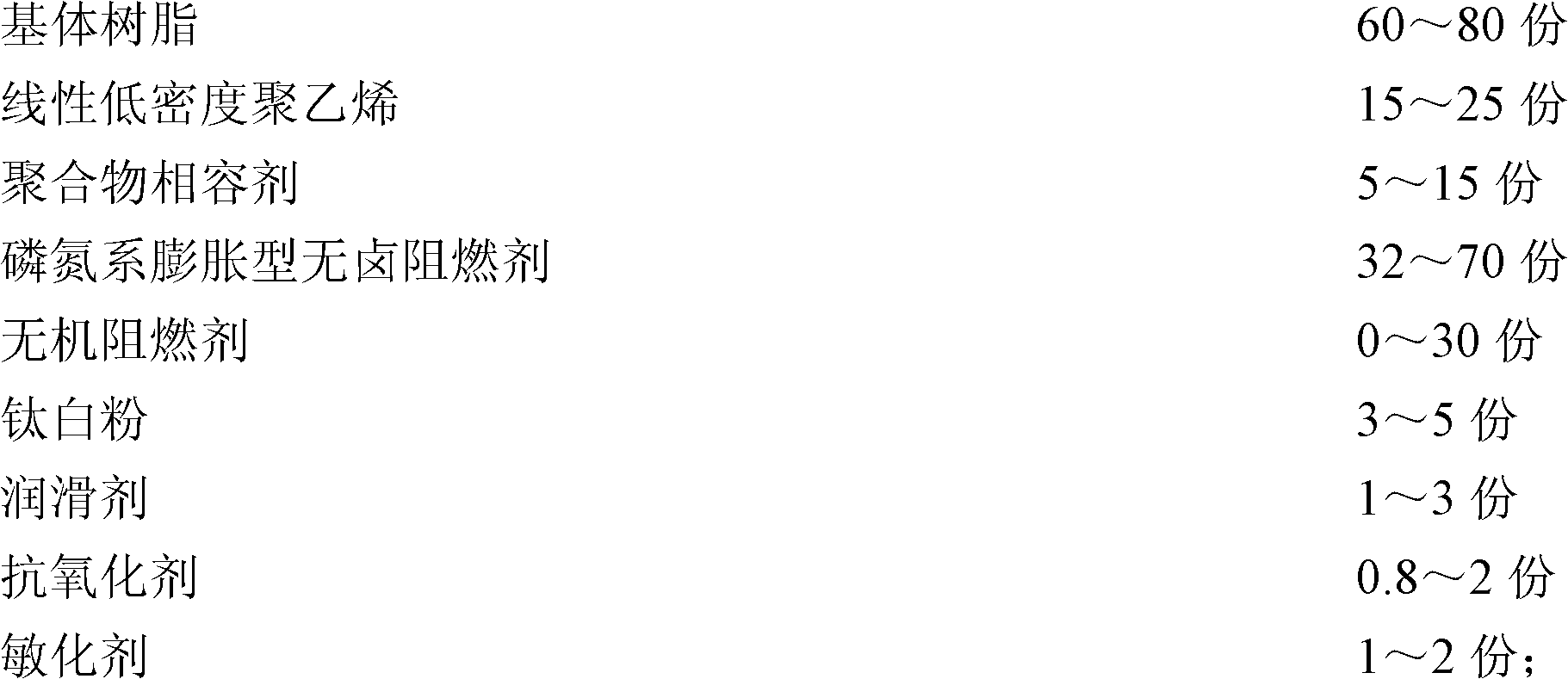

Oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve as well as preparation method and application thereof

The invention discloses an oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve and a preparation method thereof. The label sleeve consists of the following components in parts by weight: 60 to 80 parts of matrix resin, 15 to 25 parts of linear low-density polyethylene, 5 to 15 parts of polymer compatilizer, 32 to 70 parts of phosphorous nitrogen series expansible halogen-free flame retardant, 0 to 30 parts of inorganic flame retardant, 3 to 5 parts of titanium white powder, 1 to 3 parts of lubricant, 0.8 to 2 parts of antioxidant and 1 to 2 parts of sensitizer. The preparation method comprises the following steps of: mixing the raw materials uniformly, extruding with a double-screw extruder, drawing, air cooling and granulating; extruding into a pipe through a screw extruder with a neck mould and a core mould, radiating, expanding, stretching, cooling, sizing, printing the label by using a heat transfer printer to obtain the oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve. The preparation method is simple; and the product has excellent flame-retardant performance and good oil resistance, produces little smoke, permanently preserves the label, and keeps good mechanical property, electric insulating performance and heat resistance.

Owner:广州凯恒科塑有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com