Non-aqueous electrolyte secondary battery, negative electrode, negative electrode material, and preparation of si-o-al composite

一种非水电解质、二次电池的技术,应用在非水电解质蓄电池电极、电池电极、二次电池等方向,能够解决第1次循环充电/放电效率低等问题,达到高循环充电/放电效率、改善循环性能、低体积膨胀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

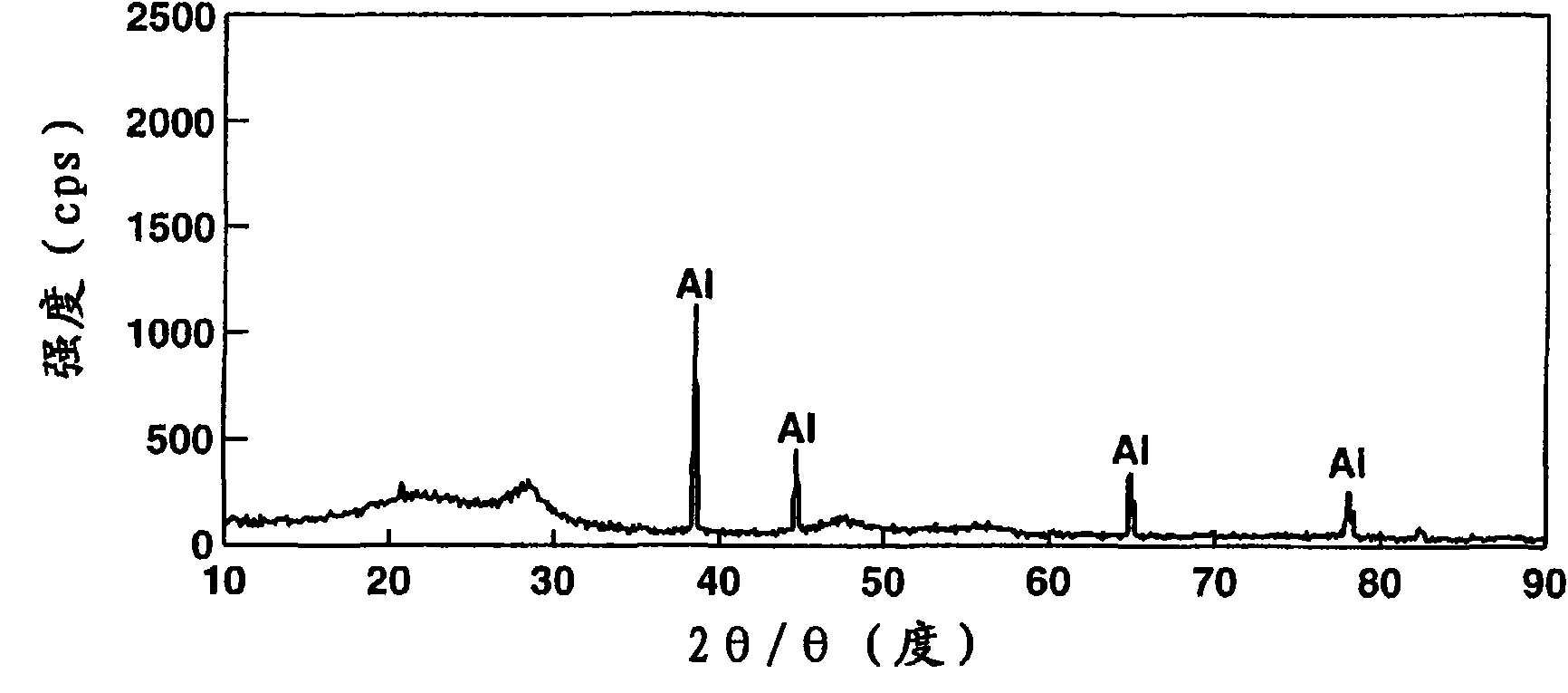

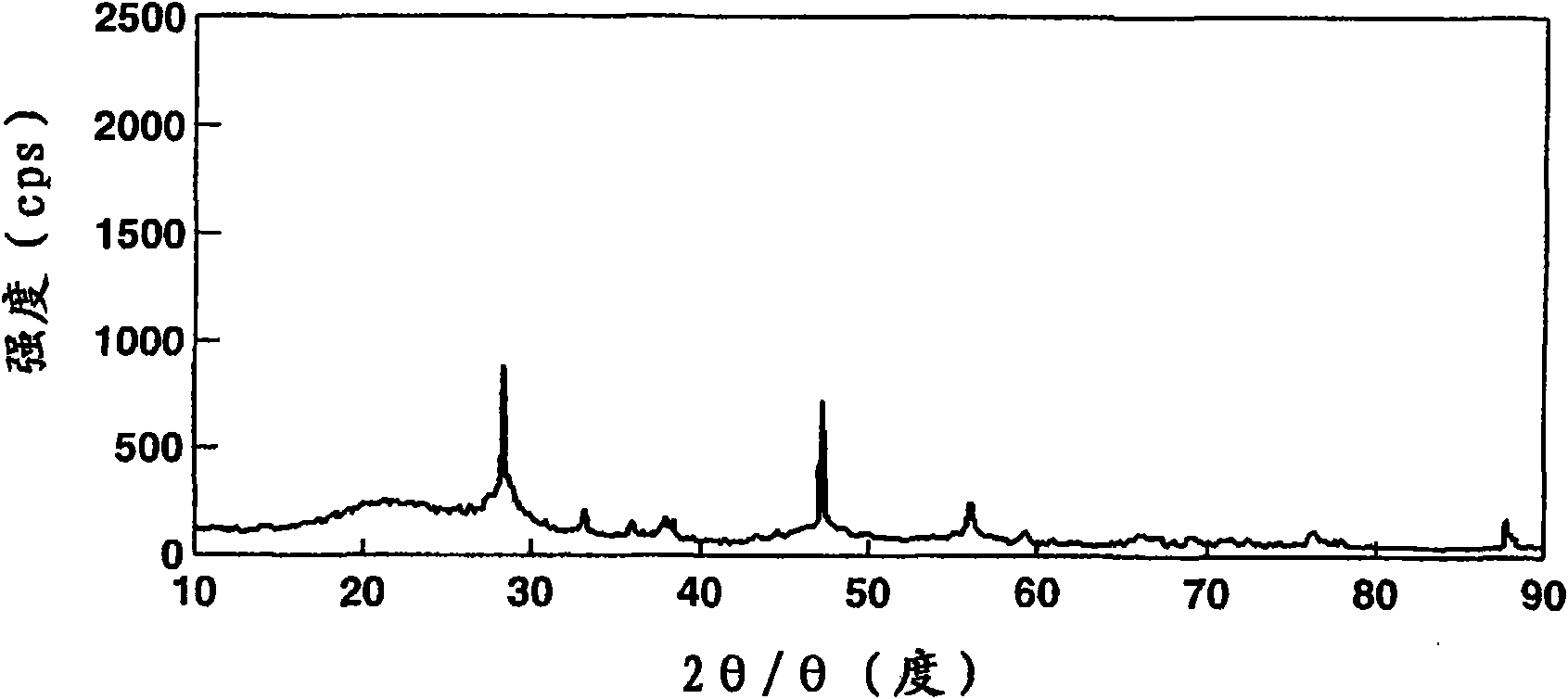

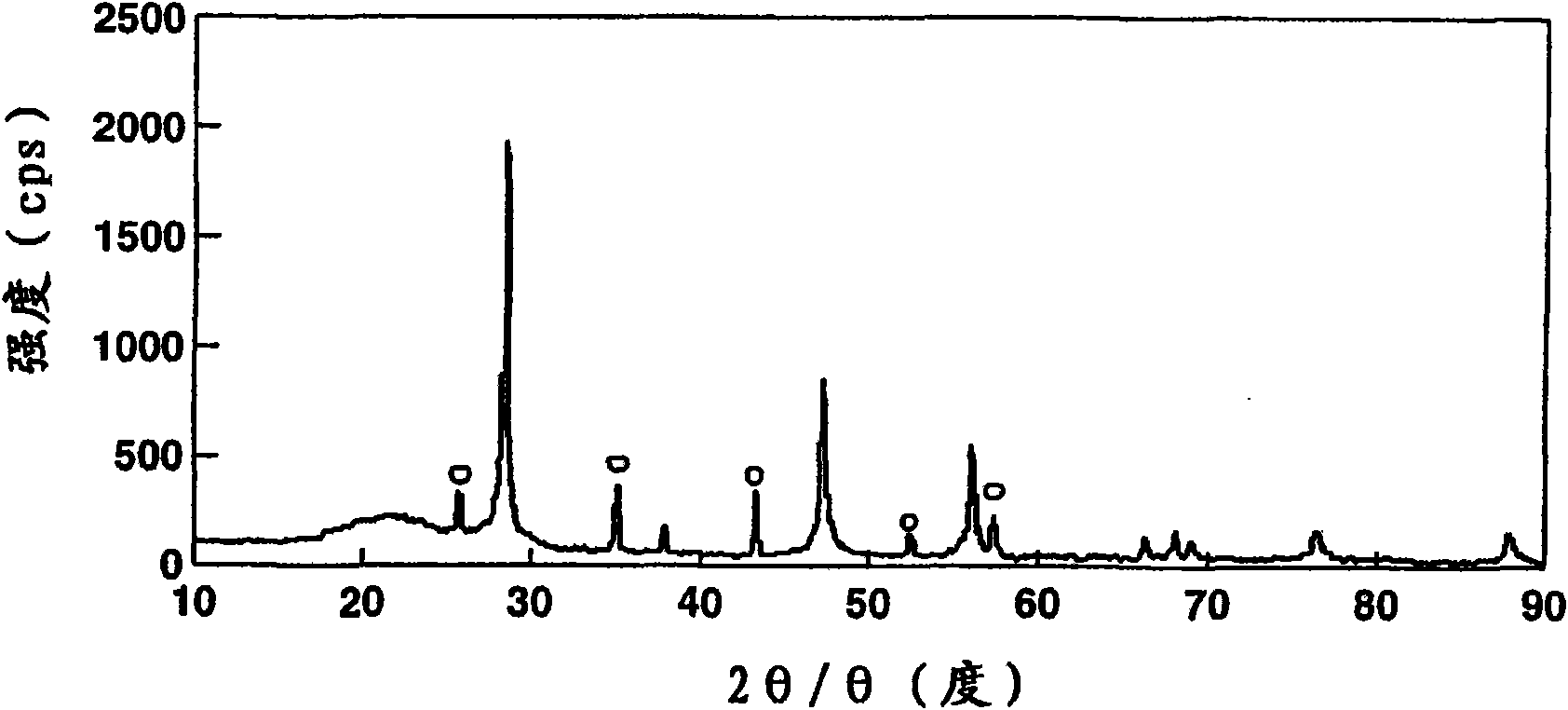

[0067] Preparation of Si-O-Al Composite

[0068] The Si-O-Al composite can be prepared by reacting silicon oxide with aluminum. As used herein, "silicon oxide" refers to an amorphous oxide form of silicon obtained by heating a mixture of silicon dioxide and silicon to produce silicon oxide gas, and cooling the gas for deposition. Specifically, silicon oxide gas is generated at a temperature of 1,100-1,500° C. under reduced pressure and transferred to a deposition chamber at 500-1,100° C. where it is solidified and collected. The "silicon oxide" consists of the general formula SiO x means, where x, as determined by elemental analysis of the deposit, is in the range: 1.0≤x<1.6, and preferably 1.0≤x≤1.2. The starting mixture contained silica and silicon in a molar ratio of about 1:1.

[0069] Silica undergoes a reduction reaction with aluminum to produce silicon and alumina according to the following reaction scheme (I).

[0070] SiO+2 / 3Al→Si+1 / 3Al 2 o 3 (I)

[0...

Embodiment 1 to 5 and comparative example 1 to 3

[0131] The active material powder was diluted with N-methylpyrrolidone, optionally mixed with a dispersion of the conductive agent acetylene black in N-methylpyrrolidone (solids 17.5% by weight). A polyimide resin (U-Varnish A of Ube Industries Ltd., solid 18.1% by weight) was added thereto as a binder to form a slurry. The slurry was coated onto a 12 μm thick copper foil by a doctor blade with a gap of 50 μm, vacuum dried at 200° C. for 2 hours, and pressed into a negative electrode shaped form by roll pressing at 60° C. Finally, punch out 2cm from this shaped form 2 and used it as the negative electrode. The compositions of the solid components are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com