Battery

A battery and cell technology, applied in secondary batteries, secondary battery manufacturing, battery pack components, etc., can solve the problems of uneven internal temperature, poor performance of cells, uncontrollable, etc., to achieve consistent reaction temperature, improve Cyclic performance, effect of reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

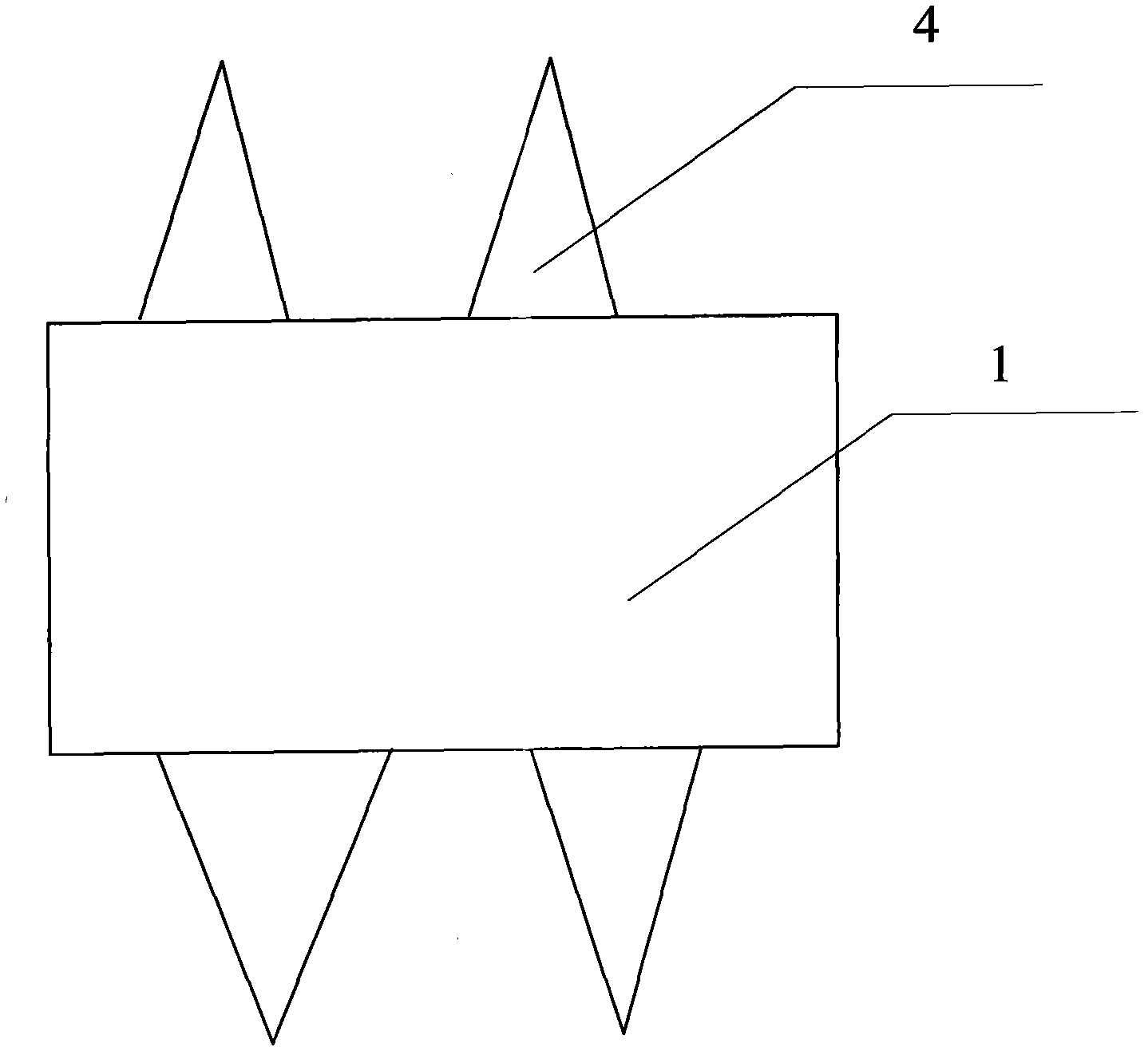

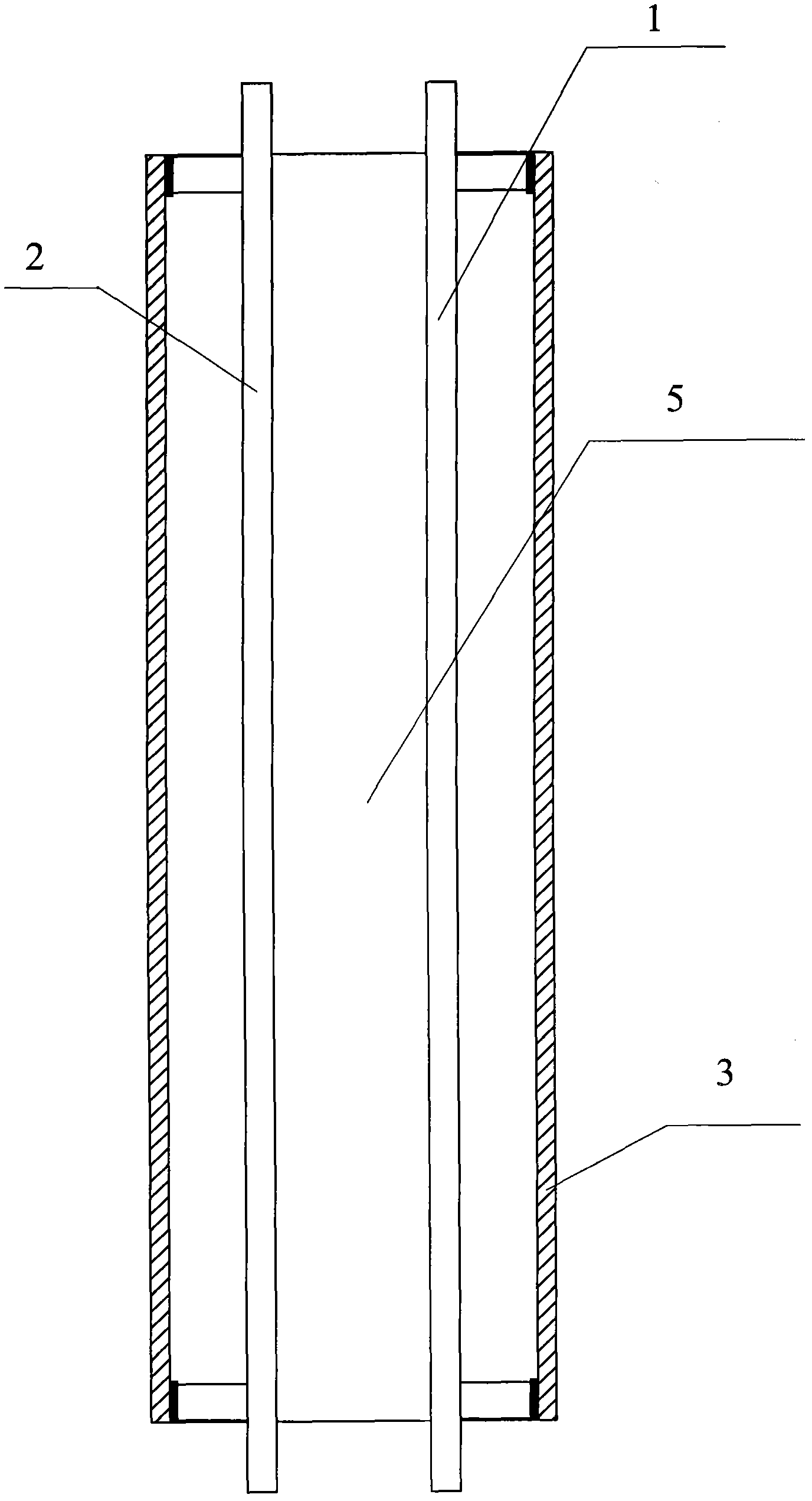

[0035] as attached Figure 1-5 It is a structural schematic diagram of an electric core of the present invention.

[0036] After placing the parallel sheet-shaped positive and negative current and heat conduction parts 1 and 2 in parallel and at intervals, injection molding is performed on their surfaces to obtain an insulating core in which both ends of the positive and negative current and heat conduction parts 1 and 2 are exposed. piece 3. Insulator 5 is filled between the positive current conduction heat conduction part 1 and the negative pole current conduction heat conduction part 2 at the same time, and the positive pole current conduction heat conduction part 1 and the negative pole current conduction heat conduction part 2 are located in the insulating core part 3, that is, the positive pole current conduction heat conduction part 1 and the negative pole heat conduction part 1 The surface of the negative electrode current and heat conduction member 2 is covered with ...

Embodiment 2

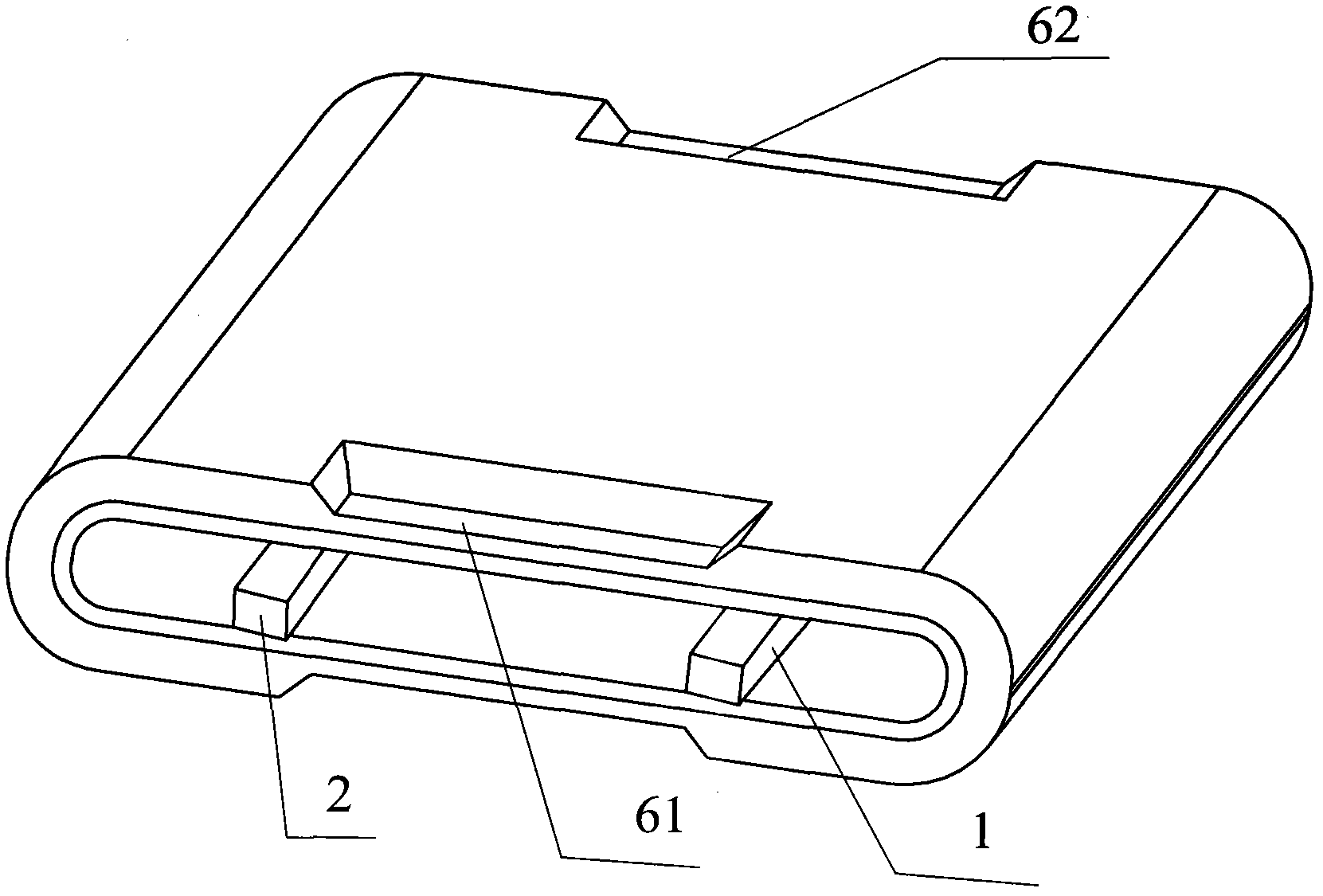

[0045] Such as Figure 6-9 As shown, the battery is prepared in the same manner as in Example 1, the difference is that both the positive electrode flow and heat conduction element 1 and the negative electrode flow and heat conduction element 2 are made into U-shaped solid rods, and the U-shaped bottoms of the U-shaped solid rods are opposed to each other. Place them at intervals and inject molding on their surfaces to obtain insulating core parts 3 in which the ends of the positive and negative current-conducting and heat-conducting parts 1 and 2 are exposed. Insulator 5 is filled between the positive current conduction heat conduction part 1 and the negative pole current conduction heat conduction part 2 at the same time, and the positive pole current conduction heat conduction part 1 and the negative pole current conduction heat conduction part 2 are located in the insulating core part 3, that is, the positive pole current conduction heat conduction part 1 and the negative p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com