Hollow silicon-based composite material, preparation method and lithium ion battery comprising composite material

A composite material, hollow silicon technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of cumbersome preparation methods, affecting practical applications, and unfavorable industrial production, reducing volume expansion, improving conductivity, and improving strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

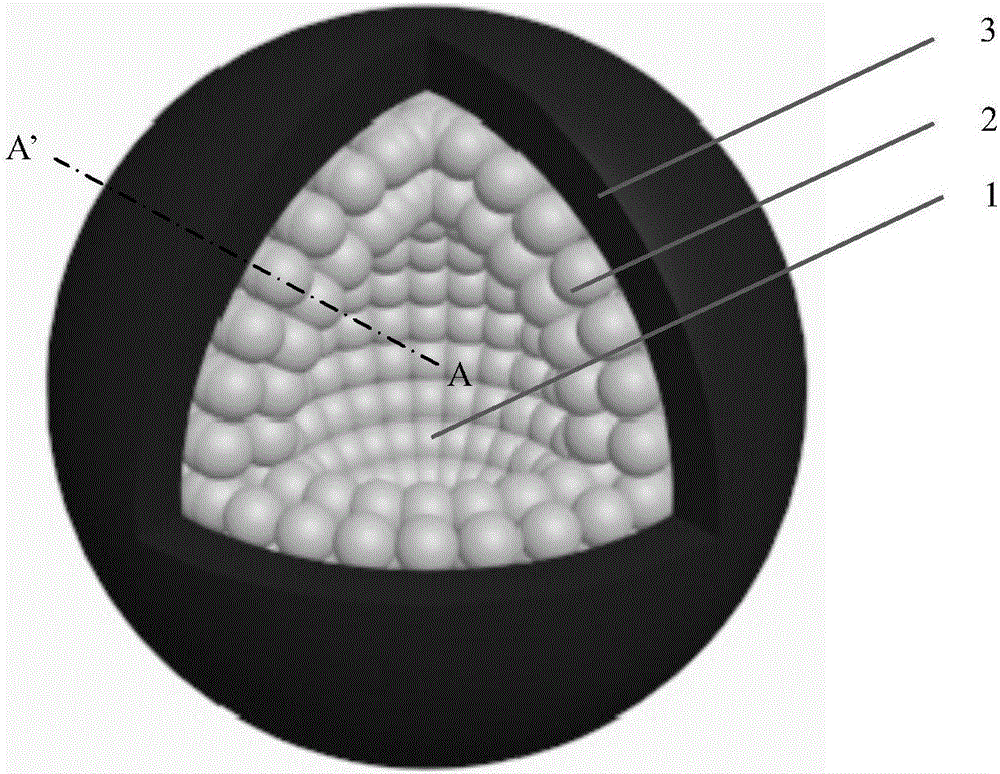

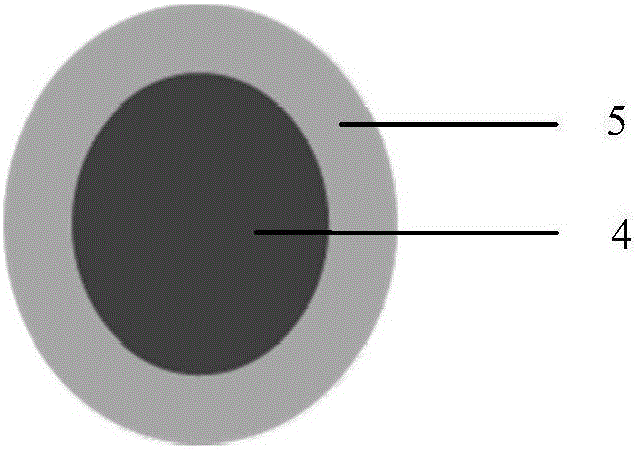

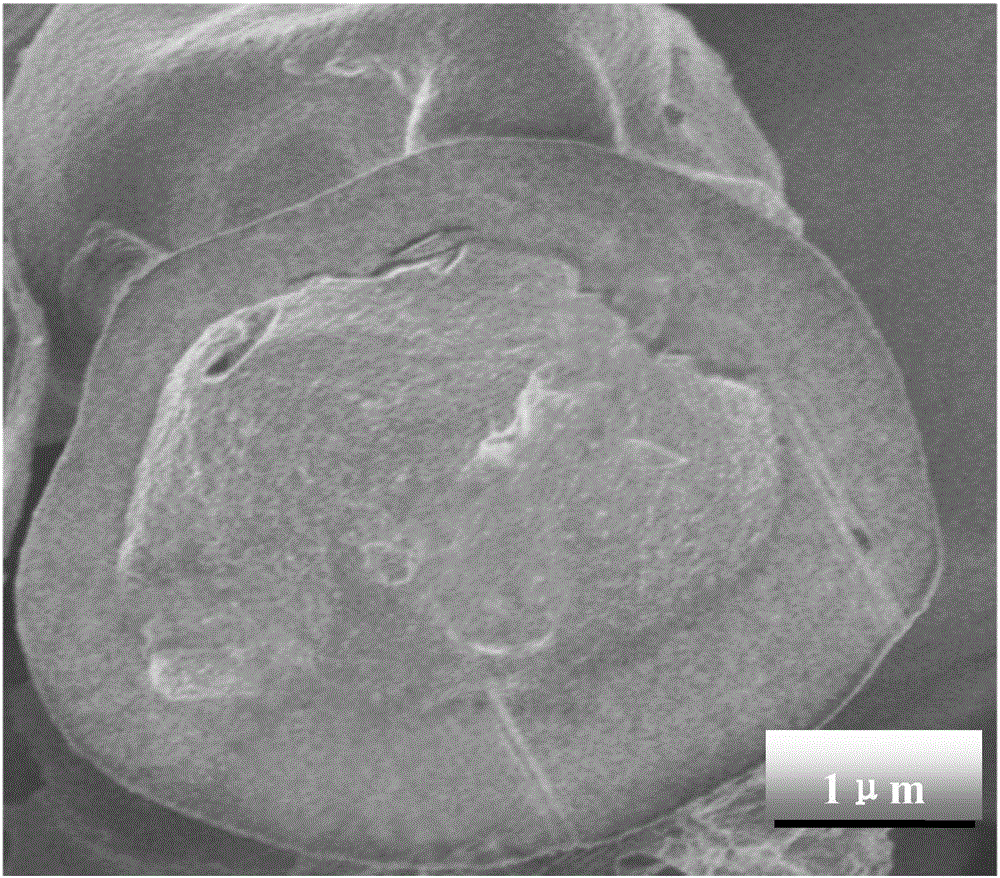

[0127] (1) The SiO with a median particle size of 50nm 2 Particles, spherical graphite particles with a median diameter of 2μm, and polyacrylamide were added to the methanol solution in a mass ratio of 1:0.5:0.5, stirred for 30 minutes, and then the solvent was spray-dried to obtain a median particle size of 3μm. Forebody one;

[0128] (2) Put the precursor obtained in step (1) in a reaction furnace, blow in air, raise the temperature to 800°C, and hold for 3 hours, and perform oxidation heat treatment on the precursor to obtain a hollow cavity and a secondary particle silicon oxide layer Formed precursor two;

[0129] (3) Then the precursor 2 obtained in step (2) and the sodium powder are mixed in a VC mixer at a mass ratio of 1:0.55 to achieve homogeneous mixing, and the homogeneously mixed product is placed in a closed container, and then Put it into a high-temperature furnace, pass in Ar gas as a protective gas, and heat up to 700°C, and the non-oxidizing heat treatment time i...

Embodiment 2

[0137] (1) Set the median diameter to 80nm SiO 1.5 The particles, spherical graphite particles with a median diameter of 3μm and polypropylene were added to the ethanol solution in a mass ratio of 1:0.8:0.4, stirred for 30 minutes, and then the solvent was spray-dried to obtain a precursor with a median particle size of 4μm One;

[0138] (2) Place the precursor obtained in step (1) in a reaction furnace, blow in air, raise the temperature to 1000°C, and keep it for 1 hour. Perform oxidation heat treatment on the precursor to obtain a hollow cavity and secondary particle silicon oxide layer Formed precursor two;

[0139] (3) Then the precursor two and magnesium powder obtained in step (2) are fused in a fusion machine at a mass ratio of 1:0.45 to achieve homogeneous mixing, and the homogeneously mixed product is placed in a closed container. Then it is placed in a high temperature furnace, and Ar gas is introduced as a protective gas, and the temperature is increased to 650°C, and ...

Embodiment 3

[0143] (1) Add Si particles with a median diameter of 5nm, spherical graphite particles with a median diameter of 0.5μm, and polyvinylpyrrolidone into the n-butanol solution in a mass ratio of 1:0.5:0.3, stir for 90 minutes, and then The solvent was spray dried to obtain precursor one with a median particle size of 1 μm;

[0144] (2) Place the precursor obtained in step (1) in a reaction furnace, blow in air, raise the temperature to 600°C, and hold for 2 hours. Perform oxidation heat treatment on the precursor to obtain a hollow cavity and a secondary particle silicon oxide layer Formed precursor two;

[0145] (3) Then the precursor 2 obtained in step (2) and the aluminum powder are mixed in a VC mixer at a mass ratio of 1:0.4 to achieve homogeneous mixing, and the homogeneously mixed product is placed in a closed container, and then Put it into a high-temperature furnace, pass in helium gas as a protective gas, and raise the temperature to 800°C. The non-oxidizing heat treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com