Battery anode material of embedding Sn-based alloy in porous carbon and preparation method of the battery anode material

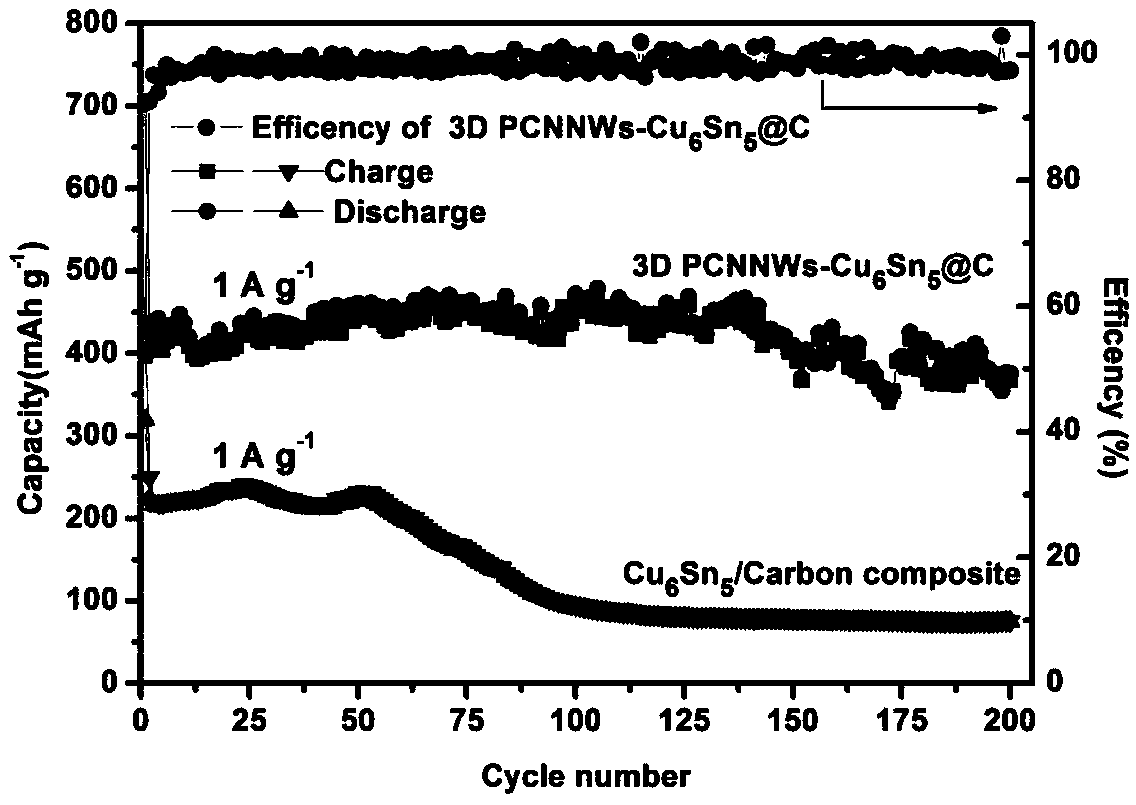

A technology of tin-based alloy and battery negative electrode, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as tin-based negative electrode materials that cannot be completely solved, and achieve excellent conductivity, lithium storage function, buffer volume change, and structure stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

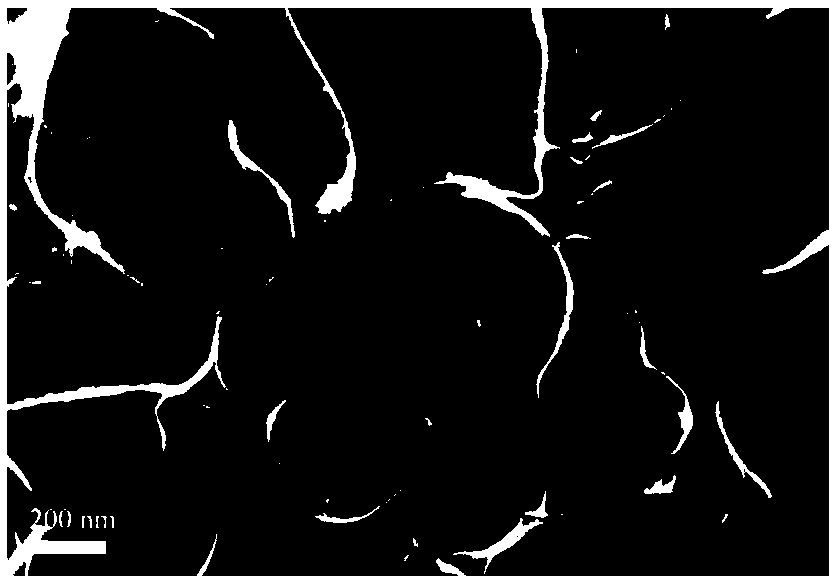

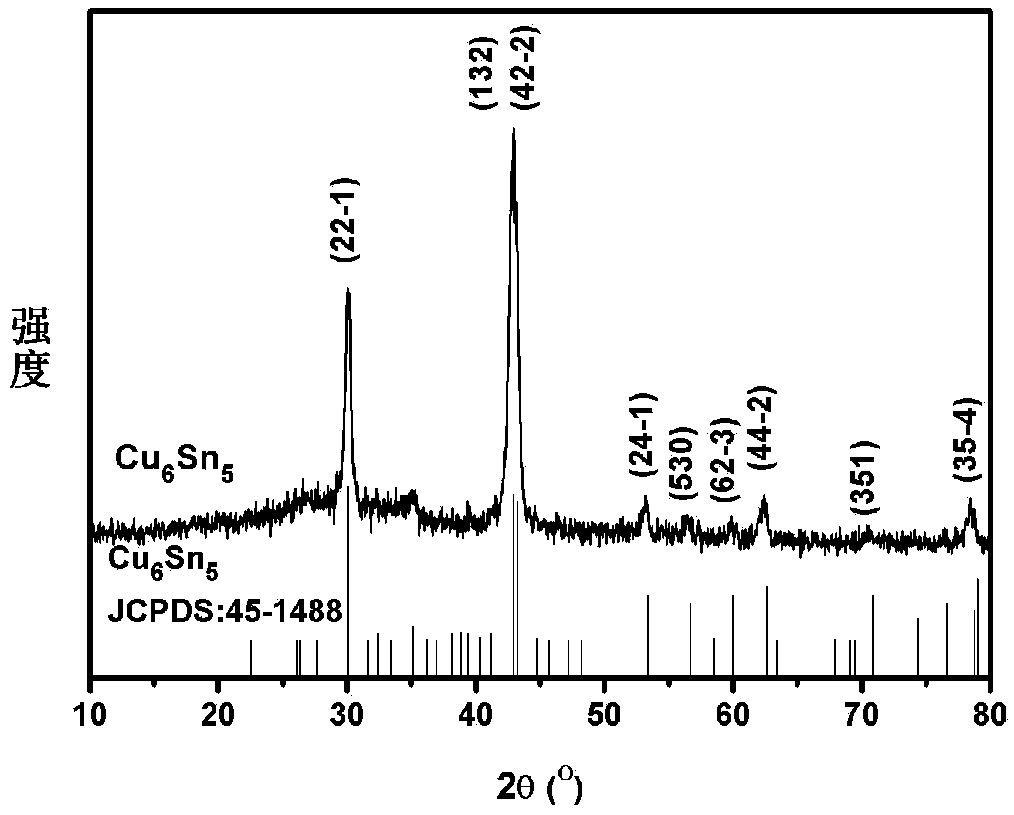

[0039] Weigh 2.5g of C 6 h 8 o 7 ·H 2 O, 20.7g of NaCl, 0.2339g of Cu(NO 3 ) 2 ·3H 2 O, 0.1849 g of SnCl 2 2H 2 O, dissolved in 75mL of water, magnetically stirred for 12h. Transfer the uniformly stirred solution into a watch glass, put it in the refrigerator to freeze, and after 24 hours, put the frozen material into a freeze dryer, and freeze-dry it at -50°C until it is completely dry. The dried powder is taken out, ground, put into the ark, and heat-treated in a tube furnace. The gas condition during heat treatment is: H 2 : Ar=250:100, with a heating rate of 20°C / min to 750°C, after holding for 2 hours, cool down to room temperature with the furnace. The obtained powder was repeatedly washed with deionized water and filtered until NaCl was completely removed. Put the washed powder in an oven to dry at 80°C, and grind to get a three-dimensional network carbon structure embedded with Cu 6 sn 5 Alloyed lithium-ion battery composite anode material, embedded Cu 6 ...

Embodiment 2

[0042] Weigh 2.5g of C 6 h 8 o 7 ·H 2 O, 20.7g of NaCl, 0.2258g of Ni(NO 3 ) 2 ·6H 2 O, 0.2324 g SnCl 2 2H 2 O, dissolved in 75mL of water, magnetically stirred for 12h. Transfer the uniformly stirred solution into a watch glass, put it in the refrigerator to freeze, and after 24 hours, put the frozen material into a freeze dryer, and freeze-dry it at -50°C until it is completely dry. The dried powder is taken out, put into the ark, and heat-treated in a tube furnace. The heat treatment condition is: H 2 : Ar=50:100, with a heating rate of 5°C / min to 750°C, after holding for 2 hours, cool to room temperature with the furnace and take it out. The obtained material was repeatedly washed with deionized water and filtered until NaCl was completely removed. Put the washed powder in an oven and dry it at 80°C, and grind it after drying to get a three-dimensional network carbon structure embedded with Ni 3 sn 4 Carbon-lithium-ion battery composite anode material, embedde...

Embodiment 3

[0045] Weigh 2.5g of C 6 h 8 o 7 ·H 2 O, 20.7g of NaCl, 0.3662 of Ni(NO 3 ) 2 ·6H 2 O, 0.1627g SnCl 2 2H 2 O, dissolved in 75mL of water, magnetically stirred for 12h. Transfer the uniformly stirred solution into a watch glass, freeze in a refrigerator for 12 hours, put the frozen material into a freeze dryer, and freeze-dry at -50°C until completely dry. The dried powder is put into the ark and heat treated in a tube furnace. The heat treatment condition is: H 2 : Ar=250:100, heat up to 750°C at a heating rate of 10°C / min, hold for 2 hours, and cool to room temperature with the furnace. The obtained powder was repeatedly washed with deionized water and filtered until NaCl was completely removed. Put the washed powder in an oven and dry it at 80°C, and grind it to get a three-dimensional carbon network structure embedded with Ni 3 sn 4 Composite anode materials for lithium-ion batteries, embedded Ni 3 sn 4 The diameter is about 30nm, and the side length of each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com