Oil-proof low-smoke halogen-free flame-retardant heat shrinkable label sleeve as well as preparation method and application thereof

A heat-shrinkable and oil-resistant technology, which is applied in the field of oil-resistant, low-smoke, halogen-free, flame-retardant heat-shrinkable marking sleeves and its preparation, can solve the problems of not conforming to the development trend of the environmental protection field, threats to personal safety, and large smoke emissions, and achieve improved Printing operation performance, good heat aging resistance, and the effect of increasing printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

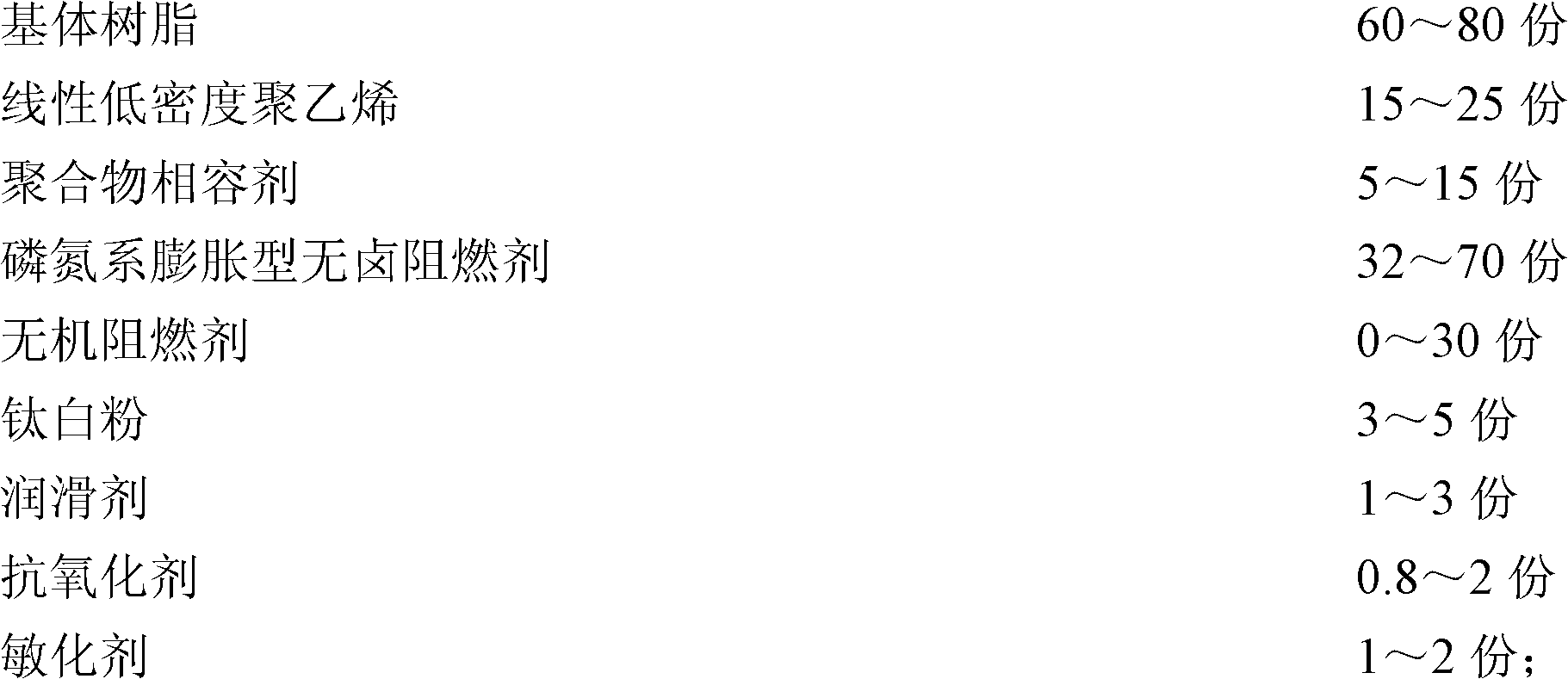

Method used

Image

Examples

Embodiment 1

[0046] Get ethylene-ethyl acrylate copolymer (EEA, Dupont, model is Elvaloy2116, following examples are the same) 80kg, linear low density polyethylene (LLDPE, Saudi Basic Industries Corporation, trade mark 218-W, melt index is 2g / 10min, The density is 0.918g / cm 3 ) 15kg, maleic anhydride functional group grafted ethylene-vinyl acetate copolymer (graft rate 1.2%, melt index is 1.1g / 10min, Shanghai Jiuju Polymer Material Co., Ltd., trade mark is JCP-851) 5kg, Phosphorus nitrogen intumescent flame retardant I (Co., Ltd. ADEKA, FP-2200) 48kg, titanium dioxide 3kg, polyethylene wax (Huizhou Huiyang Yongqing Chemical Co., Ltd.) 1kg, 0.4kg antioxidant 1010, double (2, 6-di-tert-butyl-4-methylbenzene) pentaerythritol bisphosphite 0.4kg and trimethylolpropane triacrylate 2kg, add high-speed mixer (model SHR-10A, Zhangjiagang Yili Machinery Co., Ltd., stirring speed is 800RPM, the following examples are the same), stirring for 5 minutes, and the temperature of the material is controll...

Embodiment 2

[0049] Get ethylene-ethyl acrylate copolymer 60kg, ethylene-octene copolymer (POE, ExxonMobil, brand name vistamaxx6102, the mass content of ethylene is 16%, melt flow rate is 3.0g / 10min) 14kg, linear low density Polyethylene (LLDPE, Saudi Basic Industries Corporation, brand 218-W, melt index is 2g / 10min, density is 0.918g / cm 3 ) 20kg, maleic anhydride functional group grafted ethylene-vinyl acetate copolymer (graft rate 1.2%, melt index is 1.1g / 10min, Shanghai Jiuju Polymer Material Co., Ltd., trade mark is JCP-851) 6kg, Phosphorus-nitrogen intumescent flame retardant II (Persaifur (Qingyuan) Phosphorus Chemical Co., Ltd., EPFR-100D) 70kg, titanium dioxide 4kg, zinc stearate 3kg, 0.5kg antioxidant 1010, bis(2,6- Di-tert-butyl-4-methylbenzene) pentaerythritol bisphosphite 1kg and trimethylolpropane triacrylate 1.5kg, add in the high-speed mixer and stir for 5 minutes, the material temperature is controlled at 70~80 ℃; Then the above mixture Use a twin-screw extruder at a temp...

Embodiment 3

[0052] Get ethylene-ethyl acrylate copolymer 60kg, ethylene-octene copolymer (POE, ExxonMobil, brand name vistamaxx6102, the mass content of ethylene is 16%, melt flow rate is 3.0g / 10min) 14kg, linear low density Polyethylene (LLDPE, Saudi Basic Industries Corporation, brand 218-W, melt index is 2g / 10min, density is 0.918g / cm 3 ) 20kg, maleic anhydride functional group grafted ethylene-vinyl acetate copolymer (graft rate 1.2%, melt index is 1.1g / 10min, Shanghai Jiuju Polymer Material Co., Ltd., trade mark is JCP-851) 6kg, Phosphorus Nitrogen Intumescent Flame Retardant I (ADEKA Co., Ltd., FP-2200) 25kg, Phosphorus Nitrogen Intumescent Flame Retardant II (Prosafu (Qingyuan) Phosphorus Chemical Co., Ltd., EPFR-100D) 35kg, Titanium Dioxide 4kg , zinc stearate 3kg, 0.5kg antioxidant 1010, two (2,6-di-tert-butyl-4-methylbenzene) pentaerythritol diphosphite 1kg and trimethylolpropane triacrylate 1.5kg, add Stir in a high-speed mixer for 5 minutes, and control the temperature of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com