Vinyl chloride resin composition for powder molding, vinyl chloride resin molded body, laminate, automobile interior material, and method for producing vinyl chloride resin composition for powder molding

A technology of vinyl chloride resin and composition, which is applied in the directions of transportation, packaging, thin material processing, etc., can solve the problems of poor heat aging resistance and cold resistance, and achieve excellent powder fluidity, high cold resistance, high Effect of Heat Aging Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

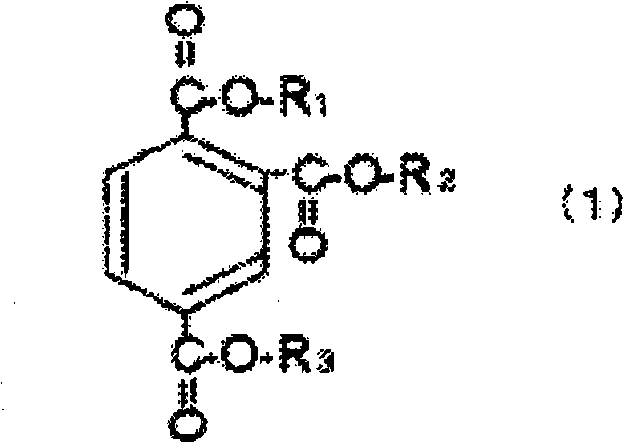

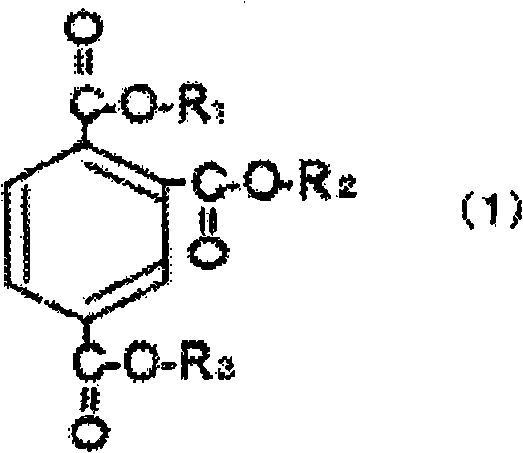

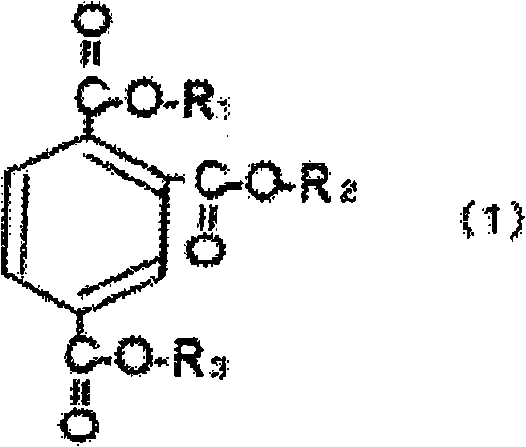

Image

Examples

Embodiment 1

[0053] 100 parts by mass of vinyl chloride-based resin particles (ZEST2000Z manufactured by New Daiichi Salt Bi Co., Ltd.) with an average particle diameter of 124 μm composed of vinyl chloride-based resins with an average degree of polymerization of 2000, and 1 part by mass of antioxidant (IRGANOX1010 manufactured by Ciba Specialty Chemicals Co., Ltd.) , light stabilizer (ADEKA STAB LA-67 manufactured by ADEKA company) 0.2 parts by mass, ultraviolet absorber (TINUVINP manufactured by Ciba Specialty Chemicals company) 0.3 parts by mass, pigment (DAP1050 white manufactured by Dainichi Seika Co., Ltd.) 0.6 parts by mass, pigment (Dainichi Seika Co., Ltd. 3.8 parts by mass of DA PX 1720 (A) black) manufactured by Nissei Chemical Co., Ltd., 0.2 parts by mass of zinc stearate (SZ2000 manufactured by Sakai Chemical Industry Co., Ltd.) were mixed in a Hengol mixer, and when the temperature of the mixture rose to 80°C, The linear ratio of each alkyl group is 100%, the ratio of the alky...

Embodiment 2

[0055] In place of the vinyl chloride resin particles used in Example 1, vinyl chloride resin particles having an average particle diameter of 130 μm (ZEST2500Z manufactured by New Daiichi Salt Bi Co., Ltd.) composed of vinyl chloride resin with an average degree of polymerization of 2500 were used. ; Use each alkyl straight chain rate as 100%, the proportion of the alkyl group with 8 carbon atoms relative to the whole alkyl group is 50 mole %, and the ratio of the alkyl group with 10 carbon atoms with respect to the whole alkyl group is In place of the trimellitate plasticizer used in Example 1, 145 parts by mass of a 50 mol % trimellitate plasticizer (Monocizer W-796 manufactured by Dainippon Ink & Chemicals Co., Ltd.) was used. Except for this, the same operations as in Example 1 were performed to prepare a vinyl chloride-based resin composition for powder molding. The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com