Preparation method for micro-grade spherical Mo-Ru brazing filler powder

A micron-scale, mo-ru technology, applied in the field of powder metallurgy, can solve the problems of unmarked Mo-Ru composite powder shape and size, etc., and achieve the effect of good powder fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

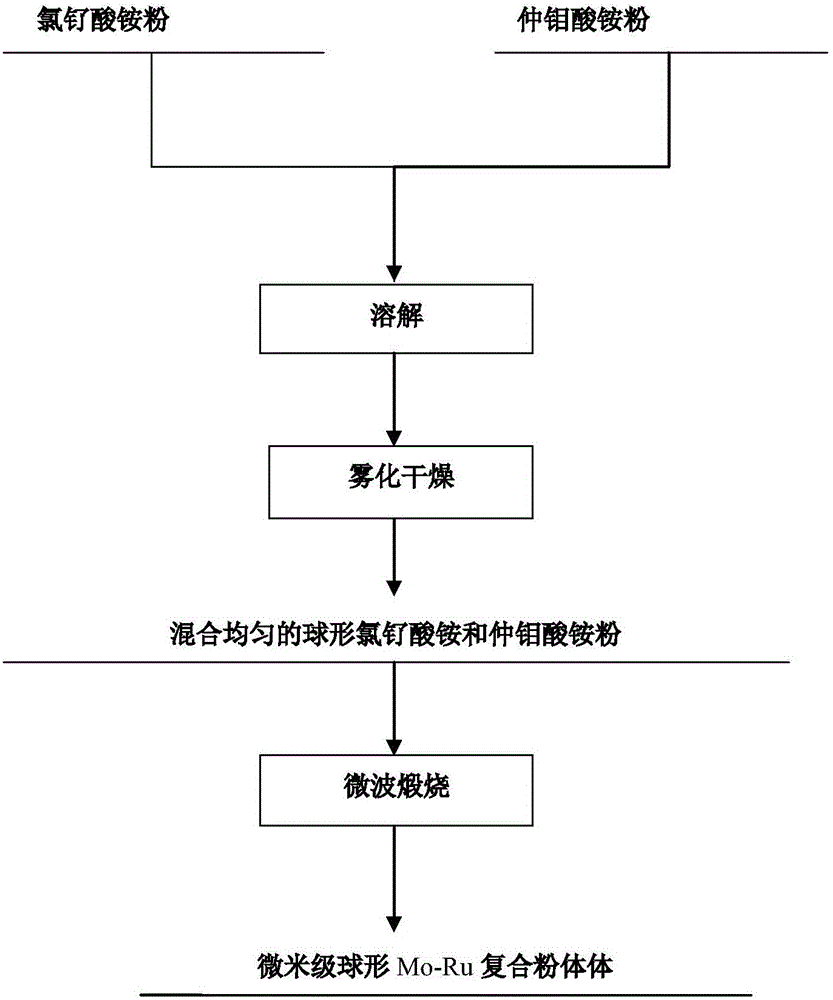

[0018] The micron-sized spherical Mo-Ru composite powder of the present invention is obtained through the following steps:

[0019] (1) atomization granulation: with (NH 4 ) 2 RuCl 6 and (NH 4 ) 6 Mo 7 o 24 4H 2 O is the raw material, weigh the material (Mo: Ru mass ratio is 6:4), configure (NH 4 ) 2 RuCl 6 and (NH 4 ) 6 Mo 7 o 24 Solution, adopt spray drying method, control liquid flow rate is 4.0ml / min, atomization air pressure is 0.4MPa, inlet temperature is 170 ℃, and hot air flow rate is 5.0L / min, makes the spherical (NH 4 ) 2 RuCl 6 and (NH 4 ) 6 Mo 7 o 24 particles;

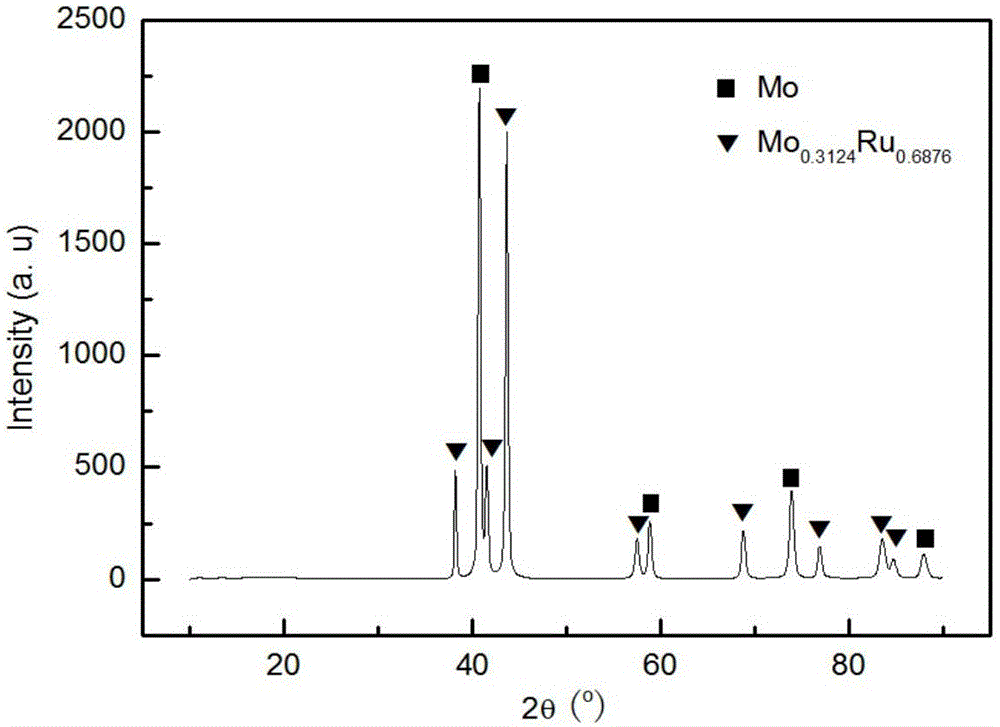

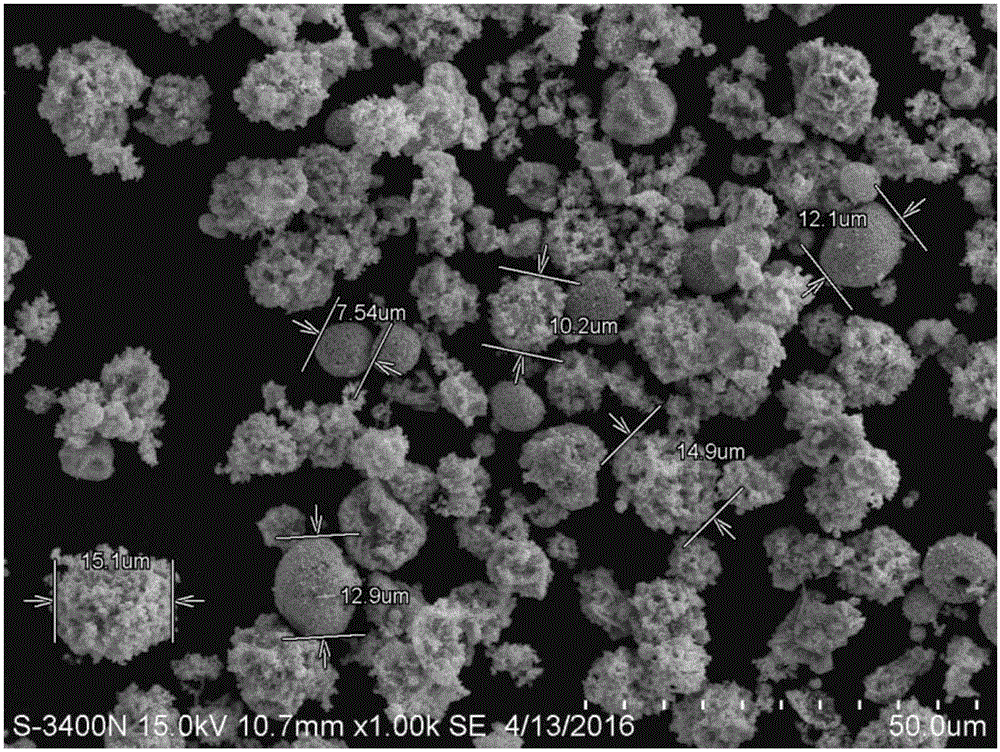

[0020] (2) Microwave calcination: the uniformly mixed spherical (NH 4 ) 2 RuCl 6 and (NH 4 ) 6 Mo 7 o 24 particles in an atmosphere of N 2 / H 2 (9:1vol) in a microwave calciner, the temperature is controlled at 400°C, kept for 3h, then raised to 900°C, and kept for 4h to prepare micron-sized spherical Mo-Ru composite powder with a particle size of 5-15μm.

Embodiment 2

[0022] The difference from Example 1 is that the atomization and granulation process is as follows: the flow rate of the control liquid is 5.0 mL / min, the atomization pressure is 0.5 MPa, the inlet temperature is 200° C., and the flow rate of hot air is 6.0 L / min. The calcination process is as follows: control the calcination temperature from room temperature to 450° C. for 2 hours, then raise the temperature to 950° C. for 4 hours, and cool with the furnace to obtain a composite powder with a particle size of 6-17 μm.

Embodiment 3

[0024] The difference from Example 1 is that the atomization and granulation process is as follows: the flow rate of the control liquid is 3.0 mL / min, the inlet temperature is 140° C., and the flow rate of hot air is 4.0 L / min. The calcination process is: control the calcination atmosphere N 2 / H 2 (Vol 9:1), heat up from room temperature to 500°C for 2 hours, then heat up to 1000°C for 4 hours, and cool in the furnace to obtain composite powder with a particle size of 4-16 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com