Repairing composite layer of amorphous/nanocrystalline cooling roller and preparation method of repairing composite layer

A technology of cooling rolls and nanocrystals, which is applied in the field of material science, can solve the problems of low absorption rate of laser beams by cooling rolls, bulky laser equipment, and low efficiency of laser cladding, and achieve excellent compatibility and wettability, Effect of improving cladding efficiency and enhancing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

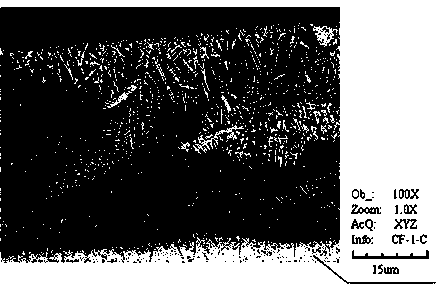

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] The repair composite layer of the amorphous / nanocrystalline cooling roll provided by this embodiment is composed of two layers, and the copper-based alloy layer is connected to the base material, and its composition is calculated by weight percentage: Ni 7-9%, Sn 8~12%, Co 5~15%, Si 0.8~2%, and the balance is Cu; the other layer is a nickel-based alloy layer, which is selected from Ni-Co alloy, Ni-P alloy, Ni-Fe alloy, One of the Ni-Cr alloys, where the weight content of Ni in the alloy is 60-75%.

[0030] Wherein, the thickness ratio of the copper-based alloy layer to the nickel-based alloy layer is 1:1-2.

[0031] Wherein, the powder of the nickel-based alloy layer is spherical or ellipsoidal, and its particle size is 109-250 μm.

[0032] The method for preparing the repair composite layer of the amorphous / nanocrystalline cooling roll pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com